Patents

Literature

179results about How to "Control structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

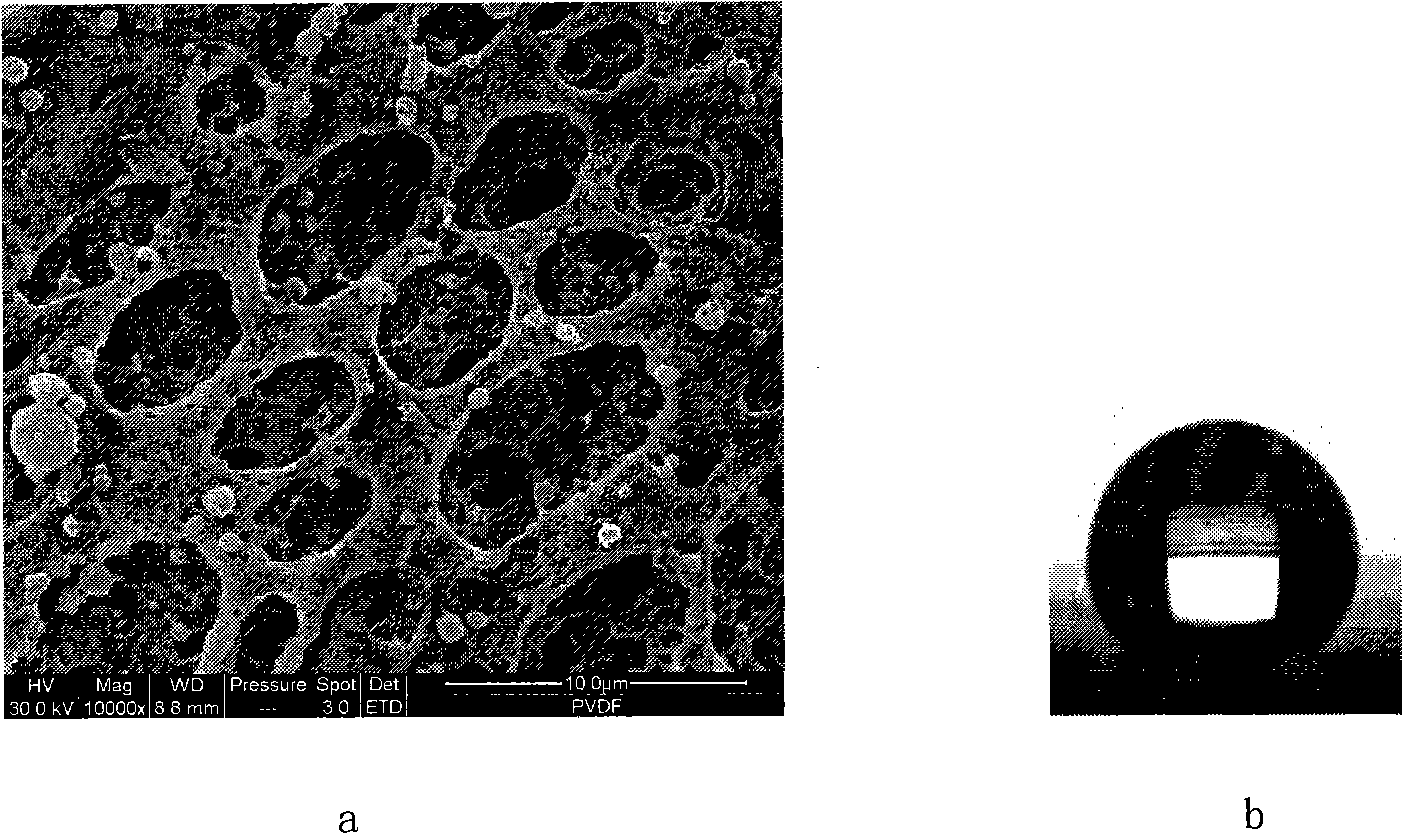

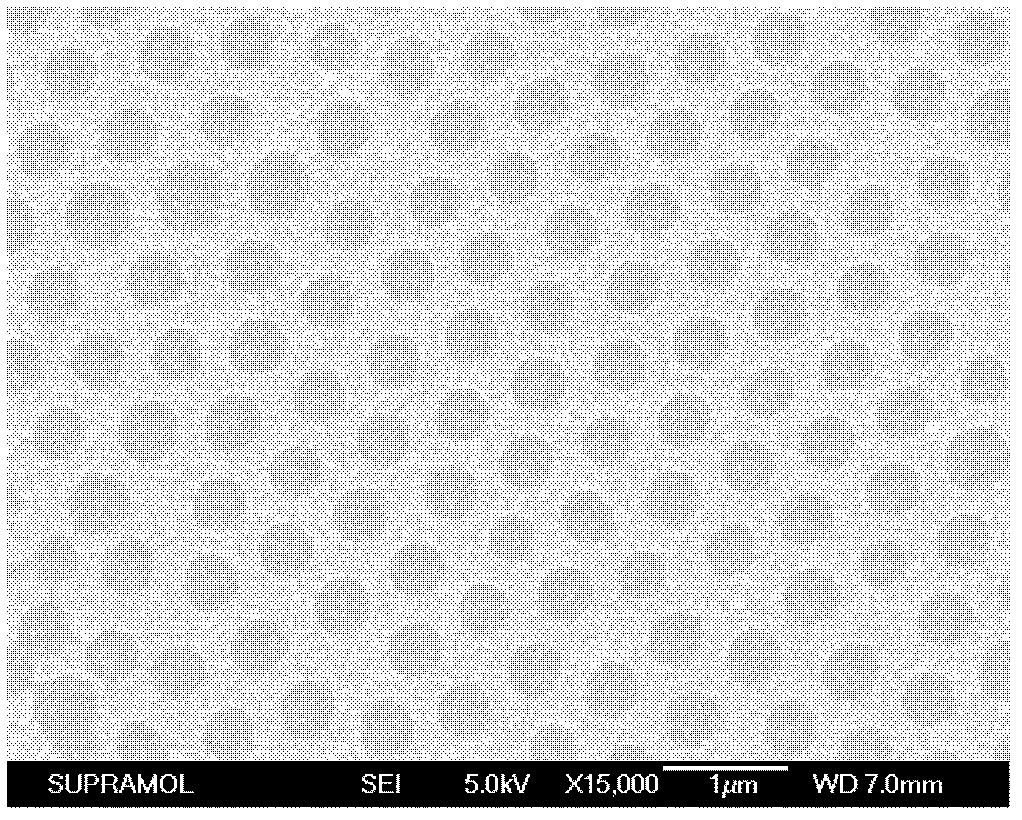

Polyvinylidene fluoride microporous film and preparation method

InactiveCN101632903AWith nanoscale dimensionsImprove hydrophobicitySemi-permeable membranesDistillationFatty alcohol

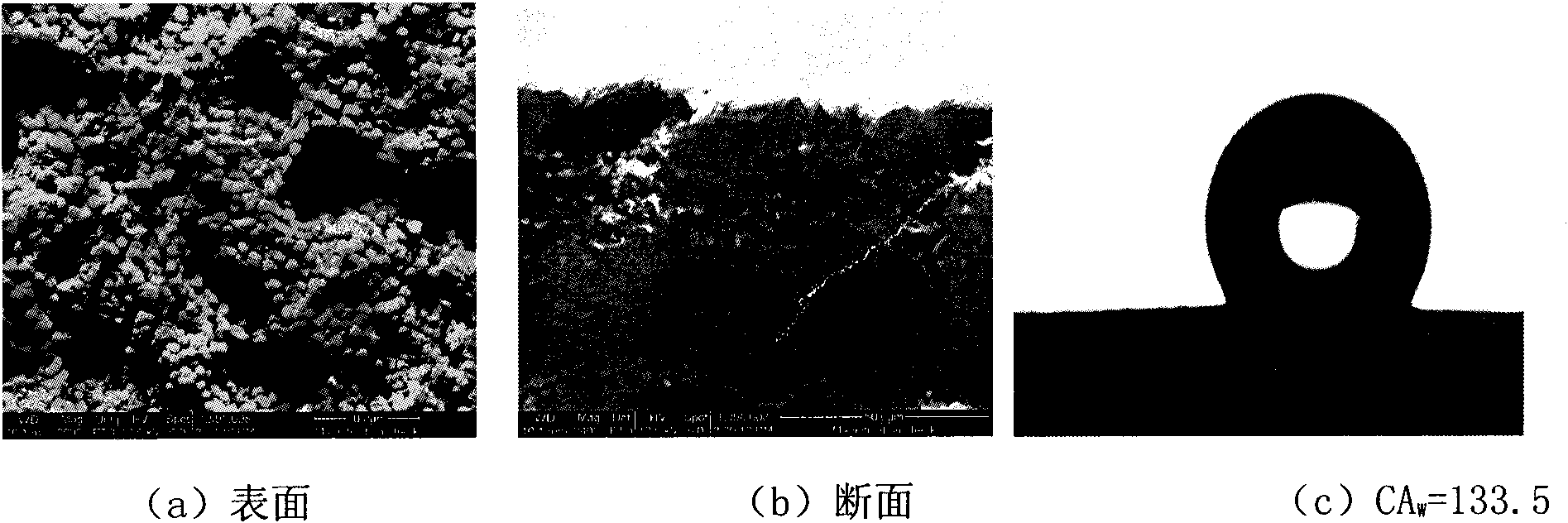

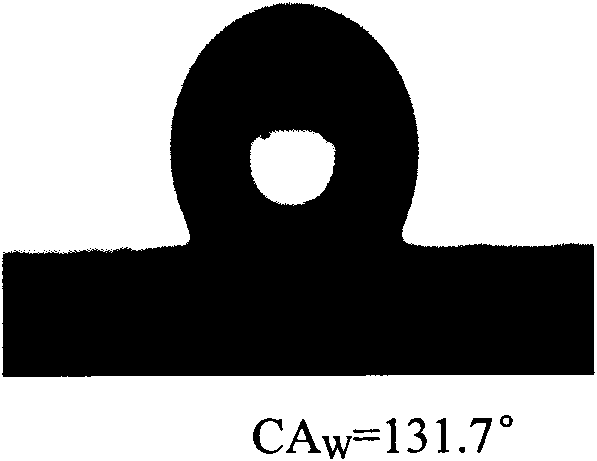

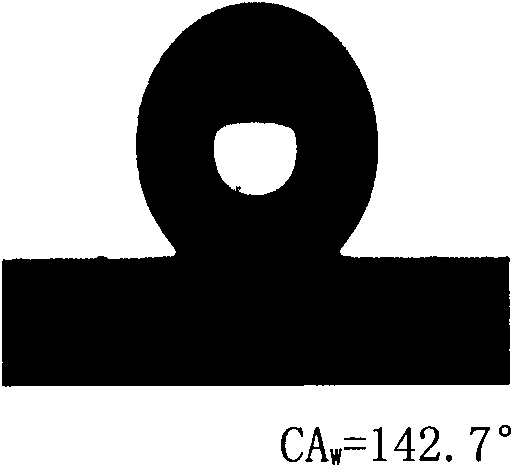

The invention provides a polyvinylidene fluoride microporous film and a preparation method; the polyvinylidene fluoride microporous film is prepared by using polyvinylidene fluoride, fatty alcohol (non solvent) and polar organic solvent as raw materials, the proportioning of which is as follows: the mass content of polyvinylidene fluoride is 10%-15%, and the content of non solvent is 6-12%; the specific steps are as follows: polyvinylidene fluoride, polar organic solvent and non solvent are mixed, dissolved and filtered, set aside and are deaerated to obtain clear casting film liquid which is struck on a coarse structure template substrate and placed in air; gel forms film in a coagulating bath, is processed by hot water, and then soaked in water and absolute ethyl alcohol to obtain high hydrophobic polyvinylidene fluoride microporous film; the contact angle between the surface of high hydrophobic polyvinylidene fluoride microporous film and water reaches 130 degrees to 140 degrees, air flux of the film reaches 6.0m<3> / (m<2>-h-kPa) under 60kPa, the maximum bore diameter is less than 0.5 mum, tensile strength reaches breaking strength which is larger than 5Mpa, and the elongation at break is larger than 50%. The invention is the polyvinylidene fluoride microporous film with high hydrophobicity, high flux and good mechanical strength and the preparation method, which is mainly applied to the film distillation and associated film process.

Owner:HEBEI UNIV OF TECH

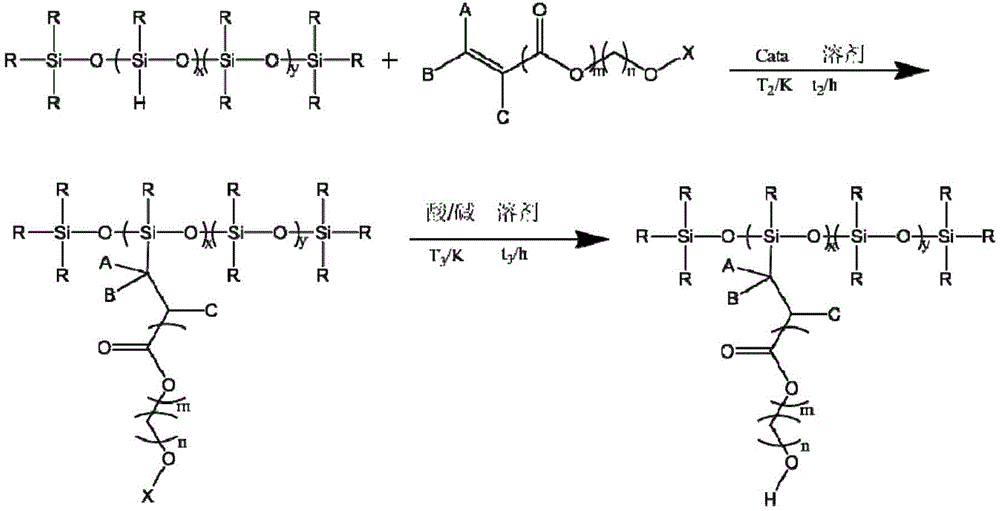

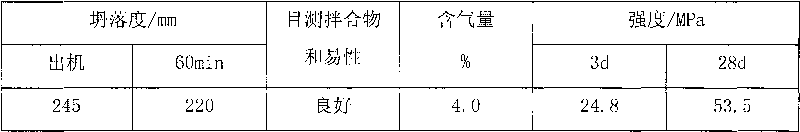

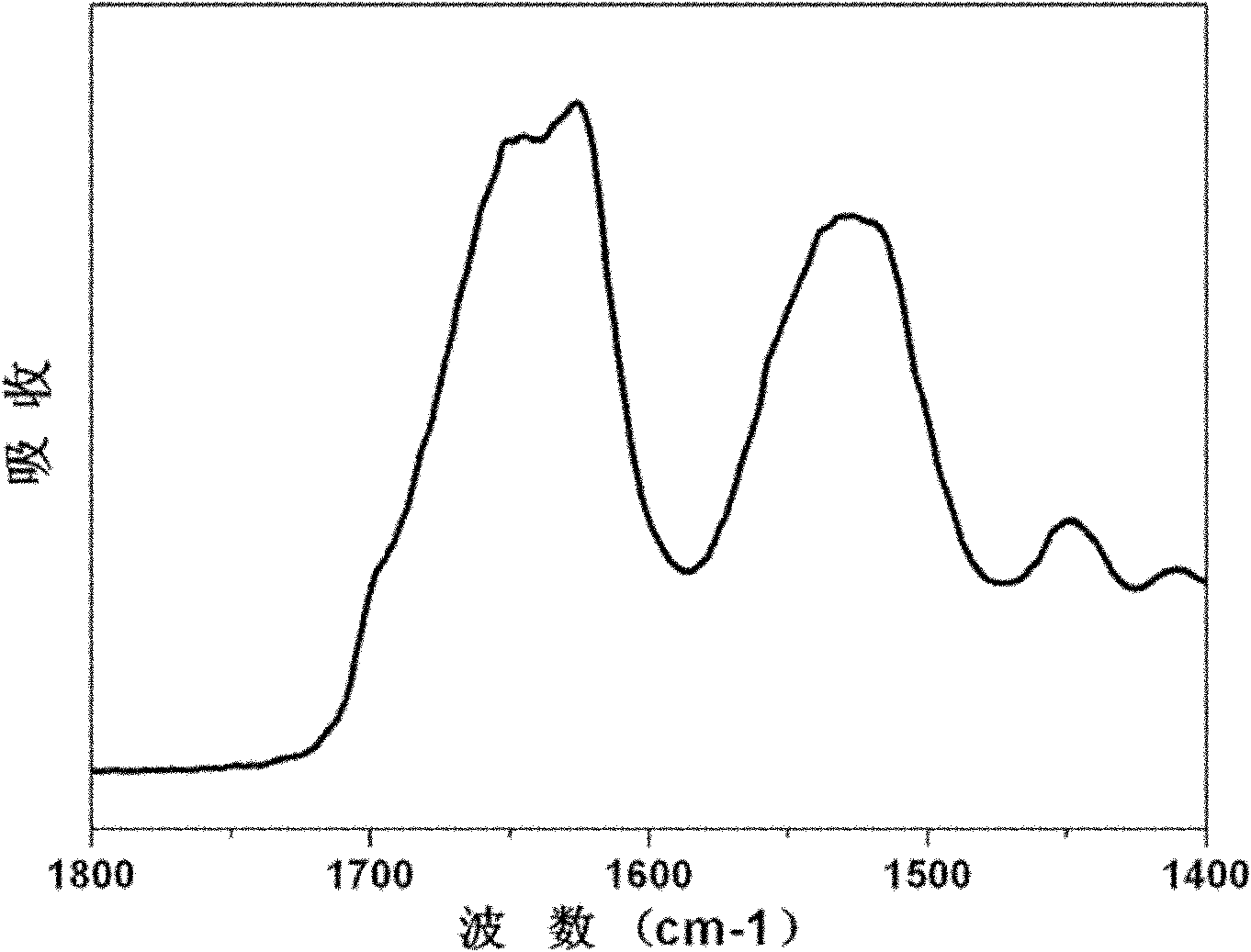

Block poly-carboxylic acid concrete high-efficiency water reducing agent and preparation method thereof

