Preparation method of non-curling high-adhesiveness glue-free flexible copper-clad plate

A flexible copper clad laminate, high viscosity technology, used in chemical instruments and methods, improvement of metal adhesion of insulating substrates, devices for coating liquid on surfaces, etc., can solve peeling product cracks, affecting product performance, polyimide Amine coating and copper foil curling, etc., to achieve excellent mechanical properties and heat resistance, improve dimensional stability, and good dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

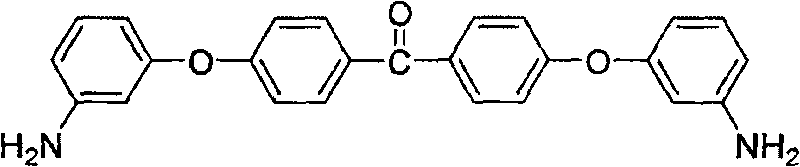

[0041] According to the ratio of BTDA: 5p-BOA: 6p-BOA: 4-BABP=100: 40: 20: 40, the three aromatic diamine monomers of 5p-BOA, 6p-BOA and 4-BABP Add NMP, and stir until dissolved under nitrogen atmosphere, then add BTDA and continue to stir, make it polymerize at 0°C in nitrogen atmosphere for 70 hours, and obtain a viscous polyamic acid homogeneous solution with a solid content of 10wt%. . Its intrinsic viscosity is 1.90dL / g.

[0042] Firstly, the obtained polyamic acid glue is coated on a rolled copper foil with a thickness of 6 microns, and then baked at 150°C for 5 minutes, and the thickness of the coating is controlled to be 10-15 µm after the solvent evaporates, and then dried in a vacuum oven. In the process, step-by-step thermal curing is carried out at 80°C, 120°C, 180°C, 220°C, and 380°C for 30 minutes each in sequence, and an adhesive-free flexible copper-clad laminate with no curl and high dimensional stability is obtained.

Embodiment 2

[0044] According to the ratio of BTDA: 6m-BOA: 4-BABP = 100: 40: 60 according to the amount of substances, first add 6m-BOA and 4-BABP two aromatic diamine monomers into DMAc, and stir under nitrogen atmosphere After dissolving, BTDA was added and stirred continuously, and polymerized at 20° C. for 24 hours in a nitrogen atmosphere to obtain a viscous polyamic acid homogeneous solution with a solid content of 15 wt%. Its intrinsic viscosity is 1.28dL / g.

[0045] Firstly, the obtained polyamic acid glue is coated on a rolled copper foil with a thickness of 9 microns, and then baked at 120°C for 60 minutes, and the thickness of the coating is controlled to be 15-20 µm after the solvent evaporates. In the high-temperature drying tunnel, step-by-step thermal curing is carried out at 80°C, 120°C, 180°C, 280°C, and 340°C for 60 minutes each, so that a non-adhesive flexible copper-clad laminate with no curl and high dimensional stability can be obtained .

Embodiment 3

[0047] According to the ratio of BTDA: 5p-BOA: 4-BABP: 3, 4'-ODA=100: 90: 5: 5 according to the amount of substances, first mix 5p-BOA, 4-BABP and 3, 4'-ODA Add a kind of aromatic diamine monomer into DMAc, and stir until dissolved under a nitrogen atmosphere, then add BTDA and continue to stir, make it polymerize at 20°C for 24 hours in a nitrogen atmosphere, and obtain a viscous mixture with a solid content of 18wt%. Polyamic acid homogeneous solution. Its intrinsic viscosity is 1.74dL / g.

[0048] First coat the obtained polyamic acid glue on a rolled copper foil with a thickness of 12 microns, then bake it at 140°C for 70 minutes, and control the thickness of the coating to 20-25 µm after the solvent evaporates, and then heat it in a vacuum oven. In the process, step-by-step thermal curing is carried out at 80°C, 120°C, 180°C, 260°C, and 380°C for 10 minutes each in sequence, and an adhesive-free flexible copper-clad laminate with no curl and high dimensional stability is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com