Magnetic suspension rail inspection vehicle chassis with guide wheel system

A technology of maglev track and guide wheel, which is applied in the direction of railway inspection vehicles, etc., can solve the problems of the distance change of the guide rail guide surface, the inability to guide the maglev track beam, and the limitation of application range, so as to achieve the effect of preventing slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

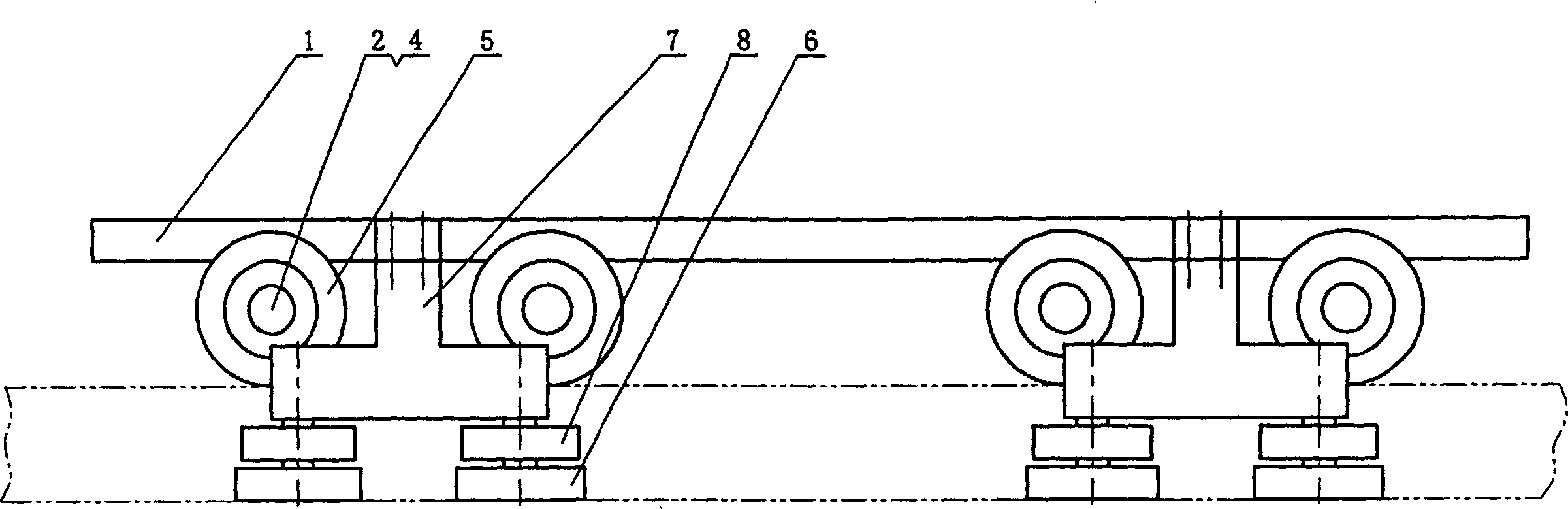

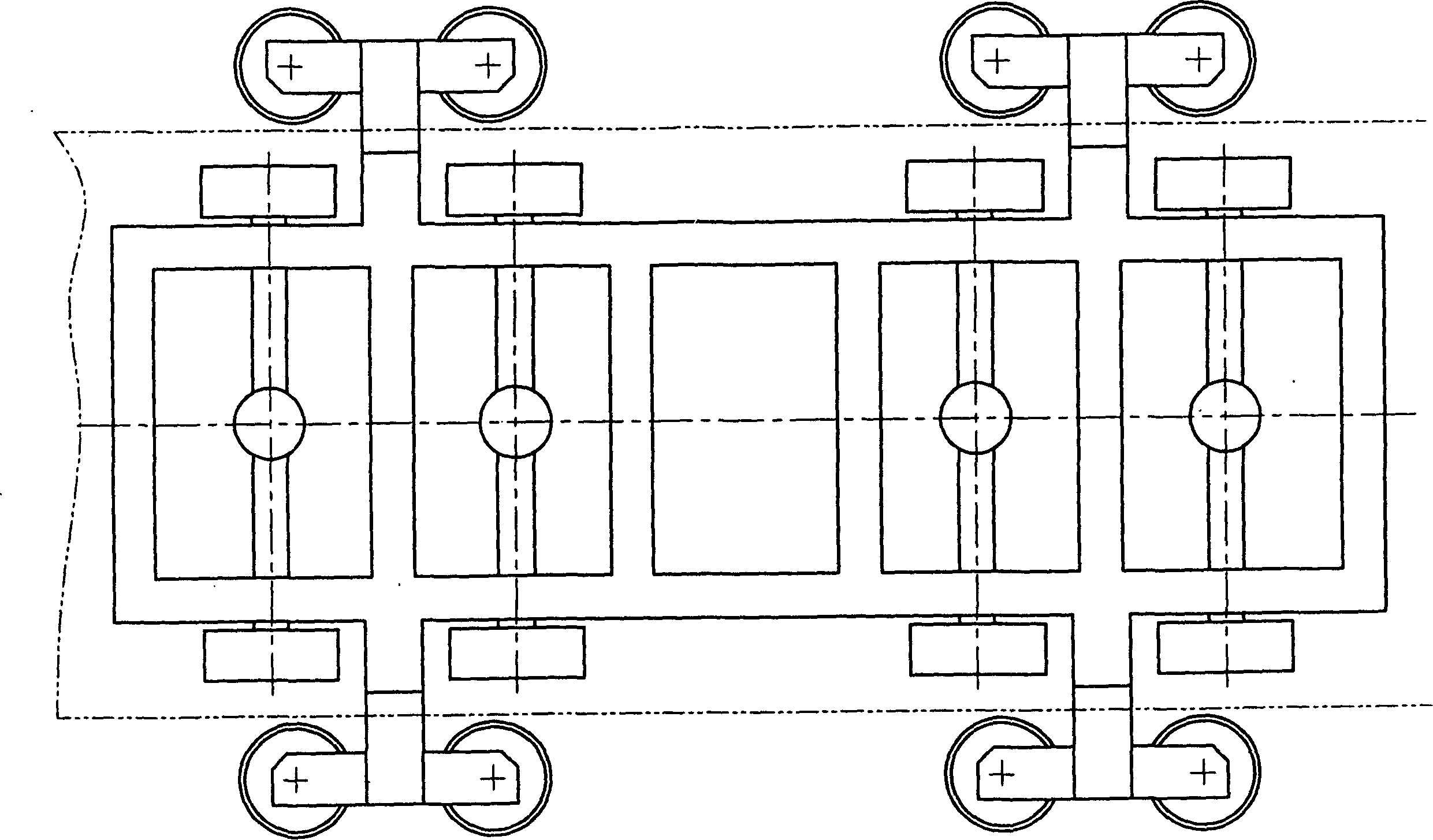

