Patents

Literature

309 results about "Mechanical watch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mechanical watch is a watch that uses a clockwork mechanism to measure the passage of time, as opposed to quartz watches which function electronically via a small battery. A mechanical watch is driven by a mainspring which must be wound either periodically by hand or via an automatic winding mechanism. Its force is transmitted through a series of gears to power the balance wheel, a weighted wheel which oscillates back and forth at a constant rate. A device called an escapement releases the watch's wheels to move forward a small amount with each swing of the balance wheel, moving the watch's hands forward at a constant rate. The escapement is what makes the 'ticking' sound which is heard in an operating mechanical watch. Mechanical watches evolved in Europe in the 17th century from spring powered clocks, which appeared in the 15th century.

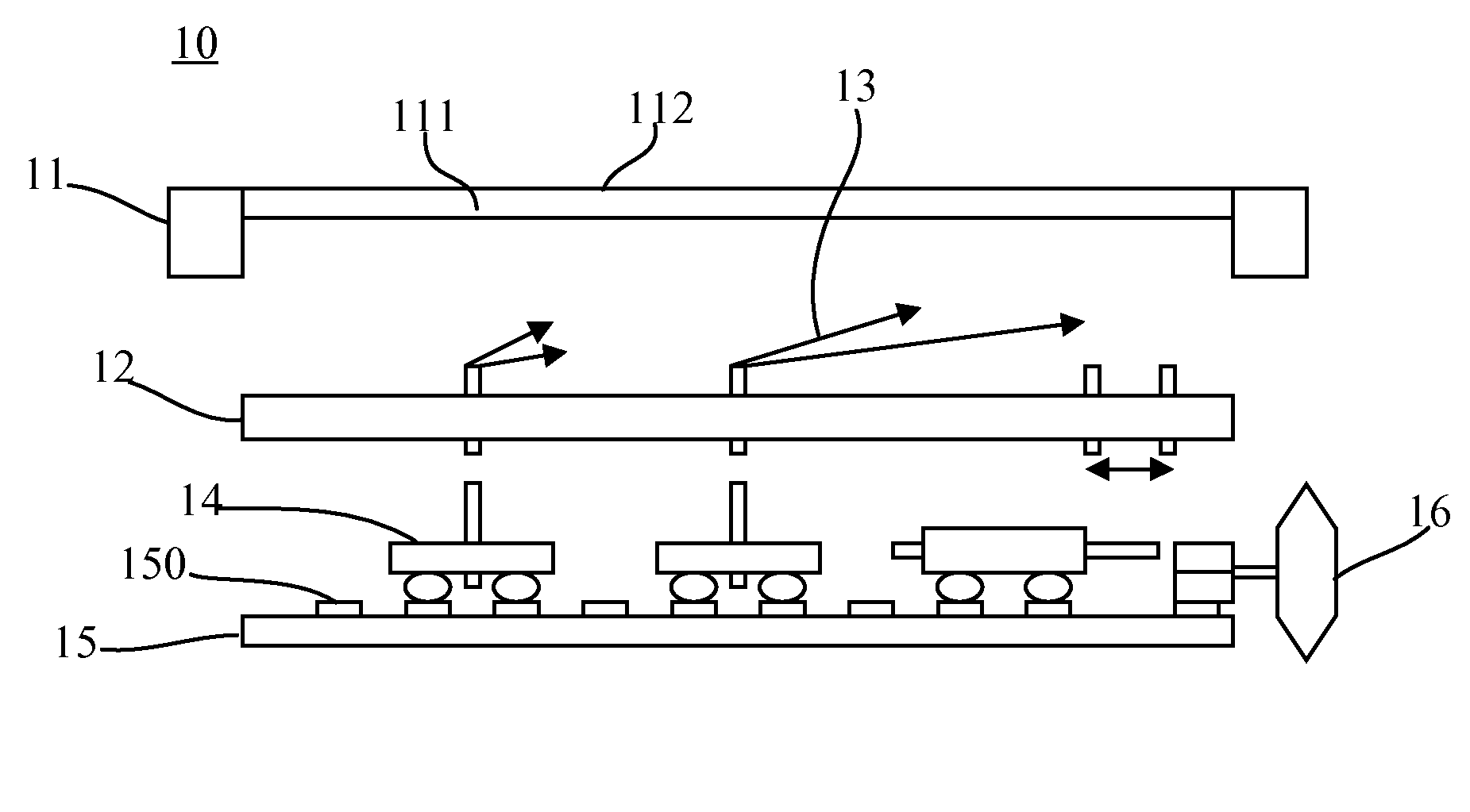

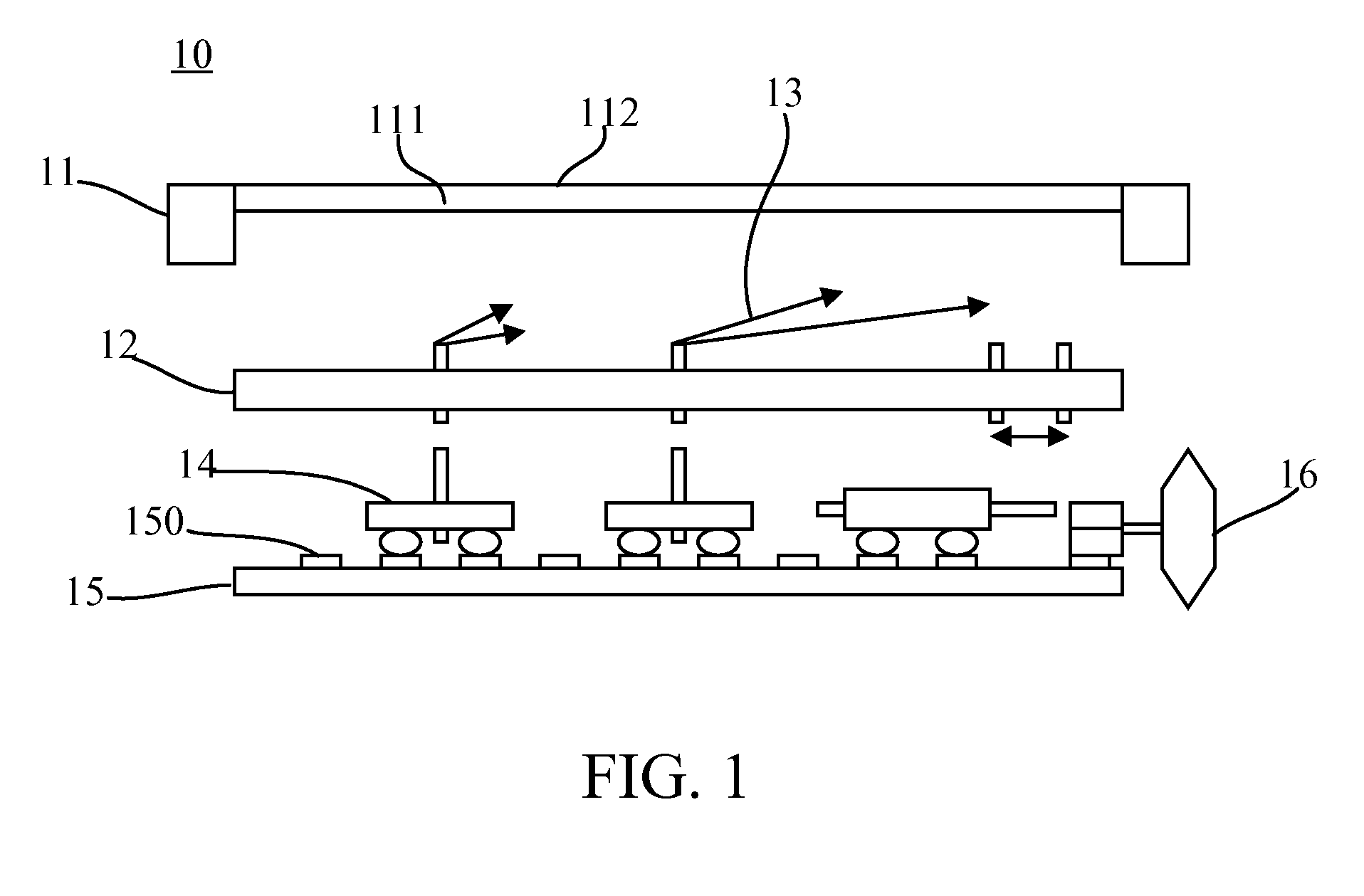

Wristwatch structure, electronic crown for wristwatch, and wristwatch having display

InactiveUS9223296B2Solve needsShorten the development cycleElectronic time-piece structural detailsVisual indicationsElectricityDisplay device

The present invention provides a wristwatch structure, an electronic crown for wristwatch, and a wristwatch having a display. The wristwatch structure comprises an electric driving component; an electronic core having a plurality of two-dimensional joints; and an electronic crown comprising a rotating portion and a fixed detecting portion, the detecting portion detecting electronic signals according to a rotation of the rotating portion; wherein the detecting portion of the electronic crown exports the electronic signals to the electronic core via one of the joints, and the electric driving component is electrically connected to one set of joints among the two-dimensional joints. The present invention can improve compatibility for various designs, thereby shortening product development cycle. Also, the present invention is suitable for developing a product with appearance similar to a mechanical watch.

