Patents

Literature

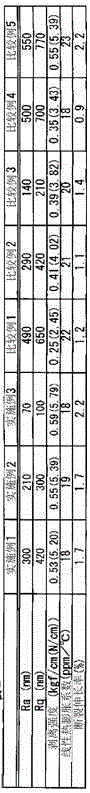

102results about How to "Low coefficient of linear thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant heat-conducting double-component epoxy resin pouring sealant and preparation method thereof

InactiveCN104152093ALow coefficient of linear thermal expansionReduce packing settlingNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermal conductivityPolymer chemistry

The invention relates to a flame-retardant heat-conducting double-component epoxy resin pouring sealant and a preparation method thereof. The pouring sealant is composed of a component A and a component B in a weight ratio of 100: 80 to 100: 120. The pouring sealant prepared in the invention has the advantages of a long operation period, a low thermal expansion coefficient after curing, a high flame retardation grade, reaching grade UL94-V0, good thermal conductivity and excellent electrical properties, and is applicable to high temperature electric packaging of power semiconductors, rectifiers, transformers, etc.

Owner:YANTAI DARBOND TECH

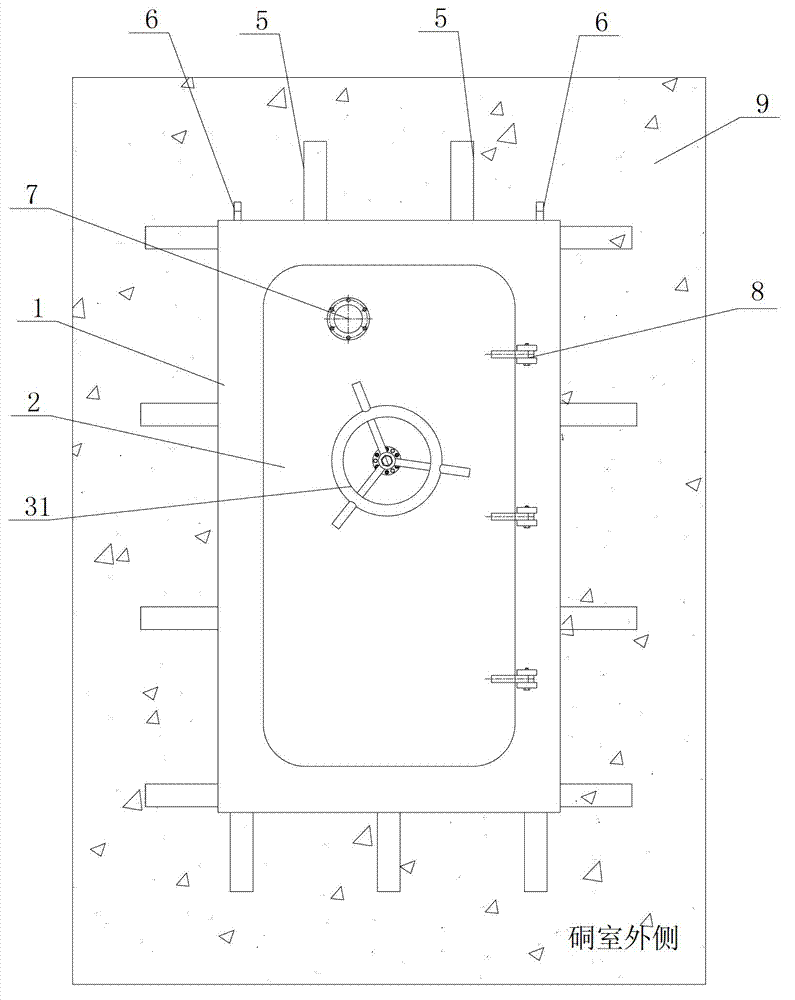

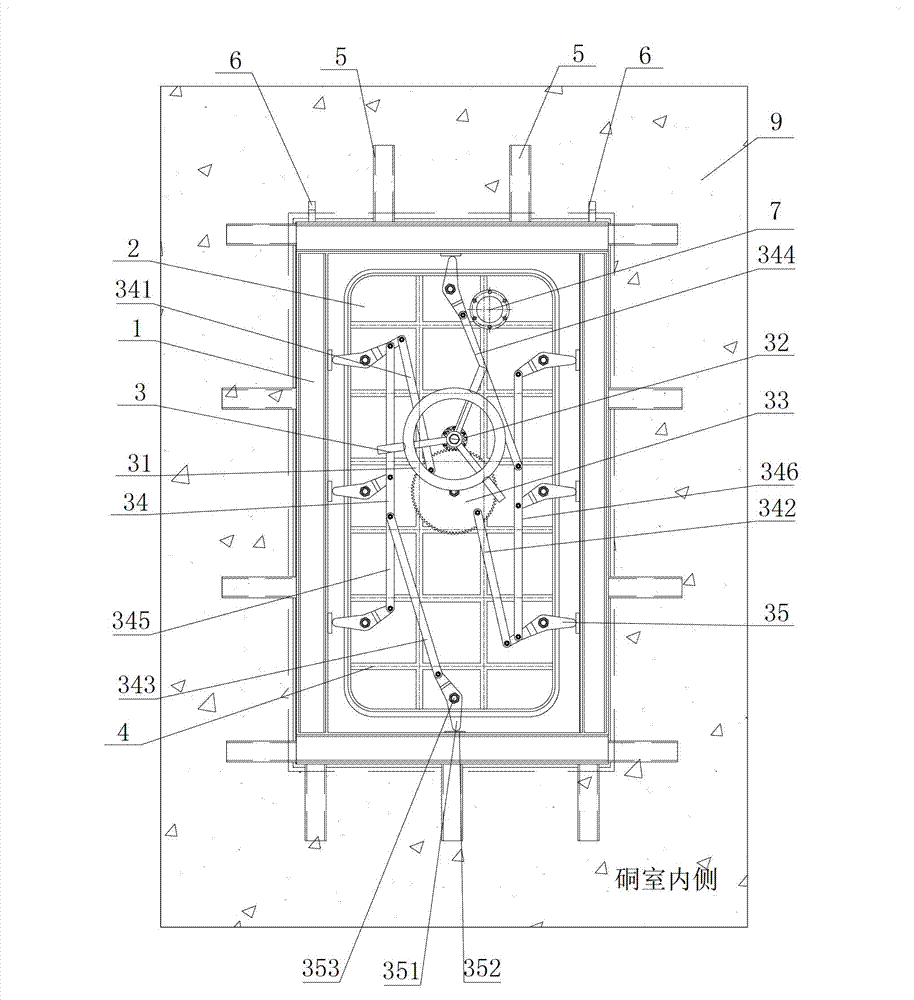

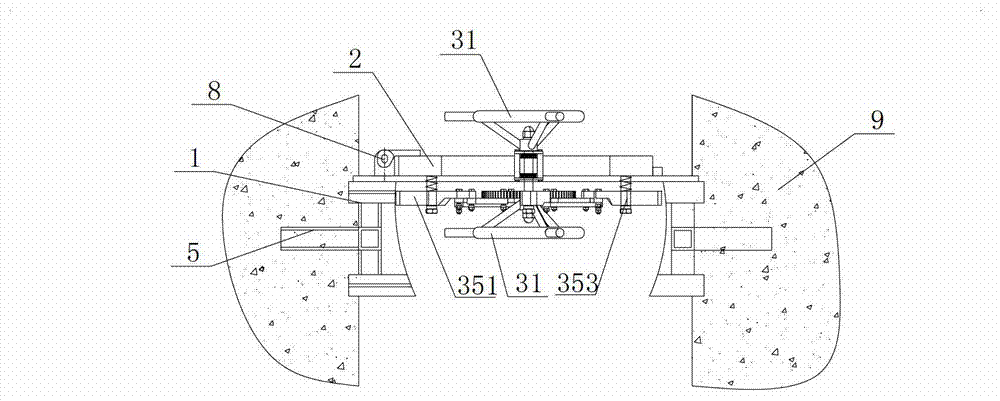

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

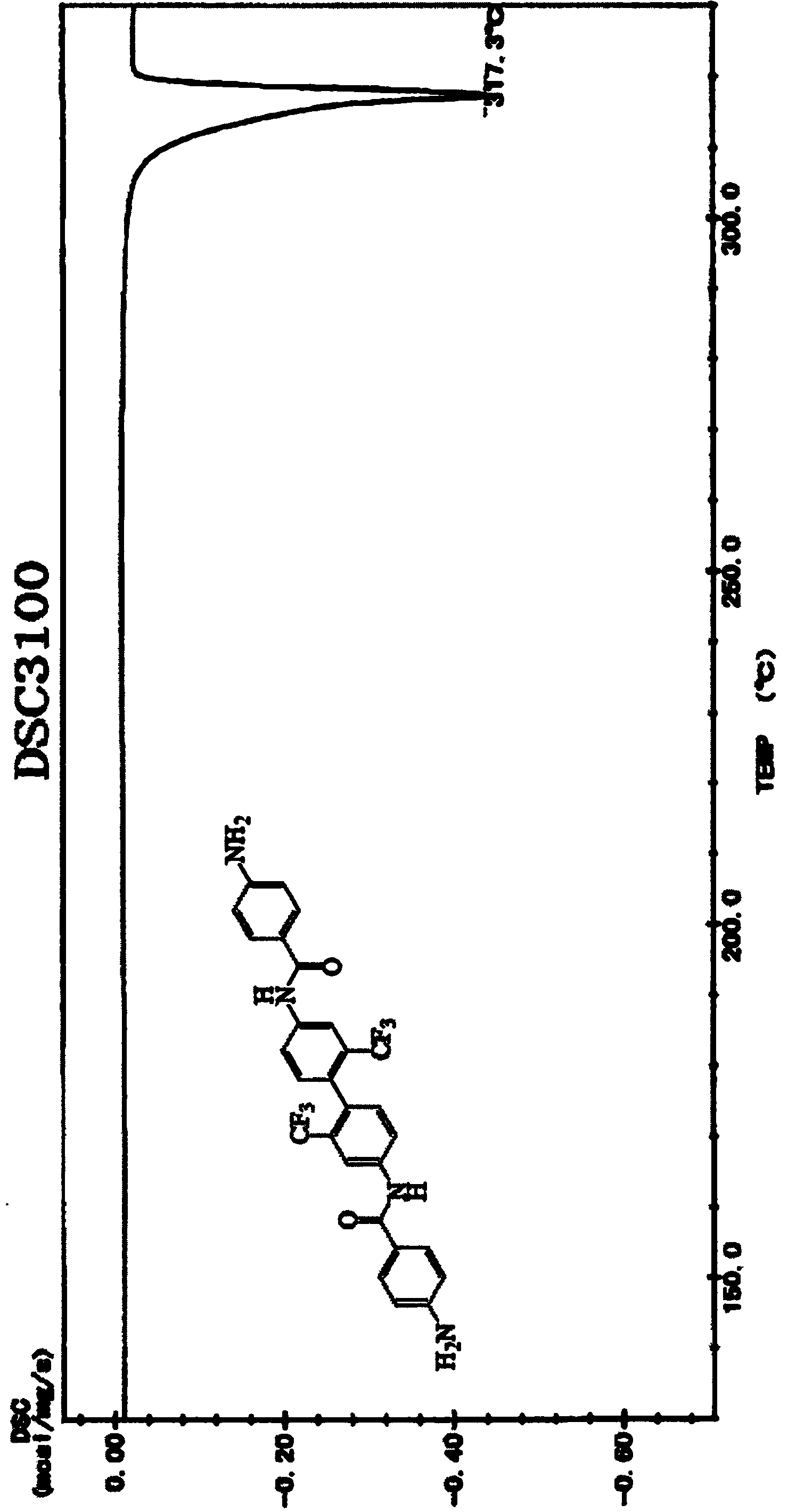

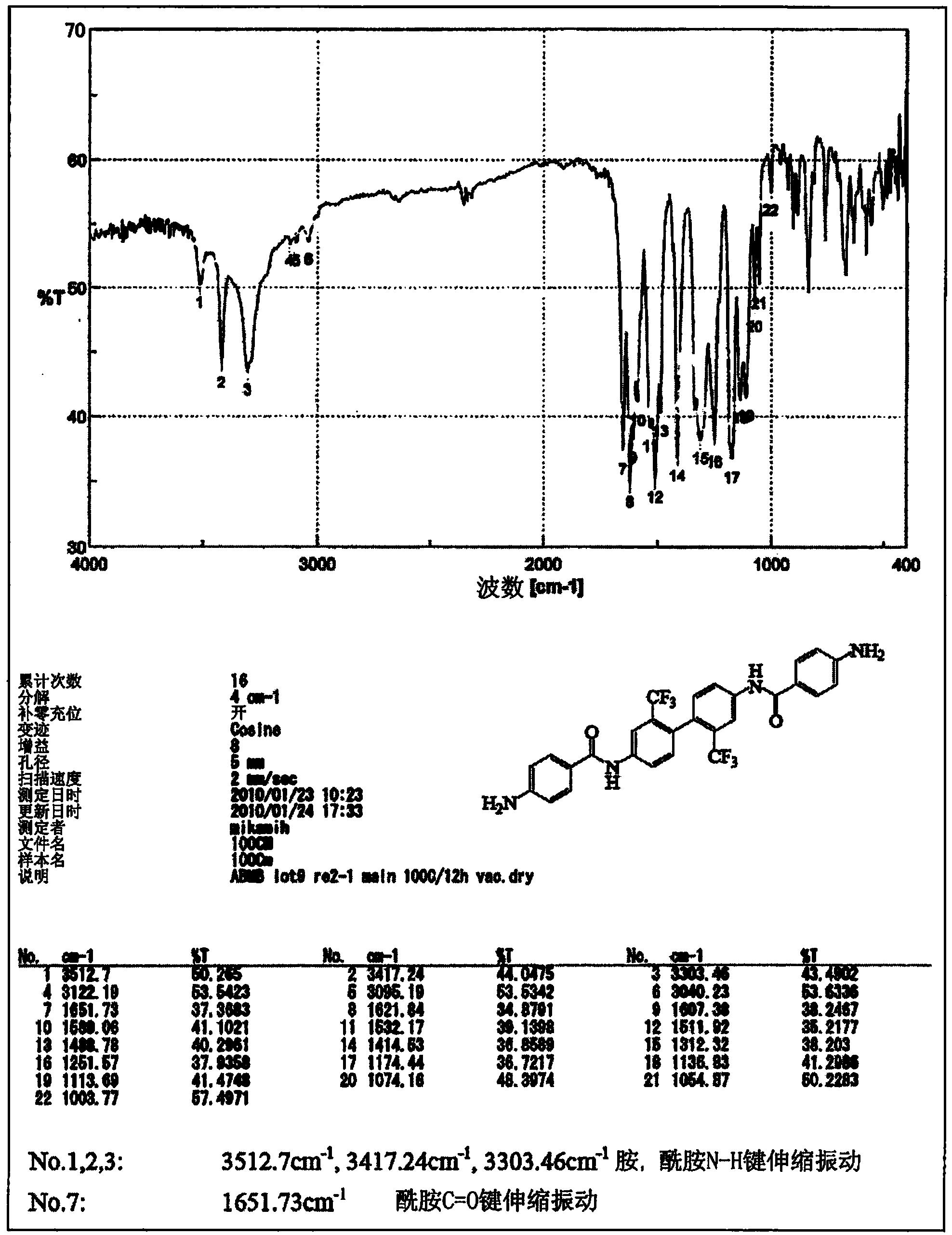

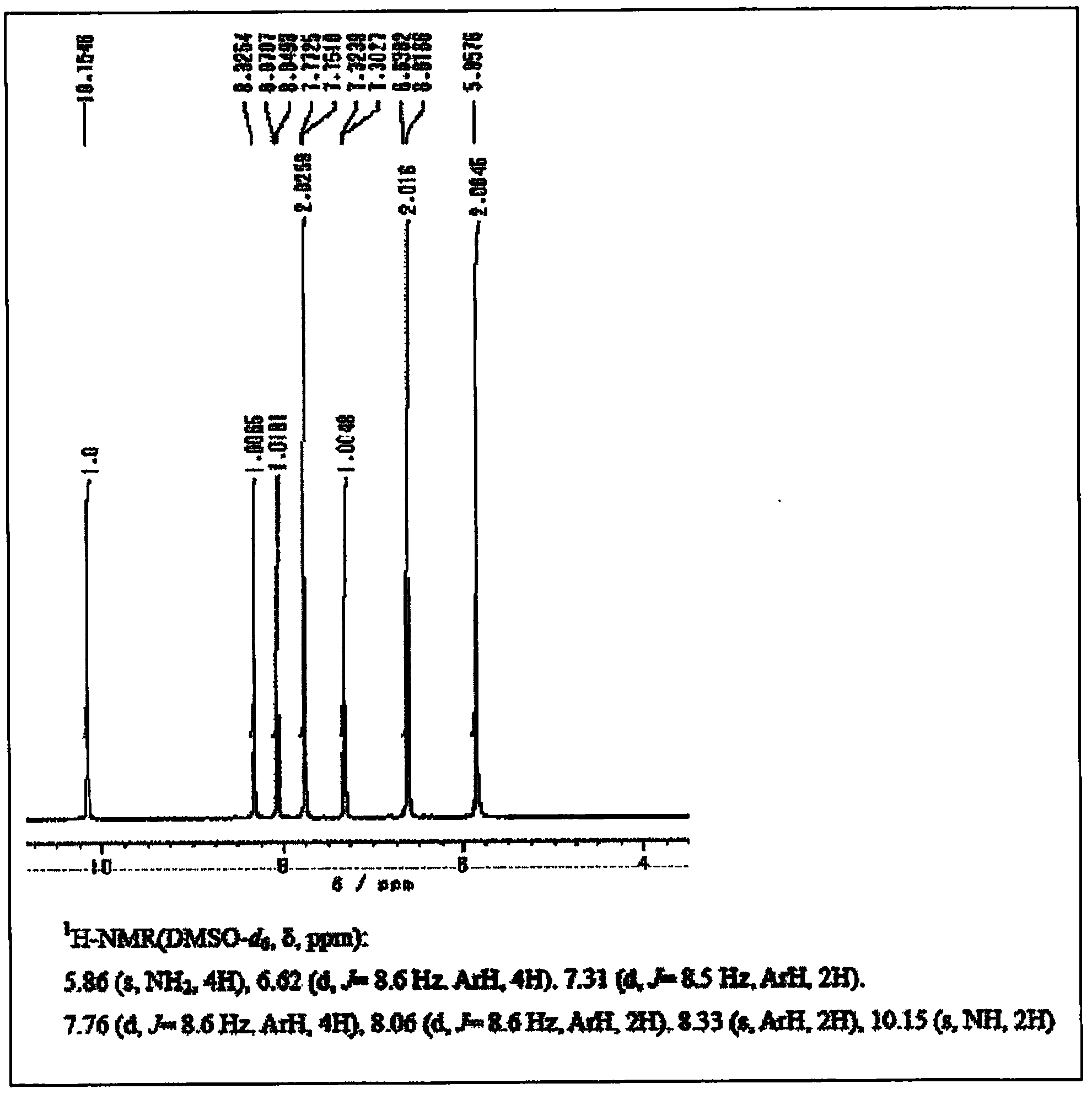

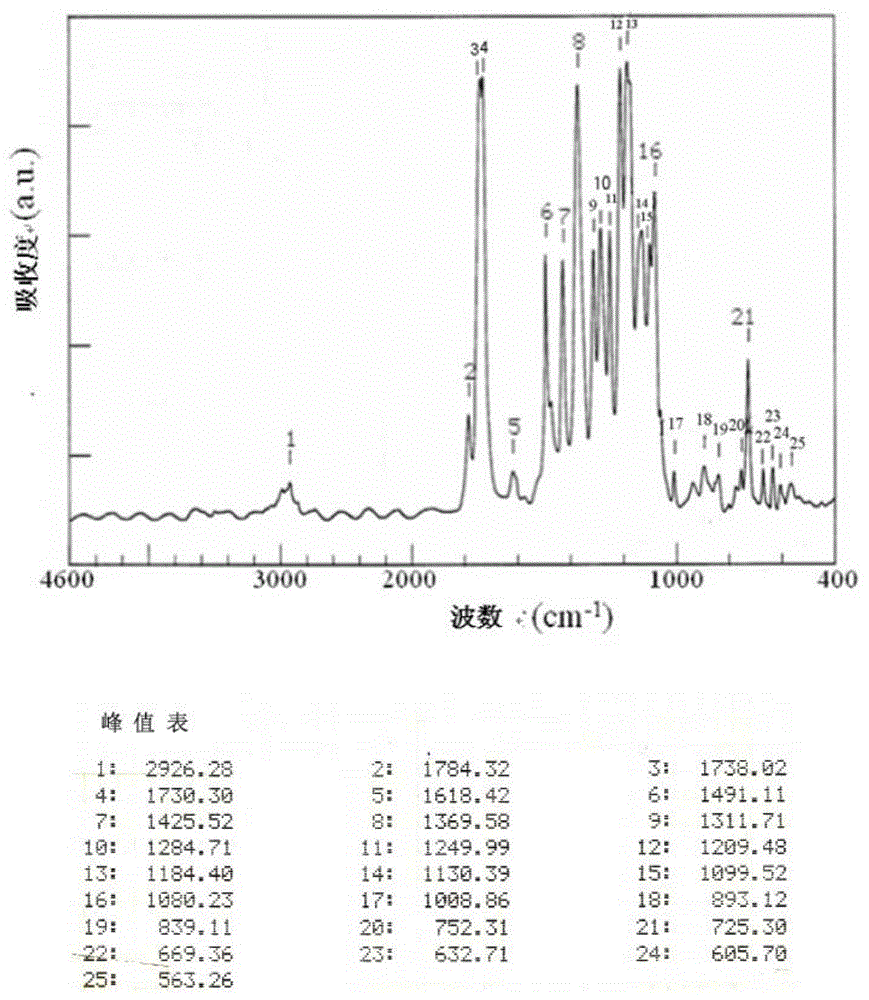

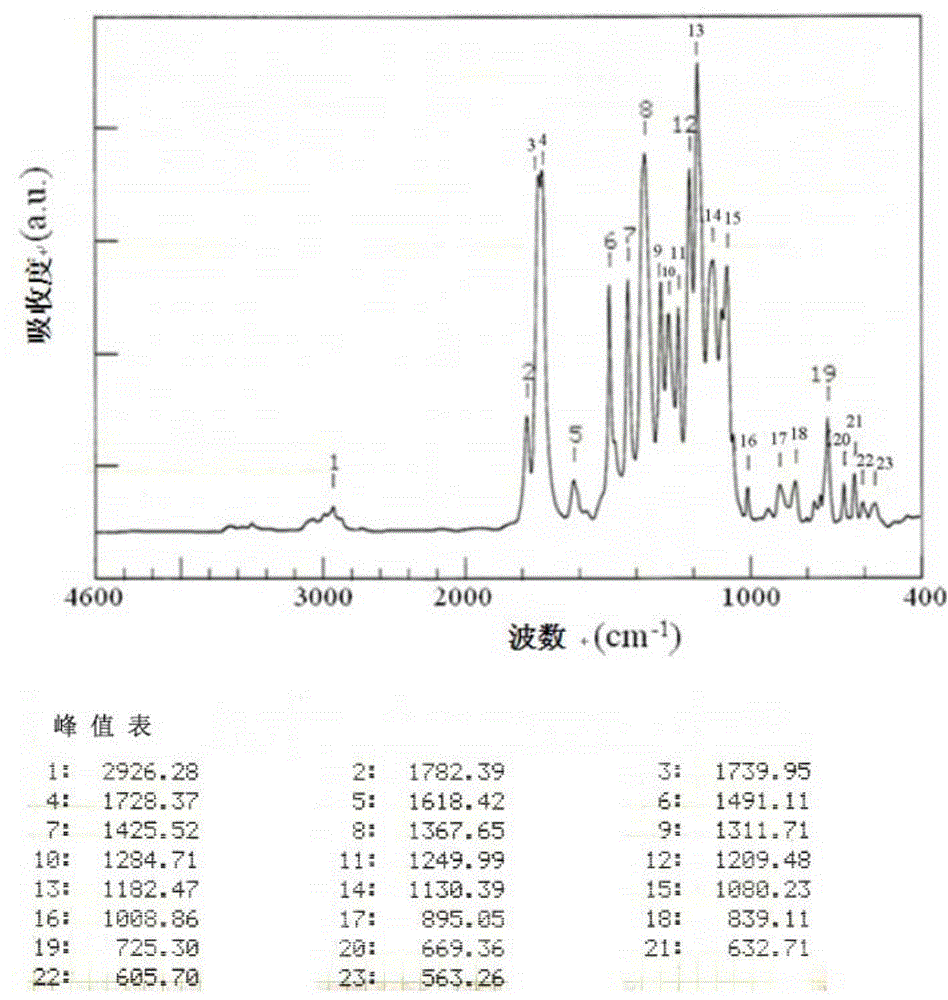

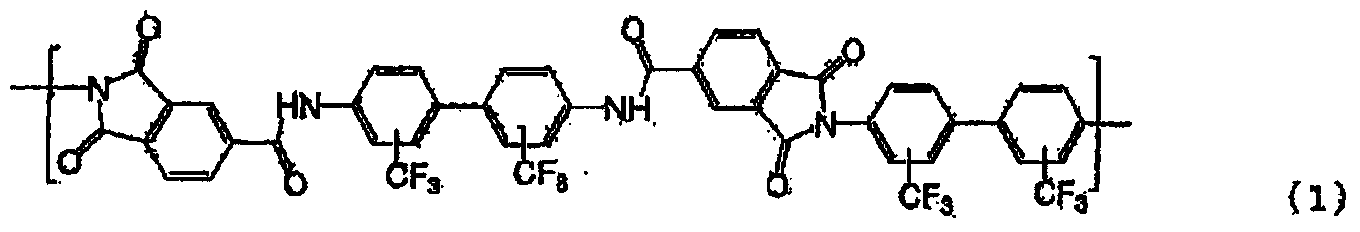

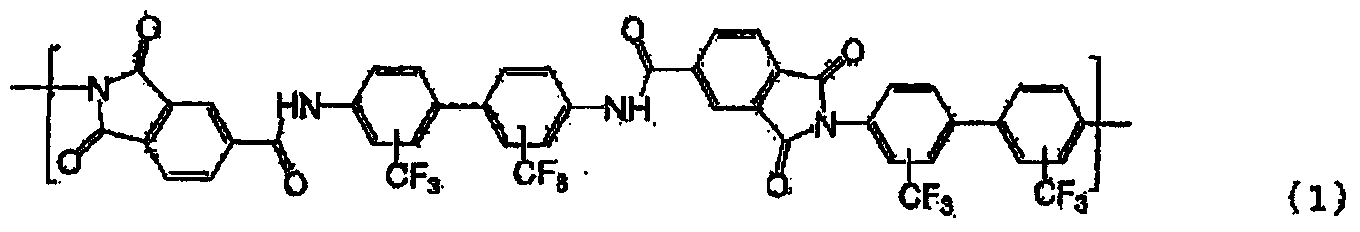

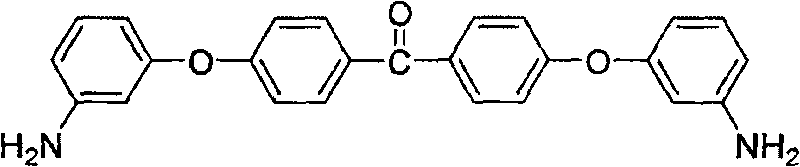

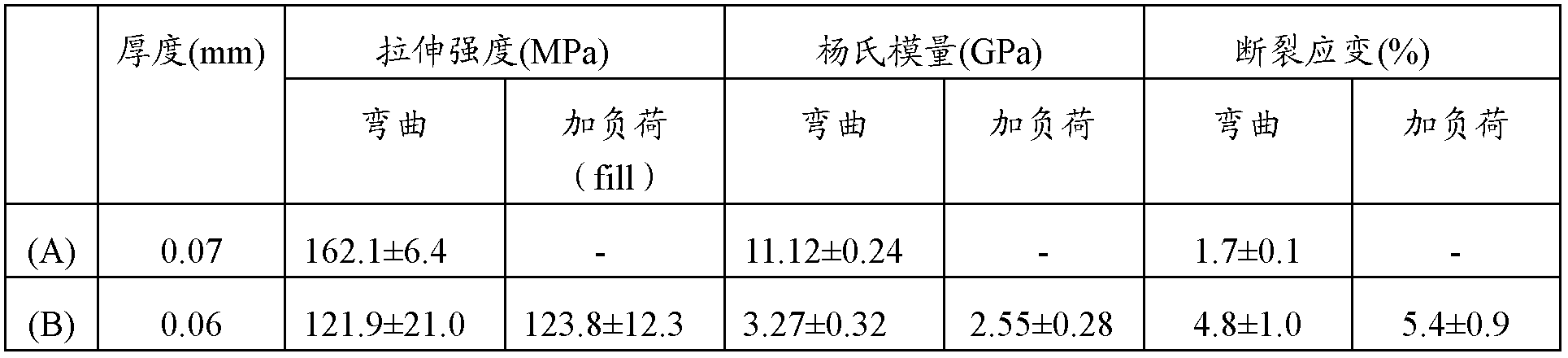

