Patents

Literature

117 results about "Paper adhesive tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface mountable delivery device

InactiveUS20110111000A1Increased internal surface areaSettlement inhibitionBiocideHydroxy compound active ingredientsSOCKSEngineering

There is described a surface mountable delivery device which has a multi layer construction comprising a liquid permeable support layer adjacent to a porous reservoir layer, the porous reservoir layer being provided with a backing layer. The surface mountable delivery device may comprise of stickers, tapes, pads, tubes, socks, etc.

Owner:SURFACESKINS

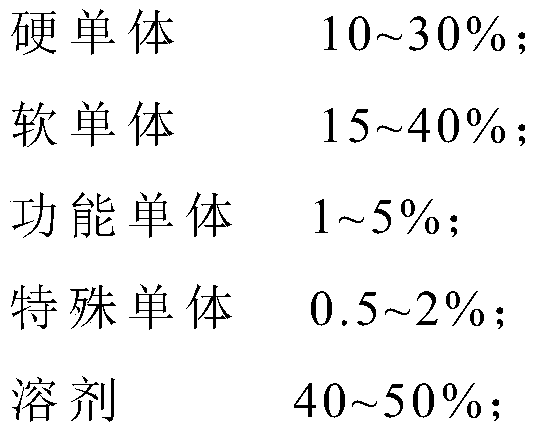

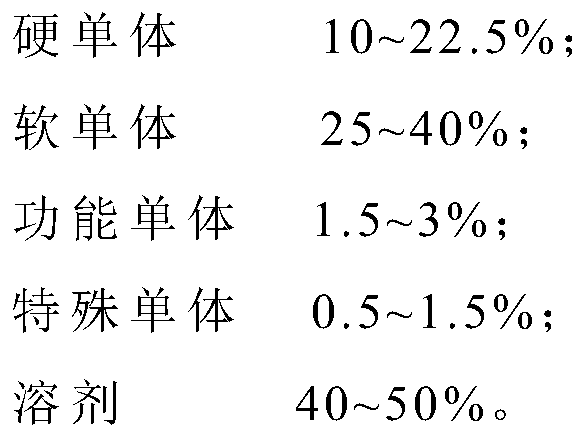

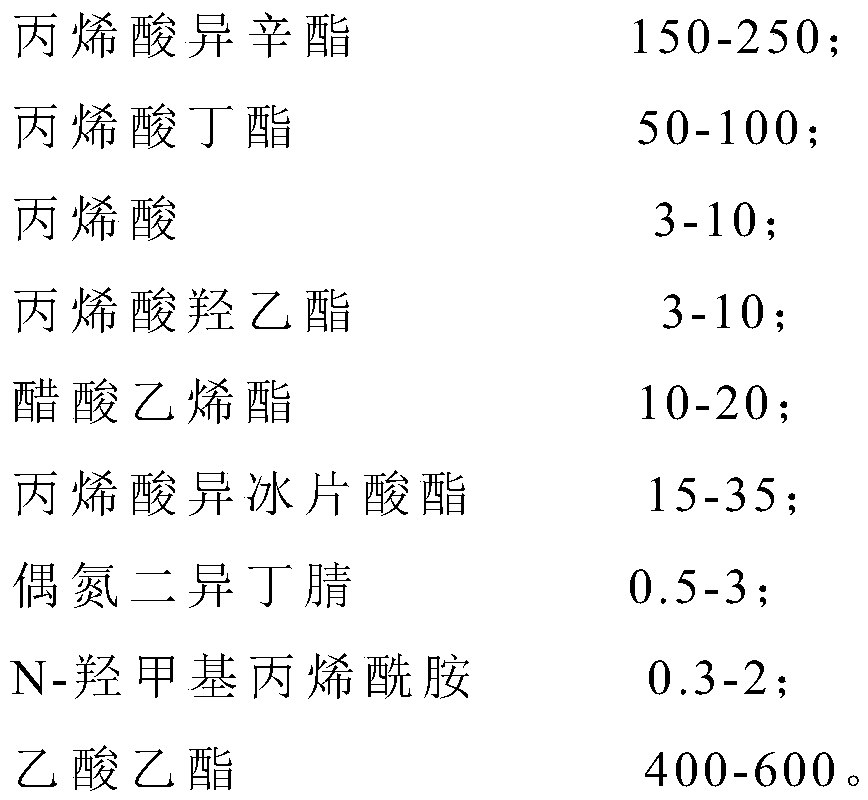

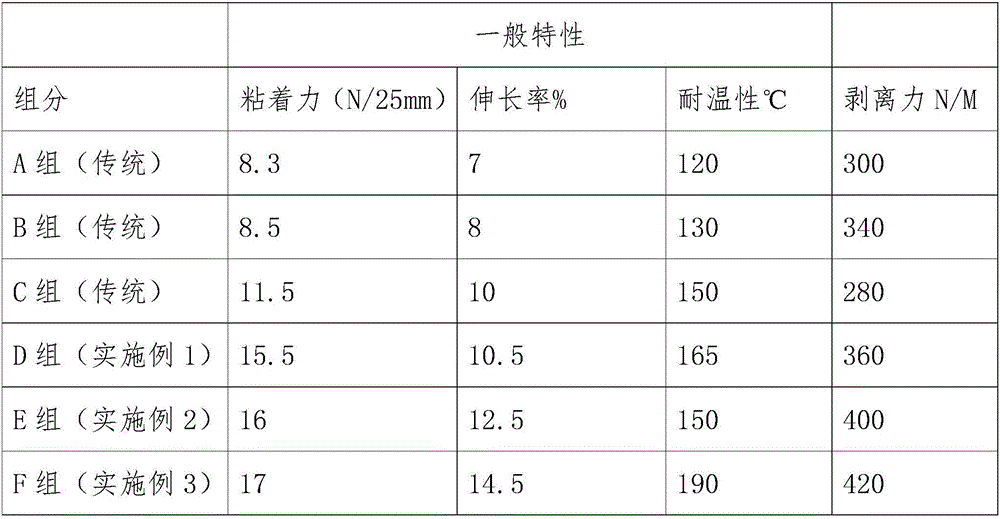

Polyacrylate, pressure-sensitive adhesive and preparation method

ActiveCN109762097AThe polymerization process is simpleHigh temperature resistance and good adhesionEster polymer adhesivesPressure sensitive film/foil adhesivesIsooctyl acrylateGlycidyl methacrylate

The invention relates to polyacrylate. Polyacrylate is synthesized from raw materials in percentage by mass as follows: 10%-30% of a hard monomer, 15%-40% of a soft monomer, 1%-5% of a functional monomer, 0.5%-2% of a special monomer and 40%-50% of a solvent, wherein the hard monomer comprises one or more of methyl acrylate, methyl methacrylate, vinyl acetate, acrylonitrile and isobornyl methacrylate; the soft monomer comprises one or more of ethyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate and n-propyl acrylate; the functional monomer comprises one or more of hydroxyethyl acrylate, acrylic acid, methacrylic acid, hydroxypropyl acrylate and 2-hydroxyethyl methacrylate; the special monomer comprises one or more of methacrylamido ethyl ethylene urea, hydroxyethyl methacrylate phosphate and glycidyl methacrylate. A pressure-sensitive adhesive has good high-temperature-resistant adhesive property, does no squeeze out, has no residue, has low cost and can be applied to masking tapesused in capacitor taping in the electronics industry as well as certain high-temperature-resistant adhesive tapes.

Owner:CYBRID TECHNOLOGIES INC

Method for rapidly propagating apocarya good variety seedlings

ActiveCN103988715AThe time to cultivate strong seedlings is shortenedLow costHorticultureRootstockPaper adhesive tape

The invention discloses a method for rapidly propagating apocarya good variety seedlings. The method comprises the steps of (1) germination acceleration; (2) grafting, wherein a scalpel is utilized for cutting off the upper portion of the position, 4cm away from seedling grains, of the bud seedlings, the cut is cut open downwards from the middle, a branch of an apocarya good variety is selected, cut into a thin wedge shape, and inserted into the kerf of the stock, one side of the branch is flush with the edge of the stock, a piece of medical paper adhesive tape is used for tight adhesion, and after being physically and completely cured, the bud seedlings are transplanted into a black polypropylene plastic nutrition bowl; (3) management after grafting. Compared with other methods for cultivating the apocarya seedlings, the method has the advantages that more than 90% of cultivated seedlings in the current year are strong, the strong seedling cultivation time is shortened by one to two years, the cost is saved, and the method has the great significance in strong seedling rapid cultivation of apocarya.

