Full-automatic elastic band seamer

A technology of elastic bands and seaming machines, which is applied to sewing machine components, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of high cost, and achieve the effects of low manufacturing cost, compact structure, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

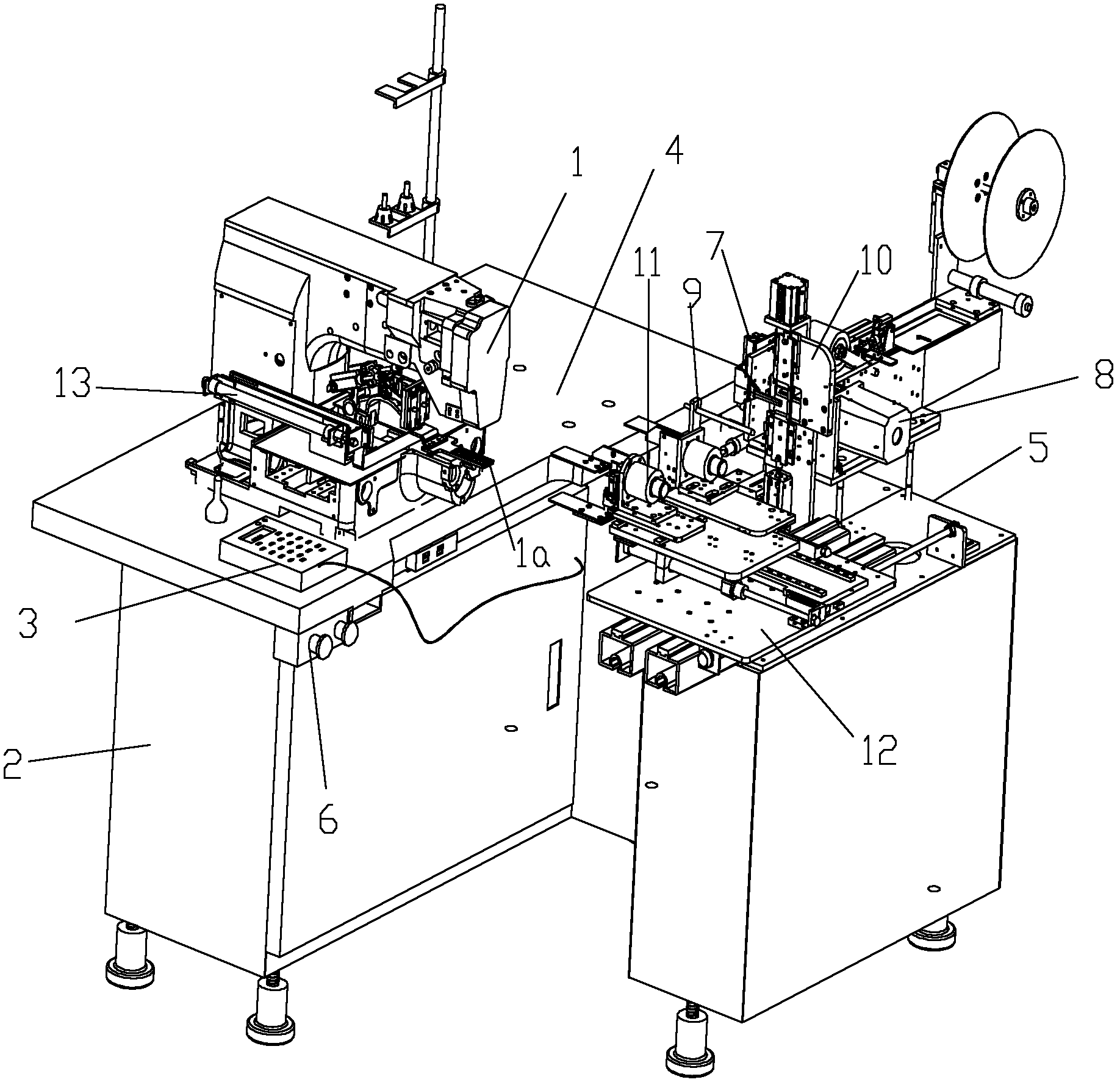

[0019] see figure 1 , the automatic elastic band seaming machine of the present invention comprises machine head 1, frame 2, the first belt feeding mechanism 7, the second belt feeding mechanism 8, supporting material balance mechanism 9, automatic shearing mechanism 10, connecting belt rotating mechanism 11, Automatic feeding transmission mechanism 12, automatic blanking mechanism 13, machine head 1 is a computer pattern machine head, is provided with an upper pressing plate 1a above the machine head 1, and machine head 1 is positioned at the rear portion left position of frame 2, by The electronic control panel 3 can be programmed to automatically sew various curved lines. Its structure and performance are consistent with the existing pattern machines, and will not be described in detail; the frame 2 is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com