Patents

Literature

1068results about "Workpiece carriers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

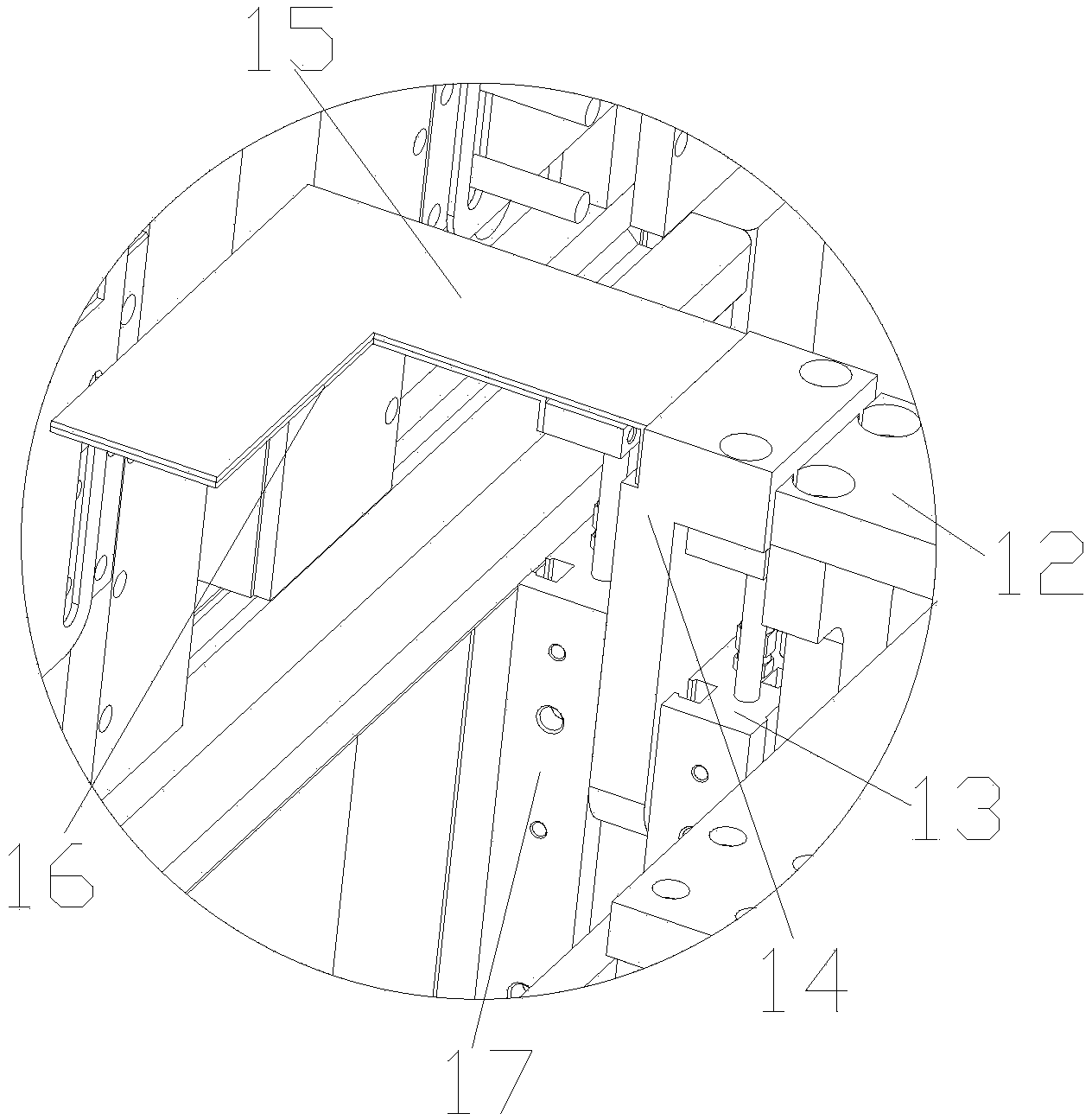

Ribbon loom

ActiveCN103696153ASimple structureImprove processing efficiencyWorkpiece carriersWork-feeding meansMechanical engineeringEngineering

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

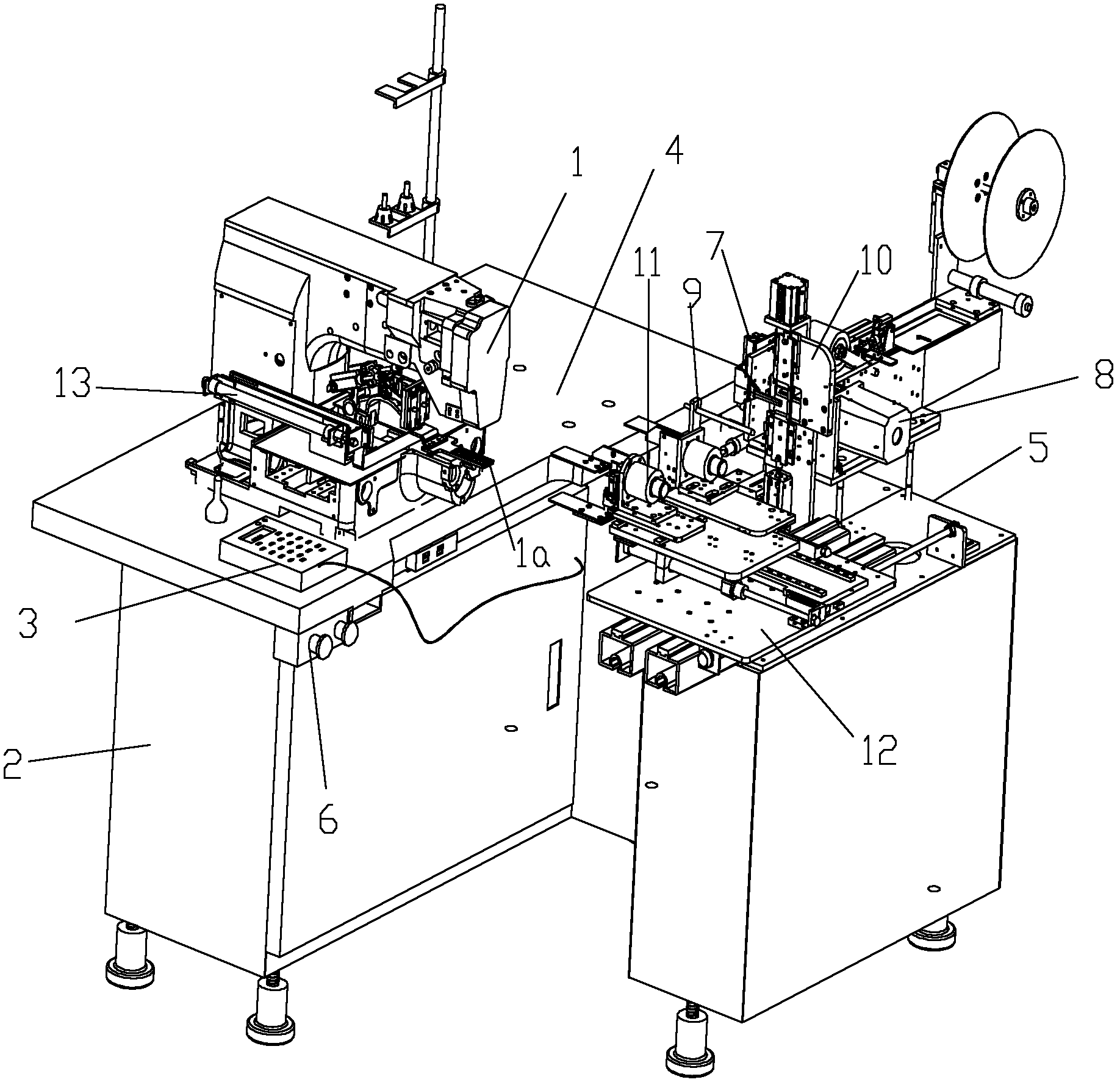

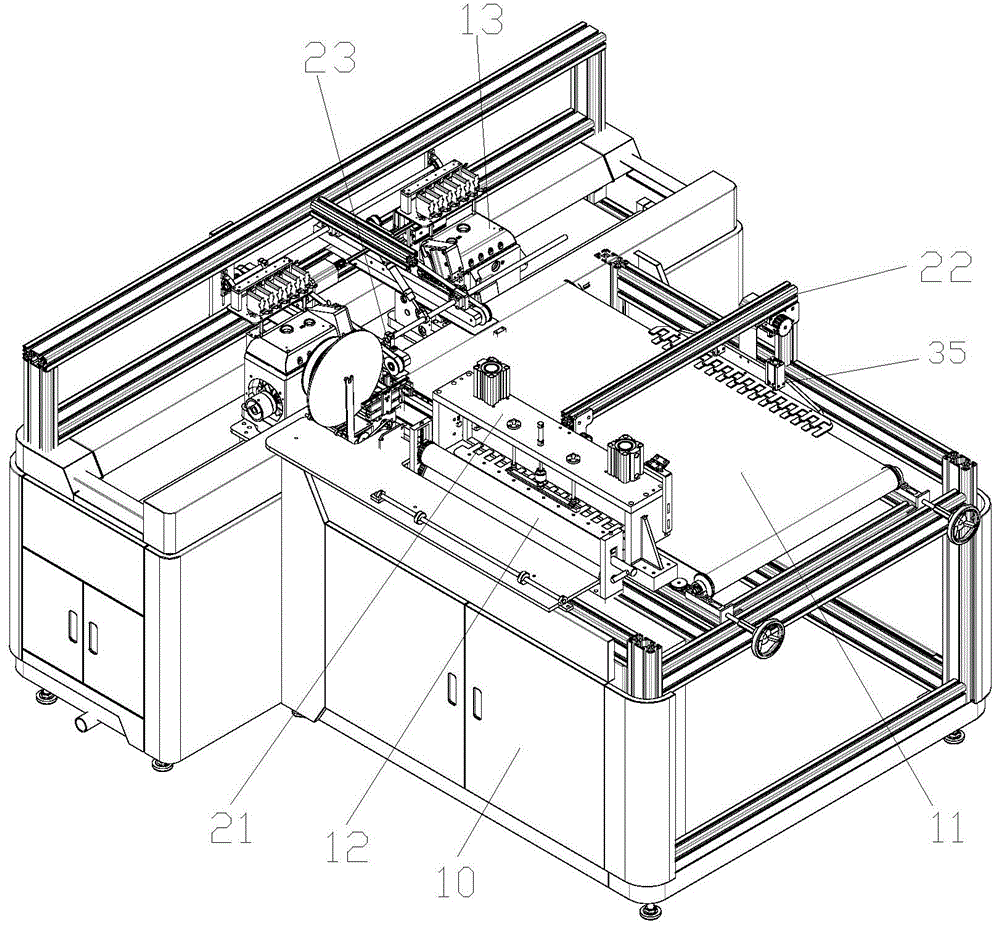

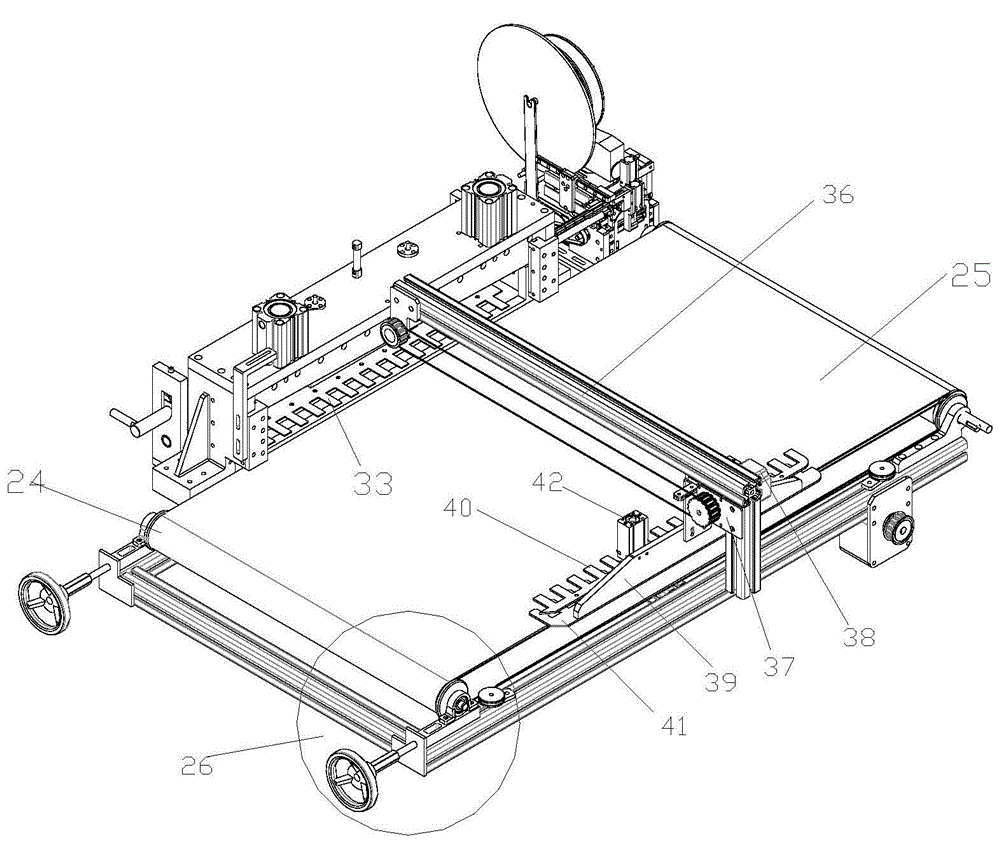

Towel machine

ActiveCN103498291AReduce manufacturing costIncrease productivityWorkpiece carriersWork-feeding meansIndustrial engineering

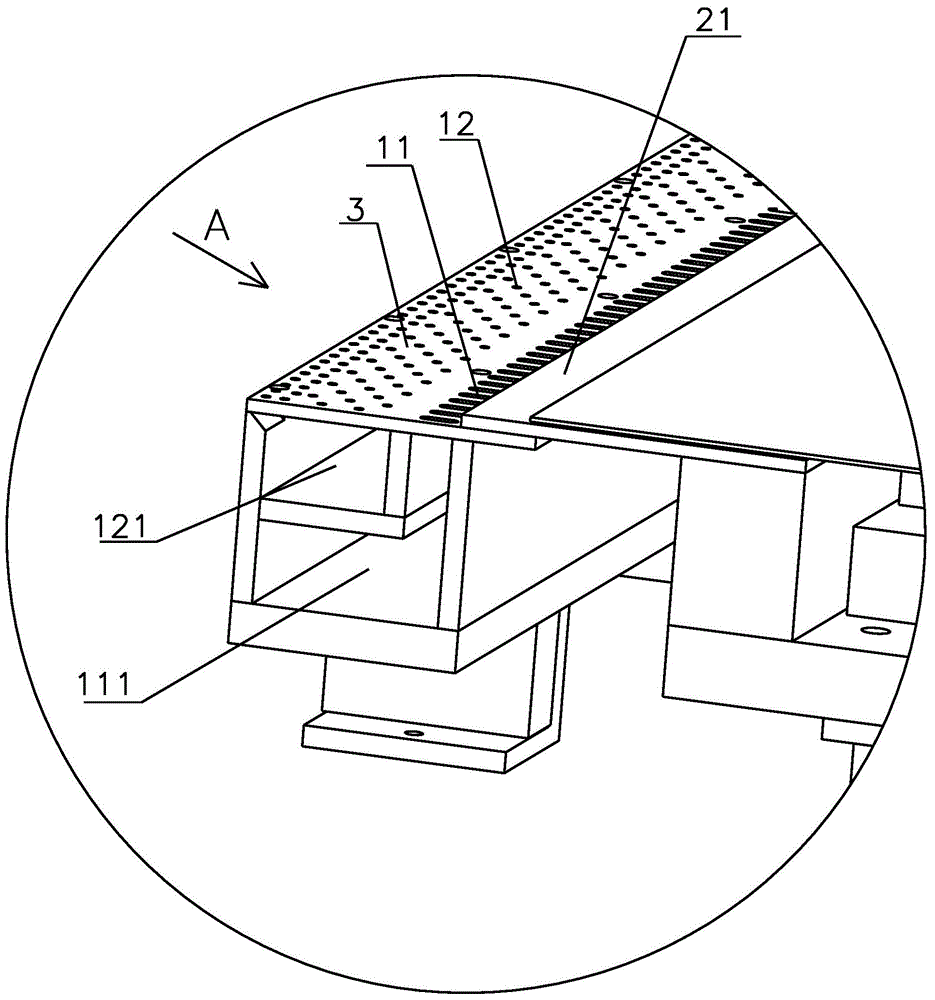

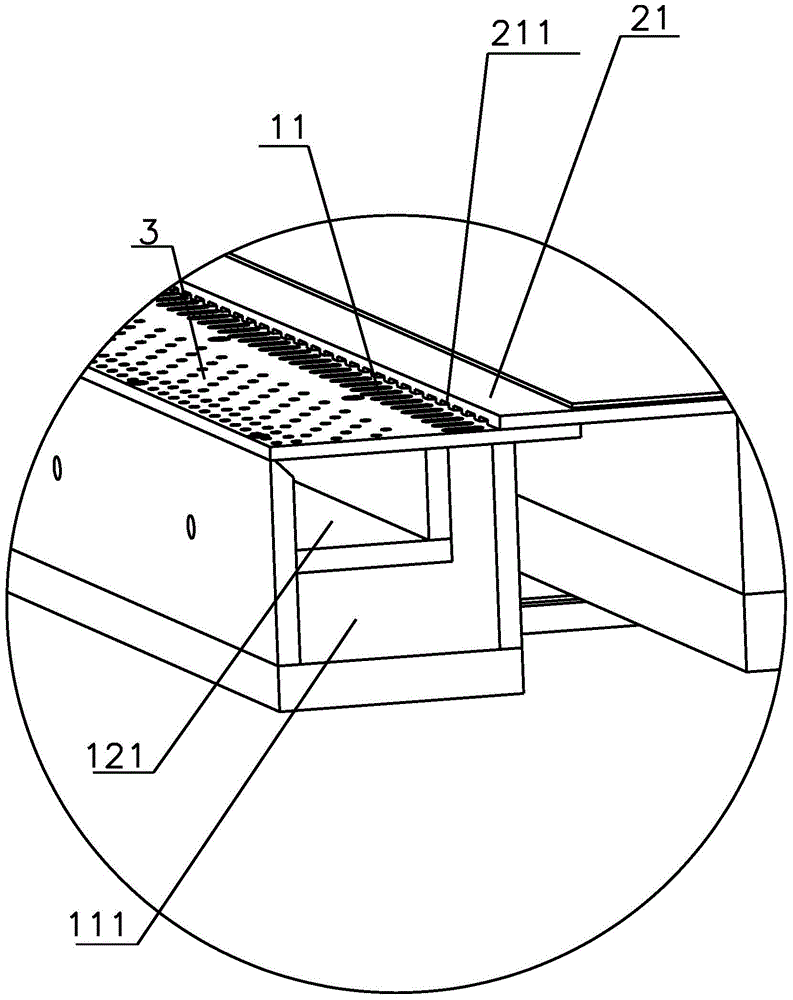

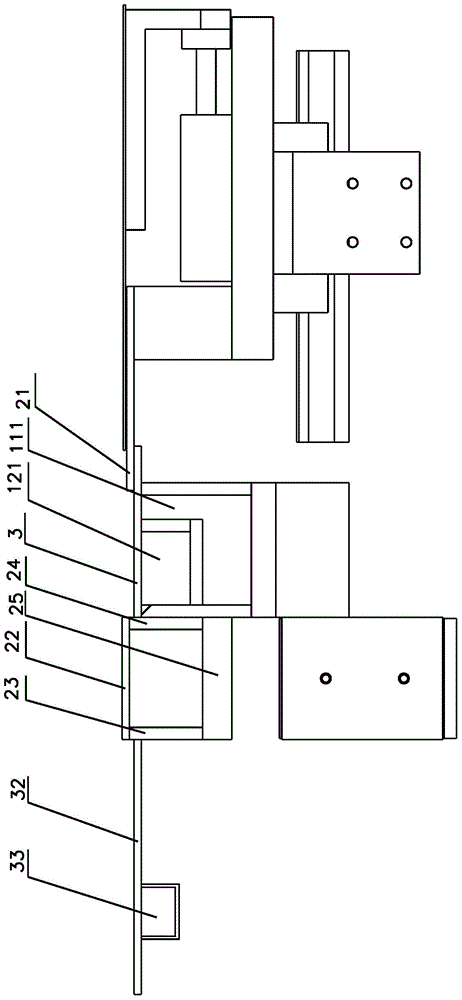

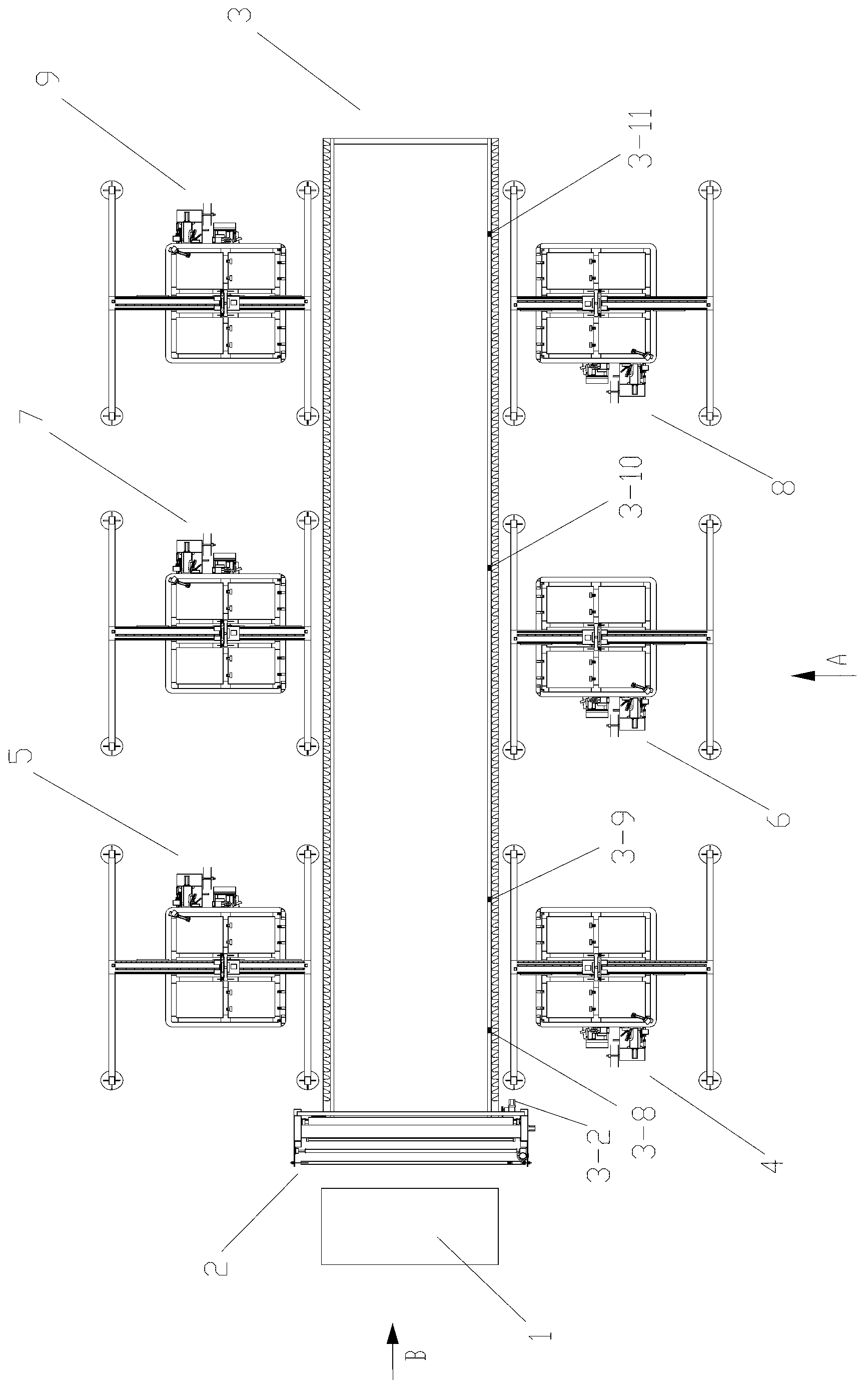

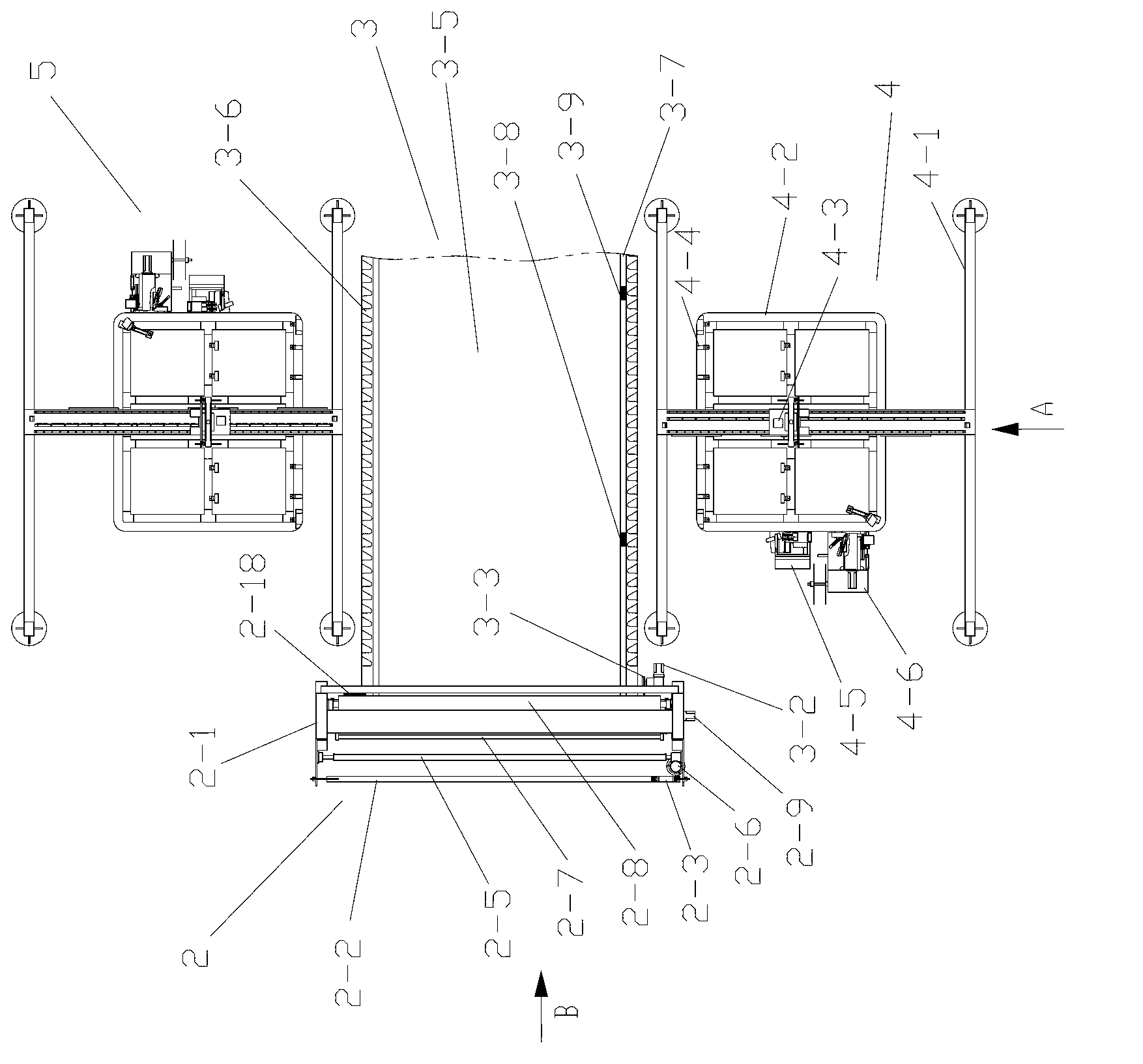

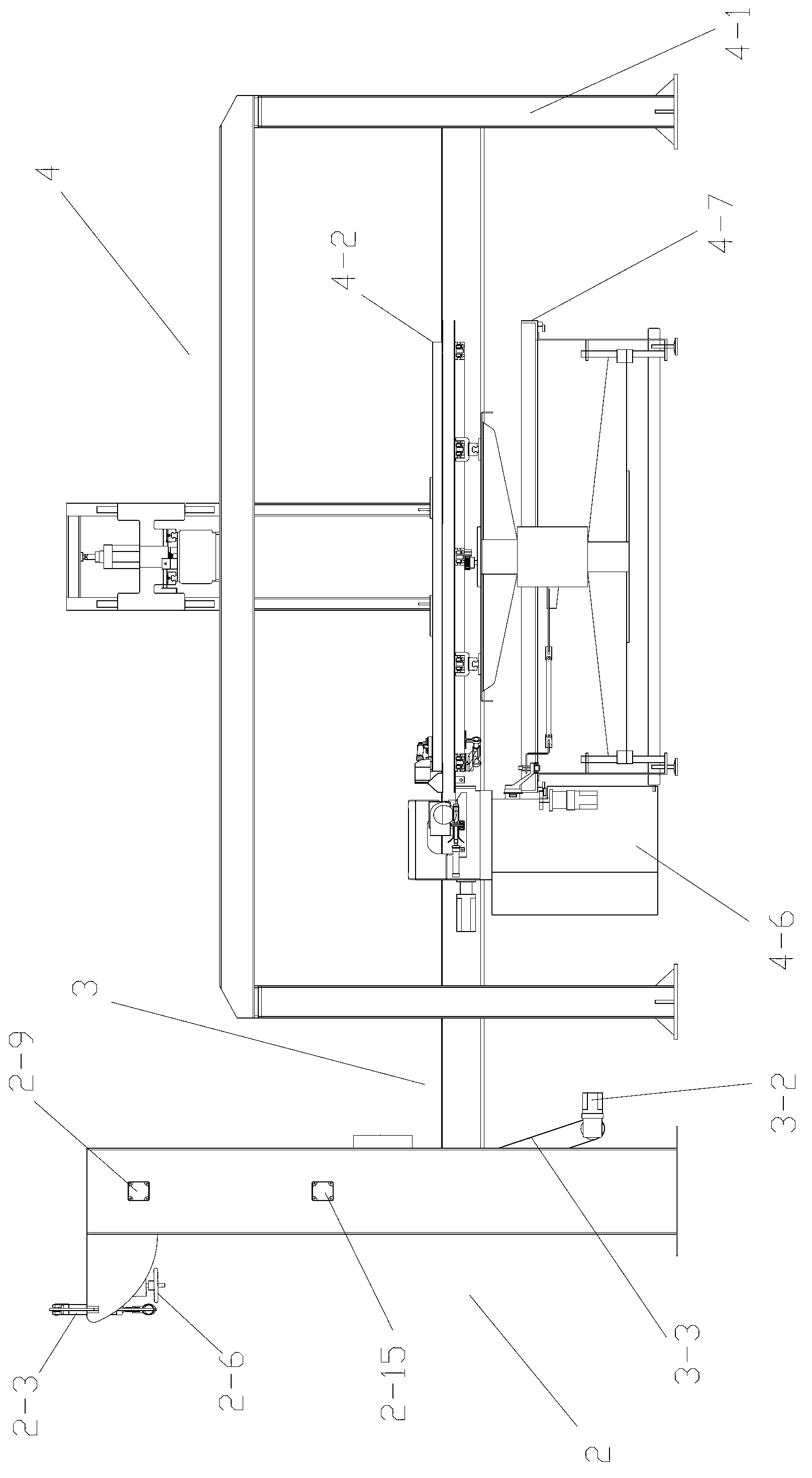

The invention discloses a towel machine. The towel machine comprises a feeding device, a first processing device and a second processing device. The feeding device, the first processing device and the second processing device are oppositely and fixedly placed in sequence. The feeding device is used for feeding cloth to the first processing device; the first processing device is used for binding off the two edges of the cloth fed by the feeding device for the first time; the second processing device is used for cutting off the cloth fed by the first processing device and then binding off the two edges of the cloth for the second time. According to the towel machine, original manual operation is replaced by mechanical automatic operation for towel production, so that labor intensity is greatly reduced for workers, the production mode that a single worker operates multiple machines can be realized in production, production efficiency of the product is improved, production cost is lowered, effective production management is facilitated, and the production value of the product is maximized.

