Patents

Literature

486 results about "Ketone solvents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pages in category "Ketone solvents" The following 14 pages are in this category, out of 14 total. This list may not reflect recent changes ().

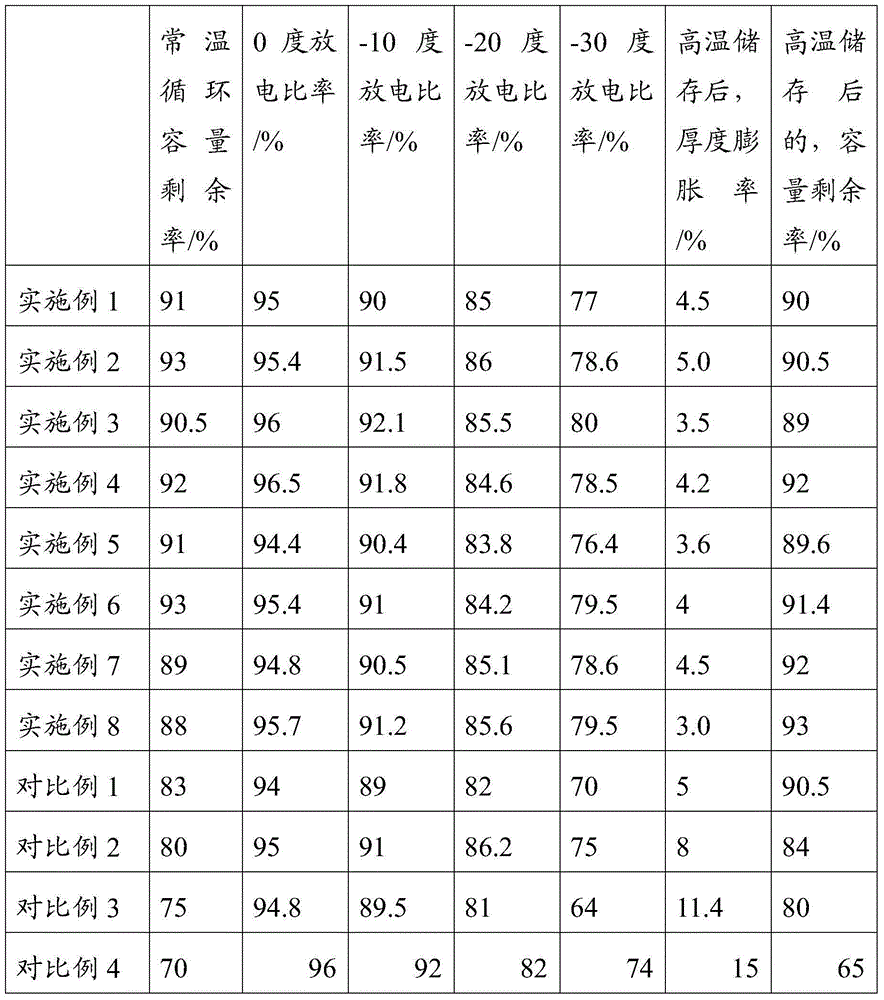

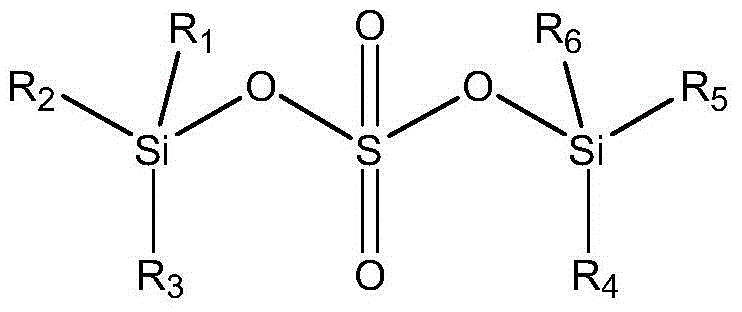

Power battery and lithium ion electrolyte thereof

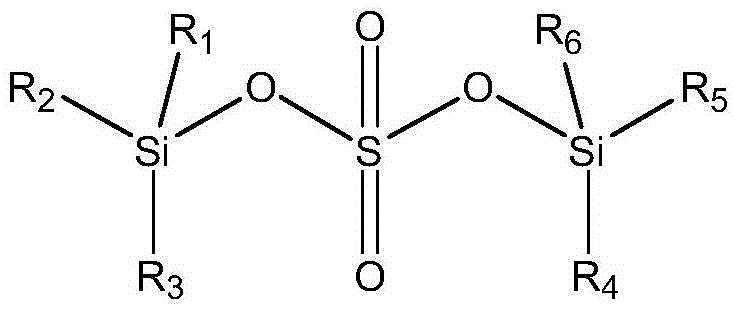

InactiveCN104600362AImprove low temperature discharge performancePromote circulationSecondary cellsSilanesKetone solvents

The invention provides a power battery and a lithium ion electrolyte thereof. The lithium ion electrolyte comprises a non-aqueous organic solvent, lithium salt and an additive, wherein the additive comprises a first additive and a second additive, and the first additive comprises silane sulfate; the first additive accounts for 0.05 to 10% of the total weight of the electrolyte, and the second additive is an auxiliary additive and comprises one or more of vinylene carbonate, propane sultone, fluoroethylene carbonate, vinyl ethylene carbonate, ethylene sulfite, adiponitrile, and succinic anhydride in any proportion; the second additive accounts for 0.1-5wt% of the total weight of the electrolyte, and the non-aqueous organic solvent is a carbonic ester solvent, a carboxylic ester solvent, an ether solvent or a ketone solvent; and the lithium salt comprises primary lithium salt and secondary lithium salt.