Diamine, polyimide, and polyimide film and utilization thereof

ActiveCN104114532AEasy to processImprove heat resistanceOrganic chemistryElectroluminescent light sourcesHeat resistanceThermal expansion

Provided are a polyimide and polyimide film having excellent solution processability, transparency, high heat resistance, and a low thermal expansion coefficient. The invention makes it possible to produce a polyimide having excellent solution processability, transparency, high heat resistance, and a low thermal expansion coefficient by using a novel diamine characterized in having an amide group and a trifluoromethyl group. This polyimide can be utilized in electronic display equipment and various other electronic devices.

Owner:KANEKA CORP +1

Polyimide and molded body thereof

ActiveCN104640907AImprove heat resistanceHigh glass transition temperatureCoatingsSolubilityHydrogen atom

The present invention addresses the problem of providing: a polyimide which has excellent transparency, high heat resistance and low linear thermal expansion coefficient at the same time, while exhibiting solvent workability (excellent solubility and film formation performance) by means of a low moisture-absorbing solvent; and a method for producing this polyimide. In order to solve the above-mentioned problem, the present invention provides a polyimide that contains a constituent unit represented by formula (1). (In the formula, each R independently represents a hydrogen atom or an alkyl group having 1-6 carbon atoms, provided that at least one of two R groups bonded to a same benzene ring is an alkyl group.)

