Patents

Literature

177results about How to "Reduce driving noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

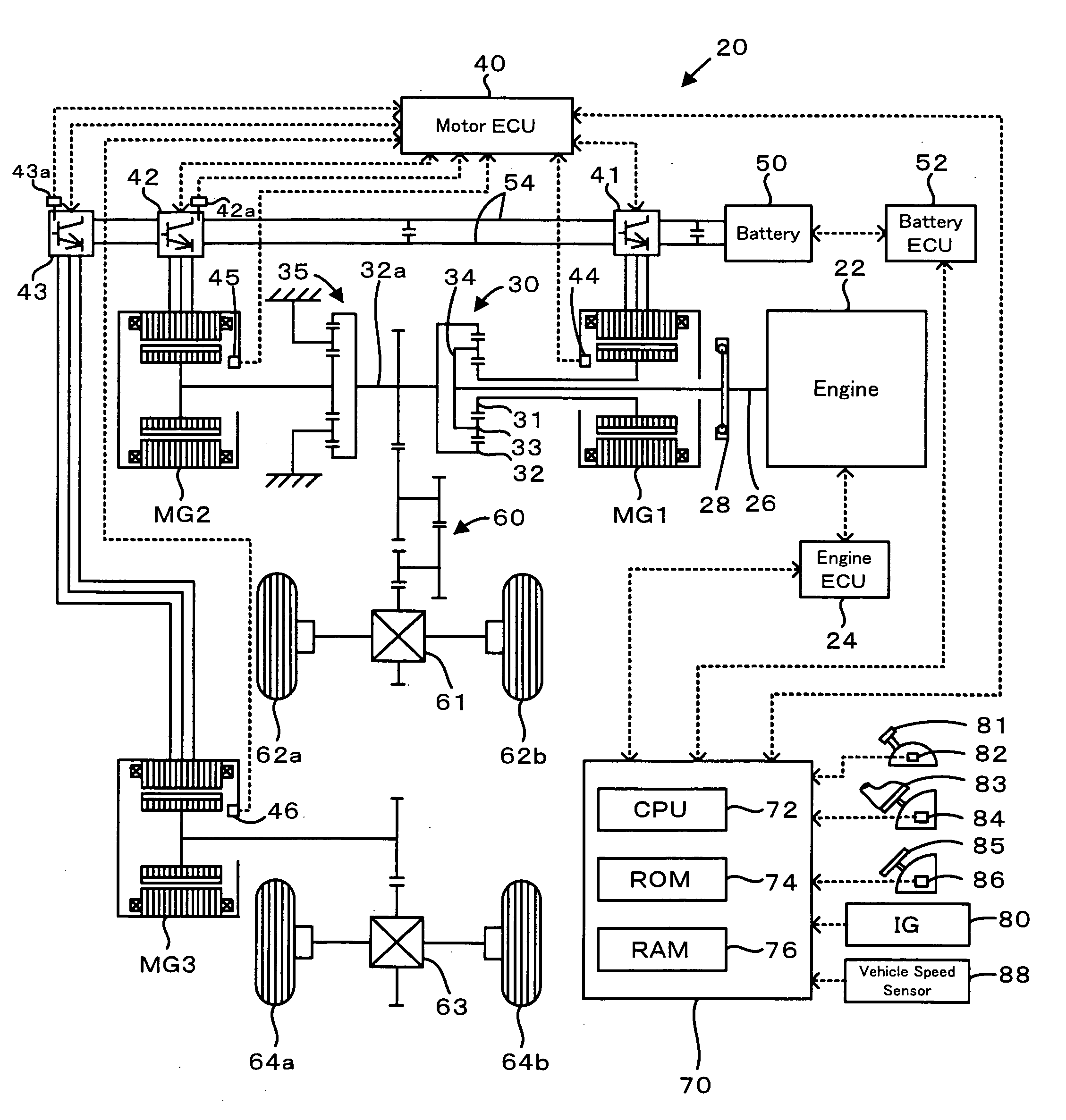

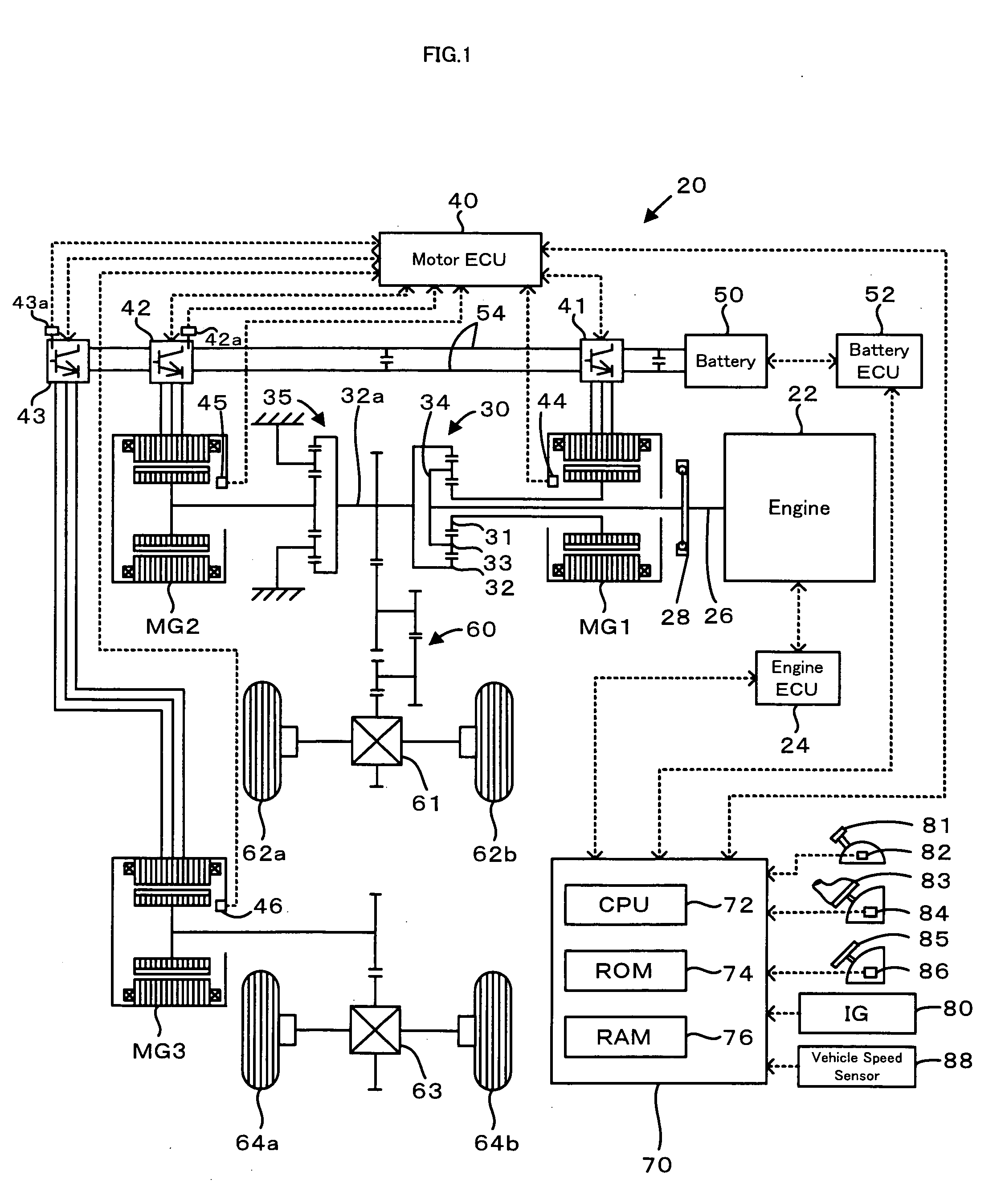

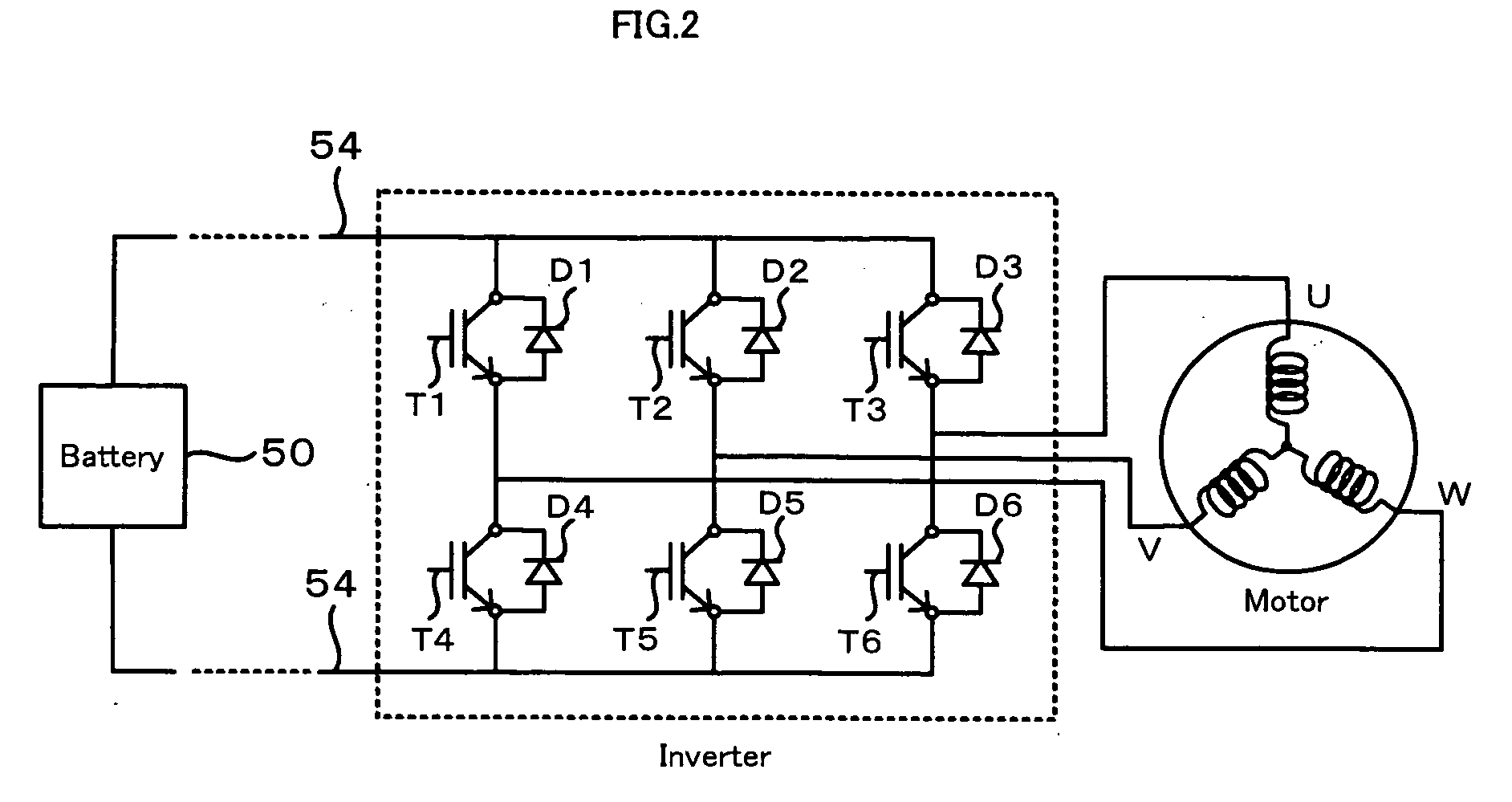

Power output apparatus, motor vehicle equipped with power output apparatus, and control method of power output apparatus

InactiveUS20060175995A1Avoid it happening againAvoid excessive loadsControl initiation meansDigital data processing detailsSwitching frequencyGradual increase

In the vehicle of the invention, when the temperature of an inverter 42 for driving a motor MG2 linked to front wheels 62a and 62b reaches or exceeds a preset restriction start temperature, the drive control of the invention controls the inverters 42 and 43 to gradually decrease the output torque of the motor MG2 simultaneously with a gradual increase in output torque of a motor MG3, which is linked to rear wheels 64a and 64b. Such torque control ensures output of a torque demand required for the vehicle. When the temperature of the inverter 42 reaches or exceeds a preset frequency switchover temperature, which is higher than the restriction start temperature, the drive control of the invention controls the inverters 42 and 43 to lower a switching frequency of transistors T1 to T6 in the inverter 42 and to ensure output of the torque demand. Such drive control effectively relieves the load of the inverter 42, while decreasing the frequency of lowering the switching frequency of the inverter 42. This arrangement thus desirably attains both prevention of overheat of the inverter 42 and reduces the switching noise.

Owner:TOYOTA JIDOSHA KK +1

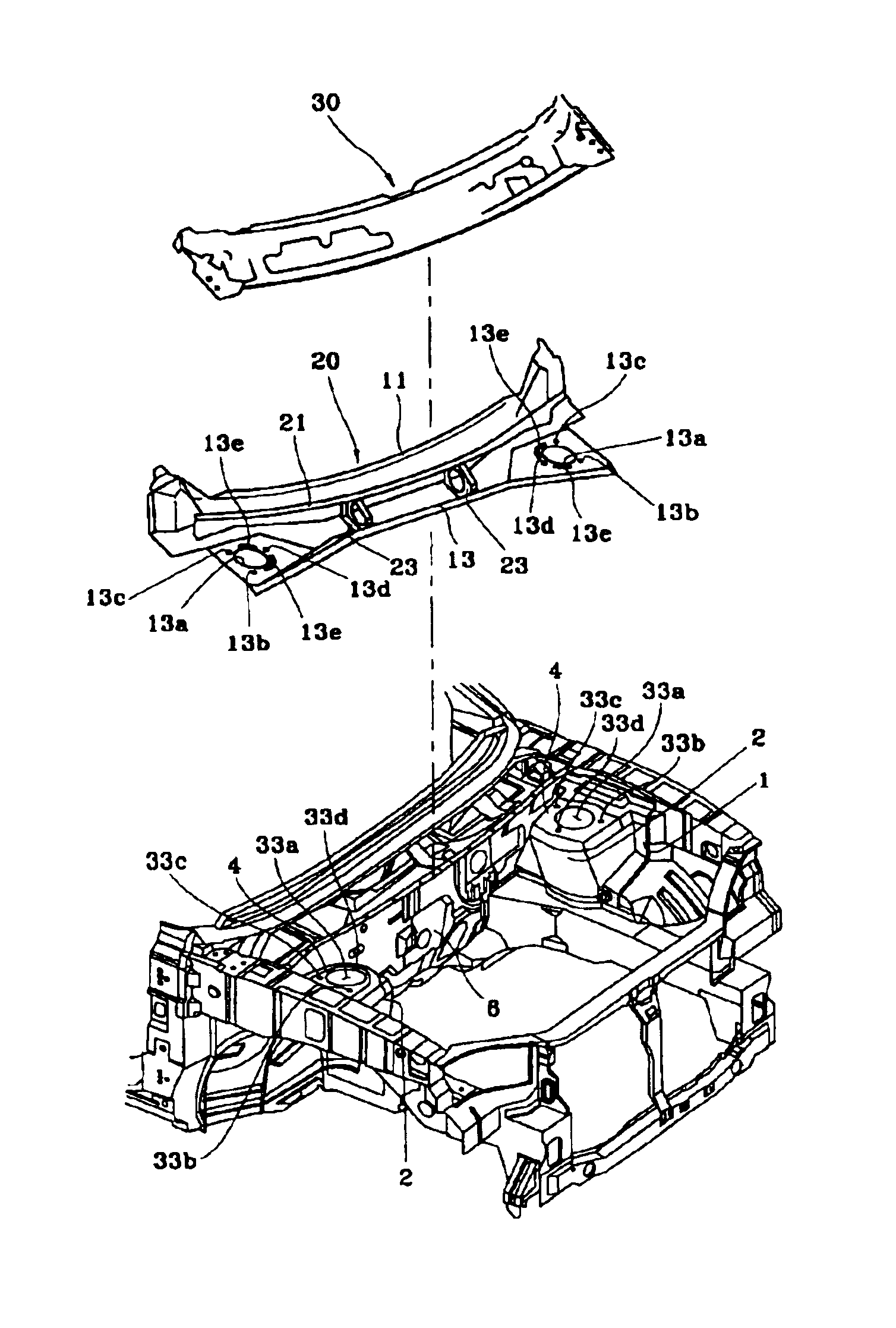

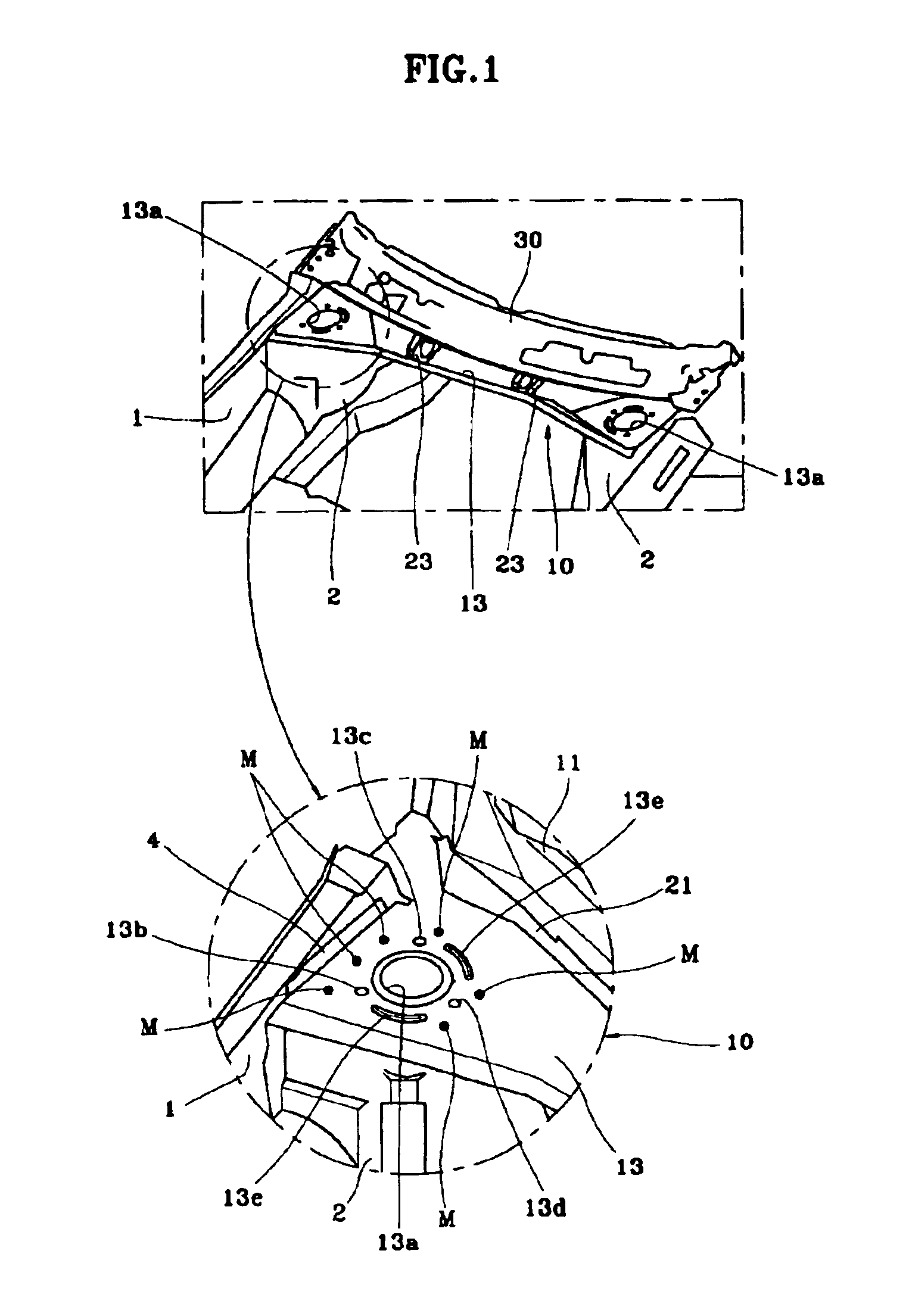

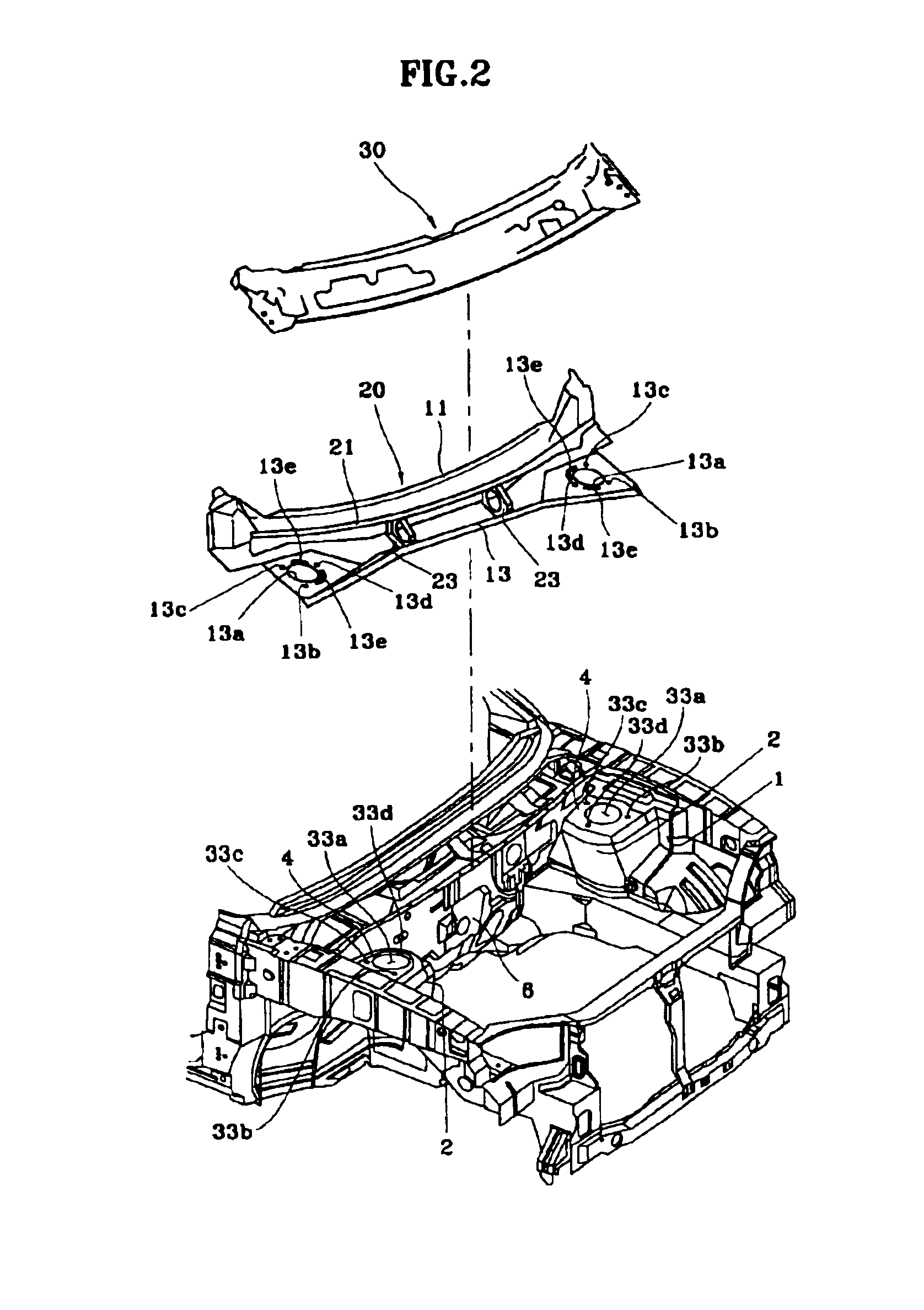

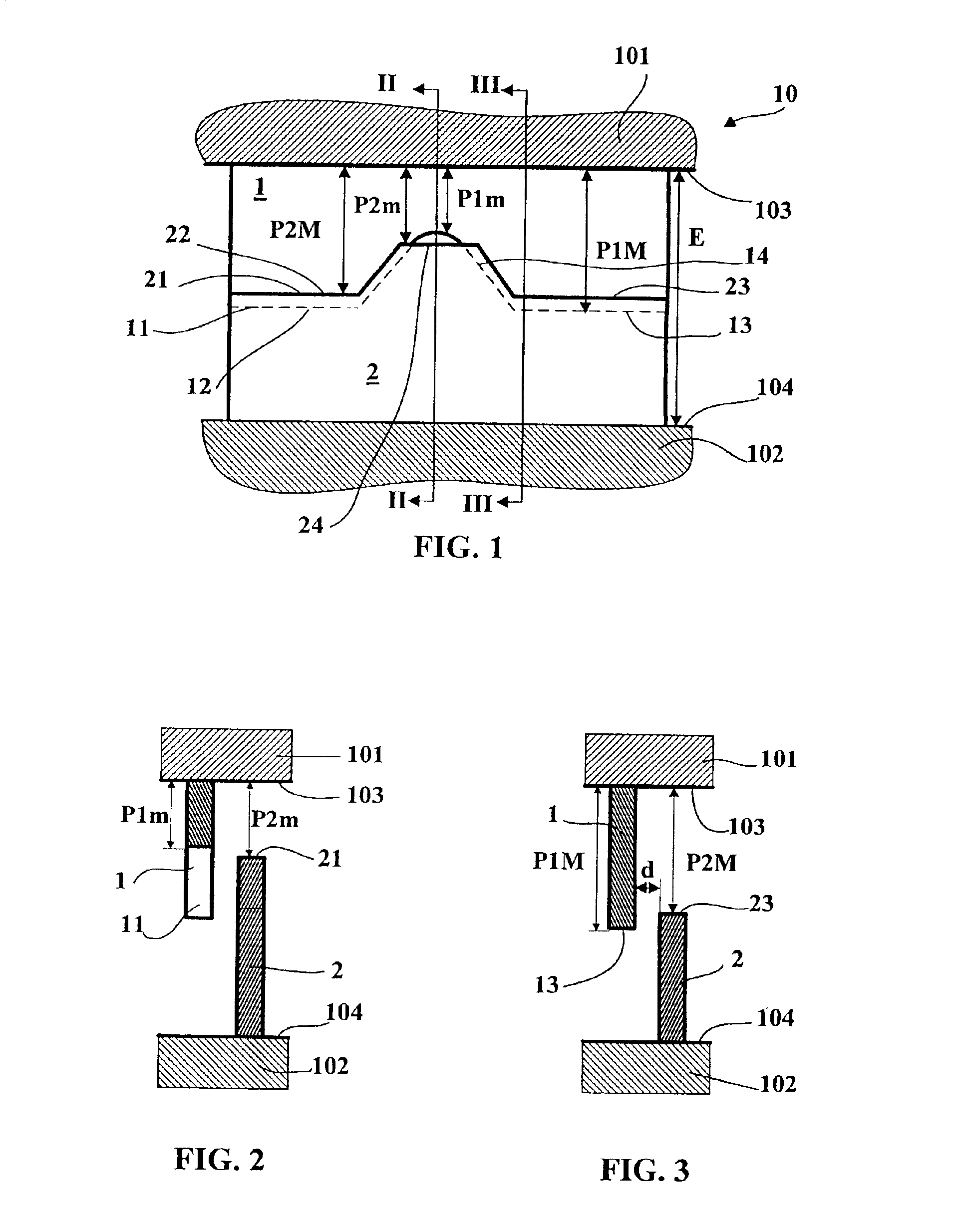

Upper mounting part structure of front strut assembly

InactiveUS6921126B2Improve rigidityMinimizing resonance generatedVehicle seatsSuperstructure subunitsResonanceShock absorber

An upper mounting part of a front strut assembly adapted to reinforce the rigidity of the periphery of a frontal mounting hole, rear mounting hole, and central mounting hole by a lower cowl panel mounted for integrally welding to the shock absorber housing upper panel placed at both sides of the engine room, and a lower cowl reinforcing means welded onto the lower cowl panel is disclosed. The structure minimizes resonance generated by the load transmitted from the outside of the vehicle, reduces driving noise and improves the vehicle ride and steering.

