Patents

Literature

827 results about "Thermal curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal curing is the process of temperature-induced chemical change in a material, such as the polymerization of a thermoset resin. This process is relevant, for example, when a precursor resin is heated and hardens during the manufacturing of composites.

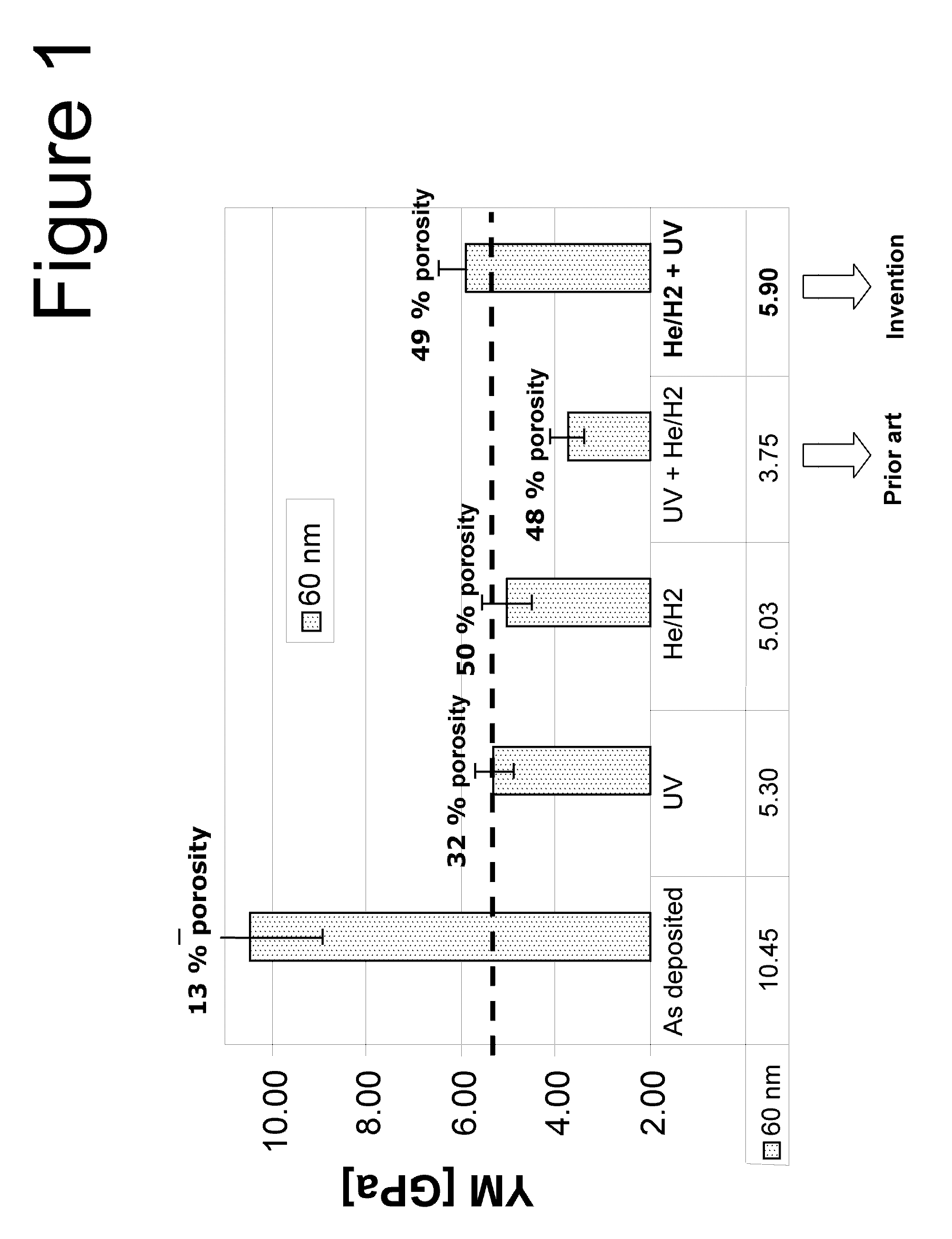

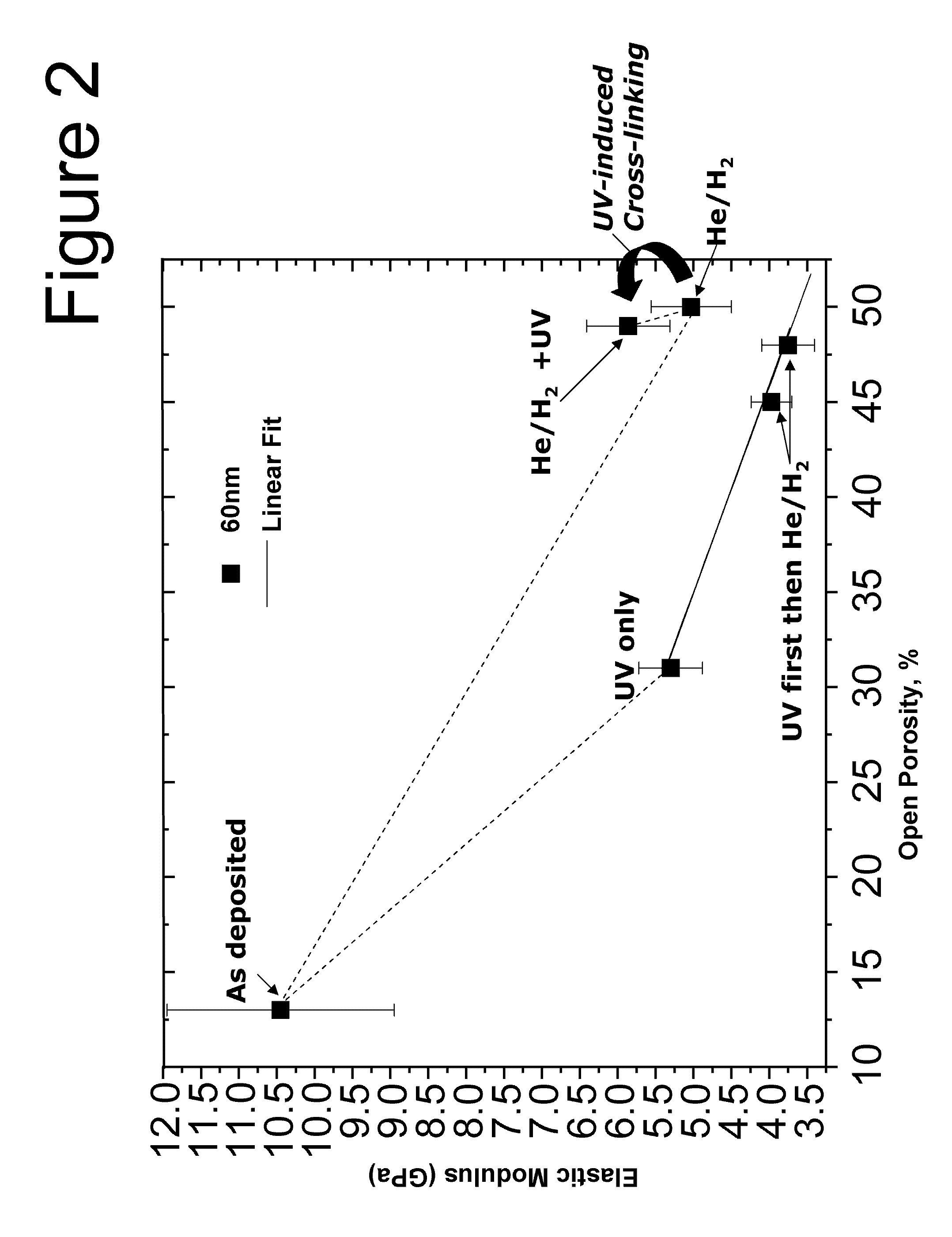

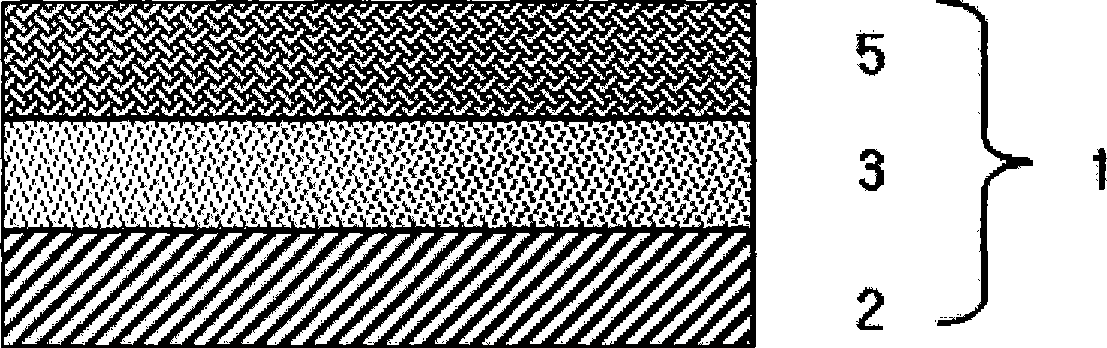

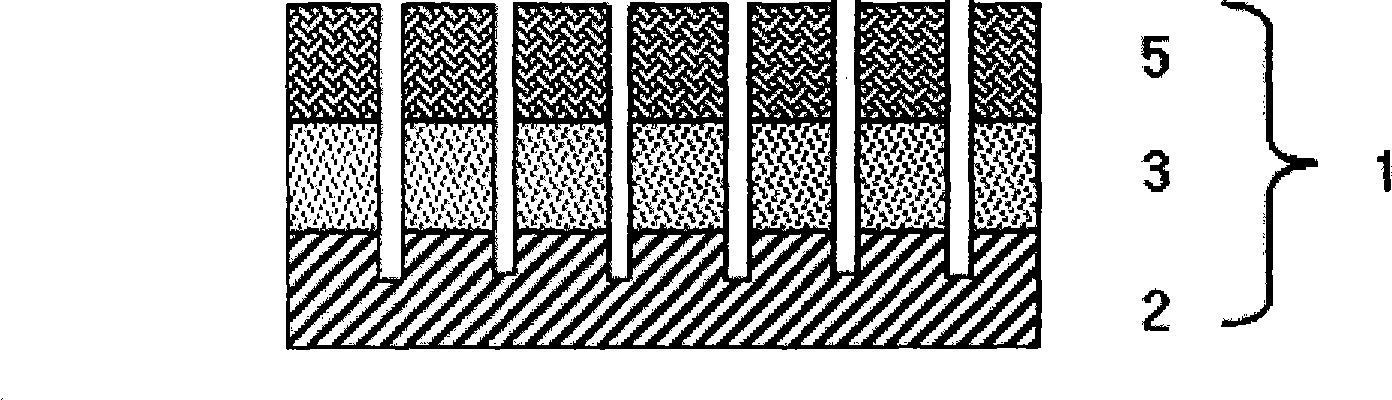

Fabrication of porogen residues free and mechanically robust low-k materials

InactiveUS20110006406A1Improve H radical concentrationHigh elastic modulusSemiconductor/solid-state device detailsSolid-state devicesPorosityHydrogen treatment

A method is provided for producing a porogen-residue-free ultra low-k film with porosity higher than 50% and a high elastic modulus above 5 GPa. The method starts with depositing a SiCOH film using Plasma Enhanced Chemical Vapor Deposition (PE-CVD) or Chemical Vapor Deposition (CVD) onto a substrate and then first Performing an atomic hydrogen treatment at elevated wafer temperature in the range of 200° C. up to 350° C. to remove all the porogens and then performing a UV assisted thermal curing step.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

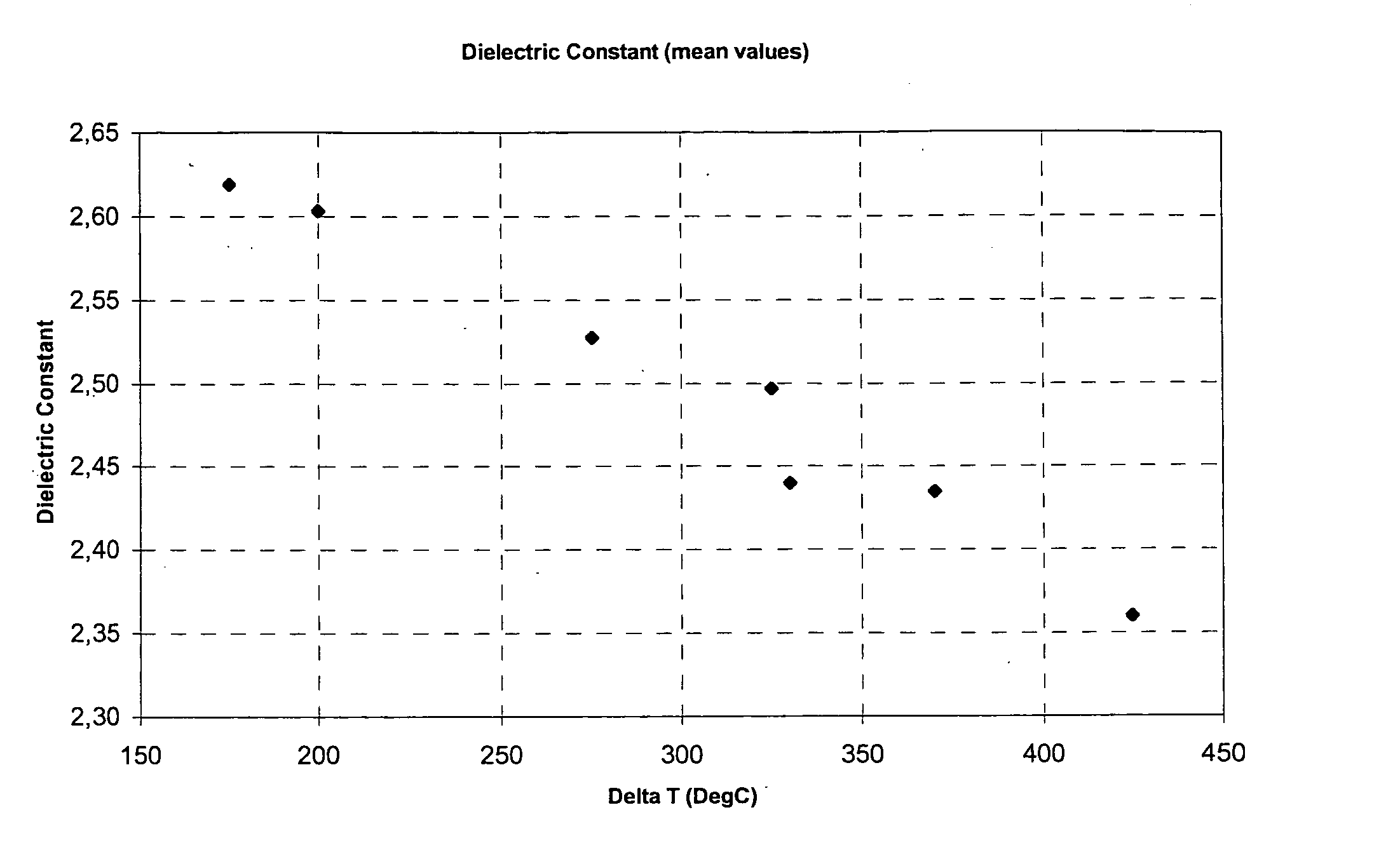

Method of forming low-k dielectrics

InactiveUS20050064726A1Improve performanceFast curingPretreated surfacesSemiconductor/solid-state device manufacturingDielectric permittivityMaterials science

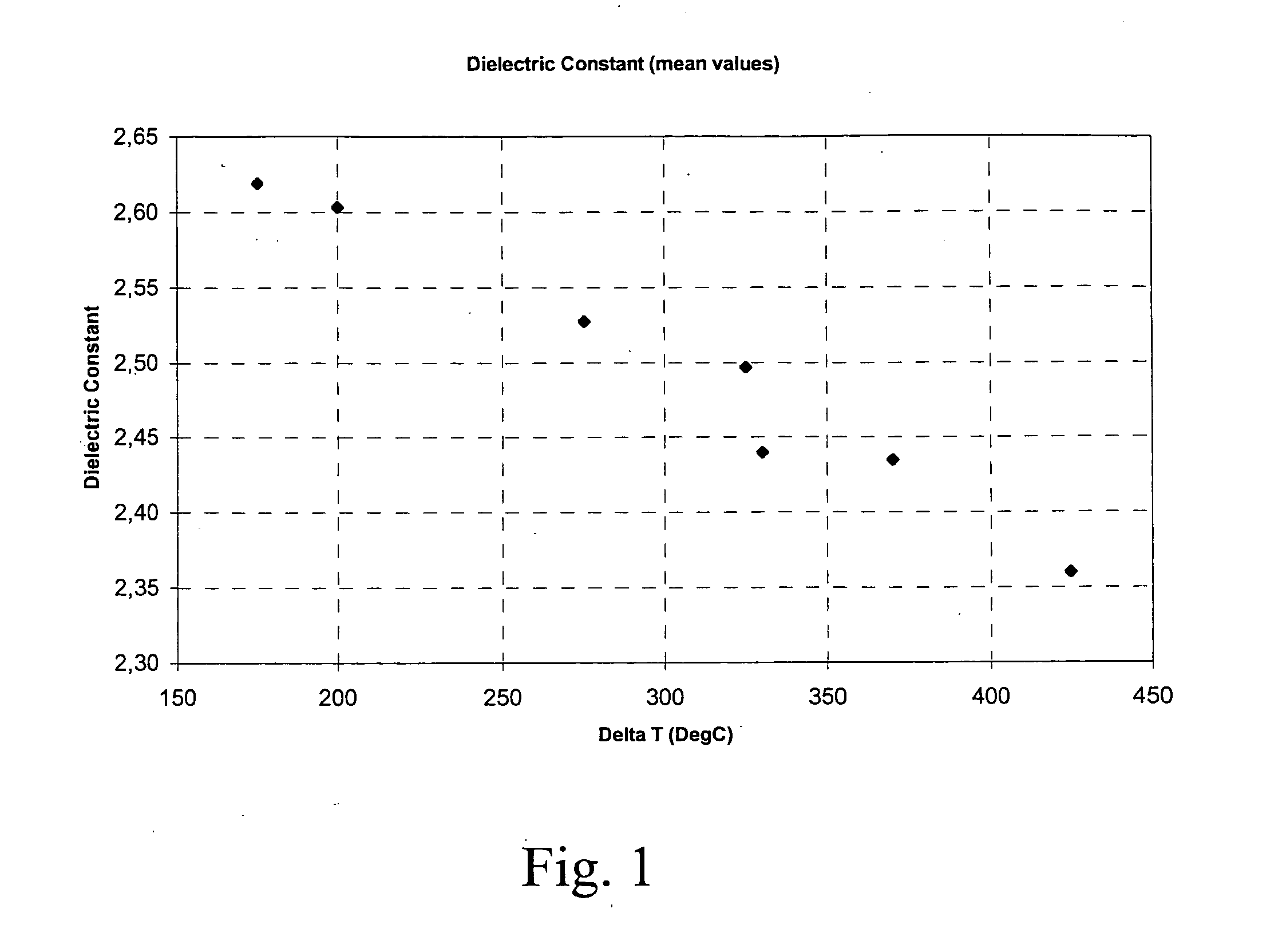

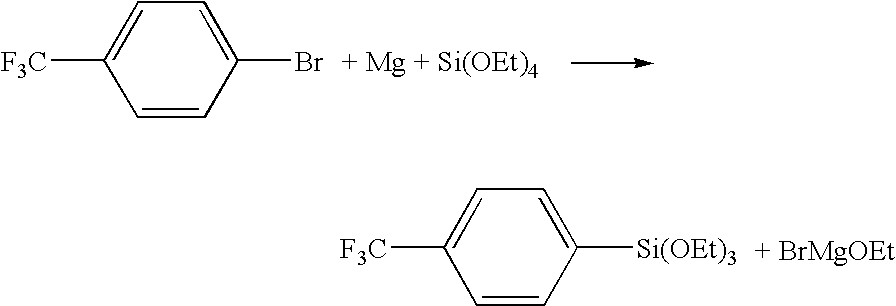

A method of forming a low dielectric constant structure. The method comprises providing at a first temperature a dielectric material having a first dielectric constant and a first elastic modulus, and curing the dielectric material by a thermal curing process, in which the material is heated to a second temperature by increasing the temperature at an average rate of at least 1° C. per second. As a result a densified, dielectric material is obtained which has a low dielectric constant.

