Patents

Literature

121results about How to "Moderate toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite type high-conductivity polymer material and preparation method thereof

ActiveCN101891914AImprove conductivityAvoid damageNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

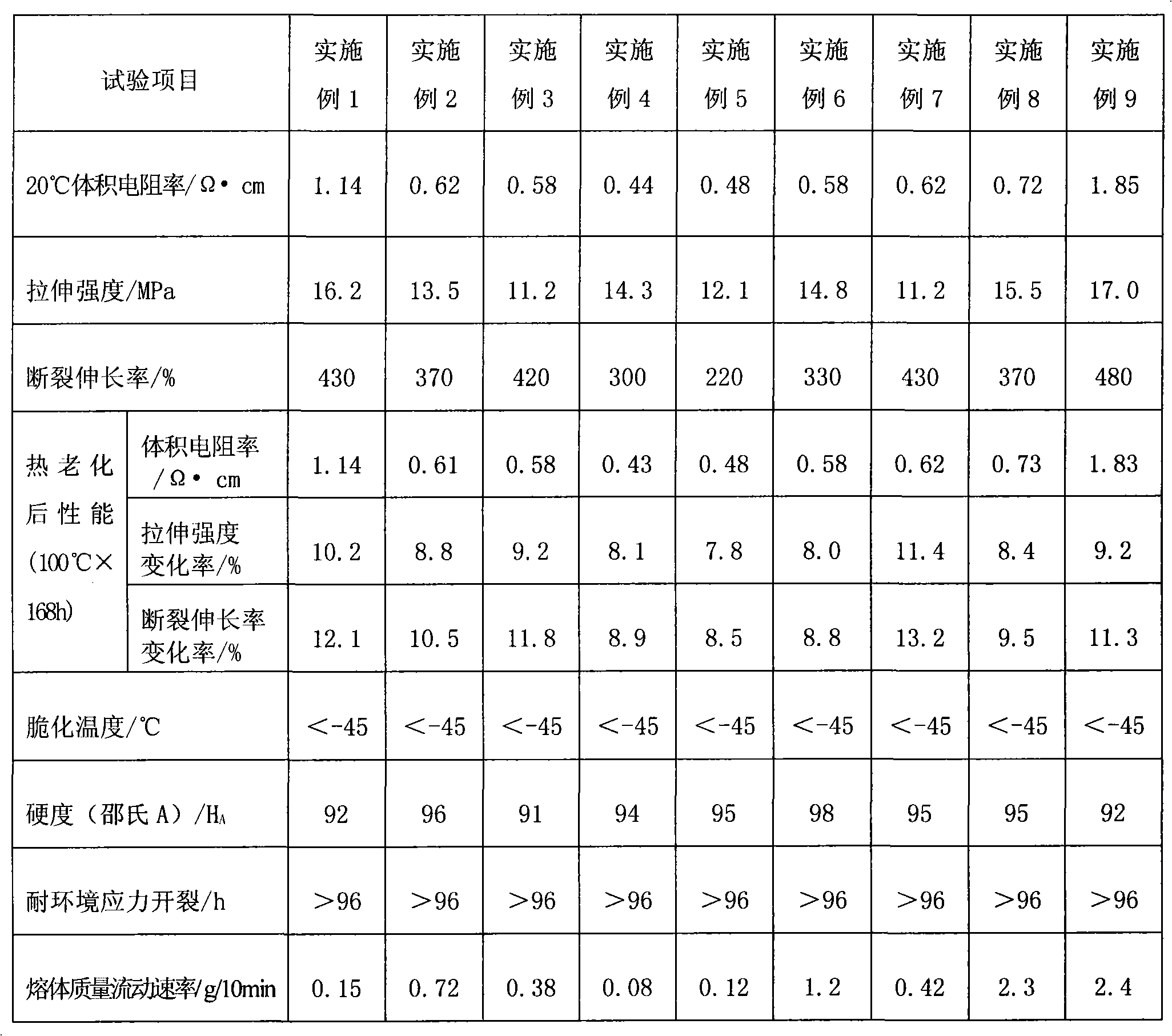

The invention discloses a composite type high-conductivity polymer material and a preparation method thereof, which belongs to the technical field of new materials. The composite type high-conductivity polymer material is characterized by comprising the following raw materials in percentage by weight: 40-62 wt% of base resin compositions, 18-25 wt% of super conductive carbon black, 10-30 wt% of rubber filling oil, 1-3 wt% of low molecular wax, 0.2-0.8 wt% of fluoroelastomer processing aid (PPA), 0.5-2 wt% of lubricant, 1.5-3 wt% of inorganic filler and 0.5-2.5 wt% of other aids. The compositetype high-conductivity polymer material has the advantages of excellent high conductivity, environmental stress cracking resistance, weatherability, ozone resistance, ultraviolet resistance, favorable high temperature resistance, high impact resistance, oil resistance, solvent resistance and mechanical property, and can be used as an environment-friendly conductive polymer sheath material of an combined through earth line, a metal anticorrosive material of other ground cable, a conductive plastic cladding material of a conductive plastic cable positive wire, an optical cable flexible sheath material, and the like.

Owner:SHANDONG KEHONG WIRE & CABLE TECH CO LTD

Sticking glue for diamond wire silicon slice and preparation method

InactiveCN109880567ALower Tg valueImprove conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesGlycidyl ethersWater circulation

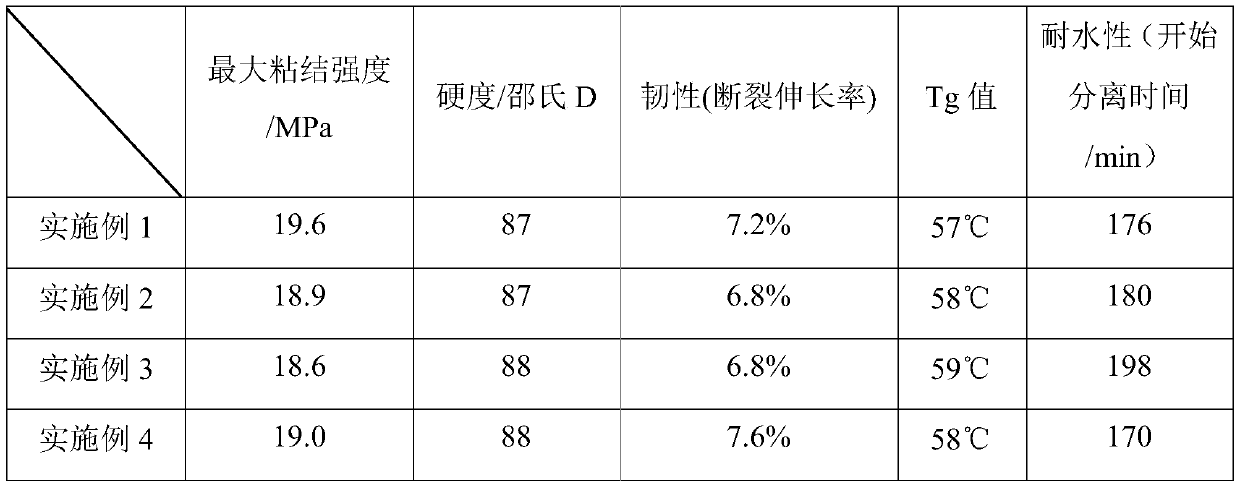

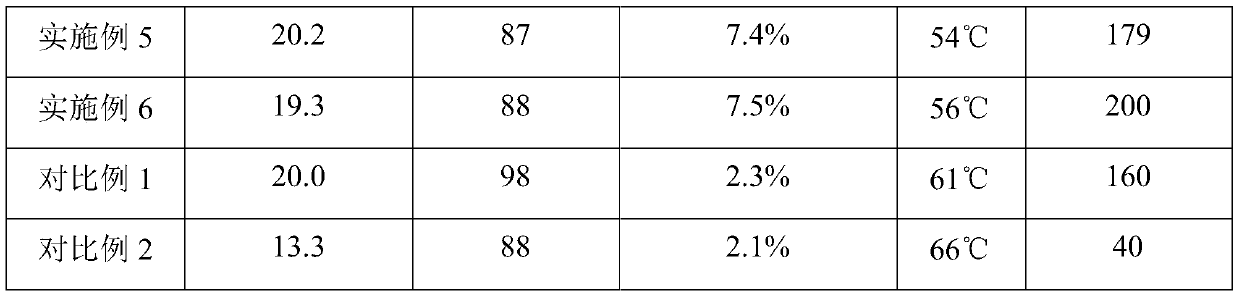

The invention discloses a sticking glue for a diamond wire silicon slice and a preparation method. The sticking glue comprises a component A and a component B; the component A includes glycidyl estertype epoxy resin, general bisphenol A epoxy resin, glycidyl ether, filler, defoaming agent, anti-settling agent and coupling reagent; the component B includes modified polythiol, self-prepared m-xylylenediamine prepolymer, accelerant, filler, defoaming agent and anti-settling agent. On the basis of the prior art, the invention modifies the last generation sticking glue and provides the sticking glue for the diamond wire silicon slice and the preparation method thereof. Boiling degumming without acid can be completed without adding degumming factors; the boiling degumming temperature is 10 DEGC lower than the present one; electrical conductivity of solution in cooling water or degumming water is reduced; normal working of cooling water circulation system is guaranteed; the service life ofmachine is prolonged; production efficiency of factory is guaranteed and potential safety hazard of easiness in causing machine failure is solved.

Owner:广西珀源新材料有限公司

Steel for high-plasticity continuous oil pipe and manufacturing method thereof

ActiveCN101168823AImprove purityModerate toughnessTemperature control deviceSteelmakingChemical composition

The invention provides a high-plastic continuous oil jacket steel and a manufacturing method thereof. The chemical composition of steel (smelting analysis) is calculated by weight percentage: C 0.04~0.14%, Si 0.15~0.40%, Mn 0.20~1.20%, Nb 0.015~0.06%, Ti 0.008~0.025%, Mo 0~0.20% , Cu 0.15-0.30%, Cr 0.20-0.50%, P 0.008-0.022%, S 0.001-0.004%, and others are iron and unavoidable inclusion elements. The specific manufacturing method involves two aspects of steelmaking process control and controlled rolling and controlled cooling process control. The cost of the steel obtained by the method of the present invention is greatly reduced, not only the produced steel has moderate strength and toughness, but also due to the micro-alloyed steel controlled rolling and controlled cooling process, the production is simple and easy, the structure uniformity of the steel is good, and due to the micro-alloyed steel The deformation resistance of the alloy steel is small during the rolling process, and the loss to the rolling mill is small, which is beneficial to popularization and application.