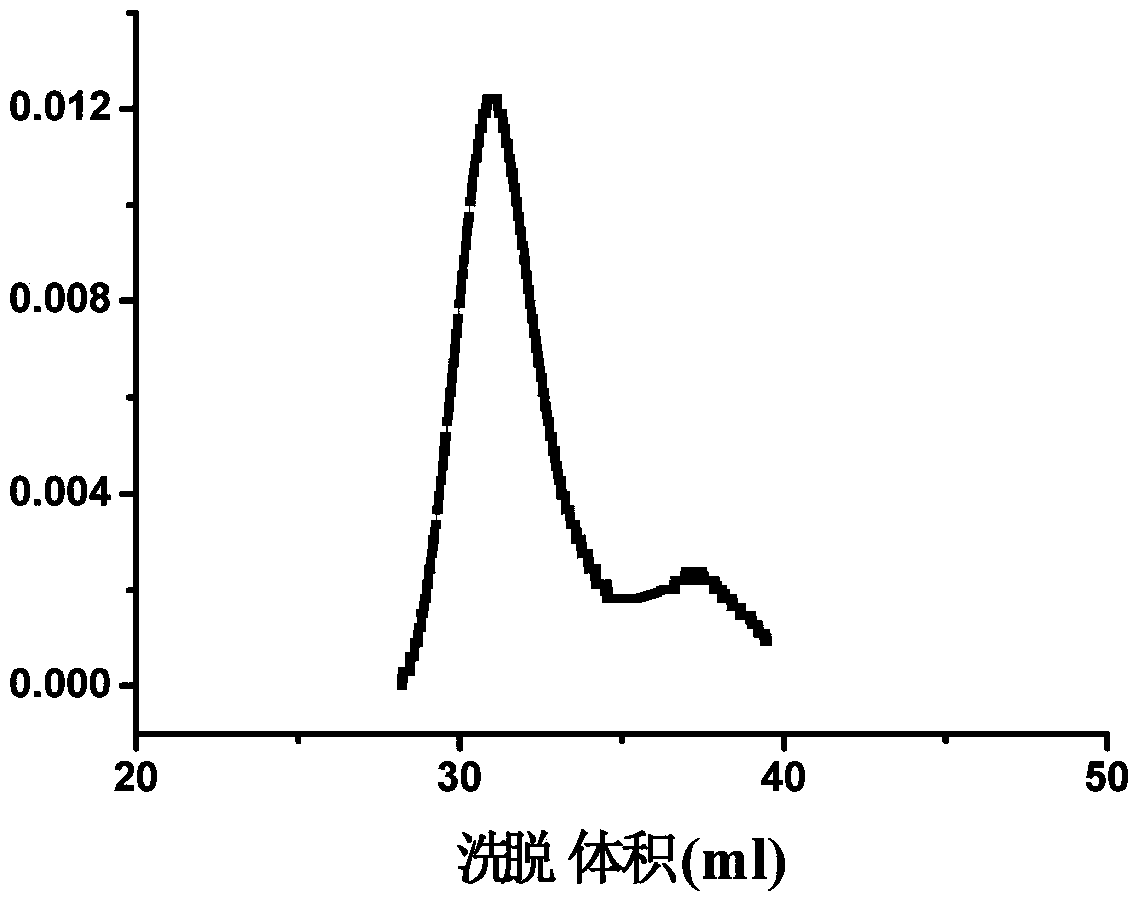

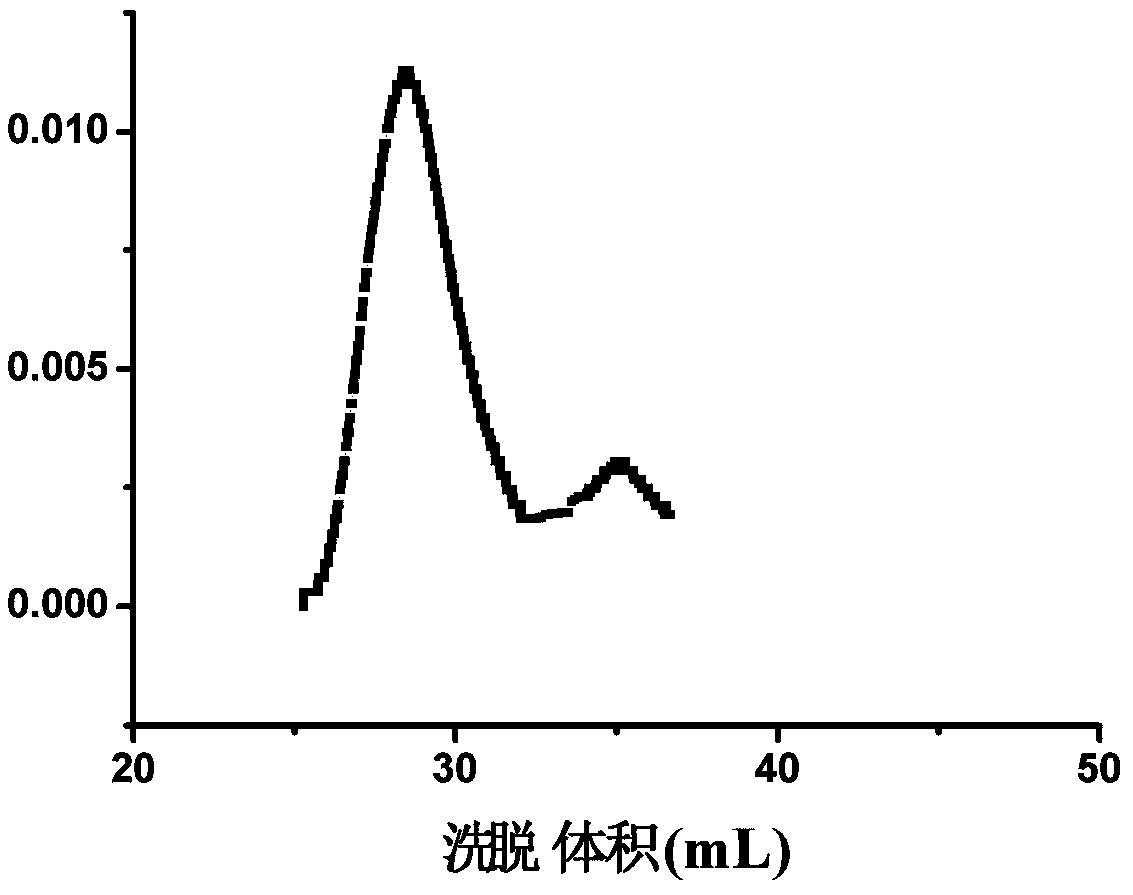

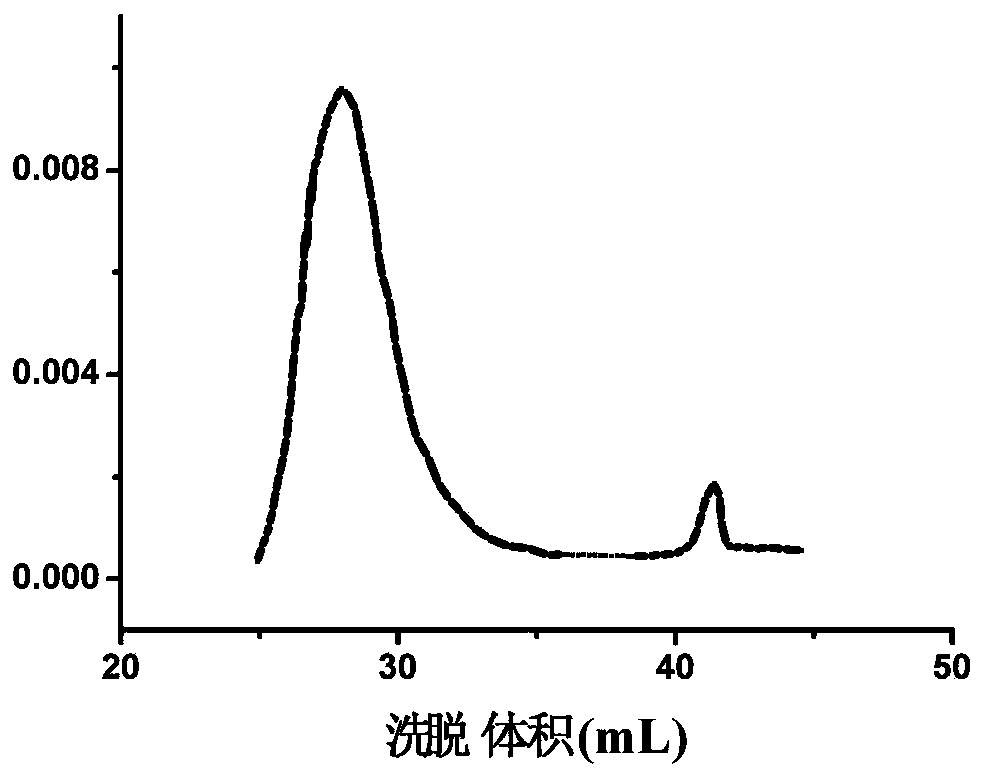

ActiveCN103482897AControl structureControl its molecular weight distributionStructural regularityPolymer science

The invention provides a block poly-carboxylic acid concrete high-efficiency water reducing agent with an ordered structure and a preparation method thereof. The block poly-carboxylic acid is prepared by using atom transfer radical polymerization, the structural regularity and the molecular weight distribution of the poly-carboxylic acid are controlled effectively, and the water reducing agent is used in a cement dispersing process. By adoption of the block poly-carboxylic acid concrete high-efficiency water reducing agent and the preparation method thereof, the problems of uncontrollable molecular weight of the poly-carboxylic acid, wider molecular weight distribution, un-designable molecular structure and the like are solved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

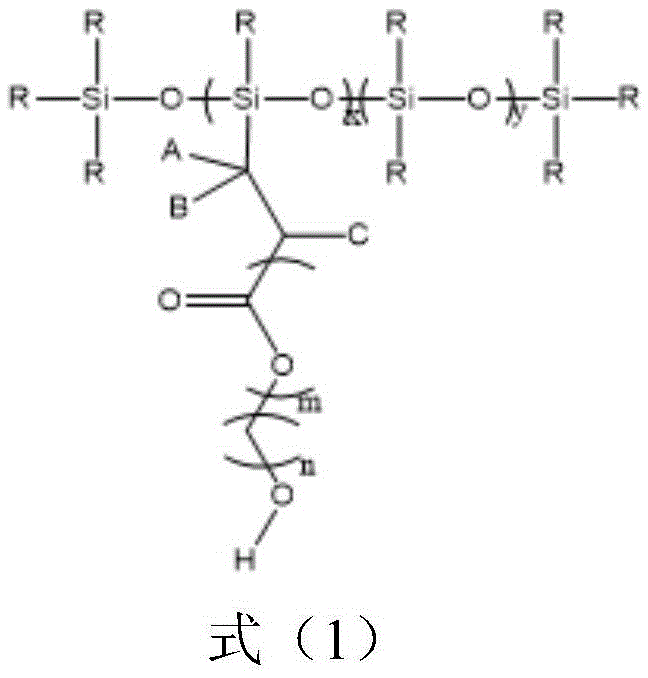

Polyhydroxy polysiloxane and wear-resisting super-hydrophobic coating and preparation method

ActiveCN105646884AImprove wear resistanceHigh temperature resistantLiquid repellent fibresAnti-corrosive paintsPolymer scienceSide chain

The invention discloses a polyhydroxy polysiloxane and wear-resisting super-hydrophobic coating and a preparation method, and belongs to the field of super-amphiphobic materials. A structural formula of polyhydroxy polysiloxane is shown in the following formula of the description. According to the method, an active hydroxyl group is introduced onto a flexible silica main chain through over protection and deprotection processes, polymethylsiloxane with active hydroxyl group on a side chain is compounded, then the polymethylsiloxane with an active hydroxyl group on a side chain is cross-linked with diisocyanate to form a three dimensional net structure, methyl is orderly and densely arranged on the surface of a substrate, the methyl is very small in polarity and volume, and low in surface tension, thus, a compact low surface energy layer is formed, and a wear-resisting super-hydrophobic material is formed by utilizing cohesive action of isocyanate.

Owner:国科广化(南雄)新材料研究院有限公司 +1

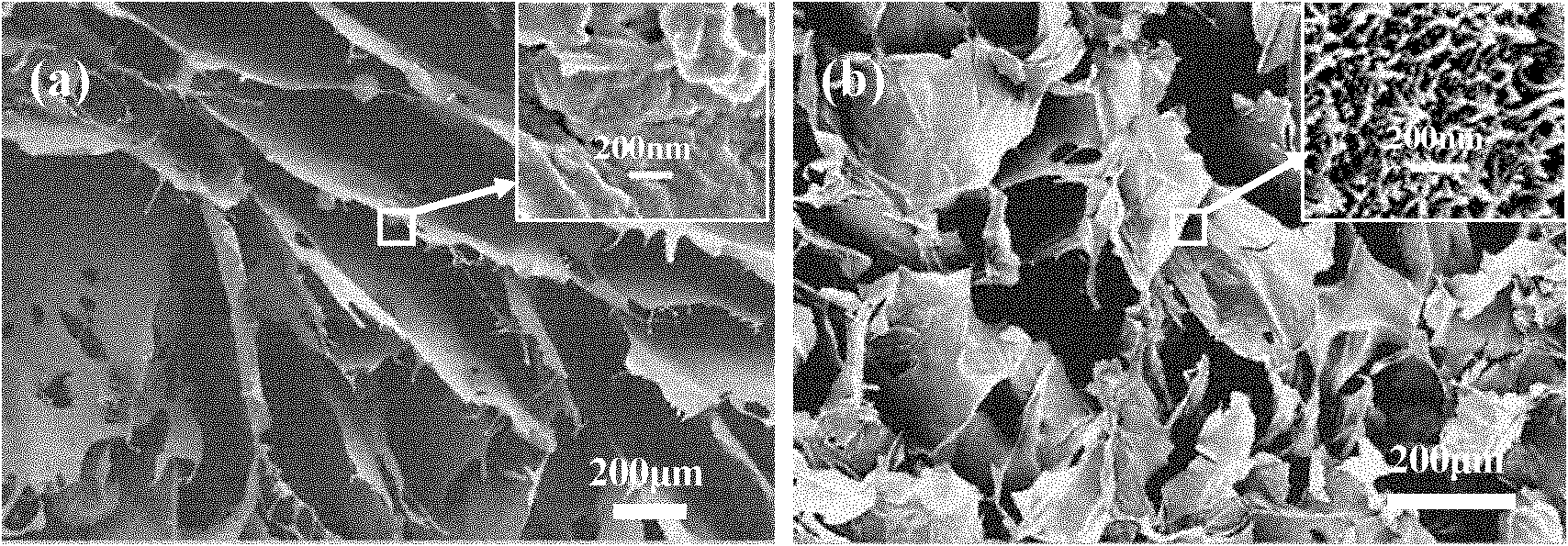

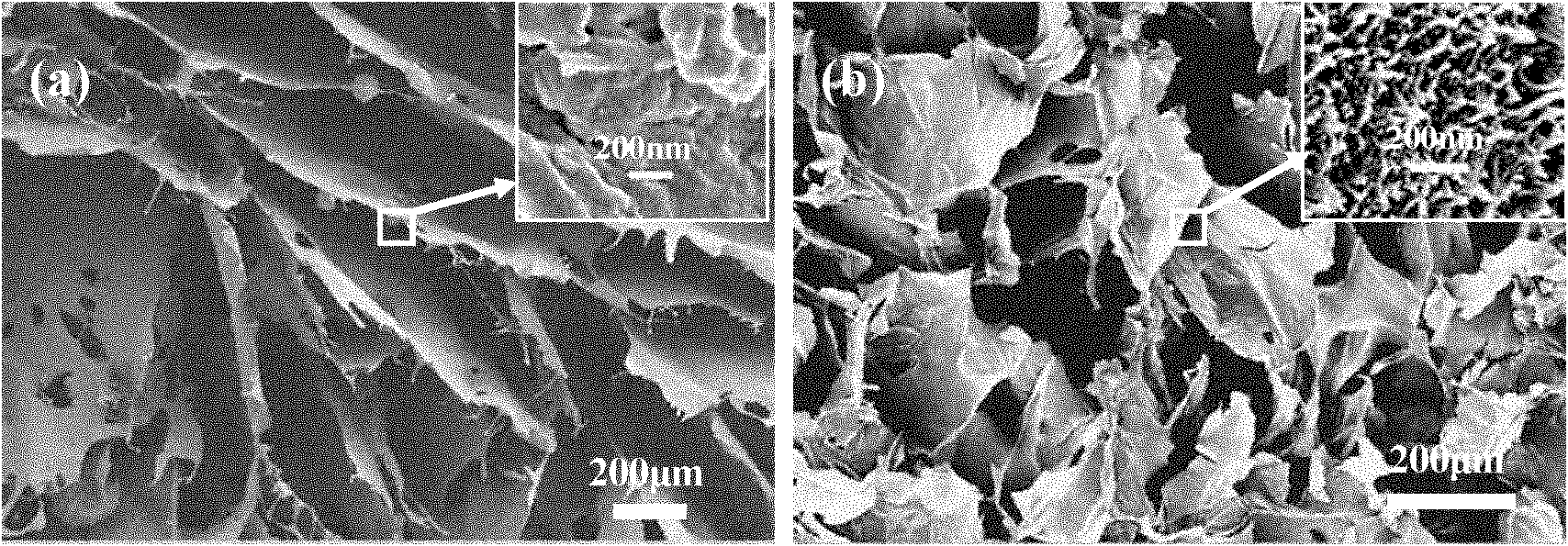

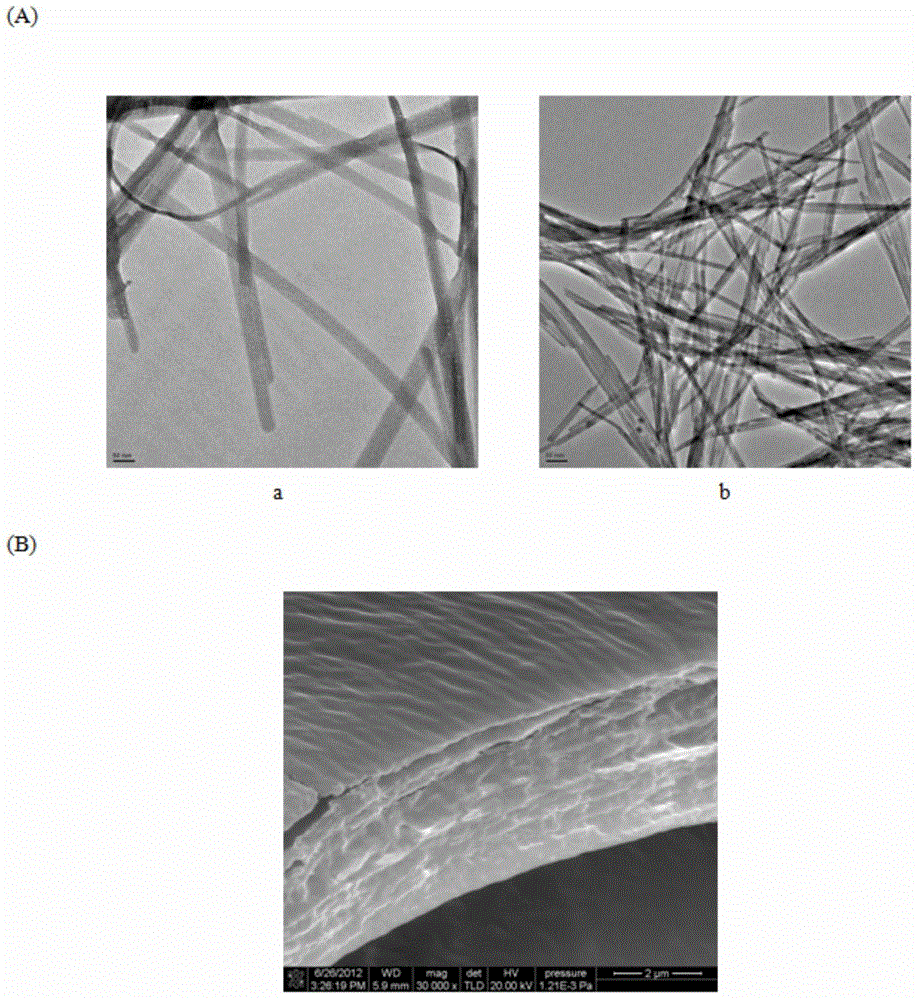

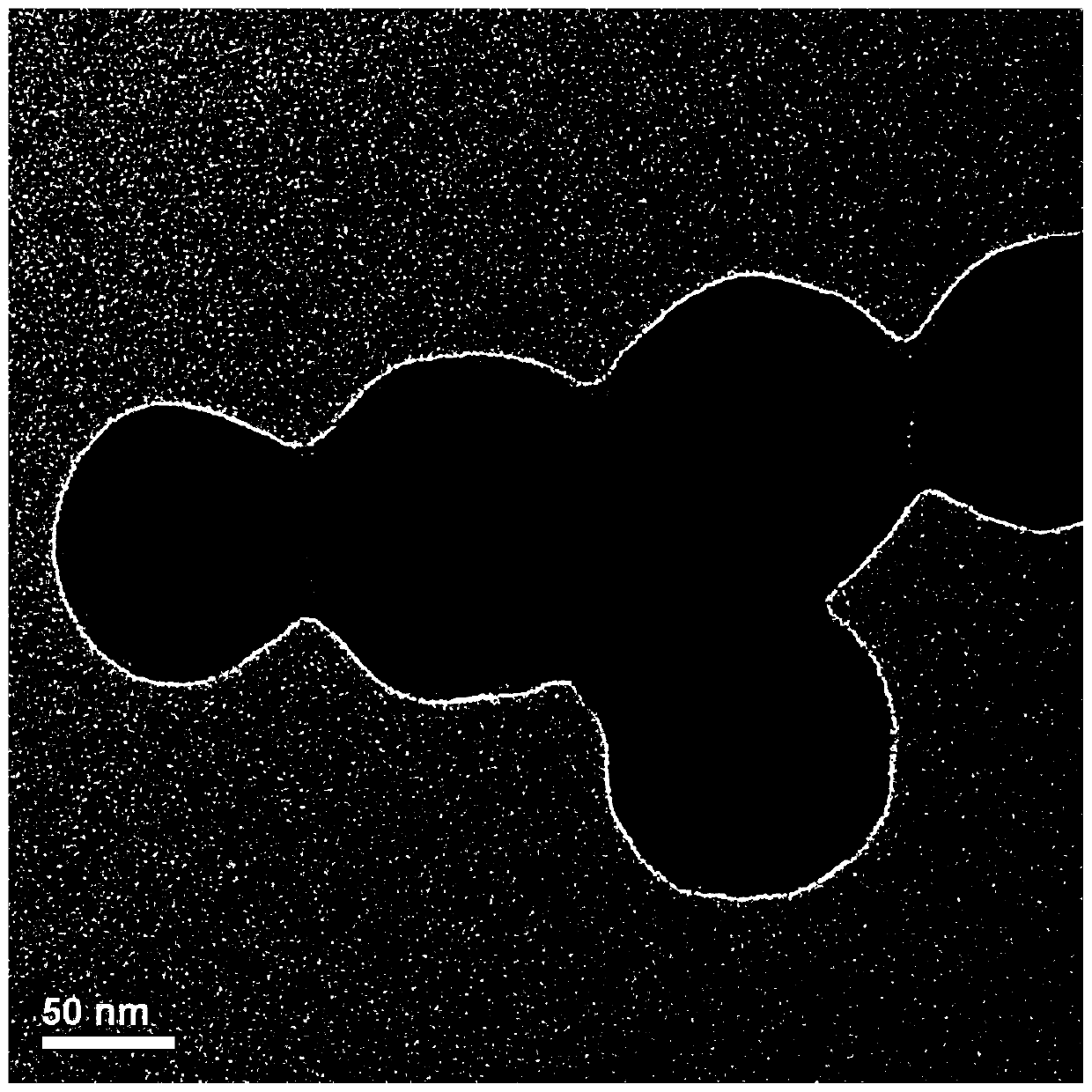

Preparation method of thermally-reduced graphene oxide/nano carbon fiber composite electrode for full-vanadium flow battery

