Patents

Literature

55 results about "Automatic watch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An automatic watch, also known as self-winding watch, is a mechanical watch in which the natural motion of the wearer provides energy to run the watch, making manual winding unnecessary. It is distinguished from a manual watch in that a manual watch, while also having no internal battery, must have its main spring wound by hand at regular intervals.

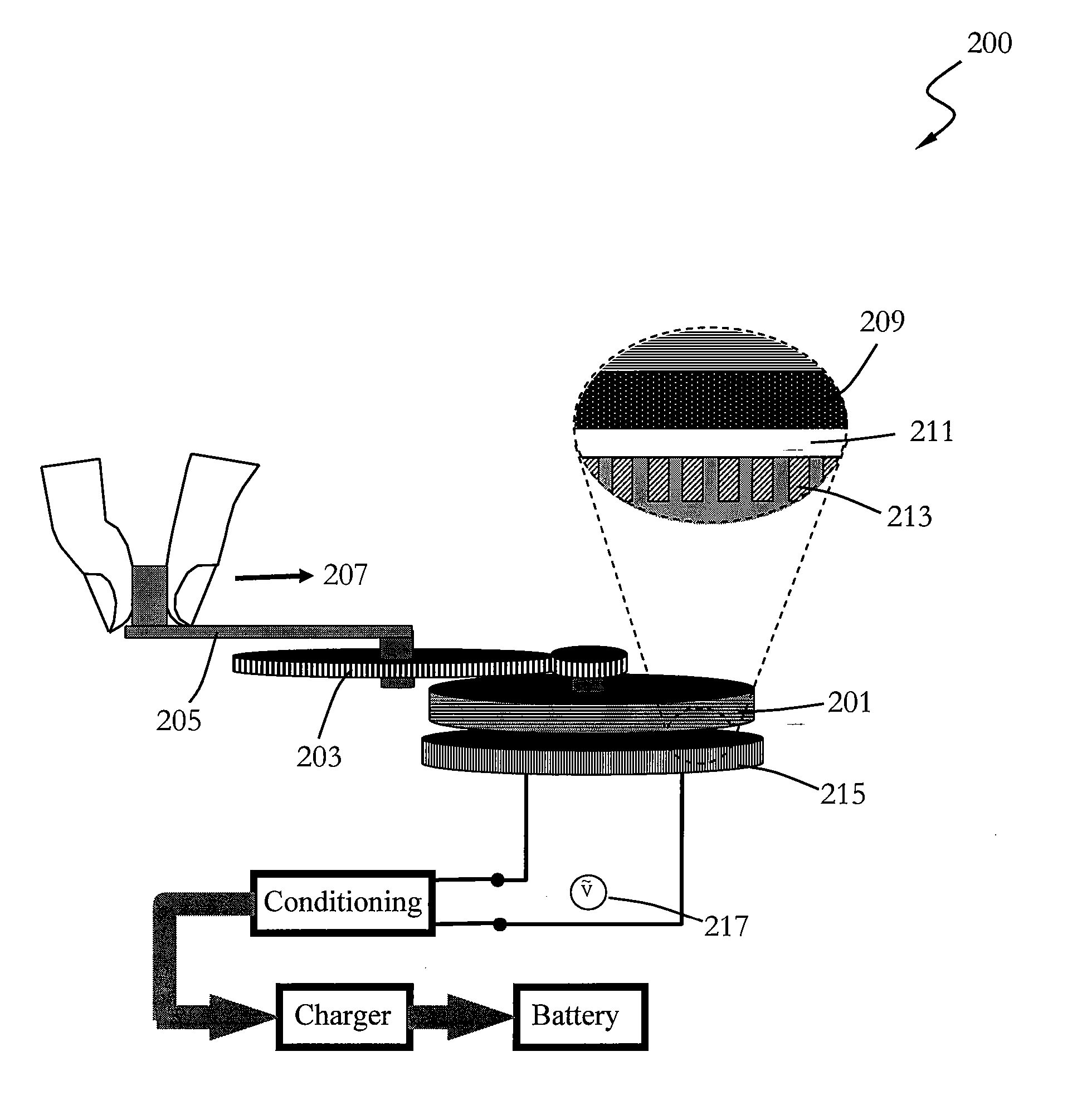

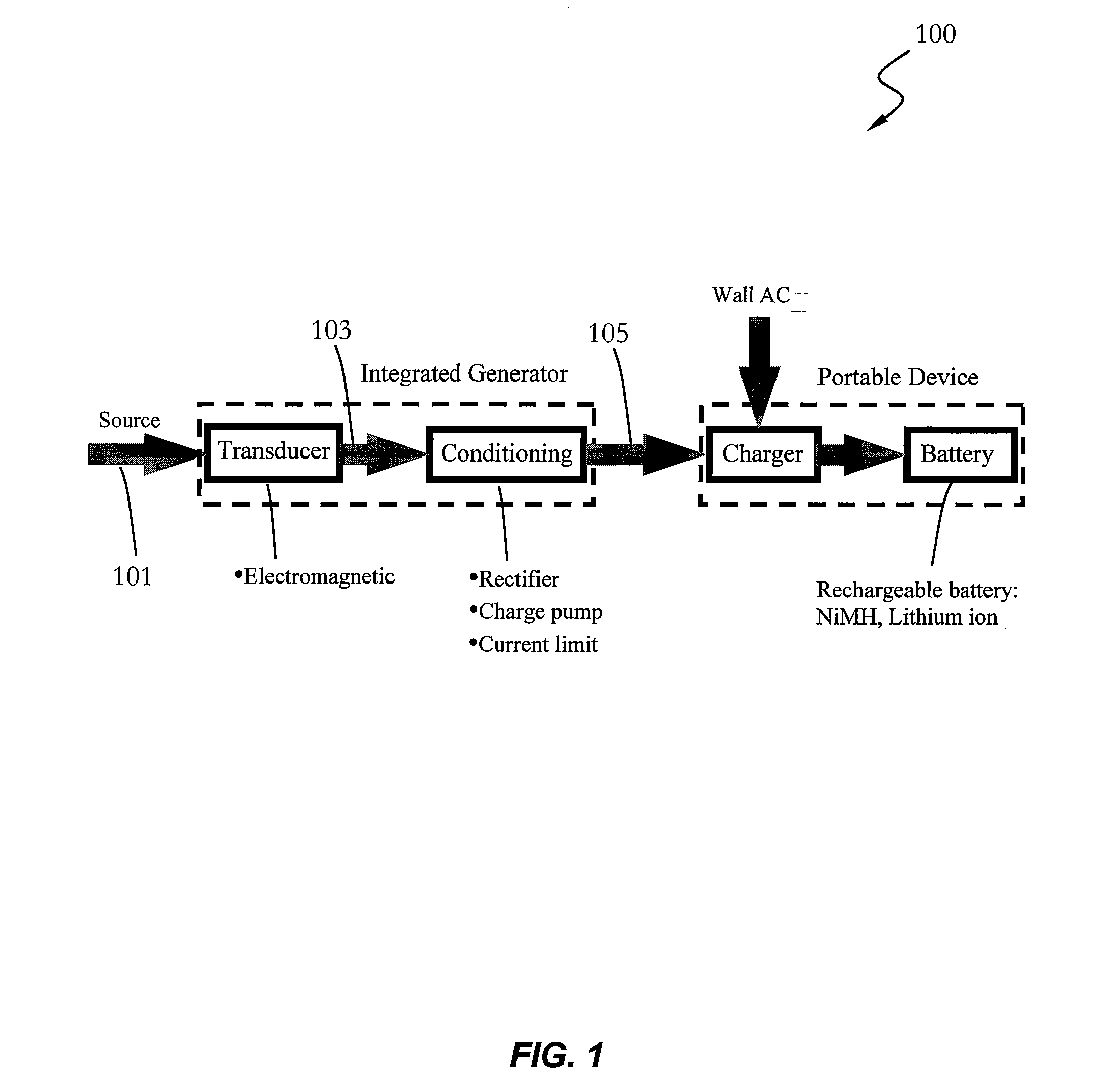

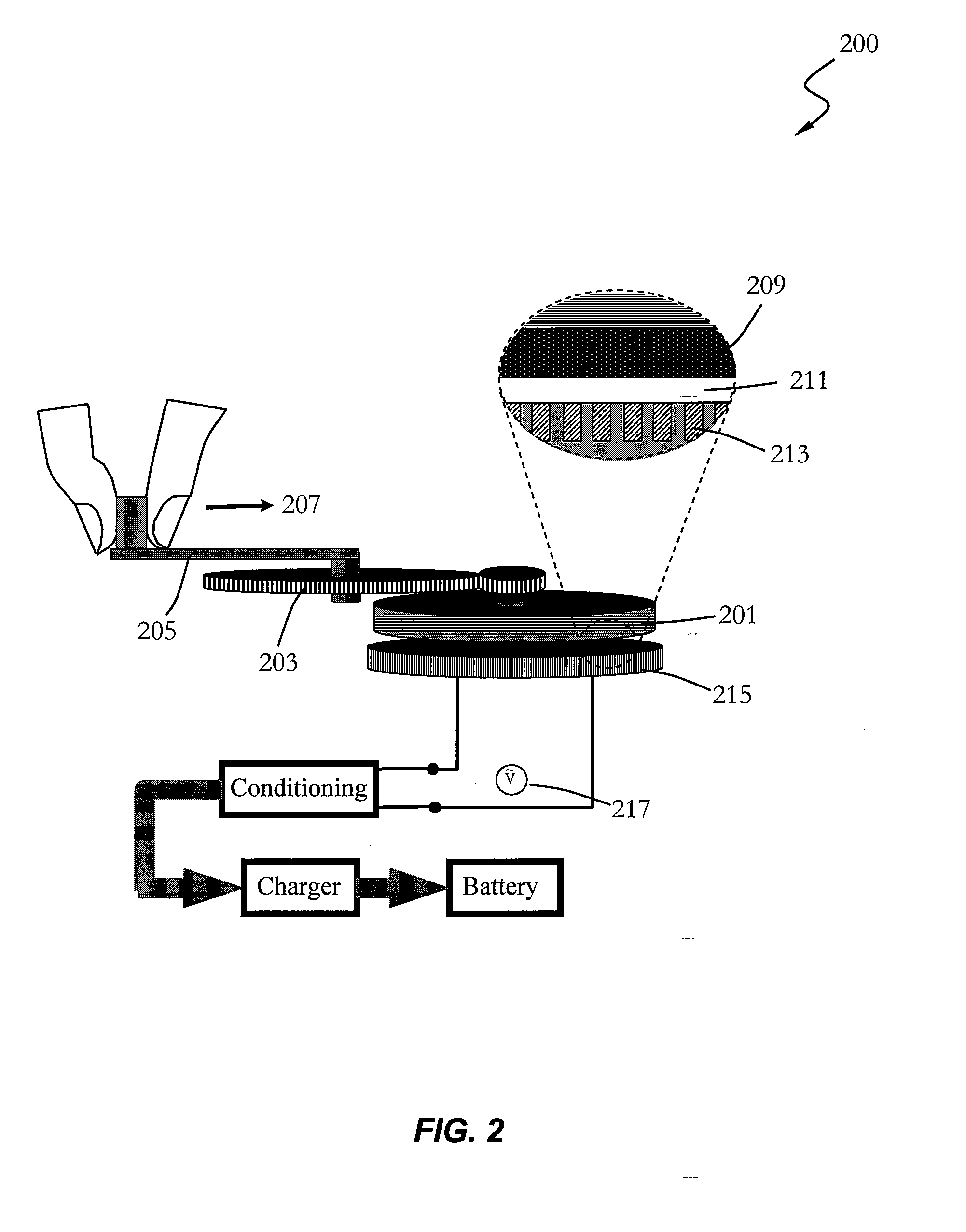

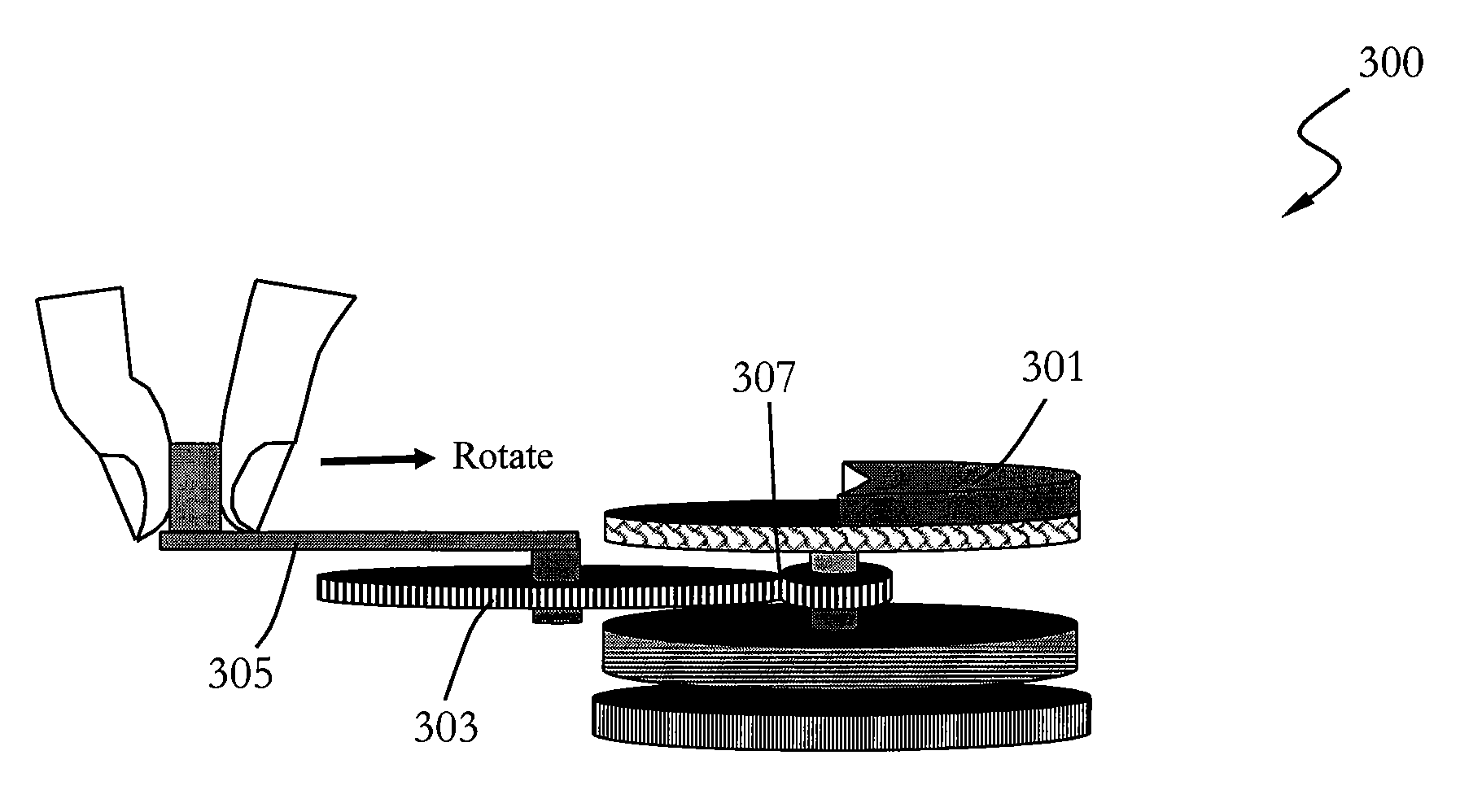

Method and Structure for Kinetic Energy Based Generator for Portable Electronic Devices

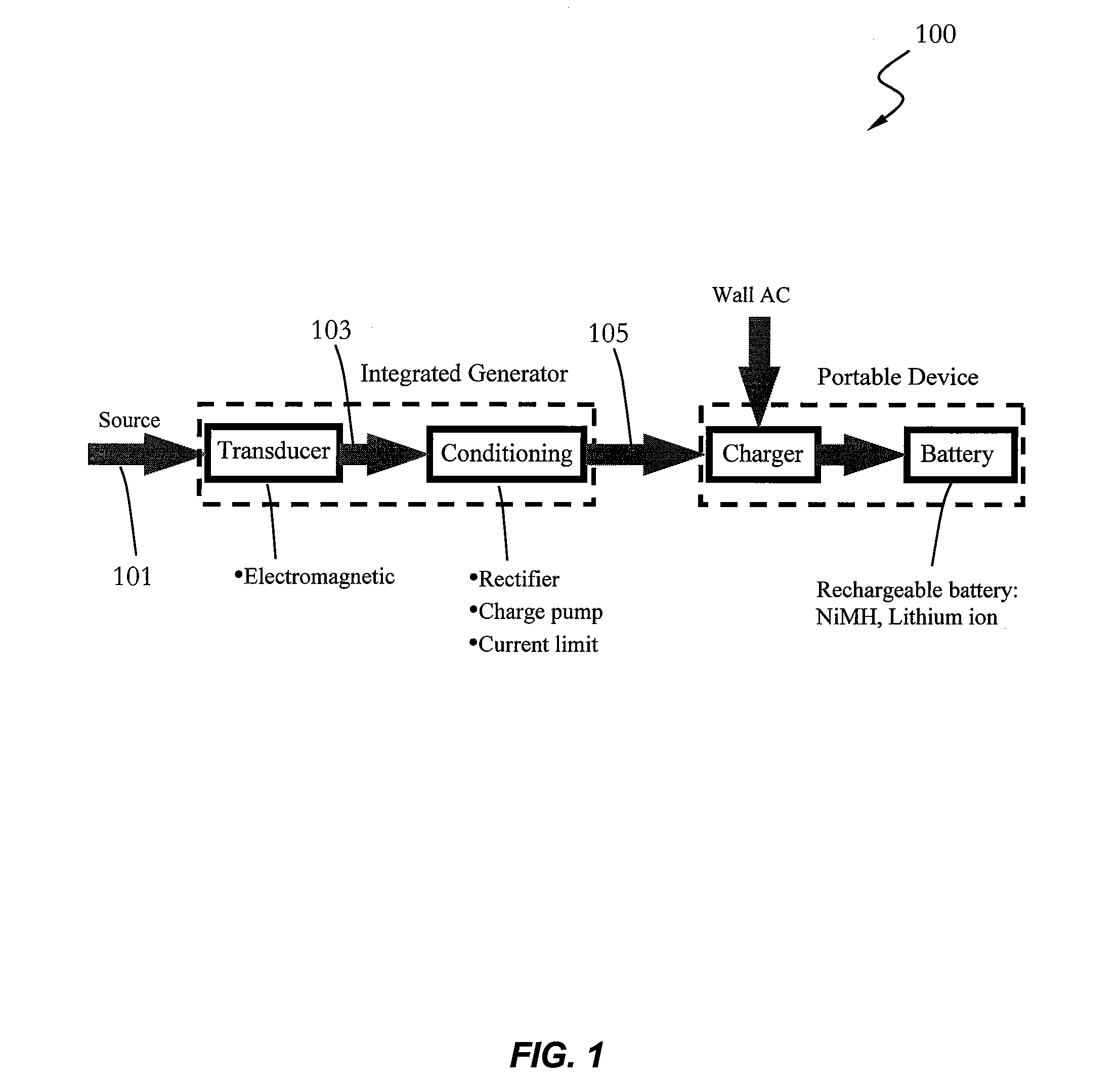

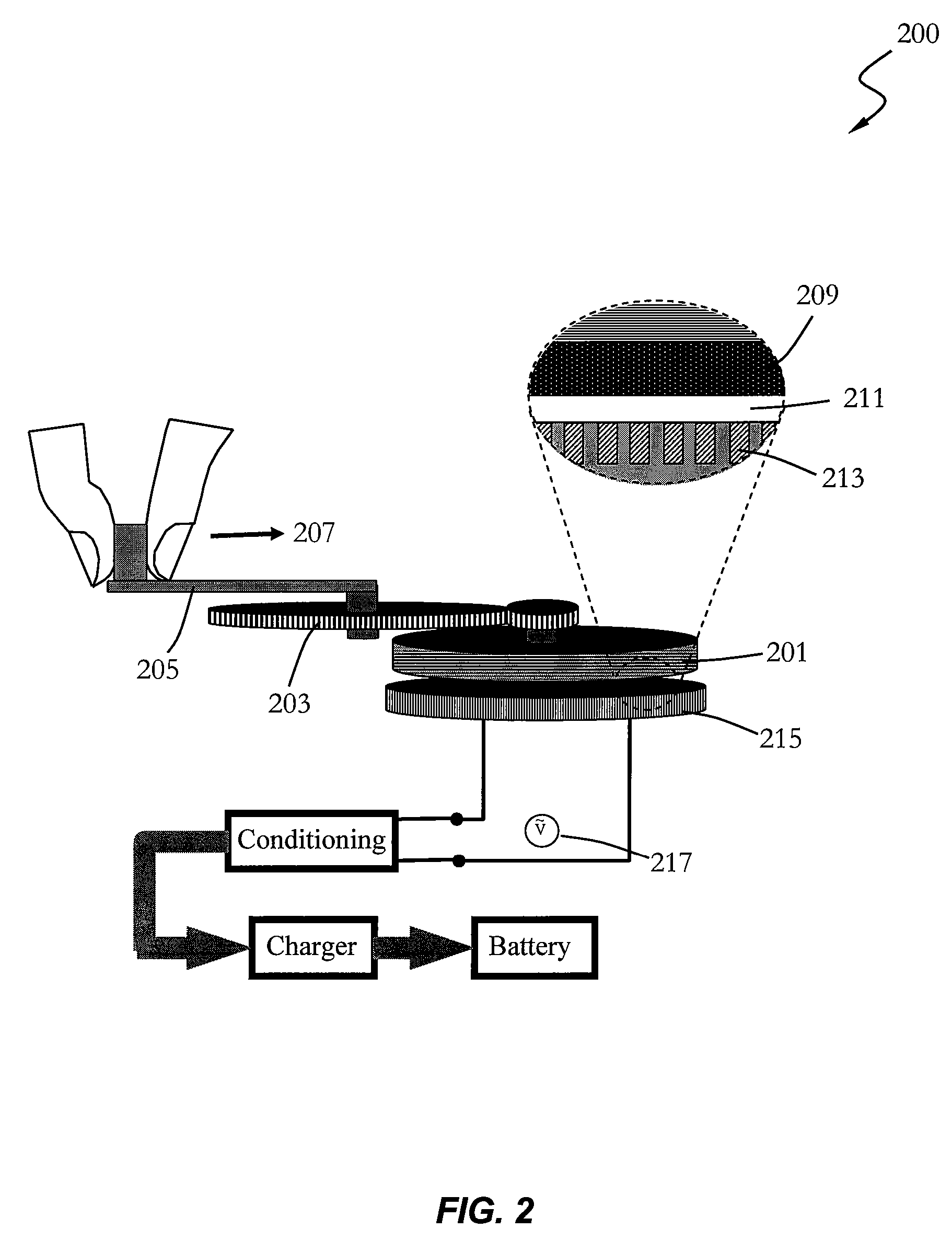

An asymmetric flywheel is coupled to an input gear that is attached to a lever or alike. The input gear and flywheel gear are engaged as the user rotates the lever. As a result, the flywheel spins and electricity is generated by the micro electromagnetic generator. When there is no direct user manual input, the input gear and the flywheel gear are disengaged. The flywheel is an unbalanced pivoted mass that rotates with inertial forces from physical accelerations by user's movement and gravitational forces, similar to a self-winding mechanism automatic watch. AC electricity is generated as a result of the flywheel's movement.