Owner:南京绿宙薄壳山核桃科技有限公司 +1

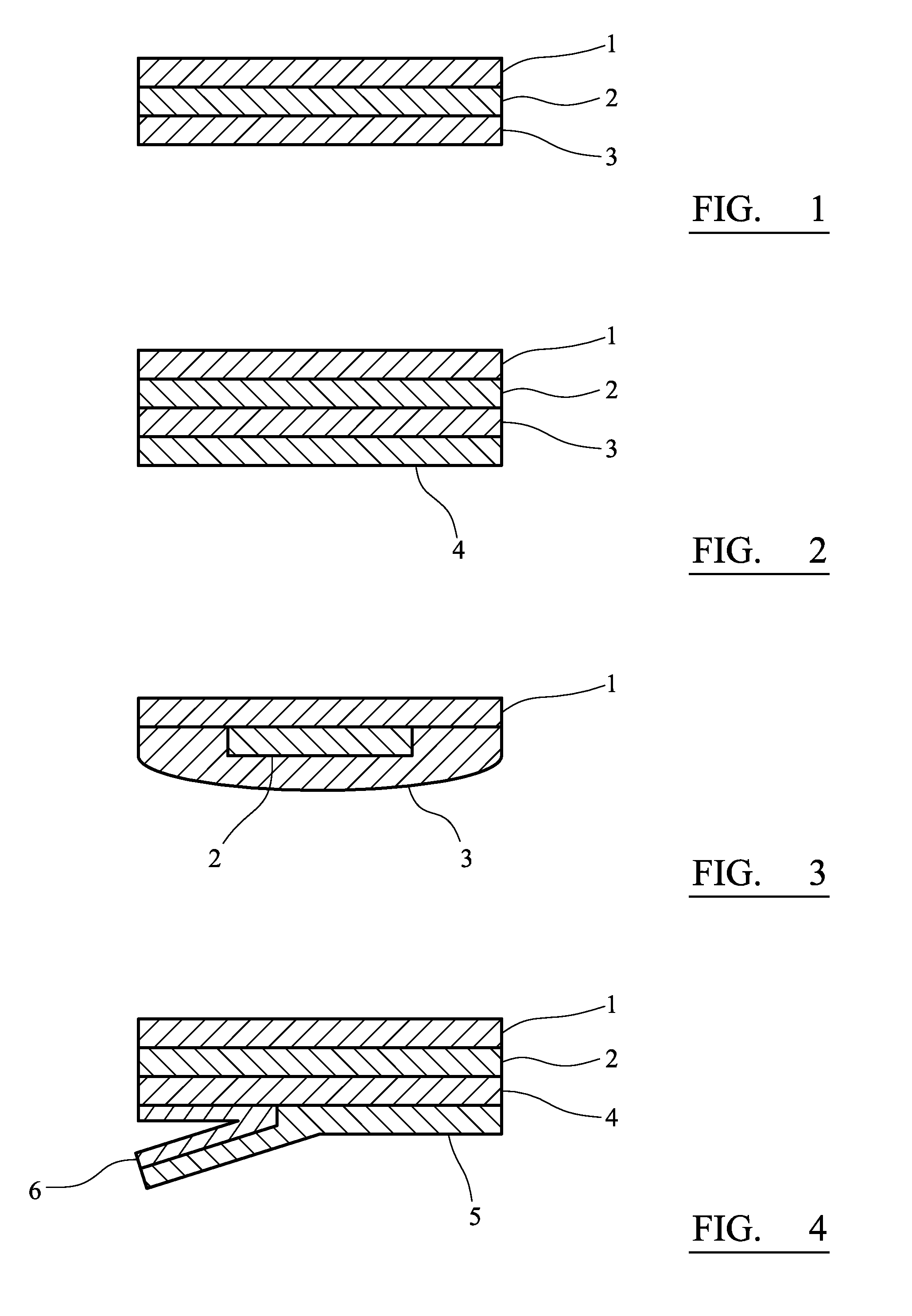

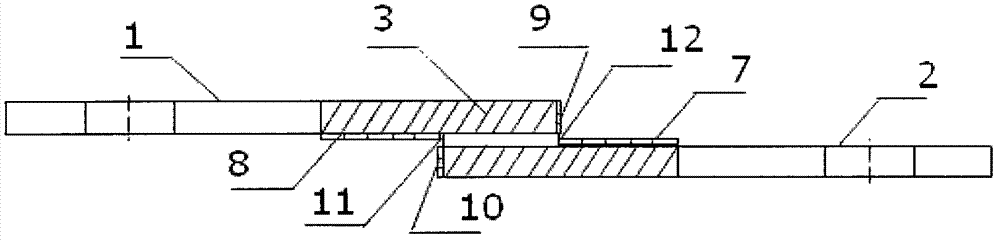

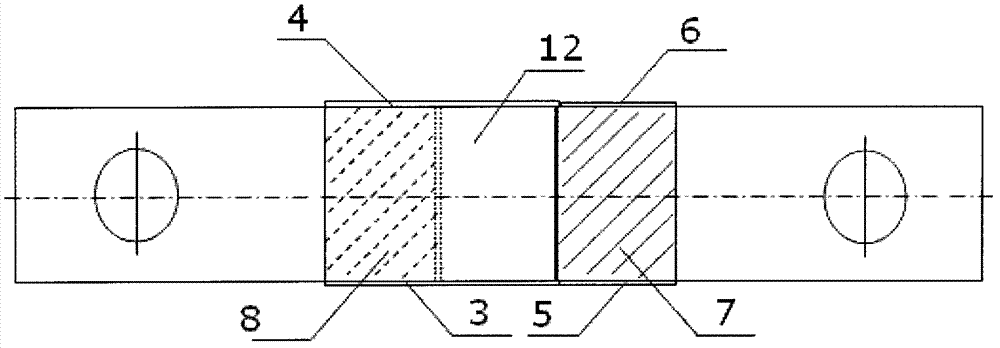

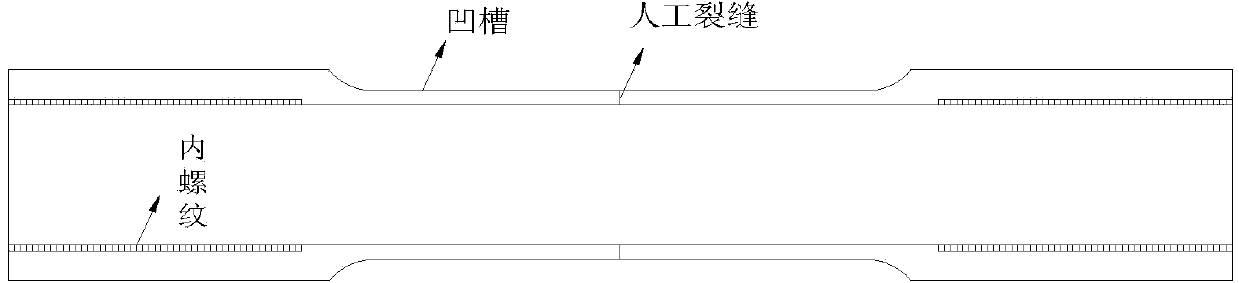

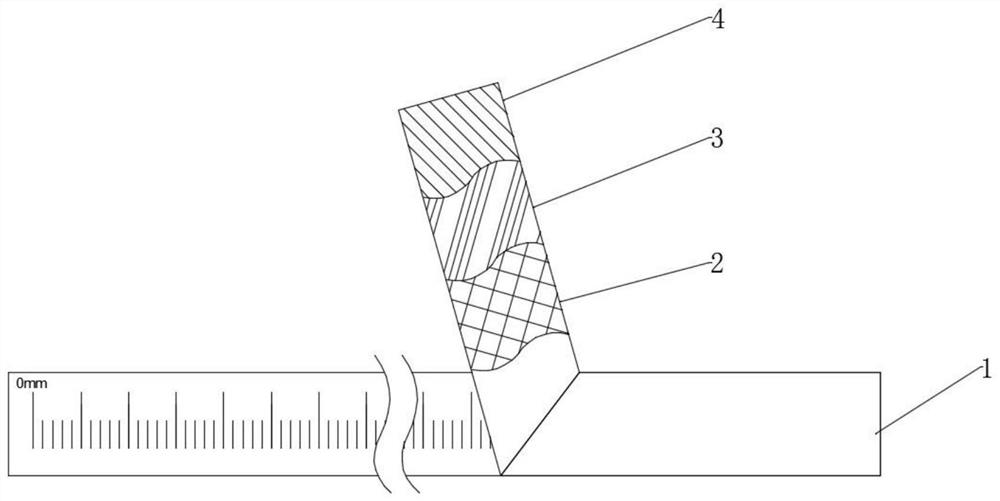

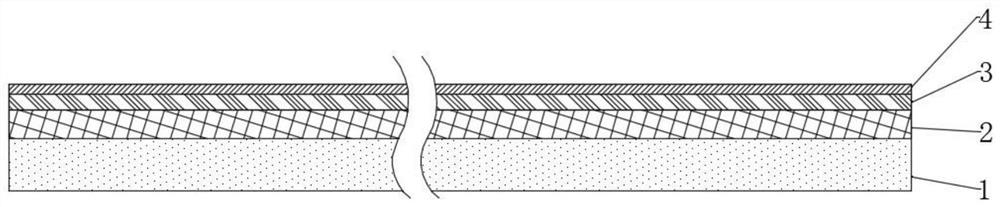

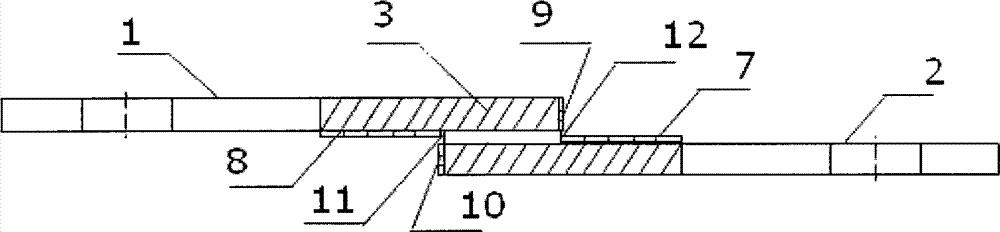

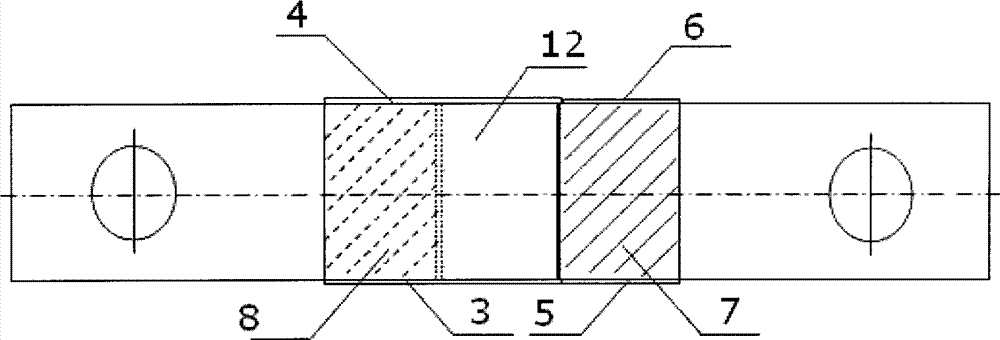

Heat-resistant coating tensile shear strength test model and production method thereof

ActiveCN102954910AGuaranteed thicknessGuaranteed compactnessPreparing sample for investigationStrength propertiesFiberPaper adhesive tape

The invention discloses a heat-resistant coating tensile shear strength test model which comprises an upper sheet metal, a lower sheet metal, an intermediate adhesive layer, fiber cloth in the adhesive layer and paper adhesive tapes pasting around tensile shear adhesive surfaces of the sheet metals. A production method provided by the invention comprises adding the fiber cloth into the adhesive layer, thereby effectively controlling thickness and uniformity of the adhesive layer; and is added with a process of pasting paper adhesive tapes around the tensile shear adhesive surfaces, thereby reducing influences of irregular glue-spilling on test results, and improving stability of the test results.

Owner:CASIC DEFENSE TECH RES & TEST CENT

High-temperature-resistant insulating paper adhesive tape

InactiveCN103642413AImprove insulation performanceImprove high temperature resistanceFilm/foil adhesivesEpoxy resin adhesivesEpoxyNomex

The invention discloses a high-temperature-resistant insulating paper adhesive tape including a substrate and an adhesive layer. The substrate is NOMEX insulating paper or TFT composite insulating paper; the adhesive layer is a coating layer of a mixed adhesion liquid of an organosilicone adhesion agent and an epoxy resin adhesion agent, and the mixing ratio of the organosilicone adhesion agent to the epoxy resin adhesion agent is 1:3-5. Through selection of the substrate and the adhesion agents, the adhesive tape is endowed with excellent insulating property, high temperature resistant property and bonding property, can meet the using requirements of an oil type transformer, adapts to new insulation technology, and has a broad application prospect.

Owner:KUNSHAN HANBAO TAPE TECH

Production process of Japanese paper adhesive tape base paper

The invention relates to a production process of Japanese paper adhesive tape base paper. The production process includes steps: a pure wood pulp is subjected to defibering and pulping to obtain size with concentration to be 3.5-4.0% and beating degree to be 18-20 oSR; b polyester chemical fibers are subjected to defibering and mixed with the size obtained from the step a to obtain mixed size with concentration to be 2-2.5%, wherein the filling quantity of polyester chemical fibers is 2-3% of the total mass of the mixed size; c wet strength agents and polyethylene oxide are filled into the mixed size and evenly mixed, then a net portion is formed through inclined wire papermaking, and after squeezing for dehydration, drying in a vat, reeling and rewinding slitting, a piece of papermaking base paper is obtained; and d the base paper is soaked by aid of a coating machine and then is coated with adhesives, the gluing amount is controlled to be in a 10-12g / m<2> range, and after drying, reeling and slitting rewinding, the Japanese paper adhesive tape base paper is obtained. The Japanese paper adhesive tape base paper is soft, high in longitudinal tensile strength and good in water seepage resistance and high temperature ageing resistance.

Owner:杭州新兴纸业有限公司

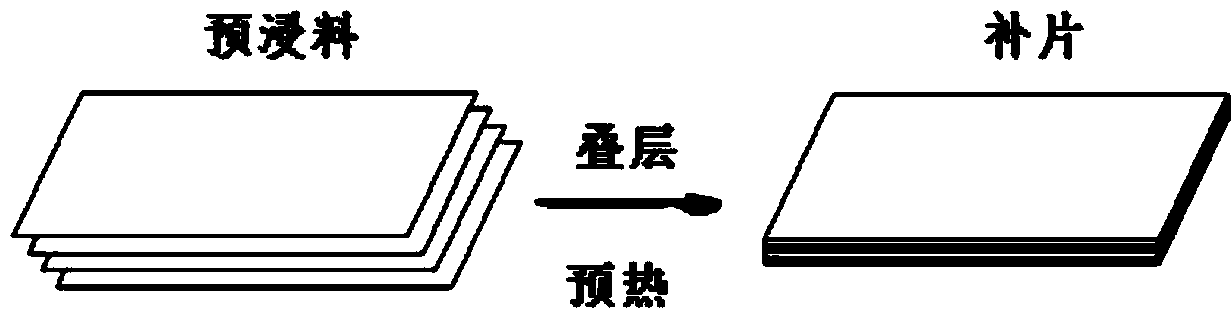

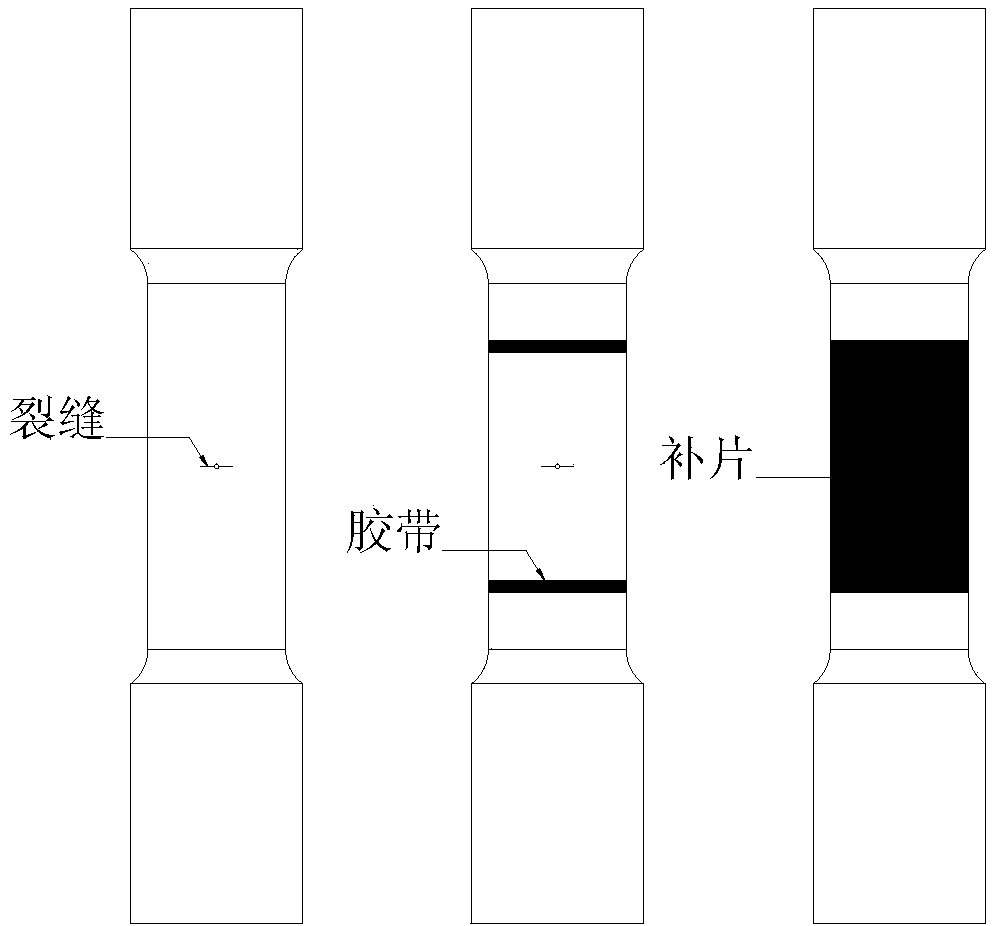

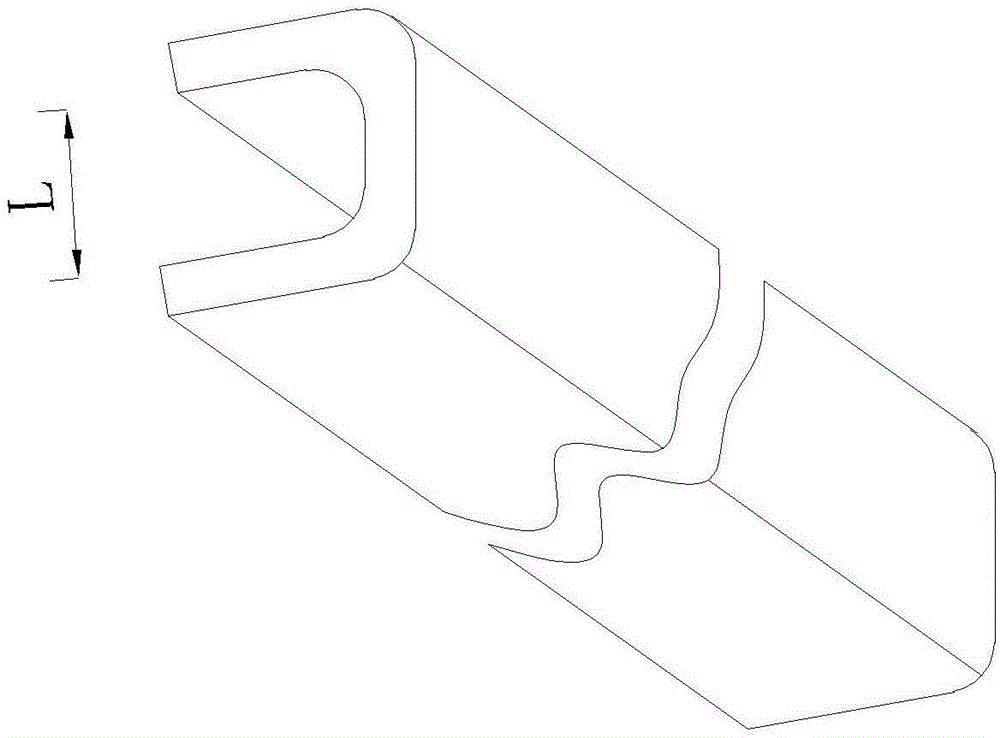

Vamp wrapping process for carbon fiber prepreg repaired aluminum alloy crack pipe

The invention discloses a vamp wrapping process for a carbon fiber prepreg repaired aluminum alloy crack pipe. The process comprises the following steps of symmetrically adhering adhesive tapes to the two ends of a crack of the aluminum alloy pipe by taking the crack of the aluminum alloy pipe as a symmetry point, wherein the space between the inner sides of the two adhesive tapes is the length of a vamp; uniformly smearing epoxy resin glue between the two adhesive tapes; cutting prepreg into rectangles, laminating the rectangles, preheating the prepreg for 10 to 15min to form the vamp at 30 to 40 DEG C, and winding the vamp between the two adhesive tapes, wherein the overlapping length is 1mm; winding a paper self-adhesive tape on the surface of the wrapped vamp for two circles, and performing heating curing. Compared with the prior art, the process has the significant advantages that (1) the bearing capacity of a pipe fitting repaired by the vamp wrapping process is improved and stabilized; (2) the phenomenon of cracking of the prepreg in a winding process can be effectively avoided.

Owner:PLA UNIV OF SCI & TECH

Repair method for aluminum coating of composite material

InactiveCN106011719AEffective recoveryAvoid damageMolten spray coatingPaper adhesive tapePre treatment

The invention relates to a repair method for an aluminum coating of a composite material. The repair method includes the following steps that firstly, a damaged position is ground, wherein the aluminum coating damaged area on the surface of the composition material is confirmed, and the aluminum coating damaged area is subjected to grinding pretreatment through abrasive paper; secondly, a repair area is designated, wherein the portion beyond the repair area is covered with paper adhesive tape and craft paper; thirdly, repairing is performed, wherein an aluminum coating is sprayed to a to-be-repaired area through a spraying device; fourthly, coating detection is performed, wherein the repaired aluminum coating is subjected to resistance measurement through a spray aluminum coating resistance detector; and fifthly, within 24 hours of repairing of the aluminum coating, a layer of epoxy hole sealing agent is sprayed on the repair area. The repair method is easy to operate, consumable items in use are cheap and easy to obtain, the damaged spray aluminum coating can be effectively restored, operation can be performed indoors, and the defects in the method of the prior art are overcome. Because local repairing is adopted, compared with overall spraying in the prior art, damage to a composite material base body is relieved as much as possible, and the repair quality is guaranteed.

