Patents

Literature

552 results about "Escapement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An escapement is a mechanical linkage in mechanical watches and clocks that gives impulses to the timekeeping element and periodically releases the gear train to move forward, advancing the clock's hands. The impulse action transfers energy to the clock's timekeeping element (usually a pendulum or balance wheel) to replace the energy lost to friction during its cycle and keep the timekeeper oscillating. The escapement is driven by force from a coiled spring or a suspended weight, transmitted through the timepiece's gear train. Each swing of the pendulum or balance wheel releases a tooth of the escapement's escape wheel, allowing the clock's gear train to advance or "escape" by a fixed amount. This regular periodic advancement moves the clock's hands forward at a steady rate. At the same time the tooth gives the timekeeping element a push, before another tooth catches on the escapement's pallet, returning the escapement to its "locked" state. The sudden stopping of the escapement's tooth is what generates the characteristic "ticking" sound heard in operating mechanical clocks and watches. The first mechanical escapement, the verge escapement, was invented in medieval Europe during the 13th century, and was the crucial innovation which lead to the development of the mechanical clock. The design of the escapement has a large effect on a timepiece's accuracy, and improvements in escapement design drove improvements in time measurement during the era of mechanical timekeeping from the 13th through the 19th century.

Mortise Lock Assembly

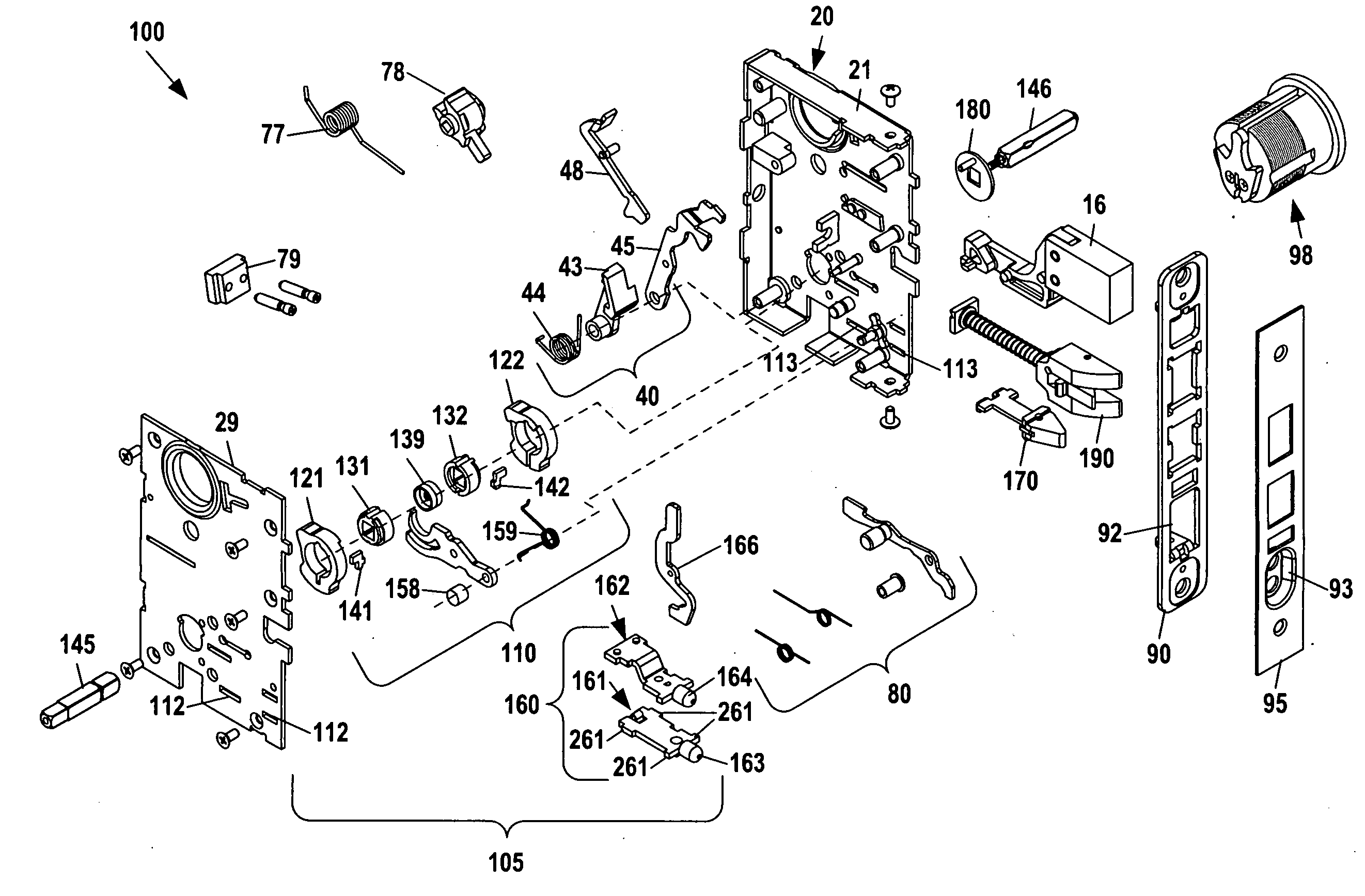

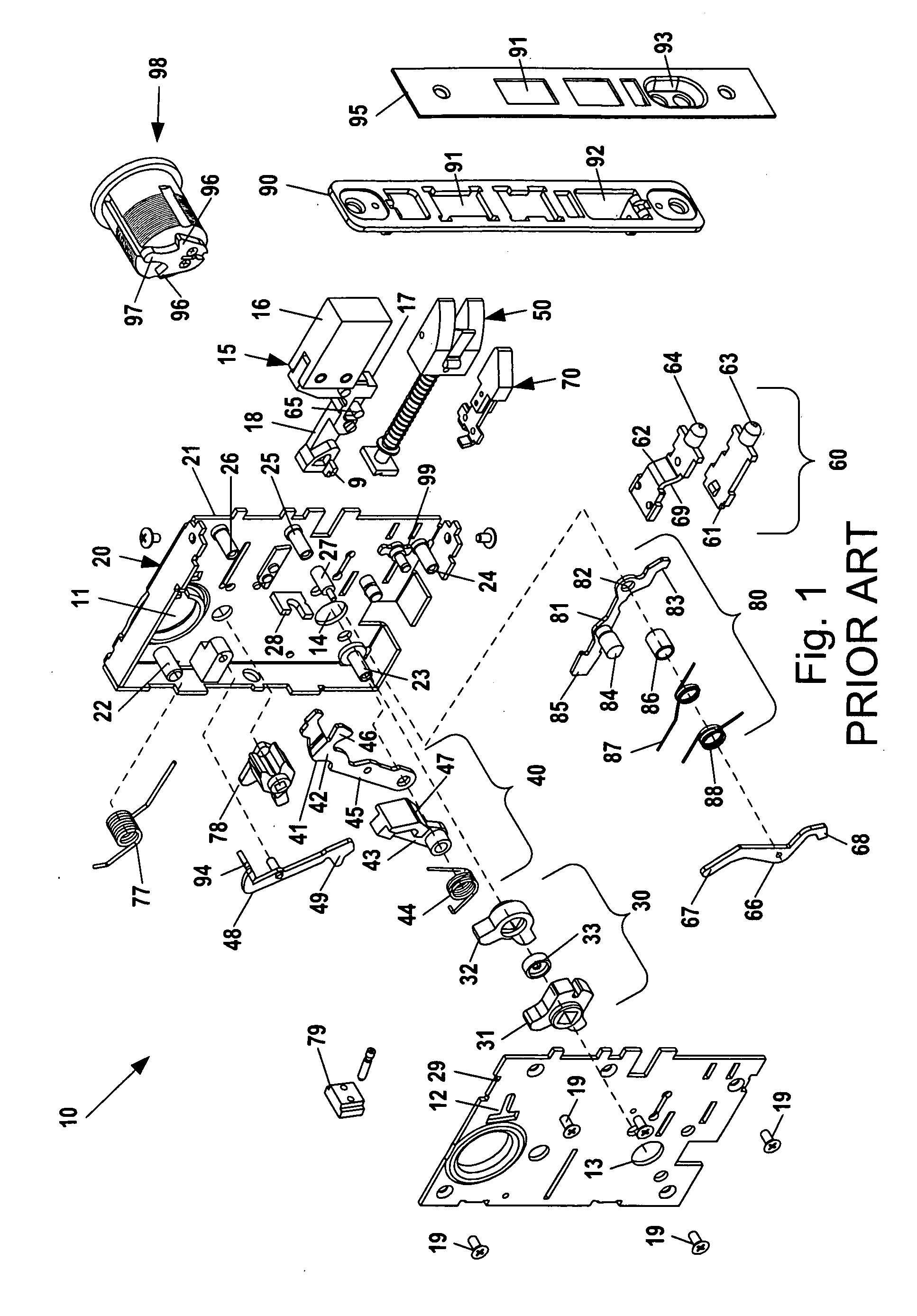

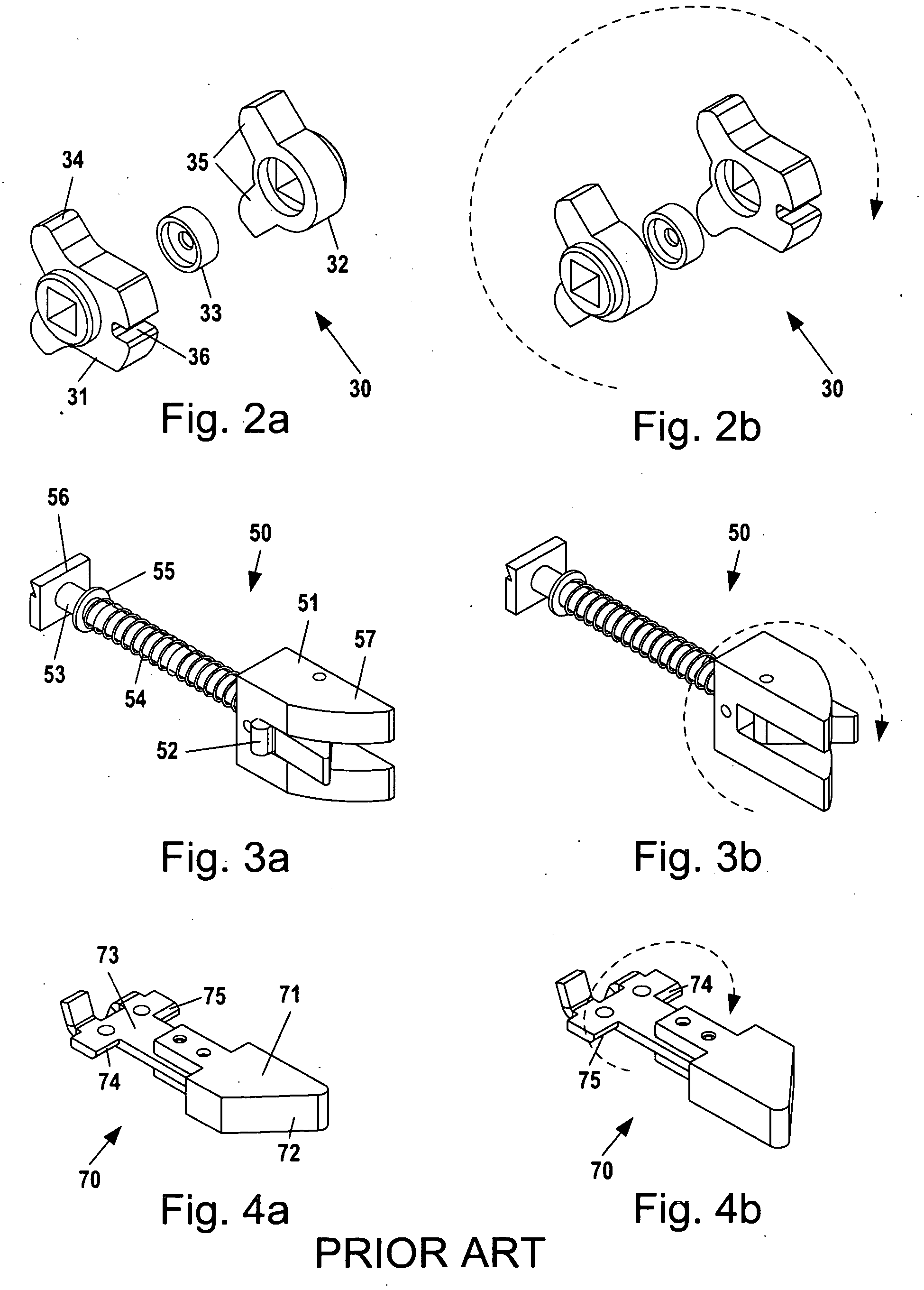

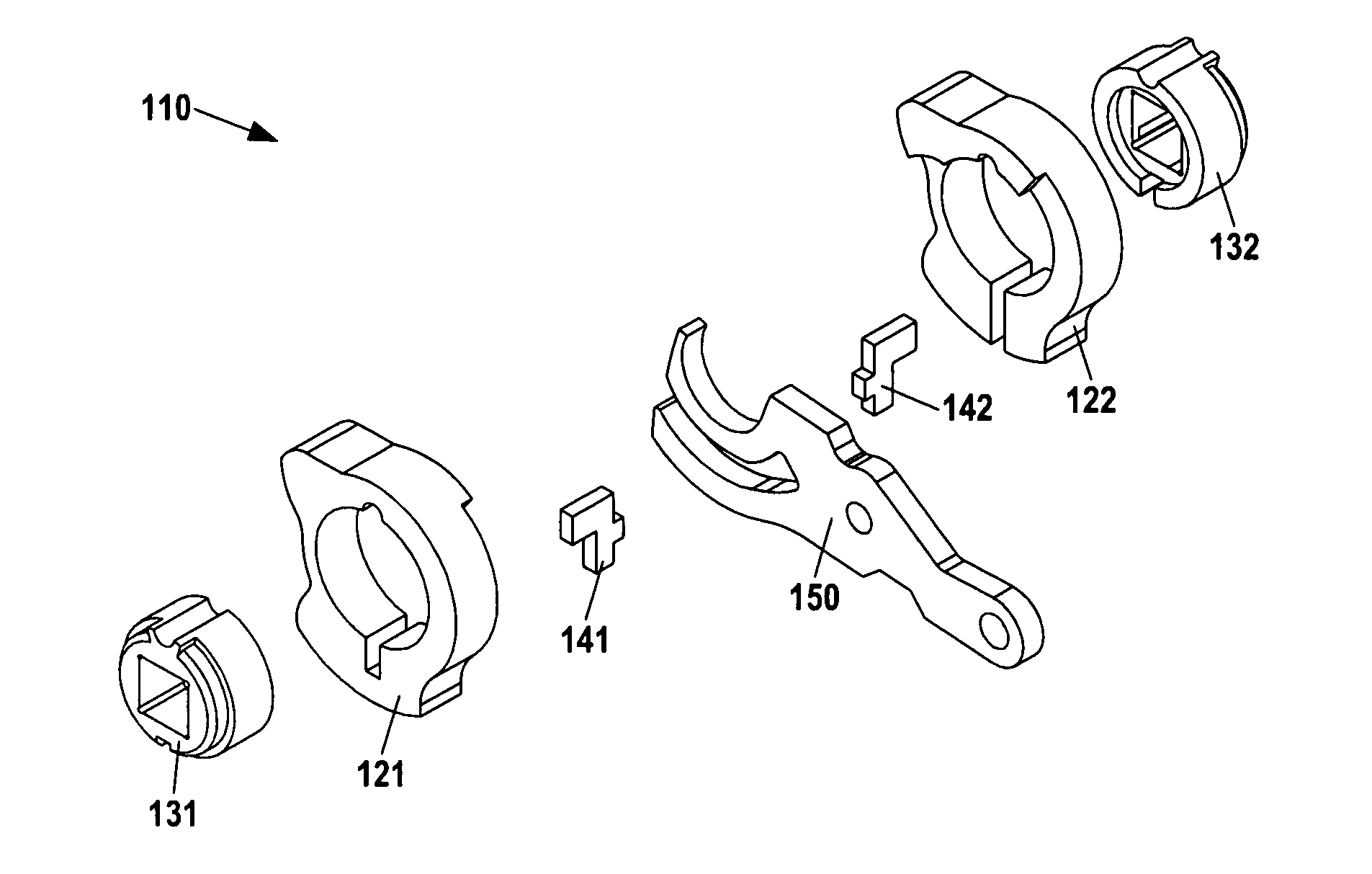

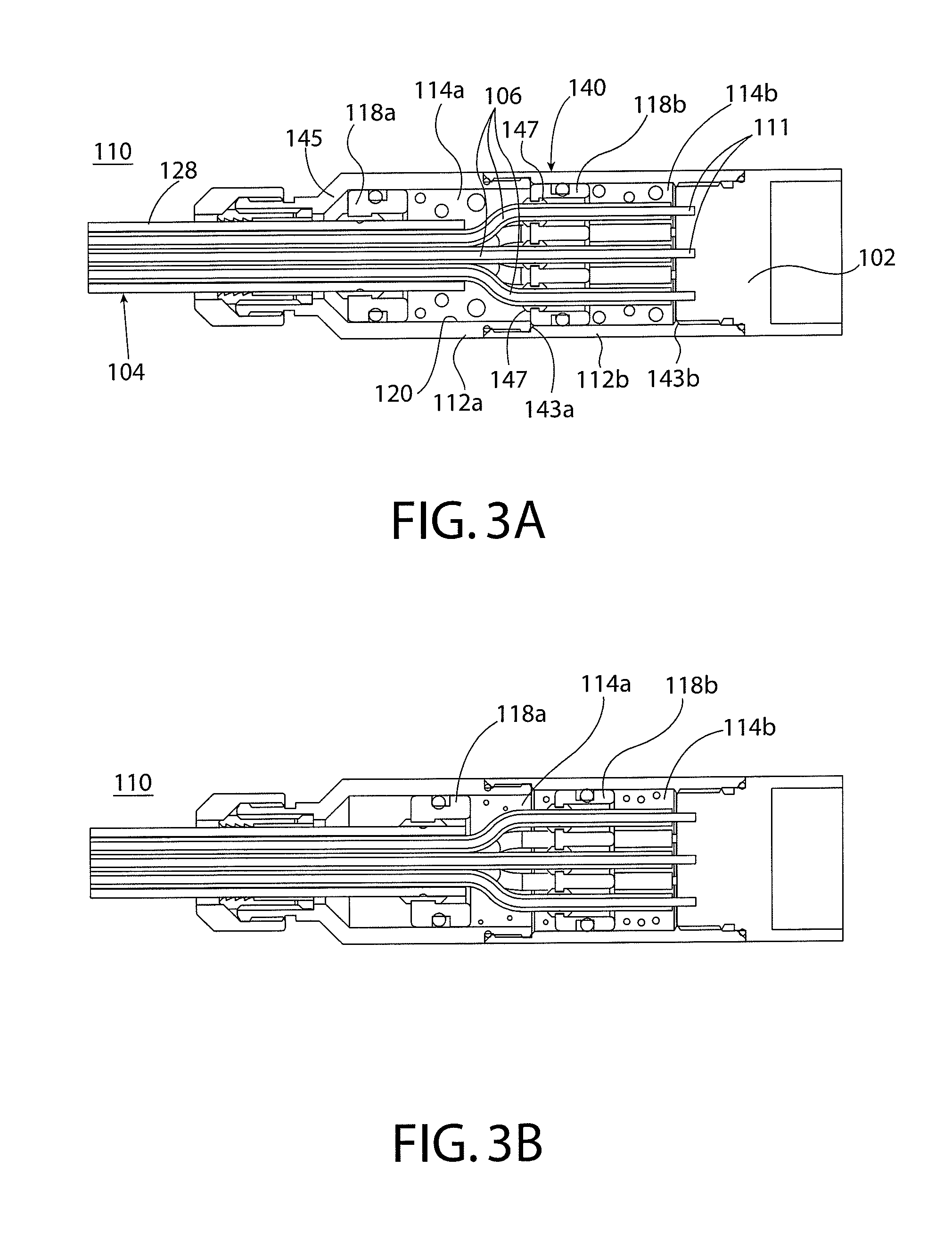

Several new components are provided for a mortise lock. First, a non-handed clutching assembly, including a pair of spindle hubs rotatable within a pair of outer hubs, is provided for a mortise lock. Second, a spindle-mounted lock-handing selector—which can be removed from one side of the lockset body while the lockset body is installed in the mortise of a door—is provided to set the handing of the clutching assembly. Third, an escapement mechanism is provided for a reciprocating-slide-based clutch-actuator assembly, enabling the slides to move into a position biasing a locker-carrying lever toward a hub-coupling position, even if the outer and spindle hubs are misaligned. Fourth, a guardbolt-actuated blocking assembly for a lockset is provided to block movement of the stop works or clutch works when the door is closed and the outside door handle is disabled.

Owner:TOWNSTEEL

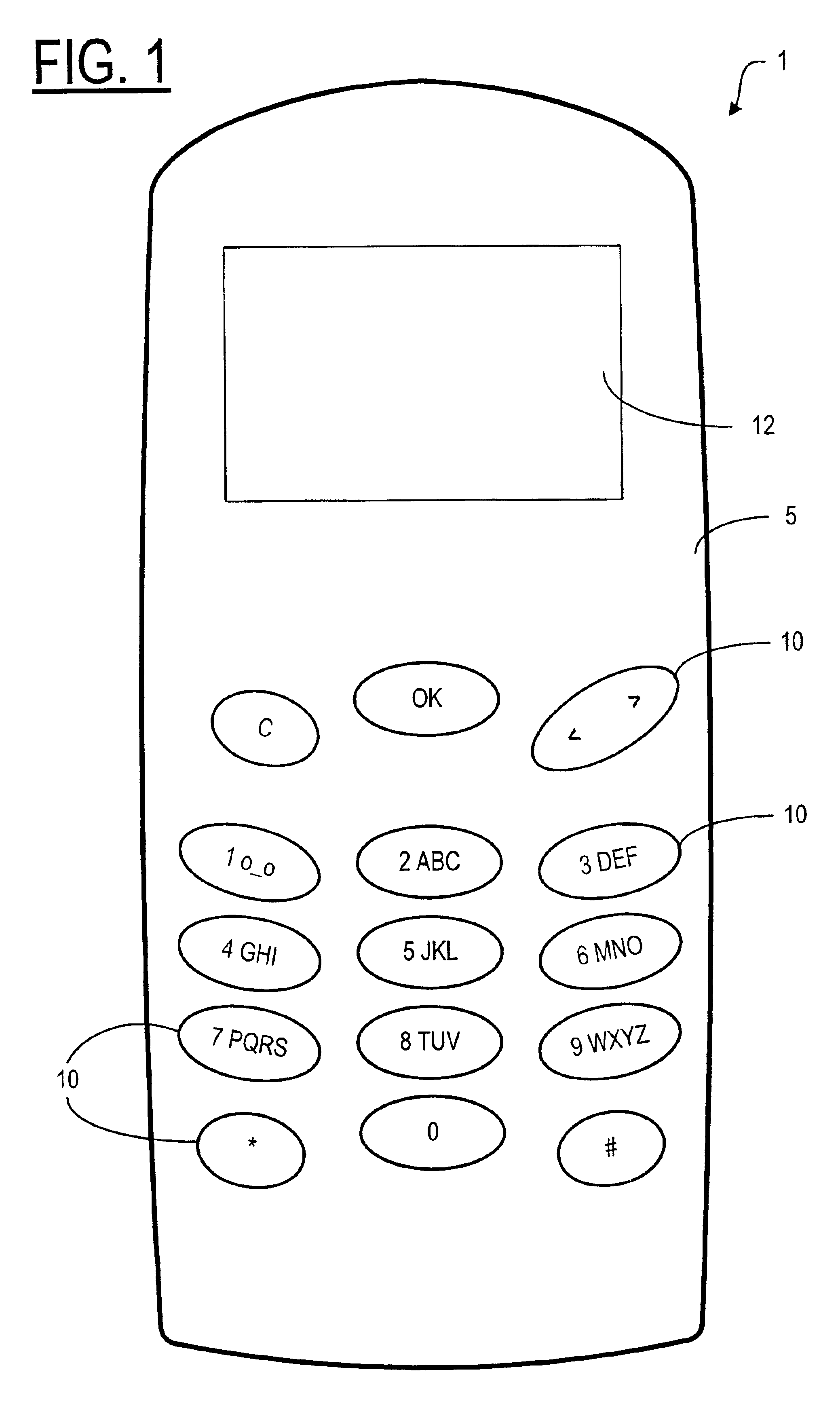

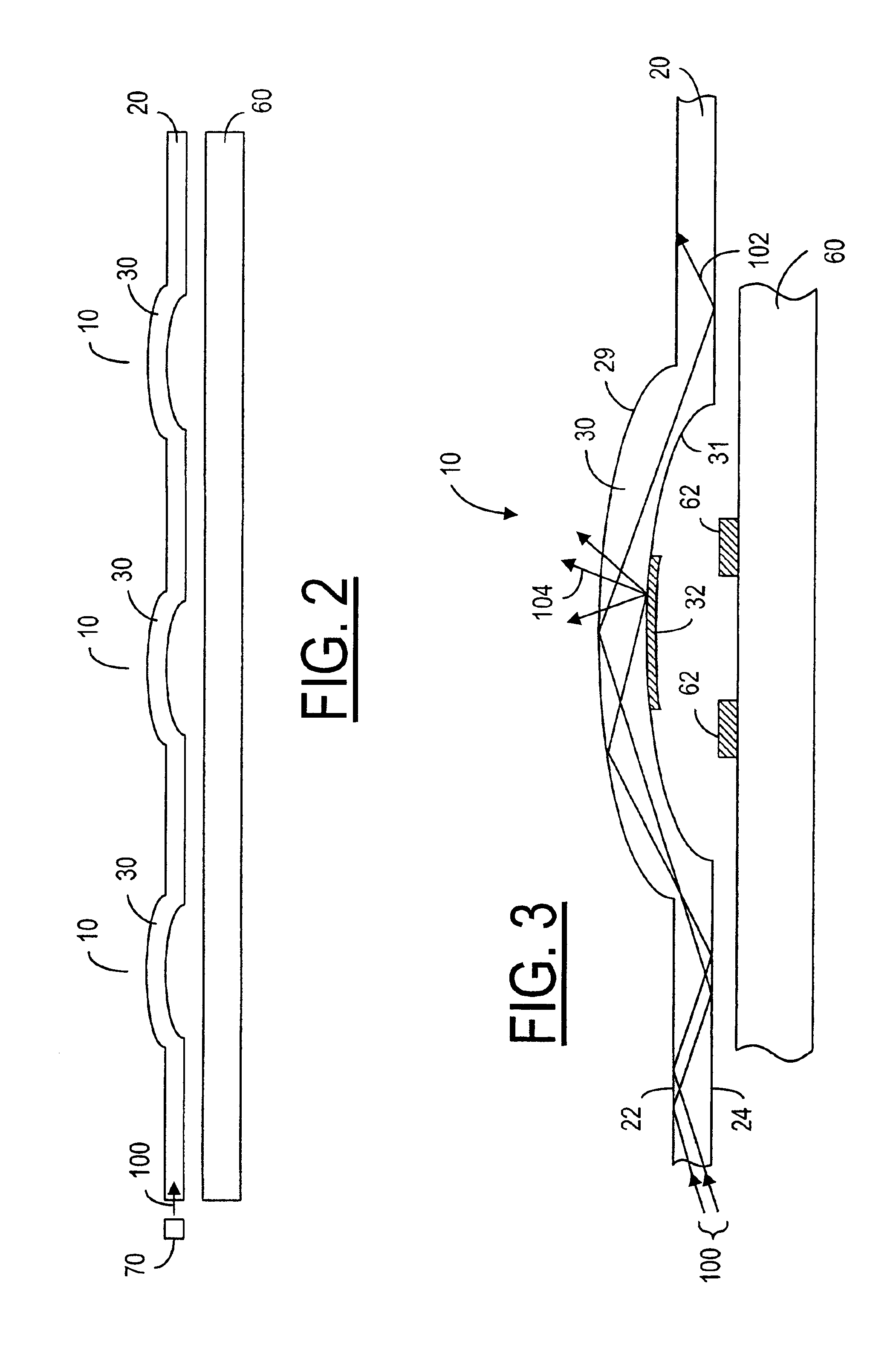

Integrated light-guide and dome-sheet for keyboard illumination

InactiveUS6926418B2Thermometer detailsInput/output for user-computer interactionKey pressingLight guide

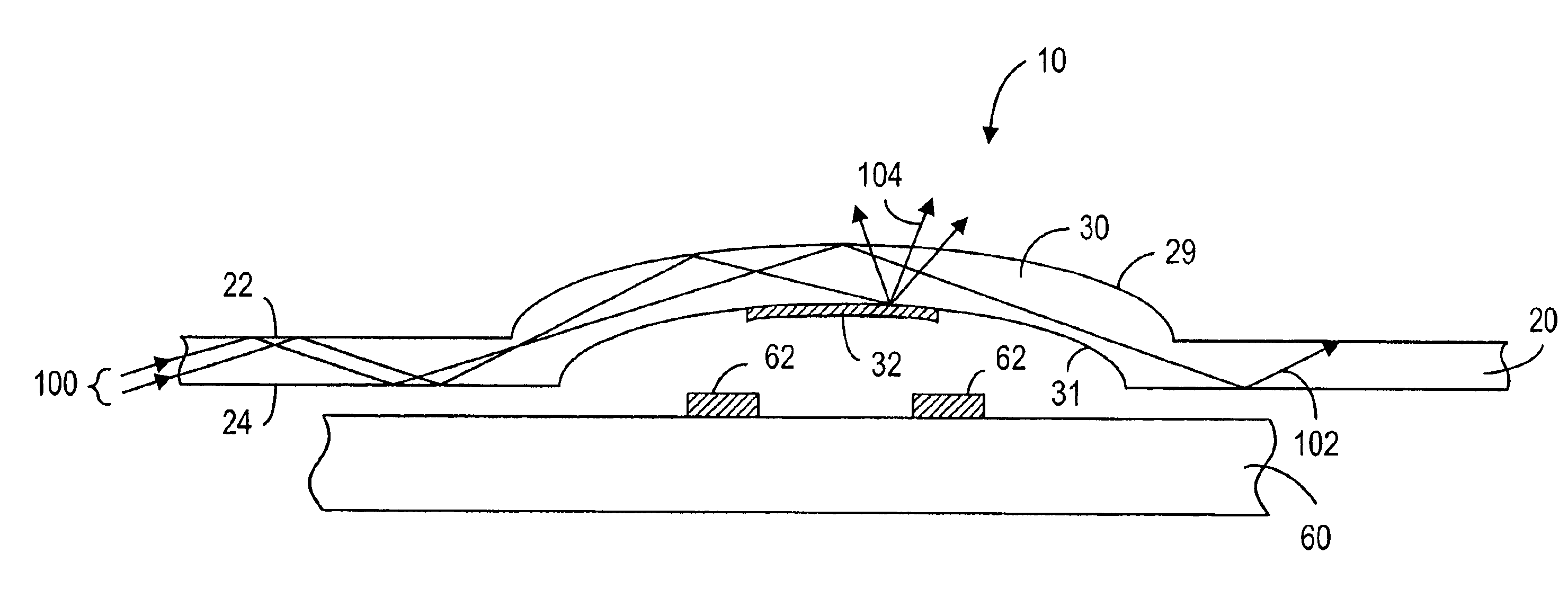

An integrated light guide for use in an electronic device having a plurality of key buttons to allow a user to input signals in the device, the light guide having a plurality of domes used as touch areas of the key buttons and a plurality of light escapement areas disposed at the domes. When coupled to a light source, a portion of the light received by the light guide from the light source escapes from the light escapement areas to illuminate the key buttons. Preferably, each dome has one or more electrically conducting patches provided under the dome such that when a touch area is pushed by the user, these patches are caused to interact with an electronic circuit placed under the light guide for activating a key.