Owner:SILECS OY

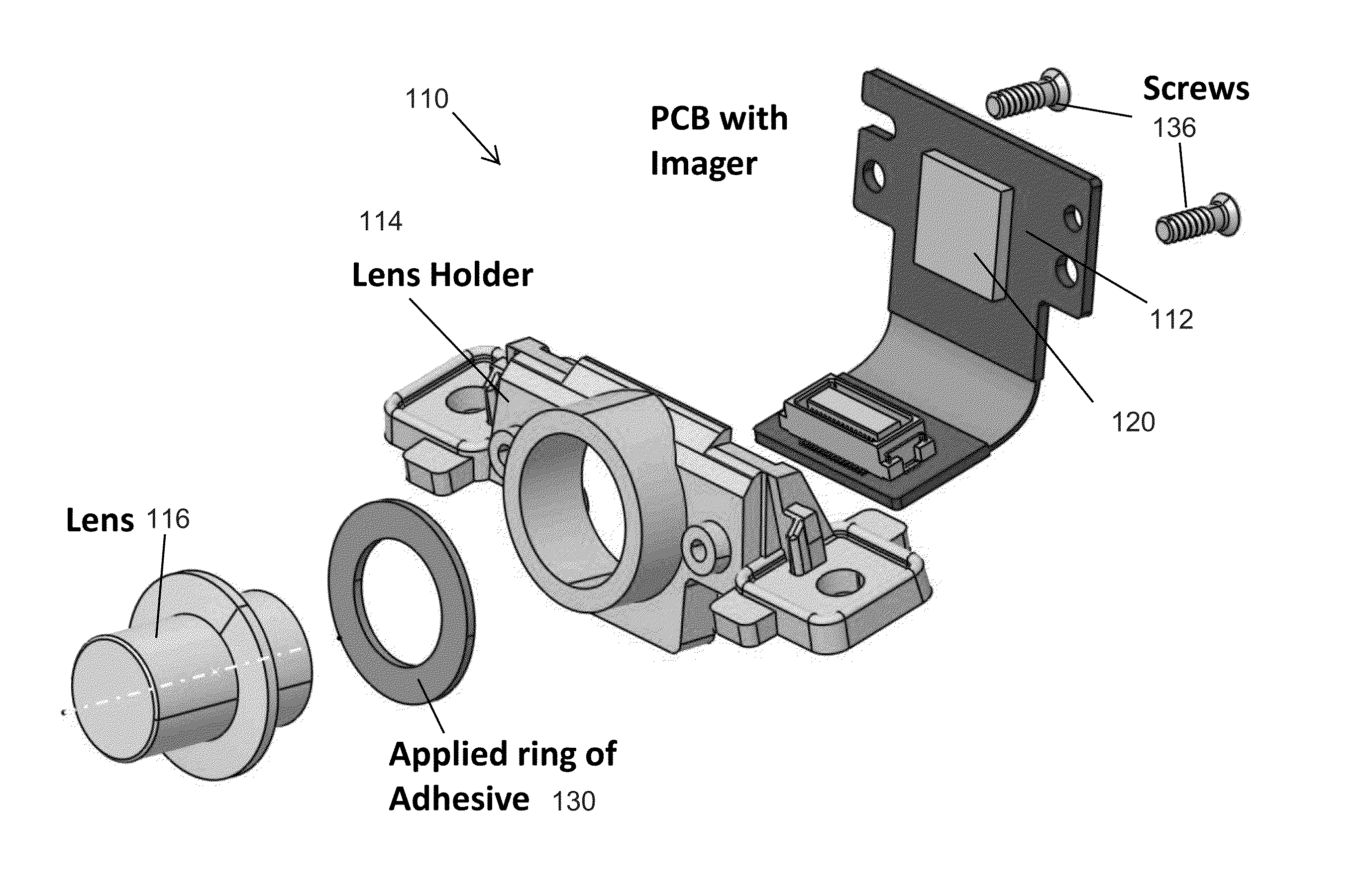

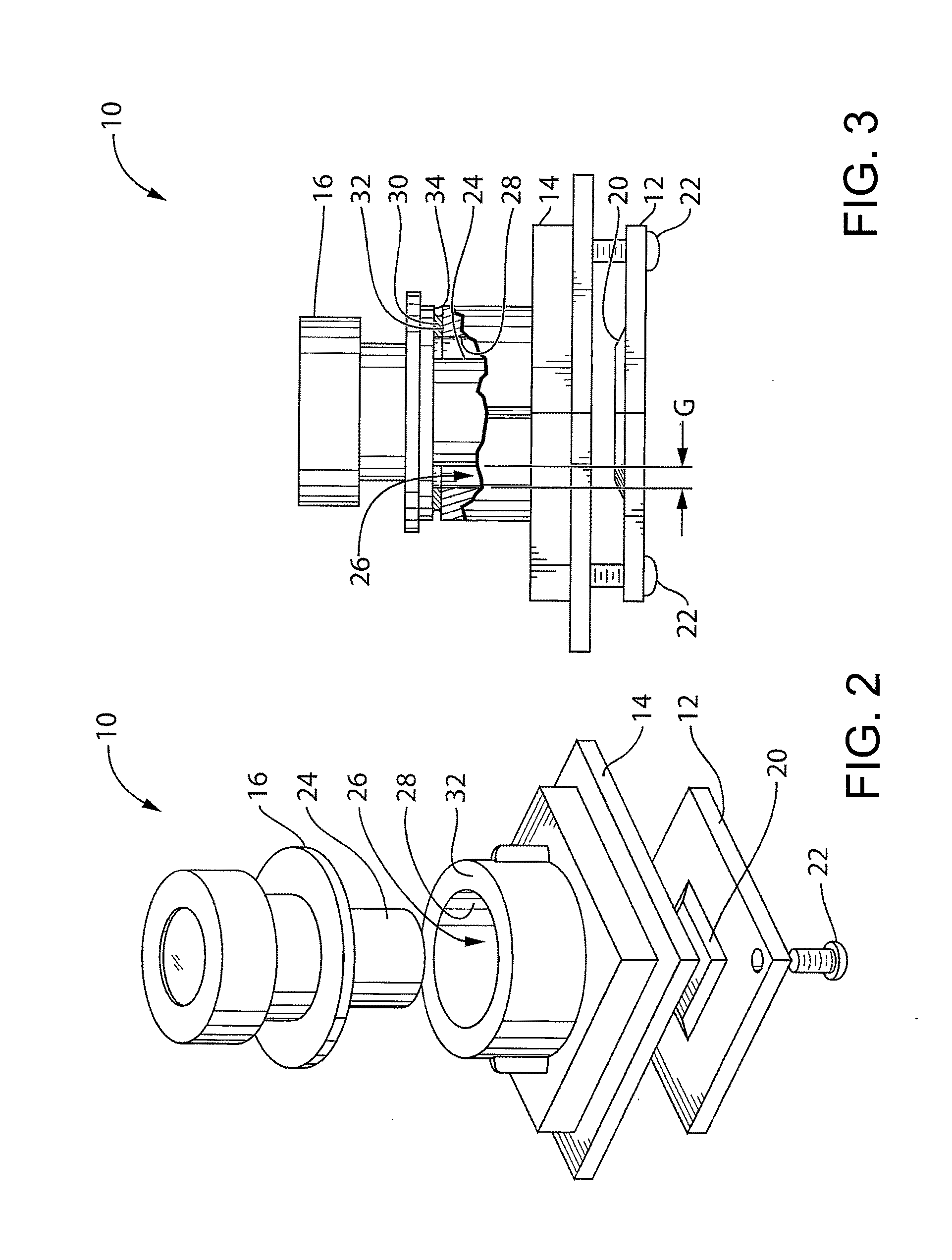

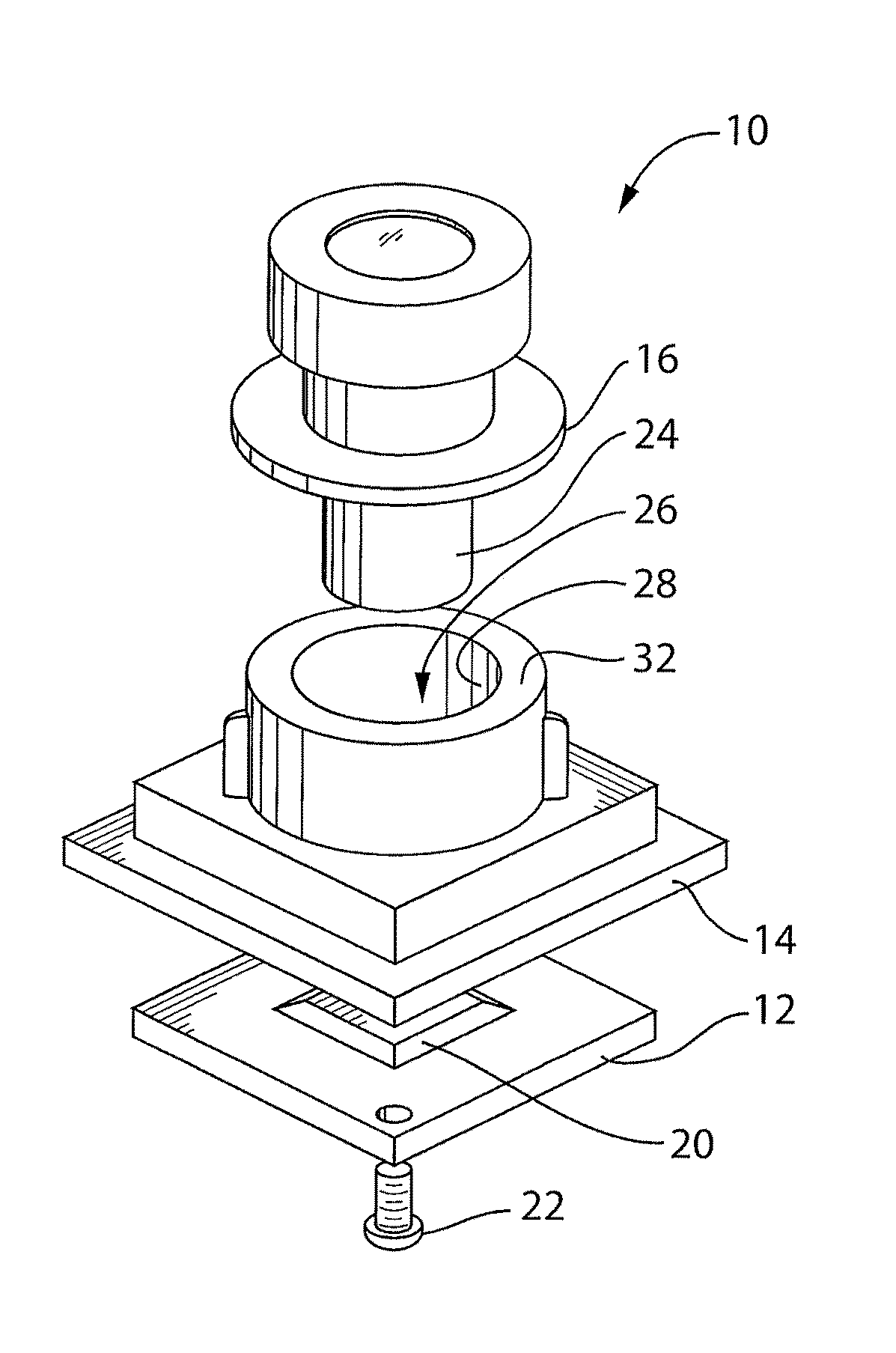

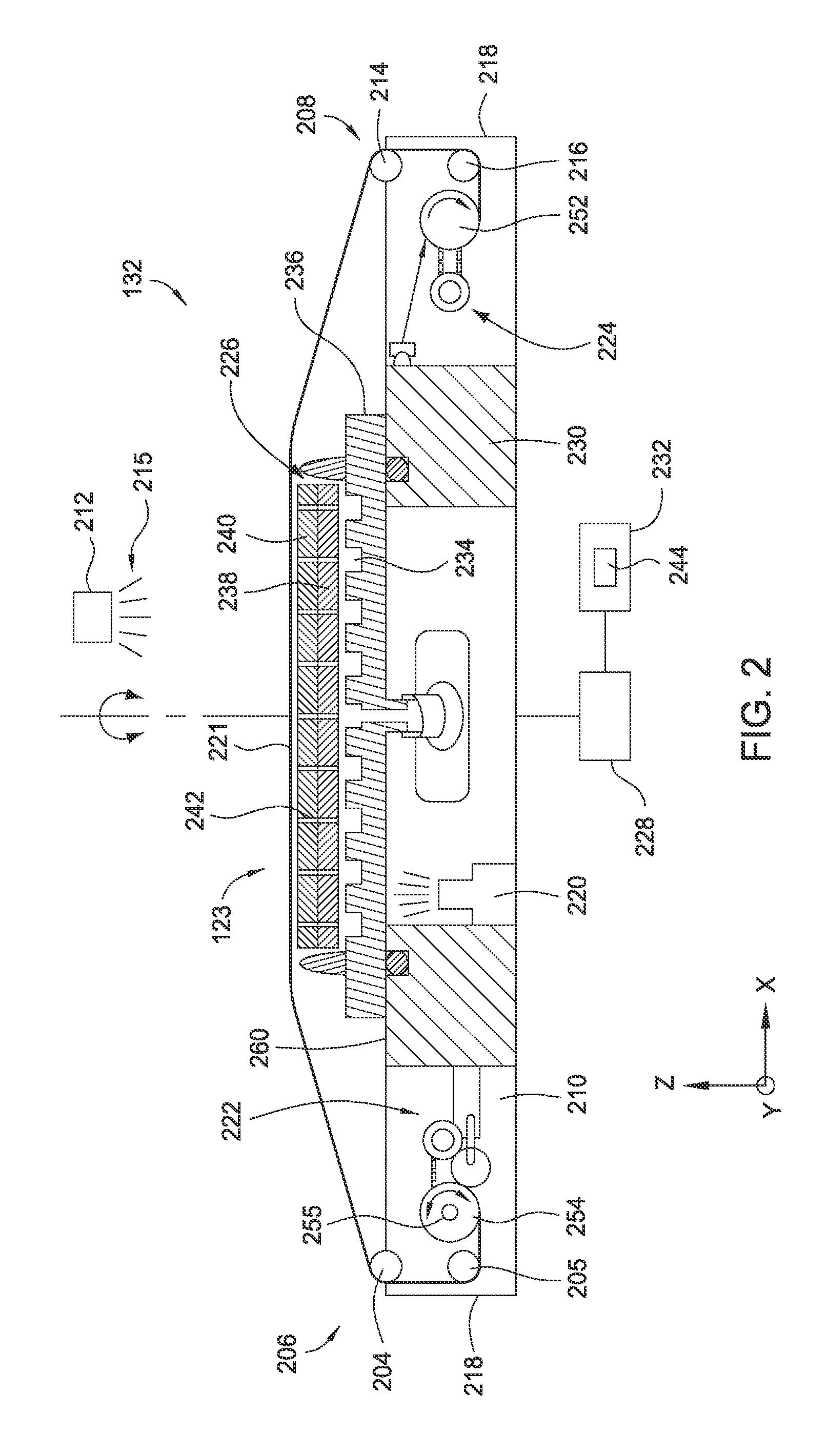

Camera for vehicle vision system

ActiveUS20150124098A1High bonding strengthImprove stabilityTelevision system detailsAdhesive processesAdhesiveEngineering

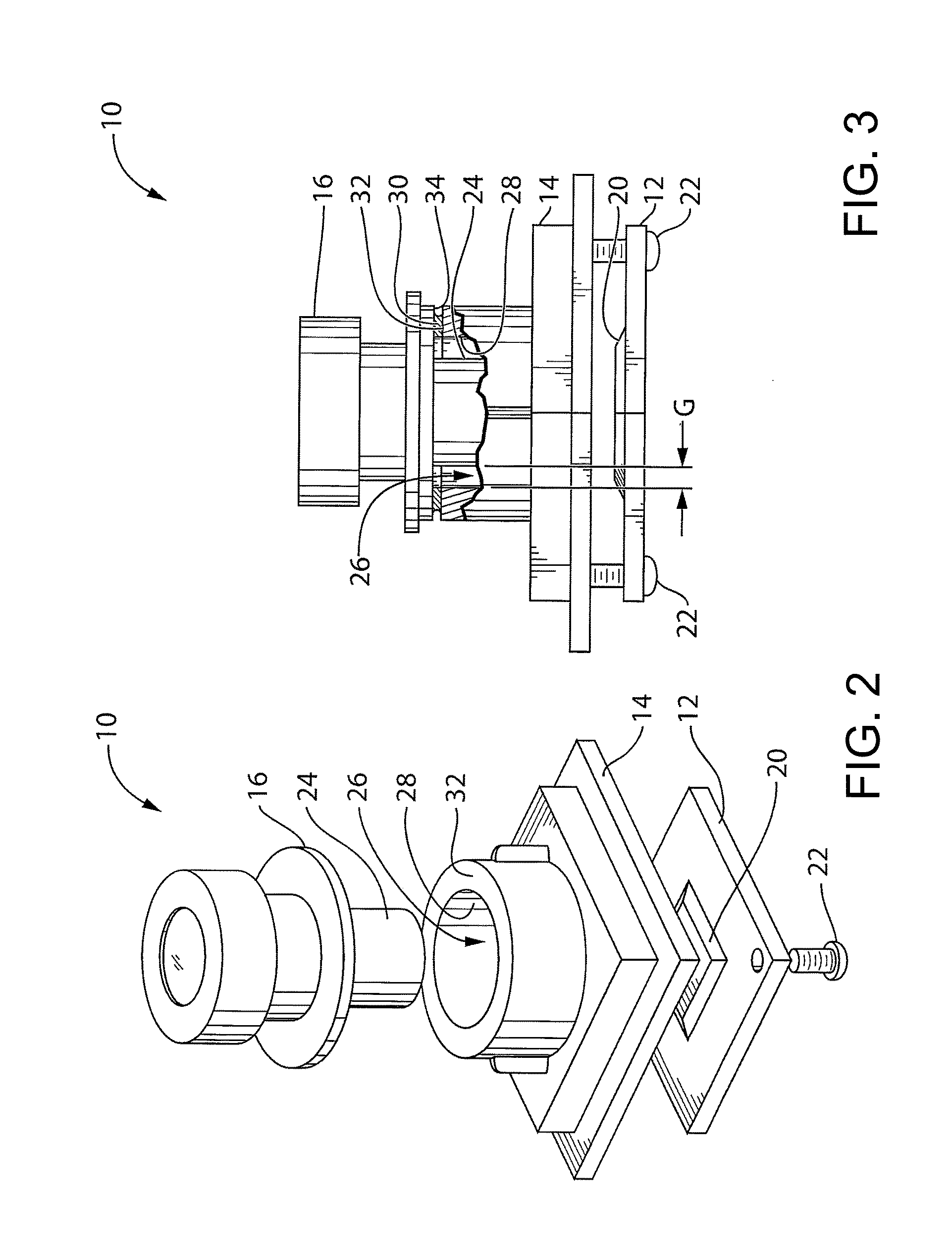

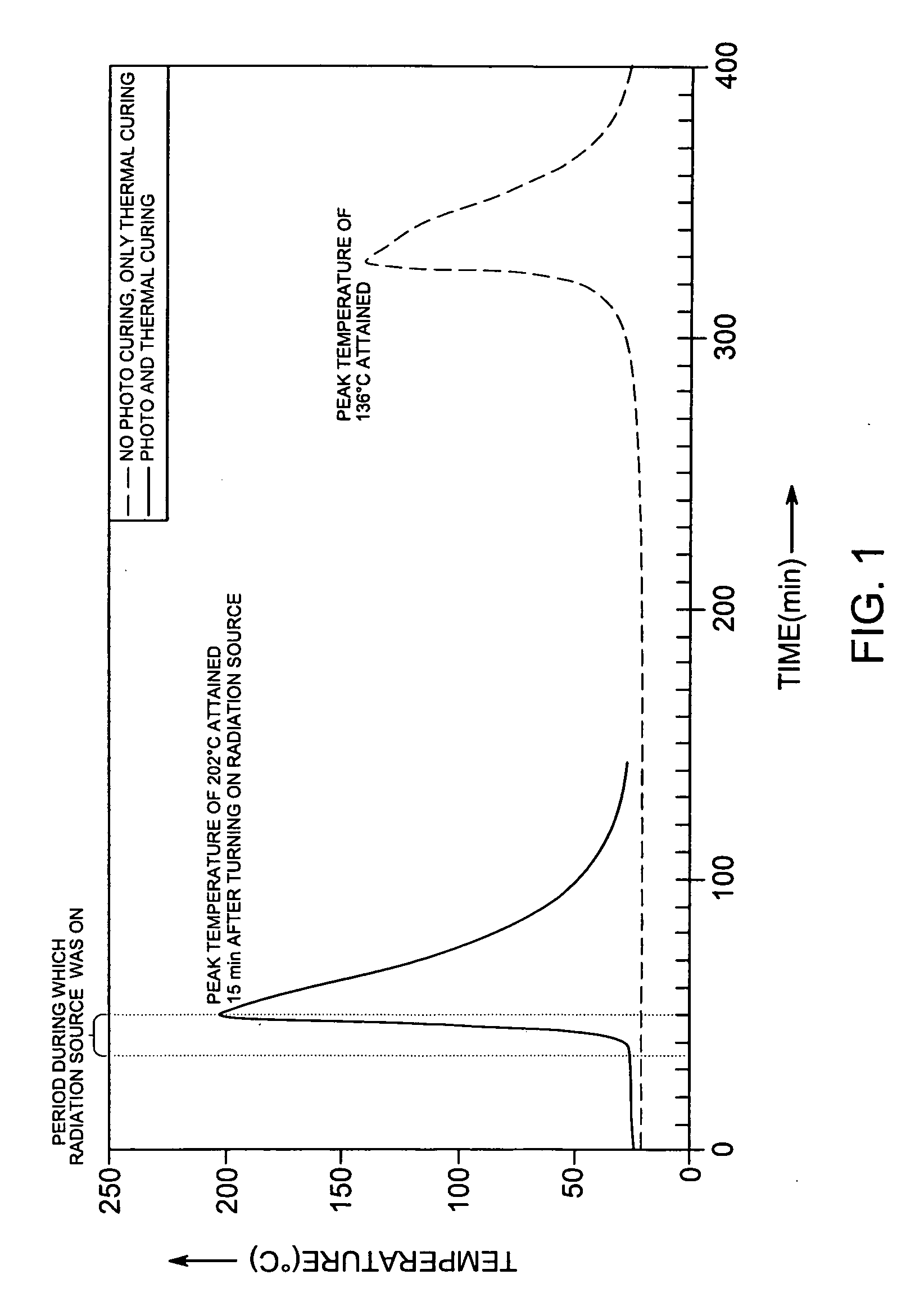

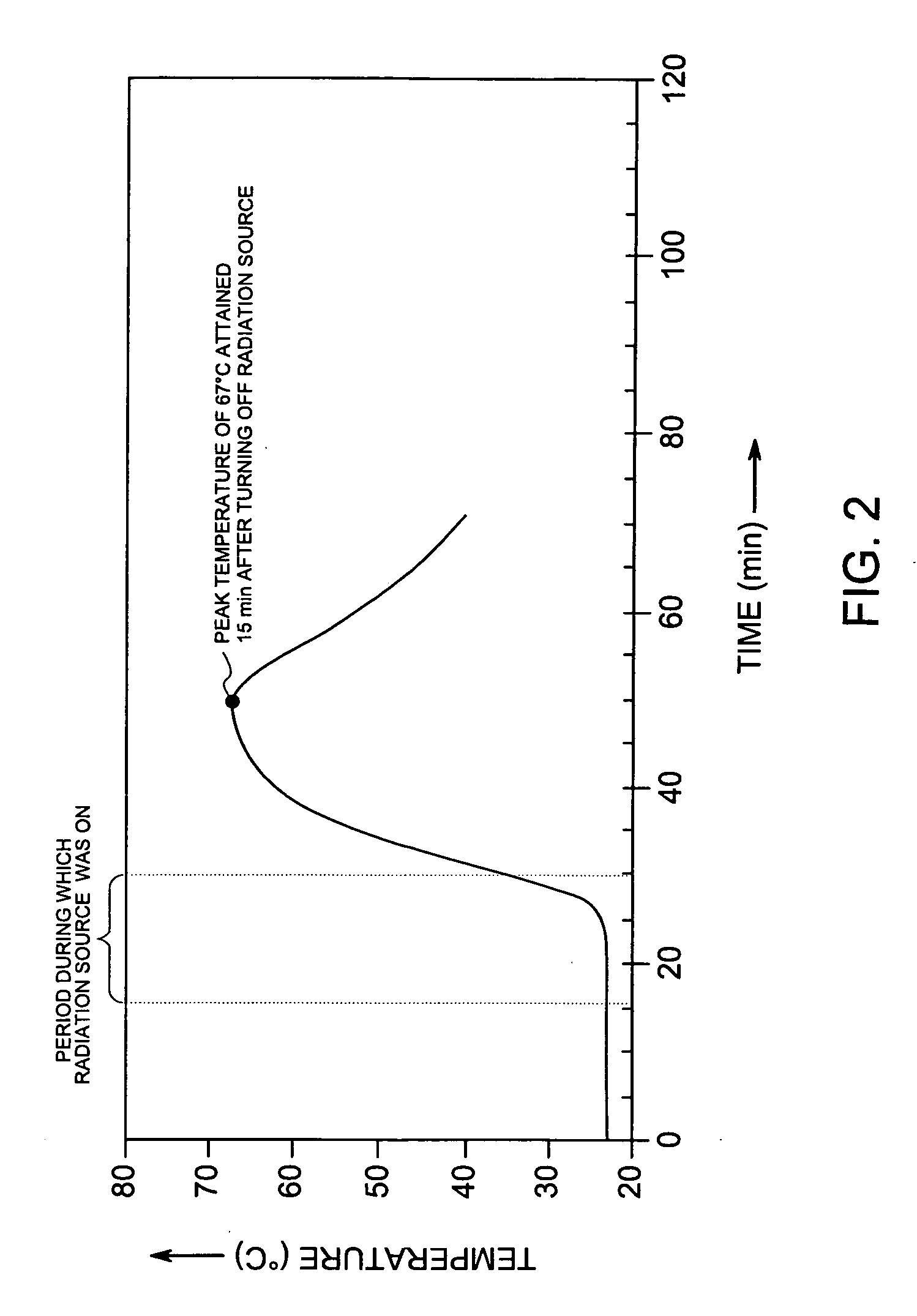

A vehicular camera includes a lens, a printed circuit board and an imager. The lens has a plurality of optical element and is disposed at a lens holder. The imager is disposed at the printed circuit board. The adhesive is initially curable in an initial radiation curing process that comprises exposure to UV light, and initially-cured adhesive is further curable to a further cured strength in a secondary thermal curing process. The adhesive is initially cured via the initial radiation curing process after the lens is brought into focus with the imager and is optically center-aligned therewith. The initially-cured adhesive, as cured via the initial radiation curing process, holds the lens optically center-aligned and in focus with the imager. After the initial radiation curing process, the lens holder, adhesively attached to one of the printed circuit board and the holding element, is moved to the secondary thermal curing process.