Owner:国营芜湖机械厂

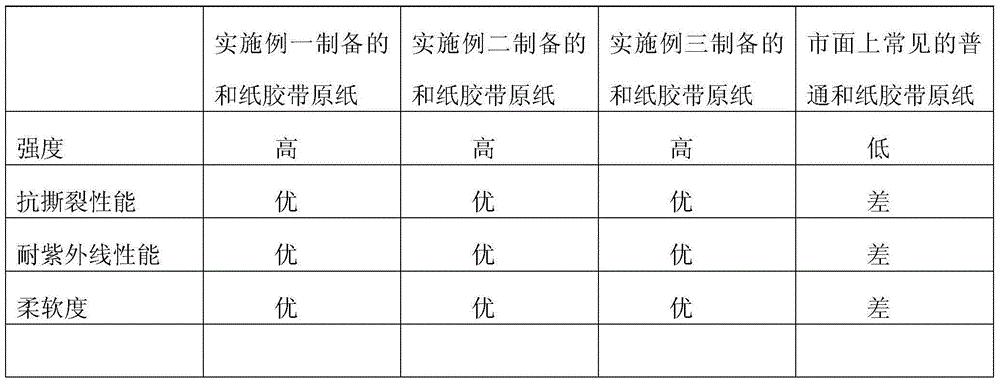

Body paper of washi adhesive tape and production method for body paper

ActiveCN105155329AExtended service lifeImproves UV resistanceVegetable material additionPaper coatingFiberUltraviolet

The invention relates to body paper of a washi adhesive tape. By taking long fiber wood pulp, short fiber chemical and mechanical pulp, a wet strength agent, coating latex and a golden cypress extraction solution as raw materials, the body paper of the washi adhesive tape is prepared by the steps of pulping treatment, addition of auxiliaries, supercooling treatment, papermaking treatment, coating treatment and paper forming. The body paper provided by the invention has the beneficial effects that the body paper has good dry and wet strength and delamination resisting strength, and good tear resistance, can satisfy the strength demands in subsequent processing and actual use, is not layered, and has good flexibility; the body paper has good water resistance and solvent resistance and excellent ultraviolet resistance and temperature resistance, and can be used for reducing aging of the washi adhesive tape and prolonging the service life of washi adhesive tape; the body paper has good surface smoothness, so that production and processing of the adhesive tape are facilitated.

Owner:ZHEJIANG HUITONG ADVANCED MATERIALS CO LTD

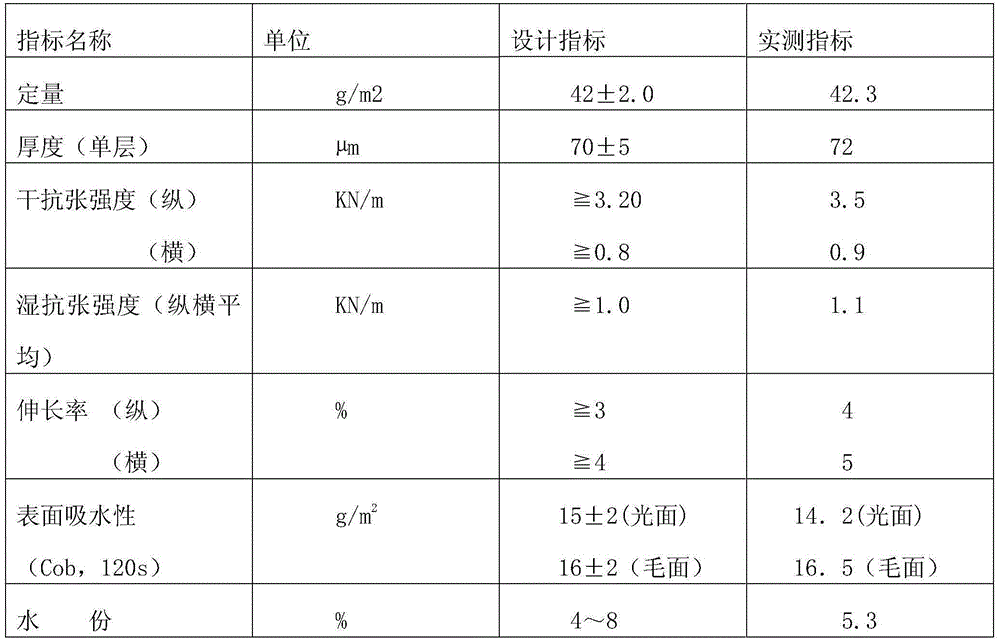

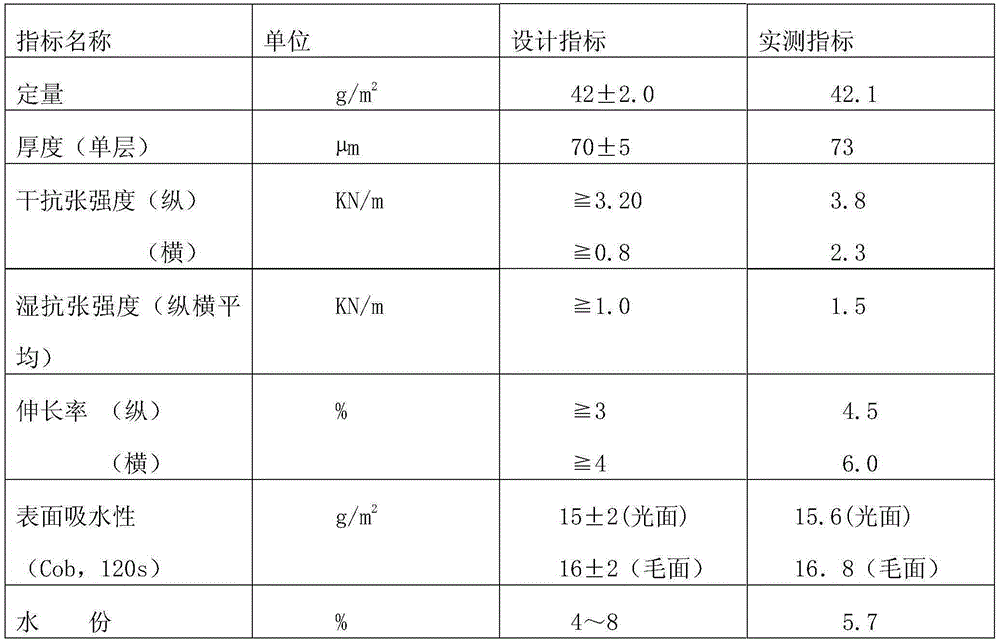

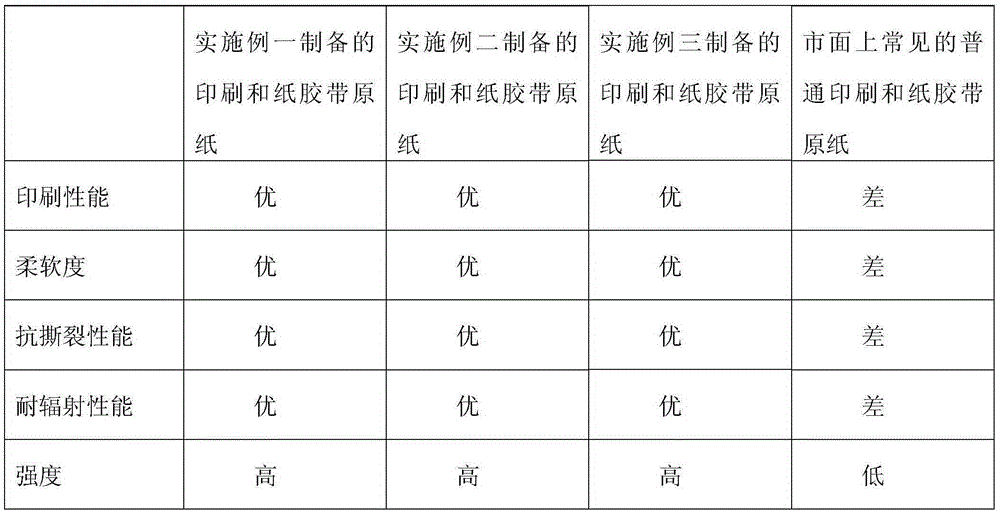

Raw paper for printing Japanese paper adhesive tape and production method of same

ActiveCN105239447AGood surface smoothnessImprove toughnessPaper coatingReinforcing agents additionFiberPaper adhesive tape

Raw paper for printing Japanese paper adhesive tapes is prepared from following raw materials: long-fiber wood pulp, short-fiber chemical mechanical wood pulp, bamboo pulp, a filling material, a wet-strength agent, coating latex and an extract liquid of cactus. The raw paper is prepared through the steps of performing pulping treatment, adding additives to the pulp, supercooling the pulp, performing papermaking, coating the paper, drying the paper and performing press polish and cutting to obtain the raw paper. The raw paper for printing Japanese paper adhesive tapes has excellent surface flatness, high printing clearness, good printing effect, excellent softness, excellent dry and wet strengths, excellent delamination resistance strength and anti-tear performance, excellent water- and solvent-resistant performances and excellent anti-radiation performance and temperature resistance. The method can reduce aging in the raw paper for printing Japanese paper adhesive tapes and prolonging the service life of the raw paper for printing Japanese paper adhesive tapes.

Owner:ZHEJIANG HUITONG ADVANCED MATERIALS CO LTD

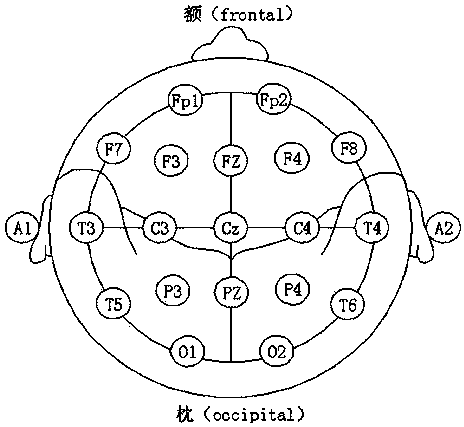

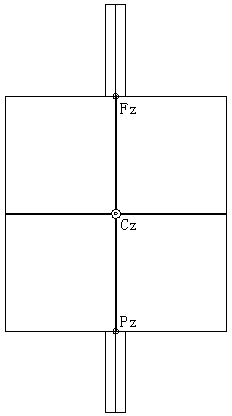

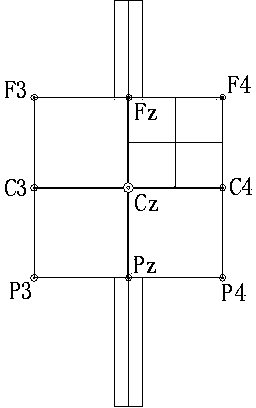

Square paper type electrode positioning method for newborn baby

InactiveCN103989473AEasy to operateShorten the timeDiagnostic recording/measuringSensorsNasionPaper adhesive tape

The invention discloses a square paper type electrode positioning method for a newborn baby. The method comprises the steps that firstly, medical paper adhesive tape passes through the center of the top of the head from the nasion portion and adheres to the external occipital protuberance portion, the length of the adhesive tape is measured, and a central point is drawn and serves as a Cz central point; according to the length of the adhesive tape, 40% of the adhesive tape is taken to form square adhesive tape by cutting and the central angle of the square adhesive tape is cut off after the square adhesive tape is folded in half; a cross is drawn and passes through the central point; the adhesive tape passes through the middle of the top of the head from the nasion portion again and adheres to the occipital bone portion; the center of the square adhesive tape is aligned with the central point drawn on the adhesive tape, the angles of the two ends of the cross are an Fz electrode position and a Pz electrode position respectively, and the four corners of the square adhesive tape are an F3 electrode position, an F4 electrode position, a P3 electrode position and a P4 electrode position respectively. The method is simple in operation and capable of saving time and being implemented by all medical staff; the number of steps is small, errors are reduced, and electrode positioning is accurate; the method is suitable for newborn babies with various diseases, accords with the international 10-20 positioning method, enables the electrode positions to be obtained by measurement and effectively solves the problem that electrode positioning of the newborn baby is difficult.