Owner:SHENZHEN 3SUN ELECTRONICS

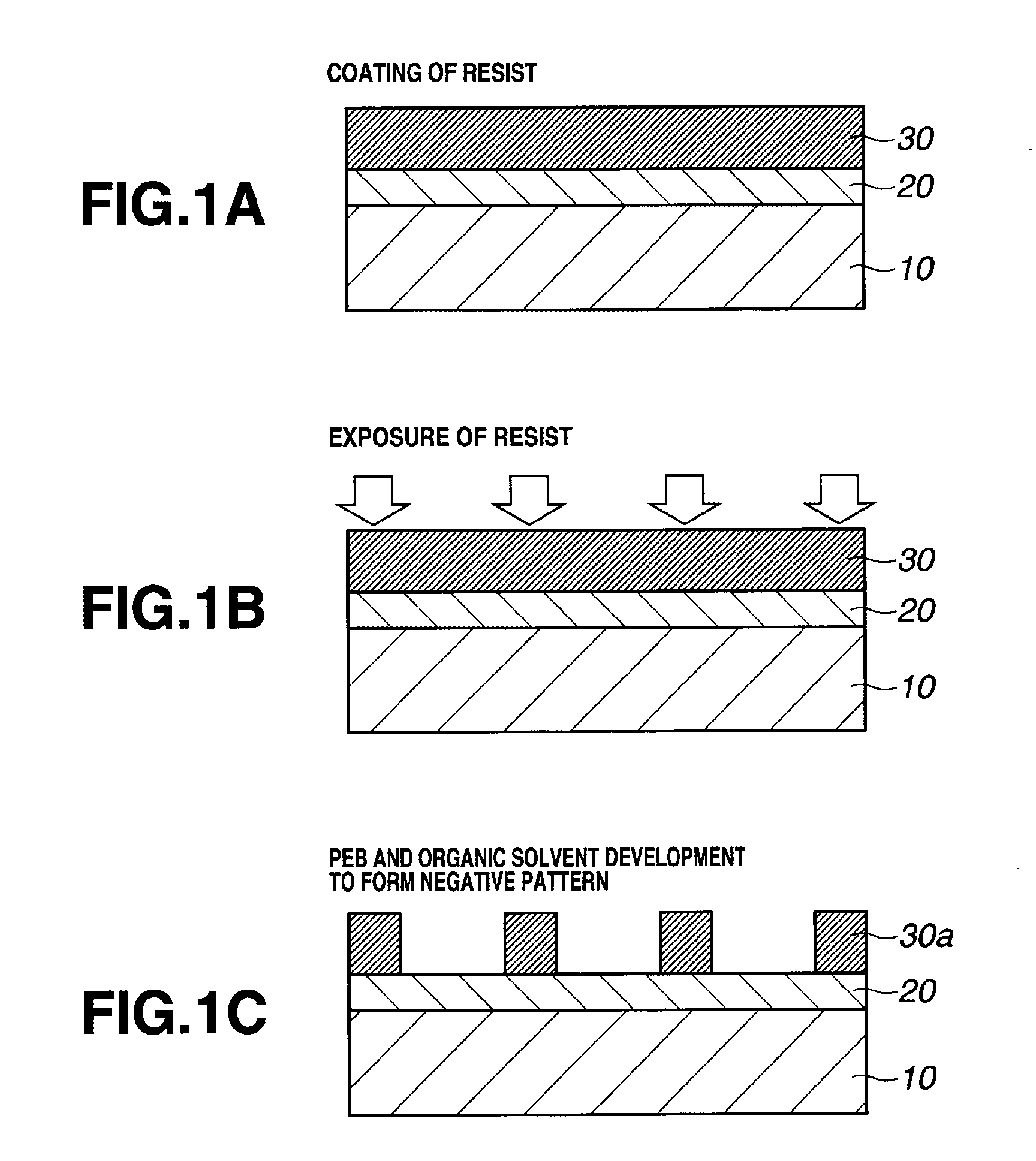

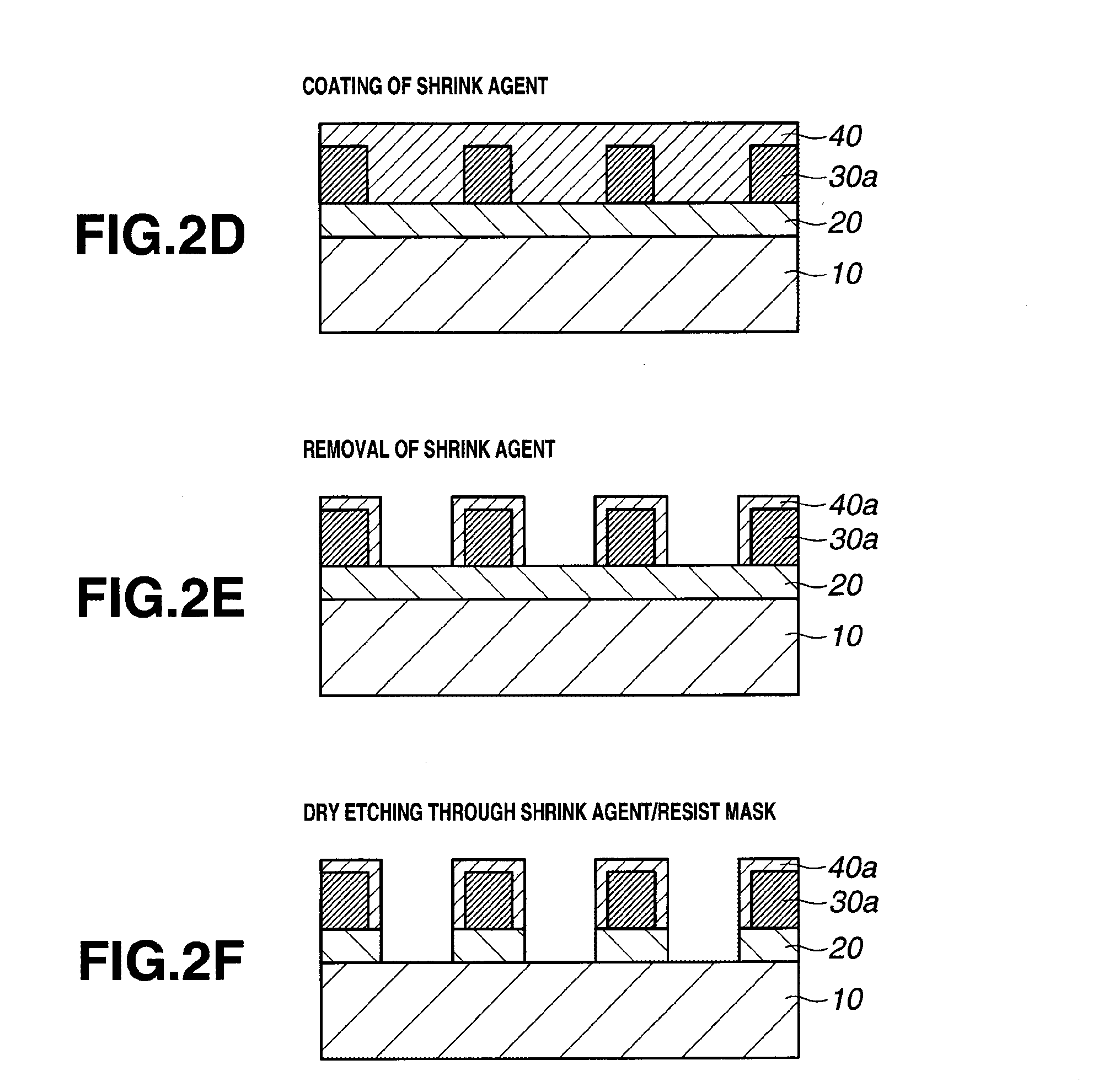

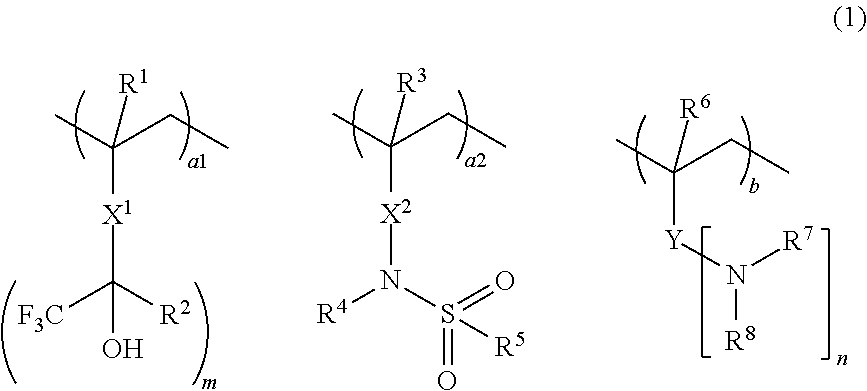

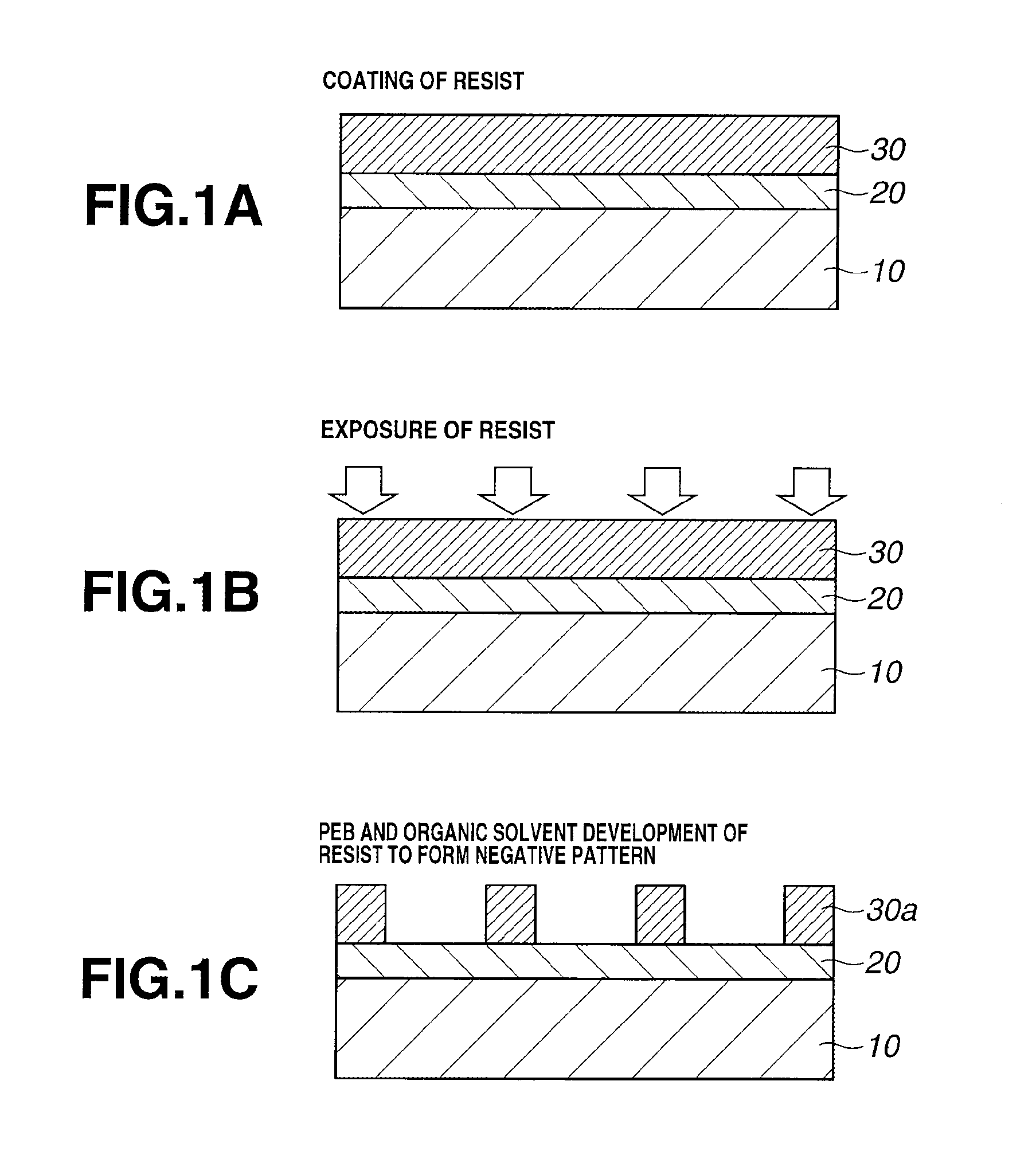

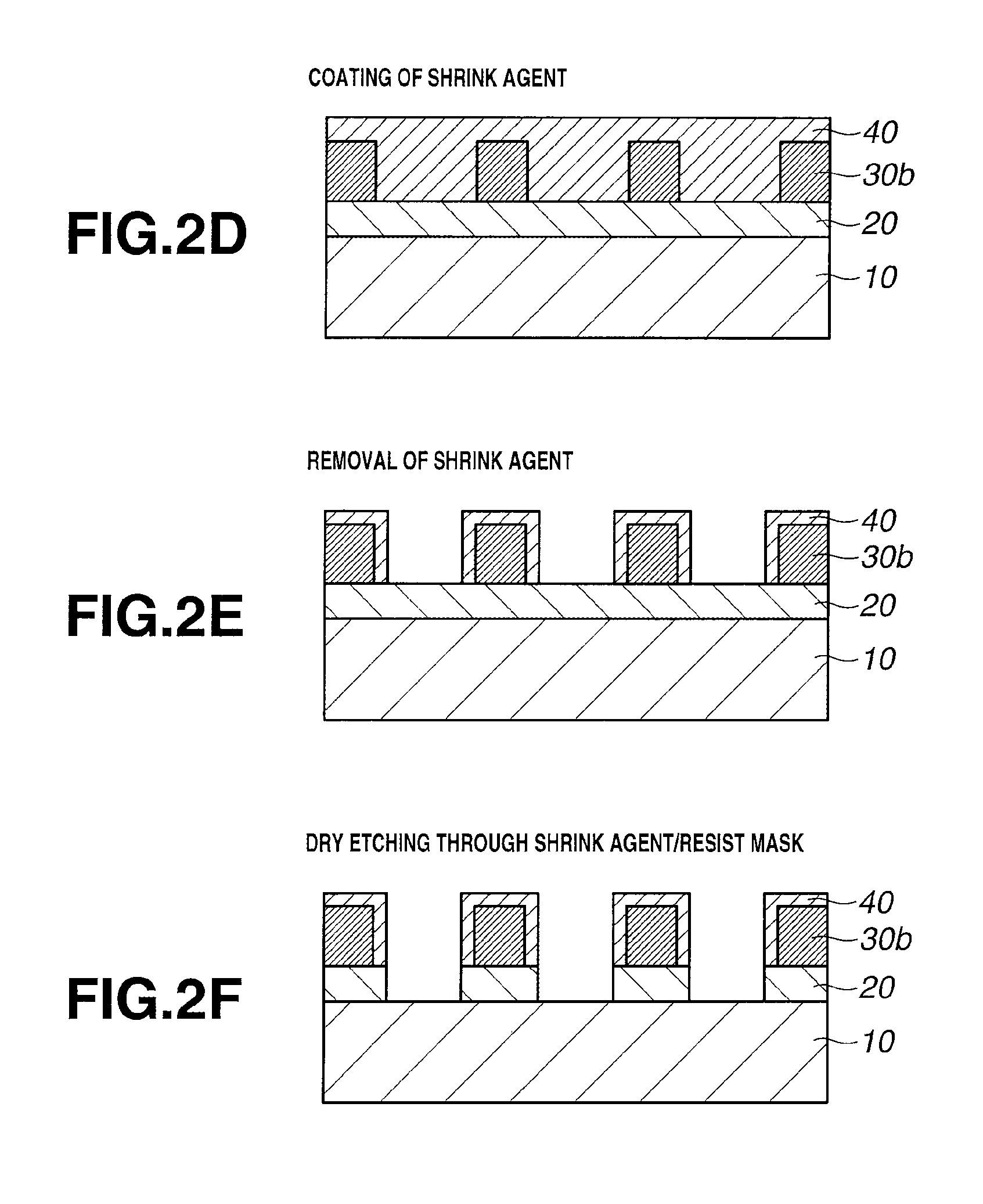

Pattern forming process and shrink agent

ActiveUS20150086929A1Photosensitive material processingOriginals for photomechanical treatmentOrganic solventAlcohol

A negative pattern is formed by applying a resist composition onto a substrate, exposing the resist film, and developing the exposed resist film in an organic solvent developer. The process further involves coating the negative pattern with a shrink agent solution of a copolymer comprising recurring units having an α-trifluoromethylhydroxy or fluoroalkylsulfonamide group and recurring units having an acid labile group-substituted amino group in a C6-C12 ether, C4-C10 alcohol, C6-C12 hydrocarbon, C6-C16 ester or C7-C16 ketone solvent, baking the coating, and removing the excessive shrink agent for thereby shrinking the size of spaces in the pattern.

Owner:SHIN ETSU CHEM IND CO LTD

Colored aluminum pigment with high color depth and preparation method thereof

InactiveCN101445675AGood acid and alkali resistanceColorfulInorganic pigment treatmentMetallic aluminumKetone solvents

The invention relates to a colored aluminum pigment with high color depth and a preparation method thereof. The colored aluminum pigment is obtained by depositing a layer of silicon dioxide on a flaky metallic aluminum sheet substrate and then depositing one or more layers of metal oxide on the surface of the silicon dioxide, and the colored aluminum pigment exists in the form of dry powder. The preparation method comprises the following steps: a. stirring to disperse commercially available aluminum pigment slurry in alcohol, alcohol ether or a ketone solvent; b. regulating the temperature to 30-80 DEG C, respectively adding tetraethoxysilane and aqueous solution to the dispersed aluminum pigment slurry with the mol ratio of the tetraethylorthosilicate to the water ranging from 1:0.5 to 1:20, adding a catalyst such as ethylenediamine solution or aqueous ammonia, and obtaining aqueous aluminum pigment slurry by vacuum filtration and washing after the reaction; and c. cladding the aqueous aluminum pigment slurry obtained in the step b with the hydrated metal oxide on the powdered aluminum surface in a liquid phase. The preparation method help prepare the colored aluminum pigment with diversified colors and high color depth without reducing brightness of the original aluminum pigment slurry.

Owner:WENZHOU YOUNGBIO CHEM

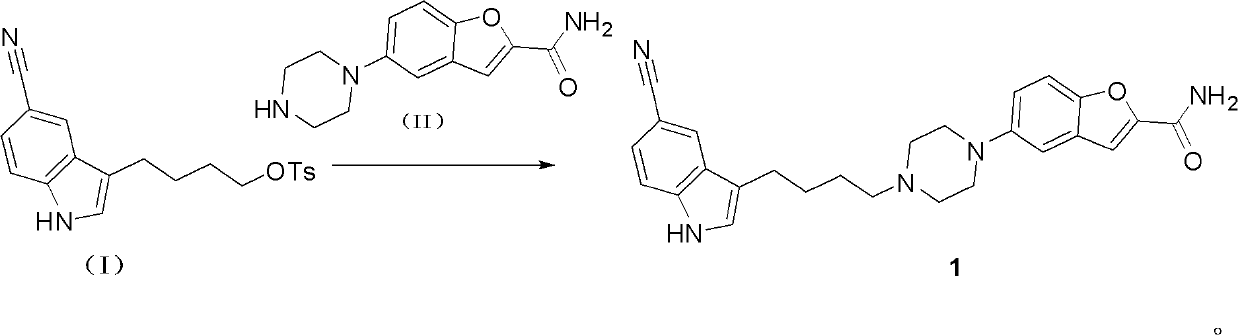

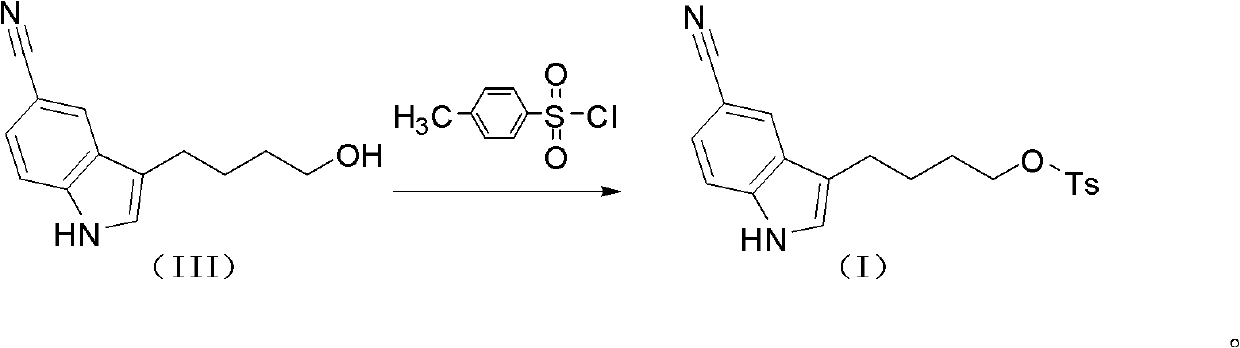

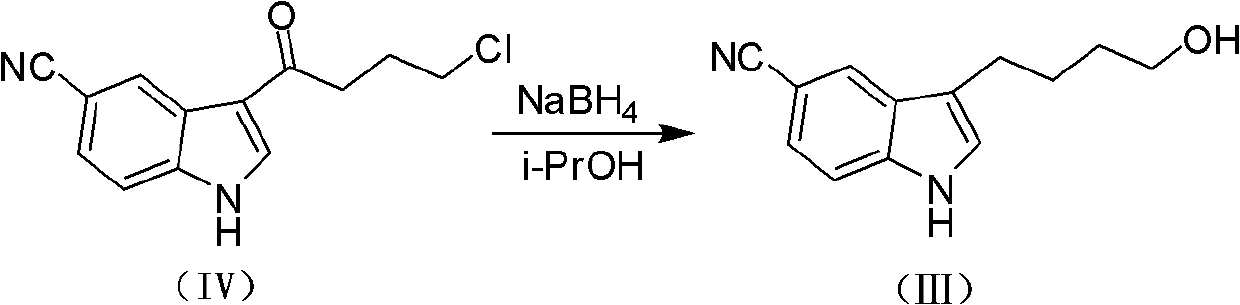

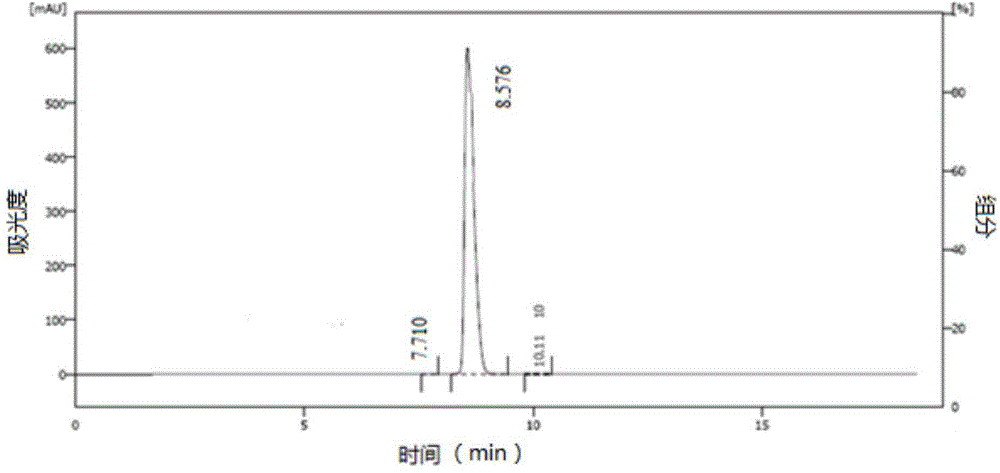

Preparation method of vilazodone or its hydrochloride

The invention discloses a preparation method of vilazodone or its hydrochloride, which comprises the following steps: the compound of formula (I) is mixed with the compound of formula (II) 5-(1 -piperazinyl)-benzofuran-2-formamide reaction, then collect vilazodone shown in formula 1 from the reaction product; Gained vilazodone 1 is in a solvent, and hydrochloric acid is salified to prepare formula (A ) shown vilazodone hydrochloride. The present invention overcomes the defects and deficiencies in the existing preparation methods of vilazodone and its intermediates, is more suitable for the large-scale industrial preparation of vilazodone hydrochloride, has obvious creativity, and has a relatively large positive progress effect and practical application value. The reaction formula is as follows:

Owner:SHANGHAI INST OF PHARMA IND

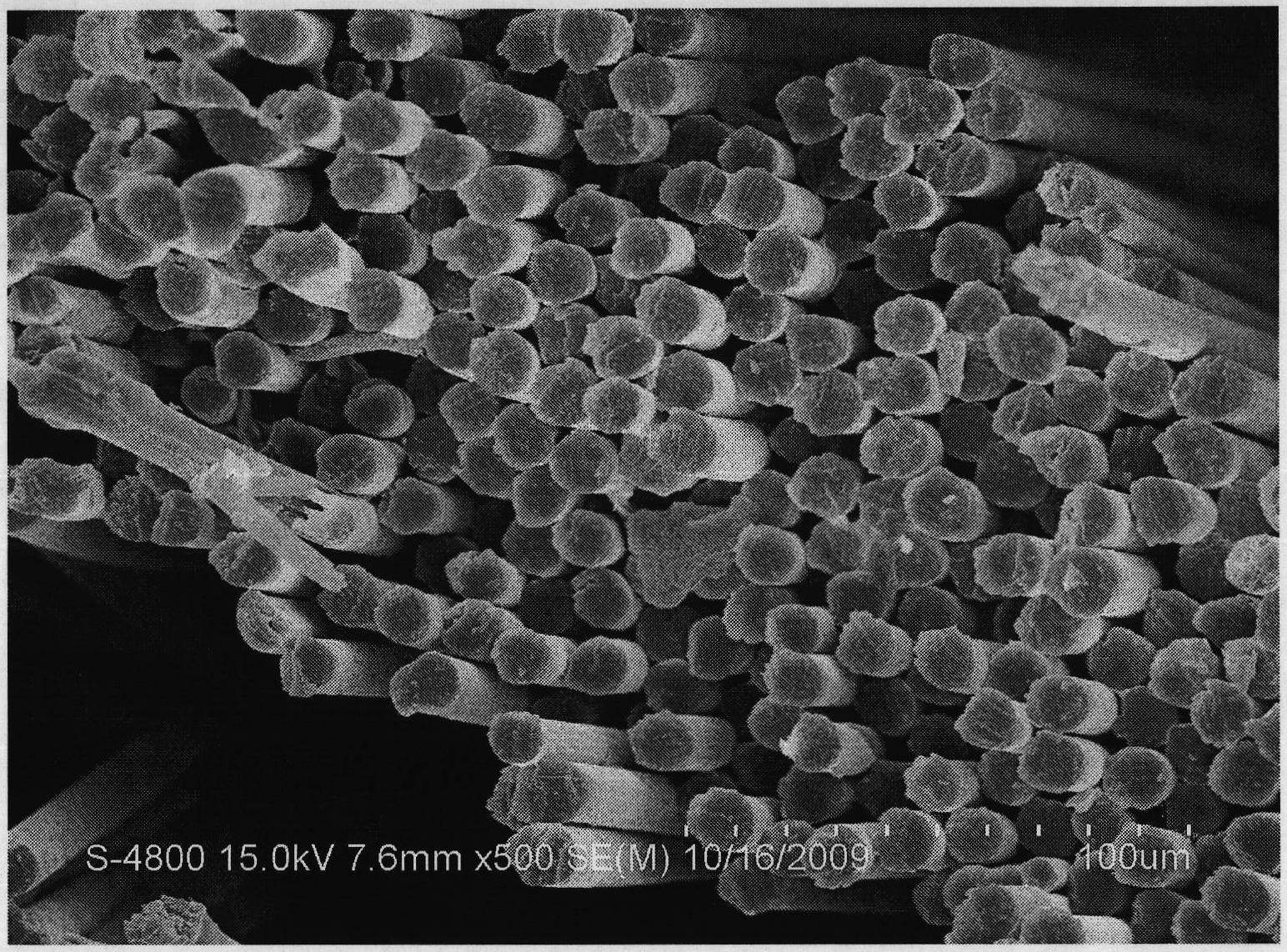

Acrylonitrile copolymer spinning solution with high molecular weight and narrow distribution and preparation method thereof

InactiveCN101805936AHigh molecular weightHigh solid contentMonocomponent synthetic polymer artificial filamentPolymer scienceAlcohol

The invention discloses an acrylonitrile copolymer spinning solution and a preparation method thereof. The spinning solution is a mixed solvent solution of an acrylonitrile copolymer; the acrylonitrile copolymer is formed by polymerization of a first acrylonitrile monomer and a comonomer, and the comonomer comprises unsaturated carboxylic acid monomers; the mass of the first acrylonitrile monomer is 90-99.5% of the total mass of monomers, and the mass of the comonomer is 0.5-10% of the total mass of monomers; the mixed solvent is a mixture comprising dimethyl sulfoxide and at least one of water, alcohol solvents and ketone solvents; and the mass percent concentration of the monomers in the spinning solution is 15-30%. In the invention, the mixed solvent of the dimethyl sulfoxide is adopted in the process of acrylonitrile copolymerization, and the proportion of each solvent is controlled to carry out copolymerization reaction in homogeneous phases; and meanwhile, the second comonomer is continuously replenished in a certain time of reaction to stabilize the instantaneous composition of the acrylonitrile copolymer to obtain the polyacrylonitrile copolymer spinning solution with high molecular weight, narrow molecular weight distribution and uniform chain structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Aqueous resin dispersion composition

InactiveUS6359030B1Excellent hot water resistanceMaintain good propertiesCoatingsKetone solventsMethyl ethyl ketone peroxide

An aqueous-dispersing composition of synthetic resin (A) having an intrinsic viscosity "eta" of from 0.3 to 2.0 measured at 35° C. in a methyl ethyl ketone solvent or a mixture of that aqueous dispersion and an aqueous dispersion of synthetic resin (B) having an intrinsic viscosity "eta" of not less than 0.6 which is larger by 0.3 or more than the intrinsic viscosity "eta" of the synthetic resin (A) when the intrinsic viscosity is measured at 35° C. in a methyl ethyl ketone solvent. The aqueous-dispersing composition and the mixture have improved film forming property and can give a coating film being excellent in chemical resistance, water resistance, mechanical properties and further hot water resistance.

Owner:DAIKIN IND LTD

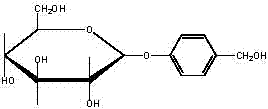

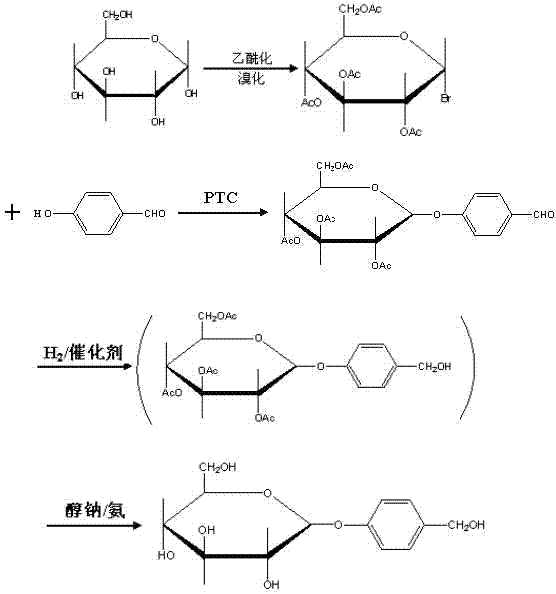

Gastrodin synthesizing method

InactiveCN102516329AReduce pollutionSuitable for industrial productionSugar derivativesSugar derivatives preparationKetone solventsPressure reduction

The invention relates to a gastrodin synthesizing method, which can effectively solve the preparation problem of gastrodin to meet the requirements of the gastrodin in pharmaceuticals. The method comprises the steps of adding catalyst perchloric acid, acetylating anhydrous dextrose by using acetic anhydride to produce per-acetyl dextrose, feeding hydrogen bromide to bromizing hemiacetal hydroxyl of the per-acetyl dextrose to produce bromo-tetraacethyl glucose, further and dropwise adding a bromo-tetraacethyl glucose solution into chloroform and tetrabutyl ammonium bromide, carbonate and para hydroxybenzene in water to obtain 4-formyl benzene-2', 3', 4', 6'- tetraacetyl-beta-D-glucopyranose, performing re-crystallization with ethanol, adding raney nickel or palladium and carbon, feeding hydrogen and pressurizing to hydrogenate, performing filtering, adding sodium alcoholate or ammonia in to filtrate to perform protecting group removal until the reaction is finished completely, performing pressure reduction and concentration to obtain crude gastrodin, and re-crystallizing the crude gastrodin by using alcohol or an alcohol and ester solvent or an alcohol and ketone solvent to obtain the gastrodin. The gastrodin synthesizing method is abundant and cheap in raw materials, simple in process, recycled in solvent, small in pollution and high in quality.