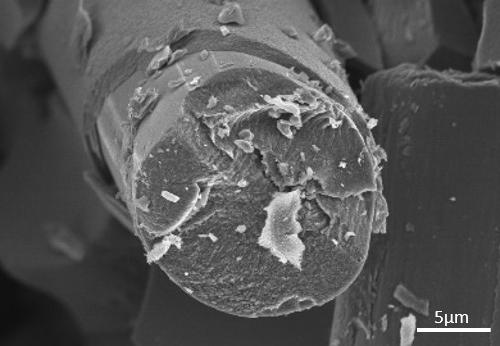

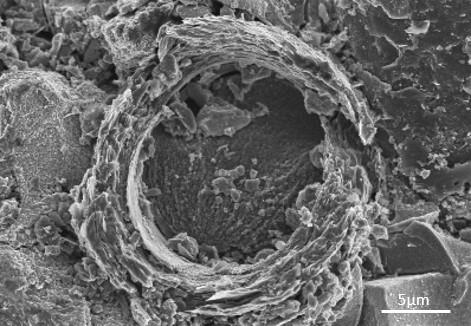

InactiveCN104332640ALarge specific surface areaIncrease the reaction areaCell electrodesFiberCarbon fibers

The invention relates to the field of battery manufacturing and energy source storage and particularly provides a preparation method of a thermally-reduced graphene oxide / nano carbon fiber composite electrode for a full-vanadium flow battery. The preparation method comprises the following steps: firstly, preparing a spinning solution for an experiment; secondly, uniformly mixing graphite oxide powder and the spinning solution; stripping the graphite oxide powder into graphene oxide by using an ultrasonic manner; preparing a nano fiber membrane by adopting an electrostatic spinning method; and then pre-oxidizing the nano fiber membrane in the air and carbonizing in an inert atmosphere pipe type furnace to obtain the needed thermally-reduced graphene oxide / nano carbon fiber composite electrode. According to the full-vanadium flow battery composite electrode prepared by the method, the diameter of carbon fibers is a nano scale; and the carbon fibers are compounded with thermally-reduced graphene oxide and the roughness of the fibers is greatly increased, so that the specific surface area of the electrode is two orders of magnitudes higher than that of a traditionally-used electrode material. Meanwhile, the high-activity thermally-reduced graphene oxide is adopted so that the electrochemical activity of the electrode is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method for combination electrode for all-vanadium redox flow battery

InactiveCN104241661AImprove electrochemical activityImprove energy efficiencySucessive textile treatmentsCell electrodesCarbon fibersCharge discharge

The invention relates to the field of battery manufacturing and energy storage, in particular to a preparation method of a bismuth-base catalyst / carbon nanofiber combination electrode for an all-vanadium redox flow battery. Firstly, spinning solution required for an experiment is prepared and then bismuth salt and the spinning solution are uniformly mixed. According to an electrostatic spinning method, a required nanofiber film is prepared and then the nanofiber film is pre-oxidized in the air and is carbonized in an inert atmosphere tube furnace so as to obtain the required bismuth-base electrocatalyst / carbon nanofiber combination electrode. After the obtained electrode material is cleaned and dried, testing of related electrochemical performance representation and charge-discharge properties can be carried out on the electrode material. The carbon fiber diameter, which is prepared according to the preparation method, is in the nano class; compared with a specific surface area of a conventionally used electrode material, the specific surface area of the bismuth-base catalyst / carbon nanofiber combination electrode is greatly increased. Moreover, the carbon nanofibers are compounded with a high-activity bismuth-base electrocatalyst, and thus, electrochemical activity of the electrode can be greatly improved, so that energy efficiency of the all-vanadium redox flow battery is greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of Wolfram-Nickel-Ferrum (W-Ni-Fe) alloy parts

The invention discloses a preparation method of W-Ni-Fe alloy parts. The preparation method includes the steps of (1) material preparing by using reducted tungsten powder, hydroxy nickel powder and hydroxy iron powder as metal powder; (2) powder blending by weighing W powder, Fe powder and Ni powder in the proportion of 95:3.5:1.5; (3) binder preparation; (4) W-Ni-Fe materials mixing and feeding; (5) pelletizing; (6) injection molding; (7) solvent degreasing; (8) thermal debinding; (9) sintering; (10) thermal treating after sintering. By the preparation method, problem caused by using the present manufacturing process of W-Ni-Fe alloy is solved, so that product shapes are diversified, product design is liberated, mass production is implemented, manufacturing cost is reduced and the like.

Owner:LUOYANG SIFON ELECTRONICS

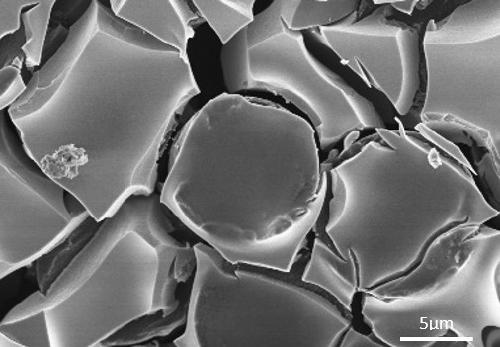

Water-insoluble silk fibroin porous material and preparation method thereof

The invention discloses a water-insoluble silk fibroin porous material and a preparation method thereof. The preparation method comprises the following steps of: adding one or more kinds of salt solution into silk fibroin solution, mixing the solution uniformly and then injecting the mixture into a metal die, freezing the mixture for 24 hours at the temperature of between 10 DEC below zero and 80 DEG C below zero, performing freeze drying on the mixture, and treating the mixture at the temperature of between 4 and 120 DEG C under the environment with the humidity of 30 to 98 percent to form the water-insoluble silk fibroin porous material. The solution loss rate of the water-insoluble silk fibroin porous material in 37 DEG C water for 24 hours is below 2 percent, and the material can be fully degraded into no-toxicity amino acid; the material has large holes and apertures, and is suitable for the growth of cells; and meanwhile, any chemical cross-linking agent, foaming agent or denaturing agent and the like does not need to be added during preparation, so good biocompatibility of the silk fibroin is kept, and the silk fibroin can be used for wound recovery materials for cell culture, skin, bones and gristles and medicinal release-controlled materials for temporary coverage, tissue isolation and hemostasis and the like.

Owner:SUZHOU UNIV +1

Polycarboxylic acid water reducing agent with excellent rust resisting function and preparation method thereof

The invention relates to a polycarboxylic acid water reducing agent with an excellent rust resisting function and a preparation method thereof, belonging to the technical field of concrete water reducing agents. The preparation method comprises the following steps of: (1) esterification reaction, i.e. using a 98% concentrated sulfuric acid as a catalyst, sequentially adding polyethylene glycol monomethyl ether, acrylic acid, sodium benzoate and benzotriazole, carrying out the esterification reaction for 4 hours under a sealing condition at 110-120 DEG C so as to obtain a mixture of a polyethylene glycol triazole-group acrylic acid esterified compound and the rest acrylic acid; (2) copolymerization reaction, i.e. using ammonium persulfate as an initiator, and directly copolymerizing the mixture of the polyethylene glycol triazole-base acrylic acid esterified compound and the rest acrylic acid, which is obtained in the step (1), for 3 hours at 90+ / -5 DEG C so as to obtain the polycarboxylic acid water reducing agent with a rust resisting group. The invention has the advantages that a polymerization inhibitor does not need to be added any more during the esterification reaction, the catalyst can be finally converted into a part of the water reducing agent; a polymerization-inhibiting functional group triazole-group is directly led during the esterification reaction, thereby product structures are controller and the requirements of product properties are met; more inexpensive acrylic acid is used as a raw material, thereby being beneficial to reducing the cost of the polycarboxylic acid water reducing agent; and in addition, the invention has relatively simpler process and moderate reaction condition and is easy for mass production.

Owner:肖尾俭

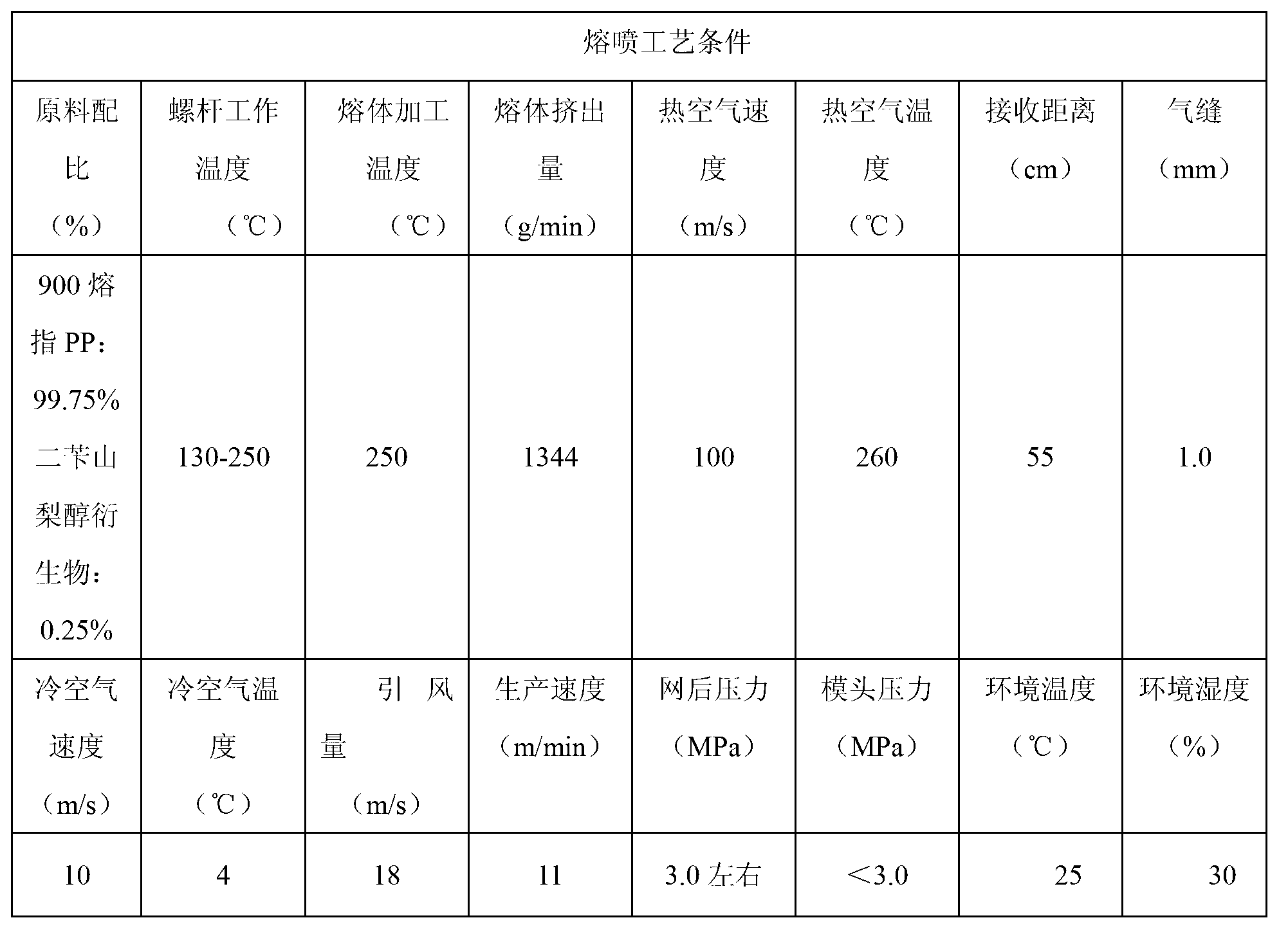

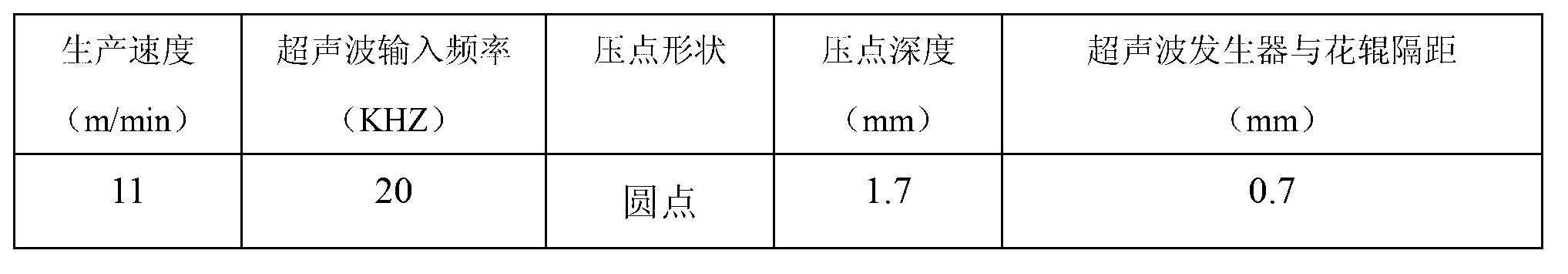

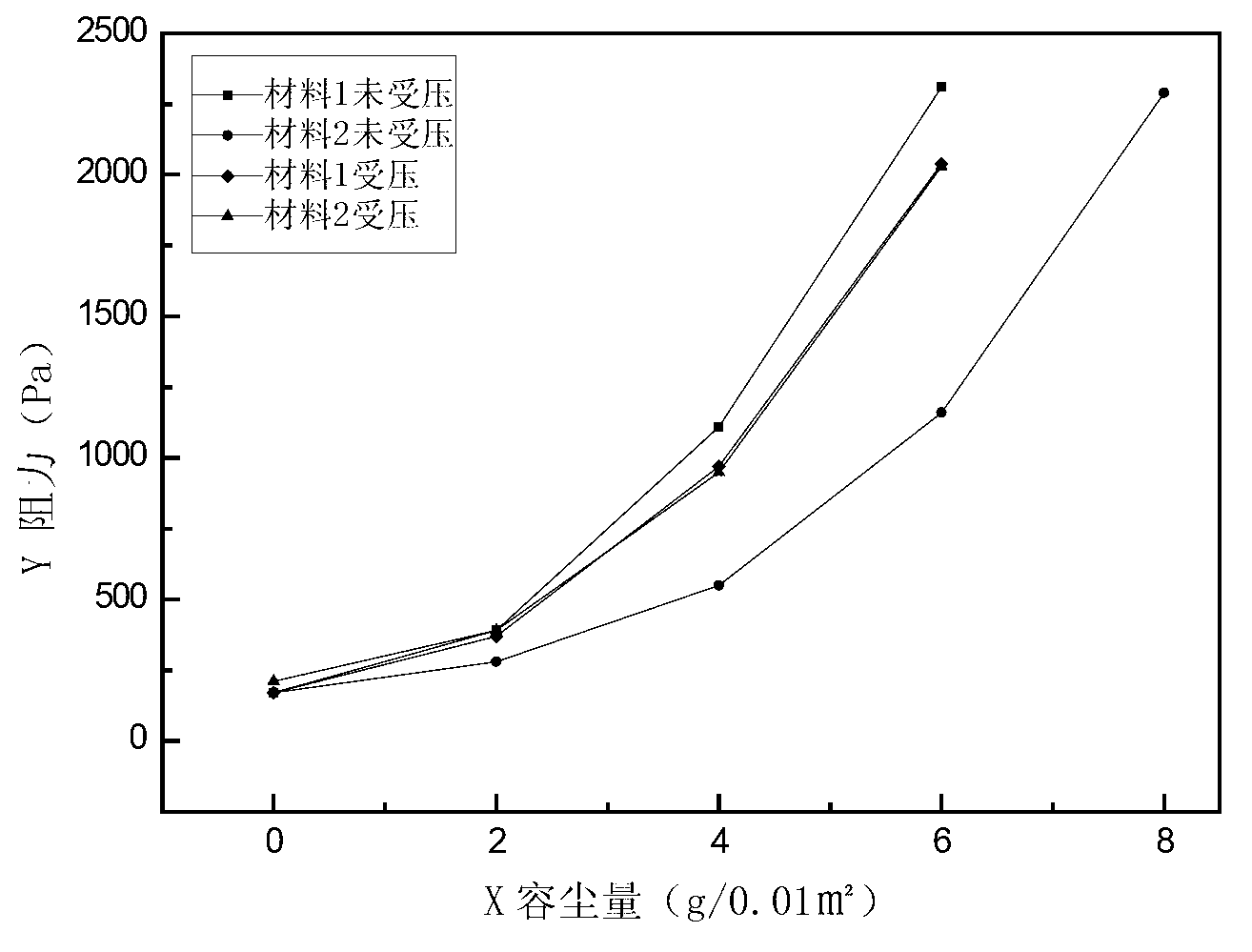

Melt spinning non-woven material and production method and application thereof

InactiveCN103046231AImprove interception effectSmall pressure lossSuction filtersLayered productsCrude fibrePolymer science

A melt spinning non-woven material is characterized in that the weight of the non-woven material weights 35 to 500 g / m<2> and being obtained by a polymer slice being directly melting to spin and the spine being weaved into webs. The melt spinning non-woven material consists of superfine fibers and crude fibers, the crude fibers are used as a framework and the superfine fibers are filled into the framework to form a fiber web to form a thickness matching structure. The fiber web has one layer or more, and when the layer number of the fiber web is more than one, a thickness increasing or gradient structure is formed through a multilayer structure. By means of the optimization of raw materials and process, the melt spinning non-woven material and a production method and an application of the melt spinning non-woven material can control a fiber web structure of the melt spinning non woven material: the distribution of fiber finenesses is controlled in a reasonable range, the fiber web has a large amount of superfine fibers and a certain amount of crude fibers; the crude fibers being used as a framework and the superfine fibers being filled into the framework improve the fluffiness of the material, and the material can still maintain some recovery capability when in use; and the fiber web forms a structure with some gradients.

