Patents

Literature

37results about How to "Fast soaking speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

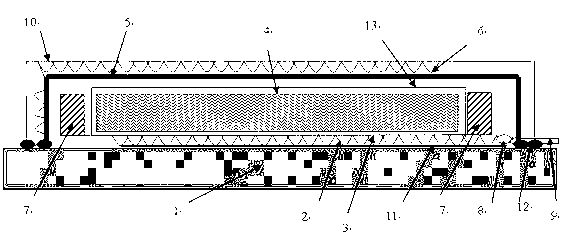

Vacuum infusion forming method for carbon fiber composite structure member

The invention discloses a vacuum infusion forming method for a carbon fiber composite structure member. The method comprises the steps as follows: making a large-size carbon fiber composite wind power blade structure member by a vacuum infusion forming technology; bonding and fixing a guide net to a mould by a transparent double-sided tape for preventing deformation of carbon fiber fabrics due to deformation of the guide net to guarantee that carbon fiber sheet is consistent in orientation so as to obtain a composite structure member with higher mechanical performance; preheating a resin mixing solution with a carbon fiber preforming body at first to guarantee the resin mixing solution to be quickly infused in a low-viscosity state; and sealing the upper surface of the carbon fiber preforming body with a unidirectional breathable film to form a surface breathable channel, and enabling the resin mixing solution to permeate from surface and to fill fully under vacuum, thus completing the vacuum infusion forming process. The method is suitable for the carbon fiber fabrics which are shaped by hot melting lines and have different surface densities; and compared with the carbon fiber prepreg forming process, the method has the advantages of long material availability period, high process stability and low product cost, and is favorable for popularization and application.

Owner:SINOMATECH WIND POWER BLADE

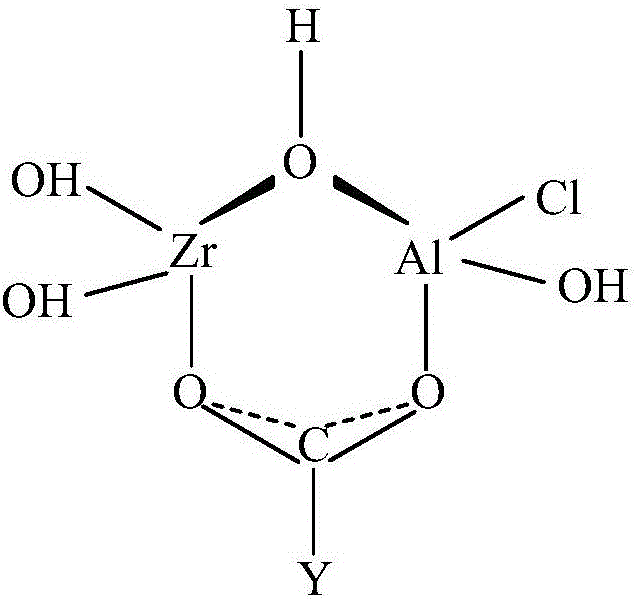

Sizing agent special for ultra-low adsorption resin concentration chopped roving

The invention discloses a special size of chopped twistless roving with ultra-low resin absorbing-capacity, comprising coupling agent, lubricant, antistatic agent A, antistatic agent B, film forming agent A, film forming agent B, film forming agent C and a pH value regulator; all the materials respectively accounts for 1 to 10 percent, 1 to 10 percent, 1 to 5 percent, 1 to 5 percent, 10 to 80 percent, 80 to 10 percent, 1 to 5 percent and 0.1 to 5 percent and water as the rest; the content of the water accounts for 85 to 95 percent of the total weight of the size; the coupling agent adopts silane coupling agent, the lubricant adopts water-soluble grease lubricant, the antistatic agent A adopts organic salt substance with good water absorptivity, the antistatic agent B adopts inorganic salt substance with good water absorptivity, the film forming agent A, the film forming agent B and the film forming agent C respectively adopts one of epoxy emulsion, polyester emulsion, polyvinyl acetate (PVAc) emulsion and polyurethane emulsion; the film forming agent C selects compound with low degree of polymerization, the pH value regulator adopts acid and the pH value of the size is 3 to 11. The size can improve the penetration velocity under the situation of meeting the requirements of the chopped technique, achieves the high content of the glass fibre and ultra-low content of resin, improves the production efficiency of the client and reduces the production cost.

Owner:JUSHI GRP CO

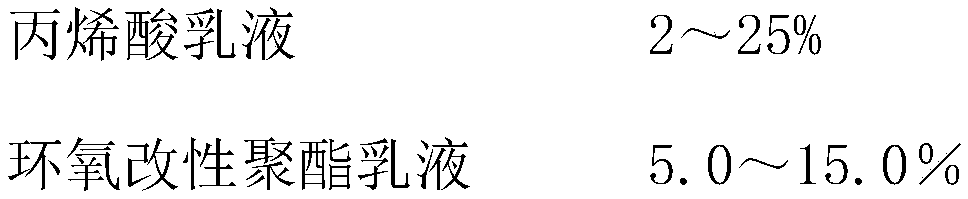

Impregnating compound for enhancing polypropylene plastic-glass fiber chopped yarn

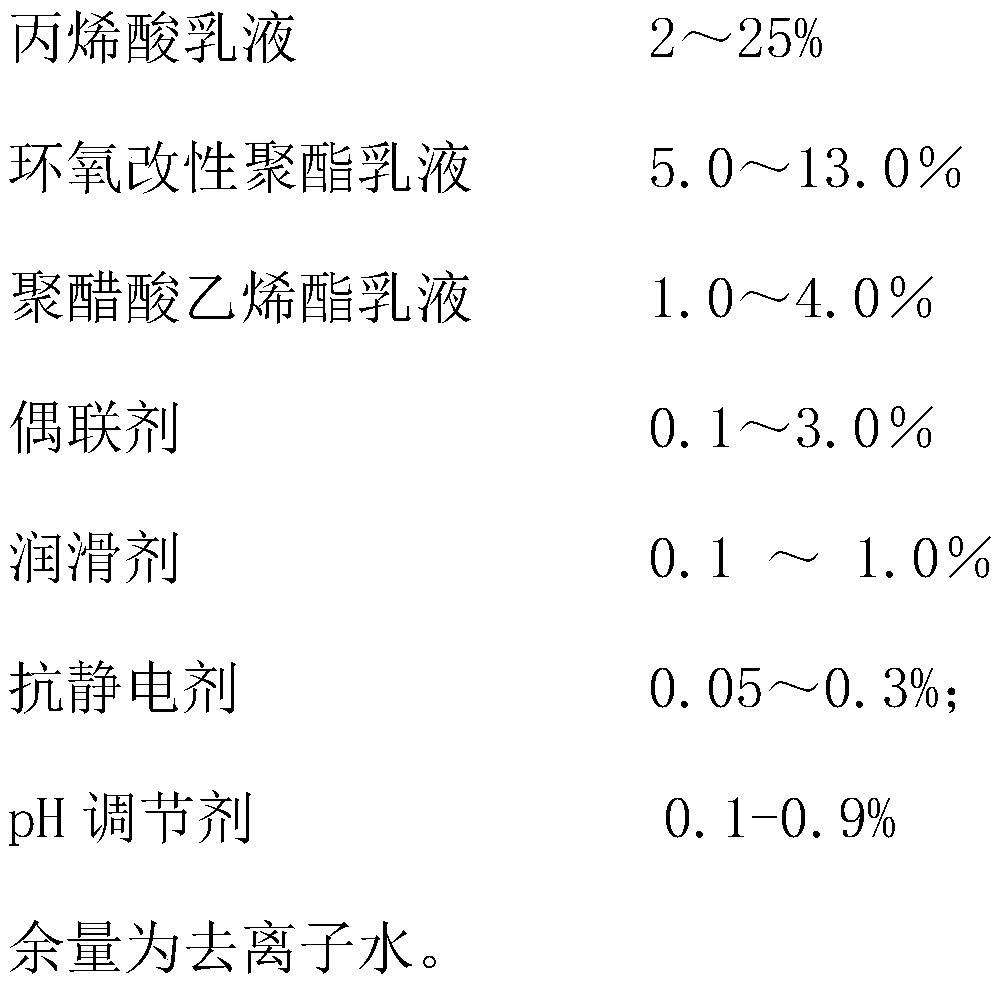

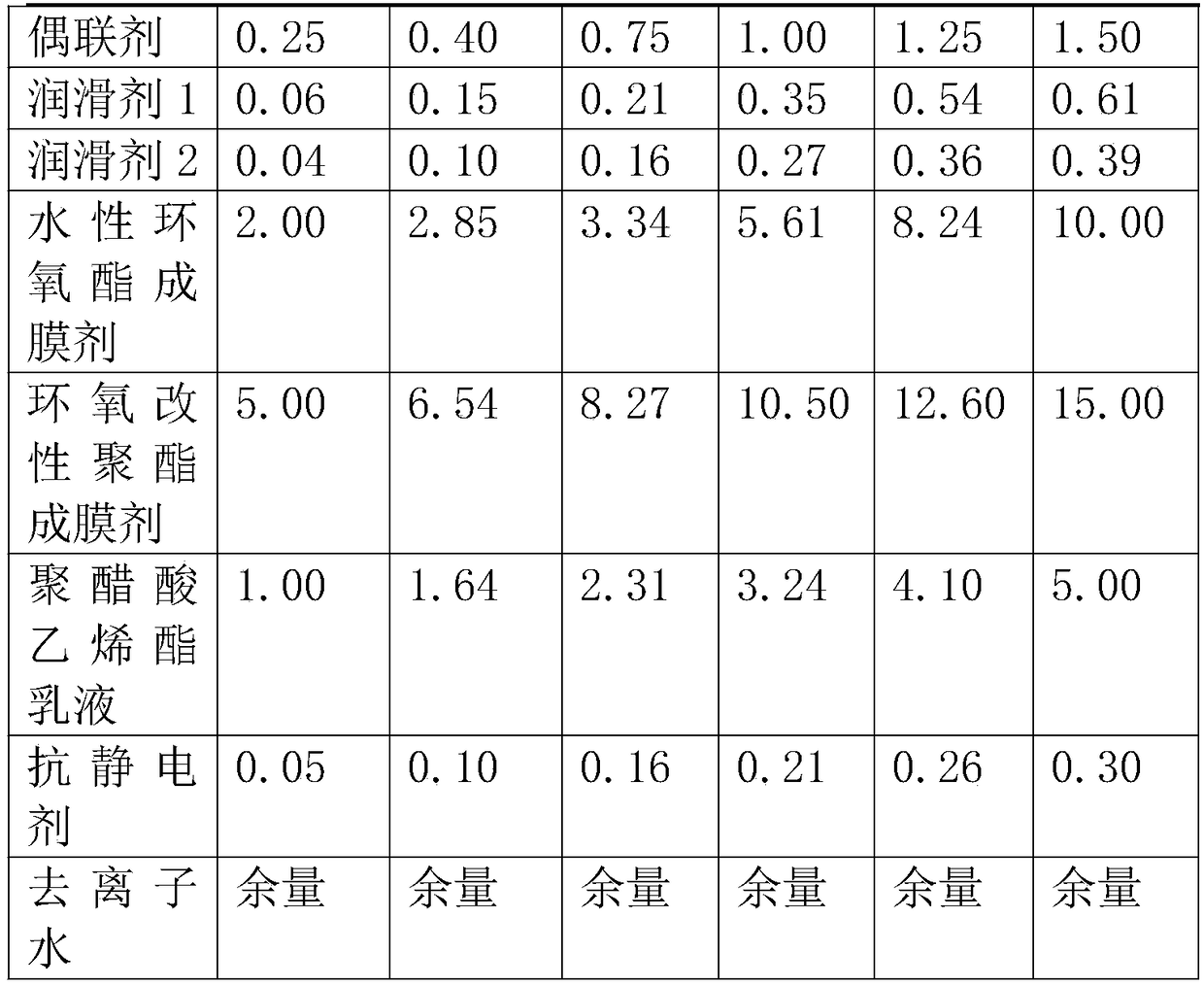

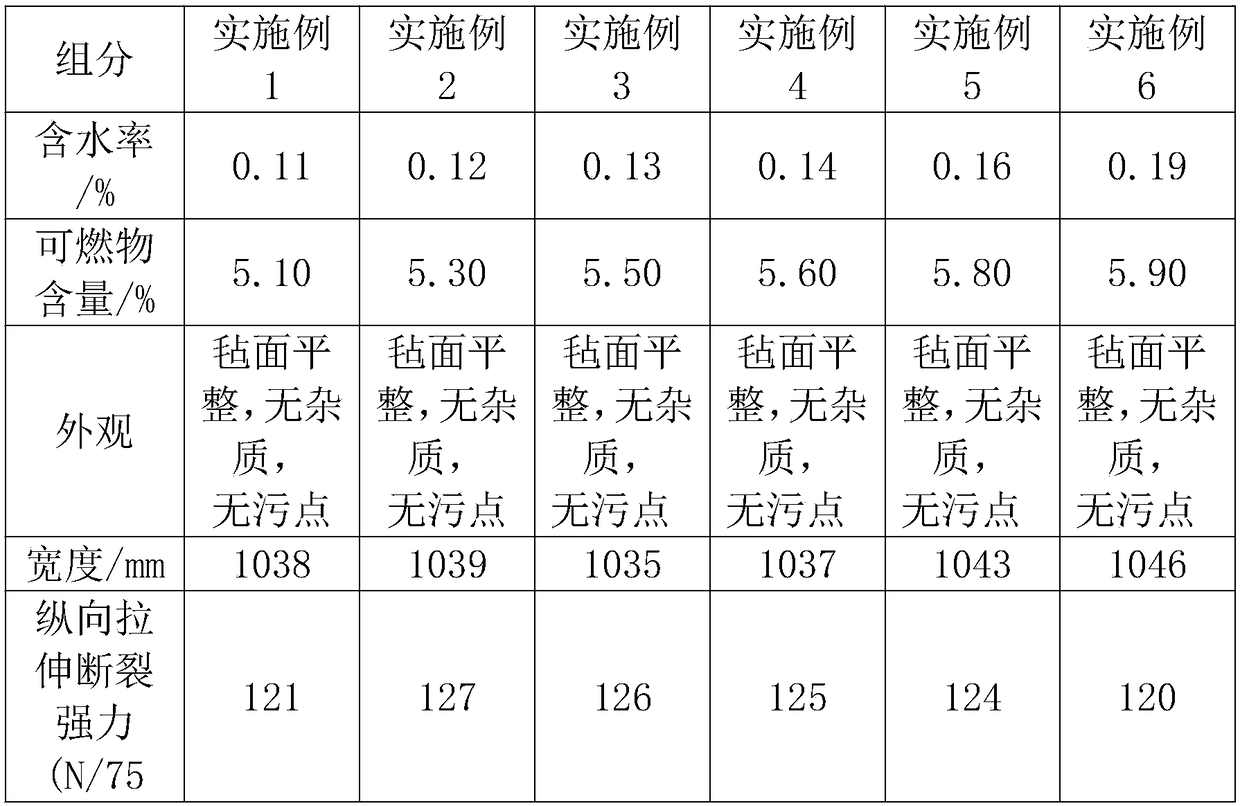

The invention relates to an impregnating compound for enhancing polypropylene plastic-glass fiber chopped yarn. The impregnating compound is prepared from components in percentage by total mass of theimpregnating compound as follows: 3%-22% of an acrylic emulsion, 5.0%-15.0% of epoxy modified polyester emulsion, 1.0%-5.0% of a polyvinyl acetate emulsion, 0.1%-1.0% of a lubricating agent, 0.05%-0.3% of an antistatic agent, 0.1%-0.9% of a pH regulator and the balance of deionized water. Compared with the prior art, the provided impregnating compound can have a good compatibility with polypropylene plastic resin, the plasticity and stiffness of the glass fiber are enhanced, and the impregnating compound has small static electricity and adjustable hardness, can be compatible with multiple resin, is high in resin permeation speed and good in bondability with resin and endows a composite with excellent mechanical properties.