Owner:PRINCO MIDDLE EAST FZE

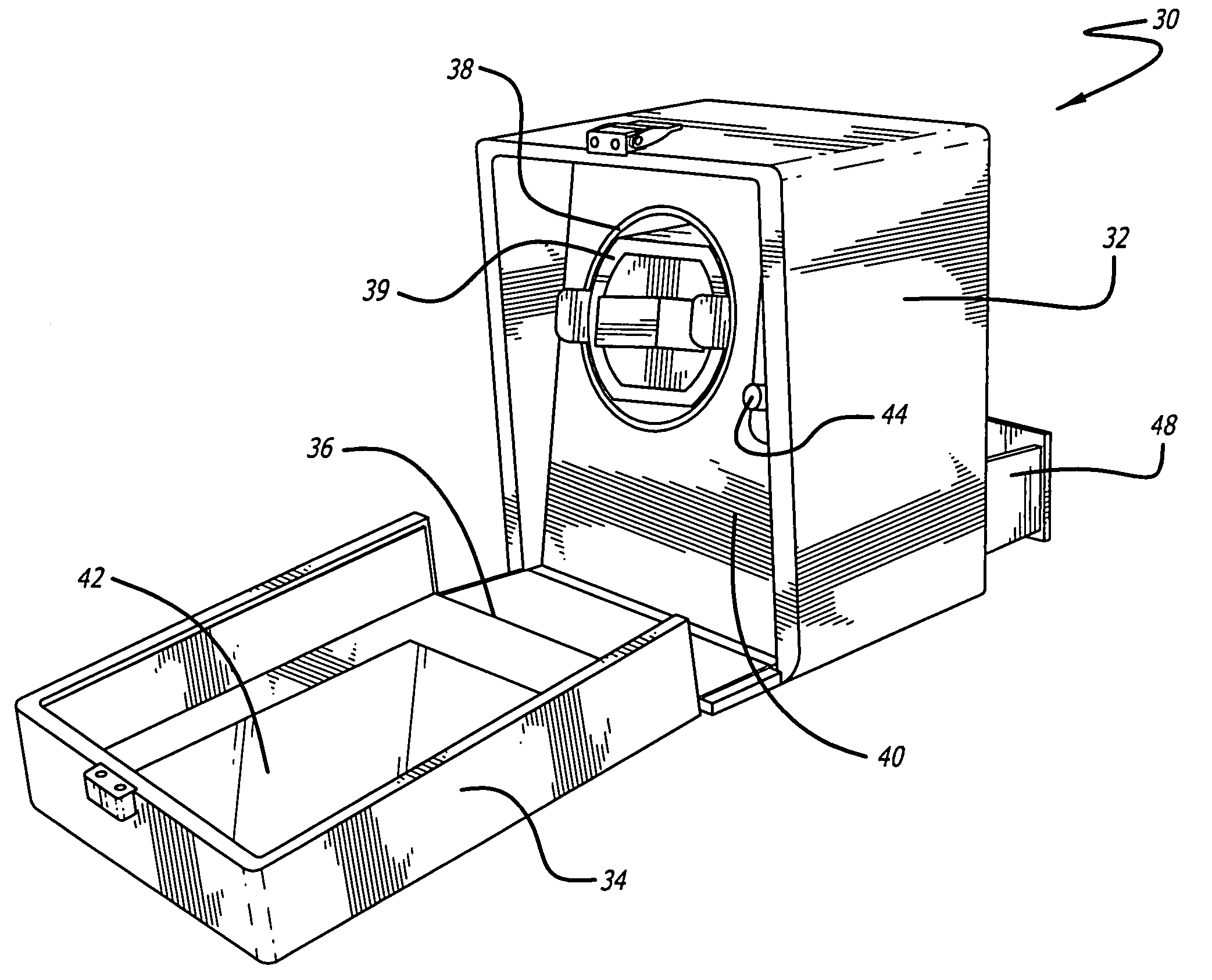

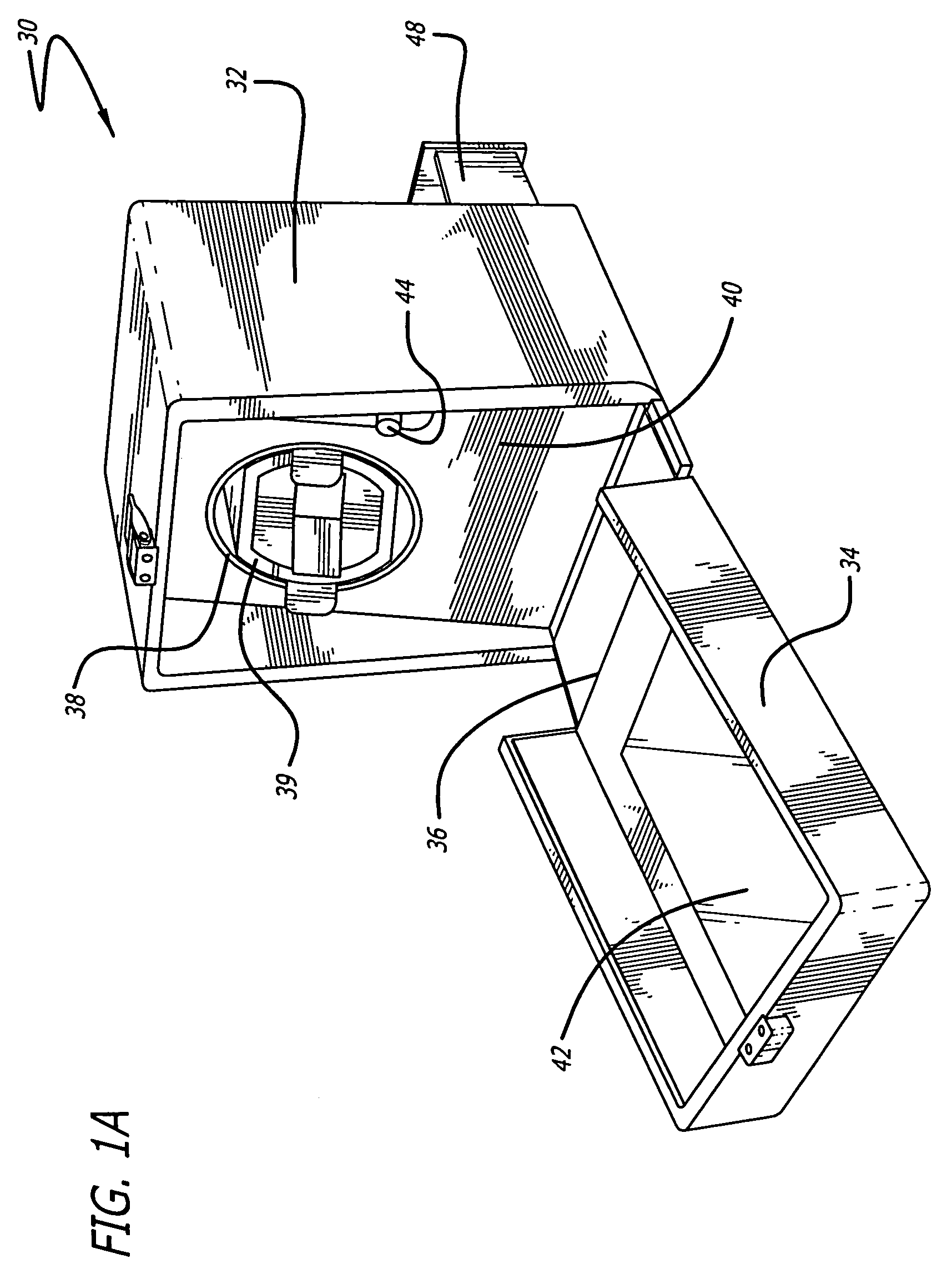

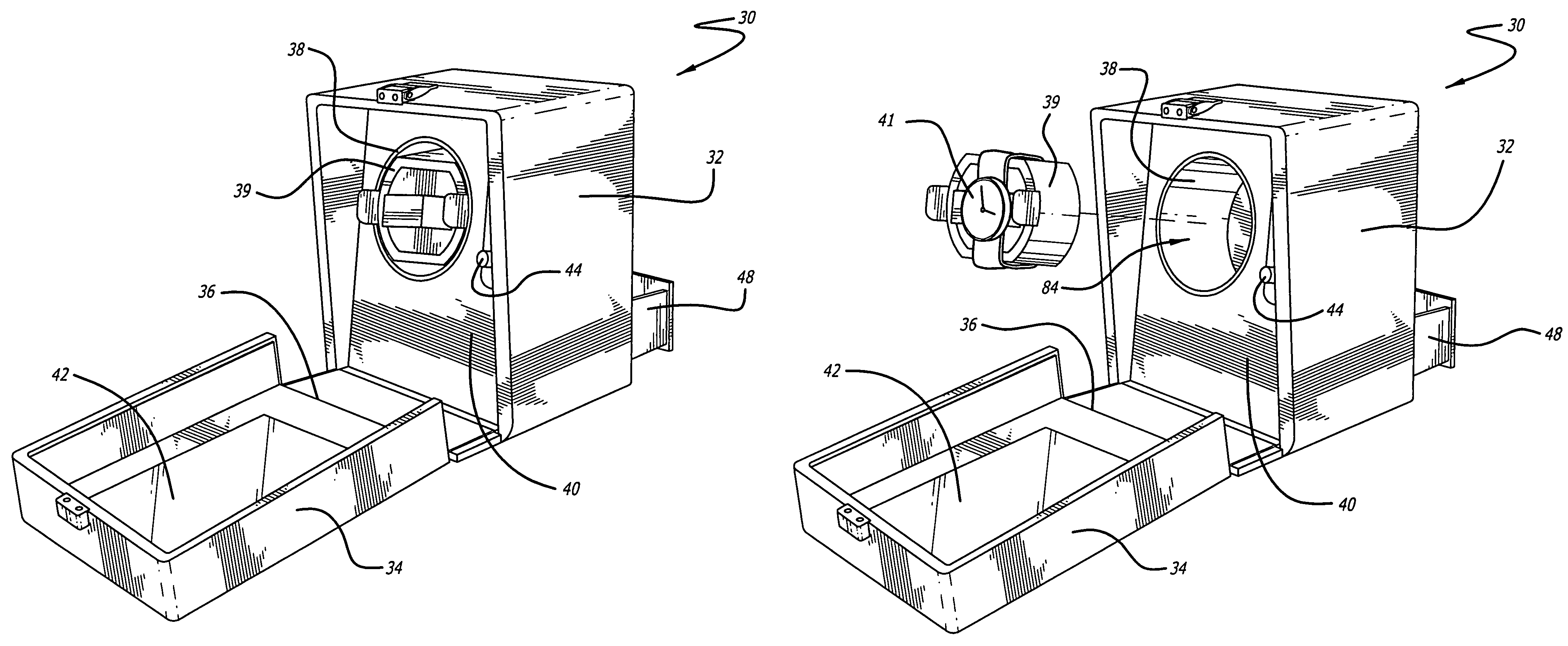

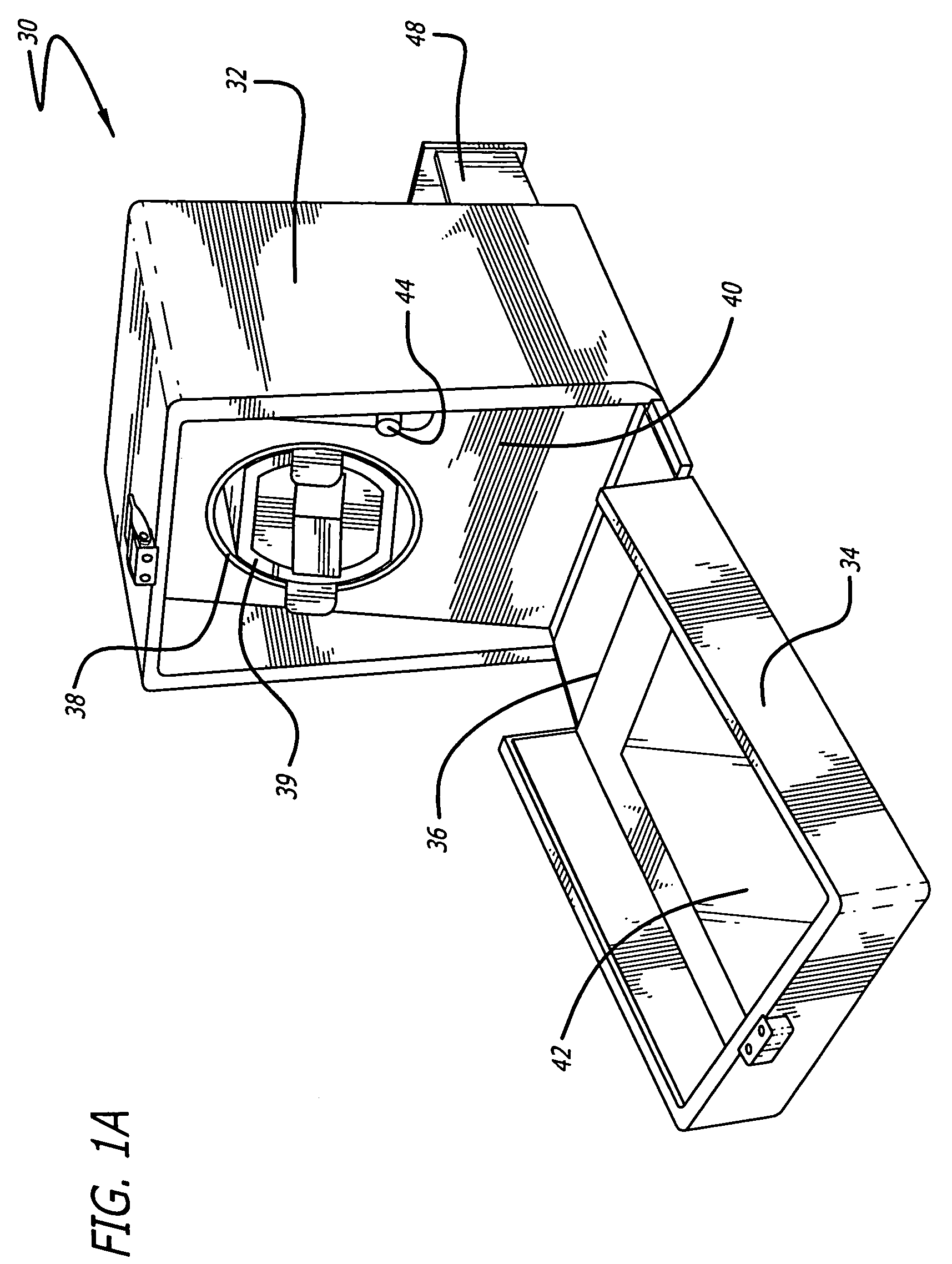

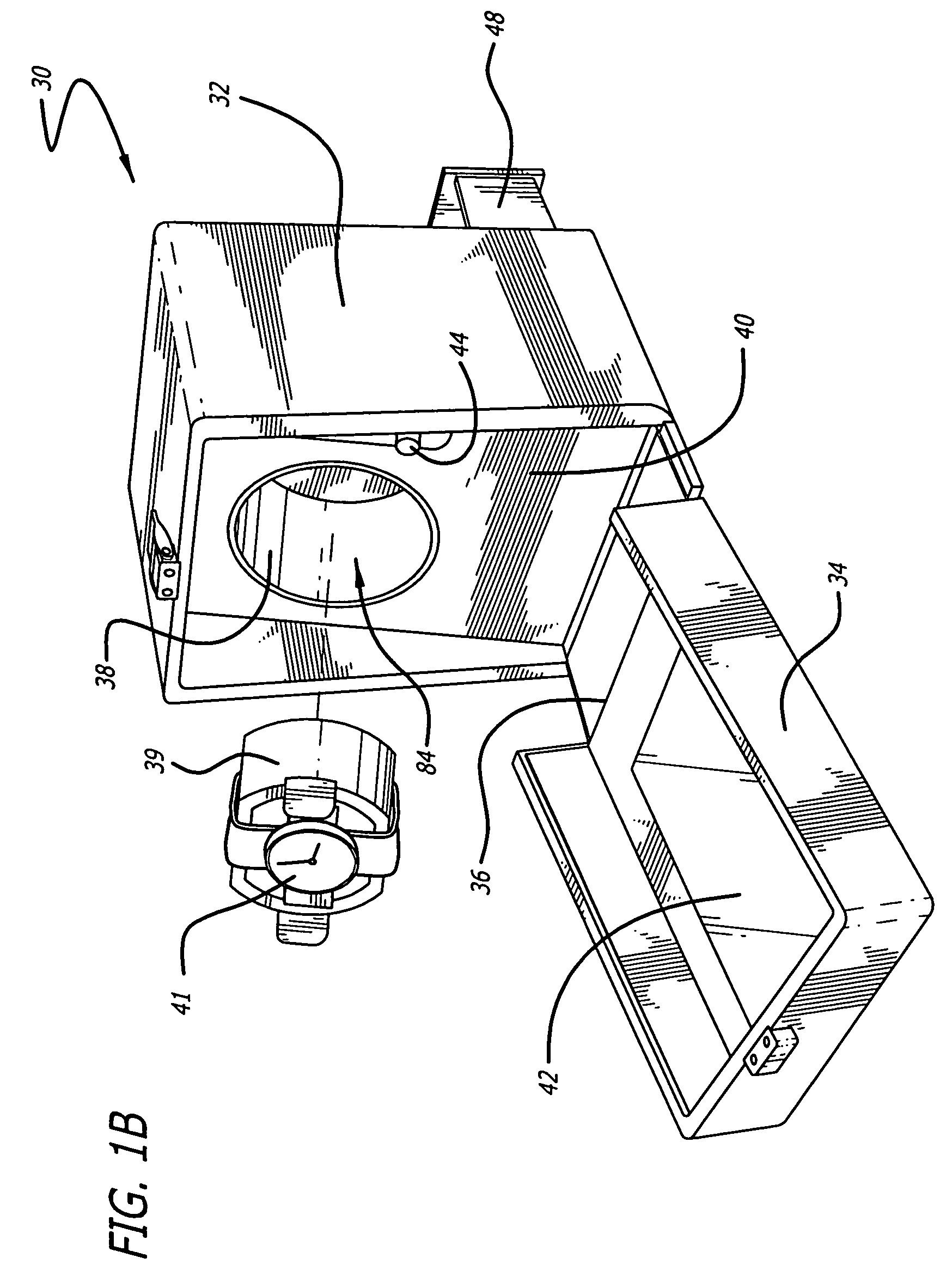

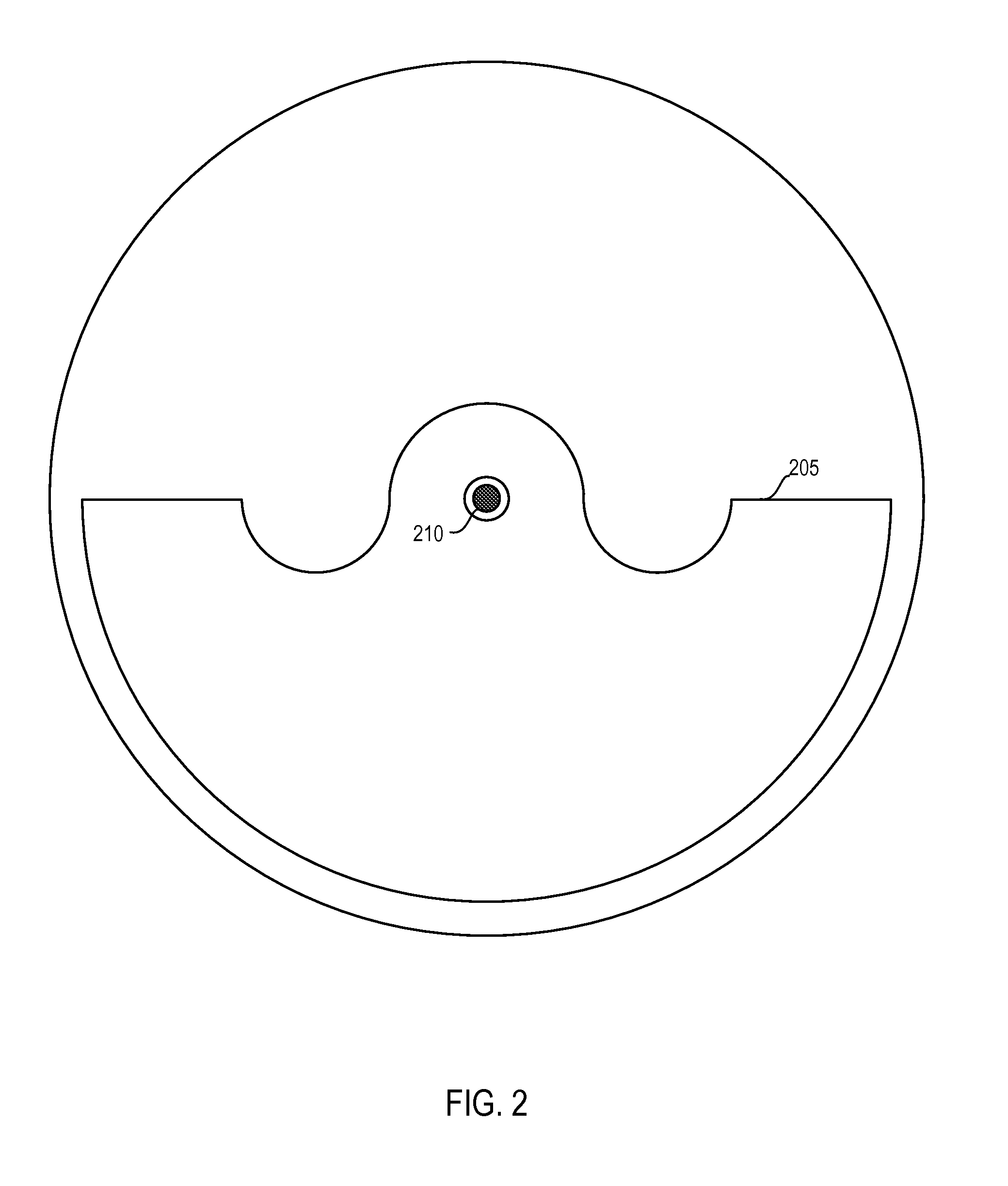

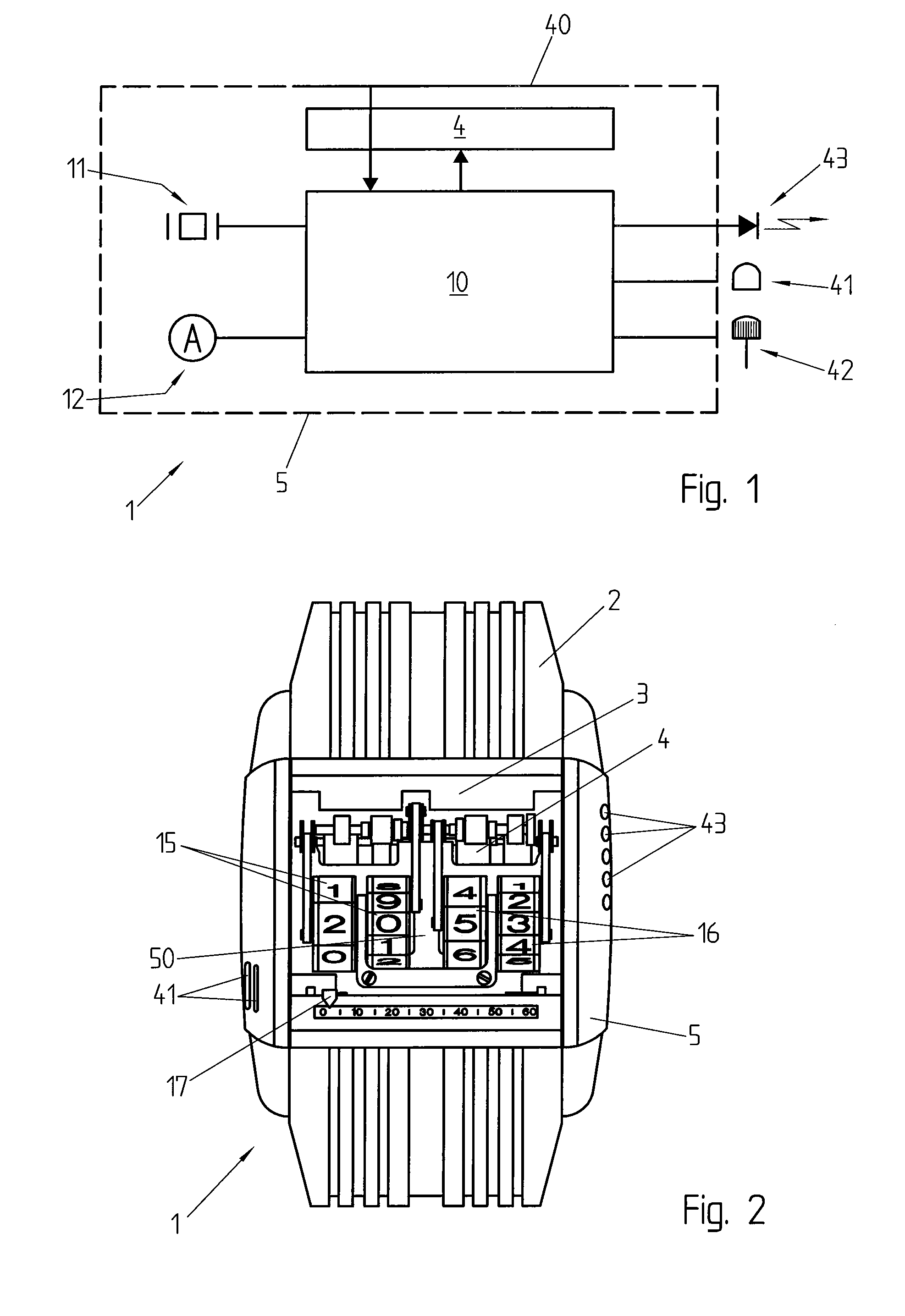

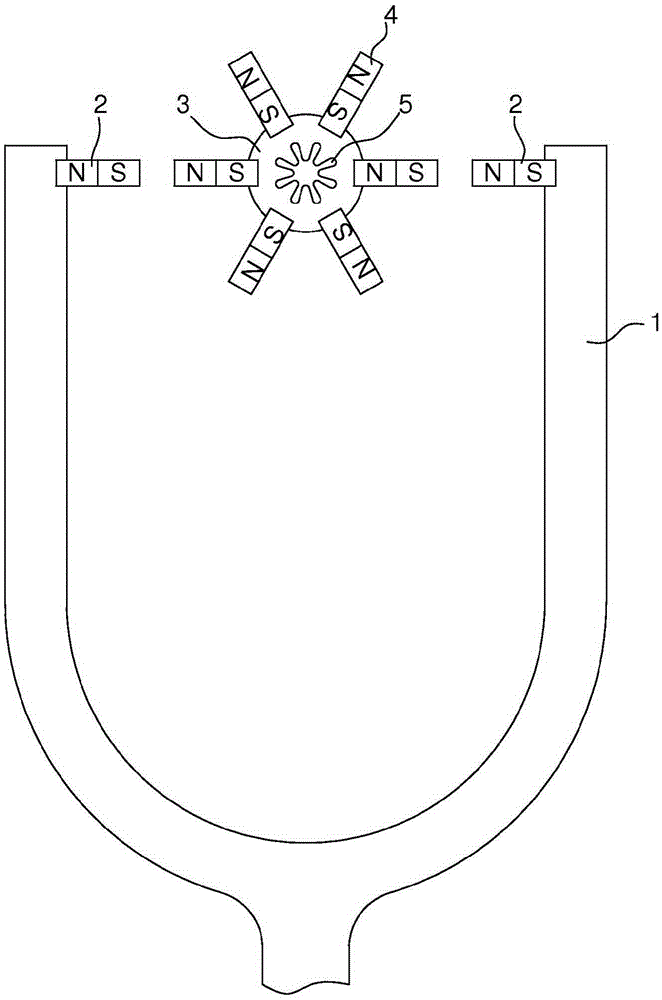

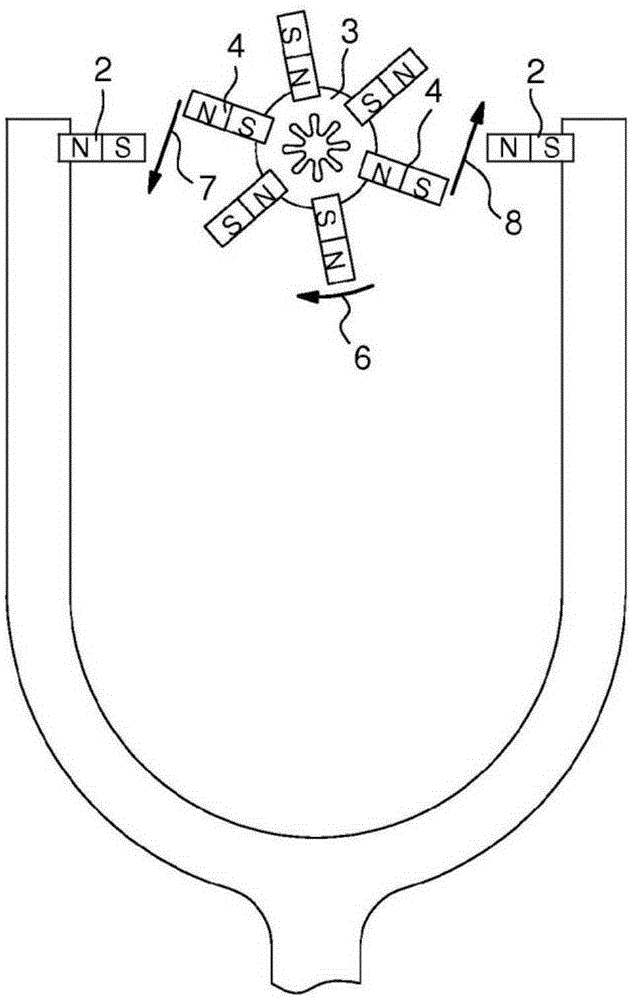

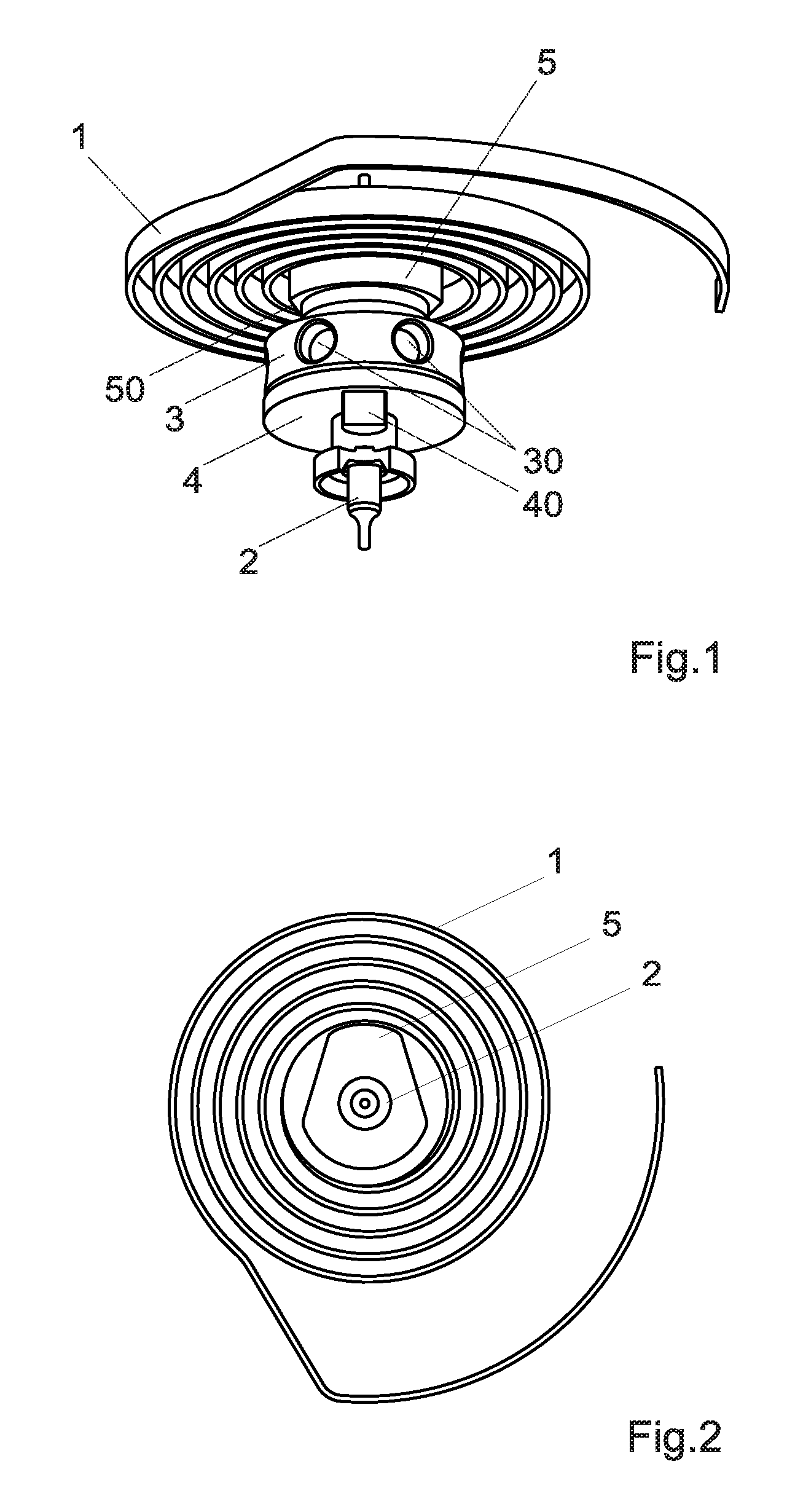

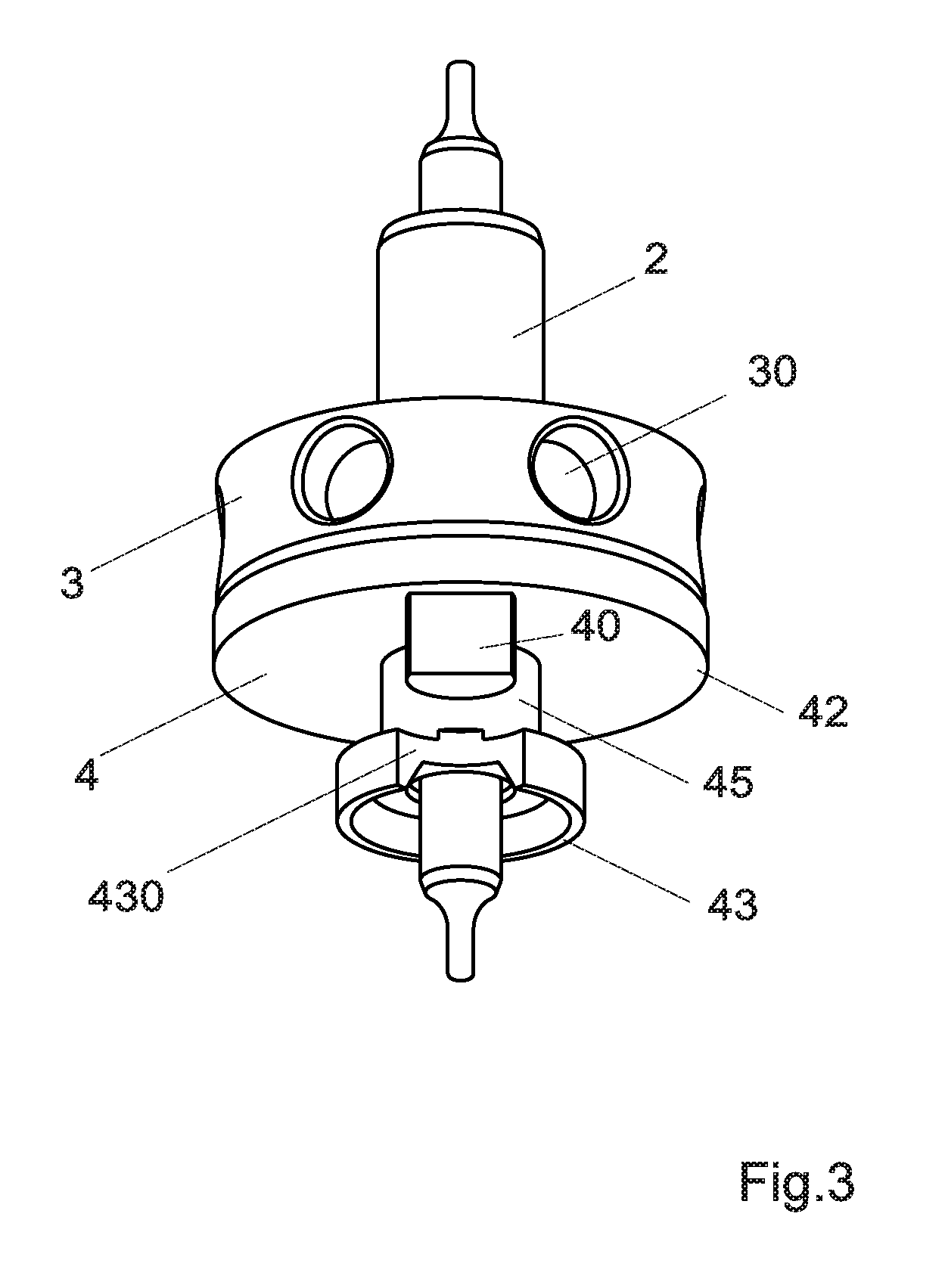

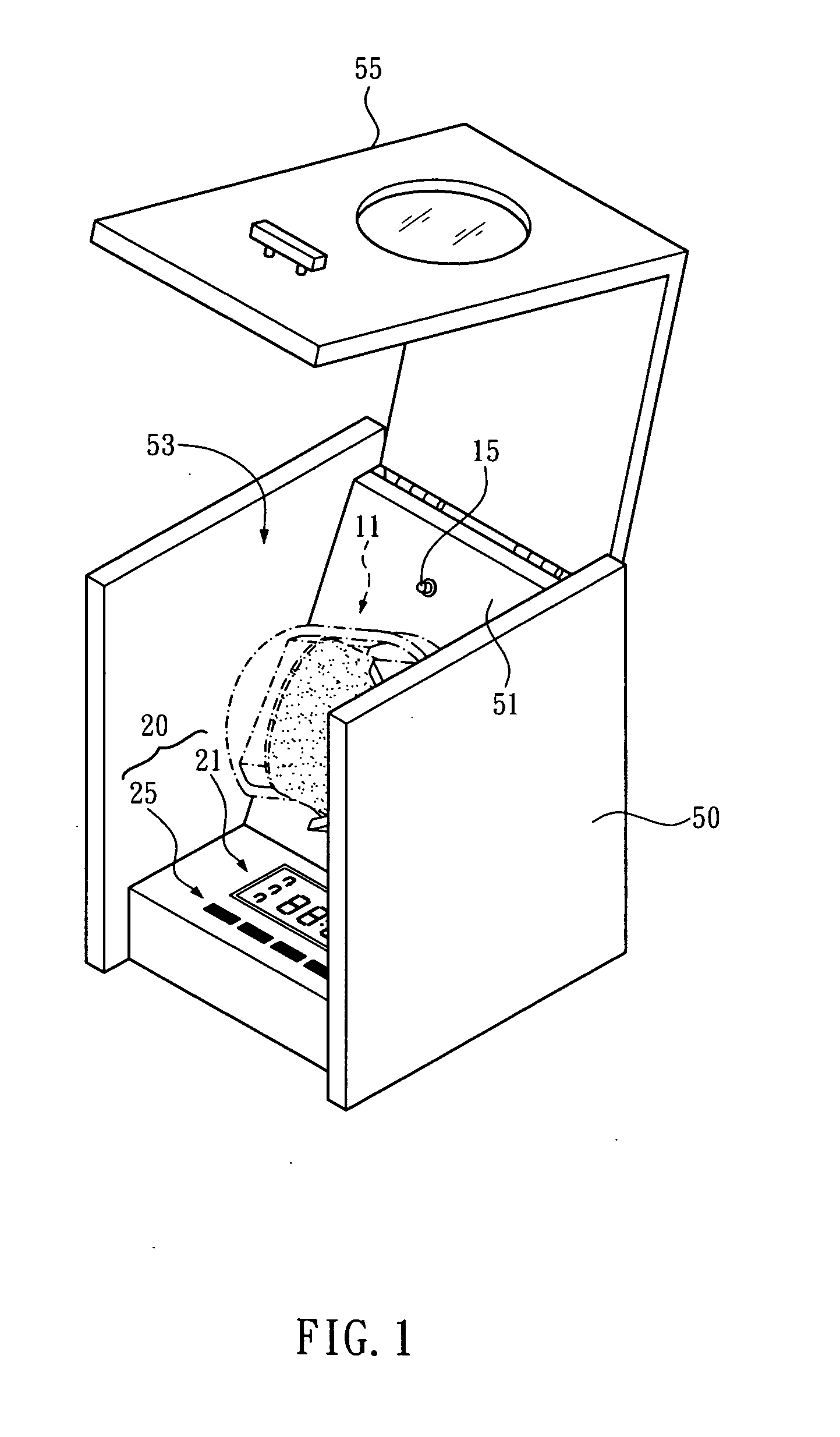

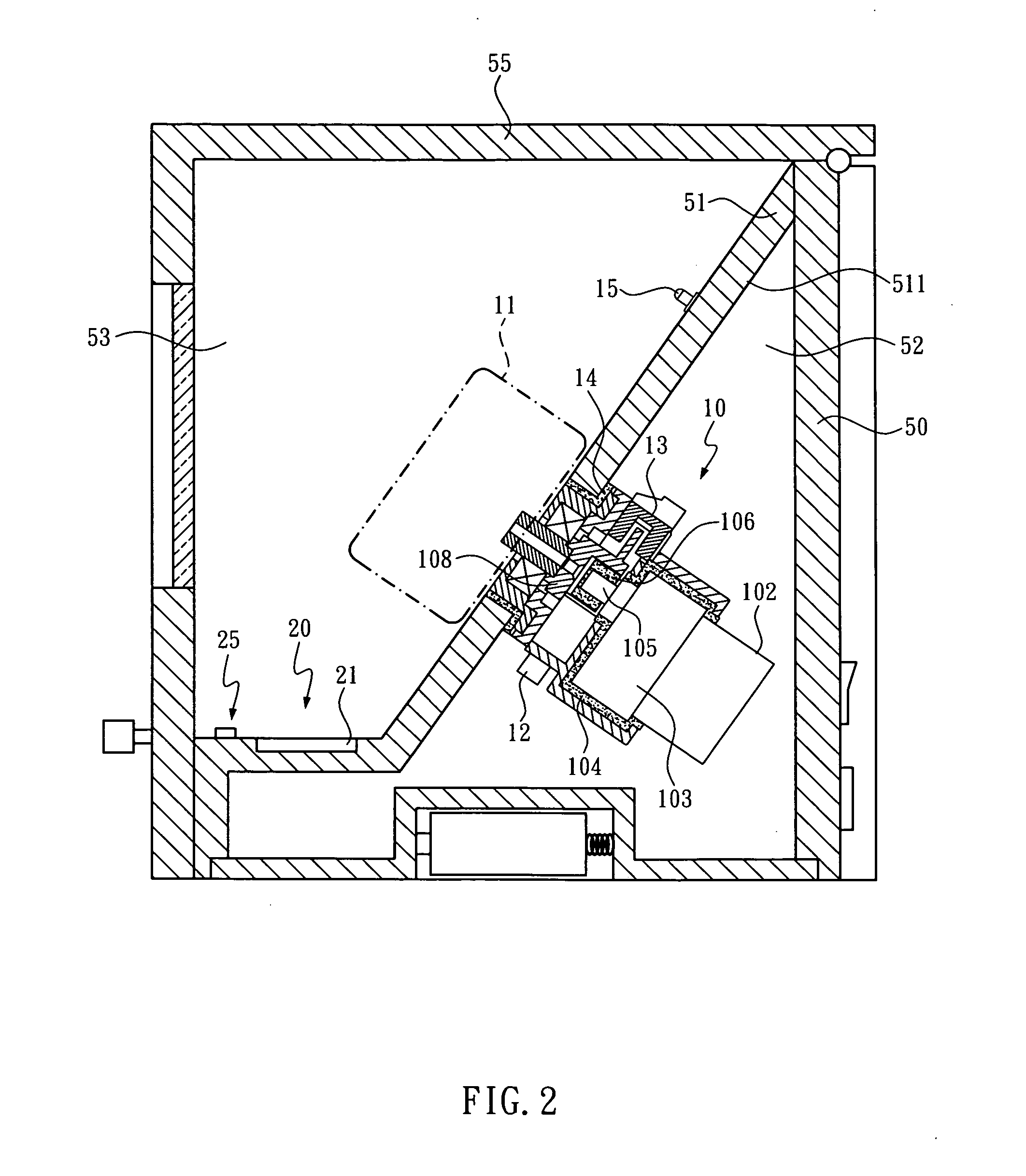

Controllable watch winder for self-winding watches

ActiveUS20050254352A1Save powerImprove adaptabilityElectric windingNormal windingMechanical watchMicroprocessor

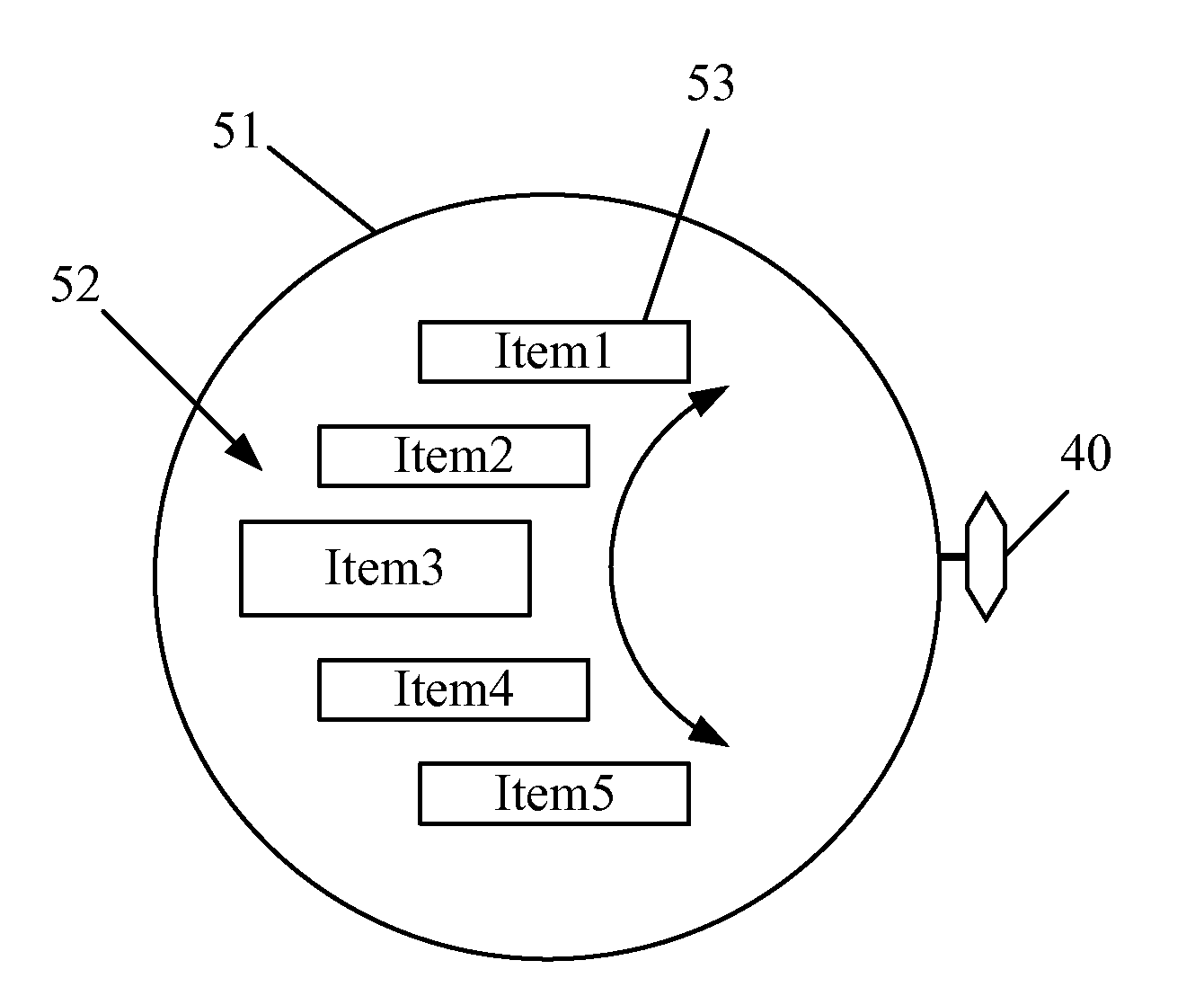

A controllable watch winder for a self-winding mechanical watch, in which a turntable is provided to hold and rotate the watch, including a programmable microprocessor circuit configured to count the number of rotations executed by the turntable. In one aspect, the watch winder is configured to introduce, after the electronic circuit is activated, a delay period before the turntable commences rotating. In another aspect, the circuit may be configured to interrupt the rotation of the turntable with pauses, to break up the rotation into cyclical sets. The circuit may be configured to automatically predetermine the number of rotations in each set. In yet another aspect, the watch winder may be configured to be manually adjustable, to variably predetermine before use, the number of rotations to be executed by the turntable and the length of any pause between rotations.

Owner:WOLF 1834 +1

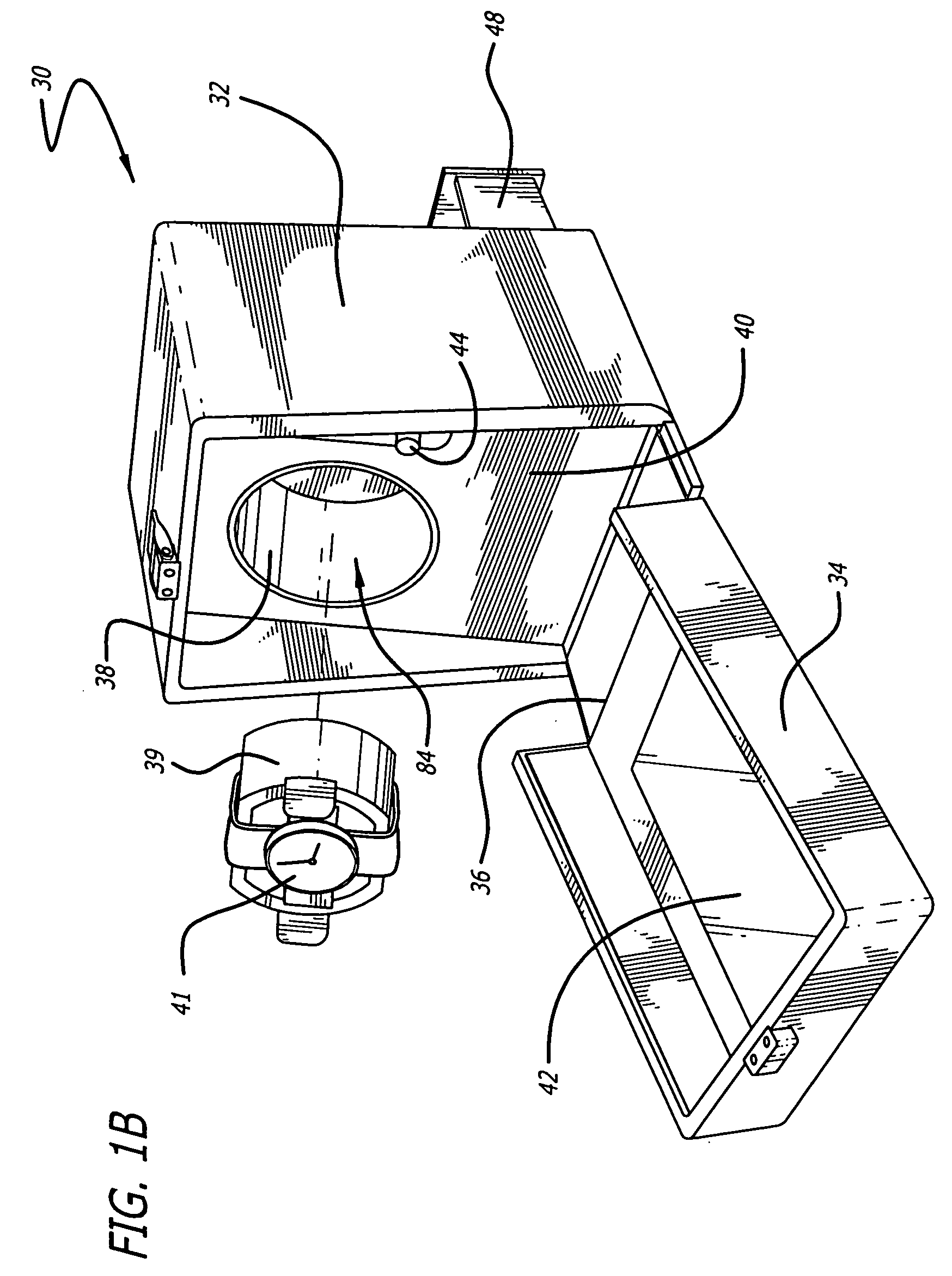

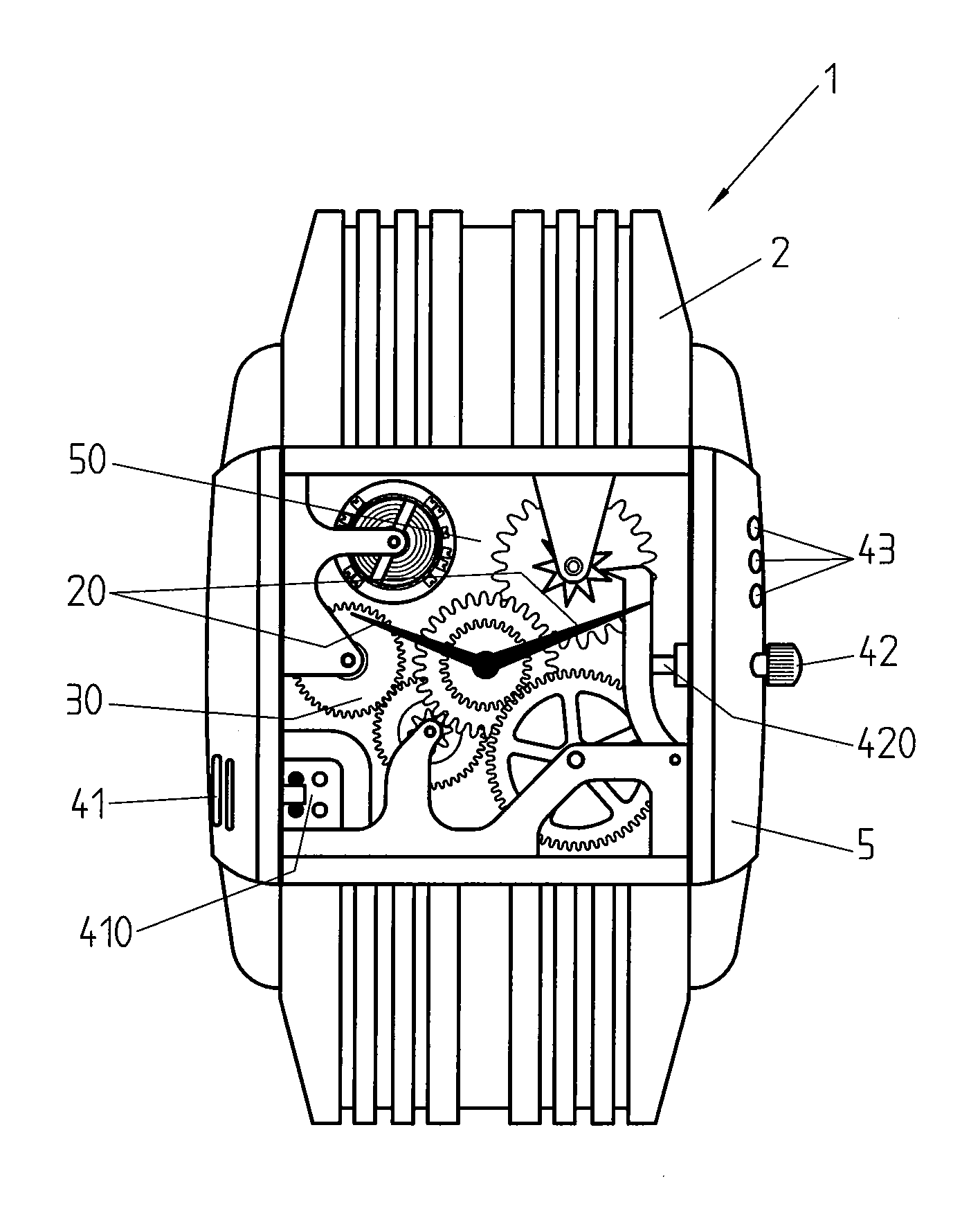

Wristwatch with electronic display

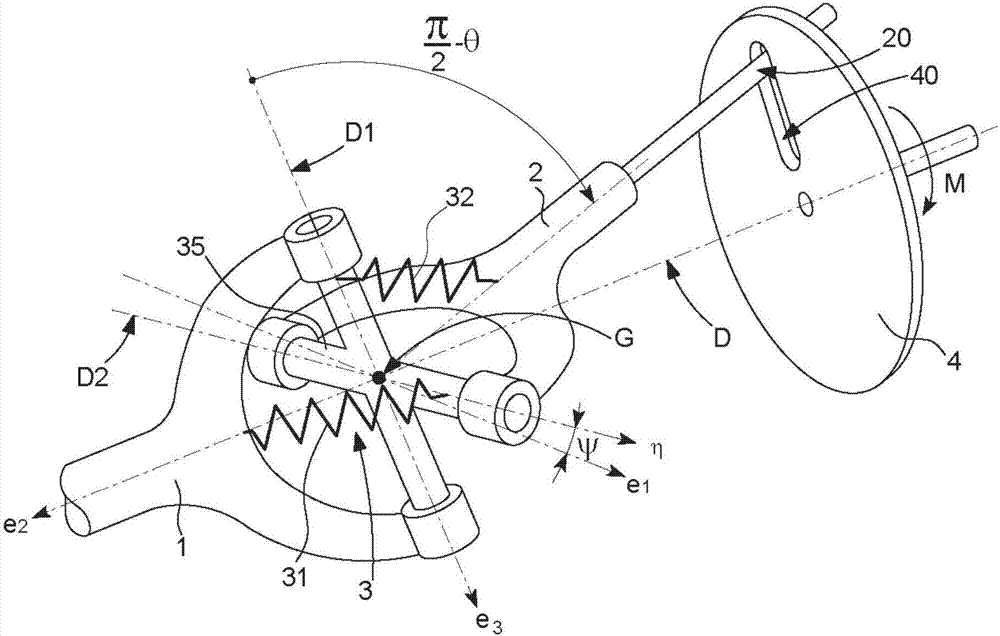

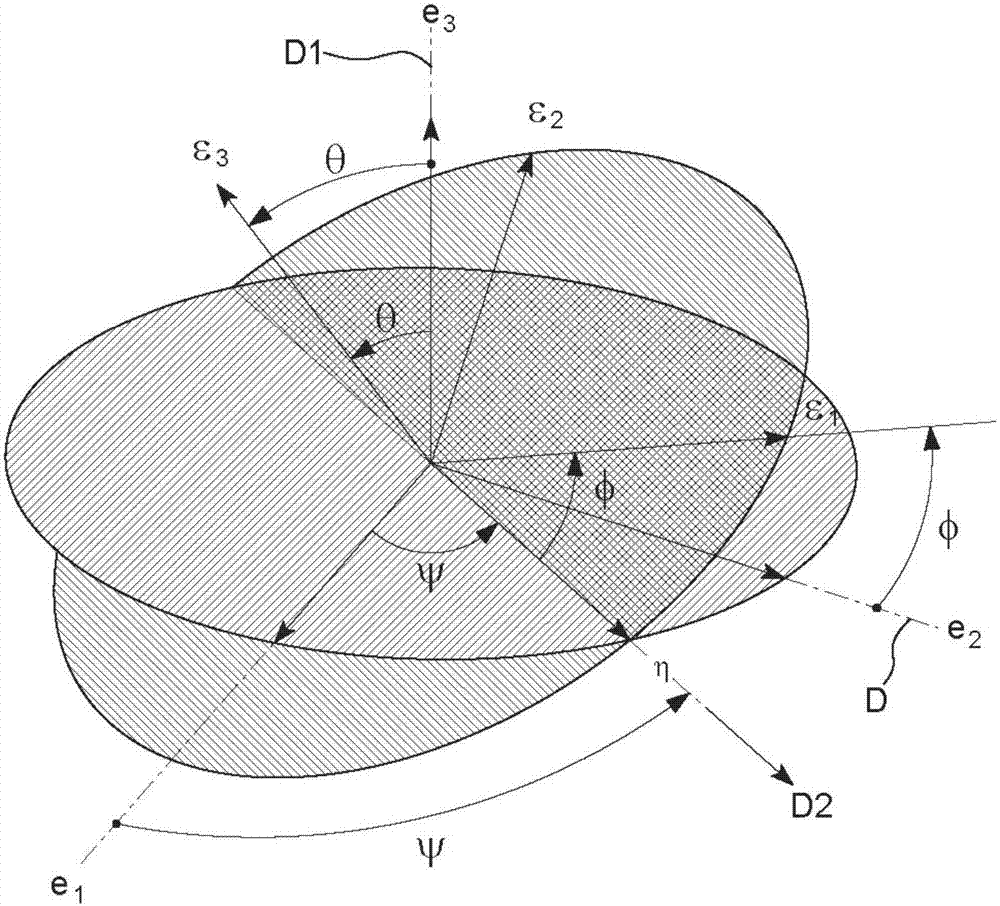

ActiveUS20130142016A1Interesting animationGreat and even infinite rigidityVisual indicationElectric indicationAccelerometerSimulation

Method for displaying the time in a wristwatch furnished with an electronic display (4) allowing the display of a simulated mechanical watch movement and of time indicators (20) so as to simulate a mechanical watch. The time displayed is advantageously calculated on the basis of the simulation of the movement and depends on the acceleration measured by an accelerometer.

Owner:SLYDE ANALYTICS LLC

Controllable watch winder for self-winding watches

ActiveUS7575367B2Improve adaptabilityEfficient use ofNormal windingElectric windingMechanical watchMicroprocessor

A controllable watch winder for a self-winding mechanical watch, in which a turntable is provided to hold and rotate the watch, including a programmable microprocessor circuit configured to count the number of rotations executed by the turntable. In one aspect, the watch winder is configured to introduce, after the electronic circuit is activated, a delay period before the turntable commences rotating. In another aspect, the circuit may be configured to interrupt the rotation of the turntable with pauses, to break up the rotation into cyclical sets. The circuit may be configured to automatically predetermine the number of rotations in each set. In yet another aspect, the watch winder may be configured to be manually adjustable, to variably predetermine before use, the number of rotations to be executed by the turntable and the length of any pause between rotations.

