Patents

Literature

33 results about "Mixed Stone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A concretion in the body that is composed of more than one substance.

Anti-freezing anti-seepage anti-cracking concrete and preparation method thereof

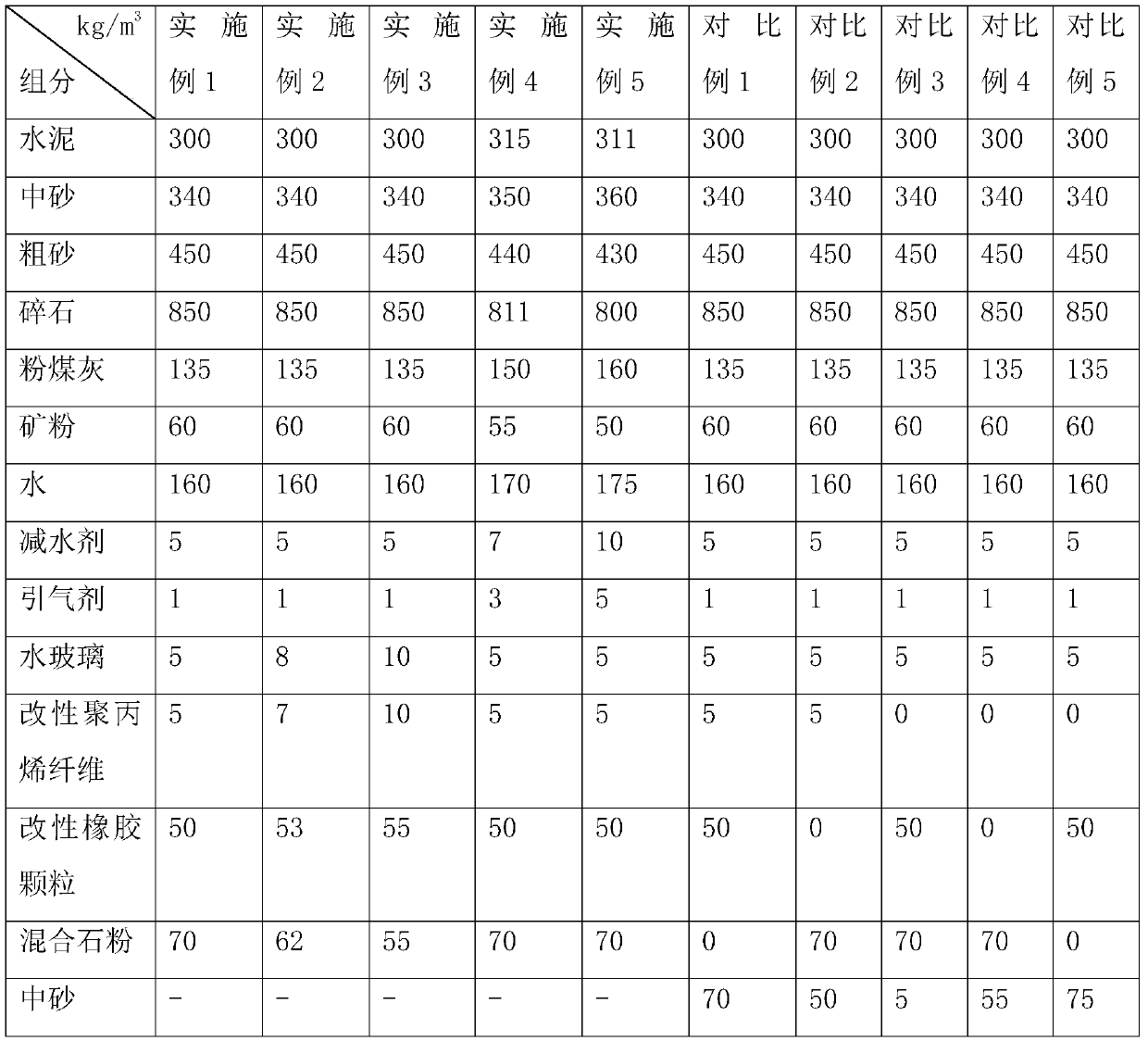

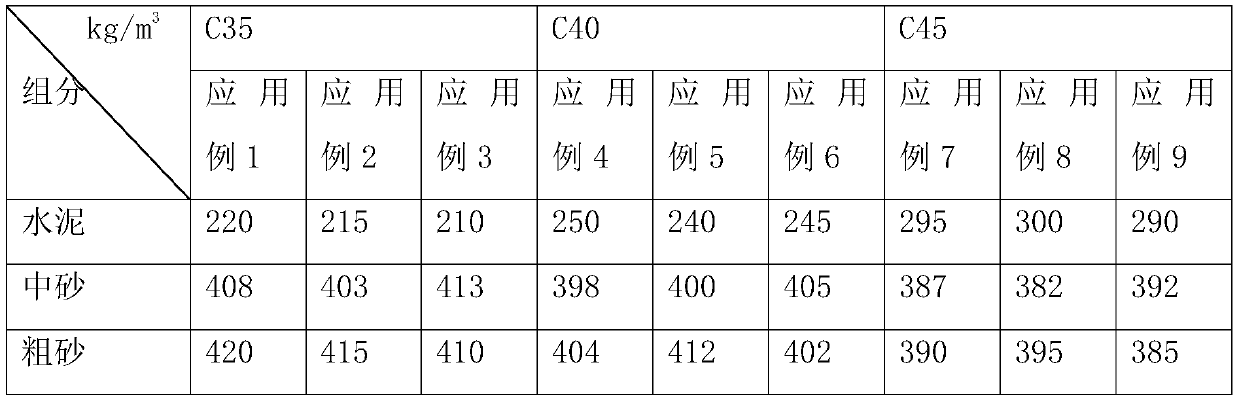

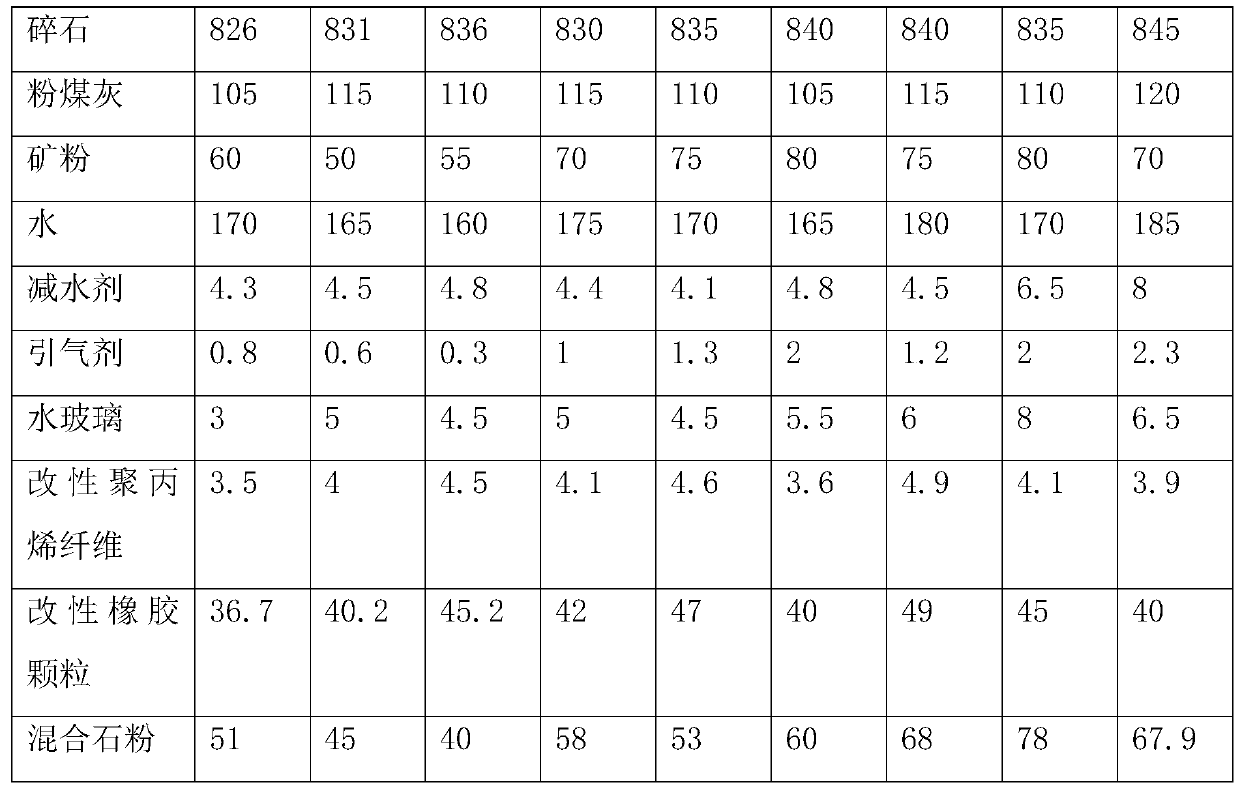

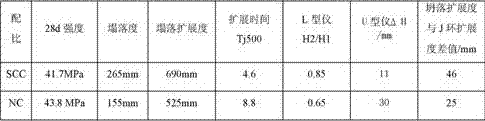

The invention discloses anti-freezing anti-seepage anti-cracking concrete and a preparation method thereof, wherein the anti-freezing anti-seepage anti-cracking concrete comprises, by weight, 300-315 parts of cement, 340-360 parts of medium sand, 430-450 parts of coarse sand, 800-850 parts of broken stone, 135-160 parts of fly ash, 50-60 parts of mineral powder, 160-175 parts of water, 5-10 parts of a water reducing agent, 1-5 parts of an air entraining agent, 5-10 parts of water glass, 5-10 parts of modified polypropylene fiber, 50-55 parts of modified rubber particles, and 55-70 parts mixed stone powder, wherein the mixed stone powder is prepared by carrying out drying treatment and grinding treatment on dolomite, slag, ceramsite and sericite powder according to a mass ratio of 1:0.5-0.8:1.1-1.5:0.6-0.9. According to the present invention, the anti-freezing anti-seepage anti-cracking concrete has advantages of strong freezing resistance, good impermeability, good crack resistance and high strength.

Owner:西安新意达建筑制品有限公司

Method and material to form a cast from gypsum

InactiveUS20080081317A1High dimensional accuracyEasy to separateImpression capsDental articulatorsArtificial EyesProsthesis

A method is disclosed for forming an accurate stone cast from an impression of a body region, used for the purpose of prosthetic fabrication, such as dental crowns and artificial eyes and hearing aids. The initial step with this unique method is to first acquire a suitable amount of dental stone catalyst. One type of a suitable stone catalyst is calcium sulfate dihydrate. The dental stone catalyst is engaged onto the internal surface of the impression. This catalyst, placed in the area between impression material and stone, will act to hasten the initial setting of wet, mixed dental stone that is in closest proximity to the impression. The result is a stratified set of the stone. Setting of the wet, mixed dental stone occurs first at the impression / stone interface. The mixed stone better resists distortion upon setting and the resultant set stone cast is more accurate.

Owner:WHITE DENNIS JOSEPH

Dental prosthesis fabrication

A method is disclosed for forming an accurate stone cast from a dental hydrocolloid impression, used for the purpose of prosthetic fabrication, such as dental prostheses. The dental stone catalyst, calcium sulfate dihydrate, is engaged onto the internal surface of set hydrocolloid impression. This catalyst, placed in the area between impression material and wet, mixed stone, will act to hasten the initial setting of dental stone that is in closest proximity to the impression. The result is a stratified set of the stone. Setting of the wet, mixed dental stone occurs first at the impression / stone interface. The setting radiates outwardly, away from the impression / stone interface. The mixed stone better resists distortion upon setting and the resultant set stone cast is more accurate.

Owner:WHITE DENNIS JOSEPH

Novel low-density synthetic paper and preparation process thereof

InactiveCN102584105ASave woodNo pollution in the processCeramic shaping apparatusAdhesiveHigh pressure

Provided are novel low-density synthetic paper and a preparation process thereof. The existing prepared high calcium carbonate product stone paper is high in density, super high in strength and large in specific weight, cannot be cut for processing easily and influences promotion and application. Novel low-density synthetic paper is composed of mixed stone powder containing certain proportion of porous materials, polyethylene and adhesives, and the proportion is that: mixed stone powder: polyethylene: adhesives= 50%-94%: 40%-5%: 10%-1%. The proportion of the mixed stone powder is that: porous materials: calcium carbonate=0-100%-100%-0. A certain amount of mixed stone powder is added in high-speed mixer for stirring, and proper liquid coupling agent, paraffins, stearic acid and poly ethylene (PE) wax are added in the mixer after the temperature rises to about 110 DEG C to obtain activated mixed stone powder. Then according to different requirements for strength and density of the synthetic paper, activated mixed stone with certain amount and high-pressure polyethylene are hot melted and mixed for granulation, then low-density synthetic paper is prepared through a film-blowing process, a rolling process or a flowing process.

Owner:张本明

Stone powder material curing agent and preparation method thereof

The invention relates to the technical field of the gravel particle materials and specifically discloses a stone powder material curing agent and a preparation method thereof. The stone powder material curing agent comprises the following components in percentage by weight: 25-55% of coal ash, 10%-30% of cement, 10%-25% of mineral powder, 5%-20% of lime, 1%-5% of gypsum and 0.3%-1% of activator; the preparation method comprises the following steps: mixing the components of the stone powder material curing agent proportioned above thoroughly and evenly, and then blending stone powder per cubic meter with 80g to 150kg of mixed stone powder material curing agent and stirring evenly; the moisture content range of the stone powder material curing agent after being mixed with the stone powder is from 7% to 30%. The stone powder material curing agent is capable of effectively solidifying various stone powder materials to meet the requirements for building materials in engineering construction, for example, a pavement surface course material having high requirement for strength; as a result, the utilization efficiency of the stone powder materials is improved, and the cost of the engineering construction is also reduced while resources are saved.

Owner:JIANGSU NATURE WAY TECH

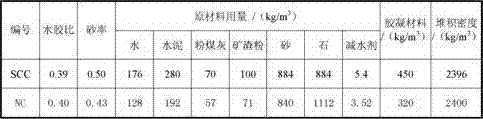

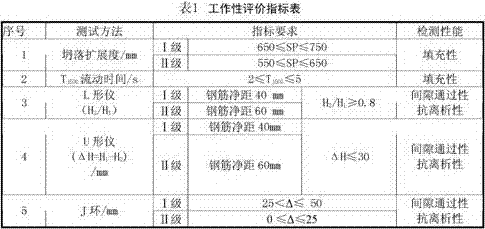

High-flow-state anti-segregation self-compacting concrete

The invention discloses high-flow-state anti-segregation self-compacting concrete. The concrete comprises the following components (cubic amount: kg / m<3>): 240-290 parts of cement, 80-110 parts of slag powder, 50-80 parts of coal ash, 860-915 parts of fine aggregate, 870-900 parts of coarse aggregate, 4.2-5.6 parts of additive, and 170-185 parts of water; fine aggregate is mixed sand of machine-made sand and superfine sand, wherein the fineness modulus of the mixed sand is not less than 2.4; and the coarse aggregate is mixed stone formed by mixing small pebbles with particle size of 5-10mm and gravels with the particle size of 10-16mm according to the mass ratio of 1:1. In use, the high-flow-state anti-segregation self-compacting concrete can flow through narrow clearances with dense reinforcements under the self weight without vibrating, and keep good cohesiveness, so that the occurrence of segregation phenomenon can be prevented, and the engineering quality and construction efficiency can be improved.