Owner:薛莹

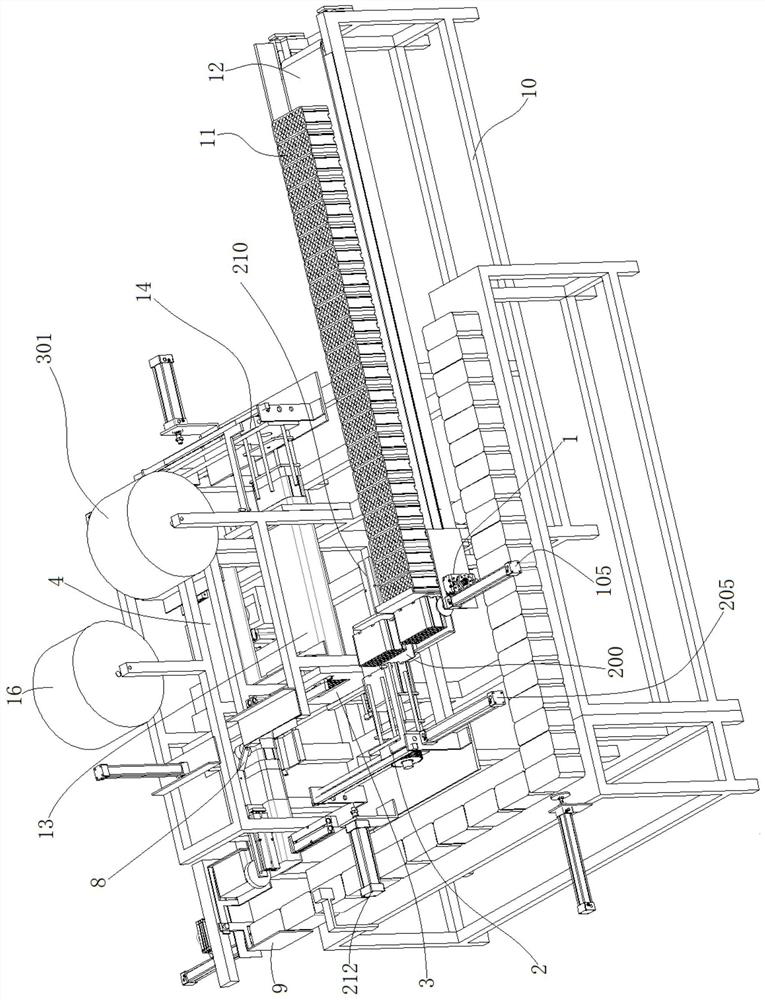

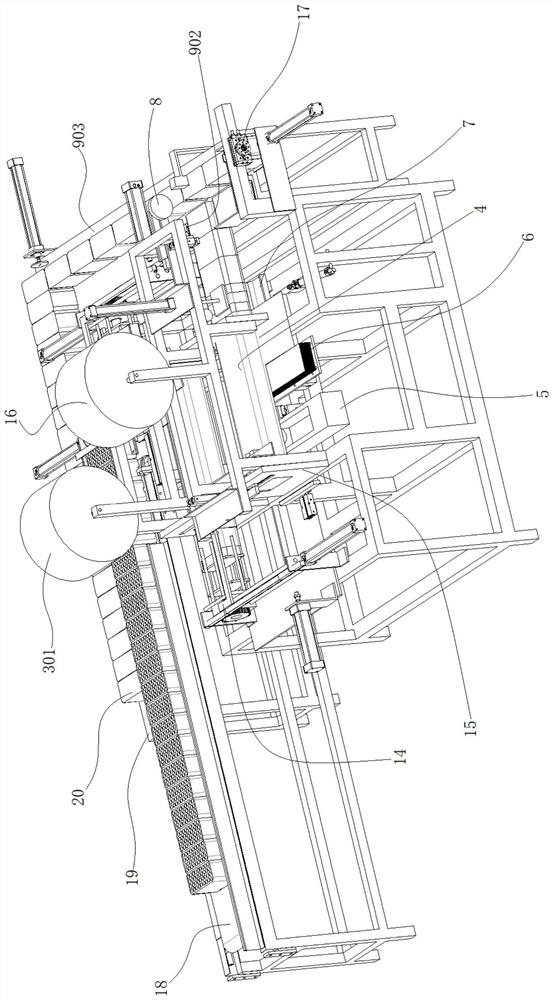

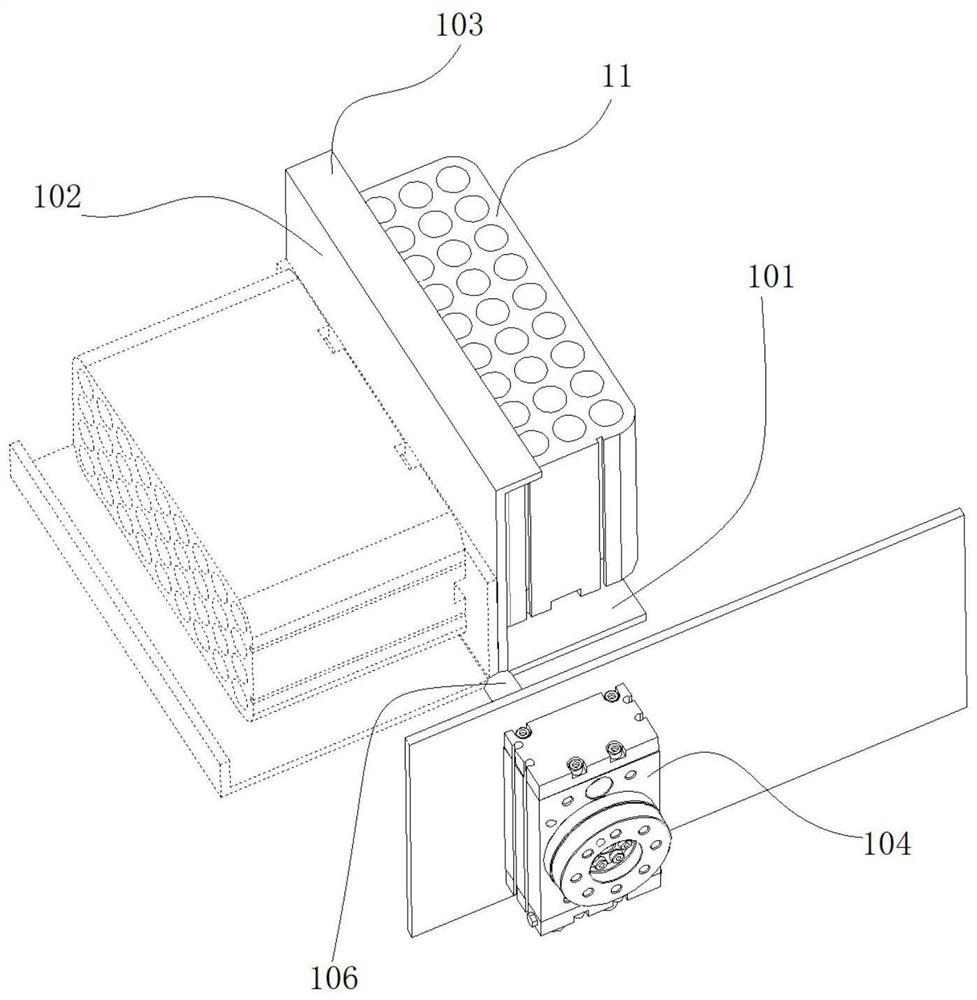

Tunnel type combined firework packaging paper wrapping device

ActiveCN113734518AAchieve solidificationFast, efficient and stable edge bandingWrapping material feeding apparatusWrappingAdhesive beltPaper adhesive tape

The invention discloses a tunnel type combined firework packaging paper wrapping device. The device comprises a machine frame and a feeding conveying belt for combined fireworks, and further comprises a posture conversion mechanism, a first rotary gluing mechanism, a first paper feeding mechanism, a first tunnel, a second rotary gluing mechanism, a second paper feeding mechanism, a second tunnel, an enclosure packaging paper gluing mechanism, an enclosure packaging paper feeding mechanism, an enclosure packaging paper shaping mechanism and an enclosure packaging paper adhesive tape edge sealing mechanism which are connected in sequence. The device has the advantages that workflow setting is reasonable, efficient and compact; each action in the whole process is stable and reliable; the design of rotary gluing of bottom packaging paper and top packaging paper and paper feeding, gluing and wrapping by using the tunnels is ingenious, and the work is stable and error-free; the glued bottom packaging paper and top packaging paper are restrained and shaped in inner cavities of the tunnels for a long time, glue curing is fully achieved, and a good foundation is laid for enclosure packaging paper wrapping in the next step; the second tunnel is used for completing enclosure packaging paper gluing, paper feeding and shaping, and the mechanism is simple, rapid, efficient and stable; adhesive tape edge sealing is rapid and stable; and therefore, packaging paper wrapping of the combined fireworks is finished with high quality.

Owner:浏阳市海立达机械科技有限公司

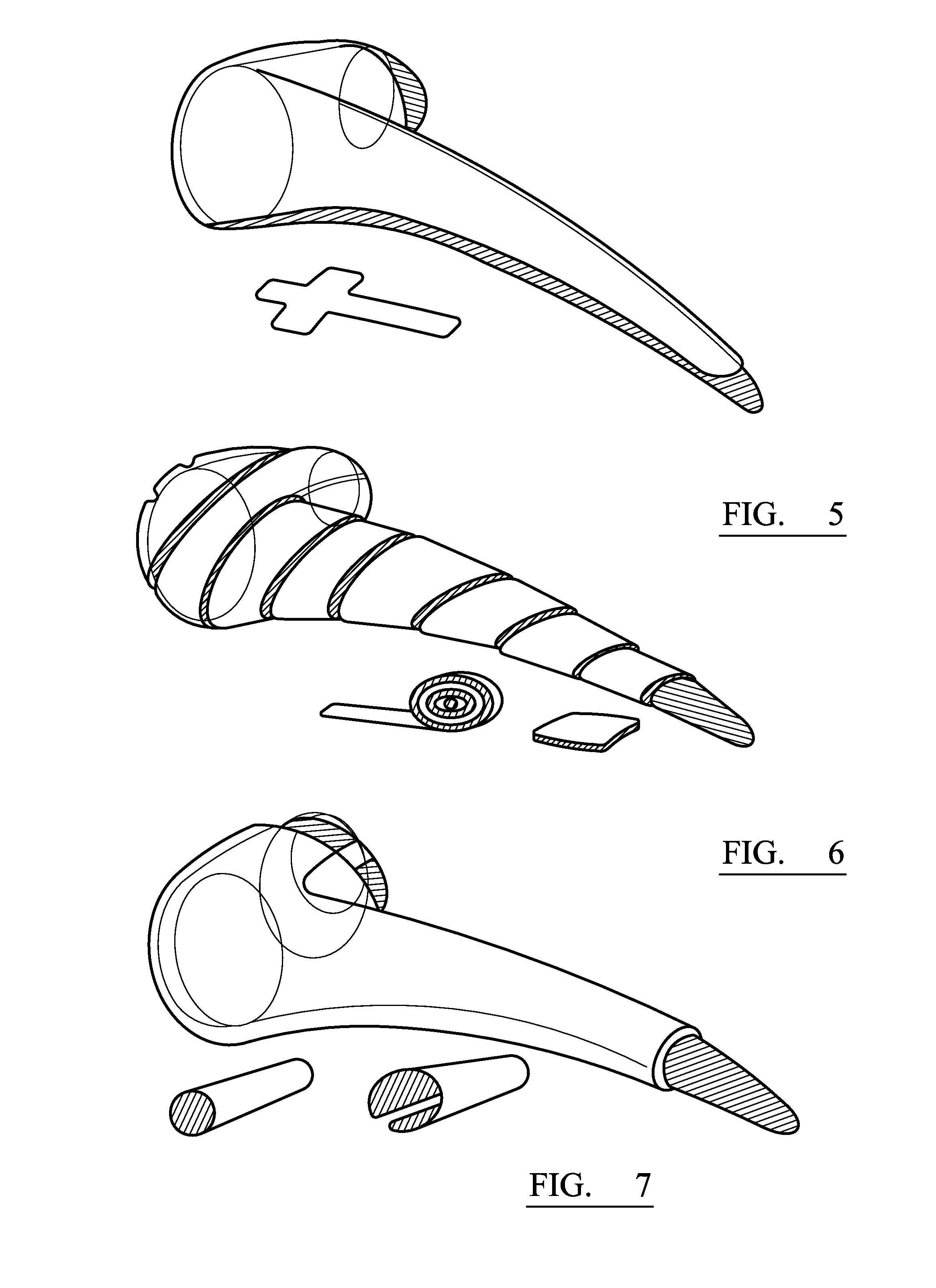

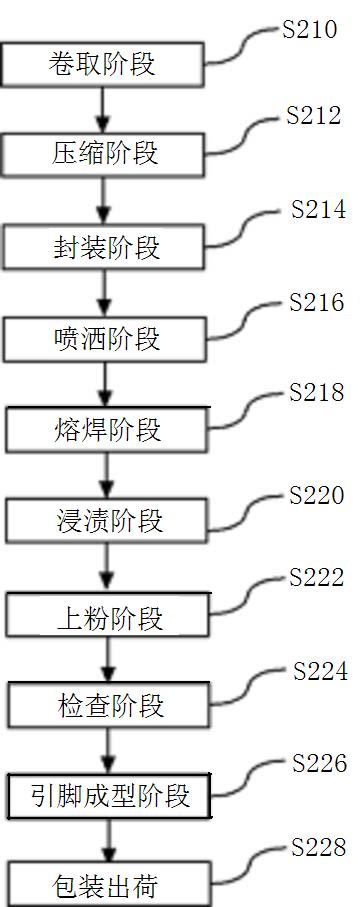

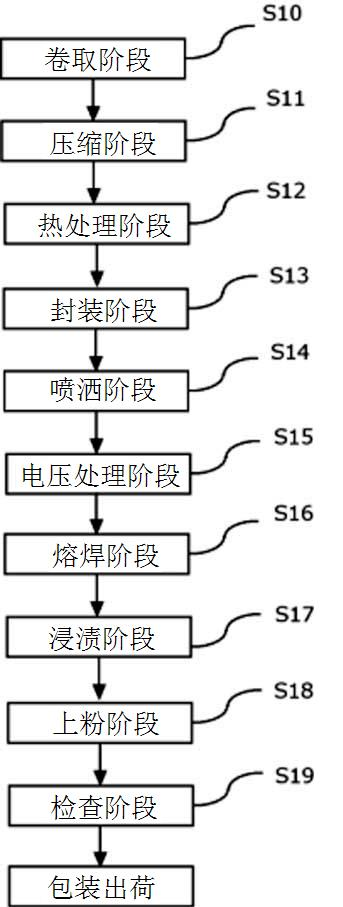

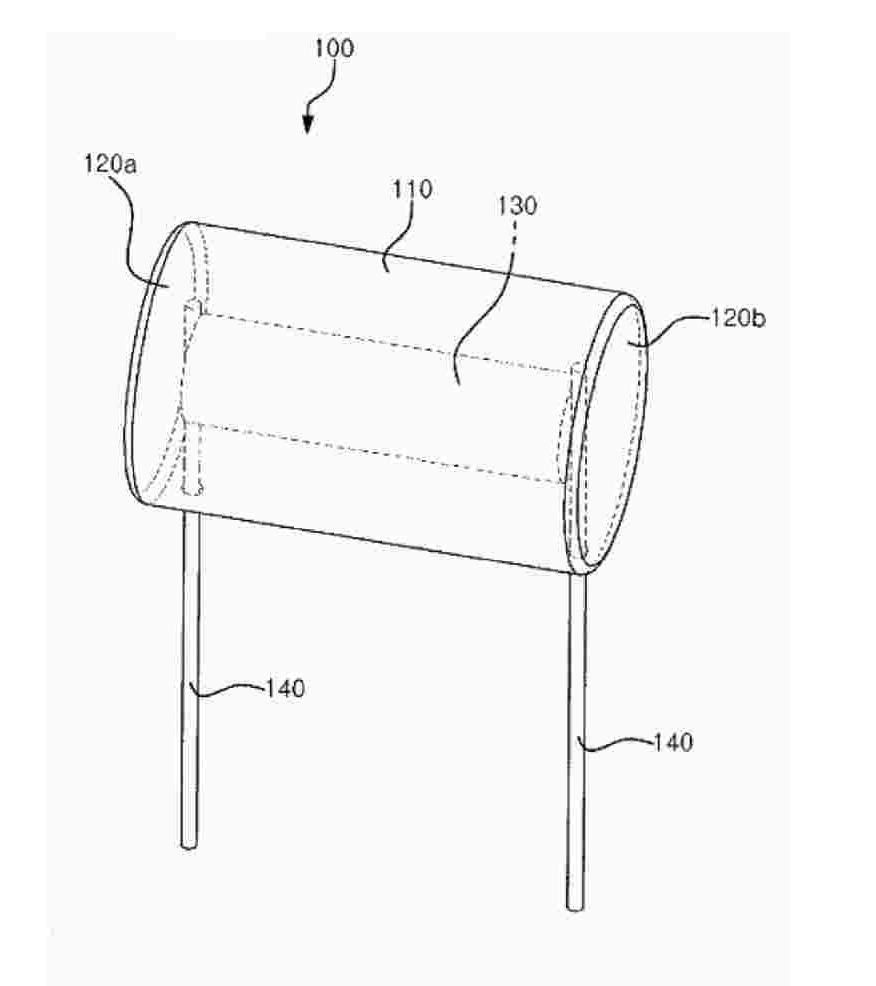

Manufacturing method of cylindrical capacitor

InactiveCN101930845AReduce noiseIncrease available currentThin/thick film capacitorStacked capacitorsCapacitancePaper adhesive tape

The invention relates to the technical field of electron, in particular to a manufacturing method of a cylindrical capacitor. The manufacturing method of the cylindrical capacitor comprises the following steps: coiling; heat treatment; packaging: packaging a prime by a paper adhesive tape so as to prevent tin powder from being sprayed on the surface of the prime in the spraying process, and spraying the tin powder on the two ends of the prime; fusion welding: welding pin lines; dipping; powder coating: carrying out external powder coating, and hardening and drying the powder; examination: examining construction, automatically selecting, and finally examining series of checked operations; and pin processing. Compare with the common compression capacitor, the invention can reduce 30-40% of noise and increase 10% of available current and has the obvious advantages of reasonable structure, convenient use, excellent performance and the like.

