Patents

Literature

44 results about "Stone mastic asphalt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stone mastic asphalt (SMA), also called stone-matrix asphalt, was developed in Germany in the 1960s with the first SMA pavements being placed in 1968 near Kiel. It provides a deformation-resistant, durable surfacing material, suitable for heavily trafficked roads. SMA has found use in Europe, Australia, the United States, and Canada as a durable asphalt surfacing option for residential streets and highways. SMA has a high coarse aggregate content that interlocks to form a stone skeleton that resists permanent deformation. The stone skeleton is filled with a mastic of bitumen and filler to which fibres are added to provide adequate stability of bitumen and to prevent drainage of binder during transport and placement. Typical SMA composition consists of 70−80% coarse aggregate, 8−12% filler, 6.0−7.0% binder, and 0.3 per cent fibre.

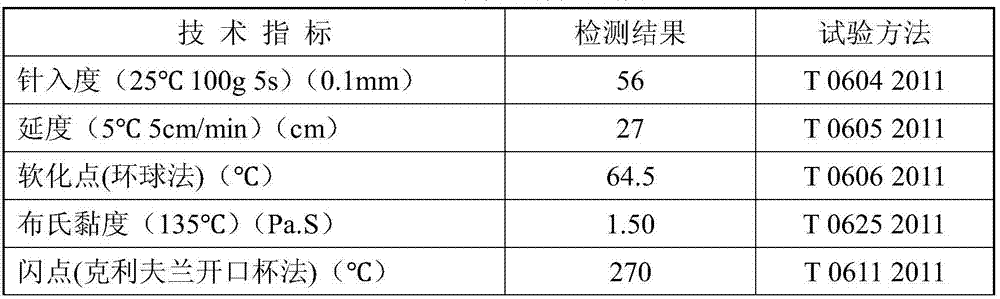

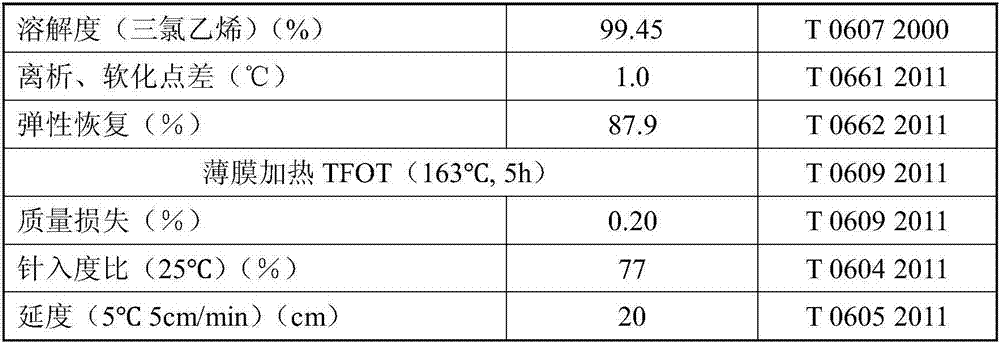

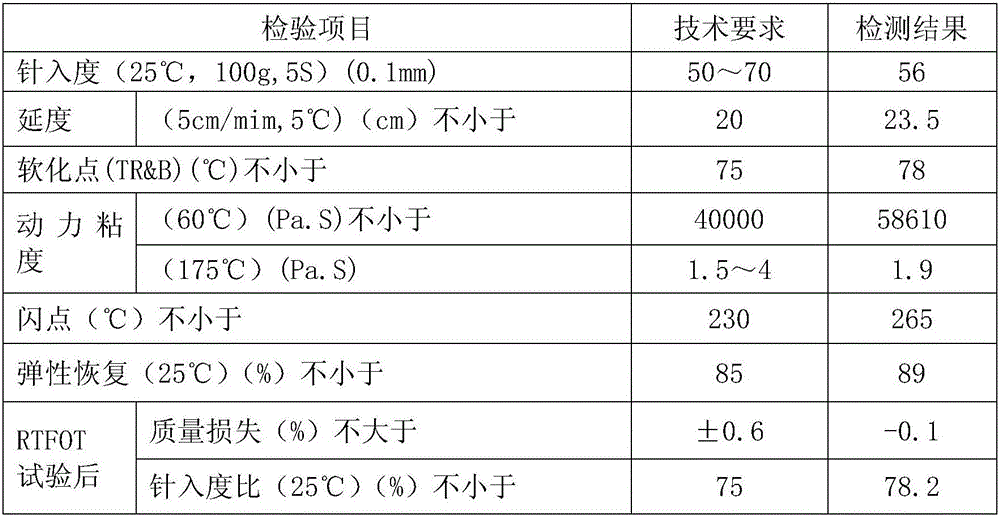

High-viscosity high-elasticity asphalt based on surface modification of rubber particles, and high-viscosity high-elasticity SMA (stone mastic asphalt) mixture based on surface modification of rubber particles and preparing method thereof

ActiveCN104725883AGood storage stabilityHigh viscoelasticityBuilding insulationsCross-linkPolymer science

The invention discloses high-viscosity high-elasticity asphalt based on surface modification of rubber particles, and high-viscosity high-elasticity SMA (stone mastic asphalt) mixture based on surface modification of rubber particles and preparing method thereof. The high-viscosity high-elasticity asphalt is made from base asphalt, activated rubber powder, a weatherable component, a tackifying component, a plasticizing component, a compatibilizing component and a cross-linking component according to a mass ratio being 100:(15-20):(4-6):(2-4):(1-3):(1-5):(0.1-1). By applying the high-viscosity high-elasticity asphalt to the production of the SMA mixture, performances of the mixture, such as ageing resistance, low temperature performance, high-temperature performance and fatigue resistance. The technical problem that the composite modified asphalt with low amount of rubber powder is difficult to use in asphalt concrete is solved; the high-viscosity high-elasticity asphalt and the high-viscosity high-elasticity SMA mixture are suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

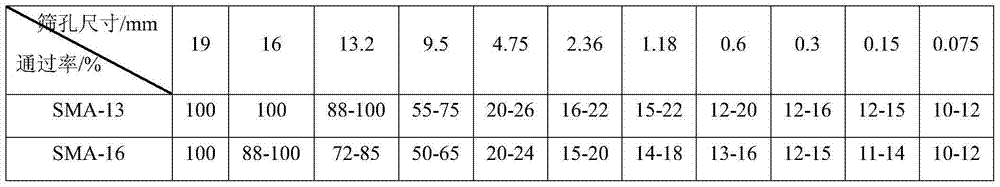

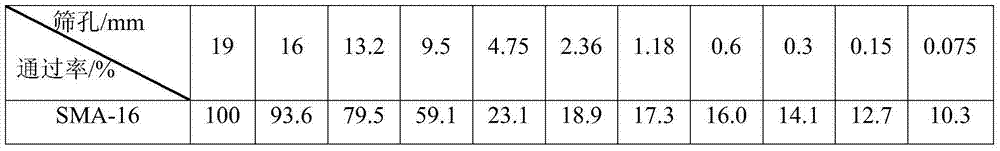

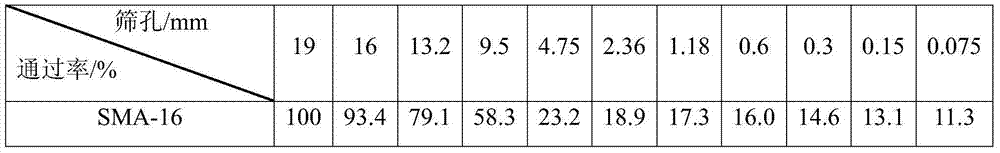

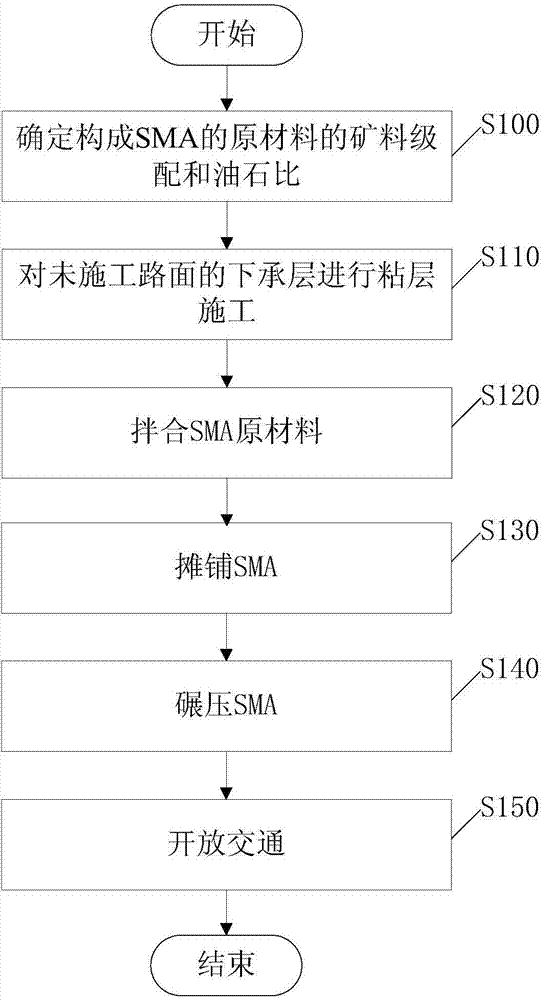

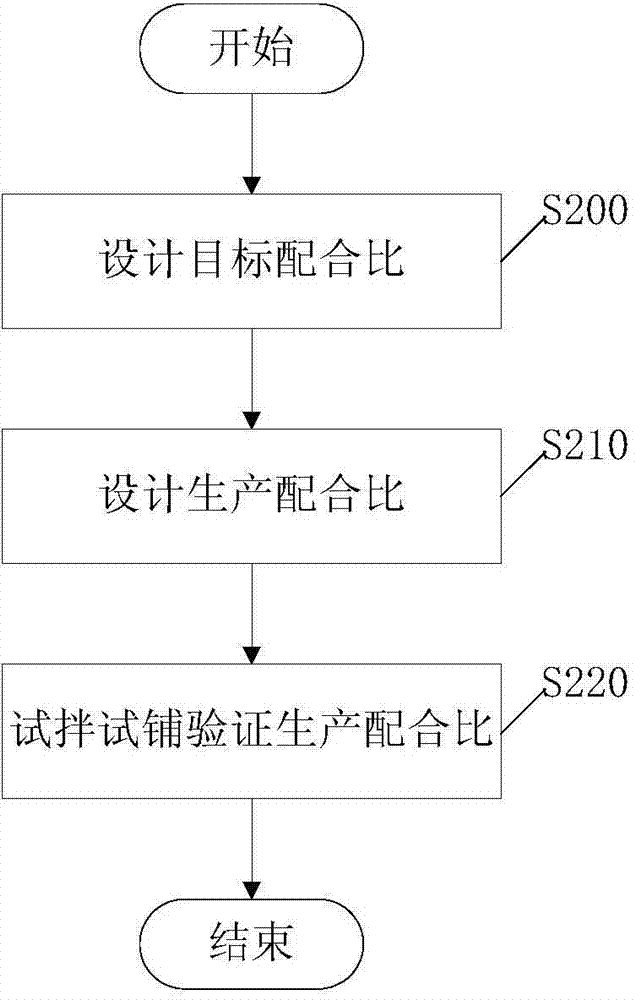

Stone mastic asphalt (SMA) pavement construction method

The invention provides a stone mastic asphalt (SMA) pavement construction method. The method comprises the following steps of determining mineral aggregate gradation and the optimal asphalt-aggregate ratio of SMA raw materials, carrying out bonding construction on a lower bearing layer, mixing the SMA raw materials, wherein an asphalt heating temperature is in a range of 170-180 DEG C, an aggregate heating temperature is in a range of 185-195 DEG C and a discharging temperature is in a range of 175-185 DEG C, spreading the materials, wherein a factory temperature is in a range of 170-185 DEG C, an attendance temperature is greater than or equal to 170 DEG C and a spreading temperature is greater than or equal to 170 DEG C, carrying out rolling compaction by primary rolling compaction, secondary rolling compaction and final rolling compaction, wherein a primary rolling compaction temperature is greater than or equal to 160 DEG C, a secondary rolling compaction temperature is greater than or equal to 140 DEG C and the final rolling compaction is greater than or equal to 120 DEG C, and opening to traffic when the pavement temperature is less than 50 DEG C. The method realizes temperature control from stirring to rolling compaction and eliminates temperature influence on construction.

