Hollow rivet shaft processing technology

A hollow rivet and processing technology technology, which is applied in the field of hollow rivet shaft processing technology, can solve problems such as the inability to guarantee product quality, product function, component production and manufacturing unity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The invention will be further described below in conjunction with the accompanying drawings.

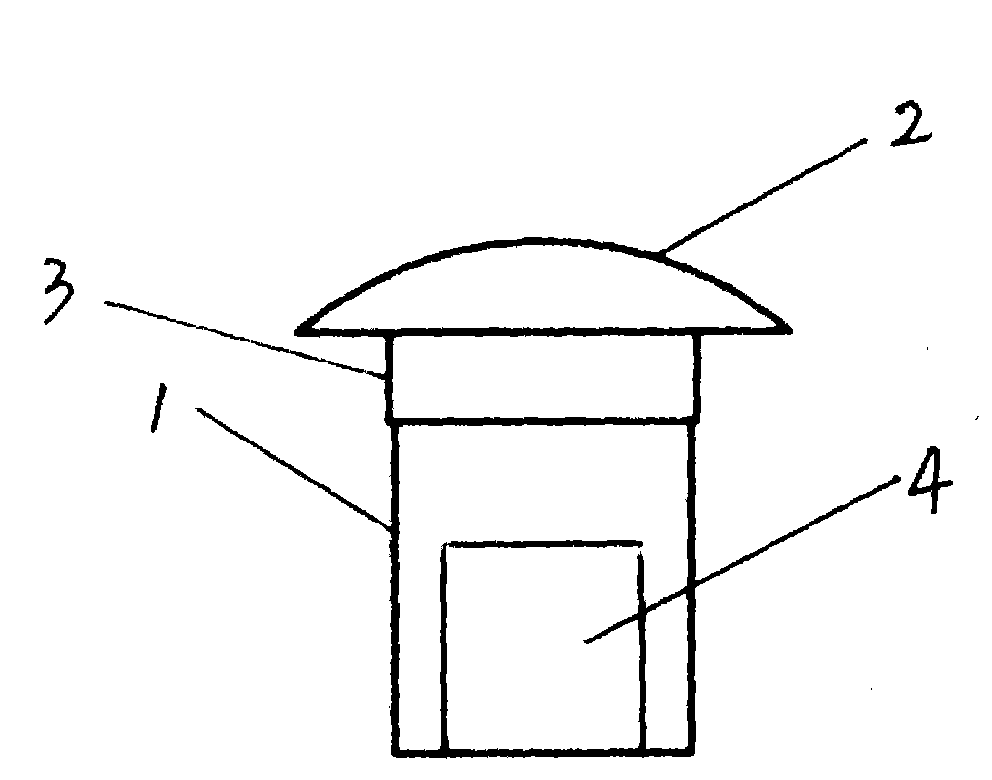

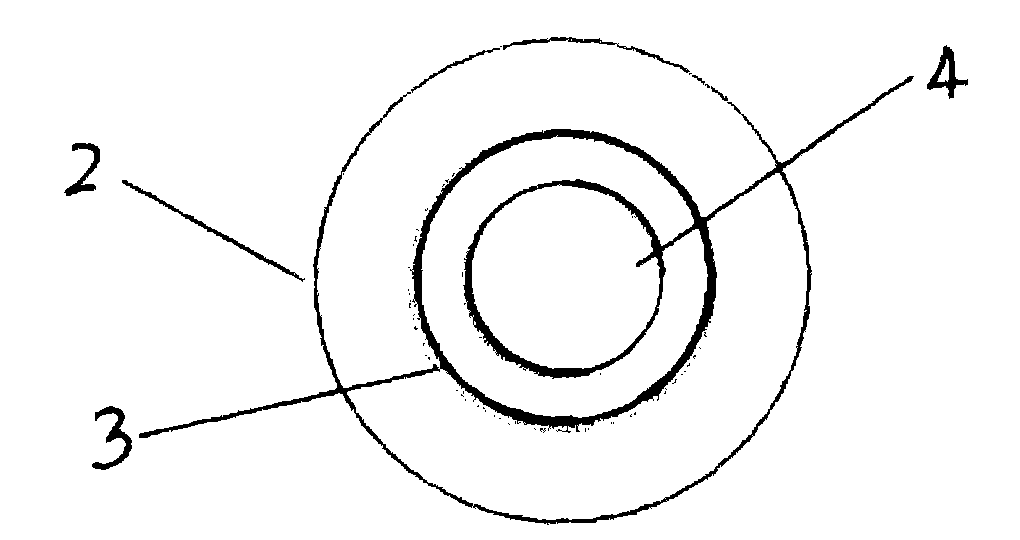