Owner:MAGNA ELECTRONICS

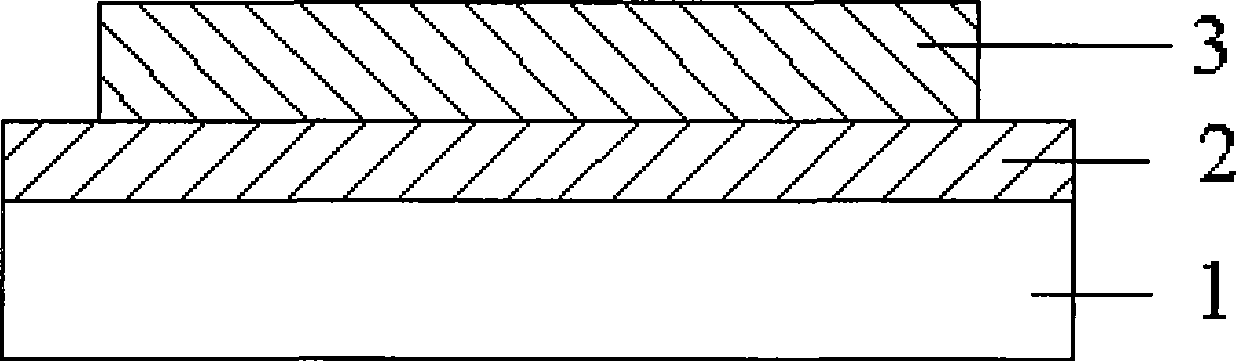

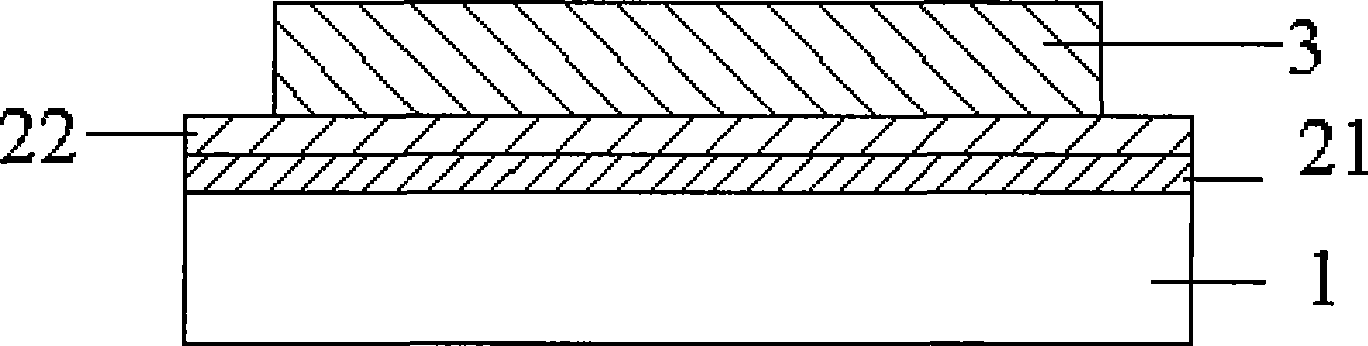

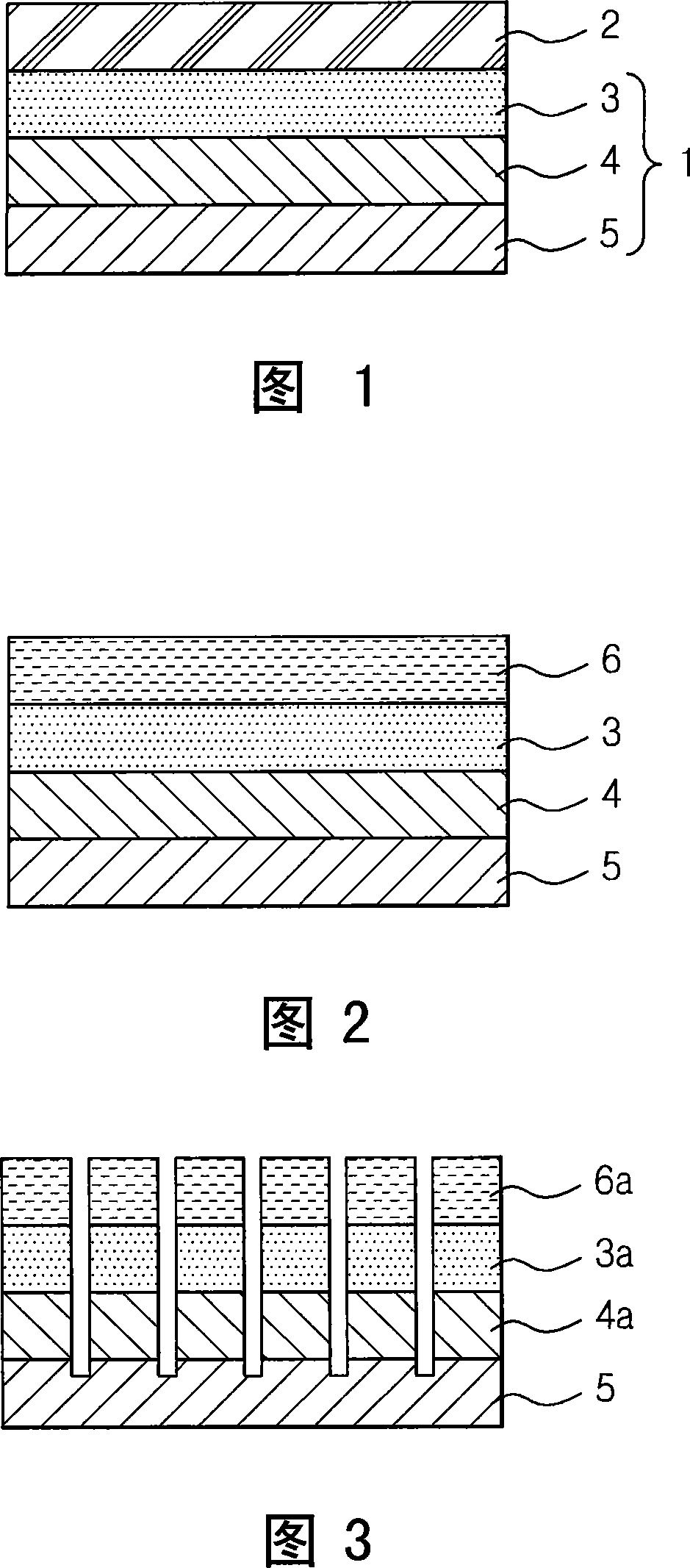

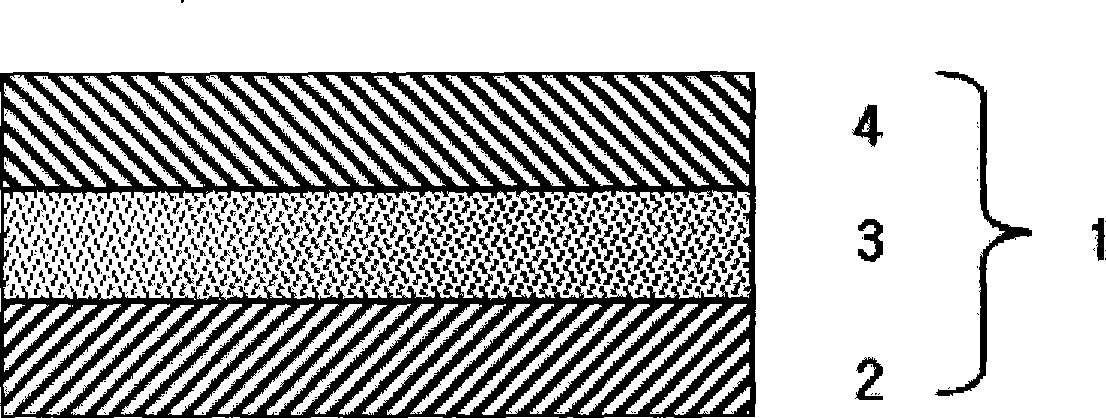

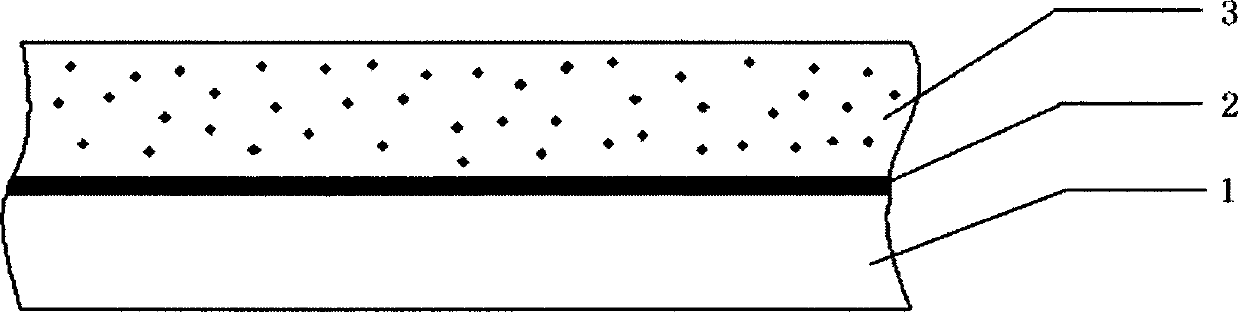

Substrate for flexible organic optoelectronic device and preparation method thereof