Owner:武汉钢铁有限公司

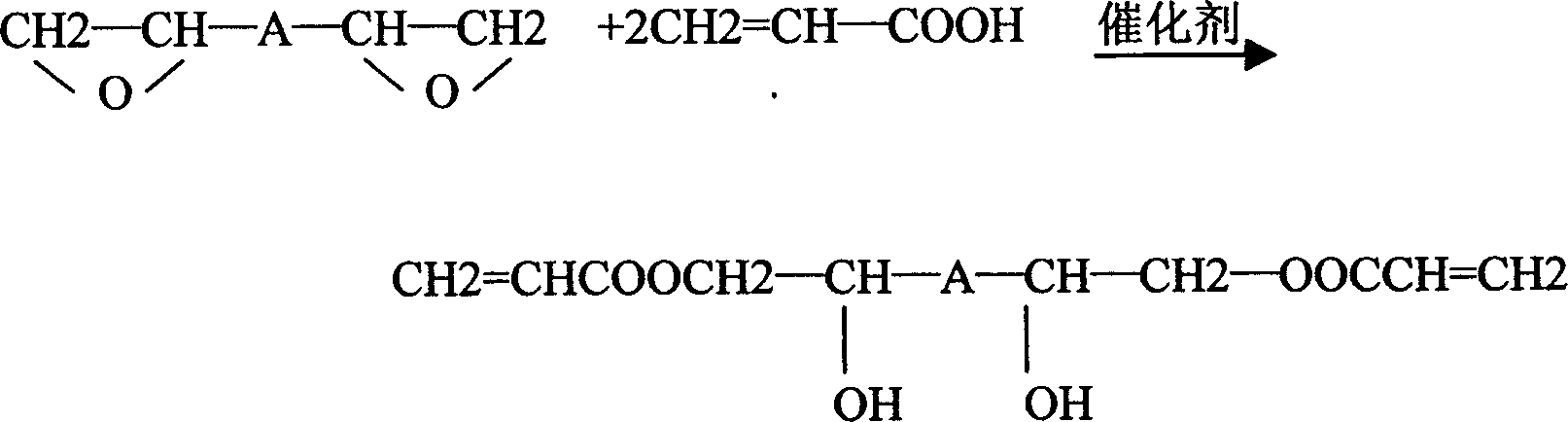

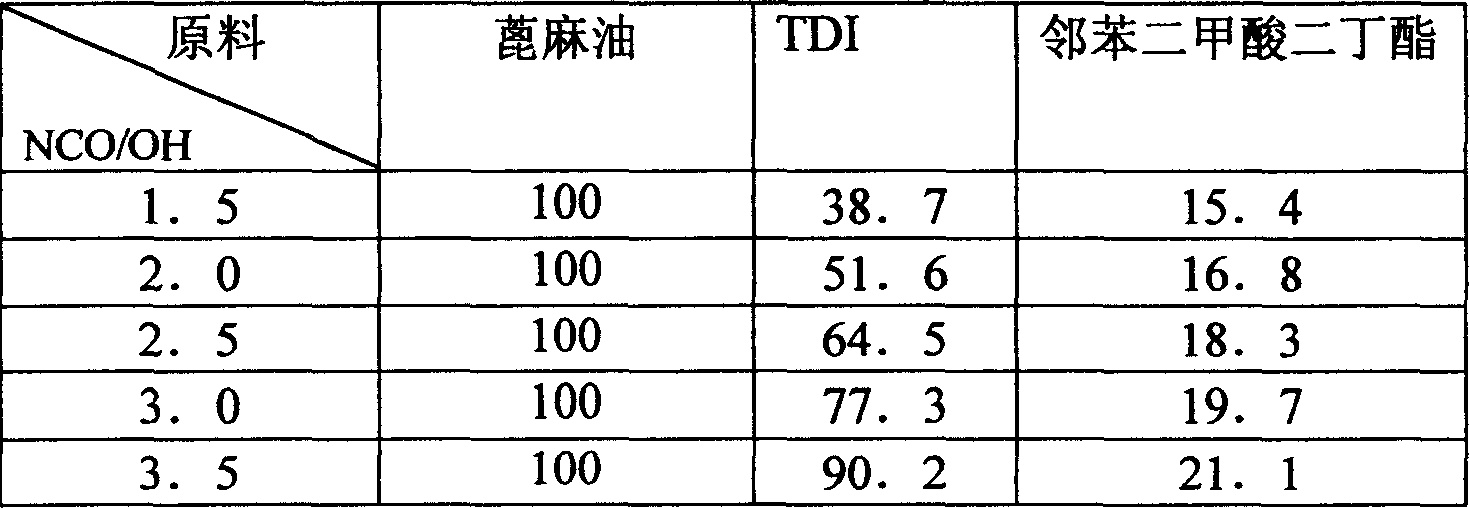

Mesh subaqueous patching material of interpenetrating polymer of epoxy/polyurethane, preparing process and application

InactiveCN1687190AImprove pourabilityImprove mechanical propertiesOther chemical processesEpoxyPolymer network

The present invention relates to an epoxy / polyurethane interpenetrating polymer network underwtaer repairing material. Its composition includes (by weight portions) acrylic epoxy resin 90-110 portions, polyurethane prepolymer 15-30 portions, diluting agent 30-60 prtions, initiator 0.5-1.0 portions of accelerator 0.1-0.2 portions. Besides, said invention also provides its excellent properties and extensive application range.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Polyvinylchloride (PVC) plastic wood plank and preparation method thereof

The invention provides a polyvinylchloride (PVC) plastic wood plank and a preparation method thereof. The PVC plastic wood plank consists of the following ingredients: PVC, calcium carbonate, wood flour, azodicarbonamide (AC) foaming agents, stabilizing agents, coupling agents, acrylicester (ACR), paraffin wax, stearic acid and fire retardants. By means of the PVC plastic wood plank, appending proportion of the calcium carbonate is enhanced by reducing the amount of the wood flour, and at the same time, by adjusting the amount of the PVC, and the type and amount of other additives, not only can hardness of the plank be greatly enhanced, but also appropriate toughness can be possessed. Therefore, the plank is guaranteed to be not only possess enough hardness when used as wood floors in public places so that damage and sinking of the surface of the plank are not prone to occurring, but also meet requirements of the wood floors due to the toughness of the plank so that the plank can be ensured to be not easy to crack.

Owner:江西铁木真装饰材料有限公司

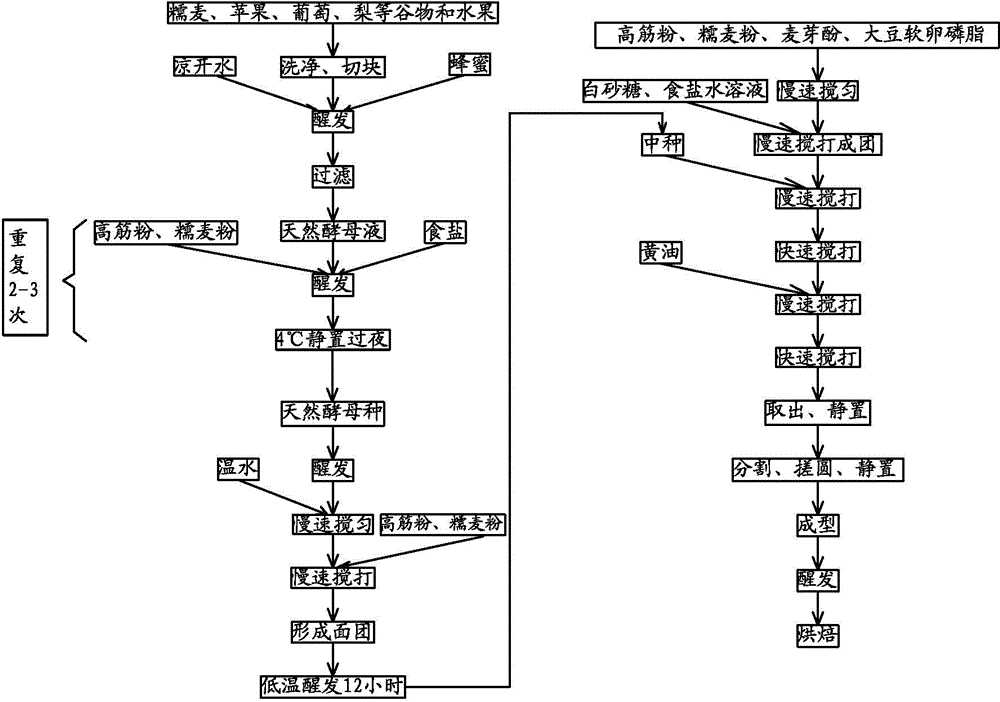

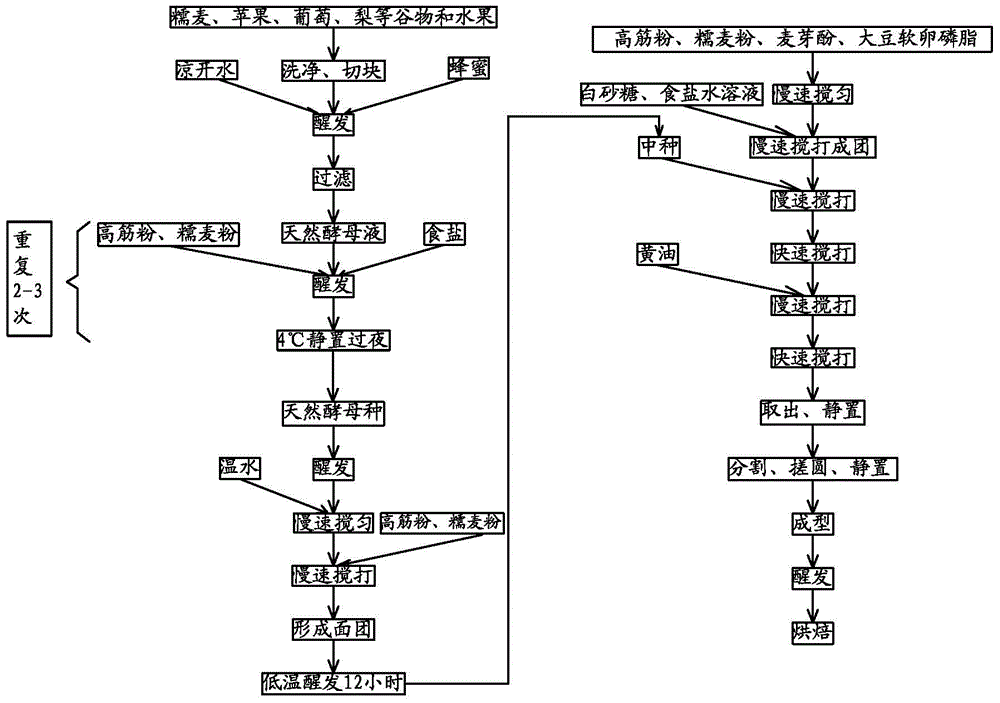

Natural yeast bread and manufacturing method thereof

InactiveCN104782702AAppropriate tasteUniform structureDough treatmentPre-baking dough treatmentNutritive valuesWarm water

The invention relates to a manufacturing method of natural yeast bread. The method includes the steps that a, natural yeast liquid raw materials selected from fruits and cereals at least including glutinous barley are fermented to obtain natural yeast liquid; b, high-gluten flour and glutinous barley flour are mixed to obtain mixed flour, the mixed flour and the natural yeast liquid are mixed to obtain a mixture, and the mixture is fermented to obtain primary natural yeast; c, after the primary natural yeast is fermented, the primary natural yeast, warm water, high-gluten flour and glutinous barley flour are stirred into mixed dough, and the mixed dough is fermented at low temperature to obtain sponge dough; d, high-gluten flour, glutinous barley flour, malt flour, soya bean lecithin and a water solution are stirred and then added into the sponge dough to form bread dough through stirring; e, the bread dough is fermented; f, a conventional method is used for baking to obtain the bread. The invention further discloses natural yeast bread manufactured by adopting the method. The high water absorption rate and the high aerogenesis capacity of the glutinous barley flour, the capacity of promoting yeast aerogenesis of the malt flour and the emulsifying capacity of the soya bean lecithin are used, and low-temperature secondary fermentation is combined to obtain the soft and healthy bread moderate in mouthfeel and high in nutritive value.