Owner:中国人民解放军63926部队

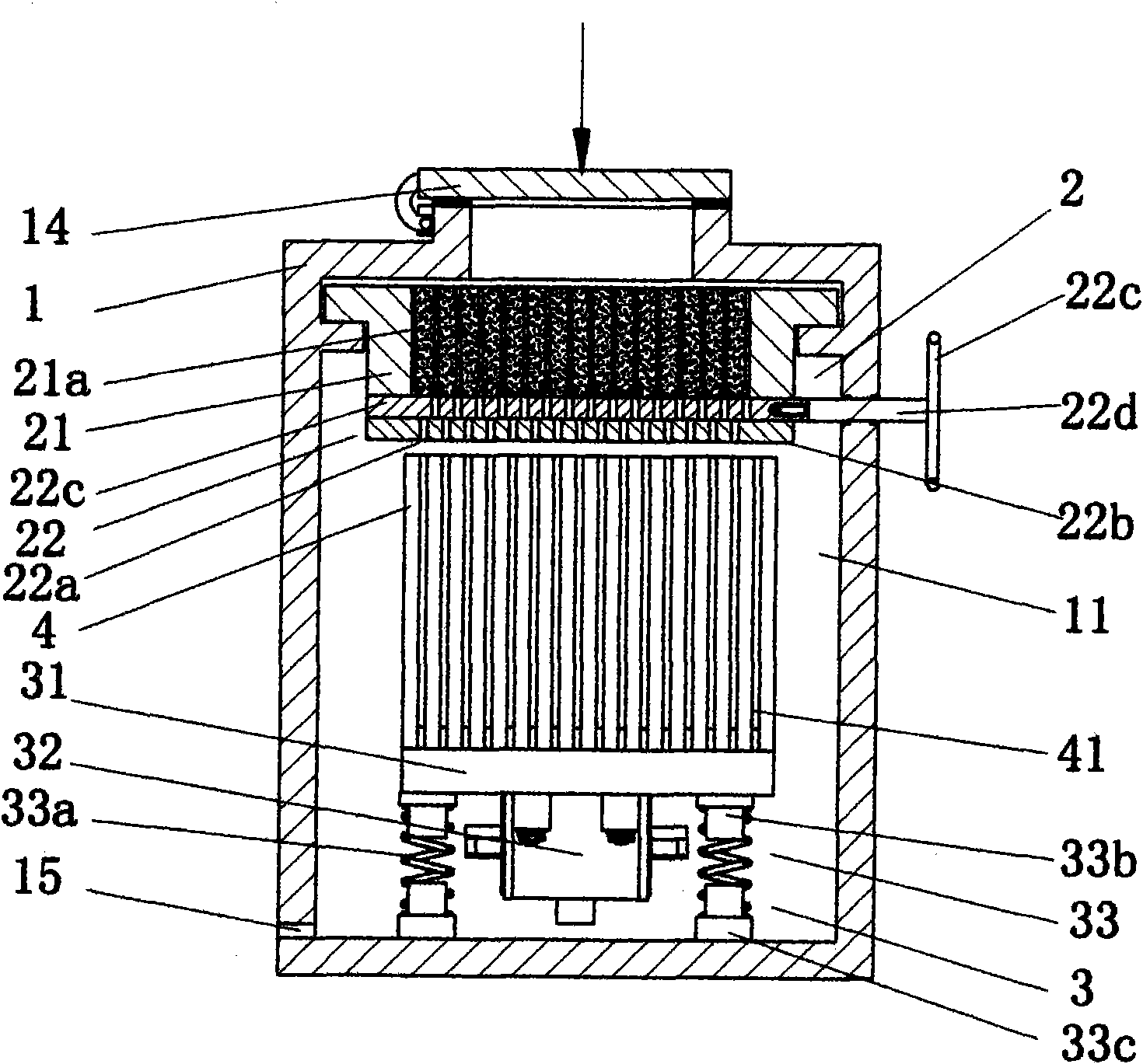

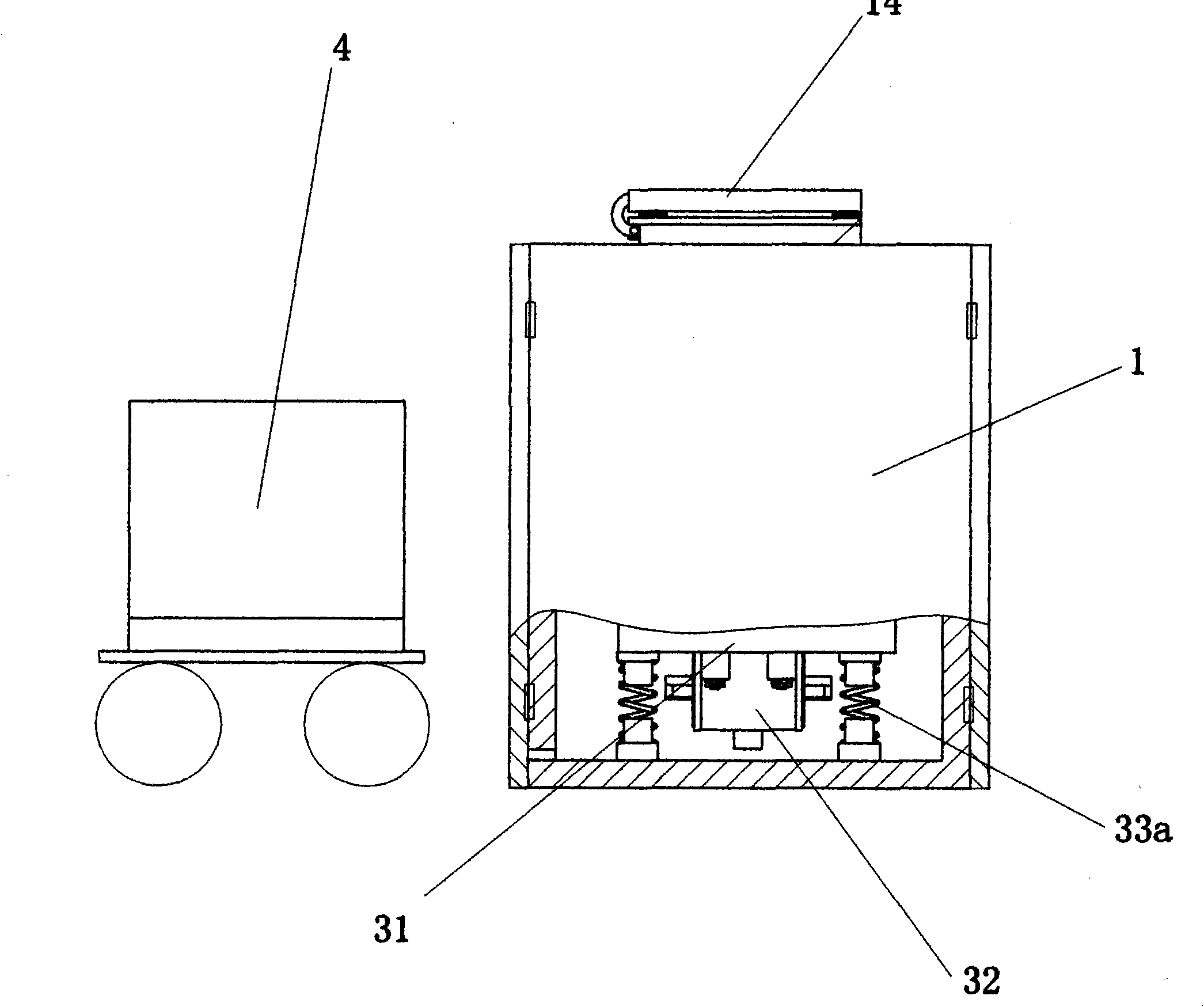

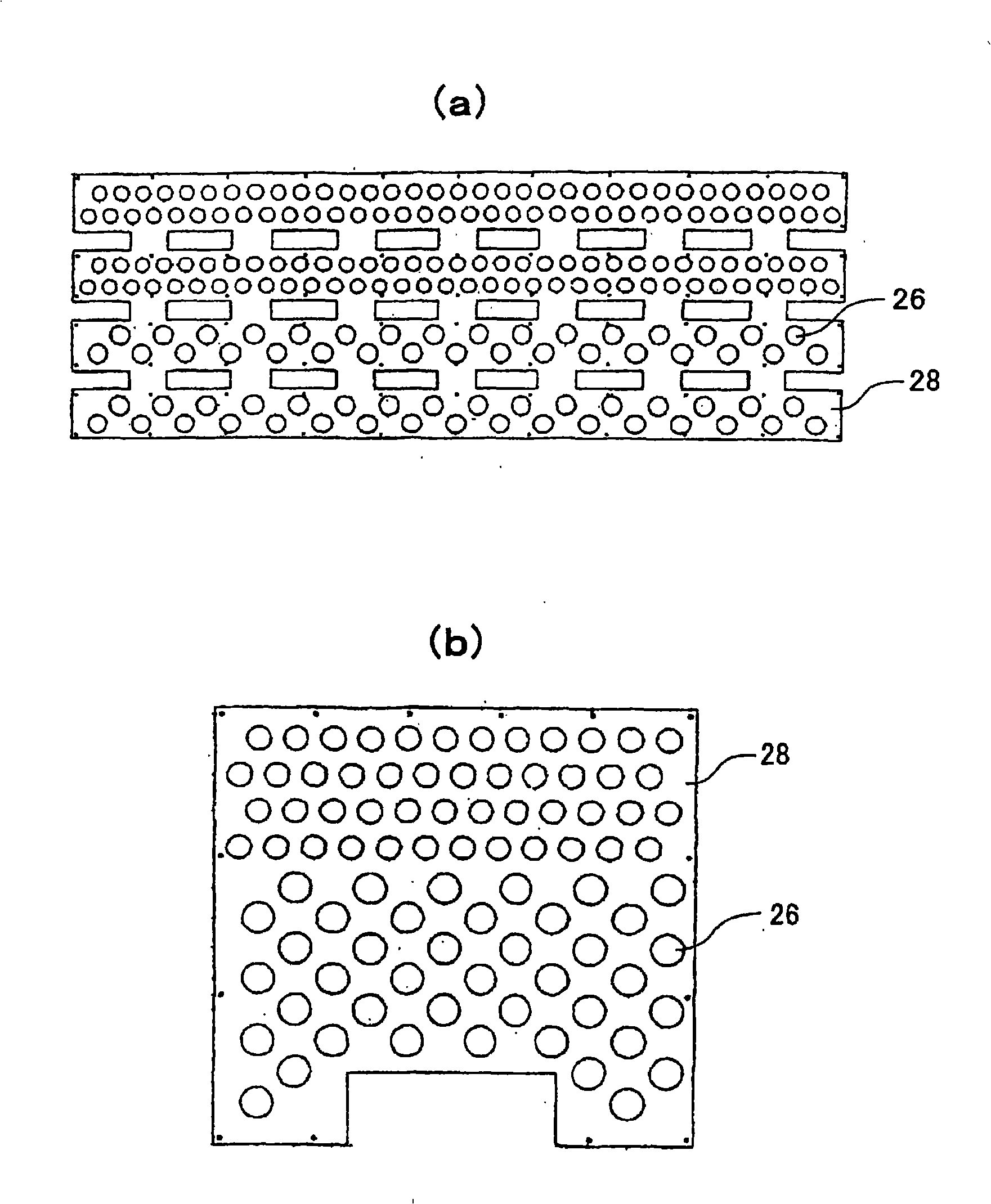

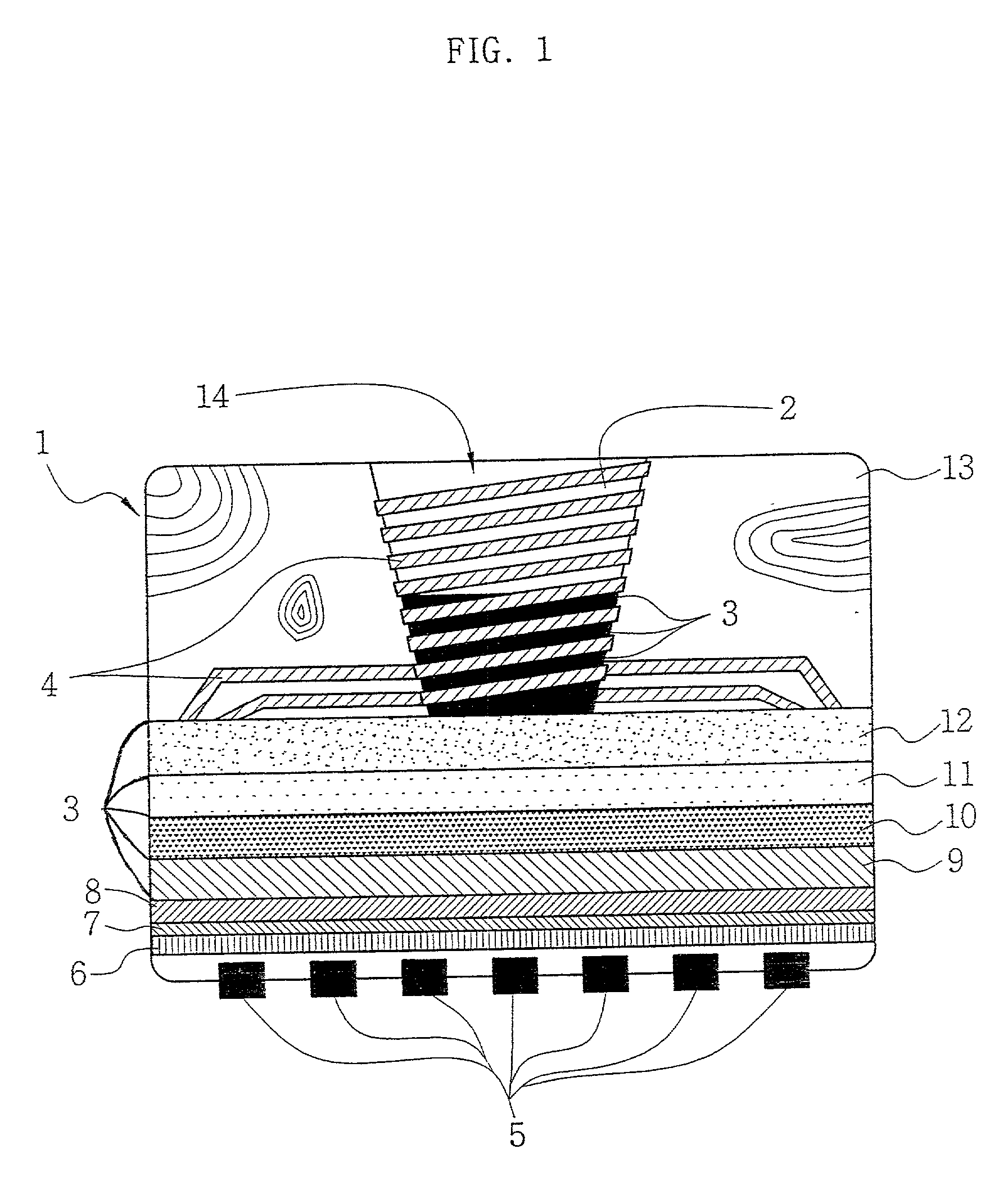

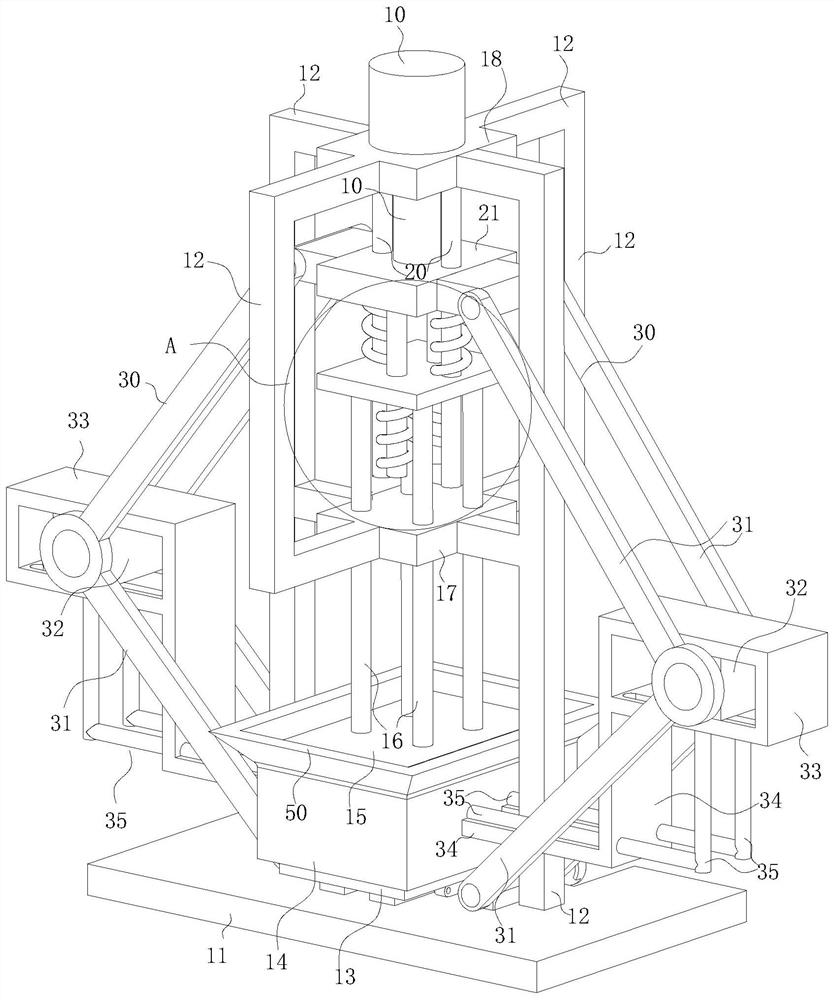

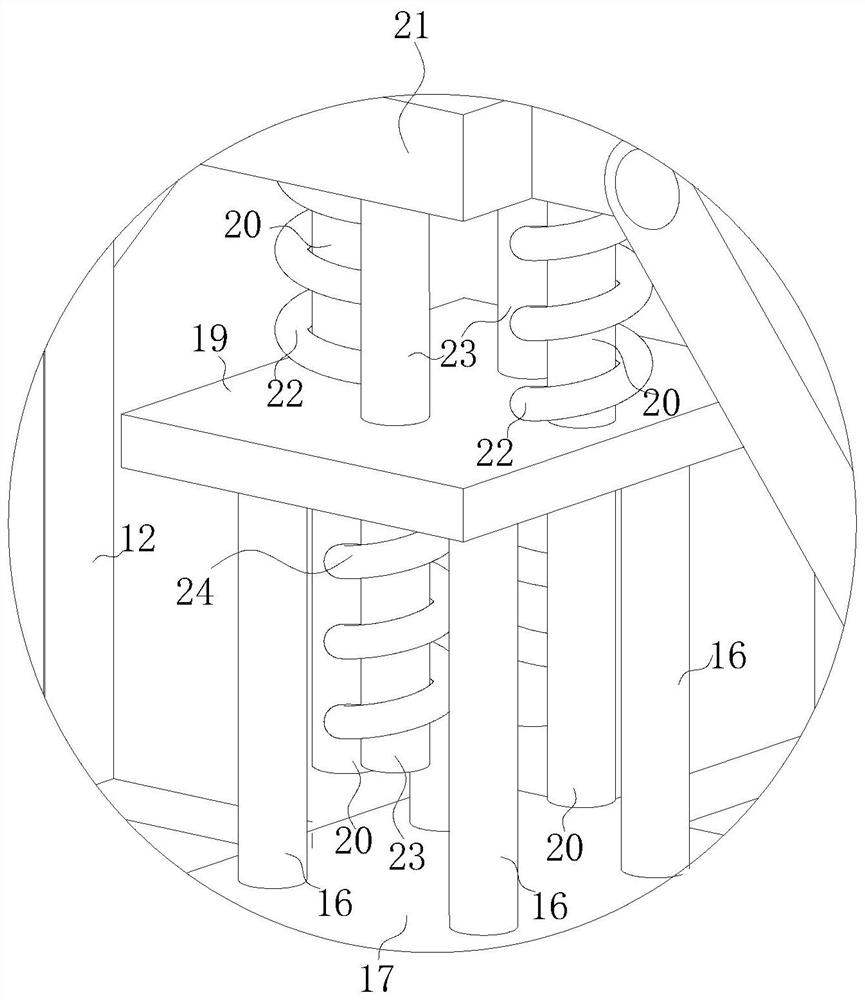

Vacuum vibration forming device for manufacturing artificial stones

ActiveCN101966721AHigh hardnessImprove wear resistanceCeramic shaping apparatusEngineeringArtificial stone

The invention discloses a vacuum vibration forming device for manufacturing artificial stones. The device comprises a box body, wherein box doors are arranged on two sides of the box body; a feed inlet is reserved at the top of the box body; the box body is provided with a vacuumized inner cavity; a packing device is arranged on the upper part, close to the feed inlet, of the inner cavity; a vibration bench is arranged on the bottom face of the inner cavity; and a die is arranged on the inner vibration bench. Due to the adoption of the structure that the packing device and the vibration benchare arranged in the vacuumized inner cavity and the die is arranged on the inner vibration bench, the generation of air holes in stone materials and the subsidence of cured particles are effectively prevented through vacuuming and vibration in a curing and forming process that the mixed stone materials enter the packing device and the die from the feed inlet. The manufactured stone materials haverelatively high rigidity, wear resistance and attractive appearance.

Owner:GUANGDONG FUSHENG INNOVATIVE MATERIAL TECH LTD