Owner:SUZHOU TRANSPARENT TECH CO LTD

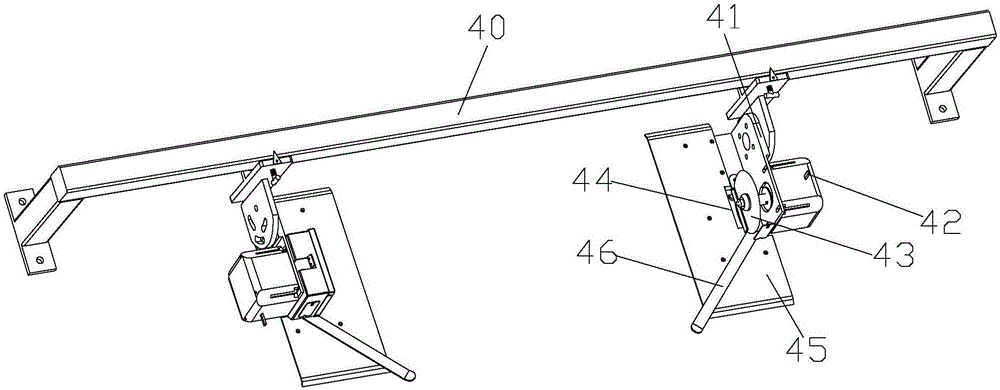

Elastic ribbon machine

ActiveCN103352330ASimple structureEasy to fix with sewingWorkpiece carriersWork-feeding meansAutomatic controlFeed drive