Owner:福建安麦高新生物技术有限公司

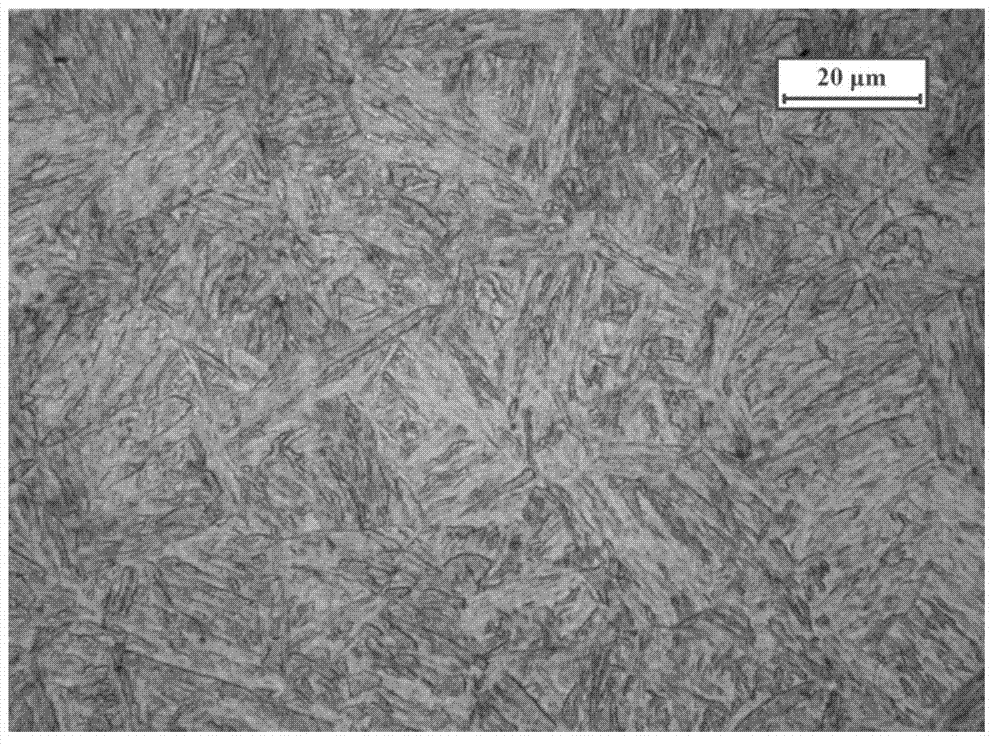

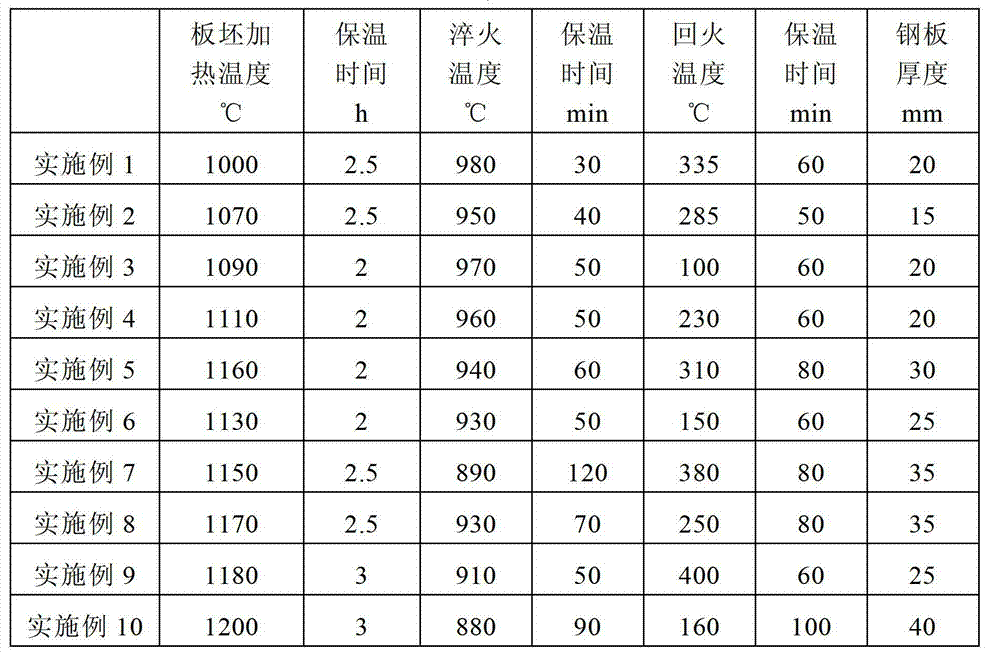

HB360-level wear-resistant steel plate and preparation method thereof

The invention discloses an HB360-level wear-resistant steel plate and a preparation method thereof. The HB360-level wear-resistant steel plate comprises the following components in percentage by weight: 0.08%-0.20% of C, 0.10%-1.00% of Si, 1.00%-2.00% of Mn, not more than 0.015% of P, not more than 0.010% of S, not more than 1.20% of Cr, not more than 0.80% of Mo, not more than 1.00% of Ni, not more than 0.080% of Nb, 0.010%-0.100% of Al, 0.0005%-0.0040% of B, 0.005%-0.050% of Ti, 0.0010%-0.0080% of Ca, not more than 0.080% of N, not more than 0.0080% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein (Cr / 5+Mn / 6+50B) is not less than 0.20% and not more than 0.55%, (Mo / 3+Ni / 5+2Nb) is not less than 0.02% and not more than 0.45%, (Al+Ti) is not less than 0.01% and not more than 0.13%. The tensile strength of the steel plate is 1100MPa-1400MPa, the elongation of the steel plate is 14%-16%, the Brinell hardness of the steel plate is 360HB-440HB, the Charpy longitudinalV-shaped longidutional impact power at -40 DEG C is 80J-120J. The steel plate obtained by the components through each thermal treatment process is high in strength hardness, good in flexibility, easy to weld, excellent in mechanical machining performances and suitable for easy-wearing components in various mechanical devices.

Owner:BAOSHAN IRON & STEEL CO LTD

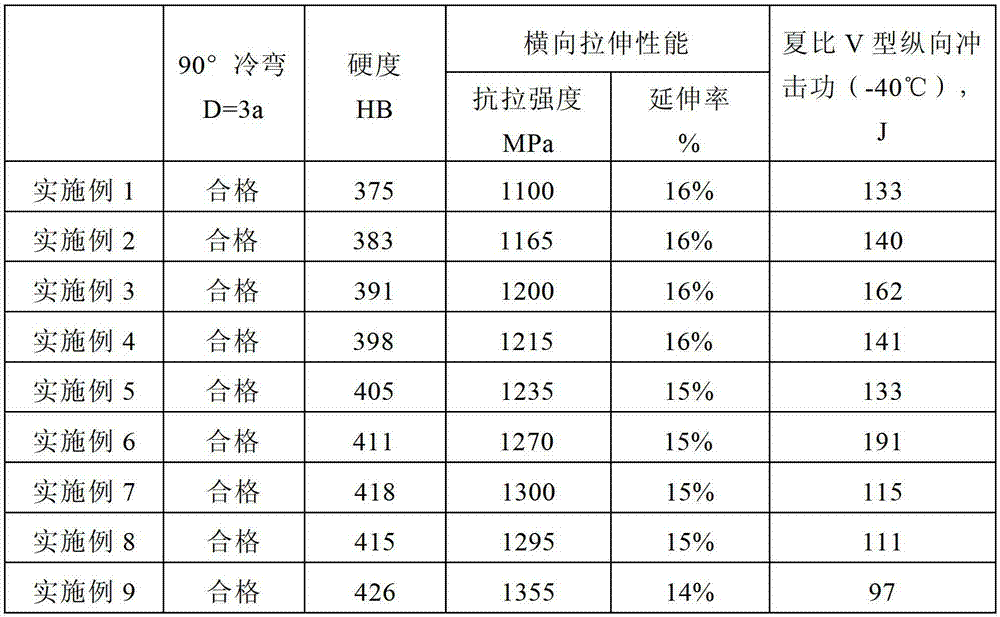

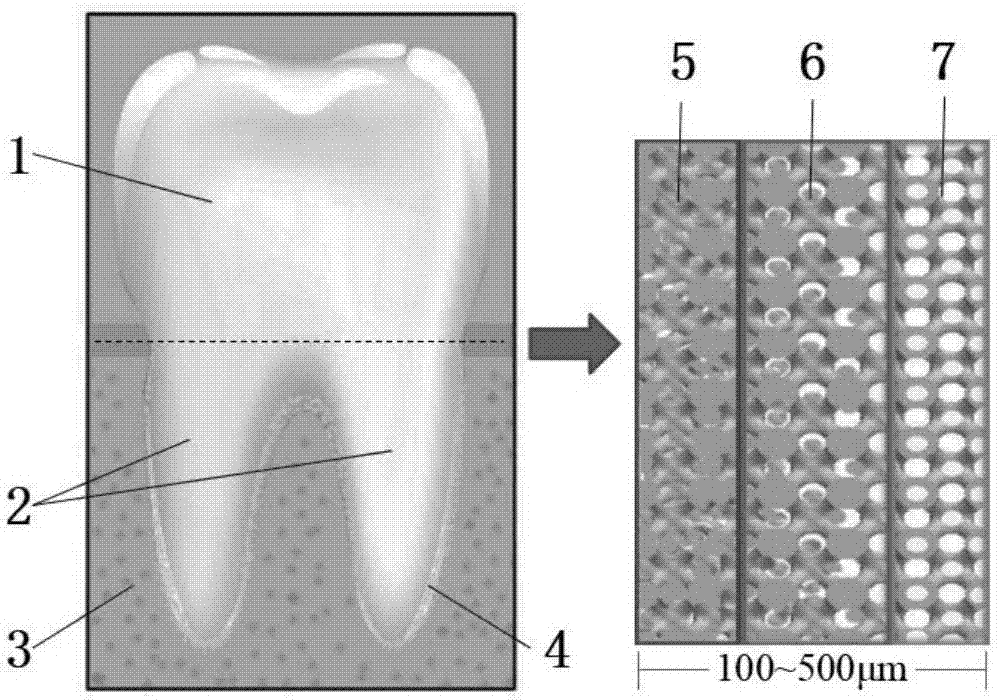

ZrO2-based all-ceramic dental implant and preparation method thereof

ActiveCN107500758AOptimal Control StructurePromote osseointegrationTissue regenerationProsthesisIonDental implant

The invention provides a ZrO2-based all-ceramic dental implant and a preparation method thereof. The method comprises steps as follows: ZrO2 nano powder with stable doping elements is obtained from soluble zirconium salt, strong base and a solution containing doping elements with a nano powder preparation technology; the ZrO2 nano powder is mixed with photosensitive resin, and ceramic-photosensitive resin prefabricated slurry is obtained; the ceramic-photosensitive resin prefabricated slurry is printed with an additive manufacturing technology according to a true tooth simulation model, a ZrO2 ceramic biscuit is obtained and subjected to gel removal and sintering, and a ZrO2 ceramic matrix is obtained; finally, ion penetration, sintering and mineralization are performed, and the ZrO2-based all-ceramic dental implant is obtained. The dental implant is controllable in structure and highly simulated with the additive manufacturing technology; in combination with ion penetration, sintering and mineralization treatment, synostosis of the dental implant and alveolar bone is advantageously improved; chemical ingredients of the dental implant are in gradient distribution on the whole, and the ZrO2-based all-ceramic dental implant has moderate strength, hardness, toughness and bioactivity.

