Patents

Literature

152results about How to "Extended soaking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

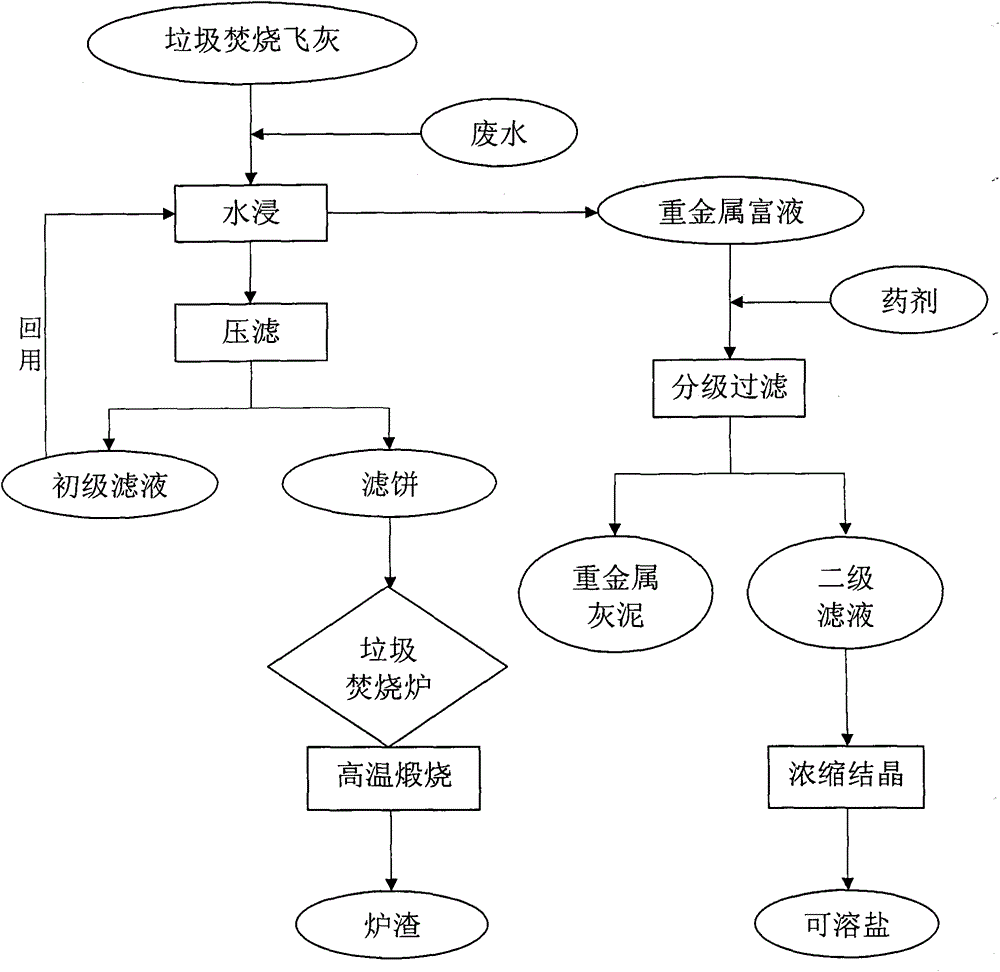

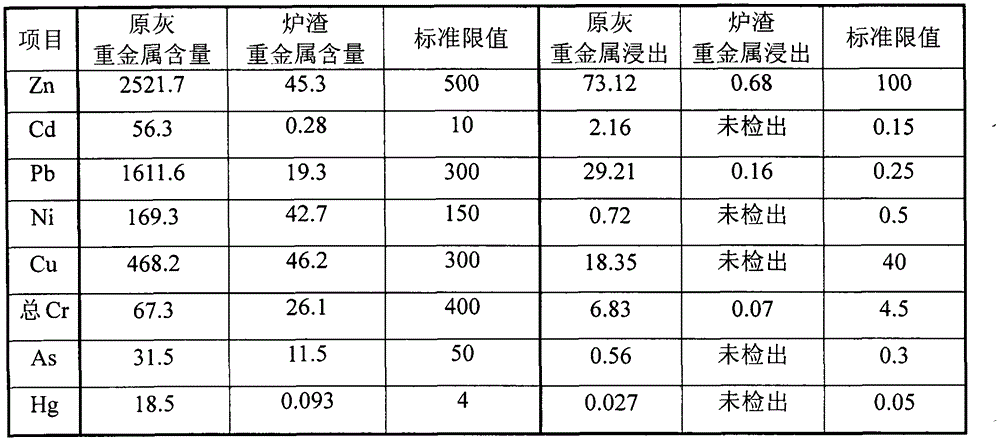

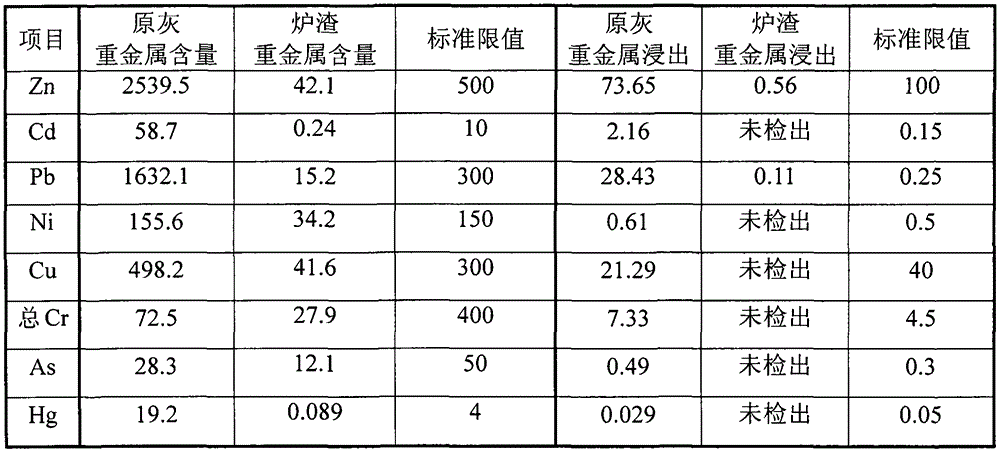

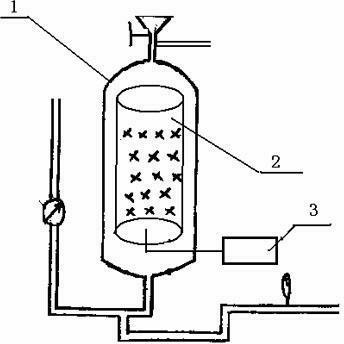

Technology for reducing waste incineration fly ash via water logging pretreatment

InactiveCN104084415AAchieve separationLoss of mobilitySolid waste disposalReduction treatmentResource utilization

The invention relates to a technology for reducing waste incineration fly ash via water logging pretreatment, and the technology is particularly suitable for the treatment of waste incineration fly ash with salt content higher than 20%. A water logging dechlorination manner is used for treating waste incineration fly ash; by prolonging the logging time, the water consumption is greatly reduced, a subsequent wastewater treatment process is simplified at the same time and a soluble salt resource is recycled; before fly ash enters into a furnace, most of heavy metals and chlorine salts are removed, a matrix of fly ash is purified, and by virtue of existing incineration equipment of waste incineration power plants, pollutants such as dioxin are thoroughly degraded, so that the overall normal running of a waste incineration line is ensured and the harmless and reduction treatment of waste incineration fly ash is realized. The technology has a characteristic of correct in-situ treatment, and is simple in process and low in investment and operation costs; by gathering most of heavy metals and salts in heavy metal plaster and gathering little of the two in secondary fly ash, the reduction of waste incineration fly ash is realized, and then a favorable foundation is laid for the subsequent further treatment or resource utilization.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

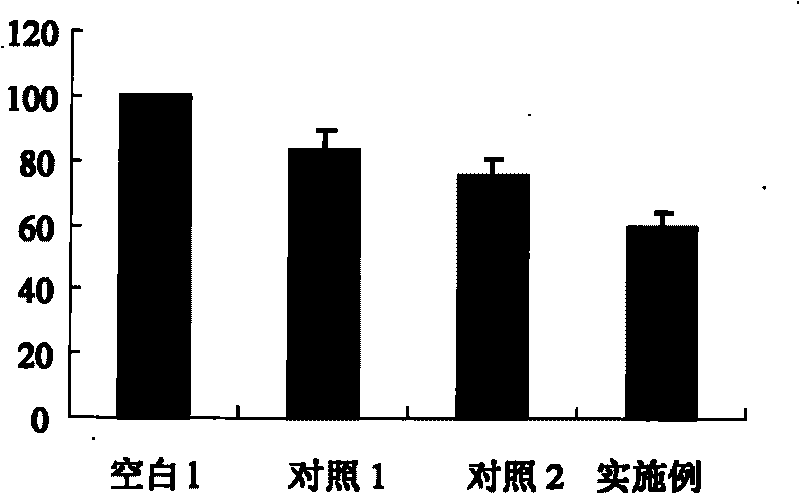

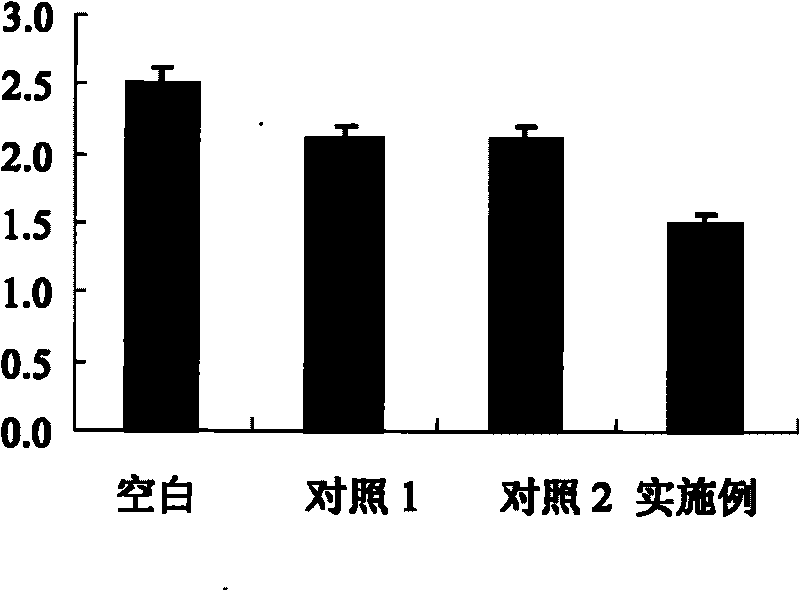

Cigarette tar-reducing harm-reducing process and supercritical extraction device for tobacco shred or tobacco leaves

The invention belongs to the technical field of cigarette production, and particularly relates to a cigarette tar-reducing harm-reducing process, which includes placing tobacco shred or tobacco leaf in a rotating device for supercritical fluid extraction, and treating the extracted tobacco shred or tobacco leaves by microwave or hot air at 80 DEG C-150 DEG C after extraction. By the cigarette tar-reducing harm-reducing process, main aromatic ingredients of the tobacco leaf are maintained, and nicotine or other harmful ingredient precursors in the tobacco leaf are selected lowered. By the cigarette tar-reducing harm-reducing process, cigarette quality can be improved, release amount of tar and harmful ingredients in cigarette smoke can be reduced, and cigarette safety can be improved.