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

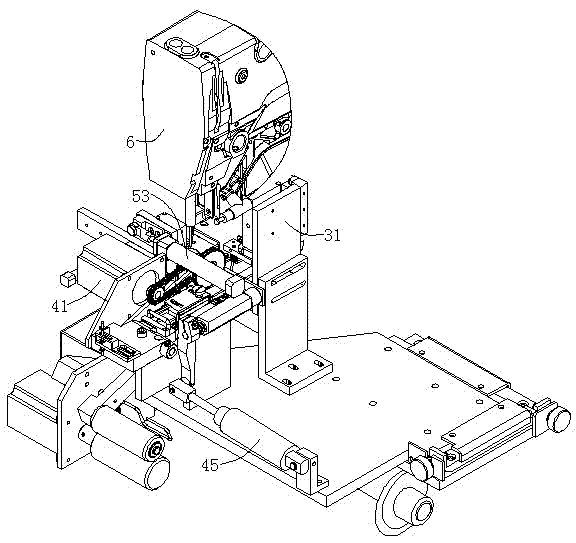

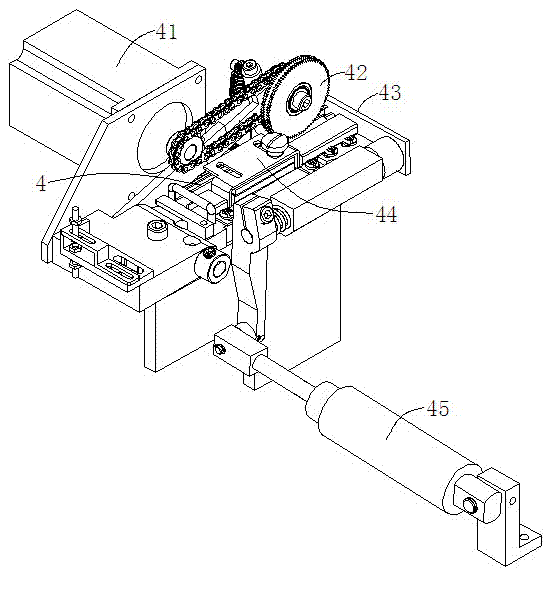

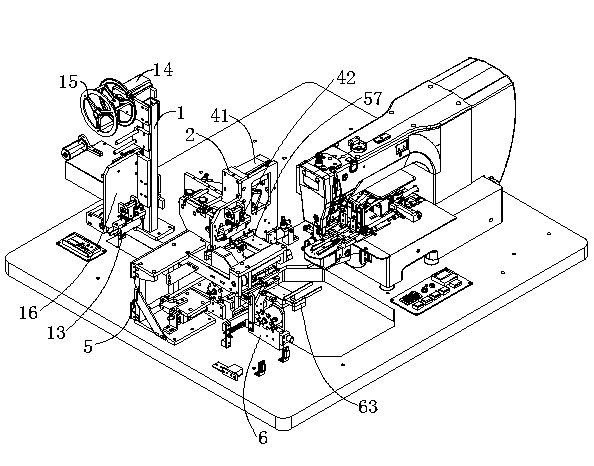

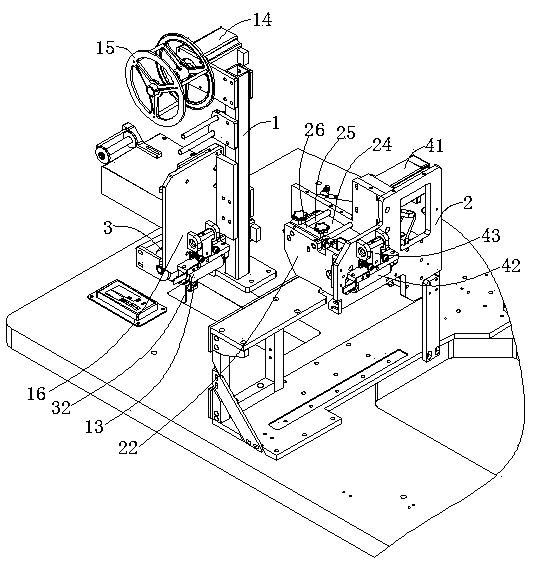

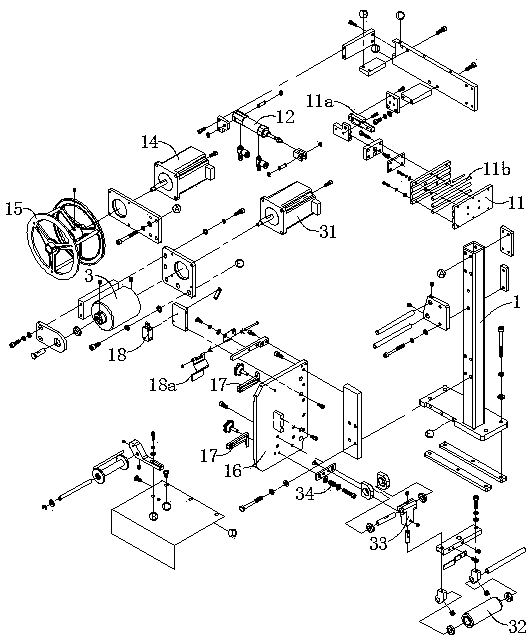

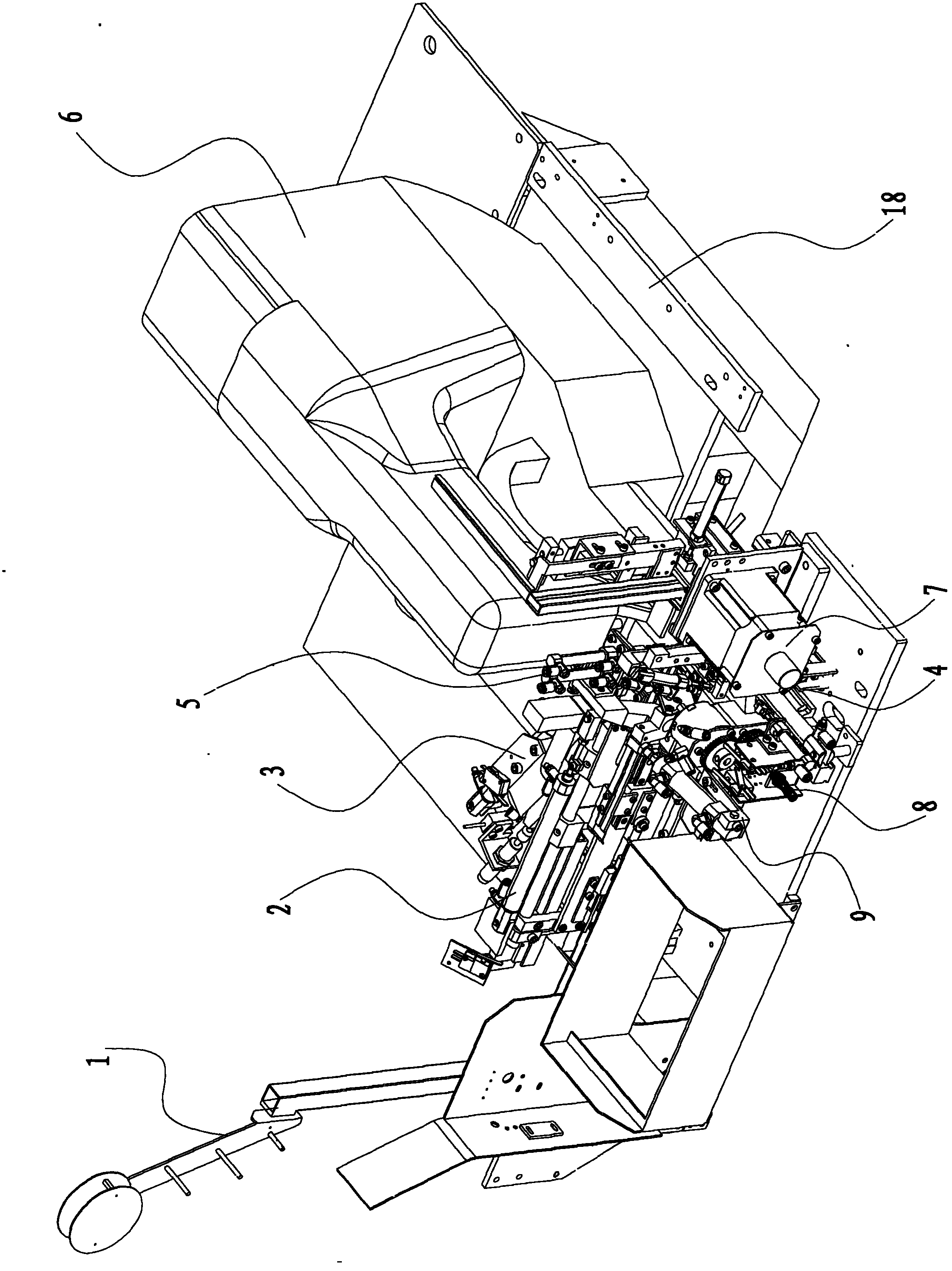

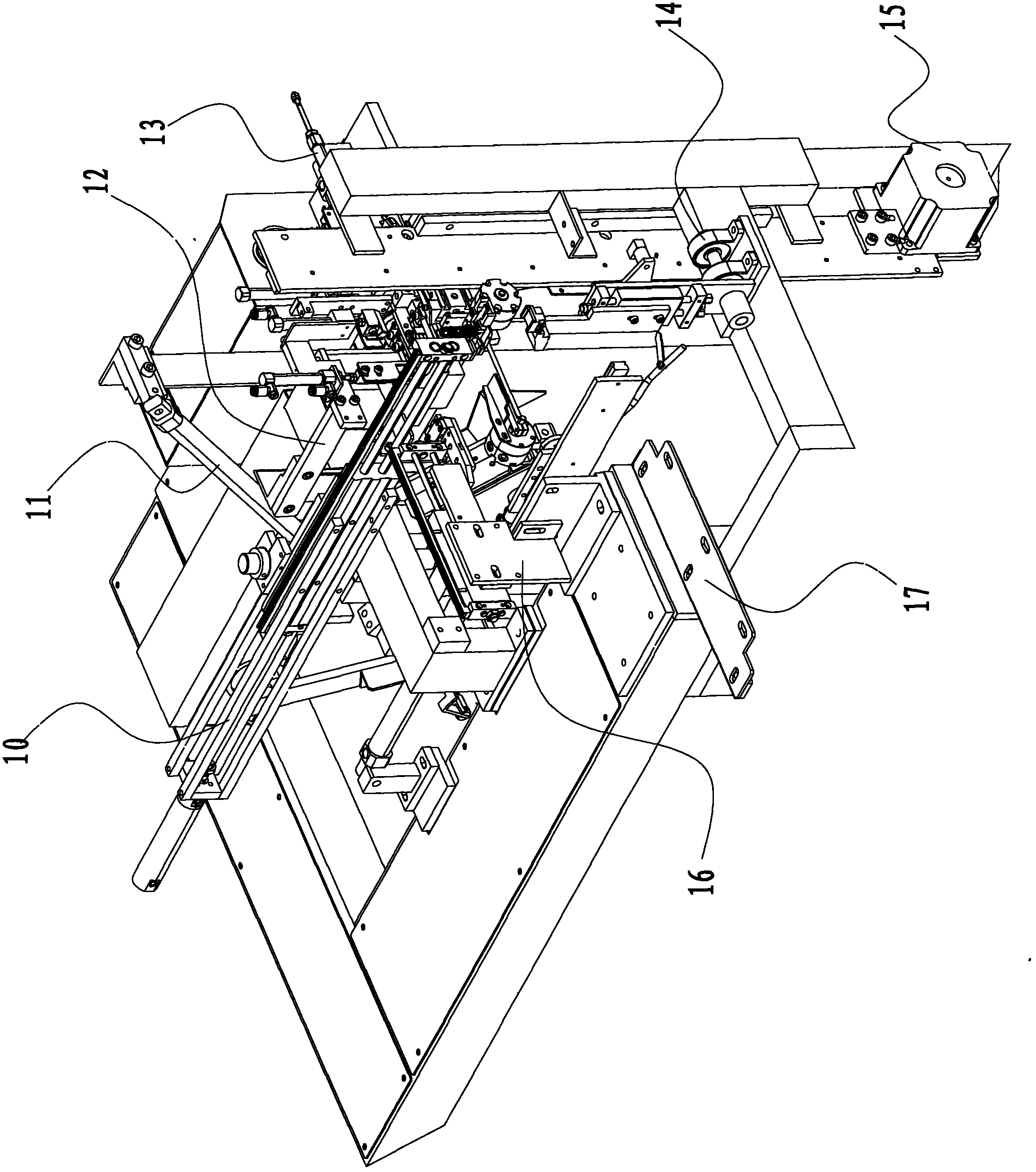

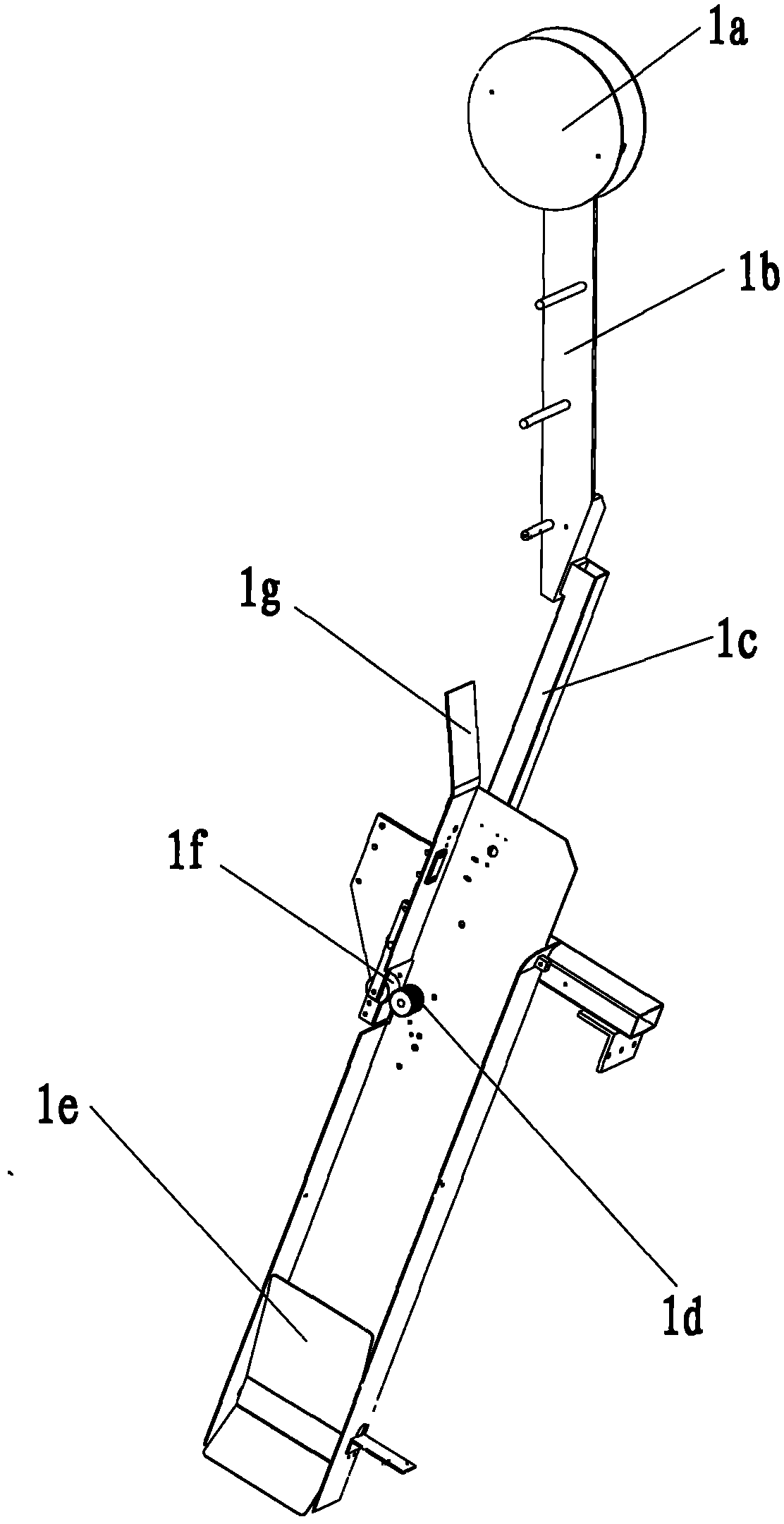

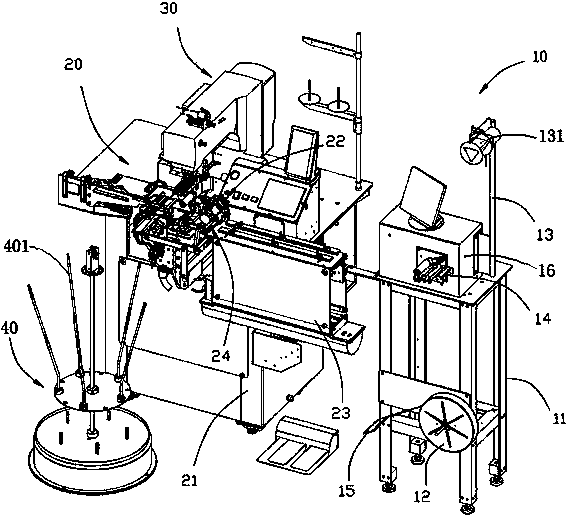

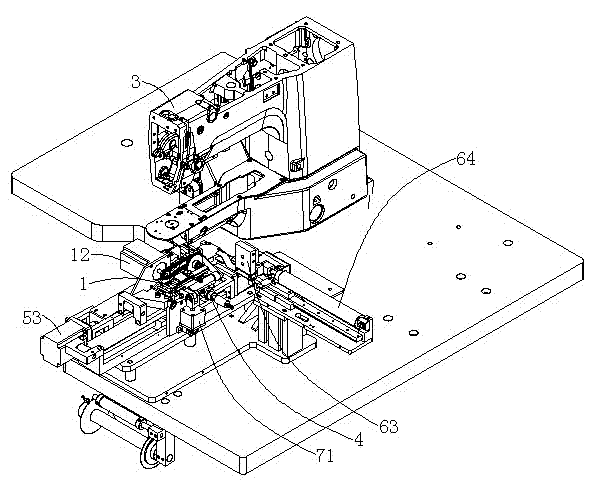

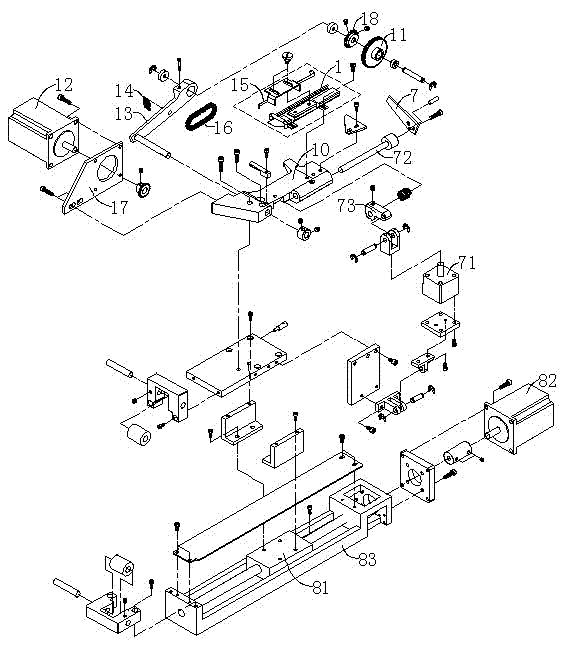

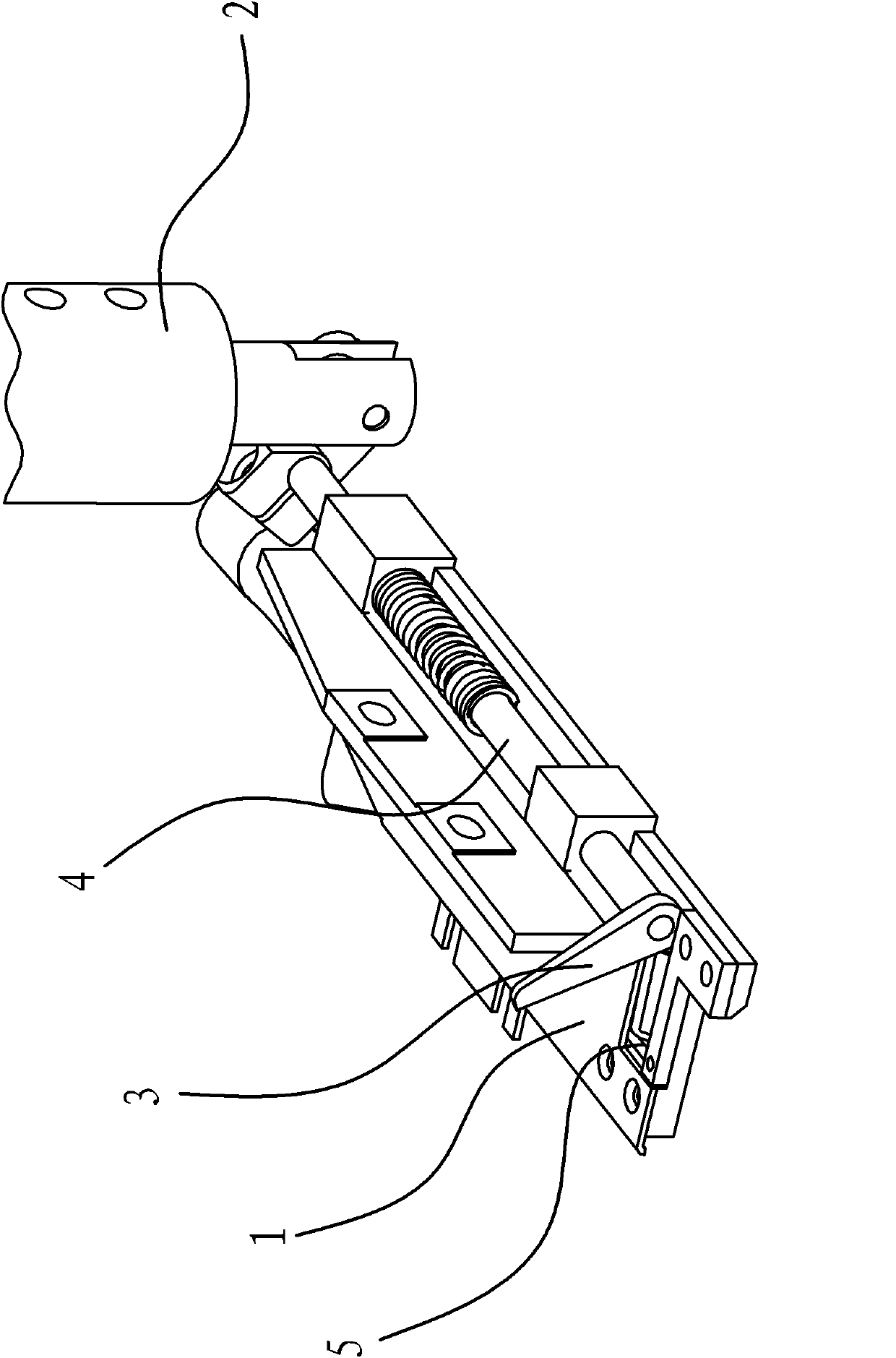

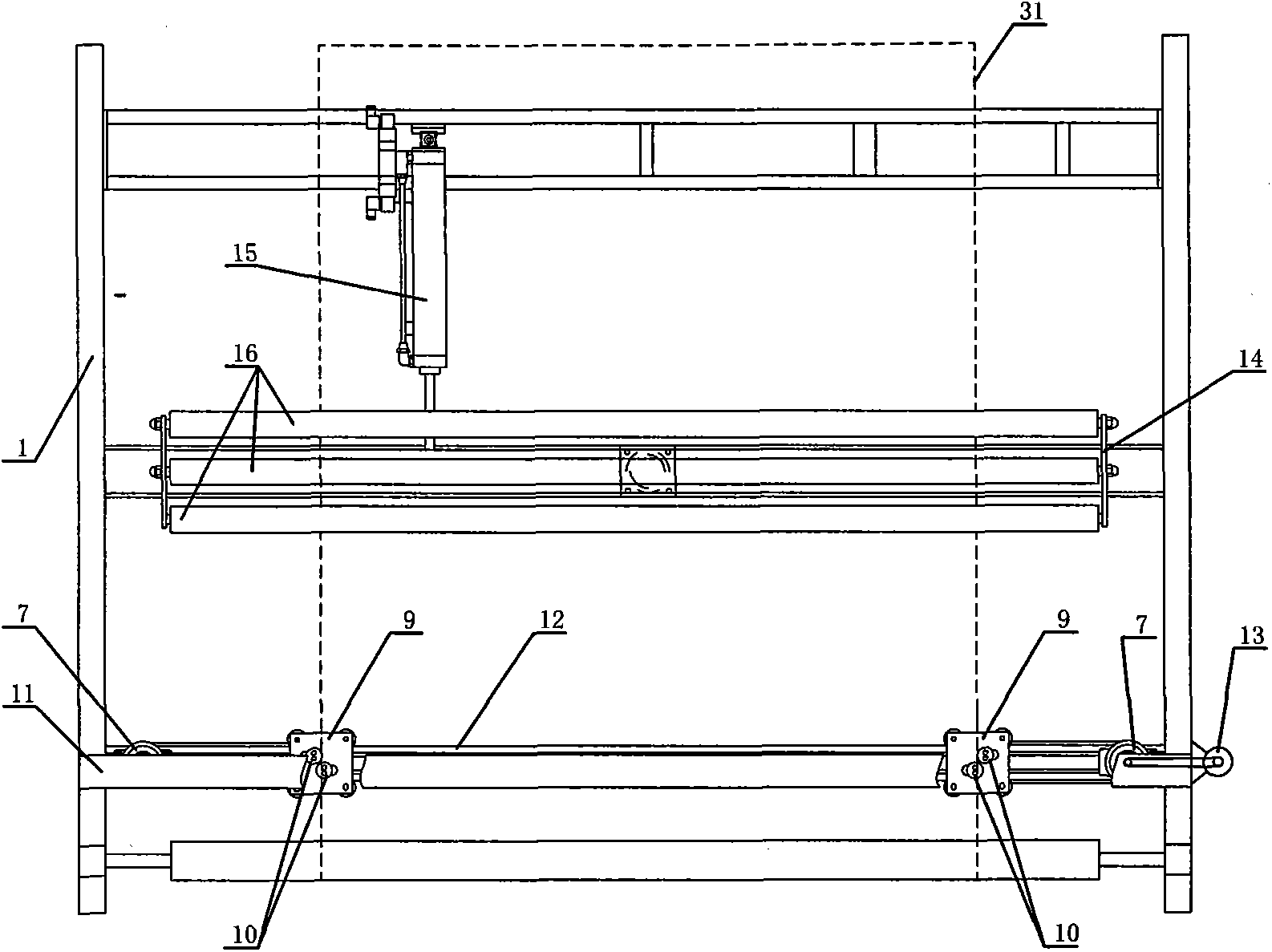

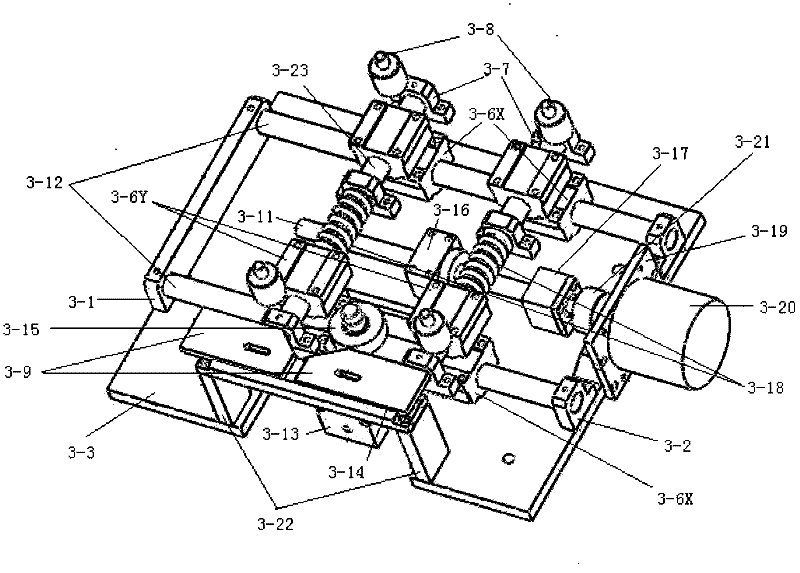

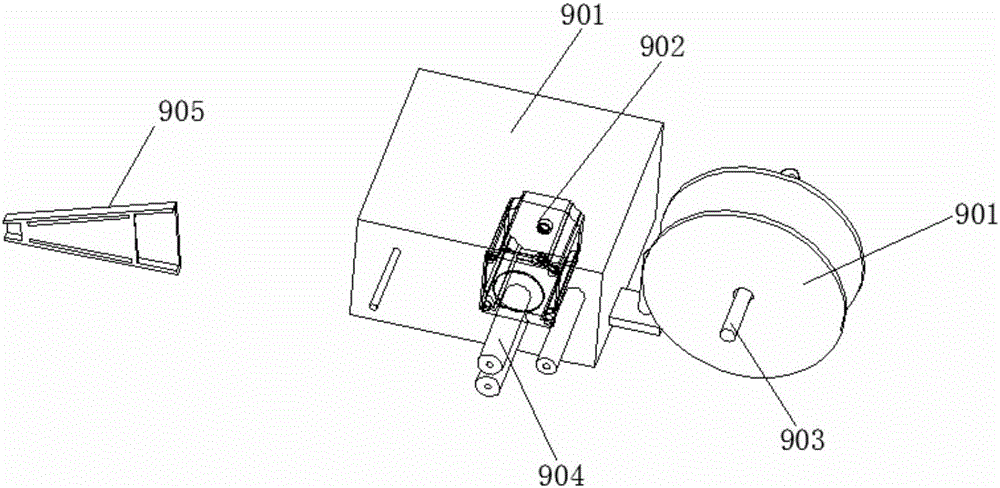

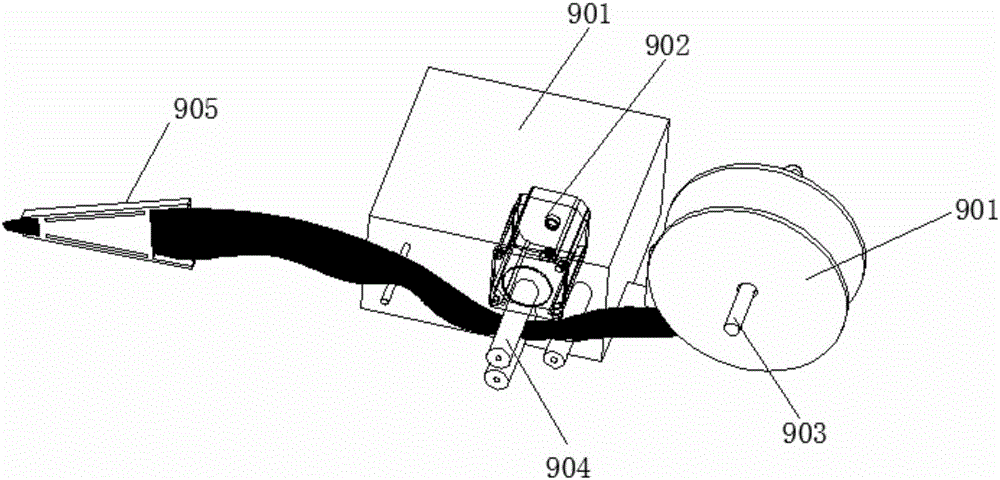

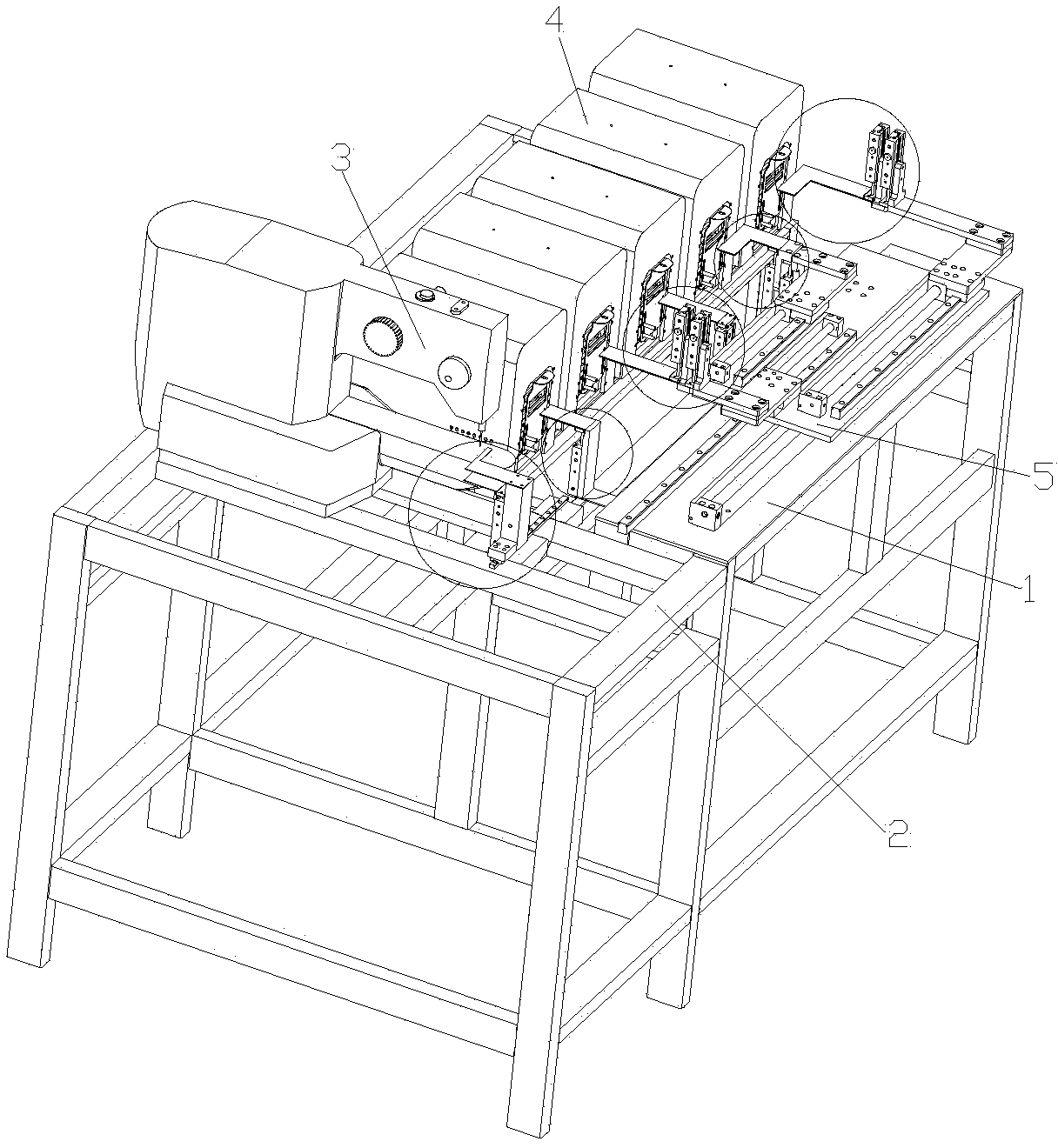

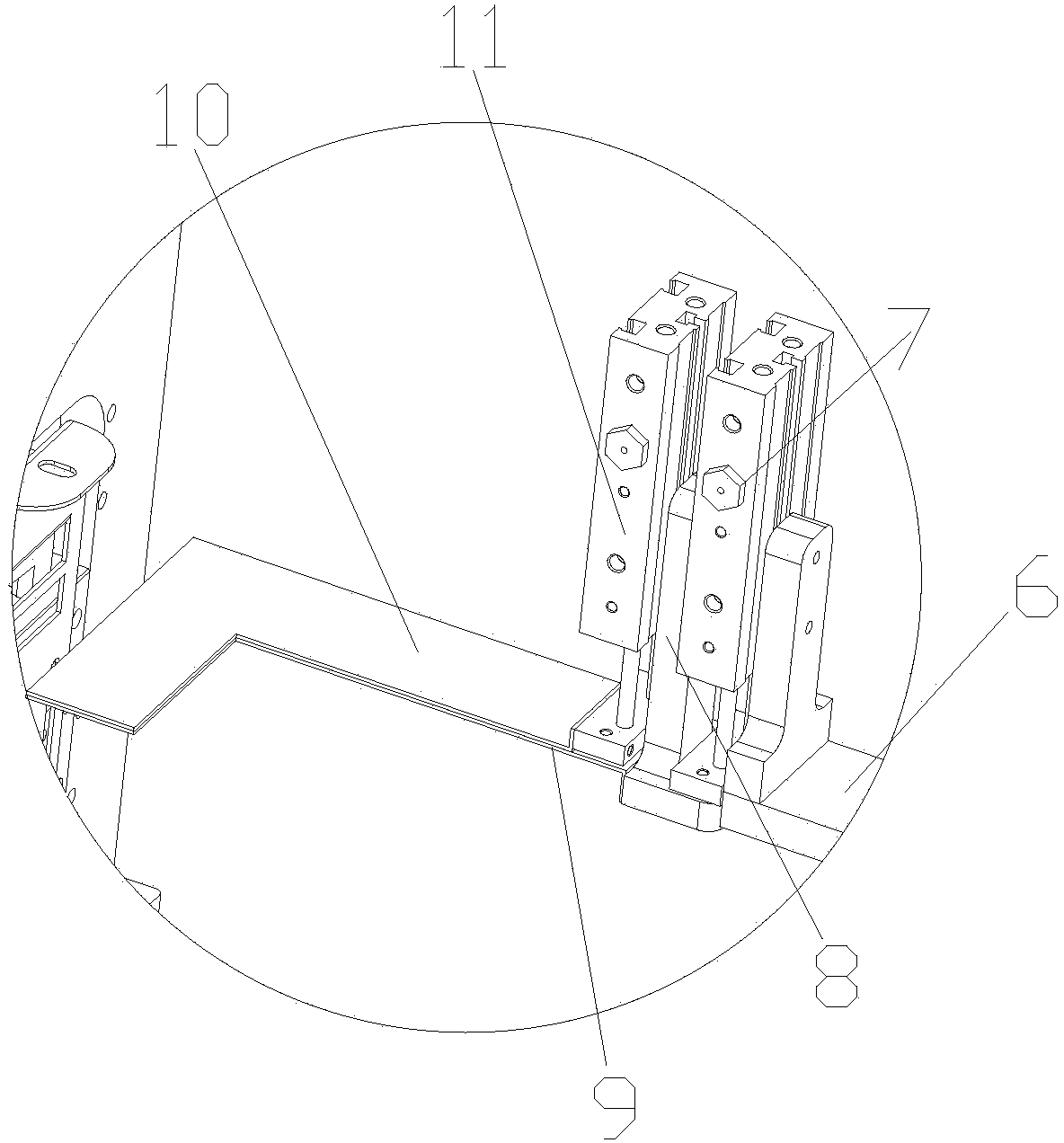

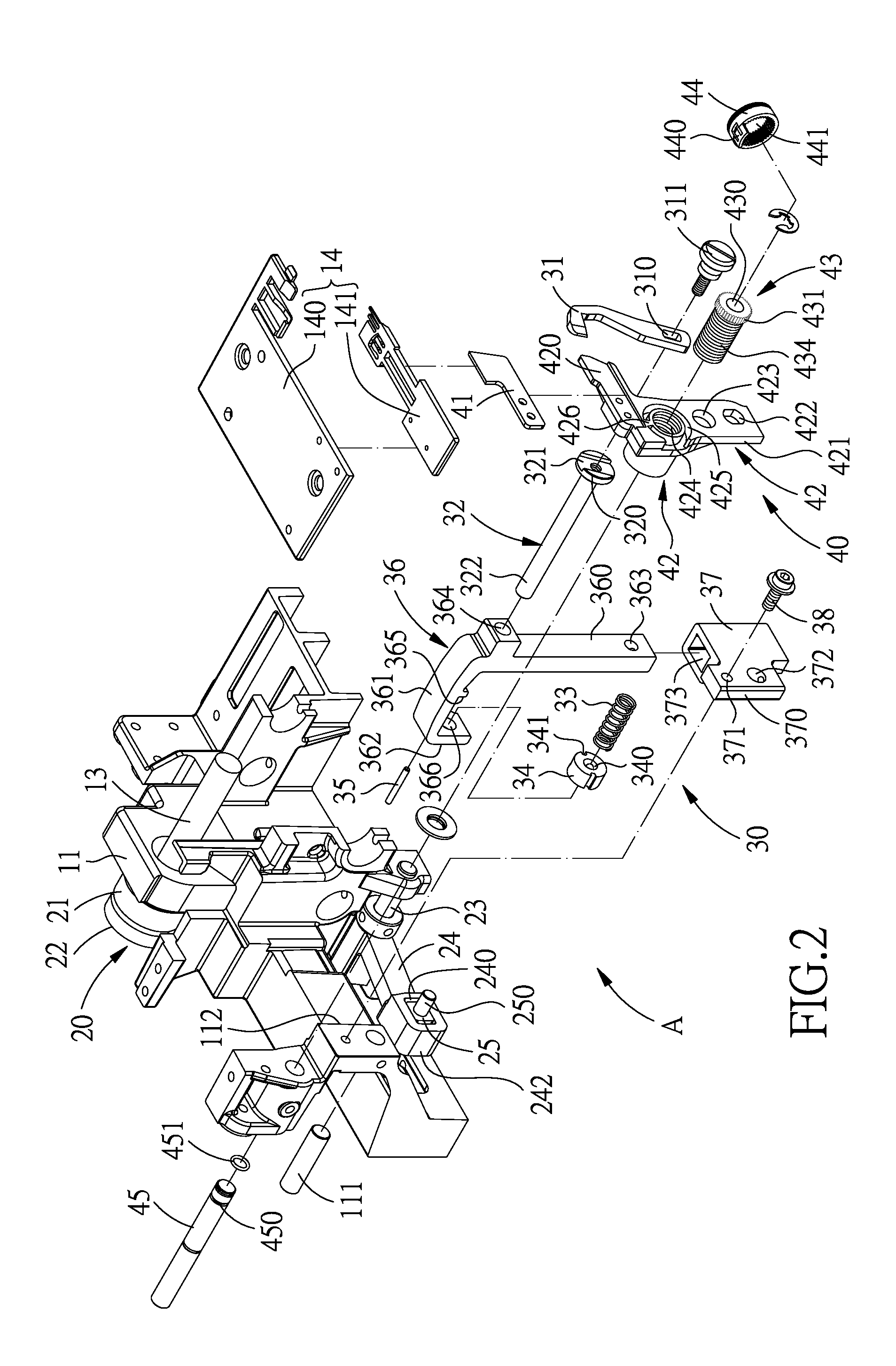

Feeding device for automatic band nailing machine

ActiveCN102493131AEasily adjust the range of motionAdjust the range of motionWorkpiece carriersWork-feeding meansEngineeringFeed tank

The invention discloses a feeding device for an automatic band nailing machine. The feeding device comprises a feeding mechanism for inputting bands, a clamping mechanism used for clamping the heads of the bands in the feeding mechanism and drawing the heads by a set length, a cutter mechanism used for cutting off the bands, and a winding mechanism used for clamping two ends of the bands and winding. The bands are input into a feeding tank through a feeding hole, are conveyed by the feeding tank to pass through a tool rest, a clamping head component can move to the tool rest to clamp the heads of the bands and draw out the bands from the feeding tank by the set length; a telescopic platform of the winding mechanism moves, two winding arms clamp and draw out the two ends of the bands; a cutter cuts off the bands at the outlet of the feeding tank; the two winding arms of the winding mechanism rotate to wind the two ends of the bands; and the telescopic platform continuously moves to feed the wound bands to a sewing area. The feeding device can automatically feed, cut and wind the bands and convey the bands to the sewing area, and has the advantages of convenience for operation, highspeed and high efficiency.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

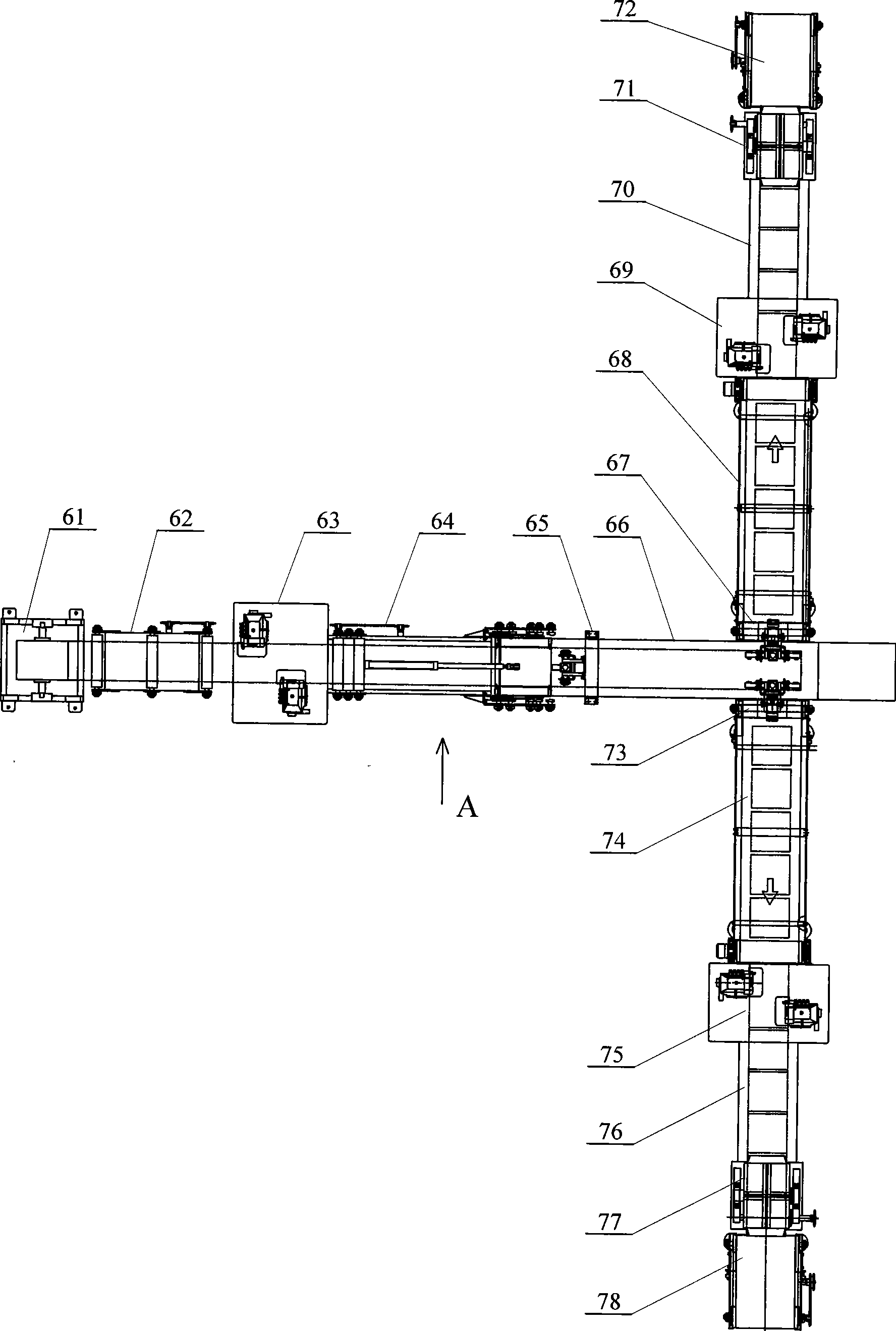

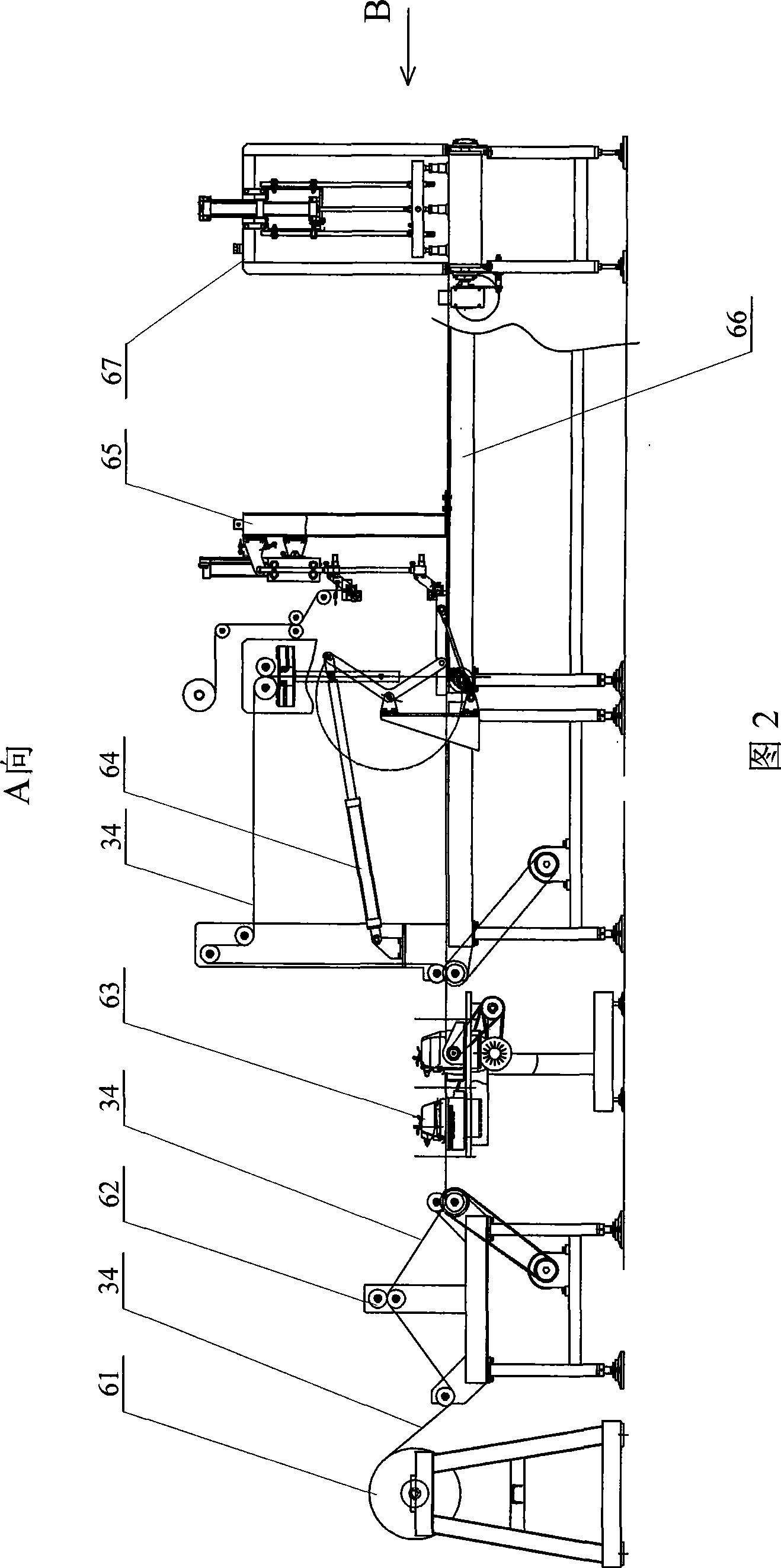

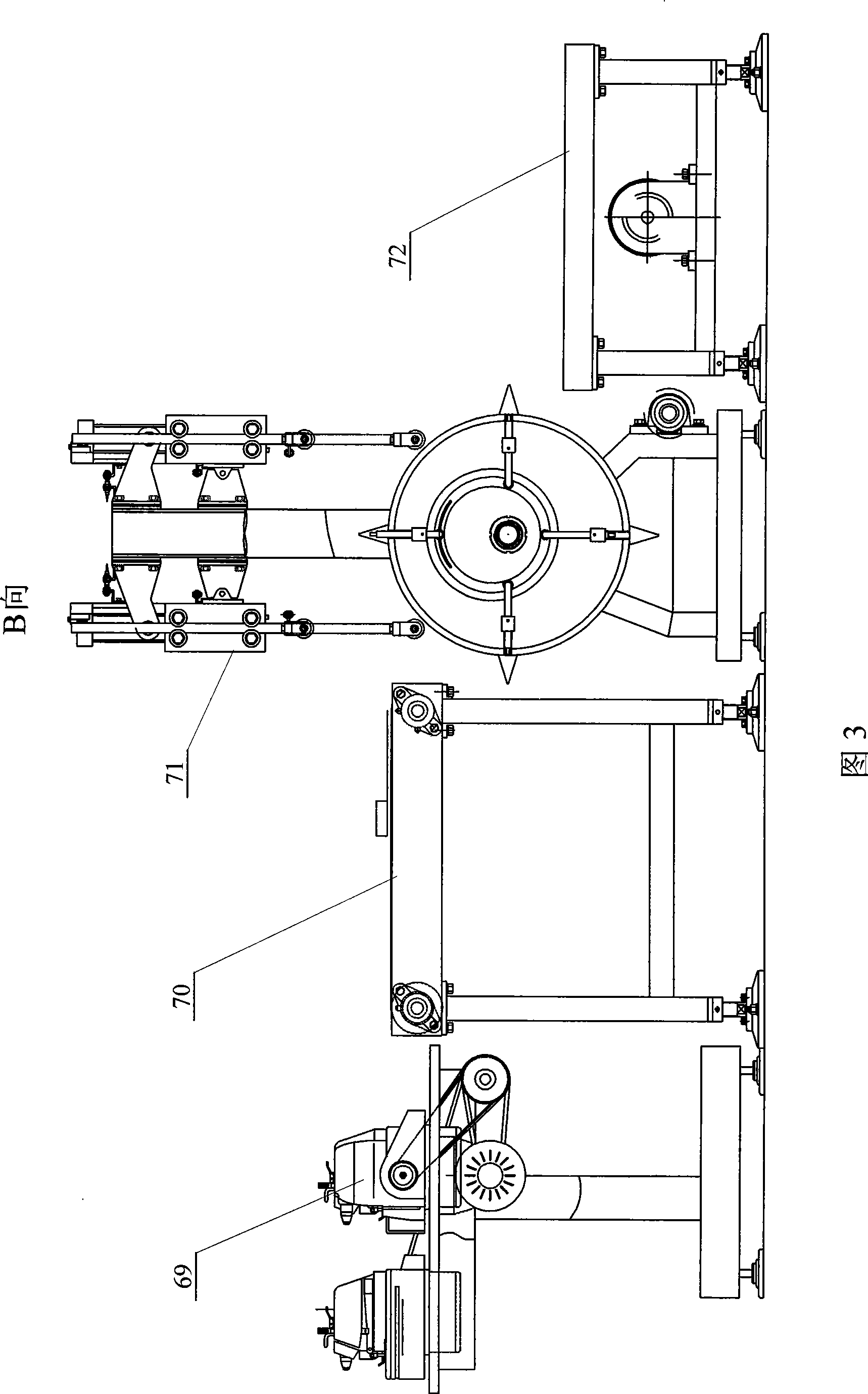

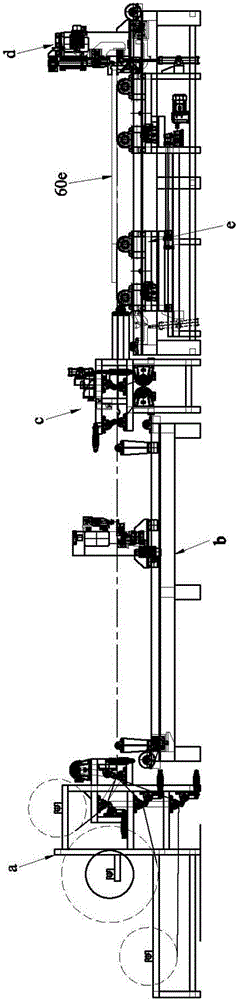

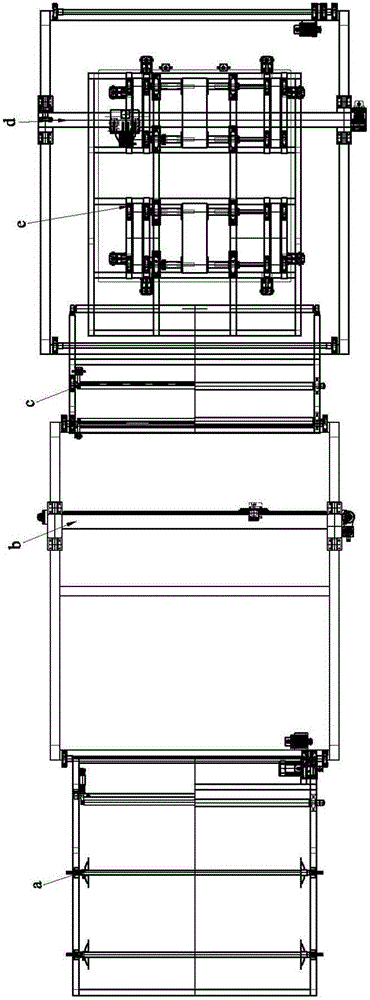

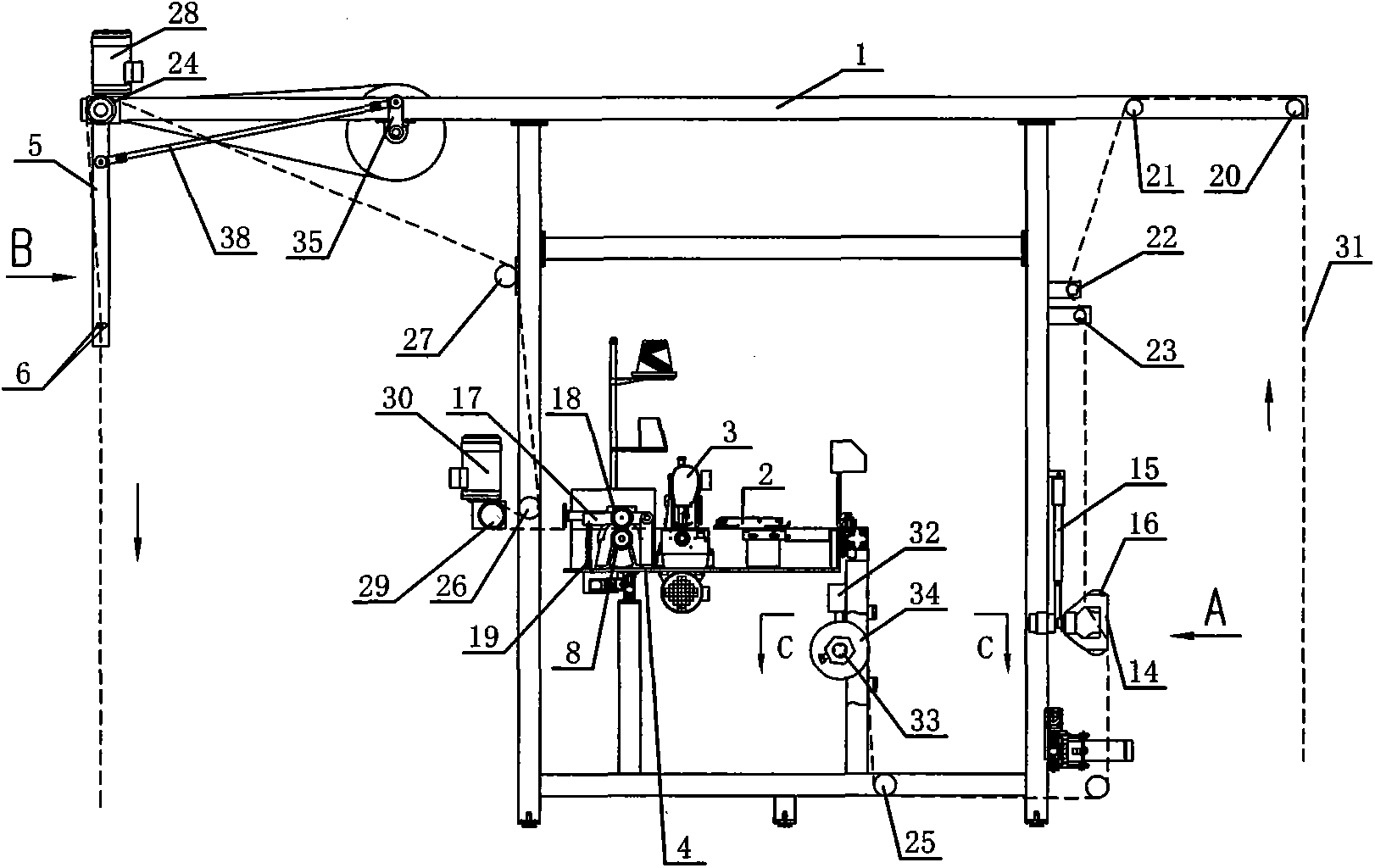

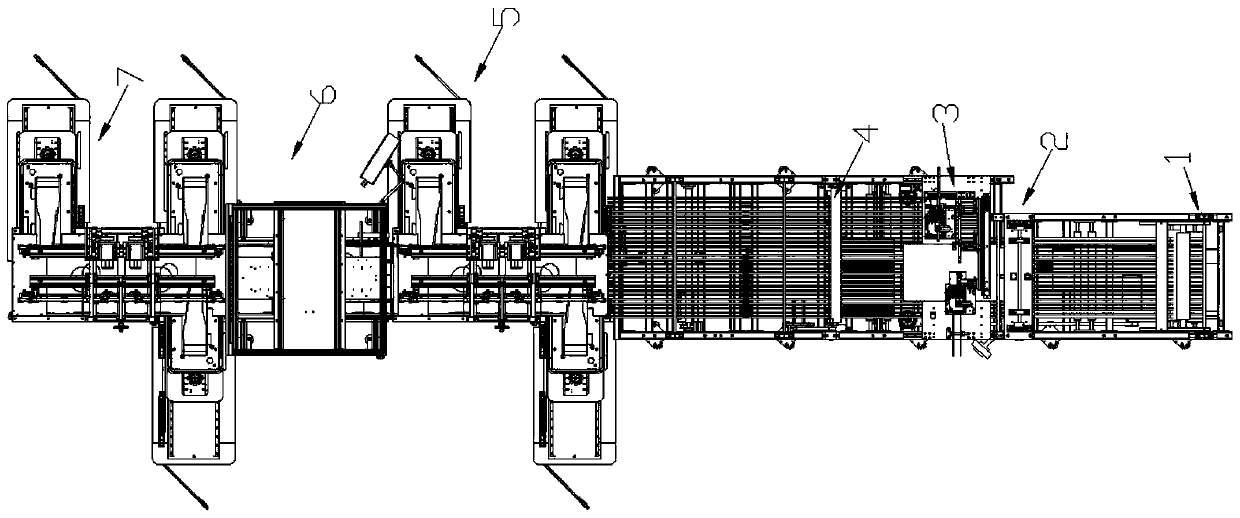

Hemming production line of face cloth

ActiveCN101392434ASimple structureReasonable designWorkpiece carriersWork-feeding meansProduction lineEngineering

The invention provides a kerchief hemming-stitch production line, and relates to a kerchief production line. The invention aims at solving the problems that the existing kerchief is produced by hand, the production efficiency is low and the production quality is difficult to be guaranteed. The invention includes a damping core arranging machine, a synchronous conveyer, a first double head overlock machine, a reclaiming conveyer and a first conveyer which are sequentially arranged; a first transverse reclaiming machine and a second transverse reclaiming machine are respectively arranged at both sides of the rear part of the first conveyer, and a second conveyer, a second double head ovelock machine, a third conveyer and a first end-cutting device are sequentially arranged behind the first transversal reclaiming machine; a fourth conveyer, a third double head overlock machine, a fifth conveyer and a second end-cutting device are sequentially arranged behind the second transversal reclaiming machine. The invention adopts the first double head overlock machine to overlock the two sides of the cloth and adopts the second or third double head overlock machine to overlock the other two sides of the kerchief, which can improve the production efficiency by 5-6 times compared with the manual operation.