Owner:GUANGDONG UNIV OF TECH

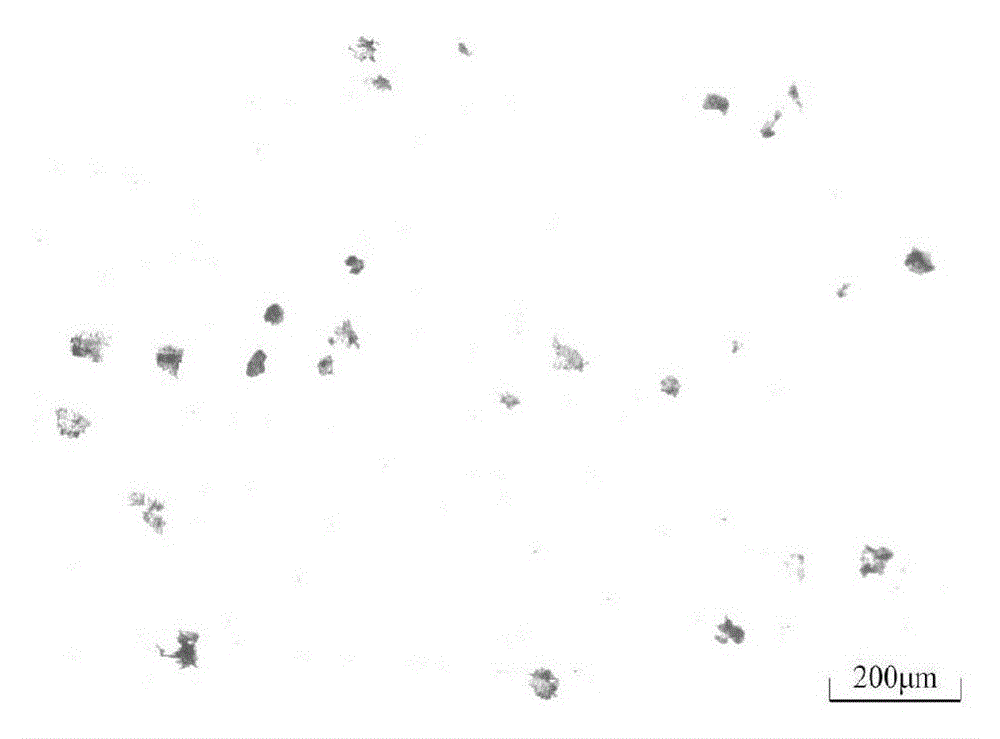

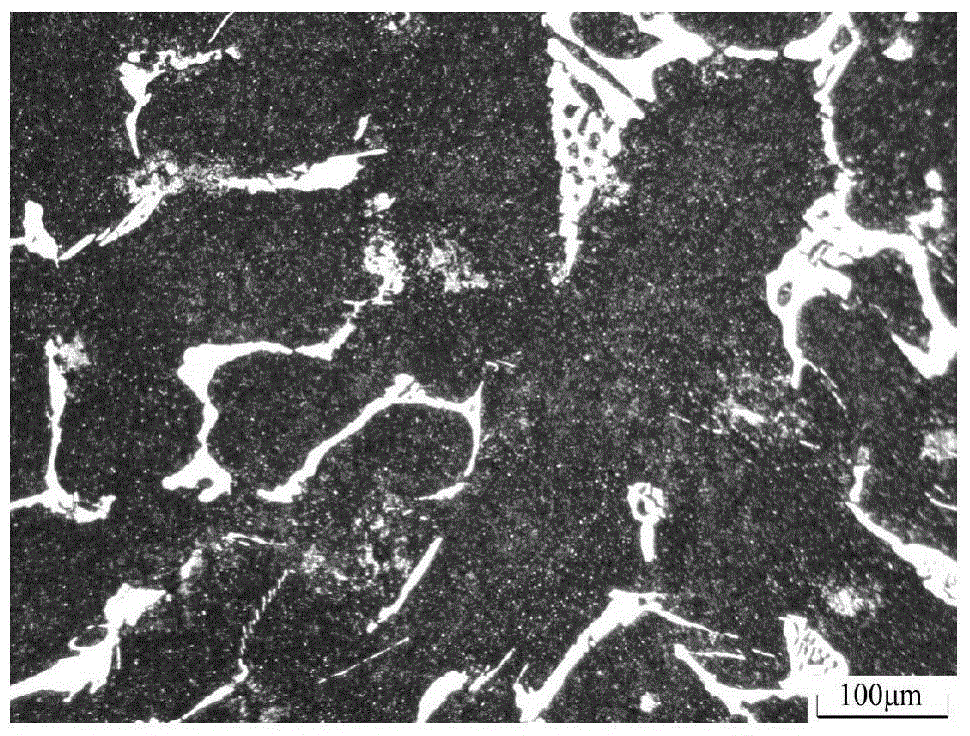

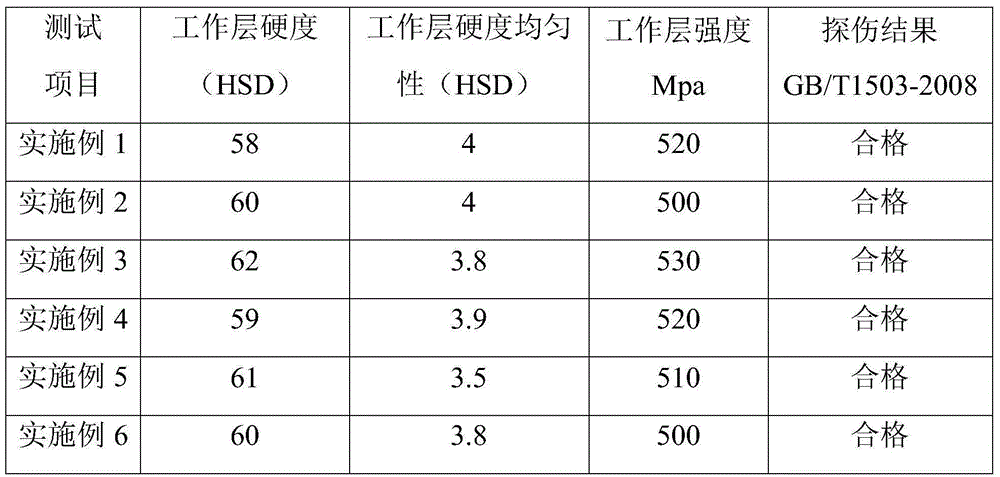

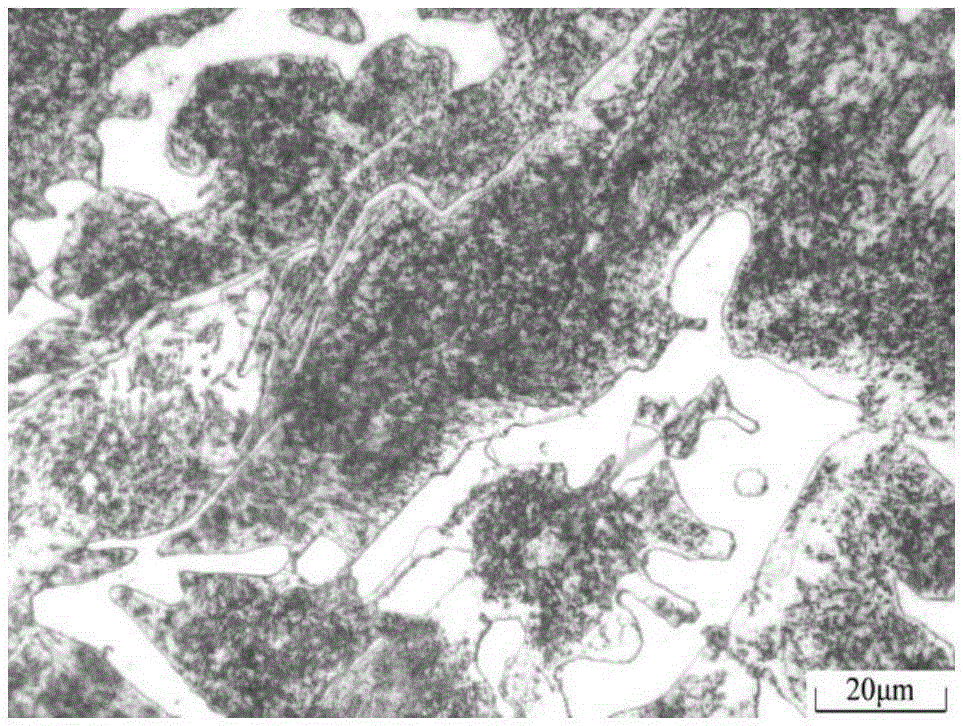

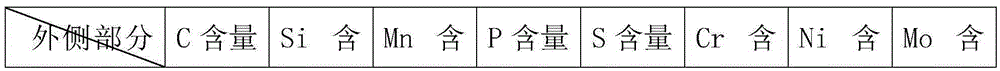

High-carbon graphitic steel roller ring for profile steel universal mill and manufacturing method of high-carbon graphitic steel roller ring

The invention discloses a high-carbon graphitic steel roller ring for a profile steel universal mill and a manufacturing method of the high-carbon graphitic steel roller ring. The outer layer of the roller ring is composed of, by mass, 1.70%-2.30% of C, 1.50%-2.20% of Si, 0.50%-1.20% of Mn, 0.03% of P or less, 0.03% of S or less, 1.00%-1.80% of Cr, 0.20%-1.20% of Ni, 0.20%-0.80% of Mo and the balance Fe. A core is composed of, by mass, 1.00%-2.00% of C, 1.00%-2.00% of Si, 0.50%-1.50% of Mn, 0.03% of P or less, 0.03% of S or less, 0.5% of Cr or less and the balance Fe. The manufacturing method comprises the steps of smelting, inoculation and spheroidizing, centrifugal casting and heat treatment. Spheroidizing is carried out at least two times. The metallographic structure of the roller ring obtained after heat treatment comprises a pearlite base body, carbide with the area rate of 10.36% and graphite, the form of the graphite is in a mass shape or a mass insect shape, and the area rate of the graphite is 1.7%. The high-carbon graphitic steel roller ring has high wear resistance, breaking resisting strength, toughness, hot crack resistance and accident impact resisting capacity, and the steel bonding tendency is avoided.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

