Small-particle-size open-graded asphalt mixture for ultra-thin overlay

A technology of asphalt mixture and small particle size, which is applied to the coagulation pavement, buildings, roads and other directions of on-site paving, can solve the problems of rutting, looseness, high noise, etc., to reduce the thickness of the cover, reduce the project cost, The effect of reducing driving noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

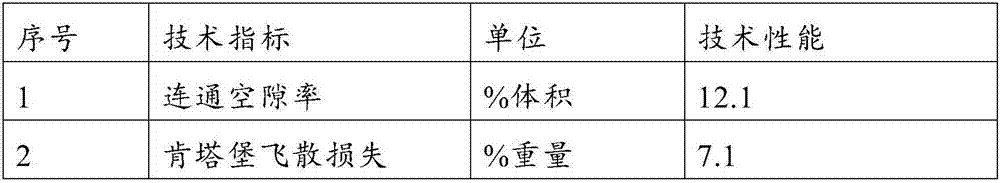

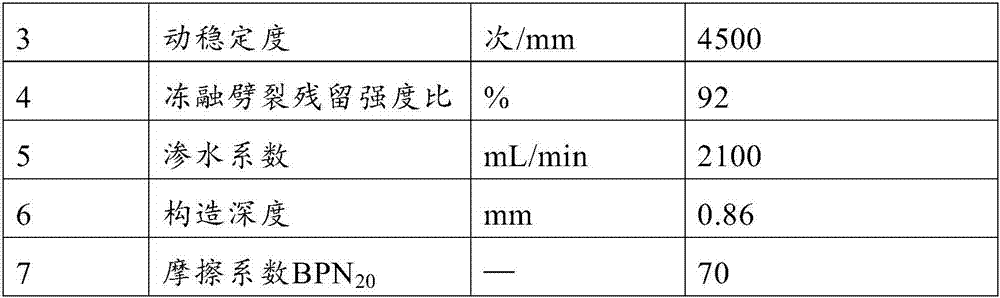

Examples

Embodiment 1

[0027] The small particle size open-graded asphalt mixture used for ultra-thin overlays in this embodiment includes 85% by weight of aggregates, 7.5% by weight of fillers and 7.5% by weight of POE composite modified asphalt. The aggregate used is basalt produced by Jintan Fulu Stone Rolling Plant (3mm~5mm continuous gradation basalt and 0mm~3mm continuous gradation basalt are mixed at a mass ratio of 78:22); the filler used is Jiangxi Kuntai Mine The mixture of limestone slag powder produced by the powder factory and P.O 42.5 cement produced by Anhui Conch Cement Co., Ltd., the mass ratio is 1:1.

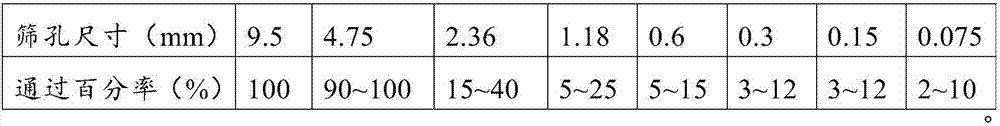

[0028] The gradation of the aggregates used and the fillers used are as follows:

[0029] Mesh size(mm)

[0030] The POE composite modified bitumen used comprises the following components: No. 50 bitumen (Sinopec Zhenhai Refining and Chemical Co., Ltd.) 100 parts by weight, POE modifier (7256 of Dow Chemical Co., Ltd. of the United States, and the melt index is 10dg / min) ...

Embodiment 2

[0037] The small particle size open-graded asphalt mixture used for ultra-thin overlays in this embodiment includes 86.5% by weight of aggregates, 8% by weight of fillers and 5.5% by weight of POE composite modified asphalt. The aggregate used is basalt produced by Jintan Fulu Stone Rolling Plant (3mm~5mm continuous gradation basalt and 0mm~3mm continuous gradation basalt are mixed at a mass ratio of 80:20); the filler used is Jiangxi Kuntai Mine The mixture of limestone slag produced by powder factory and P.O42.5 cement produced by Anhui Conch Cement Co., Ltd., the mass ratio is 3:1.

[0038] The gradation of the aggregates used and the fillers used are as follows:

[0039] Mesh size(mm)

[0040] The POE composite modified bitumen used comprises the following components: 100 parts by weight of No. 30 bitumen (Sinopec Zhenhai Refining and Chemical Co., Ltd.), 8 parts by weight of POE modifier (LC565 of Korea LG Company, melt index is 5dg / min) 1.0 parts by weight of ...

Embodiment 3

[0047] The small particle size open-graded asphalt mixture used for ultra-thin overlays in this embodiment includes 92.0% by weight of aggregates, 2% by weight of fillers and 6% by weight of POE composite modified asphalt. The aggregate used is diabase produced by Huzhou Jinheng Stone Processing Plant (3mm~5mm continuous gradation diabase and 0mm~3mm continuous gradation diabase are mixed at a mass ratio of 75:25); the filler used is It is a mixture of limestone mineral powder produced by Jiangxi Kuntai Mineral Powder Factory and P.O 42.5 cement produced by Anhui Conch Cement Co., Ltd., with a mass ratio of 2:1.

[0048] The gradation of the aggregates used and the fillers used are as follows:

[0049] Mesh size(mm)

[0050] The POE composite modified bitumen used comprises the following components: 100 parts by weight of No. 50 bitumen (Sinopec Zhenhai Refining and Chemical Co., Ltd.), 14 parts by weight of POE modifier (LC170 of LG Company, the melt index is 1dg / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com