Owner:MCC NORTHEAST CONSTR SHENYANG ENGTECH CO LTD +1

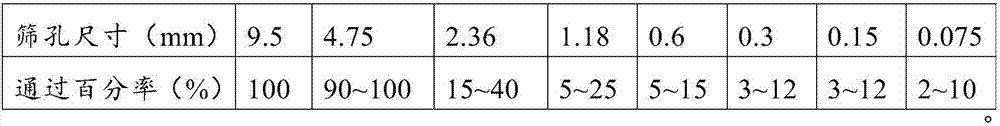

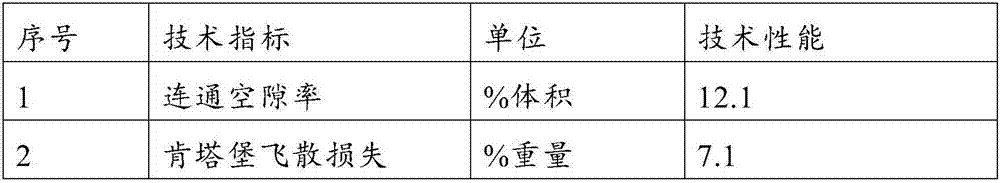

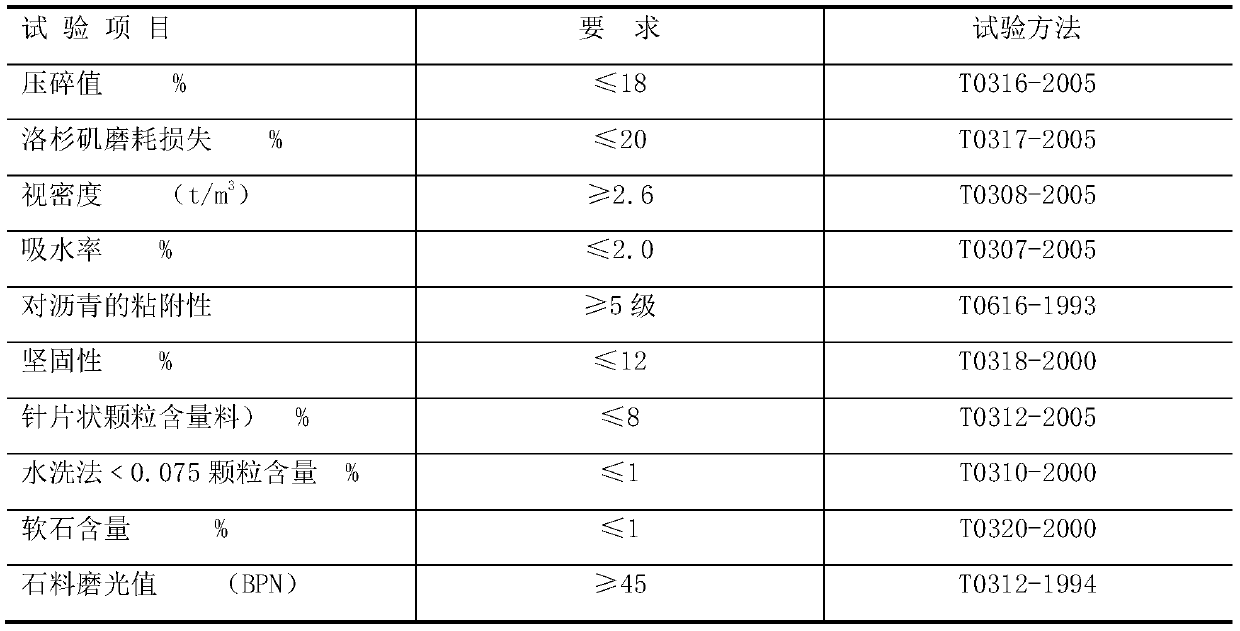

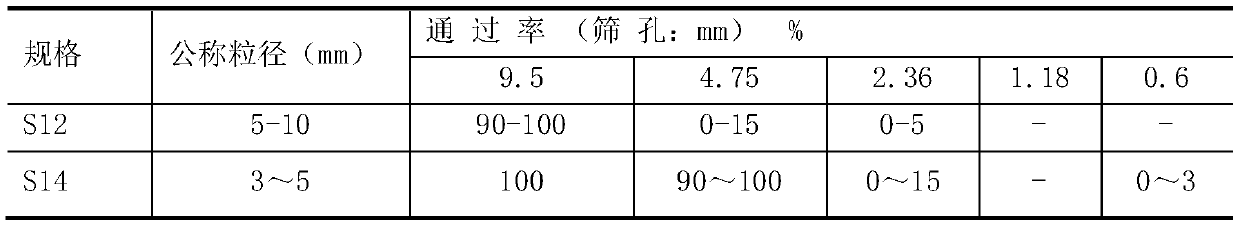

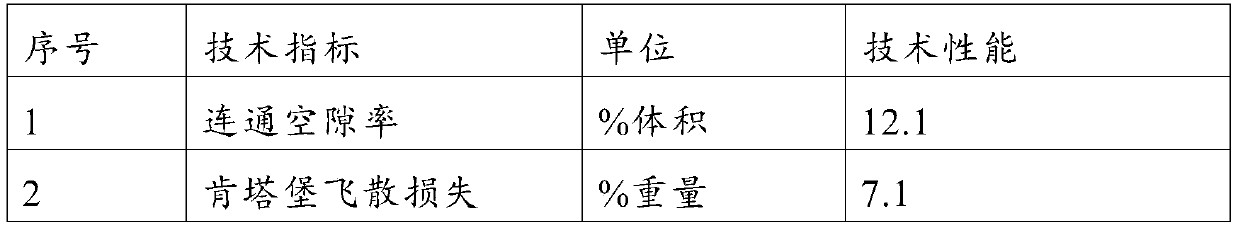

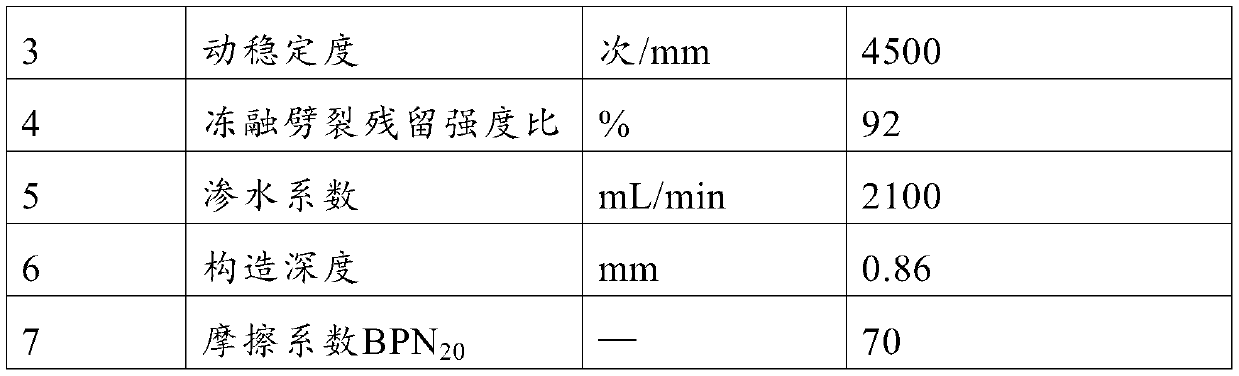

Small-particle-size open-graded asphalt mixture for ultra-thin overlay

The invention provides a small-particle-size open-graded asphalt mixture for an ultra-thin overlay. The mixture is prepared from 85%-92% by weight of aggregate, 2%-8% by weight of filler and 5.5%-7.5% by weight of polymer modified asphalt, the nominal maximum aggregate size is 4.75 mm and the thickness of a pavement layer is 1.0-1.5 cm; preferably, the aggregate is basalt or diabase, the filler is the mixture of limestone mineral powder and cement in the mass ratio being (1:1)-(3:1), and the polymer modified asphalt is POE composite modified asphalt and has the zero-shear viscosity being 30,000 Pa.s or higher at 60 DEG C and the softening point equal to or higher than 90 DEG C. The small-particle-size open-graded asphalt mixture for ultra-thin overlay can reduce the thickness of a thin overlay, reduce building cost of a project and reduce noise during driving, two levels of hard building stones with the particle size being 3-5 mm or 0-3 mm can be utilized, the environment and resource stress of superfluous corresponding building stones due to large-scale application of SMA (stone mastic asphalt) pavements is reduced, and the small-particle-size open-graded asphalt mixture is ingenious in design, simple and convenient to prepare, low in cost and suitable for large-scale popularization and application.