Owner:NOKIA TECHNOLOGLES OY

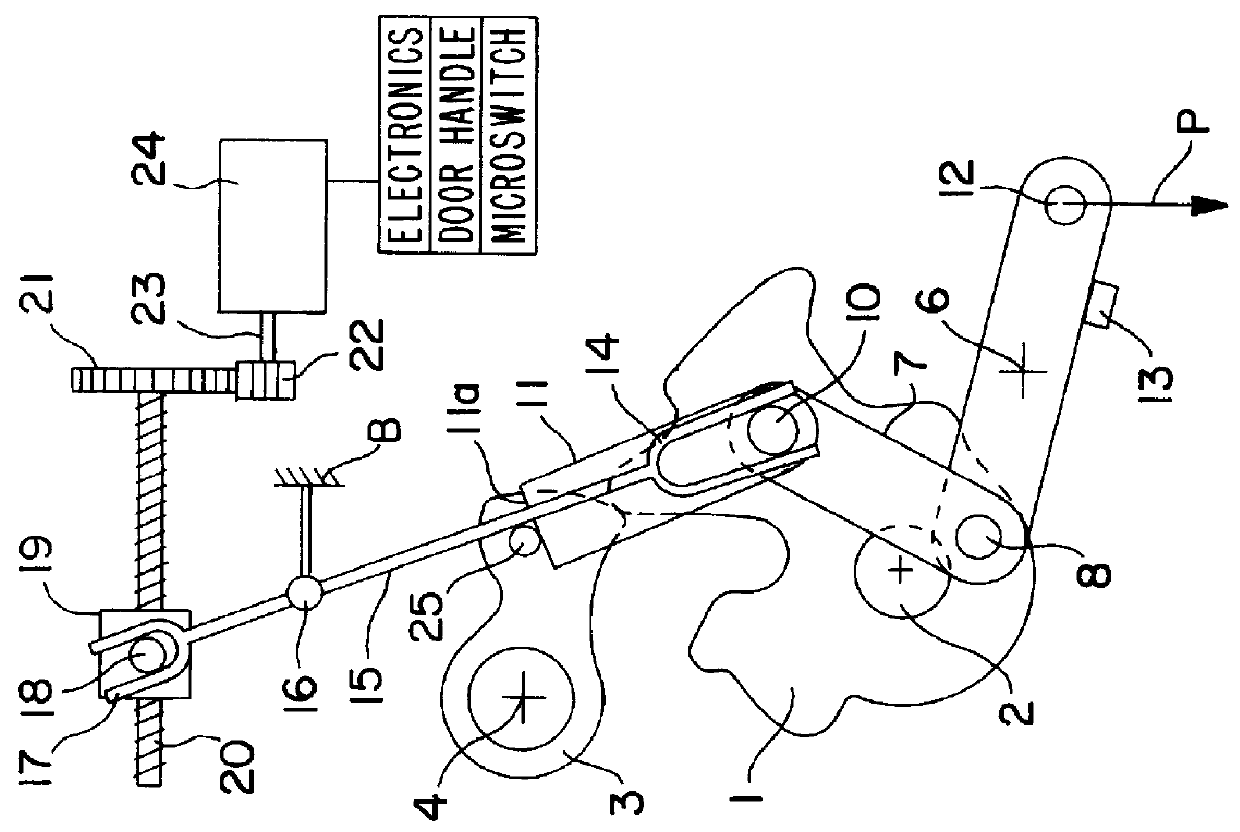

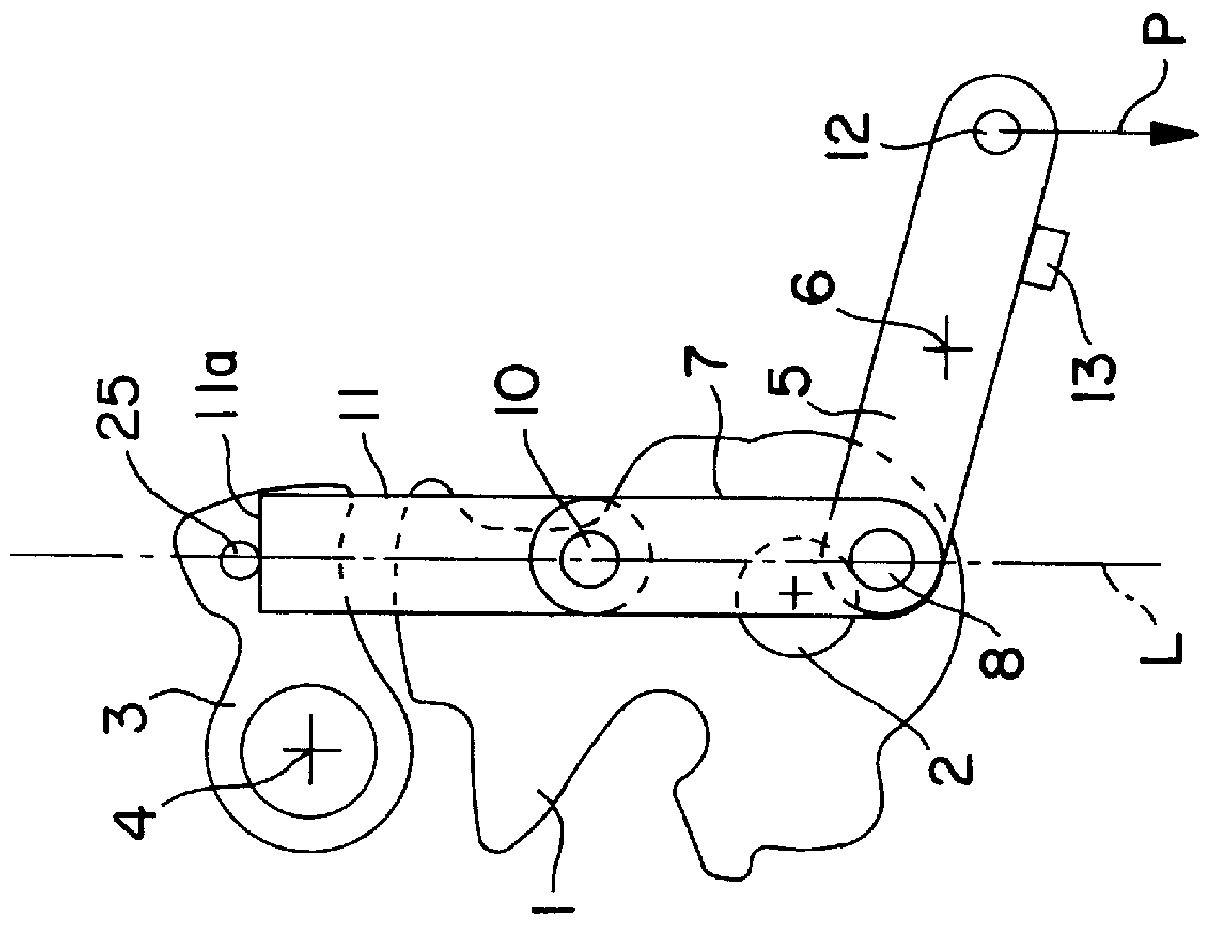

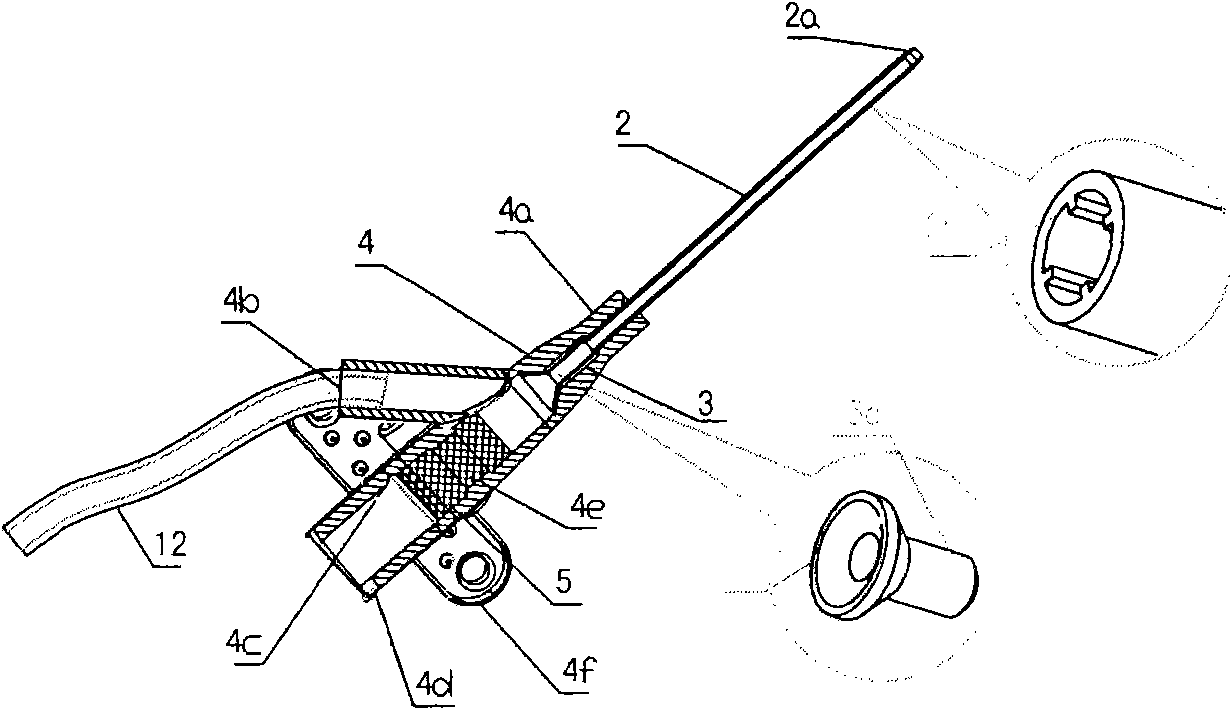

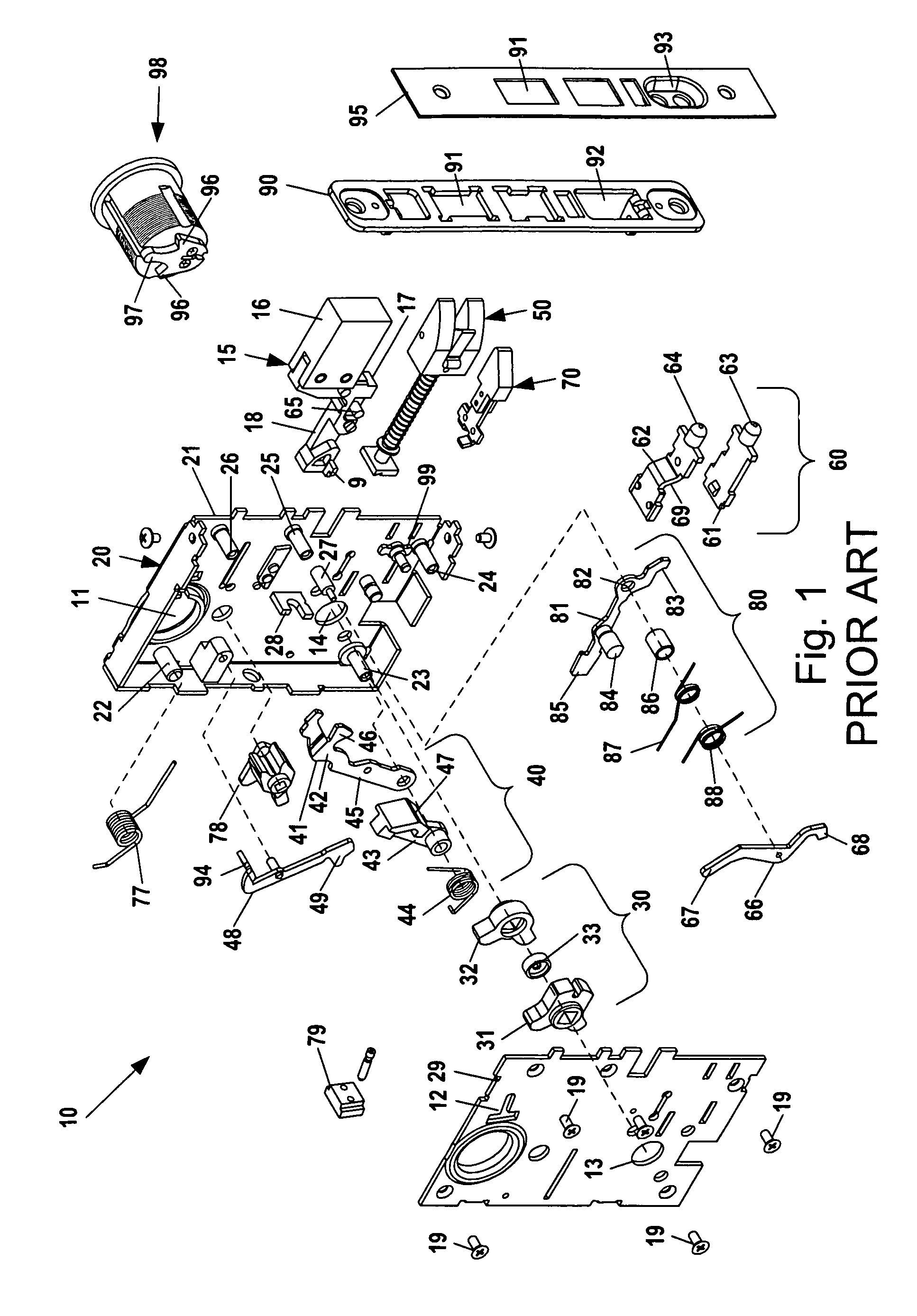

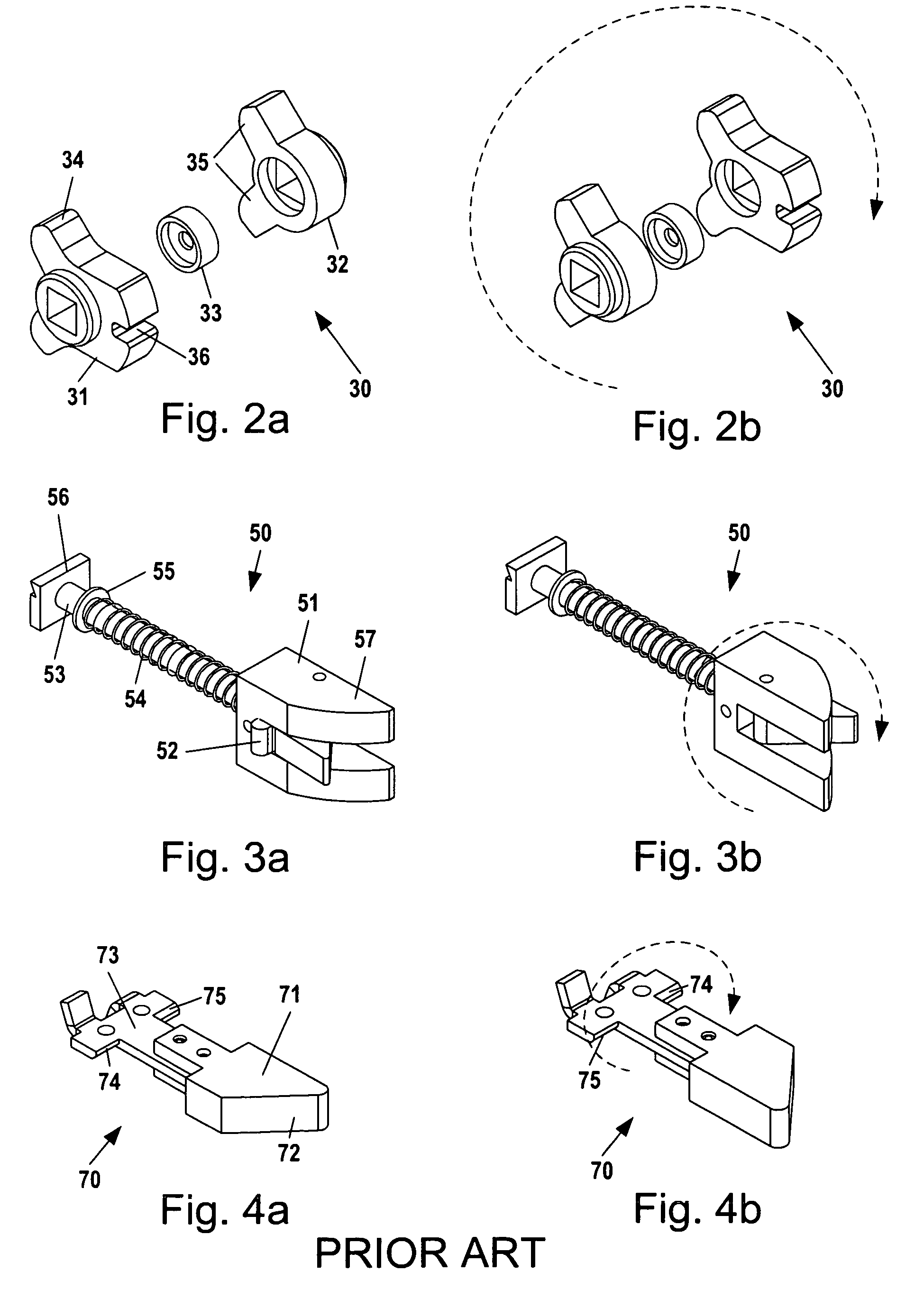

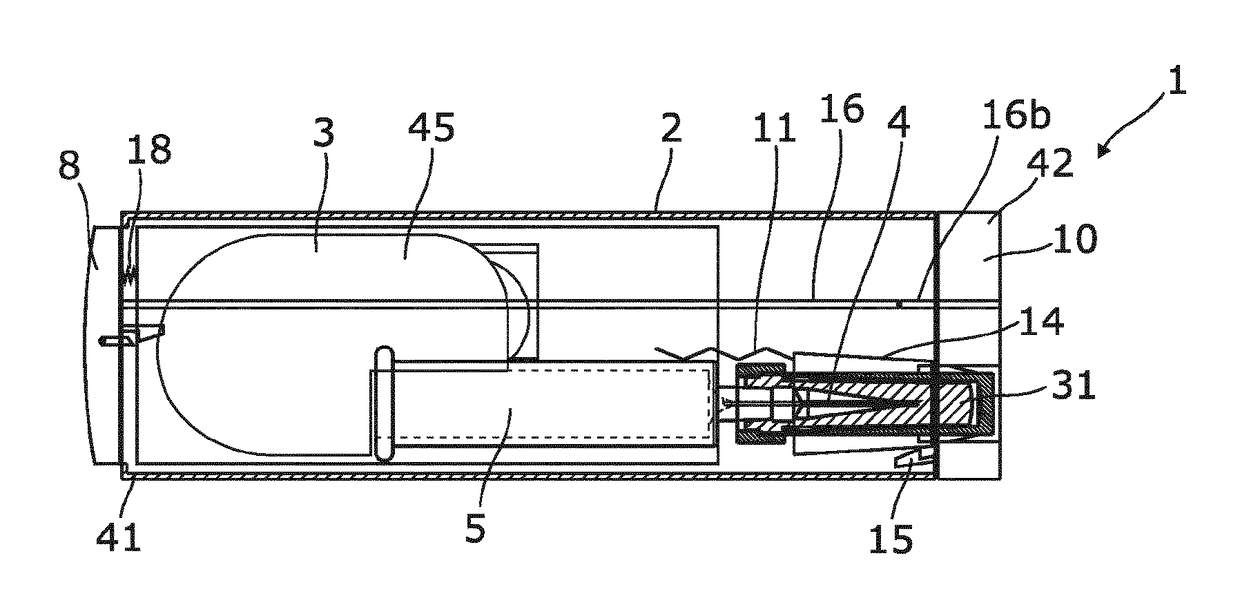

Electrically locked motor vehicle door lock

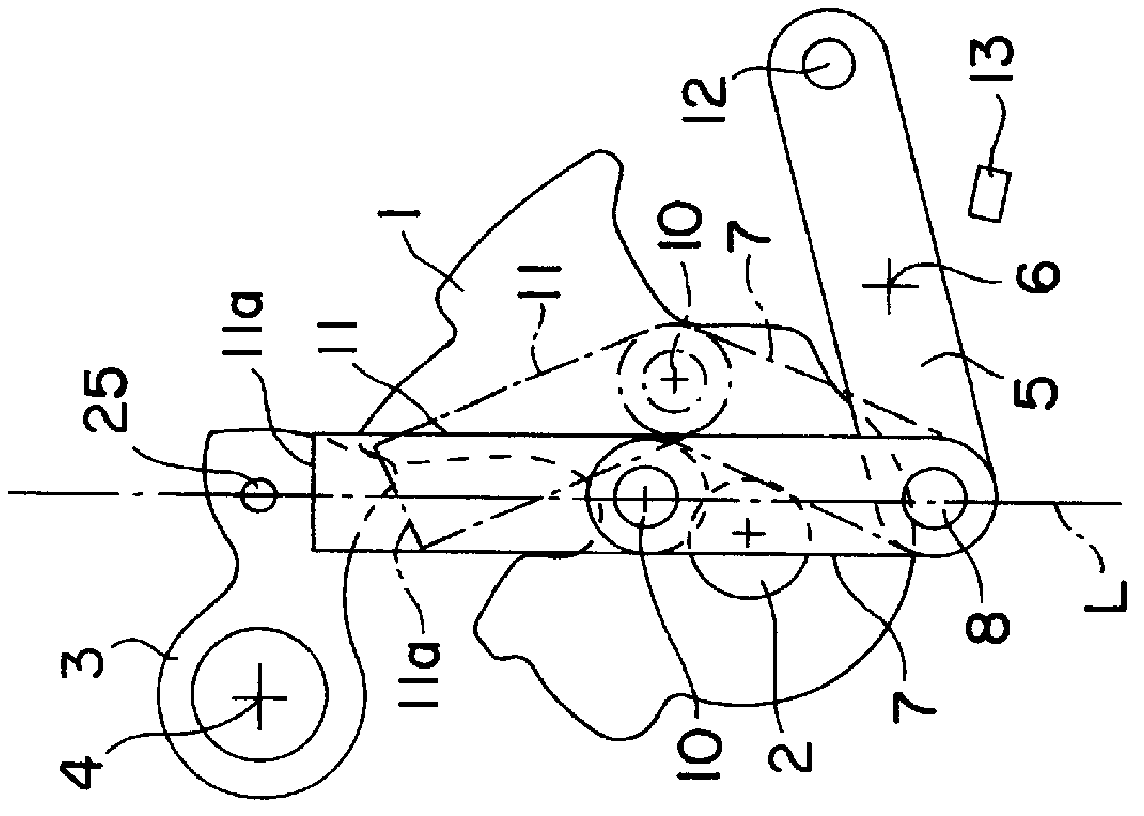

Motor vehicle door lock comprising: a latch (1); a pawl (3) which can adopt an "escapement" position; an operating member which, on the one hand, can adopt either an active position in which it acts, during its actuating movement, on the pawl to place it in the "escapement" position, or an inhibited position in which it has no effect on the pawl and, on the other hand, may experience an actuating movement in response to actuation of the door handle; and an electric device (15-24) which responds at least to an unlock signal by moving the operating member from its inhibited position as far as its active position, characterized in that the operating member consists of a set of two links (7, 11) articulated together by a hinge joint (10), of which one (11) of the links comprises a thrust surface (11a) which is positioned in such a way that, in the active position, the thrust surface comes up against and carries along a peg (25) on the pawl (3), during the actuating movement, until the said pawl has been placed in the "escapement" position, and that in the inhibited position, the thrust surface at most comes into contact with the said peg, during the actuating movement so that the operating member has no action on the pawl, and of which the other link (7) is articulated to an opening lever (5), the electric device comprising a lock / unlock lever (15) co-operating with the hinge joint (10) to make it pivot about the articulation (8).

Owner:VALEO SECURITE HABITACLE

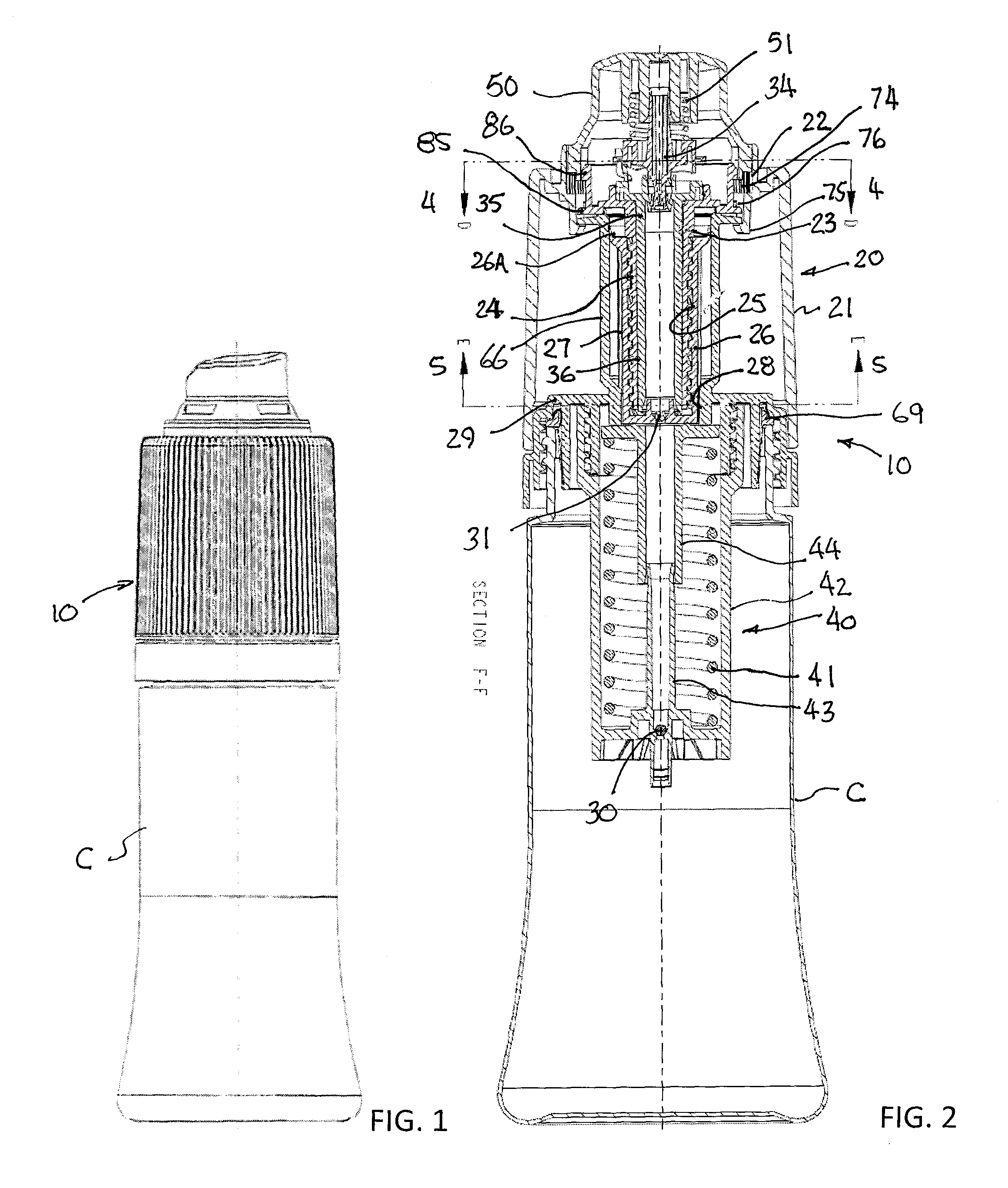

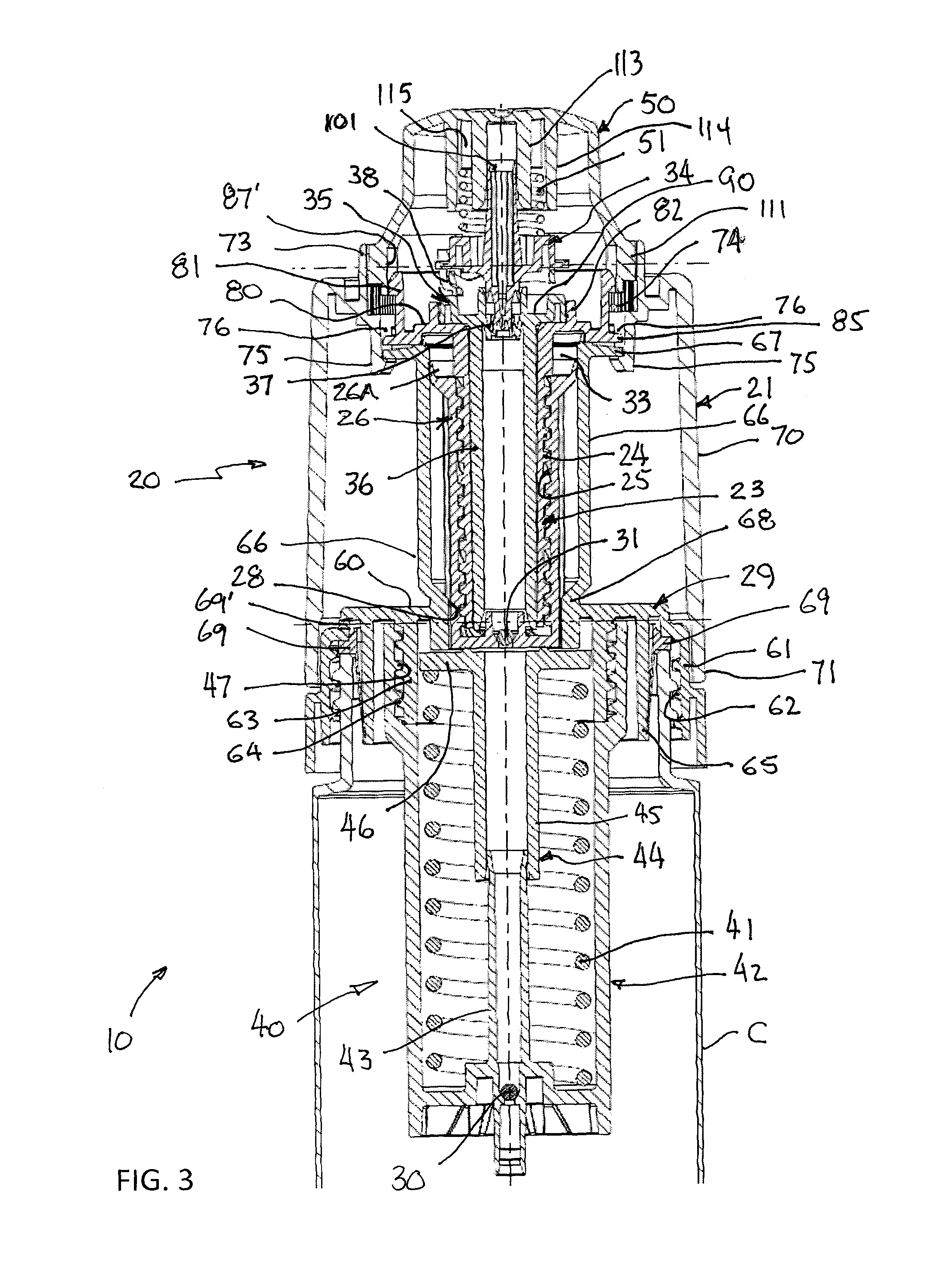

Sports Bottle and Fluid Dispensing system, device, and method.

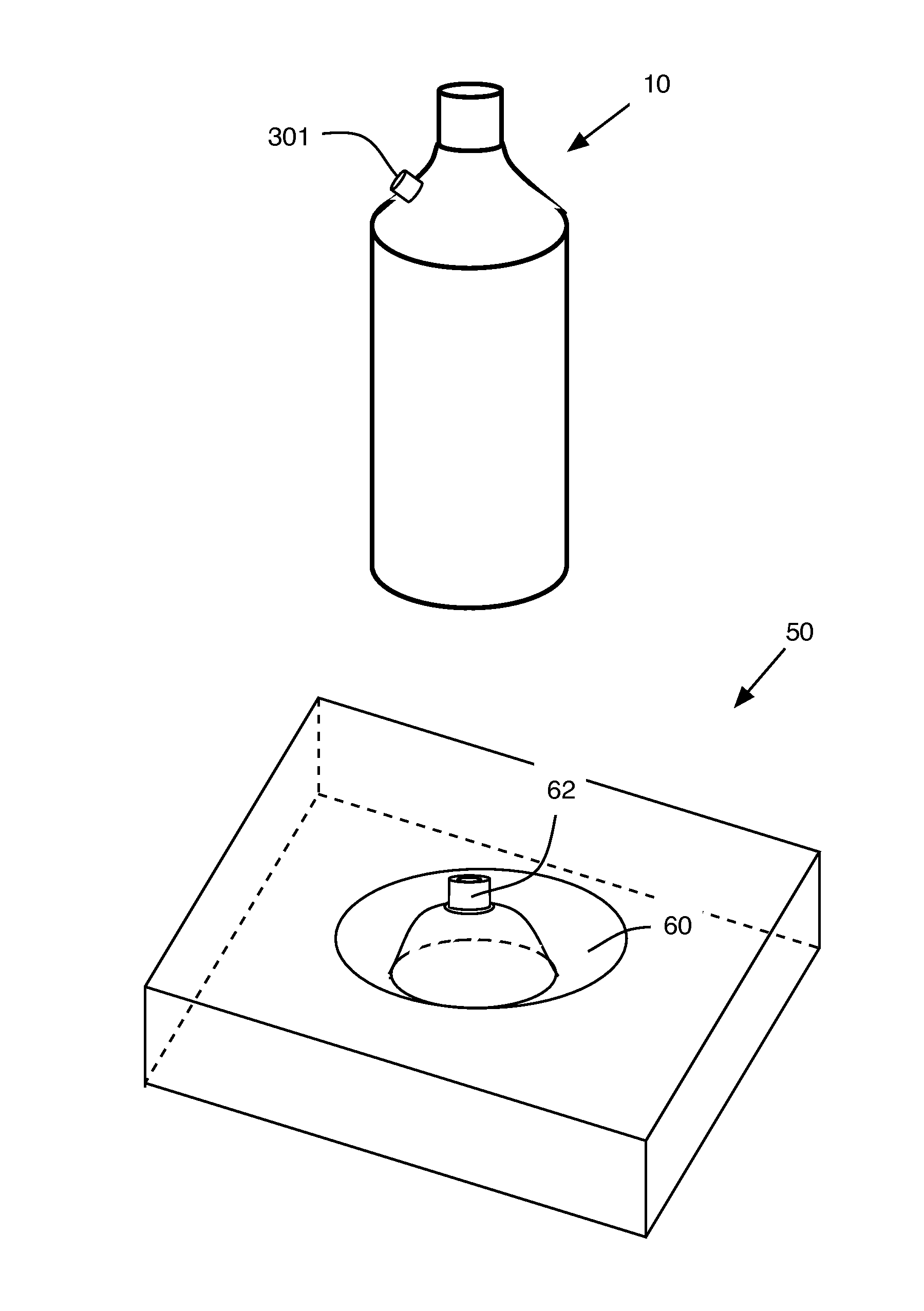

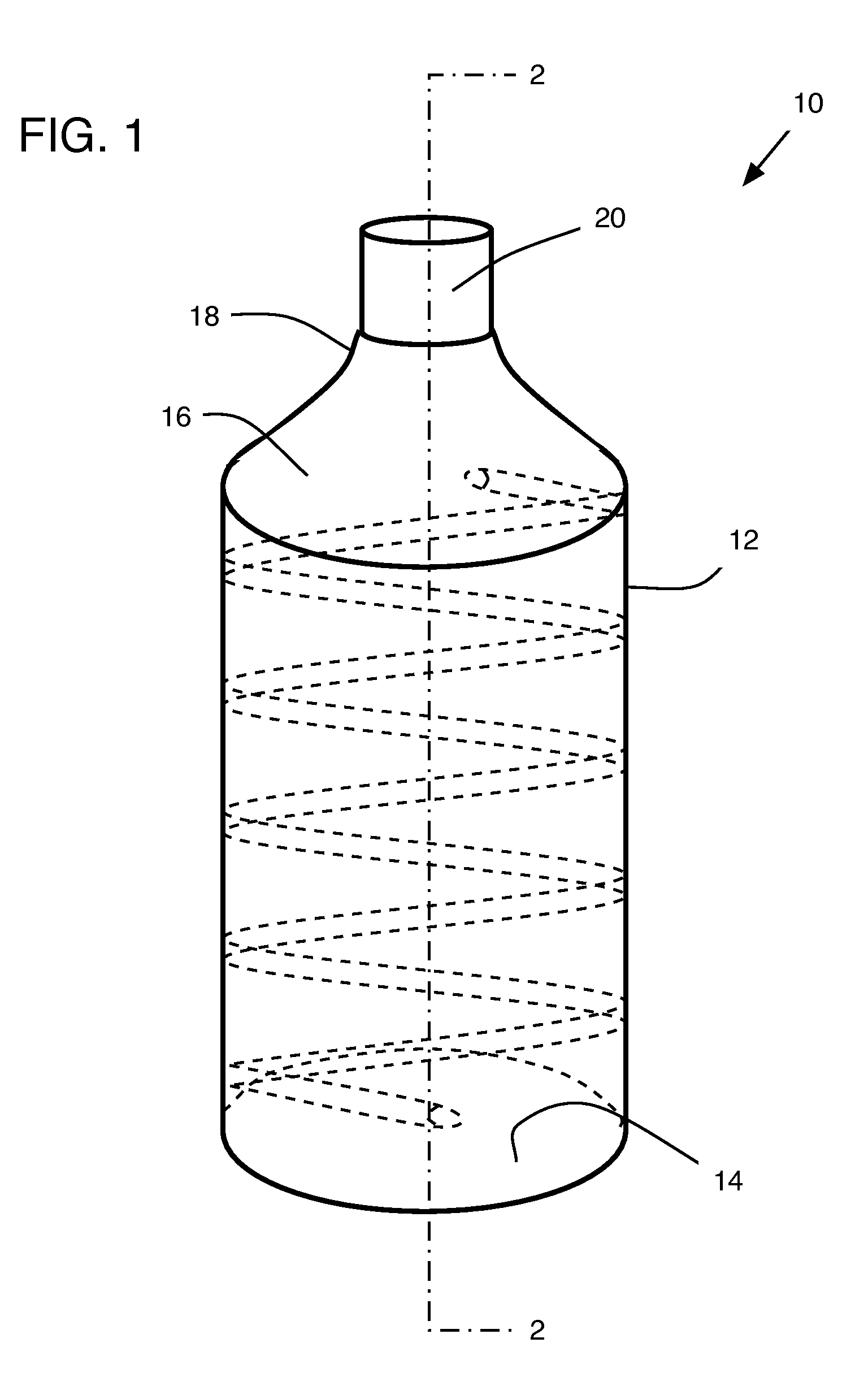

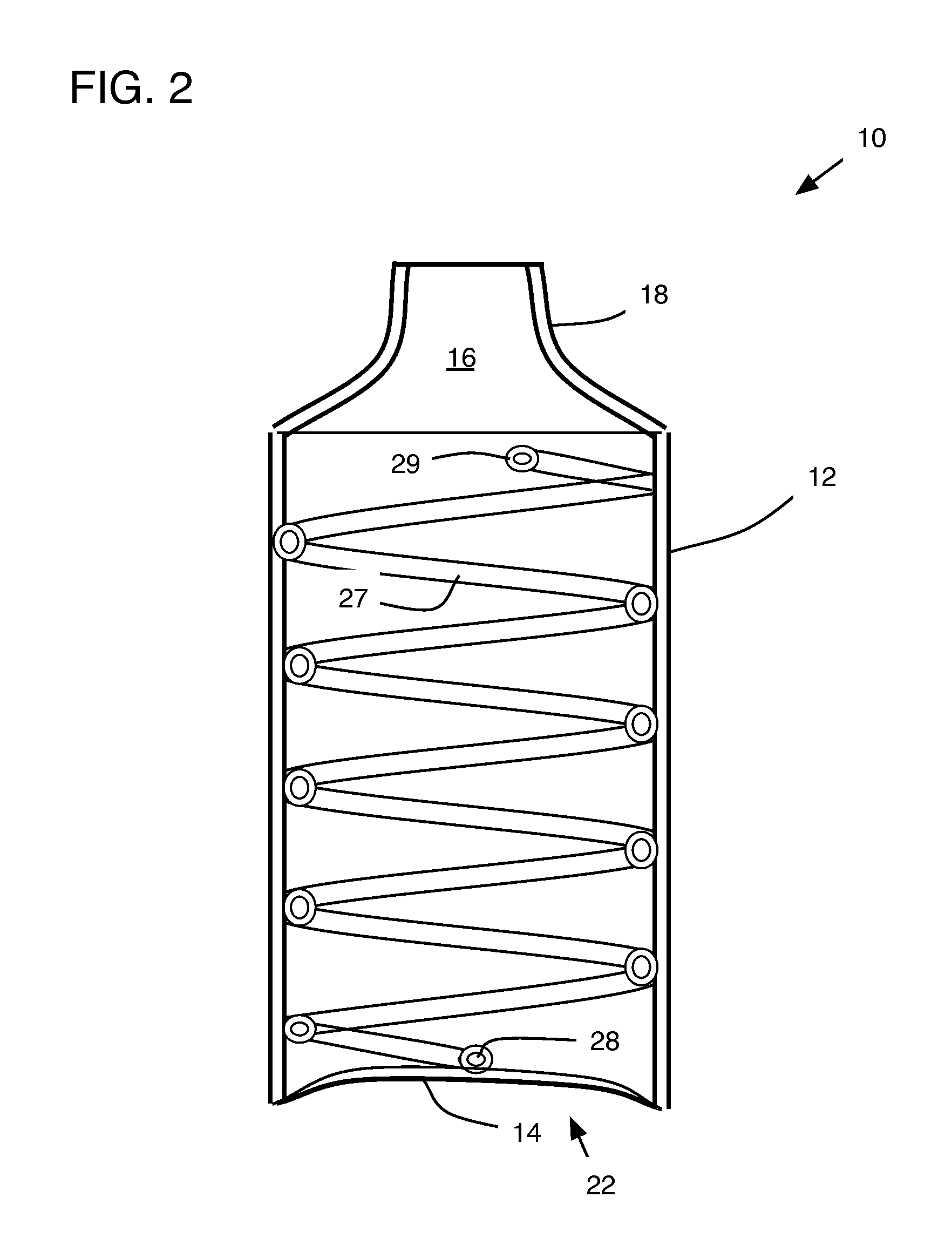

A sports bottle having a conventional open top with fitting lid, generally vertical sidewalls forming a cylinder with a bottom includes a valve mechanism for filling the bottle from a position other than the open top. The bottle further includes means for identifying the bottle to a dispensing machine. The dispensing machine interfaces with the valve mechanism to enable fluid to flow into the bottle to a pre-determined level. The valve mechanism further includes means for enabling the escapement of air or other gases during the fluid filling operation. The dispensing machine begins a pressurized flow of filtered water or other desired fluid when the bottle is positioned on the machine.

Owner:IBSIES FADI

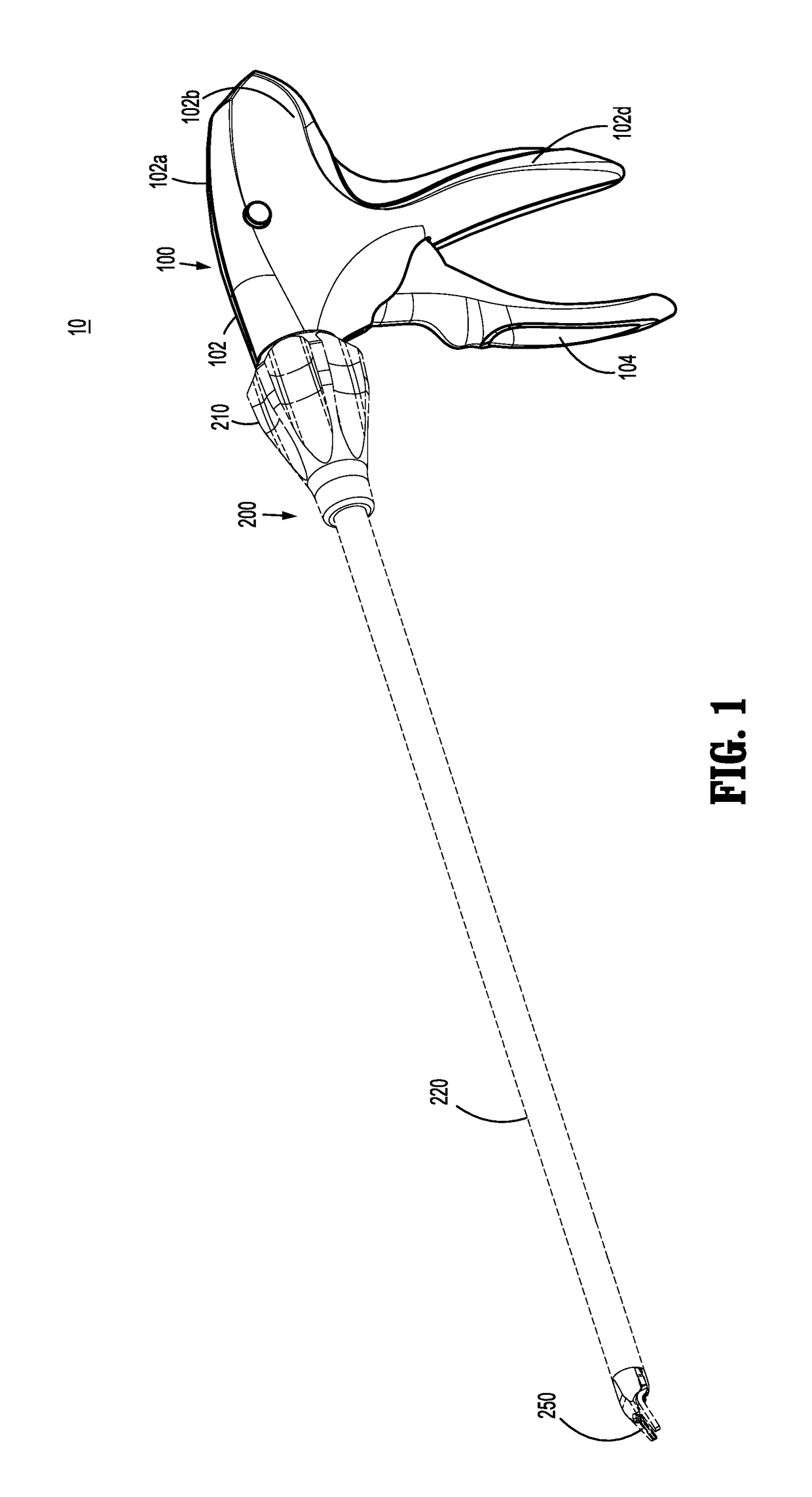

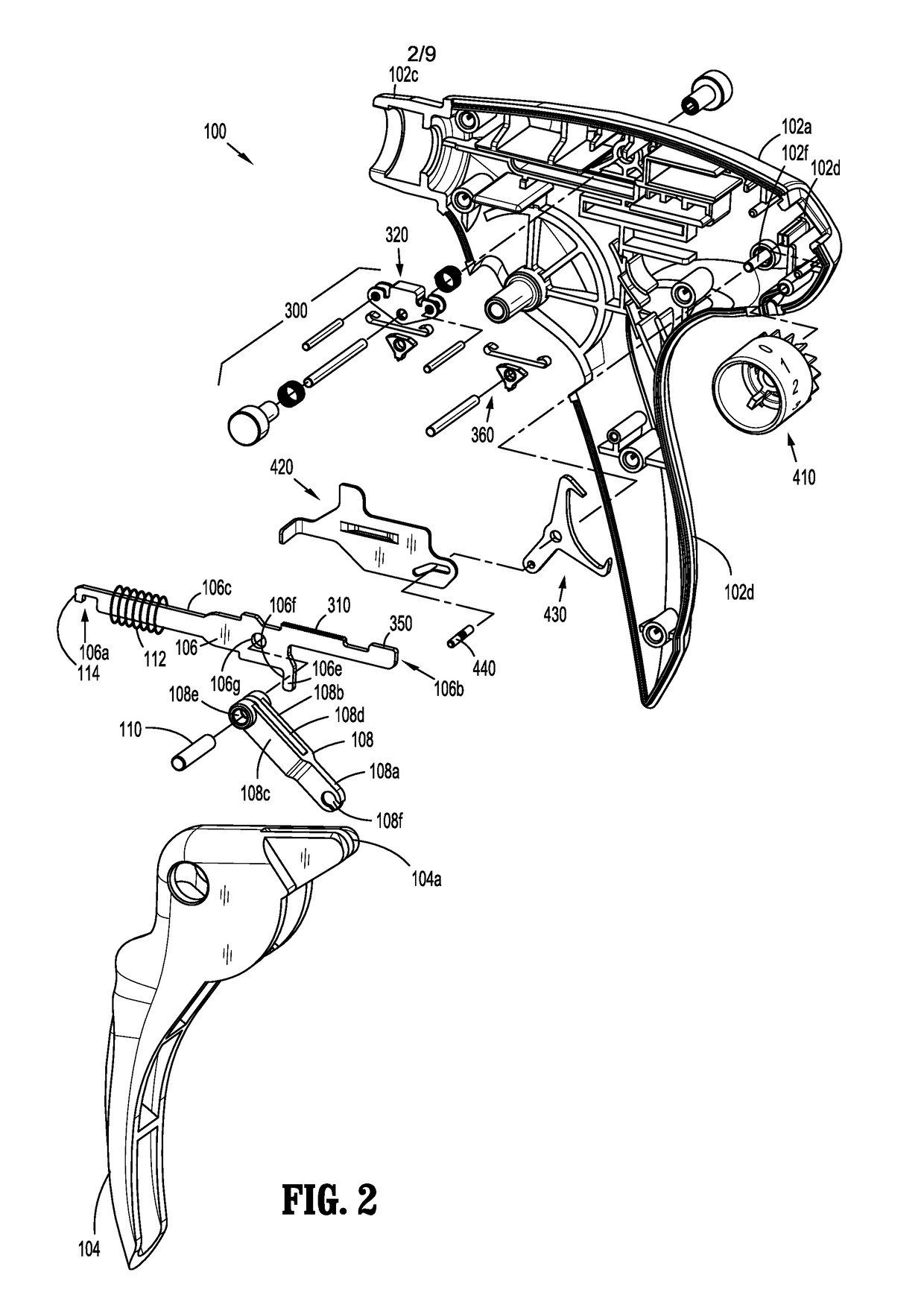

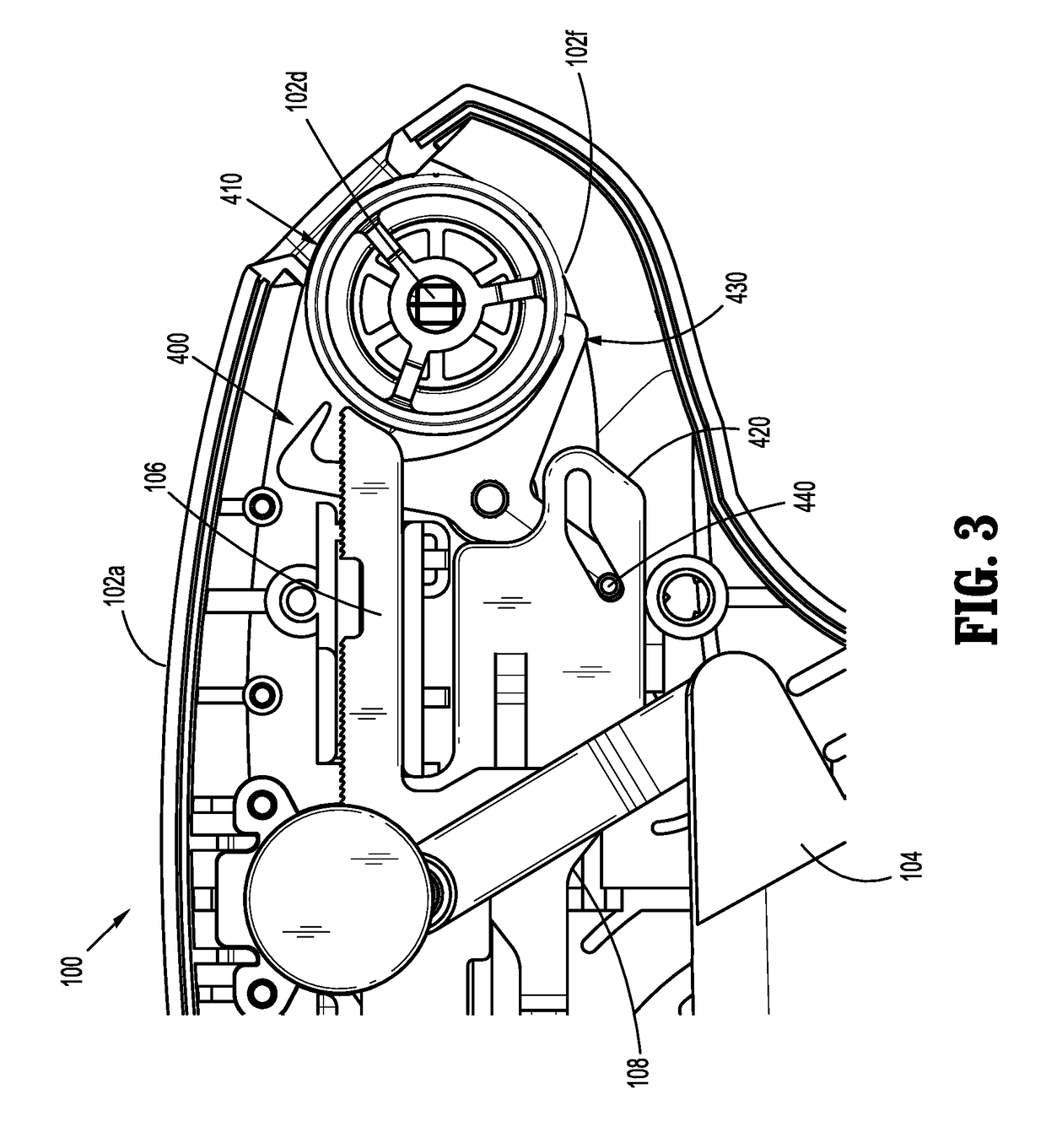

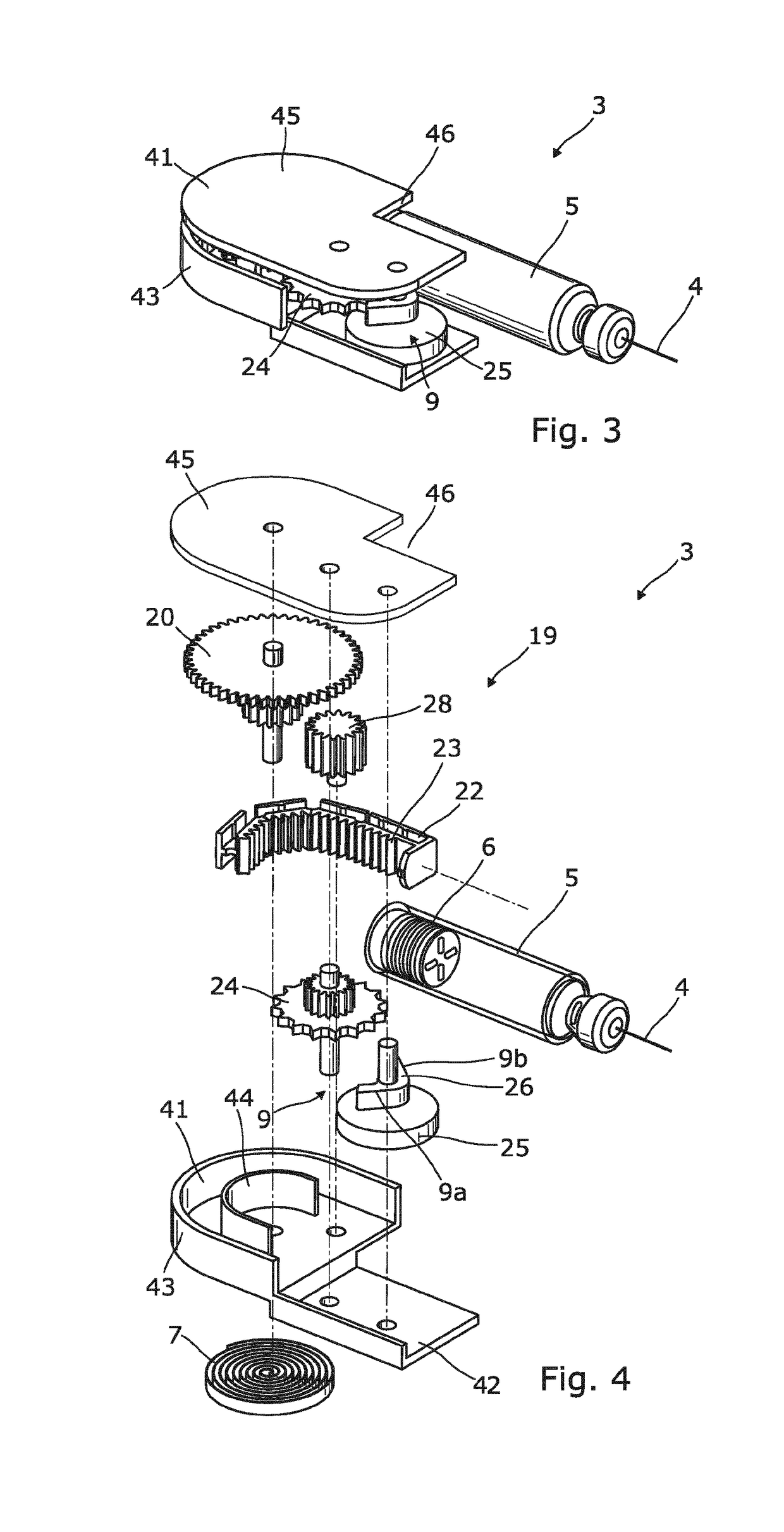

Clip counting mechanism for surgical clip applier

A clip counting mechanism for use with a surgical clip applier includes a display gear rotatably supported within a handle housing of the surgical clip applier and including an outer surface having a plurality of numbers disposed thereon, a biasing element in mechanical communication with the display gear and rotatably biasing the display gear, a counter switch reciprocally disposed within the handle housing and defining a cam slot therethrough, and an escapement gear rotatably supported within the handle housing and defining a proximal end portion in mechanical communication with the display gear and a distal end portion in mechanical communication with the cam slot. Translation of the counter switch causes the cam slot to cam the escapement gear and selectively disengage and then re-engage the display gear to enable the display gear to rotate a predetermined angle of rotation.