Owner:SHANGHAI MODERN HASEN SHANGQIU PHARMA

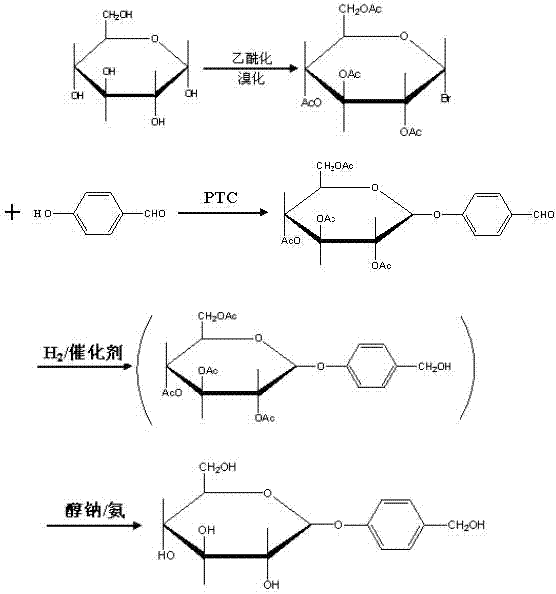

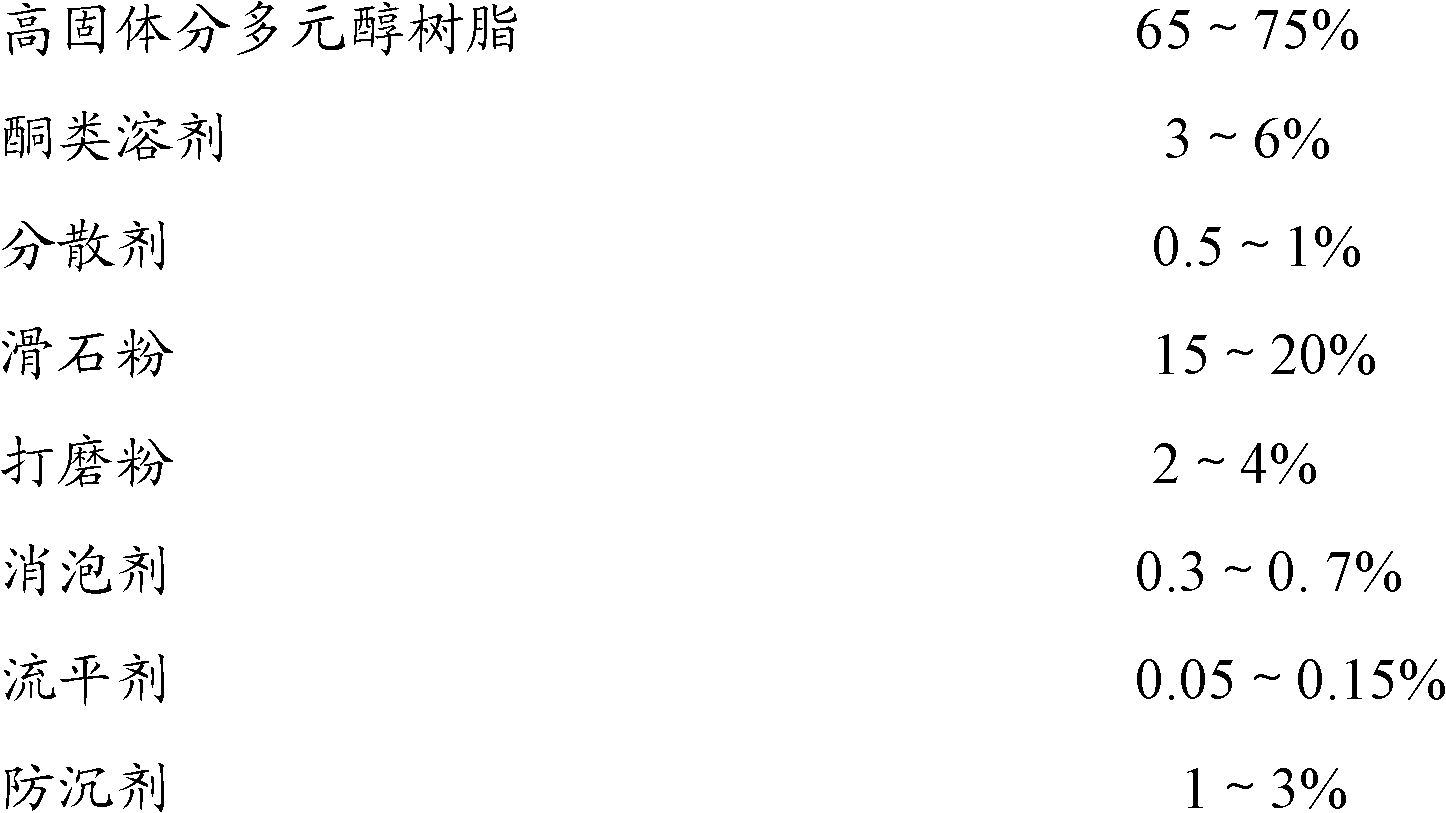

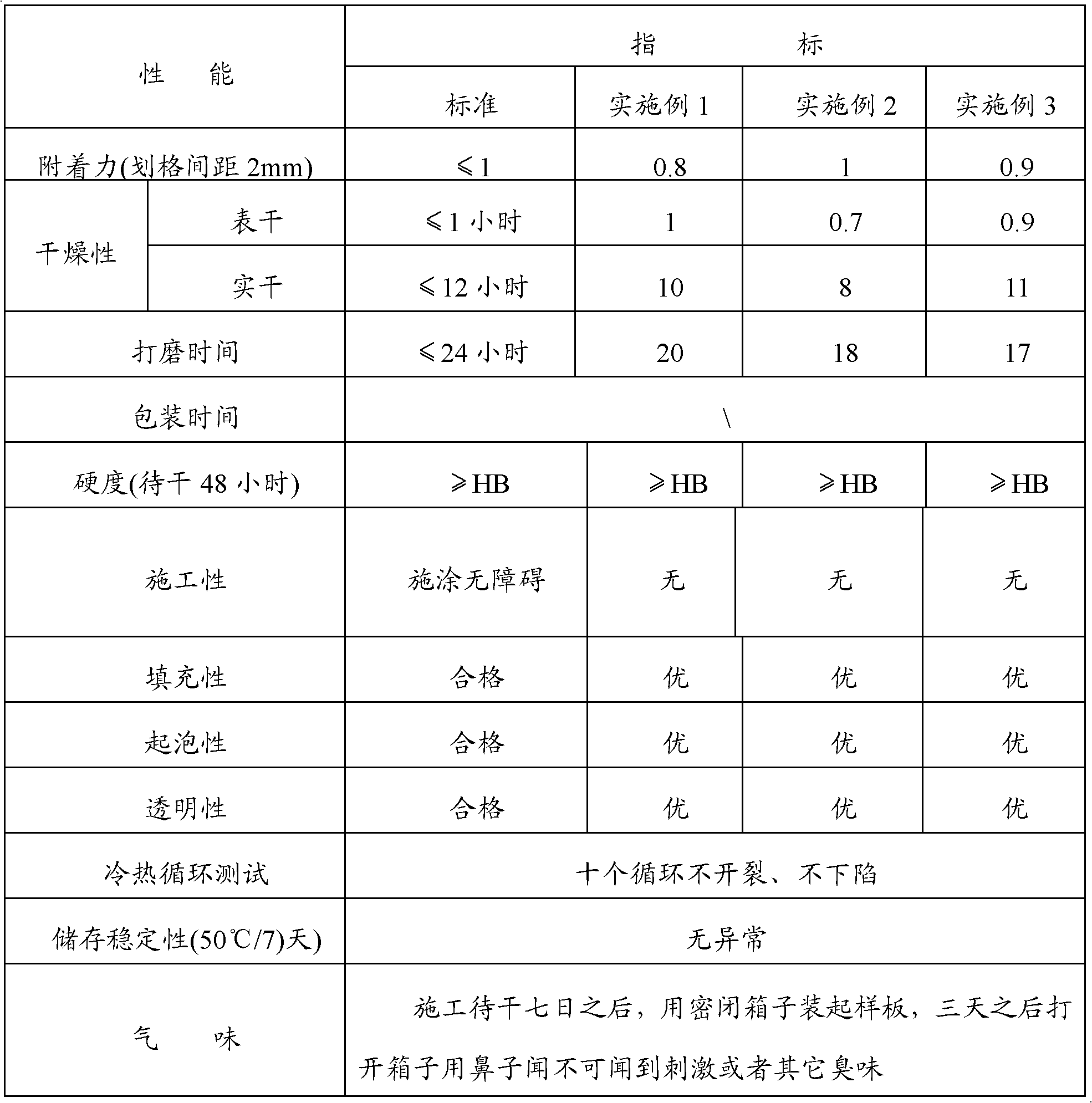

Bicomponent oily polyurethane primer with low VOC (volatile organic compounds)

The invention relates to the technical field of coatings, in particular to a bicomponent oily polyurethane primer with low VOC (Volatile Organic Compounds) and a preparation method thereof. The primer comprises a component A, a component B and a diluting agent, wherein the ratio in parts by weight of the component A to the component B is 2:1, wherein the component A comprises polyhydric alcohol resin with high solid content, an ester solvent, a dispersing agent, a matting powder, a defoaming agent and an anti-sediment agent; according to the preparation method, different molecular weights of the polyhydric alcohol resin in the component A and the polyisocyanates in the component B are respectively screened, the optimal molecular weight is intercepted so as to ensure the dissolubility of the polyhydric alcohol resin and the polyisocyanates in a ketone solvent, meanwhile, other auxiliaries are used for carrying out stem grafting improvement on a molecular structure to enhance the miscibility of the two components; and therefore, the bicomponent oily polyurethane primer not only has the characteristics of good application property, good water resisting property, high hardness and thelike owned by the traditional polyurethane paint, but also ensures that the content of the volatile organic compounds is greatly reduced and even is lower than 450g / L.

Owner:东莞大宝化工制品有限公司 +1

Preparation method of magnetic aluminum pigment

InactiveCN103319917AStrong magnetismCover tightlyPigment treatment with non-polymer organic compoundsKetone solventsSilicon dioxide

The invention provides a preparation method of magnetic aluminum pigment. The preparation method comprises the following steps of: washing flaky aluminum pigment through a ketone solvent, and performing press filtering to obtain a filter cake; placing the filter cake, an alcohol solvent, a magnetic powder material and a silane coupling agent into a reactor to be stirred and dispersed; simultaneously dropwise adding an alcohol diluent of ammonia water and an alcohol diluent of tetraethoxysilane for reaction; aging and performing press filtering on the mixed solution to obtain magnetic aluminum pigment coated by silicon dioxide; placing a ester solvent into the reactor, uniformly dispersing the magnetic aluminum pigment coated by the silicon dioxide into the ester solvent, dropwise adding acrylate monomers and an azo initiator into the reactor, sealing the reactor, and introducing inert gas into the reactor to wrap the mixture; performing press filtering on the mixture to obtain the double-layer coated magnetic flaky aluminum pigment. The magnetic aluminum pigment has excellent magnetism, the compactness in wrapping is achieved, a wrapping film is thin and uniform, the dispersion performance of the pigment in paint is good, and the magnetic aluminum pigment can be applied to 3D (three-dimensional) magic art paint.

Owner:HEFEI SUNRISE PIGMENTS

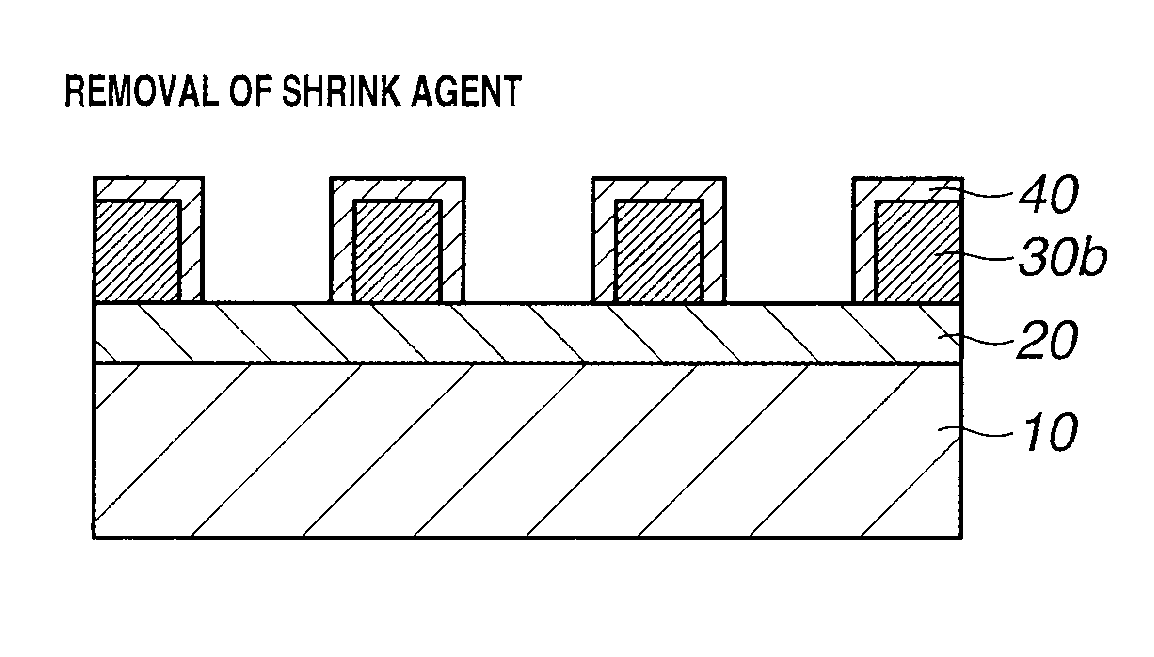

Pattern forming process and shrink agent

ActiveUS20150338744A1Reduce space sizeSemiconductor/solid-state device manufacturingPhotosensitive material processingAlcoholOrganic solvent

A negative pattern is formed by applying a resist composition onto a substrate, exposing the resist film, and developing the exposed resist film in an organic solvent developer. The process further involves coating the negative pattern with a shrink agent solution of a polymer comprising recurring units having a tertiary amino group in a C6-C12 ether, C4-C10 alcohol, C6-C12 hydrocarbon, C6-C16 ester or C7-C16 ketone solvent, baking the coating, and removing the excessive shrink agent for thereby shrinking the size of spaces in the pattern.

Owner:SHIN ETSU CHEM IND CO LTD

Luminant white paint and preparation method thereof

ActiveCN102533070AHigh hiding powerGood filling effectPolyester coatingsKetone solventsToluene diisocyanate

The invention discloses a luminant white paint. The luminant white paint is obtained by mixing a main paint, a curing agent and a diluent according to a mass ratio, wherein the main paint comprises the following components in parts by weight: 35-40 parts of alkyd resin, 3-5 parts of dispersing agent, 30-40 parts of titanium white powder, 10-20 parts of extender pigment, 0.2-0.5 parts of anti-setting agent, 0.2-0.4 parts of leveling agent, 0.2-0.5 parts of antifoaming agent, 0.5-1.0 parts of anti-yellowing agent and 20-25 parts of main paint solvent; the curing agent comprises the following components in parts by weight: 10-20 parts of curing agent solvent, 0.1-0.2 parts of dehydrating agent, 60-70 parts of HDI (Hexamethylene Diisocyanate) type curing agent and 30-40 parts of TDI (Toluene Diisocyanate) type curing agent; and the diluent comprises the following components in parts by weight: 60-70 parts of ester solvent and 30-40 parts of ketone solvent. The luminant white paint disclosed by the invention has the advantages of rapidness for leveling after being sprayed, full paint film, rockiness and scratch resistance. Meanwhile, the invention also discloses a preparation method of the luminant white paint.

Owner:NIPPON PAINT GUANGZHOU

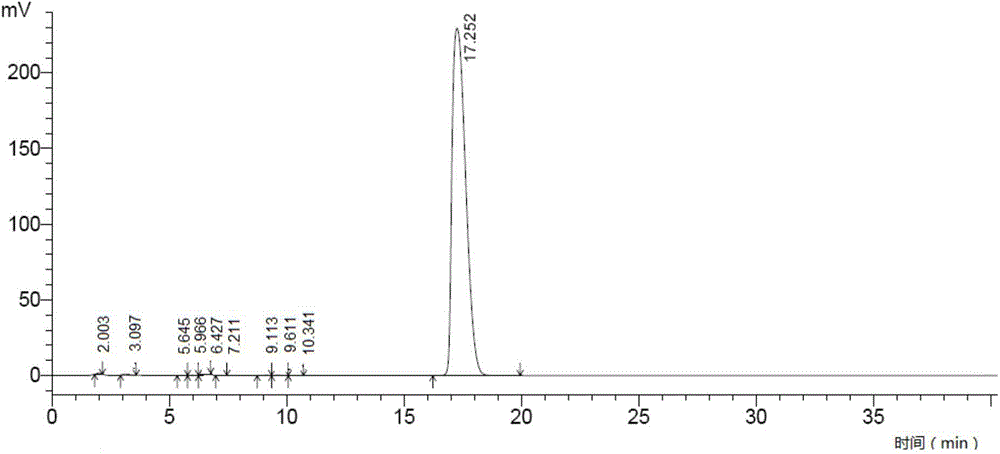

Preparation method of sofosbuvir intermediate

ActiveCN104151352AEnvironmental protection and green patentsEnvironmental Protection and Green LiteratureGroup 5/15 element organic compoundsKetone solventsKinetic resolution

The invention discloses a preparation method of a sofosbuvir intermediate, which comprises the following step: in an anhydrous non-protonic solvent, carrying out dynamic kinetic resolution on a compound disclosed as Formula (II) under the action of an organic alkali and / or inorganic alkali to prepare a compound disclosed as Formula (I), wherein the non-protonic solvent is one or more of ester solvent, ketone solvent and ether solvent, the organic alkali and / or inorganic alkali account / accounts for 0.1-10 wt% of the compound disclosed as Formula (II), the temperature of the dynamic kinetic resolution is 10-30 DEG C, and the time of the dynamic kinetic resolution is 5-10 hours. The preparation method has the advantages of high conversion rate, high product purity and low cost, and is environment-friendly.

