Patents

Literature

1064results about How to "Fast fill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

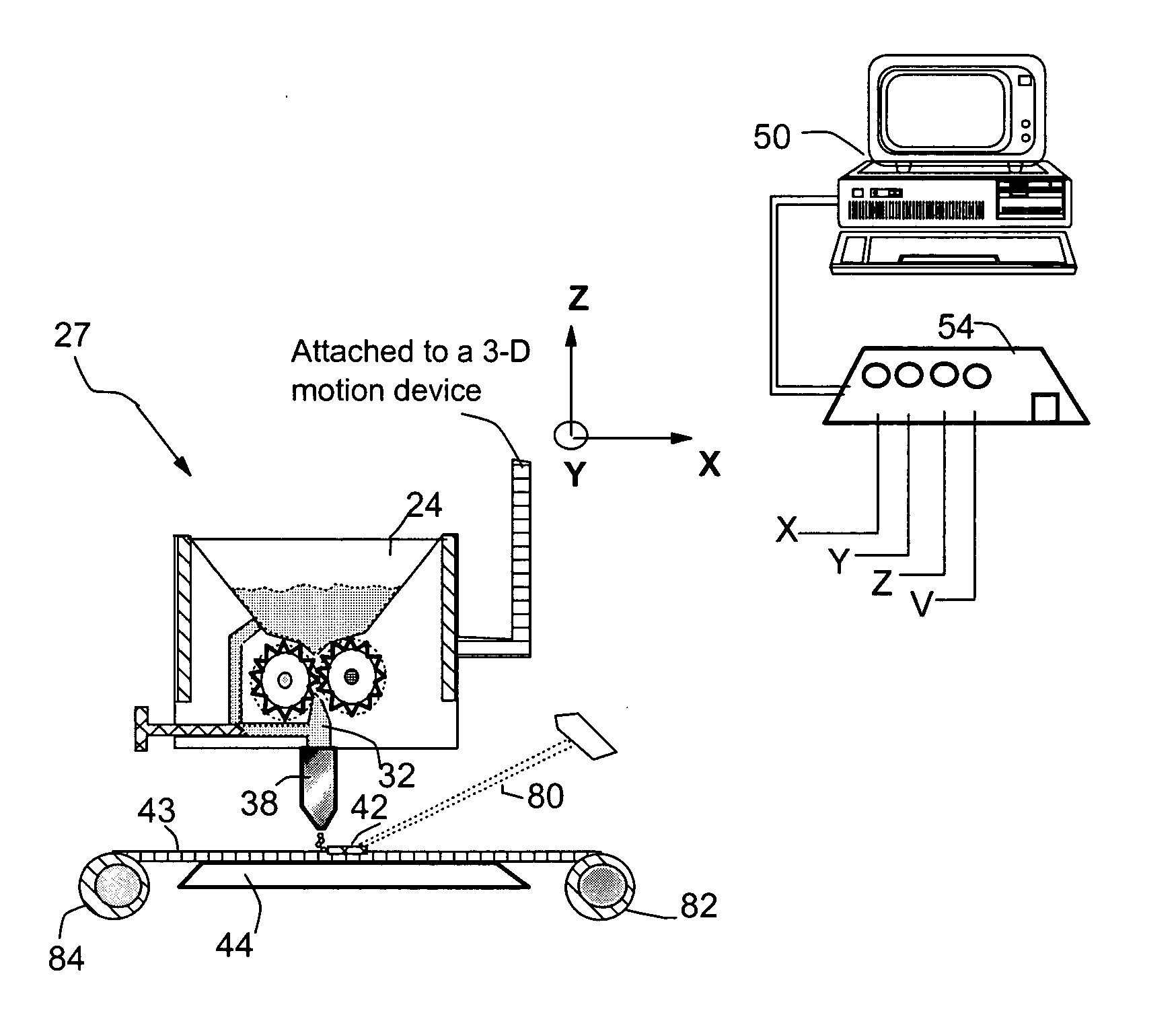

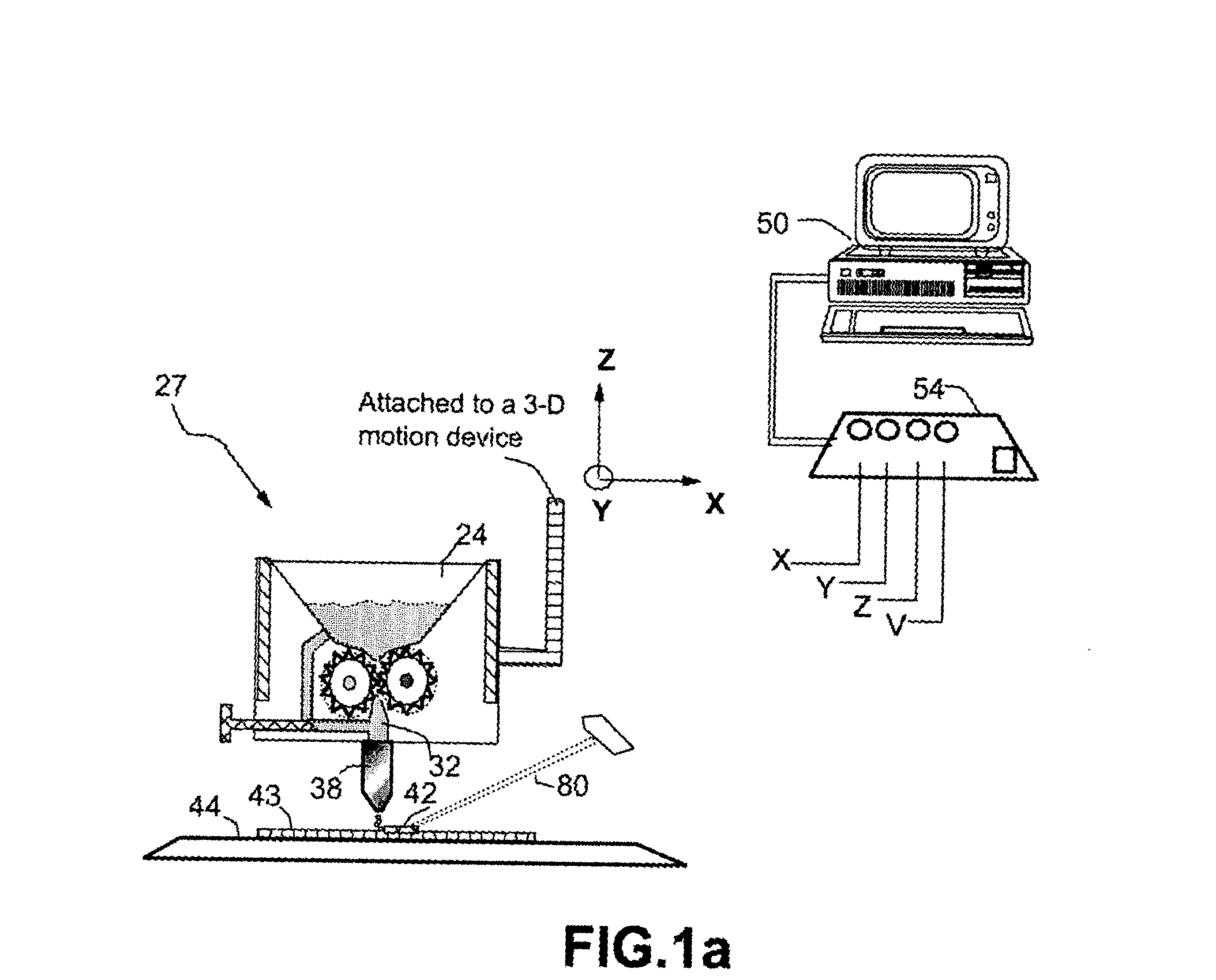

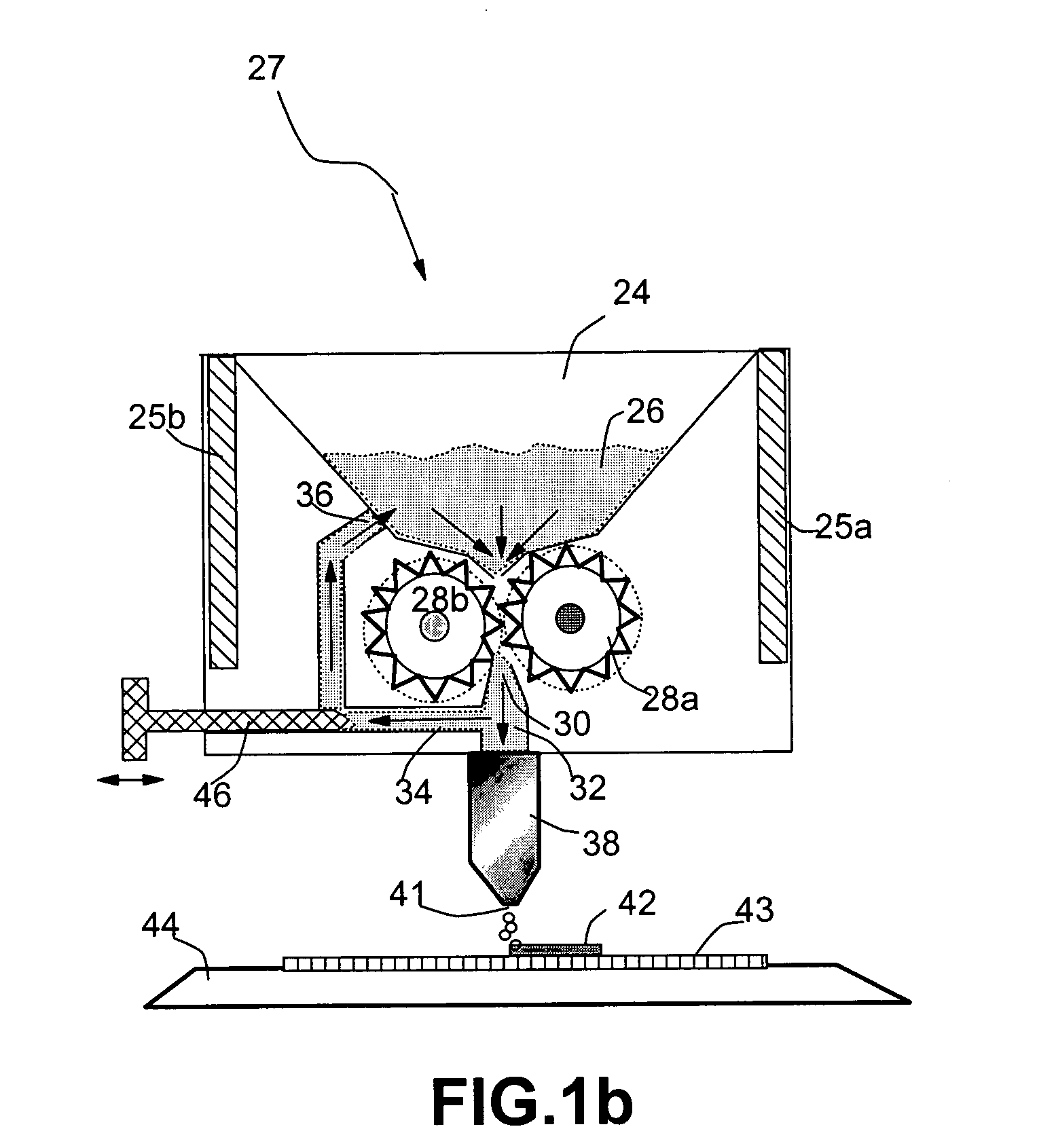

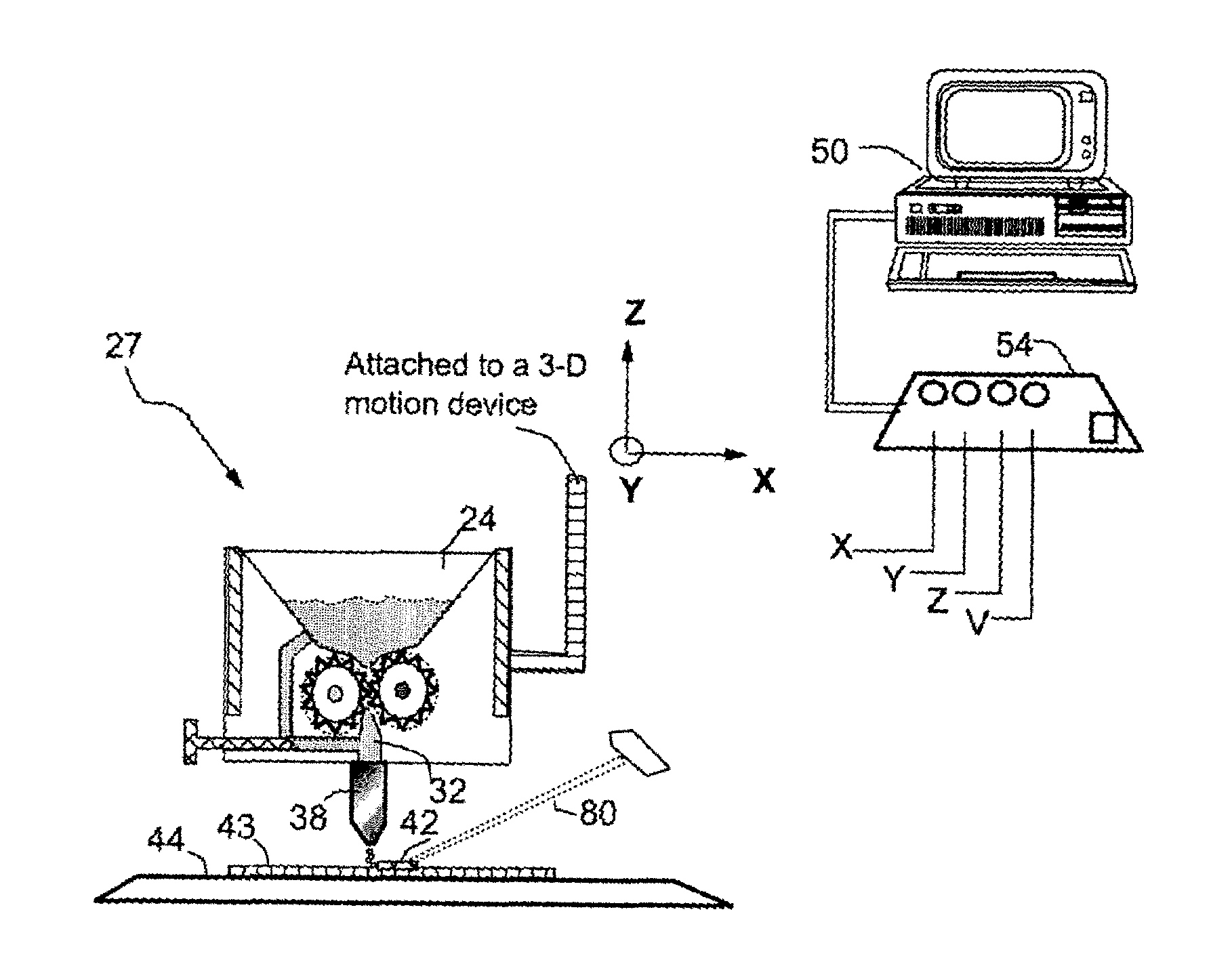

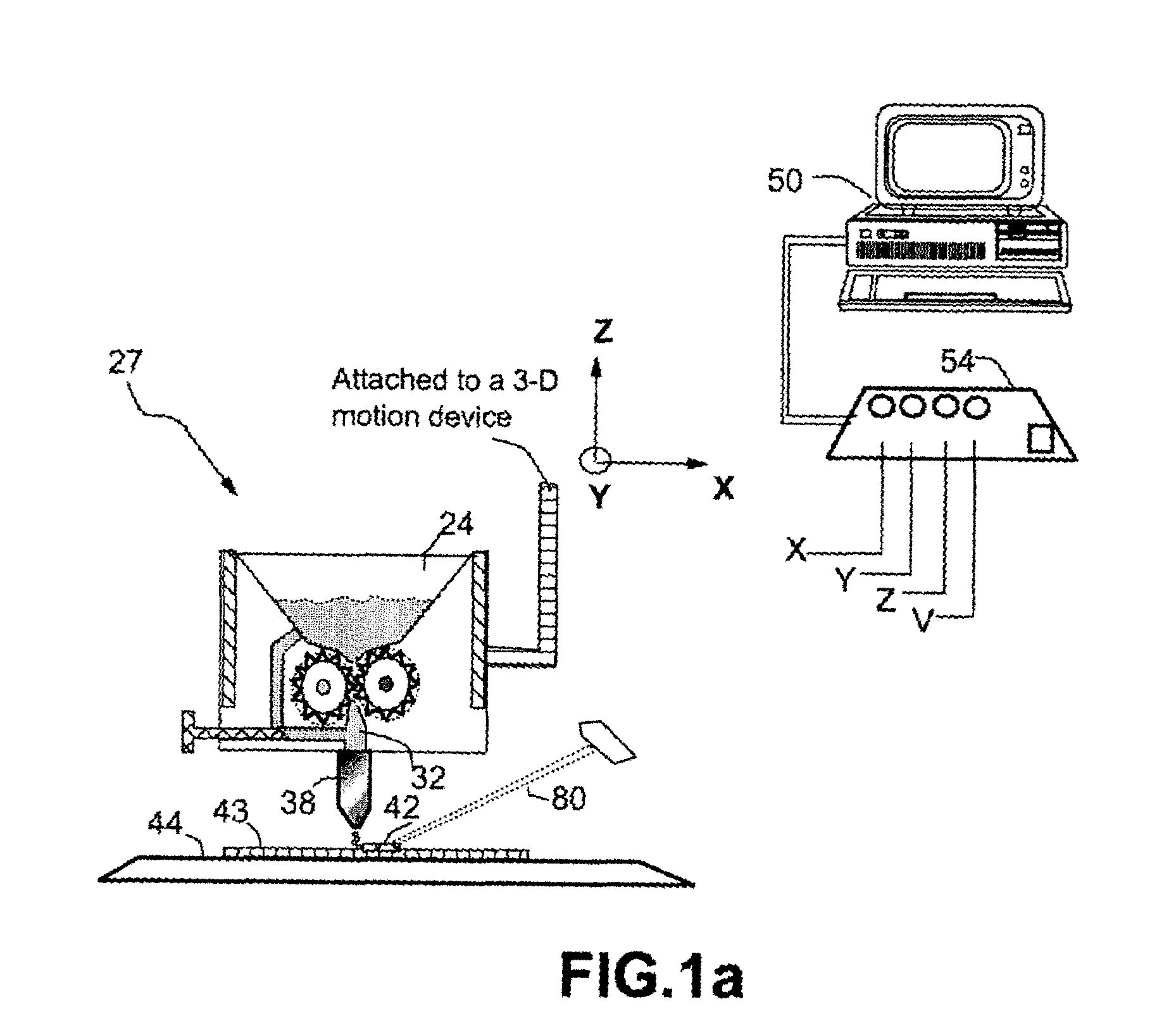

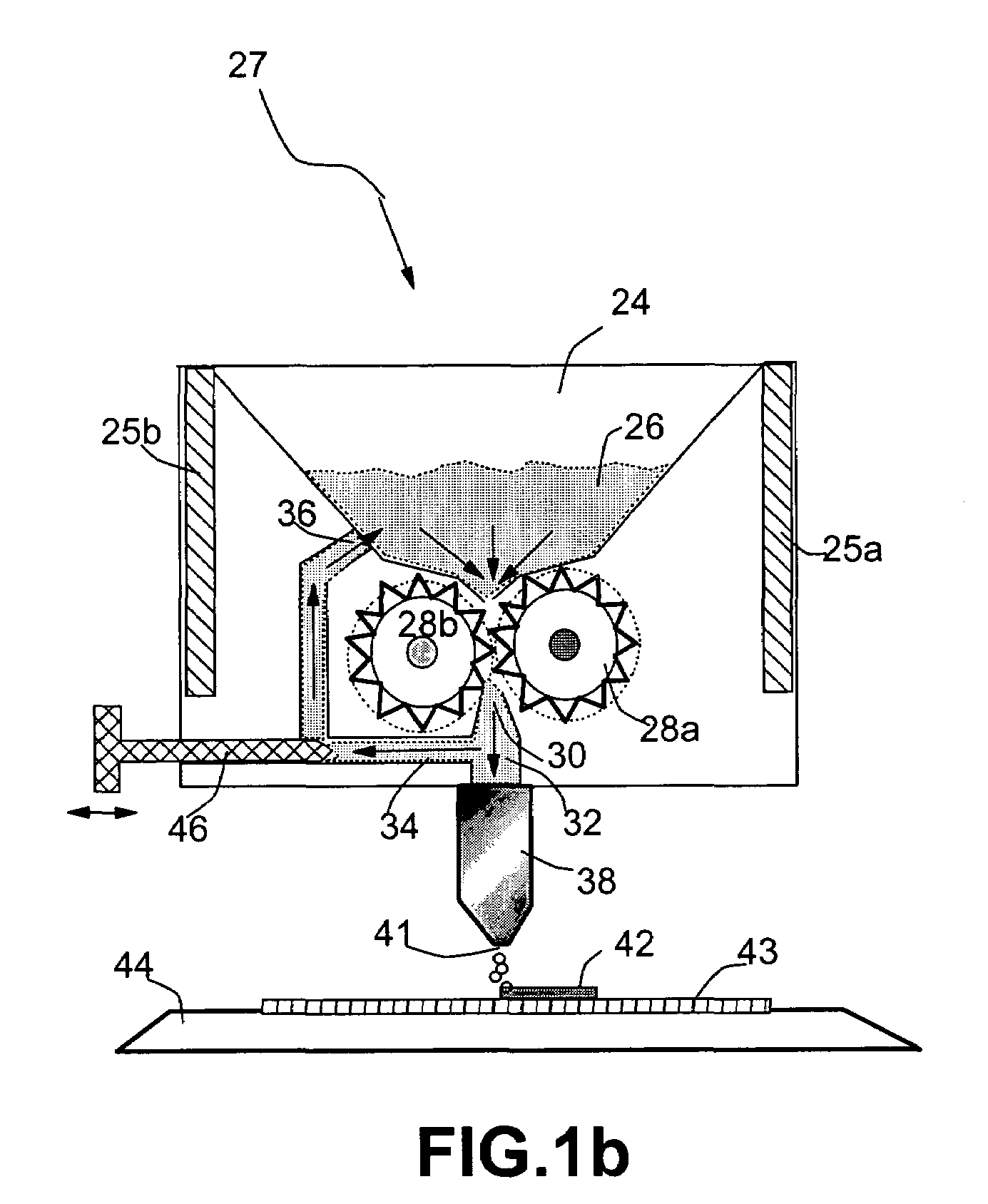

Direct write process and apparatus

ActiveUS20050015175A1Fast preparationIncrease back pressureRecording apparatusAdditive manufacturing apparatusDielectricControl signal

A direct write process and apparatus for fabricating a desired circuit component onto a substrate surface of a microelectronic device according to a computer-aided design (CAD). The process includes (a) providing a support member by which the device is supported while being fabricated; (b) providing a chamber for containing a precursor fluid material under a substantially constant pressure differential relative to the ambient pressure, with the precursor fluid material having a viscosity no less than 10 cps; (c) operating an inkjet-based dispensing head with a control valve or actuator for dispensing and depositing minute droplets of the precursor fluid material onto the substrate surface; (d) energy- or heat-treat the deposited precursor fluid material for converting it to the desired active or passive component; and (e) operating a machine controller for generating control signals in response to the CAD coordinates for controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing and depositing of the precursor material to form the desired component. The process is useful for depositing a wide range of component materials onto an electronic device, including conductor, resistor, capacitor, dielectric, inductor, antenna, solar cell electrode, battery electrode, interconnect, superconductor, sensor, and actuator element materials.

Owner:NANOTEK INSTR GRP LLC

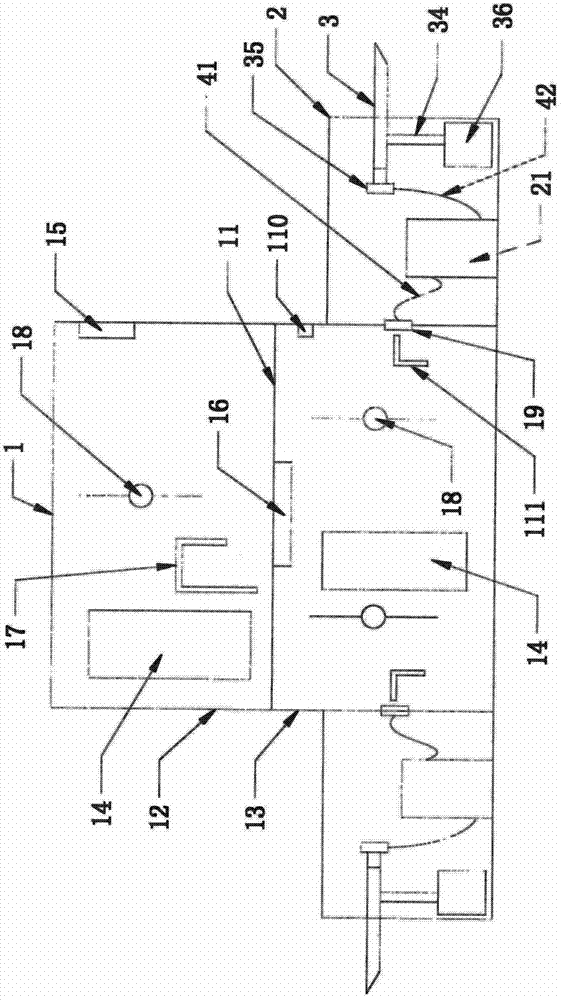

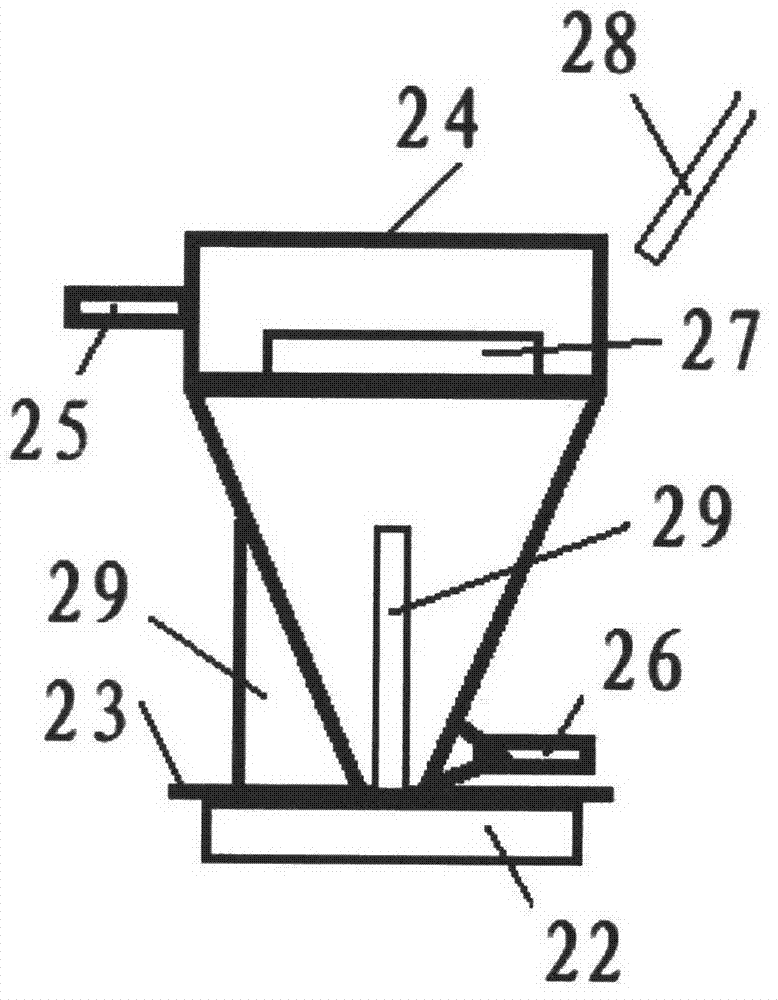

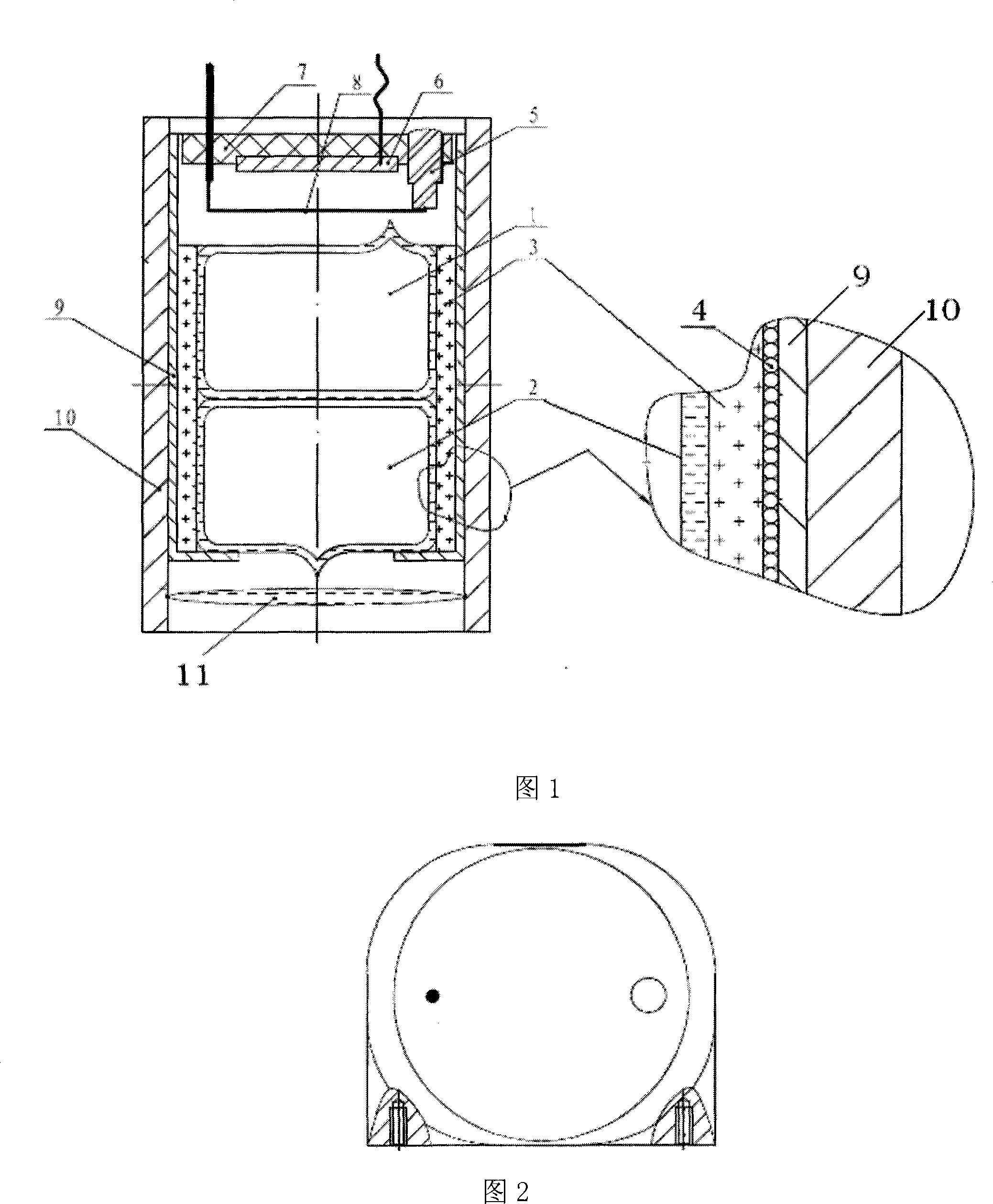

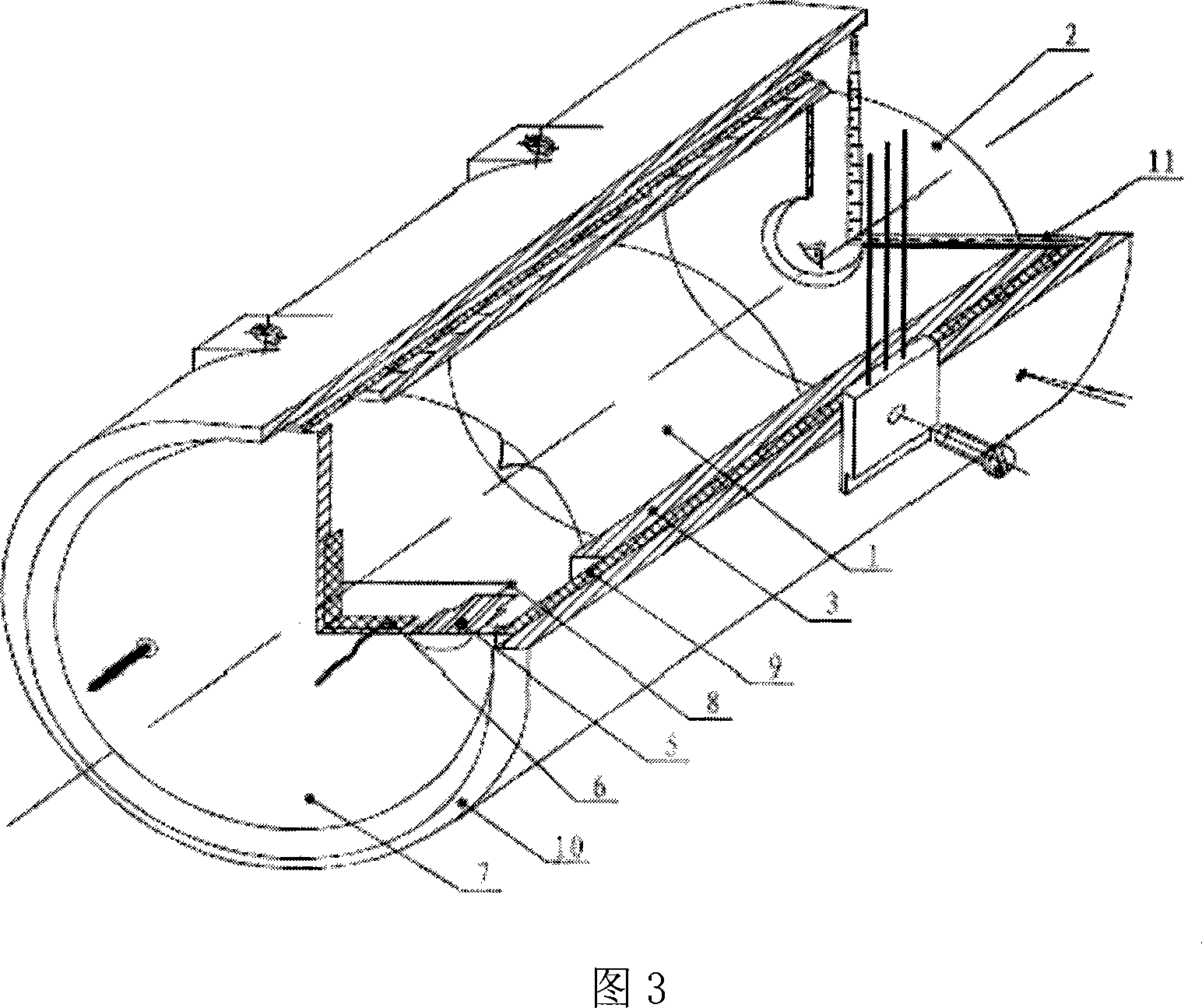

Down filling machine

ActiveCN102808245AStable outputHighly stable suedeUpholstery manufactureOakum treatmentEngineeringUltimate tensile strength

The invention discloses a down filling machine, which comprises a down storage box, weighing cabinets, down filling pipes and a programmable controller, wherein the down storage box is provided with at least two weighing cabinets; at least two weighing boxes are arranged in each weighing cabinet; the total number of the weighing boxes is equal to the total number of down outlets of the down storage box; each weighing cabinet is provided with at least one down filling pipe; the total number of the weighing boxes in each weighing cabinet is dual, and the number of the down filling pipes is a half of the total number of the weighing boxes. According to the down filling machine, the close full-automatic down filling can be carried out, the labor intensity is reduced, the production efficiency is improved, and the production cost is decreased. The down filling machine has the advantages of reasonable design, simple structure, low cost and good practicability. The down storage box of the down filling machine has stable down output, so that the down filling consistence and the down filling precision are ensured; a weighing process of the weighing boxes is independent, precise and effective; the down filling pipes cannot fill the down to airtight cutting pieces; working conditions of the multiple weighing boxes are alternatively changed and one down filling pipe is used for outputting, so that the down filling efficiency is further improved.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

