Feeding device for automatic band nailing machine

A technology of feeding device and nail loop machine, which is applied in the direction of sewing machine control device, cloth feeding mechanism, sewing machine components, etc., and can solve the problems that work efficiency needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

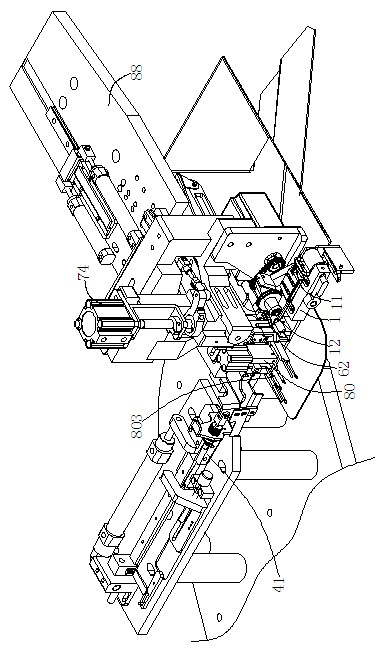

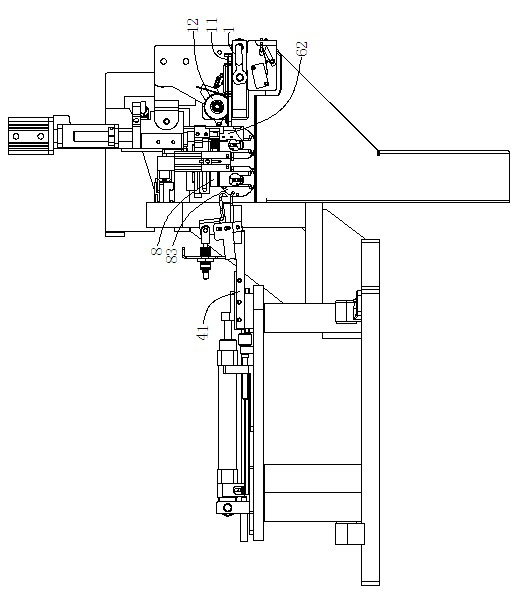

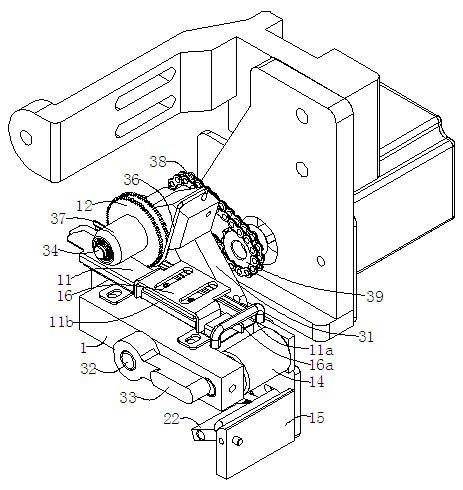

[0033] Figure 1 to Figure 16 Shown is the structural representation of the present invention.

[0034] Wherein the reference numerals are: feeding table 1, feeding chute 11, first baffle plate 11a, mounting table 11b, feeding gear 12, first wheel body 12a, second wheel body 12b, feeding roller 14, feeding back plate 15 , adjustment plate 16, second baffle plate 16a, detection sensor 21, induction plate 22, first pin shaft 23, return spring 24, induction gap 25, induction contact sheet 26, support arm 31, rotating shaft 32, adjustment arm 33, drive Shaft 34, driving wheel 35, feeding rod 36, one-way bearing 37, chain 38, motor wheel 39, installation platform 4, fixing bolt 4a, fixing frame 40, adjusting bolt 40a, clamping arm 41, slide rail assembly 42, detection Rod 43, first sensor 44, second sensor 45, limit block 46, first stopper 47, sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com