Owner:SHANDONG FIBERGLASS GRP

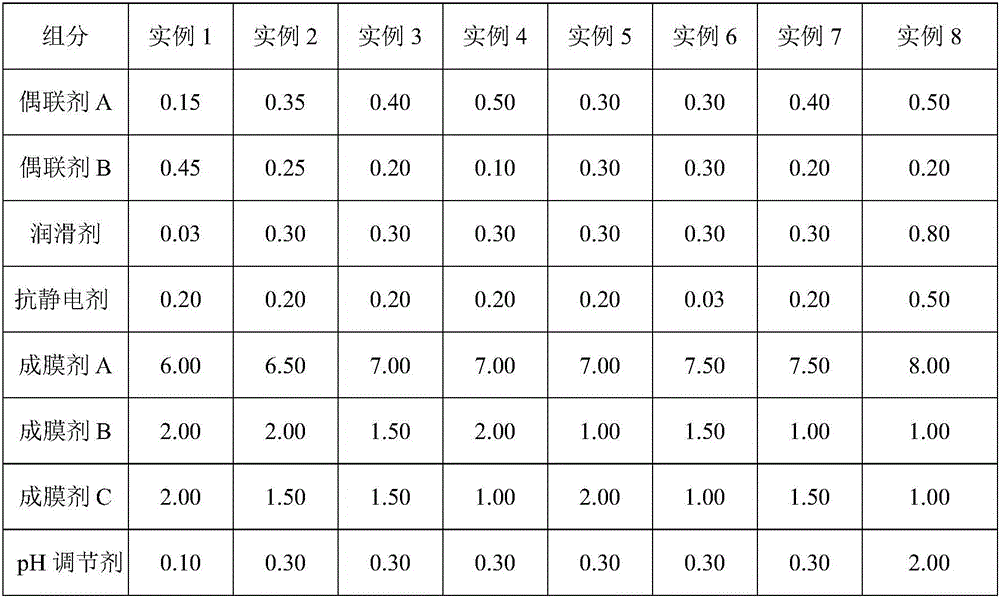

High performance jetting treating compound for twistless roving

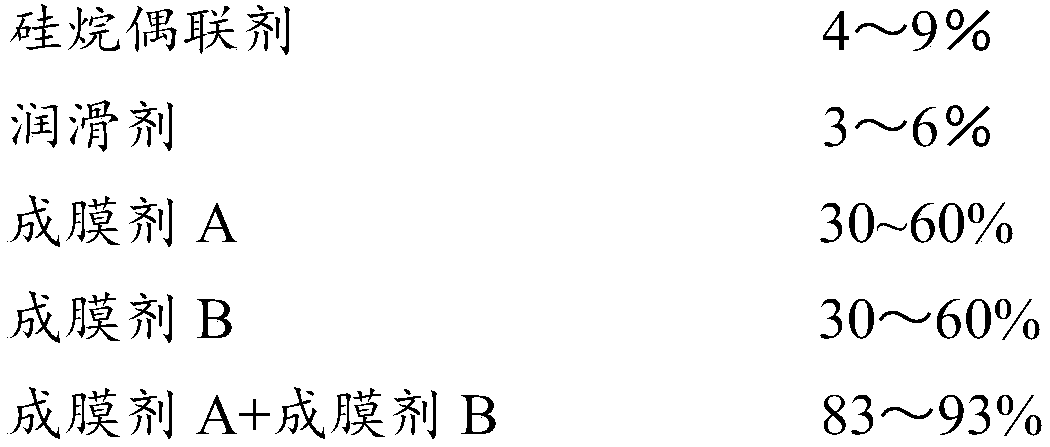

This invention discloses a formula for high-performance glass roving wetting agent for spraying. The wetting agent comprises: coupling agent, lubricating agent, antistatic agent A, antistatic agent B, film-forming agent A, film-forming agent B, pH regulator and water. The content of water is 85-95 wt. % of the wetting agent. The effective components are 5-15 wt. % of the wetting agent. The loss on ignition is 0.5-1.5%. The wetting agent comprises: coupling agent 1-10 wt.%, lubricating agent 1-10 wt.%, antistatic agent A 1-5 wt.%, antistatic agent B 1-5 wt.%, film-forming agent A 10-85 wt.%, film-forming agent B 85-10 wt.%, and pH regulator 0.1-5 wt.%. Film-forming agent A and film-forming agent B are combined, and their total amount is fixed. Film-forming agent A and film-forming agent B are epoxy resin / polyester. The wetting agent has such advantages as high permeation speed, high spraying performance, and high antistatic performance. The product has such advantages as high glass fiber content, high production efficiency and low production cost.

Owner:JUSHI GRP CO

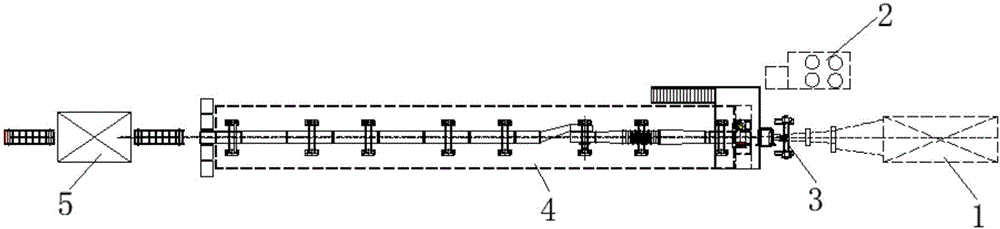

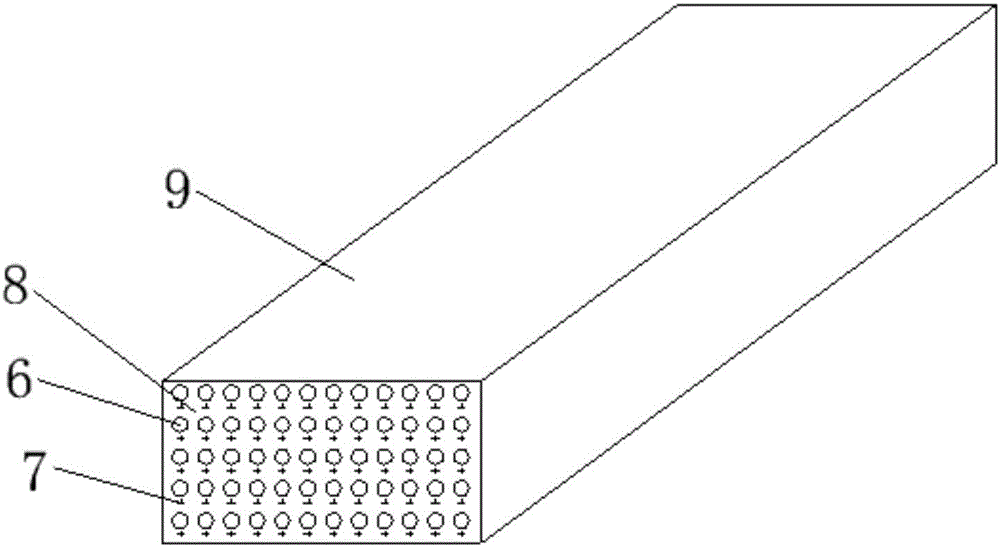

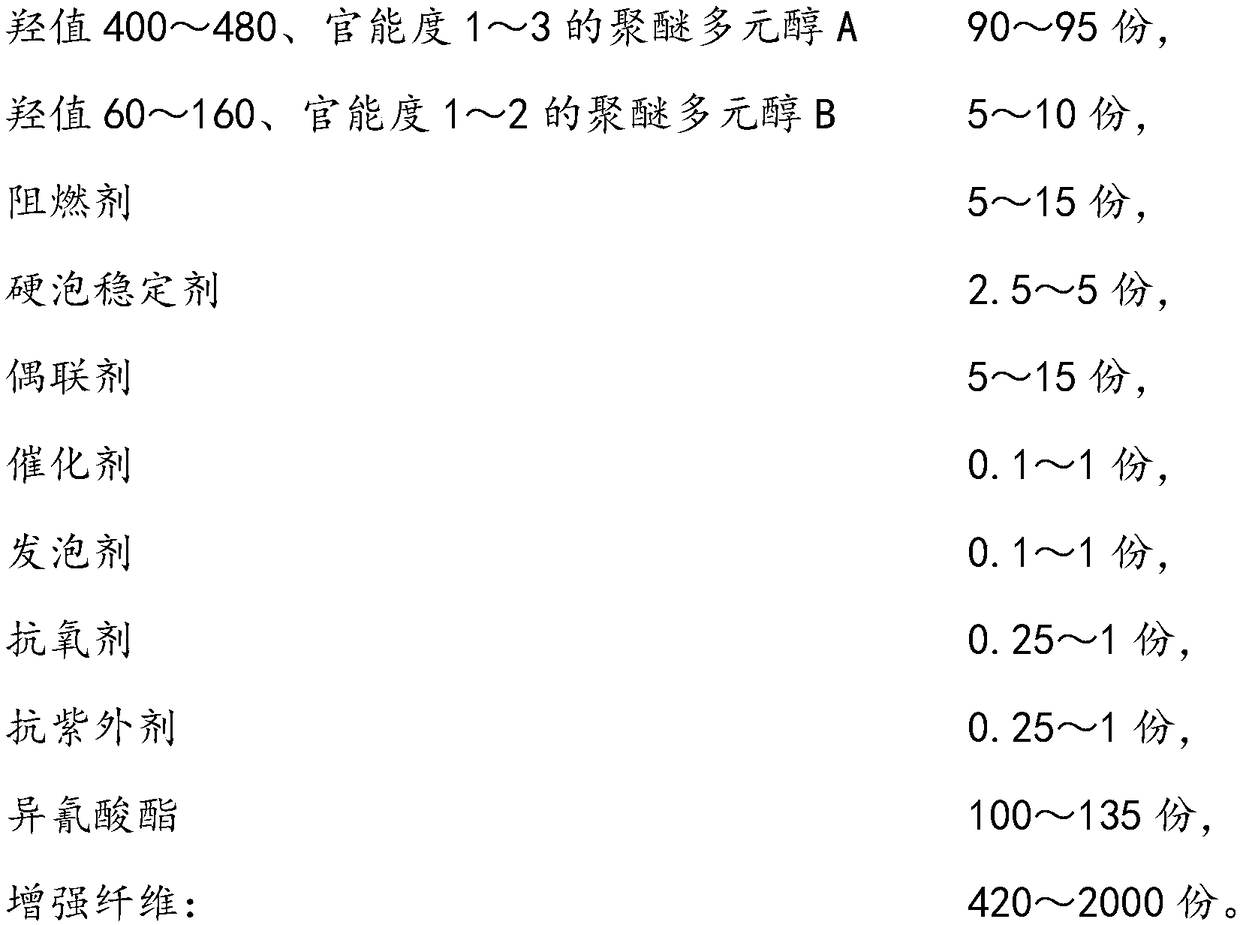

High-fiber-content fiber-reinforced rigid polyurethane foam composite board and manufacturing method thereof

ActiveCN106349446ASolve the problem of insufficient impregnationIncreased reinforcing fiber contentFoaming agentAntioxidant

The invention relates to a high-fiber-content fiber-reinforced rigid polyurethane foam composite board and a manufacturing method thereof; the high-fiber-content fiber-reinforced rigid polyurethane foam composite board is made from polyurethane resin and reinforcing fibers as base materials, as well as hybrid polyether polyol, a flame retardant, a rigid foam stabilizer, a coupling agent, a catalyst, a foaming agent, an antioxidant, an ultraviolet screening agent, an isocyanate, and reinforcing fibers, wherein the content of the reinforcing fibers is greater than 60%; by means of various techniques such as using low-hydroxyl value low-functionality hybrid polyether polyol and using the coupling agent, the problem that polyurethane resin is insufficiently steeped to reinforcing fibers is solved, the content of the reinforcing fibers is increased, a fiber-reinforced rigid polyurethane foam article higher than 840 kg / m<3> in density and higher than 60% in reinforcing fiber content can be manufactured, the technical blank of fiber-reinforced rigid polyurethane foam composite boards is filled, product specifications and properties are diversified, and the different technical index requirements are met.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Glass fiber sizing agent and application thereof

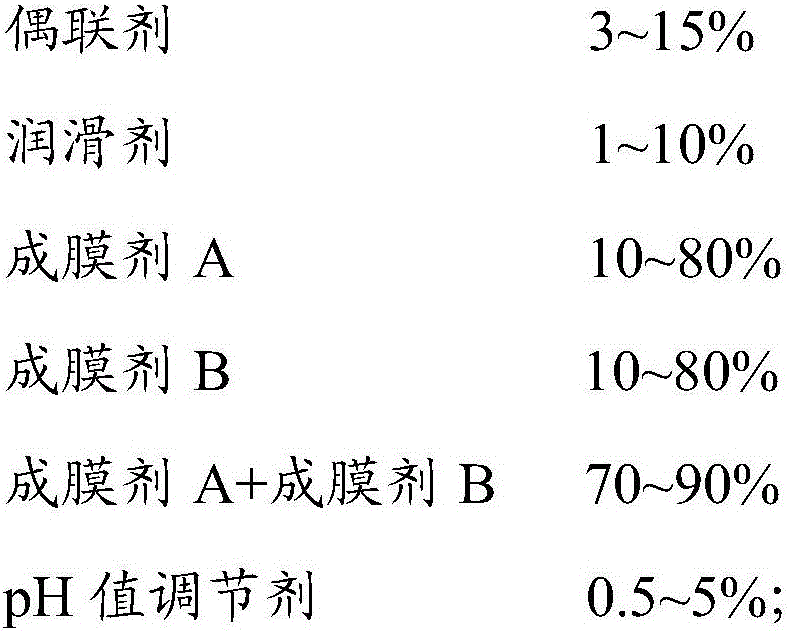

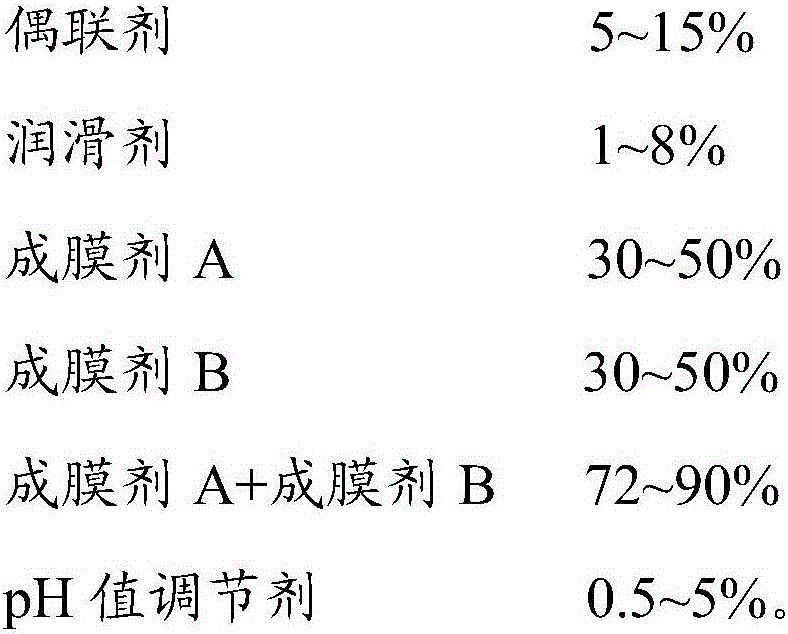

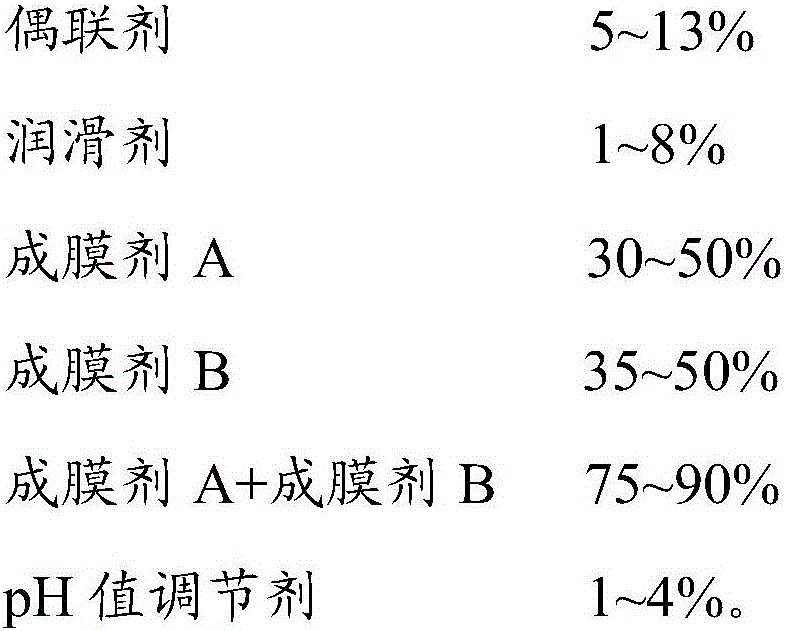

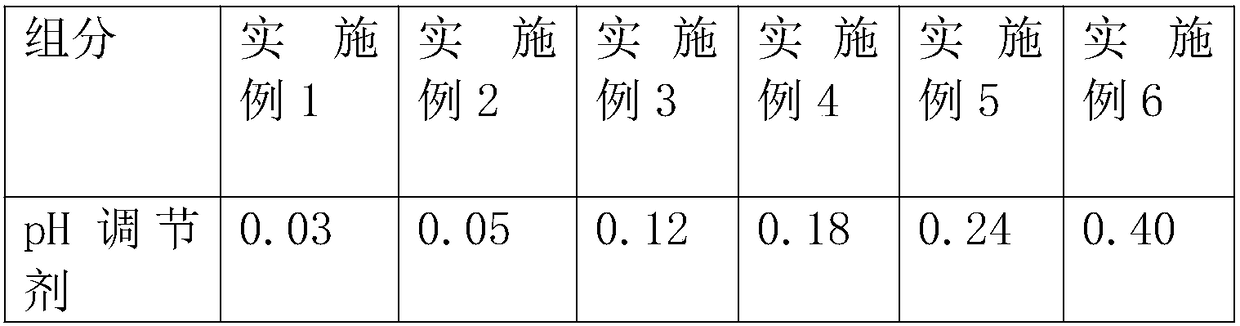

The invention provides a glass fiber sizing agent. The sizing agent comprises a coupling agent, a lubricating agent, a film forming agent A, a film forming agent B, a pH value modifier and water, the coupling agent is one or more of silane coupling agents containing vinyl, methacrylonitrile epoxide, amidogen and epoxy groups, the film forming agent A is polyester resin emulsion, and the film forming agent B is epoxy resin emulsion, wherein the solid mass of the sizing agent accounts for 4%-12% of the total mass of the sizing agent. Different kinds of film forming agents high in content are compounded and matched with the proper coupling agent, lubricating agent and pH value modifier to prepare the sizing agent high in permeation speed and good in compatible effect. Yarn prepared through the sizing agent is soft and high in permeation speed and has excellent pultrusion performance and good resin compatibility. The invention further provides application of the sizing agent in the pultrusion process of alkali-free glass fiber reinforced umbrella frames.

Owner:JUSHI GRP CO

Glass fiber continuous strand mat impregnating agent

The invention relates to a glass fiber continuous strand mat impregnating agent. The glass fiber continuous strand mat impregnating agent is prepared from a silane coupling agent, a lubricating agent,a main film-forming agent, an auxiliary film-forming agent, a pH regulator, an anti-electrostatic agent and deionized water, wherein the film-forming agent comprises water-based epoxy ester emulsion,epoxy modified polyester emulsion and polyvinyl acetate emulsion; the solid content of the impregnating agent is 4.0 to 12.0 percent. A glass fiber original tow coated with the impregnating agent haslittle static electricity and adjustable hardness, can be compatible with various types of resin, is high in resin penetration velocity and has high bondability with the resin. Continuous felt with different solubility can be obtained by adjusting the proportion of the film-forming agent, and the glass fiber continuous strand mat impregnating agent is suitable for various processes such as pultrusion, injection molding and GMT processes.