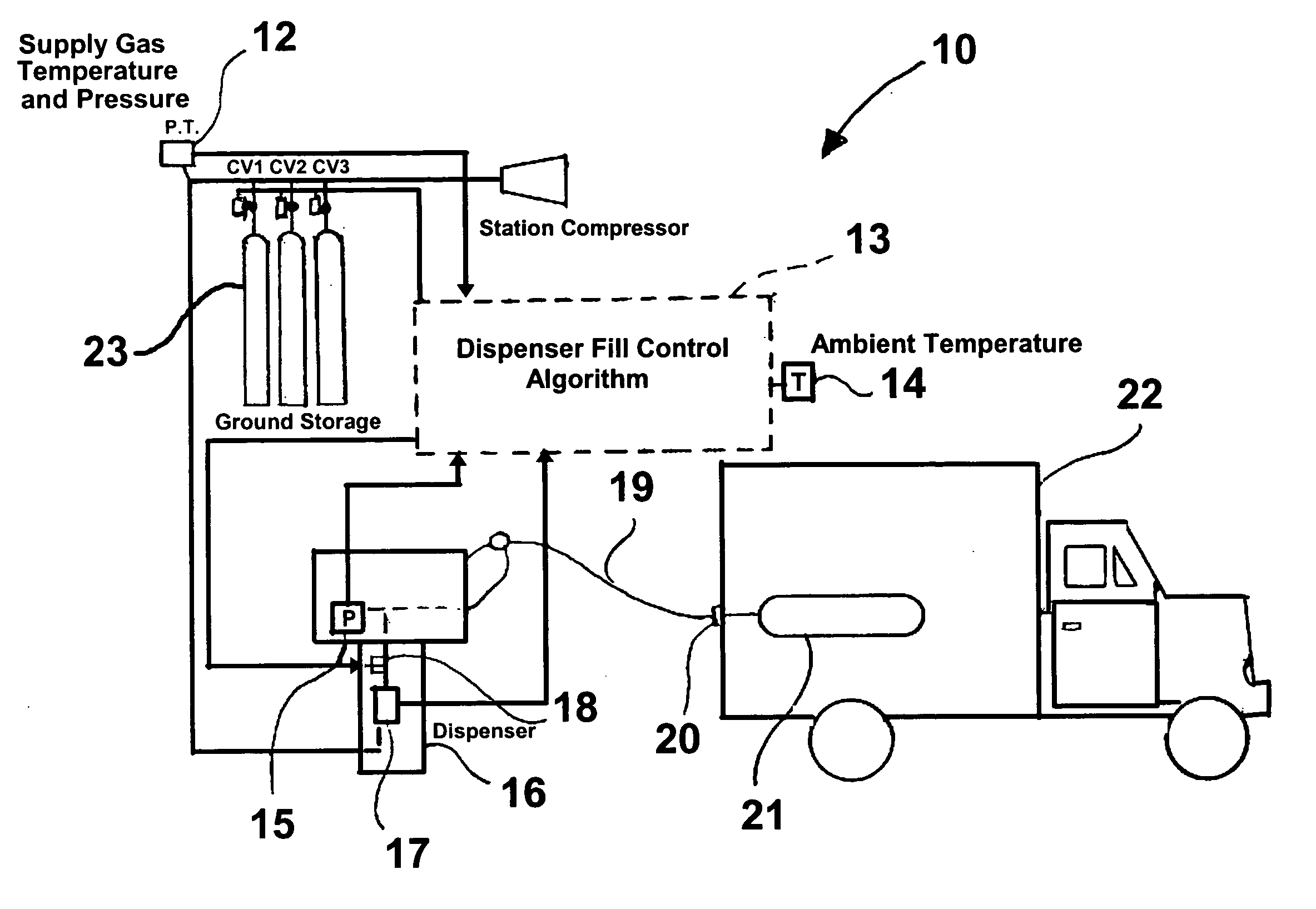

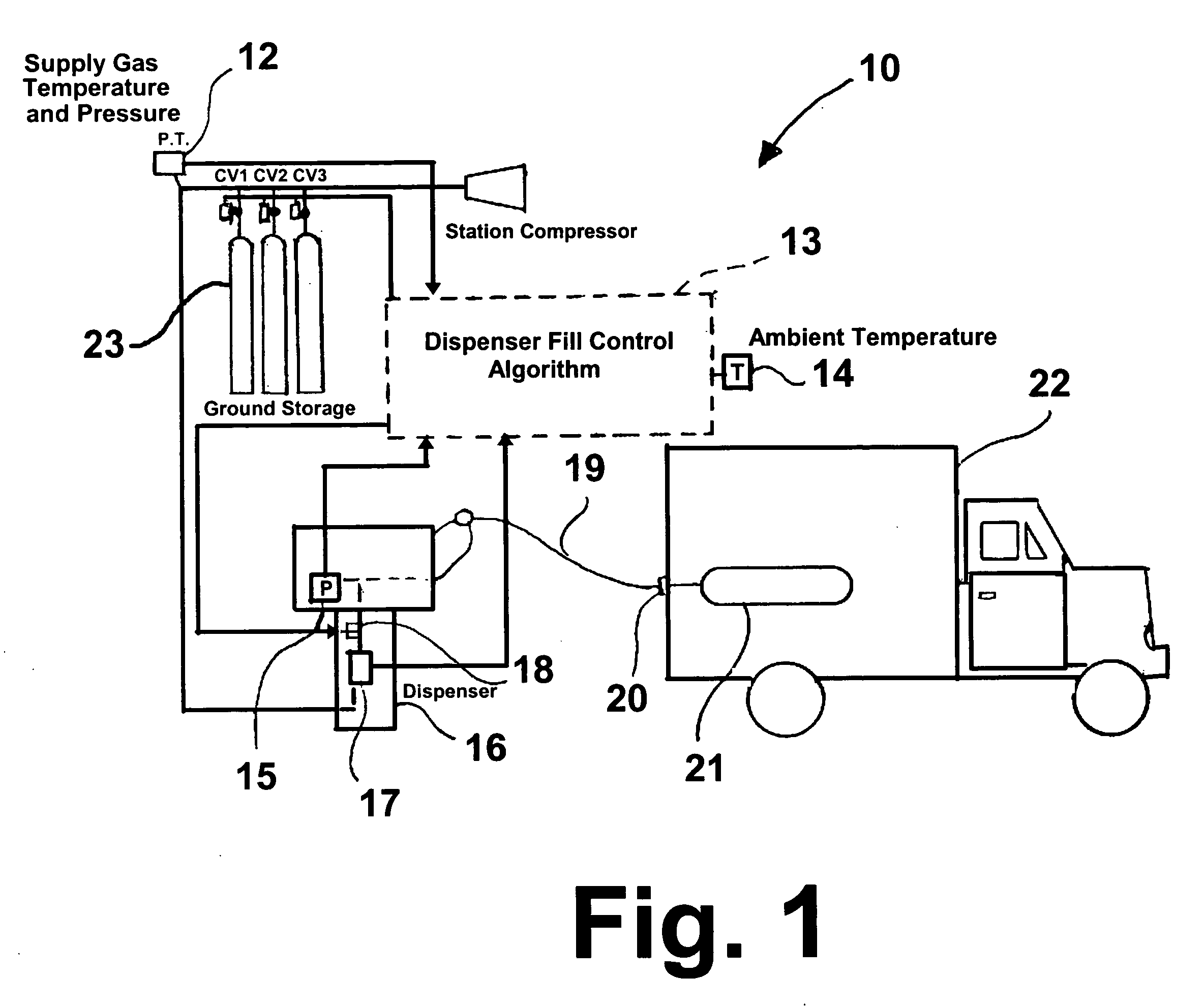

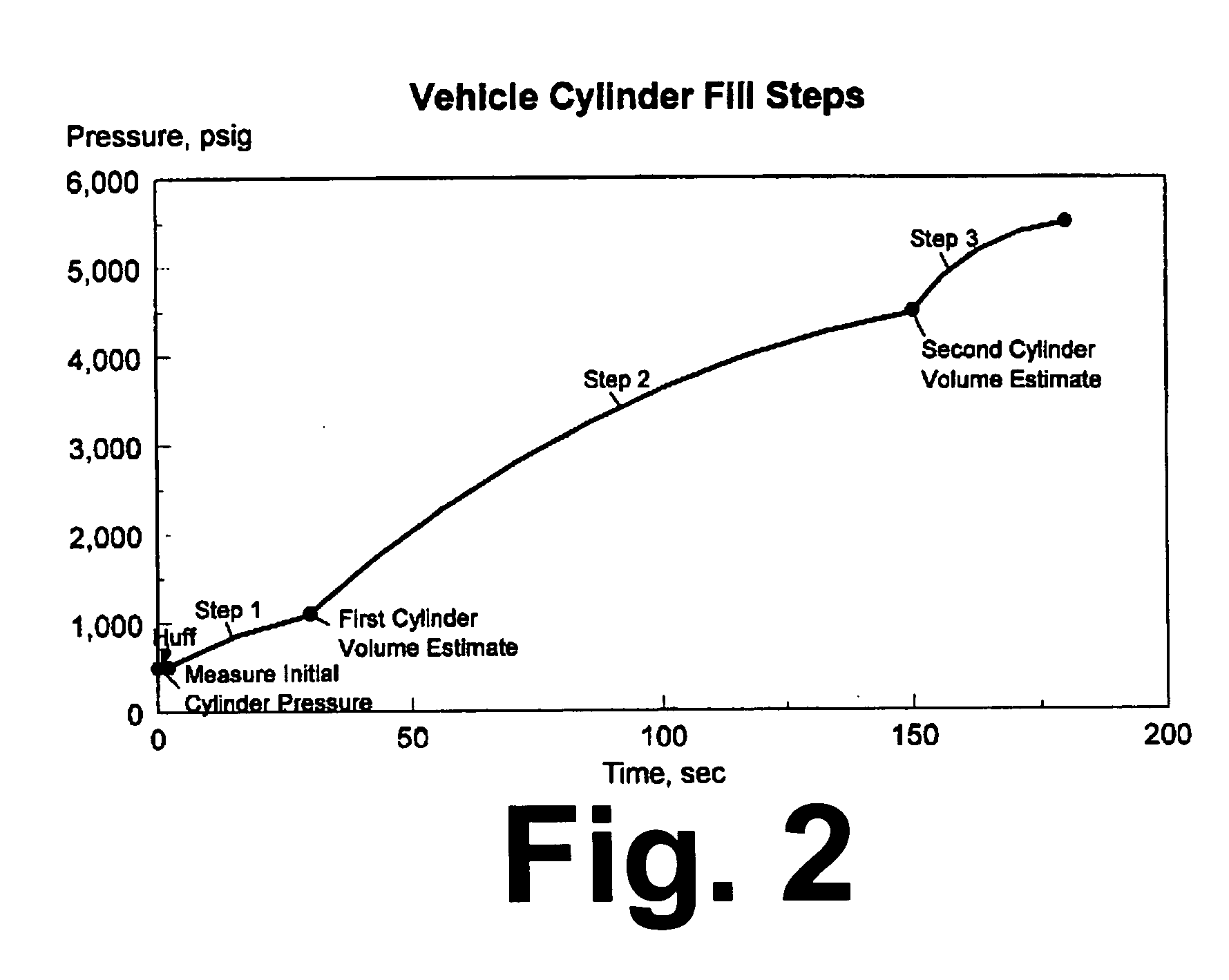

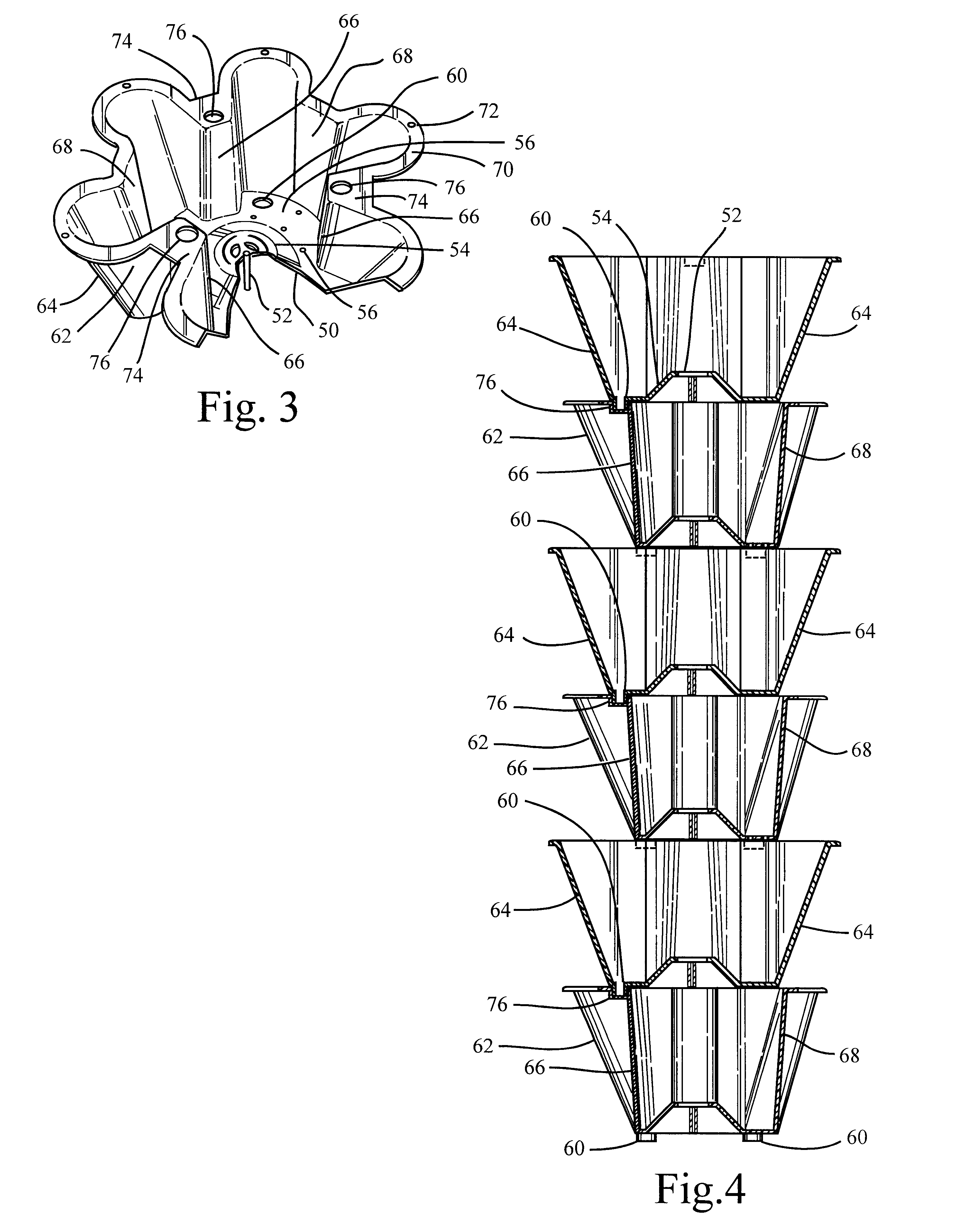

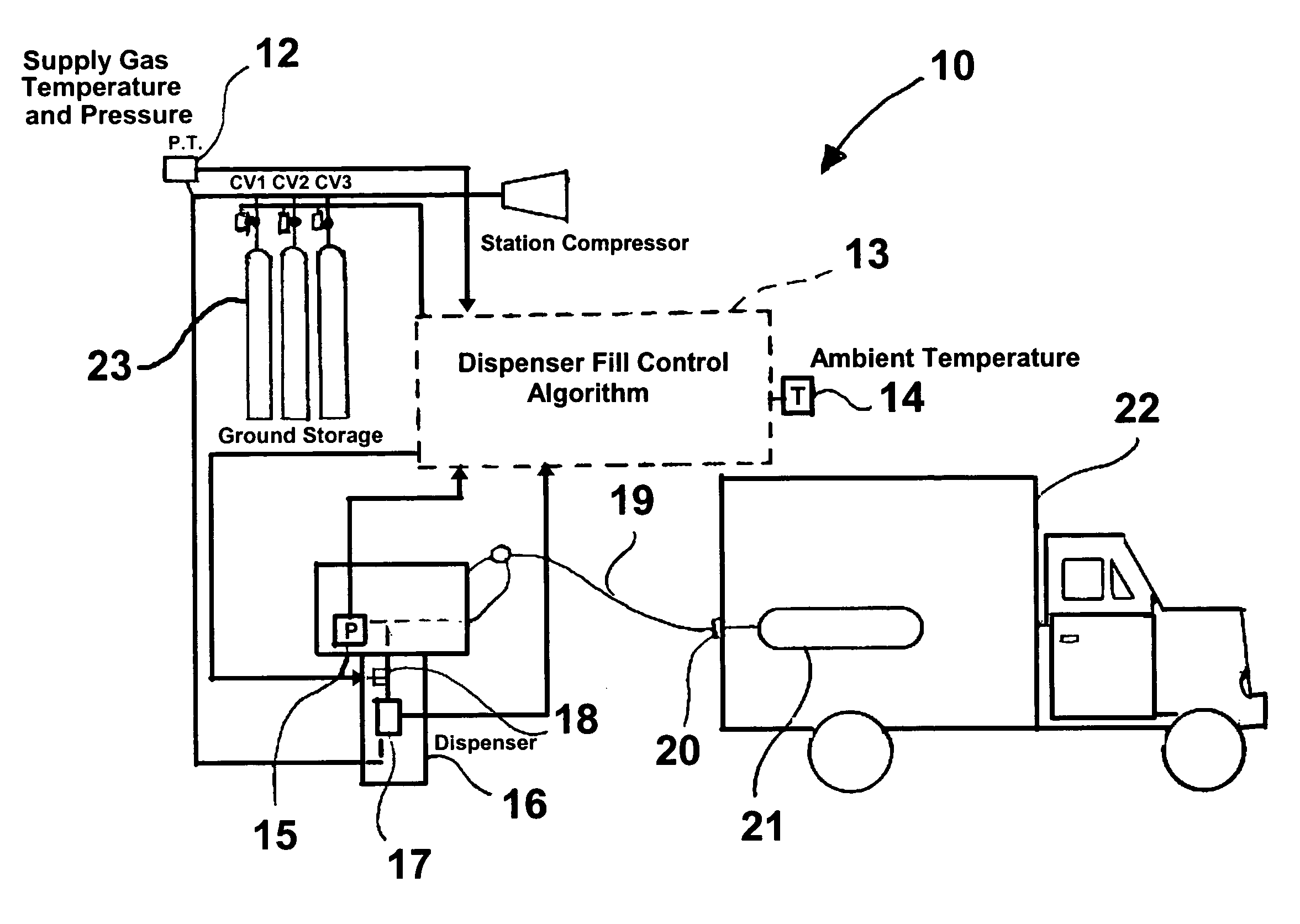

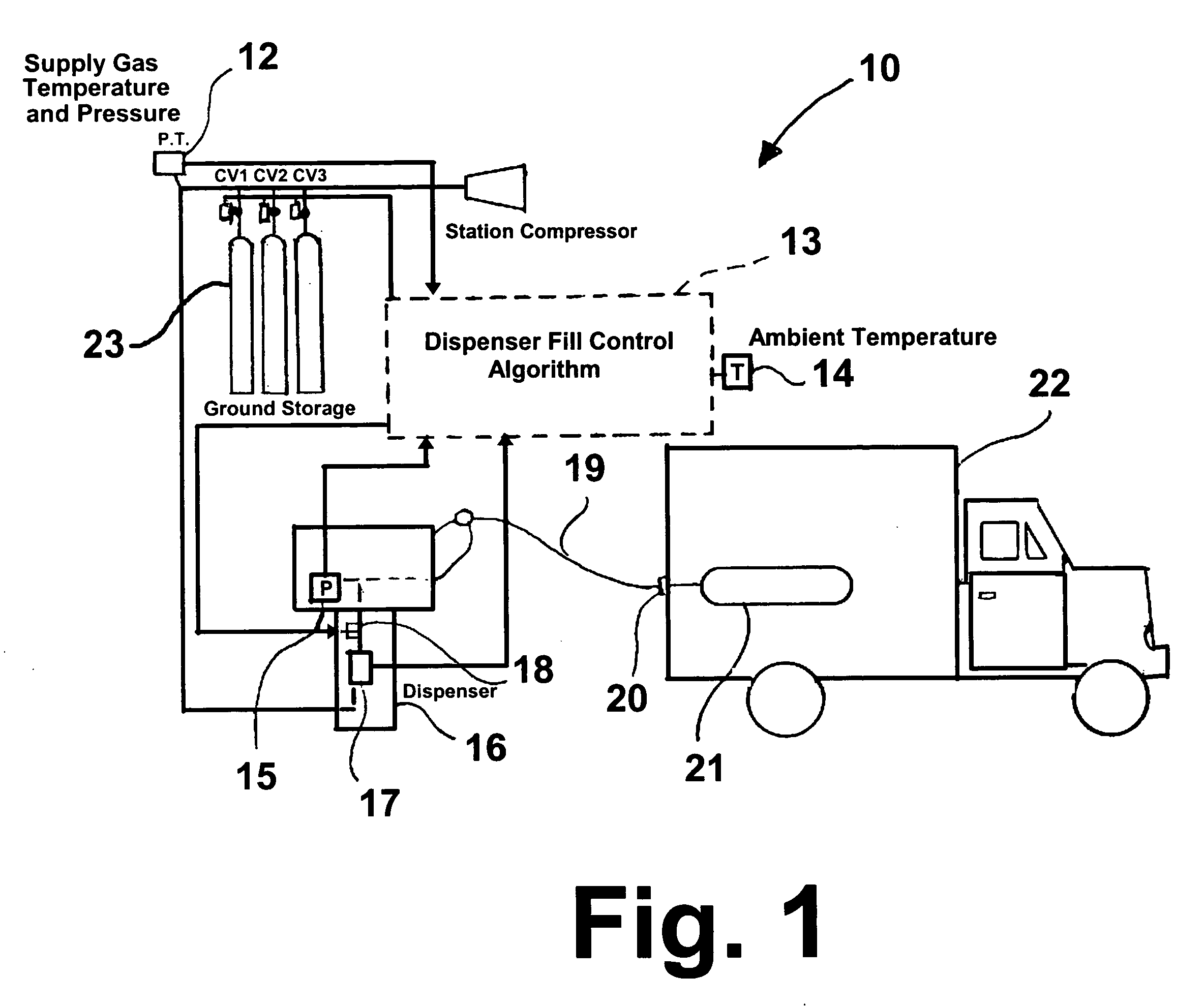

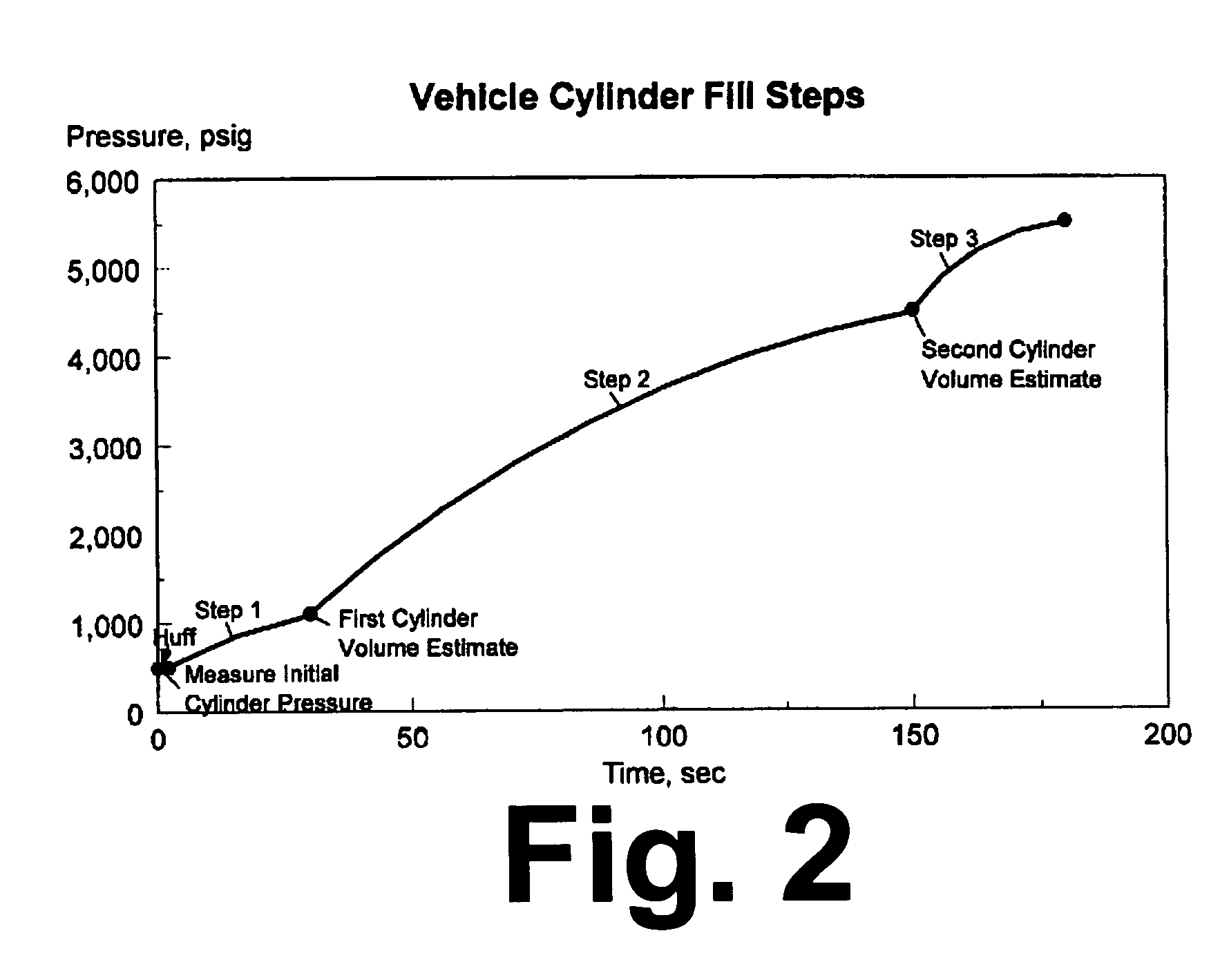

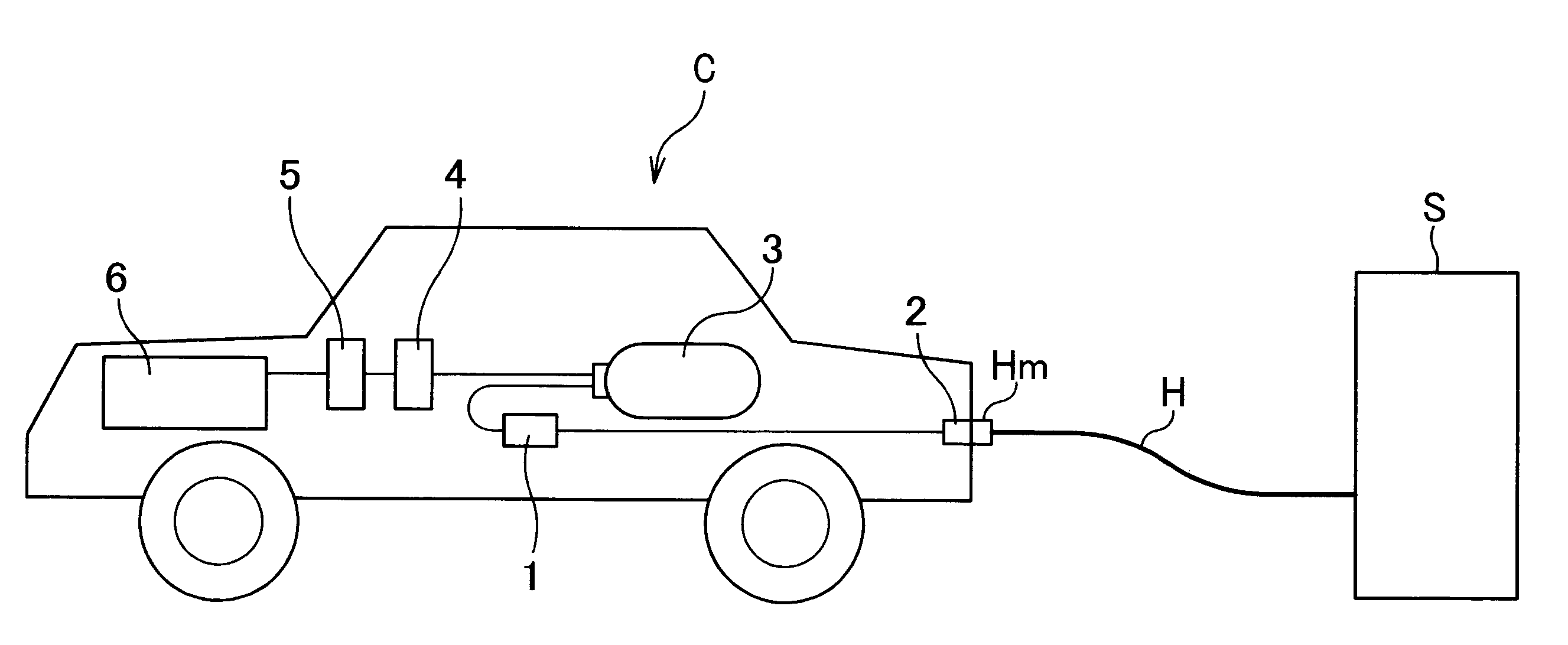

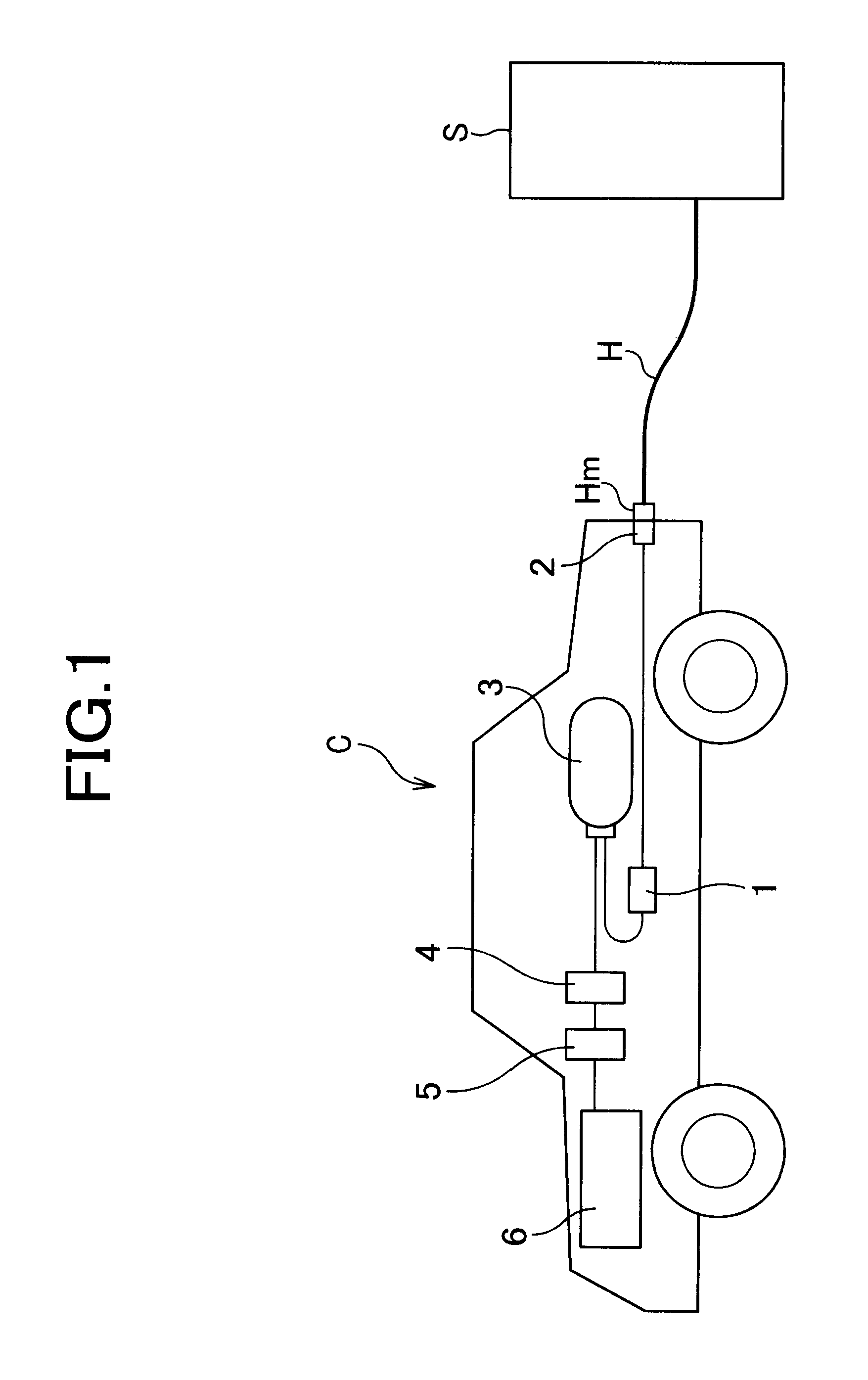

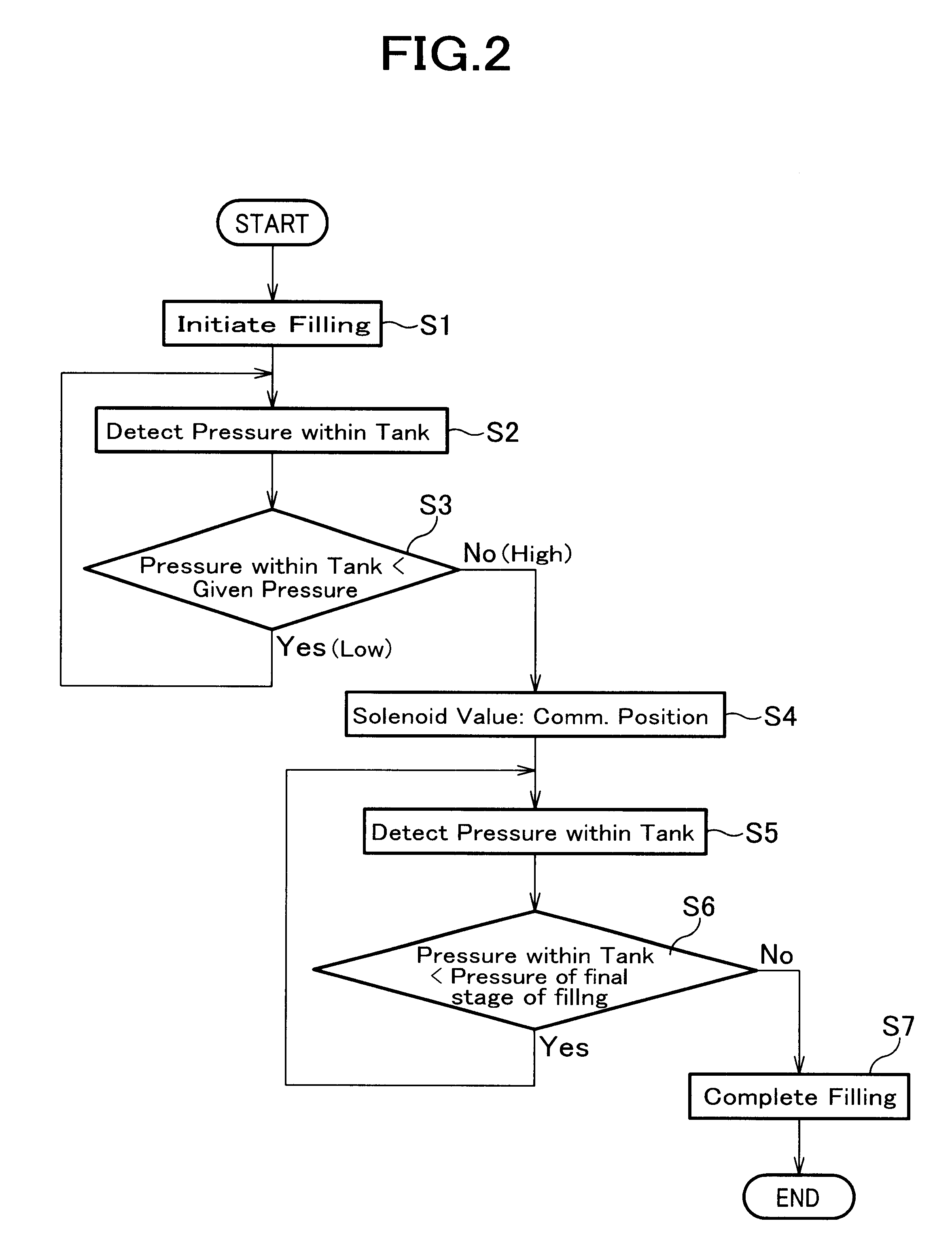

Control method for high-pressure hydrogen vehicle fueling station dispensers

InactiveUS20050178463A1Dispenser and vehicle costReduces potential for underfillingGas handling applicationsGas handling/storage effectsHigh pressure hydrogenAutomotive engineering

A method for quick filling a vehicle hydrogen storage vessel with hydrogen, the key component of which is an algorithm used to control the fill process, which interacts with the hydrogen dispensing apparatus to determine the vehicle hydrogen storage vessel capacity.