Owner:SHANGHAI MUNICIPAL PLANNING & DESIGN INST CO LTD

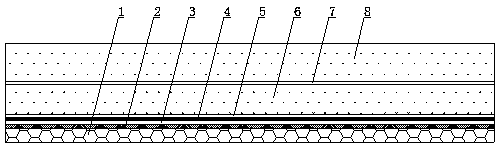

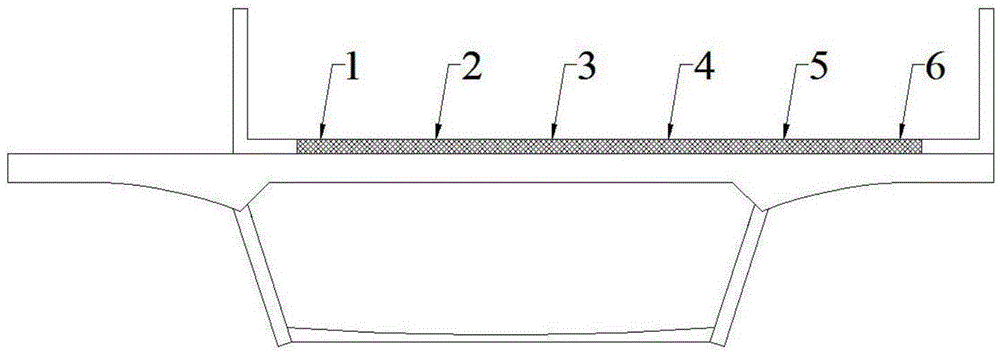

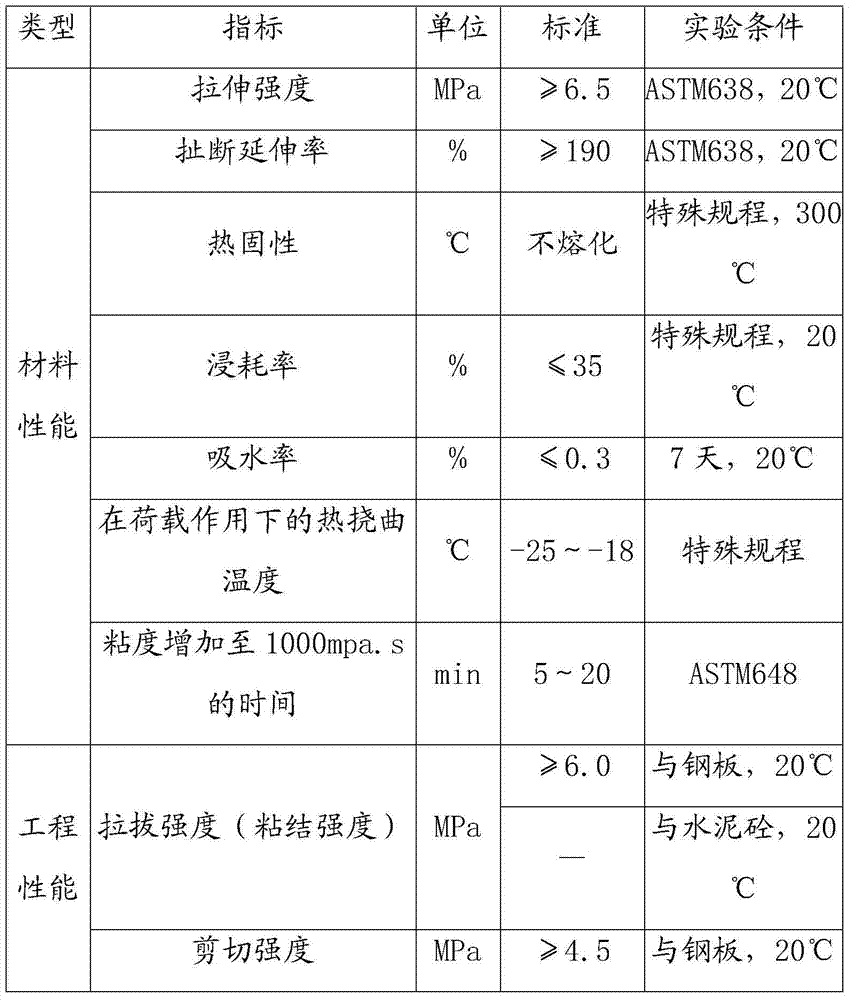

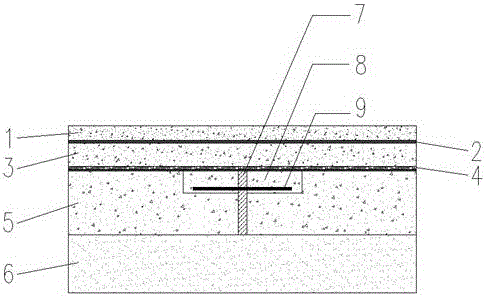

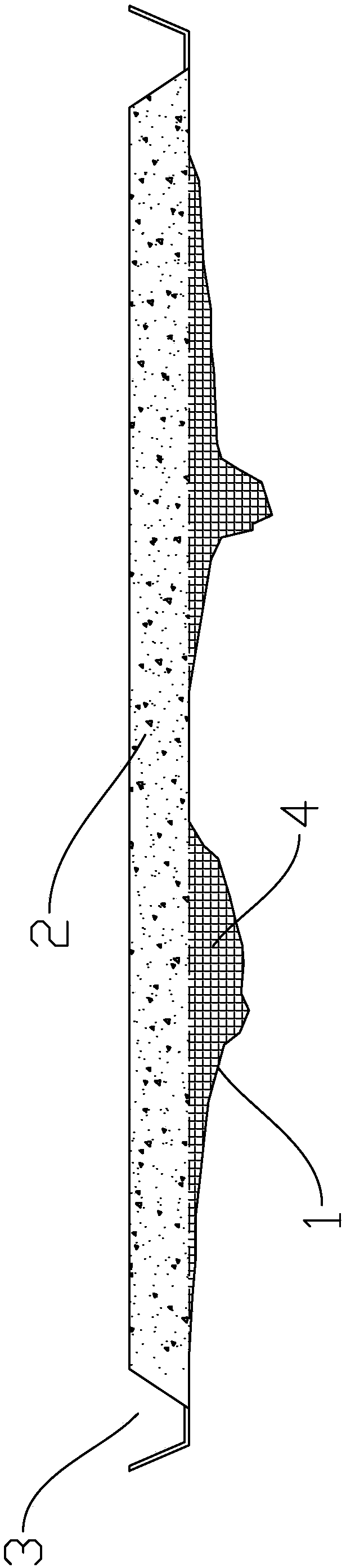

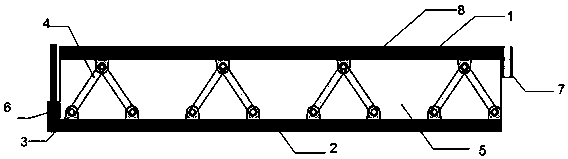

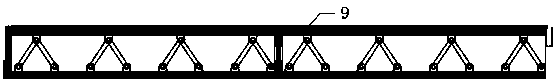

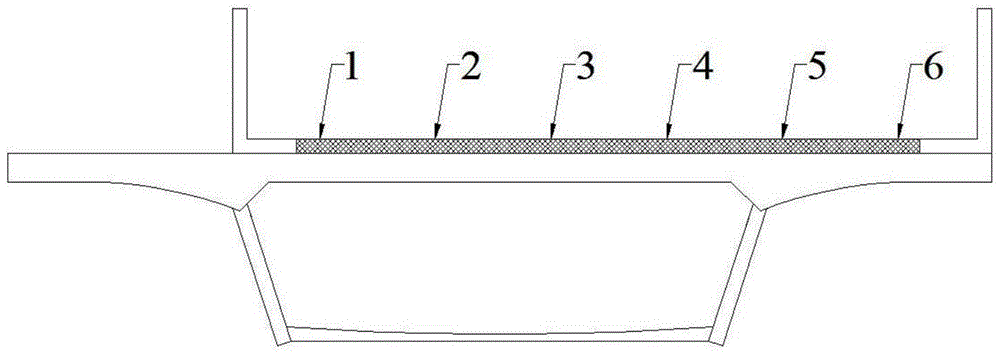

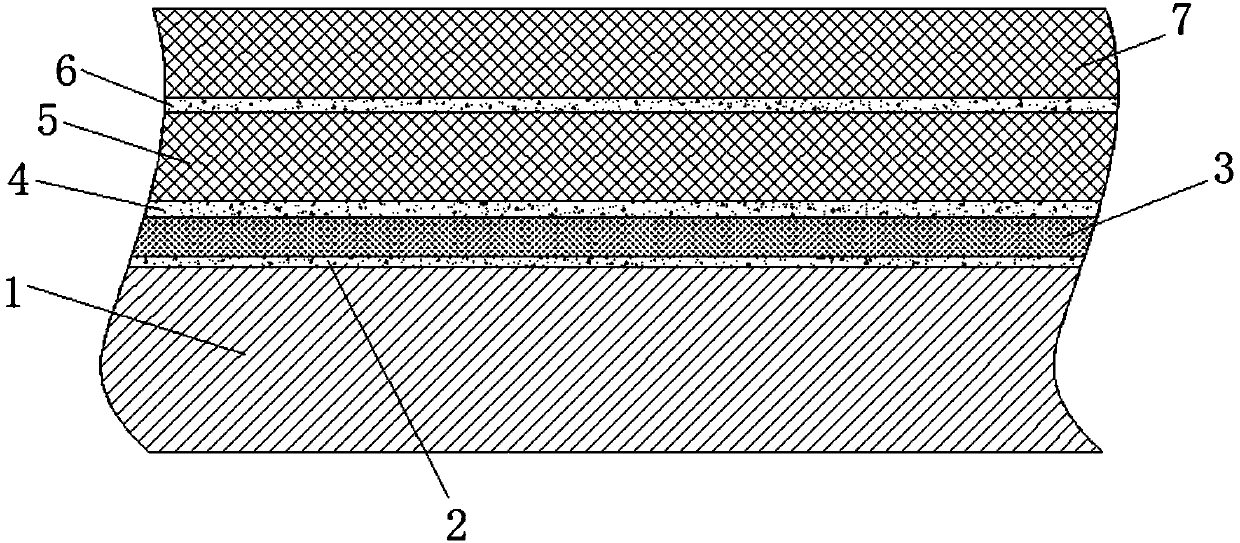

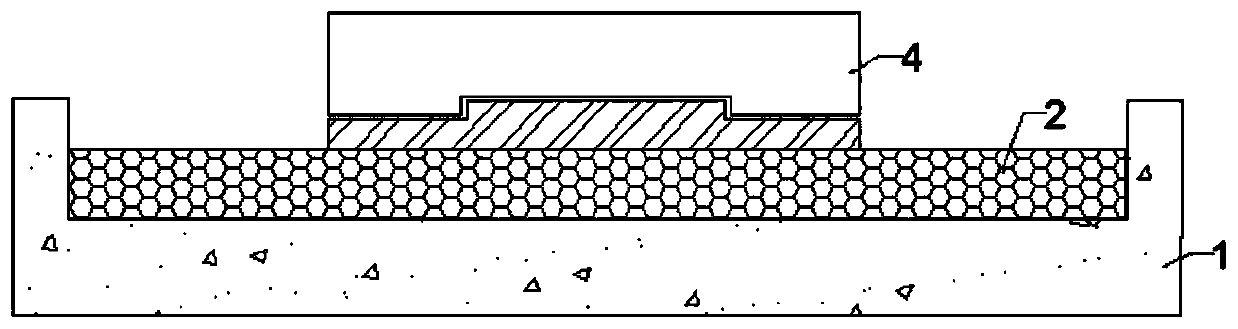

Steel box girder bridge deck pavement layer with high stability and high vibration resistance

InactiveCN104278630AHigh bonding strengthImprove bindingIn situ pavingsBridge structural detailsPolyesterEpoxy

The invention relates to a steel box girder bridge deck pavement layer with high stability and high vibration resistance. The steel box girder bridge deck pavement layer comprises a steel plate (1), wherein a waterproof bonding layer (2), a modified epoxy resin structure glue layer (3), a polyester filament and geotechnical cloth combined layer (4), a first high-viscosity modified asphalt tack coat (5), a first high-viscosity modified polyester fiber mixed stone mastic asphalt mixture layer (6), a second high-viscosity modified asphalt tack coat (7) and a second high-viscosity modified polyester fiber mixed stone mastic asphalt mixture layer (8) are arranged on the upper surface of the steel plate (1) from bottom to top. The steel box girder bridge deck pavement layer has the advantages of improving the bonding strength of an asphalt concrete pavement layer and a bridge deck slab, and improving the combining performance of the asphalt concrete pavement layer and the bridge deck slab due to high strength, good elasticity and high toughness of a geotechnical cloth; the geotechnical cloth has good traction action on the whole bridge deck slab, and finally, the purposes that the bridge deck pavement layer is prevented from shearing fracture, the asphalt pavement is prevented from translation, upheaval and other diseases in a travelling process, and the stability and vibration resistance of the bridge deck slab are effectively improved are achieved.

