Method for enhancing insulativity and mechanical strength of high-tension coil of amorphous alloy transformer

A high-voltage coil, mechanical strength technology, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., can solve the problems of coil looseness, high and low voltage coil insulation layer strengthening, amorphous alloy transformer to be improved, etc., to achieve improvement Dielectric strength, improving insulation performance, and improving the effect of the ability to withstand sudden short-circuit accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

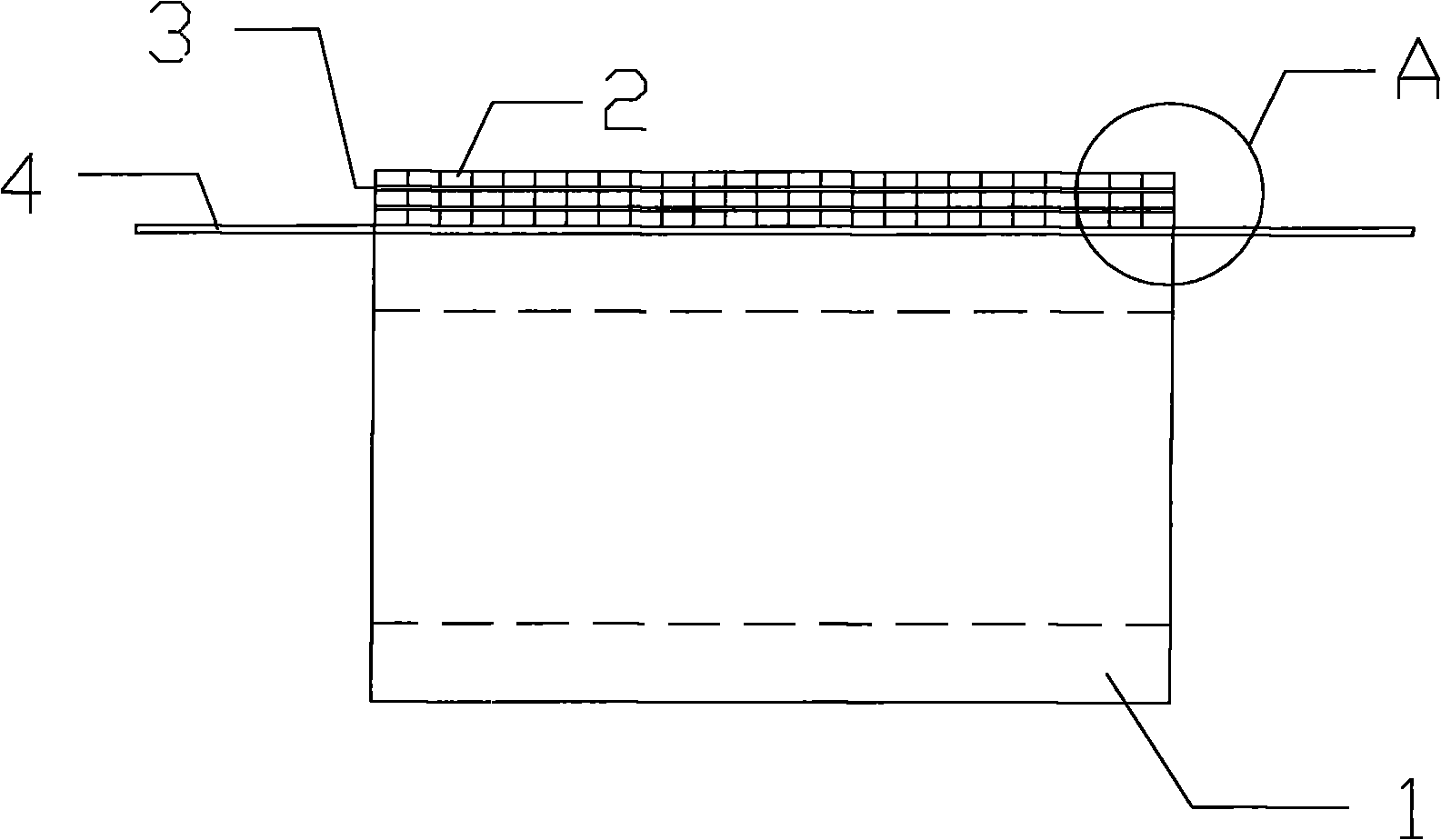

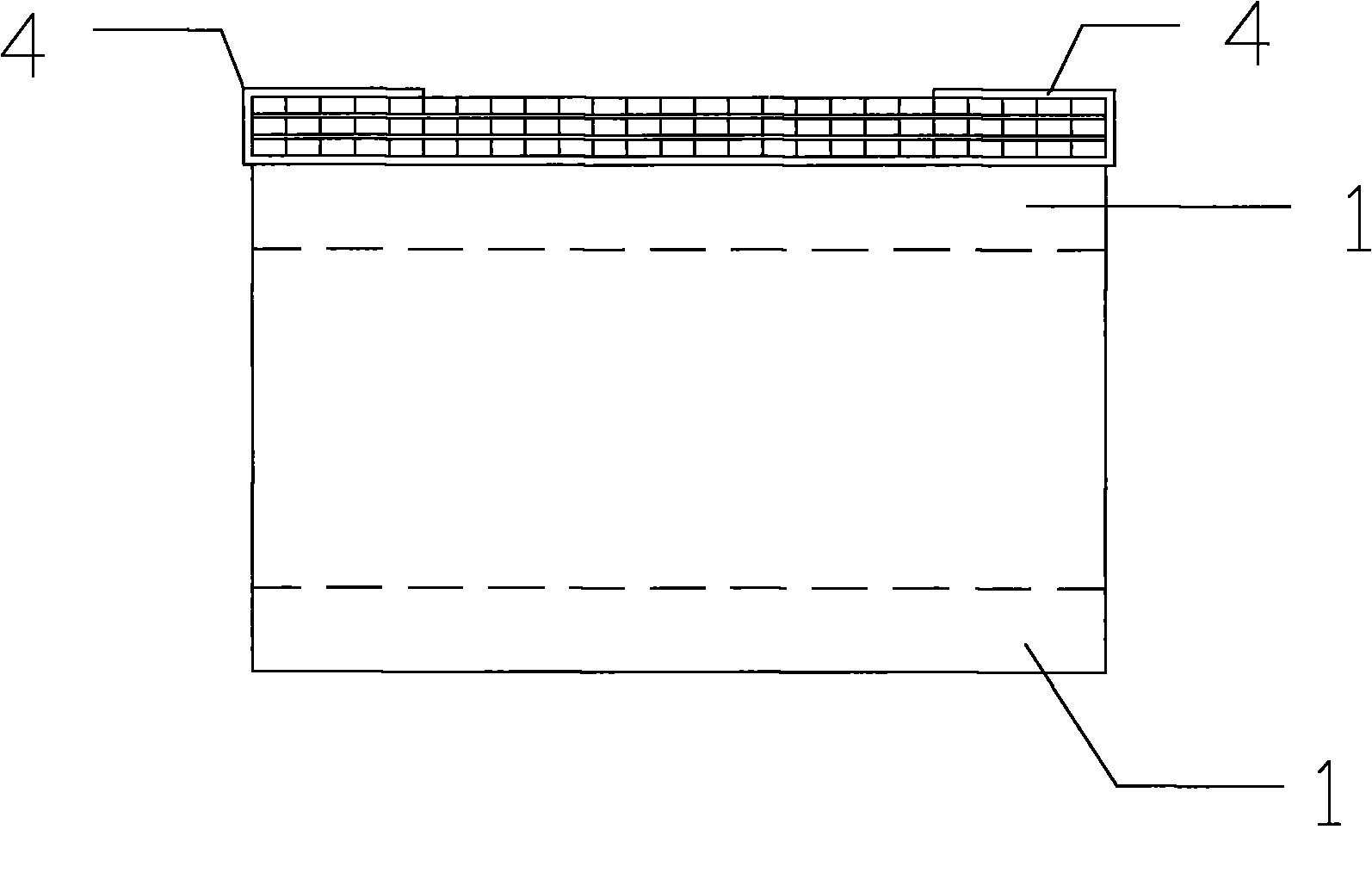

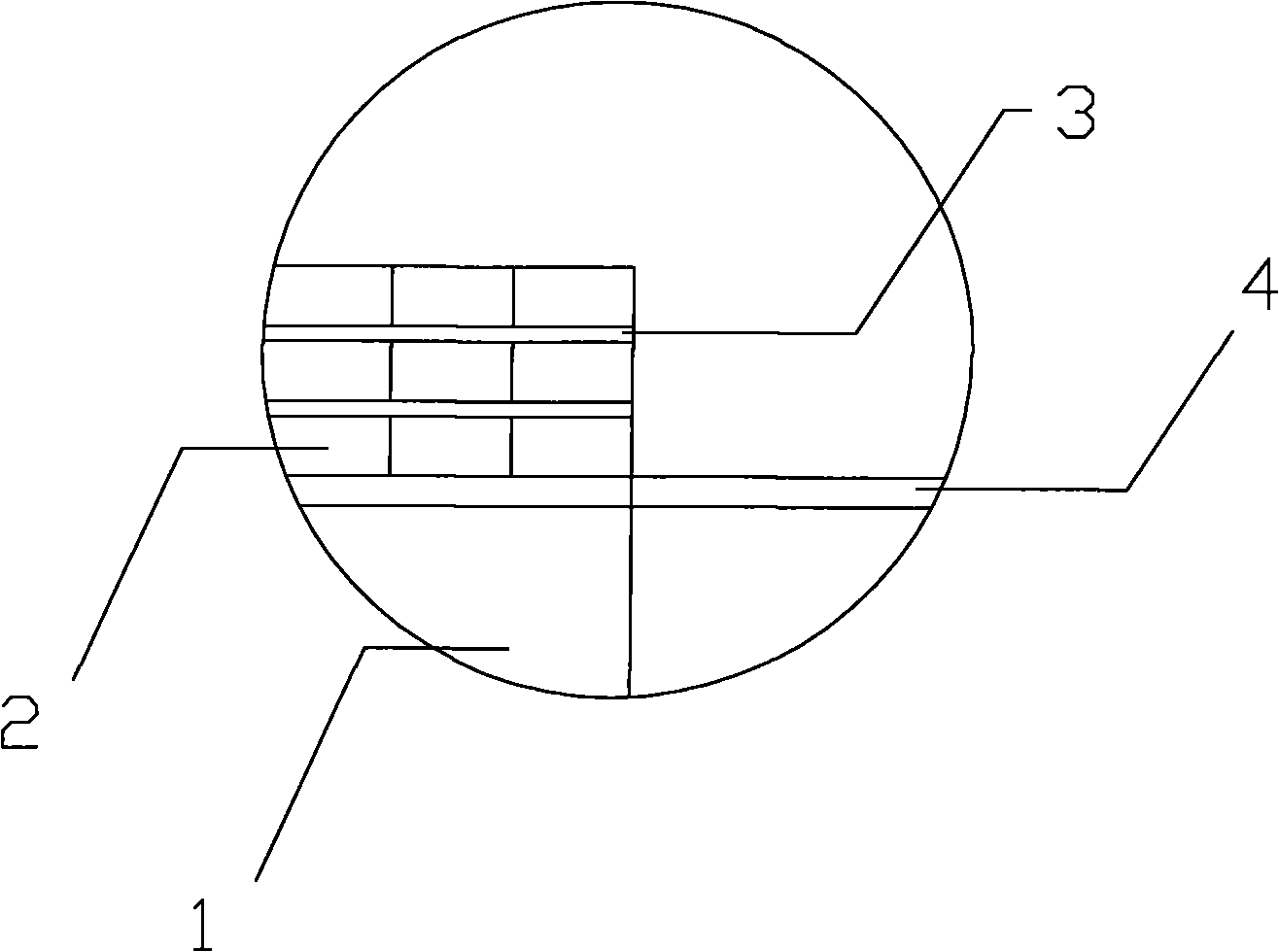

[0026] Such as Figure 1-3 As shown, after completing the winding process of the low-voltage coil except the last layer according to the traditional process, perform the following operations:

[0027] Step 1: Wrap the side ends of the special copper tape of the last layer of the transformer for the low-voltage coil 1 of the low-voltage winding with rhombic dispensing paper, and fix the rhombic dispensing paper with glass fiber paper tape;

