Full-automatic cotton quilt production line

A fully automatic, production-line technology, applied in sewing machines for sewing quilts, textiles and papermaking, garment piece transporters, etc., can solve the problem of inability to realize automatic quilt operation, improve product quality, improve production efficiency, and reduce manpower. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

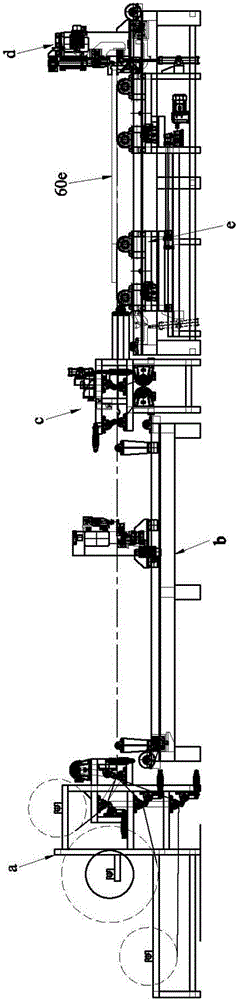

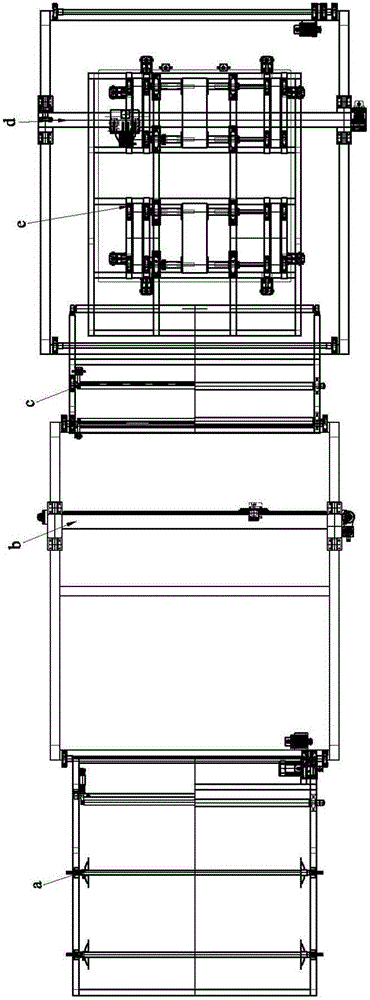

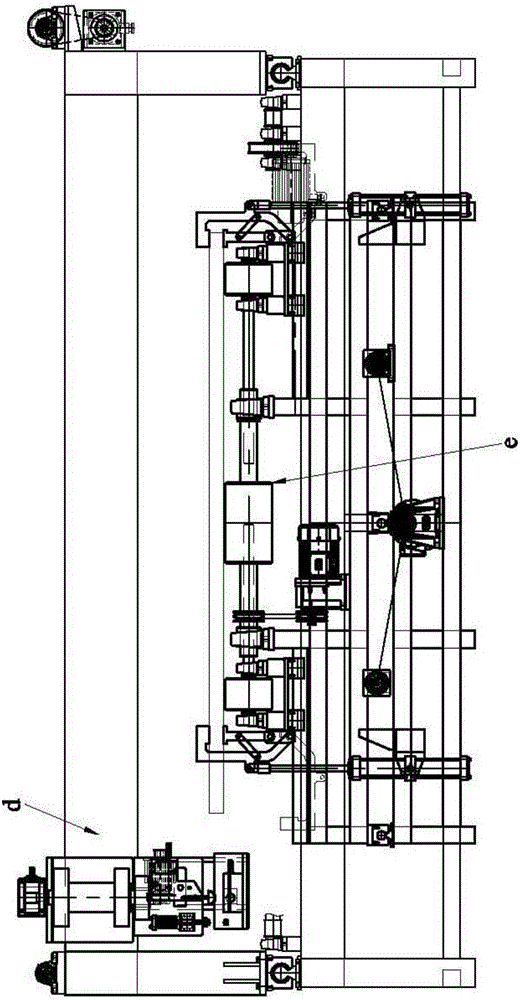

[0054] Please refer to Figure 1 to Figure 39 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a feeding frame mechanism a, an automatic quilting machine b, a cutting machine c, a hemming machine d and a hemming conveying frame mechanism e; the feeding frame Mechanism a, automatic quilting machine b, cutting machine c and hemming machine d are arranged horizontally in sequence, and hemming conveyor mechanism e is set in hemming machine d.

[0055] Such as Figure 4 to Figure 9 As shown, the feeding frame mechanism a includes a cloth roll storage frame body 10a, a plurality of cloth rolling roller assemblies 20a, a plurality of power roller assemblies 30a, a plurality of pressing roller assemblies 40a and a cloth rolling reducer 50a.

[0056] The multiple cloth rolling cylinder assemblies 20a are installed on the cloth rolling storage frame body 10a, and the multiple cloth rolling cylinder assemblies 20a are arranged in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com