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

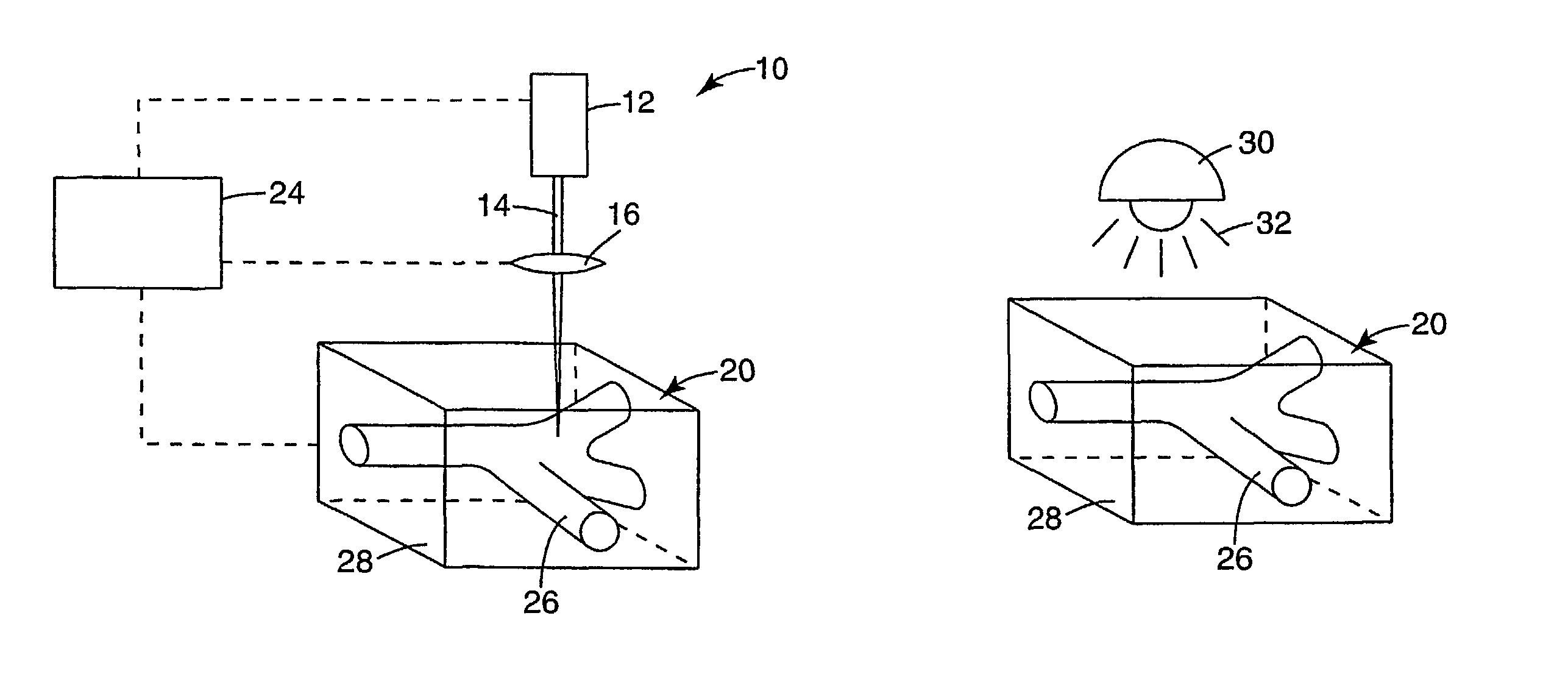

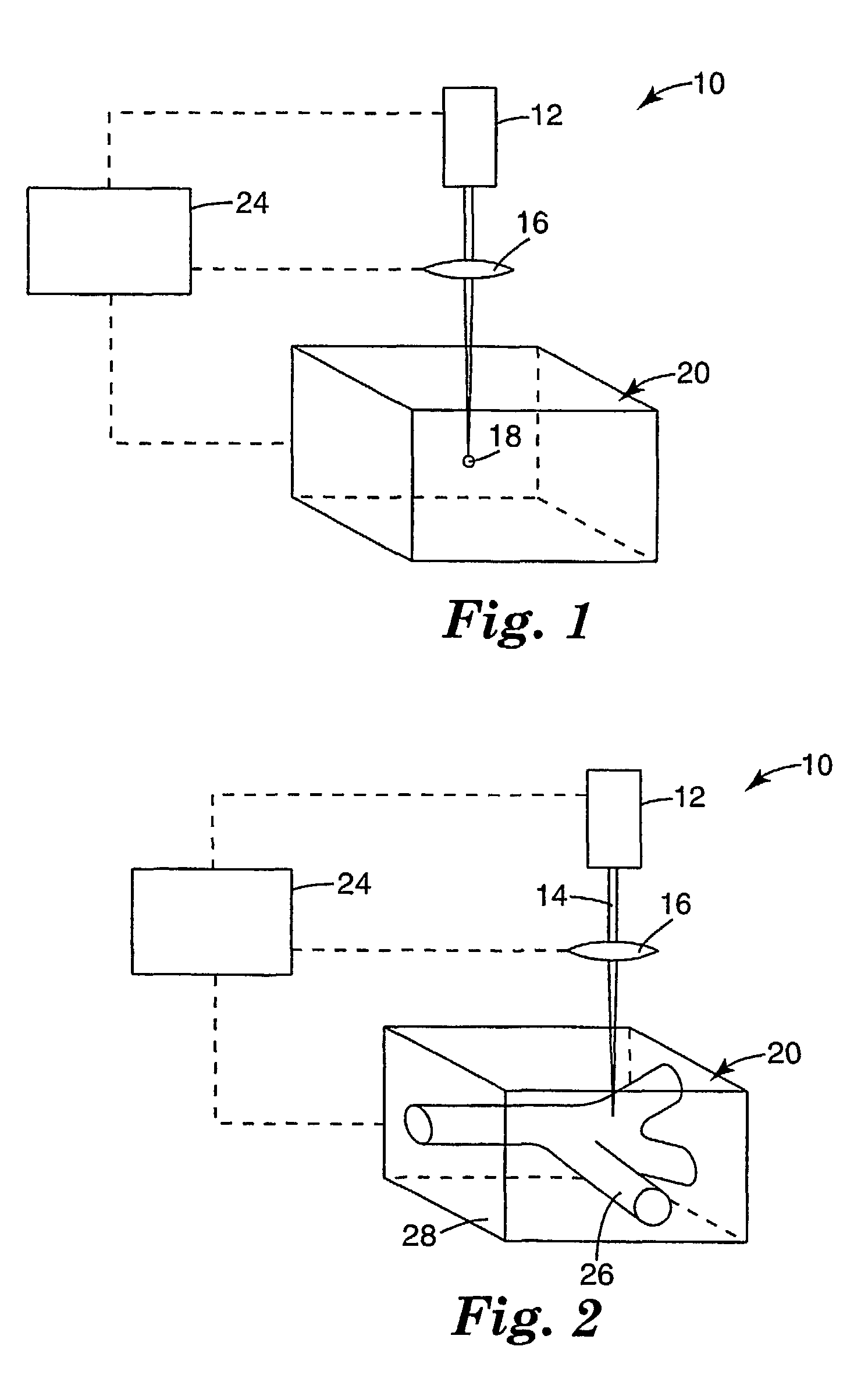

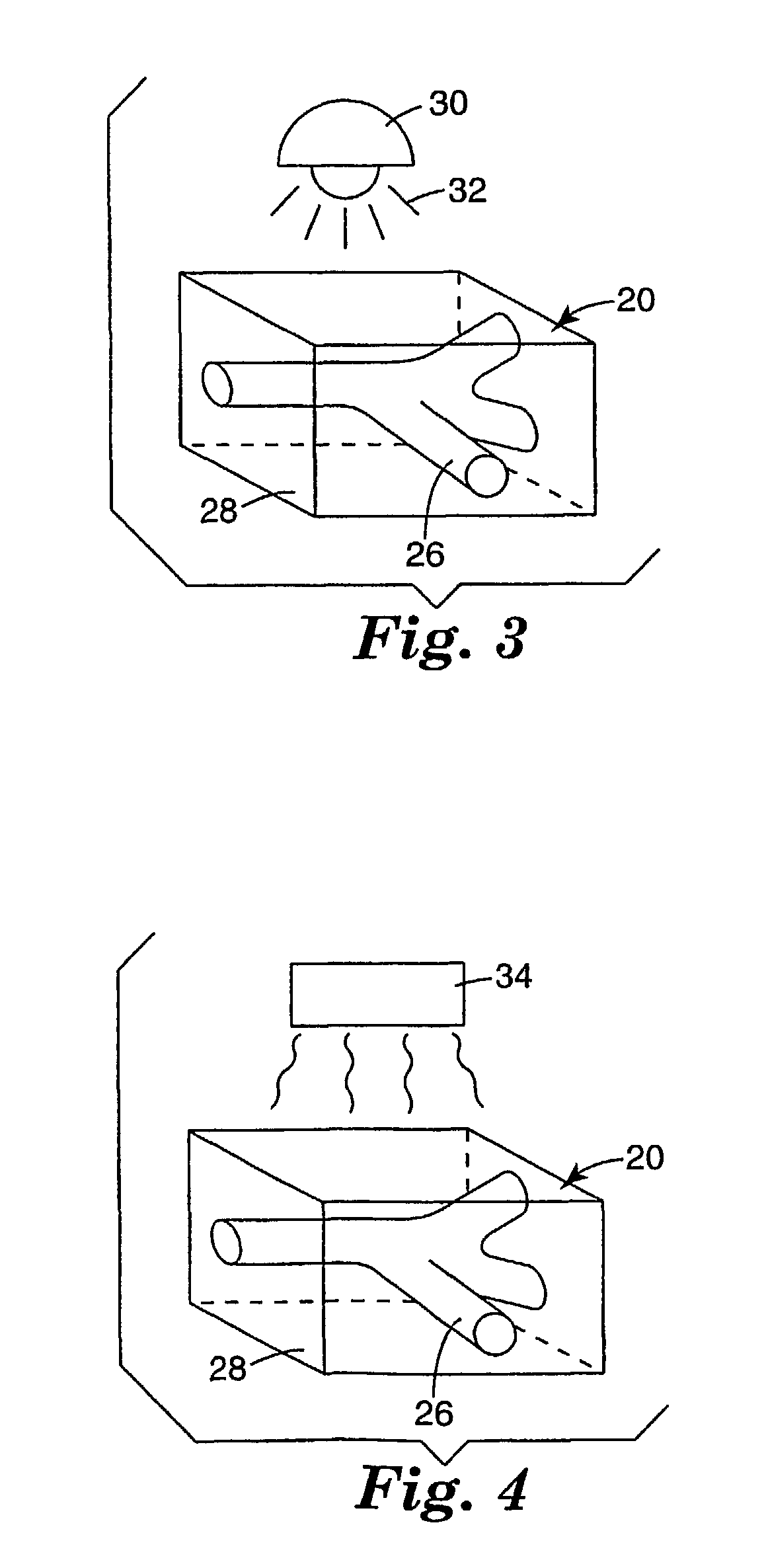

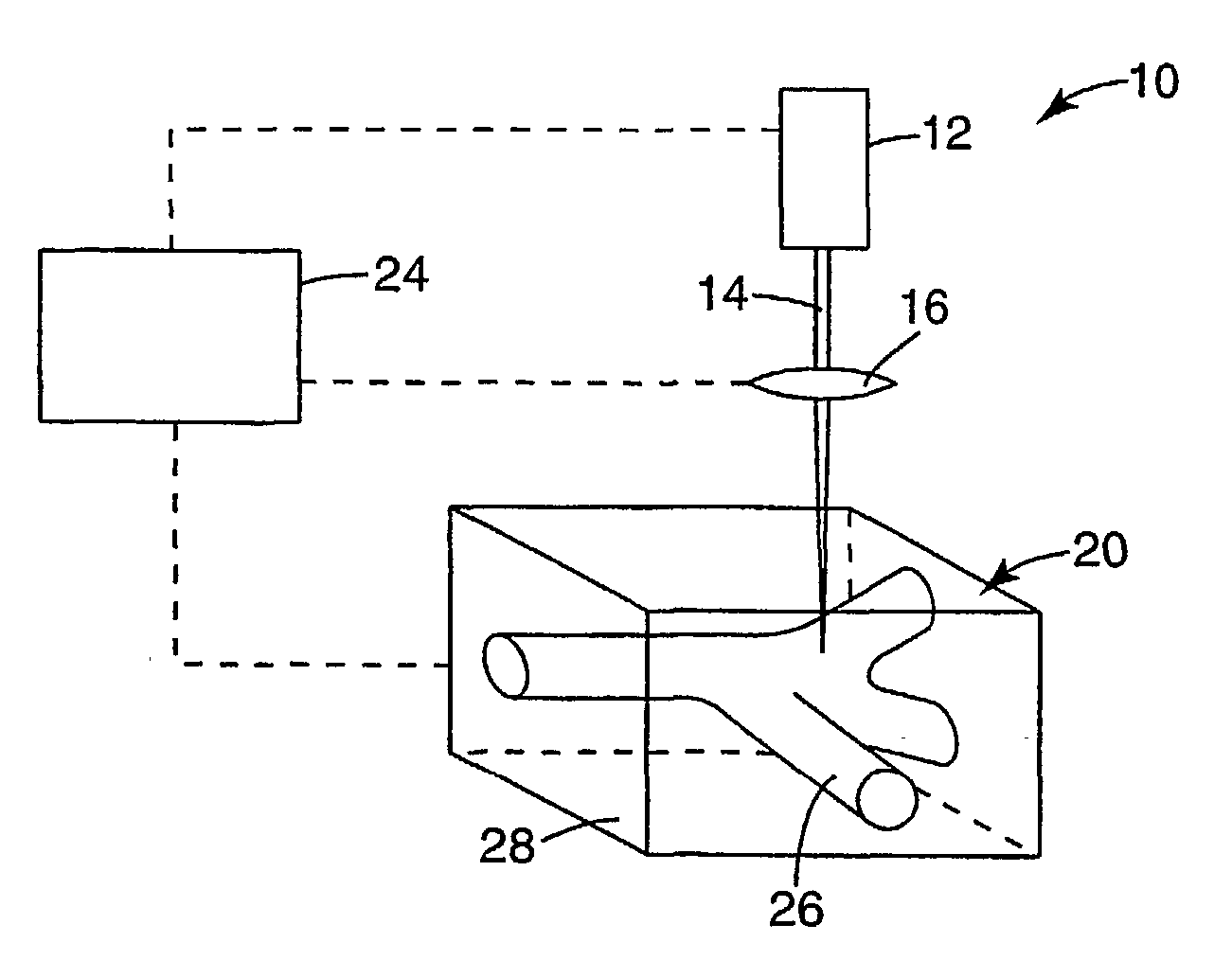

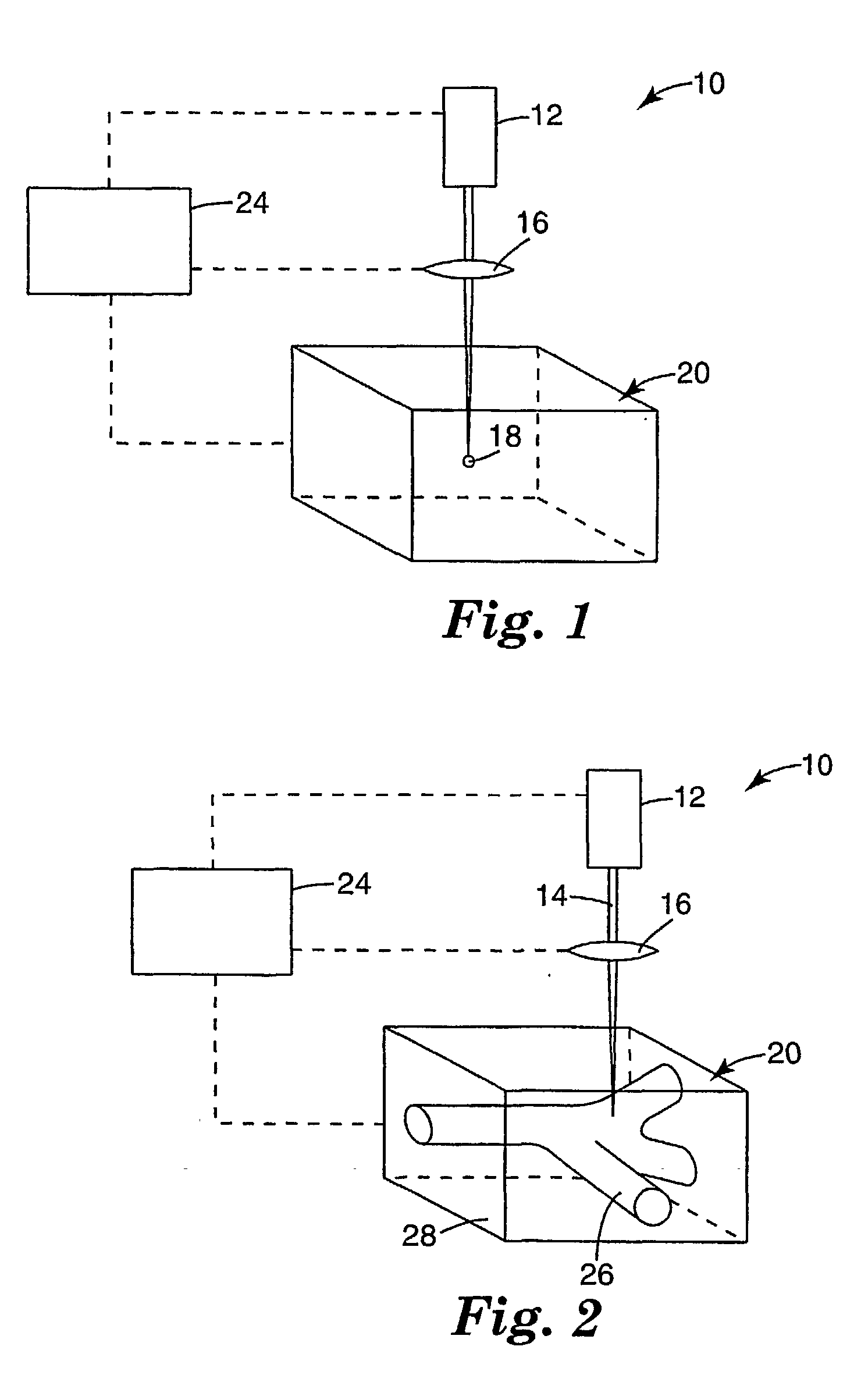

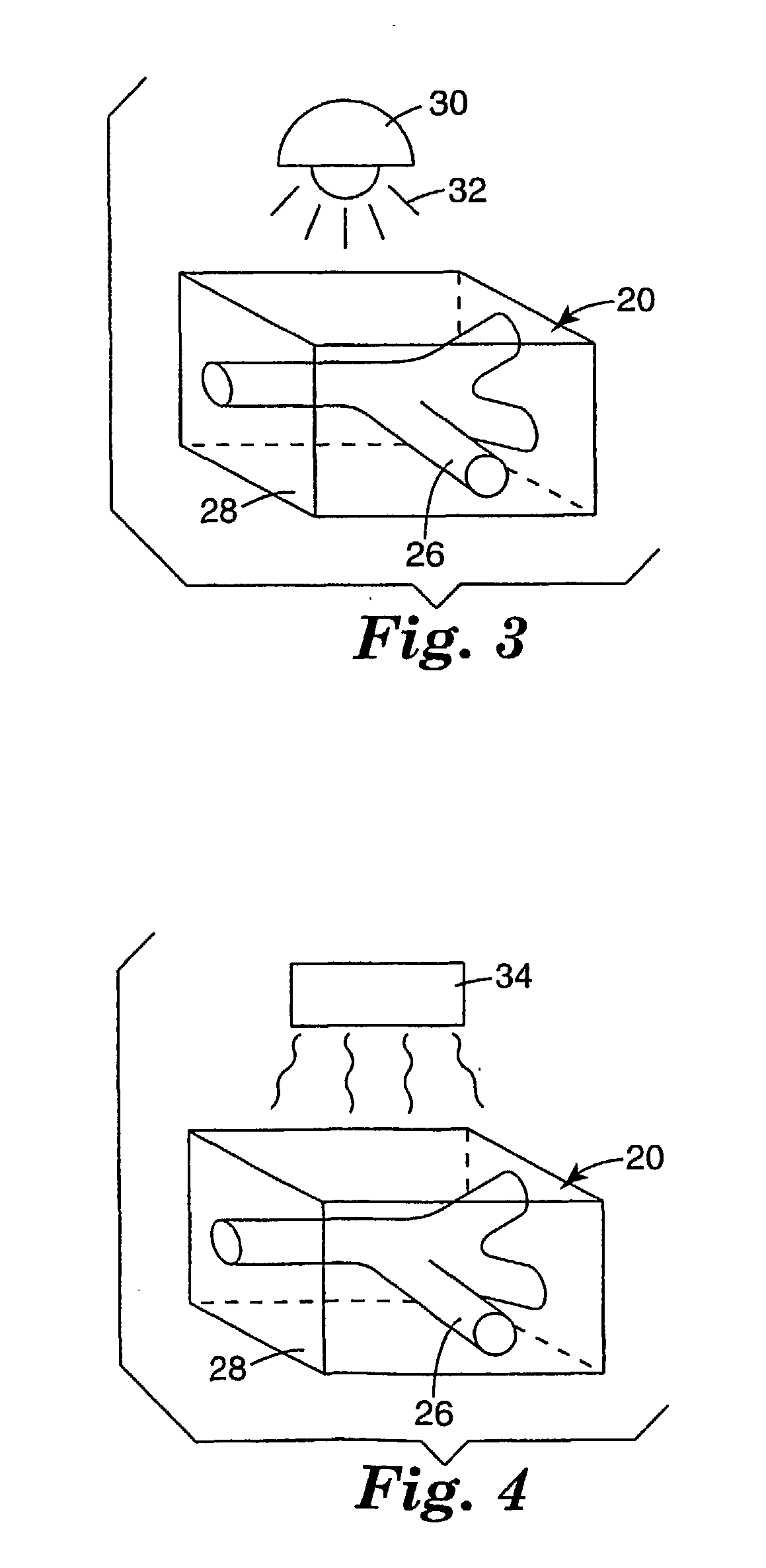

Multiphoton curing to provide encapsulated optical elements

InactiveUS7014988B2Controlled diffusionInduce single and/or multiphoton photopolymerizationAdditive manufacturing apparatusRadiation applicationsHardnessEngineering

Methods of fabricating optical elements that are encapsulated in monolithic matrices. The present invention is based, at least in one aspect, upon the concept of using multiphoton, multi-step photocuring to fabricate encapsulated optical element(s) within a body of a photopolymerizable composition. Imagewise, multi-photon polymerization techniques are used to form the optical element. The body surrounding the optical element is also photohardened by blanket irradiation and / or thermal curing to help form an encapsulating structure. In addition, the composition also incorporates one or more other, non-diffusing binder components that may be thermosetting or thermoplastic. The end result is an encapsulated structure with good hardness, durability, dimensional stability, resilience, and toughness.

Owner:3M INNOVATIVE PROPERTIES CO

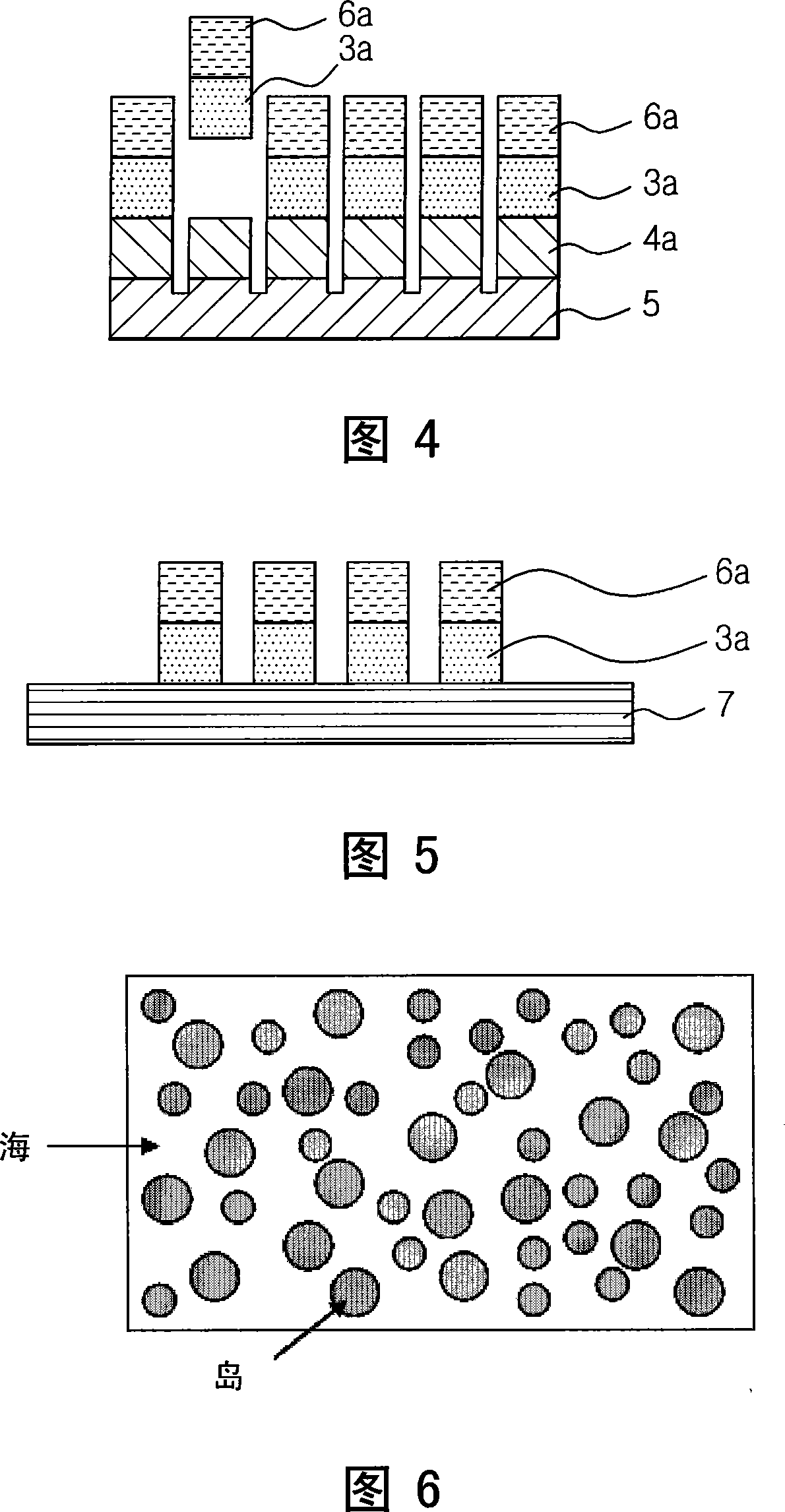

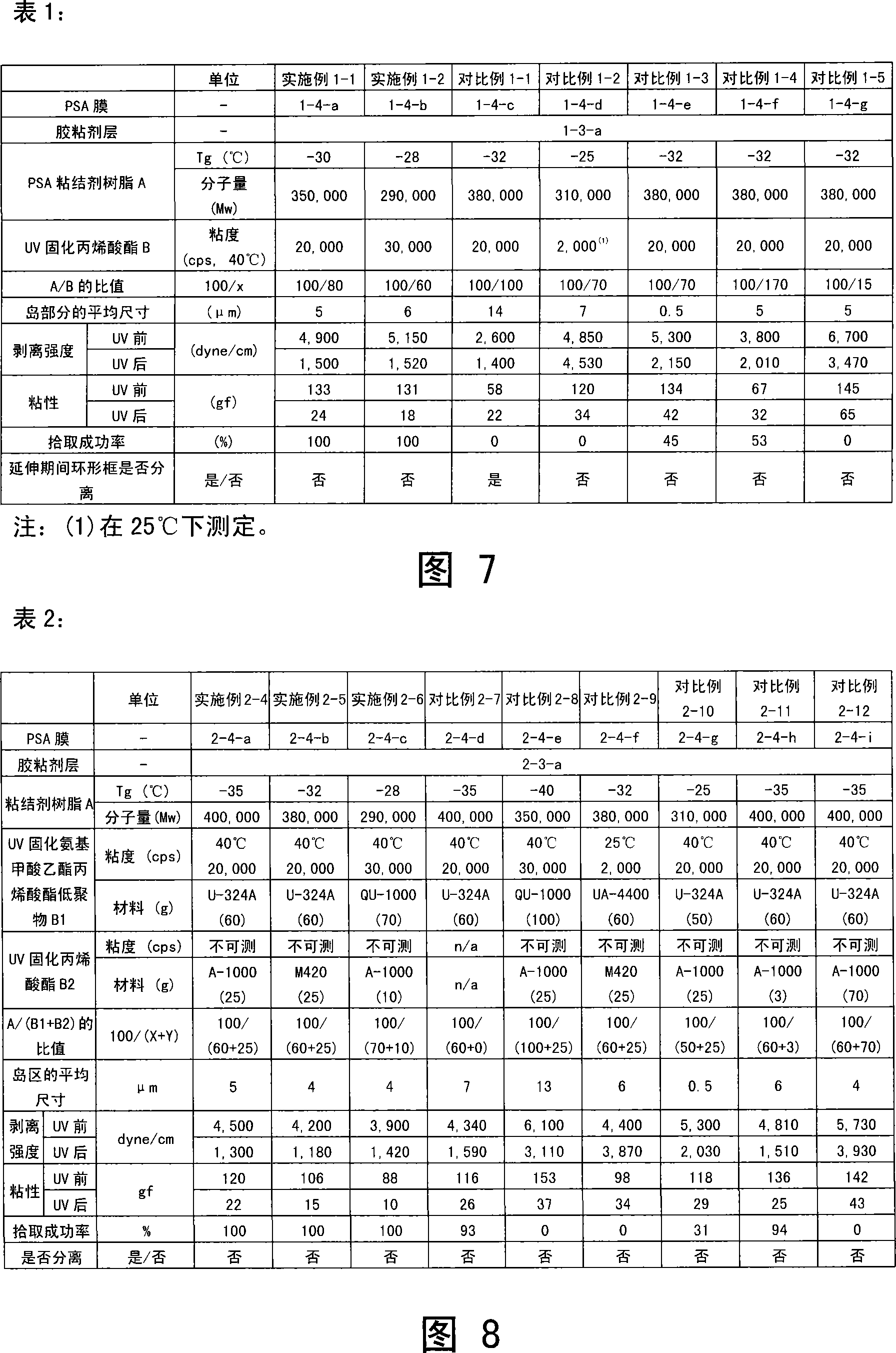

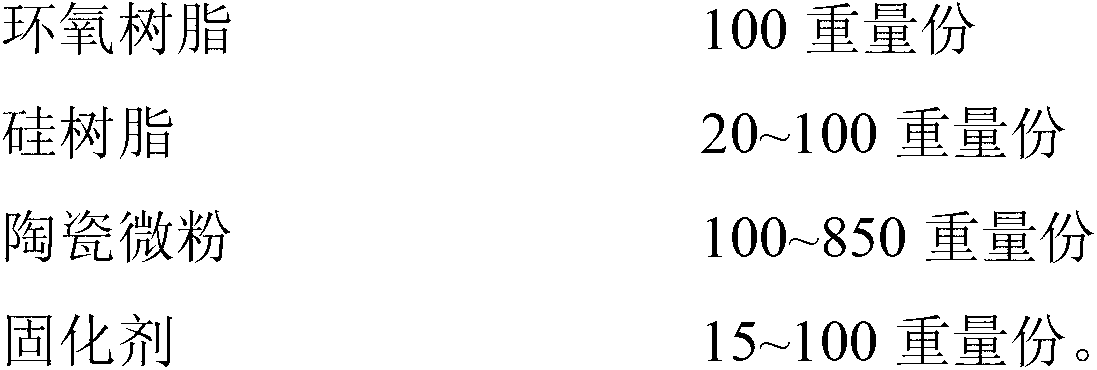

Composition for pressure sensitive adhesive film, pressure sensitive adhesive film, and dicing die bonding film including the same

A composition for forming an adhesive film is provided to prevent an acrylic adhesive binder and UV curable acrylate from being transferred to an adhesive layer when used in a dicing die bonding film, and to realize high pick-up property even in large chips greater than 10 mm X 10 mm after UV irradiation. A composition for forming an adhesive film comprises: (A) 100 parts by weight of a polymer binder resin; (B) 20-150 parts by weight of a low-molecular weight UV curable acrylate; (C) 0.1-10 parts by weight of a thermal curing agent; and (D) 0.1-5 parts by weight of a photopolymerization initiator based on 100 parts by weight of the UV curable acrylate. The adhesive film formed by the composition has a sea-island surface structure, wherein the island region has an average size of 1-10 micrometers.

Owner:CHEIL IND INC

Preparation method of stable superhydrophobic hot liquid coating

ActiveCN105440888AFix performance issuesPolyurea/polyurethane coatingsEpoxy resin coatingsCatalytic effectHydrolysis

The invention discloses a preparation method of a stable superhydrophobic hot liquid coating, and belongs to the technical field of surface coating preparation. According to the preparation method, in an acetone-water mixed system, in the catalytic effect of acid or base, organic silane and nano particles carry out hydrolysis and condensation reactions to obtain organic silane polymer / nano particle compound suspension; then organic resin adhesive is added into the compound suspension, the mixture is evenly mixed and evenly sprayed on the surface of a substrate material, and finally a thermal curing treatment is performed to obtain the stable superhydrophobic hot liquid coating. The prepared coating has an excellent superhydrophobic hot liquid performance, has the advantages of good mechanical stability, chemical stability, and environmental stability, and thus has a good application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High purity photo-thermal curing adhesive and preparation method thereof

InactiveCN101654607AHigh purityAdequate bond strengthModified epoxy resin adhesivesNon-linear opticsEpoxyAdhesive

Owner:YANTAI DARBOND TECH

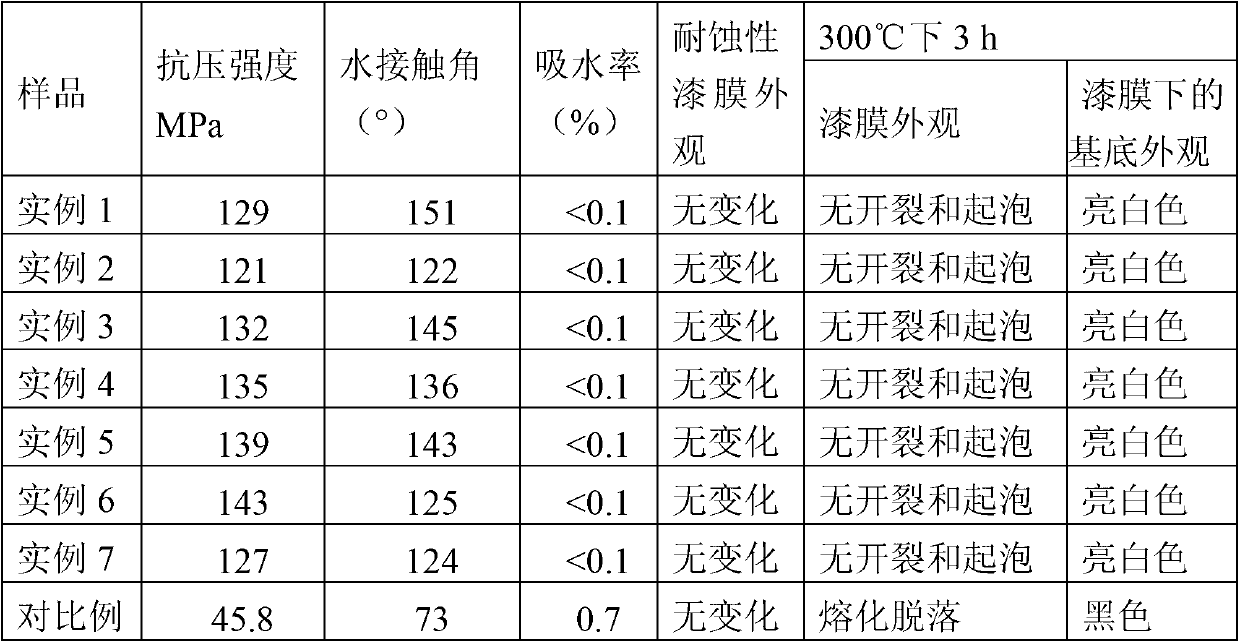

Resin-based flexible ceramic protective coating

ActiveCN103122197AExcellent waterproof and hydrophobic performanceLow water absorptionFireproof paintsAnti-corrosive paintsAviationEpoxy

The invention belongs to the field of coating preparation and discloses a resin-based flexible ceramic protective coating as well as preparation method and using methods thereof. The coating comprises the following components in parts by weight: 100 parts of epoxy resin, 20-100 parts of silicon resin, 100-850 parts of fine ceramic powder and 15-100 parts of curing agent; the fine ceramic powder has the particle size of 1-50mum; and the coating is formed through thermal curing at low temperature. The coating prepared by the invention is environmentally-friendly, free of solvent release, low in carbon content and energy-saving; and the cured coating has flexibility, high pressure resistant strength and excellent waterproof, anticorrosion and temperature resistant properties. The coating provided by the invention is simple in coating process and can be widely applied to the fields such as architectural decoration, petrochemical engineering, ocean ship, electrical equipment, aviation and aerospace.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Dicing die bond film

InactiveUS20120061805A1Good tackinessImprove workabilitySemiconductor/solid-state device detailsSolid-state devicesDie bondingPolymer chemistry

The present invention provides a dicing die bond film in which peeling electrification hardly occurs and which has good tackiness and workability. The dicing die bond film of the present invention is a dicing die bond film including a dicing film and a thermosetting type die bond film provided thereon, wherein the thermosetting type die bond film contains conductive particles, the volume resistivity of the thermosetting type die bond film is 1×10−6 Ω·cm or more and 1×10−3 Ω·cm or less, and the tensile storage modulus of the thermosetting type die bond film at −20° C. before thermal curing is 0.1 to 10 GPa.

Owner:NITTO DENKO CORP

Ultraviolet-thermal double curing coating composition with anti-oxygen inhibition effect and preparation thereof

InactiveCN101412860AEliminate oxygen barrier effectStrong adhesionPolyurea/polyurethane coatingsOligomerChain structure

The invention relates to an ultraviolet photo-thermal double curing paint with oxygen inhibition resistant effect and a manufacturing method thereof. The double paint comprise the following compositions in weight percentage: 3.0 to 57.0 percent of ultraviolet curing oligomer, 7.0 to 40.0 percent of thermal curing polyhydroxy oligomer, 10.0 to 41.0 percent of curing agent, 15.0 to 60.0 percent of active diluted monomer, 0.5 to 9.0 percent of light evocating agent and 0.5 to 5.2 percent of additive. The double curing paint composition is prepared without needing complicated equipment and has application period as long as 7 hours; the main chain structure of the oligomer is provided with a tertiary amine group which removes the influence of oxygen inhibition effect so as to greatly accelerate the curing speed and complete the light curing process in a short period of between 5 and 15 seconds; after the ultraviolet photo-thermal double curing, a thick paint film with thickness of between 60 and 120 mu m can be prepared; and the obtained paint film has good leveling, high hardness, good impact resistance, good toughness and strong adhesive force and is suitable for coating various substrates.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Camera for vehicle vision system

ActiveUS9451138B2Improve stabilityHigh strengthAdhesive processesTelevision system detailsAdhesiveEngineering

Owner:MAGNA ELECTRONICS INC

Dual cure compositions, methods of curing thereof and articles therefrom

InactiveUS20070066698A1Synthetic resin layered productsGlass/slag layered productsPolymer scienceCyclic ether

Disclosed herein are dual cure compositions, methods to cure dual cure compositions, the dual cure compositions comprising at least one filler, at least one curable monomer comprising at least one of an ethylenic unit or cyclic ether unit or mixture thereof; at least one photoinitiator; and at least one thermal initiator. The method comprises the step of photocuring by exposing the compositions to radiation to at least partially photocure the composition, which in turn generates an exotherm which initiates thermal curing. The methods may be used to make cured thick compositions and sandwich structures. Articles made by the methods are also described.