Owner:HYUNDAI MOTOR CO LTD

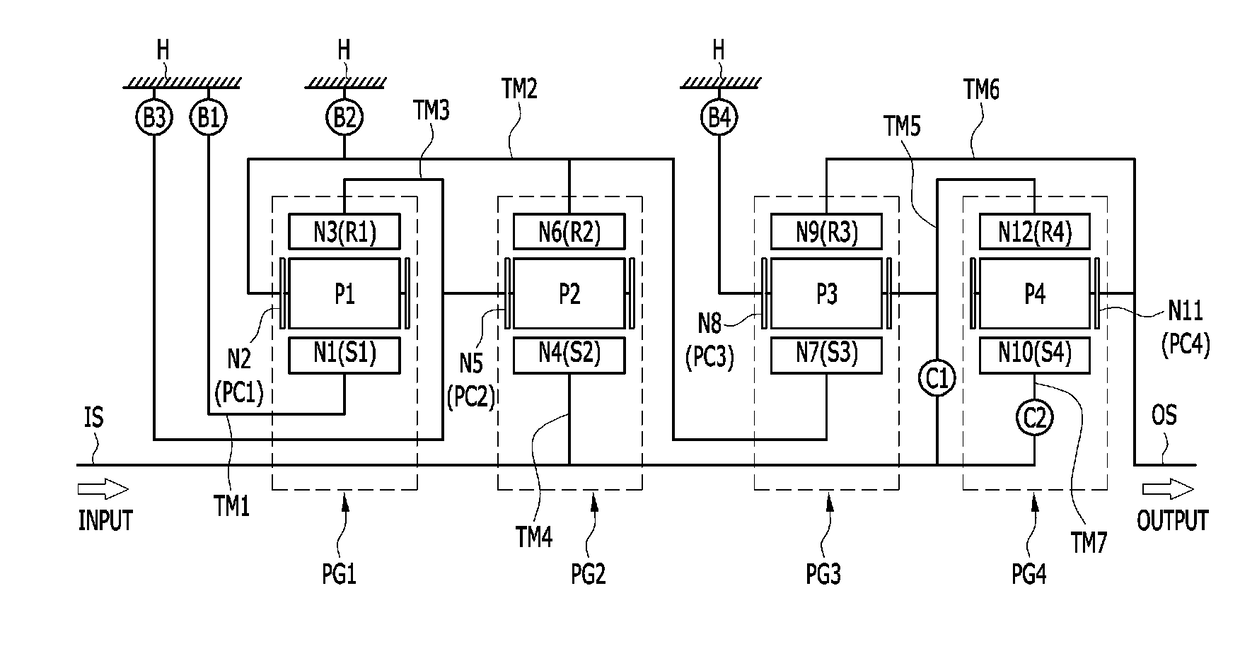

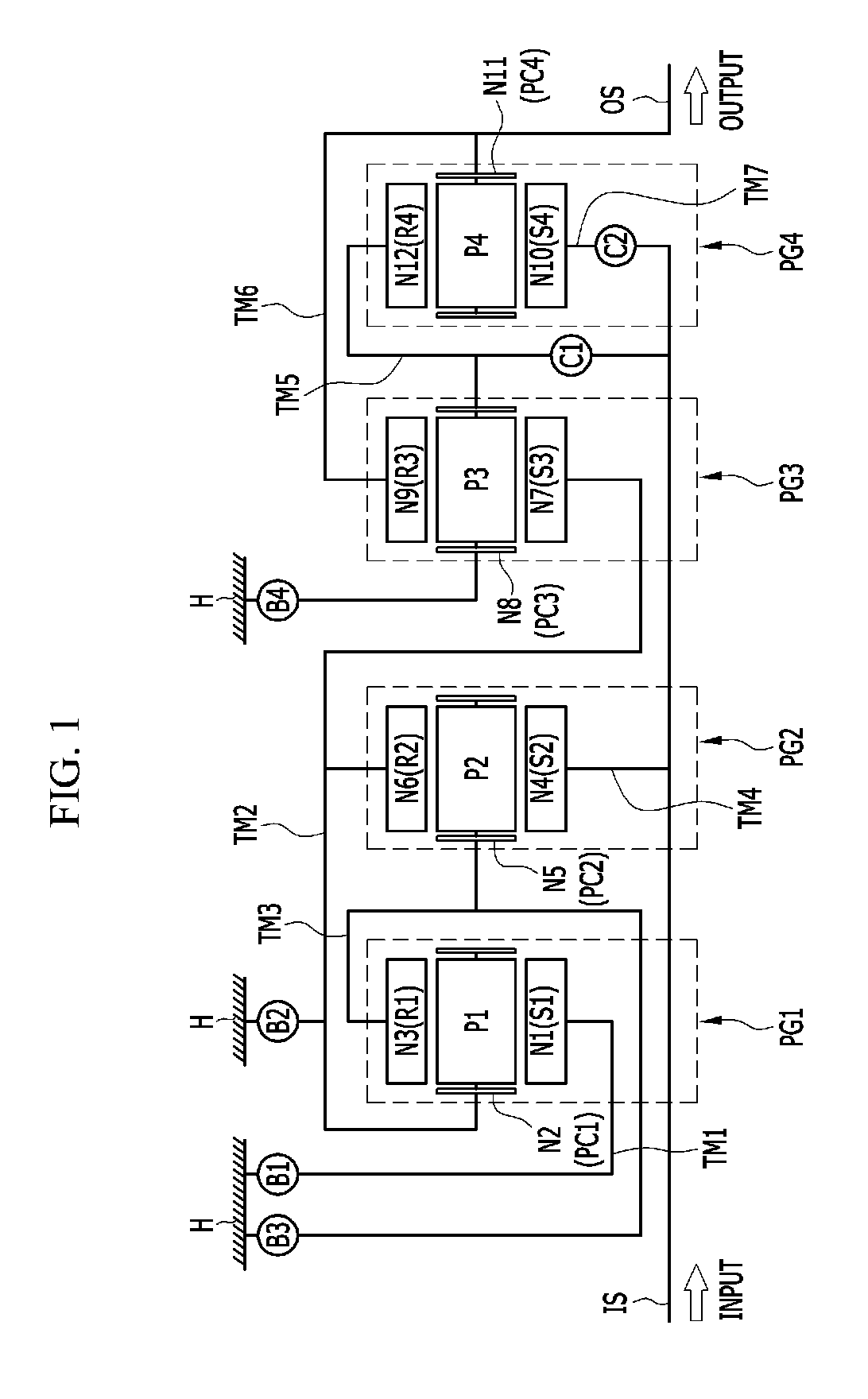

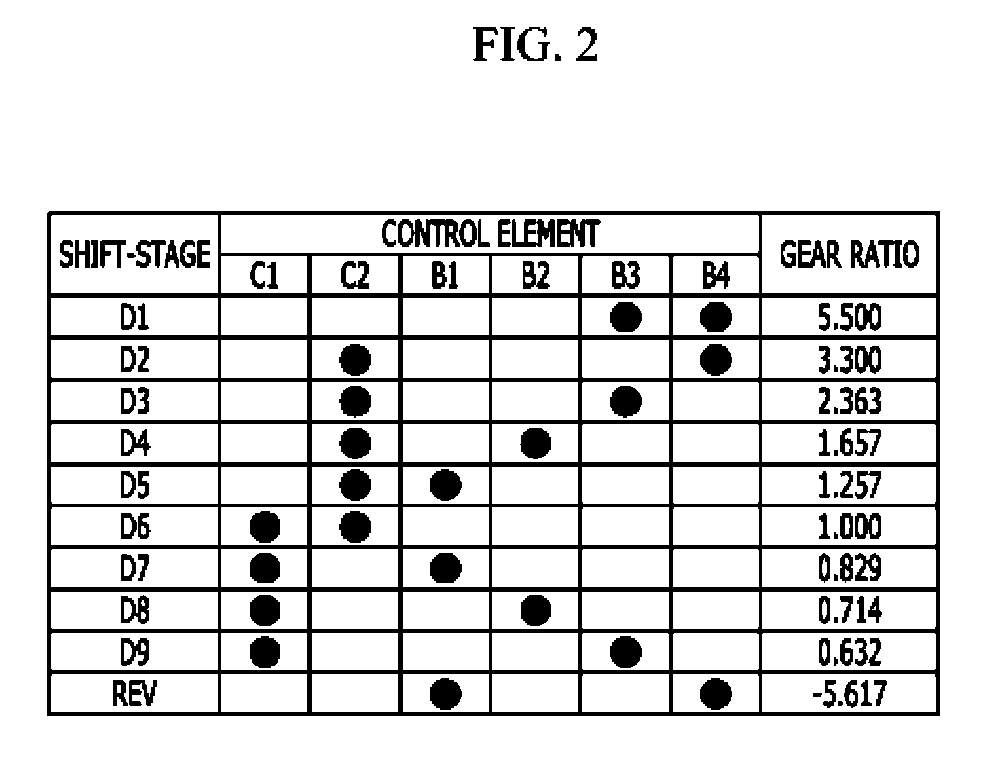

Planetary gear train of automatic transmission for vehicles

InactiveUS20170268612A1Reduce driving noiseImproving power delivery performanceToothed gearingsTransmission elementsDelivery PerformanceAutomatic transmission

A planetary gear train of an automatic transmission for a vehicle is provided. The planetary gear train includes an input shaft that receives power of an engine and an output shaft that outputs the power. Additionally, four planetary gear sets are provided, each including three rotational elements. Various shafts then either directly or selectively connect the rotational elements. The planetary gear train maximizes driving efficiency of the engine and improves power delivery performance and fuel consumption through the achievement of the increased shift-stages of the automatic transmission.

Owner:HYUNDAI MOTOR CO LTD

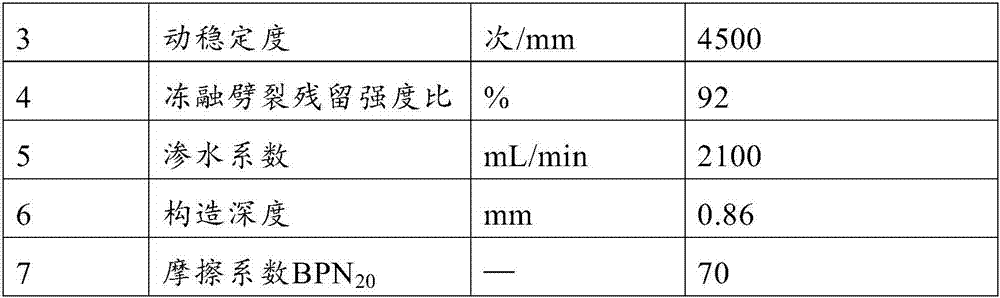

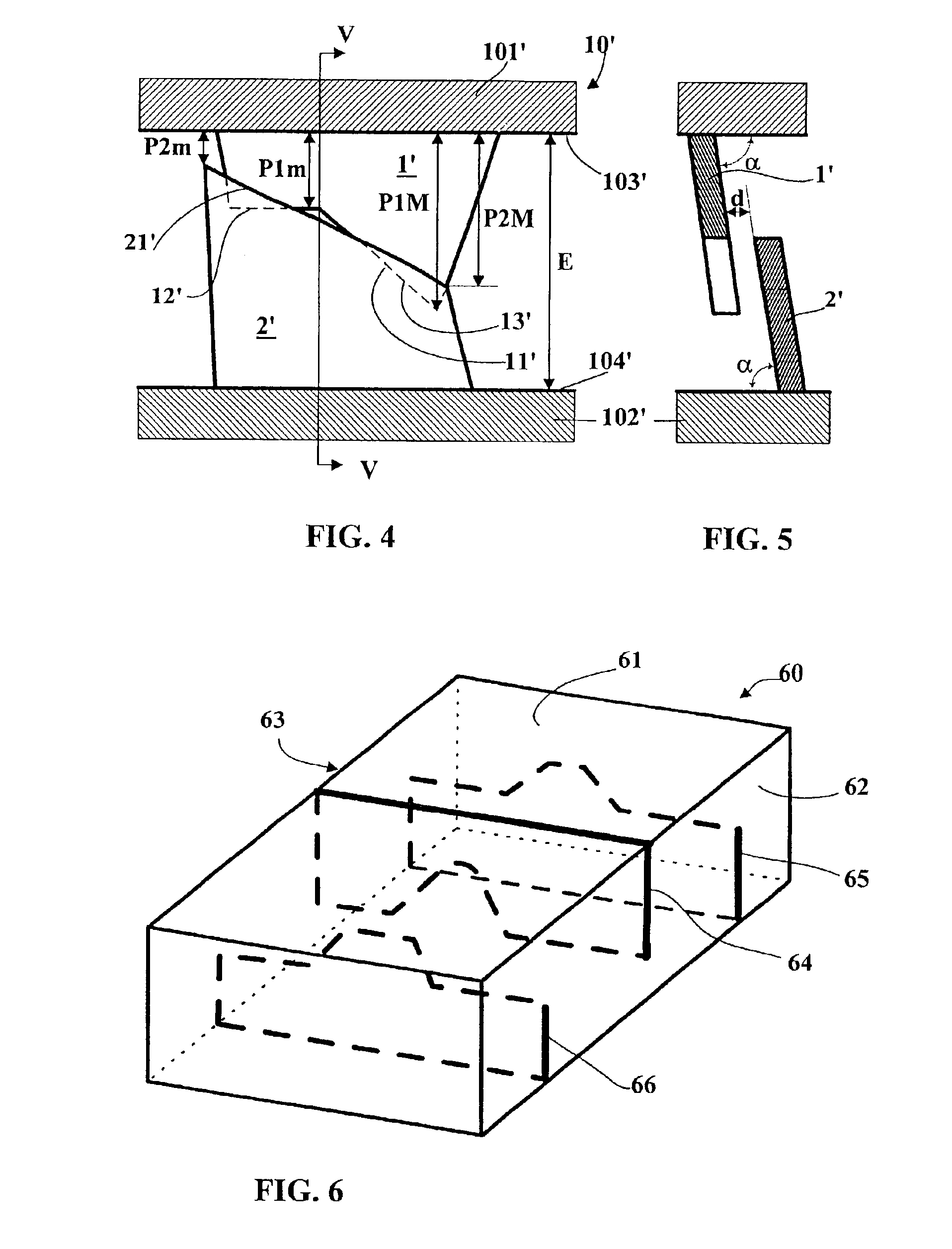

Steel slag and rubber asphalt concrete and preparation method thereof

The invention provides a steel slag and rubber asphalt concrete and a preparation method thereof. In the concrete, the steel slag is selected as a coarse aggregate and rubber asphalt is selected as a binder, and the concrete further comprises a fine aggregate and a filler; the mineral aggregate of the asphalt mixture is graded to form a coarse aggregate gap gradation framework solid type; the ratio of the rubber asphalt to the mineral aggregate is comprehensively determined through a Marshall compacting experiment to determine the range via the volume parameter of a Marshall test piece and verification on the road properties such as high-temperature rutting resistance and water damage resistance; when the rubber asphalt and the mineral aggregate are mixed and stirred, the heating temperature of the rubber asphalt is 175-180 DEG C and the heating temperature of the mineral aggregate is 10-30 DEG C higher than that of the rubber asphalt; moreover, the dry mixing time of the mineral aggregate is 15-20 s and the wet mixing time of the mineral aggregate is 35-40 s; and the ex-factory temperature of the steel slag and rubber asphalt concrete formed after the mixing and the stirring is 175-185 DEG C. The invention replaces the mineral aggregate by the steel slag, and can recycle the waste materials, save the stone resources, and reduce the destruction from the stone mining to the environment.

Owner:RES INST OF HIGHWAY MIN OF COMM

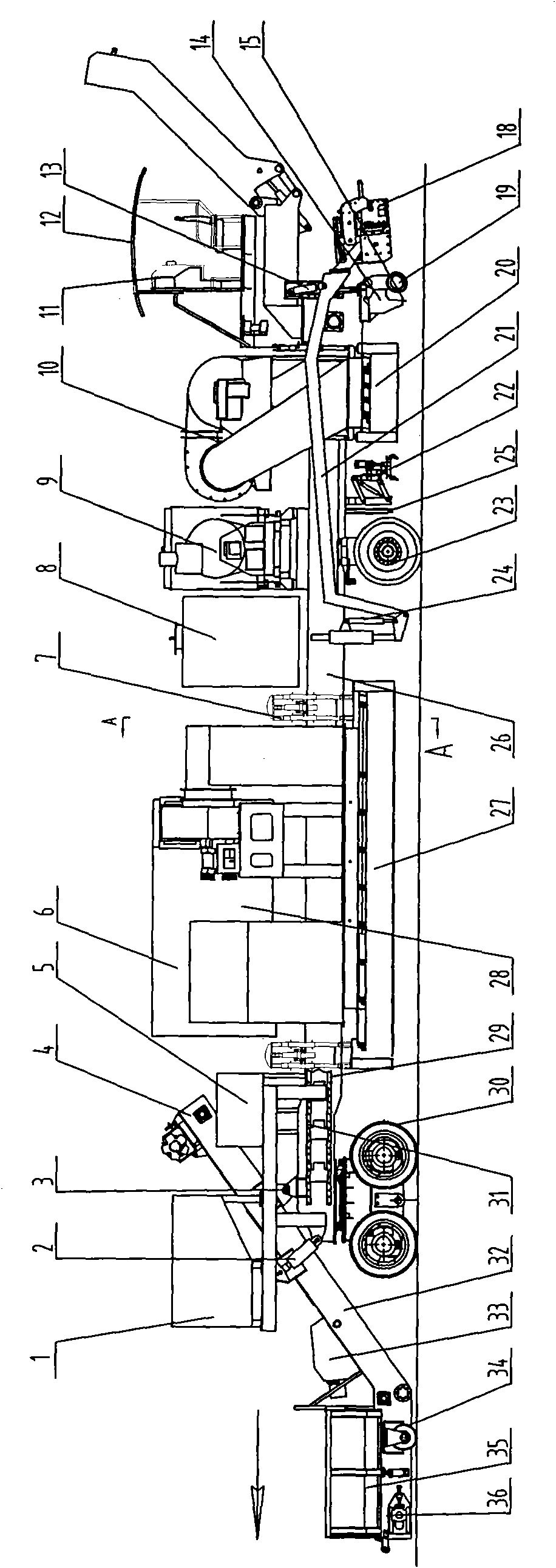

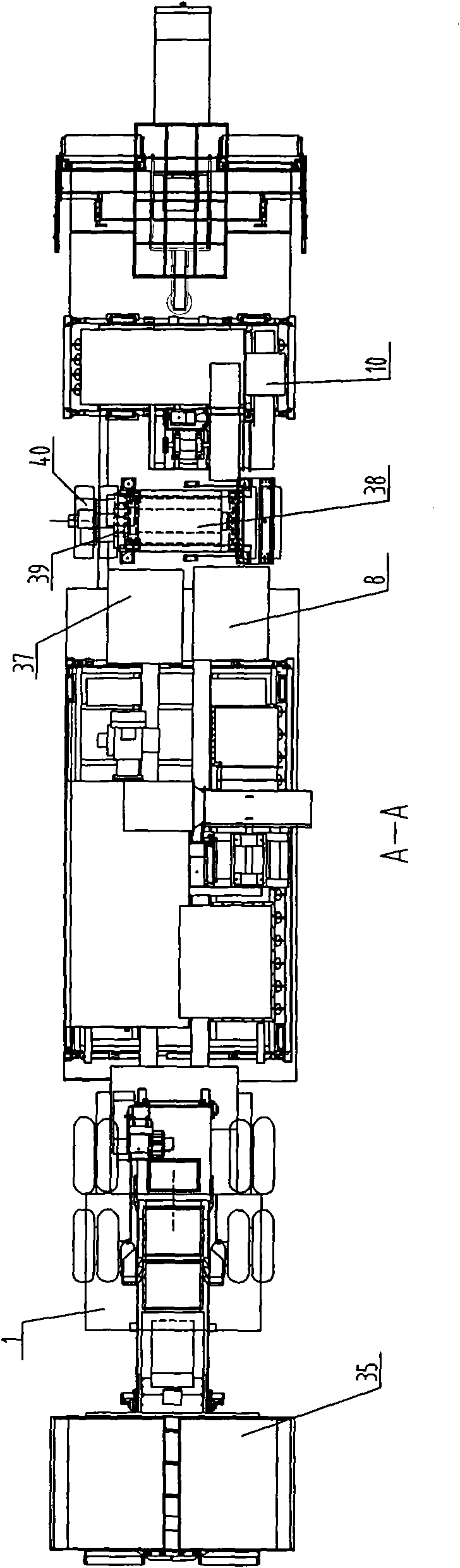

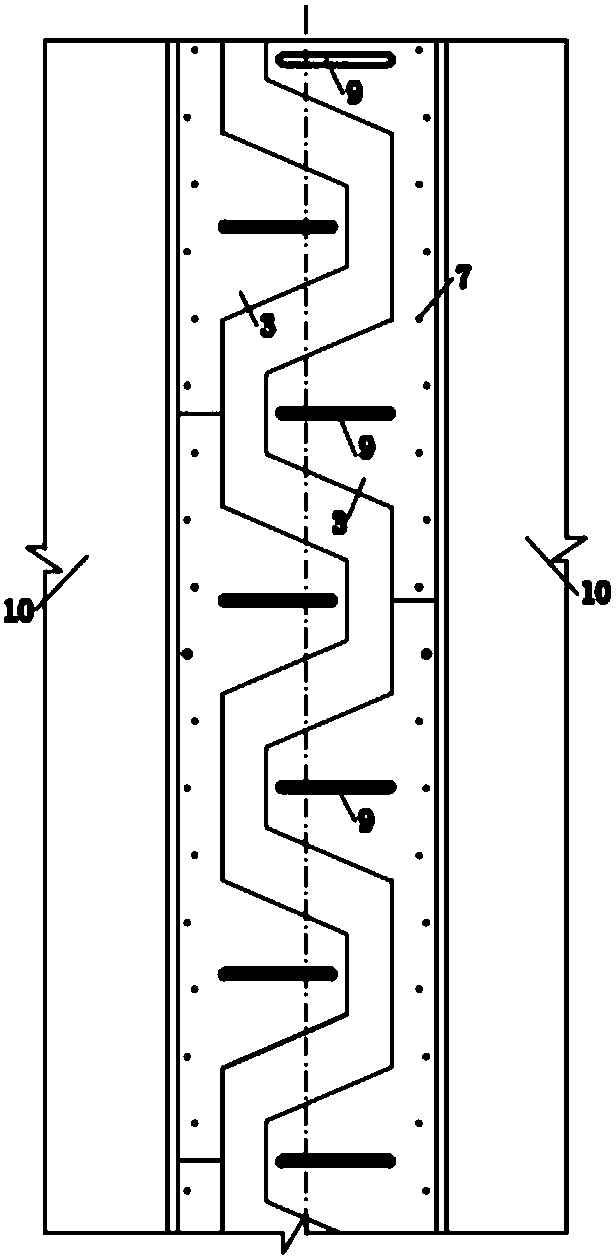

Hot in-place recycling ultrathin overlaying machine of bituminous pavement and construction method thereof