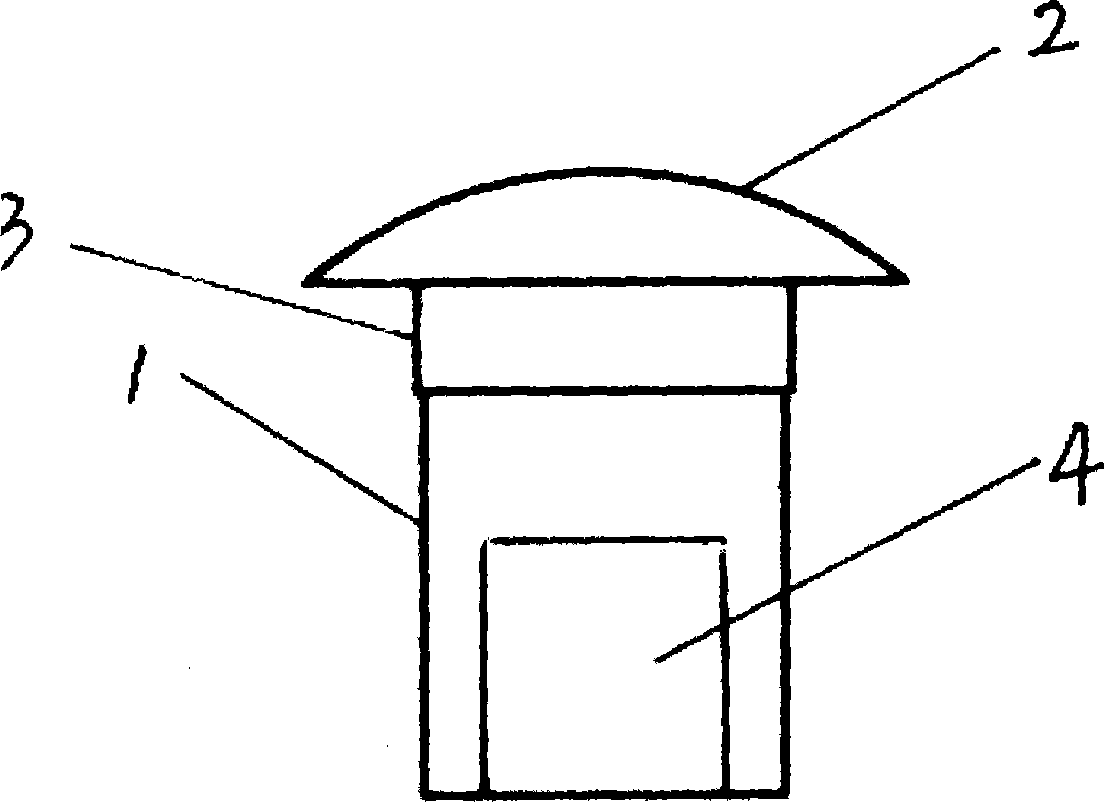

[0010] In the view, take the hollow rivet shaft as an example: select ordinary round steel material and use a press to form the shape of the hollow rivet shaft 1 and the half-round cap 2 by cold heading method - use a lathe to turn the shaft 3, drill the riveting hole 4 - clear the hollow Sharp corner burrs on the surface of the rivet shaft 1 - removal of oil, rust, cleaning - chrome plating on the surface of the hollow rivet shaft 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com