Patents

Literature

113results about How to "Improve fire and heat insulation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurea expanding type fireproof paint as well as preparation method and application thereof

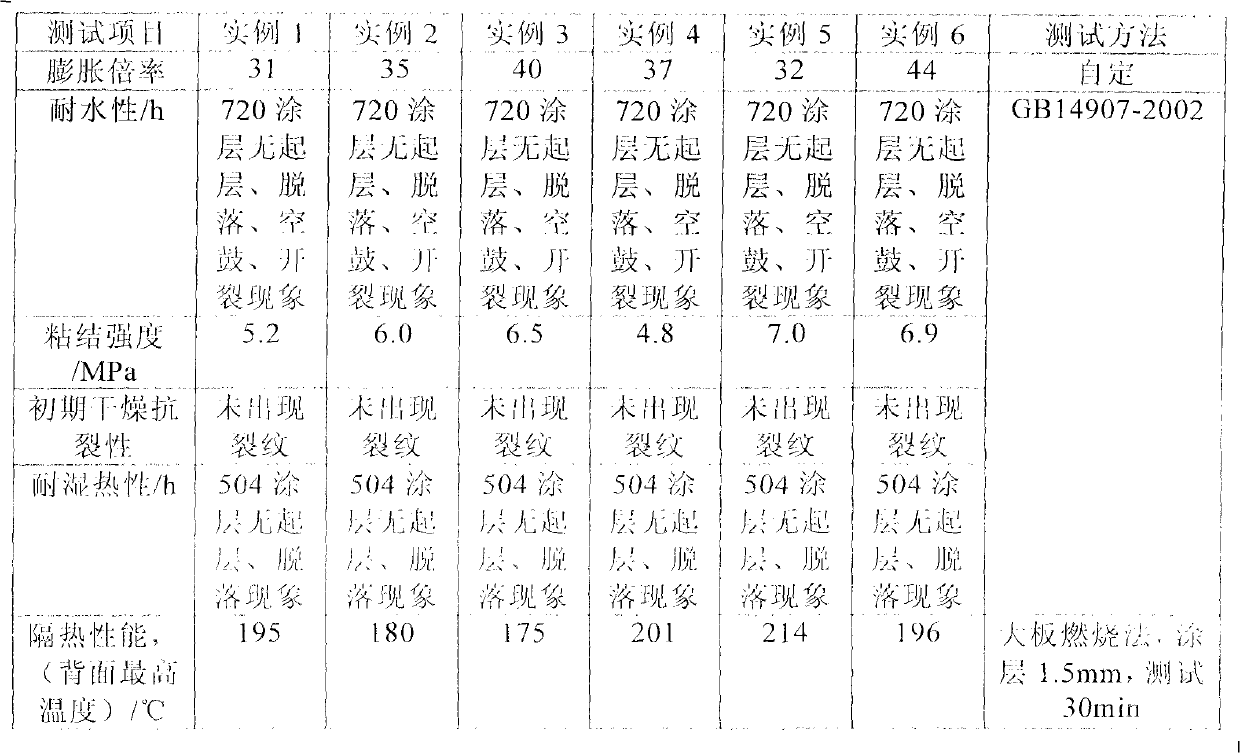

ActiveCN102559022AImprove insulation performanceImprove fire and heat insulation performanceFireproof paintsPolyurea/polyurethane coatingsFoaming agentPetrochemical

The invention relates to expanding type fireproof paint taking polyurea resin as a film forming substance and application of the expanding type fireproof paint. The expanding type fireproof paint contains a component A and a component B, wherein the component A contains an isocyanate prepolymer, the component B contains an amino-terminated polyether, a polyamine chain expanding agent, a diluting agent, a carbonizing catalyst, a carbonizing agent, a foaming agent, a flame retardant, a smoke suppressing agent, a pigment filler, an adjuvant and a mixed solvent, and the weight ratio of the component A to the component B is 1:5 to 1:7. The fireproof paint is suitable for the fireproof protection of indoor and outdoor steel structures and nonmetal structures and can be used for prohibiting the propagation of flame and the transmission of heat to a substrate. The expanding type fireproof paint is suitable for the fireproof protection in the fields of airport facilities, municipal engineering, vehicles, ships, petrochemical facilities and the like.

Owner:MARINE CHEM RES INST

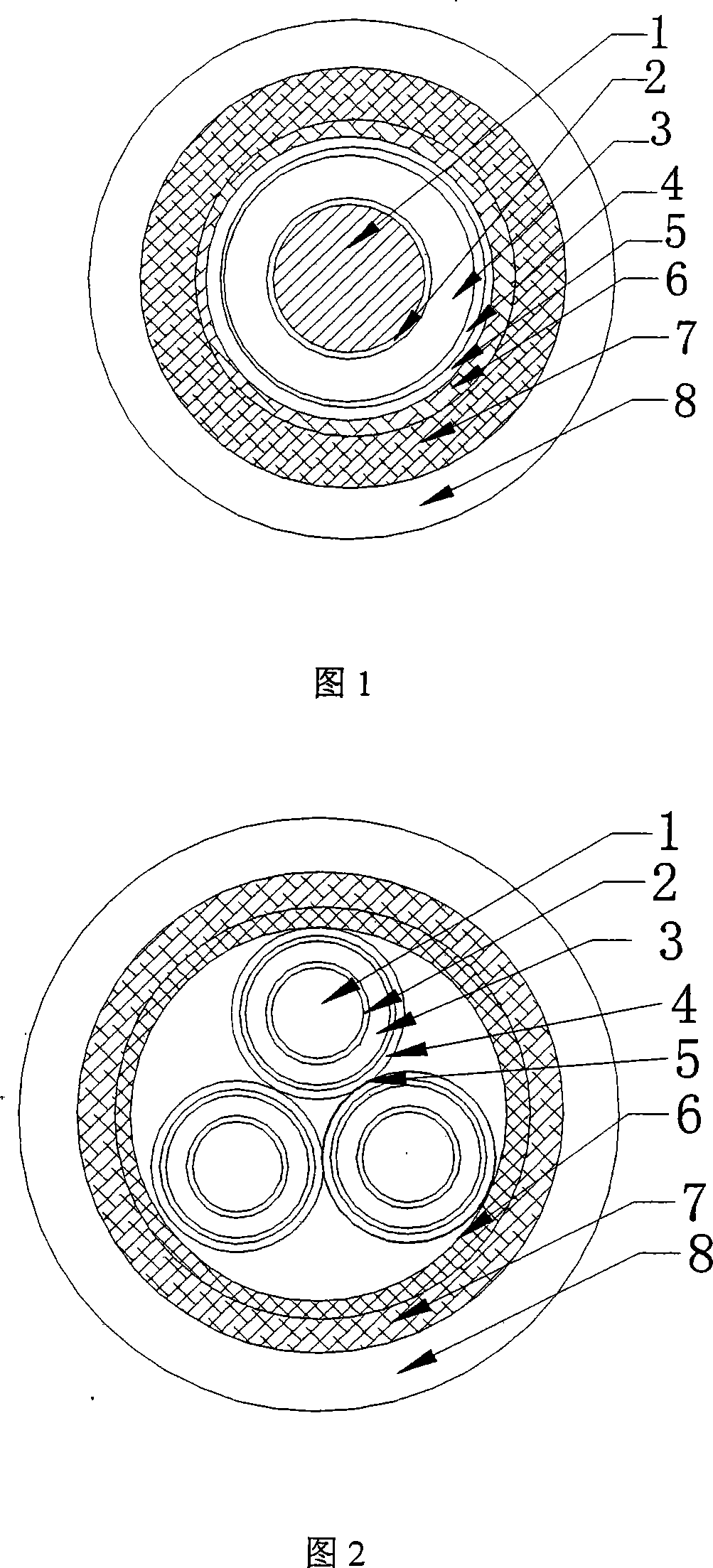

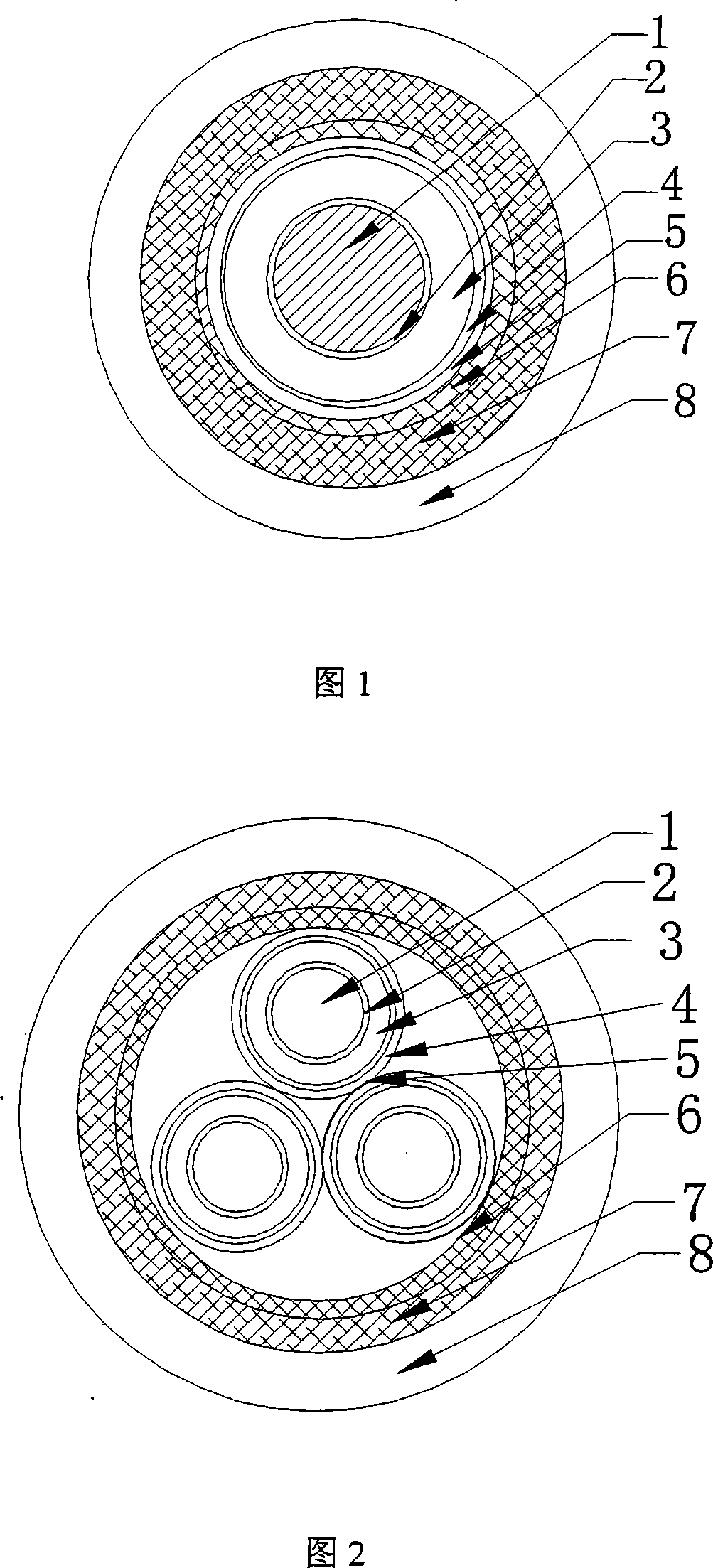

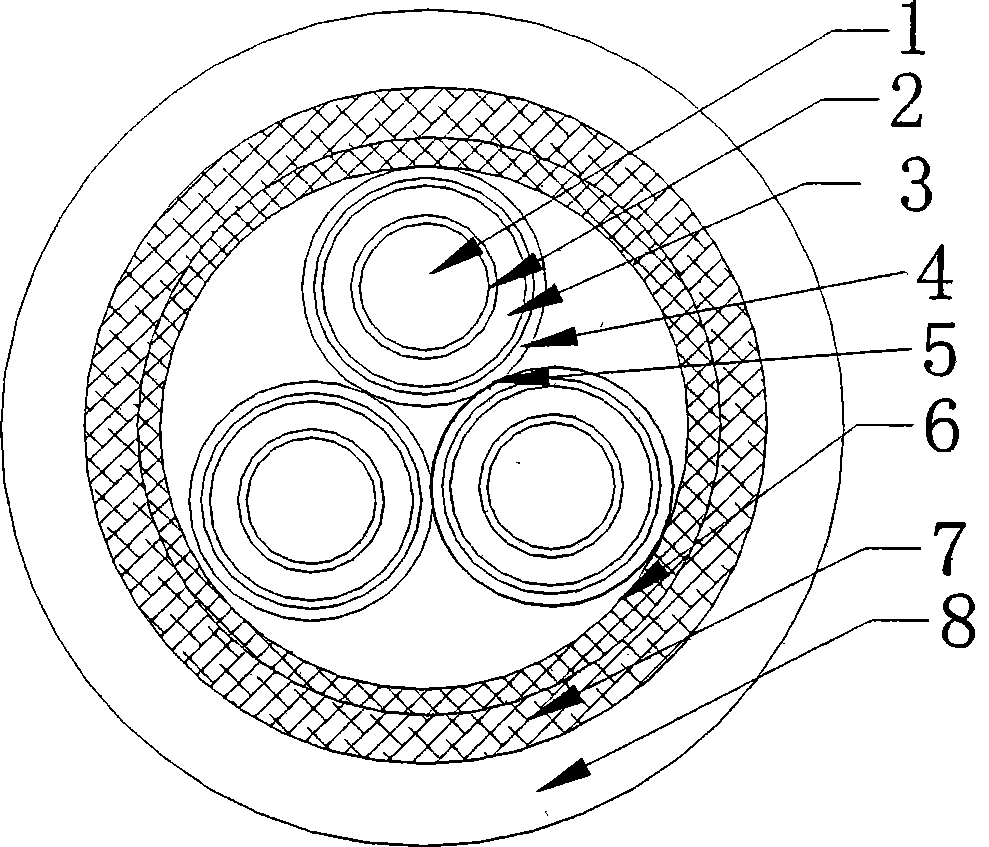

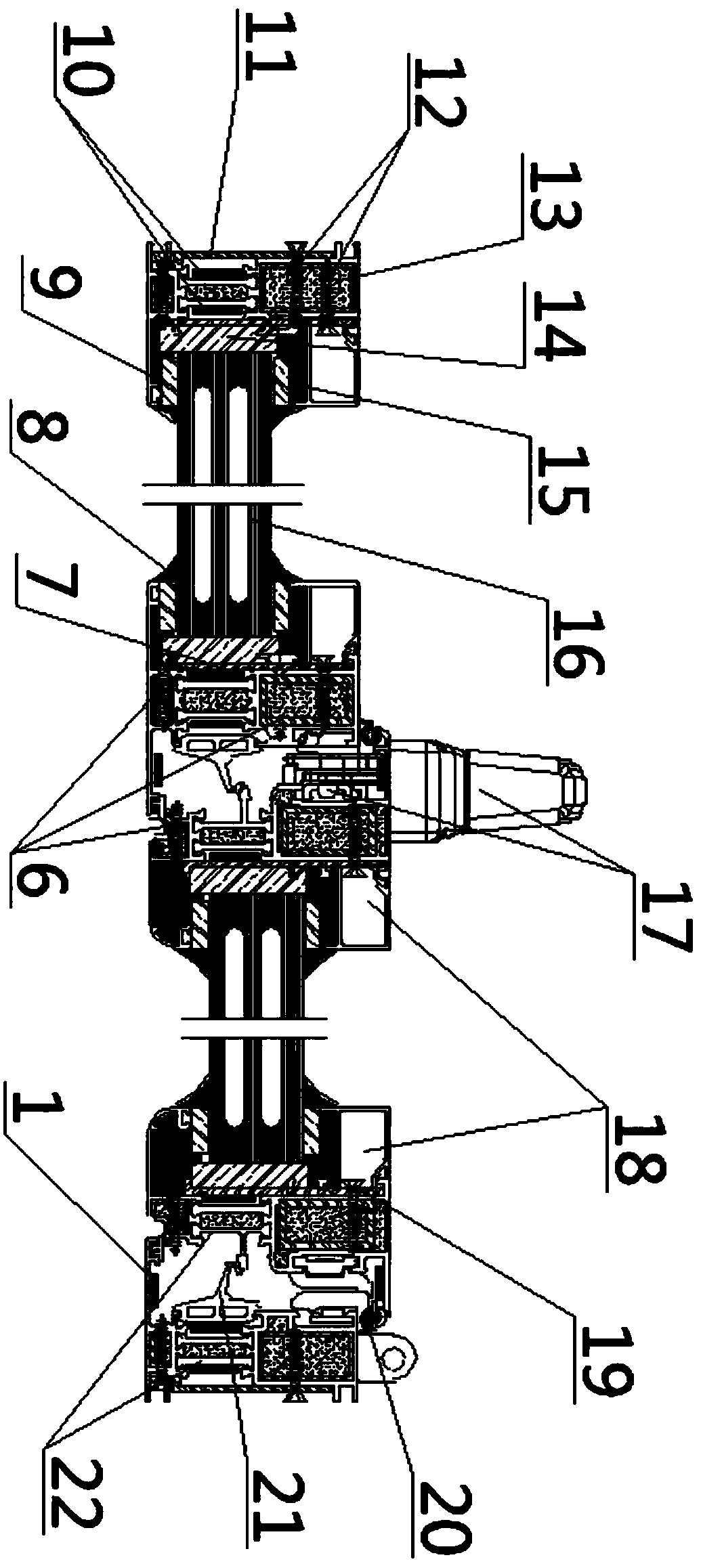

Medium-voltage fire-proof cable

ActiveCN101169993AGood tensile strengthGood fire and heat insulation performanceInsulated cablesInsulated conductorsThermal insulationCable transmission

