Patents

Literature

105results about How to "Extend the rest time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

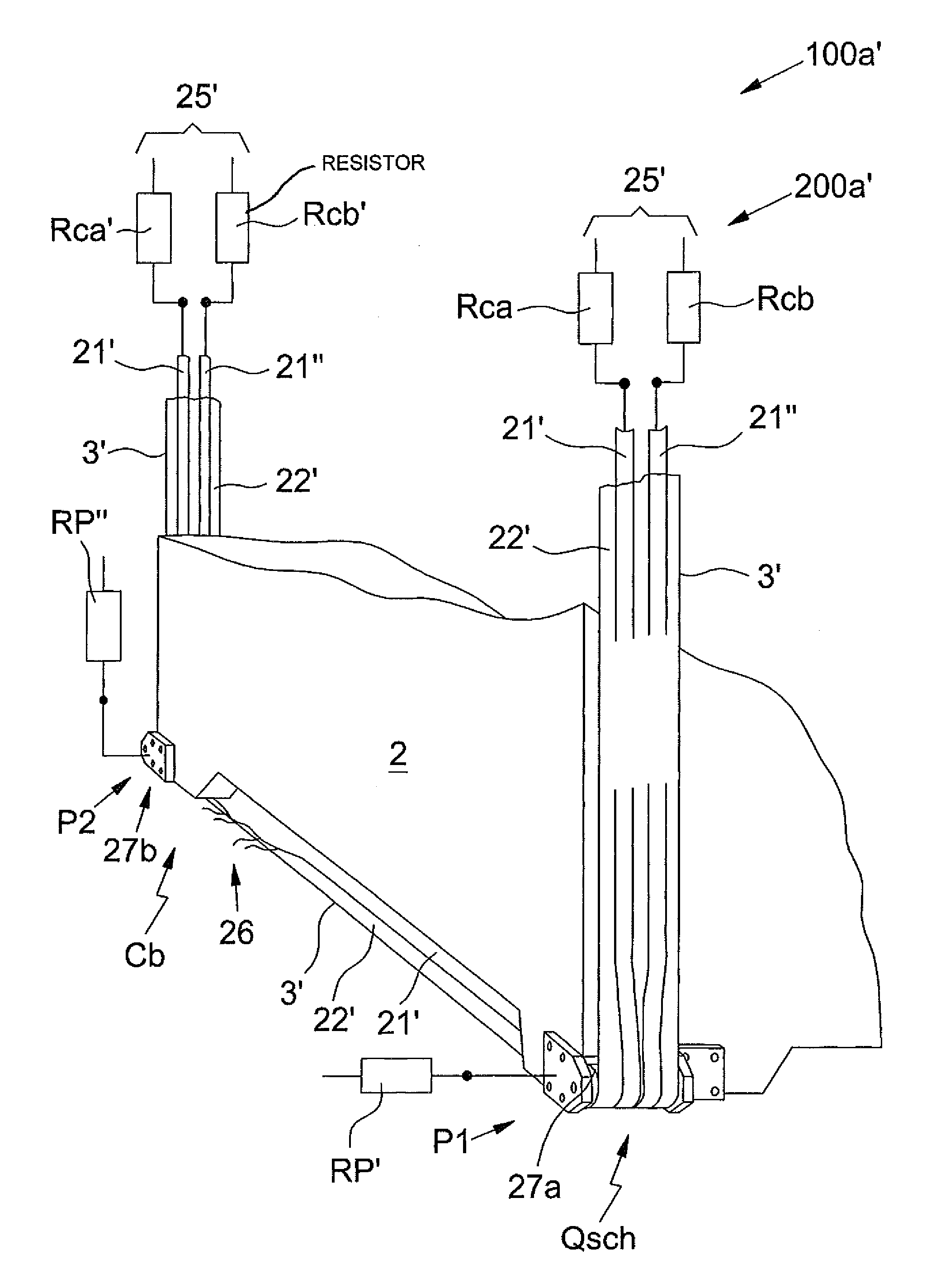

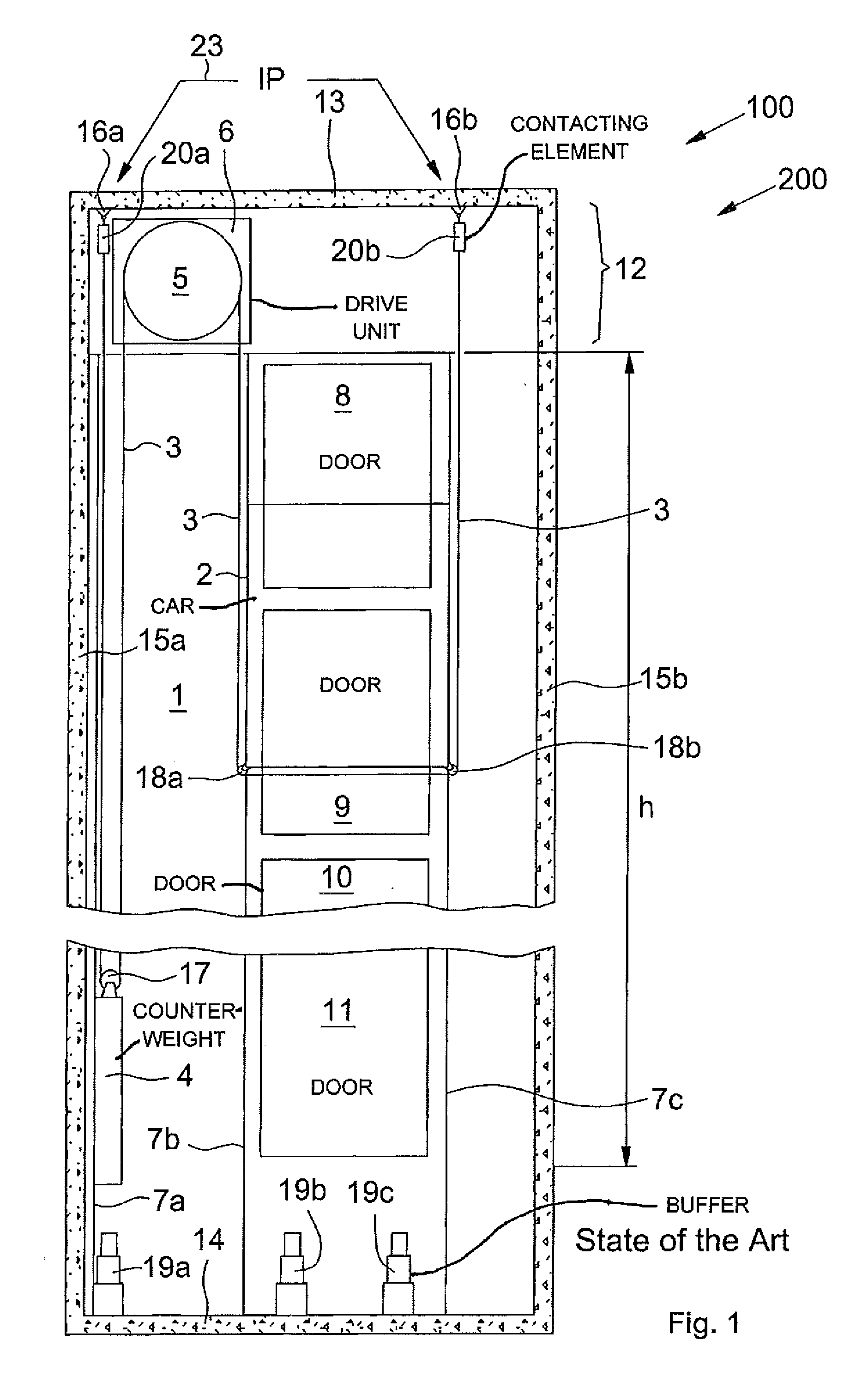

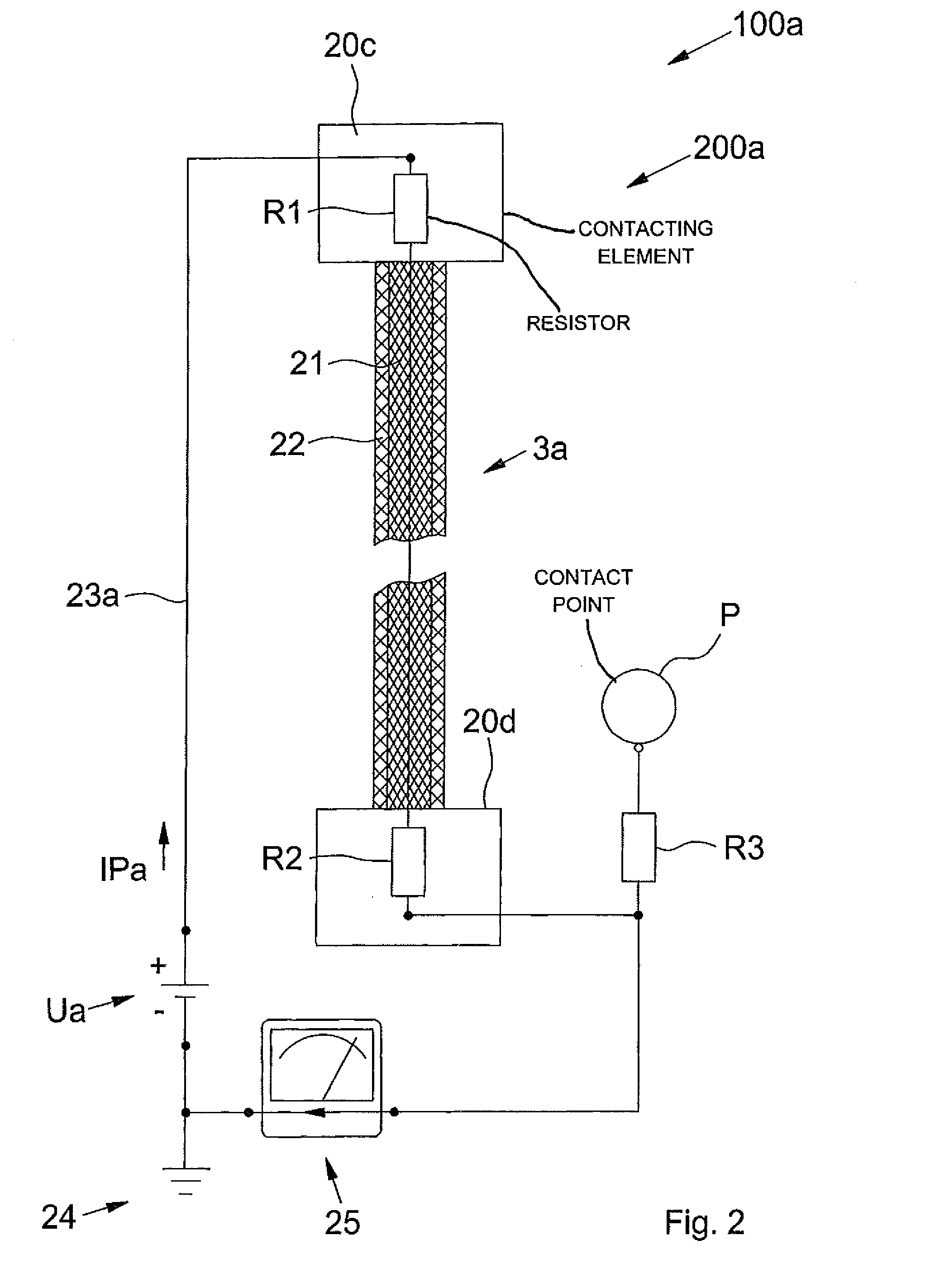

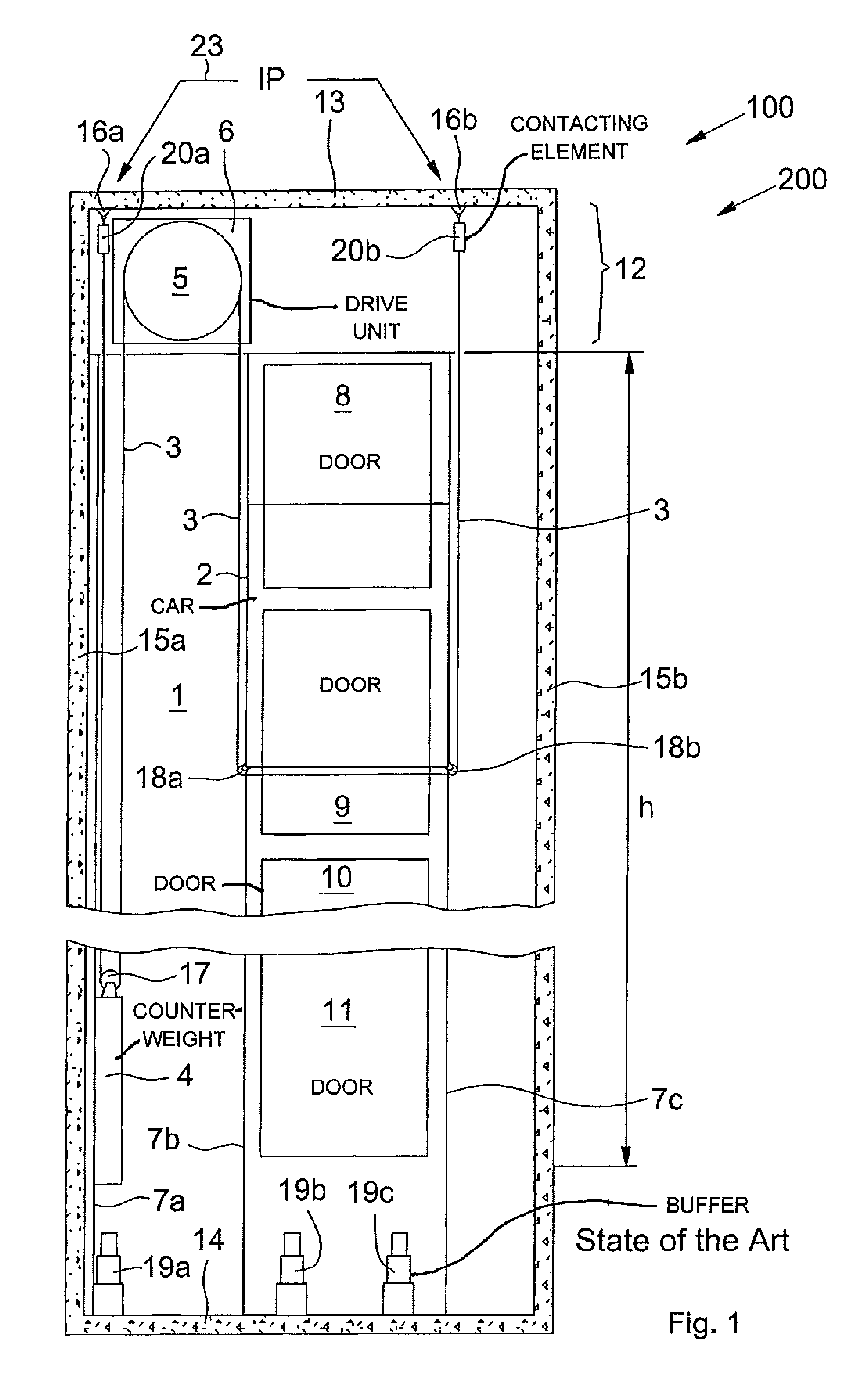

Monitoring a suspension and traction means of an elevator system

ActiveUS20110148442A1Improve security levelAvoiding cost-intensive excessively early replacementsResistance/reactance/impedenceElevatorsElectrical resistance and conductanceElevator system

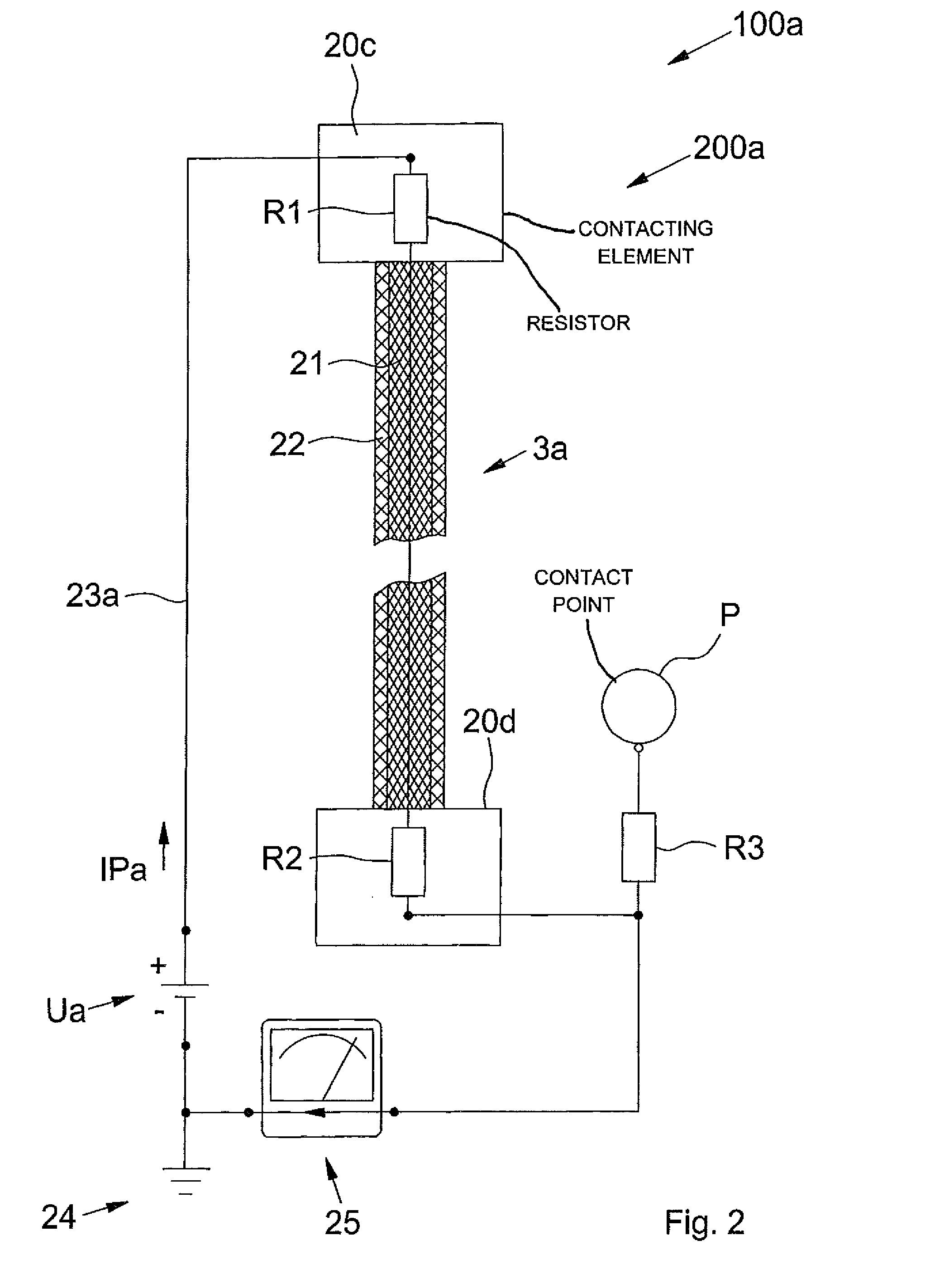

A monitoring device for a suspension-and-traction apparatus of an elevator system that includes at least one electrically conductive cord contains a measurement apparatus for determining a resulting resistance. The measurement apparatus is connected to the cord with contacting elements contacting opposite ends of cord. Damage to the suspension-and-traction apparatus is detected by a contact point that can register protruding conductive parts of the cord and, in another embodiment, the contacting elements each contain a plurality of mutually differing resistance elements such that each of at least two electrically conductive cords of the suspension-and-traction apparatus is connected to the monitoring device through two of the resistance elements.

Owner:INVENTIO AG

Repairing road surfaces

Owner:HER MAJESTY THE QUEEN & RIGHT OF THE PROVINCE OF SASKATCHEWAN

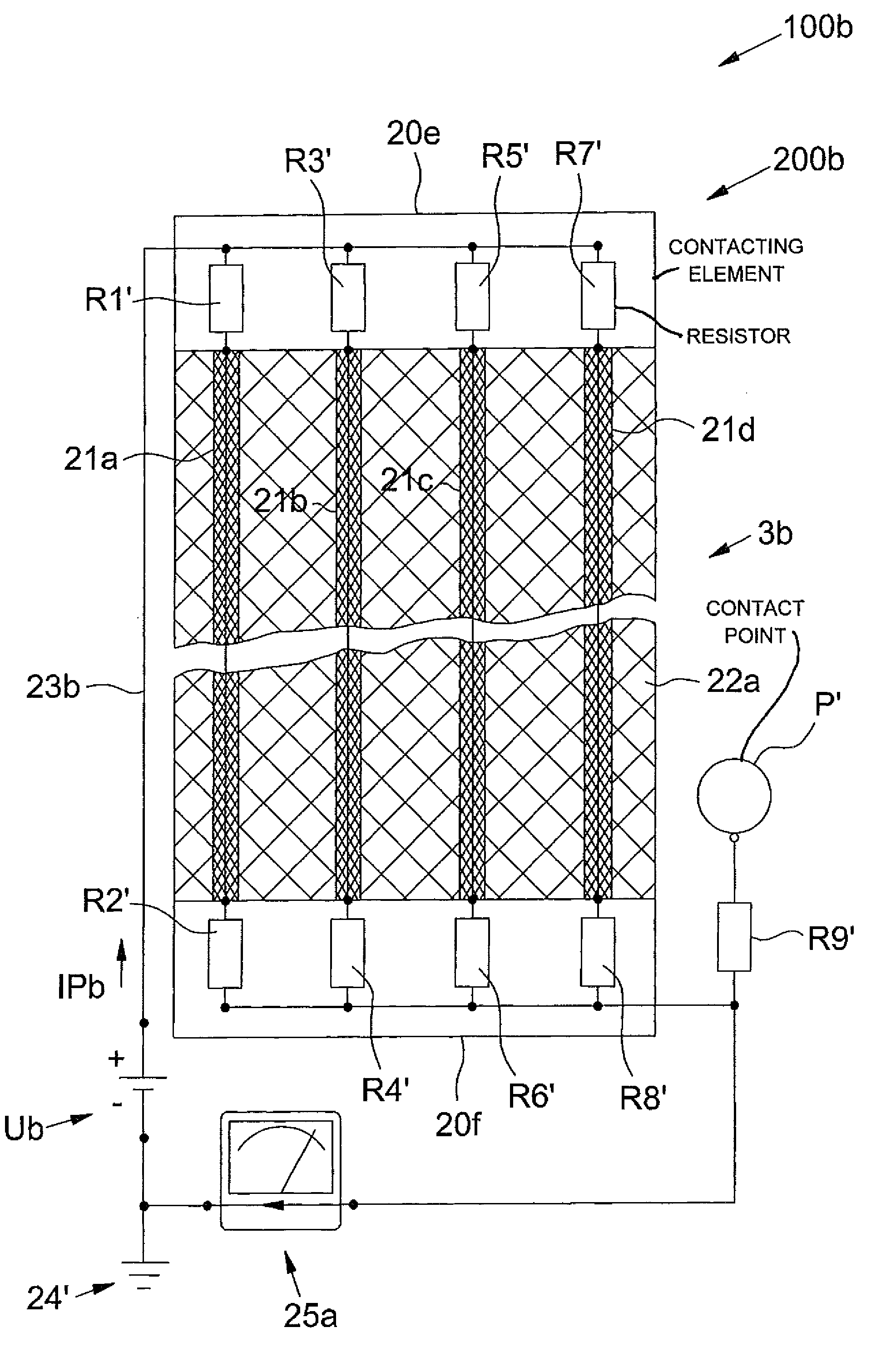

Monitoring a suspension and traction means of an elevator system

ActiveUS8686747B2Improve security levelAvoiding cost-intensive excessively early replacementsResistance/reactance/impedenceElevatorsElectrical resistance and conductanceElevator system

A monitoring device for a suspension-and-traction apparatus of an elevator system that includes at least one electrically conductive cord contains a measurement apparatus for determining a resulting resistance. The measurement apparatus is connected to the cord with contacting elements contacting opposite ends of cord. Damage to the suspension-and-traction apparatus is detected by a contact point that can register protruding conductive parts of the cord and, in another embodiment, the contacting elements each contain a plurality of mutually differing resistance elements such that each of at least two electrically conductive cords of the suspension-and-traction apparatus is connected to the monitoring device through two of the resistance elements.