Owner:GAS TECH INST

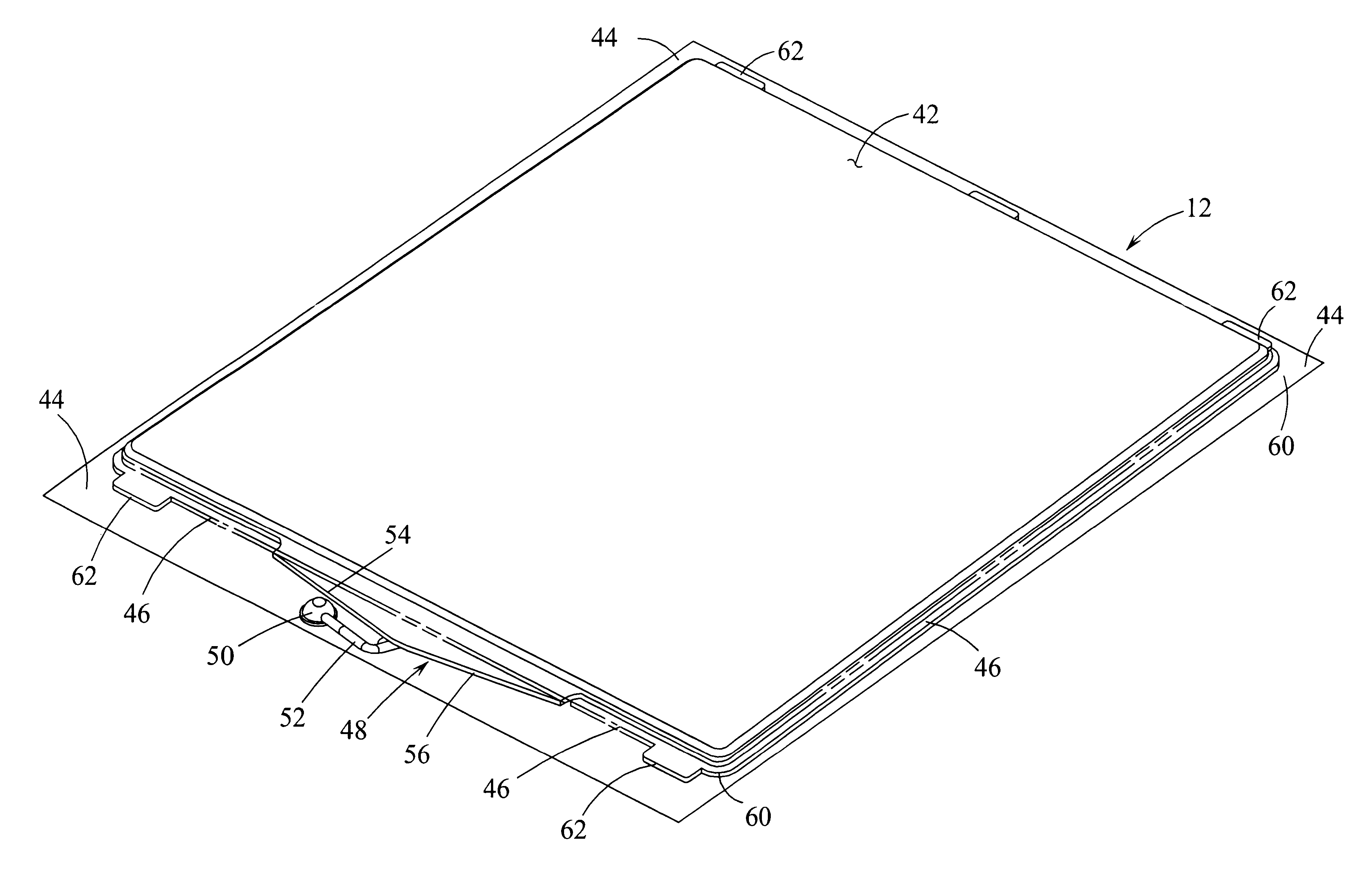

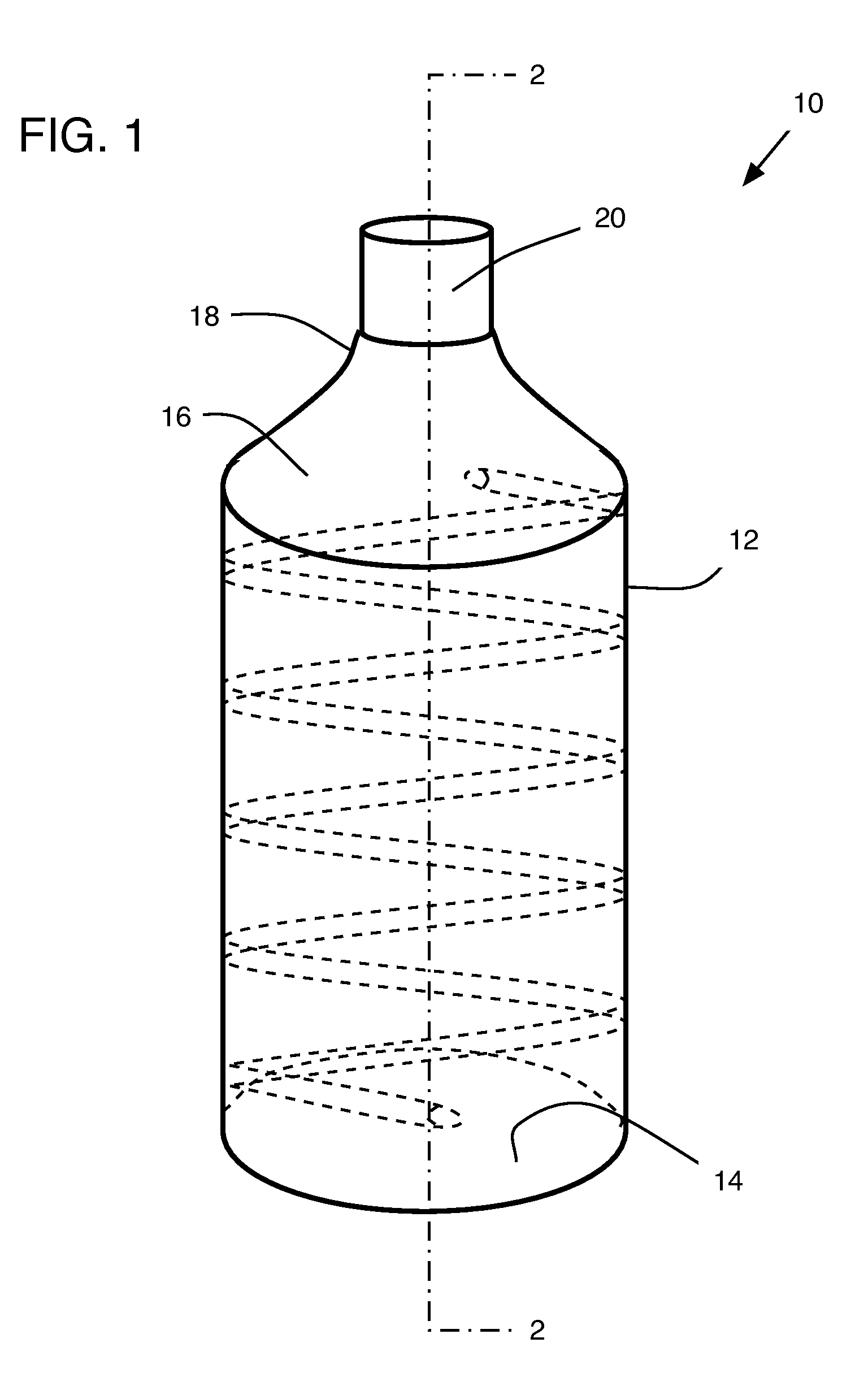

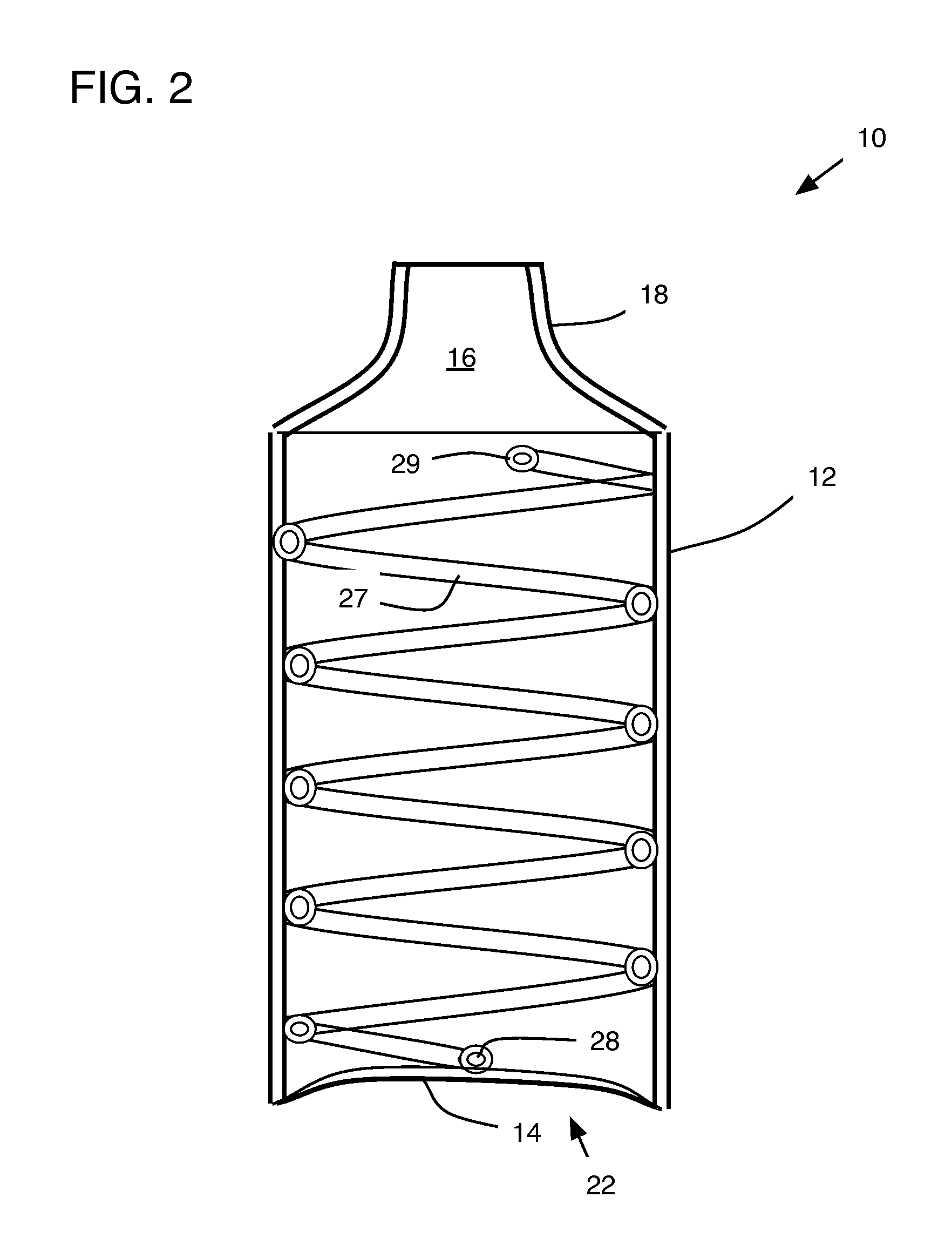

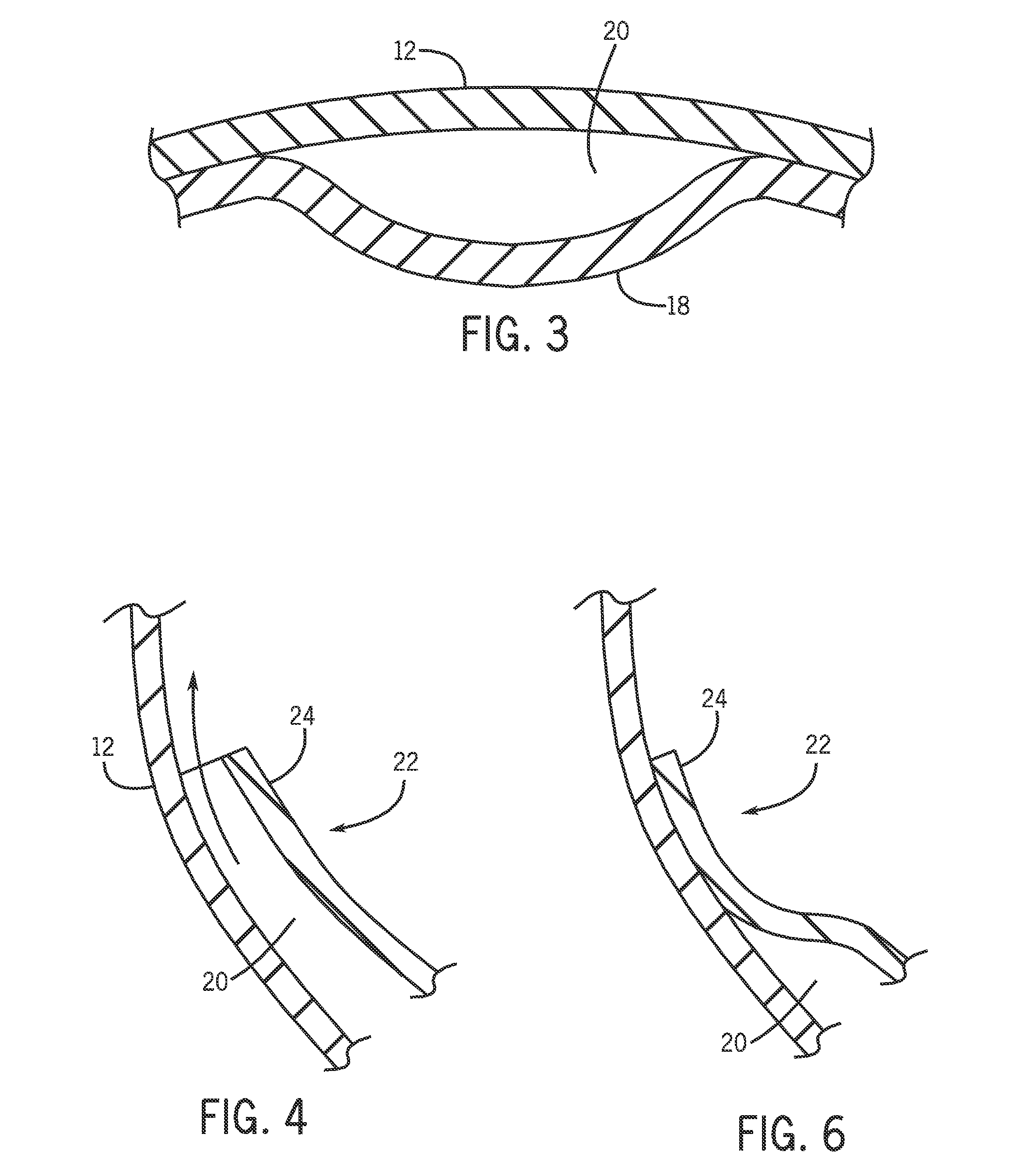

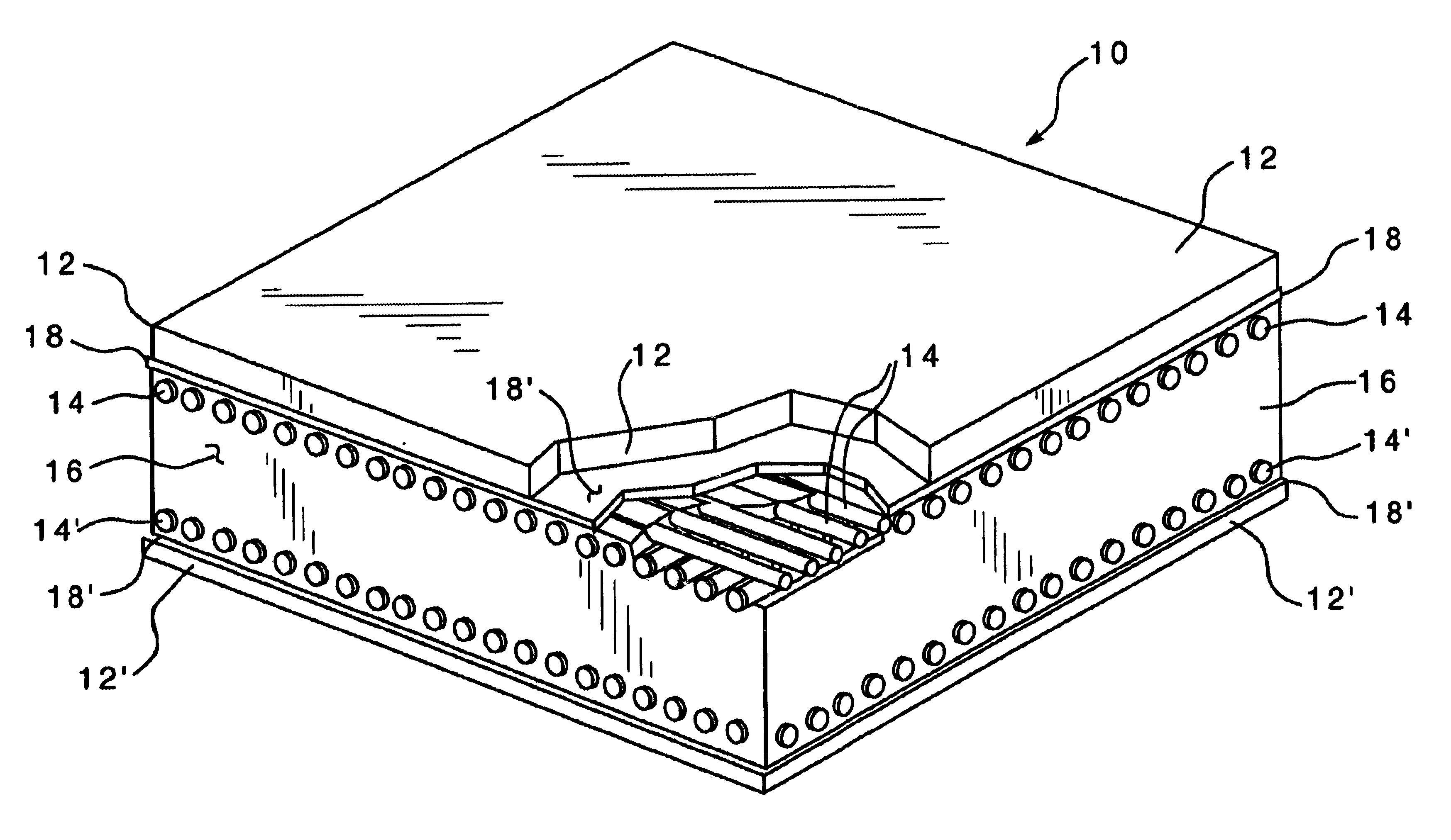

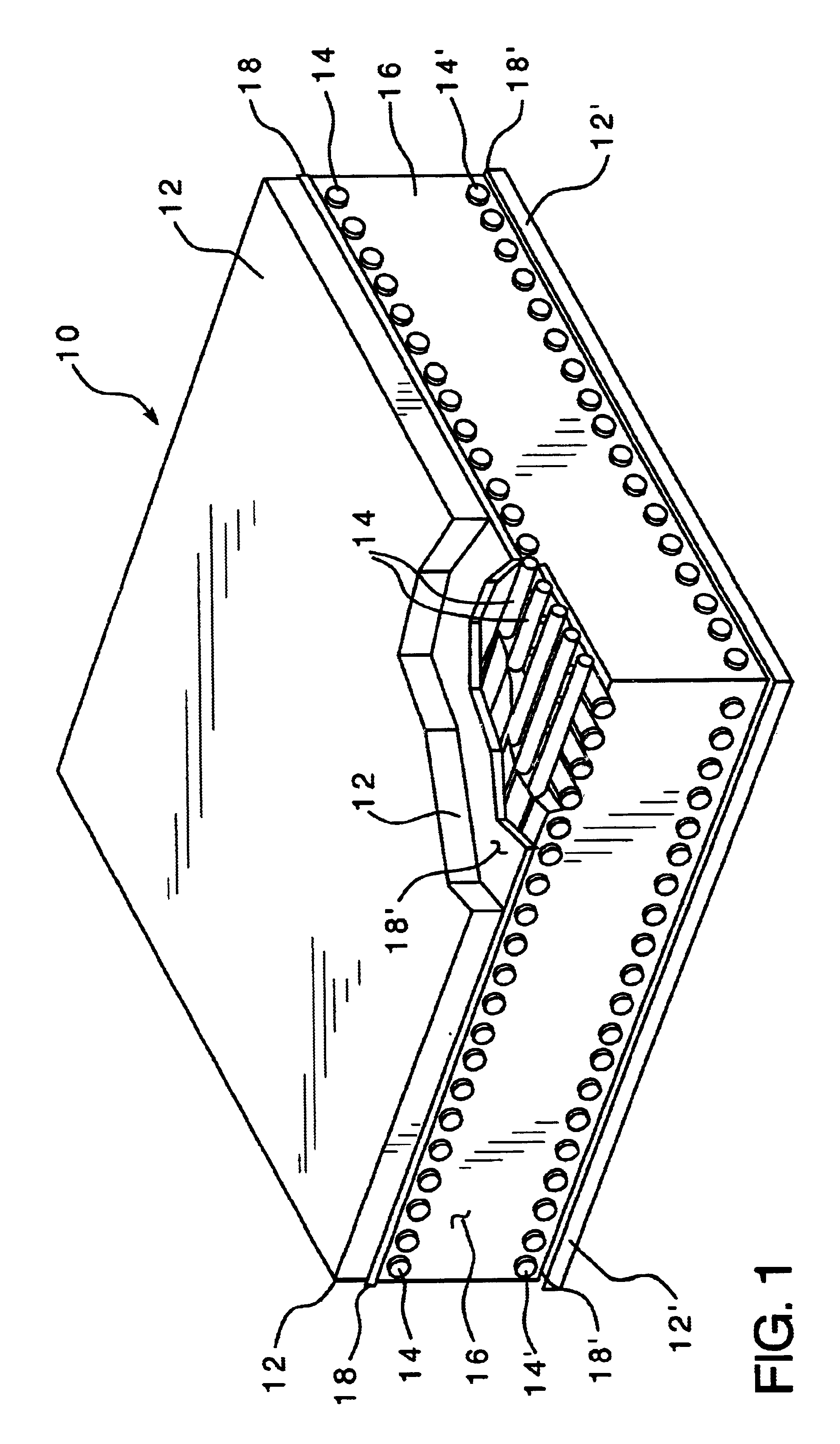

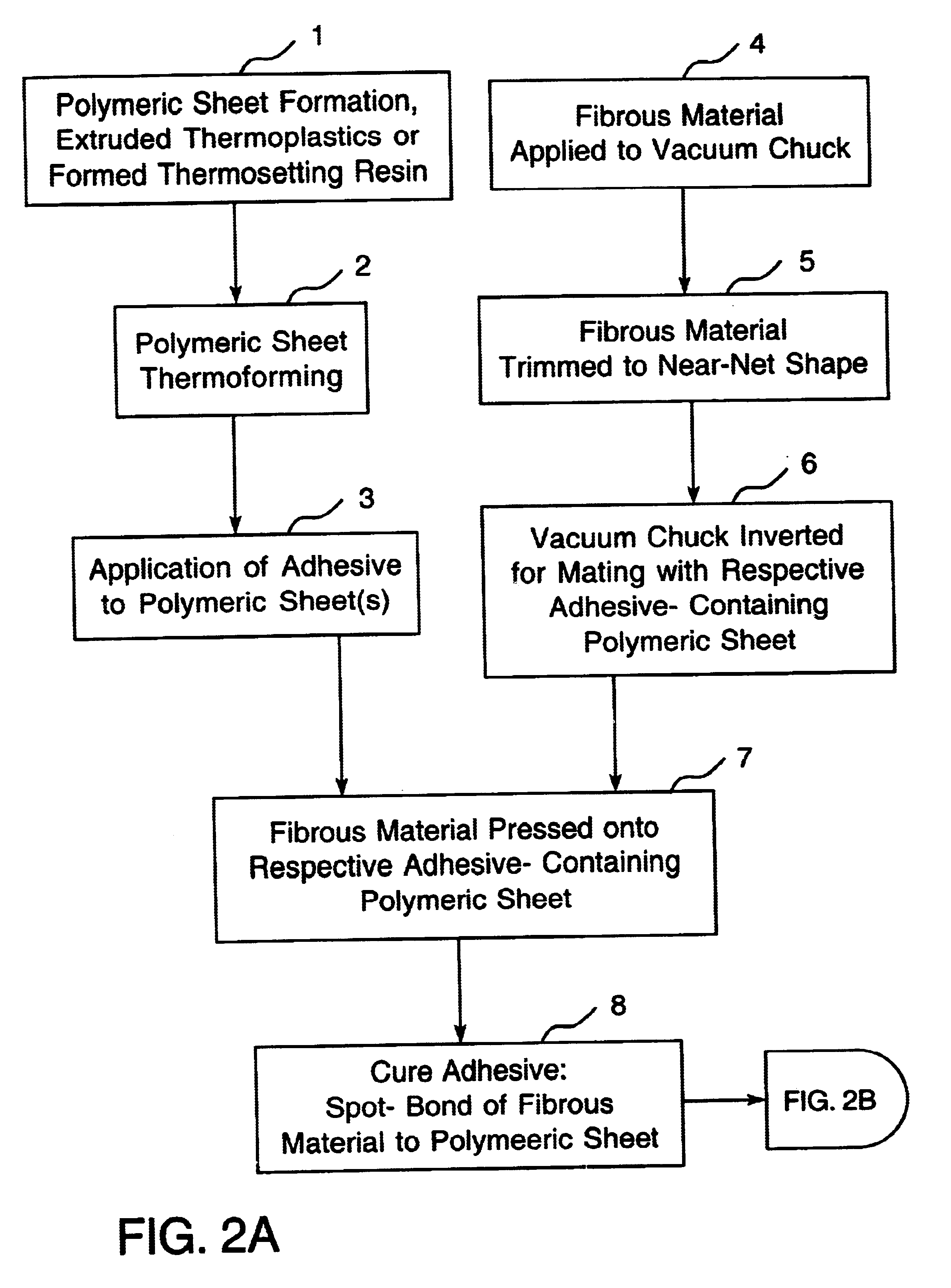

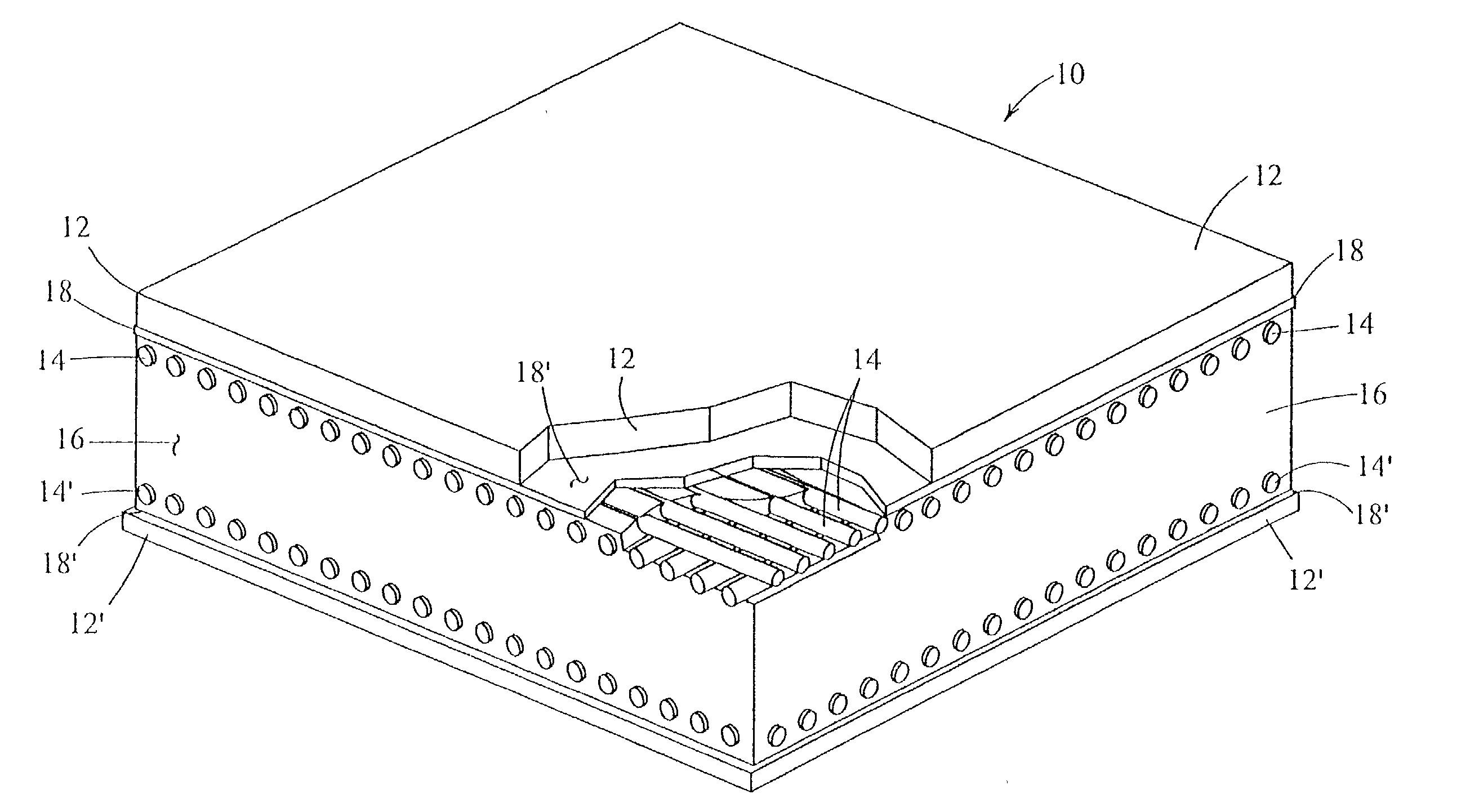

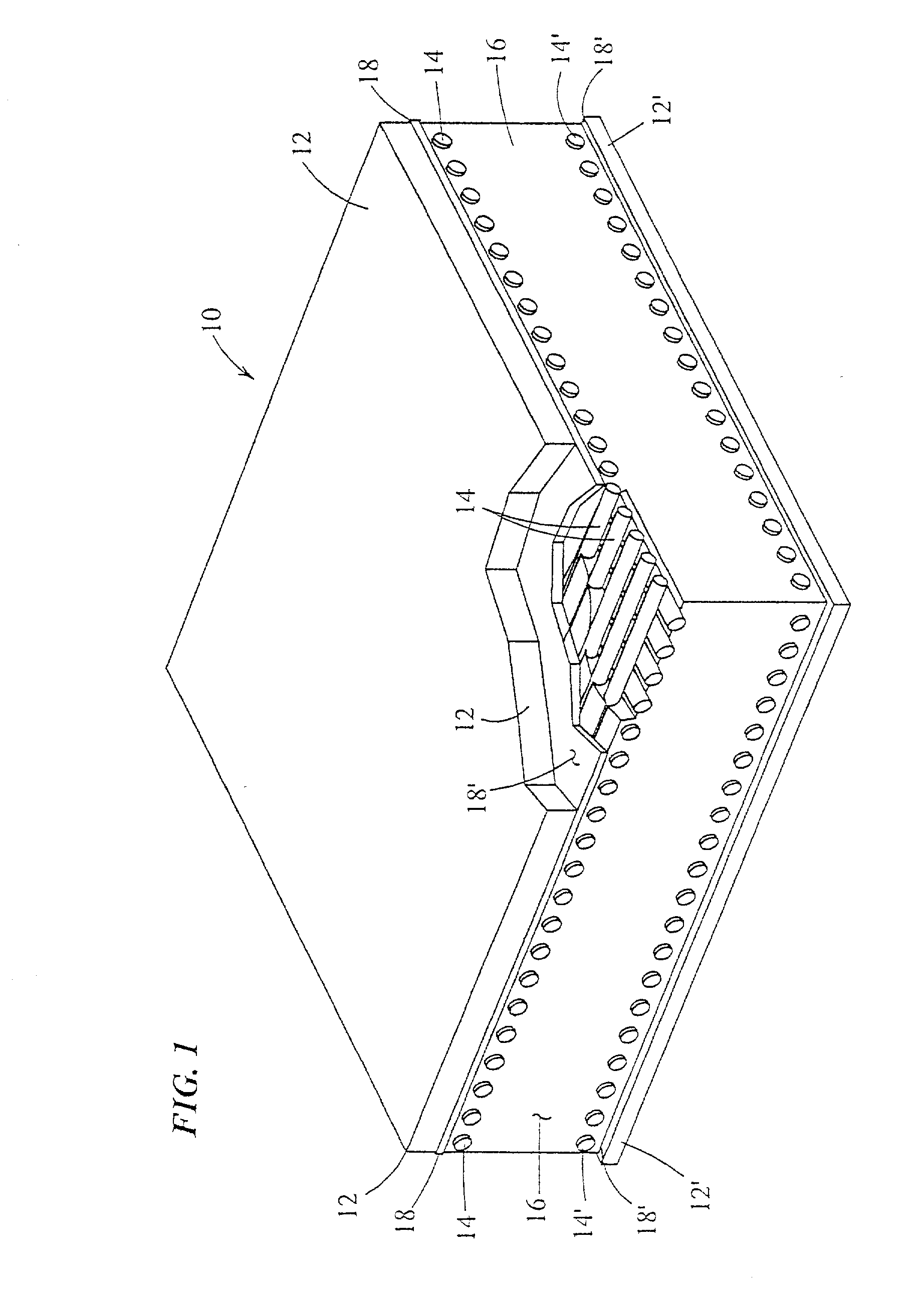

Fiber-reinforced composite structure

InactiveUS6331028B1Fast fillFast impregnationLayered productsWoven fabricsFoaming agentVacuum pressure

A fiber-reinforced composite structure has two molded outer polymeric layers spaced apart from each other and defining a cavity therebetween. Each molded outer polymeric layer defines a sealing surface extending about a periphery of the respective layer, and the opposing sealing surfaces cooperate to define a hermetic seal extending about a periphery of the cavity. One or more multi-directional fiber reinforcement layers are adhesively attached in a discontinuous manner to each outer polymeric layer, and define a first region of the cavity extending between each respective outer polymeric layer and adjacent fiber reinforcement layer, and a second region of the cavity extending between the fiber reinforcement layers. A core is located between the two outer polymeric layers, and is made of a resinous core material capable of exhibiting a foamed character and a resinous character. The resinous core material has a blowing agent activatable upon exposure to a predetermined vacuum pressure within the cavity to convert the core material within the second region of the cavity from a resinous character to a foamed character and thereby fill the second region of the cavity with the foamed core material. Each multi-directional fiber reinforcement layer is impregnated with the core material exhibiting a relatively dense, resinous character, and each first region of the cavity is substantially filled with the core material exhibiting a resinous character to fixedly secure the multi-directional fiber reinforcement layers to the outer polymeric layers. A structural insert, such as a rigid plate adapted to receive fasteners, is embedded within the core material for attaching other devices or structures thereto.

Owner:SABIC GLOBAL TECH BV

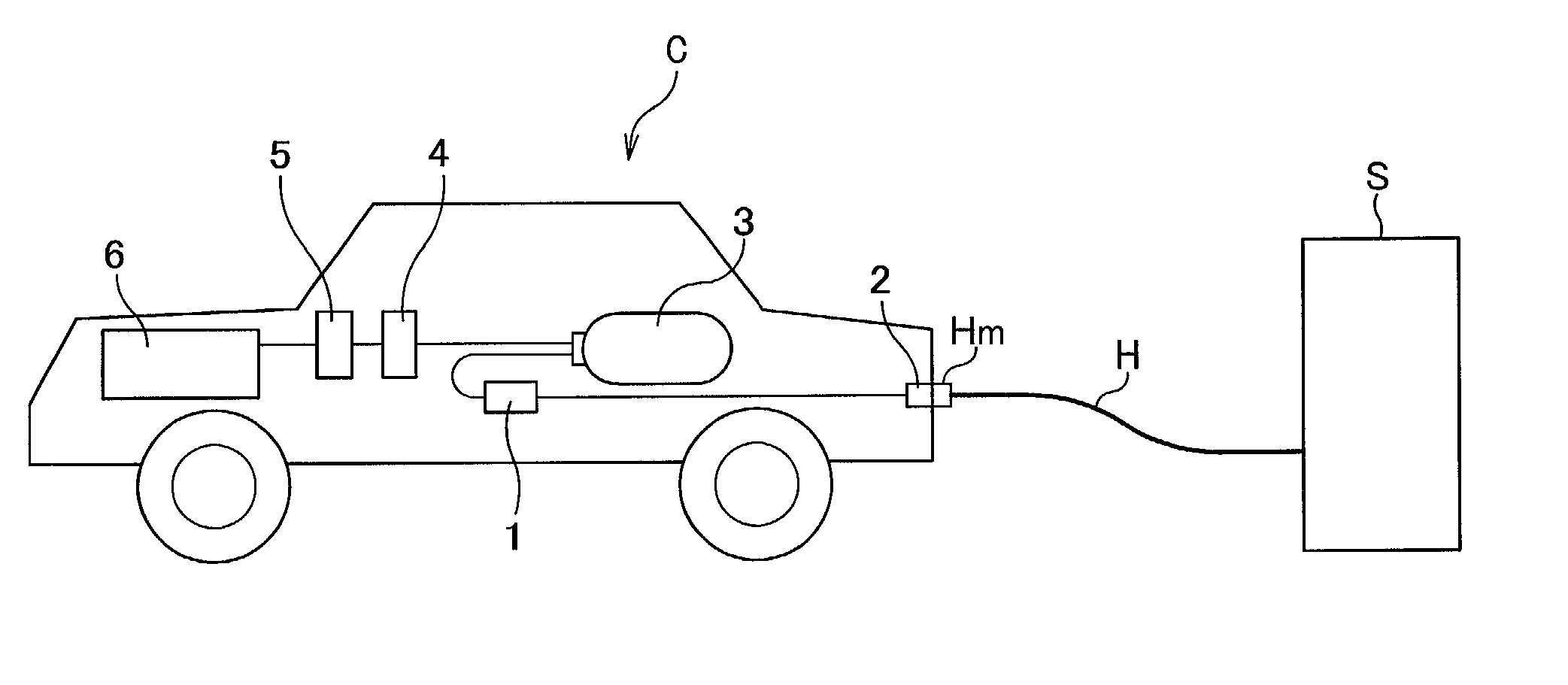

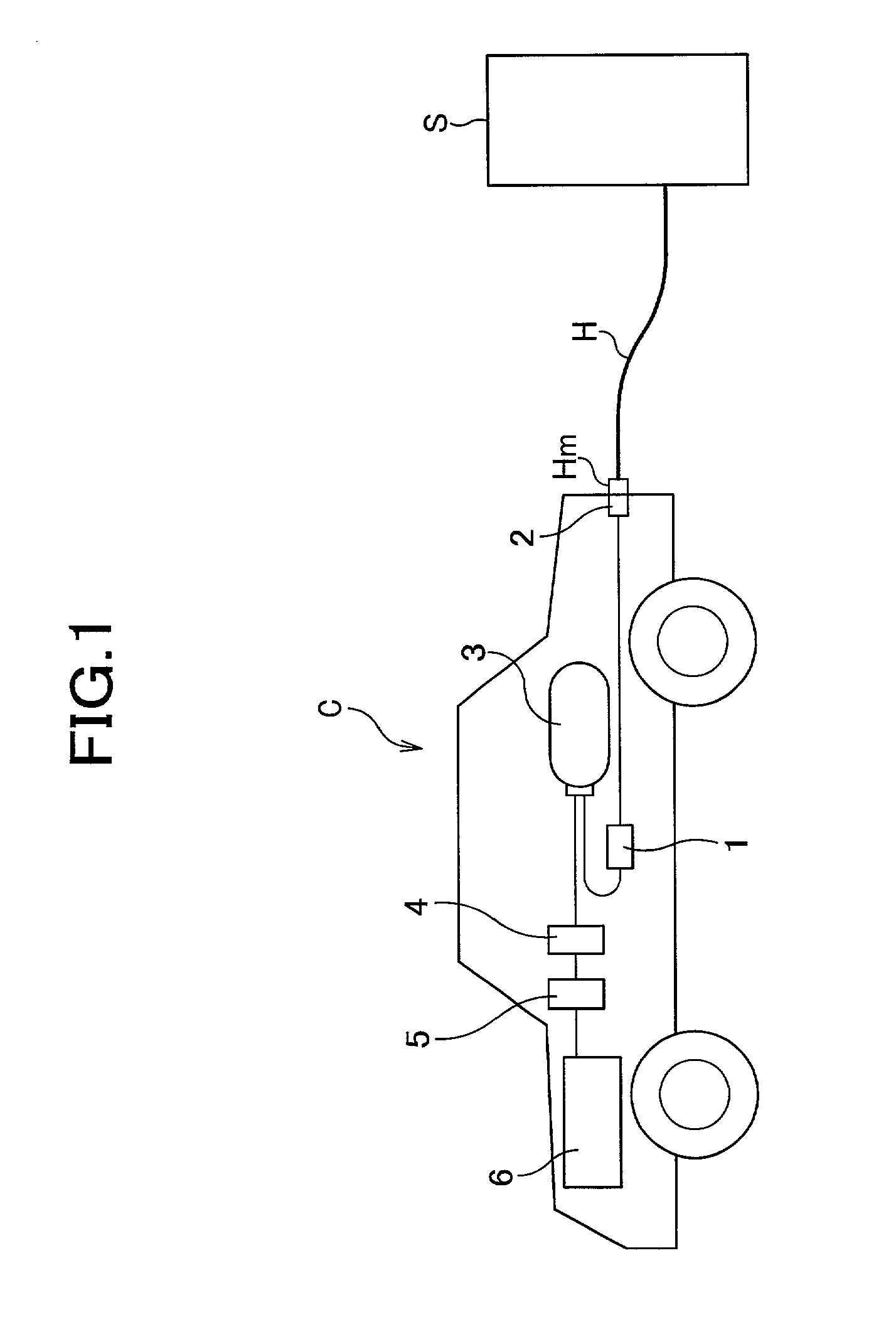

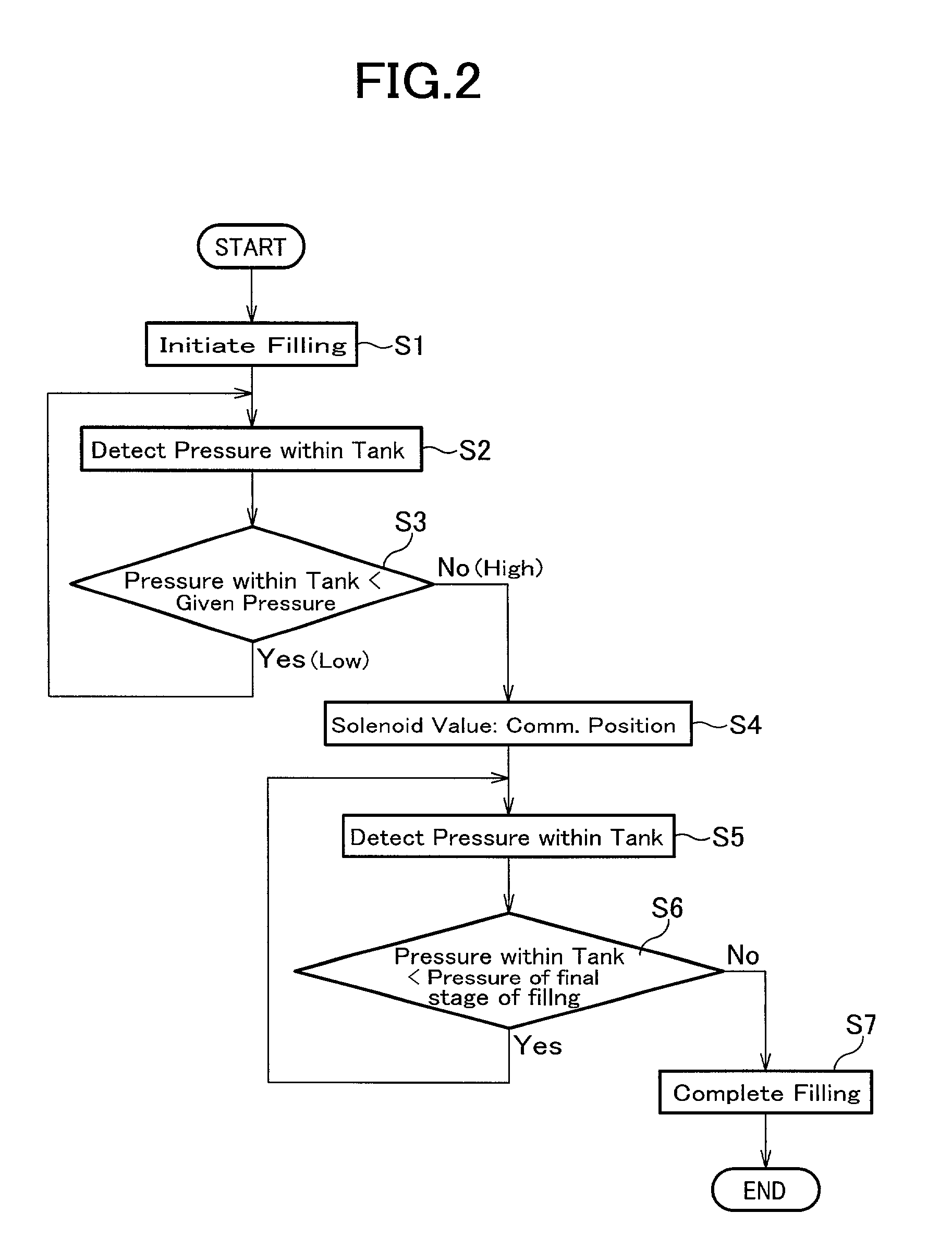

Apparatus and process for rapidly filling with hydrogen

InactiveUS20020014277A1Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

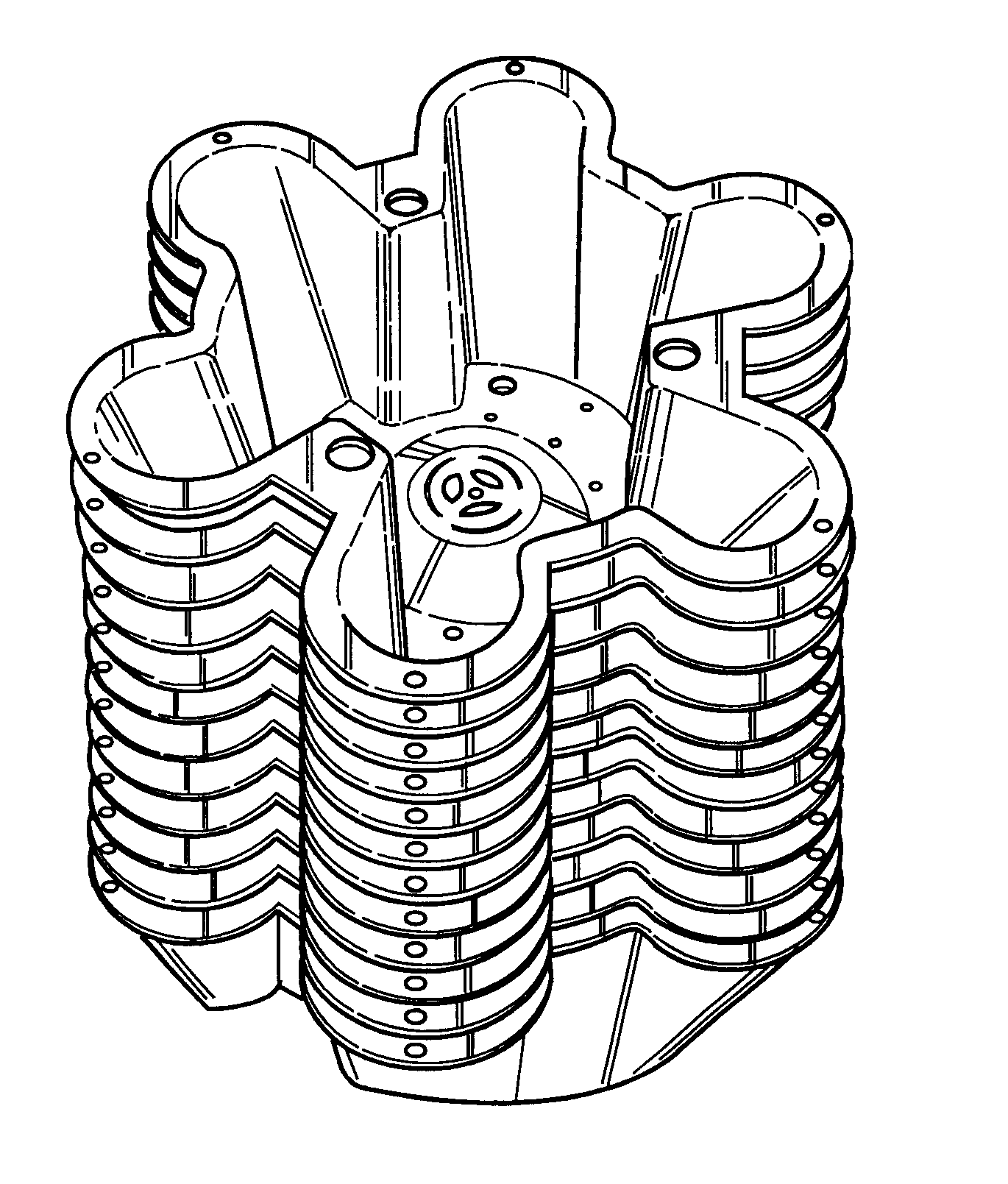

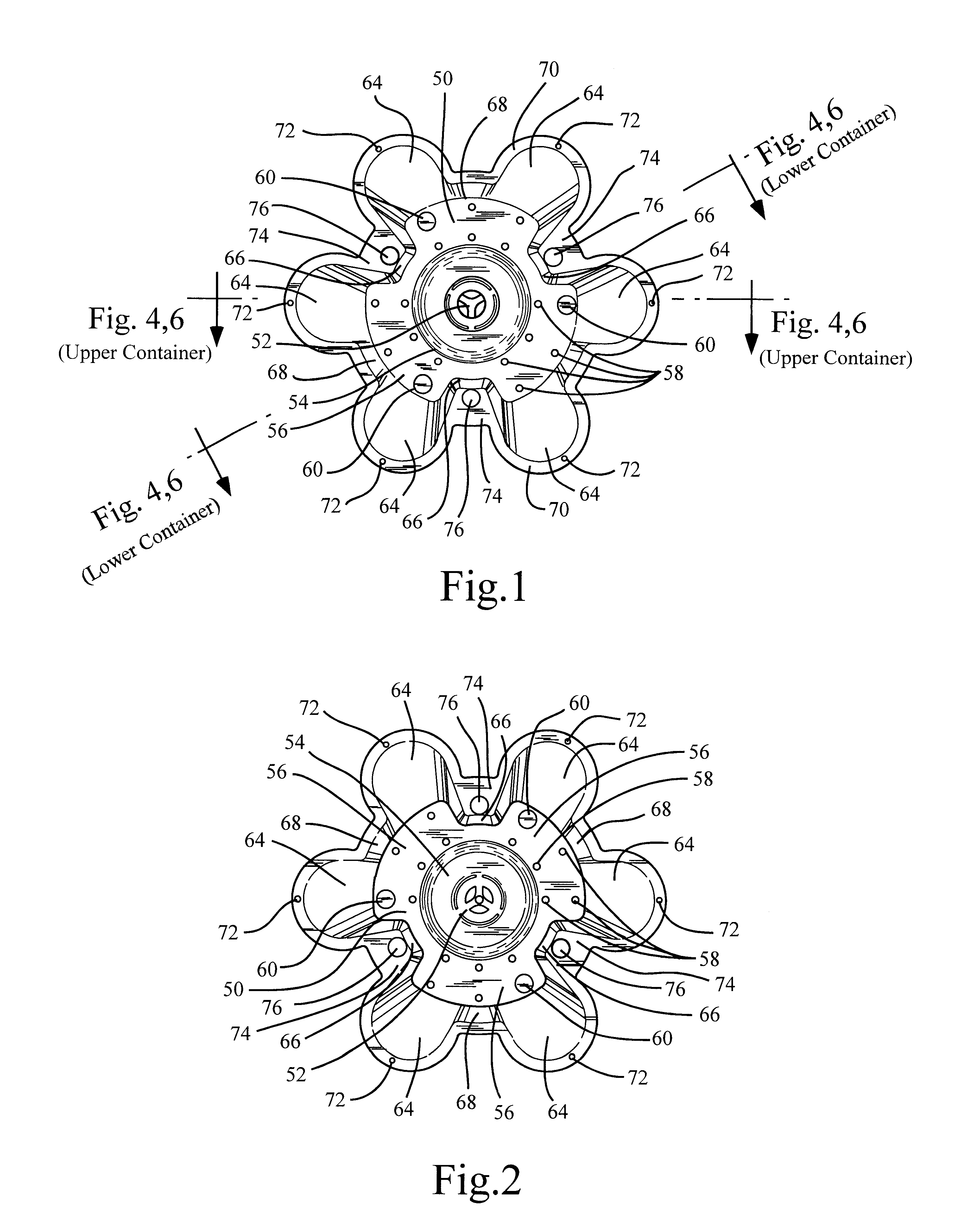

Intensive plant growing stacking container system

InactiveUS6612073B1Quickly and easily repeatedSmall sizeWatering devicesCultivating equipmentsEngineeringVertical array

A molded plant growing container system is easily stacked in a vertical array providing a self-supporting apparatus for intense horticulture. This apparatus increases crop yields over conventional growing methods. The containers nest within each other for ease of transport, are quickly and easily assembled, provide efficiency in installation and use of growing medium, increased numbers of plants in a given space, and are adaptable to a variety of irrigation methods.