The invention relates to a medium-voltage power transmission fire-resistant cable, which is characterized in that the outer fire-resistant layer of the medium-voltage cable core is made of fire-resistant inorganic fiber heat insulation layer on the inner side, and the outer side is a soft thermosetting elastomer for normal use. The composite fire-resistant and heat-insulating layer of the heat layer, the thermosetting elastomer, is composed of 30-50wt% silicon-based elastic material, 40-60wt% inorganic filler, 5-15wt% medium and low temperature frit, 4-10wt% vulcanizing agent, It is made by mixing extrusion molding and vulcanization. The composite fire-resistant and heat-insulating layer is a relatively soft sheath material when it is not exposed to flames, which can ensure good bending performance of the refractory structure in normal conditions, and quickly transforms into a shell-and-tube refractory and heat-insulating structure when it encounters fire or high temperature. In the fire-fighting environment, it can still maintain a certain period of time without being damaged, effectively preventing damage to the inner insulation caused by flames or high temperatures. When the flame temperature of the outer layer is 850°C, the temperature of the inner insulation surface is lower than 180°C. This fire-resistant and heat-insulating structure can be applied according to conventional cable production methods, and the production efficiency is extremely high.

Owner:FAR EAST CABLE +2

Self-heat-insulation light weight wallboard containing hollow ceramsites and preparation method thereof

ActiveCN104129959AUniform porous structureReduce voidsSolid waste managementCeramicwareFiberFoaming agent

The invention discloses a self-heat-insulation light weight wallboard containing hollow ceramsites and a preparation method thereof, and belongs to the technical field of building materials. The self-heat-insulation light weight wallboard comprises the following components by mass: 20-60 parts of a cementitious material, 5-30 parts of a lightweight aggregate, 0.05-0.5 part of a composite early strength agent, 2-8 parts of a foaming agent, 0.02-0.14 part of a foam stabilizing agent, 0.1-0.8 part of a catalyst, 0.05-0.6 part of a binder, 0.05-0.6 part of straw fiber and 15-30 parts of water. The preparation method is as follows: putting the cementitious materials, the straw fiber and the binder together, then mixing, then orderly adding the water, the foaming agent, the stabilizer and the catalyst, stirring to obtain a slurry mixture, adding hollow ceramsites, obturator perlite and expanded vermiculite in saturated surface-dry condition, stirring, then using an injection pump to inject into a wallboard forming machine for molding, and 3-5 hours after the concrete is solidified and hardened, demoulding to obtain the self-heat-insulation light weight wallboard containing the hollow ceramsites. The self-heat-insulation light weight wallboard containing the hollow ceramsites has energy saving, environmentally-friendly, fire insulating, sound-insulation, high-strength, lightweight, waterproof, thermal-insulation, corrosion-resistant, durable and other characteristics.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

High-density self-compacted concrete and preparation method

The invention discloses high-density self-compacted concrete and a preparation method. The high-density self-compacted concrete consists of the following components in percentage by mass: 15-32% of a cementing material, 20-35% of aggregates, 20-42% of sand, 3-12% of expanded vermiculite, 0.1-0.8 percentage of a water reducing agent, 0.04-0.5% of a thickening agent, 0.2-1.5% of a thixotropy lubricant, 0.08-0.8% of straw fiber and 10-25% of water. The preparation method comprises the following steps: stirring the cementing material, the straw fiber and the thickening agent needed for preparation for 3-6 minutes, sequentially adding the water, the water reducing agent and the thixotropy lubricant needed for preparation, and continuously stirring the mixture for 5-10 minutes so as to obtain a slurry mixed material; B, adding the aggregates, the sand and the expanded vermiculite into the slurry mixed material obtained in the step A, and stirring the mixture for 3-6 minutes, thereby obtaining the high-density self-compacted concrete. By adopting the high-density self-compacted concrete, properties of concrete can be effectively improved, a mixture can be relatively good in flowability and caking properties, and the high-density self-compacted concrete has the characteristics of being relatively good in anti-separation properties, tensile resistance, anti-cracking properties, self-filling properties, gap through properties, size stability and the like.

Owner:CHINA MCC17 GRP

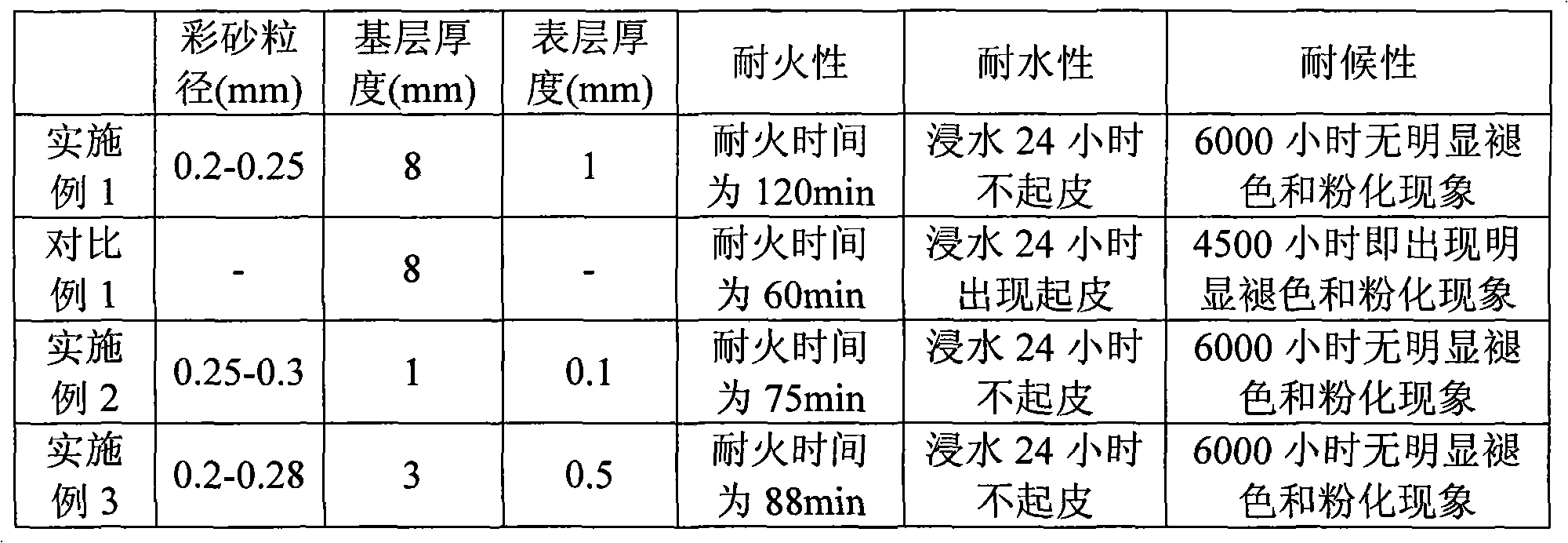

Fireproof coating composition and fireproof steel material

ActiveCN102485684AImprove fire resistanceImprove water resistanceFireproof paintsEpoxy resin coatingsSurface layerMetallurgy

The invention provides a fireproof coating composition. The coating composition comprises colored sand and a binder which are respectively and independently preserved. The invention also provides a fireproof steel material. The fireproof steel material comprises a steel material main body, a fireproof base layer coated on the steel material main body, and a fireproof surface layer coated on the fireproof base layer, wherein the fireproof surface layer is formed by curing the binder in the fireproof coating composition provided in the invention. The fireproof steel material prepared according to the invention has the advantages of fine surface, and good fire proofness, water proofness and weatherability.

Owner:北京仁创合力化工科技有限公司

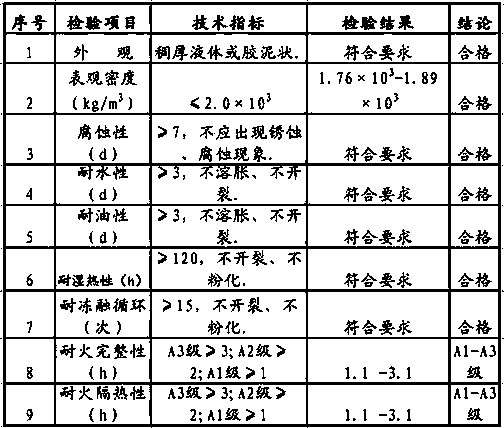

Expanded organic fireproof blocking material and preparation method thereof

ActiveCN103467004AImprove fire and heat insulation performanceExcellent physical and chemical propertiesAdhesiveSmoke

The invention belongs to the technical field of fireproof blocking materials and preparation thereof, and particularly relates to an expanded organic fireproof blocking material and a preparation method thereof. The organic fireproof blocking material comprises the following raw materials in parts by mass: 150-220 parts of an inorganic filler, 10-20 parts of high-alumina aluminum silicate cellucotton, 5-14 parts of expanded graphite, 108-130 parts of an organic fireproof adhesive and 8-12 parts of a diluent which are mixed together. The fireproof blocking material has remarkable fireproof and insulating effects, can reach the A3 grade in the GB23864-2009 Fireproof Blocking Material, has favorable physical and chemical properties and superior weatherability, can adapt to various holes, openings, gaps and the like in practical application, facilitates construction, maintenance and replacement, and can effectively prevent flame and smoke on fire scenes from diffusing and spreading through holes and gaps in walls.

Owner:应急管理部四川消防研究所

Fireproof coating for waterborne cable

InactiveCN103992708AGood fire and heat insulationGood adhesionFireproof paintsChemical industryAmmonium polyphosphate

The invention discloses a fireproof coating for a waterborne cable, belonging to the technical field of chemical industry. The fireproof coating is composed of the following components in parts by weight: 15-18 parts of acrylic resin, 10-15 parts of phenol formaldehyde resin, 20-26 parts of ammonium polyphosphate, 12-15 parts of pentaerythritol, 5-8 parts of tripolycyanamide, 5-9 parts of zinc borate, 3-7 parts of chlorinated paraffin, 0.1-0.5 part of flatting agent, 0.8-1.2 parts of defoaming agent, 2-3 parts of organic bentonite, 1-5 parts of inorganic pigment and 15-25 parts of water. The coating disclosed by the invention is good in fire resistance and heat insulation property, strong in binding power, high in strength, good in water resistance as well as acid and alkaline corrosion resistance, good in decoration and reduced in cost.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

Waterborne waterproof expansion-type fire-resistive coating for steel structures and preparation method of coating

ActiveCN106243878AAvoid fire degradation issuesLow VOC contentFireproof paintsAnti-corrosive paintsCarbon layerDefoaming Agents