Owner:CHEMVON BIOTECH CO LTD

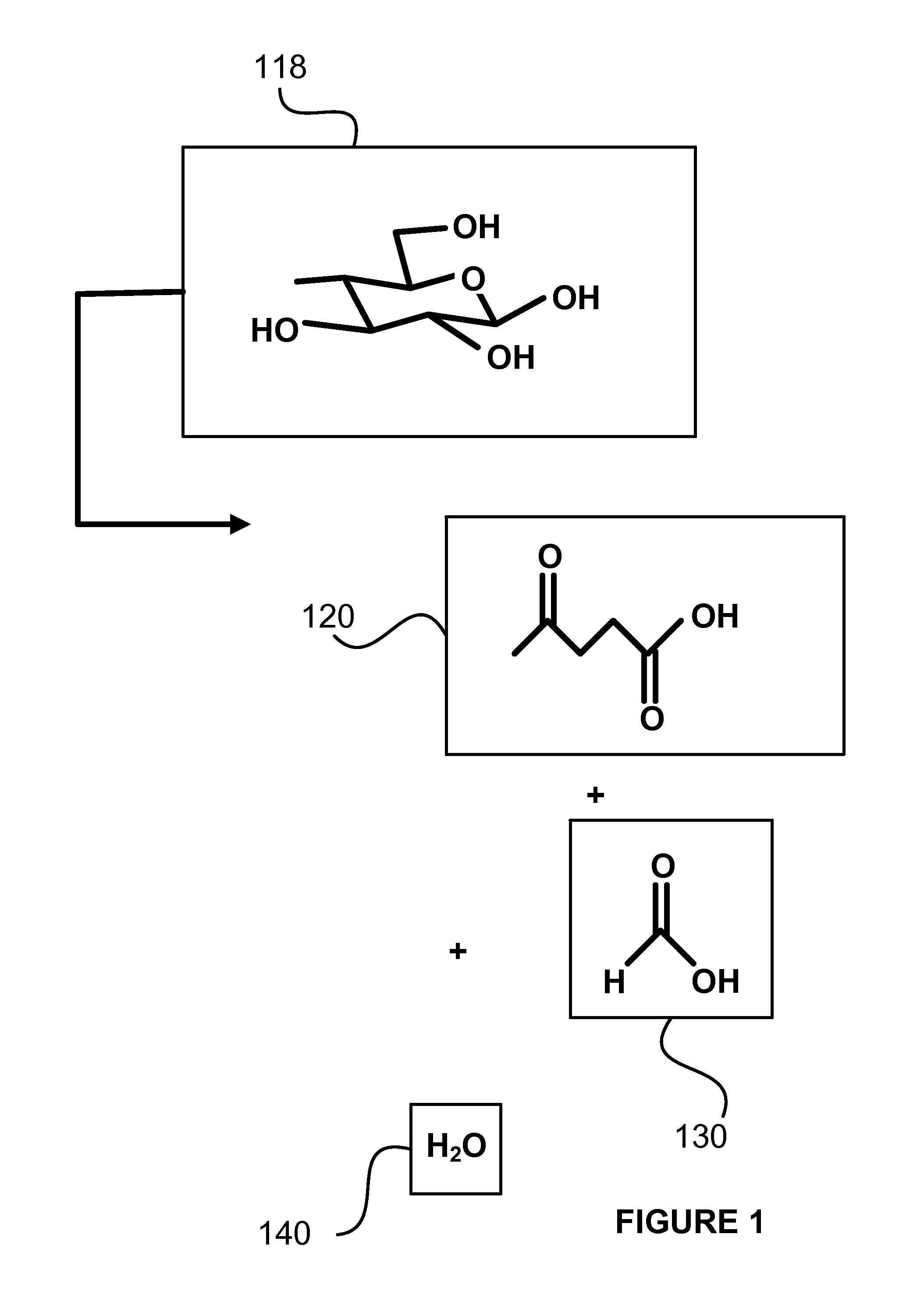

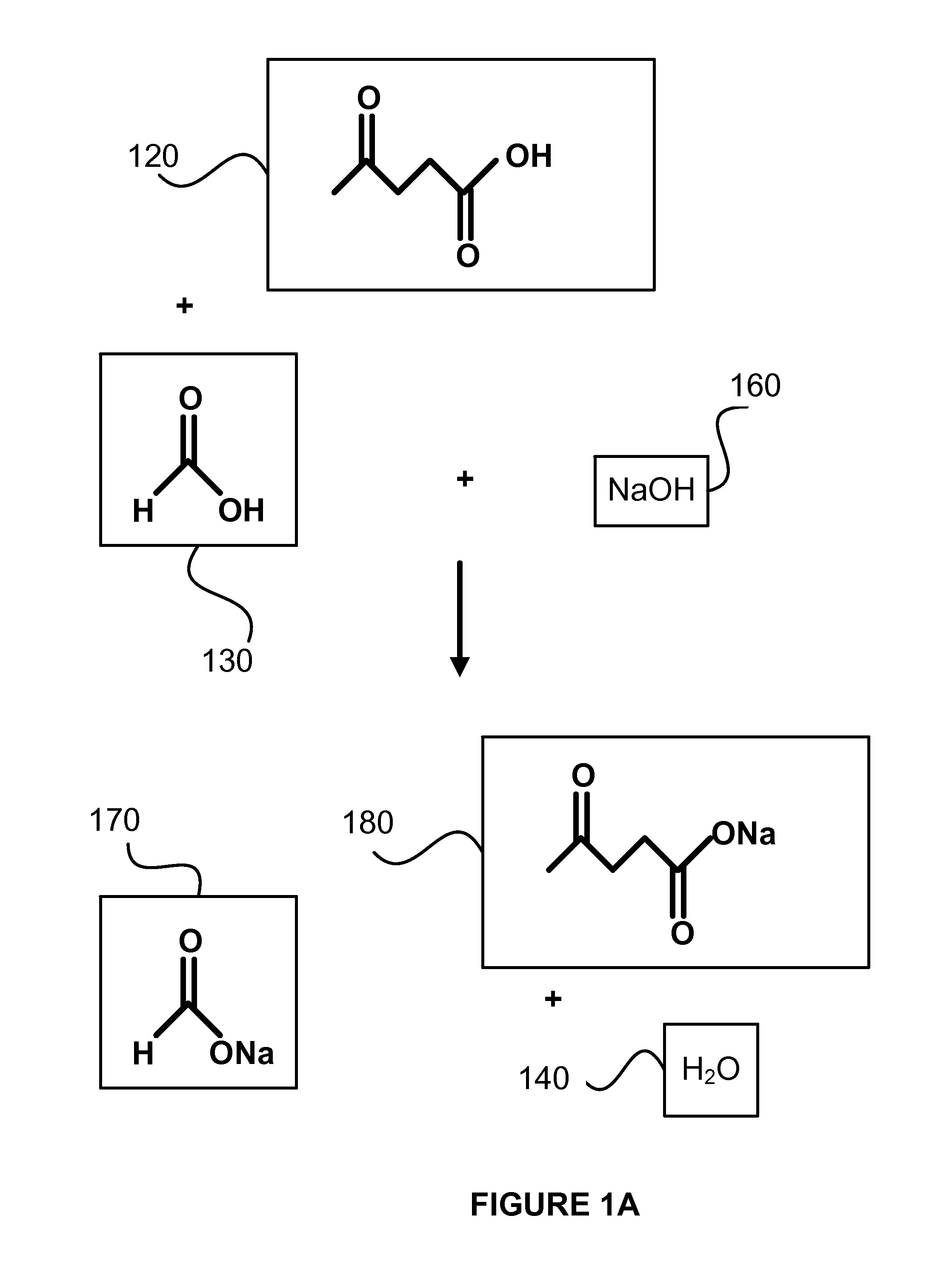

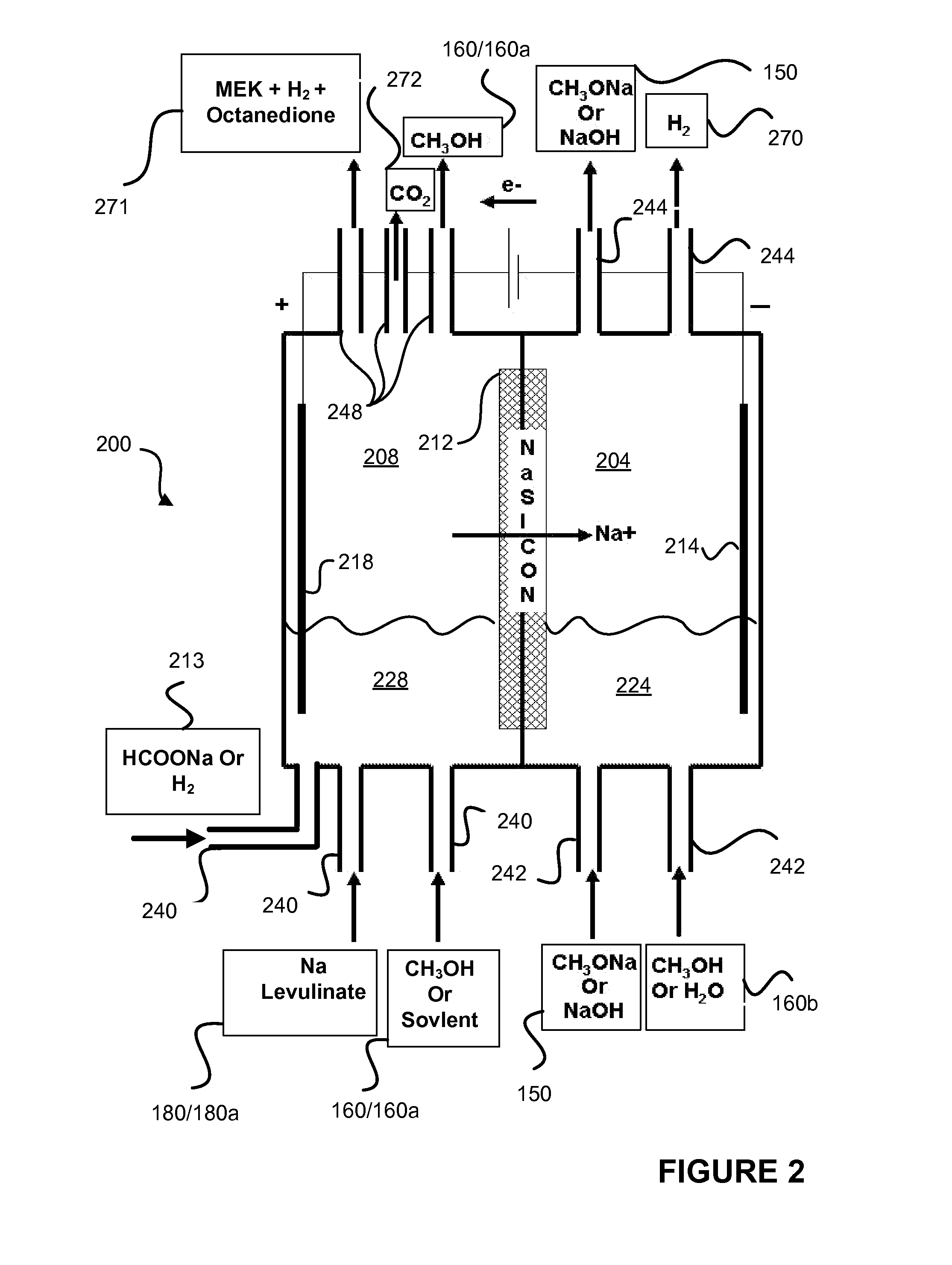

Decarboxylation of levulinic acid to ketone solvents

ActiveUS20140171688A1Low production costCellsOrganic compound preparationPropanoic acidKetone solvents

Ketones, specifically Methyl ethyl ketone (“MEK”) and octanedione, may be formed from six carbon sugars. This process involves obtaining a quantity of a six carbon sugar and then reacting the sugar to form levulinic acid and formic acid. The levulinic acid and formic acid are then converted to an alkali metal levulinate and an alkali metal formate (such as, for example, sodium levulinate and sodium formate.) The alkali metal levulinate is placed in an anolyte along with hydrogen gas that is used in an electrolytic cell. The alkali metal levulinate within the anolyte is decarboxylated to form MEK radicals, wherein the MEK radicals react with hydrogen gas to form MEK, or MEK radicals react with each other to form octanedione. The alkali metal formate may also be decarboxylated in the cell, thereby forming hydrogen radicals that react with the MEK radicals to form MEK.

Owner:ENLIGHTEN INNOVATIONS INC

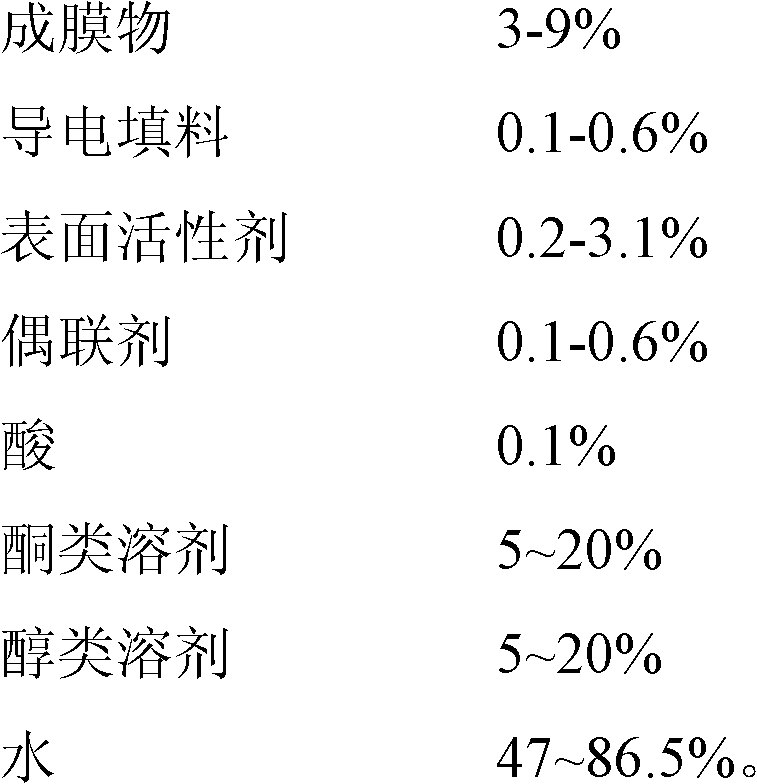

Environment-friendly washing-resistant antistatic coating and preparation method thereof

ActiveCN103173108AEasy to useEasy to processPolyurea/polyurethane coatingsElectrically-conductive paintsOrganic solventAlcohol

The invention relates to an antistatic coating and discloses an environment-friendly washing-resistant antistatic coating. The antistatic coating comprises the following components by weight percent: 3-9% of film former, 0.1-0.6% of conductive filler, 0.2-3.1% of surfactants, 0.1-0.6% of coupling agents, 0-0.1% of acid, 5-20% of ketone solvent, 5-20% of alcohol solvent and 47-86.5% of water. The preparation method can be implemented to prepare the antistatic coating which is efficient, has low toxicity and strong adhesion, is resistant to washing with water and organic solvents and is convenient to use, prepare and process; the components of the antistatic coating are the raw materials which are easily available, so the cost of the prepared antistatic coating can be effectively lowered; with water as a main solvent, the prepared antistatic coating is non-toxic and environment-friendly; and the preparation method is carried out under normal temperature and pressure, the conditions required by the preparation process are easy to reach, the preparation flow is simple and the operability is strong.

Owner:广东广麟材耀新能源材料有限公司

Aqueous bronze powder preparation method

InactiveCN103333532AGood technical effectLittle gloss effectPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsKetone solventsPrinting ink

The invention discloses an aqueous bronze powder preparation method. The method comprises the following steps: cleaning sheet bronze powder ball-milled in a ball mill with a ketone solvent in a cleaning tank, press-filtering, and carrying out solid-liquid separation to obtain a filter cake; adding the filter cake, an alcoholic solvent and a titanate coupling agent to a reaction container, and stirring; taking ammonia water and distilled water, and mixing ammonia water with distilled water for dilution; taking ethyl orthosilicate, and diluting with the alcoholic solvent; simultaneously adding to the reaction container in a dropwise manner; ageing for 6-10h, taking out, press-filtering, and carrying out solid-liquid separation to obtain inorganic silicon coated bronze powder; taking the inorganic silicon coated bronze powder and an ether solvent, and uniformly dispersing the inorganic silicon coated bronze powder in the ether solvent; and taking a hydrophilic ester monomer and an azo initiator, adding to the reactor, coating, taking out, press-filtering, and carrying out solid-liquid separation to obtain aqueous bronze powder. The method adopts an organic-inorganic double layer coating modifying treatment process to prepare the aqueous bronze powder, so the aqueous bronze powder has a high controlled release efficiency and does not change its color for a long time in alkaline printing ink.