Owner:ZHEJIANG ZHAOHUI FILTRATION TECH

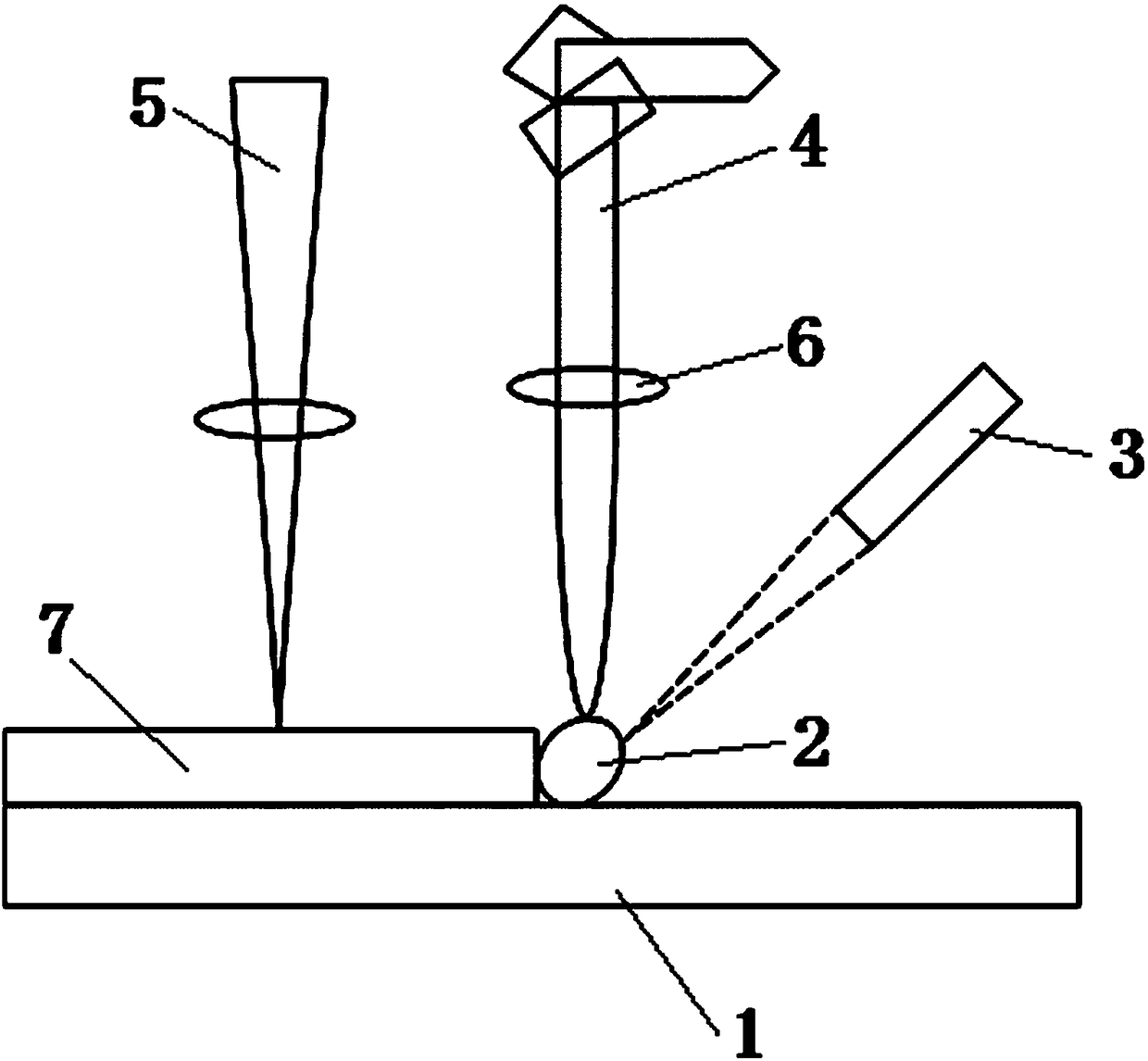

Manufacturing method of double-high-energy-beam metal additive material

InactiveCN108115137AQuality improvementImprove surface topographyAdditive manufacturing apparatusIncreasing energy efficiencyMathematical modelControl system

The invention discloses a manufacturing method of a double-high-energy-beam metal additive material. The manufacturing method comprises the following steps: (a) determining a three-dimensional entitymodel of a forming component, and modeling; and (b) manufacturing an additive material of the forming component: carrying out slicing and layering on a mathematical model in the step (a), so as to obtain two-dimensional outline information of a section of each layer and generate a machining route, inputting information into a control system of additive material manufacturing equipment, and manufacturing the double-high-energy-beam metal additive material by taking metal powder as the raw material according to a preset machining route. According to the manufacturing method, the internal defectsof pores, incomplete fusion, cracks and the like of a formed part are avoided, the system error of the formed part and an original design is small, and the formed part is relatively high in dimensional accuracy, small in residual stress, low in surface roughness and high in comprehensive quality; and compared with the prior art, the manufacturing method has significant progress and industrial application values.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method of nano-fibrous silk fibroin-based porous scaffold

InactiveCN102008756APromote formationDegradation controllableProsthesisFiberCell-Extracellular Matrix

The invention relates to a preparation method of a porous scaffold material and discloses a preparation method of a nano-fibrous silk fibroin-based porous scaffold. The preparation method comprises the following steps: blending a silk fibroin solution and a collagen solution under the temperature of 0-20 DEG C, standing to ensure the complete reaction of collagen and silk fibroin and generate nano-fiber; freezing the mixed solution to obtain a freezing body; performing freeze drying treatment on the freezing body to obtain a nano-fibrous porous scaffold material; and placing the nano-fibrous porous scaffold material in a vacuum drier with water and methanol, or an ethanol aqueous solution at the bottom, vacuumizing, and then standing to obtain the water-insoluble nano-fibrous porous scaffold. The obtained porous scaffold has 10-1000 microns of communicated pores. The pore walls consist of 10-100nm of nano-fibers; and the porous scaffold has similar nanoscale structures and micronscalestructures to extracellular matrix, is suitable for the adhesion and growth of cells and has good biocompatibility.

Owner:SUZHOU UNIV +1

Composite shielding material and preparation method thereof

InactiveCN103276254AImprove neutron shielding performanceNeutron Shielding Performance GuaranteeShieldingGamma rayNeutron

The invention discloses a composite shielding material and a preparation method thereof and aims at solving the problems that when a B4C / Al composite material is used as a shielding material and the content of B4C exceeds a certain percentage, bad mechanical performance, plastically and workability of the material bring great difficulty for preparation of the material to greatly affect the application of the material although the higher the content of the B4C is, the greater and better the shielding effect on thermal neutrons are. The composite shielding material comprises materials prepared from the following raw materials in percentage by weight: 0.01%-5% of B, 0.1%-30% of W-containing substance, 3%-50% of B4C, 40%-90% of aluminum or aluminum alloy and 0-8% of other substances. The composite shielding material has excellent neutron / gamma radiation shielding performance, good mechanical performance and processing performance and high degree of densification and is especially suitable for the field of neutron / gamma ray shielding.

Owner:SICHUAN INST OF MATERIALS & TECH

Method of preparing poly carboxylic acid series water reducer using maleic anhydride

The present invention relates to a method for preparing polycarboxylate water-reducing agent by utilizing maleic anhydride. Said method includes the following steps: (1), using solid acid SO42- / ZrO2 as catalyst, as catalyst, utilizing esterification reaction of polyethylene glycol and maleic anhydride at 80 deg.C-90 deg.C under the condition of reduced pressure to obtain the mixture of polyethylene glycol maleic anhydride esterified product (PEM) and residual maleic anhydride, the relative molecular weight of the described polyethylene glycol is 1000; and (2), using ammonium persulfate as initiator, making the above-mentioned mixture, acrylic acid and sodium methylpropenyl sulfonate undergo the process of copolymerization reaction for 3-5h at 85 deg.C so as to obtain the invented product.

Owner:HENAN POLYTECHNIC UNIV

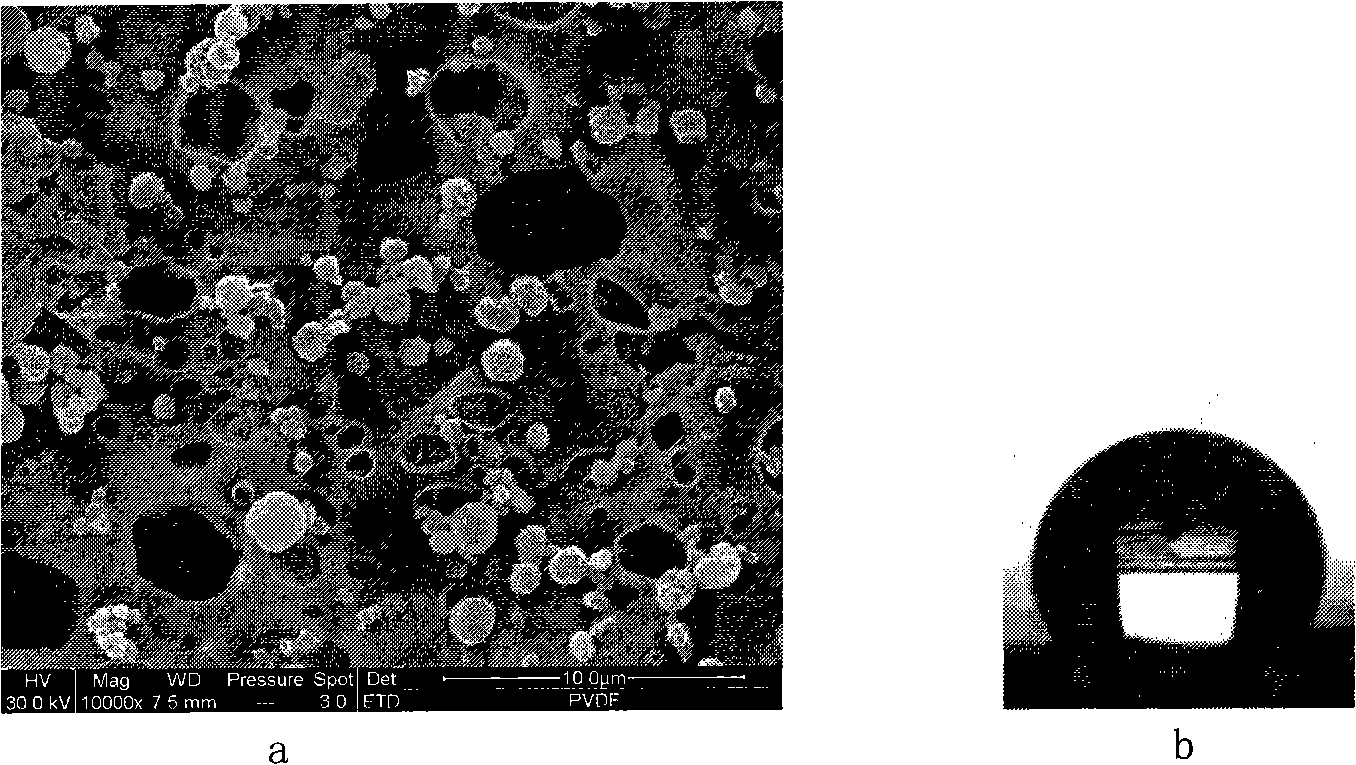

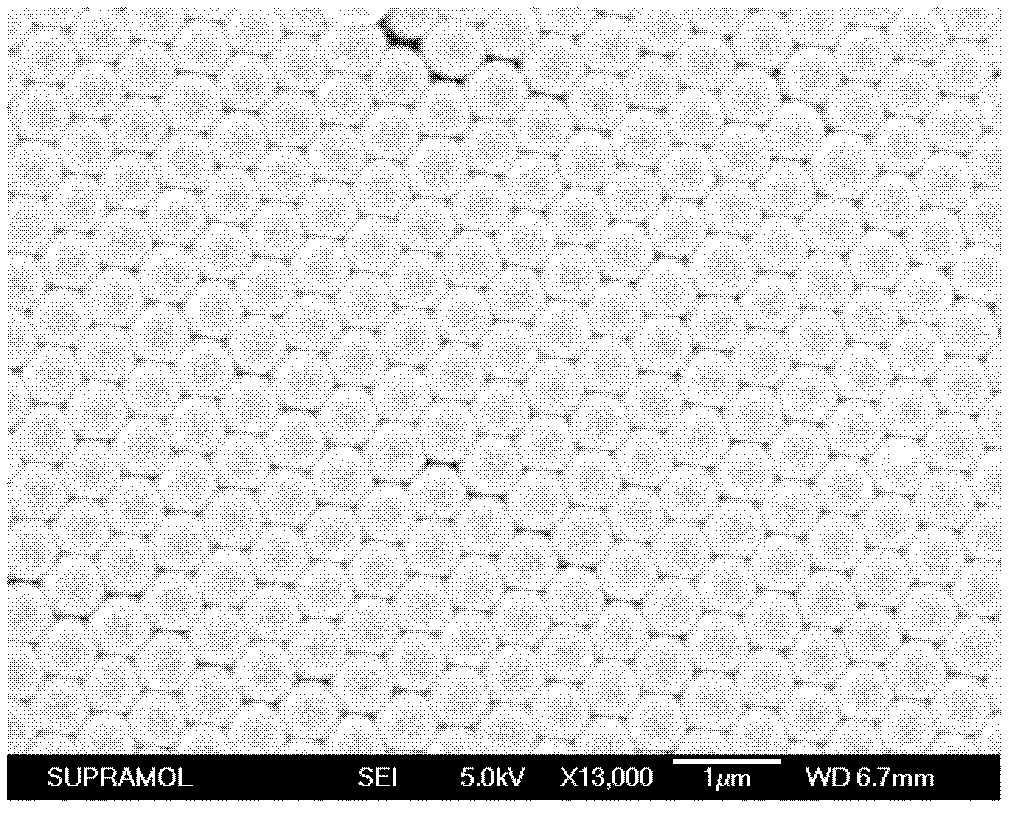

Preparation of polyvinylidene fluoride dewatering microporous film

The invention relates to a preparation method for a PVDF hydrophobic microporous membrane and belongs to the field of separation membrane and membrane separation. The invention aims at solving the problem of relatively low flux in the prior art and providing the preparation method for a PVDF microporous membrane with hydrophobic nature, which prepares the PVDF hydrophobic microporous membrane through the following steps: 1) preparing a casting solution adding with an alkoxy silane reagent; 2) placing the membrane in water with a moisture ranging from 60 percent to 85 percent or a steam atmosphere with a pH value of 0.5 to 3 or 10 to 13 for 1 to 4 min after scraping the casting membrane into a liquid membrane with a thickness ranging from 0.12 to 0.15mm; 3) immersing the membrane into water at room temperature or a coagulation bath with the pH value of 0.5 to 3 or 9 to 11. The method of the invention is simple in operation, low in cost, with the surface of the membrane prepared being a network cellular structure and accompanied by spherical particles and the cross section being a symmetrical spongy structure, while the hydrophobic nature and the pure water flux of the membrane are greatly improved.

Owner:BEIJING UNIV OF TECH

An alginate dressing for treating bedsore and a preparing method thereof

ActiveCN104758977APromote healingNo tissue proliferationAbsorbent padsBandagesPorosityComposite film

The invention relates to an alginate dressing for treating bedsore and a preparing method thereof. The dressing has a double-layer composite structure, namely the dressing comprises a base layer and a surface layer. The base layer is an alginate composite film layer. The surface layer is a natural rubber film layer. The preparing method includes following steps of: A) preparing a shark collagen solution, B) preparing a coaxial electrospinning outer layer solution, C) preparing a coaxial electrospinning core layer solution, D) spinning, E) crosslinking, F) dipping, G) preparing an epoxy natural rubber film, and H) compositing. The dressing has good biocompatibility, and has controllable growth regulation, good hygroscopicity, good anti-inflammation performance and good antibacterial performance of synthetic biological materials. The dressing is capable of improving local blood supply of wounds, promoting tissue growth and accelerating wound healing, shows good multifunctional properties, has good porosity, soft and comfort hand feeling, good compliance and using convenience, and can be used in the field of modern biomedicine, especially in the field of bedsore treatment and nursing, and the like.

Owner:HENAN YADU IND

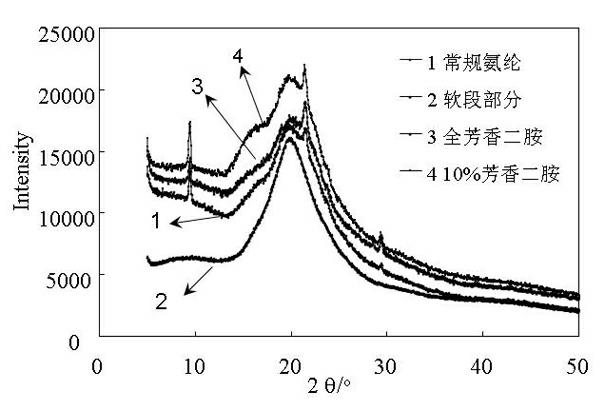

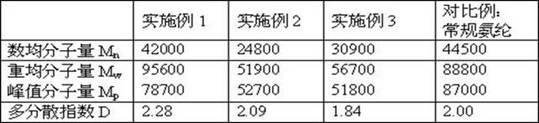

Preparation method of heat resistant spandex fiber

ActiveCN102220653AImprove heat resistanceGood lifting effectMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a preparation method of heat resistant spandex fiber, belonging to the technical field of polymer textile material and preparation thereof; the preparation method comprises the following steps of: (1) mixing polyoxytetramethylene and 4,4'-methylenebis(phenyl isocyanate) according to a mole ratio of 1 / 1.4 to 1 / 2.5 for reaction to obtain a prepolymer; (2) adding non-protonicpolar solvent to the prepolymer prepared in the step (1) so that the prepolymer is dissolved in the non-protonic polar solvent to obtain prepolymer solution; (3) adding a chain extender in the prepolymer solution obtained in the step (2) to obtain spandex spinning fluid with a molecular weight of 20-300 thousands after polymerization reaction, wherein the chain extender is aromatic diamine or themixture of aromatic diamine and aliphatic diamine; (4) using the spandex spinning fluid prepared in the step (3) to obtain the heat resistant spandex fiber with a solution spinning method. Compared with conventional spandex, the product has obviously improved resistance to heat; moreover, the viscosity stability of the polymer is good.

Owner:ZHEJIANG KAIPUTE SPANDEX +1

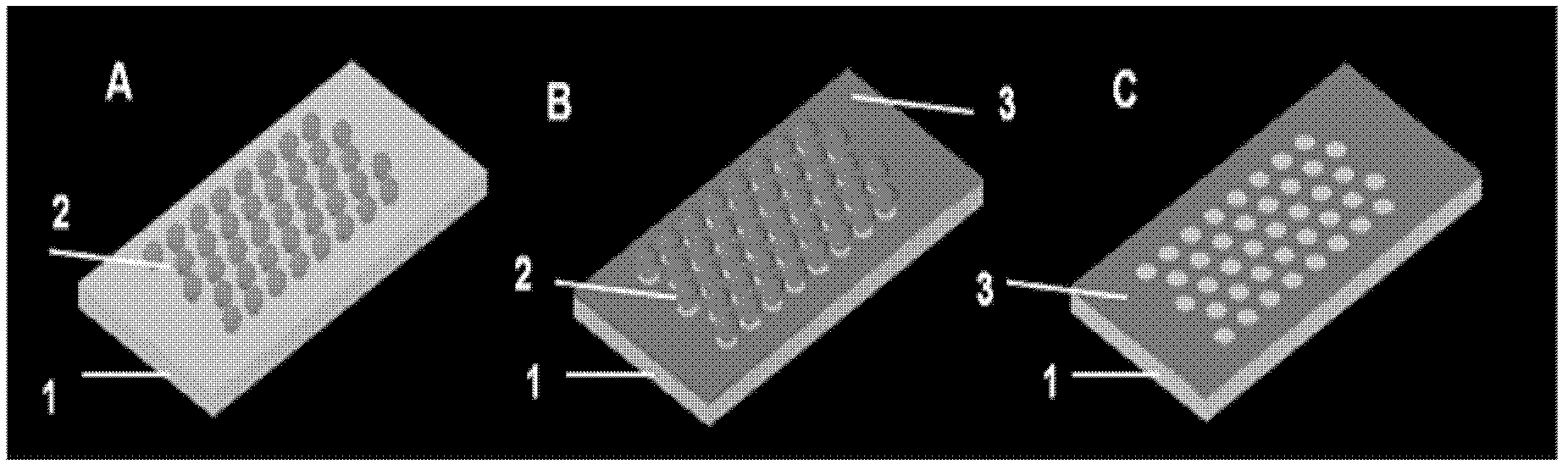

Method for preparing multilevel-structure alumina by pattern prefabrication through micro-nano ball arrangement

InactiveCN102321905AHighly orderedControl structureSurface reaction electrolytic coatingMicro nanoPhotonics

The invention belongs to the technical field of alumina templates, and particularly relates to a method for preparing multilevel-structure alumina by pattern prefabrication through micro-nano ball arrangement. The method particularly comprises the following steps: 1. selecting high-purity aluminium, performing annealing, degreasing, chemical polishing pretreatment; 2. prefabricating a pattern on a pretreated aluminium sheet by micro-nano balls; 3. performing one-step anodic oxidation by using the aluminium substrate completing step 2 as an anode, using inert metal as a cathode, and using phosphoric acid as an electrolyte, selecting a proper voltage according to the morphological size of the prefabricated pattern, and finally performing pore expanding treatment to obtain an alumina template. The alumina template prepared by the method is adjustable according to the pattern structure, has a complex period, and is provided with a multilevel structure. The multilevel period structure is applicable to optical and electronic devices; with reference to properties of photonic crystals, the multilevel structure can be used to realize bandgap regulation.

Owner:JILIN UNIV

Cf/C-SiC-ZrC composite material and preparation method thereof

The invention relates to a Cf / C-SiC-ZrC composite material and a preparation method thereof, and belongs to the field of carbon fiber toughened ceramic matrix composite materials. The Cf / C-SiC-ZrC composite material with high fracture toughness property is prepared by using a process combining chemical vapor deposition and a precursor infiltration and pyrolysis method. The specific preparation method comprises the following steps: first, performing rubber discharge and pyrolysis carbon PyC interface layer deposition on a carbon fiber preform; then immersing in a mixed solution of PCS and PZC; performing impregnation, curing and cracking treatment; circulating the impregnation-curing-cracking process to obtain the Cf / C-SiC-ZrC composite material. The Cf / C-SiC-ZrC composite material prepared by the method of the invention can effectively reduce the physical and chemical damage to the carbon fiber during the cracking process under the protection of a PyC interface layer, and cracks transmitted from a ceramic matrix to the carbon fiber is deflected on the interface layer. In addition, the PyC interface layer is beneficial to the weakening of interface bonding force between the carbon fiber and the ceramic matrix; when the Cf / C-SiC-ZrC composite material breaks, energy is dissipated through the pull-out of the carbon fiber, so that the fracture toughness property of the Cf / C-SiC-ZrC composite material is improved.