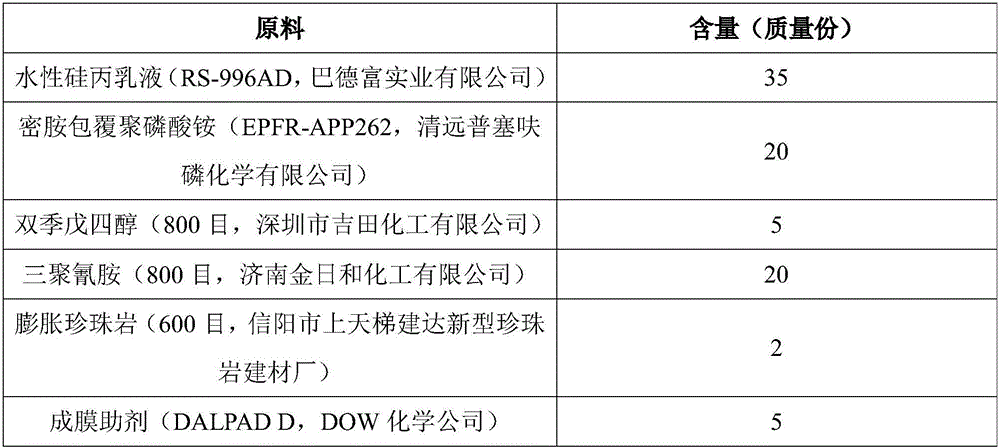

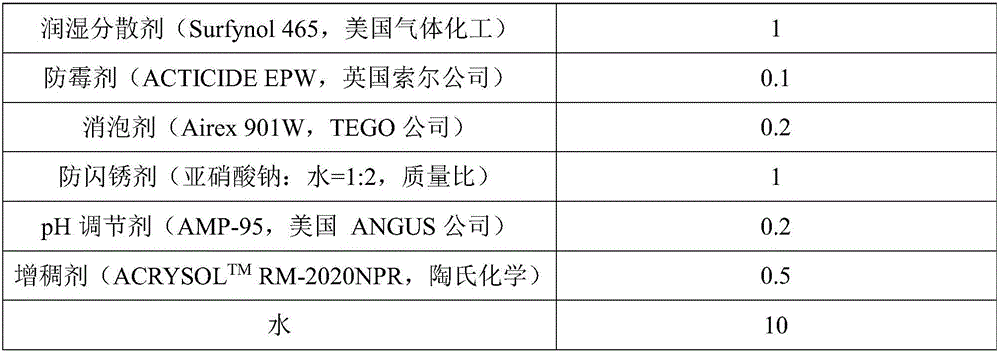

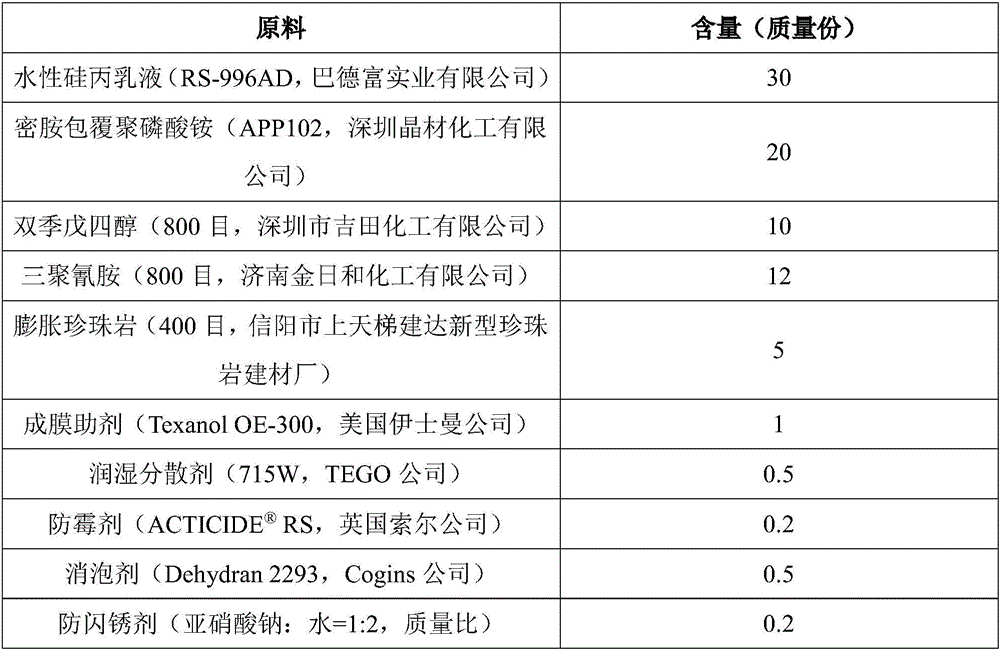

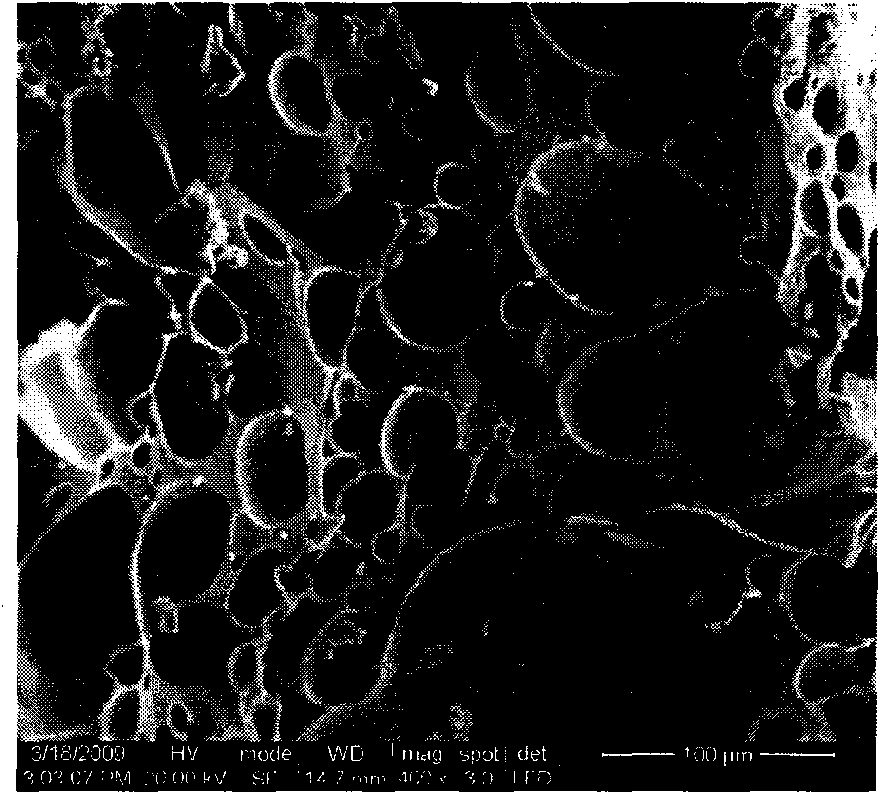

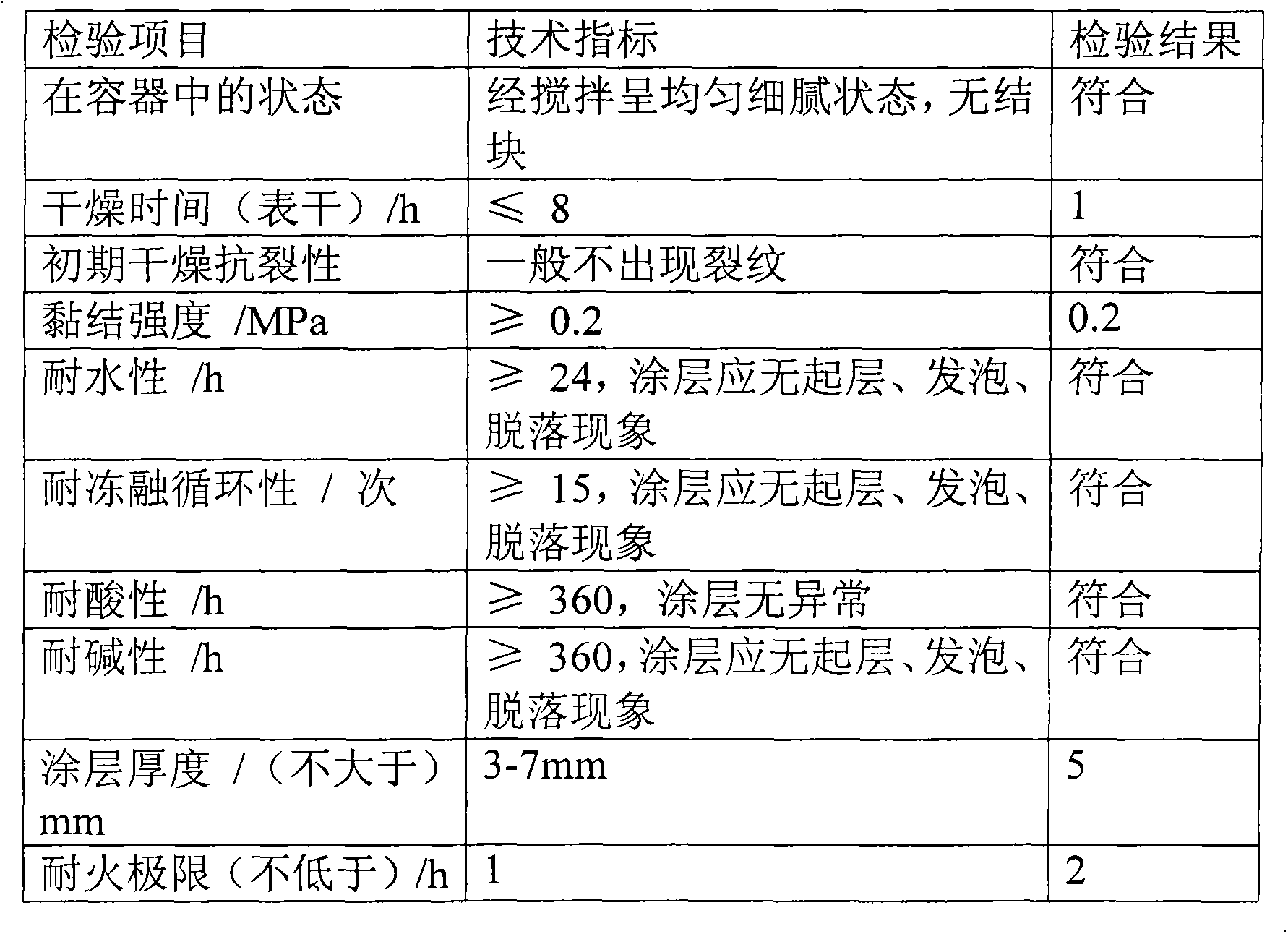

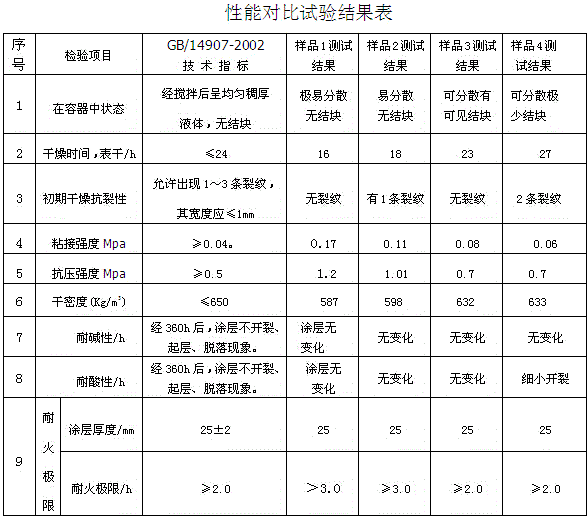

The invention discloses a waterborne waterproof expansion-type fire-resistive coating for steel structures and a preparation method of the coating. The coating is prepared from, by mass, 30-40 parts of waterborne silicone acrylic emulsion, 20-30 parts of melamine-coated ammonium polyphosphate, 5-10 parts of dipentaerythritol, 10-20 parts of melamine, 2-5 parts of expanded perlite, 1-5 parts of a film forming auxiliary, 0.5-1 part of a wetting dispersant, 0.1-0.5 part of a mildew preventive, 0.1-0.5 part of a defoaming agent, 0.1-1 part of a flash rust inhibitor, 0.1-0.5 part of a pH regulating agent, 0.1-0.5 part of a thickening agent and 10-20 parts of water. According to the waterborne waterproof expansion-type fire-resistive coating for the steel structures and the preparation method of the coating, the preparation process is simple, and the coating can be obtained only by adding the materials in proportion in batches and then mixing the materials to be uniform; the comprehensive performance of the fire-resistive coating accords with the national standard GB14907-2002 'general specifications of fire-resistive coating for steel structure', and the fire-resistive coating has the advantages of being high in expansion speed and carbon layer strength, good in medium-long-term fireproof and heat insulation effect, high in waterproofness, safe, environmentally friendly and the like.

Owner:广东达尔新型材料有限公司

Novel composite perlite board for fire prevention and heat insulation and manufacturing method thereof

InactiveCN101555121ALow costAdjustable densitySolid waste managementThermal insulationAluminium hydroxide

The invention relates to a novel composite perlite board for fire prevention and heat insulation and a manufacturing method thereof. The main components comprise perlite, sodium silicate solution, water repellent agent, aluminium hydroxide, calcium carbonate, aedelforsite, phosphoric acid, magnesium oxide, white carbon black aqueous solution; according to parts by weight, 100 parts of perlite are taken as a benchmark and the component comprises: 50-70 parts of sodium silicate solution, 3-5 parts of water repellent agent, 5-11 parts of aluminium hydroxide, 3-6 parts of calcium carbonate, 7-12 parts of aedelforsite, 4-7 parts of phosphoric acid, 4-8 parts of magnesium oxide, 1-3 parts of white carbon black and 100-160 parts of water. The technology provided in the invention can effectively solves the defects that in the market fireproof door core scatters or deforms and twists in case of burning by mass fire; meanwhile, the material manufactured by the technology has excellent fireproofing and heat-insulating capabilities, the composite perlite board with a thickness of 42mm alone can meet the requirements of GB 12955-2008 on fire prevention and heat insulation; meanwhile, the fireproof door core is also provided with advantages such as low cost, adjustable density, relatively good intensity and toughness, high production efficiency, certain waterproof capacity and the like.

Owner:HUNAN UNIV OF TECH

Medium-voltage fire-proof cable

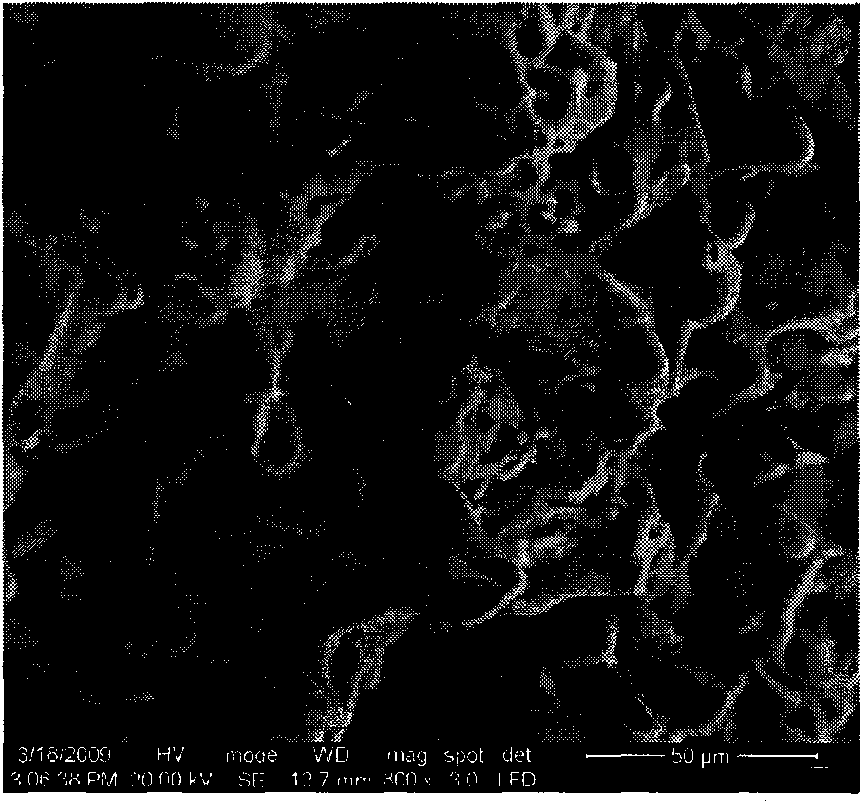

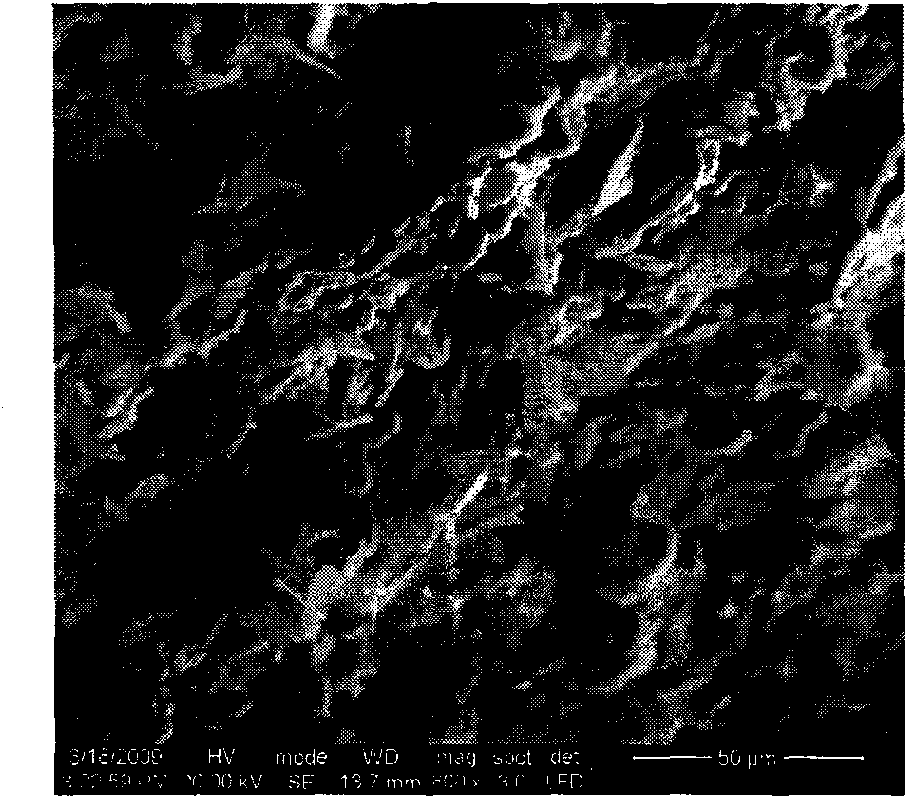

ActiveCN101169993BReduce the burden onImprove fire and heat insulation performanceInsulated cablesInsulated conductorsFiberFrit

The invention relates to a middle-voltage power transmission fire-resistant cable, which is characterized in that a fire-resistant layer out of a middle-voltage cable core includes an inner fire-resistant inorganic fiber thermal insulating layer, and an outer composite fire-resistant thermal insulating layer, which is a soft thermosetting elastic body in normal use and is a fire-resistant thermalinsulating layer when exposed to fire, wherein the thermosetting elastic body consists of 30-50wt percent silicon-based elastic material, 40-60wt percent inorganic filling material, 5-15wt percent middle- and low-temperature frit, and 4-10wt percent vulcanizing agent and is prepared by mixing, extruding, shaping and vulcanizing. The composite fire-resistant thermal insulating layer is a soft protective material for ensuring the good bending property of the fire-resistant structure under normal condition, can change to tubular fire-resistant thermal insulating structure when exposed to fire orhigh temperature and can not be damaged for a certain time in fire environment so as to effectively prevent the flame or high temperature from damaging the inner insulating layer. When the outer flame temperature is 850DEG C, the surface temperature of the inner insulating layer is less than 180DEG C. The fire-resistant thermal insulating structure can be applied in common cable protection mannerand has very high production efficiency.