Owner:张广生

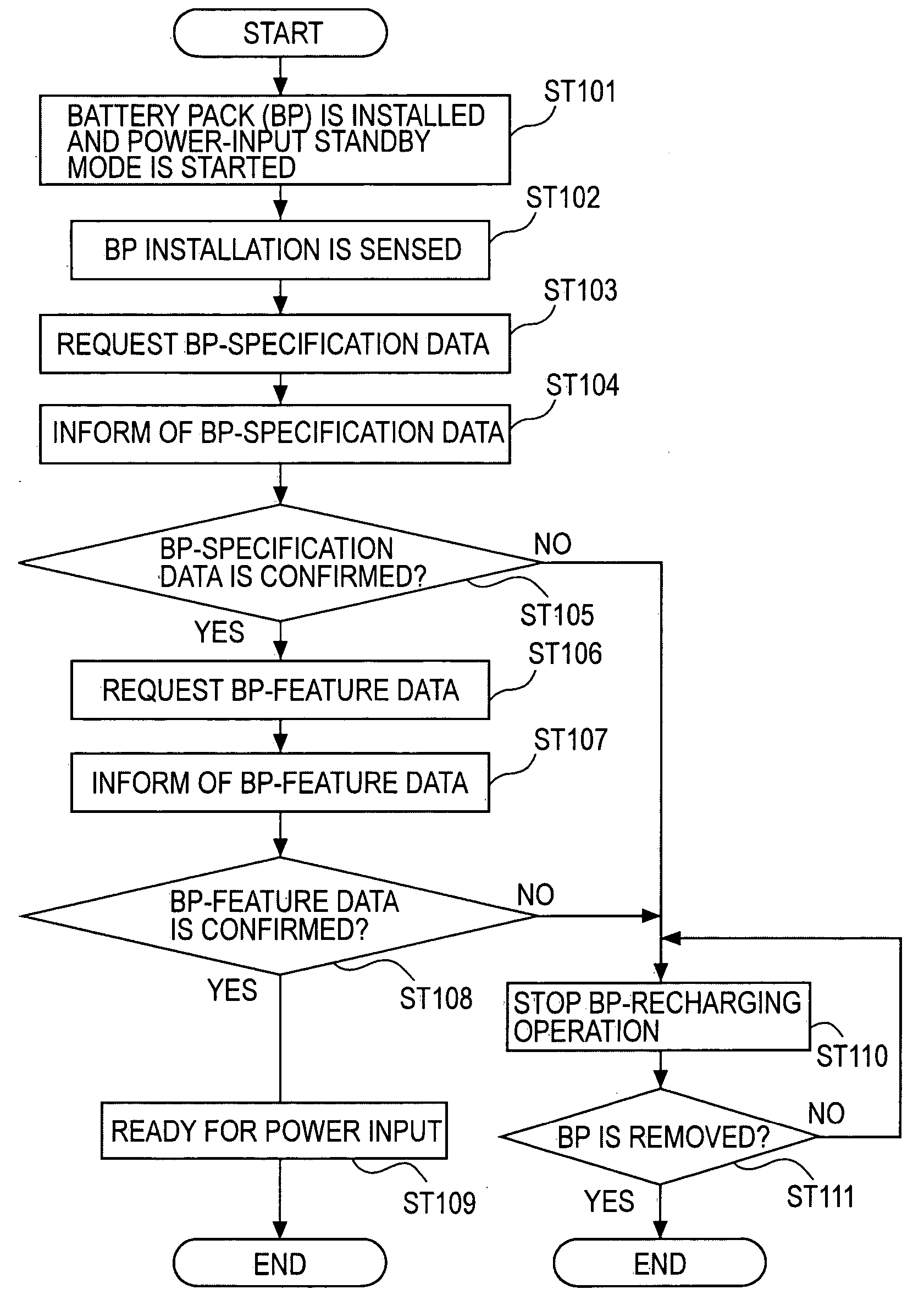

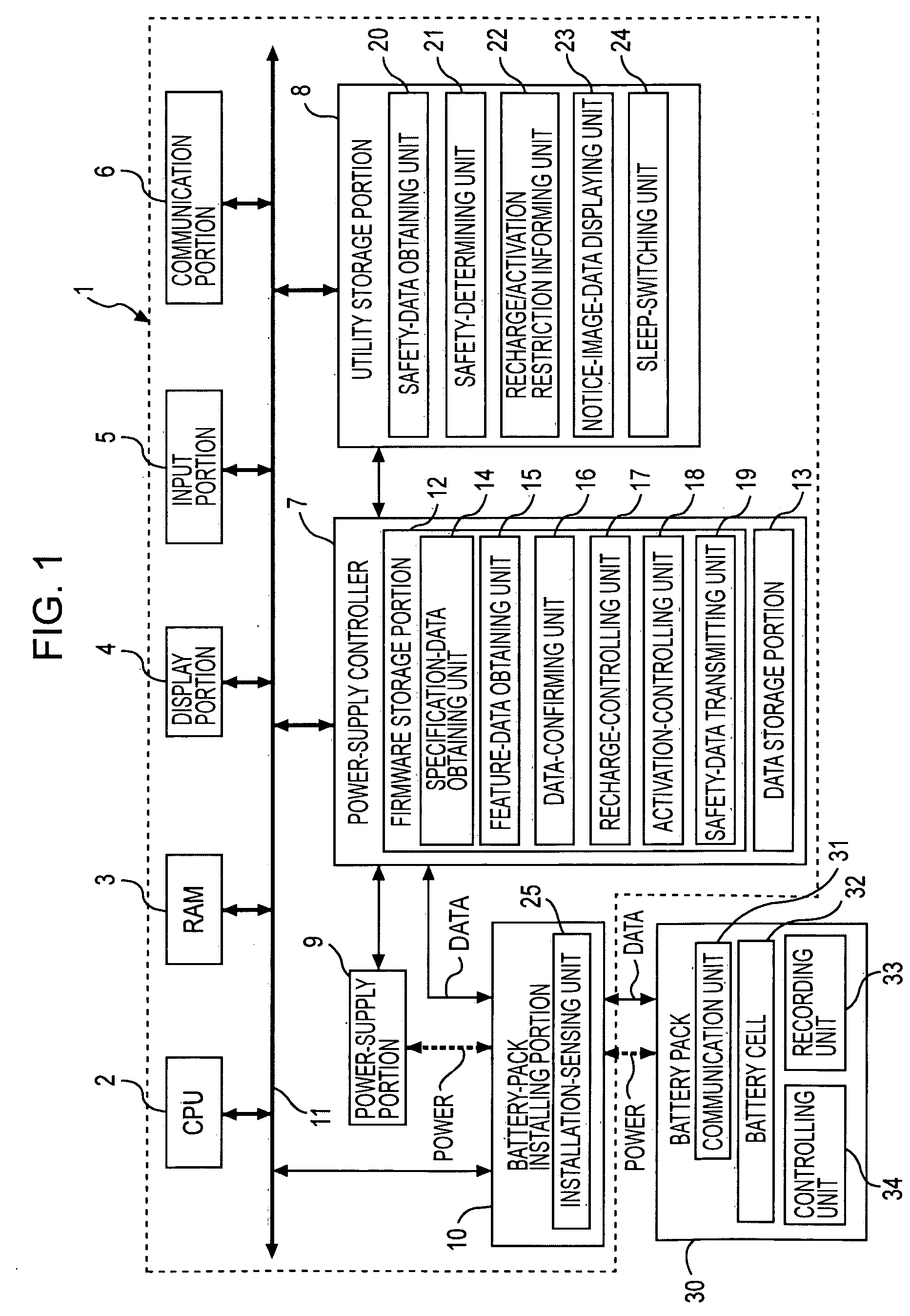

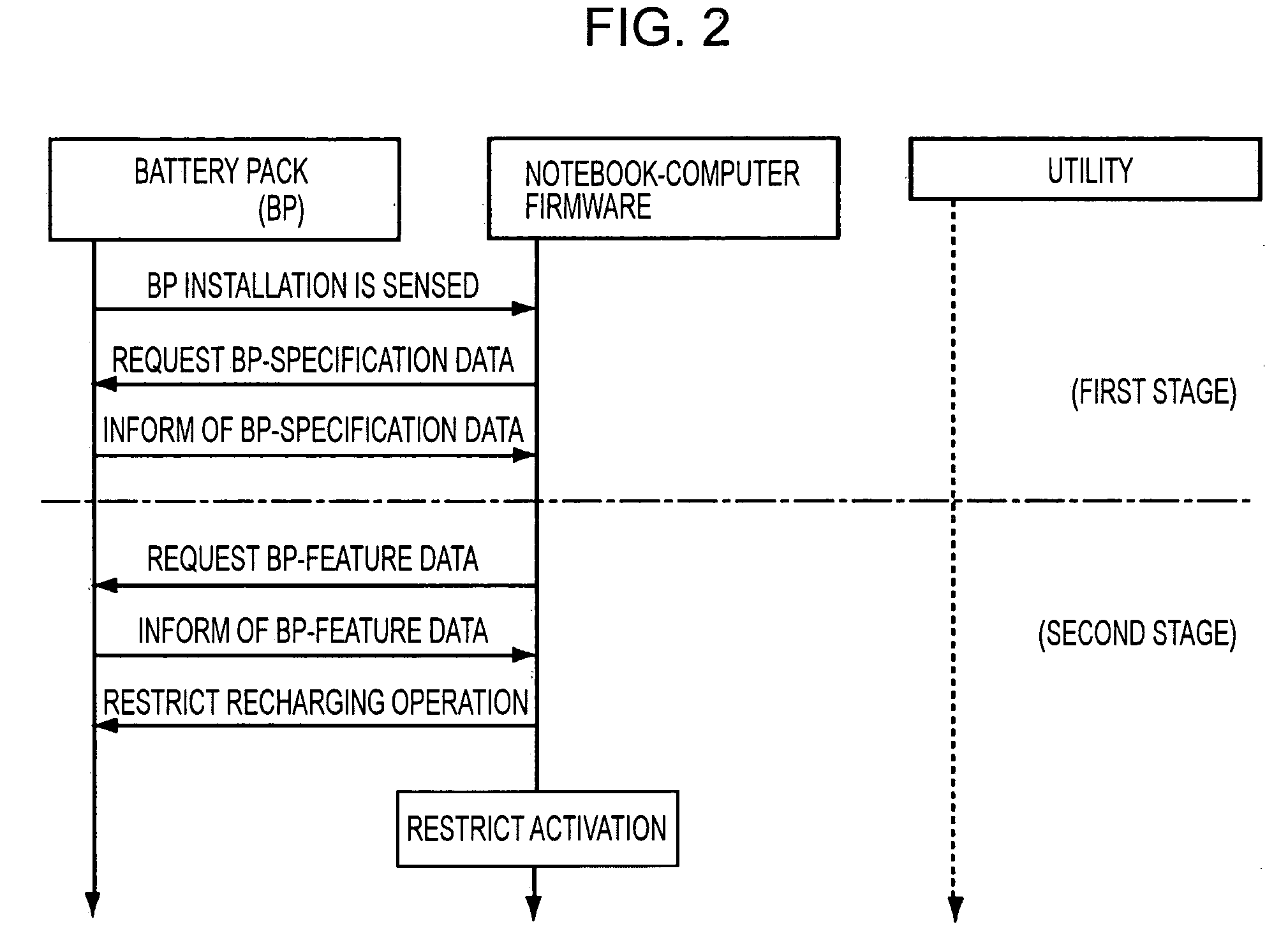

Electronic device, battery pack, power-supply controlling method for electronic device, program for controlling power supply for electronic device

InactiveUS20050248311A1Easy to limitEnsure safetyCircuit authenticationTelemetry/telecontrol selection arrangementsControl powerState dependent

An electronic device includes a battery-pack installing portion that holds a battery pack in a detachable manner; sensing means for sensing that a battery pack is installed in the battery-pack installing portion; detecting means for detecting data related with a state of the installed battery pack sensed by the sensing means; determining means for determining whether the battery pack has a fault based on the detected data; and first restricting means for restricting a recharging operation of the battery pack if the battery pack is determined to have the fault by the determining means.

Owner:SONY CORP

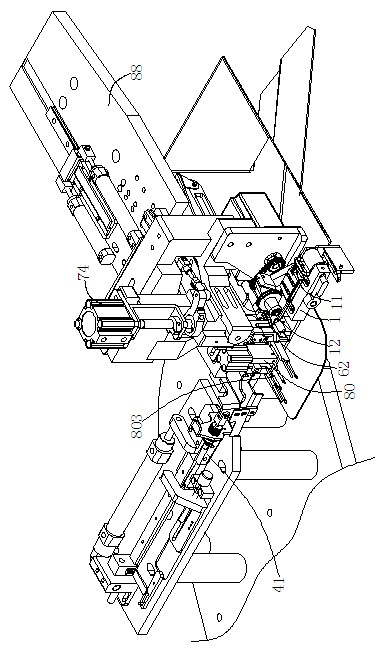

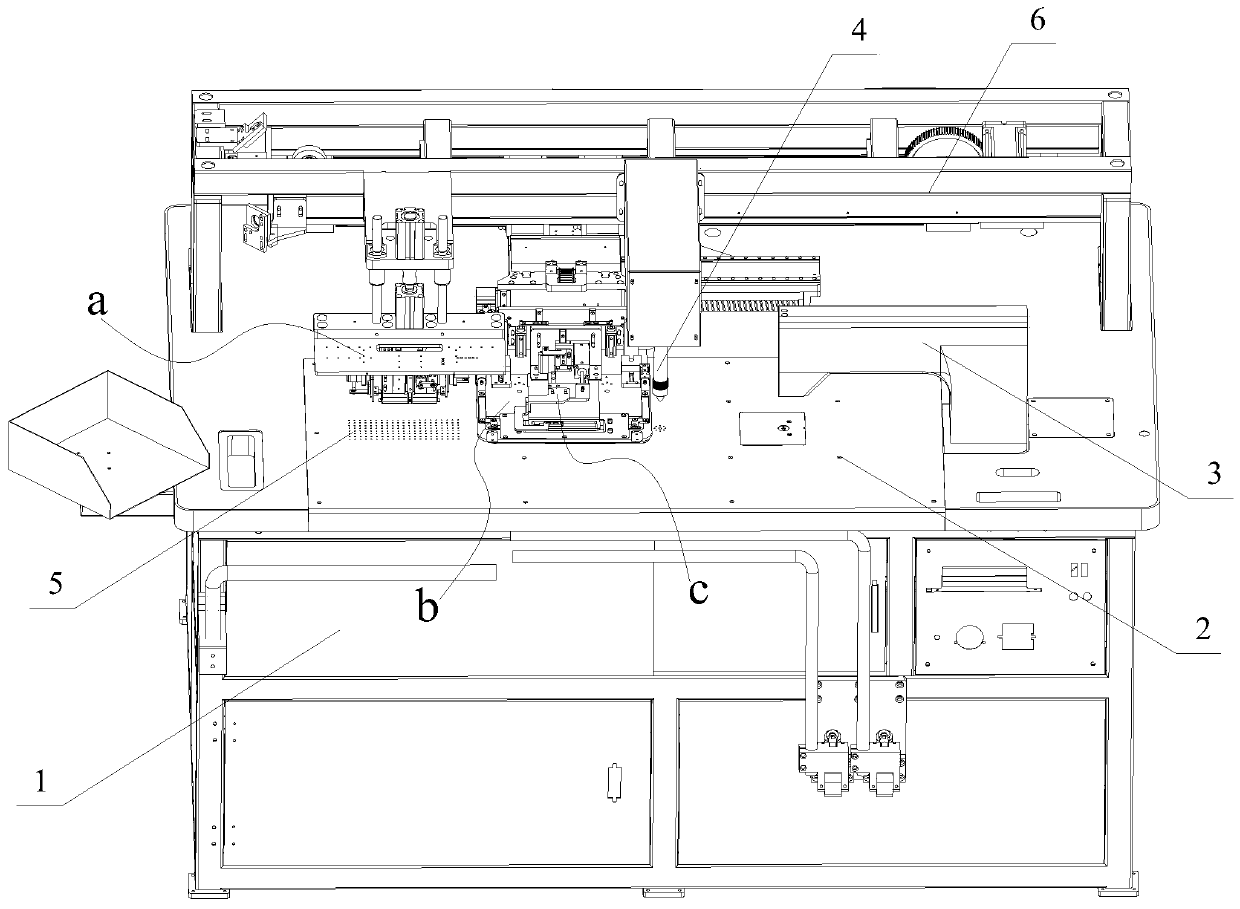

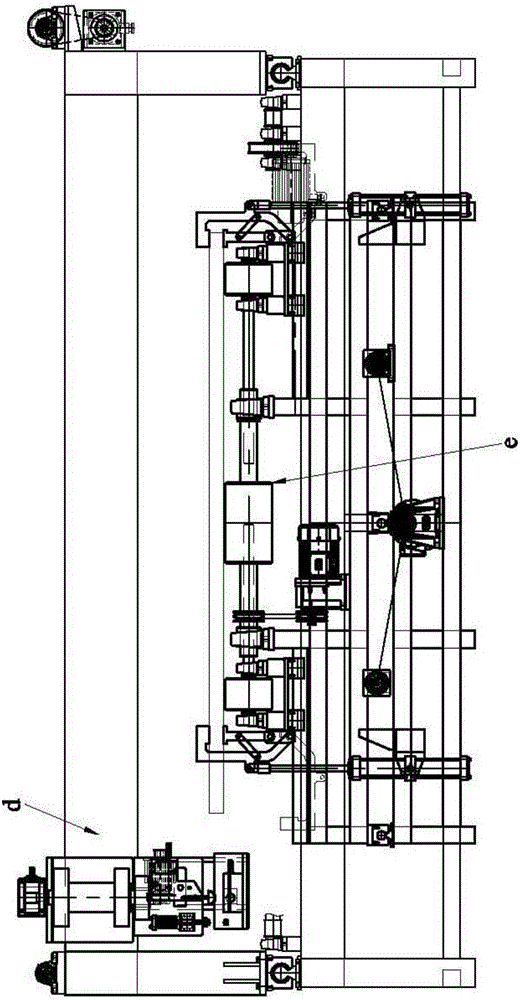

Full-automatic shoulder belt sewing machine

InactiveCN102605562AReasonable structural designEasy to useWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention relates to a full-automatic shoulder belt sewing machine which consists of a front processing machine and a rear processing machine which are spliced and fastened together by a front processing machine connecting plate and a rear processing machine connecting plate; the front processing machine mainly comprises a belt conveying device, a belt pushing device, a belt cutting device, an eight-button conveying device, a nine-button conveying device or a zero-button conveying device, a belt threading device, a rotary button turning device, a belt drawing device and a sewing device; the belt pushing device is connected with the belt conveying device; the belt threading device is connected with the belt drawing device, the eight-button conveying device, the nine-button conveying device or the zero-button conveying device; and the rear processing machine mainly comprises a belt connecting device, a rear processing belt drawing device, a belt protecting device, a secondary rotarybutton turning device, a belt head clamping device, a tensioning device and a belt connecting button pushing device. By the design of the shoulder belt sewing machine, the automatic button threading of eight buttons and nine buttons on the shoulder belt can be realized; and the front processing machine and the rear processing machine are assembled independently, thereby facilitating the conveyingsafety.

Owner:尤文聘

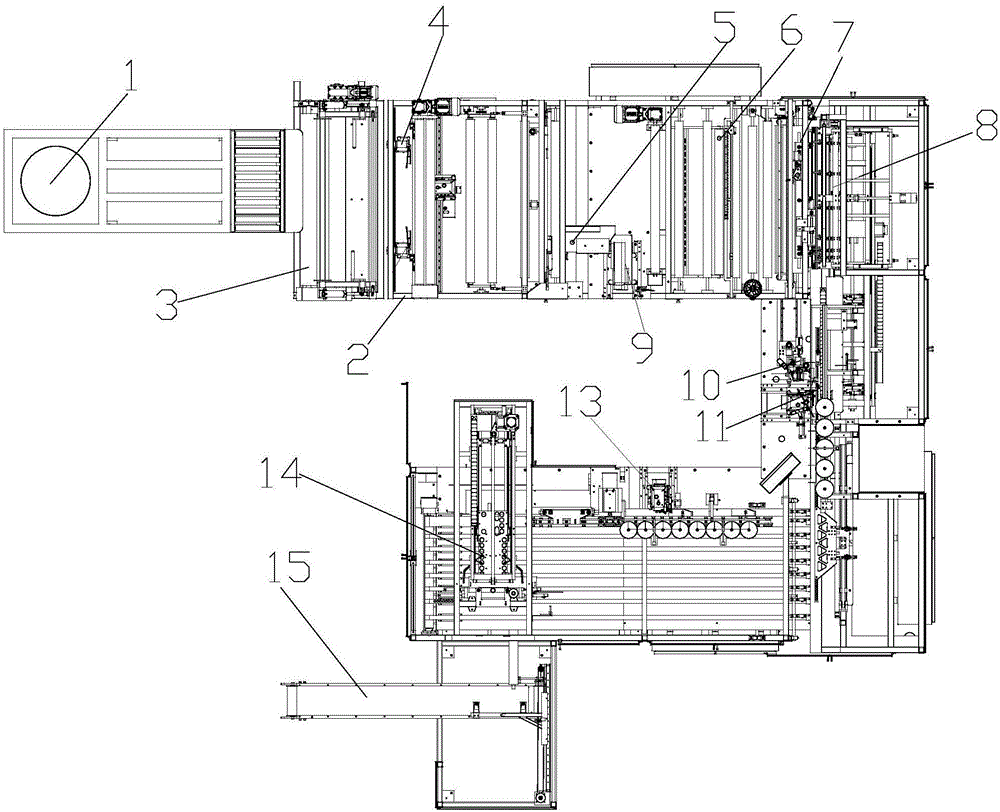

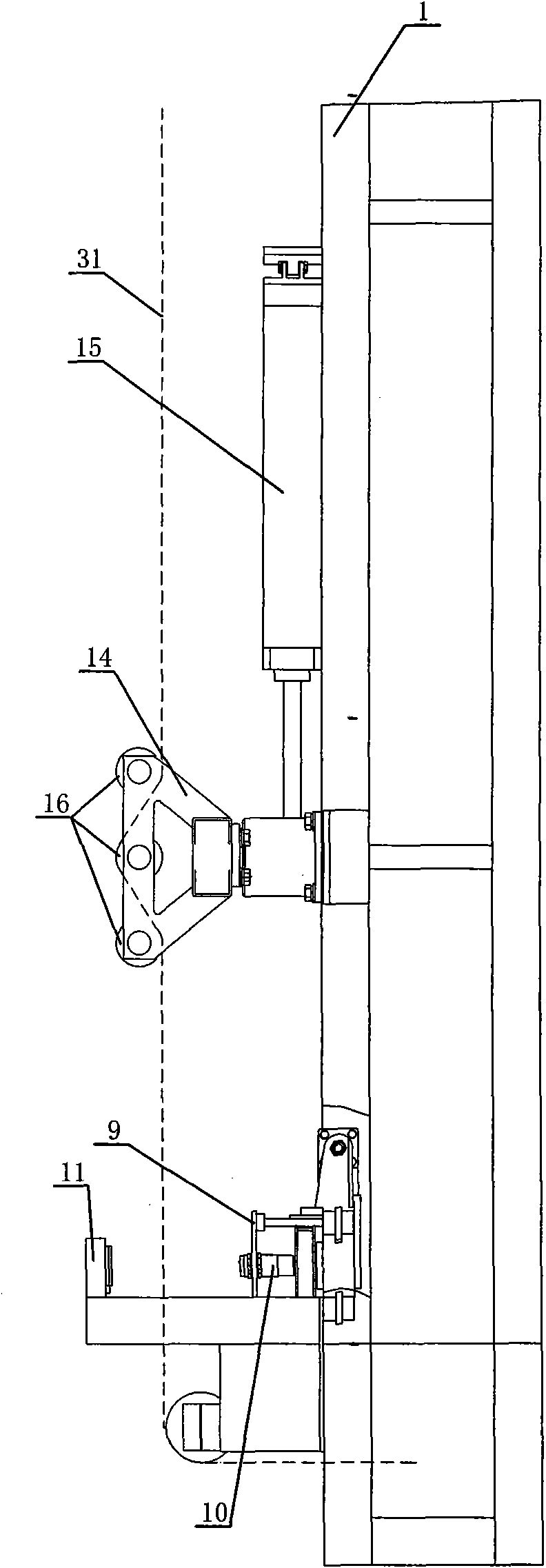

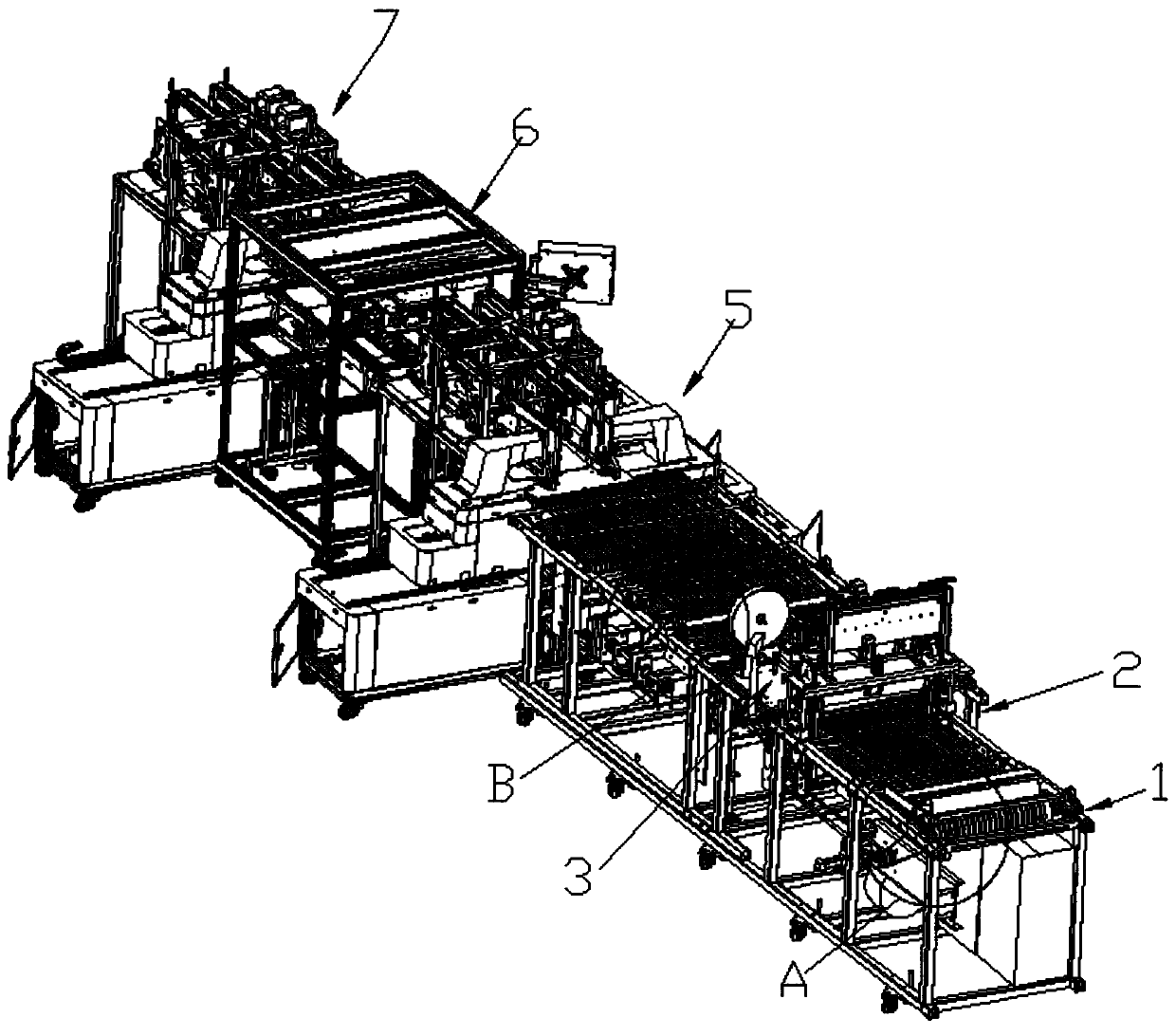

Full-automatic pillowcase machine

ActiveCN107435189AReasonable structure layoutMeet production and processing needsMechanical cleaningPressure cleaningEngineeringAssembly line

The invention relates to a full-automatic pillowcase machine. The machine comprises a feeding buffer area, a machine frame, a feeding component, a trimming device, an edge folding device, a sewing machine, a cloth slow storing mechanism, a correction device, a fixed-length cloth cutting-off mechanism, a label feeding device, a first binding-off device, a second binding-off device, a bag turning device and a collecting device, wherein the feeding component, the trimming device, the edge folding device, the sewing machine, the cloth slow storing mechanism, the correction device, the fixed-length cloth cutting-off mechanism, the label feeding device, the first binding-off device, the second binding-off device, the bag turning device and the receiving device are arranged on the machine frame; the feeding buffer area is located on one side of the machine frame; the feeding component, the trimming device, the edge folding device, the cloth slow storing mechanism, the correction device and the fixed-length cloth cutting-off mechanism are sequentially distributed on the machine frame; the label feeding device and the first binding-off device which are longitudinal distributed are arranged at the lower end of the fixed-length cloth cutting-off mechanism; the second binding-off device and the bag turning device are transversely distributed are arranged on one side of the lower end of the first binding-off device; the collecting device is arranged at the lower end of the bag turning device. The full-automatic pillowcase machine is reasonable in overall structural layout, assembly line processing of pillowcases can be automatically completed, the production efficiency is high, and the machine meets actual production and processing requirements.

