Preparation method of nano-fibrous silk fibroin-based porous scaffold

A technology of silk fibroin and nanofibers, applied in medical science, prostheses, etc., can solve the problems of lack of nanofiber structure, limitations of tissue engineering scaffold materials for tissue repair, difficulty in forming porous structures, etc., and achieve the goal of improving interaction degree, prolonging the resting time, and improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

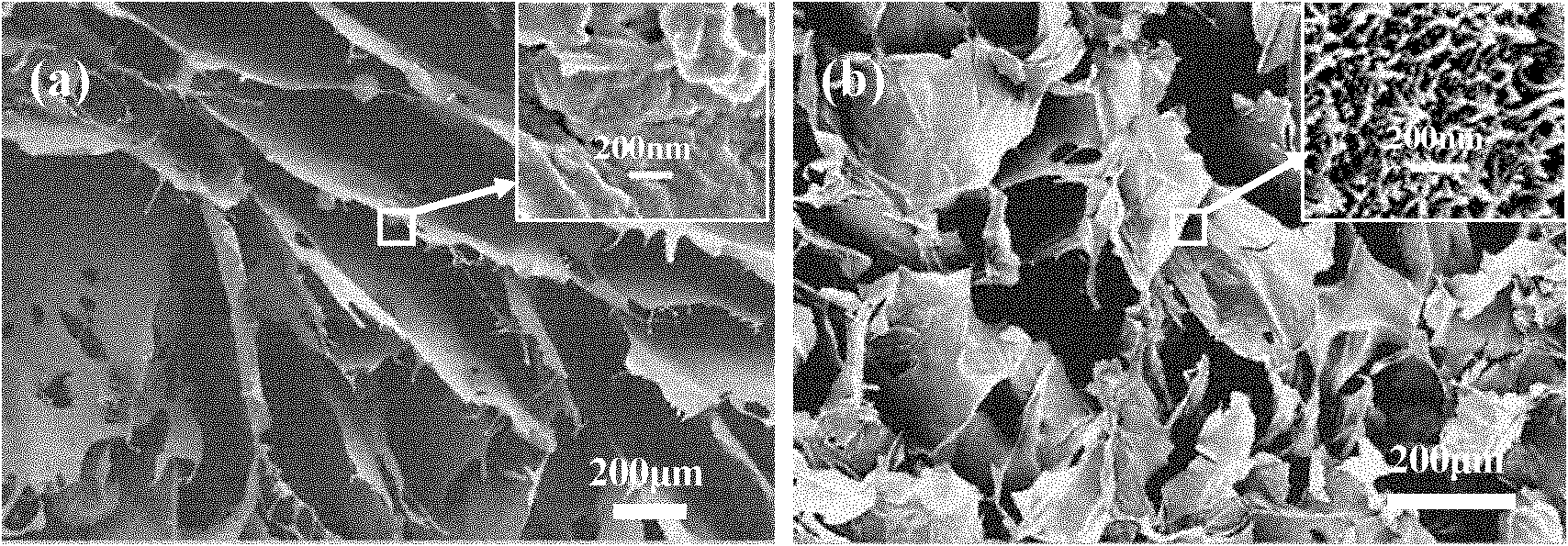

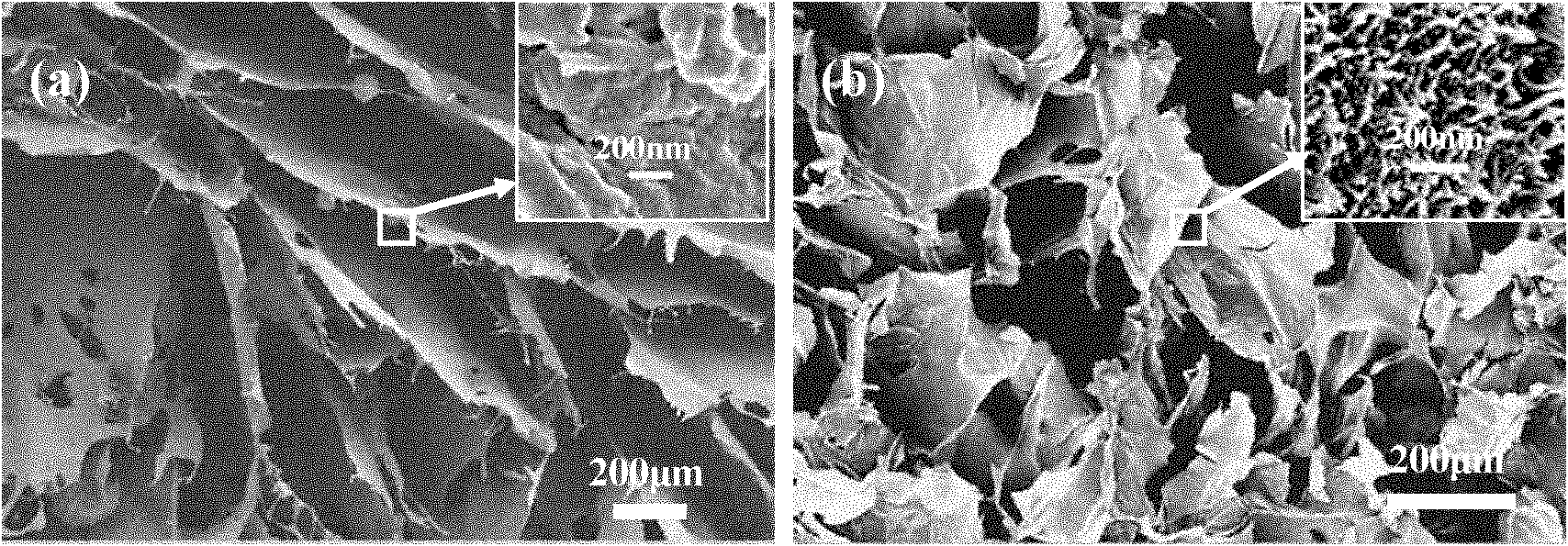

Embodiment 1

[0033] The preparation steps of the silk fibroin porous scaffold provided in this embodiment are as follows:

[0034] 1) Add 5 grams of silkworm cocoons into 2 liters of 0.5% sodium carbonate solution, treat at 98-100°C for 40 minutes, remove the external sericin, and obtain pure silk fibroin after washing thoroughly. The dried silk fibroin is dissolved in a 9.3 mol / liter lithium bromide solution at about 60° C. to obtain a silk fibroin mixed solution.

[0035] 2) Add the silk fibroin mixed solution into the cellulose dialysis membrane, and perform dialysis with deionized water to remove lithium bromide to obtain a pure silk fibroin aqueous solution.

[0036] 3) Adjust the concentration of silk fibroin to 1%, and place it at 4°C for 1 hour to stabilize the temperature of the solution at 4°C.

[0037]4) Dilute the collagen solution to 0.075%, and place it at 4°C for 1 hour to stabilize the solution temperature at 4°C.

[0038] 5) Blend the same volume of silk fibroin solution...

Embodiment 2

[0045] Add 5 grams of silkworm cocoons into 2 liters of sodium carbonate solution with a mass concentration of 0.5%, and treat them at 98-100°C for 40 minutes to remove the external sericin, and obtain pure silk fibroin after fully washing. The dried silk fibroin is dissolved in a 9.3 mol / liter lithium bromide solution at about 60° C. to obtain a silk fibroin mixed solution.