Owner:CHINA TOBACCO HENAN IND

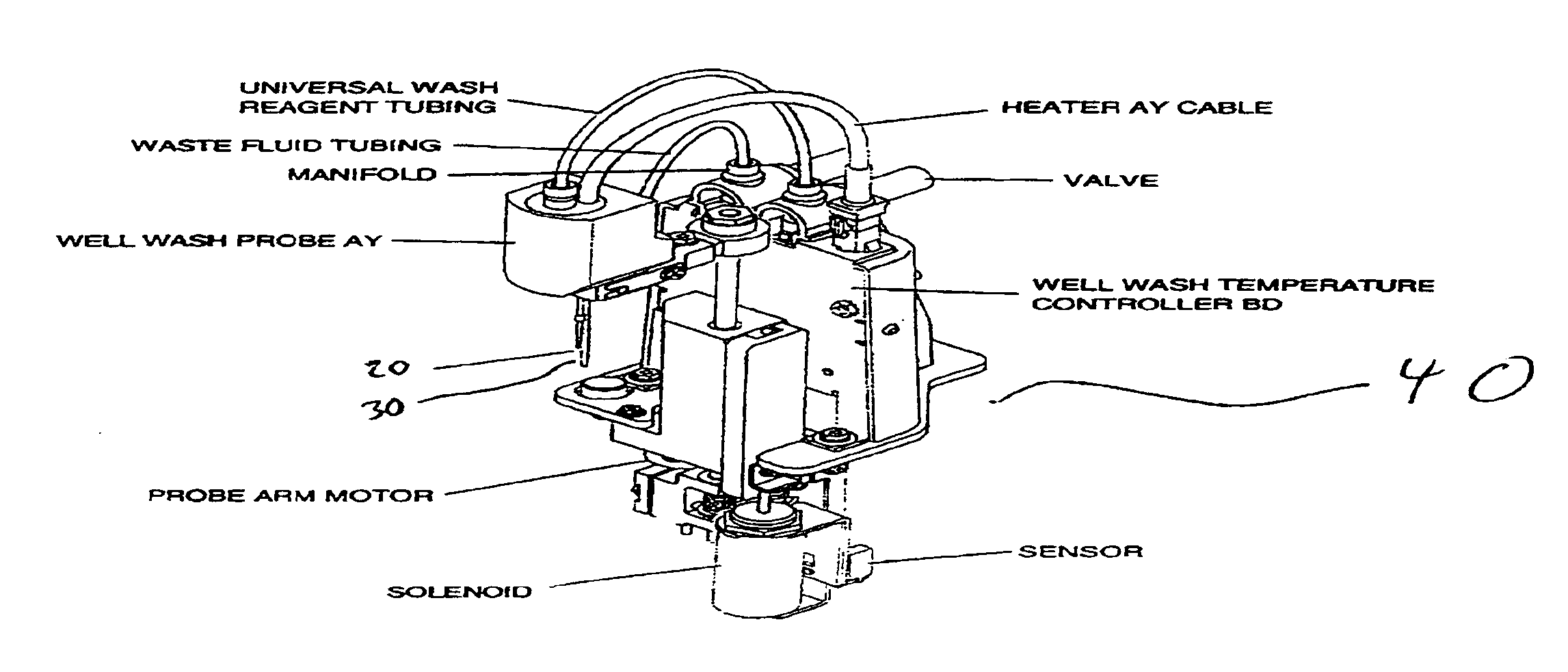

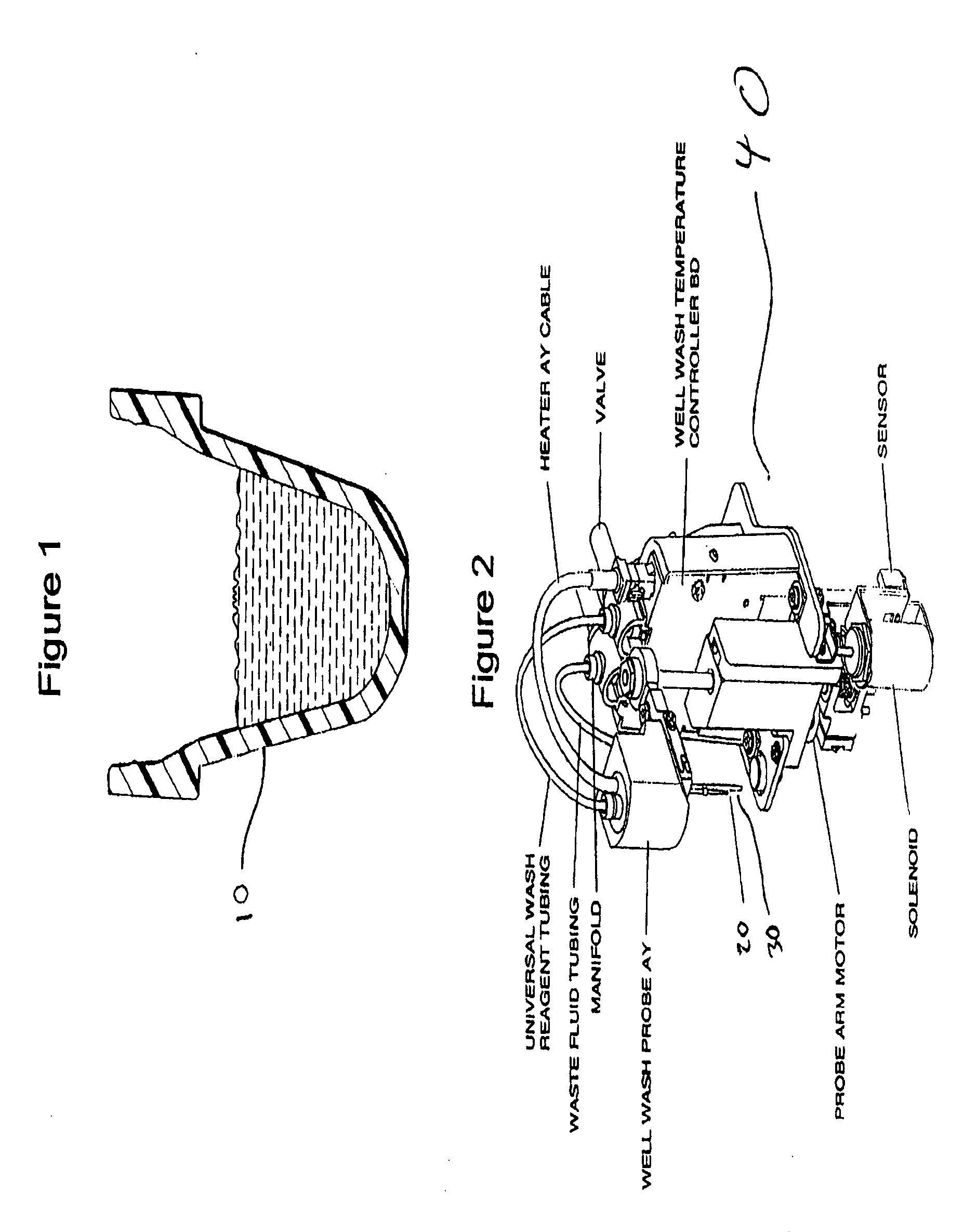

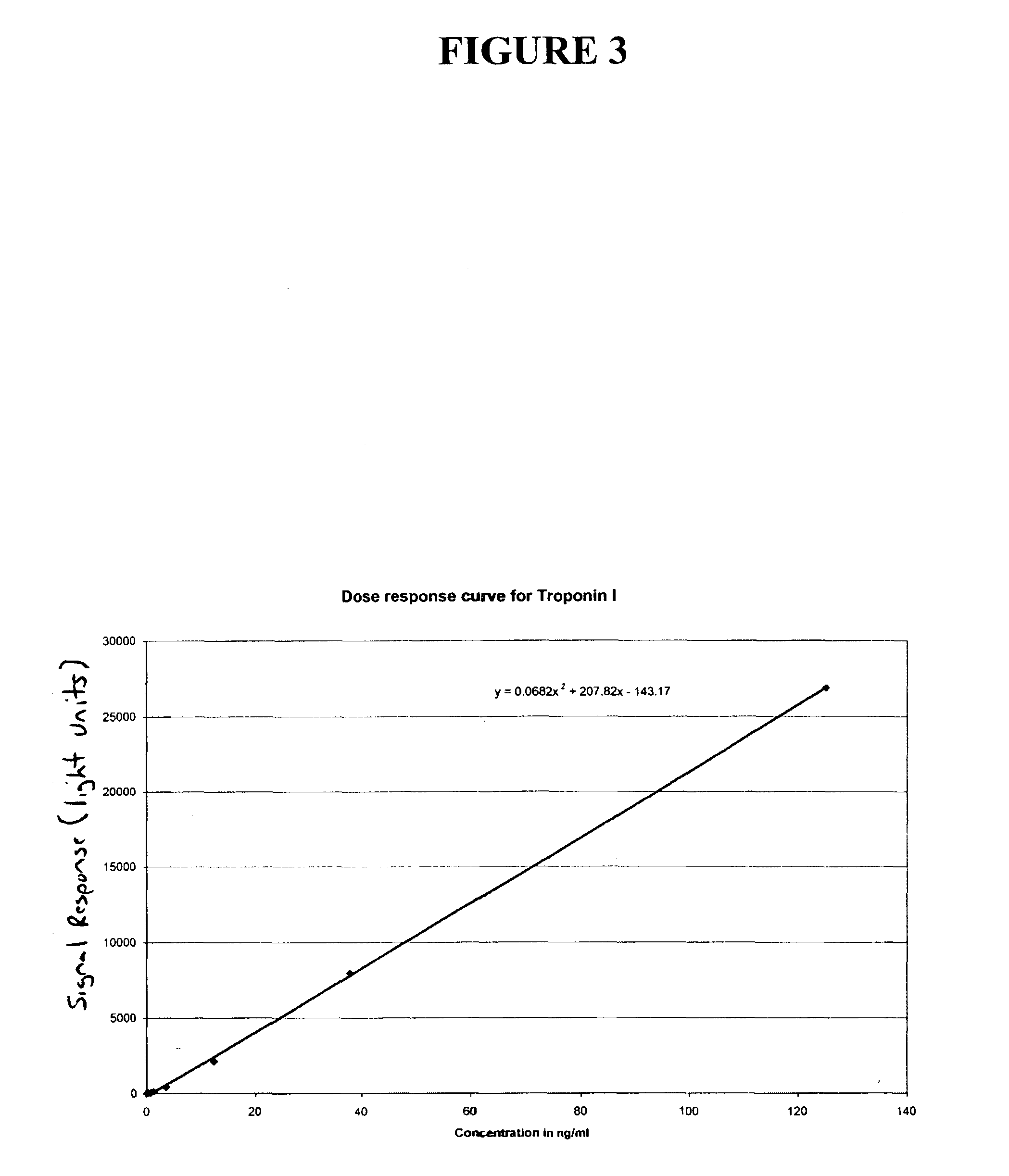

Wash process for removing undesired components in samples being analyzed

InactiveUS8329475B2Reduce the amount of solutionIncrease volumeWithdrawing sample devicesPreparing sample for investigationAnalyteEngineering

Owner:ORTHO-CLINICAL DIAGNOSTICS

Copper alloy antirust agent

InactiveCN101353793AExtended soaking timeMetallic material coating processesWater solubleCleansing Agents

The invention discloses a copper alloy anti-rusting agent which comprises a rust remover, a passivator, a surfactant, a degreaser and pure water, wherein, the weight percentage of the rust remover is 10 percent to 20 percent, the passivator is 5 percent to 15 percent, the surfactant is 1 percent to 10 percent and the degreaser is 1 percent to 5 percent, and the rest is pure water. The copper alloy anti-rusting agent is a water-soluble cleaning agent, has good dust-removing effect to the surface of copper alloy, little corrosion, high-efficiency degreasing performance and anti-rust function after cleaning, keeps an antioxidant surface for a long time, meets the requirements of environment protection and has the advantages of reasonably-designed formula, simple preparation technology and lower cost.

Owner:JIANGSU HAIXUN IND GROUP SHARE

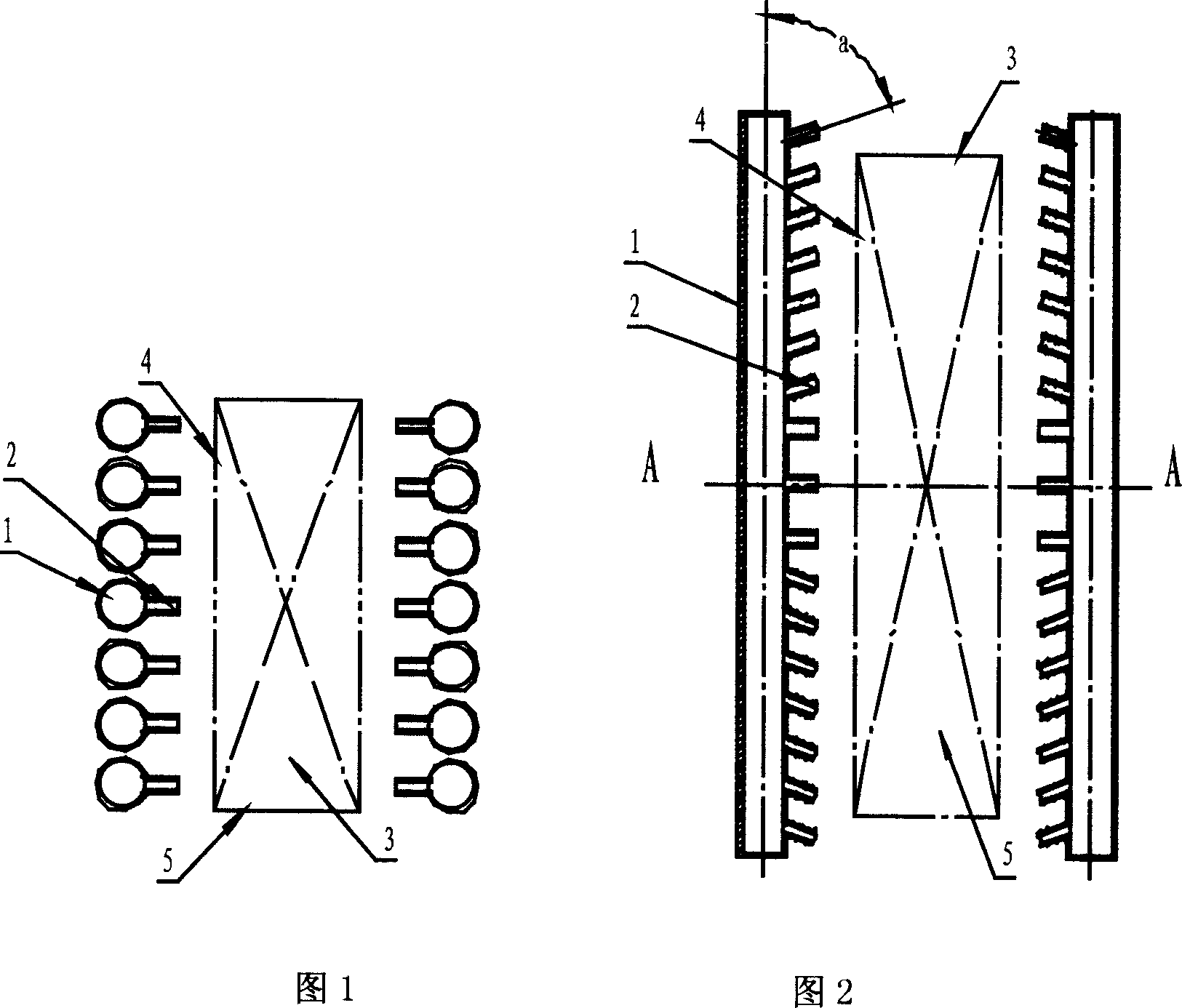

Method for preventing end-face spray quenching cracking of quenching piece by changing spray angle

InactiveCN101012491AReduce cooling intensityIncrease cooling intensityFurnace typesHeat treatment process controlDielectricQuenching

The invention discloses an end-face spray quenching crack-preventing method of quenching piece through changing spraying angle in the heat disposal domain of metal material, which is characterized by the following: placing quenching piece in the quenching equipment with pipe; making quenching piece with lateral and end faces; setting lateral face as rapid freezing face only; paralleling lateral face and pipe; setting the end face of quenching piece perpendicular to pipe; flowing quenching dielectric through pipe; displaying angle a (0-90 deg) for pipe and lateral face of quenching piece; fitting for cooling lateral face of quenching piece; avoiding crack effectively.