Owner:威海汉城成镐电子有限公司

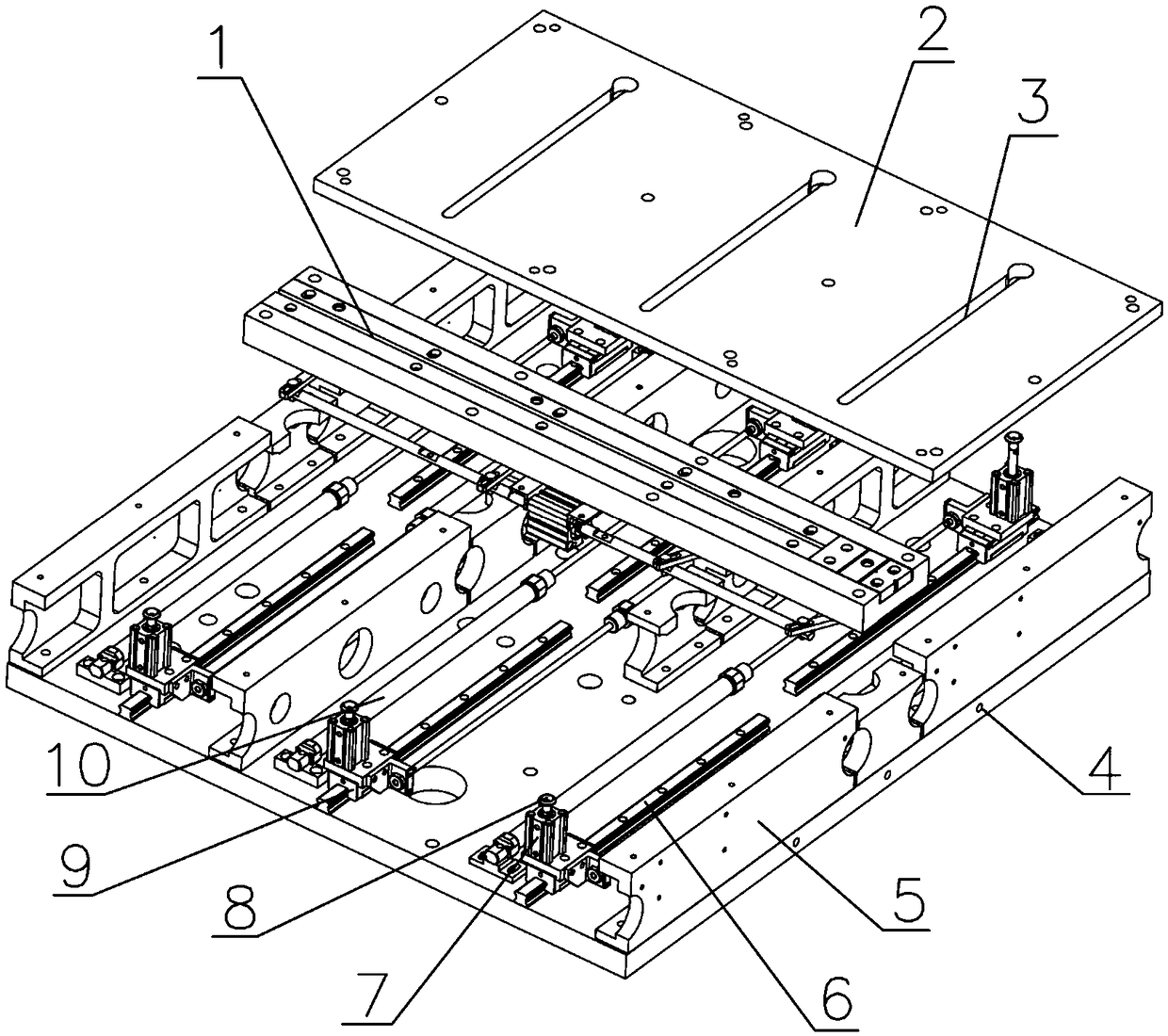

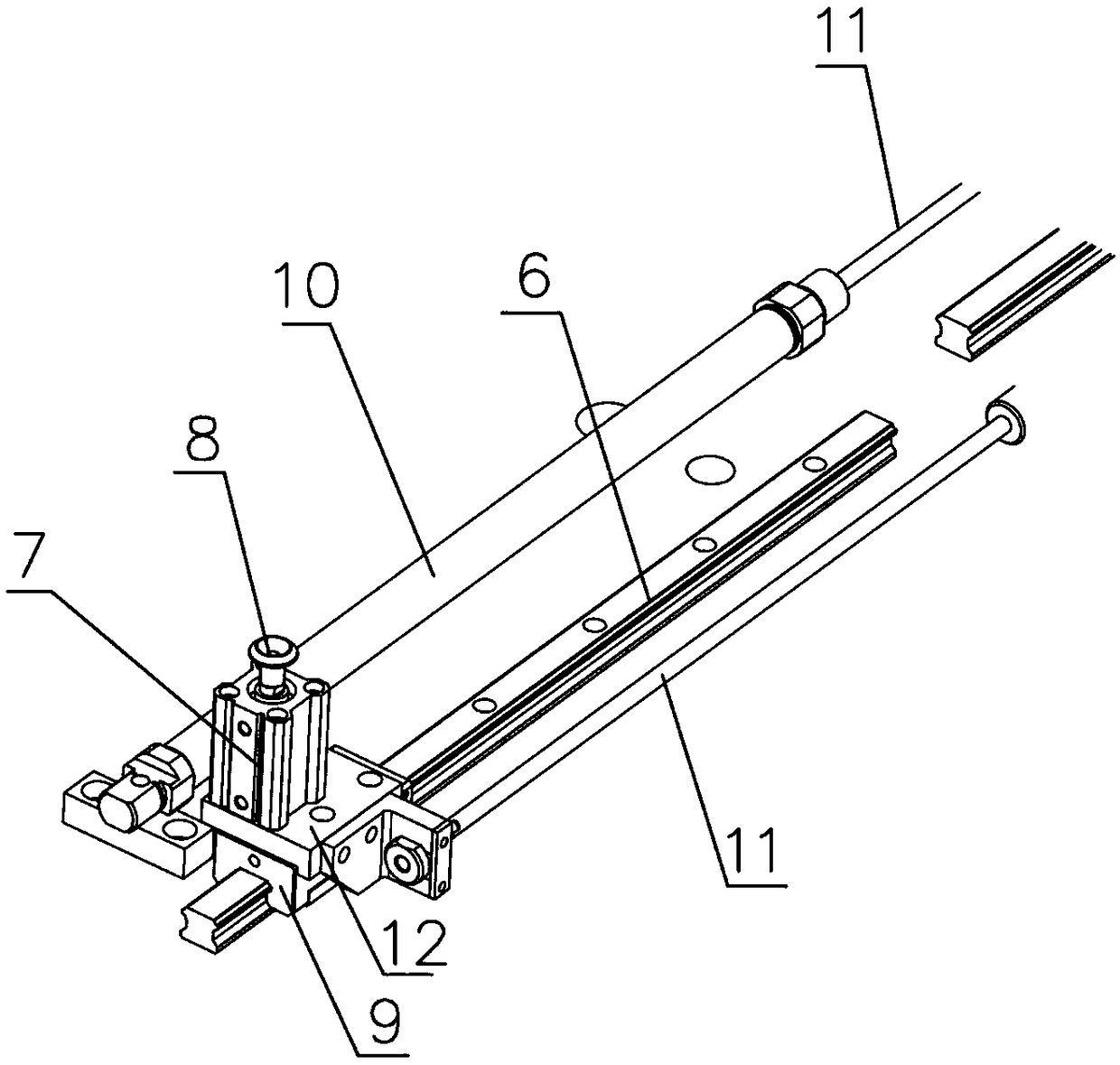

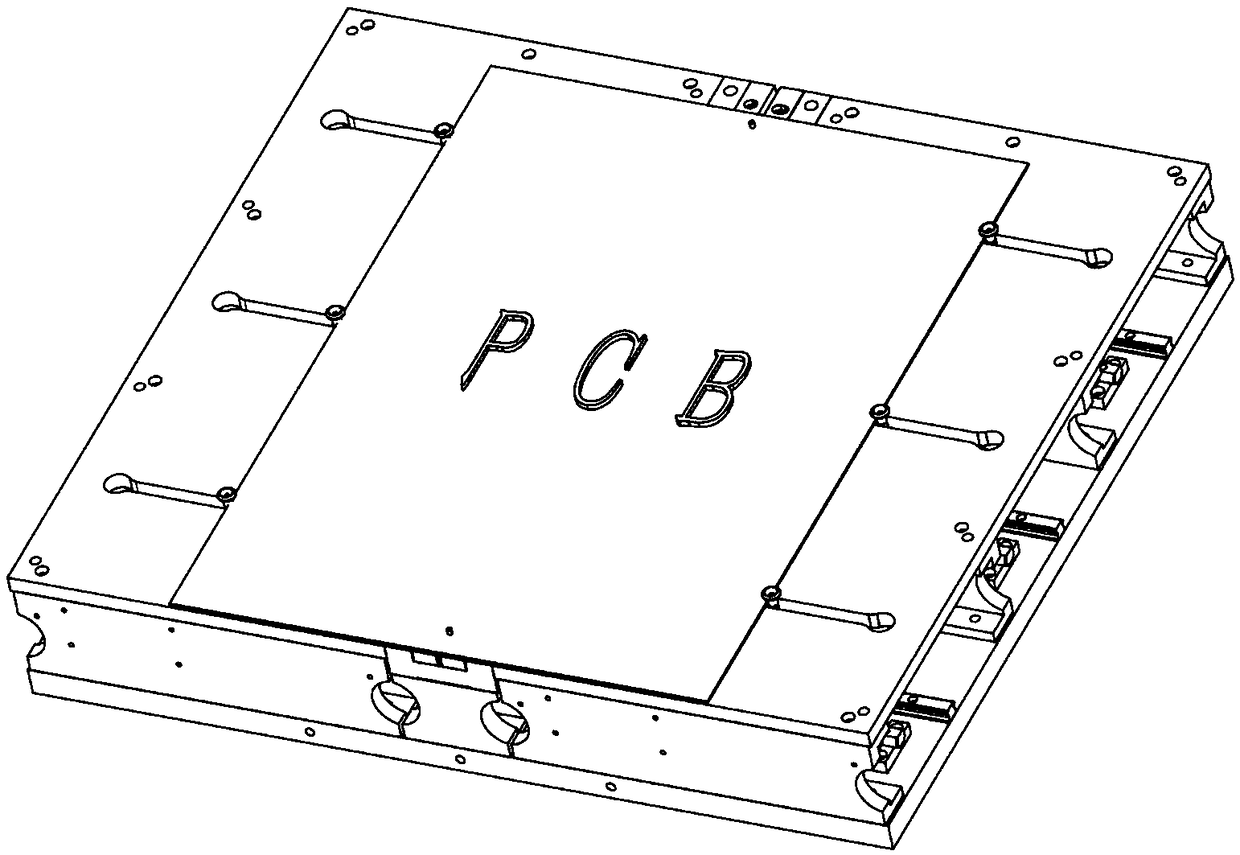

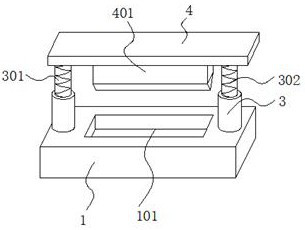

Double positioning mechanism for PCB numerical-control machine tool

ActiveCN109262320AAvoid position shiftReduce workloadWork clamping meansPositioning apparatusNumerical controlPaper adhesive tape

The invention discloses a double positioning mechanism for a PCB numerical-control machine tool. The double positioning mechanism is structurally characterized in that assistant supporting members parallel to each other are fixed on left and right sides of a workbench bottom plate, two ends of a clamping mechanism are arranged in grooves in the middles of the assistant supporting members, two workbench faceplates are fixed on two sides of the clamping mechanism and positioned above the assistant supporting member, and each workbench faceplate is at least provided with a sliding groove for cooperating with a compressing ring to move back and forth; a fastening unit is arranged in a space formed by the workbench faceplates and the workbench bottom plate and is structurally characterized in that an oriented guide rail is arranged right below a sliding groove, the oriented guide rail, an oriented slider, a compression cylinder and a compression ring are arranged sequentially, and the oriented slider is connected to a distance adjusting cylinder. The double positioning mechanism can process PCBs with various size specifications without using a paper adhesive tape to bond and compress each PCB and is flexible and multipurpose, so that time consumed by working personnel at this stage is reduced, and assistant materials are saved.

Owner:CHENGDU JINDALI TECH

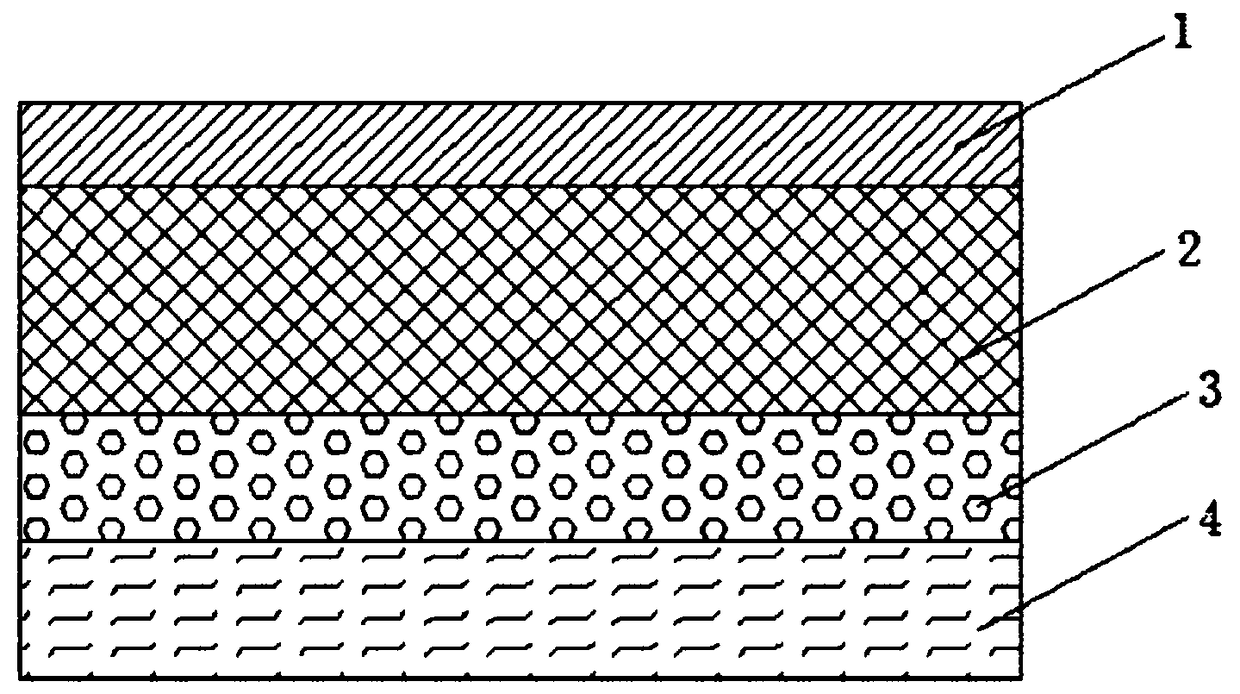

Low-viscosity waterborne paper adhesive tape and preparation method thereof

InactiveCN109749645ALow removal strengthQuick removalNon-fibrous pulp additionNon-macromolecular adhesive additivesPaper adhesive tapePaper based

The invention discloses a low-viscosity waterborne paper adhesive tape and a preparation method thereof. The adhesive tape at least comprises a paper base material layer, a surface treatment layer anda pressure sensitive adhesive layer arranged on one side of the paper base material layer at least, wherein the paper base material layer takes a paper material as a main material; the surface treatment layer is formed on at least part of the surface of the paper base material layer and is used for providing the hydrophobic capacity; the pressure sensitive adhesive layer is formed on at least part of the surface of the surface treatment layer and / or the paper base material layer and is used for providing viscosity. The adhesive tape disclosed by the invention has the characteristics of beingstrong in temperature resistance, low in peeling force, good in pasting effect, comfortable in removal hand feeling and the like.