Owner:MARKS & NOVA BALL MARKS TRUSTEES OR SUCCESSORTRUSTEE OF THE MARKS FAMILY TRUST UAD 5 13 05 ROBIN

Control method for high-pressure hydrogen vehicle fueling station dispensers

InactiveUS7059364B2Reduces potential for underfillingFast fillGas handling applicationsGas handling/storage effectsHigh pressure hydrogenHigh pressure

A method for quick filling a vehicle hydrogen storage vessel with hydrogen, the key component of which is an algorithm used to control the fill process, which interacts with the hydrogen dispensing apparatus to determine the vehicle hydrogen storage vessel capacity.

Owner:GAS TECH INST

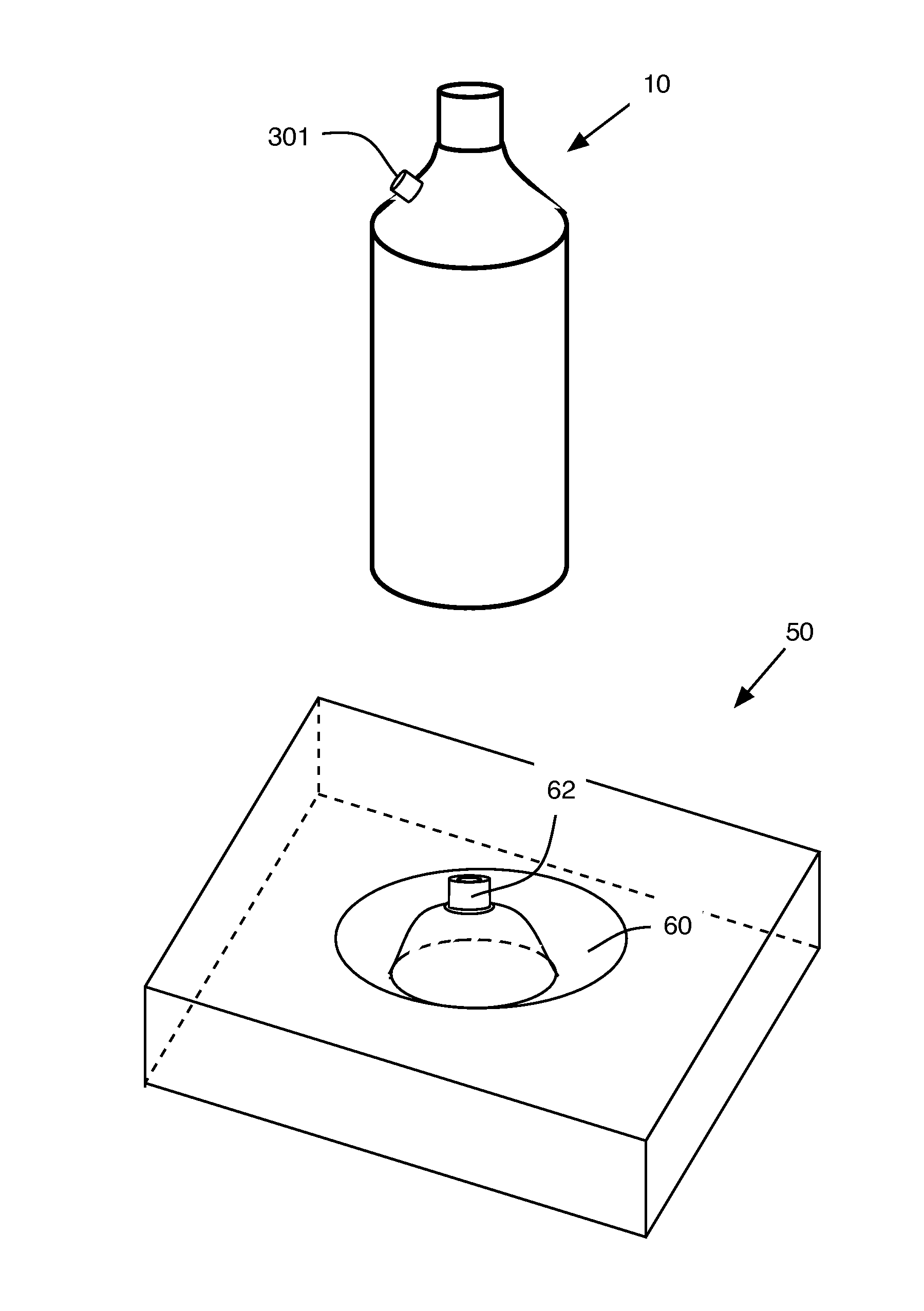

Sports Bottle and Fluid Dispensing system, device, and method.

A sports bottle having a conventional open top with fitting lid, generally vertical sidewalls forming a cylinder with a bottom includes a valve mechanism for filling the bottle from a position other than the open top. The bottle further includes means for identifying the bottle to a dispensing machine. The dispensing machine interfaces with the valve mechanism to enable fluid to flow into the bottle to a pre-determined level. The valve mechanism further includes means for enabling the escapement of air or other gases during the fluid filling operation. The dispensing machine begins a pressurized flow of filtered water or other desired fluid when the bottle is positioned on the machine.

Owner:IBSIES FADI

Apparatus and process for rapidly filling with hydrogen

InactiveUS6598624B2Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

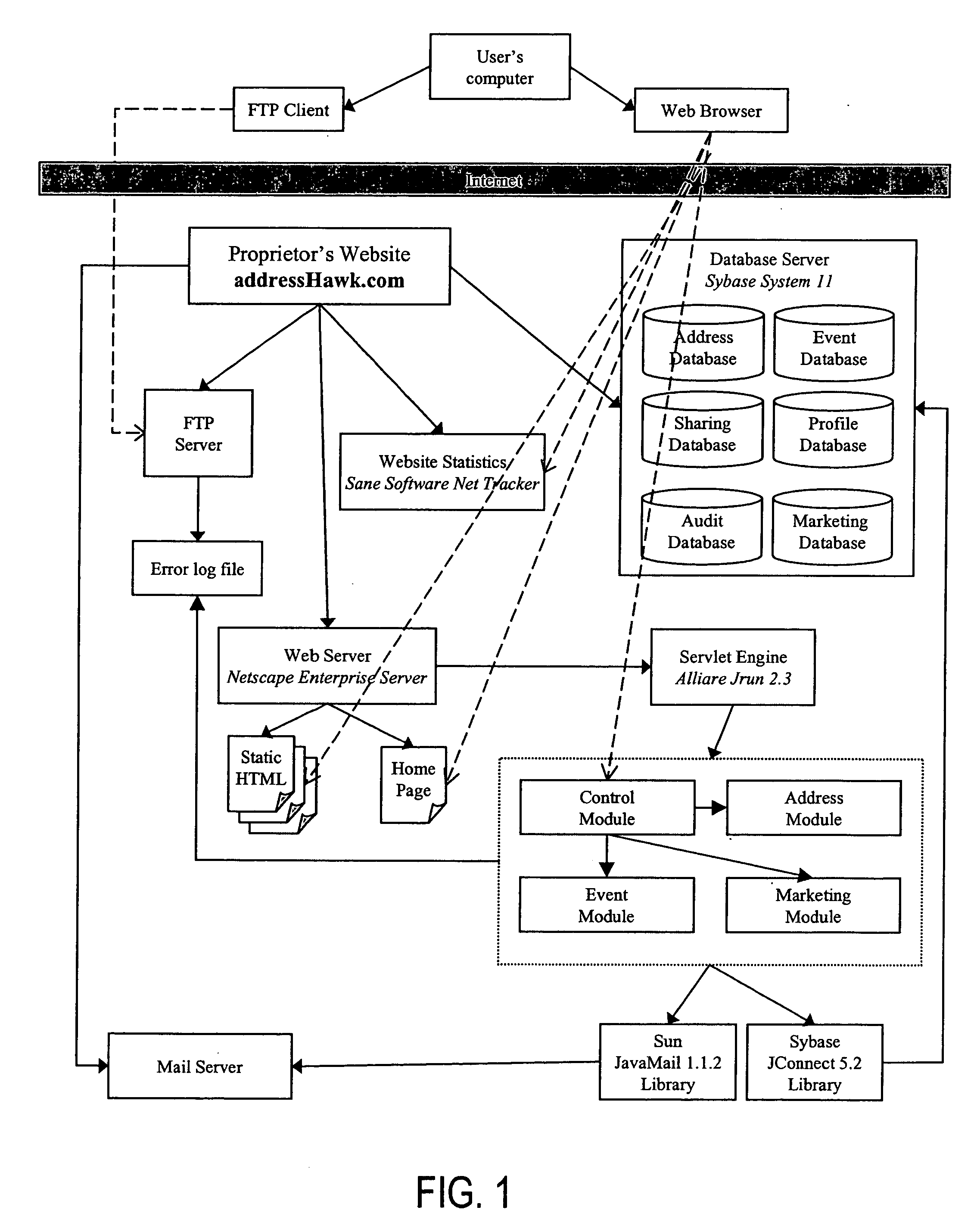

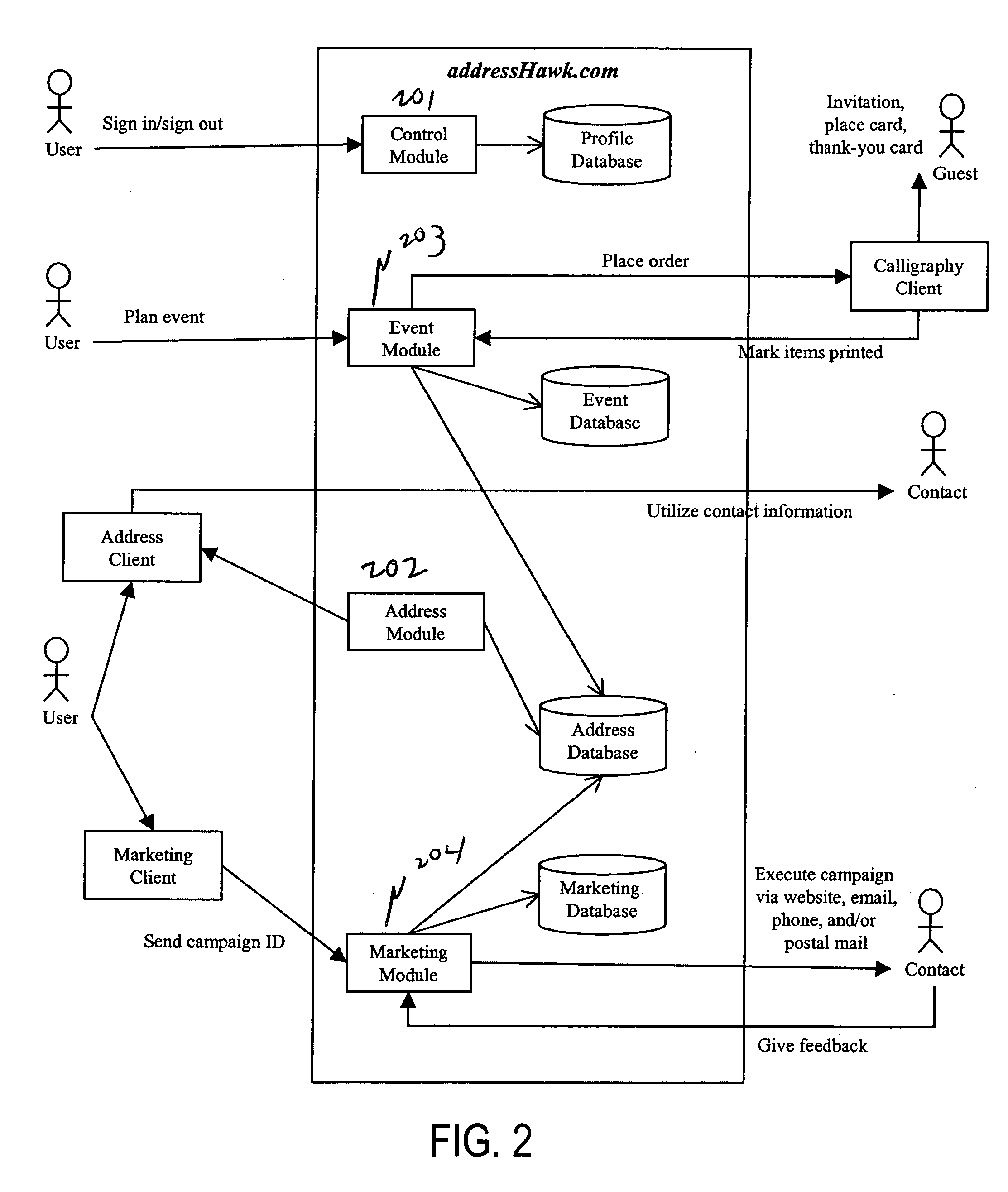

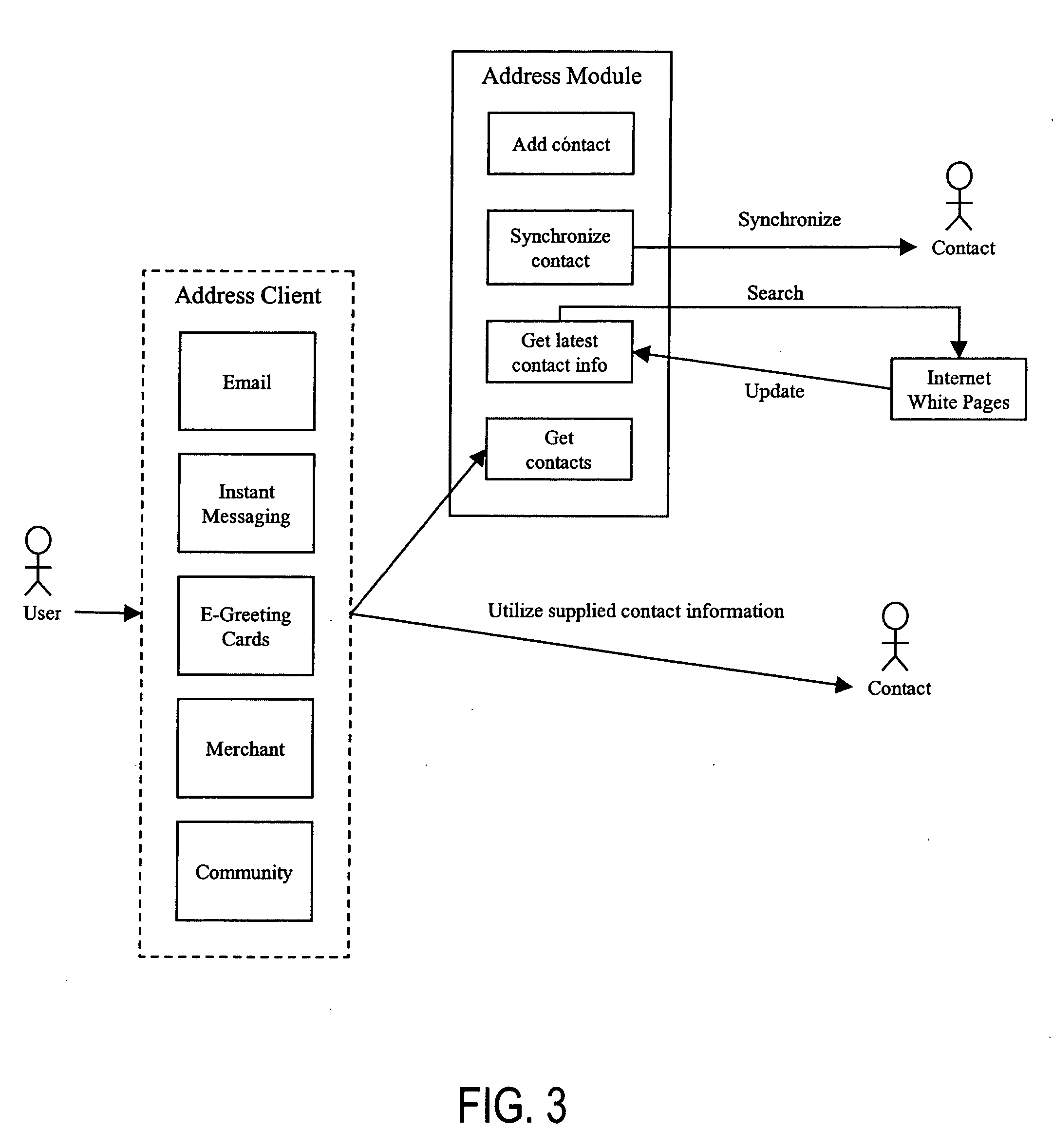

Web-based address book

InactiveUS20050075925A1Value maximizationMore serviceMarketingSpecial data processing applicationsNegative feedbackAddress book

Disclosed is an Internet-based address book that enables individuals (“users”) or (“members”) to use people (“contacts”) from their address book for event planning, purchasing gifts, marketing, and anything else anyone dreams up. The system includes the following modules: an address book whose information can be utilized by any client for any purpose, a full-fledged event planner suitable for planning formal events such as weddings, a marketing module that allows people to refer products and information to people who would be interested, and a recipient transaction module that makes recipient-based transactions such as gifts and money transfer assessable and convenient. Features of the event planner include automatic generation and reprinting of invitations, placement cards, and thank-you cards with proper etiquette. Features of the marketing module includes the ability (a) to restrict the contacts that can be marketed to based on demographics, negative feedback, missing requisite information, or other reasons, (b) to reward users that market merchandise to their contacts with a discount on the merchandise itself, and (c) to bundle all the marketing sent by all users to one contact and deliver it as a single consolidated information package. Features of the recipient transactions module include the ability to (a) send one person a gift through postal mail or email, (b) send many people a gift, and (c) allow many people to purchase a single gift together.

Owner:SASH YAAKOV

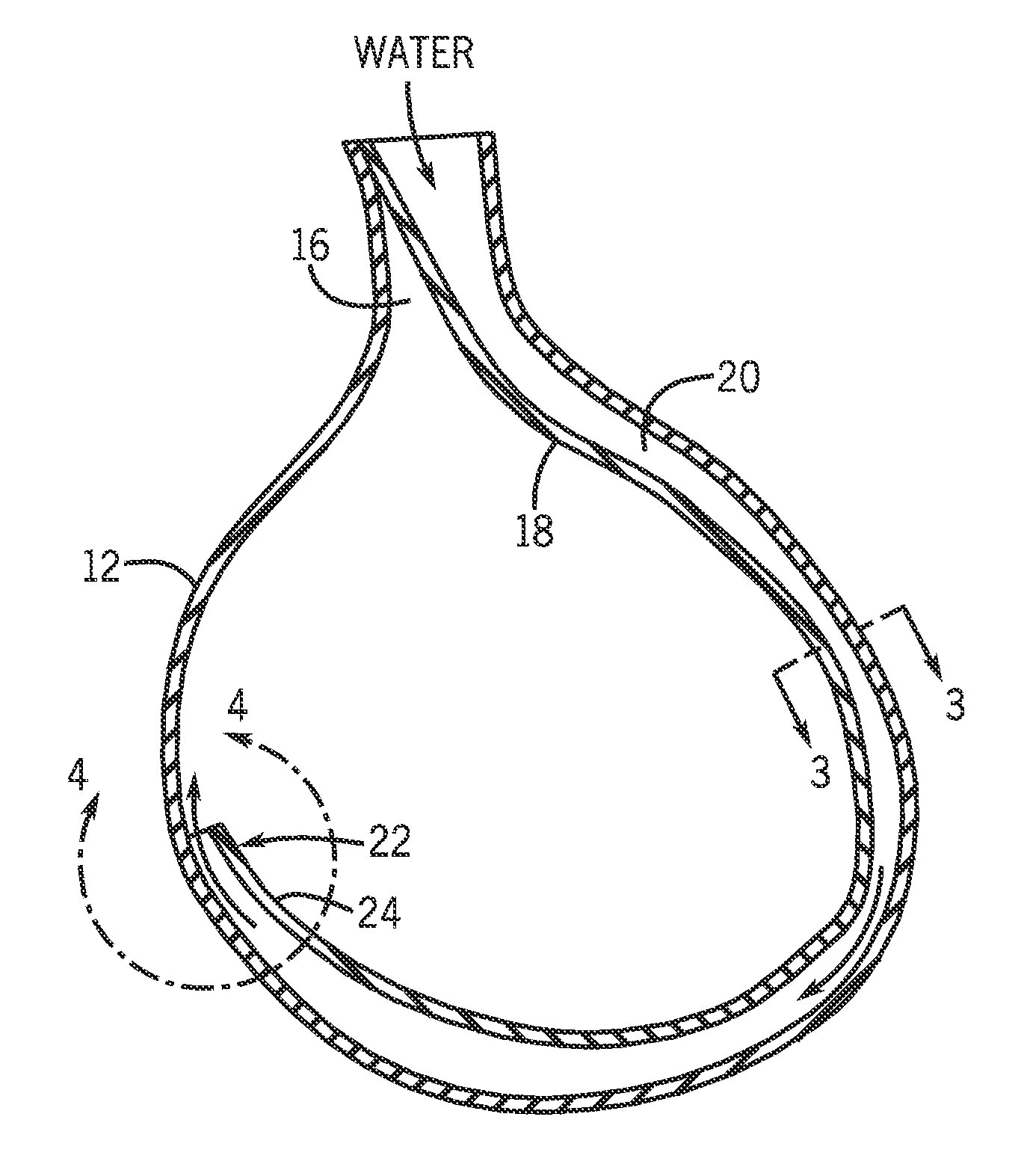

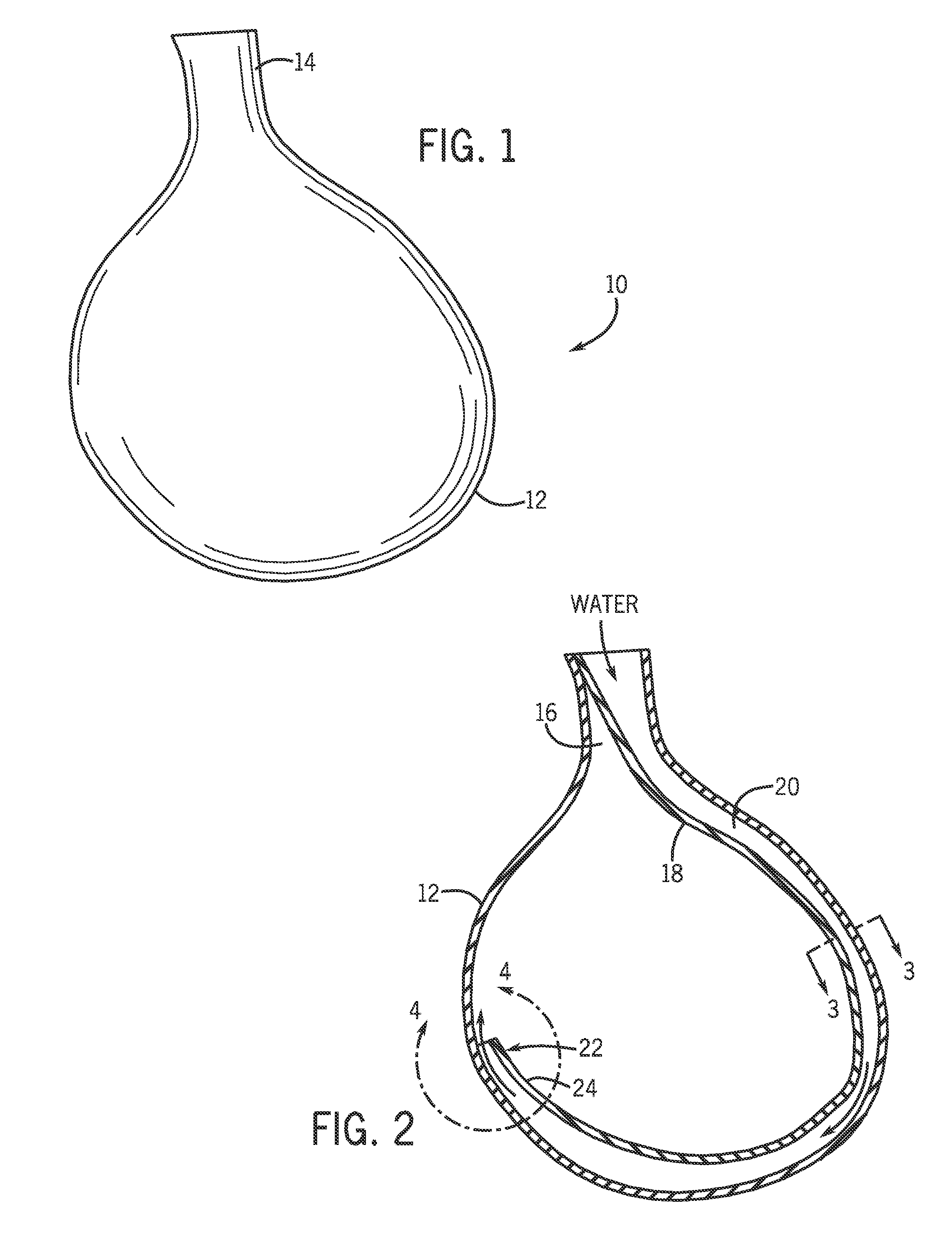

Water balloon system

A tie-less water balloon assembly includes an inner membrane for creating a one-way water flow channel. The channel includes a seal and a closure member. Water entering the balloon is directed into the flow channel and into the balloon. Once the water is inside the balloon, the water exerts pressure on the flow channel and prevents water from prematurely escaping the balloon.

Owner:SAGGIO GREG PETER

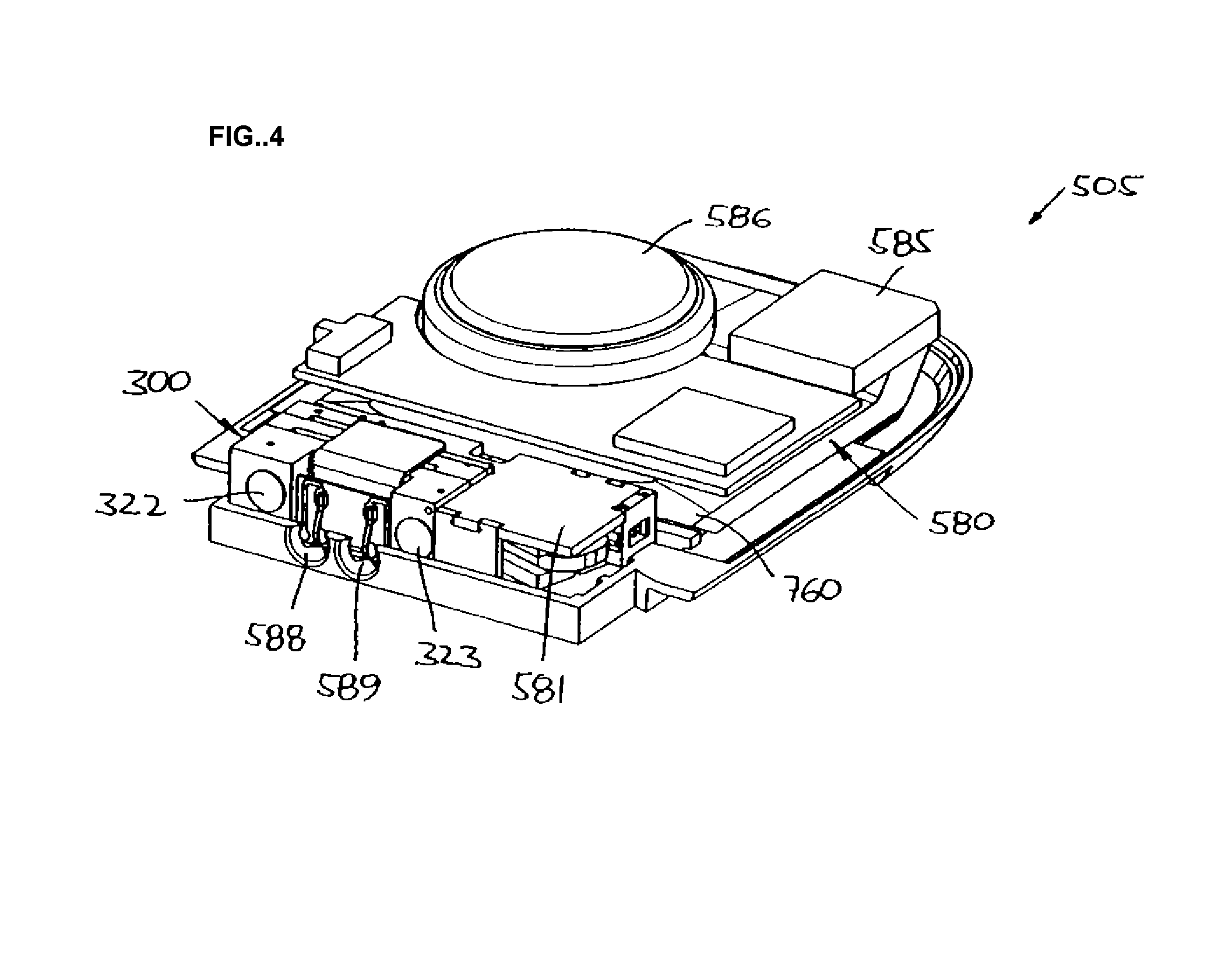

Direct write process and apparatus

ActiveUS7277770B2Fast fillSmall sizeRecording apparatusAdditive manufacturing apparatusDielectricControl signal

A direct write process and apparatus for fabricating a desired circuit component onto a substrate surface of a microelectronic device according to a computer-aided design (CAD). The process includes (a) providing a support member by which the device is supported while being fabricated; (b) providing a chamber for containing a precursor fluid material under a substantially constant pressure differential relative to the ambient pressure, with the precursor fluid material having a viscosity no less than 10 cps; (c) operating an inkjet-based dispensing head with a control valve or actuator for dispensing and depositing minute droplets of the precursor fluid material onto the substrate surface; (d) energy- or heat-treat the deposited precursor fluid material for converting it to the desired active or passive component; and (e) operating a machine controller for generating control signals in response to the CAD coordinates for controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing and depositing of the precursor material to form the desired component. The process is useful for depositing a wide range of component materials onto an electronic device, including conductor, resistor, capacitor, dielectric, inductor, antenna, solar cell electrode, battery electrode, interconnect, superconductor, sensor, and actuator element materials.

Owner:NANOTEK INSTR GRP LLC

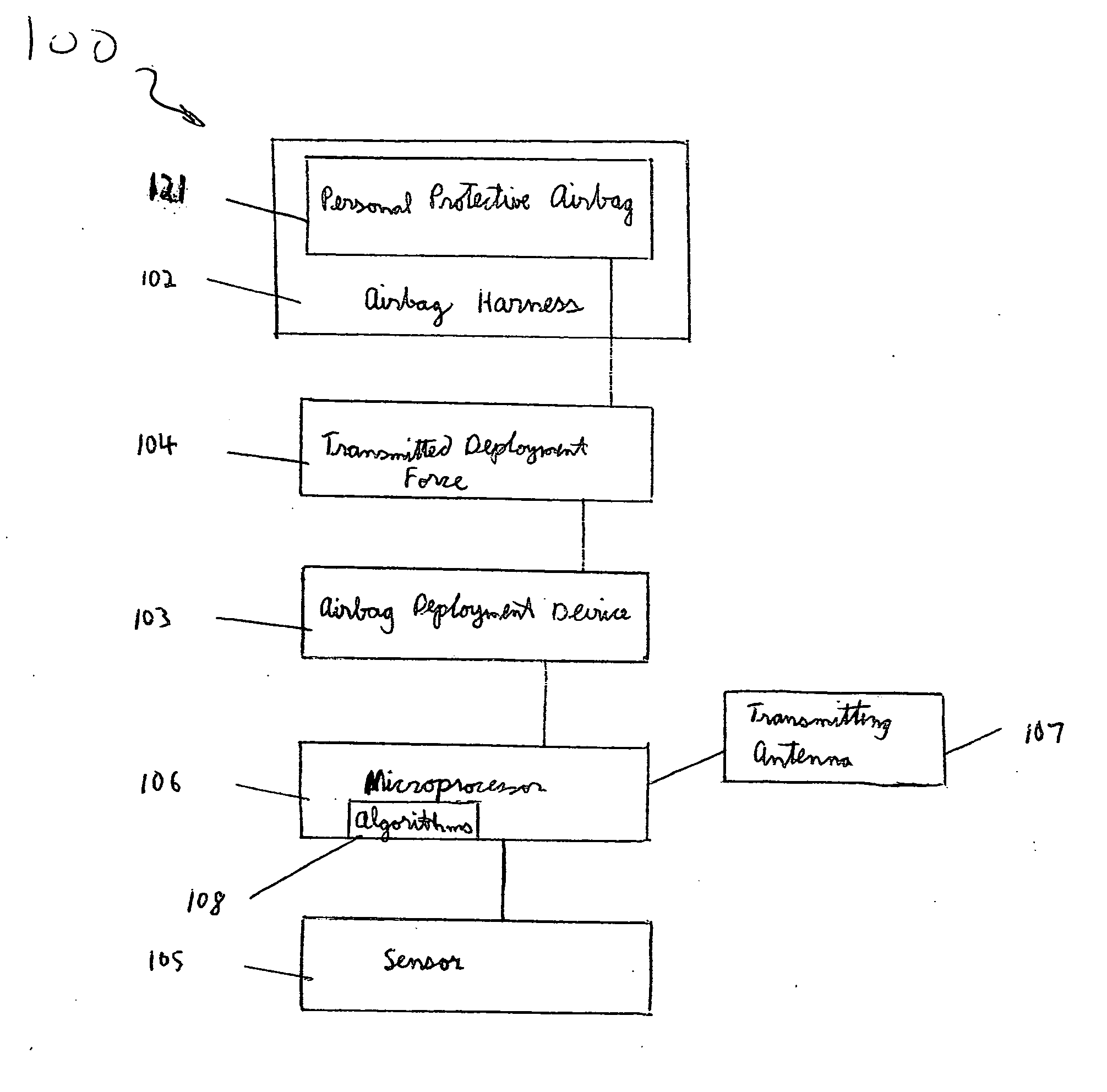

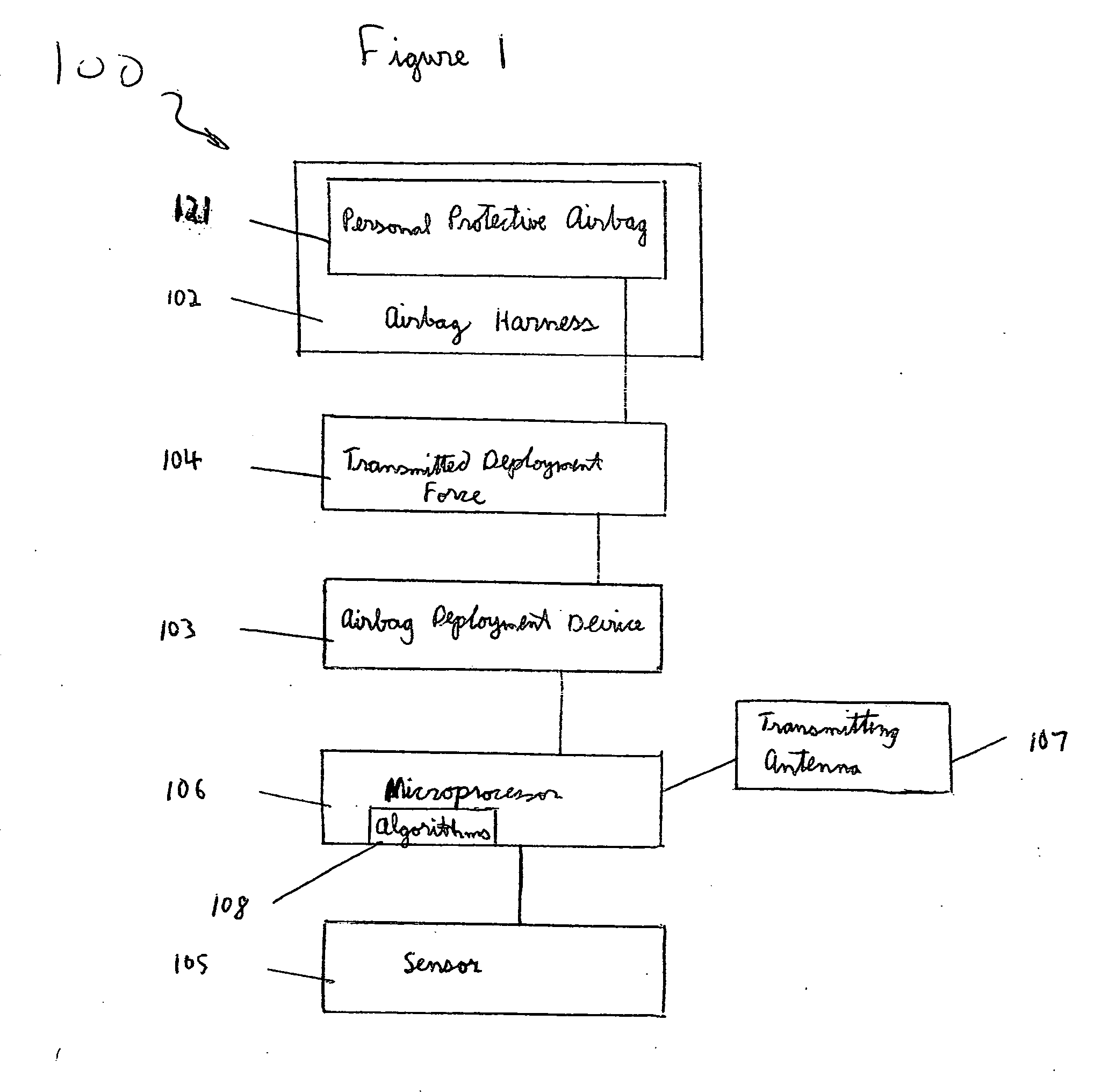

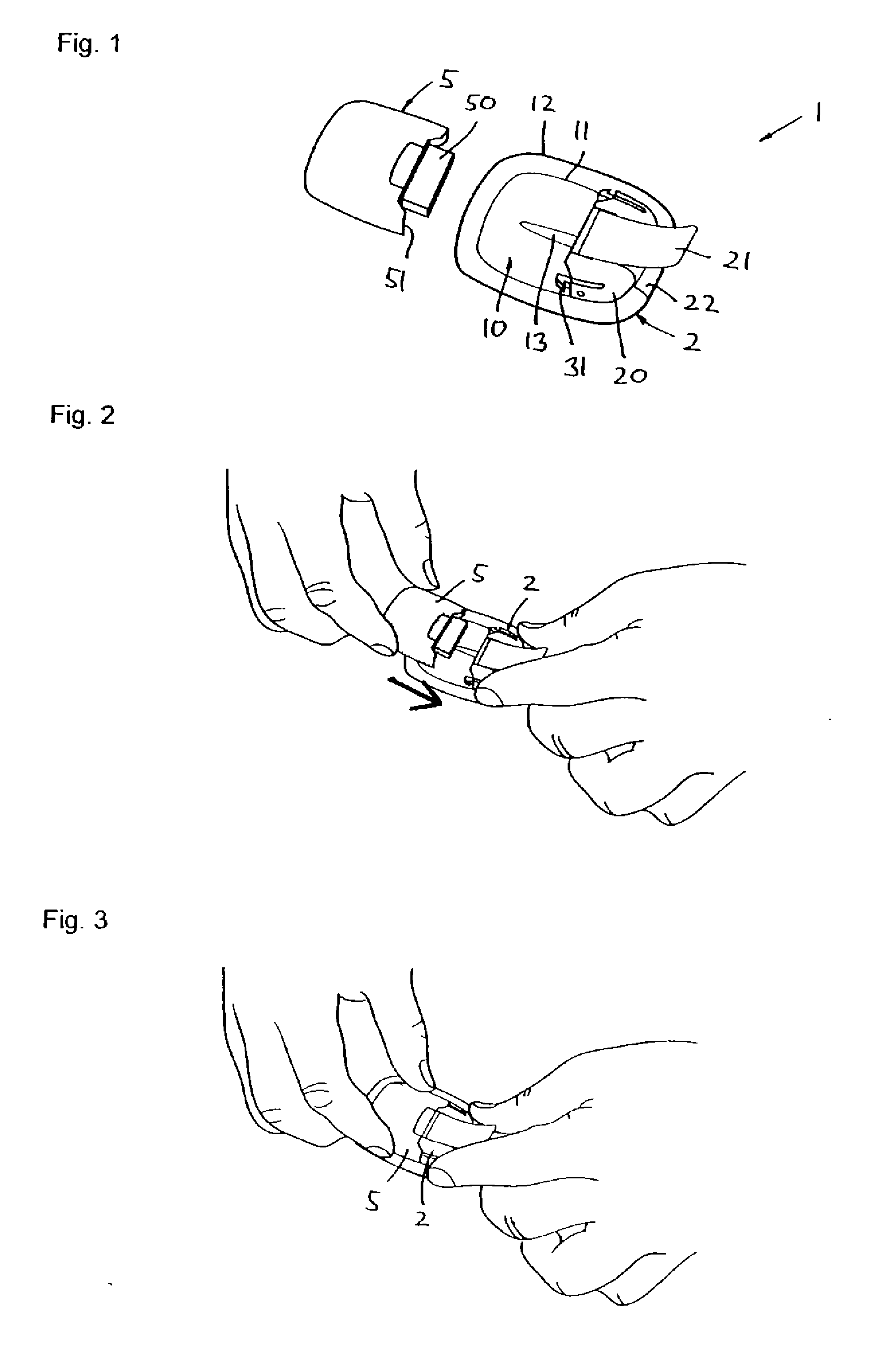

Personal protection device

A personal protection device can be used to protect individuals from falls. The device can be linked to a mechanical or electrical device, which triggers deployment of the device when the individual accelerates vertically. In this manner, a falling individual's injuries such as hip fractures, upper extremity injuries, and head injuries are minimized by the mediated gradual deceleration of the wearer of the device. The device allows mobility of the individual, because it is worn in a non-deployed compact form within a wearable article of clothing or belt. The device may also be used to protect non-ambulatory individuals who sustain falls from a bed or chair.