Owner:FAR EAST CABLE +2

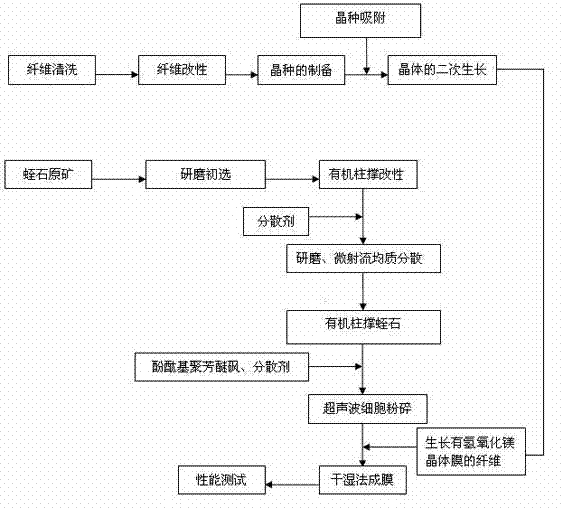

Preparation method of open-fire resistance thermal insulation textile

InactiveCN103114433AImprove insulation performanceImprove fire and heat insulation performanceFibre treatmentFiberPolymer science

The invention discloses a preparation method of an open-fire resistance thermal insulation textile. The preparation method comprises the steps of: firstly modifying fiber surfaces, so that the fiber surfaces generate a plurality of-COOH groups so as to adsorb Mg(OH)2 seed crystals, then adopting a secondary growth method to enable the Mg(OH)2 seed crystals to grow for the second time on the fiber surfaces, preparing Mg(OH)2 crystal films which are completely coated on the fiber surfaces, then mixing a high-temperature resistance polymer solution and different dosages of organic pillar vermiculites by taking a high-temperature-resistant polymer phenolphthalein-based polyether sulphone as a continuous phase, so as to realize the uniform mixing of high-temperature-resistant polymers with different proportions and the organic pillar vermiculites by a physical means of supersonic wave cell smashing, coating fiber fabrics by the prepared high-temperature-resistant polymers and a vermiculite mixed liquid, wherein magnesium hydrate crystal films grow on the surfaces of the fiber fabrics, and forming vermiculite film protective layers with different thicknesses on the fiber surfaces through appropriate thermal treatment, so as to obtain the textile with strong open-fire resistance and thermal insulation property. The open-fire resistance thermal insulation textile prepared by using the preparation method has the advantages of improving the open-fire resistance and the thermal insulation property.

Owner:NANTONG UNIVERSITY

Fireproof coating with black mica powder

ActiveCN103773170AGood fire and heat insulationGood adhesionFireproof paintsRubber derivative coatingsStyreneSodium

The invention discloses a fireproof coating with black mica powder. The fireproof coating with the black mica powder is prepared from the following raw materials in parts by weight: 10-15 parts of black mica powder, 5-8 parts of mullite powder, 8-10 parts of nano-montmorillonite, 3-5 parts of dimethyl phosphate, 10-15 parts of acrylic resin, 15-30 parts of amino resin, 2-4 parts of chlorinated rubber, 2-3 parts of carbamide phosphate, 1-3 parts of silane coupling agent, 5-6 parts of sorbitol, 7-9 parts of aluminium oxide, 3-5 parts of sodium borate, 8-10 parts of vermiculite, 3-4 parts of semi-hydrated gypsum, 3-5 parts of graphite powder, 2-3 parts of titanium dioxide powder, 8-13 parts of organic silicon modified styrene-acrylic emulsion, 5-6 parts of cellulose ether, 2-3 parts of glass powder, 6-8 parts of butyl latex, 2-3 parts of sodium fluosilicate and 3-5 parts of wood fiber. The fireproof coating has the advantages of being excellent in fireproof heat insulation property, excellent in adhesive strength, excellent in water resistance, acid-alkaline resistance and salt corrosion resistance, not easy to fall off, stable in storage, non-toxic and environmental-friendly.

Owner:ANHUI WILLY PAINT SCI & TECH LTD

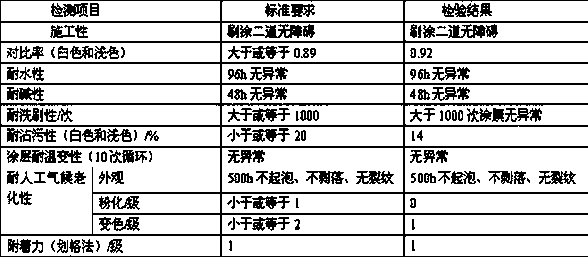

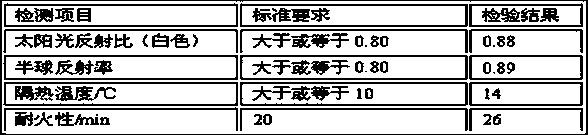

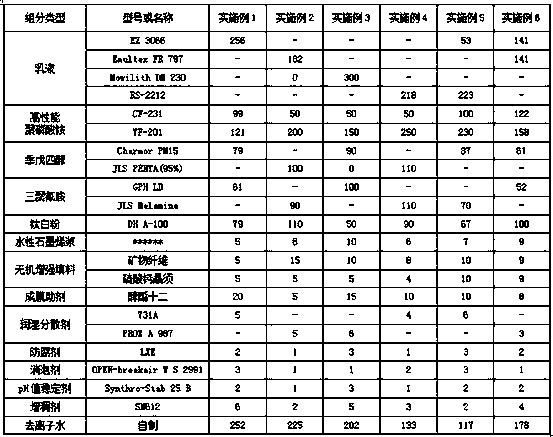

Decorative expansive-type waterborne styrene-acrylic emulsion-containing fireproof and heat-insulating coating

InactiveCN108384338ALow thermal conductivityReduce stress crackingFireproof paintsPentaerythritolDefoaming Agents

The invention provides a decorative expansive-type waterborne styrene-acrylic emulsion-containing fireproof and heat-insulating coating. The decorative expansive-type waterborne styrene-acrylic emulsion-containing fireproof and heat-insulating coating comprises the following raw material components in parts by weight: 20-30 parts of a styrene-acrylic emulsion, 2-4 parts of hollow glass microbeads,8-12 parts of titanium dioxide, 20-30 parts of ammonium polyphosphate, 8-12 parts of tripolycyanamide, 5-8 parts of pentaerythritol, 0.2-0.5 part of a silane coupling agent, 3-6 parts of a dispersingagent, 2-4 parts of a thickening agent, 0.2-0.5 part of a defoaming agent, 1.0-2.5 parts of a film-forming aid, 0.1-0.3 part of a wetting agent, 0.2-0.5 part of an OP-10 emulsifying agent and 20-30 of deionized water.

Owner:FOSHAN KANGDONG LIGHTING TECH CO LTD

Smoke-suppression and waterproof aqueous ultra-thin steel structure fireproof coating and preparation method thereof

InactiveCN109467992AHigh temperature resistantImprove integrityFireproof paintsWater basedCarbon layer

The invention discloses a smoke-suppression and waterproof aqueous ultra-thin steel structure fireproof coating and a preparation method thereof. The fireproof coating comprises the following components in parts by weight: 180-300 parts of vinegar emulsion, 190-330 parts of high-performance ammonium polyphosphate, 60-110 parts of pentaerythritol, 50-100 parts of melamine, 50-110 parts of titaniumdioxide, 5-10 parts of water-based graphene pulp, 10-20 parts of inorganic reinforcing filler, 5-20 parts of a film-forming agent, 3-6 parts of a wetting and dispersing agent, 1-3 parts of a preservative, 1-3 parts of an antifoaming agent, 1-3 parts of a pH stabilizer, 2-6 parts of a thickener and 110-260 parts of deionized water. The invention also comprises the preparation method of the coating;the fireproof coating is strong in water resistance, compact in carbon layer, good in adhesion, good in fireproof and heat insulation effect, environment-friendly and non-toxic; and the preparation method is simple.

Owner:湘江涂料科技有限公司

Gypsum-based steel structure fireproof protection material containing reinforced fibers

The invention provides a gypsum-based steel structure fireproof protection material containing reinforced fibers. The fireproof protection material is prepared by mixing the following components in percentage by mass: 82 to 95 percent of desulfurized gypsum, 3 to 15.5 percent of lightweight heat-insulating materials, 0.5 to 2 percent of reinforced fibers, 0.1 to 0.5 percent of water retaining agent, 0.1 to 1 percent of redispersible latex powder, 0.1 to 0.5 percent of retarding agent and 0.01 to 0.1 percent of air entraining agent. The lightweight heat-insulating materials can be one or two of vitrified micro-bubbles, hole-closed expanded pearlites, expanded vermiculites or sheet mica; the reinforced fibers can be one or two of glass fibers, sepiolite fibers, aluminum silicate fibers or polypropylene fibers. The fireproof heat insulation performance of the gypsum-based steel structure fireproof protection material is excellent, and the social and economic effects can be realized through waste utilization.