Owner:WOLF 1834 +1

Wristwatch structure, electronic crown for wristwatch, and wristwatch having display

InactiveUS20140328147A1Shorten product development cycleIncrease freedomElectric indicationElectronic time-piece structural detailsElectric driveMechanical watch

Owner:PRINCO MIDDLE EAST FZE

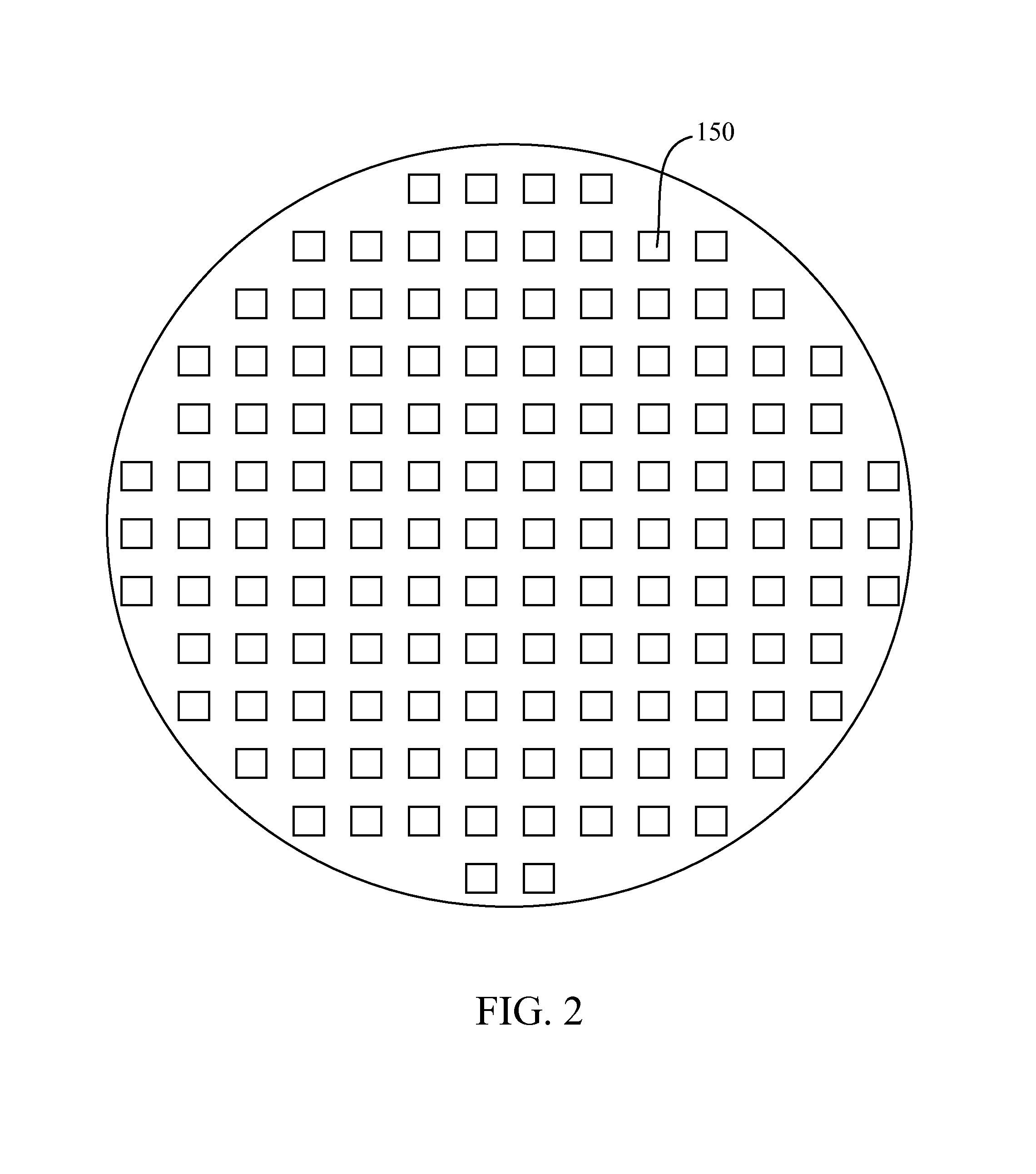

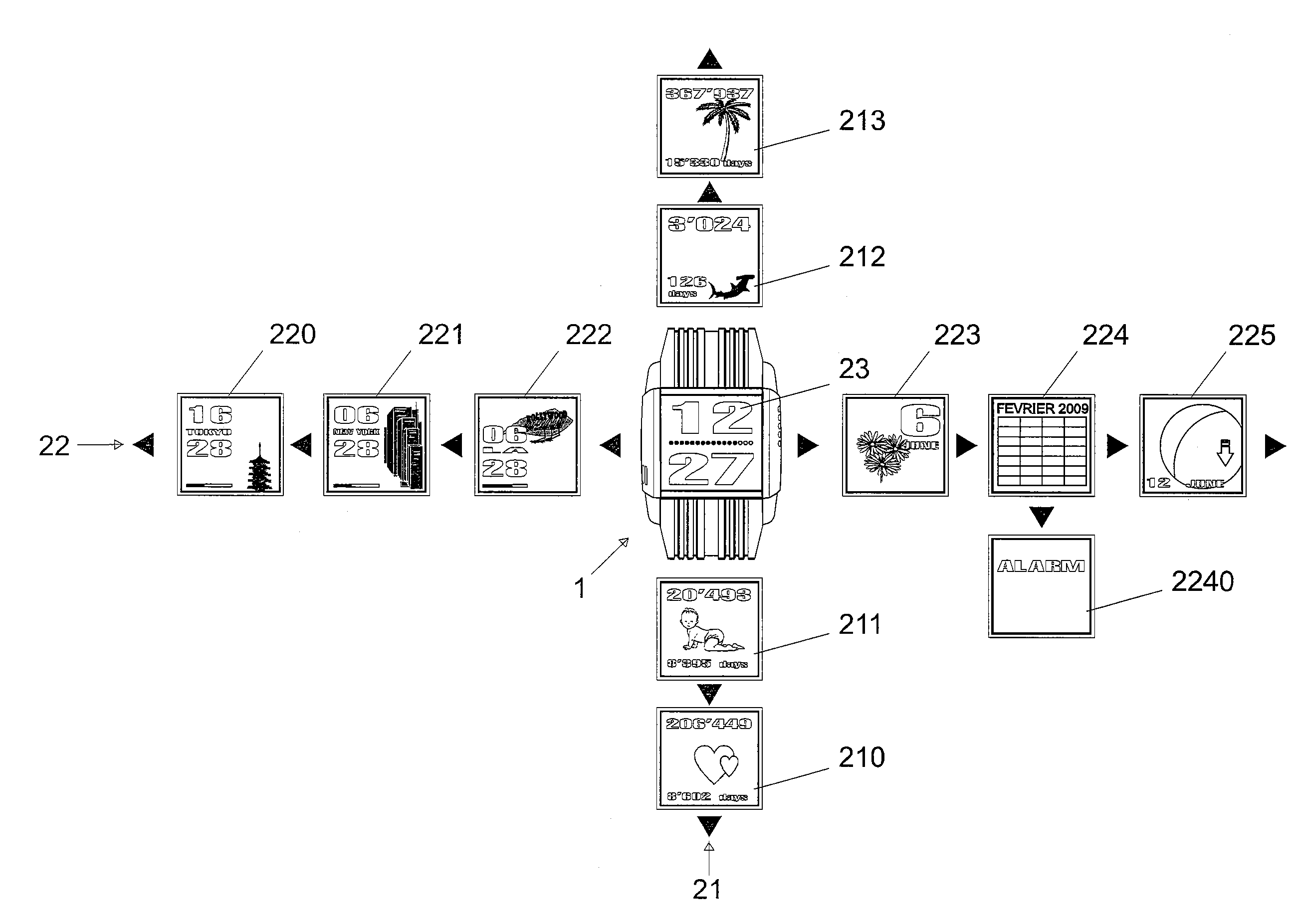

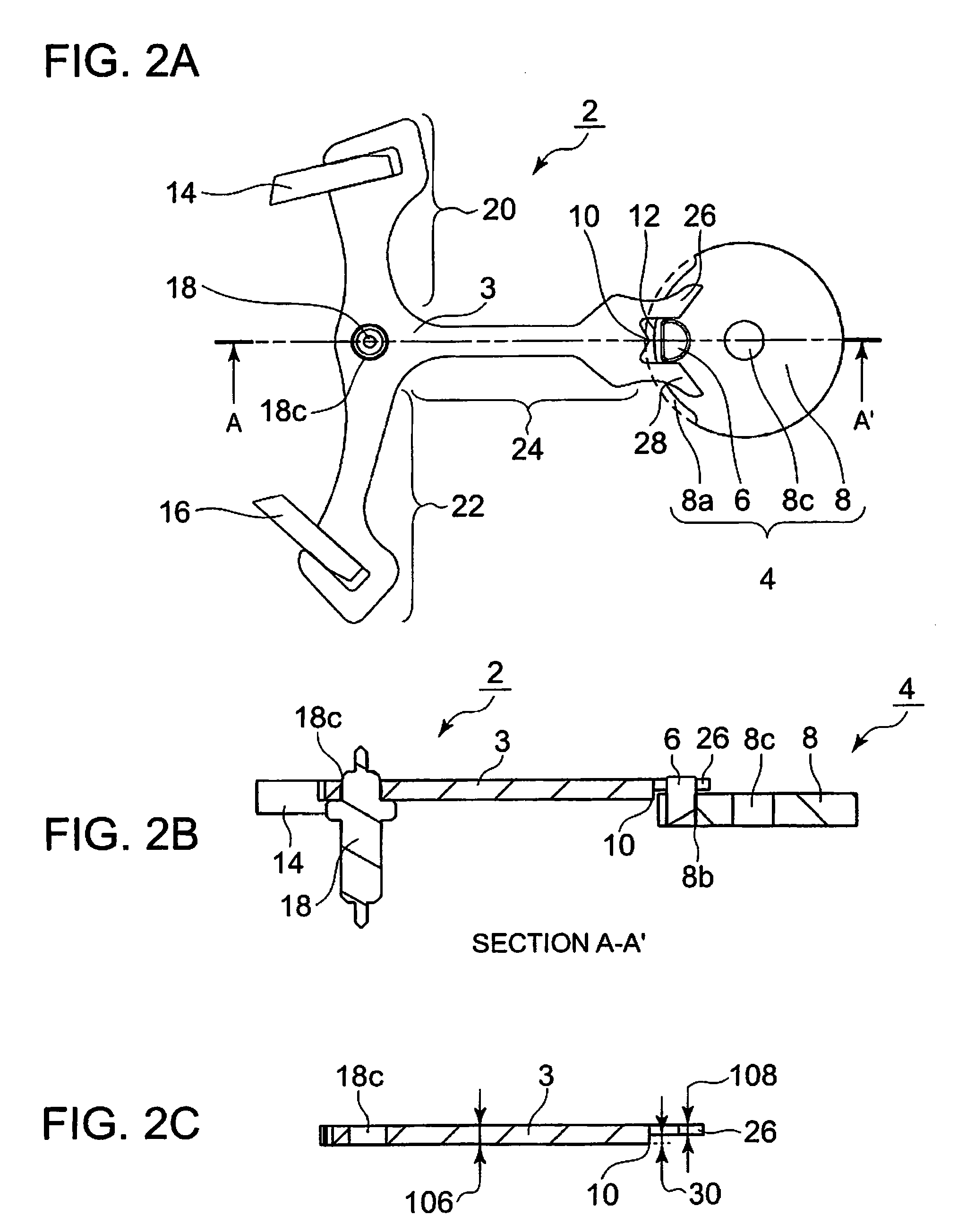

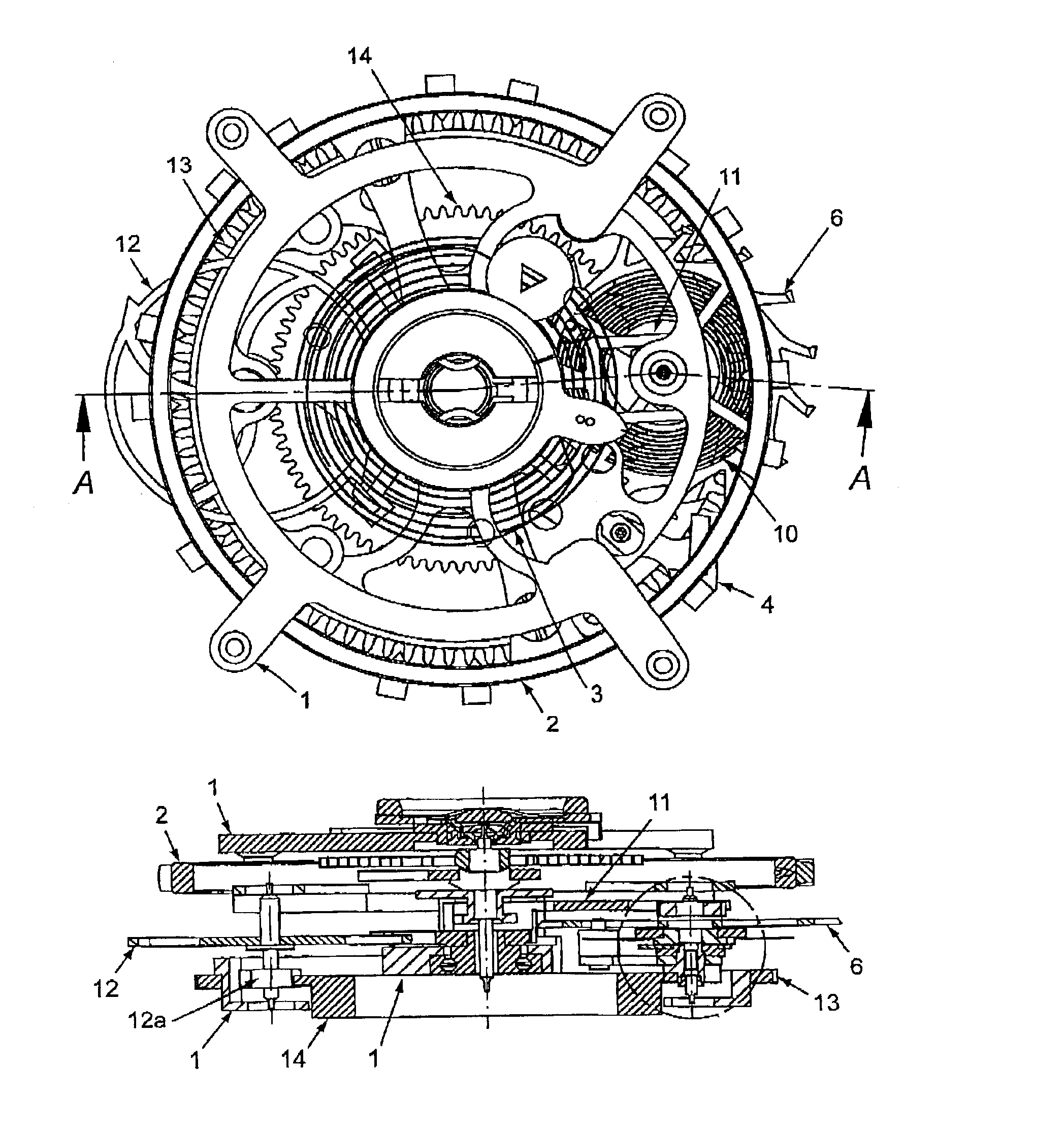

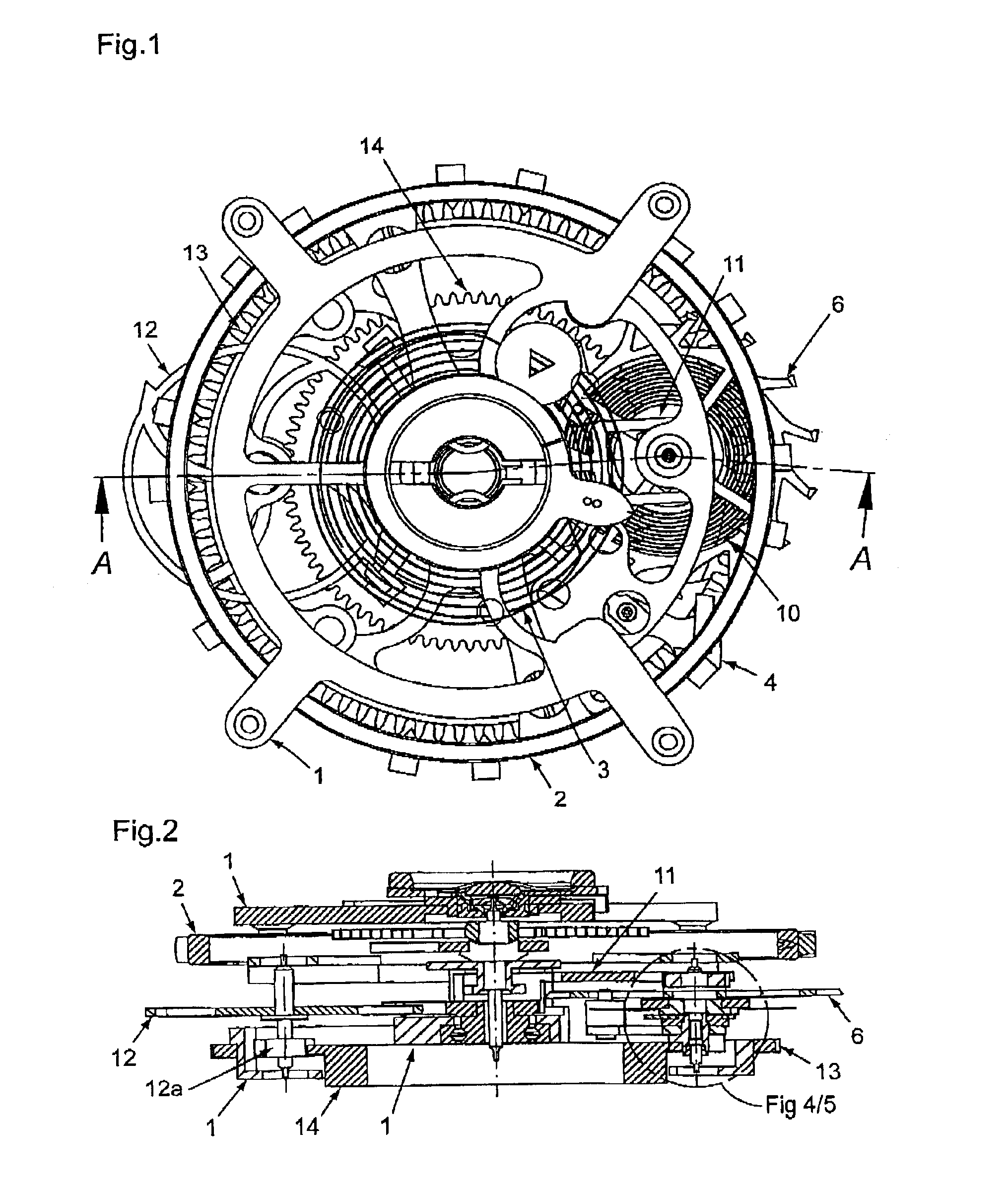

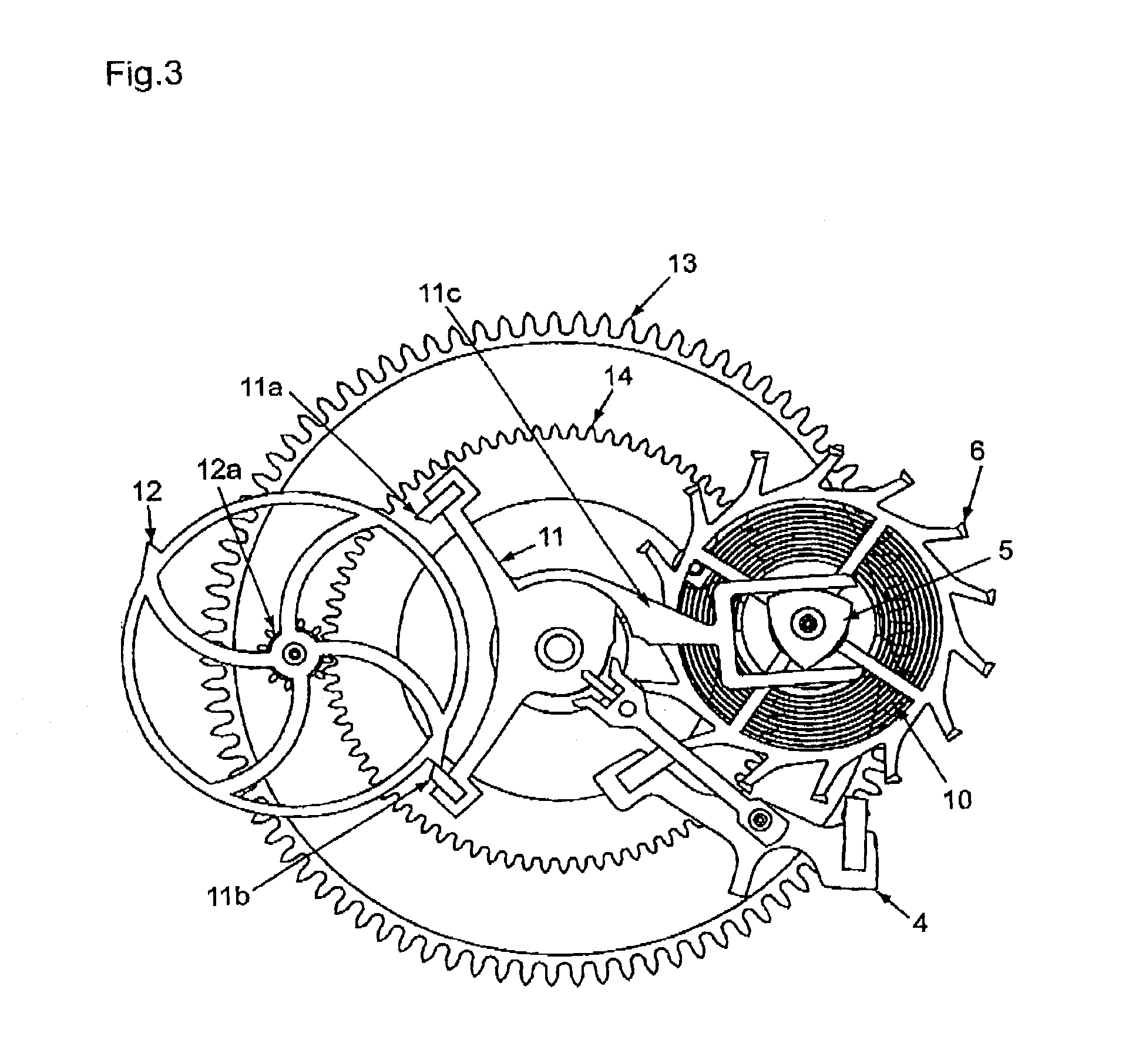

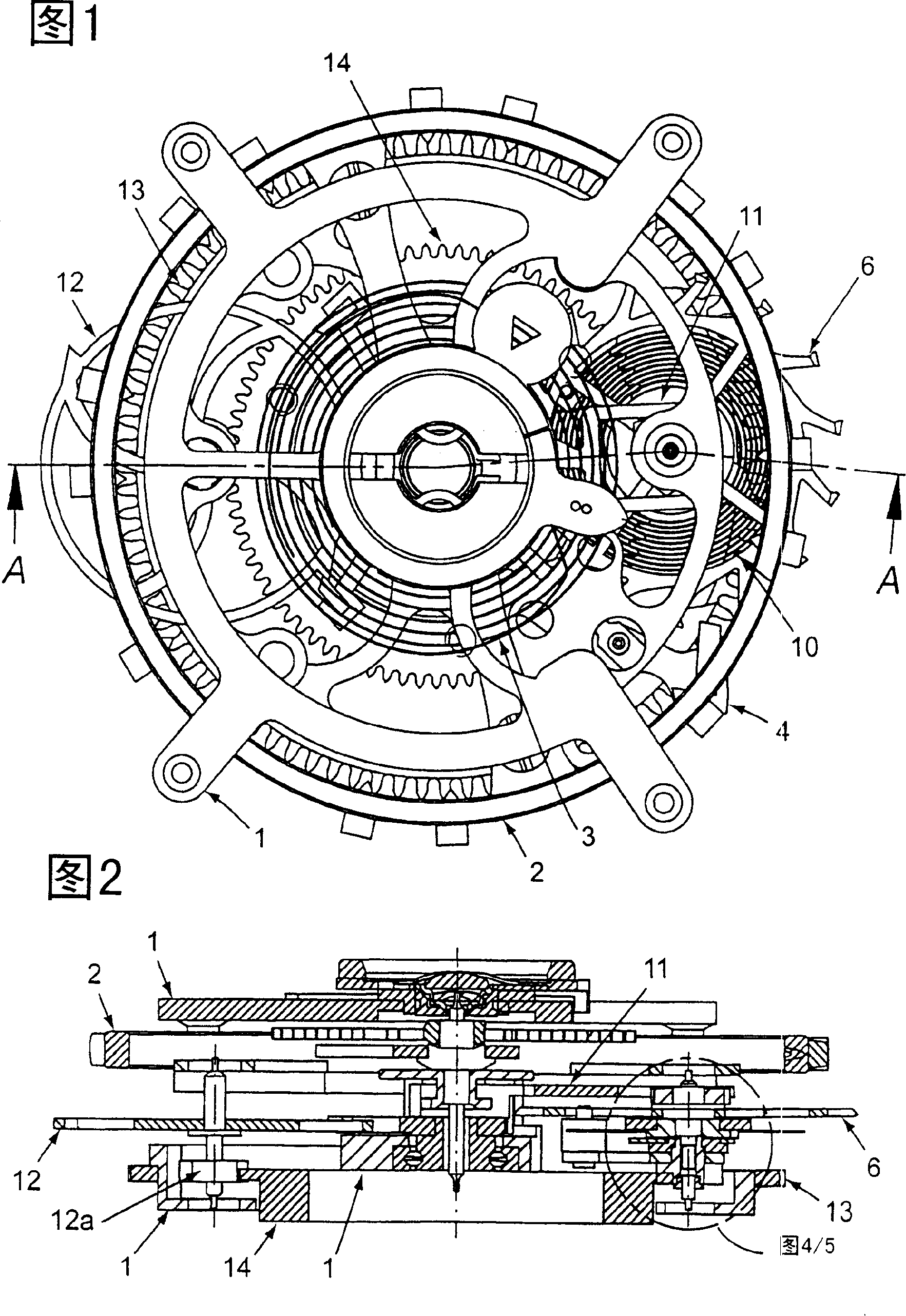

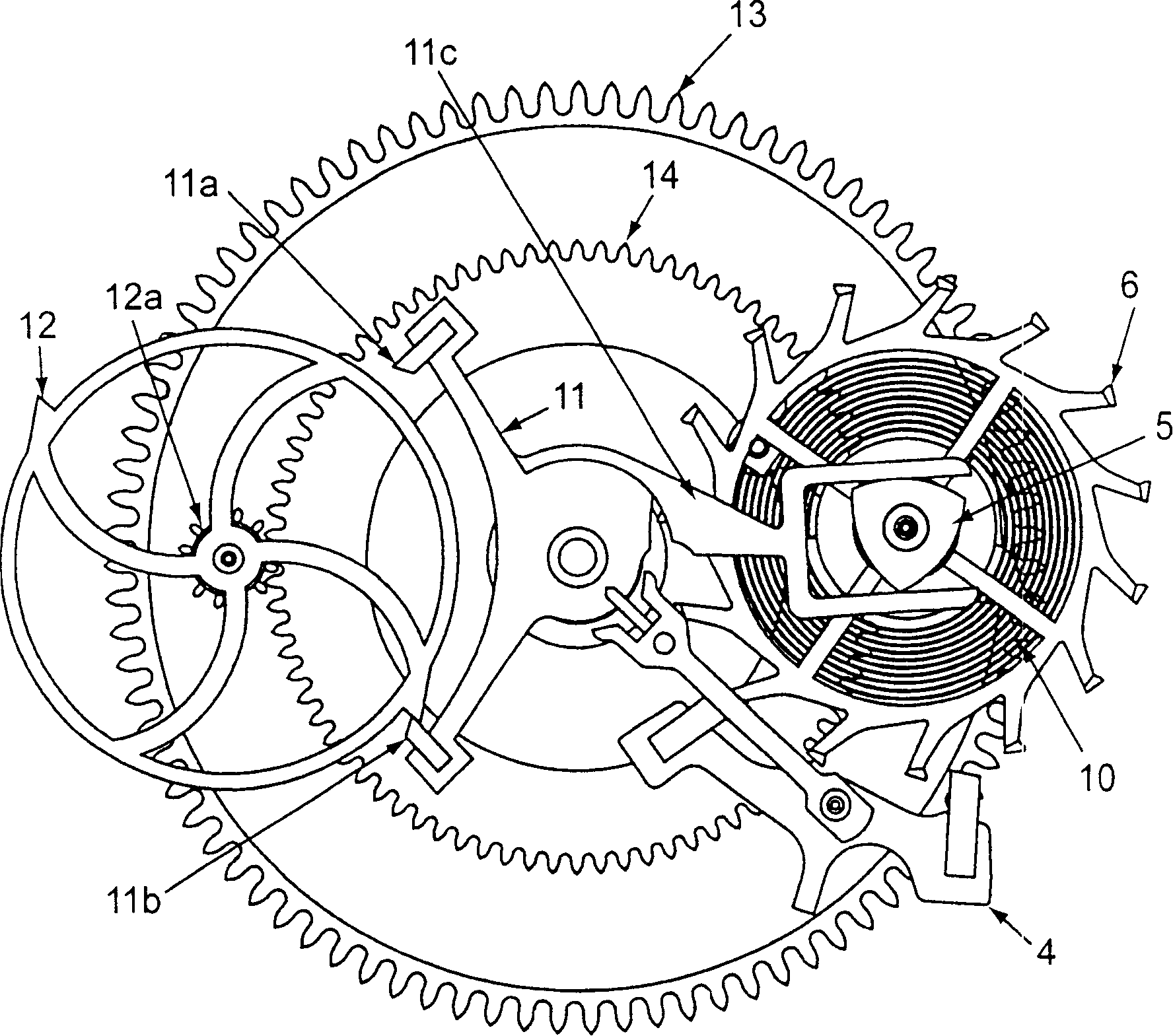

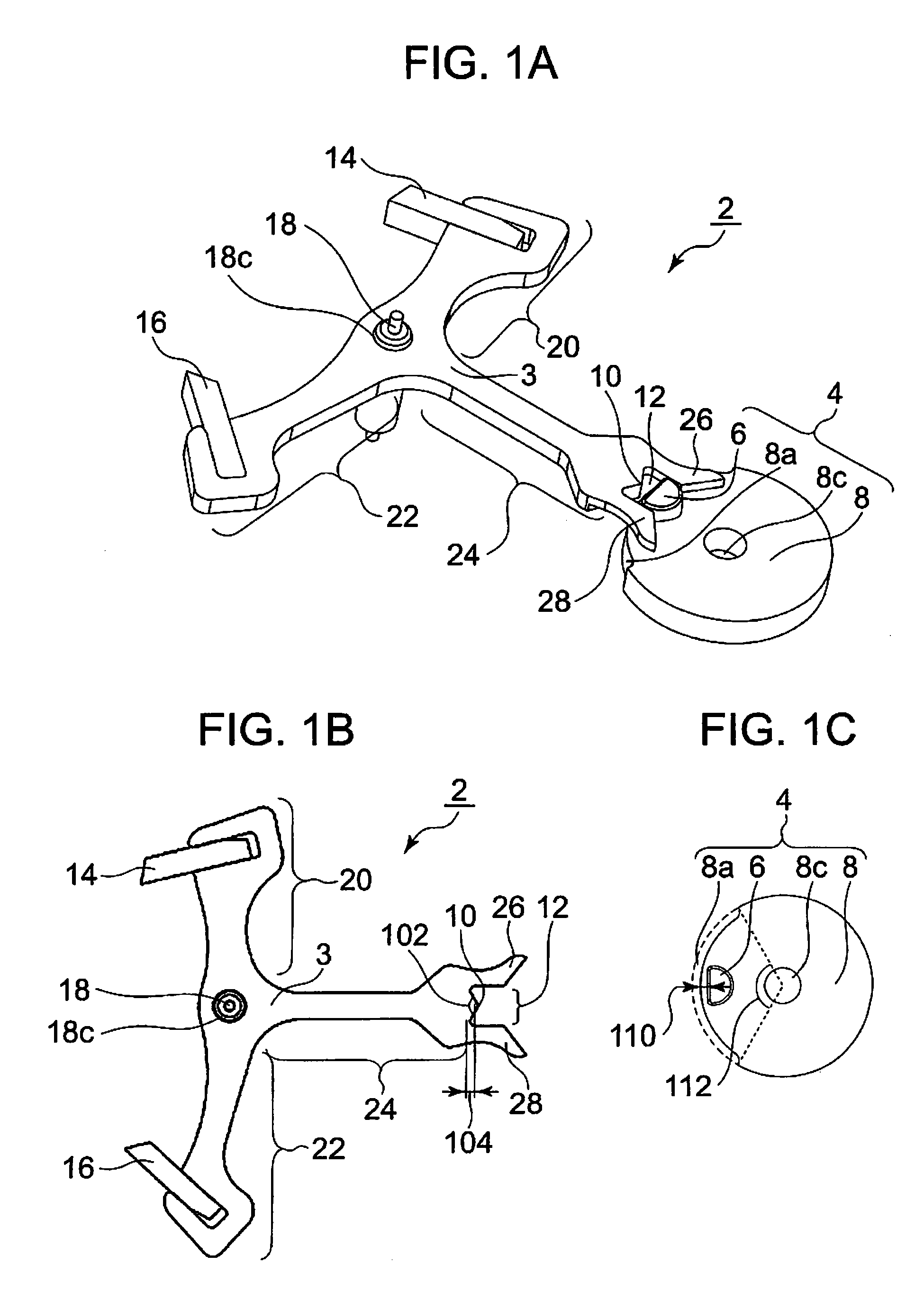

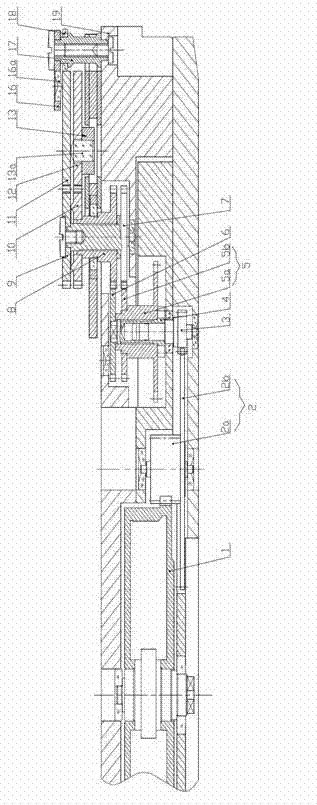

Timepiece having a mechanical movement associated with an electronic regulator

ActiveUS20050036405A1Easy to installEfficient couplingEscapementsFrequency stabilisation mechanismElectromagnetic couplingEngineering