Owner:WARDEN MATTHEW PERRY

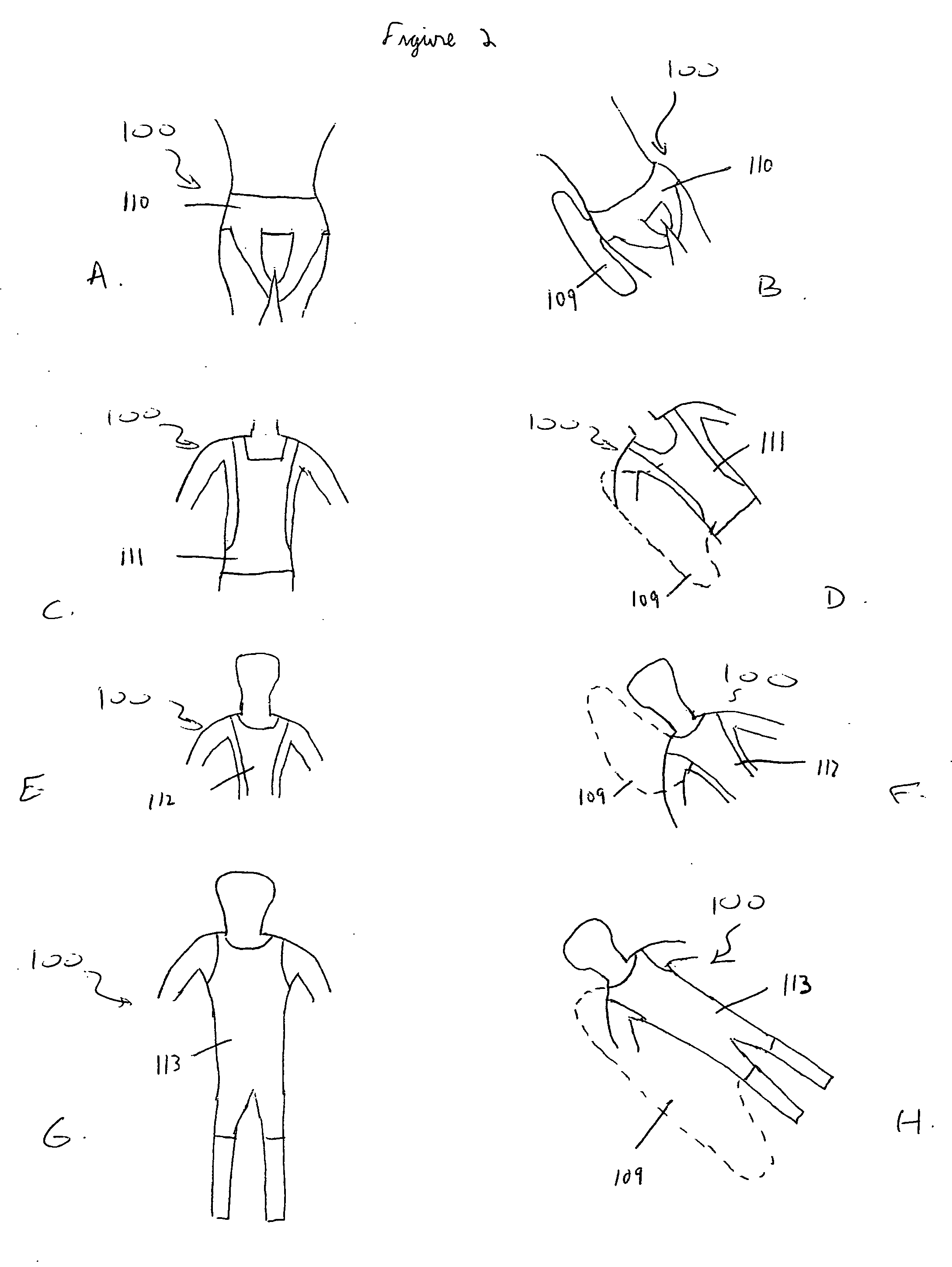

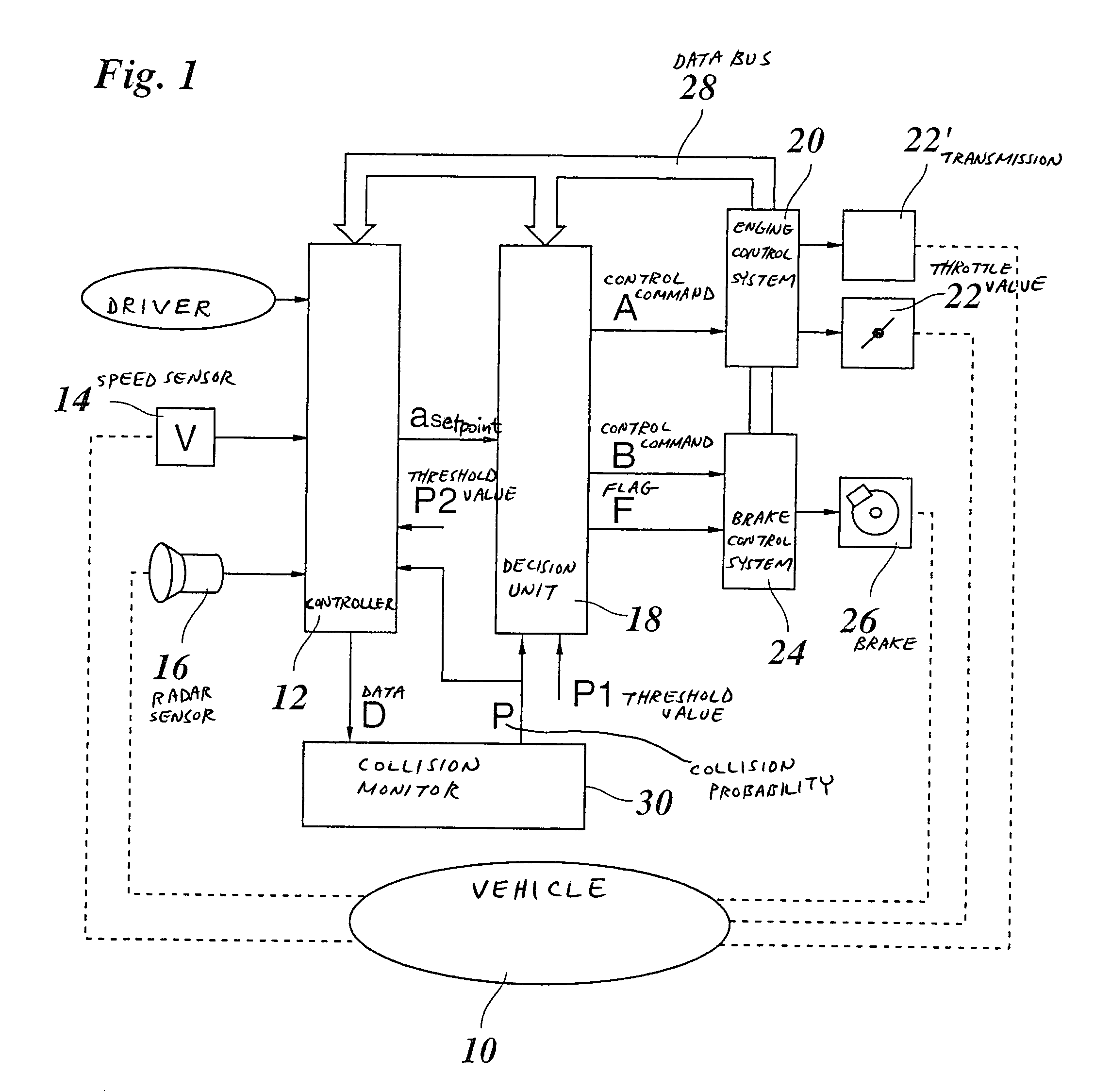

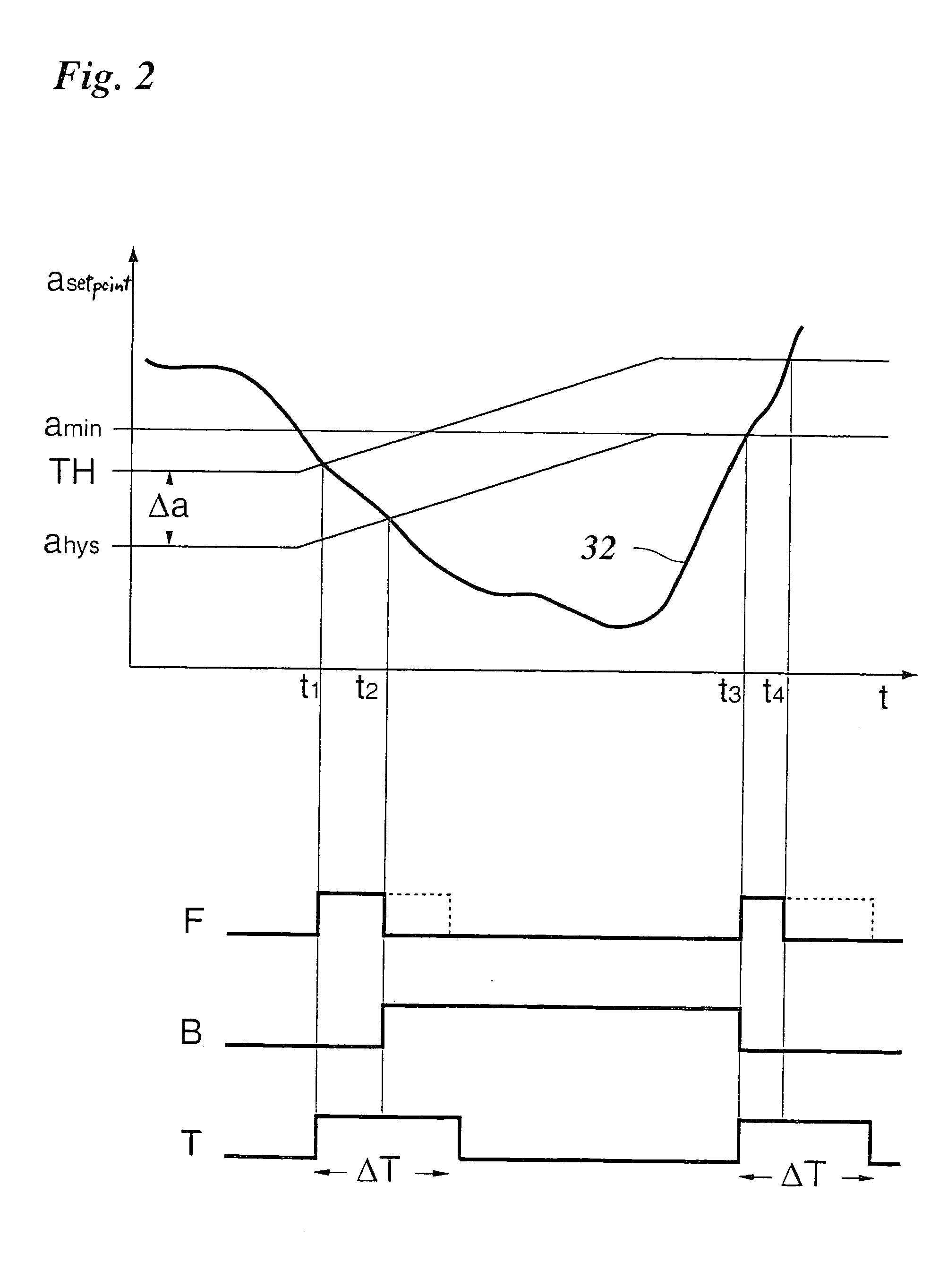

Method for preventing collisions involving motor vehicles

InactiveUS7102495B2Increase distanceIncreased braking readinessVehicle fittingsDigital data processing detailsMobile vehicleOn board

A collision prevention method for motor vehicles is provided, in which method obstacles in front of the vehicle are detected by an on-board positioning system, a collision probability is calculated from the position data, and one or more responses to prevent a collision are triggered as a function of the collision probability. At least one of the responses is a preparatory measure accelerating the implementation of a command, which may be output later, to decelerate the vehicle, without the preparatory measure itself having any significant decelerating effect on the vehicle.

Owner:ROBERT BOSCH GMBH

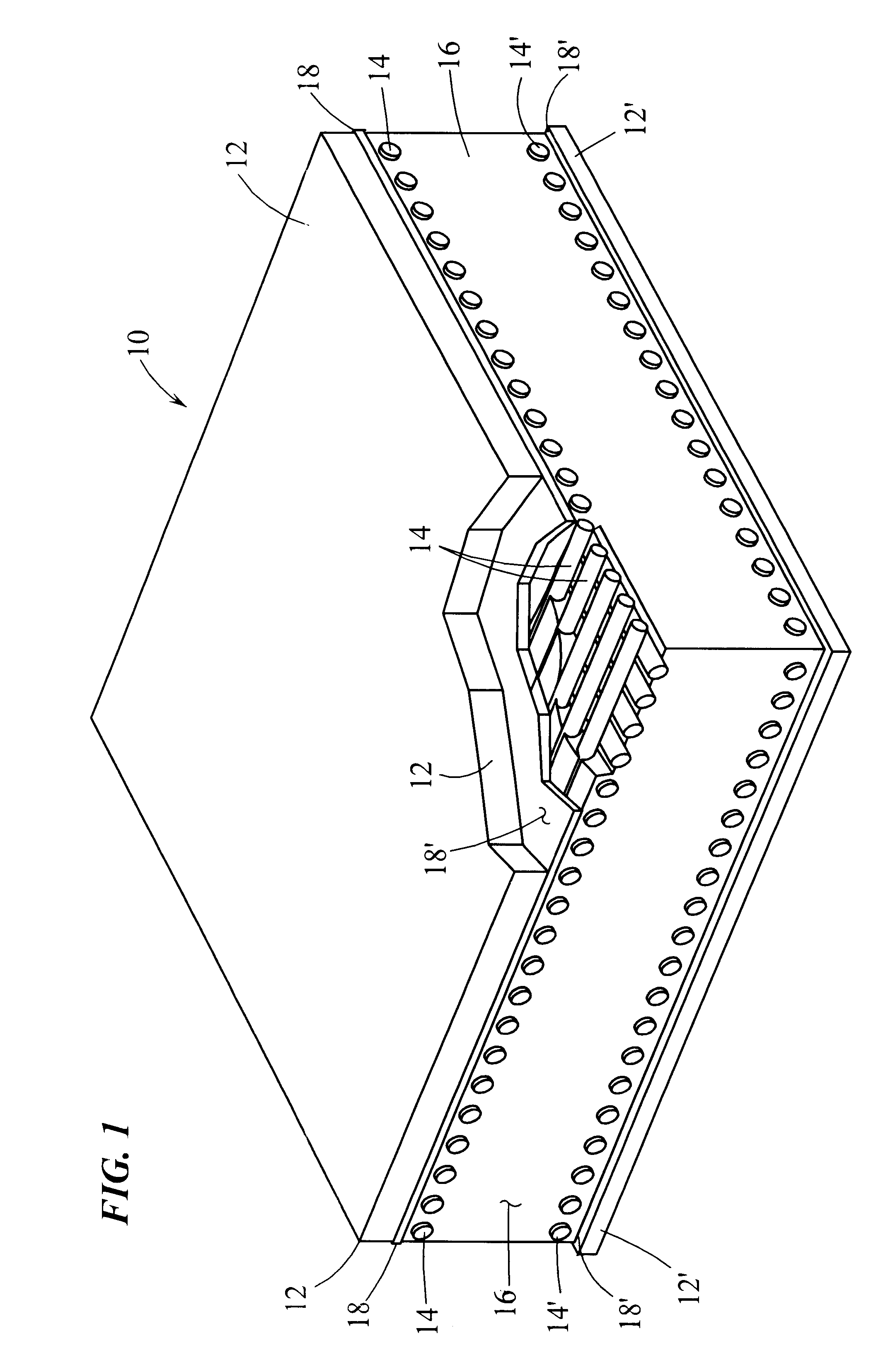

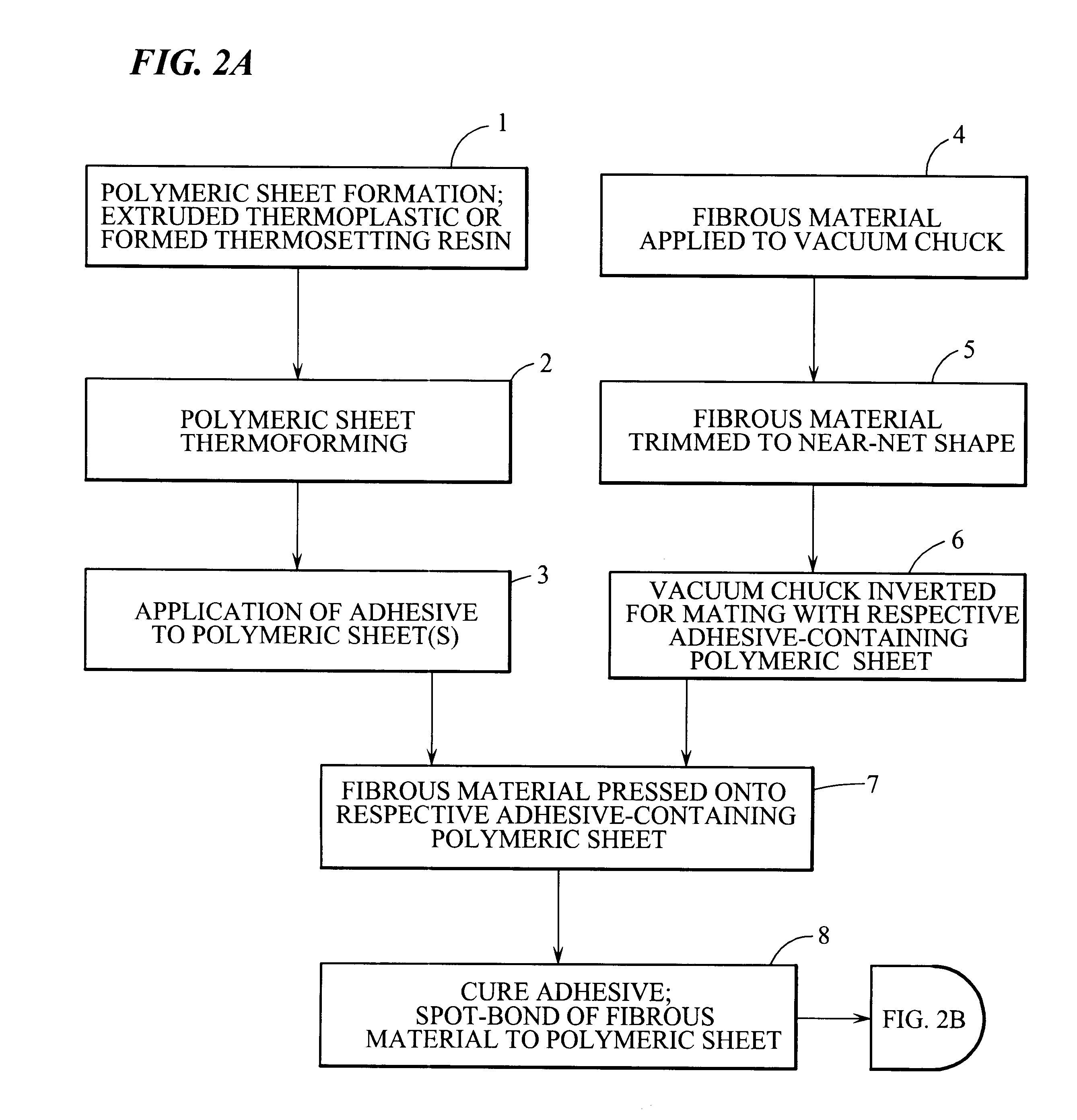

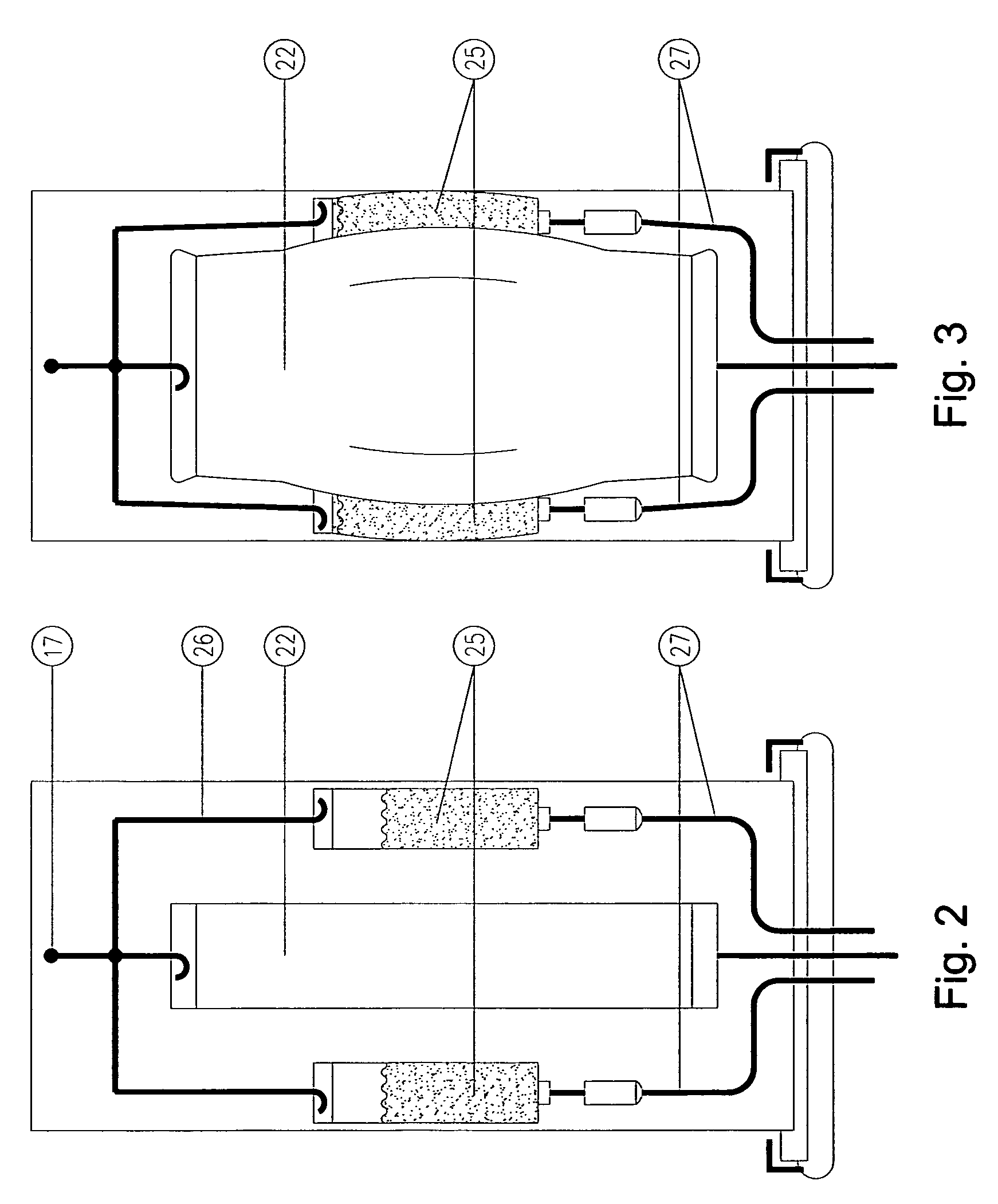

System and method of forming composite structures

InactiveUS6627018B1Large cycle timeLow viscosityLamination ancillary operationsSynthetic resin layered productsMachining processPolyresin

A system and method for forming a composite structure involves providing at least two polymeric sheets as outer layers such that a cavity is formed therebetween, adhesively bonding fibrous layers to the polymeric layers to hold the fibrous layers in place during processing, and injecting into the cavity a polymeric core material capable of exhibiting a foamed character and a resinous character. The cavity is evacuated during filling with the core material, and a blowing agent of the core material is activated upon exposure to the evacuated cavity. The core material contacting the fibrous layers is reconverted to its resinous character and forms a relative dense, resinous interface between the core and fibrous layers. Upon filling the region of the cavity between the fibrous layers, a catalytic reaction is initiated in the core. Then, each resinous interface is driven through the respective fibrous layer to impregnate the fibrous layer and form a dense, resinous layer between each fibrous layer and adjacent polymeric layer. A structural insert, such as a rigid plate adapted to receive fasteners, is embedded within the core material for attaching other devices or structures thereto.

Owner:SABIC GLOBAL TECH BV

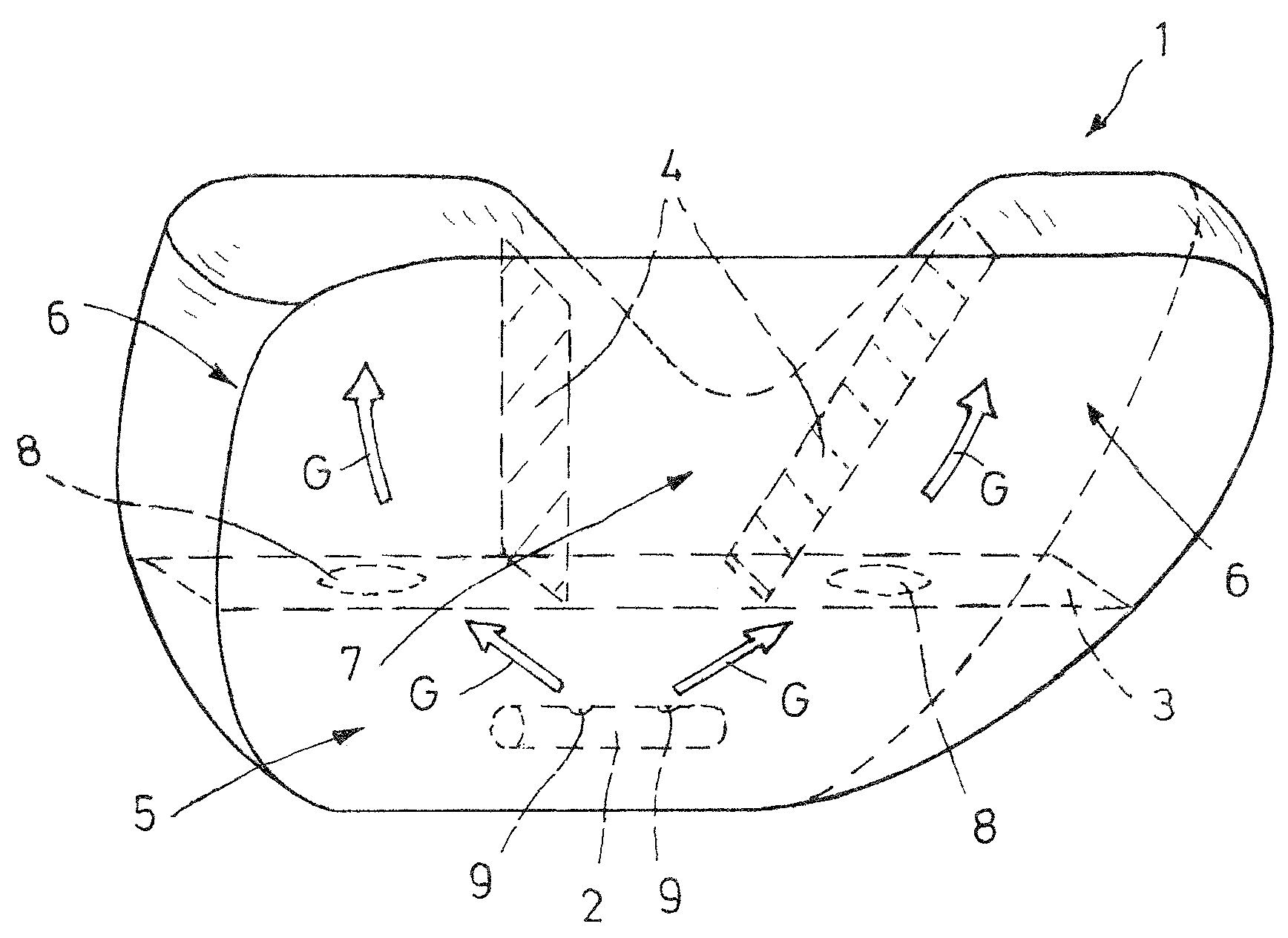

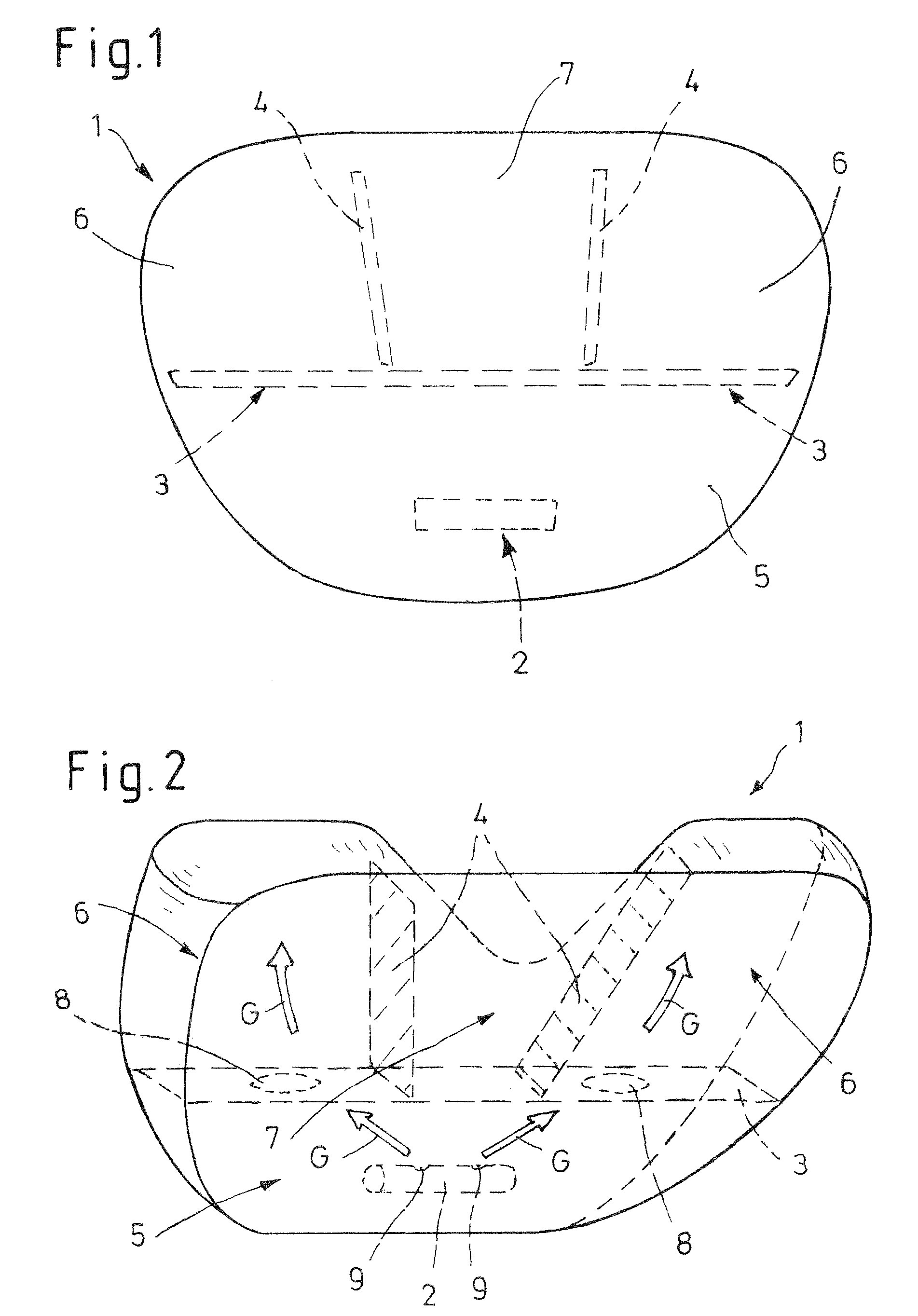

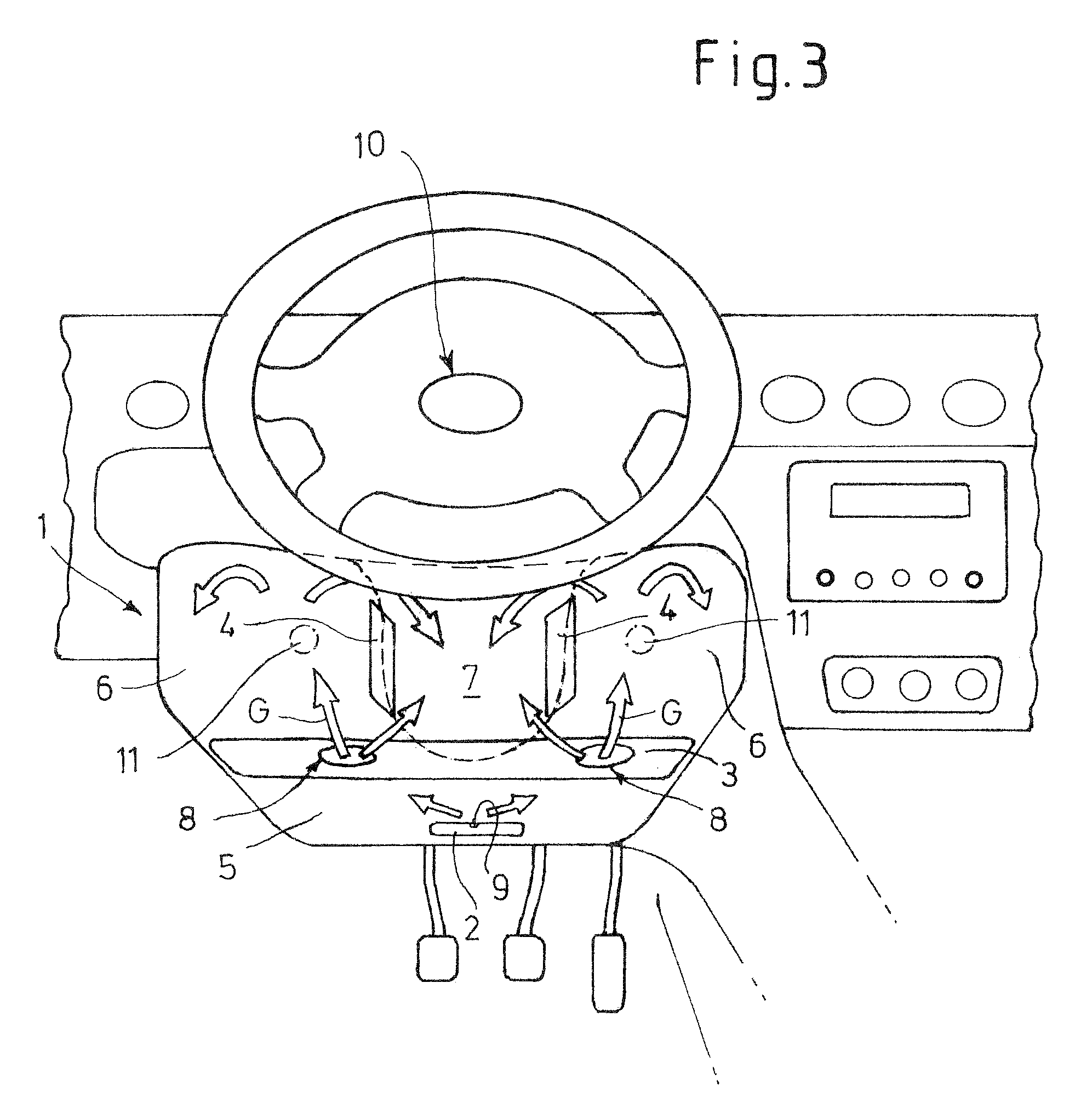

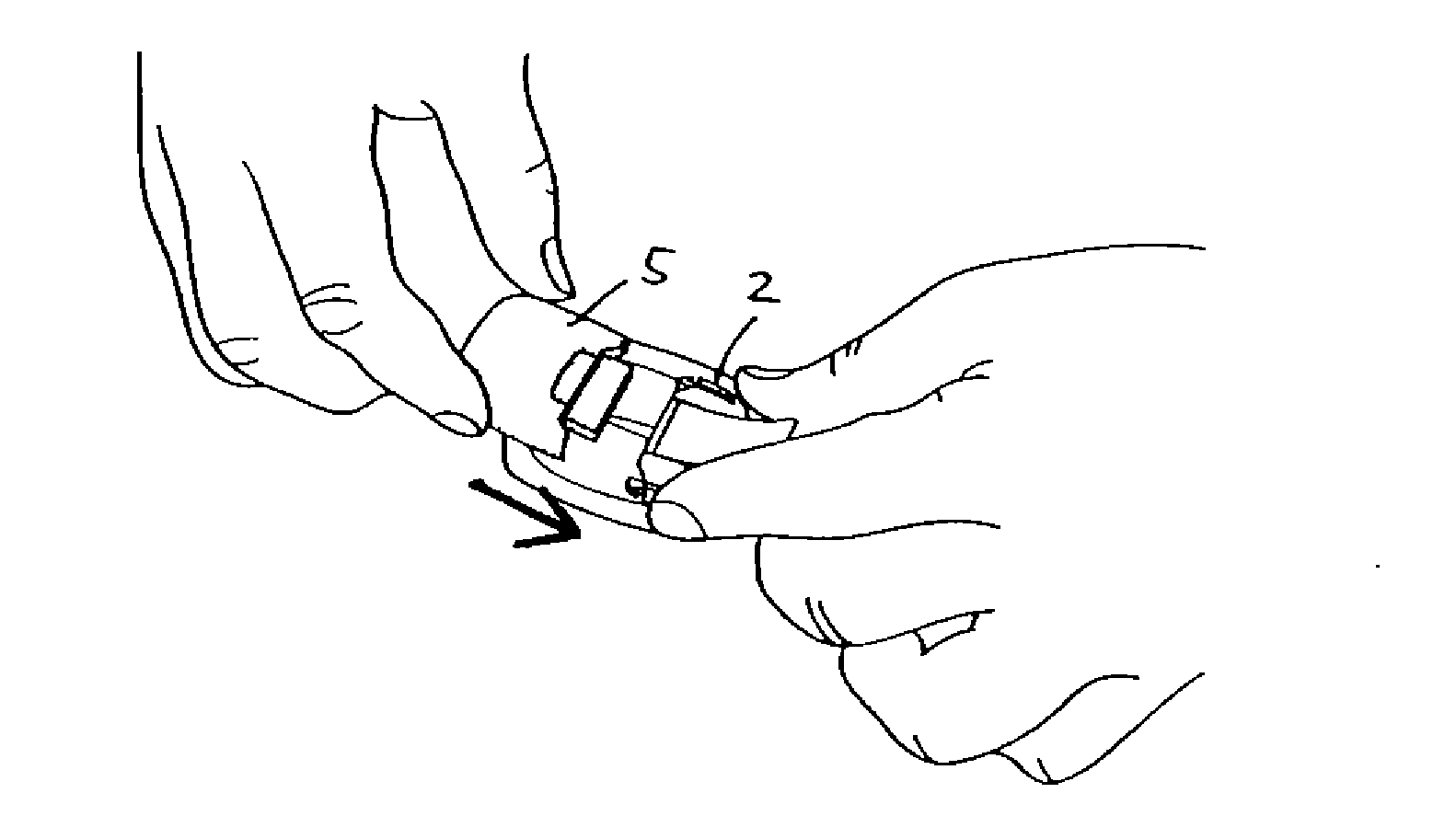

Knee airbag

InactiveUS7604252B2Improve protectionFast fillPedestrian/occupant safety arrangementMobile vehicleSteering column

The invention relates to a driver's knee airbag (1), in particular for a motor vehicle, with a gas generator (2), a plurality of chambers (5, 6, 7) and catch straps (3, 4). So that it deploys better and provides better protection for a vehicle occupant, in particular the driver, in the event of a crash, it comprises a first catch strap (3) dividing the airbag essentially horizontally, and two catch straps (4) extending essentially vertically from the first catch strap (3). The space between the steering column and the knees of the driver is therefore rapidly filled by the airbag in the event of a crash.

