Vacuum infusion forming method for carbon fiber composite structure member

A vacuum infusion and forming method technology, applied in the field of composite material forming, can solve the problems affecting the normal use of large wind power blades, loose structure, storage and transportation costs of carbon fiber raw materials, etc., and achieve the goal of adapting to large-scale continuous production and fiber orientation Consistency improvement, effect of good carbon fiber wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation principle of the present invention is:

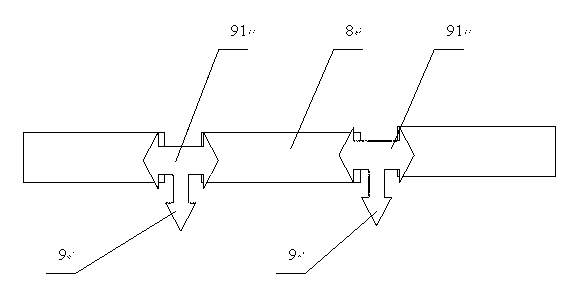

[0047] The carbon fiber cloth used in the present invention refers to a carbon fiber fabric shaped with a special hot-melt line. The carbon fiber uniaxial fabric is not easy to deform in the direction perpendicular to the fiber, the fabric structure is compact, and the surface is not easy to wrinkle when vacuuming, and a flat surface can be obtained without the use of a pressing plate. When laying carbon fiber fabrics according to the process requirements, in order to improve the fiber orientation consistency of the fabrics, it is necessary to ensure the flatness of each layer of carbon fiber fabrics and prevent artificial wrinkles. Each layer of carbon fiber fabric is a rectangle of equal width and thickness. According to the lay-up requirements of carbon fiber composite parts, multiple layers of this carbon fiber fabric with a set size are stacked together to form a carbon fiber preform. The shape of the carbon ...

Embodiment

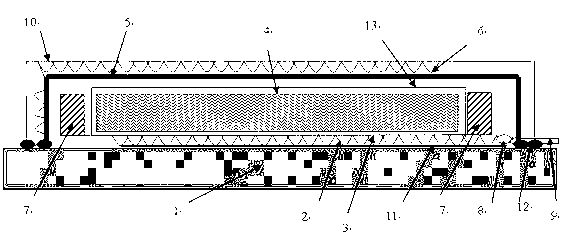

[0055] This embodiment is an example of infusion molding of a carbon fiber composite structural member with a length of 55 meters, a width of 0.5 meters, and a maximum thickness of 40 mm. The process steps are as follows:

[0056] 1) Prefabricate the mold 1 of the carbon fiber composite structural part by conventional methods, and the periphery of the mold 1 is provided with at least one vacuum port; at most dozens of them; in this example, the periphery of the mold 1 is vertically provided with 22 equally spaced on the surface of the mold 1, the transparent double-sided adhesive tape 11 is first laid, and the bottom guide net 2 is covered on it, and the release cloth 3 is laid on the bottom guide net 2; the bottom guide net 2 passes through the transparent The double-sided adhesive tape 11 is fixedly connected with the surface of the mold 1;

[0057] The transparent double-sided tape 11 used is a commercially available transparent double-sided tape with a thickness of 0.1mm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com