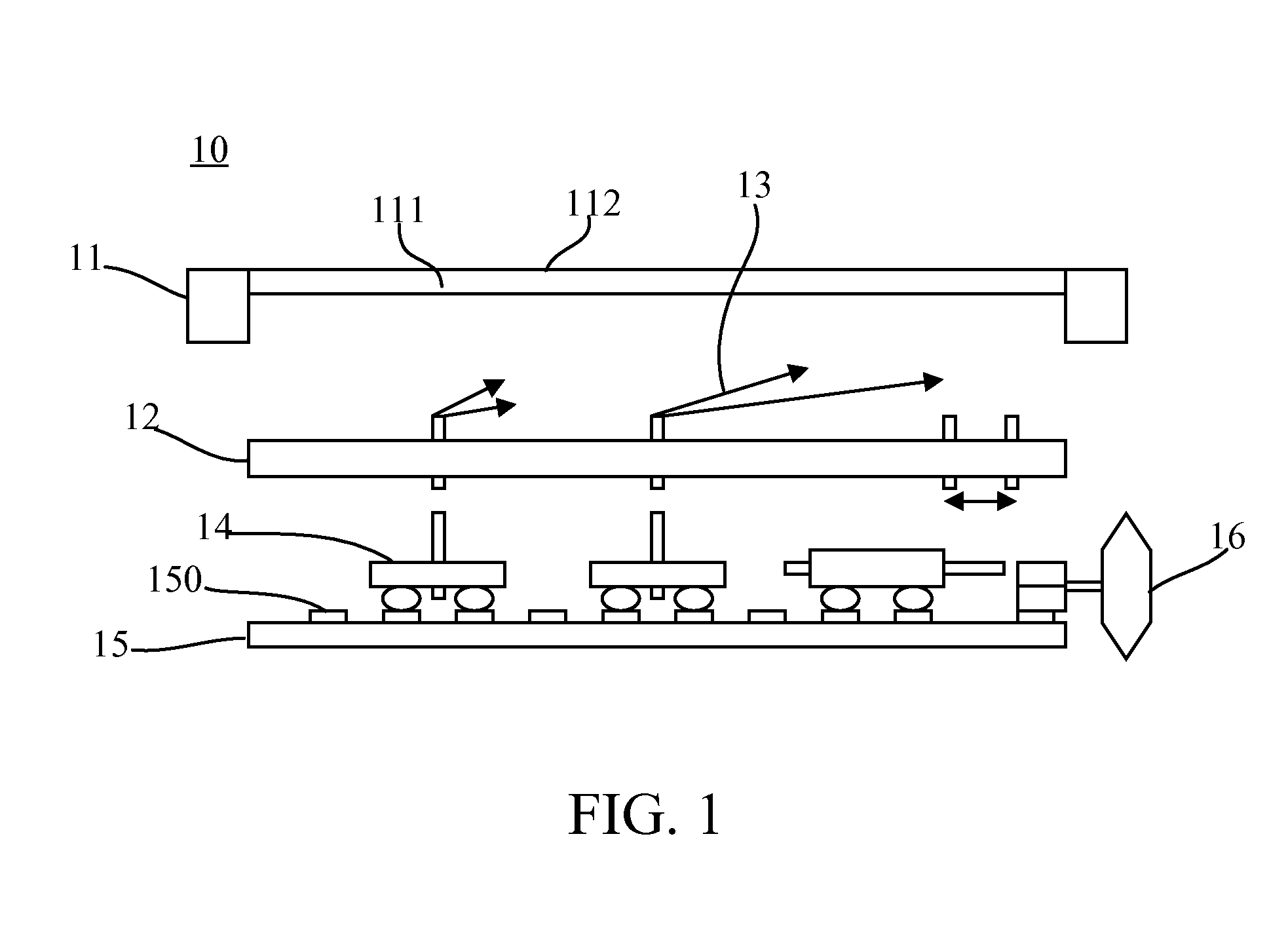

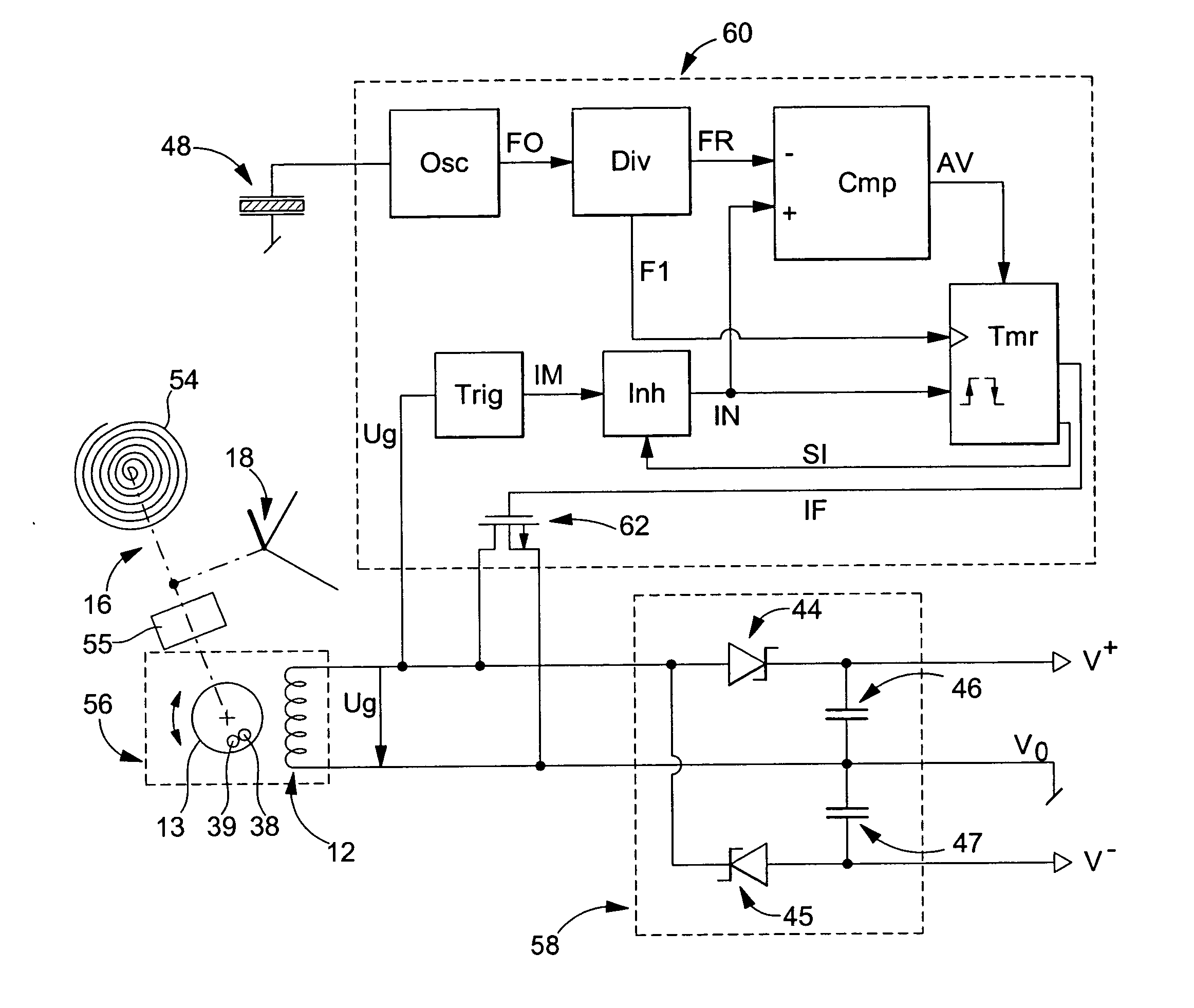

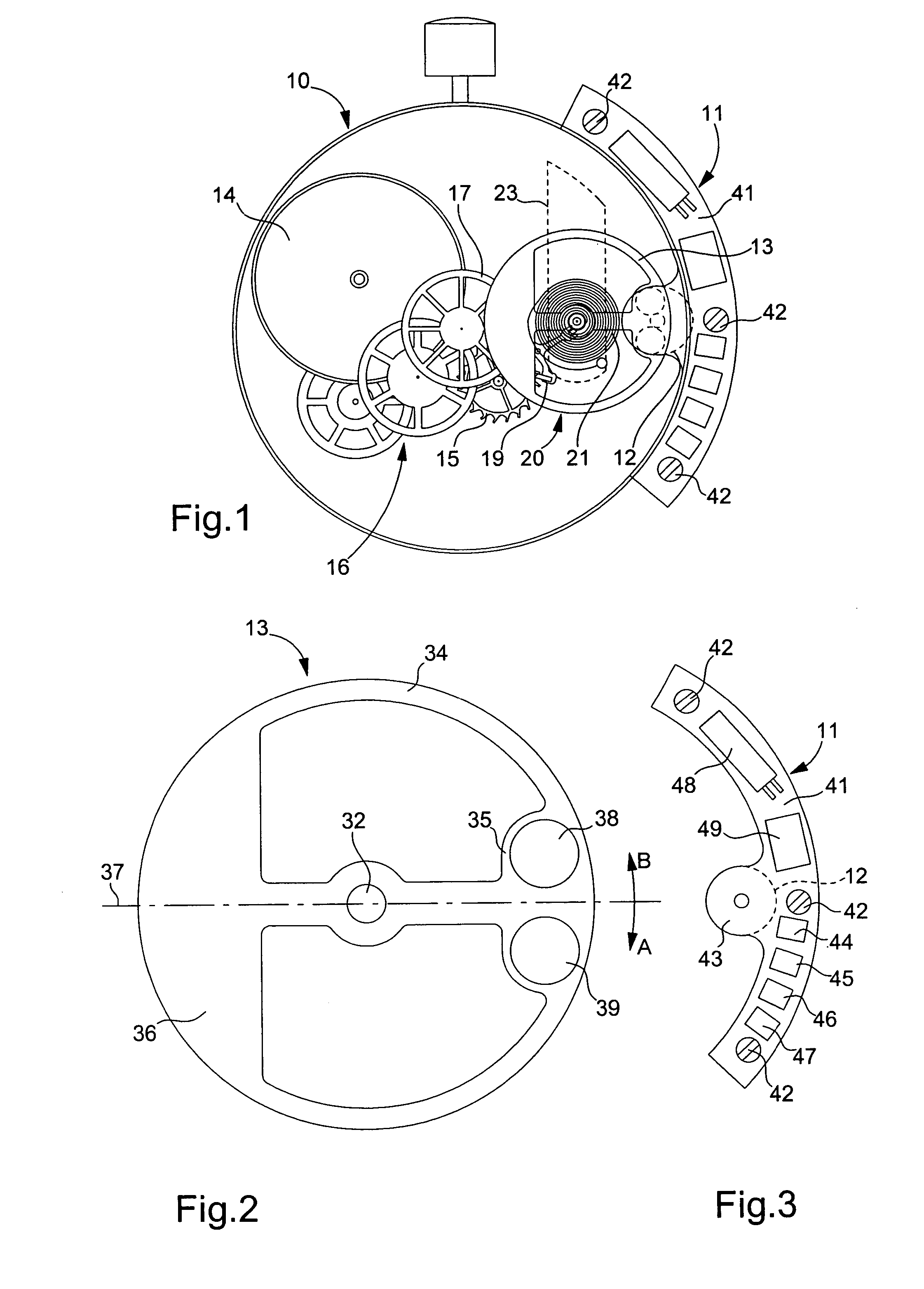

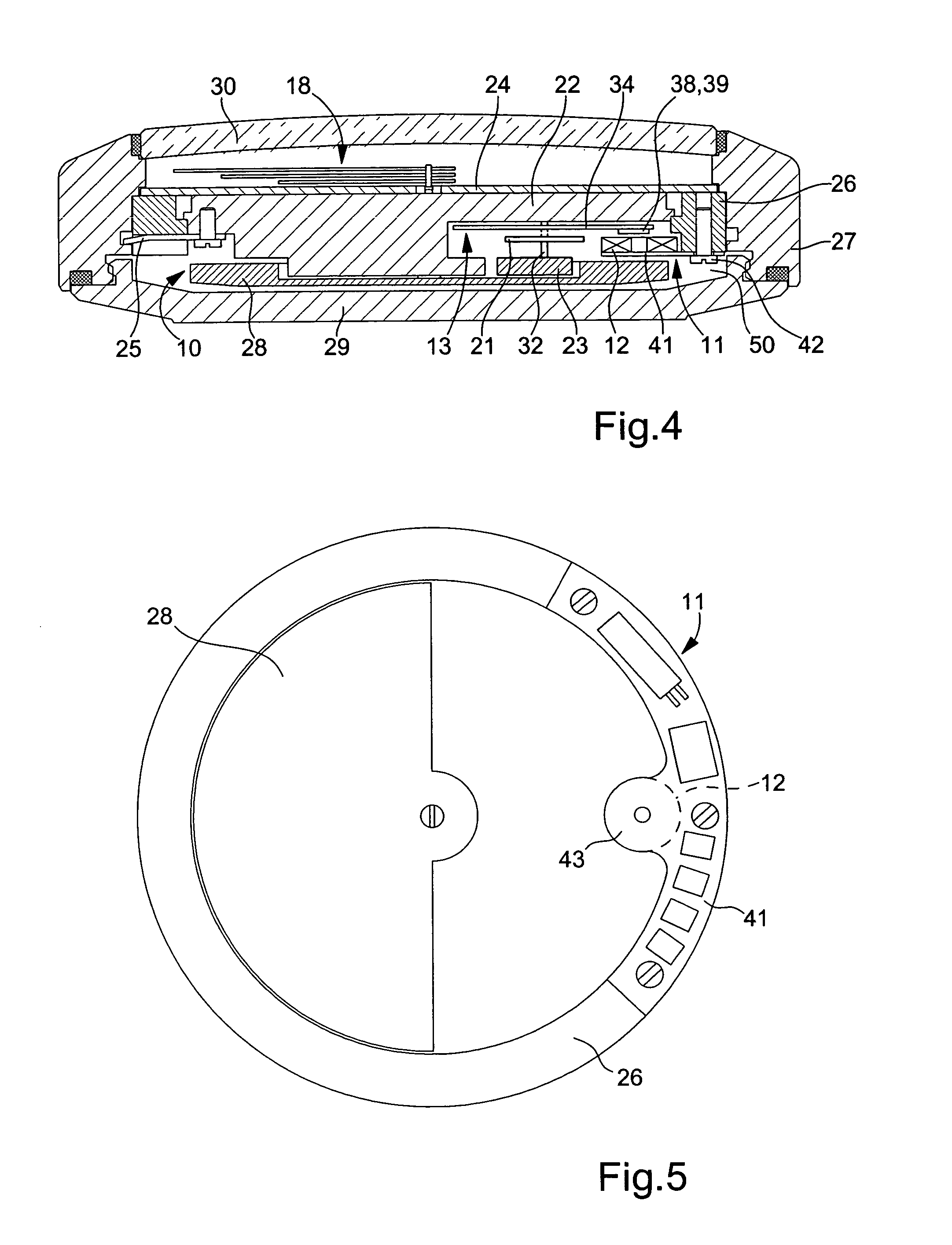

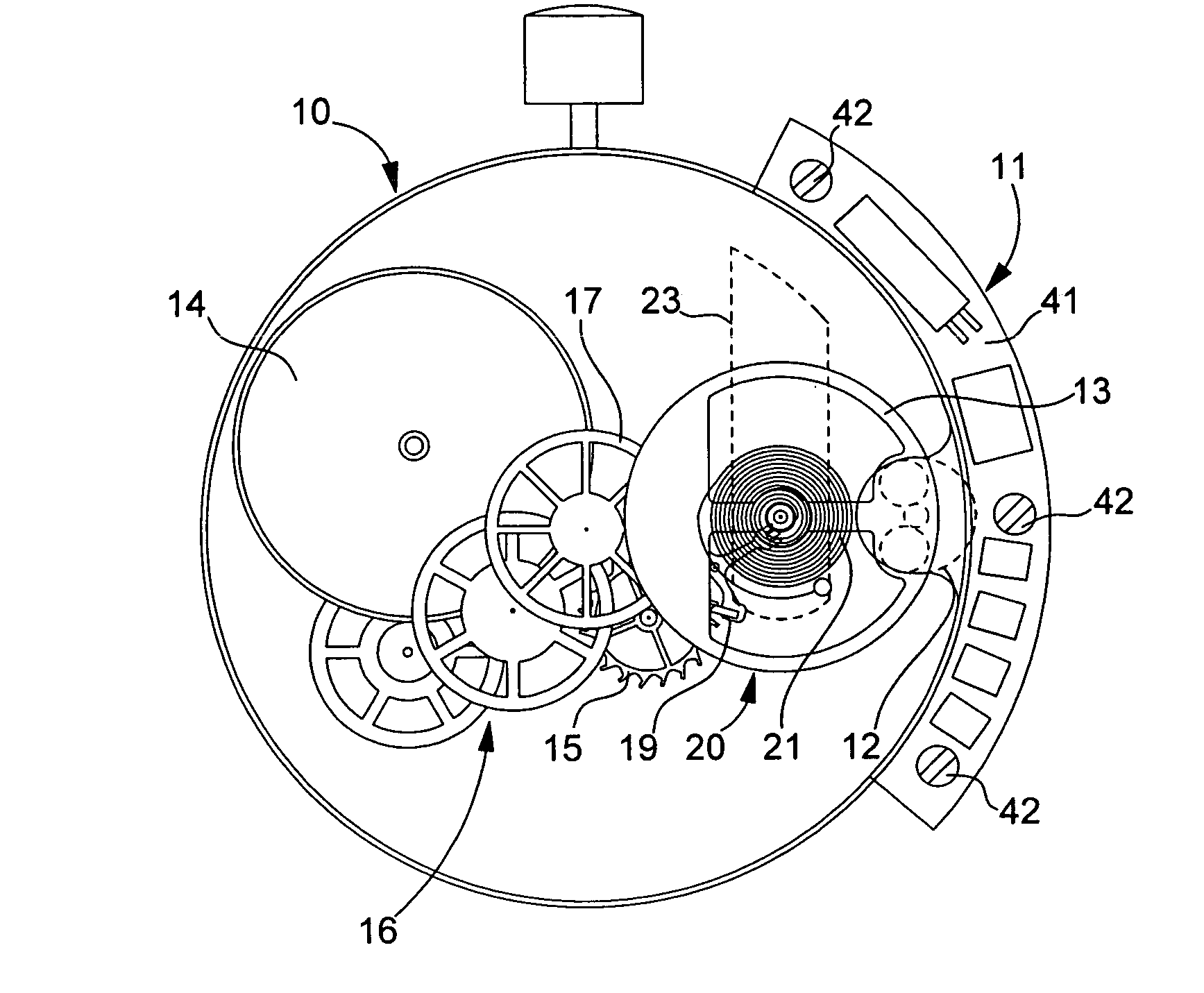

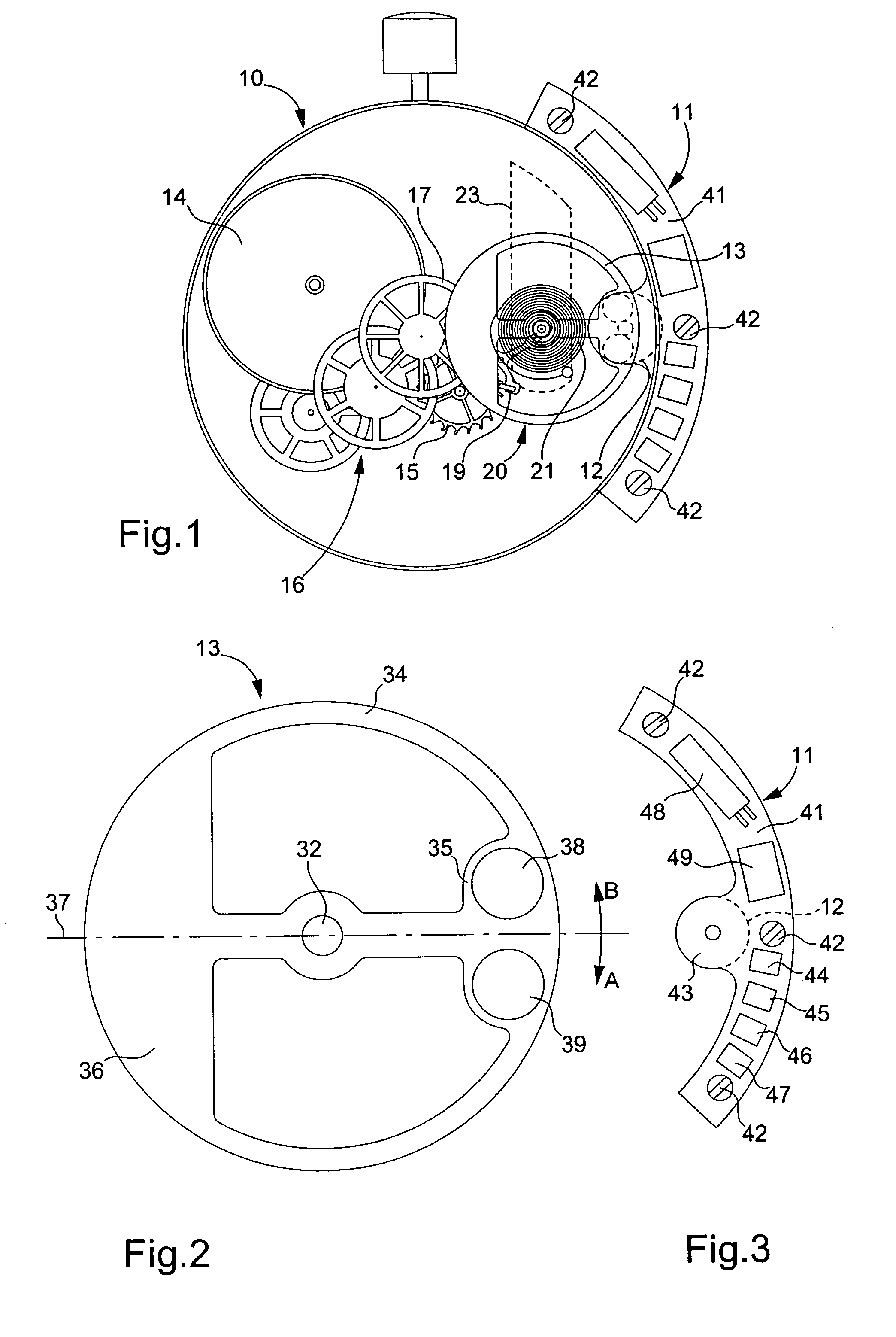

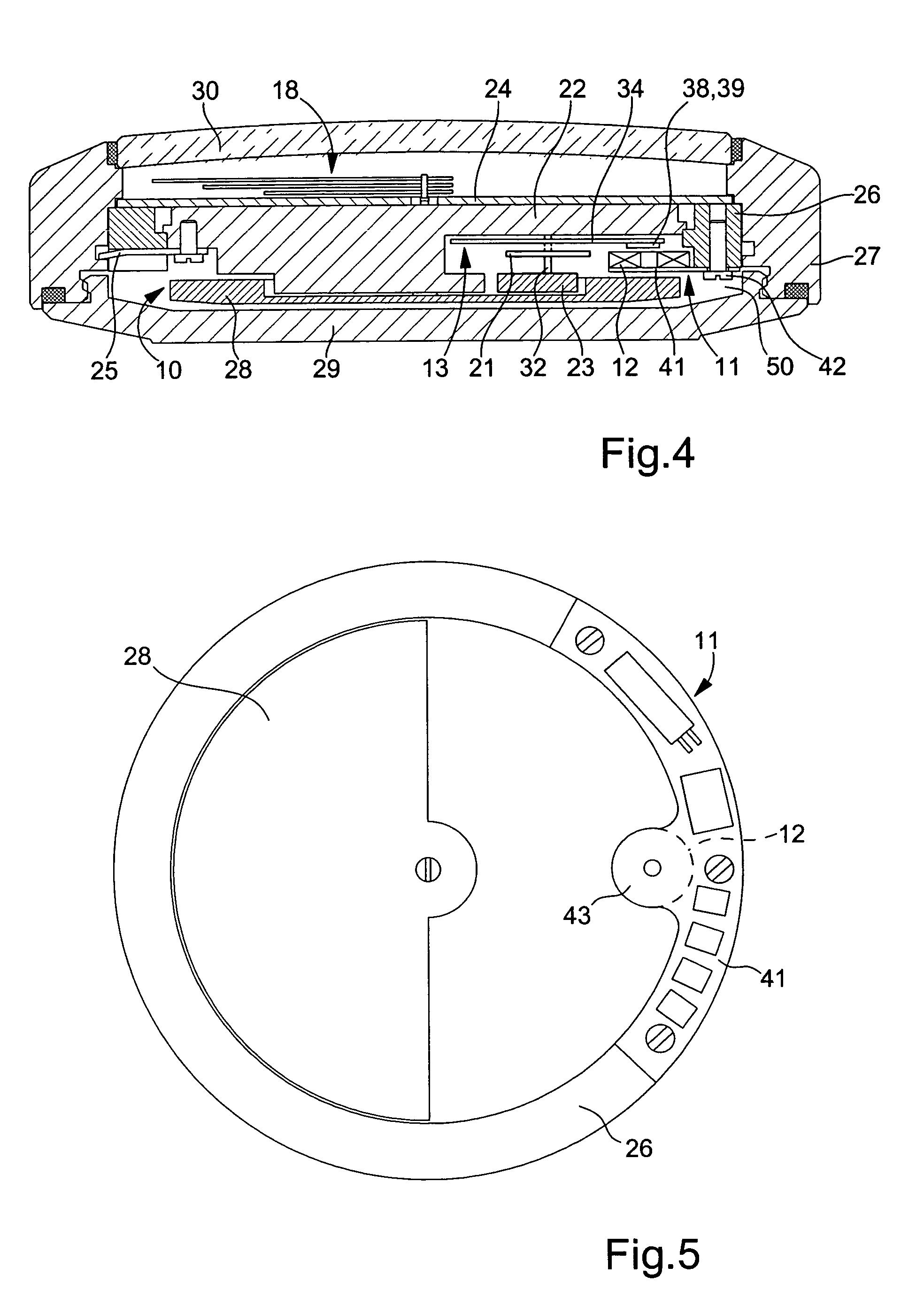

There is disclosed a wristwatch having a case containing a mechanical watch movement (10) driven by a spring barrel (14) and provided with a mechanical regulator with a balance and balance-spring, which is associated, via electromagnetic coupling, with an electronic regulator driven by a quartz resonator. The rim of the balance (13) is provided with a pair of permanent magnets (38, 39). The electronic regulator includes a fixed coil (12) arranged for cooperating with said magnets via electromagnetic coupling, a rectifier (58) provided with at least one capacitor, and a circuit (60) for enslaving the frequency of the mechanical regulator to the frequency of the oscillator by braking obtained by briefly short-circuiting the coil. In order to enable a common type of mechanical movement to be used, only the balance of which is altered, the electronic regulator is formed by a structural module (11) that is entirely separate from the mechanical watch movement (10). This module can be fixed to the movement plate, or, conversely, carried by the watchcase independently of said movement, in particular via a casing ring (26). Apart from the coil, all of the rest of the electronic module (11) is preferably located outside the mechanical movement.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Timepiece having a mechanical movement associated with an electronic regulator

ActiveUS7306364B2Efficient couplingSmall shapeFrequency stabilisation mechanismSynchronous motors for clocksElectromagnetic couplingEngineering

There is disclosed a wristwatch having a case containing a mechanical watch movement (10) driven by a spring barrel (14) and provided with a mechanical regulator with a balance and balance-spring, which is associated, via electromagnetic coupling, with an electronic regulator driven by a quartz resonator. The rim of the balance (13) is provided with a pair of permanent magnets (38, 39). The electronic regulator includes a fixed coil (12) arranged for cooperating with said magnets via electromagnetic coupling, a rectifier (58) provided with at least one capacitor, and a circuit (60) for enslaving the frequency of the mechanical regulator to the frequency of the oscillator by braking obtained by briefly short-circuiting the coil. In order to enable a common type of mechanical movement to be used, only the balance of which is altered, the electronic regulator is formed by a structural module (11) that is entirely separate from the mechanical watch movement (10). This module can be fixed to the movement plate, or, conversely, carried by the watchcase independently of said movement, in particular via a casing ring (26). Apart from the coil, all of the rest of the electronic module (11) is preferably located outside the mechanical movement.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