Owner:FORD GLOBAL TECH LLC

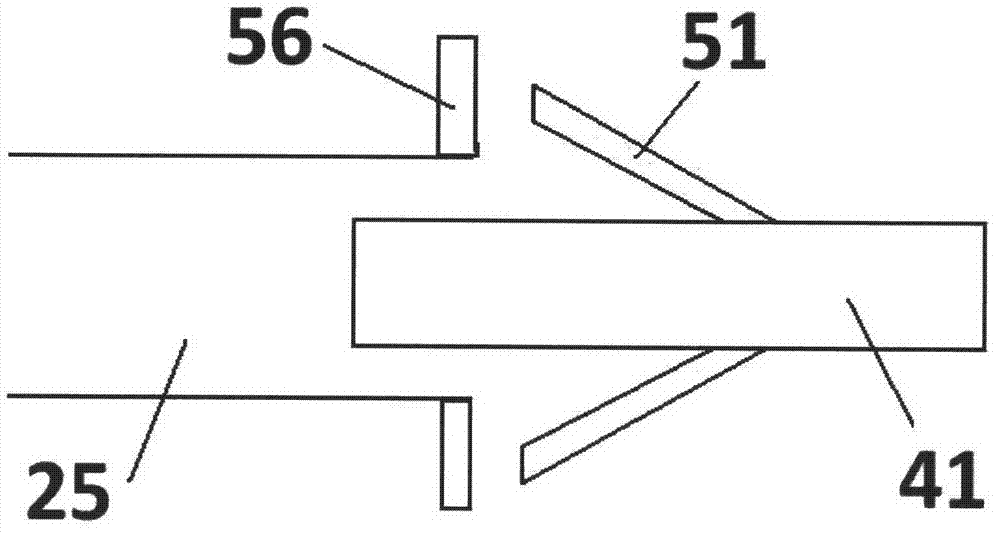

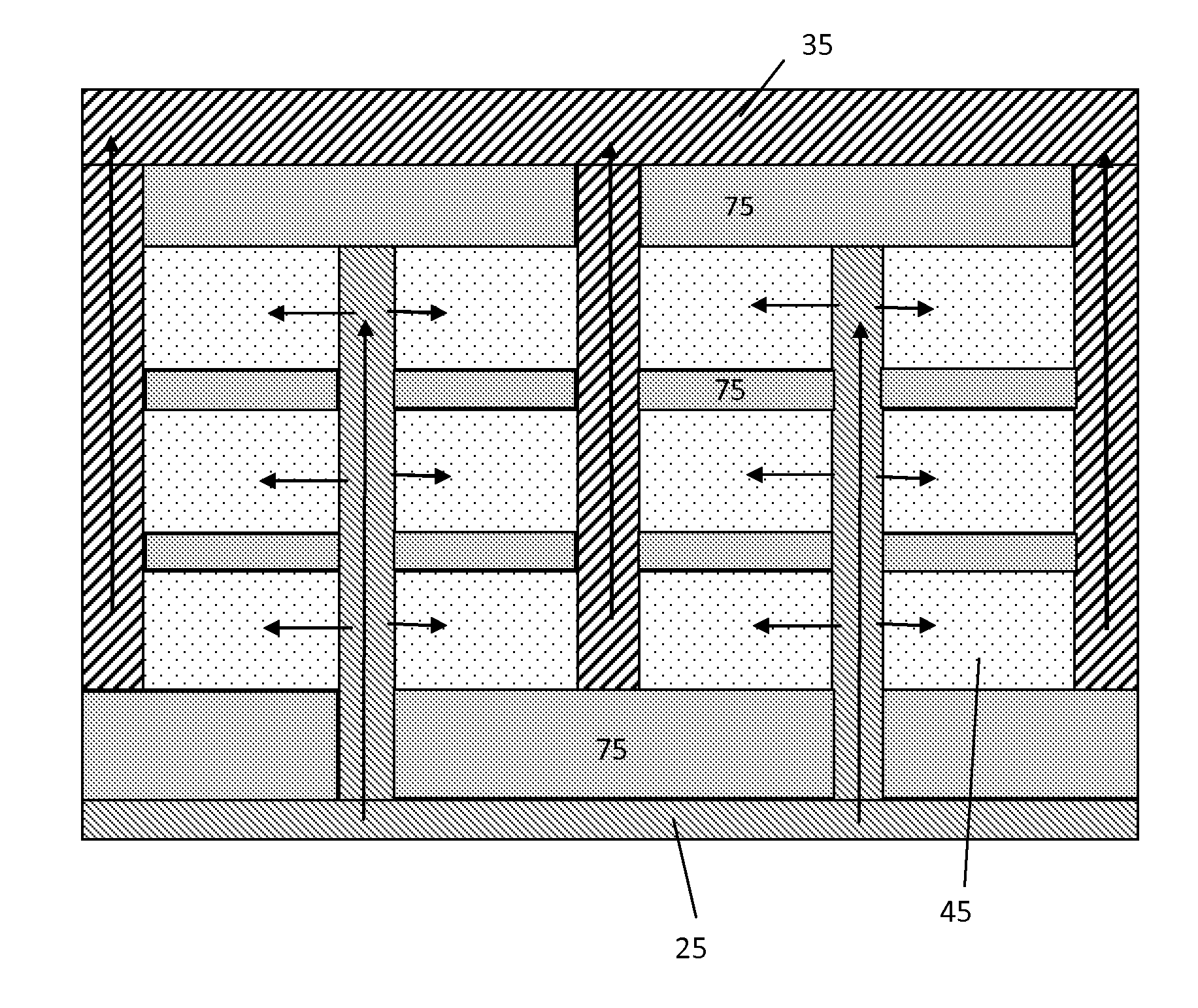

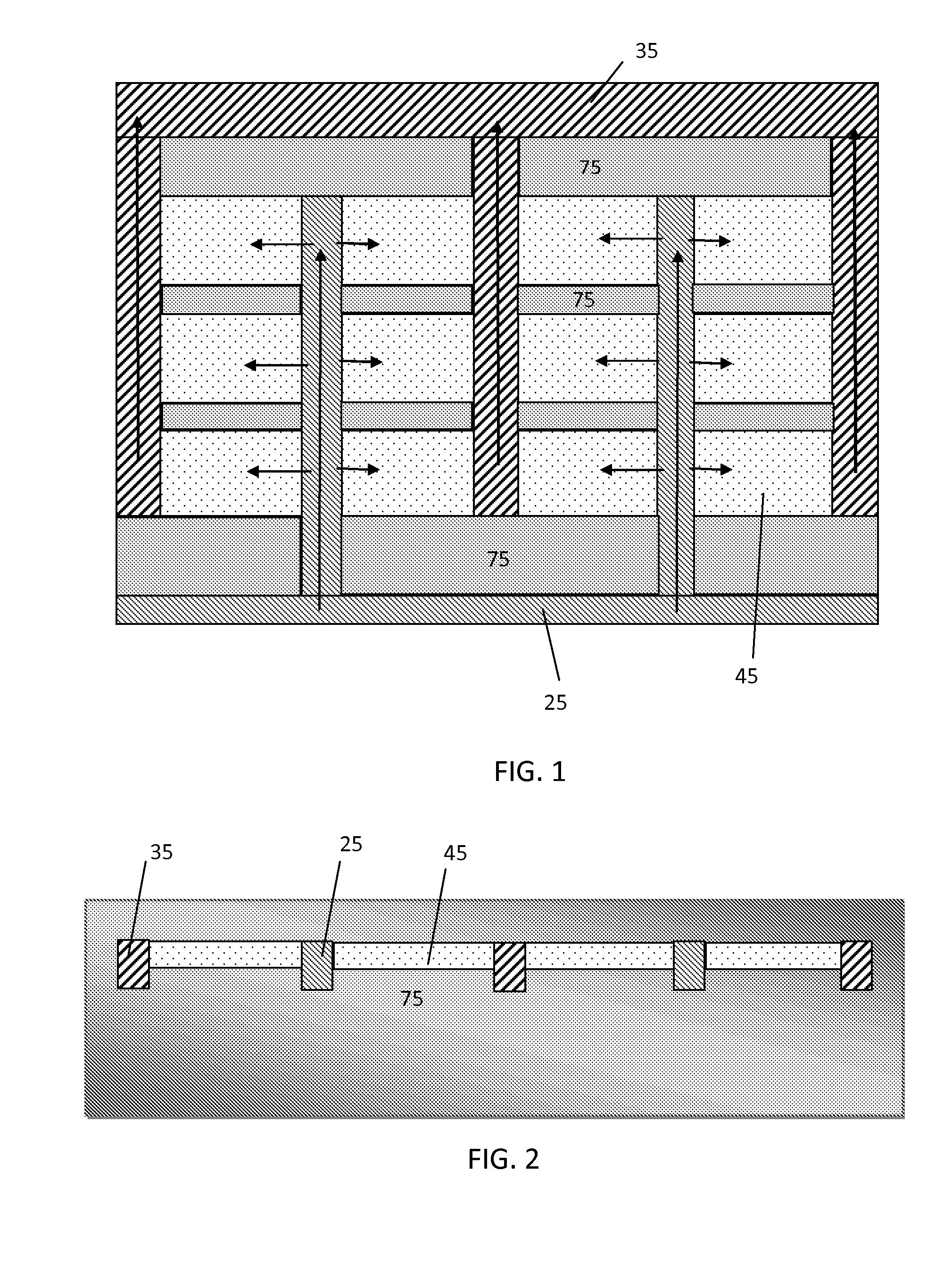

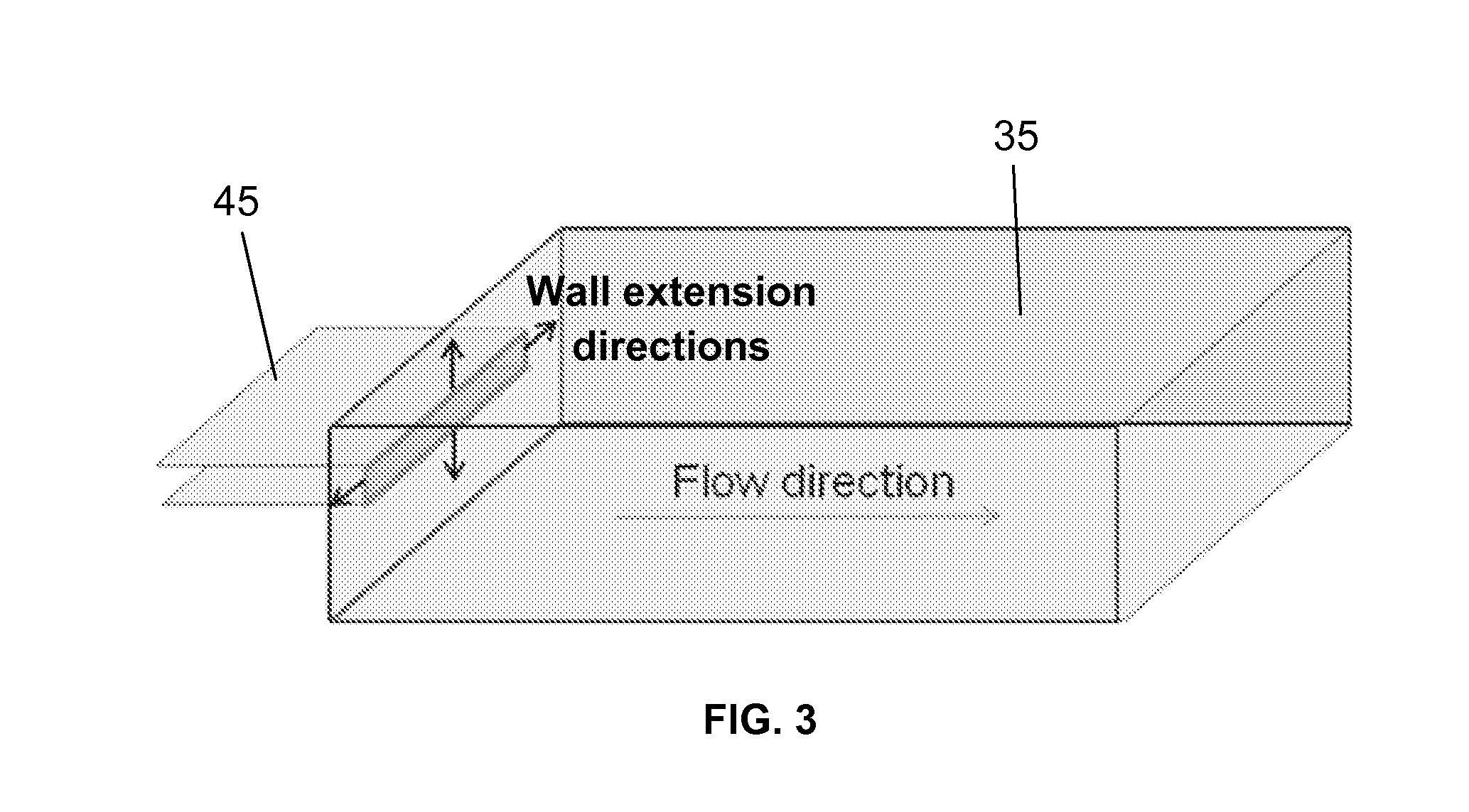

Preparation of thin layers of a fluid containing cells for analysis

ActiveUS20120225446A1Stably pinIncrease overall countBioreactor/fermenter combinationsBiological substance pretreatmentsPhysicsFluid specimen

Apparatus for producing thin layers of a fluid sample for analysis, has a two dimensional array of analysis chambers (45), and a branching pattern of entry channels (25) coupled to the array to enable the analysis chambers to be filled in parallel. The analysis chambers are planar with a height less than that of the entry channels so as to produce the thin layers when filled with the fluid sample. The array enables more spacers between chambers in a given area, so that variations in height of the chambers can be reduced, while still enabling fast filling of the chambers. The analysis chambers can be suitable for capillary filling by a specified fluid sample such as blood. A pattern of exit channels (35) can be coupled to the array. The entry and exit channels can form comb patterns, fingers of the comb patterns being interdigitated, and the analysis chambers being arranged between the interdigitated fingers of the comb patterns.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Device for Providing a Change in a Drug Delivery Rate

InactiveUS20080147041A1Adapt quicklyLow plasma drug levelMedical devicesPressure infusionDrug deliveryDrug

The present invention relates to devices for providing an effective change in a drug delivery rate. In an exemplary embodiment the invention provides a drug delivery device using a method for changing a delivery rate for a drug from a first delivery rate to a second higher delivery rate, comprising the steps of: (a) Deliver the drug at the first delivery rate, (b) deliver the drug at a third delivery rate for a first period of time, the third delivery rate being higher than the second delivery rate, and (c) after the first period of time deliver the drug at the second delivery rate. By using a higher “bolus-like” third delivery rate for a first period of time it is possible relatively fast to fill up a depot corresponding to the new second delivery rate.

Owner:NOVO NORDISK AS

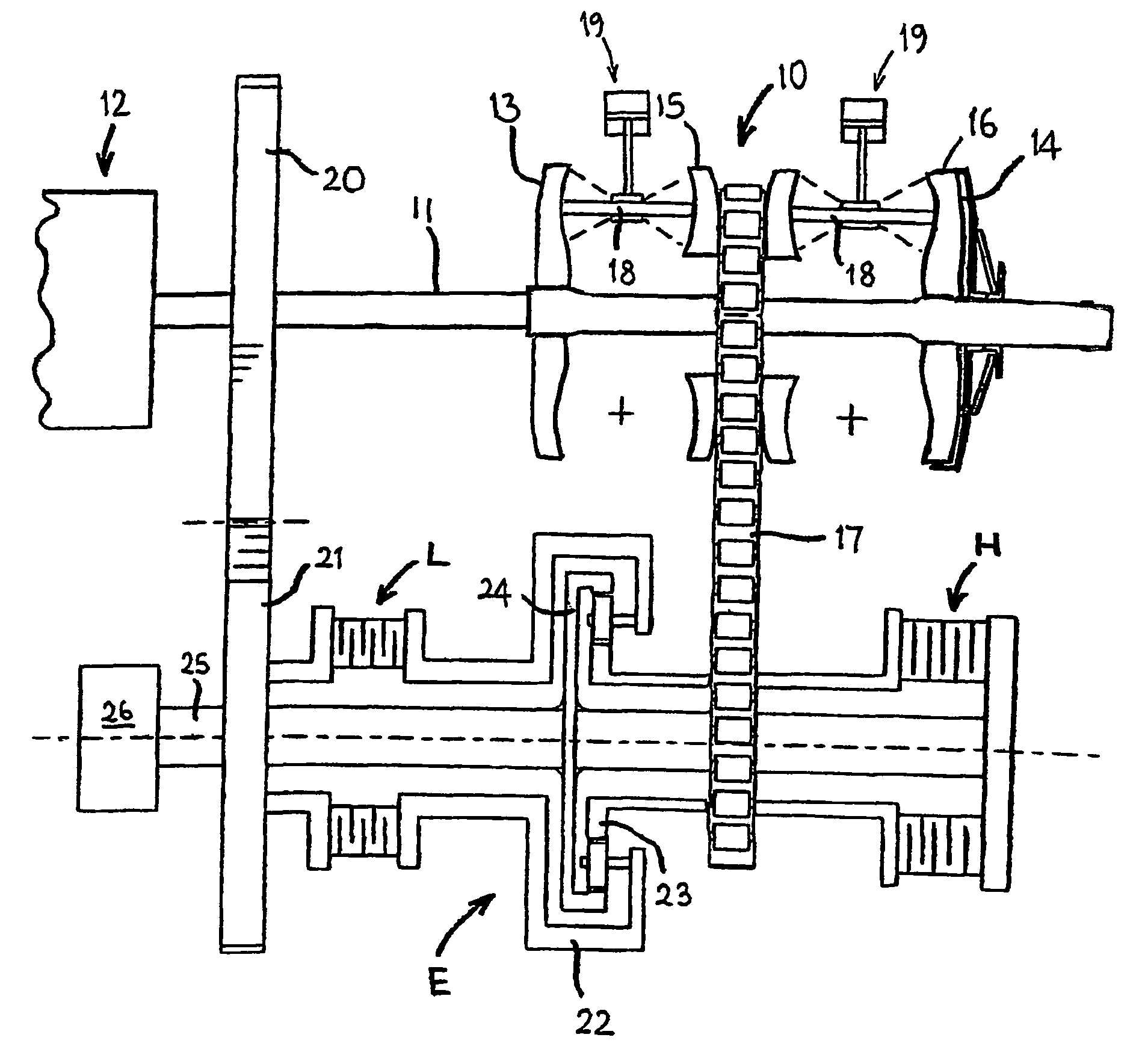

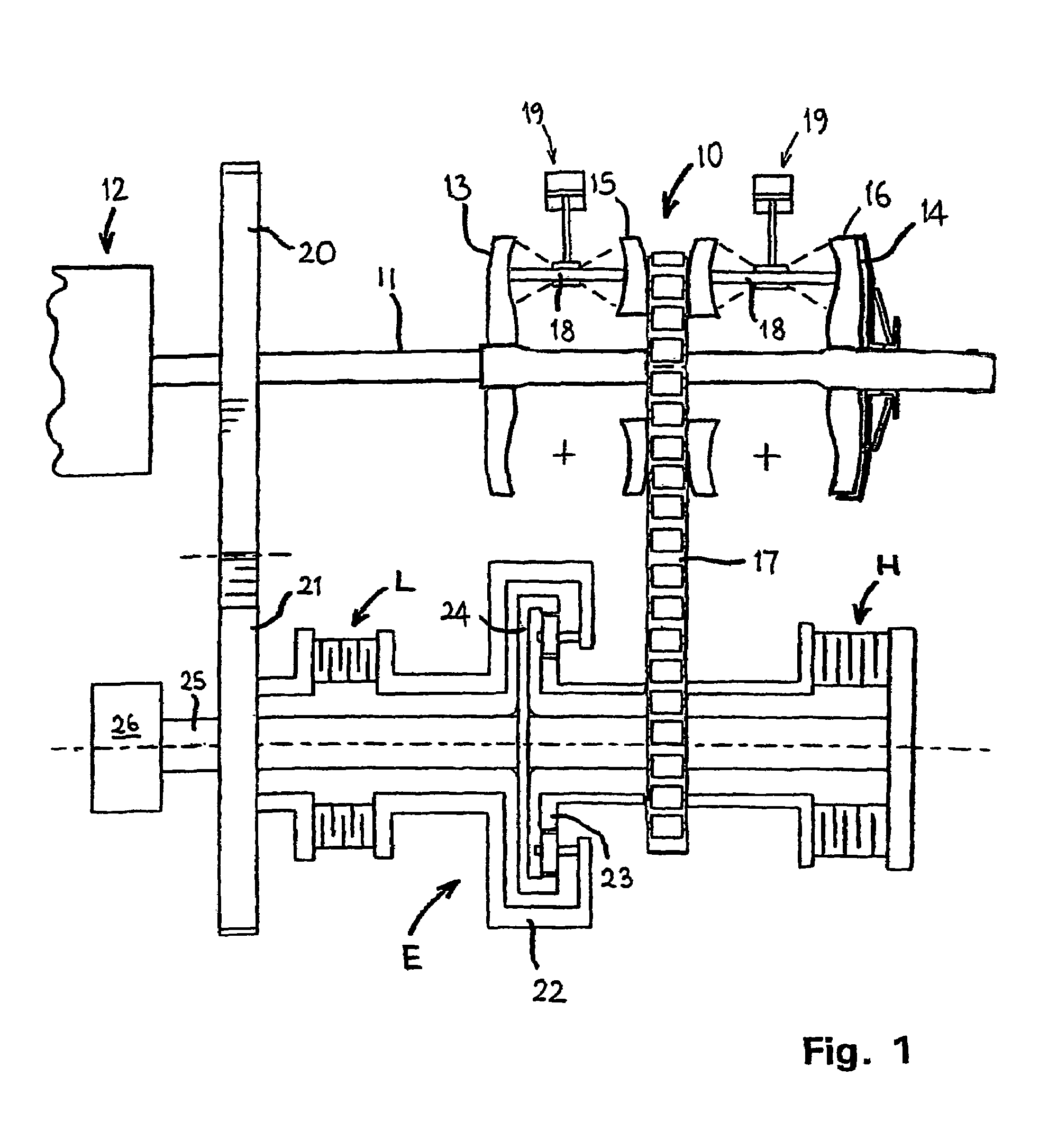

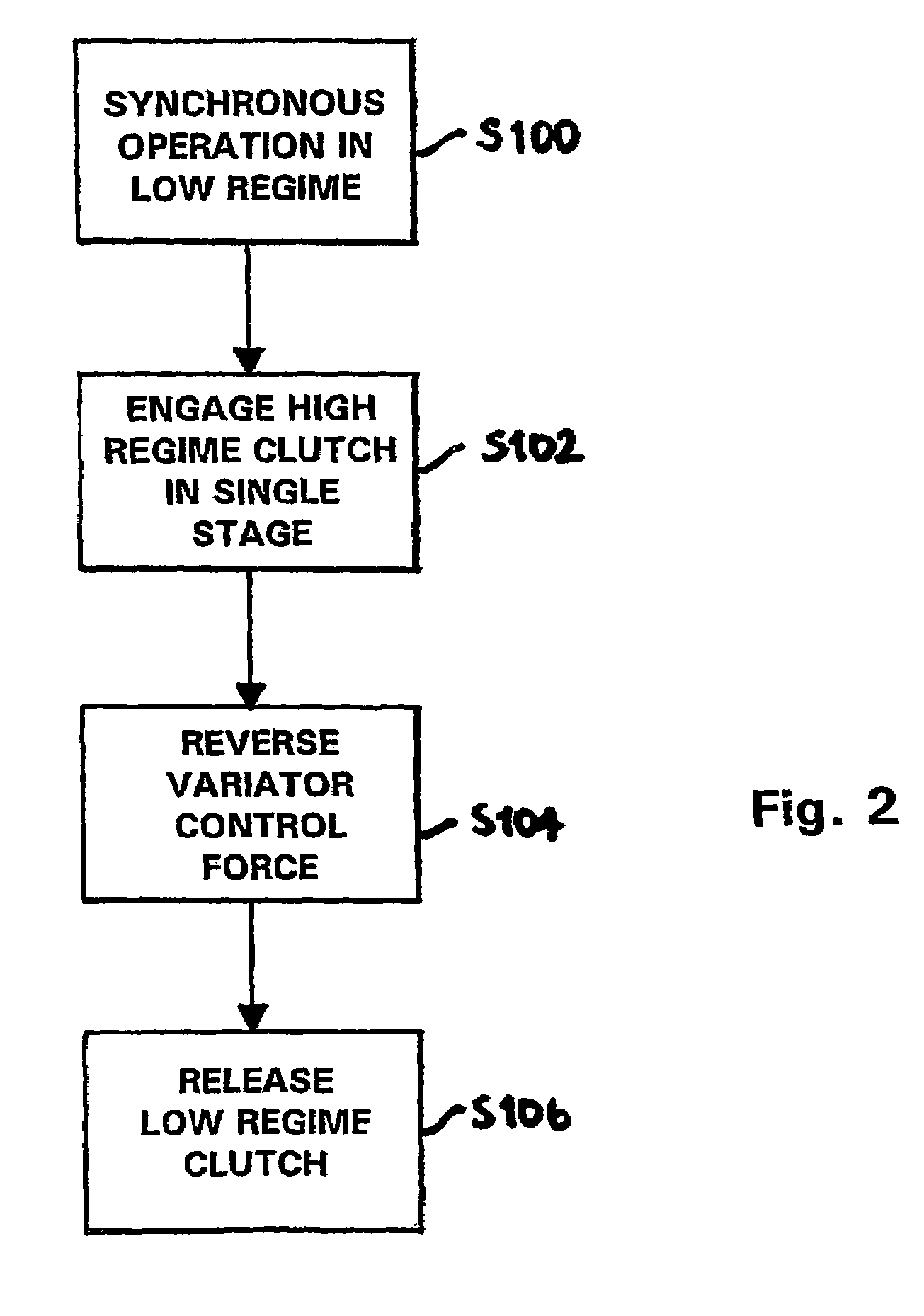

Control system and method for a continuously variable transmission

InactiveUS6979276B2Shorten the timeSacrificing control robustnessMechanical actuated clutchesGearingGear driveSingle stage

A control system for a multi-regime continuously variable ratio transmission system. The system has input and output shafts and a continuously variable ratio transmission unit (“variator”) connected to the input shaft. Also included is a mixing epicyclic gear train with a first input gear coupled to the input shaft, a second input gear connected to the variator output and an output gear driving an output shaft. Fluid-pressure actuated clutches engage the outputs and ratio combinations to operate the CVT in a number of regimes. The control system includes means for engaging the clutch of a new regime, retaining both clutches engaged in a synchronous mode and disengaging the clutch of the old regime. The control system also has means for applying fluid pressure to engage the new regime clutch in a single stage at the maximum available clutch engaging fluid pressure.

Owner:ALLISON TRANSMISSION INC

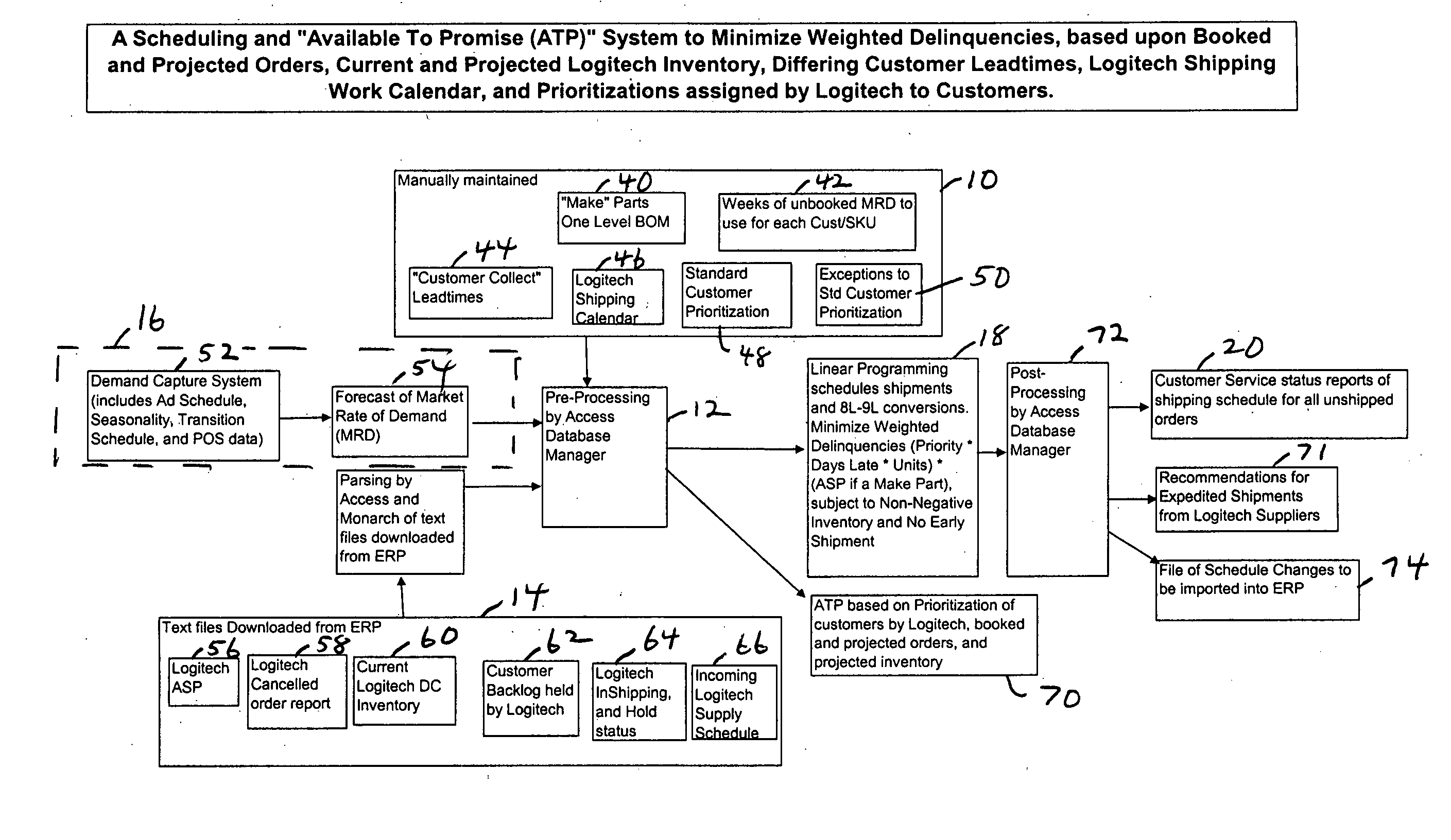

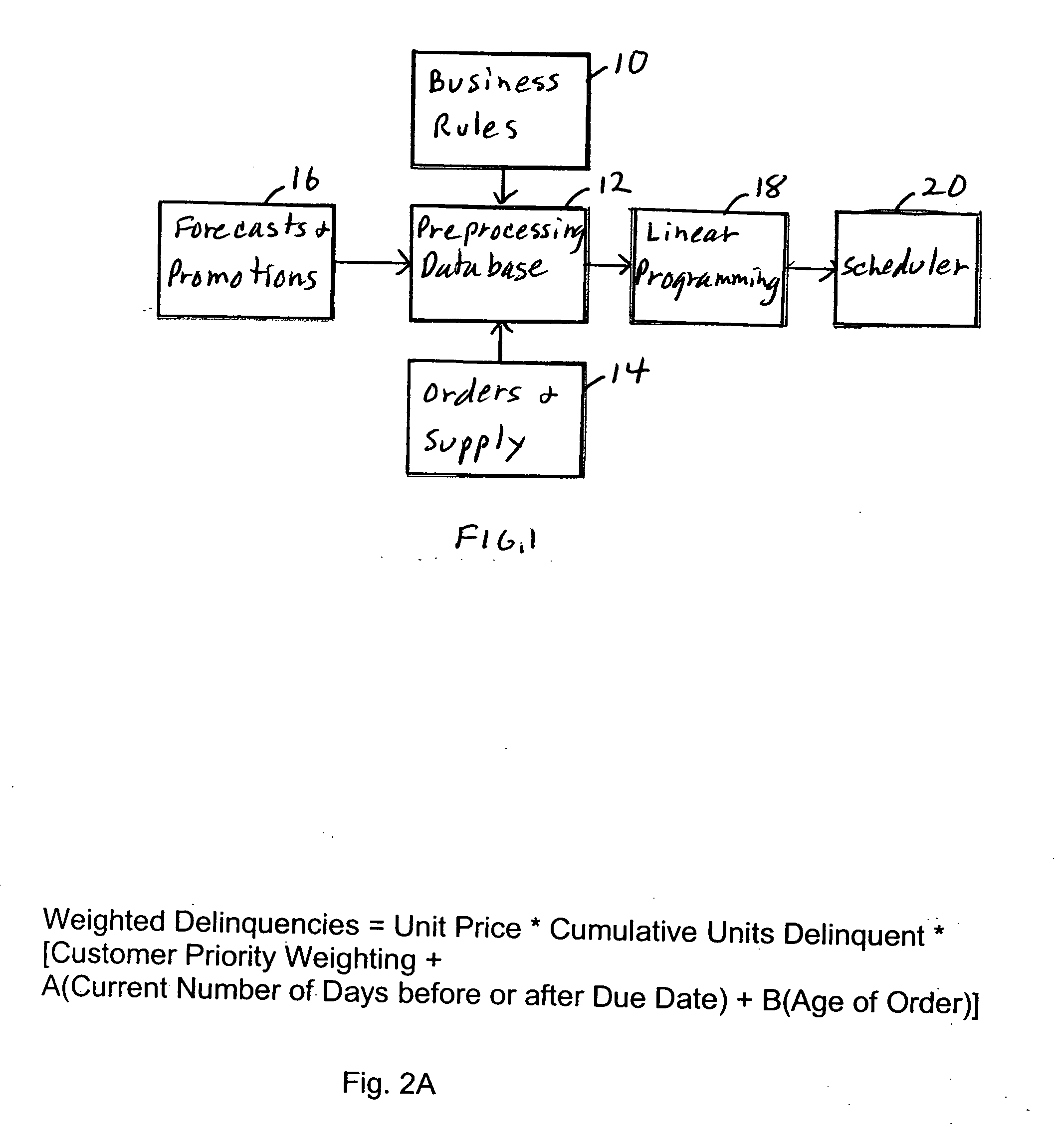

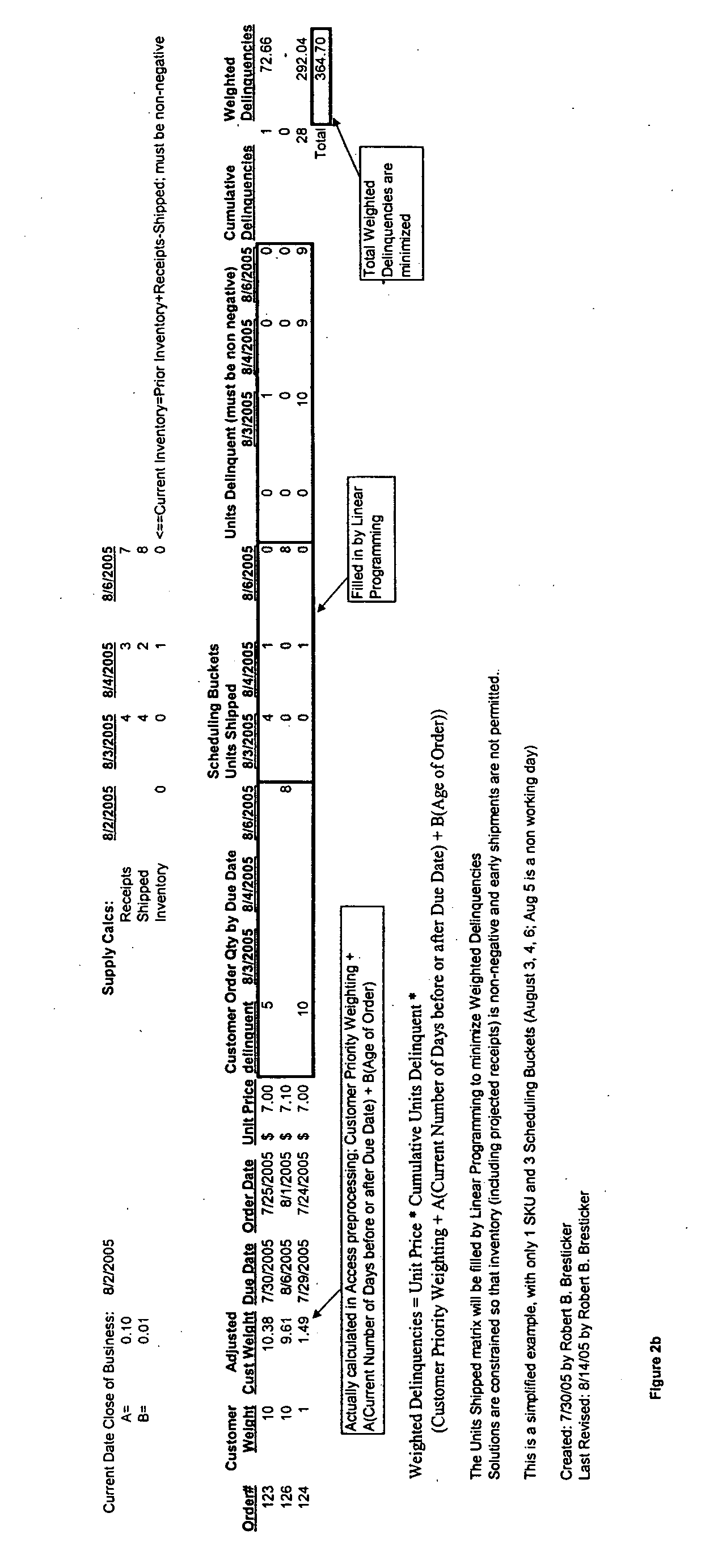

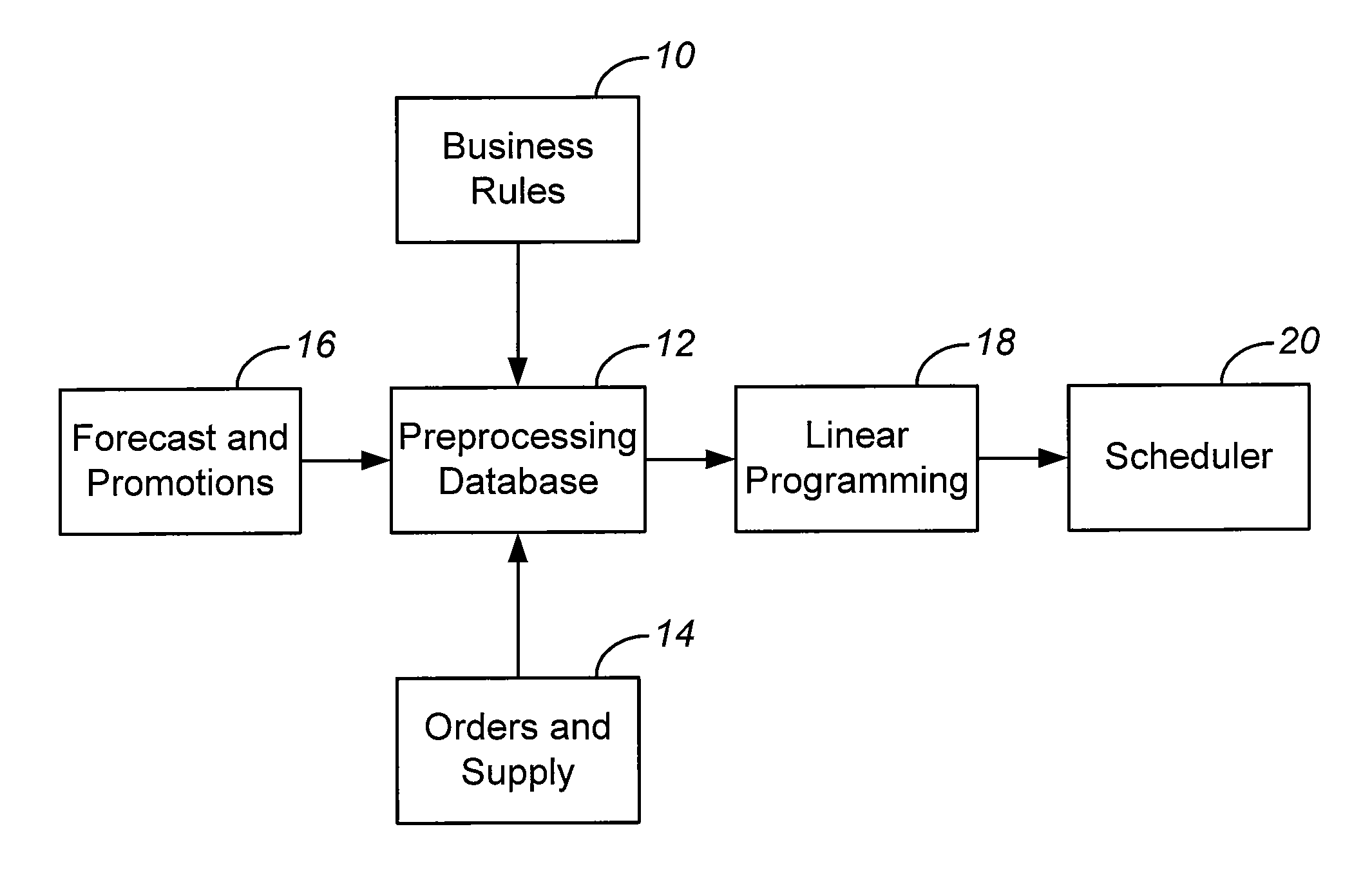

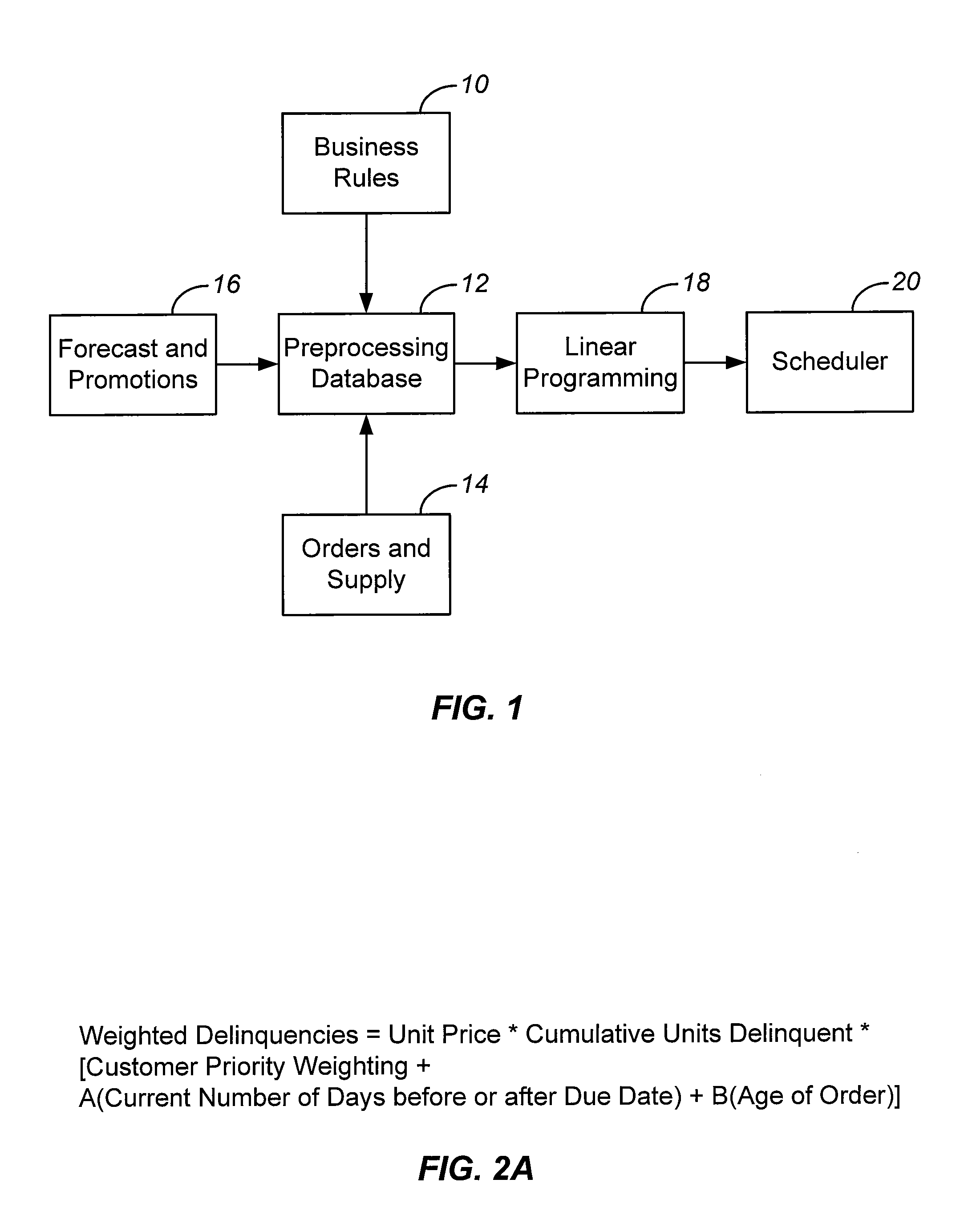

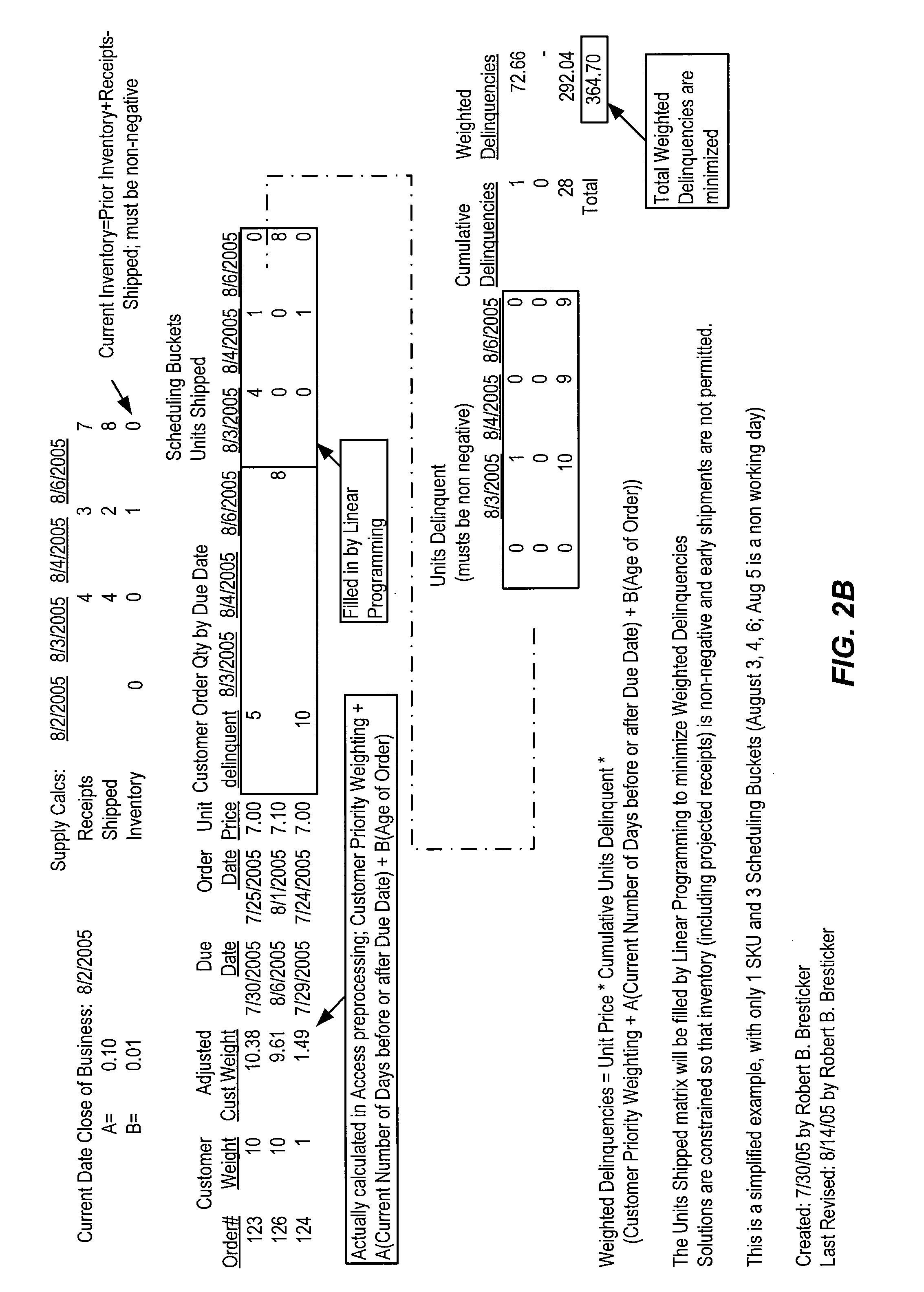

Constraint based order optimization system and available to promise system

A computer system which uses customer-based business rules that are customized for each customer. These business rules, along with order information, are provided to a linear programming engine. The linear programming engine determines the priority of customer orders based on the business rules and allocates scarce inventory accordingly. In one embodiment, linear programming assigns weights to different factors. Examples of such factors are (1) a promotion activity, (2) a customer priority, (3) the age and delinquency of an order or line item, and (4) the price of the product.

