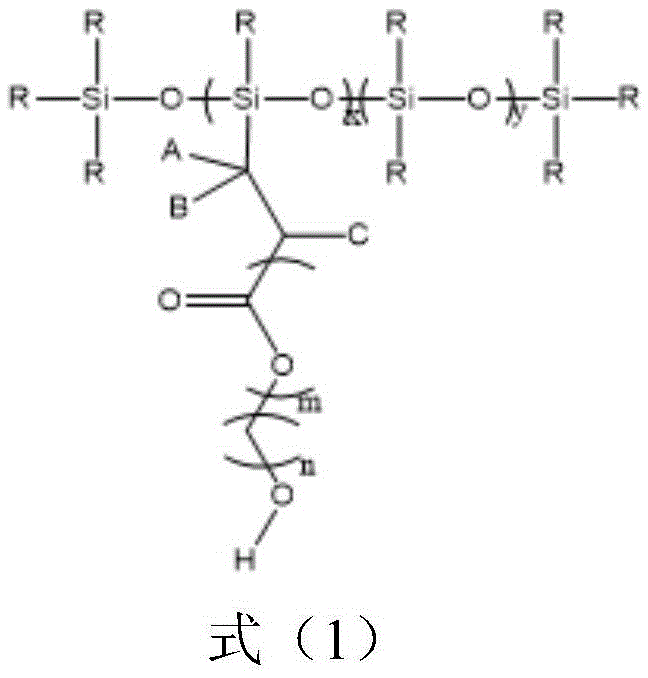

Polyhydroxy polysiloxane and wear-resisting super-hydrophobic coating and preparation method

A technology of polyhydroxypolysiloxane and superhydrophobic coating, which is applied in coatings, polyurea/polyurethane coatings, anti-corrosion coatings, etc., can solve problems such as low surface energy, and achieve low surface tension, small size, and good durability. grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

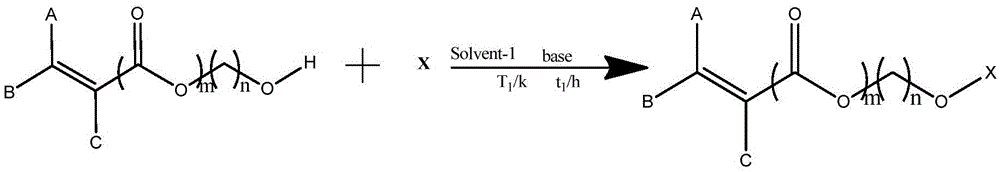

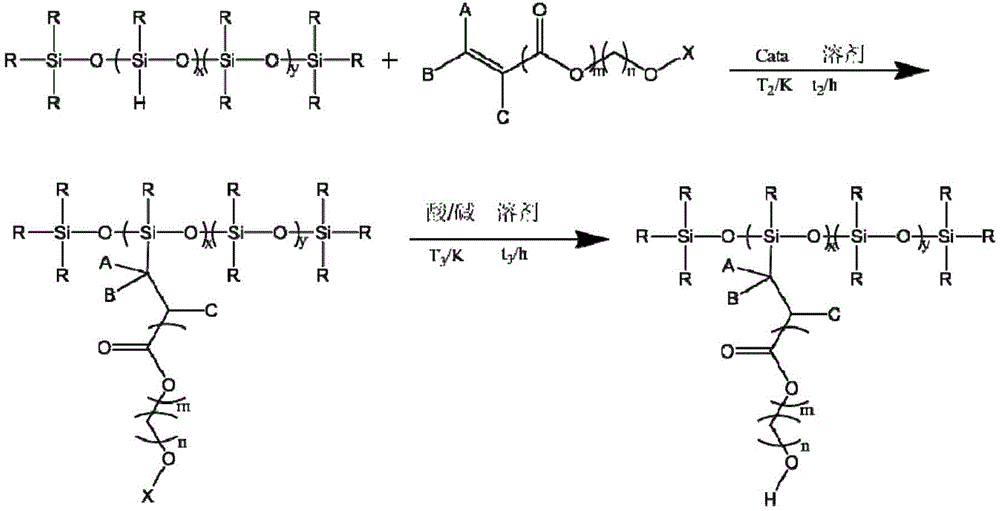

Method used

Image

Examples

Embodiment 1

[0056] Add 250-300 parts of anhydrous diethyl ether and magnets into a 500 mL round bottom flask, stir, then add 100.0 parts of allyl alcohol (AAL) and 244.0 parts of triethylamine, and seal it. Stir rapidly in an ice-water bath and slowly add 224.5 parts of trimethylchlorosilane (TMS-Cl) dropwise thereto, then let it rise to room temperature naturally, and react overnight. After the reaction, the Et was removed by suction filtration 3 N-HCl, the obtained organic phase was repeatedly washed 5 times with 20 mL of water, and then dried over anhydrous magnesium sulfate overnight. After drying, the filtrate was filtered to remove the solvent by rotary evaporation, and distilled to obtain 220 parts of pure monomer AAL-TMS with a yield of 98.2%.

[0057] Add 100 to 200 parts of anhydrous toluene and magnetons in a 250ml double-necked round bottom flask, and then add 50.0 parts of polymethylhydrogensiloxane (1% hydrogen content) (Shandong Dayi Chemical Co., Ltd., DY -H202) and 94 p...

Embodiment 2

[0061] Add 100 to 200 parts of anhydrous toluene and magneton into a 250 mL double-necked round bottom flask, and then add 50.0 parts of polymethylhydrosiloxane (0.5% hydrogen content) (Shandong Dayi Chemical Co., Ltd., DY -H202) and 47 parts of AAL-TMS prepared by Example 1, reflux and stir in an oil bath at 90°C, and slowly add 7.8ppm of karstedt catalyst dissolved in 87 parts of xylene dropwise to it in the process of stirring (platinum-tetramethyltetravinylsiloxane complex), after reacting for 24 hours, the solvent was evaporated by rotary evaporation, and then the reaction liquid was precipitated in methanol by precipitation method, and then the precipitate was washed with methanol to obtain purified polymer to obtain 90 g of PHMS-g-AAL-TMS light yellow transparent liquid with a yield of 92.8%.

[0062] In a 500mL round-bottomed flask, add 250-350 parts of tetrahydrofuran and magnetons, then add 50 parts of PHMS-g-AAL-TMS, and then drop 2-3 drops of 2mol / L hydrochloric ac...

Embodiment 3

[0065] Add 100 to 200 parts of anhydrous toluene and magneton into a 250 mL double-necked round bottom flask, and then add 50.0 parts of polymethylhydrogensiloxane (hydrogen content 0.18%) (Shandong Dayi Chemical Co., Ltd., DY -H202) and 17 parts of AAL-TMS prepared by the examples, reflux and stir in an oil bath at 90°C, and slowly add 2.81ppm of karstedt catalyst (platinum -tetramethyltetravinylsiloxane complex), after reacting for 24h, the solvent was evaporated by rotary evaporation, and then by precipitation, the reaction solution was sunk in methanol, and then the precipitate was washed with methanol to obtain a purified polymer , to obtain 60 g of PHMS-g-AAL-TMS light yellow transparent liquid with a yield of 89.6%.

[0066] In a 500mL round-bottomed flask, add 250-350 parts of tetrahydrofuran and magnetons, then add 50 parts of PHMS-g-AAL-TMS, and then drop 2-3 drops of 2mol / L hydrochloric acid solution to dissolve the mixed solution Stir at room temperature for 5h, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com