Owner:HONSHU CHEM INDAL +1

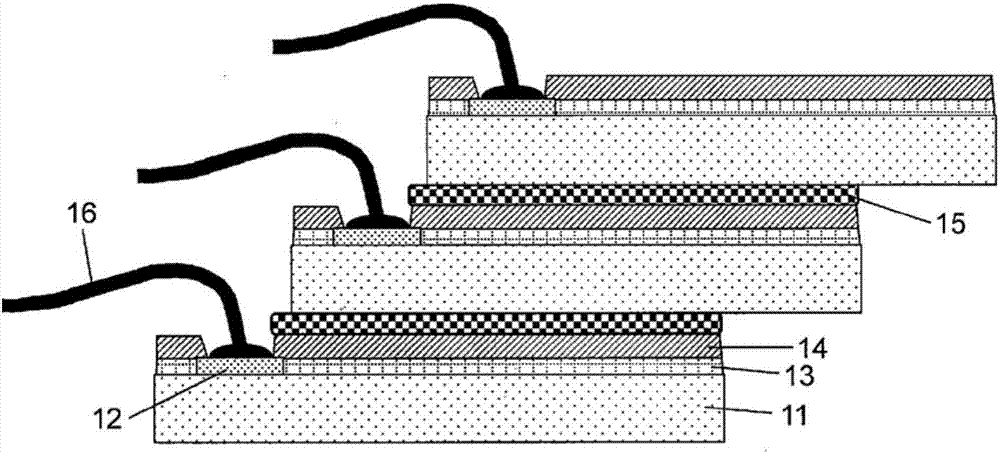

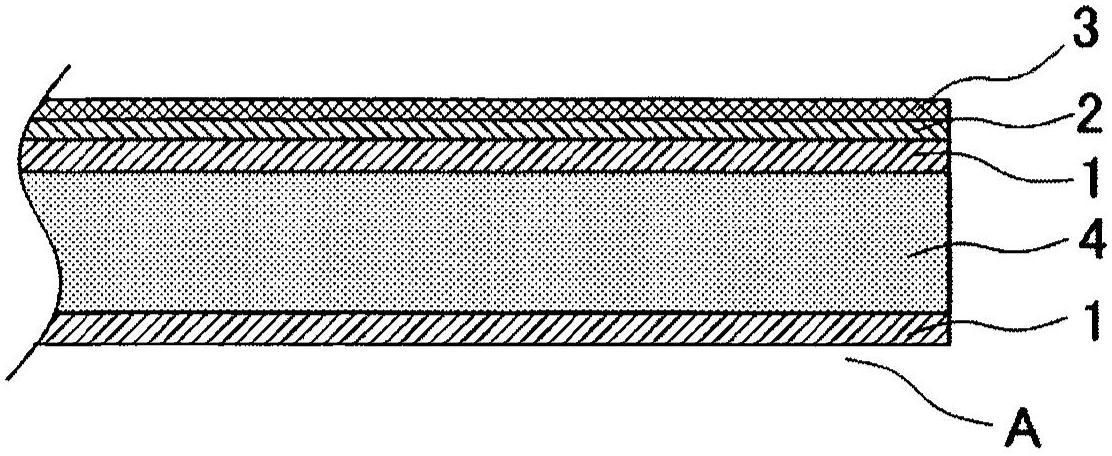

Layered structure and light-sensitive dry film used in same

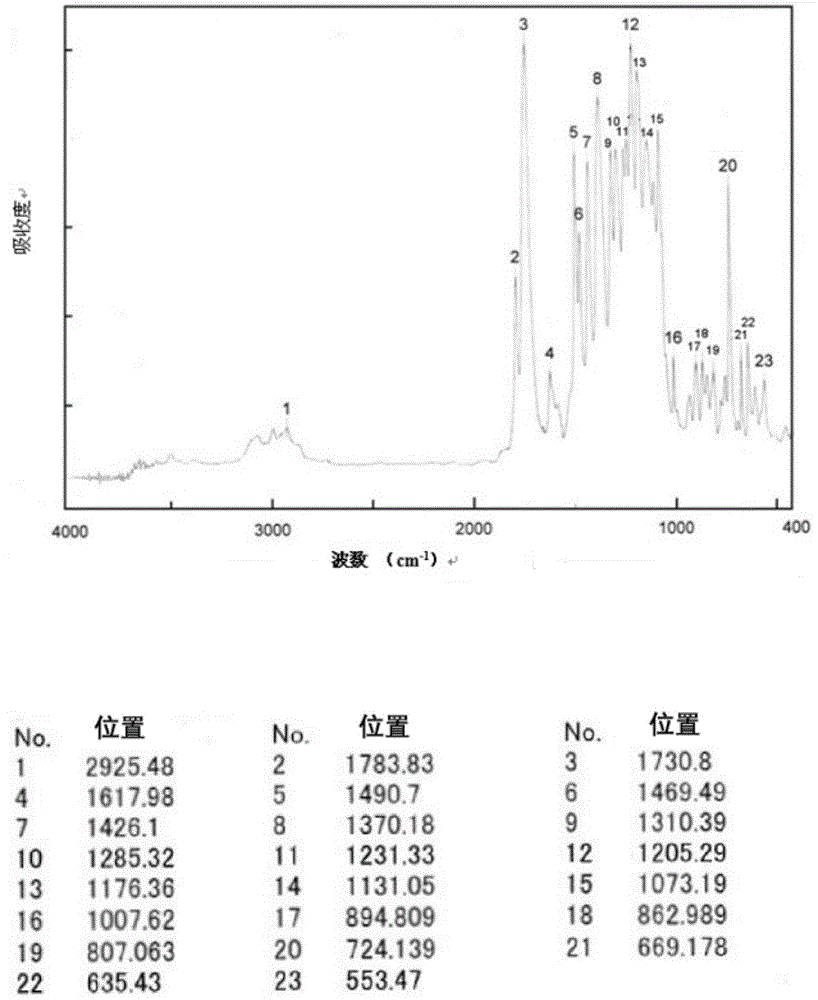

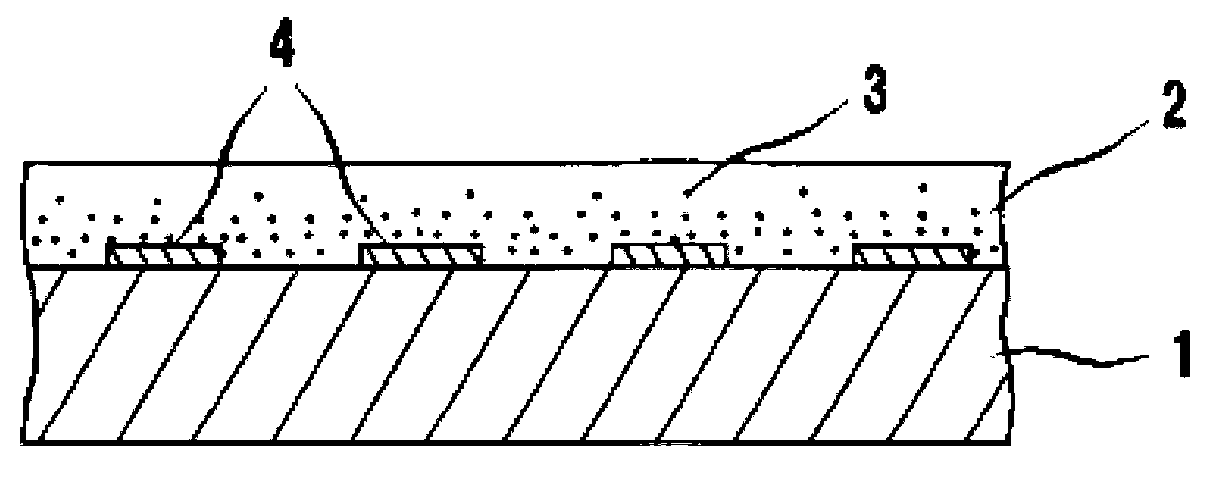

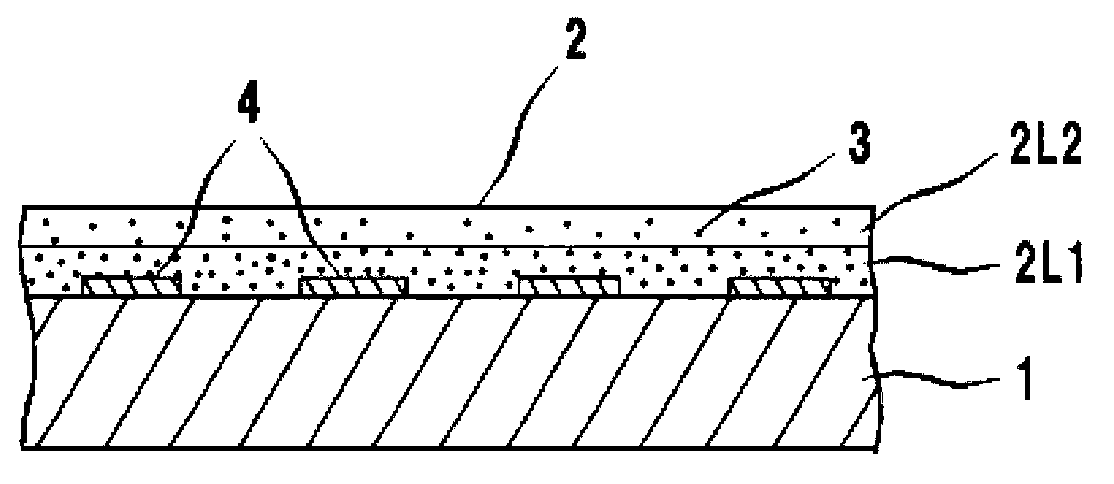

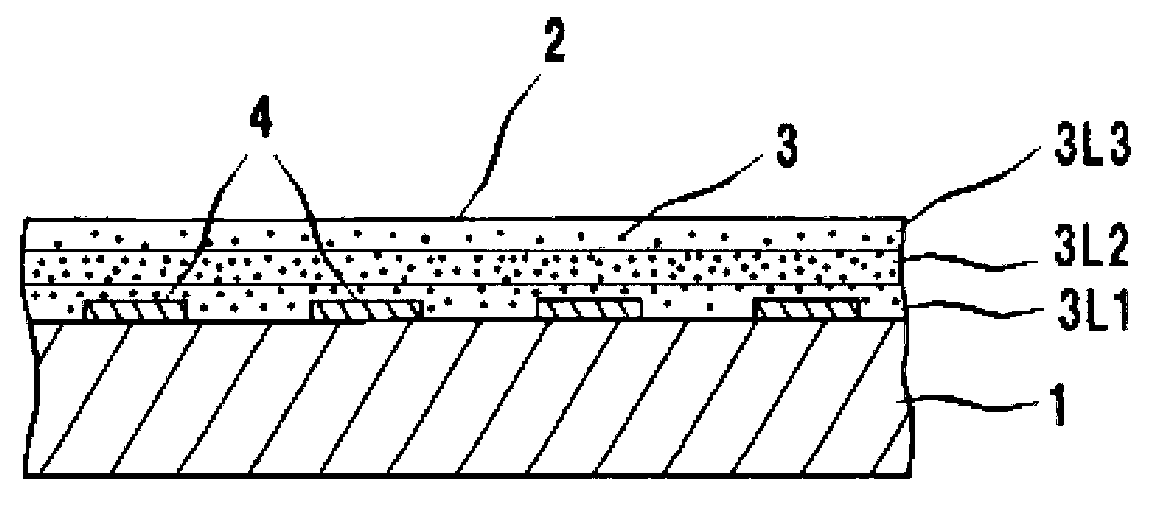

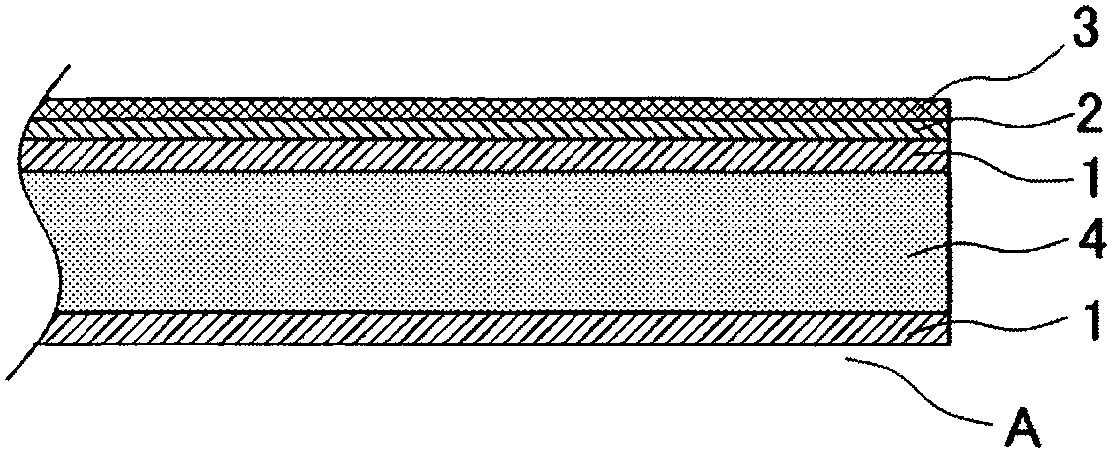

ActiveCN102763036AImprove reliabilityLow coefficient of linear thermal expansionPrinted circuit aspectsSemiconductor/solid-state device manufacturingResistInsulation layer

Provided is a layered structure that has, at least, a substrate (1) and a light-sensitive resin layer or cured coating layer (2), containing an inorganic filler (3), formed on top of the substrate. In the light-sensitive resin layer or cured coating layer, the proportion of the inorganic filler is lower in a surface region opposite the substrate than in other regions, making it possible to keep the coefficient of linear thermal expansion of the entire light-sensitive resin layer or cured coating layer as low as possible while also avoiding losses in resolution and achieving excellent adhesion to an underfill resin section or a molded resin section. Preferably, the light-sensitive resin layer or cured coating layer comprises at least two layers having different inorganic filler proportions, and the surface-side light-sensitive resin layer or cured coating layer opposite the substrate has a lower inorganic filler proportion than the other layer(s). A light-sensitive dry film containing the abovementioned light-sensitive resin layer is suitable for use as an interlayer resin insulation layer or a solder resist in a printed circuit board.

Owner:TAIYO HLDG CO LTD

Halogen-free flame-retardant PBT/PC alloy composition and method of preparing the same

InactiveCN101328305AHigh decomposition temperatureInhibition of transesterificationEpoxyProcedure Agents

The invention discloses a halogen-free fire-retardant PTB / PC alloy composition and a preparation method thereof. The formula of the composition comprises the following components in mass percentage: 40 to 50 percent of PBT, 10 to 20 percent of PC, 23 to 33 percent of active magnesium hydrate, 3 to 7 percent of organic phosphate oligomer, 3 to 7 percent of polysiloxane / acrylic ester grafting copolymer, 3 to 7 percent of novolac epoxy, 0.2 to 0.4 percent of antioxidant and 0.4 to 0.8 percent of processing aid. In the formula of the method, all components are dispersed to be mixed and are subject to melting by a double screw extruder, mixing, extrusion, cooling, drying, granulating and packaging. In the invention, the fire-retardant char-forming actions of all added components are combined with the interaction of interfaces of a substrate, which makes the components of the system form an indispensable organic whole, so that the higher fire retardant performance is achieved under the lower consumption of the magnesium hydrate, and the mechanical property, the thermal property and the processability of the system are also good.

Owner:SOUTH CHINA UNIV OF TECH

Curable Resin Composition

ActiveCN104098871AHigh strengthArithmetic mean roughness is lowPrinted circuit detailsNon-metallic protective coating applicationEpoxyAnthracene

The object of the present invention is to provide a curable resin composition which is excellent in cracking elongation rate, is low in arithmetic average roughness of an insulating layer surface in a wet roughing process, is also low in root mean square roughness, can form a plated and inlaid conductor layer having enough peel strength, and is also low in coefficient of linear thermal expansion. The curable resin composition provided by the present invention comprises a phenoxy resin (A) having an anthracene structure, an epoxy resin (B) and a curing agent (C),and is characterized in that the total quantity of the phenoxy resin (A), the epoxy resin (B) and the curing agent (C) is set as 100% by mass, the above phenoxy resin (A) is 1-15% by mass, and the epoxide equivalent of the above phenoxy resin (A) is more than 5000.

Owner:AJINOMOTO CO INC

Polyamide-imide solution and polyamide-imide film

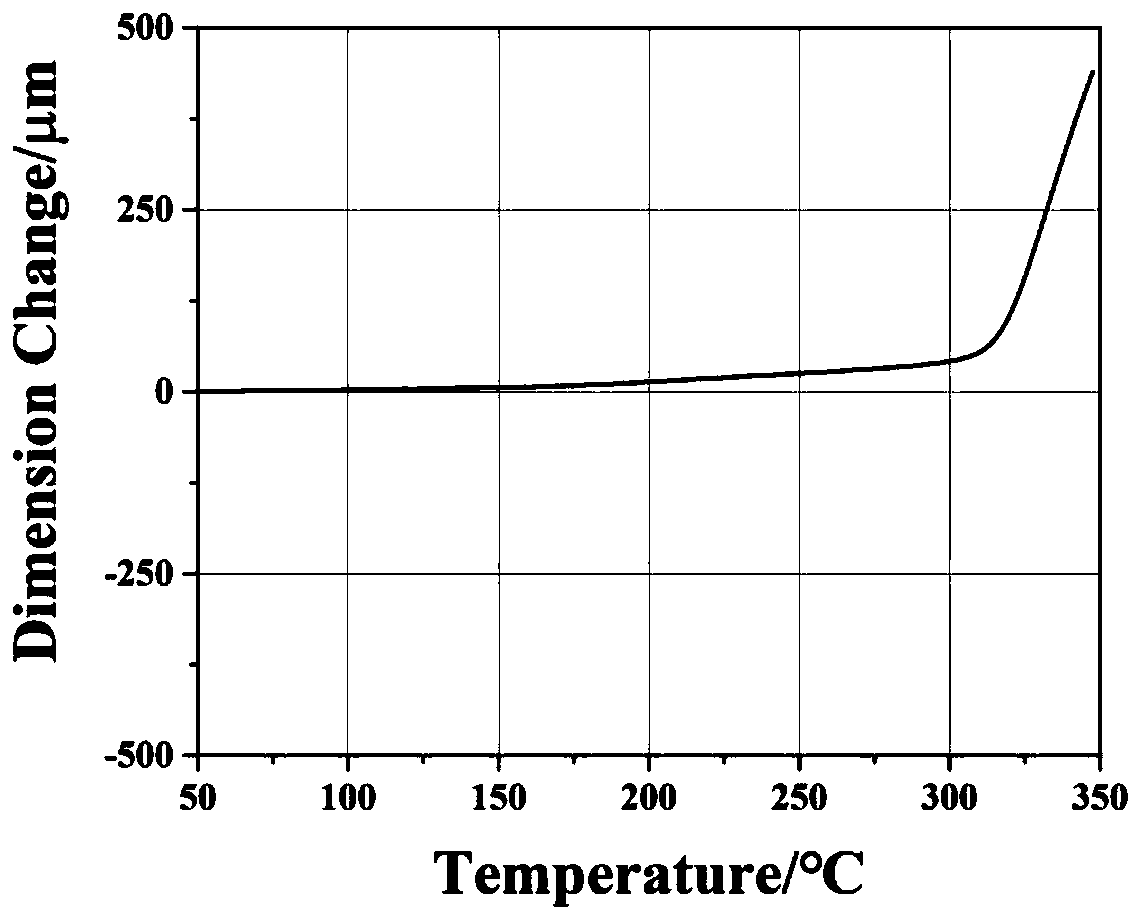

ActiveCN103502314AGood spreadabilityLow coefficient of linear thermal expansionTransistorOptical filtersKetone solventsThermal expansion

A purpose of the present invention is to obtain a polyamide-imide solution which has excellently low linear thermal expansion coefficient and excellent coatability. Another purpose of the present invention is to provide a product or member, which requires high heat resistance and very low linear thermal expansion coefficient, using the polyamide-imide solution. Another purpose of the present invention is to provide a product or member which is specifically suitable for uses wherein a polyamide-imide film that is obtained from the polyamide-imide solution of the present invention is formed on the surface of an inorganic material such as glass, a metal, a metal oxide or a single crystal silicon. The purposes are achieved by a polyamide-imide solution which contains a specific polyamide-imide and an organic solvent and which is characterized in that the organic solvent is a mixed solvent of an amide solvent and a solvent other than an amide solvent and that the solvent other than an amide solvent is composed of at least one solvent that is selected from the group consisting of ether solvents, ketone solvents, ester solvents, glycol ether solvents and glycol ester solvents.