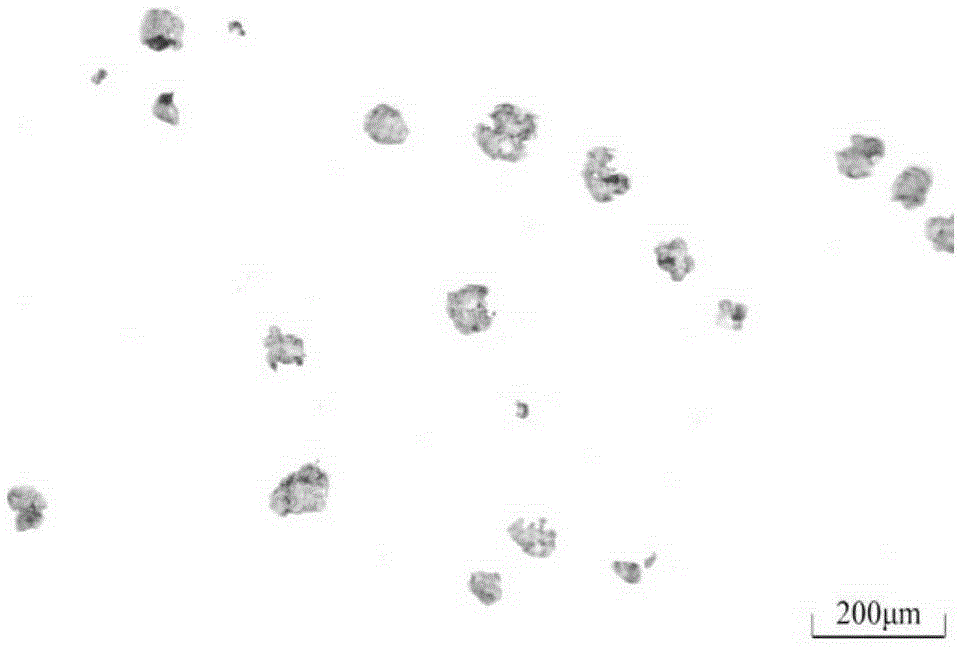

Universal type steel ball unthreaded ball iron roller ring and manufacturing method thereof

The invention discloses a universal type steel ball unthreaded ball iron roller ring which comprises an outer layer and an inner core. The proportion between the outer layer and the inner core is 2:1. The alloy component of the outer layer comprises, by weight, 3.0-3.5% of C, 1.2-2.0% of Si, 0.5-1.2% of Mn, 0.1% or less of P, 0.02% or less of S, 0.2-1.0% of Cr, 0.5-1.5% of Ni, 0.2-1.0% of Mo, and the balance Fe and inevitable impurities. The alloy component of the inner core comprises, by weight, 1.0-1.5% of C, 1.3-1.7% of Si, 0.5-1.0% of Mn, 0.08% or less of P, 0.03% or less of S, 0.5% or less of Cr, 0.3% or less of Ni, 0.13% or less of Mo, and the balance Fe and inevitable impurities. A manufacturing method comprises the steps of A, smelting, B, inoculation and spheroidizing, and C, casting. By means of the universal type steel ball unthreaded ball iron roller ring and the manufacturing method thereof, the hardness fall of rollers can become small, the steel adhesion tendency is relieved, and the comprehensive using performance of the roller ring is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

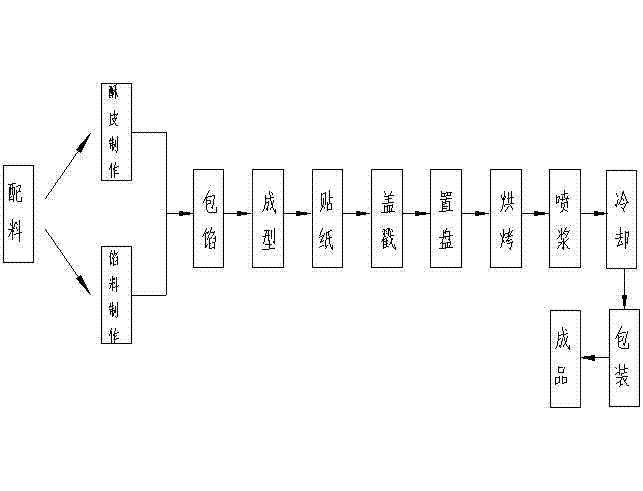

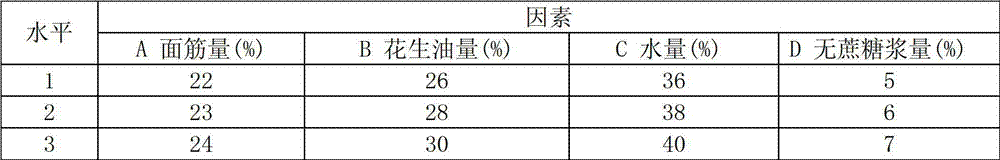

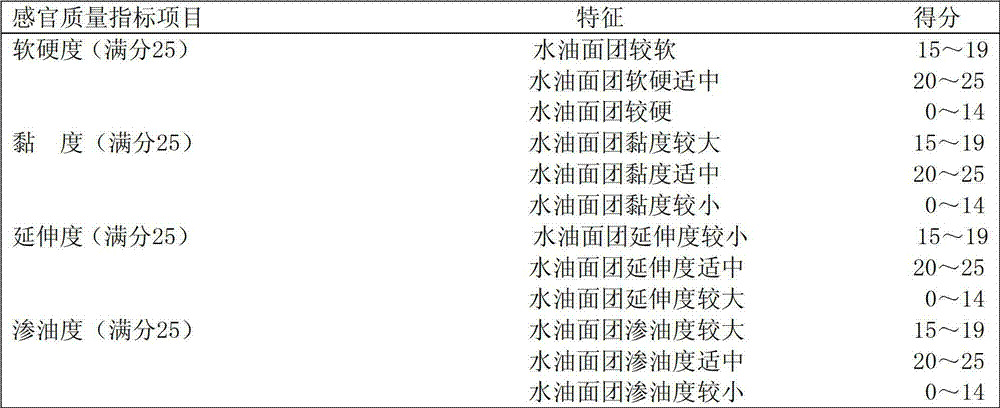

Suzhou-style mooncake with good cake crust sensation quality and production technology of mooncake

InactiveCN102919332AImprove qualityConducive to processBakery productsClear LayerAdditive ingredient

The invention relates to a production technology of a Suzhou-style mooncake with good cake crust sensation quality. The production technology of the Suzhou-style mooncake with good cake crust sensation quality comprises the following steps of: (1) preparing ingredients; (2) making crisp crust and fillings, wherein the crisp crust making comprises the following step of preparing water and oil doughs, oil crisp doughs and crisp crust doughs; (3) wrapping the fillings and forming; (4) baking; and (5) cooling. According to the production technology, the cake crust formulation is adjusted appropriately; the cake crust of the prepared Suzhou-style mooncake has favorable comprehensive sensory quality, and the Suzhou-style mooncake with good cake crust sensation quality has the advantages of low sweetness, clear layers, crisp taste, complete cake crust and nutrition and health.