Owner:SHANGHAI JIAO TONG UNIV

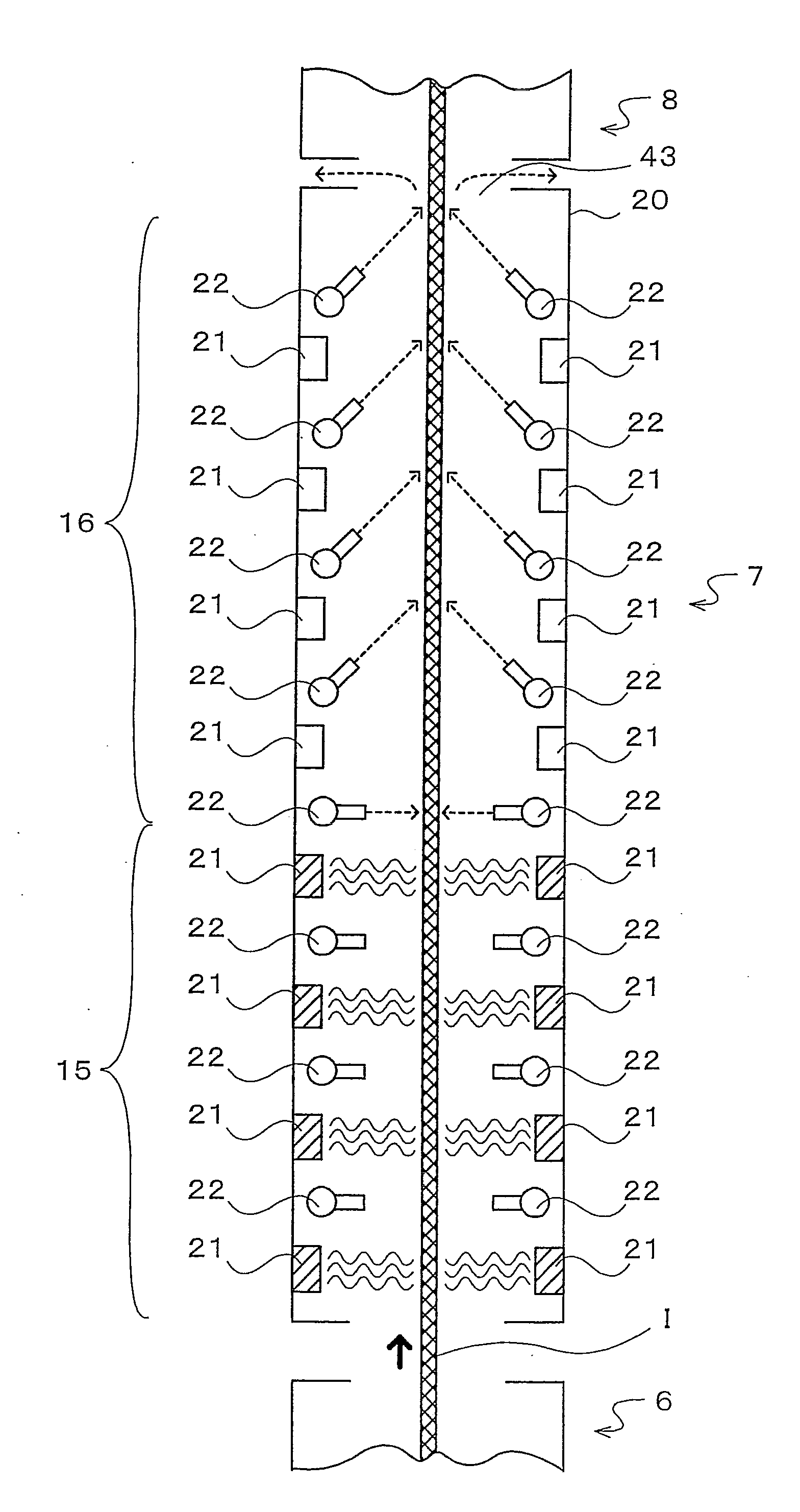

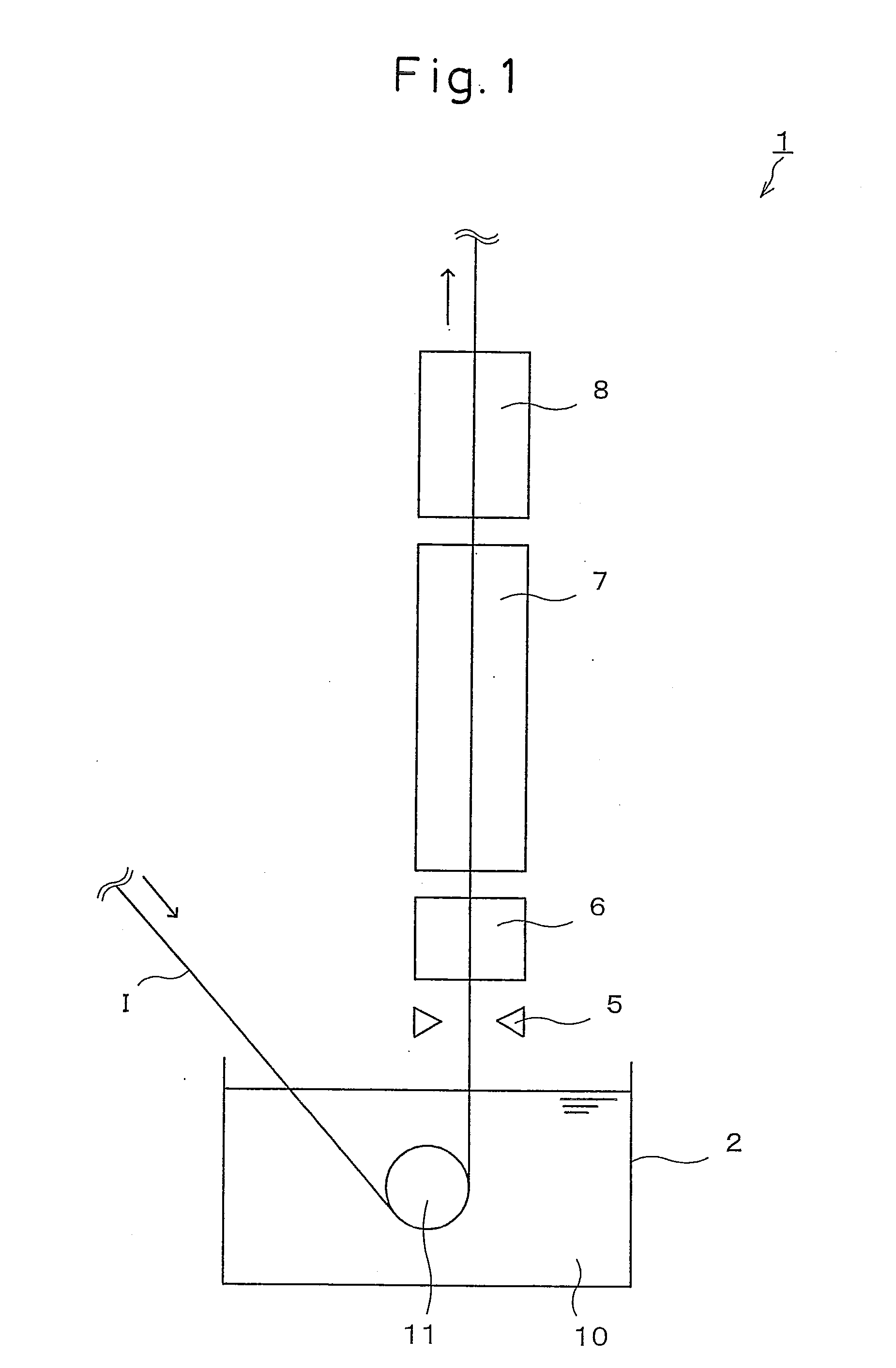

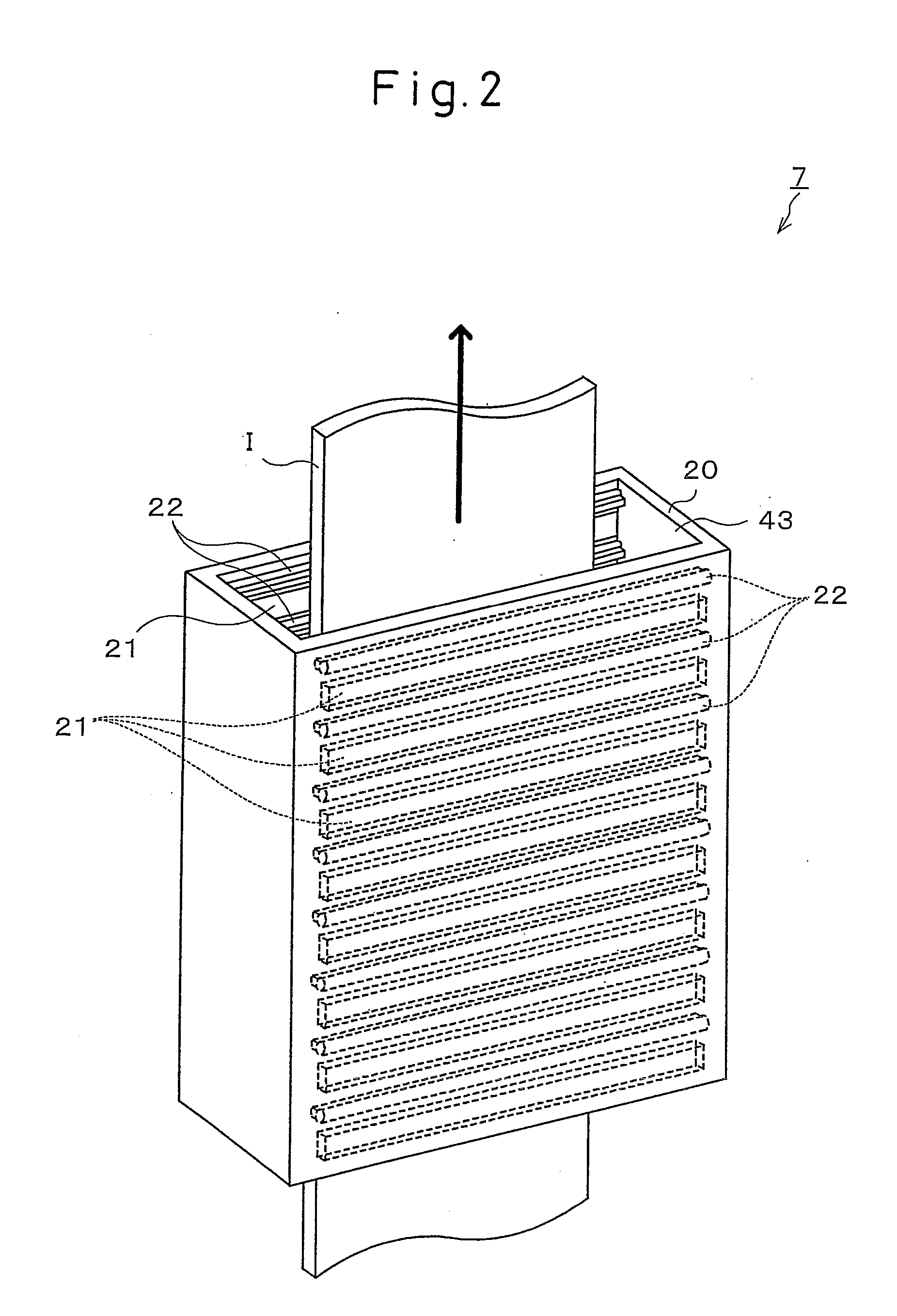

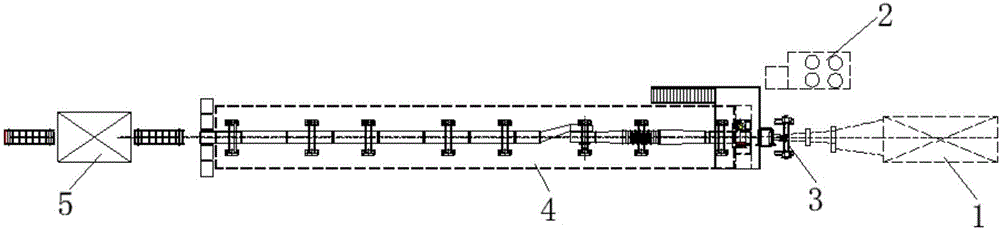

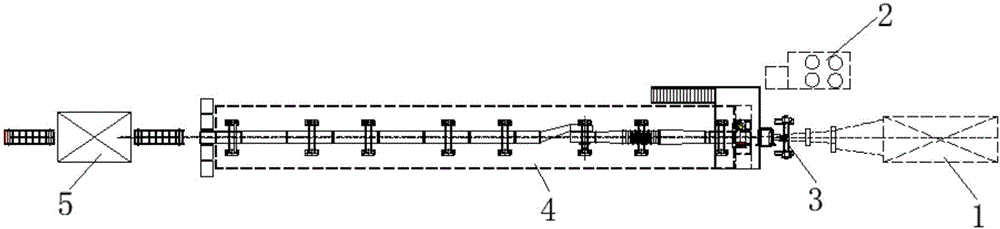

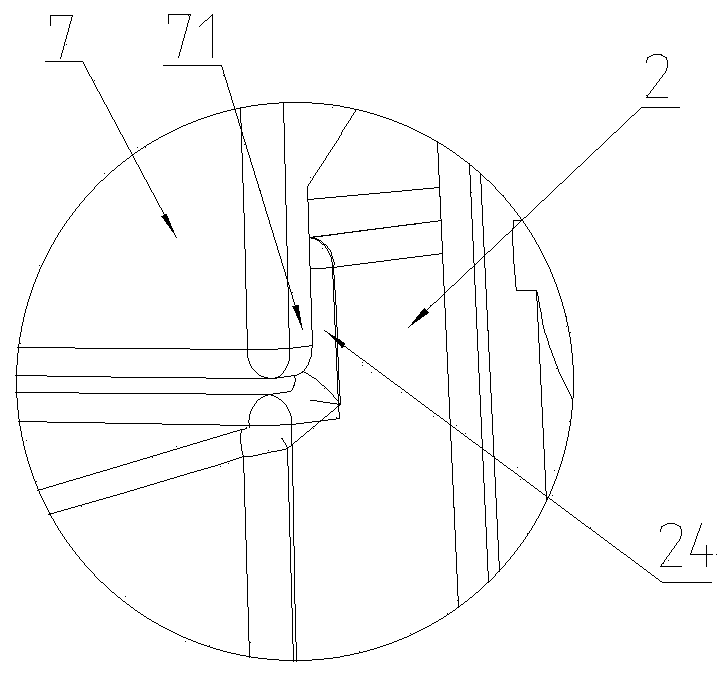

Production facility and production process for hot dip galvannealed steel plate

ActiveUS20100200126A1Easy to produceImprove adhesionHot-dipping/immersion processesLiquid surface applicatorsSpray nozzleHeating furnace

The present invention provides a production facility of hot dip galvannealed steel plate able to produce hot dip galvannealed steel plate on production conditions optimal at all times despite rapid changes in the steel type, plating deposition, and other external factors, wherein the production facility 1 of hot dip galvannealed steel plate is provided with a soaking / cooling furnace 7 for treating steel plate I running after leaving a rapid heating furnace 6 by at least one of soaking and cooling. Further, the soaking / cooling furnace 7 is configured to enable a change of the ratio in the furnace of the soaking region 15 for soaking steel plate I by soaking means 21 at a soaking temperature of 500° C. to 650° C. and the cooling region 16 for cooling the steel plate I by spray nozzles 22 by a 5° C. / sec or more average cooling rate.

Owner:NIPPON STEEL CORP

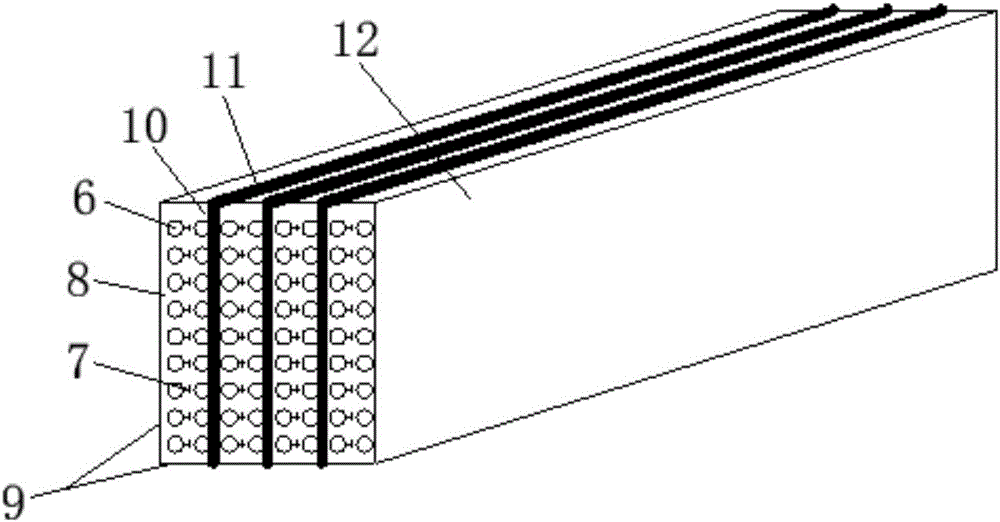

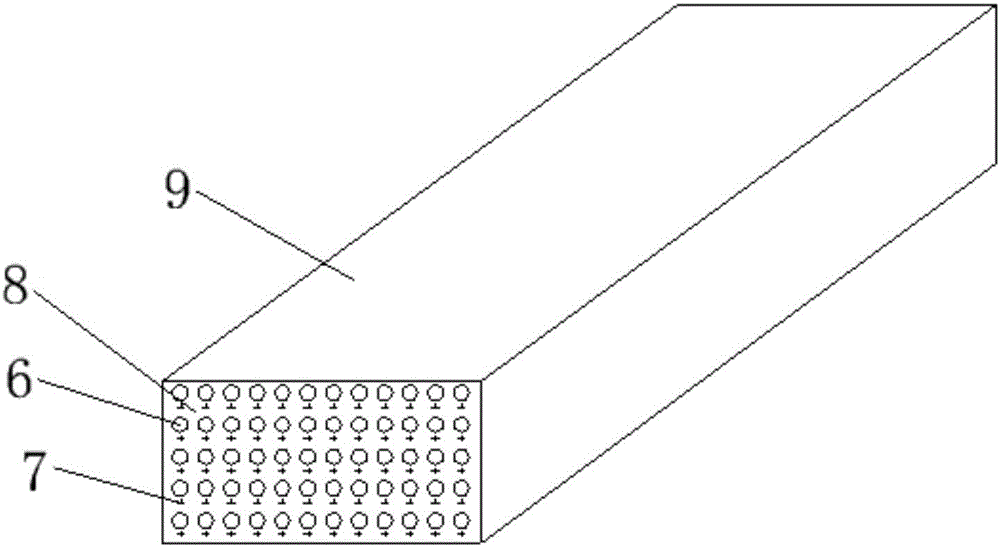

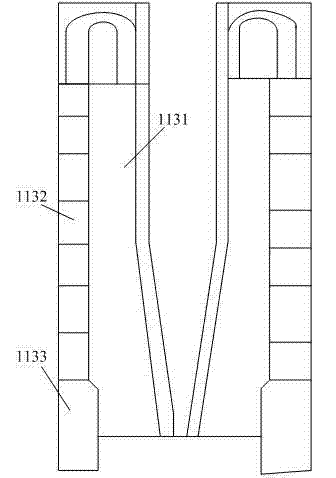

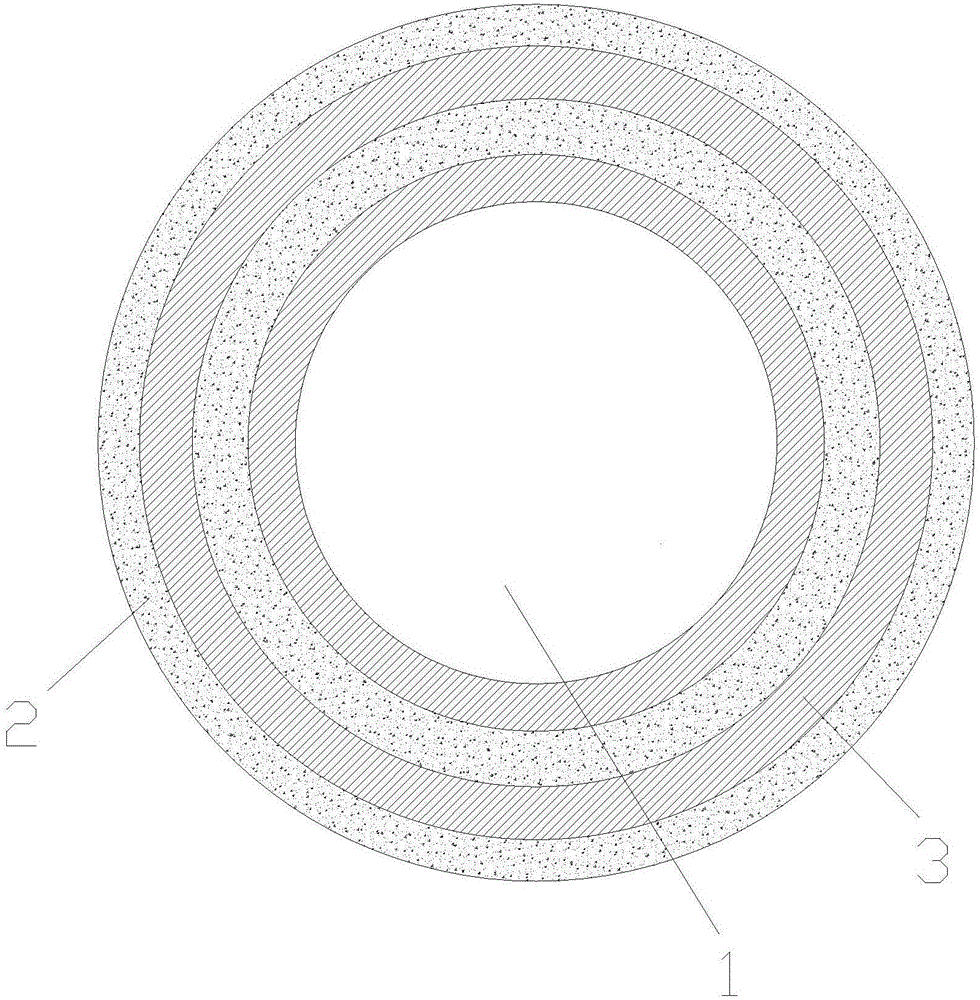

Fiber-reinforced rigid polyurethane foam synthesis sleeper with high fiber content and manufacturing method of sleeper

The invention relates to a fiber-reinforced rigid polyurethane foam synthesis sleeper with the high fiber content and a manufacturing method of the sleeper. The sleeper is formed by bonding multiple fiber-reinforced rigid polyurethane foam synthesis boards with the high fiber content through a bonding agent, an anti-corrosive paint film is arranged on the outer surface of the sleeper, and the fiber-reinforced rigid polyurethane foam synthesis boards with the high fiber content use polyurethane resin and reinforced fibers as base materials. Various technological measures such as mixed type polyether polyol with the low hydroxyl value and the low functionality degree and a coupling agent are adopted, the problem that the polyurethane resin and the reinforced fibers are not sufficiently impregnated is solved, so that the content of the reinforced fibers is increased, a fiber-reinforced rigid polyurethane foam material product with the density higher than 840 kg / m<3> and the content of the reinforced fibers larger than 60% can be manufactured, the technological blank of the fiber-reinforced rigid polyurethane foam synthesis boards is filled up, the standards and the performance of the product of the boards are diverse, and the requirements for different technical indexes are met.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

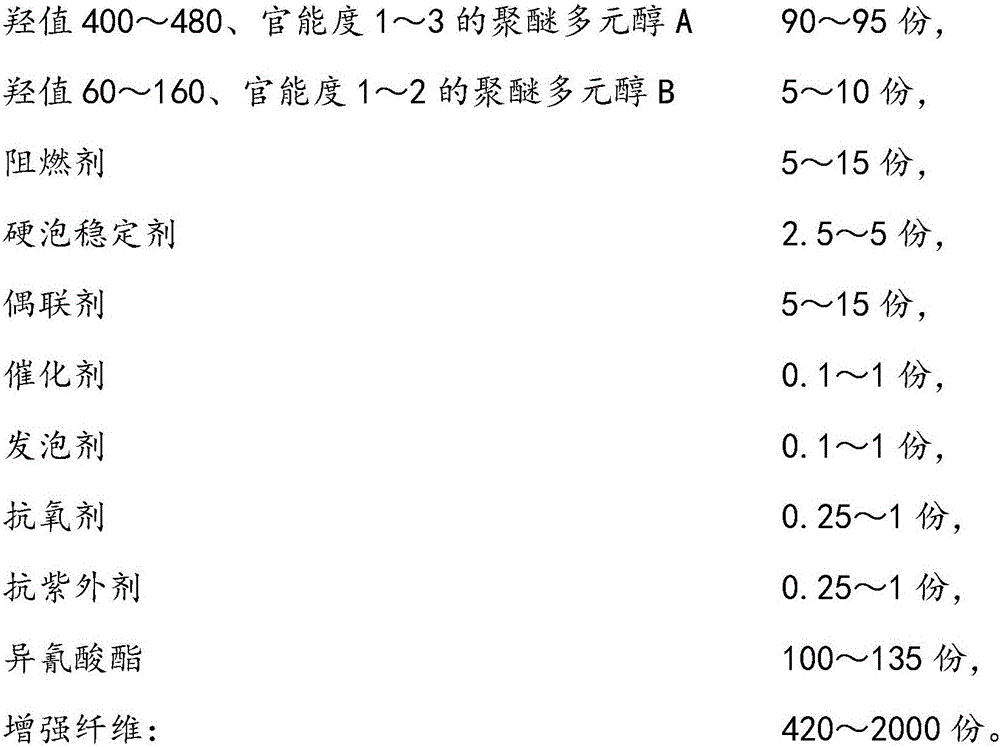

High-fiber-content fiber-reinforced rigid polyurethane foam composite board and manufacturing method thereof

ActiveCN106349446ASolve the problem of insufficient impregnationIncreased reinforcing fiber contentFoaming agentAntioxidant

The invention relates to a high-fiber-content fiber-reinforced rigid polyurethane foam composite board and a manufacturing method thereof; the high-fiber-content fiber-reinforced rigid polyurethane foam composite board is made from polyurethane resin and reinforcing fibers as base materials, as well as hybrid polyether polyol, a flame retardant, a rigid foam stabilizer, a coupling agent, a catalyst, a foaming agent, an antioxidant, an ultraviolet screening agent, an isocyanate, and reinforcing fibers, wherein the content of the reinforcing fibers is greater than 60%; by means of various techniques such as using low-hydroxyl value low-functionality hybrid polyether polyol and using the coupling agent, the problem that polyurethane resin is insufficiently steeped to reinforcing fibers is solved, the content of the reinforcing fibers is increased, a fiber-reinforced rigid polyurethane foam article higher than 840 kg / m<3> in density and higher than 60% in reinforcing fiber content can be manufactured, the technical blank of fiber-reinforced rigid polyurethane foam composite boards is filled, product specifications and properties are diversified, and the different technical index requirements are met.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