Owner:INVENTIO AG

Spark plug

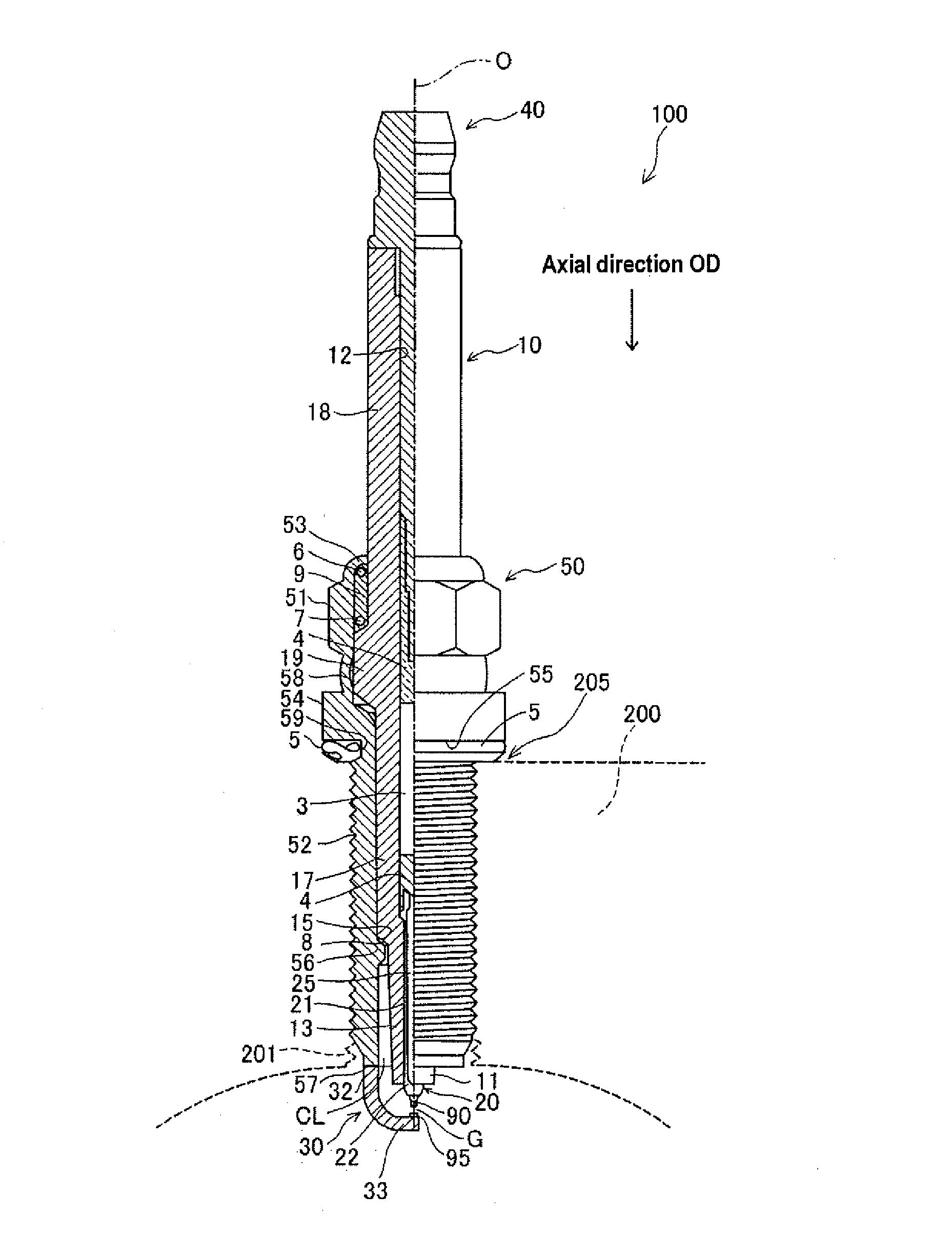

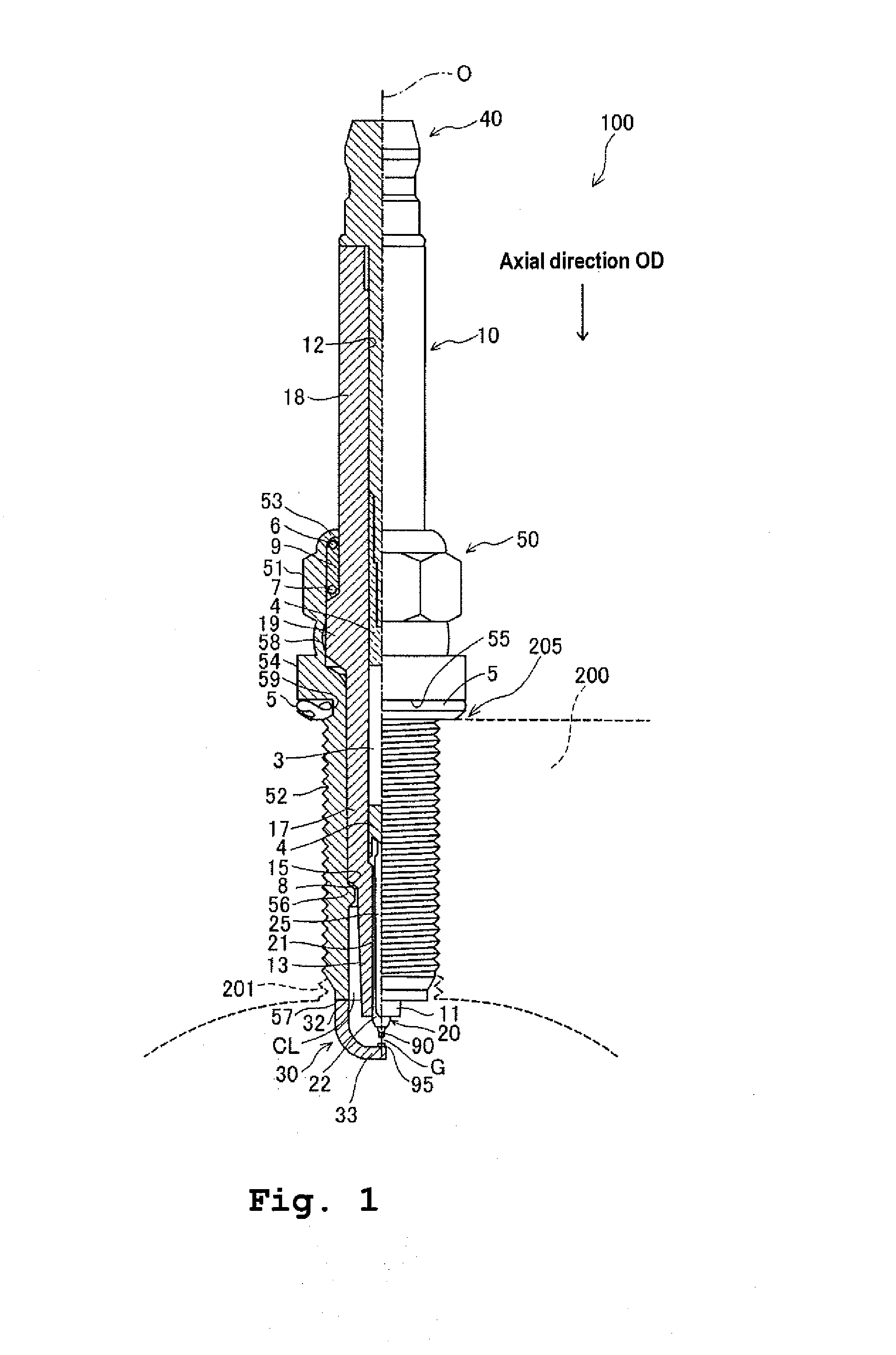

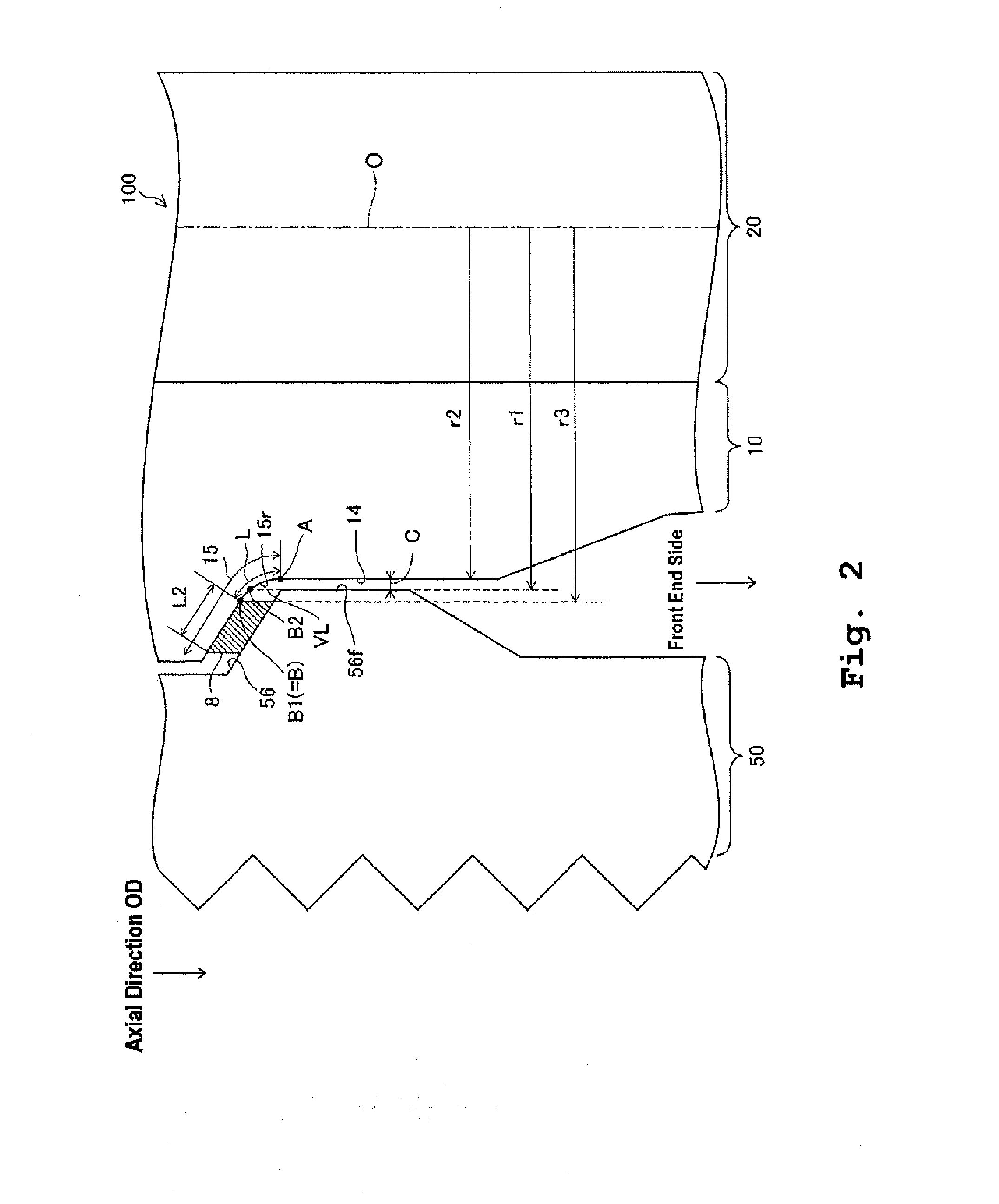

ActiveUS20130015756A1Improve fracture resistanceExtend the rest timeSparking plugsSpark plugCross point

A spark plug having an insulator with improved breakage resistance. The spark plug has a cross-section that satisfies the following relationship: 0.6 mm<=L, where “A” represents a connection point between a support portion of the insulator and an insulator trunk portion formed at a front end side with respect to the support portion, where “B” represents a position closer to the outer circumference side among the positions of (a) an innermost position of a contact portion where the support portion and a packing are in contact with each other and (b) an intersection of the support portion and a virtual straight line that is parallel to an axial line of the spark plug and extends from an innermost circumferential end of a stepped portion of a metal shell, and where “L” represents a length of a path from point “A” to point “B” along a surface of the insulator.

Owner:NGK SPARK PLUG CO LTD

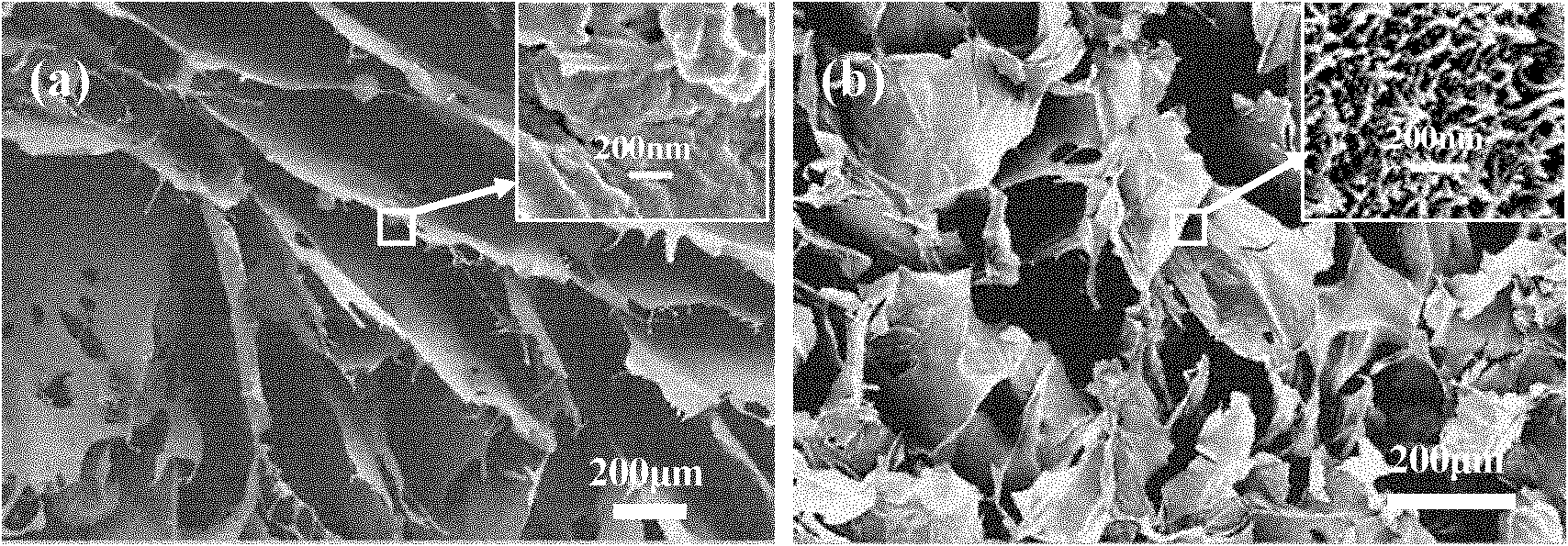

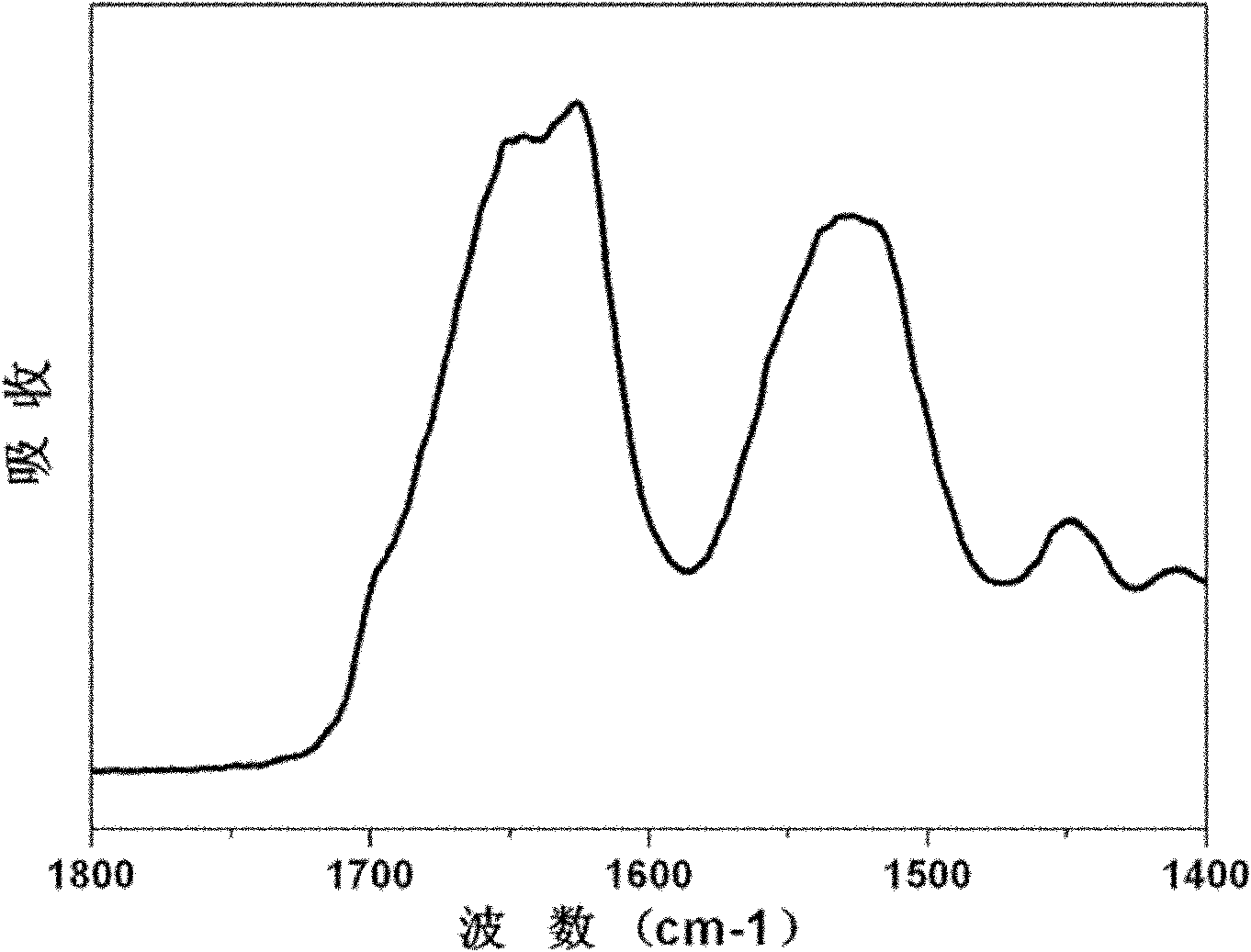

Preparation method of nano-fibrous silk fibroin-based porous scaffold

InactiveCN102008756APromote formationDegradation controllableProsthesisFiberCell-Extracellular Matrix

The invention relates to a preparation method of a porous scaffold material and discloses a preparation method of a nano-fibrous silk fibroin-based porous scaffold. The preparation method comprises the following steps: blending a silk fibroin solution and a collagen solution under the temperature of 0-20 DEG C, standing to ensure the complete reaction of collagen and silk fibroin and generate nano-fiber; freezing the mixed solution to obtain a freezing body; performing freeze drying treatment on the freezing body to obtain a nano-fibrous porous scaffold material; and placing the nano-fibrous porous scaffold material in a vacuum drier with water and methanol, or an ethanol aqueous solution at the bottom, vacuumizing, and then standing to obtain the water-insoluble nano-fibrous porous scaffold. The obtained porous scaffold has 10-1000 microns of communicated pores. The pore walls consist of 10-100nm of nano-fibers; and the porous scaffold has similar nanoscale structures and micronscalestructures to extracellular matrix, is suitable for the adhesion and growth of cells and has good biocompatibility.

