Coating method and coating device, method for manufacturing parts of display and manufacturing device

A coating method and a coating device technology, which are applied in the field of manufacturing, can solve the problems such as the inability to completely discharge the tiny gas and the difficulty of cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0132] Hereinafter, examples are shown, and the present invention will be described in more detail.

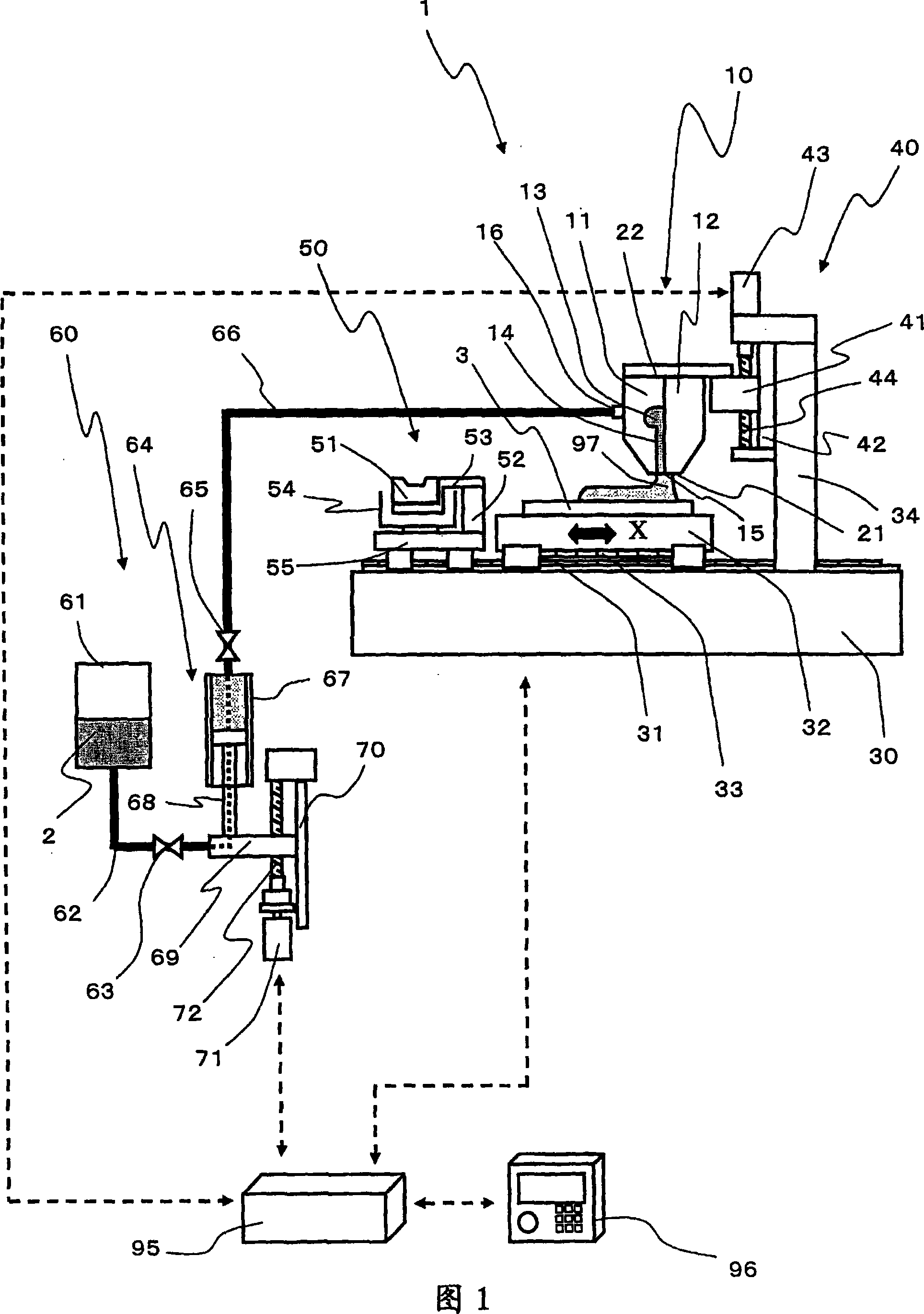