Owner:GENERAL ELECTRIC CO

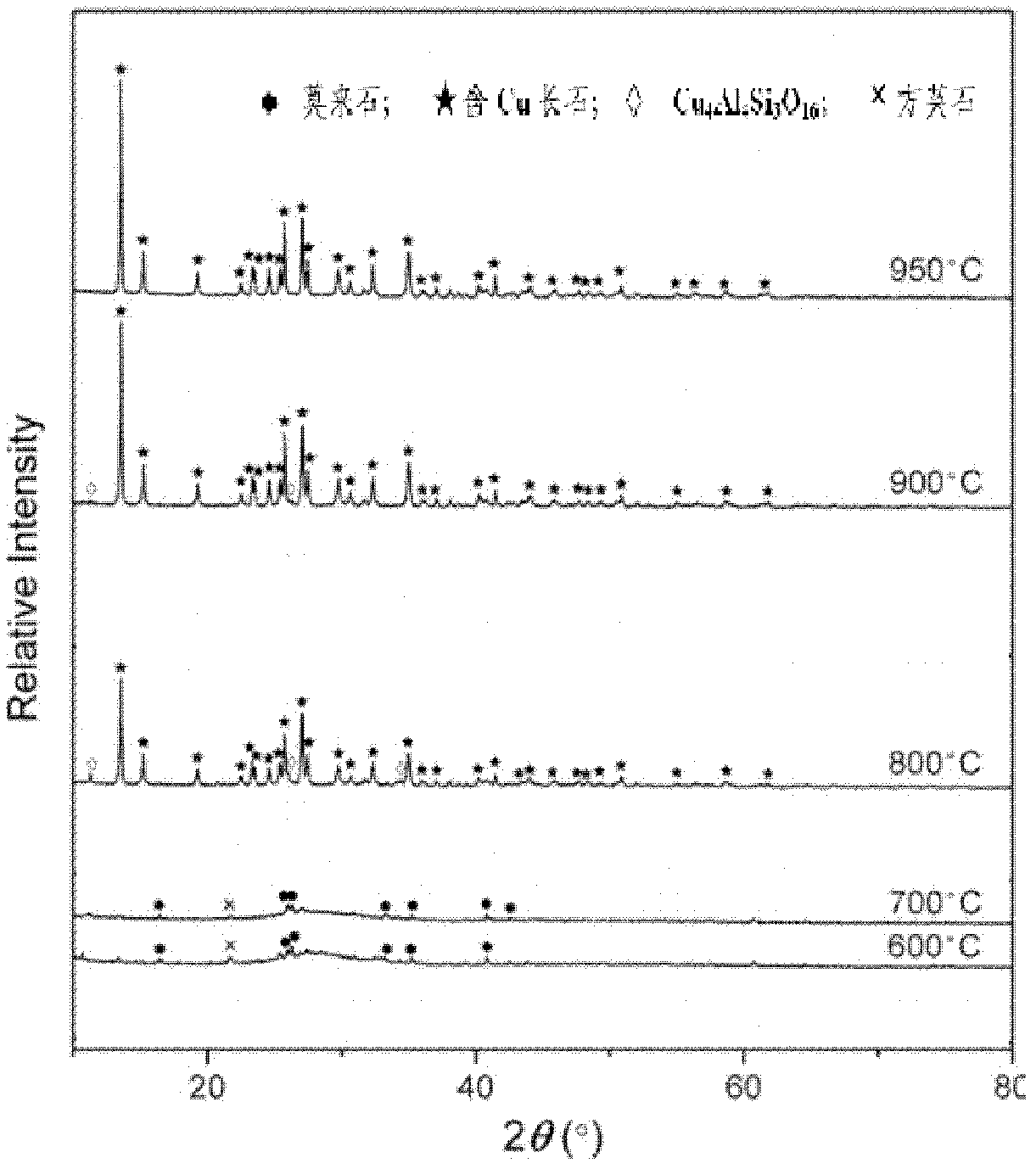

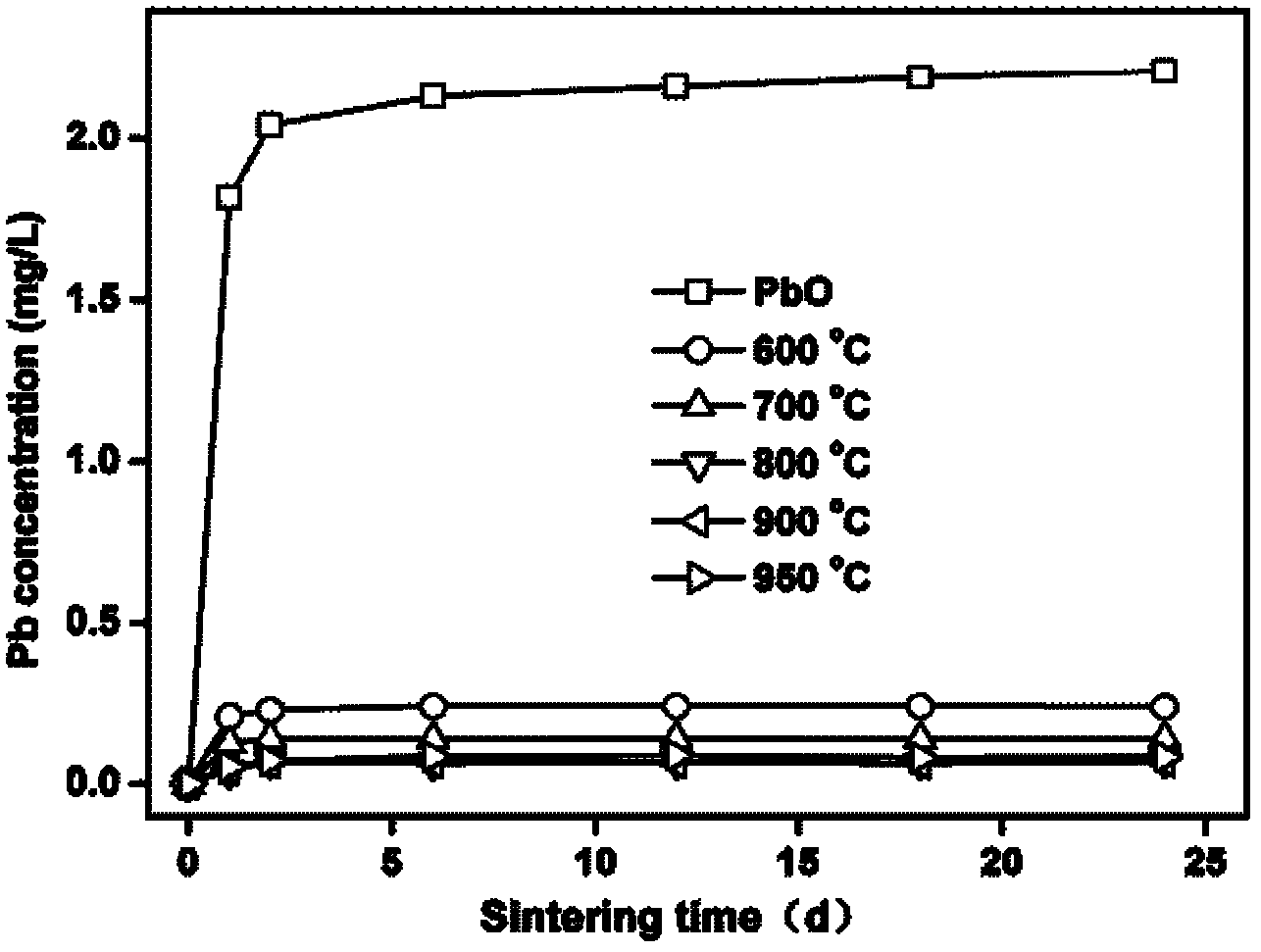

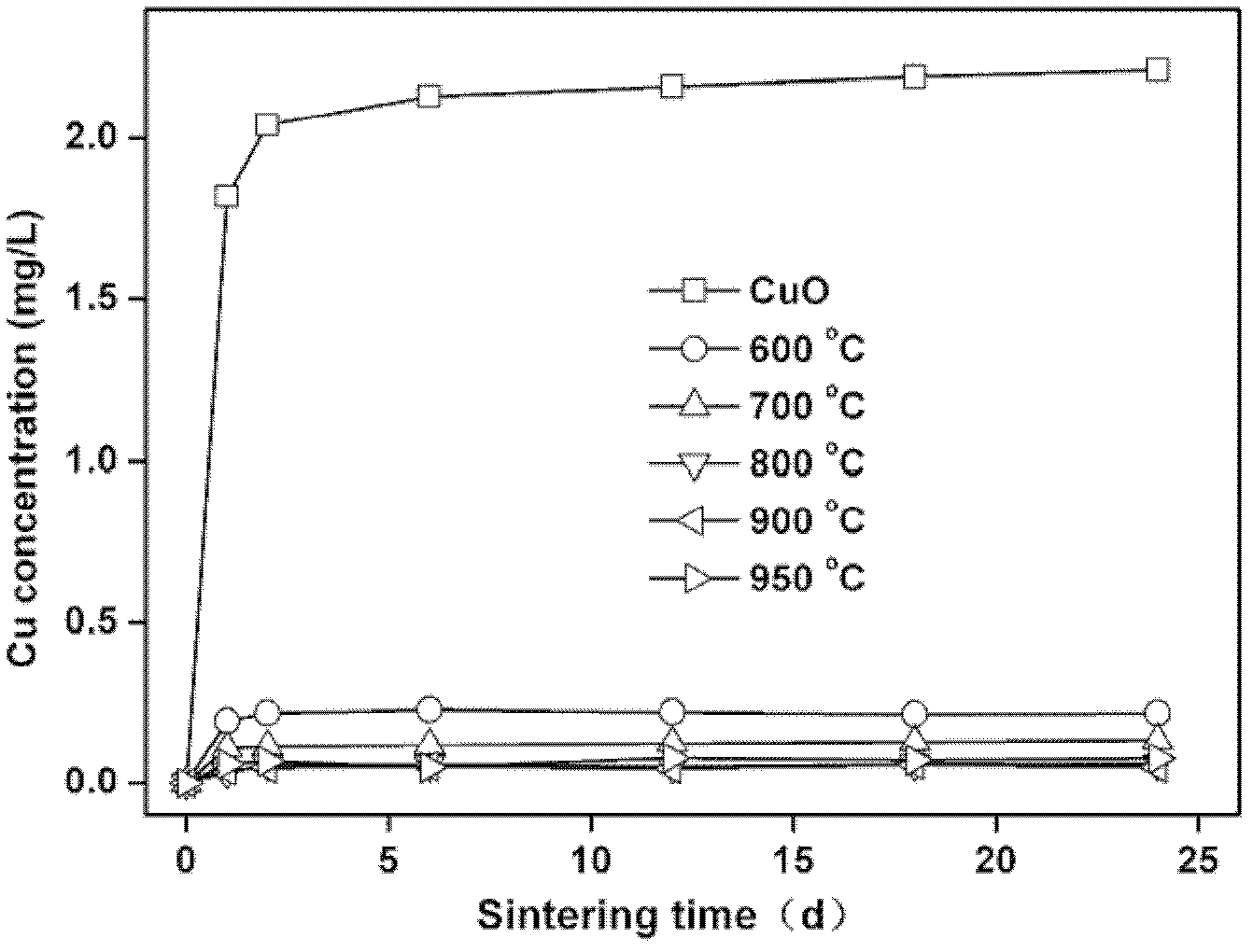

Clay-based heavy metal thermal curing agent and its method for curing heaving metal

ActiveCN102657925ANothing producedEasy to handleContaminated soil reclamationOrganic fertilisersMass ratioStone dust

The invention discloses a clay-based heavy metal thermal curing agent and its method for curing heavy metal. The clay-based heavy metal thermal curing agent comprises, by weight, 40-60% of clay, 5-15% of iron oxide, 20-30% of fly ash and 15-25% of stone flour. The method provided by the invention comprises the following steps of: uniformly mixing the clay-based heavy metal thermal curing agent and a heavy metal pollutant according to the mass ratio of 1: 5-10: 1, carrying out extrusion moulding on the mixed sample at the pressure of 300-1000Mpa, and sintering the molded sample at the temperature of more than 800 DEG C for 2-5 h to obtain a recycled material. According to the invention, heavy metal is coalesced by absorption of clay to heavy metal; fly ash and stone flour are used to fully mix heavy metal with the clay-based heavy metal thermal curing agent during the mixing process; iron oxide and alumina components in the clay-based heavy metal thermal curing agent react with heavy metal at the temperature of more than 800 DEG C for high-temperature fusion glass transition so as to form a spinel structure; and heavy metal in the form of spinel and feldspar crystal structural components is fixed in the heavy metal thermal curing agent to form the recycled material.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

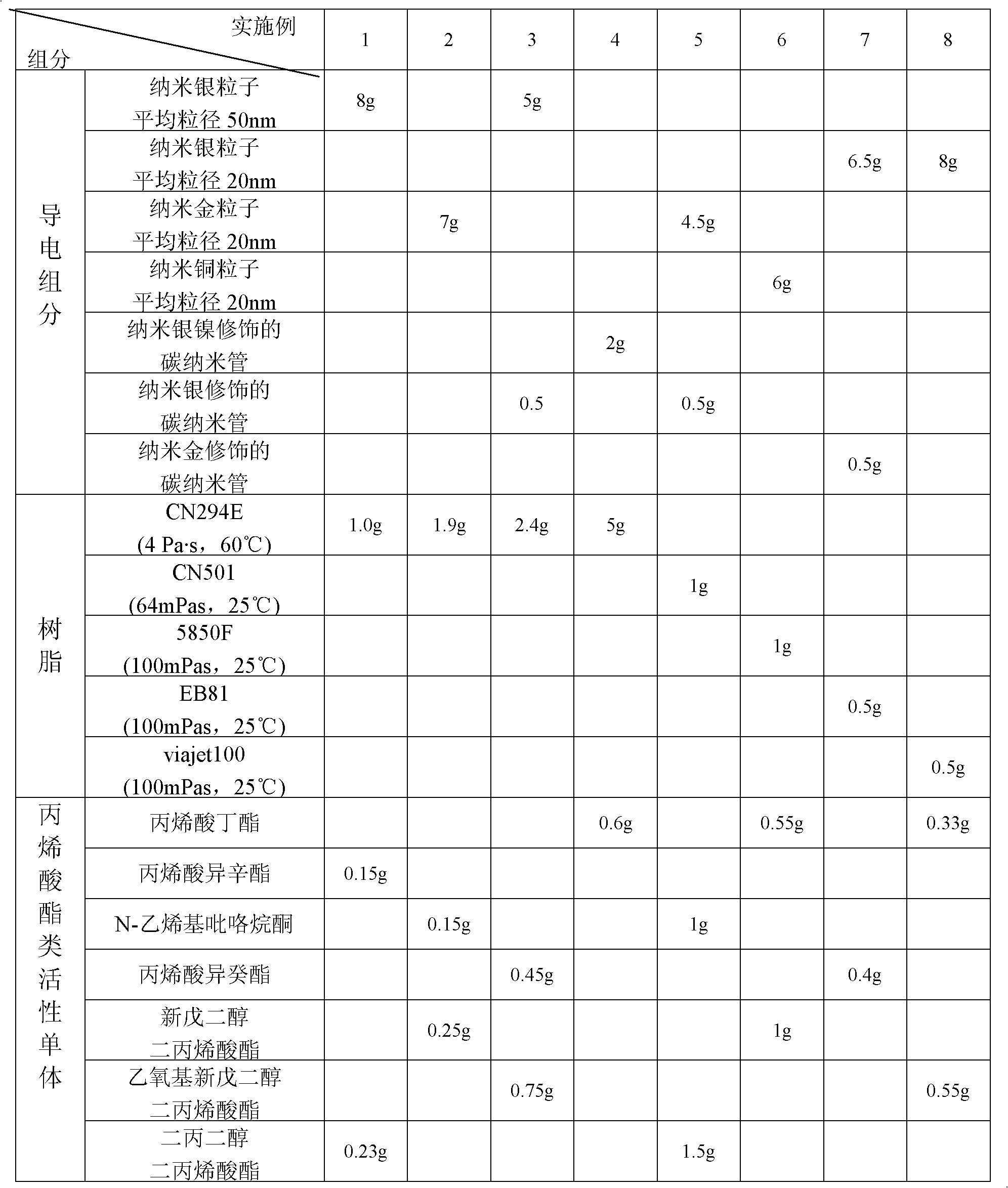

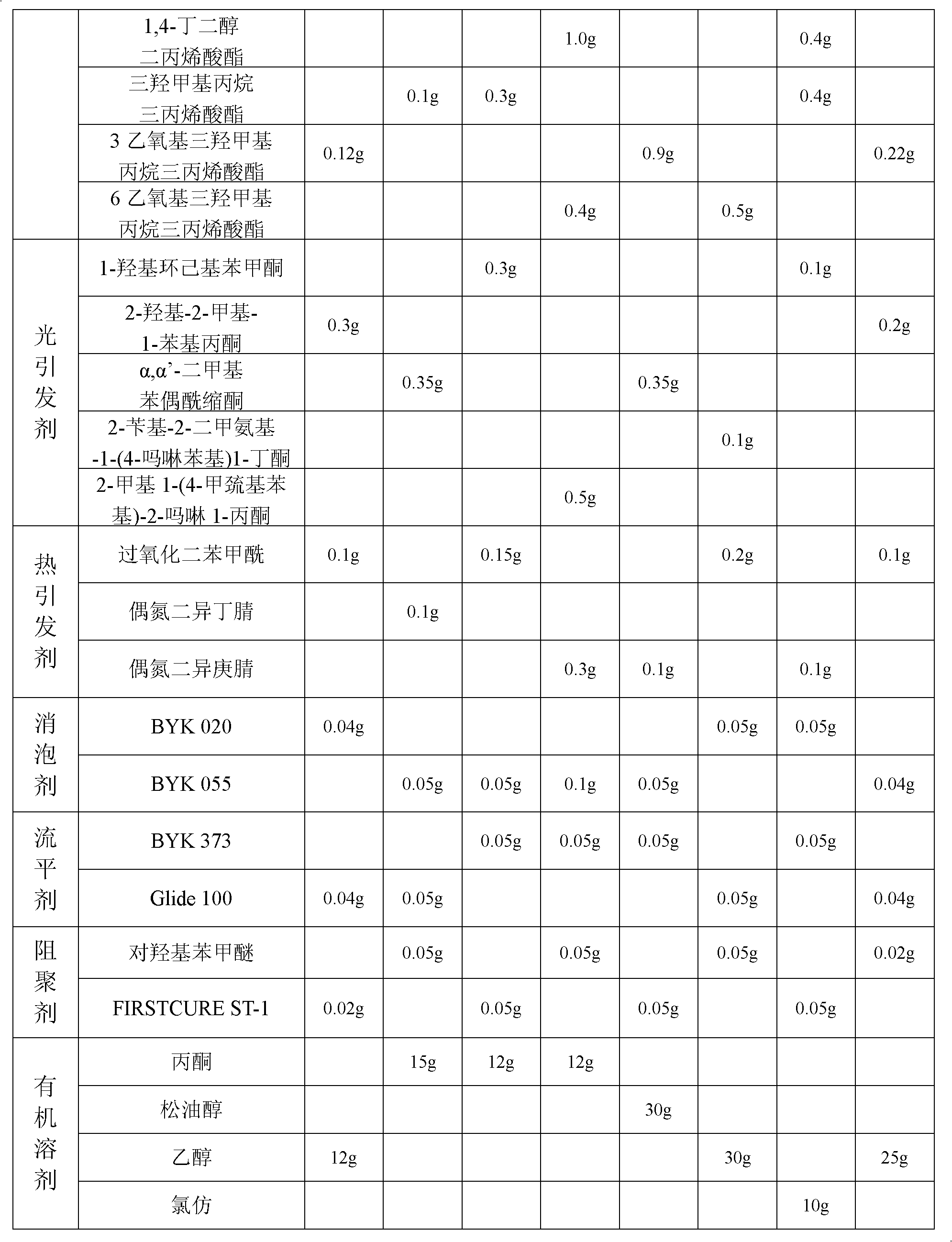

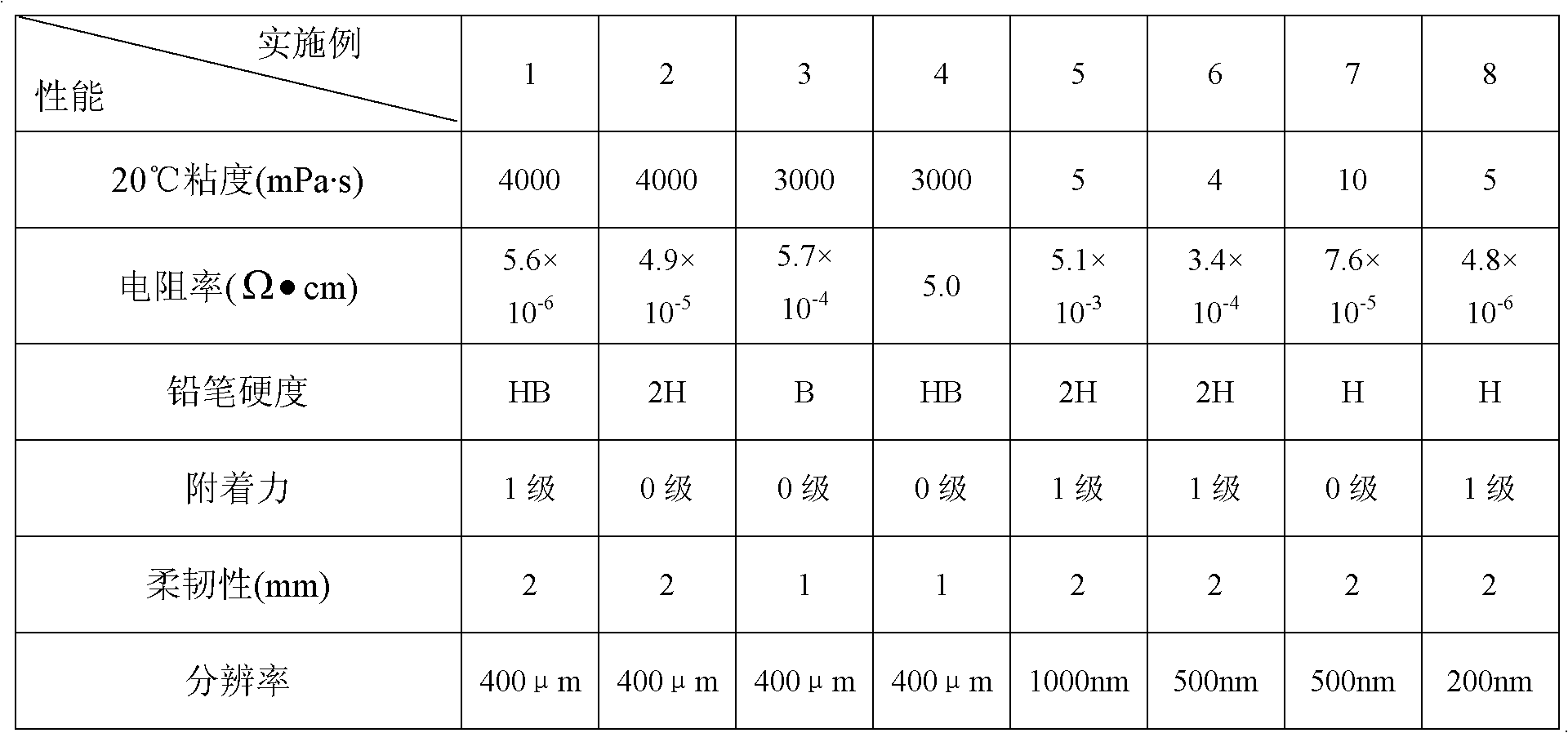

Flexible circuit conductive composition, preparation method and using method thereof

ActiveCN102212304AGuaranteed resistivityGuaranteed adhesionPhotomechanical apparatusPolyurea/polyurethane coatingsFlexible circuitsFlexible electronics

The invention relates to a flexible circuit conductive composition for a flexible printed circuit board (FPC), a preparation method and a using method thereof. The preparation method comprises the following steps of: adding photocurable resin and an optical activity monomer into a conductive nanometer material dispersion liquid and then preparing the composition by adopting a double-curing mode such as firstly photocuring and then thermal treatment. The photocuring leads the surface coating to be rapidly cured so as to achieve good mechanical property; and the thermal curing leads the coatingto be cured completely so as to reach the deep curing requirements. The thermal treatment leads nanometer metals to be sintered together so as to achieve good conductive performance. The prepared conductive system obtains a predesigned pattern in the specific area of a base material in a screen printing or nanometer impressing mode; the conductive pathway is obtained after the double curing and has the advantages of short curing time, low curing temperature, good electrical conductivity, high resolution ratio; and the prepared conductive film has the advantages of good adhesiveness, high hardness and good flexibility.

Owner:BEIJING UNIV OF CHEM TECH

Multiphoton curing to provide encapsulated optical elements

InactiveUS20050208431A1Controlled diffusionStabilization and protectionAdditive manufacturing apparatusRadiation applicationsEngineeringHardness

Methods of fabricating optical elements that are encapsulated in monolithic matrices. The present invention is based, at least in one aspect, upon the concept of using multiphoton, multi-step photocuring to fabricate encapsulated optical element(s) within a body of a photopolymerizable composition. Imagewise, multi-photon polymerization techniques are used to form the optical element. The body surrounding the optical element is also photohardened by blanket irradiation and / or thermal curing to help form an encapsulating structure. In addition, the composition also incorporates one or more other, non-diffusing binder components that may be thermosetting or thermoplastic. The end result is an encapsulated structure with good hardness, durability, dimensional stability, resilience, and toughness.

Owner:3M INNOVATIVE PROPERTIES CO

Silk screen printing fluorescent paint for color conversion and preparation method thereof

ActiveCN1990613AImprove performanceImprove color conversion efficiencyLuminescent paintsOther printing apparatusScreen printingUV curing

The invention relates to a color conversion screen printing ultraviolet curing organic fluorescence coating and the method for preparing the same. Said comprises prepolymer, active monomer, organic fluorescence coating, light initiator, dispersant agent, defoaming agent, levelling agent and adhesion promoter. The invention also relates to another color conversion screen printing waterborne thermal curing organic fluorescence coating and the method for preparing the same. It comprises film forming matter, diluting agent, organic fluorescence coating, disperant agne, waterborne defoaming agent, levelling agent and thickener. The coating is cured on ITO glass through screen printing and becomes color conversion film. The invention makes use of the property of fluorescence coating that it can emit brighter light under ultraviolet illumination. The fluorescence coating can be costed on display surface. The color and brightness will change when different light pass through said color conversion film. The invention is characaterized by simple process, fast curing speed, and good flexibility, aging resistant, good adhesion between film and glass and environmental friendly.