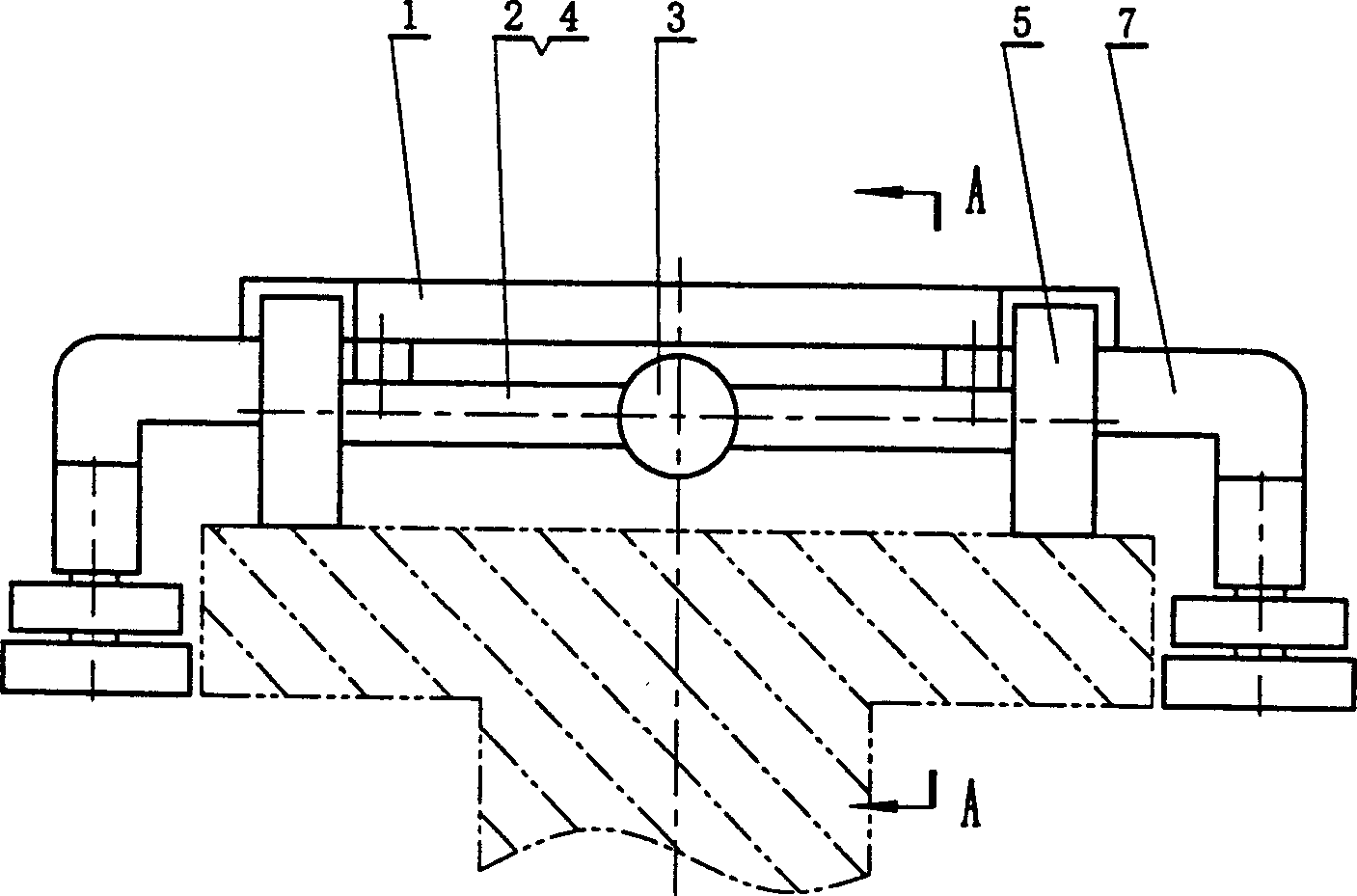

[0013] Such as figure 1, figure 2, Figure 3 and Figure 4 Shown, the present invention comprises: undercarriage 1, vehicle driving axle 2, gear differential 3, axle shaft 4, rubber tire wheel 5, rubber tire guide wheel 6, guide wheel frame 7, and its connection mode is: several without The vehicle drive axle 2 with the steering function is fixed on the undercarriage 1 in parallel, the middle part of the vehicle drive axle 2 is provided with a gear differential 3, and the two ends of the gear differential 3 are respectively connected to the half shaft 4, and the rubber tire wheels 5 Be arranged on the half shafts 4 of the two output ends of each vehicle drive axle 2, the rubber tire guide wheels 6 are arranged on the wheel shafts at the two ends of the guide wheel frame 7 and can rotate freely, the axis of the rubber tire guide wheels 6 and the axis of the rubber tire wheels 5 Vertical, the rim wheel surface of the rubber tire guide wheel 6 faces the upper side of the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com