Owner:KANEKA CORP

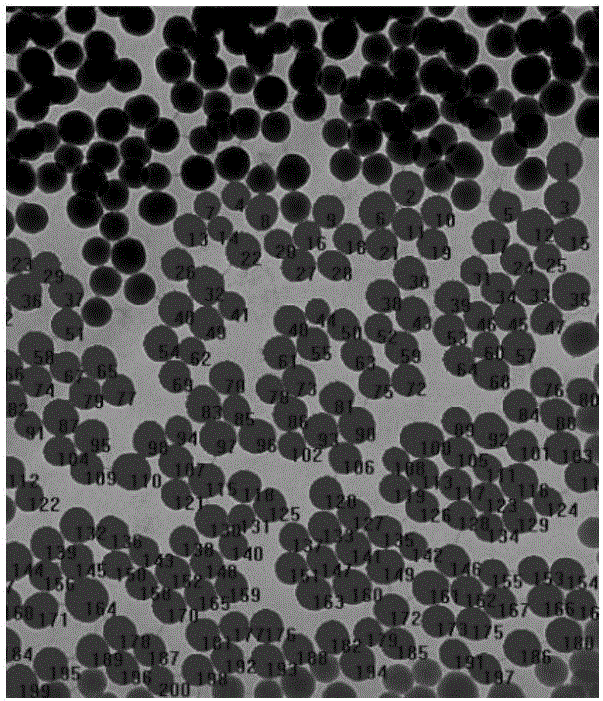

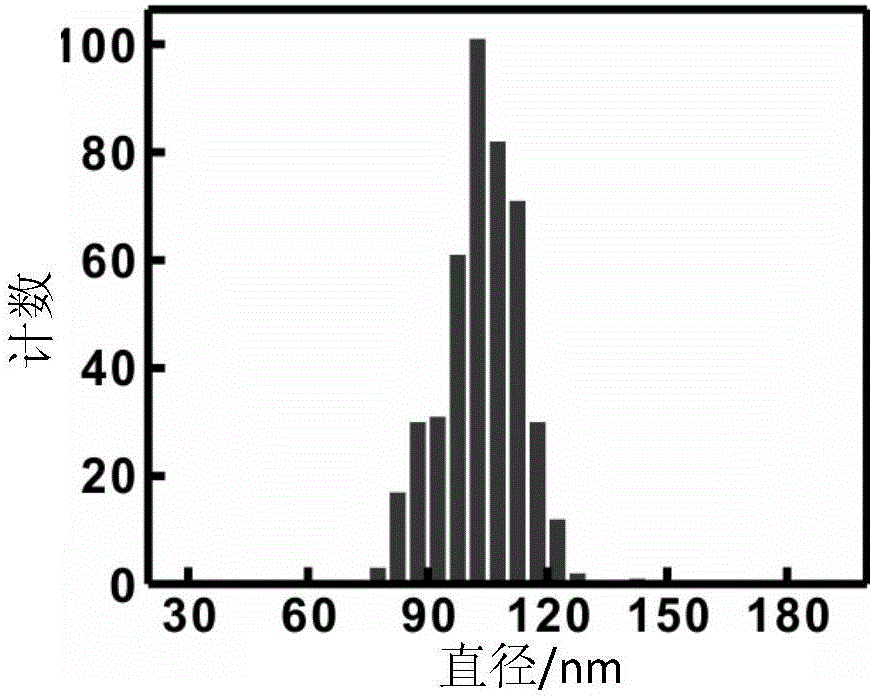

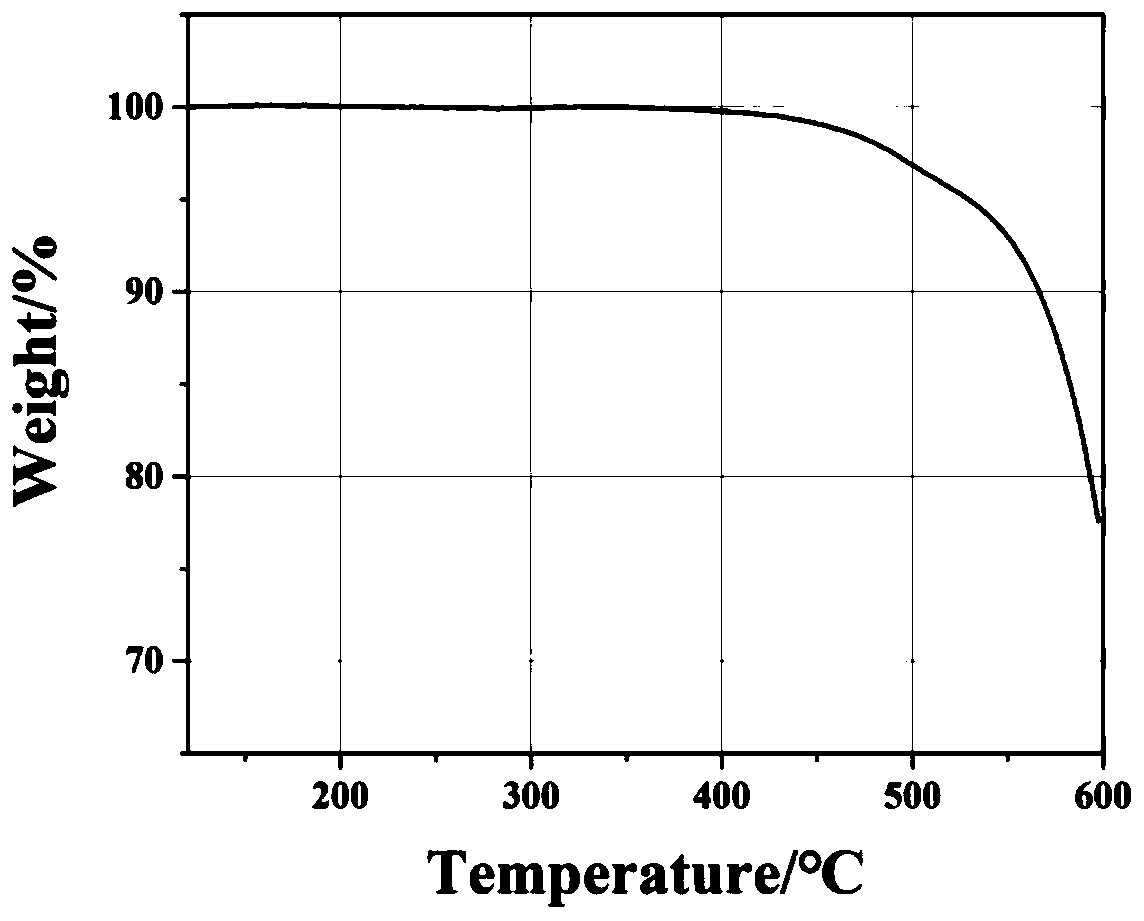

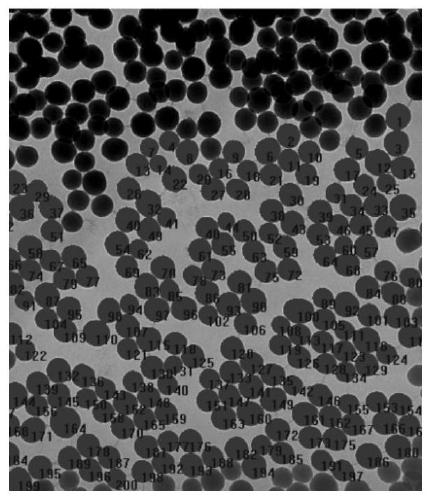

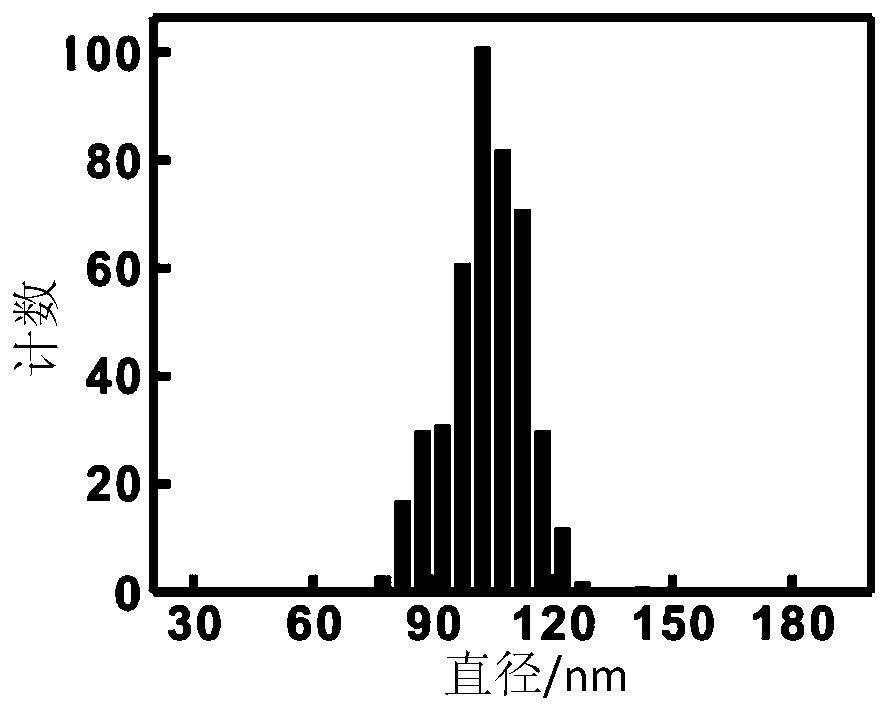

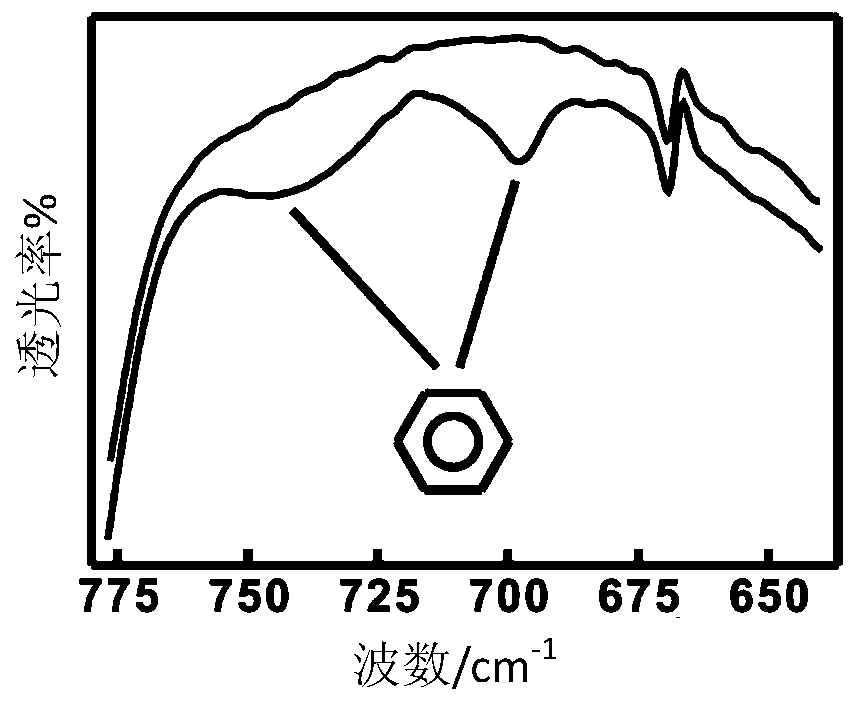

Preparation method for low-dielectric-constant ordered porous polyimide thin film

ActiveCN106750435ALow dielectric constantLow coefficient of linear thermal expansionSilicaMicrosphereThermal expansion

The invention discloses a preparation method for a low-dielectric-constant ordered porous polyimide thin film. The method comprises the steps that amino-modified silicon dioxide microspheres are prepared, then, polyimide is grafted onto the surfaces of the amino-modified silicon dioxide microspheres in the form of chemical bonds, a polyimide compound thin film is prepared, silicon dioxide is etched away in a hydrofluoric acid etchant, washing and drying are conducted, and then the low-dielectric-constant ordered porous polyimide thin film is obtained. According to the method, air holes which have the hole diameters ranging from 30 nm to 200 n, are uniform in size distribution and are uniformly distributed in the thin film are introduced into the polyimide thin film, the dielectric constant of the polyimide thin film is lowered, and meanwhile due to the fact that the hole diameters are small, and distribution of the air holes inside the thin film is uniform, the polyimide thin film keeps the high mechanical property and breakdown voltage. The preparation method has the advantages of being low in dielectric constant, high in breakdown voltage, good in mechanical property and capable of lowering the thermal expansion coefficient, and has potential application value and good application prospects in a high-frequency, high-speed and high-density integrated circuit.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Low-dielectric-constant polyimide composite resin as well as preparation method and application thereof

ActiveCN109942815ALow dielectric constantImprove flexibilityPhotosensitive materials for photomechanical apparatusCircuit susbtrate materialsResin-Based CompositeThermal expansion

The invention discloses low-dielectric-constant polyimide composite resin as well as a preparation method and application thereof. The polyimide composite resin is prepared from a polyimide resin unitand a polymethylenimine resin unit through blending and copolymerization. A net-shaped structure is formed in a copolymer structure, so that the gaps among macromolecular chains are increased. By introducing the polymethylenimine resin, the dipole moment of a polyimide molecular chain is decreased; meanwhile, fluorine-containing monomers are adopted during the polymerization, so that the dielectric constant of the polyimide composite resin is commonly decreased. By designing a flexible polyimide molecular chain through the type of monomers, a high-rigid polymethylenimine molecular chain is balanced, and the rigidity-flexibility of a molecular chain section in the final polyimide composite resin reaches a relatively good balance point, so that the polyimide composite resin has relatively good mechanical property, controllable linear thermal expansion coefficient and good application prospects in the products of flexible copper-clad plates, light-sensitive covering films and circuit board products.

Owner:HANGZHOU FIRST ELECTRONIC MATERIAL CO LTD

Preparation method of non-curling high-adhesiveness glue-free flexible copper-clad plate

InactiveCN101695222AGood adhesionHigh peel strengthInsulating substrate metal adhesion improvementPretreated surfacesPolymer scienceHeat resistance

The invention discloses a direct coating method for preparing a non-curling high-adhesiveness glue-free flexible copper-clad plate. The method comprises the following steps: firstly, dissolving an aromatic diamine monomer containing a benzoxazole structure, an aromatic diamine monomer containing a keto ether structure, an aromatic diamine monomer containing a full-ether link structure and an aromatic dianhydride monomer in an aprotic polar solvent to prepare a polyamic acid glue solution by a polymerization; then, coating the polyamic acid glue solution on a copper foil with the thickness of 6-35 microns; baking at 50-150 DEG C for 5-180 minutes; then, arranging in a vacuum oven or a high-temperature drying tunnel in nitrogen atmosphere for phasic thermocuring respectively at 80 DEG C, 120 DEG C, 180 DEG C, 220-280 DEG C and 320-380 DEG C, wherein each thermocuring phase keeps 10-90 minutes. The glue-free flexible copper-clad plate prepared by the method not only has high adhesiveness, no curling and high peeling strength, but also has excellent chemical performance, heat resistance, favorable bending resistance and lower water-absorbing rate. The method has once coating molding, simple preparation process and lower production cost.

Owner:SICHUAN UNIV

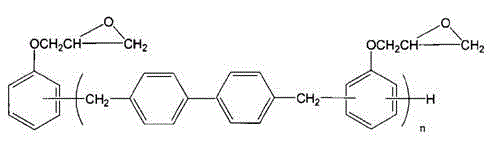

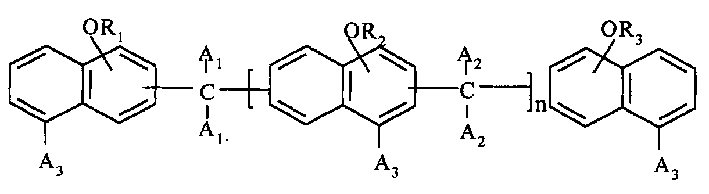

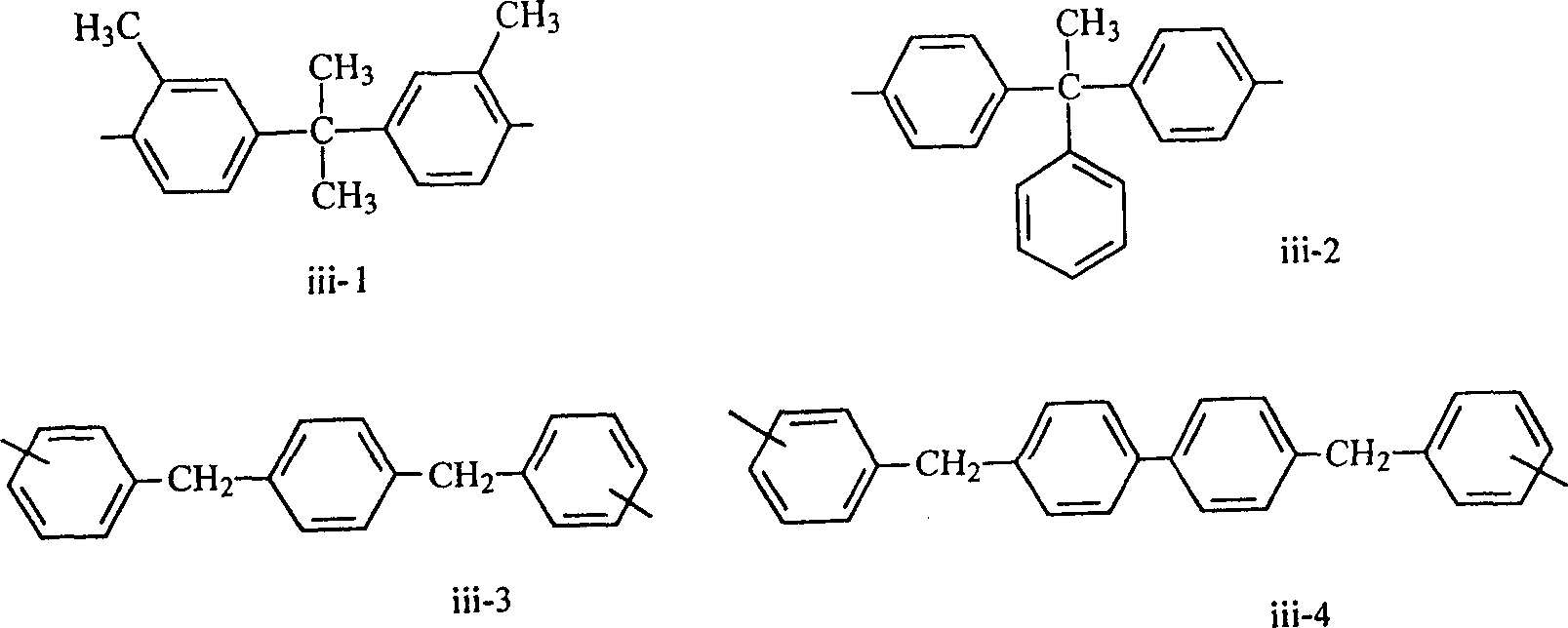

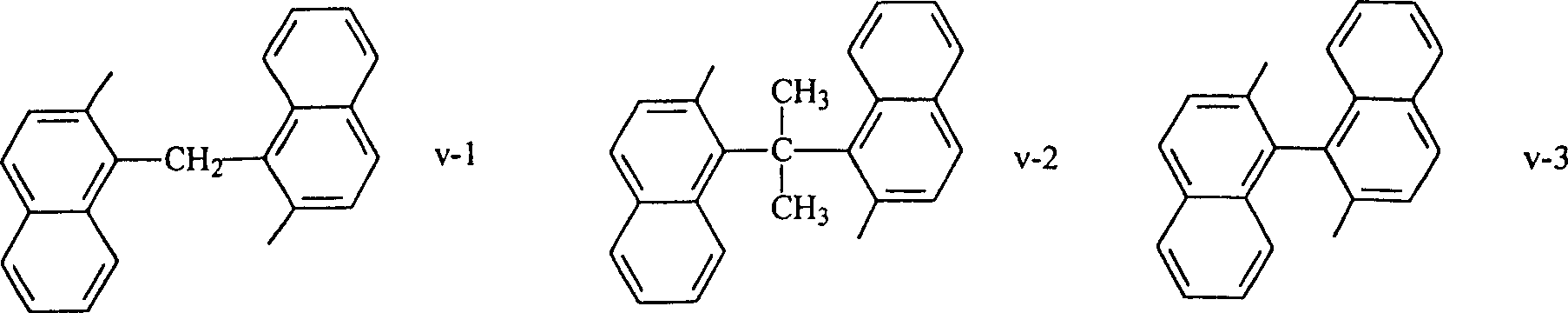

Polyfunctional epoxy resin and its preparation method

A kind of multifunctinoal epoxy resin and its preparation method is involved in this invention. In the formula, A3 is selected from hydrogen atom, cymene, methoxy, bromine atom, R1, R2, R3 are shrink glycerin aethers, the value of n lies between 0 and 8. The preparation process of the method includes: firstly, hydroxy naphthalene compound and bifunctional aldehyde or ketone shrink in the presence of proton acid activator, and multihydroxy naphthalene compound is gained, and then it makes aether reaction with PAE in the action of alkali activator. The epoxy resin has good capability such as high heat-resistance, low moisture absorption and low expandability etc., and fits madding glass cloth or epoxy resin pressing board covering copper and foil, and encapsulation of semiconductor component and IC, so it has capacious application foreground in the electronic industry.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

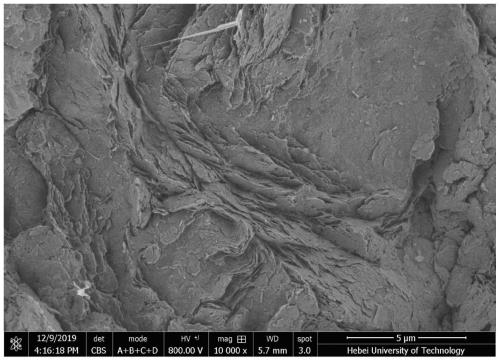

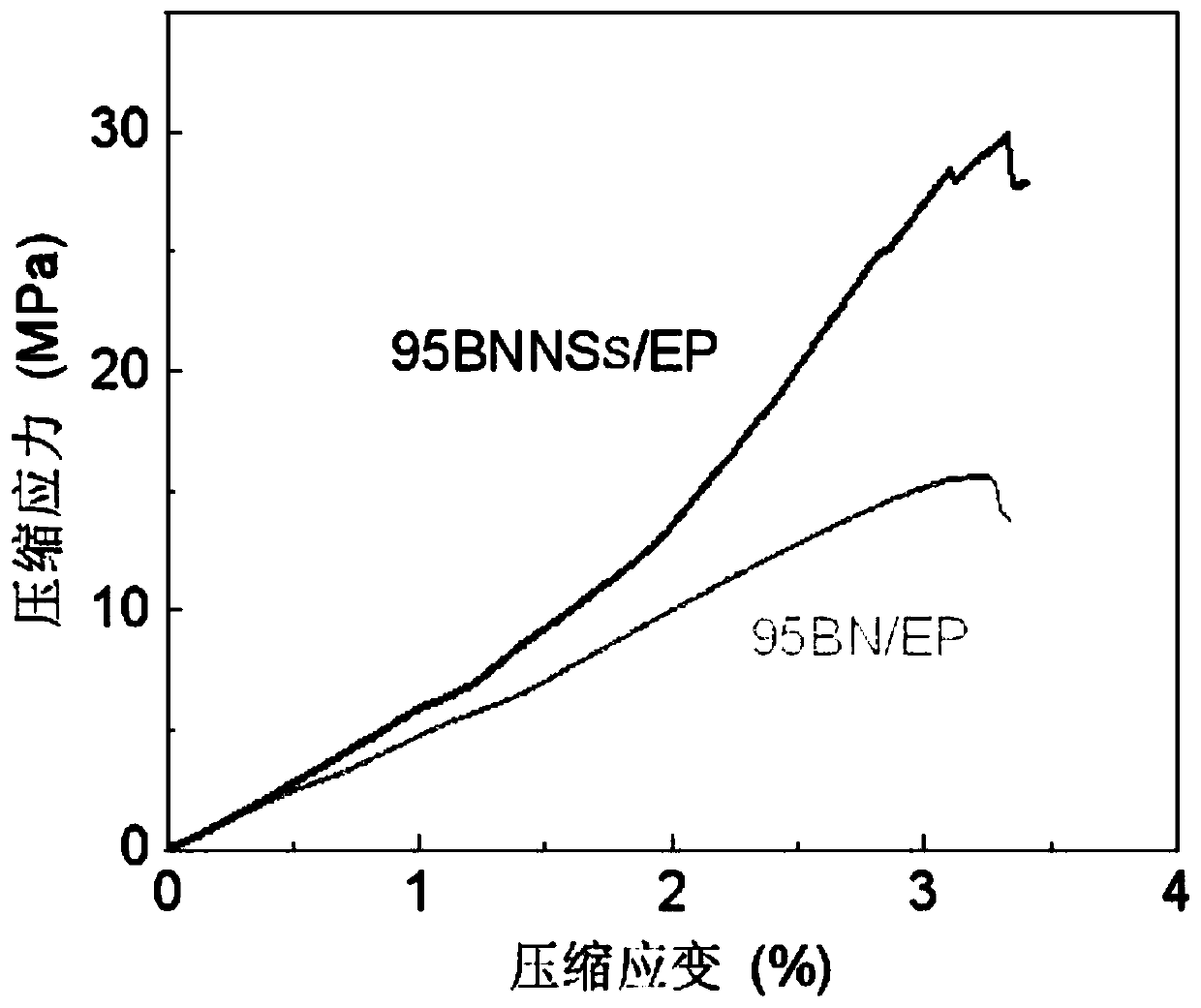

Preparation method of hexagonal boron nitride/polymer blocky composite material with high filling amount

ActiveCN111423699AStrong dense connection structureHigh compressive strengthCompression moldingPolymer science

The invention relates to a preparation method of a hexagonal boron nitride / polymer blocky composite material with high filling amount, wherein the method comprises the steps: step 1, adding hexagonalboron nitride and a polymer matrix into a mortar, grinding uniformly, and mixing to obtain a hexagonal boron nitride-polymer matrix mixture, wherein the polymer matrix is in a liquid state at normal temperature and normal pressure, and can be cured under the condition of changing temperature and / or pressure; step 2, putting the mixture obtained in the step 1 into a ball milling tank, and carryingout uniform ball milling to obtain a mixture obtained by further mixing and uniformly carrying out a reaction on hexagonal boron nitride and the polymer matrix; step 3, putting the mixture obtained inthe step 2 into a mold, and carrying out compression molding to obtain a blocky molded prototype of the polymer composite material; and step 4, polymerizing and curing the blocky forming prototype ofthe polymer composite material obtained in the step 3 to obtain the blocky material of the hexagonal boron nitride / polymer composite material with high filling amount. The composite material has ultrahigh mechanical properties and huge thermal management application potential.