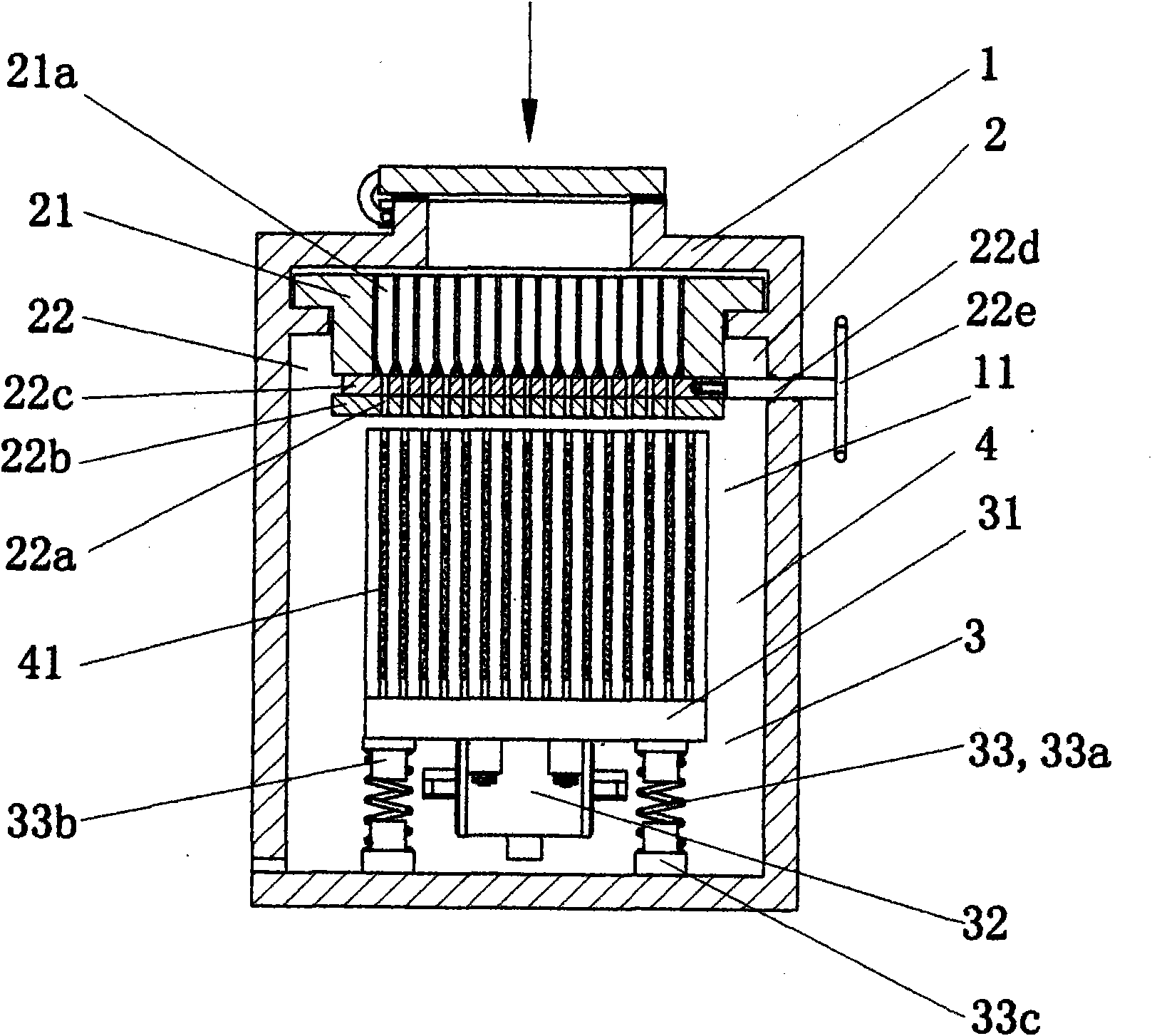

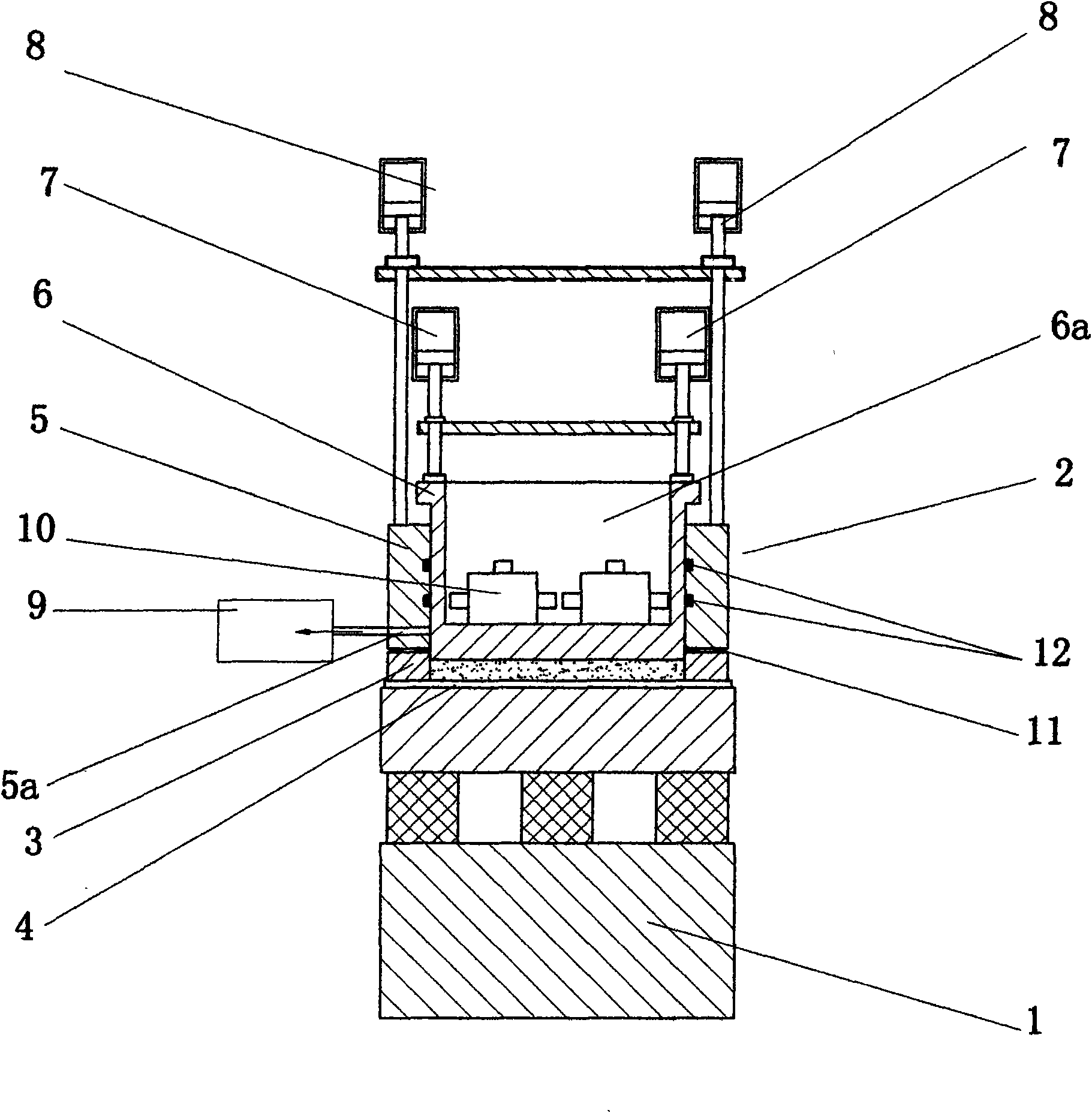

Vacuum vibration formation pressing machine producing quartzite

InactiveCN101670615AStructural Mixed ConsolidationUniform bondingShaping press ramHardnessEngineering

The invention relates to a vacuum vibration formation pressing machine producing quartzite, which comprises a pressing machine and a feeding device, wherein the pressing machine comprises a machine base and a machine frame, the feeding device comprises a mould frame and a belt, and a vacuum vibration device is arranged on the machine frame. The vacuum vibration device is directly arranged in a mould cavity of the pressing machine and comprises a vacuum cover body connected with a vacuum pump, a pressing head provided with a vibration body and a power oil cylinder which can respectively enablethe vacuum cover body and the pressing head to rise and fall. Since the vacuum vibration device is adopted, the vacuum cover body and the pressing head descend to cover and close a mixed stone material after the mixed stone material which is put into a material frame is conveyed to the mould cavity by the belt, the tissue structure of the mixed stone material is mixed and firm and is evenly bondedby the operation of the vibration body and the vacuum pump, and water bubbles are discharged. Practice shows that the invention still can ensure that a product has better strength and hardness by thetechnical scheme under a condition that the resin content of the product is 7-9%, so that the production cost can be greatly lowered.