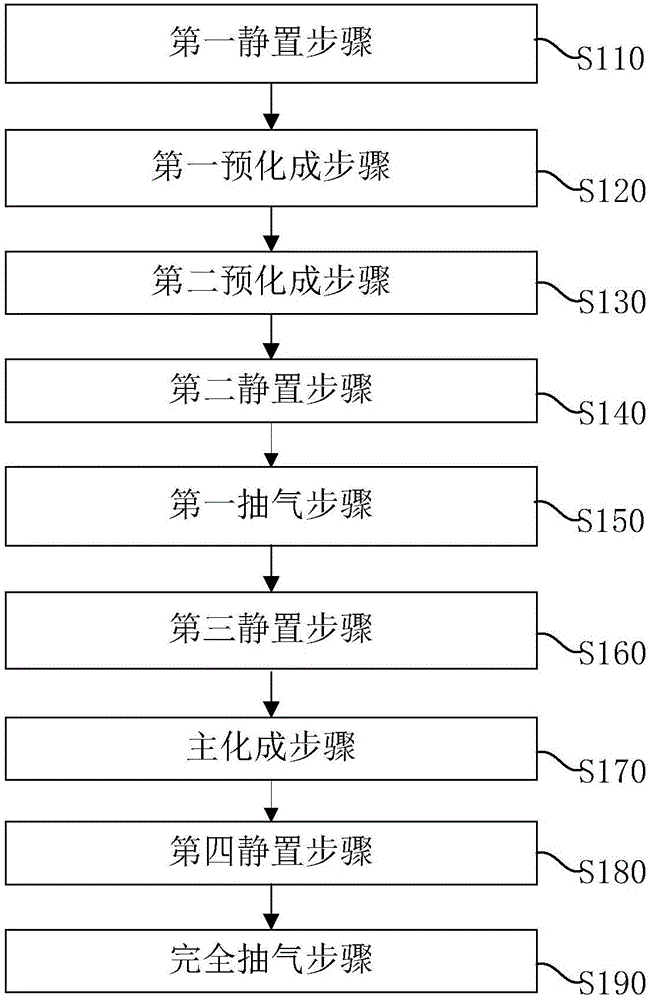

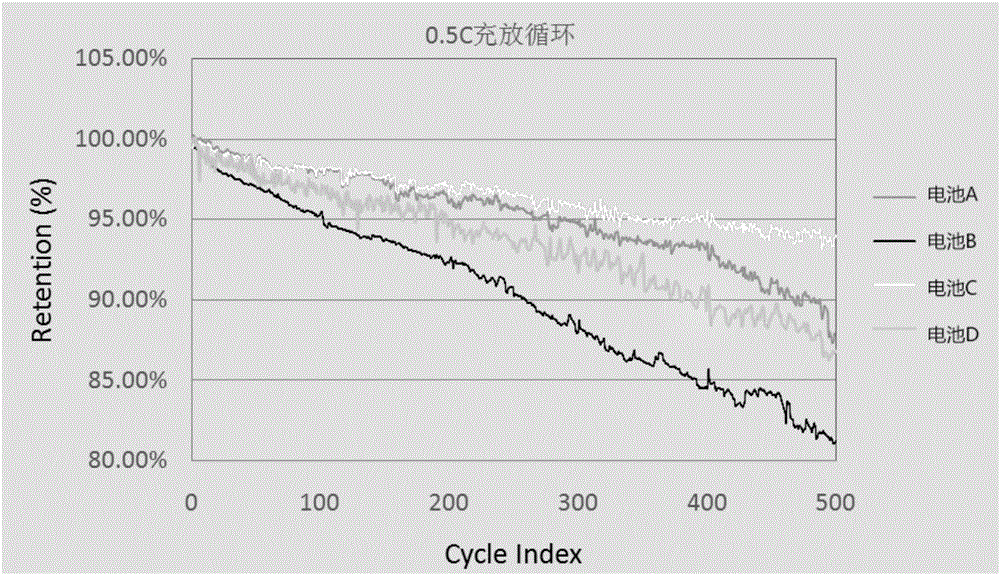

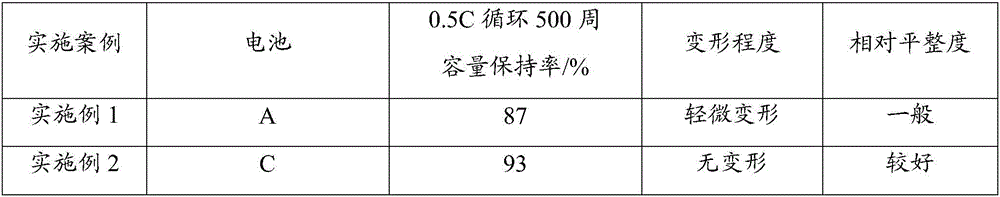

Formation method of lithium ion battery, and lithium ion battery

ActiveCN106602161AImprove cycle performanceImprove flatnessFinal product manufactureSecondary cells charging/dischargingBlack spotHardness

The invention discloses a formation method of a lithium ion battery, and the lithium ion battery. The formation method comprises the following steps: a first standing step, a first pre-formation step, a second pre-formation step, a second standing step, a first air pumping step, a third standing step, a main formation step, a fourth standing step and a complete air pumping step. According to the formation method of the lithium ion battery, the battery cycle performance of the lithium ion battery can be improved, so that the lithium ion battery is relatively good in flatness. By performing the first pre-formation step, the second pre-formation step and the main formation step on the lithium ion battery in a stress state, the deformation of the lithium ion battery in the formation process can be inhibited, the surface flatness of the ion battery is improved, and the hardness is relatively high; and meanwhile, positive and negative electrode interfaces are ensured to be in close contact in the charge / discharge process, the negative electrode interface is free from black spots and lithium precipitation, a good SEI film is formed, and the cycle performance of the battery is remarkably improved.

Owner:EVE ENERGY CO LTD

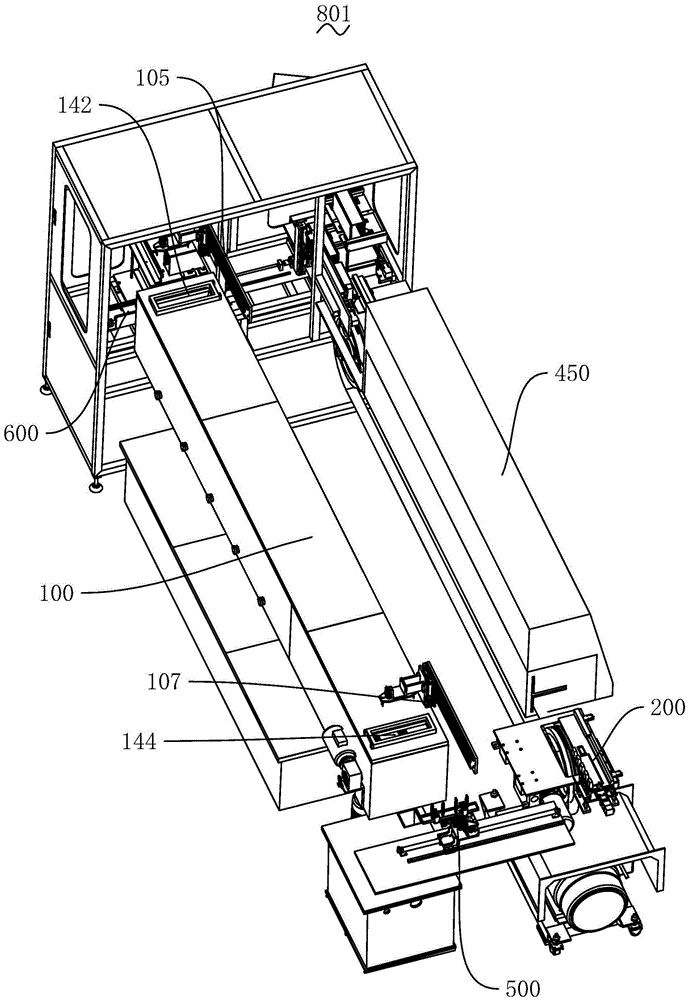

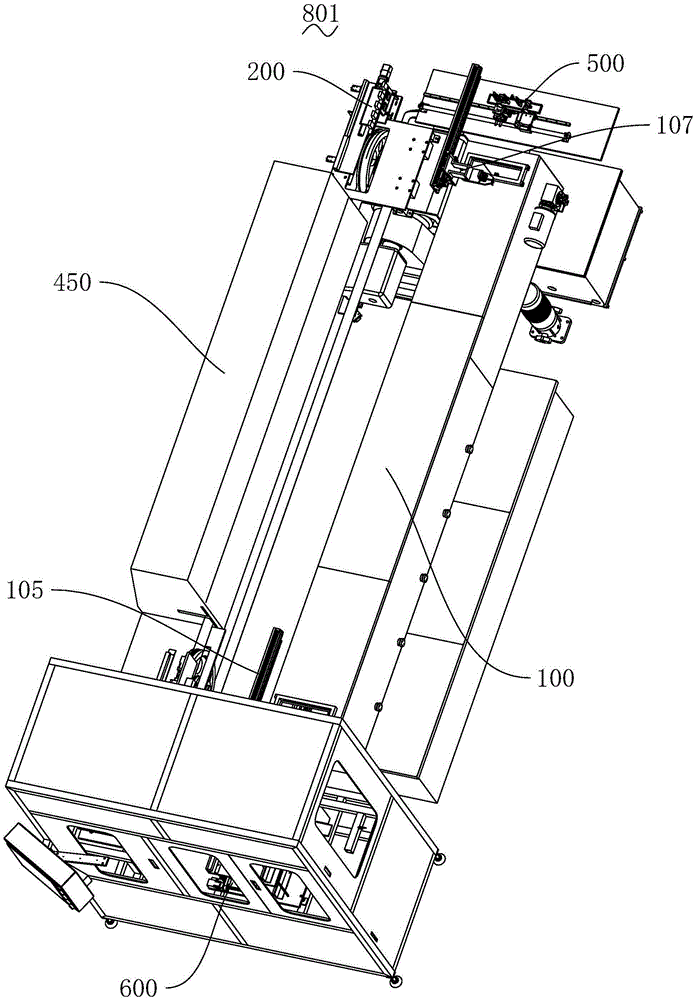

Treatment production line of lead frame

ActiveCN105428284AEasy to moveAvoid damageSemiconductor/solid-state device manufacturingProduction lineChemical treatment

The invention discloses a treatment production line of a lead frame. The treatment production line of the lead frame comprises a material taking mechanism, a lead frame treatment groove, a lead frame jig, lead frame pushing equipment and a water jet cutter, wherein a material pushing device of the material taking mechanism is driven by a first driving device and can realize automatic working; an immobilizing mechanism of the lead frame treatment groove is used for maintaining a semiconductor lead frame at a vertical position, so that the semiconductor lead frame is small in occupied space and long in soaking time, and a better soaking effect is obtained; a liquid receiving groove formed in the lead frame jig can be used for completely receiving a chemical treatment solution dripping from the lead frame, so that the phenomenon that since the chemical treatment solution drips on structures such as an air cylinder and guide rails, the corrosion is caused is avoided.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