InactiveCN102011362ARestoration of slip resistanceGood lookingIn situ pavingsRoads maintainenceTraffic noiseScreed

The invention provides a hot in-place recycling ultrathin overlaying machine of a bituminous pavement and a construction method thereof. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement comprises an automobile chassis, an integral power device, an electric control system, a diesel tank, a receiving and transporting device, a material transfer hopper, a horizontal transporting device, a heating device, a hydraulic system, a recycling agent spraying system, a harrowing device, a distributing spiral device, a paving screed device, a cab, and an electric control operating floor, wherein the automobile chassis is a special automobile chassis. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement finishes the continuous overlay repair work of the pavement through a series of processes such as receiving the materials, feeding the materials quantitatively, transporting the materials horizontally, spraying the recycling agent, harrowing, heating, distributing and paving the materials, ironing, and grinding and the like, and has the advantage of carrying out one-time maintenance on the defects such as loose, shallow vertical and horizontal cracks, track, slight crack, bituminous aging, pavement seepage and the like of a functional layer of the pavement. By adopting the invention, the antiskid resistance of the pavement is restored, the profile of the pavement is corrected, the appearance and the evenness of the pavement are improved, the pavement strength of the pavement is increased, the traffic noise is reduced, and the service life of the pavement is prolonged.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

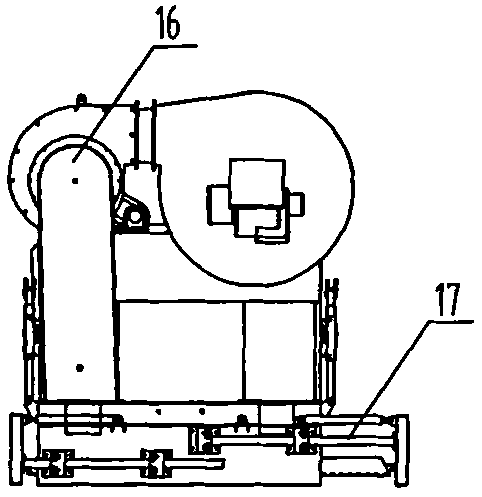

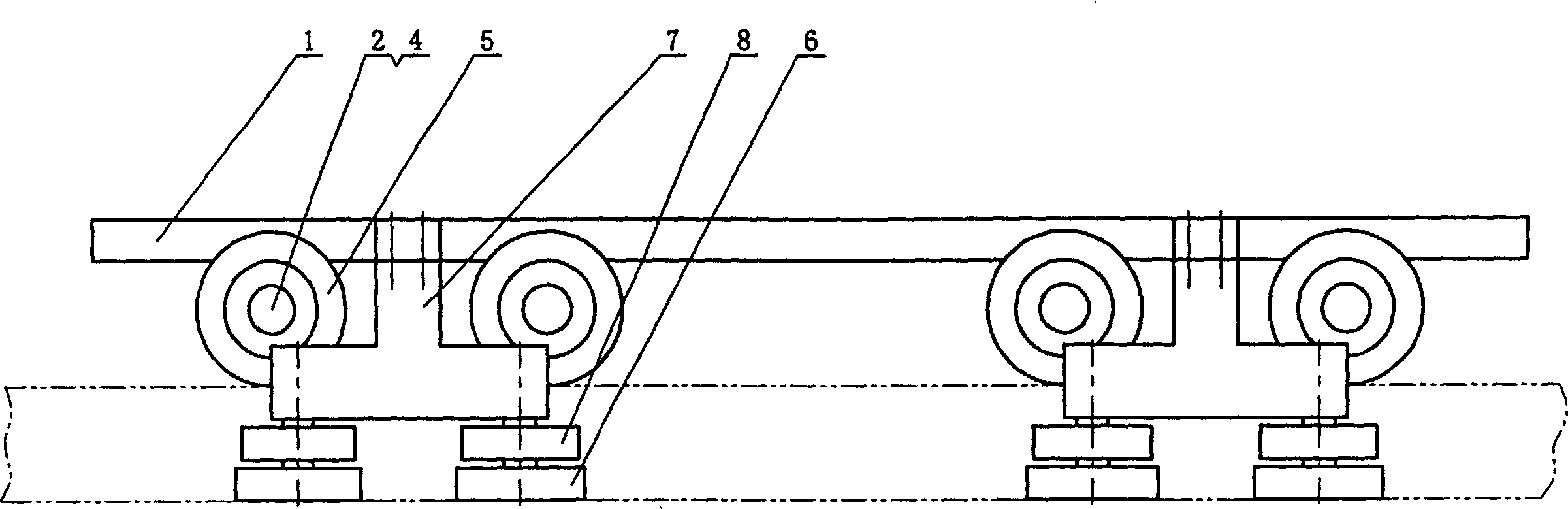

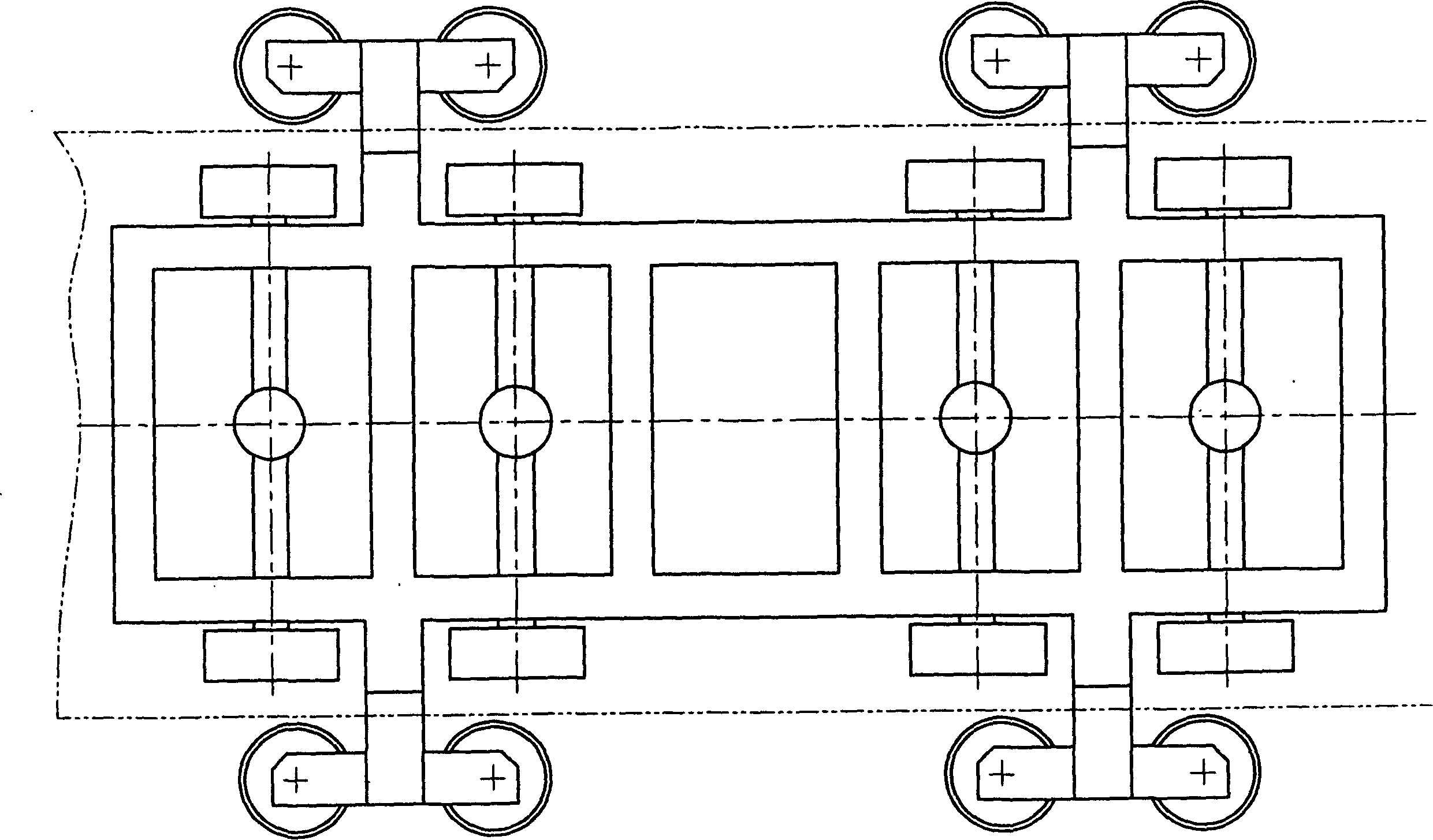

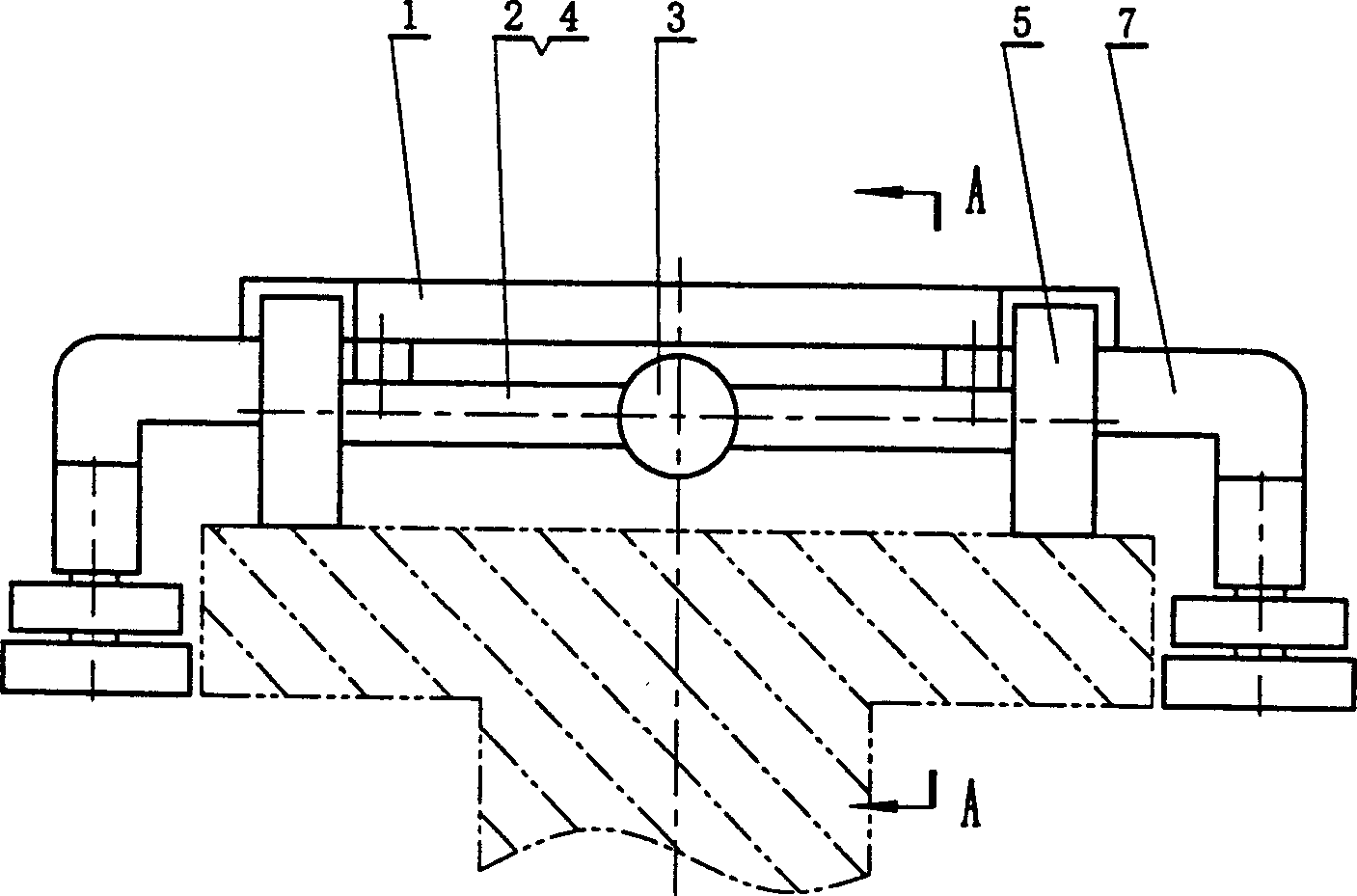

Magnetic suspension rail inspection vehicle chassis with guide wheel system

InactiveCN1544278APrevent slippingIncrease frictionRailway inspection trolleysRail inspectionEngineering

The invention is a chassis of magnetic suspension test vehicle with guide wheel system, including: underframe, vehicle driving bridge, gear differential, semishaft, rubber tyre wheel, rubber tyre guide wheels, and guide wheel frame. There are several vehicle bridges parallelly fixed on the underframe, and the middle and inside of the underframe are set with the gear differential and the semishaft, respectively, and the rubber tyre wheel are set at tow ends of the underframe, the rubber tyer guide wheels are set on the wheel shafts at two ends of the guide wheel frame and can freely rotate, many groups of guide wheel frames are allocated vertically and symmetrically along the underframe and fixed at the bottom of the two opposite sides of the underframe, the axis of the rubber tyre guide wheel is vertical to that of the rubber tyre wheel, the distance between the flanges of the corresponding guide wheels on two side of the underframe is greater than the width of the guide surface of the guide rail, and thus the flanges provide side location support and guide for the test vehicle safely running on the magnetic suspension railway beams along the railway. It has reasonable structure, smooth running and good guiding performance, and low running noise.

Owner:TONGJI UNIV +1

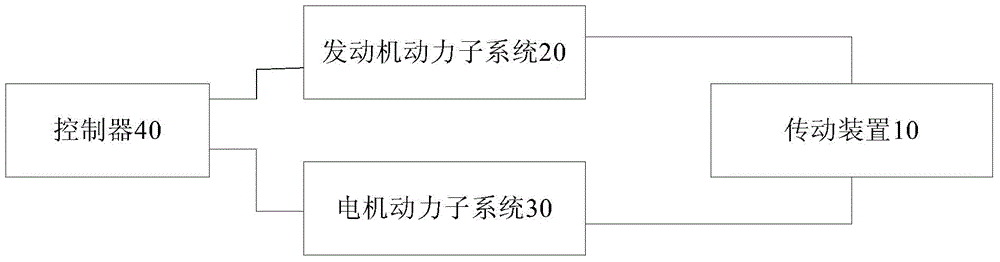

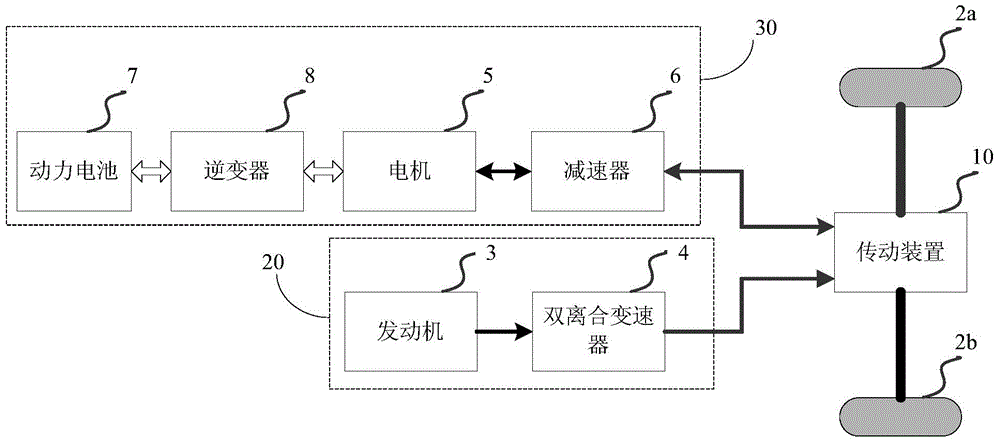

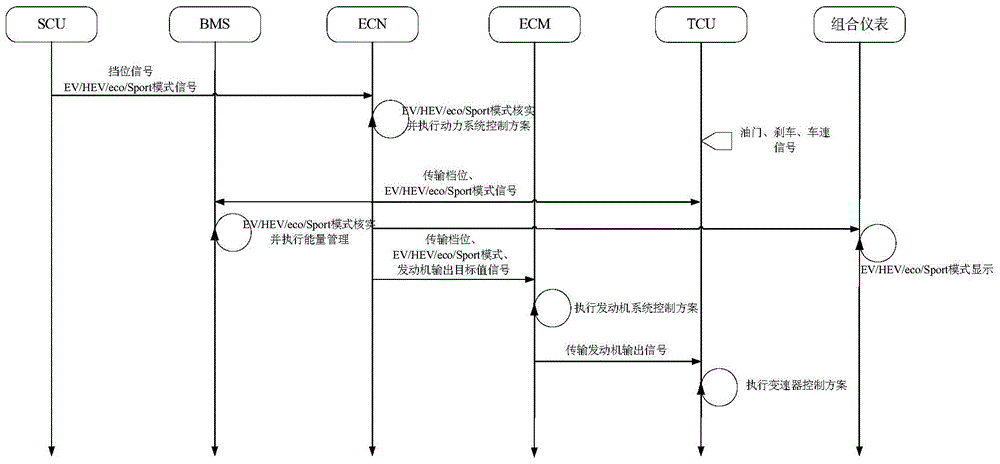

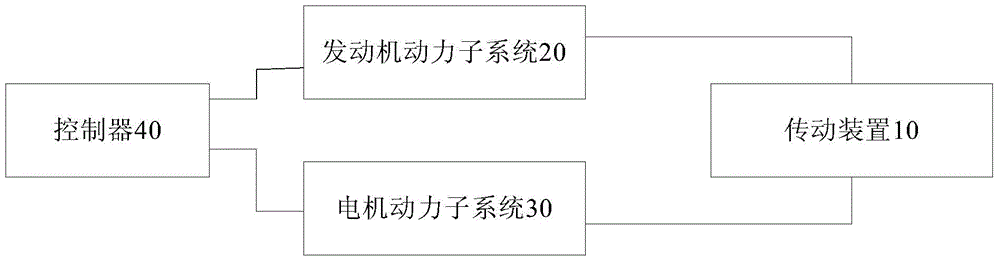

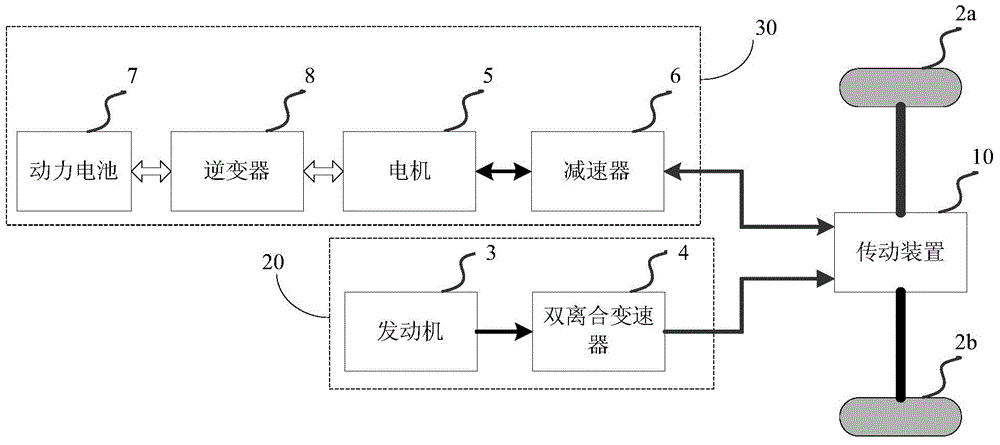

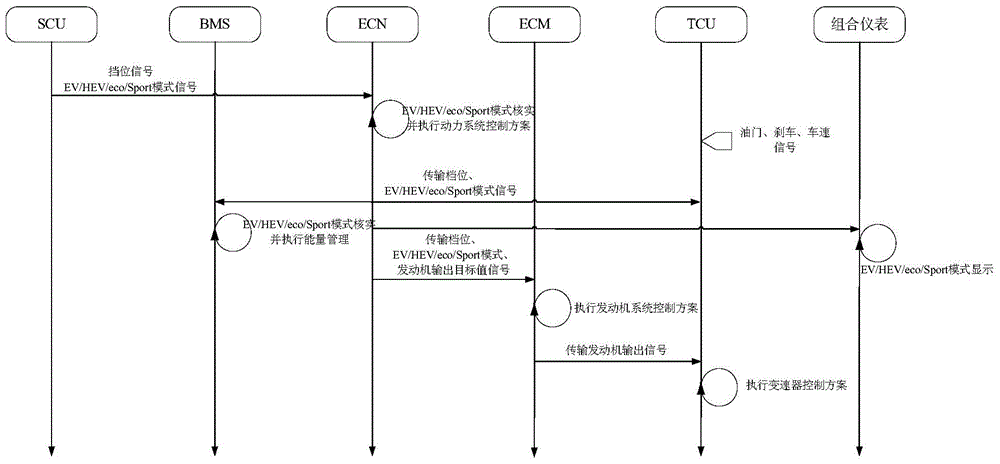

Control system and control method of hybrid electrical vehicle (HEV)

ActiveCN104417544AMeet only electricity needsMeet power needsHybrid vehiclesInternal combustion piston enginesPower modePower battery

A hybrid electrical vehicle (HEV) control system and method, the control system comprising a transmission device (10), an engine power subsystem (20), a motor power subsystem (30) and a controller (40); the controller (40) enables the HEV to enter a hybrid power economical mode by controlling the engine power subsystem (20) and the motor power subsystem (30); if a detected current gradient signal is below or equal to a gradient lower threshold, and the SOC of a power battery (7) is below or equal to a first electric quantity threshold, or if the current gradient signal is below or equal to the gradient lower threshold, and the maximum allowable discharge power of the power battery (7) is below or equal to a first power threshold, then the controller (40) controls the HEV to operate in a low-power mode. In a parallel connection, the control system enables easy power matching, and provides high conversion efficiency and a high starting point of an engine, effectively reducing fuel consumption and emissions, reducing frequent engine start and stop, thus extending the service life of a starter, reducing noise during vehicle travel, and improving driving comfort.