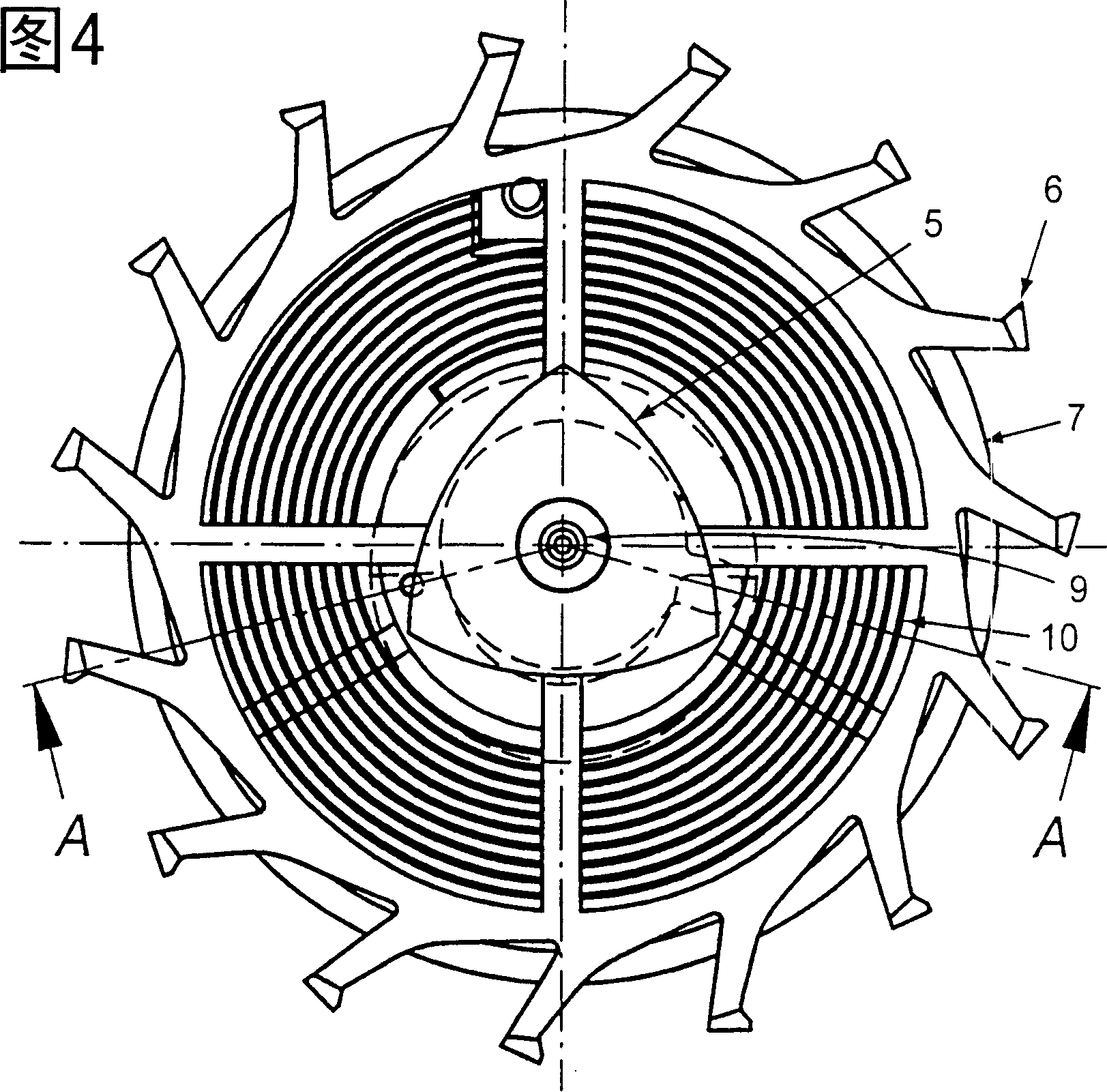

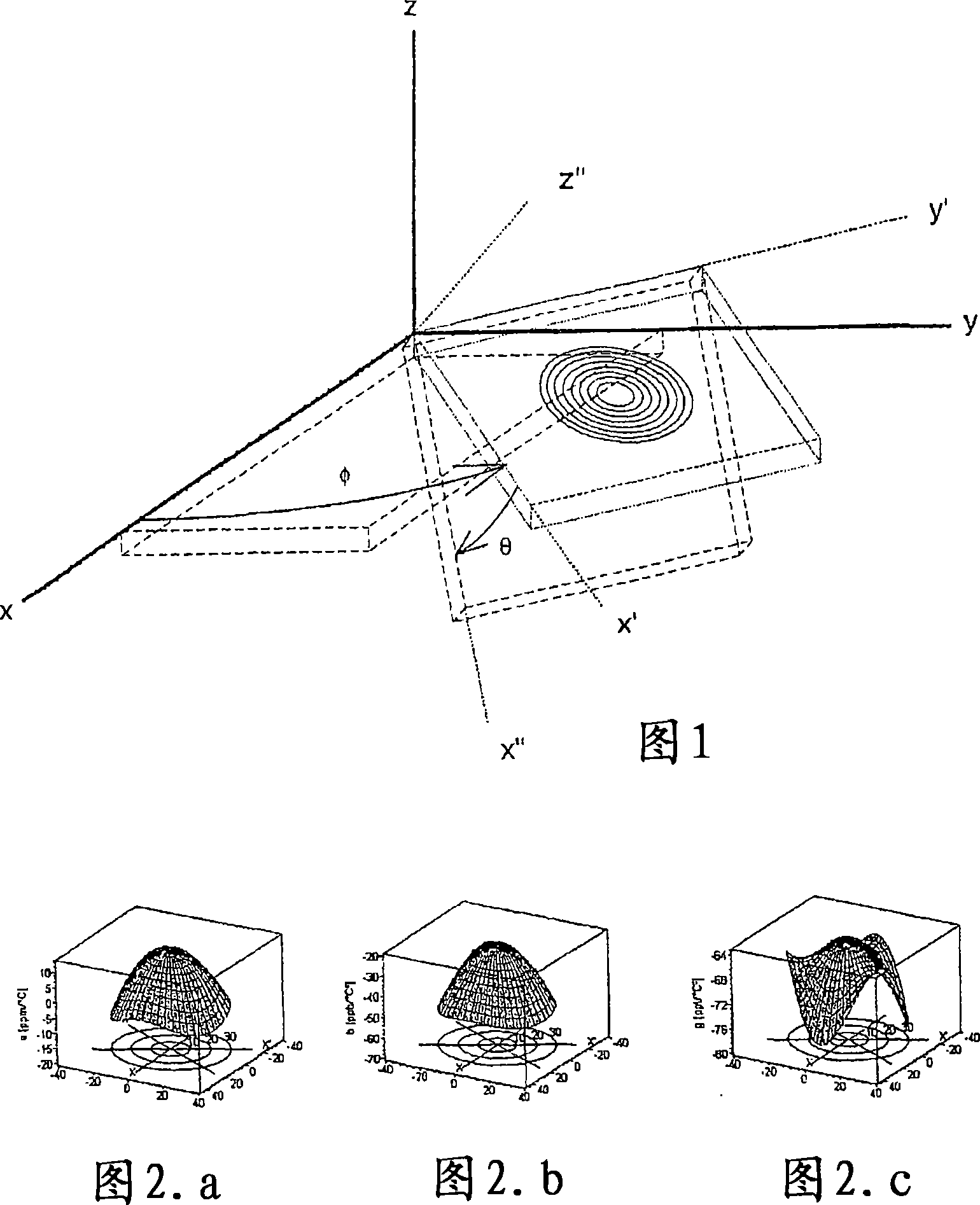

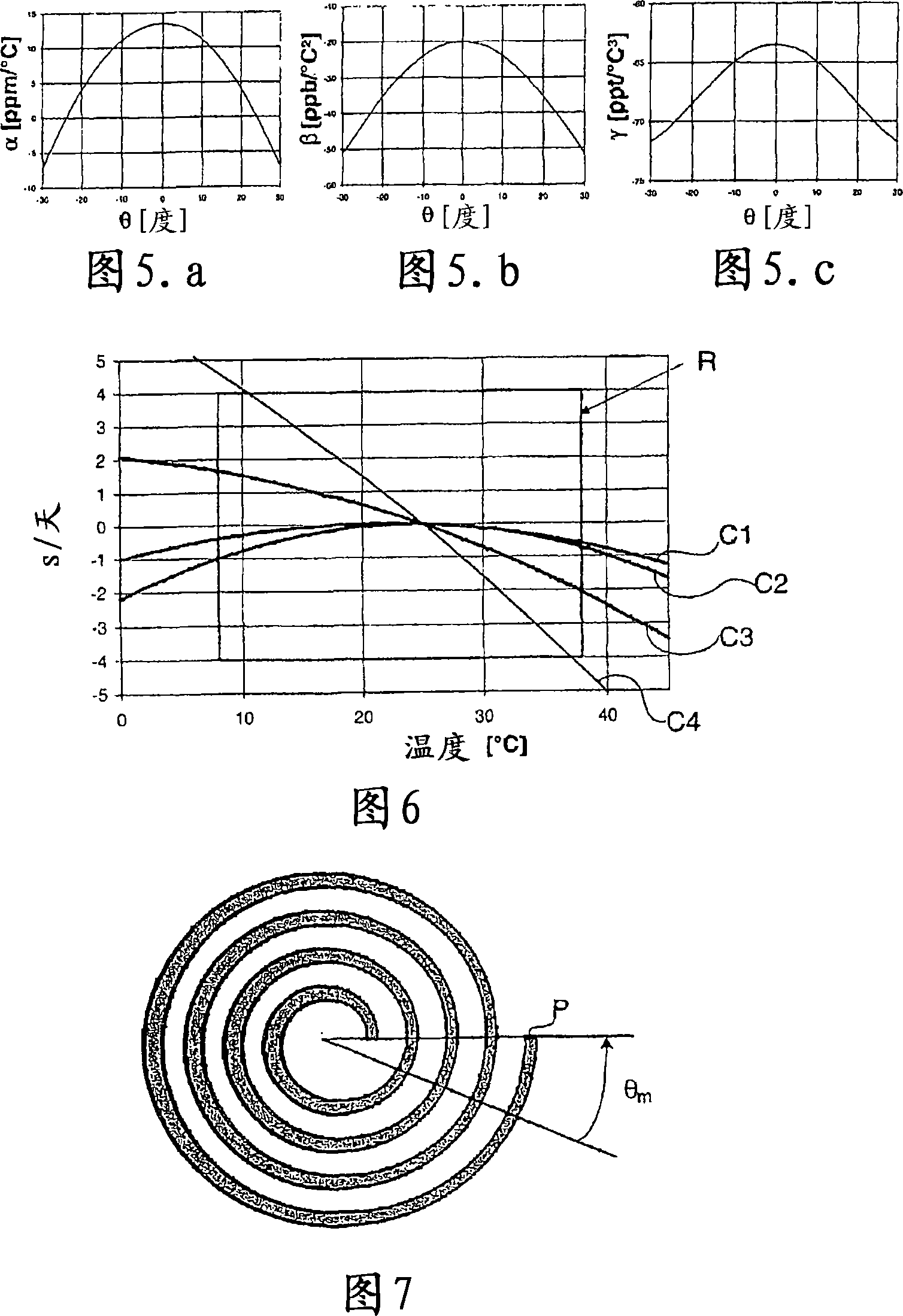

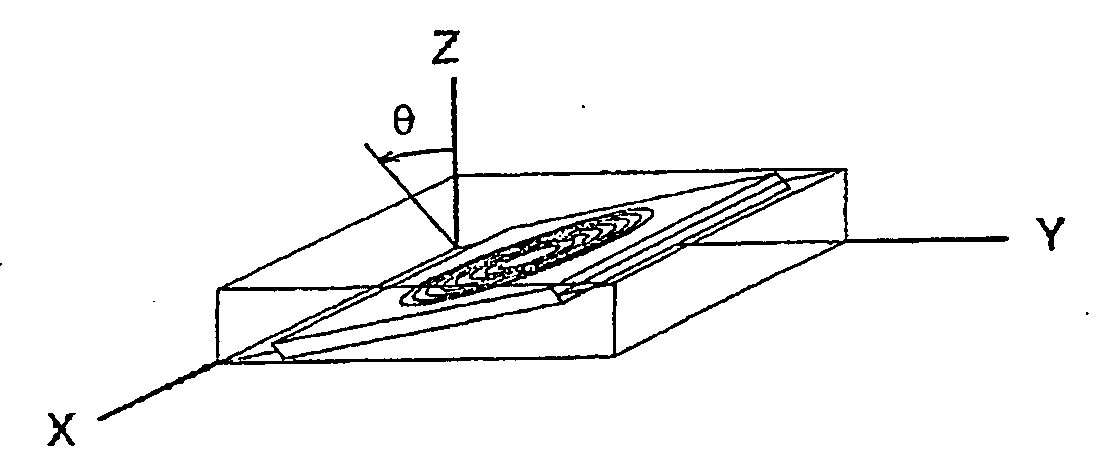

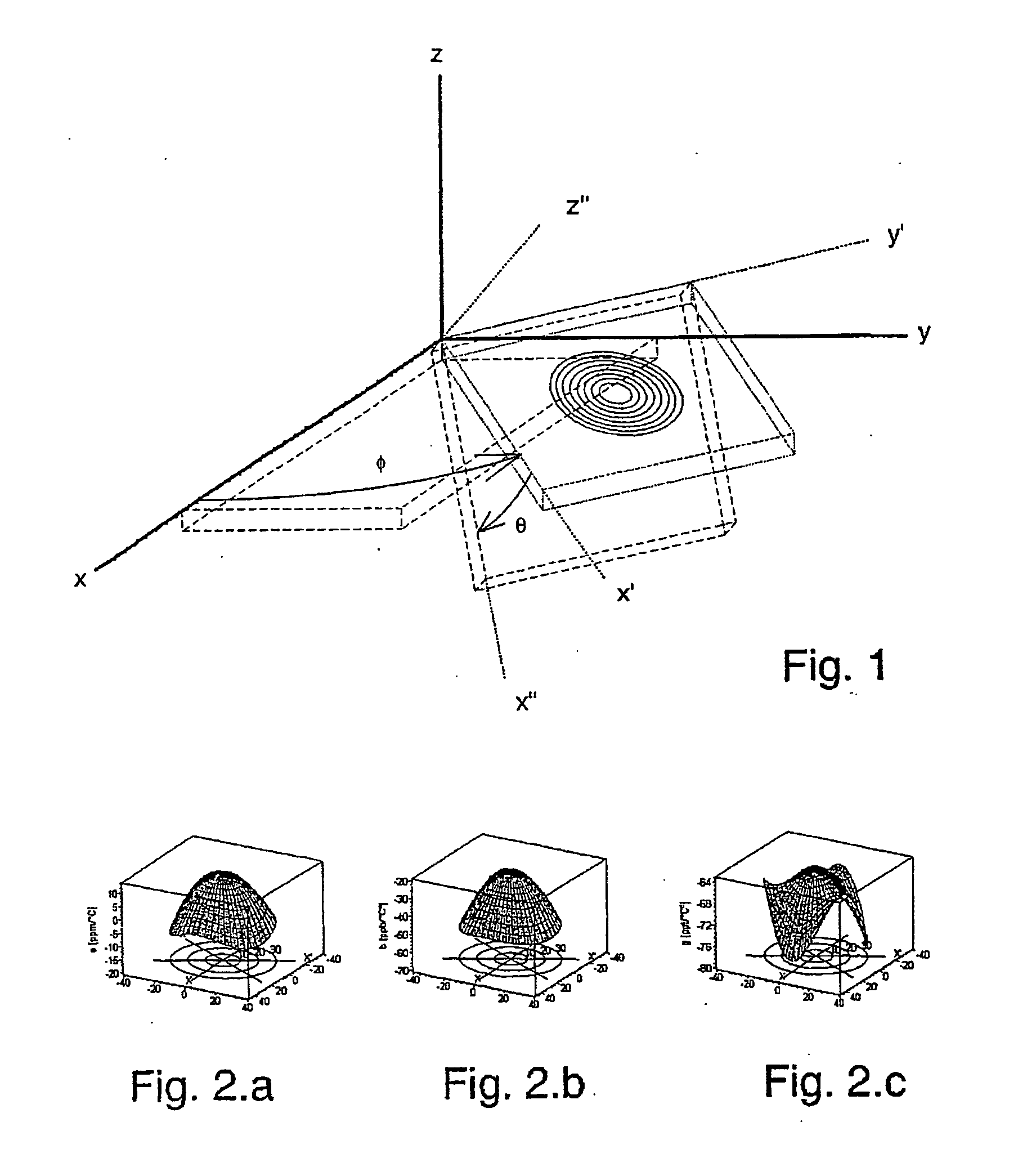

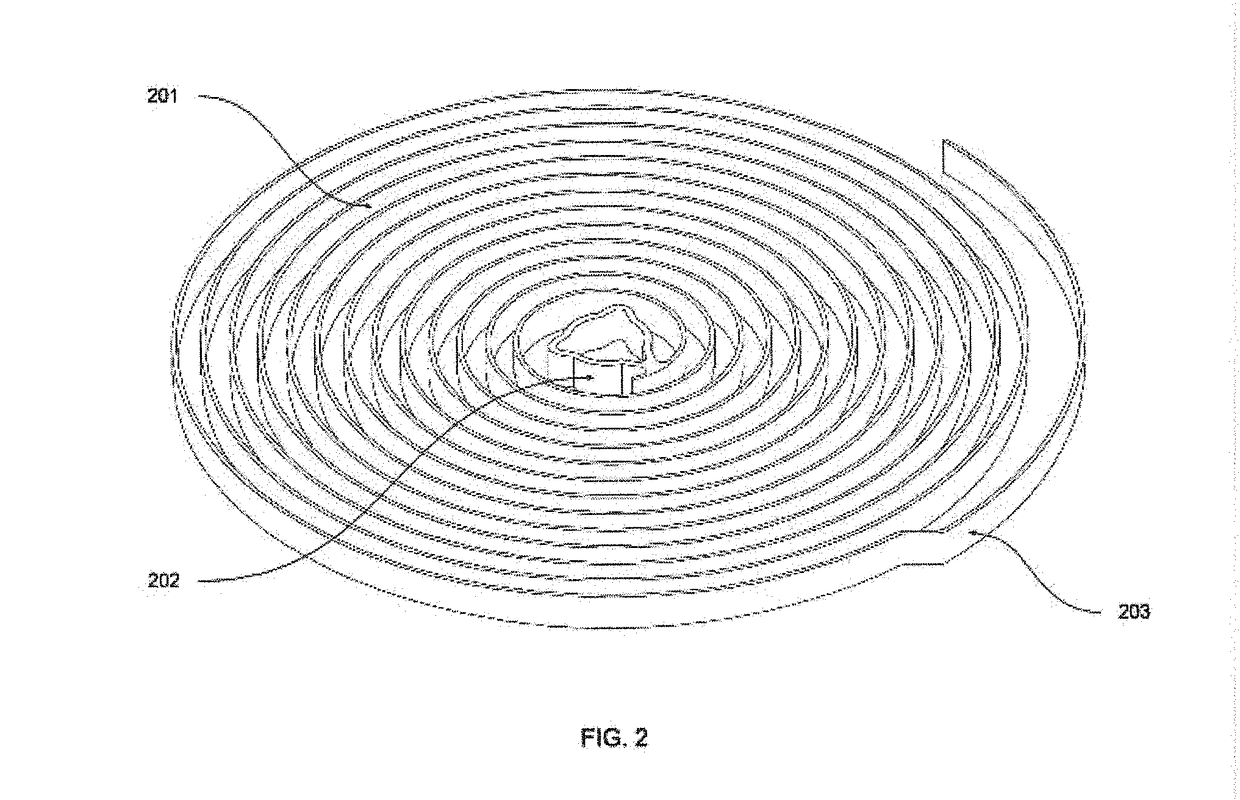

Temperature-compensated balance wheel/hairspring oscillator

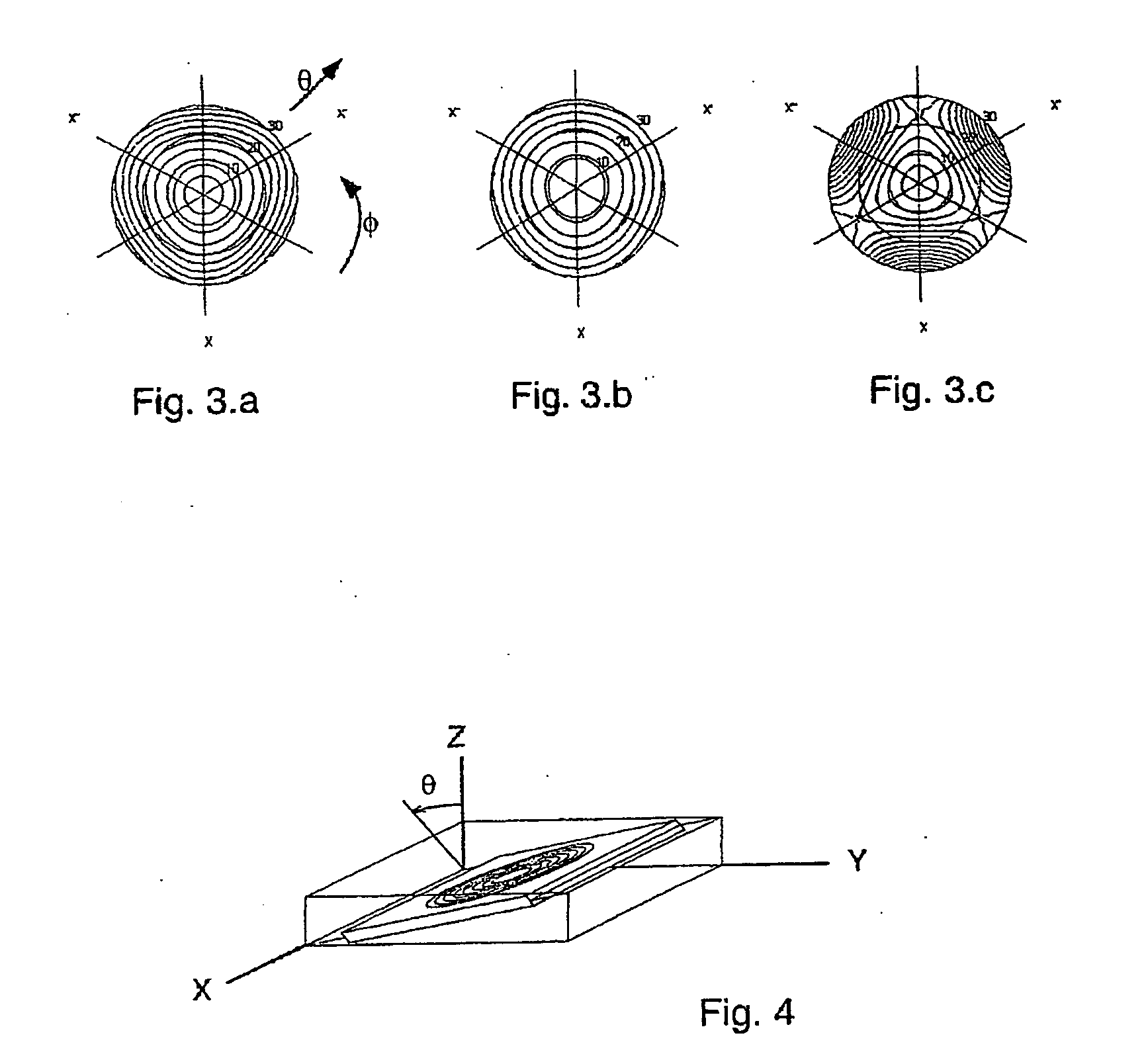

ActiveUS7682068B2Assembly is smallFrequency stabilisation mechanismWound springsEngineeringDouble rotation

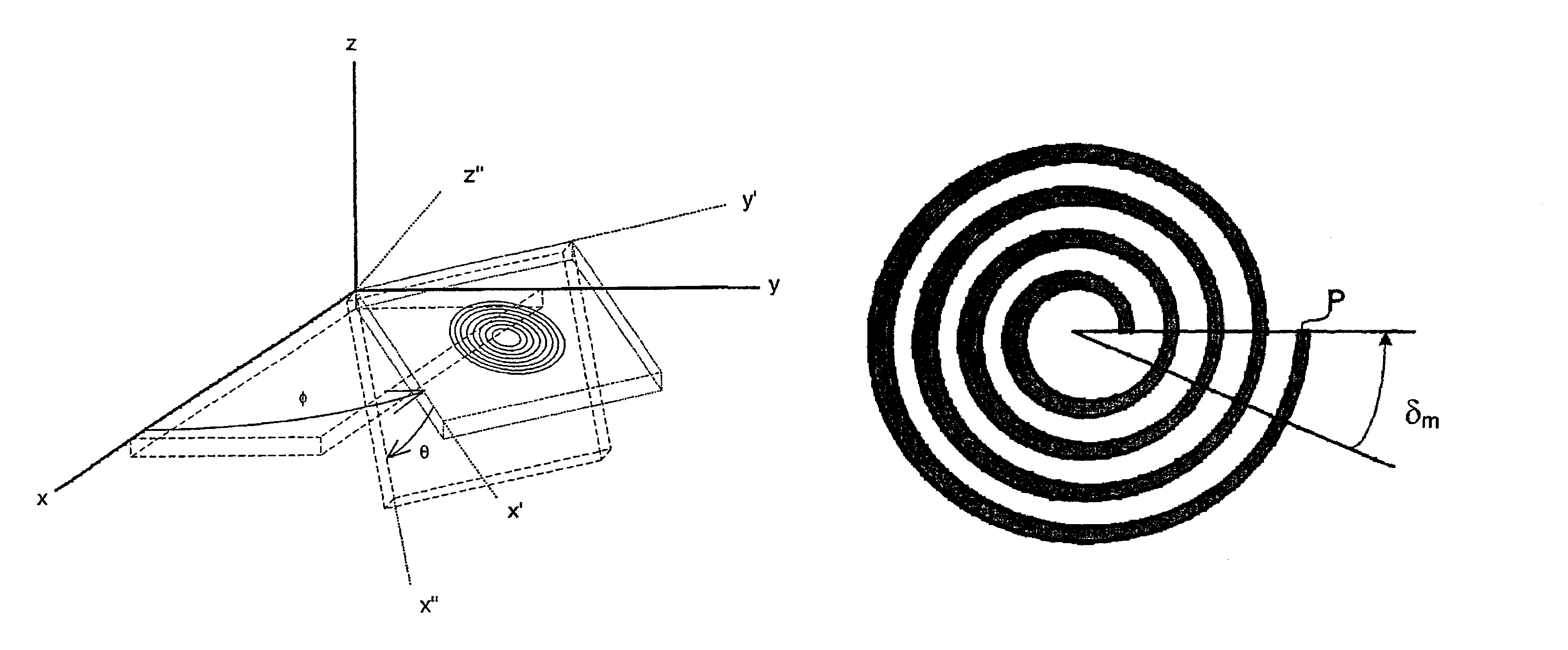

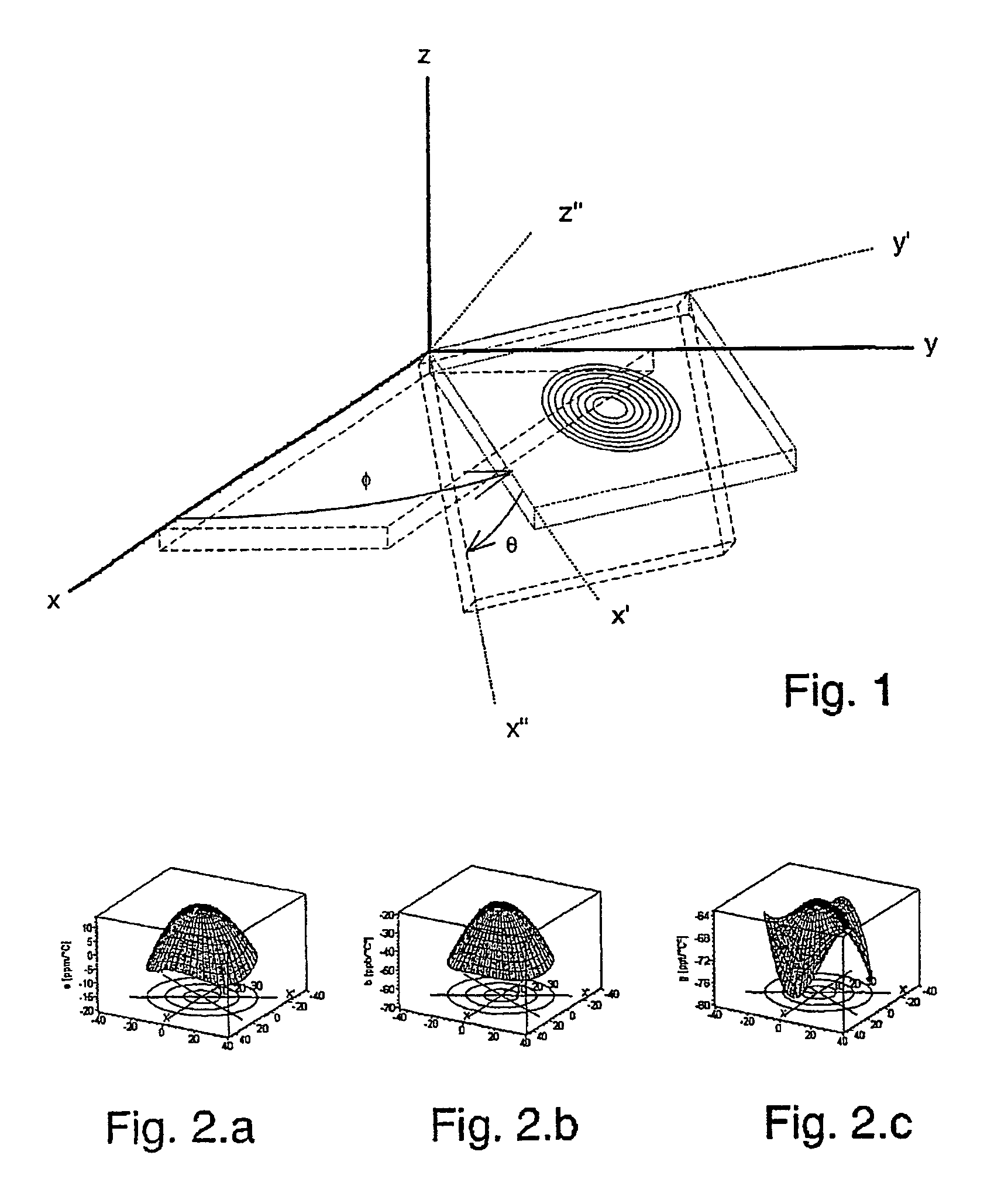

The invention relates to mechanical watch oscillators comprising an assembly consisting of a spiral and a temperature compensated balance. The spiral is embodied in a quartz substrate whose section is selected in such a way that the drifts of the spiral and of the balance associated therewith are thermally compensated. The substrate section can be embodied in the form of a section of single or double rotation.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

Pointer type intelligent watch and display method thereof

ActiveCN105159046ARealize touch display functionVisual indicationElectric indicationComputer moduleEngineering

The invention provides a pointer type intelligent watch and a display method thereof. The intelligent watch includes a cover, a watchcase, a movement layer, a watchband, a transparent display element, a control module, and a transparent solar element, the cover includes a touch control induction unit, an inner cavity is formed by the watchcase and the cover, a hour hand and a minute hand rotate in the inner cavity, the movement layer is arranged at the bottom of the watchcase and is connected with the hour hand and the minute hand to supply power to make the hour hand and the minute hand rotate in the inner cavity, the watchband is connected with two opposite ends of the watchcase, the transparent display element is arranged in the inner cavity and on the movement layer and is provided with rotating shaft holes for the rotating shafts of the hour hand and the minute hand to pass through, the control module is configured to control the work state of the transparent display element, and the transparent solar element is arranged in the inner cavity and on the movement layer and is coupled to the battery of the pointer type intelligent watch. According to the invention, a touch control display function is realized on a pointer type mechanical watch, and a conventional mechanical watch and an intelligent watch are integrated.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

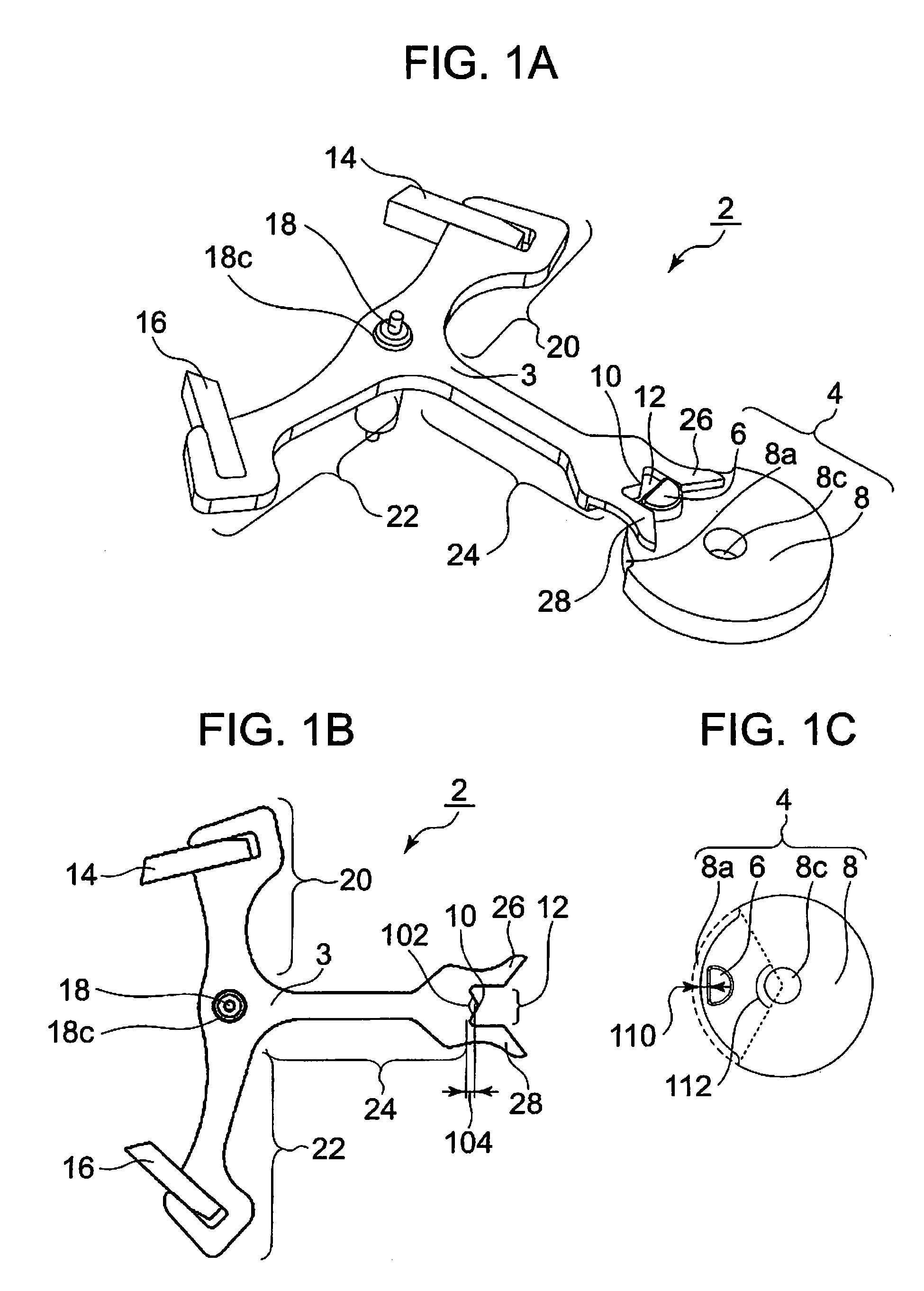

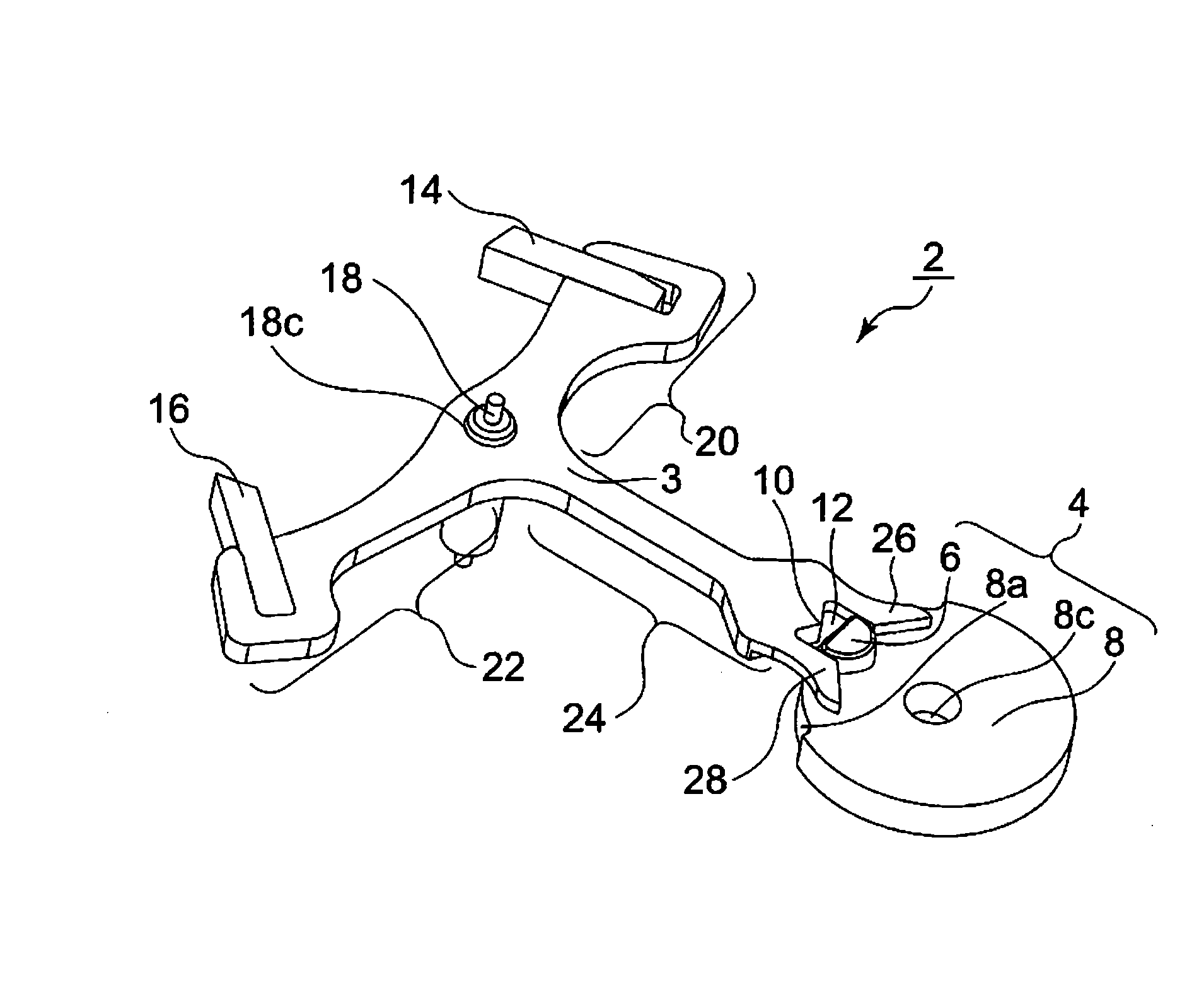

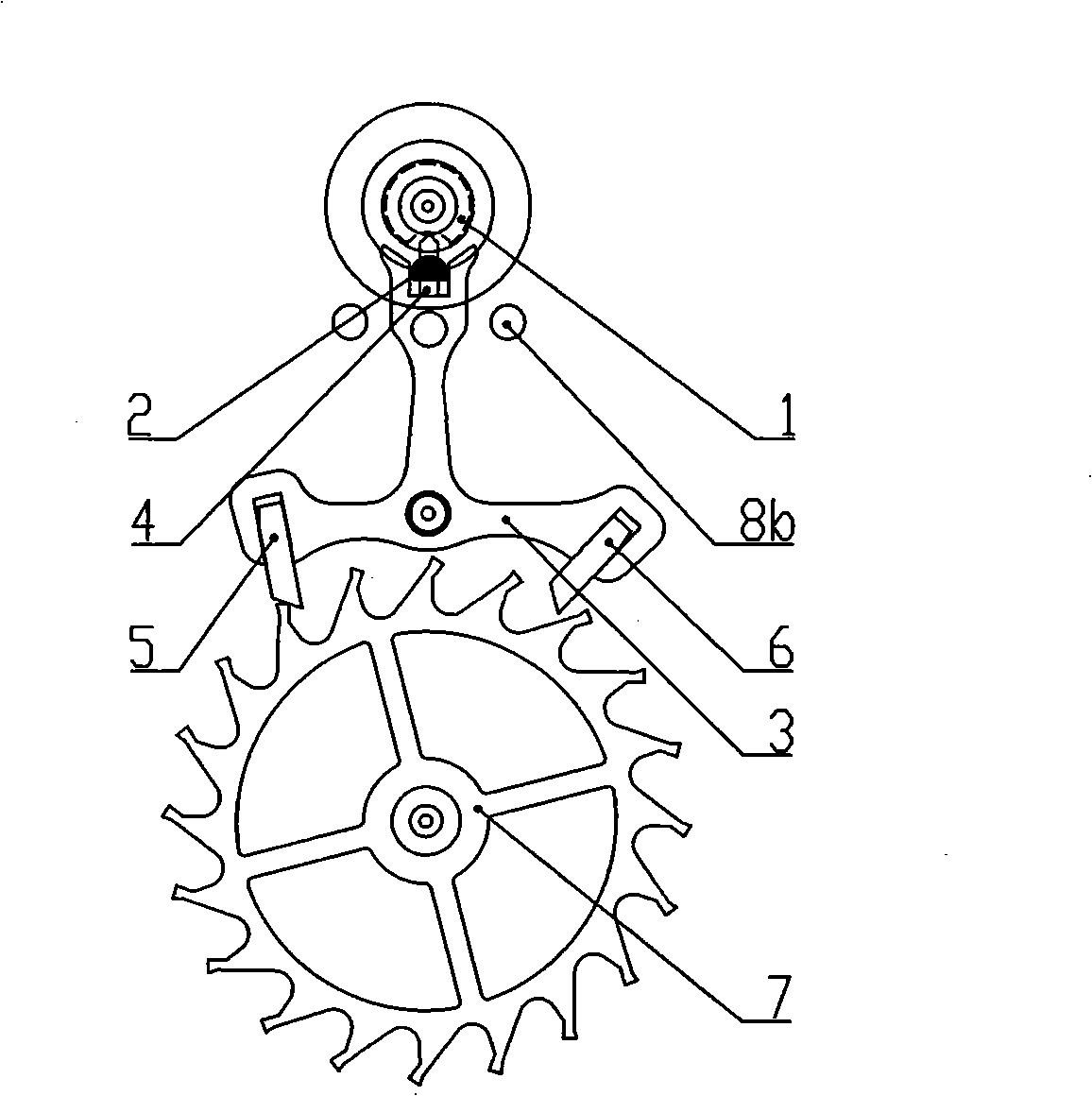

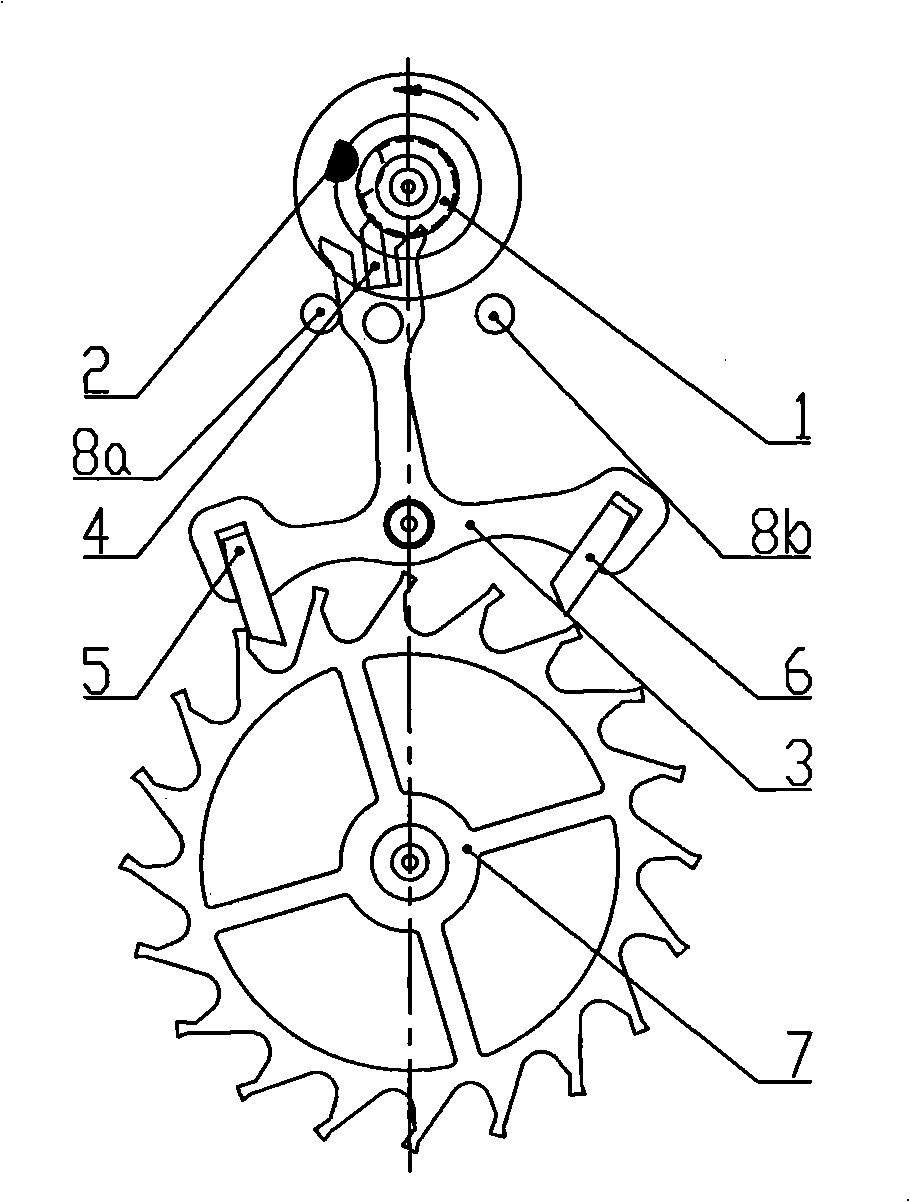

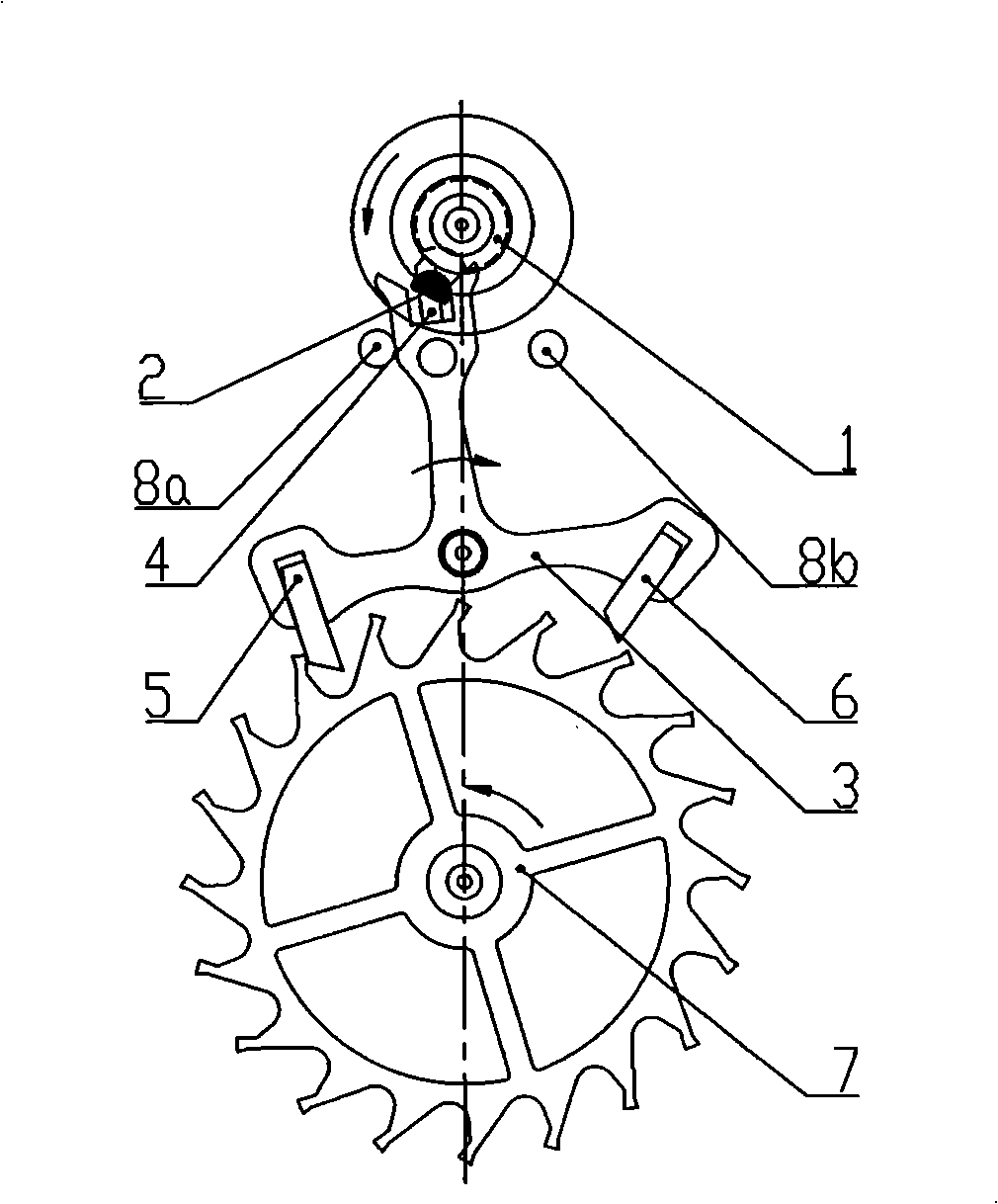

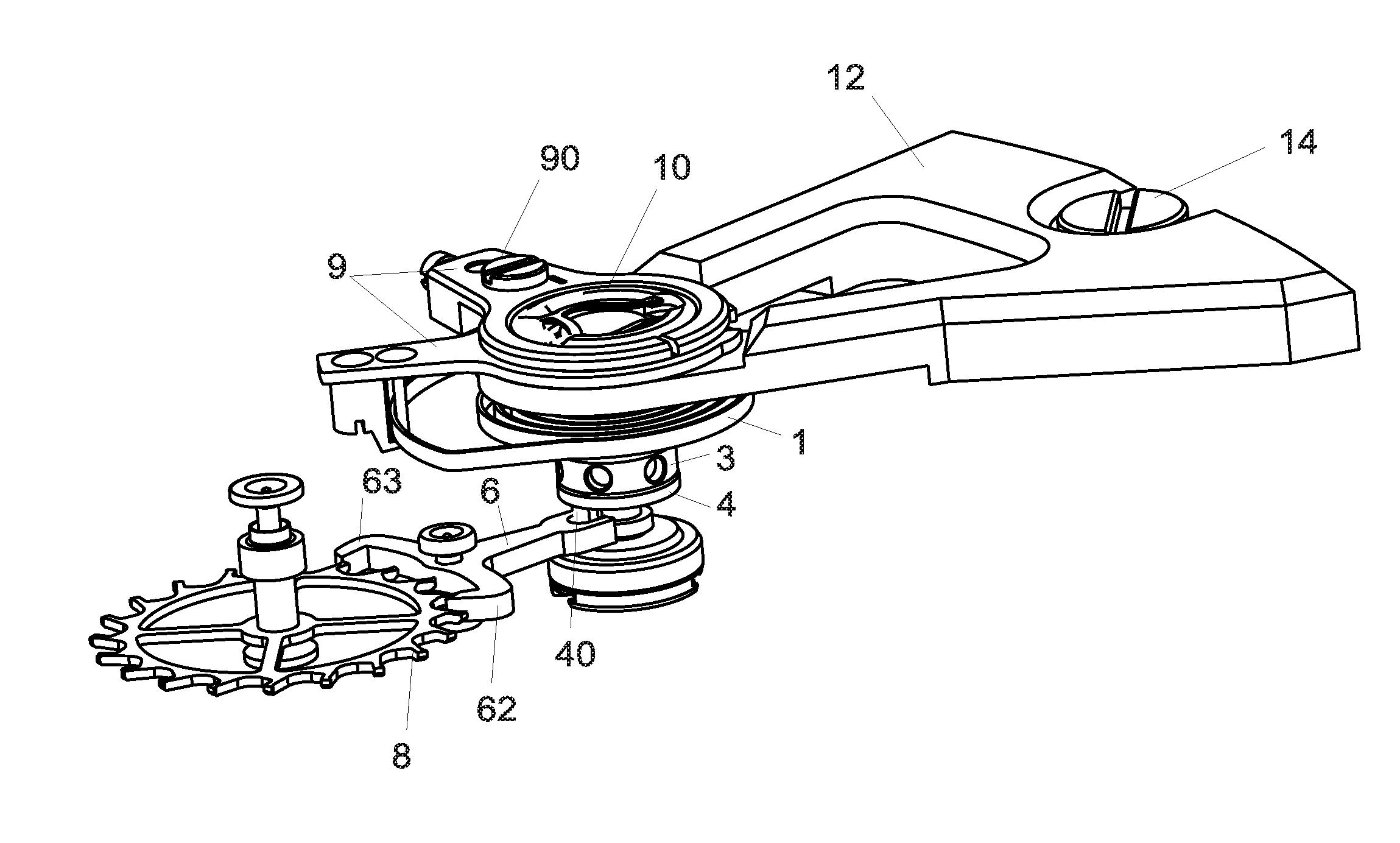

Escapement governor, mechanical watch, pallet fork (incomplete) manufacturing method, and roller manufacturing method

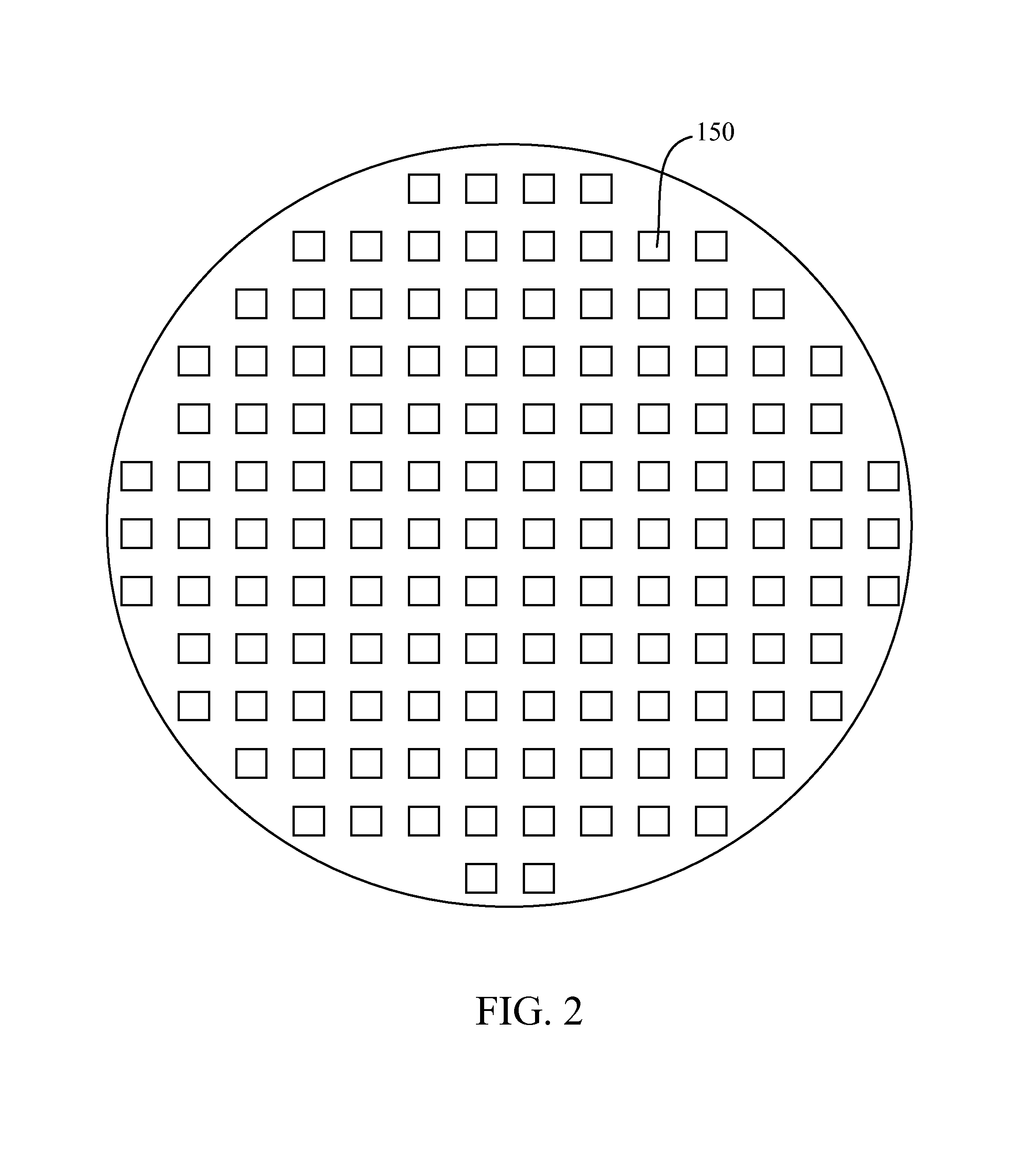

ActiveUS20100208555A1Improve accuracyReduce thicknessEscapementsPhotomechanical exposure apparatusMechanical watchCounter rotation

Disclosed are an integrally molded type pallet fork (incomplete) with a safety pin and a roller table that are formed with high precision by a simple process, a thin escapement governor including the pallet fork (complete) and the roller table, and a method of manufacturing the pallet fork (complete) and the roller table. The pallet fork (complete) of the escapement governor includes a pair of entry horn and exit horn extending from the rotation axis of the pallet fork (complete) toward the rotation axis of a balance with hairspring and adapted to transmit the power of an escape wheel to an impulse pin; and a safety pin which is provided in a side surface of the pallet fork (complete) between the pair of entry horn and exit horn, which extends from the rotation axis of the pallet fork (complete) toward the rotation axis of the balance with hairspring, which is situated at a position nearer to the rotation axis of the pallet fork (complete) than the pair of entry horn and exit horn, which enters a passing hollow to thereby cause the pallet fork (complete) to make normal rotation or reverse rotation with respect to the rotation axis of the pallet fork (complete), and which abuts a portion of a roller other than the passing hollow to thereby prevent erroneous rotation of the pallet fork (complete); and the roller is formed in a single layer.