Owner:SUZHOU TRANSPARENT TECH CO LTD

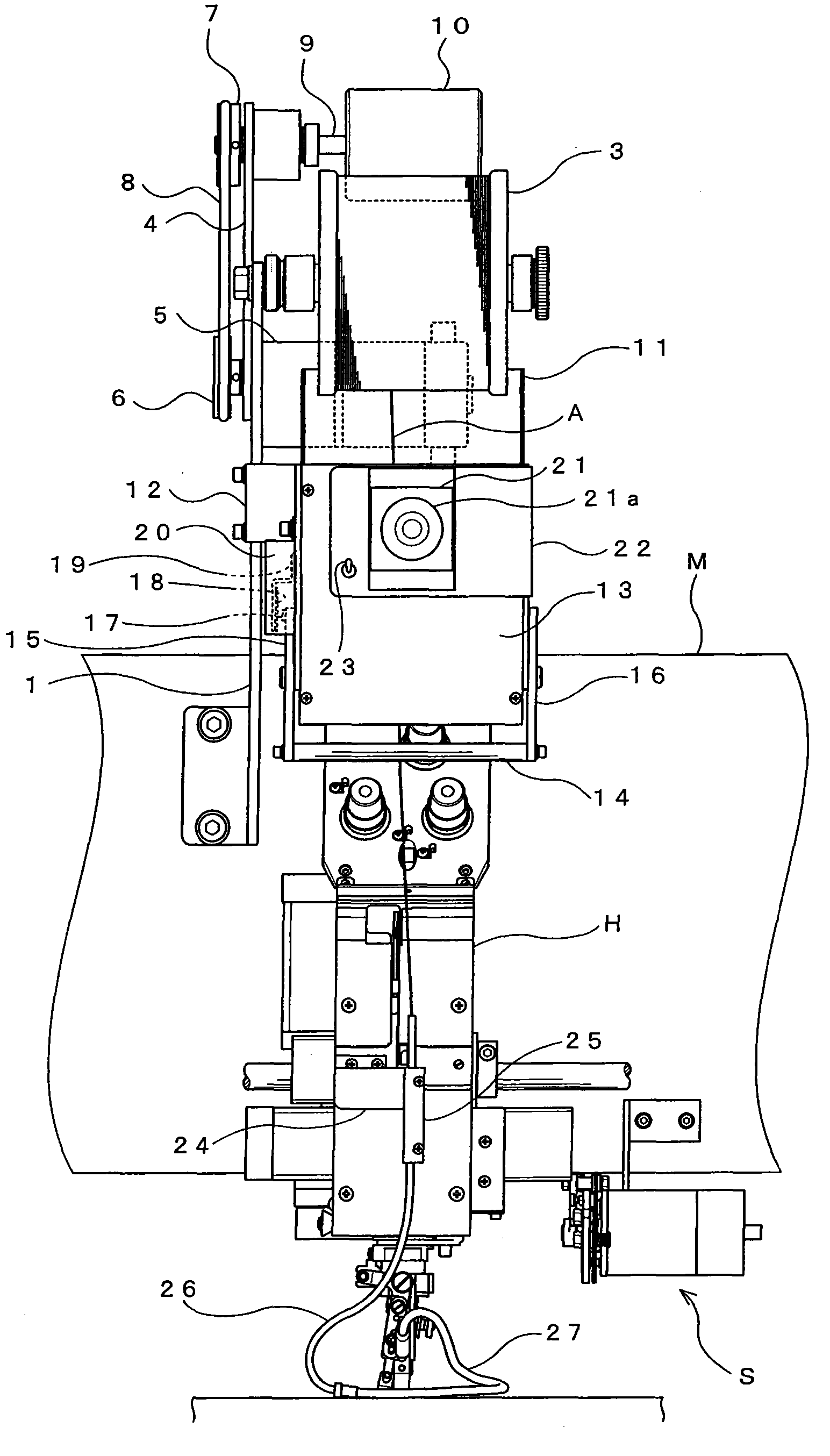

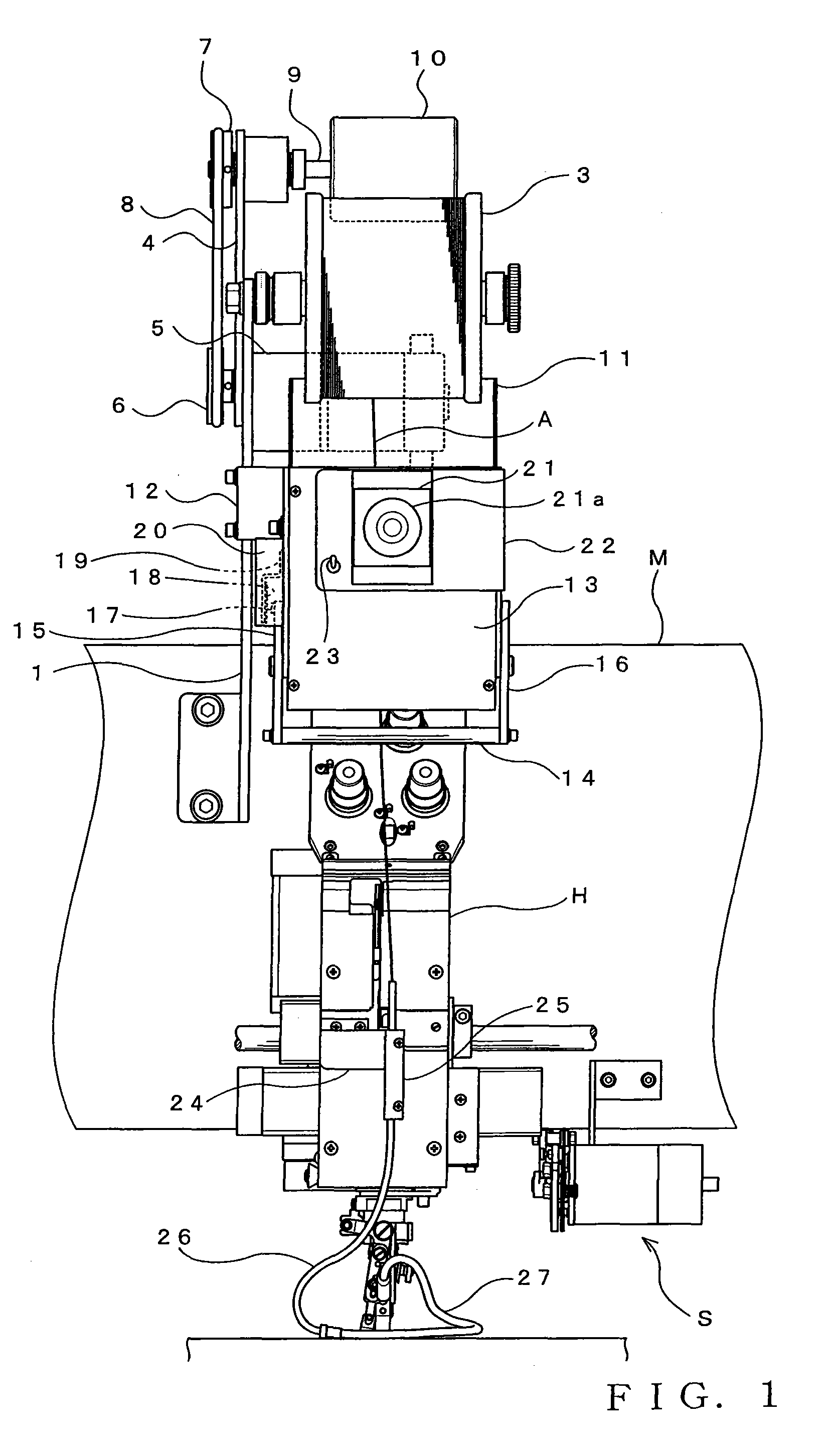

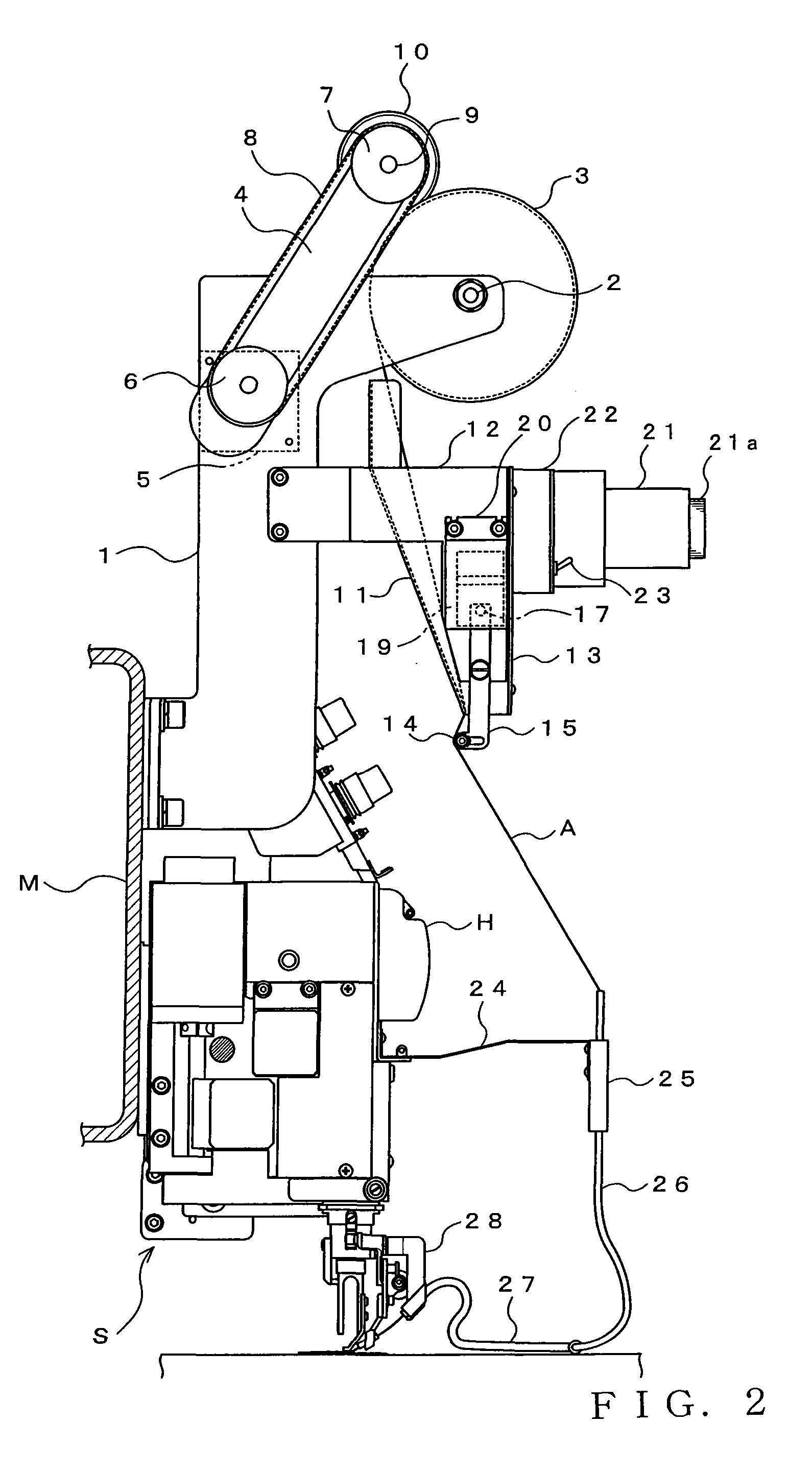

Overlock sewing machine with movable cutter

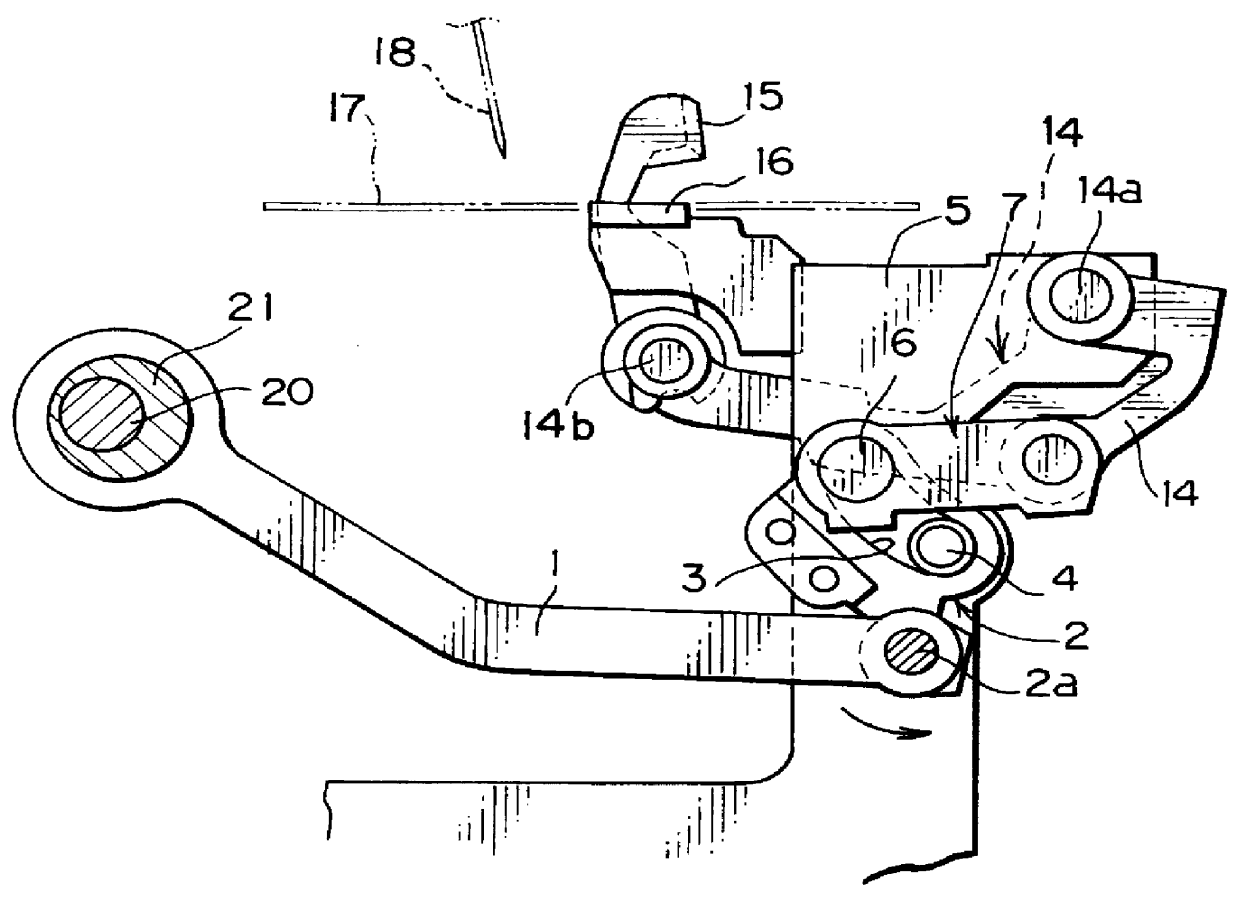

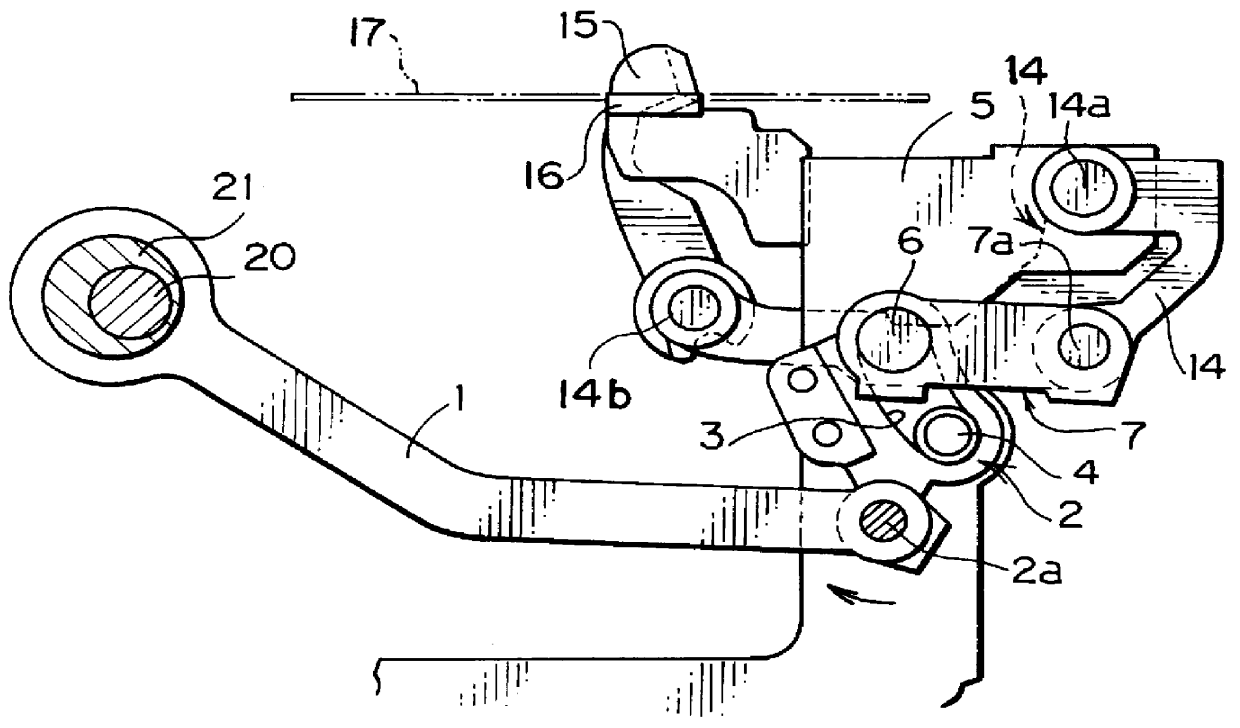

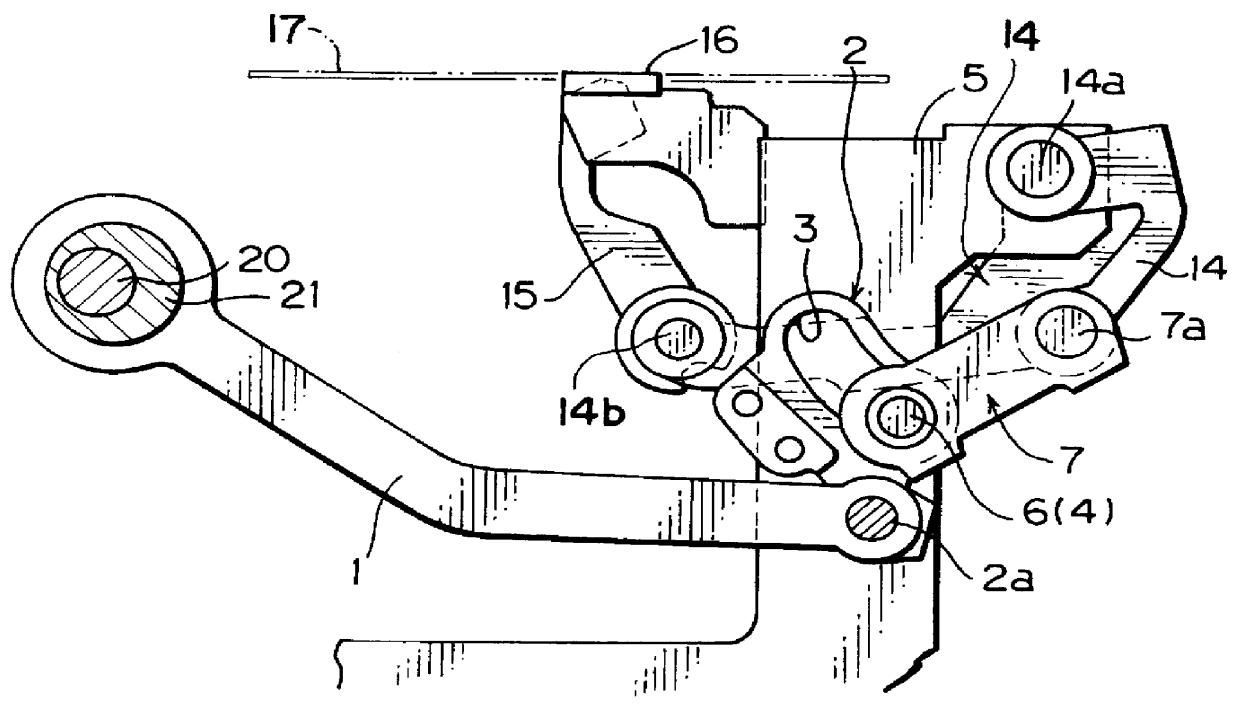

InactiveUS6101960AEasy to operateSimple structureWorkpiece carriersLoop takersDrive shaftReciprocating motion

An overlock sewing machine has a movable cutter which is activated in association with rotation of a main drive shaft to cooperate with a fixed cutter provided in the same plane with an upper surface of a needle plate, to thereby cut a work while the work is being stitched. A link mechanism includes a drive link having one end rotatably connected to a mount and the other end is connected to the movable cutter and a swingable link having an arcuate guide groove extending between one end and a center axis thereof around which the swingable link is swingingly moved. The drive link has a point between opposite ends thereof operatively connected to the arcuate guide groove of the swingable link. An operating device includes an operating shaft which is operatively connected to the point of the drive shaft so that the point of the drive link may be substantially moved along the arcuate guide groove of the swingable link between said one end and center axis thereof by manipulation of an operating knob. The drive link having the point thereof moved to one end of the swingable link will be swingingly reciprocated to activate the movable cutter, and having the point thereof moved to the central axis of the swingable link will move the movable cutter to an inoperative position below the needle plate where the movable cutter is held at standstill.

Owner:JANOME CORP

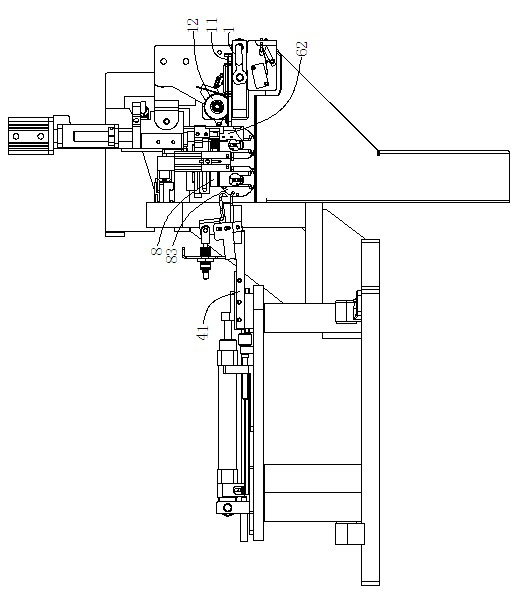

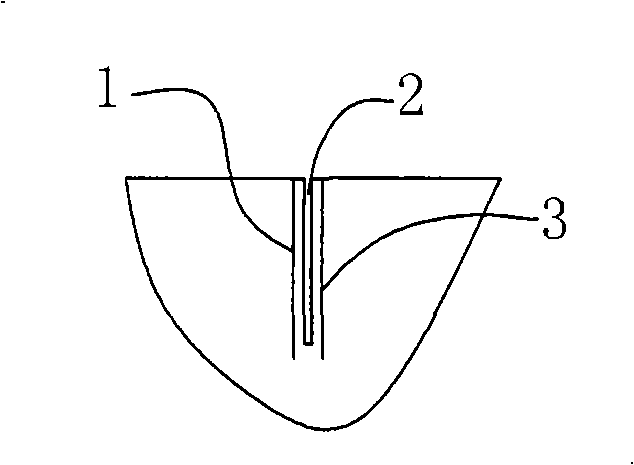

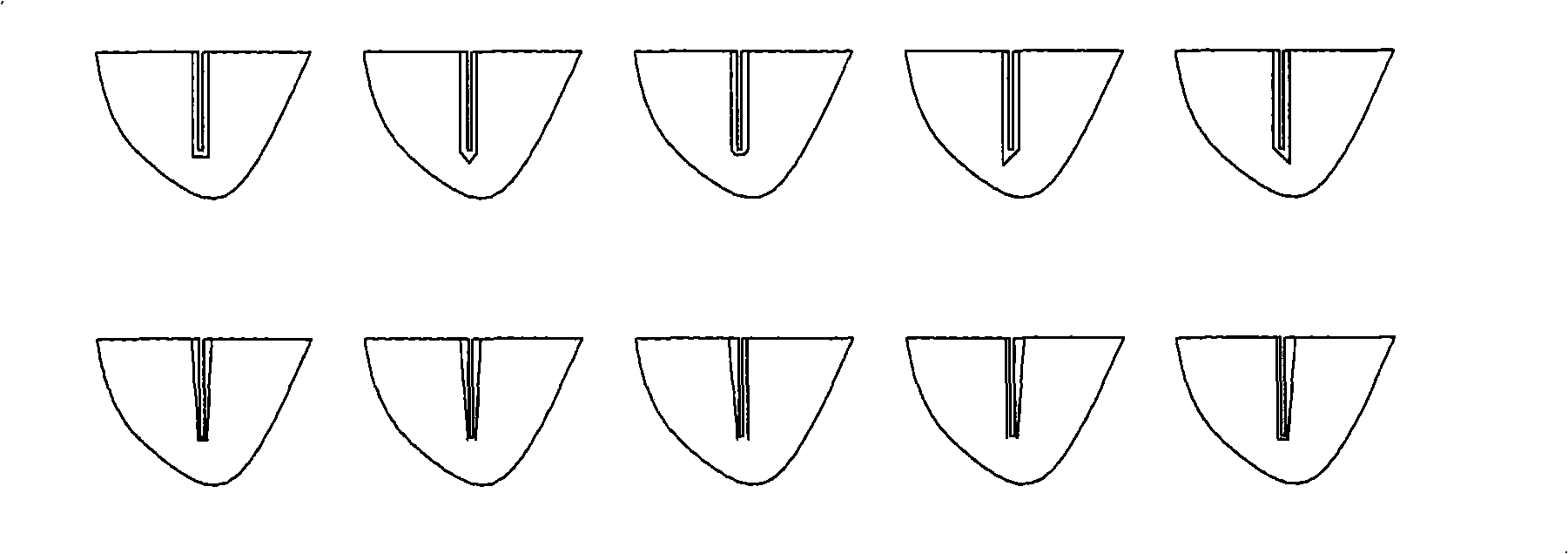

Pocket-hole sewing machine for clothing pocket mouth processing

PendingCN111575926ACompact structureIncrease productivityWorkpiece carriersWork-feeding meansIndustrial engineeringSewing machine

The invention discloses a pocket-hole sewing machine for clothing pocket mouth processing and relates to the technical field of clothing processing machines. The pocket-hole sewing machine comprises aworkbench and a sewing machine body, wherein a laser tube used for cutting a pocket mouth is arranged above the workbench, a charging port used for containing a pocket welt is arranged on the workbench, a pocket-folding mechanism located above the charging port is arranged on an upper crossbeam, and a fixing mechanism and a shaping mechanism which are connected together are arranged on the uppercrossbeam in a sliding mode. Compared with the prior art, the pocket-hole sewing machine is compact in overall structure; and by use of the fixing mechanism and the shaping mechanism which are arranged on the upper crossbeam in the sliding mode, clothing is clamped by the fixing mechanism and enters the laser tube, the charging port and a sewing machine station sequentially, the laser tube completes cutting on the pocket mouth position of the clothing, the pocket-folding mechanism and the shaping mechanism cooperate to complete alignment of the pocket welt to the pocket mouth as well as edge turn-up and pocket folding, and finally the sewing machine body sews the pocket welt and the pocket mouth. The whole process is automatically completed by the machine, so that production efficiency ishigh, pocket-hole sewing precision is high, the number of workers is reduced, and production cost is lowered.

