Photo-thermally cured hydrophilic anti-fog paint composition

A dual-curing, anti-fog coating technology, applied in coatings and other directions, can solve the problems of general anti-fog performance, complex process, long time required, etc., to achieve excellent hardness and wear resistance, good water solubility, and high cross-linking density. Effect

Active Publication Date: 2016-02-10

SHANGHAI CHENGYING NEW MATERIALS +2

View PDF7 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The hardness of the coating is greater than 2H, and the wear resistance is good, but the continuous anti-fog performance is average. The curing process takes a long time, and it needs to be cured in sections (50 ° C ~ 120 ° C), and the process is relatively complicated.

[0007] In order to overcome the contradiction between the continuous anti-fog performance and wear resistance of traditional anti-fog coatings on the market, the present invention discloses a hydrophilic anti-fog coating with dual curing of light and heat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

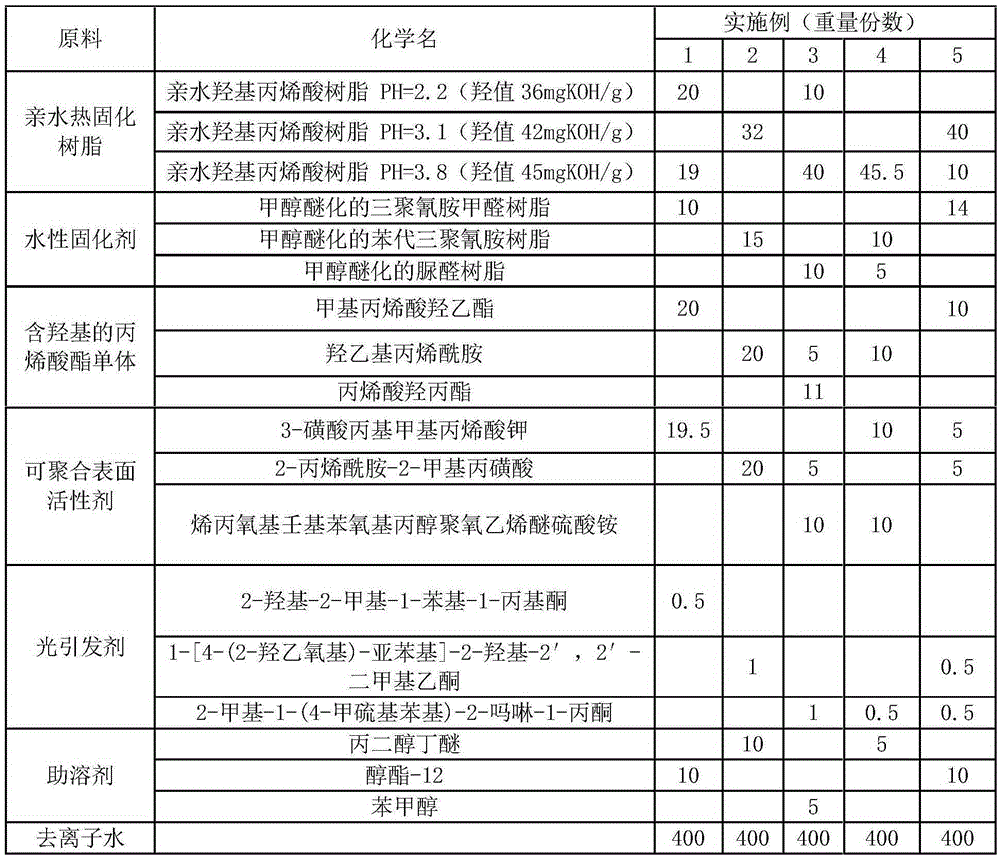

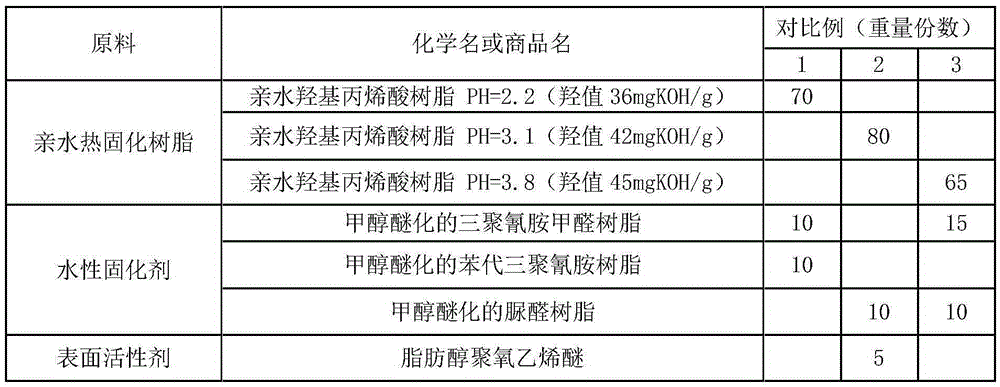

Embodiment 1~5

[0030] Examples 1-5 relate to a photothermal dual-curing hydrophilic anti-fog coating composition, including the components and parts by weight shown in Table 1.