Owner:WUHAN UNIV

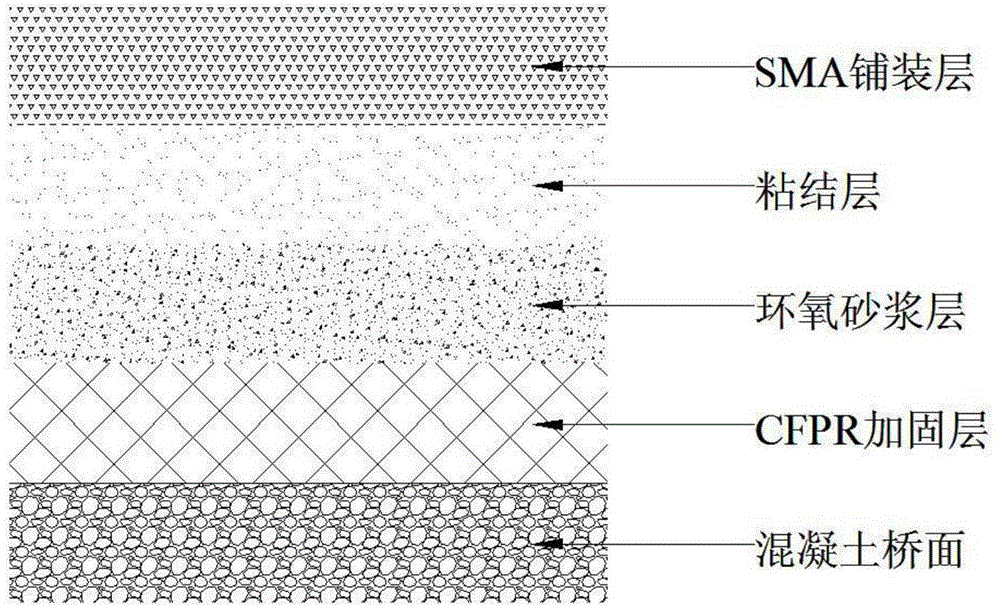

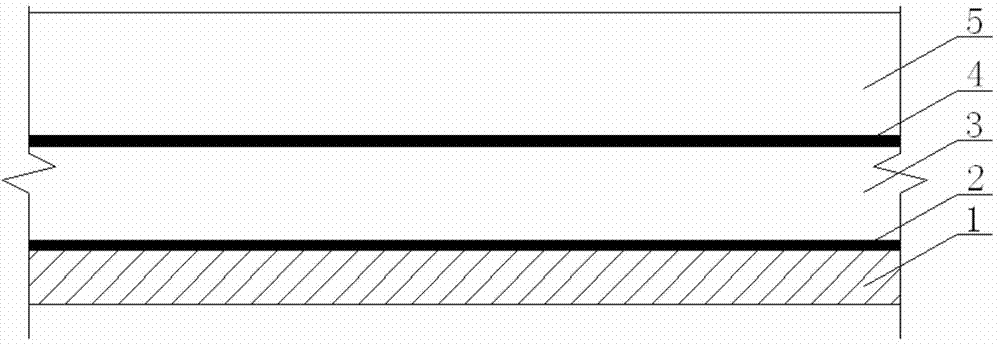

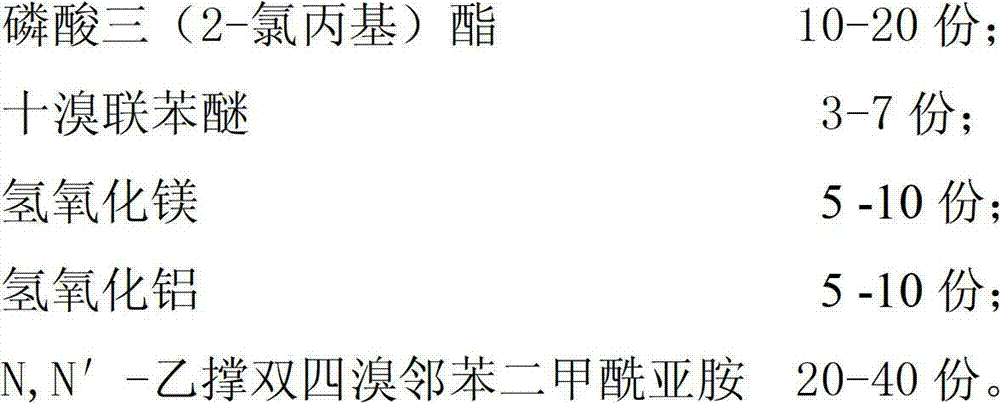

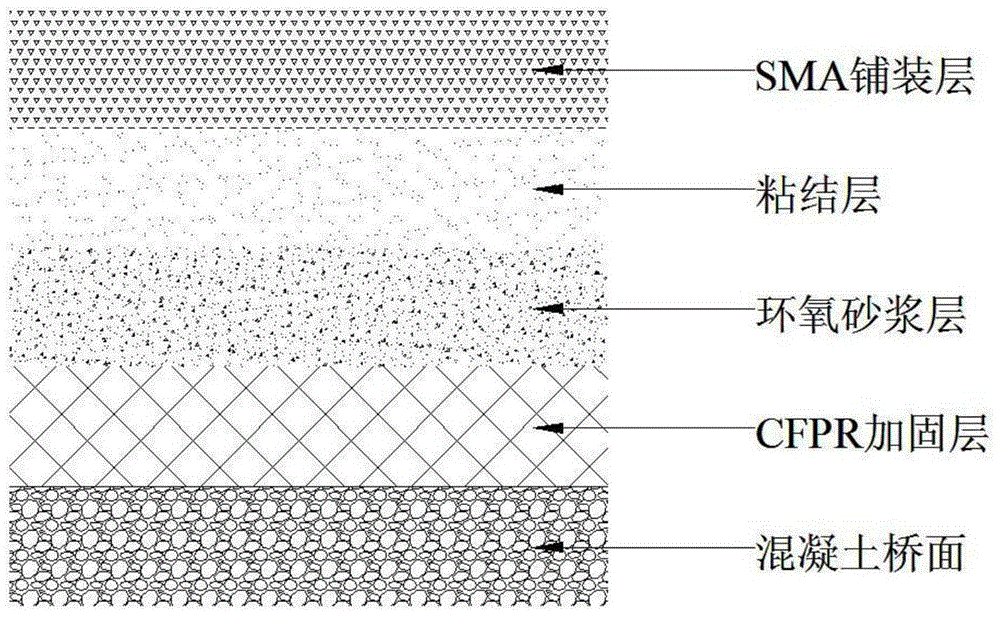

Novel compound deck repairing layer for concrete beam bridge

ActiveCN104060533AInhibit expansionGood waterproof and heat insulation functionBridge structural detailsBridge erection/assemblyThermal insulationStone mastic asphalt

The invention relates to bridge deck repairing, in particular to a novel compound deck repairing layer for a concrete beam bridge. The deck repairing layer comprises a carbon fiber plate reinforcement layer, an epoxy mortar layer and a stone mastic asphalt formation layer, wherein the carbon fiber plate reinforcement layer is formed by pressing high-strength carbon fiber and epoxy resin at high temperature; the epoxy mortar layer is formed by mixing epoxy resin and fine sand; the stone mastic asphalt formation layer is a stone mastic asphalt concrete layer. The novel compound deck repairing layer, provided by the invention, is clear in structural function; the repairing layer can effectively prevent further expansion of a crack; the formation layer has excellent water preventing and thermal insulation functions to avoid wearing and corrosion to the steel reinforcement inside the concrete bridge; the adopted carbon fiber and other materials can improve tensile strength of the repairing layer, and the service life of the deck is prolonged.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

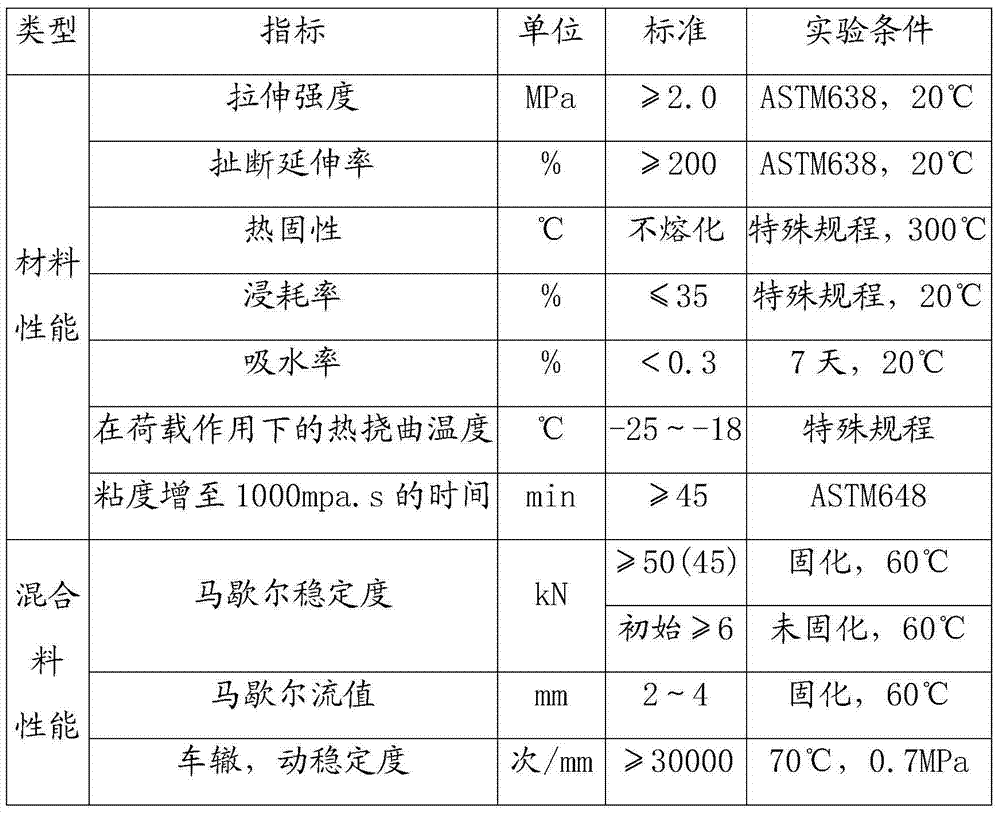

Composite pavement structure of steel bridge deck and paving method of composite pavement structure

InactiveCN103590331AReduce thicknessLow costBridge structural detailsBridge erection/assemblyBridge deckBituminous concrete

Owner:JIANGYIN BRIDGE BEIJING ENG +3

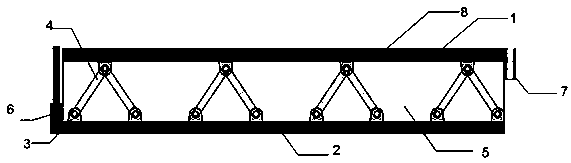

Steel bridge deck pavement structure

InactiveCN106638294ANot easy to corrodeExtended service lifeBridge structural detailsEpoxySheet steel

The invention provides a steel bridge deck pavement structure which comprises a steel bridge deck slab; an epoxy zinc-rich primer anti-corrosion course is arranged on the steel bridge panel; an epoxy asphalt bonding waterproof course is arranged on the upper side of the epoxy zinc-rich primer anti-corrosion course; an epoxy asphalt concrete paving course is paved on the upper side of the epoxy asphalt bonding waterproof course; an epoxy asphalt bonding course is paved on the upper side of the epoxy asphalt concrete paving course; and a high-elasticity modified stone mastic asphalt course is paved on the epoxy asphalt bonding course. The steel bridge deck pavement structure is high in bonding strength, and not prone to damages of delaminating, slippage and the like; the waterproof performance is good, and the situation that water permeates and erodes a steel plate is not prone to occurring; and the corrosion resistance is high, and the service life of a bridge is prolonged. Therefore, epoxy asphalt is an excellent bonder, and is particularly suitable for an orthotropic steel bridge deck slab system.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