Owner:SHANDONG FIBERGLASS GRP

Glass fiber impregnating compound high in permeating speed and application thereof in producing twistless roving

The invention discloses a glass fiber impregnating compound which is prepared from, by weight, 0.02-3.00% of a coupling agent, 3.00-30.00% of a film forming agent, 0.02-2.00% of a lubricating agent, 0.02-0.80% of an antistatic agent, 0.01-2.00% of a pH adjusting agent and deionized water. The film forming agent is prepared by mixing nanosilicon dioxide modified polyester emulsion, PVAc emulsion and polyurethane modified epoxy emulsion, and the content of the nanosilicon dioxide modified polyester emulsion is not smaller than that of the polyurethane modified epoxy emulsion. The invention further provides application of the glass fiber impregnating compound in producing twistless roving. The twistless roving produced through the impregnating compound is high in permeating speed, good in choppability, good in production smoothness and good in compatibility with enhanced resin, production efficiency and the mechanical strength of a produced composite product are greatly improved, and the glass fiber impregnating compound is applicable to an injection process or a centrifugal casting molding process.

Owner:JUSHI GRP CO

Glass fiber impregnating agent as well as preparation method and application of glass fiber impregnating agent

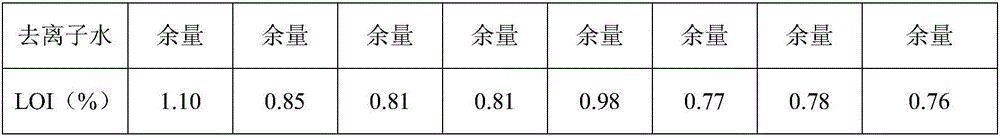

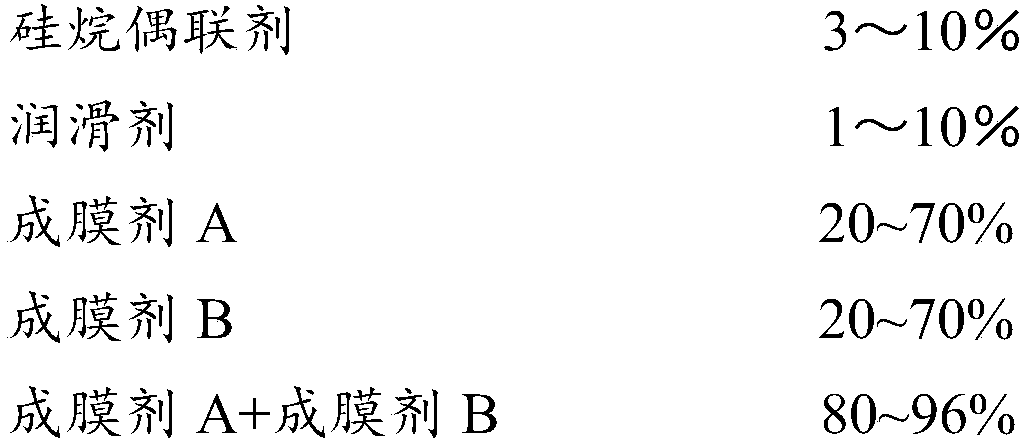

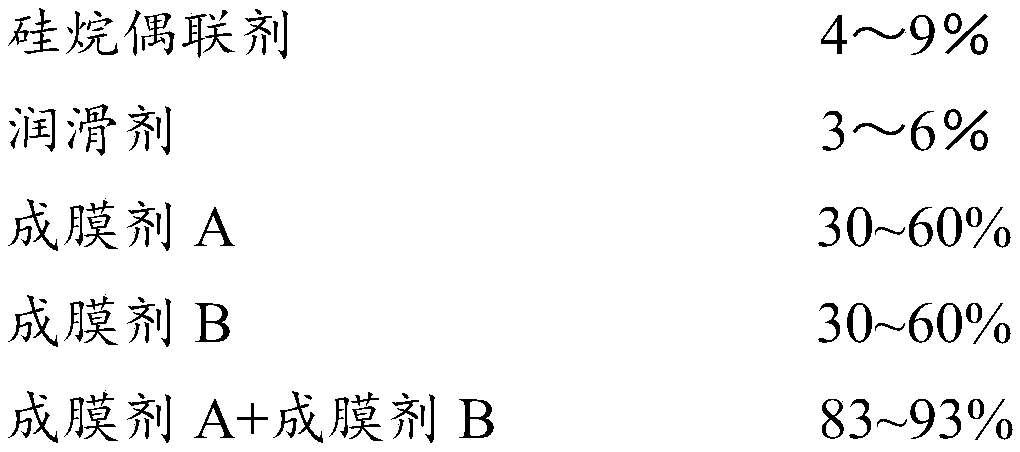

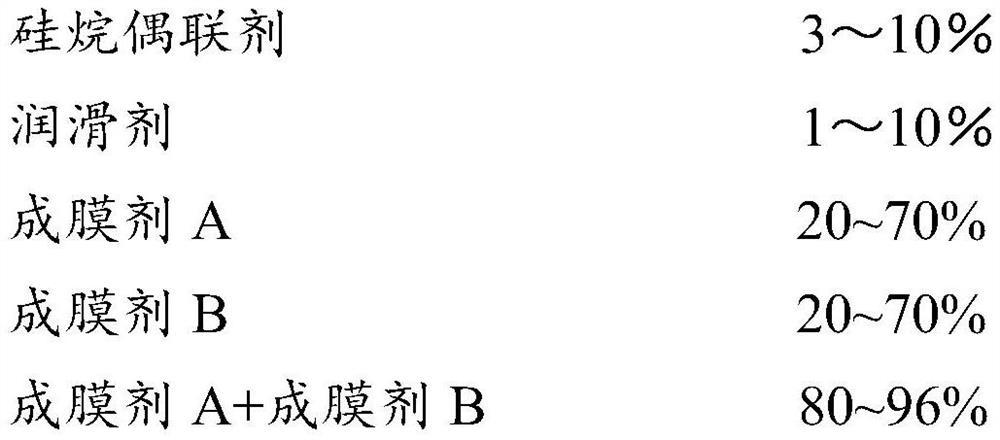

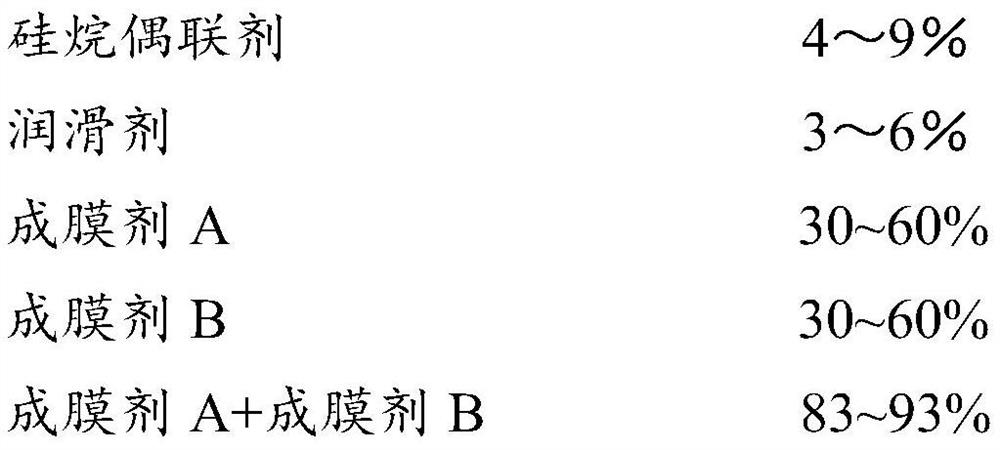

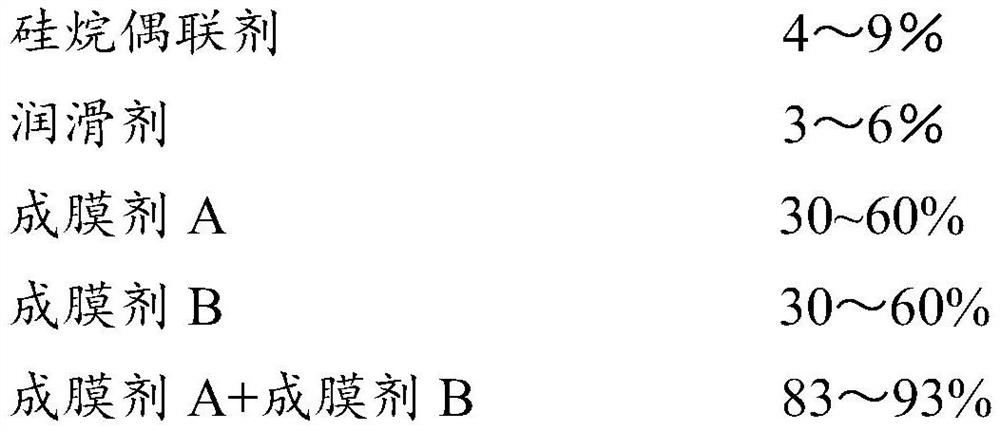

The invention discloses a glass fiber impregnating agent as well as a preparation method and application of the glass fiber impregnating agent. The glass fiber impregnating agent contains a solid component and water; the mass of the solid component accounts for 3-8% of the total mass of the impregnating agent; the solid component contains the following components, and the proportion of the mass ofeach component in the total mass of the solid component is as follows: 3-10% of silane coupling agent, 1-10% of lubricant, 20-70% of film forming agent A, 20-70% of film forming agent B and 80-96% offilm forming agent A and film forming agent B, wherein the silane coupling agent contains an amino group, and the film forming agent A and the film forming agent B are polyurethane with different relative molecular weights. A glass fiber product produced by adopting the impregnating agent is capable of meeting the requirement for few filoplumes under high tension of a polyurethane winding process, good in compatibility with polyurethane matrix resin and high in impregnation speed, and the subsequently prepared product is high in mechanical properties.