Owner:SUZHOU UNIV +1

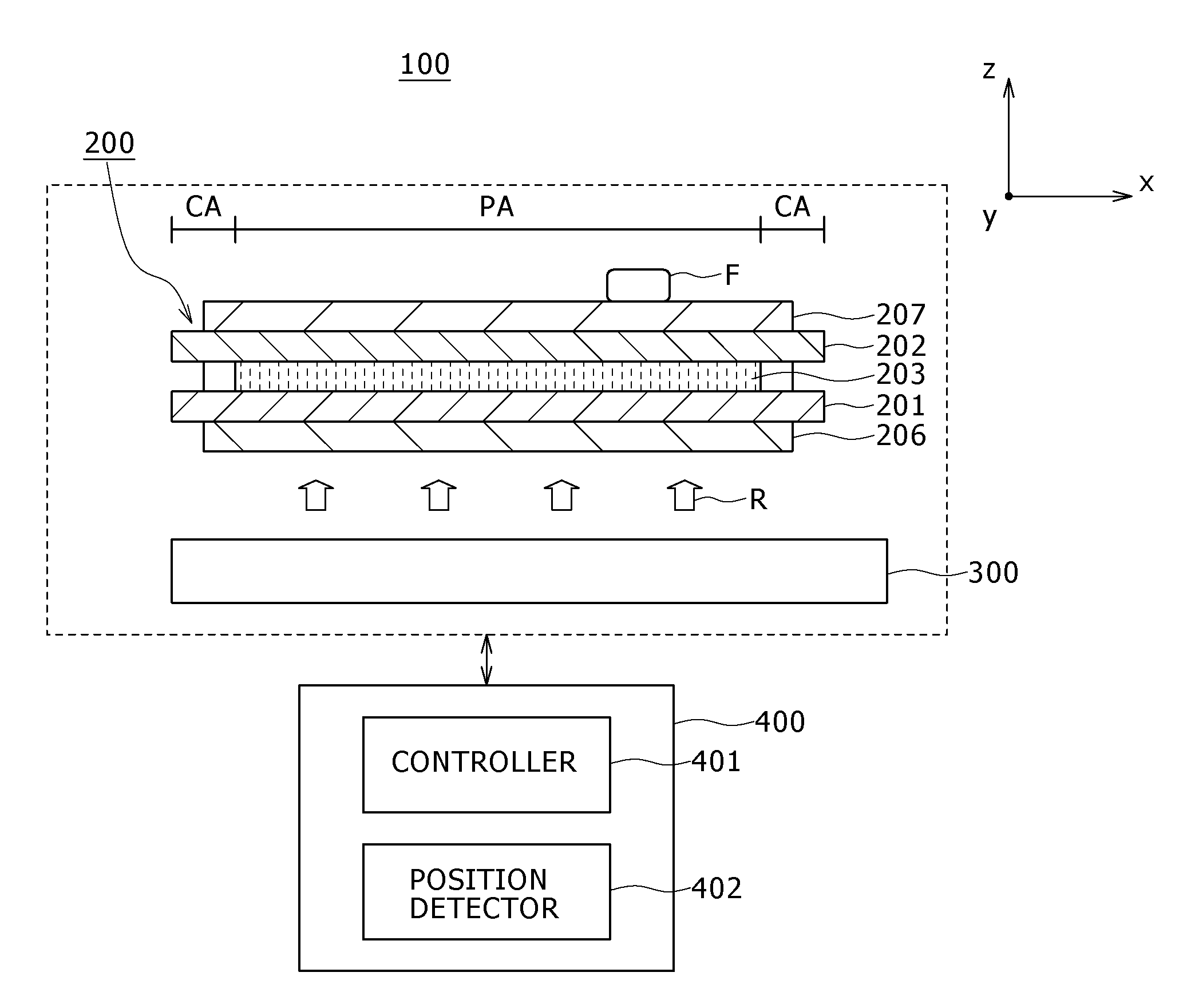

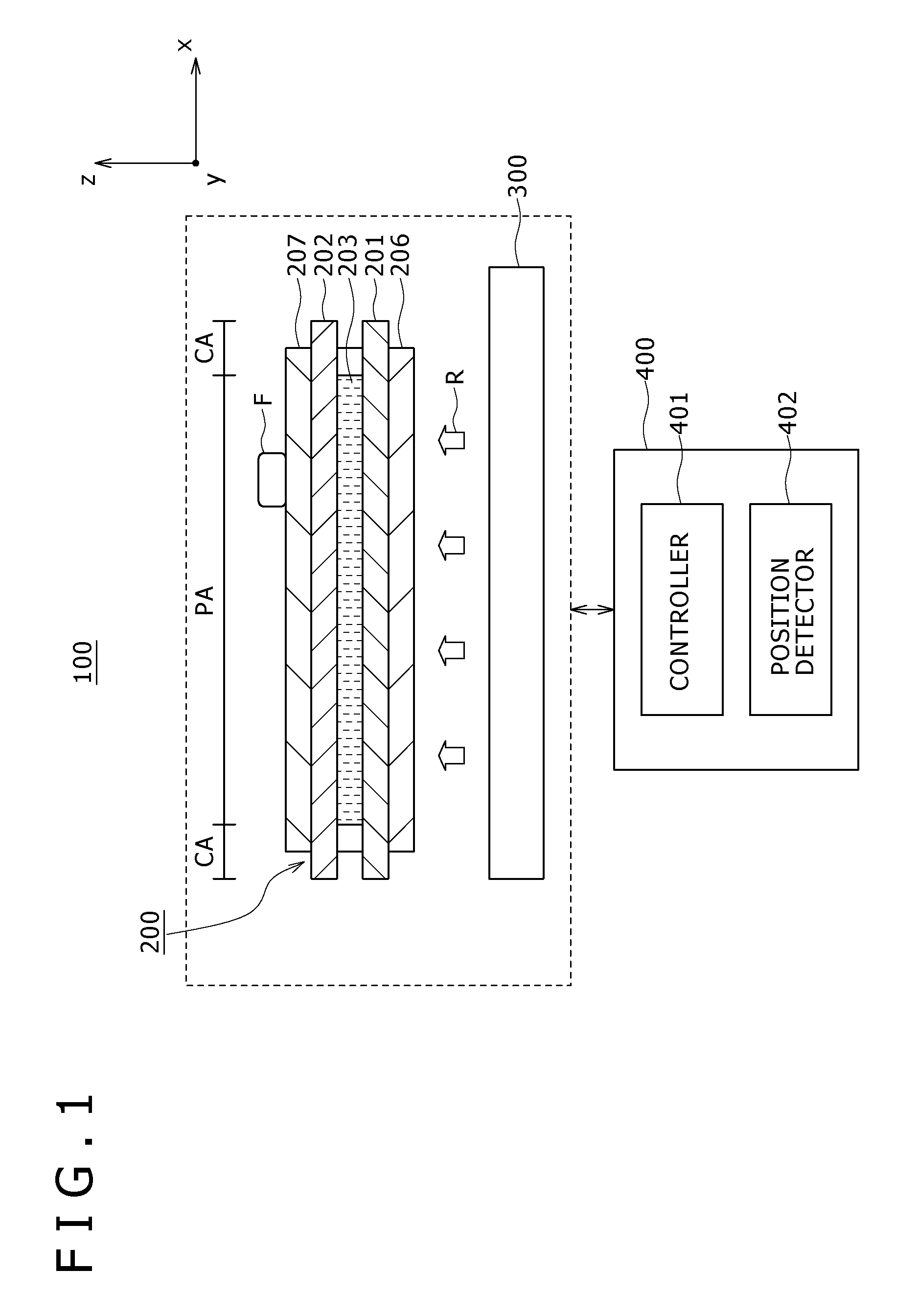

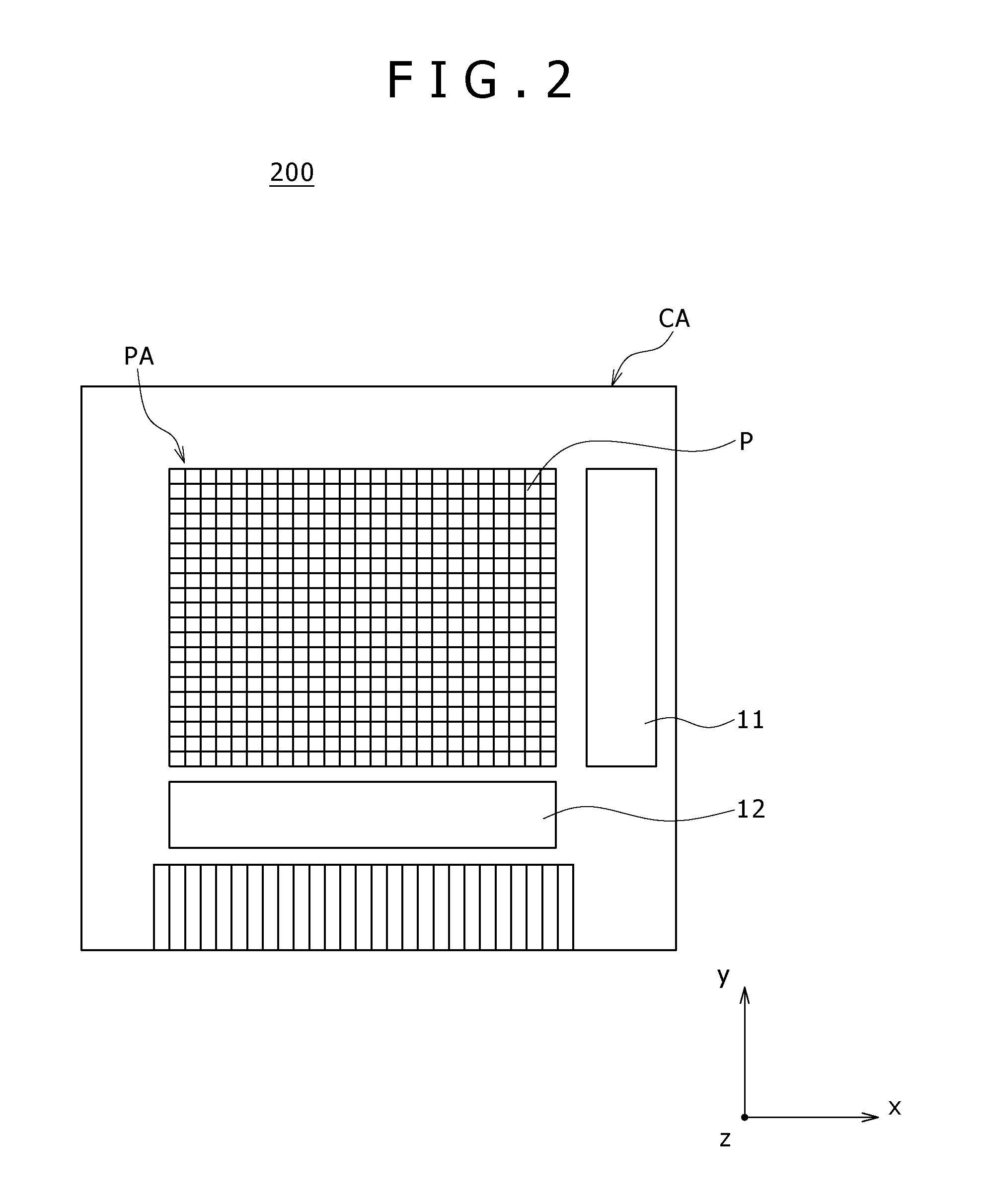

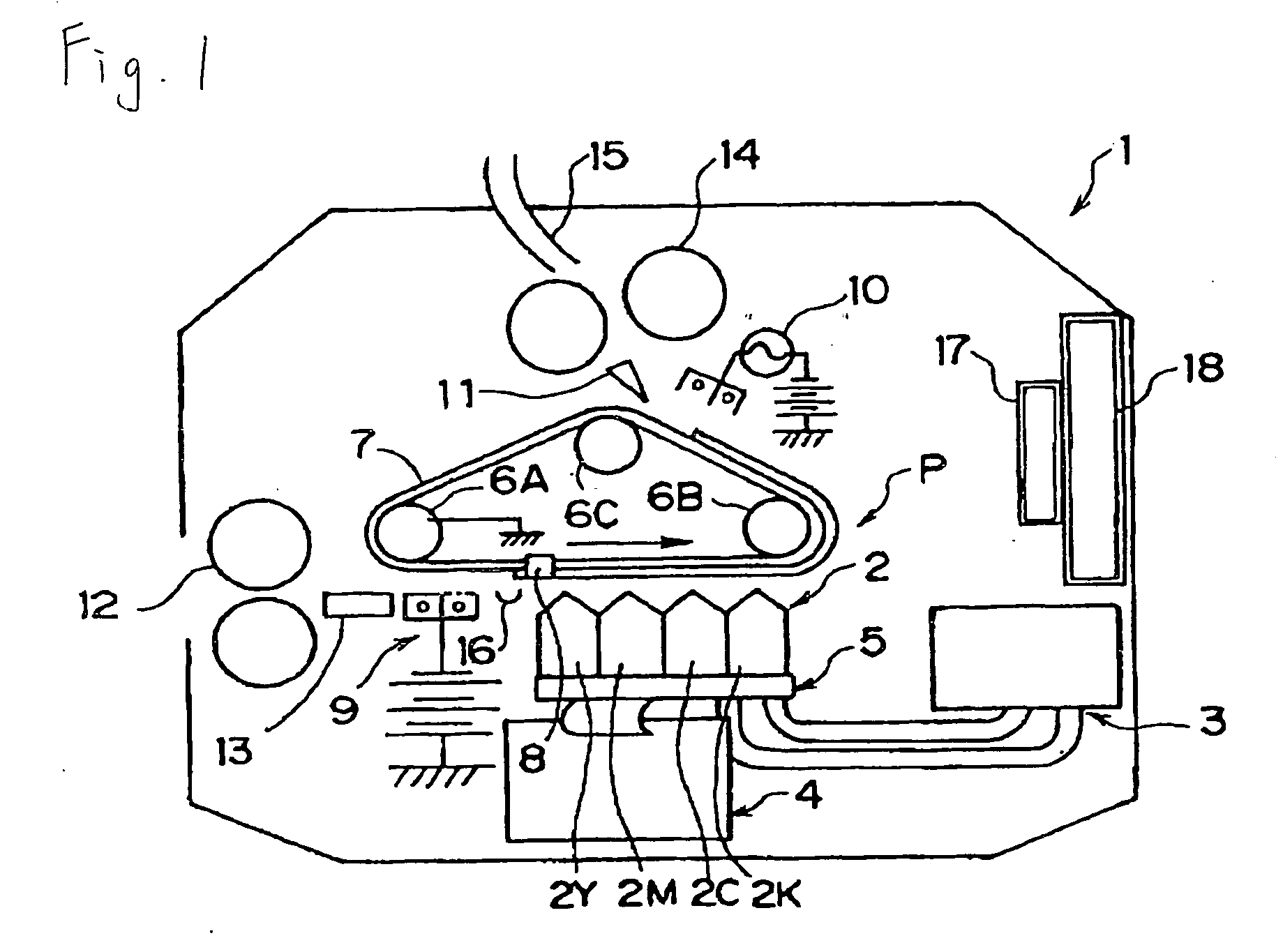

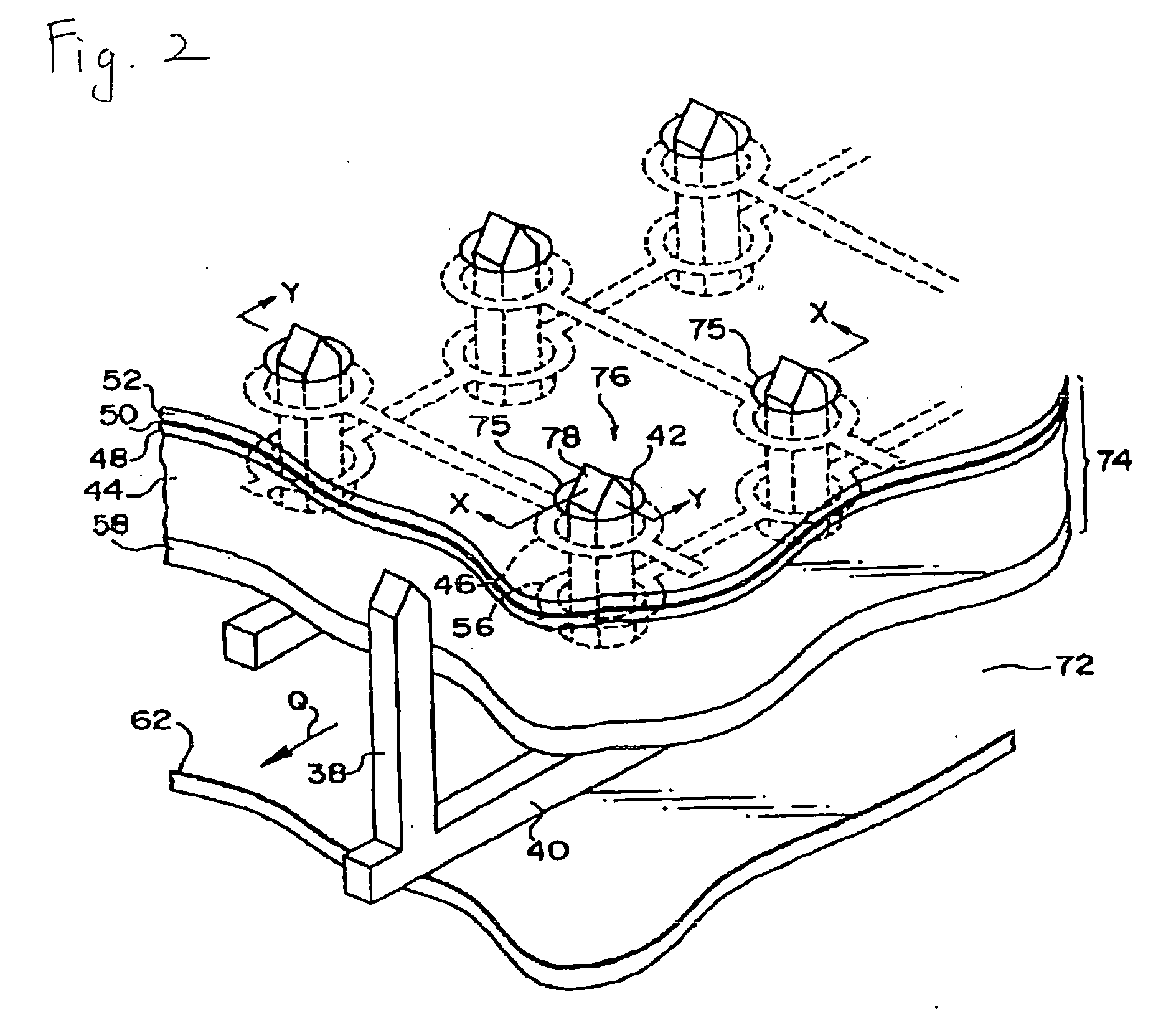

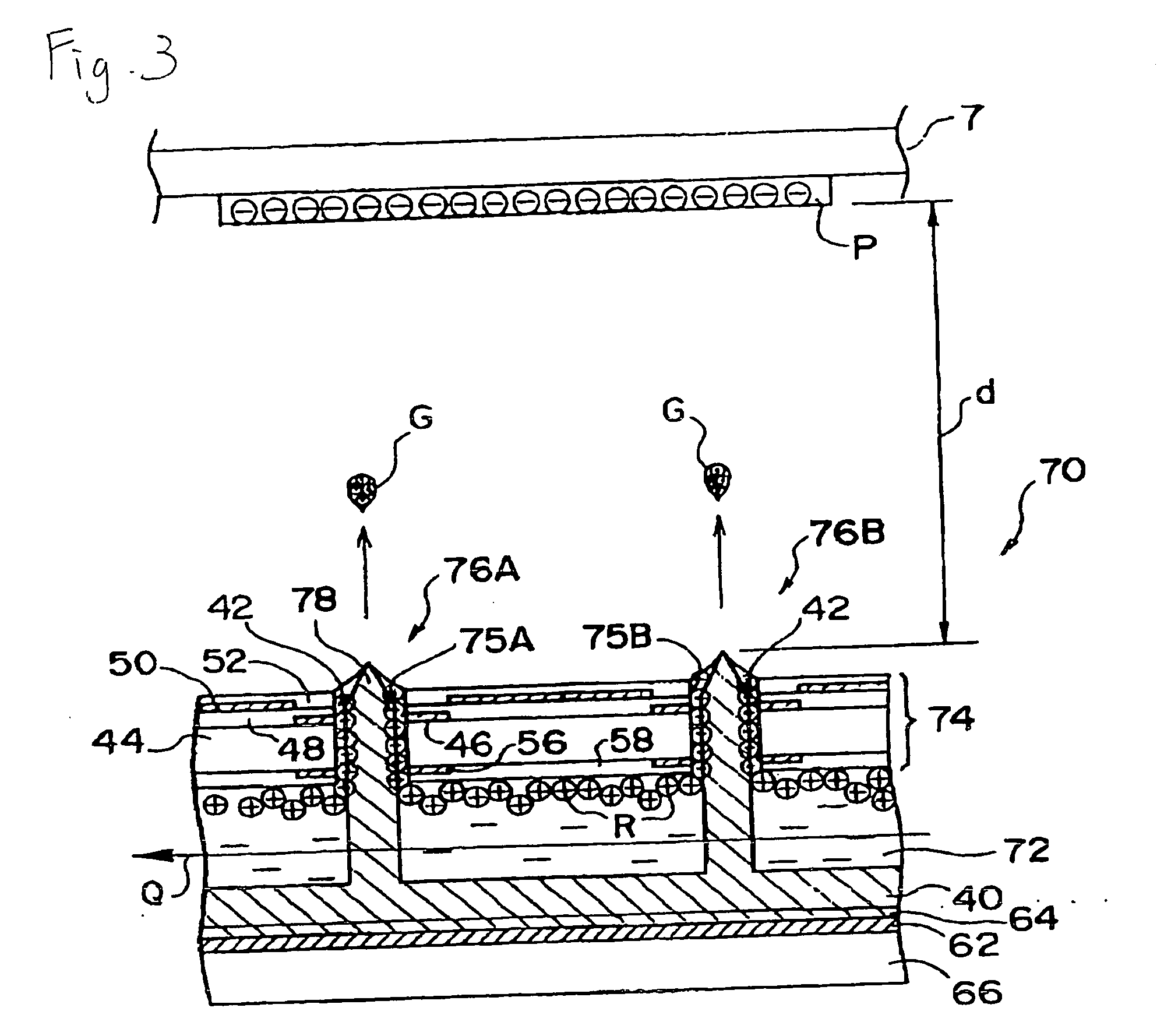

Display device, touch sensor, and method for manufacturing display device

InactiveUS20100194704A1Large deformationAvoid breakingNon-linear opticsInput/output processes for data processingDisplay deviceEngineering

Disclosed herein is a display device including: a display panel configured to display an image in a display area and have a substrate over which a protruding elastic member and an electrode provided on the elastic member are formed in the display area; wherein a plurality of steps are provided in the elastic member in a direction perpendicular to a surface of the substrate, and the electrode is so provided on the elastic member as to include part covering a surface of the plurality of steps.