Owner:GUANGDONG FUSHENG INNOVATIVE MATERIAL TECH LTD +1

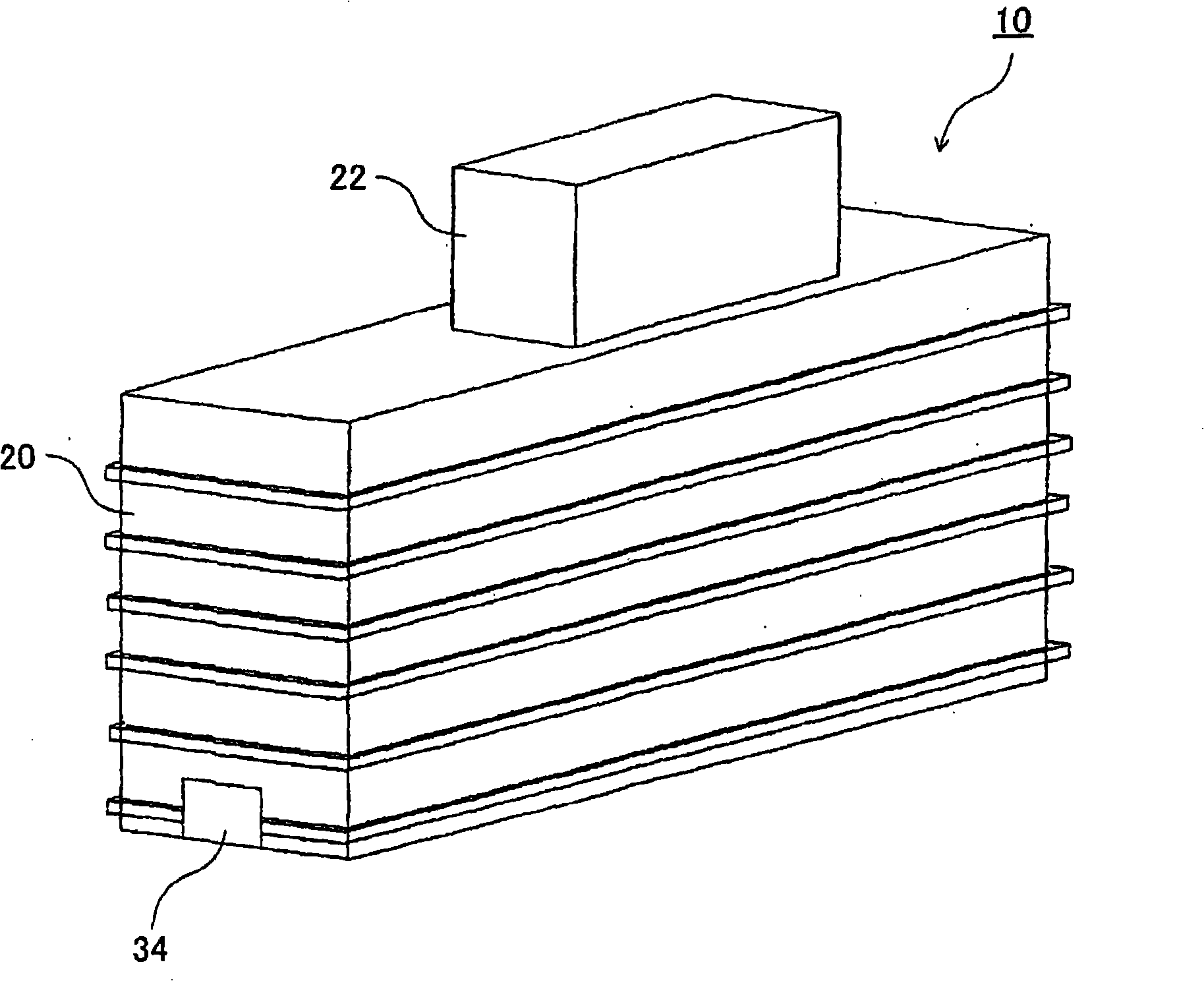

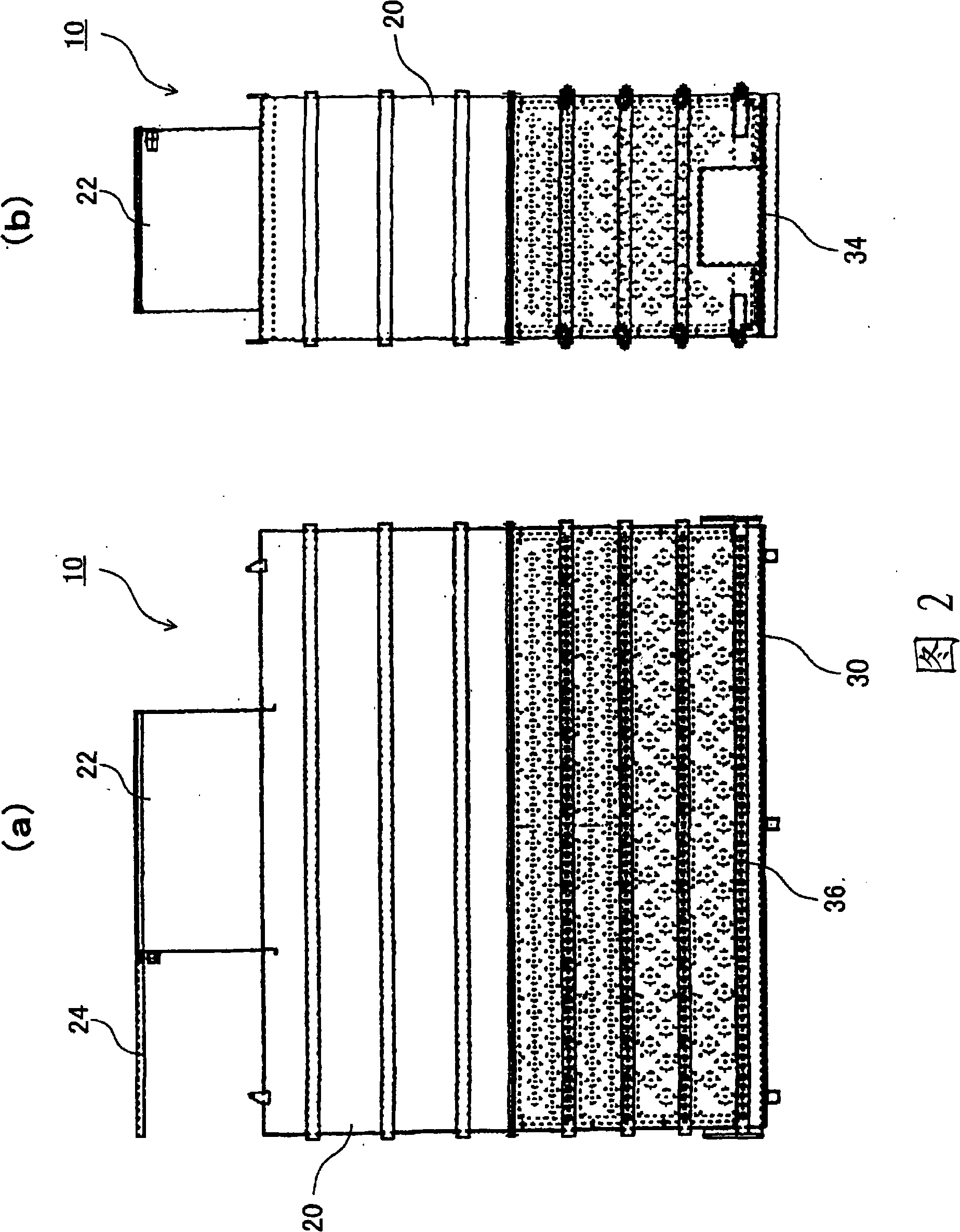

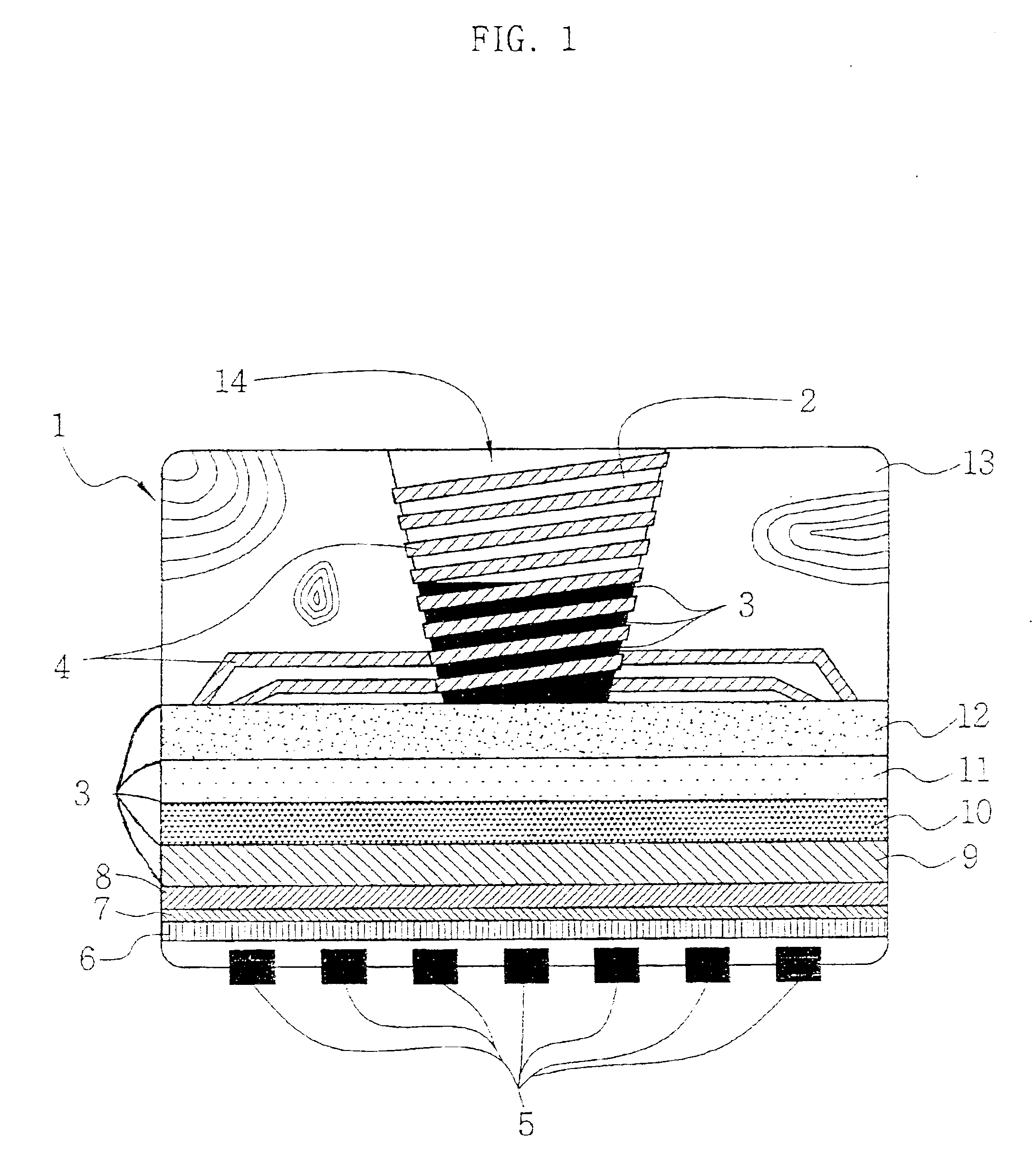

Refuse treatment apparatus

InactiveCN101326019ASimple structureEasy to operateDrying solid materials with heatTransportation and packagingEngineeringRefuse Disposals

A refuse treatment apparatus that is not a type where refuse is incinerated but a type where heat is applied to a magnetic field emitted from mixed stones to promote the generation and activation of plasma, thereby maintaining the temperature in the device at a high level to make refuse placed in the device extinct. In the refuse treatment apparatus, a refuse treating machine body of a rectangular parallelepiped shape includes a refuse inlet and a shutter provided at its upper part, an opening for charging matters to be heated which is provided near its side bottom part, and a plurality of pipe insertion holes formed in its peripheral side face. Plural pipes are fitted into all the pipe insertion holes toward the inside of the hollow refuse treatment machine body. The mixed stones emitting the magnetic field are disposed at the base parts of the plurality of pipes positioned on the outside of the side wall of the refuse treatment machine body and on the bottom face of the refuse treatment machine body.