Owner:SEIKO INSTR INC

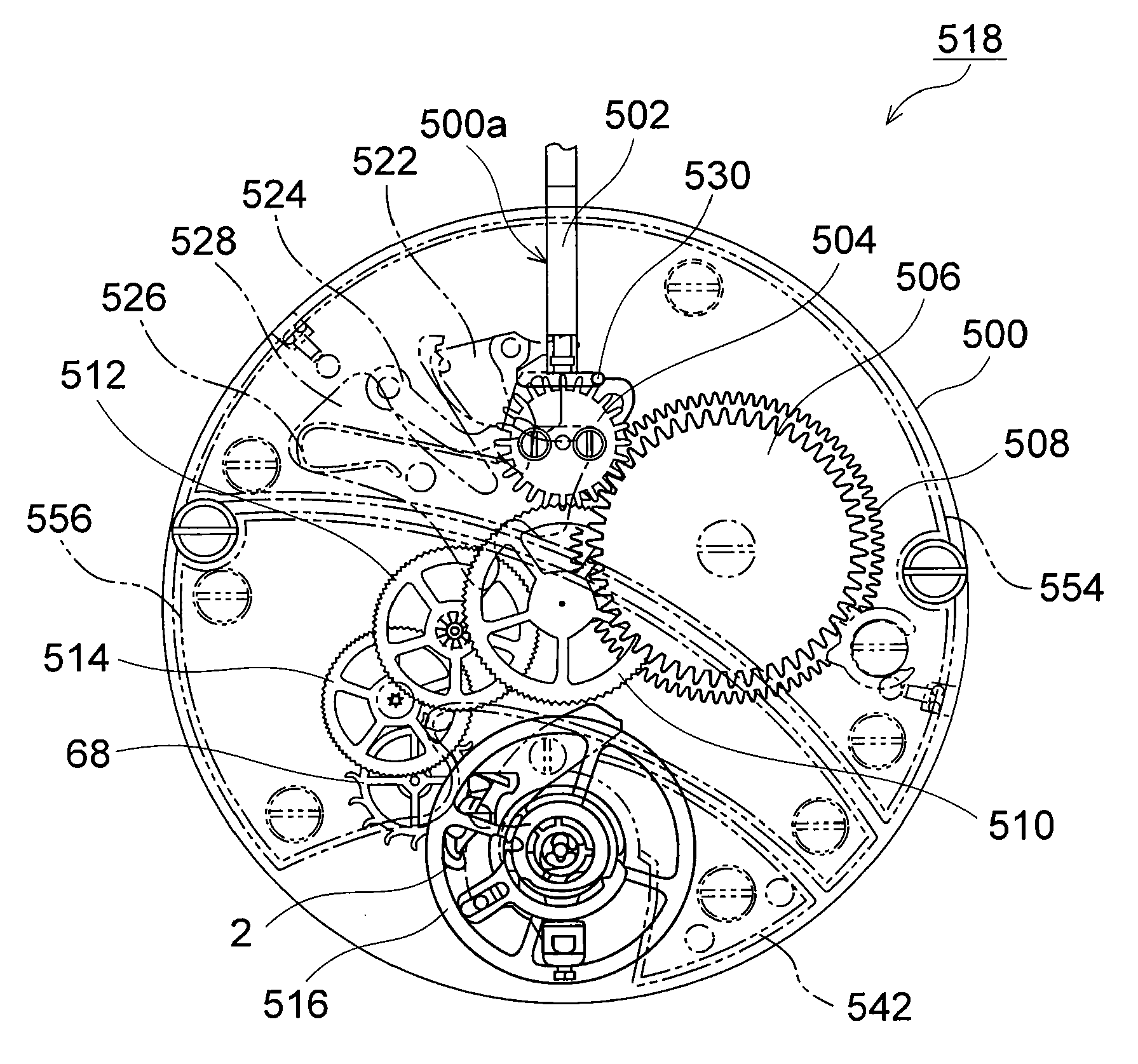

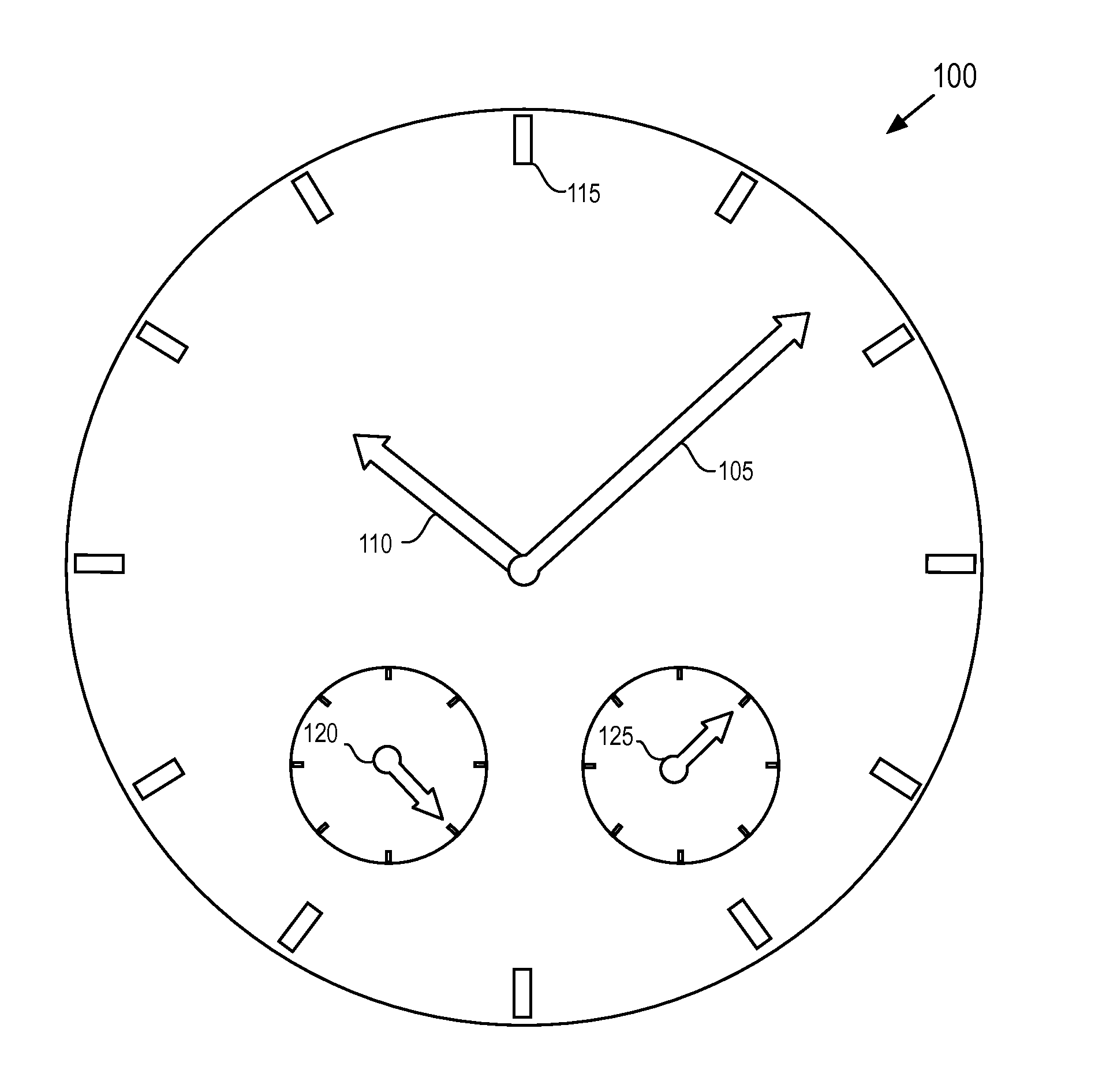

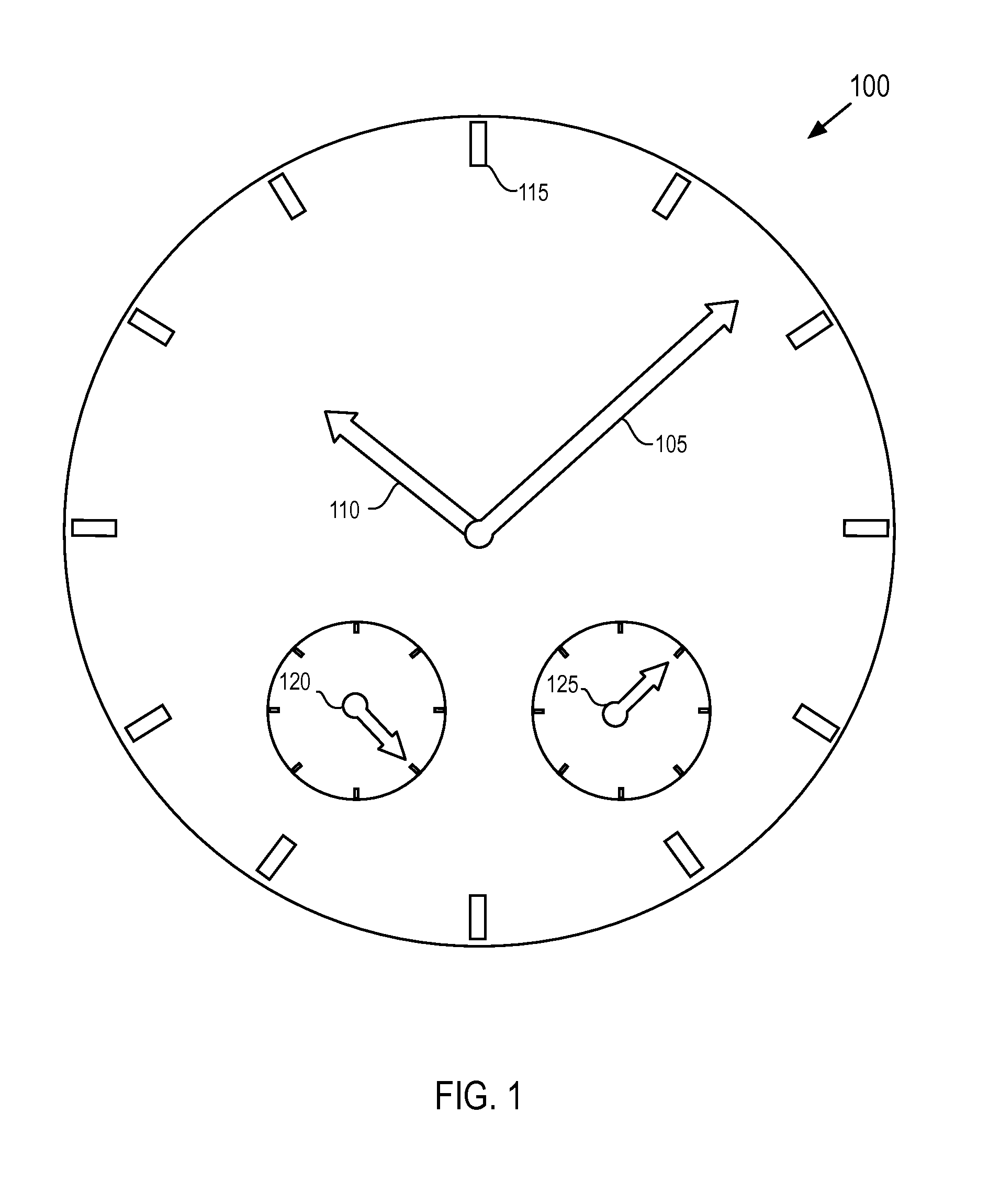

Self-winding mechanical watch with activity tracking

An exemplary mechanical watch has a face including an indicator of current time and one or more indicators of physical activity of a wearer of the mechanical watch. The watch further includes a mainspring to store energy and transfer the energy to a balance wheel and gear train to measure the passage of time, a rotor to rotate about a pivot point in response to movements of a wrist of the wearer of the mechanical watch, a rotor gear coupled to the rotor, and an activity-tracking wheel coupled to one of the one or more indicators of physical activity. Movement of the rotor causes the rotor gear to translate the movement of the rotor into winding of the mainspring and into an indication of physical activity of a wearer of the mechanical watch by causing or controlling rotation of the activity-tracking wheel.

Owner:DP TECH

Constant-force device

A constant-force device for precise regulation of mechanical watch movements by means of a uniform transmission of force from the escape wheel to the regulating organ of the watch, this device being adapted to be integrated into a Tourbillon mechanism.

Owner:RICHEMONT INT

Constant force device

The present invention relates to a constant-force device for precise regulation of mechanical watch movements by means of a uniform transmission of force from the escape wheel to the regulating organ of the watch, this device being adapted to be integrated into a Tourbillon mechanism.

Owner:瑞士维拉尔苏尔格拉讷

Wristwatch with electronic display

ActiveUS8588033B2Reduce manufacturing costImprove accuracyVisual indicationElectric indicationAccelerometerSimulation

Method for displaying the time in a wristwatch furnished with an electronic display (4) allowing the display of a simulated mechanical watch movement and of time indicators (20) so as to simulate a mechanical watch. The time displayed is advantageously calculated on the basis of the simulation of the movement and depends on the acceleration measured by an accelerometer.

Owner:SLYDE ANALYTICS LLC

Temperature compensated balance wheel/hairspring oscillator

ActiveCN1985103ACompensation for thermal driftFrequency stabilisation mechanismWound springsEngineeringDouble rotation

The invention relates to mechanical watch oscillators comprising an assembly consisting of a spiral and a temperature compensated balance. Said spiral is embodied in a quartz substrate whose section is selected in such a way that the drifts of the spiral and of the balance associated therewith are thermally compensated. The substrate section can be embodied in the form of a section of single or double rotation. Said invention is used for horology.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

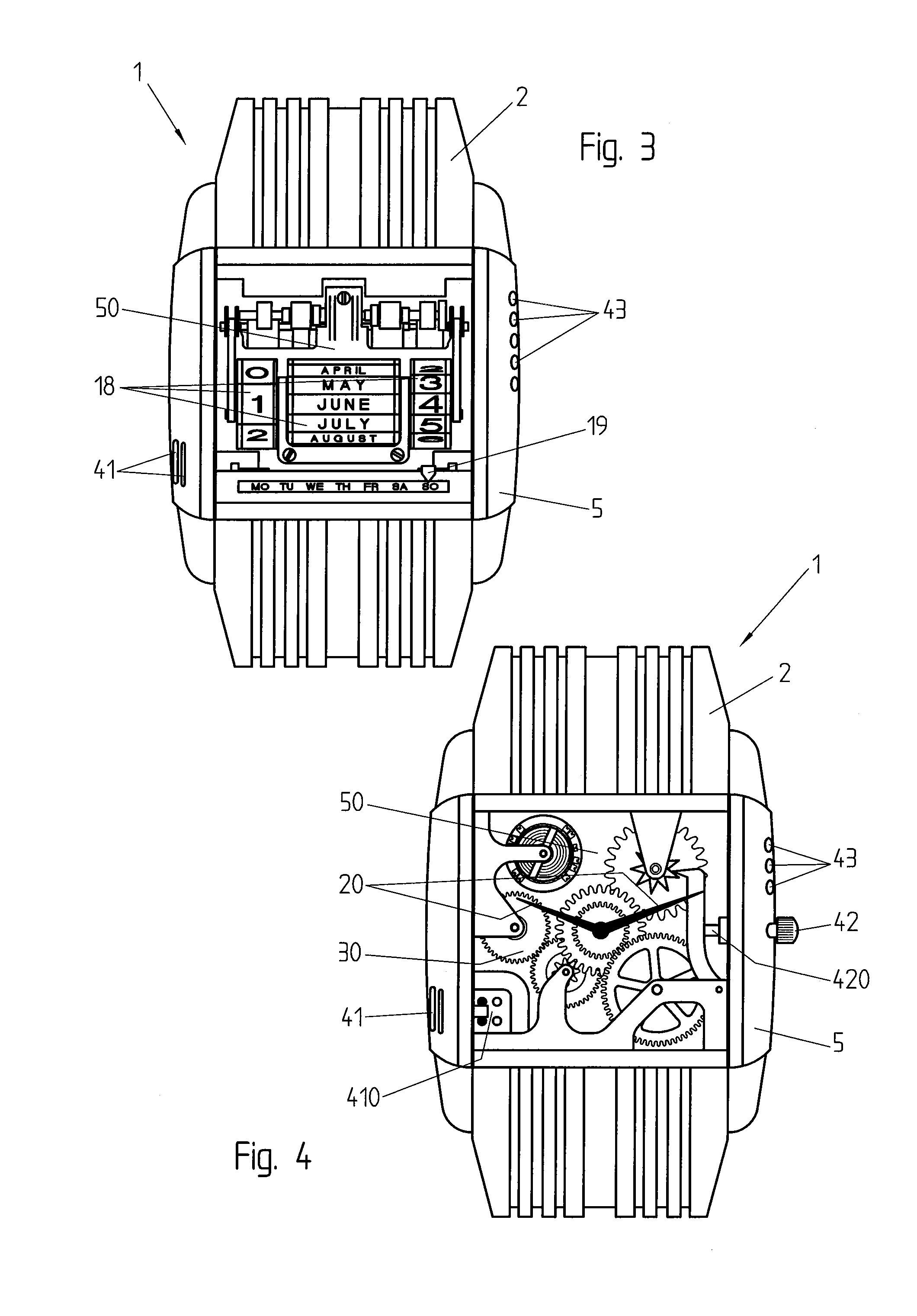

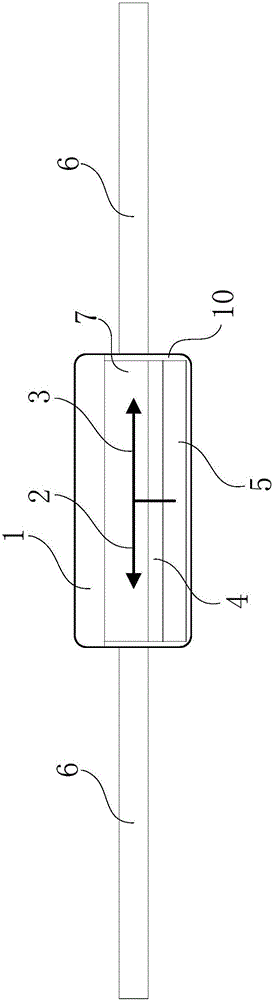

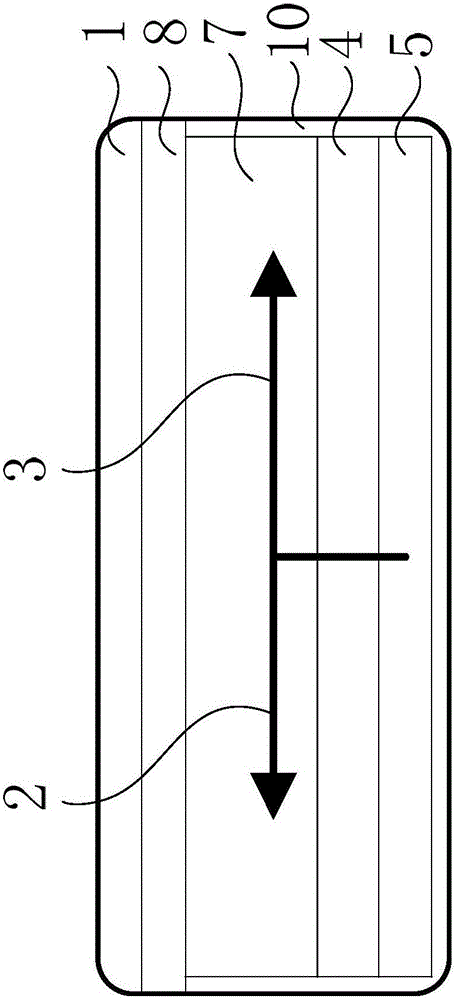

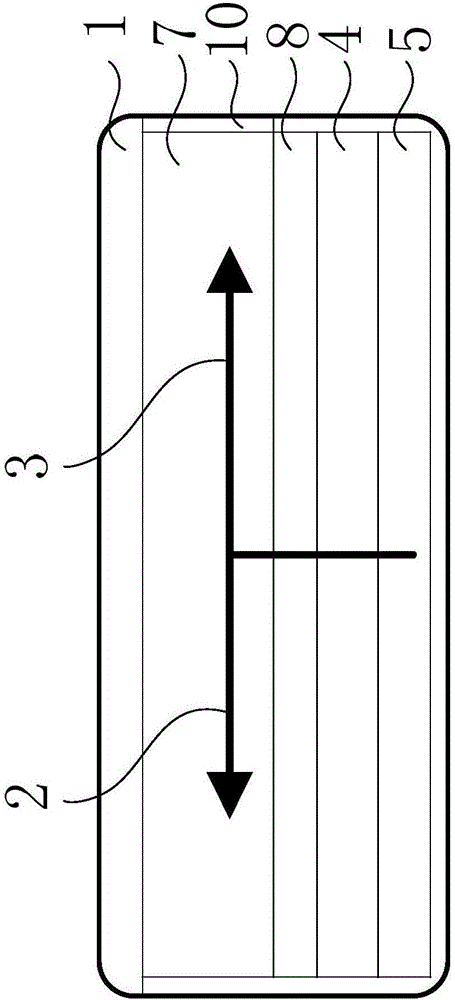

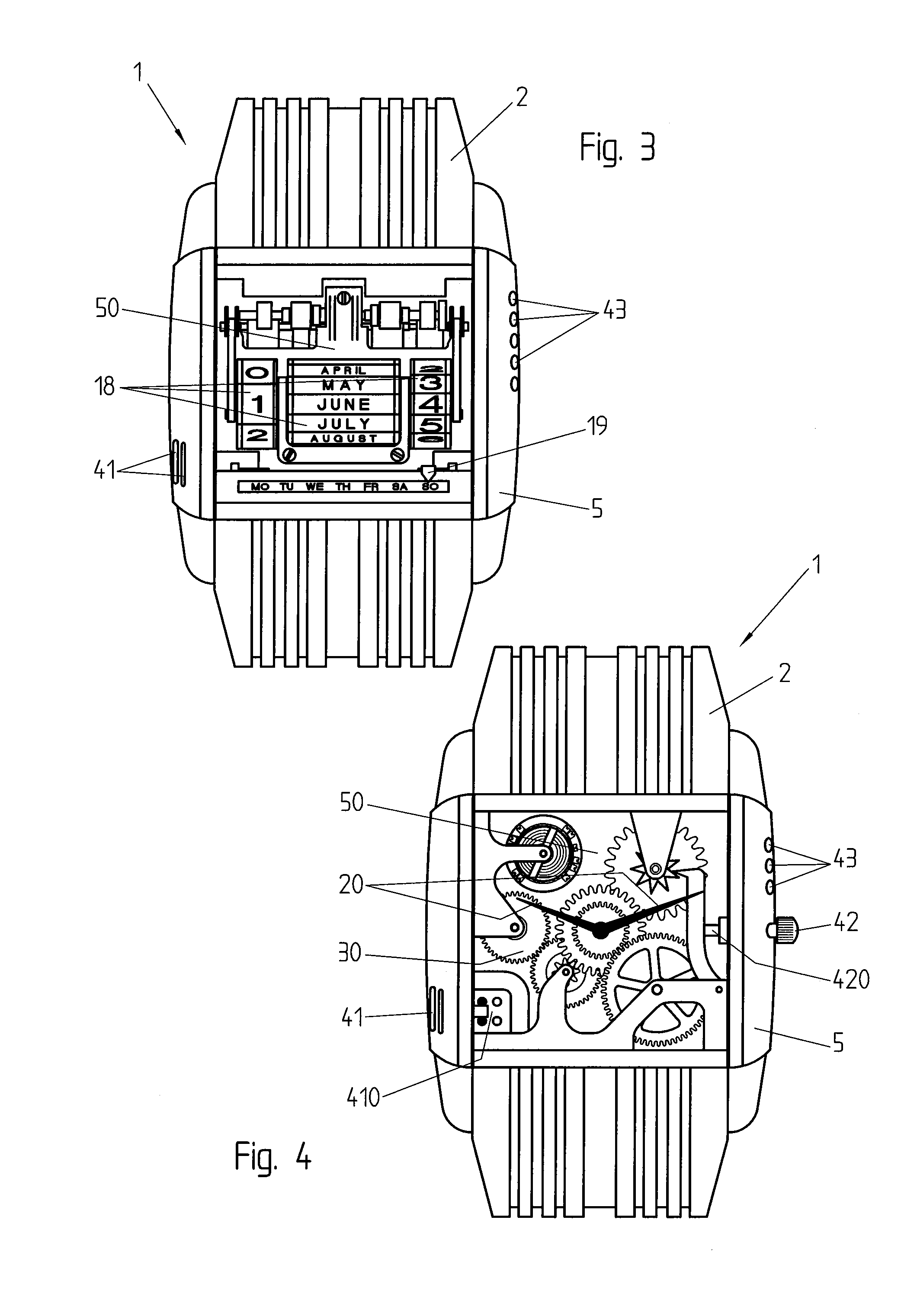

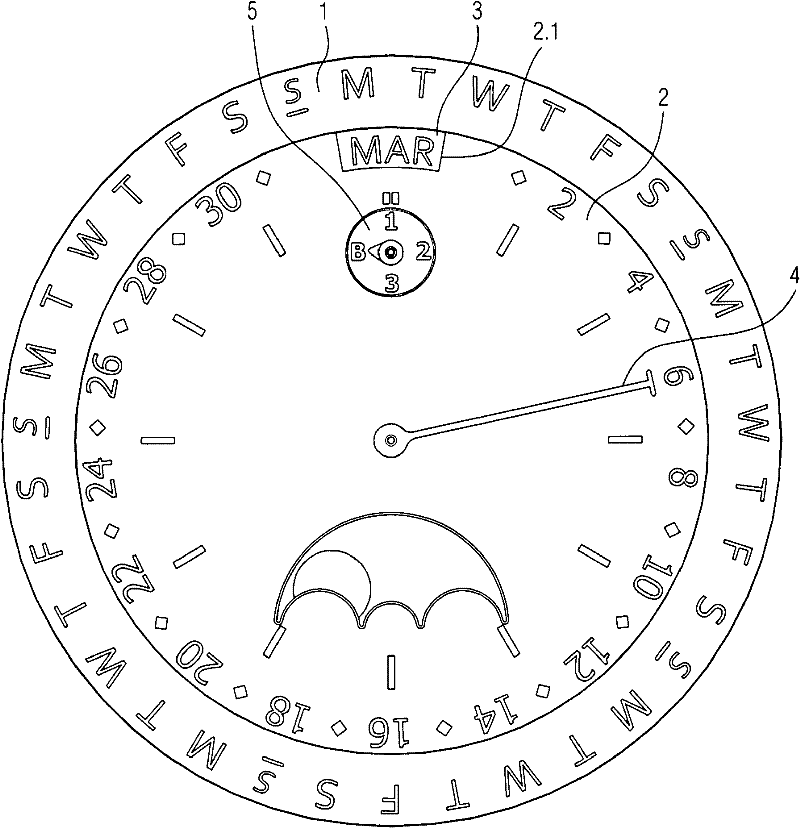

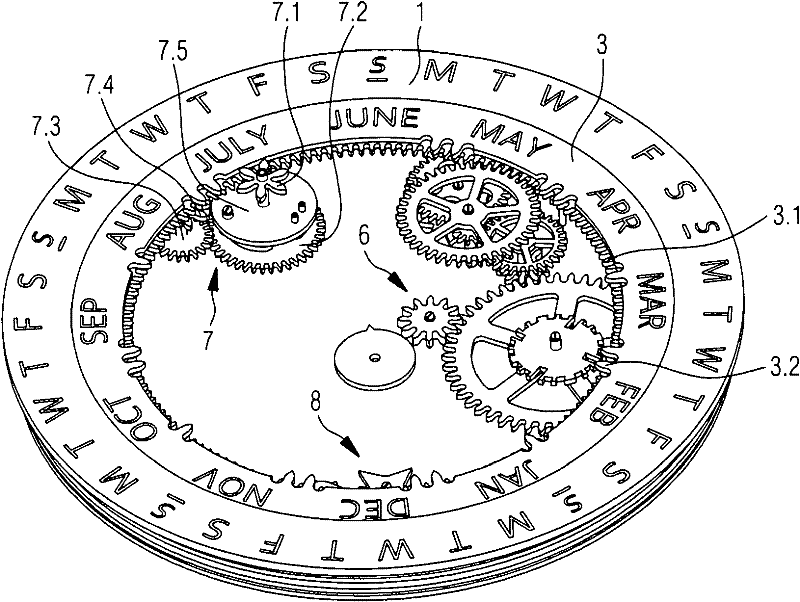

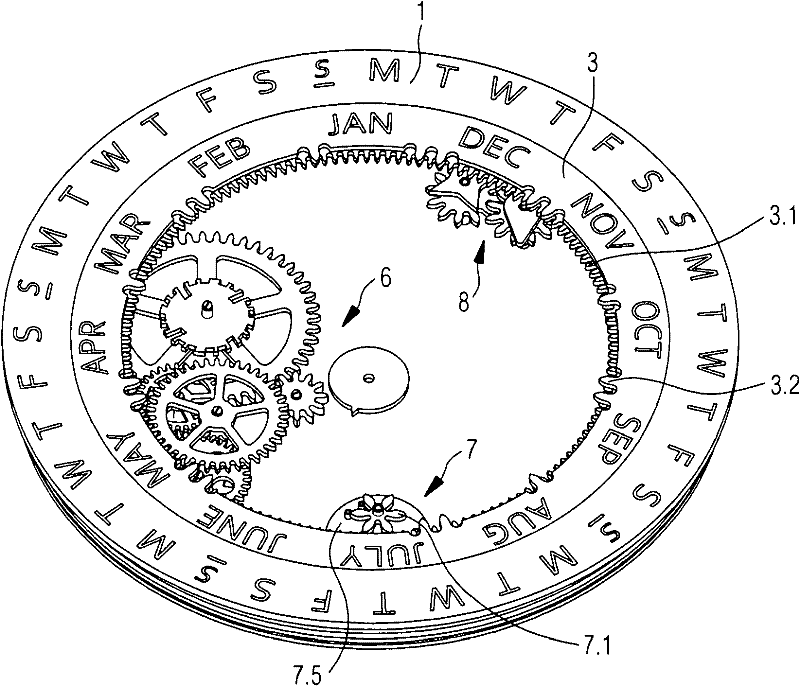

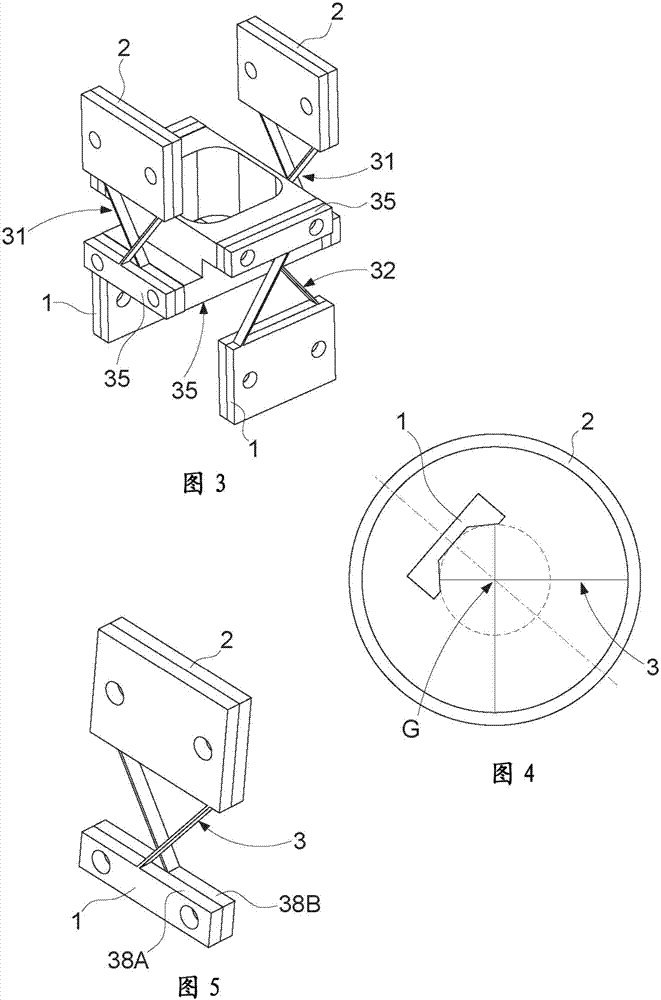

Calendar display device and calendar watch

ActiveCN102467076AAvoid disadvantagesNo added complexityVisual indicationAutomatic indexingDisplay device

The present invention relates to a calendar display device, especially relates to a calendar display device for a mechanical watch piece, including: a first disk (1), the disk of days, carrying multiple series of inscriptions symbolizing the seven days of the week; a second disk (2), the disk of dates, carrying inscriptions symbolizing the date of the month; a third disk (3), the disk of months, carrying 12 inscriptions symbolizing the months of the year. One (1, 2) of the disk of days (1) and the disk of dates (2) acts as a dial by being fixed, whereas the other (2, 1) acts as a rotary disk by being arranged concentrically and rotatably in relation to the dial. The dial includes an aperture (2.1) making it possible to see the inscription of the current month on the disk of months (3) which is mounted rotatably and is driven, either directly or indirectly, by a watch movement of said watch piece; a hand (4) placed concentrically and rotatably in relation to said dial so as to indicate simultaneously a date and a day of the week; a direct kinematic link (7, 8) between the disk of months (3) and the rotary disk (1, 2) to realize automatic indexing between the inscriptions on the rotary disk (1, 2) and the inscriptions on the rotary disk (2, 1) according to the displayed month; and a correction mechanism (9, 10) comprising equipment configured to advance and reverse the disk of months (3) so as to allow modification of the month displayed on the dial (1, 2) in a bidirectional manner. The present invention also relates to a watch piece comprising the calendar display device.