Owner:HANGXIAO STEEL STRUCTURE

Nano graphene fireproof paint and construction method thereof

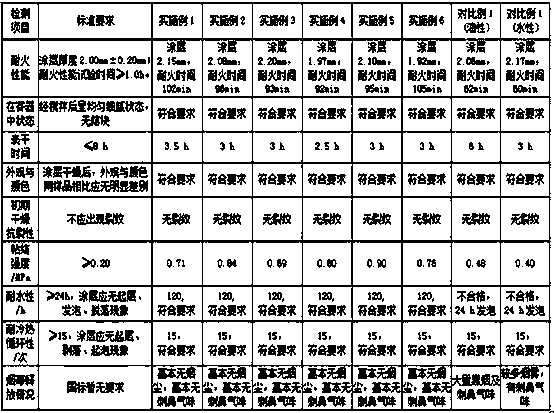

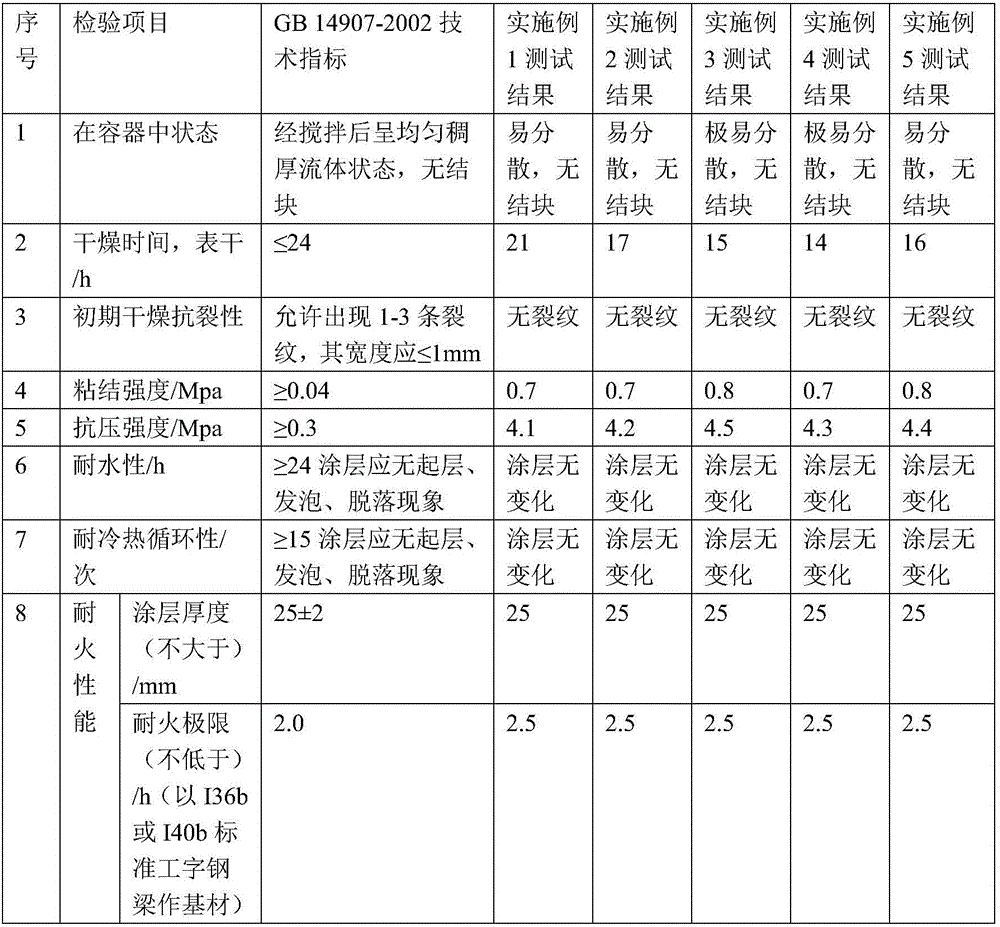

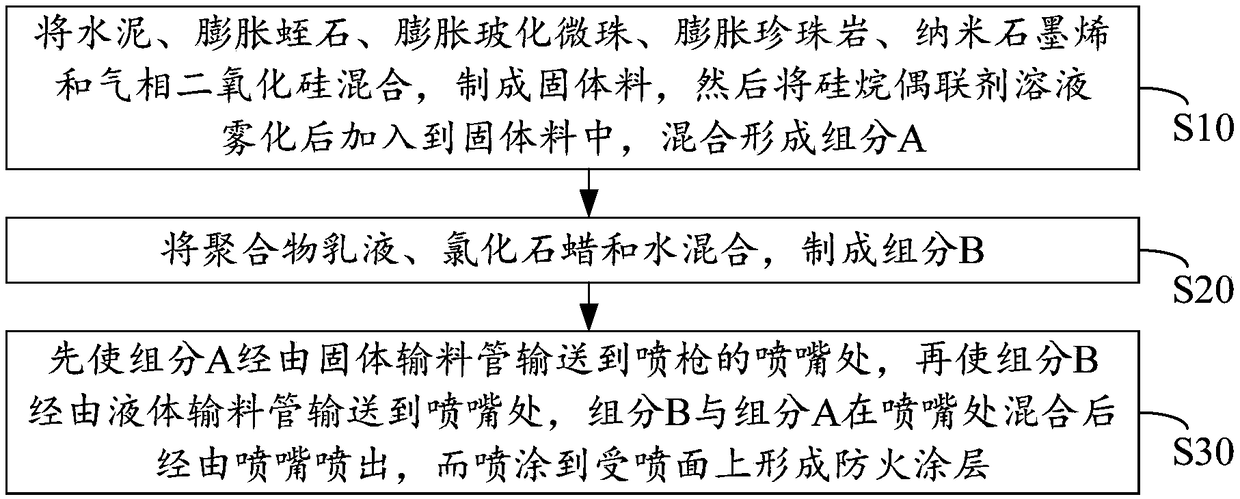

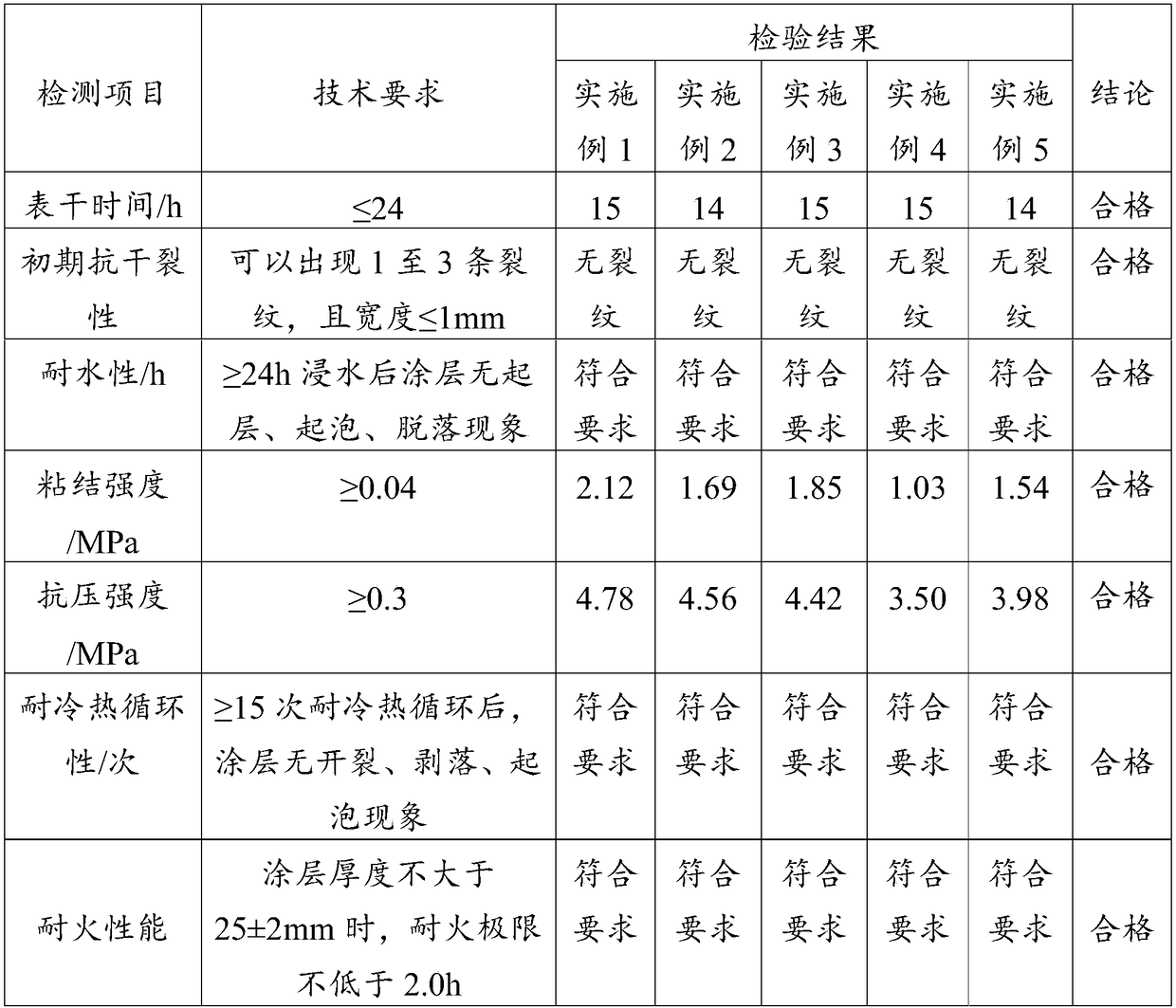

ActiveCN108892983AImprove fire and heat insulation performanceHigh strengthFireproof paintsLiquid surface applicatorsCrack resistanceSilanes

The invention discloses nano graphene fireproof paint and a construction method thereof. The nano graphene fireproof paint comprises a component A and a component B, wherein a mass ratio of the component A to the component B is (4-5):1; the component A contains the following components in parts by mass: 40-60 parts of cement, 5-10 parts of expanded vermiculite, 8-12 parts of expanded and vitrifiedsmall balls, 5-10 parts of expanded perlite, 1-3 parts of nano graphene, 8-12 parts of fumed silica and 2-5 parts of a silane coupling agent solution; and the component B contains the following components in parts by mass: 20-25 parts of polymer emulsion, 10-15 parts of chlorinated paraffin and 60-85 parts of water. According to the technical scheme provided by the invention, the fireproof coating formed by the prepared fireproof paint has high strength, is firm in bonding with the base material and excellent in cracking resistance, is difficult to cause undesirable phenomena such as crackingand dropping, and has excellent fireproof and thermal insulating properties.

Owner:深圳中天精装股份有限公司

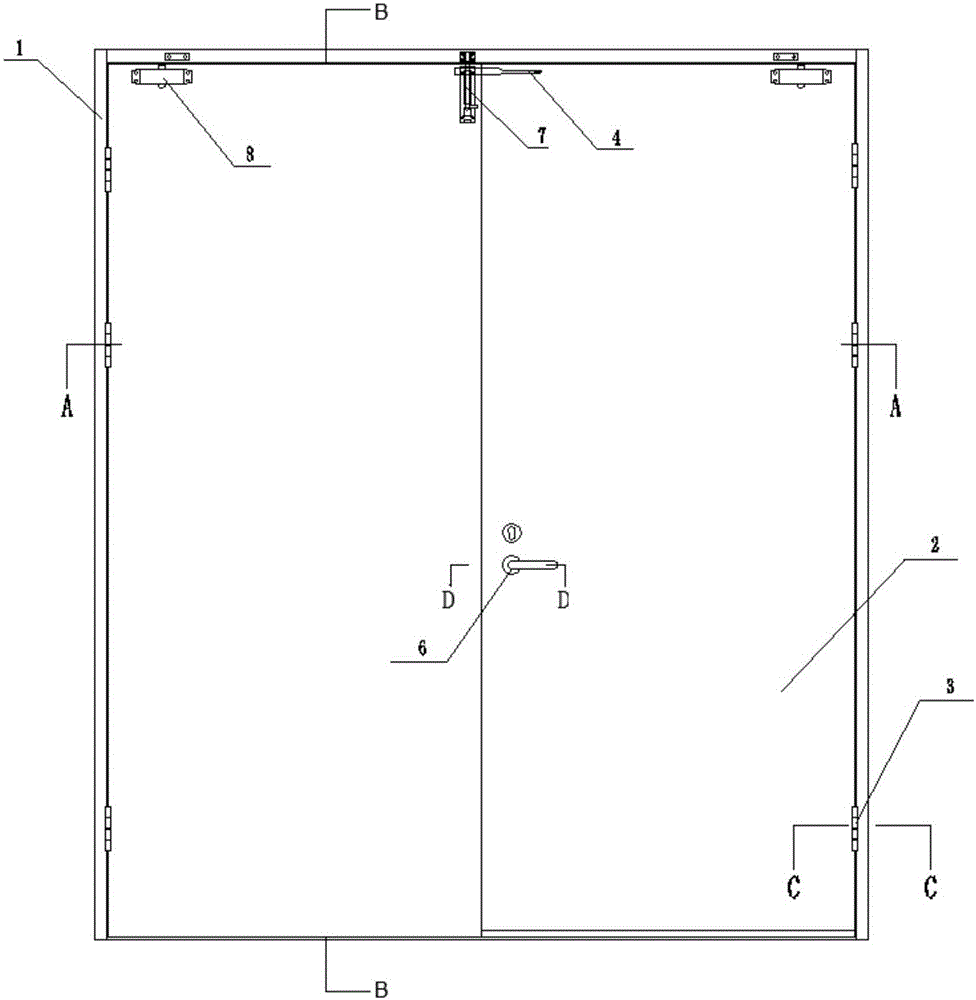

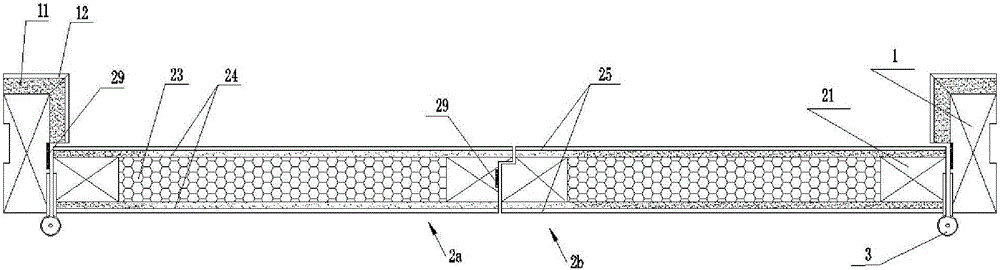

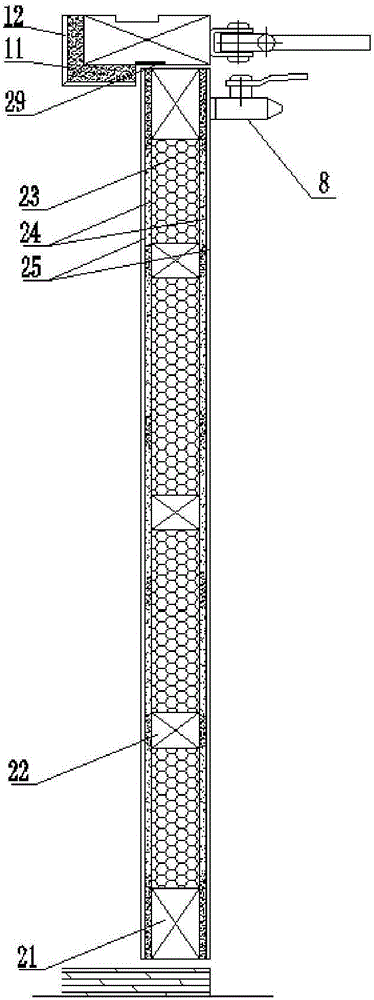

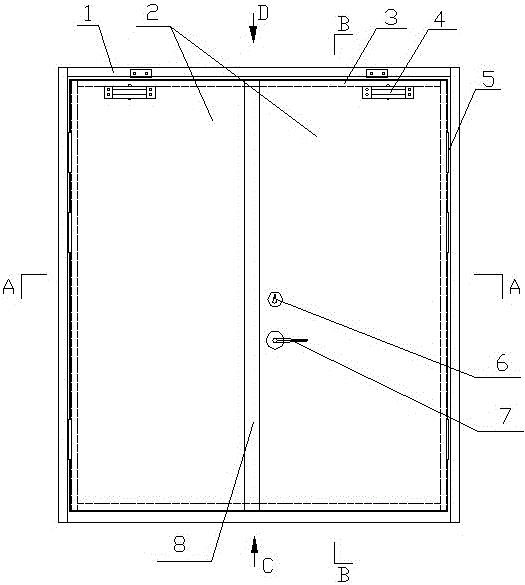

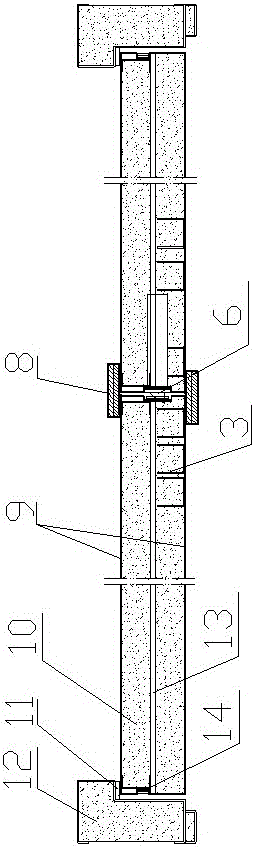

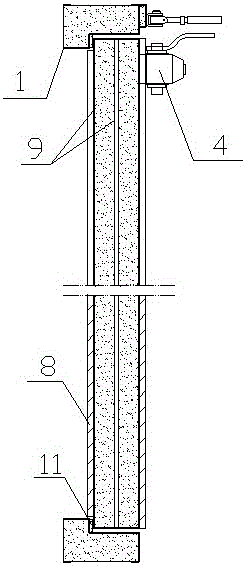

Double-side opening type wooden heat insulation fireproof door

InactiveCN105927126AHigh strengthImprove impact resistanceFireproof doorsWindow/door framesEngineeringTongue and groove

The invention provides a double-side opening type wooden heat insulation fireproof door, comprising a door frame and two door leaves, wherein the two door leaves are symmetrically fixed on side frames at the two sides of the door frame respectively by fireproof hinges; each door leaf comprises a framework; each framework is internally filled with an expanded perlite fire prevention board, and a first magnesium-silicon fire prevention board and a flame-retardant plywood are sequentially fixed on the surface of each expanded perlite fire prevention board; a fire-proof expansion sealing element is arranged between the door frame and each door leaf; a second magnesium-silicon fire prevention board is fixed at the inner side of a surface, exposed to fire, of the door frame; the two door leaves are closed in a tongue-and-groove way. The expanded perlite fire prevention boards are arranged in the door leaves, so that a fireproof effect is improved; the magnesium-silicon fire prevention boards are arranged, so that the strength and impact resistance of the door leaves are improved while the fireproof effect is further improved. The fire-proof expansion sealing elements are reasonably installed on the door frame, so that a sealing fire prevention effect is improved.