Owner:HEBEI UNIV OF TECH

Epoxy resin composition

InactiveCN1521210AImprove heat resistanceLow dielectric dissipation factorCircuit susbtrate materialsLow dissipationEpoxy

An epoxy resin cured article has a high glass transition temperature and low dissipation factor. An epoxy resin composition from which the cured article can be having excellent solubility in solvents is used to produce the cured articles. A polyester as a curing agent of an epoxy resin composition having an aromatic polyhydroxy coumpound residue including an aryloxycarbonyl group at the molecule of the terminal, an aromatic polyvalent hydrocarbon group residue, and bulky structure, is used. Since the curing agent behaves as a polyfunctional curing agent, a cured article produced therefrom has a high crosslink density. Since highly polar hydroxyl groups are not formed during curing, a cured article has high glass transition temperature and a low dissipation factor. The cured article does not release low molecular weight carboxylic acids though hydrolysis of ester bonds at crosslinked bonds. Since the polyester has a bulky structure, the crystallization of the molecular chain is prevented and the solubility of the epoxy resin composition containing the polyester is excellent.

Owner:DAINIPPON INK & CHEM INC

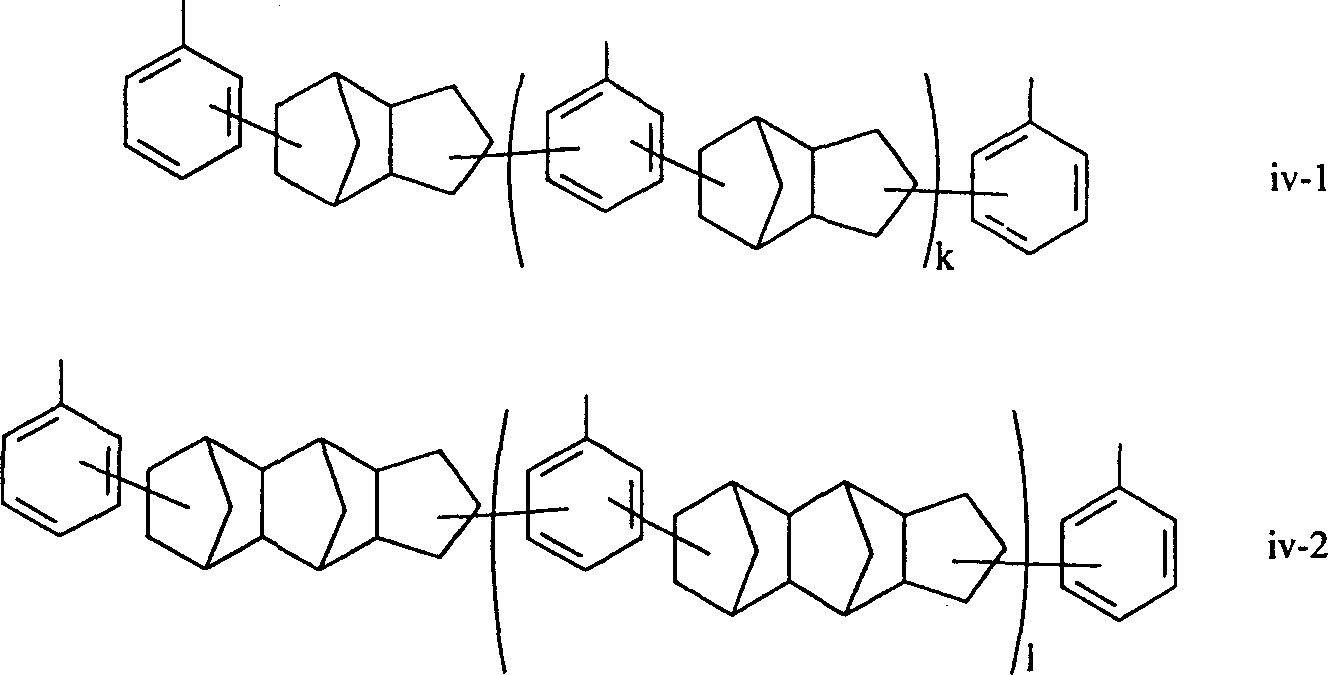

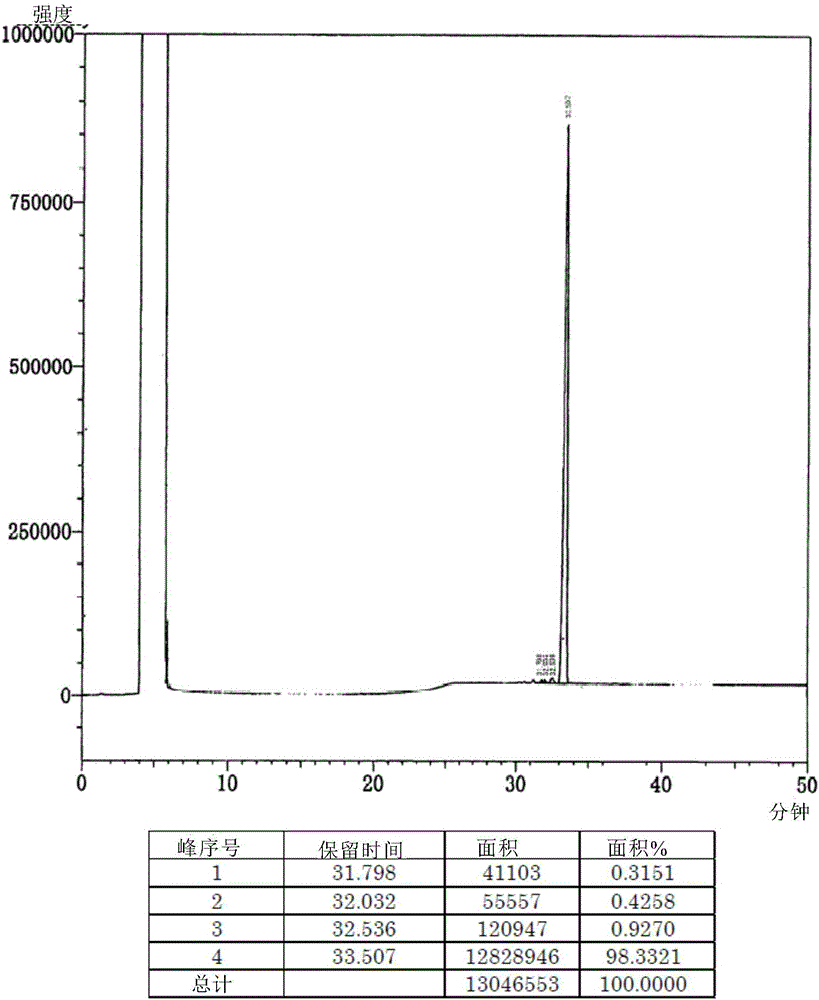

Polyimide precursor, polyimide, polyimide film, varnish, and substrate

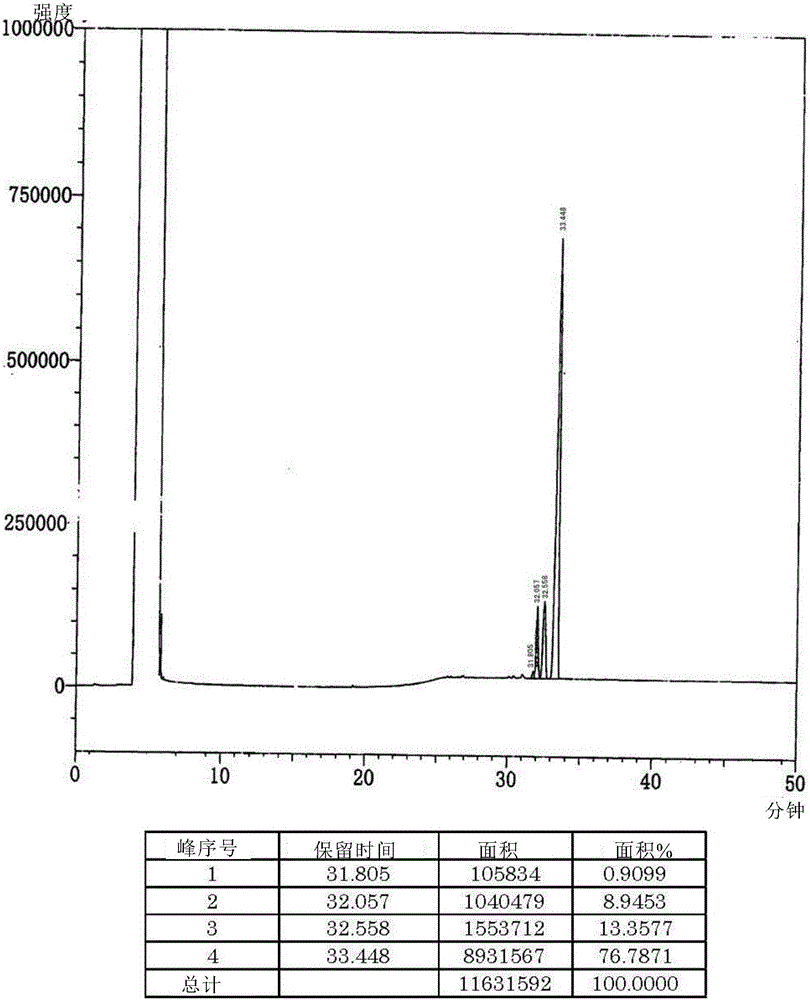

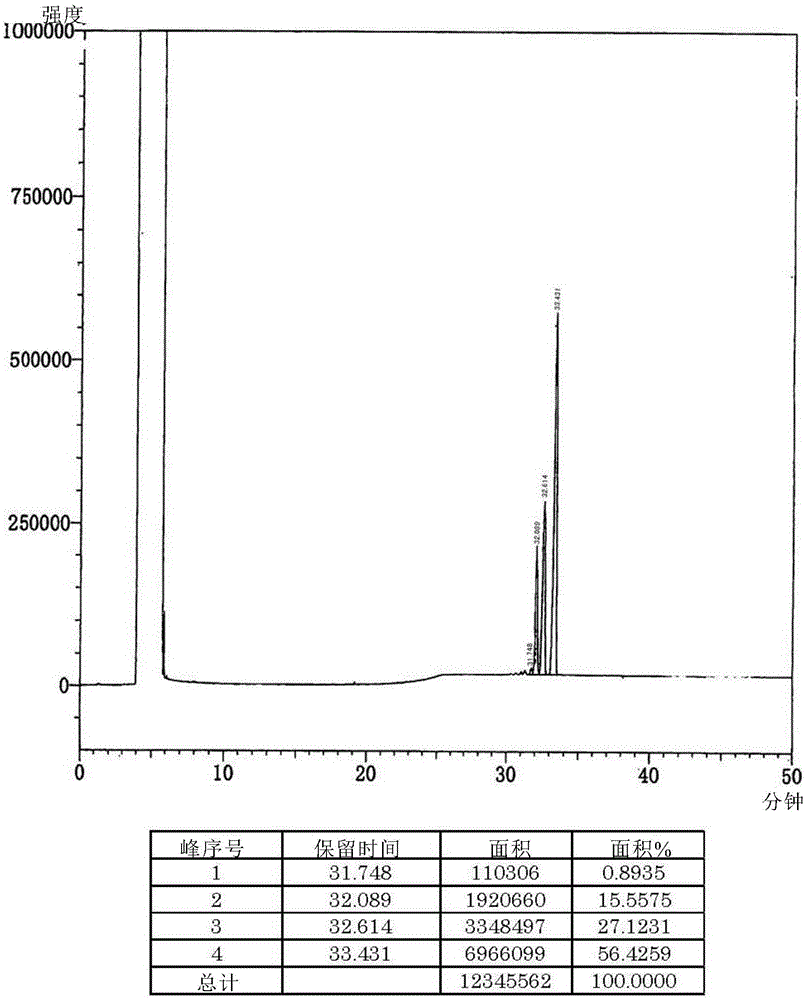

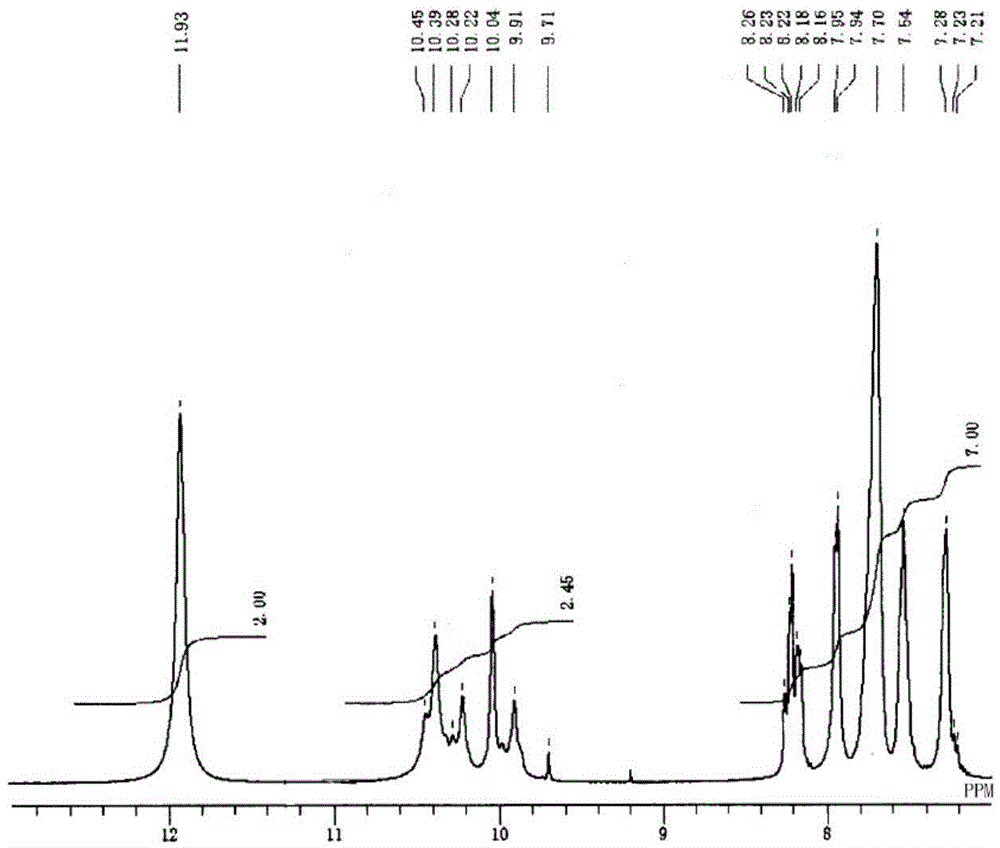

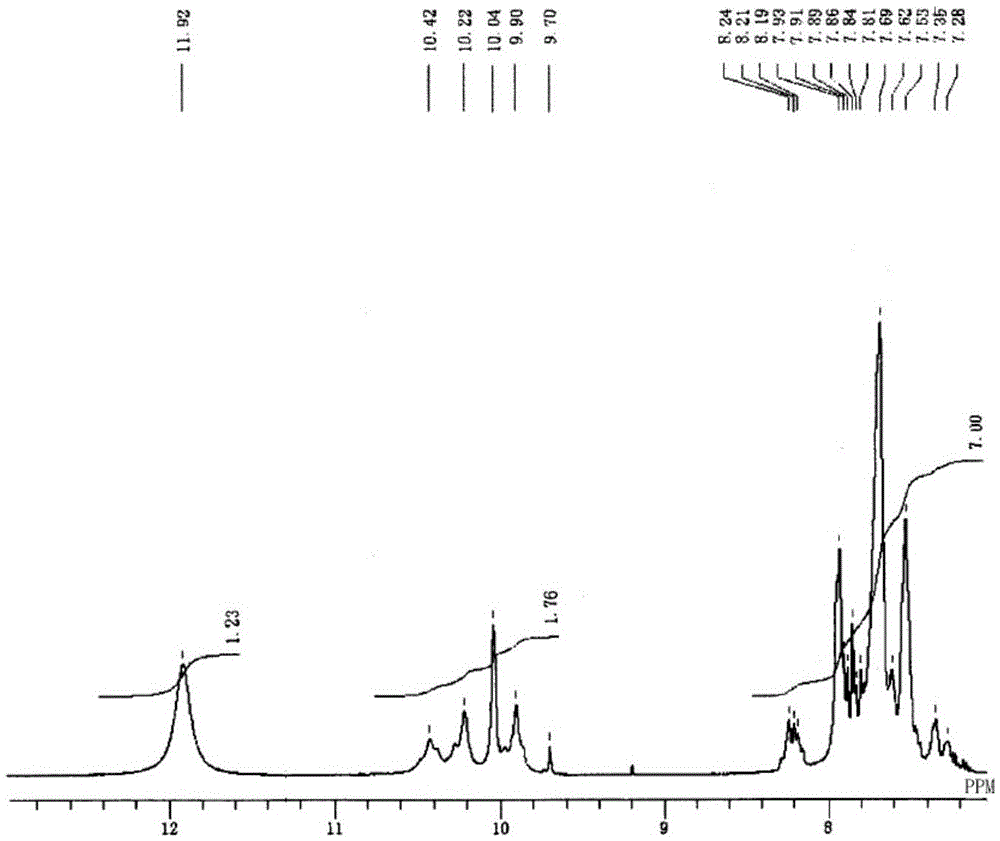

InactiveCN105814116AImprove performanceHigh transparencyCoatingsPolymer scienceGas liquid chromatographic

This polyimide precursor comprises: a tetracarboxylic acid component including a norbornane-2-spiro-alpha-cyclopentanone-alpha '-spiro-2''-norbornane-5,5'', 6, 6''-tetracarboxylic dianhydride or a derivative thereof; and a diamine component including diamine or a derivative thereof. The polymide precursor is characterized by the norbornane-2-spiro-alpha-cyclopentanone-alpha '-spiro-2''-norbornane-5,5'', 6, 6''-tetracarboxylic dianhydride having a peak area ratio for a specific peak of at least 60%, in a gas chromatograph obtained by gas chromatography analysis.