Owner:江苏晶华新材料科技有限公司

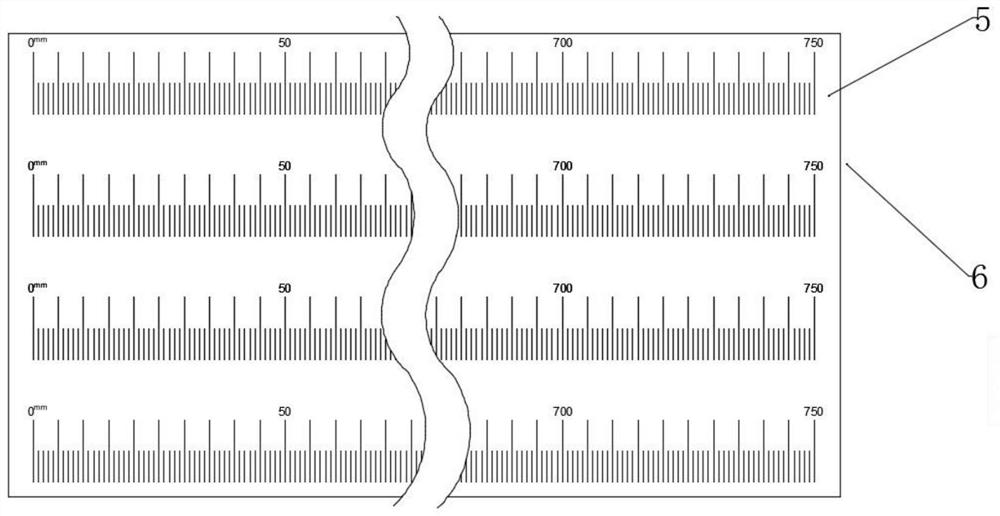

Disposable medical positioning paper adhesive tape and production process thereof

InactiveCN112063323AReduce difficultyReduce X-ray exposureFilm/foil adhesivesSurgeryPaper adhesive tapeSilicone tape

The invention provides a disposable medical positioning paper adhesive tape and a production process thereof. The disposable medical positioning paper adhesive tape comprises release paper, a medicalnon-woven fabric paper adhesive tape, a metal scale layer and an anti-sticking layer. The upper side of the release paper is covered with the medical non-woven fabric paper adhesive tape. The metal scale layer is located on the upper side of the medical non-woven fabric paper adhesive tape. The anti-sticking layer covers the surface of the metal scale layer and is completely attached to the upperside of the medical non-woven fabric paper adhesive tape. The metal scale layer is scale marking lines made of a developing material, the developing material comprises a component A and a component B,the weight part of the component A is 80-85, and the weight part of the component B is 15-20; and the component A comprises one or a combination of two of tungsten powder and lead powder, and the component B comprises mucilage. According to the invention, the metal scale layer which cannot be penetrated by X-rays is arranged, and the scale marking lines are directly displayed in an X-ray film, sothat the difficulty of comparing various organ position relations and determining various disease focus conditions by a doctor is reduced, and the problem of inaccurate detection results is avoided.

Owner:南京烨磊建设项目管理有限公司

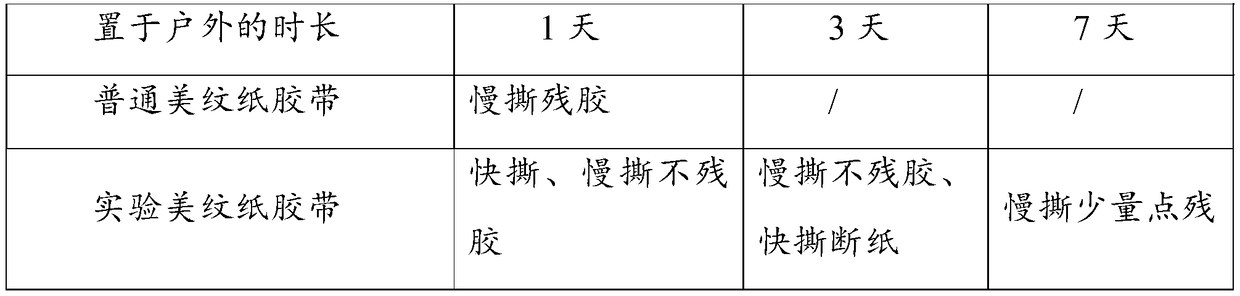

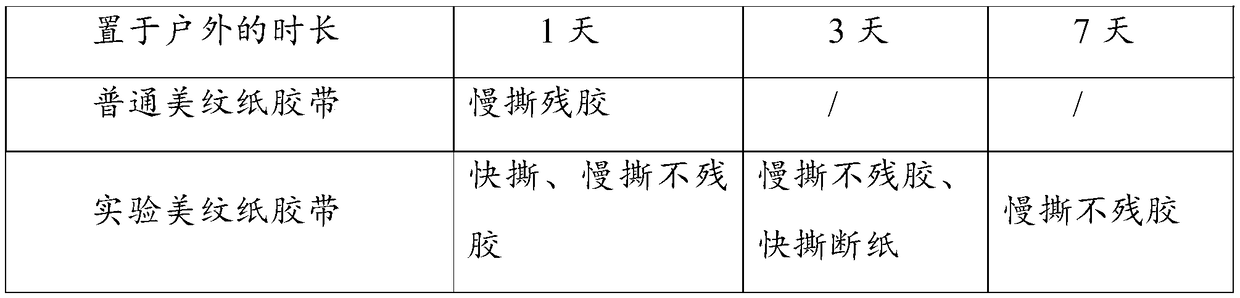

Anti-UV masking paper adhesive tape

InactiveCN109266229AGood UV resistanceMeet anti-UVMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesPetroleum resinPaper adhesive tape

The embodiments of the present invention provide an anti-UV masking paper adhesive tape, which is sequentially provided with a release layer, a masking paper substrate layer, an anti-UV adhesive layerand a common rubber-based pressure-sensitive adhesive layer, wherein the anti-UV adhesive layer comprises, by weight, 300 parts of toluene, 20-30 parts of an inorganic filler, 100 parts of a saturated synthetic rubber, 10-90 parts of a hydrogenated petroleum resin, 1-3 parts of an antioxidant, and 1-3 parts of an UV absorber. According to the present invention, the anti-UV masking paper adhesivetape is coated with the two layers of the adhesive layers, wherein the adhesive layer with characteristics of excellent anti-UV performance and poor pressure-sensitive performance is coated with the common rubber-based pressure-sensitive adhesive layer, such that the requirements of anti-UV performance and adhesion performance can be simultaneously met, and the production process is simple.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

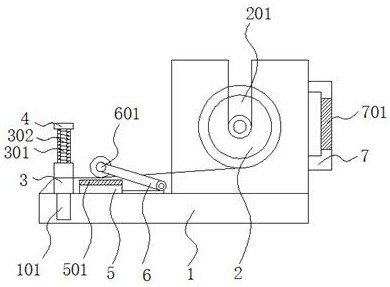

Pasting tool for high-temperature-resistant masking tape

InactiveCN111807136AImprove ease of useClosely arrangedArticle deliveryAdhesive beltPaper adhesive tape

The invention discloses a pasting tool for high-temperature-resistant masking tape, and belongs to the technical field of adhesive tape pasting. The pasting tool comprises a bottom plate, wherein an adhesive tape box is fixedly connected to the top of the bottom plate, a reel is mounted inside the adhesive tape box, two sleeves are fixedly connected to the left side of the top of the bottom plate,telescopic rods are inserted into the sleeves correspondingly, springs are installed outside the telescopic rods correspondingly, a blade is fixedly connected between the tops of the telescopic rods,a fixing block is fixedly connected to the top of the bottom plate, after adhesive tape reaches a proper position and bonding is completed, a top plate is pressed, so that the telescopic rods move towards the interiors of the sleeves, the springs are compressed, the blade moves downwards to make contact with an adhesive tape joint for cutting, after cutting is completed, the telescopic rods are jacked up under the action of the elastic force of the springs to drive the blade to reset, compared with a traditional pasting tool, no additional cutting tool needs to be used, and the use convenience of the pasting tool is greatly improved.

Owner:安徽友发包装科技有限公司

High-viscosity masking paper tape and preparation process thereof

InactiveCN106752977AFast dryingWith thickeningNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAntioxidantPaper tape

The invention relates to a tape and a preparation process thereof, in particular to a high-viscosity masking paper tape and a preparation process thereof. The invention provides the high-viscosity masking paper tape with the advantages of no toxicity, no harm, high viscosity and good use performance, and the preparation process thereof. A high-viscosity masking paper tape glue formula comprises the following raw materials in parts by weight: 60 to 80 parts of main body rubber, 2 to 4 parts of antioxidants, 3 to 5 parts of rosin ester, 4 to 6 parts of emulsifiers, 7 to 9 parts of acrylic acid, 1 to 3 parts of sodium polyacrylate, 25 to 30 parts of propylene butyrate and 1.5 to 2.5 parts of degassing agents; the preparation process comprises five steps. The prepared high-viscosity masking paper tape has high viscosity and can be used in life and industry; the condition that the falling phenomenon occurs within a short time is avoided; ageing resistance, water resistance and solvent resistance are realized; the isolation performance of base paper is improved.

Owner:嘉善弘欣化工厂(普通合伙)