Owner:JAPAN DISPLAY WEST

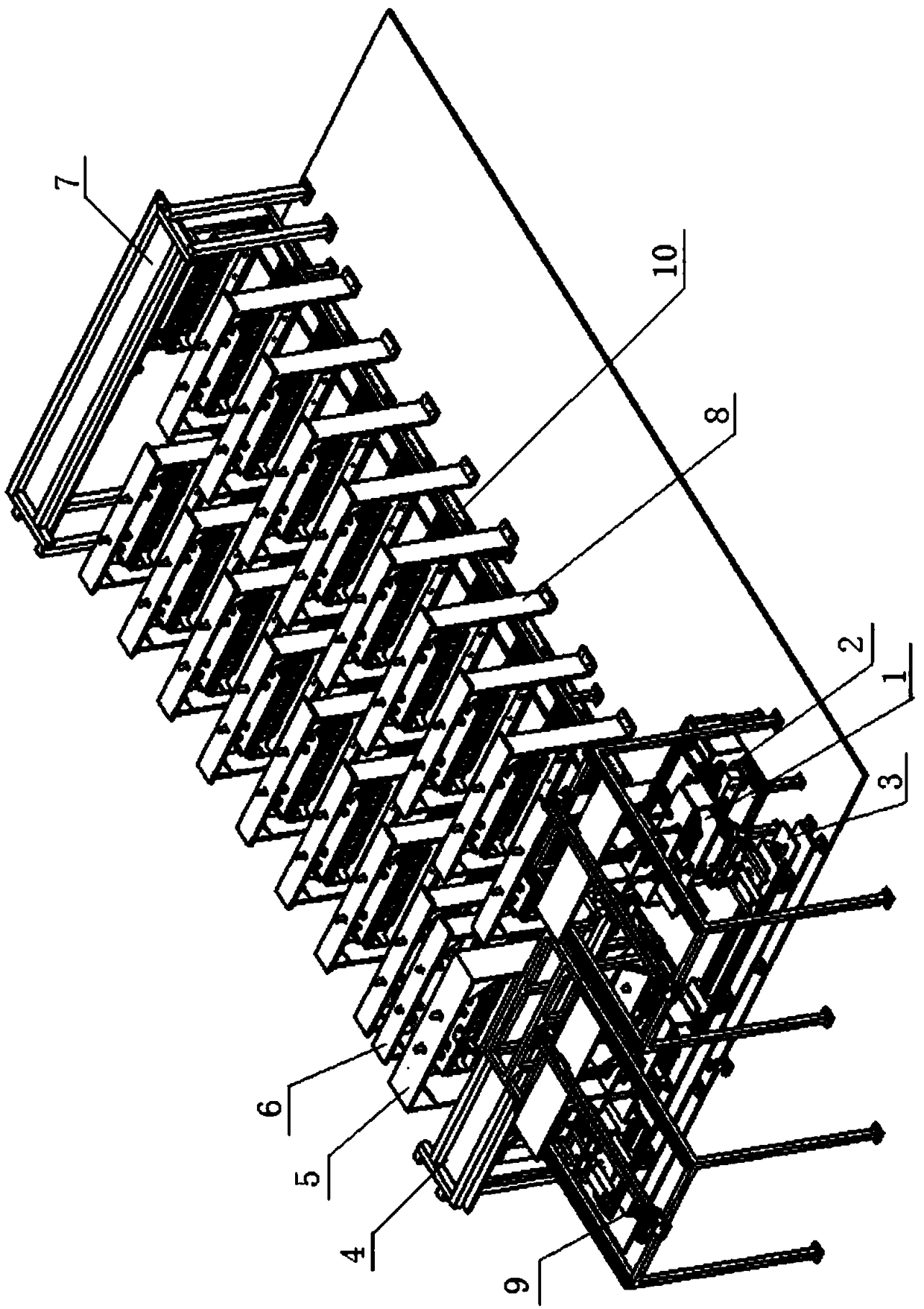

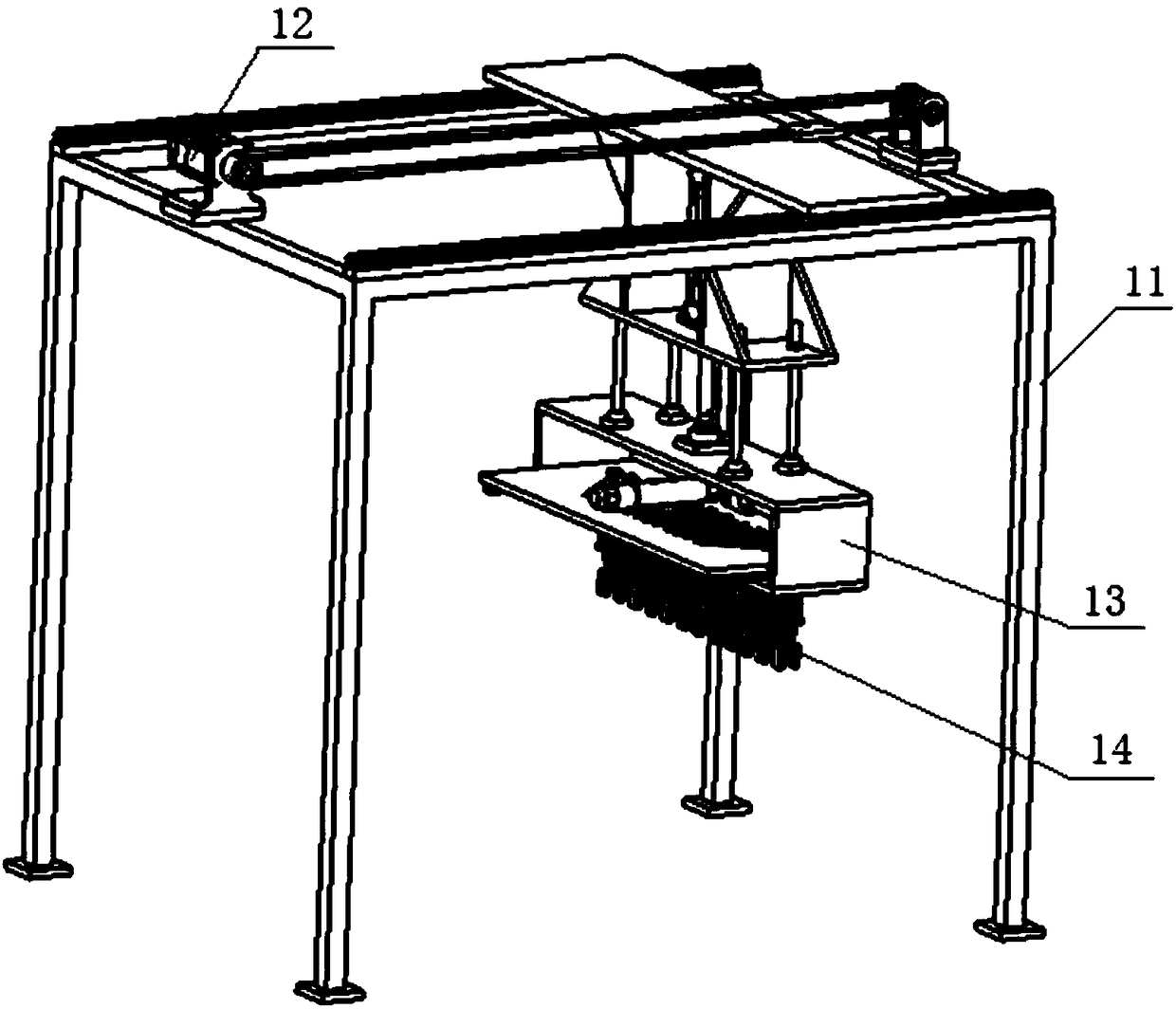

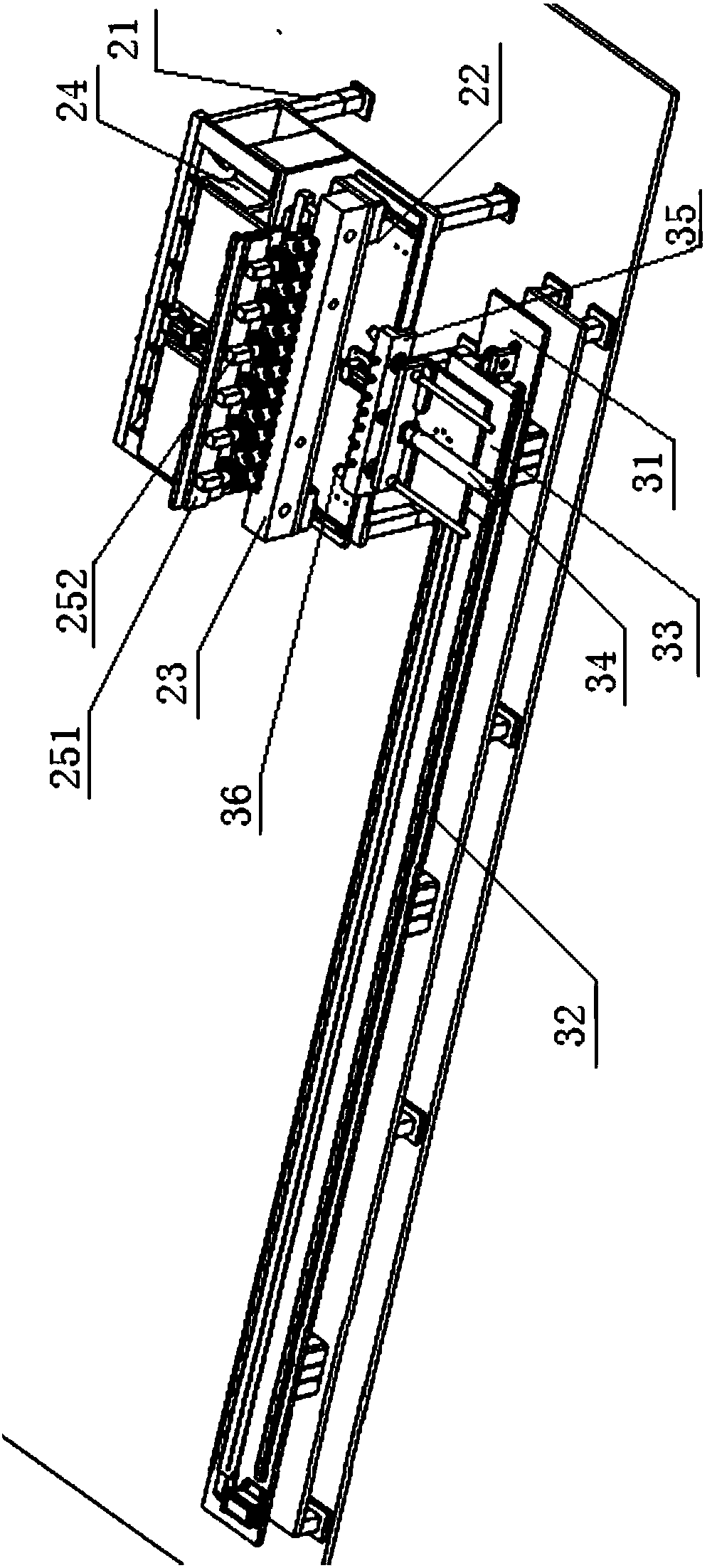

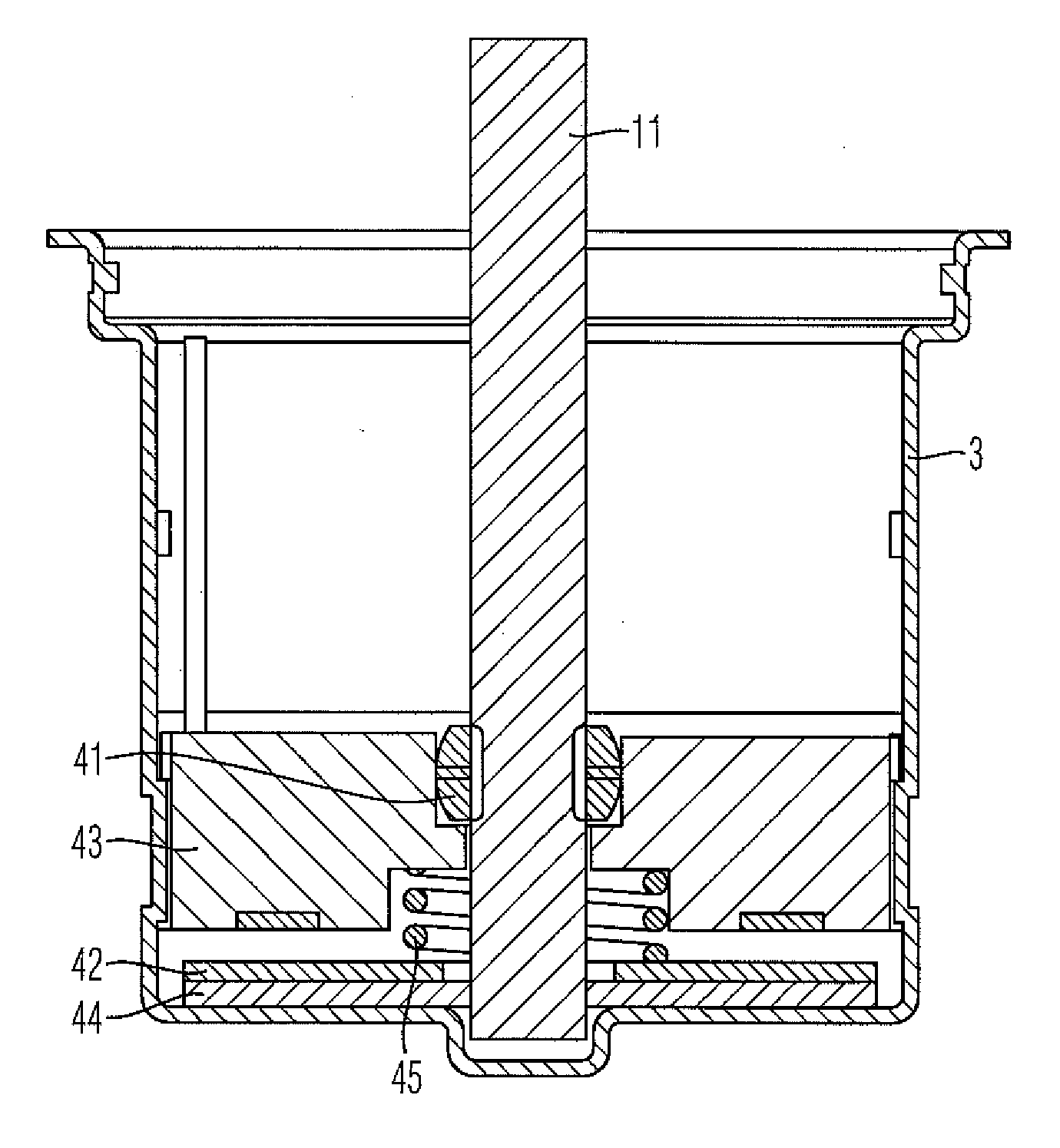

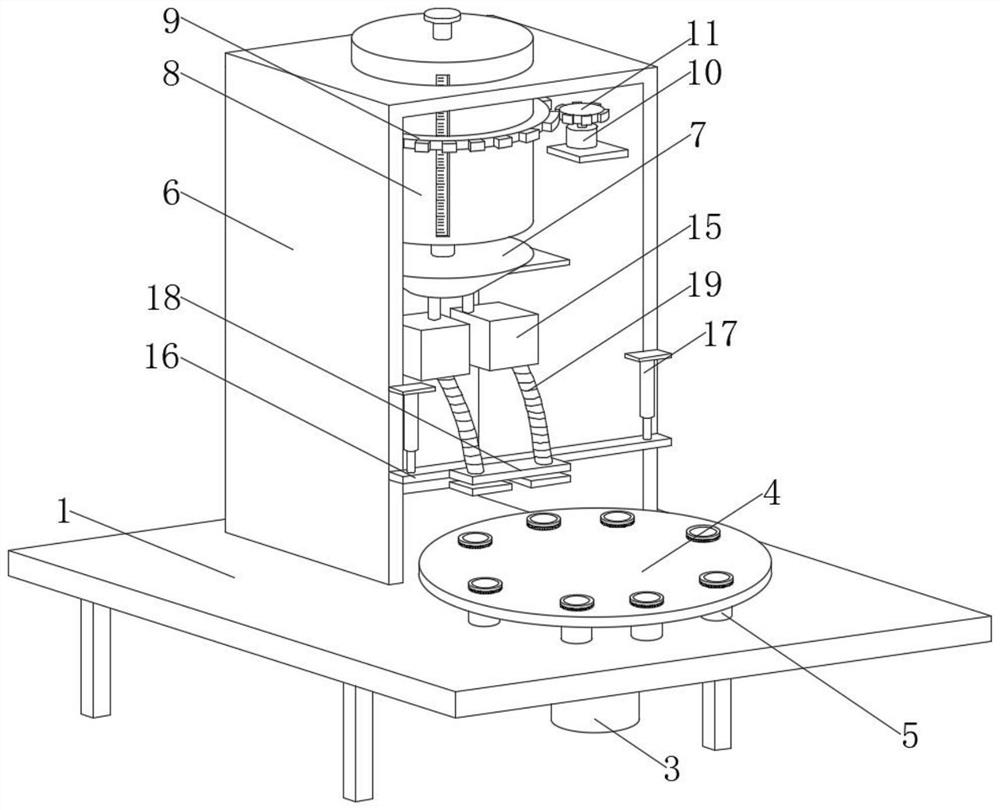

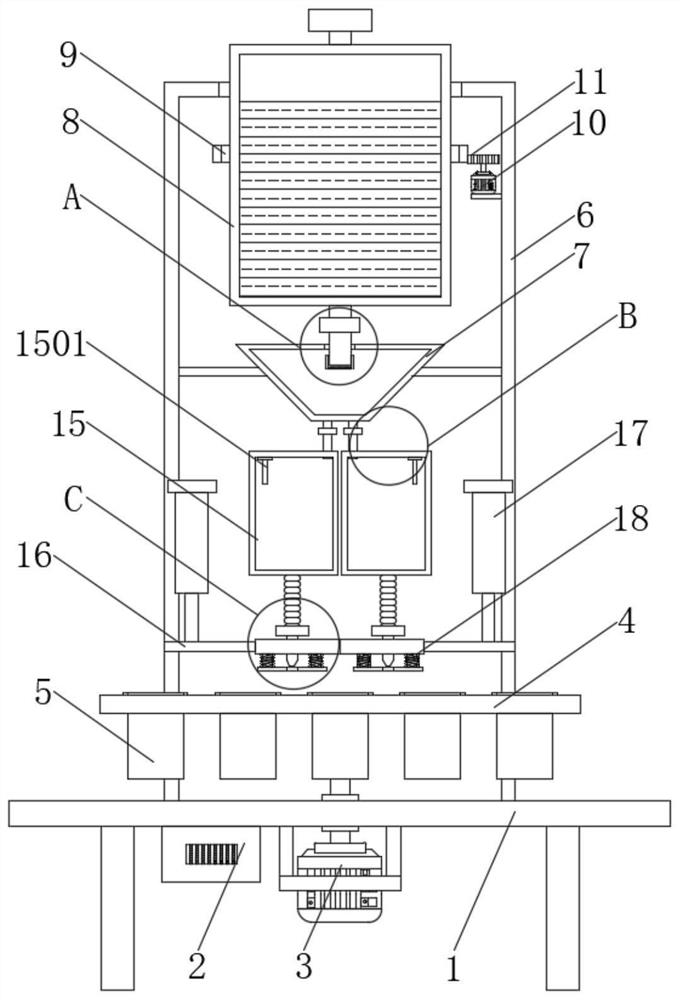

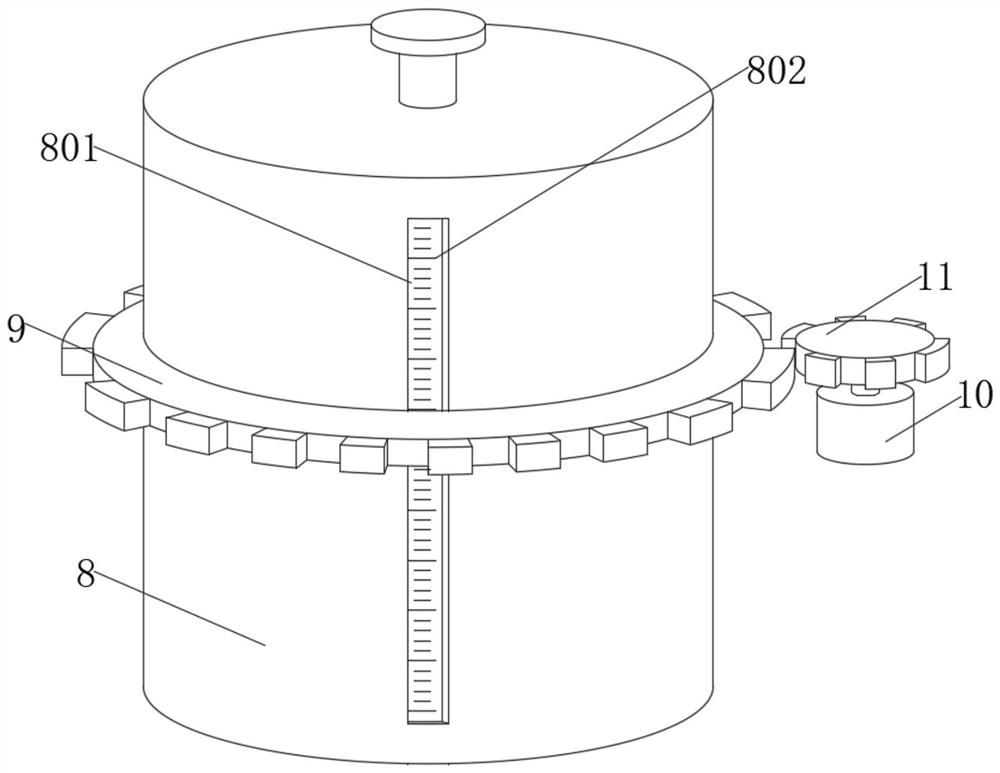

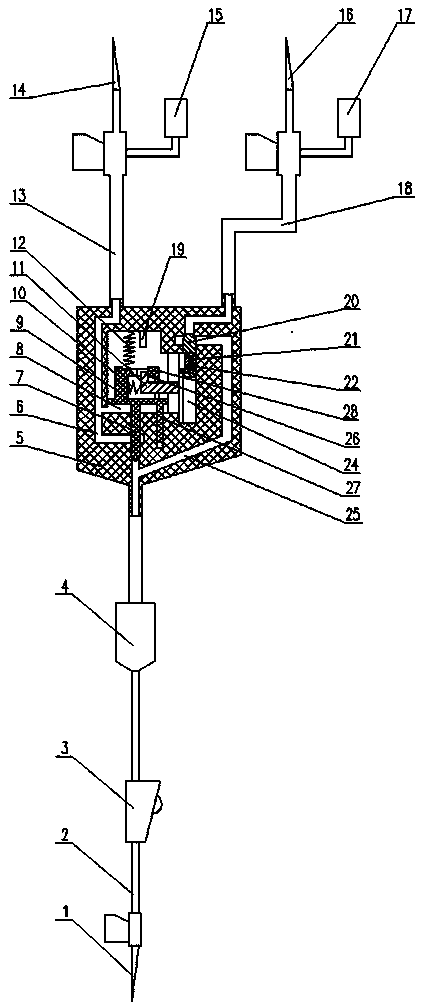

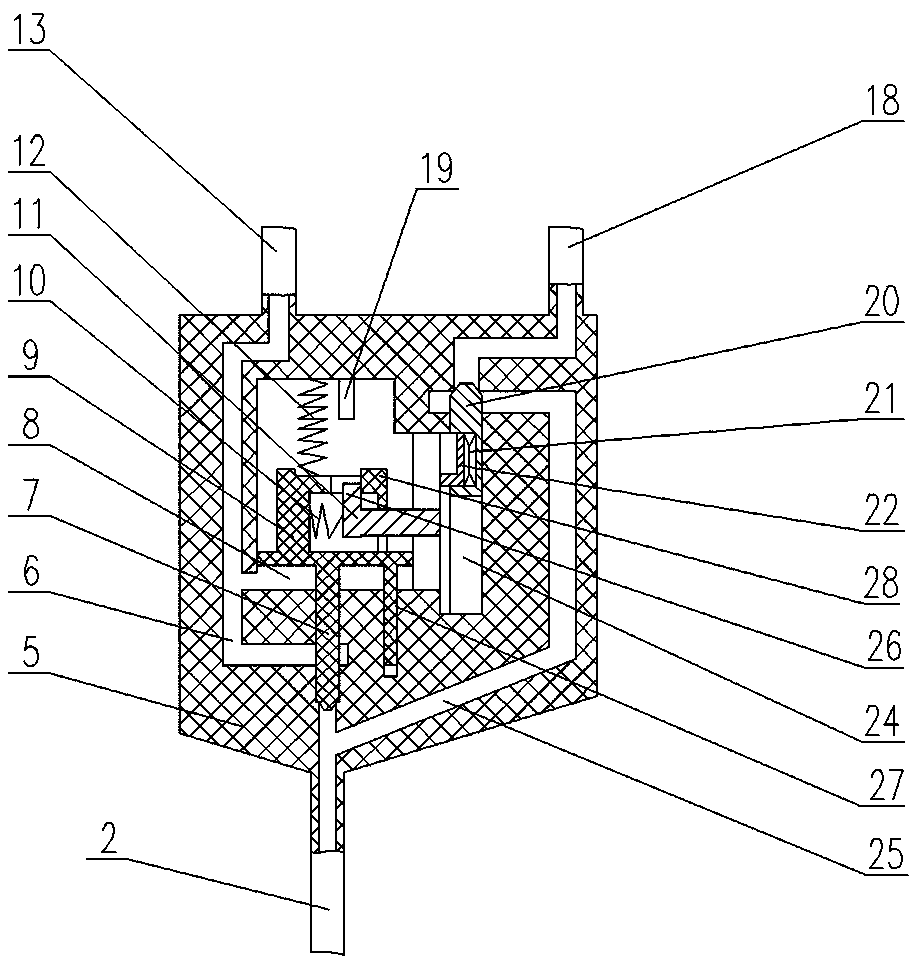

Liquid injecting and standing device for cylindrical lithium-ion batteries

ActiveCN108539117AExtend the rest timeAccurate connectionFinal product manufactureCell component detailsEngineeringHigh pressure

The invention discloses a liquid injecting and standing device for cylindrical lithium-ion batteries. The liquid injecting and standing device for the cylindrical lithium-ion batteries comprises a battery feed mechanism, a battery hole-alignment detection mechanism, a battery fixture carrying mechanism, a battery front turnover mechanism, a battery air-tightness detection mechanism, a battery liquid injection mechanism, a battery tray rear turnover mechanism, a battery high pressure and vacuum standing mechanism, a battery blanking mechanism and a battery tray carrying mechanism. The liquid injecting and standing device for the cylindrical lithium-ion batteries adopts the battery feed mechanism and the battery blanking mechanism to respectively realize the automatic feeding and blanking ofa mechanical arm, adopts the battery front turnover mechanism to realize the feeding and blanking of a liquid injection cup, adopts the battery high pressure and vacuum standing mechanism to performhigh pressure and vacuum operations alternately so as to fully prolong the standing time after liquid injection of the batteries, and adopts the battery tray carrying mechanism to realize the turnoverof a battery tray among the different mechanism. The liquid injecting and standing device realizes mechanized automatic feeding, hole-alignment, liquid injection, standing and blanking operations, isstable in standing time and high in efficiency, and guarantees the accuracy and time stability of liquid injection and standing.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

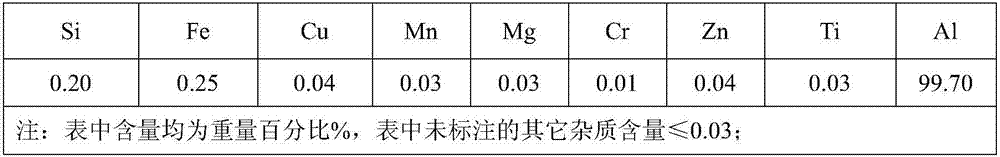

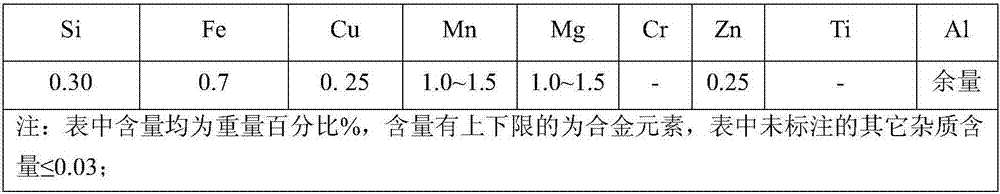

Preparation method of high-strength aluminum foil used for lithium ion battery

ActiveCN107099701AQuality assuranceRealize direct casting and rollingMetal rolling arrangementsIngotHigh intensity

The invention relates to a preparation method of a high-strength aluminum foil used for a lithium ion battery. The preparation method comprises the following steps: firstly smelting electrolytic aluminum liquid and an aluminum ingot into an aluminum melt, directly casting and rolling to obtain a cast-rolling roll with the thickness of 6.95mm, and then carrying out cold rolling, longitudinal edge shearing, low temperature intermediate annealing, foil rolling, finished product slitting, inspection and packaging, thereby obtaining the high-strength aluminum foil used for the lithium ion battery. The aluminum melt is directly prepared into the cast-rolling roll, so that a technological process is greatly shortened, the low temperature intermediate annealing reduces power consumption of an annealing furnace, and the high-strength aluminum foil used for the lithium ion battery has the tensile strength higher than or equal to 175MPa and the surface wettability tension higher than or equal to 32 dynes.

Owner:LUOYANG LONGDING ALUMINUM

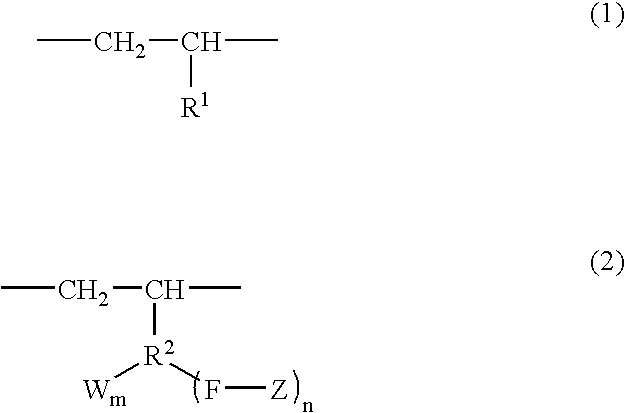

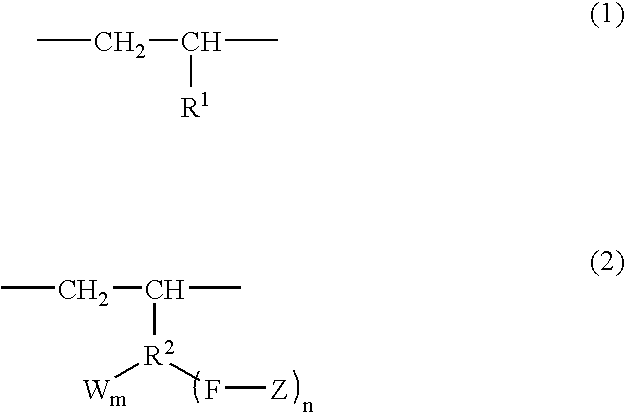

Branched olefin copolymer, process for producing the same, and use thereof

ActiveUS20040110903A1Improve elongationExtend the rest timeCoatingsGraft polymer adhesivesDouble bondOxygen atom

A branched olefin copolymer demonstrating excellent performance in various uses, comprising a building block (A) represented by formula (1) below and a building block (B) represented by formula (2) below, obtained by e.g. a method which involves sequentially conducting ( step 1) a step of synthesizing -group-containing olefin copolymer (Q) containing at least one functional group (G) selected from a hydroxyl group, a carboxylic acid group, an ester group, an amino group, an epoxy group, a silanol group and an acid anhydride group, (step 2) a step of converting the functional group (G) into a group having an ability to initiate radical polymerization, and (Step 3) a step of installing a polymer segment (Z) by radical polymerization of a monomer essentially comprising a carbon-carbon double bond-containing compound (R) containing at least one selected from an oxygen atom, a nitrogen atom, a halogen atom and an aryl group; wherein the formula (1), R<1 >represents a hydrogen atom and a C1-18 linear or branched aliphatic hydrocarbon group; in the formula (2), R<2 >represents a C1-18 linear or branched aliphatic or aromatic hydrocarbon group; F represents a heteroatom or a heteroatom-containing linking group; Z represents a polymer segment containing at least one selected from an oxygen atom, a nitrogen atom, a halogen atom and an aryl group and having a molecular-weight distribution of 1.0 to 3.0; W represents a group selected from an alcoholic hydroxyl group, a phenolic hydroxyl group, a carboxylic acid group, a carboxylate group, an acid anhydride group, an amino group, an epoxy group, a siloxy group and a mercapto group; n is an integer of 1 to 3 and m is 0, 1 or 2 provided that when n is 2 or 3, Z may be the same or different to each other, and when m is 2, W may be the same or different to each other; and W may be bound to the same or different atom of R<1 >to form a cyclic structure.

Owner:MITSUI CHEM INC

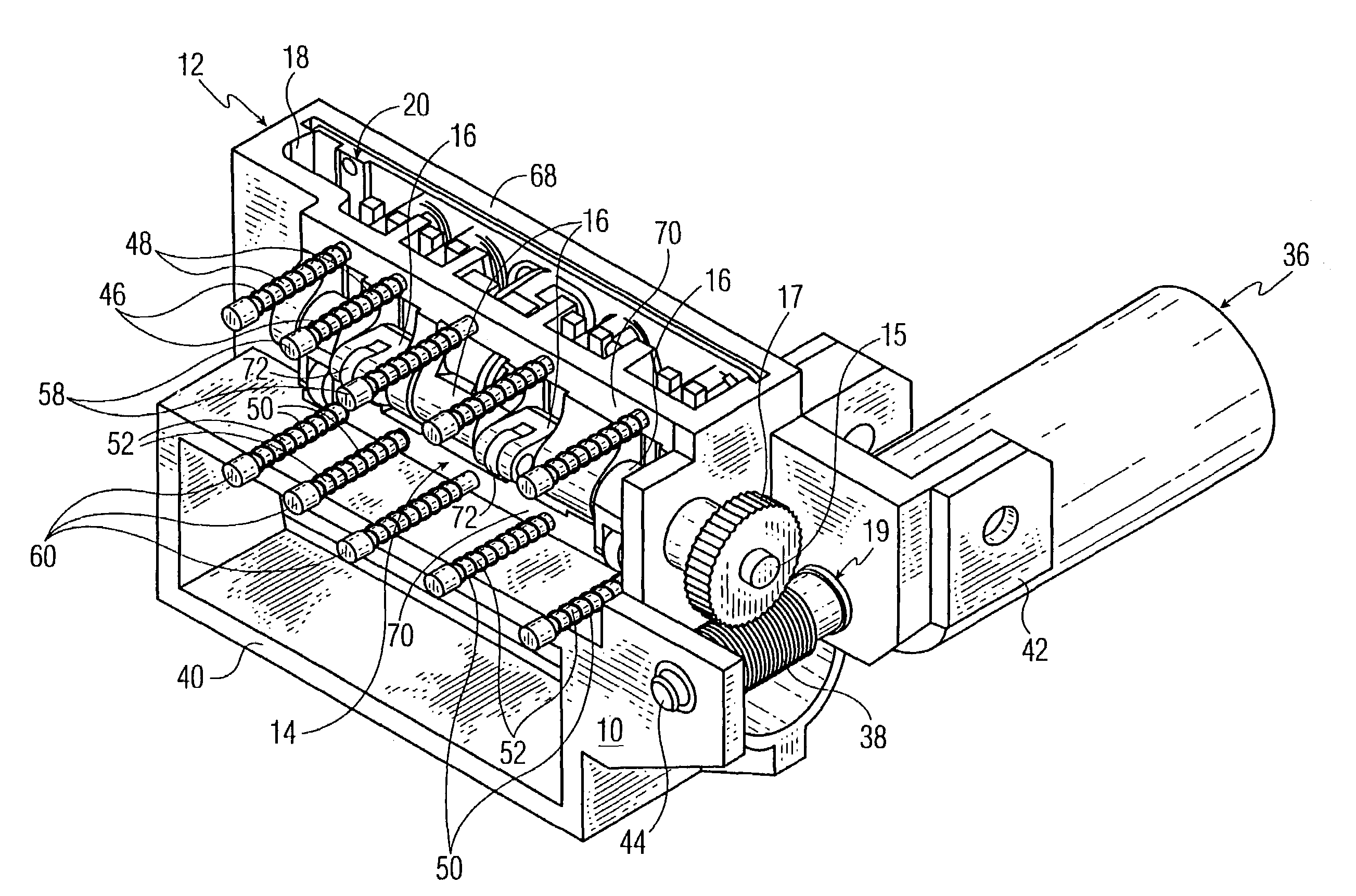

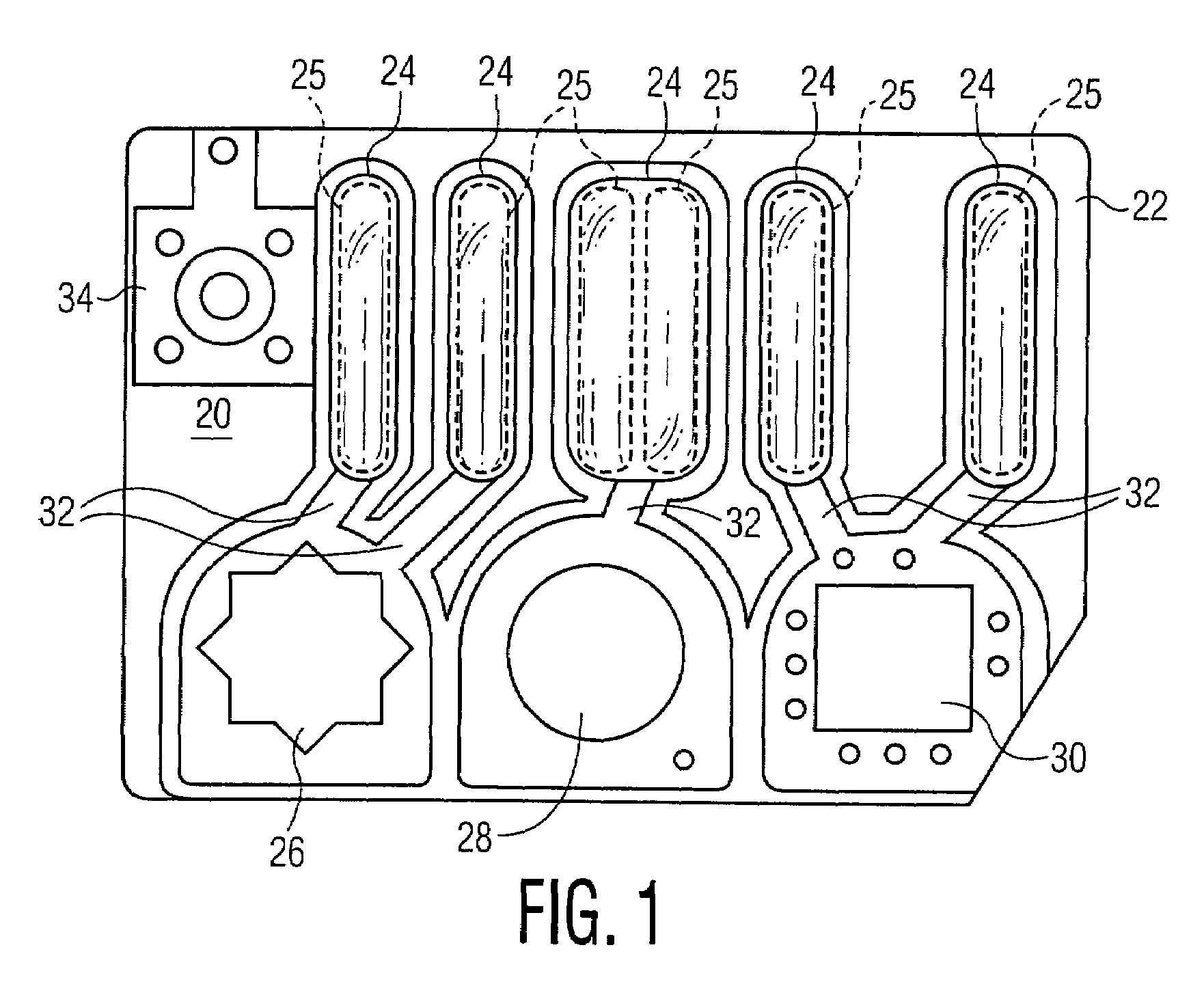

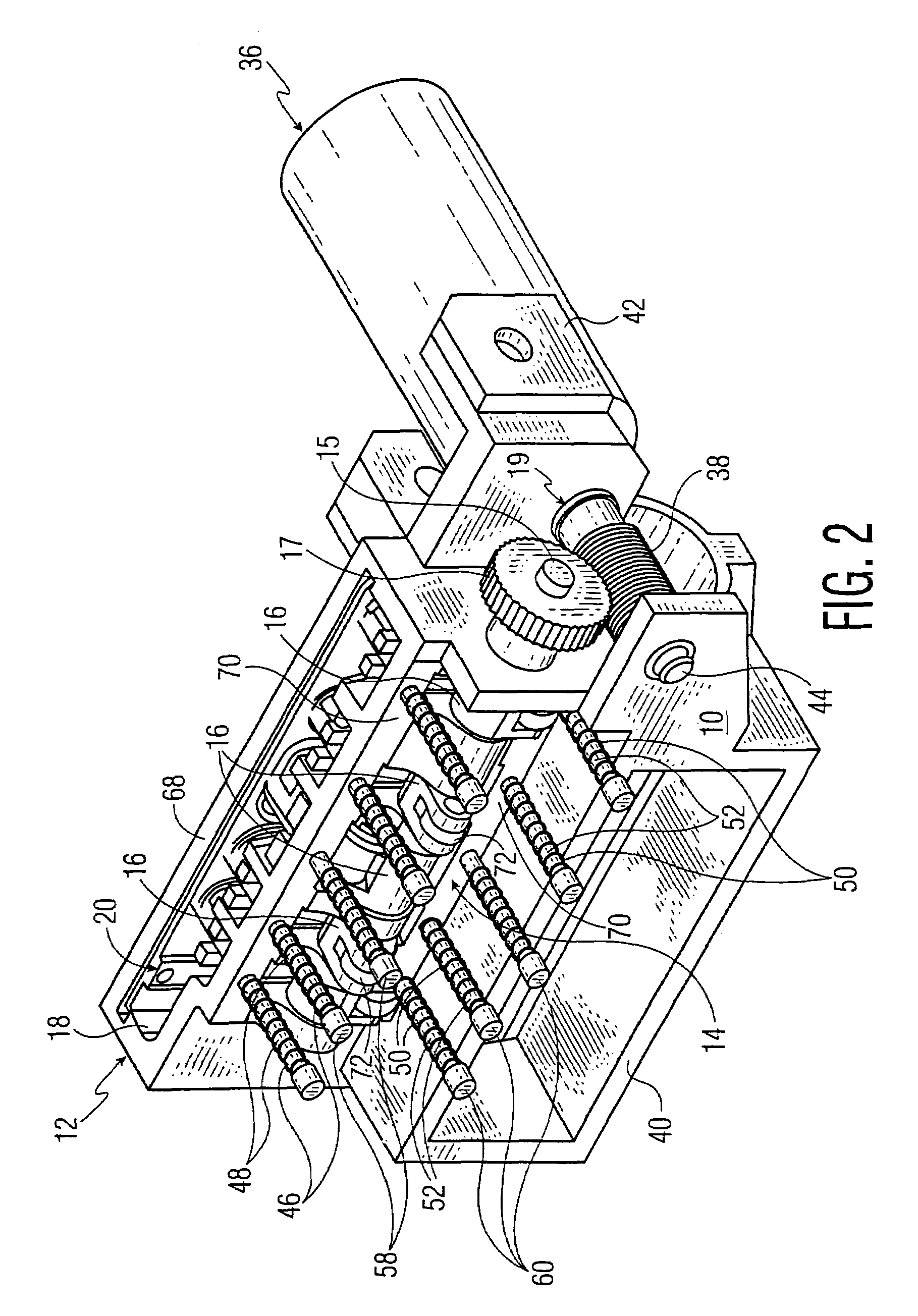

Automated ampoule breaking device

InactiveUS7445753B1Extend the rest timeImprove abilitiesAnalysis using chemical indicatorsLaboratory glasswaresBiomedical engineeringAmpoule

An automated ampoule breaking device includes a carriage having an opening for receiving and securely retaining a substrate in a substantially upright position, wherein the substrate includes at least one flexible compartment each having an outlet at the lower end and at least one ampoule contained therein; and at least one movable projection operatively associated with the carriage, wherein each of the at least one projection adapted for applying sufficient pressure progressing from the upper to the lower end of the corresponding flexible compartment to crush the at least one ampoule and direct the contents of the crushed ampoule out of the respective flexible compartment through the outlet.

Owner:UNITED STATES OF AMERICA

Preparation method of rigid silicon dioxide aerogel insulating board

InactiveCN104944887AConducive to large-scale industrial productionImprove performanceSilicaFiberSilanes

The invention provides a preparation method of a high-strength low-carbon environment-friendly rigid silicon dioxide aerogel insulating board, which comprises the following steps: (1) taking 68-120g of sodium water glass with the modulus of 3.1-3.6, adding 100-200g of pure water, and stirring uniformly to obtain diluted water glass; (2) weighing 25-100g of 40 wt% sulfuric acid, adding 10-40g of ethanol, and stirring uniformly to obtain a sulfuric acid solution; (3) mixing the diluted water glass and sulfuric acid solution, and regulating the pH value to 3.5-4.5 to obtain a sol; (4) pouring the sol into a reinforcing-fiber-filled mold, gelatinating the sol after 10-15 minutes, and standing for 2-10 hours while keeping at the temperature of 50-80 DEG C, thereby obtaining a gel board; (5) carrying out integrated aging and acid alcohol treatment on the alcoholic aquagel board; (6) putting the gel board subjected to acid alcohol treatment into 1000-250ml of trimethylethoxy silane, treating at room temperature, and completing hydrophobic modification and gel drainage in one step within 6-10 hours; and (7) after the drainage is finished, drying the wet gel board with hot nitrogen or carbon dioxide.