Owner:诸暨市鼎牛自动化科技有限公司

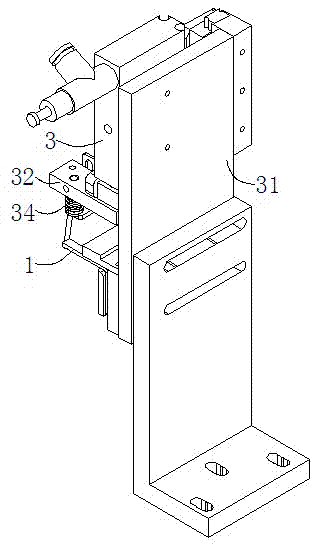

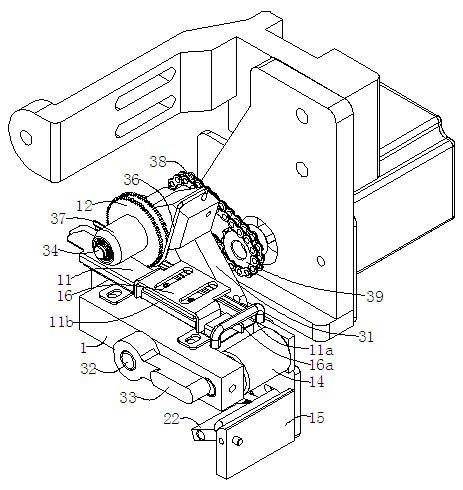

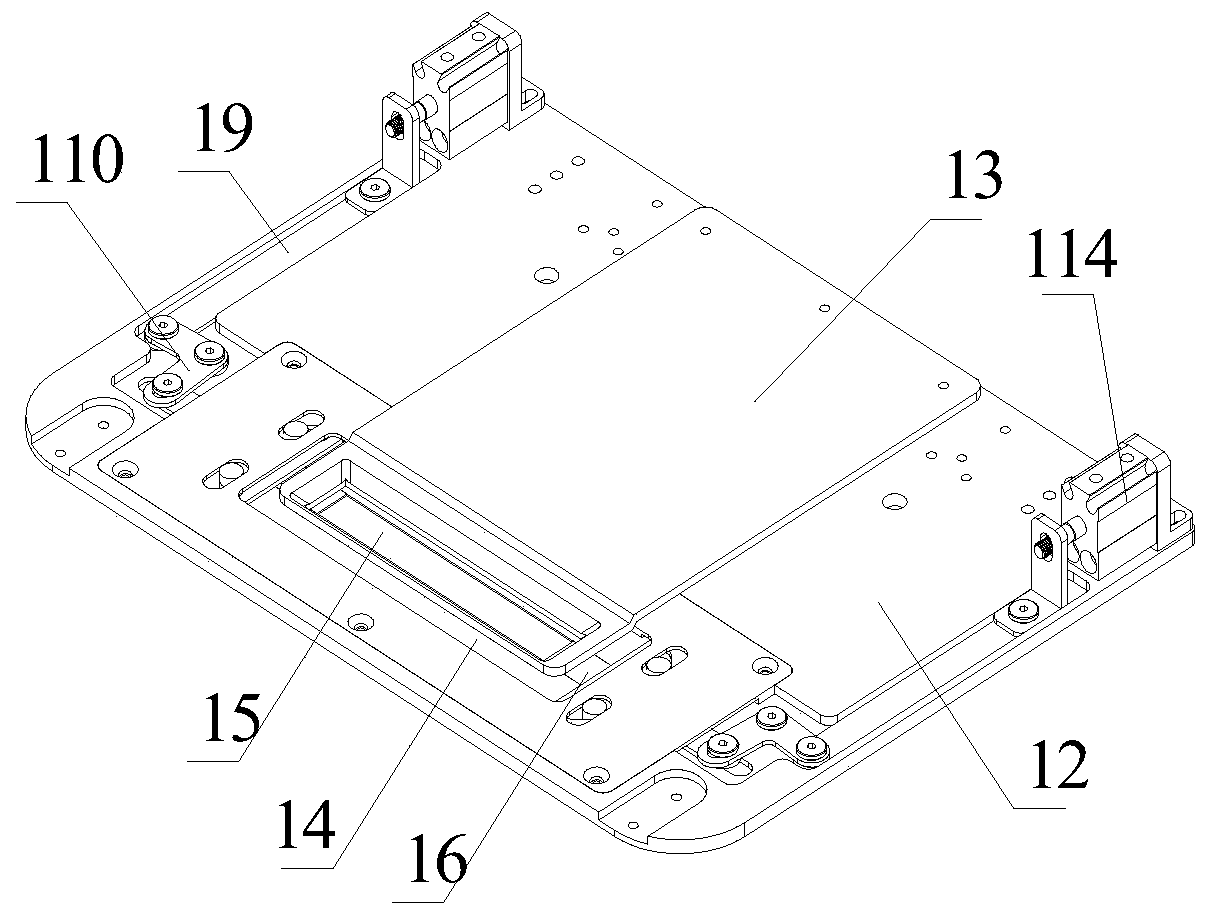

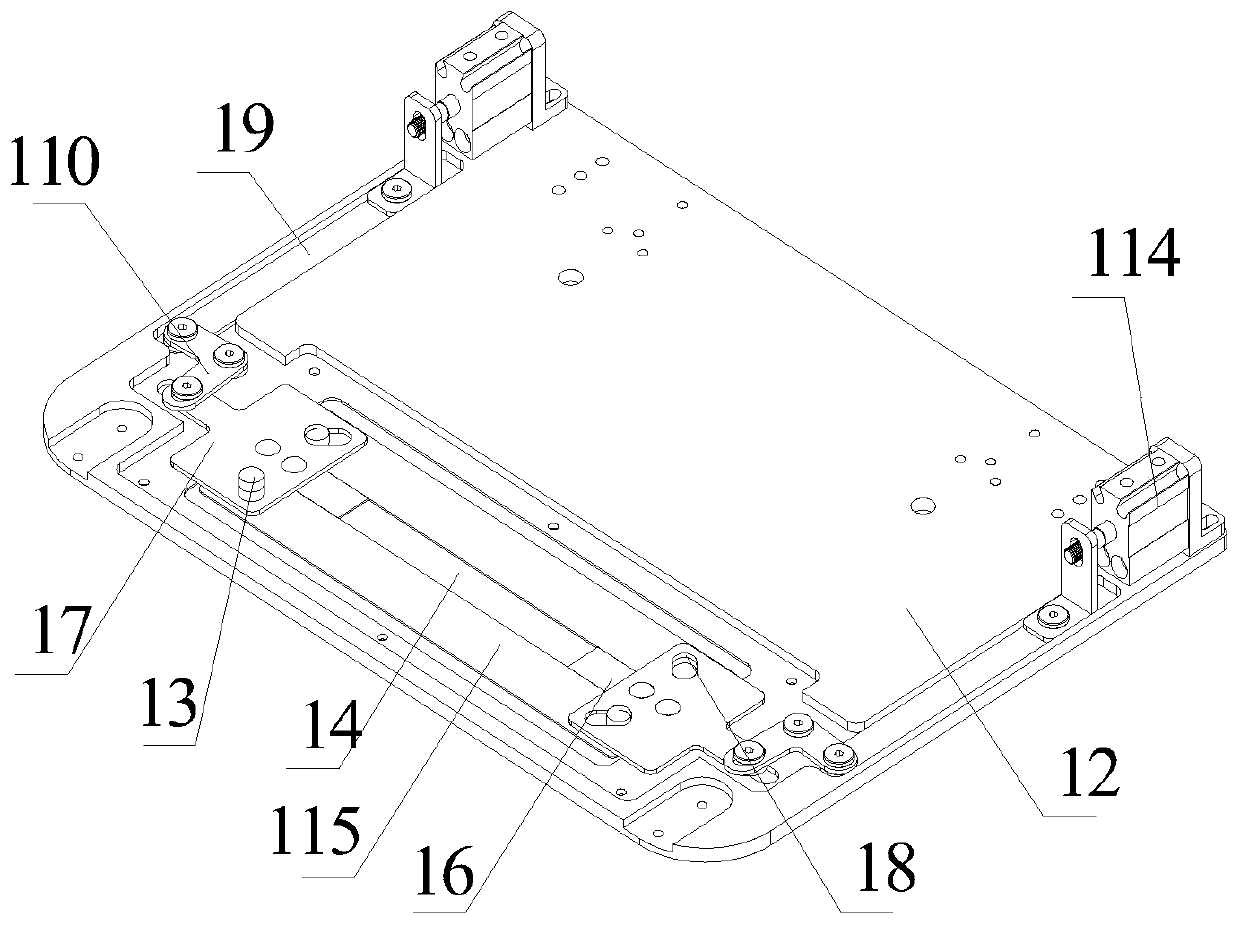

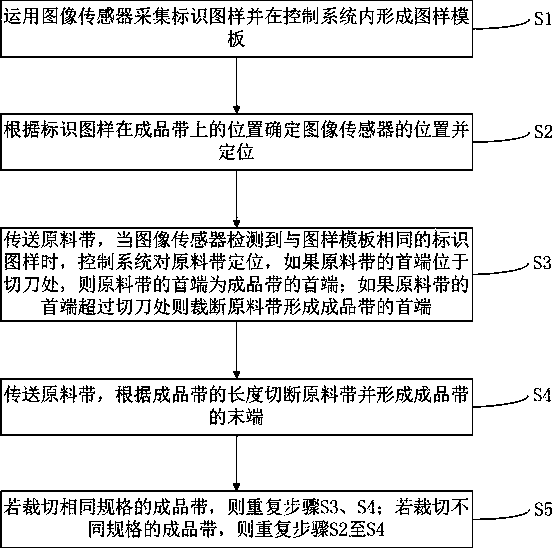

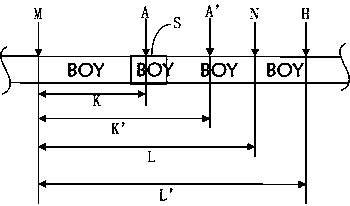

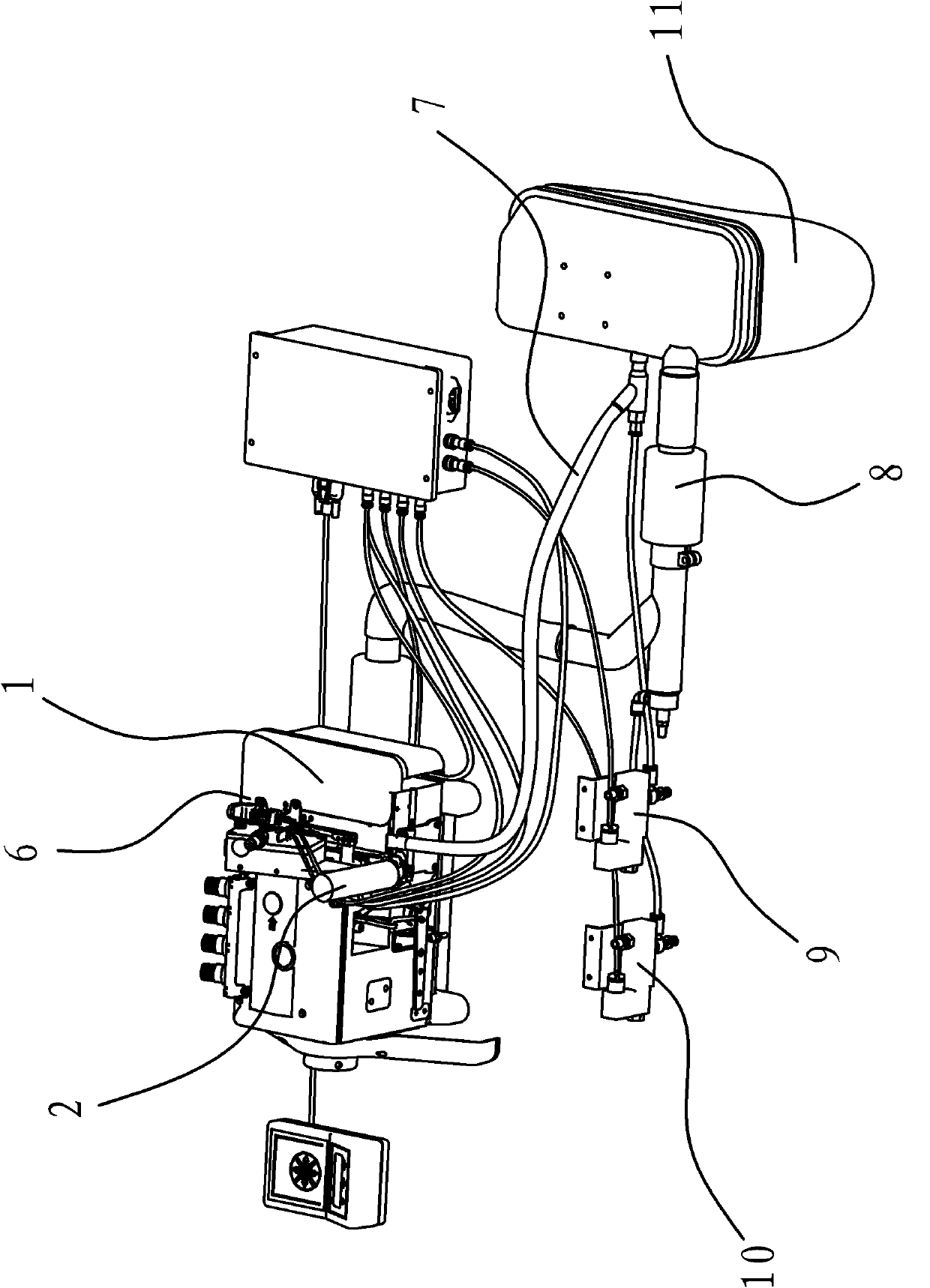

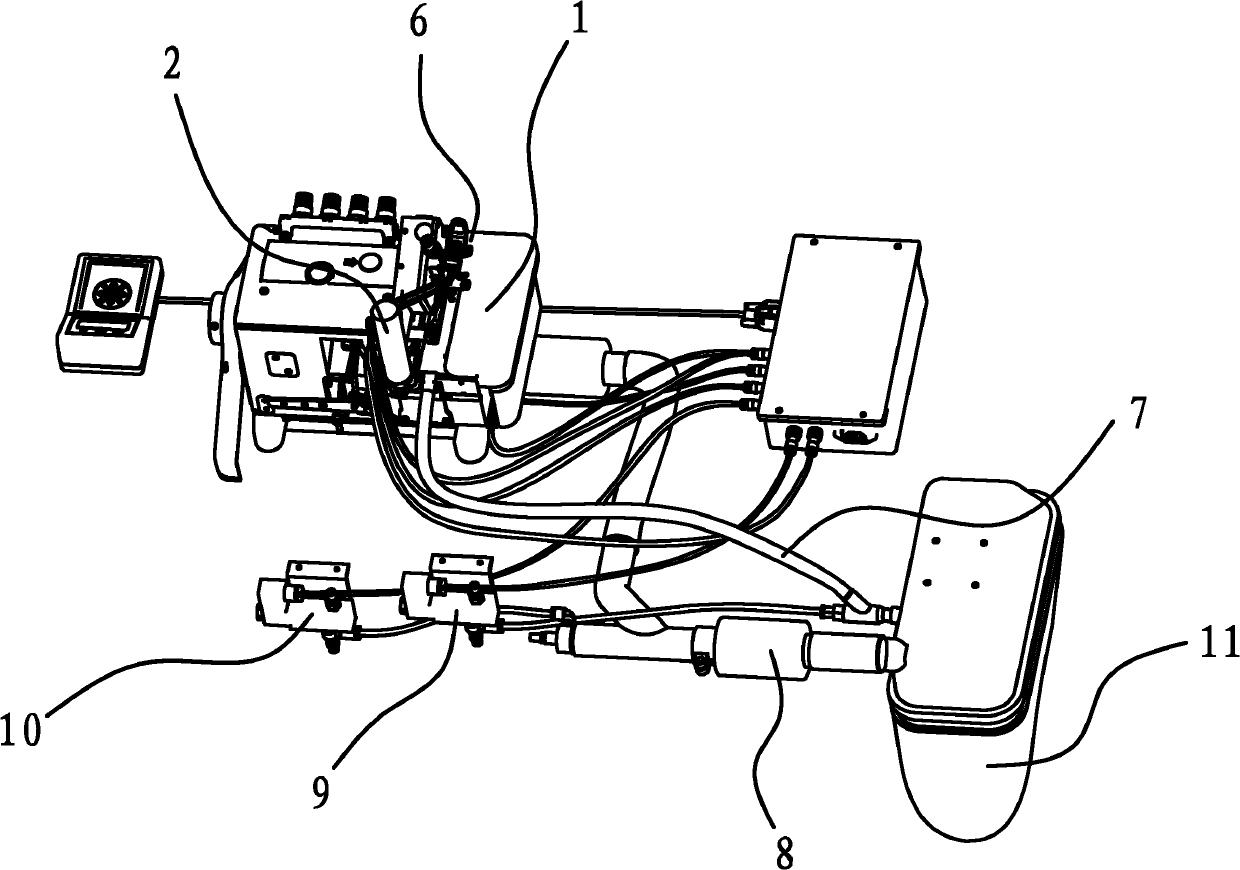

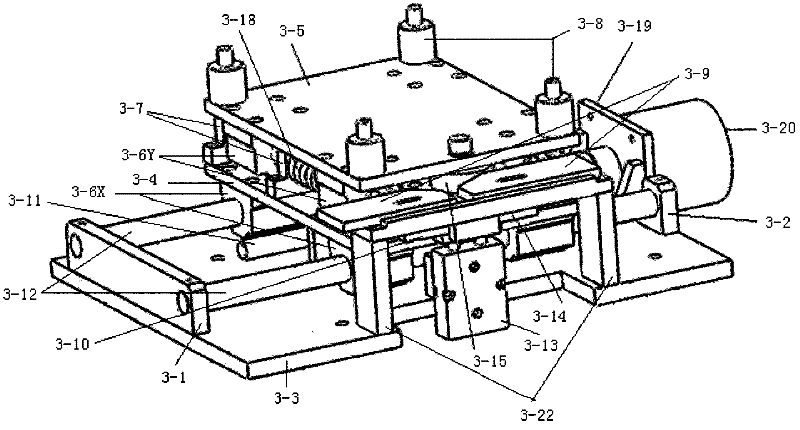

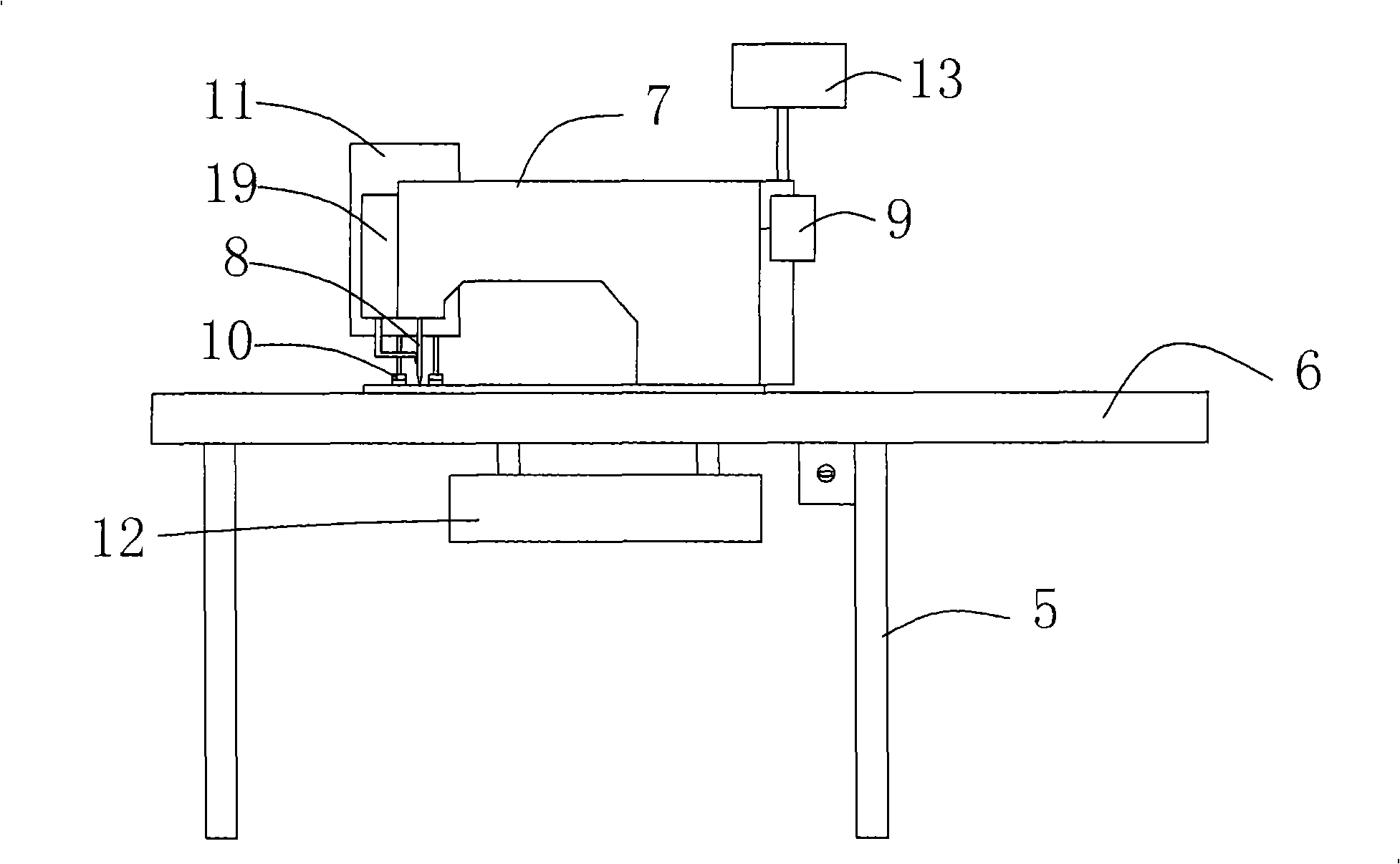

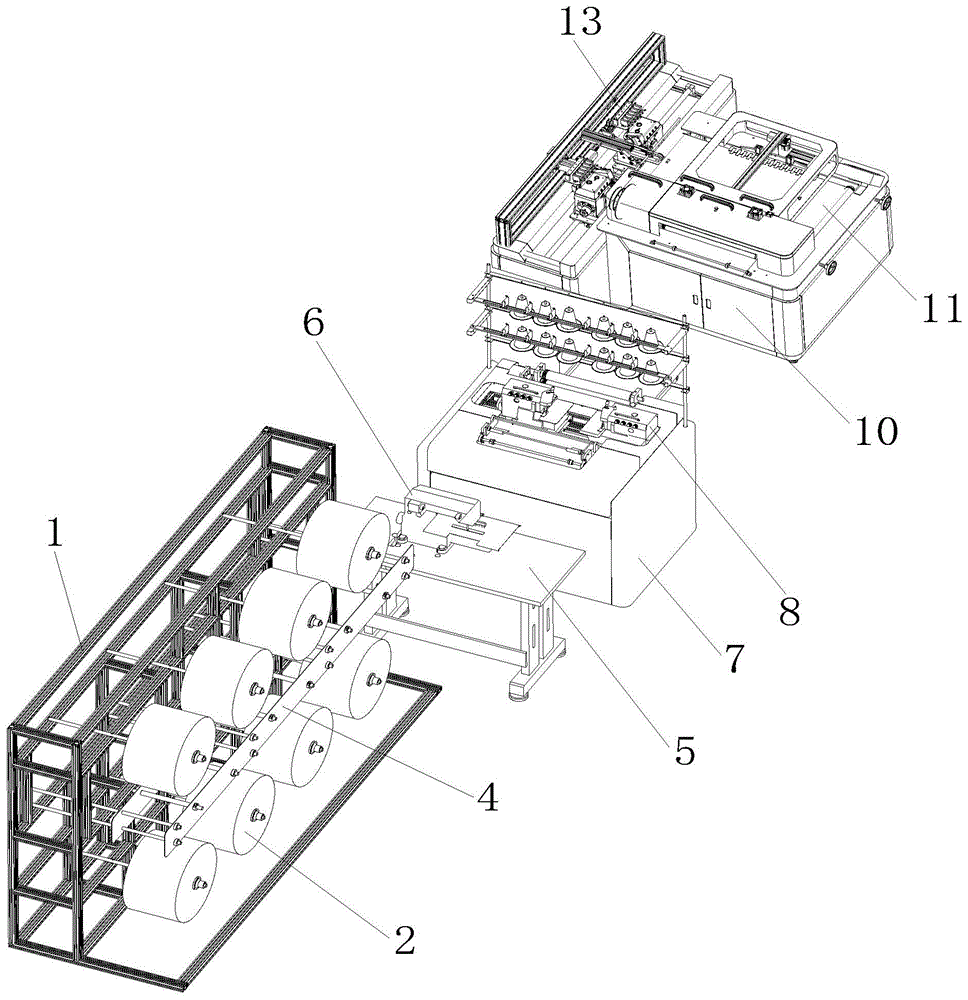

Automatic mark calibration method, mark calibration mechanism and elastic-band sewing machine

ActiveCN104233650ARealize automatic identification controlIncrease productivityWorkpiece carriersWork-feeding meansControl systemEngineering

The invention provides an automatic mark calibration method, a mark calibration mechanism and an elastic-band sewing machine. The automatic mark calibration method includes the steps of S1, acquiring a mark pattern through an image sensor and forming a pattern template in a control system; S2, determining location of the image sensor and positioning the same according to location of the mark pattern on a finished band; S3, conveying a raw band, positioning the raw band when the image sensor detects that the mark pattern is the same with the pattern template; taking the end, which is disposed at a position of a cutter, of the raw band as a head end of the finished band; cutting off the raw band to form the head end of the finished band if the end of the raw band excesses the position of the cutter; S4, conveying the raw band and cutting off the raw band to form the tail end of the finished band according to the length of the finished band; and S5, repeating the steps of S3 and S4 during cutting of the finished bands in same specification, and repeating the steps from S2 to S4 during cutting of the finished bands in different specification.

Owner:GUANGZHOU KEQI AUTOMATIC EQUIPS

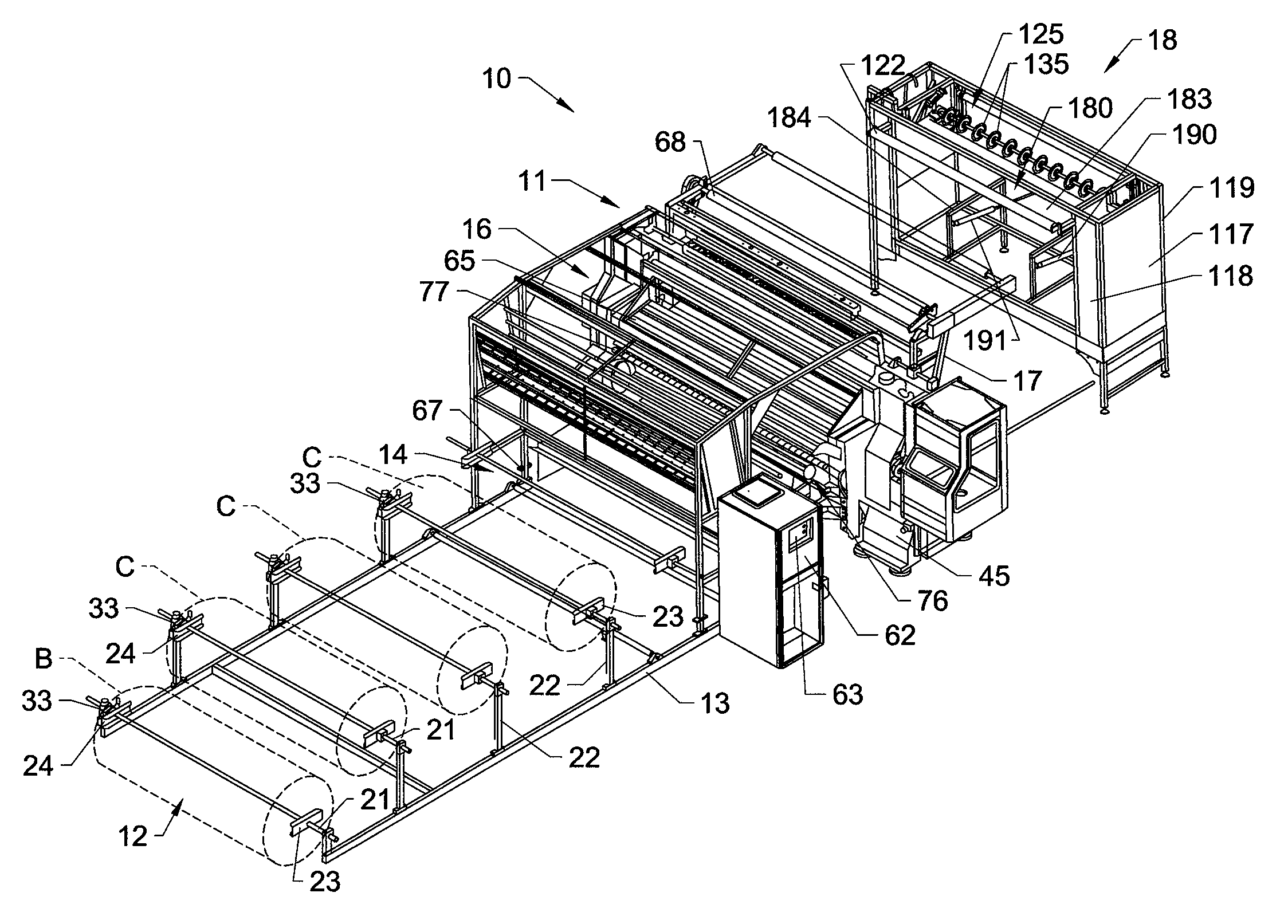

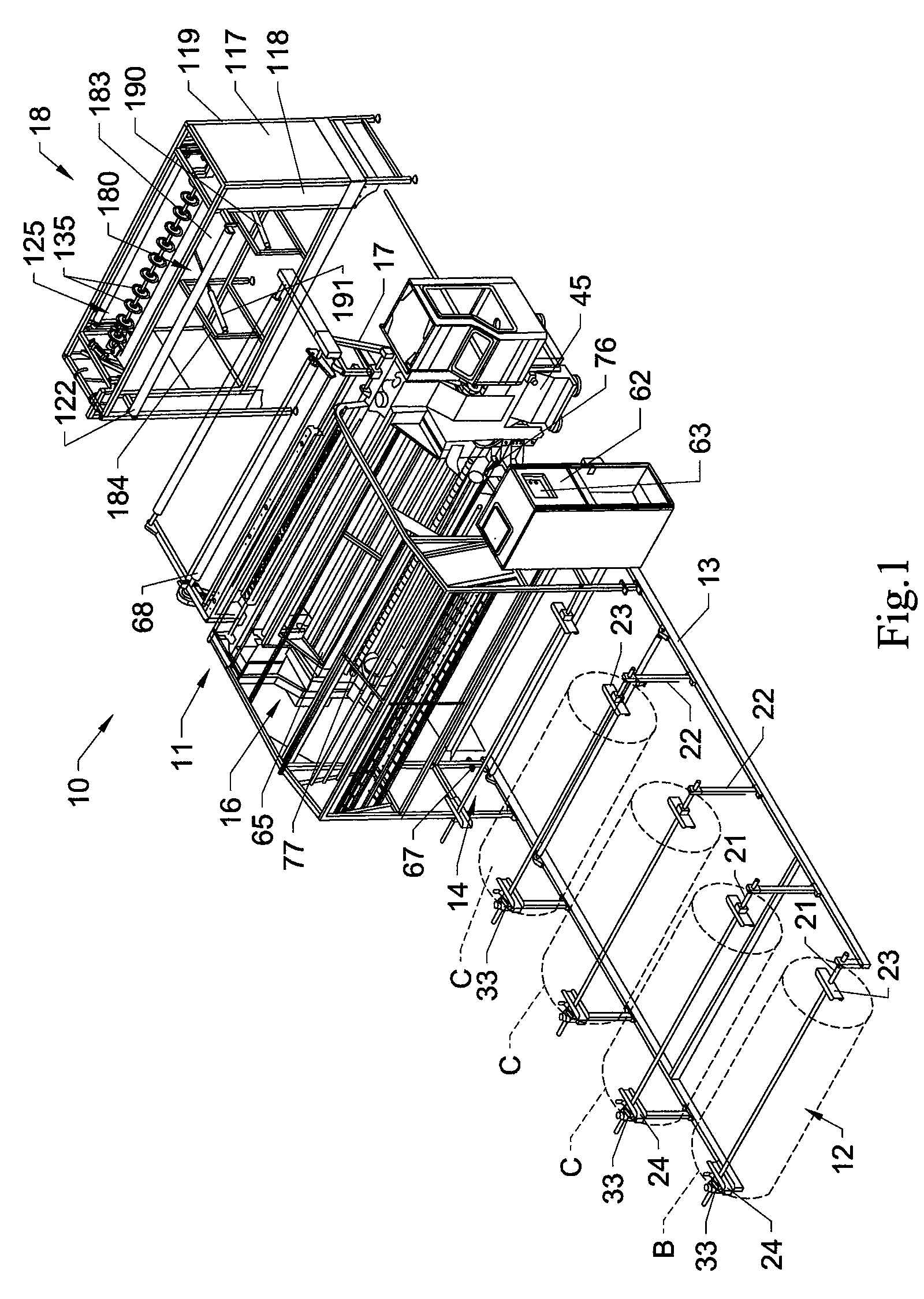

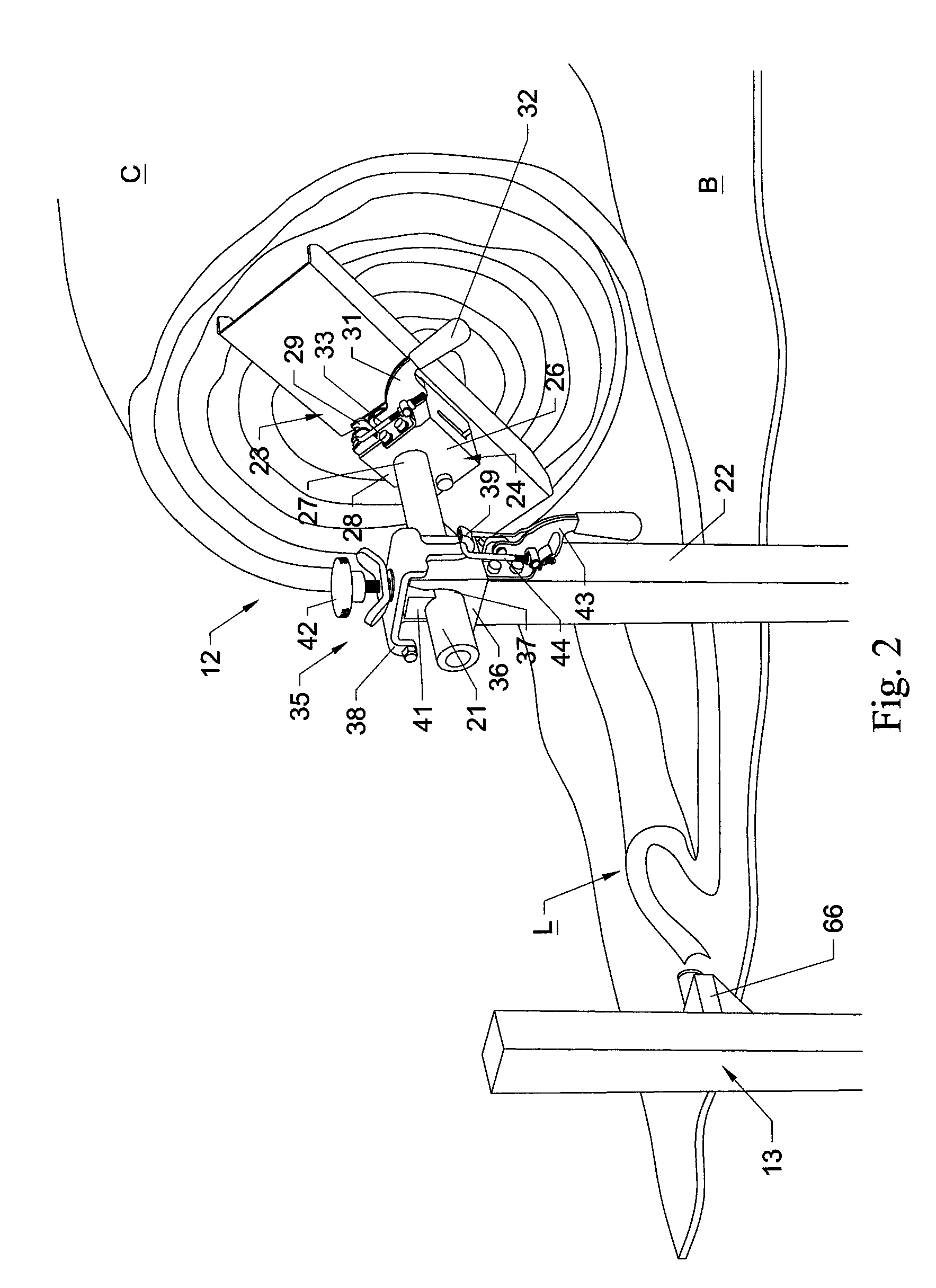

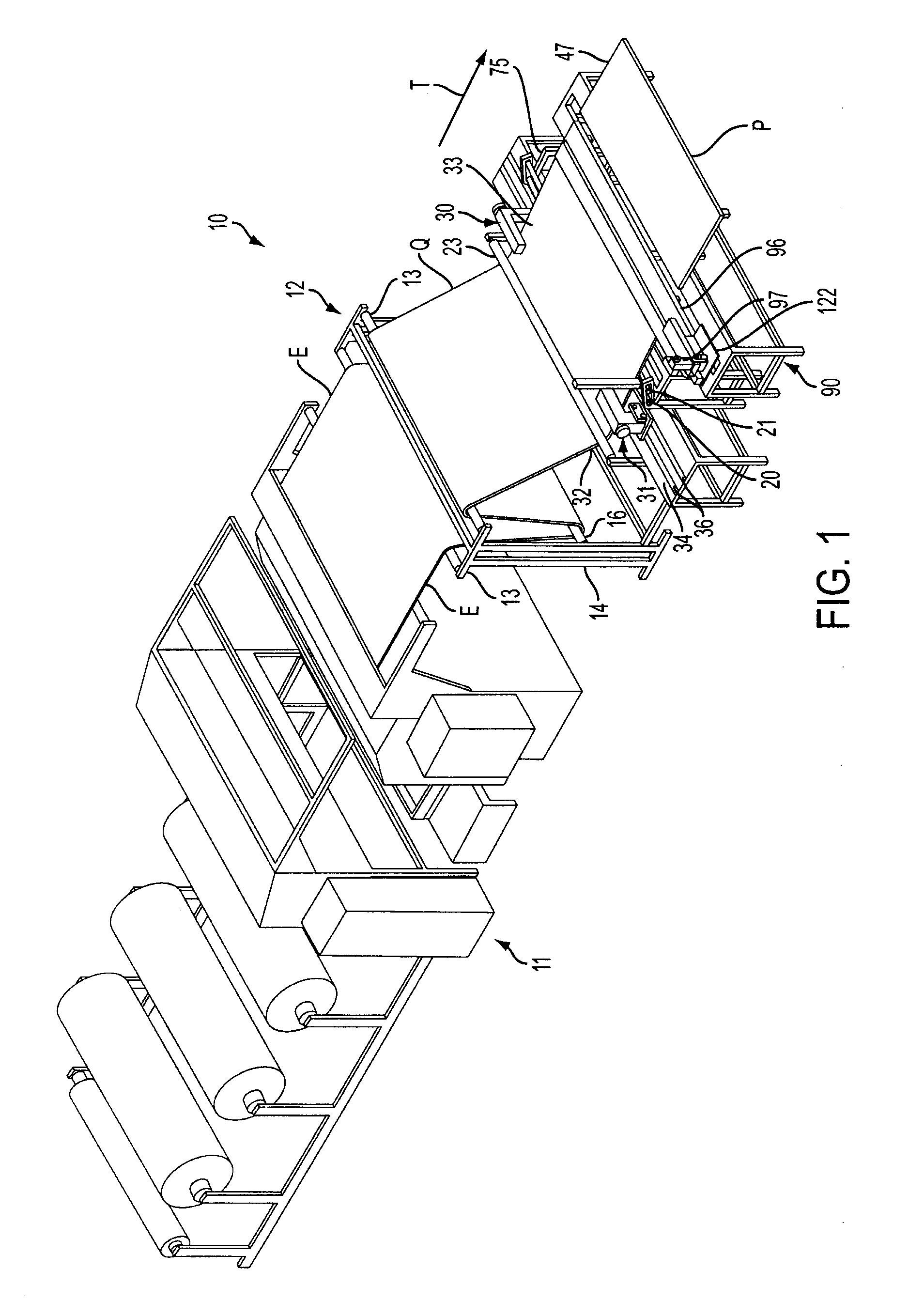

Panel quilting machine

A system for quilting fabric materials includes a quilter unit having a reciprocating needle bar with a series of needles spaced therealong and carrying a series of threads for forming quilted patterns in fabric materials passing below the needles. The quilted fabric materials then can be collected on a supply roll or fed to a panel cutter downstream from the quilter unit. The panel cutter can include a panel cutting blade for cutting the quilted material in different panel lengths or sizes, as well as a series of slitting blades that can be moved into engagement with the quilted material for forming strips of the quilted material in desired widths.

Owner:ATLANTA ATTACHMENT

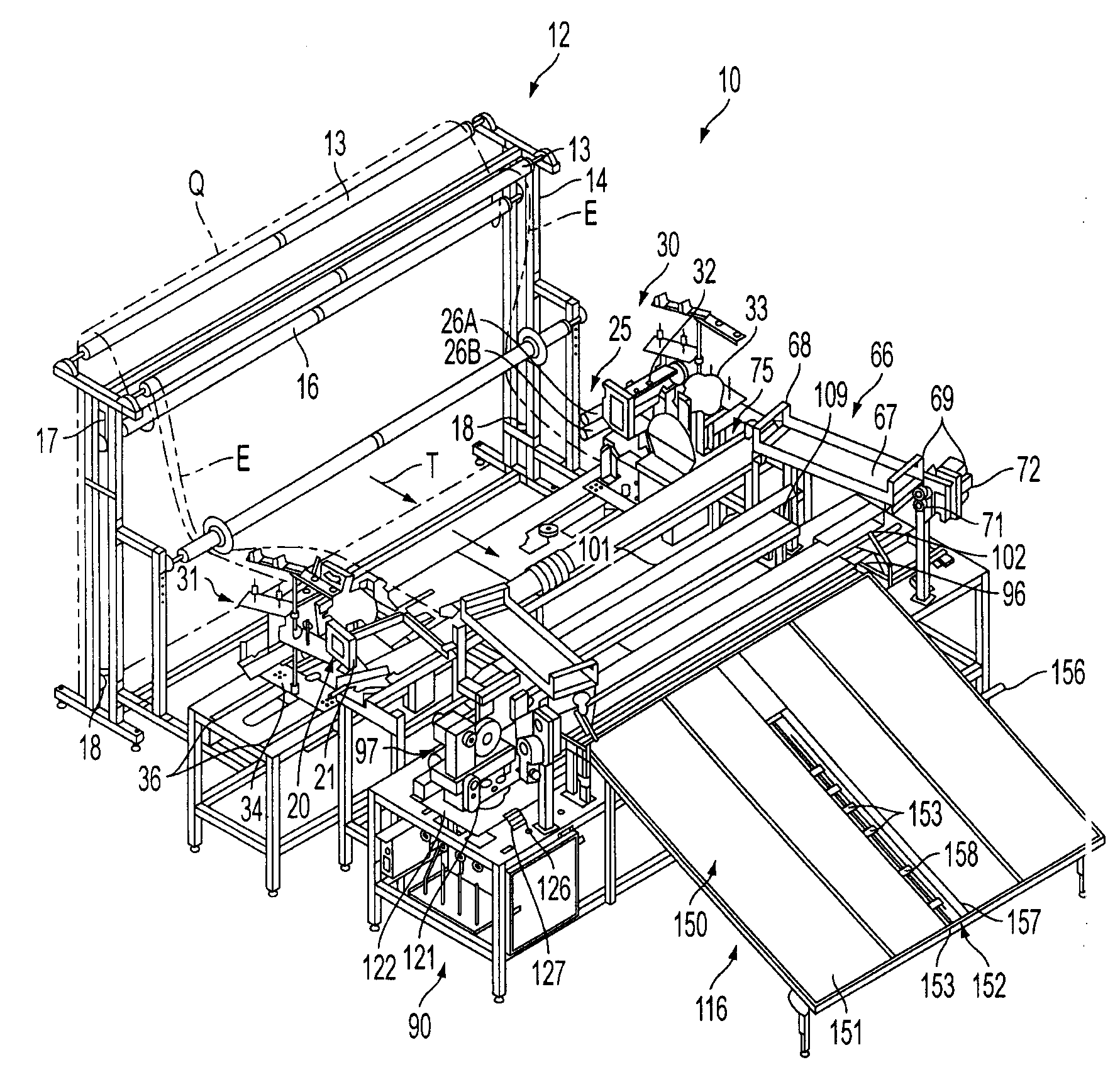

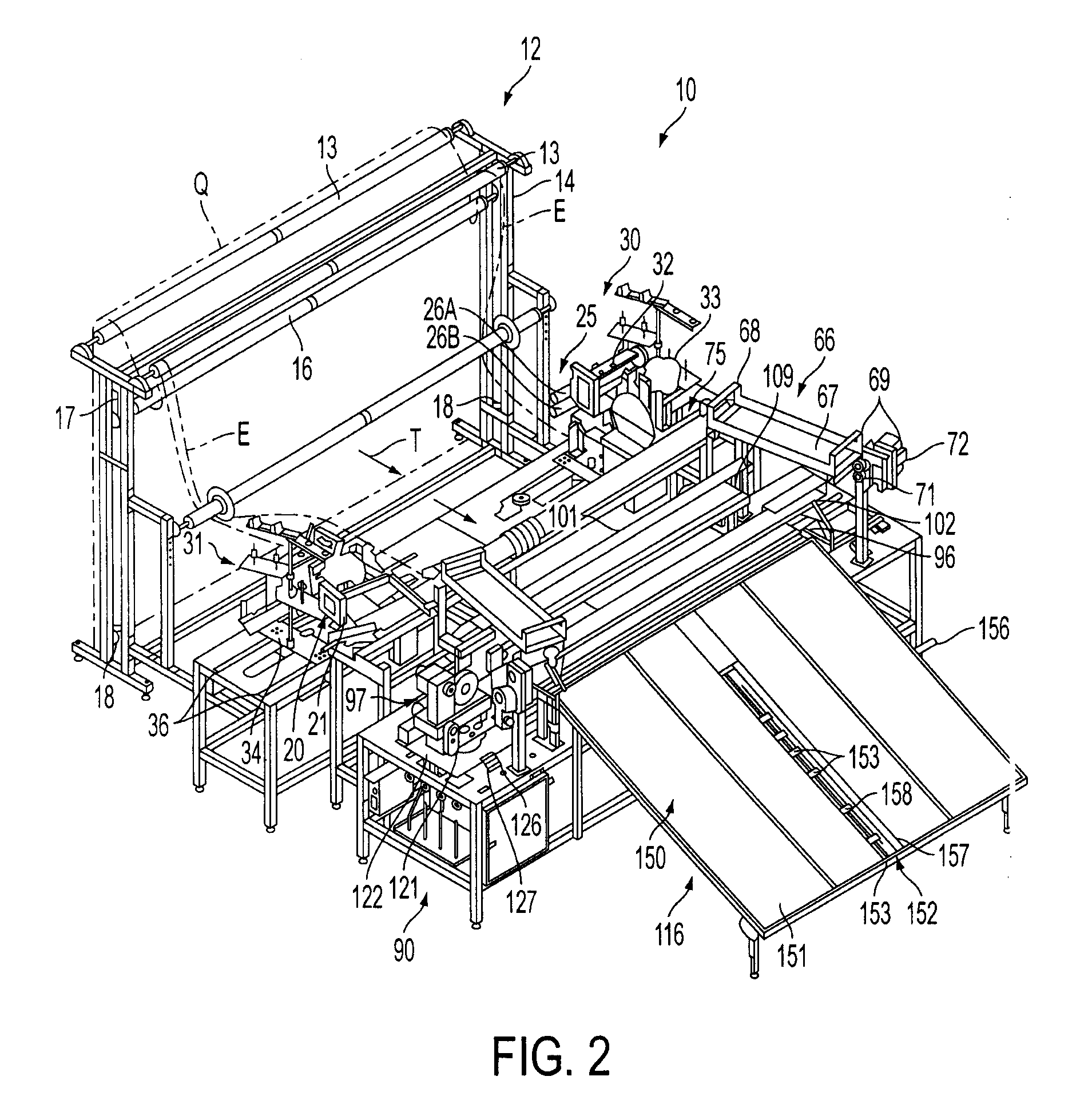

Automatic panel cutting and seaming system

ActiveUS20090064911A1Sufficient amountShort wasteWorkpiece carriersWork-feeding meansCross cutEngineering

An automatic panel cutting and edge seaming system includes a series of side edge cutting and seaming assemblies that receive a fabric material and trim and sew seams along the side edges of the fabric material to form a desired width panel. Puller rolls pull the material through the side edge cutting and seaming assemblies and feed the trimmed and seamed fabric material to a cross-cut sewing assembly. After a sufficient length of fabric material has been fed to form a desired size panel, the cross-cut sewing assembly is engaged to cut and seam the end of the panel.