Owner:BYD CO LTD

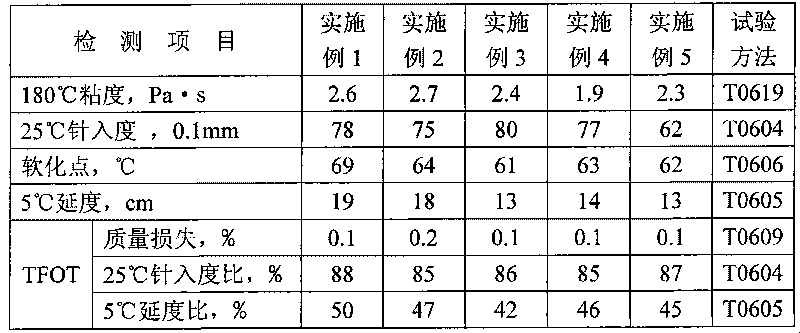

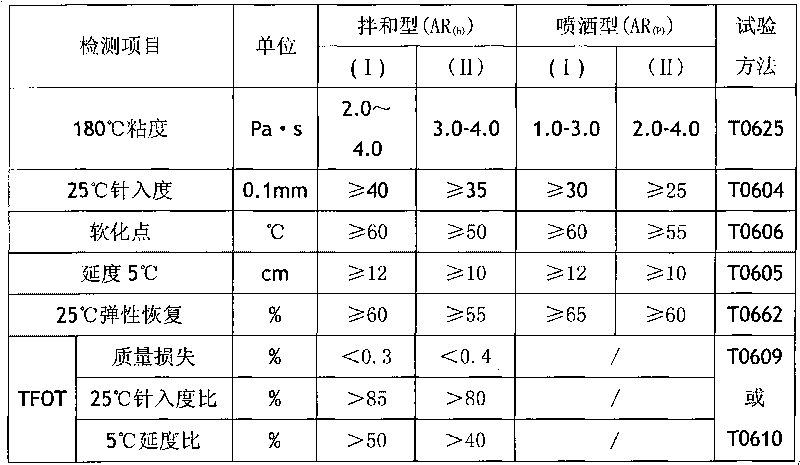

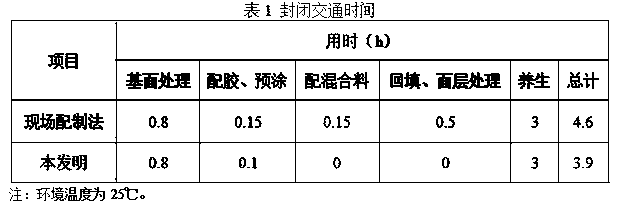

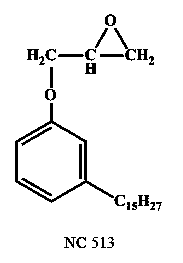

Concentrated composition of waste rubber composite modified pitch and preparation and use method

InactiveCN101717586AImprove flexibilityReduce driving noiseBuilding insulationsWaste tiresPolyolefin

The invention belongs to the technical field of road engineering materials, in particular to a concentrated composition of waste rubber composite modified pitch and a preparation and use method. The concentrated composition is prepared from waste tire rubber powder, petroleum pitch, natural pitch, synthetic tuber, polyolefin, a swelling agent and an aid by preparing procedures. When in use, a product can be proportionally mixed with substrate pitch on a construction site to prepare waste rubber composite modified pitch for spraying construction or be mixed and stirred with the substrate pitch at a pitch mixture stirring station into a rubber pitch mixture for paving construction.

Owner:CHANGAN UNIV

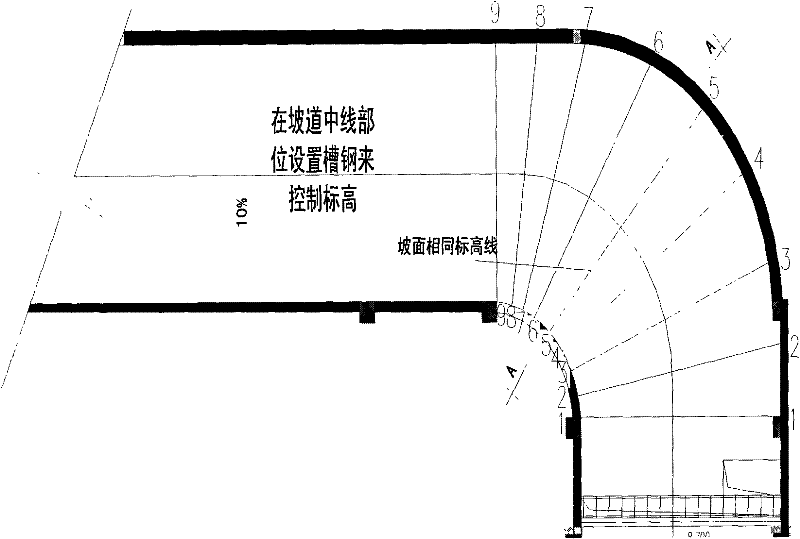

Construction method of wear-resistant non-slip ramp

InactiveCN101914886AStrong orientationReduce driving noiseIn situ pavingsClimate change adaptationWeather resistanceWear resistant

The invention discloses a construction method of a wear-resistant non-slip ramp, which comprises the following steps: clearing a concrete base, coating a base finishing agent, constructing a base coat, painting a high-strength putty layer, constructing wear-resistant non-slip size, processing a closing cover layer, constructing polished surface coating and maintaining. The ramp prepared by the invention has simple structure, convenient construction, low cost, slip prevention, wear resistance, pressure resistance, impact resistance, oil stain resistance and weather resistance.

Owner:LONGXIN CONSTR GRP

Control system and control method of hybrid electrical vehicle (HEV)

ActiveCN104417345AMeet only electricity needsMeet power needsHybrid vehiclesInternal combustion piston enginesPower batteryElectrical battery

A hybrid electrical vehicle (HEV) control system and control method, the control system comprising a transmission device (10), an engine power subsystem (20), a motor power subsystem (30) and a controller (40); the controller (40) enables the HEV to enter a corresponding working mode by controlling the engine power subsystem (20) and the motor power subsystem (30). Upon reception of a switching instruction to switch to an electrical vehicle (EV) economical mode, if the controller (40) determines that the SOC of a power battery is greater than equal to a second electric quantity threshold, and the speed of the HEV is lower than or equal to a first speed threshold, the controller (40) then causes the HEV to switch from a hybrid power economical mode to the EV economical mode. Being connected in parallel, the engine power subsystem (20) and the motor power subsystem (30) in the control system of the HEV enable easy power matching, provide high conversion efficiency, reduce fuel consumption and emissions, and frequent engine start and stop, thus extending starter service life, reducing noise during vehicle travel, and improving driving comfort.

Owner:BYD CO LTD

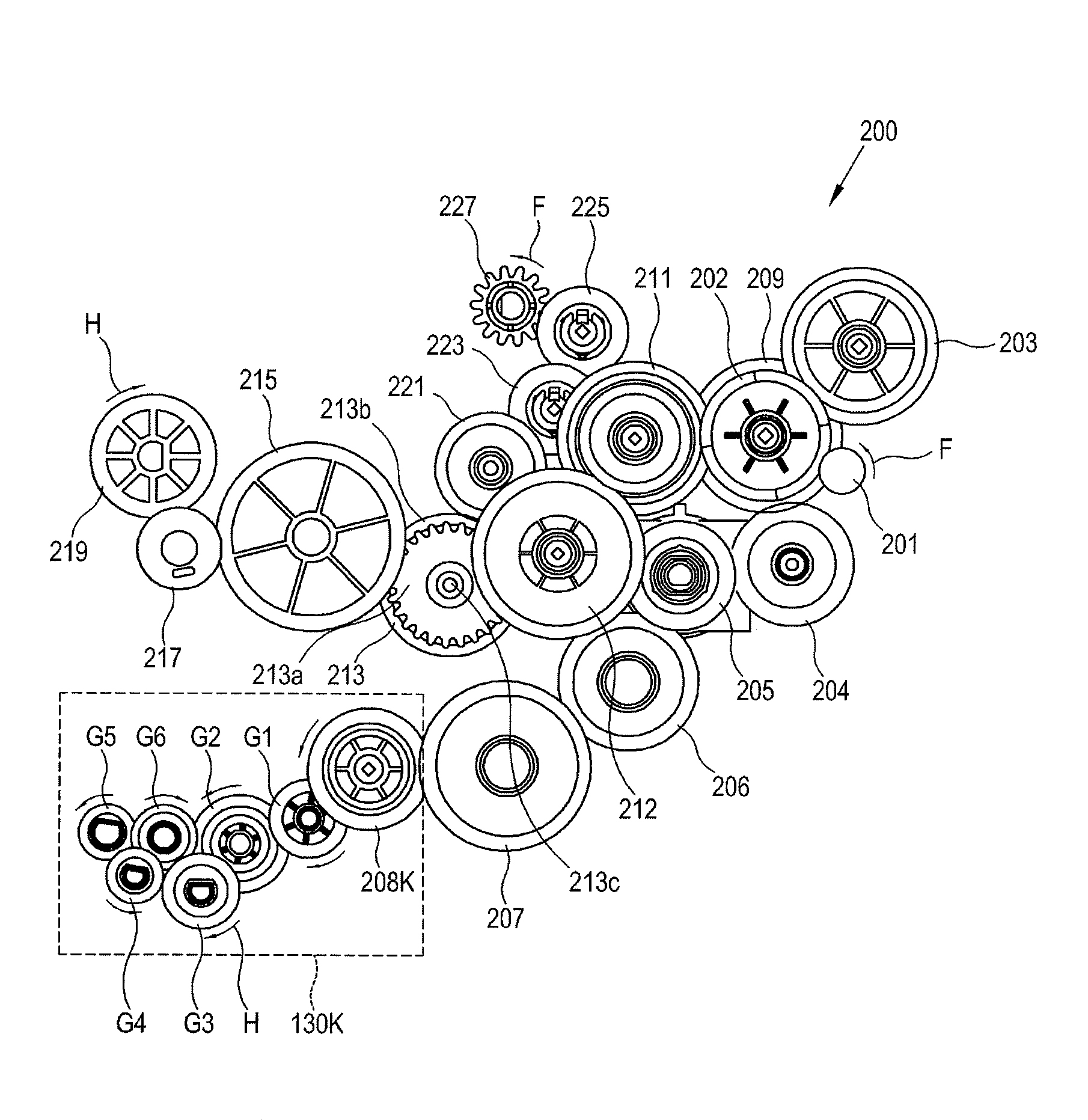

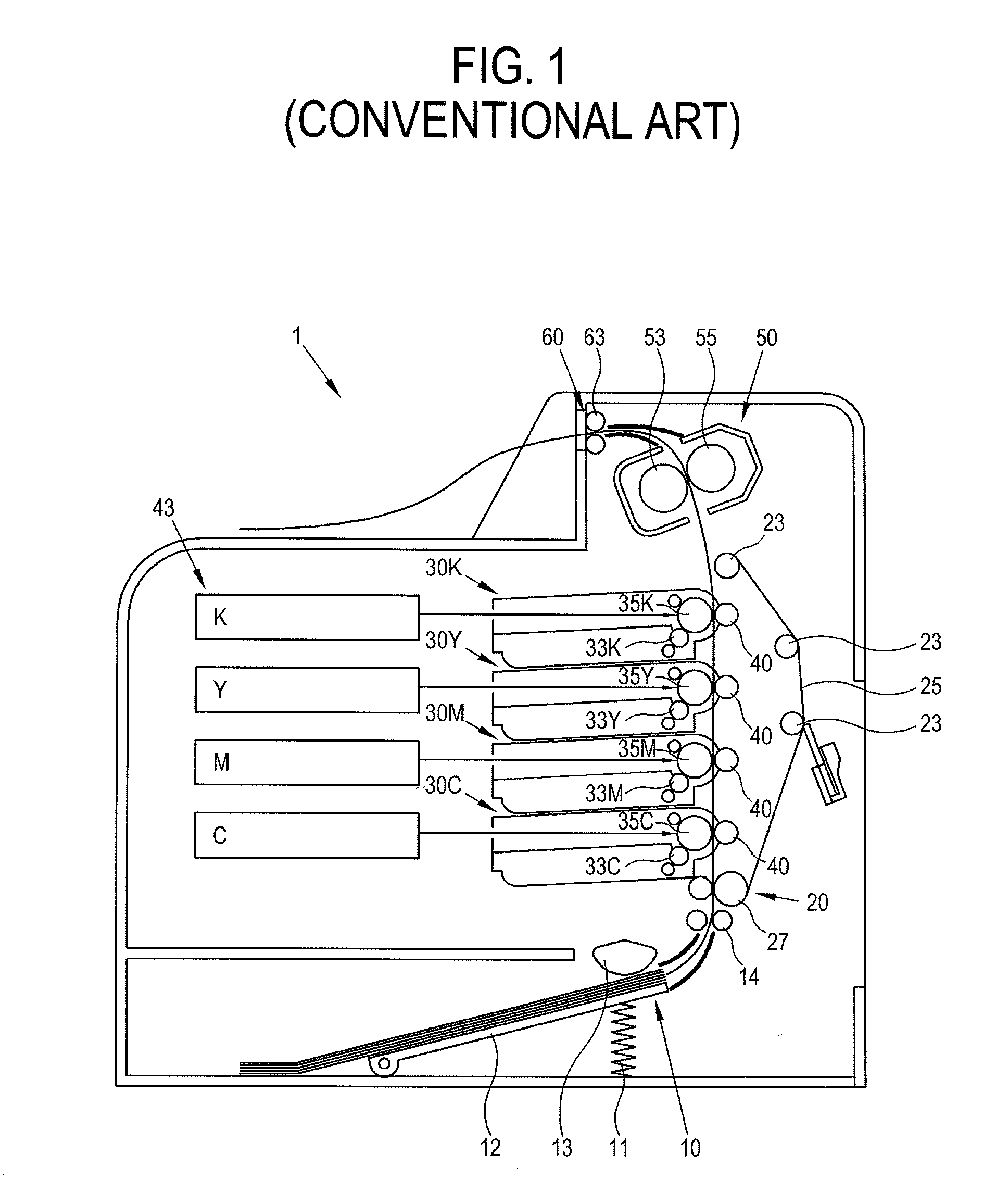

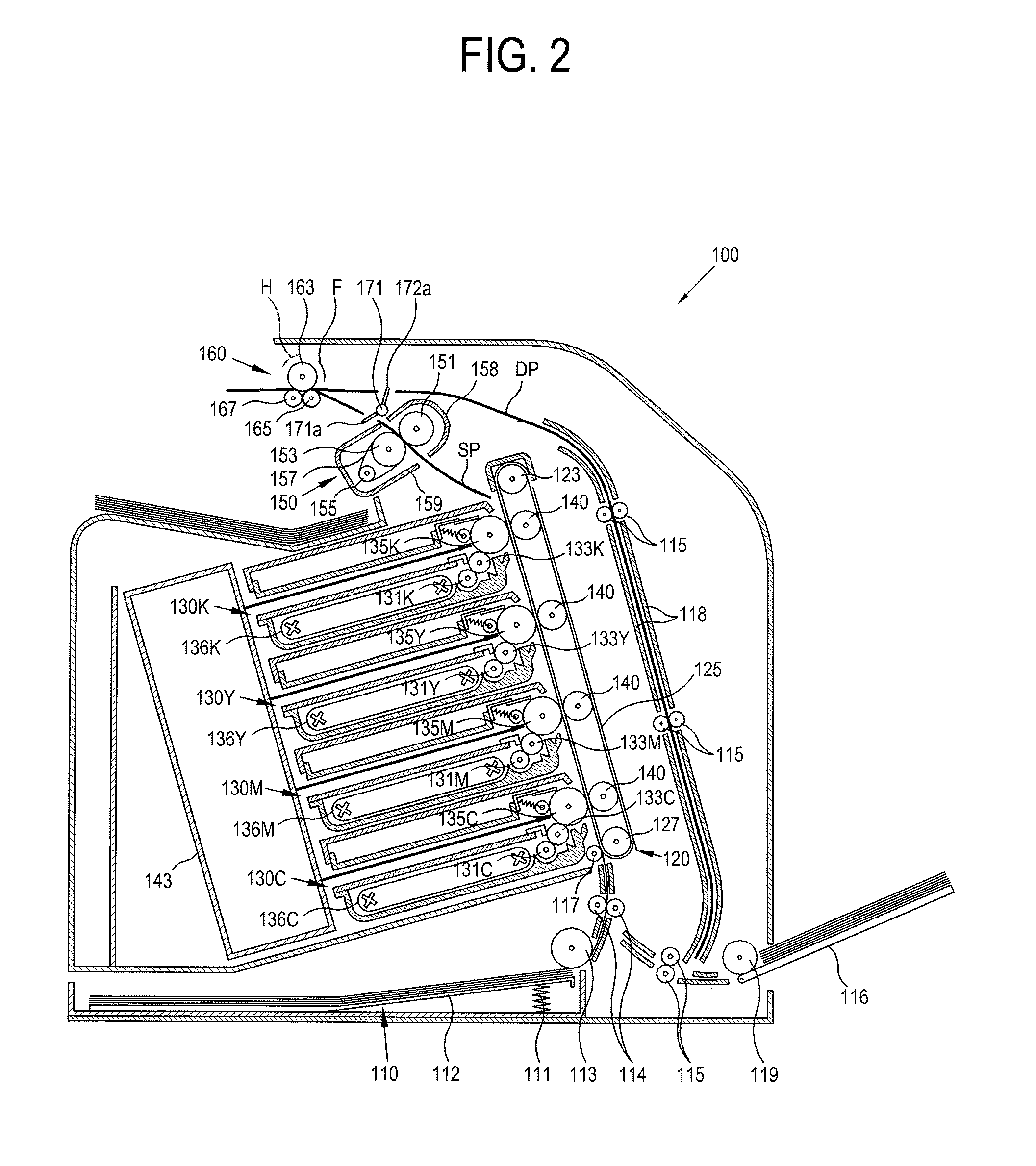

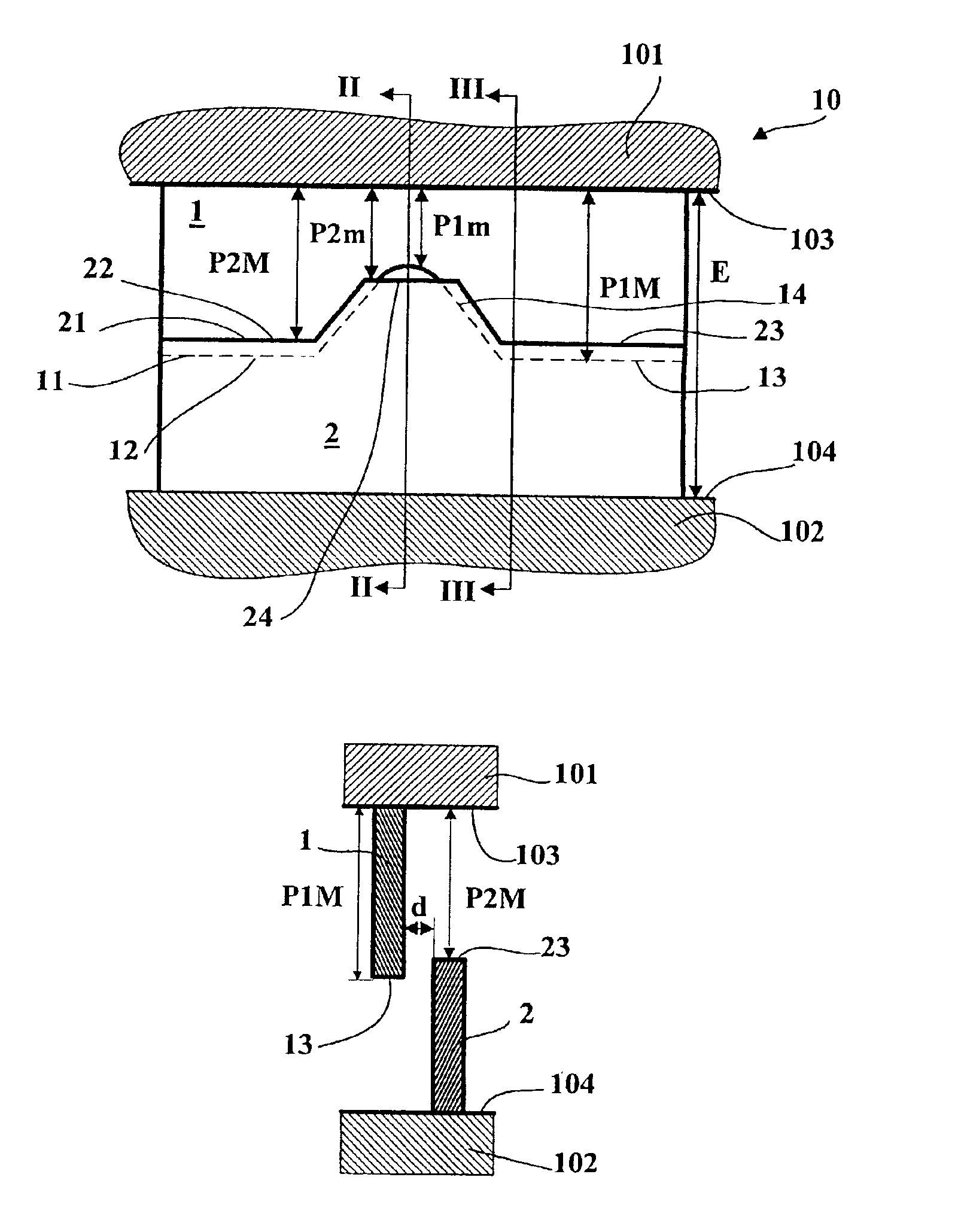

Image forming apparatus having controller to selectively control plurality of driving sources

ActiveUS20080118274A1Simple structureReduce driving noiseElectrographic process apparatusEngineeringElectrical and Electronics engineering

An image forming apparatus includes a developing unit to form an image using a developing agent on one side of a printing medium transported along a simplex printing path, a fixing unit to fix the developing agent on the printing medium, a discharging roller to discharge the printing medium that passes the fixing unit, and a first driving source to drive the developing unit, the fixing unit and the discharging roller.