Owner:UBE IND LTD

Polyimide precursor and polyimide

ActiveCN105492496AImprove heat resistanceGood solvent resistancePrinted circuit aspectsCoatingsCarboxyl radicalCarboxylic acid

Owner:UBE IND LTD

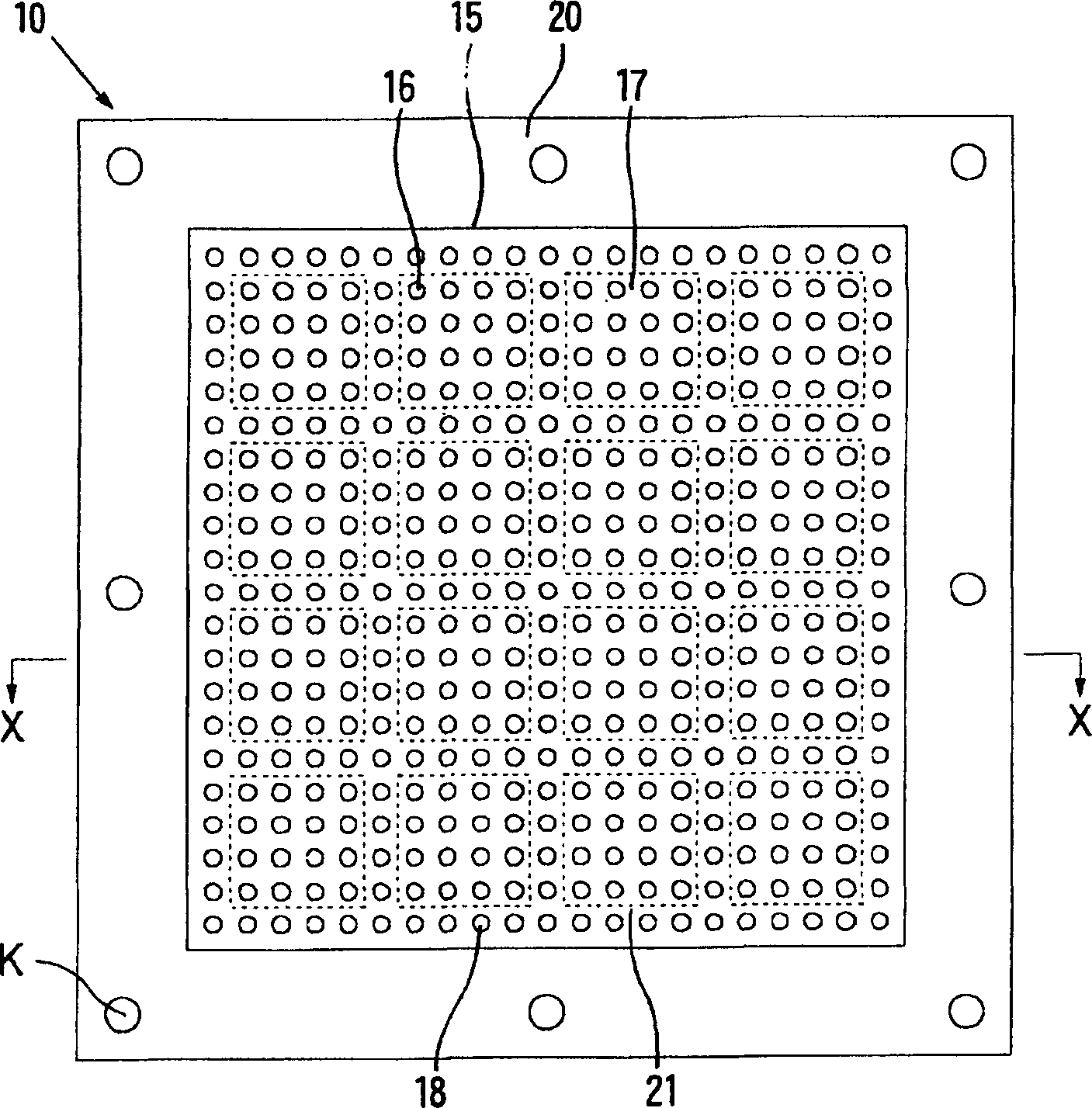

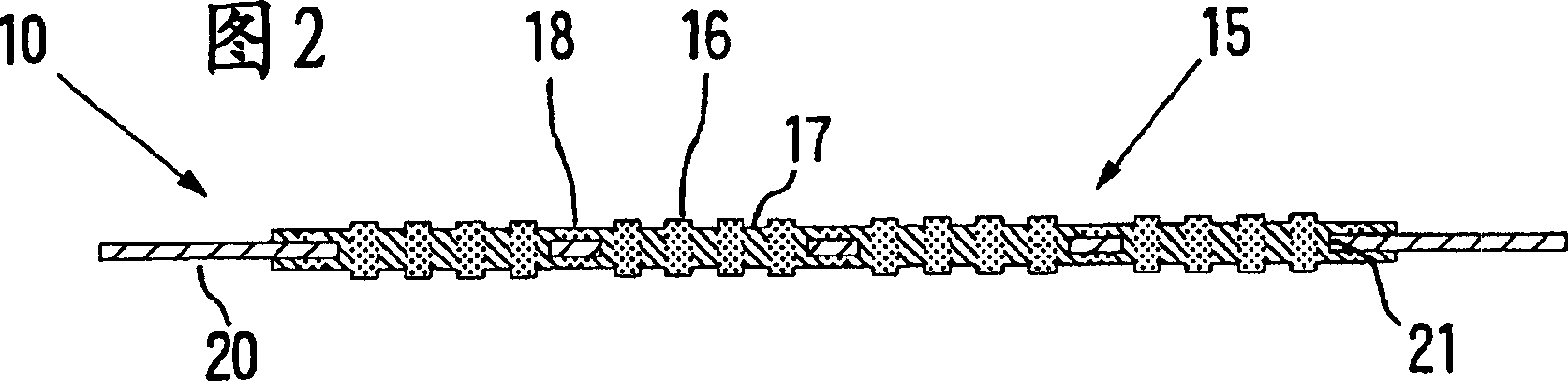

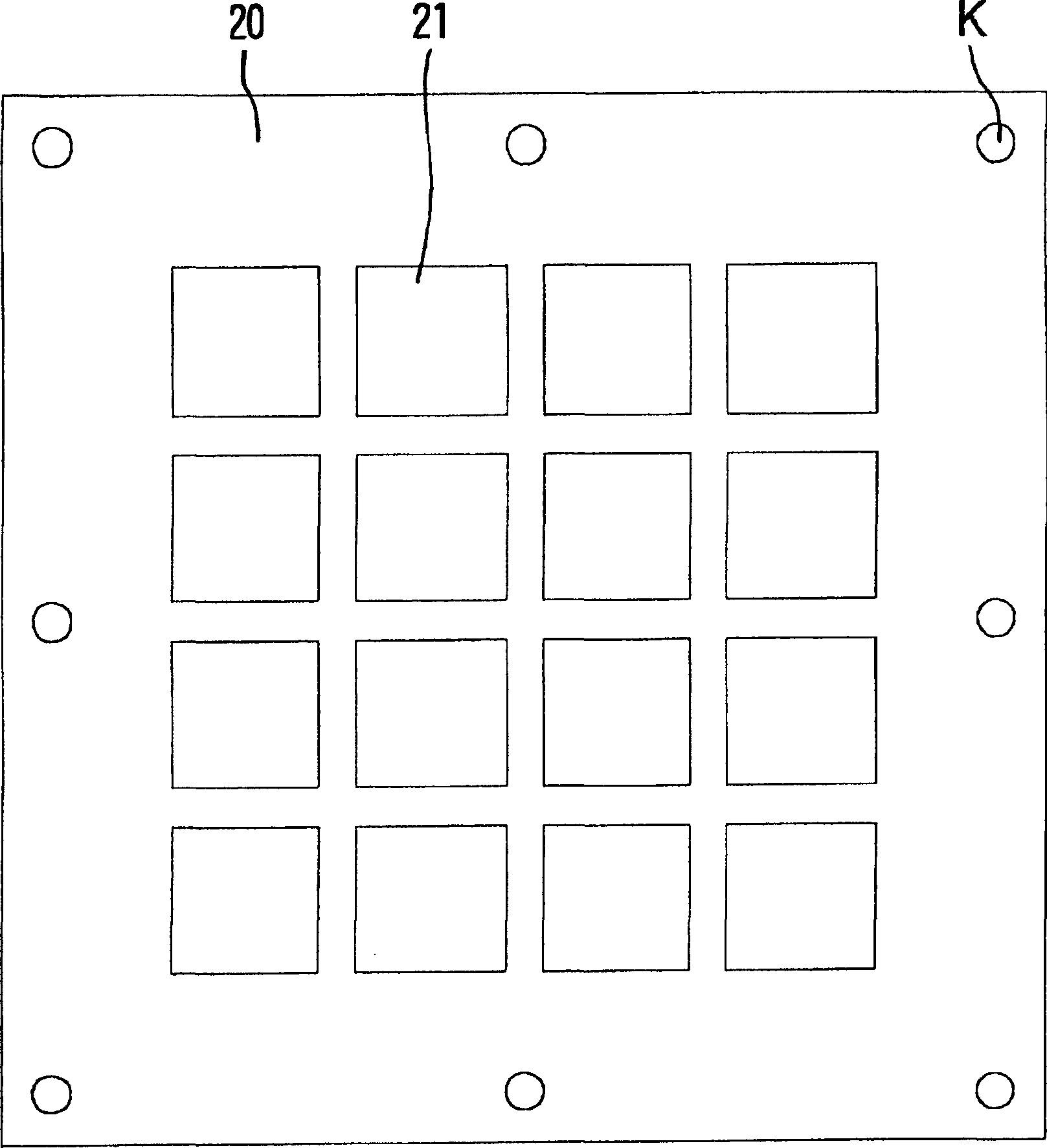

Anisotropic conductive connector and wafer inspection device

InactiveCN1806178AWill not deformEasy alignmentSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsElectrical resistance and conductanceHigh density

Disclosed herein are a wafer inspection apparatus, which is small in size, is prevented from shortening the service life of its circuit board for inspection, capable of collectively performing inspection as to a great number of electrodes to be inspected, has good electrical properties and capable of performing electrical inspection of high functional integrated circuits, and an anisotropically conductive connector suitable for use in this wafer inspection apparatus. The anisotropically conductive connector of the invention comprises an elastic anisotropically conductive film composed of a plurality of conductive parts for connection each extending in a thickness-wise direction of the film and arranged in a state separated from each other and an insulating part formed among these conductive parts for connection, and a frame plate for supporting this film. The frame plate is formed of a metallic material having a coefficient of linear thermal expansion of 3 x 10 -6 to 2 x 10 -5 K -1 , the conductive parts for connection are obtained by filling conductive particles having a number average particle diameter of 20 to 80 m and exhibiting magnetism in an elastic polymeric substance at a high density, the conductive particles have, on a surface of which, a coating layer composed of a noble metal and having a thickness of at least 20 nm, each of the conductive parts for connection has a durometer hardness of 10 to 35, and an electric resistance between the conductive parts for connection is at least 10 M CR .

Owner:JSR CORPORATIOON

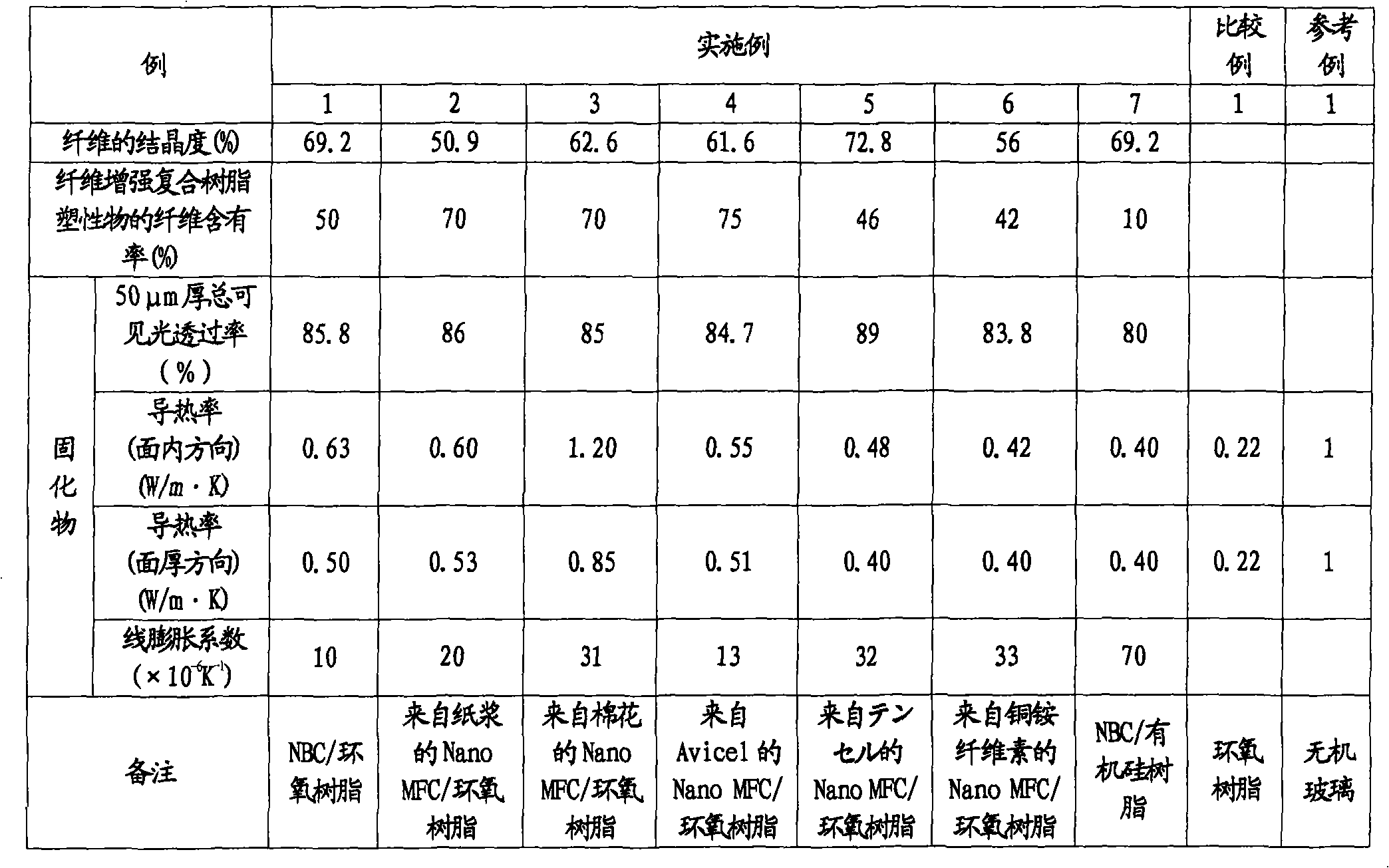

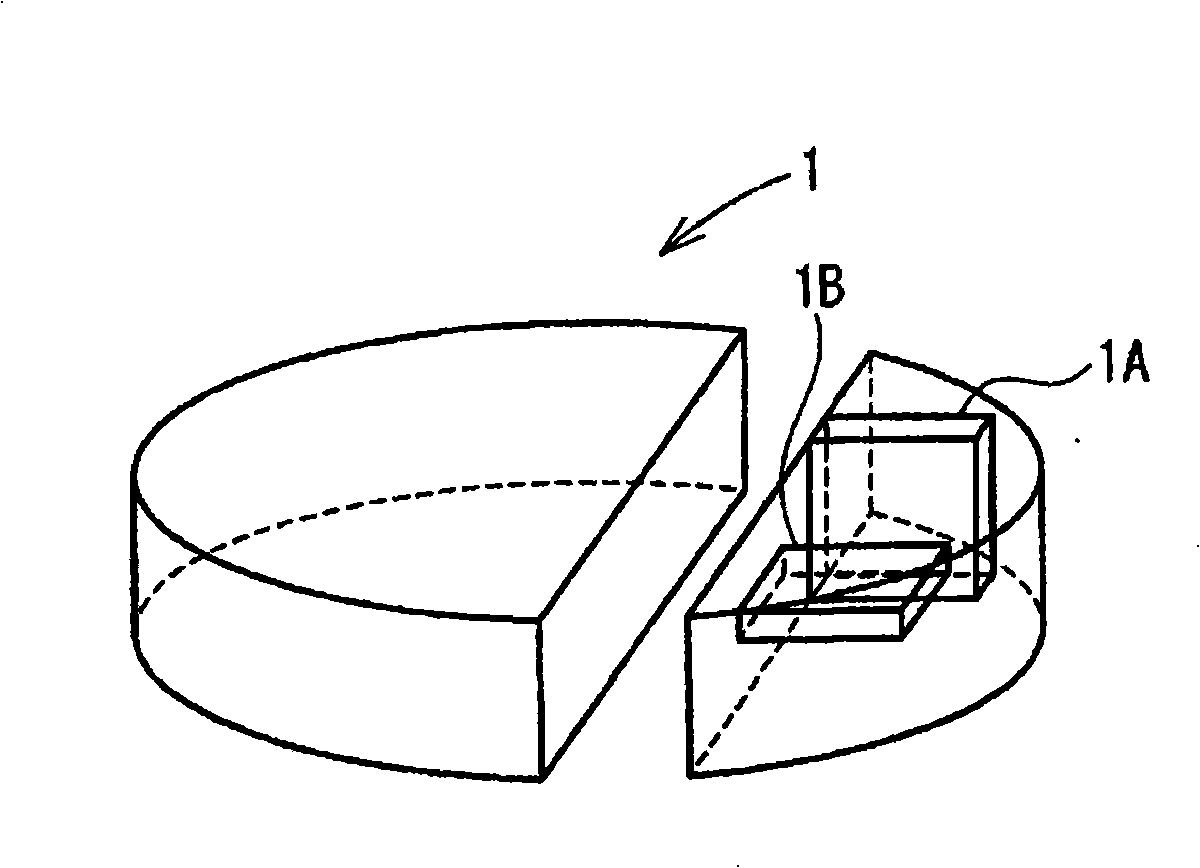

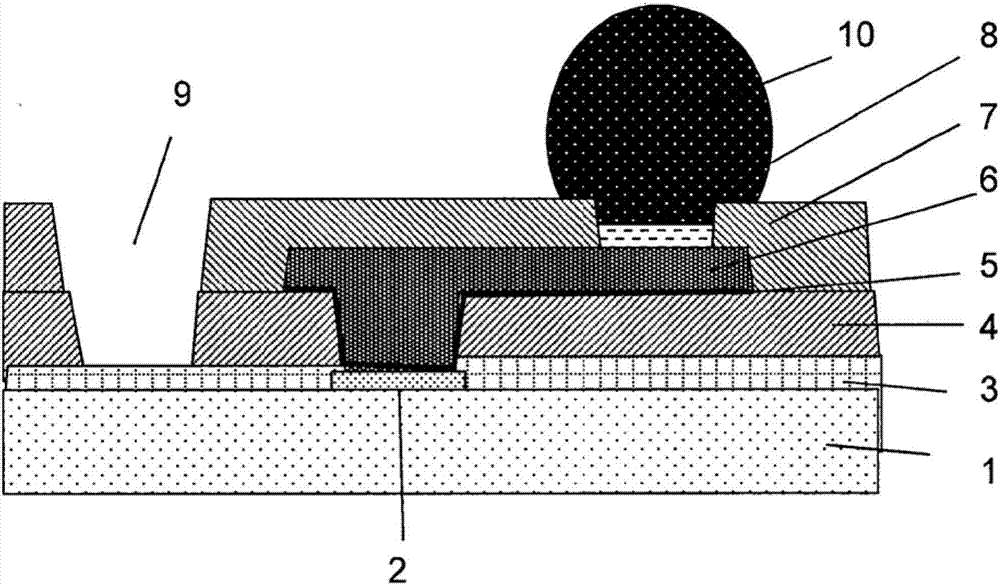

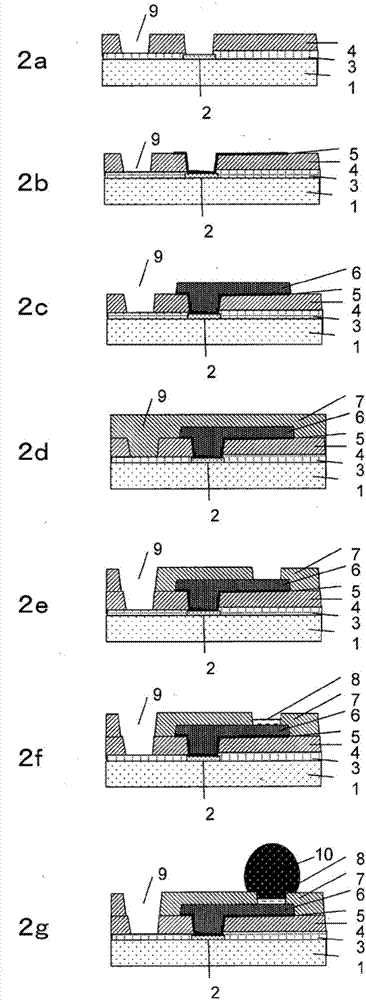

Fiber-reinforced composite resin composition, and adhesive and sealing agent

InactiveCN101297000AHigh transparencyLow coefficient of linear thermal expansionCellulose adhesivesPolymer scienceAdhesive