Owner:ATLANTA ATTACHMENT

Ribbon loom

InactiveCN103161038ARealize automatic foldingReduce stepsWorkpiece carriersWork-feeding meansReciprocating motionBand shape

The invention discloses a ribbon loom which comprises a sewing machine head, a feeding guide rail, a material cutting mechanism, a material clamping structure and a feeding structure. The feeding guide rail is used for feeding strip-shaped materials, and the material cutting mechanism is arranged on the end portion of the feeding guide rail and used for cutting off the materials. The material clamping structure can move back and forth along a straight line. The material clamping structure clamps head portions of the strip-shaped materials and moves from an original position to a final position. A material stopping rod which can move up and down is arranged between the original position and the final position. When the material stopping rod abuts against the strip-shaped materials pulled out by the material clamping structure, the material clamping structure returns to the original position from the final position, and the strip-shaped materials are folded around the material stopping rod. The feeding structure is used for fixing folded materials. The feeding structure clamps the folded materials and sends the folded materials to a sewing region of the sewing machine head after the material cutting mechanism cuts off the folded materials.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

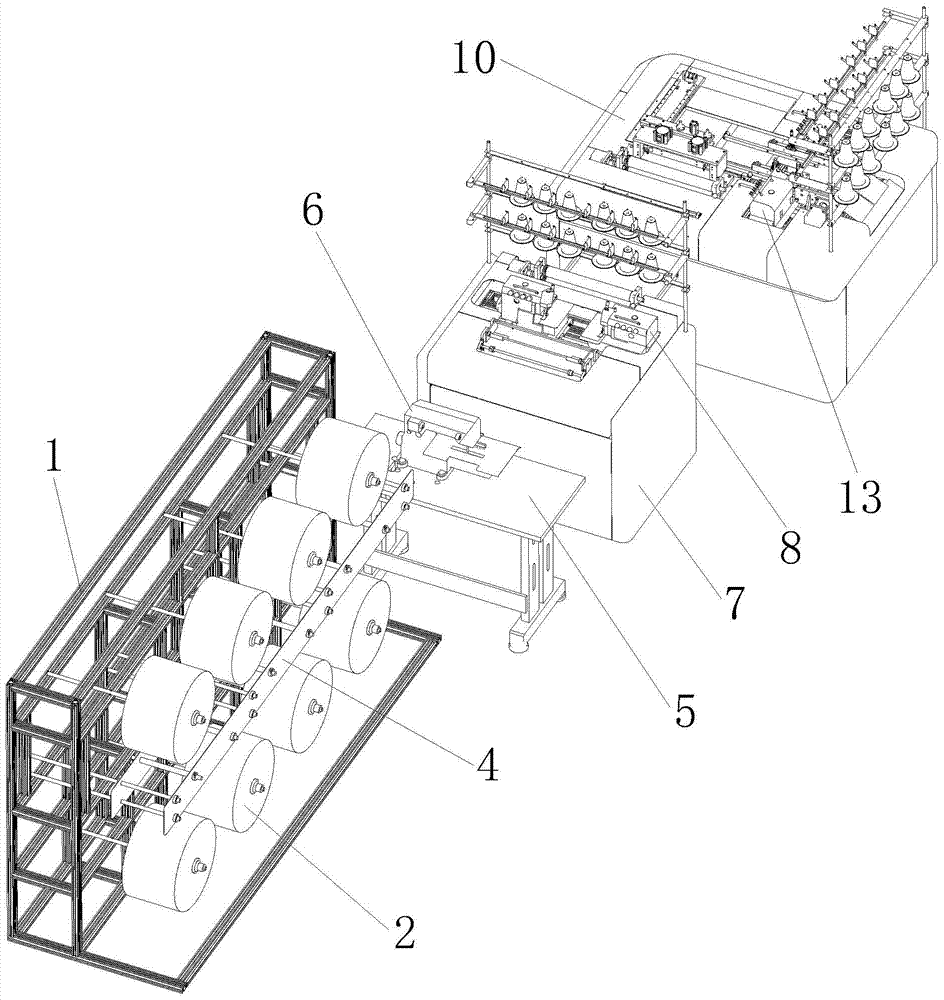

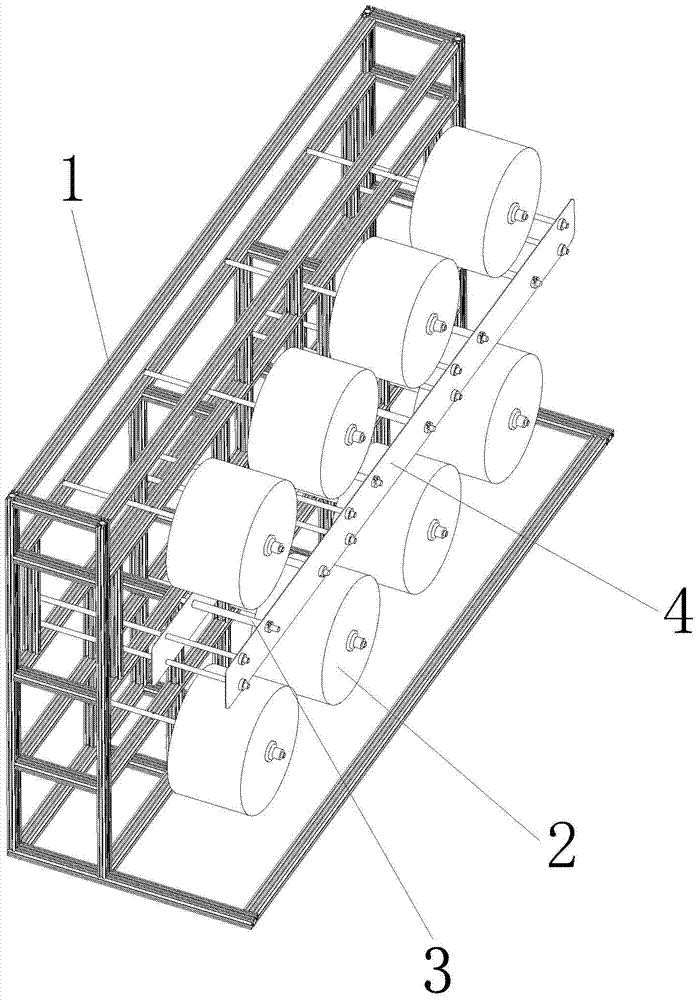

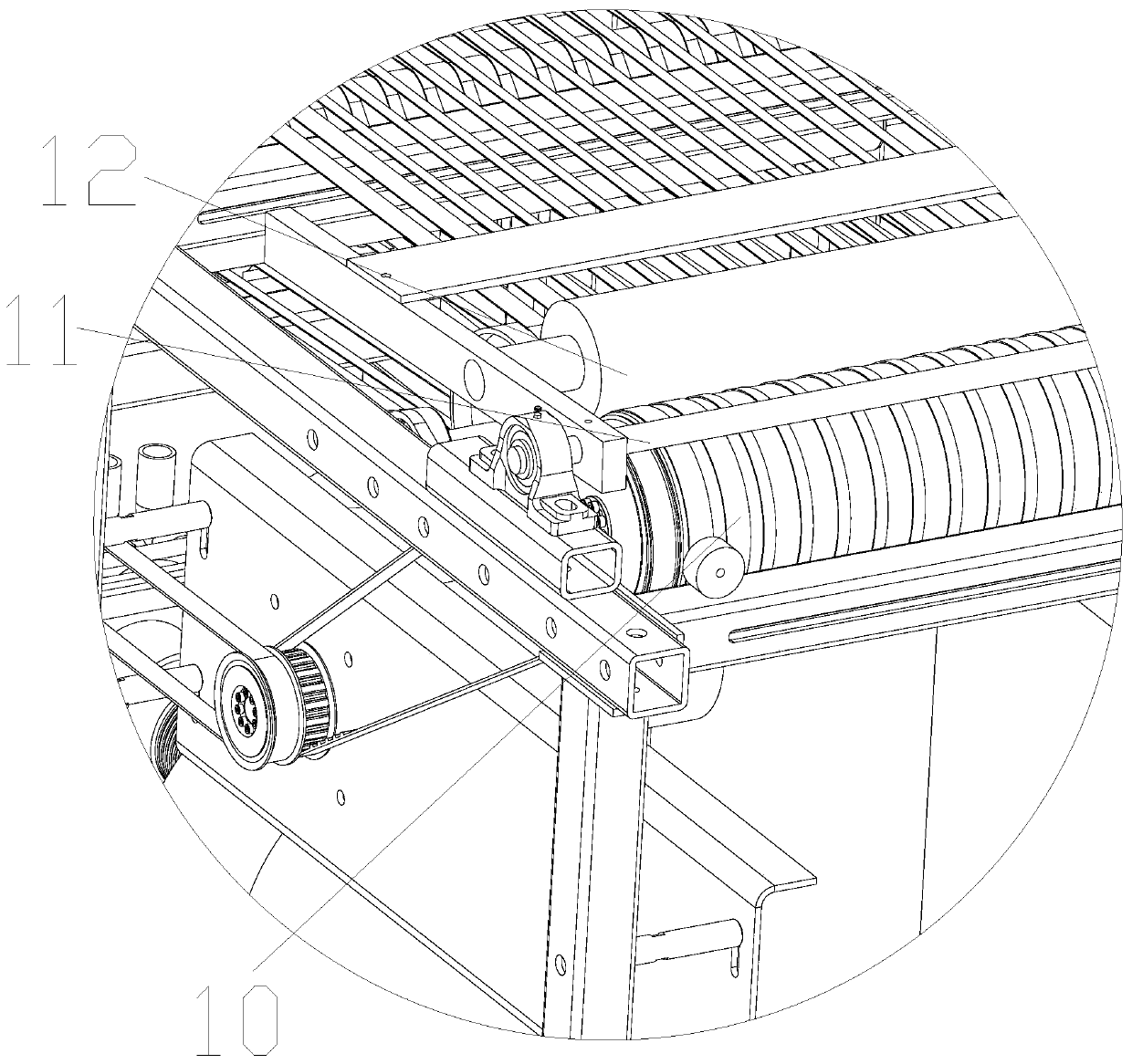

Full-automatic cotton quilt production line

InactiveCN105671797AFully automatedReduce manpower consumptionWorkpiece carriersMattress sewingProduction lineDrive wheel

The invention discloses a full-automatic cotton quilt production line which comprises a feeding frame mechanism, an automatic seam quilting machine, a cutting machine, a covering machine and a covered edge conveying frame mechanism.The feeding frame mechanism, the automatic seam quilting mechanism, the cutting machine and the covering machine are sequentially and transversely arranged.The covered edge conveying frame mechanism is arranged in the covering machine.The feeding frame mechanism comprises a batching and storing frame body, a plurality of batching roller assemblies, a plurality of power roller assemblies, a plurality of pressing roller assemblies and a batching speed reducer.The automatic seam quilting machine comprises a seam quilting machine frame, a driving wheel assembly, a driven wheel assembly, a seam quilting machine head assembly and an auxiliary wheel assembly.By using the feeding frame mechanism, the automatic seam quilting machine, the cutting machine, the covering machine and the covered edge conveying frame mechanism in cooperation, the procedures of feeding, seam quilting, cutting, covering, covered edge conveying and the like are automatically completed, the automation of all the procedures in the cotton quilt production process is achieved, labor waste is effectively reduced, production efficiency is improved, and product quality is improved.

Owner:广州京良智能设备有限公司

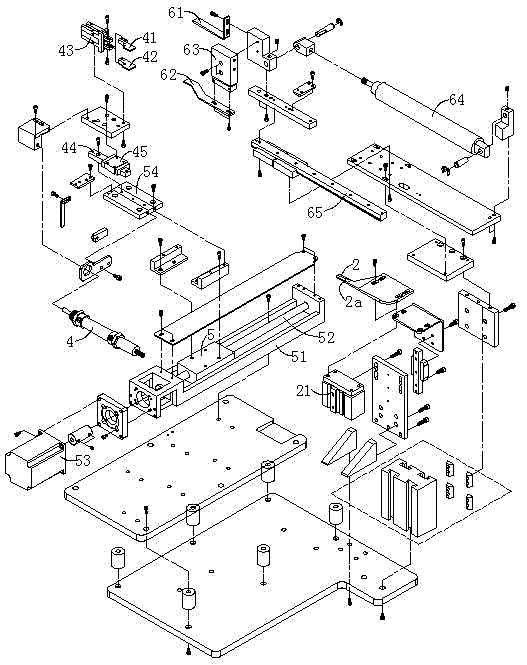

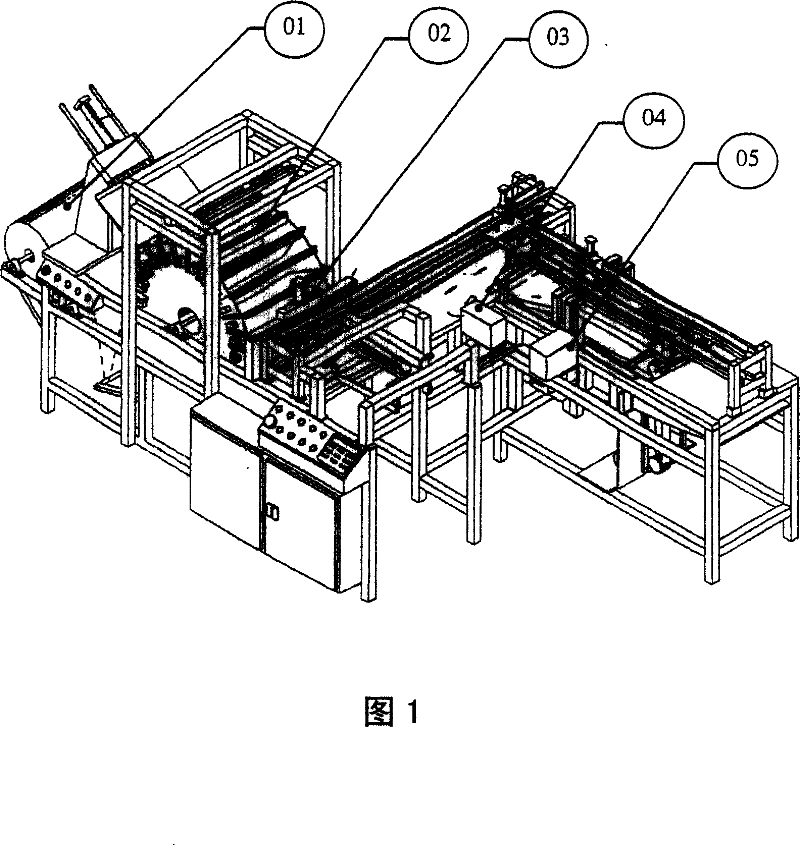

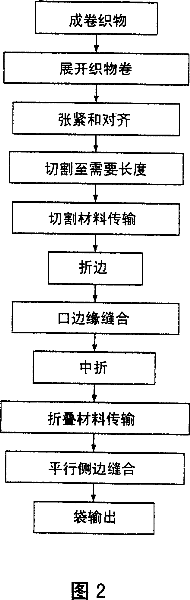

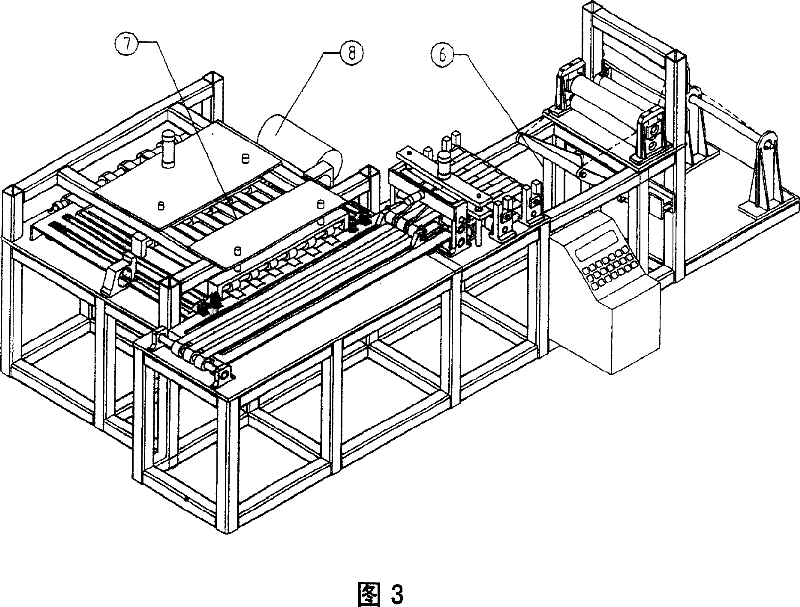

Machine for making textile bags

InactiveCN101041926AFully automatedImprove qualityProgramme-controlled sewing machinesWorkpiece carriersSemi automaticAutomation

A fabric bag making machine is the combination of a fabric cutting and conveying unit (FCCU) and a hemming table assembly which comprises a simultaneous multi-edge folding and sewing unit (SMESU), a middle folding and material guiding unit (MMGU) and a simultaneous parellel side sewing unit (SPSS) and carries out operations like cutting, hemming, middle folding and simultaneous parellel side sewing in synchronization mode. The sequential assembly operation of the combination unit is controlled by computer to achieve complete automation of all the manual, semi-automatic or partial-automatic processes. The bag making machine of the invention enables bag manufacturing in a single device; the fabric material is fed continuously by controlled expanding process, cut to required length, hem folded and sewn to form a hem opening, and then middle folded and parellel side sewn. The bag after parellel side sewing and opening folding is preferably used as bag with bottom and one side sewn for they have excellent qualities.

Owner:COUNCIL OF SCI & IND RES

Thread cutting mechanism in sewing machine

InactiveCN102002829AEasy to controlEasy to sewWorkpiece carriersNeedle severing devicesEngineeringDriven element

The invention provides a thread cutting mechanism in a sewing machine, which belongs to the technical field of machinery. The invention solves the problem that the traditional thread cutting mechanism can not absorb waste materials in a feeding position of the sewing machine. The thread cutting mechanism in the sewing machine is arranged at a needle plate of the sewing machine; the mechanism comprises a drive element and a cutter which is connected with the drive element and used for cutting threads; the cutter is provided with a sucking opening I; the feeding position of the needle plate is provided with a sucking opening II; and the lower part of the needle plate is provided with a pump sucking assembly which is connected with the sucking opening I and the sucking opening II. Both the cutter and the feeding position of the sewing machine are provided with the sucking openings for sucking the waste materials, and the two sucking openings are convenient for screwing a long sewing material.

Owner:ZHEJIANG ZOJE SEWING MACHINE

Full automatic edge cutting and edge seaming machine for cloth

InactiveCN103485086APrevent deviationIncrease productivityWorkpiece carriersWork-feeding meansUltimate tensile strengthSewing machine

The invention discloses a full automatic edge cutting and edge seaming machine for cloth. The machine comprises a rack, wherein the rack is provided with a cloth feed guiding roller group and a cloth discharge guiding roller group in sequence from front to rear along the trend of the cloth, the cloth discharge guiding roller group is driven by a power mechanism, the cloth feed guiding roller group is provided with a cloth feed deviation rectifying device which comprises two supports, each support is provided with a position finding optoelectronic switch, the support is provided with reflectors and a deviation rectifying roller rack, the middle part of the deviation rectifying roller rack is hinged to the rack through a hinge shaft, the deviation rectifying roller rack is provided with a deviation rectifying roller, the rack is also provided with a deviation rectifying air cylinder and a support plate, the support plate is provided with an automatic edge turnup device and an automatic sewing machine, and the rack is also provided with an automatic edge cutting device between the cloth feed guiding roller group and the support plate. By adopting the full automatic edge cutting and edge seaming machine, edge cutting and edge seaming are realized automatically, thus the production efficiency is high, the cloth is effectively prevented from deviation during the running process, the edge seaming quality is high, and the labor intensity is effectively reduced.

Owner:GAOMI ZHONGHE GARMENT

Automatic silk stocking toe sewing machine and use method thereof

InactiveCN102433689ANo missing stitchesDoes not produce uniformityWorkpiece carriersWork-feeding meansMan machineCrowds

The invention discloses an automatic silk stocking toe sewing machine and a use method thereof. The automatic silk stocking toe sewing machine comprises a host machine, a movable socking plate, a machine head support, a machine head, a crotch cutting system, a stocking clamping system and the like, wherein the machine head support is independently driven by a lead screw motor, and the machine head support drives the machine head to change the sewing track; because the stocking casing is stationary when the stocking toe is sewn, a movable support drives the machine head to adopt an active sewing mode, thus the rotation speed of the machine head is reduced; and the stocking clamping system is used for clamping the stocking casing, so that the crotch cutting system carries out crotch cutting on the sewn stocking casing. In the invention, through simple man-machine conversation, multiple processes and multiple persons required by stocking toe sewing are changed into one-person operation; when ultra-thin or ultra-thick stockings are sewn, the problems of missed sewing, nonuniform spacing and the like are not generated, and the sewn stockings can accord with the toe arc lines of different crowds; and the crotch cutting is carried out under the state of clamping and tightening the stocking casing, thus the cut is straight and accurate, the artificial crotch cutting error is reduced, the working efficiency is greatly improved, the product quality is guaranteed and the raw materials are saved.

Owner:韶关市新时韵针织有限公司

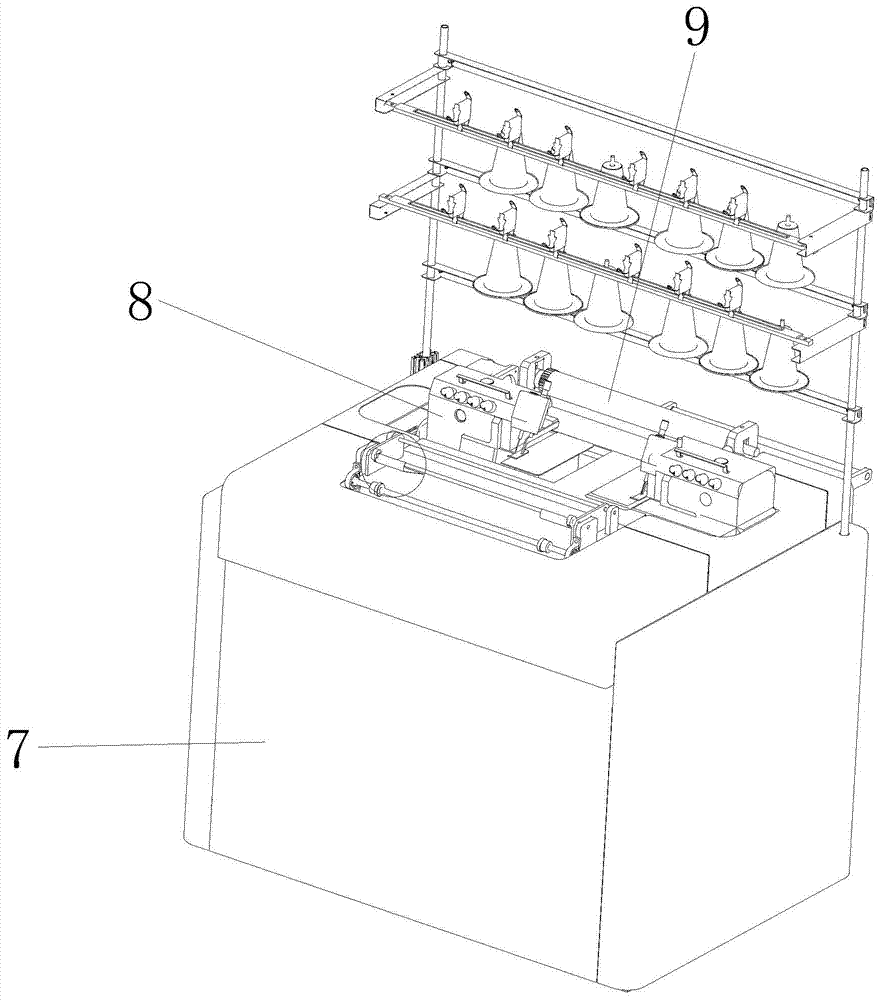

Full-automatic elastic band seamer

InactiveCN103015056ACompact structureReduce manufacturing costWorkpiece carriersWork-feeding meansEngineeringAutomation

The invention discloses a full-automatic elastic band seamer which comprises a machine head, a frame, a first conveying belt mechanism, a second conveying belt mechanism, a material supporting balance mechanism, an automatic shear mechanism, a receiving belt rotating mechanism, an automatic feeding transmission mechanism and an automatic blanking mechanism; an upper pressure plate is arranged above the machine head; the machine head is arranged at a left position behind the frame; the lower part of the right side of the frame is provided with an electrical box and a pneumatic element box; a start switch is arranged below the left side of the frame; the first conveying belt mechanism is arranged on the front side of the right part of the machine head; the second conveying belt mechanism and the first conveying belt mechanism are arranged back to back; the material supporting balance mechanism is arranged below the inner side of the first conveying belt mechanism; the automatic shear mechanism is arranged on the left front side of the second conveying belt mechanism; the receiving belt rotating mechanism is arranged on the top of the automatic feeding transmission mechanism; the automatic feeding transmission mechanism is arranged at the lower part of the receiving belt rotating mechanism; and the automatic blanking mechanism is arranged on the right side of the machine head. The full-automatic elastic band seamer has the advantages of compact structure, low manufacturing cost and high automation degree.

Owner:SHANGHAI GUIYI SEWING EQUIP MFG

Full-automatic button stay sewing machines

ActiveCN101265640ANot easy to collapseImprove straightnessProgramme-controlled sewing machinesWorkpiece carriersEngineeringSuture line

The invention discloses a full-automatic closure sewing machine, which includes a frame and a bedplate, a head fixed on the frame, a cutter and a mop device. Only a sewing machine needle is arranged on the head. The sewing machine is provided with a driving mechanism which drives the sewing machine needle to continuously finish a plurality of closure suture lines with different directions, a touch screen for inputting control commands, and a controller which receives the control commands and is electrically connected with the driving mechanism. The driving mechanism is a single-needle triaxiality driving mechanism, compared with the prior double-needle closure sewing machine, the closure sewed by the invention has adjustable width between the two left and right suture lines, the bottom of the closure can be sewed by one step, the closure after sewing has stabler quality and is aesthetic; compared with the common sewing machine, the suture lines of the two sides and the bottom of the closure can be sewed by one step without the requirements of stopping or turning cloth by hand, in addition, the cloth can be cut off in sewing, no cutting cloth by hand with a pair of scissors is required, thereby having the advantages of high efficiency, high speed, and good quality.

Owner:GUANGZHOU KEQI AUTOMATIC EQUIPS

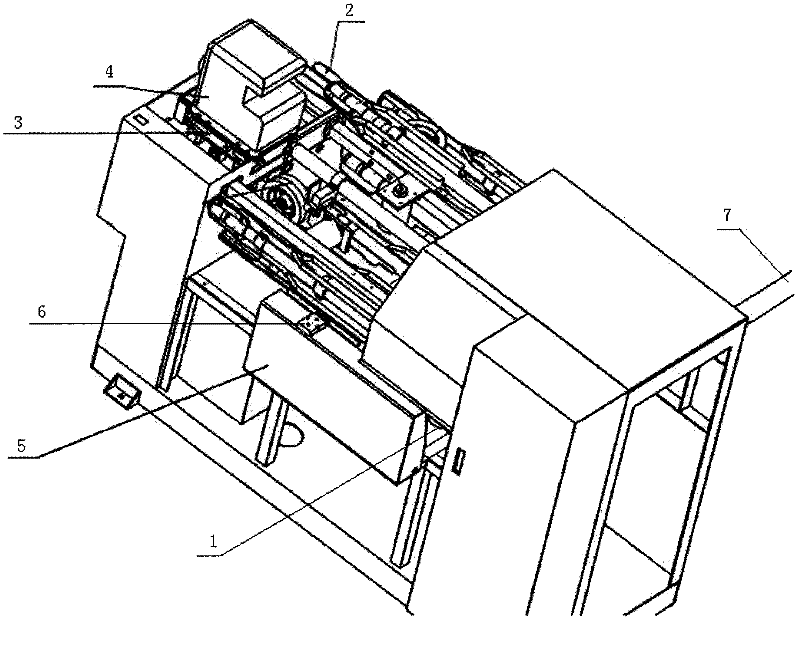

Full-automatic covered edge sewing machine

InactiveCN106757805AWon't wasteFast productionWorkpiece carriersWork-feeding meansEngineeringSewing needle

The invention relates to a full-automatic covered edge sewing machine which comprises a rack, a worktable and a machine head. The worktable is installed above the rack, the machine head is provided with a sewing needle for sewing a material with the edge to be covered, an X-axis mechanism, a Y-axis mechanism, a W-axis mechanism, a compression plate mounting seat, a compression plate, a binding tape feeding mechanism, a binding tape cutting mechanism and a unloading mechanism are installed above the worktable, the worktable is provided with a feeding station, a material sewing station and a material unloading station according to the working procedures, the X-axis mechanism, the Y-axis mechanism and the W-axis mechanism drives the compression plate to compress the material and move the material from the feeding station to the material sewing station, the binding tape feeding mechanism synchronously delivers binding tapes to the material sewing station, the binding tapes are sewn on the side of the material by using the sewing needle to achieve edge covering, the binding tape cutting mechanism cuts off too long binding tapes, the material with the edge covered is fed into the unloading station and is pushed and moved out of the worktable by the unloading mechanism.

Owner:东莞市雅满豪机械科技有限公司

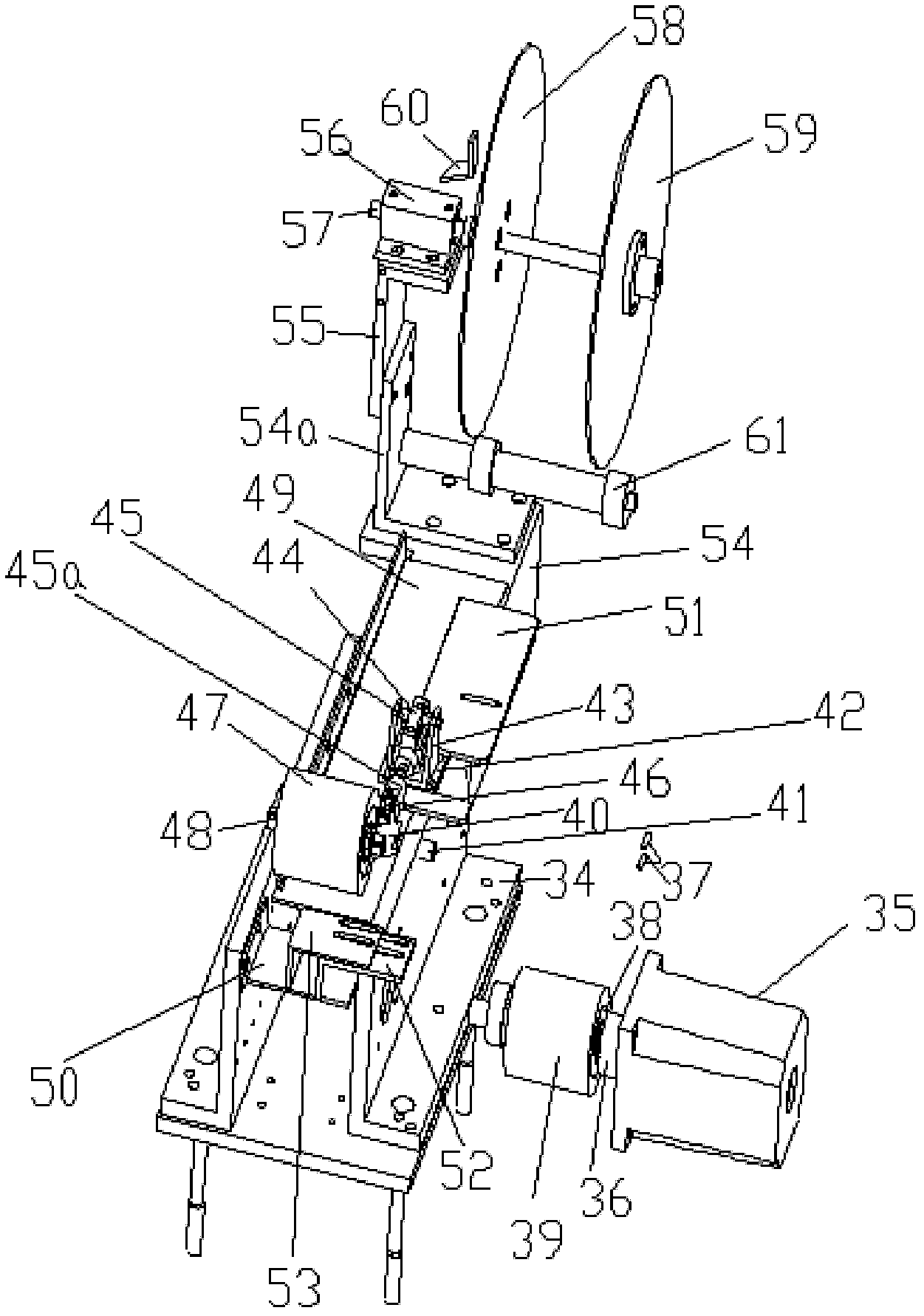

Label feeder

ActiveCN103866494AEasy to operateIncrease productivityWorkpiece carriersWork-feeding meansEmbedded systemSewing machine

The invention discloses a label feeder. The label feeder comprises a shearing device and an integrating device which are fixedly arranged on a first machine table as well as a sewing machine and a conveying device which are fixedly arranged on a second machine table; the shearing device and the integrating device are correspondingly arranged at two sides of the first machine table; the conveying device is positioned at one side of the sewing machine; multiple labels are respectively shorn by the shearing device; the multiple shorn labels are integrated together by the integrating device; the conveying device conveys the multiple integrated labels to the sewing machine for sewing. According to the label feeder, the labels are respectively shorn by the shearing device, then the shorn labels are integrated together by the integrating device, and the integrated labels are conveyed to the sewing machine for sewing by the conveying device, so the joint sewing of the labels is realized, the operation is simple and convenient, the operation for shearing and sewing the labels in sequence is automatically finished, the production efficiency is improved, and the maximization of the output value of products is ensured.