Method for catalytically degrading automobile tail gas based on stone mastic asphalt pavement

InactiveCN109012159AImprove the atmospheric environmentReduce pollutionGas treatmentIn situ pavingsSorbentPhysical chemistry

The invention relates to a method for catalytically degrading automobile tail gas based on a stone mastic asphalt (SMA) pavement, and belongs to the technical field of SMA pavements. The problems of no catalytic degradation of the automobile tail gas, poor nano-TiO2 dispersibility and poor catalytic degradation effect of existing SMA pavements are solved. Lanthanum and copper ions are adopted as adoping agent to modify TiO2, a lignin stabilizer is used as an adsorbent, a lanthanum-copper codoped modified TiO2 supported lignin stabilizer is prepared by a sol-gel technology, and the lanthanum-copper codoped modified TiO2 supported lignin stabilizer is mixed with SMA; the pavement performances and the catalytic degradation effect of main components of the tail gas are evaluated; and the pavement performances and the catalytic degradation test results of the SMA are comprehensively compared, the concentration of a lanthanum nitrate and copper sulfate solution is adjusted, and the optimumdoping amount of lanthanum and copper in TiO2 loaded on the lignin stabilizer is determined through repeated test, so the SMA is used to pave the SMA pavement with an automobile tail gas catalytic degradation function. The method can be used in the practices of the SMA pavement, and is great significance to reduce air pollution and improve the air environment quality.

Owner:NANJING FORESTRY UNIV

Rubber powder and SBS modified compound modified asphalt and preparation method thereof

InactiveCN107987540AQuality improvementEasy to manufactureBuilding insulationsGutta-perchaPolymer science

The invention discloses rubber powder and SBS modified compound modified asphalt and a preparation method thereof. The modified asphalt is prepared from SBS modified asphalt, rubber powder, gutta-percha, an ampholytic surfactant and an antiageing agent in proportion. The compound modified asphalt is prepared from the following components in percentage by weight: 87-89% of SBS modified asphalt, 11.5-9.5% of rubber powder, 0.8-0.6% of gutta-percha, 0.3-0.4% of the ampholytic surfactant and 0.4-0.5% of the antiageing agent. The high- and low-temperature and mechanical properties of the compound modified asphalt are improved greatly compared with those of single SBS modified asphalt and the compound modified asphalt used for an asphalt mixture can be equivalent to stone mastic asphalt in pavement performance. Performances in some aspects are superior to those of the SMA pavement but the cost is lower than that of the SMA pavement. The compound modified asphalt can be applied to high gradeasphalt pavements and can improve the using performance of the pavement and prolong the service life, and meanwhile, the construction cost can be reduced, and the cost is saved.

Owner:SOUTHEAST UNIV

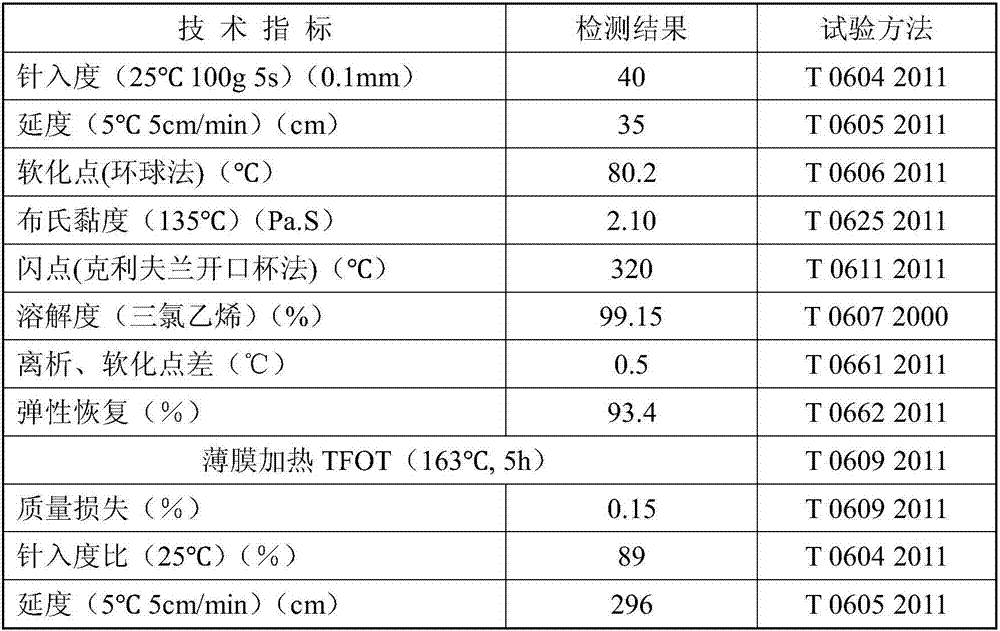

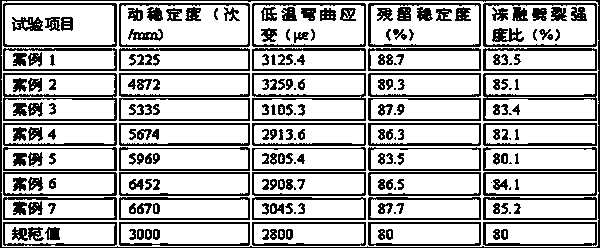

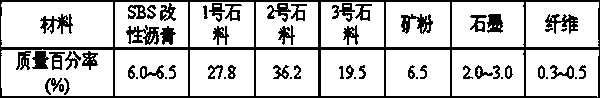

Thermal conductive SMA (stone mastic asphalt) asphalt concrete used for electric snow melting asphalt pavement

The invention discloses a thermal conductive SMA (stone mastic asphalt) asphalt concrete used for an electric snow melting asphalt pavement, the thermal conductive SMA asphalt concrete is characterized in that: the mass percentage formula for the thermal conductive SMA asphalt concrete is as follows: 6-6.5% of asphalt, 83-85% of a stone material, 7.5-6.5% of mineral powder, 2-3% of graphite and 0.3%-0.5% of fiber. The thermal conductive SMA asphalt concrete not only meets the performance requirements of SMA asphalt concrete, also has the advantages of good thermal conductivity, high temperature performance and the like, is suitable for electric snow melting asphalt pavement, and can reduce the snow melting energy consumption.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Composite structure for suppressing reflection cracks of old cement concrete pavement and reconstruction method

ActiveCN106436525AExtension reduction or blockingInhibit expansionPaving detailsEpoxyReconstruction method

The invention discloses a composite structure for suppressing reflection cracks of an old cement concrete pavement. The composite structure comprises a base layer, an old cement slab laid on the base layer and an asphalt concrete overlay laid on the old cement slab, and also comprises a multi-scale hybrid-fiber reinforced epoxy asphalt chip seal laid between the old cement slab and the asphalt concrete overlay; the asphalt concrete overlay comprises a lower layer of medium-grained asphalt concrete, a modified emulsified asphalt binder layer and an upper layer of stone mastic asphalt, which are sequentially laid from the bottom to the top. The invention further discloses a reconstruction method of the composite structure for suppressing reflection cracks of an old cement concrete pavement, and the reconstruction method comprises local constraints of steel bar forming, planting of steel bars and completion of the multi-scale hybrid-fiber reinforced epoxy asphalt chip seal. According to the composite structure and the reconstruction method disclosed by the invention, the overall bearing capacity of the pavement which is reconstructed by the old cement slab can be improved, the interlayer bonding force between the old cement slab and the asphalt concrete overlay is effectively increased, the generation of the reflection cracks is suppressed and the condition that the reflection cracks are prevented from extending to the asphalt concrete overlay is avoided.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD

Temporary road roller compacted concrete pavement reforming structure and construction method thereof

InactiveCN107805989ASuitable for retrofit constructionSimple structureIn situ pavingsRoads maintainenceRoller-compacted concreteCrushed stone

The invention relates to a temporary road roller compacted concrete pavement reforming structure and a construction method thereof. A purpose of the present invention is to provide a temporary road roller compacted concrete pavement reforming structure with characteristics of convenient construction, low cost and short maintenance time, and a construction method thereof. The technical scheme of the present invention is that a concrete road surface plate is arranged on a subgrade being subjected to leveling and filling compaction, and is formed by rolling roller compacted concrete spread on thesubgrade, a plurality of horizontal contraction joints are sawn on the surface of the concrete pavement plate, the contraction joints are subjected to crack sealing with stone mastic asphalt, and theroller compacted concrete is formed by mixing cement, water, a GQ202 type retarding water reducer, sand, 5-20 mm gravel and 20-40 mm gravel. The temporary road roller compacted concrete pavement reforming structure of the present invention is suitable for temporary road pavement reforming and other projects.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

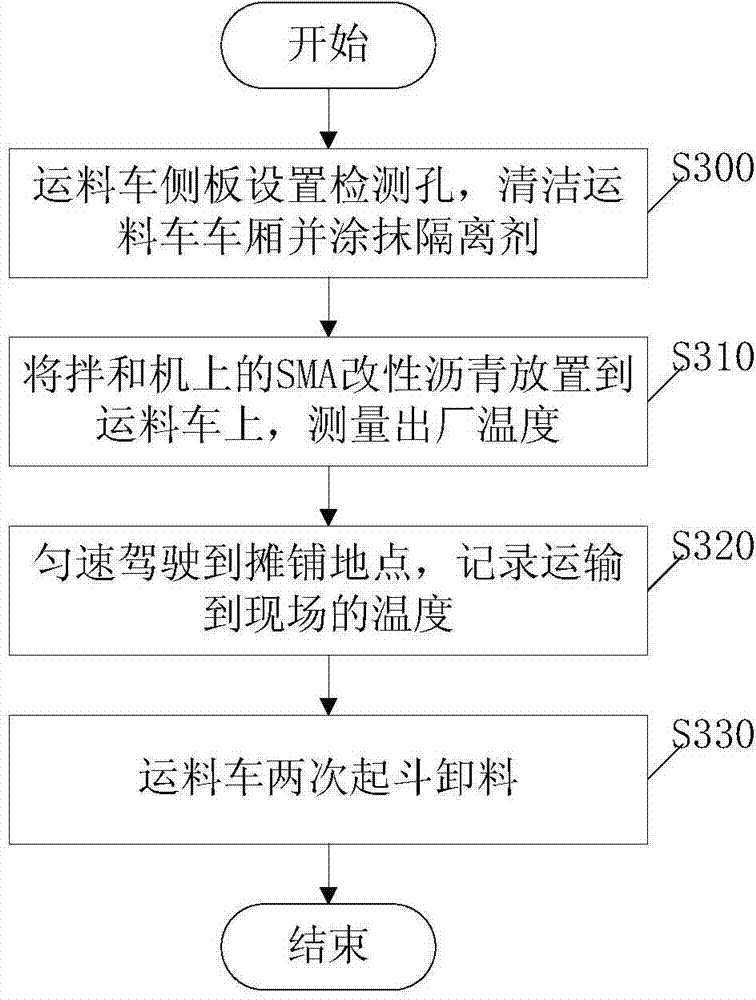

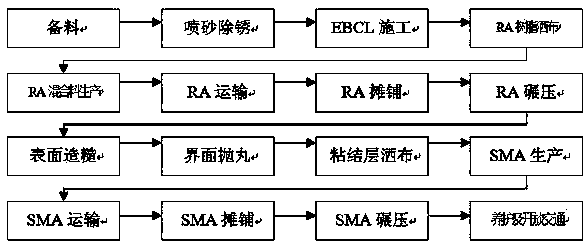

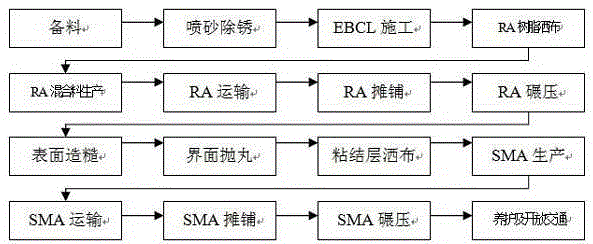

Mechanical construction method of steel deck ERS system

InactiveCN103628418AAvoid pollutionAvoid unevennessBridge structural detailsBridge erection/assemblyStone mastic asphaltAsphalt