Owner:HEWLETT PACKARD DEV CO LP

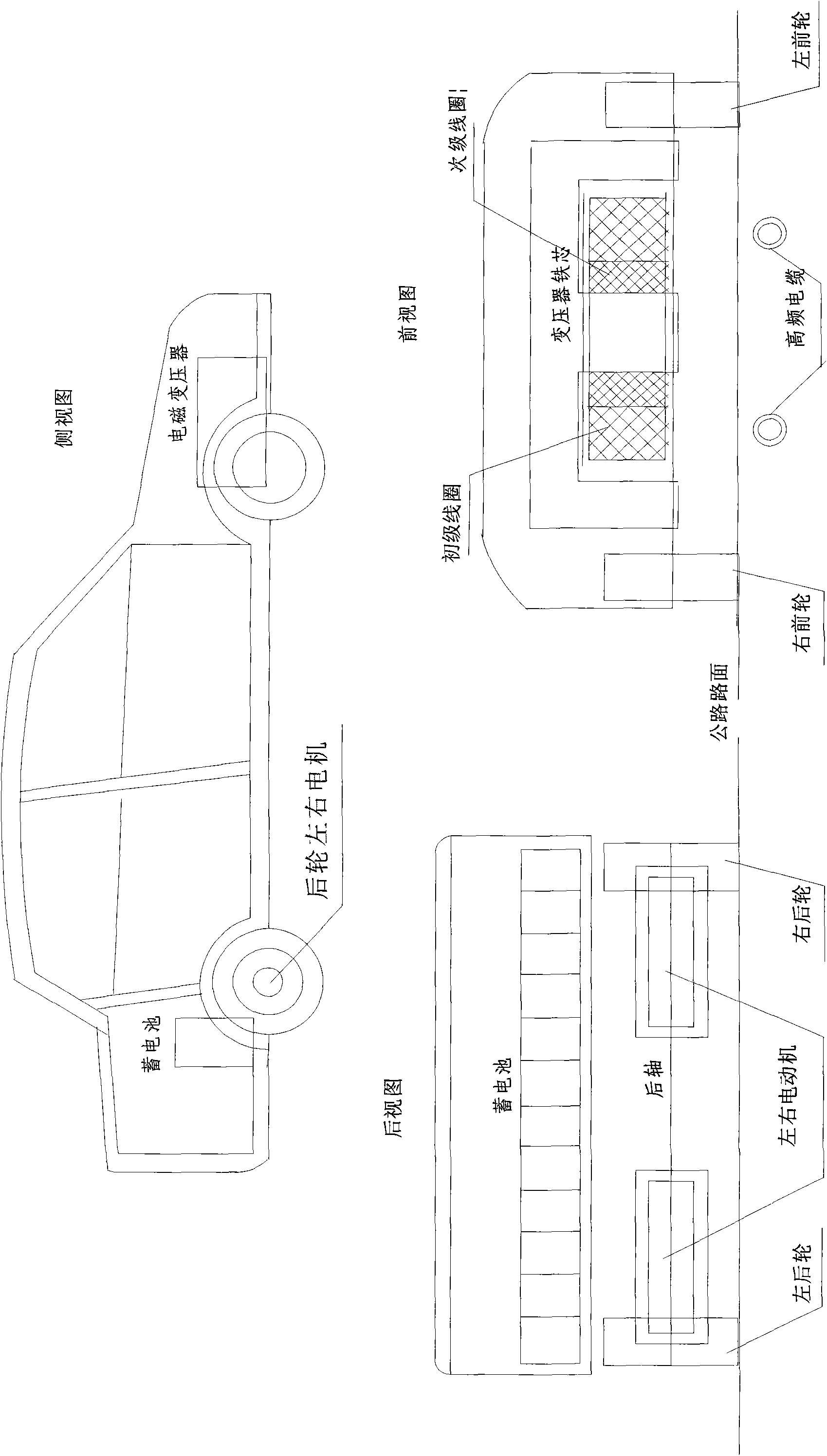

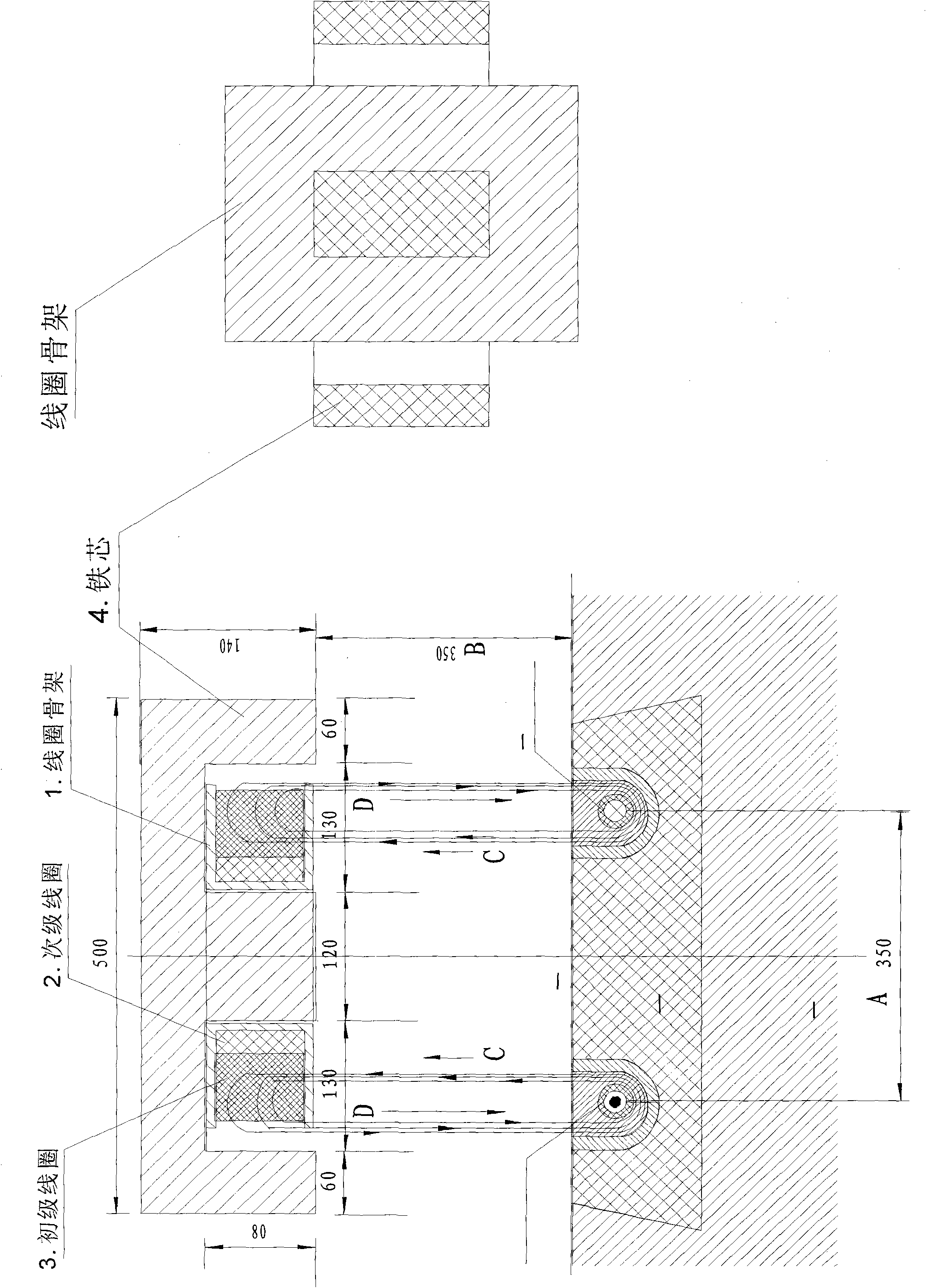

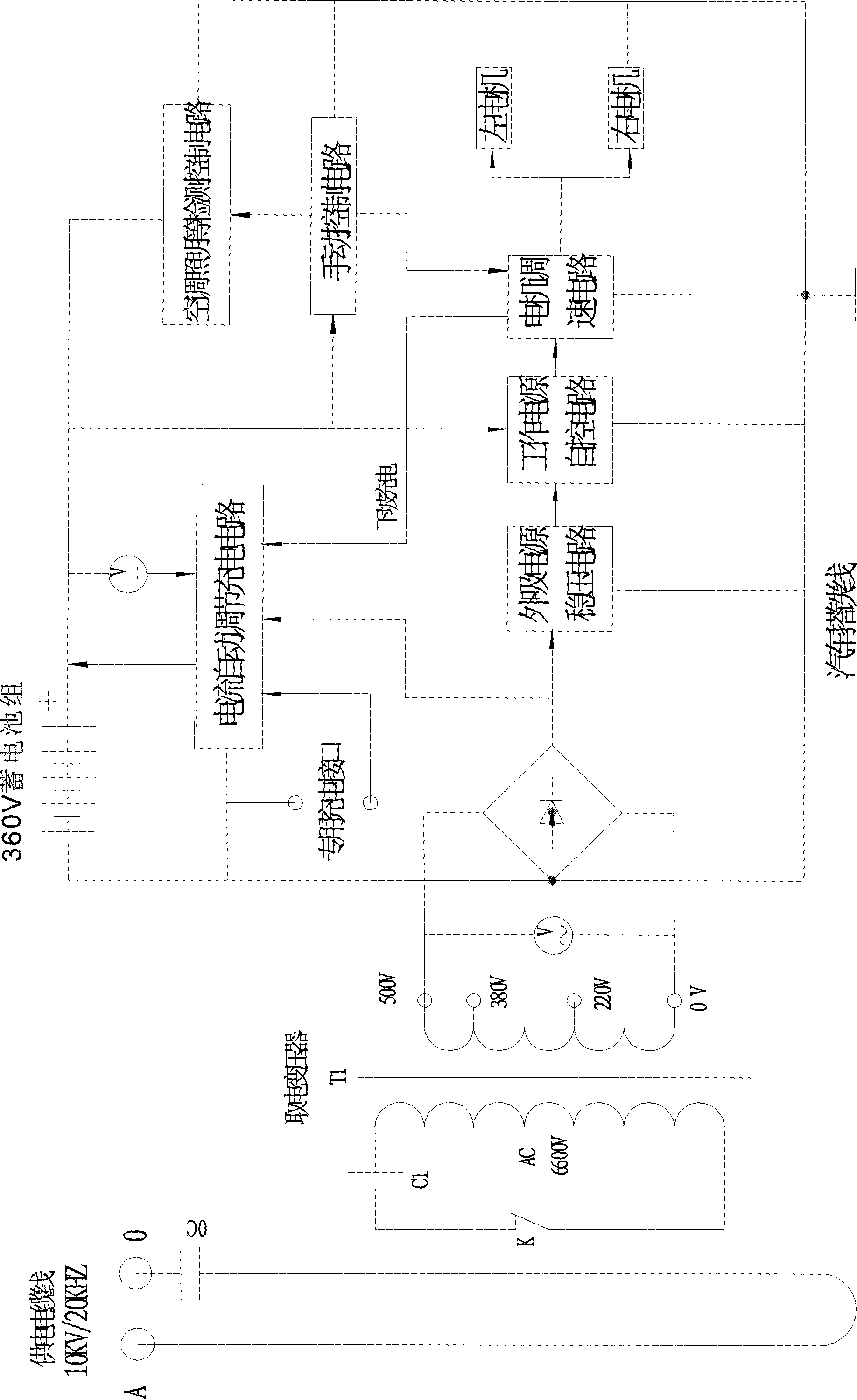

Wireless electricity-taking car and road contactless power supply system

InactiveCN101917071APowerful vertical high-frequency electromagnetic wavesStrong alternating magnetic fieldBatteries circuit arrangementsElectromagnetic wave systemHigh energyTransformer

The invention relates to a wireless electricity-taking car and a road contactless power supply system in road traffic and transport means. In the invention, a power supply is not directly input through electric wire, while a contactless electromagnetic induction transformer arranged under a chassis of a car head indirectly absorbs electric energy in a special power supply cable embedded on a road and charges a storage battery on the car while driving the car to move. Particularly by adopting electric-magnetic-electric contactless power supply and electricity-taking technologies, a 10kV / 15-40KHz high-frequency and high-voltage cable is embedded on a road surface to generate a high-energy vertical electromagnetic wave and an alternating magnetic field; and the transformer arranged under the car is applied with comprehensive induction of the high-frequency electromagnetic wave and the alternating electromagnetic field when the transformer is close to vertical distance of 150-450mm of the cable to induce resultant current in coils and restore magnetic energy into electric energy, thus providing advancing power for the car and charging the battery on the car, and guaranteeing the car can run for longer distance with sufficient electricity after leaving the power supply road. The technology of the invention thoroughly solves the difficult problems of limited energy storage and troublesome charging of the storage battery of the existing similar cars, and explores a new way for energy conservation and emission reduction of the cars.

Owner:王瑜

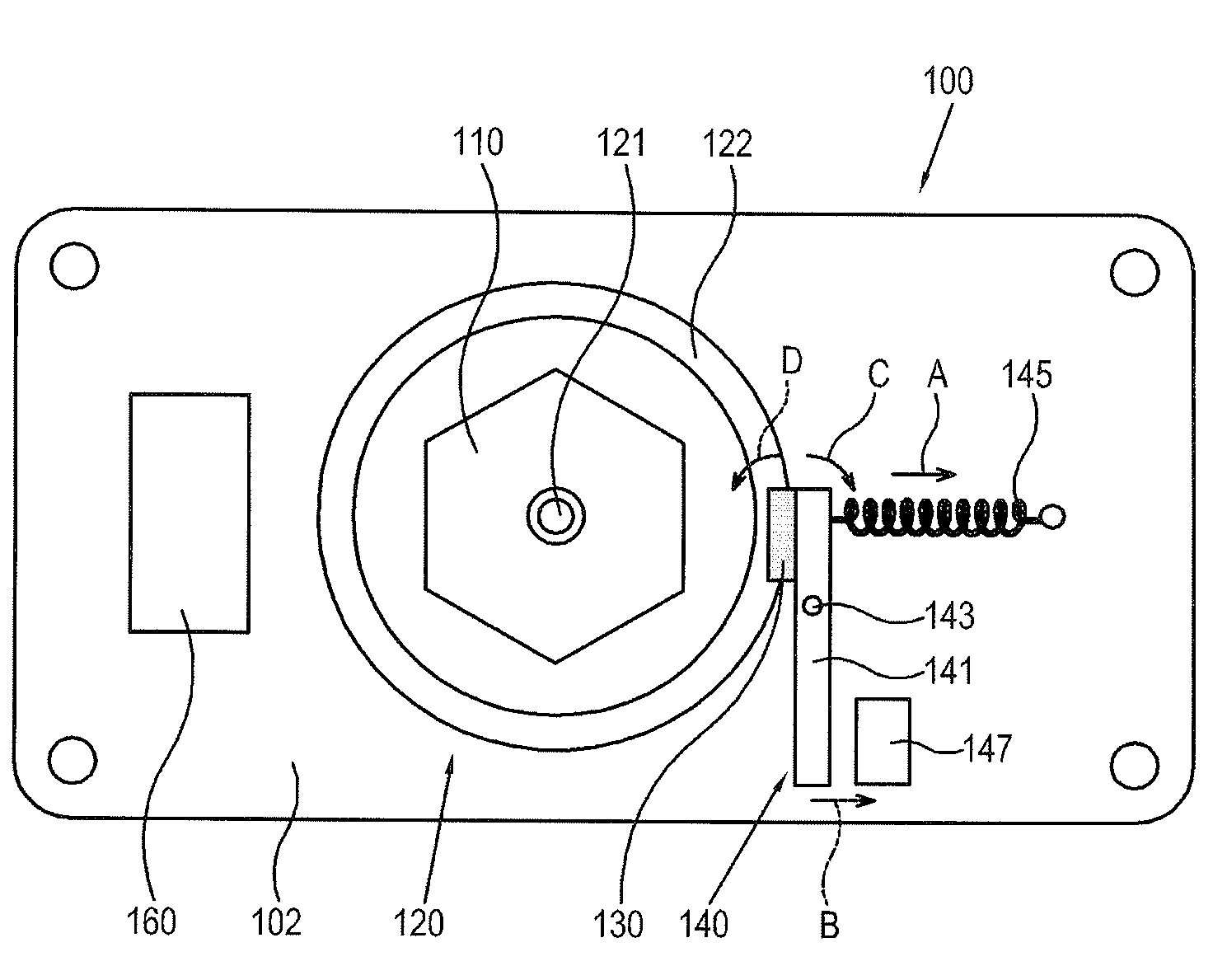

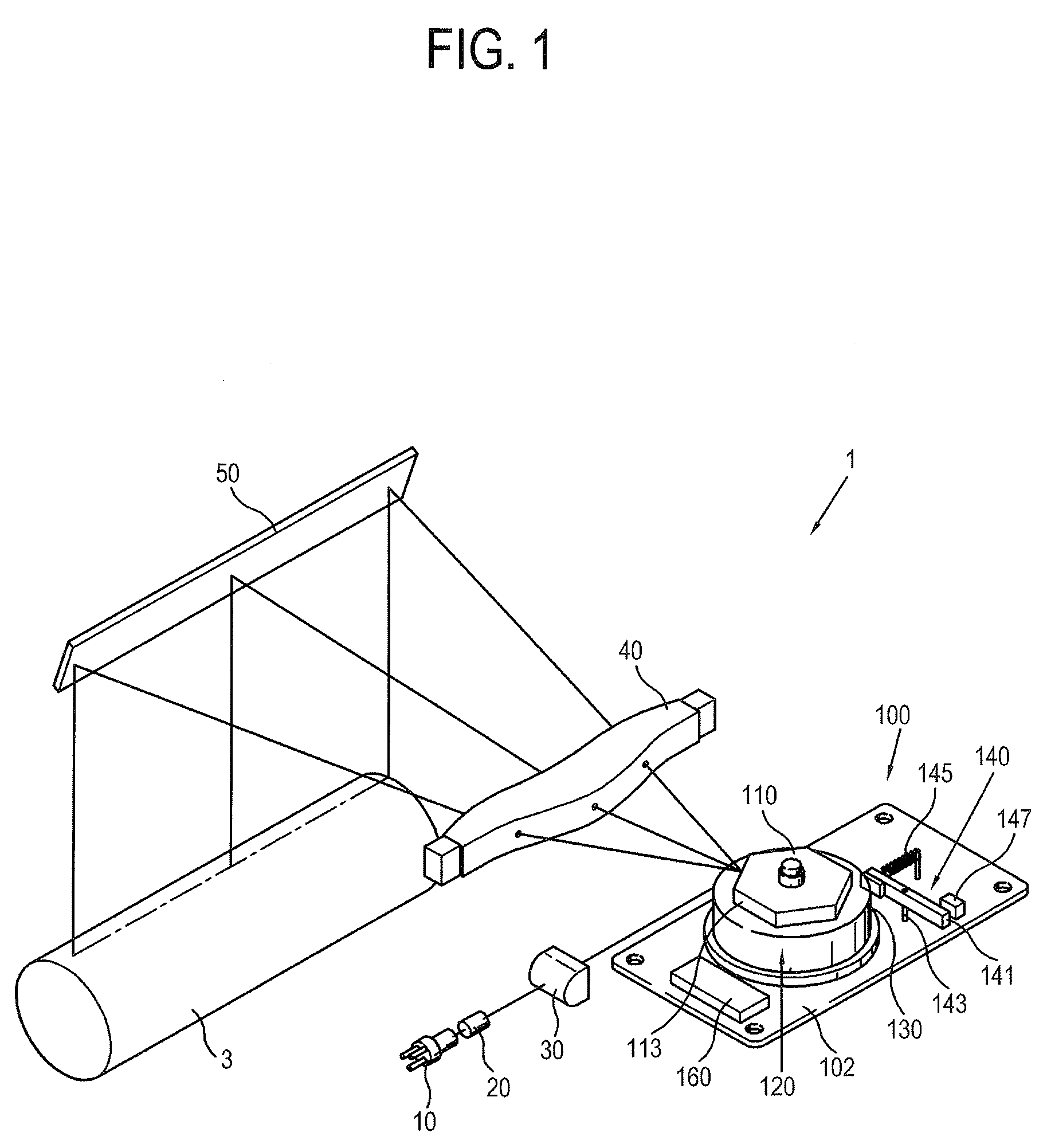

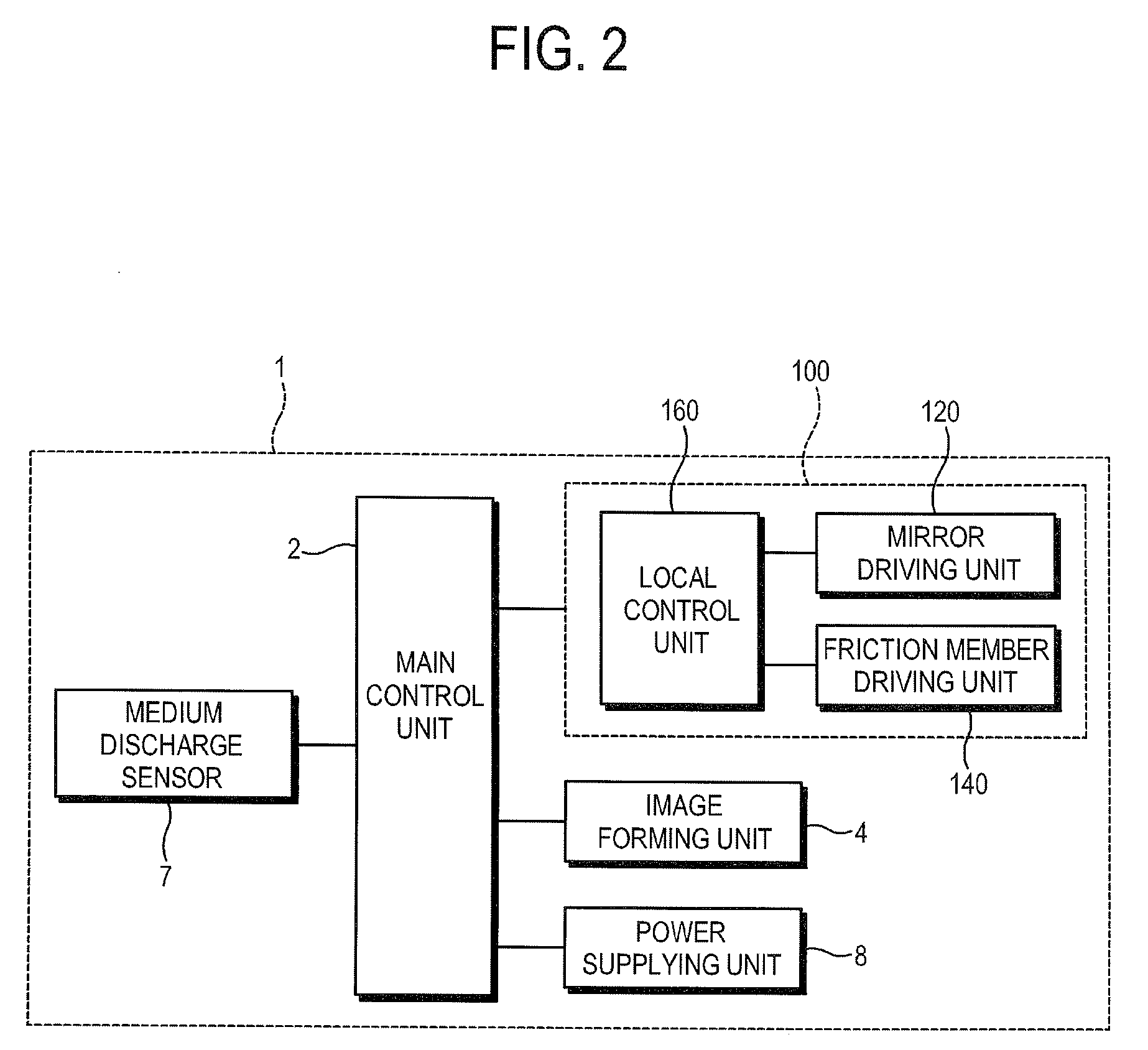

Beam deflector, light scanning unit and image forming apparatus having the same

InactiveUS20090028603A1Reduce driving noiseInking apparatusElectrographic process apparatusOptical beam deflectionLight beam

A beam deflector having a base, the beam deflector including a polygon mirror to reflect a light beam, a mirror driving unit including a rotor shaft erected from the base and a rotor to support the polygon mirror and to rotate about the rotor shaft, a friction member to contact with and be separated from the rotor so as to obstruct and release rotation of the rotor, respectively, and a friction member driving unit to drive the friction member.

Owner:S PRINTING SOLUTION CO LTD

Compressional deformation strengthened flexible hollow half axle and fabrication process thereof

InactiveCN101348055AReduce driving noiseReduce vibrationAxle unitsManufacturing technologyMetallic materials

The invention belongs to the field of automobile manufacturing, relating to a jackshaft part in an automobile power transmission system and the manufacturing technology thereof. The process adopts hyposteel bars of normalized condition as the raw stock, and heats the bar raw stock to 900 DEG C for extrusion molding. The entire extrusion molding process comprises the following extrusion technology: forward extrusion molding technology, overall backward extrusion molding technology, long-hole extrusion molding technology, drawing-down extrusion molding technology and diameter extension extrusion technology; wherein, the number of the working steps of the extrusion technique required in the extrusion molding procedures of the jackshaft parts with different structures and dimensions is different; the temperature of the metal material reduces from 900 DEG C to 100 DEG C; the extrusion workpiece, the shape and dimension of which is similar to that of jackshaft part finished product, is obtained, and the part is manufactured after mechanical cutting processing procedure, alignment and inspection procedures. After the entire extrusion molding is finished, the bending strength, shear strength and impact ductility of the extrusion workpiece are superior to the mechanical performance index of a test bar of the same material which is subject to hardening and tempering as well as heat treatment, and the tensile strength is similar to the test bar of the same material which is subject to hardening and tempering as well as heat treatment; the elastic torsion angle of the hollow jackshaft is larger than 120 degrees.