Owner:ANHUI ANWANG DOOR IND

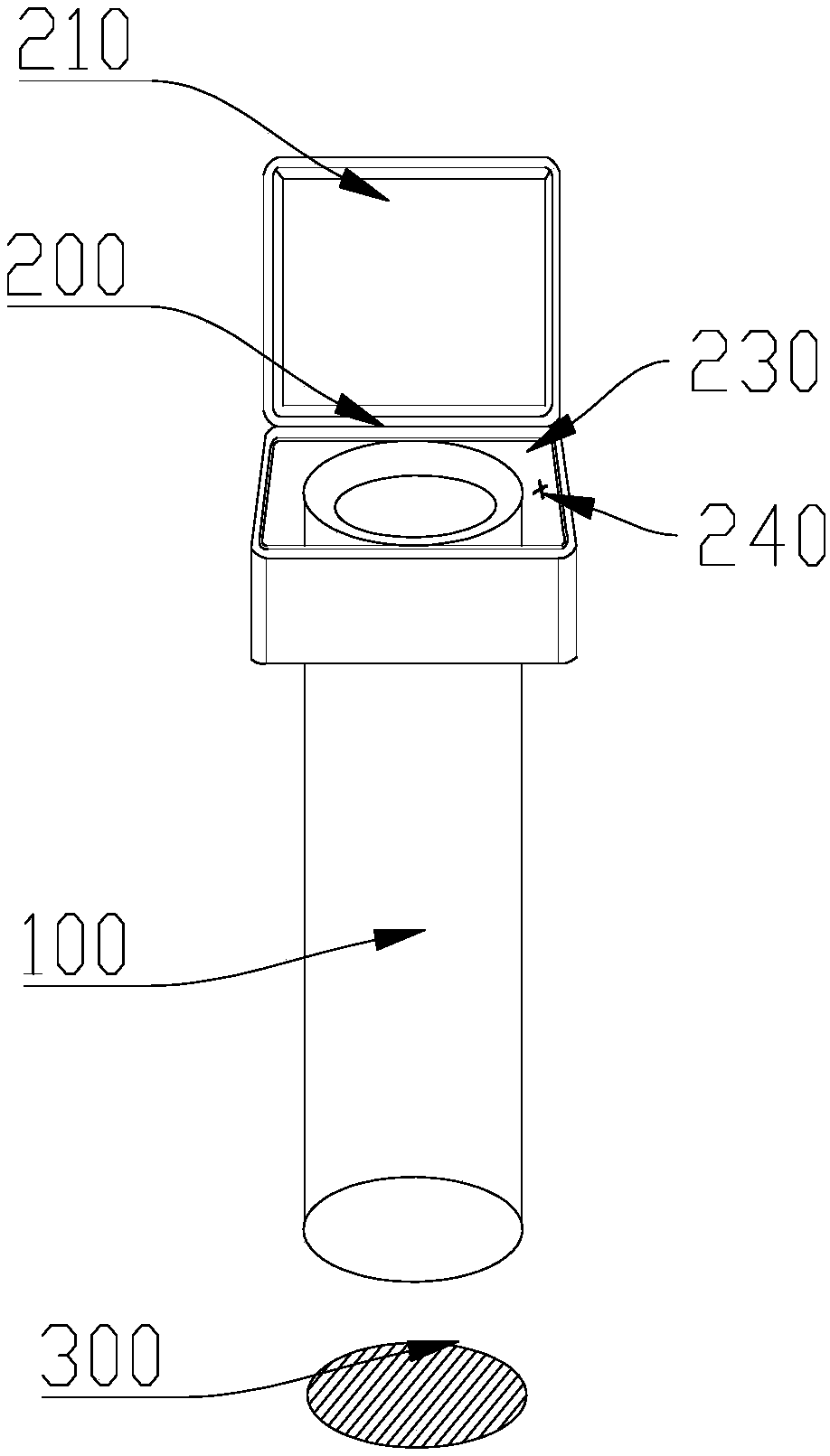

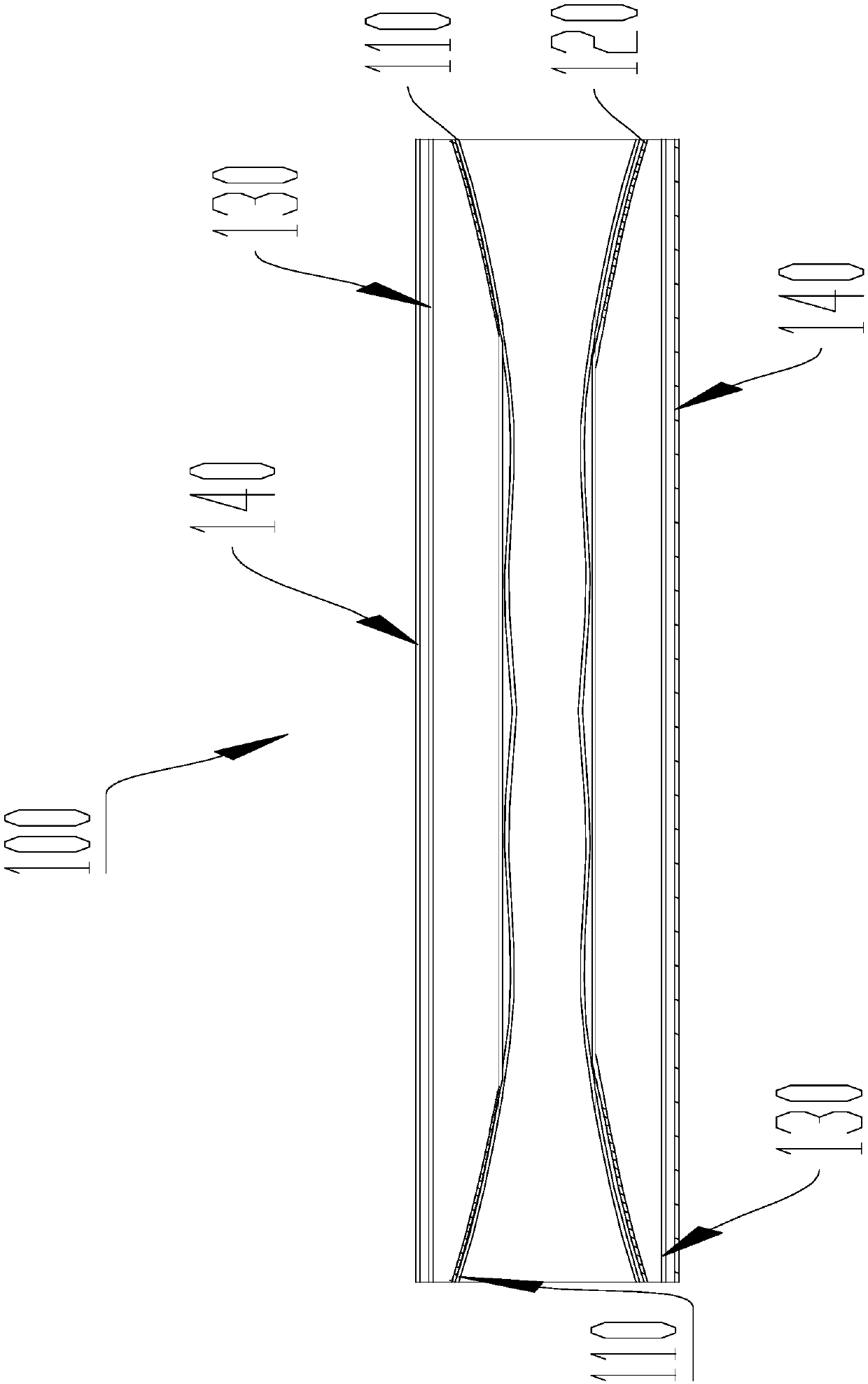

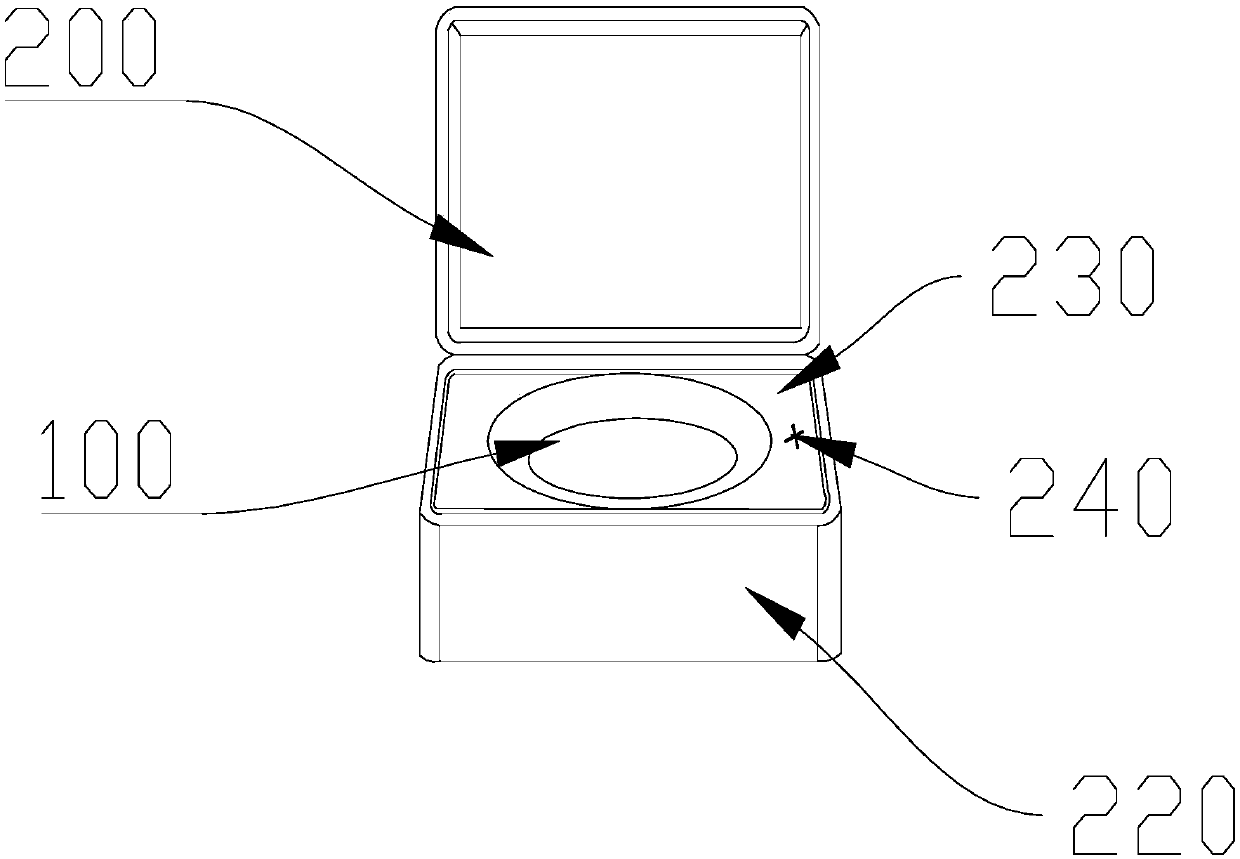

High-altitude escape fabric tube slide

Owner:深圳市昌安消防科技有限公司

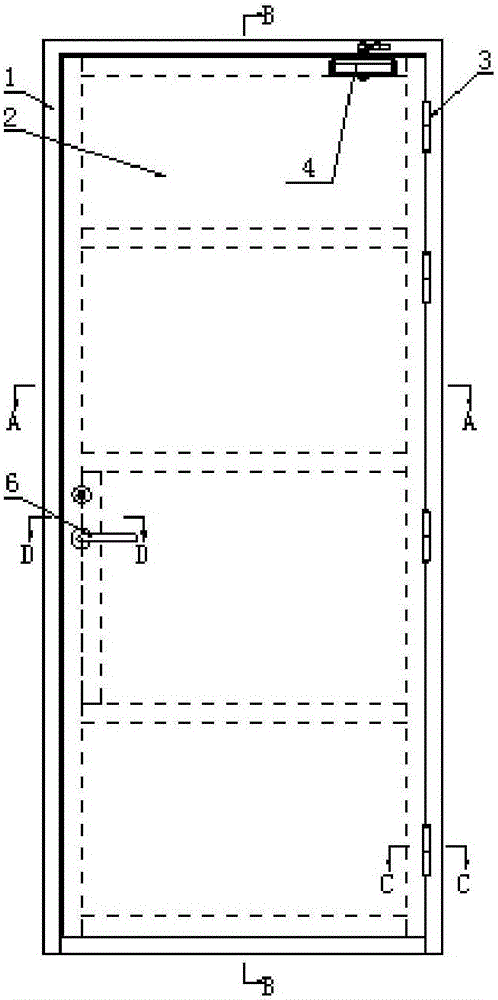

Manufacturing method of wooden fireproof door and wooden fireproof door

ActiveCN110900770AImprove fire performanceEffect on fire resistanceFireproof doorsWood treatment detailsFiberMedium density fiberboard

The invention discloses a manufacturing method of a wooden fireproof door and the wooden fireproof door, and belongs to the fireproof door technology field. The manufacturing method of the wooden fireproof door comprises the following steps that a wooden framework is impregnated with a flame-retardant impregnation liquid and dried, and the flame-retardant wooden framework is manufactured; a firstfireproof decorative plate is bonded to one side of the flame-retardant wooden framework, a filling space is formed in the wooden framework, a fireproof filling material is added into the filling space, and primary pressing is performed; then, a second fireproof decorative plate is bonded to the other side of the flame-retardant wooden framework, secondary pressing is performed, and a door plate core is manufactured; and flame-retardant medium-density fiber boards are bonded on outer surfaces of the first fireproof decorative plate and the second fireproof decorative plate of the manufactureddoor plate core, and press fit is performed. By using the manufacturing method of the wooden fireproof door, the filling space defined by the wooden framework and the fireproof decorative plates is filled with the fireproof filling material, then pressing is performed, and a situation that fireproof performance is affected due to a fact that the fireproof filling material loosens and falls off ina later use process is avoided.

Owner:河南赋安消防器材有限公司

Waterborne expansion fireproof coating and preparation method thereof

InactiveCN105694616AFormulation ScienceGood physical and chemical propertiesFireproof paintsThermal insulationCarboxylic acid

The invention discloses a water-based intumescent fireproof coating, which is mainly prepared from the following raw materials, all of which are in parts by mass: 17-23 parts by mass of ammonium polyphosphate, 9-13 parts of melamine, 8-13 parts of pentaerythritol triacrylate, and 10-14 parts of vinegar-acrylic emulsion , vinyl tertiary carbonate 5-10, phenolic resin 3-7, magnesium oxide 2-4, deionized water 16-28, emulsified silicone oil 0.18-0.3, organic bentonite 1.2-2.0, sodium polyacrylate 1-5, polycarboxylic acid Sodium salt 2-4, appropriate amount of pigment. The coating prepared by the invention has good fire-proof and heat-insulating effects, good fire-resistant performance, poor thermal conductivity, is environmentally friendly, and is economical and practical.

Owner:徐冉

Hydrocarbon-resistant indoor thin fireproofing coating for steel structures

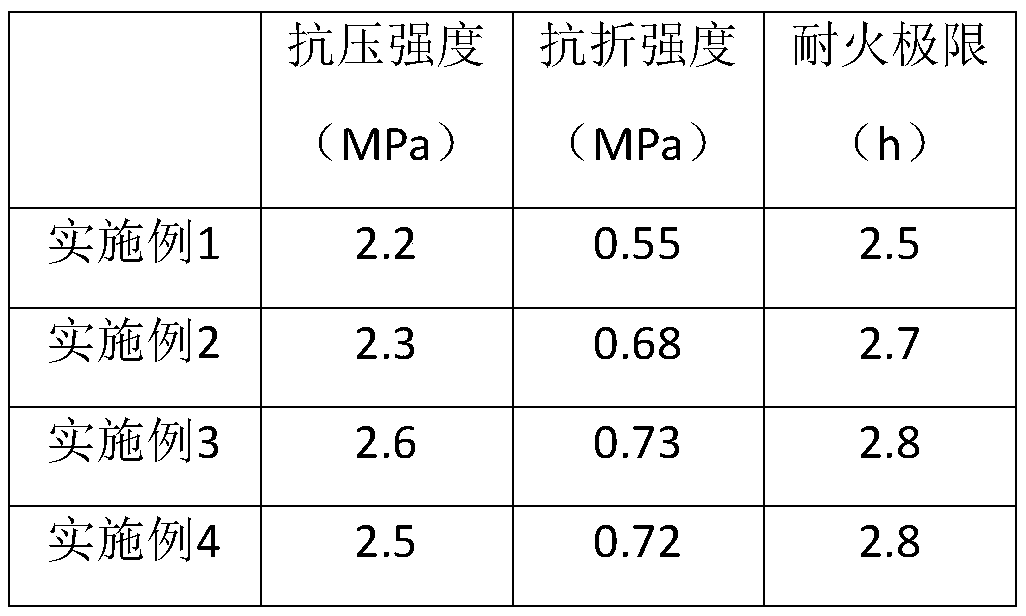

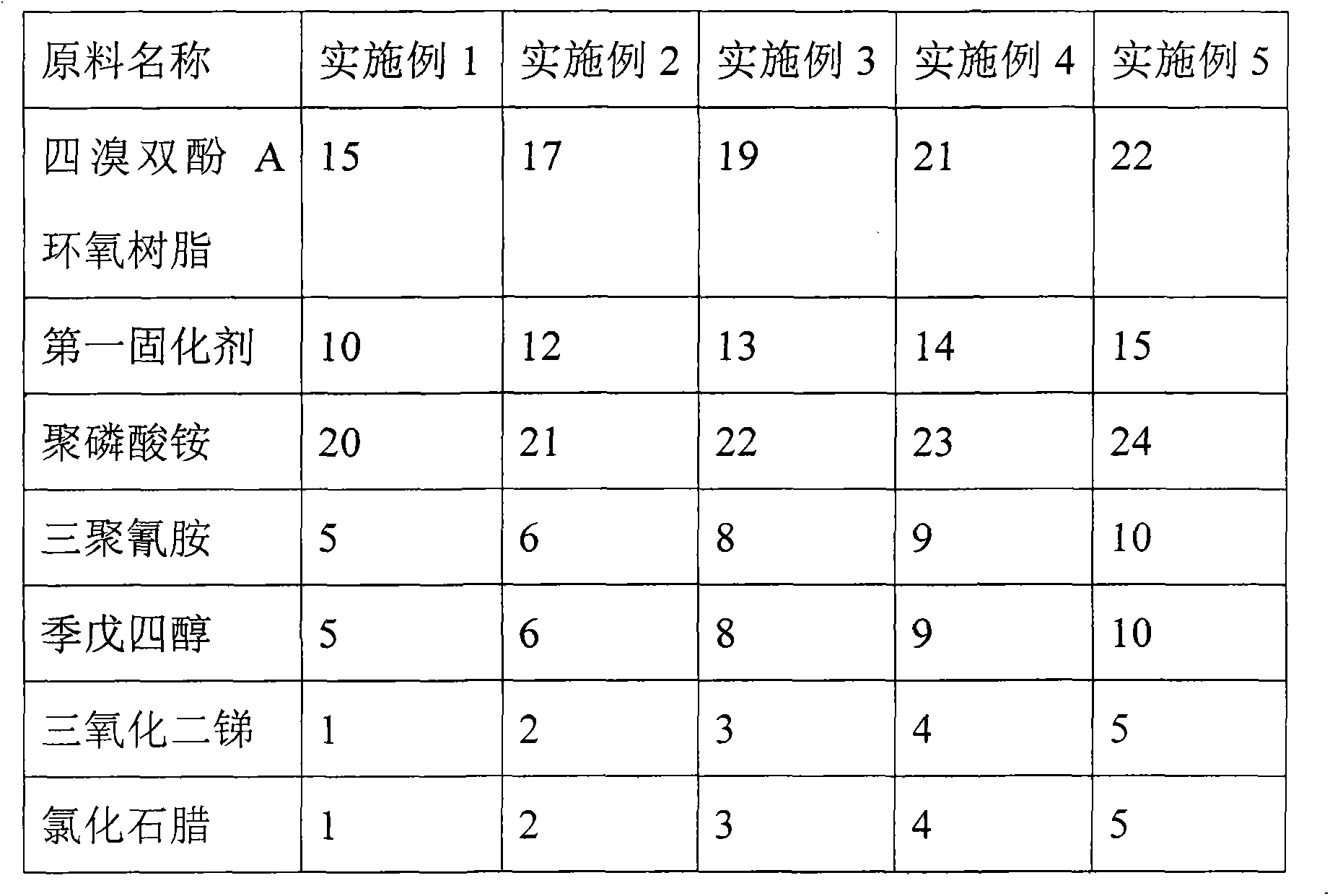

InactiveCN103450781AGood foaming effectLow smoke productionFireproof paintsEpoxy resin coatingsEpoxyTetrabromobisphenol A