Owner:MOVELLA INC

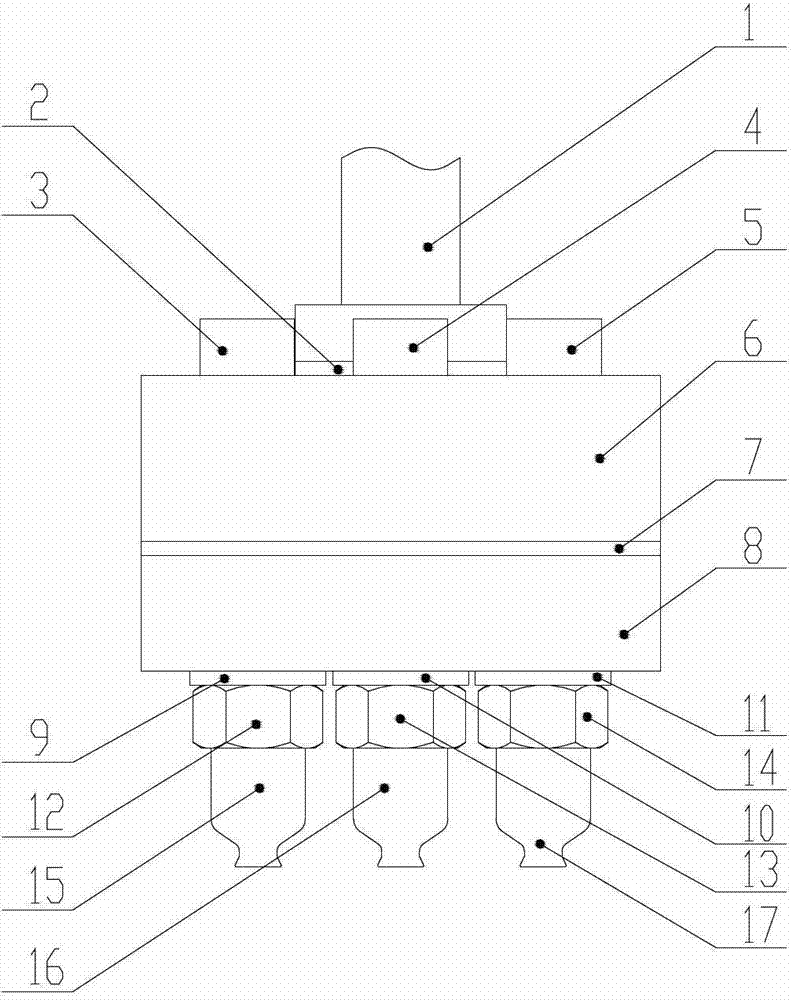

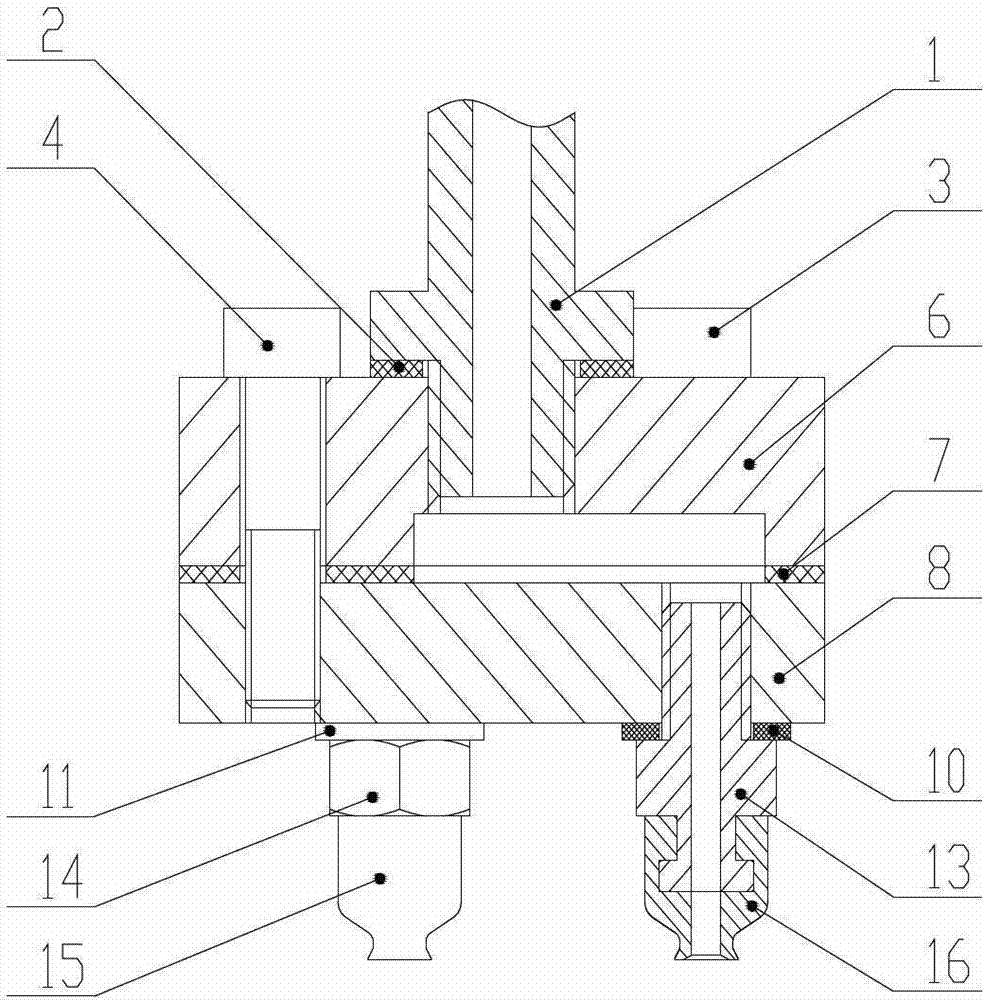

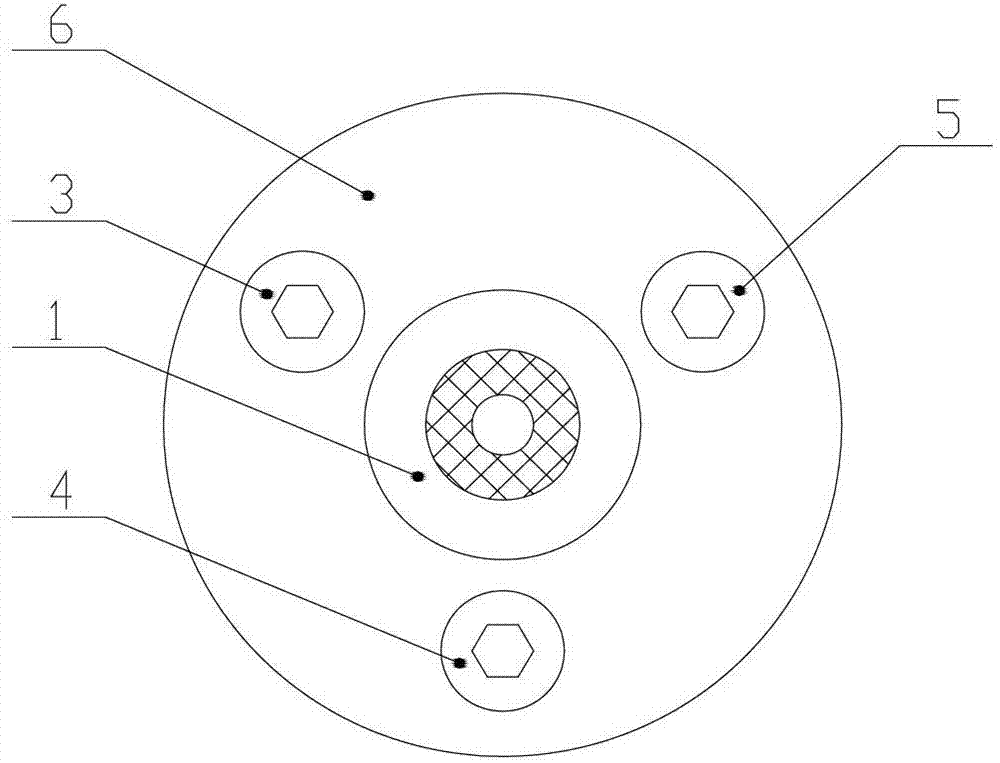

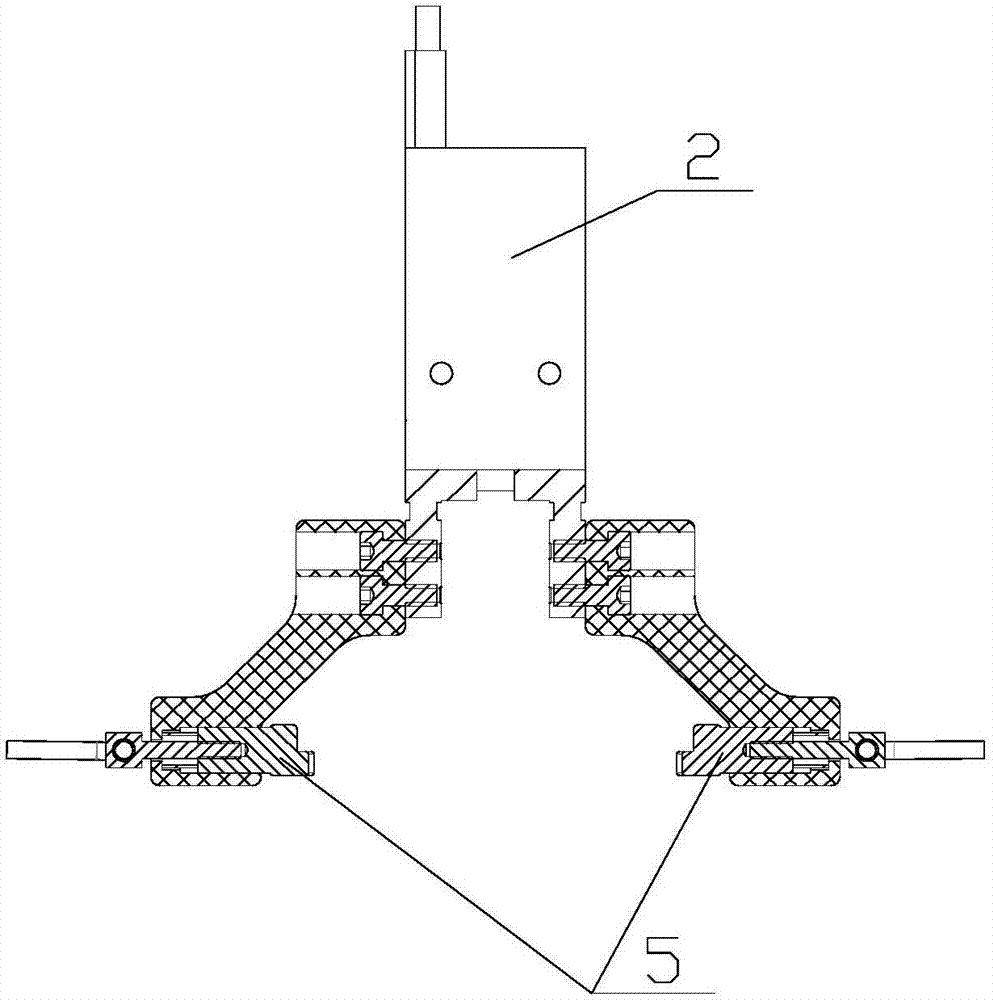

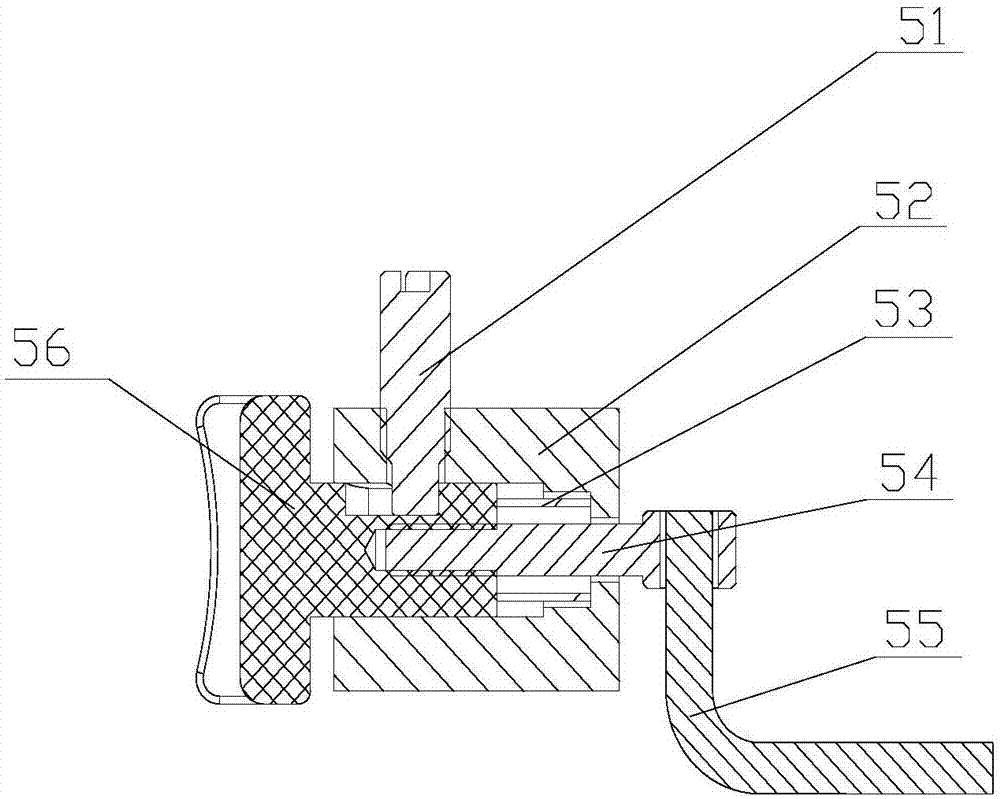

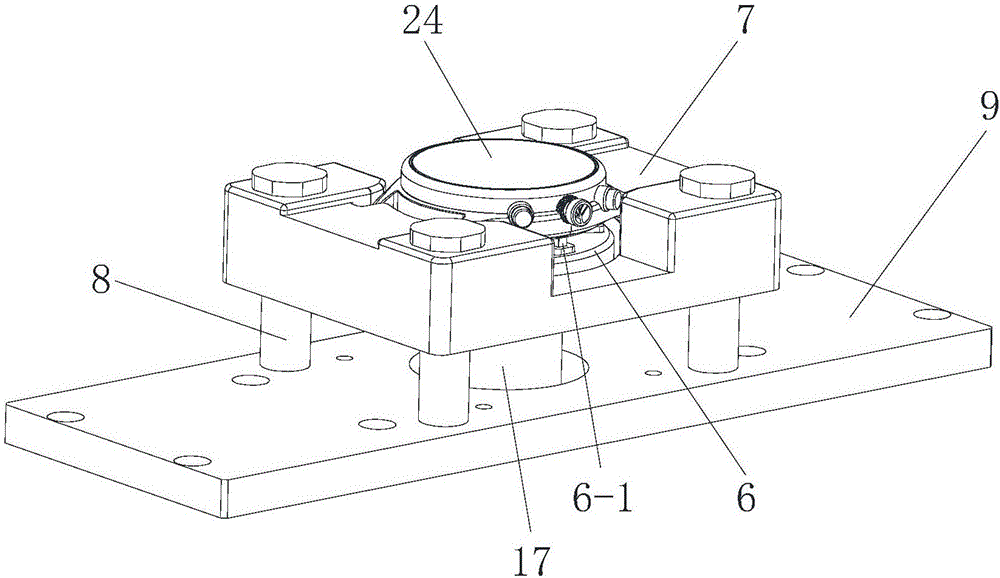

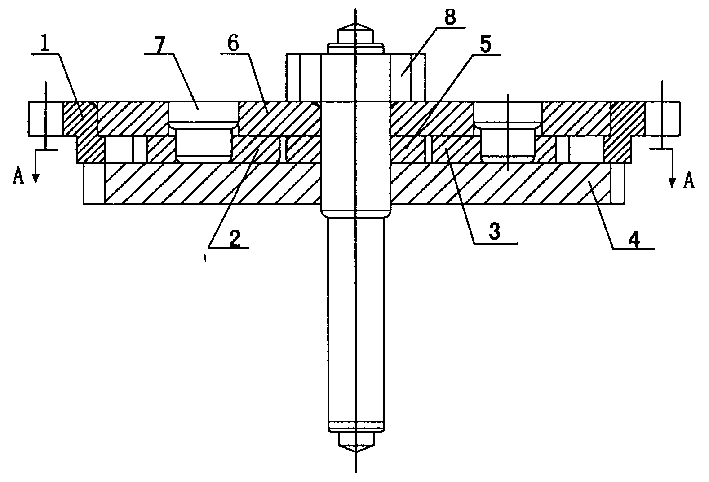

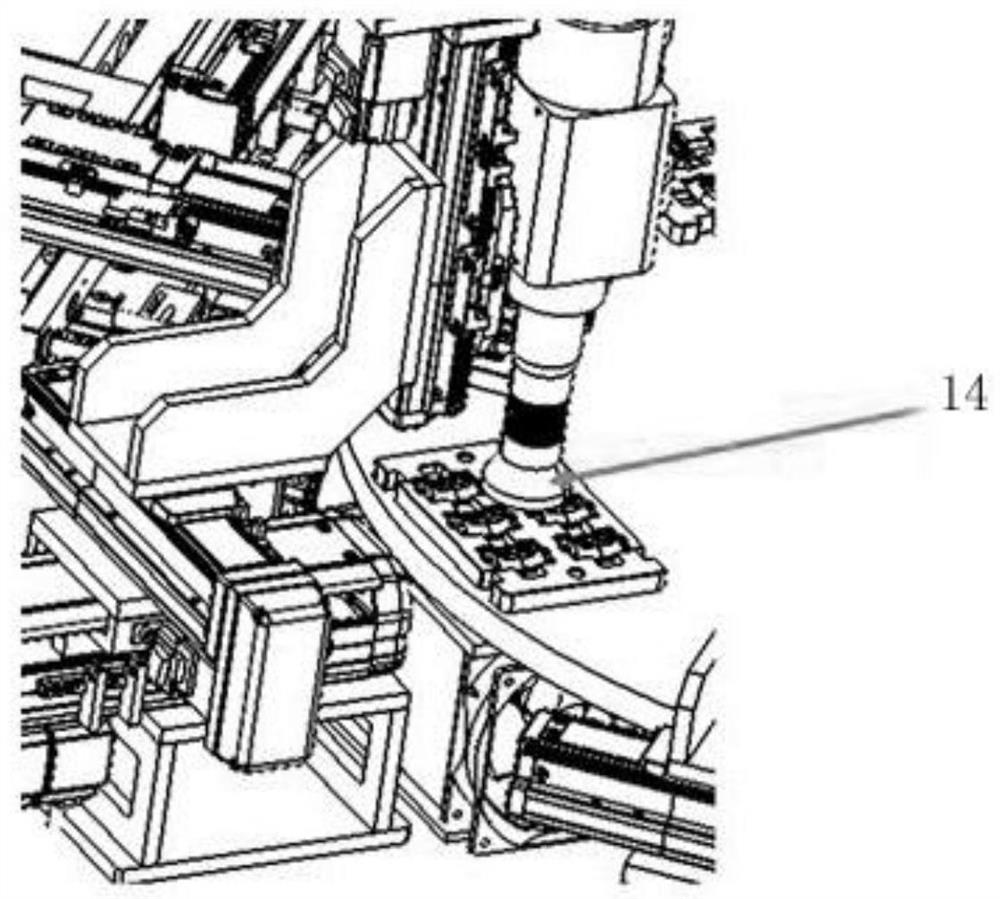

Vacuum sucker

The invention provides a vacuum sucker and relates to a vacuum sucker achieving convenient and rapid picking and placing of a small diameter annular watch component on an automatic watch production line. A connecting plate, at least 2 metal suckers and at least 2 rubber suction nozzles are arranged on the vacuum sucker. An upper plate and a lower plate are arranged on the connecting plate. The upper plate is connected with the lower plate through a fastening piece in a locking mode. A thread through hole is arranged in the upper plate. A groove is arranged in the lower surface of the upper plate. A hollow cavity is formed between the upper plate and the lower plate. At least 2 metal sucker installing holes are arranged in the lower plate. The thread through hole and the hollow cavity are communicated with the metal sucker installing hole. A metal sucker is connected with each metal sucker installing hole. A rubber suction nozzle is connected with each metal sucker. Center through holes are uniformly arranged in the metal sucker and the rubber nozzle. Due the facts that a separated type structure is adopted, the connecting plate and the metal sucker are all made of metal materials,the vacuum sucker is convenient to machine, low in cost, convenient to dismantle and convenient to clean. The component damage is easy to change. The vacuum sucker is strong in practicality.