Owner:LOGITECH EURO SA

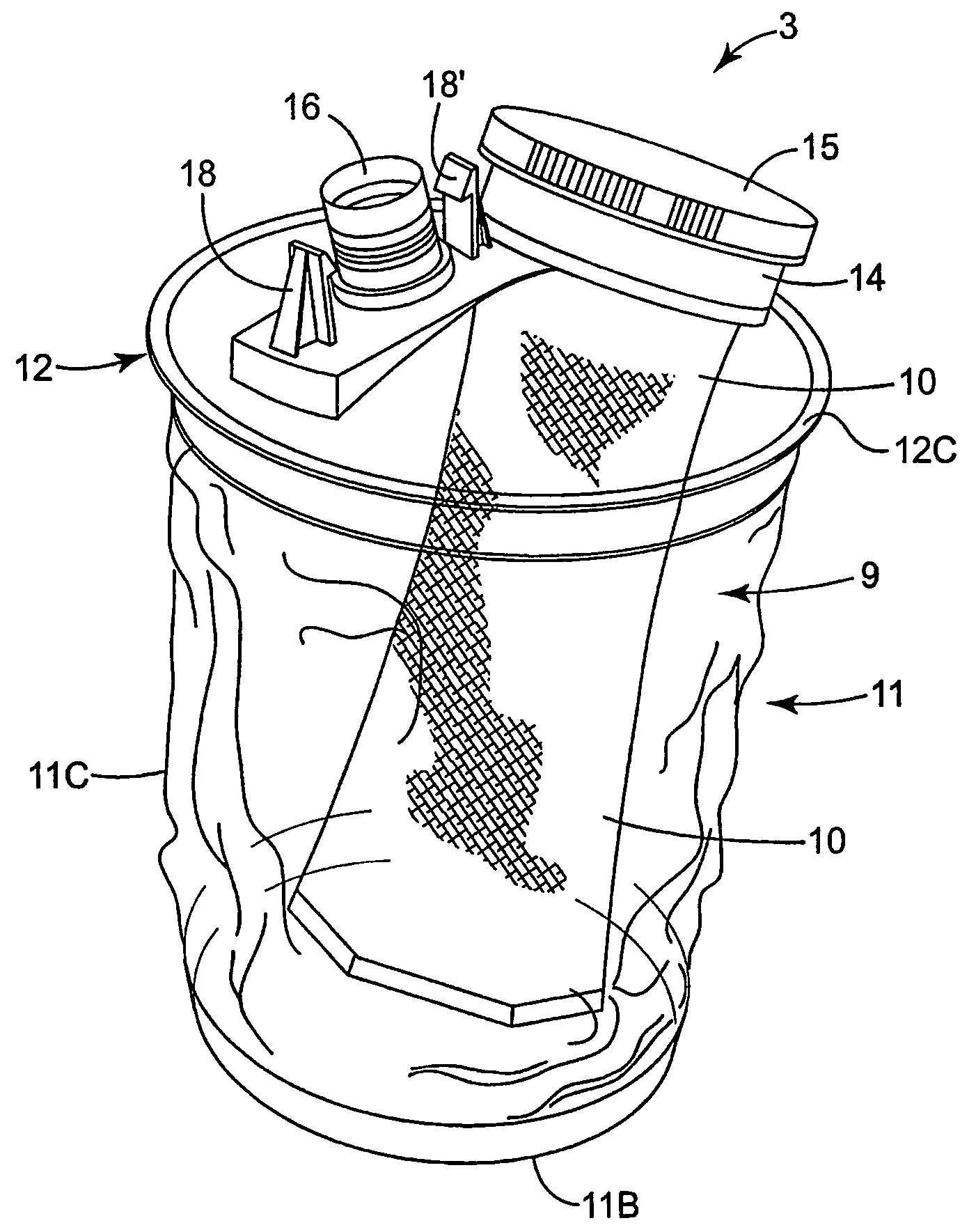

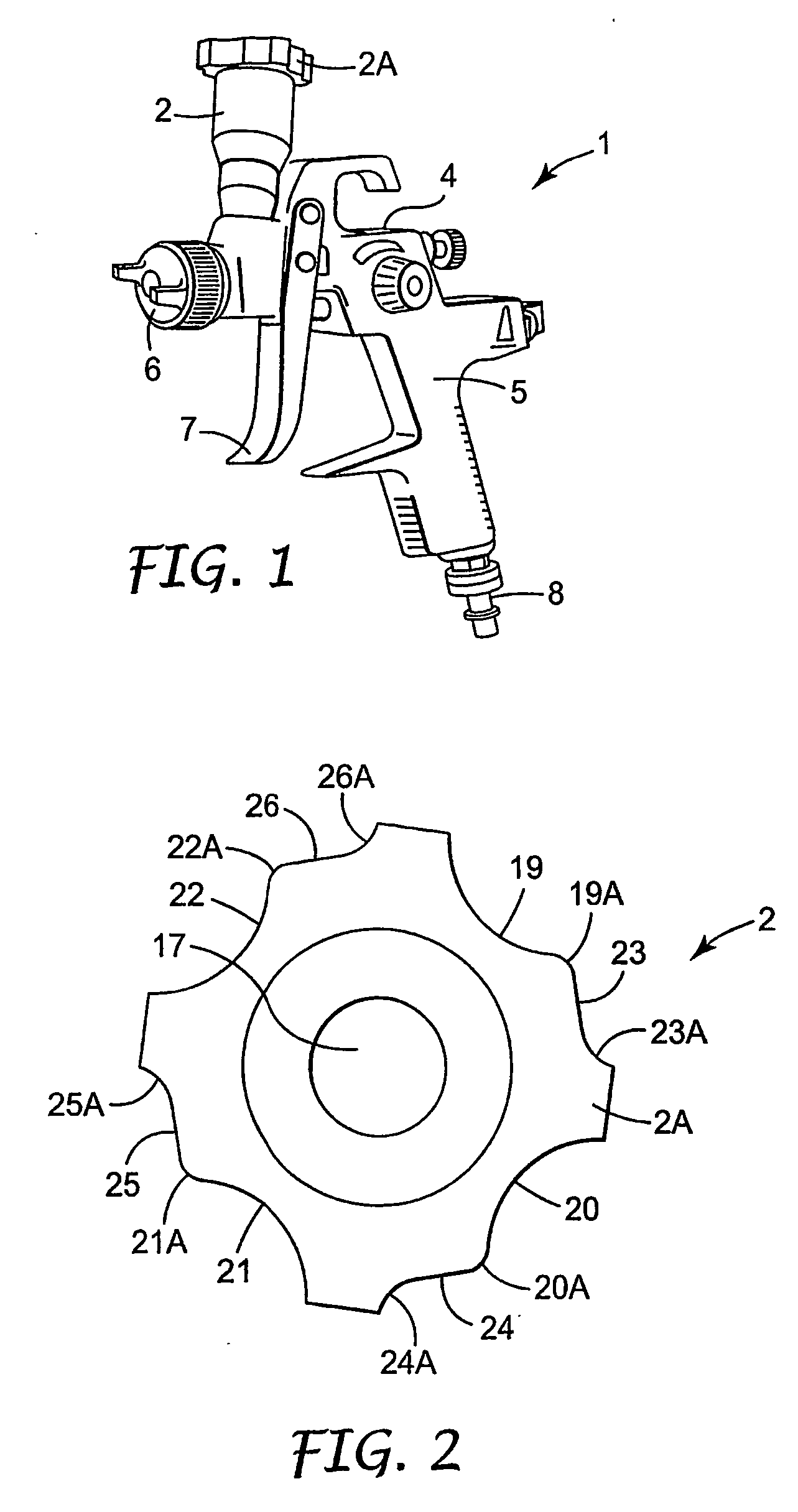

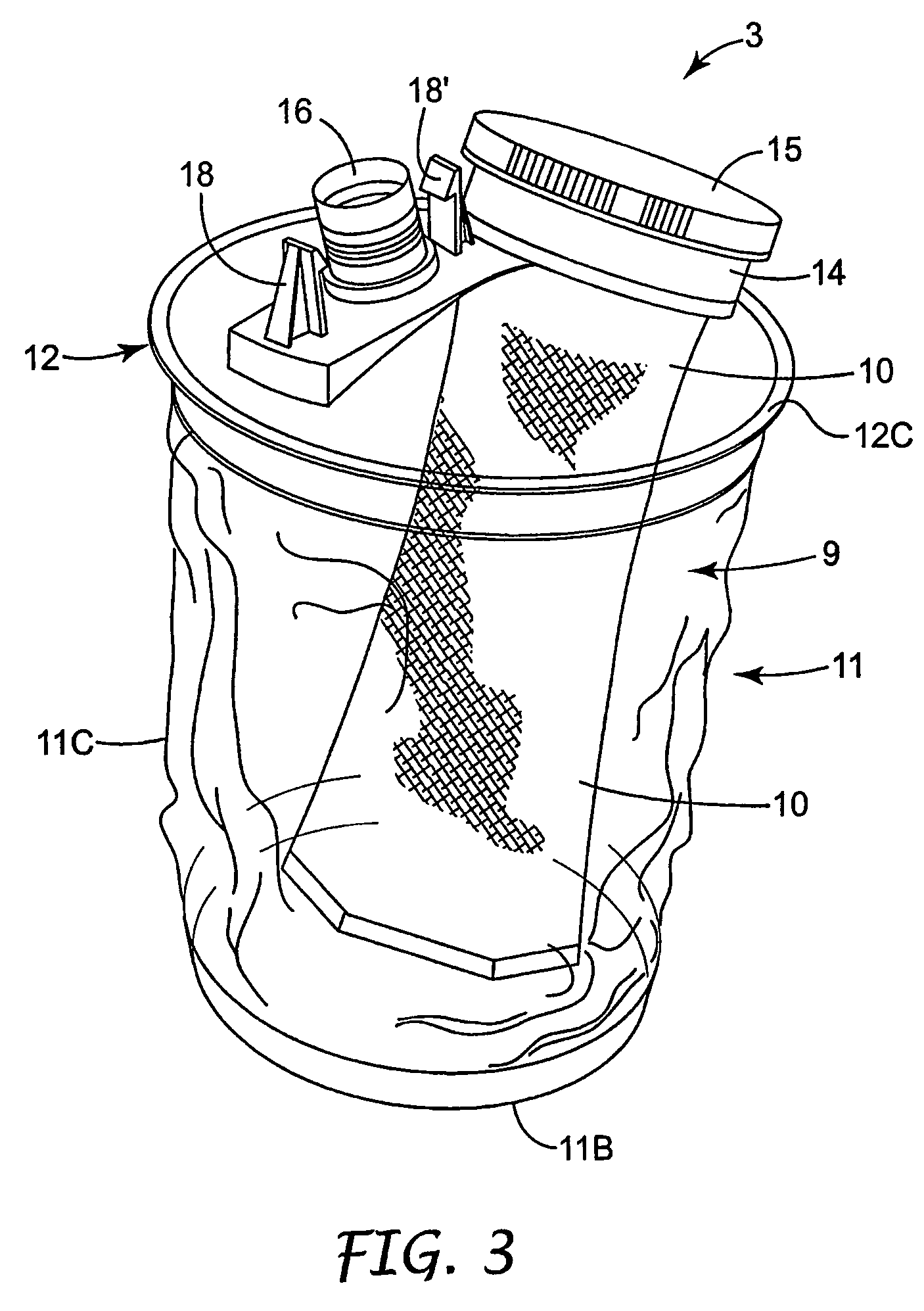

Drop-in filter for spray gun reservoir

InactiveUS20060065591A1Improve filtering effectFast fillLoose filtering material filtersCartridge filtersSolid particleEngineering

A liquid supply assembly for use with a spray gun (FIG. 1) comprises a reservoir 9 provided with a drop-in filter 10 for removing solid particles from liquid added to the reservoir 9. The reservoir 9 has a lid 12 with an outlet opening 12E connectable via a spout 16 to the spray gun and a separate inlet opening 12D in which a support collar 27 of the filter 10 is located. The filter 10 comprises a tubular mesh body 10A having an open end and a closed end. The open end is connected to the support collar 27 and the mesh body 10A extends away from the inlet opening 12D within the reservoir 9. The mesh body 10A is sized to pass through the filler opening 12D and has a high flow capacity to permit rapid filling of the reservoir 9. The filter 10 may be left in place when the reservoir 9 is connected to the spray gun and the reservoir 9 may be discarded together with the filter 10 after use.

Owner:3M INNOVATIVE PROPERTIES CO

Constraint based order optimization system and available to promise system

A computer system which uses customer-based business rules that are customized for each customer. These business rules, along with order information, are provided to a linear programming engine. The linear programming engine determines the priority of customer orders based on the business rules and allocates scarce inventory accordingly. In one embodiment, linear programming assigns weights to different factors. Examples of such factors are (1) a promotion activity, (2) a customer priority, (3) the age and delinquency of an order or line item, and (4) the price of the product.

Owner:LOGITECH EURO SA

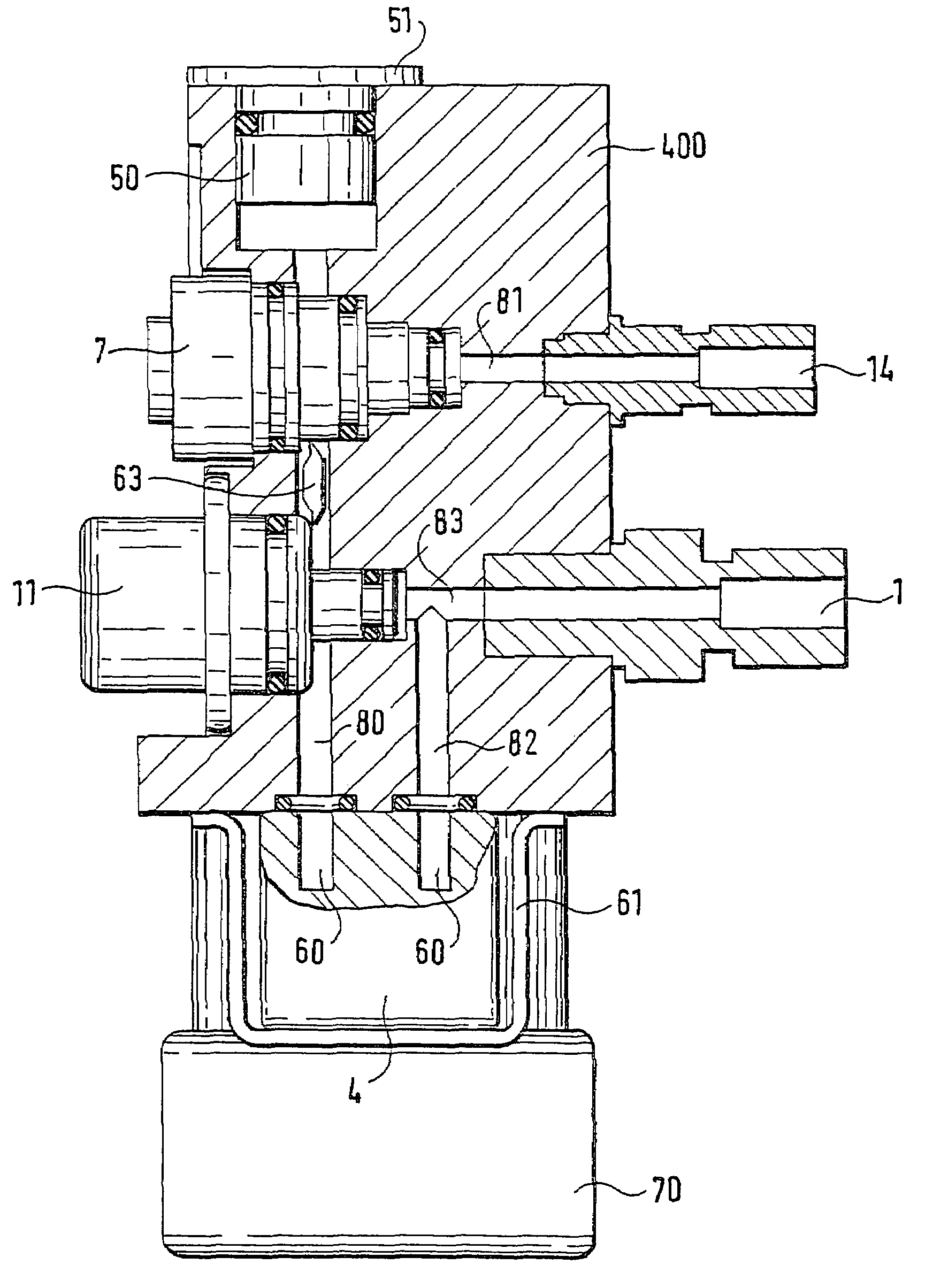

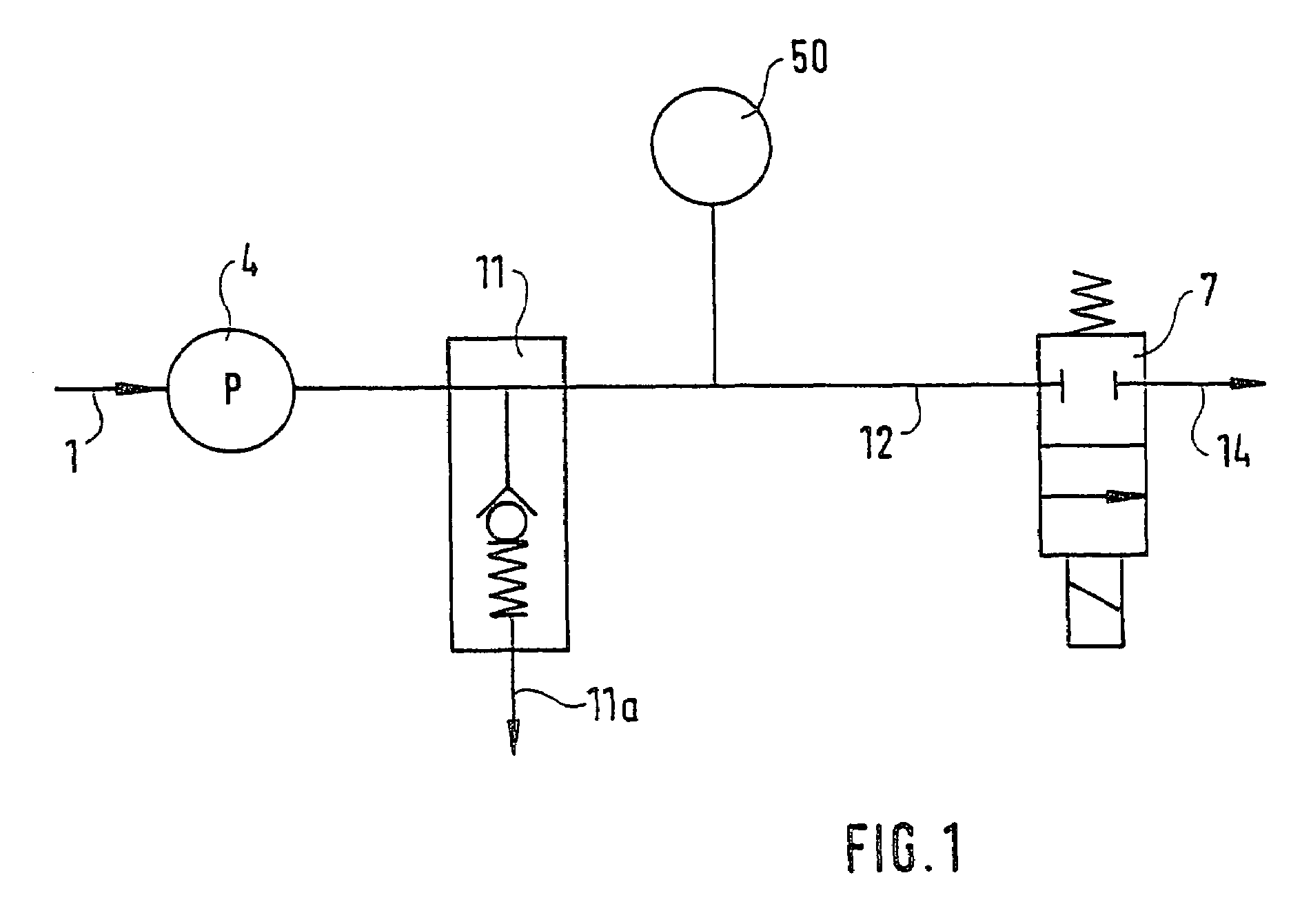

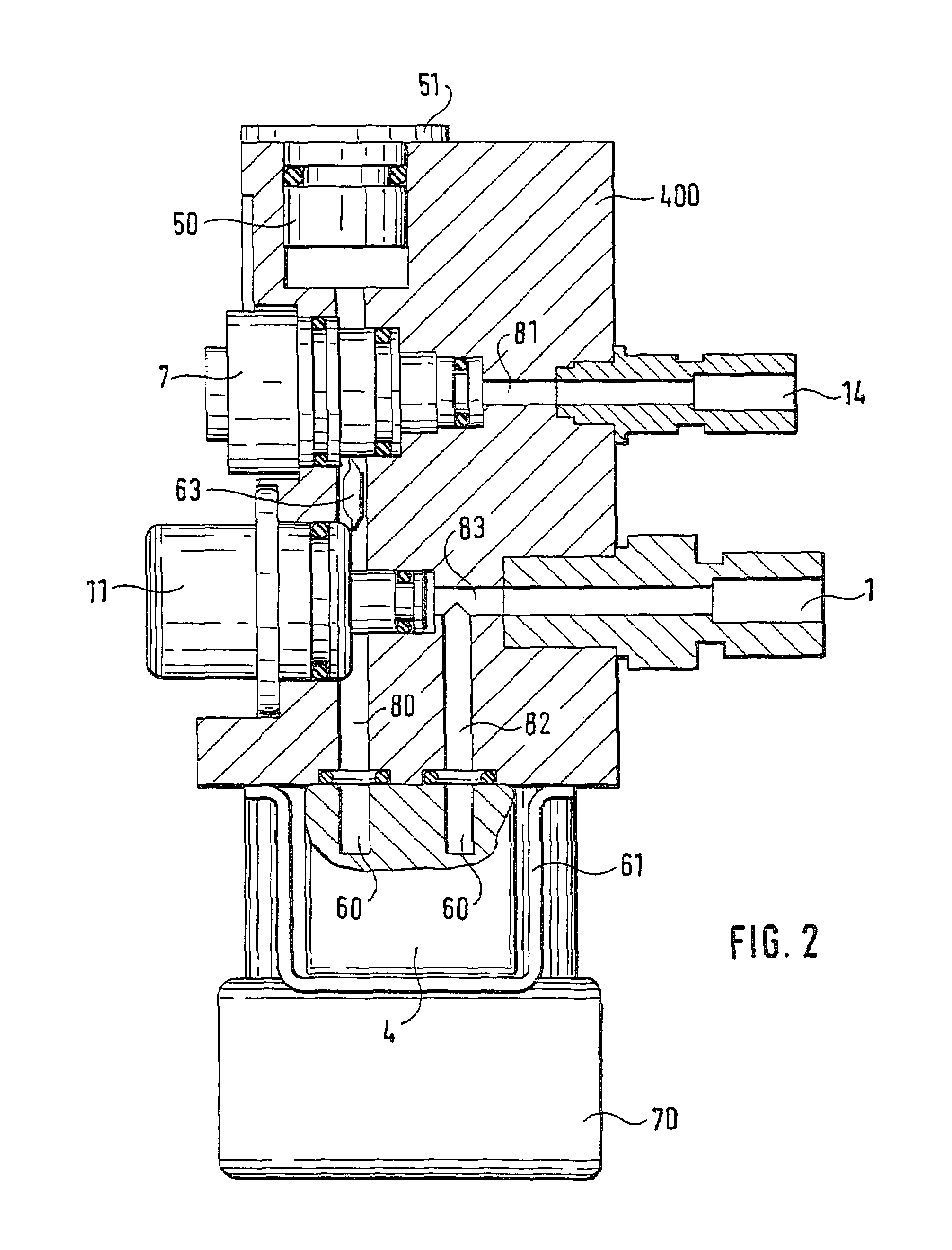

Device for the dosing of a reducing agent

InactiveUS7481049B2Produced economicallyRich basic functionsLiquid surface applicatorsInternal combustion piston enginesNitrogen oxidesEngineering

An apparatus for metering a urea or a urea-water solution for delivery to a catalytic converter assembly for removing nitrogen oxides from the exhaust gases of a Diesel engine, includes a housing block supporting function components communicating via a line, formed by recesses in the housing block, for transporting the reducing agent, and the walls of the line are formed by the housing block. This apparatus assures a simple line layout for reducing agent with a minimum number of sealing points that is accordingly appropriate for large-scale mass production.

Owner:ROBERT BOSCH GMBH

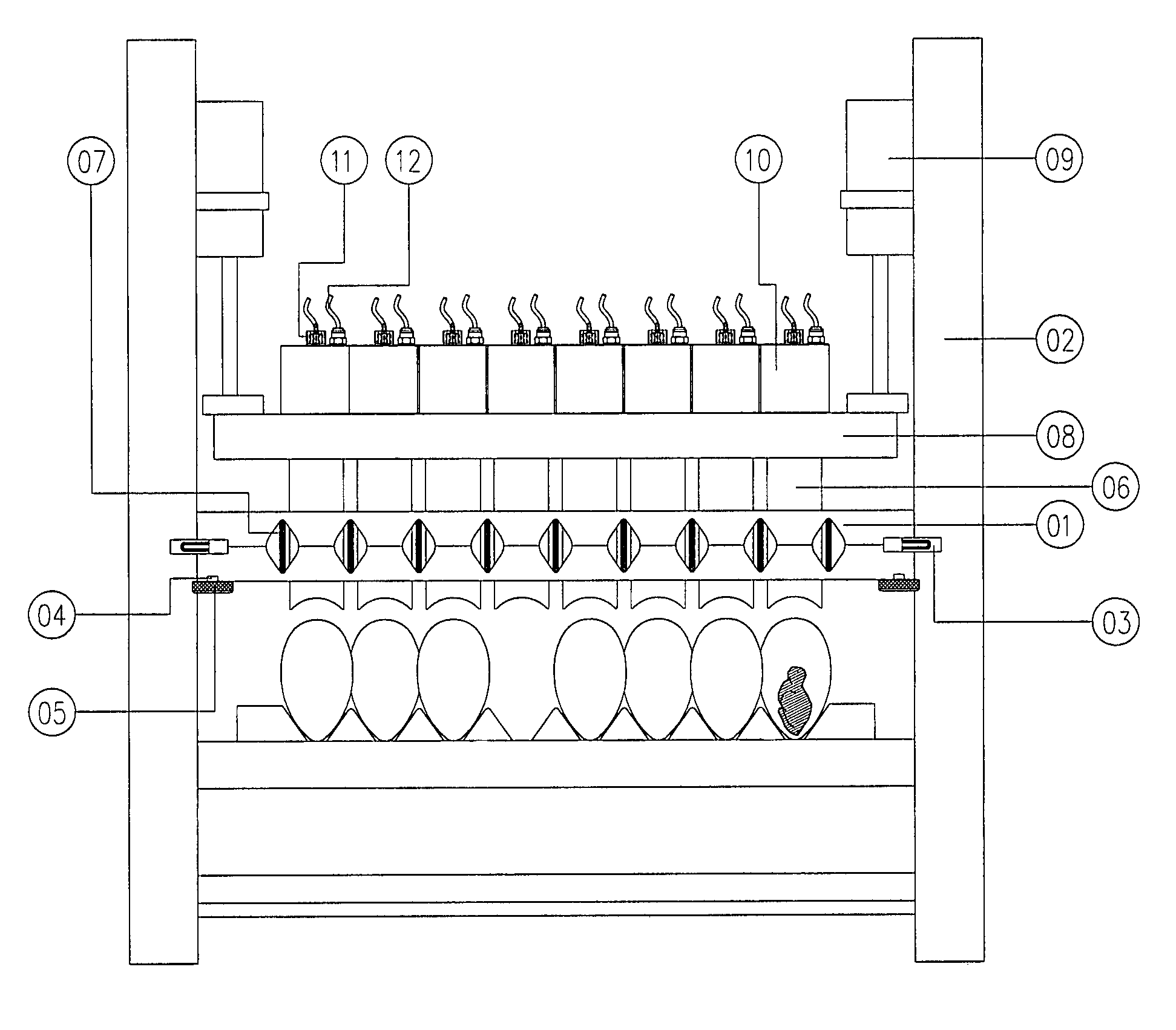

Egg vaccination apparatus

ActiveUS7721674B2Minimizing of movementMinimize the possibilityEar treatmentCannulasVaccinationCritical level

An automatic vaccinator of eggs, consisting of a system for applying vaccine with a vaccine chamber in which vaccine bags are hung and with an air bag that, when expanded, forces the vaccine from the bags and through tubing to a distribution manifold and the injectors, so that the vaccine is delivered to the eggs, is disclosed. A pressure sensor is installed in the distribution manifold and connected to a regulator, measuring the pressure in the distribution manifold at the point farthest from the vaccine chamber and controlling the pressure in the air bag to maintain a uniform quantity of vaccine being injected into the eggs and turning off the vaccinator if the pressure falls below a critical level, signaling that the vaccine bags are empty. The mechanical unit includes a system to support, align and secure the injectors over the egg tray, composed of two plates that work independently, a support plate and an alignment plate.

Owner:MERIAL INC

Small Rb atom frequency marking cavity bubble system

InactiveCN101237077AReduce volumeReduce design difficultyPulse automatic controlGaseous masersDielectric cylinderCell system

The present invention discloses a miniaturized rubidium atomic frequency standard cavity-cell system, wherein, a microwave cavity cylinder is made from high magnetic permeability material; the microwave cavity cylinder is sleeved with a heating cylinder; a pump light incident port of the heating cylinder is also provided with a convex lens which gathers and transmits rays emitted by a rubidium spectral lamp into a microwave cavity; a C field coil is directly wound on a dielectric cylinder arranged between the microwave cavity cylinder and an absorption cell; a cusp on the tail part of a light-filtering cell is concentrated at the center of a circular plane at the end of the cell; a cusp on the tail part of the absorption cell is concentrated at the edge of a circular plane at the end of the cell; a photocell and a snap-off diode are fixed on the end face of the inner wall of a cavity end cover which can be movably fixed. The present invention has no machinery regulating rod inside the cavity, uses an intracavity frequency doubling mode, adopts a cylindrical TE111 mode and a dielectric filling method to get rid of the complex structure of a magnetic shield cylinder in the prior art, and reduces the volume of the cavity-cell system. As the pump light incident port of the heating cylinder is provided with the convex lens to increase the light intensity of pump light, the performance of the cavity-cell system is guaranteed. A mobile photoelectric component is adopted for cavity frequency fine adjustment, which is convenient for debugging and cannot cause field form distortion.

Owner:SICHUAN TIANAO XINGHUA TIME & FREQUENCY

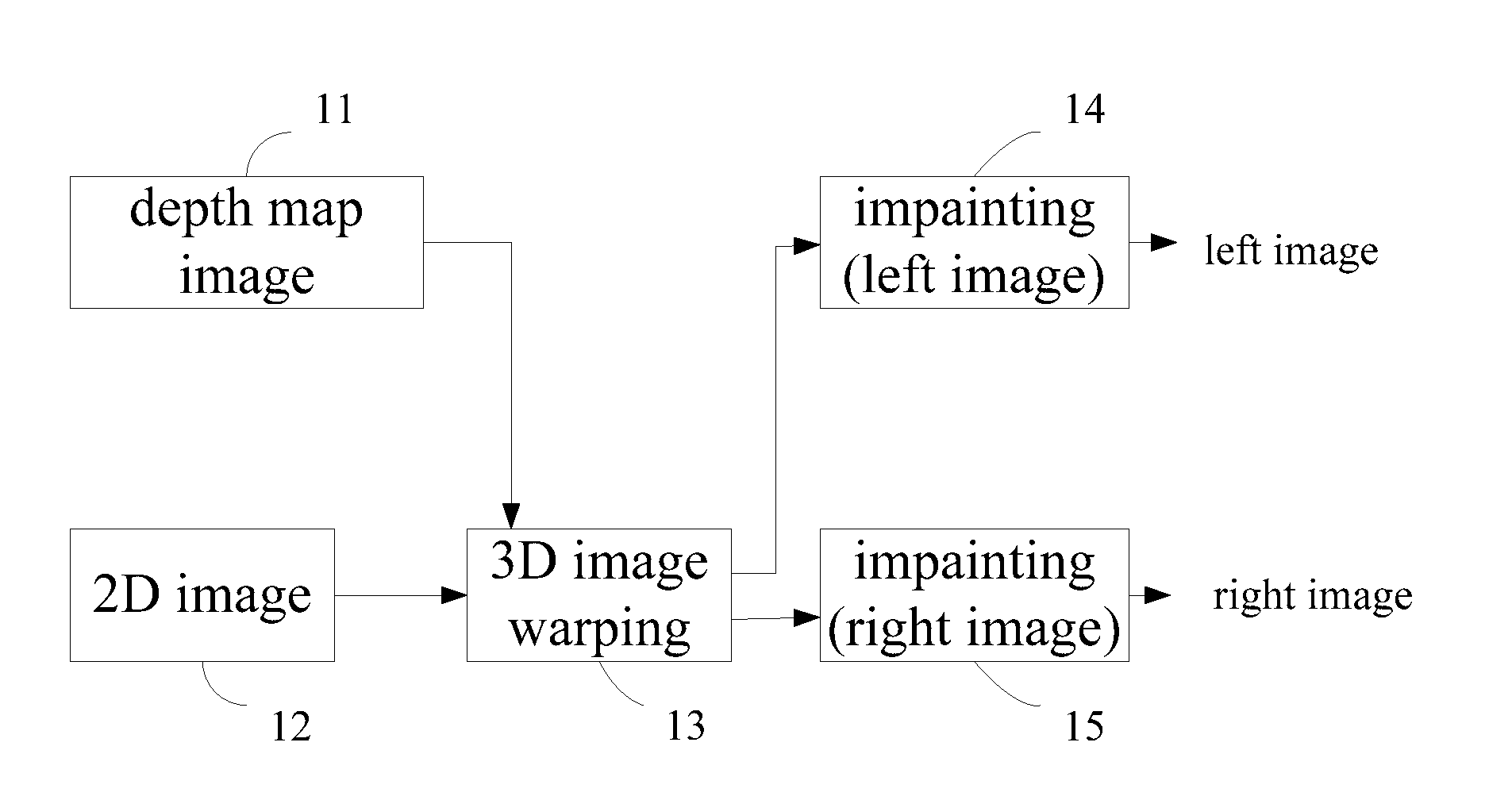

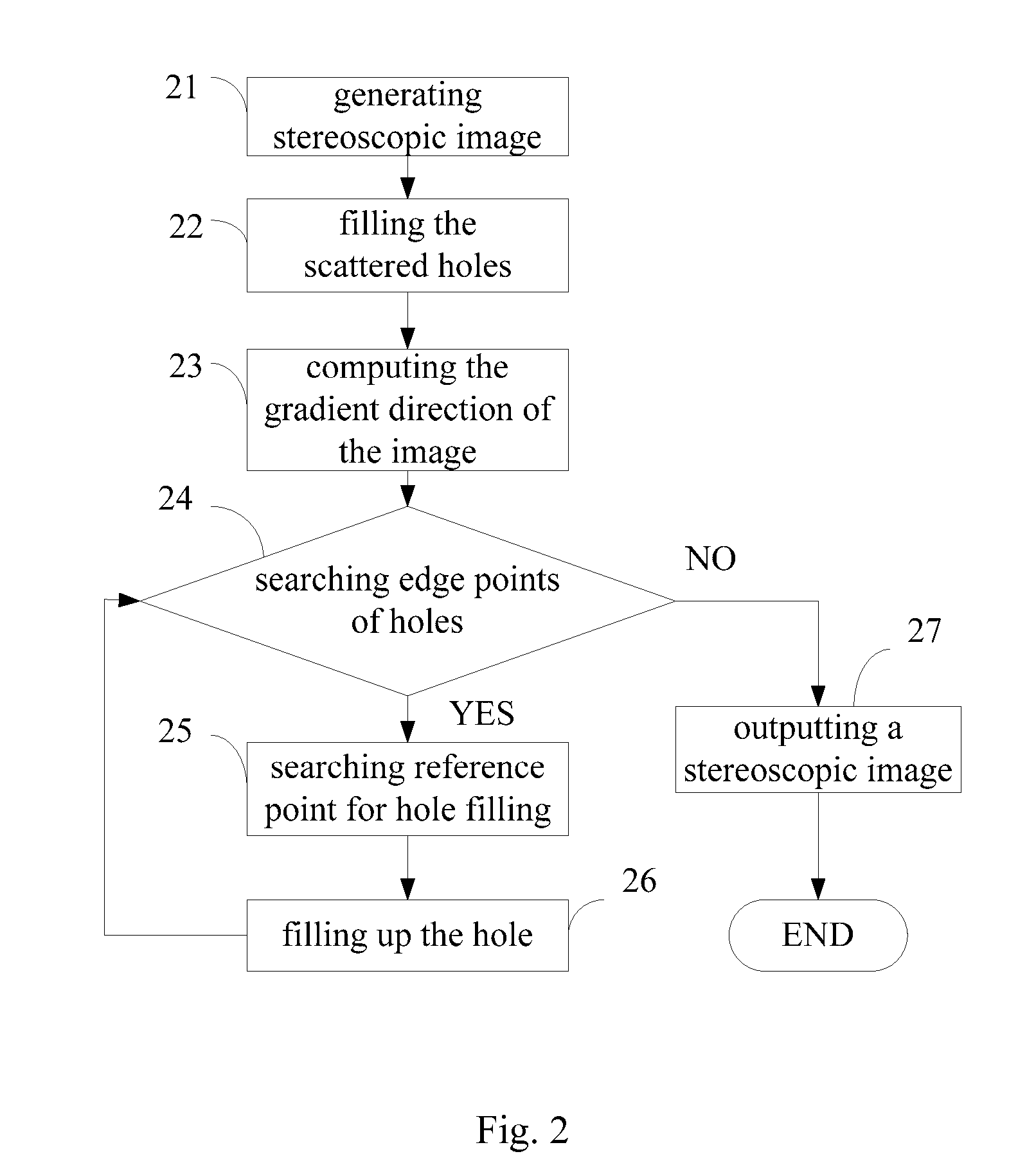

Apparatus for generating real-time stereoscopic image and method thereof

ActiveUS20120242789A1Simplify complex methodFast fillSteroscopic systemsParallaxHardware architecture

Disclosed is an apparatus and method for generating a real-time stereoscopic image from depth map. According to the depth information of the image, a depth-image-based rendering (DIBR) algorithm is used to shift (or move) the position of the object in the image to generate the stereoscopic image with parallax. When the object is shifted (or moved) away from its original position, a hole will occur in the original position. Therefore an image inpainting algorithm is developed to fill the hole. In order to achieve the real-time application, a hardware architecture and method have been developed to accomplish the DIBR and image inpainting algorithm.