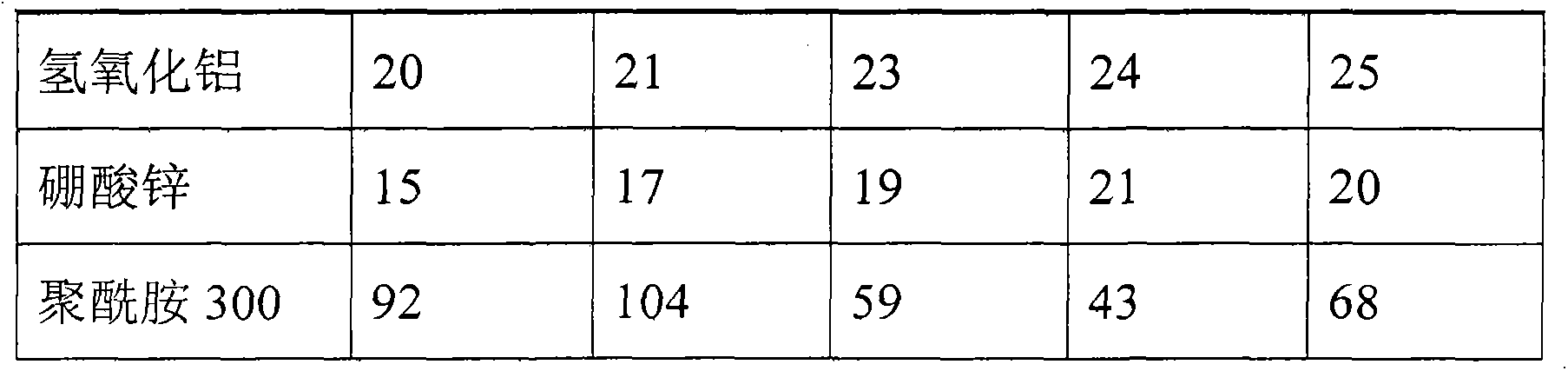

The invention discloses a hydrocarbon-resistant indoor thin fireproofing coating for steel structures, aiming at solving the problems of general thin fireproofing coatings for steel structures which are easy to peel off in case of fire disaster, poor in adhesion performance, and poor in fireproofing and heat insulation effects. The technical scheme is as follows: the fireproofing coating is prepared from a component A: TBA type epoxy resin fireproofing coating, and a component B, namely polyamide 300 curing agent, at (1-3):1 in parts by mass, wherein the component A, namely TBA type epoxy resin fireproofing coating, consists of the following materials in parts by weight: 15-22 parts of TBBP-A epoxy resin, 10-15 parts of first curing agent, 20-24 parts of ammonium polyphosphate, 5-10 parts of melamine, 5-10 parts of pentaerythritol, 1-5 parts of antimonous oxide, 1-5 parts of chlorinated paraffin, 20-25 parts of aluminum hydroxide and 15-20 parts of zinc borate. The fireproofing coating has the advantages of good foaming effect, massive generation of carbide, little smoke, strong adhesion force, good acid-base resistance property and good fireproofing and heat insulation effects.

Owner:王海辉

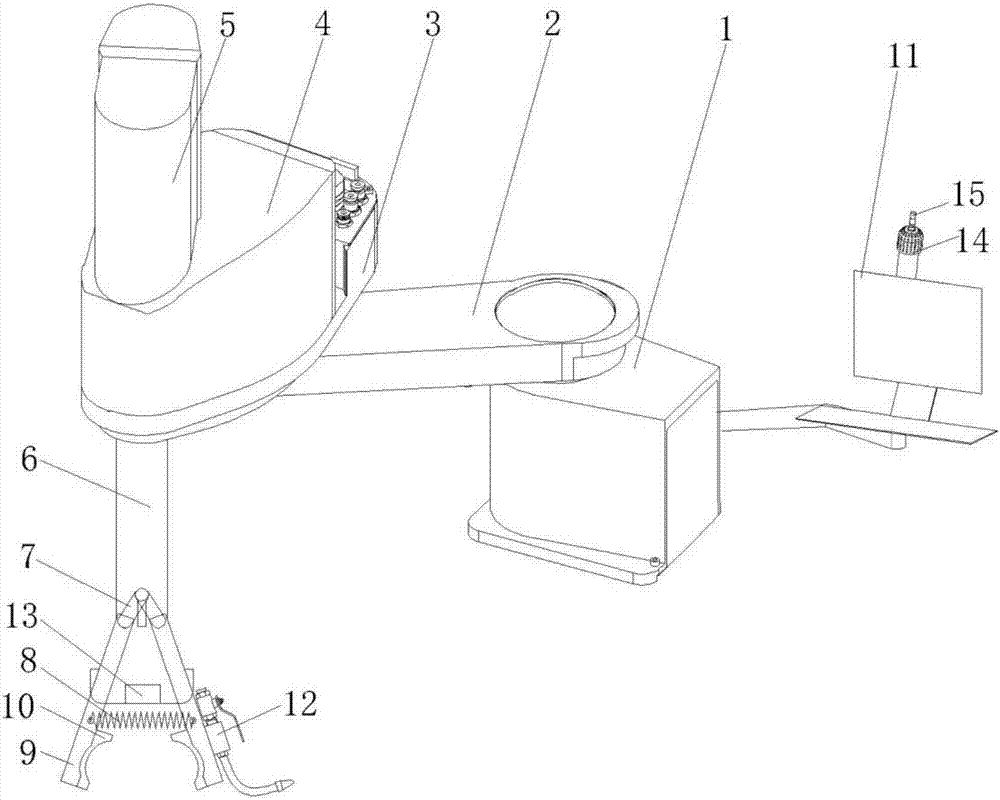

Grabbing robot with self-cleaning function

InactiveCN107243891AReduce laborAvoid damageProgramme-controlled manipulatorPhosphorMechanical equipment

The invention discloses a grabbing robot with a self-cleaning function and relates to the technical field of mechanical equipment. The upper portion of a telescopic sleeve is connected with a connection base in a matched manner through a second joint shaft, and the top of the telescopic sleeve is connected with a cylinder; a V-shaped clamping mechanism is connected with the telescopic sleeve through a connection rod; the middle portion of the V-shaped clamping mechanism is provided with a spring, and the inner side of the end portion of the V-shaped clamping mechanism is provided with a liner; a machine body is connected with an external PLC; one side of the V-shaped clamping mechanism is provided with a cleaning mechanism; the cleaning mechanism is connected with an external water tank through a plastic pipe and a water pump, and the head portion of the cleaning mechanism can rotate by 360 degrees; the surfaces of the machine body and the V-shaped clamping mechanism are each coated with a self-light-emitting layer which is made from long-lasting phosphor; and a fan is arranged on the middle portion of the V-shaped clamping mechanism. The robot is easy to operate, small in damage to workpieces in the grabbing process, high in working efficiency and positioning precision and long in service life, and has the convenient and fast cleaning function.

Owner:浩科机器人(苏州)有限公司

Manufacture method of fireproof door

ActiveCN103982121AImprove fire and heat insulation performanceTight scheduleFireproof doorsSurface layerAdditive ingredient

The invention discloses a manufacture method of a fireproof door. The manufacture method of the fireproof door includes the following steps: (1) coating the interior of a die of a door with cementing material (A) used as a surface layer of the door; (2) coating a bottom surface layer formed in the step (1) with ping-pong-table-shaped cementing material (B) used as a skeleton of the door; (3) pouring cementing material (C) in a female die after the step (2); (4) covering the female die with the flat die in the step (1), closing the dies by using 2-4 tons of pressure, and splitting the dies after solidification so as to obtain the fireproof door. The manufacture method of the fireproof door has the advantages that improvement of fire prevention and heat shielding properties is improved in the step of raw material ingredient selection, and due to affinity and seamless connections of the three types of the cementing material, the problem that a heat bridge phenomenon occurs when an existing door is manufactured is solved.

Owner:罗展华

Outdoor thick steel structure fire-retardant coating

InactiveCN104529346ALow thermal conductivityGood fire and heat insulationCrack resistanceWeather resistance

The invention relates to an outdoor thick steel structure fire-retardant coating and belongs to the field of building materials. The fire-retardant coating is prepared by mixing the following raw materials in percentage by weight: 10-20% of natural sepiolite fabric, 4-6% of light calcium carbonate, 20-30% of hole-closed perlite, 1-1.4% of high-strength water-resistant rubber powder, 1.6-2% of a hydrophobic agent, 40-44% of Portland cement and 8.0-12% of refractory cement. Since the fire-retardant coating is prepared by mixing natural sepiolite fabric, hole-closed perlite, light calcium carbonate and high-strength water-resistant rubber powder, polymer long chains in high-strength water-resistant rubber powder form continuous network structures which are interspersed one another, the bonding strength of the final product is significantly improved, and meanwhile, the water resistance, crack resistance, weather resistance and impact resistance of the cement-based products can also be improved and the fire-retardant coating has good chemical resistance and water resistance and hardly falls off.

Owner:LUOYANG DAYU IND

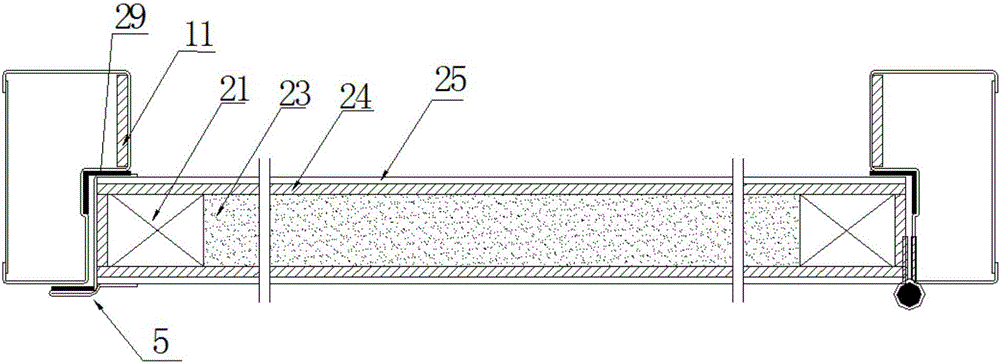

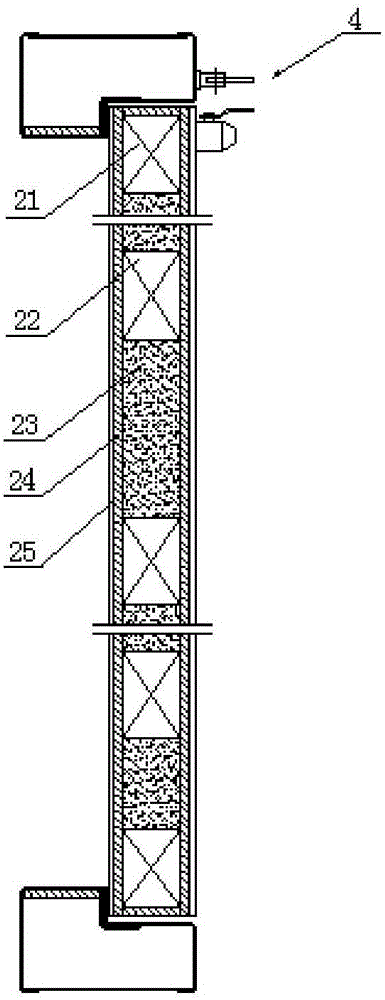

Steel heat insulation fireproof door

ActiveCN105064889AAvoid spreadingAchieve fire and heat insulation effectFireproof doorsSealing arrangementsEngineeringHigh heat

The invention relates to a steel heat insulation fireproof door. Each door leaf of the fireproof door comprises a framework and a door leaf panel; each of the frameworks and the door leaf panels is formed by cold rolled galvanized steel plates through rolling; each door leaf panel covers the outer side of the corresponding framework to form a two-layer flat box body; composite fireproof door core materials are injected into each two-layer flat box body; main bodies of two-layer door leaves are formed; the main bodies of the two-layer door leaves form an integral door leaf; a gap exists between the main bodies of the two-layer door leaves; the door leaves with the hollow middles are formed; an air inlet hole is formed in the lower end, corresponding to the hollow part, of each door leaf; the upper end and the side end of each door leaf are provided with exhaust holes; and the inner side surface and the outer side surface of each door leaf are provided with seam covering plates corresponding to door seams of the two door leaves. The steel heat insulation fireproof door has the advantages that the problem that the existing fireproof door cannot prevent fire and smoke from overflowing through the door seams; the integral flame-resistant or high-temperature-resistant performance of the fireproof door is poor; and the door can easily deform. The steel heat insulation fireproof door has the advantages that the all-around fireproof function is realized; the heated deformation of the door body after the fire catching can be prevented; and the flame and smoke overflowing can also be effectively prevented.

Owner:遵化市星多门业有限公司

Steel-wood heat insulation fireproof door and manufacturing method thereof

InactiveCN106401417AImprove fire protectionIncreased strength and impact resistanceFireproof doorsMetal-working apparatusPerliteMagnesium

The invention provides a steel and wood heat-insulating fireproof door, which comprises a door frame and a door leaf. The door frame is hinged with the door leaf through fireproof hinges; the door leaf includes a skeleton; the skeleton is filled with expanded perlite fireproof board; the surface of the expanded perlite fireproof board is wrapped with the first magnesium silicon fireproof board in turn, and a L Shaped fireproof expansion seal; the door frame is fixed with a second magnesium-silicon fireproof board on the inner side of the fire-receiving surface; a door gap seal is also set between the door leaf and the door frame. The door leaf is 2214mm high, 55mm thick and 914mm wide. The expanded perlite fire-proof board is installed inside the door leaf to improve the fire-proof effect, and the magnesium-silicon fire-proof board is installed to further improve the fire-proof effect and at the same time improve the strength and impact resistance of the door leaf. By properly installing the L-shaped fireproof expansion seal on the door frame, the effect of sealing and fire prevention can be improved and the noise generated between the door leaf and the door frame can be reduced when the door leaf is closed.

Owner:ANHUI ANWANG DOOR IND

Fireproof heat-insulating fabric for firefighting, and processing process thereof

InactiveCN107571562AImprove fire and heat insulation performanceImprove work efficiencyFibre treatmentSynthetic resin layered productsGlass fiberAdhesive

The invention provides fireproof heat-insulating fabric for firefighting. The fireproof heat-insulating fabric for firefighting comprises a fireproof heat-insulating layer, a heat-absorbing layer anda near body layer; the heat-absorbing layer and the heat-absorbing layer are in adhering connection by high-temperature flame-retardant adhesive; the heat-absorbing layer and the near body layer are in adhering connection by high-temperature flame-retardant adhesive; the fireproof heat-insulating layer is prepared by fabric formed by weaving warp yarns and weft yarns; the warp yarns of the fireproof heat-insulating layer are wool tops which are formed by blending and weaving linen fiber, aramid fiber 1313 and aluminium silicate fiber according to the ratio of 20%:45%:35%; the weft yarns of thefireproof heat-insulating layer are wool tops which are formed by blending and weaving glass fiber, flame-retardant acrylic fiber and mineral wool fiber according to the proportion of 40%:25%:35%; and the invention also provides a processing process for manufacturing the fireproof heat-insulating fabric for firefighting, which particularly comprises the following steps. The fireproof heat-insulating fabric for firefighting and the processing process thereof have the following beneficial effects: the fireproof and heat-insulating properties of the firefighting fabric are improved, the problemthat a firefighter is burned during firefighting operation is effectively avoided, the cotton fiber can absorb sweat stain generated during firefighting operation, comfortability during firefighting operation is achieved, and the work efficiency of the firefighting operation is improved.

