Polyurea expanding type fireproof paint as well as preparation method and application thereof

A kind of technology of fireproof coating and expansion type, which is applied in the direction of fireproof coating, polyurea/polyurethane coating, coating, etc. It can solve the problems of not being suitable for outdoor use and poor water resistance, so as to solve the problem of dehydration and improve heat insulation performance , Improve the effect of dispersion and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

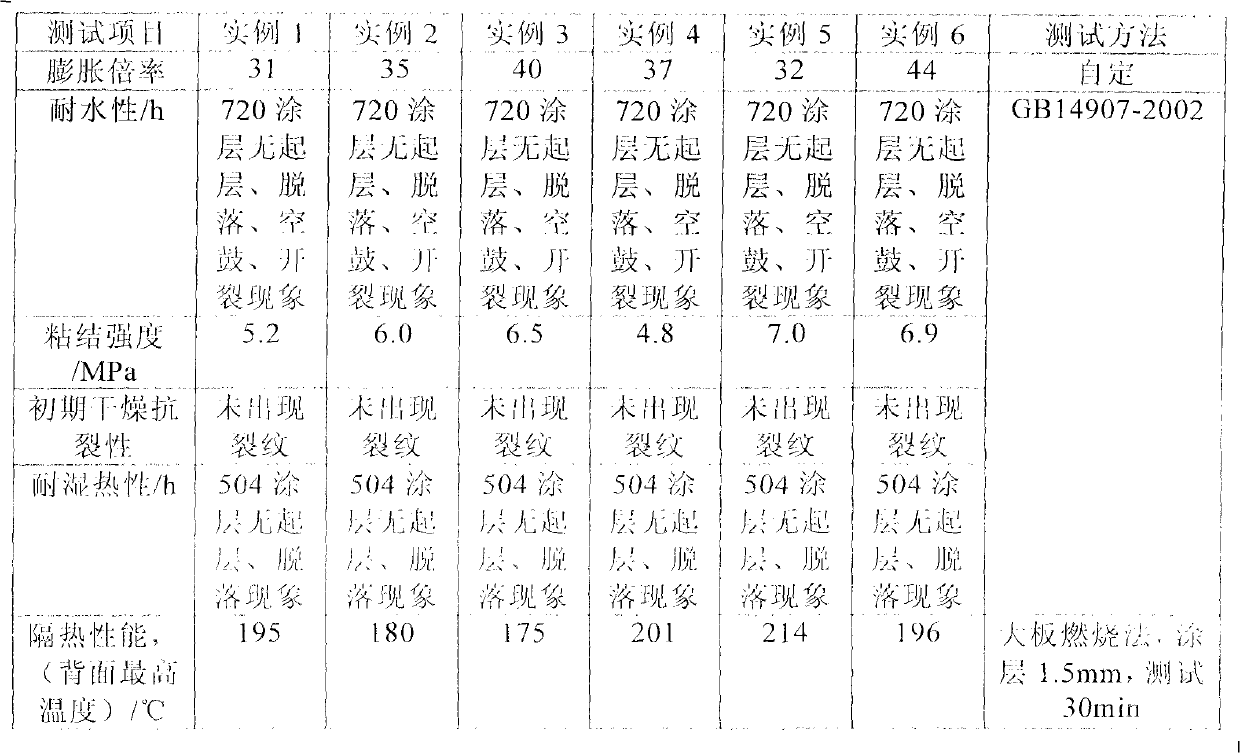

Examples

Embodiment 1

[0058] Component B: 30 parts of JeffamineT403 (amino-terminated polyether), 1 part of diethyltoluenediamine (polyamine chain extender), 5 parts of propylene carbonate (thinner), ammonium polyphosphate (polymerization degree 30≤n≤ 100, surface treatment with silane coupling agent) 8 parts, ammonium polyphosphate (polymerization degree n≥1000, surface treatment with silane coupling agent) 32 parts, pentaerythritol 15, melamine 13 parts, tricresyl phosphate 6 parts, hydroxide 4 parts of aluminum, 6 parts of magnesium hydroxide, 5 parts of titanium dioxide, 0.3 parts of KH-550, 0.4 parts of BYK-310, 0.3 parts of BYK-066N, 25 parts of mixed solvent;

[0059] Component A: Rubinate 1245 30 parts;

[0060] Mix and disperse components B evenly, and then mix components A and B at a ratio of 1:5 for use.

Embodiment 2

[0062] Component B: 50 parts of Jeffamine D2000, 2 parts of N, N'dialkylphenylenediamine, 5 parts of ethyl carbonate, 12 parts of ammonium polyphosphate (30≤n≤100, surface treated with titanate coupling agent) , ammonium polyphosphate (n≥1000, surface treated with titanate coupling agent) 36 parts, pentaerythritol 17 parts, melamine 16 parts, tricumyl phosphate 10 parts, aluminum hydroxide 5 parts, magnesium hydroxide 6 parts , 5 parts of titanium dioxide, 5 parts of calcium carbonate, 1 part of KH-550, 0.5 part of BYK-054, 0.8 part of BYK-325, 29 parts of mixed solvent;

[0063] Component A: Rubinate 1245 35 parts;

[0064] Mix and disperse components B evenly, and then mix and use components A and B at a ratio of 1:5.9.

Embodiment 3

[0066] Component B: 50 parts of BASF T403, 2 parts of isophorone diamine, 10 parts of propylene carbonate, 16.5 parts of ammonium polyphosphate (30≤n≤100, surface treated with titanate coupling agent), ammonium polyphosphate (n≥1000, surface treatment with silane coupling agent) 38.5 parts, 20 parts of dipentaerythritol, 19 parts of melamine, 15 parts of tributyl phosphate, 5 parts of magnesium hydroxide, 8 parts of magnesium hydroxide, 5 parts of aluminum oxide , 7 parts of titanium dioxide, 1 part of HK-560, 1 part of BYK-344, 0.5 parts of BYK-141, 30 parts of mixed solvent;

[0067] Component A: Rubinate 9016 41 parts;

[0068] Mix and disperse components B evenly, and then mix components A and B at a ratio of 1:7 for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com