Owner:DE LA MFG DHORLOGERIE AUDEMARS PIGUET & CIE

Escapement governor, mechanical watch, pallet fork (incomplete) manufacturing method, and roller manufacturing method

ActiveUS8591101B2Reduce thicknessReduce the moment of inertia actingEscapementsPhotomechanical apparatusEngineeringMechanical watch

Disclosed are an integrally molded type pallet fork (incomplete) with a safety pin and a roller table that are formed with high precision by a simple process, a thin escapement governor including the pallet fork (complete) and the roller table, and a method of manufacturing the pallet fork (complete) and the roller table. The pallet fork (complete) of the escapement governor includes a pair of entry horn and exit horn extending from the rotation axis of the pallet fork (complete) toward the rotation axis of a balance with hairspring and adapted to transmit the power of an escape wheel to an impulse pin; and a safety pin which is provided in a side surface of the pallet fork (complete) between the pair of entry horn and exit horn, which extends from the rotation axis of the pallet fork (complete) toward the rotation axis of the balance with hairspring, which is situated at a position nearer to the rotation axis of the pallet fork (complete) than the pair of entry horn and exit horn, which enters a passing hollow to thereby cause the pallet fork (complete) to make normal rotation or reverse rotation with respect to the rotation axis of the pallet fork (complete), and which abuts a portion of a roller other than the passing hollow to thereby prevent erroneous rotation of the pallet fork (complete); and the roller is formed in a single layer.

Owner:SEIKO INSTR INC

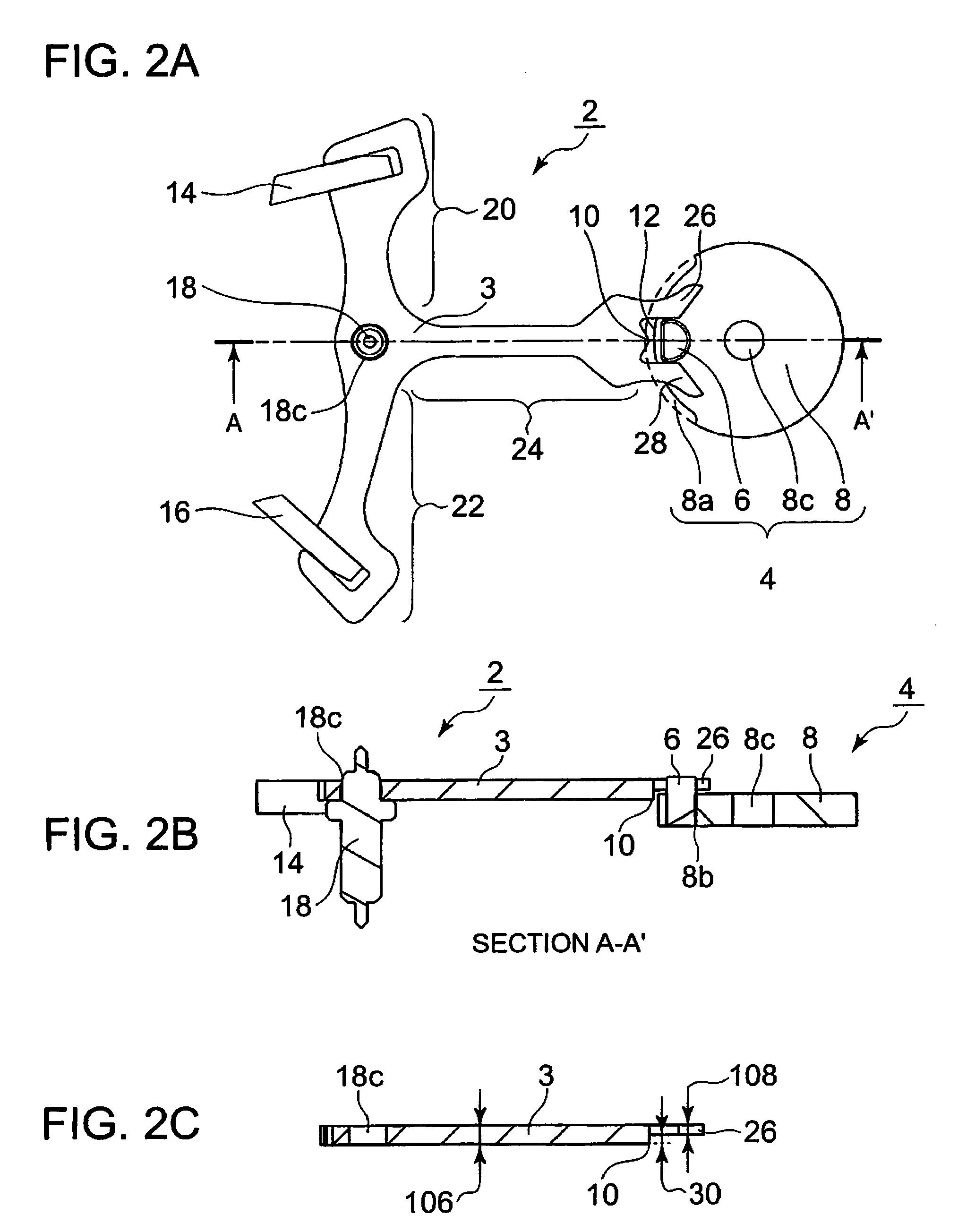

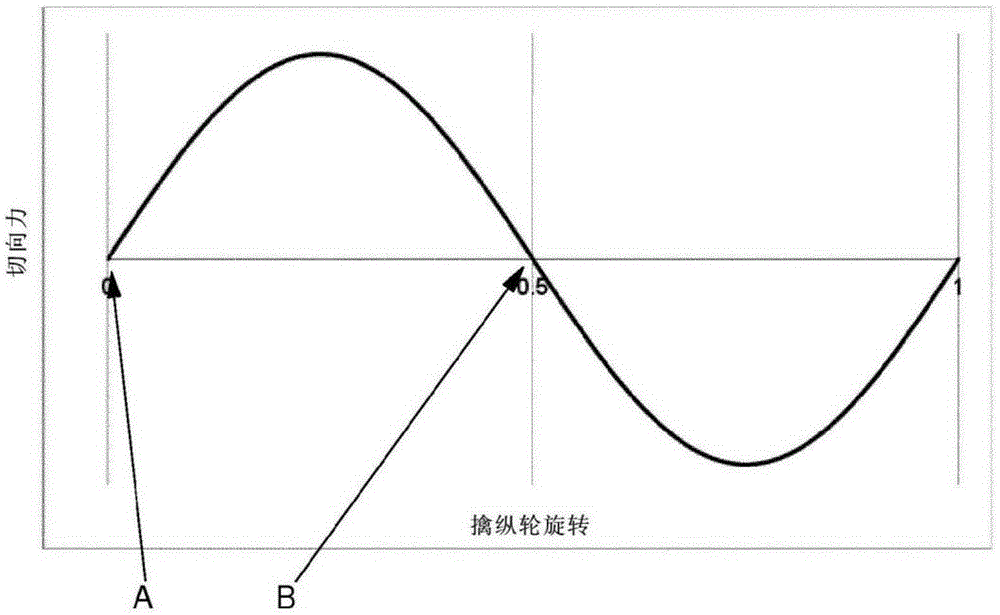

Regulator system for mechanical watch

ActiveCN105264444AImpact resistance ensuredImprove impact resistanceElectric windingTuning forkMechanical watch

The present invention relates to regulator organs for a mechanical timepiece, specifically a system based on the magnetic interaction between a resonator, for example in the form of a tuning fork, and an escapement wheel. The system is characterised in that there are several magnetic interaction zones (25) and (26) between the resonator (14) and the escapement wheel (9) that are arranged such that the torques produced at the escapement wheel by those interactions compensate each other if the escapement wheel is not synchronised with the frequency of the resonator. This results in a negligible torque on the escapement wheel when the latter rotates slowly in the direction of the arrow (24) or in the opposite direction. This makes it possible to start the timepiece at a low torque of the barrel spring and without a launch procedure or device and allows better resistance of the timepiece to withstand a loss of synchronisation in case of impact.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Temperature Compensated Balance-Spiral Oscillator

ActiveUS20080008050A1Assembly is smallEscapementsFrequency stabilisation mechanismDouble rotationMechanical watch

The invention relates to mechanical watch oscillators comprising an assembly consisting of a spinal and a temperature compensated balance. The spiral is embodied in a quartz substrate whose section is selected in such a way that the drifts of the spiral and of the balance associated therewith are thermally compensated. The substrate section can be embodied in the form of a section of single or double rotation.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

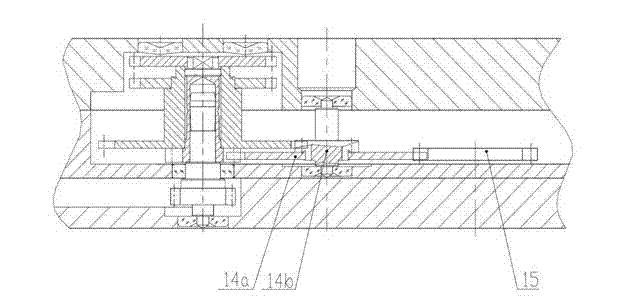

Mechanical wristwatch escapement mechanism

ActiveCN101339402AAvoid mutual interferenceReduce floor space occupiedEscapementsCircular discWhole body

The invention discloses an escapement mechanism of a mechanical watch, which comprises a double disc, a roller jewel, an escapement lever and an escapement wheel, wherein, the roller jewel is fixed on the double disc and is pressed with a pendulum shaft and a balance wheel as a whole body; the escapement lever comprises an escapement lever body, a lever body, a lever washer and a lever position nail; two arm of the escapement lever body are in a shape of 'L', a lever head of which is fixedly provided with the lever position nail; the lever position nail is fixed on the lever head of the lever body; the left lever body and the right lever body of the lever body are fixedly provided with an inlet lever and an outlet lever; the escapement wheel and an escapement gear shaft are riveted as a whole body; the escapement lever body, the lever body, the lever washer, and the lever shaft of a lamination escapement lever are directionally pressed as a whole body with a coaxial rotation by the lever position nail. The escapement mechanism of the mechanical watch has the beneficial effects that: the dual positioning of centering and directioning is used for accurately positioning the escapement lever body and the lever body ; the lever washer can effectively prevent the mutual interference of the lever body and the escapement body; the escapement lever with superposition setting reduces plane space occupied by the escapement mechanism, thus being more convenient for the plane arrangement and meeting design requirements on varying specifications.

Owner:TIANJIN SEAGULL WATCH CO LTD

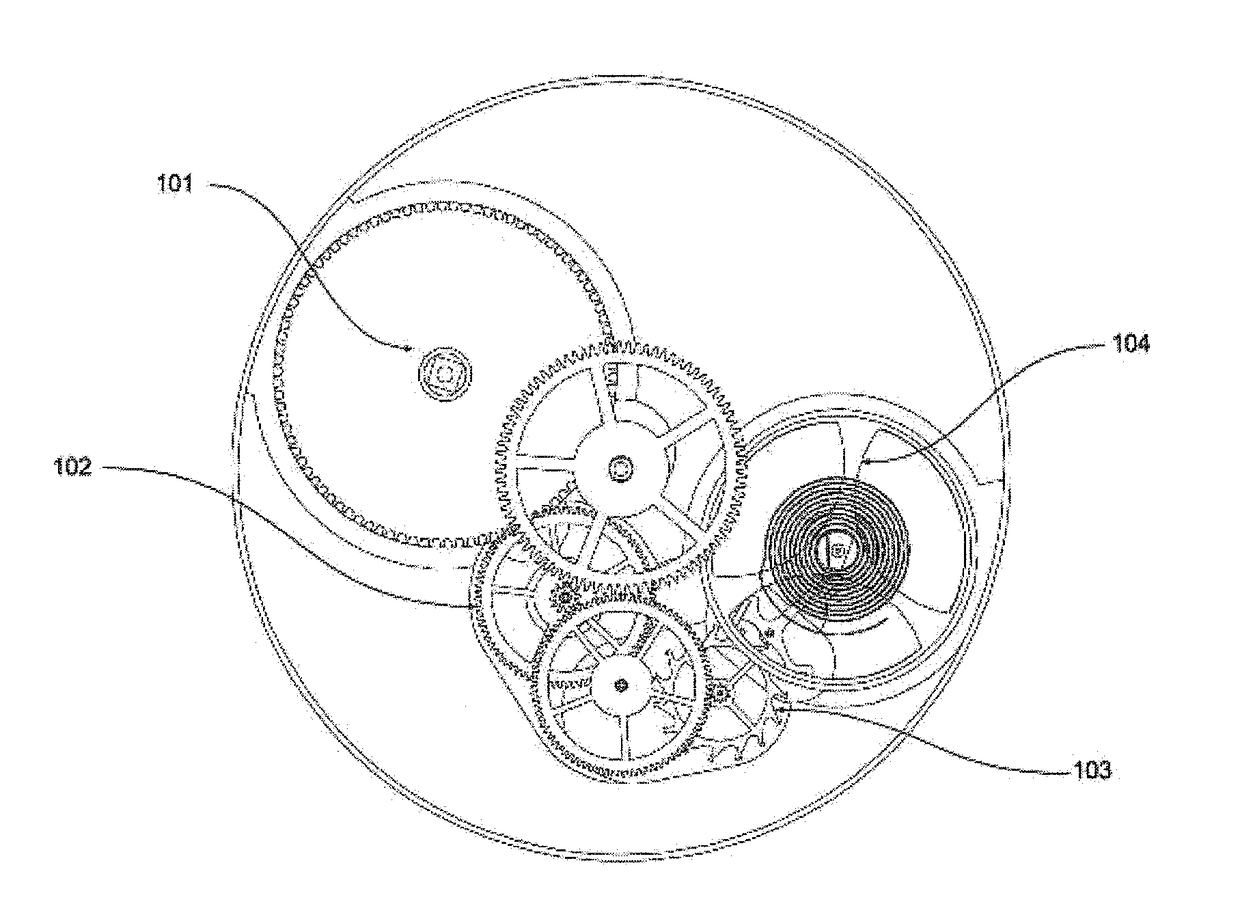

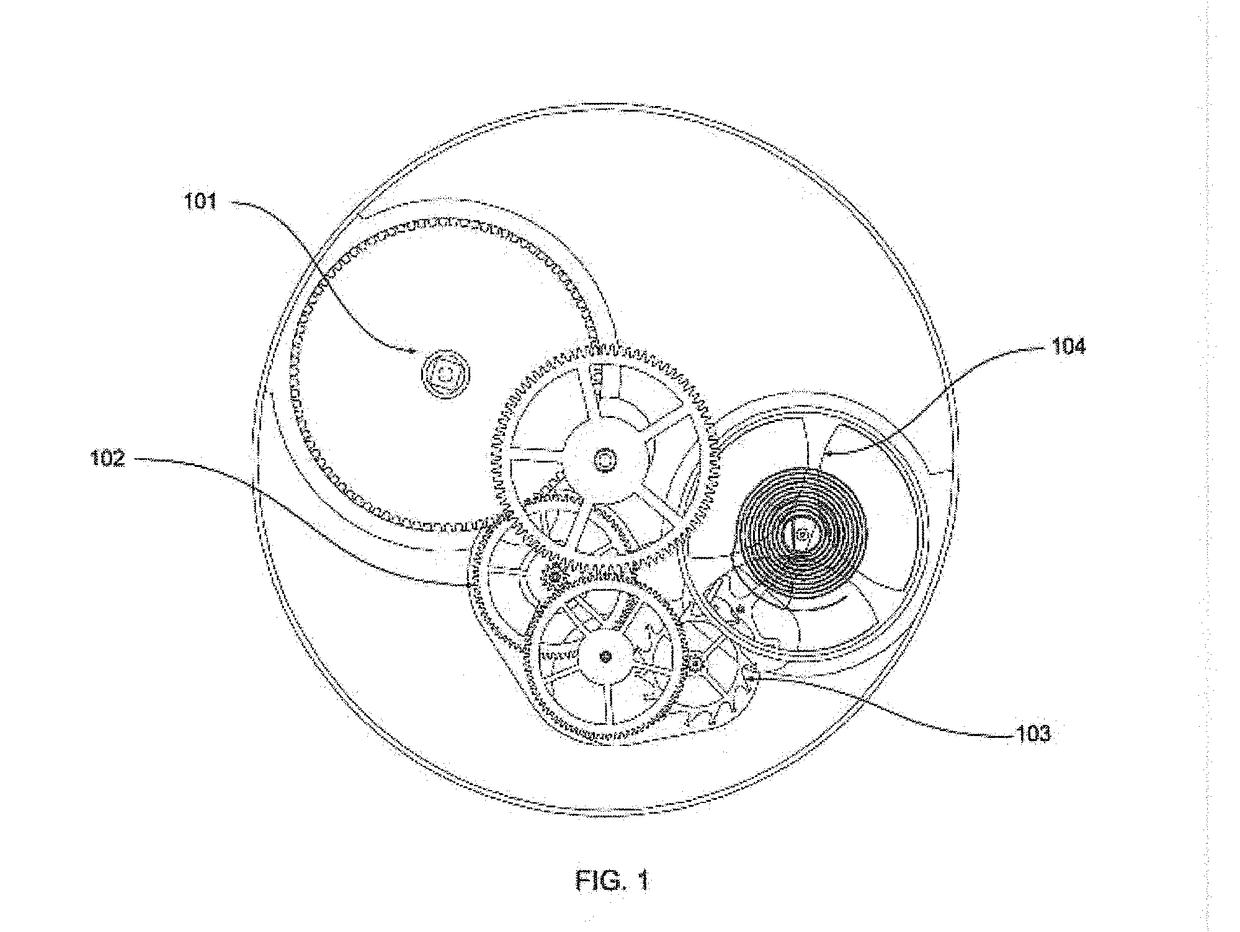

Mechanical watch movement

InactiveUS20120243386A1Shorten the lengthLengthEscapementsFrequency stabilisation mechanismEngineeringMechanical watch

Mechanical watch movement comprising a mechanical chronograph with a regulator organ for regulating the running of the chronograph, characterized in that the regulator organ of the chronograph is placed in an imaginary circle (A) coaxial to the movement and having a radius (r1) smaller than 50% of the maximum outer radius of the movement.

Owner:LVMH SWISS MFG SA

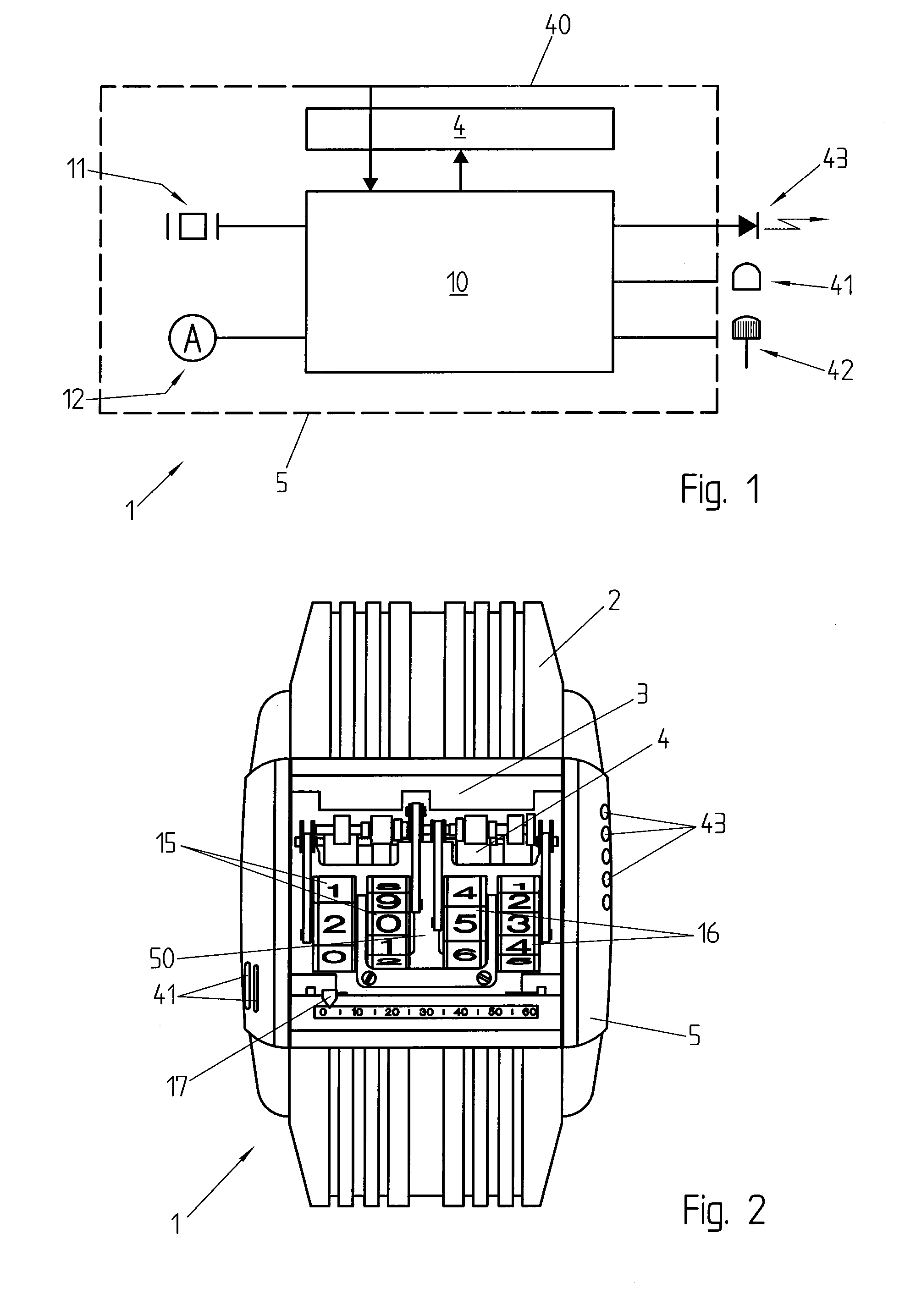

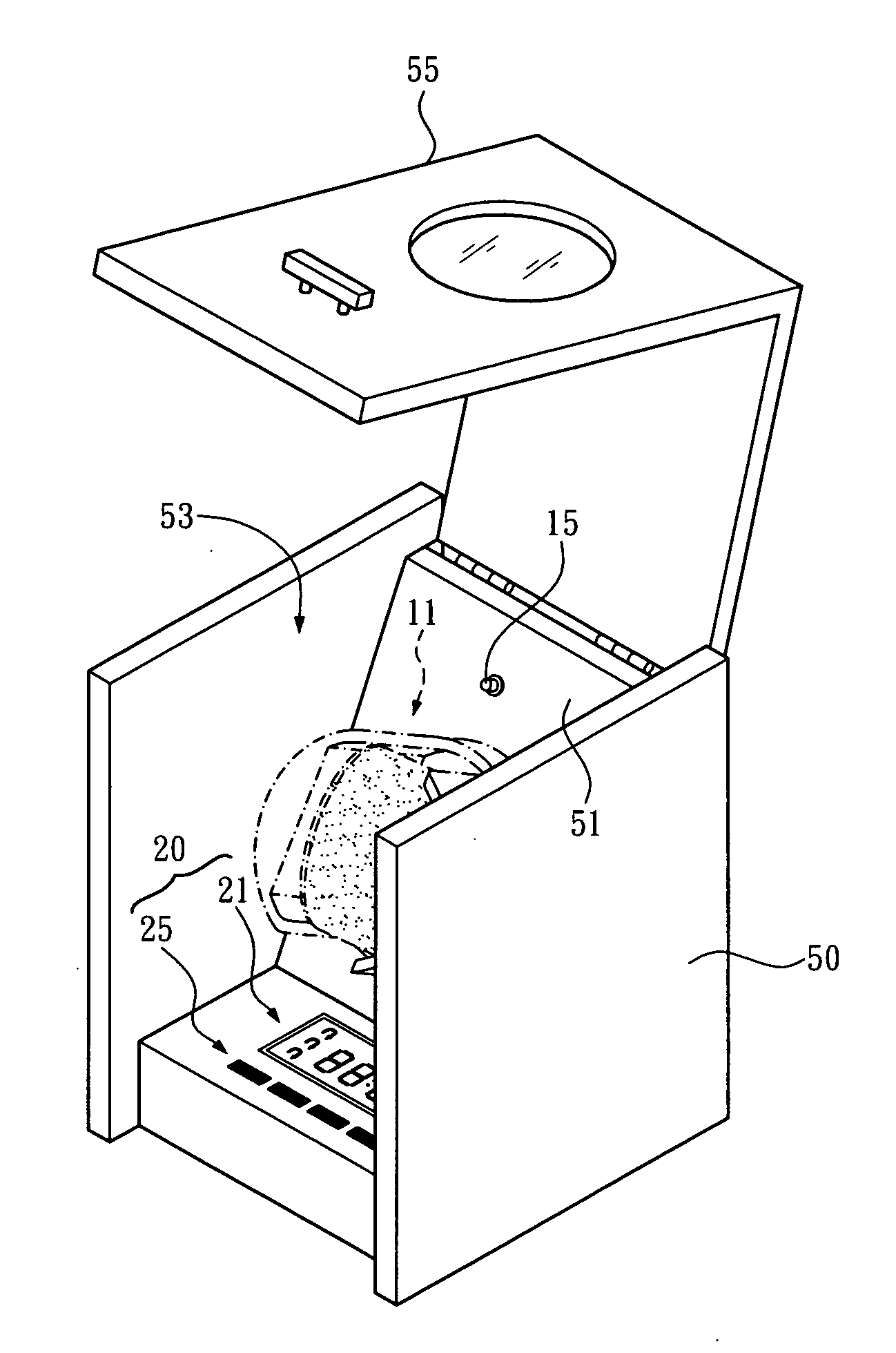

Programmable watch winding apparatus

InactiveUS20110026374A1Reduce noiseProtection from damageNormal windingElectric windingEngineeringMechanical watch

A programmable watch winding apparatus includes a user interface for users to input a winding number and rotational direction of turns the programmable watch winding apparatus performs to wind a mechanical watch, and a control unit controlling a transmission device to rotate a rotatory base according to the users' input. Thereby, the programmable watch winding apparatus is fully controlled to automatically wind the mechanical watch carried thereon.

Owner:CHANG

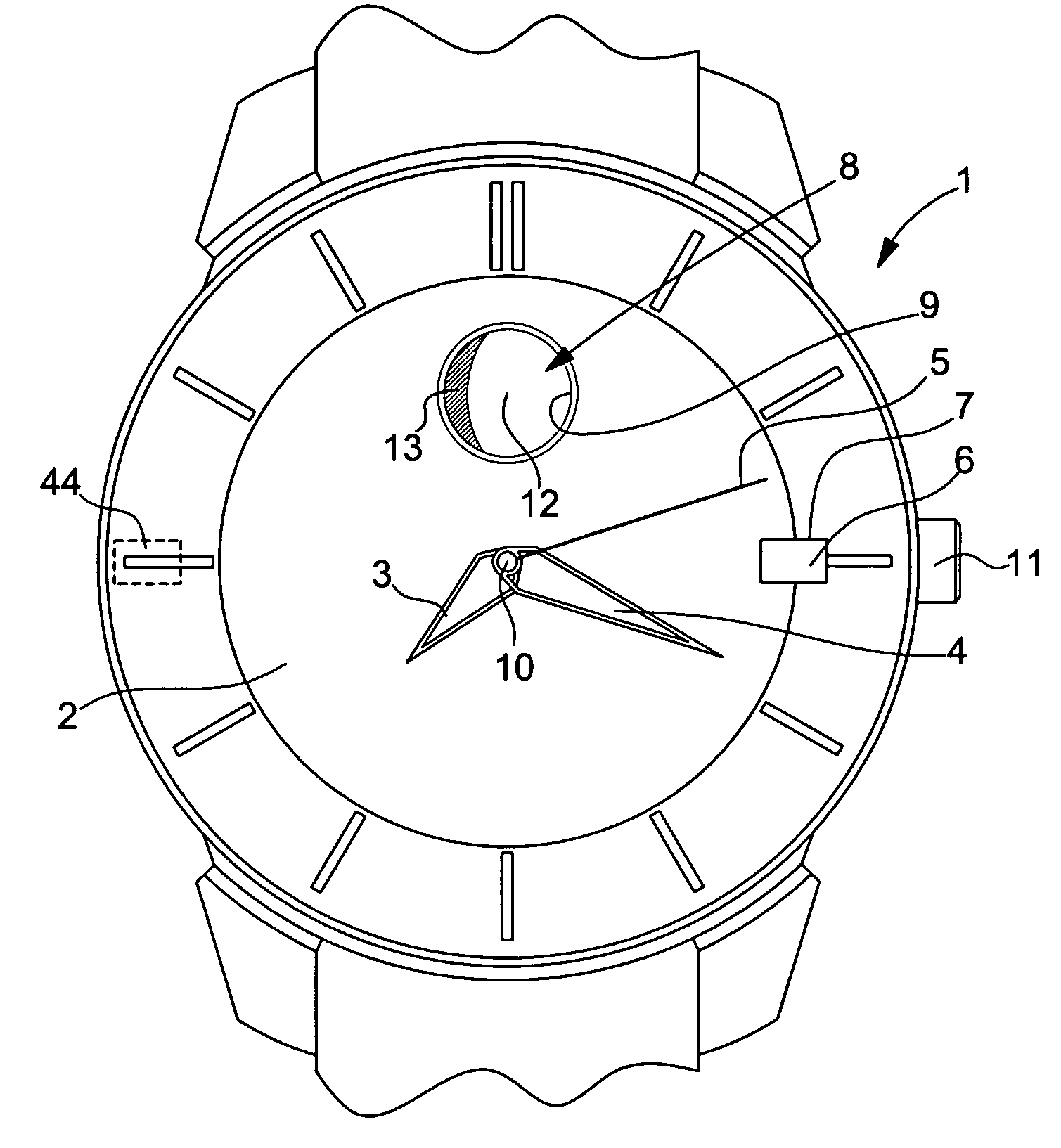

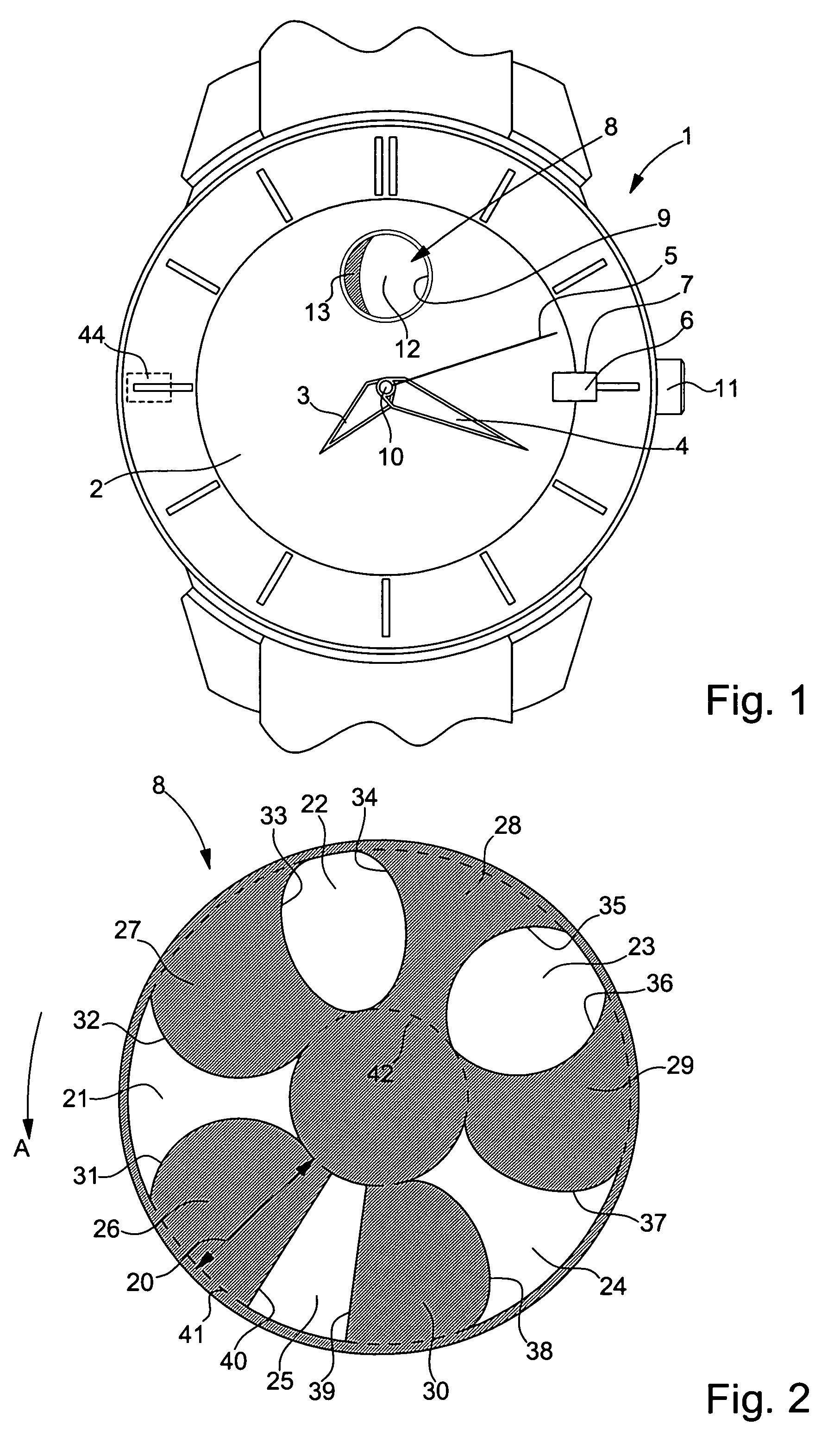

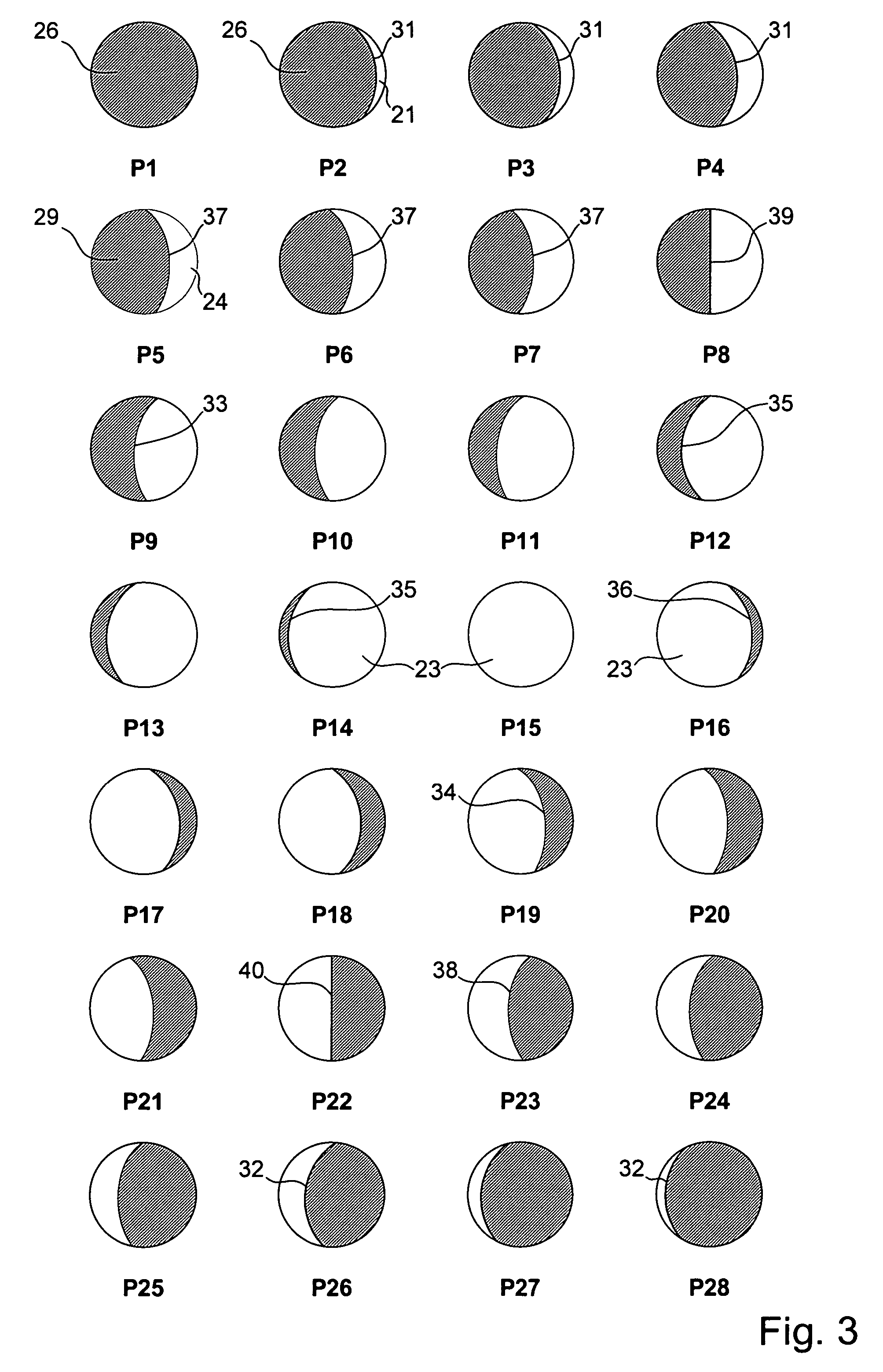

Method and device for displaying a moon image cycle, in particular for a watch

In order to display images true to the real appearance of the moon during a lunation, particularly in a watch, there is provided a rotating indicator disc (8) arranged behind a circular aperture of a dial and comprising an annular region (20) subdivided into alternatively light (21–25) and dark (26–30) fields by lines of separation (31–40) having different shapes, which can appear in succession in the aperture. The drive means impart primary movements on the indicator disc (8), each of which is large enough to replace one of the lines of separation by another in the aperture, and smaller secondary movements, to produce small movements of the line of separation inside the aperture. This allows a new image of the moon to be given every day, true to reality, with a restricted number of light and dark fields on the indicator disc and a particularly large aperture in relation to the size of the dial. A version with electric driving is disclosed and a version driven by a mechanical watch movement.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