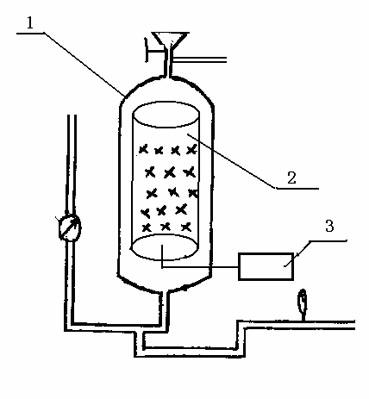

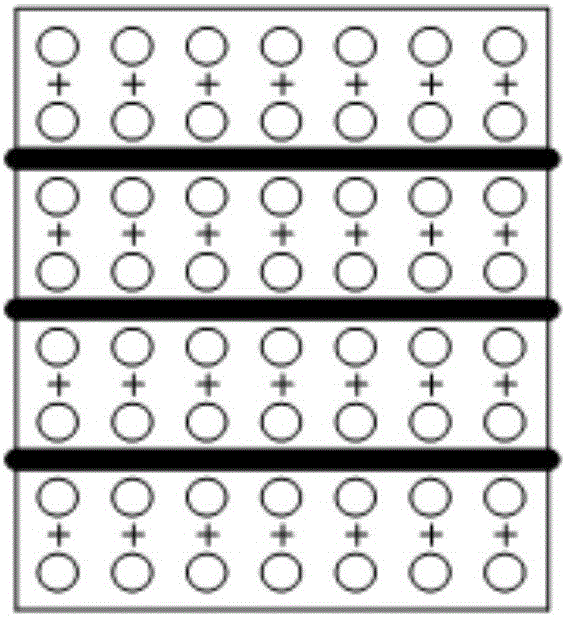

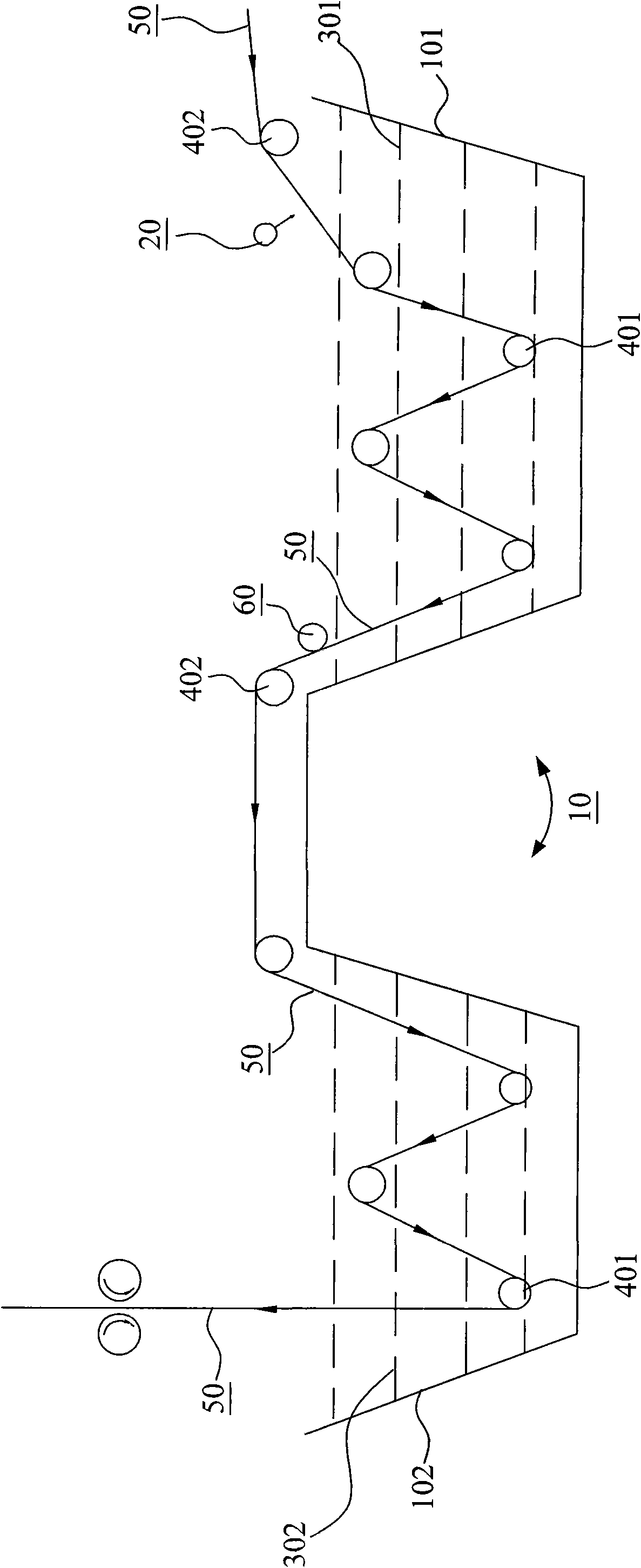

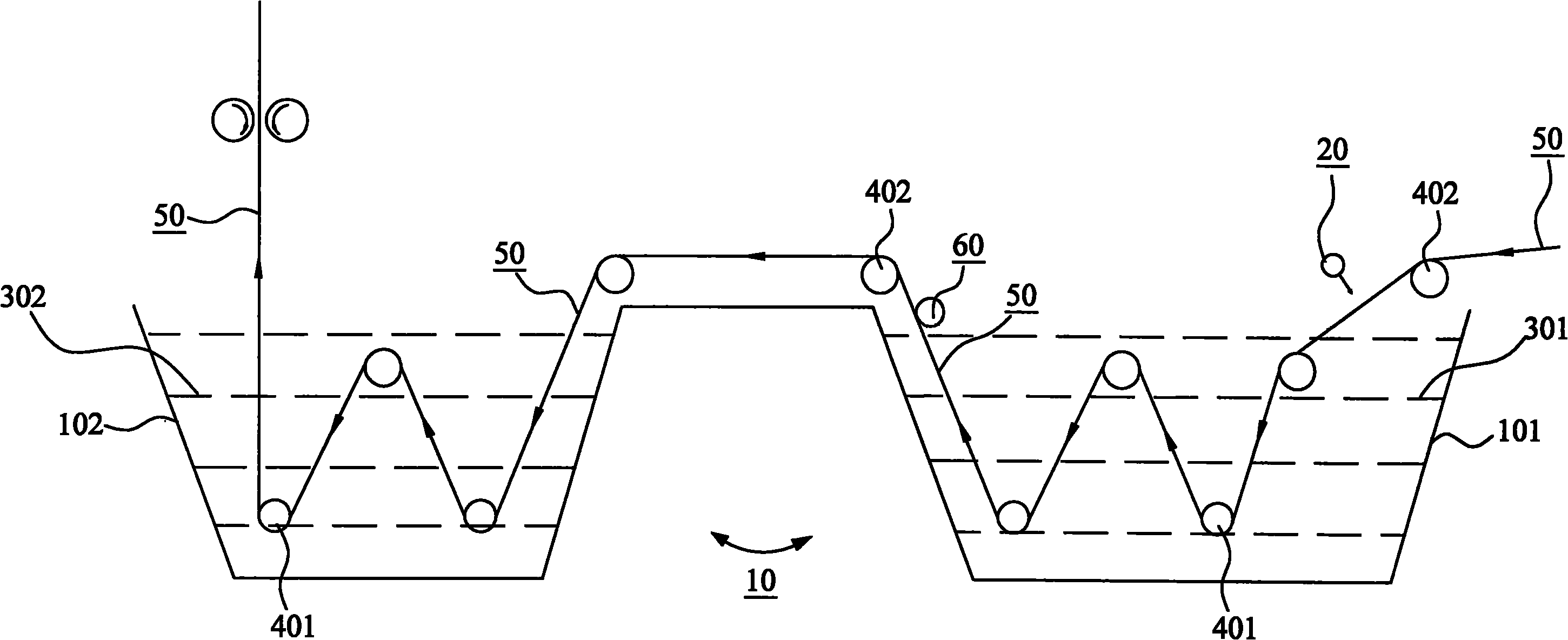

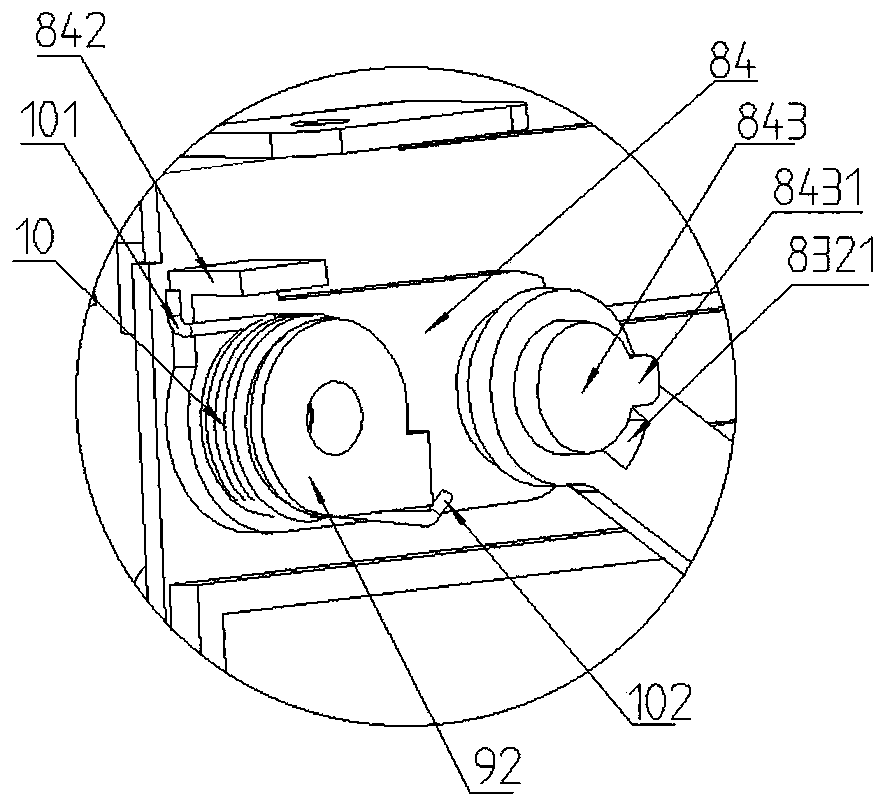

Method and device for infiltrating reinforced material and resin glue continuously

InactiveCN101856645AImprove wettabilityExtended soaking timeLiquid surface applicatorsCoatingsEngineeringHigh pressure

The invention relates to a method and a device for infiltrating a reinforced material and resin glue continuously, wherein an infiltrating tank is firstly prepared; the infiltrating tank is provided with at least two or more than two sizing grooves arranged in an array manner; the viscosity of the resin glue filled in all sizing grooves increases orderly; the reinforced material is sprayed with the resin glue by a high-pressure glue-spraying gun in advance, and then enters each sizing groove to be infiltrated in sequence; and when entering each sizing groove, the sequence of the reinforced material is from the sizing groove with the low resin viscosity to the sizing groove with the high resin viscosity. Due to the adoption of entering and exiting the sizing groove for multiple times, the method and the device can prolong the infiltrating time of the reinforced material and the resin glue so as to solve the problem of the insufficient infiltration of the reinforced material; and the reinforced material also can be sprayed with the resin glue by the high-pressure glue-spraying gun in advance and enters the sizing grooves with different viscosity to be infiltrated so as to lead bubbles remained on the reinforced material to be effectively replaced, thus leading the reinforced material to achieve good infiltrative property. The invention has simple structure and convenient operation, and is beneficial to the industrial application.

Owner:JIANGMEN HINNO TECH

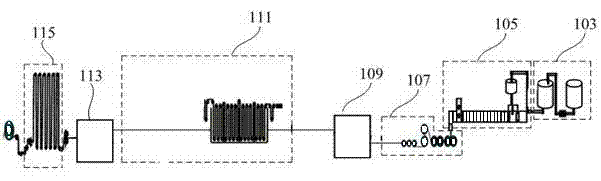

Preparation method of polyethylene microporous membrane and system thereof

InactiveCN102731883AImprove high temperature resistanceLow shrinkageCell component detailsMicrometerTemperature resistance

The invention brings forward a preparation method of a polyethylene microporous membrane and a system thereof. The preparation system of the polyethylene microporous membrane comprises a stirring device, an extrusion device, a cooling molding device, a bidirectional stretching device, an extraction device, a breadthwise stretching and a heat treatment device, wherein the stirring device, the extrusion device, the cooling molding device, the bidirectional stretching device, the extraction device, the breadthwise stretching device and the heat treatment device are connected in order. The preparation method provided by the invention can be adopted to produce an ultrathin polyethylene microporous membrane of 6 micrometers thickness and has advantages of high temperature resistance, corrosion resistance, good stability and long service life.

Owner:SHANGHAI QIANCHENG TOY TECH

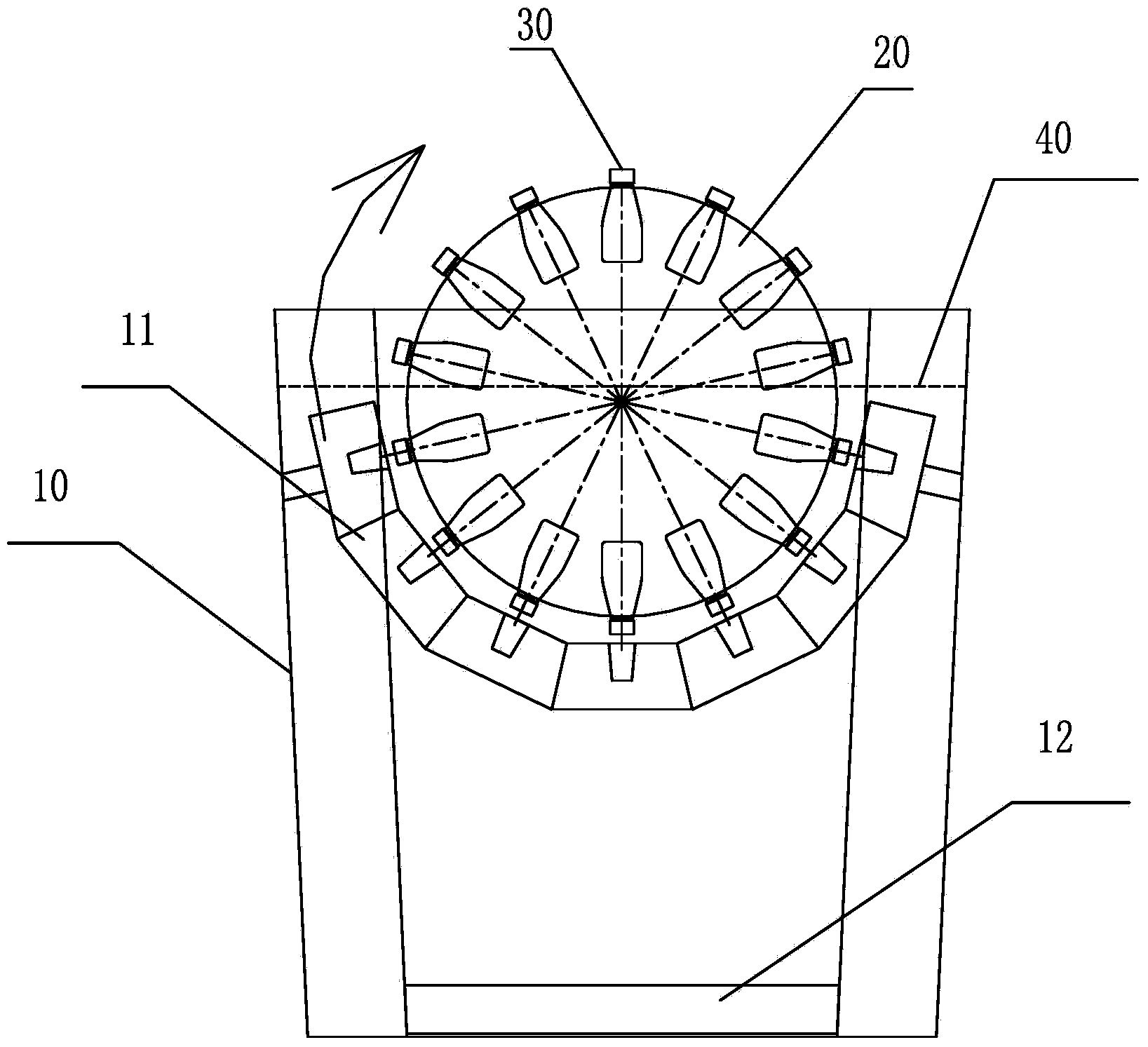

Ultrasonic wave roller bottle washing machine

ActiveCN103769387AImprove cleaning rateReduce damage rateCleaning using liquidsBottleEnergy consumption

The invention relates to an ultrasonic wave roller bottle washing machine, which comprises a soaking box body, a roller bottle carrying frame and a motive power device, wherein the soaking box body contains cleaning liquid, the roller bottle carrying frame is arranged in the soaking box body, the motive power device drives the roller bottle carrying frame to rotate, bottle carrying grooves used for loading cleaning bottles are formed in the circumference surface of the roller bottle carrying frame, a circular arc-shaped ultrasonic wave vibrator box group is arranged at the bottom of the soaking box body and is formed by ranging a plurality of ultrasonic wave vibrator boxes at the inside, the circular arc radian of the ultrasonic wave vibrator box group is matched with the circular arc angle of the roller bottle carrying frame, point-to-point cleaning is formed, dirt and alkali liquor attached on the surfaces of bottles can be flushed away, and the clean washing rate is improved. The ultrasonic wave roller bottle washing machine has the advantages that dirt and alkali liquor attached on the surfaces of bottles can be cleanly flushed in one step, the work efficiency is greatly improved, in addition, the labor and the work time are saved, the work intensity is reduced, meanwhile, the energy consumption is greatly reduced, and the ultrasonic wave roller bottle washing machine is applicable to various industries such as beer, beverage, dairy products, vinegar and automobile accessories.

Owner:诺特达新材料科技(上海)有限公司

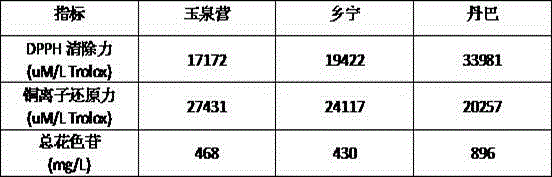

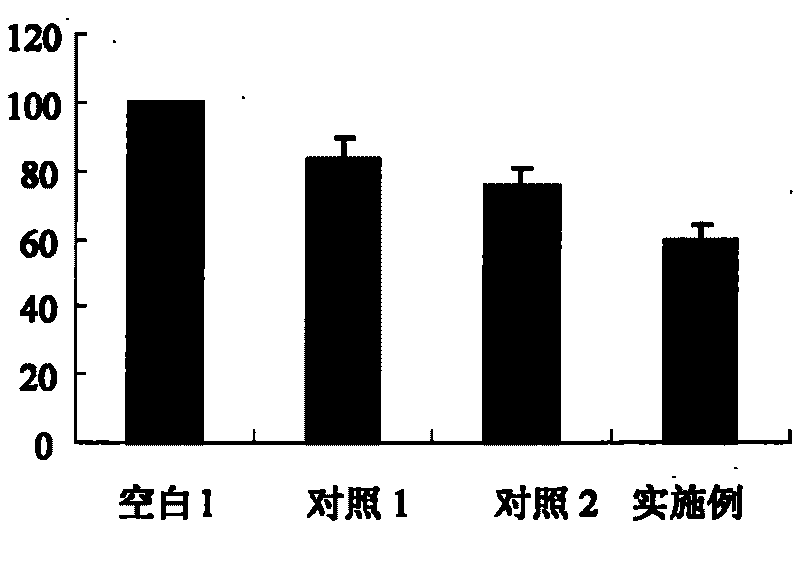

Low-temperature extended maceration method suitable for making dry red wine from plateau wine making grapes

The invention discloses a low-temperature extended maceration method suitable for making a dry red wine from plateau wine making grapes. The method comprises pre-fermentation cold maceration, alcohol fermentation and post-fermentation postmaceration, and specifically comprises the following steps: 1) crushing picked red wine making grape raw materials, removing stalks to obtain fruit pulp, pumping into a fermentation tank while adding food grade sulfurous acid and pectinase, filling CO2 into the fermentation tank for oxygen exclusion, homogenizing through pump circulation, and performing cold maceration on the fruit pulp at 6-10 DEG C for 3-4 days; 2) after the cold maceration is completed, adding Saccharomyces cerevisiae, and performing alcohol fermentation; 3) when the specific gravity is reduced to 996g / L and the reducing sugar is 2g / L, entering the post-fermentation postmaceration without performing wine-liquid separation; and 4) after the postmaceration is completed, performing wine-liquid separation to perform malic acid-lactic acid fermentation. By adopting the long-time pre-fermentation cold maceration and post-fermentation postmaceration method, the maceration time of grape berries is sufficiently extended, so that abundant phenol substances and aromatic substances in plateau wine making grapes can be effectively extracted out.

Owner:甘孜州康定红葡萄酒业有限公司

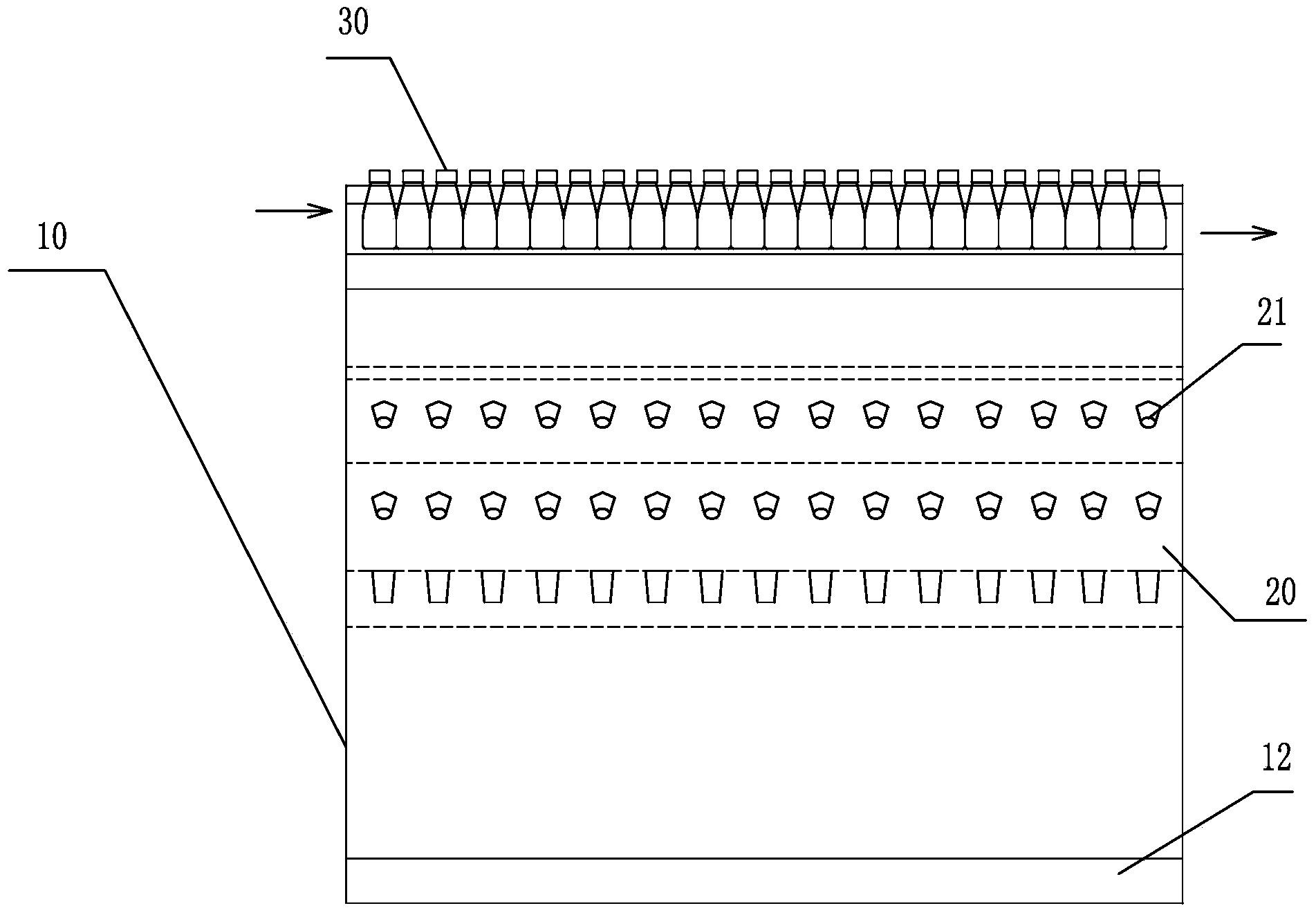

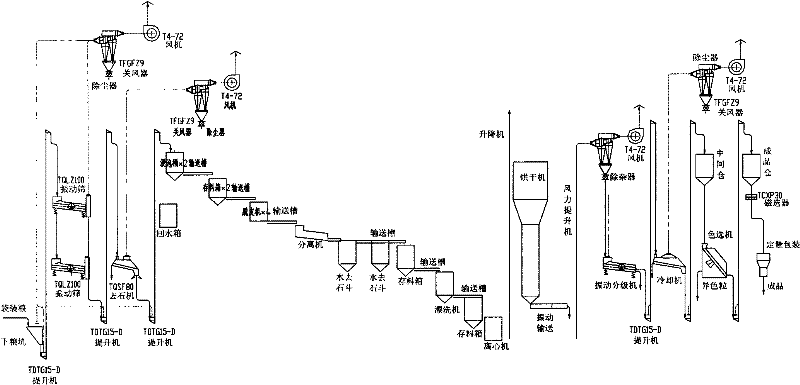

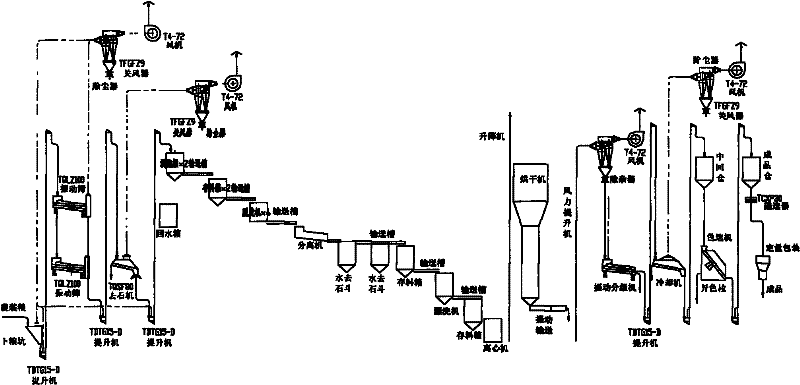

Process for washing sesame with water

InactiveCN102240653AReduce turnover timesEasy to separateCleaning processes and apparatusGeneral screeningEngineering

The invention discloses a process for washing sesame with water. The process comprises the following steps of: removing and separating impurities and stones from the sesame at first; then immersing and washing the sesame with water, stripping the sesame and separating the sesame; drying, performing color selection and magnetic separation; and finally, finishing a process of manufacturing qualified sesame meat. The whole process is extremely smooth and the transferring frequency of the sesame is low, so the production efficiency is improved greatly; various measures, such as general screening, color selection, magnetic separation and the like, are used together, so cleaning and grading can be performed simultaneously; and the later targeted deep processing of the sesame is facilitated.