The invention discloses a mechanical construction method of a steel deck ERS (Epoxy Bonding Chips Layer-Resin Asphalt-Stone Mastic Asphalt) system. The method comprises the steps of (1) preparing materials, (2) derusting by sandblasting, (3) carrying out EBCL (Epoxy Bonding Chips Layer) construction, (4) Spreading RA (Resin Asphalt), (5) producing an RA mixture, (6) transporting the RA, (7) paving the RA, (8) rolling the RA, (9) performing RA surface roughing, (10) carrying out shot interface blasting, (11) spreading a binding layer, (12) producing SMA (Stone Mastic Asphalt), (13) transporting the SMA, (14) spreading the SMA, (15) rolling and (16) carrying out closed maintenance. The mechanical construction method provided by the invention has the characteristics that the labor is saved, the production efficiency of construction is improved, the theoretical construction period is shortened and the cost of labor, machines, materials, management and the like is obviously reduced, also the construction quality is improved and the service life of a paved deck is prolonged.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

Halogen-free glass fiber reinforced PC and preparing technique thereof

InactiveCN101759986AChanging a situation that always lowers a requirementImprove mechanical propertiesFiberGlass fiber

The present invention relates to an organic polymer composite, particularly to a halogen-free glass fiber reinforced polycarbonate (PC) and a preparing technique thereof. The halogen-free glass fiber reinforced PC consists of the following constituents in a ratio by weight: 47.5 to 95% of PC, 5 to 35% of environmental protection glass fiber, 0.1 to 2.0% of antioxidant, 1 to 3.0% of stone mastic asphalt (SMA), 0.1 to 2.0% of grafted polyethylene (PE) and 1.3 to 5.5% of other auxiliaries. The halogen-free glass fiber reinforced PC and the preparing technique have the advantages that comprehensive mechanical properties are excellent, the PC does not contain halogen, no fibers are exposed outside the product, and production and procurement are convenient. The present invention changes the conditions that users always need to reduce the requirements for certain aspects, and meanwhile meets all the other environmental protection requirements. Thus, the comprehensive competitive power is improved.

Owner:KECHUANG POLYMER SUZHOU

An electromagnetic induction type thermally dispersed PAN-PE composite modified stone mastic asphalt material, a preparing method thereof and a constructing method of the material

ActiveCN105906235AAuxiliary heat efficiency improvementImprove construction efficiencyIn situ pavingsSolid waste managementStone mastic asphaltChipseal

The invention relates to an electromagnetic induction type thermally dispersed PAN-PE composite modified stone mastic asphalt material, a preparing method thereof and a constructing method of the material. The material is prepared by mixing and stirring polyoxyethylene alkyl ether, silicone oil and water to prepare a dispersing agent, mixing polyaniline and polyethylene to prepare an electromagnetic induction type PAN-PE compound polymer modifying agent, adding the modifying agent into matrix asphalt, stirring, mixing, shearing, blending weighed aggregate and lignin fibres, blending the PAN-PE compound modified asphalt, the aggregate and the lignin fibres, adding the dispersing agent and a warm-mix agent, adding ore powder, blending, and discharging from a kettle to obtain the material. The material can be used for local damage repair of SMA pavements of bridge floors, tunnels, airports and highways of various grades, is capable of pre-mixing, free of blocking and capable of long-term storage, is a high-performance hot-repair material that can be heated when the material is to be used for pits and slots, is suitable for repairing SMA type pavements and fully matches original pavements.

Owner:CCCCRUITONG ROAD & BRIDGE MAINTENANCE TECH

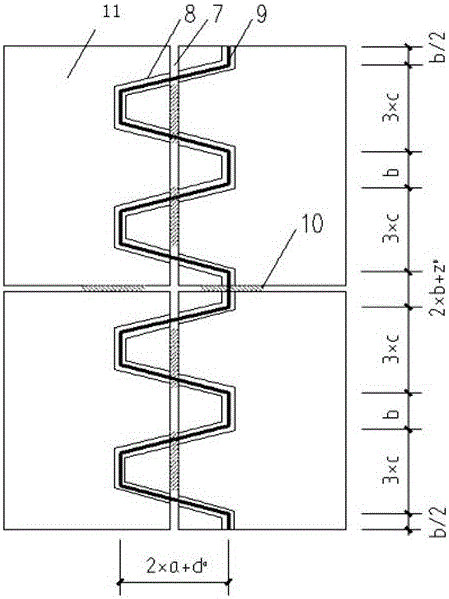

Assembled type anti-shear asphalt pavement and laying method thereof

ActiveCN106758653AHigh bonding strengthImprove water stabilityIn situ pavingsSolid waste managementCrack resistanceCement composites

The invention relates to an asphalt pavement structure and a construction method thereof, specifically to an assembled type anti-shear asphalt pavement and a laying method thereof. The assembled type anti-shear asphalt pavement comprises the following structural courses which are laid in sequence from top to bottom, wherein the structural courses are a (3.5-4.5) cm wearing course, which is waste tire rubber powder and SBS composite modified stone mastic asphalt mixture SMA-13, a waterproof adhesive course and a bearing course, which is modified emulsified asphalt and cement composite grouting asphalt mixture SFC-20. The assembled type anti-shear asphalt pavement has the advantages of good integral strength, good flexibility, long fatigue life, good crack resistance, convenient construction and maintenance, short construction period and less construction pollution.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

Mixing and stirring method and device in construction of SBS modified stone mastic asphalt

ActiveCN101691733AImprove productivityHigh measurement accuracyRoads maintainenceStone mastic asphaltLeather belt

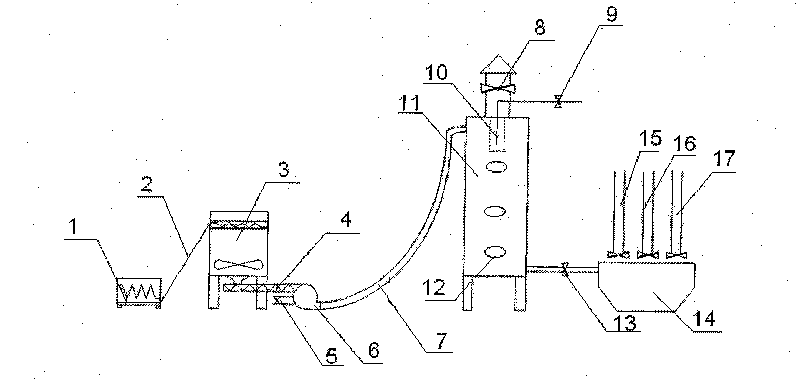

The invention relates to a mixing and stirring method and a device in construction of SBS modified stone mastic asphalt (SMA), enhancing the measuring accuracy. The invention is characterized in that a crusher 1 performs primary crushing on cellulose fiber, the cellulose fiber processed by the primary crushing is conveyed to a batchmeter 3 via a conveying belt 2 connected to the crusher 1, and accurate measurement is carried out by a self decrement scale of the batchmeter 3; the cellulose fiber processed by the secondary crushing and accurate measuring is conveyed to an air blower 6, an air inlet valve 5 and an air outlet valve 8 are opened, a blowback valve 9 and a discharge valve 13 are closed, the air blower 6 is started to blow the cellulose fiber into a measurement storing barrel 11 via a channel 7, after all the measured cellulose fiber is blown into the measurement storing barrel, the air outlet valve is closed, the air inlet valve, the discharge valve and the blowback valve are opened, all the cellulose fiber is sent into an agitating tank to be dryly agitated with the aggregate of coarse aggregate and fine aggregate, and finally mineral powder and asphalt are added to perform wet agitating to produce qualified SMA concrete.

Owner:CCCC SHEC DONGMENG ENG CO LTD

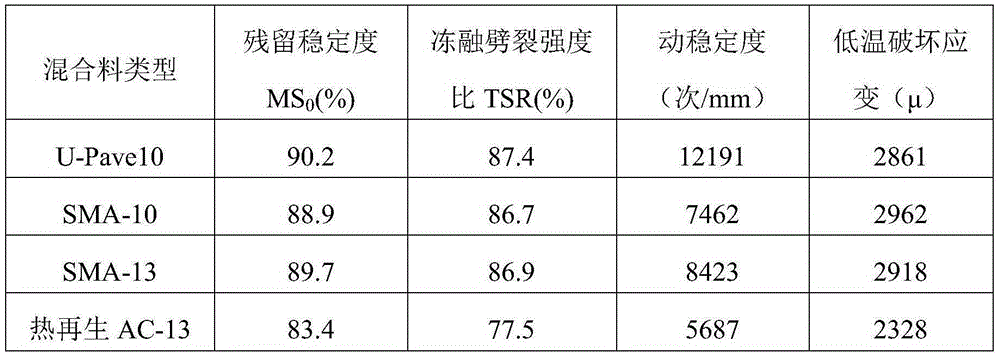

Pavement crack disposal structure and technology

InactiveCN105332329AReduce oil consumptionImprove fatigue resistanceIn situ pavingsPaving detailsUltrasound attenuationEpoxy

The invention discloses a pavement crack disposal structure and technology. The technology comprises operation steps as follows: slotting is performed on two sides of a pavement crack of a lower surface layer in the crack direction, then crack pouring is performed, a crack pouring material is a high-permeability epoxy resin material, fine milling is performed after high-permeability epoxy resin is cured, and a repair overlay is backfilled. The repair overlay is a U-Pave (Ultra-thin asphalt pavement) and adopts an integrated spreading and paving construction technology, so that upper and lower surface layers of a pavement form a whole, and the anti-fatigue performance is significantly enhanced. Test pavement tracking and monitoring data indicate that the structure depth of the U-Pave10 is slightly smaller than SMA (stone mastic asphalt) in the initial period after completion, however, attenuation resistance is higher during long-term usage, the longer the time is, the more obvious the advantages are, besides, the traffic noise of a U-Pave10 pavement is reduced by 1-2 db according to on-site inspection, and the driving comfort is improved.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

Composite insulation material and insulation method thereof

ActiveCN104879612AEfficient use ofSave resourcesThermal insulationLaminationCalcium silicateInsulation layer

The invention provides a composite insulation material and an insulation method thereof. The composite insulation material comprises an inner insulation layer, an isolation layer, more than one outer insulation layer and a protective layer arranged in order from inside to outside. The inner insulation layer comprises a transitional layer and a calcium silicate insulating layer arranged in order from inside to outside. The transitional layer is a felt layer and / or a polysilicon fiber layer. The isolation layer comprises a polysilicon fiber layer and a flame-retardant stone mastic asphalt layer arranged in order from inside to outside. The outer insulation layer comprises an aerosol layer and a multi-condensation foam glass layer arranged in order from inside to outside. The composite insulation material is low in cost, small in size and light in weight, has good, lasting insulation effect and is widely applicable.