Owner:苏州琼派瑞特科技股份有限公司

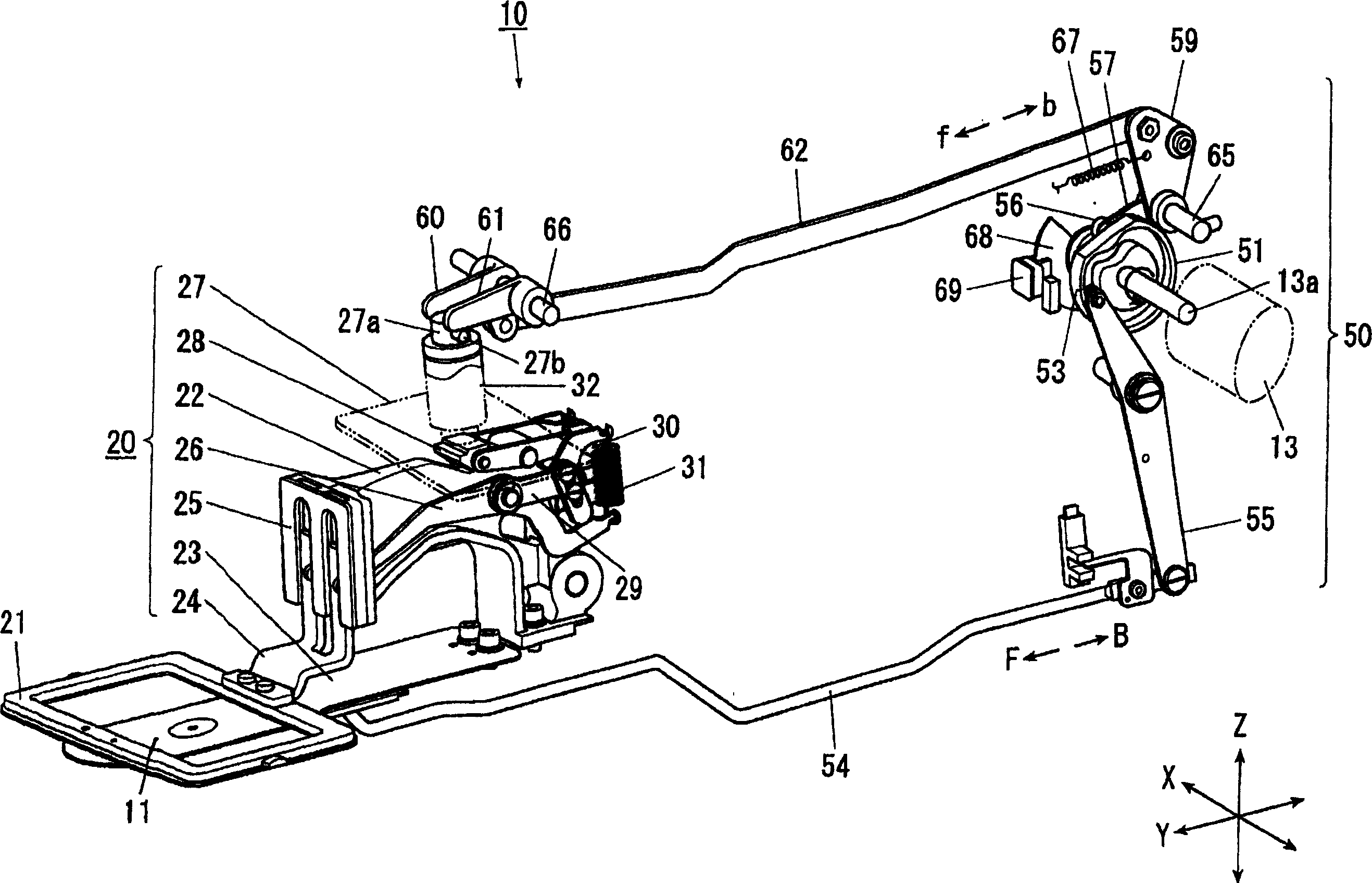

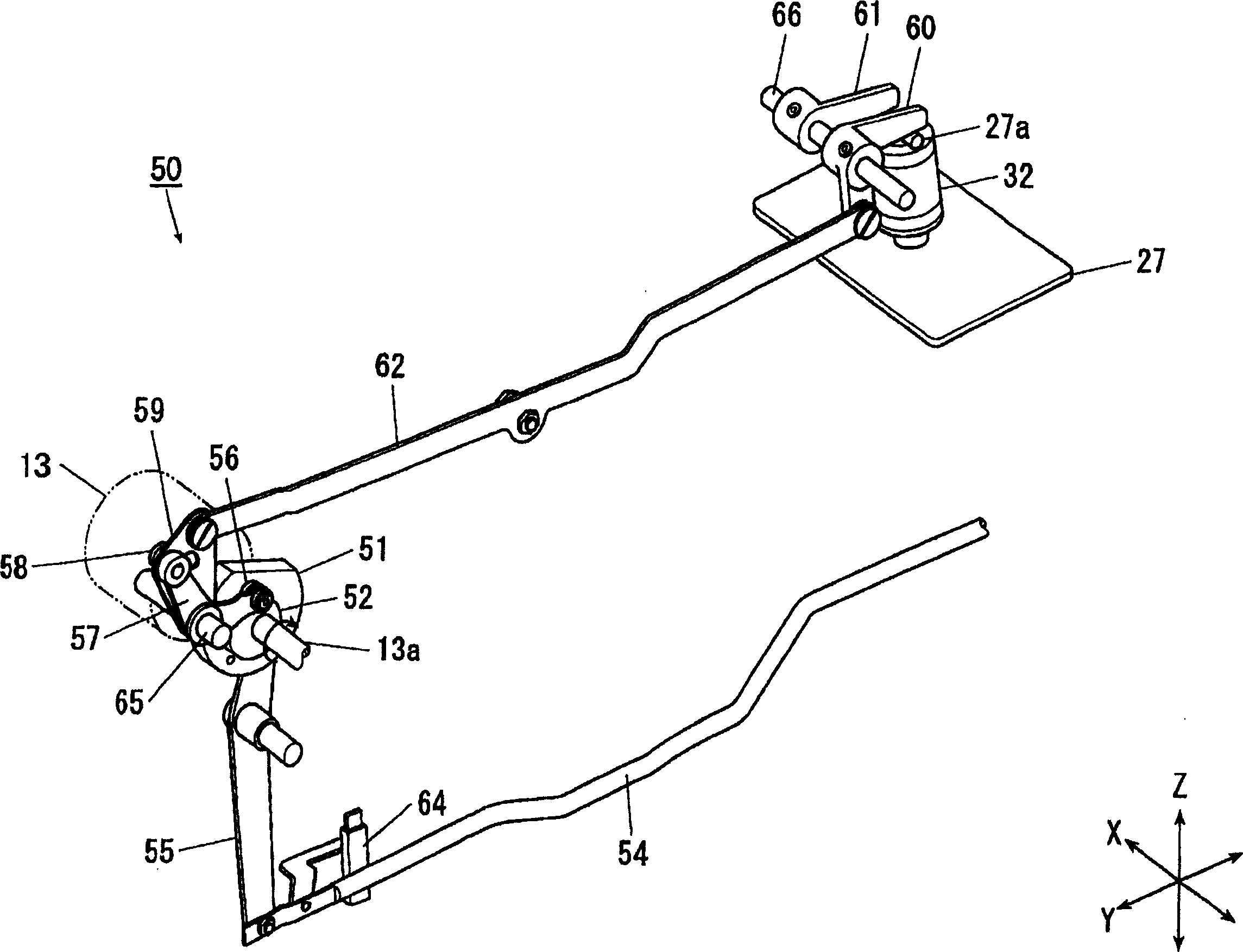

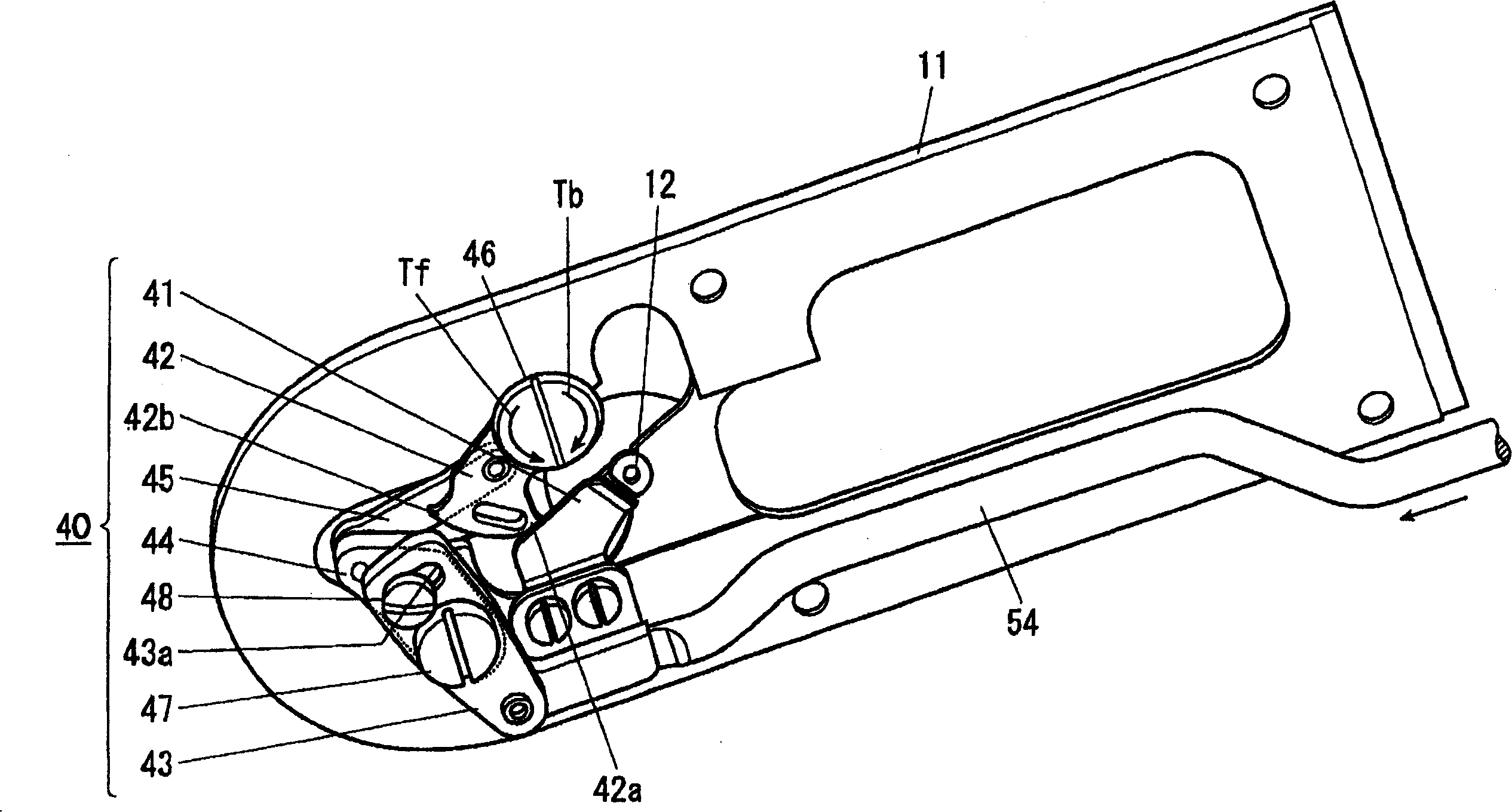

Sewing machine

InactiveCN1757812AAvoid burdenThe state that hinders the rotationWorkpiece carriersNeedle severing devicesTransmitterSewing machine

A seaming machine comprises a cloth press (20) capable of lifting up and down to support a press stand (21), a cutter (40) arranged under a needle plate (11) and provided with a fixed blade (41) and a movable blade (42), a step motor (13) as the drive source of the cloth press (20) and the cutter (40), and a power transmitter (50) for transmitting rotary drive force of the step motor (13) to each mechanism, wherein the power transmitter is provide with two rotary cams (51, 52) driven by the step motor, while the cams can transmit drive force on each mechanism. And an actuating quantity adjuster (59) is arranged between the cloth press and the rotary cams to adjust the driving quantity. The seaming machine can realize optimized rotation of step motor.

Owner:JUKI CORP

Automatic shirt under fly sewing machine

ActiveCN105177875ASolve the positioning problemSolving Sewing DifficultiesWorkpiece carriersWork-feeding meansSewing machineSurface plate

The invention relates to an automatic shirt under fly sewing machine which comprises a worktable and an edge folding mechanism. The edge folding mechanism comprises a table top plate, the table top plate is provided with a first low air suction area formed by multiple lower air suction through holes, a column of side air suction through holes is formed in the right side of the first low air suction area on the face plate, a cover plate capable of covering the side air suction through holes is arranged on the upper surface of the table top plate, grooves are formed in the lower surface of the cover plate, the groove openings of the grooves face the side air suction through holes and cover the side air suction through holes, one end of each groove extends to the edge of the cover plate close to the center of the table face plate, and a transverse cloth dragging device and a sewing machine head are further installed on the worktable. The automatic shirt under fly sewing machine is provided with the cover plate with the grooves formed in the lower surface on the table with the holes, so that lower air suction is changed into side air suction, the edge of a fabric is folded, and the fabric is erected at the position provided with the grooves at the edge position of the cover plate to form a folded edge.

Owner:中山市阿米达机电设备有限公司

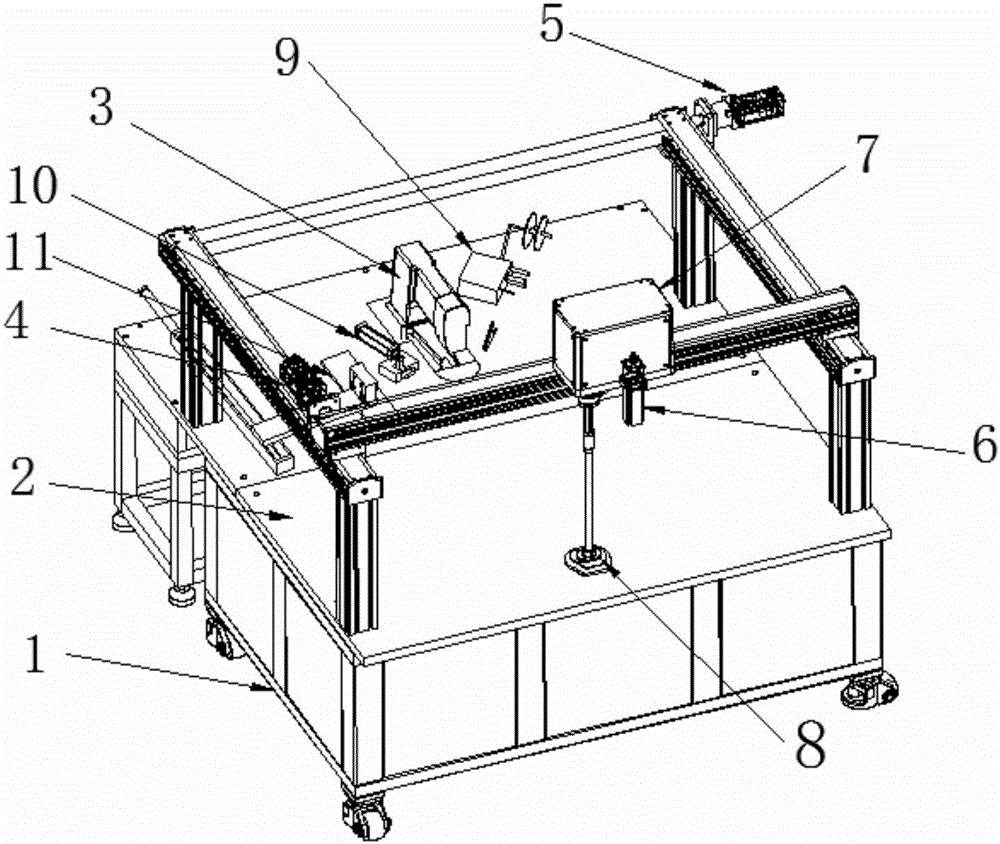

Automated production line for carpet flat seams

ActiveCN103015046ASimple structureGuaranteed uptimeWorkpiece carriersCombination sewing machinesProduction lineConveyor belt

The invention discloses an automated production line for carpet flat seams. The automated production line comprises a coiled carpet, a carpet feeding mechanism, a conveyor belt mechanism, and more than two automatic carpet flat seam stages, wherein the more than two automatic carpet flat seam stages are respectively arranged at two sides of the conveyor belt mechanism. The automated production line for carpet flat seams can automatically complete the technique processes of feeding of the coiled carpet, shearing into strips, automatic conveying, automatic capturing, shearing of residual corners of the carpet, automatic flat seam of straight lines and fillets of the carpet, and the like, multiple middle links on traditionally manually processing the flat seams of the carpet can be omitted, the fast and high-efficiency automatic streamlined production for carpet flat seams can be realized, the labor force can be liberated, and the production efficiency can be improved.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

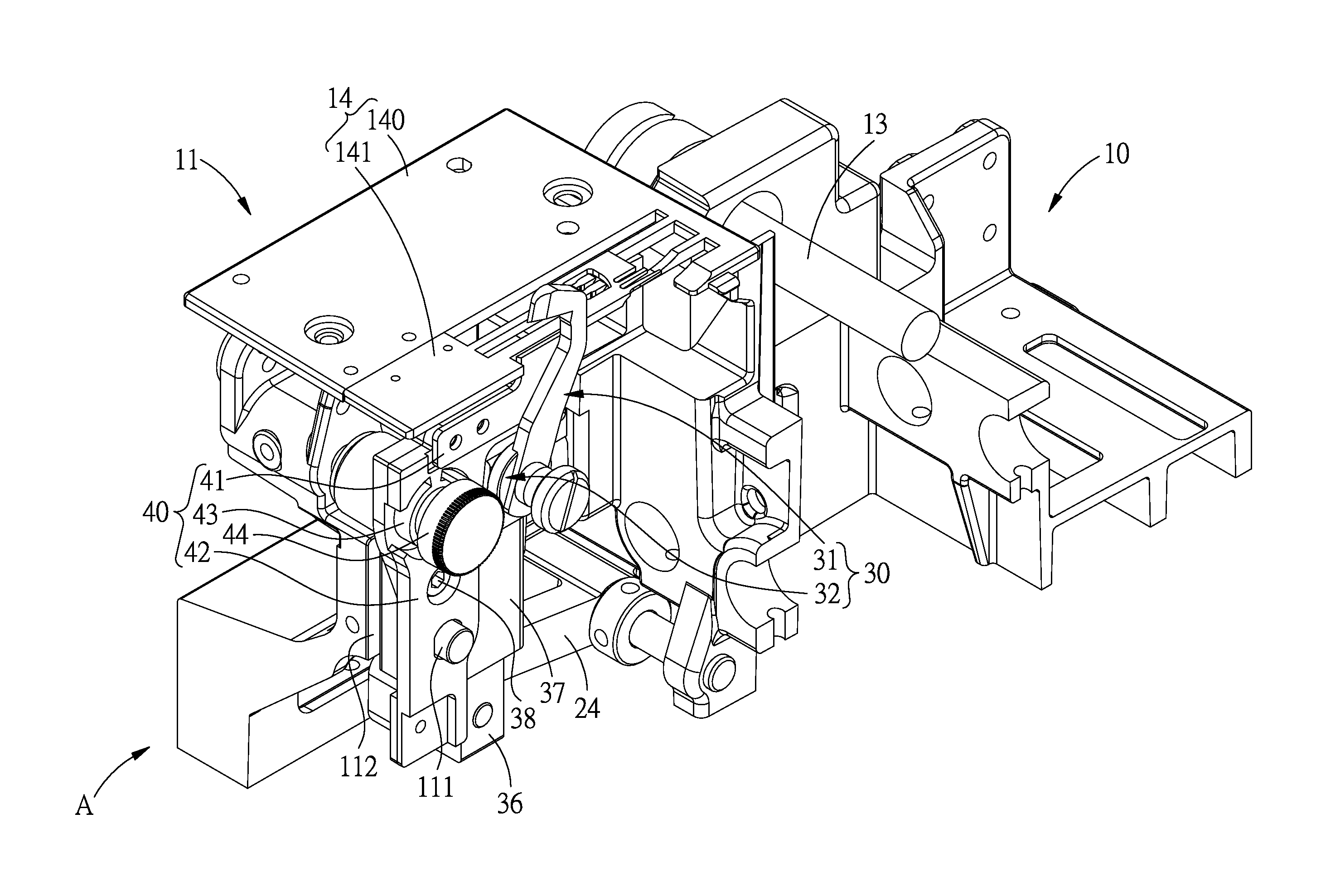

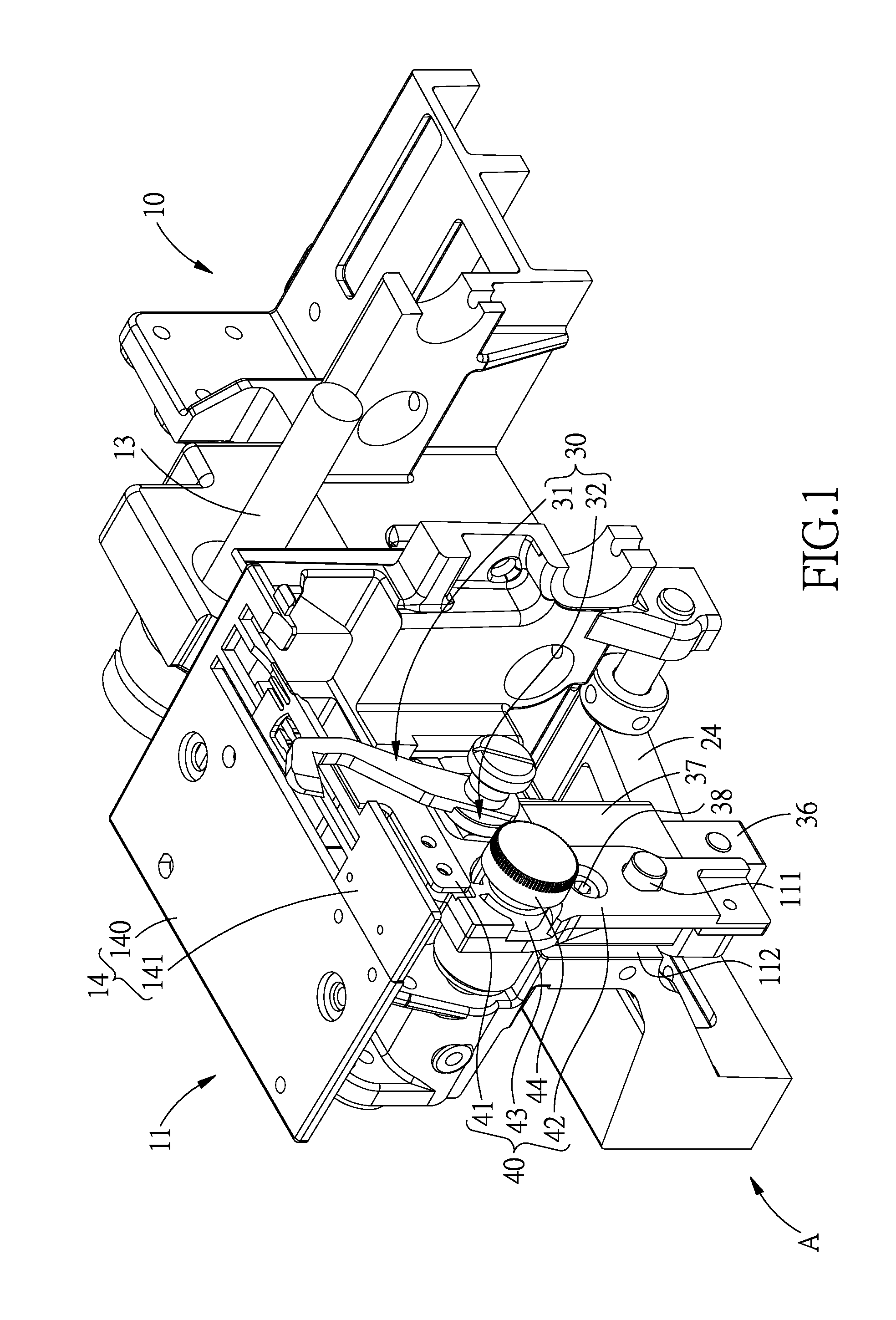

Cutting Device for a Sewing Machine

ActiveUS20140261122A1Low costPrecise positioningWorkpiece carriersNeedle severing devicesEngineeringKnife holder

A cutting device for a sewing machine includes an upper-blade positioning device and a lower-blade positioning device. The upper-blade positioning device includes an upper blade upper blade fixed at a head portion of the upper-blade holder, and a spring and a restricting member sleeved on a body portion of the upper-blade holder. A restricting pin is engaged between an upper-blade drive member and the restricting member. A guide member includes a guide hole for insertion of a rod portion of the upper-blade drive member and is fixed to the base. The upper-blade drive member is inserted through a guide member of the base and moved by a connecting rod. The lower-blade positioning device includes a lower-blade holder, an adjustment member. A lower-blade shaft has one end fixed to the base and another end extended out of the base, rotating the adjustment member can adjust the position of the lower-blade holder.

Owner:TSENG HSIEN CHANG

Apparatus and method for cutting sewn material in sewing machine

InactiveUS20070062427A1Easy to pullLow costWorkpiece carriersWork-feeding meansEngineeringKnife blades

A cutting apparatus which is comprised of a main body including a hook section for hooking thereon a sewn material, a fixed blade fixed to a predetermined position of the main body, a cutting blade that cuts the sewn material by moving toward the fixed blade, and a drive device that moves the main body between a predetermined retracted position that does not interferer with sewing operation and a predetermined cutting position for cutting the sewn material. In sewing the sewn material, the main body is held at the retracted position, and in cutting the sewn material, the main body is caused to move from the retracted position to the cutting position by the drive device. The hook section is provided in the main body and at such a position as to hook thereon the sewn material as the main body moves to the cutting position. In cutting the sewn material, the cutting blade moves toward the fixed blade in response to driving operation of the drive device. The cutting apparatus is disposed a predetermined distance away from the sewing position.

Owner:TOKAI IND SEWING MACH CO LTD

Abdominal cushion machine

PendingCN109763272ASimple structureEasy to operateWorkpiece carriersWork-feeding meansEngineeringSpot welding

The invention relates to an abdominal cushion machine. The machine comprises a feeding assembly, a fixed length cutting mechanism, an ultrasonic spot welding labeling mechanism, a folding assembly, afirst sewing assembly, a rotating table and a second sewing assembly which are sequentially distributed, wherein the feeding assembly is used for conveying a fabric forwards; the fixed length cuttingmechanism is used for cutting the fabric after the fabric is fixed in length; the ultrasonic spot welding labeling mechanism is used for sewing cotton labels and glue labels together to the fabric; the folding assembly is used for folding and turning the fabric; the first sewing assembly is used for sewing two side edges of the fabric and the middle of the two side edges; the rotating table is used for rotating the fabric by 90 degrees; the second sewing assembly is used for sewing the other two side edges of the fabric and the middle of the other two side edges. The abdominal cushion machineautomatically finishes fixed-length cutting of the fabric, the cotton labels and the glue labels are sewn on the fabric, first sewing, rotation and second sewing are performed, accordingly, productionof an abdominal cushion is completed automatically, a small number of workers are needed in the whole process, production cost is high, production efficiency is high, competitiveness of enterprises is improved, and development requirements of the market are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

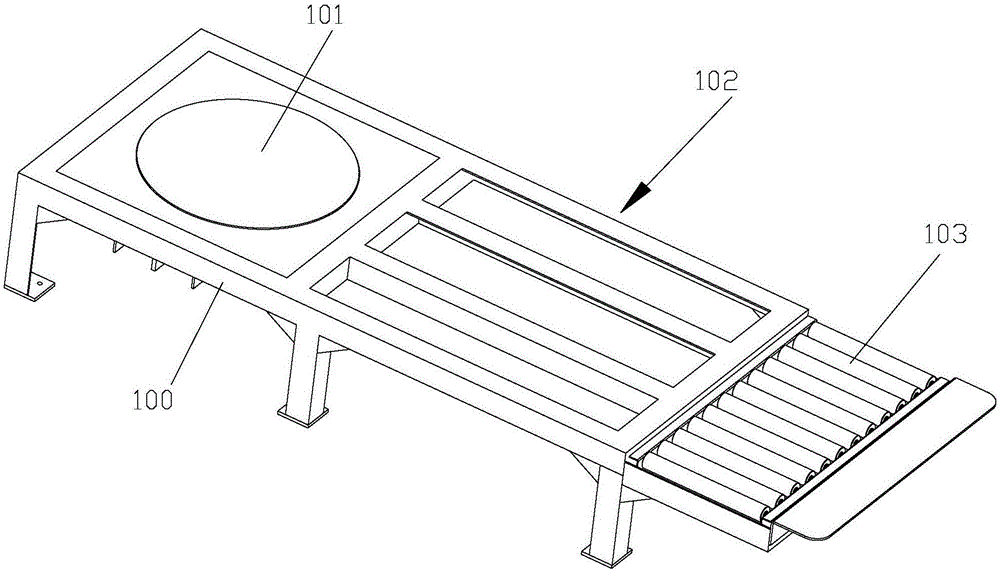

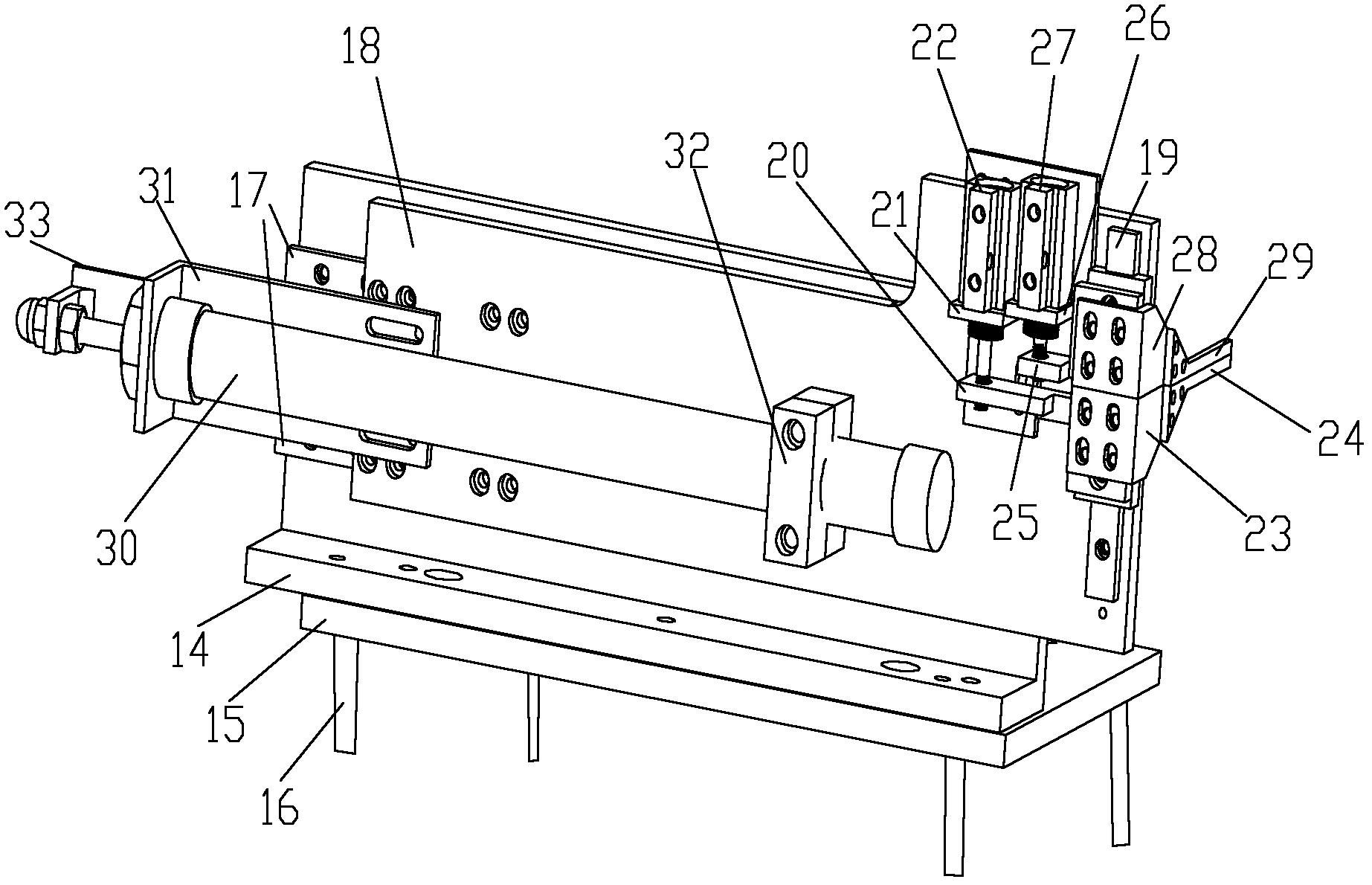

Improved towel machine

InactiveCN104611846AImprove processing efficiencyWorkpiece carriersWork-feeding meansEngineeringAutomation

The invention relates to an improved towel machine which comprises a first processing device and a second processing device. A feeding device, the first processing device and the second processing device are oppositely and fixedly arranged in sequence. The second processing device comprises a third machine table, a belt conveying mechanism, a pair of synchronous second rubber rollers, a cutting mechanism, a clamping mechanism, a mark folding and sending mechanism and a second double-needle machine. The belt conveying mechanism, the pair of synchronous second rubber rollers, the cutting mechanism, the clamping mechanism, the mark folding and sending mechanism and the second double-needle machine are fixed to the third machine table. The cutting mechanism is arranged between the synchronous second rubber rollers and the belt conveying mechanism. The clamping mechanism is fixedly hung above the belt conveying mechanism and clamps cloth to the belt conveying mechanism. The discharging outlet of the belt conveying mechanism is fixedly provided with the second double-needle machine. The mark folding and sending mechanism is fixedly arranged on one side of the belt conveying mechanism and located between the synchronous second rubber rollers and the double-needle machine. The improved towel machine produces towels through mechanical automation instead of manual operation, the labor intensity of workers is lowered, and the processing efficiency of the improved towel machine is effectively improved.

Owner:SUZHOU JUKANG SEWING ROBOT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com