Owner:XIAMEN UNIV

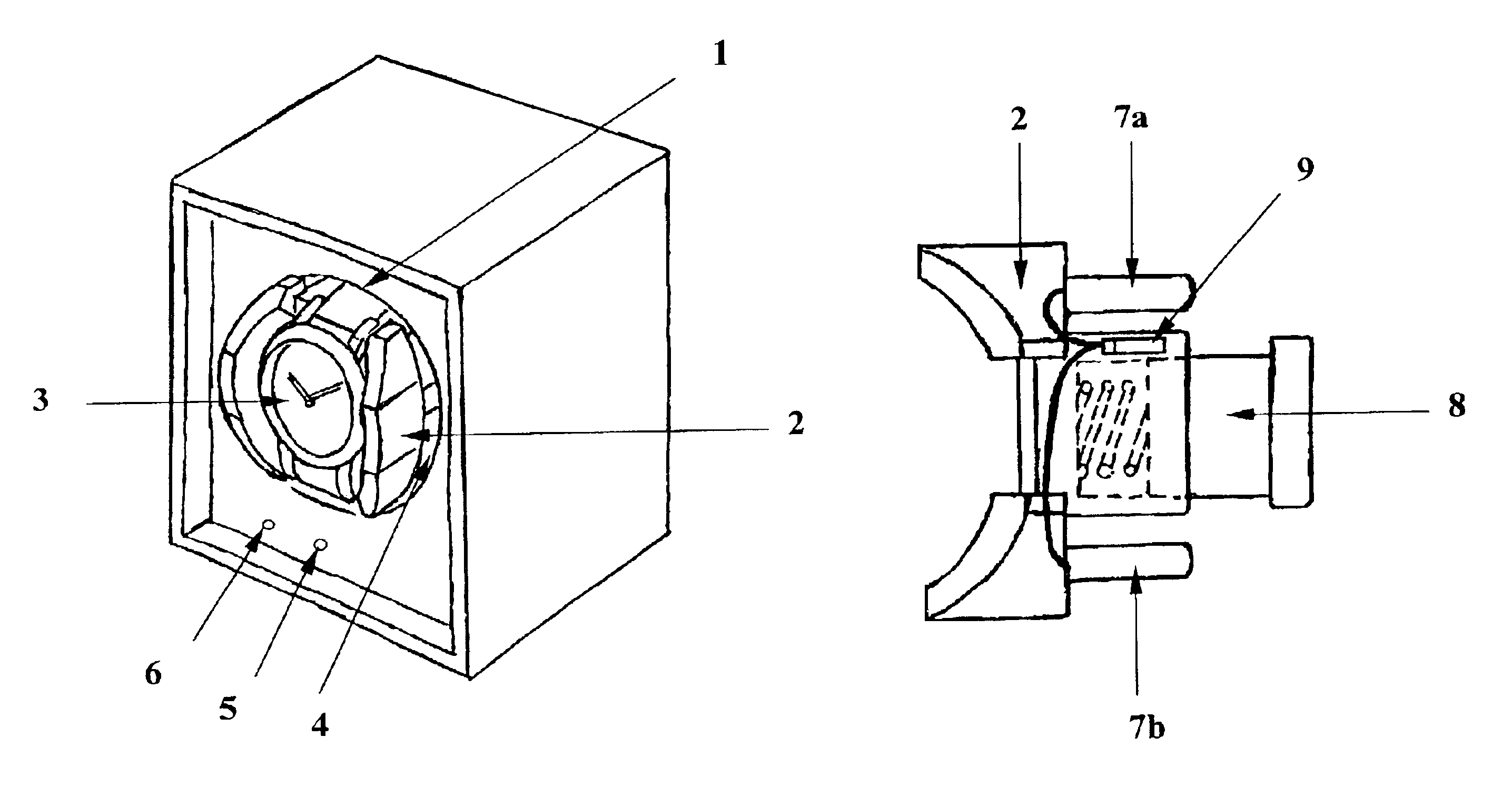

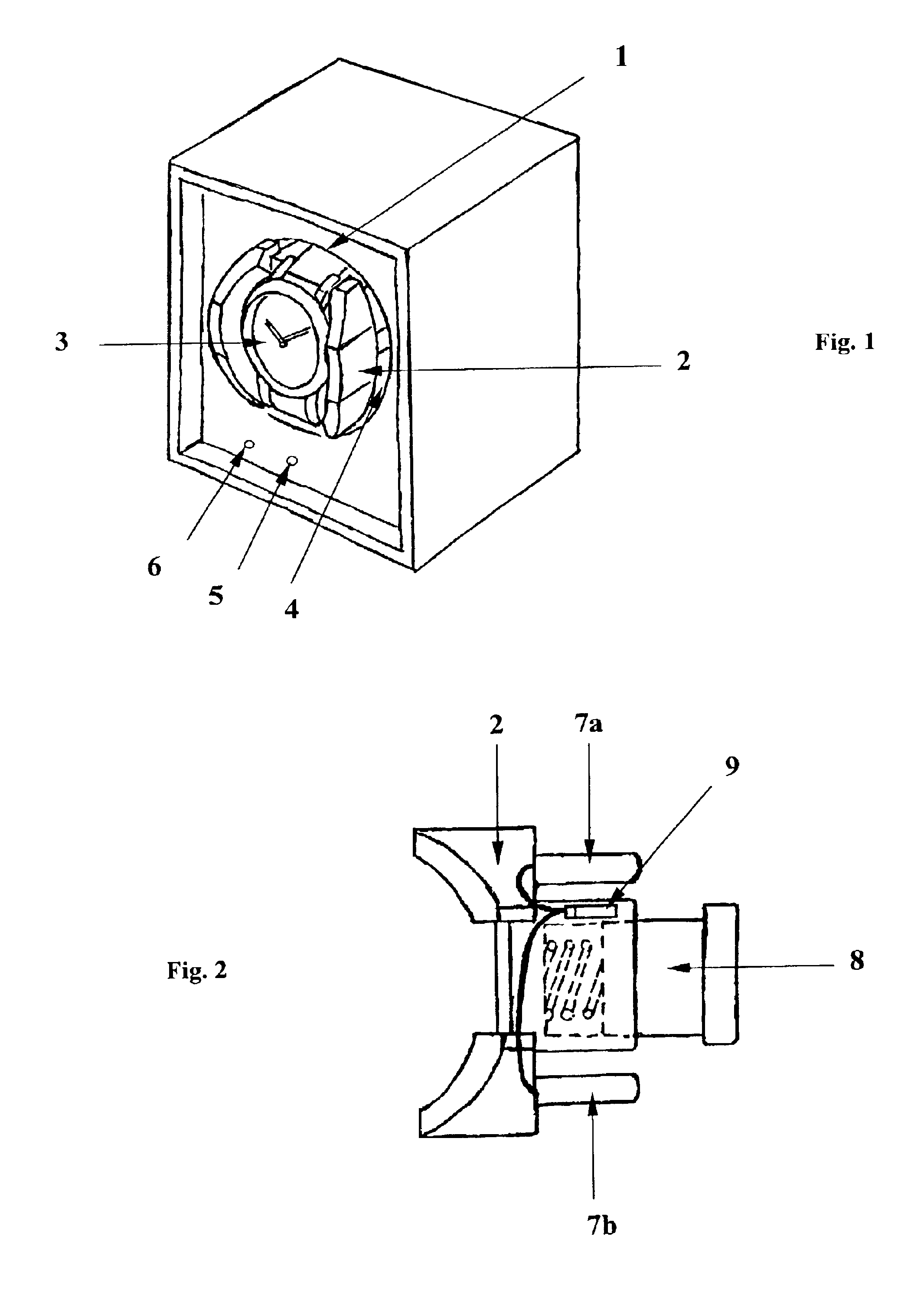

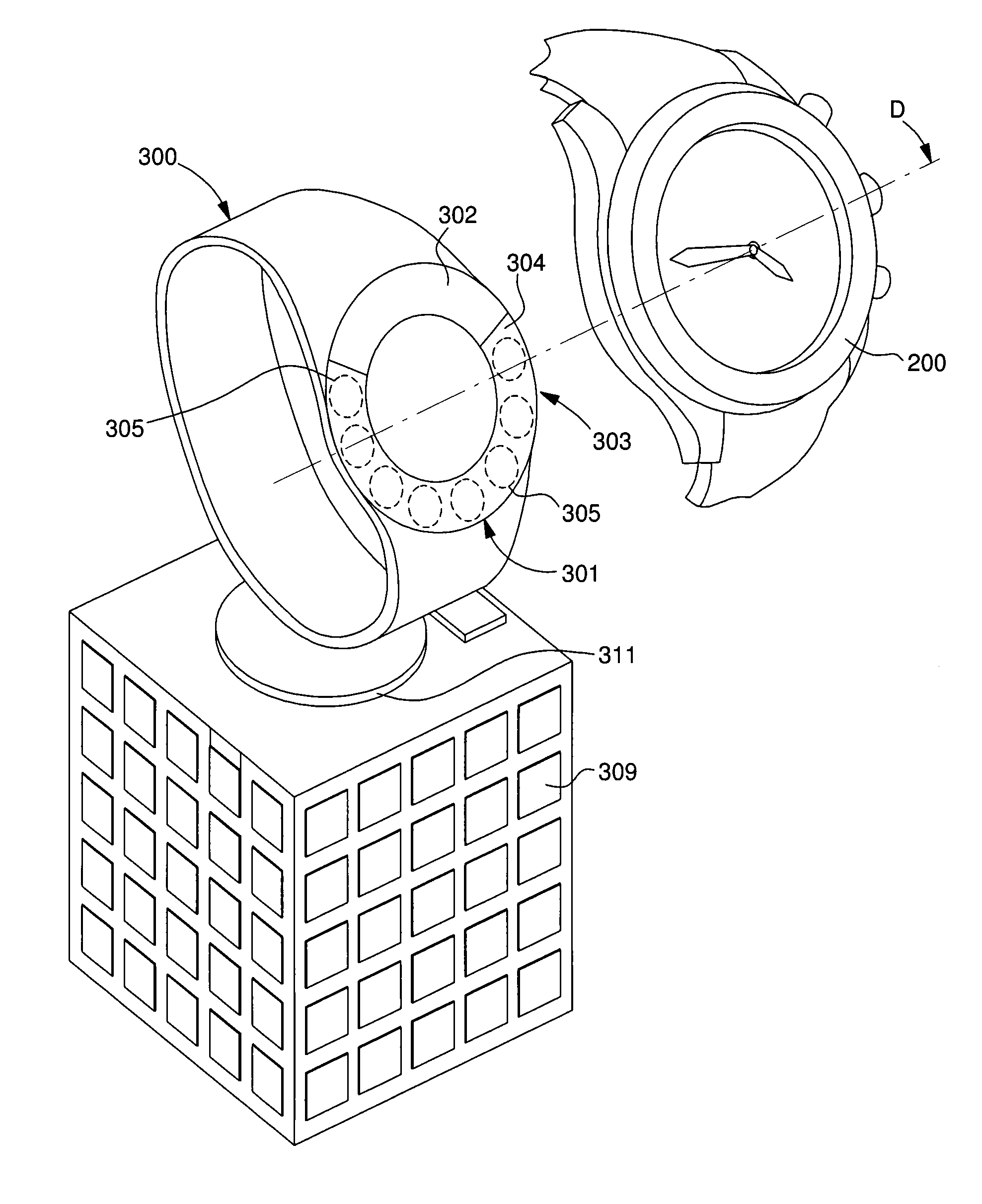

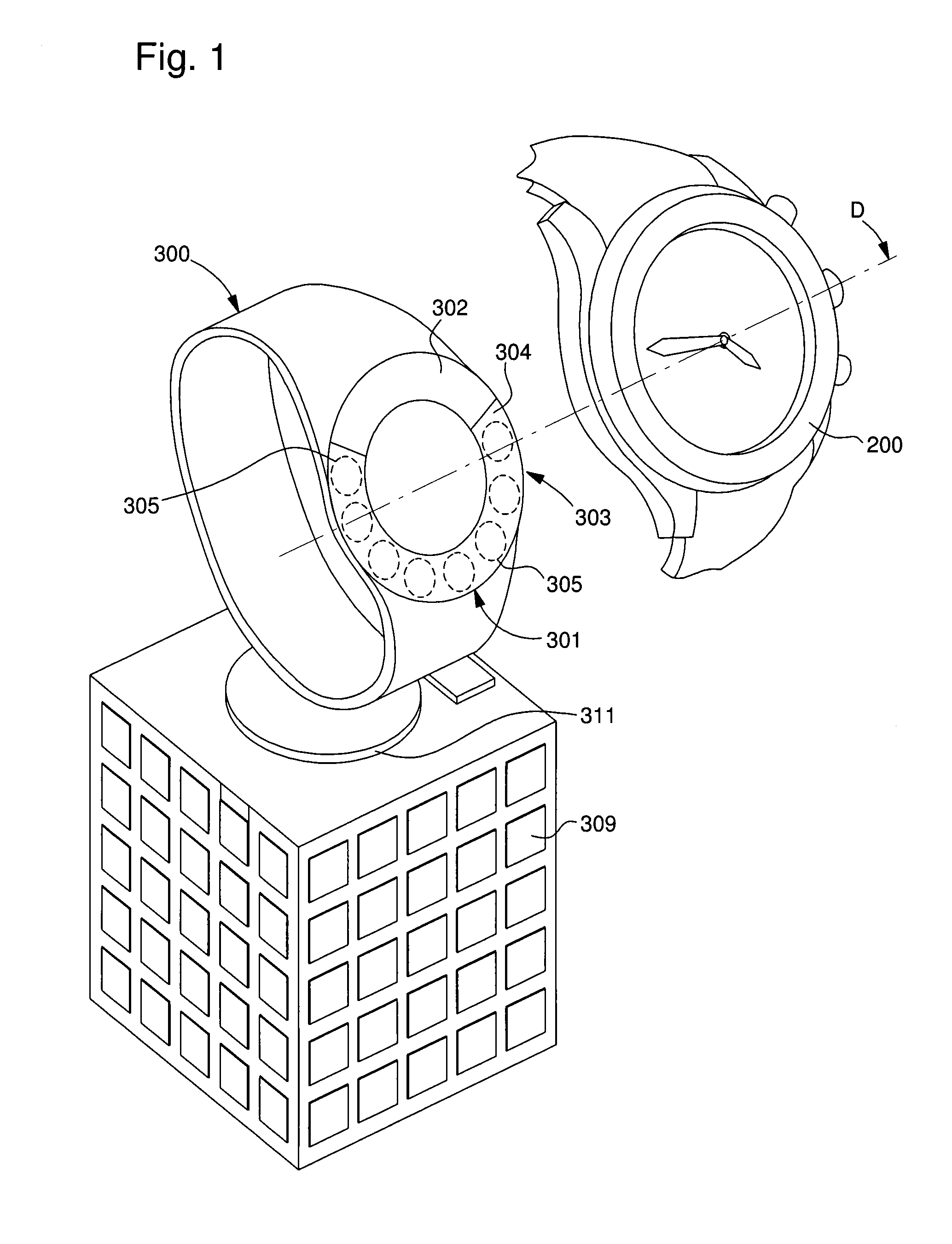

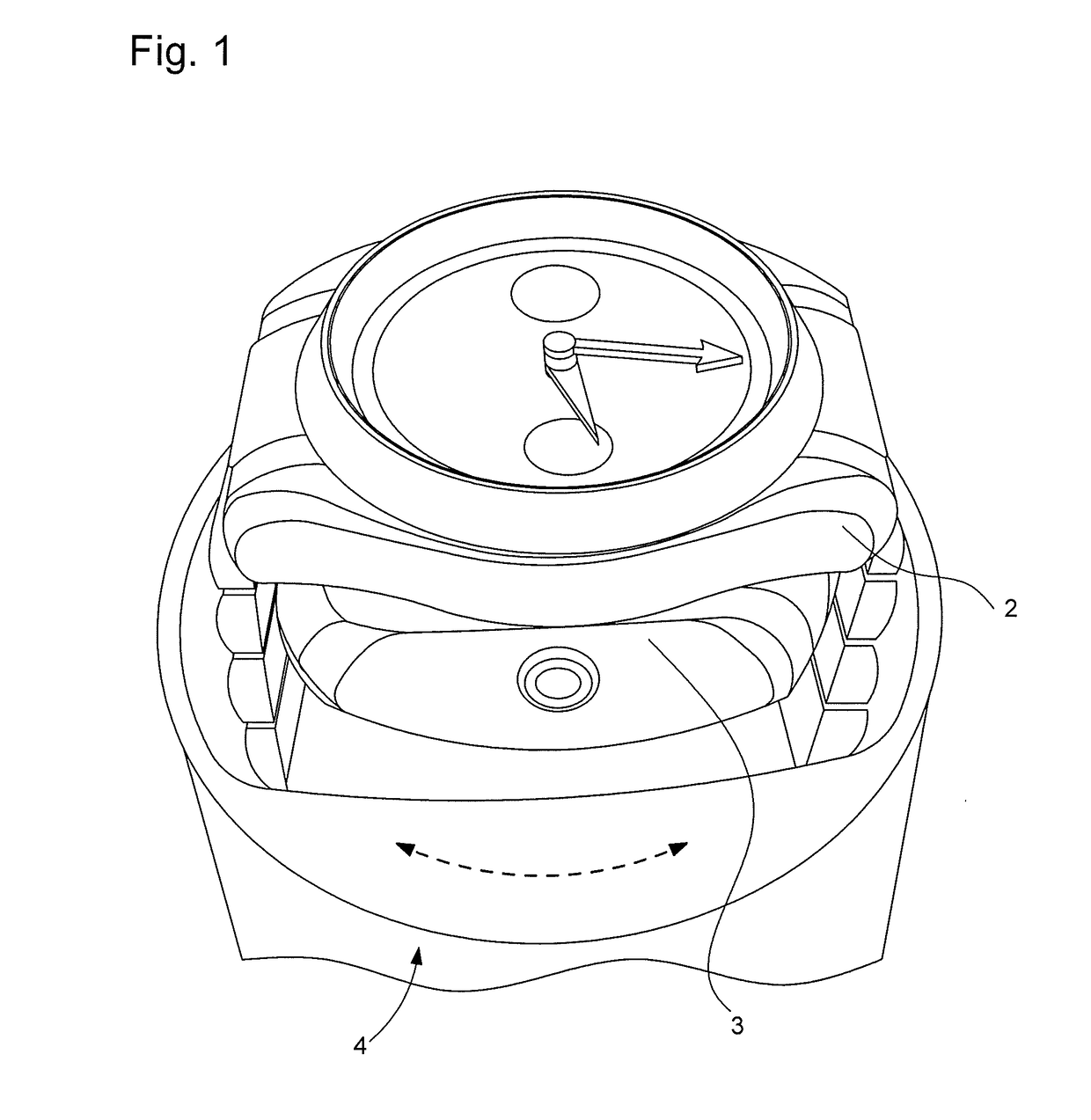

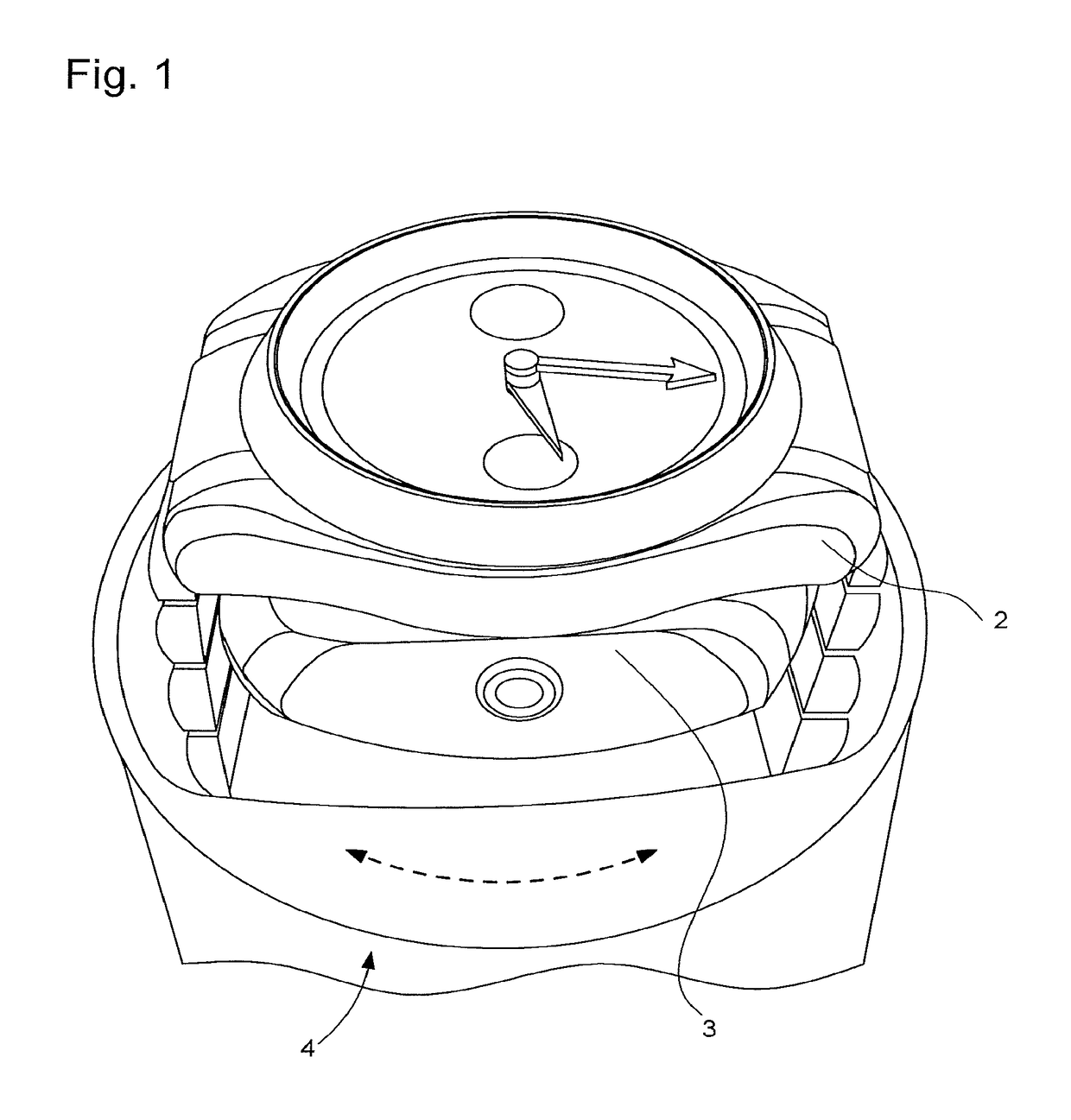

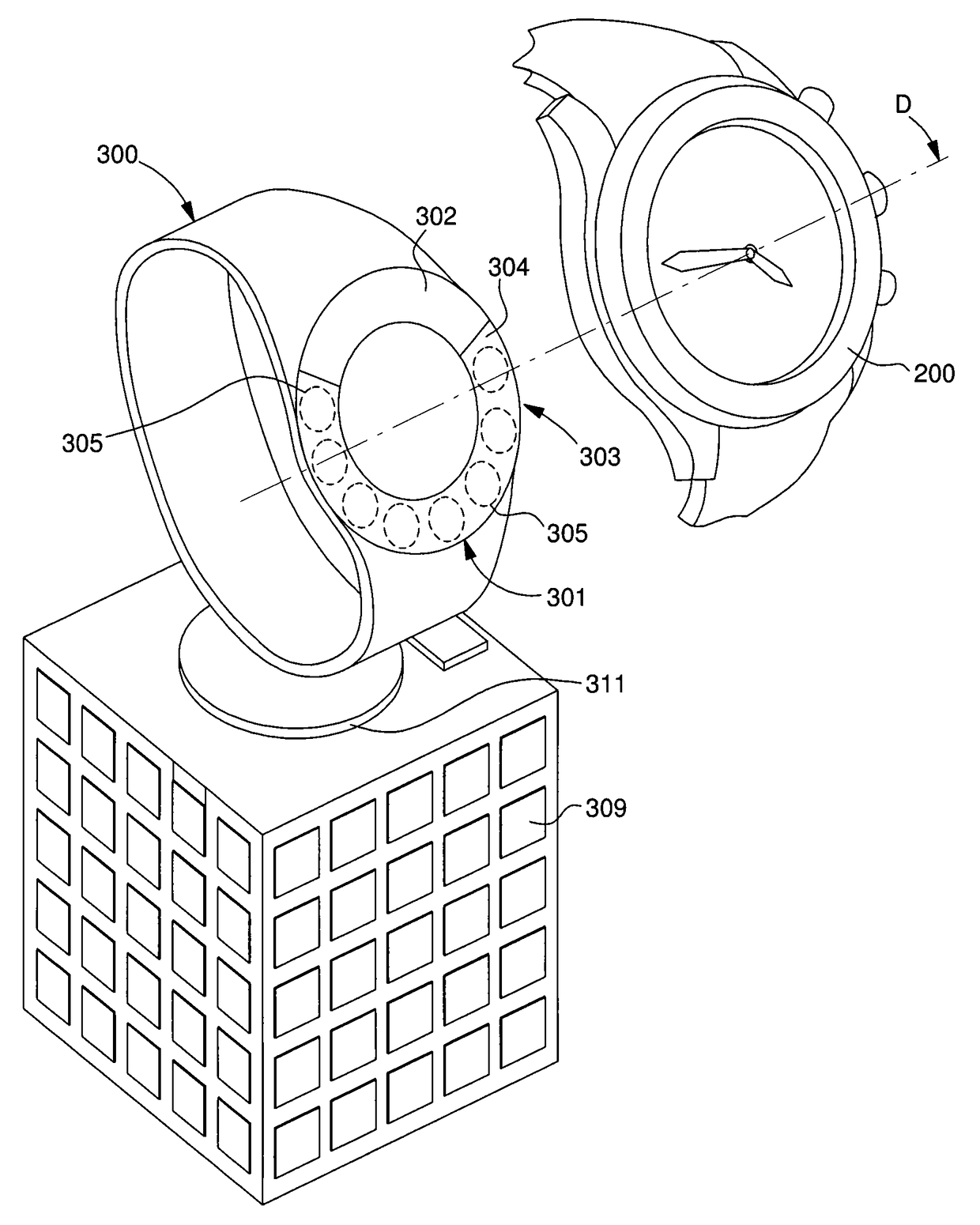

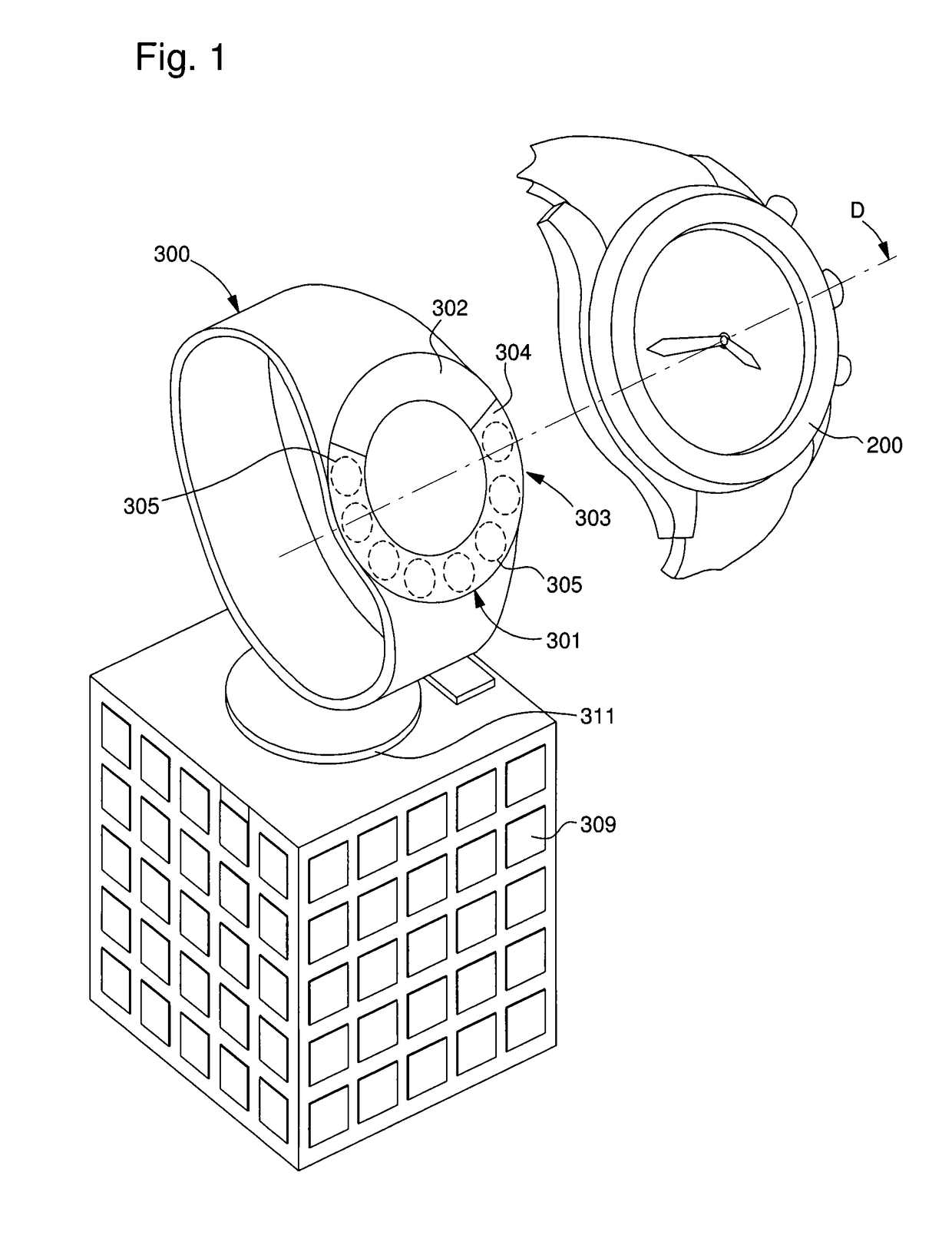

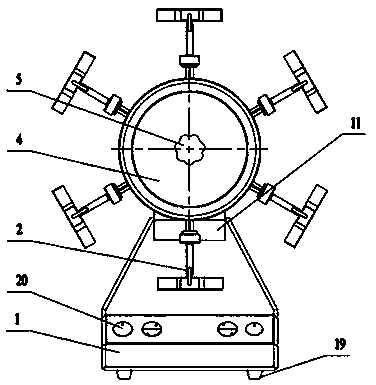

Watch winding device

Automatic watches use the movements of the wrist to re-wind the barrel spring and thus supply the necessary energy for the correct functioning of the watch. When the user cannot wear the watch it is proposed to place it on an automatic re-winding device. The device according to the invention is compact and modular. Furthermore, in order to avoid any error of manipulation, the starting and stopping of the re-winding device is done automatically by means of a detection of the presence of the watch (3). The passing of the strap in the detachable base (2) produces the tension of the device.

Owner:UNDERWOOD LONDON

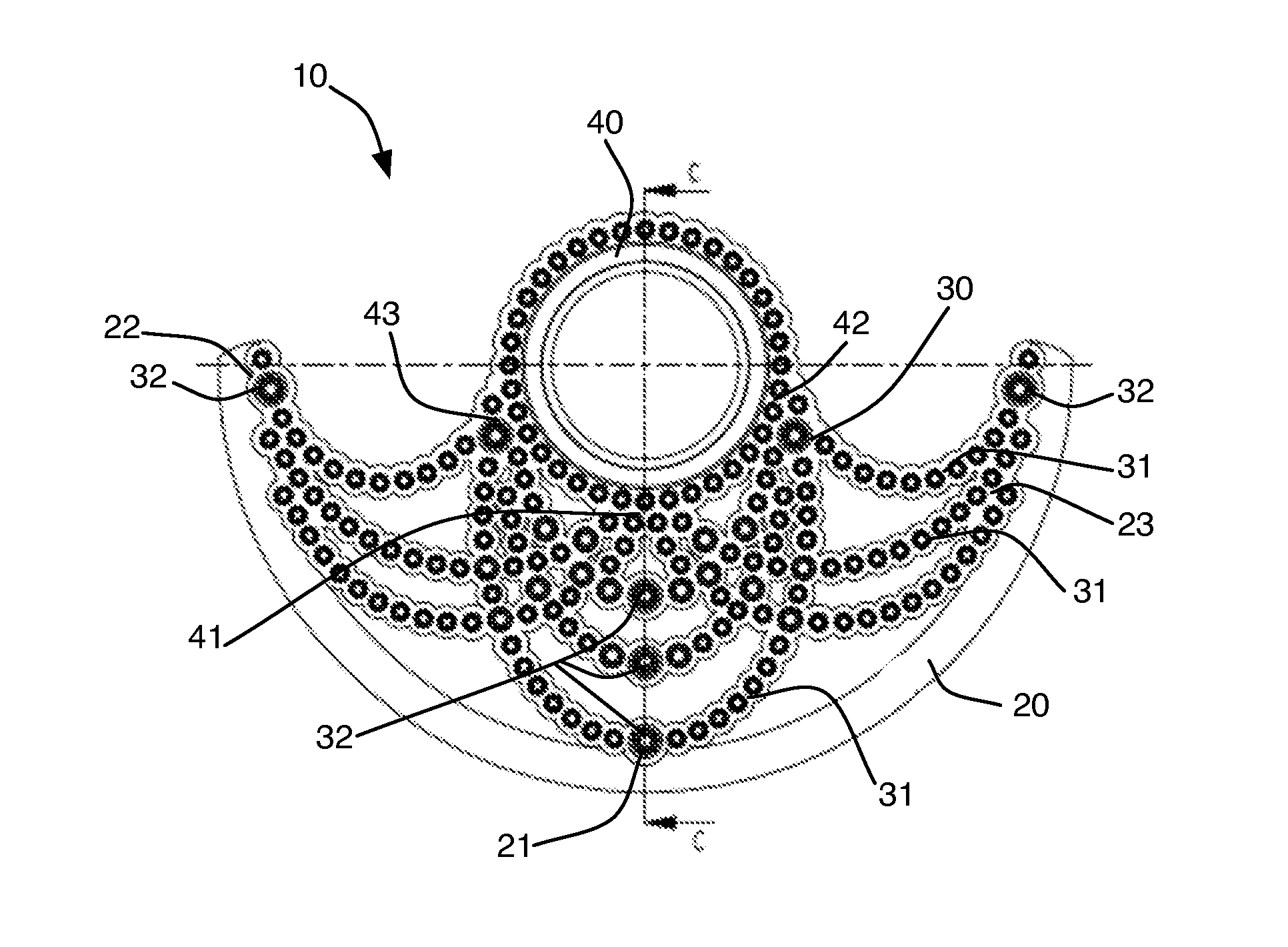

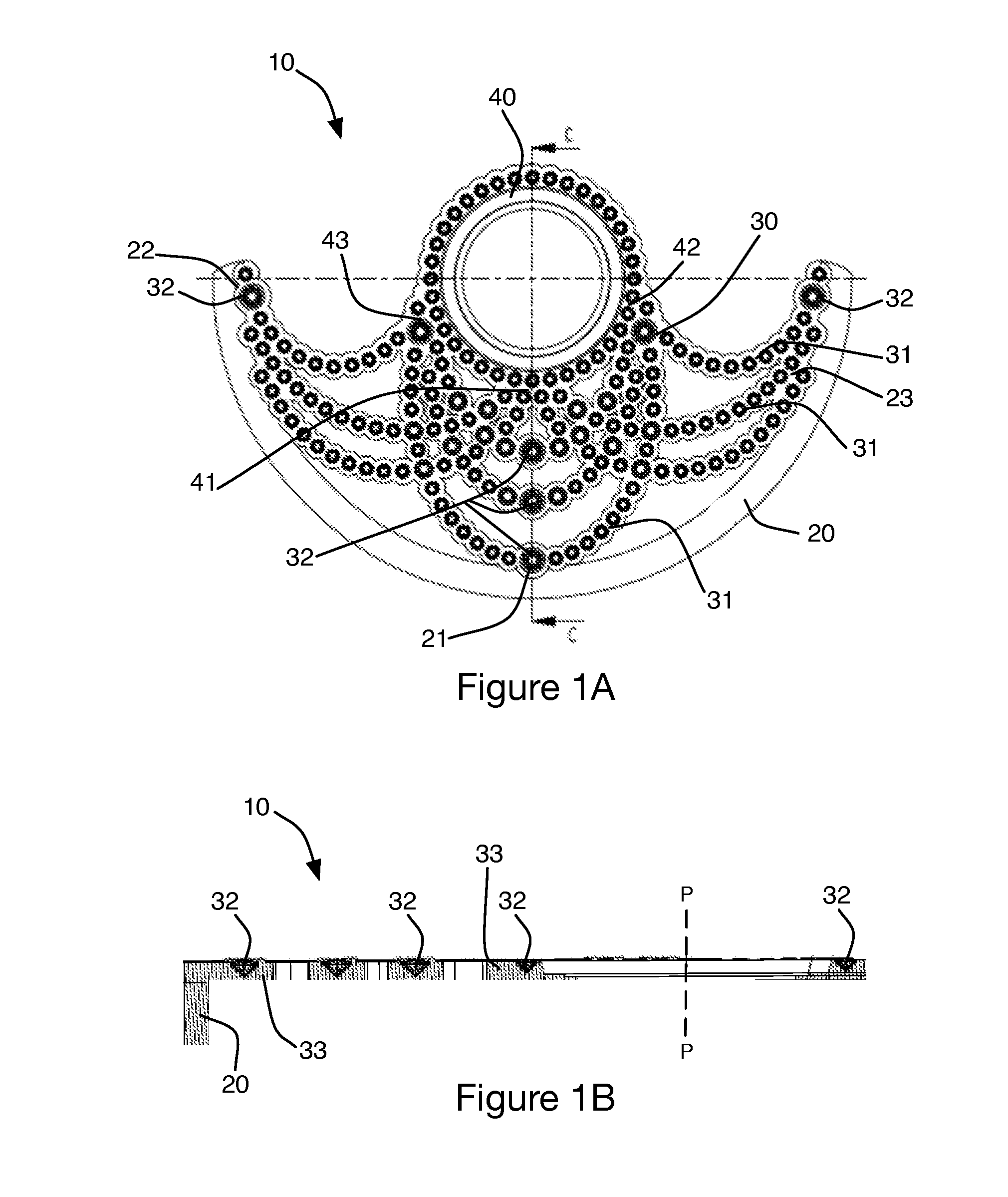

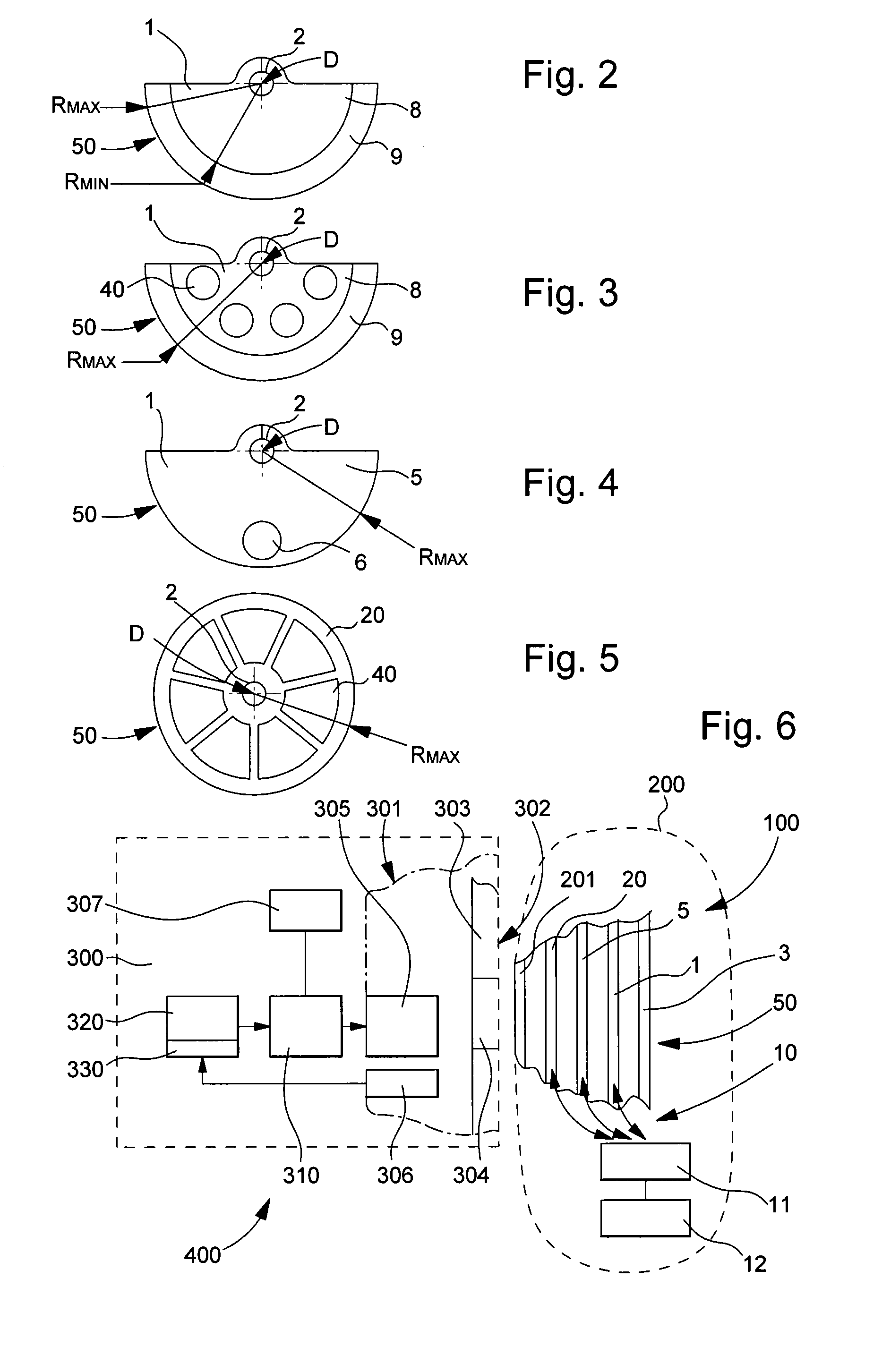

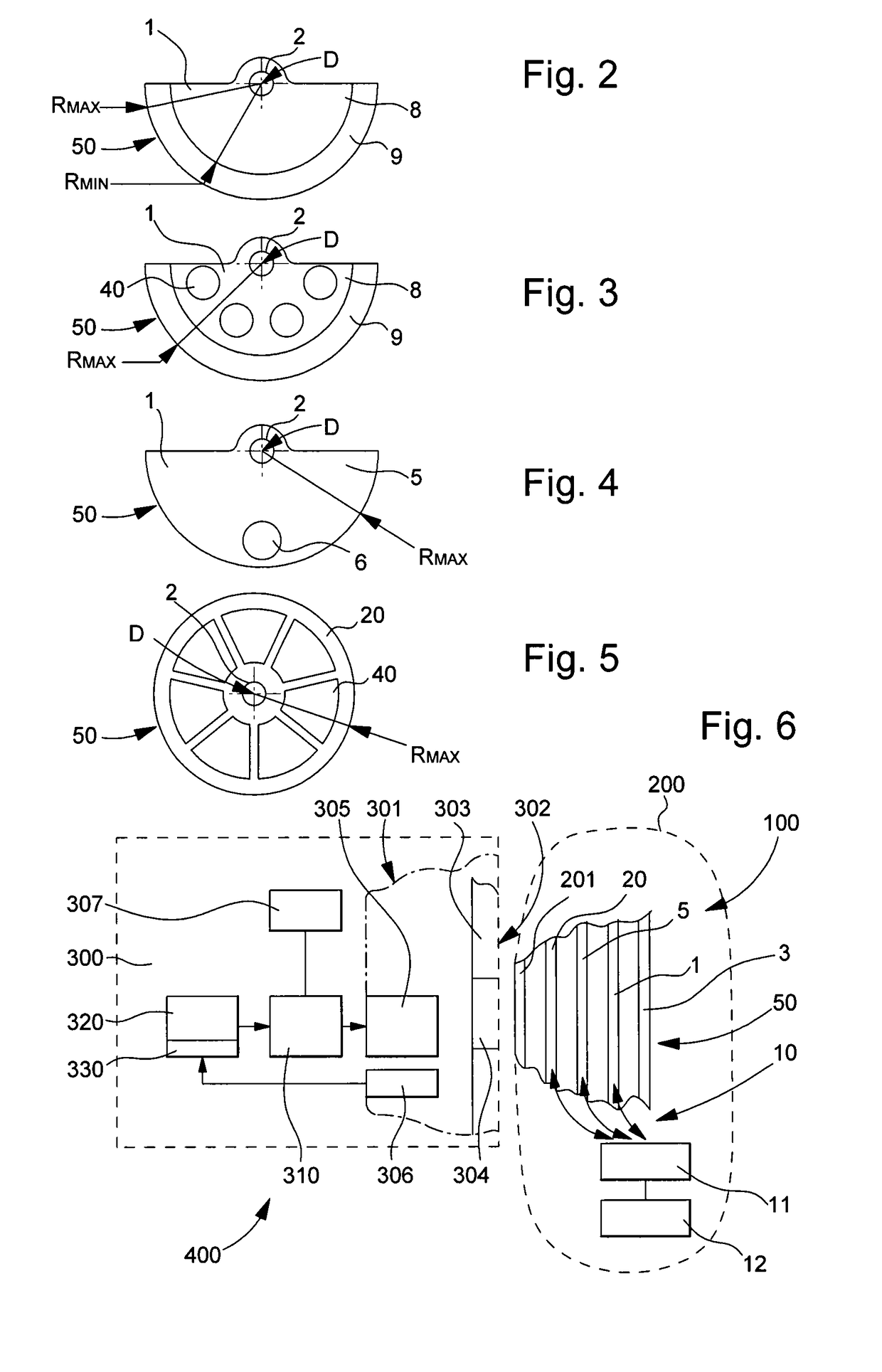

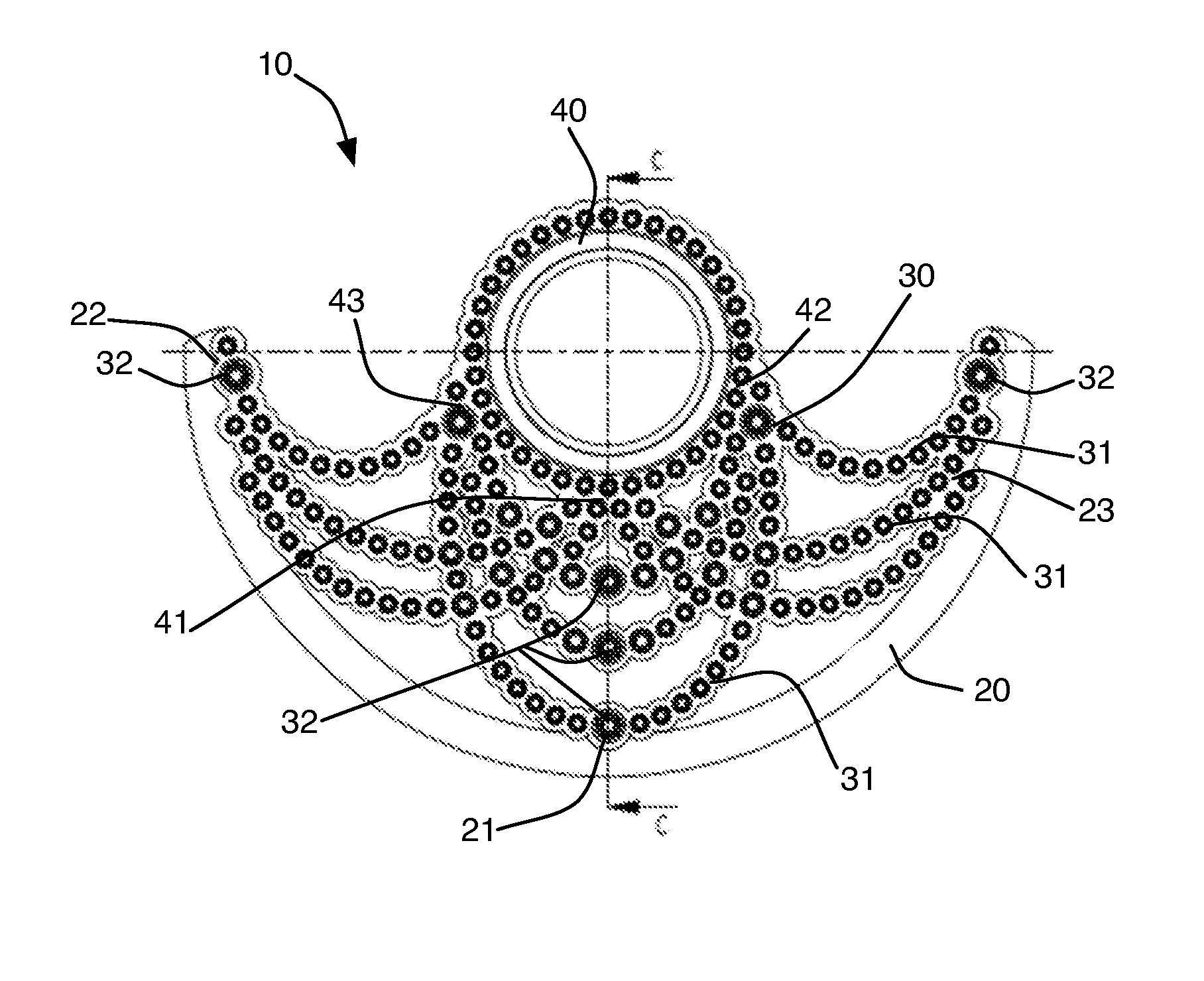

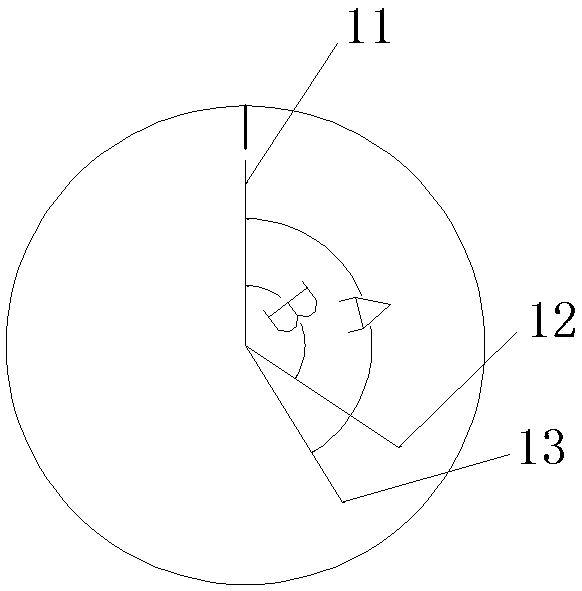

Oscillating weight for automatic watch

ActiveUS20120243387A1Improve aesthetic qualityMechanical time indicationAutomatic windingAutomatic watchEngineering

Oscillating weight for automatic watch movement, having a massive peripheral ring in the shape of an arc of circle, a connecting element connecting the peripheral ring to the weight's pivoting center, wherein the connecting element is set with a plurality of stones.

Owner:CHRISTIAN DIOR COUTURE

Method and structure for kinetic energy based generator for portable electronic devices

An asymmetric flywheel is coupled to an input gear that is attached to a lever or alike. The input gear and flywheel gear are engaged as the user rotates the lever. As a result, the flywheel spins and electricity is generated by the micro electromagnetic generator. When there is no direct user manual input, the input gear and the flywheel gear are disengaged. The flywheel is an unbalanced pivoted mass that rotates with inertial forces from physical accelerations by user's movement and gravitational forces, similar to a self-winding mechanism automatic watch. AC electricity is generated as a result of the flywheel's movement.