Owner:ZHUO DA NEW MATERIAL TECH GRP

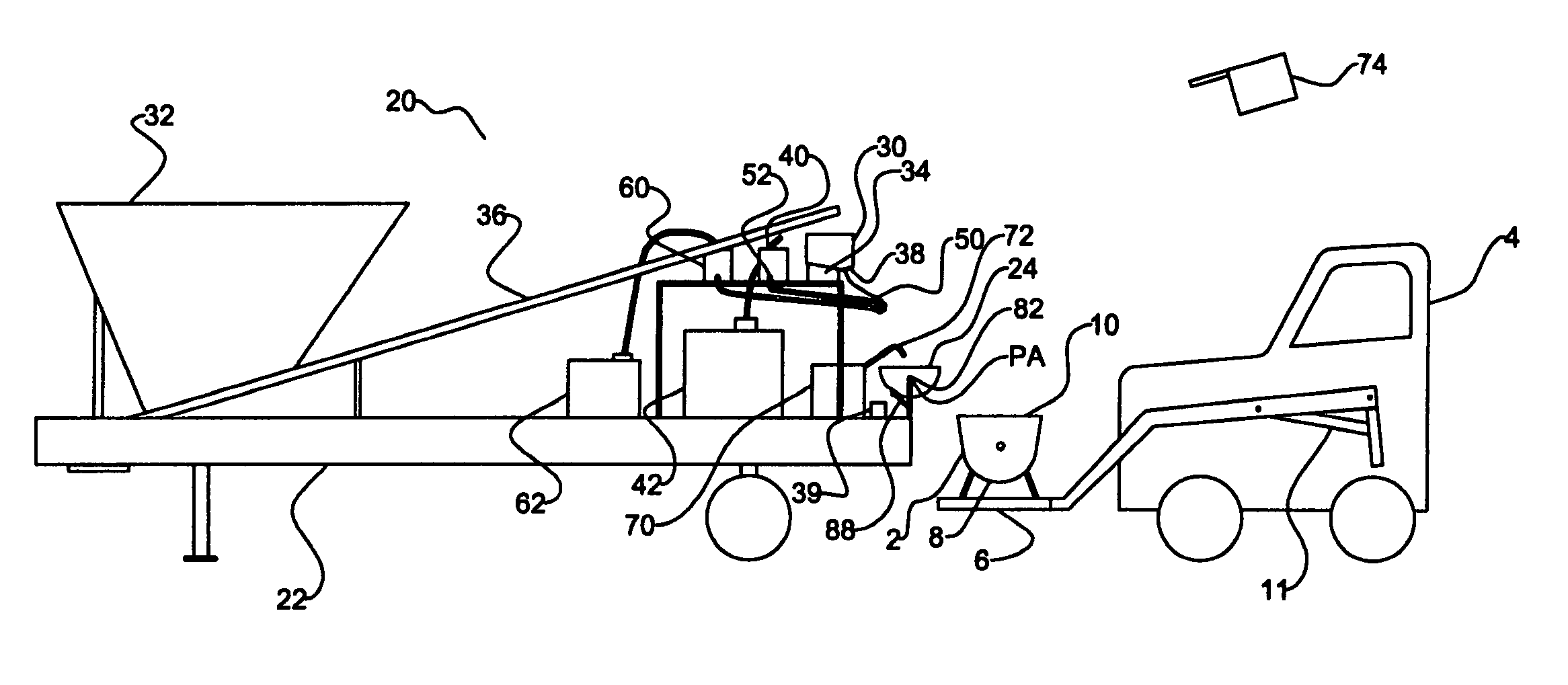

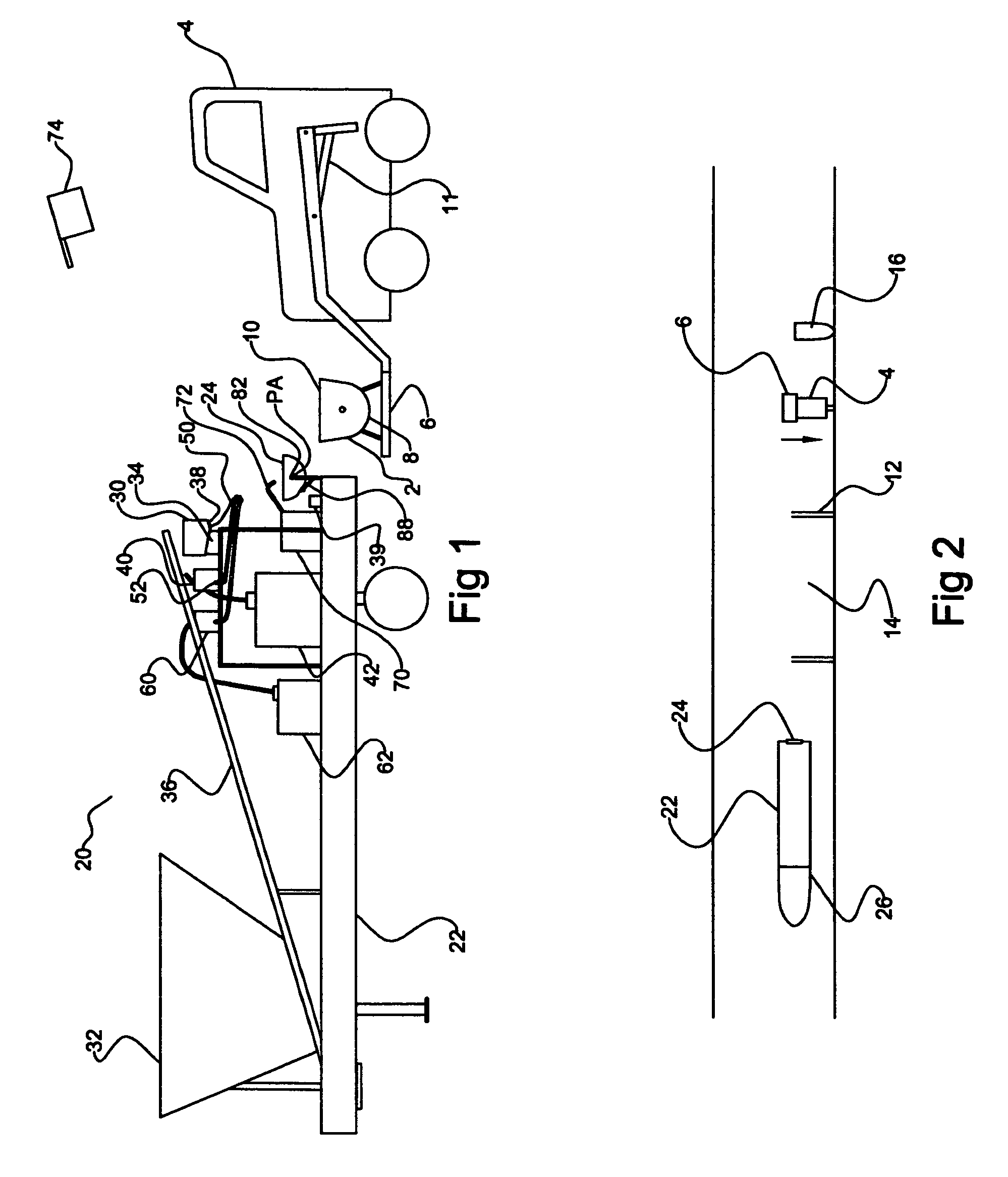

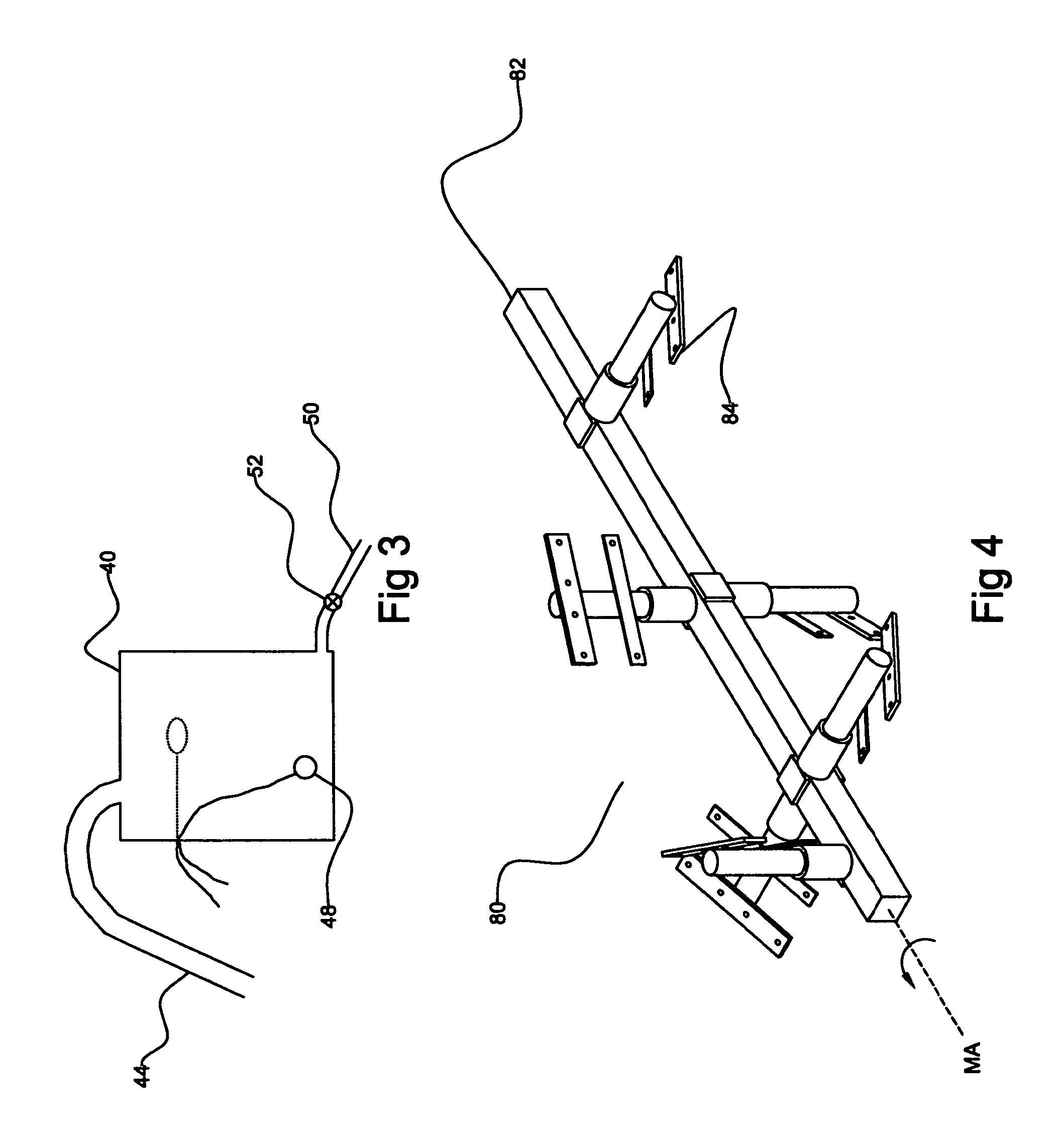

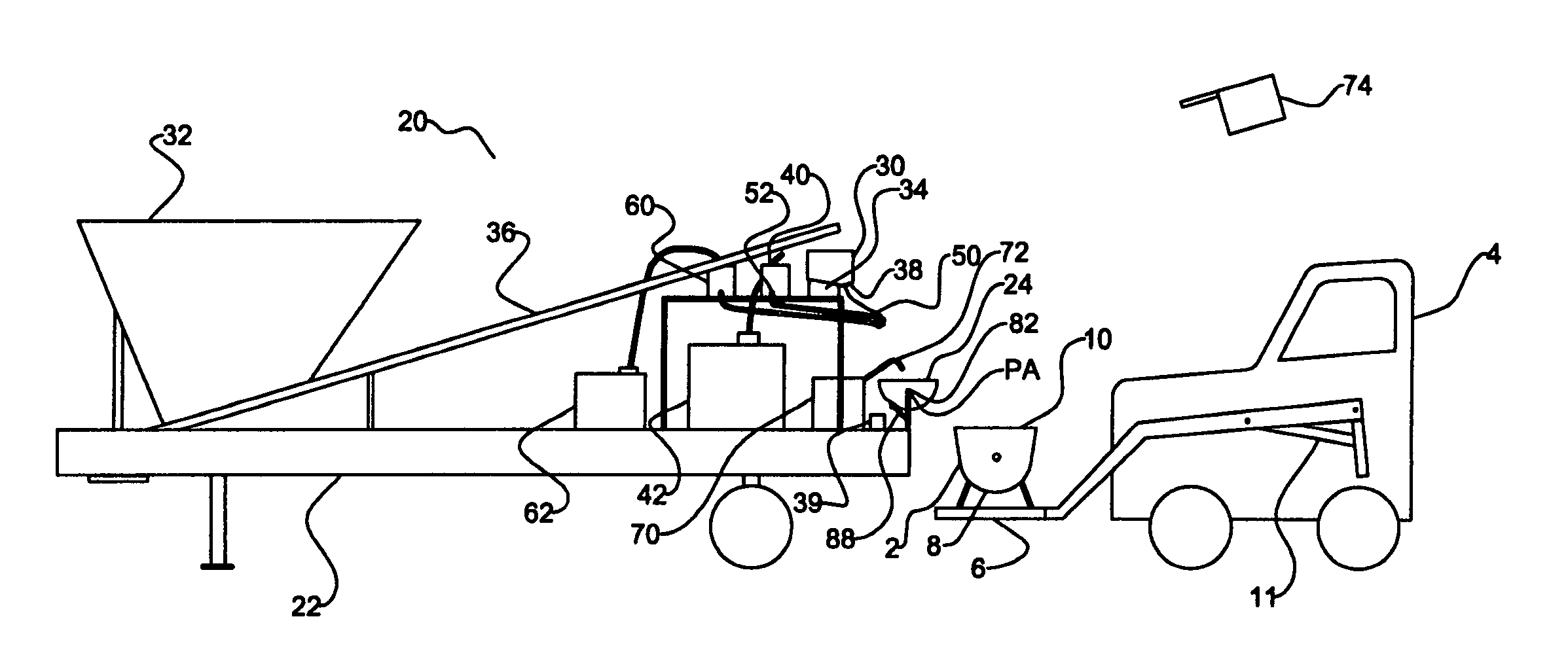

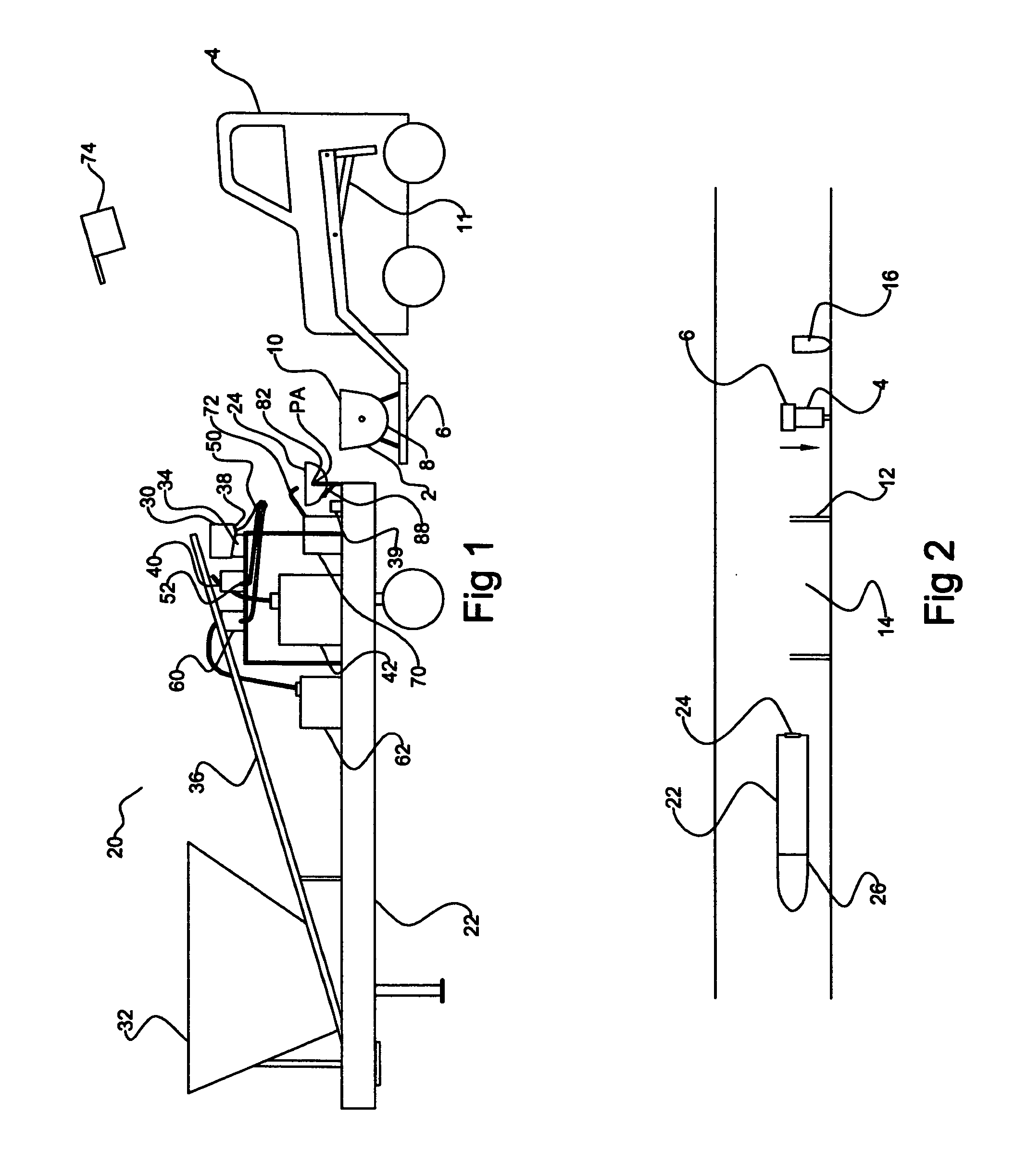

Repairing road surfaces

InactiveUS20060088379A1Hardens quicklyExtend the rest timeIn situ pavingsRoads maintainenceEmulsionPortland cement

A method of repairing a road surface comprises providing a hopper mounted on a spreading vehicle and means to spread material carried in the hopper over depressed areas of the road surface to fill them with the material. At ambient temperature, a batch of patching slurry is mixed comprising aggregate, asphalt emulsion, water, Portland cement, and a retarding agent operative to increase a break time of the patching slurry, and the batch is deposited into the hopper. The spreading vehicle is maneuvered to spread the patching slurry successively over a plurality of depressed areas until the hopper is empty. The ingredients of the patching slurry are adjusted to provide a patching slurry having a break time sufficiently long to allow the hopper to be emptied before the patching slurry begins to set, and sufficiently short to allow traffic to pass over a filled depressed area within a desired time.

Owner:HER MAJESTY THE QUEEN & RIGHT OF THE PROVINCE OF SASKATCHEWAN

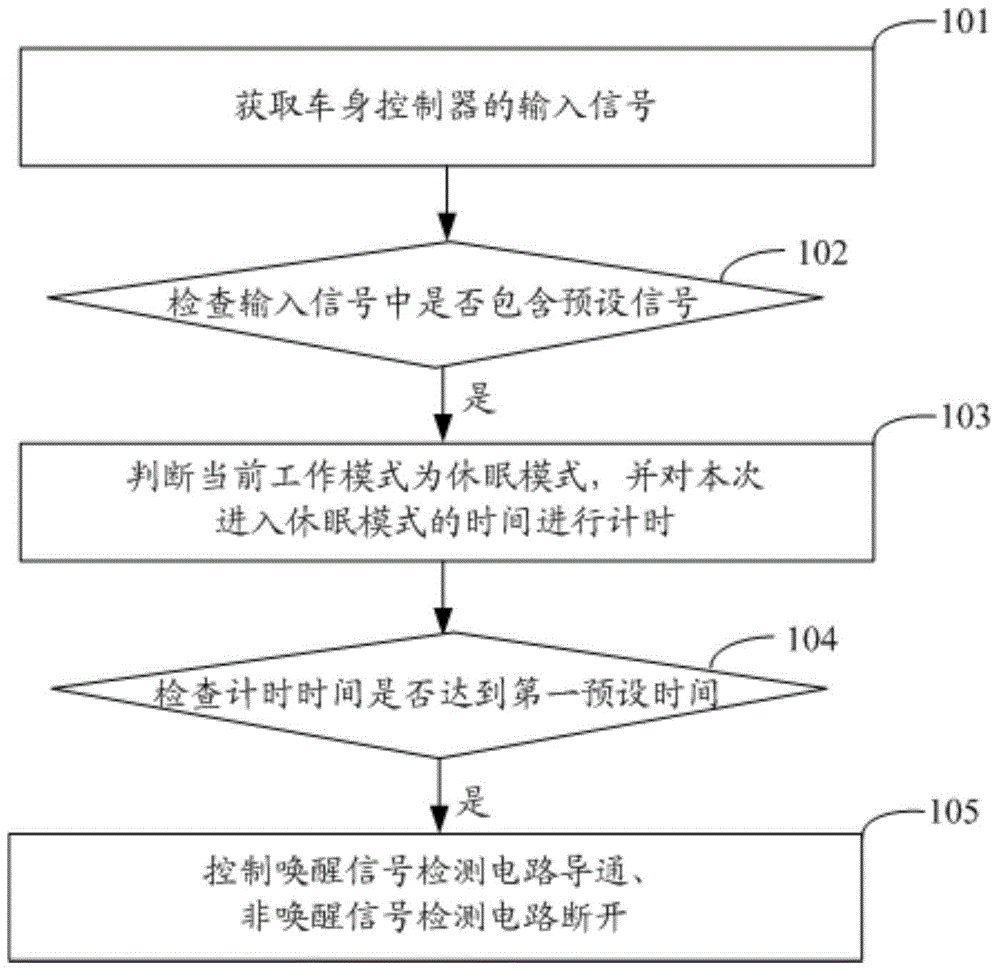

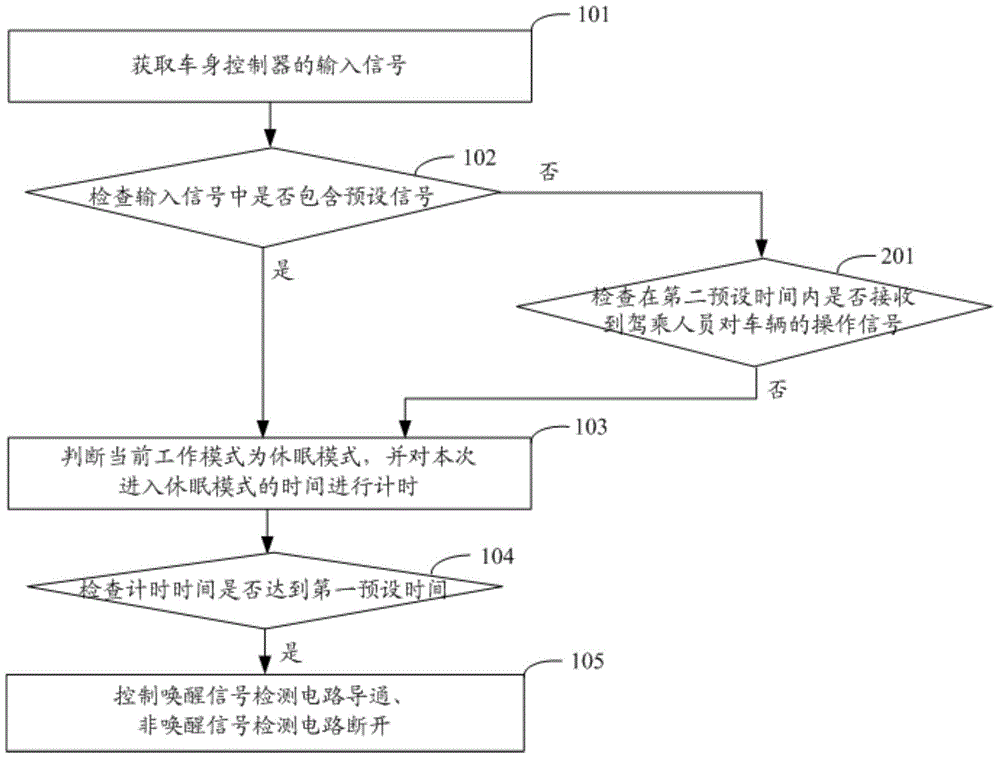

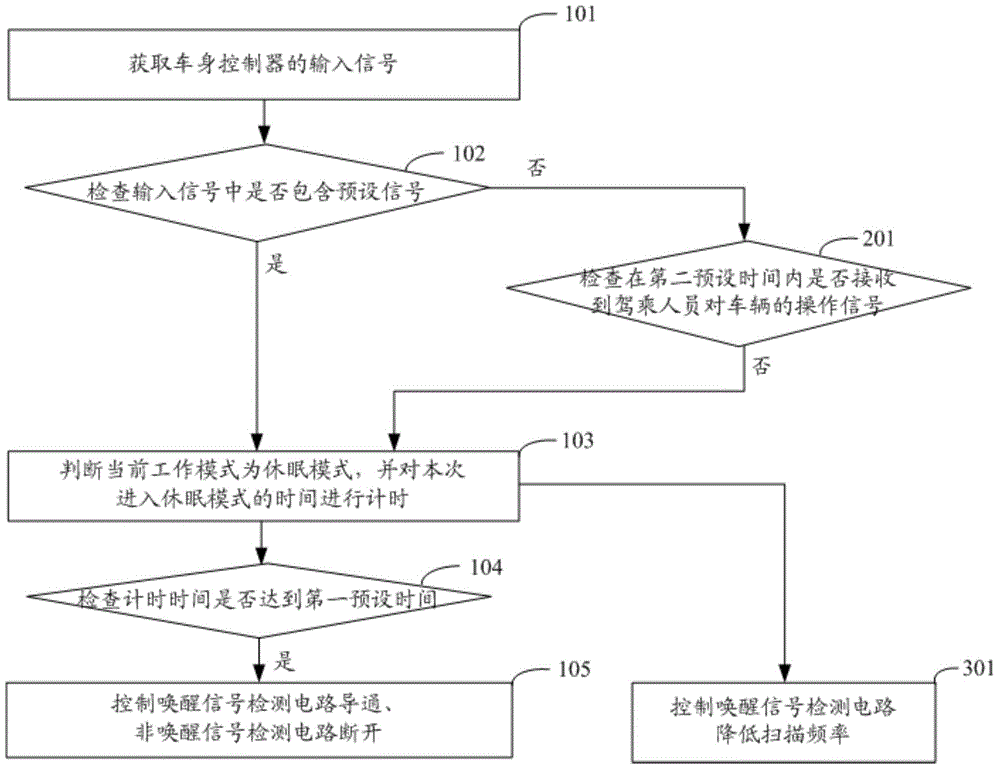

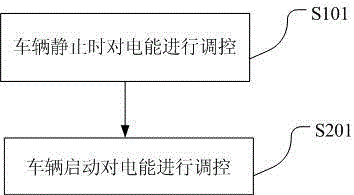

Method and system for reducing static power consumption of automobile body controller

ActiveCN104691451AReduce static power consumptionExtend the rest timeElectric/fluid circuitPower consumptionAutomotive engineering

The invention discloses a method and a system for reducing static power consumption of an automobile body controller and belongs to the technical field of automobiles. The method for reducing static power consumption of the automobile body controller comprises steps as follows: acquiring an input signal of the automobile body controller; checking whether the input signal comprises a preset signal or not; if the input signal comprises the preset signal, judging that the current working mode is a sleep mode, and keeping the time in the sleep mode; checking whether the kept time reaches first preset time; if the kept time reaches the first preset time, controlling a wakeup signal detection circuit to be closed and controlling a non-wakeup signal detection circuit to be opened. With the adoption of the method for reducing static power consumption of the automobile body controller, the static power consumption of the automobile body controller can be effectively reduced, and the standing time of a whole automobile can be prolonged.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Tap assembly