Owner:河原 武史 +2

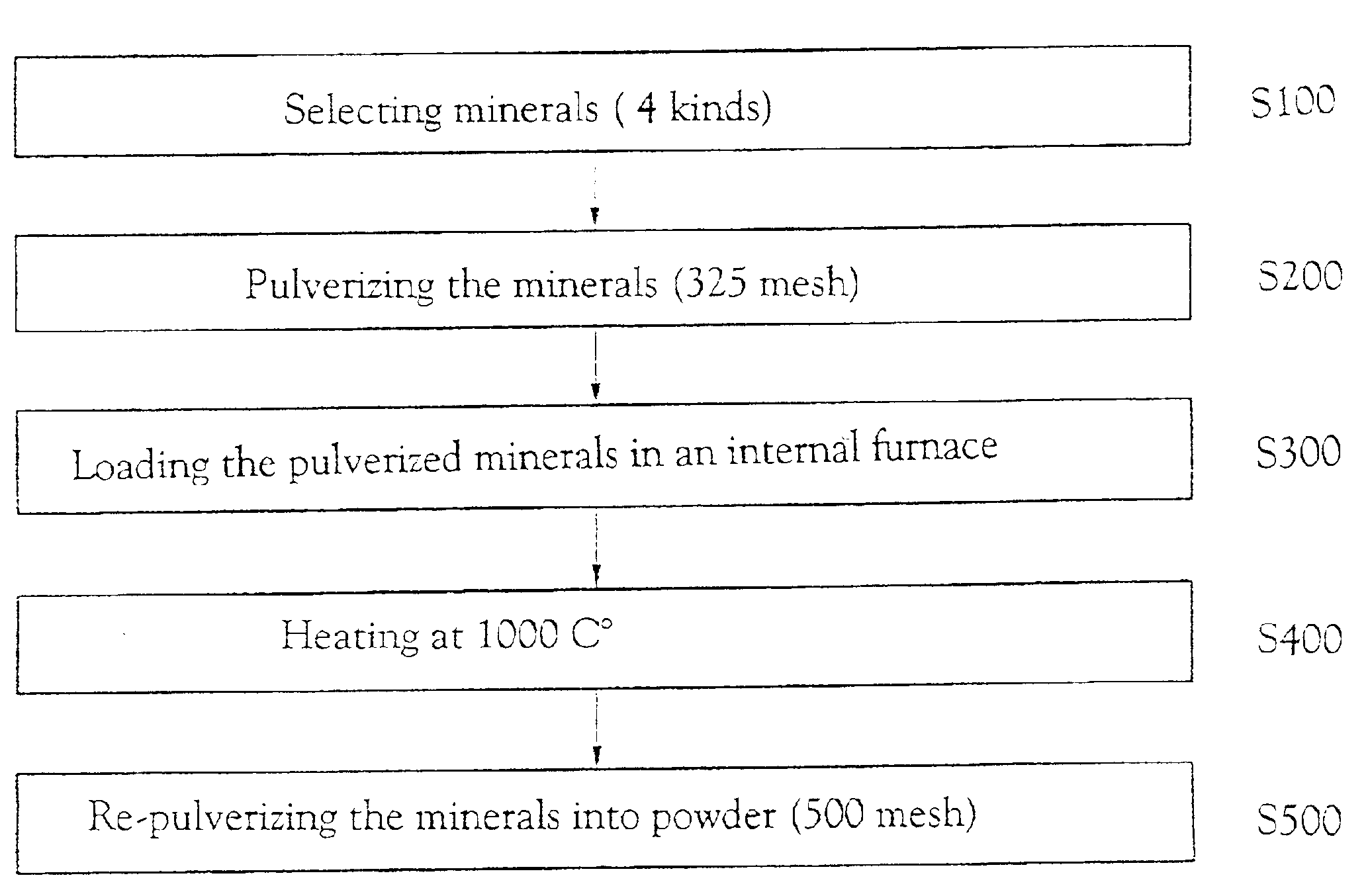

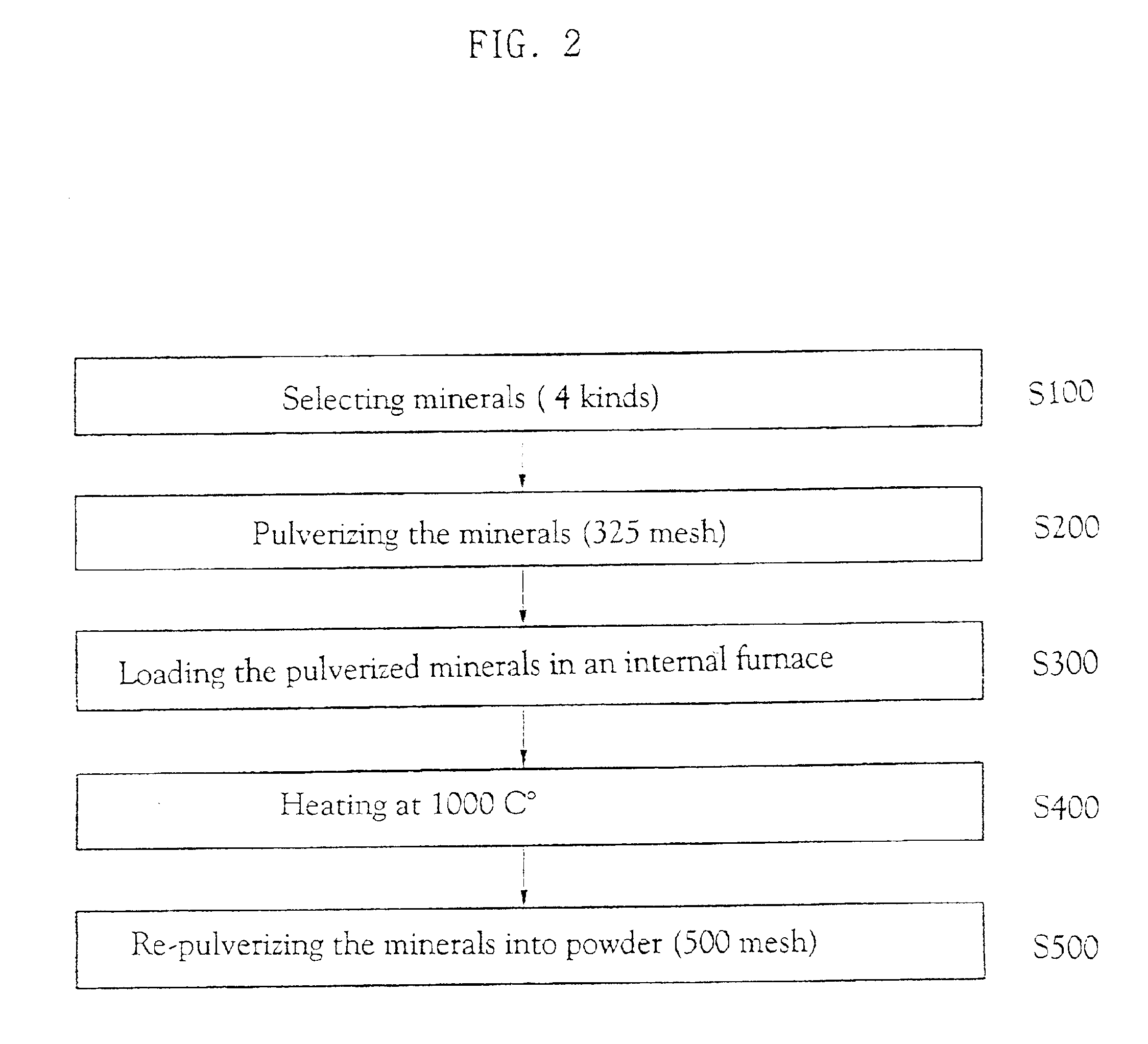

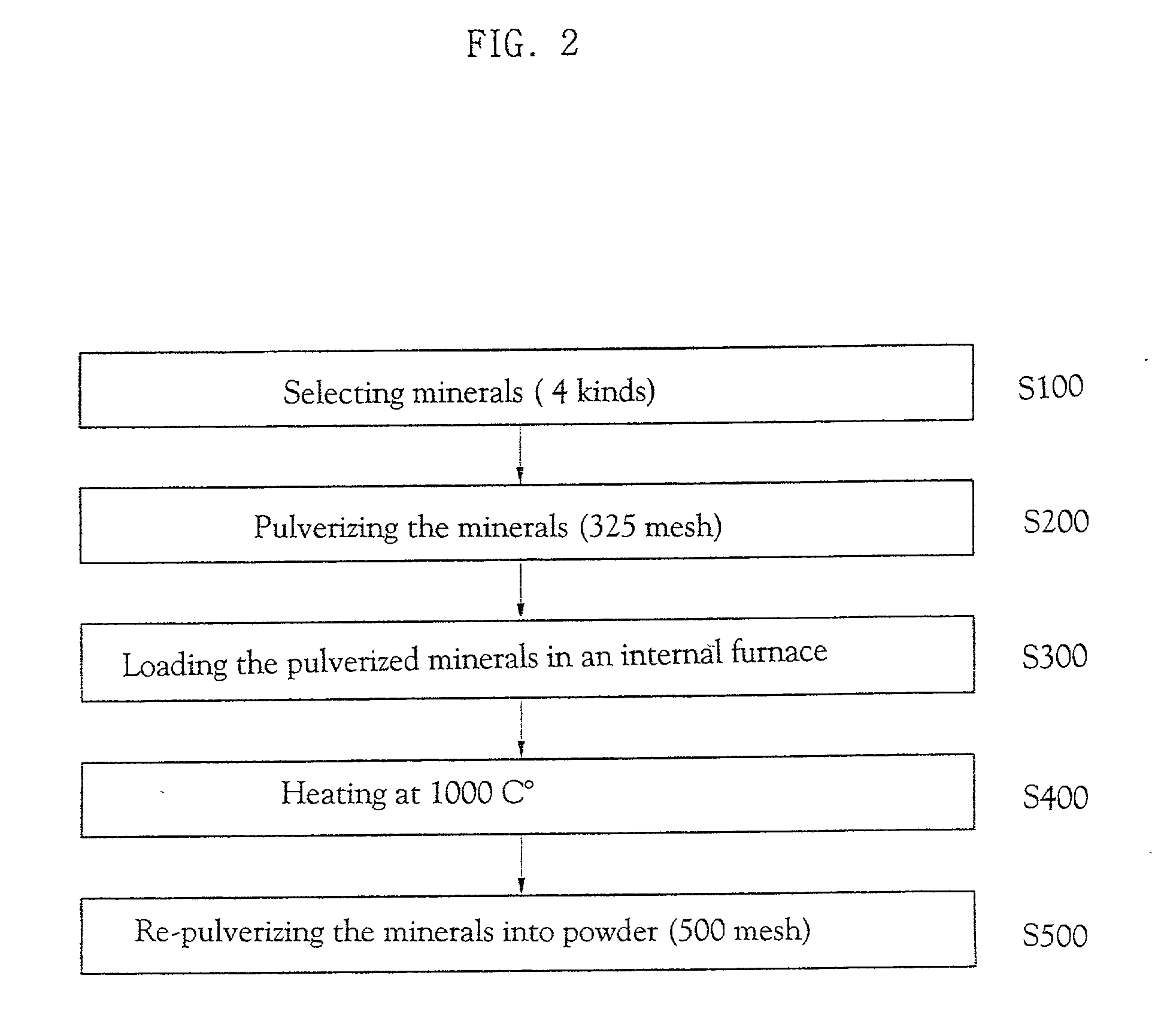

Mineral composition and method for manufacturing the same

InactiveUS6936557B2Low priceEasy accessPolycrystalline material growthCeramic shaping apparatusOxygenFar infrared

A novel multipurpose mineral composition capable of emitting a large quantity of far infrared rays, negative ions and oxygen heat is manufactured by setting up an iron railing, an iron rod and an iron plate on a brazier, placing a tinfoil on the iron plate, and layering yellow soil, kaolin, sericite, and biomineral in sequence on the tinfoil, while inserting the tinfoil between the layers, loading a pulverized elvan in the furnace, pulverizing a mixed stone including 40 wt % of germanium, 15 wt % of tourmaline, 30 wt % of zeolite, and 15 wt % of franklinite, to the particle size under about 44 μm, and loading the pulverized mixed stone in an internal furnace which is made by winding a copper plate with a tinfoil and placed on the plurality of layers of the furnace, heating the pulverized mixed stone at about 1,000° C. for about seven days into a lump, and repulverizing the lump.

Owner:PARK YONG JIN

Stem cell preparation and oral fluid prepared therefrom

ActiveCN103356697ANo pollution in the processLow costHeavy metal active ingredientsAntinoxious agentsHalloysiteSide effect

The invention belongs to the field of medicaments and relates to a stem cell preparation and an oral fluid prepared therefrom. The stem cell preparation is prepared from the following raw materials in weight percentage according to the following technical steps: mixing and crushing 20% of medical stone, 10% of stone needle, 10% of green frontiers stone, 10% of tinospora root radix tinosporae, 10% of talc, 10% of stalactite, 20% of marmor serpentinatum and 10% of red halloysite to nanometer particles so as to obtain mixed stone powder; and then sterilizing the mixed stone powder to obtain the stem cell preparation. The stem cell oral fluid is prepared after adding auxiliary materials into the stem cell preparation. The stem cell preparation disclosed by the invention causes no toxic and side effects, is good for health of human body, and replenishes mineral substances and a plurality of trace elements, so the stem cell preparation is a substitute product following antibiotic and hormone medicaments.