Owner:NANTONG GRAIN MACHINERY

Production method of pea starch

The invention discloses a production method of pea starch. Since the technical processes of cleaning-soaking, grinding and residue removing, pulp mixing and separating, and settling are adopted in the method, the purification rate of the starch is enhanced greatly, the color and the luster of the starch are very good, the original toughness can be kept, the nutritive value is high, and the starch is very suitable for processing cold noodles, bean jelly and bean vermicelli.

Owner:孟祥帅

Moisture-absorbing cool double-layer fabric and preparation method

ActiveCN111172652AExcellent cooling performanceIncrease evaporation areaWeft knittingTwo or more solvent application treatmentPolyesterPolyamide

The present invention relates to a preparation method of a moisture-absorbing cool double-layer fabric. The method comprises the following steps of firstly weaving a double-layer knitted fabric with an inner layer with the contact cool feel and the moisture-guiding effect and an outer layer with the moisture-absorbing effect, then performing light non-continuous hydrophilic finishing on the surface of the inner layer and performing light non-continuous hydrophobic finishing on the surface of the outer layer to obtain the moisture-absorbing cool double-layer fabric; the inner layer is mainly formed by weaving cool polyamide, polyester fibers containing natural minerals or composite cool yarns prepared by adopting a novel spinning technology; the finally prepared moisture-absorbing cool double-layer fabric is of a double-layer composite structure composed of a contact cool moisture-guiding diffusion layer and a moisture-absorbing diffusion layer; one partial region of the contact cool moisture-guiding diffusion layer is hydrophilic, and the other partial region of the contact cool moisture-guiding diffusion layer is hydrophobic; one partial region of the moisture-absorbing diffusionlayer is hydrophilic, and the other partial region of the moisture-absorbing diffusion layer is hydrophobic; the hydrophilicity of the moisture-absorbing diffusion layer is higher than that of the contact cool moisture-guiding diffusion layer; and the fabric is good in integrated effect of contact cool feel and moisture diffusion cool feel, thereby being suitable for use as summer fabrics.

Owner:DONGHUA UNIV

Solution and method for removing flash

The invention relates to a solution for removing flash, which comprises the following components in percentage by mass: 10-60% of 1,3-dimethyl-2-imidazolidinone, 10-30% of ethanolamine, 10-60% of hexamethyl phosphoric triamide and 0-10% of deionized water. The ethanolamine is monoethanolamine, diethanolamine or triethanolamine. Particularly, the solution comprises the following components in percentage by mass: 30% of 1,3-dimethyl-2-imidazolidinone, 30% of monoethanolamine, 35% of hexamethyl phosphoric triamide and 5% of deionized water. The invention also relates to a method for removing flash, which comprises the following steps: corroding metal under flash by using the prepared solution, and when the combination of the metal under flash and the flash becomes loose, removing the flash in a mechanical mode. All the components can be dissolved in water, and thus, the solution is easy to clean; the solution is weakly alkaline, and thus, can not discolor the packaged colloid; the application temperature is high, and thus, the operation can be performed at 50-110 DEG C; the solution can be used for treating the product with severe flash only by enhancing the soaking temperature or prolonging the soaking time; and the invention can be used for removing oxides on the substrate surface without excessively corroding the substrate.

Owner:JIANGSU XIYAN SEMICON TECH

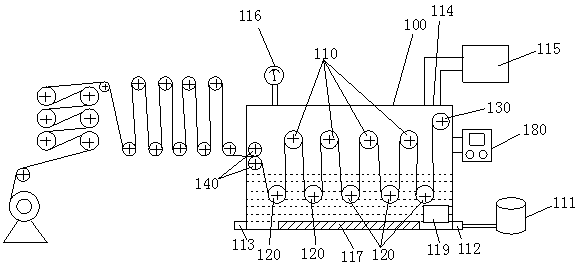

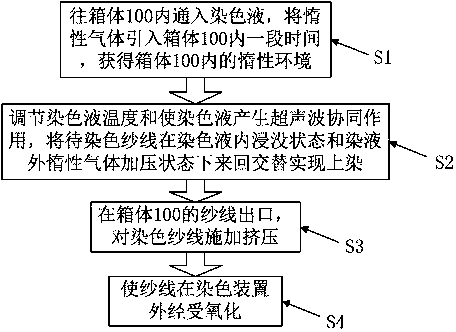

Dyeing apparatus and dyeing method

ActiveCN109487469AExtended soaking timeWill not oxidizeTextile treatment containersTextile treatment machine arrangementsFiberYarn

The invention discloses a dyeing apparatus and a dyeing method. A rectangular box is provided; a dye liquid is charged into the rectangular box; an inert gas is introduced into the rectangular box toform an inert environment; therefore, yarns are dyed in the dye liquid. The yarns are switched in the state of being soaked in the dye liquid and the state of being outside the dye liquid under inertgas pressurizing; so that full soaking time is extended for the yarns in the dye liquid, the dye liquid is never oxidized; dye molecules have a concentration difference when on the surface of yarn fibers and when inside the yarn fibers, so that the dye molecules can migrate from the surface of the yarn fibers to the inside of the fibers, the dye diffusion and fixing processes are more sufficient,yarn dyeing rate is increased, and dye utilization rate in the whole dyeing process is increased by about 8-18%; the quantity of dye vats is greatly decreased, so that equipment space is diminished; total volume of the dye liquid sealed by the inert gas is 2 / 5 of the total volume of a traditional dye liquid.

Owner:GUANGDONG FORWARD DENIM

Moisture-absorbing and quick-drying double-layer knitted fabric and preparation method thereof

ActiveCN111172651AStrong moisture absorption and quick drying performanceIncrease evaporation areaWeft knittingTwo or more solvent application treatmentPolymer sciencePolymer chemistry

The invention relates to a moisture-absorbing and quick-drying double-layer knitted fabric and a preparation method thereof. The preparation method comprises the following steps of weaving a double-layer knitted fabric with the inner layer having a moisture conducting function and the outer layer having a moisture absorbing function; and performing mild discontinuous hydrophilic finishing on the inner layer surface and performing mild discontinuous hydrophobic finishing on the outer layer surface to prepare the moisture-absorbing and quick-drying double-layer knitted fabric. The prepared moisture-absorbing and quick-drying double-layer knitted fabric is of a double-layer composite structure consisting of a moisture-conducting diffusion layer and a moisture-absorbing diffusion layer; the moisture-conducting diffusion layer is partially hydrophilic and partially hydrophobic; the moisture-absorbing diffusion layer is partially hydrophilic and partially hydrophobic; and the overall hydrophilic property of the moisture-absorbing diffusion layer is higher than that of the moisture-conducting diffusion layer. The preparation method of the moisture-absorbing and quick-drying double-layer knitted fabric is simple and convenient and is easy to operate, and the prepared moisture-absorbing and quick-drying double-layer knitted fabric has excellent moisture-absorbing and quick-drying effects.

Owner:DONGHUA UNIV

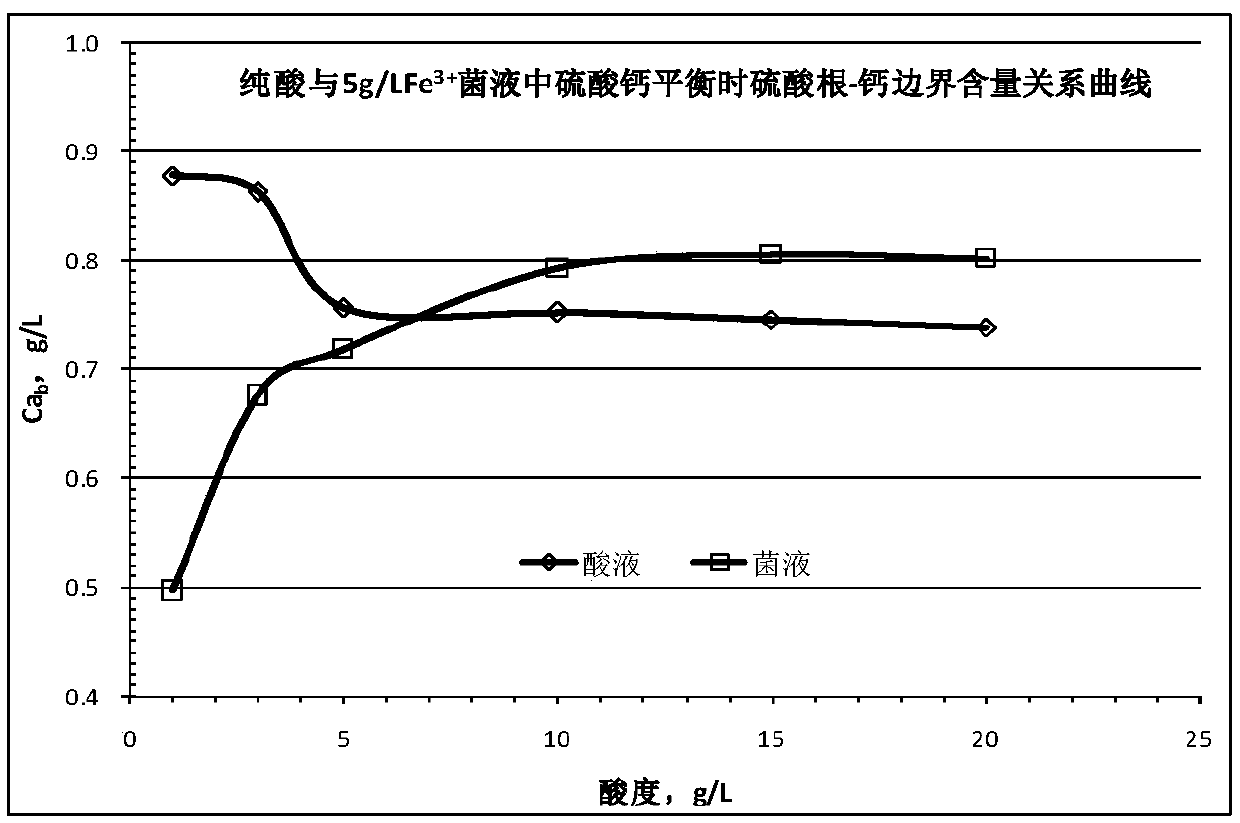

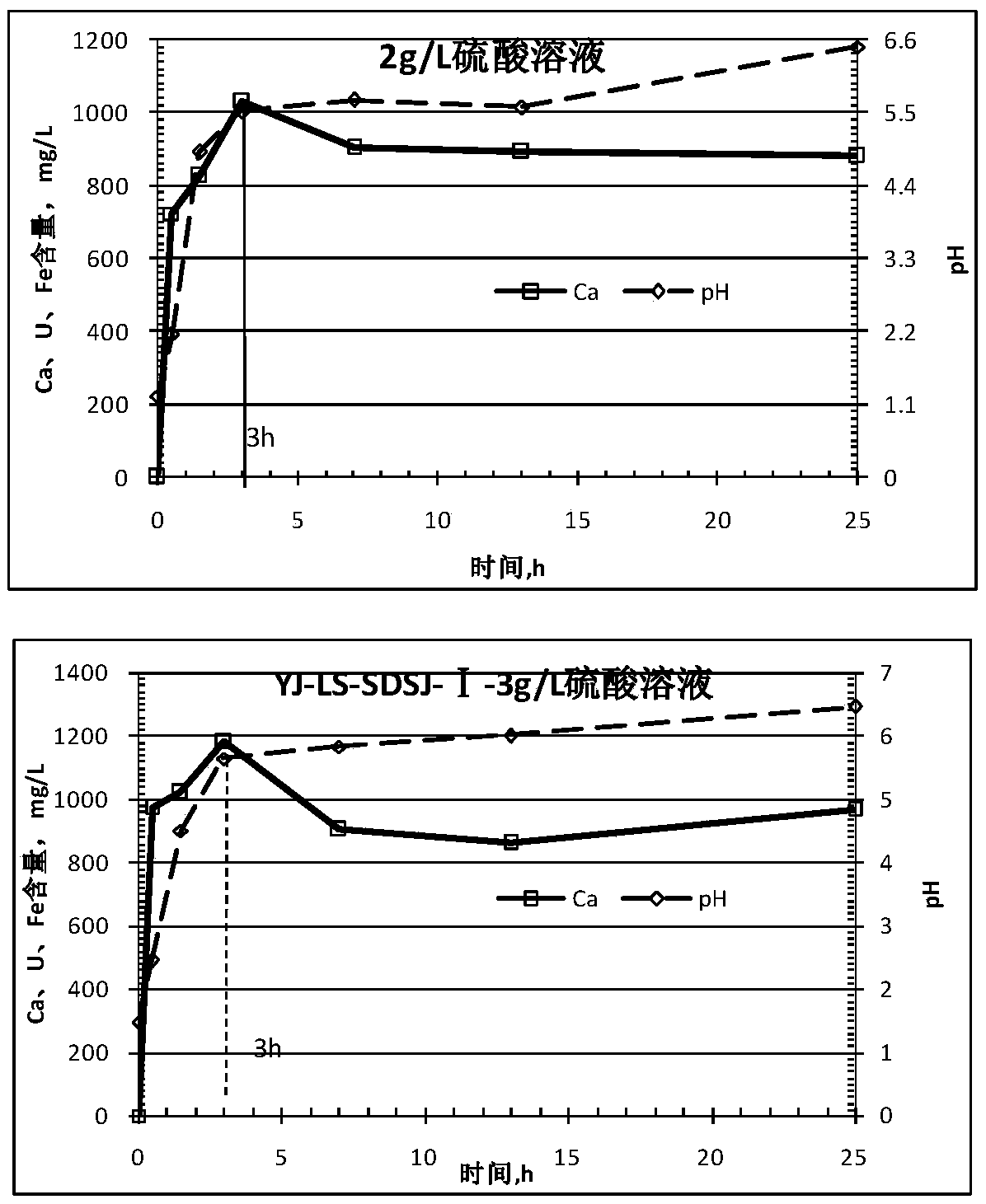

Flow uranium leaching process

The invention discloses a flow uranium leaching process which adopts flow of a leaching solution to complete uranium leaching, wherein the leaching solution comprises a sulfuric acid solution, a bacterial liquid and a uranium leaching reagent. According to the hydrogeochemical principle, the following three novel hydrogeochemical parameters are established: (1) a reaction condition boundary value related to chemical thermodynamics, (2) peak value reaching time related to reaction kinetics, and (3) residence time or flow speed related to a hydrodynamic condition; residence, in ores, of the leaching solution meets the following principles: (1) leaching is within time quantum of highest uranium leaching efficiency; (2) the residence time must meet the principle that the solution flows out of the system as soon as possible once the peak value is reached; (3) the principle that acidity of the leaching solution meets uranium leaching requirements, and other components irrelevant to uranium leaching are leached as many as possible; and (4) the principle that harmful components do not exceed the boundary value. According to the flow uranium leaching process, a conventional batch type tank and pile type uranium leaching process is changed into a continuous uninterrupted flow uranium leaching process, so that good effect is achieved.

Owner:EAST CHINA UNIV OF TECH

Pearl beverage raw material and preparation method thereof

InactiveCN1666673AImprove the crushing finenessIncrease iodic acidFermentationAnimal proteins working-upInorganic saltsAquatic animal

The invention discloses a pearl beverage raw material and preparation process which comprises, disintegrating pearl raw material, charging iodic acid and edible acid to steep 24-72 hours, adjusting pH to neutral, charging minced aquatic animal meat, mixing and placing in reaction still, adjusting pH to neutral, charging 0.1-0.25% papain and 0.1-0.25% trypsin, carrying out catalytic reaction for 1.5-4 hours at 40-65 deg. C, finally filtering and removing the filtering deposit to obtain filter liquor.