Owner:苏州稻香村食品工业有限公司

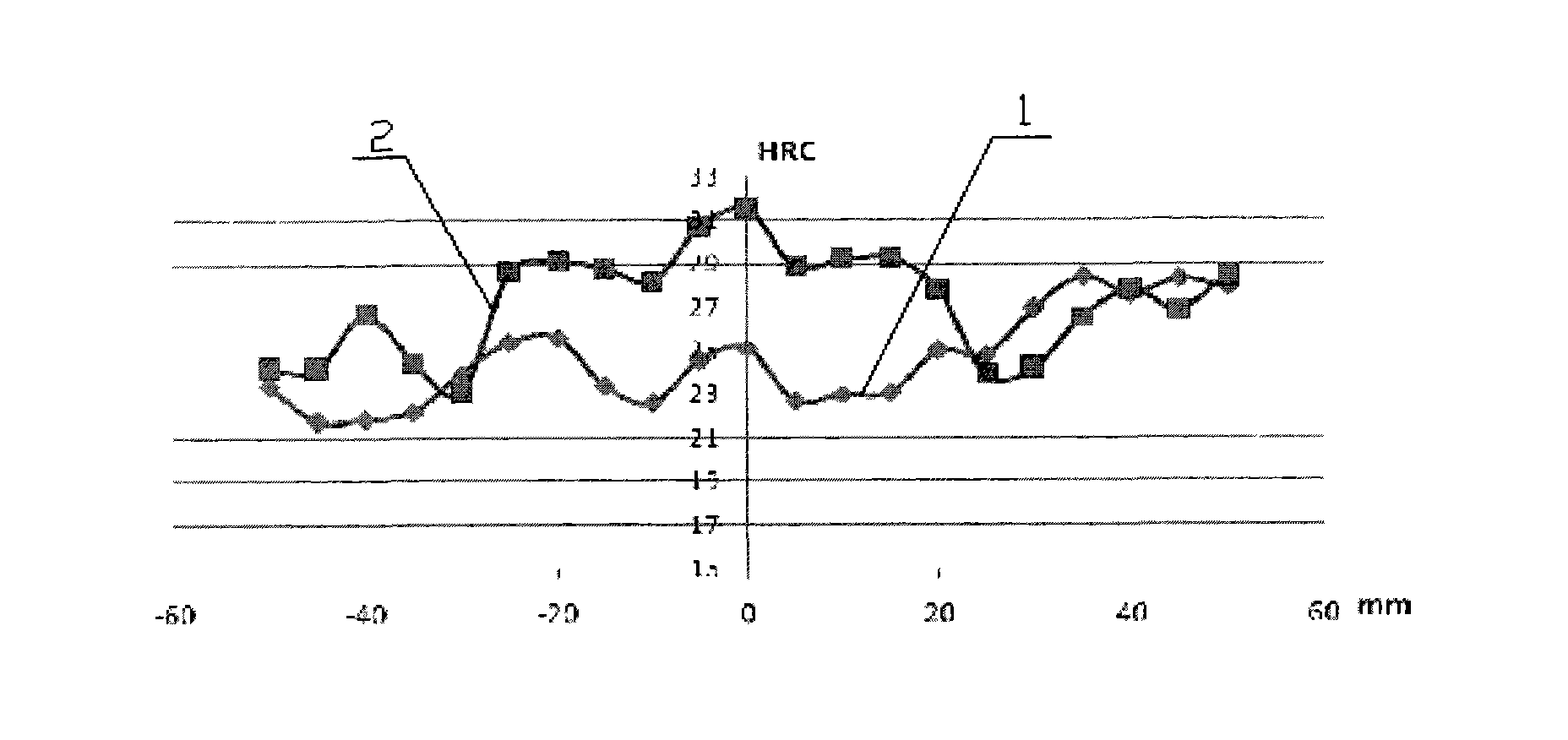

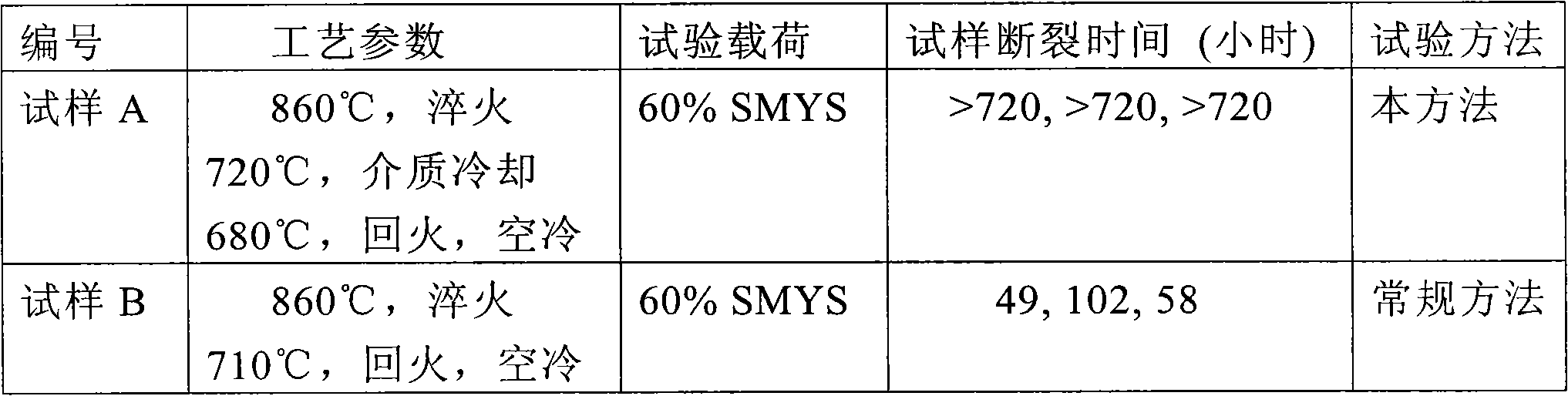

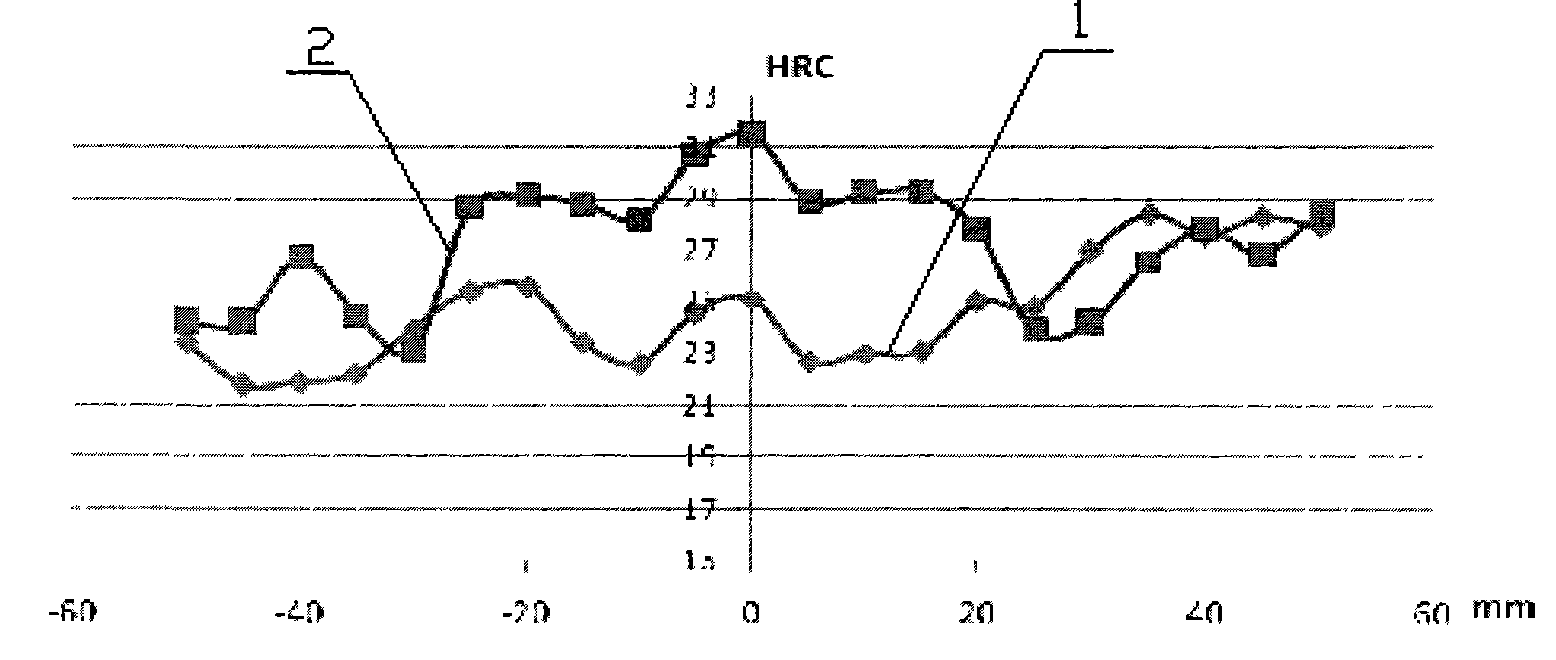

Treatment method for welding zone of high-performance sulfur-resisting drill pipe body and joint

InactiveCN101988147AAvoid lostImproved resistance to sulfide stress corrosion crackingIncreasing energy efficiencyFurnace typesStress corrosion crackingQuenching

The invention discloses a treatment method for a welding zone of a high-performance sulfur-resisting drill pipe body and a joint, which comprises the following steps: respectively carrying out overall quenched-tempered heat treatment on the pipe body and the joint with the same components, and then connecting the pipe body and the joint into a whole by friction welding; carrying out medium-frequency induction heating on the welding zone to 300 DEG C-600 DEG C, then carrying out stress-relief annealing, turning flashing and burrs, and carrying out post-welding heat treatment; carrying out medium-frequency induction heating on the welding zone to 780 DEG C-900 DEG C, preserving the temperature for 3-30 minutes, and then carrying out spray quenching by using a quenching medium of 20 DEG C-40 DEG C; carrying out medium-frequency induction heating on the welding zone to 690 DEG C-750 DEG C, preserving the temperature for 5-30 minutes, and then carrying out spray cooling by using a quenching medium of 20 DEG C-40 DEG C; and carrying out medium-frequency induction heating on the welding zone to 600 DEG C-700 DEG C, preserving the temperature for 5-30 minutes, and then air cooling to room temperature. After the drill pipe is treated by the method, the cracking-resisting capacity of the welding zone is improved, and the welding zone has appropriate strength, toughness, lower hardness and even distribution, thereby avoiding loss caused by sulfide stress corrosion cracking of the drill pipe.

Owner:SHANGHAI HILONG DRILL PIPE MATERIALS INST +1

A kind of straight dry rice flour processing method

The invention relates to a processing method of straight stripped dry rice noodles. The processing method comprises the following steps: 1, pretreating a raw material; 2, immersing; 3, burdening, and crushing; 4, pregelatinizing; 5, extrusion molding; 6, scattering through twisting, and spreading and airing; and 7, drying and packaging. The straight stripped dry rice noodles produced with the processing method of the invention, which have the advantages of fast rehydration, good taste, moderate toughness, and no burnt soup occurring, can be rehydrated when the straight stripped dry rice noodles are immersed for 10-15min at about 25DEG C, and not more than 30min at a low temperature in winter.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Aluminum alloy welding wire for automobile fuel tank and preparation method of aluminum alloy welding wire

InactiveCN107414339AInhibition of recrystallizationInhibition of grain growthWelding/cutting media/materialsSoldering mediaFuel tankAluminium alloy

The invention discloses an aluminum alloy welding wire for an automobile fuel tank. The raw materials of the aluminum alloy welding wire comprise, by weight, 6.3-6.7% of Mg, 0.5-0.8% of Mn, 0.16-0.18% of Ti, 0.0001-0.005% of Be, 0.2-0.4% of Fe, 0.01-0.08% of B, 0.22-0.25% of Cr, 0.3-0.4% of Si, 0.16-0.25% of Zr, 0.15-0.2% of V, 0.2-0.3% of Sc, less than or equal to 0.1% of Cu, less than or equal to 0.2% of Zn, less than or equal to 0.05% of the single content of other impurity elements, less than or equal to 0.1% of the total content of other impurity elements and the balance Al. The invention further discloses a preparation method of the aluminum alloy welding wire for the automobile fuel tank. The aluminum alloy welding wire for the automobile fuel tank is compact in welding joint tissue, good in impact resistance, toughness and tension strength, good in crack resistance, and good in fatigue resistant property.

Owner:安徽飞弧焊业股份有限公司

Preparation method for dry lotus root-sweet potato vermicelli

The invention discloses a preparation method for dry lotus root-sweet potato vermicelli. The preparation method comprises the steps of: processing raw materials-batching-steaming sheet jelly-pre-drying-cutting into slices-drying and packaging. Natural dry lotus root and sweet potatoes are used as raw materials. The raw materials are safe and no chemical substance is added during a production process, thereby guaranteeing the product quality. The product combines nutrition ingredients of the dry lotus root and the sweet potatoes; the vermicelli is transparent and flat; and the product is moderate in toughness, can be cooked easily without being broken and has a good taste.

Owner:杨舒翔

Fish skin and pig skin compounded nutrition crystal jelly and preparing method thereof

The invention belongs to the field of food processing and mainly relates to fish skin and pig skin compounded nutrition crystal jelly and a preparing method thereof. Fish skin and pig skin serve as raw materials, an extract gel solution is extracted through heat extraction, a primary extract gel solution is obtained through boiling, secondary gel extraction is carried out through steaming, the extract gel solution is cooled at a low-temperature to form the jelly food, the gel property pf the product is high, nutrition is rich, the texture is crystal clear, and the fat content is very low. The jelly prepared by compounding the pig skin and the fish skin is moderate in hardness, elasticity and toughness and has good heat resistance and stability.

Owner:BOHAI UNIV

Multifunctional phase change composite material and preparation method thereof

ActiveCN109486473AModerate elasticity and toughnessGood hold and leak-proofHeat-exchange elementsParaffin oilsRail traffic

The invention discloses a multifunctional phase change composite material and a preparation method thereof. The multifunctional phase change composite material contains the following components by mass percentage: 15-35% of EPDM, 40-75% of paraffin, 5-25% of expanded graphite, 5-25% of fire retardant, 0.5-5% of cross-linking agent, 0.01-5% of cross-linking aid, and 0-10% of processing aid; the mass percentage sum of the components is 100%. The phase change energy storage composite material disclosed by the invention has partial features of thermal vulcanized rubber, is moderate in elasticity and toughness, and good in sizing and antiseep effect, and meanwhile has the advantages of high latent heat of phase change, high conductivity coefficient, flame resistance and insulation, is simple inproduction process, and has good application prospect in multiple thermal design and heat management fields including new-energy vehicles, rail traffics, communication base stations, laser equipment,unmanned aerial vehicles and intelligent terminal equipment.

Owner:深圳航美新材料科技有限公司

Cable insulation layer material with good heat stability and excellent mechanical property

InactiveCN105482227AImprove mechanical propertiesModerate toughnessPlastic/resin/waxes insulatorsInsulation layerBenzoyl peroxide

The invention discloses a cable insulation layer material with the good heat stability and the excellent mechanical property. The cable insulation layer material is prepared from, by weight, 50-80 parts of polyethylene, 10-20 parts of ethylene vinyl acetate, 15-20 parts of modified polypropylene, 1-3 parts of polydimethylsiloxane with vinyl as the end group, 0.5-1 part of benzoyl peroxide, 1-2 parts of dien, 0.4-1.2 parts of triallyl cyanurate, 1-2 parts of dibutyltin dilaurate, 0.8-1.4 parts of styryl-N-phenylaniline, 1-2 parts of 3,5-tertiary butyl-4-hydroxy cinnamic acid, 0.8-1.5 parts of tricresyl phosphite (2,4-di-tert-butylphenyl) ester, 1-2 parts of sorbitol, 1-2 parts of hydroxyl silicone oil, 1-2 parts of magnesium stearate, 1-2 parts of zinc stearate, 3-7 parts of polyurethane hot melt adhesives and 20-40 parts of a composite filler. The cable insulation layer material is good in heat stability, good in mechanical performance and long in service life.

