Smoke-suppression and waterproof aqueous ultra-thin steel structure fireproof coating and preparation method thereof

A kind of fireproof coating, ultra-thin technology, applied in the field of coatings, can solve the problems of unreachable, poor fire resistance, reduced fire resistance, etc., achieve the effect of moderate expansion ratio of foaming, good fire and heat insulation effect, and improve fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

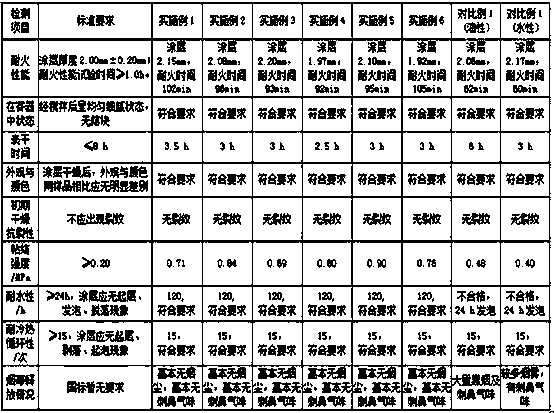

Examples

Embodiment 1~6

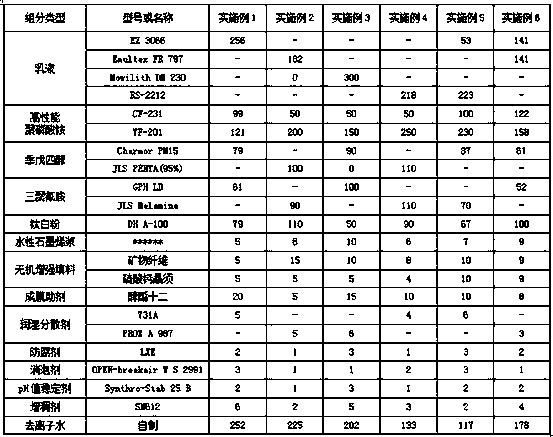

[0049] The mass parts of components in each embodiment are as shown in table 1:

[0050] Table 1 Mass parts list of each component in Examples 1 to 6 of the present invention

[0051]

[0052] Note: "******" in the table indicates that there is no requirement for the model.

Embodiment 1

[0054] The preparation method comprises the following four steps:

[0055] (1) While stirring at 500 r / min, add part of deionized water (95% of the total amount), wetting and dispersing agent, pH value stabilizer, and part of the defoamer (40% of the total amount) in sequence, pay attention Do not let the material splash on the cylinder wall and the stirring shaft, then stir for 5 minutes;

[0056] (2) Increase the rotation speed to 1000r / min, and add titanium dioxide, inorganic reinforcing filler, pentaerythritol, and melamine in order under stirring, taking care not to cause serious dust and powder accumulation, and add part of deionized water (2% of the total amount) %) Rinse the inner wall of the tank and the stirring shaft, increase the speed to 2000r / min after adding, and continue stirring for 20 min;

[0057] (3) Reduce the rotation speed to 1000r / min, add high-performance ammonium polyphosphate under stirring state, be careful not to cause serious dust and powder accu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com