Owner:HEFEI SUNRISE PIGMENTS

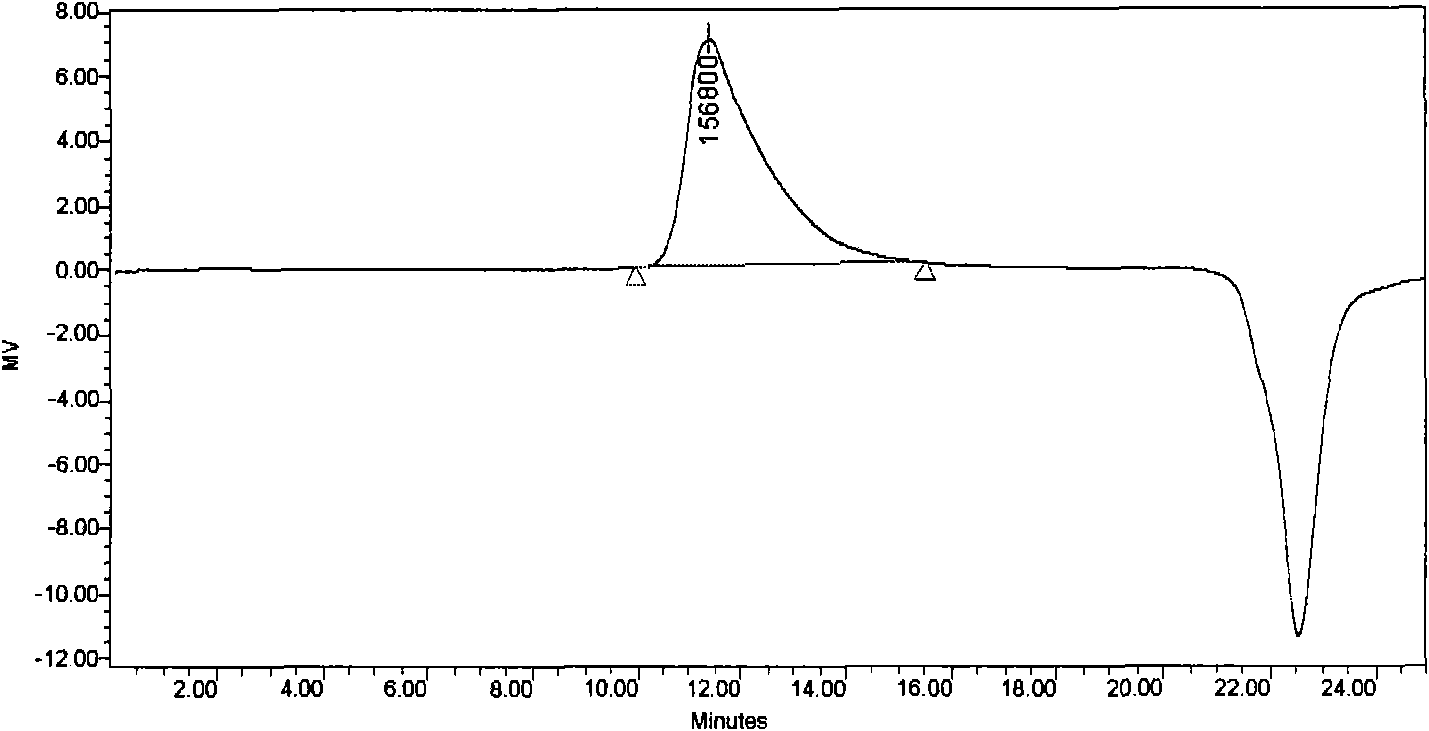

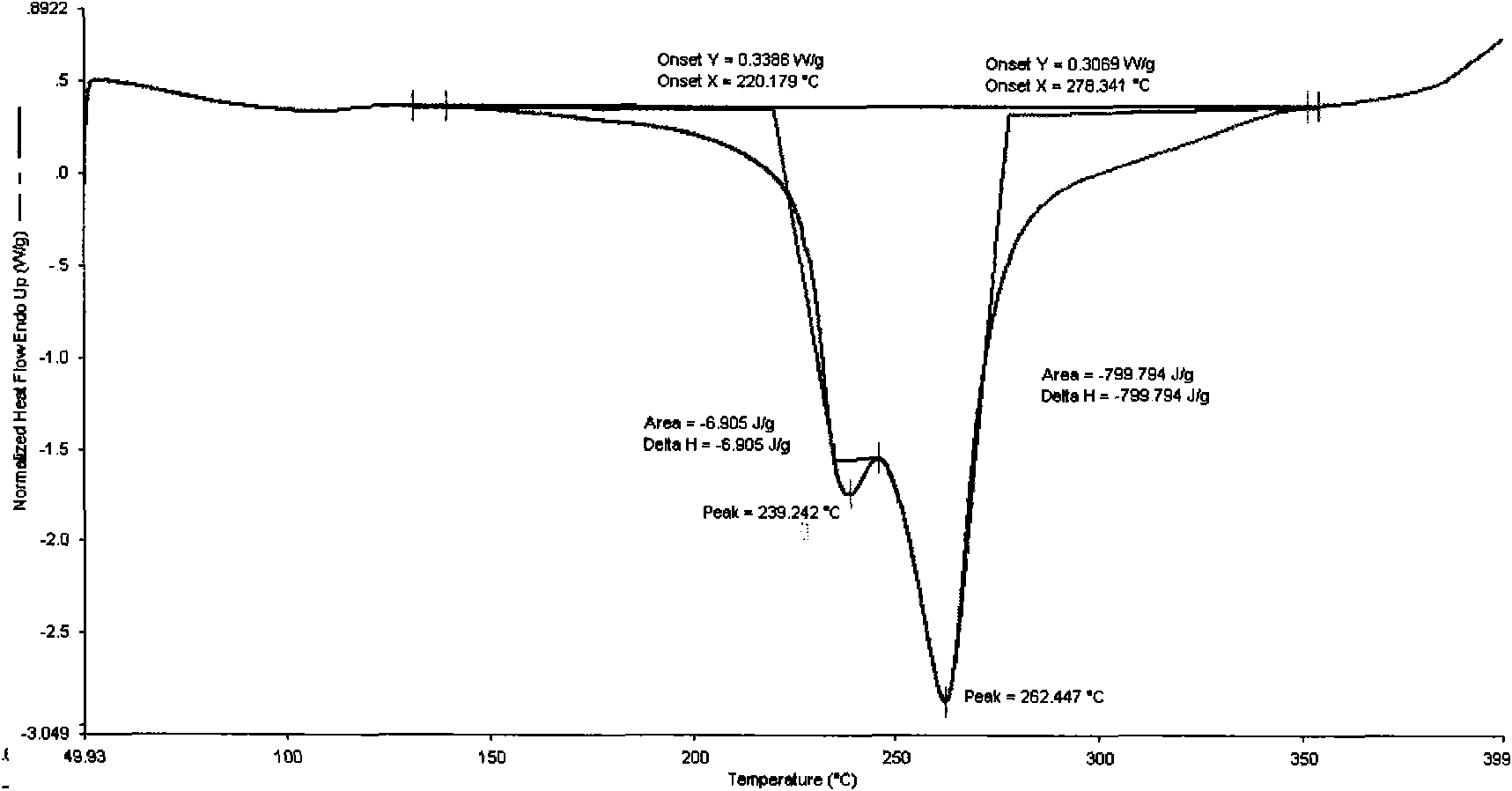

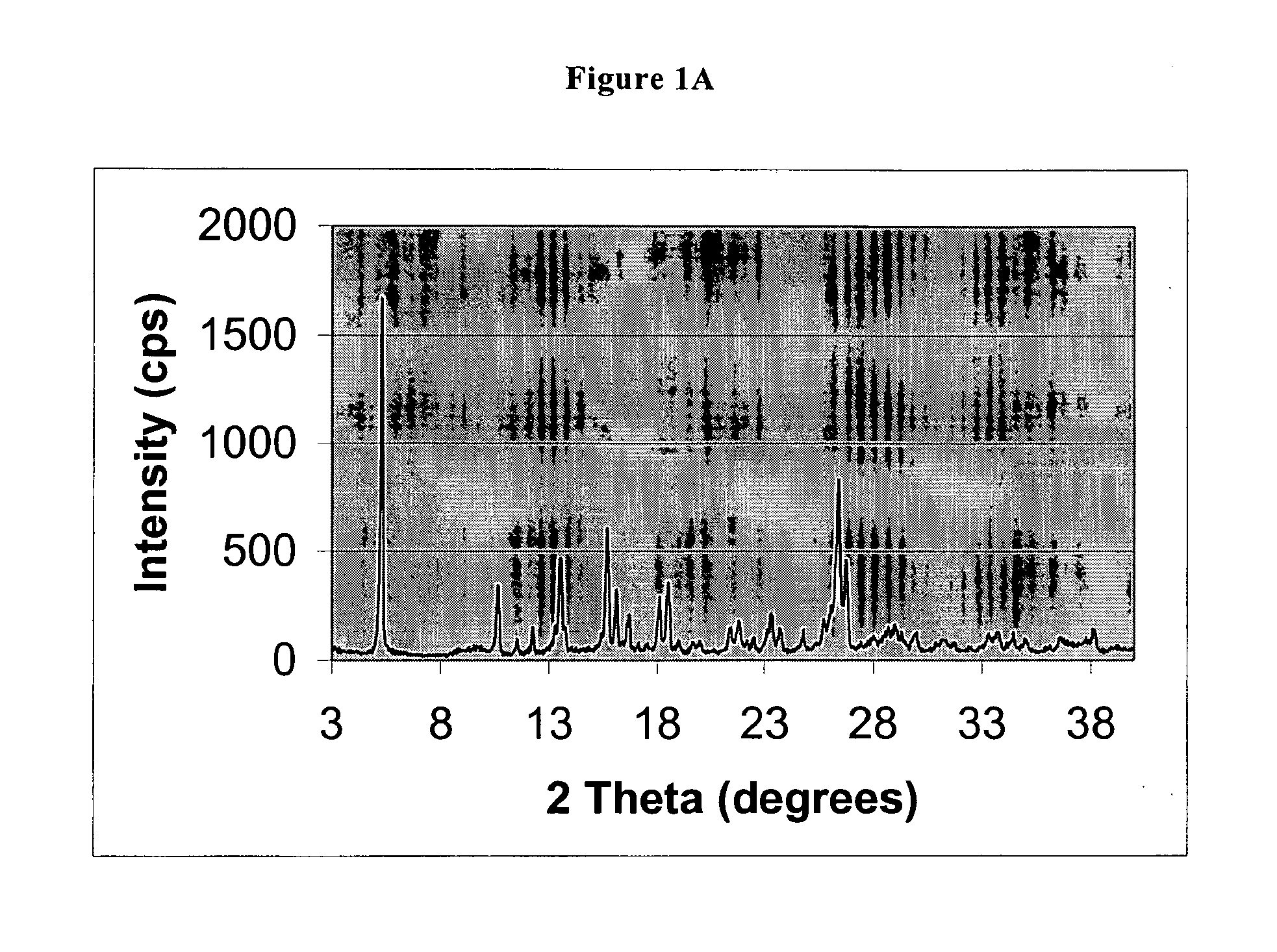

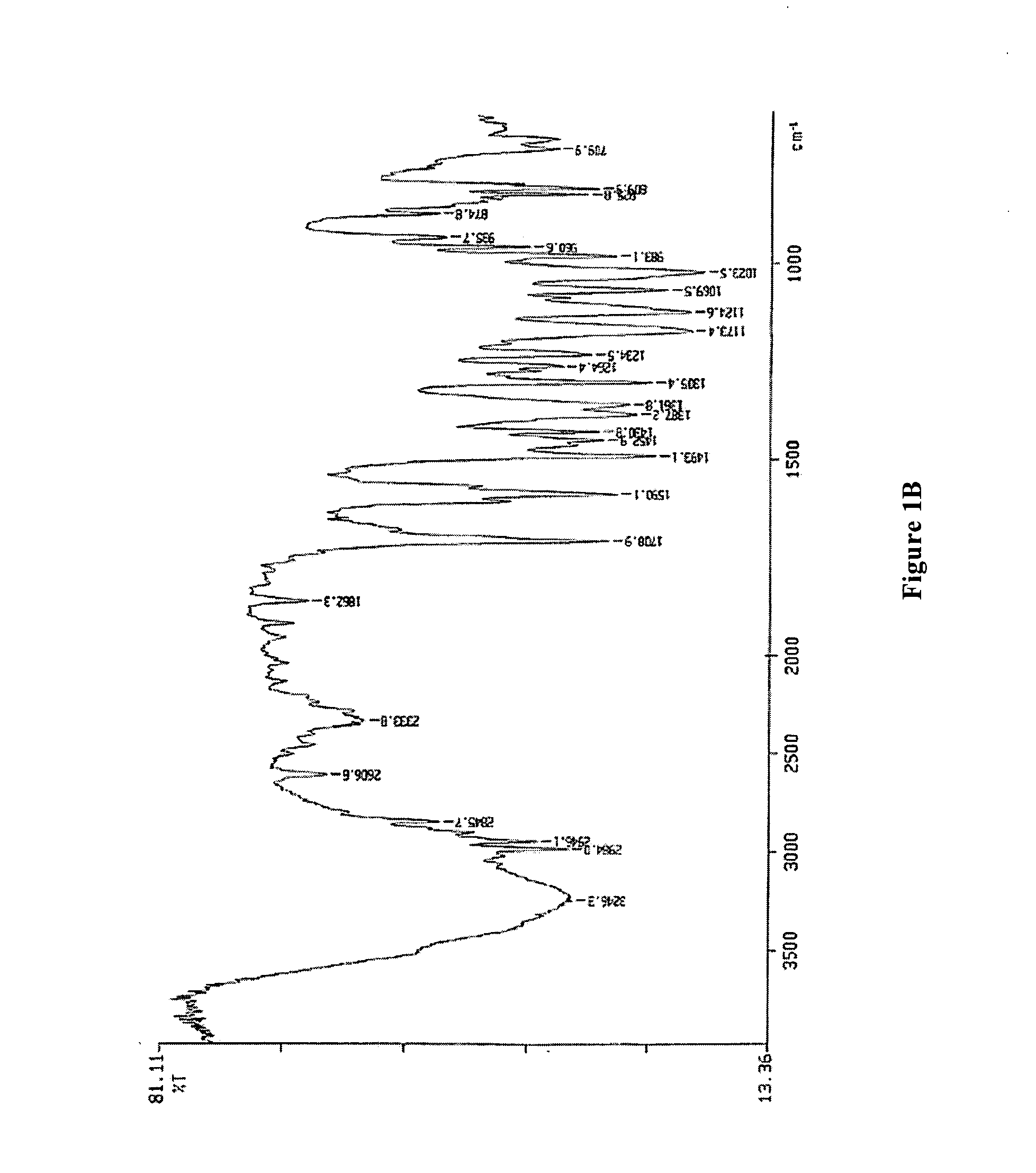

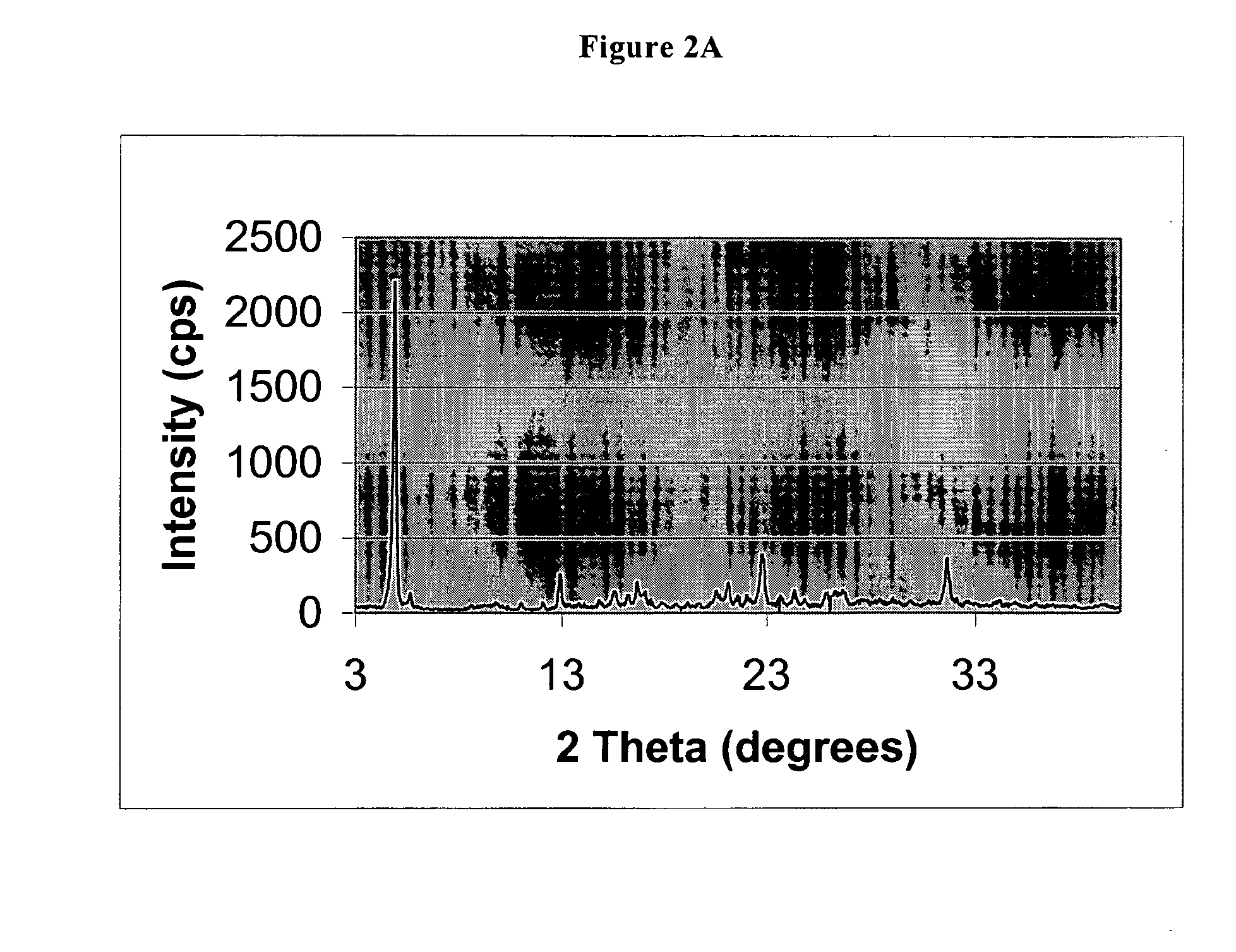

Polymorphs of pantoprazole sodium salt and process for the preparation thereof

Novel crystalline forms of pantoprazole sodium salt solvate with ketone solvents, a process for the preparation thereof, the use of the forms for the purification of pantoprazol, pharmaceutical compositions therefrom and the use thereof in therapy.