Owner:JUSHI GRP CO

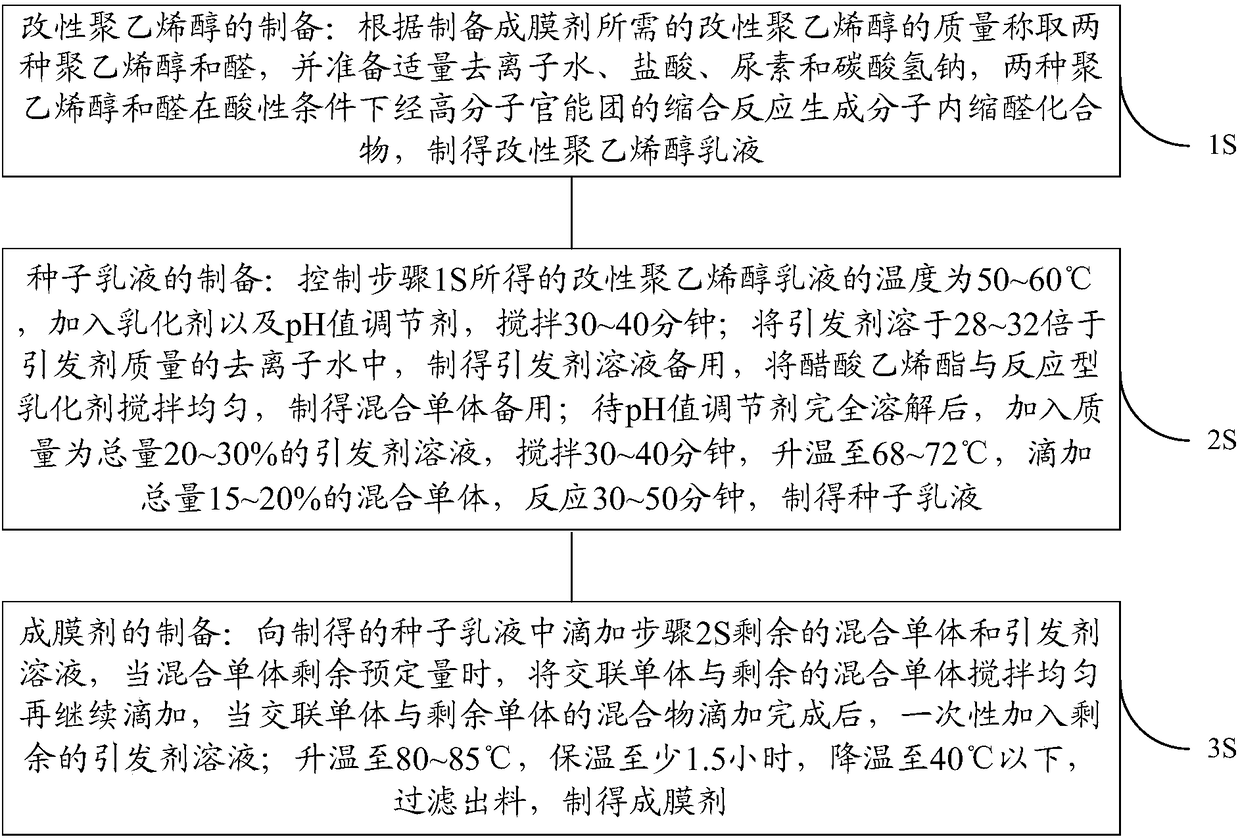

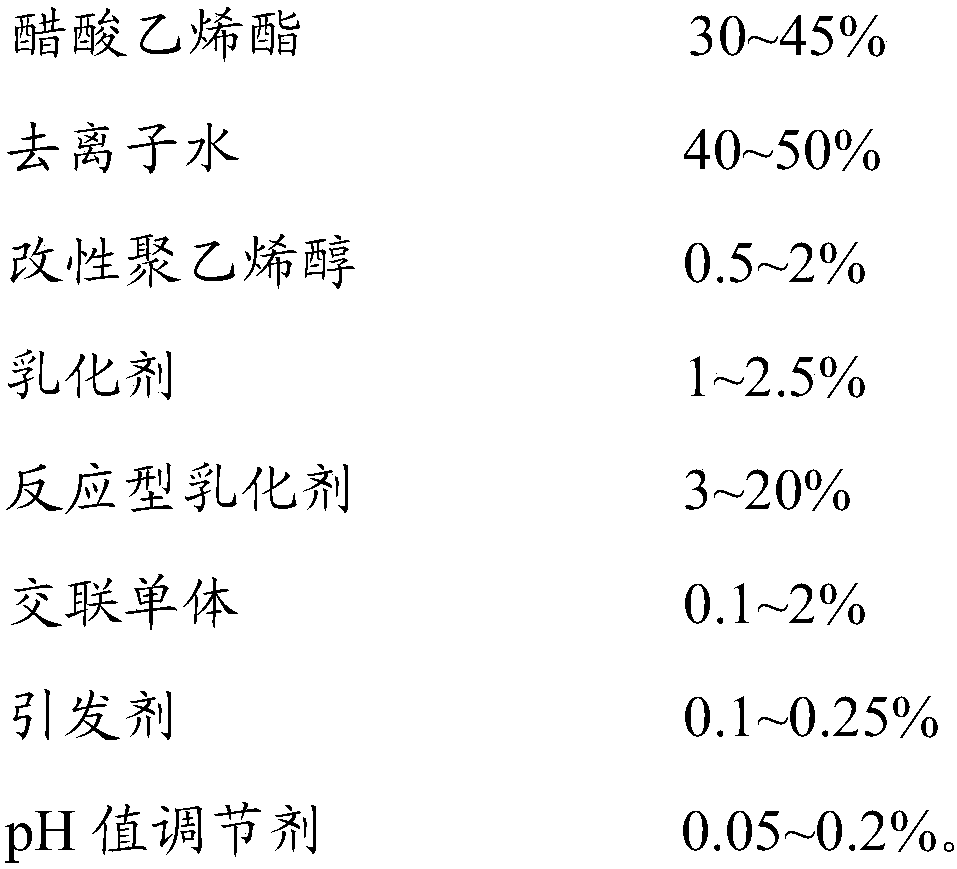

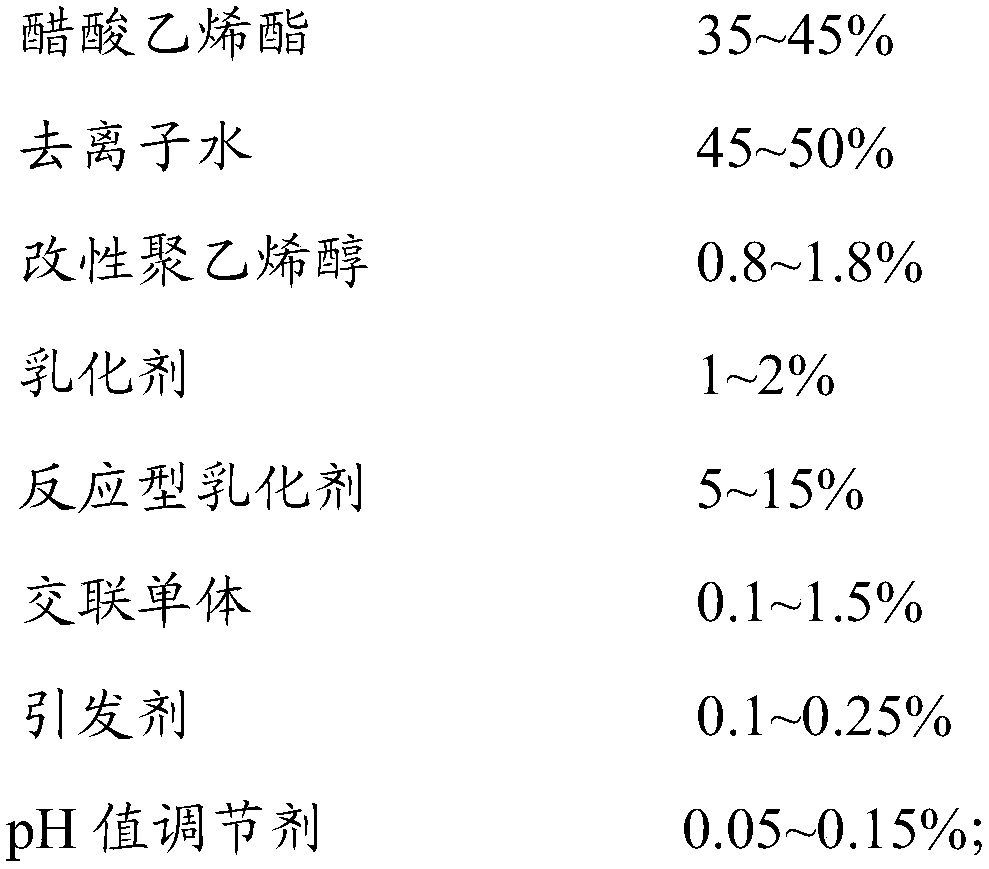

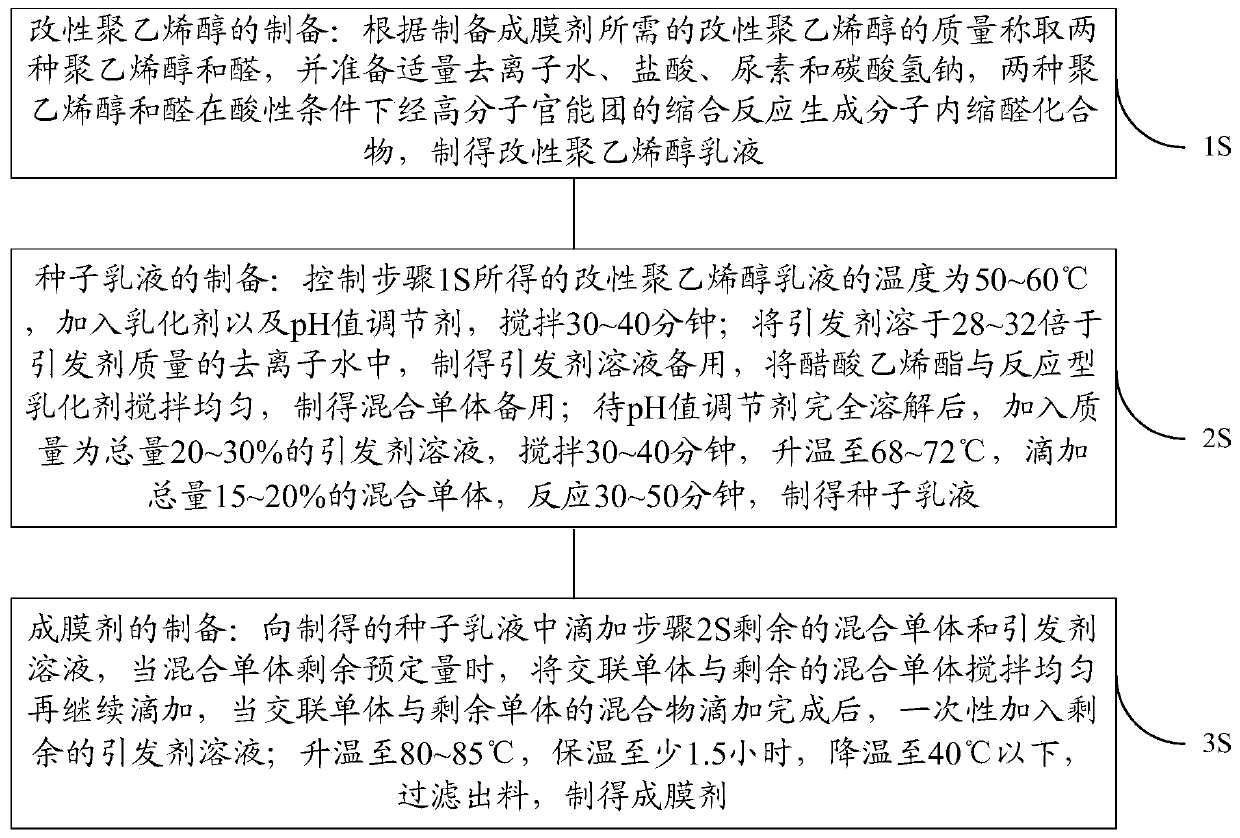

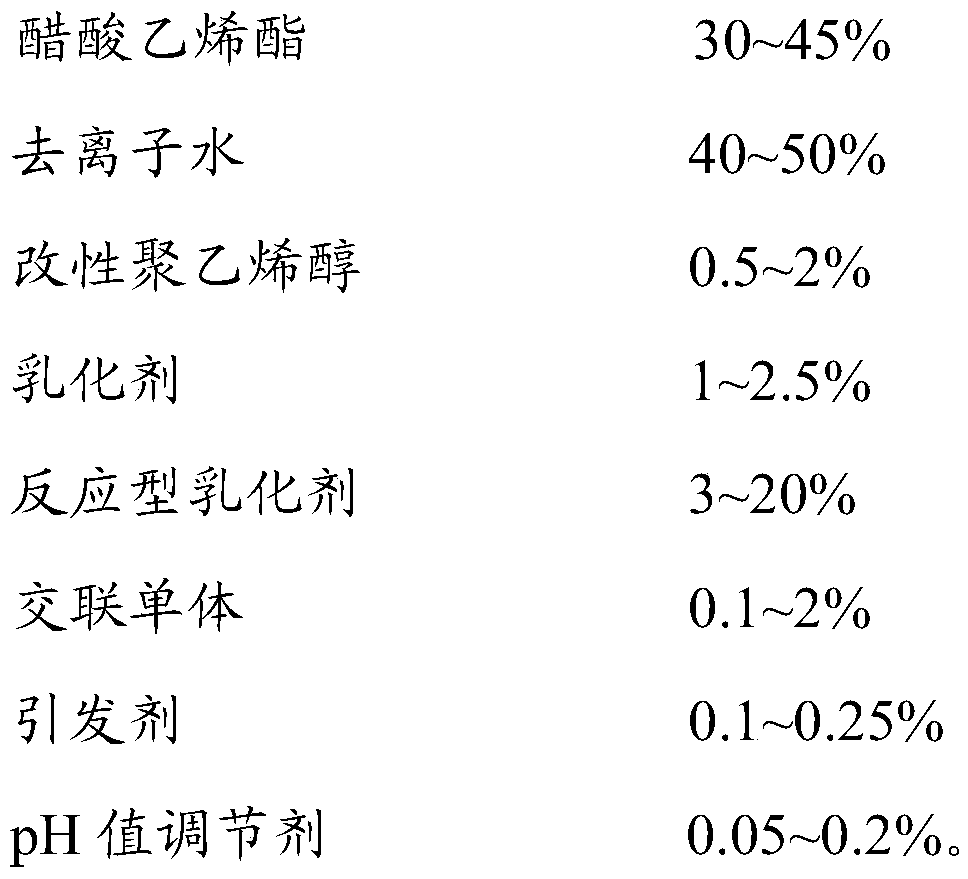

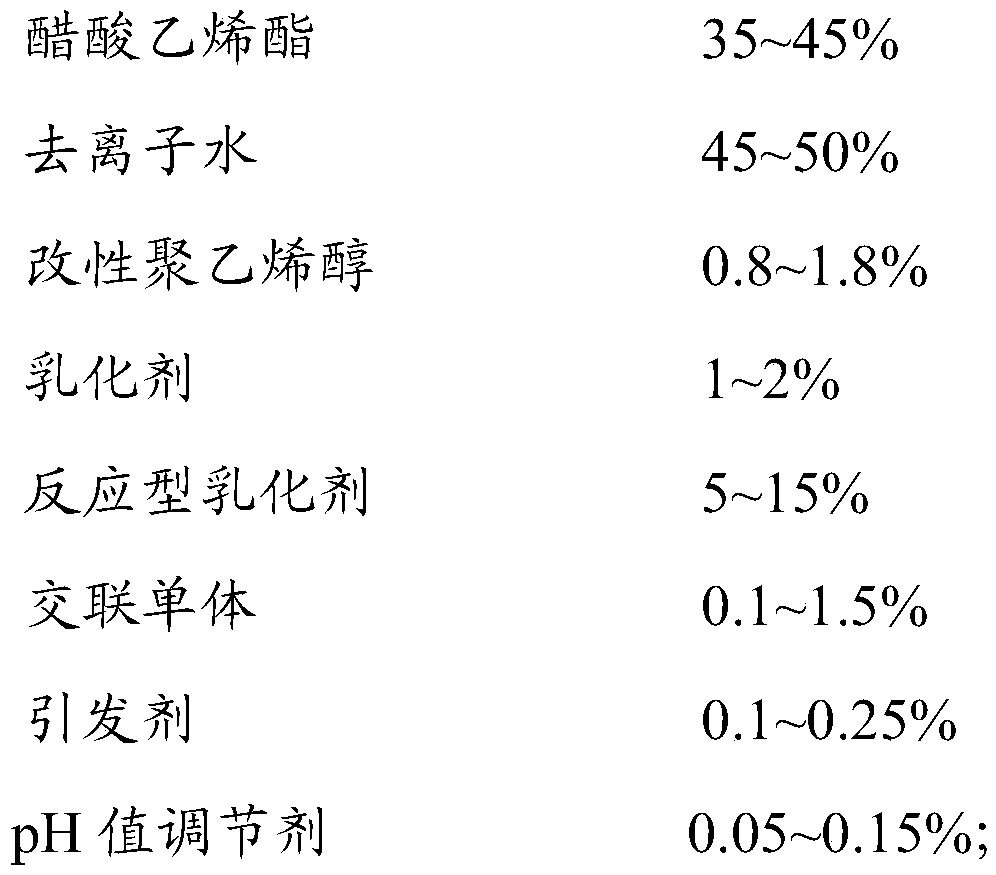

Self-crosslinking polyvinyl acetate film-forming agent, preparation method and uses thereof

The invention provides a self-crosslinking polyvinyl acetate film-forming agent, wherein the raw materials comprise vinyl acetate, deionized water, modified polyvinyl alcohol, an emulsifier, a reactive emulsifier, a cross-linking monomer, an initiator and a pH value adjuster, and the cross-linking monomer is an amide compound. According to the present invention, through the mutual cooperation of the components, the prepared film-forming agent has characteristics of strong precursor bundling property, excellent high-temperature performance, high stiffness, good self-crosslinking property, goodsolvent resistance and the like. The invention further provides a preparation method and uses of the self-crosslinking polyvinyl acetate film-forming agent.

Owner:JUSHI GRP CO

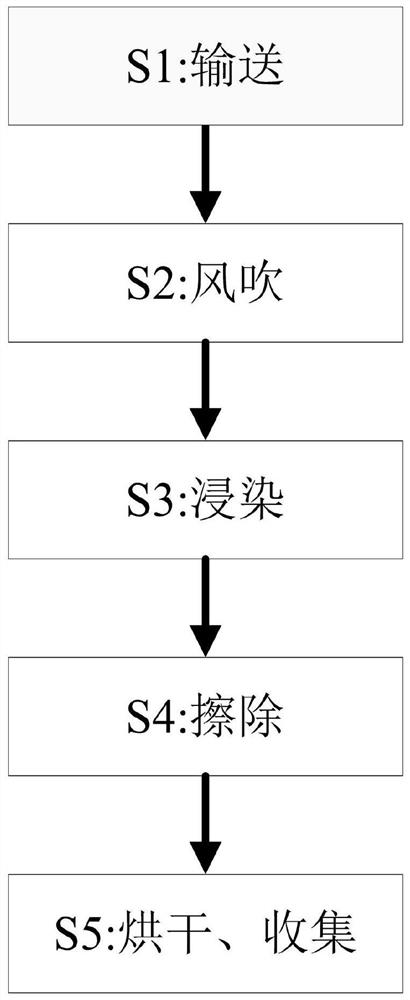

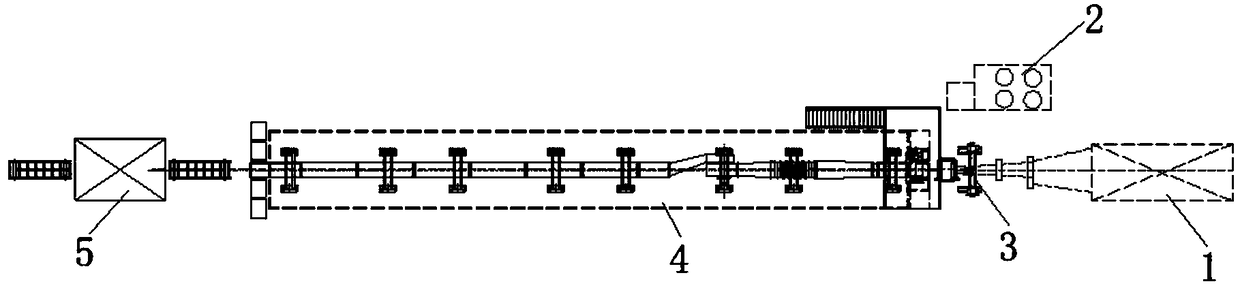

Batch dyeing and drying treatment process for textile yarn

InactiveCN112391757AFast soaking speedUniform soaking effectLiquid/gas/vapor removal by squeezingTextile treatment carriersTextile yarnProcess engineering

The invention provides a batch dyeing and drying treatment process for textile yarn. The process is completed through cooperation of a base, a tightening type turning device, an accelerated dipping device, a sealing cover, a drying frame and a wiping device, and can solve the problems that dust particles may be attached to the surface of the yarn in a conveying process, and the state during conveying is not in a tightening state, so that the above-mentioned conditions influence a dip dyeing effect; and the traditional dip dyeing time is short, the yarn is possibly not soaked thoroughly, dye separation is facilitated, and the dye on the separated yarn is distributed unevenly, so that part of the redundant dye is directly attached to the yarn after being dried, and thus a solidified fuel layer appears on the surface of the yarn, and the percent of pass of the yarn is influenced.

Owner:黄远明

Production method of unsaturated polyester emulsion binder for chopped strand mats

ActiveCN101792649ASmall particle sizeImprove stabilityNon-macromolecular adhesive additivesNon-woven fabricsGlass fiberEmulsion

The invention discloses a production method of an unsaturated polyester emulsion binder for chopped strand mats, which is characterized by comprising the following steps of: putting 55-70 percent of unsaturated polyester resin, 10-15 percent of acetone and 20-30 percent of reactive emulsifier in percent by weight in a high-speed dispersion machine for evenly stirring and mixing; then adding deionized water until the system generates phase inversion; keeping stirring for a while and then adding the deionized water for dilution to obtain an unsaturated polyester emulsion with a certain concentration, wherein the reactive emulsifier is a polymerizable emulsifier which contains double bonds and can participate in reaction. The production method of the unsaturated polyester emulsion binder is simple and easy to operate; the produced unsaturated polyester binder has smaller grain size, good stability, strong binding power and high penetration velocity in cinnamene, thereby being very suitable for preparing glass fibre chopped strand mats.

Owner:JUSHI GRP CO

Anti-wear and anti-corrosion glass fiber impregnating agent

The invention discloses a wear-resistant and anti-corrosion glass fiber impregnating agent. Ethylene glycol phthalate 0.2‑1%, bis(acetylacetone) ethoxy isopropoxy titanate% 0.1‑0.4, sodium dodecyl diphenyl ether disulfonate 0.03‑0.15%, new Pentylene glycol diglycidyl ether 0.4-0.8%, nano-magnesium oxide 0.2-0.6%, glacial acetic acid 0.1-0.4%, and deionized water as the balance. The glass fiber produced by the formula of the invention has good dispersibility, fast soaking speed, no static accumulation, and good bonding performance with resin.