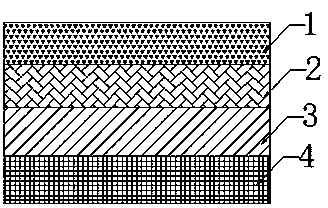

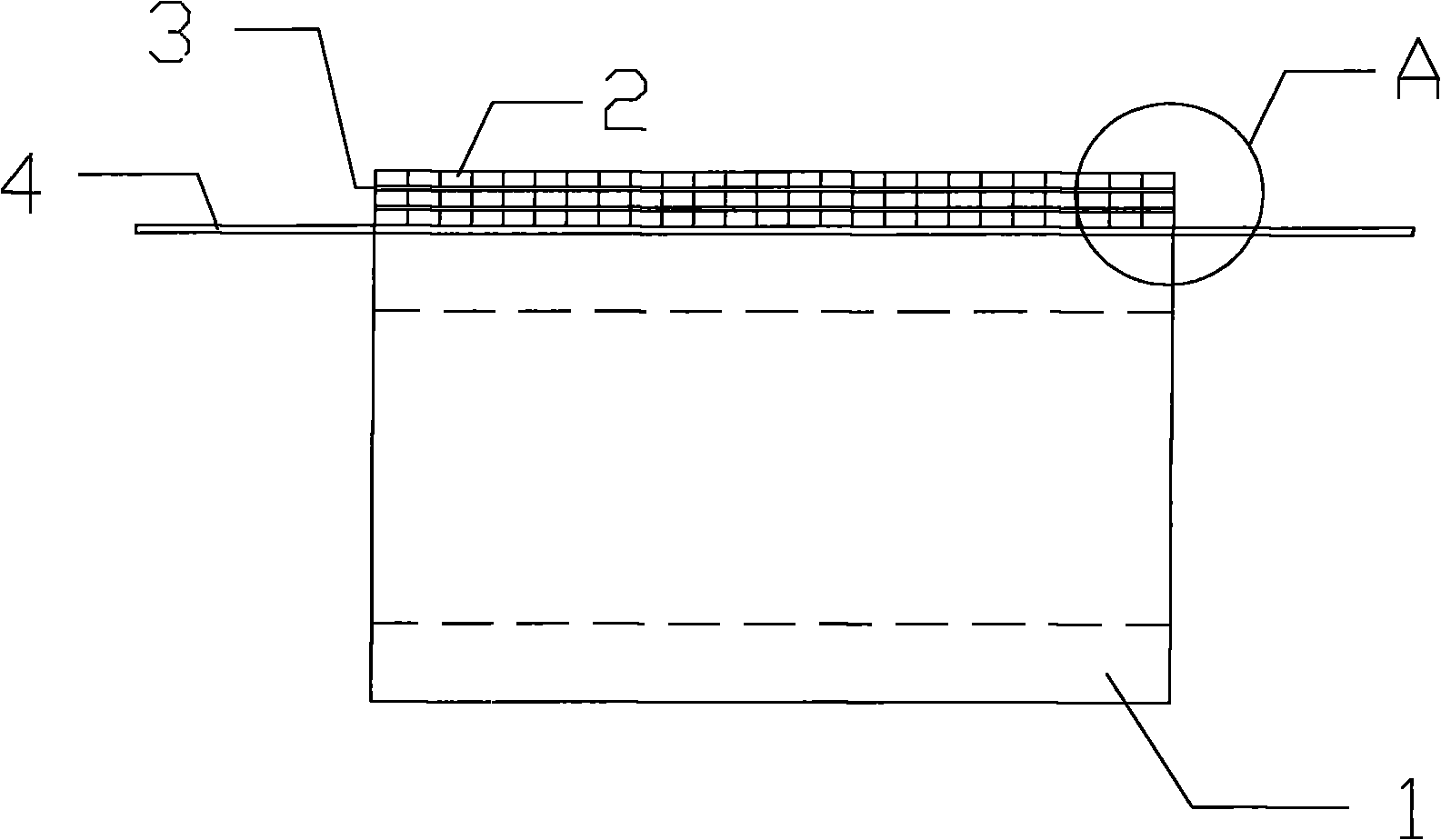

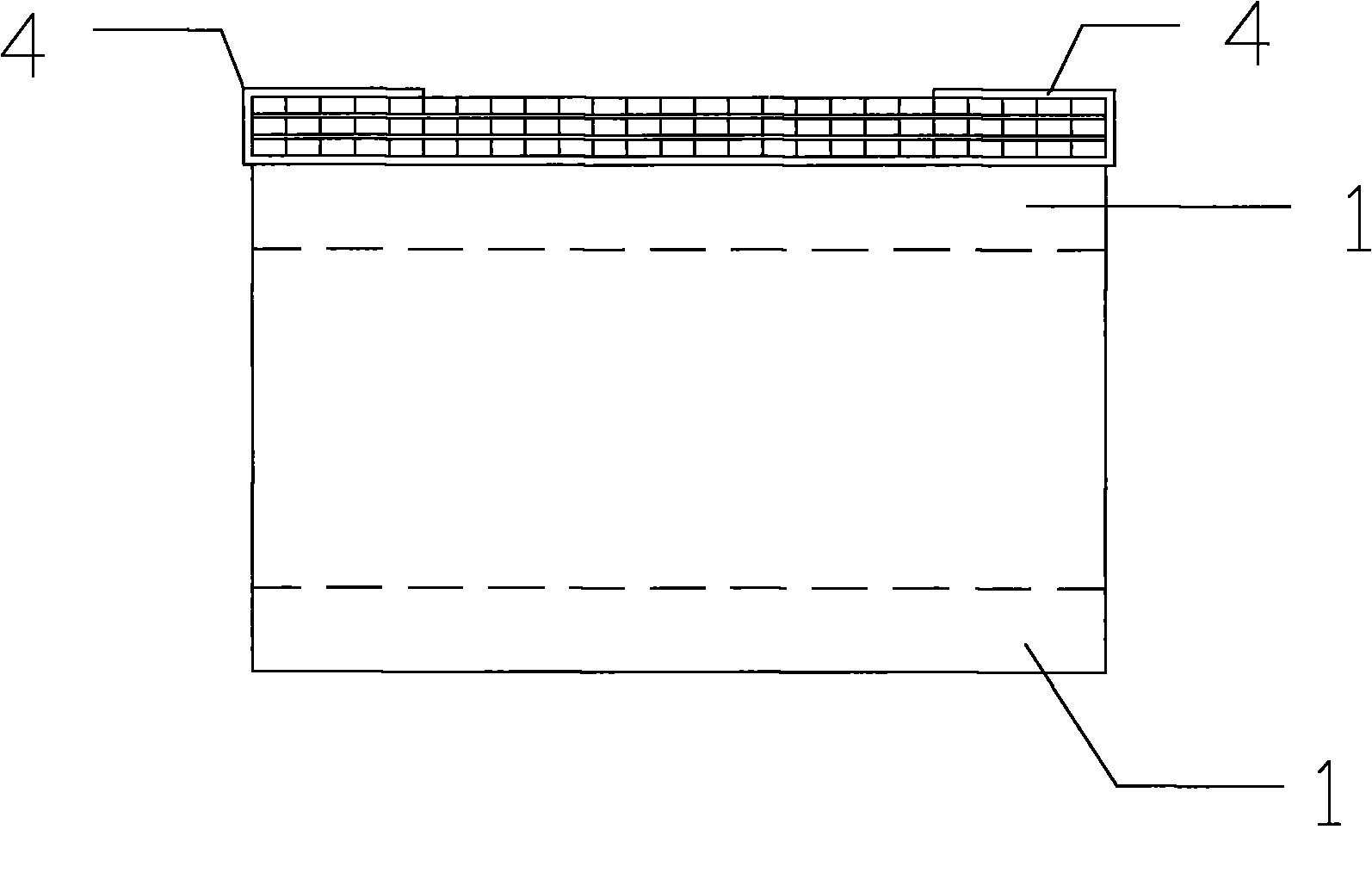

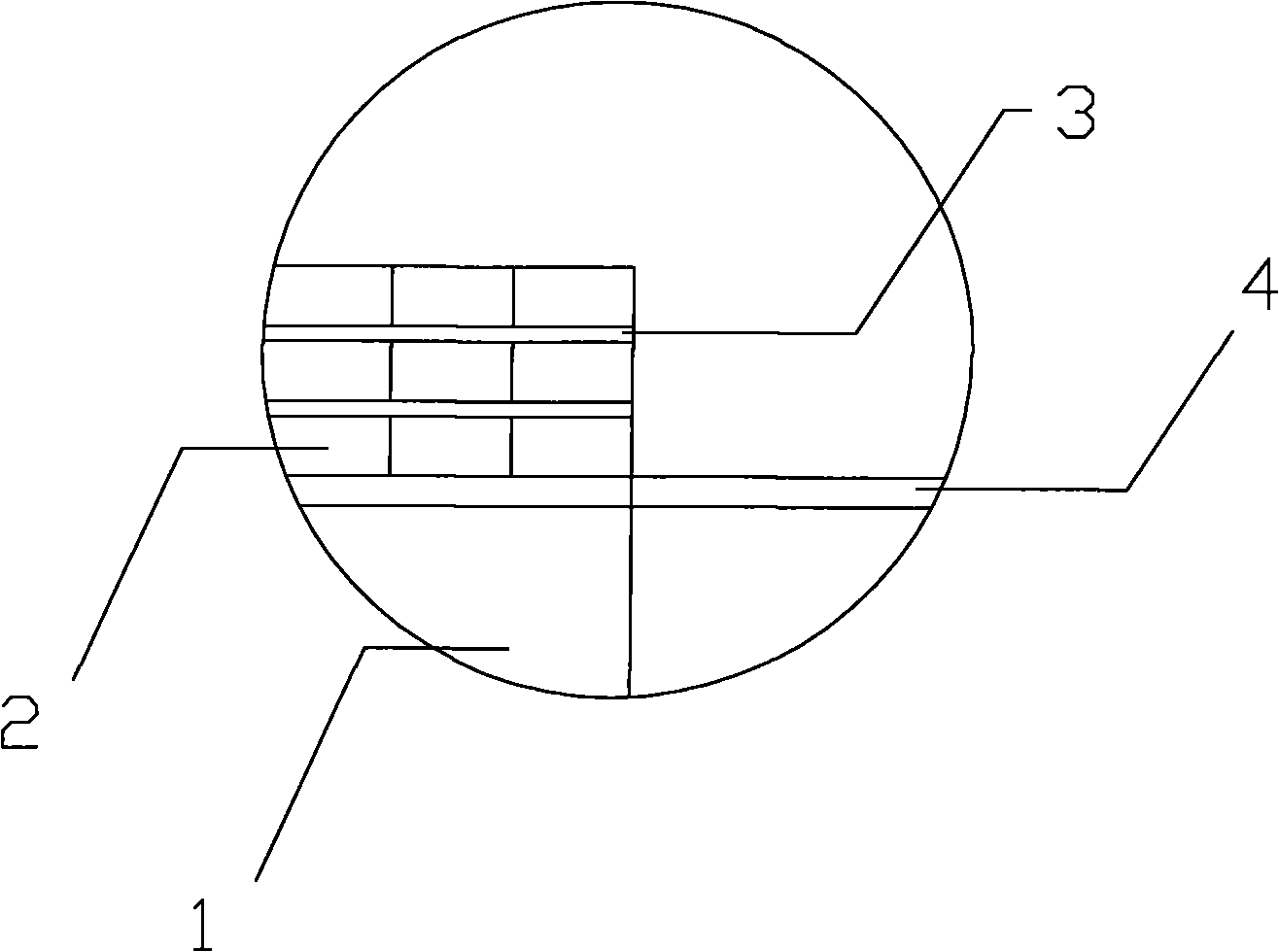

High wear-resisting insulation paper adhesive tape

ActiveCN104371586AImprove heat resistanceImprove cold resistanceFilm/foil adhesivesPaper/cardboard layered productsPaper adhesive tapeTransformer

The invention discloses a high wear-resisting insulation paper adhesive tape. The high wear-resisting insulation paper adhesive tape comprises a gel layer, a rubber layer, a paper layer and a wear-resisting layer which are orderly laminated and compounded from top to bottom, wherein the rubber layer is a mixed rubber layer of nitrile rubber and silicon rubber, the wear-resisting layer is a glass fiber cloth layer, and the glass fiber cloth layer is integrated with the paper layer through the bonding of an adhesive. The high wear-resisting insulation paper adhesive tape disclosed by the invention has the following advantages: 1) the mixed rubber layer of the nitrile rubber and the silicon rubber is adopted so that the adhesive tape has good heat resistance and cold resistance, and the proper working temperature range is -30 to 130 DEG C; 2) a layer of glass fiber cloth is adhered at outside of the paper layer so as to effectively improve the wear-resisting property of the adhesive tape. The adhesive tape disclosed by the invention has the advantages of being high-low temperature resistant, wear-resisting and high in strength, and can be widely applied to the fields such as transformers, vacuum electroplating and generator insulation and the like, and the use range is broadened.

Owner:CHANGSHU CHANGJIANG TAPE

Method for enhancing insulativity and mechanical strength of high-tension coil of amorphous alloy transformer

InactiveCN101901674AImprove insulation performanceHigh dielectric strengthTransformers/inductances coils/windings/connectionsCoils manufacturePaper adhesive tapeAlloy

The invention relates to a method for enhancing the insulativity and mechanical strength of a high-tension coil of an amorphous alloy transformer, which comprises the following steps of: wrapping and fixing both ends of the lateral surface of a copper strip special for the transformer which is positioned on an outer layer of a low-tension winding by using rhombic lattice point gummed paper, winding the copper strip on an insulating layer of the rhombic lattice point gummed paper tightly, fixing the copper strip, and winding a layer of rhombic lattice point gummed paper outside the copper strip to perform layer insulation; performing coiling of a high-tension winding to press high-tension electromagnetic wires and the insulating layer of the rhombic lattice point gummed paper firmly, fixing the high-tension electromagnetic wires, and winding a layer of a widened insulating layer of the rhombic lattice point gummed paper on an outer layer of a first layer of high-tension electromagnetic wire; after continuing to wind a second layer of high-tension electromagnetic wire and a third layer of high-tension electromagnetic wire, turning over the widened part in the first layer of the insulating layer of the rhombic lattice point gummed paper along an end in an insulating mode, pressing and winding the widened part by a fourth layer of electromagnetic wire tightly, and fixing the rhombic lattice point gummed paper by using a glass fiber paper adhesive tape. Compared with the prior art, the method has the advantages of enhancing the insulativity and mechanical strength of the high-tension coil of the amorphous alloy transformer and the like.

Owner:SHANGHAI FLYING KING ELECTRIC

A kind of silicone pressure-sensitive adhesive for masking tape and preparation method thereof

ActiveCN110283543BAdjust crosslink densityAdjust the peel force effectNon-macromolecular adhesive additivesPressure sensitive film/foil adhesivesPolymer sciencePtru catalyst

Owner:无锡雅达科技有限公司

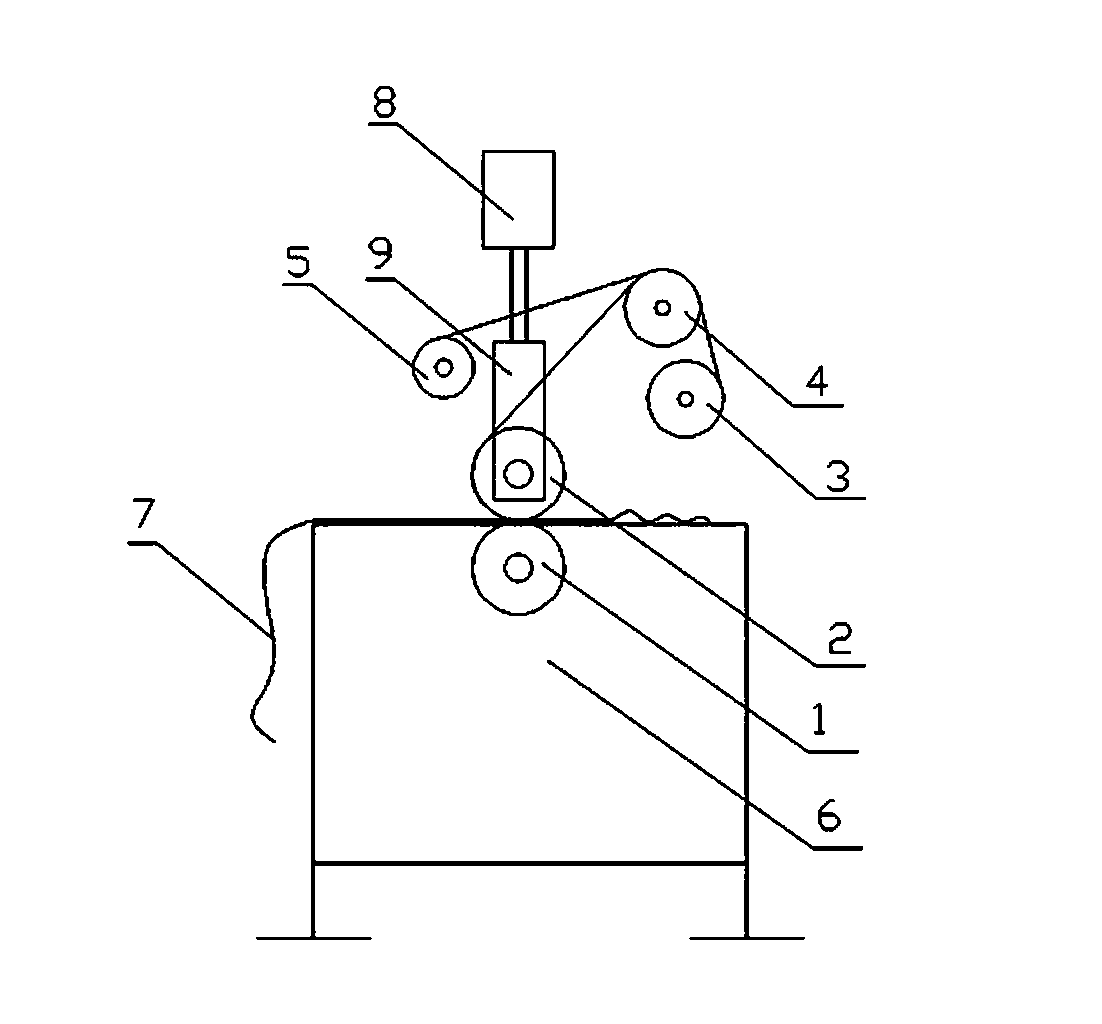

Cloth edge connecting machine

InactiveCN103374815AReduce waste rateNo obvious increase in thicknessSeaming textilesDrive wheelPaper adhesive tape

The invention discloses a cloth edge connecting machine. A main driving wheel, a pressing wheel, an adhesive tape wheel, a cloth strip wheel and a paper adhesive tape collecting wheel are rotatably located on a machine frame. A first driving device drives the main driving wheel to rotate, the outer side of the circumference of the pressing wheel abuts against the outer side of the circumference of the main driving wheel, two-sided adhesive tape is led out from the adhesive tape wheel, one side of the two-sided adhesive tape having glue is attached to a cloth strip of the cloth strip wheel, paper adhesive tape of the two-sided adhesive tape is wound around the paper adhesive tape collecting wheel, a second driving wheel drives the paper adhesive tape collecting wheel to rotate, one side of the cloth strip provided with the two-sided adhesive tape covers center seams of splicing cloth leftovers to form cloth which is to be subjected to press fit, and the cloth which is to be subjected to press fit is clamped between the main driving wheel and the pressing wheel. Two pieces of cloth can be subjected to edge connection rapidly, the edge connecting position is smooth, the thickness of the edge connecting position is not increased remarkably, an overlock machine does not jump when met with connected edges in work, the waste cloth rate of the overlock machine is reduced, the cloth utilization rate is improved, production cost is reduced, and production efficiency is improved.

Owner:王克勤

Masking paper adhesive tape and preparation method thereof

InactiveCN108676508AAvoid brittleLow viscosityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPaper adhesive tapeSilanes

The invention discloses a masking paper adhesive tape and a preparation method thereof. The masking paper adhesive tape is prepared from a masking paper substrate, a waterproof agent and a pressure-sensitive adhesive, wherein the waterproof agent and the pressure-sensitive adhesive are arranged on the masking paper substrate; the pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 100 to 150 parts of organic silicon modified rubber, 30 to 60 parts of solvents, 20 to 50 parts of tackifying resin, 5 to 20 parts of plasticizers, 5 to 10 parts of silane coupling agents and 5 to 20 parts of filling materials, wherein the plasticizer is prepared from cyclohexane 1,2-diisononyl diformate or / and tributyl acetocitrate; the silane coupling agent is one kindof materials or a mixture of several kinds of materials from 3-aminopropyltriethoxysilane, gamma-methacryloxy propyl trimethoxyl silane and Gamma-Mercaptopropyltrimethoxysilane. The masking paper adhesive tape has excellent primary sticking performance in various climates; the sticking duration effect is good; embrittlement cannot occur; fracture cannot easily occur; the excellent unreeling effects are realized.

Owner:XIAMEN NUORUITE IND CO LTD

Composite high-temperature-resistant PET Meguiar's paper adhesive tape

InactiveCN105969241AImprove tensile propertiesEnhanced adhesionEster polymer adhesivesPressure sensitive film/foil adhesivesDi-tert-butyl peroxidePaper adhesive tape

The invention discloses composite high-temperature-resistant PET Meguiar's paper adhesive tape and mainly solves the problem that compared with general adhesive tape, paper self-adhesive tape is poor in adhesion and poor in high-temperature resistance. The composite high-temperature-resistant PET Meguiar's paper adhesive tape comprises a release agent layer, a paper base material layer, an adhesive layer, a plastic layer and an adhesion layer which are arranged in sequence from top to bottom; the paper base material layer is composed of Meguiar's paper, and the adhesion layer is composed of silicone adhesive; the adhesive layer is composed of, by weight, 1-3 parts of dibenzoyl peroxide, 90-100 parts of organic silicon pressure sensitive glue, 1-4 parts of diisocyanate, 200-210 parts of acrylate pressure-sensitive glue, 50-60 parts of silicone adhesive and 1-3 parts of polymethyl triethoxy silane; the plastic layer is composed of, by weight, 60-70 parts of polyethylene terephthalate, 3-5 parts of silicone and 1-2 parts of di-tert-butyl peroxide. The composite high-temperature-resistant PET Meguiar's paper adhesive tape has the advantages of being high in tension resistance, adhesive force and heat resistance and the like.