Owner:DIPHARMA SPA

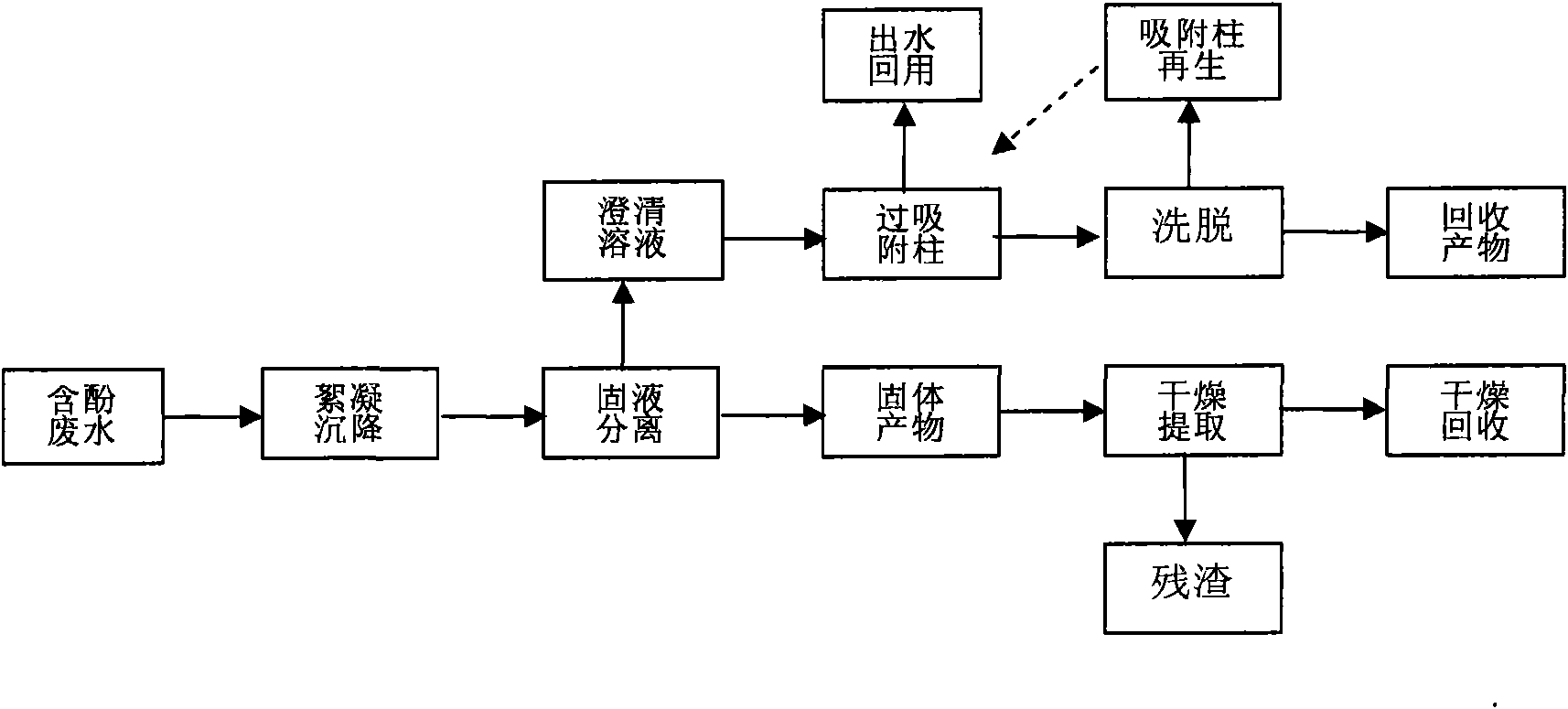

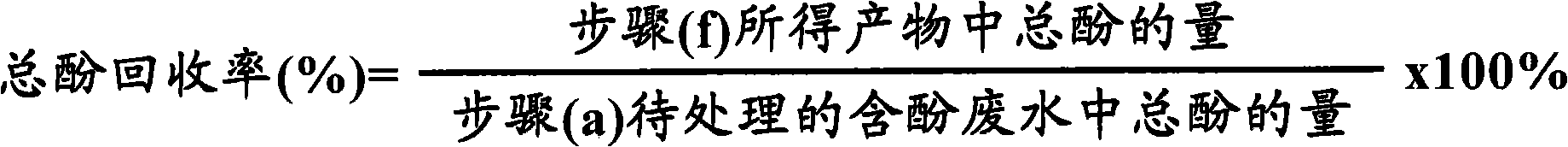

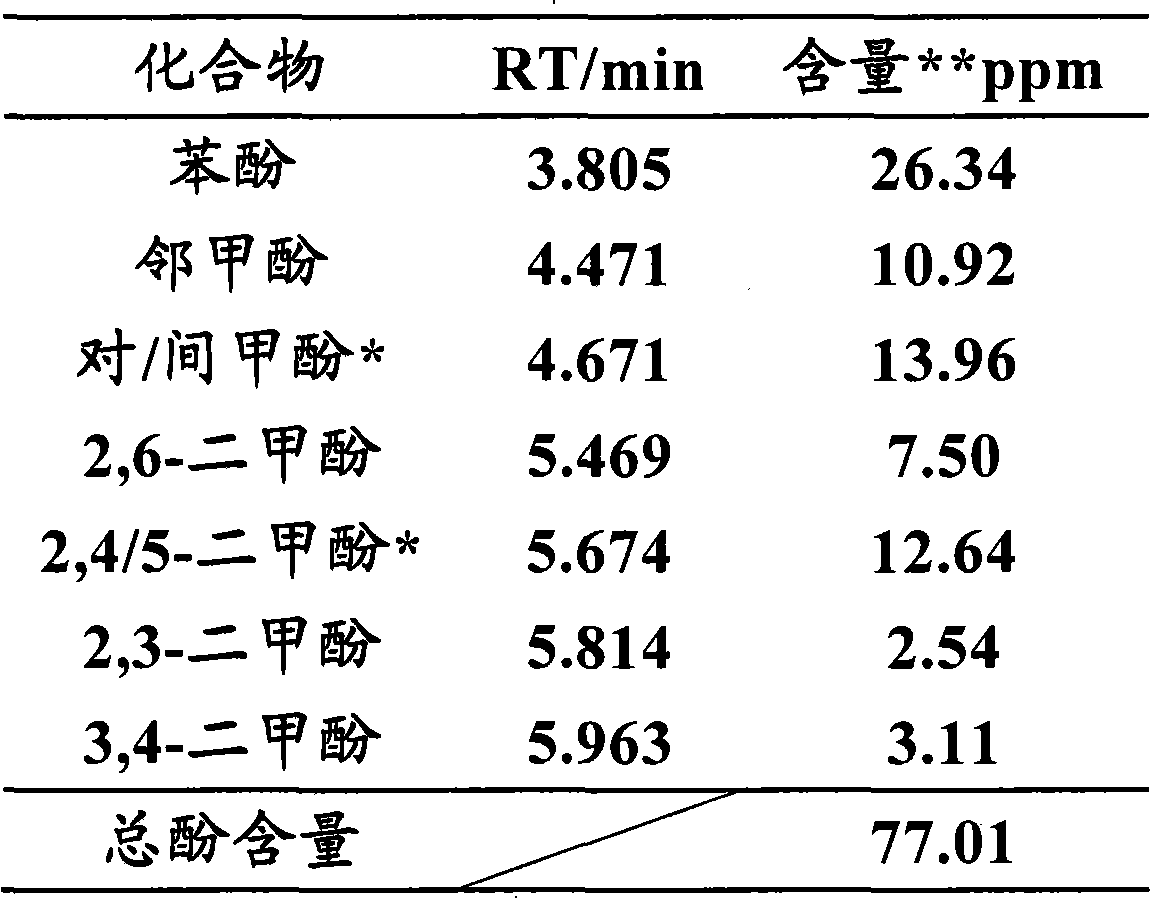

Method for processing and recycling waste water containing phenolic compounds

InactiveCN102417248AEasy to purifyRealize automatic continuous productionOrganic chemistryOrganic compound preparationFlocculationAlcohol

The invention relates to a method for processing and recycling waste water containing phenolic compounds, in particular to a method for recycling phenolic compounds from the phenolic waste water, comprising the following steps: (a) adding a flocculating agent in the phenolic waste water to be processed for flocculation; (b) carrying out solid-liquid separation on the material of the step (a); (c) determining the pH value of the liquid material obtained by the step (b), and adjusting the pH value to acidity; (d) letting the material obtained by the step (c) pass through a resin column, and measuring the total phenol content in water; (e) eluting the resin column which absorbs the phenolic compounds with a small molecular alcohol and / or ketone solvent; and (f) recovering the solvent from the eluate, and drying to obtain a product which is rich in phenolic compounds. Correspondingly, the invention further provides a method for processing the waste water containing phenolic compounds and the obtained phenolic product. According to the invention, the method disclosed herein is suitable for processing the waste water with low phenol content, and is environmental friendly; by using the raw materials which has the advantages of low pollution, or low price, or easy processing, and or recycling property, the method has the advantages of low cost and low energy consumption.

Owner:ENN SCI & TECH DEV

Resin anti-corrosive paint

InactiveCN101525514AEasy to get formulaLow priceAnti-corrosive paintsTetrafluoroethyleneKetone solvents

The invention discloses a resin anti-corrosive paint which is prepared from 10-35 of resin composition, 5-15 of plasticiser, 45-70 of solvent, and 1-5 of assistant according to the weight percent, wherein the resin composition is prepared from 30-60 of polyvinyl chloride, 20-50 of chlorinated polyvinyl chloride and 0-20 of polyfluortetraethylene according to the weight percent; the plasticiser is phthalic acid esters; the solvent is one or more of a ketone solvent, a benzene solvent or an ester solvent; the assistant is antioxidant or age inhibitor; and the polyvinyl chloride uses powder as the raw material. The anti-corrosive paint has the advantages of corrosion resistance, long service life, simple and convenient coating and mending, little pollution and cheap price, can be widely used for flue gas purification and surface corrosion of chemical equipment, engineering construction, ships, and the like, and has a good market prospect.

Owner:沈福昌

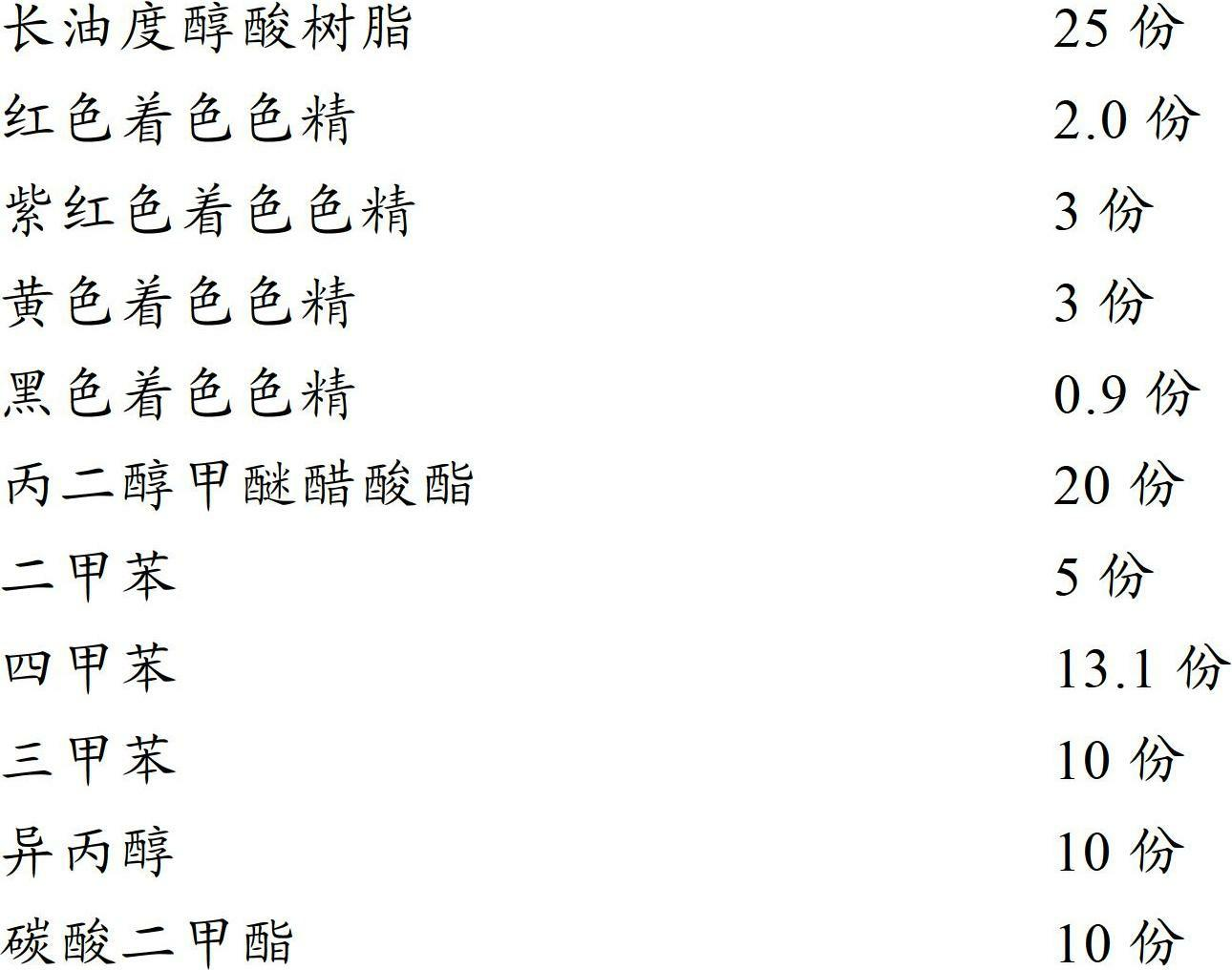

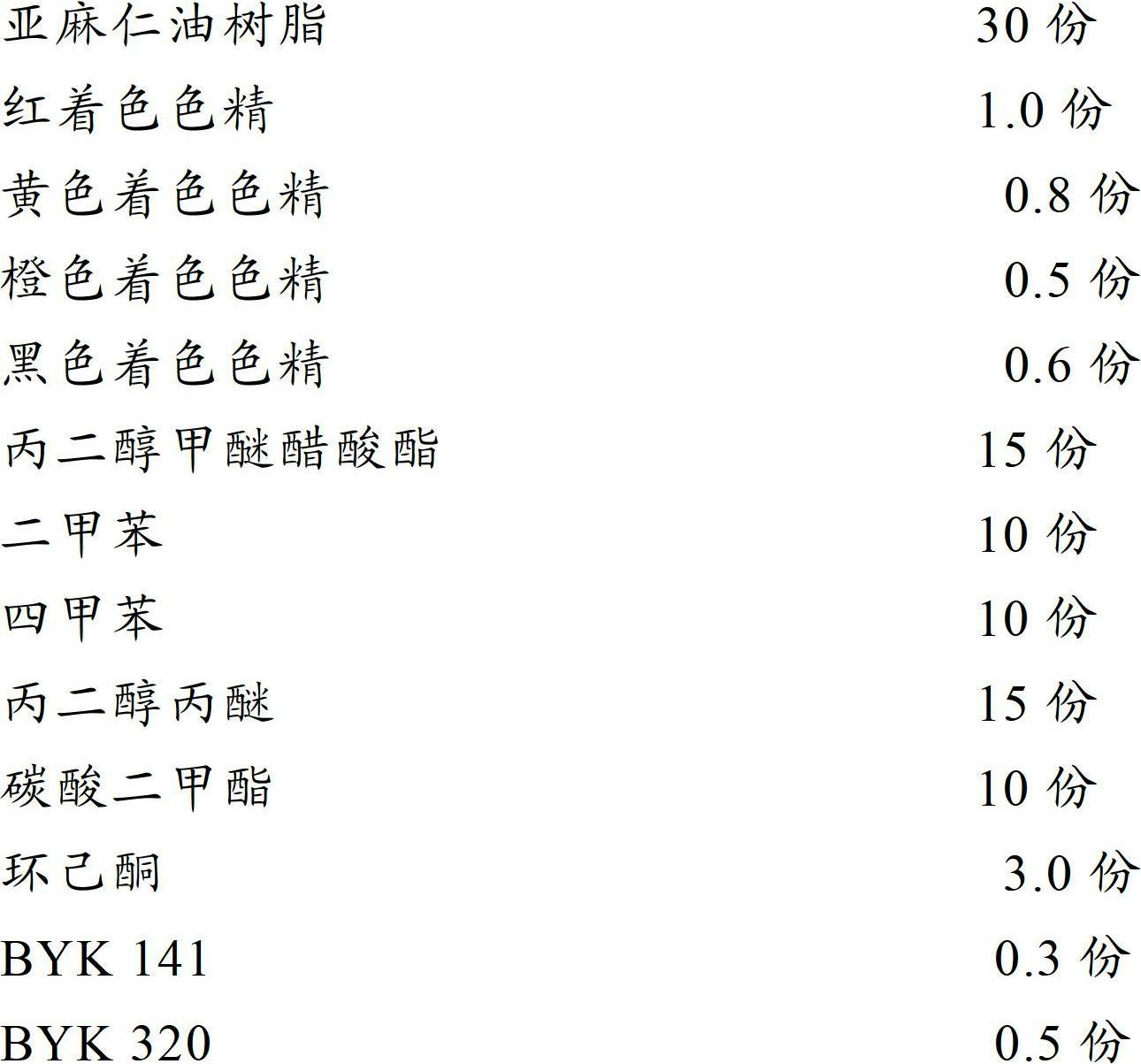

Coloring agent composition for wood lacquer as well as preparation method and coating and construction method thereof

ActiveCN102660176AEasy constructionImprove the level ofCoatingsSpecial surfacesLacquerKetone solvents

The invention provides a coloring agent composition for wood lacquer, which is prepared from the following components: 5-40 parts of matrix resin, 0.5-10 parts of metal complex dye, 8-40 parts of esters solvent, 15-50 parts of aromatic hydrocarbon solvent, 0.5-20 parts of ketone solvent, wherein the matrix resin is plant oleoresin or long oil-length alkyd resin. The coloring agent composition for wood lacquer provided by the invention has favorable coloring performance, has short coloring time, is convenient for coating and construction, can be used for personnel without long-term construction experience, and can obtain a good coating effect. The invention also provides a preparation method of the coloring agent composition for wood lacquer..

Owner:广东嘉宝莉科技材料有限公司

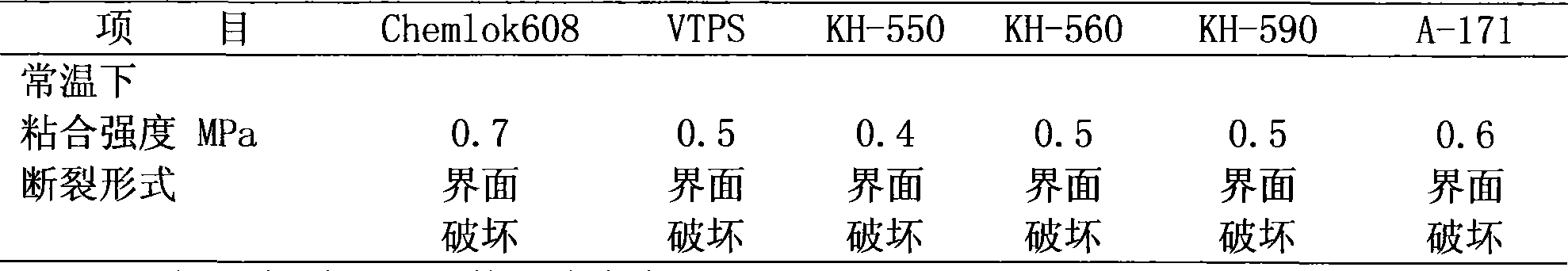

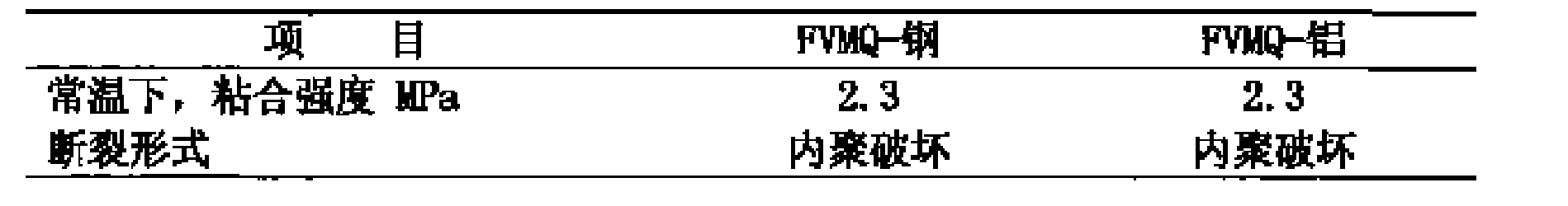

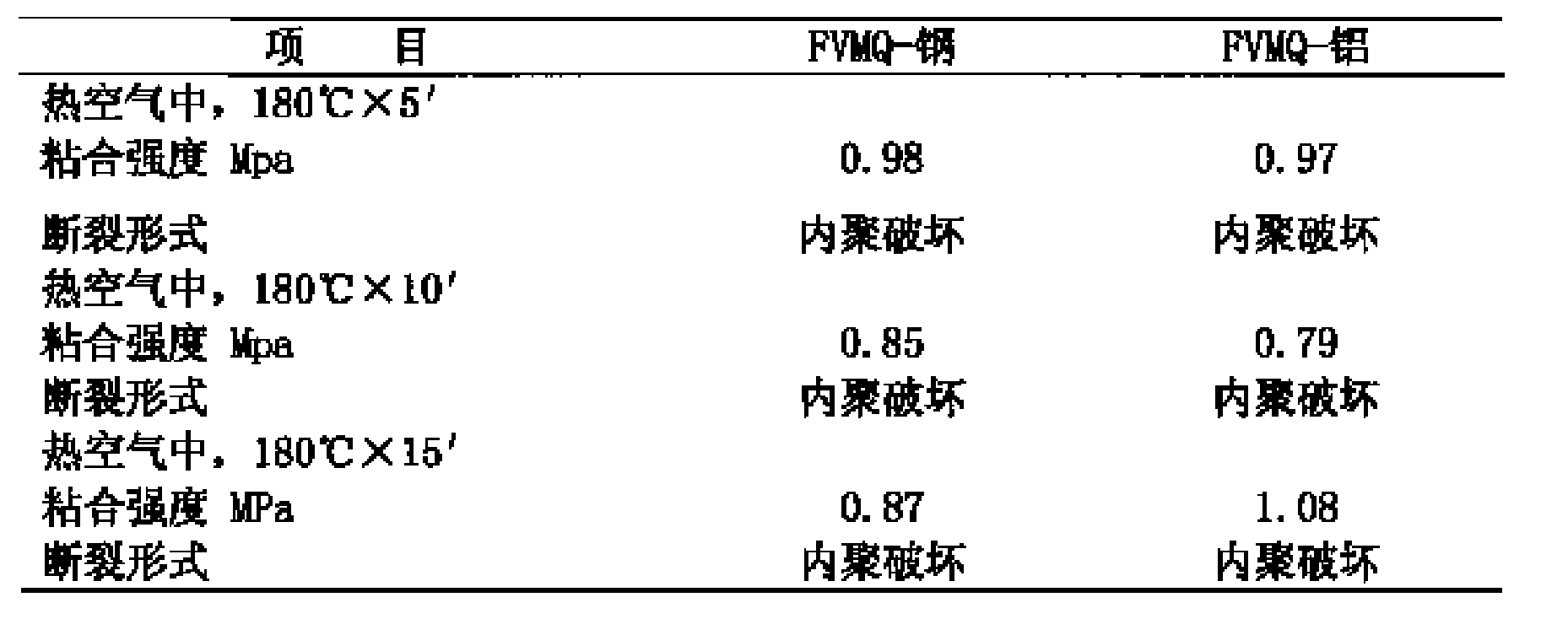

Bonding adhesive for bonding fluorocarbon silicone rubber with metals and preparation method thereof