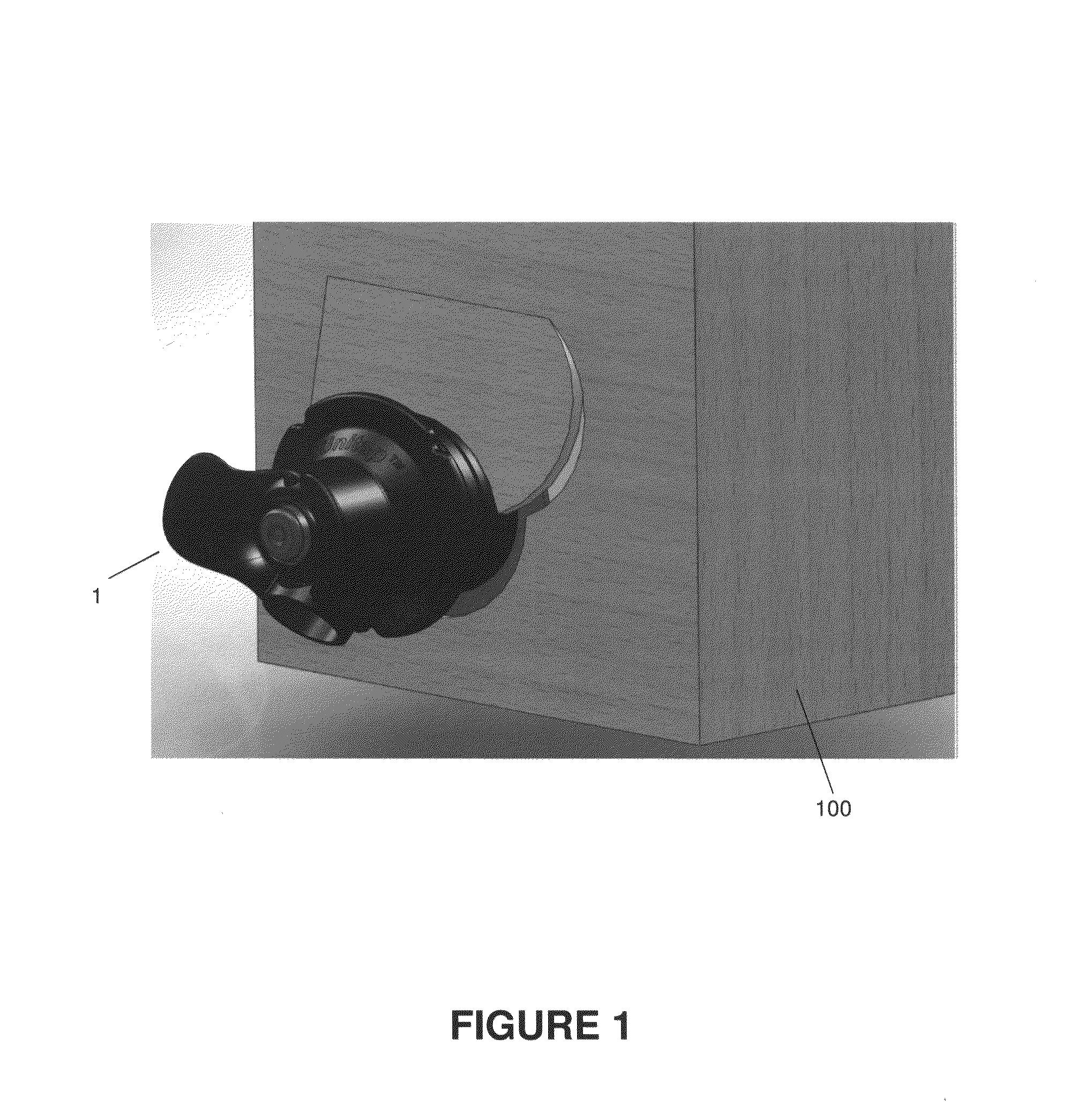

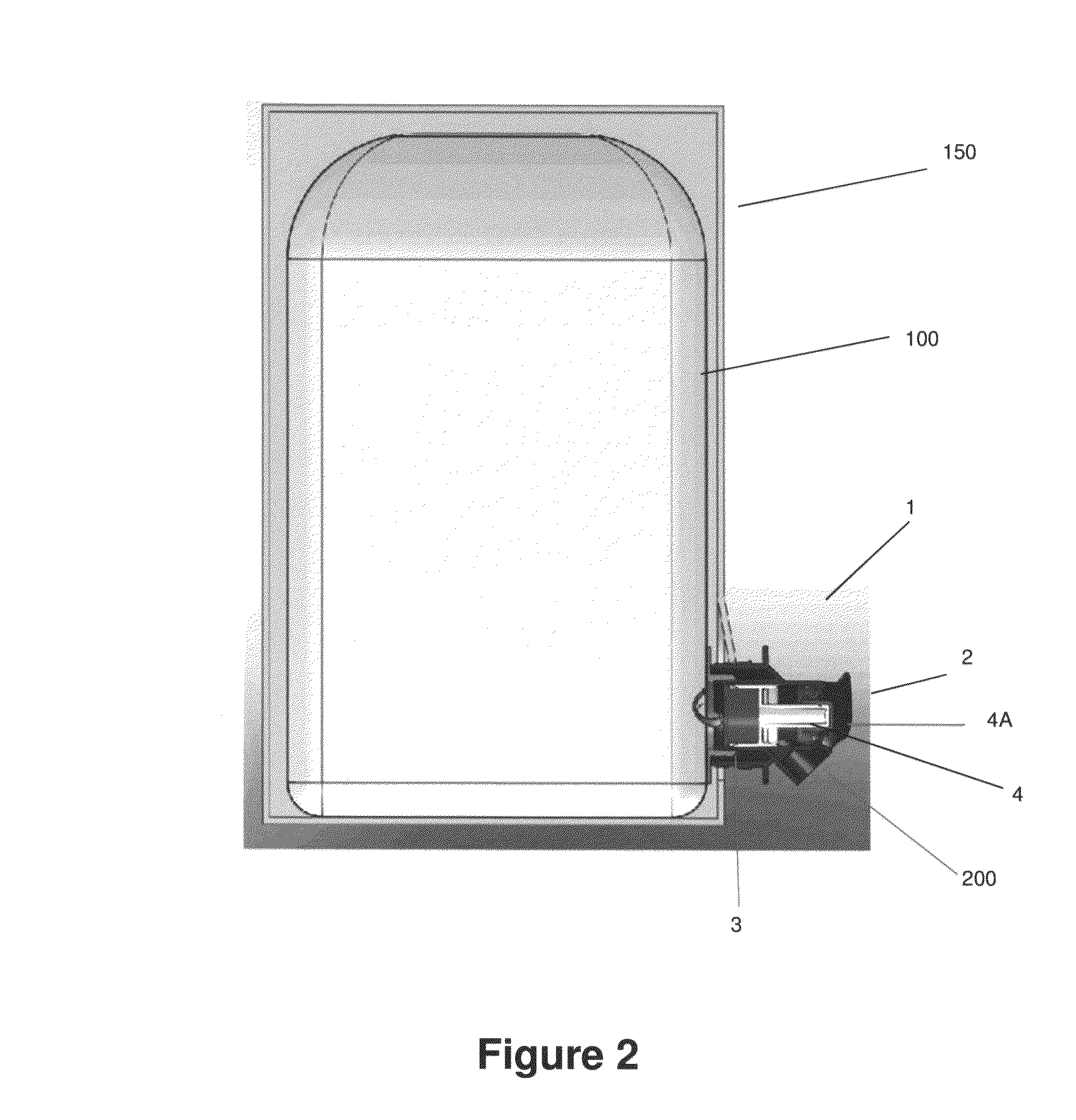

ActiveUS8967430B2Extend the rest timeLiquid flow controllersLiquid transferring devicesEngineeringBag-in-box

The present invention relates to a tap assembly for dispensing fluids from a flexible film bag such as a “bag-in-box”. Known taps associated with such flexible bags do not efficiently dispense fluid from a bag which is partially collapsed and / or can damage the opposite wall of the partially collapsed bag. The tap assembly includes a body with a bore, an actuation member to cover at least a portion of the bore and a piercer which is configured to pivot within the bore and pierce and cut a sterility membrane positioned over an open end of the bore upon movement of the actuation member by a user. The piercer comprises a curved surface which functions to position the piercer away from the plane of the adjacent bag wall after initial piercing.

Owner:STOMA GUARD APS +1

Distributed automobile electric energy regulating method

ActiveCN105128783ANo feed phenomenonSmall quiescent currentElectric/fluid circuitEnergy efficient vehicular chargingOutput deviceControl unit

The invention relates to a distributed automobile electric energy regulating method and belongs to the technical field of automobile electric energy control. Static electric energy is regulated: when a vehicle is in a standing state, controllers meeting the conditions first enter a primary sleep state; if a message is not detected during a certain time, the controllers having entered the primary sleep state are ordered to enter a secondary sleep state, a storage battery closes power supply of related loads according to different states of the current vehicle and makes related control units enter a sleep mode, a quiescent current is lowered, and the standing time is improved. Dynamic electric energy is regulated when the vehicle runs, and the state of the storage battery is detected; if it is detected that the storage battery is in a negative balance state, real-time state data of the vehicle are collected and compared with a set threshold, current-using equipment does not meet the set threshold is shut down, and a generator is made to continuously supply power to the storage battery. Through the mode, negative balance does not occur in electric energy consumed by an electric energy output device and electric appliance loads, and it is guaranteed that feed does not occur in the storage battery.

Owner:BRILLIANCE AUTO

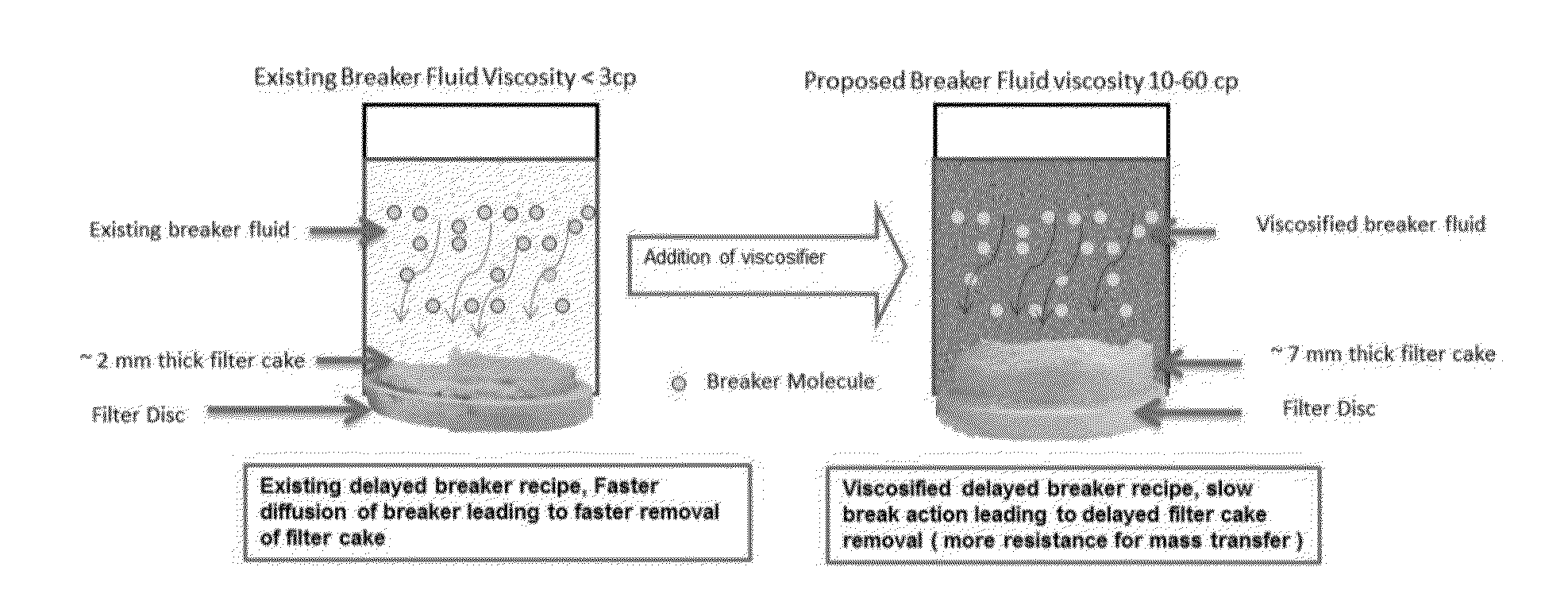

Viscosified breaker fluid compositions for extended delay in filtercake removal at high temperature

The present invention relates to a method of treating a subterranean formation. The present invention also relates to a method of delivering an acid to a subterranean formation. The methods include obtaining or providing a composition that includes filter cake breaker, viscosifier, corrosion inhibitor, and pH buffering agent. The methods also include contacting the composition with a subterranean material downhole. The present invention also relates to a composition for the treatment of a subterranean formation. The composition includes: filter cake breaker, viscosifier, corrosion inhibitor, pH buffering agent, and at least one of drilling fluid, stimulation fluid, fracturing fluid, spotting fluid, clean-up fluid, production fluid, completion fluid, remedial treatment fluid, abandonment fluid, pill, acidizing fluid, cementing fluid, and packer fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

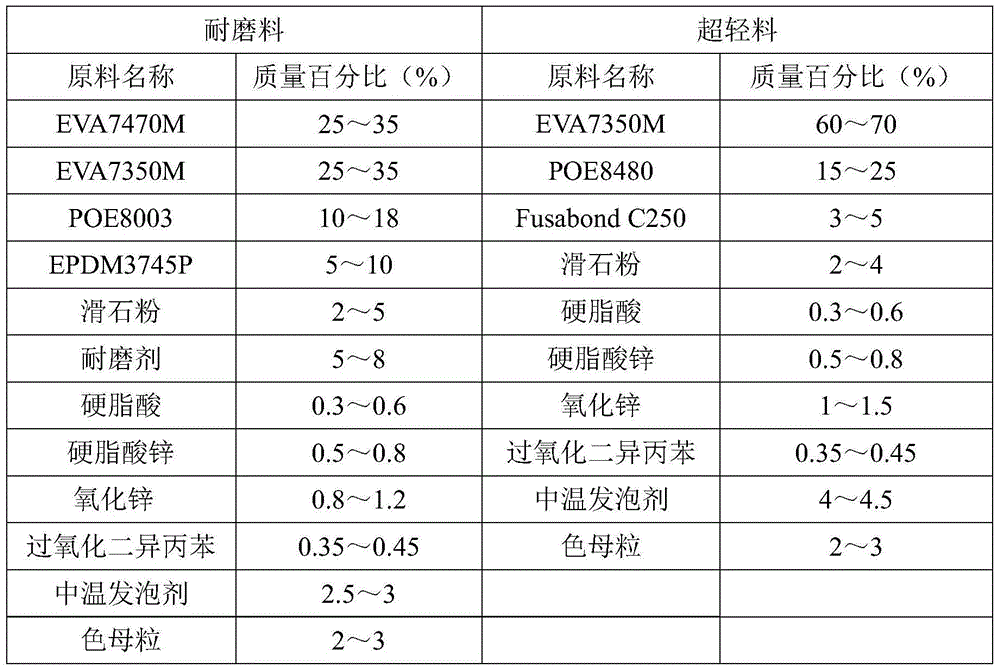

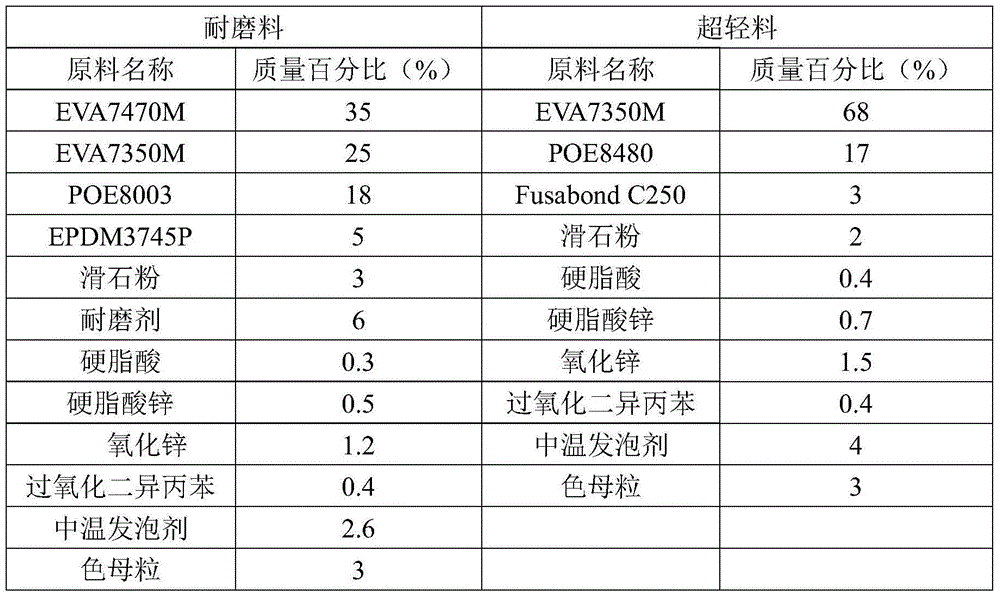

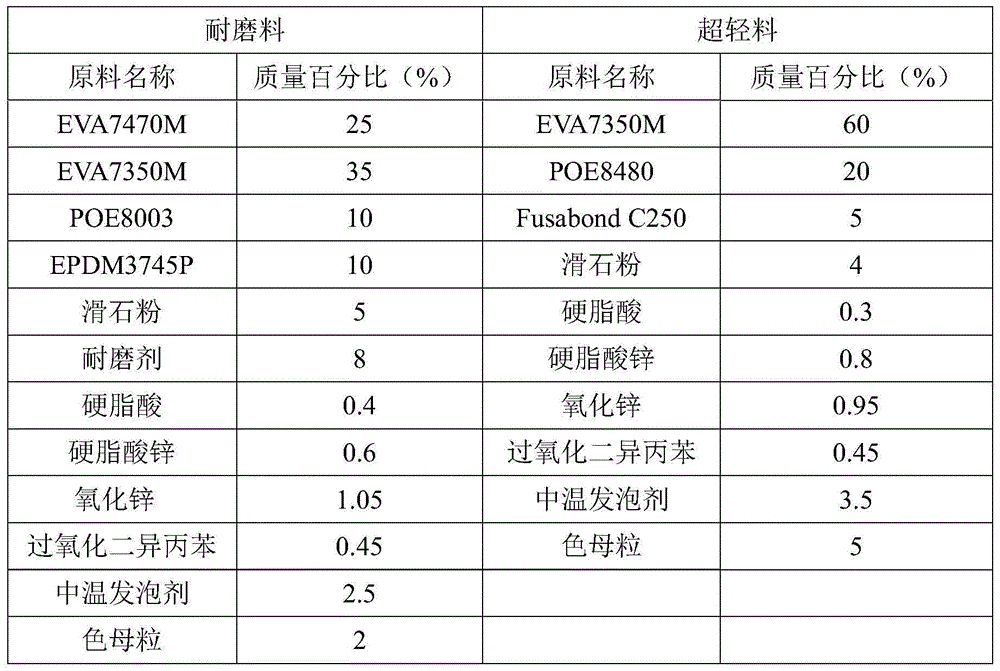

Secondary molding sandwich EVA foaming wear-resistant sports sole and manufacture method thereof

ActiveCN104856344AAchieving wear resistanceMeet portability requirementsSolesDomestic footwearWear resistantCarvacryl acetate

The present invention discloses a secondary molding sandwich EVA foaming wear-resistant sports sole and a manufacture method thereof, and relates to a sole. The secondary molding sandwich EVA foaming wear-resistant sports sole has an upper wear-resistant layer and a lower wear-resistant layer; and a super light material layer is set between the upper wear-resistant layer and the lower wear-resistant layer. The raw material of the super light material layer comprises ethane-vinyl acetate copolymer, ethane- octene copolymer, terpolymer EP rubber, powdered steatile, wear-resisting agent, eleaostearic acid, zine stearate, zinc oxide, dicumyl peroxide, azodicarbonamide and color master batch. The raw material of the super light material layer comprises ethane-vinyl acetate copolymer, ethane- octene copolymer, ethane-acrylic acid copolymer, powdered steatile, eleaostearic acid, zine stearate, zinc oxide, dicumyl peroxide, azodicarbonamide and color master batch. The product is manufactured by secondary molding, therefore the product is wear-resistant and light.

Owner:泉州泰亚鞋业有限公司

Production method of pea starch

The invention discloses a production method of pea starch. Since the technical processes of cleaning-soaking, grinding and residue removing, pulp mixing and separating, and settling are adopted in the method, the purification rate of the starch is enhanced greatly, the color and the luster of the starch are very good, the original toughness can be kept, the nutritive value is high, and the starch is very suitable for processing cold noodles, bean jelly and bean vermicelli.

Owner:孟祥帅

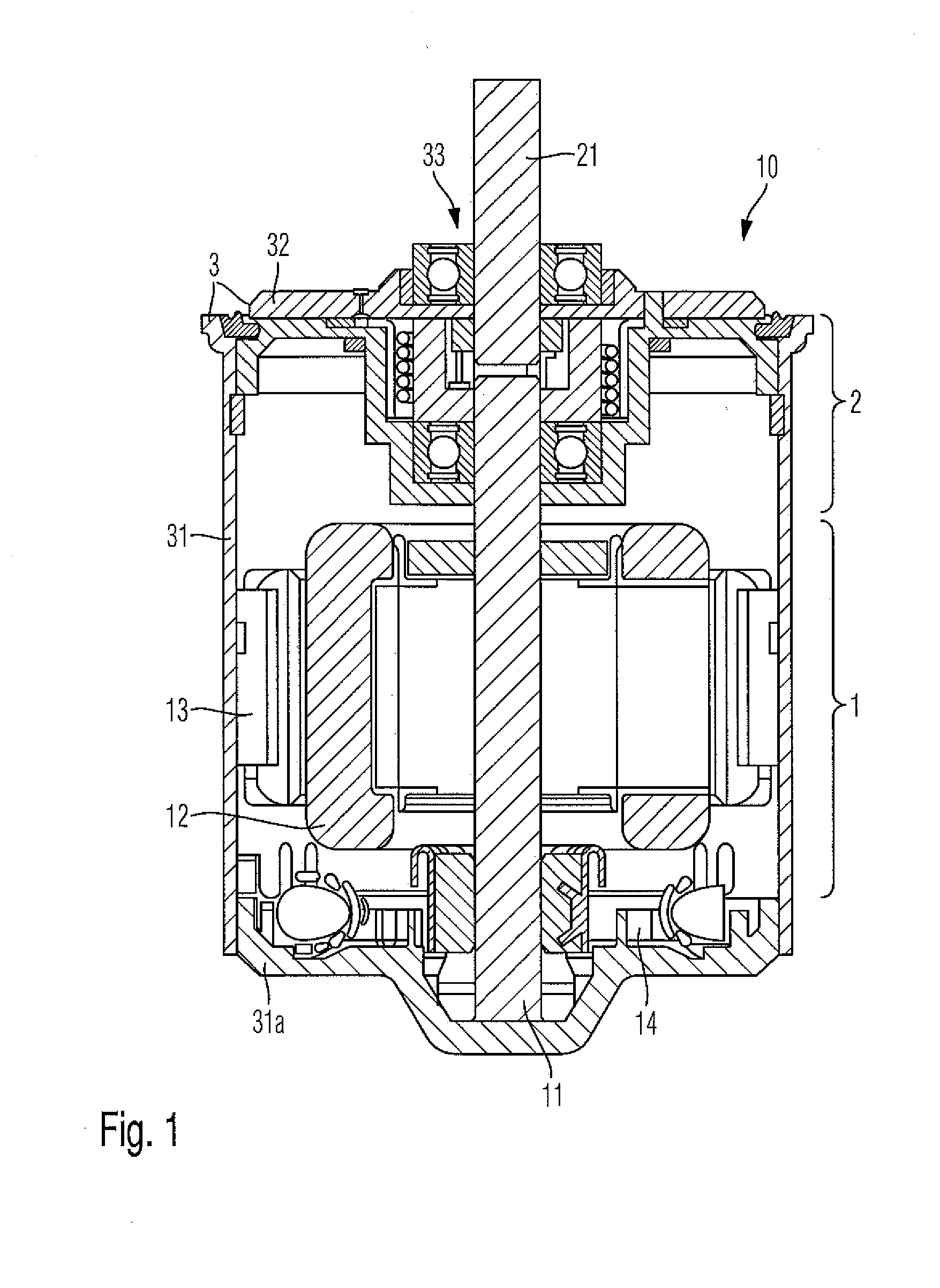

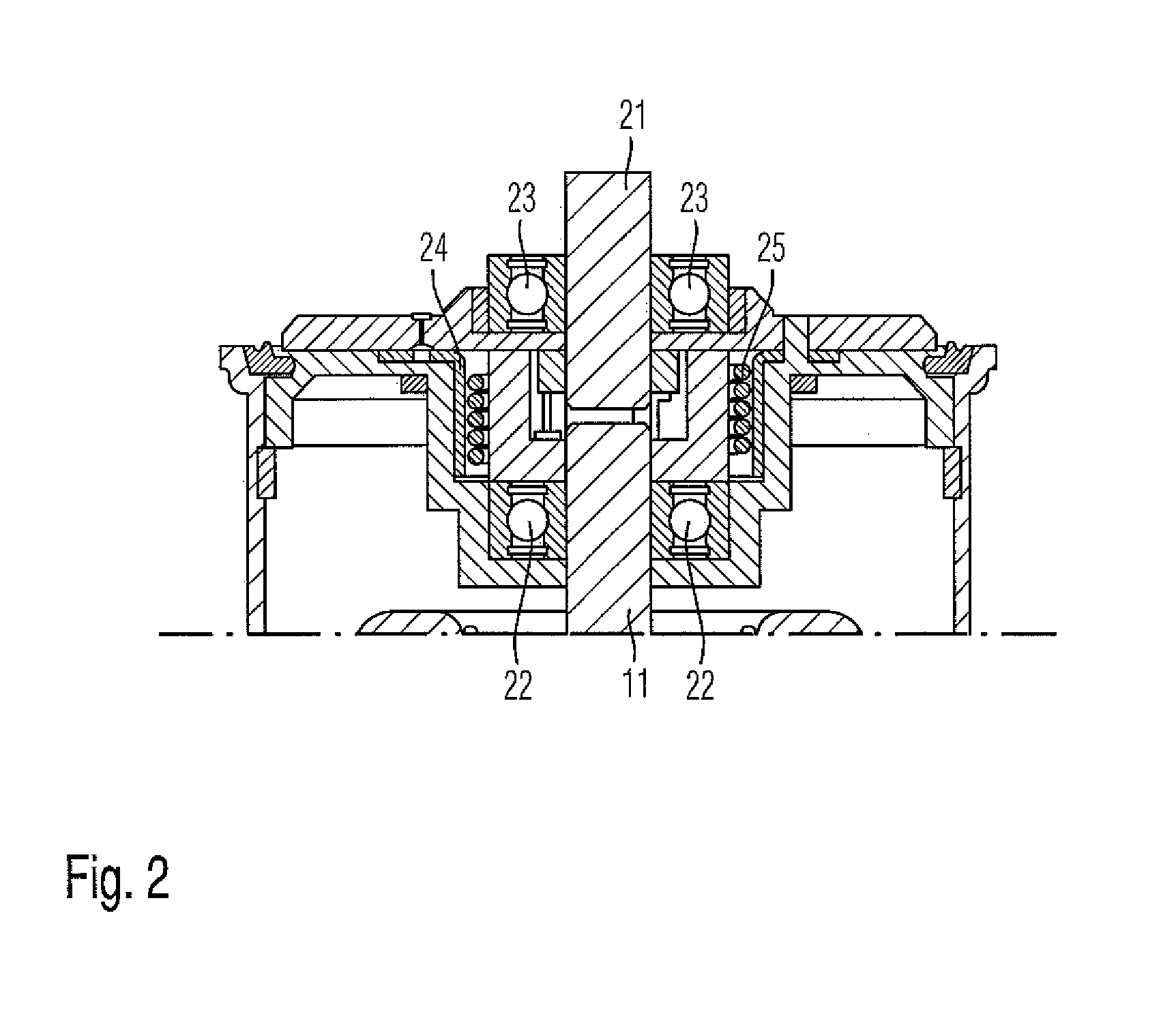

Drive unit and method for operating the drive unit

InactiveUS20140232303A1Robust and durable drive unit constructionSmall sizeElectric motor controlDynamo-electric converter controlEngineeringSelf locking

A drive unit for operating a device, in particular a device in a vehicle and a method for operating a drive unit are provided. An electrical drive assembly and a break assembly are combined and arranged together in a common housing. The breaking assembly could be a mechanical breaking assembly or an electrical break assembly. The break assembly automatically locks the shaft of the electrical drive assembly and thus provides self-locking capabilities.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

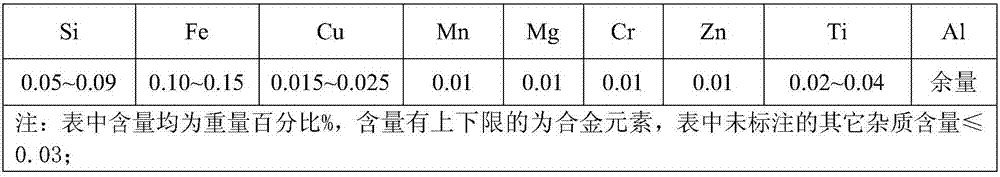

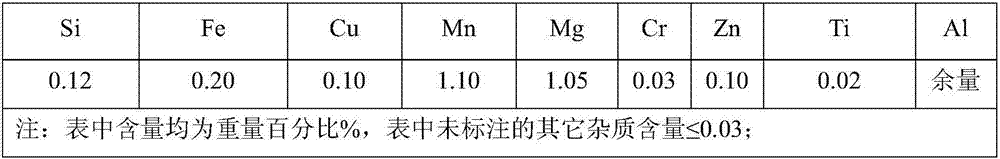

Preparation method of high-strength tableware aluminum foil

ActiveCN106929714AExtend the rest timeEnergy savingMetal rolling arrangementsAluminiumHigh intensity

The invention discloses a preparation method of high-strength tableware aluminum foil. The preparation method comprises the following steps that electrolytic aluminum liquid and an aluminum ingot are smelted into an aluminum melt, an aluminum foil coil with the thickness of 3-5 mm is prepared through a continuous casting process and a continuous rolling process, and then the aluminum foil coil is subjected to cold rolling, longitudinal shearing and side shearing, foil rolling, finished product slitting, finished product annealing and inspection and packaging to prepare the high-strength tableware aluminum foil, wherein the longitudinal shearing and edge shearing, the finished product slitting and the inspection and packaging are carried out according to conventional processes, an aluminum foil roll with the thickness of 0.05-0.095 mm after the finished product annealing is made into the tableware aluminum foil, and after detecting, the tensile strength of the tableware aluminum foil is larger than or equal to 220 Mpa, the elongation rate is larger than or equal to 6%, and the cupping value is larger than or equal to 4 mm. According to the preparation method, the casting process and the secondary remelting process of the aluminum ingot are omitted, and measurement shows that 0.4-0.5% of aluminum loss can be reduced during the process that the aluminum liquid is cast into the aluminum ingot, 2-4% of the aluminum burning loss can be reduced during the secondary remelting process of the aluminum ingot, the energy is saved, and the production efficiency and the finished product ratio are improved.