Owner:旌德县源远新材料有限公司

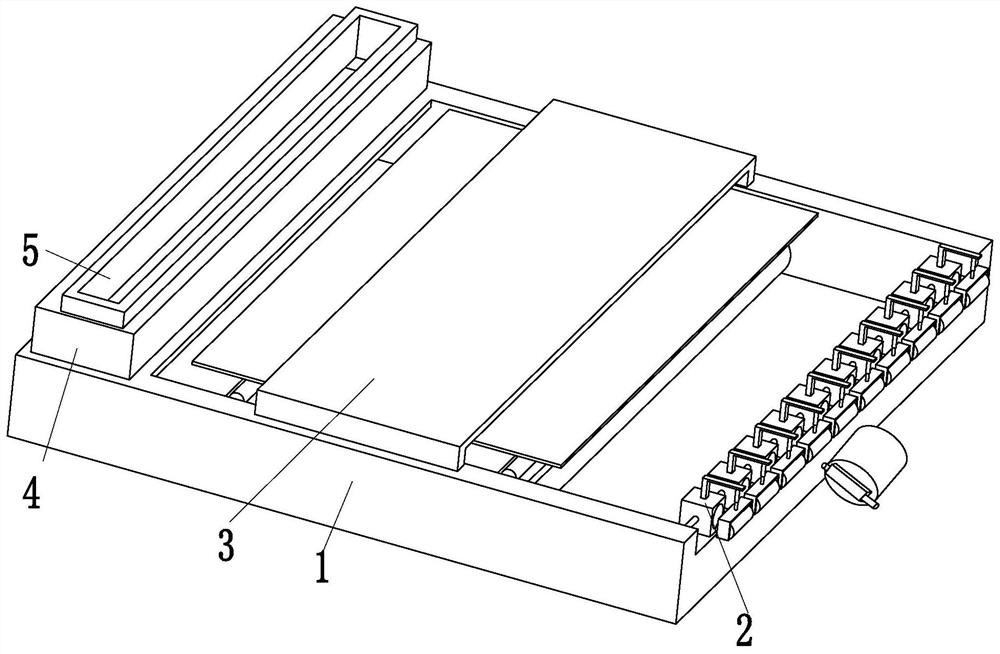

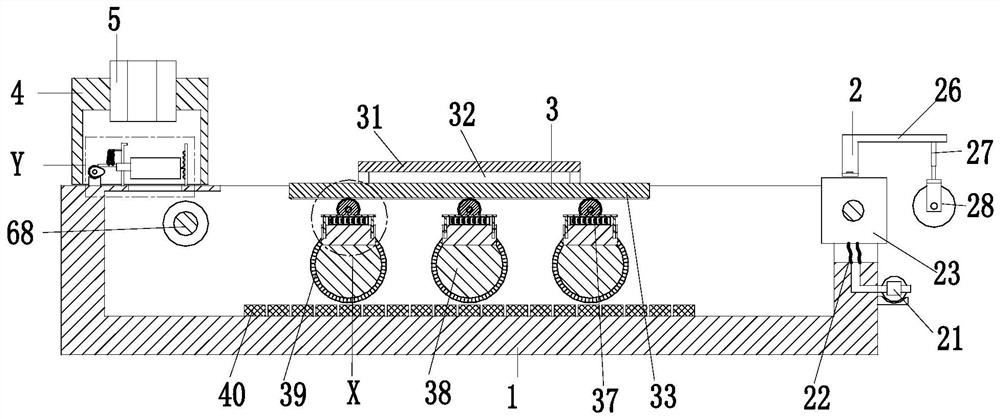

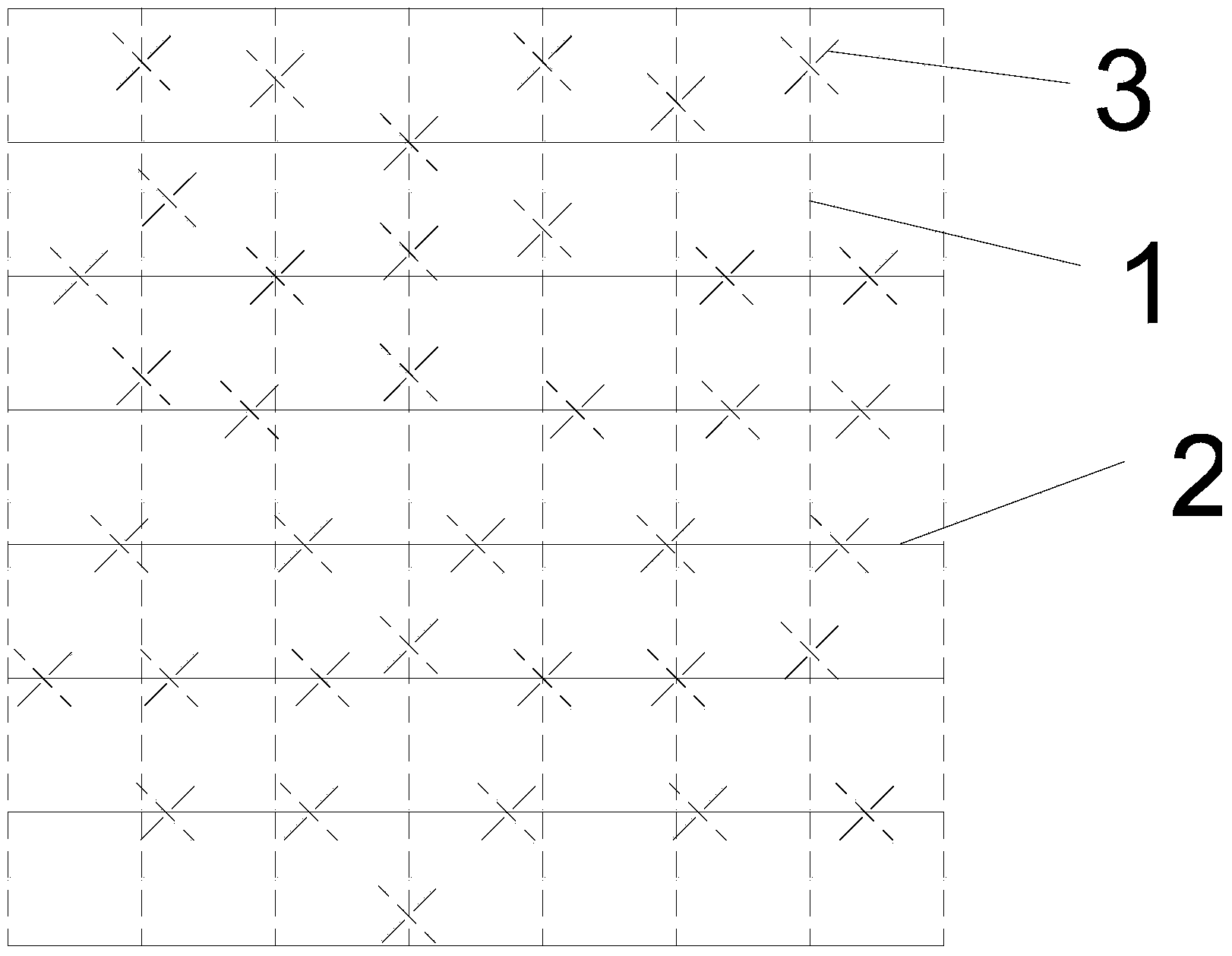

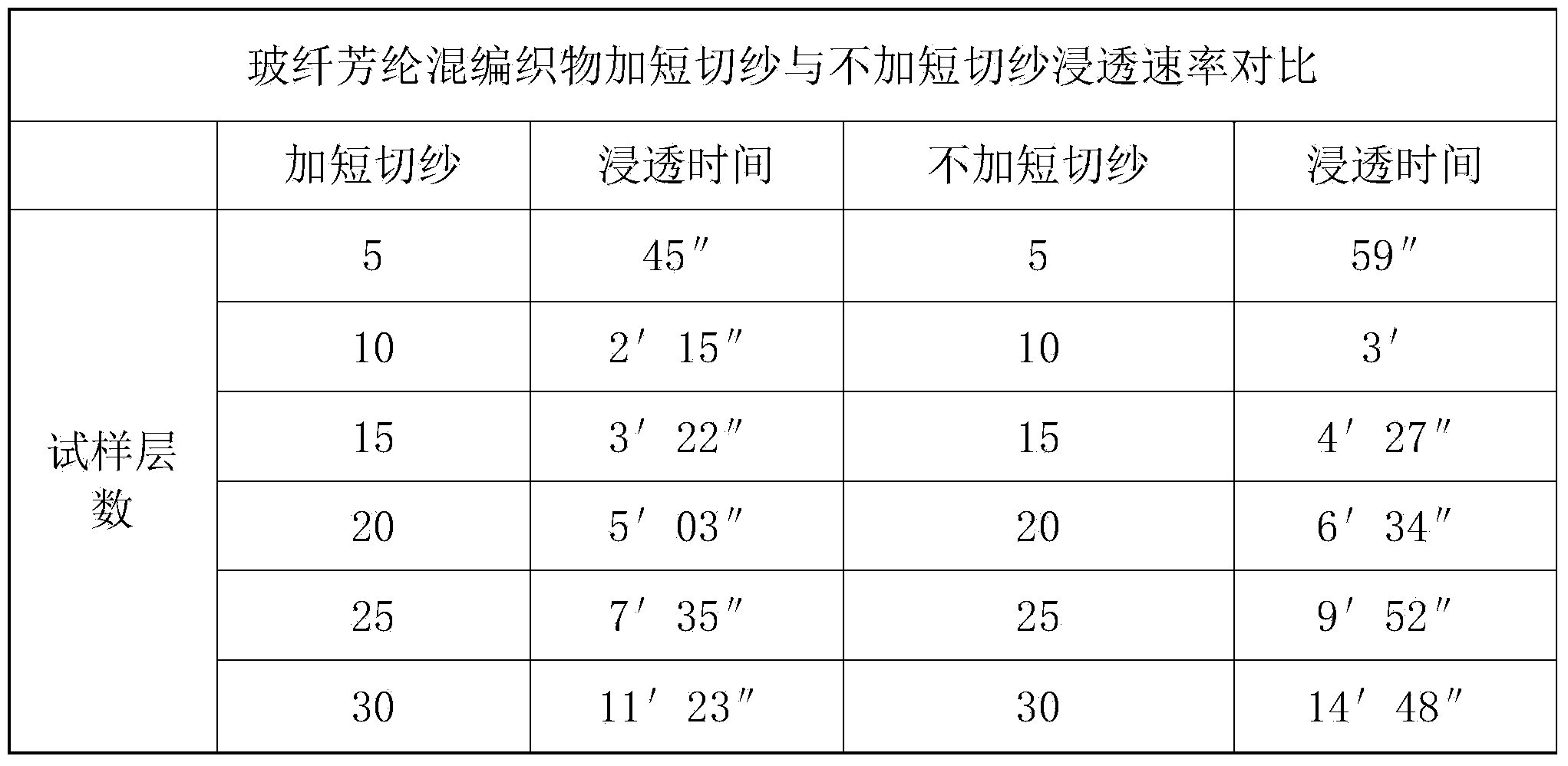

Glass fiber-aramid fiber mixed fabric and production method thereof

The invention relates to glass fiber-aramid fiber mixed fabric and a production method thereof. The glass fiber-aramid fiber mixed fabric comprises warp fiber bundles, weft fiber bundles and chopped strands, wherein the warp fiber bundles and the weft fiber bundles are uniformly distributed respectively; the warp fiber bundles and the weft fiber bundles are mutually staggered in a crossing way and are laminated; a layer of chopped strands is uniformly scatted between the warp fiber bundles and the weft fiber bundles; the warp fiber bundles are large-strand aramid fibers; the weft fiber bundles are large-strand glass fibers; the warp fiber bundles, the weft fiber bundles and the chopped strands are woven into fabric in a warp knitting and binding way. The conventional technology that single glass fibers are woven into fabric is changed, and by the production method, the warp fiber bundles, the weft fiber bundles and the chopped strands are woven into a low-cost and high-toughness complex structure in a warp knitting and binding way, so that the glass fiber-aramid fiber mixed fabric has both rigidness and flexibility and is impact-resistant; through arrangement of the chopped strands, the impregnating speed during impregnation of a finished product is greatly improved.

Owner:江苏宏飞复合新材料有限公司

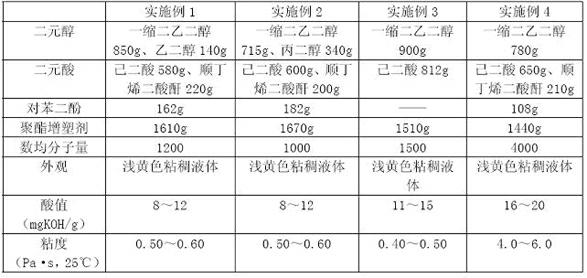

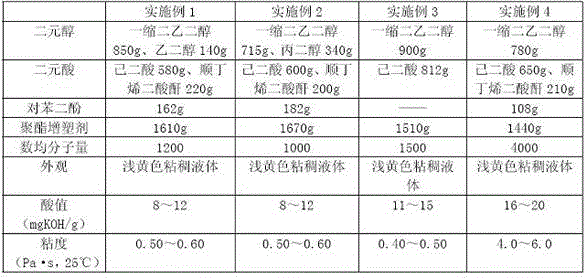

Polyester plasticizer for leading glass fiber to form felt and preparation method of polyester plasticizer

ActiveCN102432854AHigh number average molecular weightGood compatibilityMacromolecular adhesive additivesPolyesterFiber

The invention discloses a polyester plasticizer for leading glass fiber to form a felt and a preparation method of the polyester plasticizer. The polyester plasticizer is prepared from dihydric alcohol and dibasic acid. The preparation method comprises the following steps of: 1) adding the dihydric alcohol and the dibasic acid into a reactor, introducing nitrogen, stirring, rising the temperature to be 200-220 DEG C, and under the temperature, reacting till the acid value of the system is less than or equal to 20mgKOH / g; and 2) reducing the temperature to be 180-190 DEG C, adding hydroquinone, cooling to be 0-40 DEG C, filtering, and obtaining filtrate, i.e. the polyester plasticizer; or directly cooling to be 0-40 DEG C, filtering, and obtaining filtrate, i.e. the polyester plasticizer. In the invention, the compatibility of the polyester plasticizer and a bonding agent for leading the glass fiber to form the felt is good, the softness and the impregnability of a glass-fiber chopped felt can be improved and the use range is wide.

Owner:CHANGZHOU TIANMA GROUP CO LTD

Glass fiber impregnating agent for transparent plate

The invention discloses a glass fiber impregnating agent for a transparent plate, which basically comprises the following components in percentage by weight: 0.15-1.0 percent of silane coupling agent, 3.0-20.0 percent of binding agent, 0.02-1.0 percent of lubricating agent, 0.05-0.8 percent of antistatic agent, 0.1-2 percent of pH value adjusting agent and the balance of deionized water, wherein the binding agent is epoxy-ester emulsion or a mixture of PVAc emulsion and the epoxy-ester emulsion, and the contents of the PVAc emulsion and the epoxy-ester emulsion are calculated by respective solid content. The invention adopting the epoxy-ester emulsion or the mixture of the PVAc emulsion and the epoxy-ester emulsion as the binding agent can improve the glass fiber impregnating speed and the production efficiency; in addition, the light refractive rates of the impregnating agent and matrix resin are close, and the transmittance of the produced plate is high.