Owner:UNIV OF JINAN

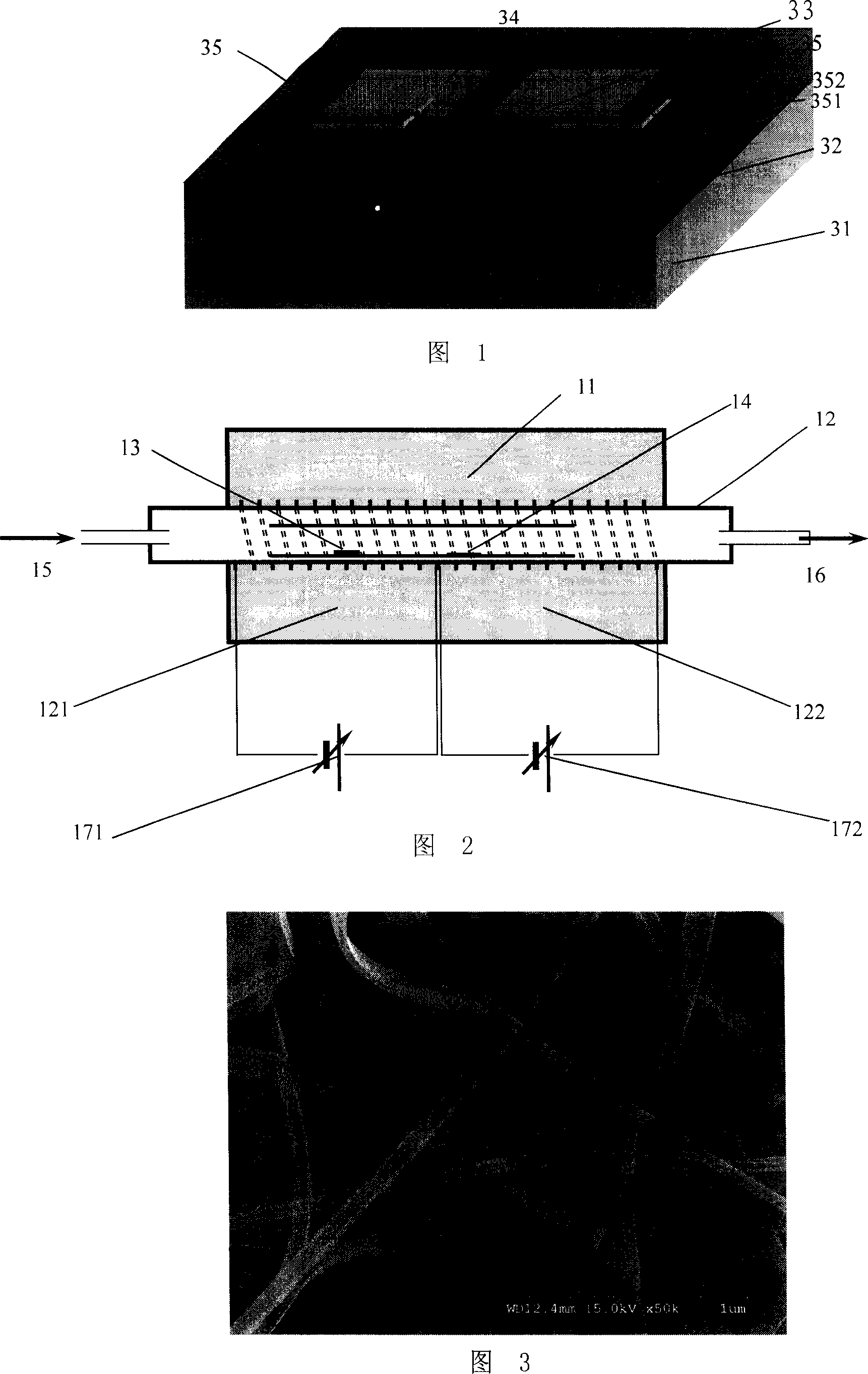

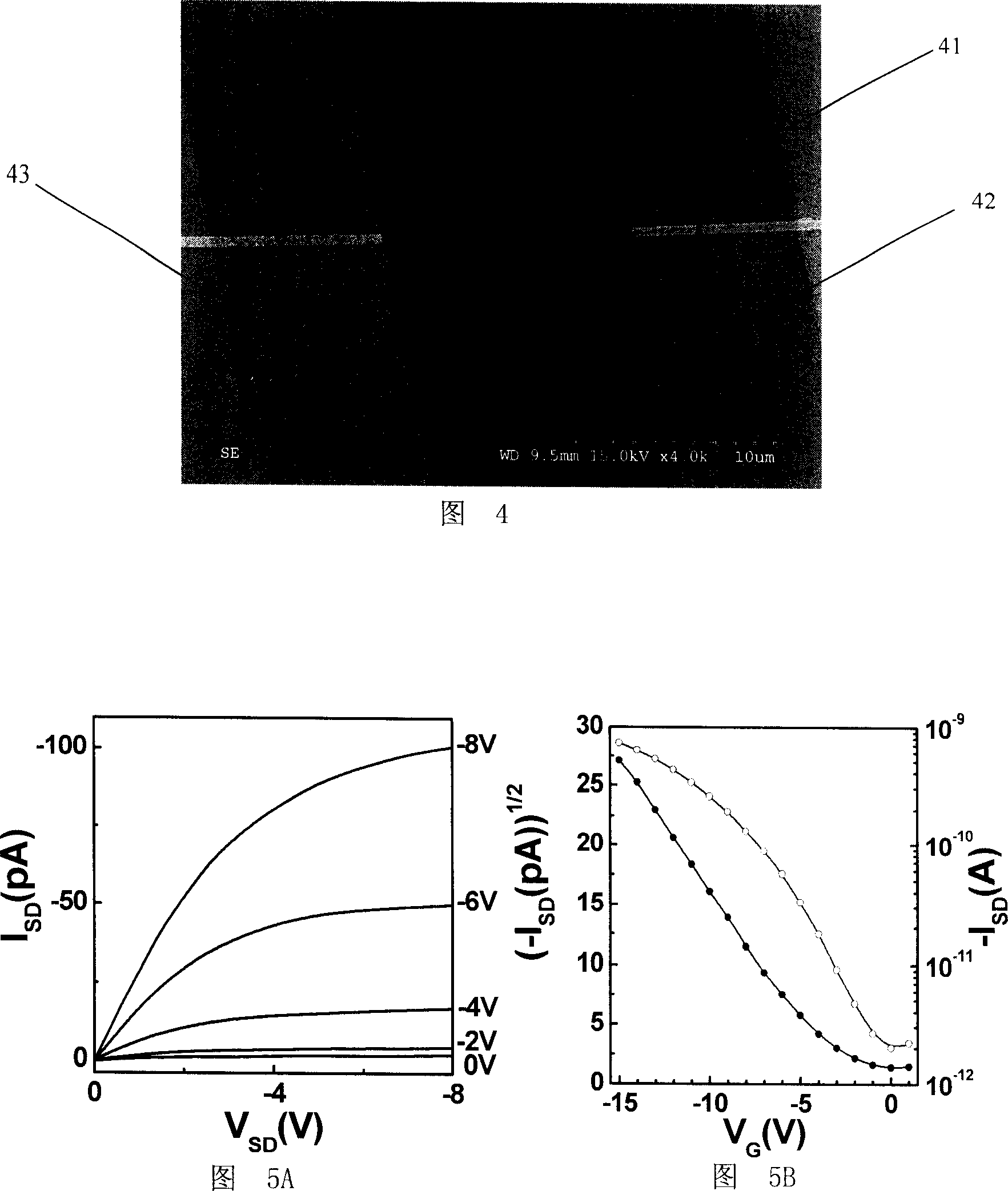

An organic field effect transistor and its manufacture method

InactiveCN1953231AImprove mobilityAvoid destructionSolid-state devicesSemiconductor/solid-state device manufacturingNanowireOrganic field-effect transistor

The invention relates to an organic field-effect transistor, and relative production. Wherein, said transistor comprises a base plate as grid, an insulated layer on the base plate, a source grid and a leak electrodes on the insulated layer; there is an organic semi-conductor single-crystal micrometer / nanometer material between source and leak electrodes, whose two ends are connected to source and leak electrodes via two distanced metal films; the distance between two metal films is 5-20micrometer. The inventive transistor has high transfer rate and lower threshold voltage. And its production has following advantages that (1), it avoid organic solvent while will damage the nanometer material; (2), it has simple device to avoid radiating and damaging nanometer line by high-energy particles; (3), it can obtain controllable device; (4), it can control the structure of transistor, with better electrode contact.

Owner:INST OF CHEM CHINESE ACAD OF SCI

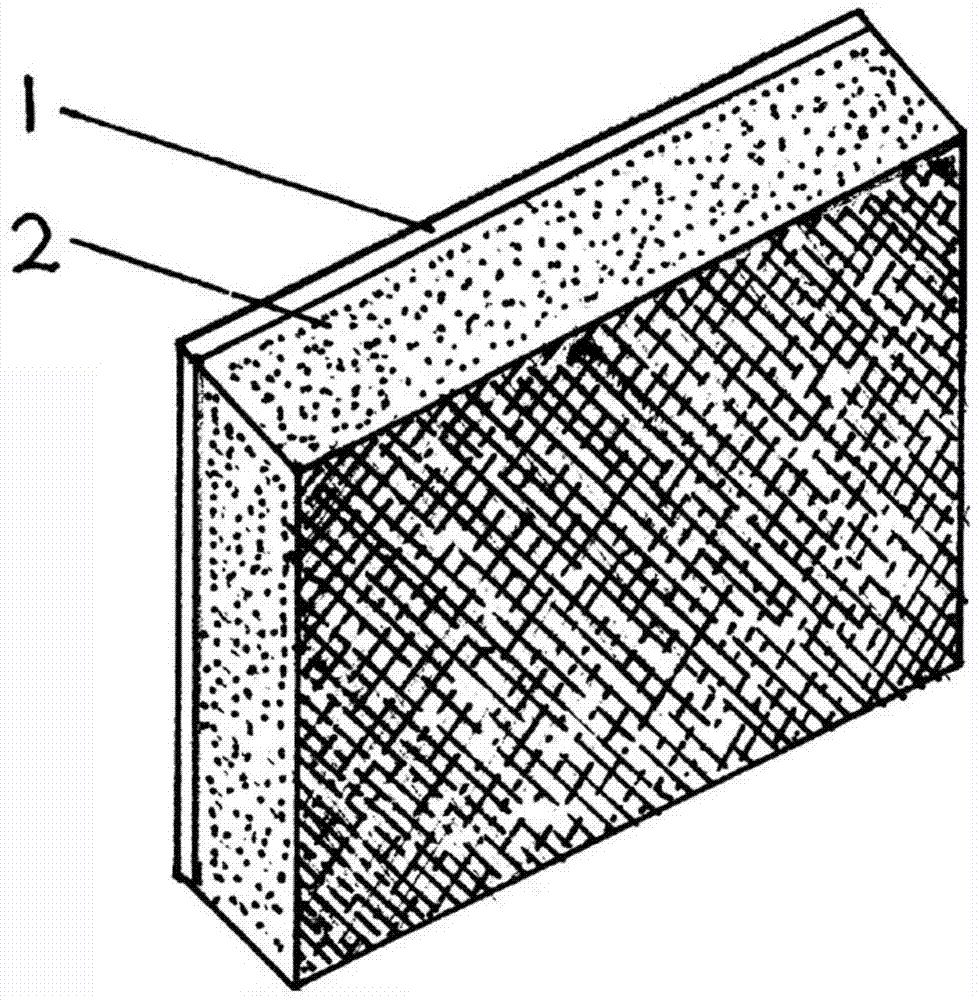

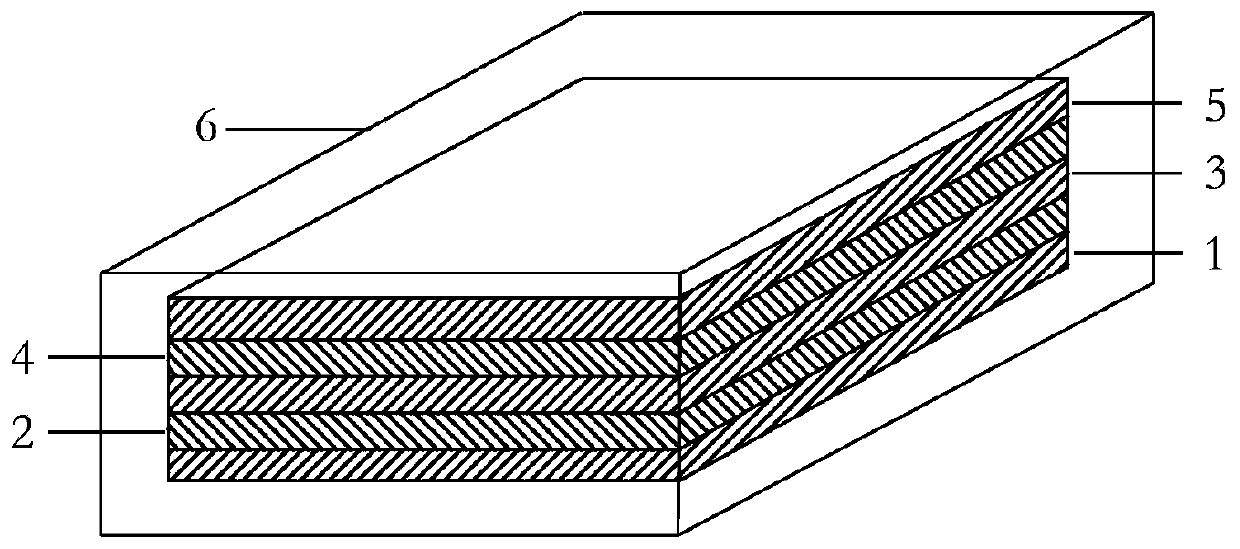

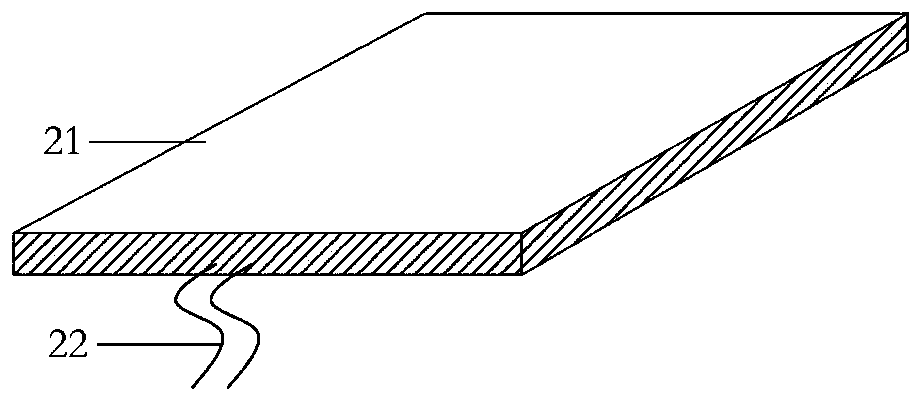

Electrical heating anti-icing assembly with superhydrophobic property and preparation method of electrical heating anti-icing assembly

InactiveCN109794404AHas superhydrophobic propertiesReduced adhesion strengthDe-icing equipmentsLaminationElectricityHeating time

The invention discloses an electrical heating anti-icing assembly with a superhydrophobic property and a preparation method of the electrical heating anti-icing assembly. The anti-icing assembly comprises an insulation heat insulating layer, an electrically heating layer, an insulation heat conduction layer, a heat conduction metal layer, a superhydrophobic coating and waterproof adhesive tape, wherein the insulation heat insulating layer, the electrically heating layer, the insulation heat conduction layer, and the heat conduction metal layer are successively spliced from bottom to top, the superhydrophobic is coated on the surface of the heat conduction metal layer, and the waterproof adhesive tape is sealed around the assembly. The electrical heating anti-icing assembly with the superhydrophobic property has the beneficial effects that the anti-icing assembly has the superhydrophobic property and can remarkably reduce the adhesive strength of a surface ice layer, thus formation of the surface ice layer and removing difficulty of the ice layer can be reduced in a certain level, the ice layer covered on the surface can be removed quickly and completely, heating time is shortened,the removing efficiency of the ice layer is greatly improved, waste of energy is reduced, and great application prospects are provided for equipment such as an airplane in the ice removing field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Degradable environment-friendly plant fiber product and manufacturing method thereof

The invention relates to a degradable environment-friendly plant fiber product and a manufacturing method of the degradable environment-friendly plant fiber product, in particular to a flowerpot, tableware, a compressed panel or a tray made of the degradable environment-friendly plant fiber and the manufacturing method of the flowerpot, the tableware, the compressed panel or the tray made of the degradable environment-friendly plant fiber. The raw materials comprise plant fibers from crop straws, food processing wastes, annual wild plant stem parts, bamboos, and woods. The raw materials are added with modified starch and organic pigments to be molded at high temperature to produce the plant fiber product. The degradable environment-friendly plant fiber product has the advantages that the main raw materials can be completely from the wastes of agricultural products; the materials are simple; the cost is low; the product is green and environment-friendly and can be naturally degraded in a natural environment; the production method is simple and high-efficiency; and the product is mild in surface color, high in strength, waterproof and not easy to deform, and can be used for substituting the current products made of plastic, argil and wood, so that the plant fiber product is an ideal degradable environment-friendly plant fiber product.

