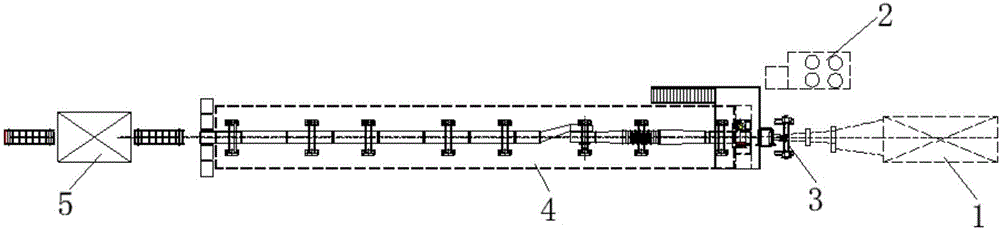

Fiber-reinforced rigid polyurethane foam synthesis sleeper with high fiber content and manufacturing method of sleeper

A polyurethane rigid foam, fiber-reinforced technology, used in tracks, ballast layers, buildings, etc., can solve the problems of unstable quality, uneven impregnation of polyurethane and fibers, increased production costs, etc., to increase impregnation capacity and adhesion capacity. , The effect of product specification and performance diversification, production method and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

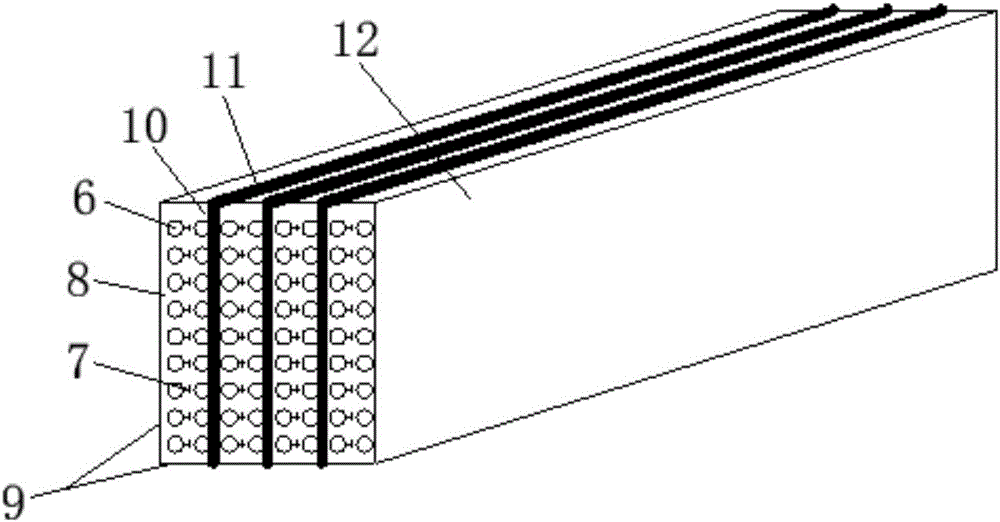

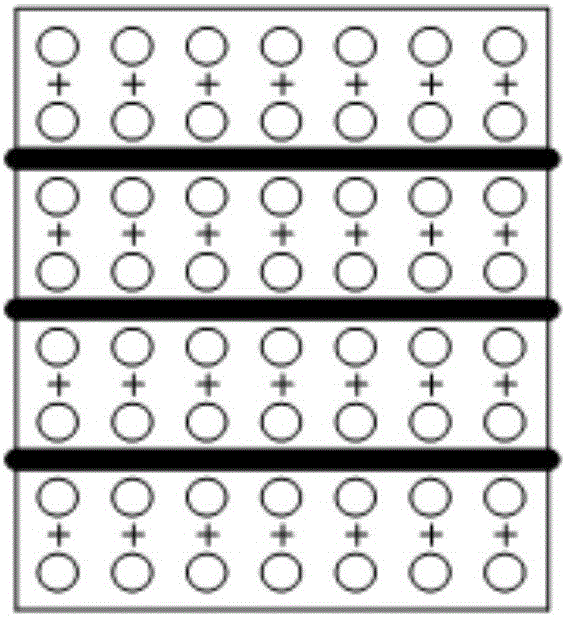

[0076]In terms of parts by mass, the formula of the polyurethane resin and the ratio of the polyurethane resin to the reinforcing fiber are as follows: 90 parts of polyether polyol A with a hydroxyl value of 400-480 and a functionality of 1-3, a hydroxyl value of 60-160 and a functionality of 1-2 10 parts of polyether polyol B, 10 parts of flame retardant, 5 parts of hard foam stabilizer, 15 parts of coupling agent, 0.3 part of catalyst, 0.1 part of foaming agent, 0.3 part of antioxidant, 0.3 part of anti-ultraviolet agent, 120 parts of isocyanate; 430 parts of long fiber, 10 parts of chopped fiber, 5 parts of fiber mat. Among them, the reinforcing fiber content is 64%, and the production density is 1400±50Kg / m 3 Fiber-reinforced polyurethane rigid foam composite sheet specification: 260mm×50mm×3000mm. Parameter setting of crawler lamination host: running speed: 0.4m / min, temperature: 90°C / 60°C. Grind the surface of the composite board, use vinyl resin as the binder, and bon...

Embodiment 2

[0080] In terms of parts by mass, the formula of the polyurethane resin and the ratio of the polyurethane resin to the reinforcing fiber are as follows: 95 parts of polyether polyol A with a hydroxyl value of 400-480 and a functionality of 1-3, a hydroxyl value of 60-160 and a functionality of 1-2 5 parts of polyether polyol B, 10 parts of flame retardant, 3 parts of hard foam stabilizer, 5 parts of coupling agent, 0.3 parts of catalyst, 0.1 part of foaming agent, 0.3 parts of antioxidant, 0.3 parts of anti-ultraviolet agent, 110 parts of isocyanate; 410 parts of long fiber, 10 parts of chopped fiber, 0 parts of fiber mat. Among them, the reinforcing fiber content is 65%, and the production density is 1200±50Kg / m 3 Fiber-reinforced polyurethane rigid foam composite sheet specification: 240mm×50mm×3000mm. Parameter setting of crawler lamination host: running speed: 0.6m / min, temperature: 90°C / 60°C. Mechanically grind one of the composite boards to a thickness of 40mm, use fiv...

Embodiment 3

[0085] In terms of parts by mass, the formula of the polyurethane resin and the ratio of the polyurethane resin to the reinforcing fiber are as follows: 90 parts of polyether polyol A with a hydroxyl value of 400-480 and a functionality of 1-3, a hydroxyl value of 60-160 and a functionality of 1-2 5 parts of polyether polyol B, 15 parts of flame retardant, 5 parts of rigid foam stabilizer, 10 parts of coupling agent, 0.2 part of catalyst, 0.3 part of foaming agent, 0.5 part of antioxidant, 0.5 part of anti-ultraviolet agent, 115 parts of isocyanate; 520 parts of long fiber, 5 parts of chopped fiber, and 1 part of fiber mat. Among them, the reinforcing fiber content is 68.5%, and the production density is 1000±50Kg / m 3 Fiber-reinforced polyurethane rigid foam composite sheet specification: 500mm×30mm×3000mm. Parameter setting of crawler lamination host: running speed: 0.5m / min, temperature: 90°C / 70°C. The composite board of 500mm×30mm is machined into a composite board of 250...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com