Owner:邓晓光

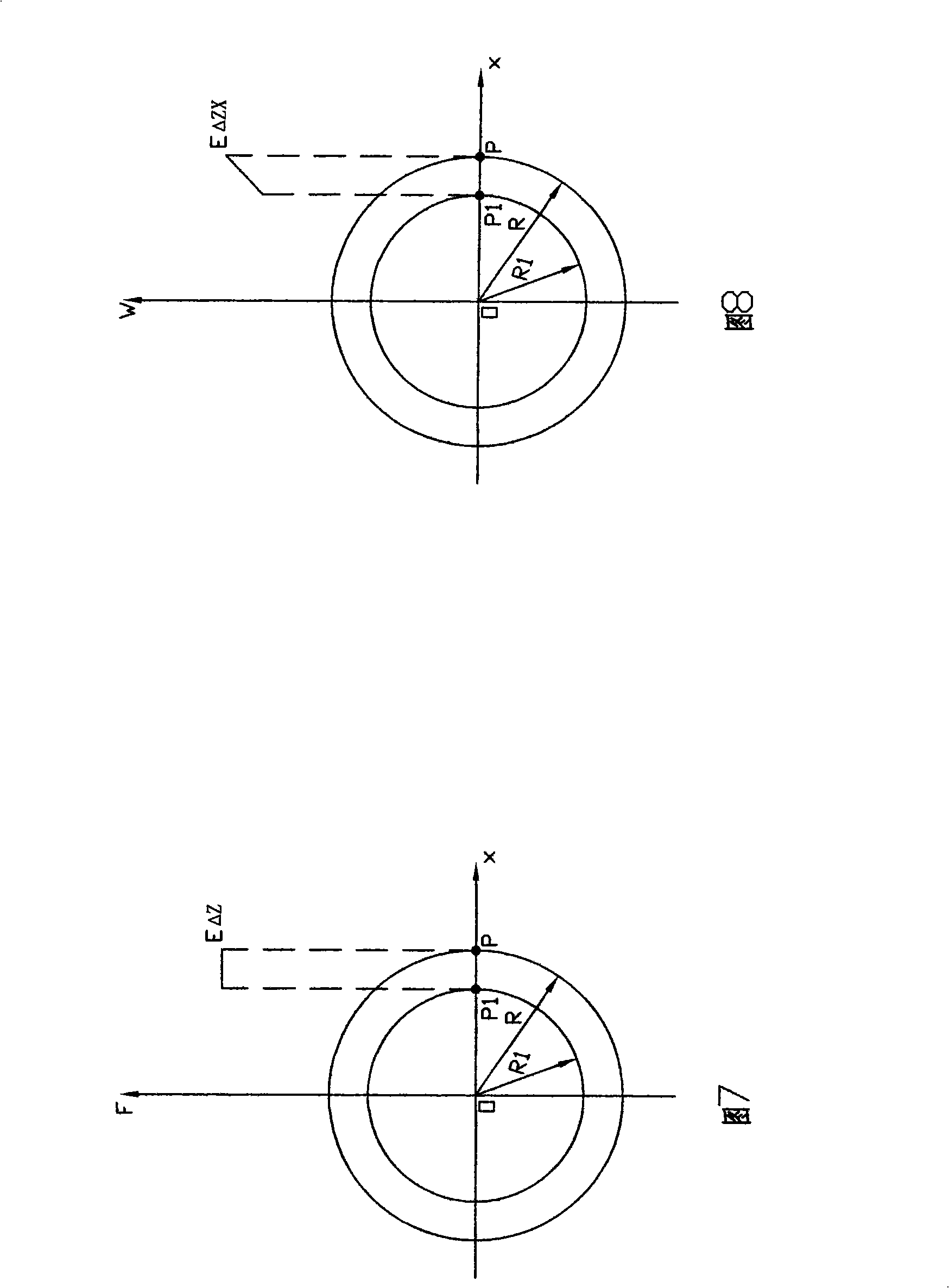

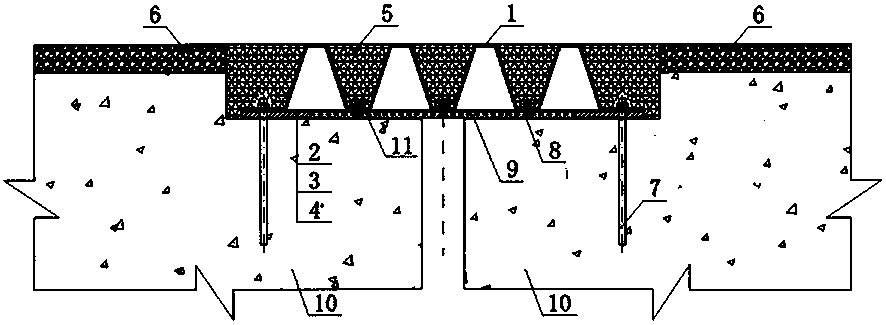

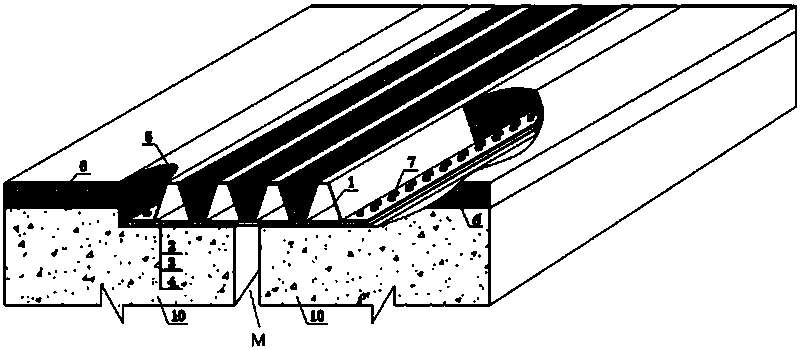

Slipping type seamless telescopic device

InactiveCN104818669AReduce warpingAlleviation deficiencyBridge structural detailsElastomerArchitectural engineering

The invention discloses a slipping type seamless telescopic device. A telescopic seam is arranged between main beams, upper surfaces of the main beams are provided with comb plates, and the comb plate arranged at the upper part of the telescopic seam is a trans-seam comb plate, and a fixing comb plate is connected with the trans-seam comb plate; a top paving layer is arranged at the upper part of the trans-seam comb plate, and both sides of the top paving layer are respectively provided with elastomer prefabricating blocks; left and right sides of the elastomer prefabricating blocks are respectively arranged with bituminous concrete paving layers. The slipping type seamless telescopic device and a bridge face paving layer can be formed to be a continuous body, so as to guarantee stable and comfortable driving; the driving noise is small and waterproof performance is good, and the slipping type seamless telescopic device is convenient to clean and remove snow, and other maintaining works; the structural design is more reasonable, and construction is convenient; the comb plates are respectively arranged beneath the paving layer and above the main beam, and can be fixedly moved; and thereby, the problem of empty lower part of the tooth end of the comb plate is effectively solved, and the shortcoming that the traditional seamless telescopic device is easy to crack is overcame.

Owner:JSTI GRP CO LTD +1

Surface treatment method for achieving low noise and skid resistance of road

InactiveCN106012746AFast constructionGood value for moneyIn situ pavingsPaving detailsLow noiseCrushed stone

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

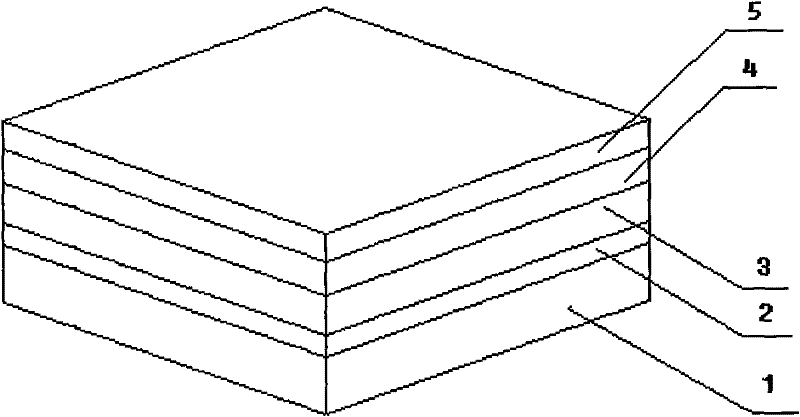

Vibration-free anti-slip lane and construction method thereof

InactiveCN102251455AUniform particlesHigh coefficient of frictionIn situ pavingsPaving detailsPropionateRough surface

The invention discloses a vibration-free anti-slip lane. The lane is characterized by consisting of a concrete ground, a sealing layer, a compressive layer, an anti-slip layer and a surface maintenance layer from bottom to top, wherein the sealing layer is formed by coating a permeable carbonization interface sealant on the concrete ground through a sprayer, and the thickness of the sealing layer is 1 millimeter; the compressive layer is formed by coating macromolecular polymer aggregate and modified resin on the sealing layer through a flat trowel, and the coating thickness is 3.0 millimeters; the anti-slip layer is formed by coating the macromolecular polymer aggregate and the modified resin on the compressive layer in a guniting form, and the coating thickness is 3.0 millimeters; and the surface maintenance layer is formed by coating a vinyl propionate polymer curing agent with thickness of about 0.1 millimeter on the anti-slip layer. The lane has rough surface, uniform granularity and large friction coefficient; when vehicles run on the lane, obvious vibration is not produced, and the vehicles run safely; and the lane is easy for maintenance. The invention also discloses a construction method of the lane.

Owner:ZHEJIANG ZHONGFU CONSTR GRP

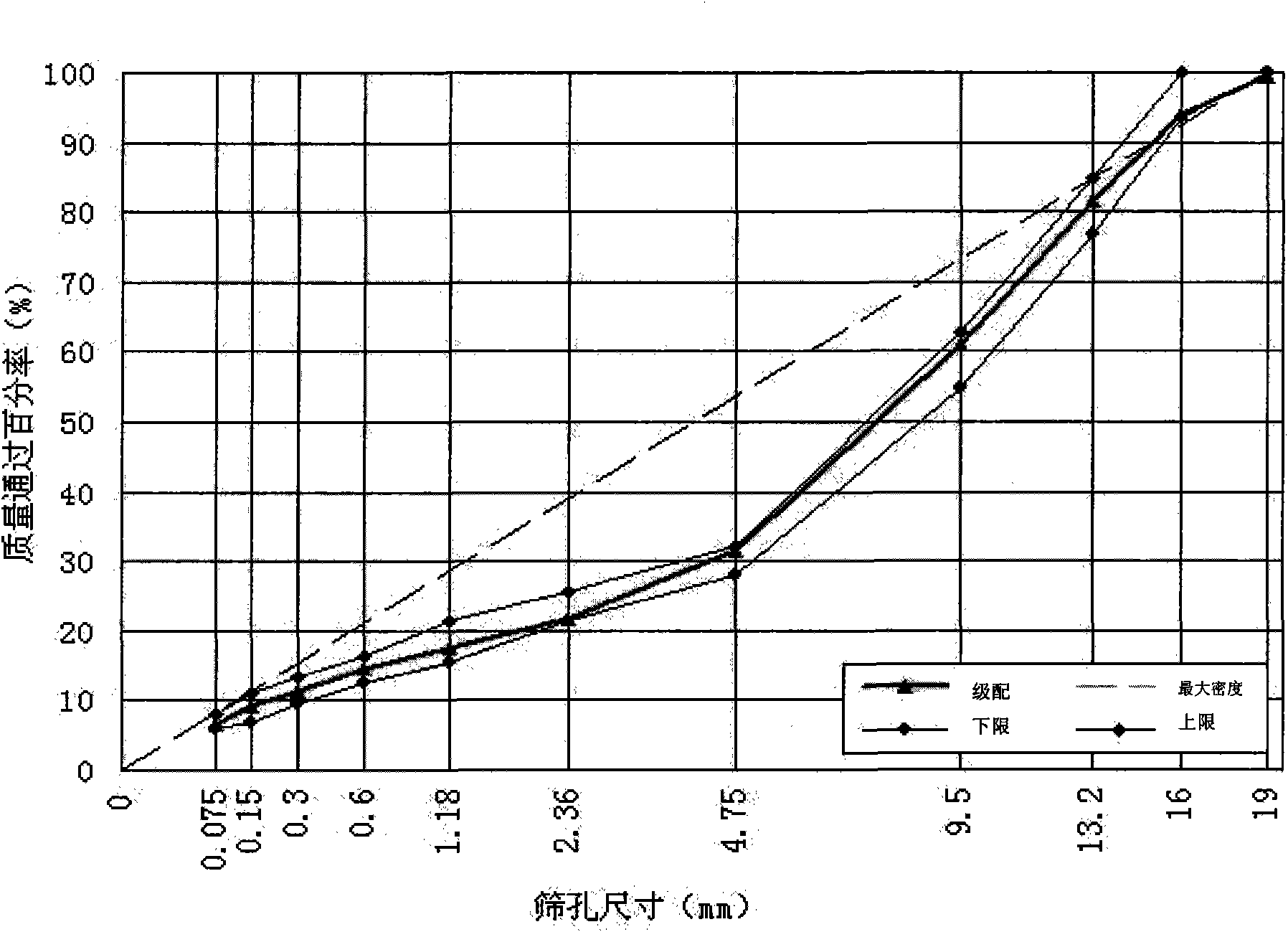

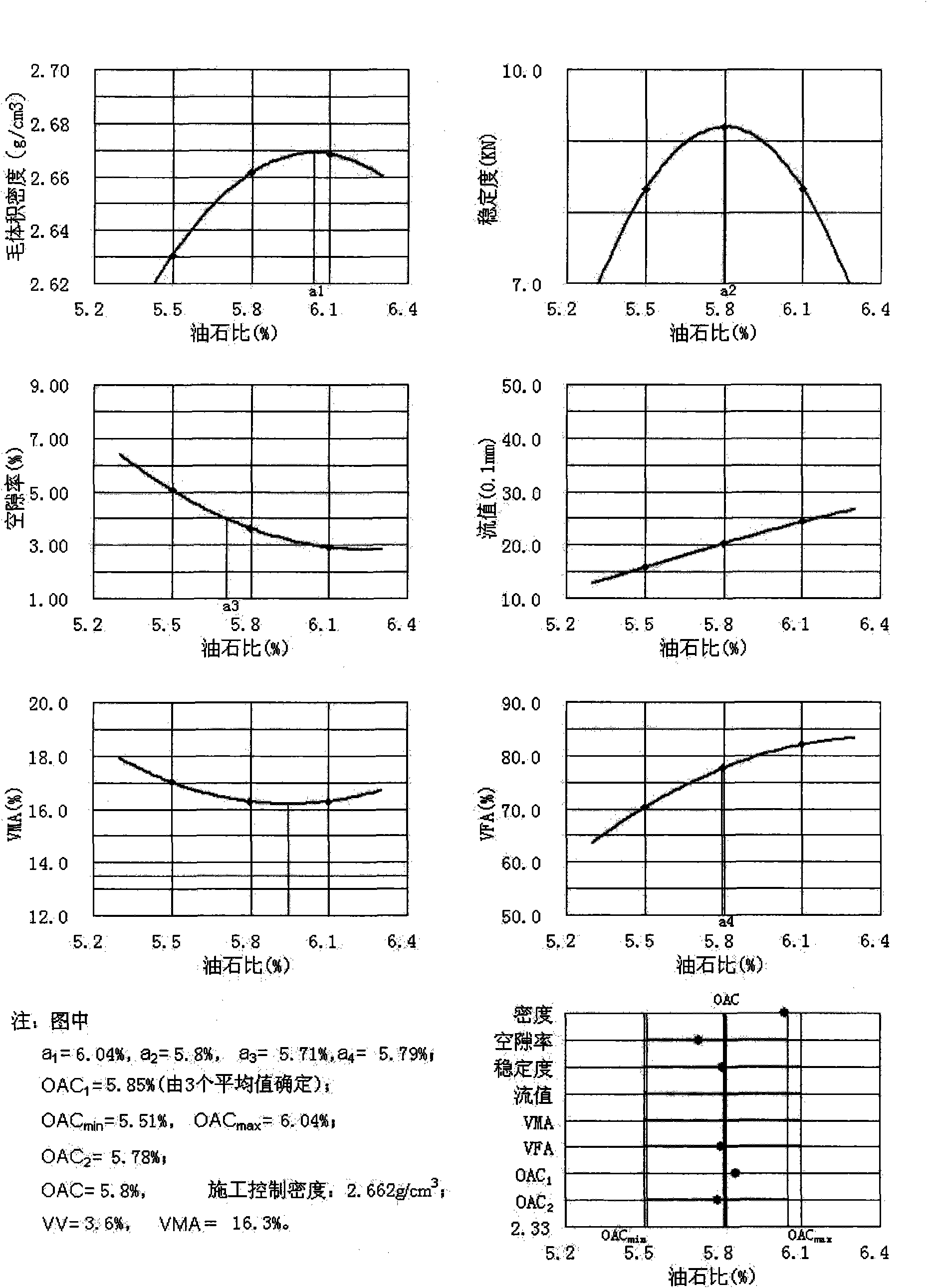

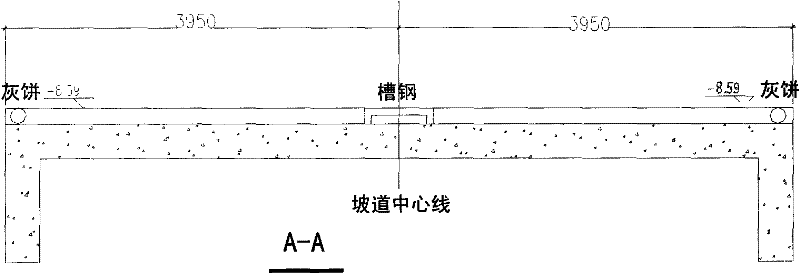

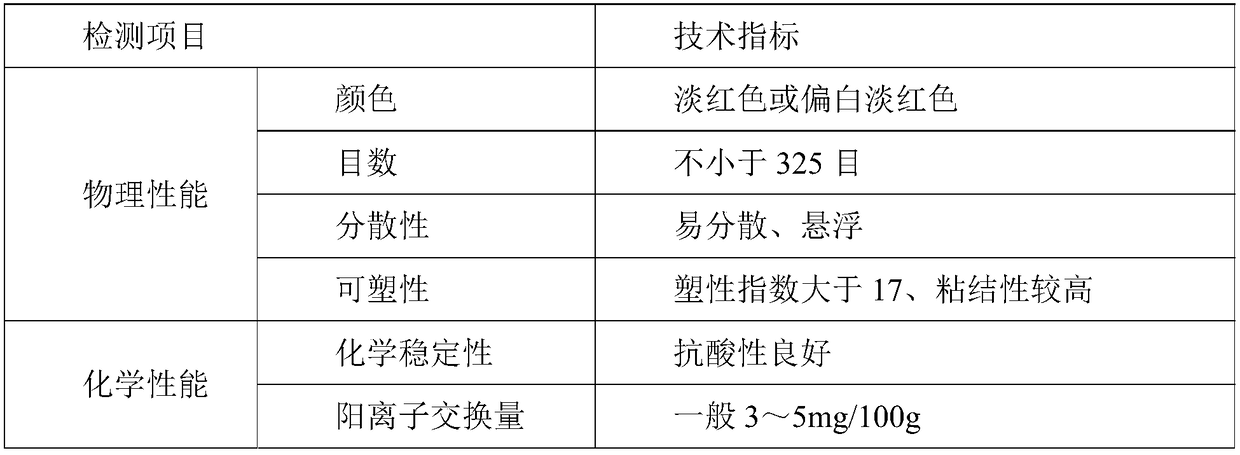

Small particle size gap gradation compact-type low-noise rubber asphalt concrete

ActiveCN101746994AReduce driving noiseGood high temperature resistance to shear deformationSolid waste managementLow noisePorosity

The invention provides a small particle size gap gradation compact-type low-noise rubber asphalt concrete. The mixture has the characteristics that: 1) for the mineral aggregate gradation scope of small particle size coarse aggregate gap gradation, the maximum nominal particle size of the gradation is 7.2 mm; in order to ensure compactness, the percentage composition of padding smaller than 0.075 mm in the mixture is from 7 to 11 percent; and in order to ensure skid resistance, the percentage composition of small particle size gravels larger than 2.36mm in the mixture is from 65 to 75 percent; 2) cement or slaked lime is used to replace mineral powder; 3) rubber asphalt is used as binder material in the mixture; scrap tire crumb rubber in the rubber asphalt is crumb rubber which has the specification of 40 to 80 meshes, is pulverized in normal temperature and has higher content of natural rubber, and the addition amount of the scrap tire crumb rubber reaches 21 to 23 percent of the weight of the asphalt; and the 180 DEG C brook field viscosity index of the rubber asphalt is 2.5 to 4Pa. s; 4) the design porosity of the mixture is 5 to 6 percent. The invention not only has good road performance such as skid resistance and high temperature deformation resistance, but also has the comprehensive characteristics of good durability, wide application range and obvious reduction of noise.

Owner:交通部公路科学研究院

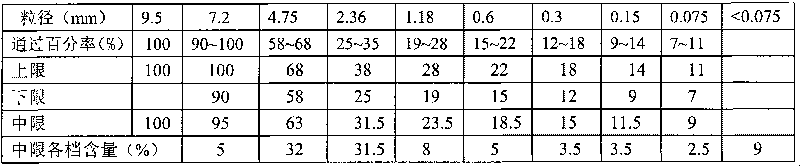

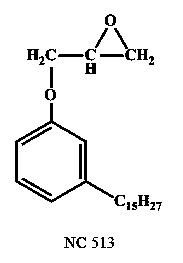

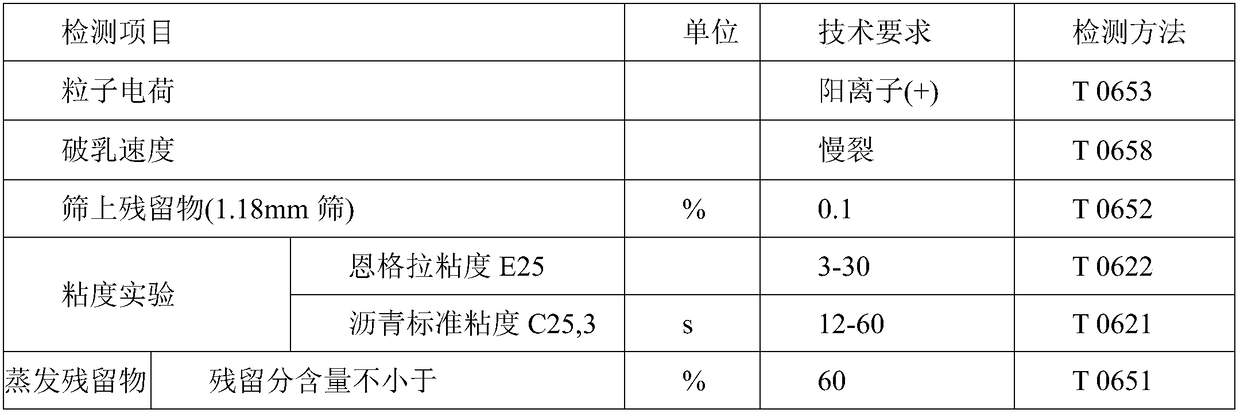

Composition of cationic asphalt emulsifier, preparation method and application thereof

InactiveCN101845228AImprove road performanceStable storageTransportation and packagingMixingFatty amineNon ionic

The invention discloses composition of a cationic asphalt emulsifier, a preparation method and application thereof. The cationic asphalt emulsifier comprises the following components in percentage by weight: (A) 15 to 35 percent of C12 to C22 aliphatic amine; (B) 10 to 25 percent of C12 to C22 aliphatic alkyl propenyl diamine; (C) 10 to 30 percent of C12 to C22 fatty amido polyamine; (D) 10 to 30 percent of a non-ionic component namely fatty amine polyethenoxy ether; and (E) 20 to 55 percent of solvent small molecule alcohol. The preparation method comprises the following steps of: putting a solvent E into a reaction kettle; heating the solvent E to the temperature of between 40 and 90 DEG C; adding the components of A, B, C and D into the reaction kettle; and uniformly stirring the mixture to obtain the cationic asphalt emulsifier. The cationic asphalt emulsifier of the invention can directly emulsify SBS modified asphalt, and overcomes the defects that other emulsifiers can only emulsify matrix asphalt, and the emulsified asphalt is easy to be segregated and has low high-temperature resistance after being added with an SBS latex.

Owner:北京万博汇佳科贸有限公司

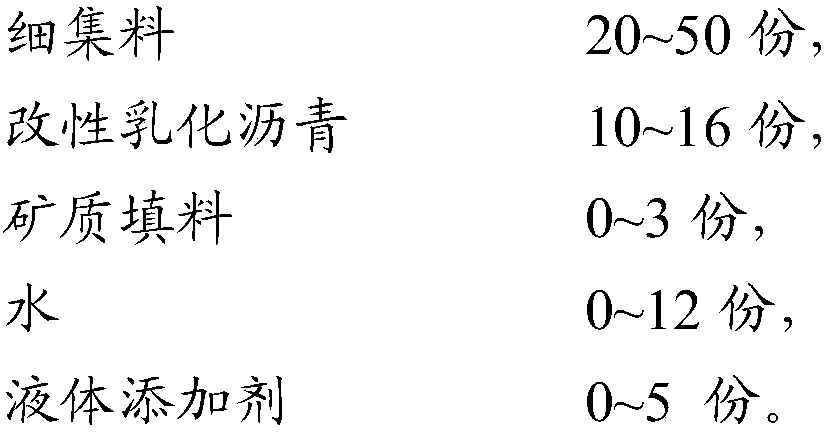

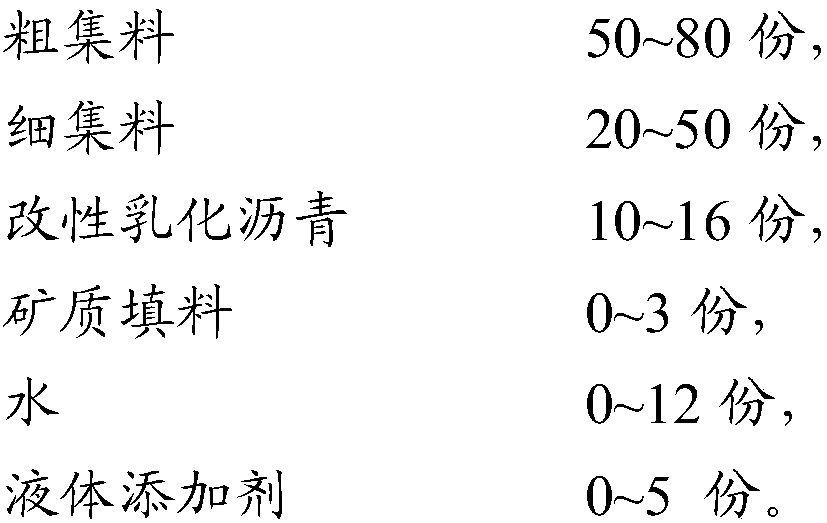

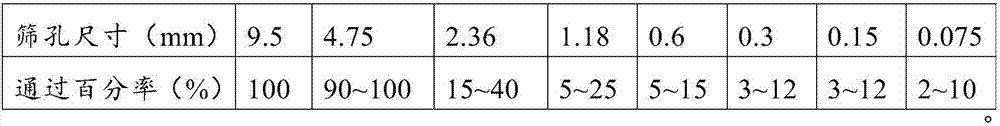

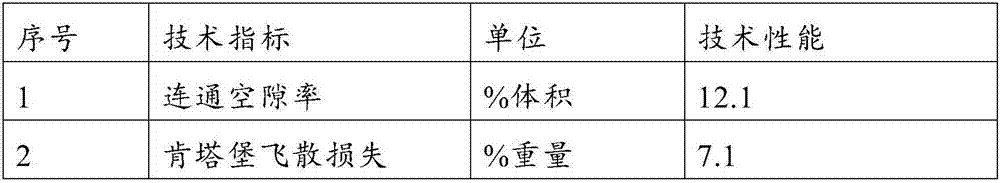

Cold-mixed and cold-laid asphalt mixture, and cold-mixed and cold-laid asphalt mixture wearing layer

ActiveCN108129073AImprove bonding effectReduce driving noiseIn situ pavingsPitch blendeHigh resistance

The invention provides a cold-mixed and cold-laid asphalt mixture, and a cold-mixed and cold-laid asphalt mixture wearing layer, and belongs to the technical field of road engineering. The cold-mixedand cold-laid asphalt mixture comprises coarse aggregates, fine aggregates, high-performance modified emulsified asphalt, a mineral filler, water and a liquid additive. The asphalt mixture prepared from above cold-mixed and cold-laid material components according to a special mineral grading range can be closely bonded to an old asphalt pavement and a cement pavement; and compared with traditionalmicro-surfacing and super-sticky wearing layer materials, the mixture has higher resistance to crack, water and skid and lower driving noises.