Owner:TYCO HEALTHCARE GRP LP

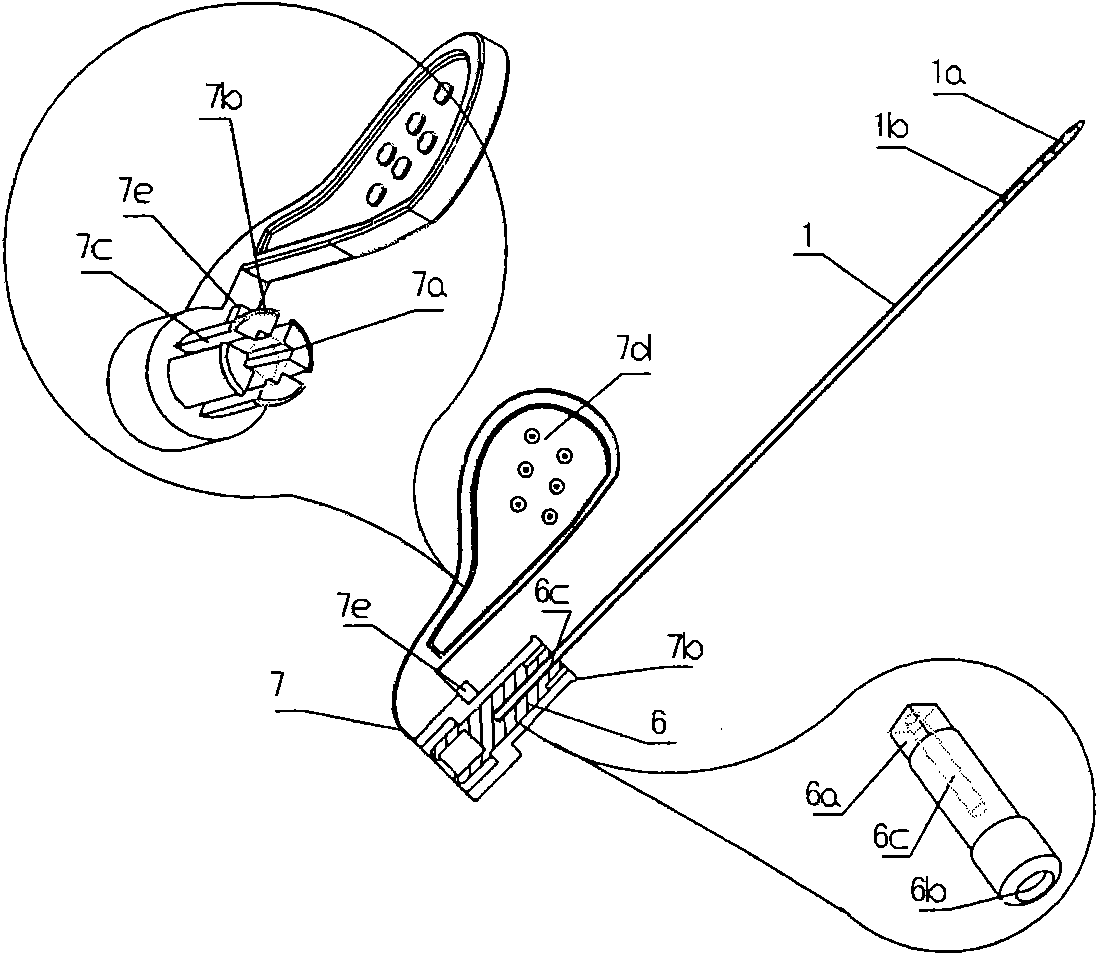

Safety venous indwelling needle with needleless interface positive-pressure closing valve

InactiveCN101879341AGuaranteed operating spacePrevent prolapseGuide needlesInfusion needlesVeinVenous blood flow

The invention discloses a safety venous indwelling needle with a needleless interface positive-pressure closing valve, comprising a puncture needle, a puncture needle seat and a handle, wherein, the puncture needle is formed into a puncture needle protection assembly by a puncture protection sleeve, a spring, a plunger latch and an escapement clamp; a venous indwelling needle is formed by an indwelling needle soft tube, a puncture needle guide tube, an indwelling needle seat and a sealing plug; a needless interface positive-pressure closing valve is formed by a shell, a piston, a seal ring, a spring, a connecting soft tube and a base; the positive-pressure closing valve and a liquid out plug separated structure do not involve the indwelling needle, are easy to operate, can reduce pain, and avoid the indwelling needle from taking off; the puncture needle protection sleeve can protect the puncture needle before and after the use of the indwelling needle, has the advantages of without added length, small and exquisite volume, good hand feel, accurate control, high puncture precision, and convenience for puncture operation and the like, can automatically retract to protect the puncture needle, can avoid acupuncture injury on medical workers, has positive pressure closing function, can prevent venous blood flowing back and overflowing, prevent blood from being polluted and avoid the blood from forming blocking in the indwelling needle, does not need heparin tube closing and other operation, has needless connection function, and can avoid needle injury, improve working efficiency and protect the safety of medical workers and patients.

Owner:张亚平

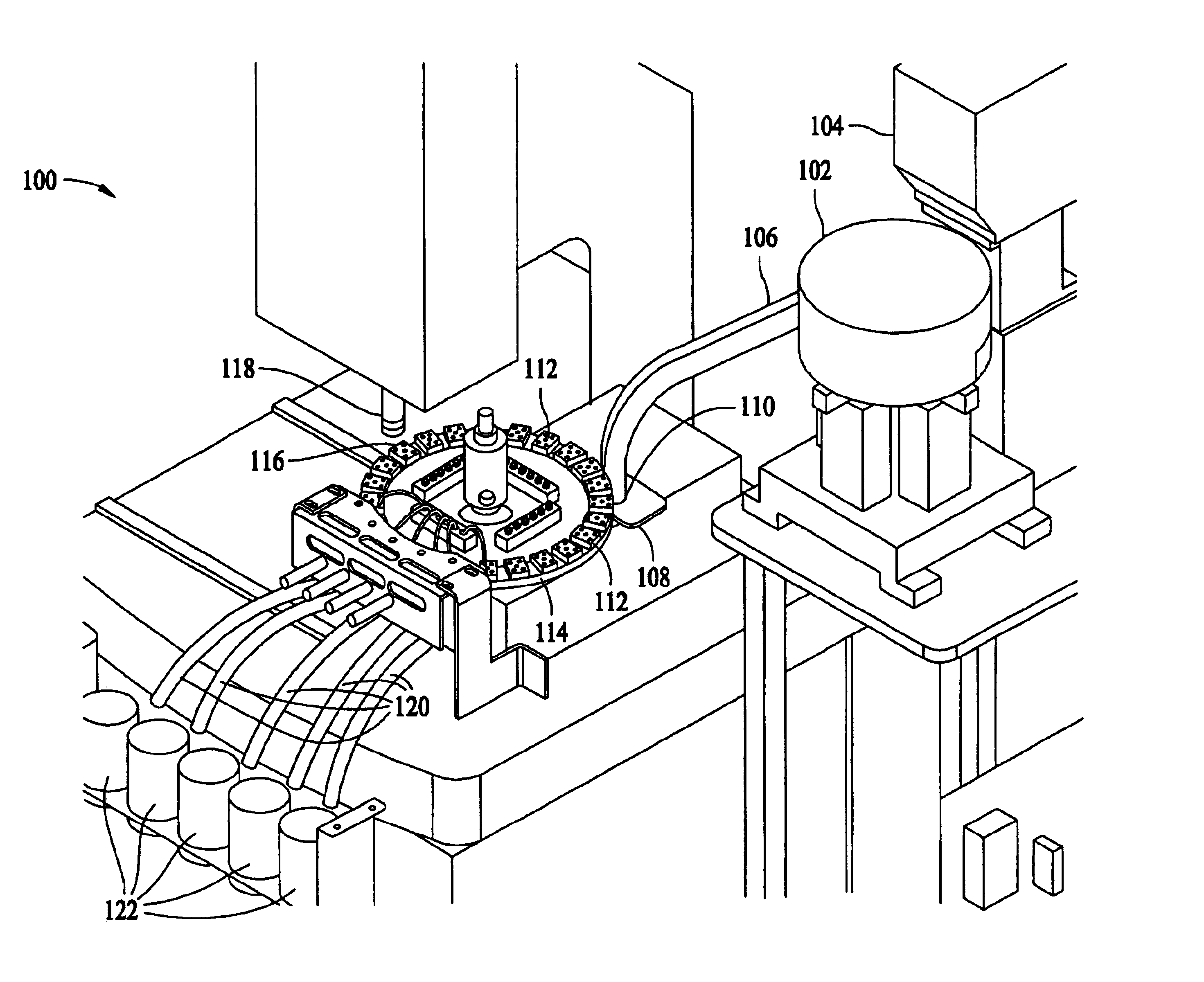

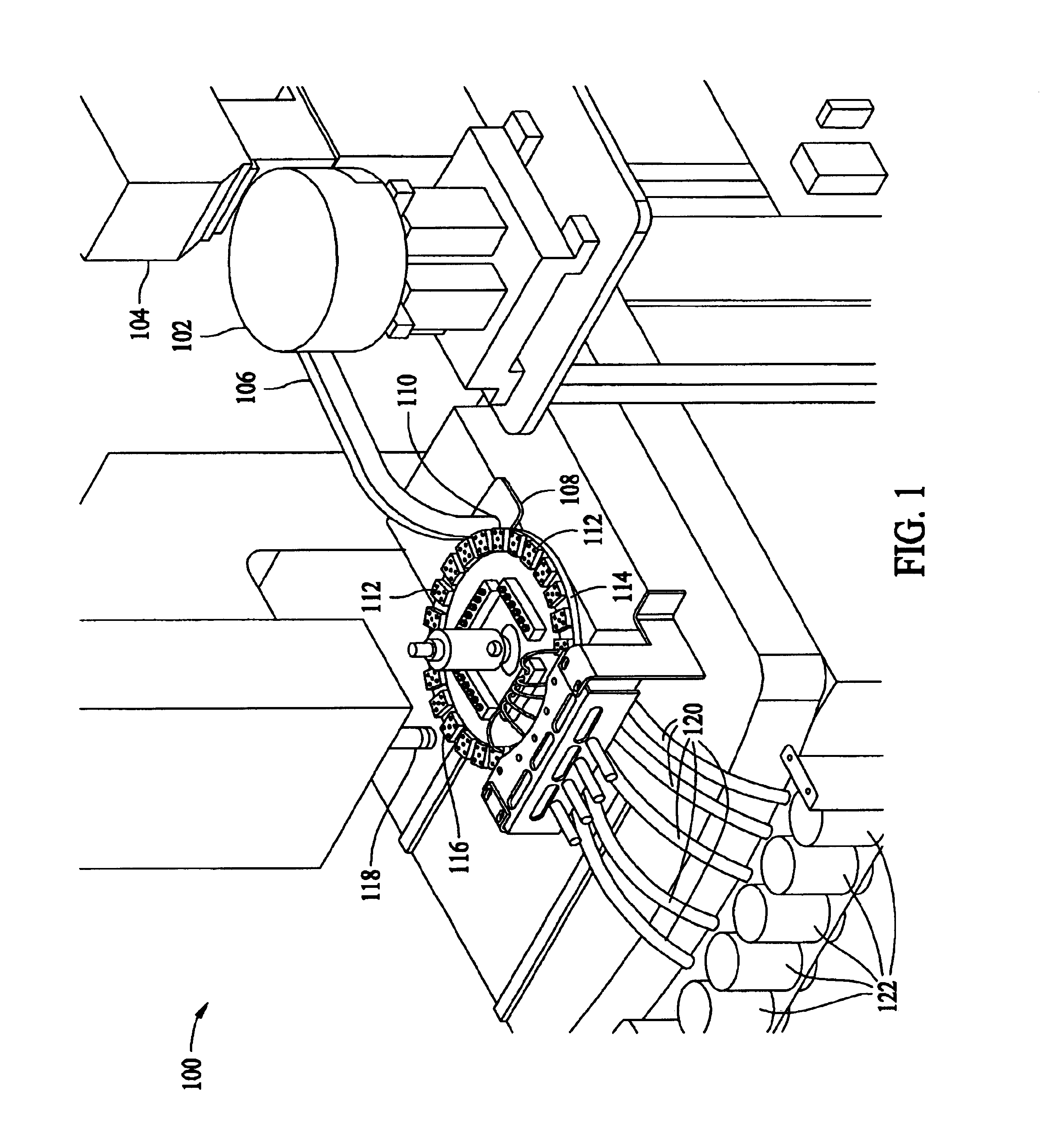

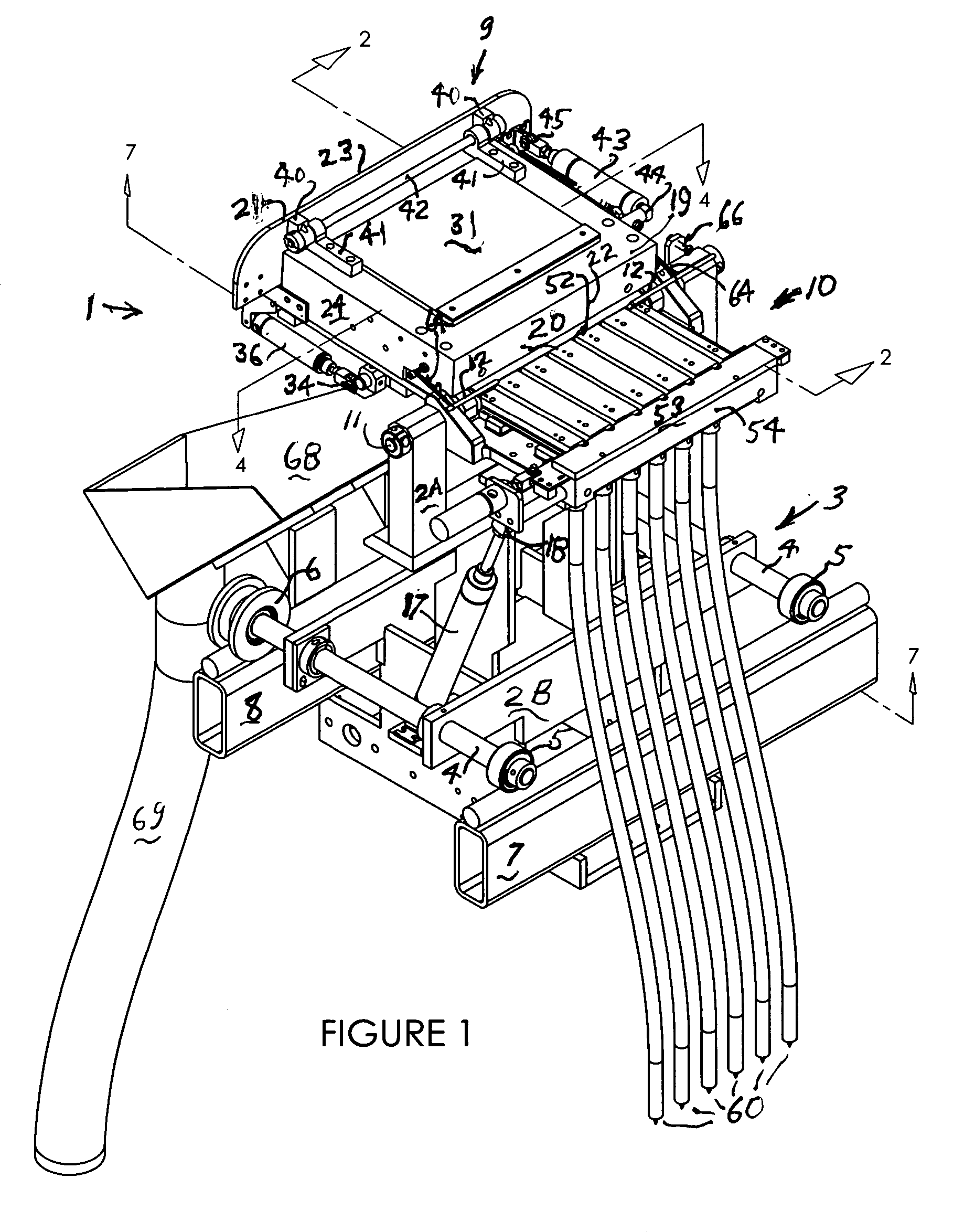

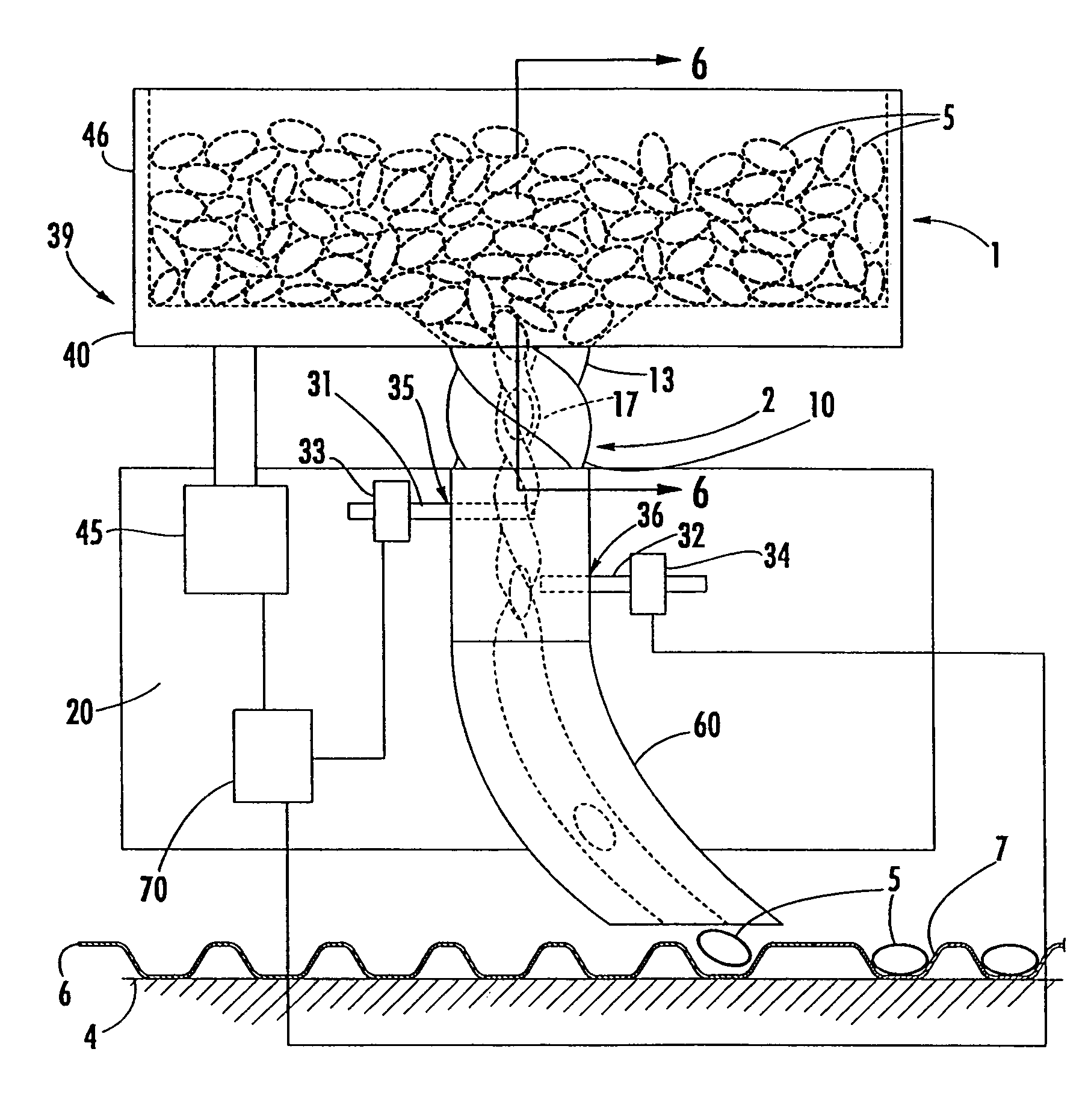

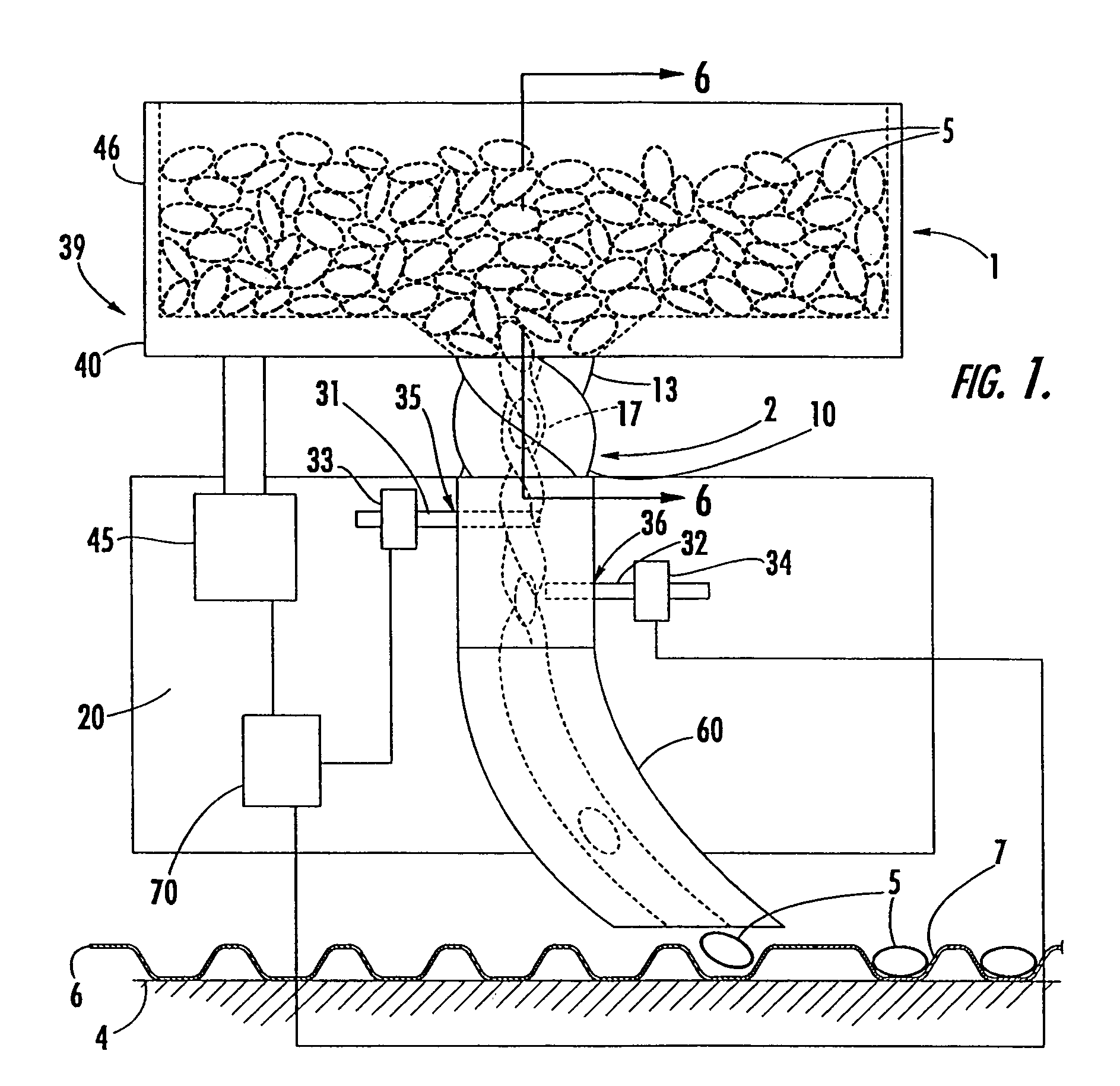

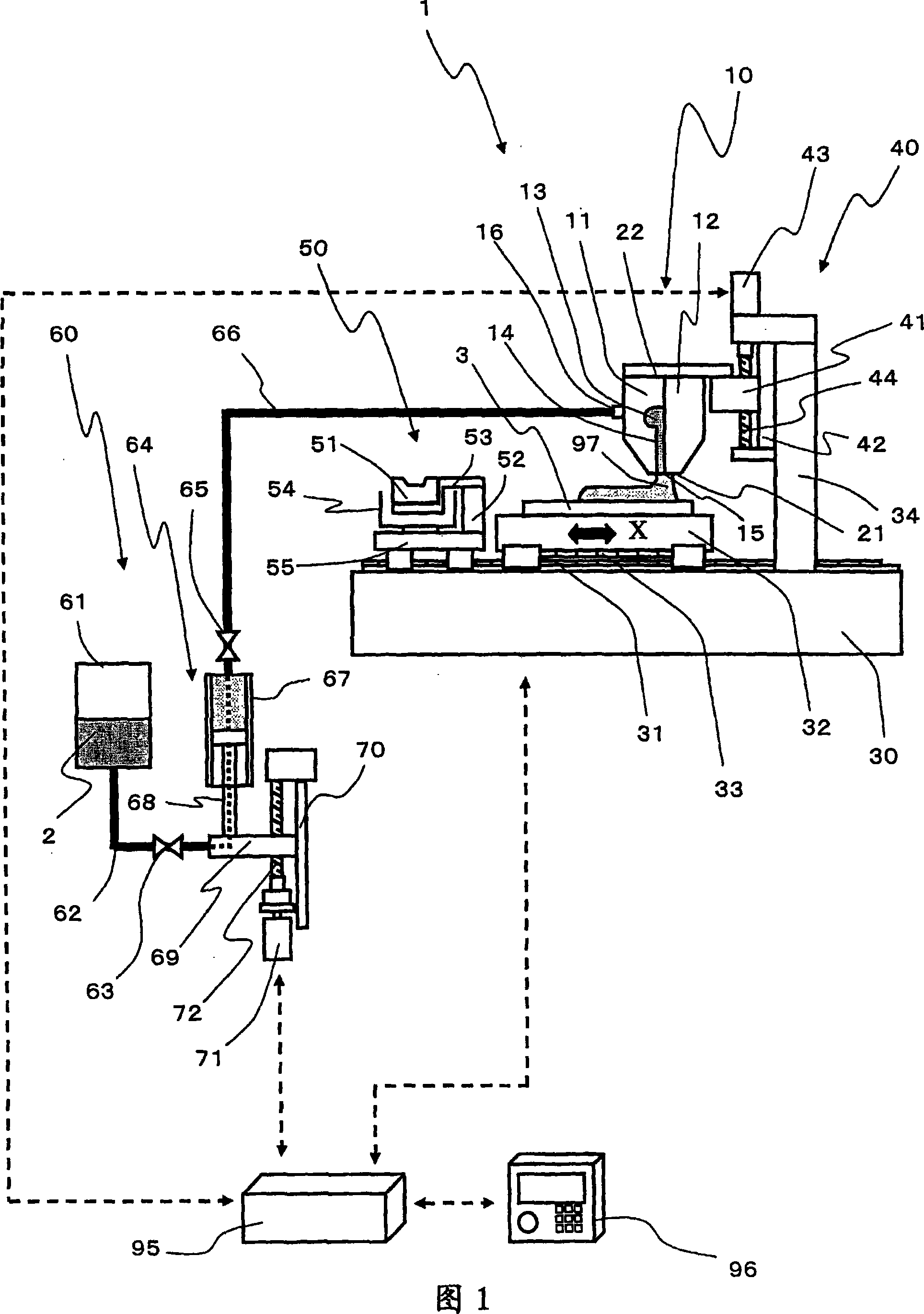

Methods and systems for small parts inspection

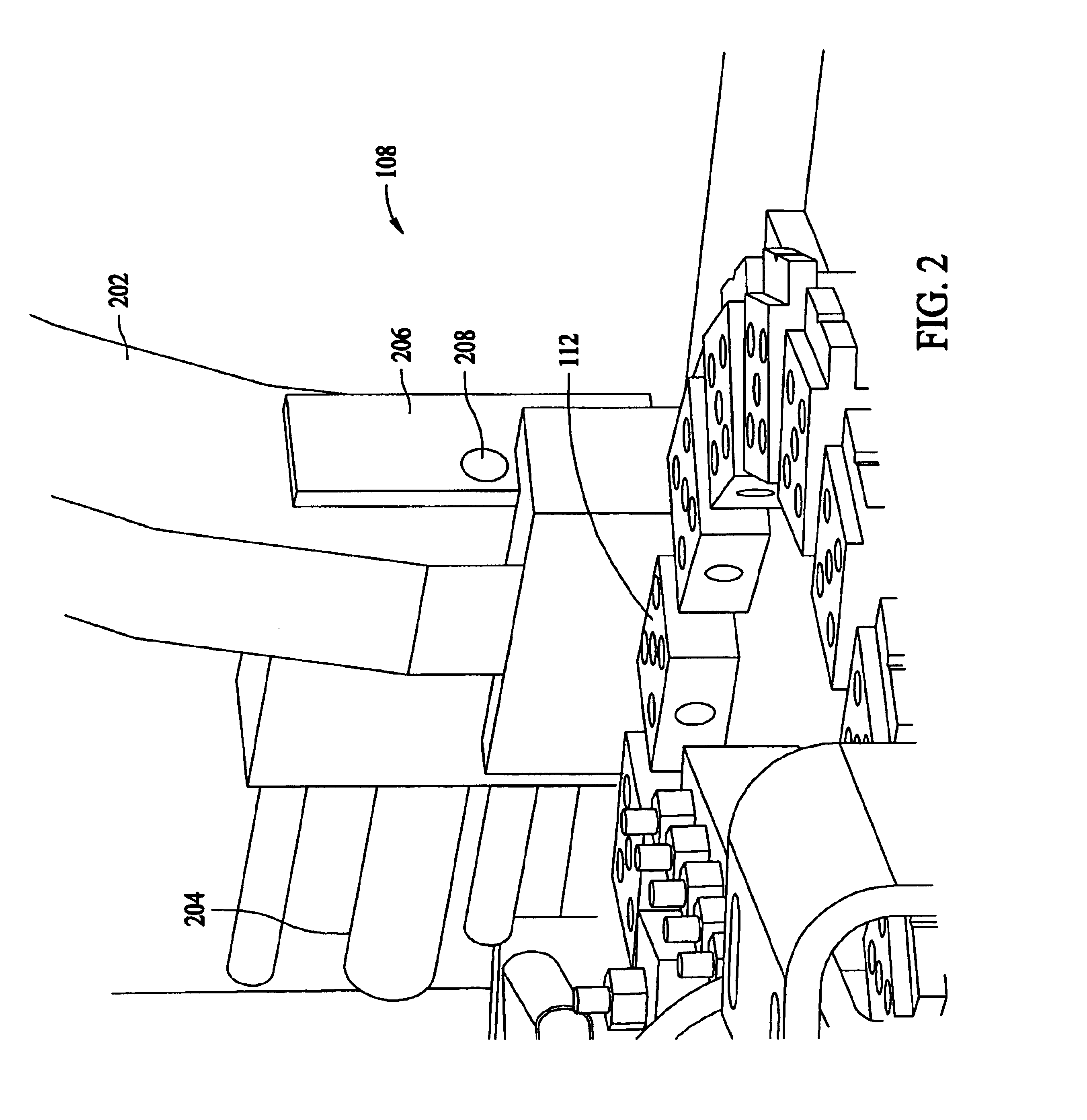

A method of automatically sorting and placing parts for inspection is described which includes orienting the parts within a feeder and delivering the oriented parts from the feeder to an escapement. Once the parts are delivered, they are advanced from the escapement, one at a time, down a ramp, and caught by a resilient material. The parts are then transferred ring from the resilient material to a parts fixture and positioned for inspection in the parts fixture within ±0.001 inch in a vertical direction and within 0.002 inches in x and y directions, x and y defining a horizontal plane.

Owner:INNOVENTOR ENG

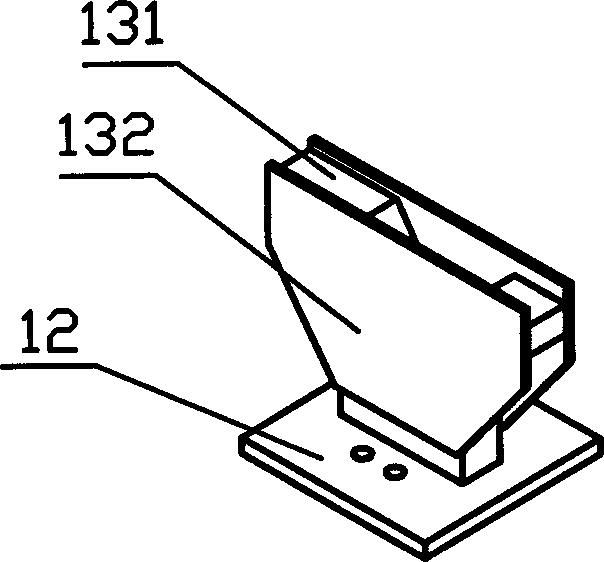

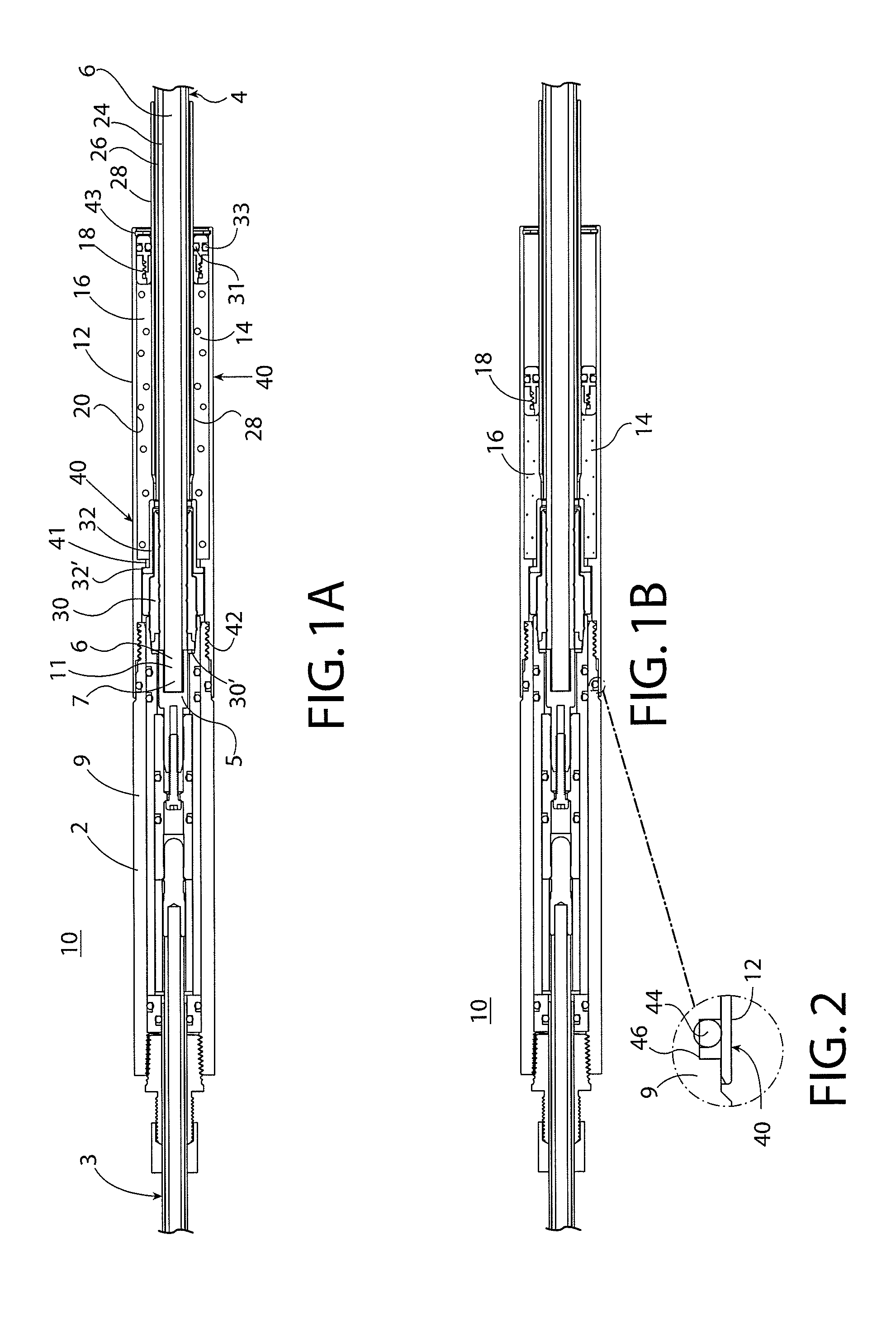

Mortise lock assembly

Several new components are provided for a mortise lock. First, a non-handed clutching assembly, including a pair of spindle hubs rotatable within a pair of outer operating cams, is provided for a mortise lock. Second, a spindle-mounted lock-handing selector—which can be removed from one side of the lockset body while the lockset body is installed in the mortise of a door—is provided to set the handing of the clutching assembly. Third, an escapement mechanism is provided for a reciprocating-slide-based clutchworks, enabling the slides to move into a position biasing a clutch lever arm toward a hub-coupling position, even if the outer and spindle hubs are misaligned. Fourth, a guardbolt-actuated blocking assembly for a lockset is provided to block movement of the stop works or clutchworks when the door is closed and the outside door handle is disabled.