Owner:INESA ELECTRON

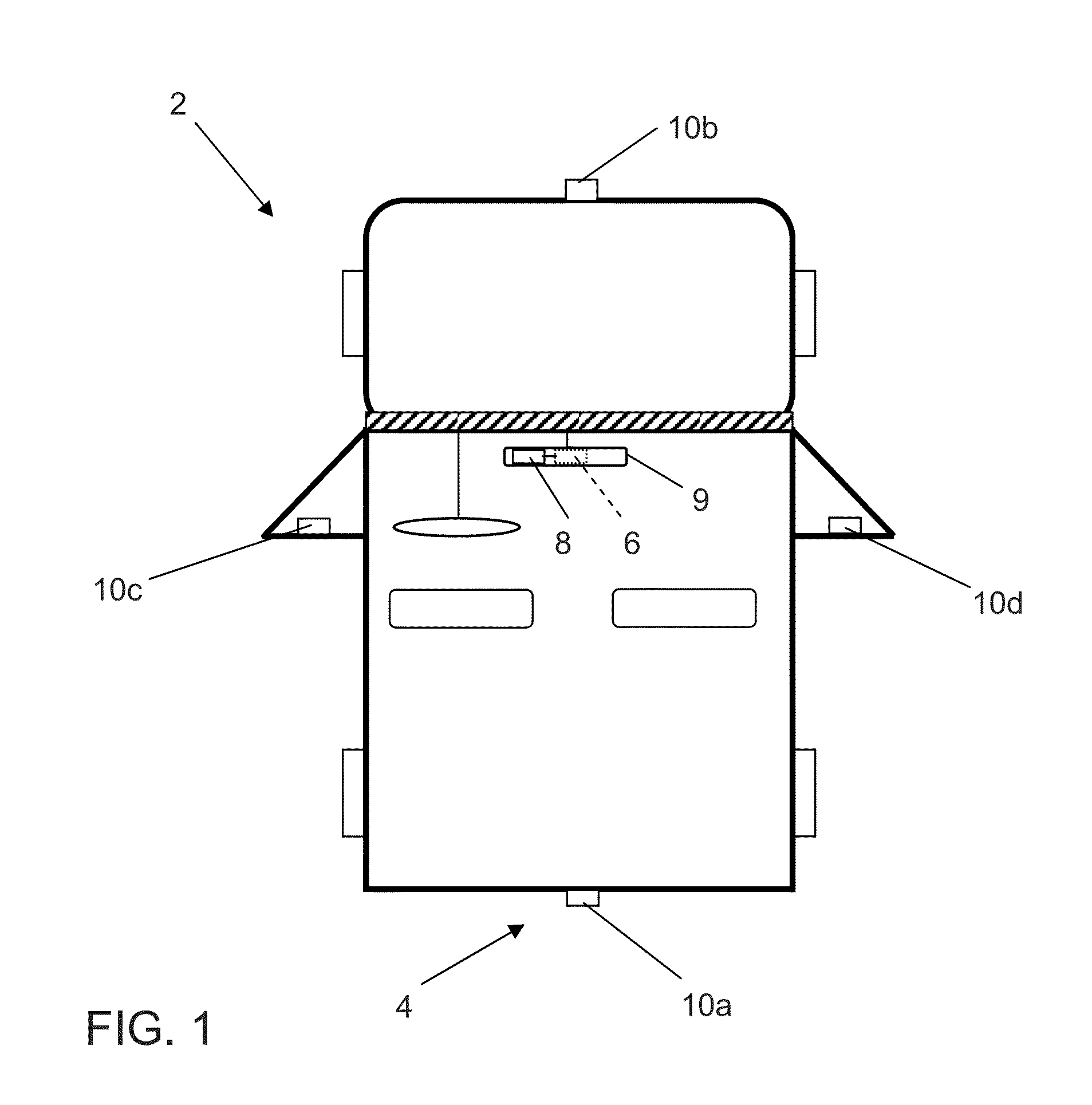

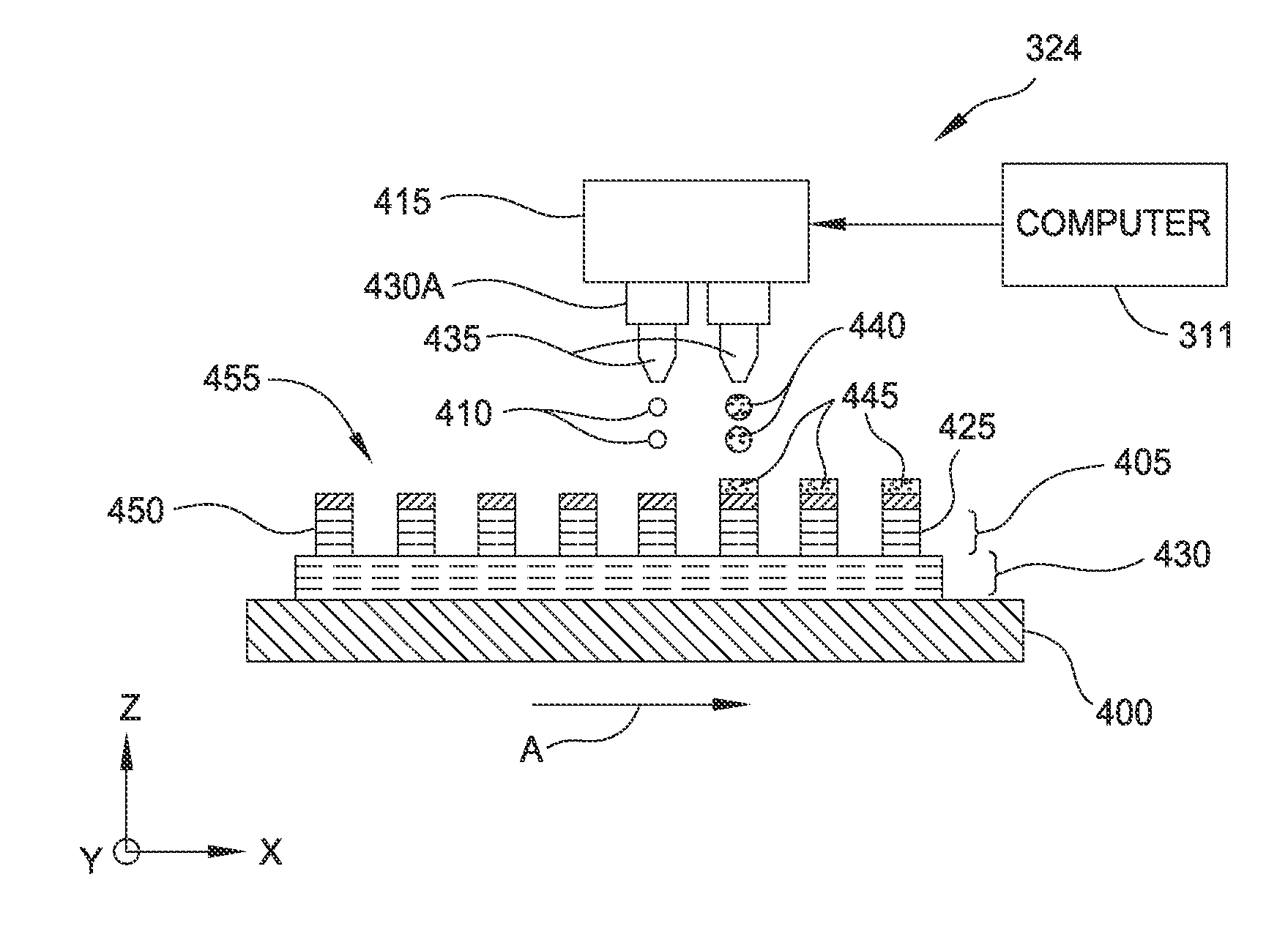

Polishing articles and integrated system and methods for manufacturing chemical mechanical polishing articles

A polishing article manufacturing system includes a feed section and a take-up section, the take-up section comprising a supply roll having a polishing article disposed thereon for a chemical mechanical polishing process, a print section comprising a plurality of printheads disposed between the feed section and the take-up section, and a curing section disposed between the feed section and the take-up section, the curing section comprising one or both of a thermal curing device and an electromagnetic curing device.

Owner:APPLIED MATERIALS INC

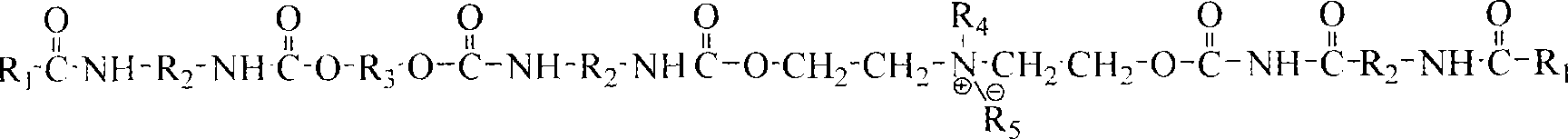

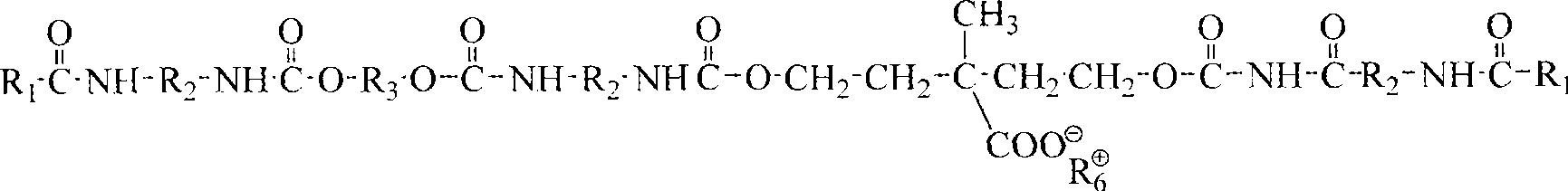

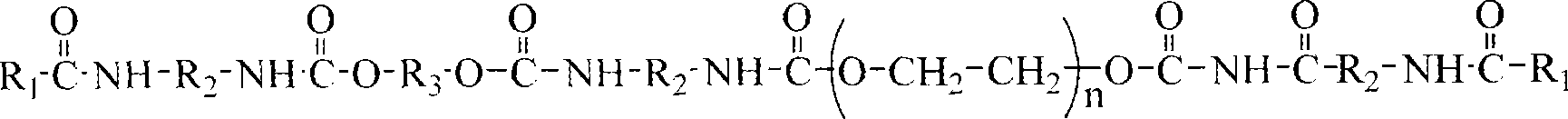

Waterborne ultraviolet-heat dual curing coating composite and preparation method thereof

InactiveCN101418147AImprove adhesionHigh hardnessPolyurea/polyurethane coatingsFunctional methodsSpray coating

The invention provides a water-dilutable ultraviolet-thermal double curing coating composition and a preparation method thereof. The components of the double curing coating composition in percentage by weight are: 3.5 to 60 percent of water-dilutable urethane acrylate oligomer, 17 to 47 percent of water-dilutable polyurethane polylol, 20 to 49 percent of water-dilutable curing agent, 0.4 to 9 percent of light trigger and 0.4 to 1.6 percent of auxiliary agent. The preparation method for the double curing coating is simple and does not require complex equipment; and the working life of the coating is long and reaches as long as 9 hours; the coating obtained can be used for preparing a coating by the functional methods of spray coating, brush coating and roller coating; ultraviolet curing can be completed within a short period of time between 10 and 30 seconds, and thermal curing can be completed within a period of time between 1 and 3 minutes at a temperature of between 40 and 60 DEG C; a paint film obtained after double curing has good leveling property, flexibility, shock resistance and adhesion and high hardness; and the coating does not contain an organic solvent and a reactive diluent, and is an environment-friendly coating.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Photocurable composition for the formation of pressure-sensitive adhesive layer and dicing tape produced using the same

InactiveCN101376797ALow maximum peel strengthGood pickupNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer resinDicing tape

The present invention discloses a photocurable composition used for forming pressure sensitive adhesive layer. The photocurable composition comprises pressure sensitive adhesive binder, reactive acrylate, thermal curing agent and phtoinitiator. The pressure sensitive adhesive binder is composed of pressure sensitive adhesive polymer resin and low molecular weight acrylate which comprises carbon-carbon double bond and is led into side chain of pressure sensitive adhesive resin. The reactive acrylate comprises dimethyl cyclosiloxane unit in molecular chain. The invention also discloses a cutting rubber belt which comprises a pressure sensitive adhesive layer formed by the photocurable composition. When a thin wafer is installed on cutting rubber belt, cut and radiated by UV, no connection occurs. Therefore the maximum peeling strength between the pressure sensitive adhesive layer and thin wafer is quite low, and the collecting capability of thin wafer is excellent.

Owner:CHEIL IND INC

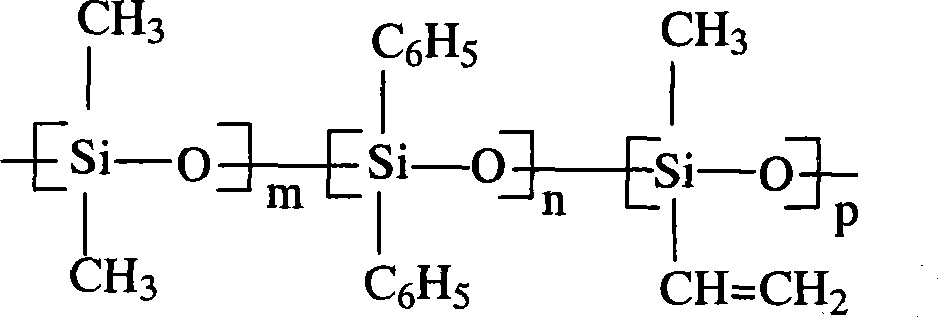

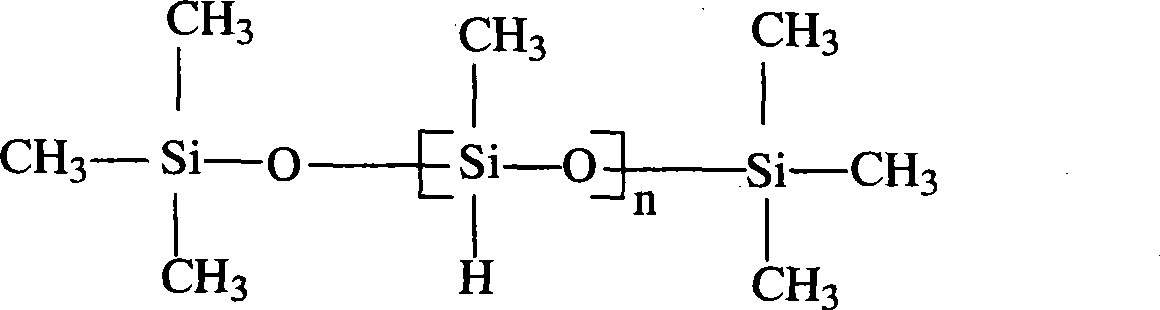

Organosilicon conductive adhesive

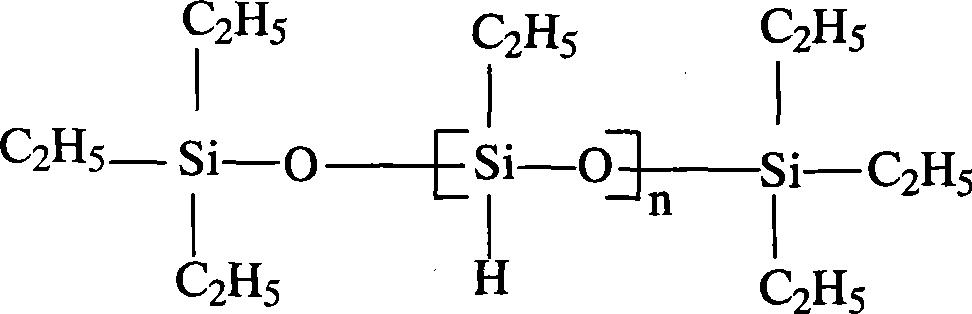

ActiveCN101412851ANon-conductive material with dispersed conductive materialElectrically-conducting adhesivesAdhesiveDimethyl siloxane

The invention relates to an organic silicon conductive adhesive which comprises a resin composition, an organic solvent and argent powder, wherein the resin composition comprises: (1) 40 to 65weight percent of ethenyl end capped polydimethylsiloxane; (2) 8 to 10 weight percent of trimethyl silicyl end capped poly(dimethyl siloxane-co-dimethyl silicone); (3) 10 to 30 weight percent of polysiloxane silicone oil with hydrogen-silicon bonds and / or ethenyl; (4) 0.1 to 2 weight percent of a polymerization inhibitor; and (5) 0.01 to 0.2 weight percent of a platinum complex catalyst; the weight ratio of the resin composition to the argent powder is 10-40 to 90-60; and the use amount of the organic solvent is 5 to 10 percent of the weight of the resin composition. The preparation process of the organic silicon conductive adhesive is as follows: the resin composition is stirred for 20 to 30 minutes, is added with the argent powder, is stirred for 10 to 20 minutes, is transferred to a three-roller machine, and is continuously rolled and mixed for three times to prepare the organic silicon conductive adhesive. The storage life of the organic silicon conductive adhesive is half a year at the temperature of 5 DEG C below zero . The organic silicon conductive adhesive is subjected to thermal curing for 1 to 2 hours at the temperatures of 160 DEG C, 180 DEG C and 240 DEG C respectively. As a result, a product has the following performances: flake thrust force is between 1.5 and 3.0 kgf; volume resistivity is less than or equal to 6X10< -4 > Omega.cm; and pencil hardness is less than 6 B.

Owner:SHANGHAI PLASTICS RES INST CO LTD

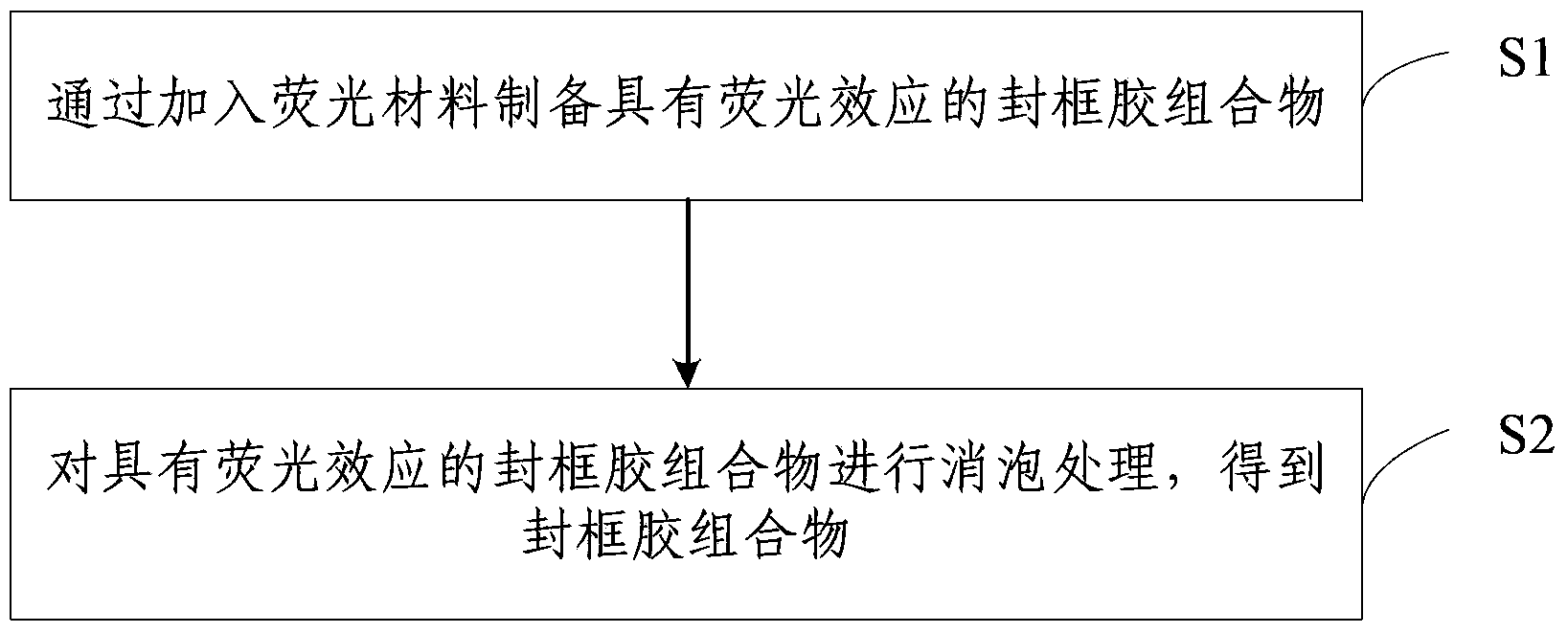

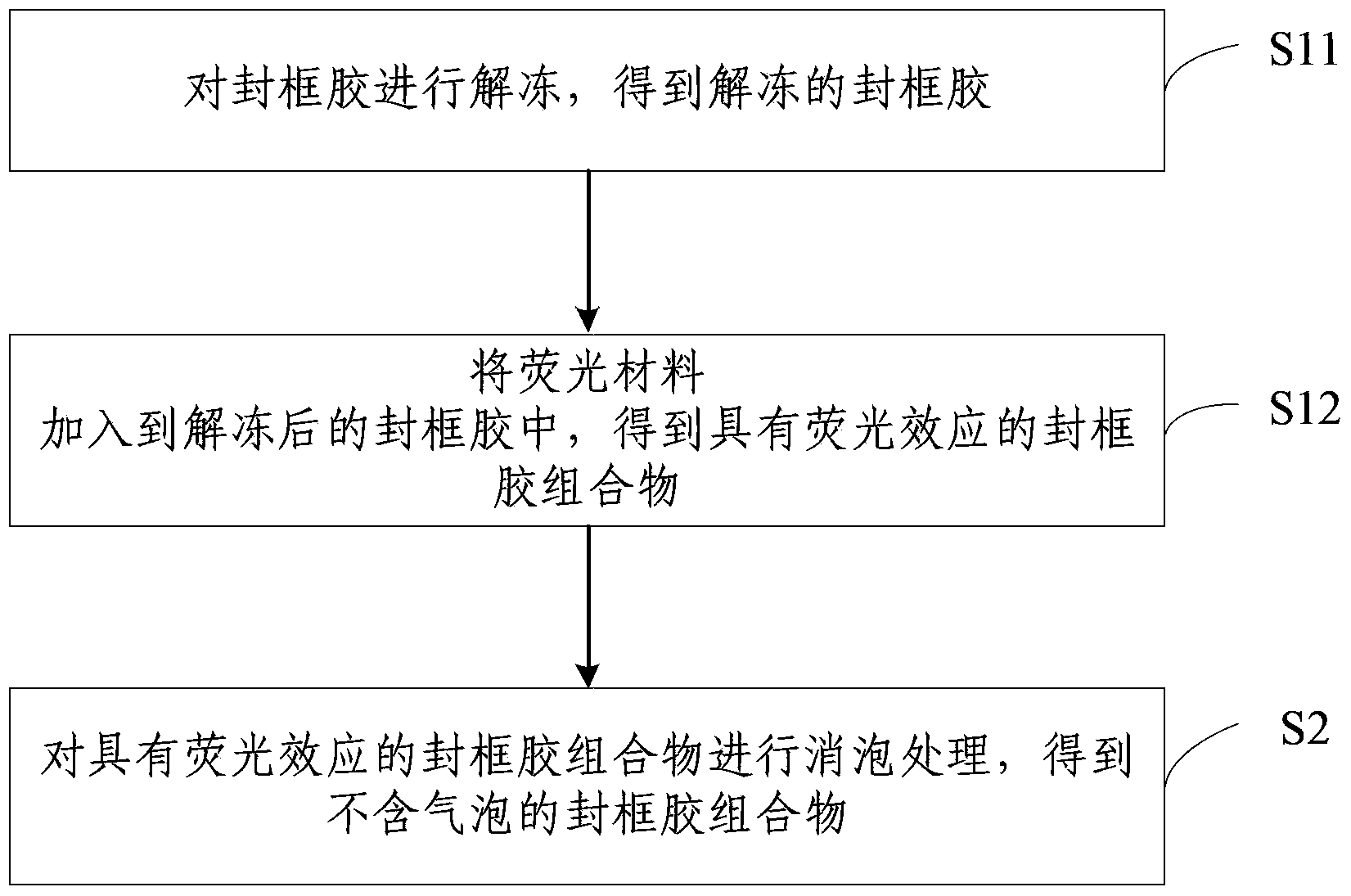

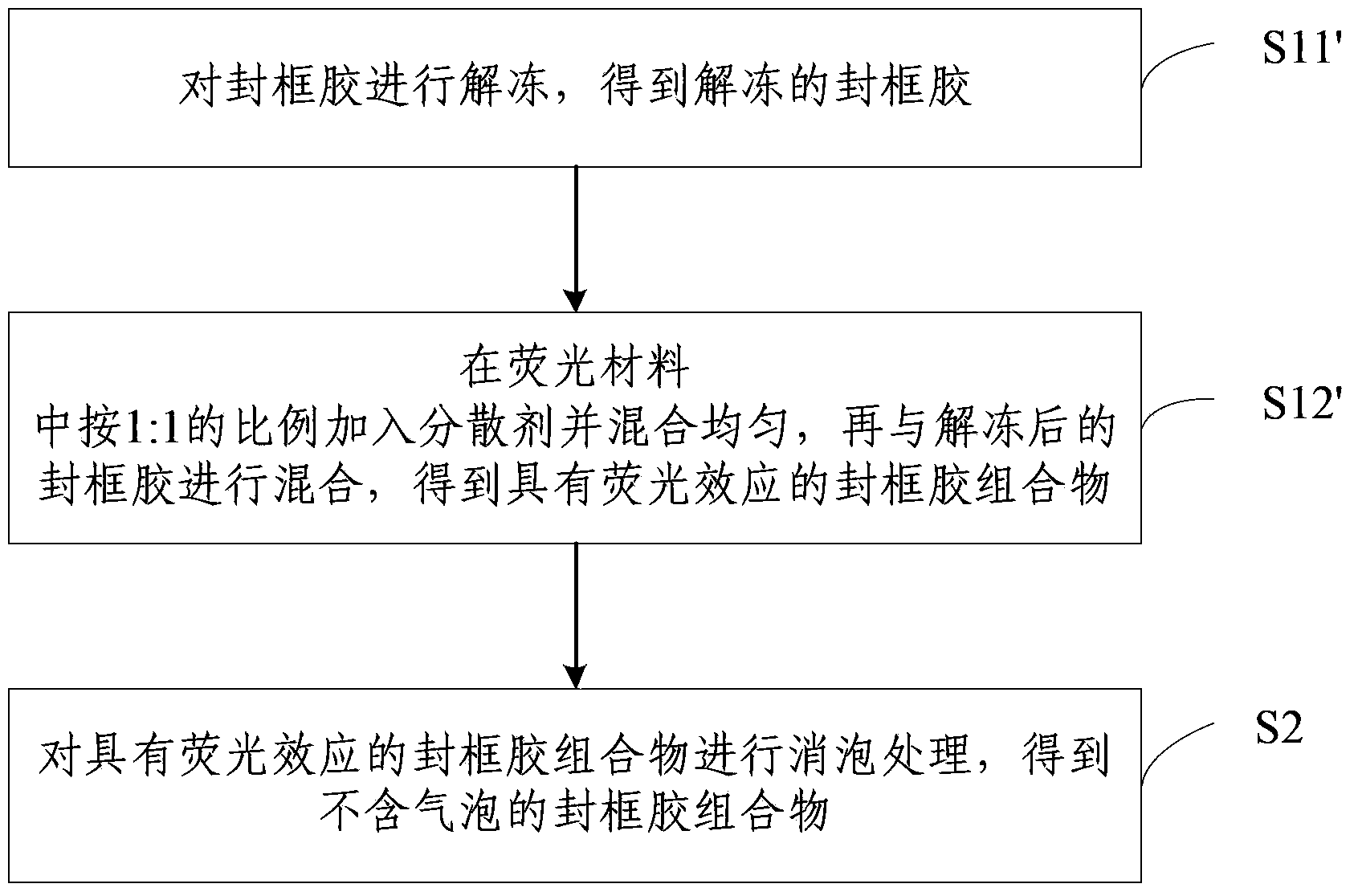

Frame sealing glue composition, display device and detection method

InactiveCN103409084AAchieve adhesionWith fluorescent effectFluorescence/phosphorescenceAdhesivesDisplay deviceEngineering

The invention discloses a frame sealing glue composition. The frame sealing glue composition comprises a frame sealing glue, a fluorescent material and a dispersant, wherein the frame sealing glue comprises a prepolymer, an active monomer, a thermal curing agent and a photoinitiator. Through addition of the fluorescent material with a fluorescent effect into the conventional frame sealing glue, the obtained frame sealing glue composition exerts a same adhesive effect as that of the conventional frame sealing glue and facilitates detection of bonding effects on frame sealing glue layers through the fluorescent effect. The invention further discloses a display device and a detection method based on the frame sealing glue composition. The frame sealing glue layers are irradiated by invisible light with wavelength of less than 400 nm, and sealing conditions of the frame sealing glue layers are determined according to the fluorescent effect of the frame sealing glue layers. Thus, bonding effects on the frame sealing glue layers can be conveniently and effectively detected without detection in a special environment, breaking of panels in the process of carrying is avoided, and detection results can be effectively and rapidly obtained.