Owner:闫斌

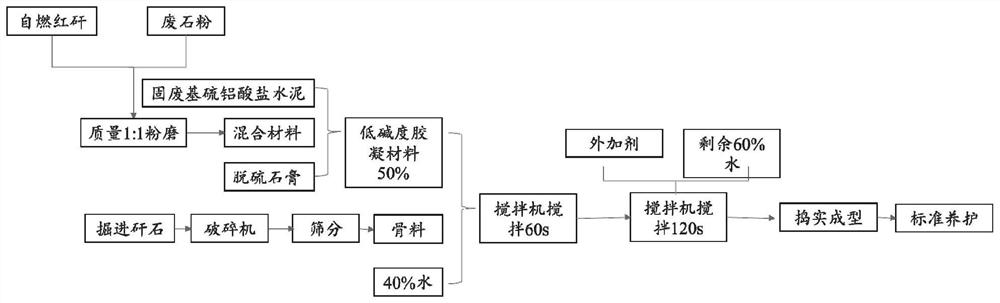

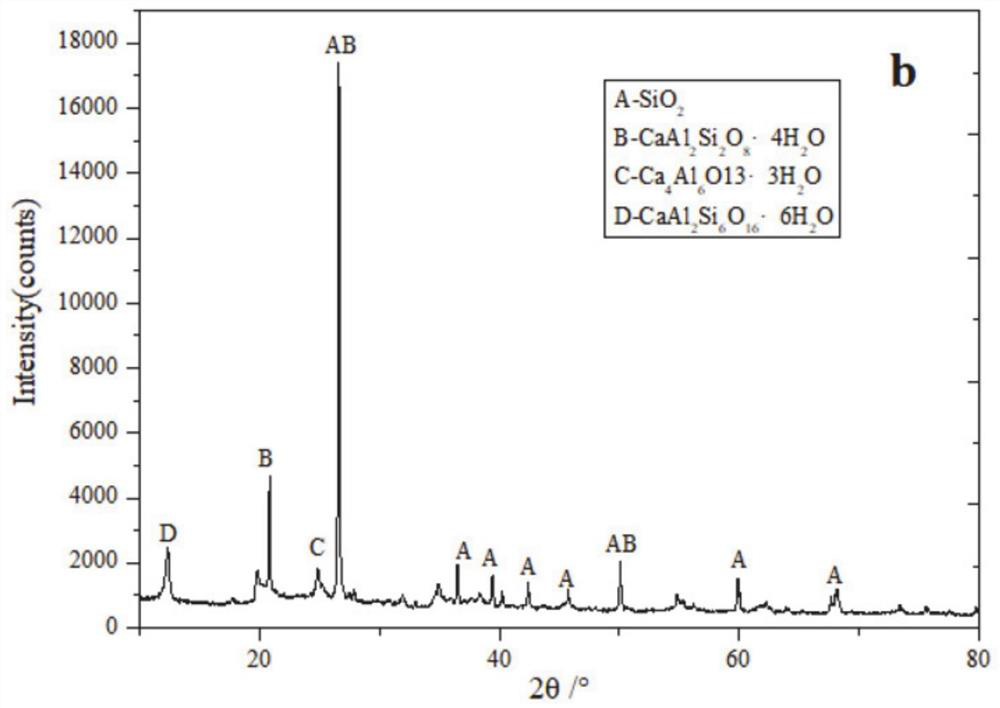

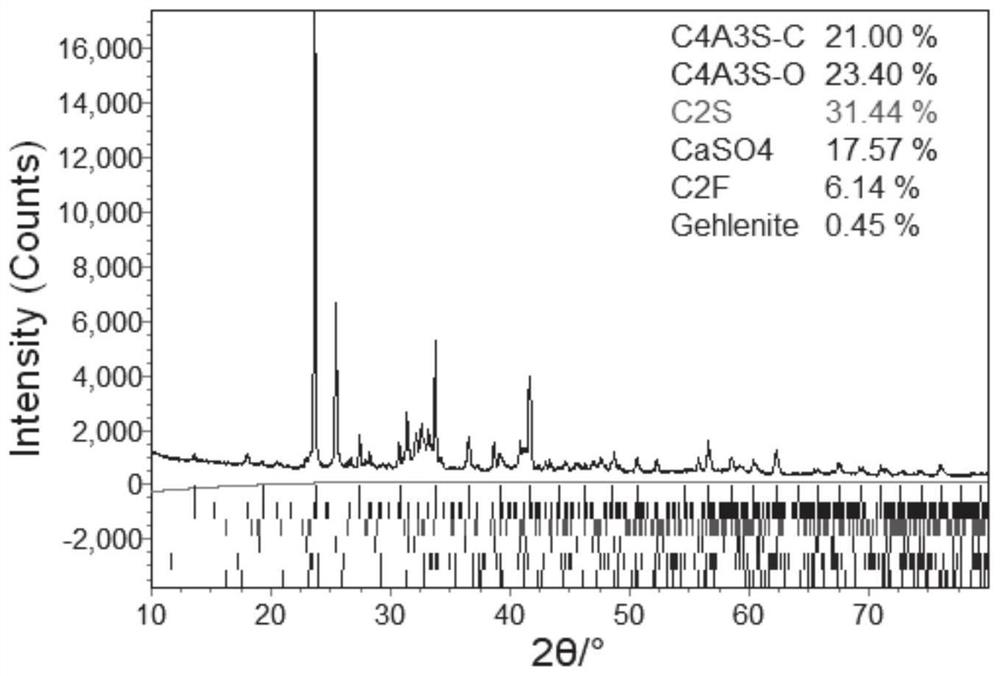

Solid-waste-based low-alkalinity porous ecological pervious concrete and preparation method thereof

ActiveCN112759343AImprove early strengthLow pore alkalinityCement productionExcavationsAluminateAdhesive

The invention discloses solid-waste-based low-alkalinity porous ecological pervious concrete and a preparation method thereof, and the solid-waste-based low-alkalinity porous ecological pervious concrete is prepared from the following raw materials in parts by mass: 10-20 parts of a low-alkalinity cementing material, 75-85 parts of tunneling gangue aggregate, 0.1-0.2 part of an adhesive, 0.03-0.04 part of a water reducing agent and 3.0-4.5 parts of water; the low-alkalinity cementing material is composed of a solid waste-based sulphoaluminate cementing material, mixed stone powder and desulfurized gypsum in a mass ratio of (75-85): (10-20): (3-5), and the mixed stone powder is a mixture of red gangue powder and waste stone powder. The preparation method comprises the following steps: stirring and mixing the tunneling gangue aggregate, a part of the tunneling gangue aggregate and a part of water, then adding the adhesive, the water reducing agent, the rest of the tunneling gangue aggregate and the rest of water, and continuously performing stirring and mixing. The pH value of the concrete can be compatible with the pH value of a soil environment required by normal growth of plants, and the cost of the ecological concrete can be greatly reduced.

Owner:SHANDONG UNIV

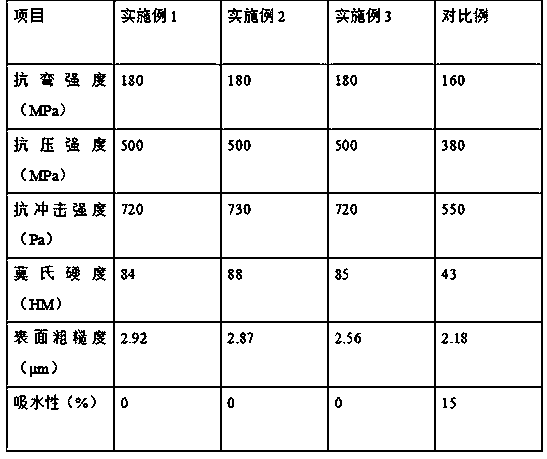

Waterproof anti-permeability aerated brick

The invention relates to a waterproof anti-permeability aerated brick, belonging to the field of aerated bricks. Mixed stone is taken as a raw material, the added effective components are agglomerated, so that the anti-permeability and waterproof effect are obviously improved; in the using process, the carbomer molecular structure with negative charges can be well adsorbed on the surface of a cement base material, so that the anti-permeability of the aerated brick system is improved, and cracking and leakage phenomena are avoided; bentonite, coal gangue and fly ash are premixed and soaked in an acid solution to remove impurities and activate effective components in the mixture, so that the modified bentonite can show expansion force in the process of meeting water, and a small amount of water absorption can be achieved to further improve the anti-permeability and waterproof effect; and during mixing, a silane coupling agent is dissolved and released under the action of water, and the combination of the composite modified stone, waterproof materials, ordinary silicon cement and other components is closer, and the hydrophobicity is better, so that the anti-permeability and waterproofperformance of the aerated brick is improved. The waterproof anti-permeability aerated brick solves the problem of poor anti-permeability and waterproof performance of common aerated bricks at present.

Owner:苏成康

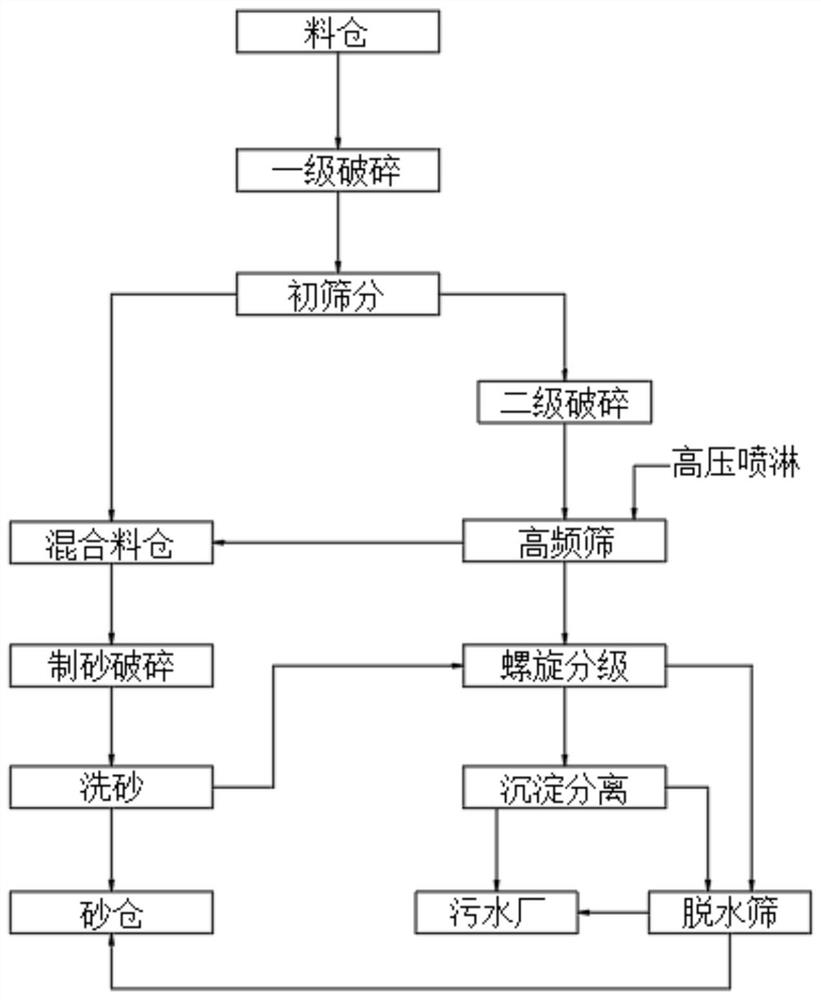

Gravel production process capable of suppressing dust and preventing sand flying under strong wind condition

PendingCN112916181AAvoid it happening againPrevent cavitiesGrain treatmentsWet separationCrushed stoneProcess engineering

The invention provides a gravel production process capable of suppressing dust and preventing sand flying under a strong wind condition. The gravel production process comprises the following steps of: performing primary crushing, performing primary screening after crushing, enabling small stone materials to enter a mixing bin, and enabling large stone materials to enter secondary crushing; conveying the materials subjected to secondary crushing to a high-frequency screen by using a sealing-tape machine, spraying at an outlet of the sealing-tape machine by using a high-pressure spraying pipe, conveying the stone materials on the screen surface to the mixing bin to be mixed with the small stone materials, and enabling screened slurry to enter a spiral classifier to recover gravel; and enabling the mixed stone materials to enter a sand making crusher to be crushed, washing out stone powder by washing sand after crushing, and finally enabling the crushed stone materials to enter a sand bin. By adopting the gravel production process, the generation of flying dust is effectively prevented, the hole blocking probability is greatly reduced, the screening effect and the gravel quality are guaranteed, and energy is saved. By mixing the stone materials, the water content of the feeding materials of the sand making crusher is lower than 2 percent, the cavity blocking of the crusher is prevented, the production efficiency is guaranteed, and the potential safety hazard is reduced.

Owner:SINOHYDRO BUREAU 9

Novel mineral composition and method for manufacturing the same

InactiveUS20030176274A1Low priceEasy to getPolycrystalline material growthCeramic shaping apparatusOxygenFar infrared

A novel multipurpose mineral composition capable of emitting a large quantity of far infrared rays, negative ions and oxygen heat is manufactured by setting up an iron railing, an iron rod and an iron plate on a brazier, placing a tinfoil on the iron plate, and layering yellow soil, kaolin, sericite, and biomineral in sequence on the tinfoil, while inserting the tinfoil between the layers, loading a pulverized elvan in the furnace, pulverizing a mixed stone including 40 wt % of germanium, 15 wt % of true marine, 30 wt % of zeolite, and 15 wt % of franklin, to the particle size under about 44 mum, and loading the pulverized mixed stone in an internal furnace which is made by winding a copper plate with a tinfoil and placed on the plurality of layers of the furnace, heating the pulverized mixed stone at about 1,000° C. for about seven days into a lump, and repulverizing the lump.

Owner:PARK YONG JIN

Stone-plastic composite material and stone-plastic composite material ceiling plate

The invention relates to a stone-plastic composite material and a stone-plastic composite material ceiling plate. The stone-plastic composite material comprises stone powder and molding powder which are prepared from the follwoing raw materails in parts by weight, wherein the weight ratio of the stone powder to the molding powder is 3: 10-1: 2, the density of the stone powder is 3.55-4.67 g / cm < 3>, and a powdery natural fiber material is added into the composite material obtained after the stone powder and the molding powder are mixed. The stone-plastic composite material comprises stone powder and molding powder, the stone powder and the molding powder are mixed in proportion, and the powdery natural fiber material is added into the mixed stone powder and molding powder so that the rigidity of the manufactured ceiling plate can be improved, the brittleness is reduced, the probability of deflection deformation of the ceiling plate is reduced to a great extent, and thus the probability that the ceiling plate generates adverse consequences such as cracks is reduced, and popularization and application of the ceiling plate in the market are facilitated.

Owner:ZHEJIANG YASHA DECORATION

High-quality high-yield planting method of pod peppers

InactiveCN107182500AWill not increase the cost of planting too muchImprove germination rateBiocidePlant growth regulatorsCapsicum baccatumObserved Survival

The invention discloses a high-quality high-yield planting method of pod peppers. The method comprises the following operation steps that pepper seeds are disinfected with a potassium permanganate solution and then put into a germination accelerating solution to be soaked for 12-15 h, and then germination accelerating and sowing are conducted; the seeds obtained after germination accelerating are mixed with probiotics powder, and then the seeds are sown on a seedbed and covered with mixed sand with the thickness of 0.3-0.8 cm; root soil of the pod peppers is slightly turned, and mixed stones are mixed into the root soil of the pod peppers. The high-quality high-yield planting method of the pod peppers is easy to operate, and the planting cost of the peppers cannot be increased too much; by adopting the method, the germination rate of the pepper seeds can be relatively high, and the survival rate of germinated pepper seedlings is high; besides, the yield of the pod peppers is high, and the quality is good.

