Full-automatic watch crown assembling equipment

An assembly equipment, fully automatic technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor cost, manpower consumption, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

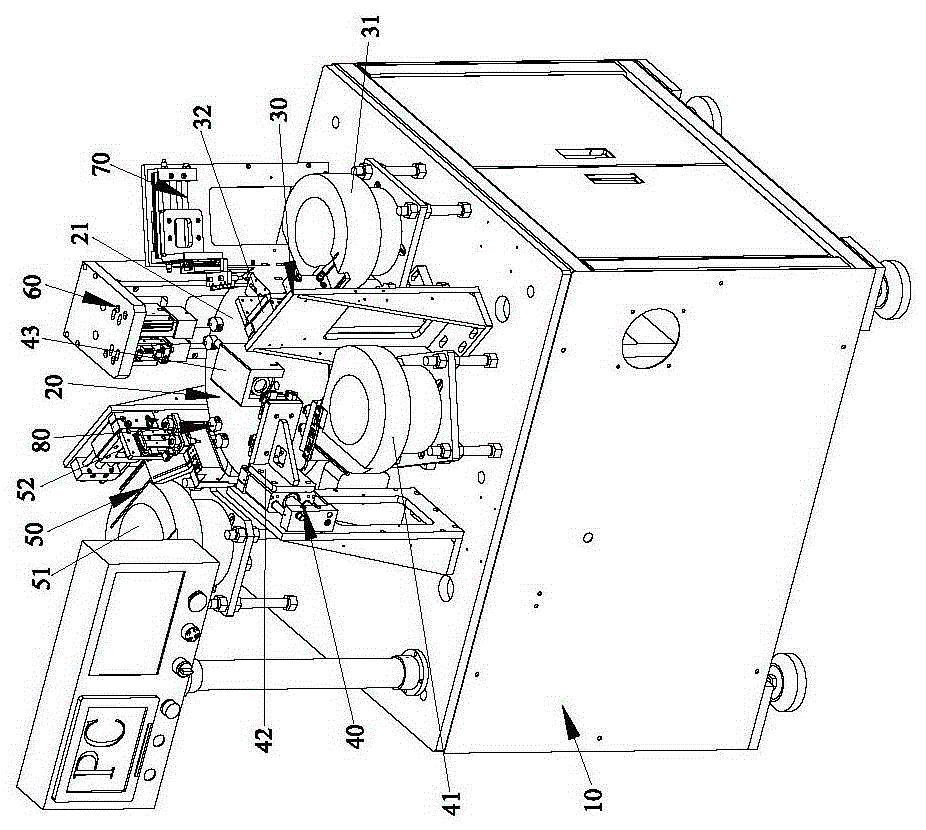

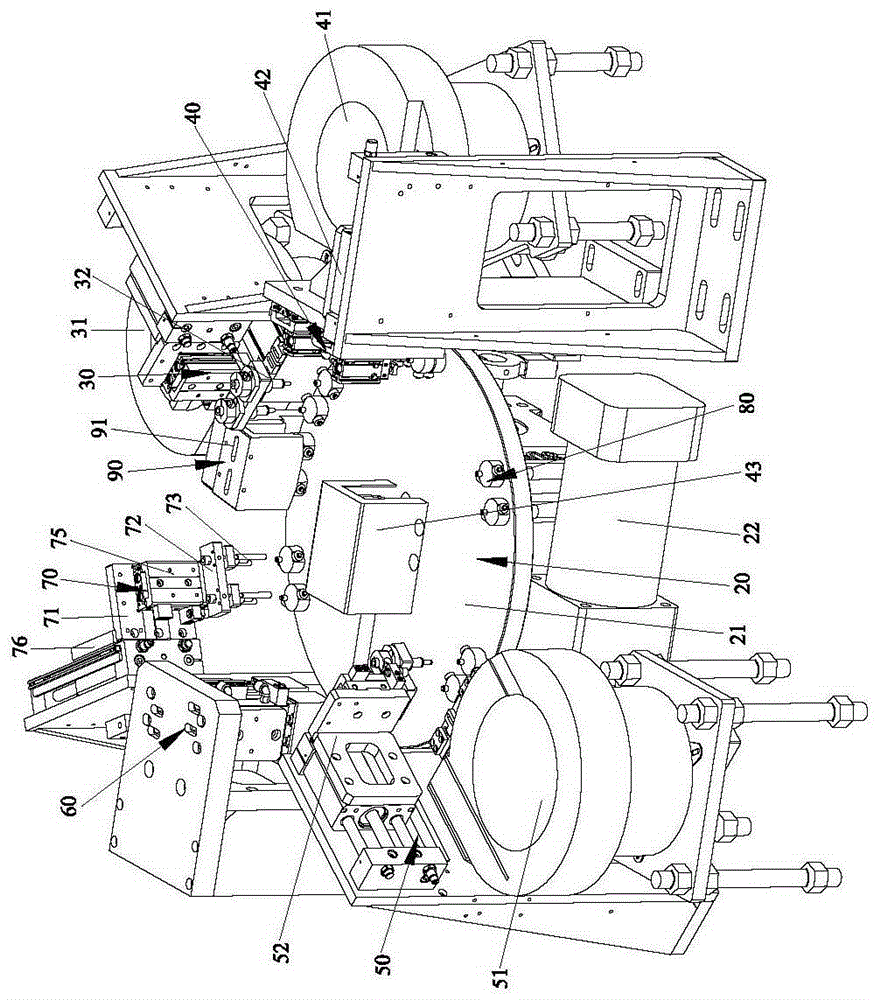

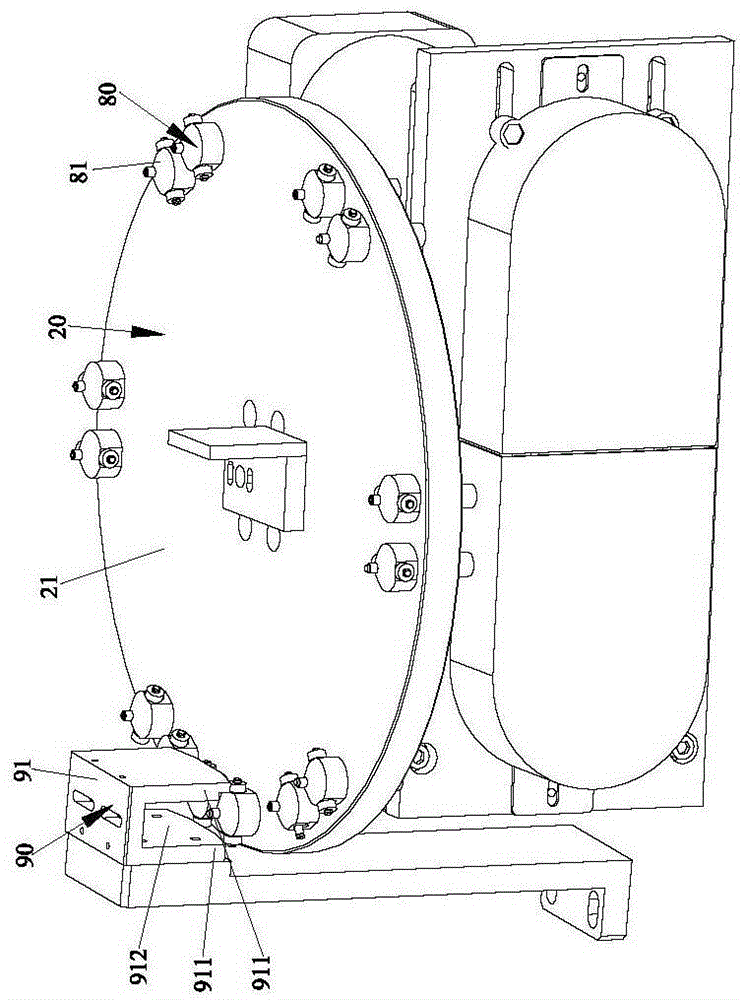

[0068] Please refer to Figure 1 to Figure 16 As shown, it shows the specific structure of the preferred embodiment of the present invention, including frame 10, conveying module 20, meson pick-and-place material module 30, O-ring pick-and-place material module 40, bar take-off Unloading module 50 , stamping module 60 and finished product blanking module 70 .

[0069] The conveying module 20, the meson picking and discharging module 30, the O-ring picking and discharging module 40, the bar picking and discharging module 50, the stamping module 60 and the finished product blanking module 70 are all arranged on the frame 10 Above, the conveying module 20 is provided with a positioning fixture 80, and the conveying module 20 drives the positioning fixture 80 to move along the conveying direction; the meson taking and discharging module 30, the O-ring taking and discharging module 40, bar The loading and unloading module 50 , the stamping module 60 and the finished product unload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com