Owner:李宁

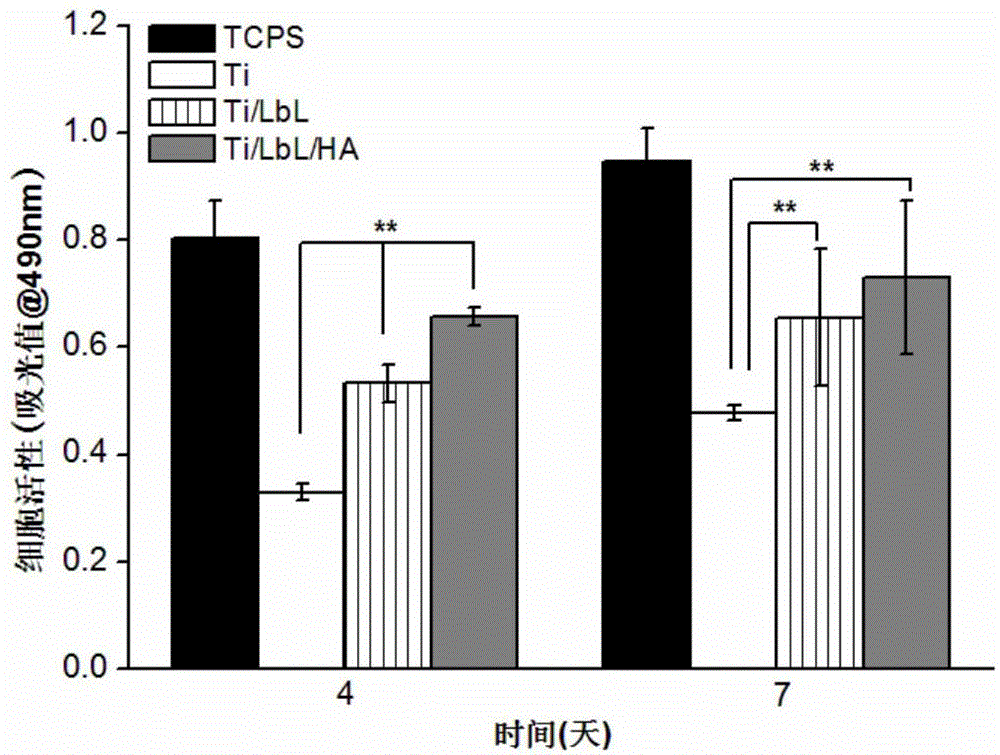

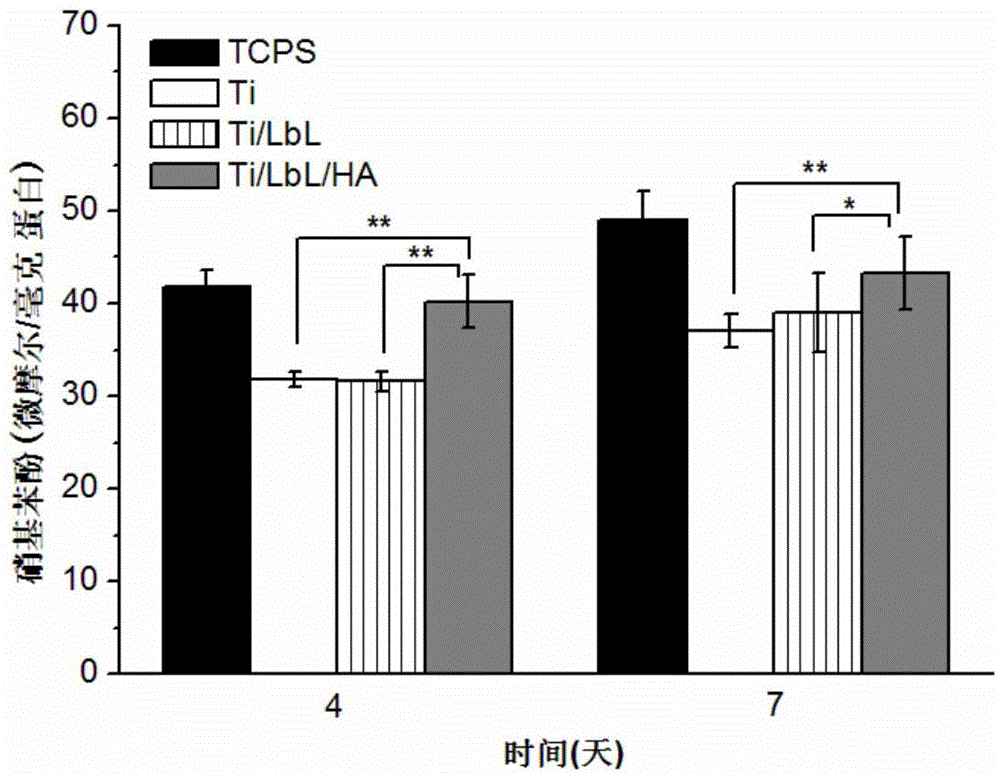

Method for preparing medical titanium alloy with bionic multilayered structure interface

ActiveCN104013997AEasy constructionFunction increaseCoatingsPhosphorus compoundsNanowireNatural bone

The invention discloses a method for preparing a medical titanium alloy with a bionic multilayered structure interface. The method comprises the following steps: preparing a hydroxyapatite nanowire through a precursor hydrothermal replacement method, and taking the nanowire as an intercalation material for constructing a simulated natural bone laminar film; and assembling the hydroxyapatite nanowire into a gelatin / chitosan multilayer film by utilizing a layer-by-layer self-assembly technology (a spin-coating method), and thus constructing a film for simulating the natural bone nano layered structure from the bionic angle on the surface of a titanium material. Therefore, the biological function of osteoblast is controlled, and the biocompatibility and bone integration of a titanium alloy transplant are improved.

Owner:CHONGQING UNIV

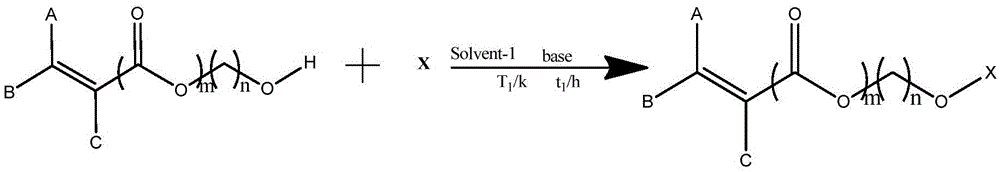

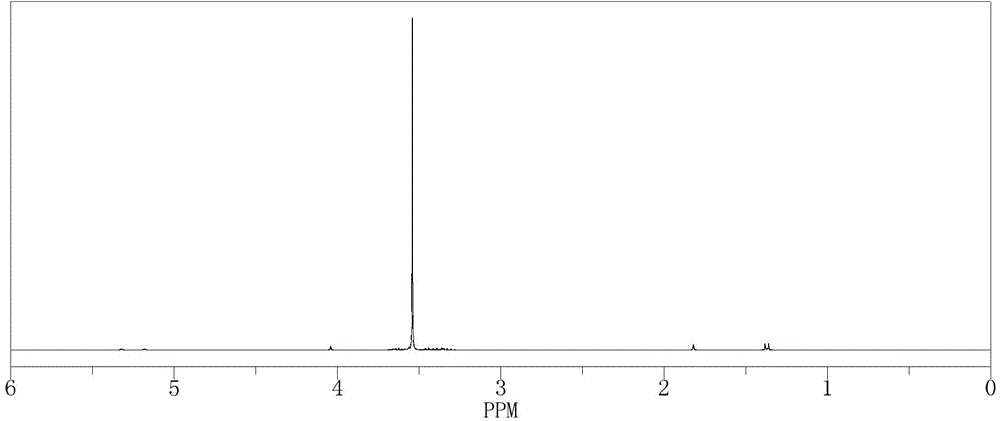

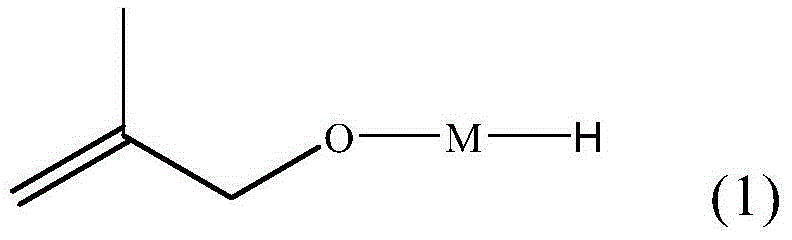

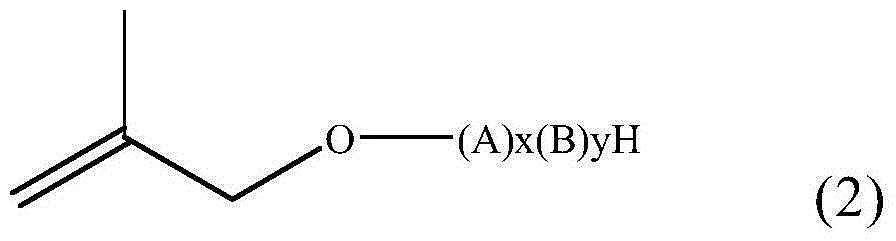

Terminal alkenyl nonsaturated polyether and purpose thereof

ActiveCN105330830AGood performance for decentralized applicationsFlexible adjustment of densityAcid waterReducer

The invention provides terminal alkenyl nonsaturated polyether shown in a formula (1), and the invention also provides a purpose of the terminal alkenyl nonsaturated polyether. According to the provided terminal alkenyl nonsaturated polyether, a polyether chain segment can be adjusted through different structural units, so that dispersion effect of a prepared water reducer on concrete is increased, and water-reducing rate of a polycarboxylic acid water reducer and slump constant are obviously increased. The preparation method has the advantages of simple operation, mild condition and easy industrial application.