Owner:ANHUI RUIKAN SCI CABLE

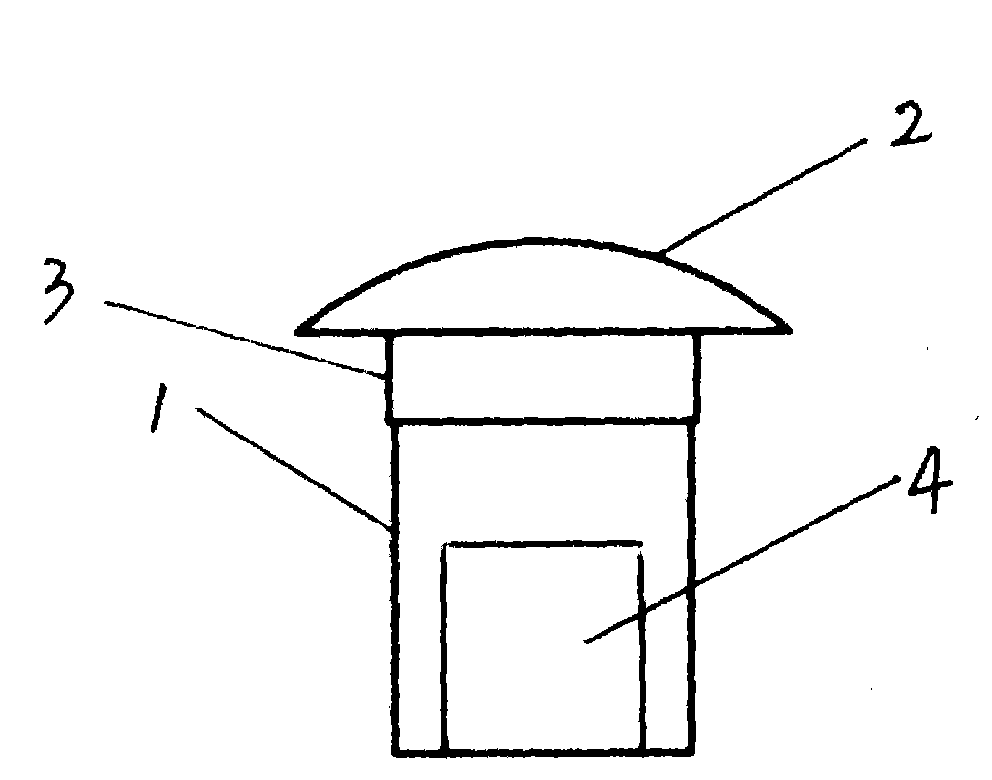

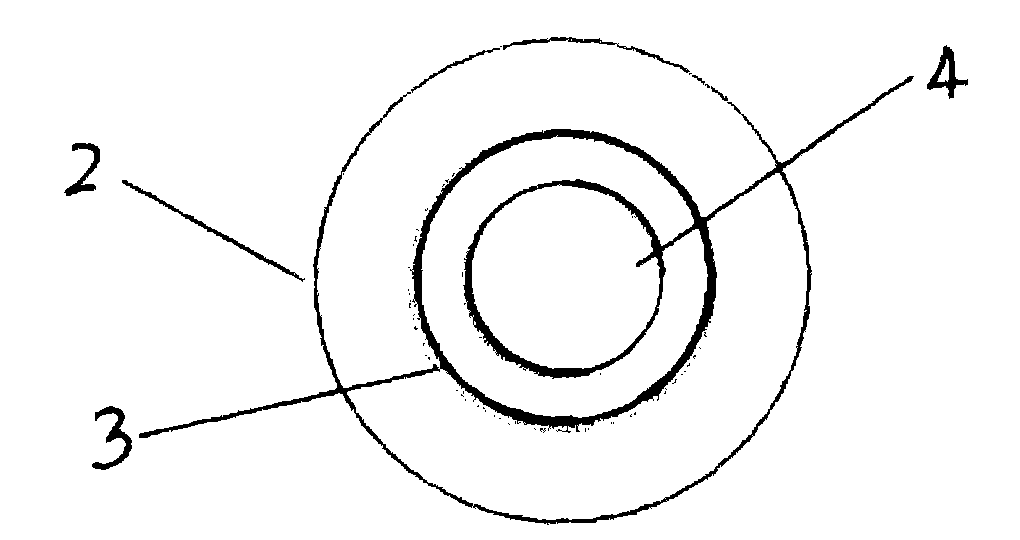

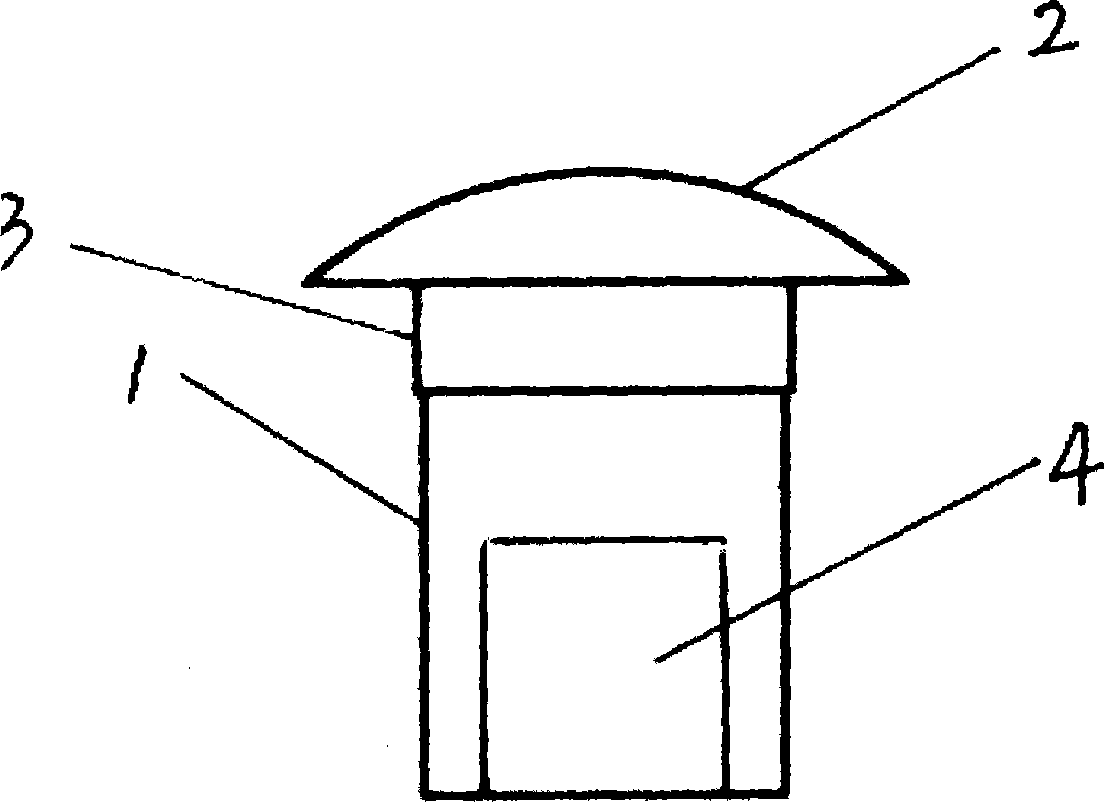

Hollow rivet shaft processing technology

The invention relates to a hollow rivet shaft processing technology, which comprises the following steps of: cold heading common round steel materials through a press machine to form a hollow rivet shaft and semi-circle cap appearance; turning a rotating shaft through a turning lathe, and drilling a riveting hole; removing sharp corners and burrs on the surface of the hollow rivet shaft; removing oil contamination and rusty sport, and cleaning; and chroming the surface of the hollow rivet shaft. The hollow rivet shaft processing technology can ensure the manufacturing quality and the product requirement of parts.

Owner:温永林

Natural yeast bread dough and manufacturing method thereof

InactiveCN104782703AAppropriate tasteUniform structureDough treatmentPre-baking dough treatmentNutritive valuesWarm water

The invention discloses a manufacturing method of natural yeast bread dough. The method includes the steps that a, natural yeast liquid raw materials selected from fruits and cereals at least including glutinous barley are fermented to obtain natural yeast liquid; b, high-gluten flour and glutinous barley flour are mixed to obtain mixed flour, the mixed flour and the natural yeast liquid are mixed to obtain a mixture, and the mixture is fermented to obtain primary natural yeast; c, after the primary natural yeast is fermented, the primary natural yeast, warm water, high-gluten flour and glutinous barley flour are stirred into mixed dough, and the mixed dough is fermented at low temperature to obtain sponge dough; d, high-gluten flour, glutinous barley flour, malt flour, soya bean lecithin and a water solution are stirred and then added into the sponge dough to form bread dough through stirring. The invention further discloses natural yeast bread dough manufactured by adopting the method. The high water absorption rate and the high aerogenesis capacity of the glutinous barley flour, the capacity of promoting yeast aerogenesis of the malt flour and the emulsifying capacity of the soya bean lecithin are used, and low-temperature secondary fermentation is combined to obtain soft and healthy bread moderate in mouthfeel and high in nutritive value.

Owner:福建安麦高新生物技术有限公司

Anatomical wax tray and production method thereof

The invention provides an anatomical wax tray. The anatomical wax tray contains the following components in parts by mass: 7-20 parts of microcrystalline wax, 14-31 parts of paraffin, 6-17 parts of ozocerite, 7-15 parts of polybutylene, 14-28 parts of beewax, 7-12 parts of polyethylene wax, 3-11 parts of calcified rosin, 2-8 parts of castor oil, 4-11 parts of liquid paraffin, 2-9 parts of butyl rubber, 2-5 parts of albolene and 2-6 parts of white oil. The wax tray produced according to the formula is smooth in surface, moderate in toughness and not liable to rupture due to brittlement; wax chippings are hardly generated and needle holes are easily restored after the anatomical wax tray is punctured by a dissecting needle or an insect needle for many times; the anatomical wax tray is odour-free and convenient to remodel and form; under an extreme environment temperature condition (0-50 DEG C), the anatomical wax tray has low-temperature toughness and impact resistance and is not liable to rupture due to brittlement; at a high temperature, the anatomical wax tray is hardly softened to be sticky and does not volatilize odour. The anatomical wax tray provided by the invention is simple in production method, stable in performance, and capable of meeting anatomy needs on biological and medical experiment specimens in different temperature environments.

Owner:SHANXI UNIV

Nutritionally balanced feed for sheep fattening period

InactiveCN106343174AUniform immunityImprove immunityFood processingAnimal feeding stuffPhytaseRhizopus oryzae

The invention discloses nutritionally balanced feed for the sheep fattening period. The nutritionally balanced feed comprises, by weight, 3-7 parts of sea-foam stone powder, 4-8 parts of lard oil, 1-1.8 parts of soybean oil, 4-12 parts of a composited coated material, 0.04-0.1 part of phytase, 0.06-0.12 part of rhizopus oryzae, 0.04-0.12 part of selenium-enriched yeast, 0.3-0.8 part of methionine, 0.12-0.2 part of lysine, 2-4 parts of Chinese herbal medicine additives, 15-30 parts of corn gluten meal, 10-16 parts of fish meal, 35-55 parts of corn, 10-20 parts of broussonetia papyrifera powder, 12-18 parts of wheat, 5-12 parts of hay meal, 10-20 parts of silkworm chrysalis, 4-12 parts of cotton seeds and 10-20 parts of sweet potato leaves. The nutritionally balanced feed is green and healthy, balanced in nutrition and good in fertilizer effectiveness.