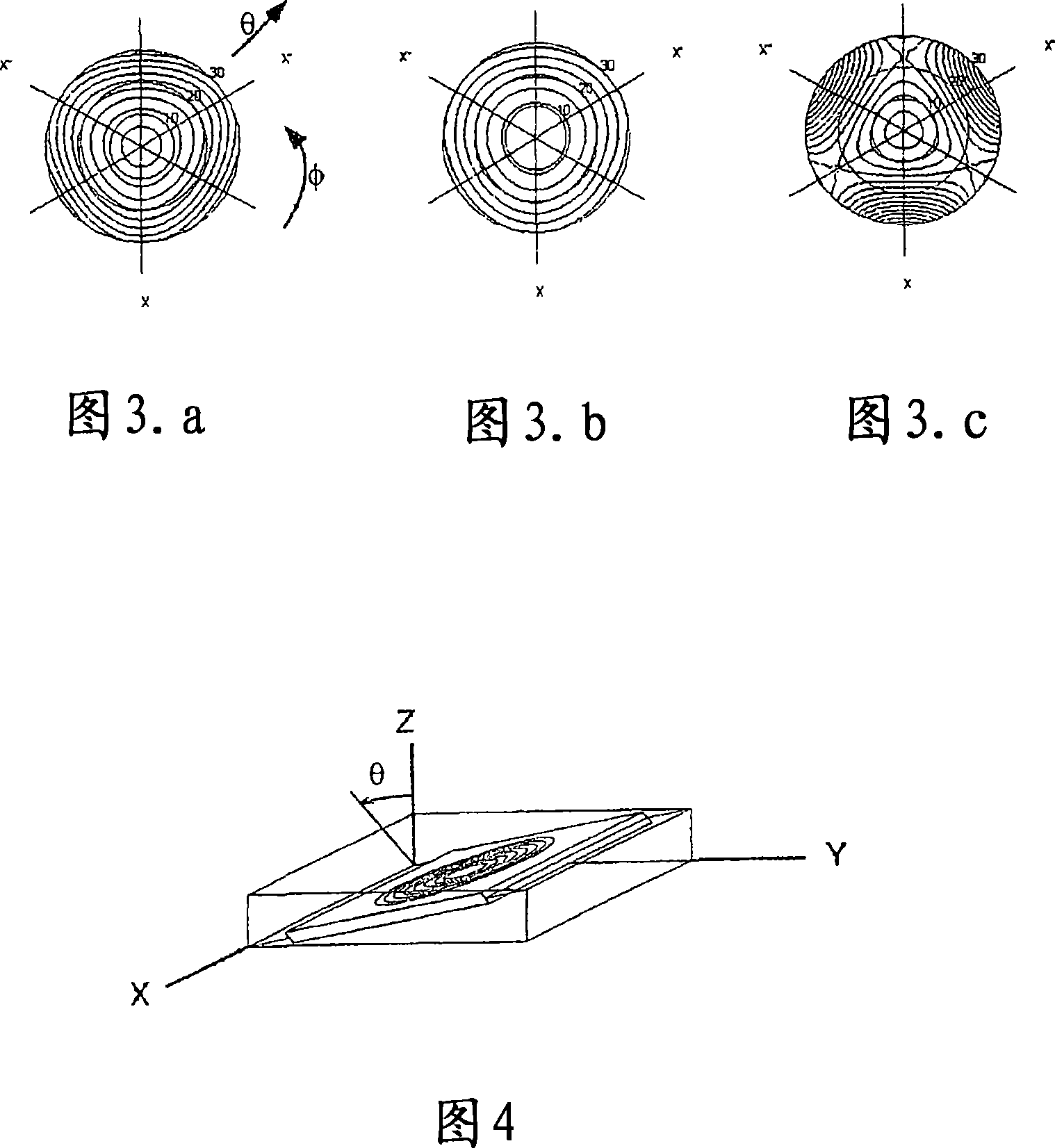

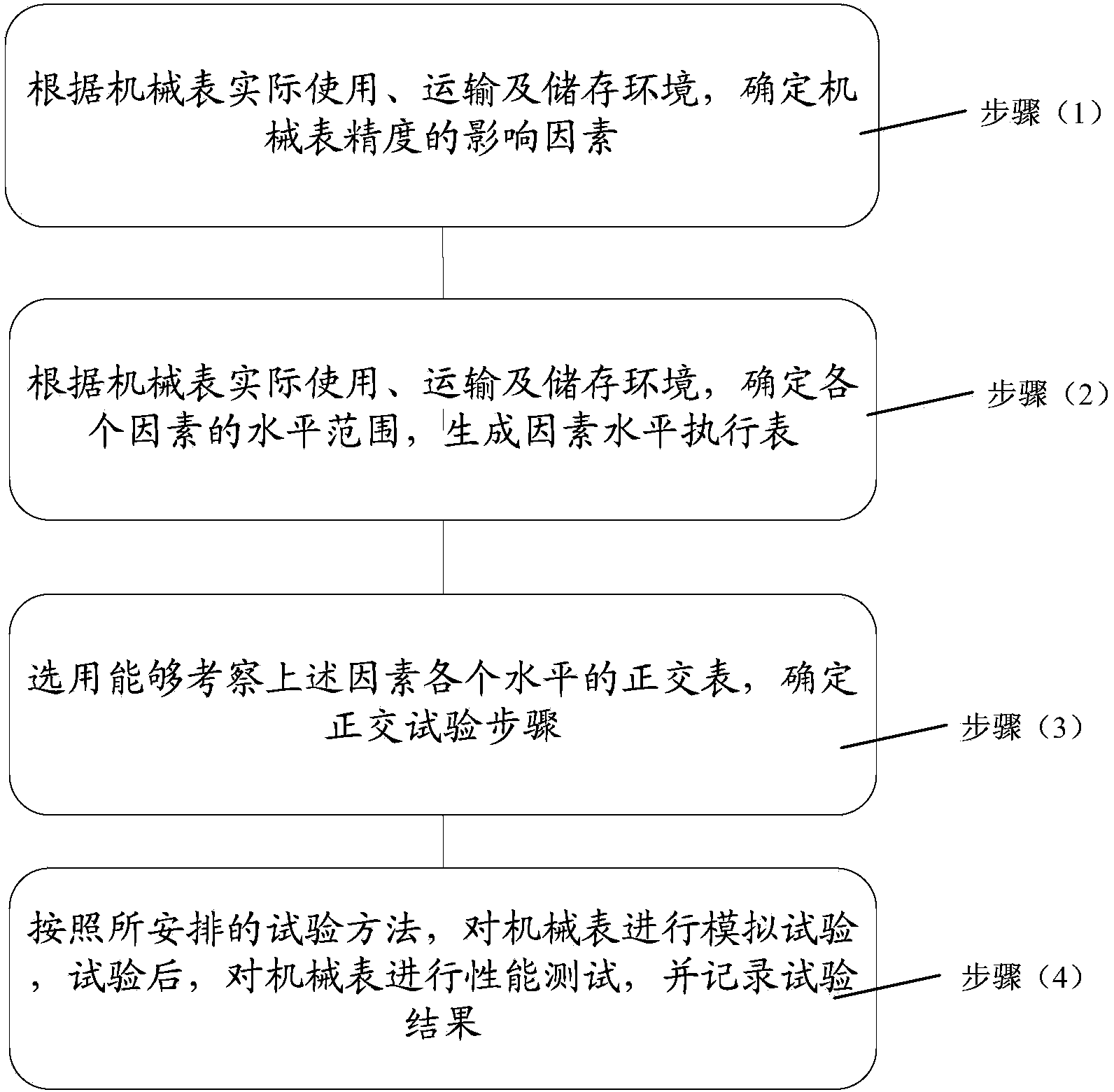

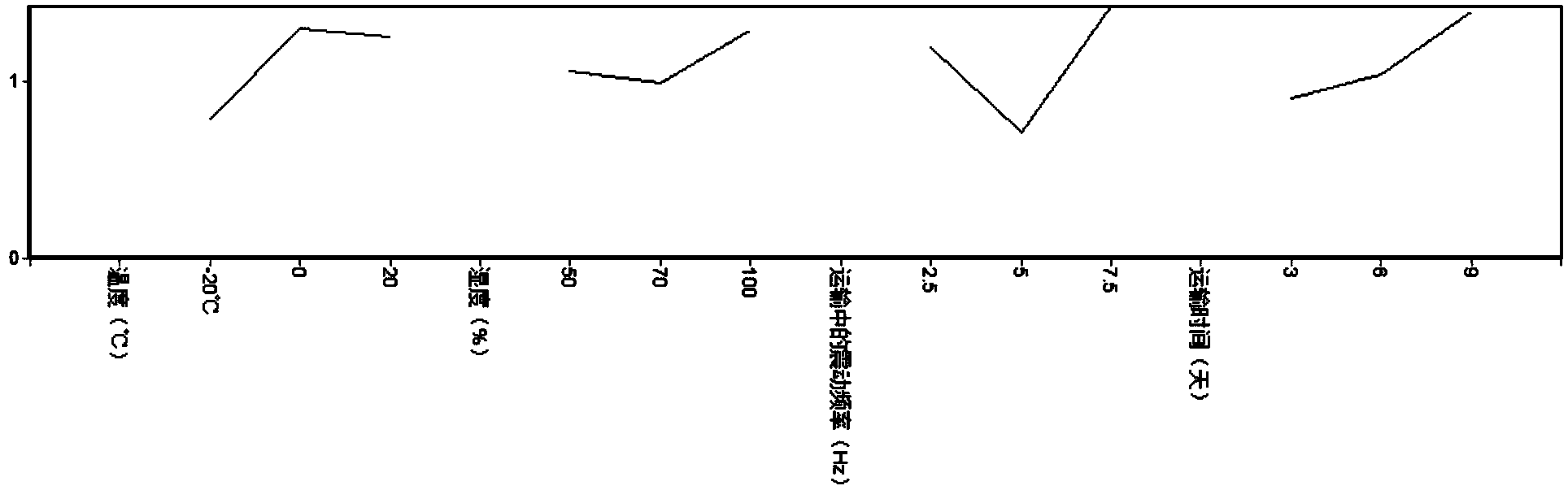

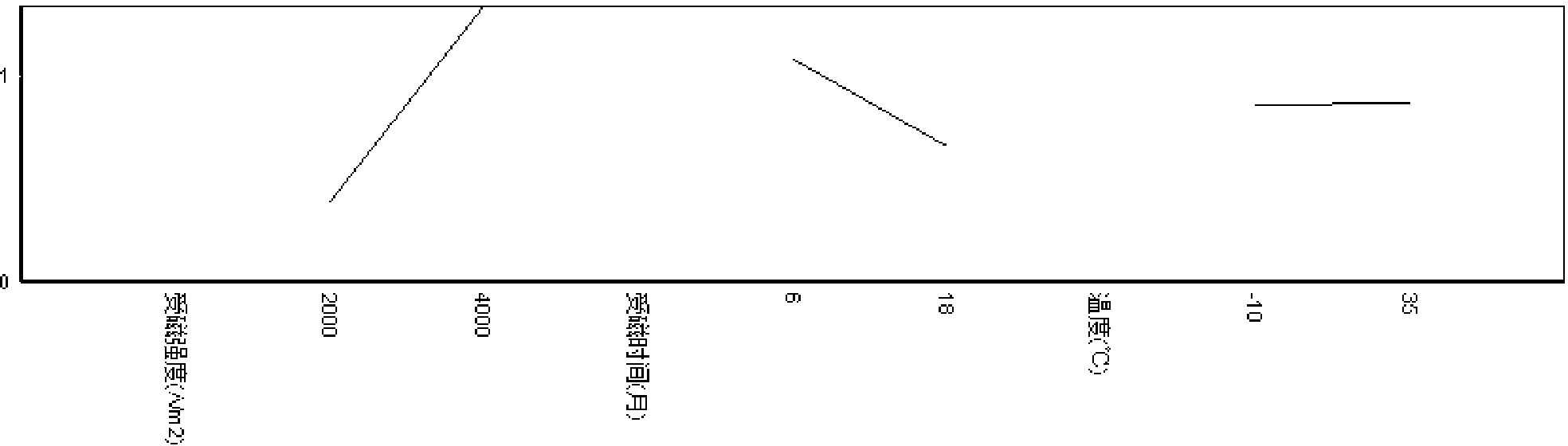

A method for detecting precision influence factors of a common mechanical watch

Provided is a method for detecting precision influence factors of a common mechanical watch. The common mechanical watch does not comprise a quakeproof mechanical watch and a mechanical watch, of which the antimagnetic performance is above 4800A / m<2>. The detection method comprises the followings steps: 1) determining influence factors of precision of the mechanical watch according to actual use, transportation and storage environment of the mechanical watch; 2) determining level range of each factor and generating a factor level execution table according to the actual use, transportation and storage environment of the mechanical watch; 3) selecting and using an orthogonal table capable of checking each level of the factors and determining orthogonal test steps; and 4) carrying out simulation test on the mechanical watch, and after test, carrying out performance test on the mechanical watch and recording test results. According to the method, not only various factors influencing the precision of the mechanical watch and the influence degree can be obtained in the trial production stage of the products, thereby providing basis for actual use, transportation and storage of the product; but also the quantitative evaluation can be carried out on the various factors influencing the precision of the mechanical watch.

Owner:ZHUHAI ROSSINI WATCH IND

High quality factor resonator for mechanical watches

ActiveCN107957671AEscapementsFrequency stabilisation mechanismEngineeringRotational degrees of freedom

Owner:ETA SA MFG HORLOGERE SUISSE

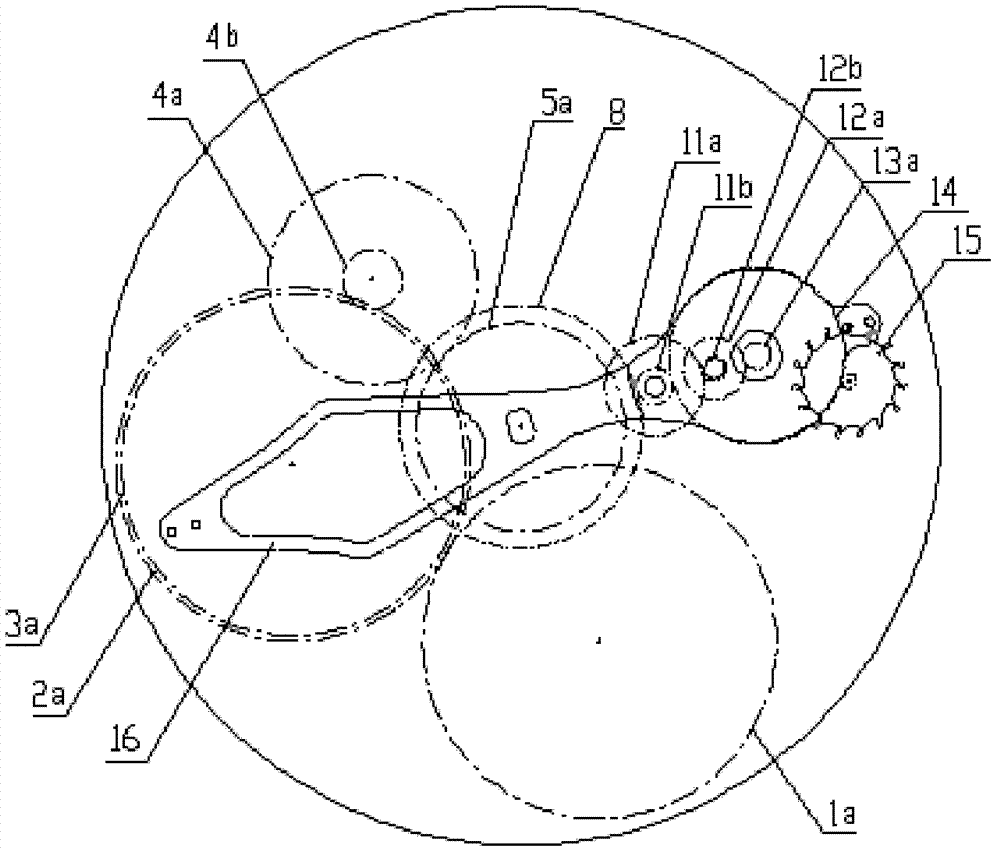

Annular hour-minute hand display mechanism of mechanical watch

ActiveCN103713510AReduce thicknessFlexible and precise rotationGearworksVisual indicationMoon phasesDrive wheel

The invention discloses an annular hour-minute hand display mechanism of a mechanical watch. The display mechanism comprises a first center wheel component engaged with a driving wheel on barrel, a second center wheel engaged with the first center wheel component, an hour wheel, a minute wheel, a control mechanism and the like. The hour wheel and the minute wheel that are driven by idle wheel components are arranged at the center of a movement and are supported by a track mechanism or a support rack, wherein the hour wheel and the minute wheel are annular inner gears. The control mechanism limits the positions and the gap of the radial direction and the axial direction of the hour wheel and the minute wheel. The provided display mechanism has the following beneficial effects: because of the annular hour-minute hand display mechanism, a problem that the time can not be displayed normally because the center of the movement is occupied by other structures can be solved. The provided mechanism with the simple structure can be processed conveniently; demands of watch components including a middle-mounted flying tourbillion, a middle-mounted speed-regulating mechanism, a central moon-phase display unit and other units can be satisfied, wherein the watch components are arranged at the center of the movement. In addition, the control mechanism carries out limiting on the axial direction and the radial direction of the minute wheel and the hour wheel effectively, so that the frictional resistance force is reduced and thus the rotation of the minute wheel and the hour wheel becomes flexible and accurate.

Owner:TIANJIN SEAGULL WATCH CO LTD

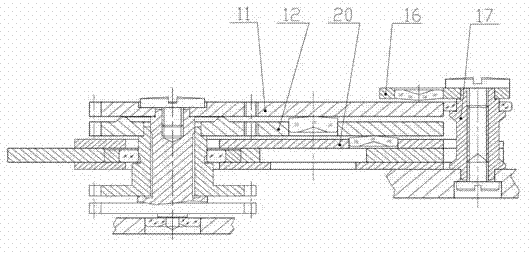

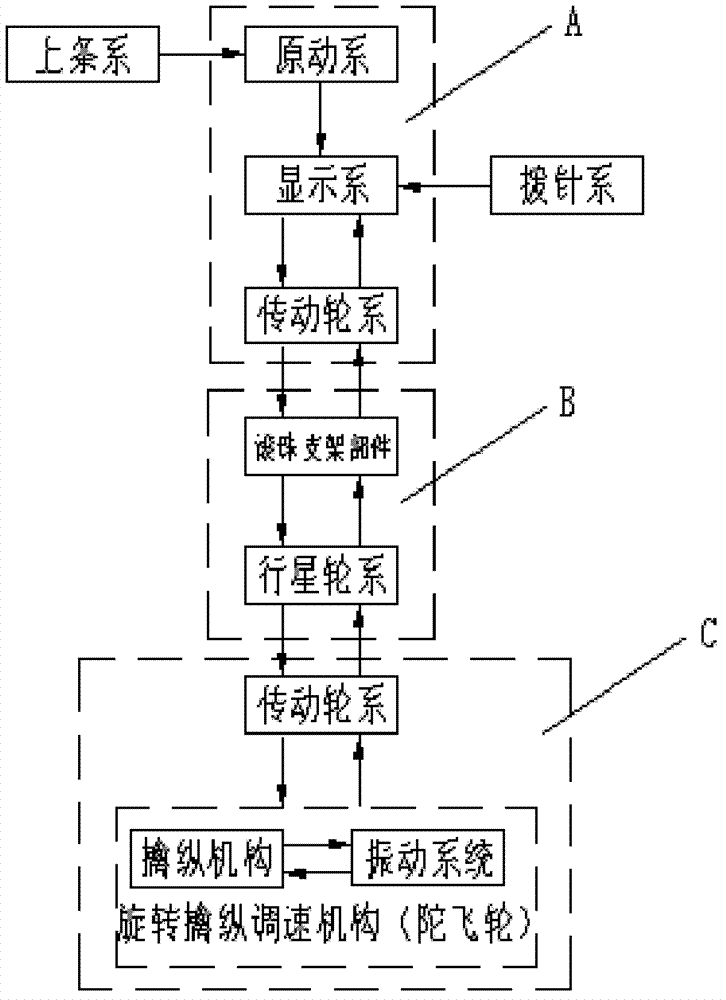

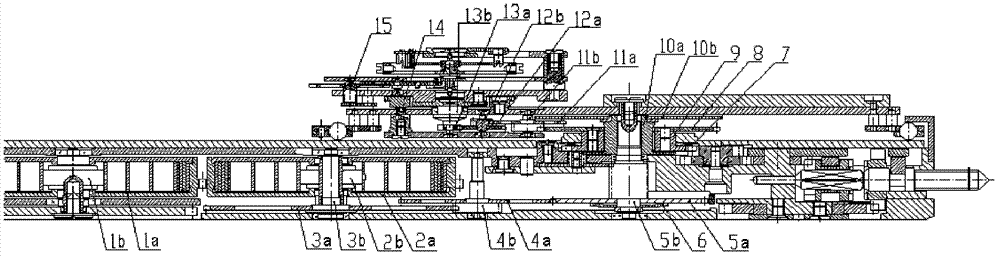

Floating rotation tourbillion mechanical watch

ActiveCN103092051ASimple adjustment and maintenanceRealize the friction functionVisual indicationEscapementsFriction lossEngineering

The invention discloses a floating rotation tourbillion mechanical watch which comprises a winding series, a basic series A, a needle setting series, a transition series B and a rotation series C. The basic series A comprises an initiative series, a display series and a transmission wheel series. The transition series B comprises a ball support part and a planet wheel series. The rotation series C comprises a transmission wheel series and a rotation escapement speed regulating mechanism. The winding series, the initiative series and the display series are connected in sequence. The needle setting series is connected with the display series. The display series is sequentially connected with the transmission wheel series included by the basic series A, the planet wheel series and the ball support part which are included by the transition series B, and the transmission wheel series and the rotation escapement speed regulating mechanism which are included by the rotation series C in a double-direction mode. The floating rotation tourbillion mechanical watch has the advantages that due to the fact that a sun wheel is of a friction structure, a friction function is achieved through elastic deformation of a leaf spring between a clamping plate and the sun wheel, a needle setting wheel series drives the sun wheel directly to adjust the position of a rotation support, stability is strong. In addition, friction loss of contacted faces and rotation parts is reduced by the ball support structure, the structure is simple, and performance is stable.

Owner:TIANJIN SEAGULL WATCH CO LTD

Crystalline Compounds for Use in Mechanical Watches and Methods of Manufacture Thereof

InactiveUS20170285573A1Improve performanceNeutralize effectGearworksVisual indicationEvaporationVarying thickness

This invention teaches a new class of materials that can be used to manufacture hairsprings and / or other components of mechanical watches, and methods for manufacturing these components. The new class of materials is crystalline compounds, including, but not limited to, gallium arsenide, extrinsically doped gallium arsenide, extrinsically doped silicon, gallium nitride, extrinsically doped gallium nitride, gallium phosphide, extrinsically doped gallium phosphide, and quartz. This invention also teaches laminated / coated crystalline compounds. The lamination / coating may be applied by one of the following methods, including but not limited to: plasma enhanced chemical vapor deposition, atomic layer deposition, sputtering, electron beam evaporation, and thermal evaporation. Using crystalline compounds, in particular extrinsically doping the crystalline compounds, affords the possibility to controllably alter the mechanical, electrical, thermal, magnetic, and / or other properties of the watch components. These properties can be further altered by applying single or multiple laminates / coatings of varying thicknesses and / or geometries.

Owner:FIREHOUSE HOROLOGY INC

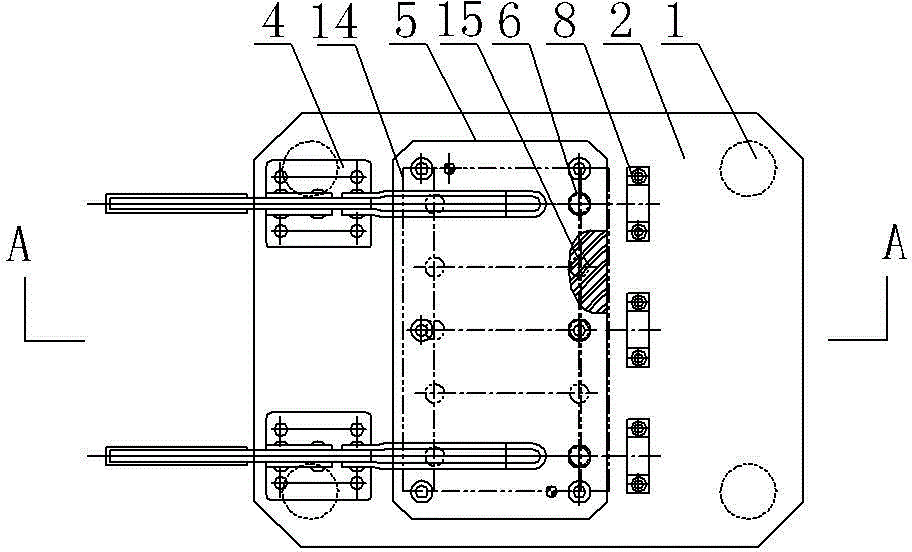

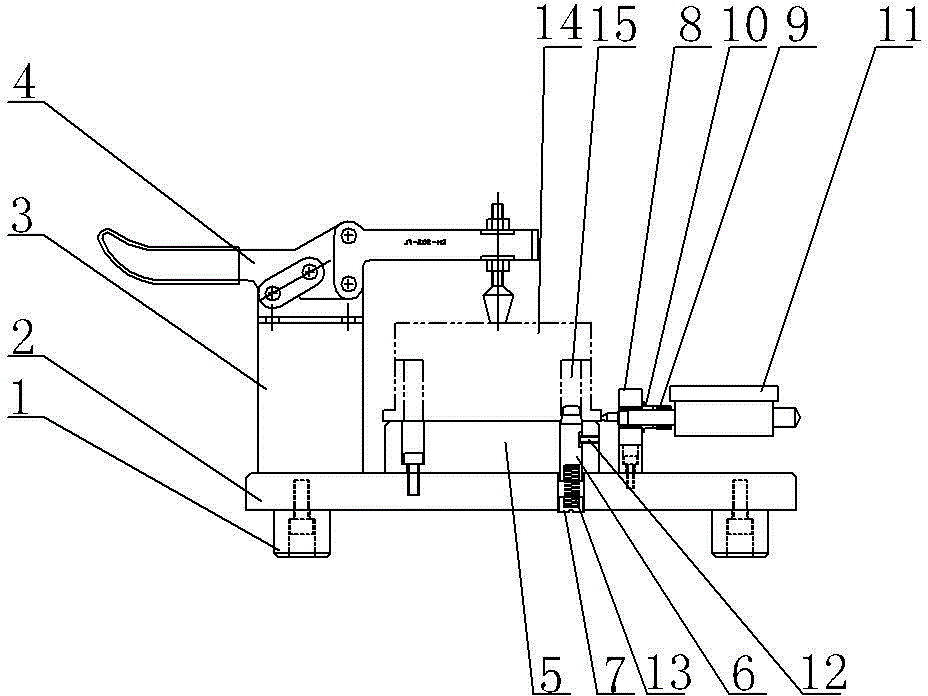

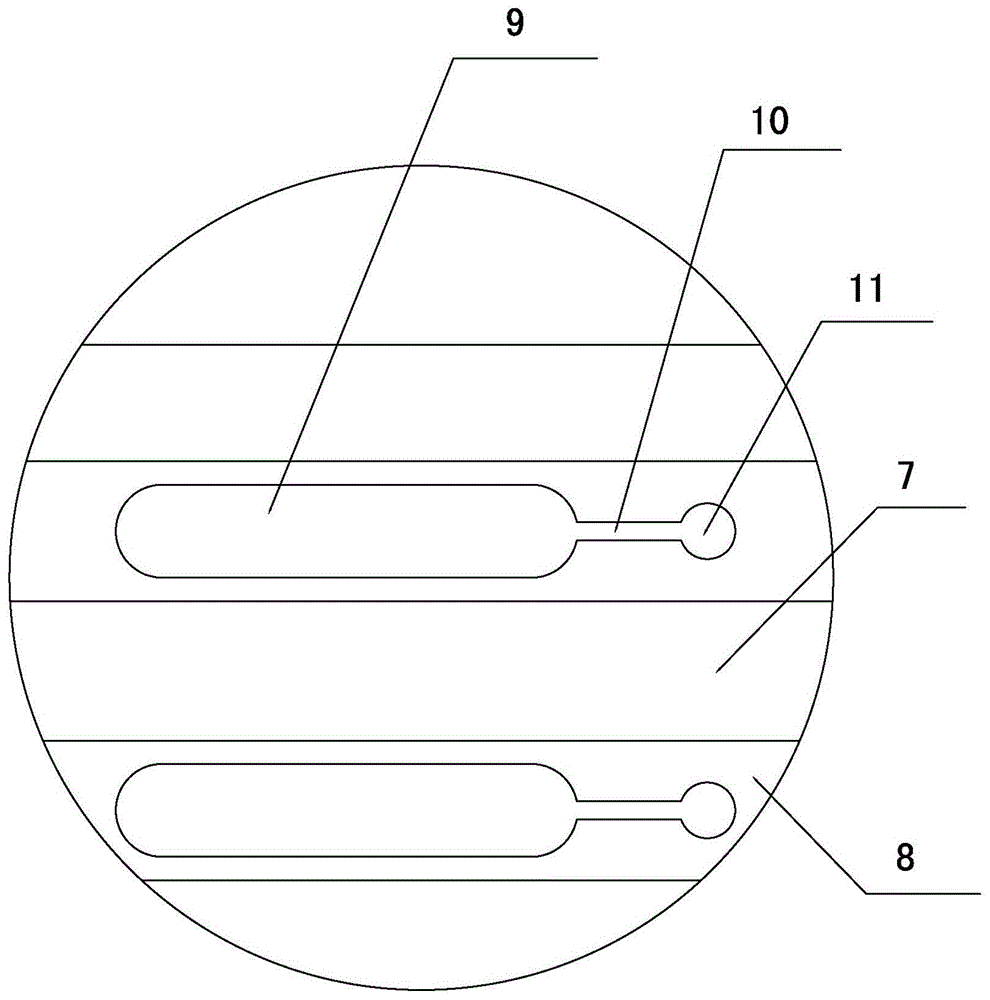

Connecting rod cap semifinished product true position detecting tool

ActiveCN102980466AReduce usage requirementsEasy to operateMechanical measuring arrangementsWork in processMechanical watch

The invention provides a connecting rod cap semi-finished product true position detecting tool. The detection is simple and rapid and therefore the detection efficiency is improved. The connecting rod cap semi-finished product true position detecting tool is suitable for the rapid detection of the connecting rod cap semi-finished product. Meanwhile, the operation is simple and therefore the operating requirement for the testing personnel is reduced and the testing cost is further reduced. The connecting rod cap semi-finished product true position detecting tool comprises a base plate. Footings are installed on the bottom corners of the base plate through bolts. The connecting rod cap semi-finished product true position detecting tool is characterized by comprising a quick clamping, a quick clamping seat, a reference seat, a taper pin and a mechanical watch. One side of the reference seat is fixed on the base plate through bolts, and the other side of the reference seat is located on the base plate in a plug-in mounting mode through two taper pins distributed vertically and uniformly. The two quick clamping seats are longitudinally arranged on two ends of the left side of the reference seat. The quick clamping is fixed on the quick clamping seat through a flange face. The bottom screw holes of the connecting rod cap semi-finished product waiting to be detected are positioned through cone points of taper pins, and the two longitudinal ends of the upper surface is clamped and fixed through the quick clamping.

Owner:泰州市海通资产管理有限公司

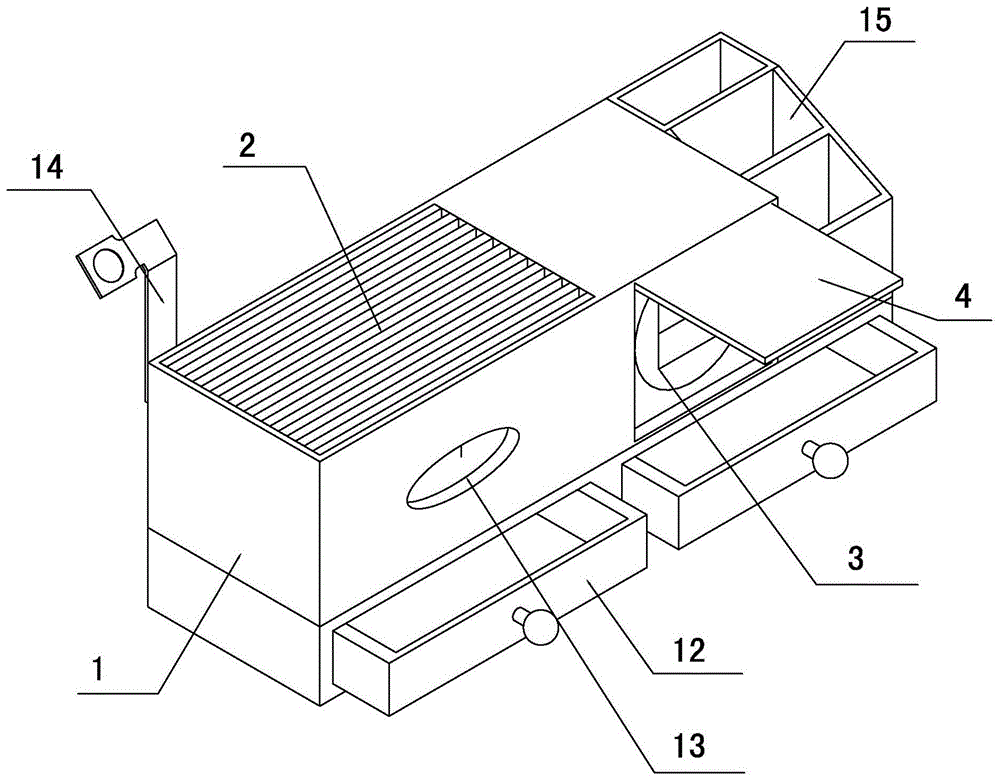

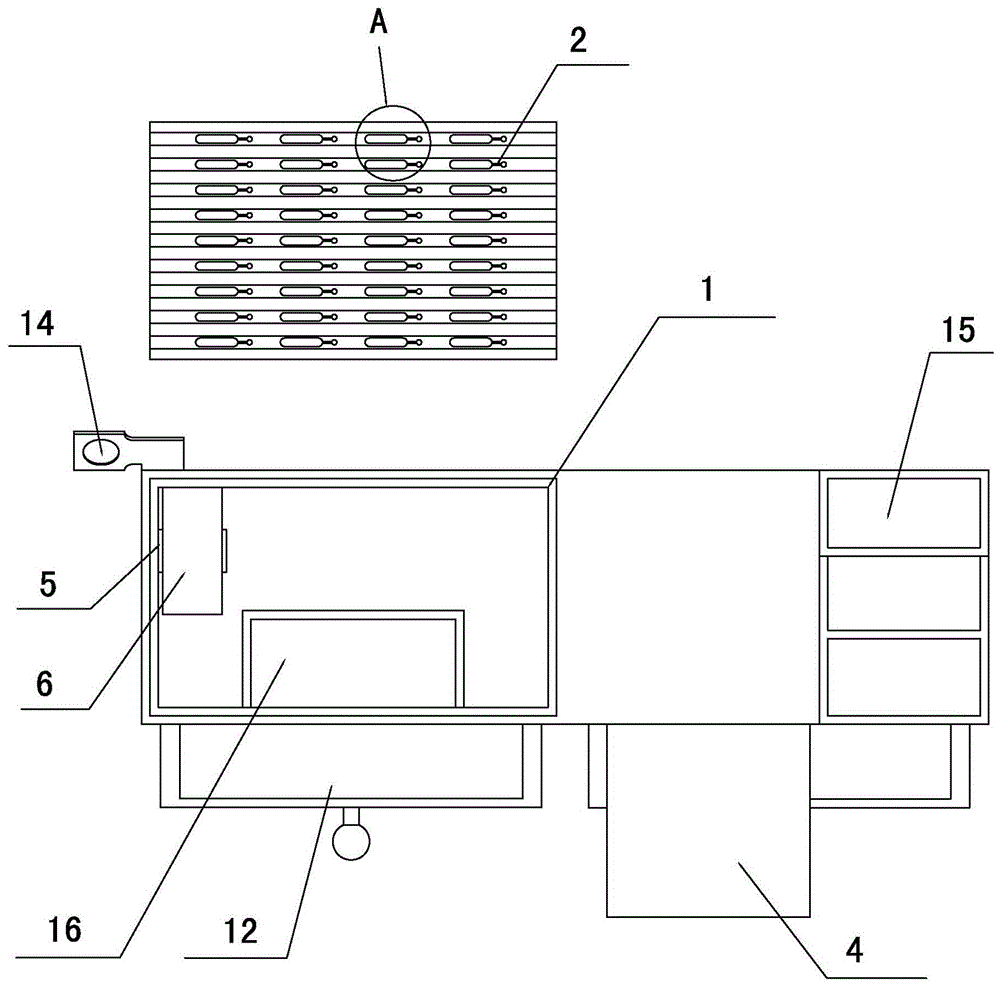

Multifunction charging device with watch swing device

InactiveCN105762881AFunction increaseEasy to useBatteries circuit arrangementsElectric powerTransformerSpecial design

The invention discloses a multifunction charging device with a watch swing device, the charging device comprises a charging device main body and a watch swing device, the watch swing device is fixed to the charging device main body. The watch swing device is arranged on the charging device main body, when a mechanical watch is not in used, the mechanical watch can be put on the watch swing device, swing operation is performed on the watch, so that the automatic watch cannot stop without being worn. The charging device also comprises functions of mobile phone supporting, mobile phone charging, wireless charging and the like, the functions are various, and the device is convenient to use. A charge opening of the charging device adopts a special design of structure, so that a charge interface of a charge cable cannot fall, and the operation is more convenient than before. A lock position is arranged in the charging device, a transformer or a portable power source module can be locked on the lock position, so that the transformer or the module is convenient to carry and is more convenient to be changed for repair and maintenance than before.

Owner:涂军华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com