[0046] The silk fibroin mixed solution is added to the cellulose dialysis membrane, and deionized water is used for dialysis to remove lithium bromide to obtain a pure silk fibroin aqueous solution.

[0047] Place the silk fibroin solution at 60°C for 24 hours, then adjust the concentration of silk fibroin to 2%, and place it at 4°C for 1 hour to stabilize the temperature of the solution at 4°C.

[0048] Dilute the collagen solution to 0.2%, and place it at 4°C for 1 hour to stabilize the temperature of the solution at 4°C.

[0049] Under the condition of 4°C, the same volume of silk fibroin solution an...

Embodiment 3

[0054] Add 5 grams of silkworm cocoons into 2 liters of sodium carbonate solution with a mass concentration of 0.5%, and treat them at 98-100°C for 40 minutes to remove the external sericin, and obtain pure silk fibroin after fully washing. The dried silk fibroin is dissolved in a 9.3 mol / liter lithium bromide solution at about 60° C. to obtain a silk fibroin mixed solution.

[0055] The silk fibroin mixed solution is added to the cellulose dialysis membrane, and deionized water is used for dialysis to remove lithium bromide to obtain a pure silk fibroin aqueous solution.

[0056] Place the silk fibroin solution at 60°C for 24 hours, then adjust the concentration of silk fibroin to 1%, and place it at 4°C for 1 hour to stabilize the temperature of the solution at 4°C.

[0057] Dilute the collagen solution to 0.075%, and place it at 4°C for 1 hour to stabilize the solution temperature at 4°C.

[0058] Under the condition of 4°C, the same volume of silk fibroin solution and col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com