Owner:SICHUAN SEDAR CHEM

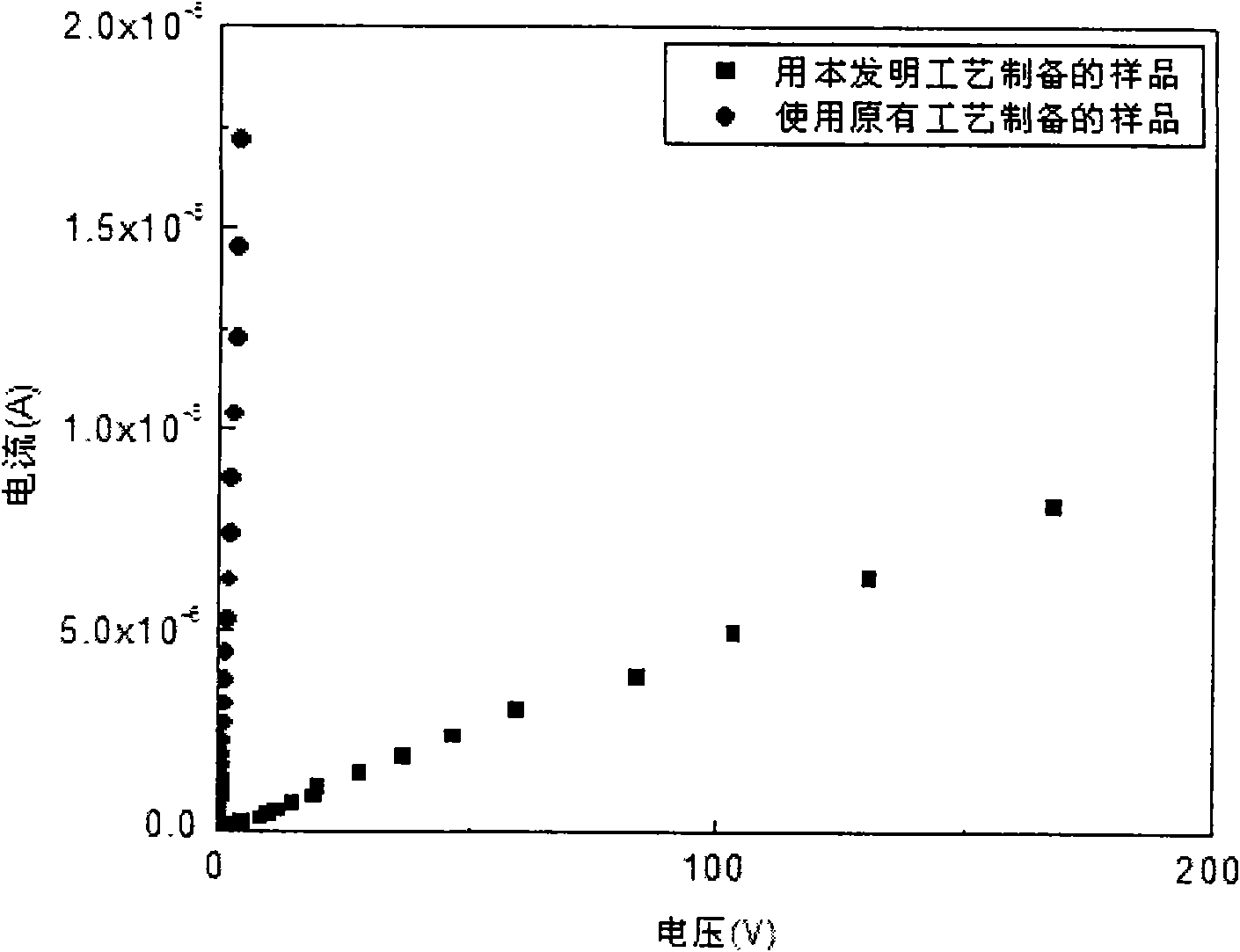

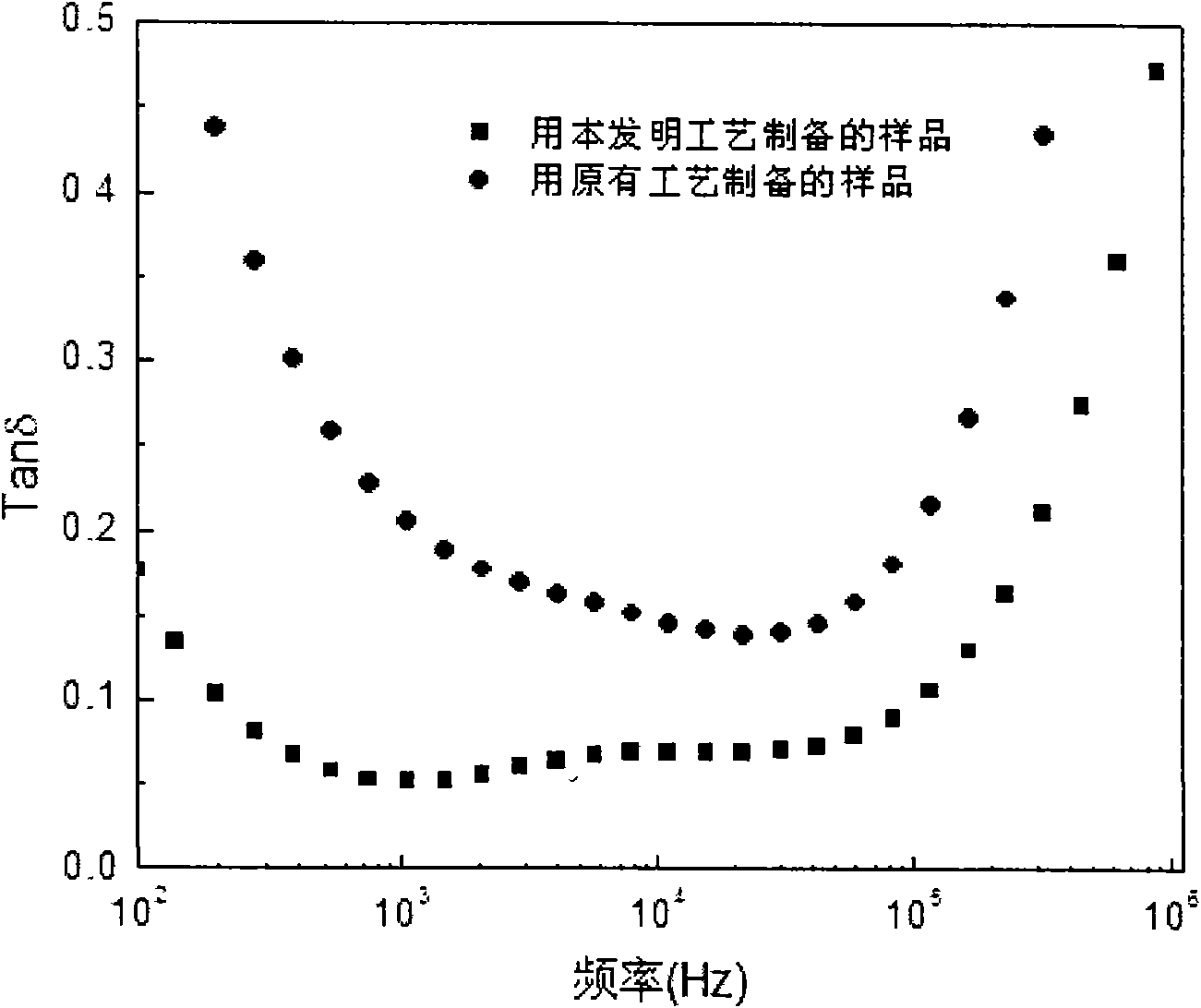

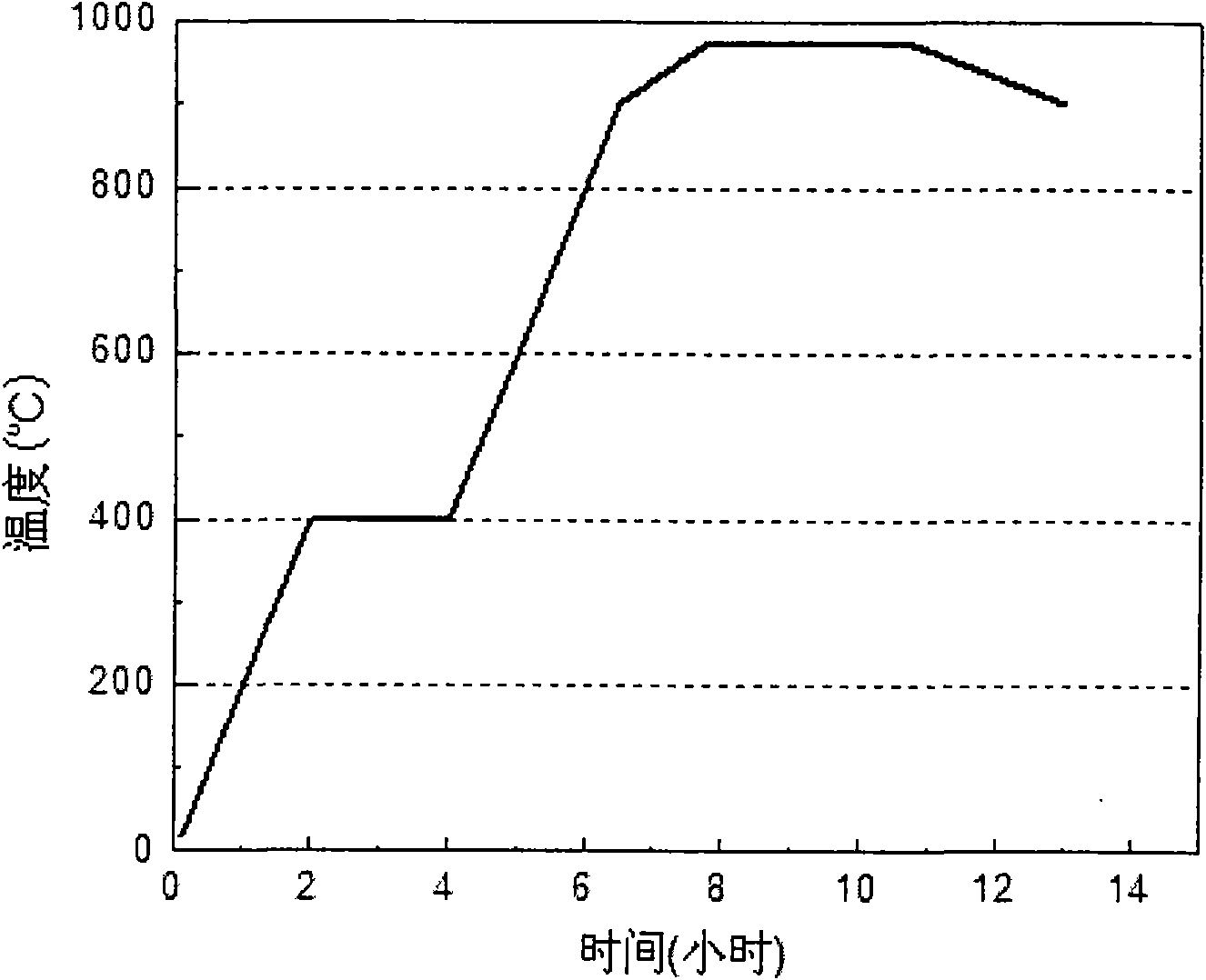

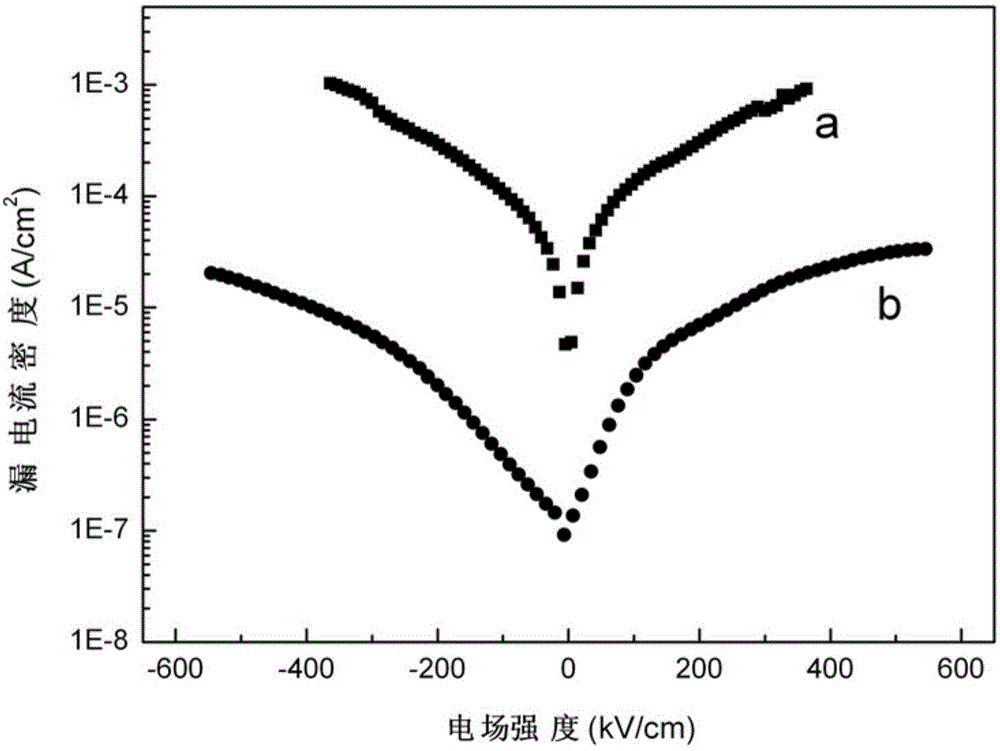

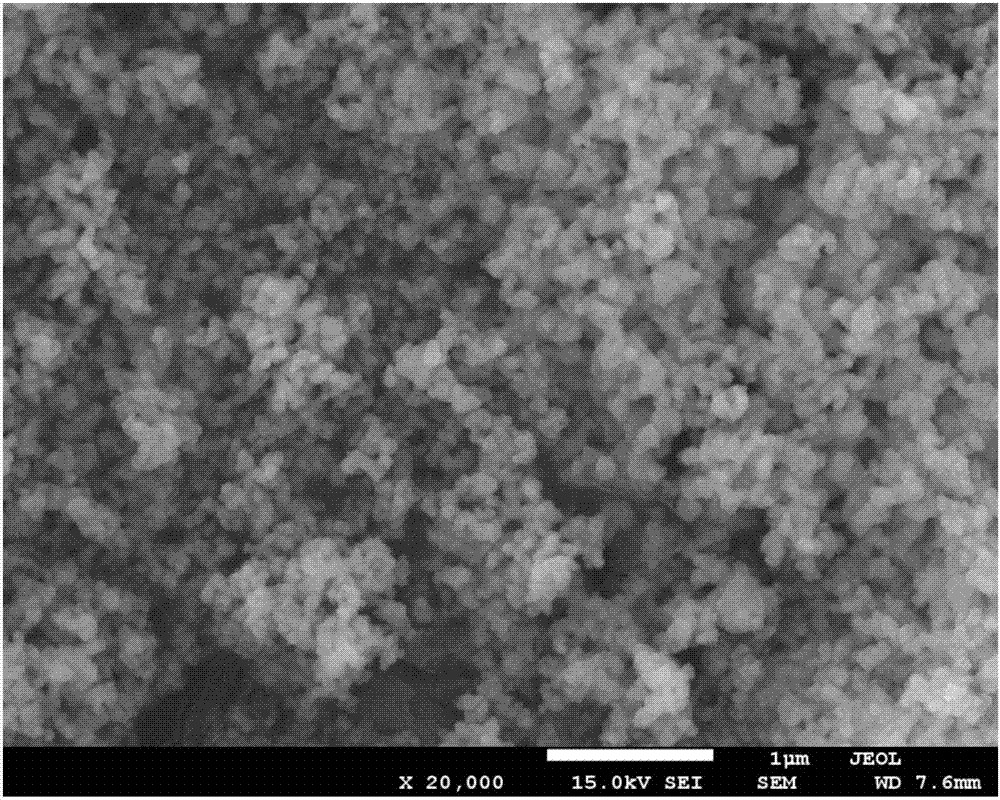

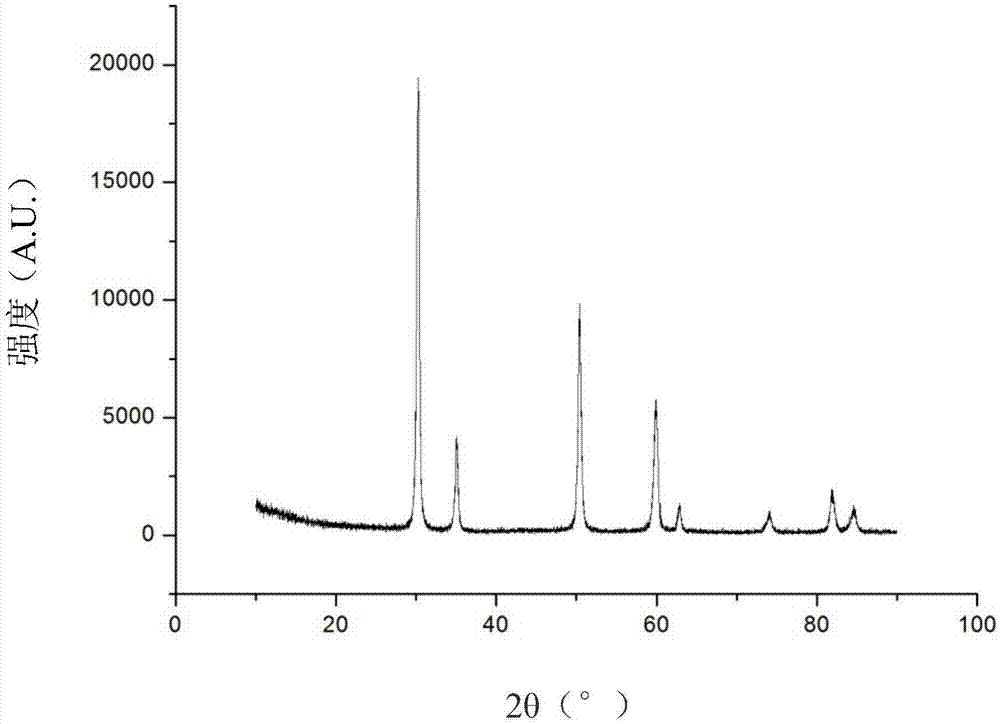

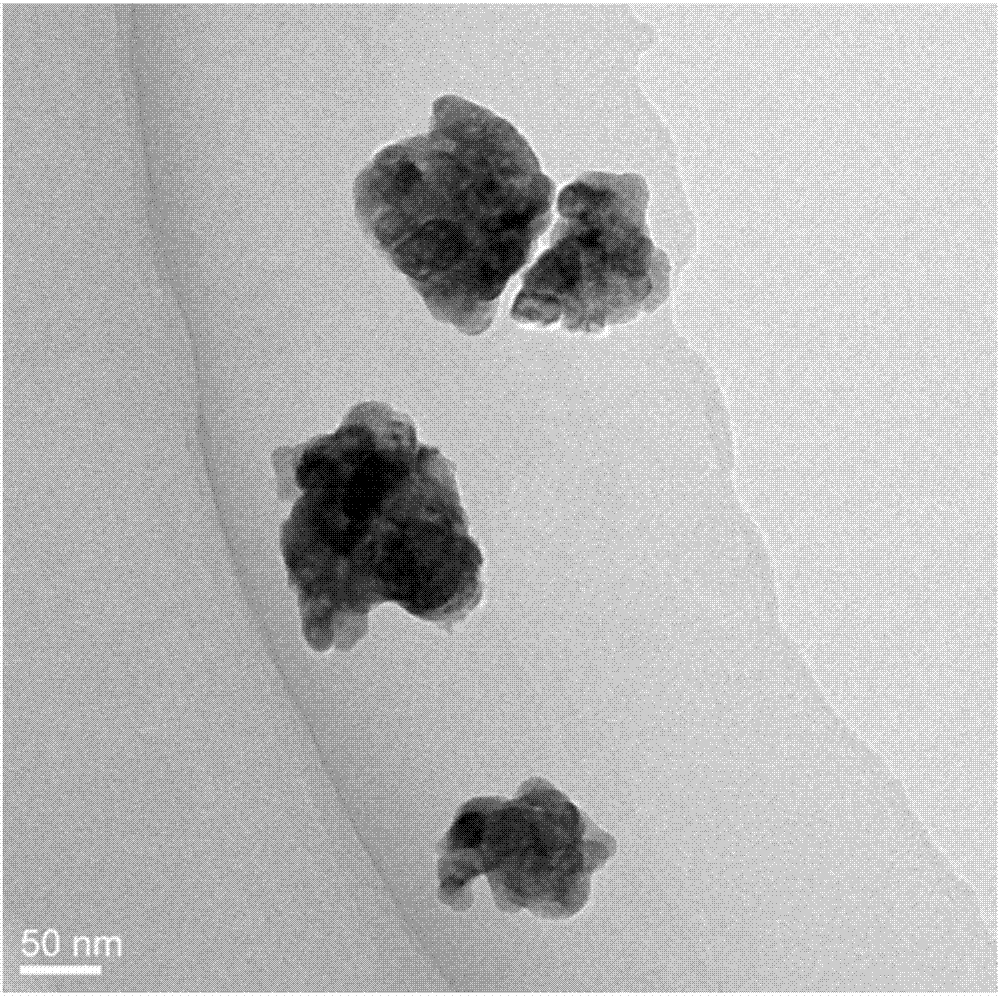

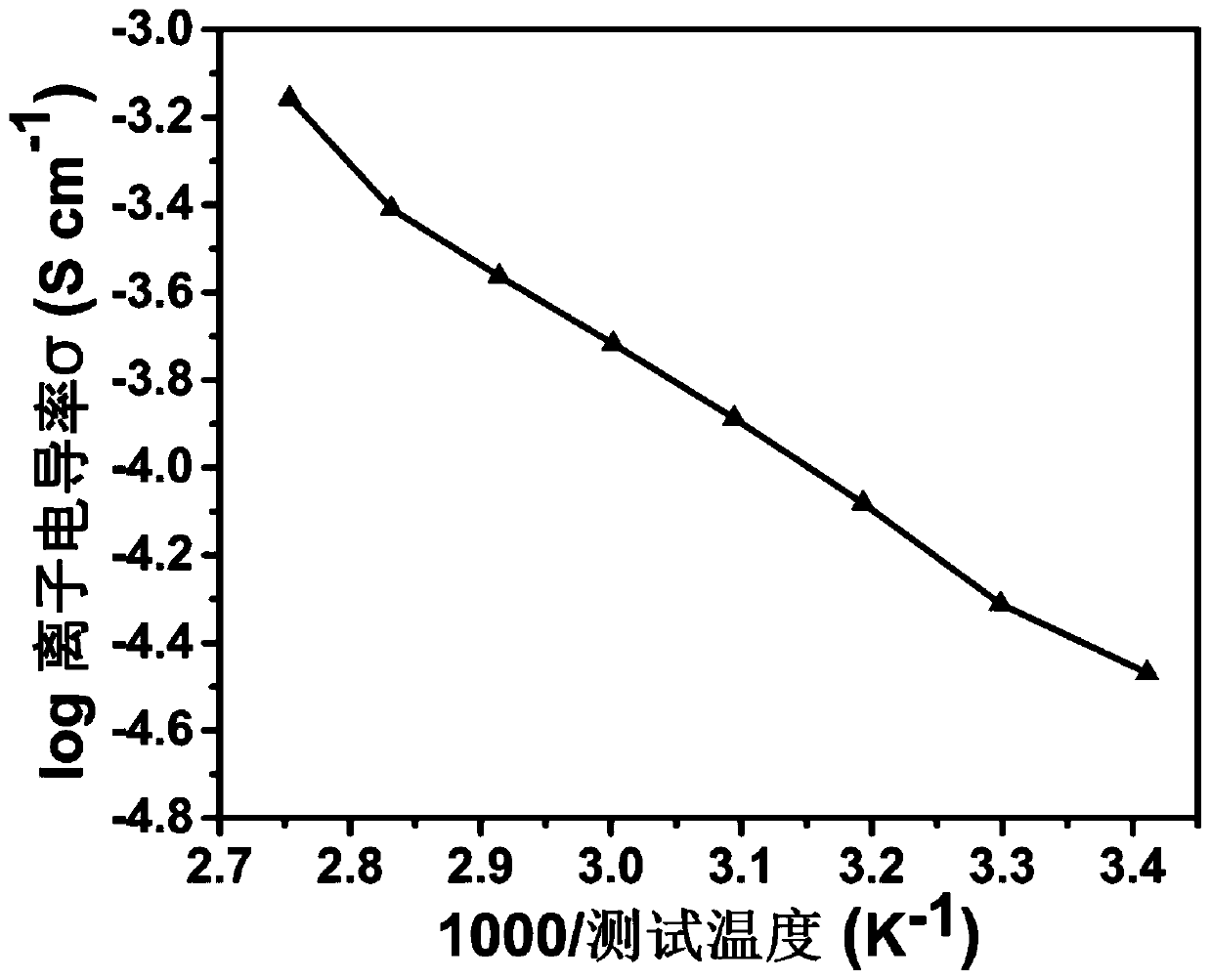

Method for preparing high dielectric, low-loss and insulating calcium copper titanate ceramics

ActiveCN101671174ASolve the problem of too much conductivitySuitable for industrial applicationsCeramic sinteringChemical reaction

The invention relates to a method for preparing high dielectric, low-loss and insulating calcium copper titanate ceramics, belonging to the technical field of high dielectric ceramic materials. The calcium copper titanate ceramics are prepared from initial raw materials of CaCO3 or CaO, CuO and TiO2, wherein after being mixed, the raw materials are processed by mix grinding and then processed by presintering at the temperature from 800 DEG C to 950 DEG C after mix grinding, hard blocks after presintering are cracked to be ground, and the powdered materials after presintering and grinding are prepared into green bodies with predetermined shapes; and the green bodies are heated to the sintering temperature ranging from 960 DEG C to 990 DEG C from room temperature, and heat preservation is carried out for 1 to 24 hours at the sintering temperature, thereby realizing the sintering densification of the ceramics. The preparation method controls performance parameters by controlling technological parameters, and structural changes and chemical reactions in a sintering process. The ceramic materials prepared by the method can meet the requirement on industrial application; and simultaneously, compared with the prior art, the preparation method can obviously reduce the energy consumption, is environment-friendly and reduces the production cost.

Owner:TSINGHUA UNIV

Preparation method of nano graphite powder/carbon nanofiber composite electrode for all-vanadium redox flow battery

InactiveCN104319405AIncrease roughnessImprove electrochemical activityCell electrodesCarbon fibersCarbon nanofiber

The invention relates to the field of battery manufacturing and energy source storage, in particular to a preparation method of a nano graphite powder / carbon nanofiber composite electrode for an all-vanadium redox flow battery. Firstly, a spinning solution required by an experiment is prepared, and then nano graphite powder with different particle sizes and the spinning solution are uniformly mixed. By an electrospinning technology, a required nanofiber membrane is prepared, and then is pre-oxidized in the air and is carbonized in an inert atmosphere tubular atmosphere furnace to obtain a required nano graphite powder / carbon nanofiber composite electrode. According to the all-vanadium redox flow battery composite electrode prepared by the method provided by the invention, the carbon fiber diameter is at the nanoscale, and the carbon fiber is compounded with nano graphite powder with high electrical conductivity, so that the roughness of the fiber is substantially increased, and thus the specific surface area of the electrode is two orders of magnitude larger than that of the conventionally used electrode material. Meanwhile, the high-activity nano graphite powder enables the electrochemical activity of the electrode to be improved, so that the energy efficiency of the all-vanadium redox flow battery is greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