Owner:界首市祥润家庭农场

Mixed stone ceramic material

The invention discloses a mixed stone ceramic material. The mixed stone ceramic material is prepared through grinding raw materials and sintering the ground raw materials, and the raw materials comprise 100-150 parts of mullite powder, 50-60 parts of quartz stone powder, 80-85 parts of calcite powder, 30-45 parts of olivine powder, 50-55 parts of amarella Mauro powder, 5-8 parts of diatom ooze, 3-5 parts of polydimethylsiloxane, 8-10 parts of carboxymethylcellulose sodium, 6-8 parts of hydroxyethyl cellulose, 5-8 parts of rosin, 6-8 parts of glycerin and 10-12 parts of limestone. The mixed stone ceramic material has the characteristics of high heat conductivity, high radiation coefficient, low cost, and realization batch production, and solves the disadvantages of high cost and low productivity of present alumina ceramics and low heat conductivity and low radiation coefficient of steatite ceramics. The special ceramic material with the advantages of high heat conductivity, high heat radiation and low cost is prepared through the following steps: processing the raw materials, carrying out a hot pressing or dry pressing molding technology, and carrying out high temperature sintering. The ceramic material is suitable for high-power and low-power LED light fixture, comprising lamp holders, LED supports, substrates or COB substrates, and can be widely applied to the fields of commercial illumination and indoor illumination.

Owner:邳州嘉禾四季农业发展有限公司

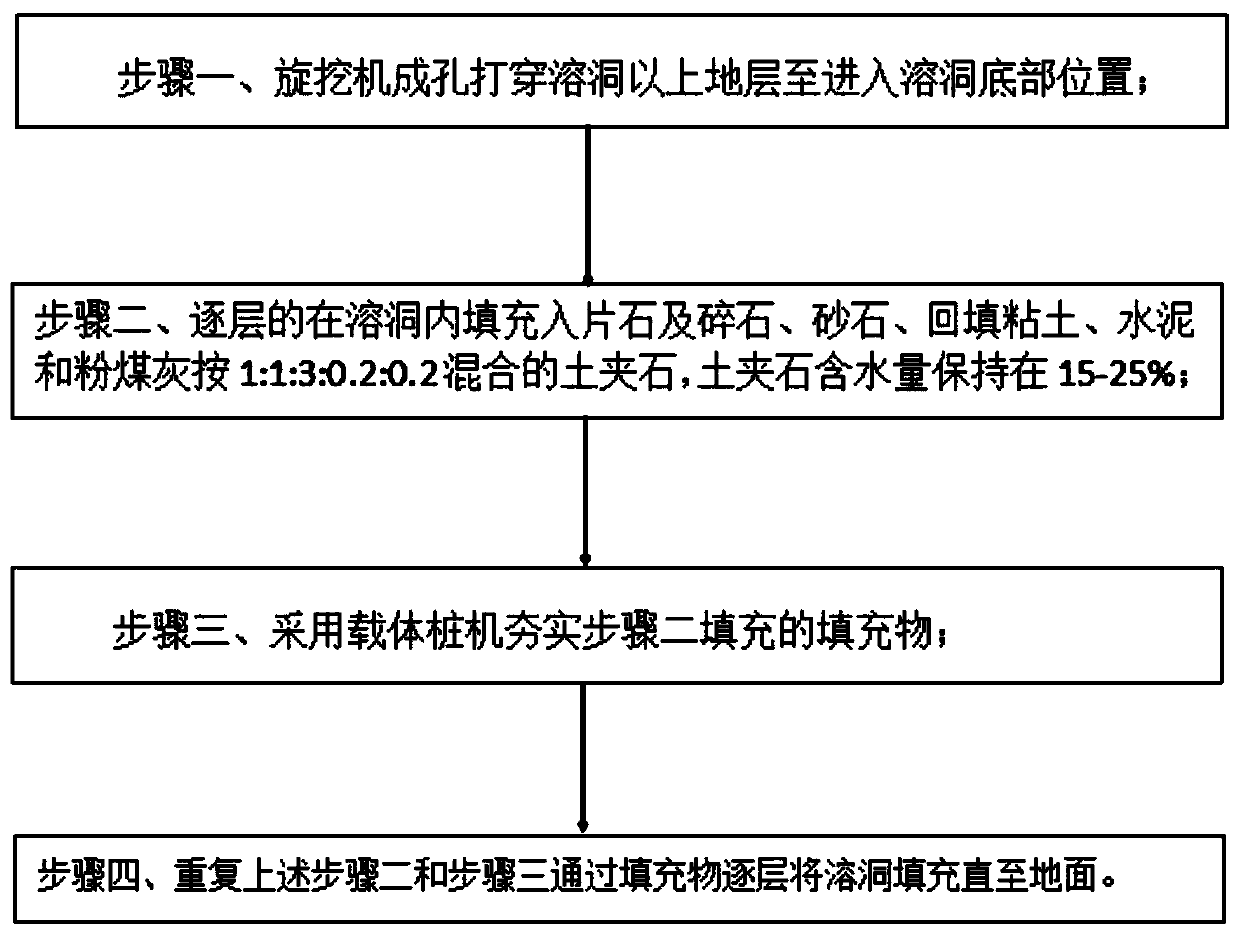

Carrier pile machine compaction karst cave filler and karst cave filling method

InactiveCN111333374AGuarantee the pile qualityRaw materials are easy to obtainEmbankmentsSoil scienceCrushed stone

The invention discloses a carrier pile machine compaction karst cave filler and a karst cave filling method, and relates to the technical field of karst cave filling. According to the karst cave filler, soil mixed stone prepared by mixing stone flakes and broken stone, gravels, backfill clay, cement and fly ash according to a ratio of 1:1:3:0.2:0.2 is used as a filler, drilling is performed by a rotary drilling machine, karst cave is filled to the ground layer by layer through a carrier pile machine, stone flakes are used as bottom, soil mixed stone prepared by mixing broken stone, gravel, backfill clay, cement and fly ash is used for gap filling, and compaction is performed layer by layer. According to the invention, the adopted raw materials are simple and easy to obtain, the used engineering instruments are convenient and conventional, the requirement and specification of karst cave filling can be met after layer-by-layer compaction, the pile forming quality of a karst cave area isensured, the filling efficiency and the pile forming quality are high, and the method is suitable for application and popularization.

Owner:云南建投第一勘察设计有限公司

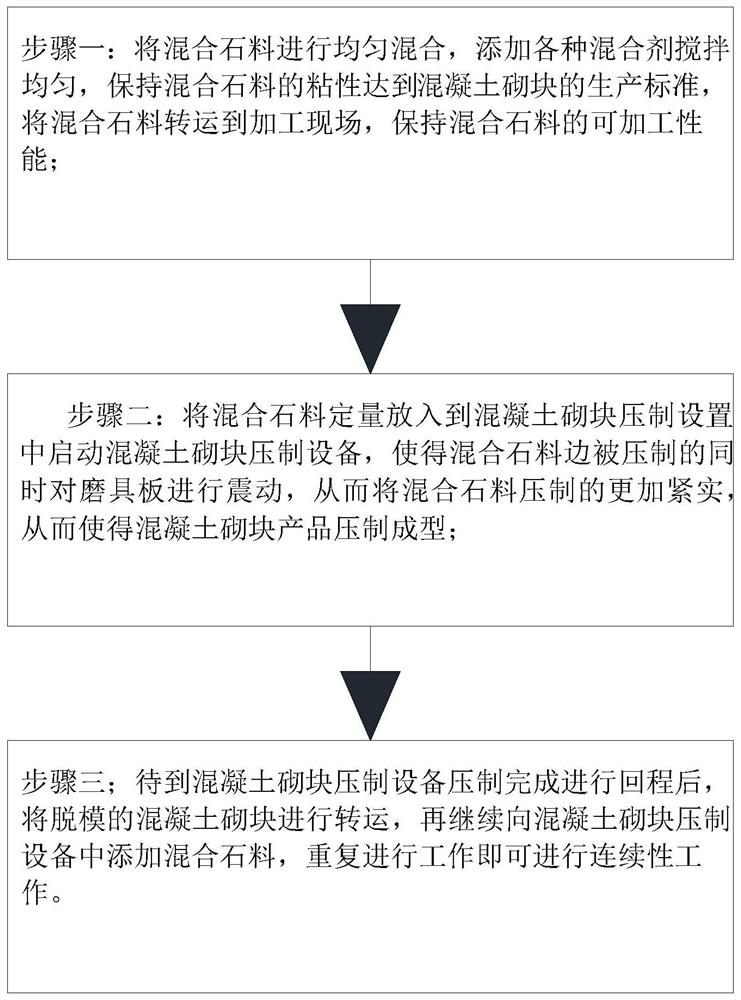

Production and preparation process of light heat-preservation concrete building block

ActiveCN113771191ASolve the phenomenon of poor quality and easy to breakPress tight and evenDischarging arrangementClimate change adaptationArchitectural engineeringMixed materials

Owner:安徽清水岩生态科技有限公司

A kind of preparation method of rust stone sand

ActiveCN111187038BAchieve the effect of imitation rust stoneWill not fadeEngineeringMaterials science

The invention provides a preparation method of rust stone sand, comprising the following steps: (1) weighing 17-25 parts of black stone; adding 0.8-1.3 parts of water and mixing well to obtain premixed stone; (2) weighing iron oxide yellow 0.88-1.12 parts of powder, 0.017-0.022 parts of iron oxide red powder, 0.008-0.01 part of iron oxide black powder, 0.07-0.082 parts of polymer concentrated glue powder, 0.8-1.3 parts of 525 white cement; stir evenly to obtain a mixture; (3 ) Add the mixture into the premixed stone, stir to obtain the total mixture; (4) heat up to 80-90°C, take it out after baking, let it air naturally, crush it, and pass it through an 8mm sieve; crush the residue of the sieve again , through an 8mm sieve until all of them are less than 8mm; get rusty stone sand; (5) pack into bags. The surface of the rust stone sand prepared by the invention has the effect of rusting, and after using the rust stone sand produced by the invention, the simulation degree of the product is greatly improved.

Owner:深圳市点绿科技有限公司

Preparation method of microcrystalline glass

The invention discloses a preparation method of microcrystalline glass and belongs to the technical field of glass making. The preparation method has the advantages that straw, quick lime and water are mixed to release heat and absorb silicon dioxide generated by a mixed stone material, and accordingly the mechanical performance of a microcrystalline fiber system is increased; the silicon dioxideadsorbed in straw particle fibers can have reaction with carbon under the catalytic effect of sodium fluoride and nano iron powder to generated hard and wear-resistant silicon carbide, surface roughness is increased effectively, bonding strength among various system components is further increased, and product thermal stability and mechanical performance are effectively increased; sepiolite, bauxite and copper alloy powder are used as the materials, potassium permanganate, sodium alginate and xanthan gum are mixed to prepare coating liquid, sintering is performed after granulation, exothermicreaction is performed, sintering efficiency is increased, and mechanical performance is further improved; the problems that current microcrystalline glass is poor in wear resistance and mechanical performance, and the heat resistance and the toughness of the current microcrystalline glass need to be increased are solved.

Owner:朱文杰

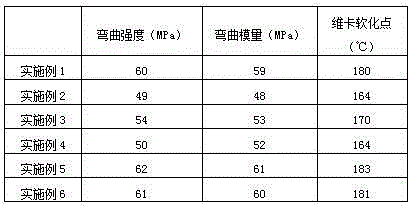

Novel mixed stone and manufacturing method thereof

The invention discloses novel mixed stone and a manufacturing method thereof. The novel mixed stone is prepared from, by weight, 25 parts of composite acrylic-based resin, 22-50 parts of quartz powder, 22-50 parts of aluminum hydroxide powder and 3 parts of anti-crack complexing agent. The manufacturing method comprises the sequential following steps of a, material preparation and stirring; b, feeding and curing agent adding for stirring; c, pouring; d, pattern making; e, vacuum extrusion formation; f, roasting; g, thickness fixation; h, polishing; i, quality testing; j, packaging. The rigidity and toughness of the novel mixed stone are moderate, the novel mixed stone has the rigidity similar to natural stone and can be applied to counters of kitchen table tops and commercial space, a cylinder with the diameter of 800 mm can be defined, molding can be achieved, the demands of home decoration and commercial space can be met, and the defects of natural stone and artificial stone in the prior art can be met.

Owner:重庆蜂鸟装饰材料有限公司

Environmental-protection green rubber medicine material

The present invention discloses an environmental-protection green rubber medicine material, which is prepared mainly from the following components by weight: 50-60 parts of rubber powder, 10-15 parts of a fire retardation agent, 5-10 parts of a film forming auxiliary agent, 15-20 parts of mixed stone powder, 10-15 parts of corn straw, 10-20 parts of soybean straw, 15-20 parts of sweet potato straw, 5-8 parts of diatomite, 3-6 parts of a pigment, 5-8 parts of thickening powder, 2-3 parts of a defoamer, 2-3 parts of a bactericidal agent, and 100 parts of water. The rubber material of the present invention does not contain aromatic chemical products, has characteristics of no toxicity, no harm, and assurance of elimination of safety risks of consumers and users.

Owner:江苏广达医材集团有限公司

A mixed stone ceramic material

The invention discloses a mixed stone ceramic material, which is made of the following components after being ground and fired: 100-150 parts of mullite powder, 50-60 parts of quartz stone powder, 80-85 parts of calcite powder, 30-150 parts of calcite powder, 45 parts of olivine powder, 50‑55 parts of golden hemp stone powder, 5‑8 parts of diatom mud, 3‑5 parts of polydimethylsiloxane, 8‑10 parts of sodium carboxymethylcellulose, 6‑8 parts of hydroxy Ethylcellulose, 5‑8 parts rosin, 6‑8 parts glycerin, 10‑12 parts limestone. The mixed stone ceramic material has the characteristics of high thermal conductivity, high emissivity, low cost, and mass production, which solves the shortcomings of existing alumina ceramics such as high cost, low production capacity, and low thermal conductivity and low emissivity of steatite porcelain. The raw materials are processed, and then processed by hot pressing or dry pressing, and then fired at high temperature to prepare special ceramic materials with high thermal conductivity, high heat dissipation, and low cost, which are suitable for high-power and low-power LED lamps, including lamp holders, LED brackets, substrates or COB substrates are widely used in commercial lighting, indoor lighting and other fields.

Owner:邳州嘉禾四季农业发展有限公司

A kind of stem cell preparation and oral liquid prepared therefrom

ActiveCN103356697BNo pollution in the processLow costHeavy metal active ingredientsAntinoxious agentsHalloysiteSide effect

The invention belongs to the field of medicaments and relates to a stem cell preparation and an oral fluid prepared therefrom. The stem cell preparation is prepared from the following raw materials in weight percentage according to the following technical steps: mixing and crushing 20% of medical stone, 10% of stone needle, 10% of green frontiers stone, 10% of tinospora root radix tinosporae, 10% of talc, 10% of stalactite, 20% of marmor serpentinatum and 10% of red halloysite to nanometer particles so as to obtain mixed stone powder; and then sterilizing the mixed stone powder to obtain the stem cell preparation. The stem cell oral fluid is prepared after adding auxiliary materials into the stem cell preparation. The stem cell preparation disclosed by the invention causes no toxic and side effects, is good for health of human body, and replenishes mineral substances and a plurality of trace elements, so the stem cell preparation is a substitute product following antibiotic and hormone medicaments.