Owner:BOE TECH GRP CO LTD

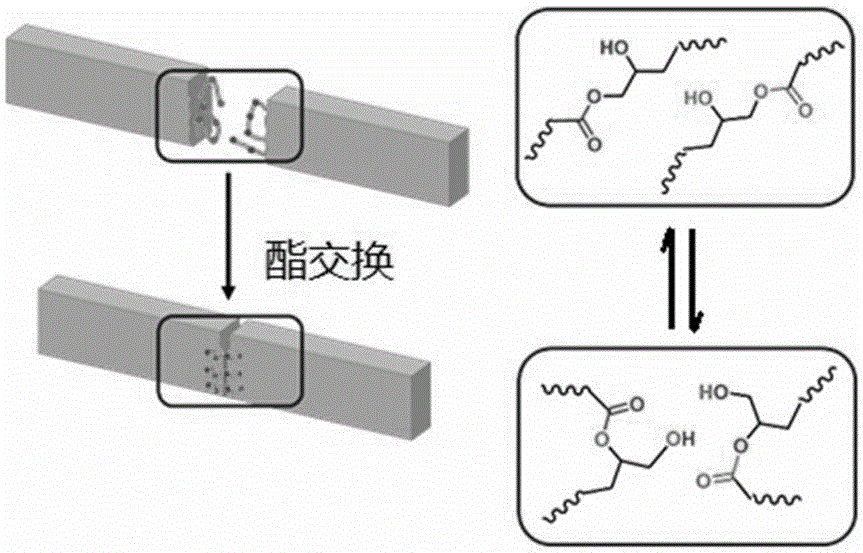

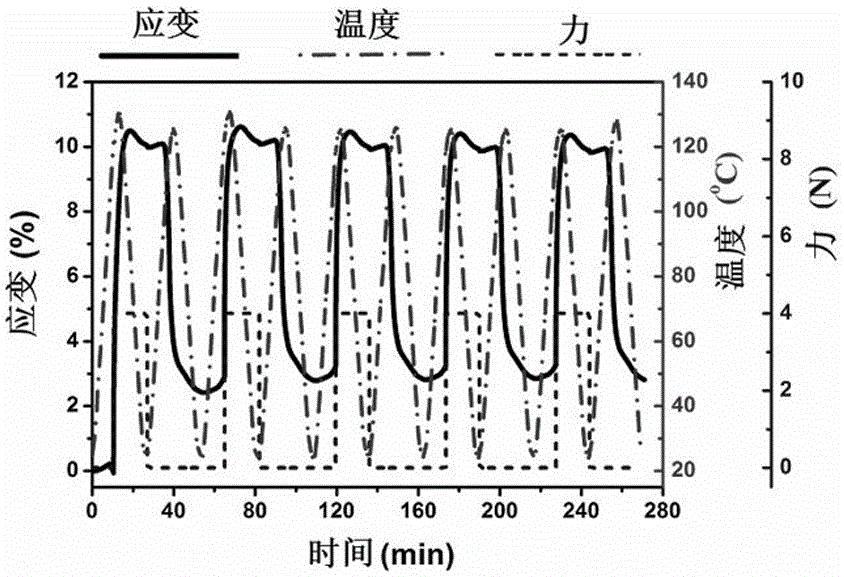

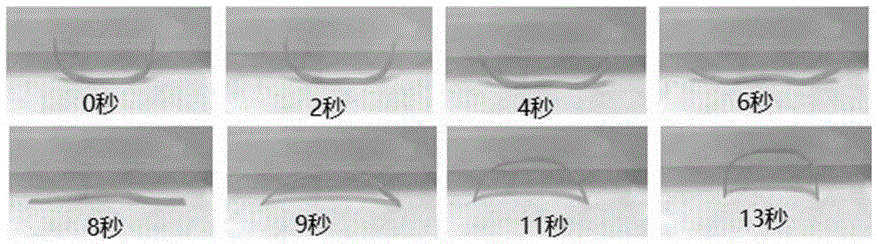

Self-repair re-molded multi-deformation thermosetting shape memory resin material and preparation method thereof

Owner:南通雅瑞新材料科技有限公司

Preparation method of manmade quartz stones

InactiveCN104325539AWide variety of sourcesReduce labor intensityCeramic shaping apparatusQuartzMaterials science

The invention relates to a preparation method of manmade quartz stones. The preparation method comprises the following steps: after raw materials are weighed, the raw materials are stirred, spread, pressed, demolded and thermally cured to obtain cured boards, wherein the thermal curing time is 6-10 hours, and the curing temperature is 70-160 DEG C; and the cured boards are thickened, polished, cut, checked and packaged to obtain the manmade quartz stones. The preparation method simplifies a preparation process, is convenient and simple in operation, is wide in source of the raw materials, reduces the labor intensity of workers, decreases the production cost, and improves the production efficiency of enterprises. Meanwhile, the manmade quartz stones, prepared by the method, have beautiful shapes, bright patterns and unique colors, enrich the types and the patterns to a greater extent, can be applied to various decoration occasions, and are wide in application.

Owner:TIANJIN JUHUAJING TECH DEV

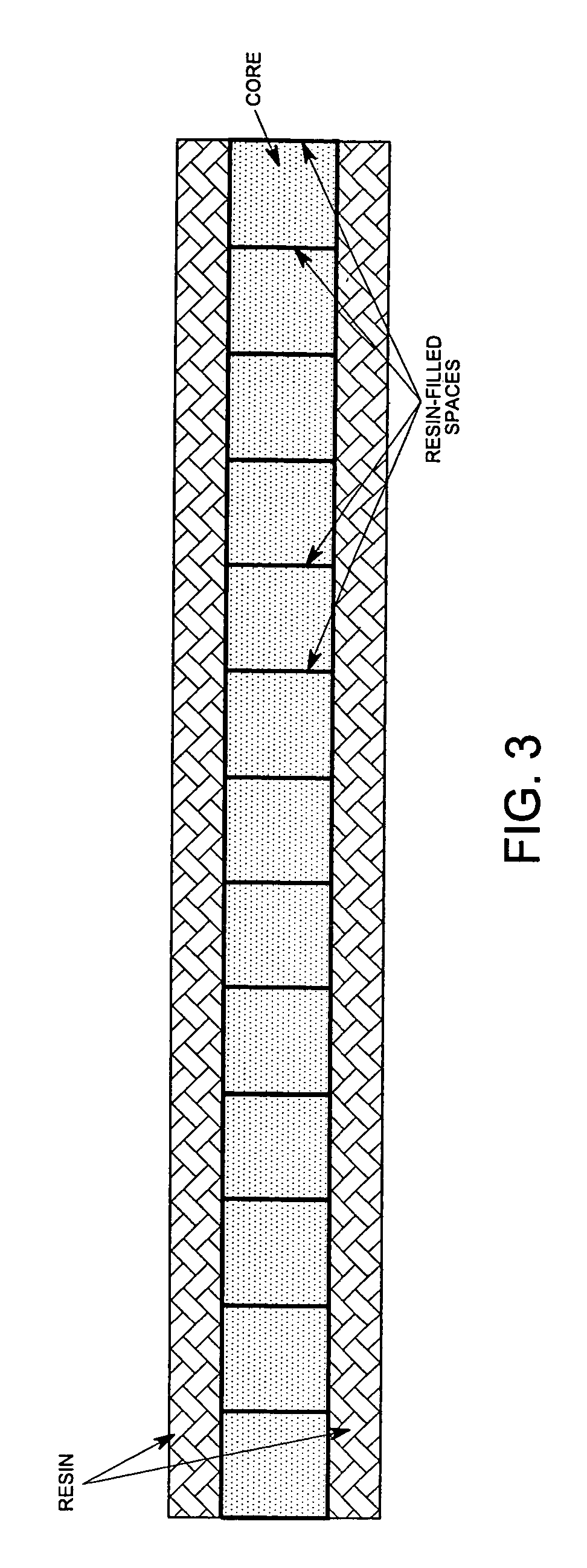

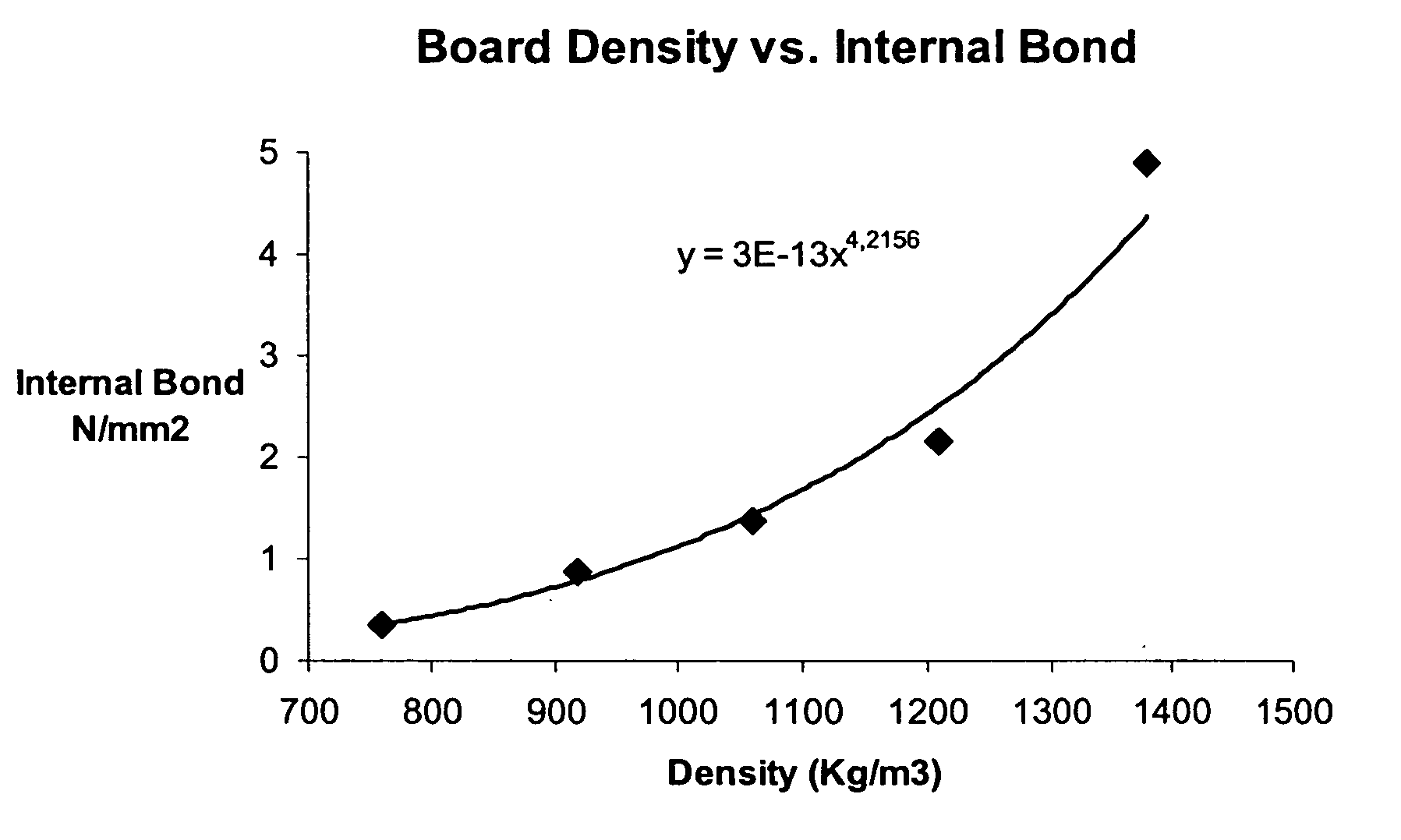

Method for making dimensionally stable composite products from lignocelluloses

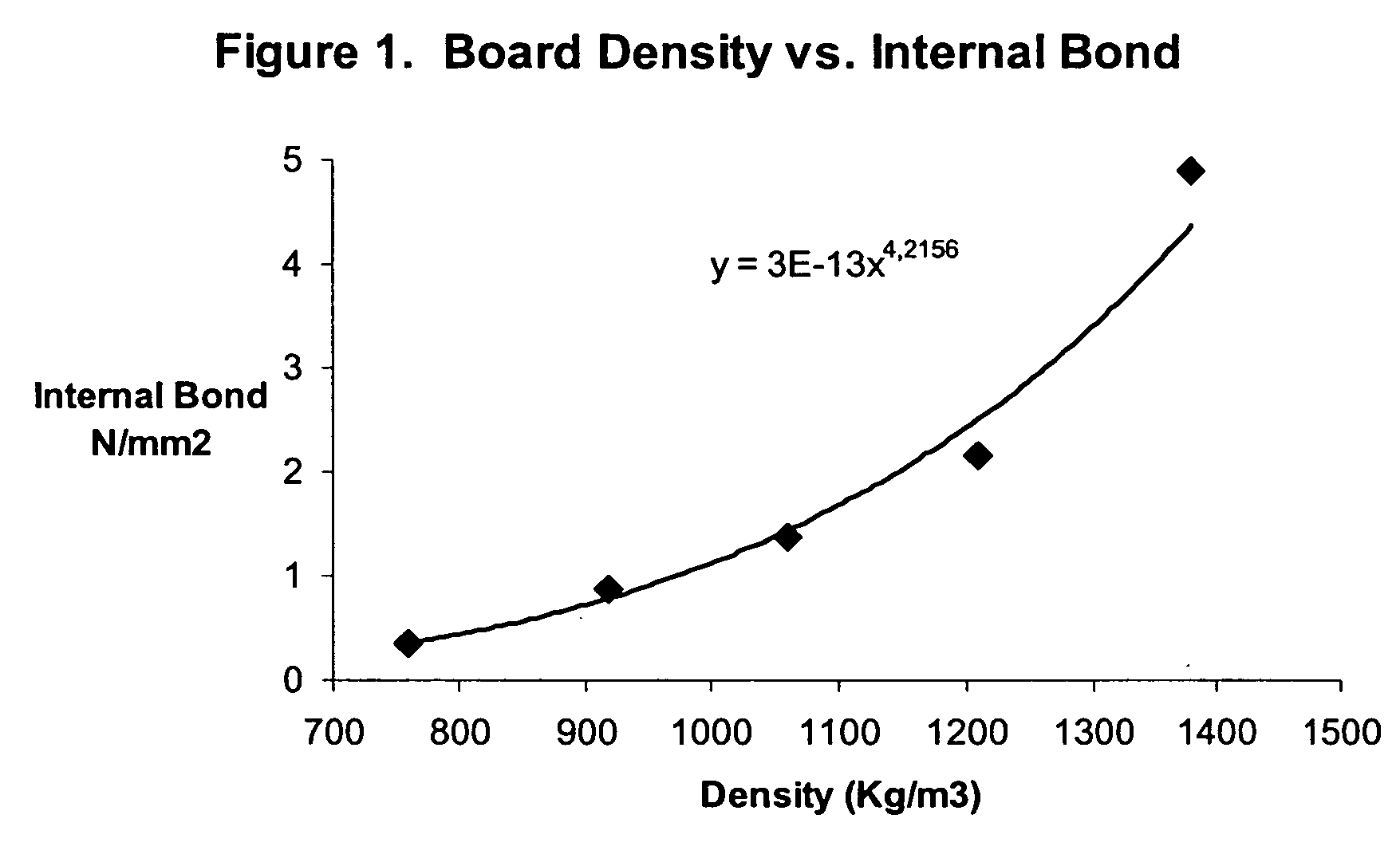

InactiveUS20060091577A1Good physical propertiesImprove water resistanceCeramic shaping apparatusCork mechanical workingHigh densityDecomposition

This invention relates to a process for making dimensionally stable reconstituted composite products from lignocellulosic material. By treating lignocellulose with high pressure steam to decompose and hydrolyse the hemicellulose, cellulose and lignin fractions of the lignocellulose and using those decomposition products as both a bonding and bulking agent, it converts, under heat and pressure in a moulding operation, the treated lignocellulose into moulded composite products such as panel boards and moulded articles. The composite products thus produced possess good physical and mechanical properties. Specifically, the dimensional stability in terms of the thickness swelling and linear expansion of panel boards such as fibreboards and particleboard, can be minimized to very low levels when the panel boards are made in high density. The adhesive bond developed from thermosetting of the decomposition products of hemicellulose, cellulose and lignin is strong and stable, and resistant to boiling water and acid hydrolysis, and is free of formaldehyde emissions. Thus, the reconstituted panel boards and moulded products are suitable for exterior and particularly for indoor applications. The absence of free formaldehyde emissions makes the product very suitable for interior applications. The manufacturing cost for the reconstituted products is significantly lower in comparison to the conventional process because expensive synthetic resin is not used.

Owner:SHEN KUO C +1

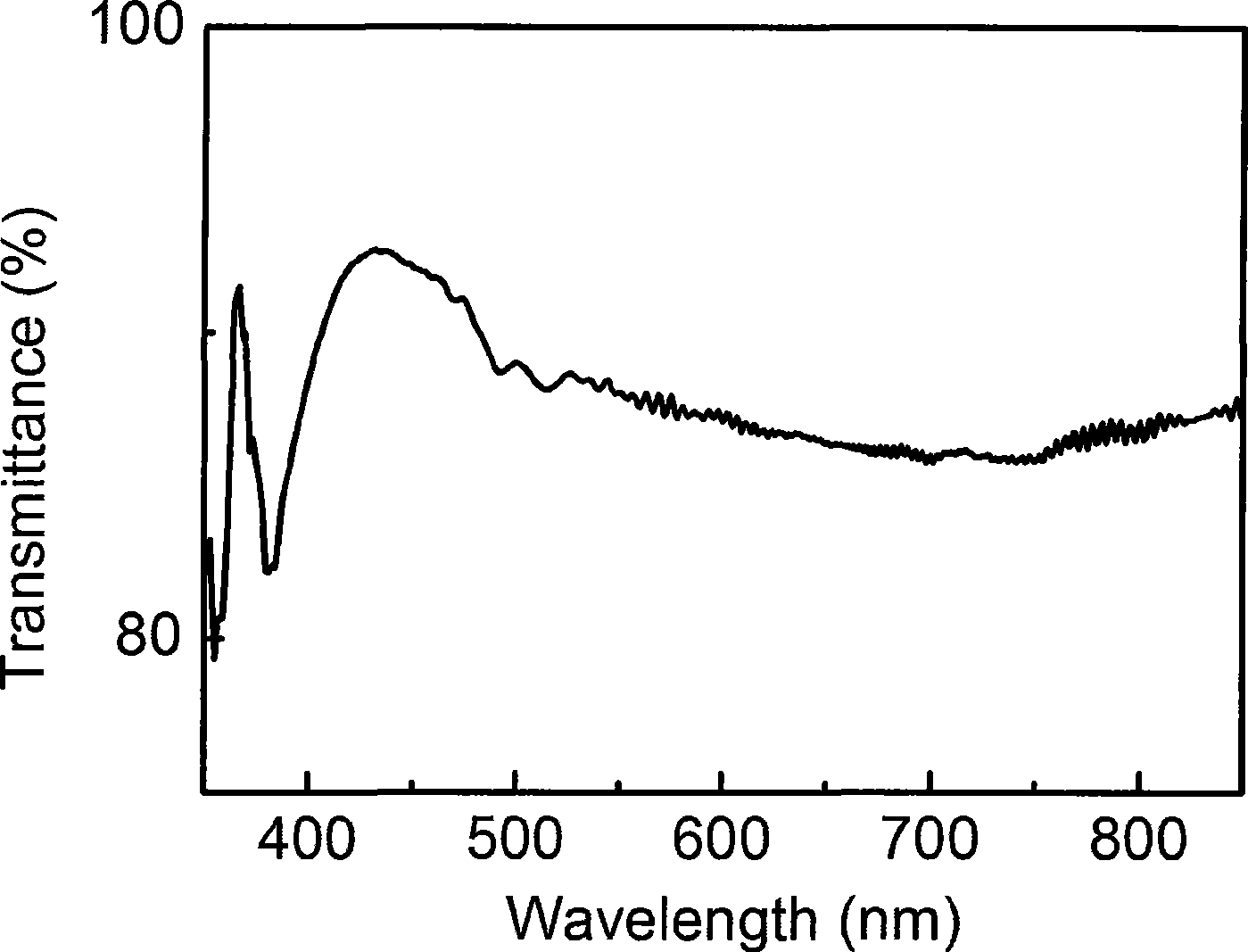

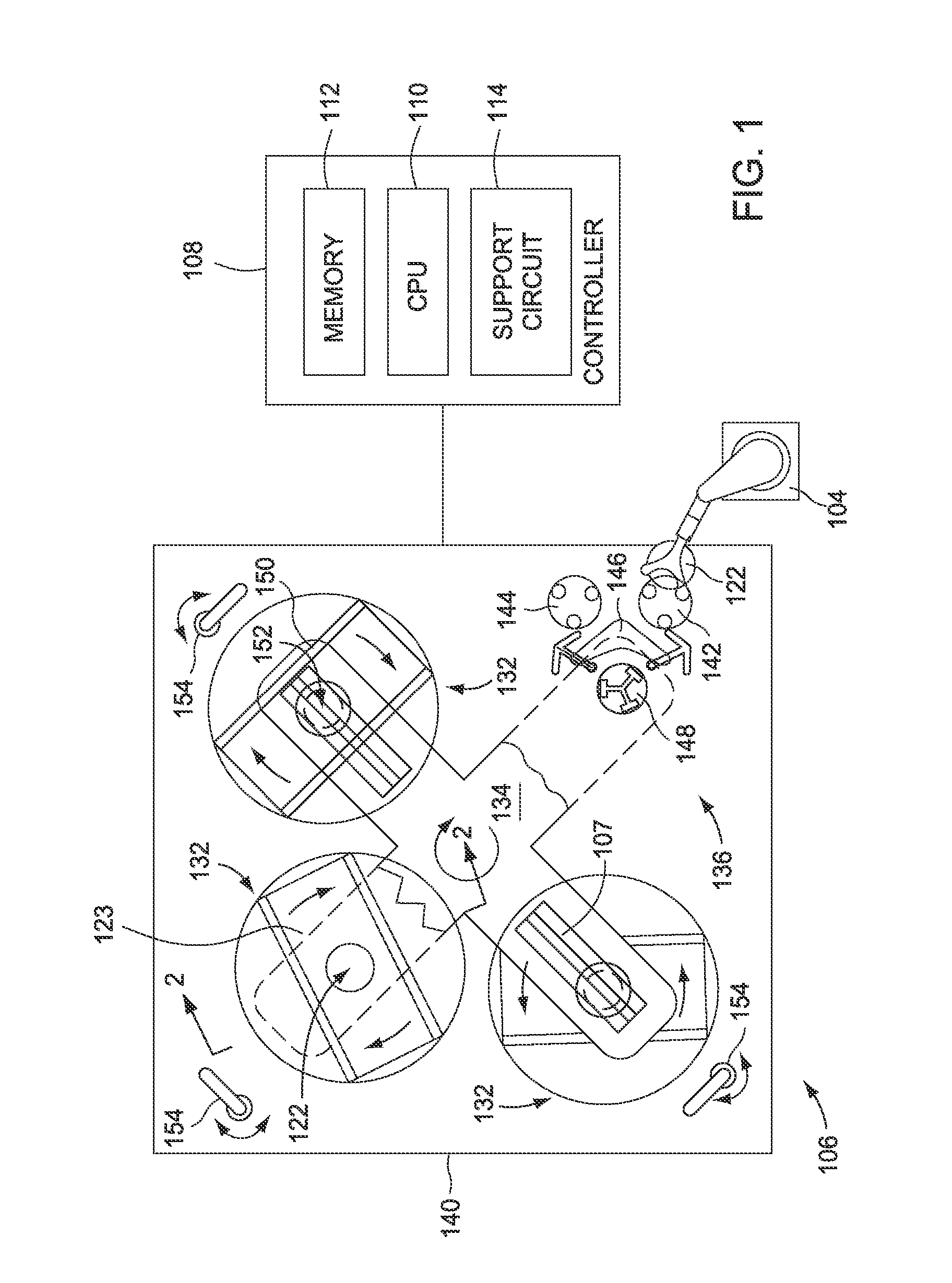

Light emitting device, resin package, resin-molded body, and methods for manufacturing light emitting device, resin package and resin-molded body