Owner:TOWNSTEEL

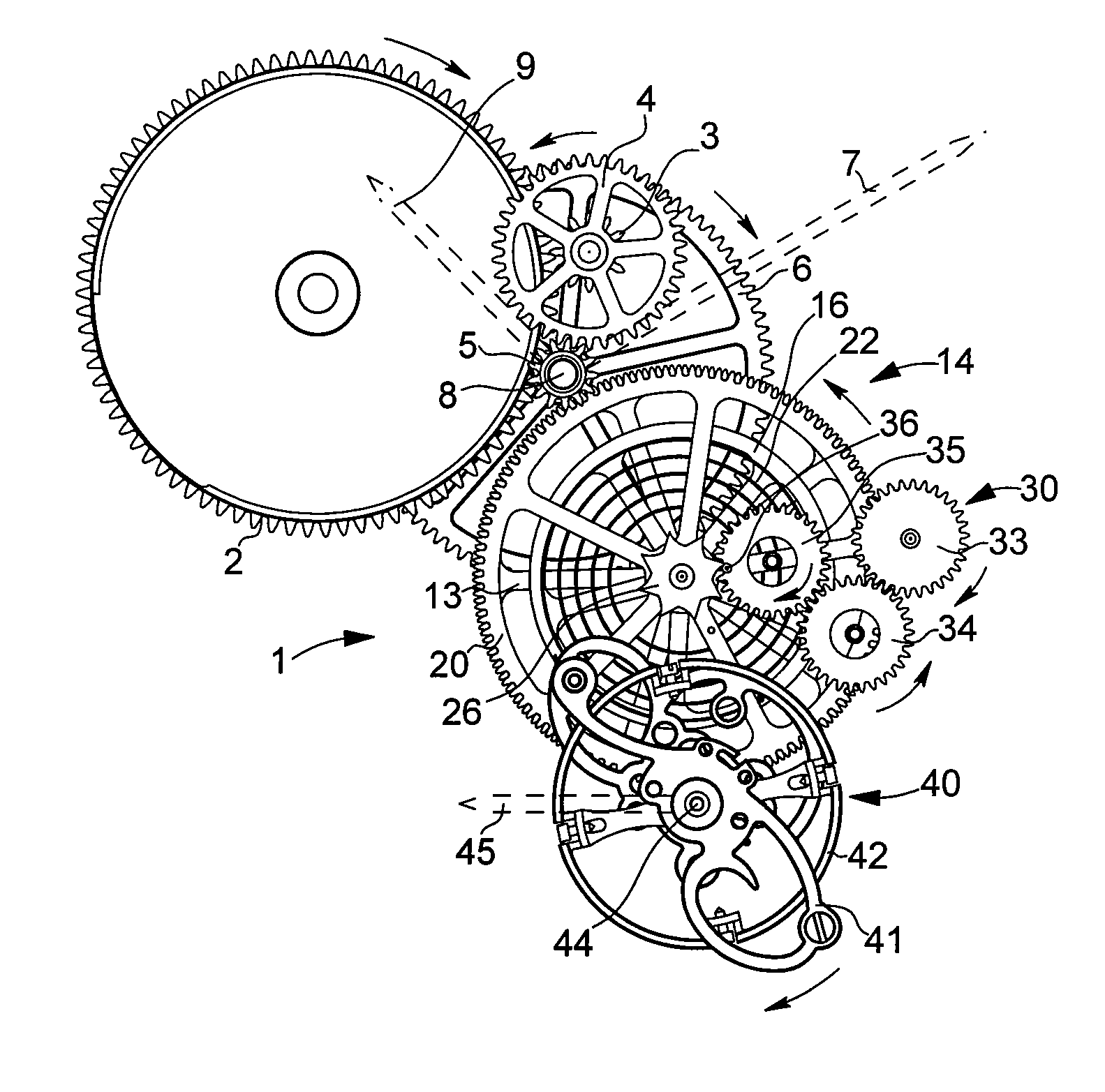

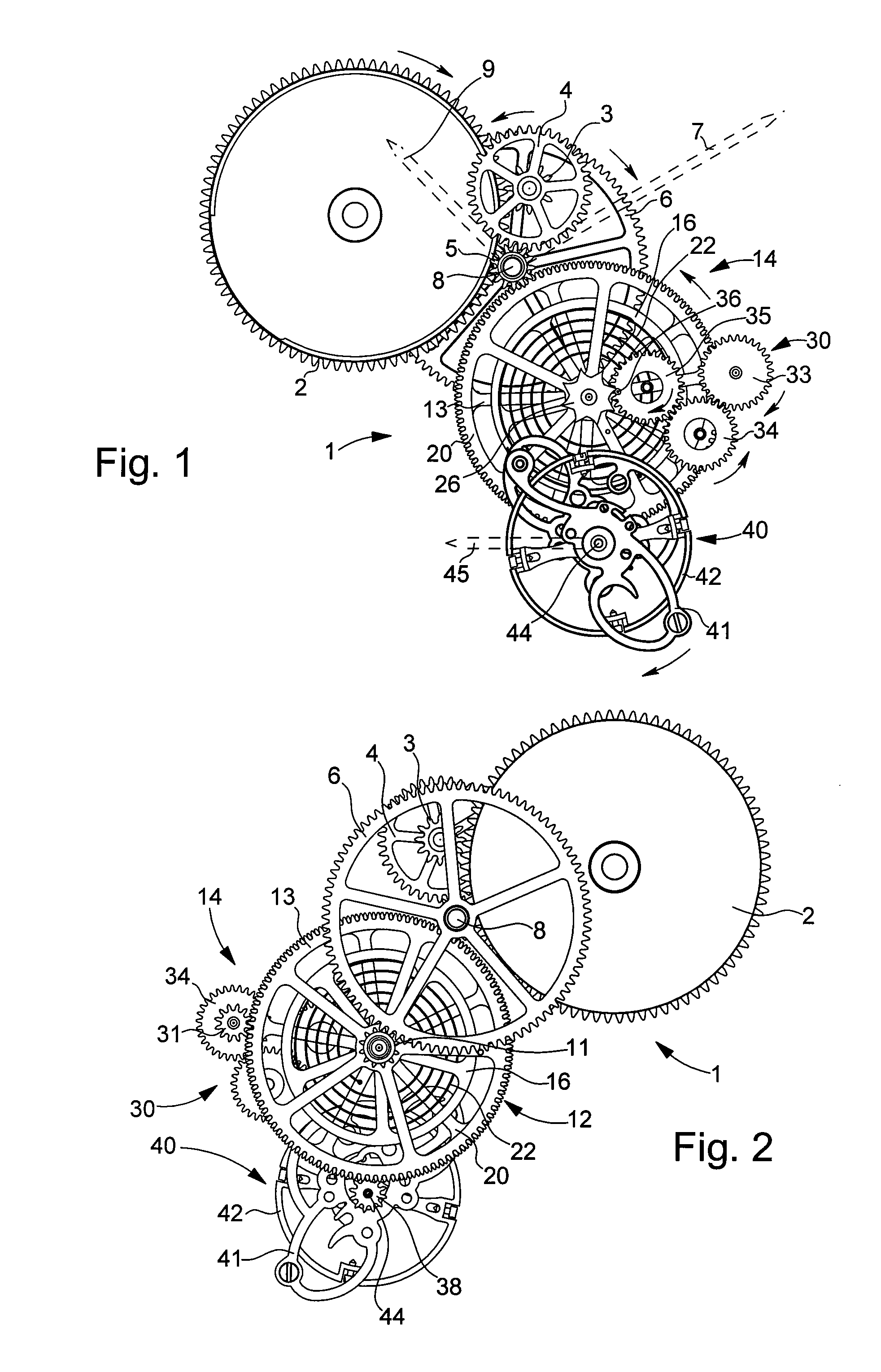

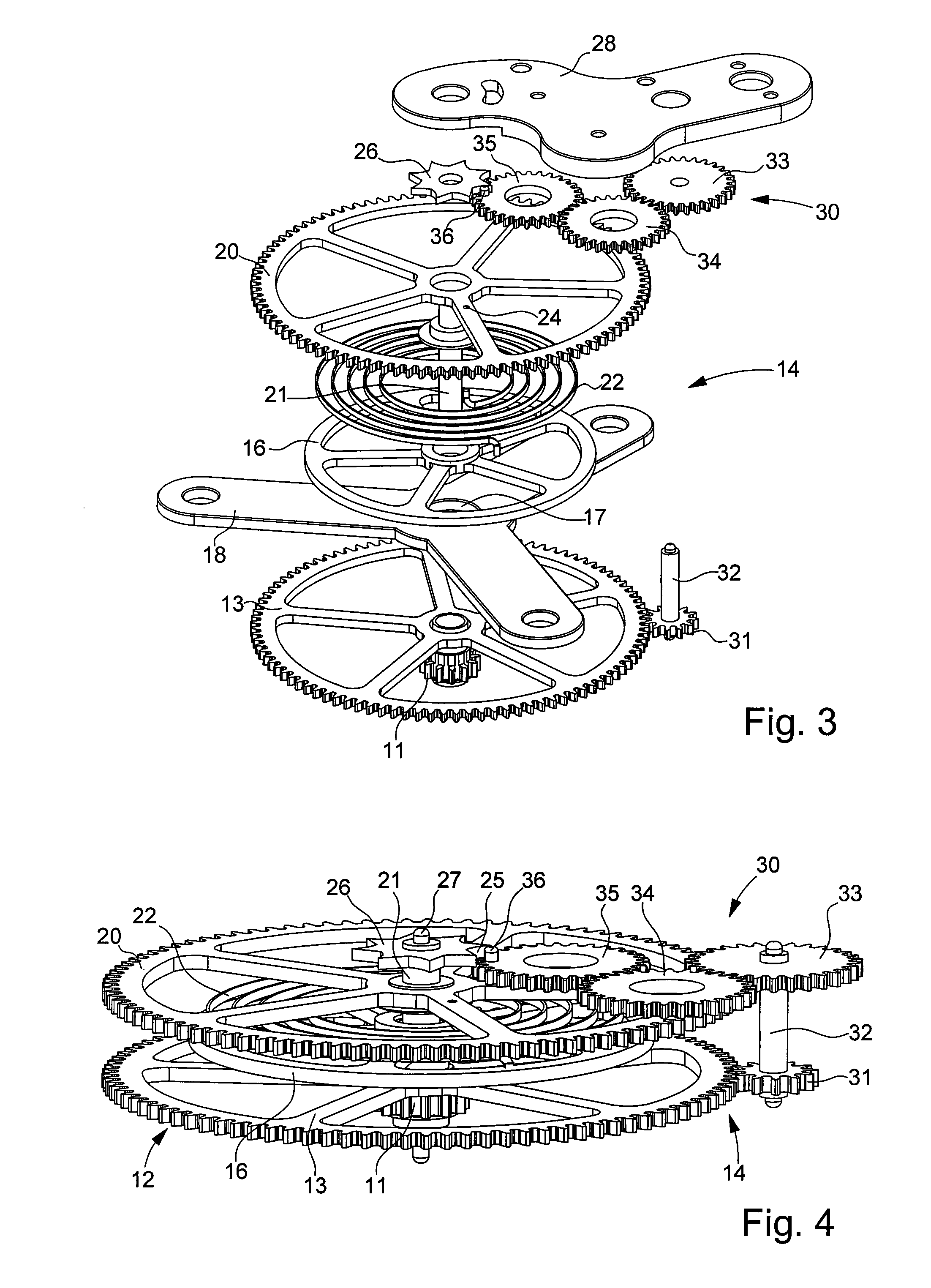

Watch including at least two regulating systems

ActiveUS20060221775A1Improve regularity of workingImprove regularityEscapementsFrequency stabilisation mechanismDifferential displayDisplay device

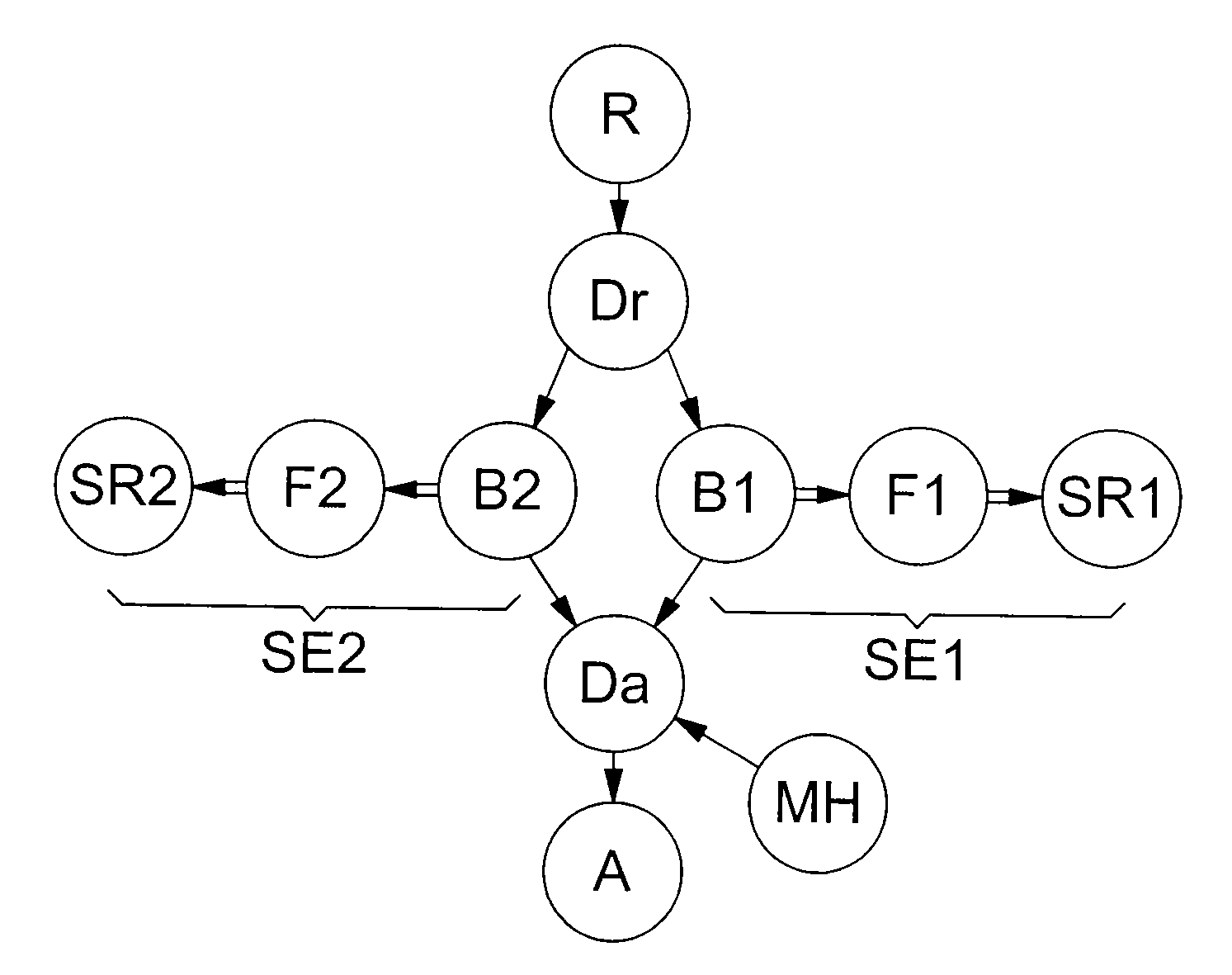

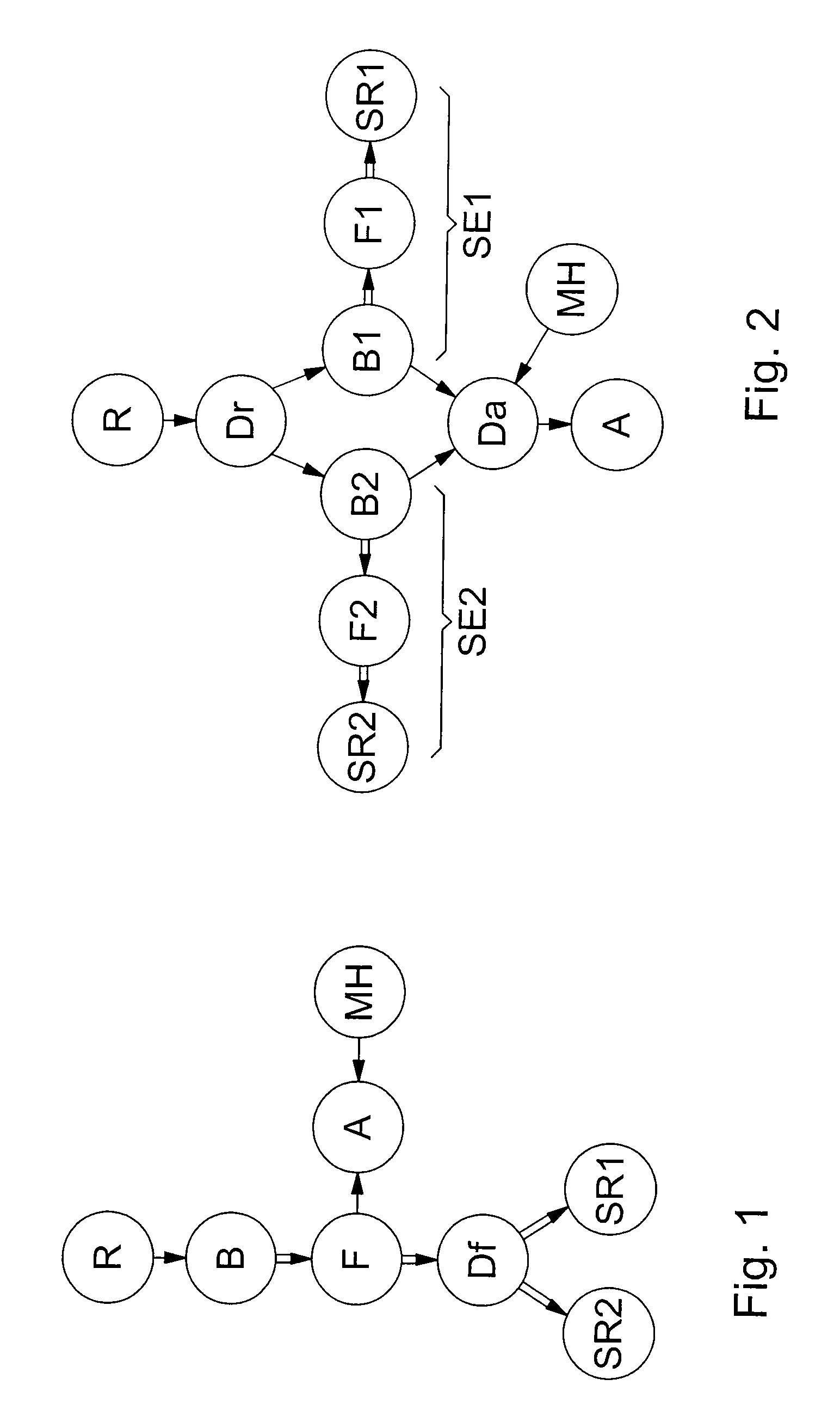

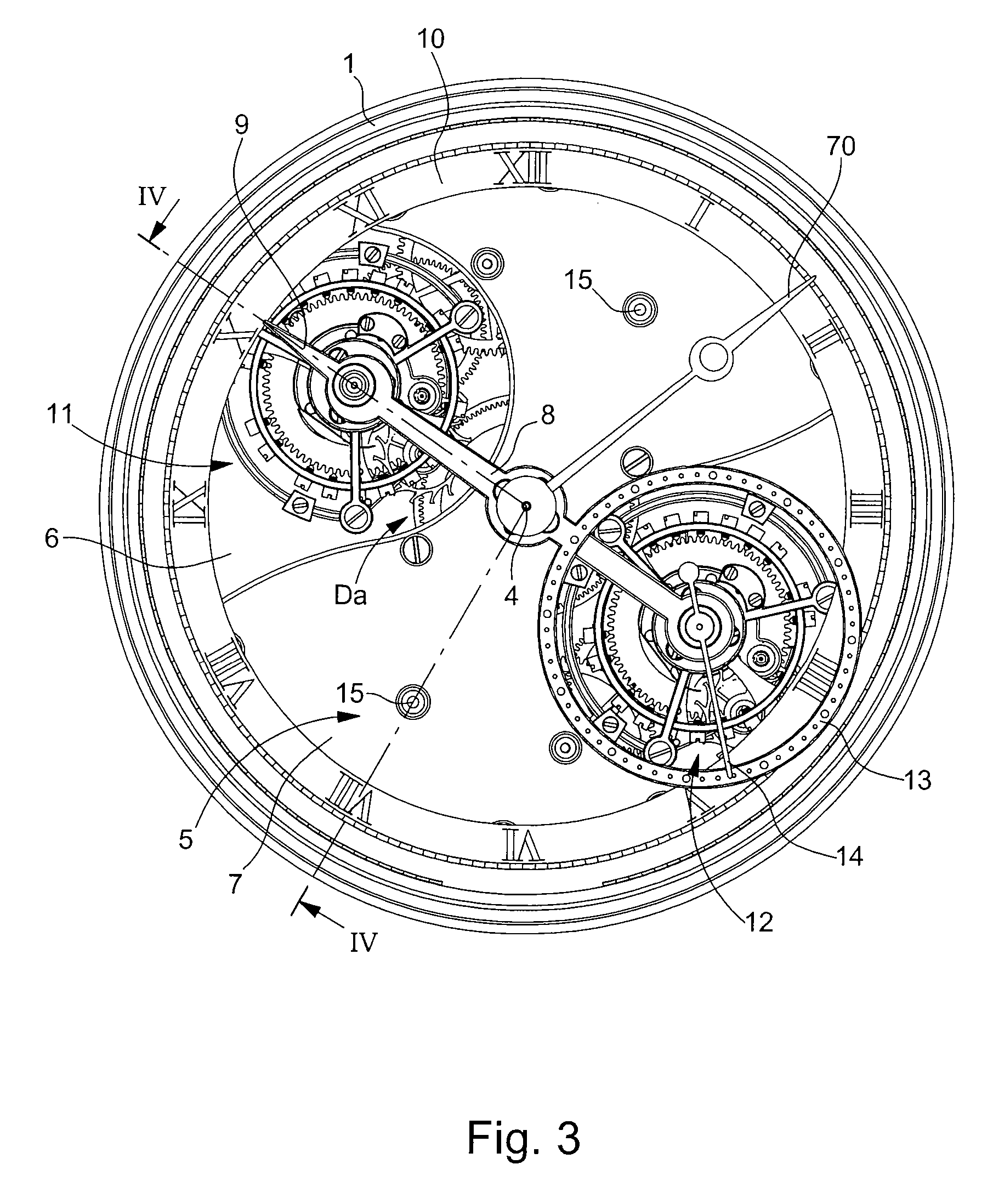

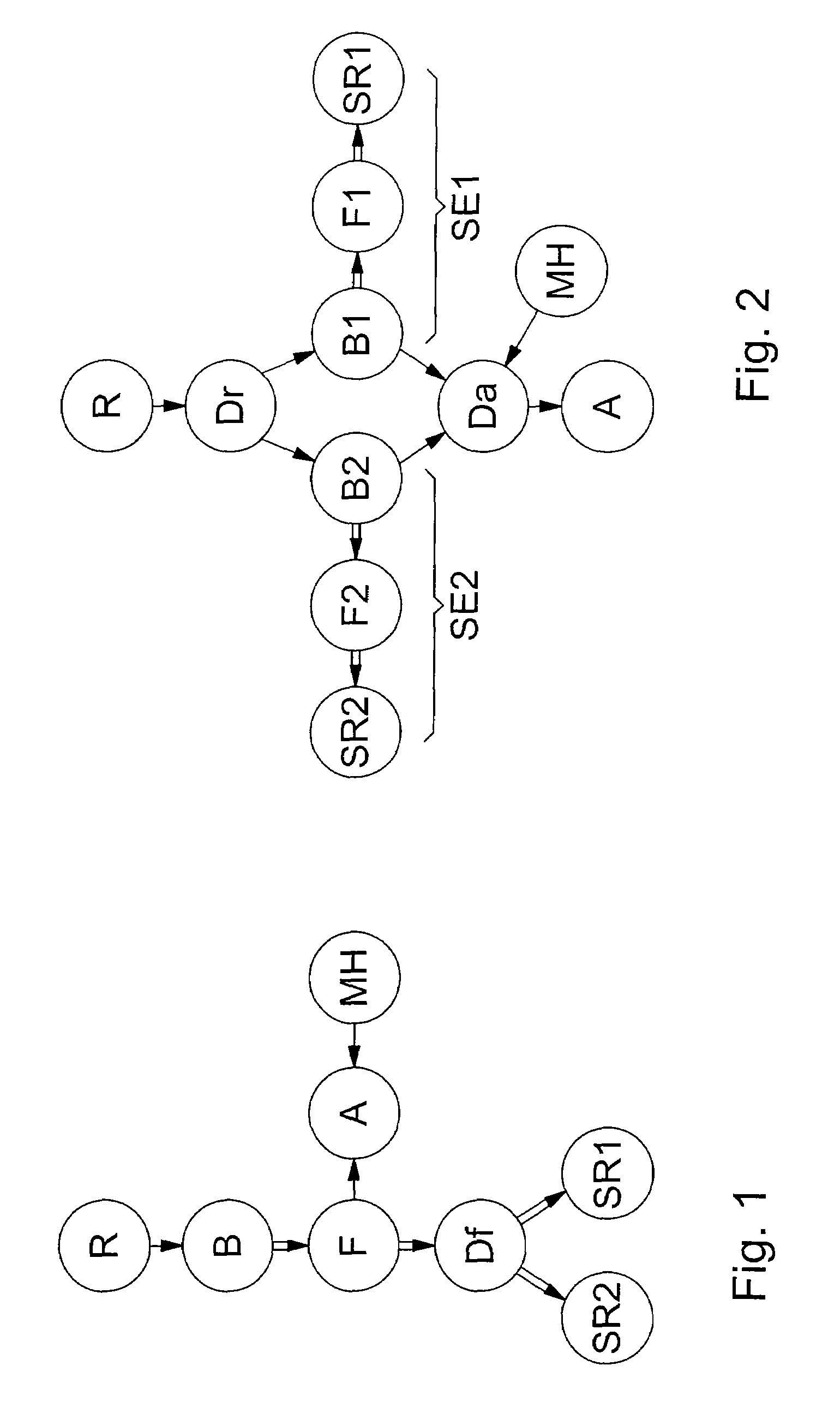

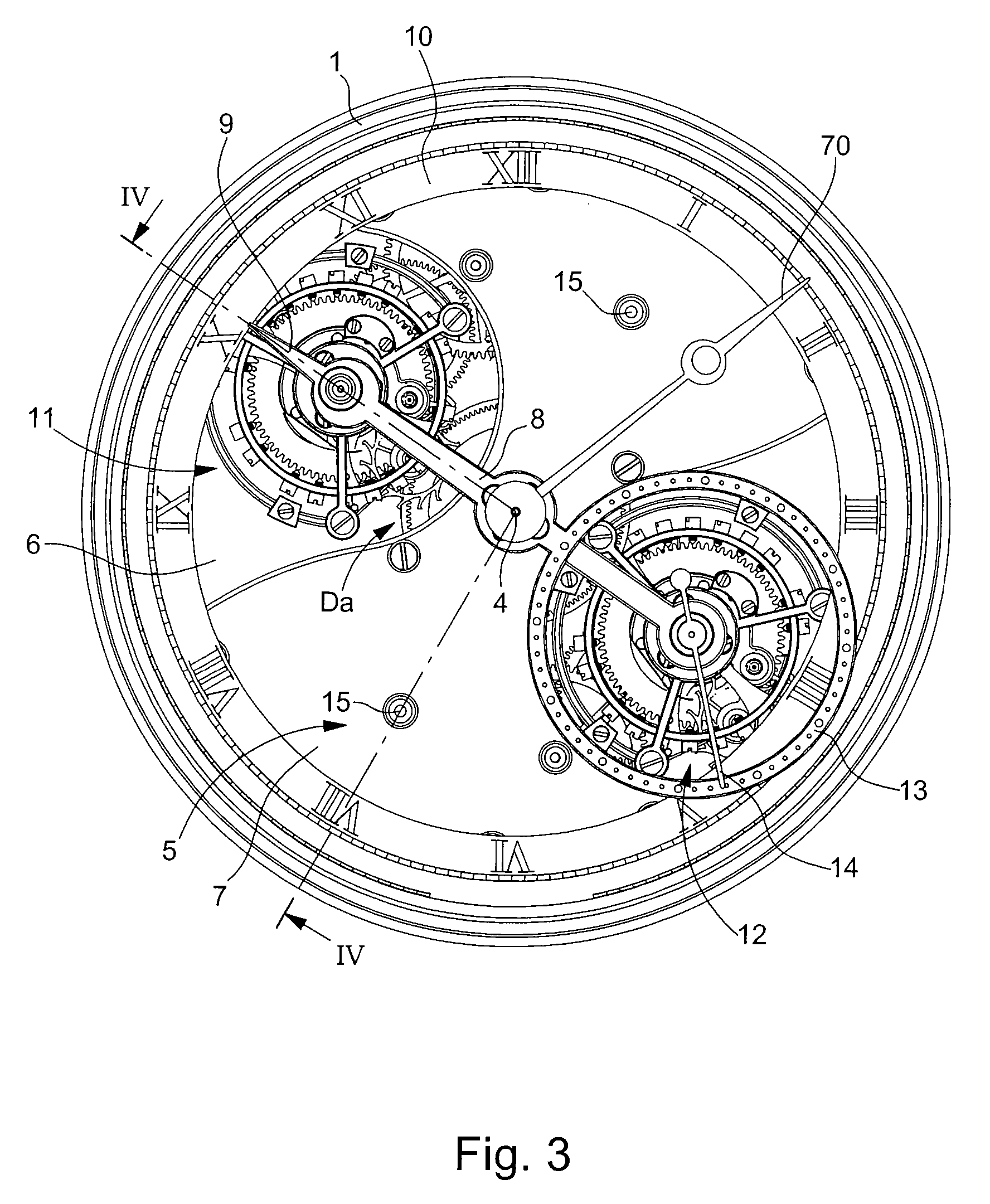

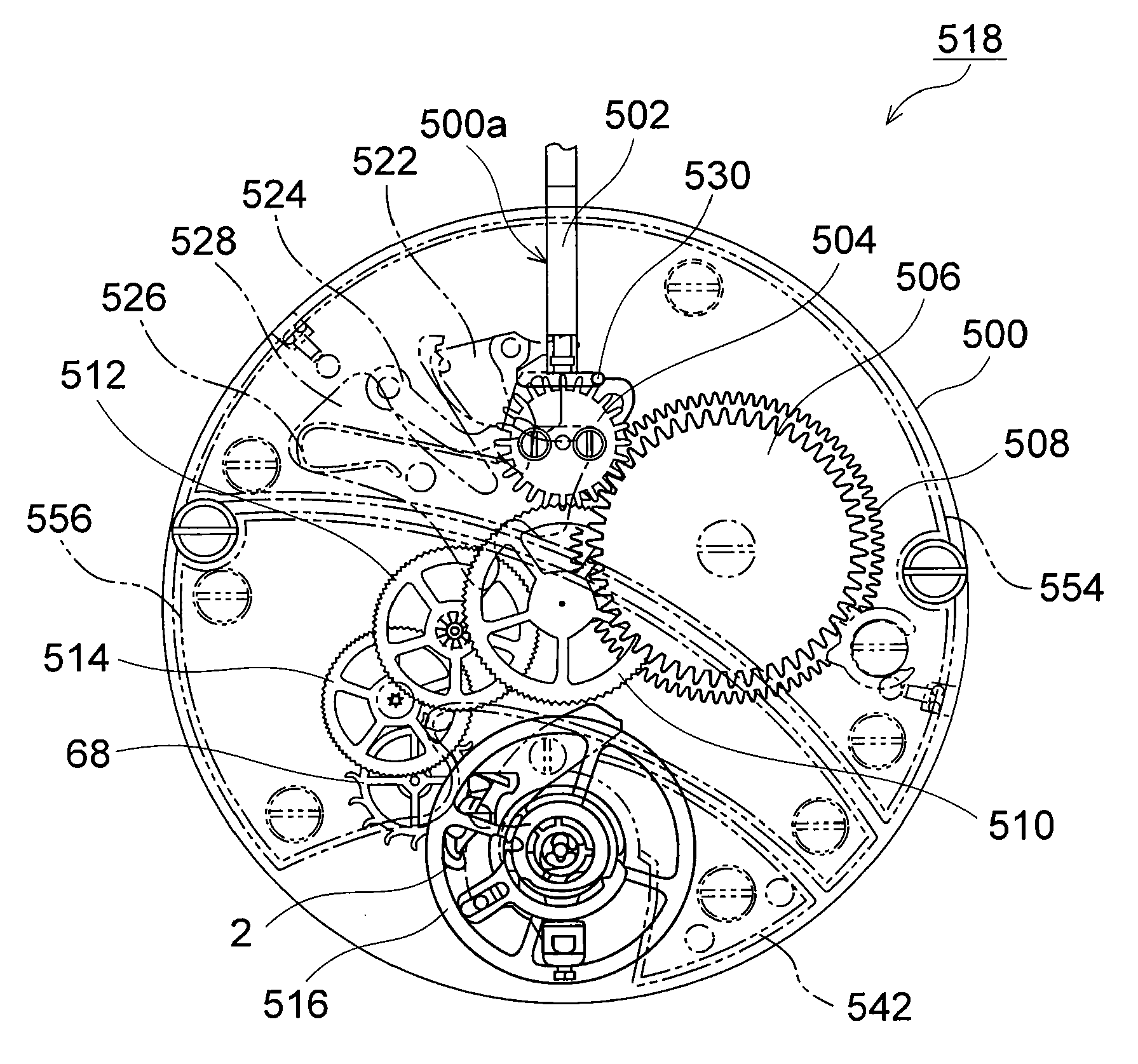

The invention concerns a watch with a mechanical movement of the type comprising at least two regulating systems (SR1, SR2) each including a mechanical oscillator and an escapement. The movement includes as many sub-assemblies (SE1, SE2) as there are regulating systems, each of said sub-assemblies including a regulating system (SR1, SR2), a barrel (B1, B2) and a going train transmitting energy from the barrel to the regulating system inside the sub-assembly. A differential display gear (Da) connects the barrel or the going train of each sub-assembly to the display (A) to average out the rate of the two sub-assemblies. In a preferred embodiment, the two sub-assemblies are mounted on a common rotating support (5) and their regulating systems are tourbillons which make an orbital movement about the centre of the watch dial.