Owner:DAHU AQUACULTURE +1

Red coat separating equipment of uncooked peanuts

ActiveCN108514127AIncrease contact areaExtended soaking timeHuskingHullingWarm waterElectric machinery

The invention provides red coat separating equipment of uncooked peanuts. The red coat separating equipment comprises supporting legs, wherein a red coat peeling tank is welded to the surfaces of thesupporting legs; a warm water soaking mechanism is arranged at the top of the red coat peeling tank in a penetrating manner; a friction peeling mechanism is arranged in the red coat peeling tank; a drying and red coat collecting mechanism is arranged on the surface of the red coat peeling tank in a penetrating manner; a drain pipe is in sleeving connection to the side surface of the red coat peeling tank; a filter screen is fixedly connected to the inner wall of the red coat peeling tank; and the surface of the filter screen is fixedly connected with the surface of the drain pipe. The invention relates to the field of processing of agricultural products. According to the red coat separating equipment of uncooked peanuts disclosed by the invention, a second motor is arranged and is used fordriving a second rotating shaft to rotate, and the second rotating shaft is used for driving a stirring and peeling rod to rotate, so that red coats which are not thoroughly peeled can be peeled, andthe problems that peeling and processing of red coats cannot be performed in batch at the same time, the processing time is long, and the working efficiency is influenced to a certain extent, are effectively solved.

Owner:杨开村

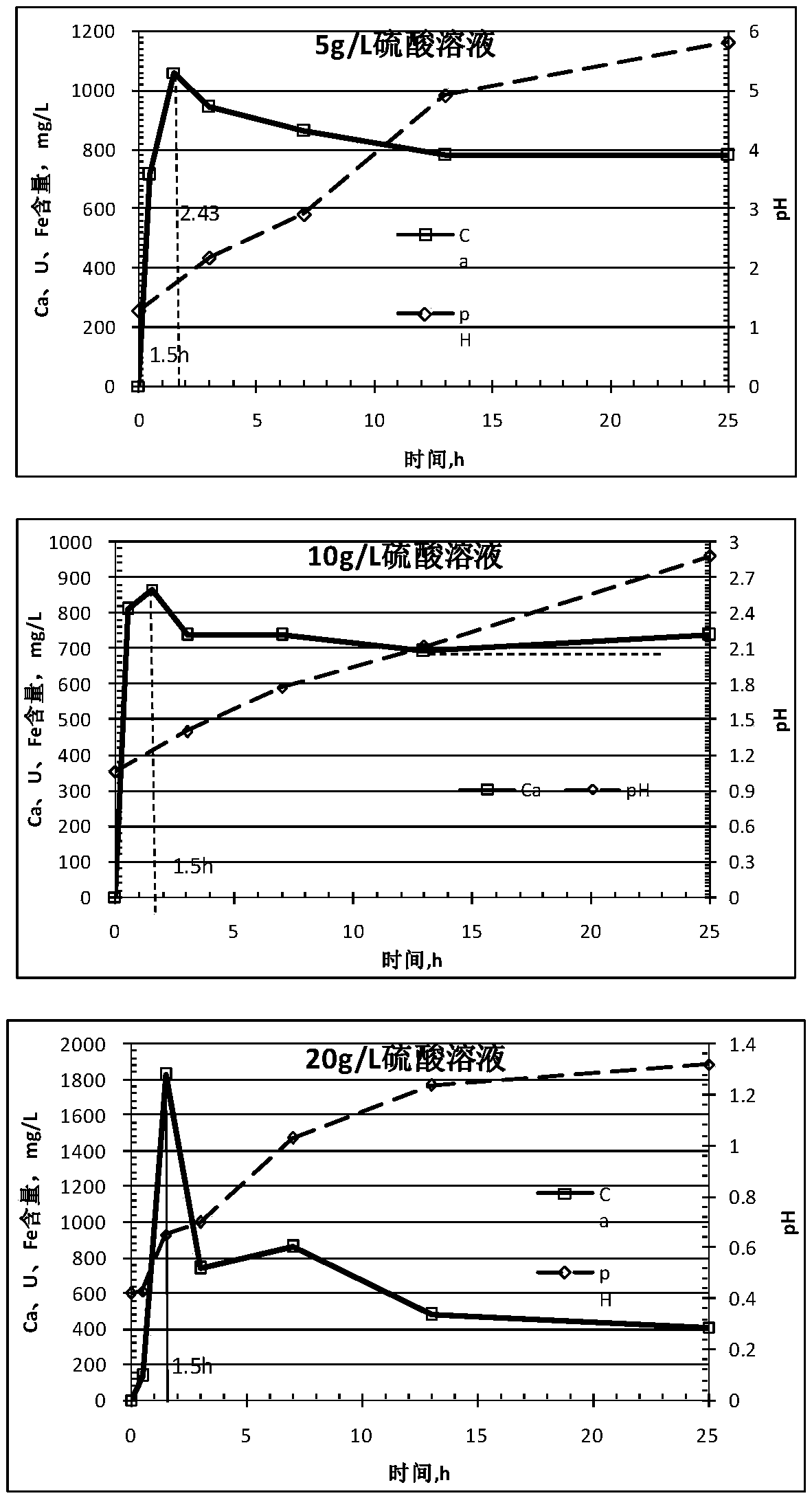

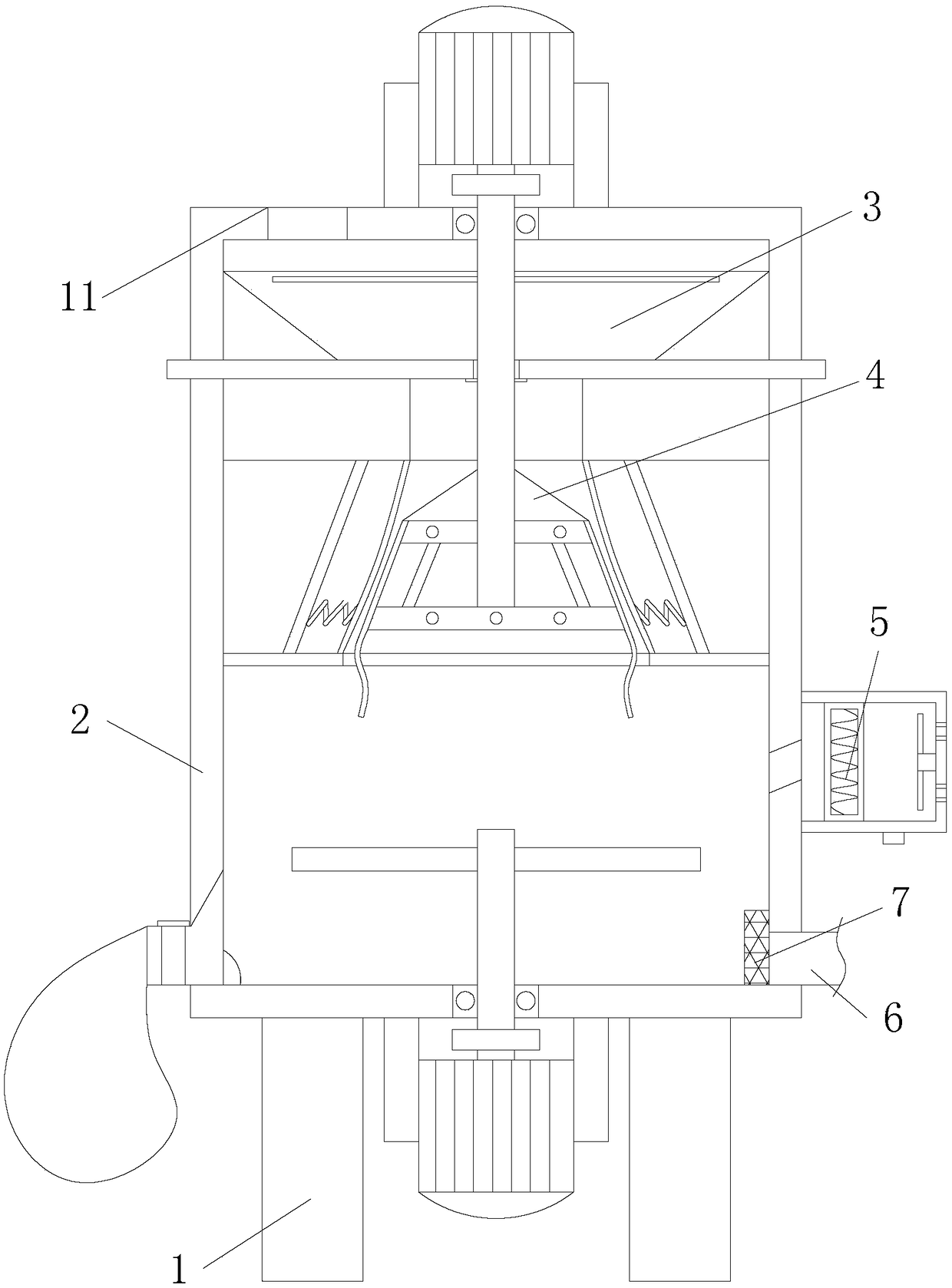

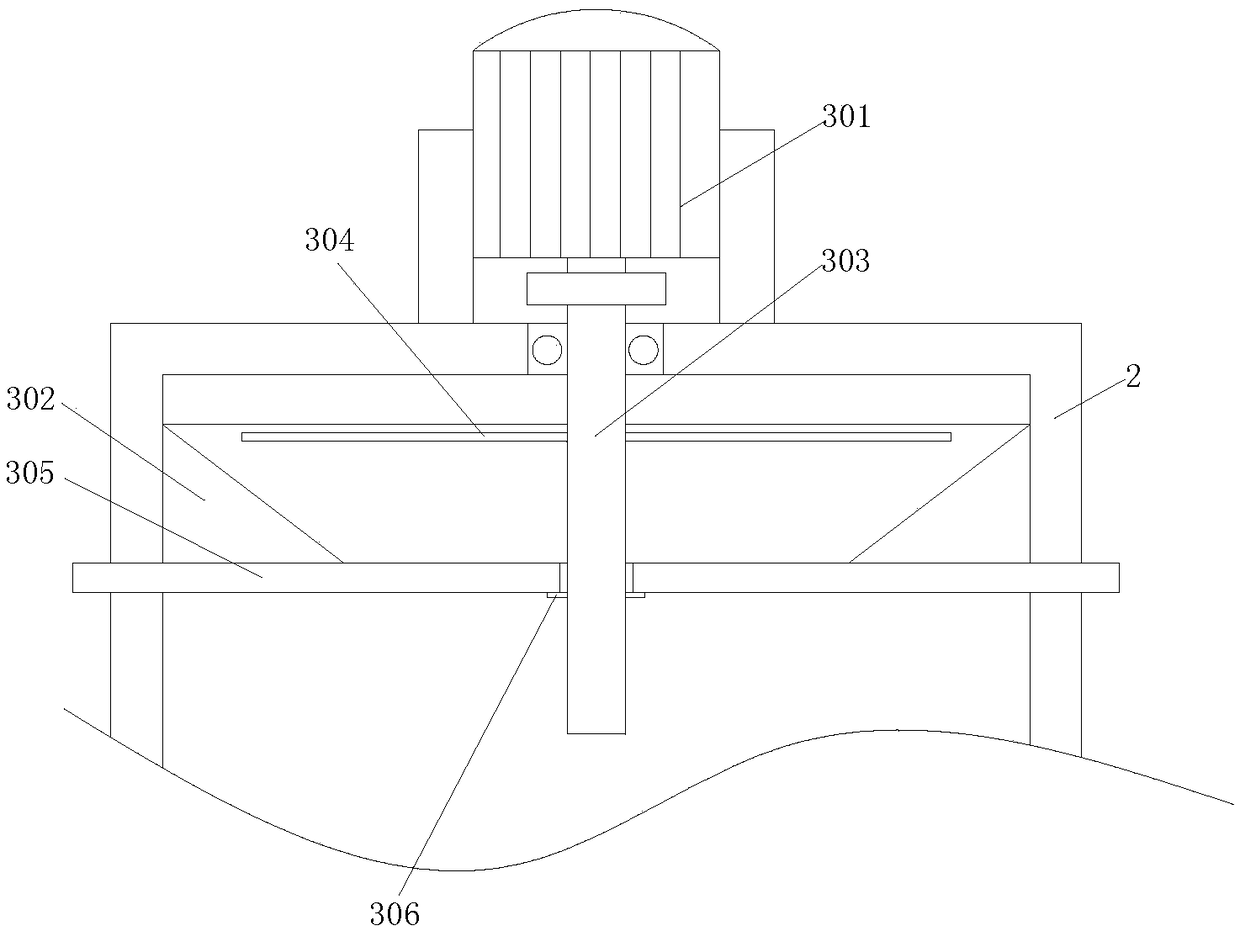

Flow uranium leaching system and flow uranium leaching process

The invention discloses a flow uranium leaching system and a flow uranium leaching process. The flow uranium leaching system comprises a liquid dispensing tank, a flow uranium leaching tank, a primary liquid slot, an adsorption tower, a tail liquid slot, an oxidization slot and a communication pipeline, wherein the outlet of the liquid dispensing tank is communicated with a leaching solution inlet in the bottom of the flow uranium leaching tank; the liquid outlet in the upper part of the tank body of the flow uranium leaching tank is communicated with the primary liquid slot; the primary liquid slot is communicated with the inlet of the adsorption tower; the outlet of the adsorption tower is communicated with the tail liquid slot and the liquid dispensing tank; the tail liquid slot is communicated with a culture solution dispensing slot; one path of the outlet of the culture solution dispensing slot is connected to the liquid dispensing tank through an oxidization slot; and the other path of the outlet is communicated with the liquid dispensing tank. According to the invention, the flow uranium leaching system is adopted to replace strong acid used in the past, to strength an oxidant, and to prolong the soaking time, so that the uranium leaching efficiency can be improved, and therefore, the conventional batch type tank and pile type uranium leaching process is changed into a continuous uninterrupted flow uranium leaching process, and good effect is achieved.