Owner:MOVELLA INC

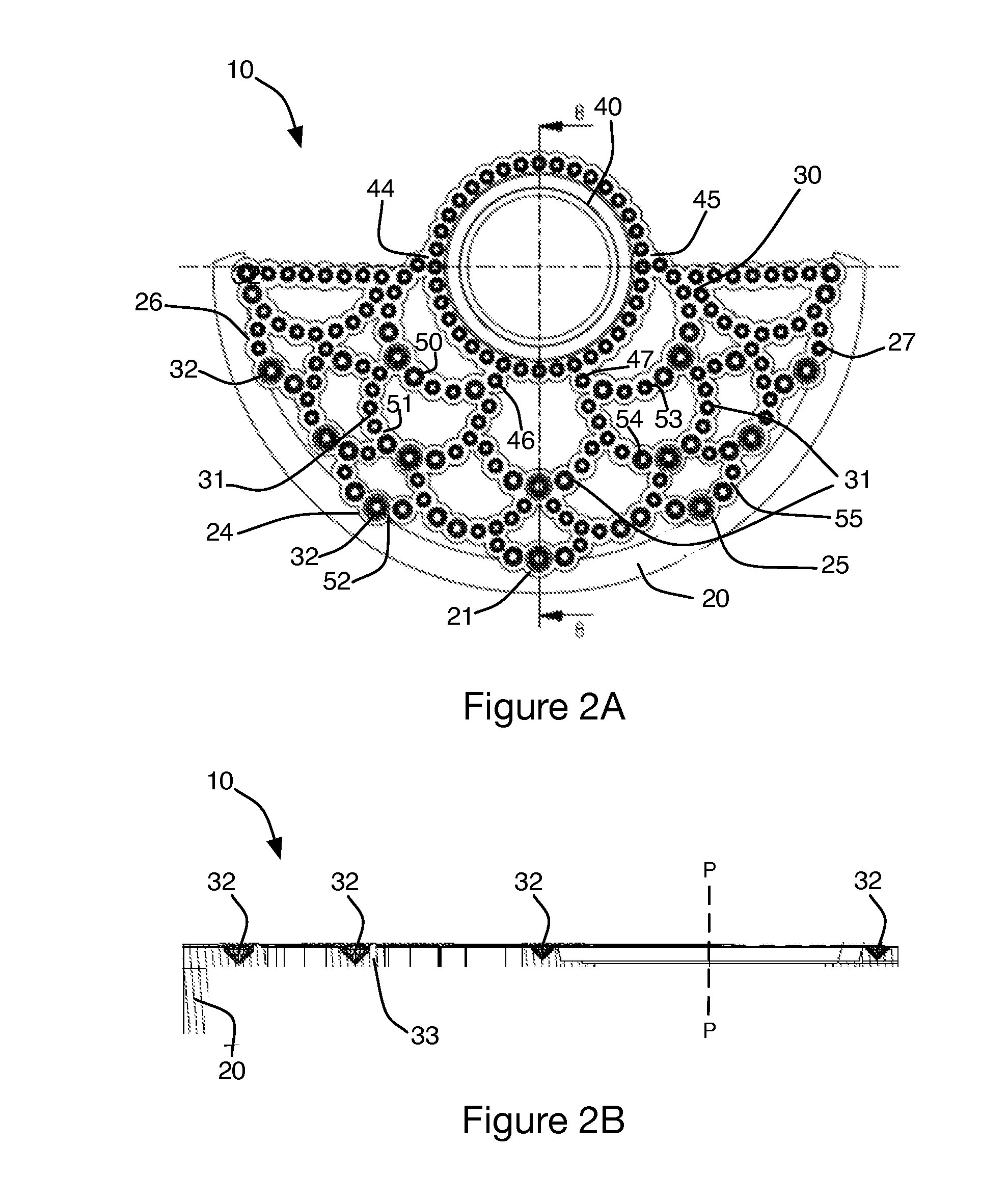

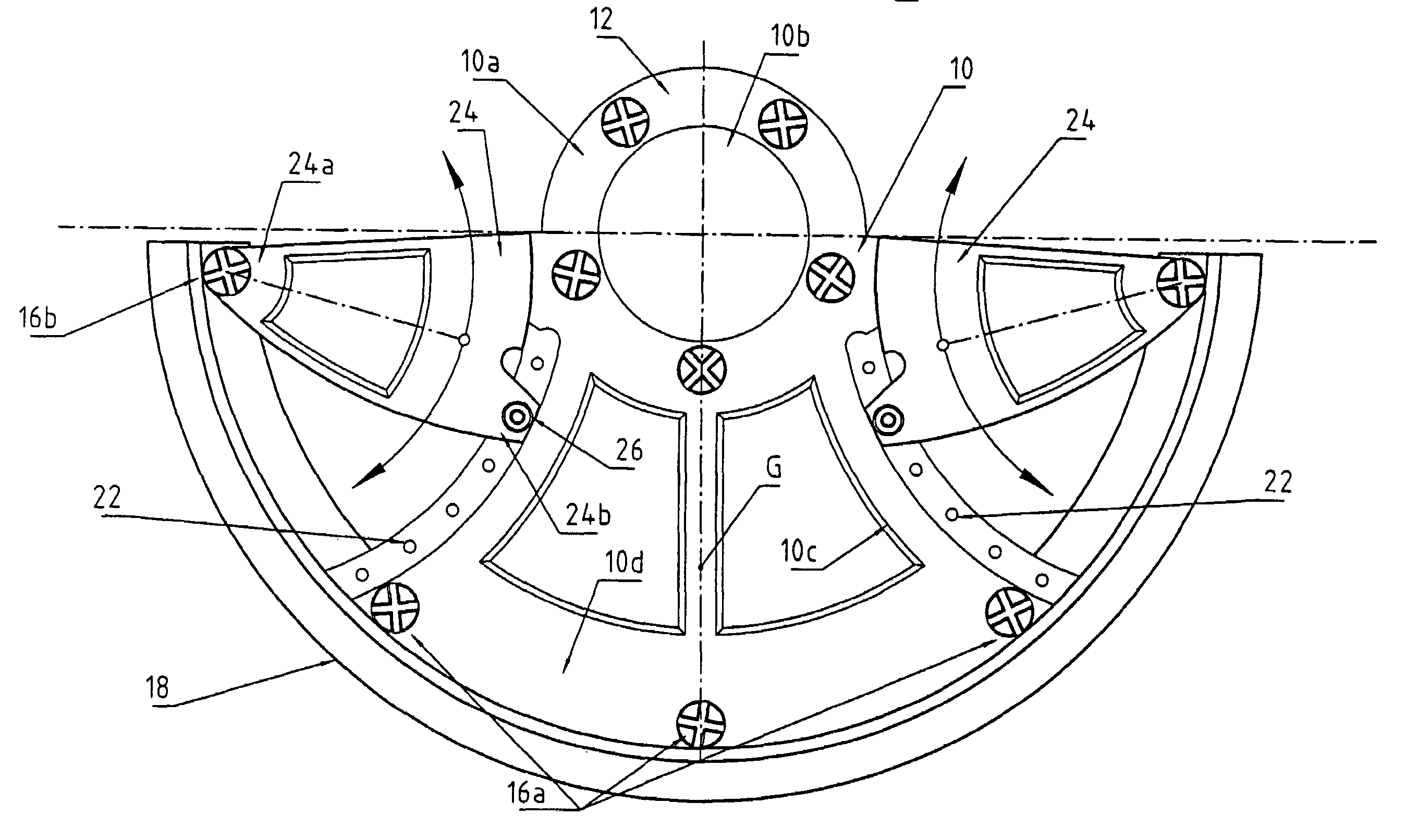

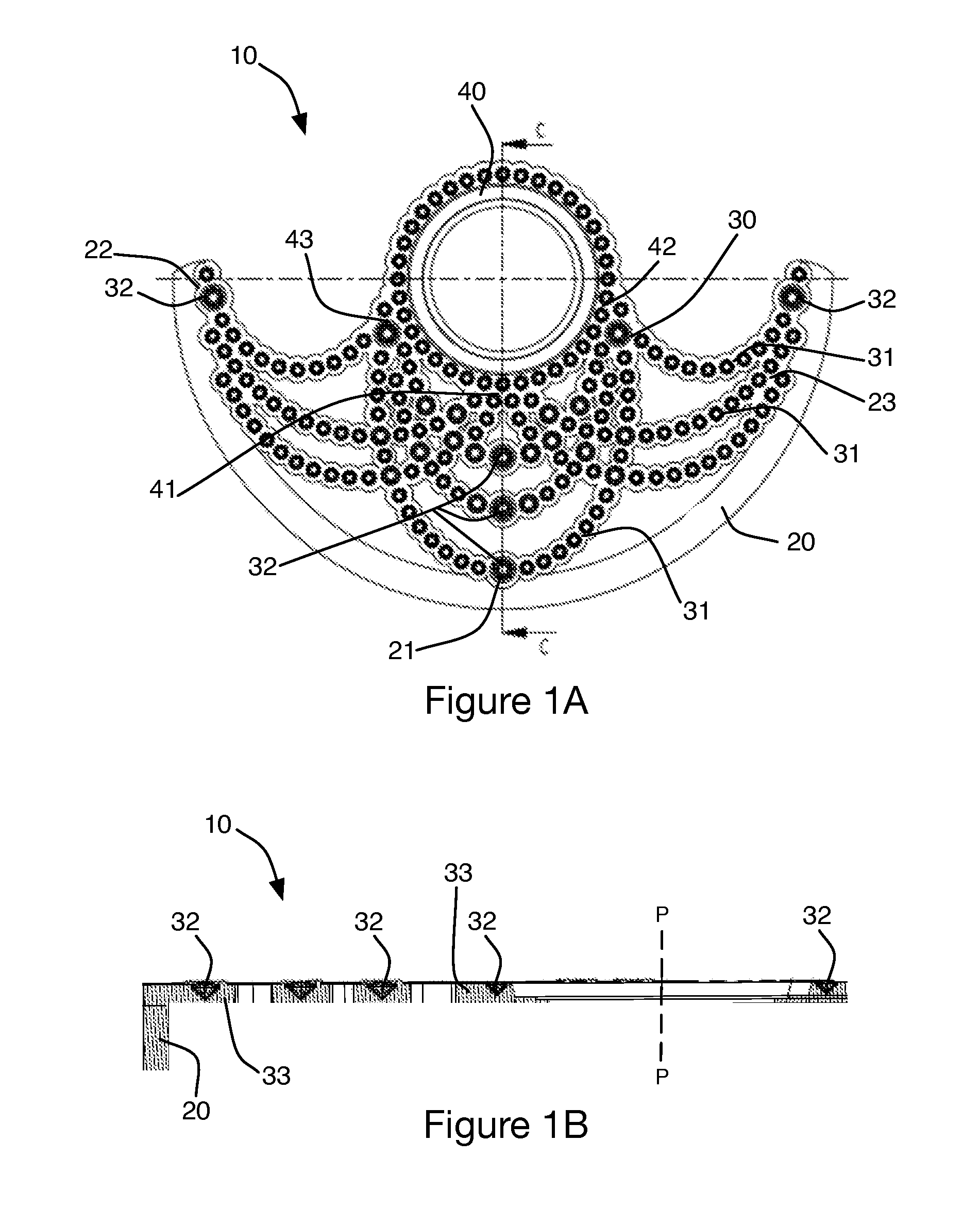

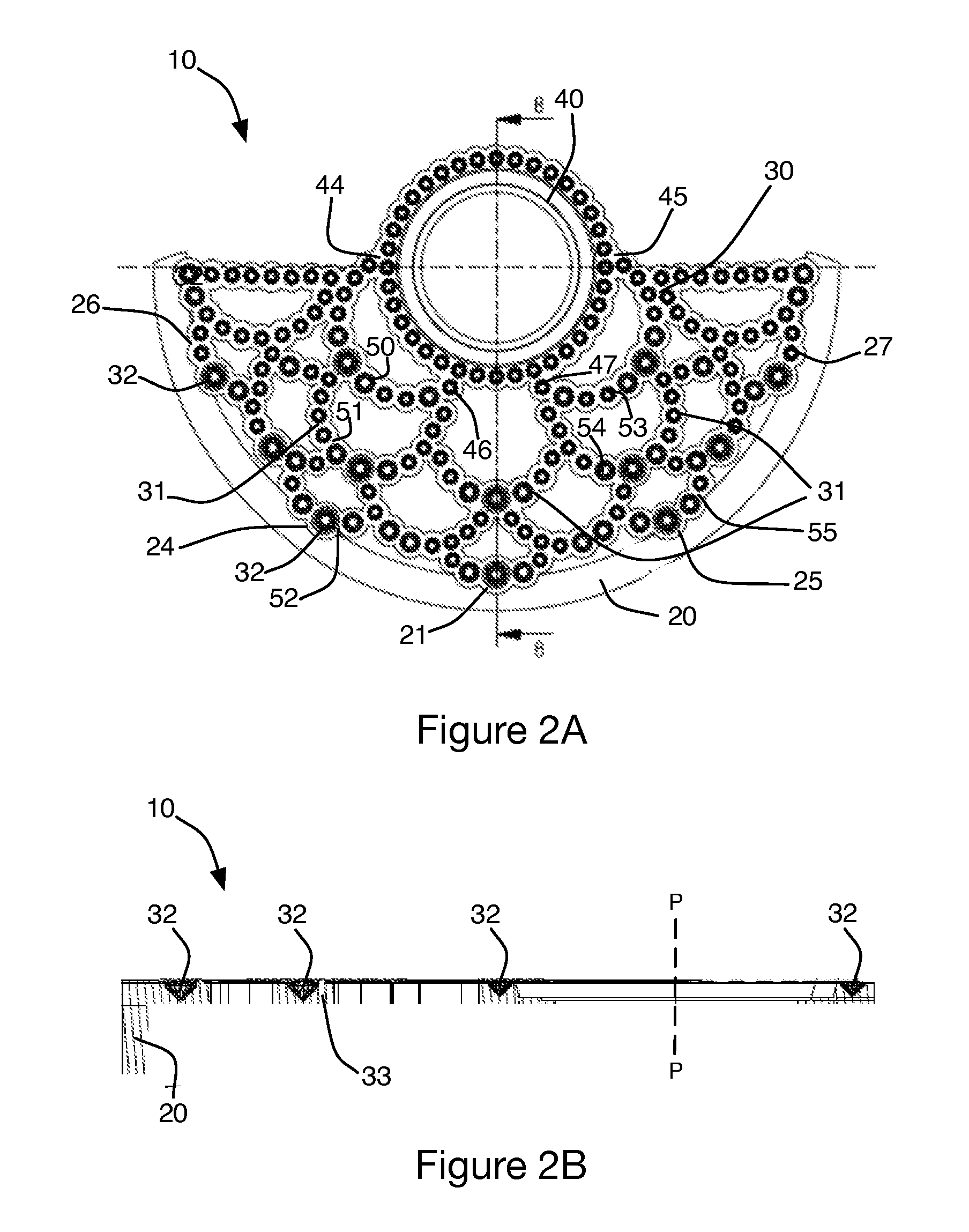

Oscillating weight

ActiveUS20060050617A1High adjustment accuracyEasy to adjustElectric indicationElectric windingRelative motionEngineering

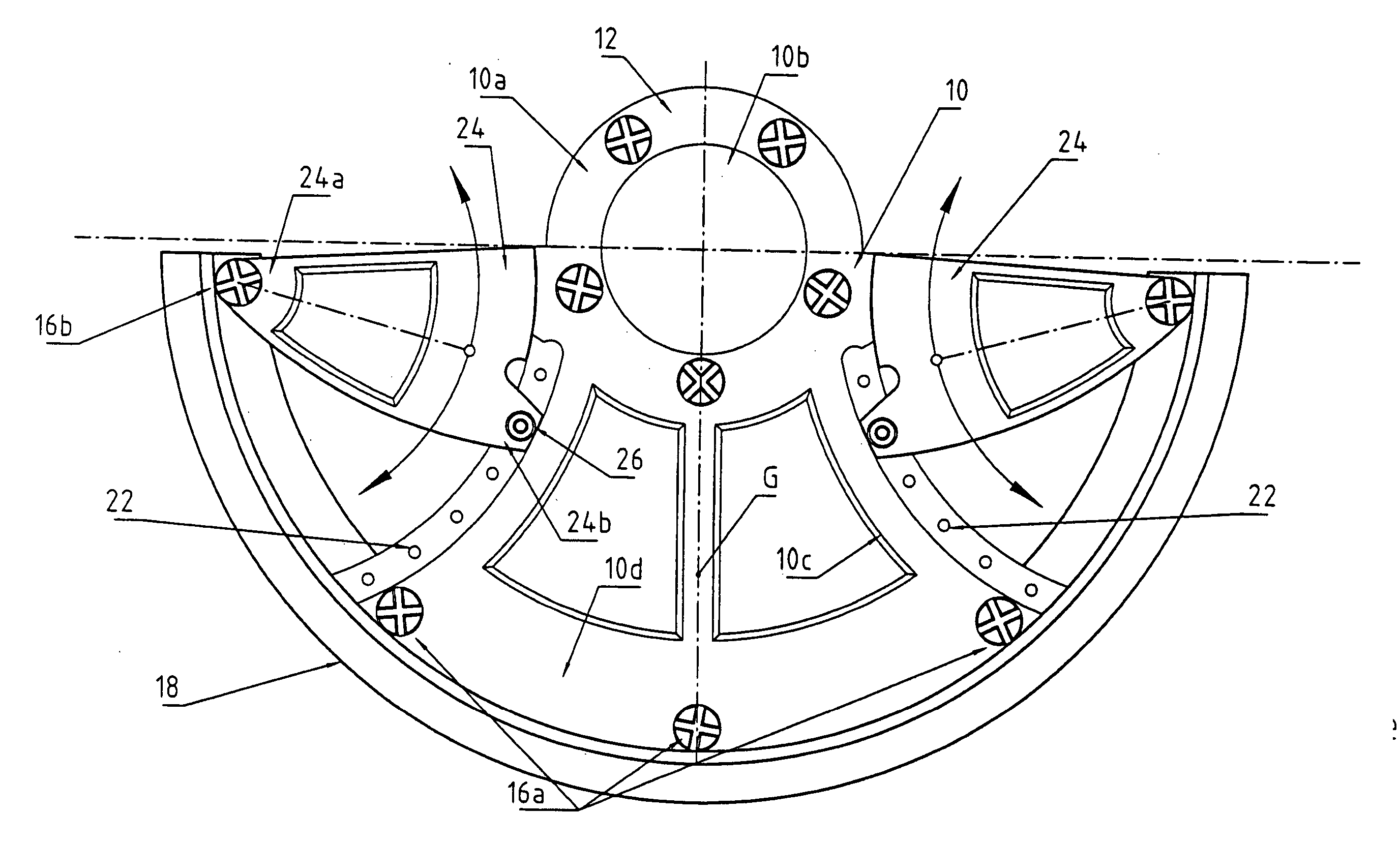

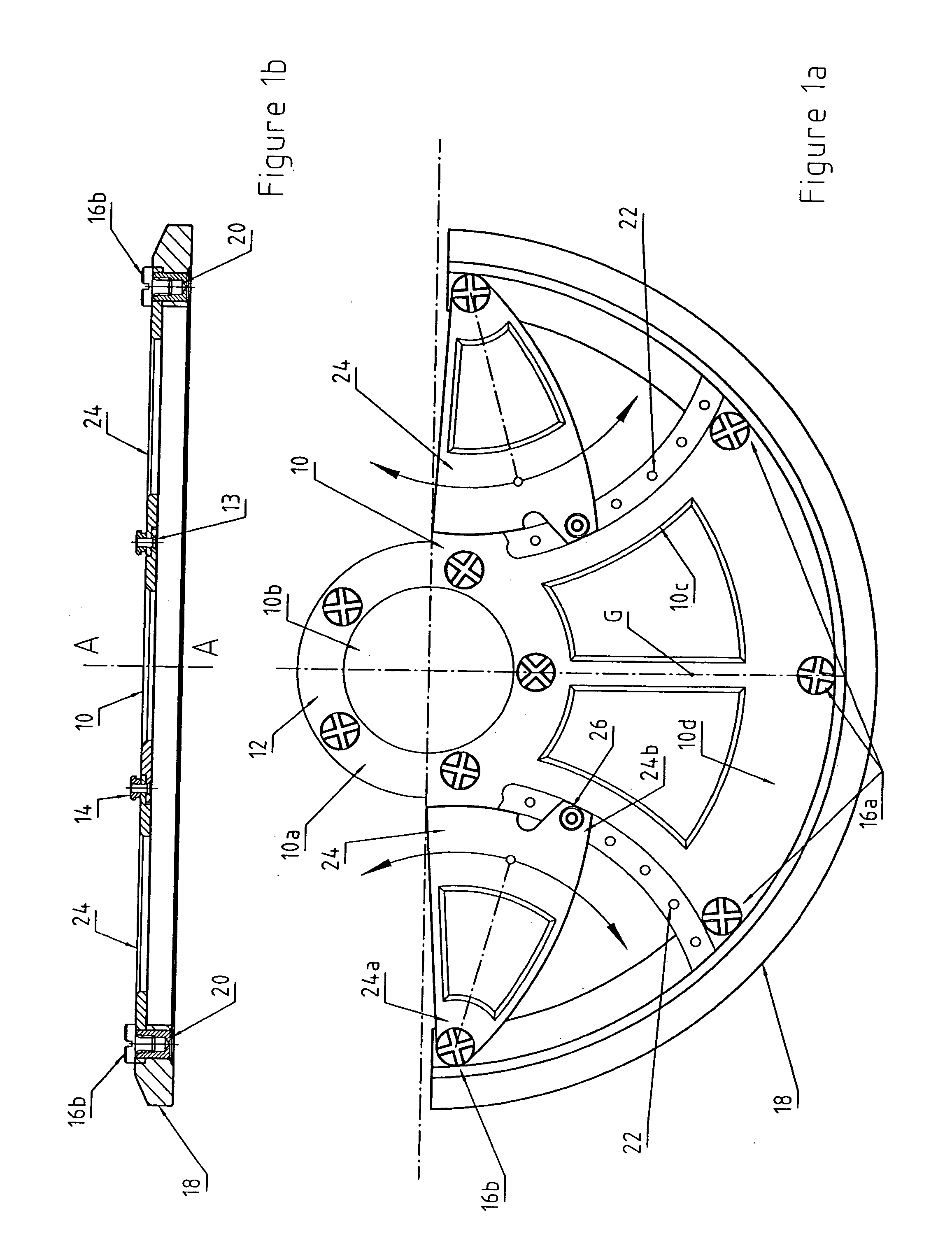

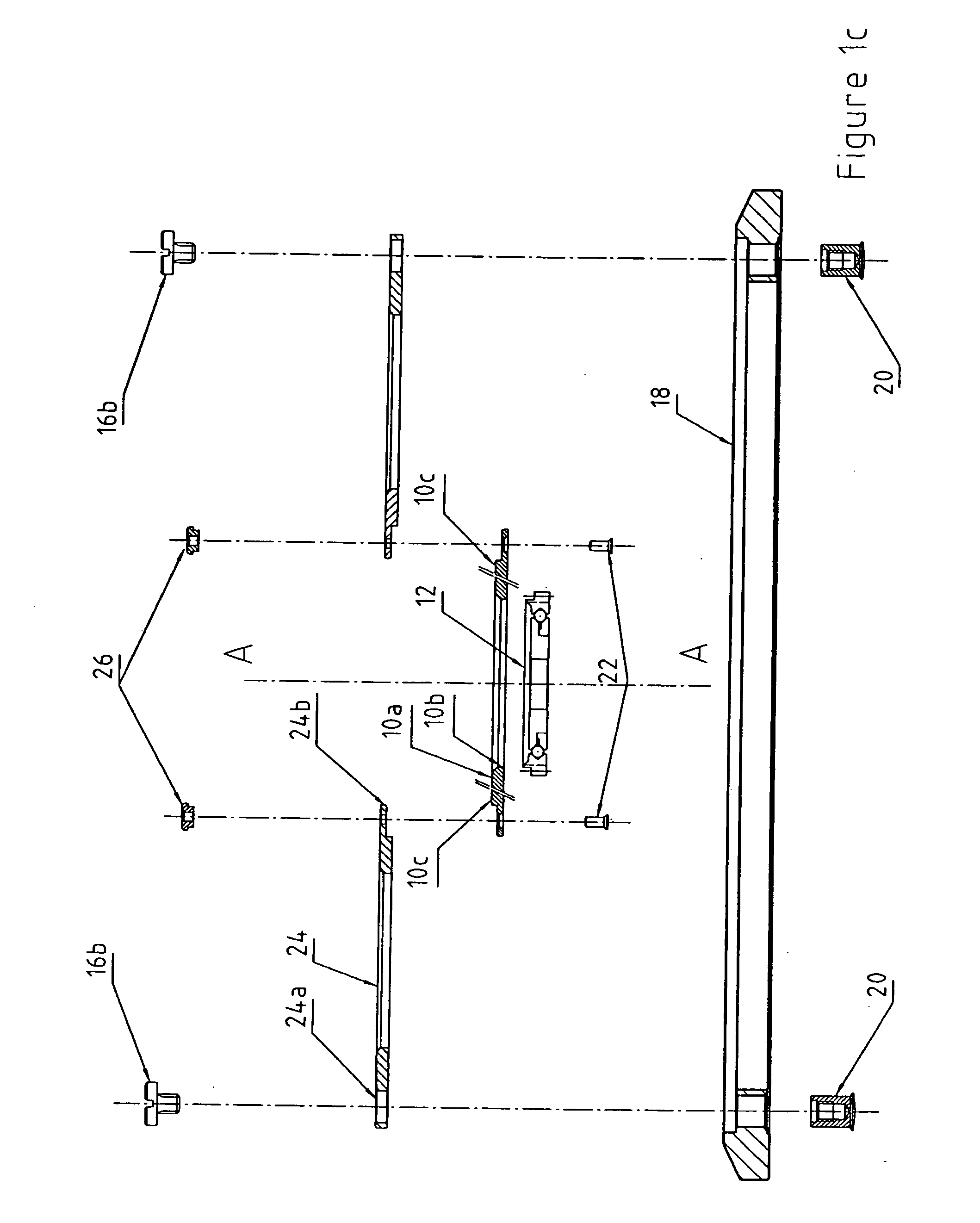

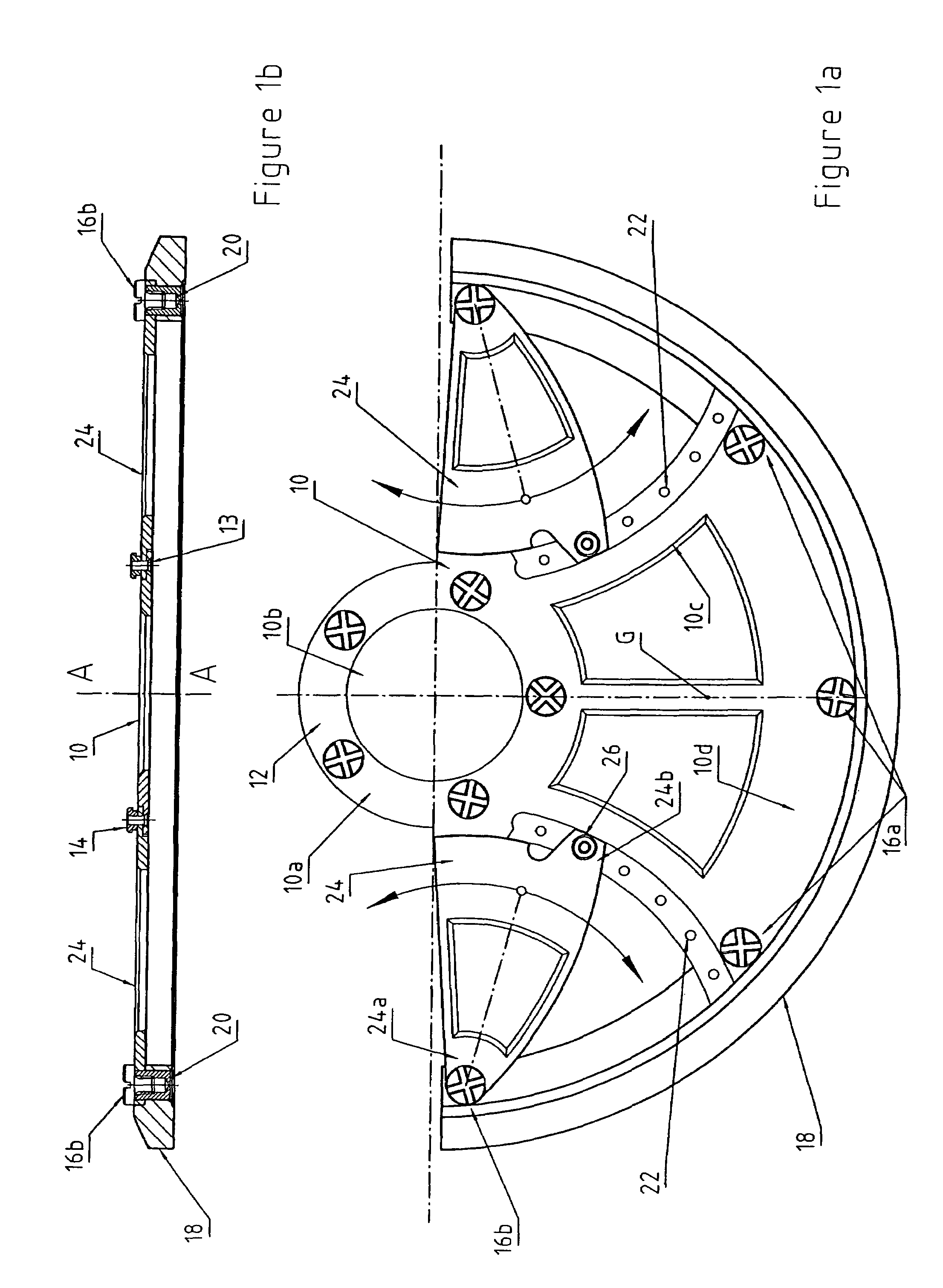

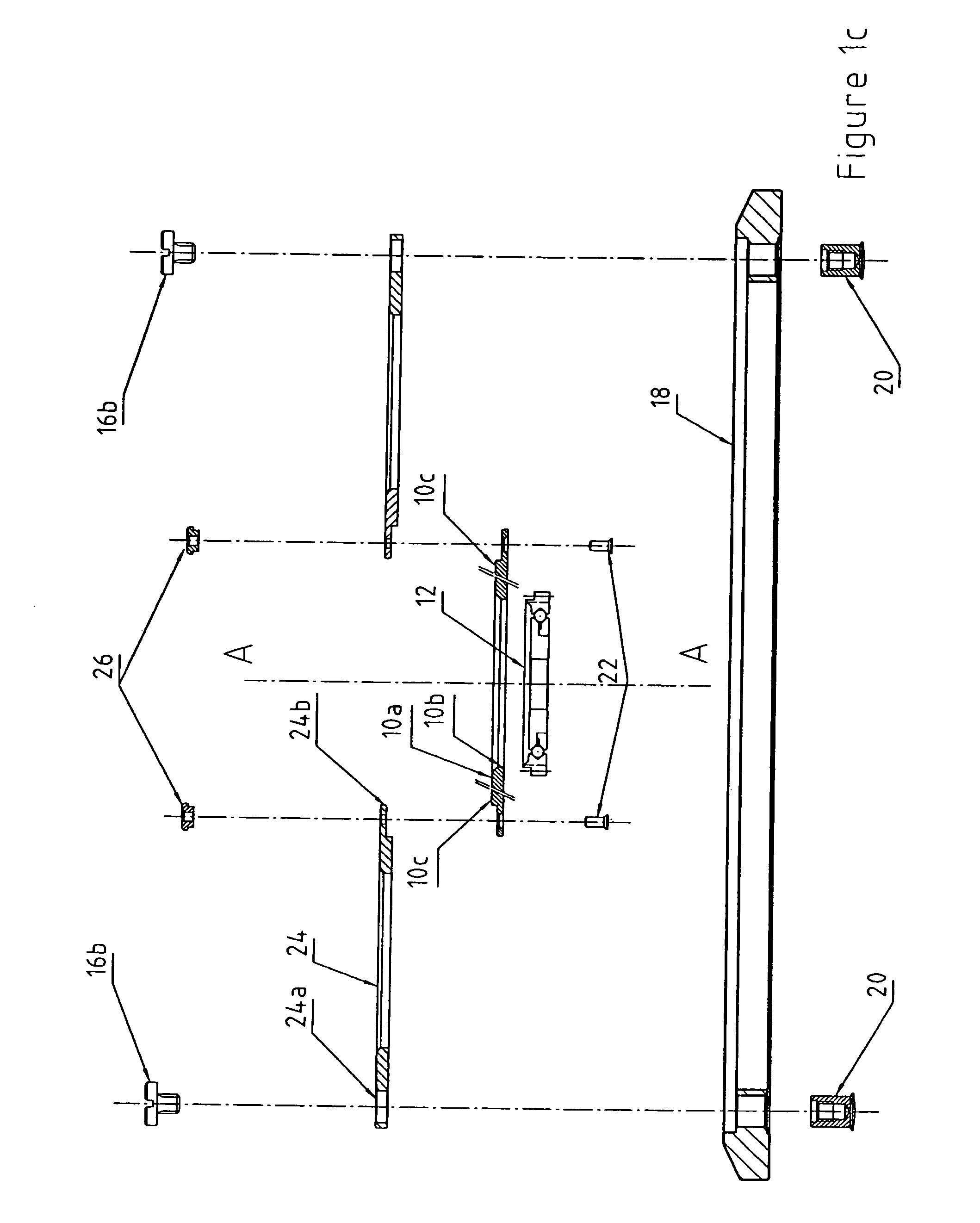

Oscillating weight for an automatic watch, arranged to carry a bearing defining an axis of rotation (A-A) and intended to be mounted on the frame of the watch, including a mass member having a centre of gravity (G) shifted with respect to the axis of rotation. In this weight, this mass member includes: two parts that can be moved one (10, 18) in relation to the other (24), and arranged such that their relative movement causes a radial movement of the centre of gravity (G) of the mass member, and a securing device (13, 14, 16b) cooperating with the first and second parts, capable of occupying a first state in which said parts can be moved with reference to each other, and a second state in which said parts are rigidly secured to each other.

Owner:HOROMETRIE SA

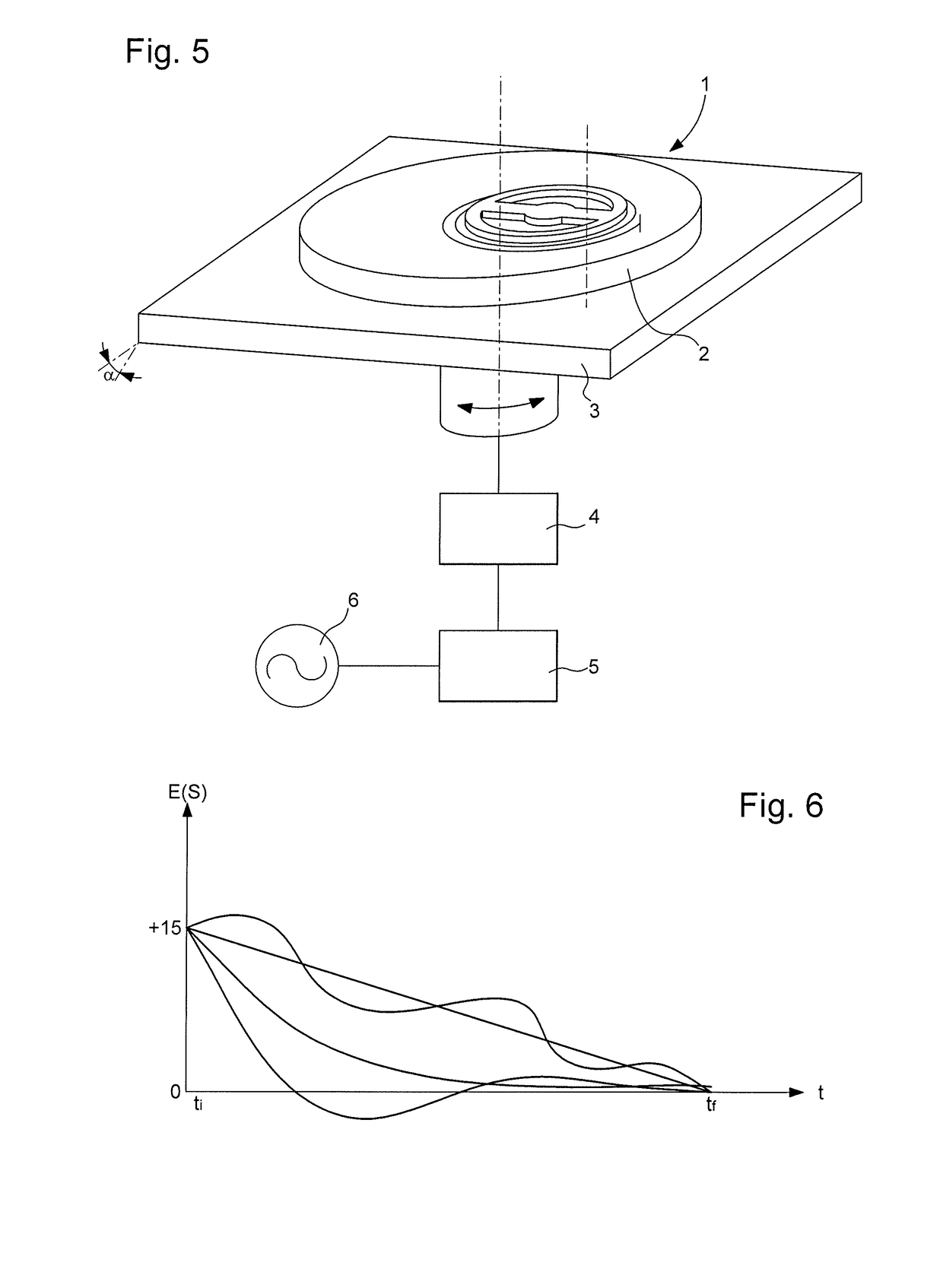

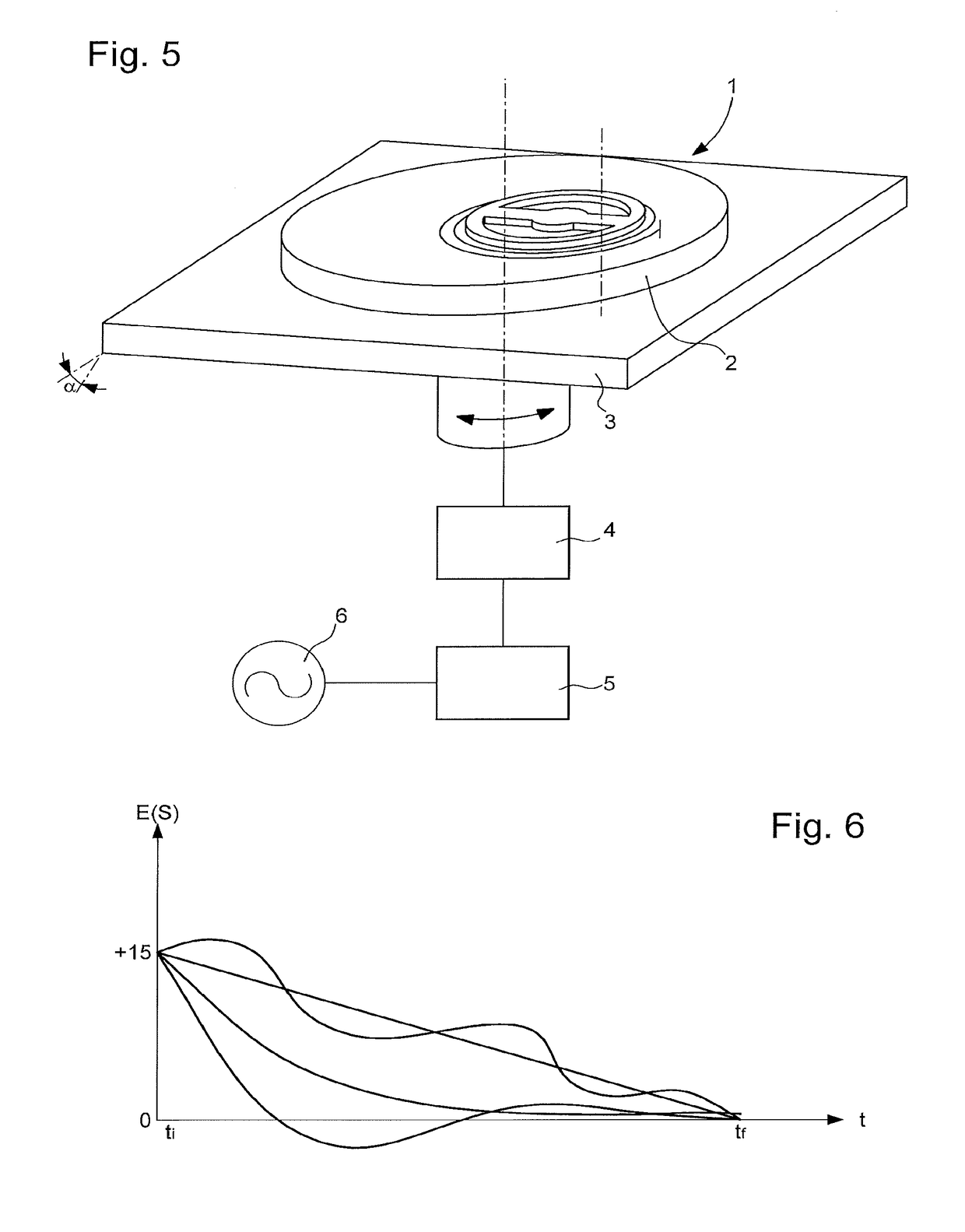

Winding device for self-winding automatic watch

ActiveUS20160004223A1Simple and inexpensive and compactAvailable to the user simple, inexpensive and compact meansGearworksElectric windingEddy currentAbutment