Owner:JUSHI GRP CO

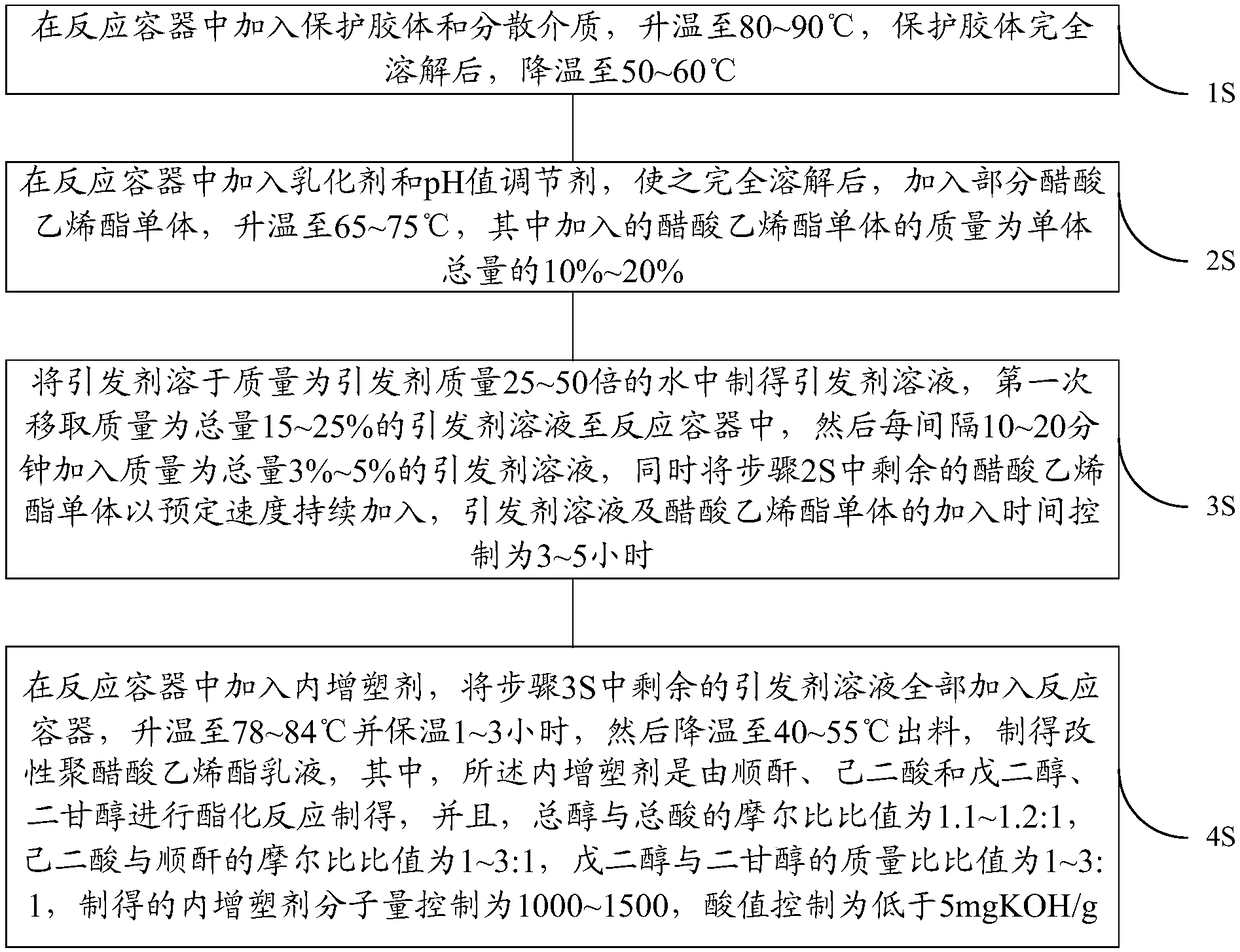

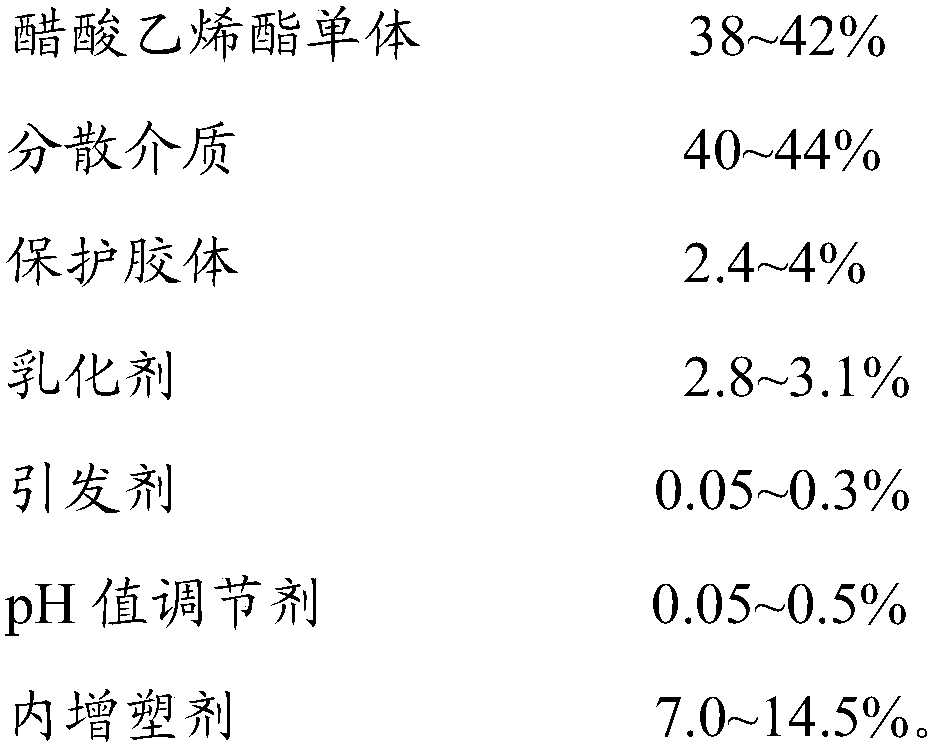

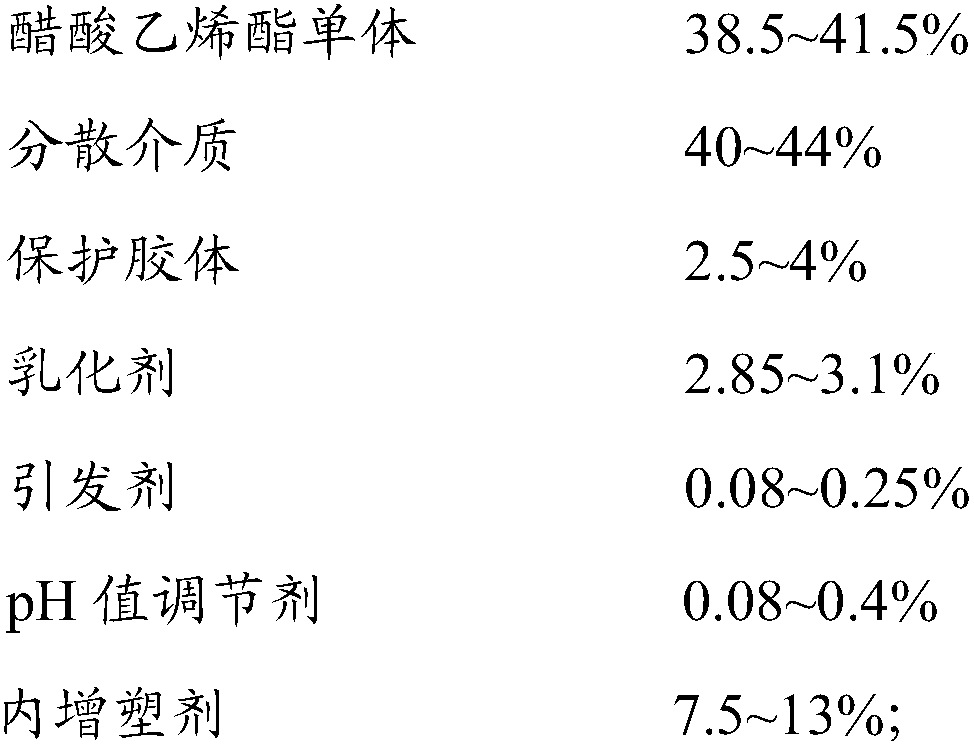

Modified polyvinyl acetate emulsion, preparation method and uses thereof

InactiveCN108623753AFast soaking speedGood mechanical propertiesNon-woven fabricsGraft polymer adhesivesEmulsionChemistry

The invention provides a modified polyvinyl acetate emulsion, which comprises a vinyl acetate monomer, a dispersion medium, a protection colloid, an emulsifier, an initiator, a pH value adjuster and an internal plasticizer, wherein the internal plasticizer is unsaturated polyester, and the emulsifier is the mixture of a nonionic emulsifier and an anionic emulsifier. According to the present invention, with the modified polyvinyl acetate emulsion, the plasticizer migration and other related technical problems can be effectively solved, the mechanical property of the glass fiber mat and the penetration speed to the resin can be effectively improved, the performance is excellent, and the production cost is reduced. The invention further provides a preparation method and uses of the modified polyvinyl acetate emulsion.

Owner:JUSHI GRP CO

A kind of self-crosslinking polyvinyl acetate film-forming agent and its preparation method and application

The invention provides a self-crosslinking polyvinyl acetate film-forming agent, wherein the raw materials comprise vinyl acetate, deionized water, modified polyvinyl alcohol, an emulsifier, a reactive emulsifier, a cross-linking monomer, an initiator and a pH value adjuster, and the cross-linking monomer is an amide compound. According to the present invention, through the mutual cooperation of the components, the prepared film-forming agent has characteristics of strong precursor bundling property, excellent high-temperature performance, high stiffness, good self-crosslinking property, goodsolvent resistance and the like. The invention further provides a preparation method and uses of the self-crosslinking polyvinyl acetate film-forming agent.

Owner:JUSHI GRP CO

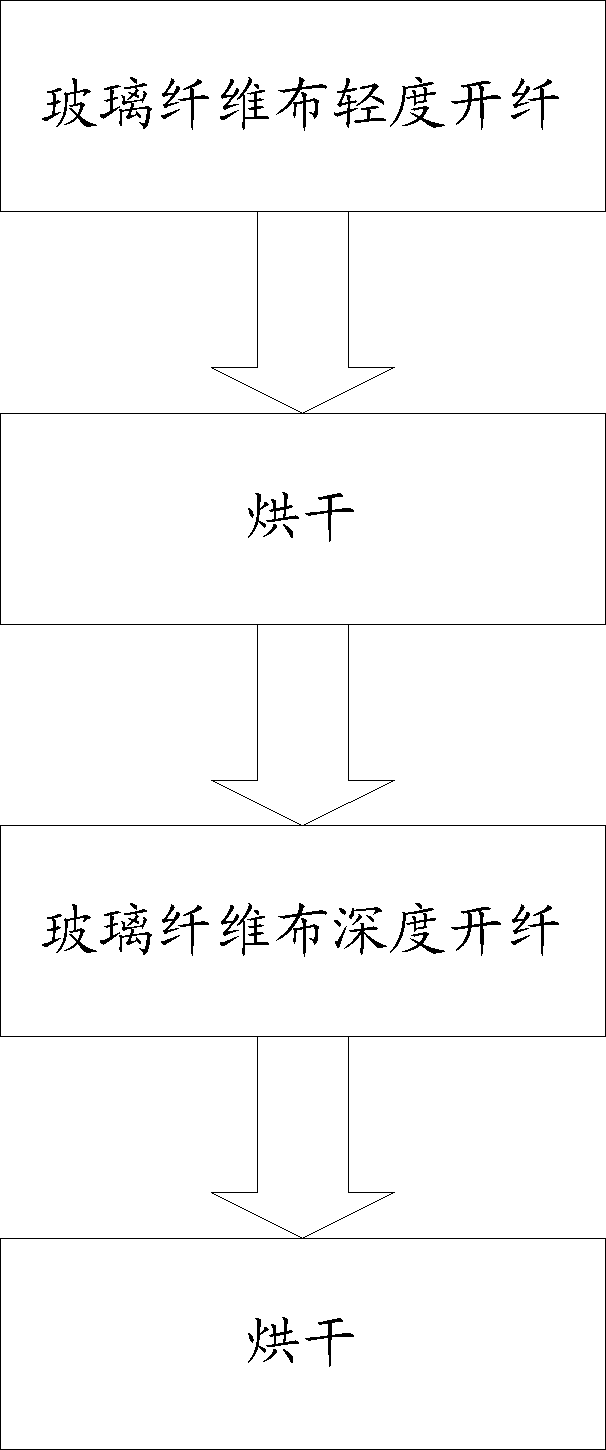

Ultra-high-performance electronic glass fiber cloth production process

ActiveCN102758335BGap narrowingSignificant improvement in impregnationTextile treatment by spraying/projectingLiquid/gas/vapor yarns/filaments treatmentGlass fiberSingle fiber

The invention discloses an ultra-high-performance electronic glass fiber cloth production process which specifically includes the steps: A, slightly splitting electronic glass fiber cloth; B, drying the slightly split electronic glass fiber cloth; C, deeply splitting the dried electronic glass fiber cloth; and D, drying the deeply split electronic glass fiber cloth so that ultra-high-performance electronic glass fiber cloth is obtained. During slight splitting, cloth surfaces are humidified by a water-washing oscillating trough, so that warp and weft yarns are bulked, and fibers are loosened; and during deep splitting, purified water is sprayed from holes of nozzles to be directly jetted to the cloth surfaces, the front and the back of the glass fiber cloth are sprayed by water columns, the warp and weft yarns are broken apart after the cloth surfaces are subjected to impact pressure of the purified water columns, the compactness of the glass fiber cloth is greatly reduced, and gaps among the warp and weft yarns are mostly filled by loose single fibers to be smaller, so that the surfaces of the glass fiber cloth become dense and uniform, and the surfaces of the glass fiber cloth are smoother after splitting.

Owner:建滔(清远)电子材料有限公司

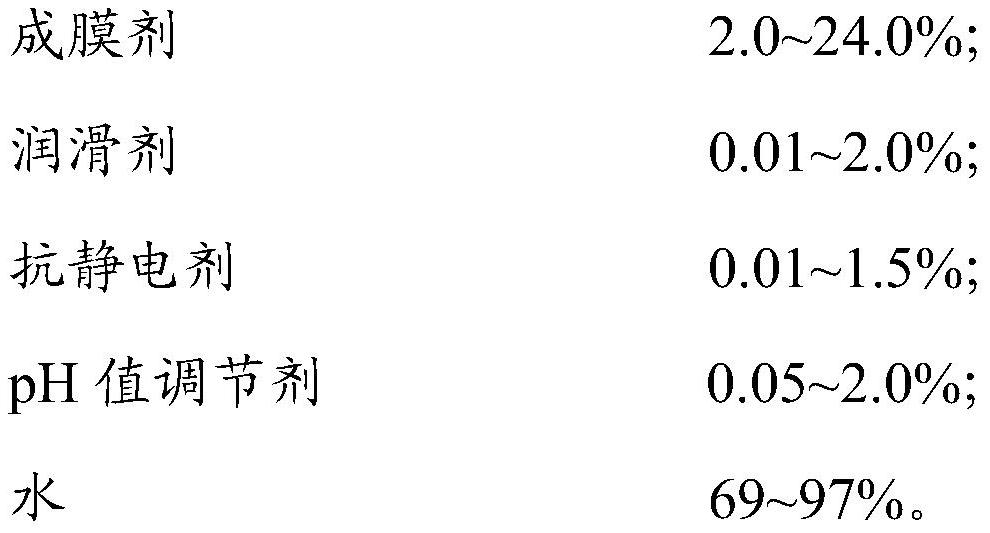

A kind of glass fiber sizing agent for transparent mat and its preparation method and application

The invention provides a glass fiber sizing agent for transparent felt, the content of each component is expressed in weight percentage as follows: 0.15-2.0% of silane coupling agent; 2.0-24.0% of film-forming agent; 0.01-2.0% of lubricant; Static agent 0.01-1.5%; pH regulator 0.05-2.0%; water 69-97%. Coating the glass fiber with this sizing agent can change the physical and chemical properties of the glass fiber surface, effectively improve the dispersion of the glass fiber in the process of producing the glass fiber mat, and increase the penetration speed of the glass fiber mat; solve the problem of glass fiber mat and The matching problem of the refractive index of the matrix resin improves the transparency of the glass fiber felt products; the produced glass fiber felt products have very good light transmittance, high product strength, and long service life.

Owner:JUSHI GRP CO

Polyester plasticizer for leading glass fiber to form felt and preparation method of polyester plasticizer

ActiveCN102432854BHigh number average molecular weightGood compatibilityMacromolecular adhesive additivesPolyesterFiber

The invention discloses a polyester plasticizer for leading glass fiber to form a felt and a preparation method of the polyester plasticizer. The polyester plasticizer is prepared from dihydric alcohol and dibasic acid. The preparation method comprises the following steps of: 1) adding the dihydric alcohol and the dibasic acid into a reactor, introducing nitrogen, stirring, rising the temperature to be 200-220 DEG C, and under the temperature, reacting till the acid value of the system is less than or equal to 20mgKOH / g; and 2) reducing the temperature to be 180-190 DEG C, adding hydroquinone, cooling to be 0-40 DEG C, filtering, and obtaining filtrate, i.e. the polyester plasticizer; or directly cooling to be 0-40 DEG C, filtering, and obtaining filtrate, i.e. the polyester plasticizer. In the invention, the compatibility of the polyester plasticizer and a bonding agent for leading the glass fiber to form the felt is good, the softness and the impregnability of a glass-fiber chopped felt can be improved and the use range is wide.