Owner:DATANG INT POWER GENERATION +2

Ultrathin asphalt mixed material and preparation method thereof

InactiveCN110590235AImprove high temperature stabilityGuaranteed fatigue resistancePolyesterFatigue damage

The invention provides an ultrathin asphalt mixed material and a preparation method thereof. The ultrathin asphalt mixed material comprises the following components: 10-50 parts of an aggregate of 5-10mm, 20-50 parts of an aggregate of 3-5mm, 15-35 parts of an aggregate of 0-3mm, 4-10 parts of mineral powder, 5-8 parts of modified asphalt, 0.2-0.5 part of a special ultrathin asphalt mixed materialadditive and 0.2-0.4 part of polyester fiber. Compared with common SMA (stone mastic asphalt) and AC (asphalt concrete) asphalt mixed materials, the ultrathin asphalt mixed material has good high temperature stability and low temperature cracking resistance, excellent fatigue damage resistance and outstanding anti-sliding performance.

Owner:上海同沥新材料科技有限公司

Fast assembly type anti-explosion protective plate for steel bridge main girders and method for manufacturing and assembling fast assembly type anti-explosion protective plate

ActiveCN108560401AReduced dynamic responsePrevent softening and bucklingBridge structural detailsBuilding constructionsShock waveSheet steel

The invention discloses a fast assembly type anti-explosion protective plate for steel bridge main girders and a method for manufacturing and assembling the fast assembly type anti-explosion protective plate. The fast assembly type anti-explosion protective plate comprises a plurality of assembly type anti-explosion protective plate single bodies. The assembly type anti-explosion protective platesingle bodies are combined with one another to form the fast assembly type anti-explosion protective plate, a top steel plate and a bottom steel plate of each assembly type anti-explosion protective plate single body are integrally connected with each other by hinges and energy dissipation soft steel bars, spaces between the top steel plates and the bottom steel plates are filled with foamed aluminum layers, variable-section steel bars are adhered on the bottom steel plates, round steel ingots with holes are adhered on the top steel plates, basalt fiber cloth is adhered on the top steel plates, and SMA (stone mastic asphalt) flame-retardant asphalt concrete abrasion layers are paved on the surfaces of the fast assembly type anti-explosion protective plate after the fast assembly type anti-explosion protective plate is completely assembled. The fast assembly type anti-explosion protective plate and the method have the advantages that the excellent explosion shock wave energy absorptioncapacity of foamed aluminum, the support and energy dissipation capacity of the steel bars, the high-temperature resistance of the basalt fiber cloth and the disguise power and the abrasion resistanceof the SMA flame-retardant asphalt concrete abrasion layers are utilized, and accordingly the purpose of bearing upper load and protecting the steel bridge main girders can be achieved; the cost canbe saved, the quality of the fast assembly type anti-explosion protective plate can be controlled, and the fast assembly type anti-explosion protective plate is convenient to construct.

Owner:SOUTHEAST UNIV

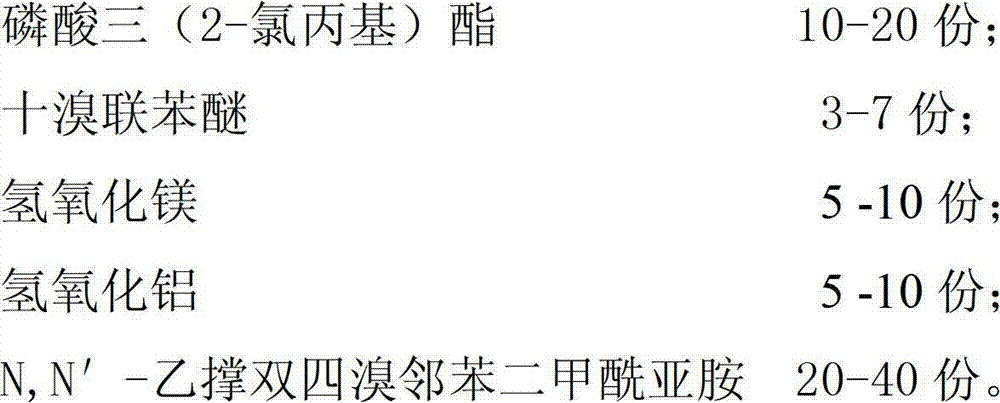

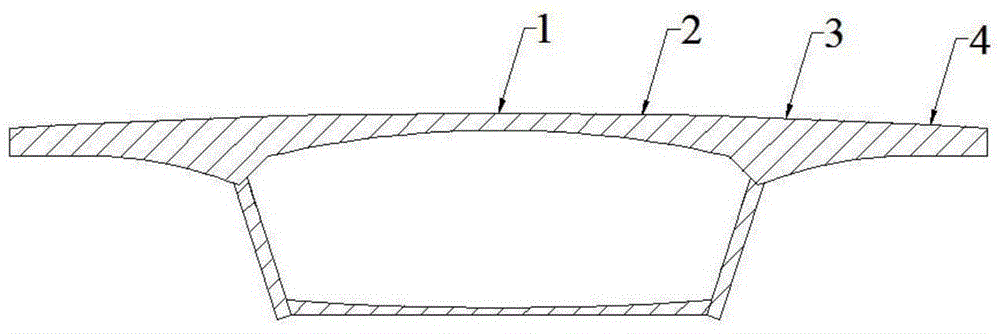

Flame retardant stone mastic asphalt for tunnel pavement

InactiveCN103588421AGood heat insulationImprove flame retardant performanceDecabromodiphenyl etherPhosphate

The invention discloses a flame retardant stone mastic asphalt for tunnel pavement. The flame retardant stone mastic asphalt comprises the following components by weight: 3-5 parts of limestone powder, 1-2 parts of an organic flame retardant, 8-12 parts of asphalt and 100 parts of macadam. Further, the organic flame retardant comprises the following components by weight: 10-20 parts of tris(1-chloro-2-propyl) phosphate, 3-7 parts of decabromodiphenyl ether, 5-10 parts of magnesium hydroxide, 5-10 parts of aluminum hydroxide and 20-40 parts of N,N'-ethylene-bis(tetrabromophthalimide). The stone mastic asphalt for tunnel pavement provided by the invention has the advantages of good heat insulation effect, good flame retardance, safety and environment-friendliness.

Owner:SHANGHAI XILUO BUSINESS CONSULTING

Preparation method of high-strength graphene material

The invention discloses a preparation method of a high-strength graphene material. The preparation method comprises the following steps of: taking raw materials of graphite, diester phthalate, methylisobutyl ketone, trinonyl phenyl ester phosphite, SEBS (Styrene-Ethylene-Butylene-Styrene), fibrilia, calcium stearate, polyvinylidene fluoride, zinc oxide, titanium dioxide, PVC (polyvinyl chloride),CPE (Chlorinated Polyethylene), SMA (Stone Mastic Asphalt), graphene oxide and a crosslinking agent, uniformly mixing, plastically granulating, and then calcining to obtain the high-strength graphenematerial. The preparation method disclosed by the invention has the beneficial effects that the raw materials are wide in source and low in cost, the Rockwell hardness is 110-150, the high-strength graphene material can be self-extinguished after leaving from a fire, and the thermal deformation temperature is increased by 20-30%; the elongation at break is up to 300-500%, and the tensile strengthis 80-120MPa; the permanent compression deformability is good, the energy density is high, the conductivity is good and the thermal conductivity is 35-55W / (m.k); the high-strength graphene material is good in printing electrode property, is high-efficiency and energy-saving and can be accurately prepared; all the components generate a synergistic effect, and the notched impact strength is 70-110J / m; the high-strength graphene material is convenient in use, good in thermal conductivity and simple in process, and can be widely used.

Owner:苏州牛麦田新材料科技有限公司

A Novel Composite Deck Repair Layer for Concrete Beam Bridges

ActiveCN104060533BInhibit expansionGood waterproof and heat insulation functionBridge structural detailsBridge erection/assemblyEpoxyFiber

The invention relates to bridge deck repairing, in particular to a novel compound deck repairing layer for a concrete beam bridge. The deck repairing layer comprises a carbon fiber plate reinforcement layer, an epoxy mortar layer and a stone mastic asphalt formation layer, wherein the carbon fiber plate reinforcement layer is formed by pressing high-strength carbon fiber and epoxy resin at high temperature; the epoxy mortar layer is formed by mixing epoxy resin and fine sand; the stone mastic asphalt formation layer is a stone mastic asphalt concrete layer. The novel compound deck repairing layer, provided by the invention, is clear in structural function; the repairing layer can effectively prevent further expansion of a crack; the formation layer has excellent water preventing and thermal insulation functions to avoid wearing and corrosion to the steel reinforcement inside the concrete bridge; the adopted carbon fiber and other materials can improve tensile strength of the repairing layer, and the service life of the deck is prolonged.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

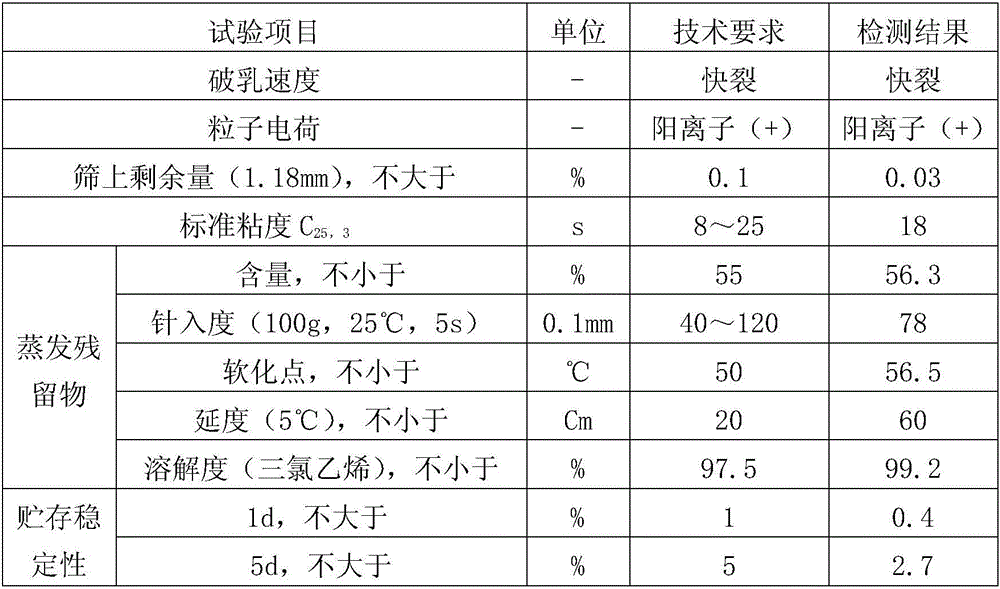

Waterproof and anti-corrosion construction technology for steel box girder bridge deck paved with double-layer SMA (stone mastic asphalt)

InactiveCN109811656ALow costImprove structural durabilityBridge structural detailsBridge erection/assemblyBridge deckEconomic benefits

The invention discloses a waterproof and anti-corrosion construction technology for a steel box girder bridge deck paved with double-layer SMA (stone mastic asphalt). The technology comprises following steps: performing sandblast derusting on the steel box girder bridge deck; spraying an anti-corrosion coating; paving a waterproof layer; paving a first modified emulsified asphalt bonding layer; pouring an SMA10 asphalt concrete layer which is 4 cm thick; paving a second modified emulsified asphalt bonding layer; pouring an SMA13 asphalt concrete layer which is 4 cm thick. Compared with the prior art, one new paving construction technology is provided for the steel box girder bridge deck which is paved with the double-layer SMA and has a smaller area range; with the adoption of a coating-resistant ET material for paving the waterproof layer, project cost is reduced, and structural durability is improved; with the adoption of the construction technology, production cost can be saved, efficiency is improved, and quite good economic benefit is created.