Owner:LUOYANG LONGDING ALUMINUM

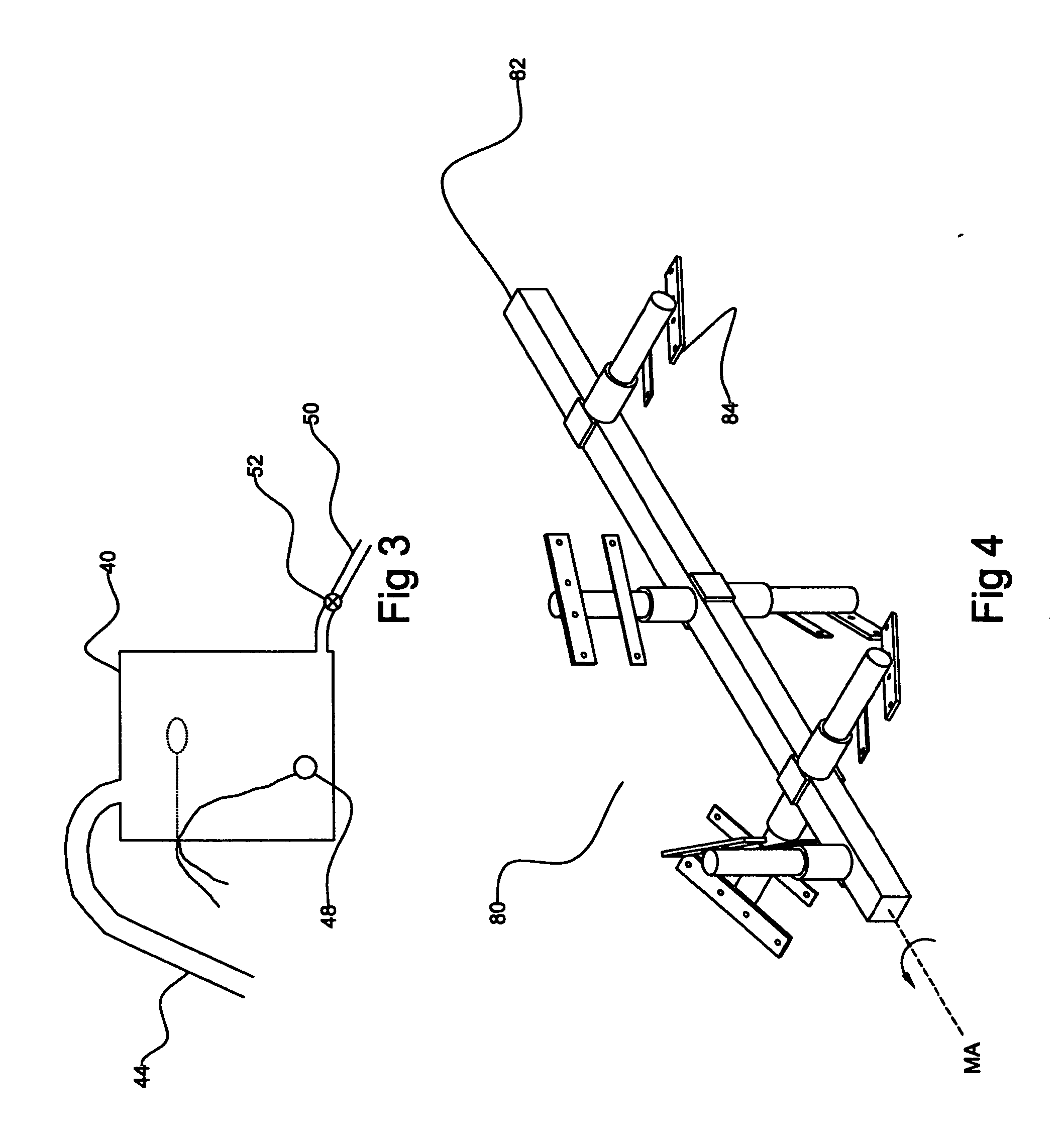

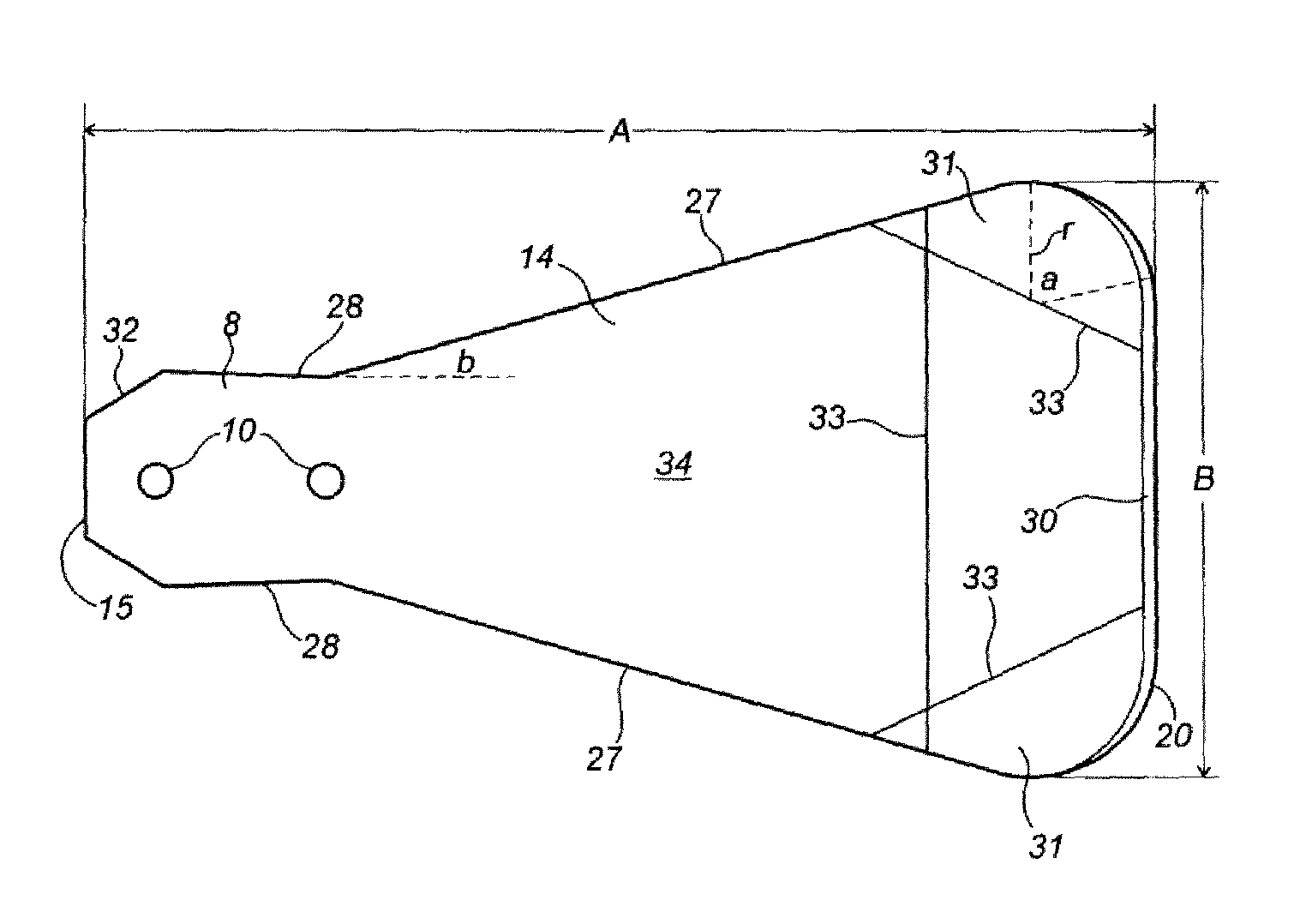

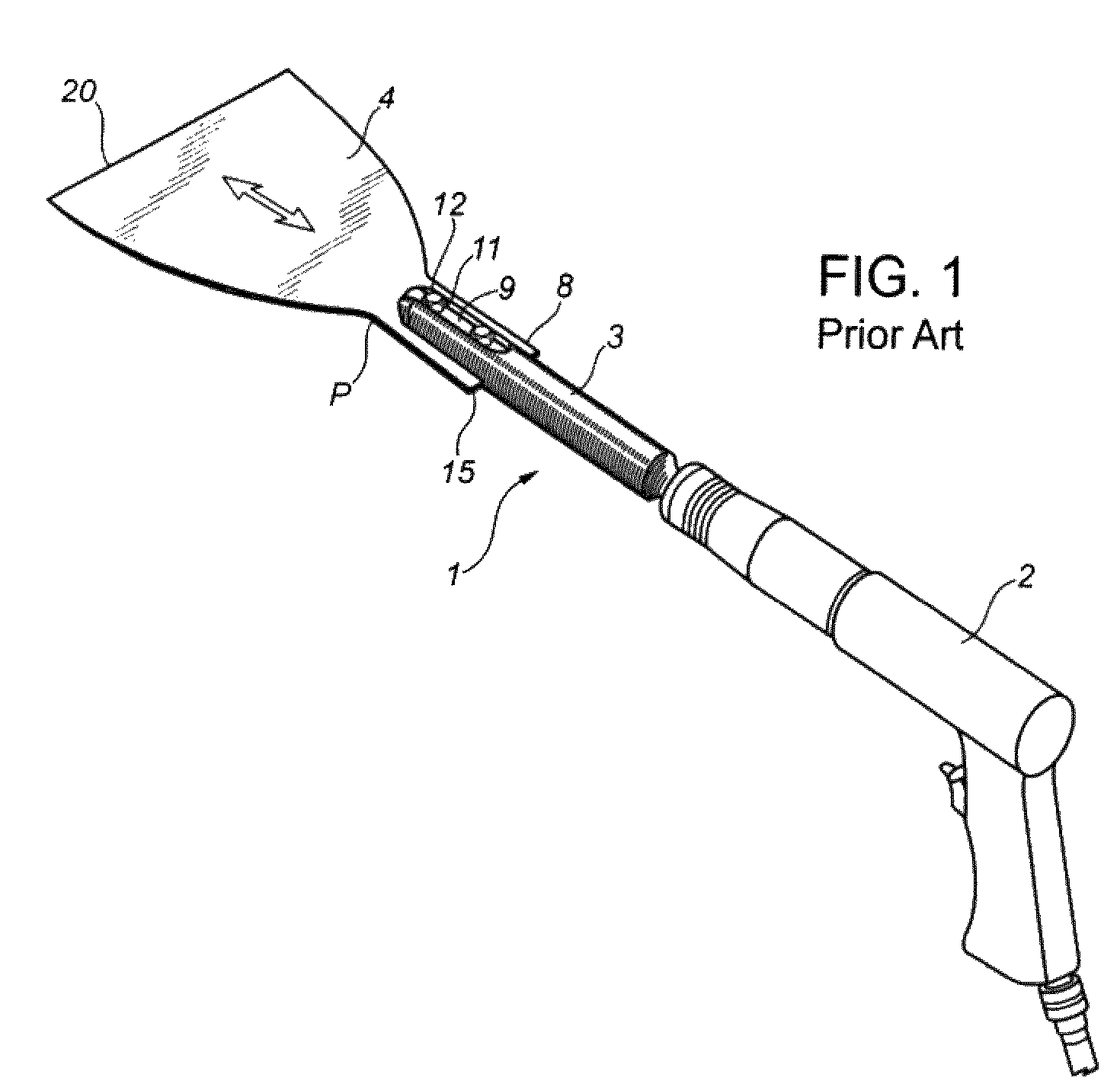

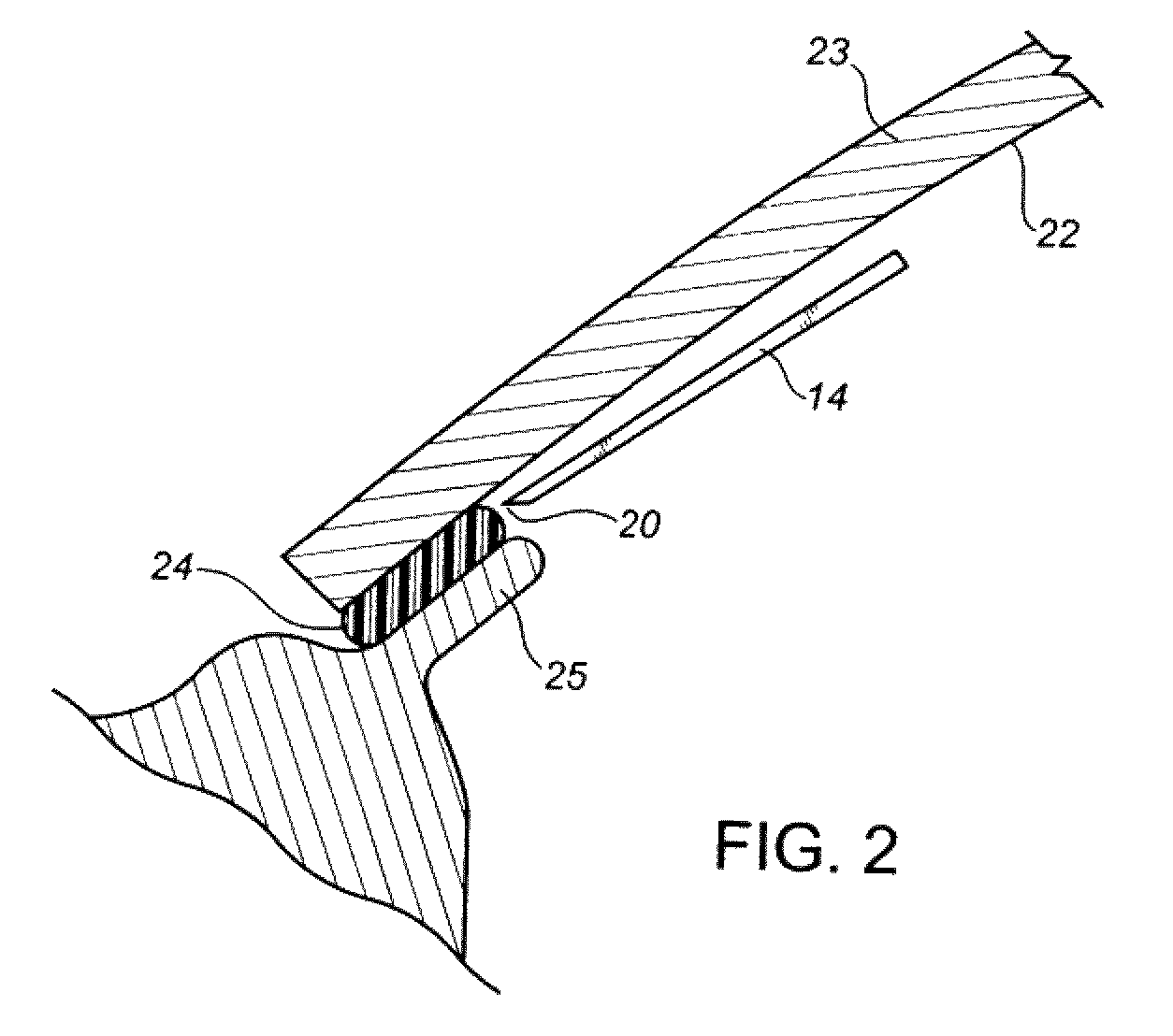

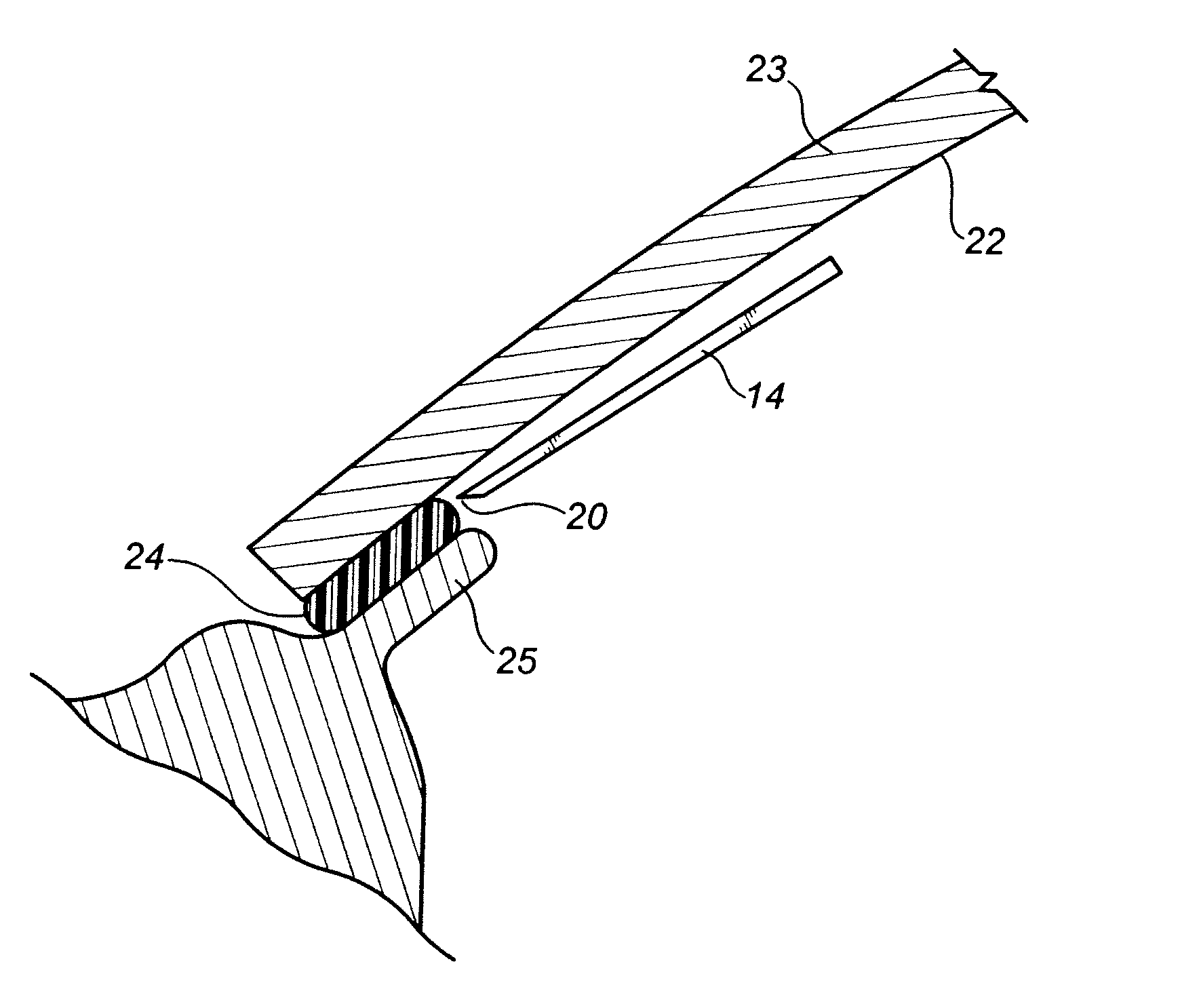

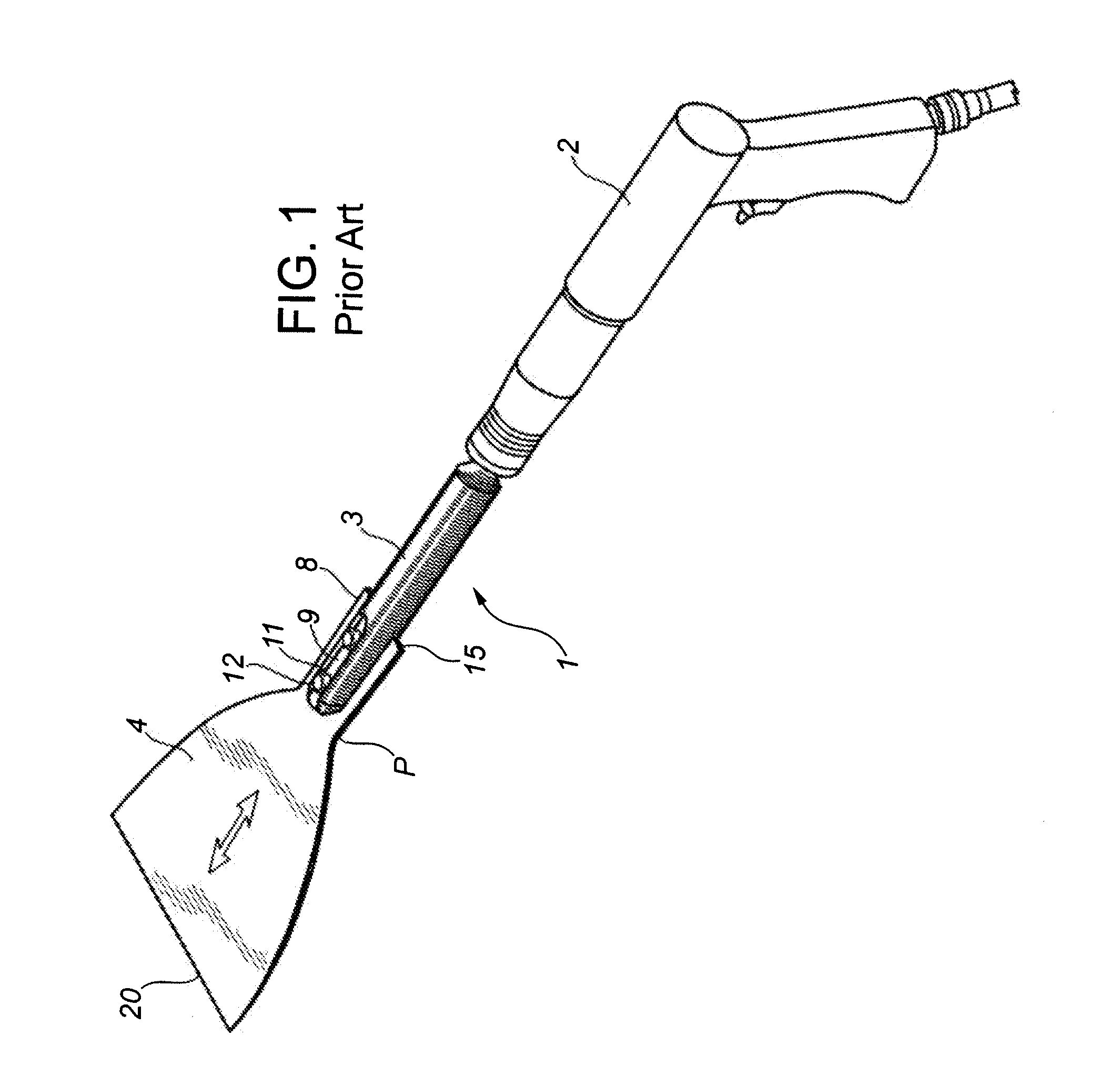

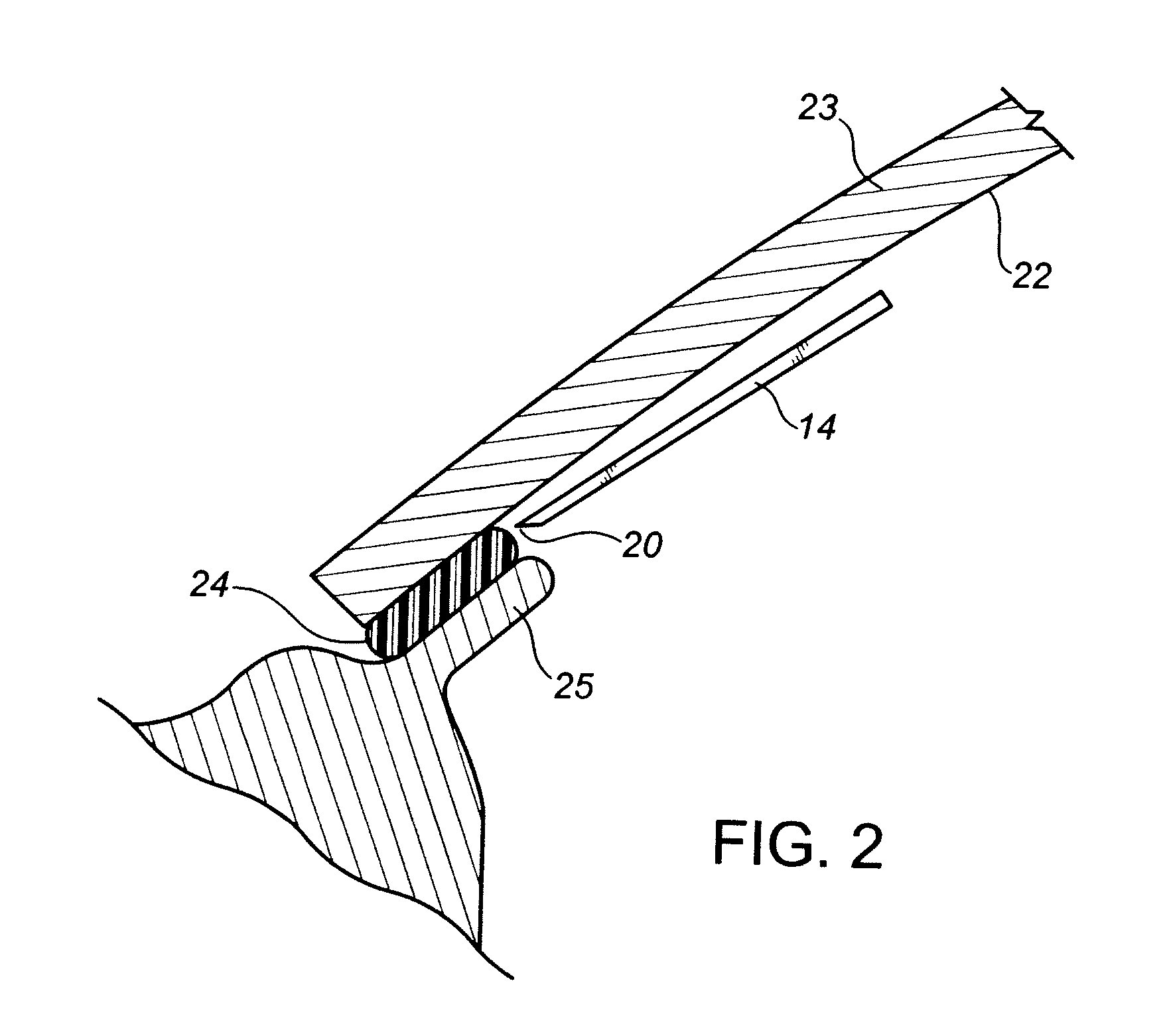

Windshield removal assembly, method and blade for same

InactiveUS7908949B2Rigid enoughSolve the lack of flexibilityMetal sawing devicesTransportation and packagingThin metalReciprocating motion

A windshield removal assembly, method and blade for same, with the thin metal blade having a unique delta-shape. The blade connects at its narrowed shank portion to the shaft of a reciprocating power tool. The blade has front and rear ends, the front end being substantially straight and wider than the blade rear end. The top edge of the blade forms a non-sharpened top edge on the front end and arc portions, while the bottom edge of the blade forms a sharpened bottom cutting edge which extends across the front end of the blade and along at least half of the arc portions. The blade has sufficient rigidity to cut the urethane bed when reciprocated, and sufficient lateral flexibility to conform to the curved surface of the windshield when pressed thereagainst.