Owner:ROHM CO LTD +2

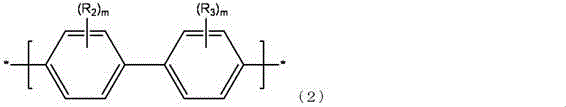

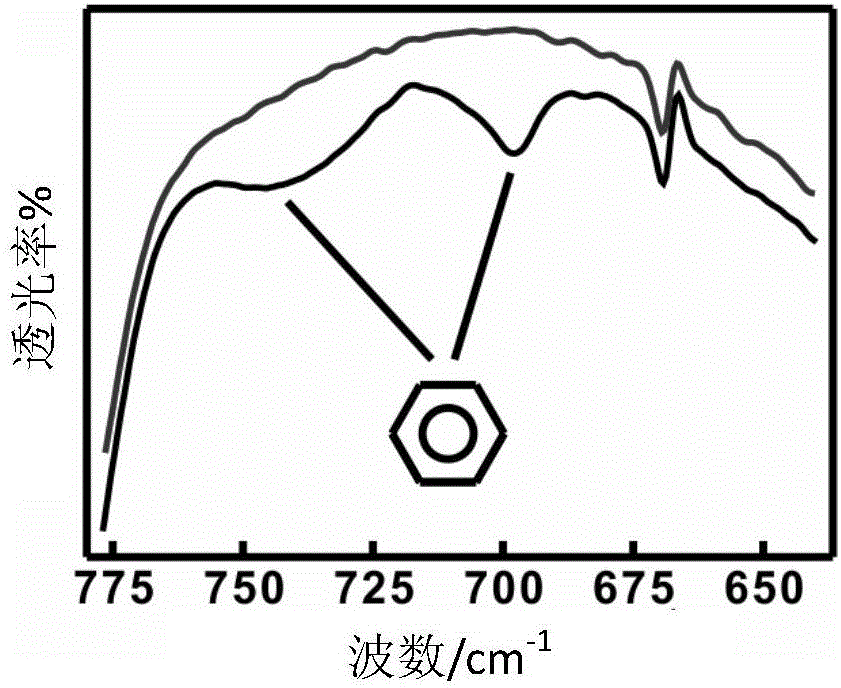

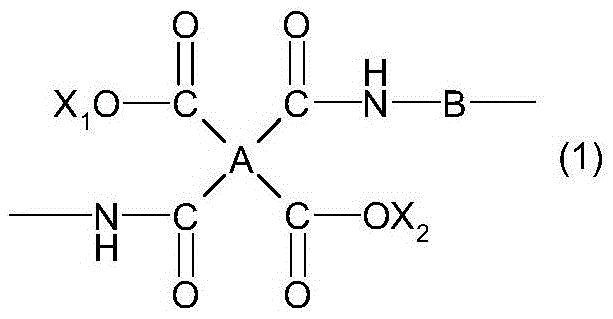

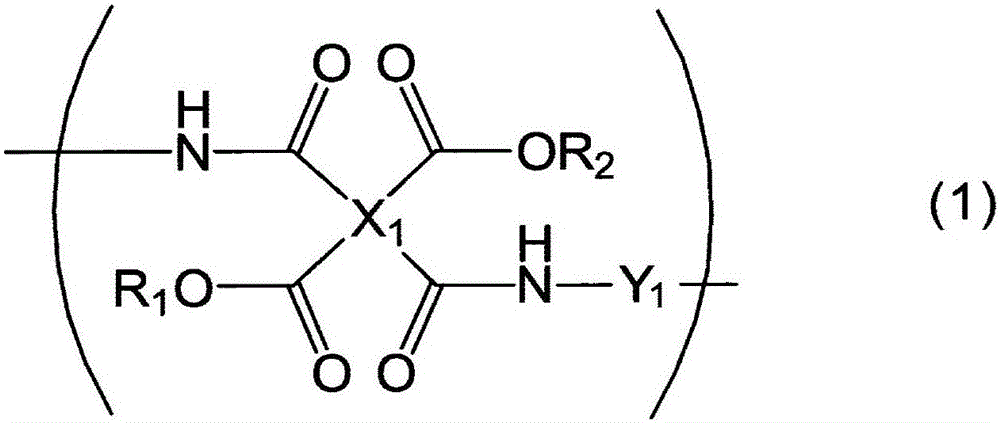

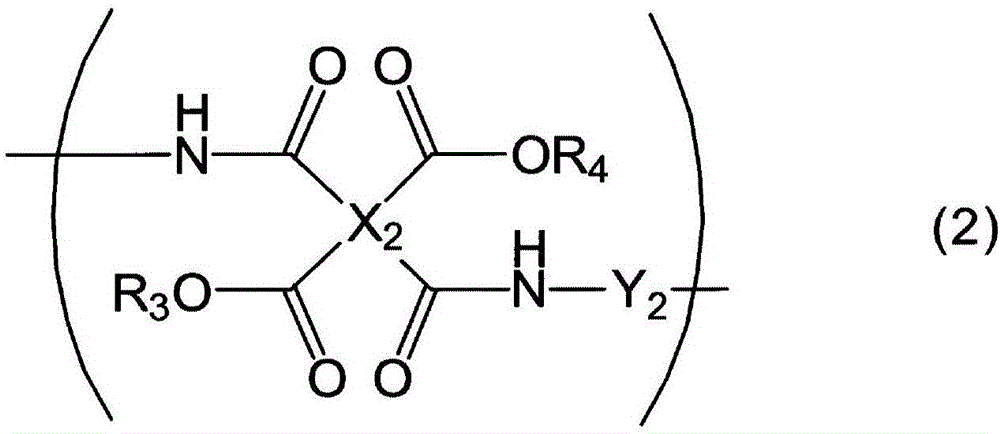

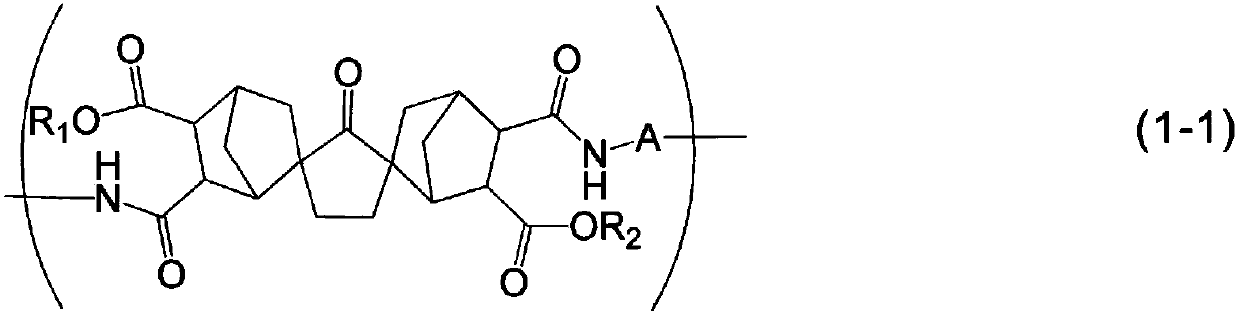

Resin, photosensitive resin composition, and electronic component and display device each using same

ActiveCN107406590ALow coefficient of linear thermal expansionLow absorbanceCarbamic acid derivatives preparationSemiconductor/solid-state device detailsThermal dilatationPolymer science

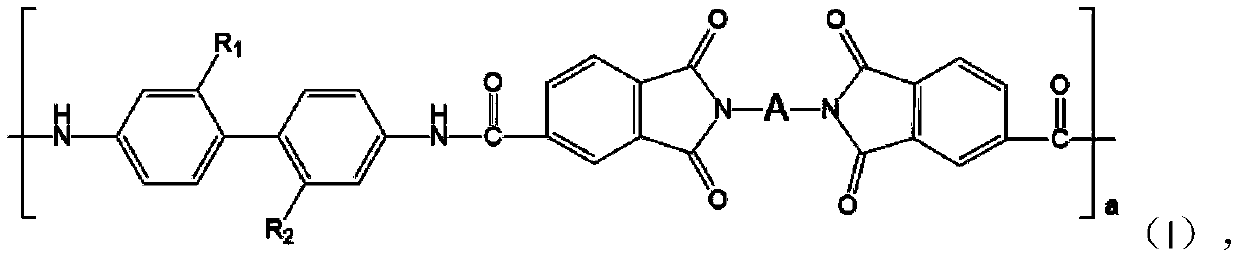

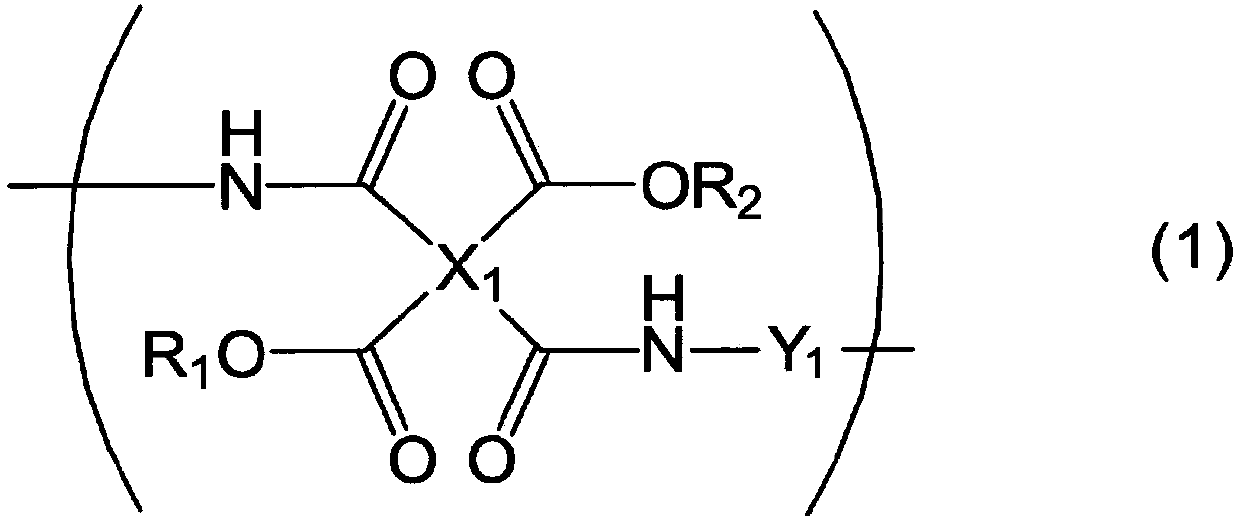

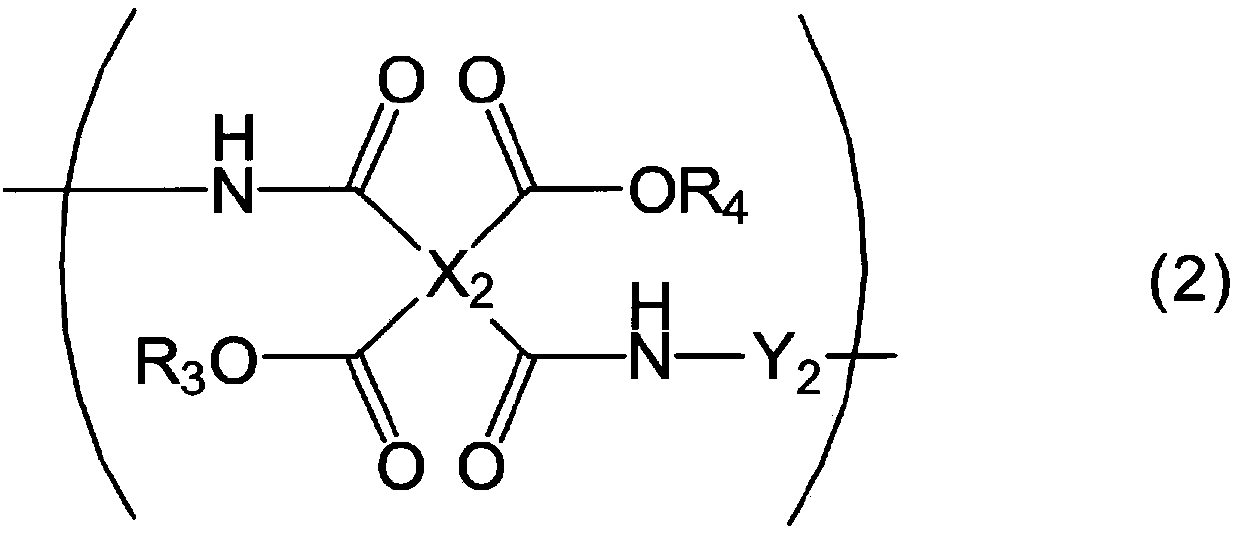

Provided is a resin which has a low linear thermal expansion coefficient and a low absorbance. The resin is characterized by comprising at least one structure that is selected from among structures represented by general formula (1) or (2).

Owner:TORAY IND INC

Polyimide precursor composition, polyimide production method, polyimide, polyimide film, and substrate

The present invention pertains to a polyimide precursor composition characterized by containing a polyimide precursor and an imidazole-based compound, and further characterized in that the content of the imidazole-based compound is less than four moles with respect to one mole of repeating units of the polyimide precursor.

Owner:UBE IND LTD

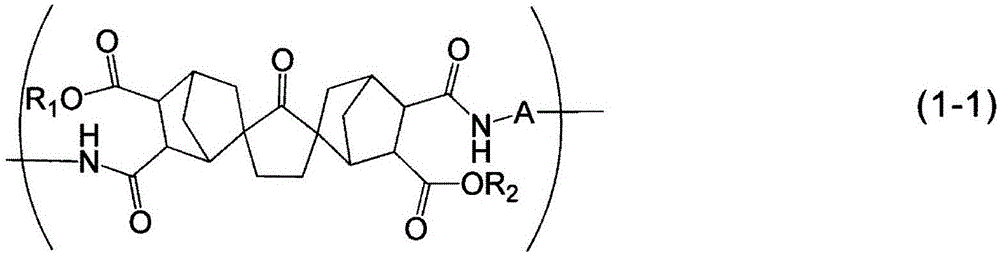

Polyimide precursor, polyimide, varnish, polyimide film, and substrate

ActiveCN104769013AHigh transparencyLow coefficient of linear thermal expansionCoatingsHydrogenOptical transmittance

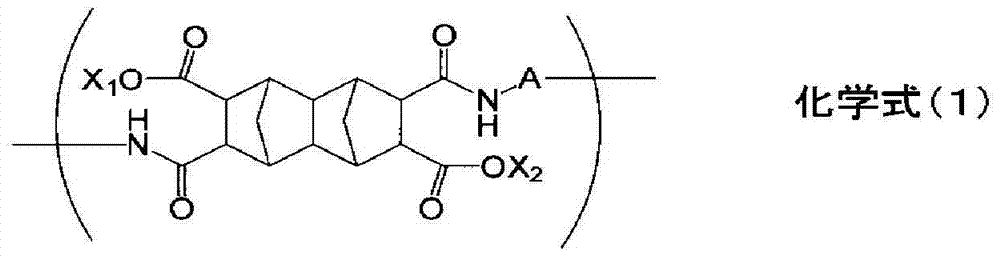

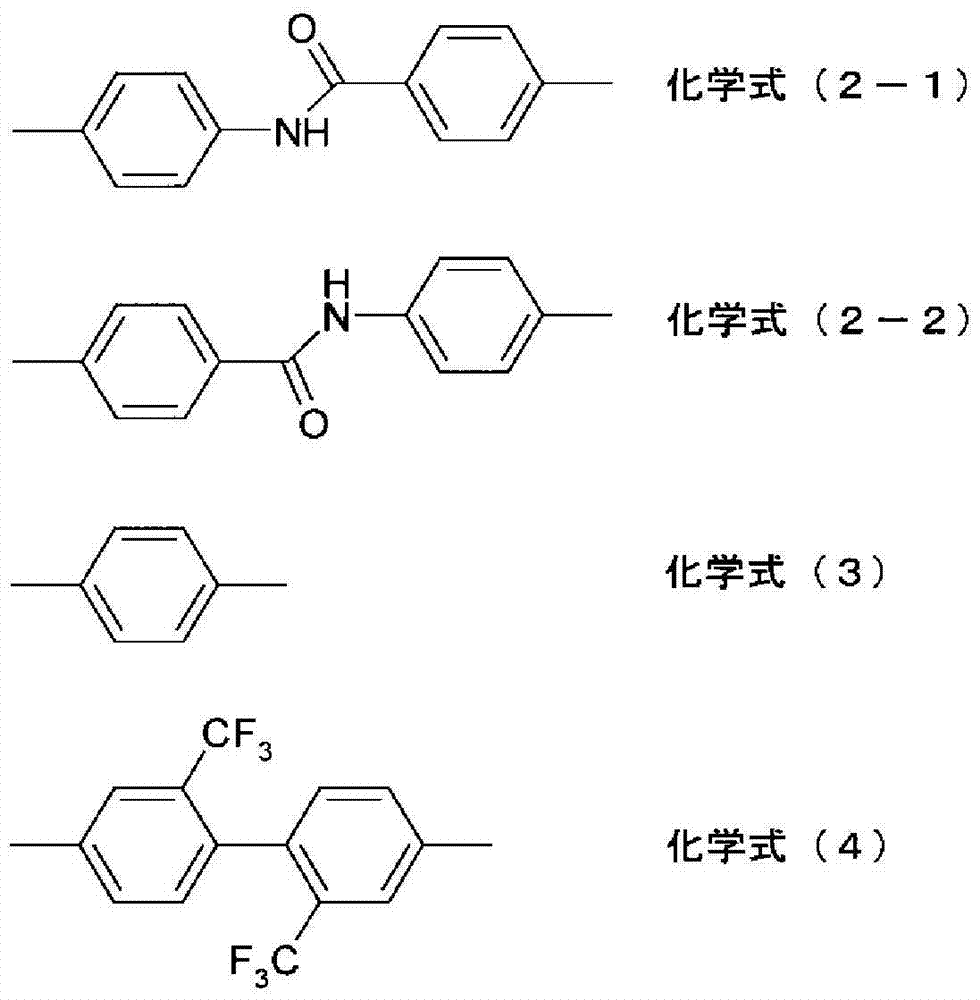

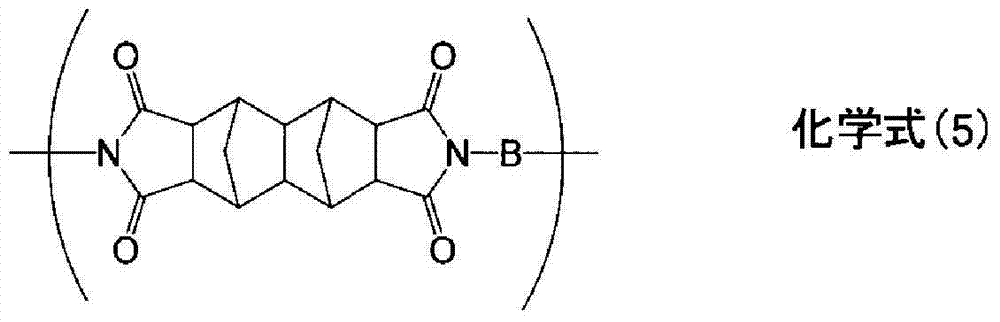

The present invention relates to a polyimide precursor including a repeating unit expressed by chemical formula (1), wherein the polyimide precursor is characterized in that A includes at least two repeating units expressed by chemical formula (1) that is a group expressed by any of chemical formulas (2-1), (2-2), (3) or (4), and a polyimide obtained from the polyimide precursor has a linear thermal expansion coefficient of 50 ppm / K or less at 50 to 200°C, and a transmittance of at least 75% at a wavelength of 400 nm and a polyimide film thickness of 10 mum (in the formula, A represents a bivalent group excluding an amino group from an aromatic diamine or an aliphatic diamine; and X1 and X2 individually represent hydrogen, a C1-6 alkyl group, or a C3-9 alkylsilyl group).