A device for winding automatic watches, including an electrical energy source and a receptacle support including a surface configured to receive in abutment a back cover of a watch, the device configured to generate a magnetic and / or electrostatic field or eddy currents, in a fixed position underneath the bearing surface and generate, on a substantially annular angular sector, a magnetic and or electrostatic field that varies as a function of time and whose direction is orthogonal to the bearing surface, or generating eddy currents that vary as a function of time. The device can be provided for a watch including an automatic winding mechanism with an oscillating weight including a first ferromagnetic inner part and a second heavy metal peripheral part, and possibly with a paramagnetic conductive disc coaxial to the oscillating weight.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

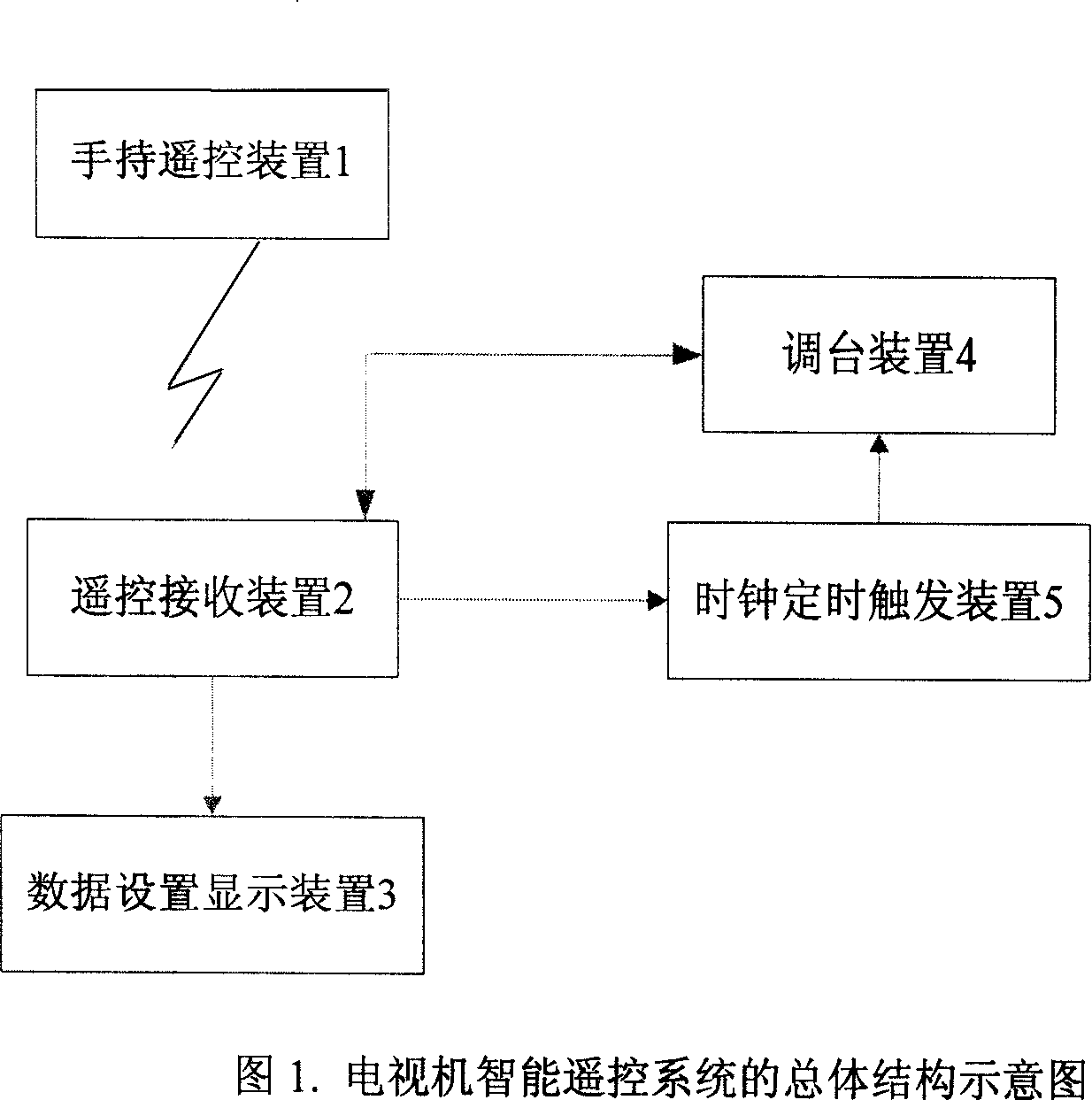

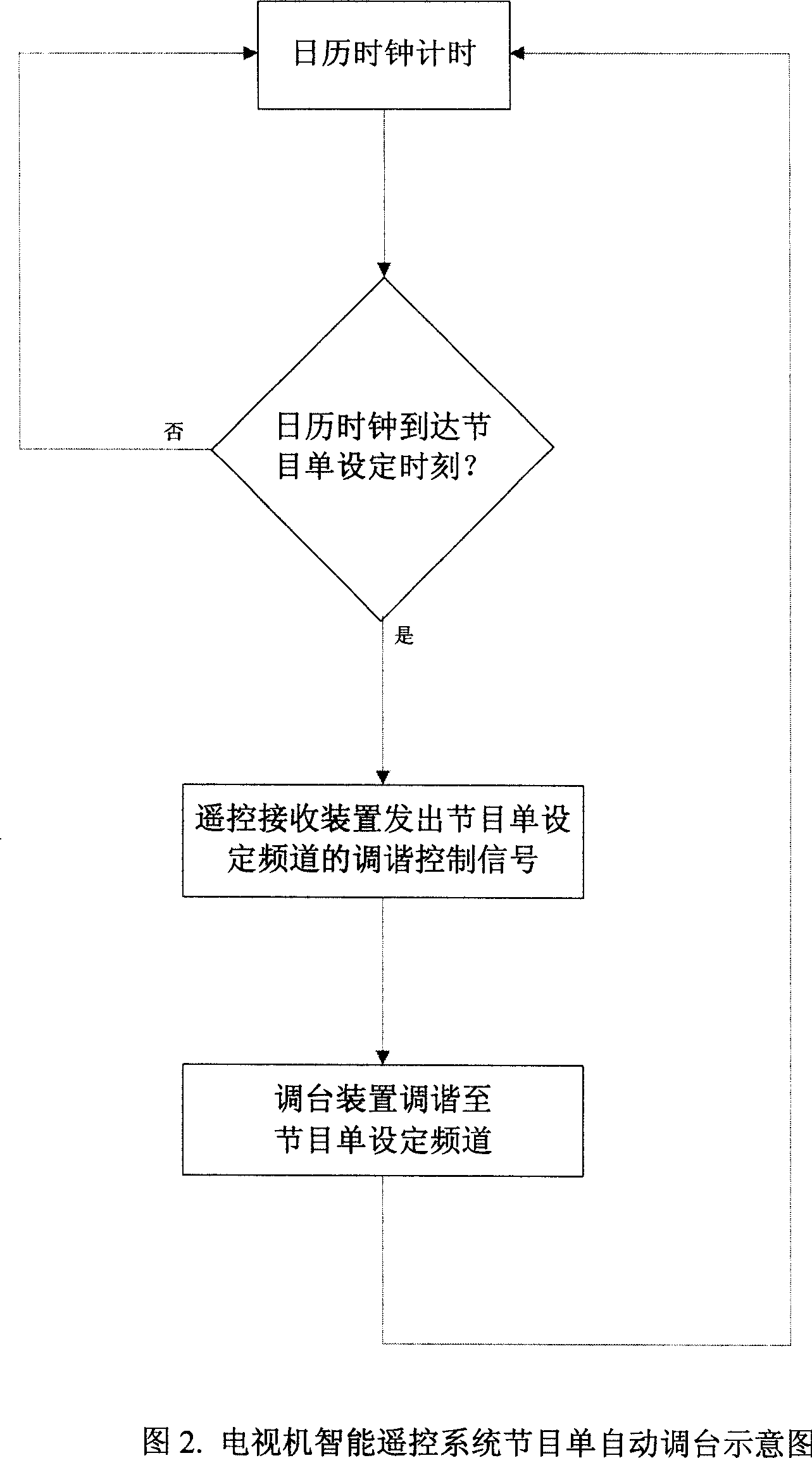

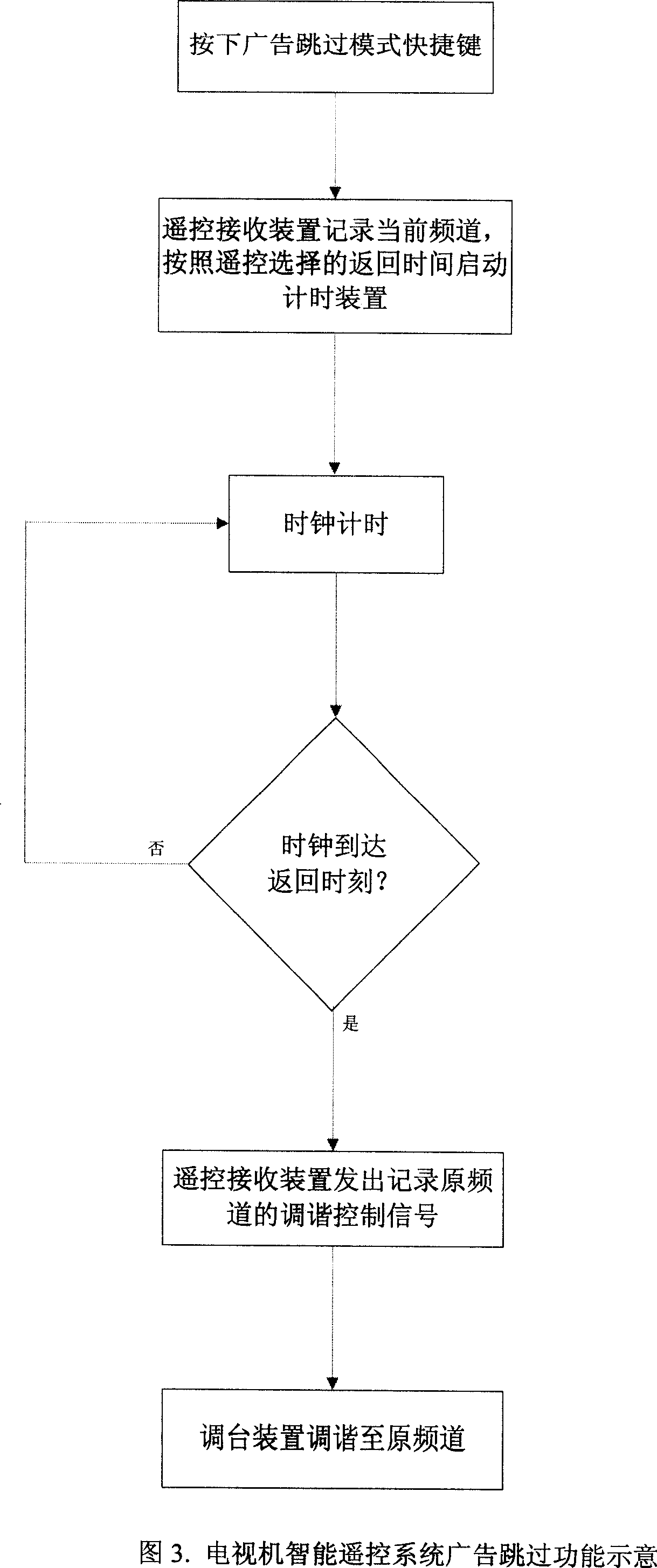

Remote controller for TV set

InactiveCN101155254AFully automatedPersonalizeTelevision system detailsTransmission systemsPersonalizationSelective calling

The present invention is an intellectualized TV remote control device, including: remote control unit, TV remote control receiving unit, data setting display unit, selecting volumn unit, clock timing springing unit. By means of the TV intellectualized remote control system of the present invention, it is possible to implement automatization and individuation of TV selective calling. In addition, the audience information stored in the system can be used for impersonal gist of analyzing TV column audience of correlative mechanism and organization. The TV intellectualized remote control system has advantage as follows: 1. channel selection can be completed automatically under the control of a timing device, so as to implement the automatic selection of prescribed column as well as recover automatic watching channel, which avoids the instance that user forgets to select column. 2. audience information is stored in a device automatically, so as to implement information-based processing for audience statistics data. 3. the present invention can awoke user to keep distance to protect eyesight availably, and is convenient to seek remote control machine.

Owner:丁智勇

Oscillating weight

An oscillating weight for an automatic watch is arranged to carry a bearing defining an axis of rotation (A—A) and is intended to be mounted on the frame of the watch. The mass member of the weight has a center of gravity (G) shifted with respect to the axis of rotation. In this weight, this mass member includes two parts that can be moved one (10, 18) in relation to the other (24), and arranged such that their relative movement causes a radial movement of the center of gravity (G) of the mass member. The mass member also has a securing device (13, 14, 16b) cooperating with the first and second parts, capable of occupying a first state in which the parts can be moved with reference to each other, and a second state in which the parts are rigidly secured to each other.

Owner:HOROMETRIE SA

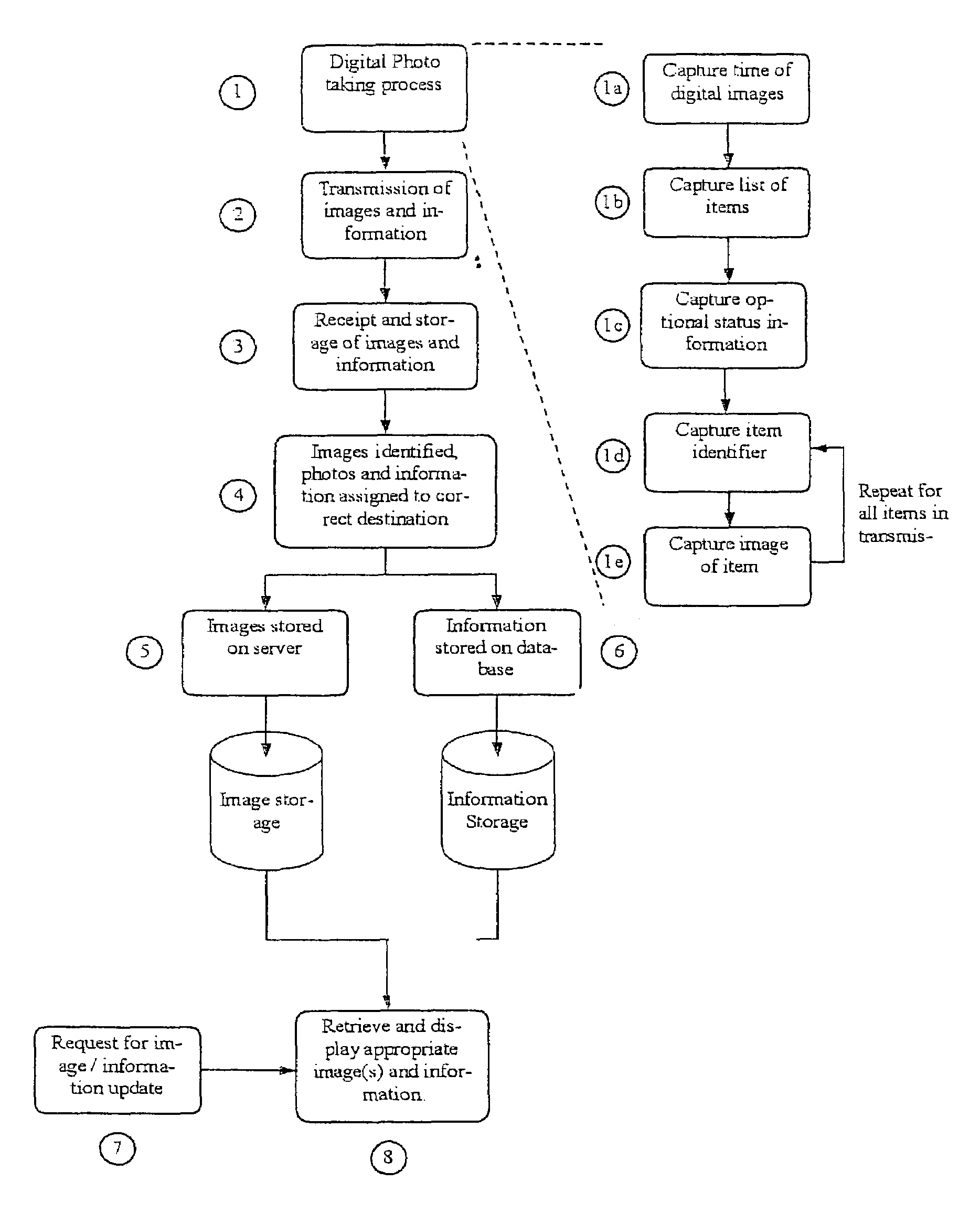

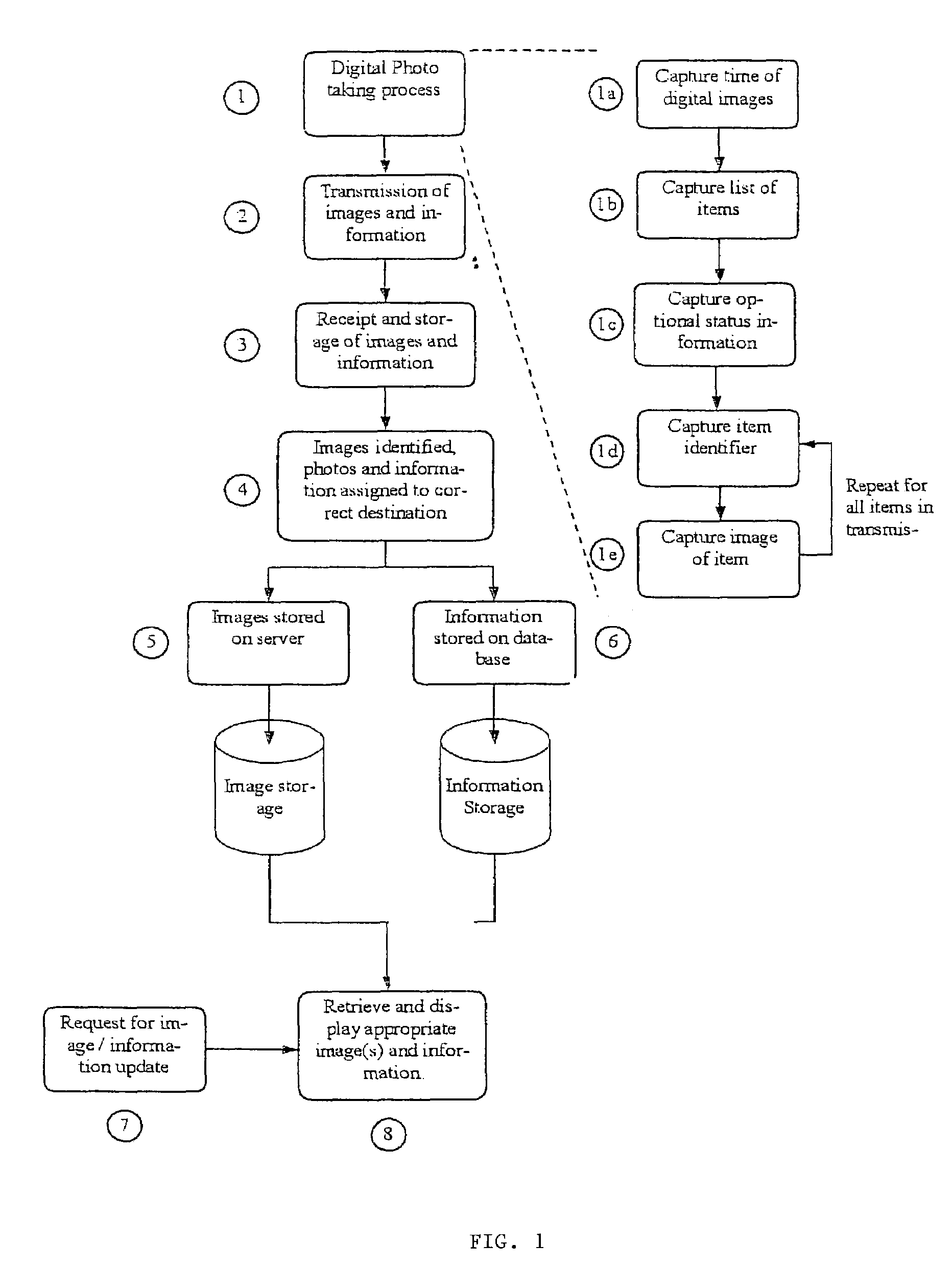

Automatic watching system

There is provided a monitoring system for remotely monitoring an item or activity, the monitoring system including a recording device for recording a visual record of the item, a communicator for communicating the visual record, and a security device for controlling access to the monitoring system. Also provided is a method of remotely monitoring an item by recording a digital image of the item, communicating the digital image of the item through a communication system, and accessing the digital image using a secured access device.

Owner:SEE PROGRESS LLC

Multifunction charging device with watch swing device

InactiveCN105762881AFunction increaseEasy to useBatteries circuit arrangementsElectric powerTransformerSpecial design

The invention discloses a multifunction charging device with a watch swing device, the charging device comprises a charging device main body and a watch swing device, the watch swing device is fixed to the charging device main body. The watch swing device is arranged on the charging device main body, when a mechanical watch is not in used, the mechanical watch can be put on the watch swing device, swing operation is performed on the watch, so that the automatic watch cannot stop without being worn. The charging device also comprises functions of mobile phone supporting, mobile phone charging, wireless charging and the like, the functions are various, and the device is convenient to use. A charge opening of the charging device adopts a special design of structure, so that a charge interface of a charge cable cannot fall, and the operation is more convenient than before. A lock position is arranged in the charging device, a transformer or a portable power source module can be locked on the lock position, so that the transformer or the module is convenient to carry and is more convenient to be changed for repair and maintenance than before.