ActiveCN101531881AImprove performanceQuality improvementNon-macromolecular adhesive additivesPolymer scienceKetone solvents

A bonding adhesive for bonding fluorocarbon silicone rubber with metals and a preparation method thereof are characterized in that: the bonding adhesive comprises the following components: A. a fluorocarbon silicone rubber compound, B. a silane coupling agent containing peroxide groups, C. a silane coupling agent containing olefin functional groups, D. a ketone solvent, and E. an ester solvent. The bonding adhesive has stable and reliable property and can be used for bonding fluorocarbon silicone rubber with common metals such as copper, steel, aluminum and the like; the obtained adhesive strength is stable; and the bonded part has excellent properties of heat-resistance, oil-resistance, medium-resistance and the like, which are equivalent to those of the fluorocarbon silicone rubber.

Owner:SHANGHAI PLASTICS RES INST CO LTD

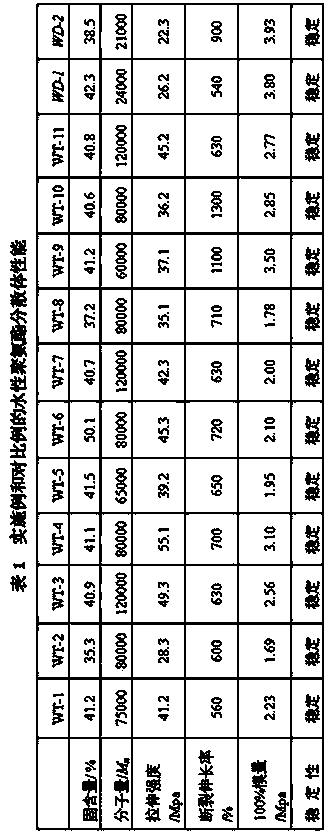

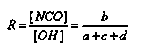

Waterborne polyurethane dispersion with high performance and preparation method thereof

ActiveCN103382253AImprove mechanical propertiesOvercome the problem of low modulus and low tensile strengthPolyurethane dispersionPolymer science

The invention discloses a waterborne polyurethane dispersion with high performance and a preparation method thereof. The preparation method comprises the following steps: (1) solvent-free synthesis of a waterborne polyurethane particle: a step of preparing a waterborne polyurethane melt from a molten waterborne polyurethane synthesis raw material by using a solvent-free continuous twin-screw production process for TPU and then preparing the waterborne polyurethane particle from the waterborne polyurethane melt; and (2) nonreactive emulsification of the waterborne polyurethane particle: a step of dispersing and emulsifying the waterborne polyurethane particle in a mixed solvent containing ketone and water and then extracting a ketone solvent to prepare the waterborne polyurethane dispersion with solid content of 0 to 60 wt%. According to the invention, a continuous production process is adopted for the waterborne polyurethane dispersion with high performance; the prepared waterborne polyurethane dispersion has higher molecular weight, low modulus and high tensile performance; a solvent produced in the preparation process can be recycled without purification; and the preparation method has the advantages of stable process operation, low requirements for emulsification equipment, high production efficiency and wide application prospects.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +2

Method of preparing chloropy gra hydrogen sulphate type I

The present invention discloses a method for preparing I-type clopidogrel hydrosulfate. Said method includes the following steps: a), oblaining clopidogrel free alkali; b), adding ketone solvent into clopidogrel free alkali, and drop-adding sulfuric acid, after the drop-adding process is completed, heating to 20-50deg.C, heat-insulating and stirring, filtering and washing, vacuum drying wet product at 50-55deg.C so as to obtain the invented I-type clopidogrel hydrosulfate. The described ketone solvent is selected from five-carbon ketone or six0carbon ketone.

Owner:ZHEJIANG CHARIOTEER PHARMA

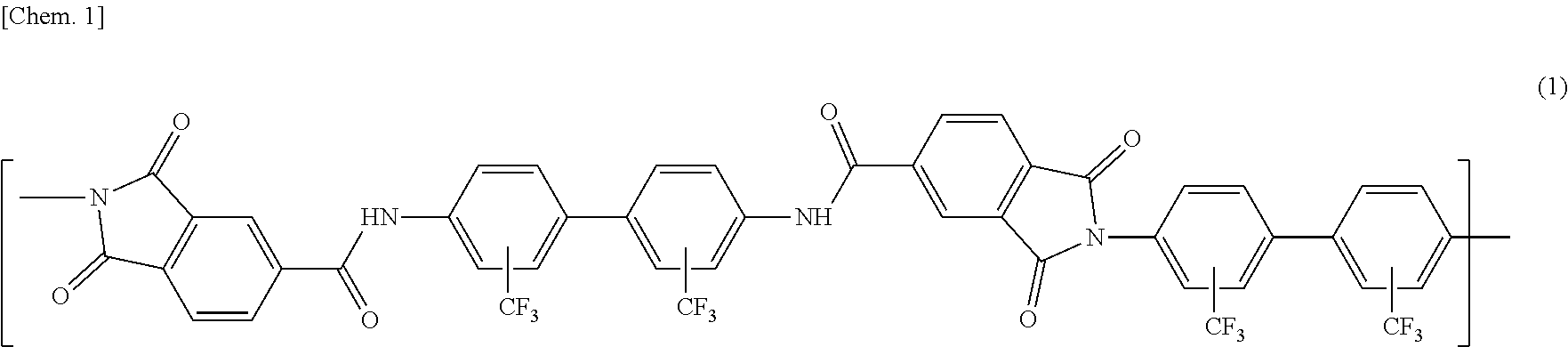

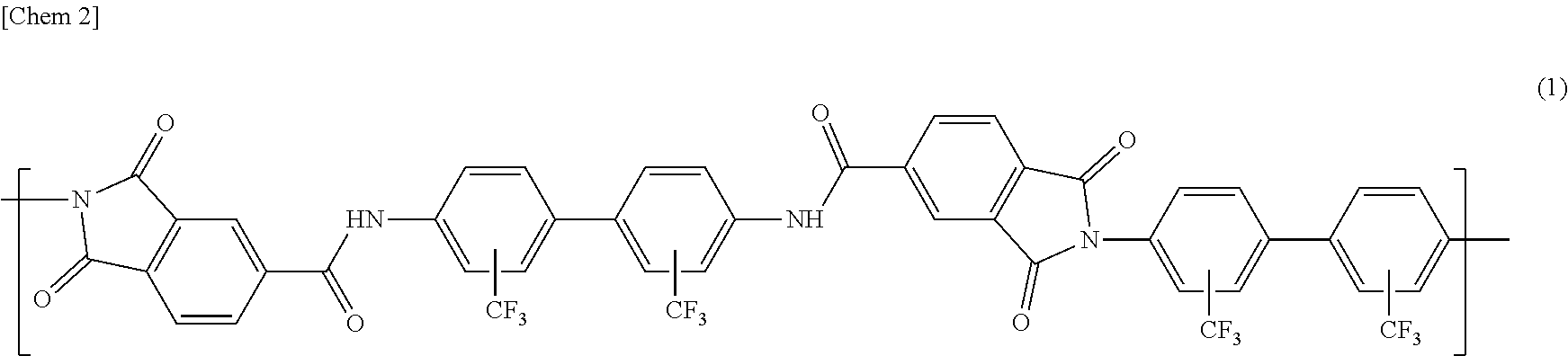

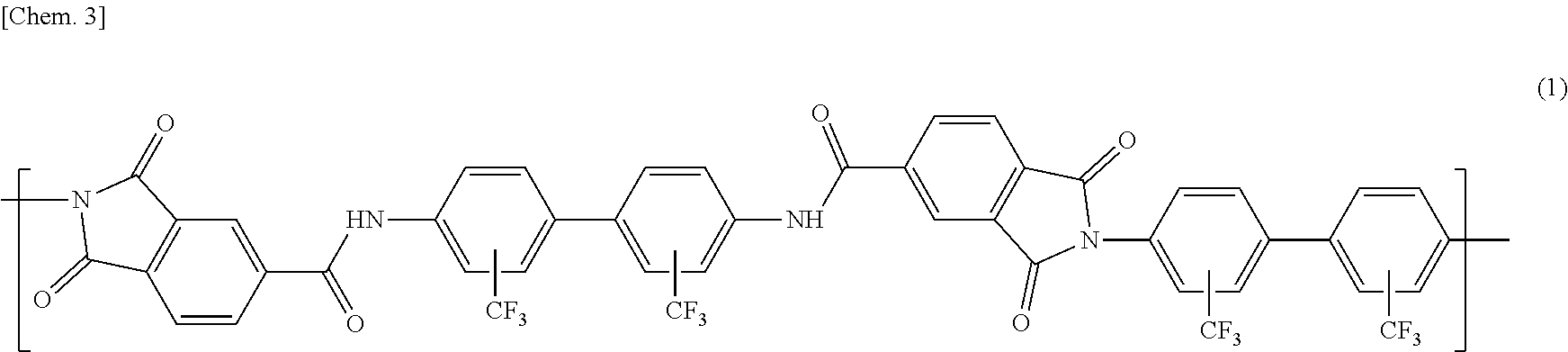

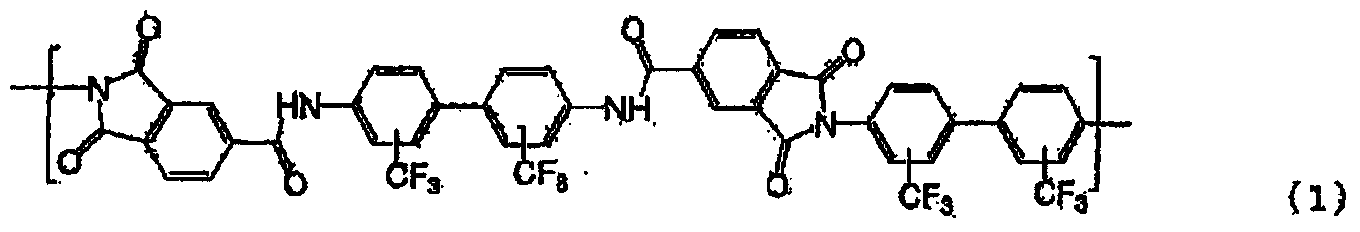

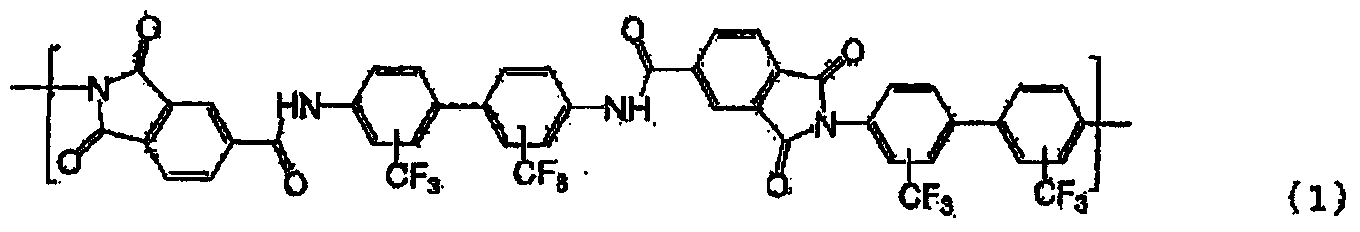

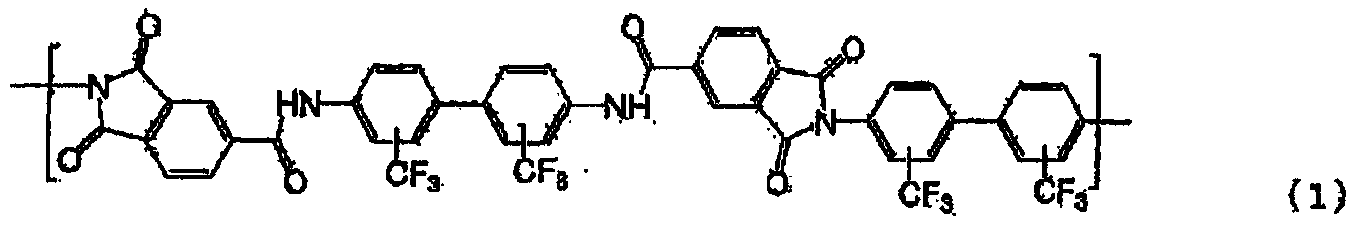

Polyamide-imide solution and polyamide-imide film

InactiveUS20140072813A1Low linear thermal expansion coefficientImprove applicabilityTransistorOptical filtersKetone solventsThermal expansion

An object of the present invention is to obtain a polyamide-imide solution that has a low linear thermal expansion coefficient, that is, an excellent linear thermal expansion coefficient, and that also is excellent in coating applicability. A further object of the present invention is to provide, with use of the polyamide-imide solution, a product or member which has high requirements for heat resistance and a low linear thermal expansion coefficient. In particular, the present invention is intended to provide a product or member that is suitably used for applications in which the polyamide-imide film obtained from the polyamide-imide solution of the present invention is formed on a surface of an inorganic material such as metal, metal oxide, or monocrystalline silicon.The above objects can be achieved by a polyamide-imide solution including: a specific polyamide-imide; and an organic solvent, the organic solvent being a mixture solvent of an amide solvent and a non-amide solvent, the non-amide solvent being at least one solvent selected from the group consisting of ether solvents, ketone solvents, ester solvents, glycol ether solvents, and glycol ester solvents.

Owner:KANEKA CORP

Comprehensive method for preparation of raffinose and gossypol from cottonseed meal

ActiveCN102898486AValue maximizationRealize processingSugar derivativesPeptide preparation methodsHalohydrocarbonFiltration

The invention discloses a comprehensive method for preparation of raffinose and gossypol from cottonseed meal. The method comprises the technological steps of: (1) extracting oil-extracted cottonseed meal with a polar solvent so as to obtain an extracted solution; (2) filtering the extracted solution, and removing an organic solvent in vacuum so as to obtain an aqueous phase and a solid phase; (3) subjecting the aqueous phase to filtration, flocculation, decoloration and desalination, decoloration, as well as desolventizing, thus obtaining raffinose; (4) first adding enzymes into the solid phase to carry out hydrolysis, then using an acid to adjust the solution to acidic, and performing precipitation and separation, thus obtaining a solid; (5) adding ether, halohydrocarbon, ester and / or low level ketone solvents to dissolve gossypol, and then filtering out impurities to obtain a gossypol-containing filtrate; and (6) subjecting the gossypol-containing filtrate to crystallization and crystal growing under nitrogen protection, then conducting filtration and drying, thus obtaining acicular crystals. The method can realize combined industrial production of dephenolized cottonseed protein, raffinose and gossypol, is suitable for large-scale production, and realizes comprehensive processing as well as maximum valuation of cottonseeds.

Owner:邯郸晨光植物蛋白有限公司

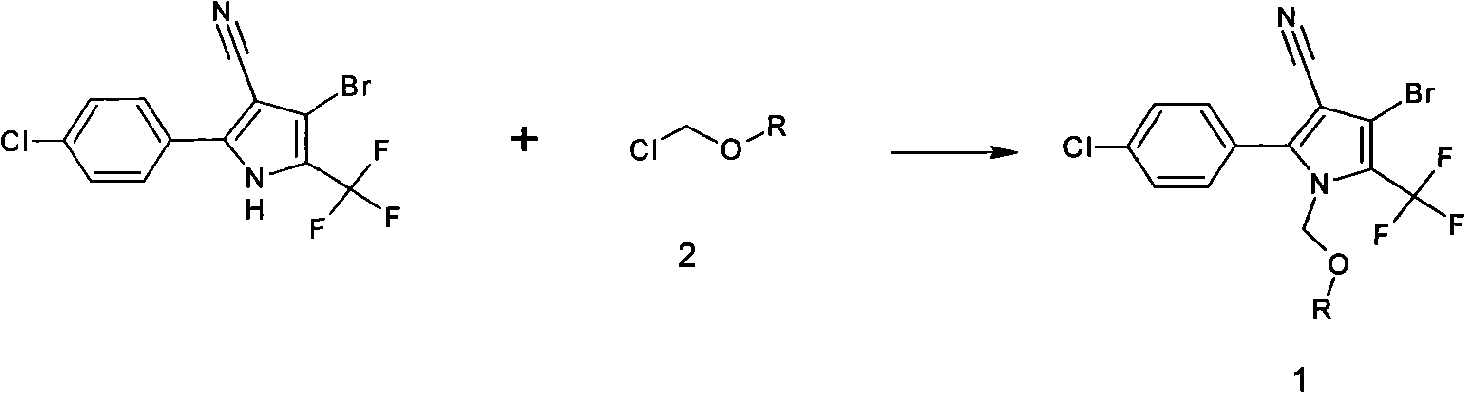

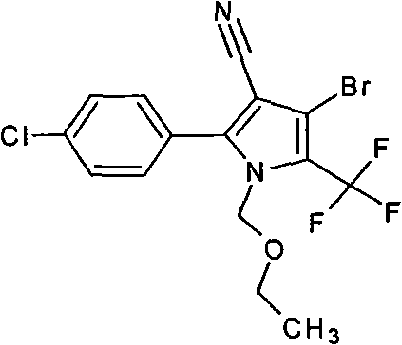

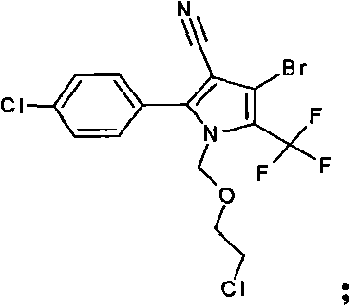

Method for preparing chlorfenapyr and analog thereof

ActiveCN101591284ASimple processMild reaction conditionsOrganic chemistryChemical reactionKetone solvents

The invention discloses a method for preparing chlorfenapyr and analog thereof by using 4-bromo-2-(4-chlorphenyl)-5-trifluoromethylpyrrole-3-nitrile and chloromethyl ether as raw materials in the presence of ketones solvent and inorganic alkali acid-binding agent. The chemical reaction formula is as above. The method for synthesizing the chlorfenapyr and the analog thereof by adopting the ketones solvent and the inorganic alkali acid-binding agent has the advantages of simple process, mild reaction condition, low production cost and the like, and has good industrial application prospect.