Owner:SOUTH CHINA UNIV OF TECH +1

Tire sidewall rubber combination comprising 1,2-syndiotactic polybutadiene

InactiveCN104311908AReduce driving noiseImprove rolling resistanceSpecial tyresRolling resistance optimizationRolling resistanceStearic acid

The invention relates to the technical field of rubber, in particular to a tire sidewall rubber combination comprising 1,2-syndiotactic polybutadiene. 100 weight parts of rubber components serve as the standard, and the combination further includes, by weight, 35-65 parts of carbon black, 5-25 parts of environmentally-friendly aromatic oil, 1.0-5.0 parts of tackifying resin, 1.0-4.0 parts of zinc oxide, 0.5-2.5 parts of stearic acid, 1.5-3.5 parts of sulphur and 0.5-3.0 parts of accelerant. The rubber components include, by weight, 5-50 parts of polybutadiene rubber, 5-45 parts of 1,2 syndiotactic polybutadiene and 35-55 parts of natural rubber. According to the tire sidewall rubber combination comprising the 1,2-syndiotactic polybutadiene, the tire running noise is effectively lowered, the driving comfort is improved, the rolling resistance of a tire is relieved, the physical and mechanical performances of tires made of the tire sidewall rubber combination are basically identical with those of common tires, and the advantages of the wet land griping force and the dry land controllability of the tires are maintained.

Owner:TRIANGLE TIRE

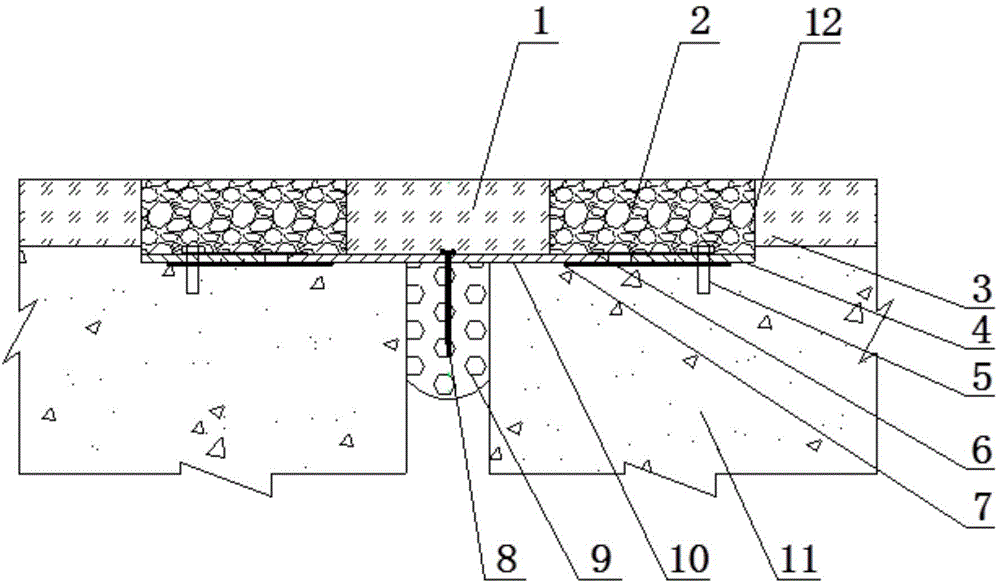

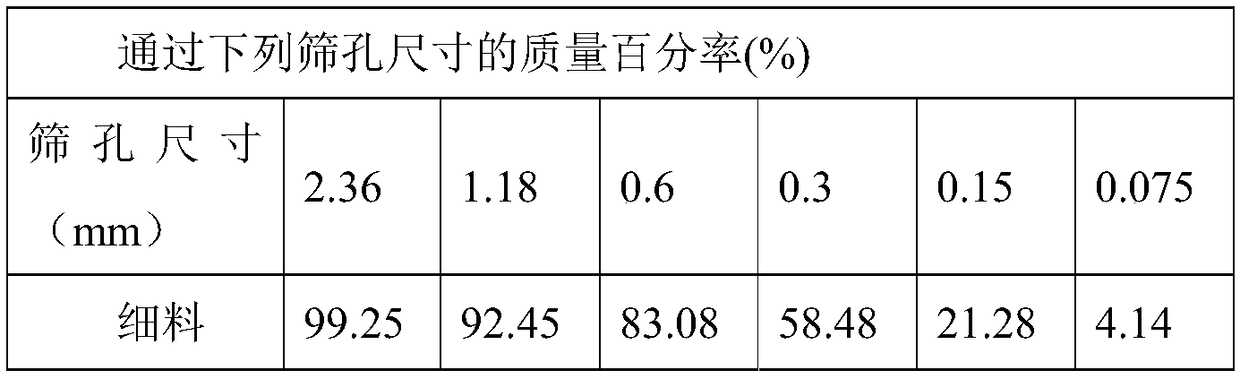

Small-particle-size open-graded asphalt mixture for ultra-thin overlay

The invention provides a small-particle-size open-graded asphalt mixture for an ultra-thin overlay. The mixture is prepared from 85%-92% by weight of aggregate, 2%-8% by weight of filler and 5.5%-7.5% by weight of polymer modified asphalt, the nominal maximum aggregate size is 4.75 mm and the thickness of a pavement layer is 1.0-1.5 cm; preferably, the aggregate is basalt or diabase, the filler is the mixture of limestone mineral powder and cement in the mass ratio being (1:1)-(3:1), and the polymer modified asphalt is POE composite modified asphalt and has the zero-shear viscosity being 30,000 Pa.s or higher at 60 DEG C and the softening point equal to or higher than 90 DEG C. The small-particle-size open-graded asphalt mixture for ultra-thin overlay can reduce the thickness of a thin overlay, reduce building cost of a project and reduce noise during driving, two levels of hard building stones with the particle size being 3-5 mm or 0-3 mm can be utilized, the environment and resource stress of superfluous corresponding building stones due to large-scale application of SMA (stone mastic asphalt) pavements is reduced, and the small-particle-size open-graded asphalt mixture is ingenious in design, simple and convenient to prepare, low in cost and suitable for large-scale popularization and application.

Owner:SHANGHAI MUNICIPAL PLANNING & DESIGN INST CO LTD

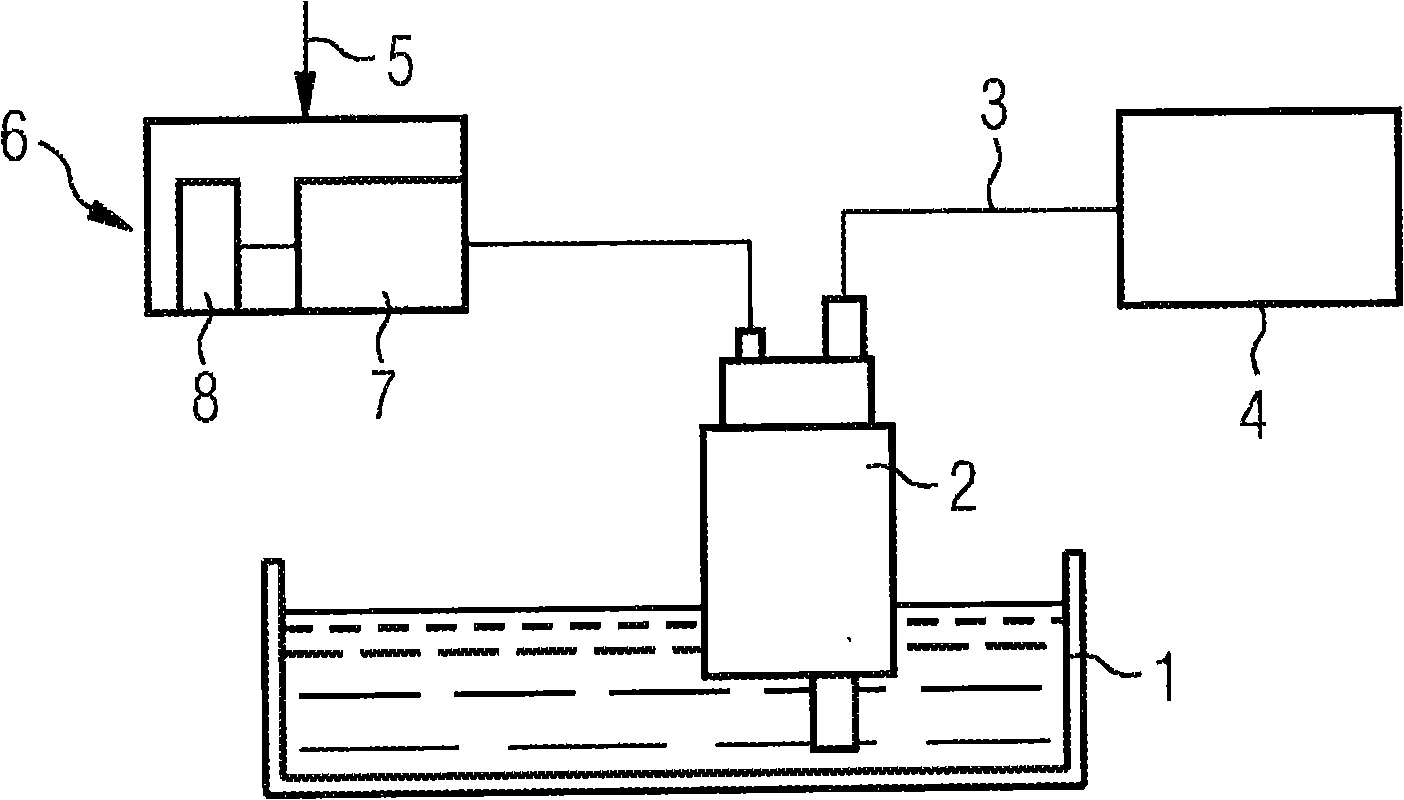

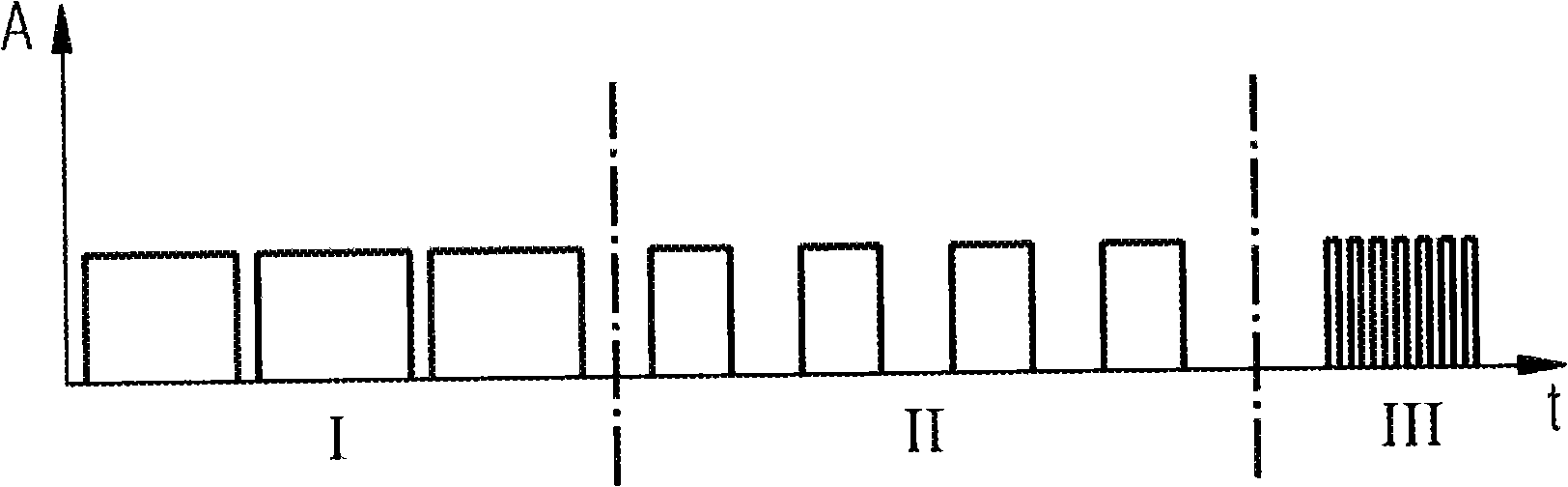

Method for operating a fuel pump

ActiveCN101278115AAvoid solid soundWon't noticeElectrical controlMachines/enginesInternal combustion engineElectric energy

The invention relates to a method for operating a fuel pump in order to guide fuel from the fuel container of an internal combustion engine, wherein the electric energy, which is in the form of pulses, is periodically guided to the fuel pump and the duration of the pulses is controlled according to the fuel required by the internal combustion engine. The frequency of the pulses is controlled in such a manner that, in the event of low pump capacity of the fuel pump, the frequency is controlled to a higher level than in the even of a high pump capacity.

Owner:VTESCO TECH GMBH

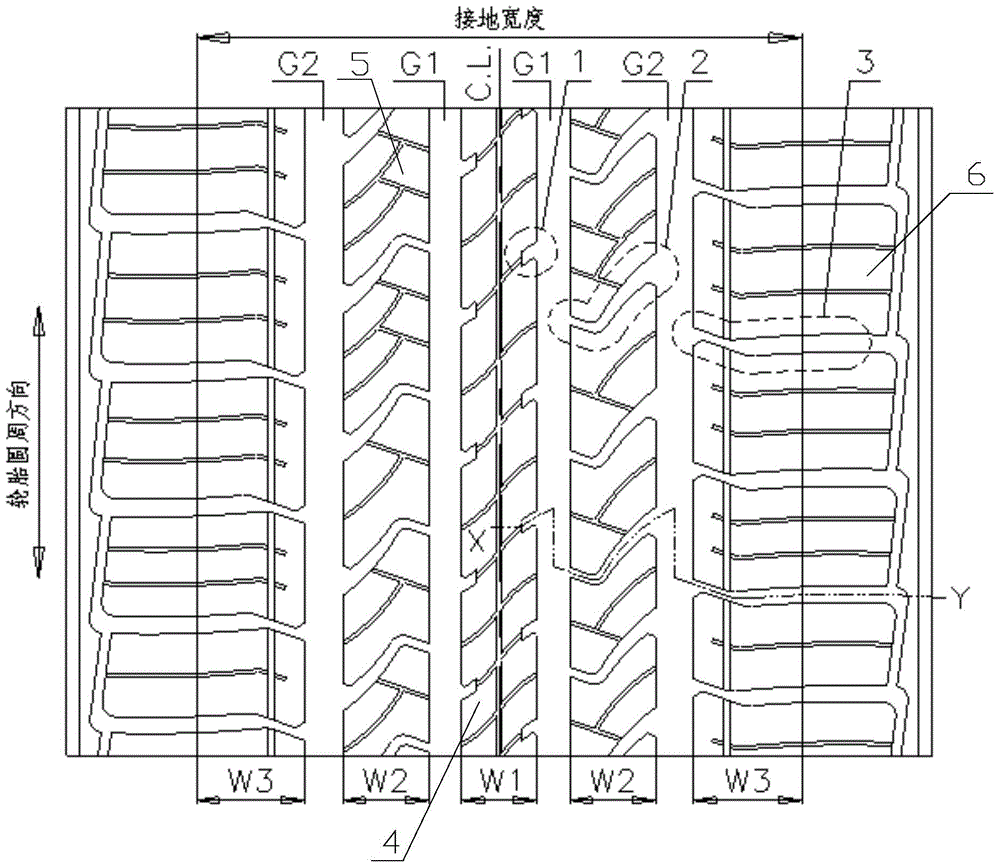

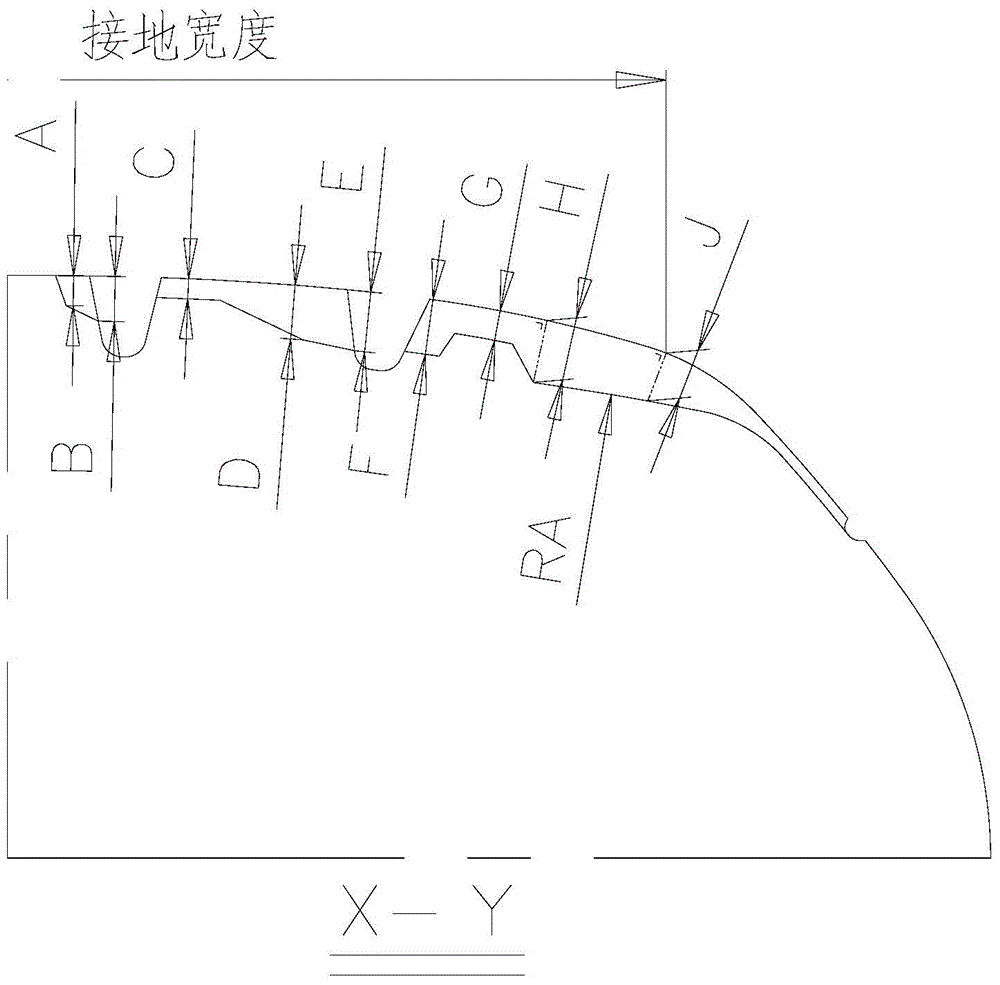

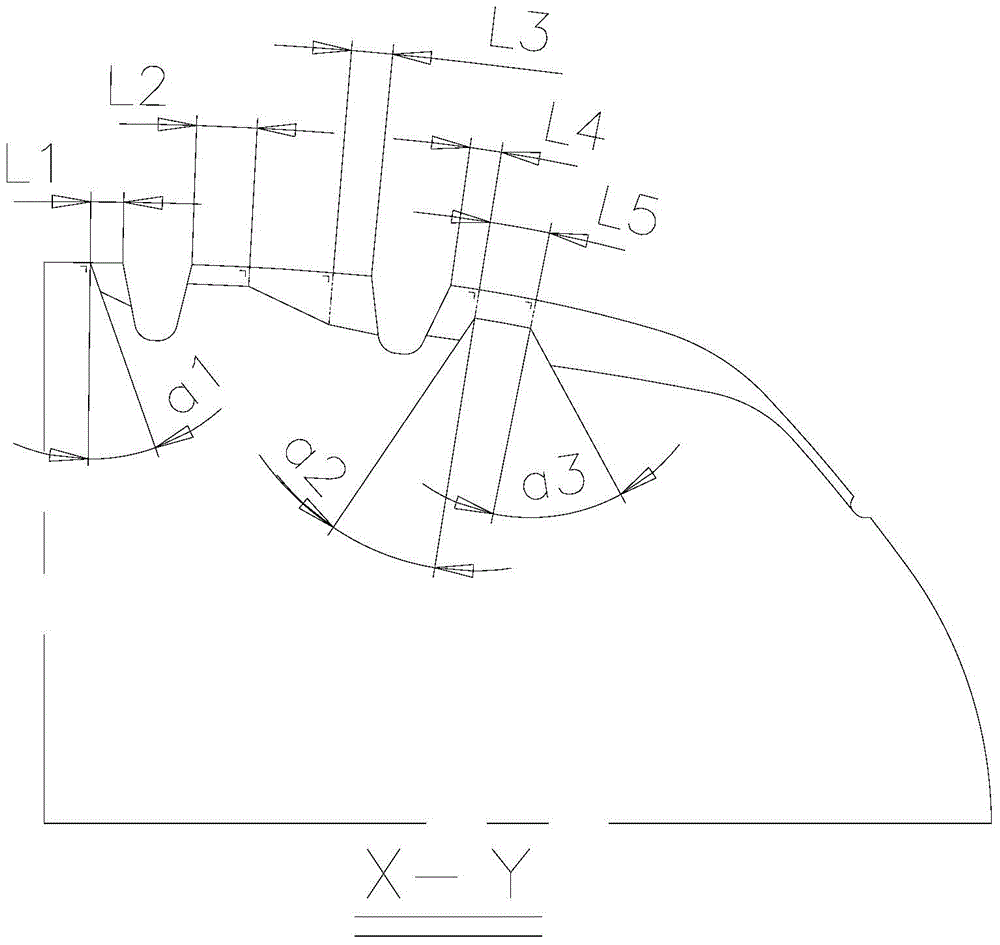

Tread having offset first and second incisions

InactiveUS6874552B2Reduce traveling noiseReduce noiseTyresTyre tread bands/patternsRidgeElectrical and Electronics engineering

A tire tread comprising grooves defining motifs in relief, at least one of these motifs being provided with first and second incisions, said incisions each being defined by two main lateral surfaces connected by an end surface, each of the first incisions opening on to the running surface of the tread when new and extending at most as far as the depth, and each of the second incisions extends at least as far as the depth. The tread is characterized in that the bottom surfaces of the first incisions and the apex surfaces of the second incisions are functionally arranged such that, whatever the level of wear the length of the ridges on the running surface is at least equal to 75% of the length of the ridges when new.

Owner:MICHELIN RECH & TECH SA

Construction method for rapidly repairing expansion joint heightening leveling layer

InactiveCN103966941AEasy to operateFast constructionBridge structural detailsRoads maintainenceEpoxyConstruction engineering

The invention discloses a construction method for rapidly repairing an expansion joint heightening leveling layer. The construction method the following steps: (1) preparing a repairing material prefabricated slab: mixing epoxy resin adhesive and aggregate to prepare a repairing material, laying the repairing material on a baseplate, and curing to obtain the repairing material prefabricated slab; (2) for a repaired area of the expansion joint heightening leveling layer, slotting according to the size of the repairing material prefabricated slab, removing a whole overlay in the slot until a concrete basal plane is exposed, removing sundries in the slot and leveling the slot, and forming a bonding plane of the repairing material prefabricated slab by the slot bottom and the slot side walls; (3) spraying the epoxy resin adhesive on the bonding plane, mounting the repairing material prefabricated slab in the slot, bonding the baseplate of the repairing material prefabricated slab with the slot bottom, and preserving for 2-4 hours to complete repairing of the expansion joint heightening leveling layer. The construction method is simple to operate, rapid in construction, carried out at a normal temperature, short in traffic closing time, and easy to control construction quality, and has high interface bonding strength of the repairing material prefabricated slab.

Owner:广州溪山环保科技有限公司

Environment-friendly nonslip ultrathin seal material and preparation method thereof

ActiveCN109486421AHigh softening pointHigh viscosityAntifouling/underwater paintsPaints with biocidesRoad surfaceConstruction aggregate

The invention discloses an environment-friendly nonslip ultrathin seal material and a preparation method thereof and solves the problems that the asphalt pavement has water penetration, poor slip resistance, slightly pitted surface and small cracks. A stable durable seal is provided to protect the asphalt pavement, aggregate of an original asphalt pavement can be locked, oil shortage can be repaired, post-construction traffic opening time is short, little influence is caused to transportation, and the material herein has great technical significance and social significance; the preventive maintenance process used herein helps maintain pavement service level and retard maintenance time of extensive and medium repair, and save lifecycle maintenance cost.