[0031] Using PET as the substrate, coat the paint (30% solid content) on its surface with a No. 10 wire rod, put it in an oven at 130°C for 2 minutes, and then undergo UV curing with an energy of 500mJ / cm 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

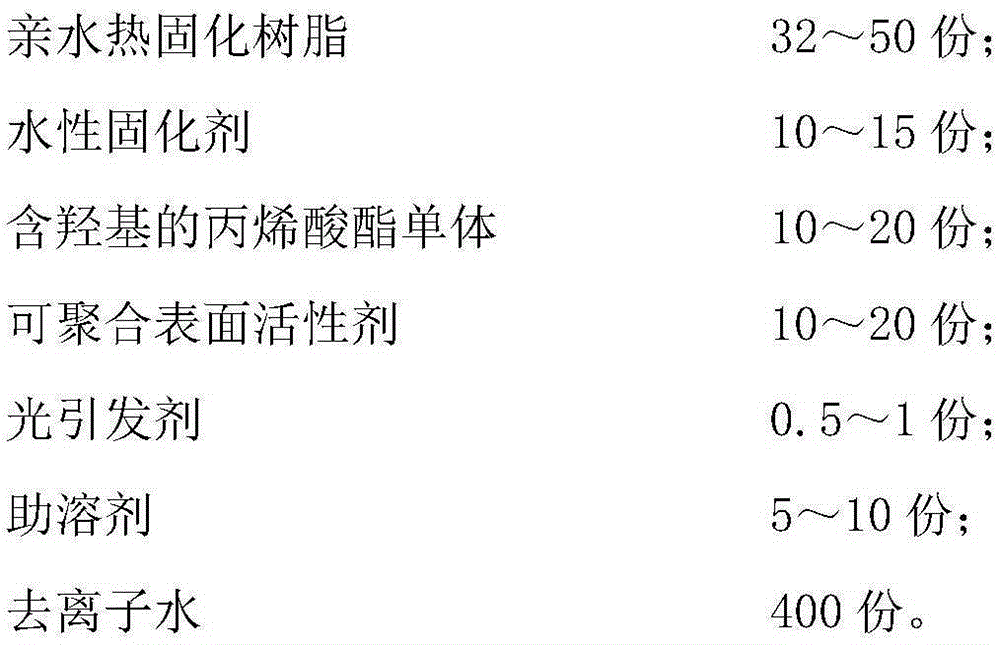

The invention discloses a photo-thermally cured hydrophilic anti-fog paint composition which comprises the following ingredients: 32-50 parts of hydrophilic thermal-curing resin, 10-15 parts of a waterborne curing agent, 10-20 parts of hydroxy acrylate monomer, 10-20 parts of a polymerizable surfactant, 0.5-1 part of a photoinitiator, 5-10 parts of a cosolvent and 400 parts of water. The photo-thermally cured hydrophilic anti-fog paint composition provided by the invention can be applied to the surface of a plastic base material, is firstly thermally cured and then photo-cured, has good constant fogging resistance and abrasion resistance, meanwhile, has good adhesive force to the plastic base material, can be widely applied to anti-fog vehicle window film, anti-fog vehicle headlights, bathroom mirrors and the like and has a good application prospect.

Description

technical field [0001] The invention belongs to the field of photothermal dual curing coatings, in particular to a hydrophilic anti-fog coating composition with photothermal dual curing. Background technique [0002] In daily life, due to the obvious temperature difference and humidity difference on both sides of the glass. When the vaporized liquid in the air on the higher temperature side encounters the glass, it will condense on the glass surface to form small liquid droplets with poor fluidity, which will cause fog on the glass surface. Small droplets on the glass surface can cause irregular scattering, reflection and diffraction of light, which significantly affects the transmission ability of light. [0003] In order to solve these problems, the surface of the material is generally treated with hydrophobic or hydrophilic treatment. Hydrophobic resins are commonly used as perfluorinated resins. On the one hand, the price is high. On the other hand, this type of resin ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D4/02C09D4/06C09D7/12C08J7/04

Inventor 虞明东李桐蒋天龙

Owner SHANGHAI CHENGYING NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com