Owner:UBE IND LTD

High heat resistance nylon/acrylonitrile-butadiene-styrene resin mixing material

The invention discloses a high heat-resistant nylon / acrylonitrile-butadiene-styrene resin mixed material, which consists of nylon in an amount of 50 to 75 parts by weight, ABS resin in an amount of 10 to 25 parts by weight, styrene-N-phenyl maleimide copolymer in an amount of 5 to 15 parts by weight, and an inorganic filler in an amount of 5 to 15 parts by weight. The heat-resistant nylon / acrylonitrile-butadiene-styrene resin mixed material has excellent heat resistance, chemical resistance and mechanical property, and has the characteristics of low coefficient of linear thermal expansion, and excellent liquidity, so as to be sprayed on line, and be used for manufacturing such components as automobile fenders, rearview mirrors, tank cups and so on.

Owner:SHANGHAI PRET COMPOSITES

Cured organopolysiloxane resin film having gas barrier properties and method of producing the same

InactiveCN102712828AExcellent gas barrier performanceHigh tensile strengthWoven fabricsCoatingsFiberOrganic group

A cured organopolysiloxane resin film having gas barrier properties comprising a fiber-reinforced film made of a hydrosilylation-cured organopolysiloxane resin and having a transparent inorganic layer selected from silicon oxynitride layer, silicon nitride layer, and silicon oxide layer formed on the fiber-reinforced film wherein a layer of cured organopolysiloxane that contains an organic functional group, silanol group, hydrosilyl group, or an organic group produced by the polymerization of polymerizable organic functional groups is interposed between said fiber-reinforced film and inorganic layer. Also, a method of producing this cured organopolysiloxane resin film having gas barrier properties.

Owner:DOW CORNING TORAY CO LTD +1

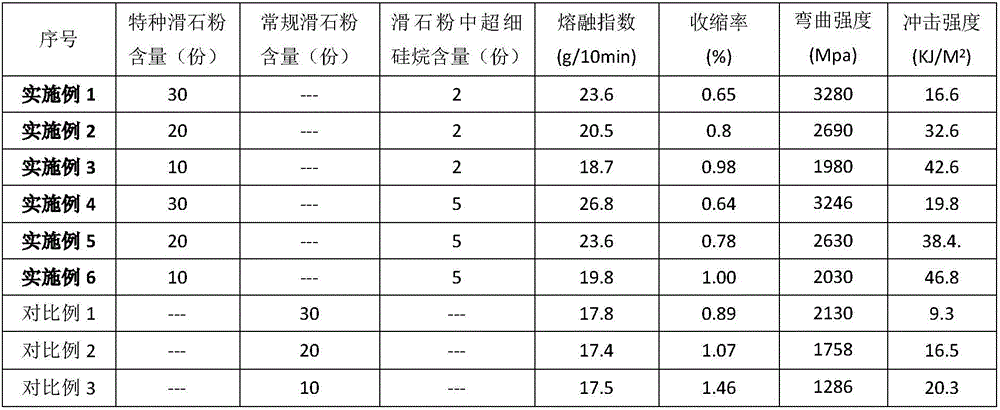

PP (polypropylene) composite for thin-walled automobile bumper and preparation method of PP composite

InactiveCN106674742ALow coefficient of linear thermal expansionGood dimensional stabilityElastomerPolypropylene composites

The invention discloses a PP (polypropylene) composite for a thin-walled automobile bumper and a preparation method of the PP composite. The PP composite is mainly prepared from 10-30 parts of novel talcum powder subjected to surface modification with an ultrafine silane dispersant and having high regularity and large diameter-thickness ratio, 50-80 parts of conventional PP, 8-20 parts of an elastomer, 0.1-1 part of an antioxidant and 0-3 parts of other auxiliaries. The modified special talcum powder which is subjected to surface modification with the ultrafine silane functional dispersant and has the large diameter-thickness ratio and high lamella integrity is adopted as a filling modification component of the PP composite and is subjected to extrusion pelletization with PP, the elastomer, the antioxidant, an illumination auxiliary and the like by a double-screw extruder, and the PP composite is prepared accordingly. According to the prepared composite, liquidity of the composite is greatly improved while impact toughness and rigidity of the composite are improved, linear thermal expansion coefficient and shrinking percentage of the composite are reduced and dimensional stability and corresponding mechanical properties of a thin-walled bumper sample piece are guaranteed.

Owner:SHANGHAI PRET COMPOSITES +4

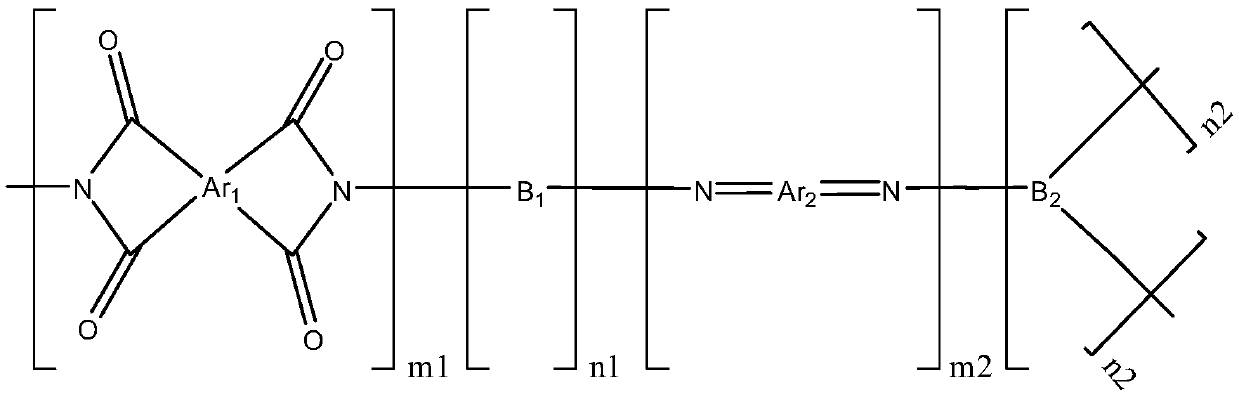

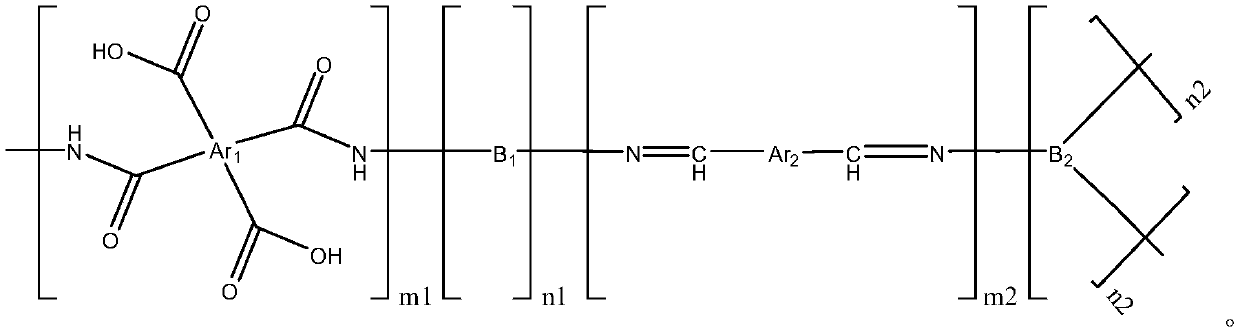

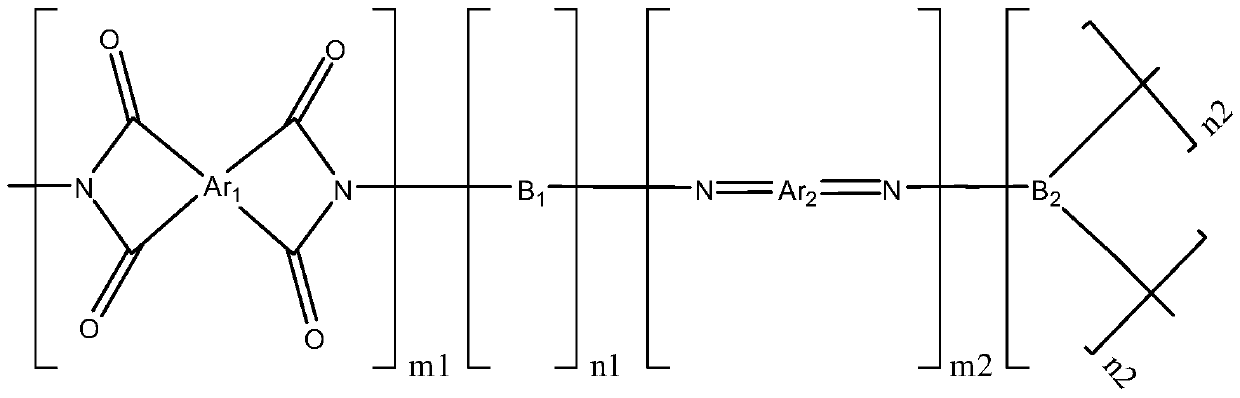

Polyamide-imide, polyamide-imide film and display device

ActiveCN111533909ASmall coefficient of thermal expansionImprove mechanical propertiesPhotovoltaic energy generationIdentification meansThermal dilatationImide

The invention discloses a polyamide-imide, a polyamide-imide film and a display device comprising the film. The polyamide-imide comprises at least two different block structures, wherein the first block has a repeating unit with a structure shown in the following formula I, and the second block has a repeating unit with a structure shown in the following formula II. The film prepared from the multi-block polyamide-imide has excellent solubility, heat resistance and mechanical properties, low thermal expansion coefficient performance, high light transmittance and relatively low cut-off wavelength, so that the film can be used as a display device material of a flexible display, and is particularly suitable for being used as a substrate material in the display.

Owner:武汉柔显科技股份有限公司 +1

Polyimide precursor composition, polyimide production method, polyimide, polyimide film, and substrate

The present invention pertains to a polyimide precursor composition characterized by containing a polyimide precursor and an imidazole-based compound, and further characterized in that the content ofthe imidazole-based compound is less than four moles with respect to one mole of repeating units of the polyimide precursor.

Owner:UBE IND LTD

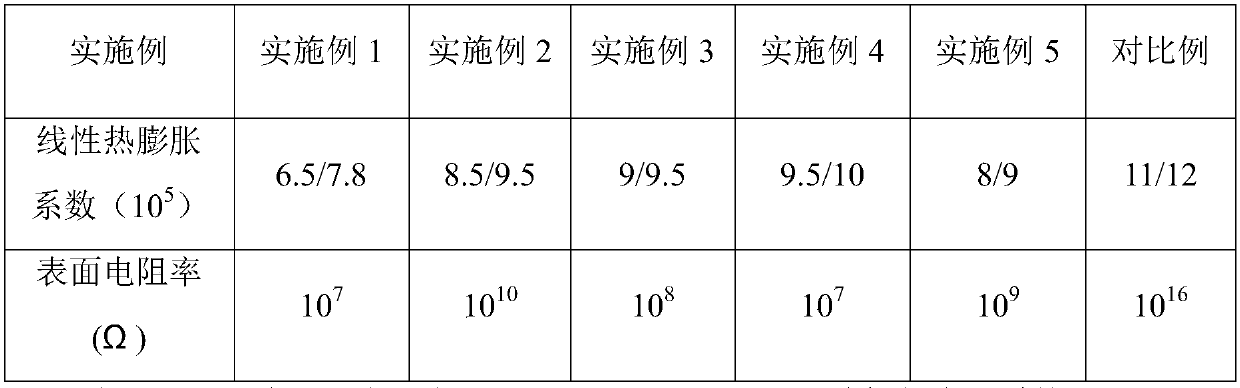

Antistatic spray-free polypropylene composite material with low linear thermal expansion coefficient and preparation method of antistatic spray-free polypropylene composite material

ActiveCN110408120AIncreased crystallinity and crystallization speedReduced after contractionAntioxidantWhiskers

The invention discloses an antistatic spray-free polypropylene composite material with low linear thermal expansion coefficient and a preparation method of the antistatic spray-free polypropylene composite material. The antistatic spray-free polypropylene composite material is prepared by mixing and extruding polypropylene, mineral filling, a toughening agent, a functional assistant, a metal pigment, a coupling agent, an antioxidant, a lubricant and a light stabilizer. The functional assistant is prepared by compounding wollastonite whisker and glyceryl monostearyl ester according to the mixing mass ratio of 1:1 to 4:1. According to the antistatic spray-free polypropylene composite material, the polypropylene is compounded with the mineral filling and the toughening agent, the strength, rigidity and toughness of the composite material are ensured, in addition, the crystallization velocity is shortened and the degree of crystallization of the material is increased by adding the functional assistant, the post shrinkage of the product is lowered, the forming period of the product is shortened, meanwhile a conductive network is formed in the material, the material has a certain conductive performance, the surface antistatic property of the material is improved, and thus the modified polypropylene composite material can be widely used in spray-free products.

Owner:HEFEI GENIUS NEW MATERIALS

Reinforced ABS resin composition suitable for electroplating, and preparation method and application thereof

ActiveCN104045962ALow coefficient of linear thermal expansionMeet performance requirementsPolymer chemistryAnoxomer

The invention discloses a reinforced ABS resin composition suitable for electroplating. The composition comprises 85-96wt% of an ABS resin, 3-10wt% of a carbon fiber, 0.1-1.0wt% of a dispersant, 0.01-1.0wt% of a lubricant, 0.1-1.0wt% of a main antioxidant and 0.5-2.0wt% of an auxiliary antioxidant. The reinforced ABS resin composition suitable for electroplating can reduce the linear thermal expansion coefficient of a plastic electroplating product, has an above 50% lower linear thermal expansion coefficient than a common ABS resin, and can well meet the performance requirements of the plastic electroplating product. The adoption of the carbon fiber enhances the conductivity of the ABS resin, effectively increases the bonding force between the ABS resin and an electroplating layer, shortens the pretreatment time of electroplating, improves the electroplating production processing efficiency, and is in favor of the electroplating production. The reinforced ABS resin composition suitable for electroplating has high mechanical strength and good dimensional stability.

Owner:KINGFA SCI & TECH CO LTD

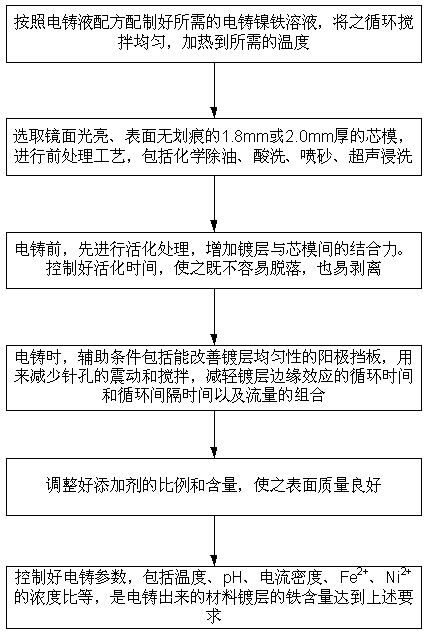

A metal mask plate for vapor deposition produced from a nickel-iron alloy

InactiveCN103205702ALow costLow coefficient of linear thermal expansionVacuum evaporation coatingSputtering coatingInvar alloyNickel alloy

The invention discloses a metal mask plate for vapor deposition produced from a nickel-iron alloy. The metal mask plate is produced by using an electroforming process, and from a nickel-iron alloy material; and the nickel alloy material comprises two elements of nickel and iron, wherein the iron content is 40% to 55% and the nickel content is 45% to 60%. The metal mask plate for vapor deposition of the invention has physical properties similar to an Invar alloy plate, high plate surface brightness, high uniformity, good plate surface quality, and a lower cost compared with a mask plate produced from an invar alloy, thus saving the cost. At the same time, the linear thermal expansion coefficient of the metal mask plate for vapor deposition provided by the present invention is small, thus satisfying the vapor deposition requirements; and additionally, the mask plate provided by the present invention has the properties of high hardness and high magnetism.

Owner:KUN SHAN POWER STENCIL

A kind of preparation method of low dielectric constant ordered porous polyimide film

ActiveCN106750435BLow dielectric constantLow coefficient of linear thermal expansionSilicaMicrosphereThermal expansion

The invention discloses a preparation method for a low-dielectric-constant ordered porous polyimide thin film. The method comprises the steps that amino-modified silicon dioxide microspheres are prepared, then, polyimide is grafted onto the surfaces of the amino-modified silicon dioxide microspheres in the form of chemical bonds, a polyimide compound thin film is prepared, silicon dioxide is etched away in a hydrofluoric acid etchant, washing and drying are conducted, and then the low-dielectric-constant ordered porous polyimide thin film is obtained. According to the method, air holes which have the hole diameters ranging from 30 nm to 200 n, are uniform in size distribution and are uniformly distributed in the thin film are introduced into the polyimide thin film, the dielectric constant of the polyimide thin film is lowered, and meanwhile due to the fact that the hole diameters are small, and distribution of the air holes inside the thin film is uniform, the polyimide thin film keeps the high mechanical property and breakdown voltage. The preparation method has the advantages of being low in dielectric constant, high in breakdown voltage, good in mechanical property and capable of lowering the thermal expansion coefficient, and has potential application value and good application prospects in a high-frequency, high-speed and high-density integrated circuit.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com