Owner:闫斌

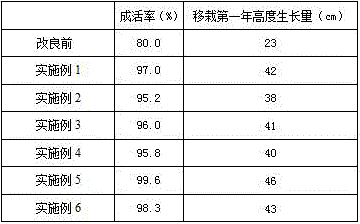

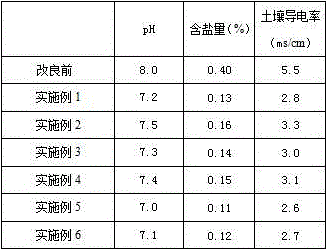

Salt drainage pipe containing water permeable layer and application thereof to salt drainage of saline and alkaline land

InactiveCN106171090AImprove bending strengthExcellent flexural modulusSoil lifting machinesHydrogenAlkali soil

The invention provides a salt discharge pipe with a water-permeable layer, which includes a hidden pipe and a water-permeable layer. The permeable layer includes a lower permeable layer and an upper permeable layer, and the lower permeable layer is laid sequentially from bottom to top: non-woven fabric layer, red jade soil layer, first mixed stone layer; the upper permeable layer is sequentially laid from bottom to top Laying: the second mixed stone layer, leaf humus layer. The invention also provides the application of the salt discharge pipe with a water-permeable layer in salt discharge in saline-alkali land. The hidden pipe of the present invention has good flexural strength, flexural modulus, and Vicat softening point; after using the salt discharge pipe of the present invention to discharge salt for one year, the pH in the 0-30cm soil of saline-alkali land is 7.0-7.5; After the invented salt discharge pipe improves the saline-alkali land, the survival rate of the plants is high and the growth speed is fast.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

wine preparation method

The invention relates to a method for preparing wine. In the method, the wine base is mixed with oak particles and / or fruit cores and then boiled and refluxed to obtain the wine. Because the contact area between wine and oak particles is much larger than that of oak barrels, The wine can better absorb the color, aroma and tannin of oak. The heating and boiling operation is adopted. Compared with the static and low-temperature contact in the prior art, a large amount of steam and bubbles are generated during boiling. The bubbles contact the surface of the oak particles, which can improve the absorption of the color and aroma of the oak by the wine, and shorten the time for wine making. cycle; the wine made by the method of the present invention has better color, aroma, smaller floor space for its production and storage equipment, higher production efficiency, and reflux of condensation reduces the volatilization loss of wine in the preparation process, greatly reducing the cost .

Owner:SHANGHAI KAISHENG BIOLOGICAL PROD CO LTD

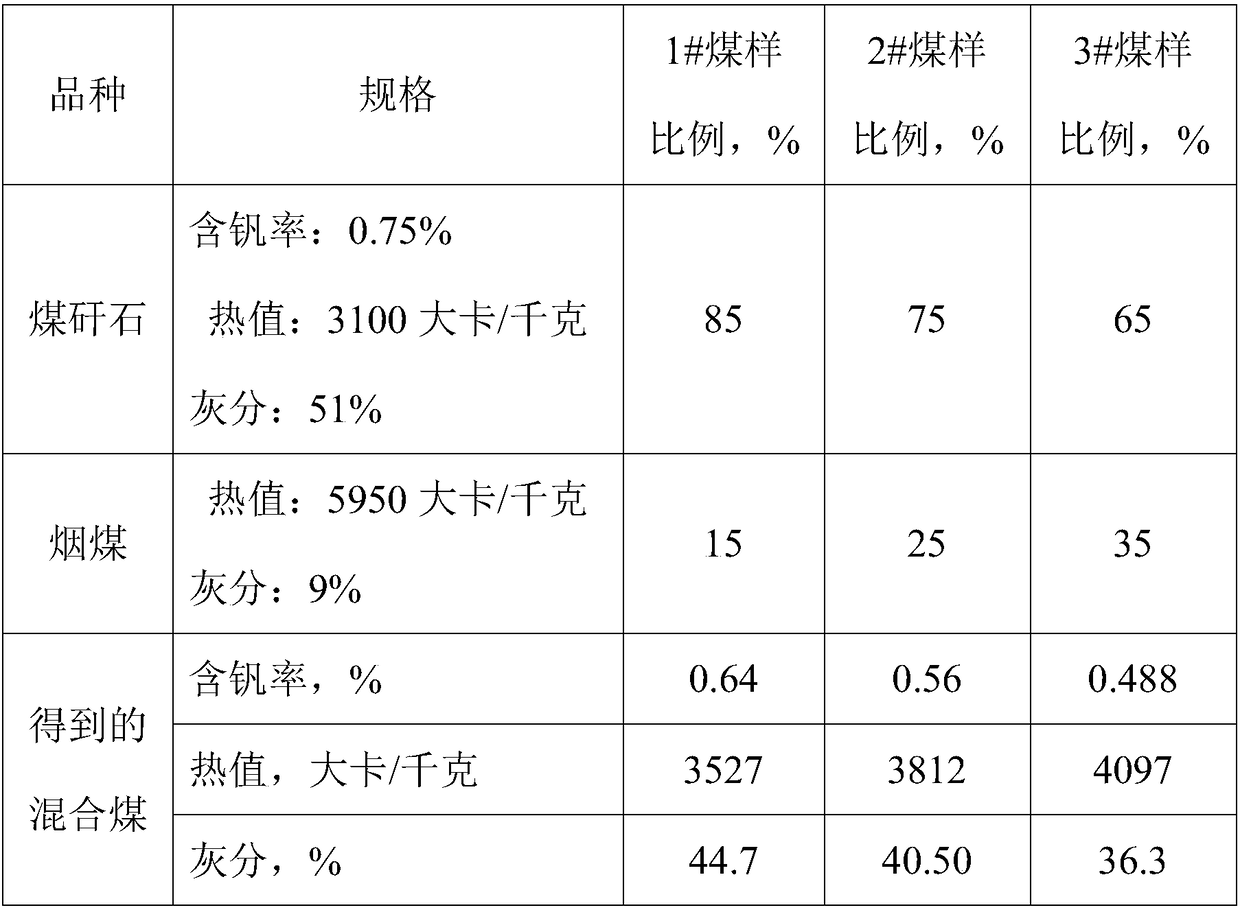

Method for combined production of fuel and steam and vanadium pentoxide raw material based on vanadium-bearing stone coal

The invention discloses a method for combined production of a fuel and steam and a vanadium pentoxide raw material based on vanadium-bearing stone coal, and the method comprises the following steps: S1, proportioning the vanadium-bearing stone coal as a basic fuel, bituminous coal and a modified filler to obtain a mixed fuel, wherein 15-40 by weight parts of the bituminous coal and 3 by weight parts of the modified filler are added into every 100 parts of the vanadium-containing stone coal; S2, uniformly mixing the mixed fuel, and sequentially crushing and screening to obtain fuel particles with the particle size of 3-5 mm; S3, feeding the processed mixed fuel as a fuel of a circulating fluidized bed boiler into the circulating fluidized bed boiler for combustion; and S4, and taking combusted ash discharged from all the parts of the circulating fluidized bed boiler for mixing to obtain a mixture for extracting the vanadium pentoxide raw material; according to the method, the fuel ratiois reasonably designed, the mixed stone coal is combusted in the fluidized bed boiler, the vanadium content of the obtained slag residual ash is generally about 0.95-1.7%, and the obtained slag residual ash is suitable for extracting the vanadium pentoxide, so that the coal gangue fuel ratio and the feasibility of extracting vanadium from boiler furnace slag are realized.

Owner:湖北谷城新和有限公司 +1

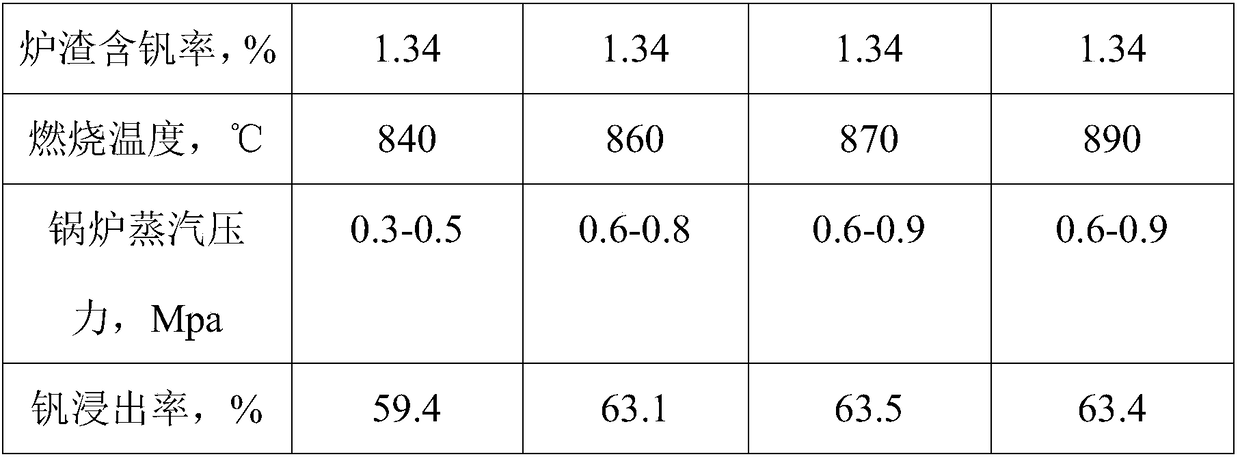

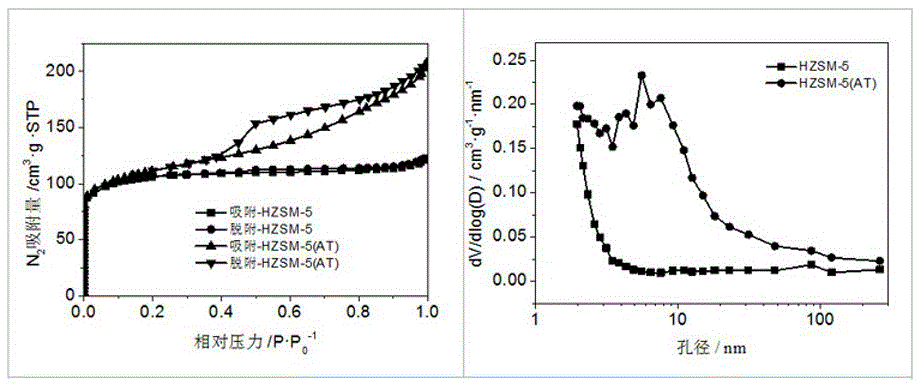

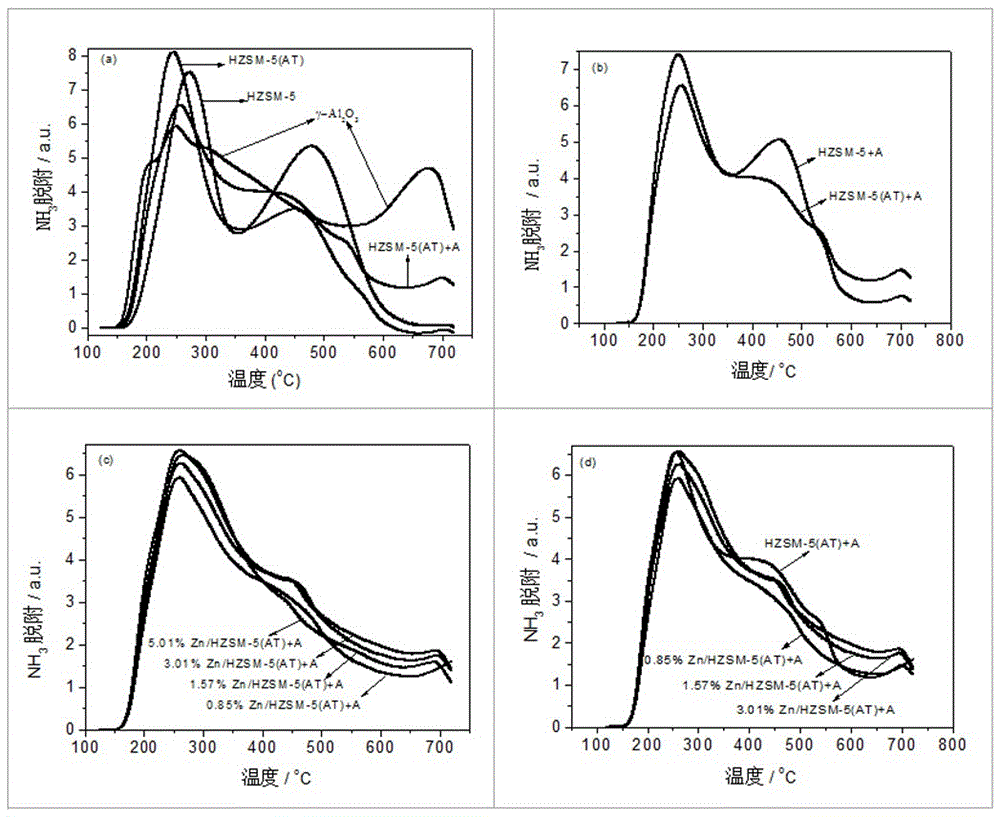

Zn-modified hierarchically porous hzsm‑5 catalyst and its application in liquefied gas aromatization

ActiveCN104759290BHigh selectivityReduce lysisMolecular sieve catalystsLiquid hydrocarbon mixtures productionMolecular sieveBTEX

The invention relates to a Zn modified multi-level pore HZSM-5 catalyst, a NaOH solution is used for alkali treatment of HZSM-5 molecular sieve to prepare the HZSM-5 (AT), the the HZSM-5 (AT) is mixed with binder pseudo-boehmite mixed stone and roasted to obtain industrial catalyst HZSM-5 (A-T) + A, and finally Zn (NO3) 2 modification of the HZSM-5 (A-T) + A is performed by equivalent-volume impregnation method to obtain Zn / (HZSM-5 (A-T) + A). The alkali modified industrial catalyst is used in liquefied gas aromatization reaction, due to the formation of a small amount of mesopores, the stability is improved; and after combination of alkali modification and Zn modification, the stability is improved, at the same time due to the existence of proper amount of Zn-L medium-strong acid center, he synergetic catalysis effect of B and L acid and strong and weak acids can be improved, splitting action of strong B acid and the generation of C9 + in liquid aromatic hydrocarbons can be reduced, and the BTEX selectivity can be improved.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com