Owner:MONTRES BREGUET

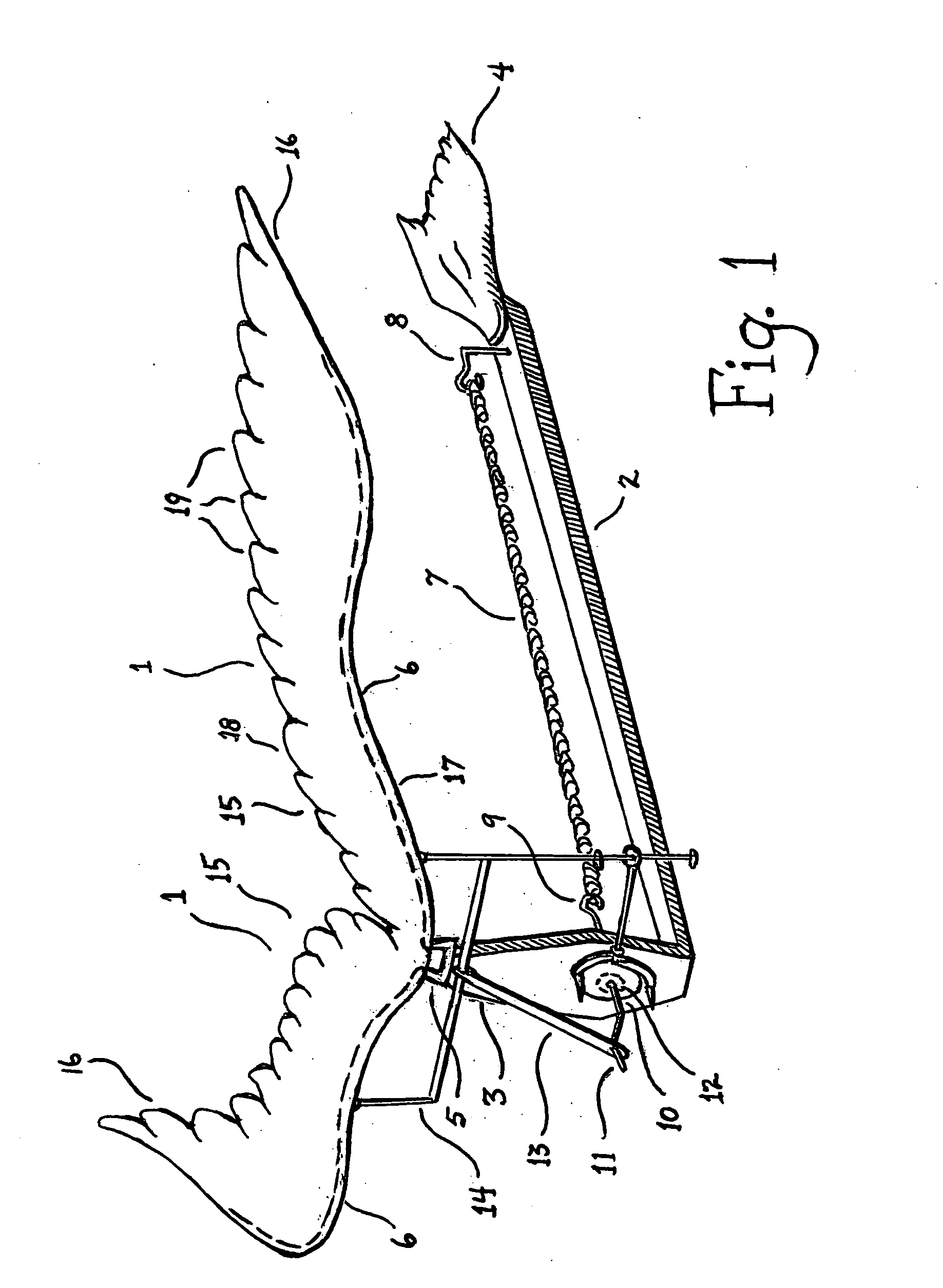

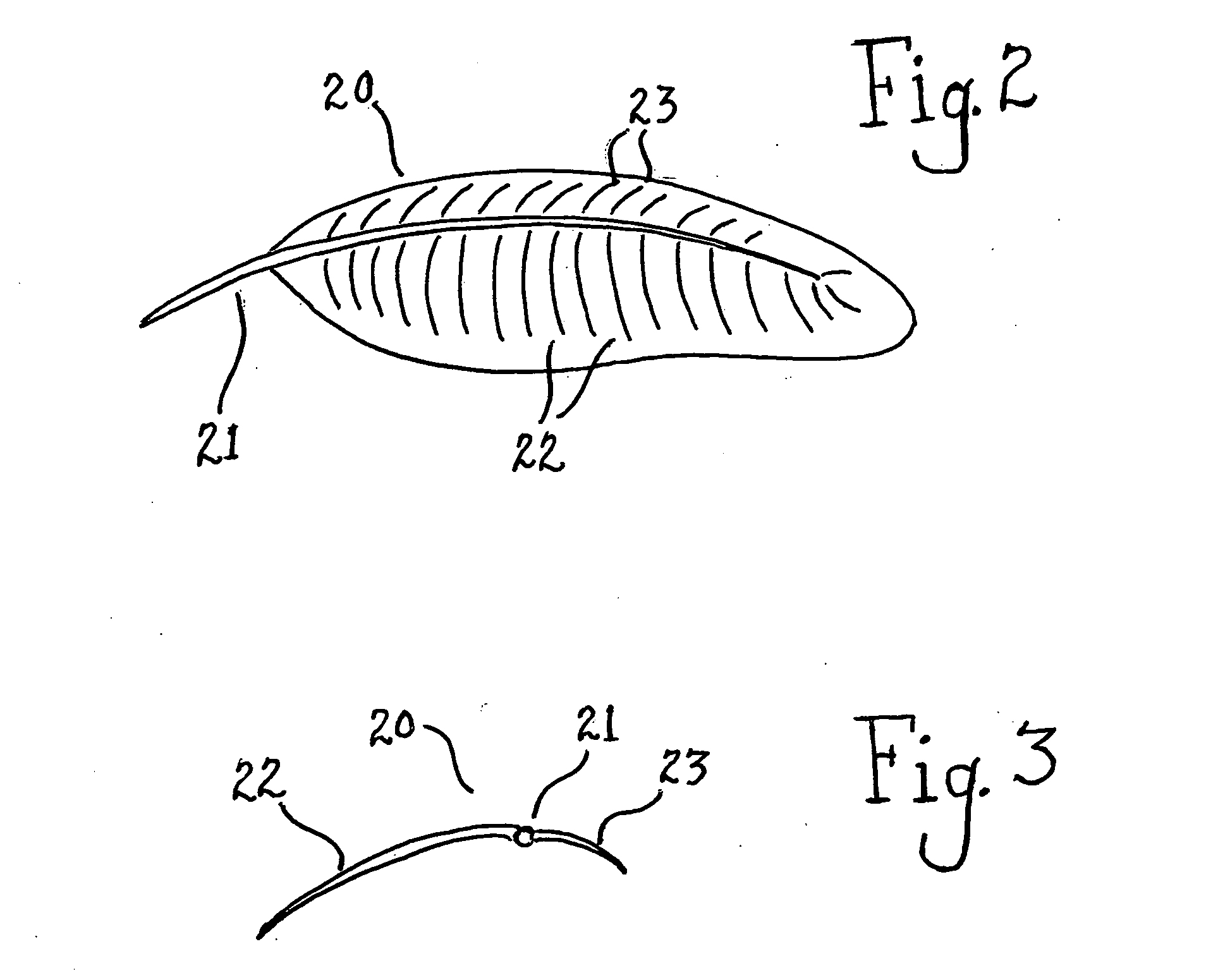

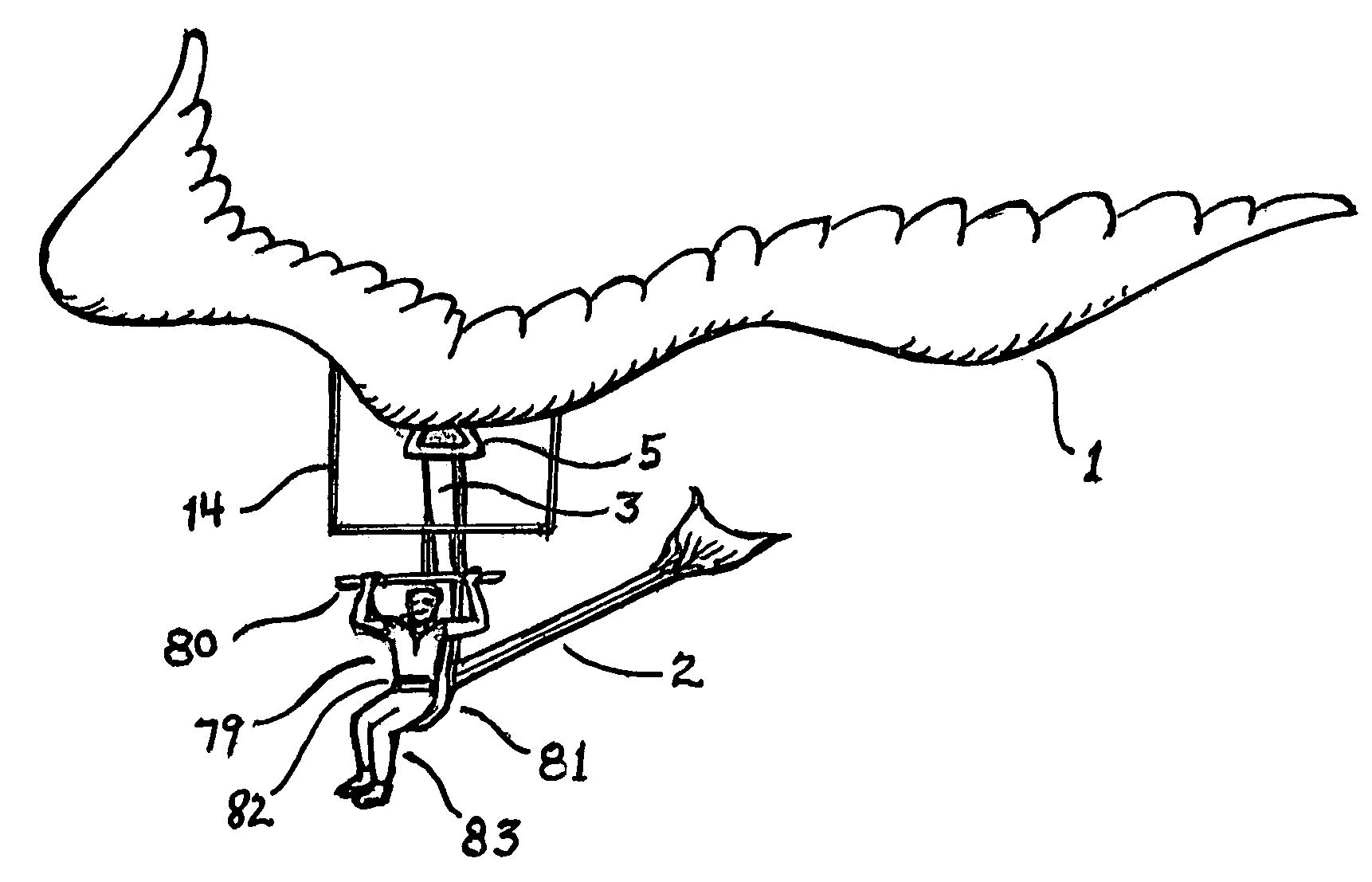

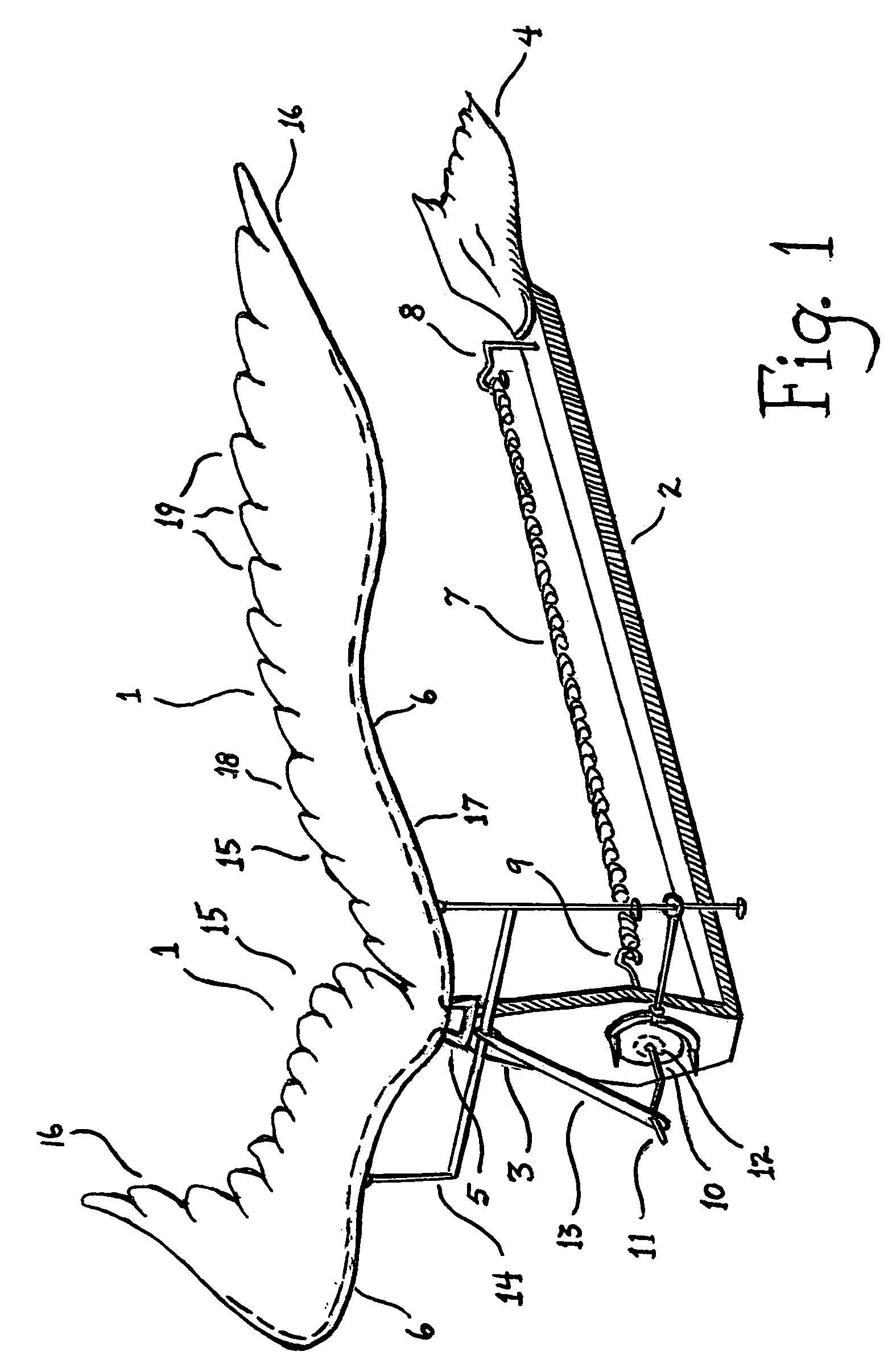

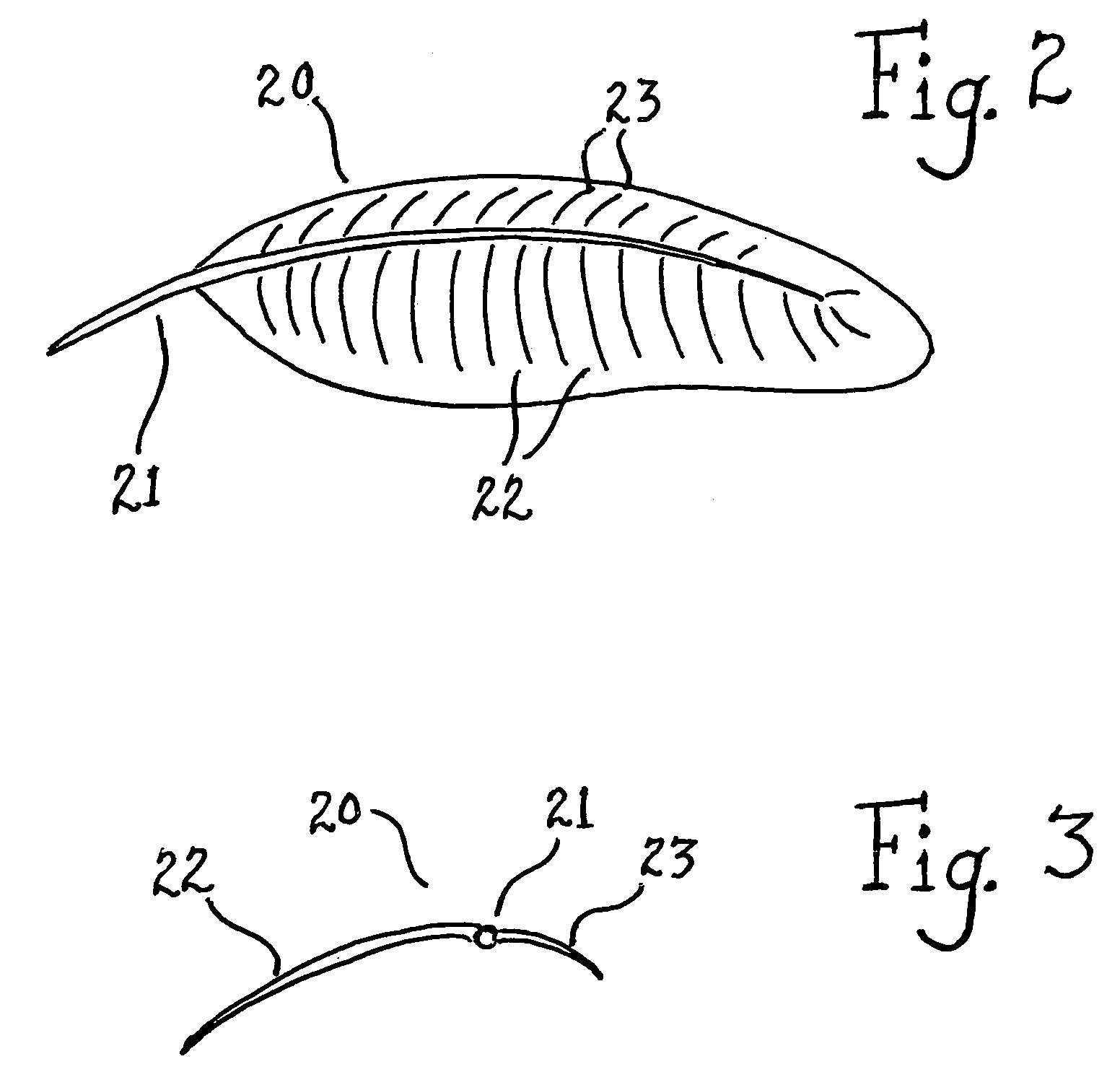

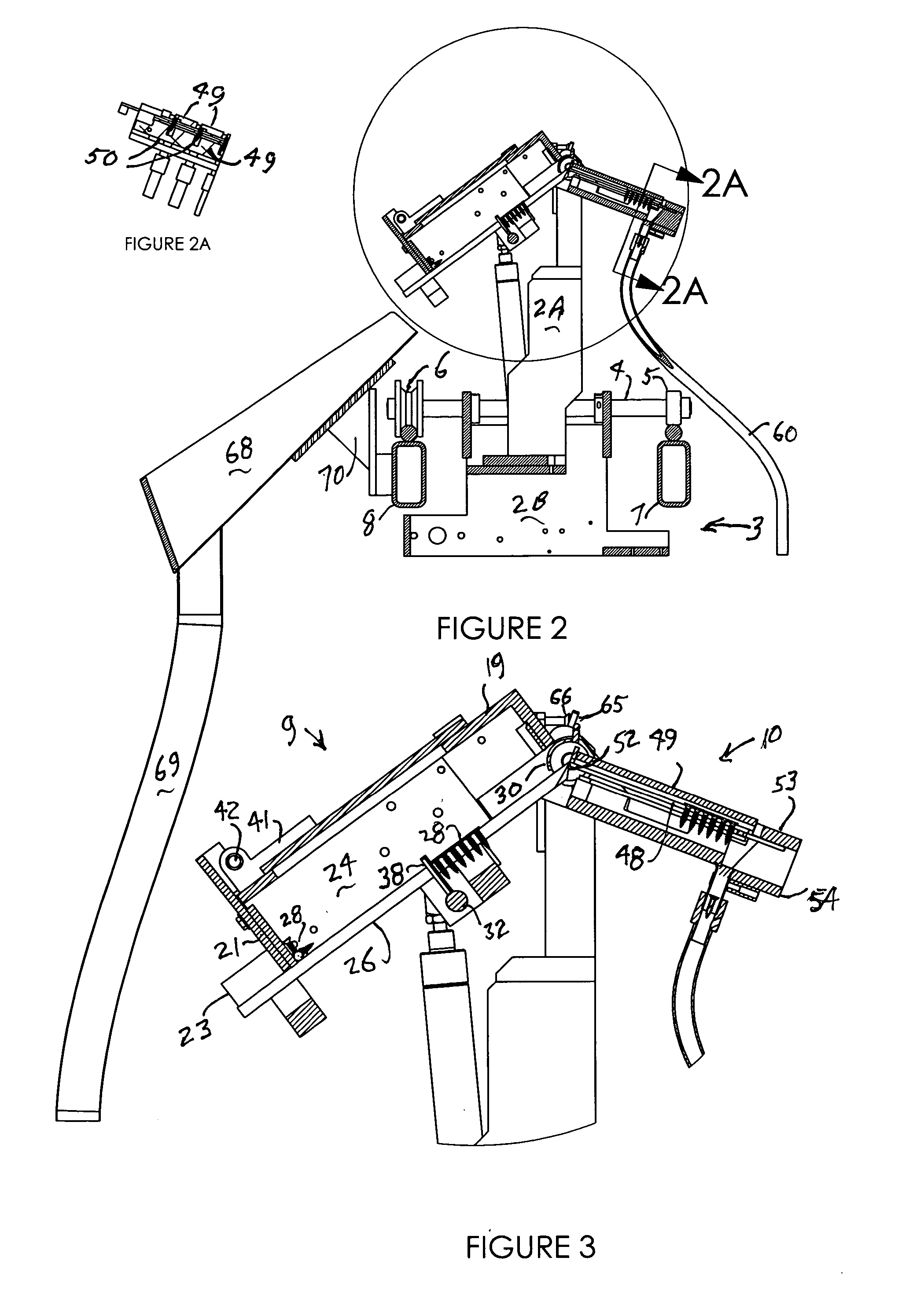

Flying device utilizing natural principles

InactiveUS20060102782A1Efficient forward propulsionReducing undesirableRigid airshipsOrnithoptersFlapping wingBird flight

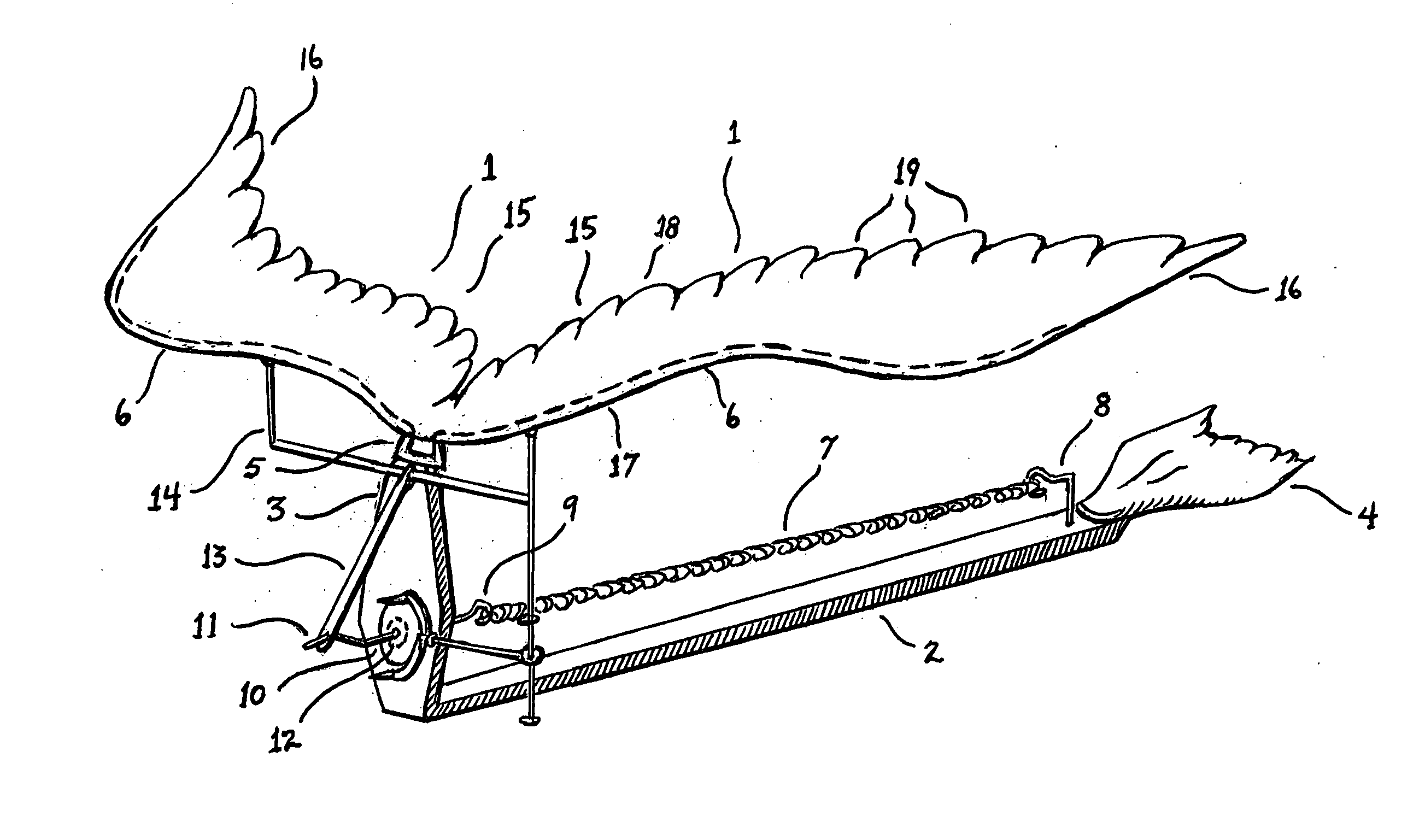

An efficient flying device having flapping wings, an ornithopter, which uses many of the principles seen in bird flight, is presented herein. The wings are highly flexible, translationally stable and oscillate as a natural pendulum. Described as a springboard, the wings have a singular natural frequency, and a pumping means drives the wings at that frequency. Feedback means are described by which to accomplish this, whereby deflection of the wing affects an escapement mechanism which controls the timing and direction of the pumping means. Wing design is described whereby camber, flexure, torsion and directionality of wing components affect efficient propulsion, lift and differential reactivity with air during downstrokes and upstrokes. A crook element in the wing spar at a location proximal to the body of the device redirects vertical oscillation to horizontal. Other features are addressed, such as rearward vortex production and reaction, a double aerofoil wing construction, lateral and vertical wing curvature, rearward wing and featherlike element flexure to produce thrust, and connection of separate elastic elements to reduce power requirements.

Owner:EARL MILAN DENNIS +1

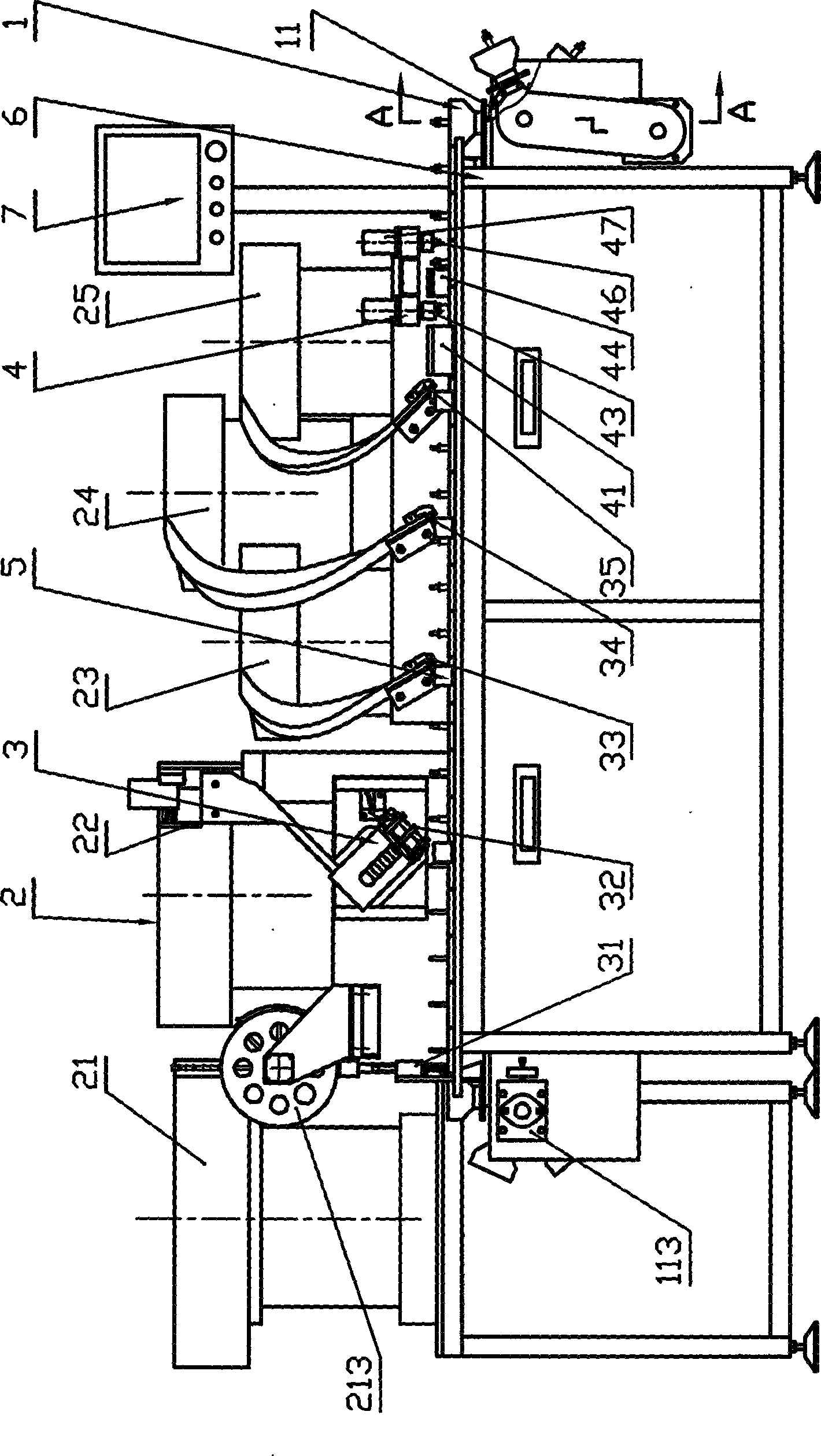

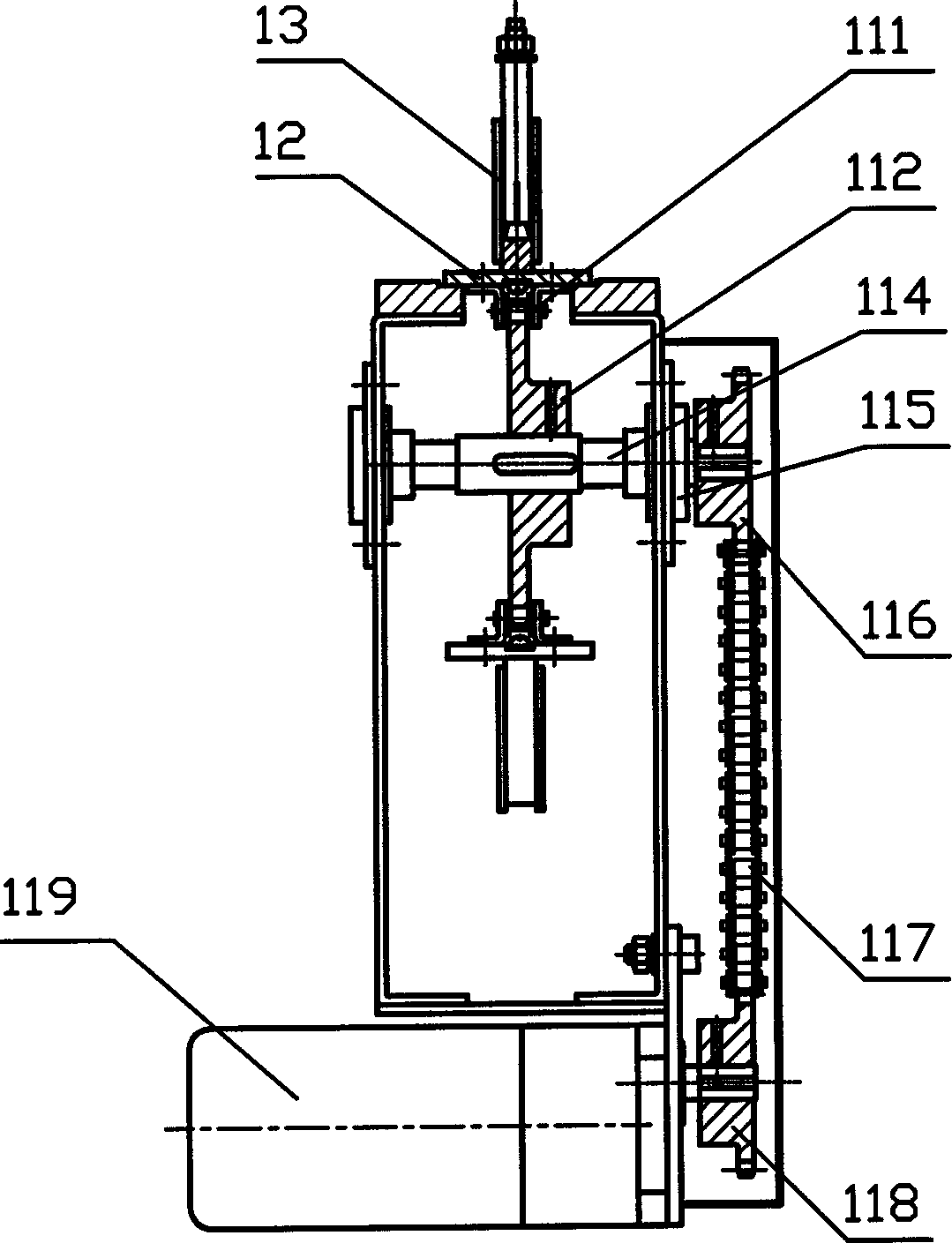

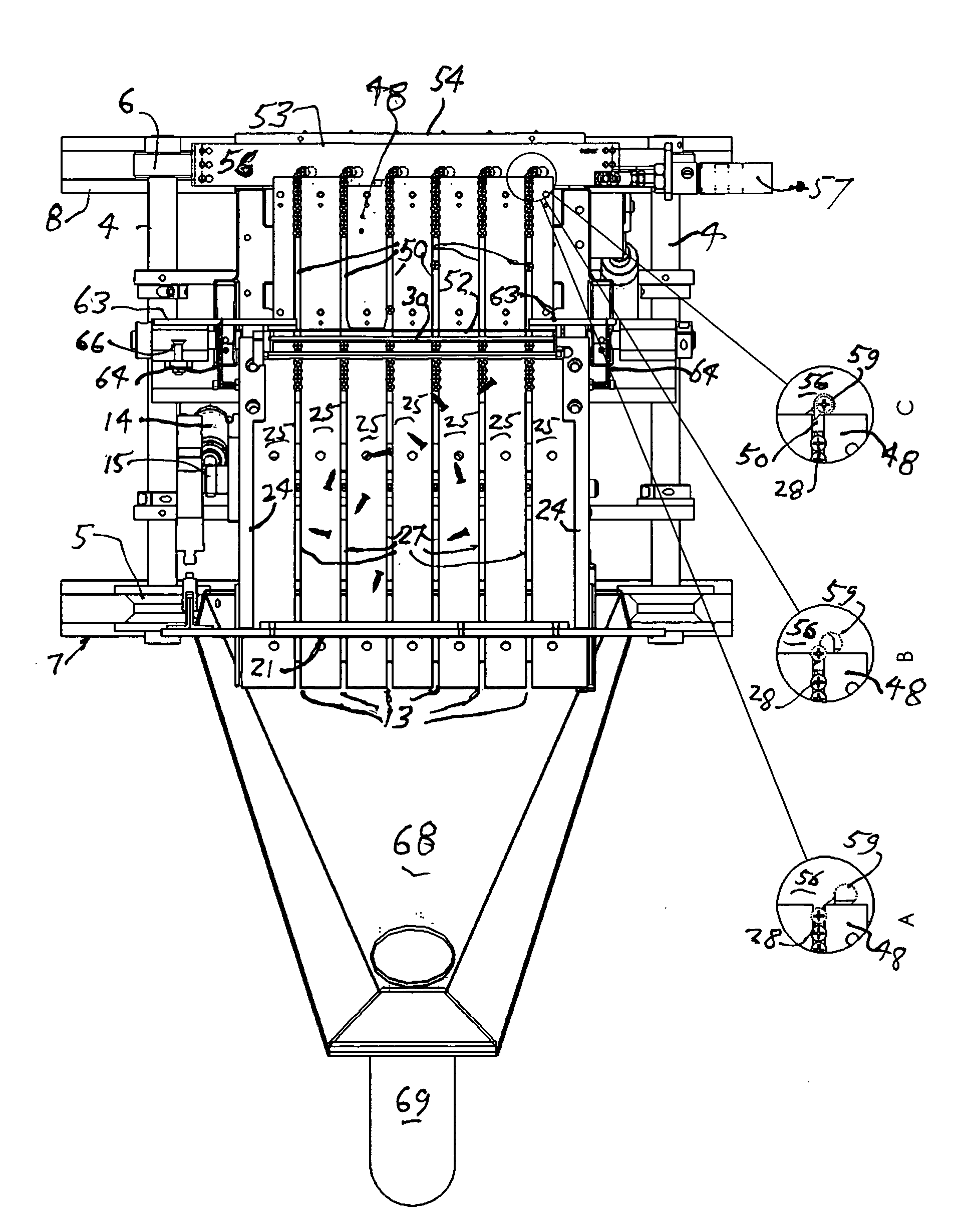

Automatic assembling machine of expansion screw bolts

The invention relates to an automatic assembling machine of expansion screw bolts and belongs to the field of hardware machinery. The assembling machine consists of a chain plate type conveying device, a part feeding device, a part escapement device, a screw nut screwing device, a screw rod small head lateral positioning device, a machine frame and a control system, wherein the part feeding device and the part escapement device are used for the ranging, the storage for package and the one-by-one release of parts, the chain plate type conveying device is arranged on the machine frame, semi-finished products and finished products with different stations are transferred through expansion screw bolt seat combination elements arranged on a chain plate, the screw rod small head lateral positioning device is arranged at the front end of the part escapement device for realizing the lateral positioning of each station screw rod, the screw nut screwing device comprises a screw nut pre-screwing friction plate, a first screw nut screwing wheel, a clamping stagnation release friction plate, a second screw nut screwing wheel, a small motor and the like. The assembling machine can realize the automatic assembly of each part of the expansion screw bolts and has the characteristics that the assembly efficiency is high, and the cost is low; and screw nuts are subjected to two links of pre-screwing and screwing, and the assembly quality is ensured.

Owner:ZHENGZHOU UNIV

Flying device utilizing natural principles

InactiveUS7255305B2Reducing undesirable up and down movementEfficient forward propulsionRigid airshipsOrnithoptersFlapping wingBird flight

An efficient flying device having flapping wings, an ornithopter, which uses many of the principles seen in bird flight, is presented herein. The wings are highly flexible, translationally stable and oscillate as a natural pendulum. Described as a springboard, the wings have a singular natural frequency, and a pumping means drives the wings at that frequency. Feedback means are described by which to accomplish this, whereby deflection of the wing affects an escapement mechanism which controls the timing and direction of the pumping means. Wing design is described whereby camber, flexure, torsion and directionality of wing components affect efficient propulsion, lift and differential reactivity with air during downstrokes and upstrokes. A crook element in the wing spar at a location proximal to the body of the device redirects vertical oscillation to horizontal. Other features are addressed, such as rearward vortex production and reaction, a double aerofoil wing construction, lateral and vertical wing curvature, rearward wing and featherlike element flexure to produce thrust, and connection of separate elastic elements to reduce power requirements.

Owner:EARL MILAN DENNIS +1

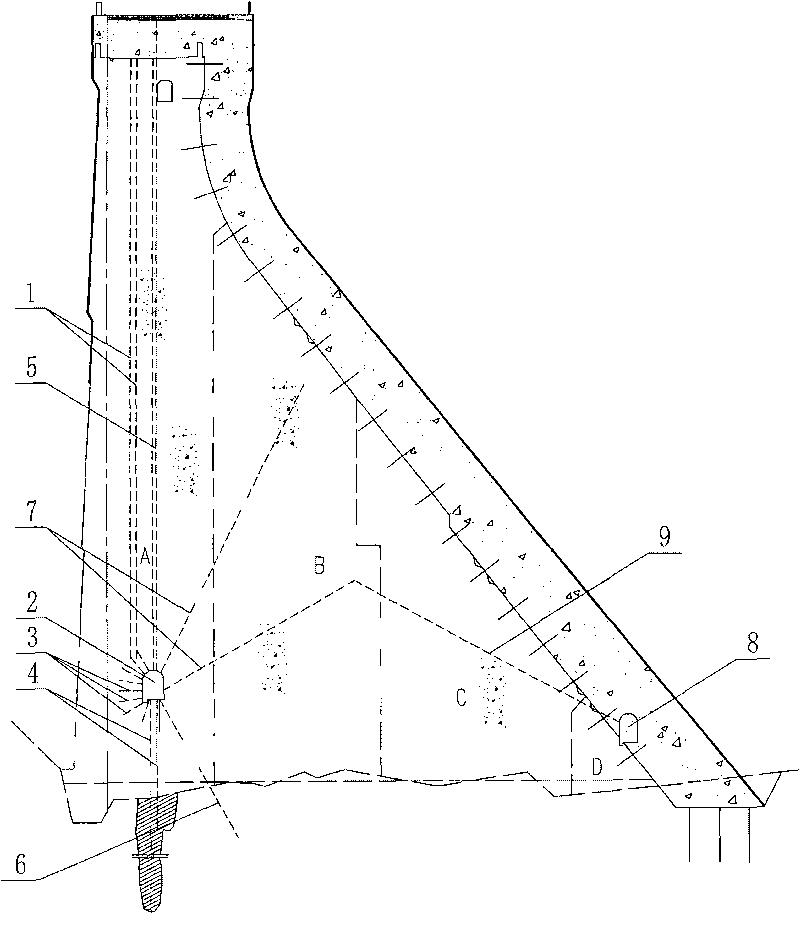

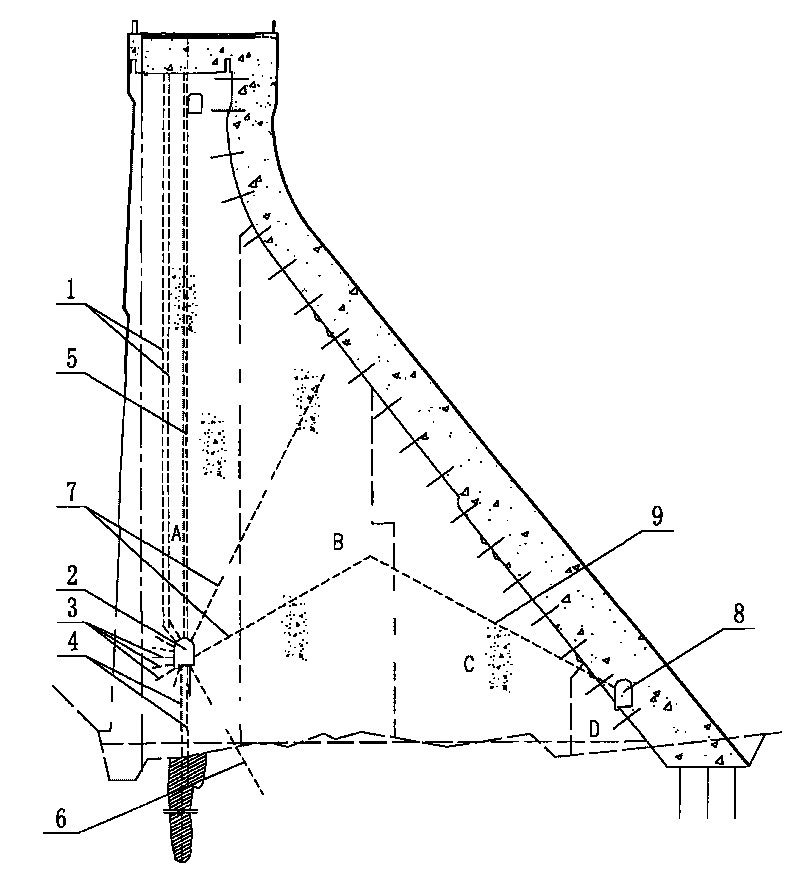

Construction method for dam body seepage preventing curtain grouting

ActiveCN101736719AIncreasing the thicknessIncreased durabilityMarine site engineeringWater dischargeSlurry

The invention relates to a construction method for dam body seepage preventing curtain grouting and provides a construction method for the dam body seepage preventing curtain grouting. The grouting is carried out by a technology of dense holes, high pressure, fine cement wet grinding and concentrated slurry, and the seepage preventing ability, the corrosion resistance and the durability of a dam body curtain are improved; the seepage is prevented in a way of front blockage and rear discharge, the downstream seepage escapement point elevation of a dam body and the uplifting pressure in a dam are reduced, and the problems of frozen thawing and frozen expansion of concrete are solved. The construction method for the dam body seepage preventing curtain grouting comprises the following steps of: a. downwards drilling a group of curtain grouting holes at the top of the dam; b. drilling radial grouting holes on the upstream surface in a basic gallery; c. downwards drilling curtain connection grouting holes extending into a dam foundation in the basic gallery; d. carrying out grouting by high pressure, fine cement wet grinding and concentrated slurry; and e. drilling a water discharge structure which is communicated with the basic gallery in the dam body. The invention is mainly used for the seepage prevention and discharge reinforcement processing of the concrete dam.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

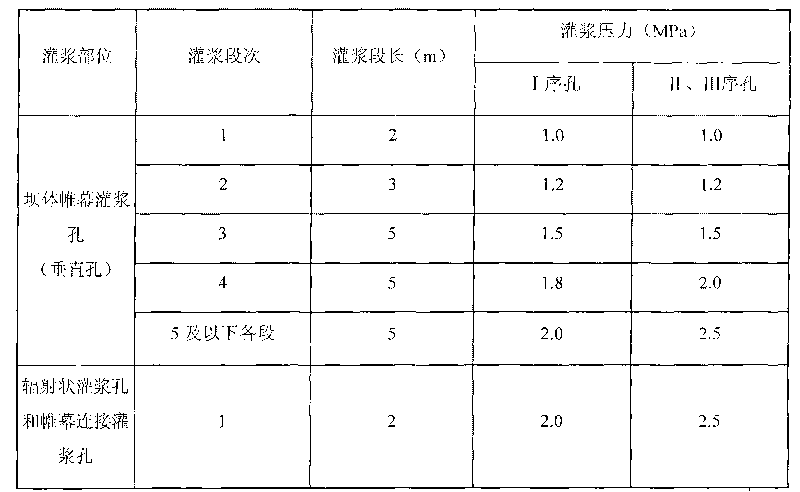

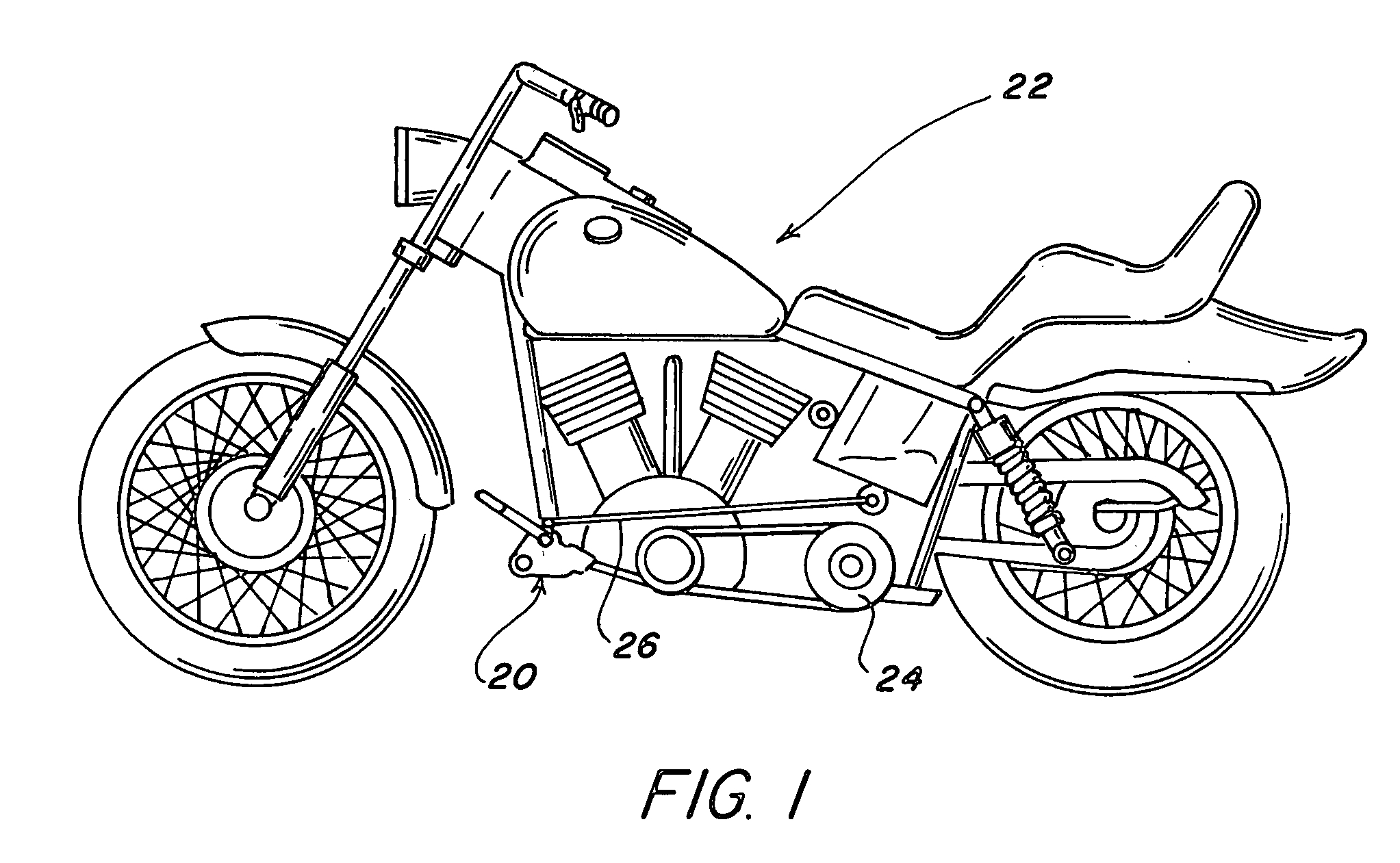

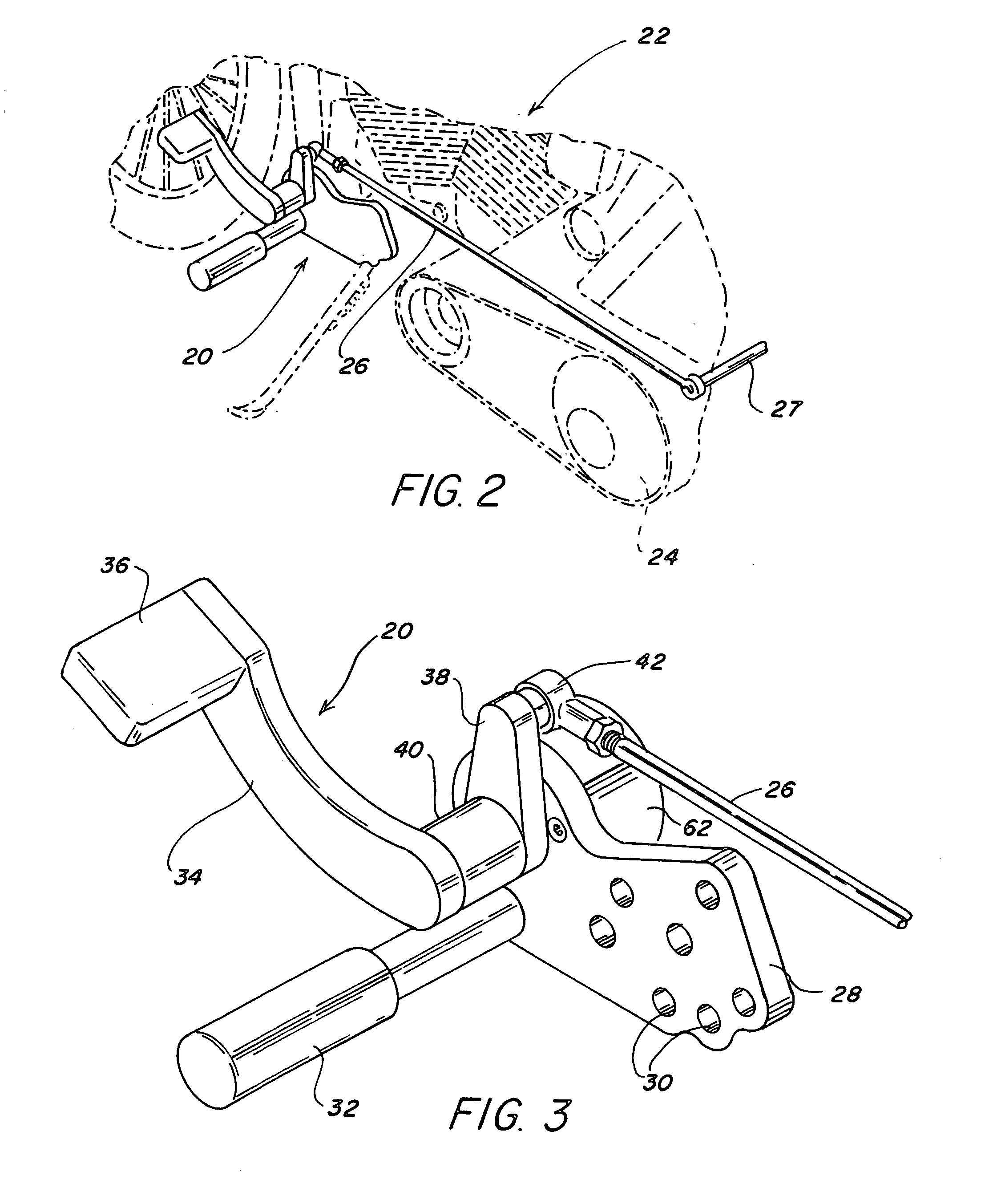

Foot operated motorcycle clutch

InactiveUS6945376B1Readily reengagedControlling membersCycle control systemsPositive pressureEngineering

A mechanism to retrofit modern motorcycles with a foot operated clutch or to be installed as original equipment is disclosed. The mechanism has an escapement mechanism, such as a pawl and ratchet, for holding the clutch in disengaged condition when a rider applies positive pressure on a foot pedal without requiring the rider to hold the foot pedal down with his or her left foot. This frees the rider to balance the motorcycle. The mechanism then allows the clutch to be readily reengaged when the rider desires to move the motorcycle by applying further positive pressure to the foot pedal.