Owner:CHANGZHOU TIANMA GROUP CO LTD

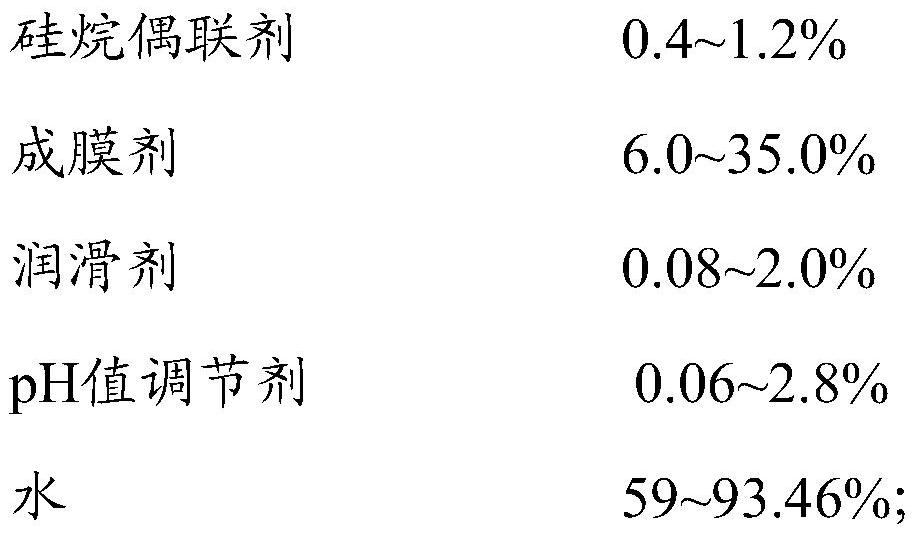

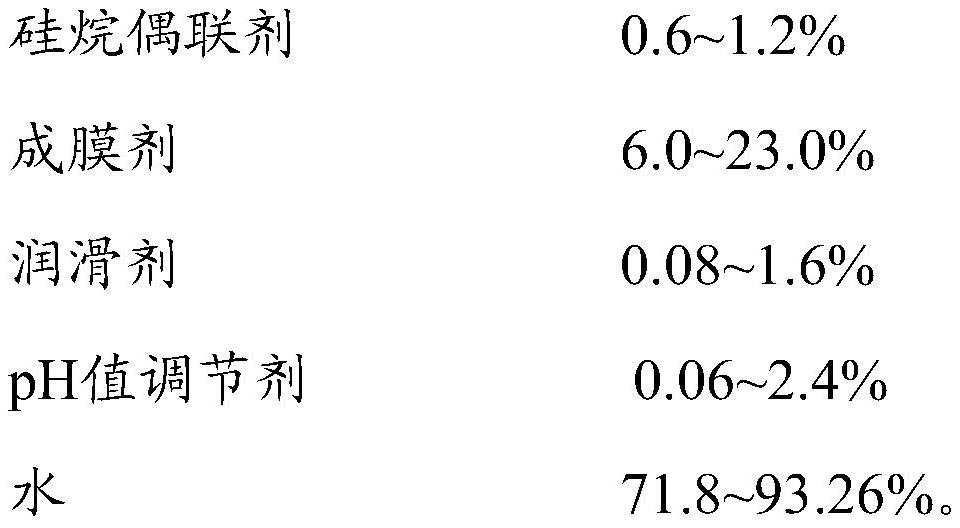

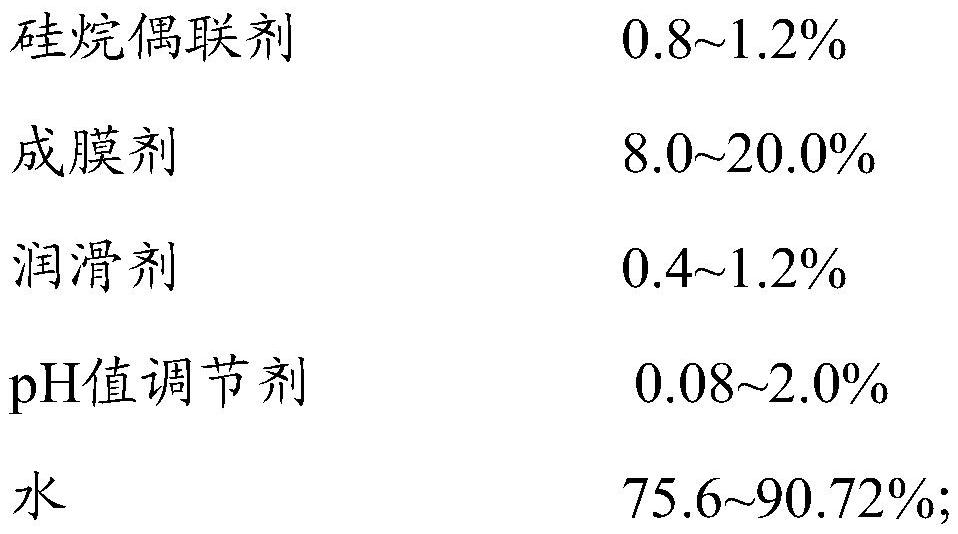

A kind of glass fiber sizing agent and its application

Owner:JUSHI GRP CO

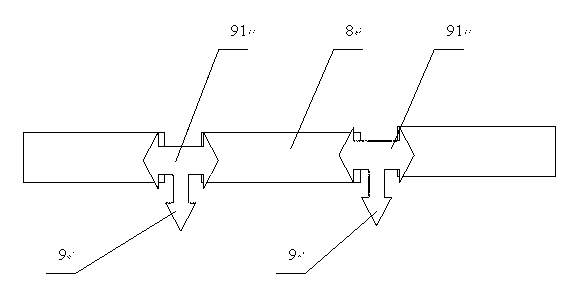

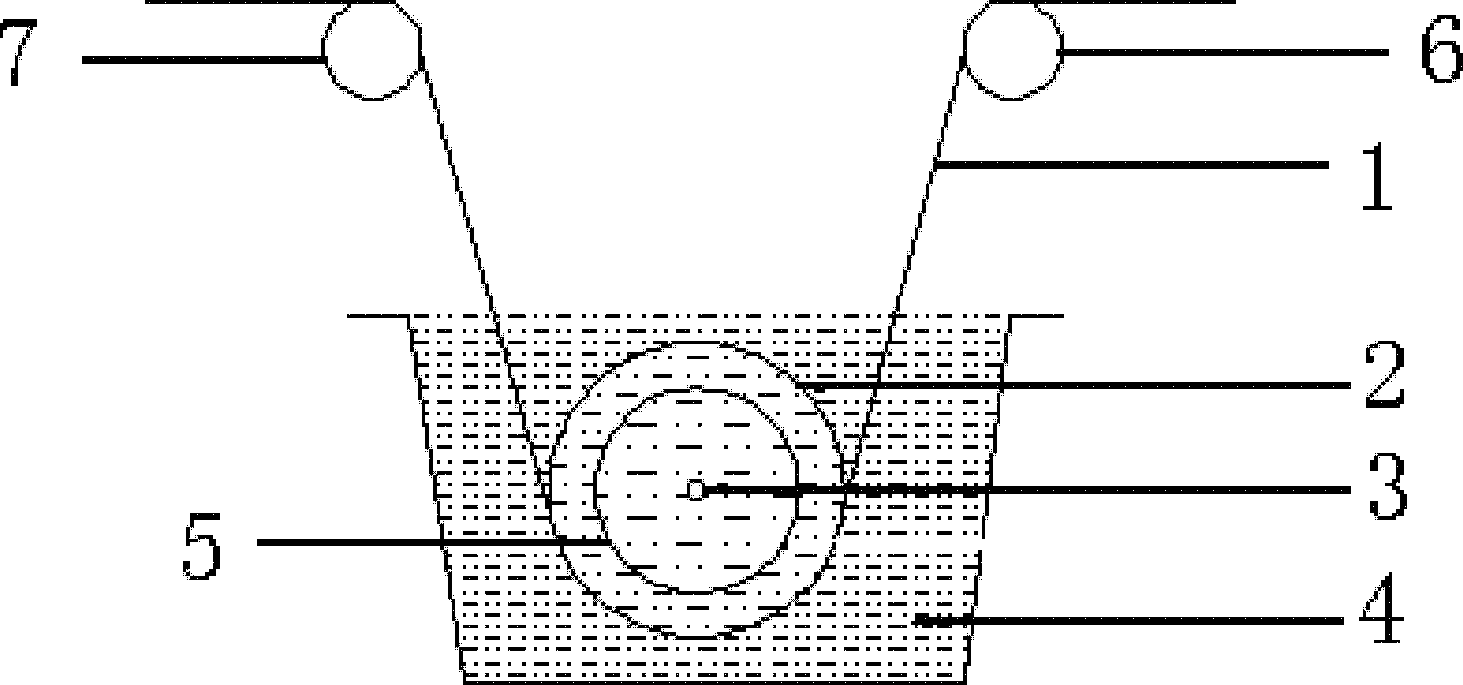

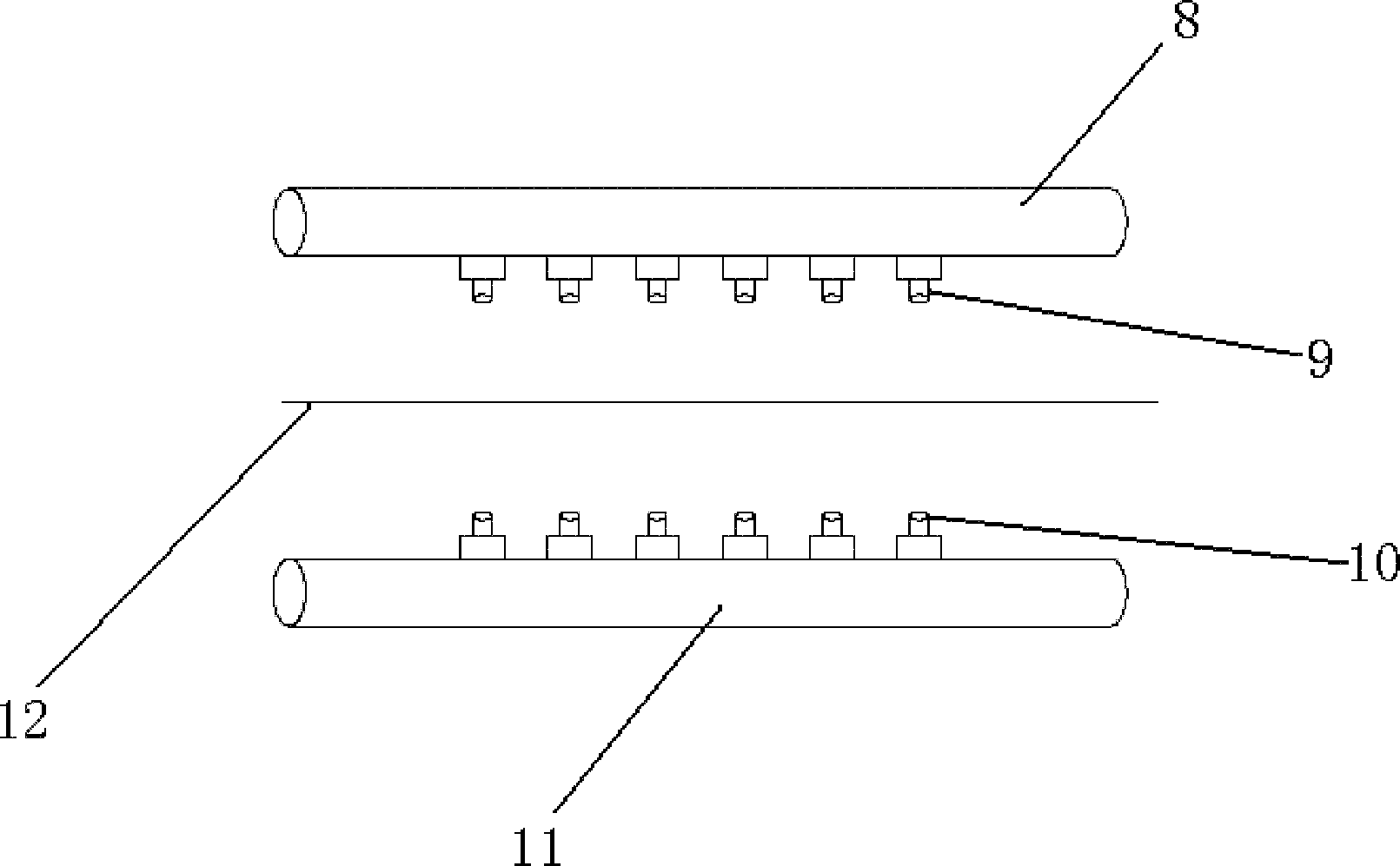

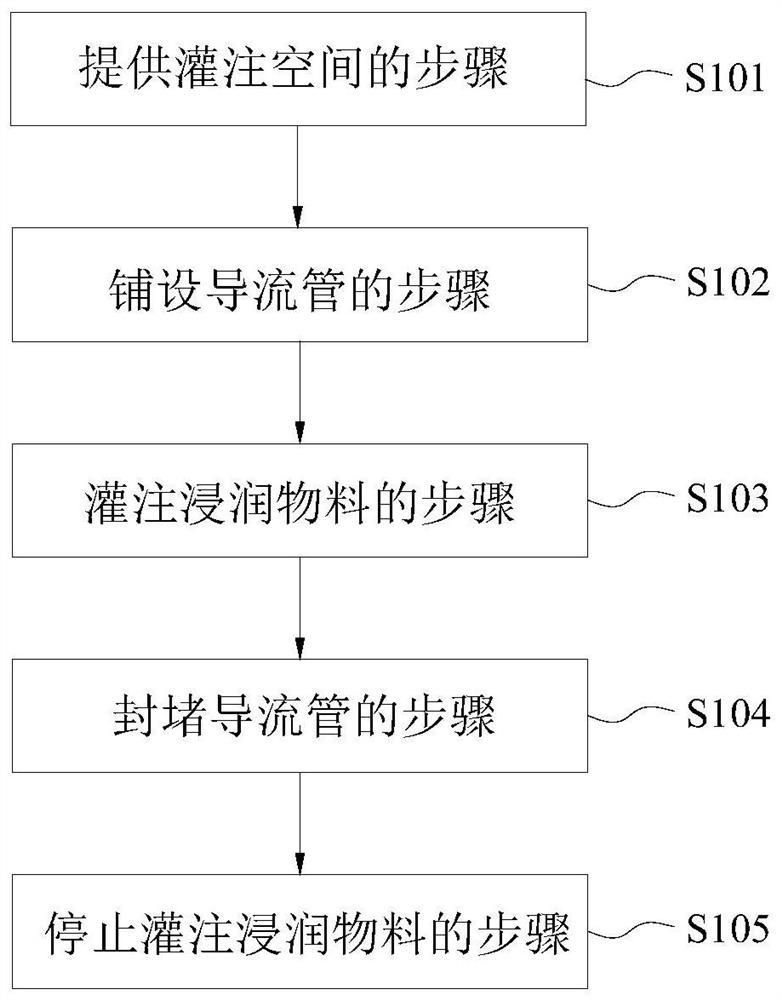

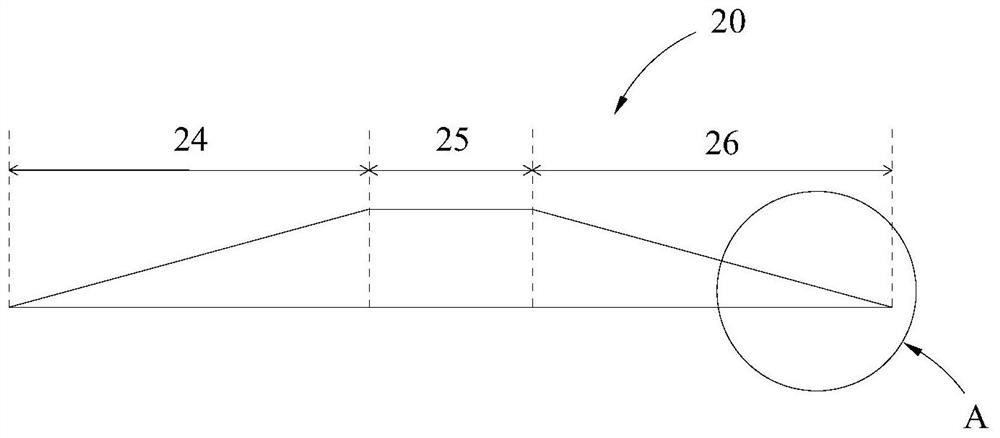

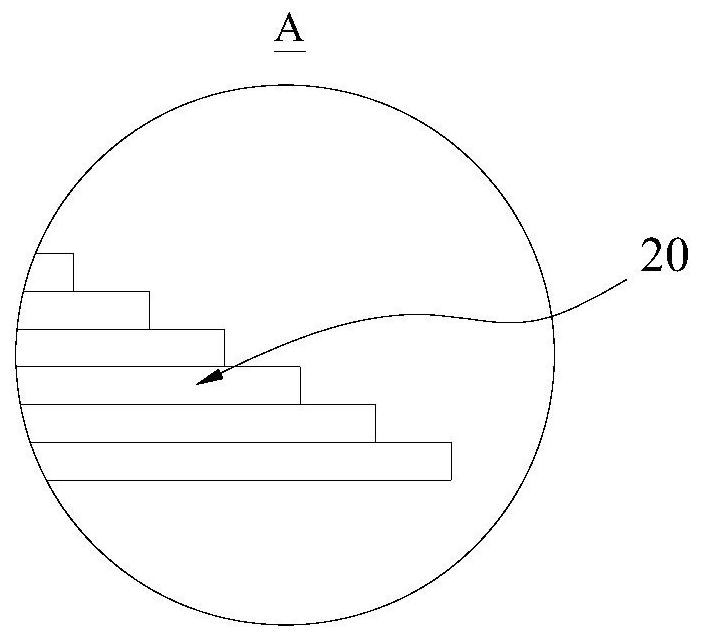

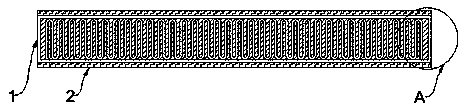

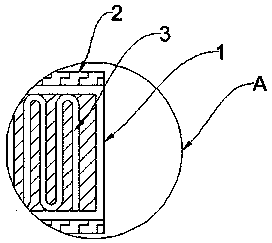

Vacuum infusion process

The invention provides a vacuum perfusion technology. The vacuum perfusion technology comprises the following steps: providing a perfusion space; paving a reinforcing material on the perfusion space;paving a flow guide pipe, wherein the flow guide pipe is provided with a perfusion opening, a first flow channel, a second flow channel and a filling opening, the first flow channel is communicated with a first region and the second flow channel is communicated with a second region; perfusing a wetting material; enabling the wetting material to enter the corresponding first region and second region from the first flow channel and the second flow channel respectively; blocking the flow guide pipe; when the reinforcing material reaches a first pre-set wetting degree, filling the flow guide pipewith a filling material through the filling opening, so as to enable the filling material to gradually block the first flow channel, reduce the flowing of the wetting material in the flow guide pipe toward the first region, and increase the flowing the wetting material toward the second region through the second flow channel. By adopting the vacuum perfusion technology, a condition that excessivewetting materials are retained in the flow guide pipe can be avoided and one or more aims of improving the vacuum perfusion efficiency and reducing the vacuum perfusion cost can be realized.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

High-speed thermal coating process for water-base fire-retardant dipping coating paper

A high-speed thermal coating process for dip-coating paper products with water-based flame retardants, which is characterized in that the water-based flame retardants are heated so that the paper products moving at high speed on the coating machine are immersed in the water-based flame retardants and passed through the water base flame retardant. The heating temperature of the water-based flame retardant is: higher than room temperature and lower than 100°C. The invention speeds up the immersion of the water-based flame retardant on the paper product by heating the water-based flame retardant, so that the water-based flame retardant can be soaked into the paper product in a short time, and the broad spectrum of flame-retardant treated paper products is increased. It realizes industrialized high-speed coating on paper products with high water repellency that cannot be solved by traditional normal temperature dip coating.

Owner:淄博豪特集成房屋制造有限公司

A kind of glass fiber sizing agent and its preparation method and application

The invention discloses a glass fiber sizing and its preparation method and application. The glass fiber sizing contains solid components and water; the mass of the solid components accounts for 3-8% of the total mass of the sizing; the solid components contain the following components , the ratio of the mass of each component to the total mass of the solid component is as follows: silane coupling agent 3-10%, lubricant 1-10%, film-forming agent A 20-70%, film-forming agent B 20-70%, Film-forming agent A+film-forming agent B 80-96%; wherein, the silane coupling agent is an amino-containing silane coupling agent, and the film-forming agent A and film-forming agent B are polyurethanes with different relative molecular weights. The glass fiber products produced by using this sizing agent can meet the requirement of less hairiness under high tension in the polyurethane winding process, have good compatibility with the polyurethane matrix resin, fast soaking speed, and high mechanical properties of the subsequent products.