[0028] Step 2: Put the copper tape of the transformer that has been wrapped with rhombic dispensing paper on both ends of the side, tightly wrap it on the insulating layer of the upper rhombic dispensing paper, and then use the glass fiber paper adhesive tape on the low voltage coil 1 The last layer of copper tape is fixed, and then a layer of rhombus dispensing paper is used for interlayer insulation;

[0029] Step 3: Winding the high-voltage winding, firstly use the high-voltage magnet wire 2 itself to insulate and laminate the upper layer of r...

Embodiment 2

[0034] A method for enhancing the insulation and mechanical strength of high-voltage coils of amorphous alloy transformers. The method includes the following steps:

[0035] (1) Wrap the side ends of the transformer special copper tape on the outer layer of the low-voltage winding with diamond dispensing paper, and fix the diamond dispensing paper with glass fiber paper adhesive tape;

[0036] (2) Wrap the transformer special copper tape wrapped with rhombic dispensing paper on both ends of the side tightly on the insulating layer of rhombic dispensing paper, then fix the copper tape with a glass fiber paper adhesive tape, and then wrap it around the copper tape A layer of rhombus dispensing paper for interlayer insulation;

[0037] (3) The winding of the high-voltage winding is to insulate and laminate the high-voltage part of the magnet wire with the rhombic dispensing paper, and fix the magnet wire with the glass fiber paper adhesive tape;

[0038] (4) On the outer layer of the fir...

Embodiment 3

[0041] A method for enhancing the insulation and mechanical strength of high-voltage coils of amorphous alloy transformers. The method includes the following steps:

[0042] (1) Wrap the side ends of the transformer special copper tape on the outer layer of the low-voltage winding with diamond dispensing paper, and fix the diamond dispensing paper with glass fiber paper adhesive tape;

[0043] (2) Wrap the transformer special copper tape wrapped with rhombic dispensing paper on both ends of the side tightly on the insulating layer of rhombic dispensing paper, then fix the copper tape with a glass fiber paper adhesive tape, and then wrap it around the copper tape A layer of rhombus dispensing paper for interlayer insulation;

[0044] (3) The winding of the high-voltage winding is to insulate and laminate the high-voltage part of the magnet wire with the rhombic dispensing paper, and fix the magnet wire with the glass fiber paper adhesive tape;

[0045] (4) On the outer layer of the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com