Owner:HUNTER ROBERT M

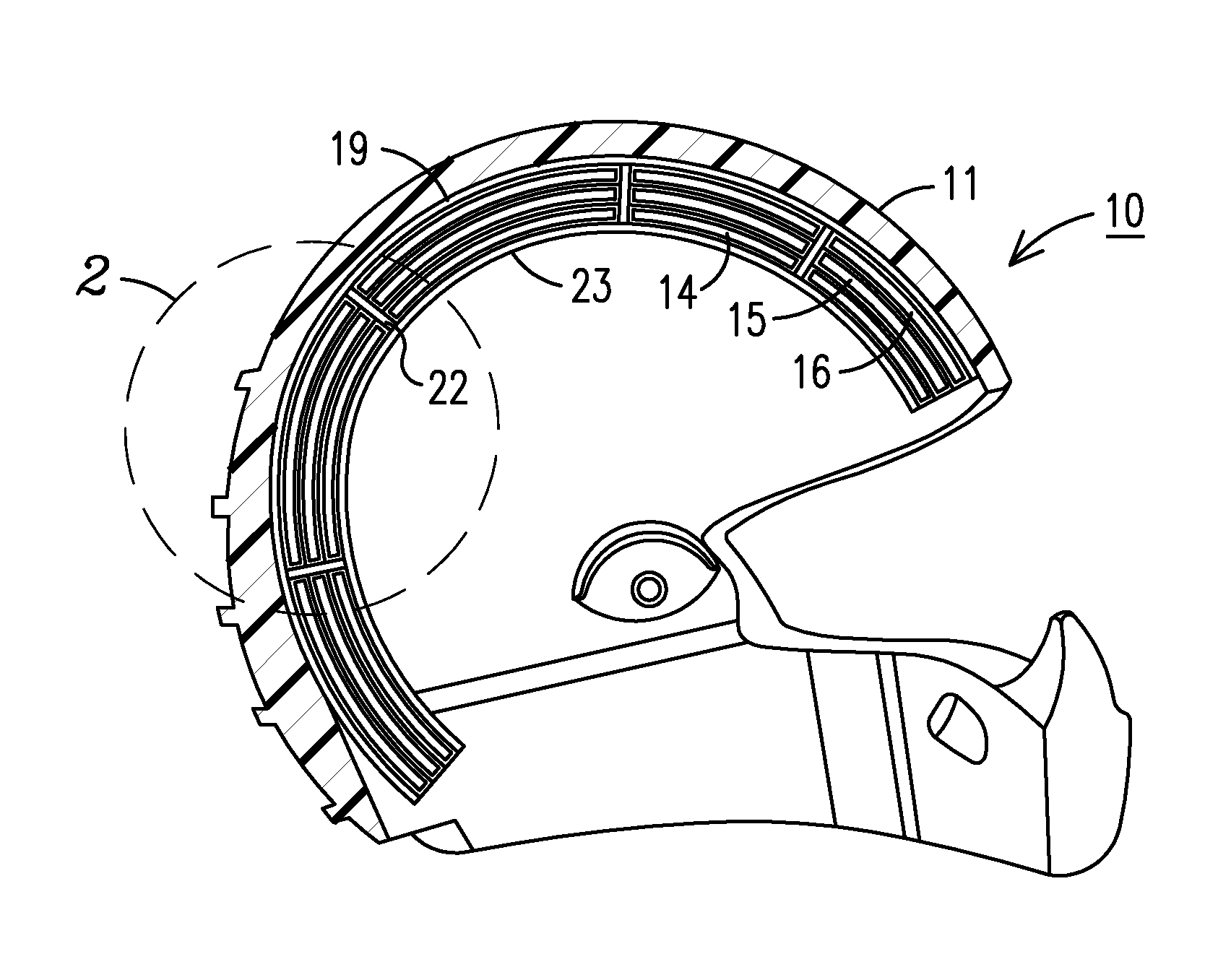

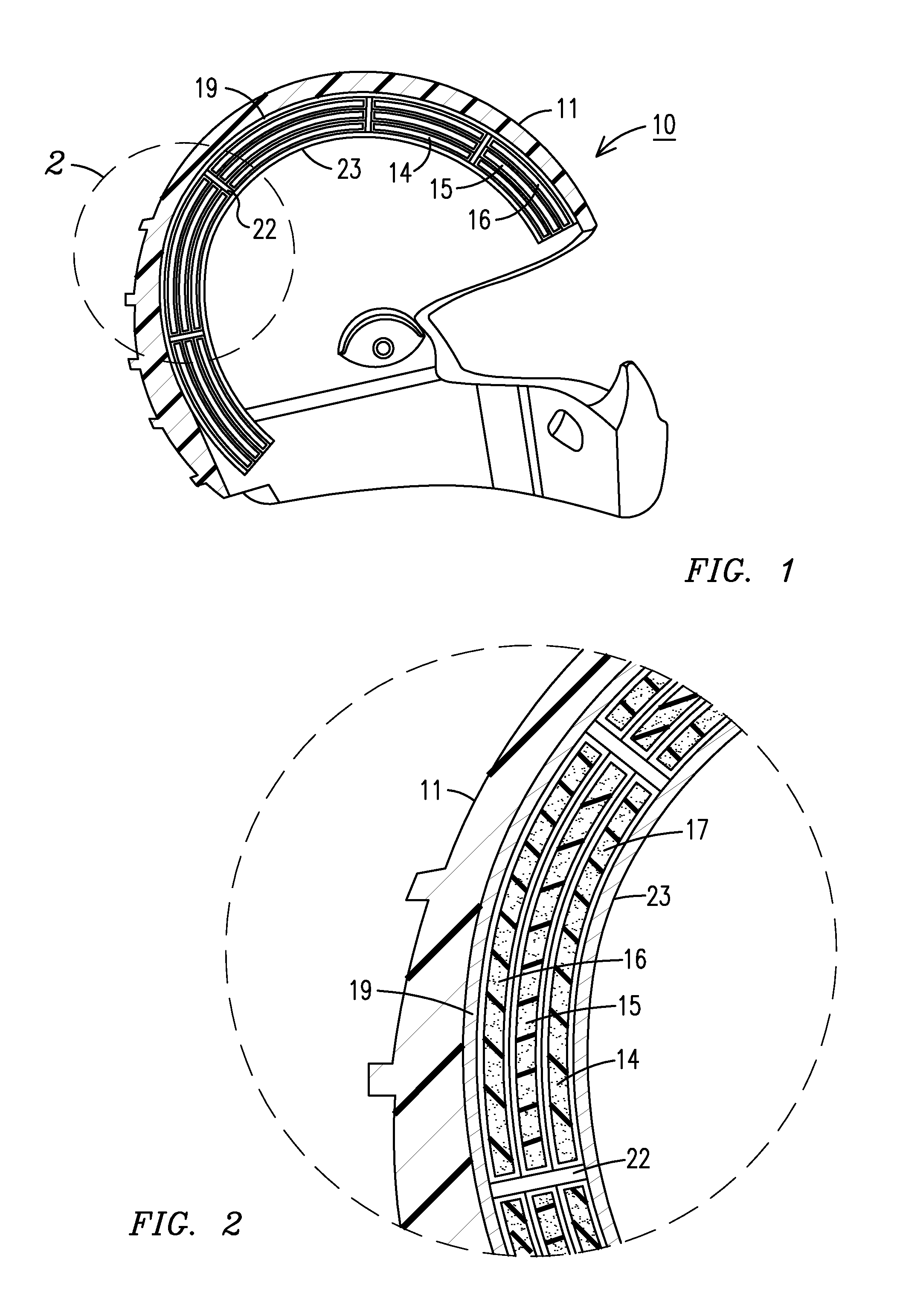

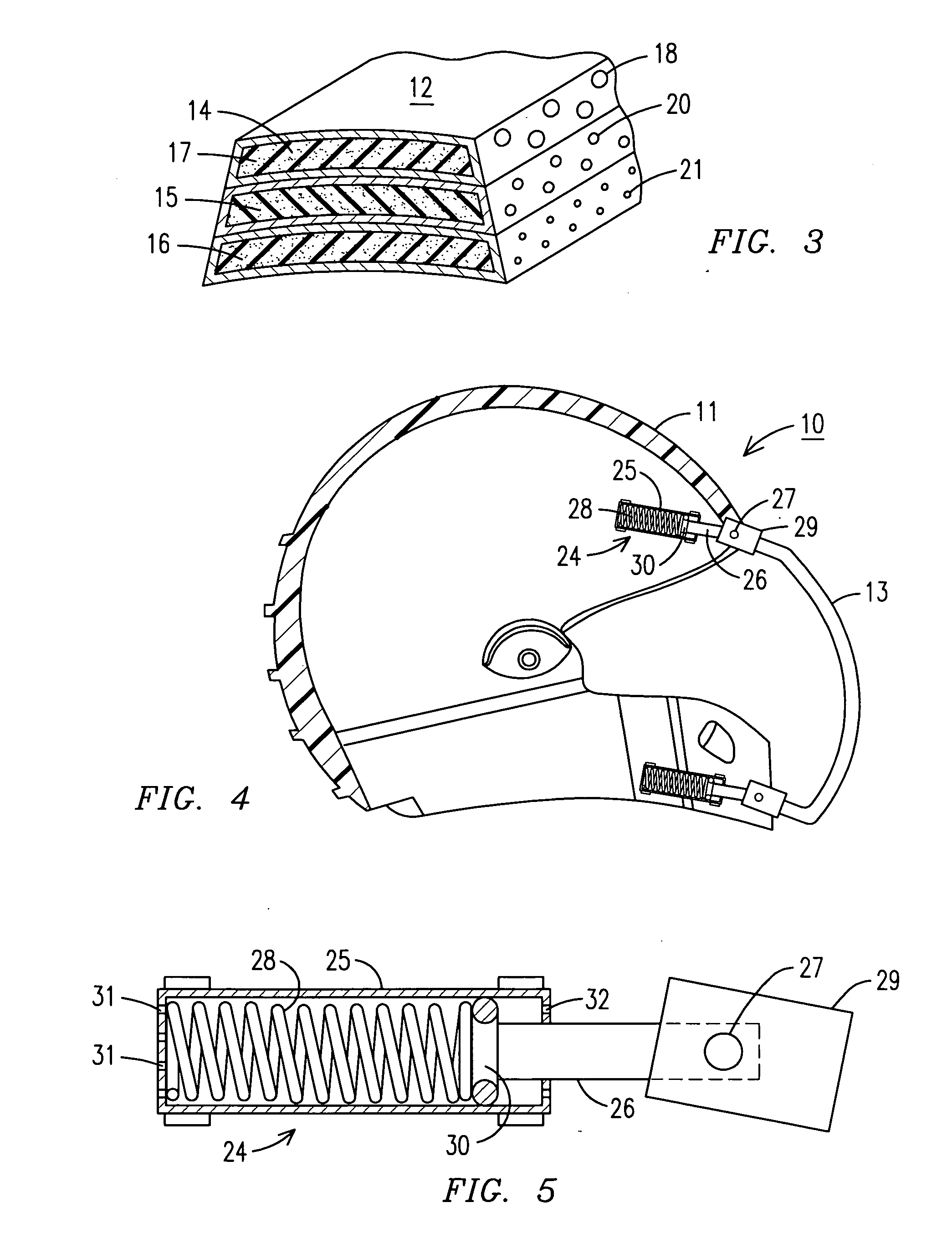

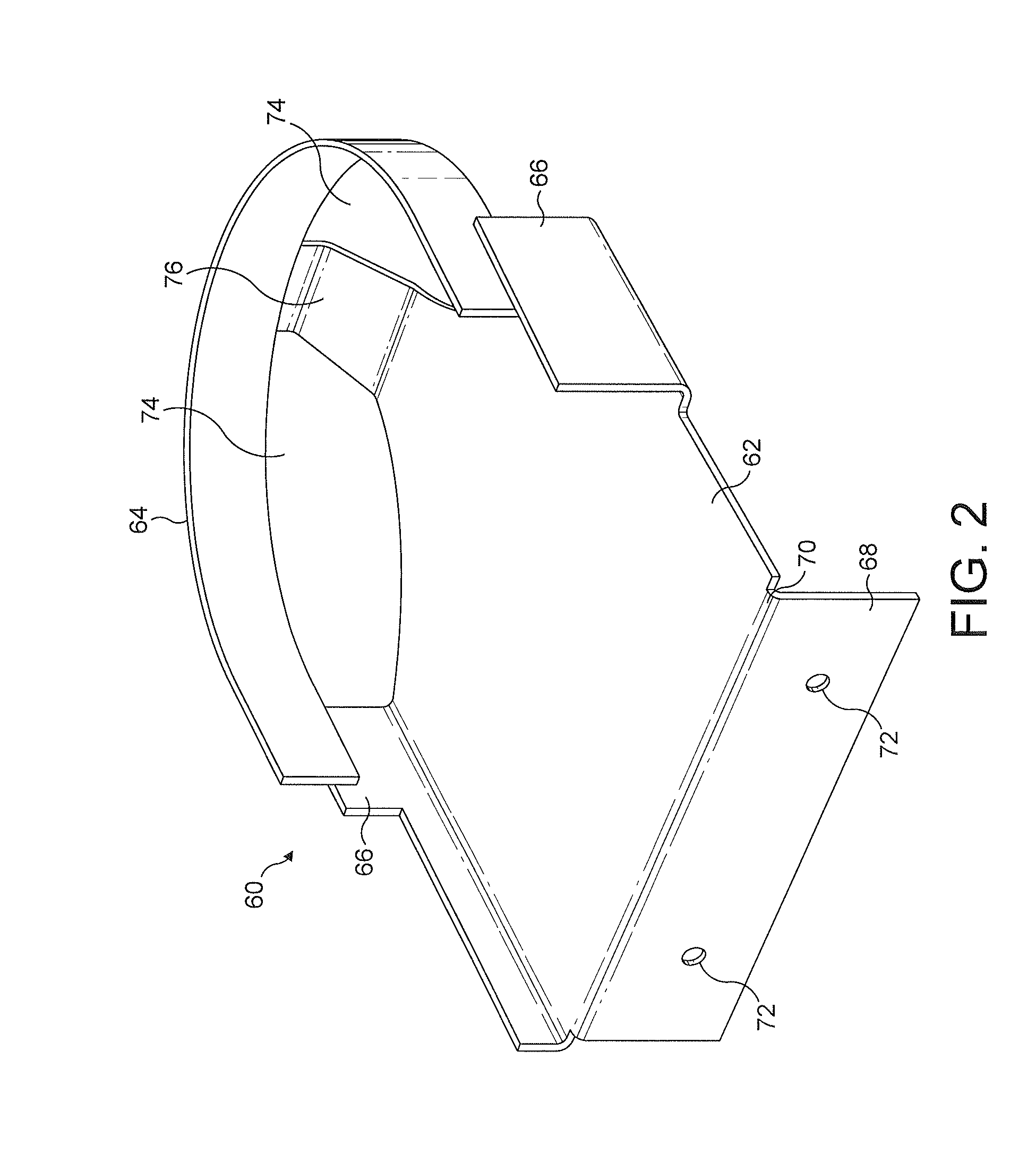

Safety helmet

The present invention is for a safety helmet having a hard outer shell having a plurality of protective flexible air bags for protecting a person's head against blows to the helmet outer shell and having a shock absorbing face guard. Each air bag may have a plurality of cushioning air bags enclosure layers mounted to a thin foamed polymer shell lining. Each enclosure layer of each air bag has an interior filled with a resilient multi-cellular sponge like material, such as a shaped foamed polyurethane sponge, and has a plurality of air escapement openings sized to meter the release of air under impact to the helmet hard shell under predetermined pressure with a different air release pressure for each enclosure layer.

Owner:BRANTLEY CHARLES W

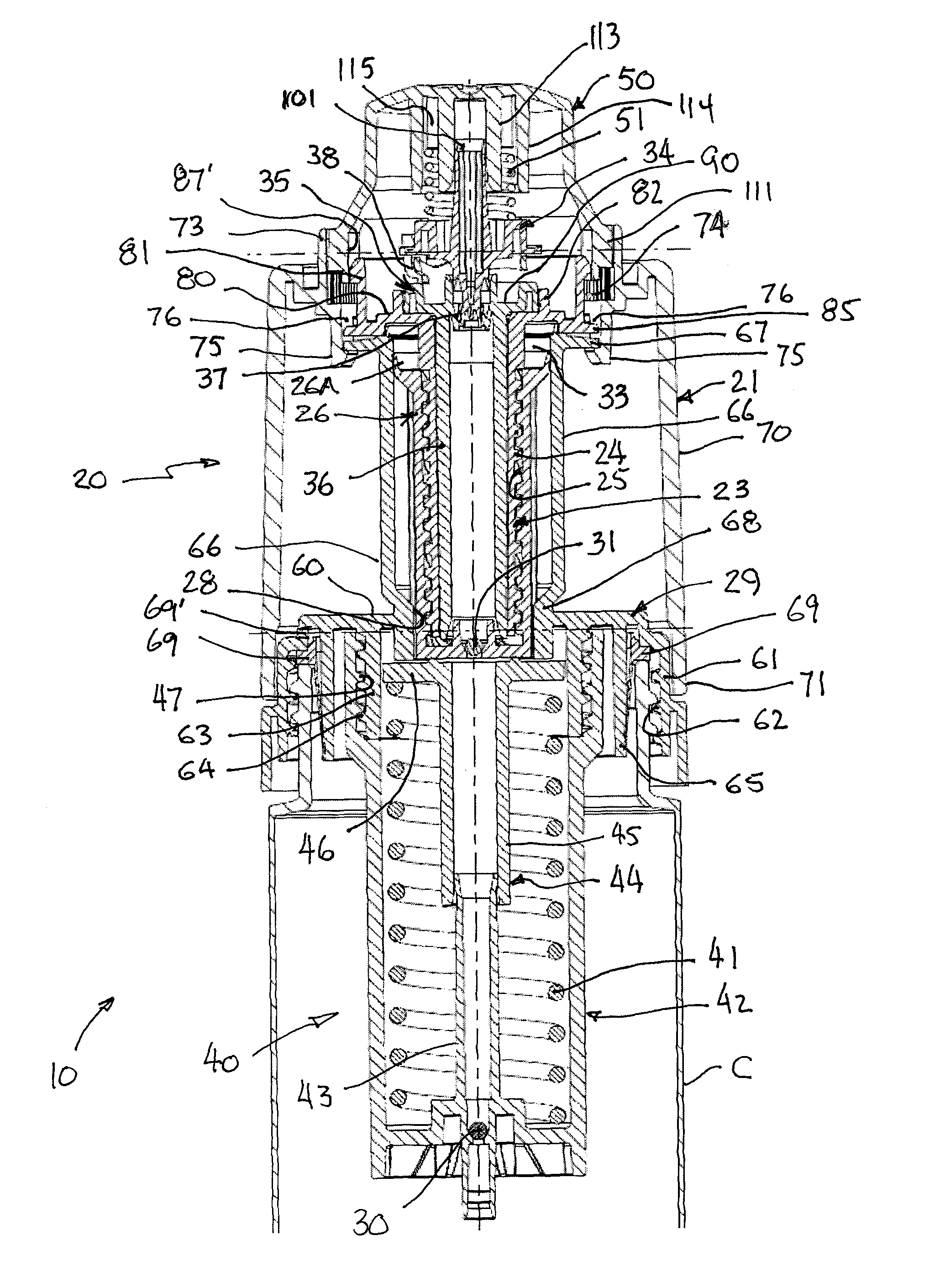

One turn actuated duration dual mechanism spray dispenser pump

ActiveUS8286837B1Prevent rotationReduce stepsContracting/expanding measuring chambersBagsRest positionPump chamber

A power assembly for dispensing product from a container includes a pump mechanism and an energy storage mechanism. The pump mechanism includes a rotatable actuating collar connected through an escapement mechanism with a drive screw with an externally threaded shaft engaged with internal threads in a piston. Rotation of the collar reciprocates the piston to store energy in the energy storage mechanism and to draw product into a pump chamber from which the product is dispensed. An actuator is connected with a stem valve to open it when the actuator is depressed, enabling the energy storage mechanism to push the piston back to its at-rest position to force product from the pump chamber and ready it for another dispensing cycle. Disengagement of the escapement mechanism when the actuator is depressed prevents rotation of the actuating collar. Different energy storage mechanisms can be interchangeably attached to the pump mechanism.

Owner:ALTERNATIVE PACKAGING SOLUTIONS

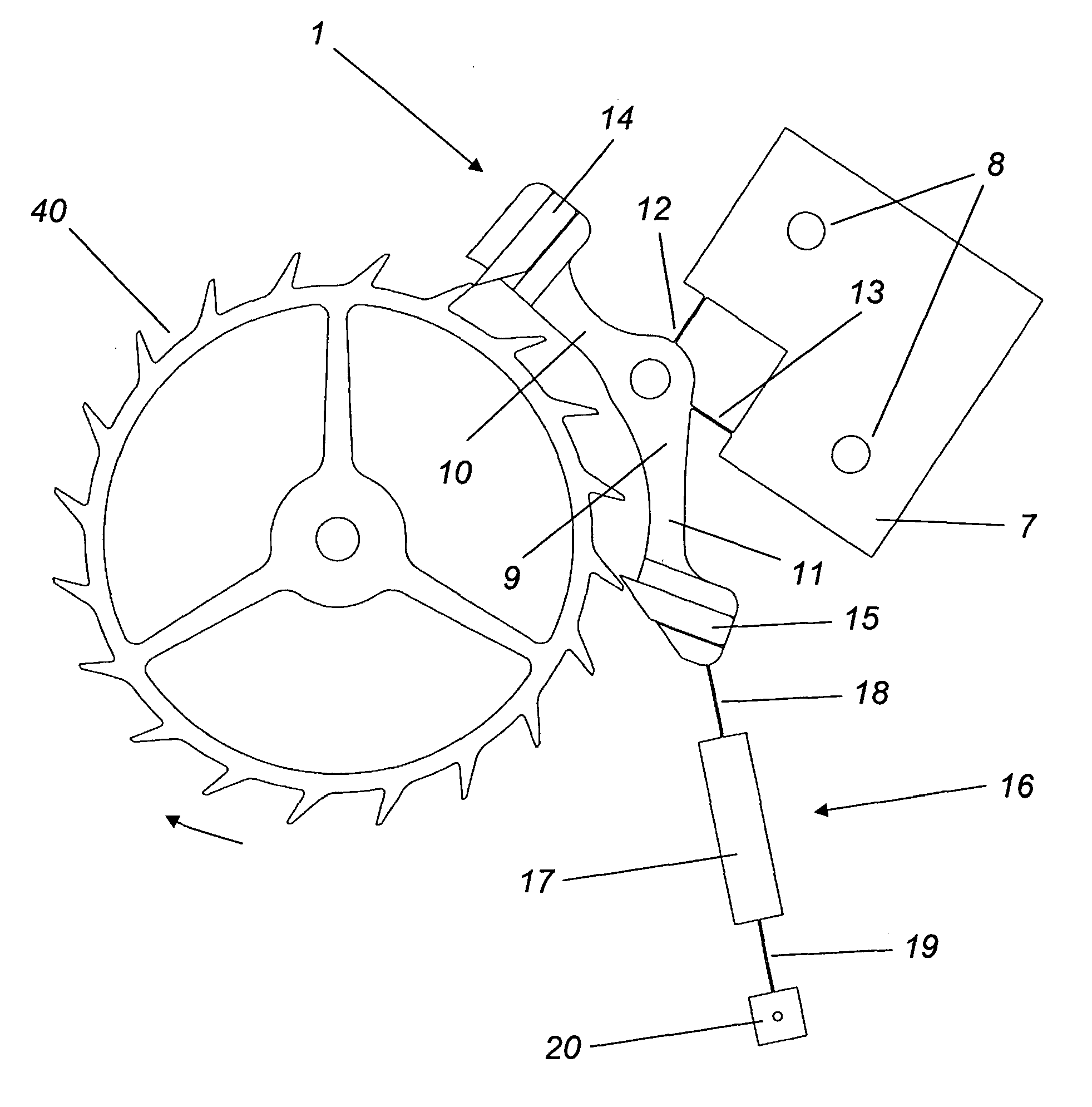

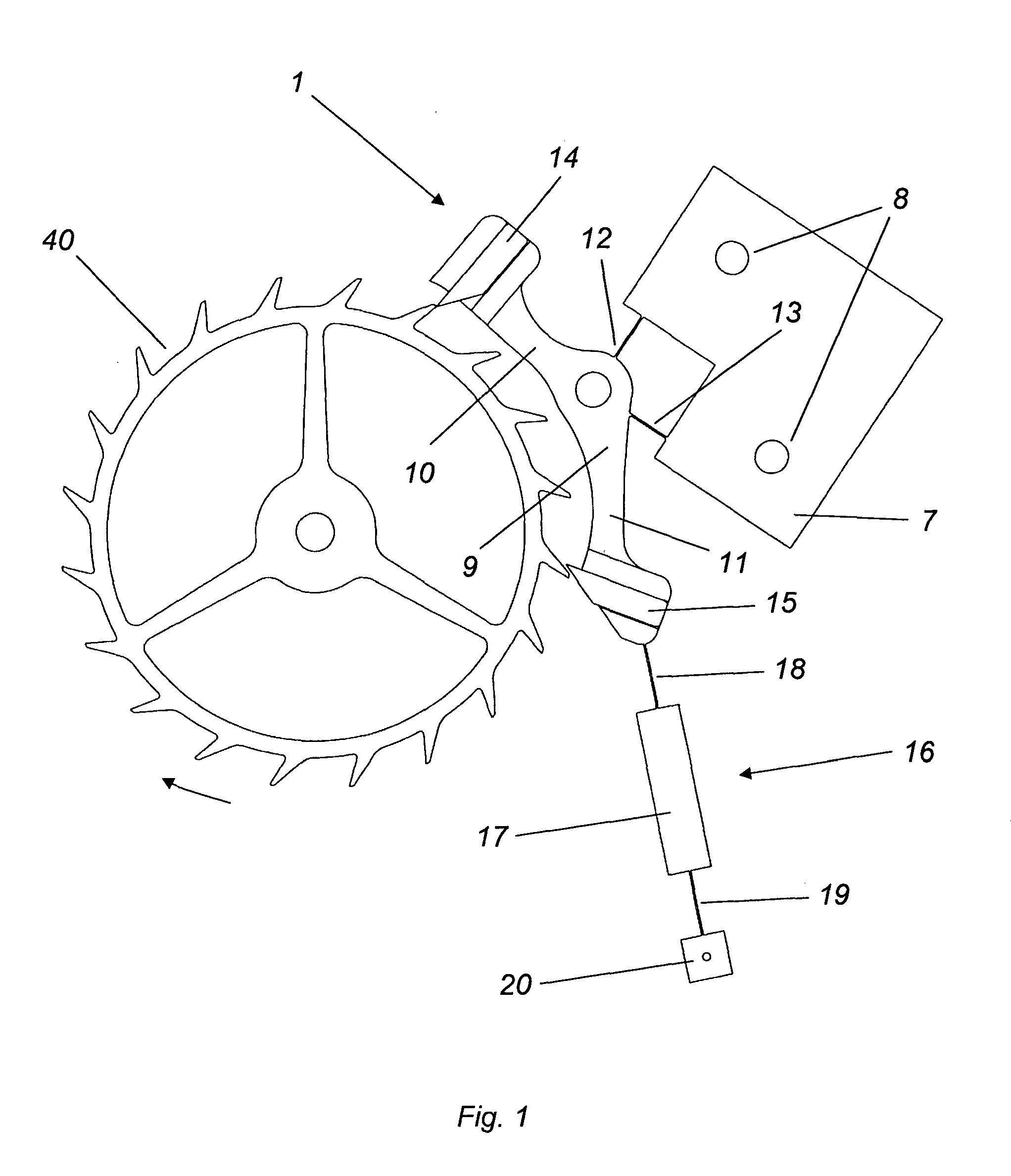

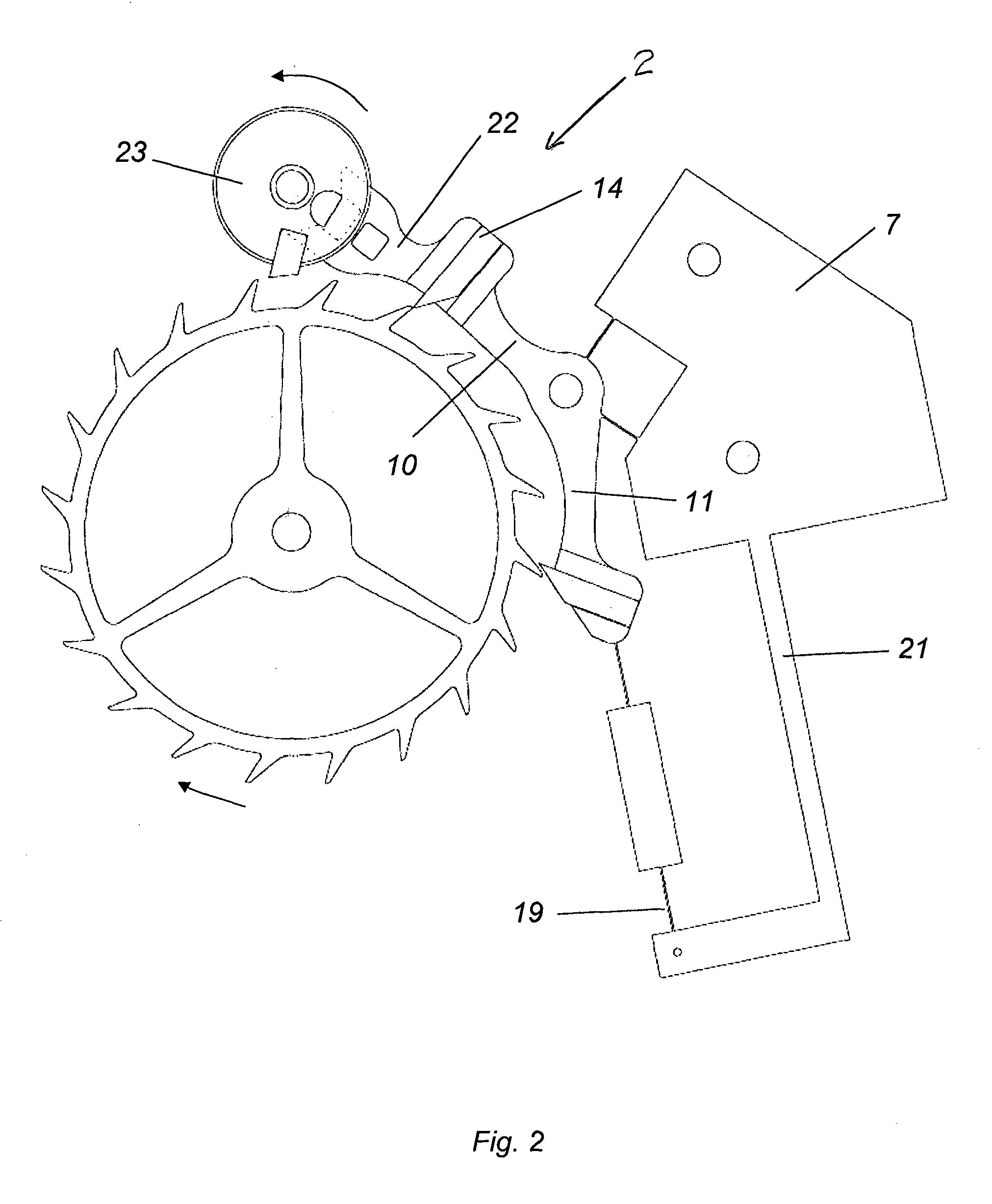

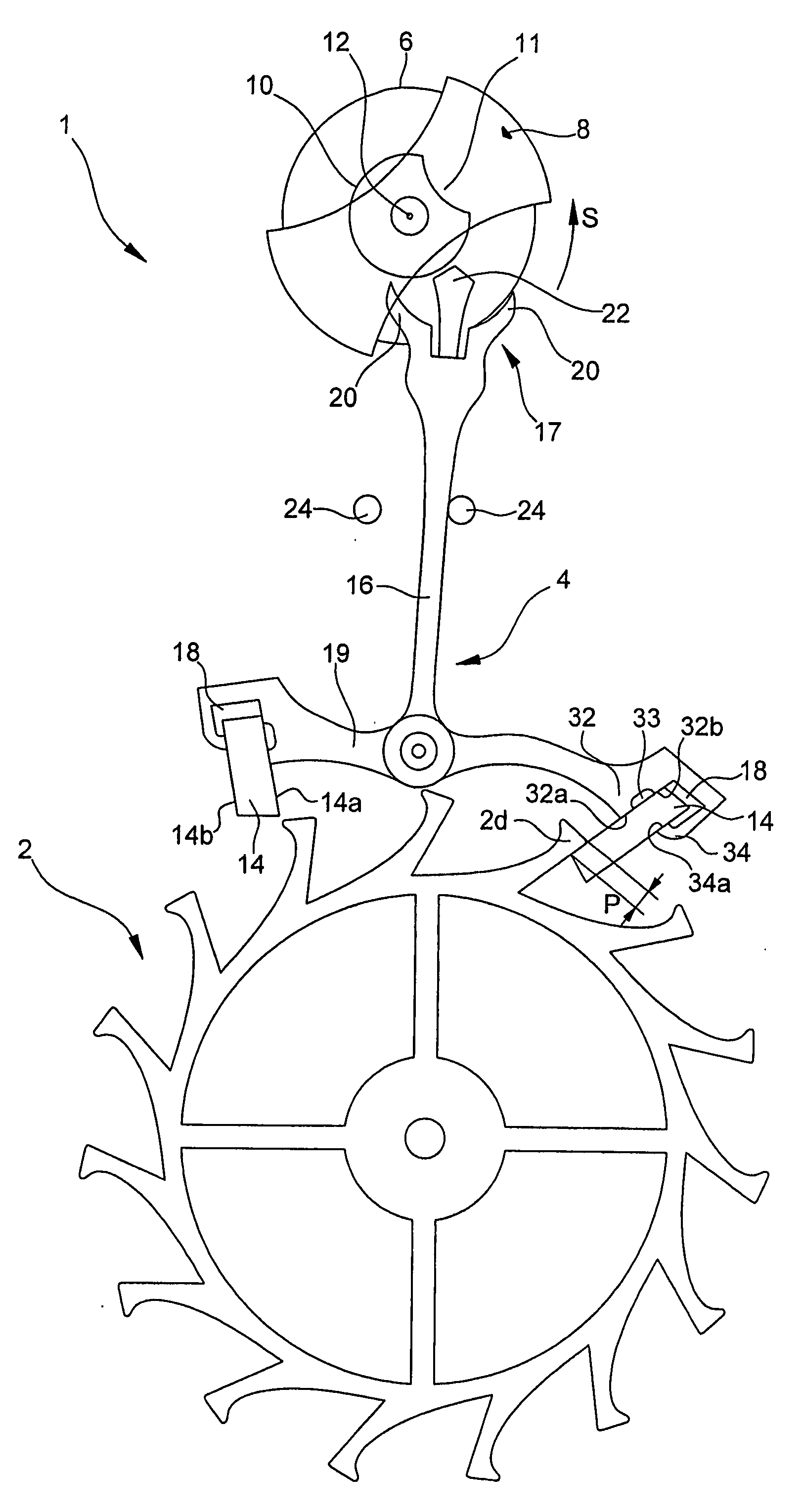

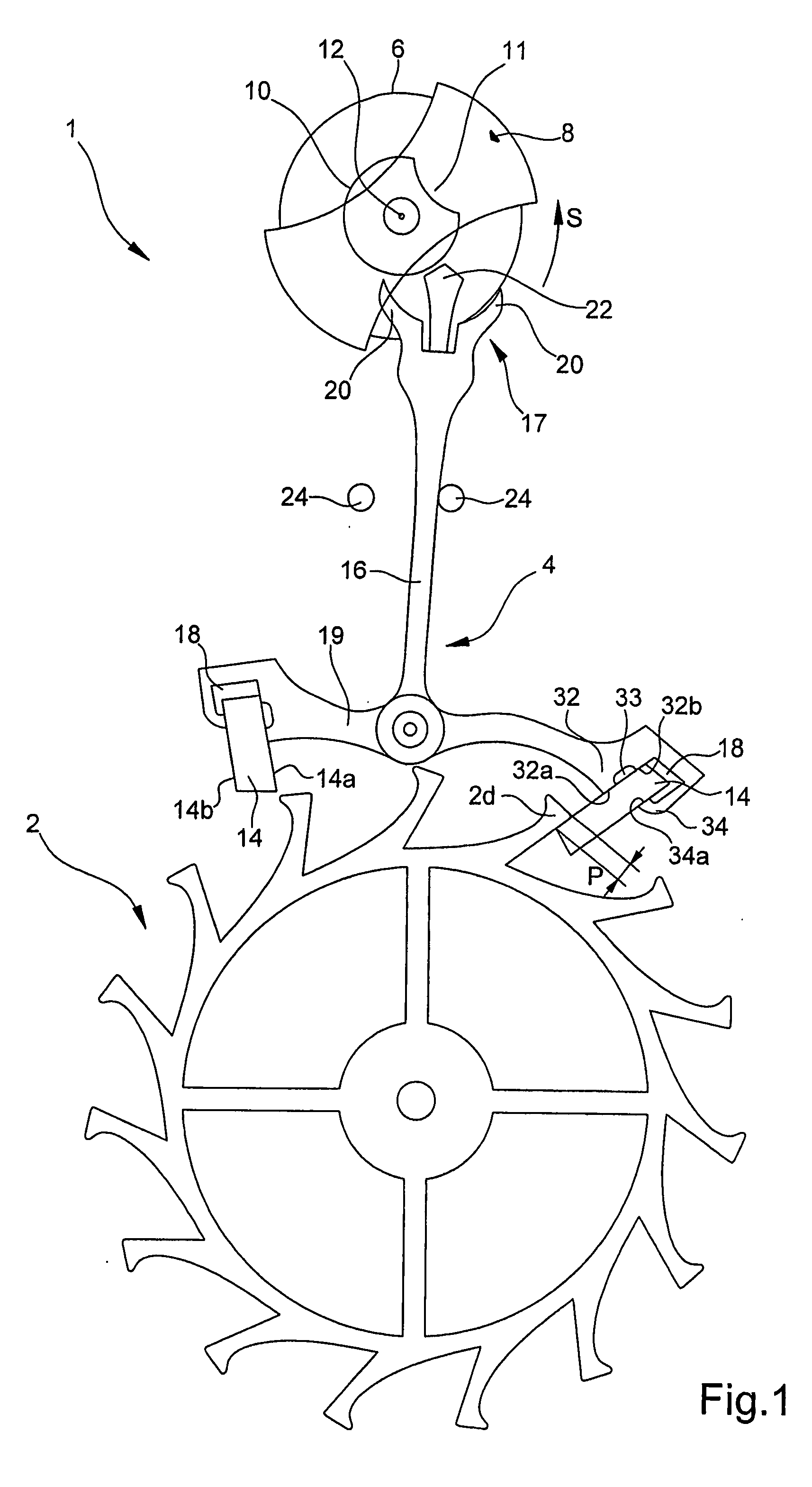

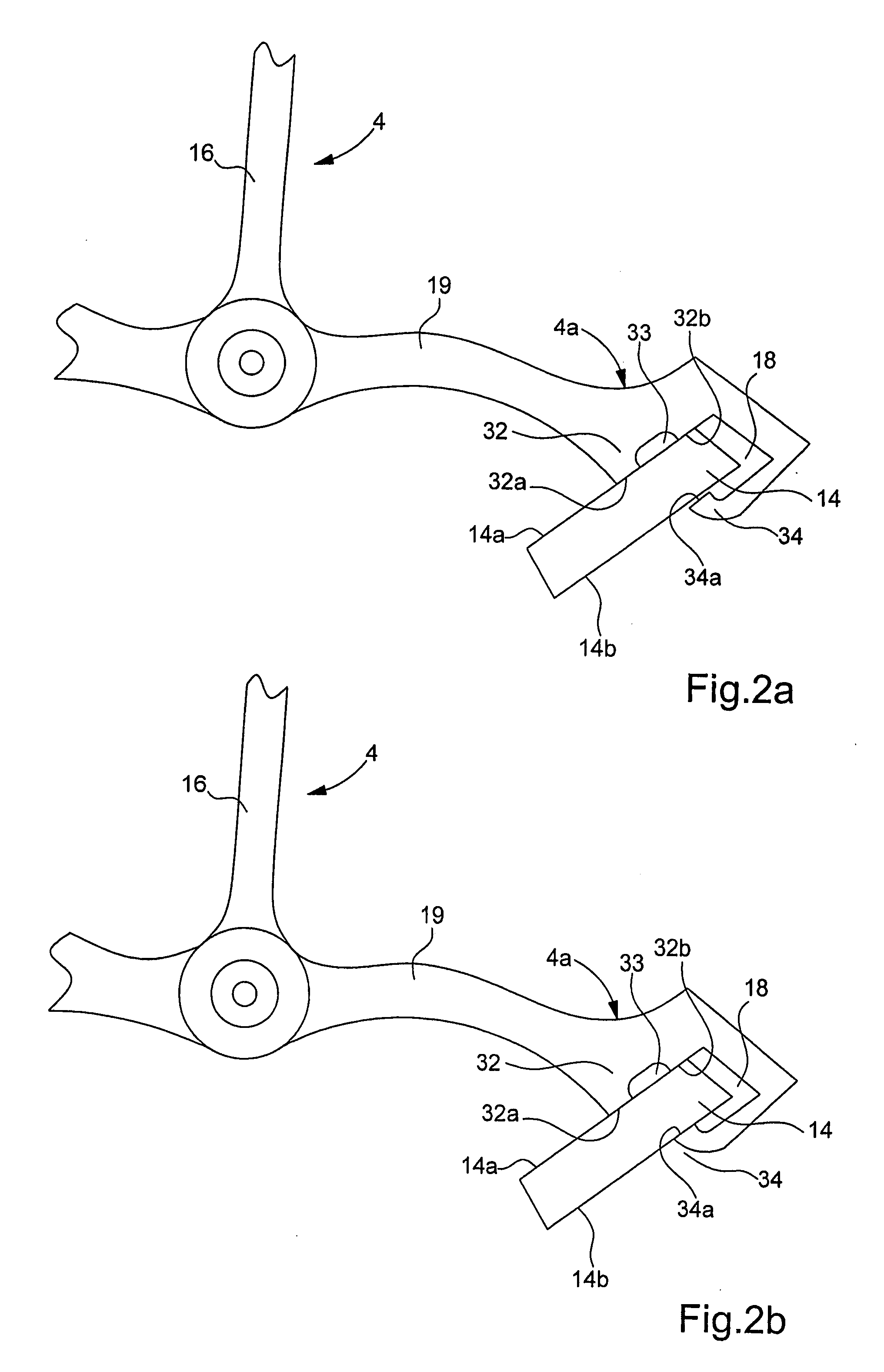

Immobilizing device for a toothed wheel

ActiveUS20130070570A1Minimize and even and clearanceMechanism performance is stableEscapementsRepair toolsEngineeringPallet

The invention relates to an immobilizing device for a toothed wheel suitable for the field of horology where it can be part of a direct- or indirect-impulse escapement, in particular in a wristwatch. This immobilizing device (1, 2, 3, 4, 5, 6) comprises: —a base (7); —an immobilizer (9) comprising two arms (10, 11) each provided with a pallet (14, 15) intended to come into contact with a tooth of the toothed wheel (40); —a first and a second elastic element (12, 13) each having an end connected to the immobilizer (9) and another end connected to the base (7); —a third elastic element (16) connected to the immobilizer (9), and it has the particular feature that it is in one piece or in one piece apart from at least one of the pallets (14, 15). The invention also relates to a timepiece and to a method for assembling such a timepiece.