Owner:涂军华

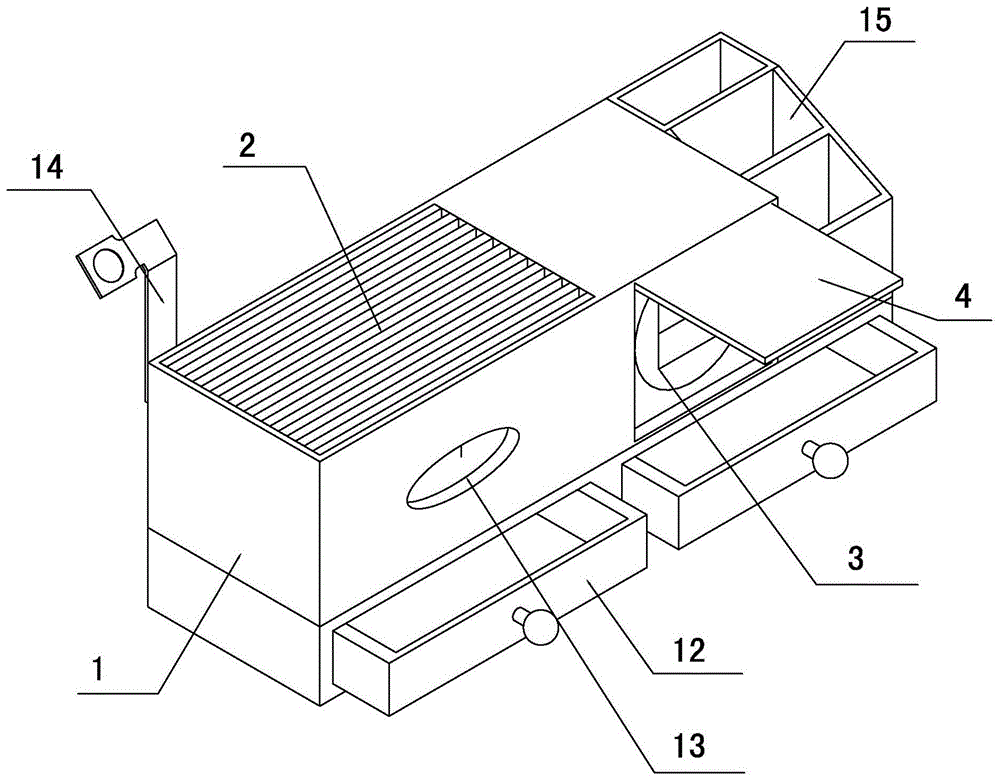

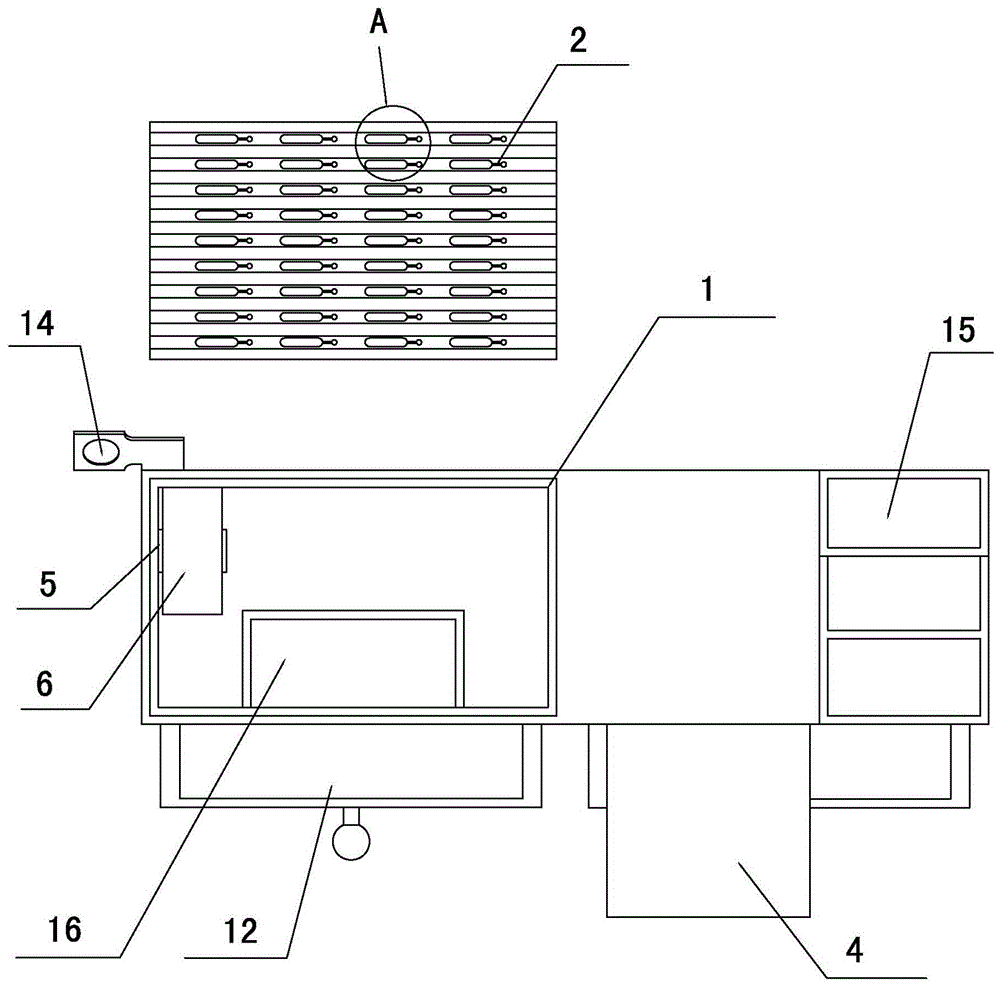

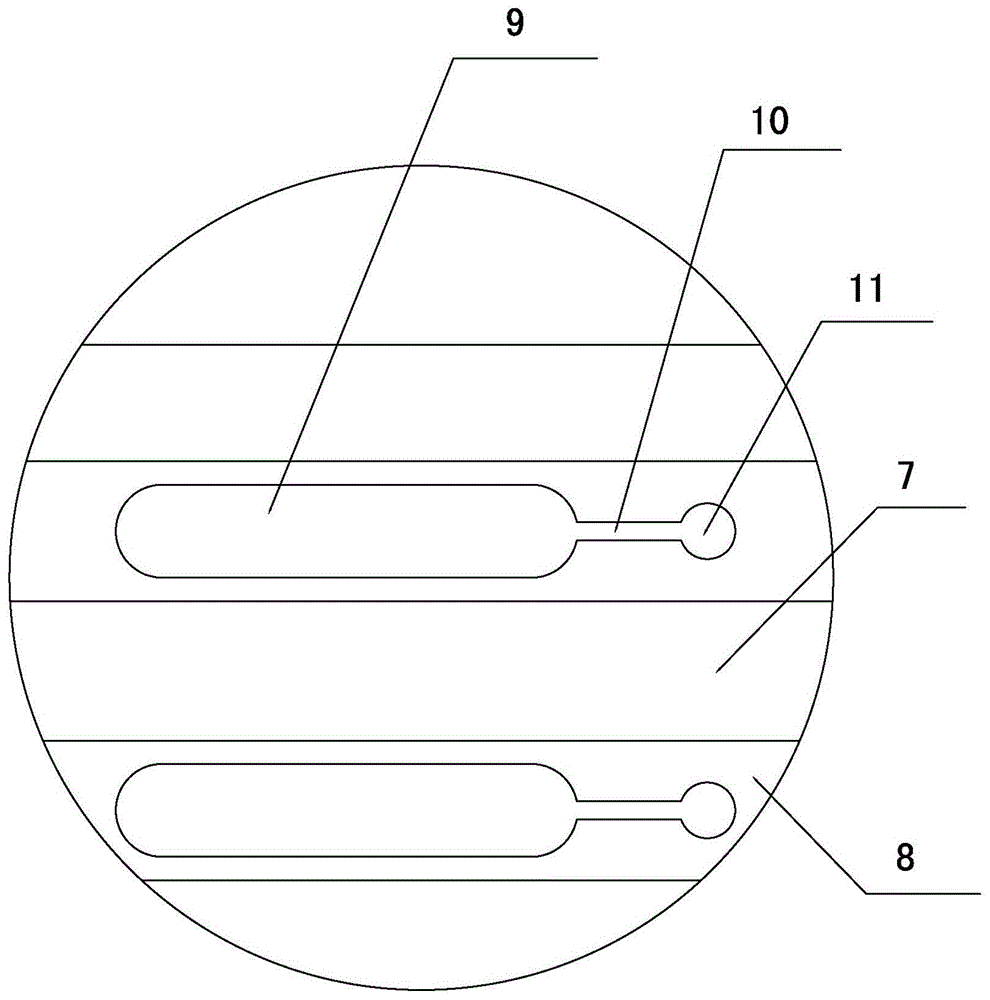

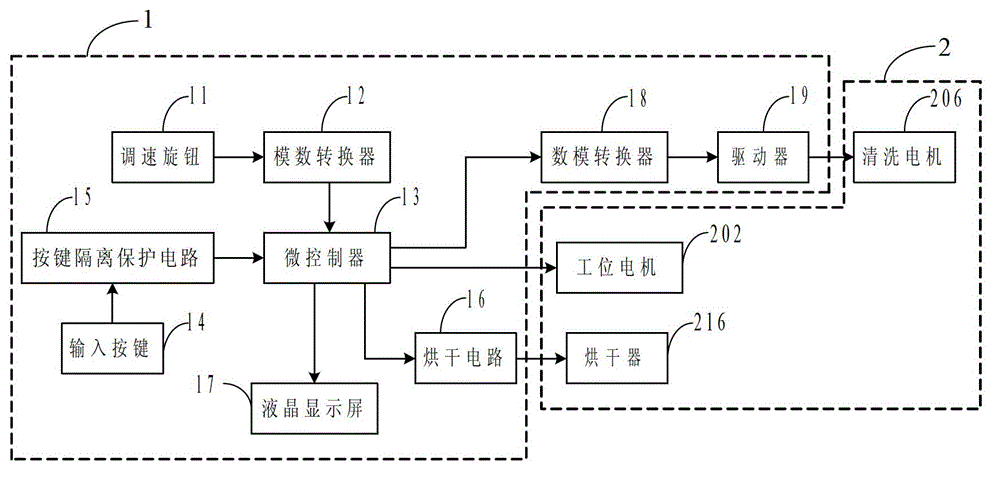

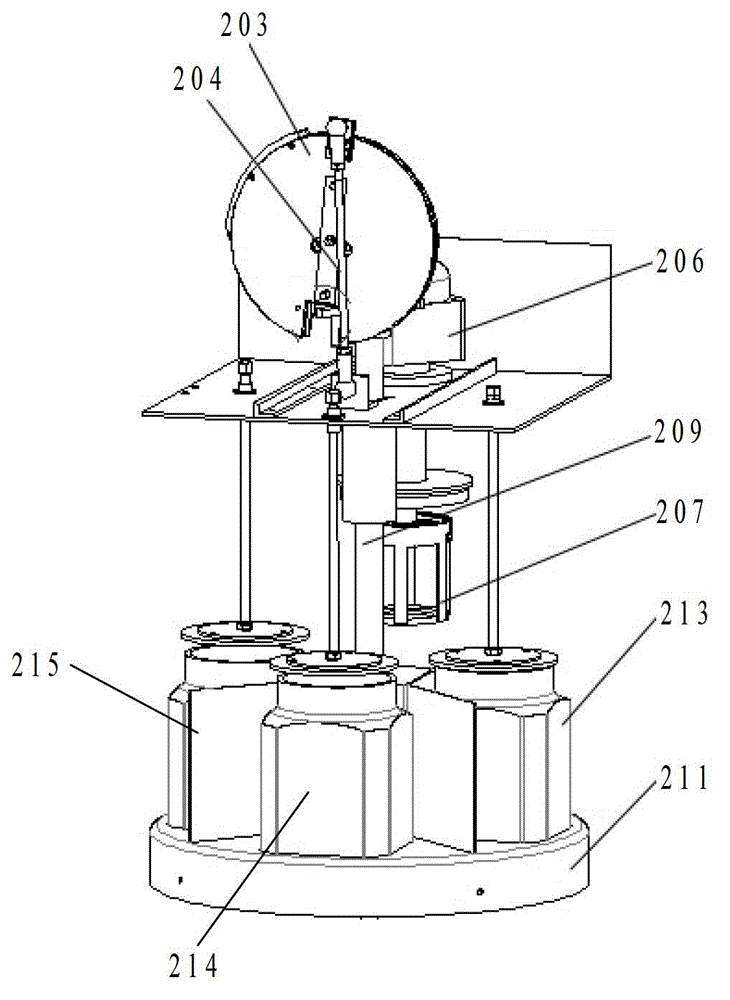

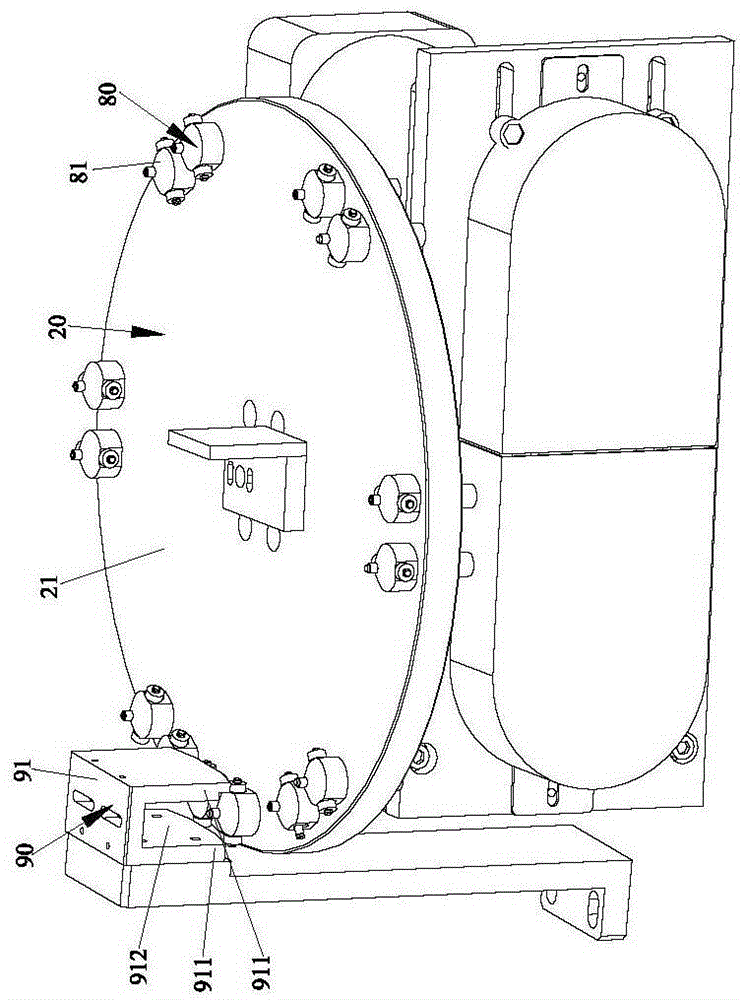

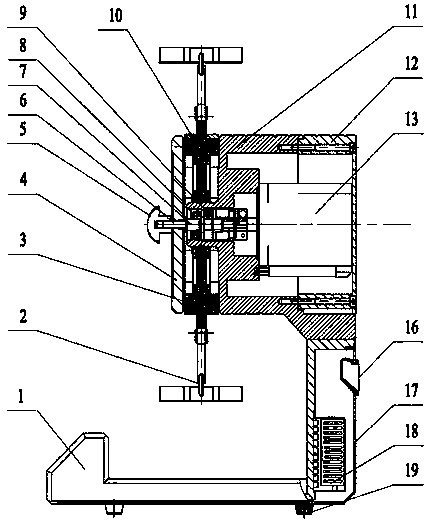

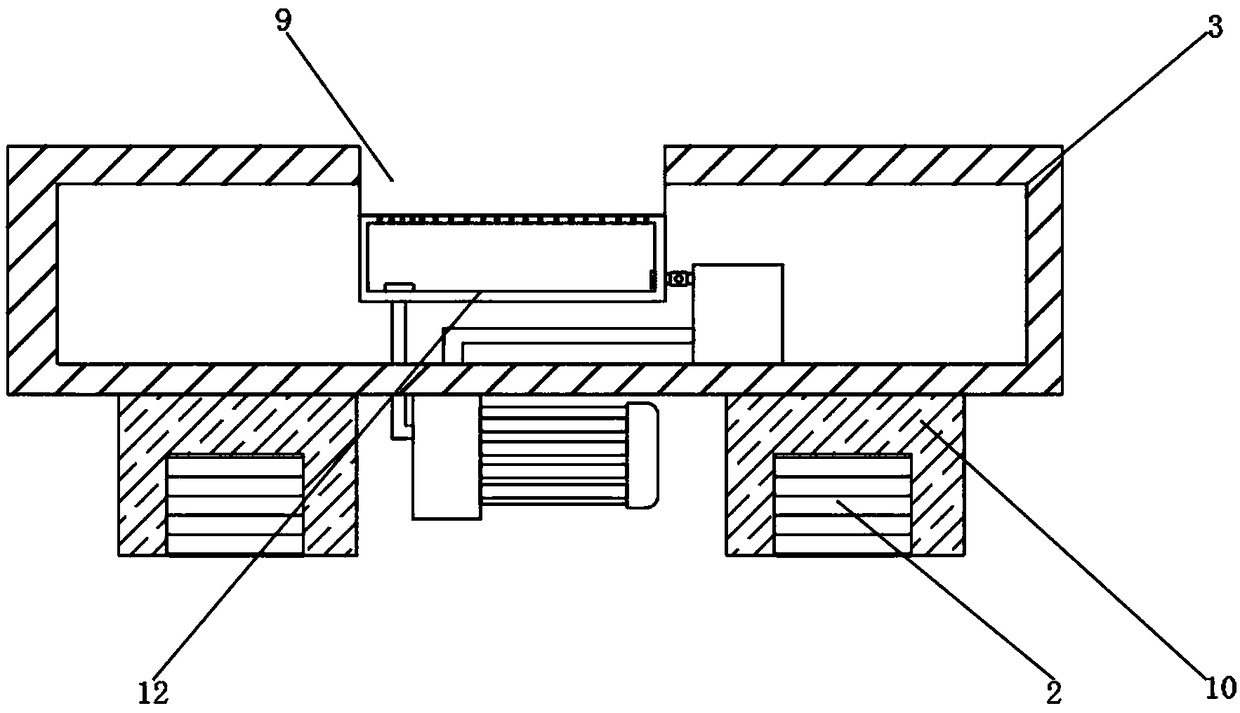

Full-automatic watch cleaning machine

InactiveCN103143527ASolve the problem of accidental injuryPracticalCleaning using liquidsControl signalElectrical control

The invention belongs to the technical field of clock maintenance, and provides a full-automatic watch cleaning machine. An electric control module outputs a control signal to pre-clean, clean, rinse and dry watch parts; a mechanical transmission mechanism receives the control signal outputted by the electric control module, automatically converts stations and adjusts the running state, and automatically pre-cleans, cleans, rinses and dries the watch parts; the full-automatic watch cleaning machine can carry out full-automatic cleaning and drying on the watch parts, radically solves the problems that in the past, an operator can finish the tasks by hands according to experience, the cleaning efficiency is lower, and accident damage to the parts in the cleaning process is often caused, has great significance to improvement on the clock maintenance industry service, is strong in practicability, and has strong popularization and application values.

Owner:西安轻工业钟表研究所有限公司

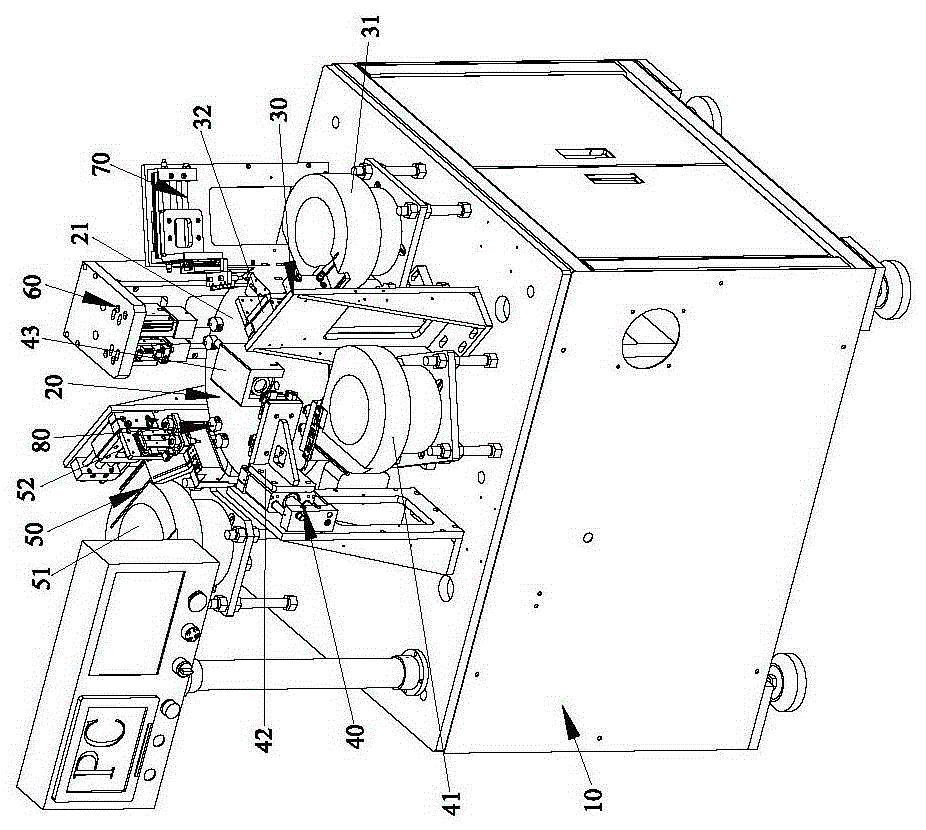

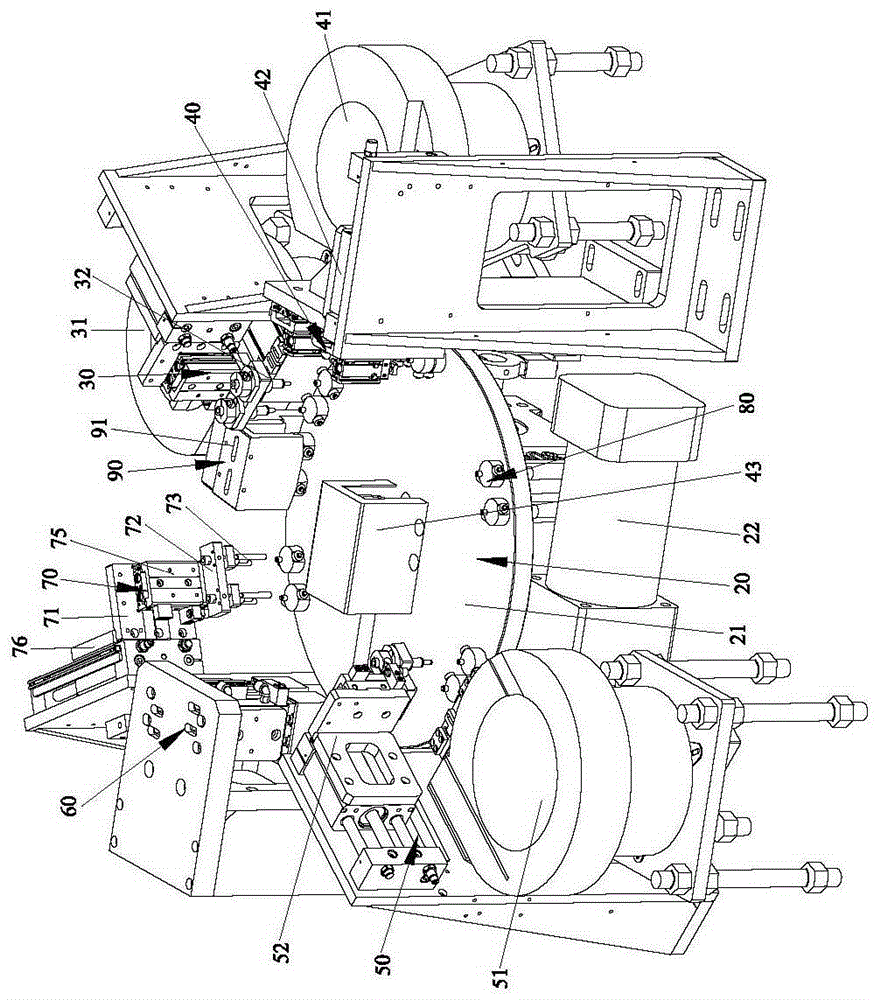

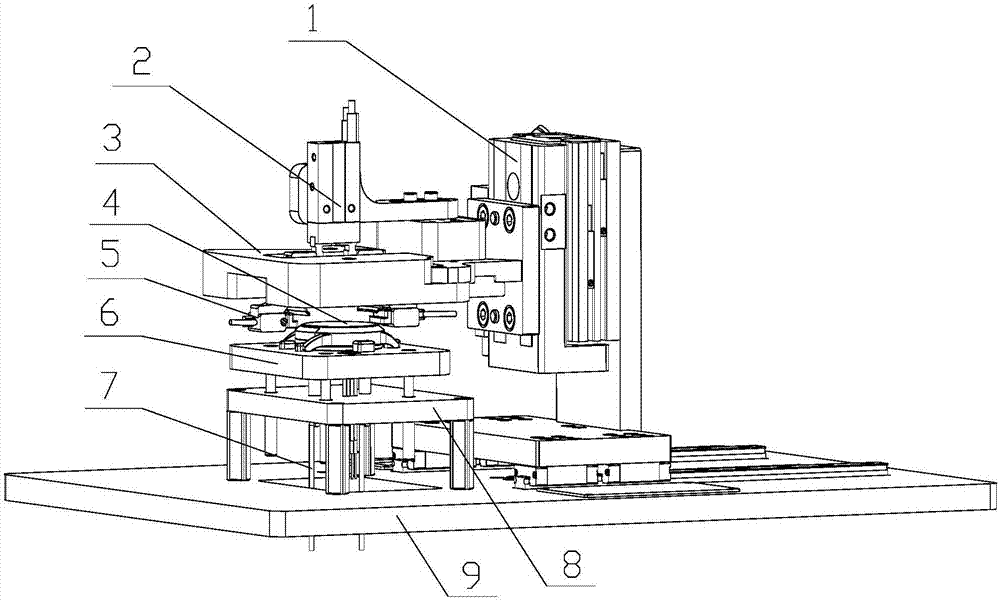

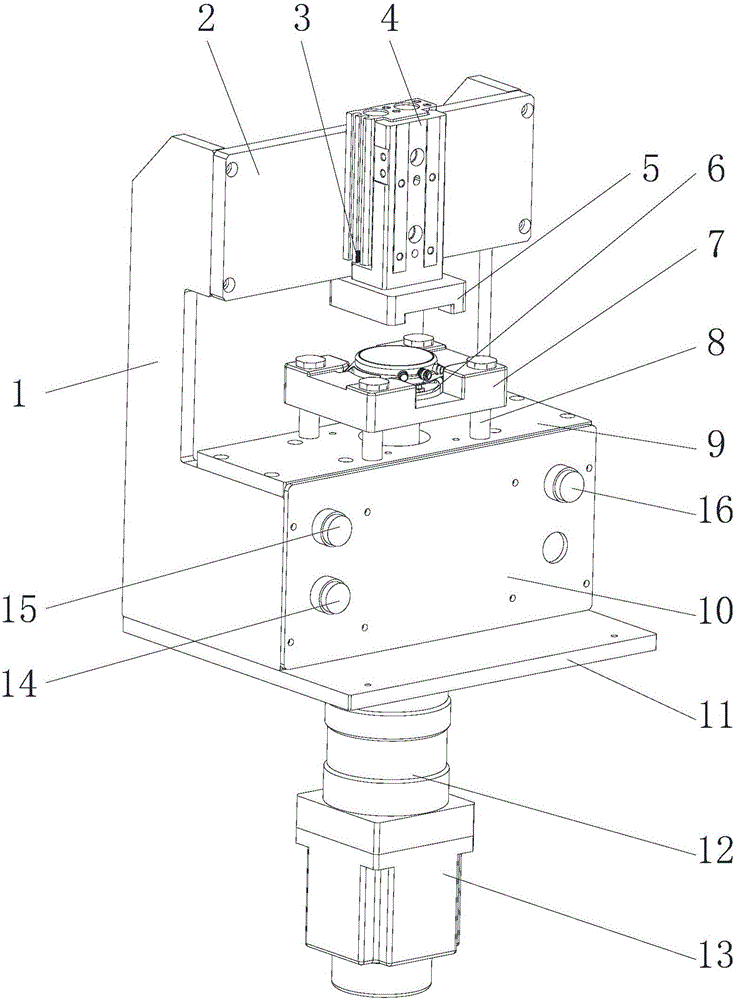

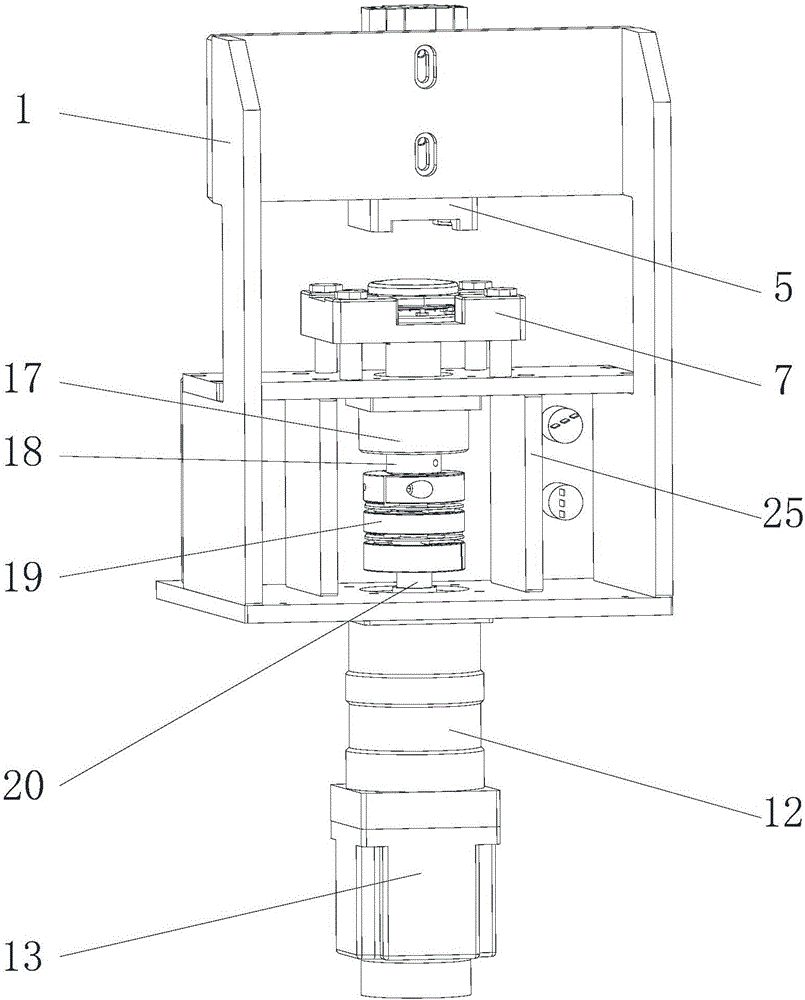

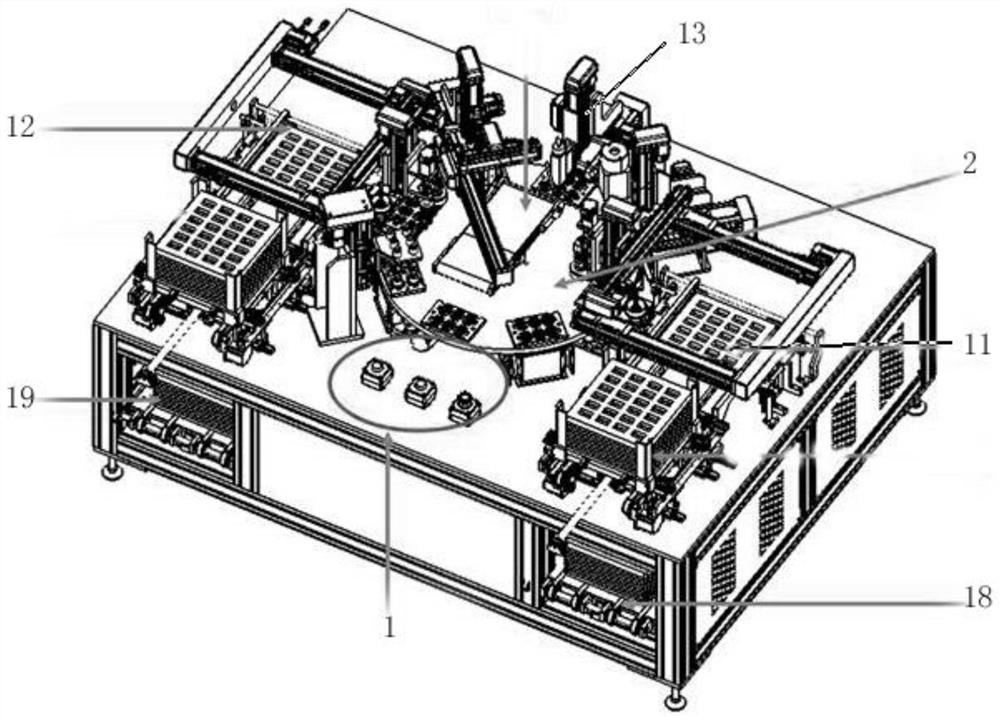

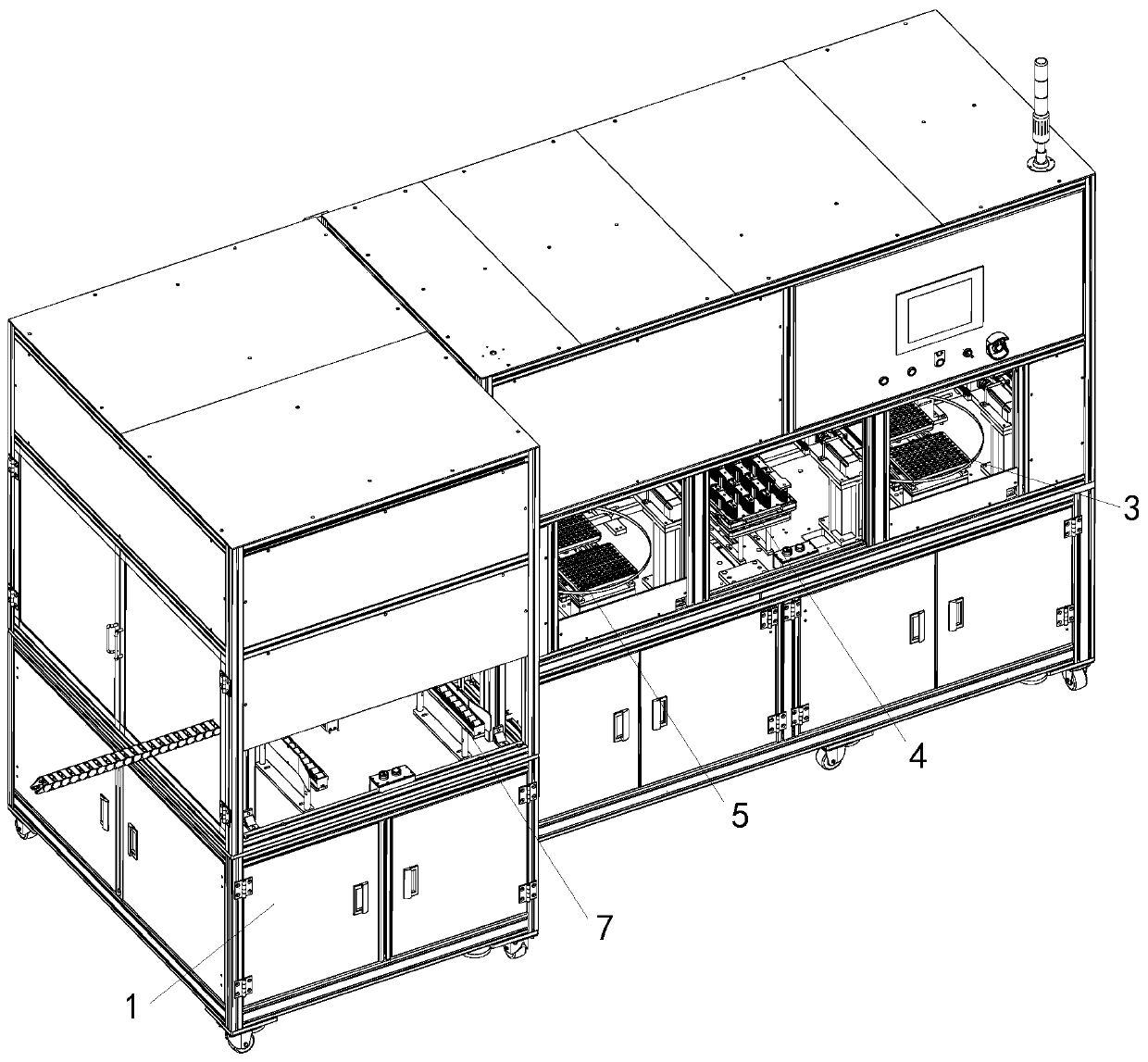

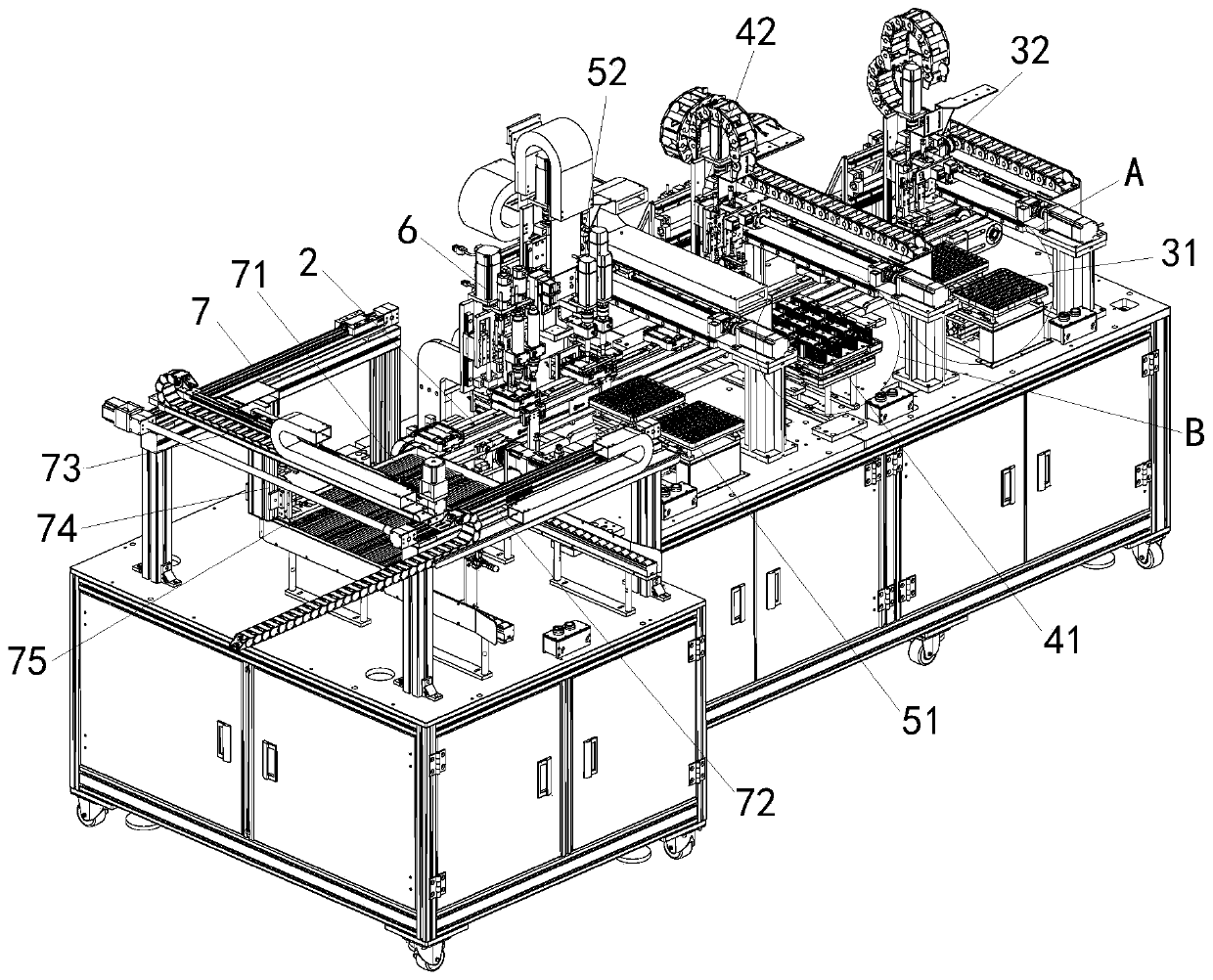

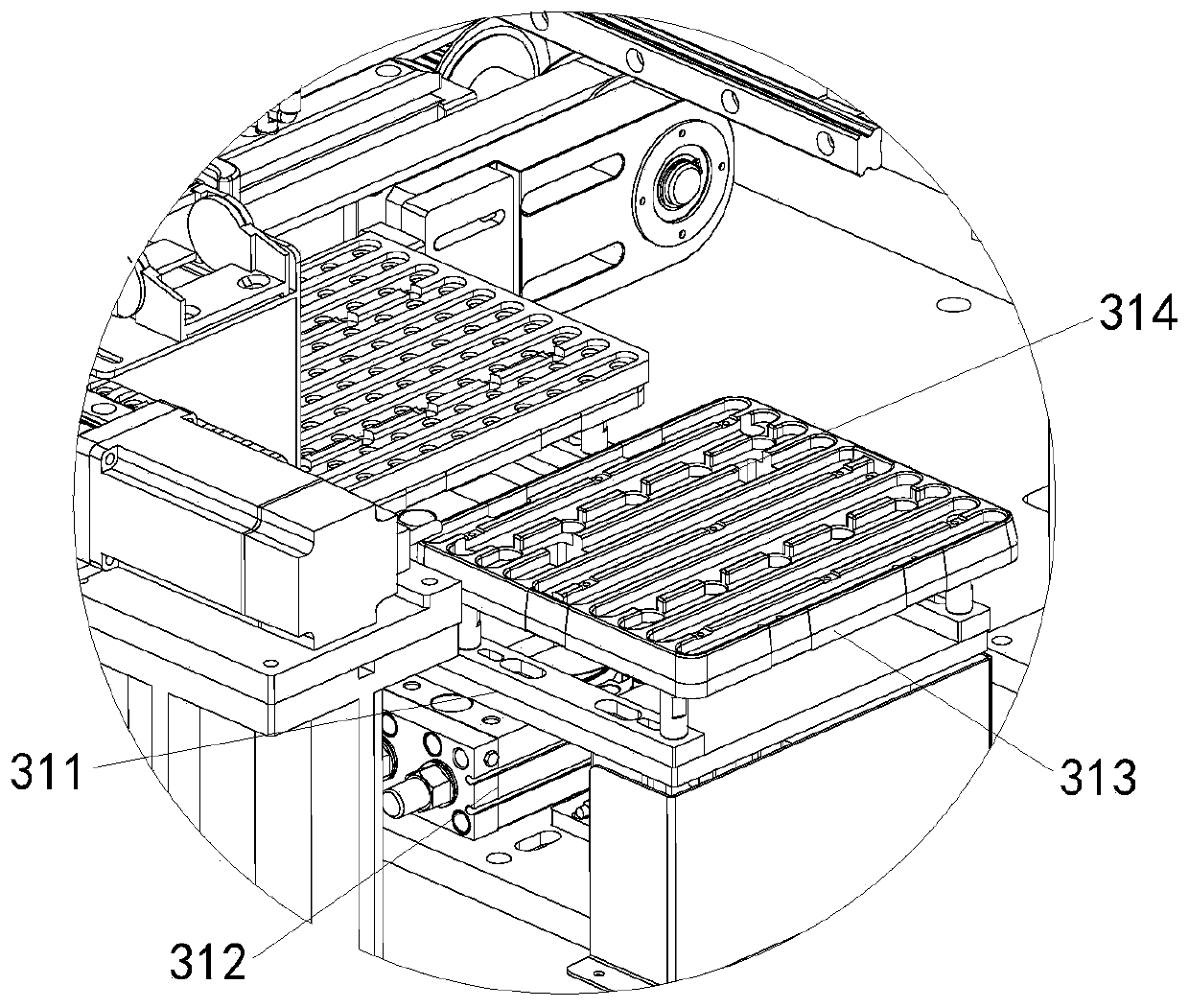

Full-automatic watch crown assembling equipment

ActiveCN105215675AReduce manpower consumptionReduce labor costsAssembly machinesEngineeringOperation safety

The invention discloses full-automatic watch crown assembling equipment which comprises a rack, a conveying module, a meson taking and placing module, an O-type ring taking and placing module, a crown taking and placing module, a stamping module and a finished product discharging module. Locating jigs are arranged on the conveying module and driven by the conveying module to move in the conveying direction. The meson taking and placing module, the O-type ring taking and placing module, the crown taking and placing module, the stamping module and the finished product discharging module are arranged in the conveying direction of the conveying module. The conveying module, the meson taking and placing module, the O-type ring taking and placing module, the crown taking and placing module, the stamping module and the finished product discharging module are used in cooperation, so that meson feeding, O-type ring feeding, crown feeding, stamping, finished product discharging and other motion are achieved automatically; no manual participation is needed in the whole watch crown assembling process, manpower consumption is reduced, manpower cost is reduced, and operation safety accidents are avoided; automatic operation efficiency is high, and productivity is effectively improved; and the product assembling quality is guaranteed, and the full-automatic watch crown assembling equipment is worth of use and popularization.