Owner:HUNAN CHEM RES INST

Polyamide-imide solution and polyamide-imide film

ActiveCN103502314AGood spreadabilityLow coefficient of linear thermal expansionTransistorOptical filtersKetone solventsThermal expansion

A purpose of the present invention is to obtain a polyamide-imide solution which has excellently low linear thermal expansion coefficient and excellent coatability. Another purpose of the present invention is to provide a product or member, which requires high heat resistance and very low linear thermal expansion coefficient, using the polyamide-imide solution. Another purpose of the present invention is to provide a product or member which is specifically suitable for uses wherein a polyamide-imide film that is obtained from the polyamide-imide solution of the present invention is formed on the surface of an inorganic material such as glass, a metal, a metal oxide or a single crystal silicon. The purposes are achieved by a polyamide-imide solution which contains a specific polyamide-imide and an organic solvent and which is characterized in that the organic solvent is a mixed solvent of an amide solvent and a solvent other than an amide solvent and that the solvent other than an amide solvent is composed of at least one solvent that is selected from the group consisting of ether solvents, ketone solvents, ester solvents, glycol ether solvents and glycol ester solvents.

Owner:KANEKA CORP

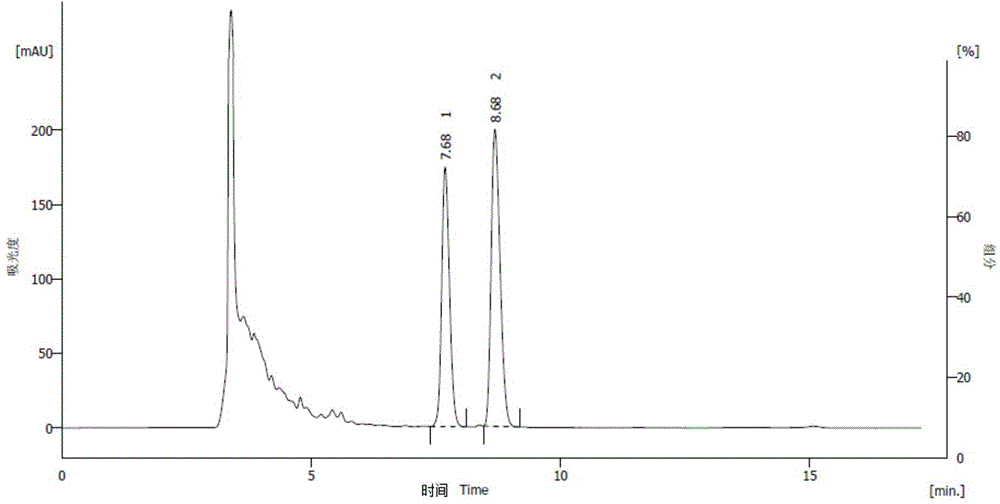

Preparation method of high-purity naringenin

The invention provides a preparation method of naringenin. The preparation method comprises the following steps: (1) preparing solution of naringin in lower alcohol or lower ketone solvent, leading the naringin in the prepared solution to be subjected to acid hydrolysis in an acidic condition to obtain naringenin, distilling under reduced pressure to remove solvent to obtain a naringenin crude product; (2) dissolving the naringenin crude product in absolute ethanol or absolute methanol, adding active carbon, stirring to decolor; and (3) filtering the active carbon, separating and purifying the prepared solution to obtain the naringenin. The preparation method has the advantages of few reaction steps, less used solvent, less emission of the 'three wastes', mild reaction condition and complete reaction and easy operation, is suitable for industrial production, and has higher practical value; and the prepared product has more stable quality, the purity is higher than 99 percent, which is higher than the drug standard.

Owner:HENAN TOPFOND PHARMA

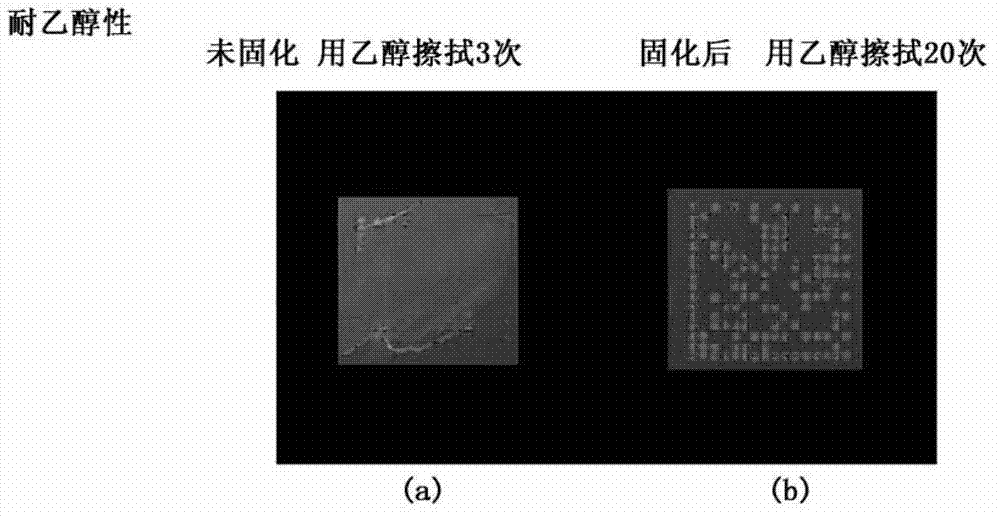

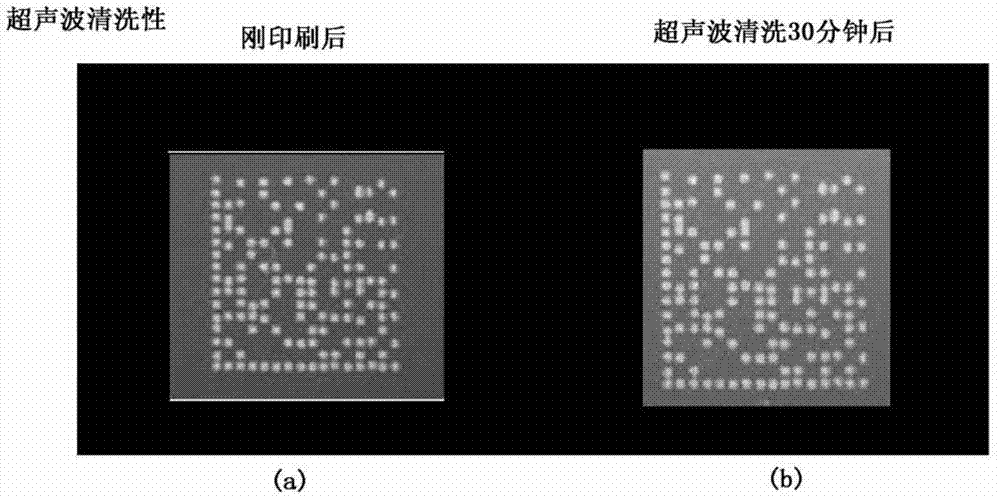

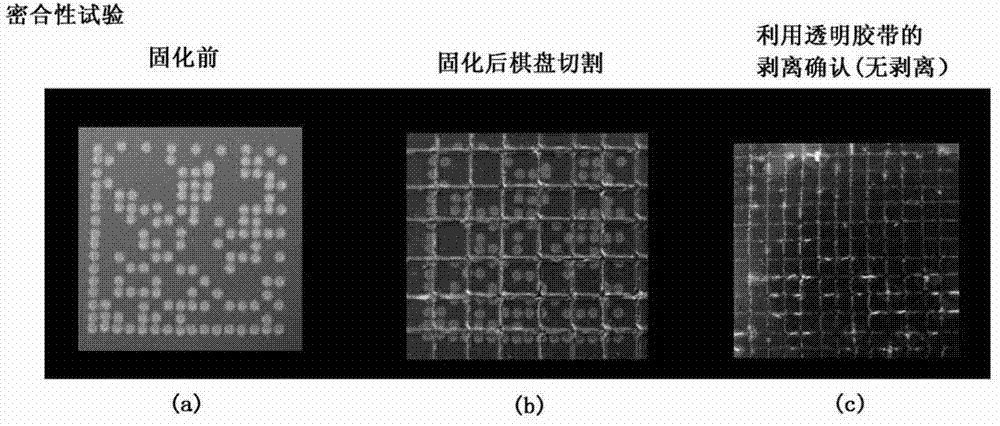

Inkjet ink and printing methods

ActiveCN102876113AImprove stabilityImprove solubilityDuplicating/marking methodsInksSolubilityKetone solvents

The invention relates to an inkjet ink and printing method, particularly in terms of related to solubility good resin is fully dissolved, and has good stability in the inkjet printer ink, need to be fully with density and resistance to washing after printing ink and solvent resistance. An ink jet ink, by making the inkjet ink with ketone solvents in to match the enclosed isocyanate well, can realize fully have to be print on the surface of the density and resistance, resistance to washing after printing and inkjet ink solvent resistance. That is, the inkjet ink for containing ketone solvents and colorants used inkjet printer ink, its characteristics is also contains enclosed isocyanate. As a result, as shown in figure 1 (b), printing data matrix YinShuaDian use dip cotton swab to wipe 20 times with ethanol will not dissolve.

Owner:KISHU GIKEN INDS

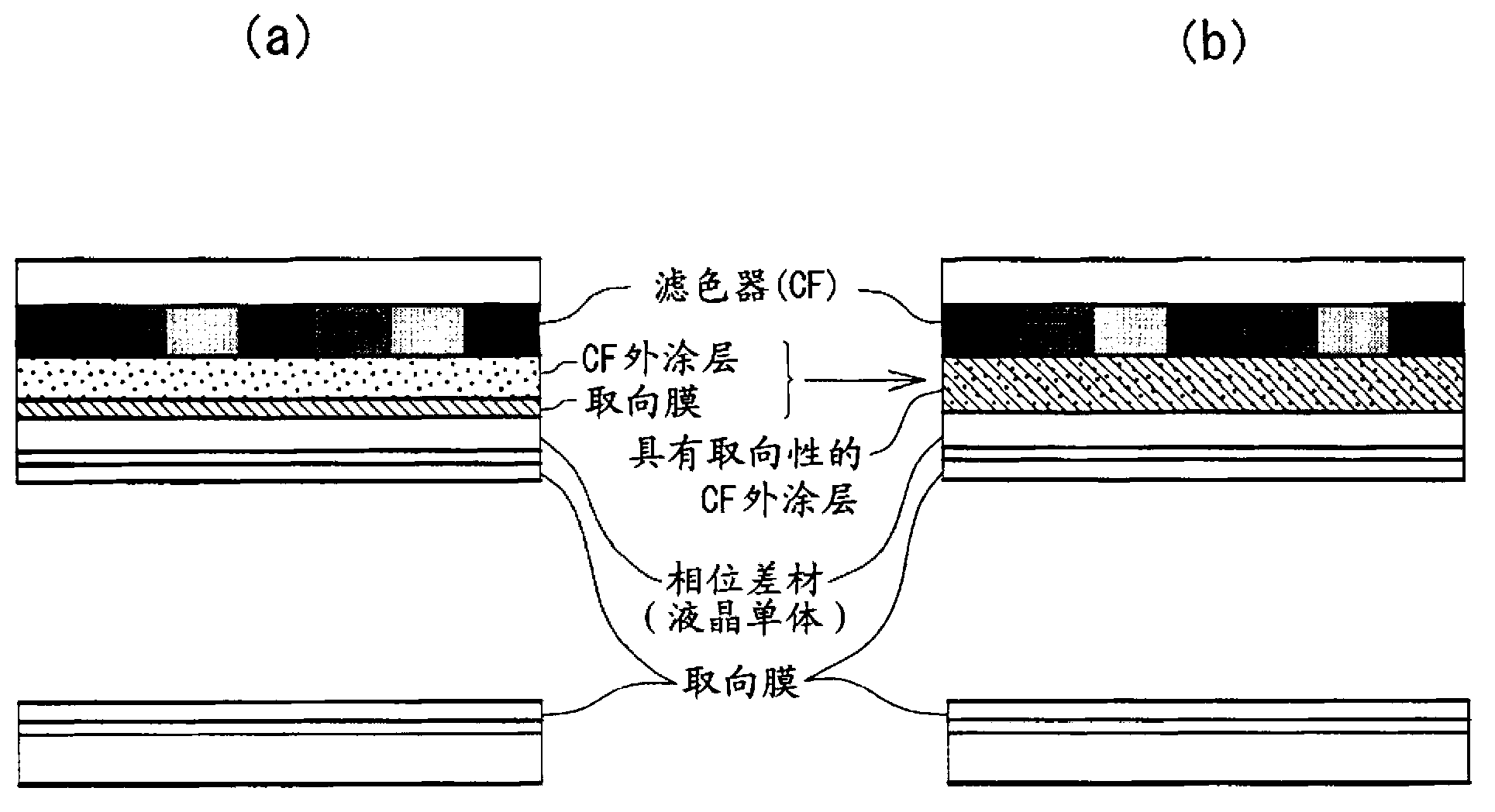

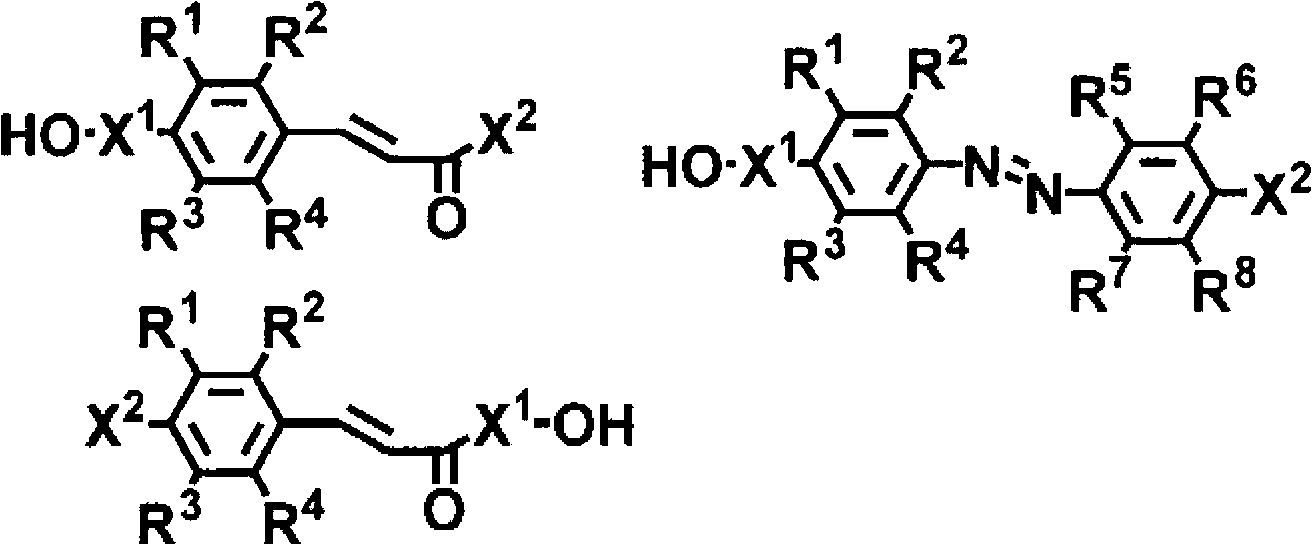

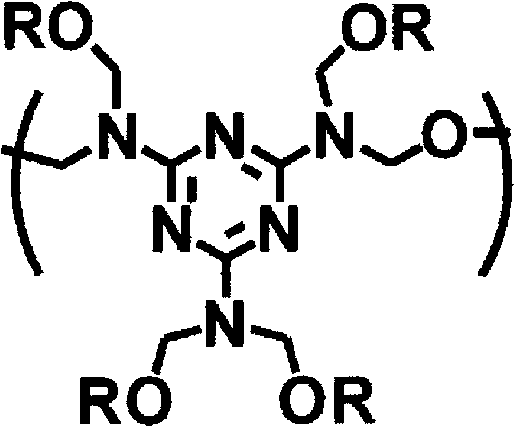

Thermosetting film forming composition having photo-alignment property

ActiveCN102834455AHigh transparencyGood solvent resistanceOptical filtersPolarising elementsHeat resistanceKetone solvents

Owner:NISSAN CHEM CORP

Method for improving hardness and toughness of flexibly-packaged battery

InactiveCN102653656AHigh hardnessImprove toughnessFinal product manufactureElectrolyte accumulators manufactureManufacturing technologyKetone solvents

The invention discloses and provides a method capable of improving wrinkle-resistant capability of an ultrathin battery greatly. The method provided by the invention comprises the following steps: taking an alcohol or ketone matter as a solvent, adding one kind or multiple kinds of alcohol soluble or ketone soluble resin slowly into the solvent according to certain proportion at the normal temperature under the condition of high-speed stirring, wherein stirring times lasts for 15-60 minutes; adding a defoaming agent and a flatting agent to the mixed solution and stirring uniformly; adding alcohol or ketone solvent continuously so as to adjust the viscosity of the mixed solution, and stirring for 10-60 minutes, thus obtaining a resin solution; uniformly spraying the obtained resin solution between an ultrathin battery electrode plate and an aluminum plastic film by a spraying gun; and standing the ultrathin battery processed by the above steps at the normal temperature or standing and drying in an anaerobic sealed vacuum box at a high temperature, wherein the drying time depends on the thickness of the sprayed resin. The method capable of improving wrinkle-resistant capability of the ultrathin battery greatly provided by the invention can be widely applied to the field of manufacturing technology of lithium batteries.

Owner:珠海格力新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com