Owner:ROLEX SA

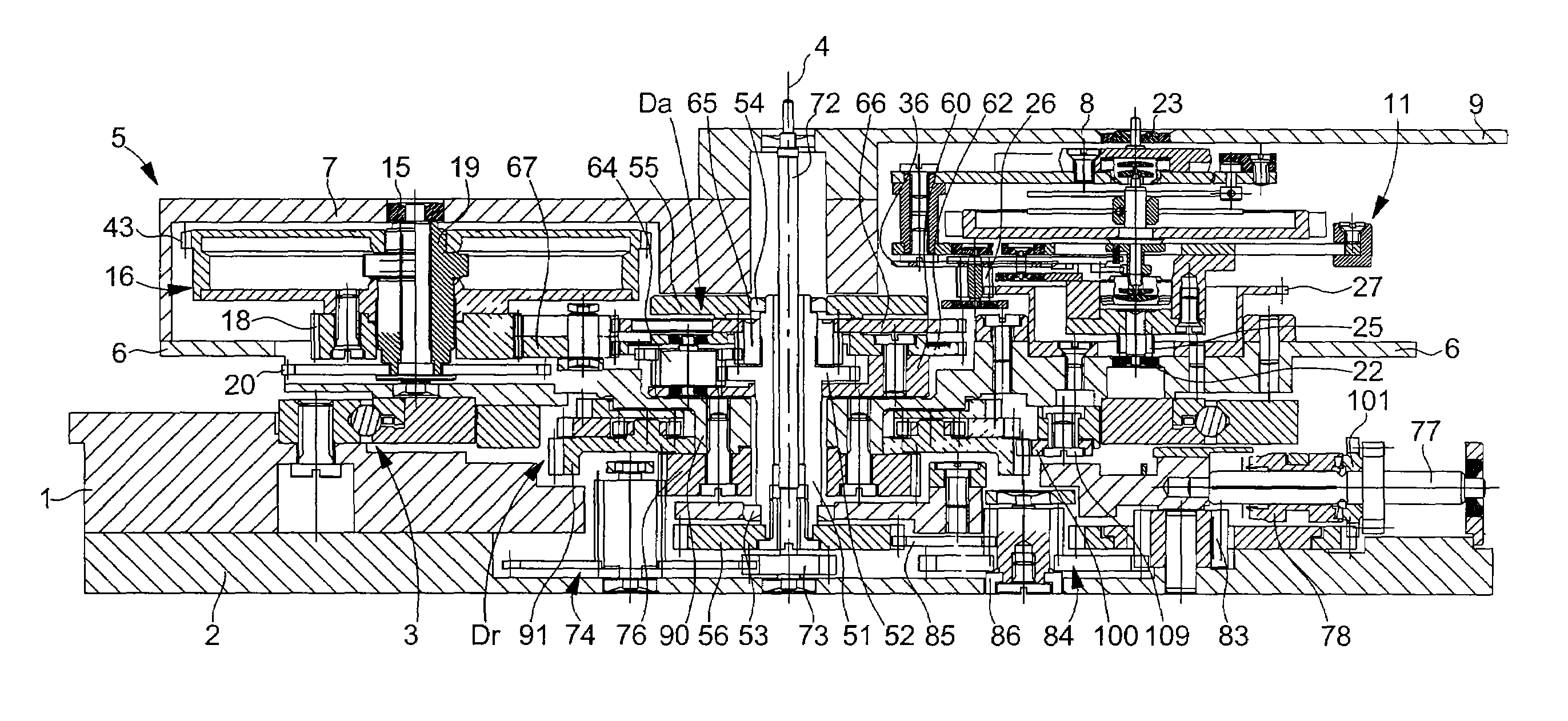

Watch including at least two regulating systems

ActiveUS7350966B2Improve regularity of workingImprove regularityEscapementsFrequency stabilisation mechanismDifferential displayDisplay device

The invention concerns a watch with a mechanical movement of the type comprising at least two regulating systems (SR1, SR2) each including a mechanical oscillator and an escapement. The movement includes as many sub-assemblies (SE1, SE2) as there are regulating systems, each of said sub-assemblies including a regulating system (SR1, SR2), a barrel (B1, B2) and a going train transmitting energy from the barrel to the regulating system inside the sub-assembly. A differential display gear (Da) connects the barrel or the going train of each sub-assembly to the display (A) to average out the rate of the two sub-assemblies. In a preferred embodiment, the two sub-assemblies are mounted on a common rotating support (5) and their regulating systems are tourbillons which make an orbital movement about the center of the watch dial.

Owner:MONTRES BREGUET

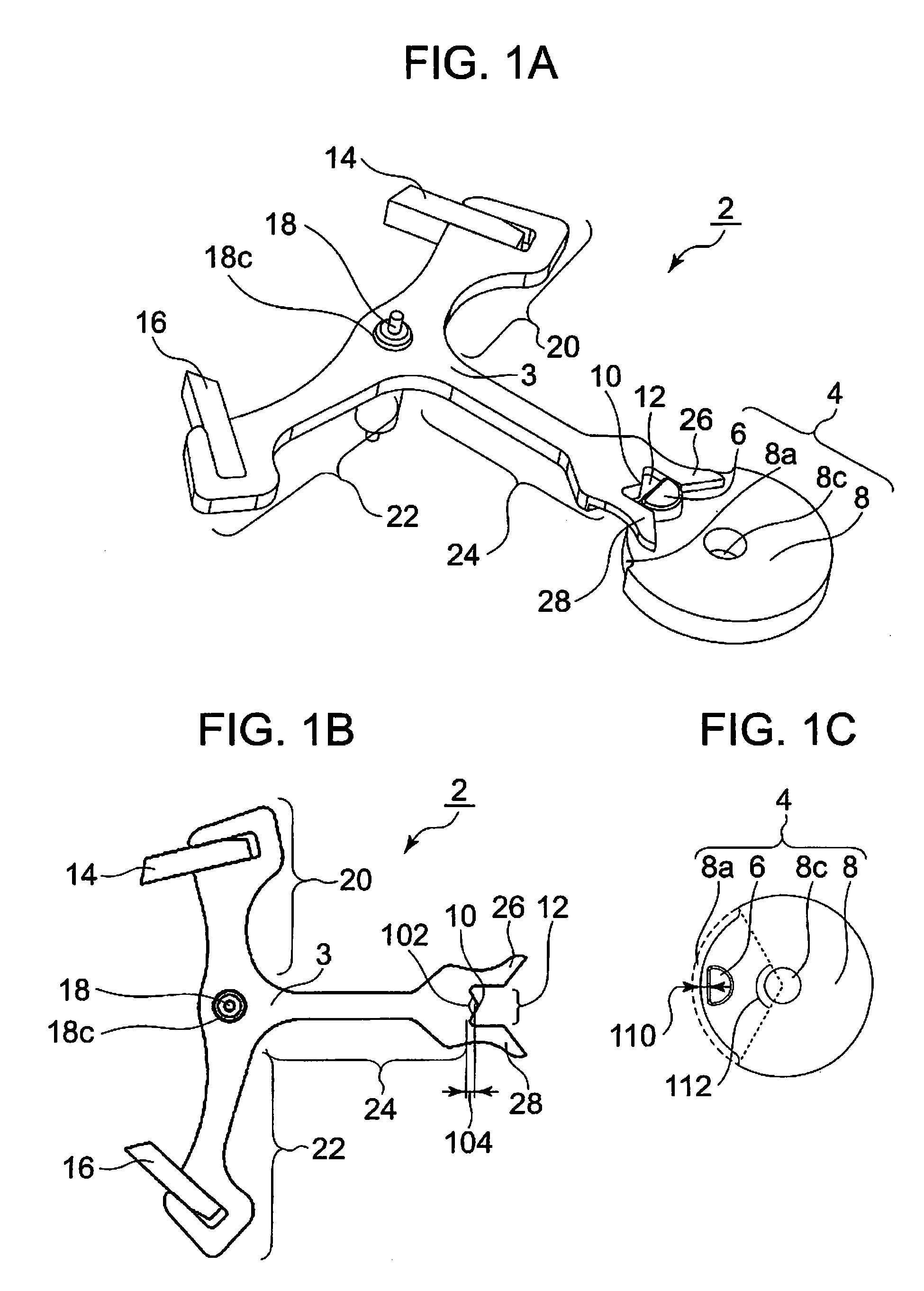

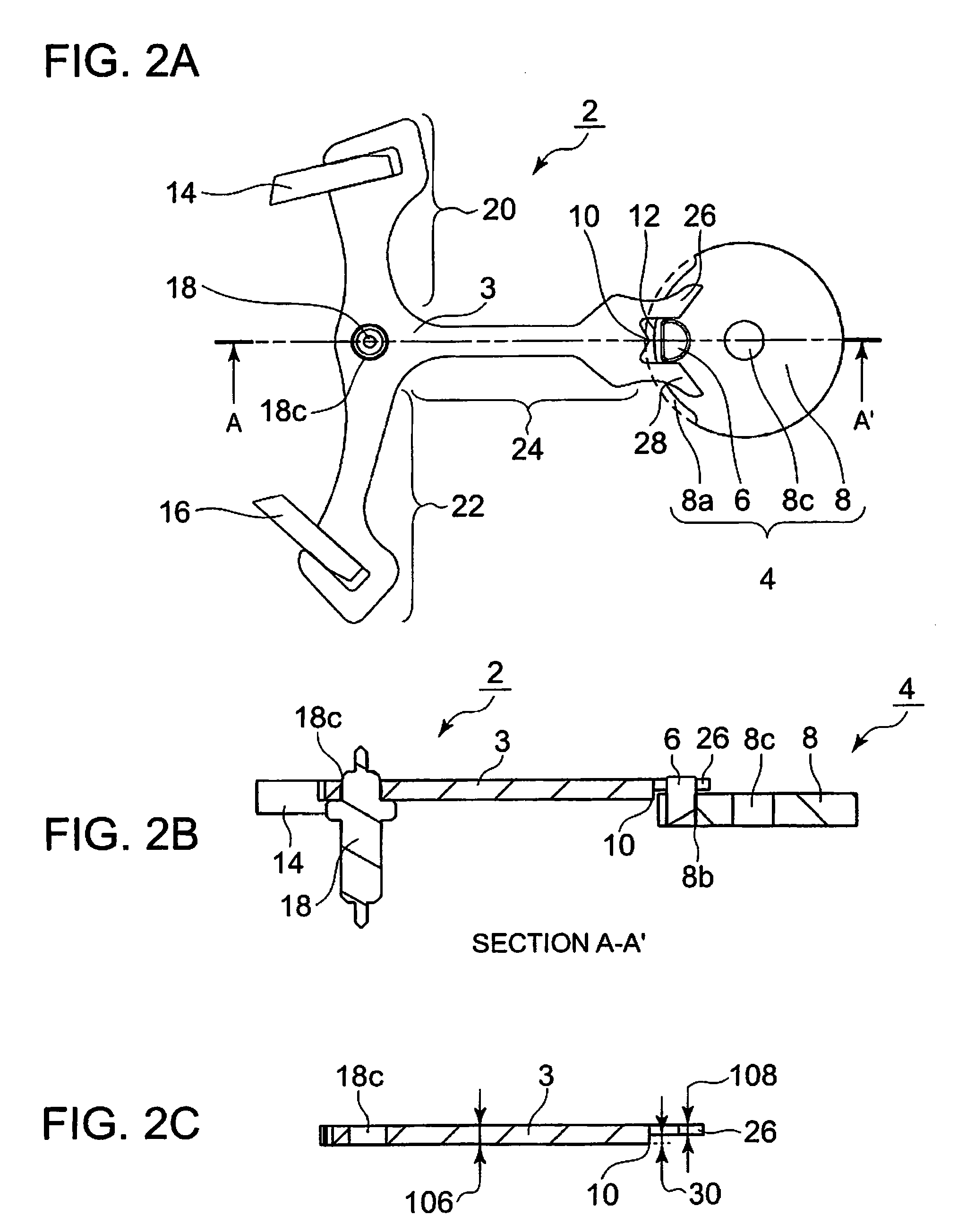

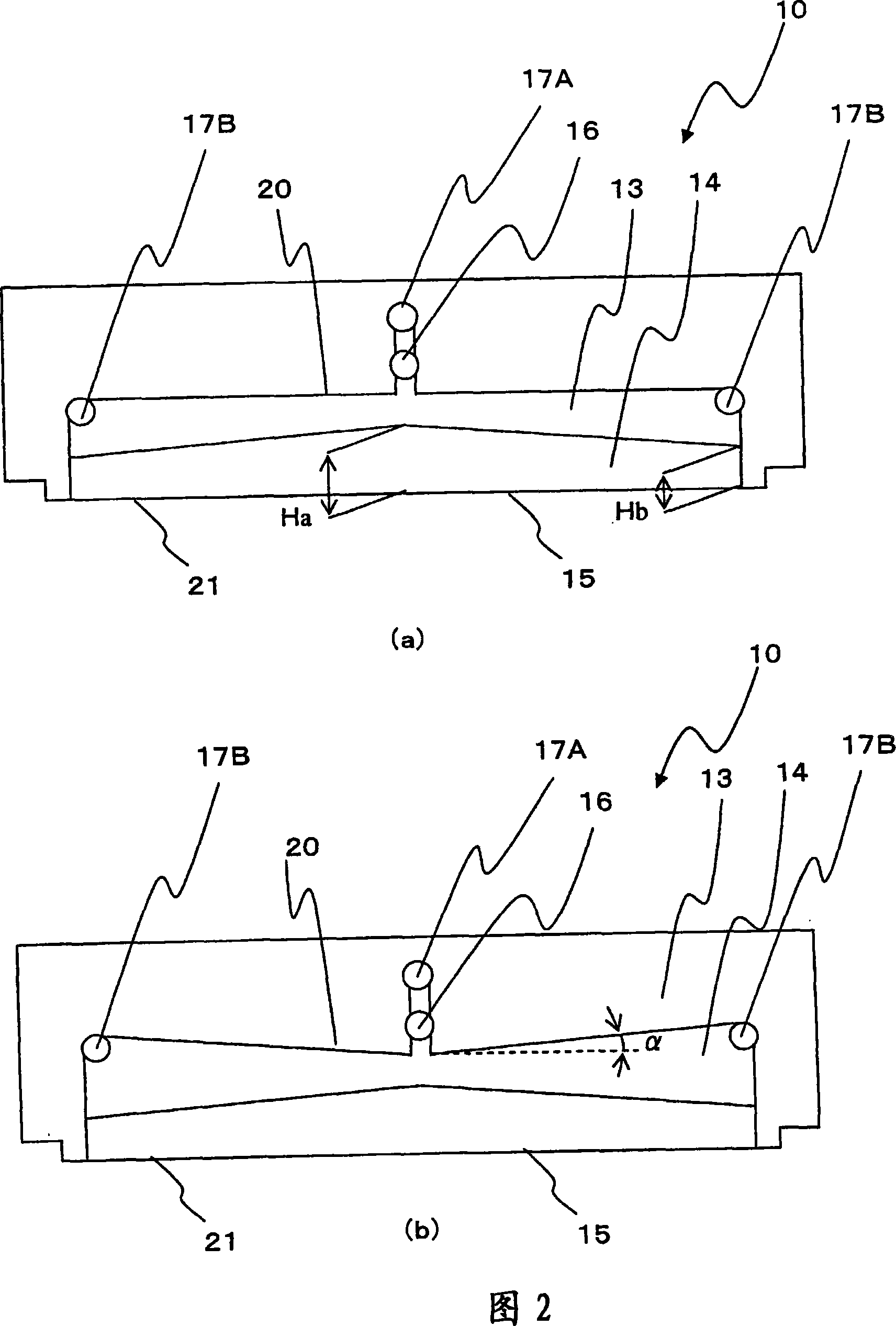

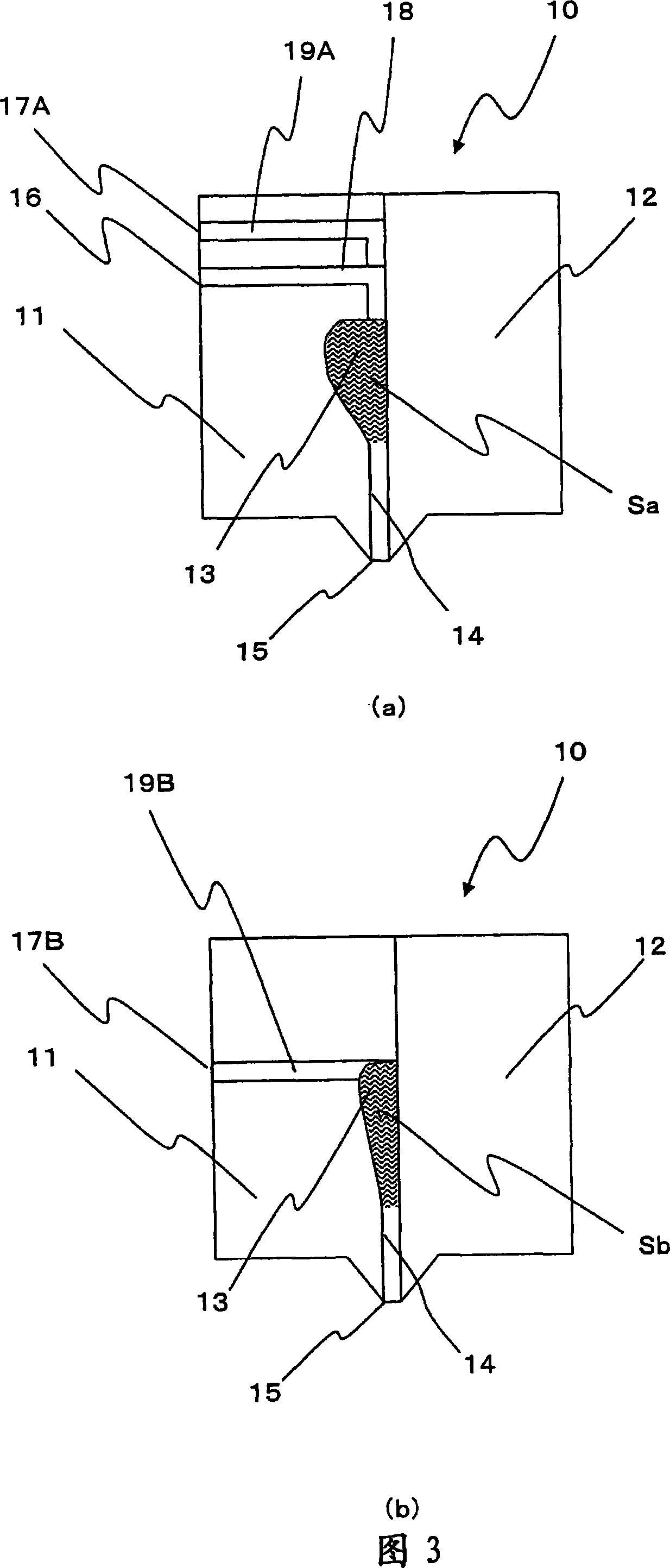

Escapement governor, mechanical watch, pallet fork (incomplete) manufacturing method, and roller manufacturing method

ActiveUS20100208555A1Improve accuracyReduce thicknessEscapementsPhotomechanical exposure apparatusMechanical watchCounter rotation

Disclosed are an integrally molded type pallet fork (incomplete) with a safety pin and a roller table that are formed with high precision by a simple process, a thin escapement governor including the pallet fork (complete) and the roller table, and a method of manufacturing the pallet fork (complete) and the roller table. The pallet fork (complete) of the escapement governor includes a pair of entry horn and exit horn extending from the rotation axis of the pallet fork (complete) toward the rotation axis of a balance with hairspring and adapted to transmit the power of an escape wheel to an impulse pin; and a safety pin which is provided in a side surface of the pallet fork (complete) between the pair of entry horn and exit horn, which extends from the rotation axis of the pallet fork (complete) toward the rotation axis of the balance with hairspring, which is situated at a position nearer to the rotation axis of the pallet fork (complete) than the pair of entry horn and exit horn, which enters a passing hollow to thereby cause the pallet fork (complete) to make normal rotation or reverse rotation with respect to the rotation axis of the pallet fork (complete), and which abuts a portion of a roller other than the passing hollow to thereby prevent erroneous rotation of the pallet fork (complete); and the roller is formed in a single layer.

Owner:SEIKO INSTR INC

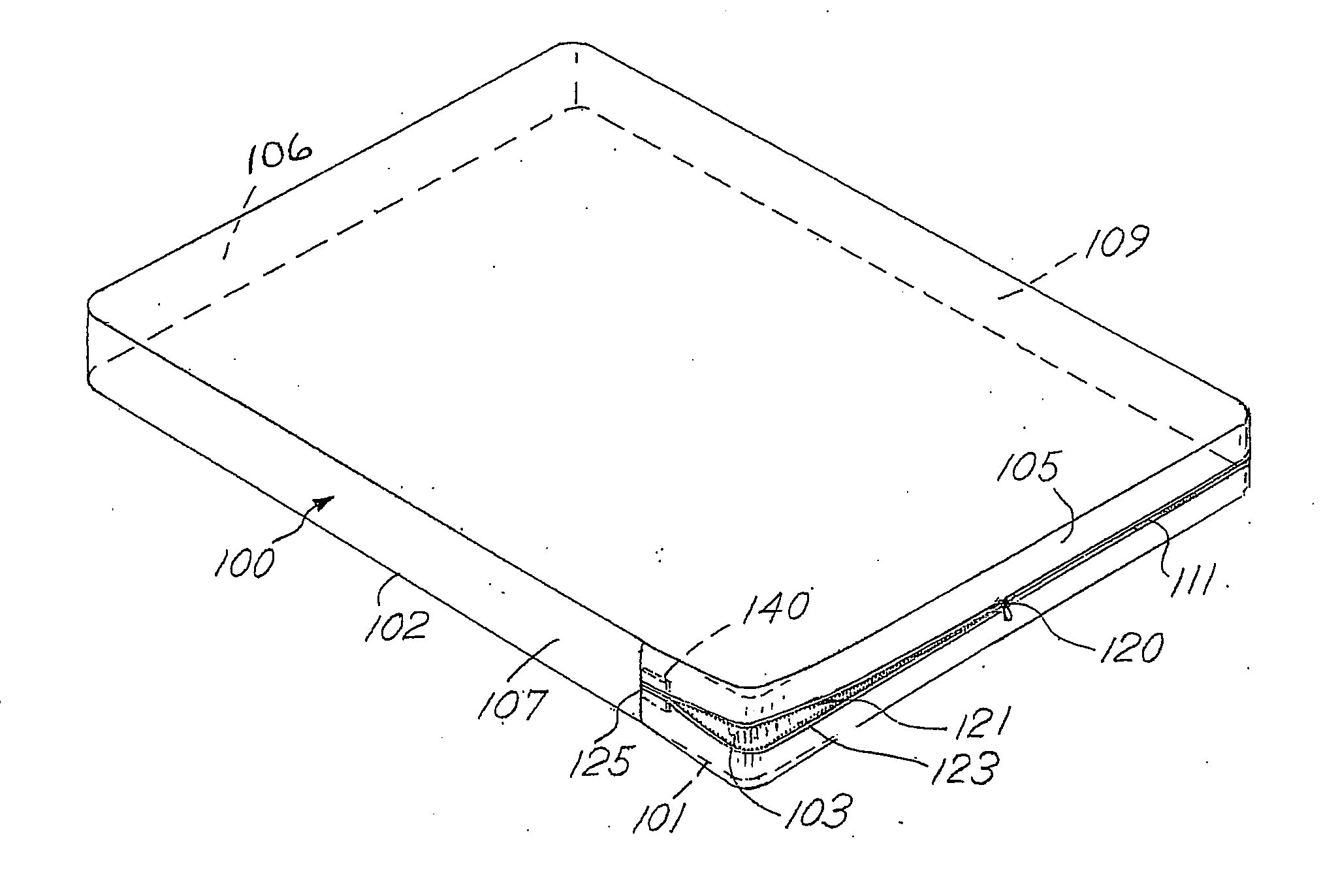

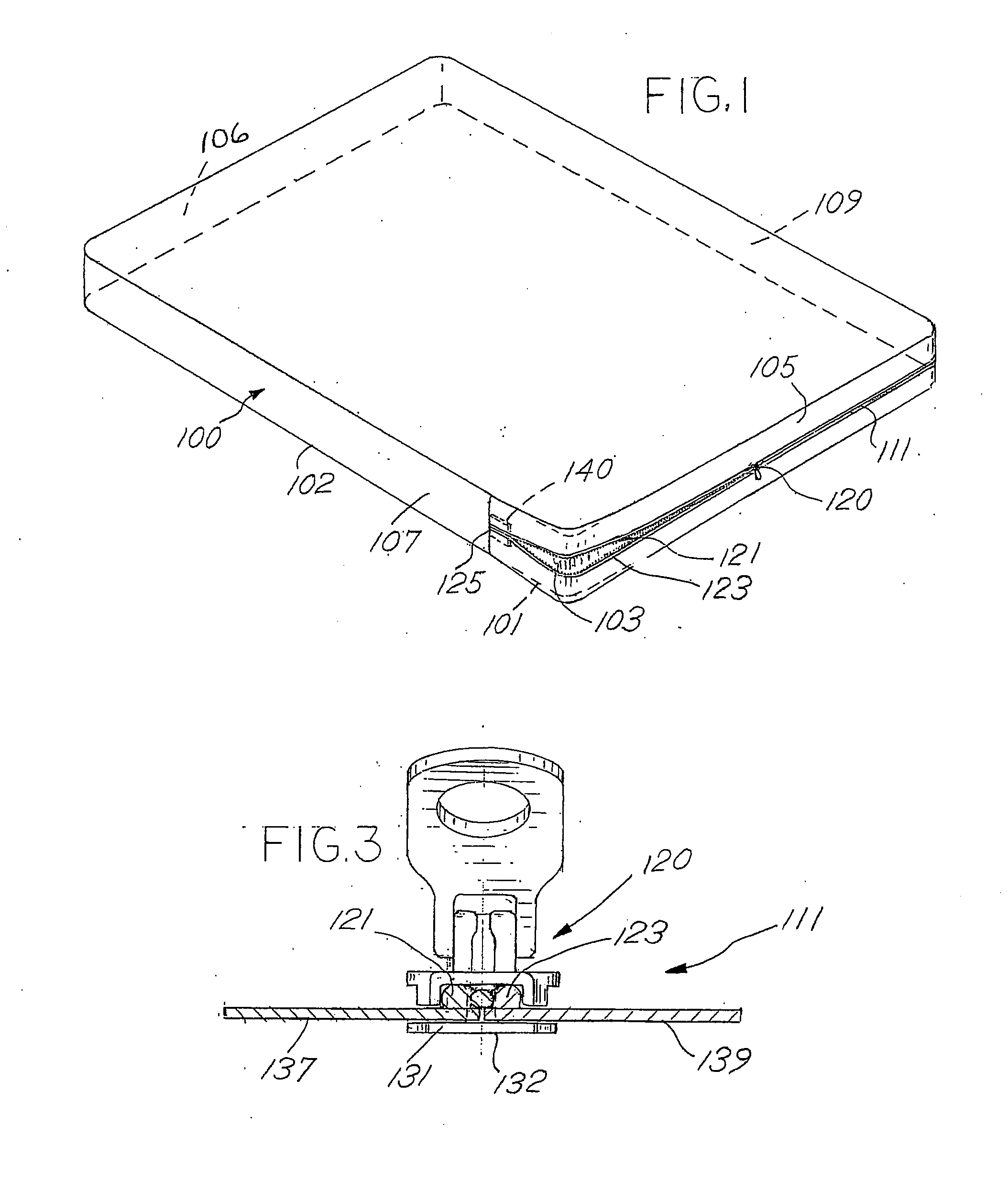

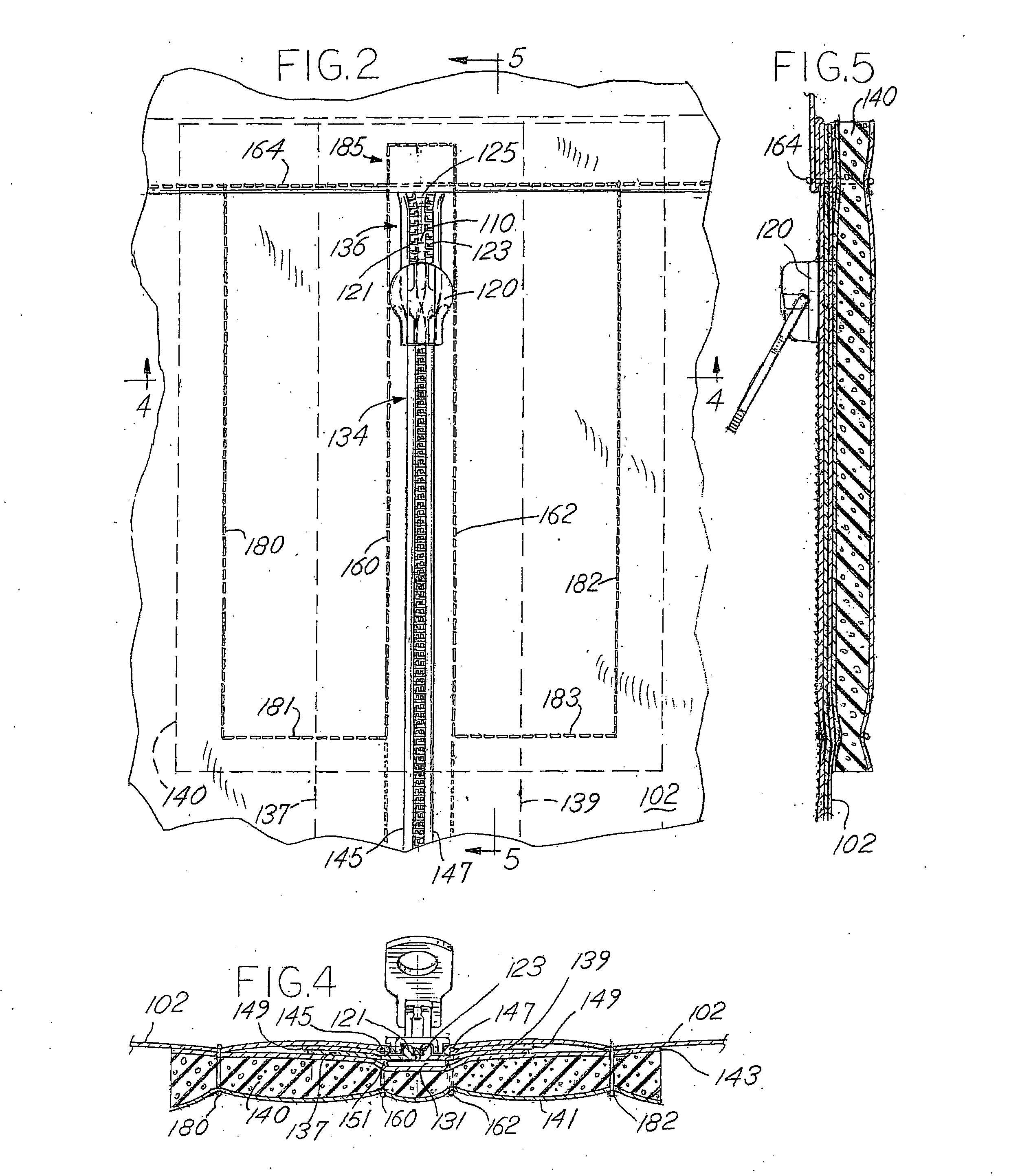

Mattress Encasement For Preventing Bed Bug Escapement Via A Zipper Opening

A mattress encasement made of bug impervious fabric provides a zipper opening for removal of the mattress. A foam pad is stitched at an end of the zipper closure such that when the zipper is located at or near the end, a channel is provided to prevent or obstruct the escapement of bed bugs via the channel and out from a mattress encased by the mattress encasement.

Owner:BEDDING ACQUISITION LLC

Device and Method for Securing a Pallet-Stone to an Escapement Pallet of a Timepiece Movement

The invention concerns a device for securing a pallet stone to an escapement pallet including at least one housing for receiving said pallet stone, characterized in that the portion of the pallet including said housing is made of a shape memory alloy able to undergo a reversible transformation from an austenitic crystallographic phase to a martensitic crystallographic phase.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

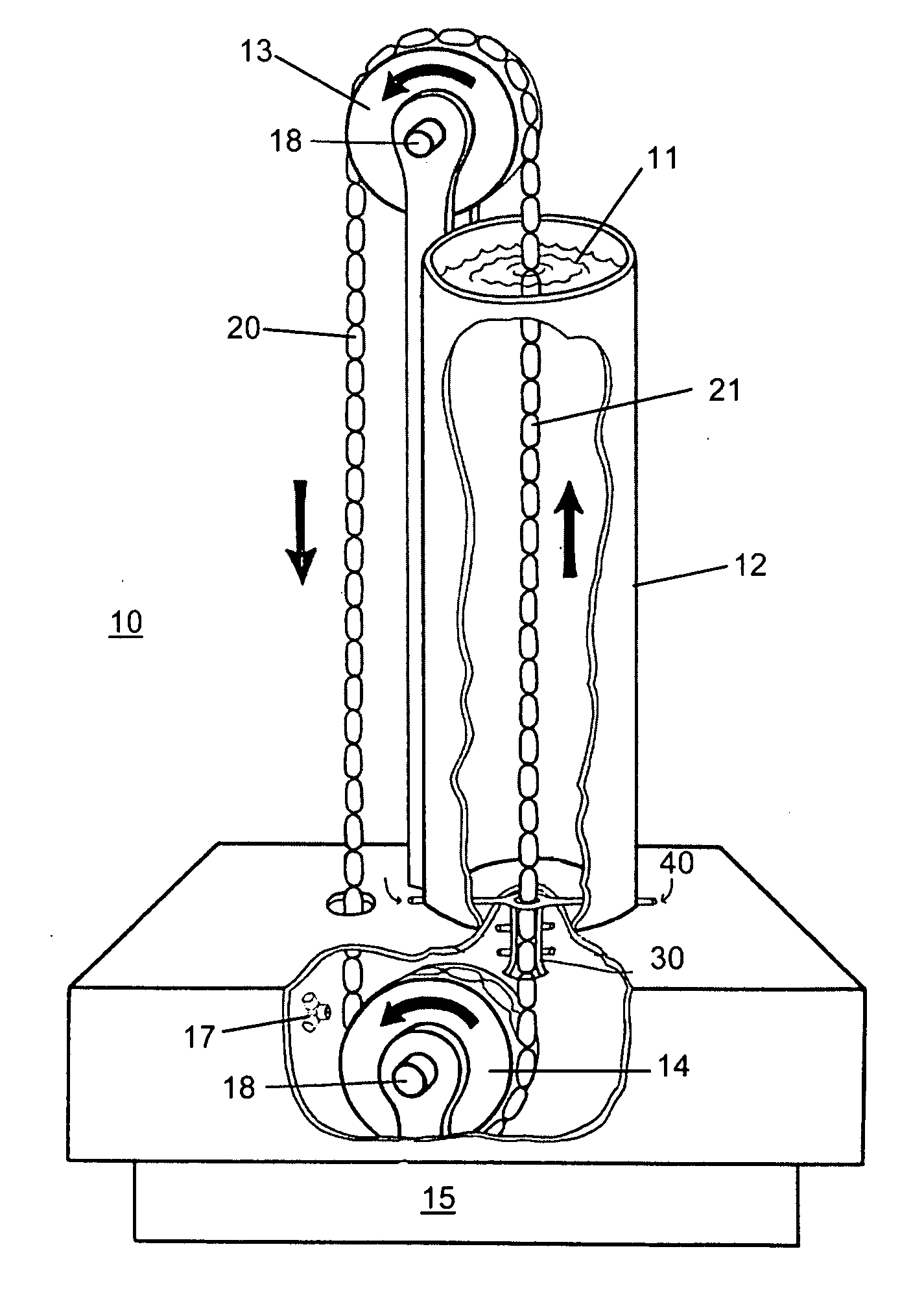

Economy of motion machine

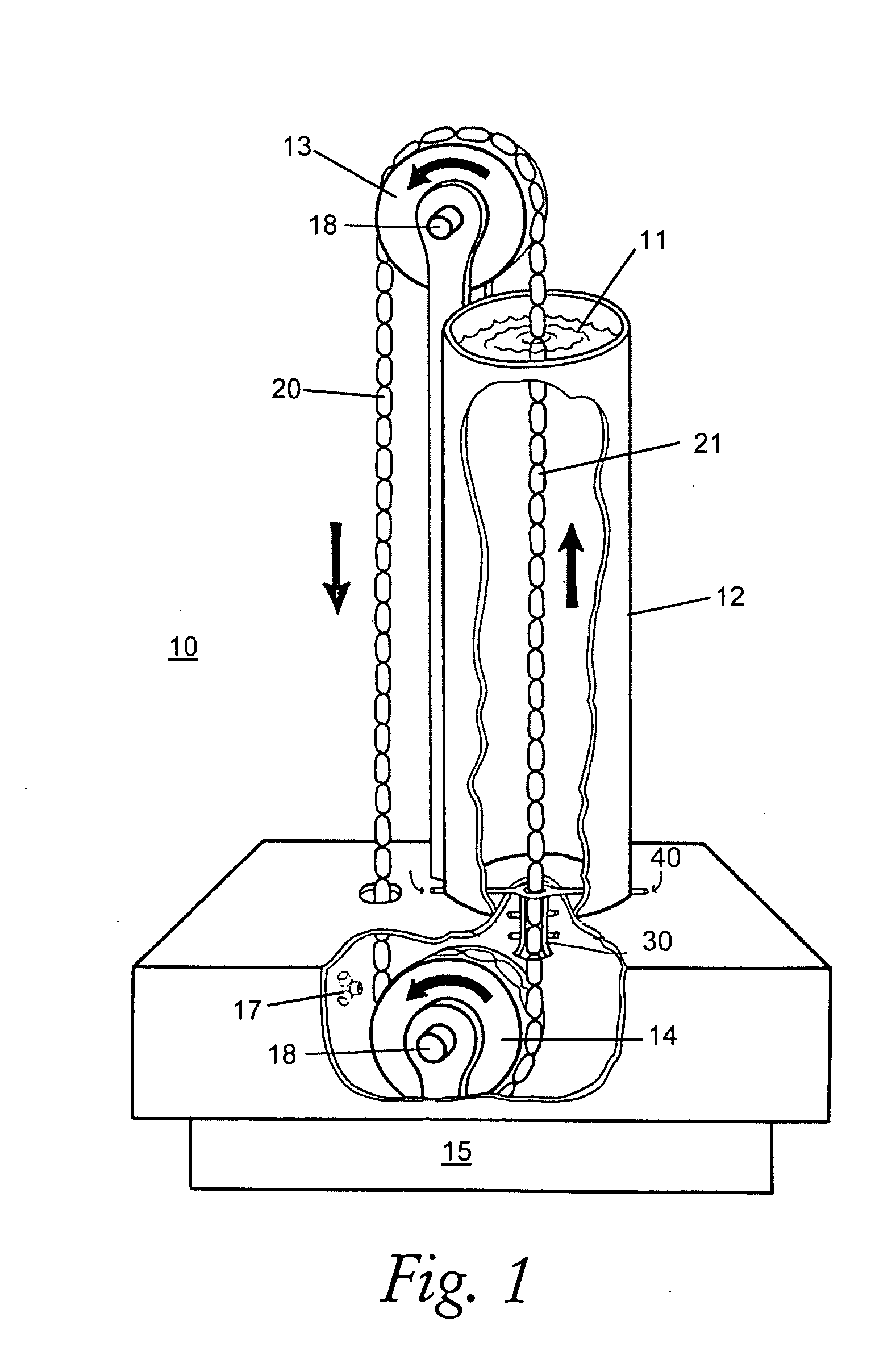

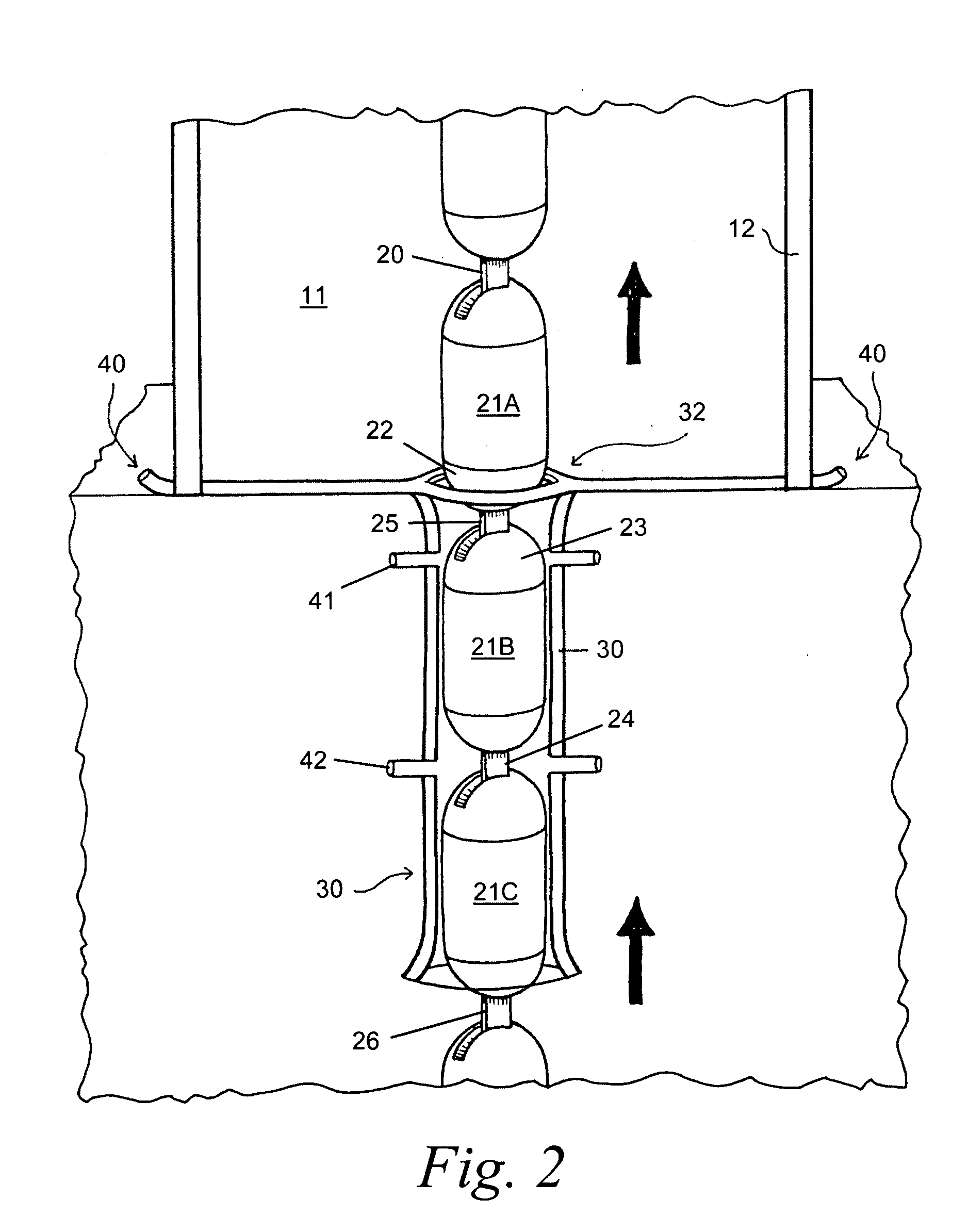

InactiveUS20070283689A1Increase heightEliminate entirely the consumingHydro energy generationMachines/enginesMarine engineeringBuoyancy function

The invention is a method and apparatus for extracting power from a buoyant source within a contained column of liquid. It is comprised of an endless chain of movable buoyant objects, a means to convert the movement of the chain into useful work and a tank filled with a constant volume column of water. The buoyant objects comprising the chain sequentially enter the bottom of the water column, move up through the column and emerge at the surface. The emerging buoyant objects leave the tank and are directed to the tank bottom were each buoyant object repeats the cycle. As the chain of buoyant objects cycle through the water column, the volume of water remains constant, with one buoyant object of the chain entering the bottom of the water column as one is exiting at the top surface. The movement of the chain is a function of the buoyancy of the buoyant objects and the movement is converted to work by any conventional means using a rotary drive or linear escapement motor.