Owner:DONGGUAN DIANHANG AUTOMATION EQUIP TECH CO LTD

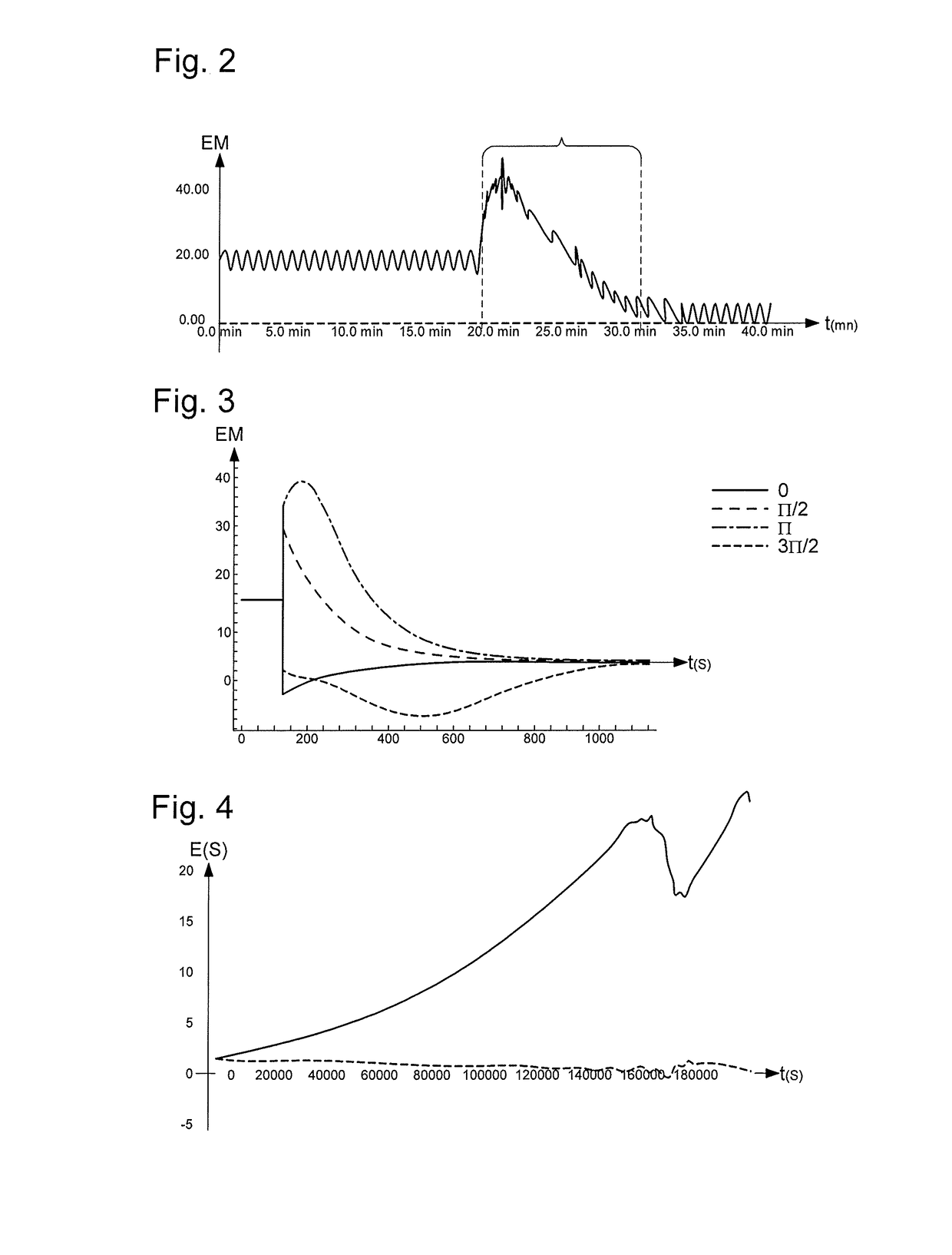

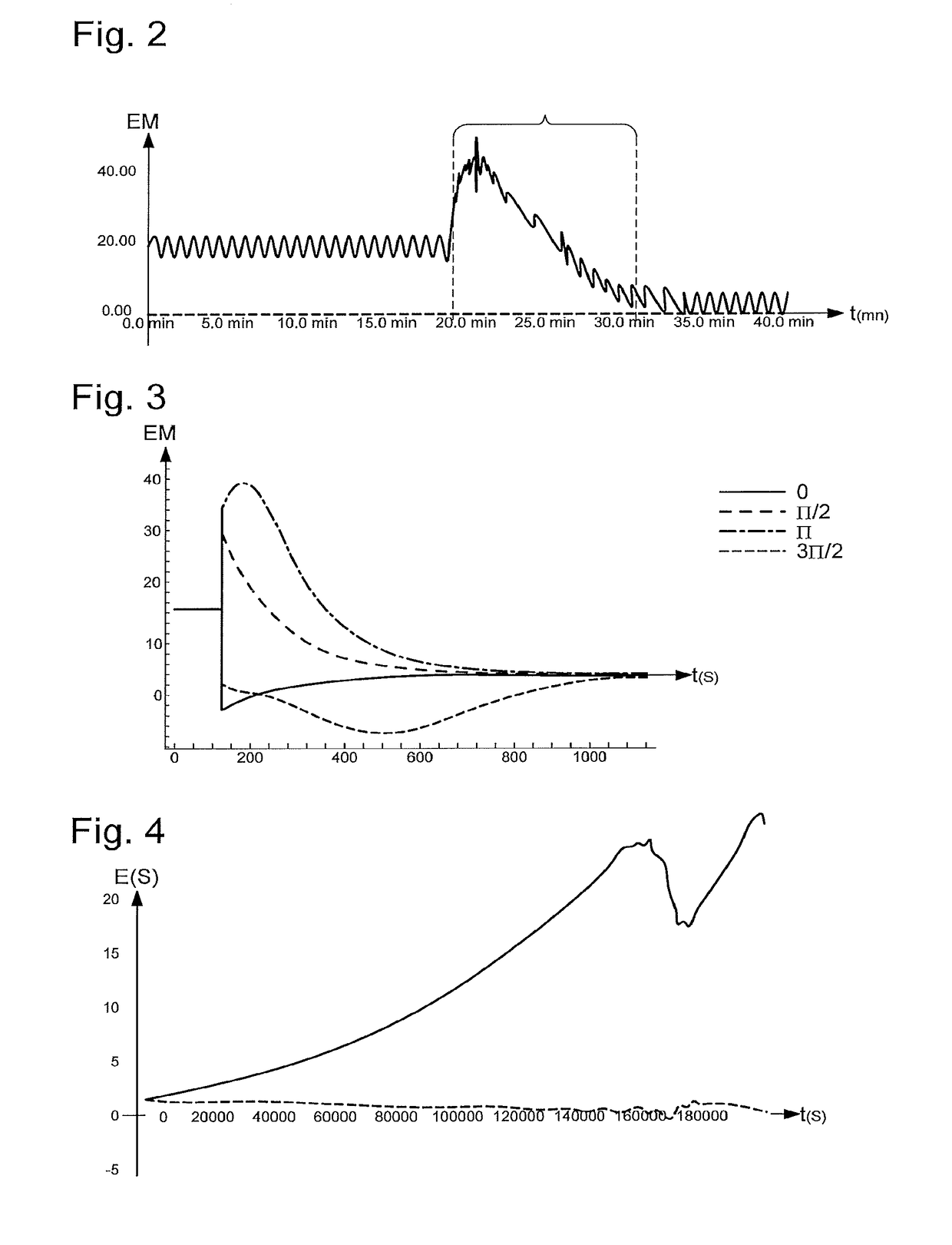

Device and method for adjusting the rate of a watch

ActiveUS20180341226A1Easy to controlFrequency setting mechanismMaster clocksMaster oscillatorNominal frequency

A method for adjusting the rate of a watch with an oscillator arranged to generate oscillation at a nominal frequency N0, with a servo-system including a master oscillator arranged to generate excitation oscillation at an excitation frequency NE, which is approximately equal to, or equal to the nominal frequency N0, or to an integer multiple of this nominal frequency N0, the watch is subjected to excitation oscillation or to a modulated motion, generated by the master oscillator, during a transition phase after which the oscillator of the watch is stabilised at excitation frequency NE, and there is incorporated in the servo-system a winder for mechanical or automatic watches, arranged to move a support on which such a watch is fixed.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Automatic watch detection device and method

ActiveCN107329393ARealize automated detectionTest speed blockRegulating apparatusEngineeringElectrical and Electronics engineering

The present invention provides an automatic watch detection device and method. The device comprises a base plate, a press-fit module arranged on the base plate, a positioning bracket, and a clamping jaw cylinder fixedly connected with the press-fit module. The positioning bracket is provided with a product positioning block capable of moving in the vertical direction relative to the positioning bracket. A watch to be tested is restricted to the product positioning block. A horizontal electrode module is arranged on the clamping jaw cylinder. A vertical electrode module is embedded in the positioning bracket. The press-fit module is used for driving the clamping jaw cylinder to move in the vertical direction. The clamping jaw cylinder is used for driving the horizontal electrode module to move in the horizontal direction so that the horizontal electrode module and the internal electrode of the watch to be tested come into elastic contact and are switched on. The press-fit module is also used for driving the product positioning block and the watch to be tested on the product positioning block to move in the vertical direction so that the watch to be tested and the vertical electrode module come into elastic contact and are switched on. The automatic watch detection device and method can automatically detect the performance of smart wearable watches.

Owner:GOERTEK INC

Device and method for adjusting the rate and correcting the state of display of a watch

ActiveUS20180341225A1Easy to controlFrequency stabilisation mechanismFrequency setting mechanismMaster oscillatorCorrection method

Method for adjusting the rate of a basic oscillator of a watch arranged to oscillate at a nominal frequency N0, with a master oscillator generating an excitation frequency NE approximately equal to an integer multiple of this nominal frequency N0, the master oscillator subjecting the watch to excitation or a modulated motion during a transition phase after which the basic oscillator is stabilised at the excitation frequency NE, and a state of display correction method with a winder for mechanical or automatic watches, moving a support carrying the watch and comprising a state of display correction oscillator, having a lower variation of rate value than the initial variation of rate value DI of this basic oscillator, and oscillating at a correction frequency NC to impose oscillation or a motion on the watch, during a state of display correction phase whose duration is adjusted to exactly correct a state of display error measured at the initial moment of actuation.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Winding device for self-winding automatic watch

ActiveUS9836027B2Available to the user simple, inexpensive and compact meansSolve the power is smallGearworksElectric windingEddy currentEngineering

A device for winding automatic watches, including an electrical energy source and a receptacle support including a surface configured to receive in abutment a back cover of a watch, the device configured to generate a magnetic and / or electrostatic field or eddy currents, in a fixed position underneath the bearing surface and generate, on a substantially annular angular sector, a magnetic and or electrostatic field that varies as a function of time and whose direction is orthogonal to the bearing surface, or generating eddy currents that vary as a function of time. The device can be provided for a watch including an automatic winding mechanism with an oscillating weight including a first ferromagnetic inner part and a second heavy metal peripheral part, and possibly with a paramagnetic conductive disc coaxial to the oscillating weight.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

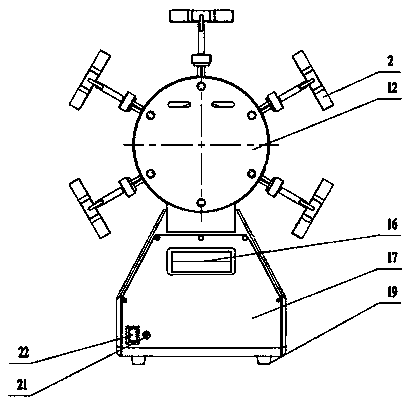

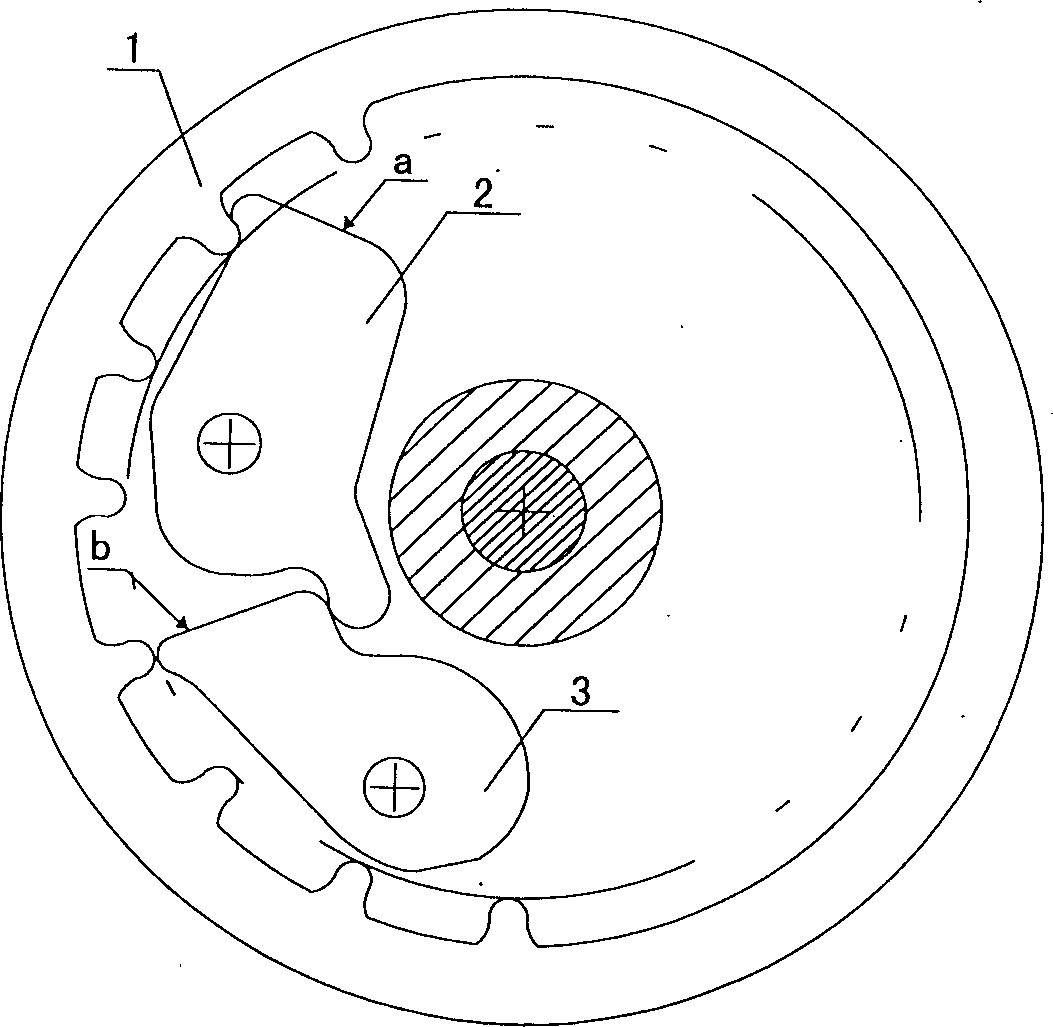

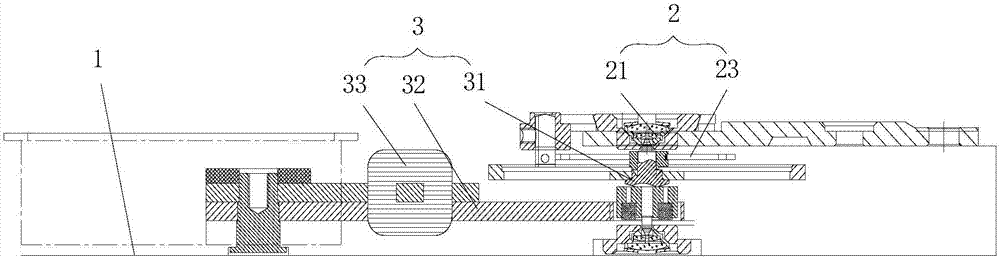

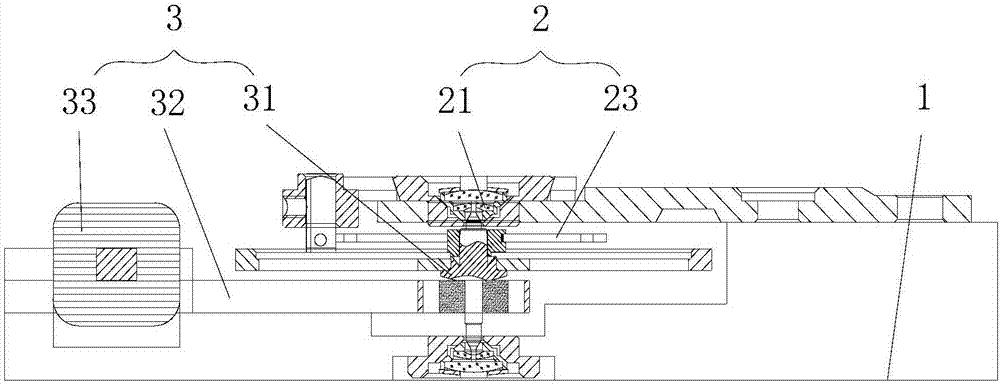

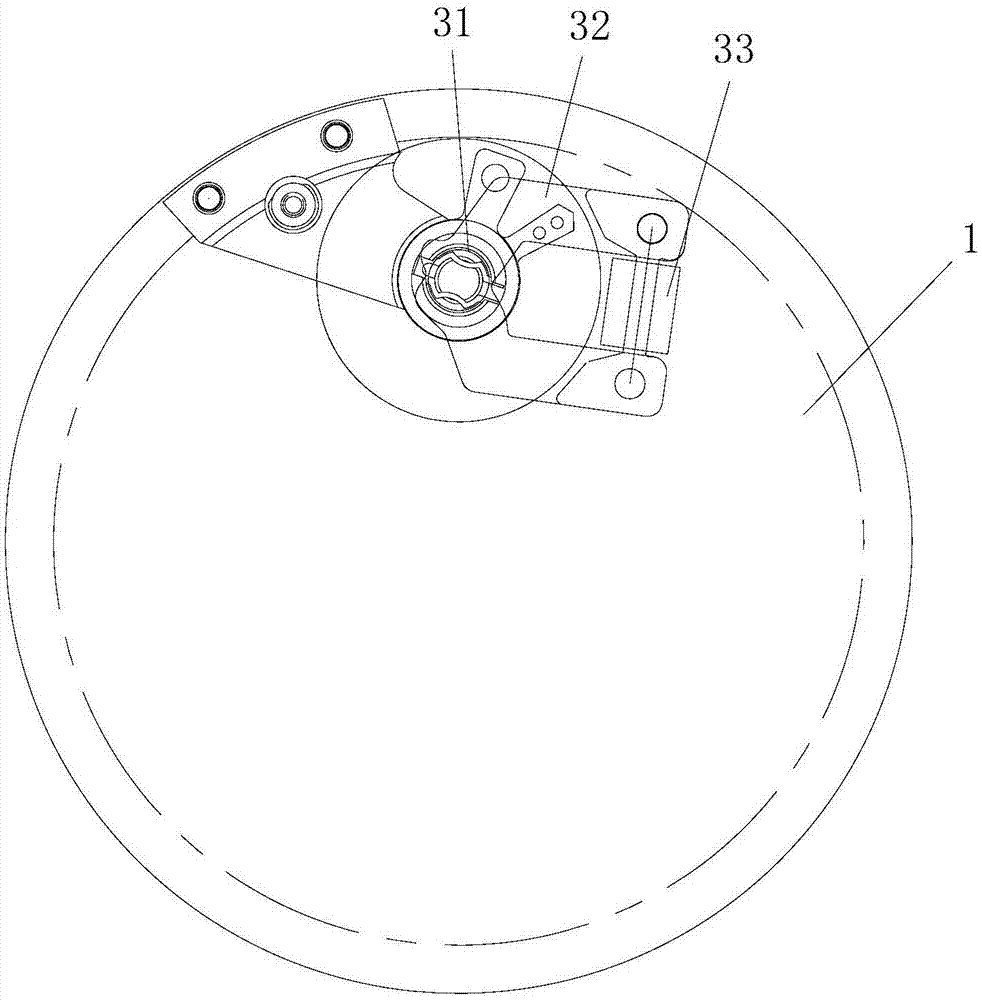

Automatic watch case disassembling and assembling equipment

ActiveCN106736459AReduce fatigueImprove work efficiencyMetal working apparatusDrive shaftEngineering

The invention discloses automatic watch case disassembling and assembling equipment which solves the technical problems that in the prior art, a rear watch case needs to be manually disassembled and assembled, the labor intensity is high, operation efficiency is low, and the assembling effect is not ideal. The automatic watch case disassembling and assembling equipment comprises a frame, a watch case fixing block is fixedly mounted in the frame, a watch head to be disassembled and assembled is positioned in the watch case fixing block, and a rear watch head case is placed downwards; a vertical through hole is formed in the watch case fixing block, a watch case disassembling and assembling block is mounted in the through hole and can rotate relative to the watch case fixing block, and a plurality of upward positioning claws are arranged on the watch case disassembling and assembling block and stretch into clamping grooves in the rear watch head case. A servo motor is mounted in the frame, and a transmission shaft of the servo motor is connected with the watch case disassembling and assembling block and drives the watch case disassembling and assembling block to rotate, so that the rear watch head case is disassembled and assembled.

Owner:GEER TECH CO LTD

Wristwatch chaining machine

The invention relates to a wristwatch chaining machine. According to the structure, a motor is arranged on a motor base, a cylindrical boss at the front end of the motor base is connected with a center hole of a rotary disc, the rotary disc is formed by connecting an inner ring, a middle ring and an outer ring, through holes corresponding to one another in position are formed in each ring, and self-lubricating bearings are arranged on the through holes of the inner ring and the middle ring. A rotating rod seat of the elastic sheet-shaped wristwatch fixing seat is inserted into self-lubricatingbearing inner holes of an outer ring through hole of the rotary disc, the friction wheel, an inner ring of the rotary disc and a middle ring of the rotary disc; the rear end of the driving shaft penetrates through an inner hole of the bearing and is connected with an output shaft of the motor through a coupler, two platforms are machined on a threaded column at the front end of the driving shaft,and the platforms penetrate through a square hole in the center of the pressing disc and are connected with knobs. Compared with the prior art, the wristwatch chaining machine has the advantages thatthe design is scientific, automatic chaining work of a wristwatch can be completed, labor is saved, the economical efficiency is good, and the efficiency is high; and a plurality of automatic mechanical watches of the same type or different types can be chained at the same time.

Owner:盘锦追光电子科技有限公司

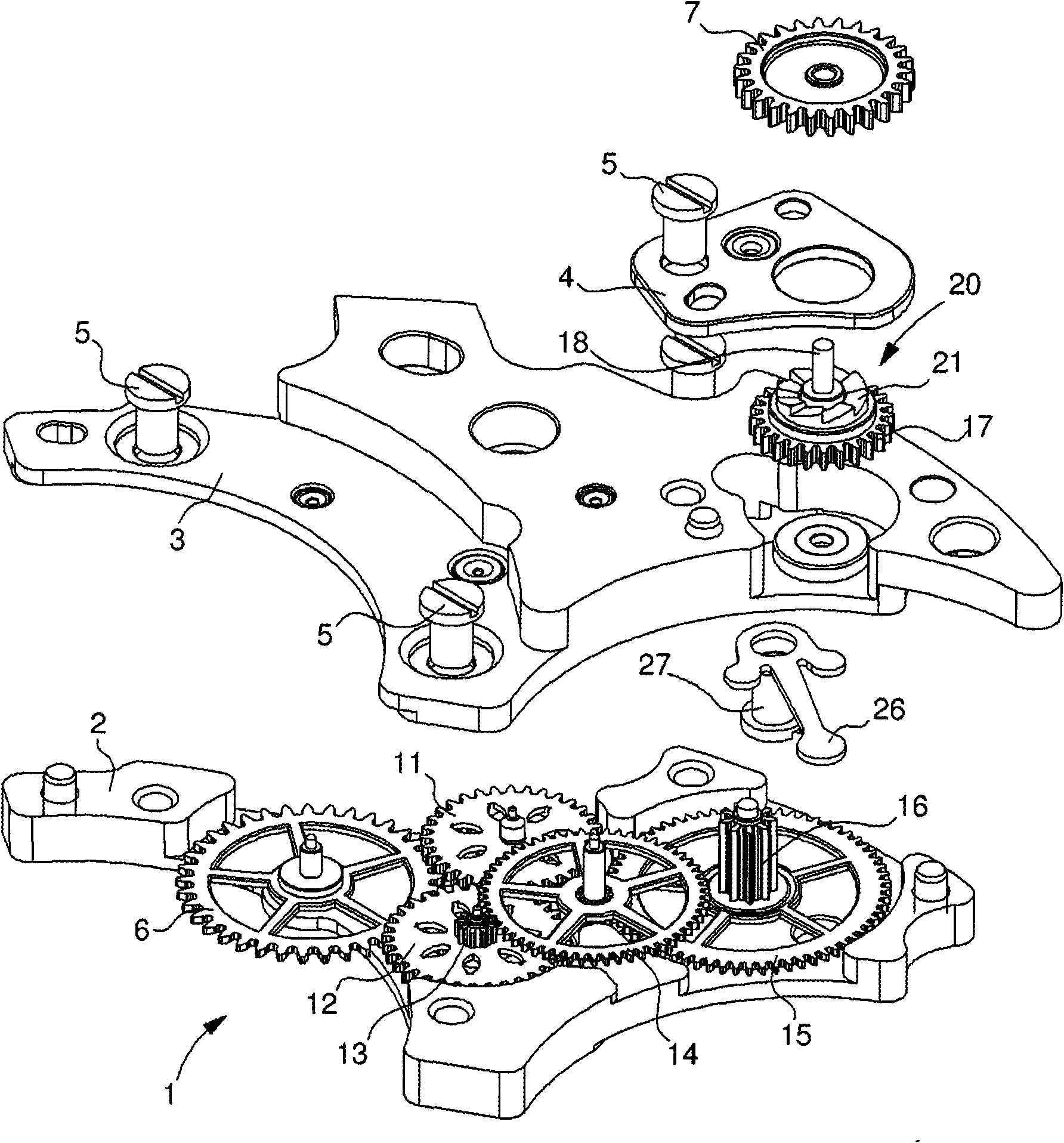

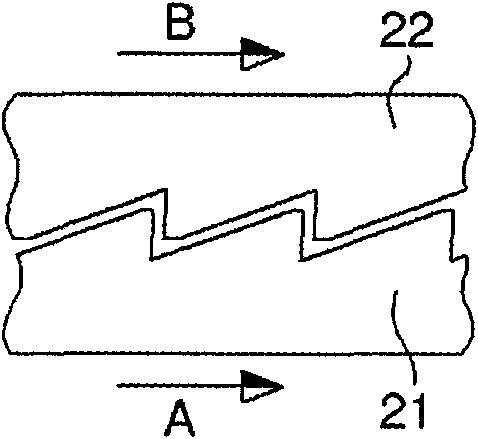

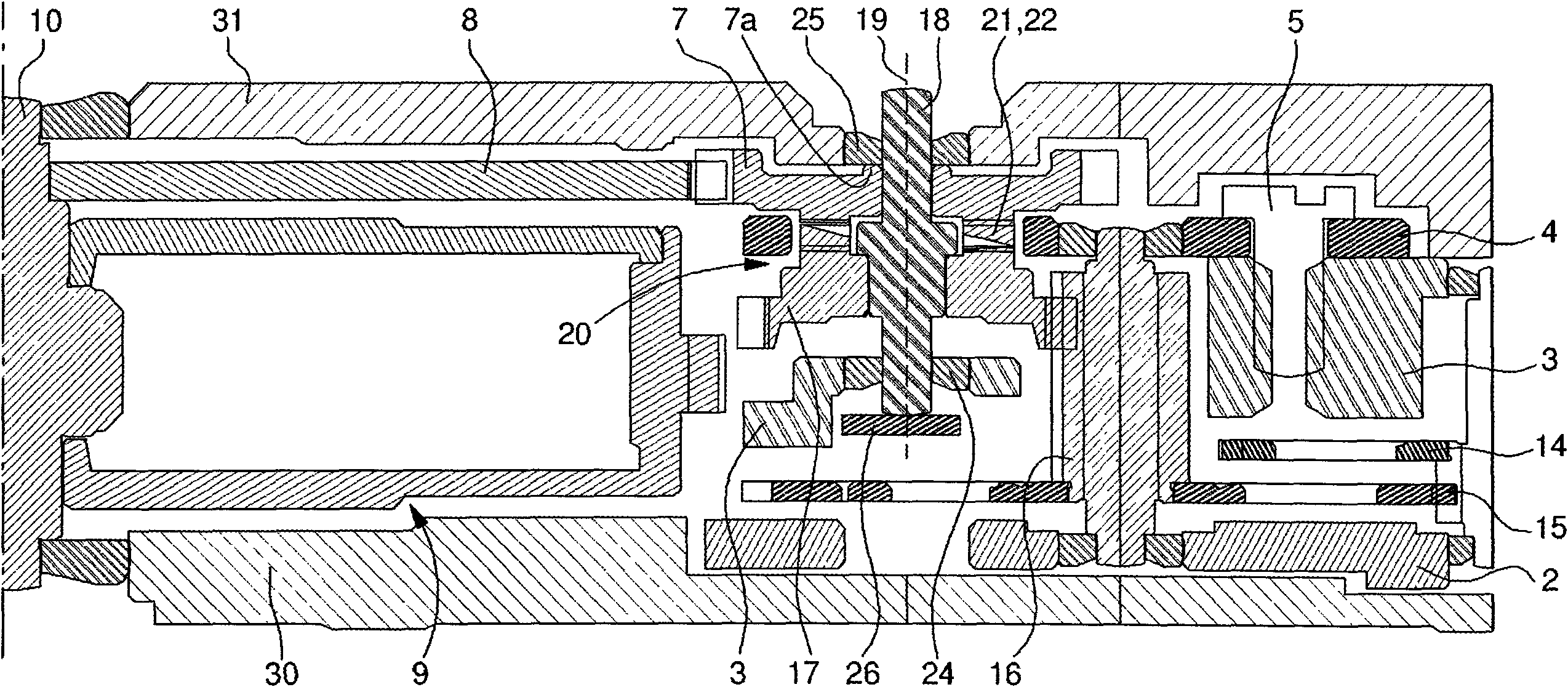

Disengaging device for timepiece mechanism, and watch movement comprising this device

The invention concerns a vertical type uncoupling device, in particular in an automatic watch winding mechanism that includes an oscillating mass and a gear train connecting the oscillating mass to a barrel (9), wherein said gear train includes a direction reverser device (11, 12), a reduction gear (13, 14, 15, 16) and the uncoupling device (20). The uncoupling device includes two coaxial wheels (17, 7) that can be coupled in rotation in one direction owing to respective Breguet toothings (21, 22) arranged on the opposite flanks of said wheels. The coaxial wheel (17), which is mobile in the axial direction, is secured to a sliding arbour (18), which is mounted so as to rotate and slide in fixed bearings (24, 25). A return spring (26) includes an elastic strip that abuts against one end ofthe sliding arbour (18) to tend to engage and keep meshed the Breguet toothings. This design reduces friction and saves space. Other applications of this type of uncoupling device in a watch movementare described.