Owner:CHUNG HUA UNIVERSITY

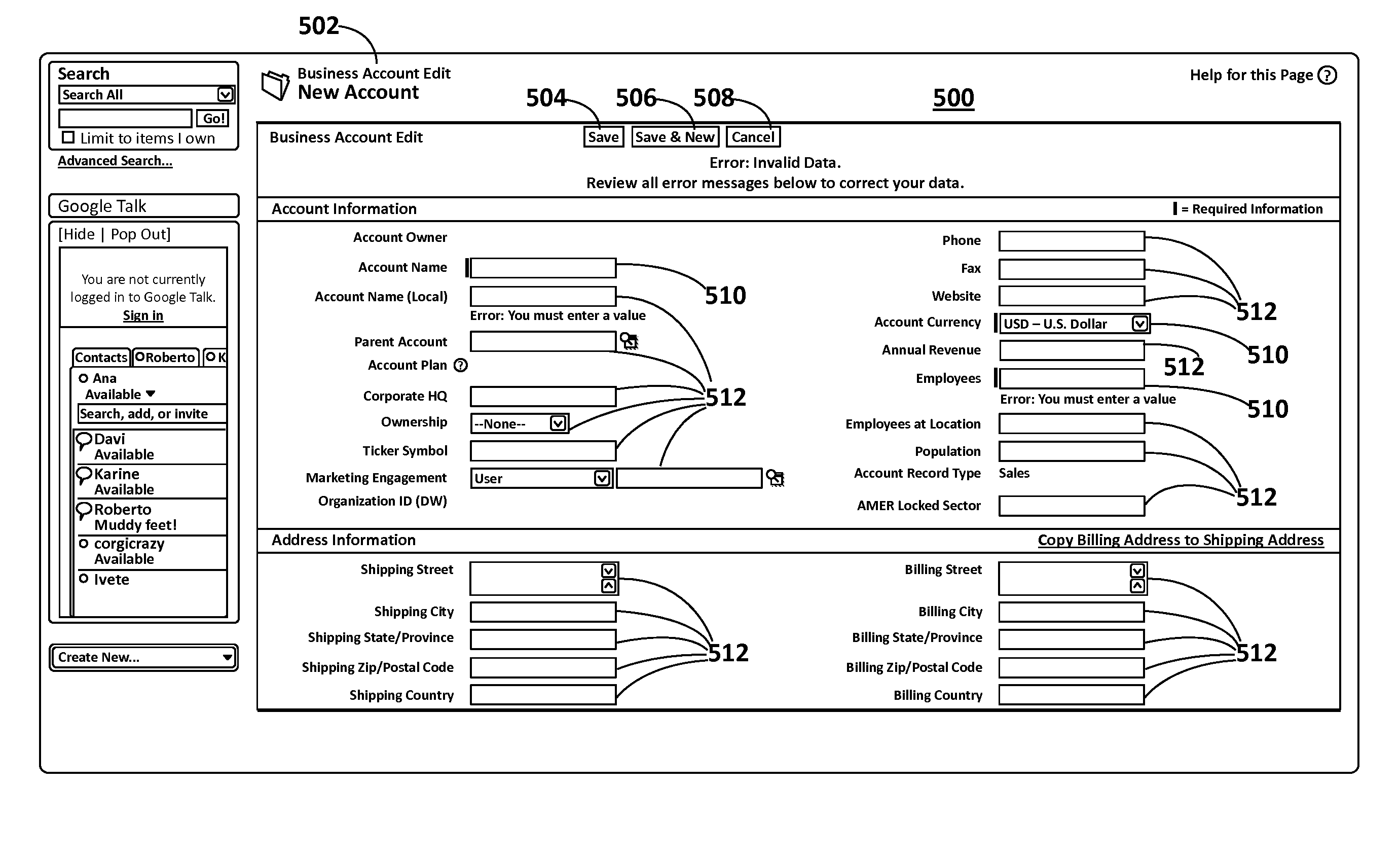

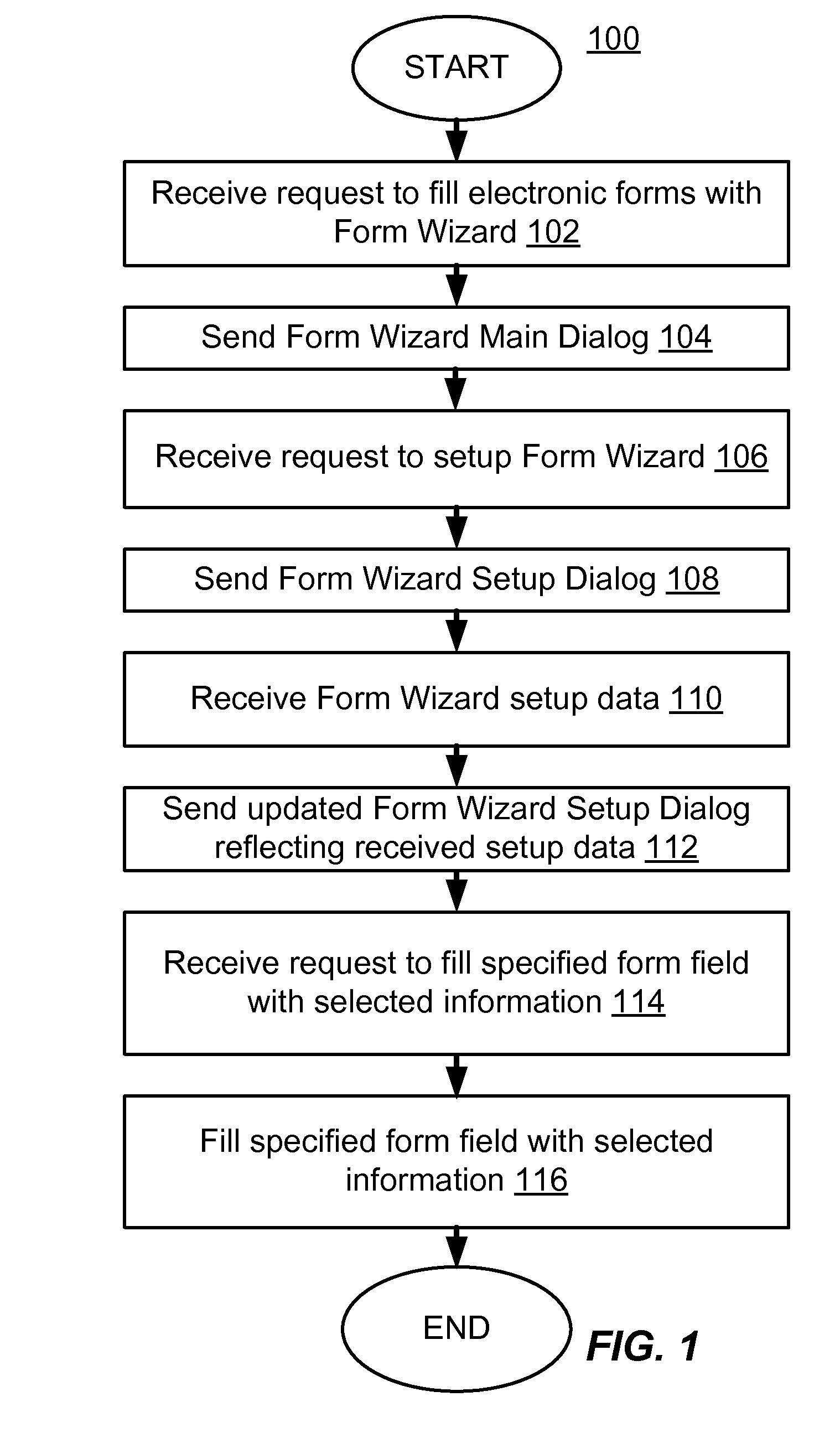

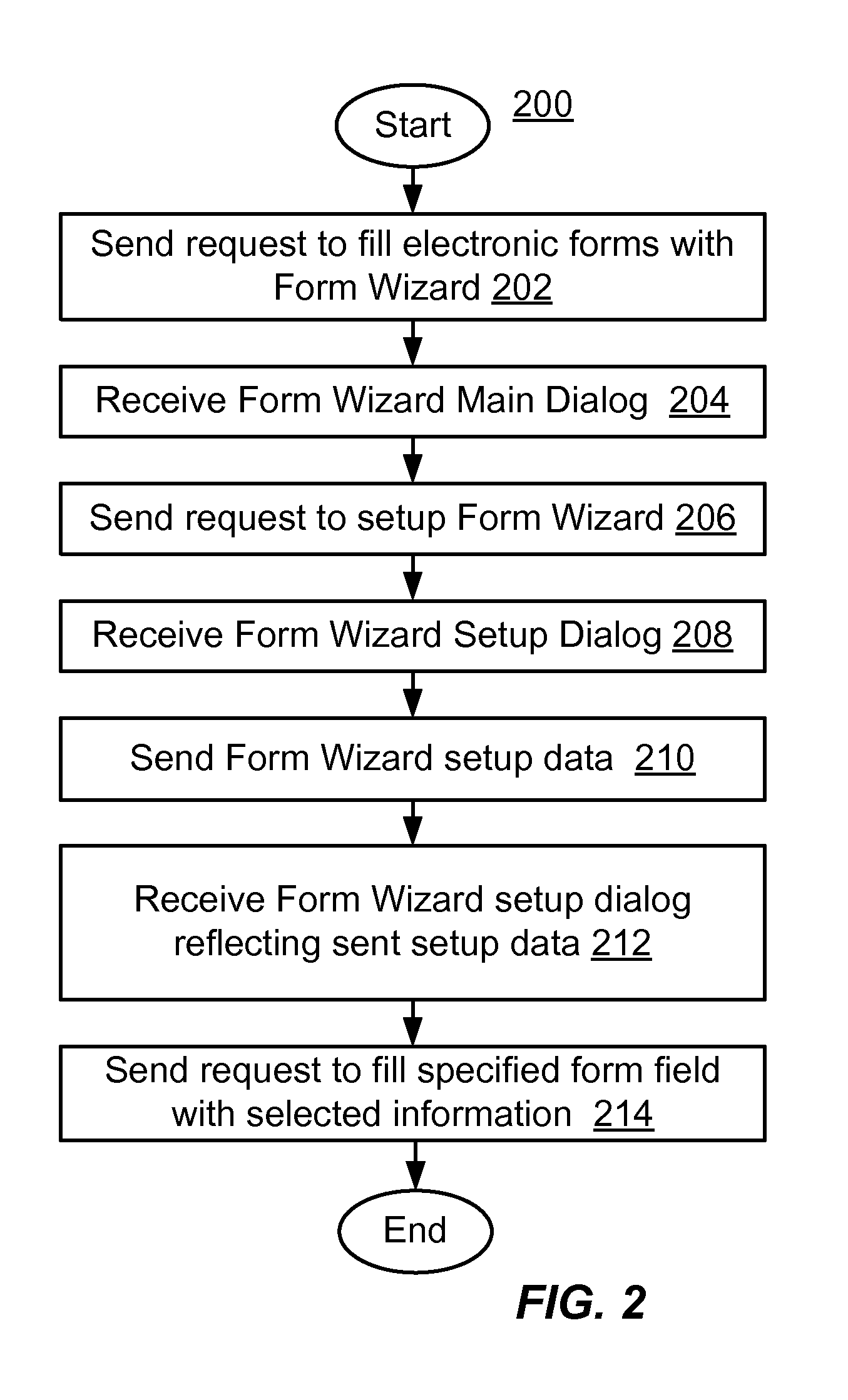

Method and system for providing simplified form filling in an on-demand service

ActiveUS20120054593A1Rapid fillingFast fillNatural language data processingSpecial data processing applicationsFilling-inOn demand

In accordance with embodiments, there are provided mechanisms and methods for providing simplified form filling in an on-demand service in a database system. These mechanisms and methods can enable embodiments to provide users with an efficient form wizard for filling electronic forms. The ability of embodiments to provide a form wizard can enable users to efficiently accomplish the rapid filling of multiple forms without the need to scroll through the electronic forms and entering the same information repeatedly.

Owner:SALESFORCE COM INC

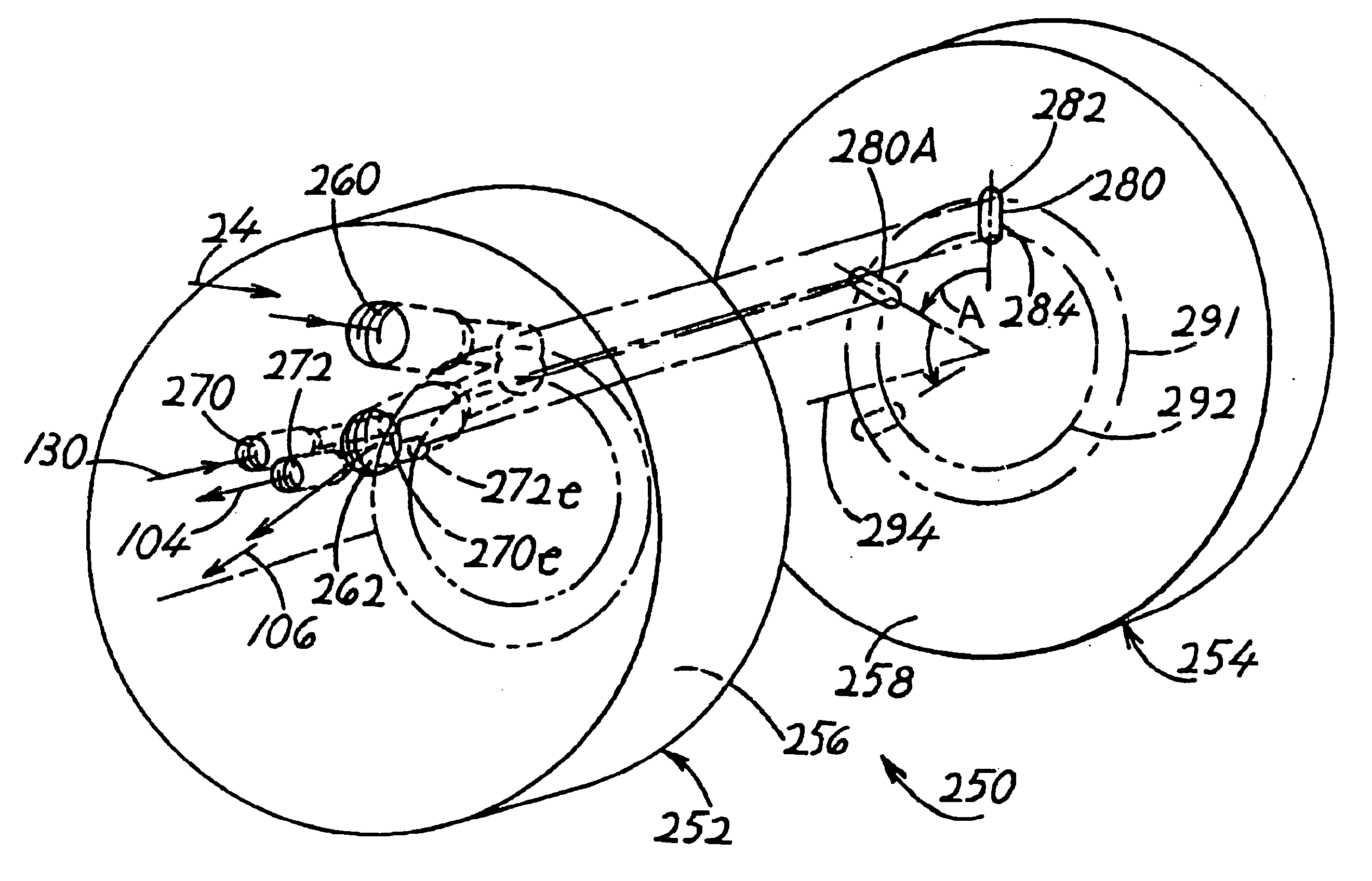

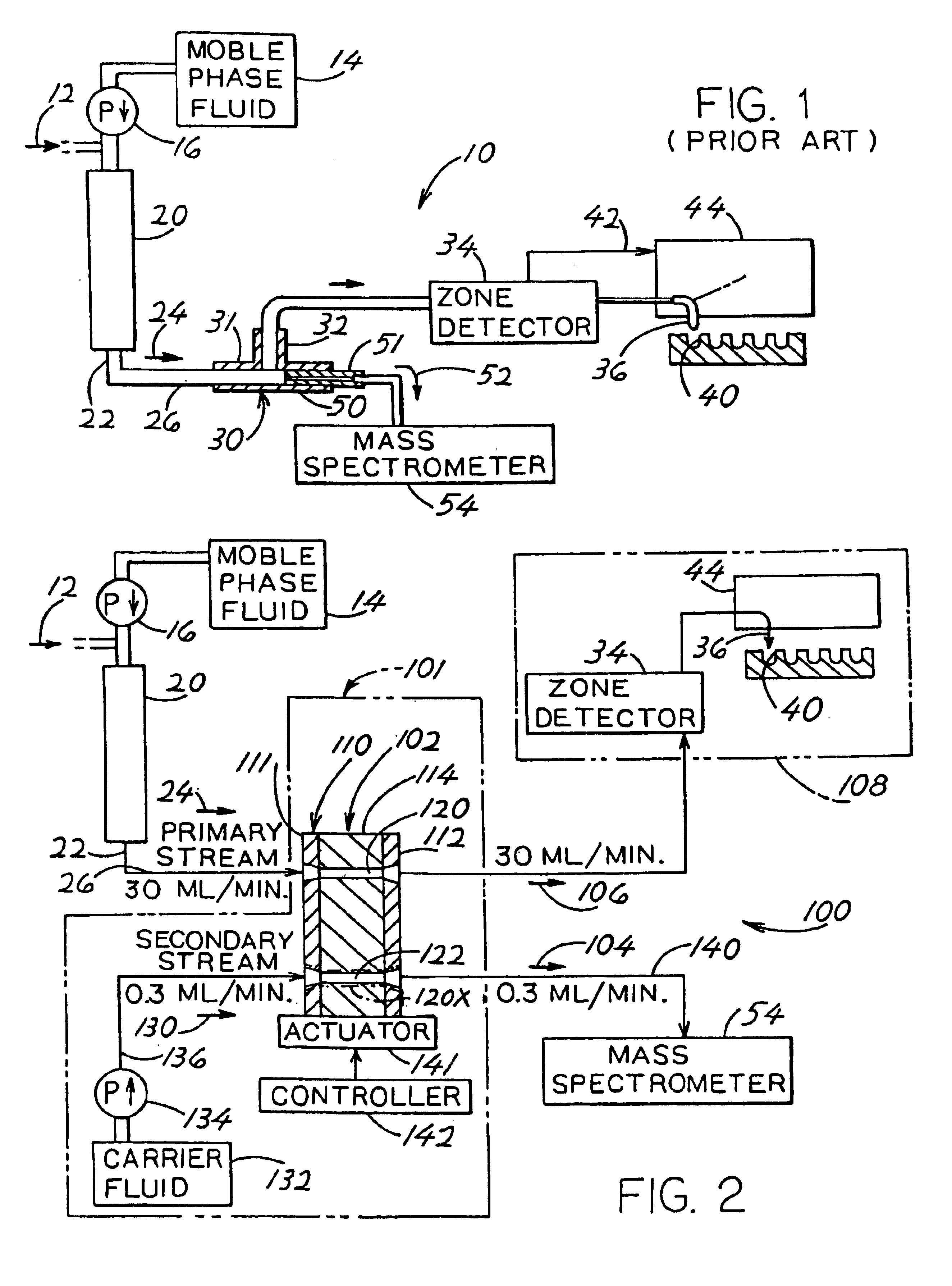

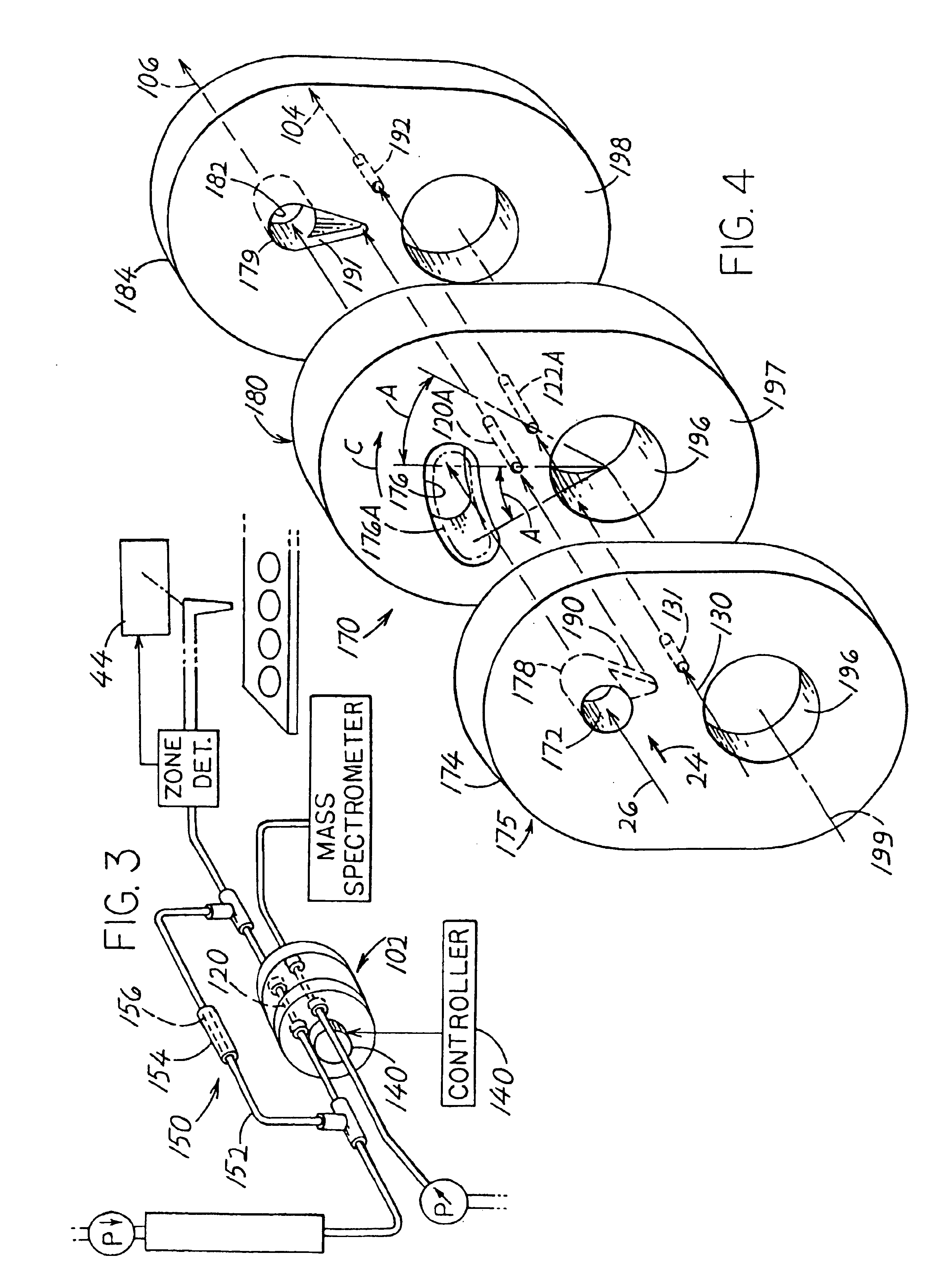

Mass rate attenuator

While a large primary stream (24) of analytes flow from a chromatographic column (20) to containers of a receiver (108), small samples of the analytes are diverted for flow to a mass spectrometer (54) for analysis, by use of a transfer module (102). The transfer module includes a stator (110) and a rotor or shuttle (114). The shuttle has an aliquot passage (120) that initially lies in a first position where the primary stream flows through it so the aliquot passage receives a small sample. The shuttle then moves to a second position where the aliquot passage (at 122) is aligned with a pump (134) that pumps fluid out of the aliquot passage to the mass spectrometer.

Owner:IDEX HEALTH & SCI

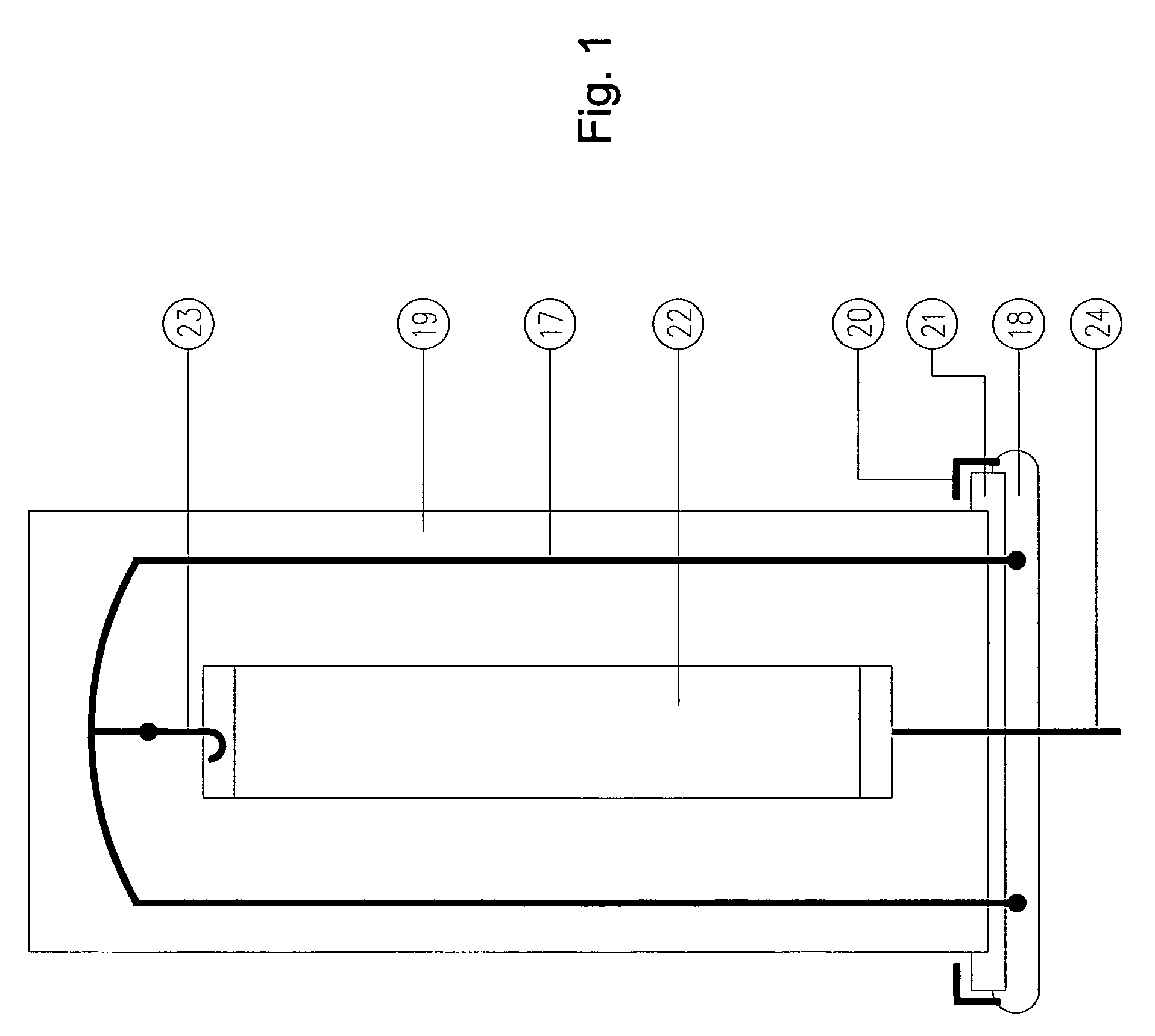

Fiber-reinforced composite structure

InactiveUS20020102390A1Fast fillFast impregnationCellulosic plastic layered productsSuperstructure subunitsVacuum pressureHermetic seal

A fiber-reinforced composite structure has two molded outer polymeric layers spaced apart from each other and defining a cavity therebetween. Each molded outer polymeric layer defines a sealing surface extending about a periphery of the respective layer, and the opposing sealing surfaces cooperate to define a hermetic seal extending about a periphery of the cavity. One or more multi-directional fiber reinforcement layers are adhesively attached in a discontinuous manner to each outer polymeric layer, and define a first region of the cavity extending between each respective outer polymeric layer and adjacent fiber reinforcement layer, and a second region of the cavity extending between the fiber reinforcement layers. A core is located between the two outer polymeric layers, and is made of a resinous core material capable of exhibiting a foamed character and a resinous character. The resinous core material has a blowing agent activatable upon exposure to a predetermined vacuum pressure within the cavity to convert the core material within the second region of the cavity from a resinous character to a foamed character and thereby fill the second region of the cavity with the foamed core material. Each multi-directional fiber reinforcement layer is impregnated with the core material exhibiting a relatively dense, resinous character, and each first region of the cavity is substantially filled with the core material exhibiting a resinous character to fixedly secure the multi-directional fiber reinforcement layers to the outer polymeric layers. A structural insert, such as a rigid plate adapted to receive fasteners, is embedded within the core material for attaching other devices or structures thereto.

Owner:SABIC GLOBAL TECH BV

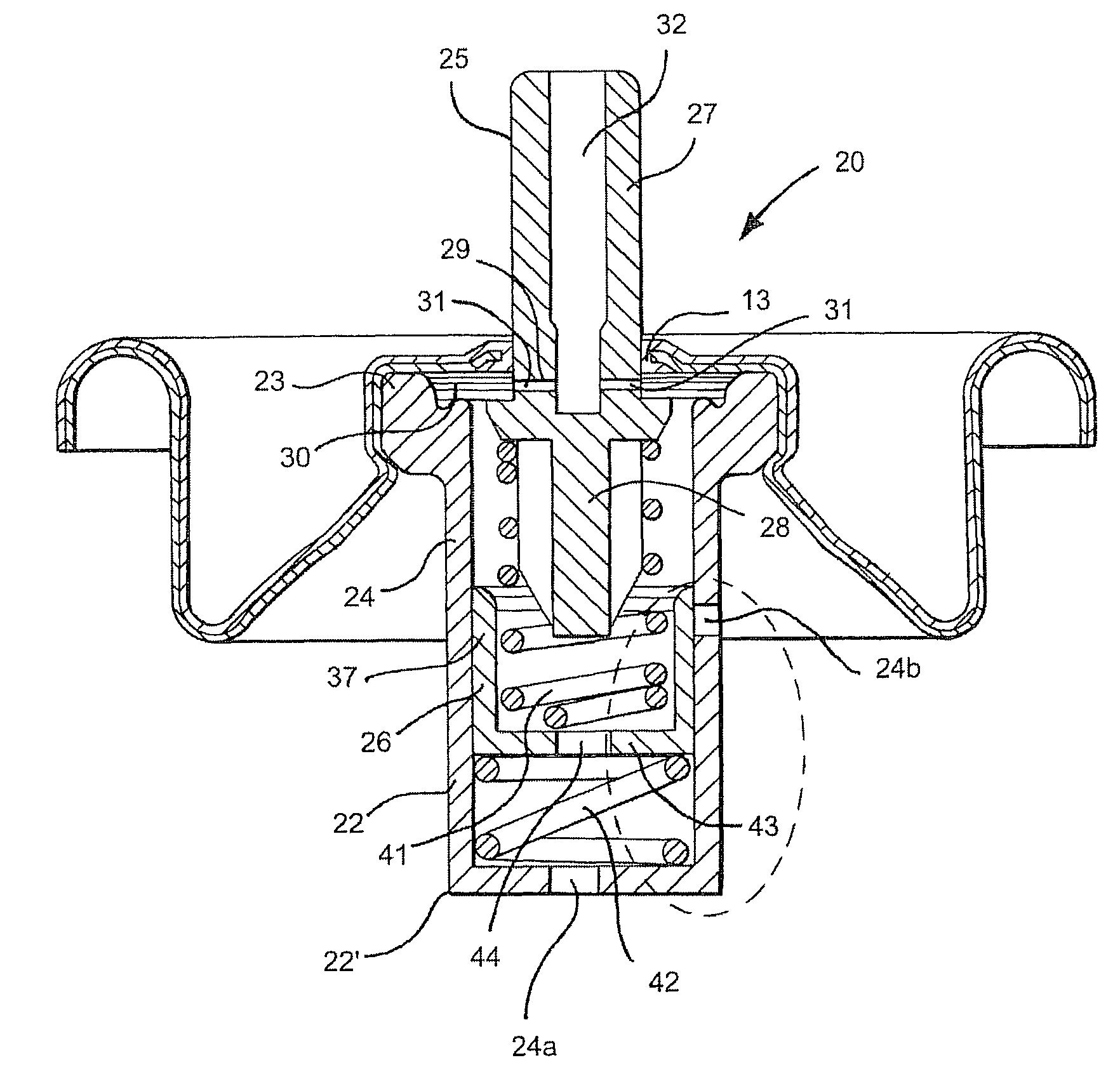

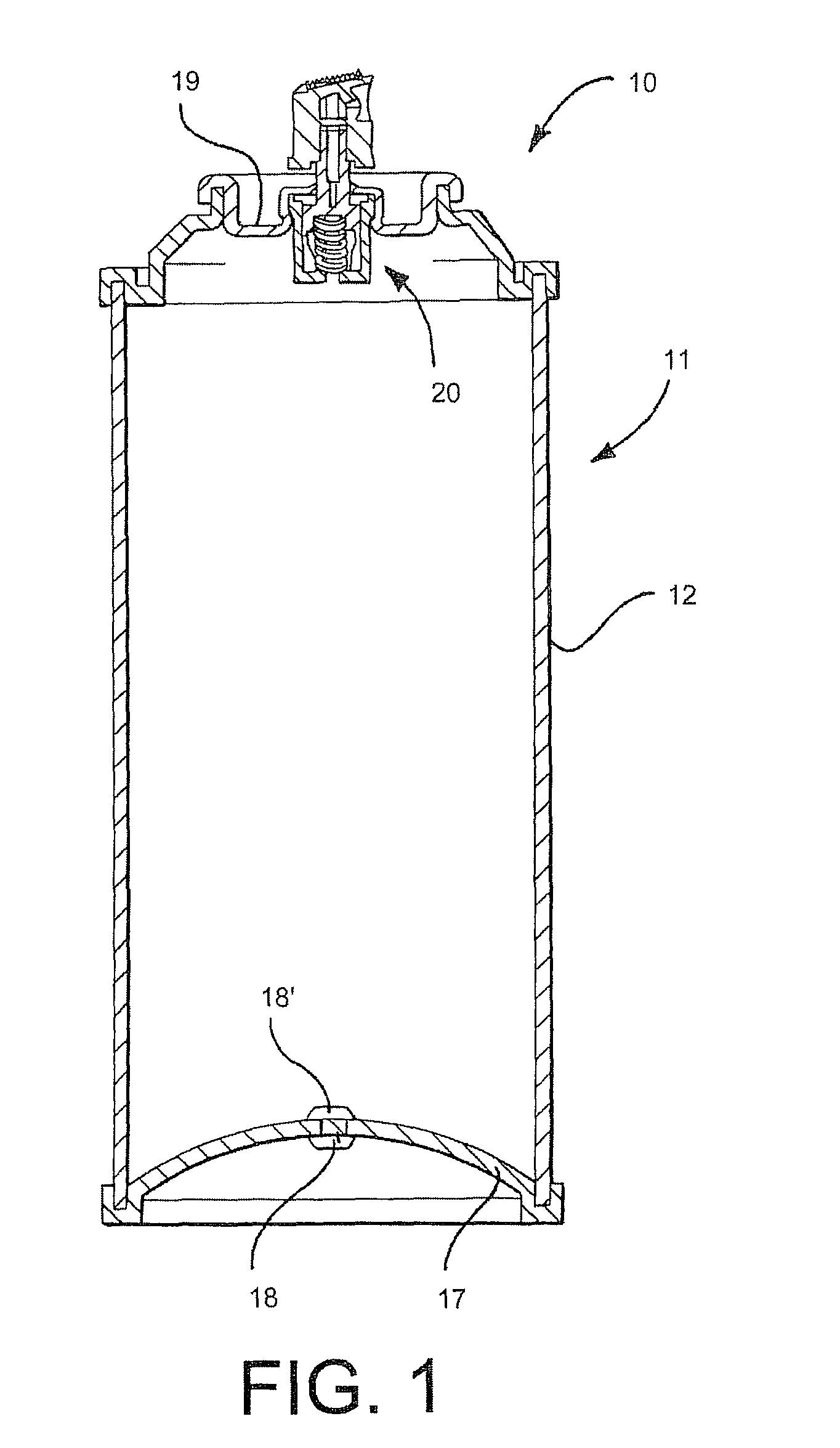

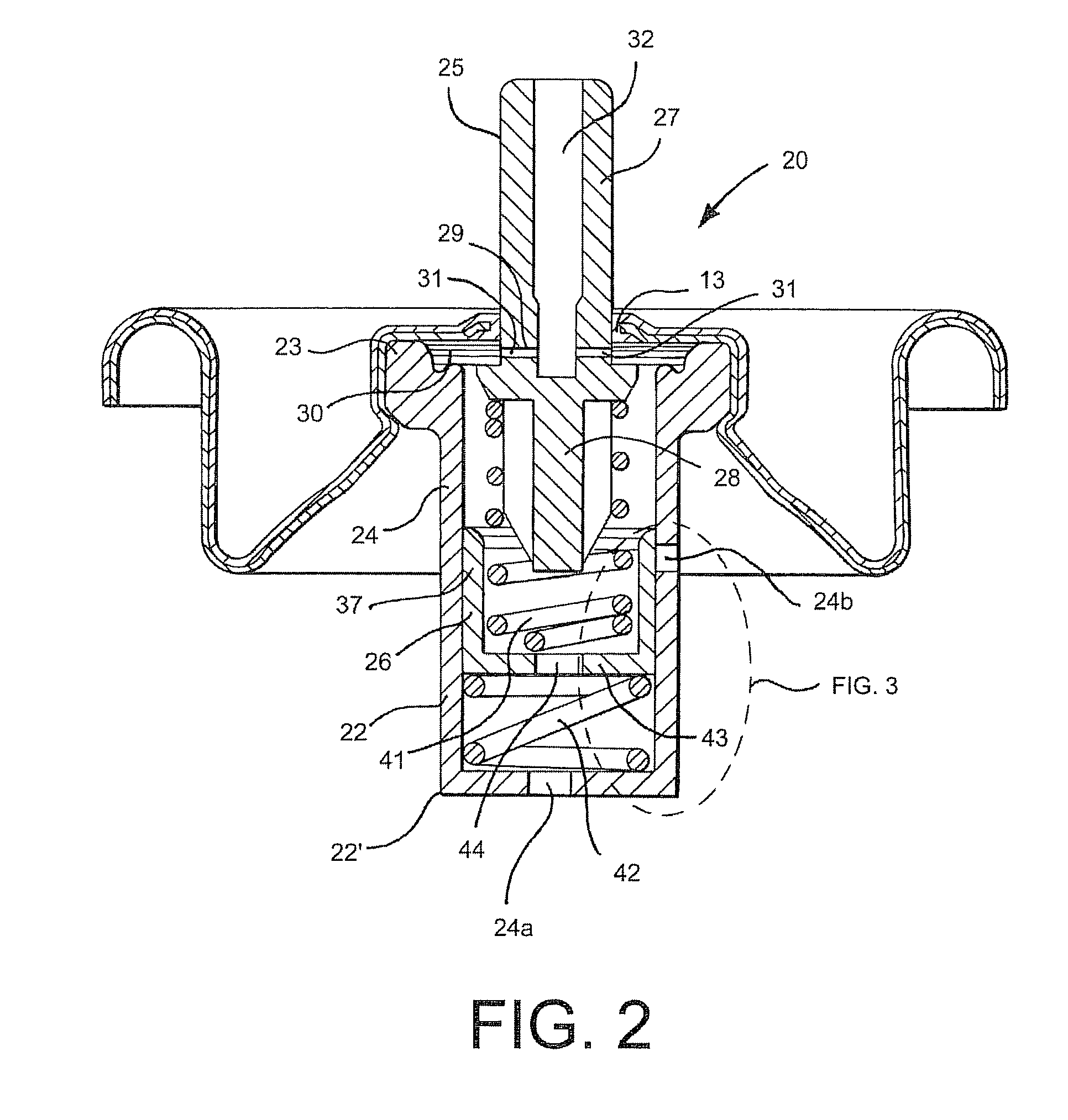

Valve assembly for pressurized dispensers

ActiveUS7959041B2Increase flow rateFast fillSolid materialLiquid dispensingEngineeringMechanical engineering

An improved valve assembly for use in a pressurized dispenser is disclosed. The disclosed valve assembly may include a valve housing and a blocking member operatively associated with the valve housing, wherein the wall of the valve housing includes at least one transverse primary opening and at least one transverse secondary opening thereon. The blocking member is slidable from a filling position, in which fluid communication between the interior and exterior of the valve housing is established through both primary and secondary openings, to a dispensing position, in which fluid communication between the interior and exterior of the valve housing is established only through the primary opening and not through the secondary opening. The blocking member may include a slidable sleeve, a slidable piston plate, or a combination of both. In operation, the disclosed valve member may provide an increased flow rate during product and / or propellant filling while retaining a regular flow rate during dispensing.

Owner:SC JOHNSON & SON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com