Owner:EAST CHINA UNIV OF TECH

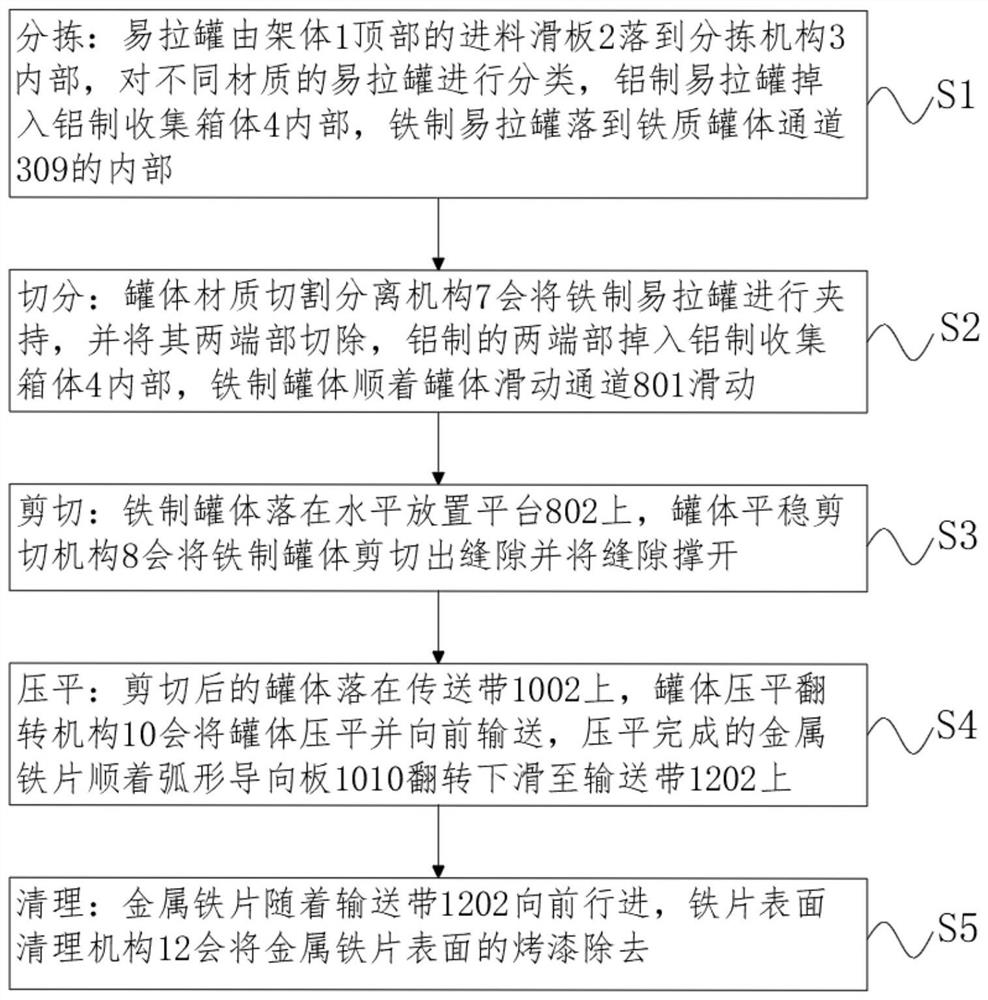

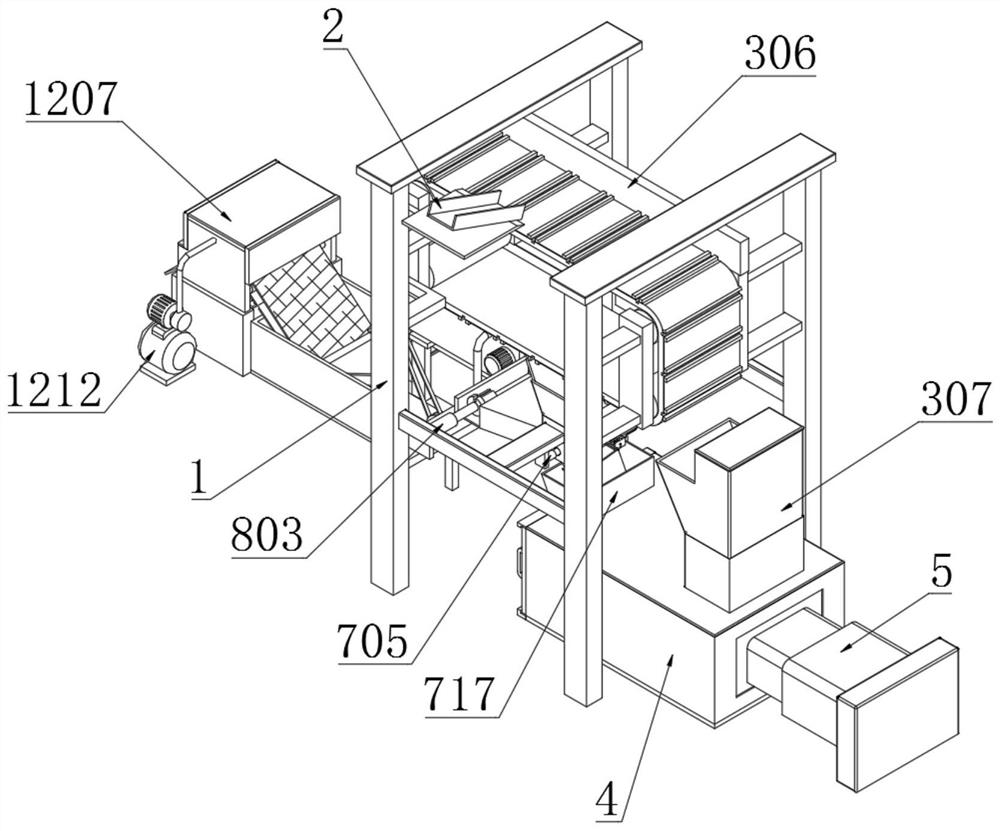

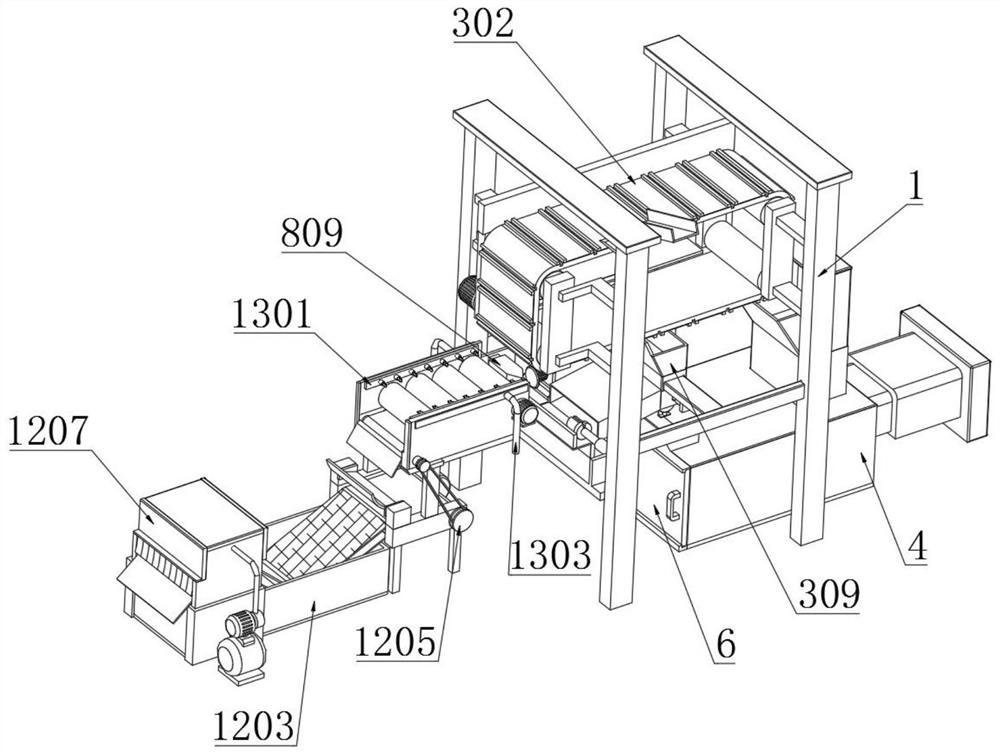

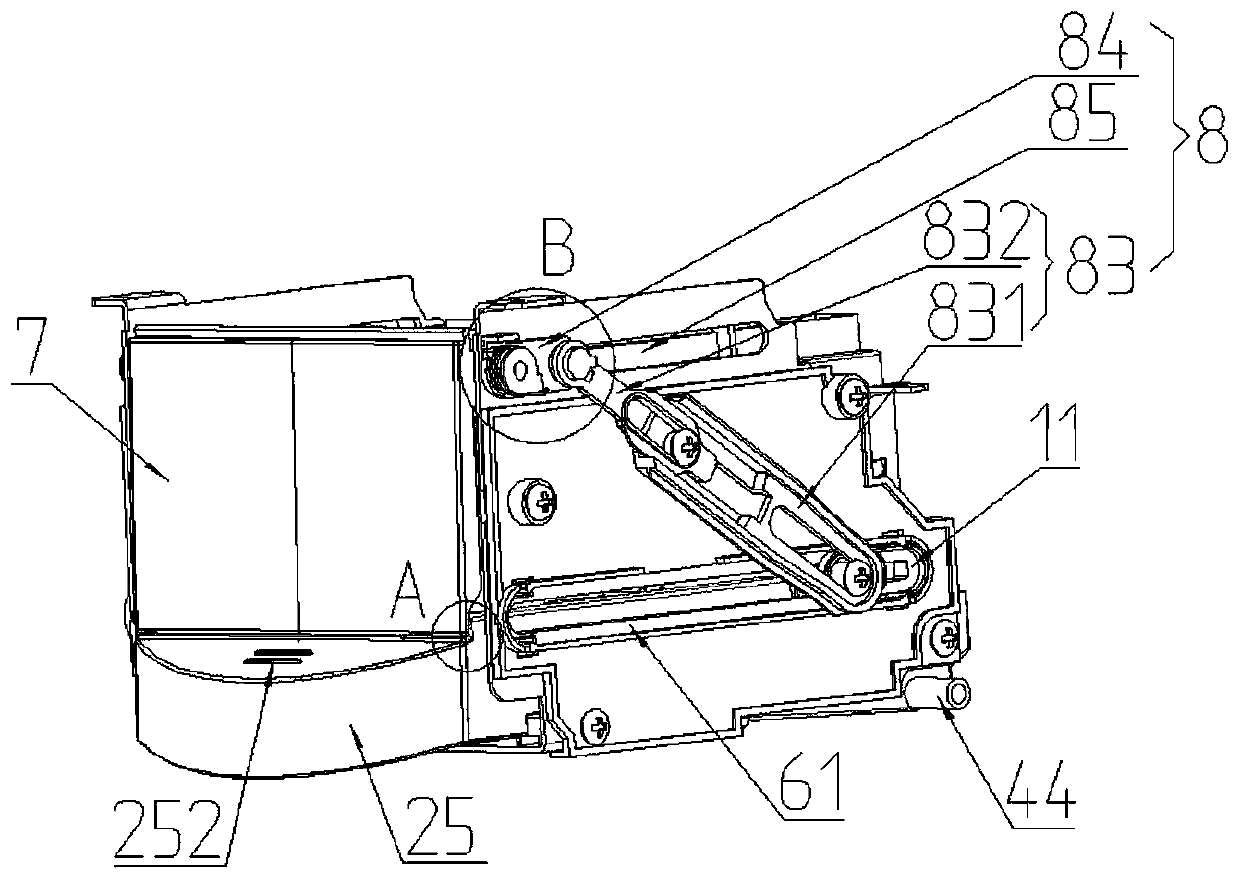

Zip-top can recycling method

PendingCN112157114AScientific and reasonable structureEasy to useTransportation and packagingSolid waste disposalStructural engineeringMechanical engineering

The invention discloses a zip-top can recycling method which comprises the following steps: sorting: zip-top cans fall into a sorting mechanism from a feeding plate at the top of a frame body, the zip-top cans made of different materials are classified, aluminum zip-top cans fall into an aluminum collecting box body, and iron zip-top cans fall into an iron can body channel; cutting: a can body material cutting and separating mechanism can clamp the iron zip-top cans and cut off two ends of the iron zip-top cans, the two aluminum ends fall into the aluminum collecting box body, and iron can bodies slide along a can body sliding channel; shearing: the iron can bodies fall onto a horizontal placing platform, and a stable can body shearing mechanism shears each iron can body to form a gap andexpands the gap; and flattening: the sheared can bodies fall on a conveying belt, a can body flattening and overturning mechanism flattens the can bodies and conveys the can bodies forwards, and flattened iron sheets overturn and slide down to the conveying belt along an arc-shaped guide plate.

Owner:秦金铭

Ultrasonic device and clothes treating apparatus

PendingCN110685107AEasy to operateImprove experienceTextiles and paperVibration washing machinesWater flowAcoustics

The invention belongs to the technical field of ultrasonic waves, and aims to solve the problem that an existing ultrasonic device without a proper liquid drainage mode cannot timely drain liquid in awater containing component when a user does not use the existing ultrasonic device. The ultrasonic device comprises a shell, a water containing component and an opening-closing assembly, the opening-closing assembly is closed when the water containing component is pulled out of the shell to stop water in the water containing component from flowing out, and the opening-closing assembly is opened when the water containing component is pushed into the shell to allow the water in the water containing component to flow out. When the user does not use the ultrasonic device, the liquid in the watercontaining component can be timely drained, so that bacteria breeding caused by liquid accumulation in the water containing component is avoided.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Composite processing method for preventing corrosion, keeping fresh and clearing agricultural chemical after picking cherry tomatoes

InactiveCN101715801AExtended soaking timeNo burns occurredFruits/vegetable preservation by heatingSodium bicarbonateCarriomycin

The invention discloses a composite processing method for preventing corrosion, keeping fresh and clearing agricultural chemical after picking cherry tomatoes. The composite processing method comprises the following steps of: choosing cherry tomatoes in a hard-ripe stage, soaking by hot water and storing, wherein the hot water contains sodium bicarbonate, the concentration of the sodium bicarbonate in the hot water is 1.5-2.5 percent (m / v), the temperature of the hot water is 45 DEG C, the soaking time of the cherry tomatoes is 8-12 minutes, and the storing temperature is no higher than 20 DEG C. The cherry tomatoes do not have a cracking phenomenon after being soaked in the hot water containing sodium bicarbonate at 45 DEG C. The composite processing method can delay the decrease of the fruit hardness and the soluble solids of the cherry tomatoes, reduce the generation and the development of rottenness and has optimal clearing effect for agricultural chemical carriomycin.

Owner:NINGBO UNIV

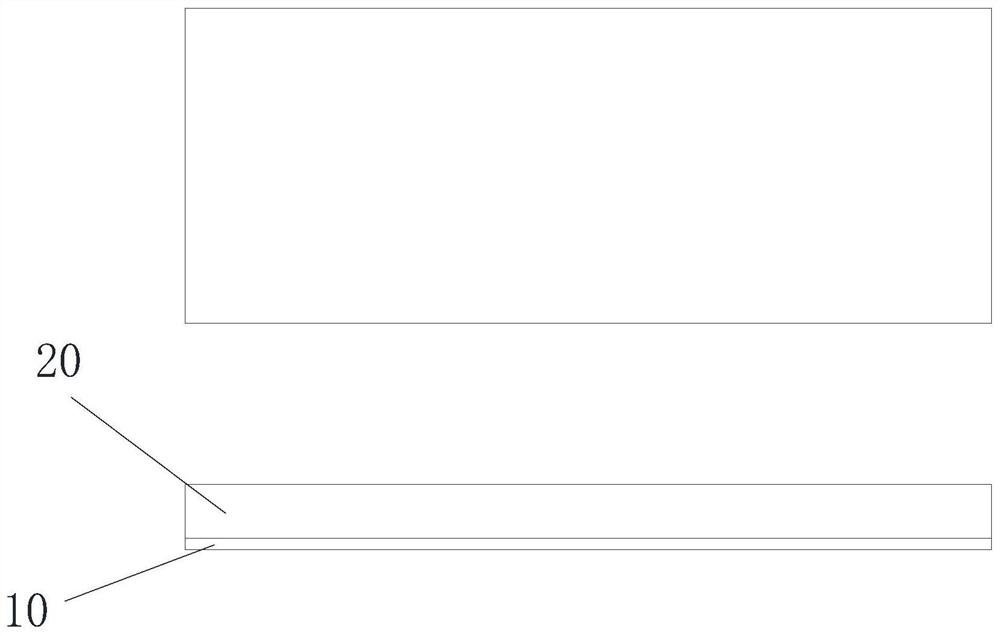

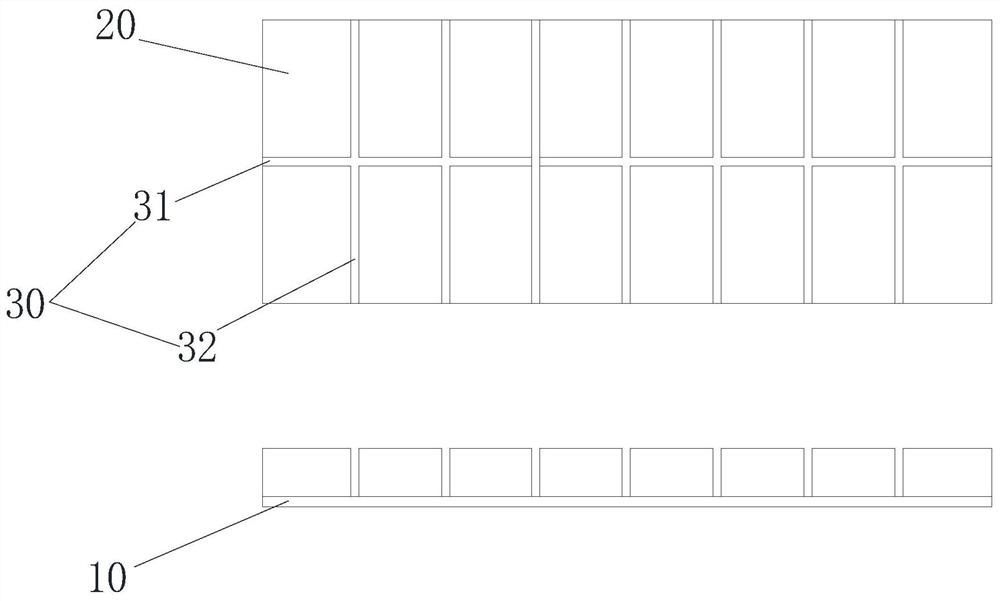

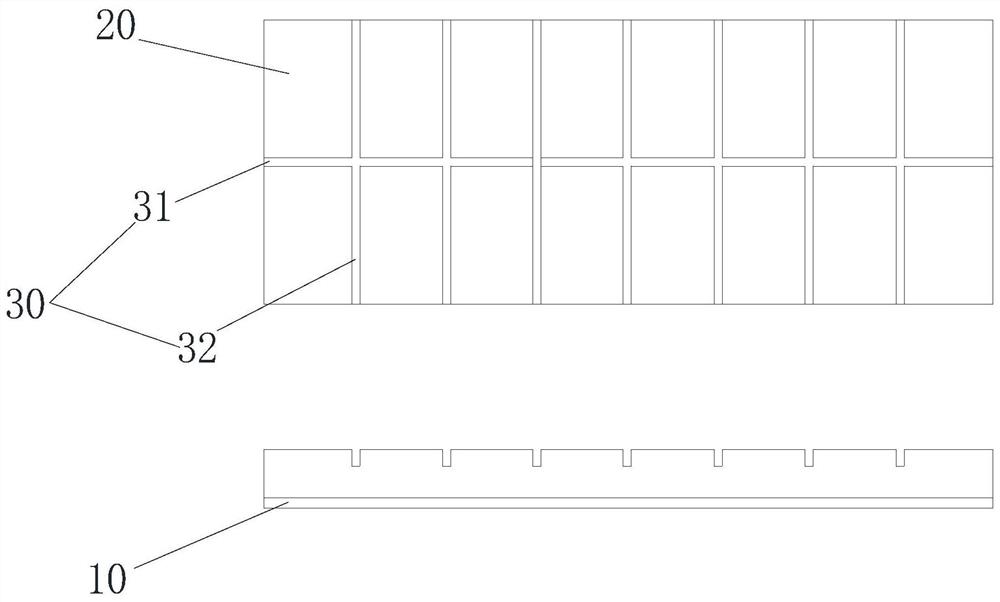

Lithium ion battery pole piece and preparation method thereof

InactiveCN112467073AImprove cycle lifeExtended soaking timeSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrolytic agentCell fabrication

The invention relates to a lithium ion battery pole piece which comprises a current collector, an active substance layer coating the surface of the current collector and an electrolyte immersion channel distributed on the active substance layer, and the electrolyte immersion channel comprises at least one transverse infiltration channel and at least one longitudinal infiltration channel perpendicular to the transverse infiltration channel. The invention provides the lithium ion battery pole piece and a preparation method thereof, aiming at overcoming the defects that the manufacturing cost ofa battery is increased and the electrical property is reduced due to the fact that a high-compaction-density electrode piece is difficult to infiltrate in an electrolyte in the prior art.

Owner:JIANGSU FRONT NEW ENERGY +1

Sustained release formula bait for fishing grass carps and crucian carps

The invention relates to sustained release formula bait for fishing grass carps and crucian carps. The sustained release formula bait comprises a carrier; the carrier is circular or square, and the carrier is externally wrapped with a bait formula layer; the bait formula layer sequentially comprises a disintegration layer and a sustained release layer from outside to inside. In a finishing process, the disintegration layer and the sustained release layer are arranged, so that the bait is decomposed layer by layer from outside to inside and can attract fish by smelling; the disintegration layer can be rapidly dispersed when encountering water so as to send out a smell and attract the fish; the sustained release layer is slowly decomposed in the water so as to maintain the shape of the bait and enable the bait not to be rapidly dissolved in the water, thus prolonging the fishing time.

Owner:JIESHOU JINGHUA TECH INFORMATION CONSULTING SERVICE CO LTD

Application of general alkaloid of bocconia cordata for treating schistosomiasis

InactiveCN1957990AMolluscicide effect increasedExtended soaking timeAntiparasitic agentsAgainst vector-borne diseasesMedicineAlkaloid

An application of the alkaloid of pink plumepoppy in preventing and treating schistosomiasis and killing on comelania and its ova and Japanese schistosome cercaria is disclosed.

Owner:长沙世唯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com