Owner:CRYSTAL GLASS CANADA

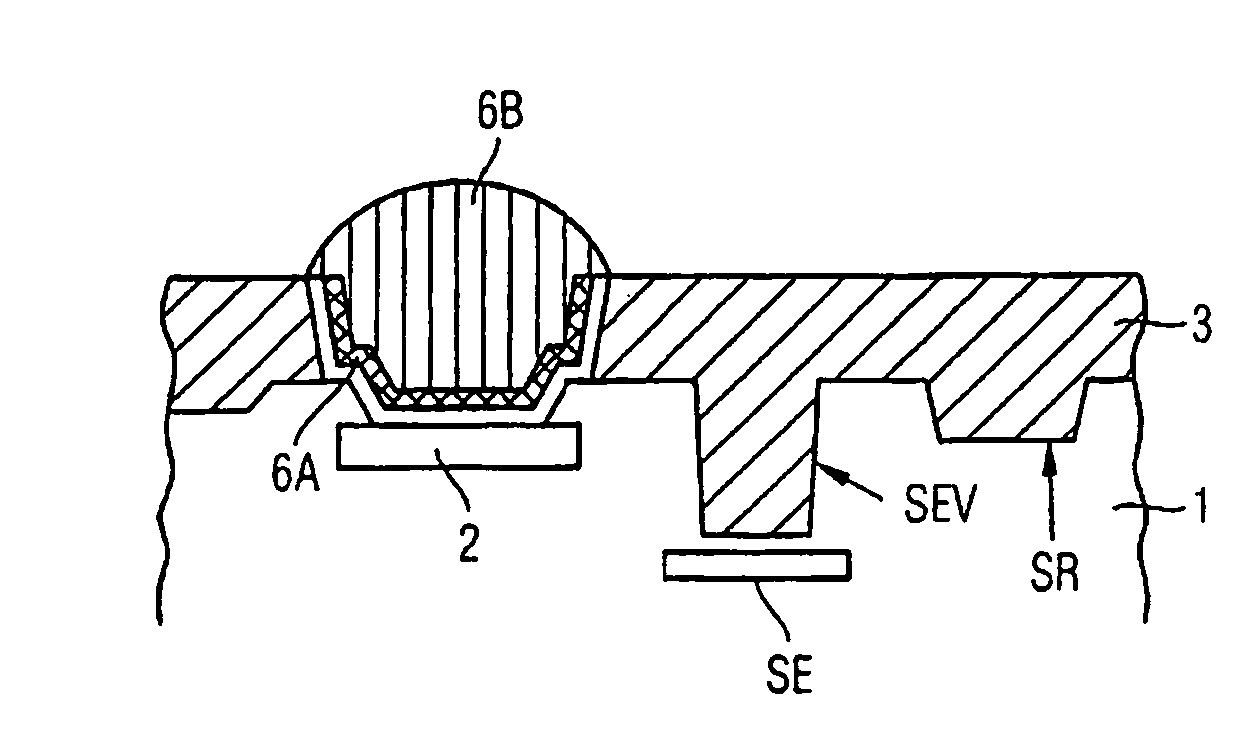

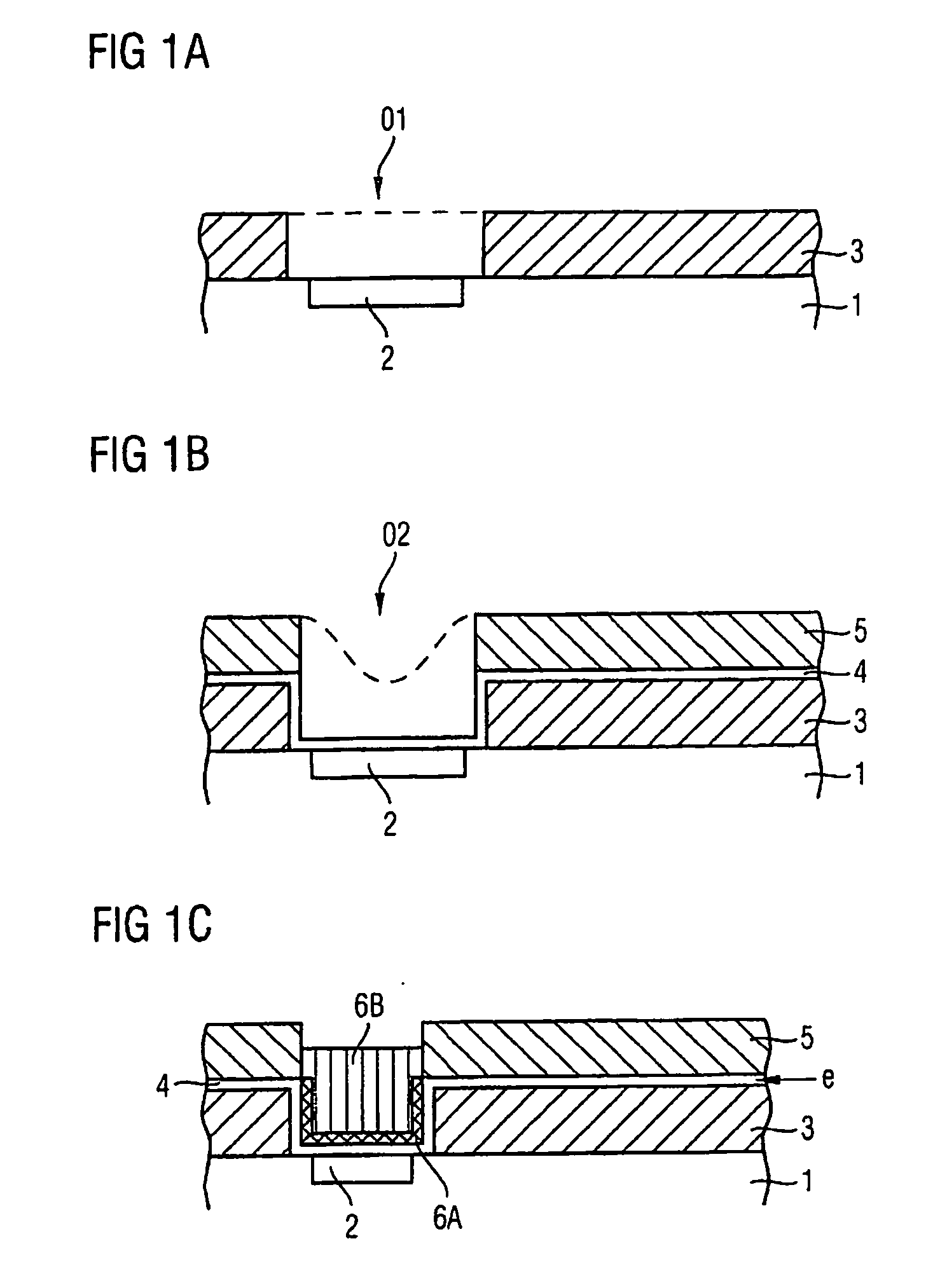

Ultrathin semiconductor circuit having contact bumps and corresponding production method

InactiveUS20060292849A1Improve adhesionReduce breakageSemiconductor/solid-state device detailsSolid-state devicesMicrometerContact layer

The invention relates to an ultrathin semiconductor circuit having contact bumps and to a corresponding production method. The semiconductor circuit includes a bump supporting layer having a supporting layer thickness and having a supporting layer opening for uncovering a contact layer element being formed on the surface of a semiconductor circuit. An electrode layer is situated on the surface of the contact layer element within the opening of the bump supporting layer, on which electrode layer is formed a bump metallization for realizing the contact bump. On account of the bump supporting layer, a thickness of the semiconductor circuit can be thinned to well below 300 micrometers, with the wafer reliably being prevented from breaking. Furthermore, the moisture barrier properties of the semiconductor circuit are thereby improved.

Owner:INFINEON TECH AG

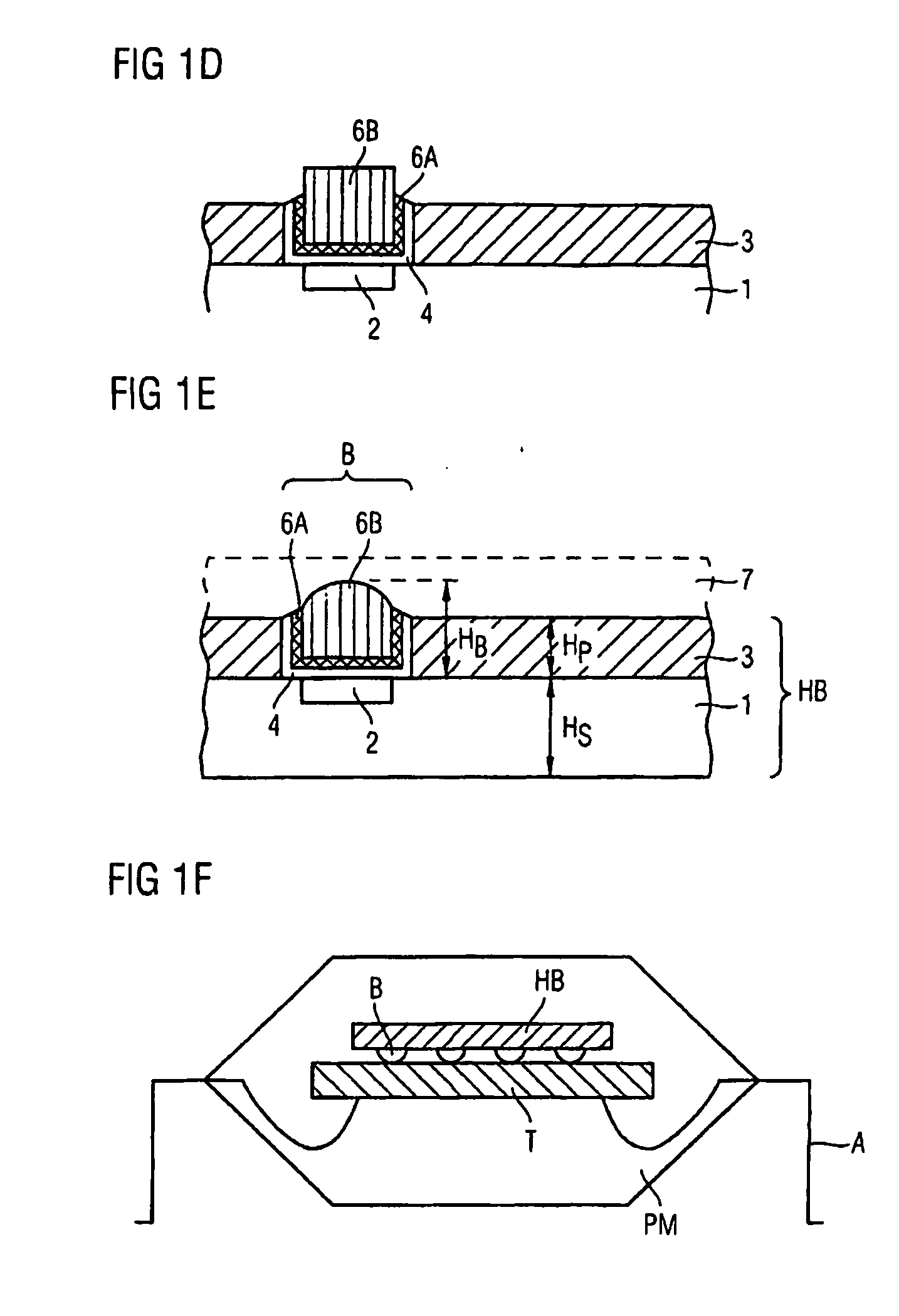

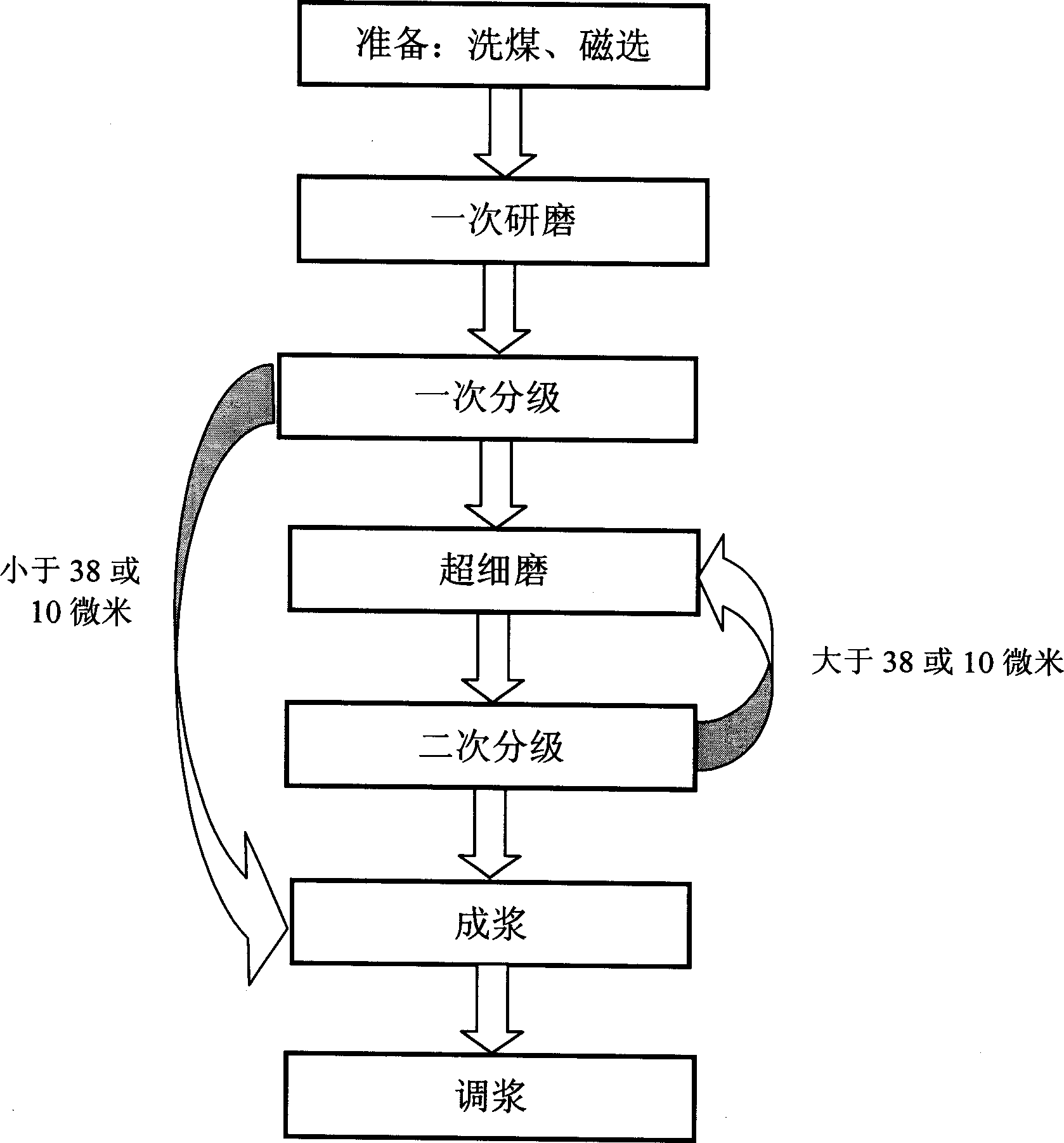

Superfine coal based fluid fuel and its preparation

InactiveCN1456642AReduce apparent viscosityEasy to pumpLiquid carbonaceous fuelsApparent viscositySlurry

A superfine coal-base fluid fuel is prepared from coal particles (4-5 microns in average), water, disperser, stabilizer, sulfur-fixing agent and combustion promoter through preparing raw materials, grinding, classifying, superfine grinding, classifying again, preparing slurry and regulating. Its advantages are low apparent viscosity, high atomizing and combustion effect, and good stability.

Owner:北京金泓毅新技术有限公司

Windshield removal assembly, method and blade for same

InactiveUS20070251361A1Rigid enoughSufficient lateral flexibilityMetal working apparatusMetal-working hand toolsThin metalReciprocating motion

A windshield removal assembly, method and blade for same, with the thin metal blade having a unique delta-shape. The blade connects at its narrowed shank portion to the shaft of a reciprocating power tool. The blade has front and rear ends, the front end being substantially straight and wider than the blade rear end. The top edge of the blade forms a non-sharpened top edge on the front end and arc portions, while the bottom edge of the blade forms a sharpened bottom cutting edge which extends across the front end of the blade and along at least half of the arc portions. The blade has sufficient rigidity to cut the urethane bed when reciprocated, and sufficient lateral flexibility to conform to the curved surface of the windshield when pressed thereagainst.

Owner:CRYSTAL GLASS CANADA

Efficient filling machine for clothing detergent processing and processing technology of efficient filling machine

PendingCN112850614AHigh precisionPracticalRotating receptacle mixersLarge containersMachining processManufacturing engineering

The invention discloses an efficient filling machine for clothing detergent processing and a processing technology of the efficient filling machine, and belongs to the field of detergent production. According to the technical scheme, the efficient filling machine comprises a workbench, the top of the workbench is fixedly connected with a frame, and the bottom of the workbench is fixedly connected with a first motor. An output shaft of the first motor penetrates through the workbench and is fixedly connected with a containing disc, filling bottles which are uniformly distributed are arranged at the top of the containing disc, penetrate through the containing disc and extend to the outside of the containing disc, a controller is fixedly connected to the bottom of the workbench, a storage hopper is fixedly connected to the inner wall of the frame, and a pretreatment tank is rotationally connected to the top of the frame. According to the efficient filling machine, by arranging pressing devices, under driving of electric push rods and fixing plates, perfect contact between pressing plates and the filling bottles is achieved, a third electromagnetic valve enters the filling bottles, the filling precision is high, the situation of drip leakage in the filling process is avoided, and practicability is high.

Owner:时协全

Process for producing ink composition

InactiveUS20060116441A1Good storage stabilityImprove brittlenessInksCoatingsDispersed mediaPolymer chemistry

Owner:FUJIFILM HLDG CORP +1

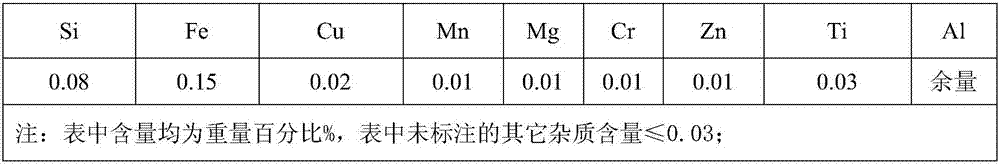

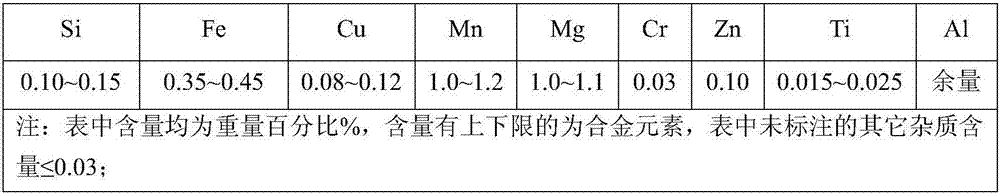

Preparation method of high-strength domestic aluminum foil

InactiveCN110484755AGuaranteed melt qualityExtend the rest timeMetal rolling arrangementsSocial benefitsEconomic benefits

The invention discloses a preparation method of a high-strength domestic aluminum foil. Compared with 8006 alloy composition, the contents of Si and Mn are unchanged, the content of Fe is decreased to1.1 to 1.2 from 1.4 to 1.5, the content of Cu is decreased to 0.05 from 0.25, the content of Zn is decreased to 0.02 from 0.25, trace amounts of Cr and Ti are added, Al comprises 80 to 90 parts of electrolytic aluminum liquid and 10 to 20 parts of aluminum ingots with the impurity of greater than or equal to 99.7% in parts by weight, an aluminum roll with the thickness of 3 to 5 mm is prepared through a continuous casting and rolling working procedure, and the high-strength domestic aluminum foil is prepared through cold rolling, longitudinal edge trimming, foil rolling, finished product slitting, finished product annealing and packaging after inspection. According to the method, one to two times of sub-processing is omitted compared with a traditional production technology, the production cost is reduced, the method is energy-saving and cost-reducing, emission of carbon dioxide is reduced, the production cost is reduced, and the method has obvious economic benefits and social benefits.

Owner:LUOYANG LONGDING ALUMINUM

Medical auto-switchable infusion tube

The invention discloses a medical auto-switchable infusion tube, characterized by comprising a lower infusion hose, a left upper infusion hose, and a right upper infusion hose; the lower infusion hoseis provided with a dropper, a speed regulator and a venous needle sequentially from top to bottom; the left upper infusion hose is provided with a left air filter and a left cork puncture unit sequentially from bottom to top; the right upper infusion hose is provided with a right air filter and a right cork puncture unit sequentially from bottom to top; the upper end of the lower infusion hose iscommunicated with a lower outlet of a switch box; the lower ends of the left and right upper infusion hoses are communicated with left upper inlet and right upper inlets of the switch box respectively; a left flow path allowing the left upper left inlet of the switch box to be communicated with its lower outlet and a right flow path allowing the right upper inlet of the switch box to be communicated with its lower outlet are arranged in the switch box correspondingly; a liquor auto-switching structure is arranged inside the switch box. The medical auto-switchable infusion tube can provide automatic switching of medicinal liquors and has the advantages that workload is reduced for medical personnel and rest time is extended for a patient.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

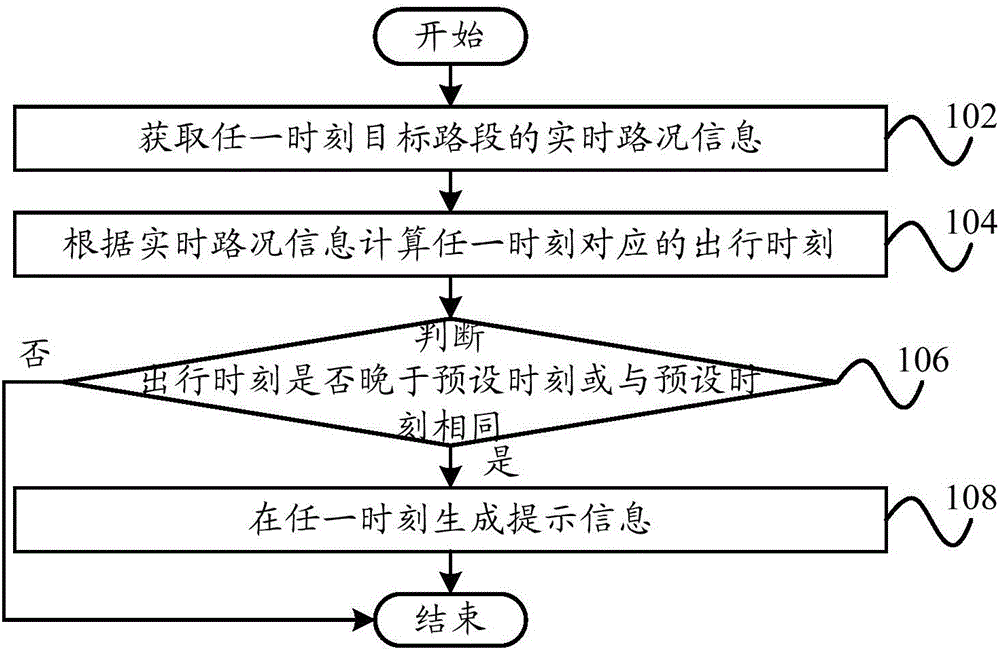

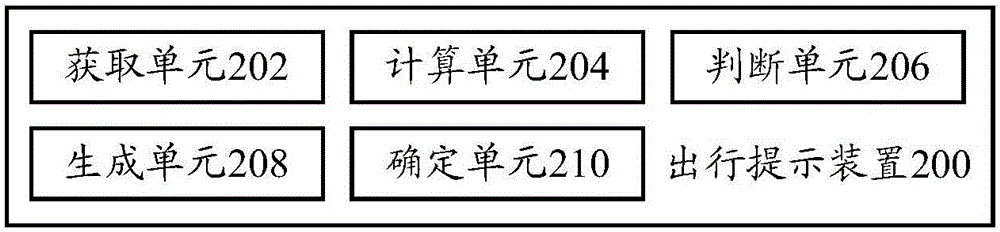

Travel prompting method, travel prompting device, and terminal

InactiveCN106056364AReduce the chance of being late for a tripExtend the rest timeOffice automationResting timeRest time

The invention provides a travel prompting method, a travel prompting device, and a terminal. The travel prompting method includes acquiring the real-time road condition information of the target road at any time; calculating the travel time corresponding to any time based on the real-time road condition information; determining whether the travel time is later than the preset time or the same as the preset time; and generating the prompting information at any time when the travel time is determined to be later than the preset time or the same as the preset time. According to the invention, the user has no needs to manually set the prompting time, the travel late probability of the user can be reduced, and also the rest time of the user can be prolonged, so that the flexibility of prompting is improved, and the user's experience is enhanced.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Front labeling transparent tag and production method thereof

InactiveCN101823400AReduce manufacturing costShortened decorative effectDecorative surface effectsSynthetic resin layered productsSolventComputer science

The invention discloses a front labeling transparent tag and a production method thereof. The production method comprises the following steps that: PP transparent film of different specifications is selected firstly to be spread and adhered onto a working table surface, then the film is silk-screened with color and is dried, then the film is silk-screened with separation gold oil and is dried again, the film is silk-screened with white color as paint base, finally the film is silk-screened with positive-rotation viscose, after being dried, the film is arranged into a drying chamber to be statically held, and after being attached with separation paper, the film is rolled. The entire structure adopts the transparent PP film as a carrier to be sequentially attached with a pattern layer, a separation gold oil layer, a white color paint-base layer and a positive-rotation viscose layer, and the adhesion position can be observed through the PP transparent film, so the adhesion accuracy and convenience can be improved, the adhesion quality and the adhesion speed can be ensured, and the harm of the traditional solvent on the operator and the pollution on the environment can be prevented; and moreover, the front labeling transparent tag has low production cost and good decorative effect, and is particularly suitable for being directly adhered onto the top-grade light material.

Owner:刘桂清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com