Owner:MCGAHEE VINCENT DEPAUL

Watch whose movement includes a constant force device

InactiveUS20070127319A1Easy to readEasy disposalVisual indicationEscapementsConstant forceEngineering

The movement (1) of the watch includes a constant force device (14) inserted in a going rain connecting a spring barrel (2) to an escapement having an escapement wheel and including a third wheel which completes one revolution in several minutes. The input element of the constant force device (14) is the third wheel (12), the output element of said device (14) being a second third wheel (20) connected via gearing to the seconds pinion (38). The second third wheel is secured to a star wheel (26) that only releases the train upstream of the constant force device once per minute, thus forming an independent minutes display because the minute hand (7) jumps forward at each minute. This arrangement minimises the transmission of shocks between the constant force device and the escapement and can advantageously be combined with a tourbillon (40).

Owner:MONTRES BREGUET

Article feeder

InactiveUS20050077310A1Reduce distanceEnhances proclivityCoin-freed apparatus detailsTobacco pipesDetentEngineering

A screw feeder adapted for rapid changeover of the type of screws to be fed. The feeder has a collator section having a floor with slots to collate random screws into rows and an enclosure about the floor for retaining random screws on the floor. The collated screws are fed along the slots into slots in a dispensing section of the feeder where they are then moved in queues to an escapement to be picked off one by one for deposit into a receiver. The collator section floor is oscillated about an axis between a position where the floor slopes downward from a downstream end in the slot direction from an upstream end in the opposed slot direction to a position where the floor slots slope upward to the upstream end. The collator section enclosure has a gate closure at the upstream end of the floor and the slots on the floor extend completely to the upstream end so that, with the gate open and the collator section oscillated to tilt the slots downward toward the upstream end, the screws in the slots will slide to the upstream end and out of the feeder to empty it. A chute is provided below the upstream end to collect the screws falling from the feeder. The screw feeder may have a collator section that collates and feeds screws along slots to the slots of a separate dispenser section for dispensing. For emptying the feeder for screw changeover, the dispensing section is raised so that the screws slide back to the collator section held at the lower position for screw removal. A flow regulator gate adjacent the dispenser section is openable on rotation downward of the collator section to clear screw jambs. The regulator gate also opens when the dispensing section is raised to clear the screws back to collator section for changeover. Detents are provided in the collator section slots at an intermediate location therealong to maintain the collated screws closer to dispensing section for ease of transfer thereto. The detents are selectively removable so that they will not interfere with emptying the feeder on changeover to new screws.

Owner:KVAL

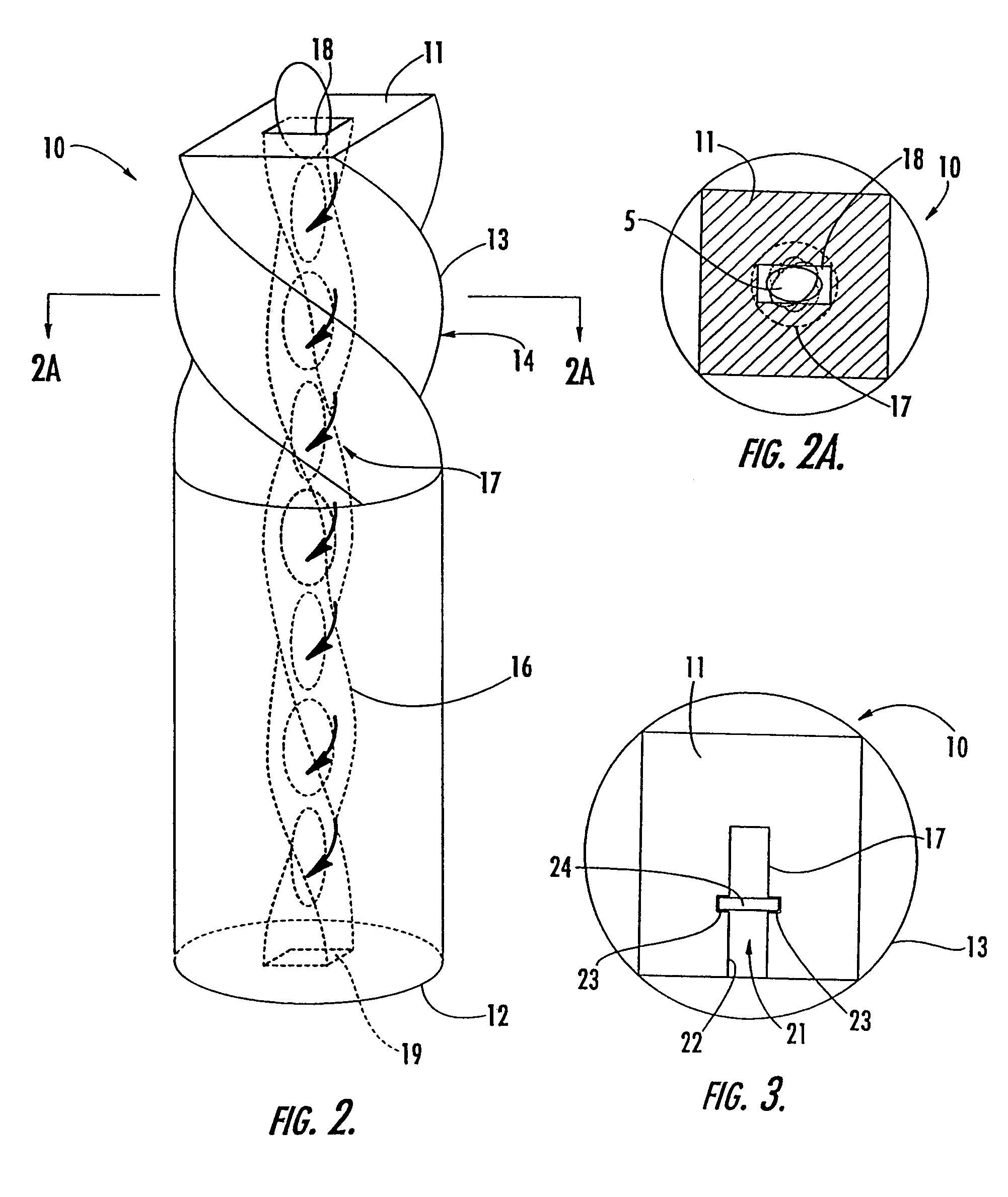

Method of delivering pills through a feeder tube

InactiveUS7007821B2Reduce the possibilityFacilitate entryAdditive manufacturing apparatusCoin-freed apparatus detailsBiomedical engineeringExit side

A pill delivery and packing apparatus having a feeder tube for delivering pills is provided. The feeder tube has a helical delivery chute that extends between an inlet side and an exit side of the tube. The delivery chute has a helical inner contour and a rectangular cross section that corresponds to the shape of the pills. The helical delivery chute is configured such that each of the pills rotates while proceeding through the delivery chute, whereby such rotation of the pills prevents jamming of the pills in the delivery chute. Independently extendable pins are used to alternately block and open the delivery chute, thus providing an escapement mechanism for dispensing pills. The tube also has an outer surface defining a helical outer contour that guides a rotatable tray on which pills are disposed. Associated apparatuses and methods are also provided.

Owner:AYLWARD ENTERPRISES

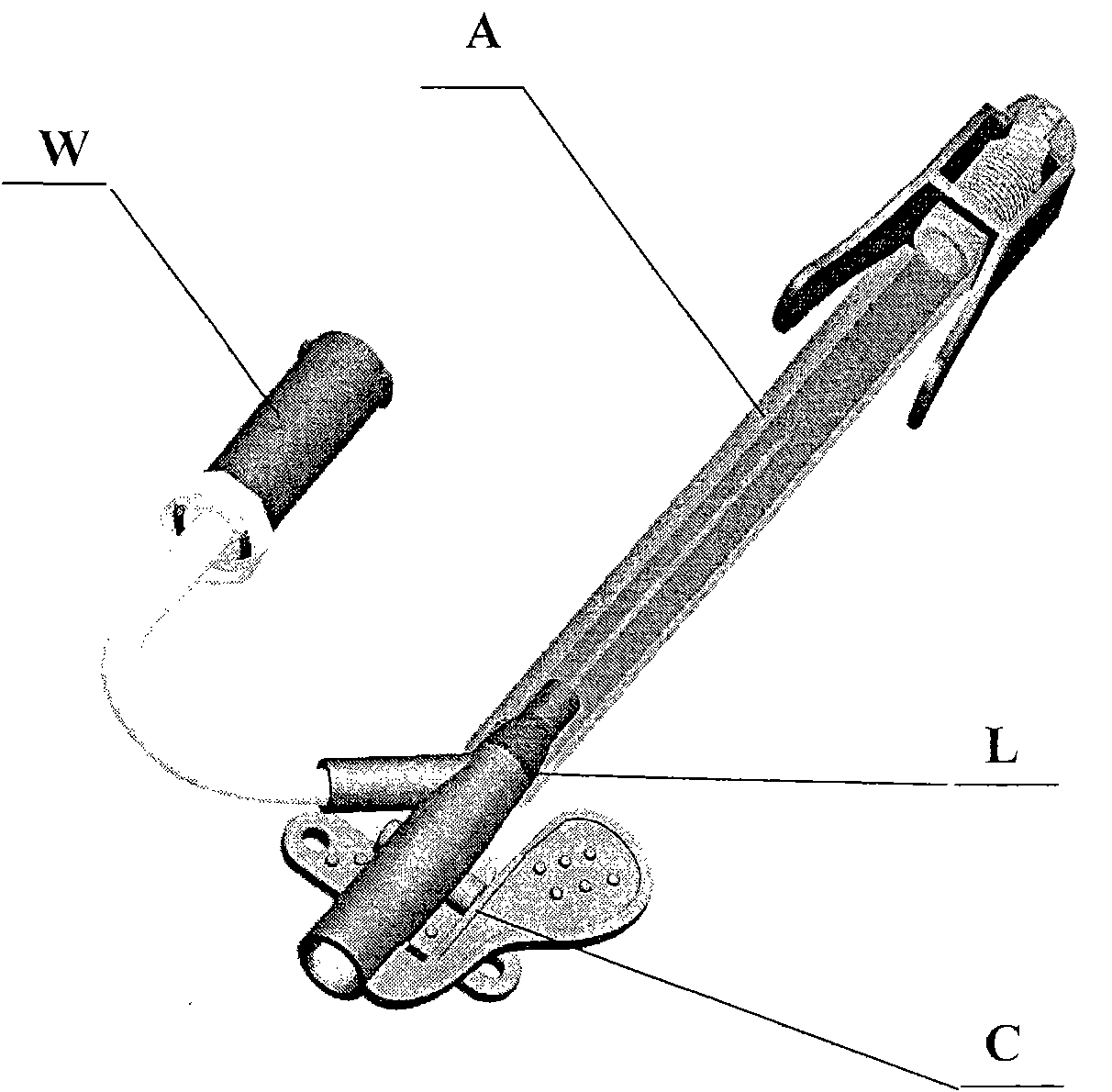

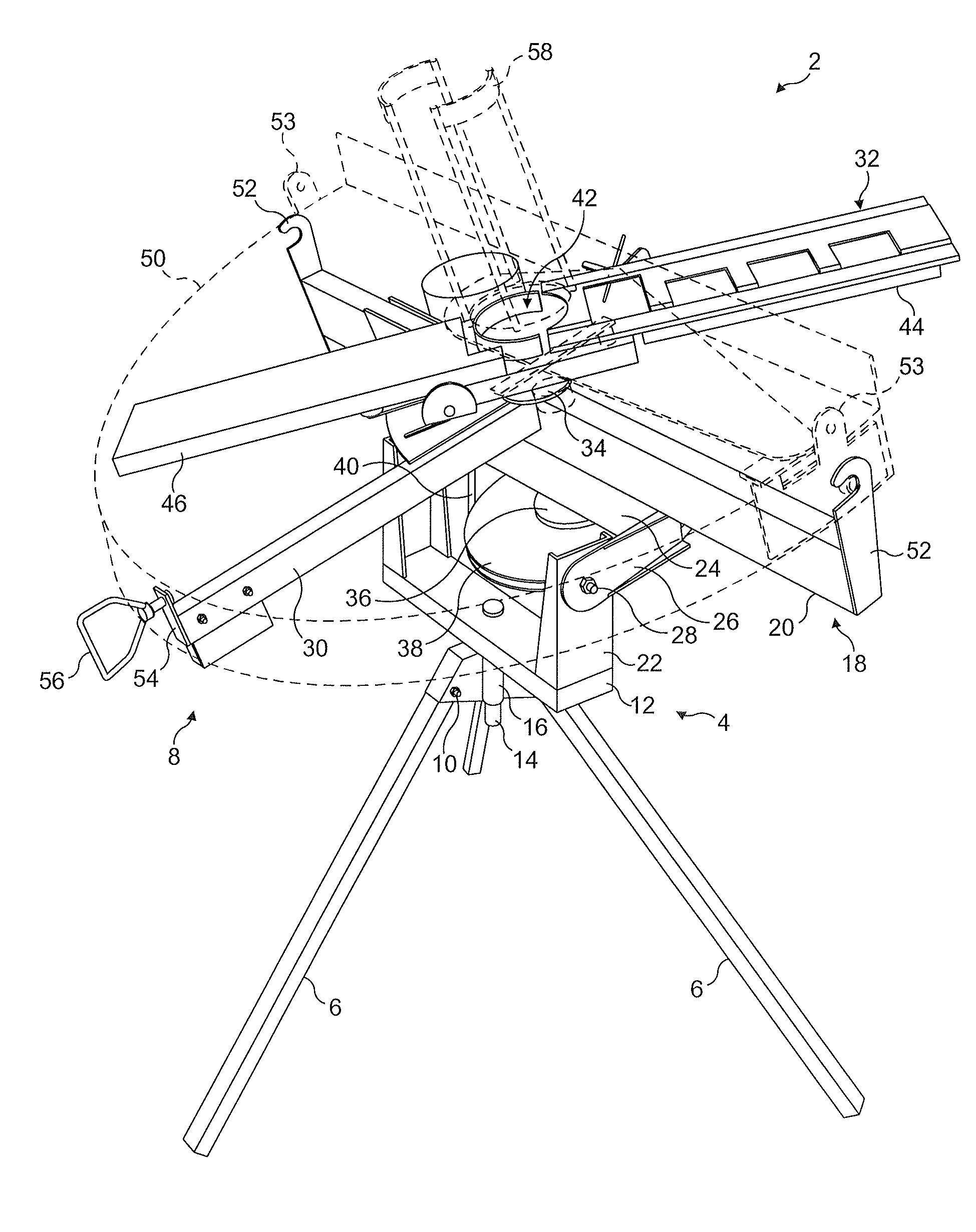

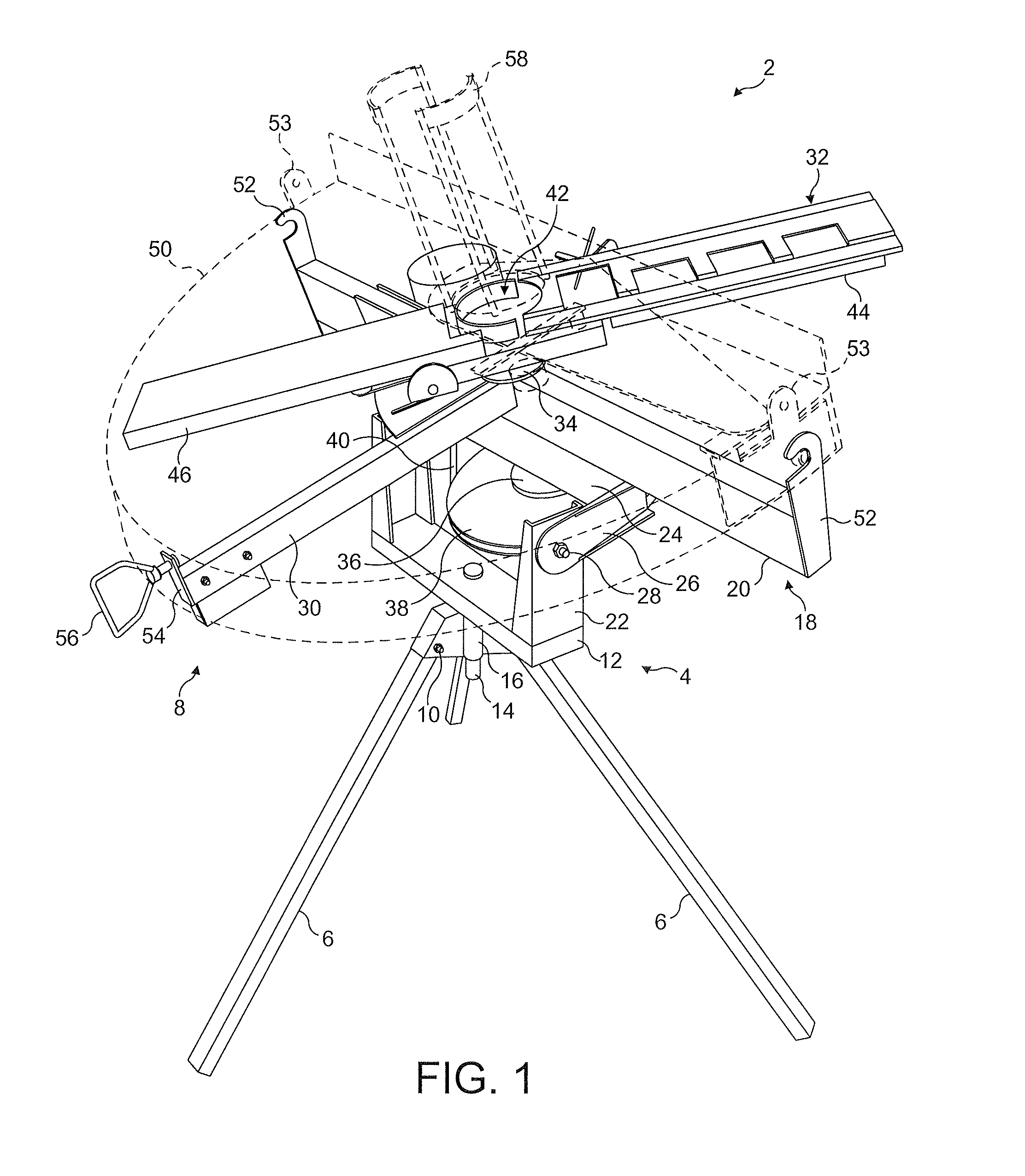

Launching device for clay targets

InactiveUS20120138034A1Increase ratingsReduce the risk of injuryMovable targetsSling weaponsEngineeringAirflow

A launching device for a clay target including a throwing arm supported to be rotatable continuously about an axis, and including means to load a clay target substantially at said axis, wherein the throwing arm includes an escapement mechanism operable between a first position in which a clay target is prevented from being launched from the throwing arm and a second position in which a clay target is permitted to be launched from the throwing arm. Loading means may be provided including a resilient loading receptacle located substantially at the axis to provide cushioning to a clay target as it is loaded. Further, the throwing arm may include a base portion for bearing a clay target and a top cover spaced from the base portion and adapted to disrupt the airflow over the clay target.

Owner:WHIDBORNE FERRIS

Pressure balanced connector termination

ActiveUS20140096992A1Coupling device detailsInsulated cablesPressure balanceElectrical and Electronics engineering

A pressure-balanced sleeve assembly for an electrical cable termination is disclosed. The sleeve assembly includes an outer sleeve surrounding the electrical cable; a chamber defined between the outer sleeve and the electrical cable; dielectric fluid contained within the chamber; and a seal that is positioned between the outer sleeve and the electrical cable to delimit and seal an end of the chamber to prevent the escapement of the dielectric fluid from the chamber, the seal being moveable along the cable in response to differences between a pressure within the chamber and a pressure outside of the chamber. Also disclosed herein is a pressure-balanced electrical cable assembly and a method of pressure-balancing a termination of an electrical cable.

Owner:ITT MFG ENTERPRISES LLC

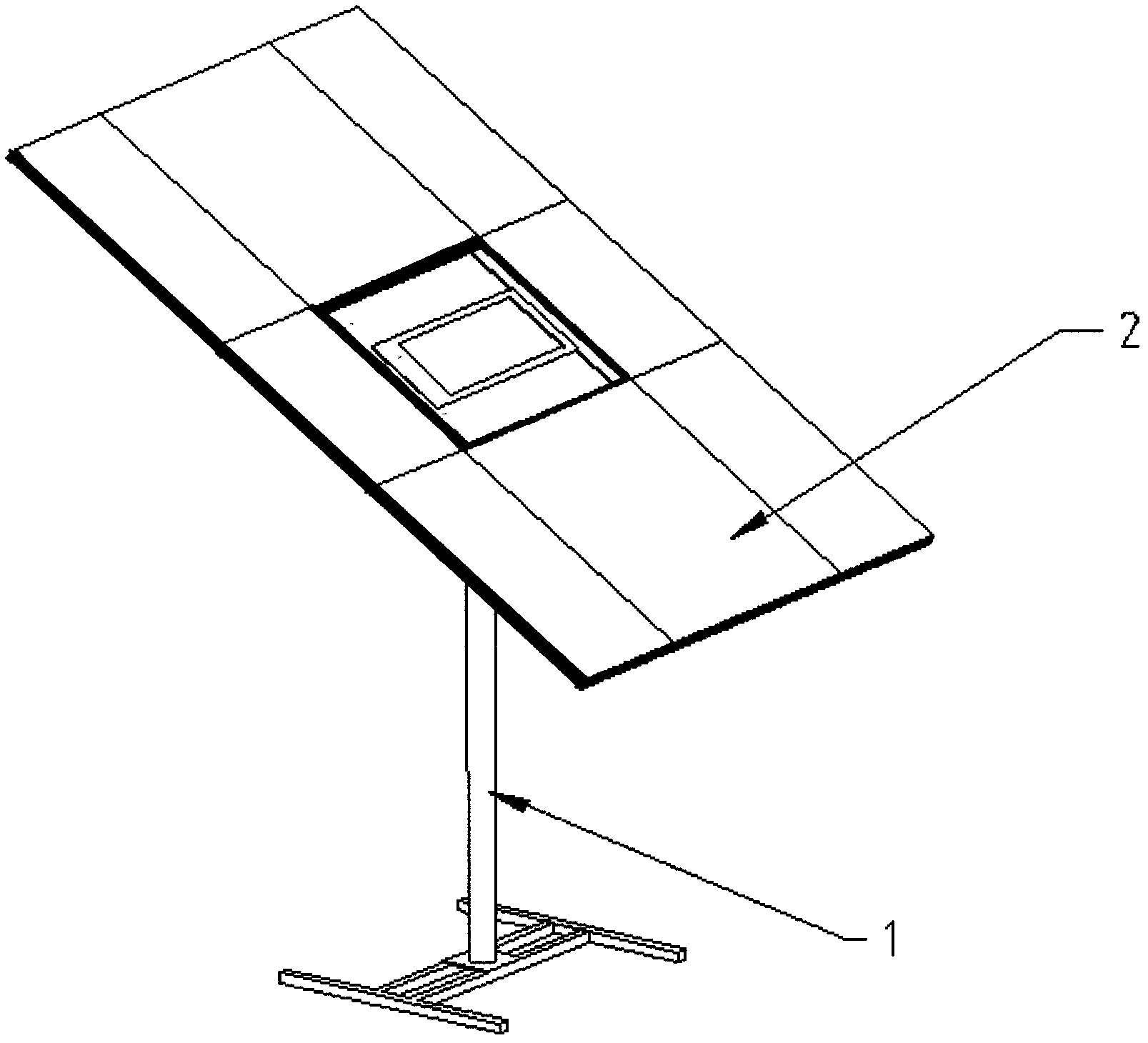

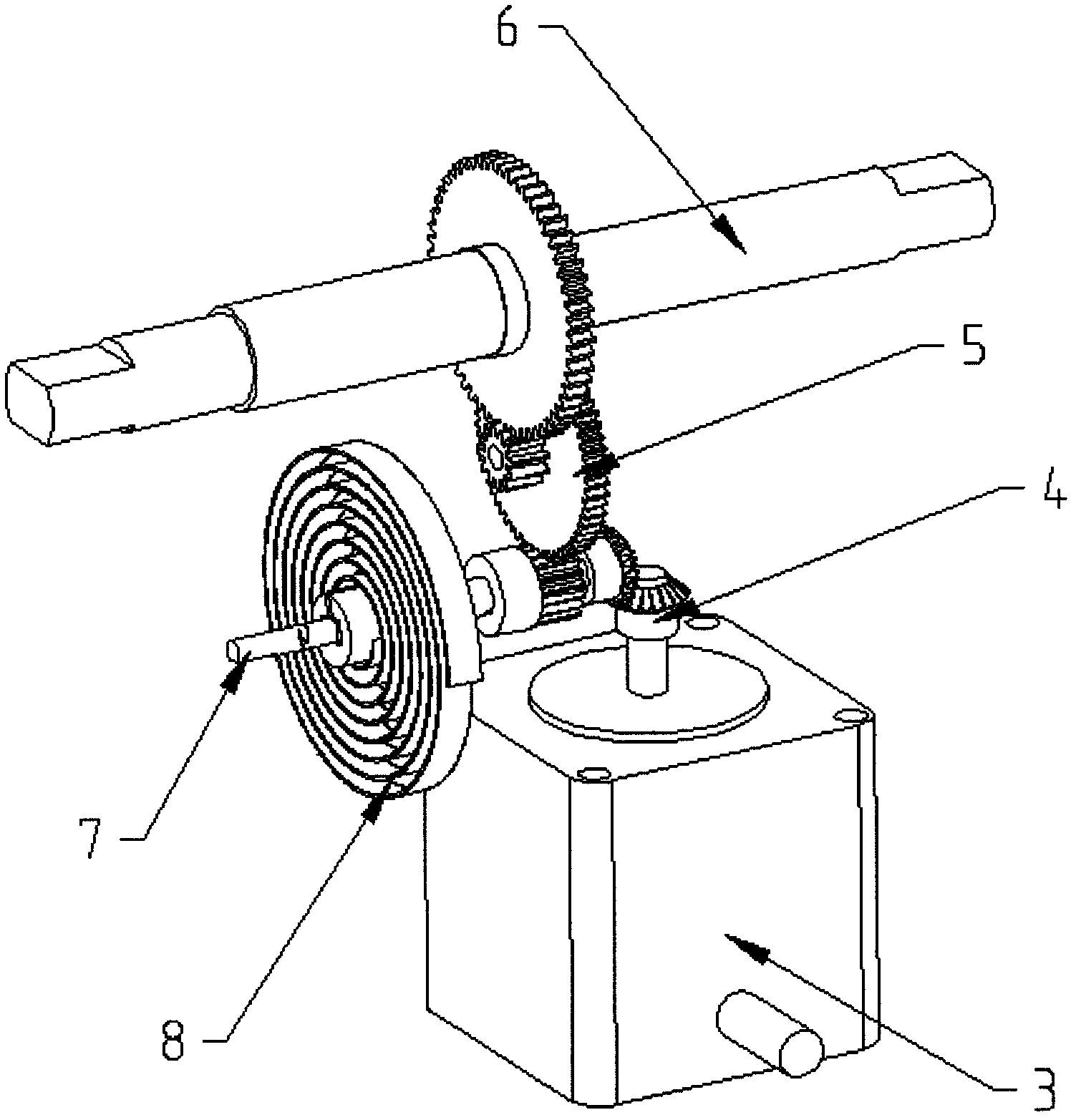

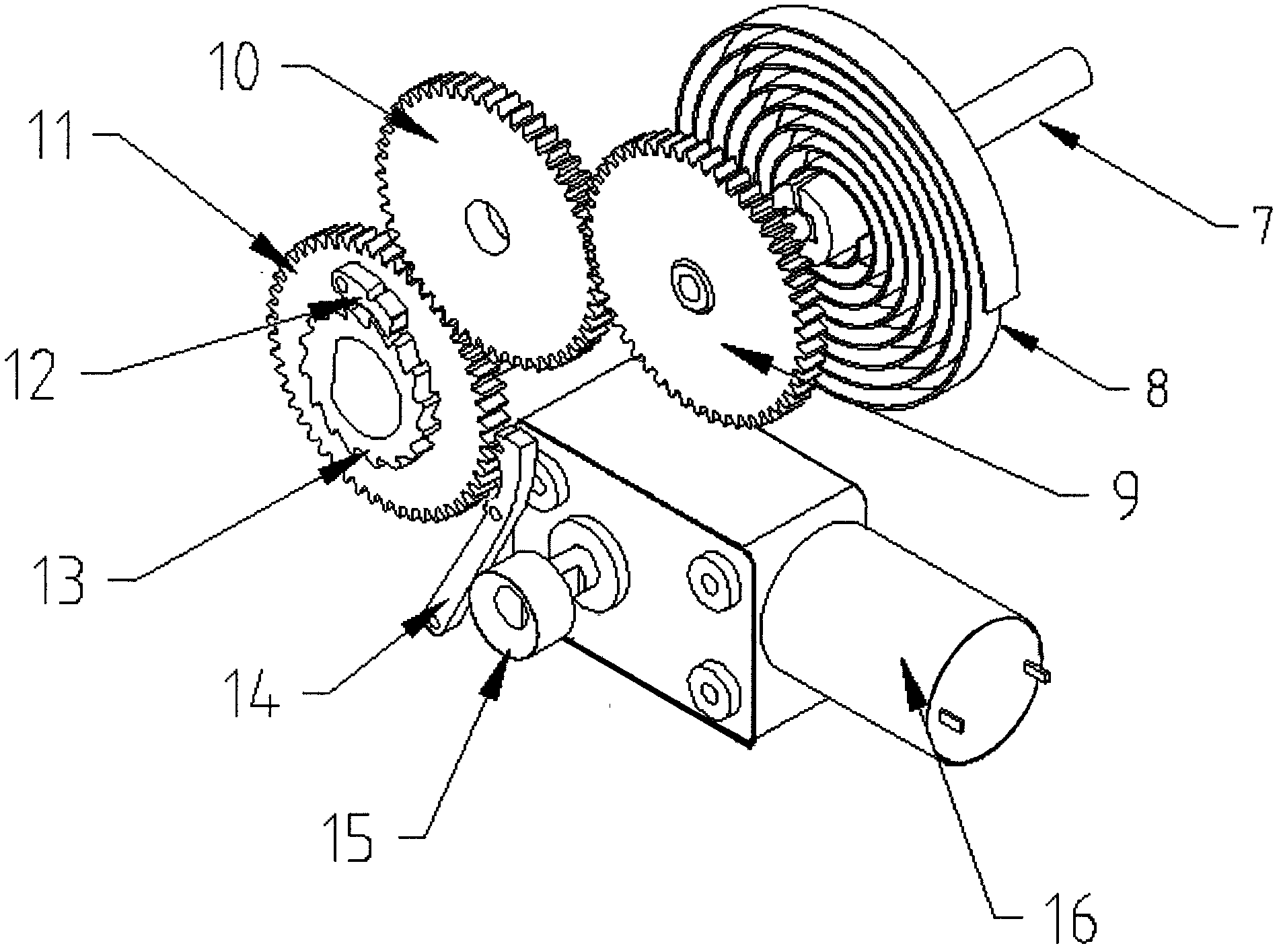

Mechanical double-shaft solar tracking bracket

InactiveCN102427088AReduce running timeReduce operating frequencyPhotovoltaic supportsControl using feedbackLocking mechanismSpring force

The invention relates to a mechanical double-shaft solar tracking bracket which comprises a vertical column, a sun hour angle tracking mechanism, a spiral spring force accumulating mechanism, an escapement speed regulating mechanism, a transmission locking mechanism, an altitude angle tracking mechanism and a solar cell panel, wherein the vertical column is installed on the lower end of a sun hour angle tracking motor in the sun hour angle tracking mechanism; one end of a spiral spring shaft of the spiral spring force accumulating mechanism is connected with a gear of the sun hour angle tracking mechanism; the escapement speed regulating mechanism is connected with a spiral spring shaft output gear which is arranged at the other end of the spiral spring shaft in the spiral spring force accumulating mechanism by a transition gear; a locking claw of the transmission locking mechanism locks or releases an input gear of the escapement speed regulating mechanism; a solar cell installation panel is installed outside a sun hour angle installation panel of the altitude angle tracking mechanism; and the solar cell panel is fixedly installed on the solar cell installation panel. The mechanical double-shaft solar tracking bracket has the advantages of simple mechanical structure, stable running, low production cost, short running time of an electric control system and low start frequency and prolongs the service life of the system to a great extent.

Owner:卢序

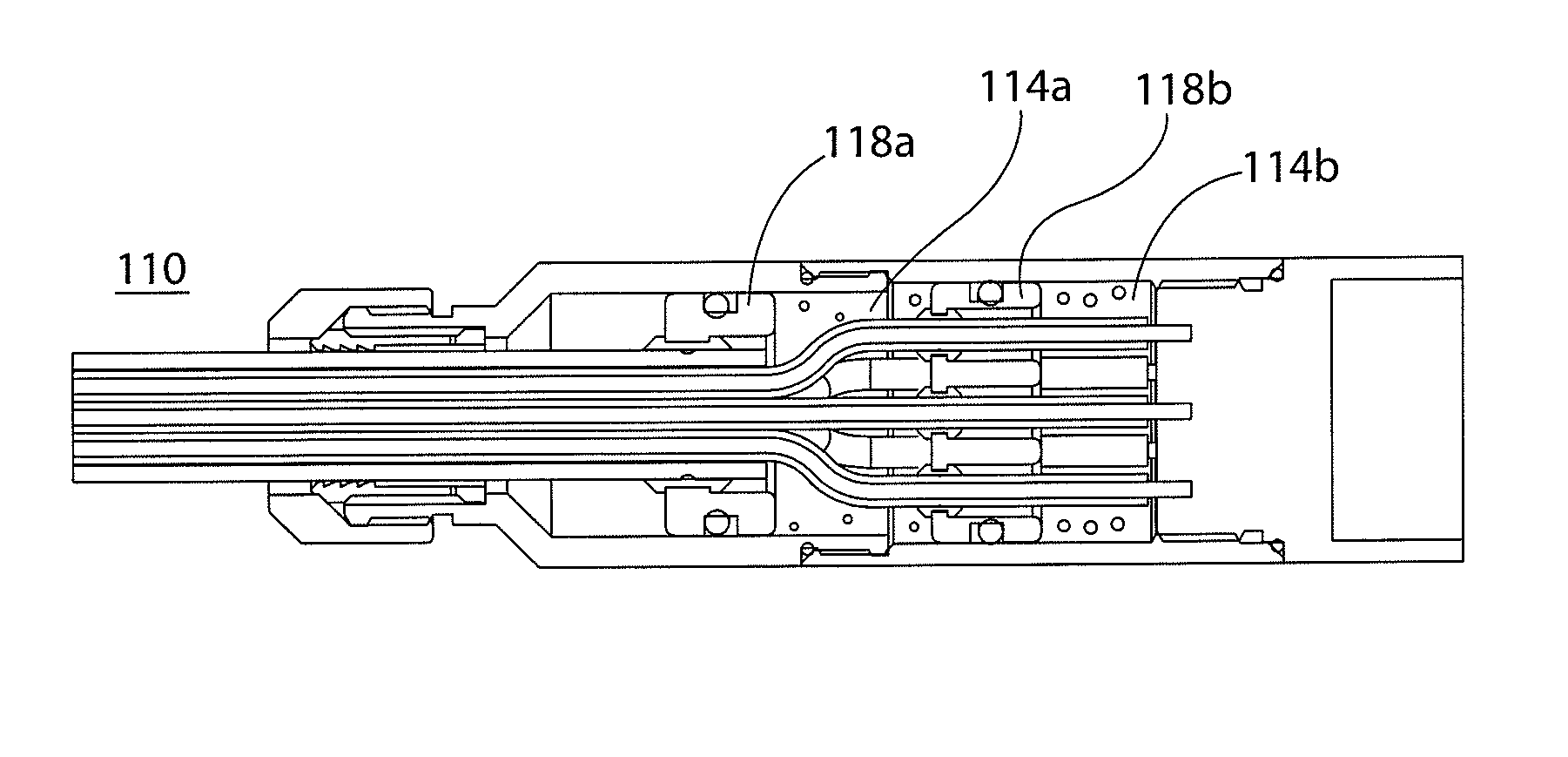

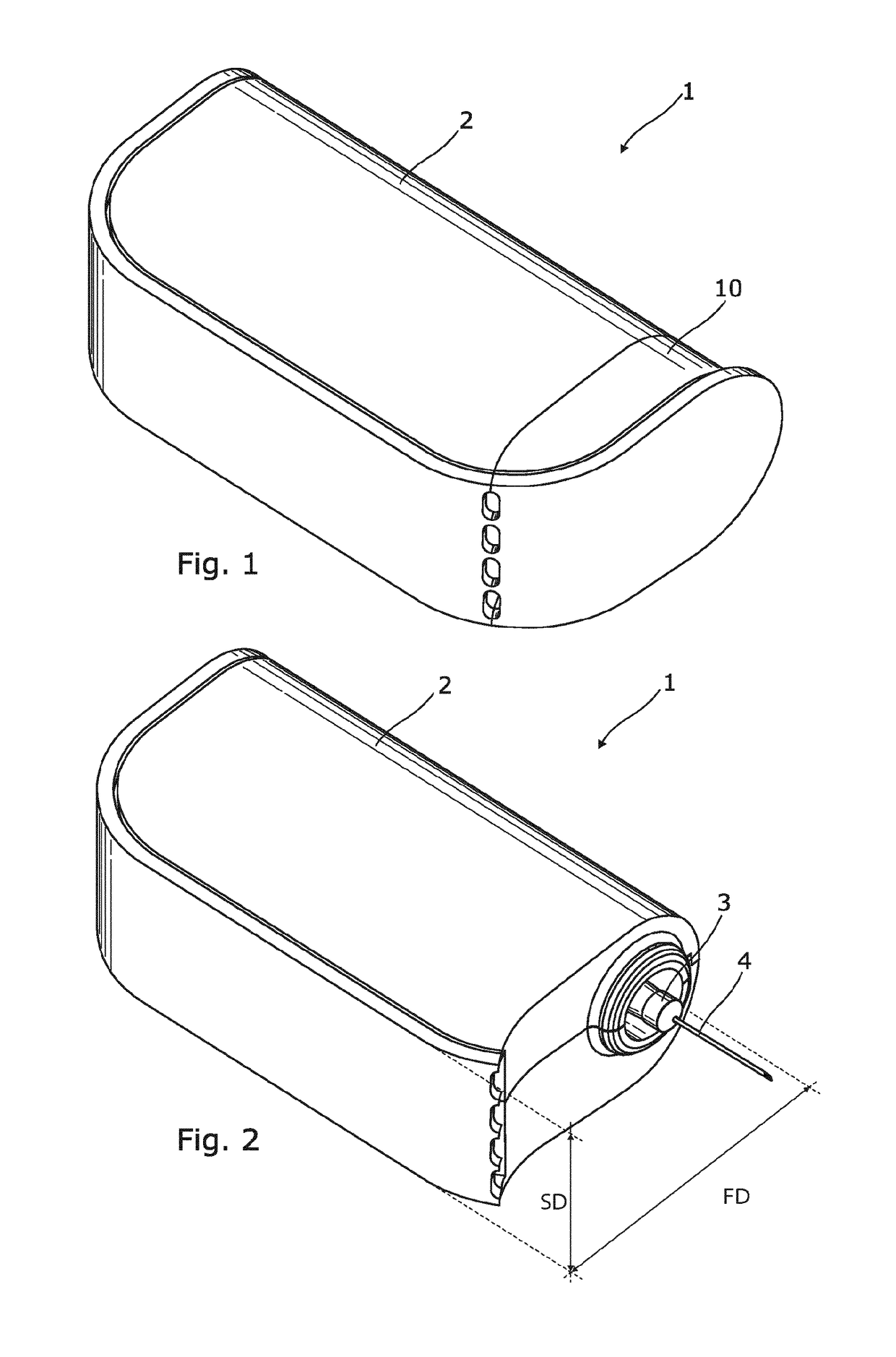

Single-use auto-injector

ActiveUS20180304014A1Provide protectionEliminate riskAutomatic syringesPressure infusionBiological activationDosing units

A single-use auto-injector includes a housing and a dosing unit in at least part of the housing. The dosing unit includes a needle, a drug container with drug, a piston movable in the container, a first mechanical power supply for moving the piston to deliver the drug, an activation mechanism, and a mechanical escapement mechanism for controlling the movement of the piston. The auto-injector has a first state in which the needle is protected from needle damage or contamination, a second state in which the needle is ready to penetrate a human body, a third state in which the needle has penetrated the human body and is ready to dose, and a fourth state in which the needle is shielded to avoid unintended needle sticks. A second mechanical power supply is configured to shift state of the auto-injector from the third state to the fourth state.

Owner:AMGEN INC

Coating method and coating device, method for manufacturing parts of display and manufacturing device

ActiveCN101045228AEasy dischargeReliable dischargeLiquid surface applicatorsCoatingsLiquid wasteDisplay device

A sort of coating method used to discharge the air which invades to the inner part of the applicator in the mould-type coating machine and the setting for carrying out the method, a manufacturing method of the monitor part which uses the coating method and the setting for carrying out the method. Utilizing the liquor-supplying device which can supply coating liquor to the applicator, a applicator which have inset of the coating liquor and escapement of the gas and coating liquor, an outset path with a opening and closing valve which is connect to the escapement and is about located at the same or lower location, a waste liquid pot which stores the waste liquid discharged from the gas escapement, a holding device which holds the coated part, and a coating equipment which makes the applicator and holding device do relative movement. The equipment moves the applicator corresponding to the coated parts and supplies the coating liquor to form a coated film on the surface. Before or after the coasted film has come into being, supply the liquor from the liquor-supplying device, and discharge the coating liquor and gas from the mentioned above opening and closing valve at the same time.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com