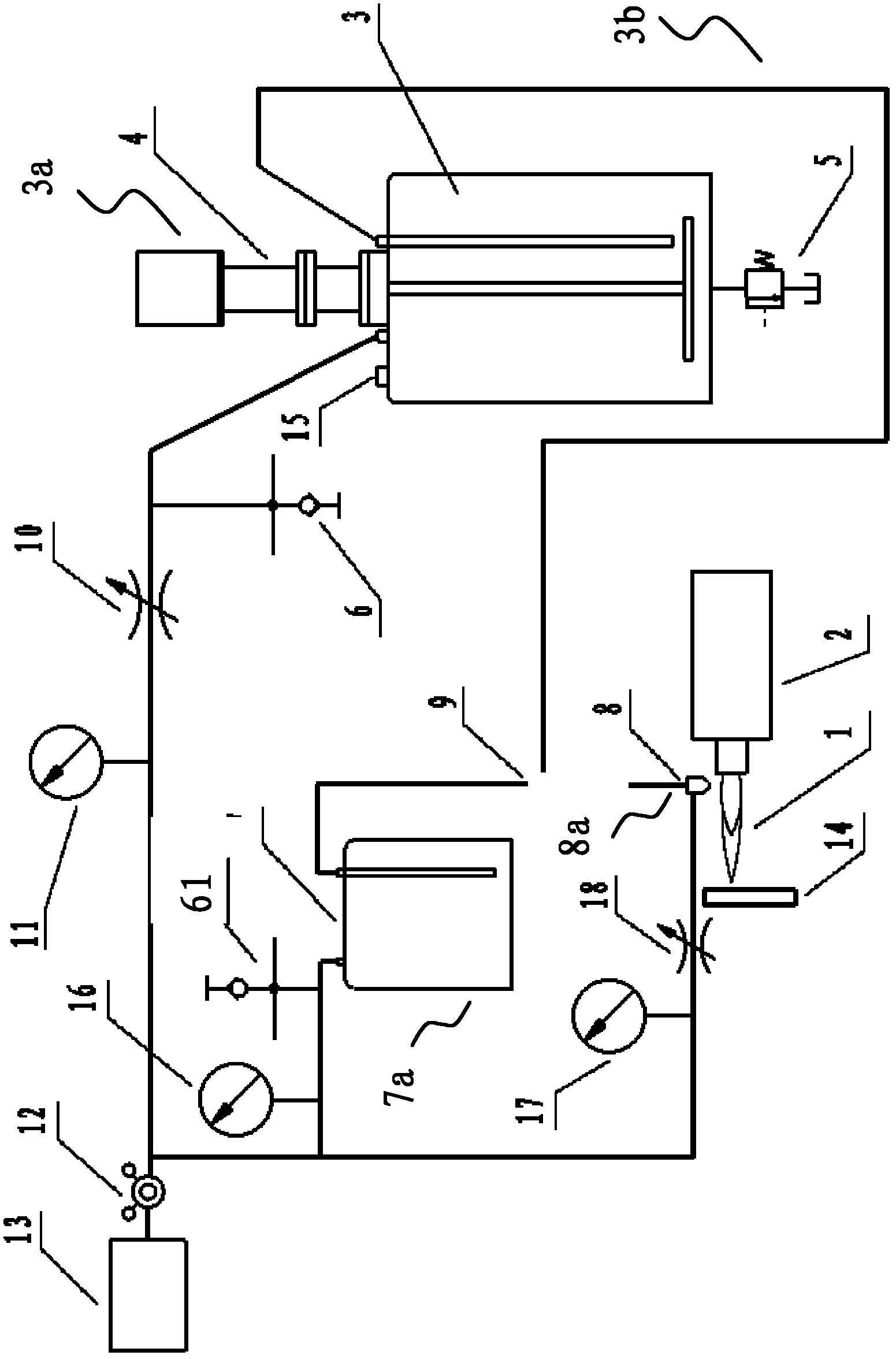

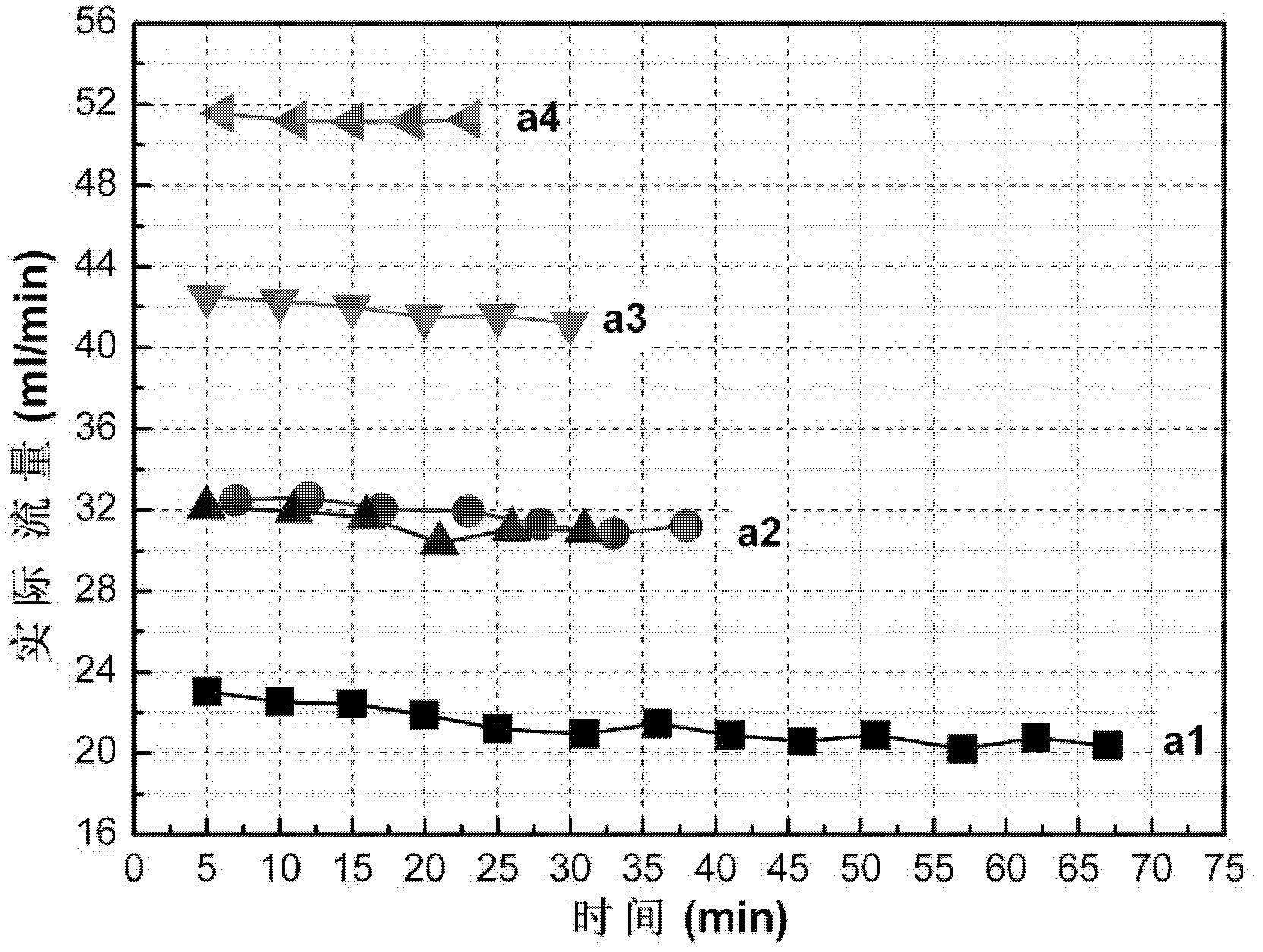

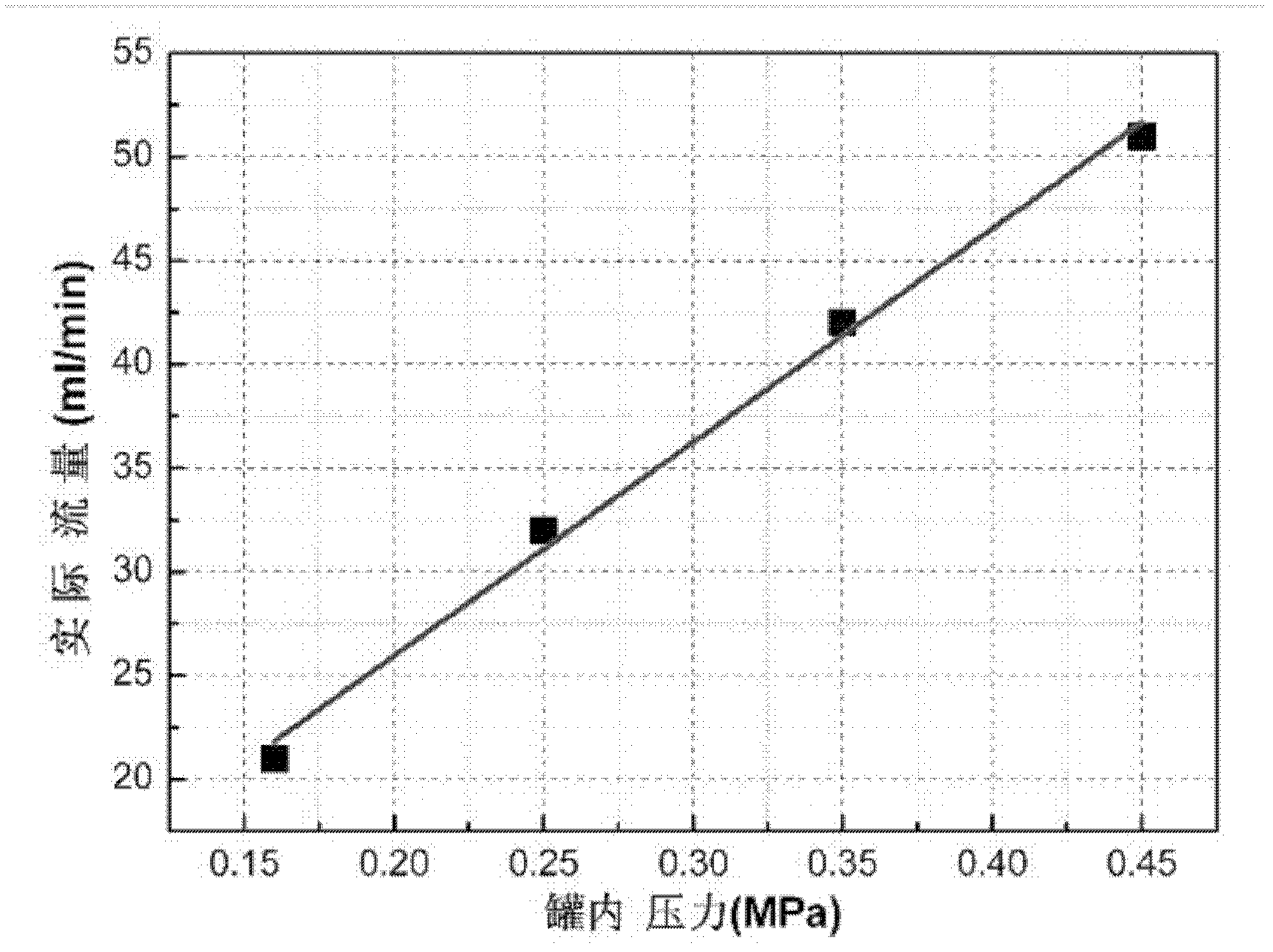

Liquid feedstock plasma spraying device

InactiveCN103031508AImprove production efficiencySkip powder preparationMolten spray coatingNanotechnologyPlasma jetNano structuring

The invention provides a liquid feedstock plasma spraying device, which is used for the preparation of a ceramic coating in a nano structure on a basal body. The liquid feedstock plasma spraying device comprises a plasma system and a liquid feedstock conveying device, wherein the liquid feedstock conveying device comprises a liquid feedstock conveying system and a liquid feedstock injection system; the liquid feedstock conveying system comprises a gas source and a liquid feedstock conveying power device; the liquid feedstock conveying power device is connected with the gas source; the liquid feedstock injection system comprises a two-fluid gas atomization spray nozzle; the two-fluid gas atomization spray nozzle is connected with the liquid feedstock conveying power device; meanwhile, the two-fluid gas atomization spray nozzle is arranged in a manner of corresponding to a high temperature area of plasma jet of the plasma system and further connected with the gas source; moreover, the two-fluid gas atomization spray nozzle atomizes a liquid feedstock in the liquid feedstock conveying power device into liquid drops with certain speed and further sends the liquid drops into the high temperature area of the plasma jet; and after being heated by the plasma jet to speed up, the liquid drops are deposited on the basal body for the formation of the ceramic coating in the nano structure.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

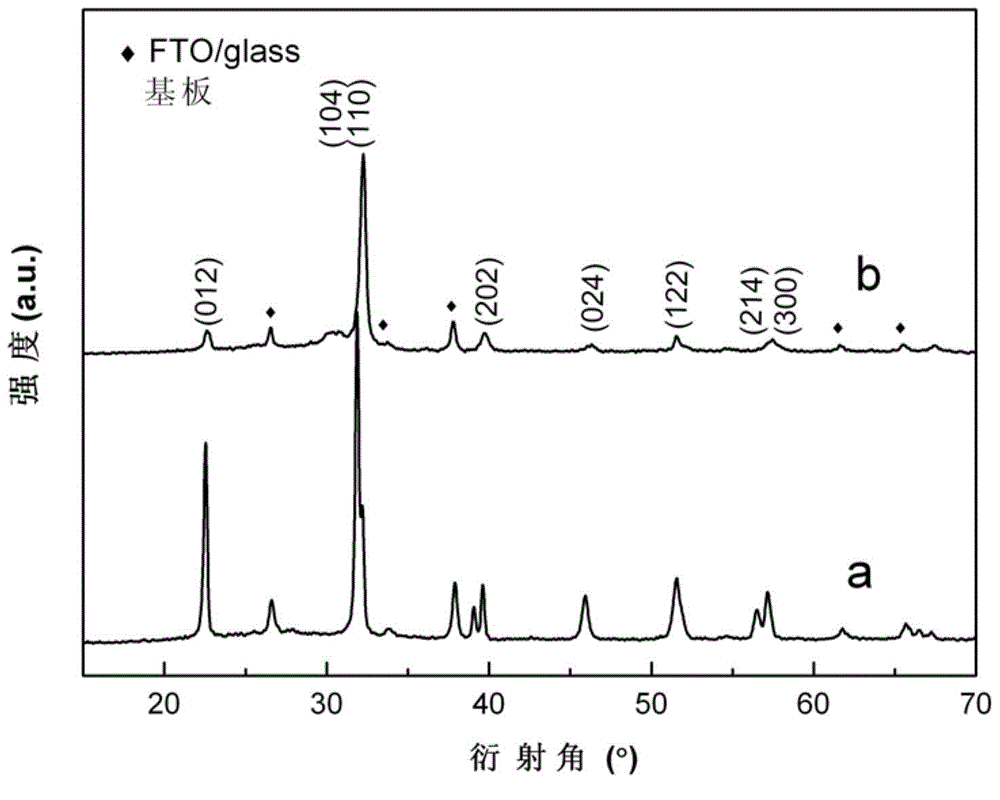

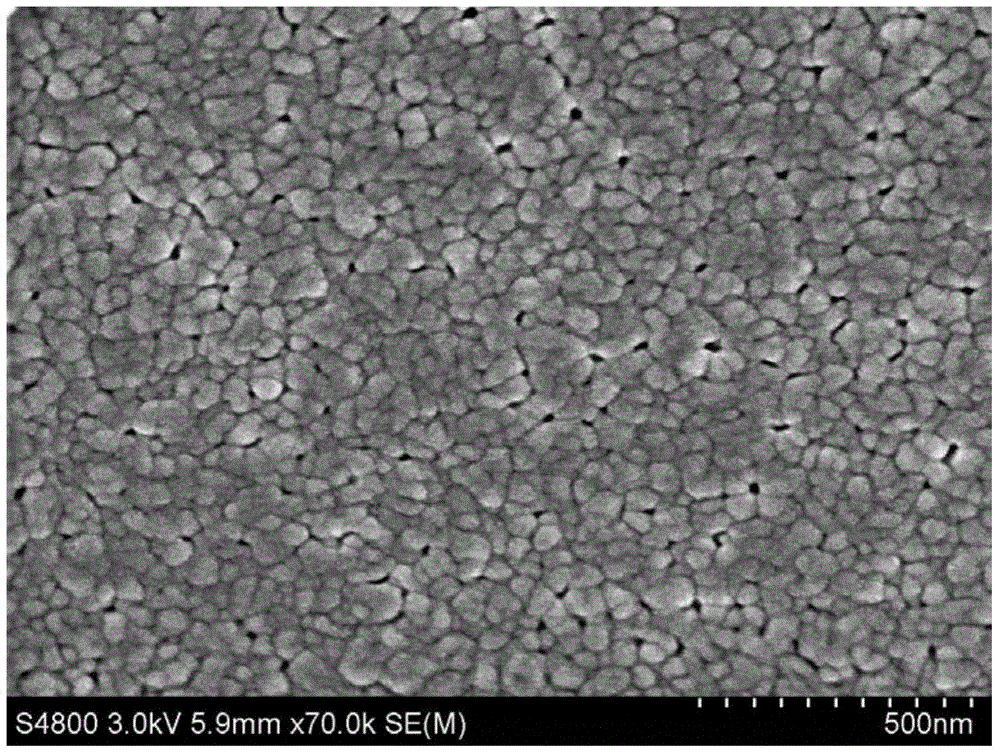

Layer-by-layer alternatively doped low-leakage-current BiFeO3 film and preparation method thereof

ActiveCN103601250AReduce generationImprove insulation performanceIron compoundsNitrateAcetic anhydride

The invention discloses a layer-by-layer alternatively doped low-leakage-current BiFeO3 film and a preparation method thereof. The preparation method comprises the steps of dissolving bismuth nitrate, ferric nitrate and nitric acid into mixed liquid of ethylene glycol monomethyl ether and acetic anhydride so as to obtain a precursor solution A; dissolving bismuth nitrate, ferric nitrate and samarium nitrate in mixed liquid of ethylene glycol monomethyl ether and acetic anhydride so as to obtain a precursor solution B; coating the precursor solution A on a FTO / glass substrate by way of spin coating, baking and annealing the FTO / glass substrate so as to obtain a Tb doped crystalline BiFeO3 film, coating the precursor solution B on the Tb doped crystalline BiFeO3 film by way of spin coating, baking and annealing the Tb doped crystalline BiFeO3 film so as to obtain a Sm doped crystalline BiFeO3 film, and alternatively preparing the Tb doped crystalline BiFeO3 film and the Sm doped crystalline BiFeO3 film on the Sm doped crystalline BiFeO3 film so as to obtain the layer-by-layer alternatively doped low-leakage-current BiFeO3 film. The method disclosed by the invention adopts a sol-gel process, and is simple in equipment requirements and suitable for preparing films on large surfaces and irregularly-shaped surfaces, and chemical components are precise and controllable.

Owner:盐城市鹤业实业投资有限公司

Preparation method of loose zirconium hydroxide or zirconium oxide nano powder

The invention relates to a preparation method of a loose zirconium hydroxide or zirconium oxide nano powder, and belongs to the field of inorganic nano powder preparation. The preparation method comprises the steps of preparing a precipitant A solution and a precipitant B solution which have different pH (potential of hydrogen) values, adding a zirconium salt solution to the precipitant A solution at a certain flow rate, keeping the flow rate of the zirconium salt solution and simultaneously adding the precipitant B solution to the precipitant A solution at a certain flow rate after the solution becomes clarified from turbid, ageing, filtering, cleaning and drying to obtain the loose zirconium hydroxide nano powder, and then performing roasting and cooling to obtain the zirconium oxide nano powder. Zirconium hydroxide precursor slurry prepared by the method has no colloidality and is easy to filter; the dried zirconium hydroxide nano powder has no hard aggregation; the zirconium oxide powder generated after the roasting reaches a nanoscale; the particle size is 60-100nm; a pattern is regular; the distribution is narrow; the cleaning is easy; a ball milling process is not required; technological operation is simple and convenient; an equipment requirement is low; the preparation method is suitable for large-scale industrial production.

Owner:GUOBIAO BEIJING TESTING & CERTIFICATION CO LTD

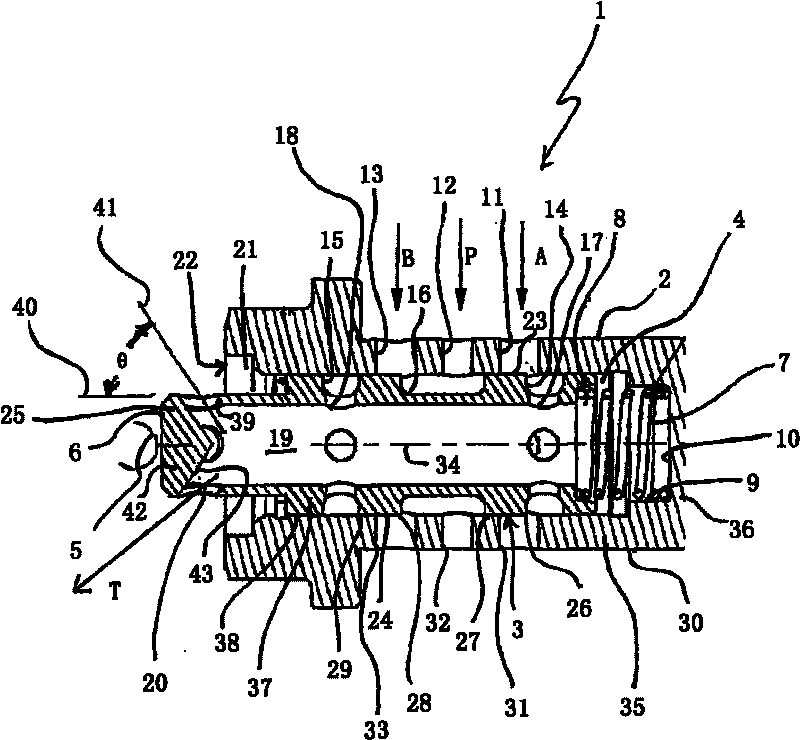

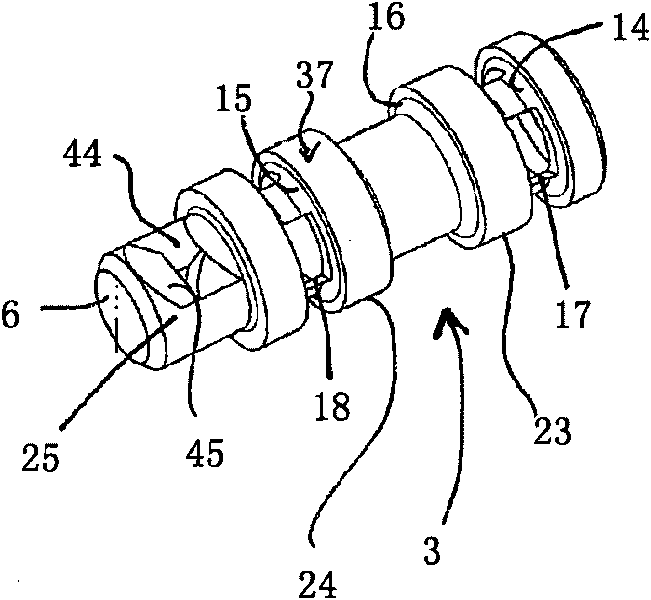

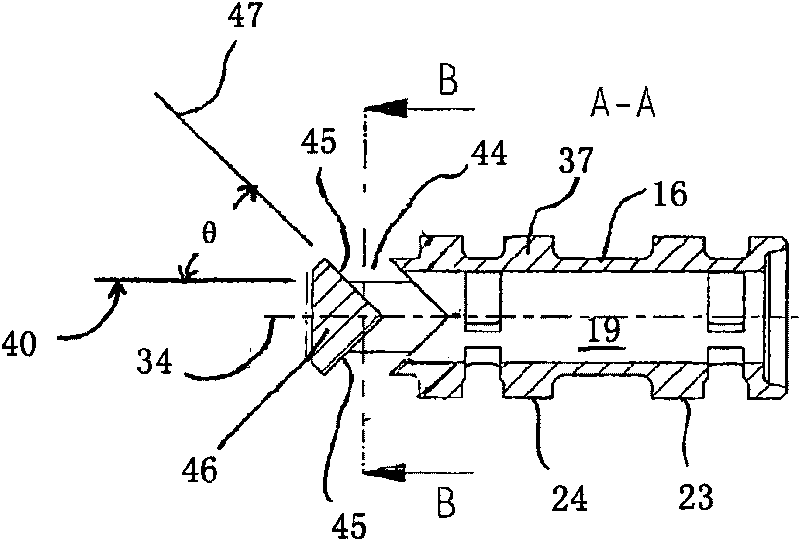

Valve part for a control valve for control of pressure medium flows

ActiveCN101755154AReduce shock pressureReduce formationMultiple way valvesMachines/enginesAxial displacementEngineering

The invention relates to a valve part for a control valve for control of pressure medium flows, comprising a cylindrical valve housing (2) with a first cylinder sleeve section (35) running in the axial direction and a first cylinder base section running perpendicular to the axial direction, defining a valve housing chamber (4) open at one end, wherein the first cylinder sleeve section is provided with a first working connector (A), a second working connector (B) and a pressure connector (P) which each open out in the valve housing chamber and a cylindrical control piston (3) housed in the valve housing chamber such a as to move axially with a second cylinder sleeve section running in the axial direction and a second cylinder base section running perpendicular to the axial direction, defining a control piston chamber which is open to one side, wherein the second cylinder sleeve section, adjacent to the second cylinder base section is provided with a radial outer connection (T) opening in the control piston chamber and the control piston is designed such that the working connections may be made with a fluid connection to pressure connector and the outlet connector by axial displacement of the control piston. The valve part is characterised in that the outlet connection of the control piston has at least one inclined opening, the wall direction of which has an angle of less than 90 DEG to the axial direction.

Owner:SCHAEFFLER TECH AG & CO KG

Self-healing composite polymer electrolyte and preparation thereof, and application thereof

InactiveCN110148780AImprove electrochemical performanceGrowth inhibitionSecondary cellsSilica nanoparticlesSelf-healing

The invention belongs to the technical field of polymer electrolytes and discloses a self-healing composite polymer electrolyte, preparation thereof, and application thereof. The polymer electrolyte is mainly formed by the composition of surface-functionalized nanoparticles and a self-healing polymer matrix with the mass ratio of 1 / 49 to 2 / 5. According to the invention, by improving the composition of key composite components in a composite polymer electrolyte, an overall corresponding microstructure of the composite and the design of the overall process flow of the preparation method, the self-healing composite polymer electrolyte with excellent performance can be obtained by using a supramolecular network constructed by UPy functionalized silica nanoparticles and the self-healing polymermatrix, compared with the prior art, the dispersion of the nanoparticles in the matrix is better, and the electrochemical performance, mechanical performance, self-healing efficiency of the composite polymer electrolyte can be effectively improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com