Owner:中山市易路美智能装备有限公司 +1

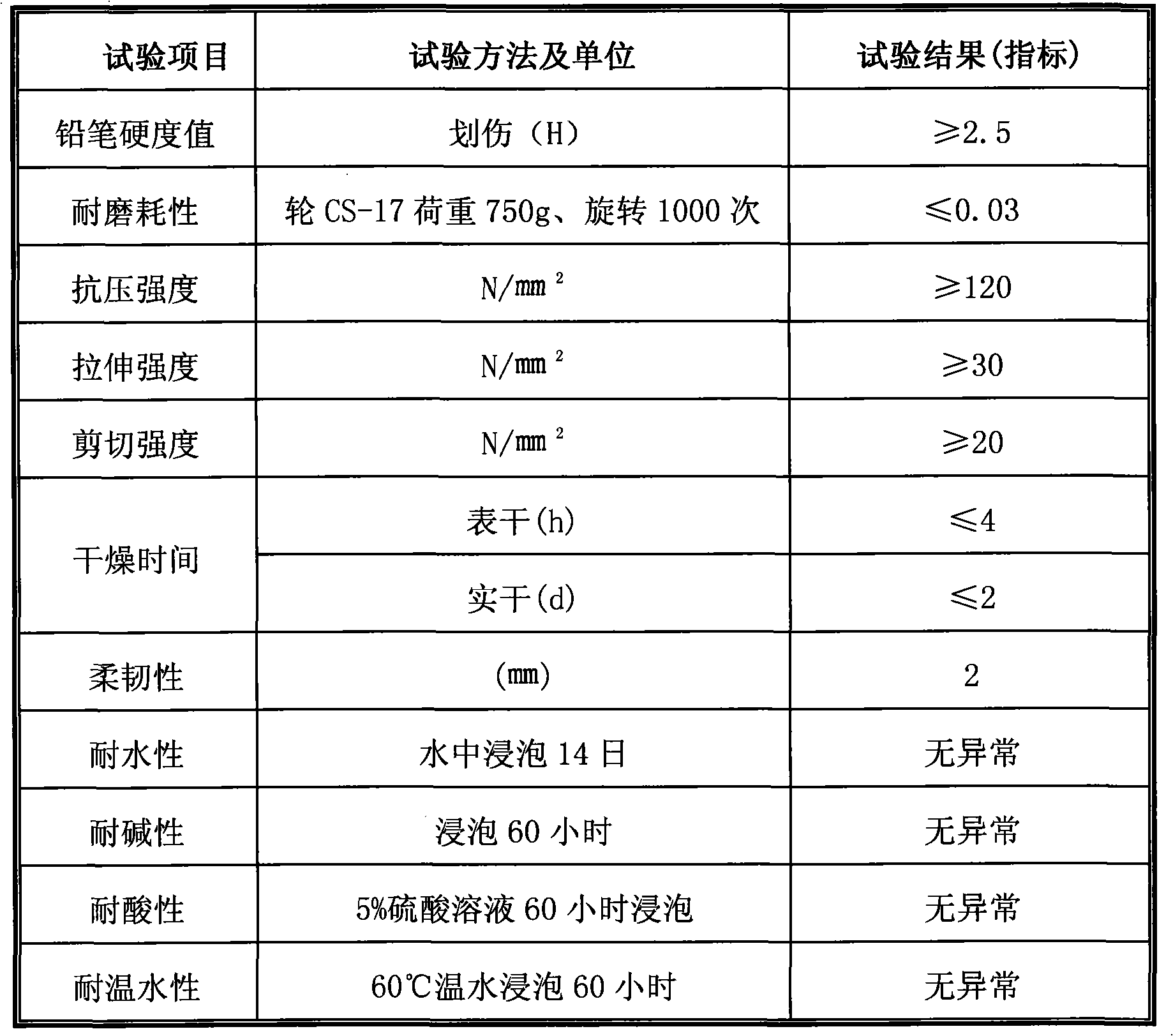

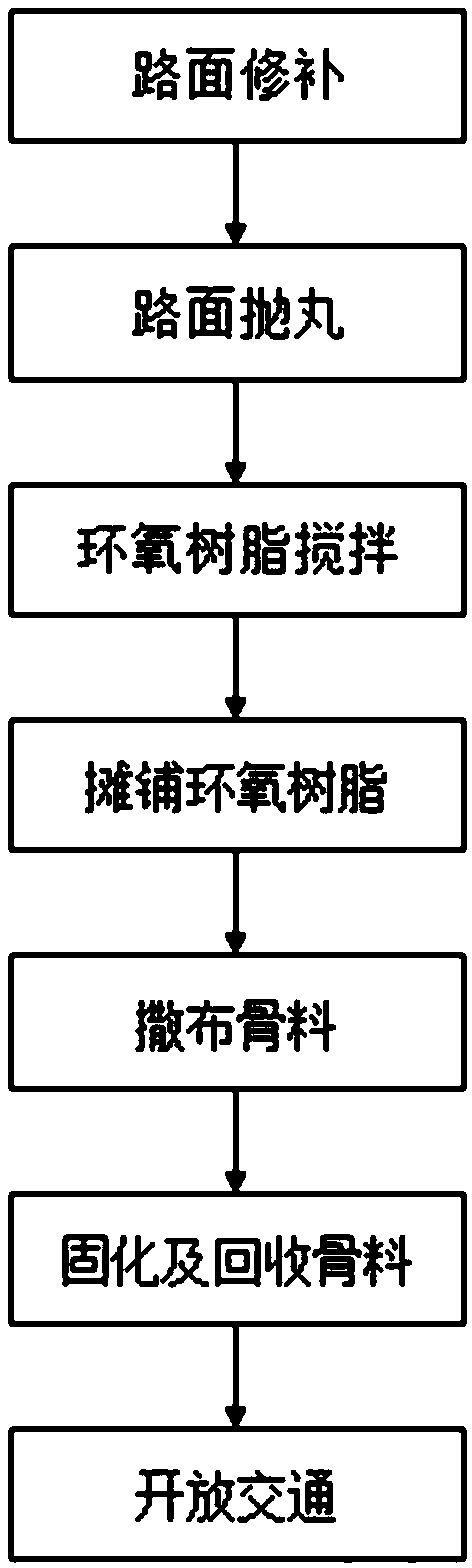

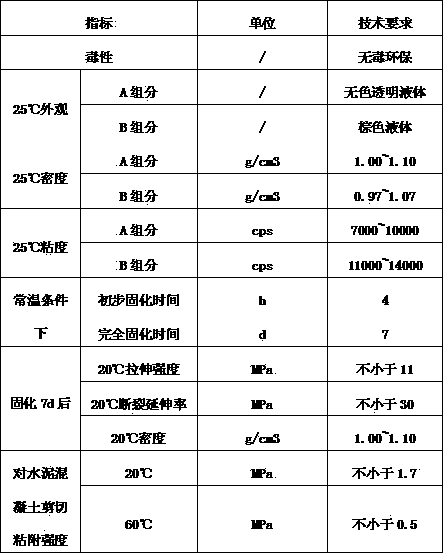

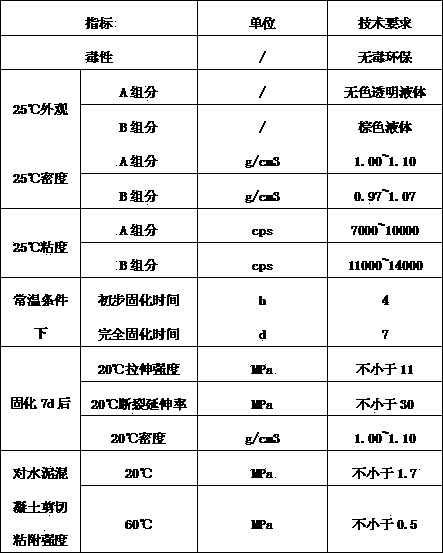

Construction process of colored pavement epoxy non-slip wearing layer structure

ActiveCN103938513ASimple construction processEasy constructionIn situ pavingsPaving detailsEpoxyRoad surface

The invention discloses a construction process of a colored pavement epoxy non-slip wearing layer structure. The construction process comprises the following steps: (1) pavement patching; (2) pavement shot blasting; (3) epoxy resin stirring; (4) paving of epoxy resin; (5) spreading of aggregates; (6) curing and recovering of the aggregates; and (7) opening of transit. Compared with the prior art, the construction process has the advantages that the wearing layer structure is simple in process, easy to operate, good in non-slip performance, high in bonding strength, small in thickness, convenient in construction, rapid in curing and high in material water resistance; running noise of vehicles is lowered; driving conditions are improved; the wearing layer structure is excellent in corrosion resistance, high in flame retardant property, high in ductility, uniform in expansion, high in low-temperature resistance, low in low-temperature brittleness, excellent in thermal ageing resistance, high in high-temperature stability and high in wear resistance, the surface aggregate is high in wear resistance, a conventional road elevation and the conventional clear height of a bridge are not changed, existing various structural and non-structural pavement diseases can be repaired at a time, the maintenance cost is saved, and the service life of a pavement is greatly prolonged.

Owner:上海仁路科技有限公司

Motor vehicle and pneumatic tyre

ActiveCN104401190AExtended service lifeReduce driving fuel consumptionTyre tread bands/patternsTransverse grooveMotor vehicle part

The invention discloses a pneumatic tyre. The middle of the tyre surface of the pneumatic tyre is orderly provided with several central decorative patterns in an end-to-end way along a circumferential direction, two side edges of the tyre surface are respectively provided with several edge decorative patterns orderly arranged in an end-to-end way along the circumferential direction of the pneumatic tyre, several side decorative patterns orderly arranged in an end-to-end way along the circumferential direction of the pneumatic tyre are located between the central decorative patterns and the edge decorative patterns, a first longitudinal groove is arranged between the central decorative patterns and the side decorative patterns, a second longitudinal groove is arranged between the side decorative patterns and the edge decorative patterns, a first transverse groove is arranged between each two adjacent central decorative patterns, a second transverse groove is arranged between each two adjacent side decorative patterns, and a third transverse groove is arranged between each two adjacent edge decorative patterns. The pneumatic tyre has a long service life, has good brake performances and control performances after use, substantially shortens a brake distance, has small driving noise and properly reduces whole vehicle driving oil consumption. The invention also discloses a motor vehicle with the pneumatic tyre.

Owner:CHENG SHIN RUBBER CHINA

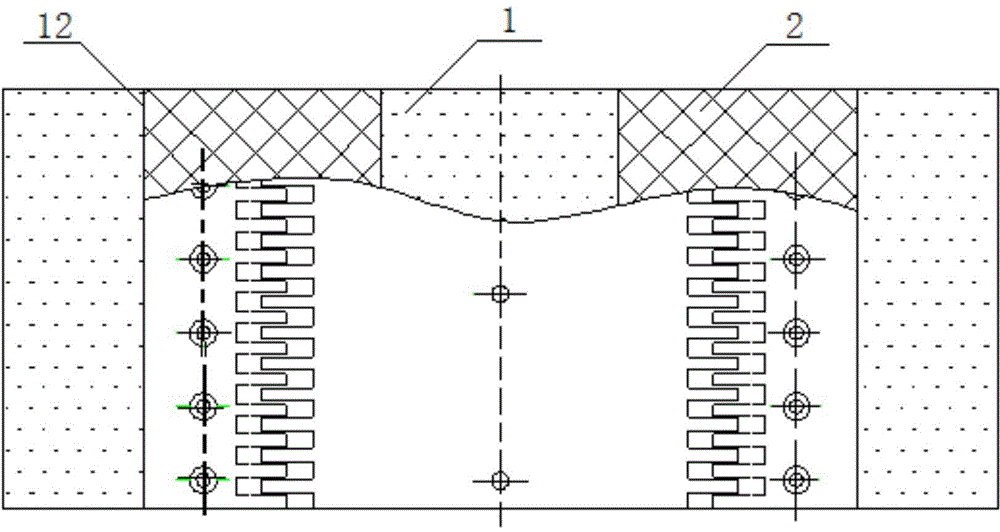

Novel assembly type seamless expansion device and construction method thereof

ActiveCN108035245AReduce adverse effectsReduce the impactBridge structural detailsWhole bodySurface roughness

The invention relates to a novel assembly type seamless expansion device and a construction method thereof. The novel assembly type seamless expansion device comprises main girder span expansion device bodies arranged on a construction bridge and expansion device bodies arranged on the portions, at bridge abutment expansion seams, of bridge abutments of the construction bridge, and each main girder expansion seam and each bridge abutment expansion seam are each provided with one expansion device body. Accordingly, the device and a deck can be paved to form a continuous whole body, the problemsthat bridge expansion seams are prone to bridge surface roughness, dislocation, distortion, expansion seam irregularity and the like can be solved, and driving is stable and comfortable; by arrangingrubber pads between comb type span seam steel plates and telescopic corrugated steel plates, driving noise can be reduced, the defects that traditional expansion seams are prone to leakage, and the service life in bad conditions is short can be overcome, and the maintenance workload is low. In addition, the device has the advantages that the input cost is low, the stress performance is good, thedurability is good, the practicability is high, and maintaining and replacing are conducted conveniently.

Owner:FUZHOU UNIV

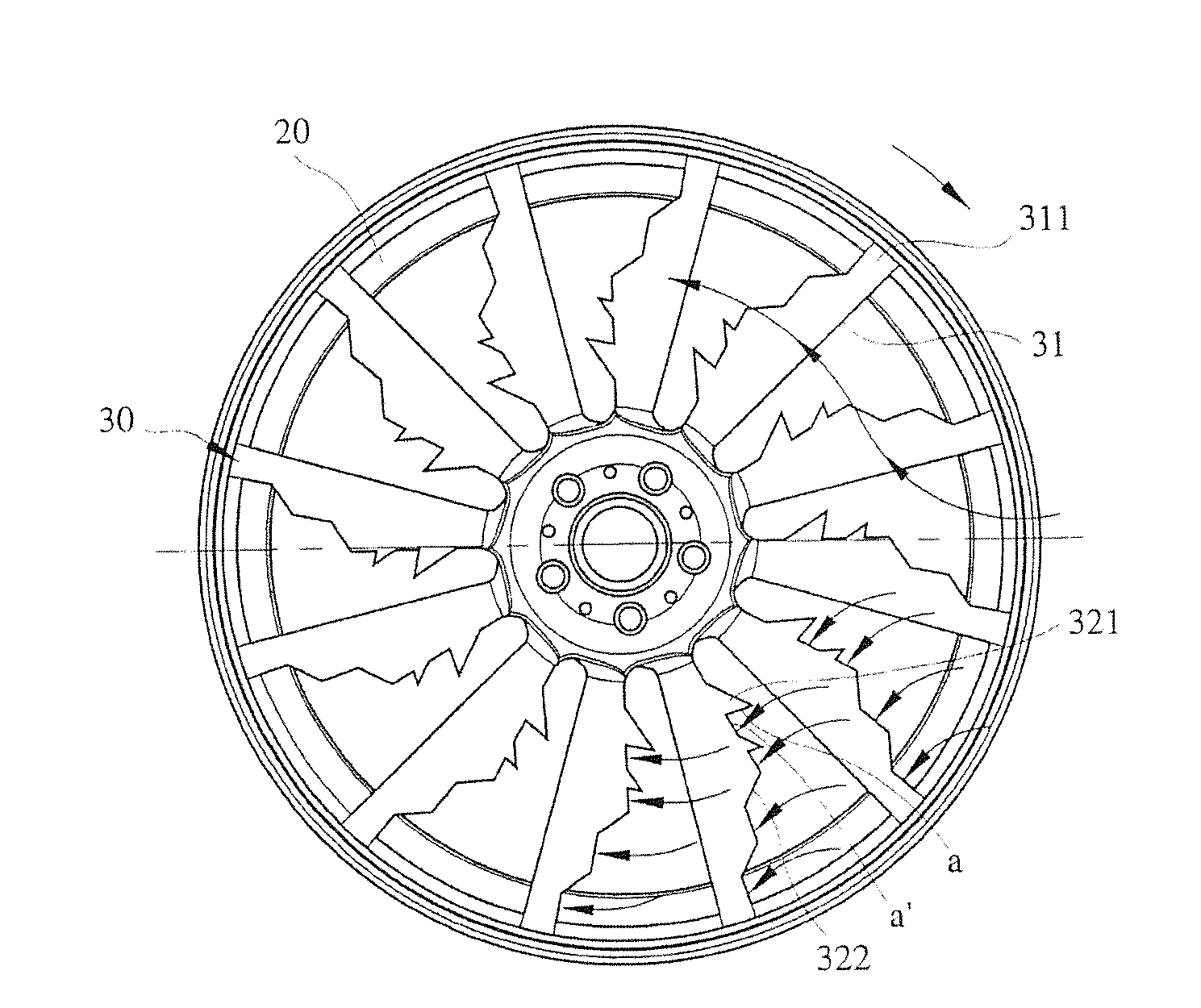

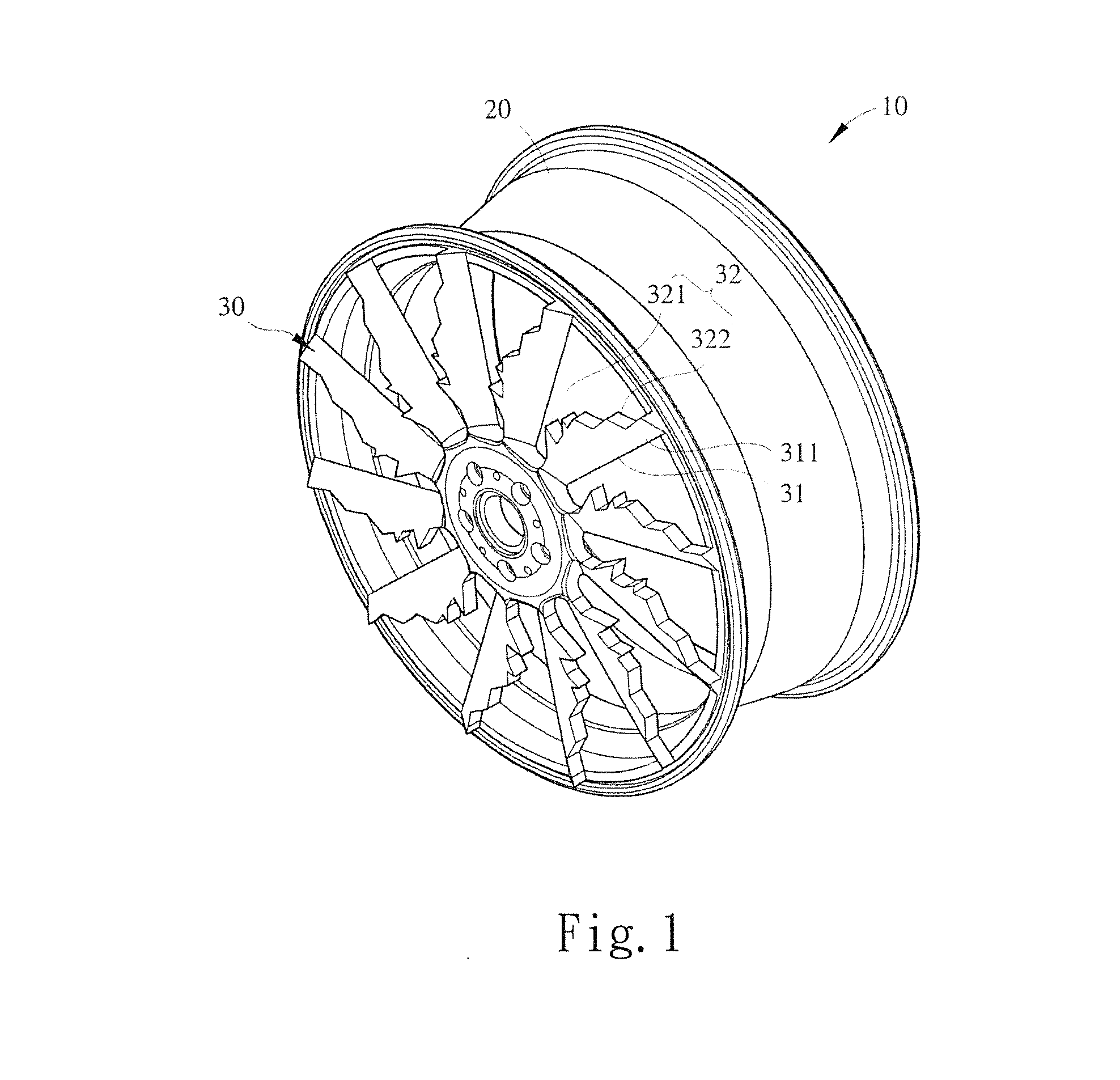

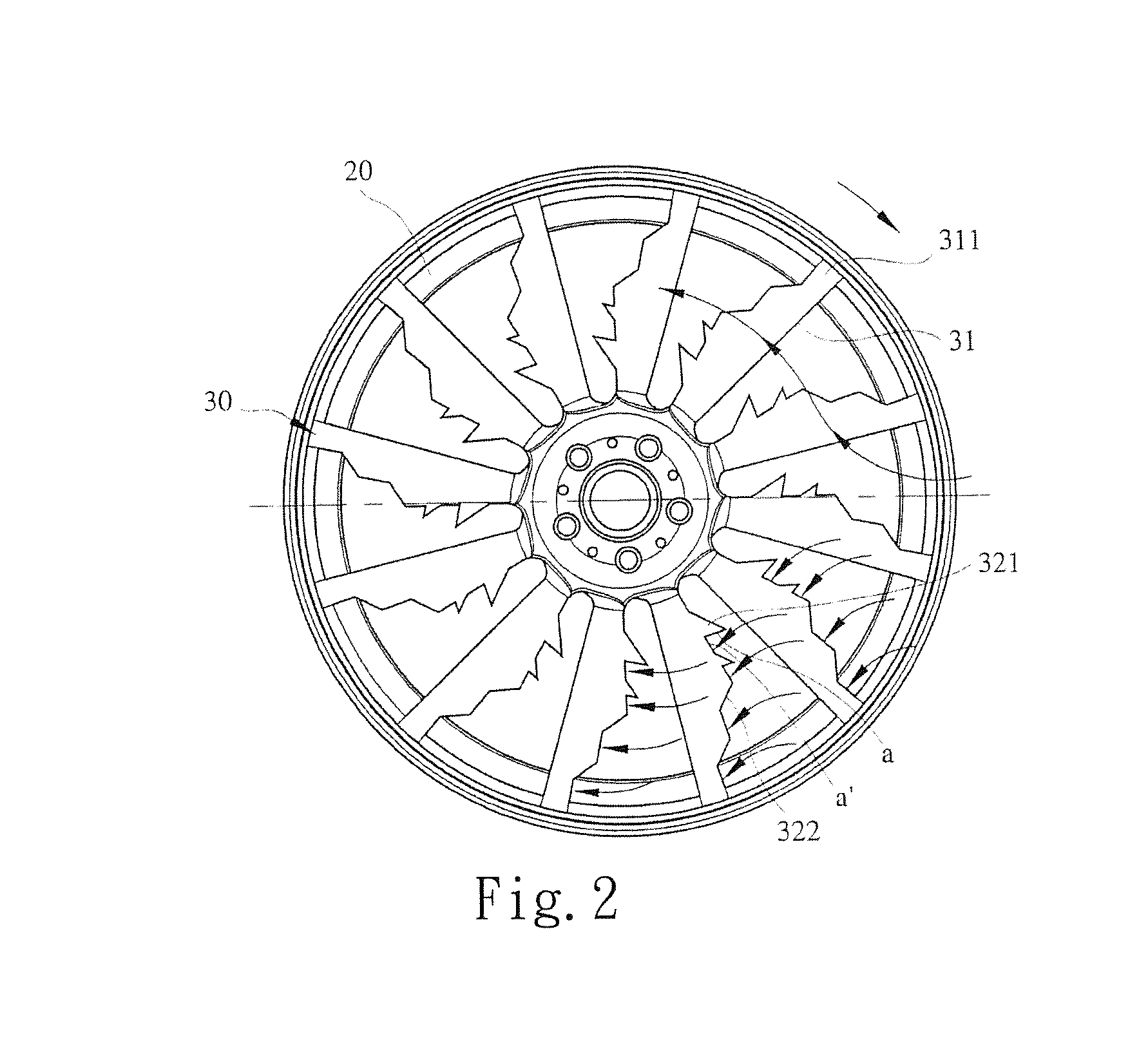

Vehicle wheel

ActiveUS20140339887A1Reduce driving noiseReduce fuel consumptionWheel protectionDisc wheelsEngineeringAirflow

A vehicle wheel includes a wheel body and a plurality of rim blades. The plurality of rim blades is coupled to at least one side surface of the wheel body. Each of the rim blades is provided with at least one airflow guide section and at least one airflow-assisting section. The airflow guide section and the airflow-assisting section are arranged in the form of front and rear series on the rim blade. When the vehicle wheel is coupled with a tire, the airflow guide section is located at the side of the rim blade facing a forwarding direction of rotation of the wheel and the airflow-assisting section is located at the side of the rim blade opposite to the forwarding rotation of the wheels. As such, airflow is increased, wind resistance is reduced, and noise is reduced.

Owner:CHEN KUAN TING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com