Owner:CHENGDU HUIJIA ADHESIVE PROD CO LTD

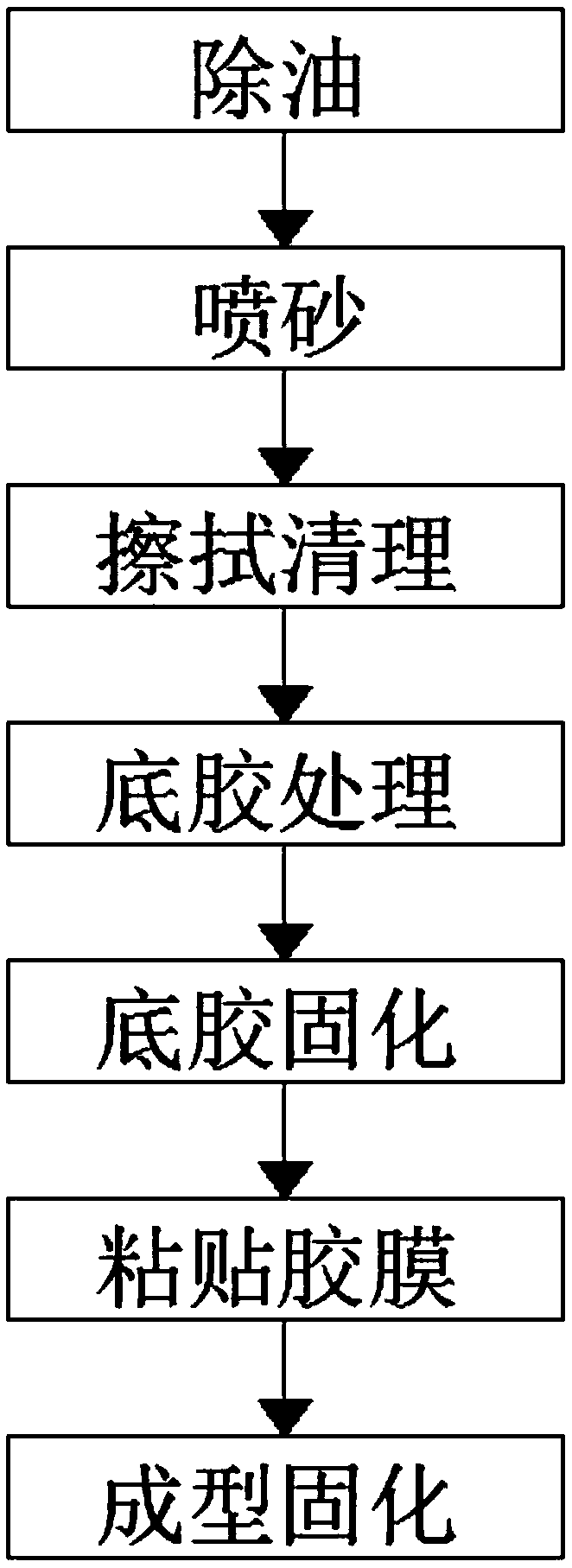

Treatment method of metal surface

The invention discloses a treatment method of a metal surface. The treatment method of the metal surface comprises the following specific steps that a white cotton cloth is adopted to be used for dipping an oil stain cleaning agent to wipe oil stains on the surface of a metal part; a non-adhesive junction face of the metal part is sealed and isolated by adopting a paper adhesive tape, then sand blasting is carried out, the surface of the metal part is cleared and coarsened by utilizing the impact action of a high drift sand, so that the coarsening of the junction face of the metal part is facilitated, and the surface roughness of the metal part is increased; the oil stain cleaning agent is used for wiping the surface of the metal part until the surface of the metal part is completely clean, and the metal part is left to stand for 1.5 hours under the condition of room temperature after clearing; a bottom glue is taken out of a cold storage at a temperature of minus 18 DEG C, then the bottom glue evenly coats the surface of the metal part, after the surface is coated with the bottom glue and the glue liquid is solidified, then the bottom glue can be put in a furnace for solidification; the constant-temperature solidification is performed for 1-2 hours; a layer of glue film is pasted to a part glue joint area; and the constant-temperature solidification is performed for 1-3 hours. The treatment method of the metal surface has the advantages that the bonding strength of a composite material and the metal part is enhanced, the service life is prolonged.

Owner:合肥联合飞机科技有限公司

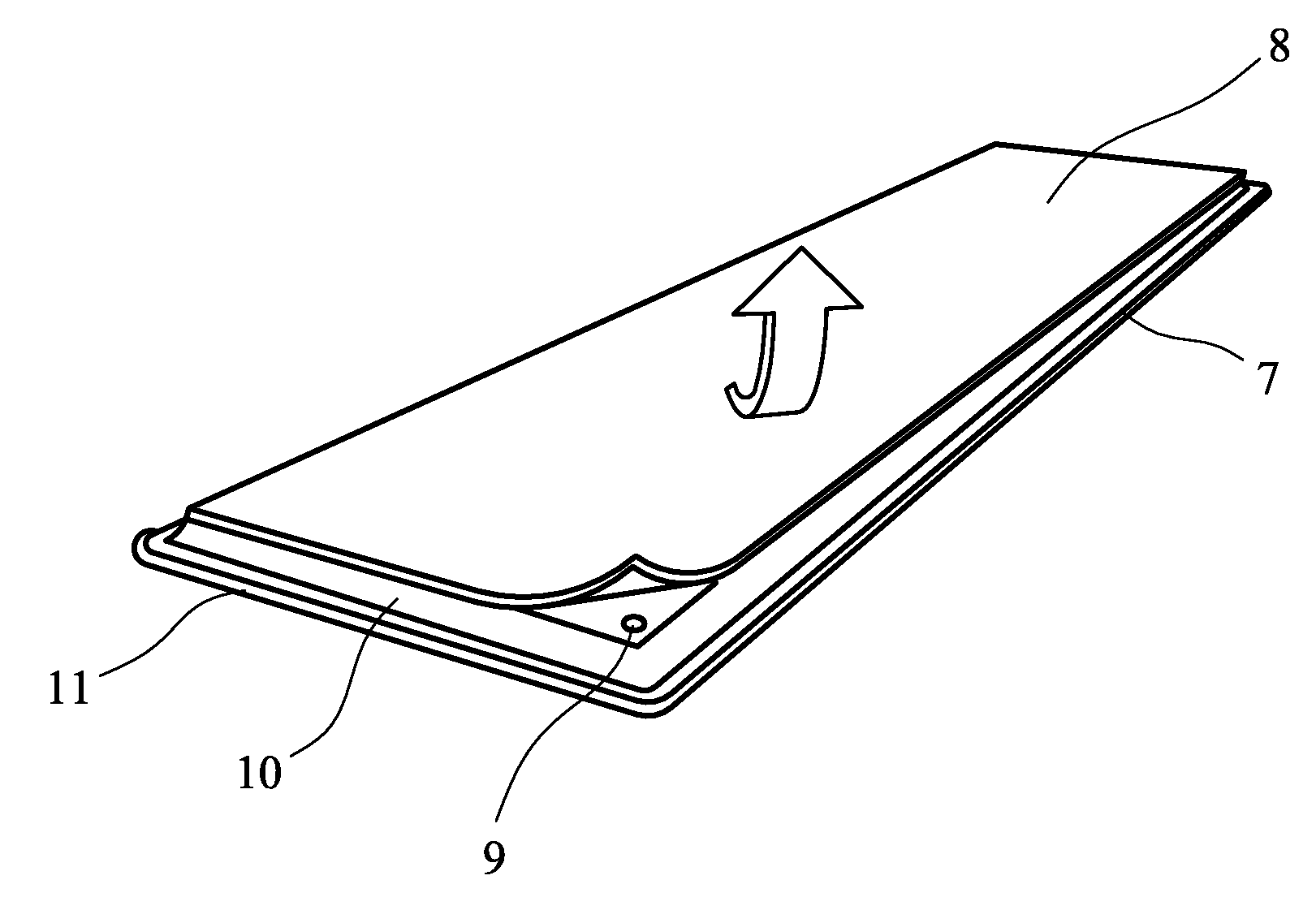

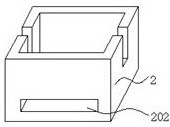

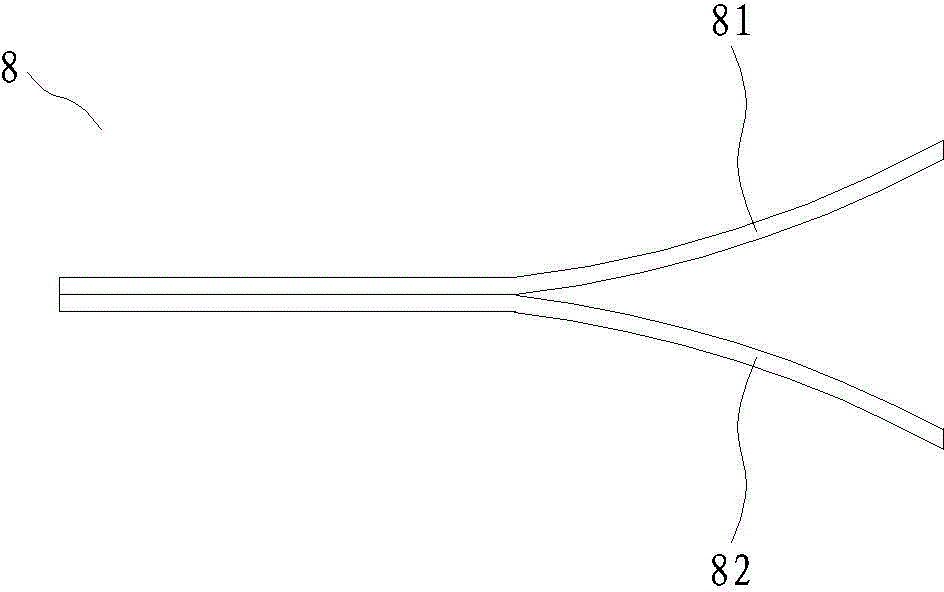

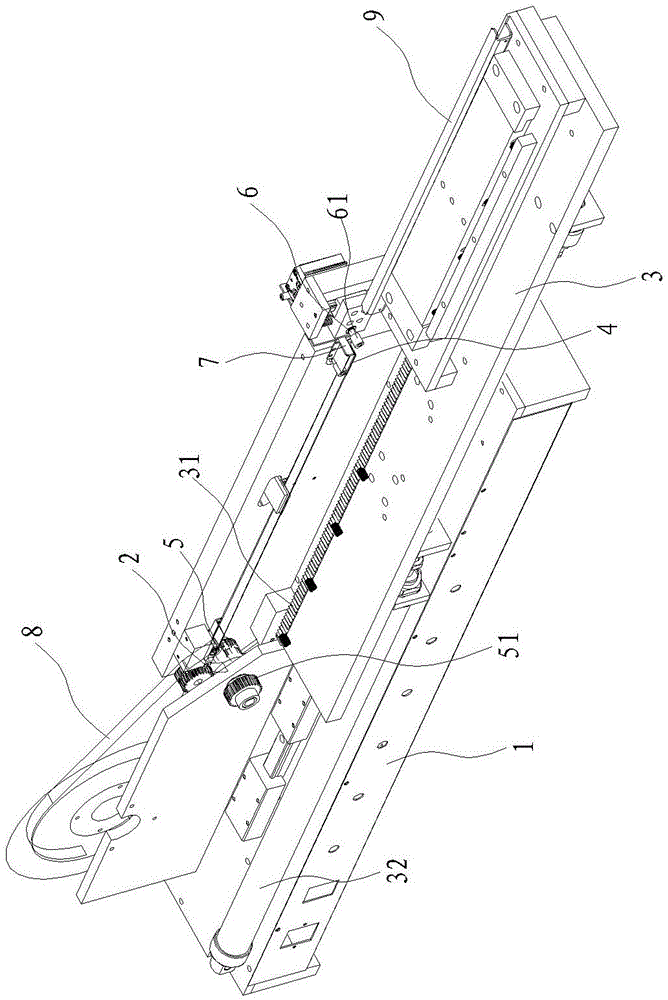

Device for sticking release paper adhesive tape

The invention relates to a device for sticking release paper adhesive tape. The device is simple in structure and high in work efficiency, and can be used for sticking the release paper adhesive tape on a concave workpiece. The device comprises a rack, a plurality of guide rollers and a clamping seat, wherein the guide rollers are rotationally arranged on the rack, and used for guiding the release paper adhesive tape; the clamping seat is arranged on the rack in a left-right sliding manner, and used for clamping the workpiece; an adhesive tape separating plate is arranged on the rack; a winding roller used for winding the release paper of the release paper adhesive tape is arranged on the rack.

Owner:XIAMEN INTRETECH

Heat-resistant coating tensile shear strength test model and its manufacturing method

ActiveCN102954910BGuaranteed thicknessGuaranteed compactnessPreparing sample for investigationStrength propertiesFiberPaper adhesive tape

The invention discloses a heat-resistant coating tensile shear strength test model which comprises an upper sheet metal, a lower sheet metal, an intermediate adhesive layer, fiber cloth in the adhesive layer and paper adhesive tapes pasting around tensile shear adhesive surfaces of the sheet metals. A production method provided by the invention comprises adding the fiber cloth into the adhesive layer, thereby effectively controlling thickness and uniformity of the adhesive layer; and is added with a process of pasting paper adhesive tapes around the tensile shear adhesive surfaces, thereby reducing influences of irregular glue-spilling on test results, and improving stability of the test results.

Owner:CASIC DEFENSE TECH RES & TEST CENT

Wood end sealing and cracking preventing method based on high molecular materials

InactiveCN108789768AImprove work efficiencyLabor savingWood working apparatusDomestic articlesPaper adhesive tapeHigh intensity

The invention discloses a wood end sealing and cracking preventing method based on high molecular materials. The wood end sealing and cracking preventing method comprises the following steps that A, wood needing to be subjected to end sealing and cracking preventing and the high molecular materials are prepared; B, the high molecular materials are subjected to heating treatment, and after heating,the high molecular materials become fluid from solid; C, the ends of the two ends of the wood are coated with the fluid-state high molecular materials, so that attaching force is generated between the high molecular materials and the wood; D, the high molecular materials are subjected to air cooling and become solid from fluid; E, the high molecular materials are cooled and solidified, and finally a high-strength coating layer is formed; F, the coating layer is ground or tailored; and G, the cooled wood coated with the high molecular materials is transferred to other procedures to be subjected to slicing machining. By means of the wood end sealing and cracking preventing method, the functions that the high molecular materials are used for replacing paper adhesive tape, batten slicing or saw cutting is conducted, after wood is rotationally cut or subjected to saw cutting, manual paper adhesive tape pasting is not needed, the work efficiency is improved, manual work is saved, the wood is fixed and dragged, and the wood cannot be cracked are achieved.

Owner:纪合建

Kraft paper tape and preparation process thereof

InactiveCN112341943AEasy to writeWrite freely and clearlyPressure sensitive film/foil adhesivesHeat-activated film/foil adhesivesPaper adhesive tapeSilicone tape

The invention discloses a kraft paper adhesive tape and a preparation process thereof. The kraft paper adhesive tape comprises a base material, a first dipping layer, a second dipping layer, a releaselayer and an adhesive layer, wherein the first dipping layer and the second dipping layer are formed on two sides of the base material, the release layer is positioned on the first dipping layer, andthe adhesive layer coats thesecond dipping layer. The kraft paper adhesive tape provided by the invention can be used for easily writing, and can be used for freely and clearly writing regardless ofpencils, ballpoint pens and water color pens, so that the practicability of the adhesive tape is greatly improved.

Owner:江苏晶华新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com