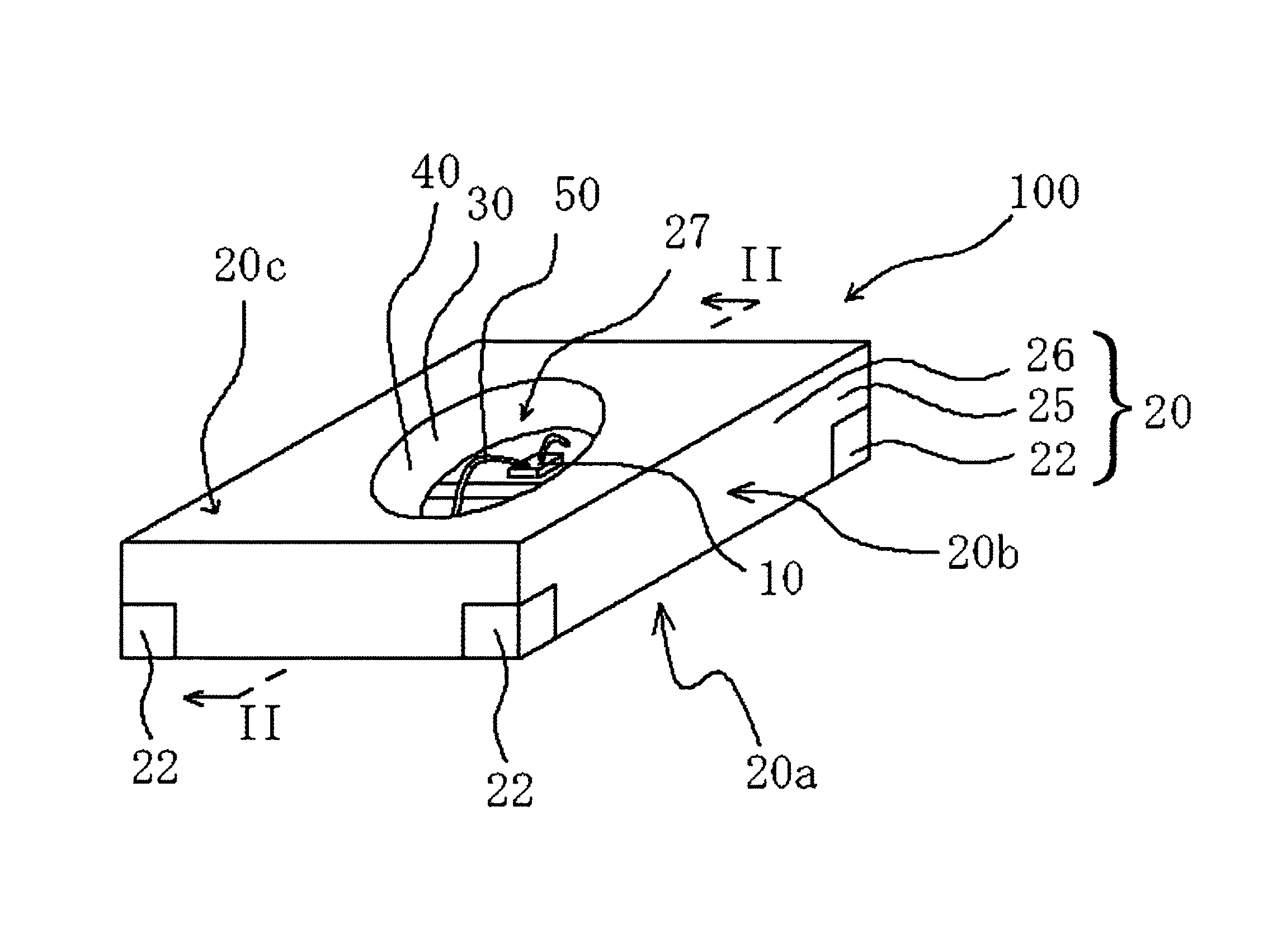

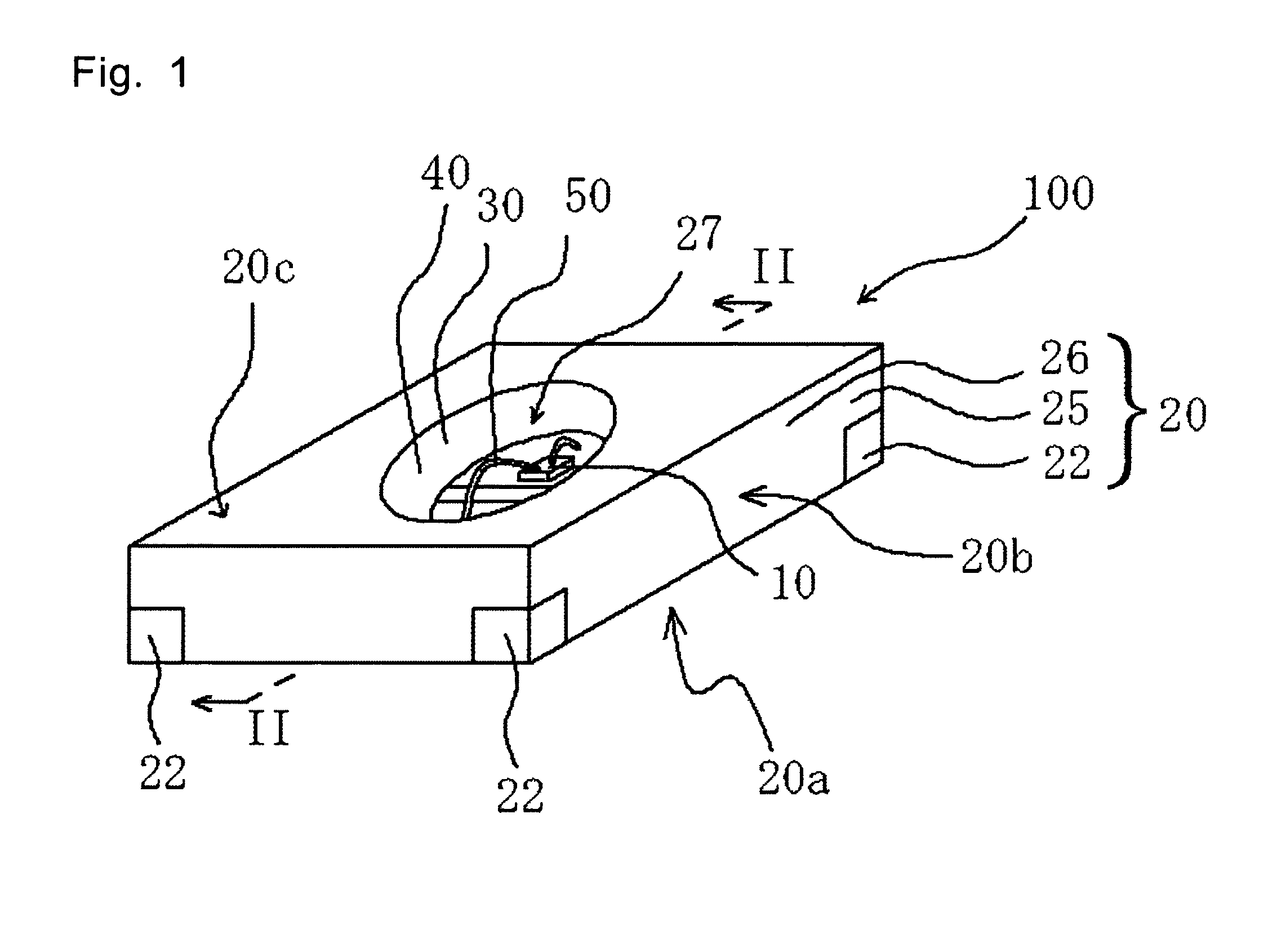

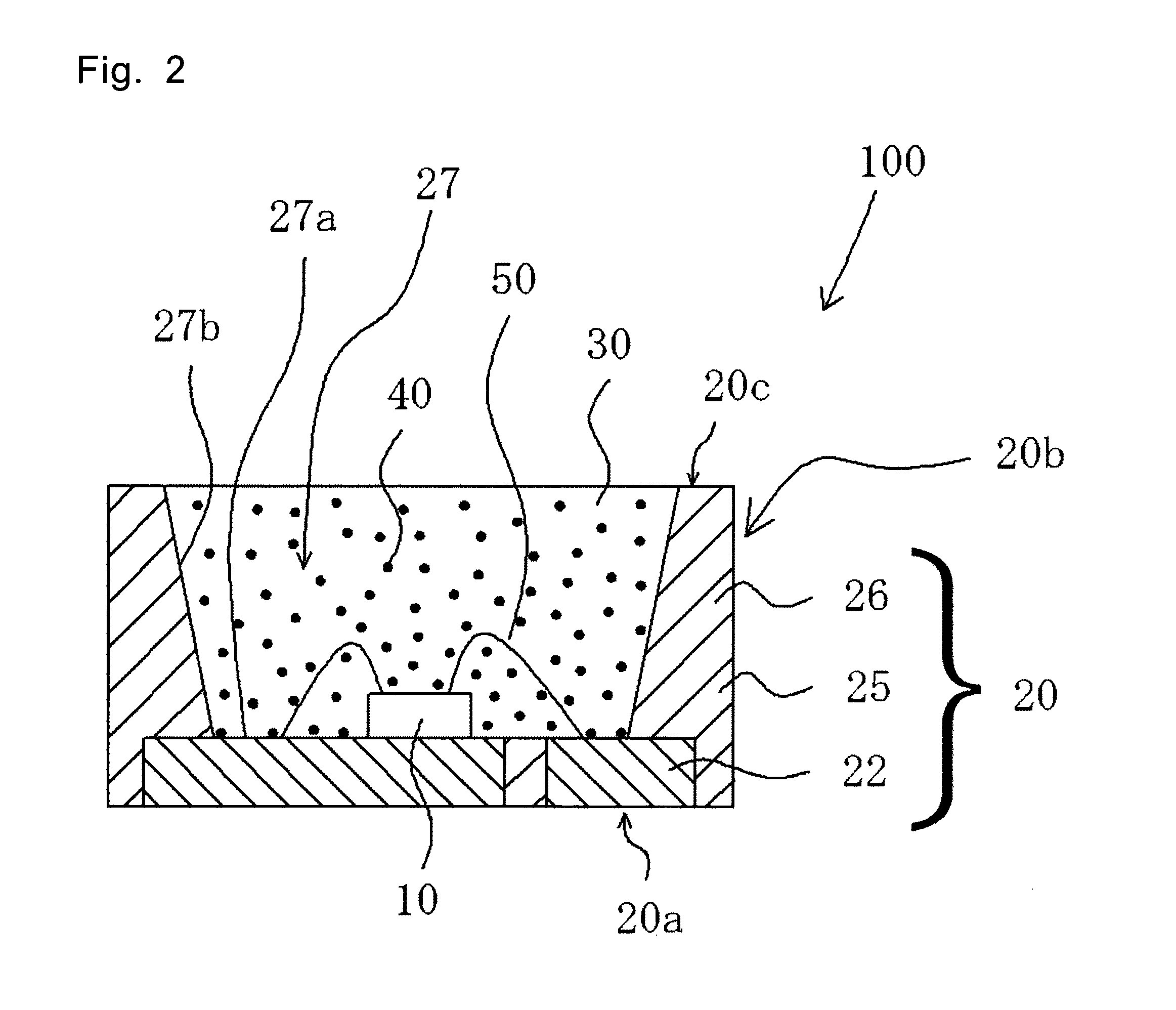

ActiveUS8530250B2Improve adhesionReduce discardingSemiconductor/solid-state device detailsSolid-state devicesTransfer moldingEngineering

Provided is a simple and low-cost method for manufacturing, in a short time, many light emitting devices wherein adhesiveness between a leadframe and a thermosetting resin composition is high. The method for manufacturing the light emitting device having a resin package (20) wherein the optical reflectivity at a wavelength of 350-800 nm after thermal curing is 70% or more and a resin section (25) and a lead (22) are formed on substantially a same surface on an outer surface (20b) has: a step of sandwiching a leadframe (21) provided with a notched section (21a) by an upper molding die (61) and a lower molding die (62); a step of transfer-molding a thermosetting resin (23) containing a light-reflecting substance (26), in a molding die (60) sandwiched by the upper molding die (61) and the lower molding die (62) and forming a resin-molded body (24) on the leadframe (21); and a step of cutting the resin-molded body (24) and the leadframe (21) along the notched section (21a).

Owner:NICHIA CORP

Ultraviolet-heat dual curing polyaniline anti-corrosive paint and preparation method thereof

ActiveCN101418146ANo emission issuesNo pollution problemAnti-corrosive paintsPolyurea/polyurethane coatingsUltravioletChromium

The invention provides an ultraviolet-thermal double curing polyaniline anti-corrosive coating and a preparation method thereof. In the coating, polyaniline is adopted as a main anti-corrosive material, and oligomer, a reactive diluent, polyurethane polylol, polyaniline, filler, light trigger and an auxiliary agent are used for preparing filtrate of the coating; and the filtrate and a polyurethane curing agent are stored respectively and uniformly mixed in proportion for use. The anti-corrosive paint has good anti-corrosive effect on different metals, not only can perform ultraviolet curing crosslinking but also can perform thermal curing crosslinking, well overcomes the defect of incomplete curing of an ultraviolet curing anti-corrosive paint, has the characteristics of resisting acid medium corrosion and alkali medium corrosion, is suitable to be used under the condition of a severe environment and particularly suitable for corrosion protection under the condition of a marine environment, does not contain heavy metals such as plumbum, chromium and zinc, and simultaneously does not contain any organic solvent in a formula. Therefore, the coating does not have the problem of environmental pollution during the production process and the use process, and is a completely environment-friendly coating.

Owner:中科应化(长春)科技有限公司

Hardenable pressure-sensitive adhesive sheet for semiconductor and process for producing semiconductor device

InactiveUS20050208296A1Excellent in versatility and adherenceImprove reliabilityLamination ancillary operationsSolid-state devicesEpoxyDevice material

Disclosed herein is a hardenable pressure-sensitive adhesive sheet enabling production of a semiconductor device of high reliability while preventing the occurrence of package cracking and other failure; and a process for producing a semiconductor device with the use of the hardenable pressure-sensitive adhesive sheet. There is provided a hardenable pressure-sensitive adhesive sheet having a hardenable pressure-sensitive adhesive layer comprising a pressure-sensitive component (A) and an epoxy resin (B), wherein the hardenable pressure-sensitive adhesive layer after thermal curing has a storage modulus of 1.0×107 Pa or below at 100° C. and 1.0×105 Pa or above at 160° C.

Owner:LINTEC CORP

Photo-thermally cured hydrophilic anti-fog paint composition

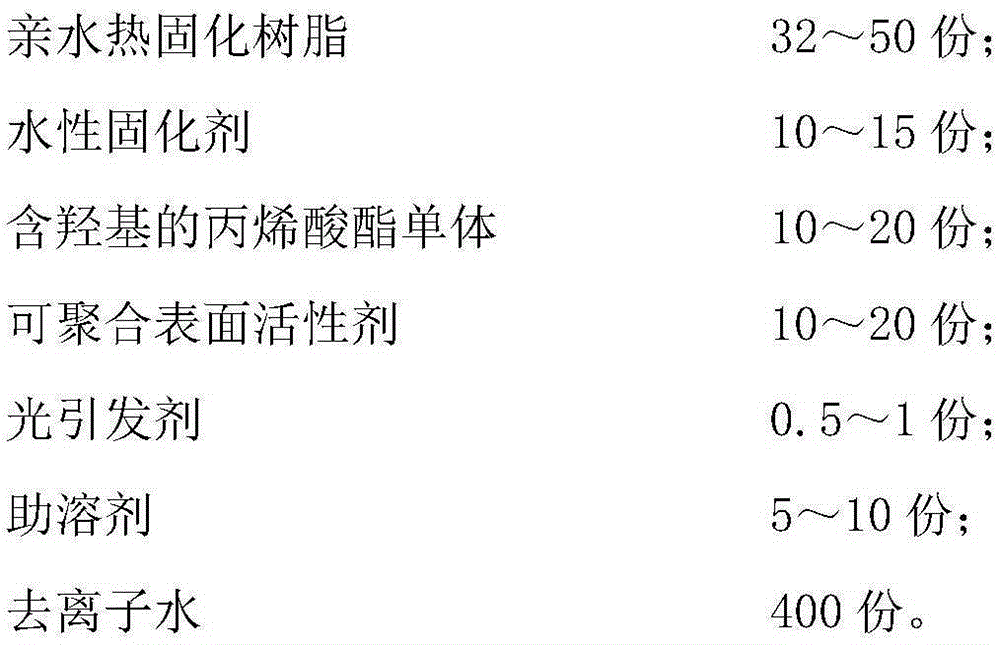

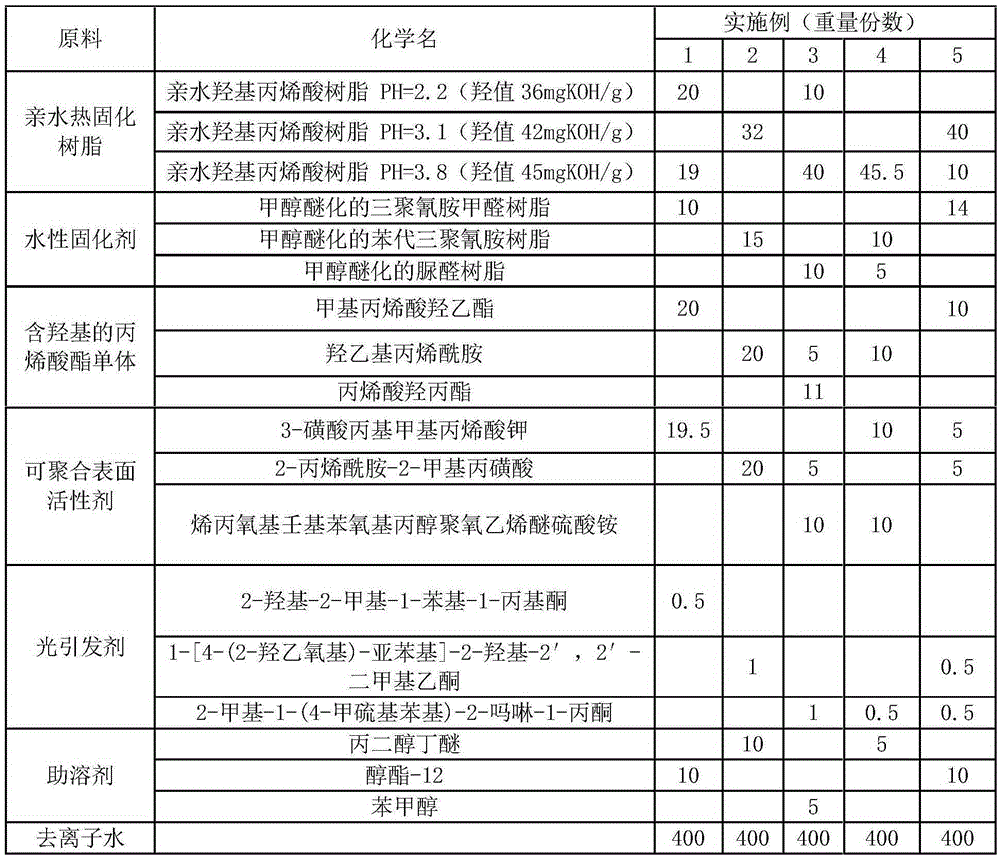

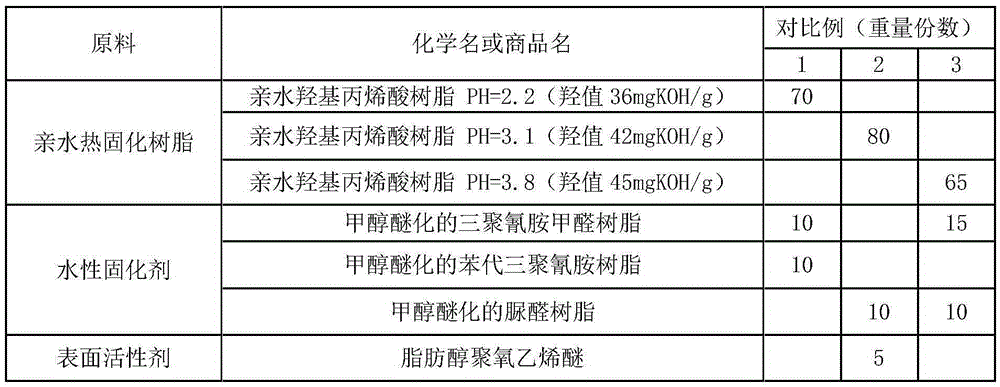

The invention discloses a photo-thermally cured hydrophilic anti-fog paint composition which comprises the following ingredients: 32-50 parts of hydrophilic thermal-curing resin, 10-15 parts of a waterborne curing agent, 10-20 parts of hydroxy acrylate monomer, 10-20 parts of a polymerizable surfactant, 0.5-1 part of a photoinitiator, 5-10 parts of a cosolvent and 400 parts of water. The photo-thermally cured hydrophilic anti-fog paint composition provided by the invention can be applied to the surface of a plastic base material, is firstly thermally cured and then photo-cured, has good constant fogging resistance and abrasion resistance, meanwhile, has good adhesive force to the plastic base material, can be widely applied to anti-fog vehicle window film, anti-fog vehicle headlights, bathroom mirrors and the like and has a good application prospect.

Owner:SHANGHAI CHENGYING NEW MATERIALS +2

Thermal curing type printless organic silicon pressure-sensitive adhesive tape and preparation method thereof

A disclosed thermal curing type printless organic silicon pressure-sensitive adhesive tape comprises a base material layer and an organic silicon pressure-sensitive glue layer by coating with an organic silicon pressure-sensitive glue, and a primer layer is arranged between the base material layer and the organic silicon pressure-sensitive glue layer by coating with a primer; the organic silicon pressure-sensitive glue comprises, in parts by weight, 100 parts of the organic silicon pressure-sensitive glue, 30-100 parts of toluene, 0.5-3 parts of benzoyl peroxide and a shadow-removing agent accounting for 70%-230% by mass of benzoyl peroxide; and the primer comprises, in parts by weight, 100 parts of a primer, 1.4 parts of a bridging agent and 500-2000 parts of toluene. According to the thermal curing type printless organic silicon pressure-sensitive adhesive tape and a preparation method thereof both provided by the invention, the preparation process is simple, the cost is low, no corrosion is generated on a pasted object and no difficult-to-removed prints are generated, so that the bad appearance of the pasted object is avoided.

Owner:SUZHOU BANLID NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com