Owner:江门市政企业集团有限公司

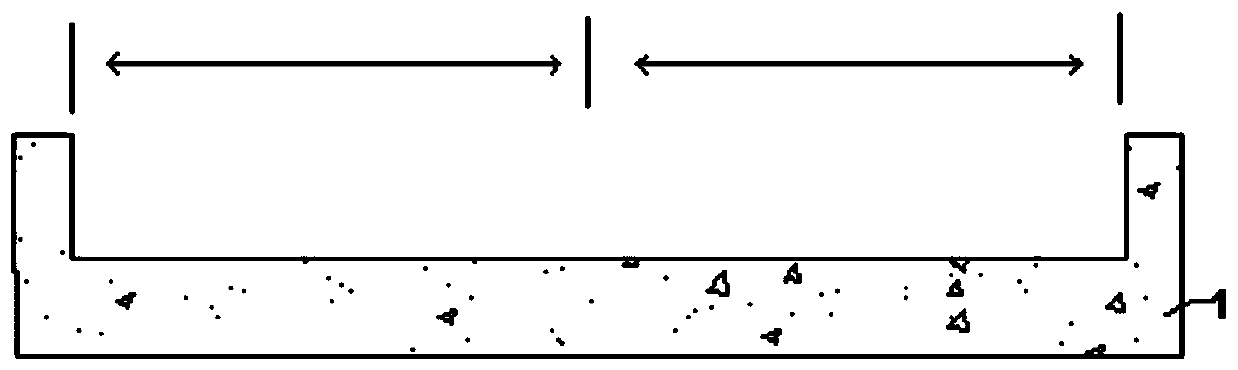

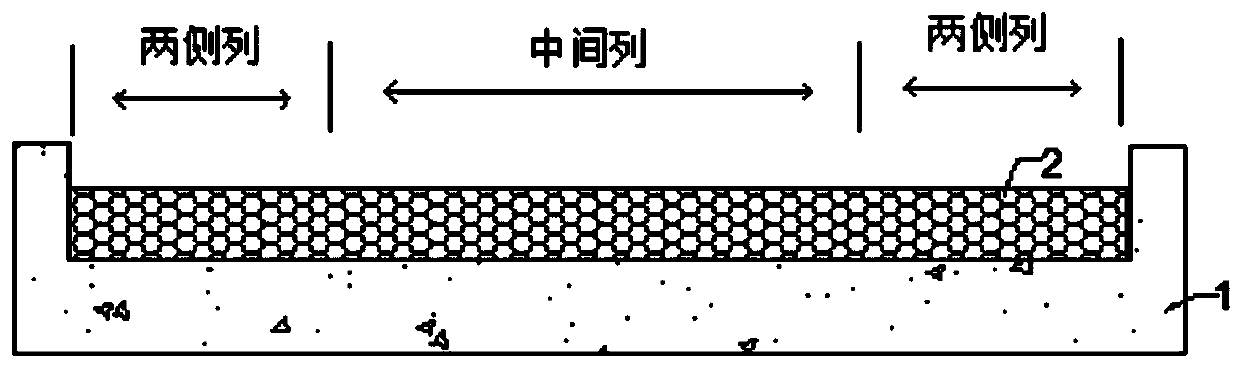

Construction method of expressway stone mastic asphalt (SMA) road surface

InactiveCN110172888AReduce depthReduce the probability of crackingIn situ pavingsRoads maintainenceScreedRoad surface

The invention discloses a construction method of an expressway stone mastic asphalt (SMA) road surface. An expressway is divided into a plurality segments for pavement. The construction method of theexpressway SMA road surface comprises the following steps that S1, a roadbed is paved, the roadbed is rolled by adopting a heavy road roller, the roadbed is measured by a three-meter ruler method, andthe flatness of the roadbed is controlled as 8mm; S2, first pavement is carried out, specifically, the expressway is divided into two same columns for pavement according to the width, and a paver with a lengthened screed plate is used for paving asphalt fillers on the roadbed for each column; and second pavement is carried out, specifically, the expressway is divided into odd number columns for pavement according to the width, separately recorded as a middle column and two-side columns, and each paver is used for paving the asphalt fillers on the road surface of the asphalt fillers paved forthe first time for each column; S3, the road surface is rolled; and S4, when the temperature of the asphalt fillers lowers below 50 DEG C, the SMA road surface is formed. The construction method of the expressway SMA road surface has the effect of reducing cracking probability occurring at seams of the expressway SMA road surface.

Owner:CCCC THIRD HIGHWAY ENG

A quick-assembled steel bridge main beam anti-explosion protective plate and its production and assembly method

ActiveCN108560401BReduced dynamic responsePrevent softening and bucklingBridge structural detailsBuilding constructionsIngotBasalt fiber

The invention discloses a fast assembly type anti-explosion protective plate for steel bridge main girders and a method for manufacturing and assembling the fast assembly type anti-explosion protective plate. The fast assembly type anti-explosion protective plate comprises a plurality of assembly type anti-explosion protective plate single bodies. The assembly type anti-explosion protective platesingle bodies are combined with one another to form the fast assembly type anti-explosion protective plate, a top steel plate and a bottom steel plate of each assembly type anti-explosion protective plate single body are integrally connected with each other by hinges and energy dissipation soft steel bars, spaces between the top steel plates and the bottom steel plates are filled with foamed aluminum layers, variable-section steel bars are adhered on the bottom steel plates, round steel ingots with holes are adhered on the top steel plates, basalt fiber cloth is adhered on the top steel plates, and SMA (stone mastic asphalt) flame-retardant asphalt concrete abrasion layers are paved on the surfaces of the fast assembly type anti-explosion protective plate after the fast assembly type anti-explosion protective plate is completely assembled. The fast assembly type anti-explosion protective plate and the method have the advantages that the excellent explosion shock wave energy absorptioncapacity of foamed aluminum, the support and energy dissipation capacity of the steel bars, the high-temperature resistance of the basalt fiber cloth and the disguise power and the abrasion resistanceof the SMA flame-retardant asphalt concrete abrasion layers are utilized, and accordingly the purpose of bearing upper load and protecting the steel bridge main girders can be achieved; the cost canbe saved, the quality of the fast assembly type anti-explosion protective plate can be controlled, and the fast assembly type anti-explosion protective plate is convenient to construct.

Owner:SOUTHEAST UNIV

A kind of mechanized construction method of steel bridge deck ers system

InactiveCN103628418BAvoid pollutionAvoid unevennessBridge structural detailsBridge erection/assemblySystem constructionAsphalt

The invention discloses a mechanical construction method of a steel deck ERS (Epoxy Bonding Chips Layer-Resin Asphalt-Stone Mastic Asphalt) system. The method comprises the steps of (1) preparing materials, (2) derusting by sandblasting, (3) carrying out EBCL (Epoxy Bonding Chips Layer) construction, (4) Spreading RA (Resin Asphalt), (5) producing an RA mixture, (6) transporting the RA, (7) paving the RA, (8) rolling the RA, (9) performing RA surface roughing, (10) carrying out shot interface blasting, (11) spreading a binding layer, (12) producing SMA (Stone Mastic Asphalt), (13) transporting the SMA, (14) spreading the SMA, (15) rolling and (16) carrying out closed maintenance. The mechanical construction method provided by the invention has the characteristics that the labor is saved, the production efficiency of construction is improved, the theoretical construction period is shortened and the cost of labor, machines, materials, management and the like is obviously reduced, also the construction quality is improved and the service life of a paved deck is prolonged.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

Open-graded asphalt mixture with small particle size for ultra-thin overlay

The invention provides a small-particle-size open-graded asphalt mixture for an ultra-thin overlay. The mixture is prepared from 85%-92% by weight of aggregate, 2%-8% by weight of filler and 5.5%-7.5% by weight of polymer modified asphalt, the nominal maximum aggregate size is 4.75 mm and the thickness of a pavement layer is 1.0-1.5 cm; preferably, the aggregate is basalt or diabase, the filler is the mixture of limestone mineral powder and cement in the mass ratio being (1:1)-(3:1), and the polymer modified asphalt is POE composite modified asphalt and has the zero-shear viscosity being 30,000 Pa.s or higher at 60 DEG C and the softening point equal to or higher than 90 DEG C. The small-particle-size open-graded asphalt mixture for ultra-thin overlay can reduce the thickness of a thin overlay, reduce building cost of a project and reduce noise during driving, two levels of hard building stones with the particle size being 3-5 mm or 0-3 mm can be utilized, the environment and resource stress of superfluous corresponding building stones due to large-scale application of SMA (stone mastic asphalt) pavements is reduced, and the small-particle-size open-graded asphalt mixture is ingenious in design, simple and convenient to prepare, low in cost and suitable for large-scale popularization and application.

Owner:SHANGHAI MUNICIPAL PLANNING & DESIGN INST CO LTD

Composite thermal insulation material and thermal insulation method

ActiveCN104879612BEfficient use ofSave resourcesThermal insulationLaminationCalcium silicateInsulation layer

The invention provides a composite insulation material and an insulation method thereof. The composite insulation material comprises an inner insulation layer, an isolation layer, more than one outer insulation layer and a protective layer arranged in order from inside to outside. The inner insulation layer comprises a transitional layer and a calcium silicate insulating layer arranged in order from inside to outside. The transitional layer is a felt layer and / or a polysilicon fiber layer. The isolation layer comprises a polysilicon fiber layer and a flame-retardant stone mastic asphalt layer arranged in order from inside to outside. The outer insulation layer comprises an aerosol layer and a multi-condensation foam glass layer arranged in order from inside to outside. The composite insulation material is low in cost, small in size and light in weight, has good, lasting insulation effect and is widely applicable.

Owner:DATANG INT POWER GENERATION +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

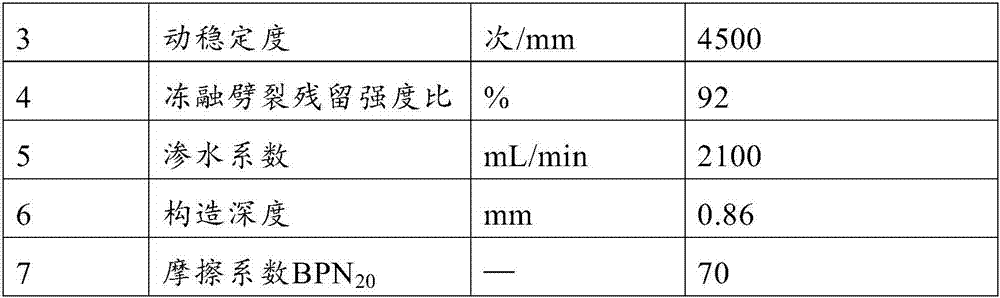

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com