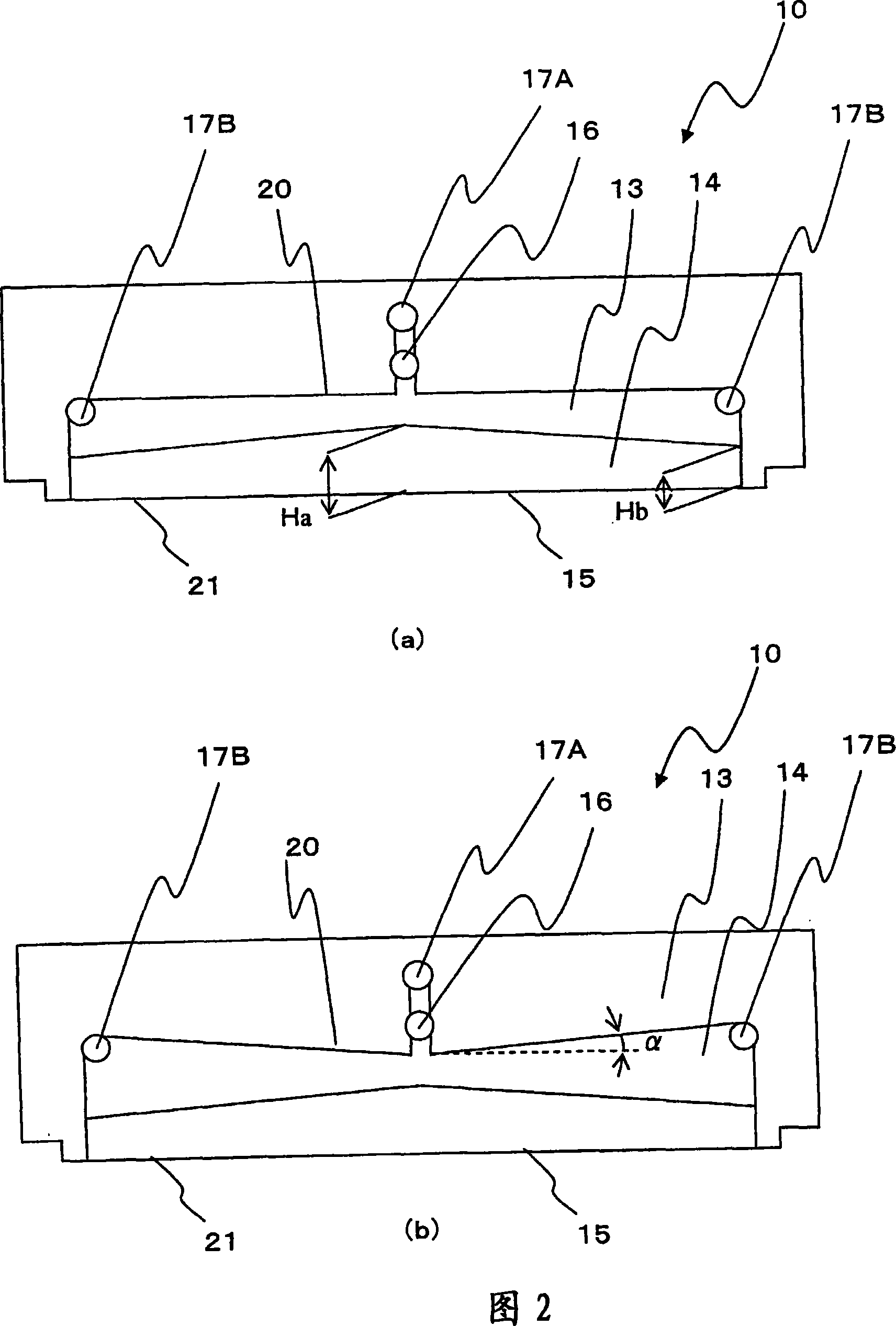

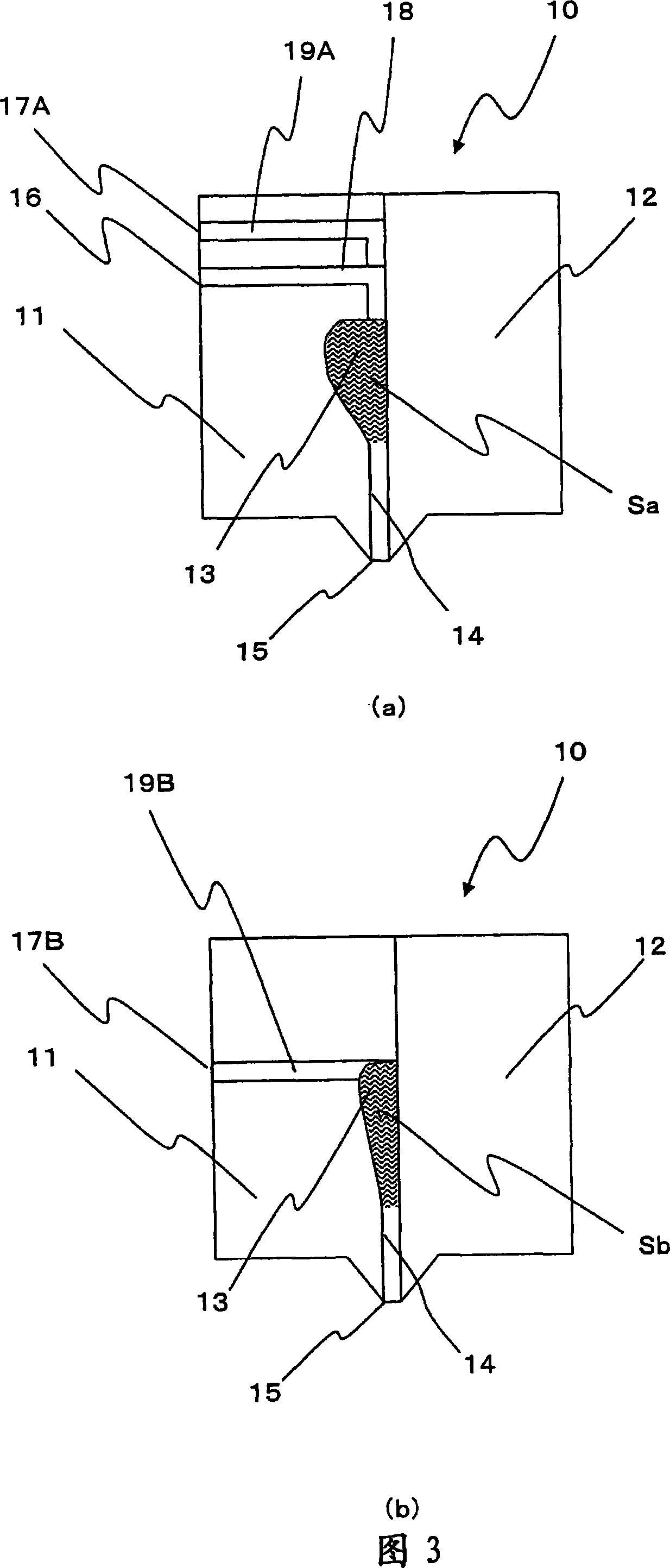

[0133] Directly follow the die-type coater shown in Figure 1 and Figure 4 to manufacture color filters. Here, as the applicator, the gap of the discharge port is 100 μm, the length in the longitudinal direction is 1300 mm, the coating width is 1100 mm, and "the length of the central part of the mold surface = 40 mm" > "the length of the end part of the molded surface Hb = 38 mm" , The gas discharge port with a diameter of 4mm is arranged on the supply port and the two ends of the manifold in a total of three positions, the upper edge of the manifold is parallel to the discharge port surface, Sa (the cross-sectional area of the manifold at the supply port) = 34mm 2 , Sb (cross-sectional area of the gas outlet manifold at both ends) = 8.5mm 2 An applicator in which Sb (the cross-sectional area of the manifold at the gas discharge port) / Sa (the cross-sectional area of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com