Owner:天长市金农农业发展有限公司

TMCP type steel plate and die welding heat treatment method thereof

InactiveCN108823497AModerate toughnessModerate yield ratioFurnace typesHeat treatment furnacesChemical compositionSheet steel

The invention discloses a TMCP type steel plate and a die welding heat treatment method thereof. The steel plate comprises following chemical components in percentage by weight: not more than 0.10% ofC, 0.20 to 0.40% of Si, 1.52 to 1.62% of Mn, not more than 0.015% of P, not more than 0.003% of S, not more than 0.70% of Cr+Mo+Ni+Cu, 0.020 to 0.050% of Al, not more than 0.008% of N, not more than0.11% of Nb+Ti+V, and the balance being Fe and inevitable impurities. The die welding heat treatment method comprises steps of tempering and cooling. After the die welding heat treatment, in the wholethickness direction, uniform tissues composed of grain-refined ferrite, granular bainite and pearlite are obtained; the grain size is not less than 8.0 grade; the comprehensive performance is excellent, and the steel plate can be used to build a seaborne fixing structure through welding. The method has the advantages of simple steps, stable product quality, and massive production.

Owner:WUYANG IRON & STEEL

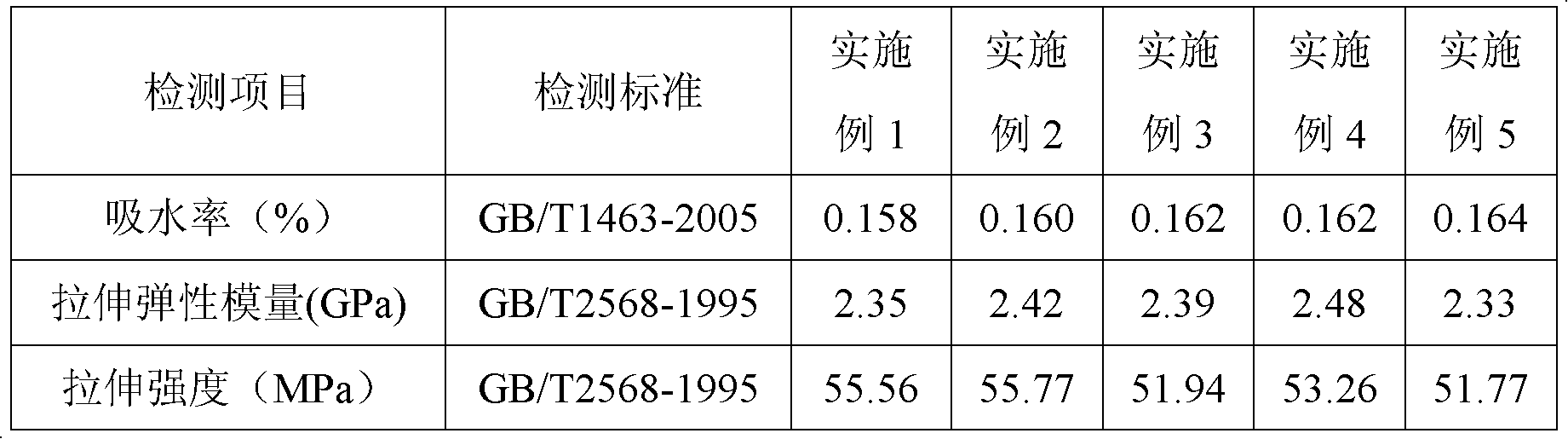

Unsaturated polyester resin for button and preparation method thereof

ActiveCN102585107ADoes not produce whitening after water absorptionMeet the content requirementsAntioxidantPhthalic anhydride

The invention discloses unsaturated polyester resin for a button and a preparation method thereof. The resin is mainly prepared form the following components in parts by weight: 2,000-3,000 parts of phthalic anhydride, 800-1,500 parts of maleic anhydride, 600-1,300 parts of 1,2-propylene glycol, 300-800 parts of ethylene glycol, 1,000-1,500 parts of diethylene glycol, 2,100-3,100 parts of styrene, 1-5 parts of a polymerization inhibitor, 1-5 parts of an antioxidant, 0.01-0.08 part of a retarder and 1-5 parts of paraffin, wherein the retarder consists of a high-temperature retarder and a low-temperature retarder. Compared with the prior art, the unsaturated polyester resin for the button meets the requirements of the European Union Environment Protection Laws and Regulations and is suitable for button process requirements.

Owner:宜兴市兴合树脂有限公司

Making method of WK160 (160-mesh WK nickel screen) rotary printing screen

ActiveCN105922717AReduce jumpingImprove printing efficiencyPlate printingFoil printingMicrometerEngineering

The invention provides a making method of a WK160 rotary printing screen. The method comprises making of a base die, making of the base die comprises making of a male die, the male die is in conical surface involute form, the width of a rib line on the male die is not greater than 2 micrometers, the width of the rib line on the base die after press rolling is not greater than 15 micrometers, and the making method of the WK160 rotary printing screen also comprises primary nickel plating and secondary nickel plating. According to the making method, the thickness, the aperture ratio and the pulp passing capacity of the WK160 screen are high, which are more than twice those of an existing 155-mesh rotary screen and are larger than those of a rotary screen with the mesh number being lower than 155, the thickness and the aperture ratio in the length and circumferential directions are uniform, the strength is good, and the toughness is moderate.

Owner:SHANDONG TONGDA PRINTING SYST CO LTD

Aluminium alloy welding wire and preparation method thereof

InactiveCN107252990AReduce secondary dendrite spacingHigh tensile strengthWelding/cutting media/materialsSoldering mediaToughnessImpurity

The invention discloses an aluminium alloy welding wire. The aluminium alloy welding wire comprises the following raw materials in percentage by weight: 5.8-6% of Mg, 0.6-0.7% of Mn, 0.18-0.2% of Ti, 0.1-0.2% of Re, 0.005-0.02% of B, 0.1-0.2% of Fe, 0.3-0.4% of Cr, 0.25-0.35% of Si, 0.15-0.25% of Zr, 0.1-0.15% of Ce, 0.15-0.25% of Er, not greater than 0.1% of Cu, not greater than 0.2% of Zn, other impurities elements and the balance Al, wherein the content of each of the other impurities elements is not greater than 0.05%, and the total content of the other impurities elements is not greater than 0.1%. The invention further discloses a preparation method of the aluminium alloy welding wire. A welding joint disclosed by the invention is high in tensile strength and toughness, and not liable to crack.

Owner:安徽飞弧焊业股份有限公司

Method for processing green potato silk noodles and vermicelli

InactiveCN102823829AImprove adsorption capacityAvoid absorptionFood preparationFood additiveWarm water

The invention discloses a method for processing green potato silk noodles and vermicelli. The method comprises adding 1.5 to 2.5 parts of konjac glucomannan into every 500 parts of potato starch, adding 2000 to 5000 parts of warm water, and continuously stirring for 1 hour to form paste starch; sending the paste starch into a sheet jelly steaming machine, feeding high-temperature steam, and steaming the paste starch to sheet jelly with continuous shape having a thickness of 1 to 1.5 mm; and then air-cooling, cryogenic cooling, aging, cutting, drying and finally hanging the silk noodles or the vermicelli to dry in the air or stoving, and then clearing up and packaging. The silk noodles and the vermicelli prepared by the konjac glucomannan instead of alum has crystal and translucent color, and are resistant to boiling, clear in noodle soup, non-adhensive, moderate in toughness, good in quality and safe in eating. Dishes cooked therefrom have a much better mouthfeel than those cooked from the silk noodles and the vermicelli added with the alum. Through detection, the silk noodles and the vermicelli provided by the invention correspond with national "hygienic Standards for uses of food additives", and reach each indicator of national green food certification.

Owner:ZHENBA COUNTY ZHENYUAN AGRI DEV

Ceramic slurry for preparing multilayer electrocaloric ceramic element and preparation method of ceramic slurry

The invention provides ceramic slurry for preparing a multilayer electrocaloric ceramic element and a preparation method of the ceramic slurry. The ceramic slurry is prepared from the following components: barium titanate based ceramic powder, a modifying additive accounting for 0-1% of the weight of the barium titanate based ceramic powder, a sintering aid accounting for 0-5% of the weight of the barium titanate based ceramic powder, a dispersing agent accounting for 2%-10% of the weight of the barium titanate based ceramic powder, a first solution accounting for 30%-50% of the weight of the barium titanate based ceramic powder and a second solution accounting for 28%-48% of the weight of the barium titanate based ceramic powder, wherein the first solution contains an adhesive, ketone solvents and alcohol solvents; the second solution contains an adhesive, ketone solvents, alcohol solvents and a plasticizer. The ceramic slurry has the advantages that the ceramic slurry has good dispersibility and superior performance; the prepared multilayer electrocaloric ceramic refrigerating element has high capacitance, low dielectric loss and good electrocaloric characteristic.

Owner:KUSN HISENSE ELECTRONICS

Waterproof tear-resistant cable

InactiveCN106800685AImprove heat resistanceImprove mechanical propertiesRubber insulatorsInsulated cablesPolyvinyl alcoholSuccinic acid

The invention discloses a waterproof tear-resistant cable which comprises a conductor and a sheath layer coating the outer side of the conductor, wherein the sheath layer comprises the following raw materials in parts by weight: 50-80 parts of chloroprene rubber, 15-25 parts of ethylene-propylene-diene copolymer, 10-20 parts of ethylene-propylene-diene monomer, 1-2 parts of succinic acid peroxide, 0.5-1.2 parts of tert-butyl hydrogen phthalate, 0.1-0.5 part of zinc oxide, 0.2-0.8 part of diisopropylbenzene hydrogen peroxide, 20-30 parts of modified zeolite powder, 15-35 parts of sepiolite powder, 10-18 parts of corn straw fiber, 10-20 parts of turf powder, 1-2 parts of polyvinyl butyral, 0.2-0.8 part of stearic acid, 0.1-0.6 part of polyethylene wax, 0.5-1.2 parts of epoxidized soybean oil and 1-3 parts of anti-aging agent. The waterproof tear-resistant cable disclosed by the invention has the advantages of good hydrophobic and tear-resistant property, excellent toughness and relatively high thermal stability.

Owner:JINYUAN ELECTRIC GRP

Preparation method of compound feed for promoting growth of live pigs

InactiveCN107660649AHigh nutritional valueSmall side effectsFood processingAnimal feeding stuffNutritive valuesCarrageenan

The invention discloses a preparation method of compound feed for promoting growth of live pigs. The preparation method comprises the following steps of crushing expanded soybean meal, glutinous millet flour, water hyacinth dry powder, highland barley powder, watermelon peels and milk vetch, adding the glutinous millet flour, oat powder, fermented slaughterhouse wastes and vinasse, and performinguniform mixing to obtain a first prefabricated material; uniformly mixing corn germ protein powder and a formaldehyde solution, adding a sodium hydroxide solution for stirring, adding melamine for continuous stirring, rising temperature, performing stirring, adding carrageenan, performing uniform stirring, and cooling a mixture to obtain a second prefabricated material; uniformly mixing the firstprefabricated material, microcrystalline cellulose, medical stone powder, montmorillonite, coconut oil, choline chloride, astragalus polysaccharide, vitamins and trace elements, then adding the secondprefabricated material, performing mixing, and performing granulation to obtain the compound feed for promoting the growth of the live pigs. The obtained feed is high in nutritive value, is green andsafe, can enhance the immune function of the live pigs, increases the utilization ratio of the feed, can lower the morbidity of the live pigs, avoids from using antibiotics and is more beneficial tofood safety and environmental protection.

Owner:全椒县王震家禽养殖专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com