Owner:海宁市泰达针织有限公司

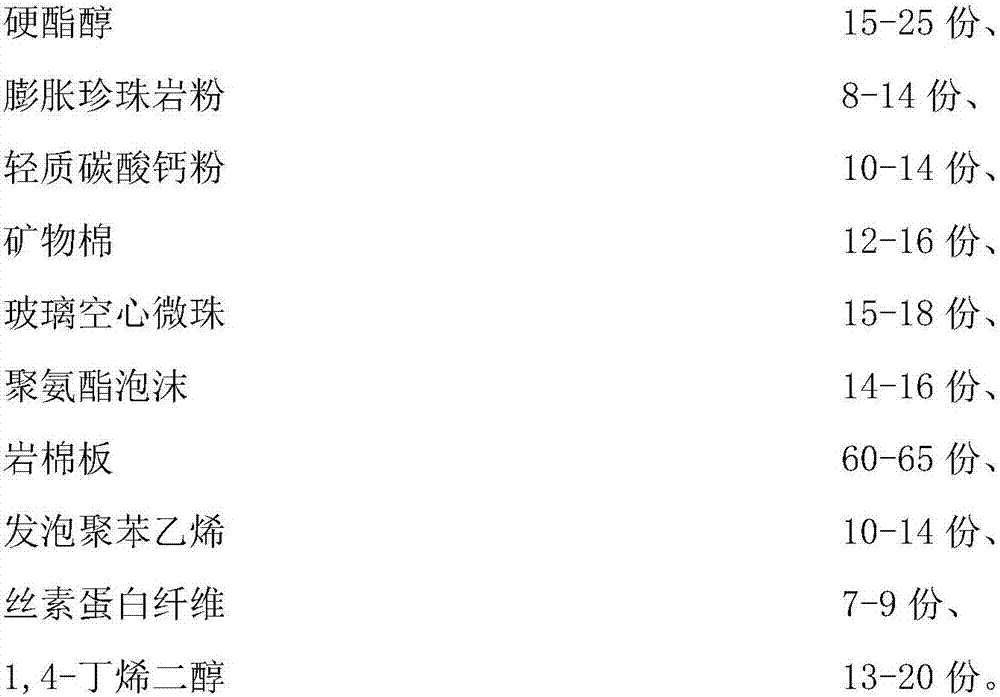

Novel fireproof heat-insulating building material and preparation method thereof

The invention provides a novel fireproof heat-insulating building material and a preparation method thereof, and relates to the field of building materials. The building material is prepared from the following raw materials in parts by weight: 15 to 30 parts of stearyl alcohol, 8 to 15 parts of expanded perlite powder, 10 to 15 parts of light calcium carbonate powder, 12 to 18 parts of mineral wool, 15 to 20 parts of glass hollow microbeads, 14 to 18 parts of polyurethane foam, 60 to 70 parts of rock wool board, 10 to 15 parts of foamed polystyrene, 7 to 9 parts of silk fiber and 13 to 22 parts of 1,4-butylene glycol. The preparation method of the building material comprises the following steps: smashing, stirring, casting and cooling. By adopting the building material, the problems of poor fireproofing and heat-insulating effects and high cost of a conventional fireproof heat-insulating building material are solved.

Owner:肥西县碧涛建材有限公司

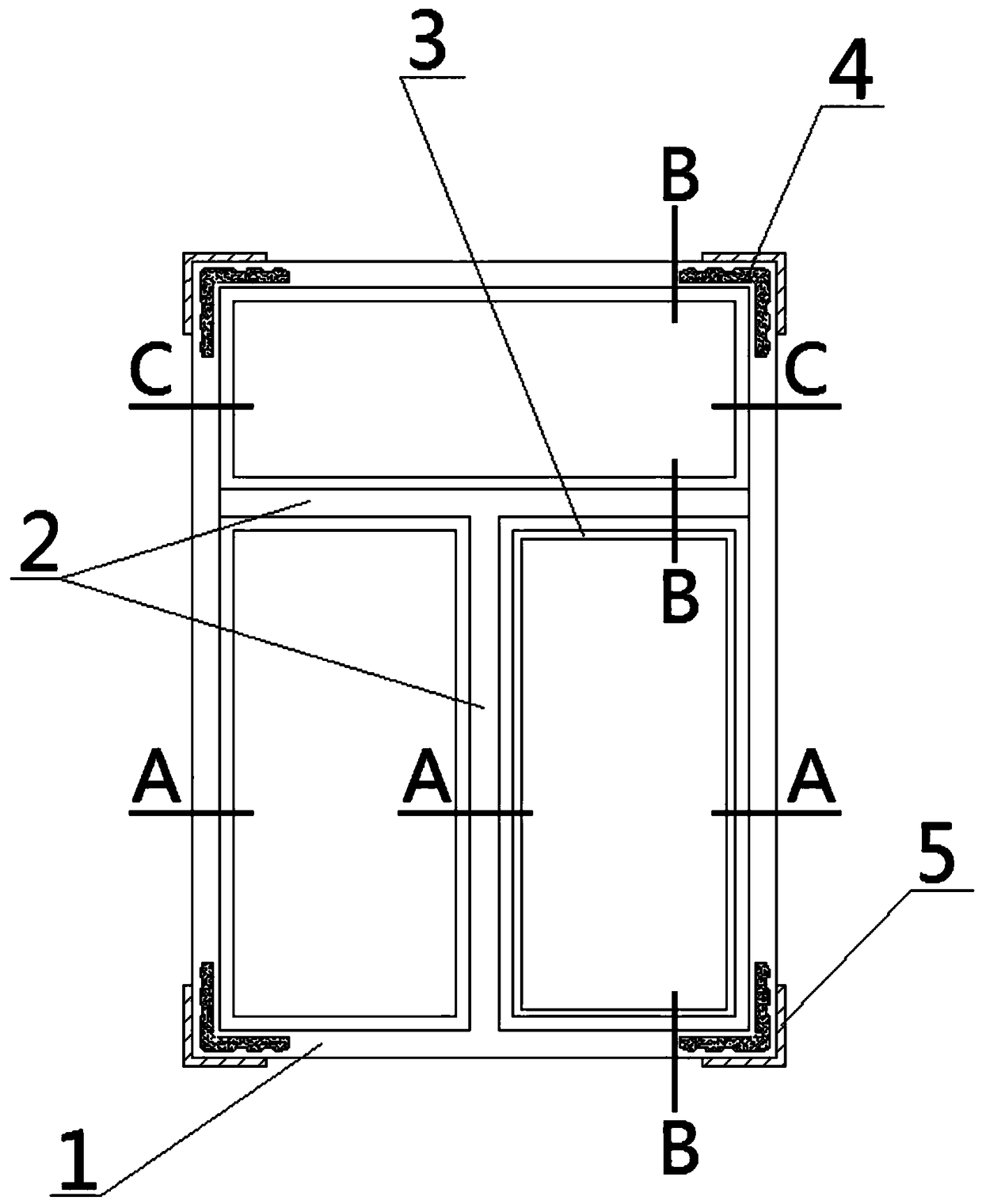

Fireproof bridge-cutoff aluminum alloy casement window

InactiveCN108894696AGood fire and sound insulationReduce heat transferFireproof doorsSealing arrangementsSealantCasement window

The invention discloses a fireproof bridge-cutoff aluminum alloy casement window. The fireproof bridge-cutoff aluminum alloy casement window is characterized in that inward opening sashes, a glass fixing sash glass pressing strip, a window frame, a window beam, corner connectors, heat insulation and fire prevention glass, inflaming retarding sealing rubber strips, inflaming retarding weather strips, an unlocking device, glass fixing supports, outer frame reinforcing steel sheets, cavity steel bushes, sash reinforcing steel sheets, steel bush corner connecting sheets, stainless steel screws, glass periphery clearance parts, refractory glass cushion blocks, fireproof expansion strips, fireproof silver, cavity injection mud and fireproof sealant. The fireproof bridge-cutoff aluminum alloy casement window is high in overall strength and good in overall fire prevention and sound insulation effect, the overall heat conduction performance of a heat insulation bridge-cutoff aluminum alloy profile is lower than that of a common aluminum alloy profile, the fire prevention and heat insulation effect is better, the inflaming retarding sealing rubber strips and the inflaming retarding weather strips have the performance of fire prevention, inflaming retarding and water prevention, and the fireproof bridge-cutoff aluminum alloy casement window is suitable for being used and popularized on various buildings with high fireproof performance requirements.

Owner:HEFEI JIAWEI DECORATION ENG

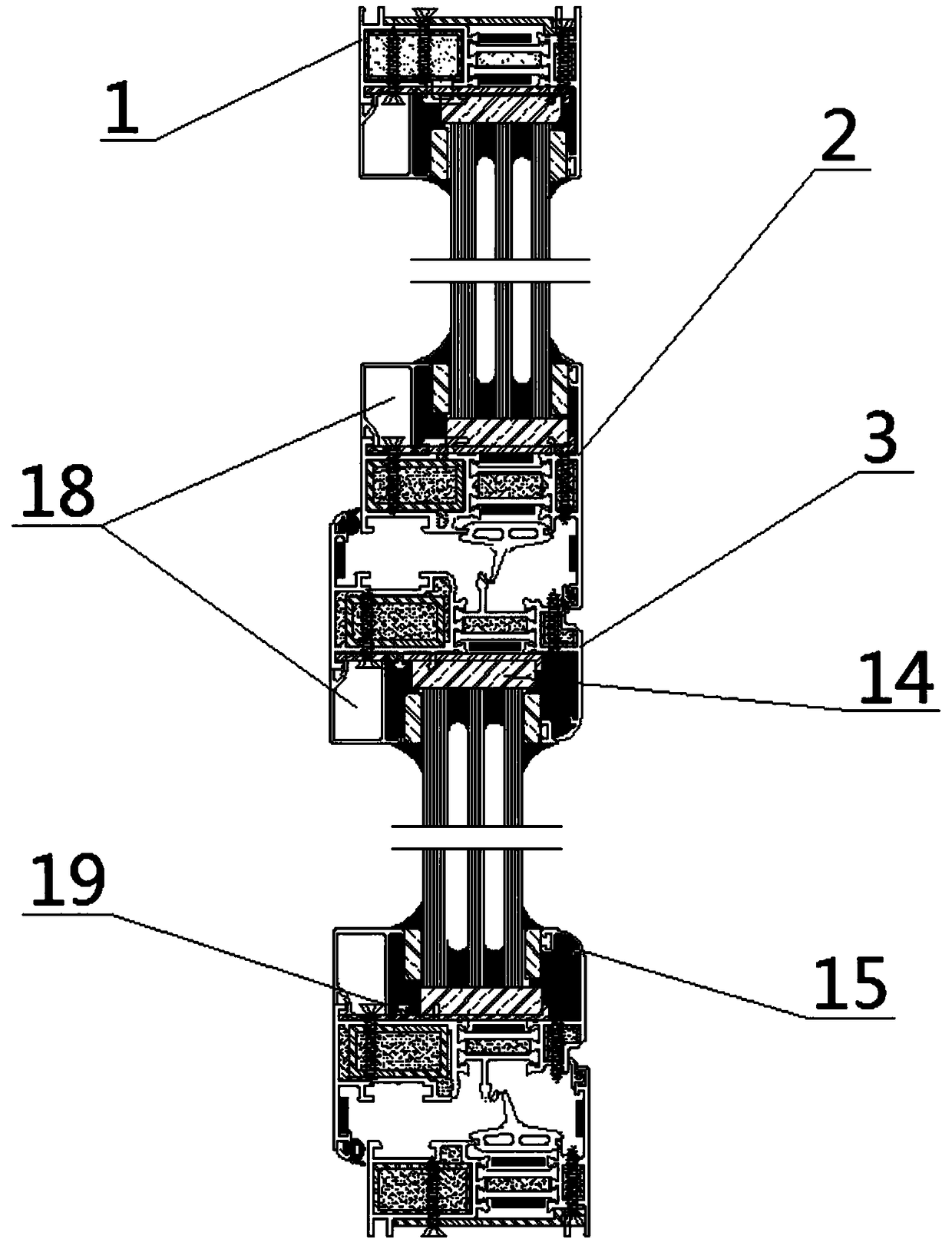

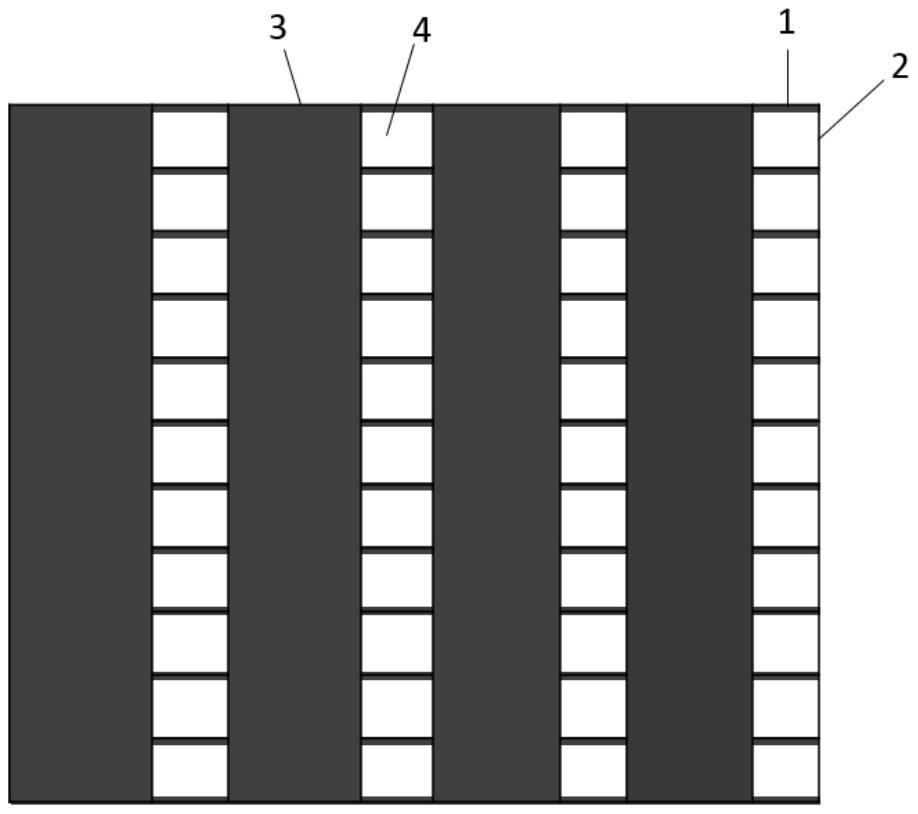

Novel explosion-proof flame-retardant belting material for cable

The invention provides a novel explosion-proof flame-retardant belting material for a cable, which comprises the following components in percentage by mass: 70-97% of a flame-retardant rubber materialand 3-30% of a framework material, and the framework material is a flame-retardant fiber mesh material with the strength of more than 25g / denier. The flame-retardant rubber material comprises a halogen-free flame retardant, liquid rubber, a filler, a chain extender and a catalyst. The framework material is controlled to be designed to be a flame-retardant fiber mesh type, good ventilation performance is achieved, air circulation is facilitated, heat generated by the cable in the operation process can be dissipated to the external environment in time, the temperature of the cable is reduced, and the service life of the cable is prolonged. By controlling the mass percentage of the halogen-free flame retardant in the flame-retardant rubber material to be 35-70%, the explosion-proof flame-retardant belting material can be instantly expanded and foamed under the action of open fire, thereby playing a good role in fire prevention and heat insulation on the internal cable and effectively protecting the cable from being damaged by fire accidents.

Owner:蔡晨灿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com