Owner:JUSHI GRP CO

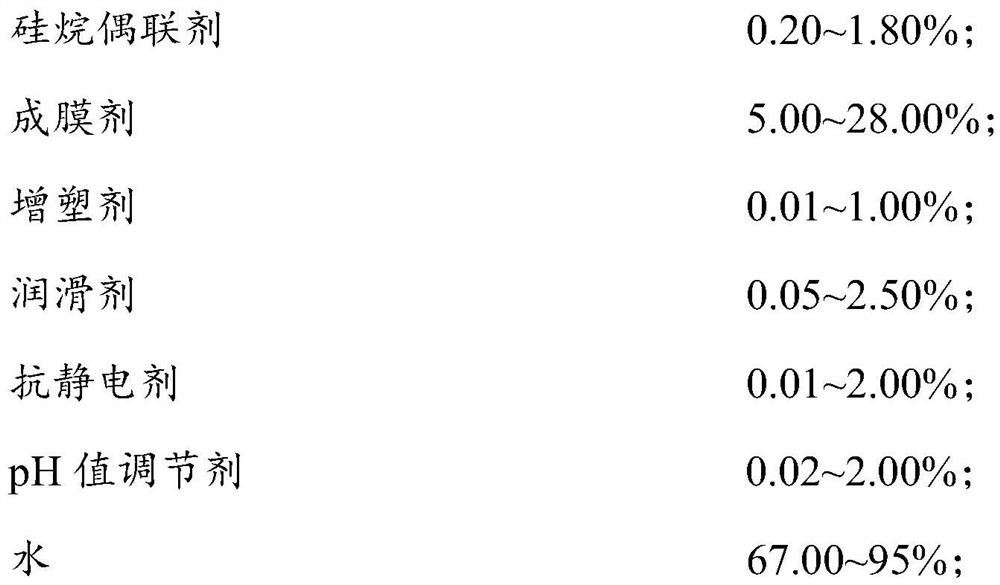

A kind of sizing agent for high-speed injection molding glass fiber and its preparation method and application

The invention relates to a sizing agent for high-speed spray-molded glass fiber and its preparation method and application. The sizing agent for high-speed spray-molded glass fiber comprises the following components, and the content of each component is expressed in weight percentage as follows: silane coupling agent 0.20~ 1.80%; film-forming agent 5.00-28.00%; plasticizer 0.01-1.00%; lubricant 0.05-2.50%; antistatic agent 0.01-2.00%; pH regulator 0.02-2.00%; and water 67.00-95%; Wherein, the film forming agent is composed of unsaturated polyester emulsion, epoxy emulsion and polyurethane emulsion. The use of the sizing agent of the present invention to produce glass fibers can effectively increase the spraying speed of glass fibers during use, accelerate the soaking speed of glass fibers, improve the banding of glass fibers, and reduce the rolling time of the spraying process, which is very beneficial to industrial production. usage of.

Owner:JUSHI GRP CO

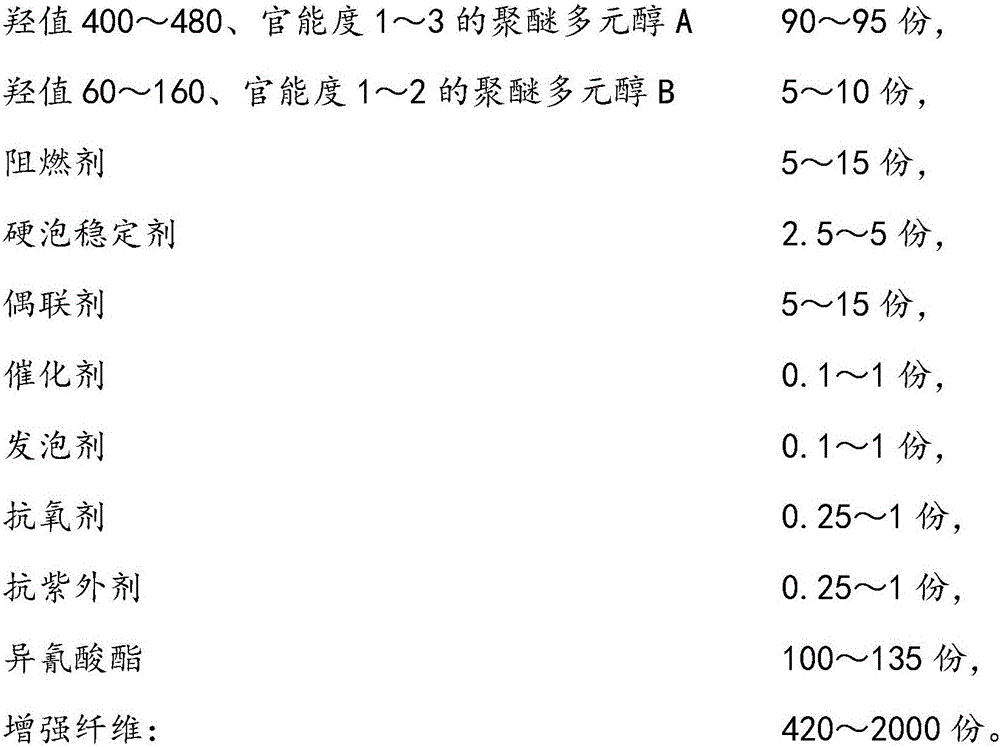

A kind of fiber-reinforced polyurethane hard foam synthetic board with high fiber content and its manufacturing method

Provided are a high-fiber-content fiber-reinforced rigid polyurethane foam composite panel and method for manufacturing same; polyurethane resin is employed as a matrix material; comprised are a hybrid polyether polyol, a fire retardant, a hard-foam stabilizing agent, a coupling agent, a catalyst, a blowing agent, an antioxidant, an anti-UV agent, and isocyanate; fiber is employed as a reinforcing material and its content is greater than 60%. Using such technical means as a low-hydroxyl and low-functionality hybrid polyether polyol and a coupling agent solves the problem of insufficient impregnation of polyurethane resin with reinforcing fiber, thereby increasing the reinforcing-fiber content; it is thus possible to manufacture a fiber-reinforced rigid polyurethane foam material product having a density higher than 840 kg / m3 and a reinforcing-fiber content of more than 60%, compensating for the technical deficiency of fiber-reinforced polyurethane hard-foam composite panels, making their product specifications and performance more diverse, and satisfying different technical requirements.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

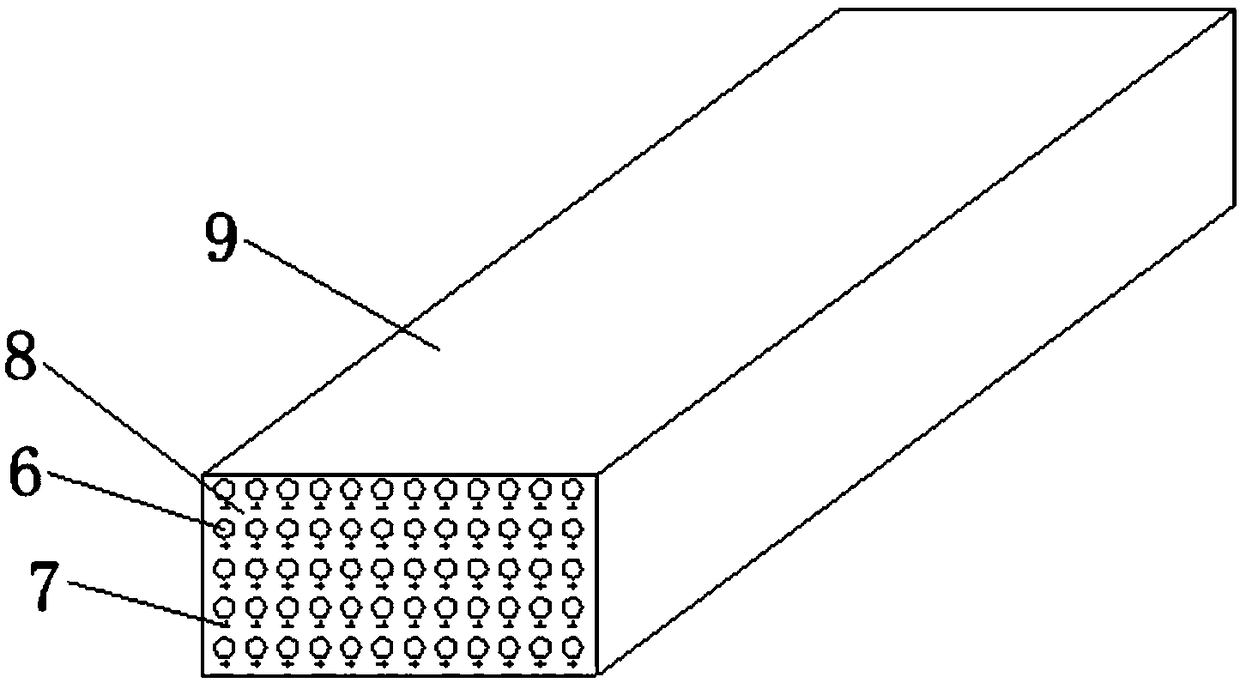

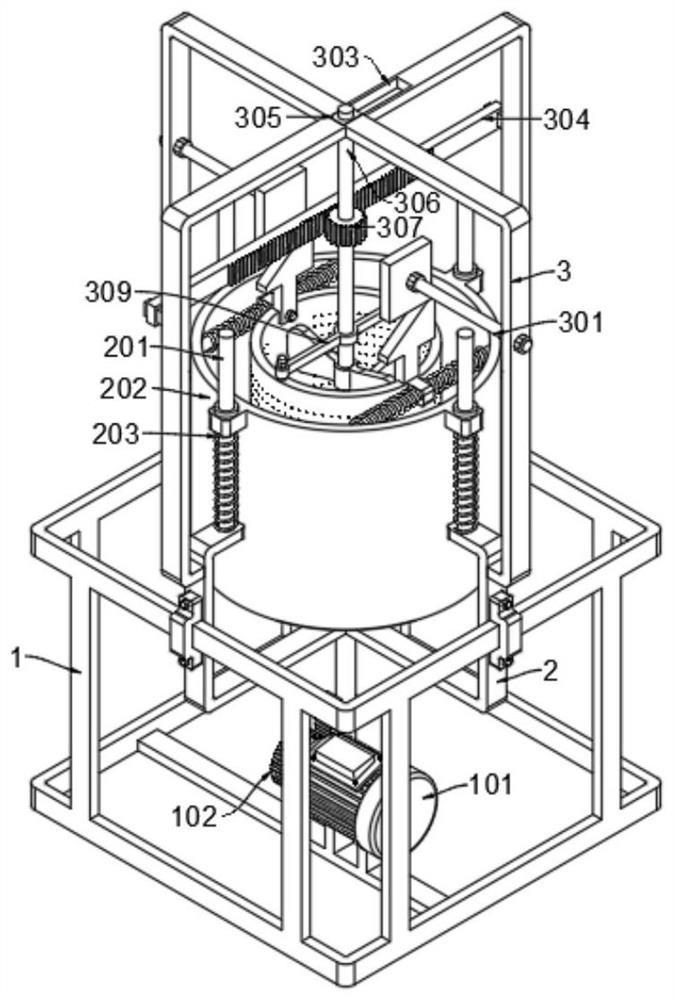

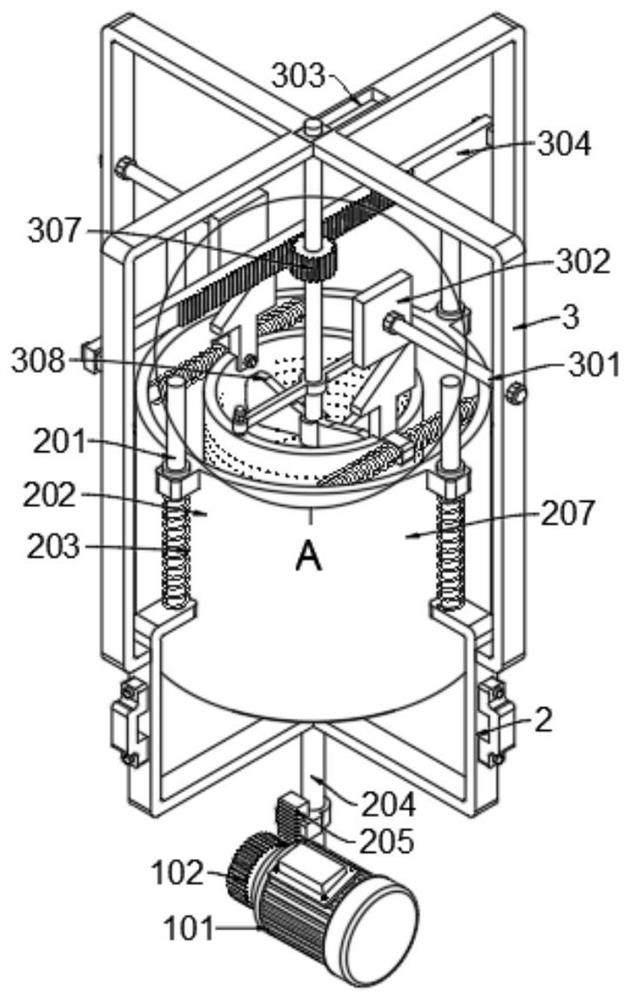

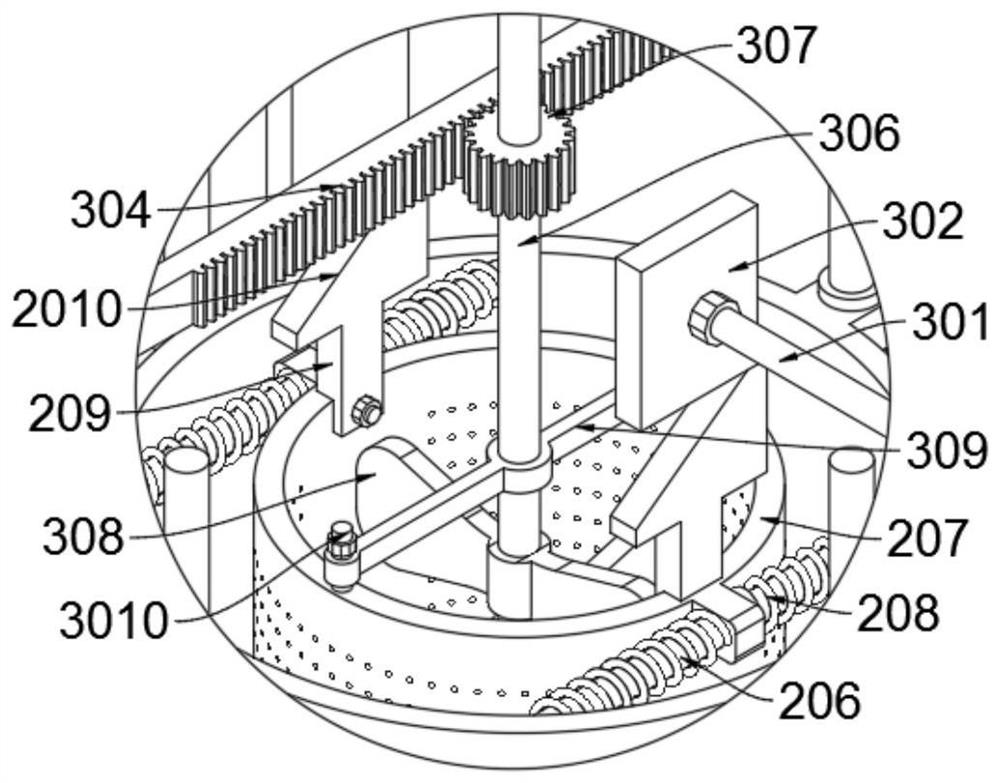

High-efficiency seed soaking and germination accelerating device for planting

InactiveCN114710993AFast soaking speedSeed soaking high efficiencySeed and root treatmentAgriculture gas emission reductionElectric machineryGermination

The invention provides a high-efficiency seed soaking and germination accelerating device for planting, and relates to the technical field of agricultural equipment, the high-efficiency seed soaking and germination accelerating device comprises a main body frame, the bottom of the main body frame is fixedly provided with a motor; a gear A is arranged on an output shaft of the motor, and the gear A is an incomplete gear; a seed soaking frame is fixedly mounted at the top of the main body frame; a supporting frame is fixedly mounted on the outer side of the seed soaking frame; a vertical guide rod is fixedly mounted at the top of the seed soaking frame; and a liquid cylinder is mounted on the vertical guide rod in a sleeving and sliding manner. The device is provided with the up-down movement mechanism, the left-right movement mechanism and the seed stirring mechanism, seeds can be always in a movement state during soaking through the three mechanisms, the problem that the seed soaking efficiency is low due to standing soaking of the seeds is avoided, and the problem that when an existing device is used, most of the seeds are soaked in a water tank in a standing mode, and the soaking efficiency is poor is solved. And the standing of the seeds causes the problem that the soaking speed is too slow and the purpose of efficient seed soaking cannot be achieved.

Owner:赵成燕 +2

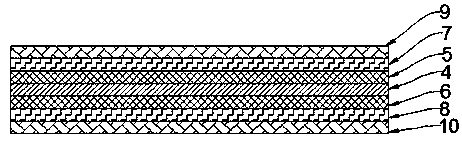

Glass fiber polyester needled felt and manufacturing method

PendingCN111251679AImprove the protective effectExtended service lifeSynthetic resin layered productsGlass/slag layered productsGlass fiberPolyester

The invention discloses a glass fiber polyester needled felt. The needled felt comprises a needled felt body, wherein a glass fiber precursor pierces the interior of the needled felt body; PTFE protective layers are arranged on the upper surface and the lower surface of the needled felt body; the needled felt body comprises a base cloth layer; a first superfine fiber layer and a second superfine fiber layer are respectively arranged on the upper surface and the lower surface of the base cloth layer; and a first composite fiber layer and a second composite fiber layer are arranged on the sides,away from each other, of the first superfine fiber layer and the second superfine fiber layer correspondingly. The glass fiber precursor pierces the interior of the needled felt body in a needling manner, so the needled felt is free of adhesive suture lines in the forming process, and a product is more attractive; the needled felt body is well protected under the action of the PTFE protective layers, so the service life of the needled felt body is prolonged; and the needled felt has the advantages of long service life, good dust removal effect, high strength and high abrasion resistance.

Owner:南京强晟玻纤复合材料有限公司

A glass fiber sizing agent for manipulator spraying yarn

The invention discloses a glass fiber sizing agent for yarns used for manipulator spraying, and belongs to the technical field of glass fiber sizing agents. The glass fiber sizing agent for the yarn used for manipulator spraying includes: a two-component coupling agent, a two-component film-forming agent, a two-component lubricant, an antistatic agent, a pH value regulator and deionized water. The spray yarn produced by the glass fiber sizing agent of the present invention can be used for spraying by a manipulator, has good chopping property, excellent slip performance, good dispersibility, fast soaking speed, static electricity accumulation, good bonding performance with matrix resin, and stable quality.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com