Owner:MONTRES JAQUET DROZ SAMONTRES JAQUET DROZ AGMONTRES JAQUET DROZ LTD

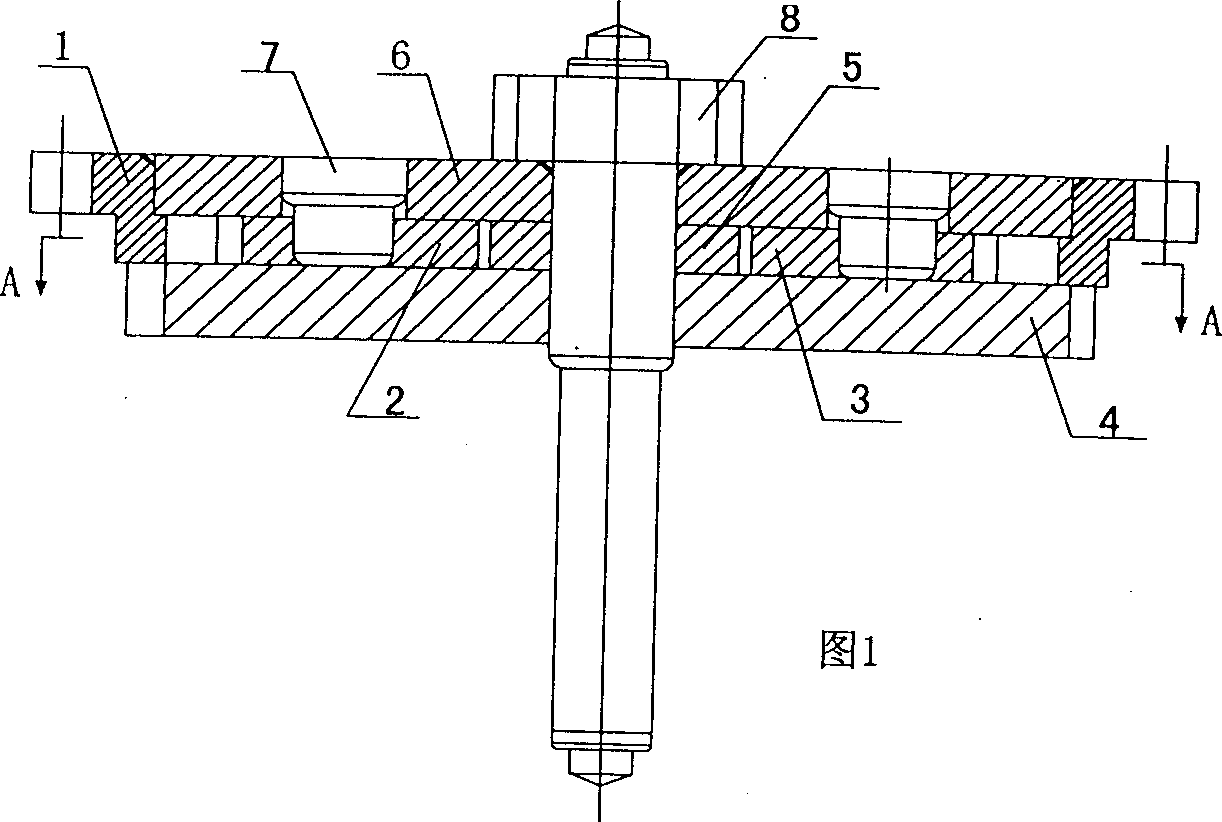

Double-lever interlocking change-over mechanism and method for automatic watch

InactiveCN1374570AImprove wear resistanceReduced wear resistanceAutomatic windingManufacturing technologyGear wheel

The present invention relates to the manufacture of watch. The double-lever interlocking change-over mechanism consists of gear, double swing links, ratchet wheel, isolating ring, wheel sleeve, nail and toothed shaft assembled together. The key point of the mechanism is that the gear with both inner and outer teeth and the double swing links constitute one enclosed transmission chain for transferring motion and force in single way. The mechanism has mesh between gear and automatic hammer and mesh between toothed shaft and automatic spring winding wheel. The mechanism is high in reliability, long in service life, low in cost and high in efficiency.

Owner:刘越雄

Oscillating weight for automatic watch

ActiveUS9256205B2Improve aesthetic qualityAutomatic windingMechanical time indicationEngineeringAutomatic watch

Oscillating weight for automatic watch movement, having a massive peripheral ring in the shape of an arc of circle, a connecting element connecting the peripheral ring to the weight's pivoting center, wherein the connecting element is set with a plurality of stones.

Owner:CHRISTIAN DIOR COUTURE

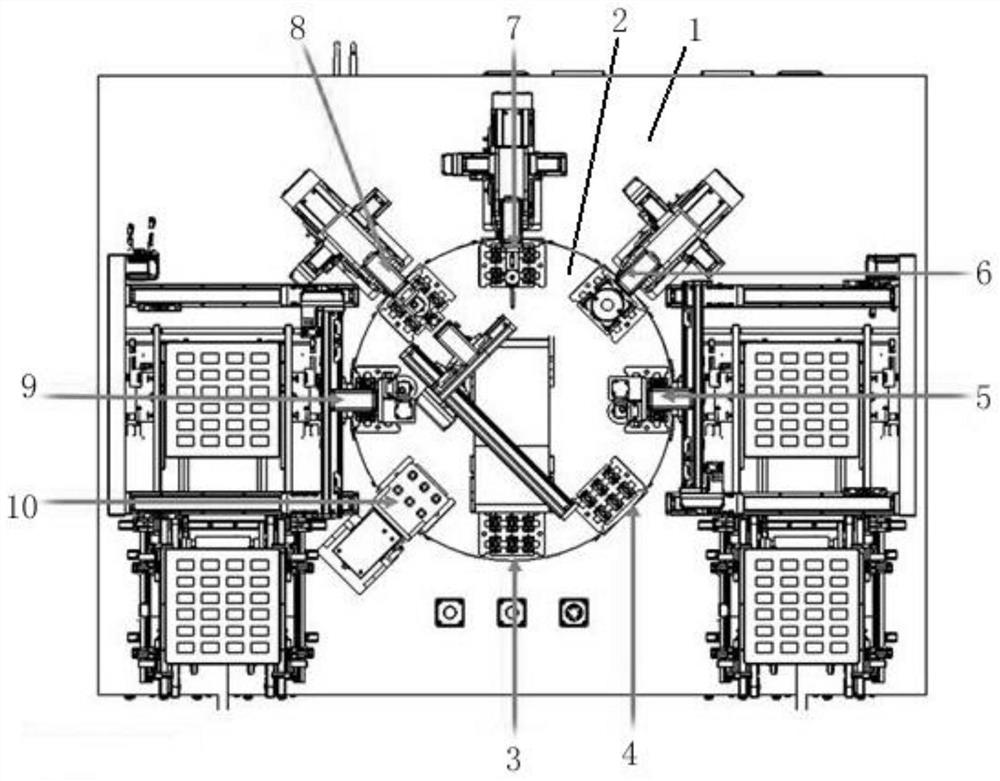

Fully-automatic watch cover fitting and pressing equipment

PendingCN111644833ASave manpower for assemblyImprove performanceMetal working apparatusProcess engineeringWorkbench

The invention relates to fully-automatic watch cover fitting and pressing equipment. The fully-automatic watch cover fitting and pressing equipment is provided with a workbench, wherein the center ofthe workbench is provided with an automatic-rotation high-precision high-speed rotary platform; the periphery of the surface of the high-precision high-speed rotary platform is provided with a carrying plate adding first station; in the anticlockwise direction of the carrying plate adding first station, a second station, a watch cover raw material adding third station, a watch cover surface plasmacleaning fourth station, a dispensing fifth station are sequentially arranged. The fully-automatic watch cover fitting and pressing equipment realizes complete automation in an assembly process, cansave assembly power, integrates a visual detecting system in aspect of function, can automatically pick out defective products, and improves efficiency to the greatest extent.

Owner:苏州倍苏自动化科技有限公司

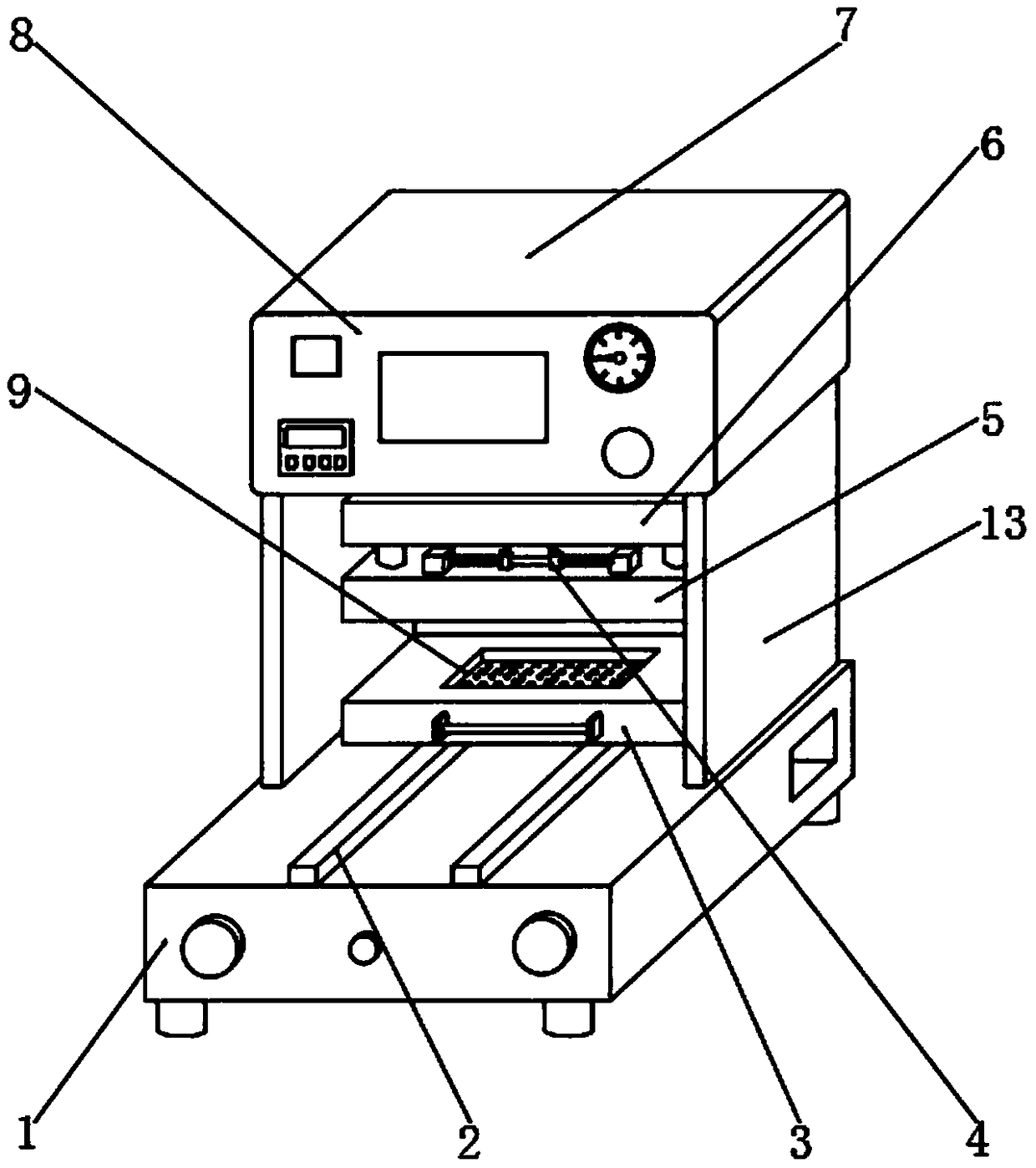

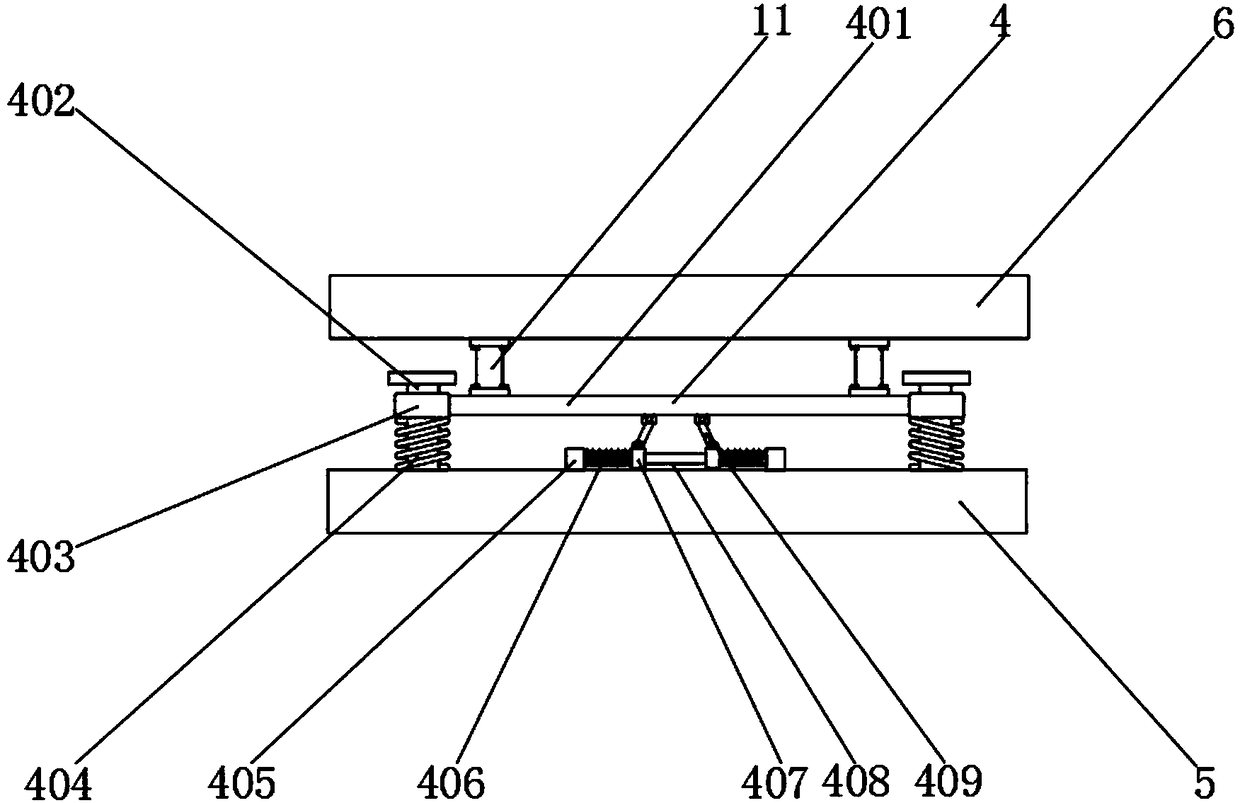

Full-automatic watch full-lamination all-in-one machine

PendingCN108445733AExtended service lifeGuaranteed qualityRepair toolsClock support devicesEngineeringAutomatic watch

The invention discloses a full-automatic watch full-lamination all-in-one machine. The all-in-one machine comprises a base. The top end of the base is provided with a cabinet, and the base and the cabinet are fixedly connected through a frame. The upper surface of the base is fixedly provided with a sliding rail. The all-in-one machine is clever in design, excellent in structure, and low in cost,and is simple and practical. The all-in-one machine is provided with a buffer device. Through the buffer device, pressing strength and speed of an upper laminating plate are buffered and decelerated,overall service life of the upper laminating plate and a lower laminating plate is prolonged, and quality of a laminating piece is guaranteed. The all-in-one machine solves a problem that when a pushing impulsive force of the upper laminating plate is excessive, the upper laminating plate and the lower laminating plate of a laminating piece are easily damaged, and cost waste is reduced. A laminating piece rapid fixing device is arranged. Through the laminating piece rapid fixing device, the laminating piece can play a role of rapid fixing, stability is improved, and laminating quality is improved, product quality is guaranteed, market reputation is improved, rework rate is reduced, and cost waste is saved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

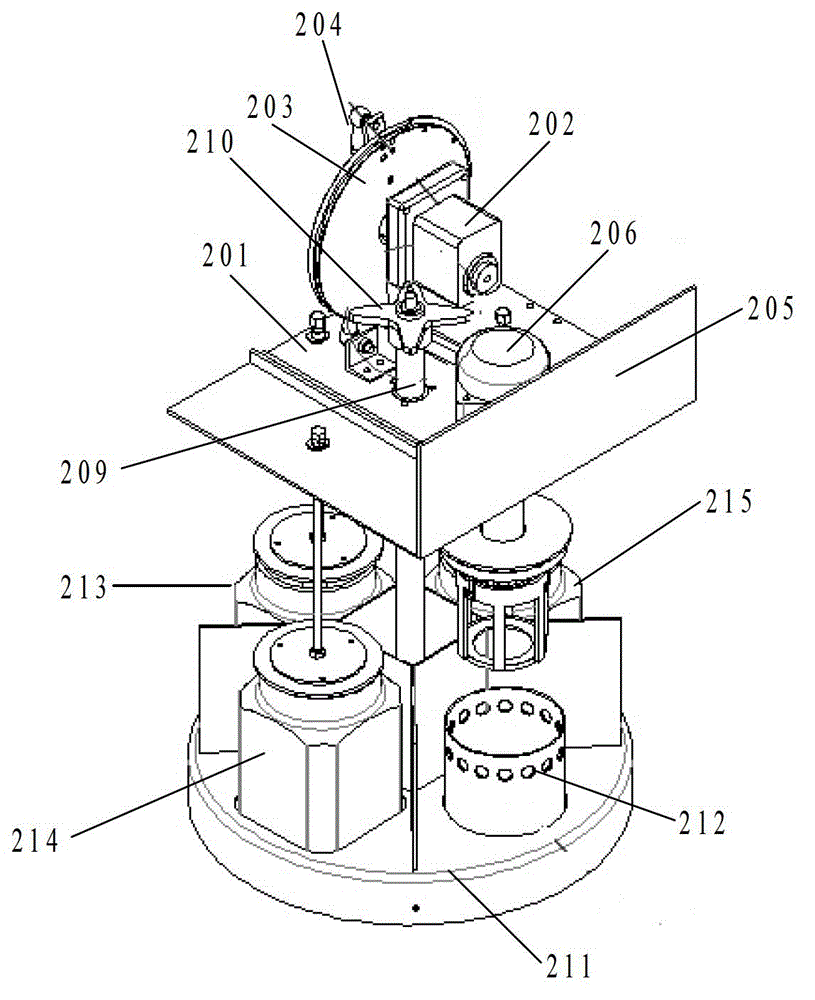

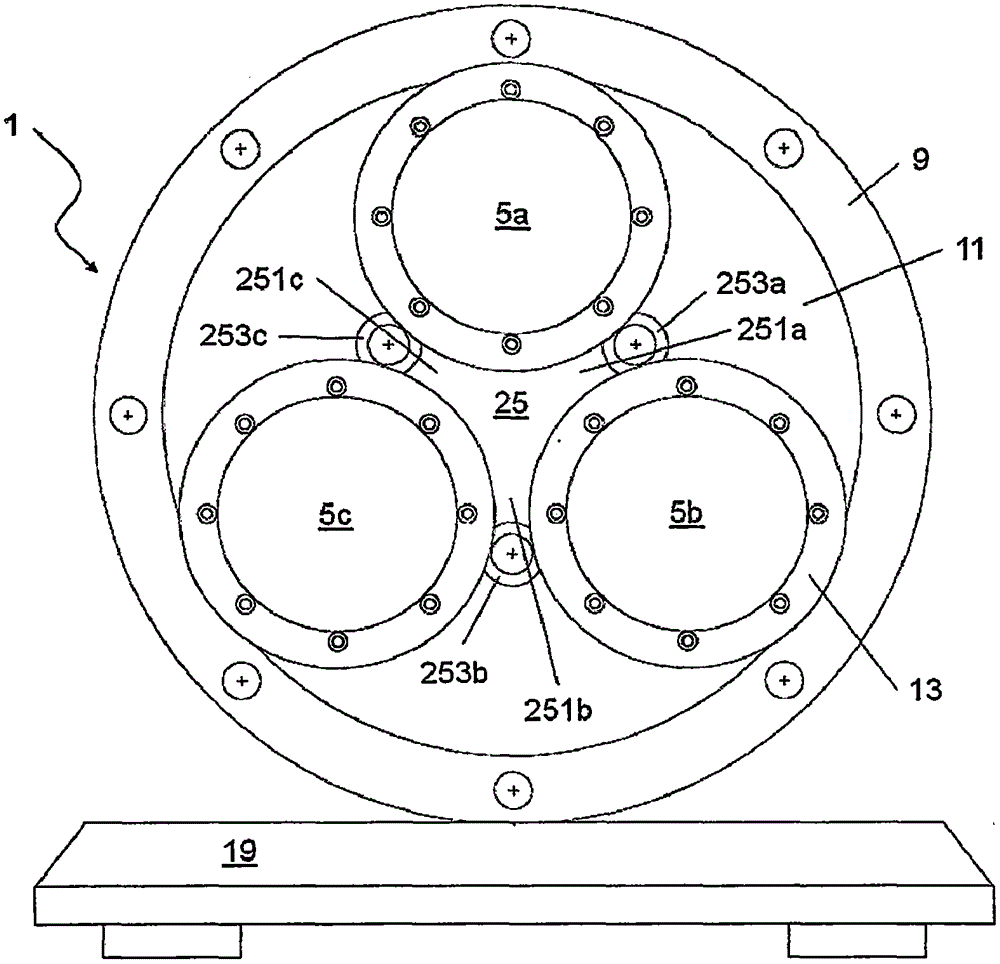

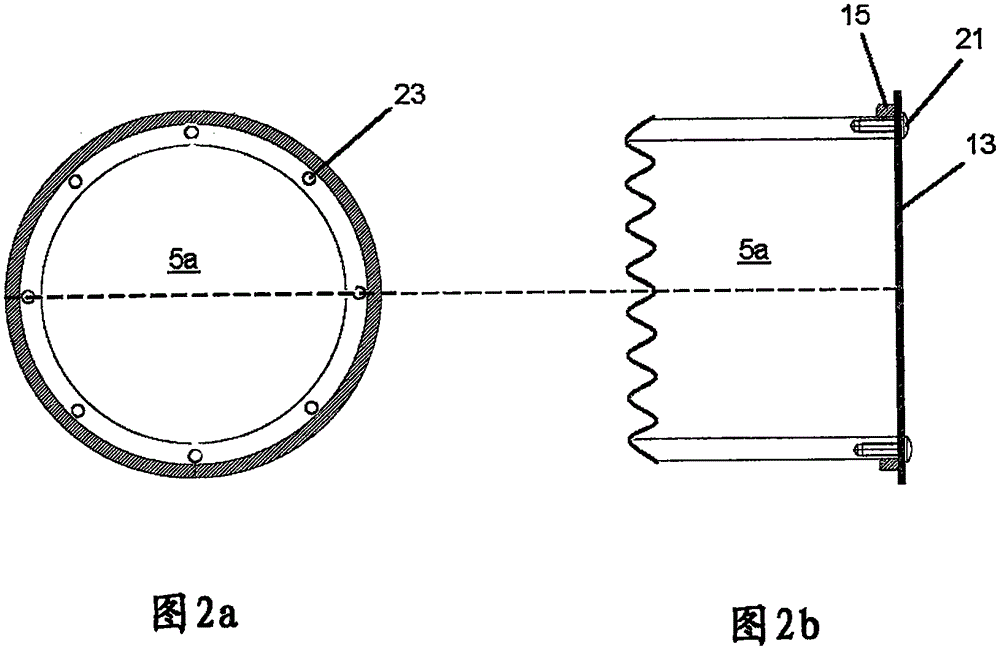

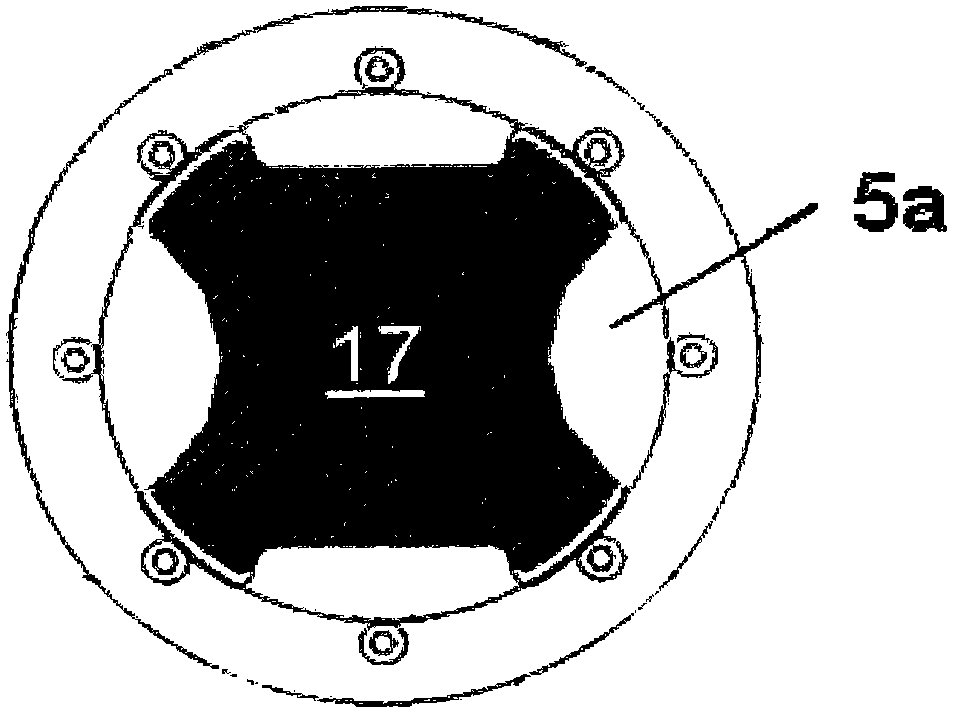

Watch spring winding apparatus

The invention relates to a watch spring winding apparatus (1) which comprises a transmission component (25) mounted along the longitudinal axis of the apparatus in a rotation manner, a motor (27) to drive the transmission component (25) mounted along the longitudinal axis of the apparatus, a plurality of collection cylinder bodies (5a, 5b, 5c, 5d, 5e, and 5f) mounted along the longitudinal axis of the apparatus also in a rotation manner, and at least one housing component (9) with an almost round opening (11). The plurality of collection cylinder bodies and the transmission components are held in the opening (11) in a paired manner wherein the collection cylinder bodies with the guided manner are mutually independent from each other and can rotate around the transmission component (25) and are arranged on the concentric circle path (K1) in a rotation manner to make sure that the transmission component is in a force locked contact wherein the collection cylinder bodies and the almost round opening (11) of the housing component (9) are in the force locked contact. The invention also discloses a method for winding the spring of a mechanical automatic watch by using the watch spring winding apparatus proposed by the invention.

Owner:M & E UHRENBEWEGER MANUFAKTUR

Oscillation structure controlled by electrical energy conversion for balance spring oscillating system

PendingCN107390500AImprove bindingAccurate timingFrequency stabilisation mechanismElectric windingElectric machinePhysics

The invention discloses an oscillation structure controlled by electrical energy conversion for a balance spring oscillating system. The oscillation structure comprises a movement main clamping plate and a balance spring oscillating system arranged on the movement main clamping plate, wherein the movement main clamping plate is further provided with a stepping motor driving system; and the stepping motor driving system is used for driving oscillation of the balance spring oscillating system. According to the oscillation structure, the balance spring oscillating system of an automatic watch and an oscillating circuit of a quartz watch can be perfectly combined, and the characteristics of accurate timing, low cost and easy processing can be achieved.

Owner:广西天睿精工精密电子有限公司

Automatic watch setting method based on flexible strain sensor

ActiveCN107703731AAutomatic time synchronizationNo manual operation requiredElectric windingDrive motorStrain sensor

The invention relates to an automatic watch setting method based on a flexible strain sensor. The automatic watch setting method provided by the invention comprises the following steps: firstly adjusting pointers to a preset position; secondly, acquiring the current time; thirdly, sending the current time to a watch, and adjusting the pointers to the current exact time; the step one comprises steps (described in the specification); the watch comprises a surface, and an opening is formed in the surface; the flexible strain sensor is arranged at a position, dead against the opening of the surface, of the watch movement; length of the flexible strain sensor stretching out the opening is greater than height of any point from the surface; and the flexible strain sensor is connected with a processor of the watch, the processor stores a strain threshold value of the flexible strain sensor, the processor drives the pointers to drive, and when a strain value of the flexible strain sensor reaches the strain threshold value, the processor controls a driving motor of the pointer contacted with the flexible strain sensor to drive the pointer to rotate for a rotation threshold value and then stop at the preset position.

Owner:SHANDONG LANDBRIDGE PETROCHEMICAL CO LTD

Automatic watch buckle assembling equipment

PendingCN110385579ARealize automated assemblyEfficient productionAssembly machinesMetal working apparatusLocking mechanismEngineering

The invention provides automatic watch buckle assembling equipment. The automatic watch buckle assembling equipment comprises a rack and a conveying mechanism arranged on the rack and further comprises a bottom buckle feeding mechanism, a watchband feeding mechanism, an upper buckle feeding pre-locking mechanism, a locking attachment mechanism and a discharging mechanism which are sequentially arranged along the conveying mechanism. The conveying mechanism forwards conveys product carrier plates, the bottom buckle feeding mechanism feeds bottom buckles to the product carrier plates, the watchband feeding mechanism feeds and places watchbands to the positions above bottom buckles, the upper buckle feeding pre-locking mechanism conveys and places upper buckles to the positions above the watchbands, the upper buckles, the watchbands and the bottom buckles are pre-locked, then enter the position below the locking attachment mechanism to be locked and then enter the discharging mechanism for discharging, automatic watch buckle assembling is achieved, production is efficient, and manpower is saved.

Owner:重庆创璟自动化设备有限公司

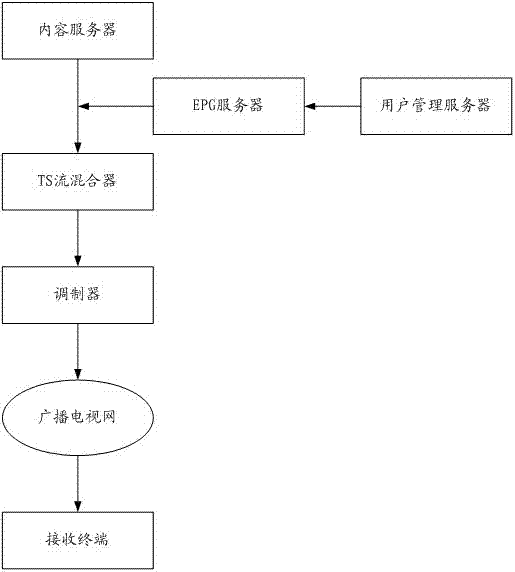

Automatic watching method of near video on-demand program

ActiveCN102413360AImprove convenienceMuch funSelective content distributionClick-through rateDigital television

The invention provides an automatic watching method of a near video on-demand program, which is suitable for the field of digital televisions. The method comprises the following steps: in a digital television front end server, a service type parameter value in a SDT (Service Description Table) of one or more channels in a near video on-demand business channel is changed into a type reference value of a common television channel which can be recognized by a receiving terminal; and the receiving terminal places the modified near video on-demand business channel program and other common television channel programs into the same program list. The method realizes the aim that a user can automatically watch the program of the near video on-demand business in the process of watching a common television under the condition of not changing the watching habit of the user, greatly improves the convenience for enjoying the business by the user, enriches the interest for watching the digital television by the user and can improve the click rate of the near video on-demand business, help to popularize the value added service and prevent the no use and waste of the business resource.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

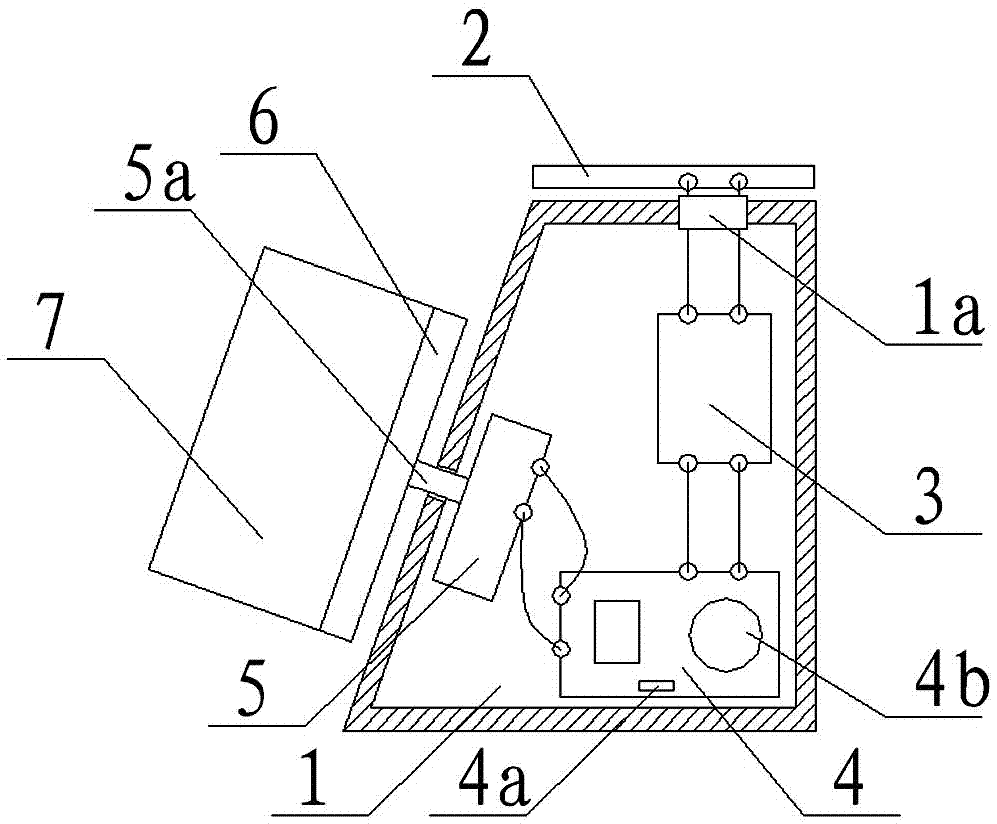

Automatic watch winder

InactiveCN106911180AEasy to install watchEasy to pick up the watchBatteries circuit arrangementsAutomatic windingElectric machineComputer module

The invention discloses an automatic watch winder, comprising a watch winder housing (1), characterized in that a solar panel (2) is arranged on the top of the housing (1), and the output end of the solar panel (2) It is connected to the input end of the storage battery (3) in the casing (1), and the output end of the storage battery (3) is connected to the fingerprint module (4). The fingerprint module (4) includes a fingerprint recording button (4a) and a fingerprint identification Window (4b), the output end of the fingerprint module (4) is connected to the motor (5), and the rotating shaft (5a) of the motor is set with a turntable (6), and the turntable (6) is equipped with a watch box (7); the invention design Simple and ingenious, using solar energy for power supply is environmentally friendly and energy-saving. Using fingerprint module technology to control the motor on and off is more convenient for users to install and take out the watch. Affected by factors such as power outages, it is very suitable for promotion and popularization.

Owner:重庆华威龙科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com