Patents

Literature

643 results about "Magnet wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnet wire or enameled wire is a copper or aluminium wire coated with a very thin layer of insulation. It is used in the construction of transformers, inductors, motors, generators, speakers, hard disk head actuators, electromagnets, and other applications that require tight coils of insulated wire.

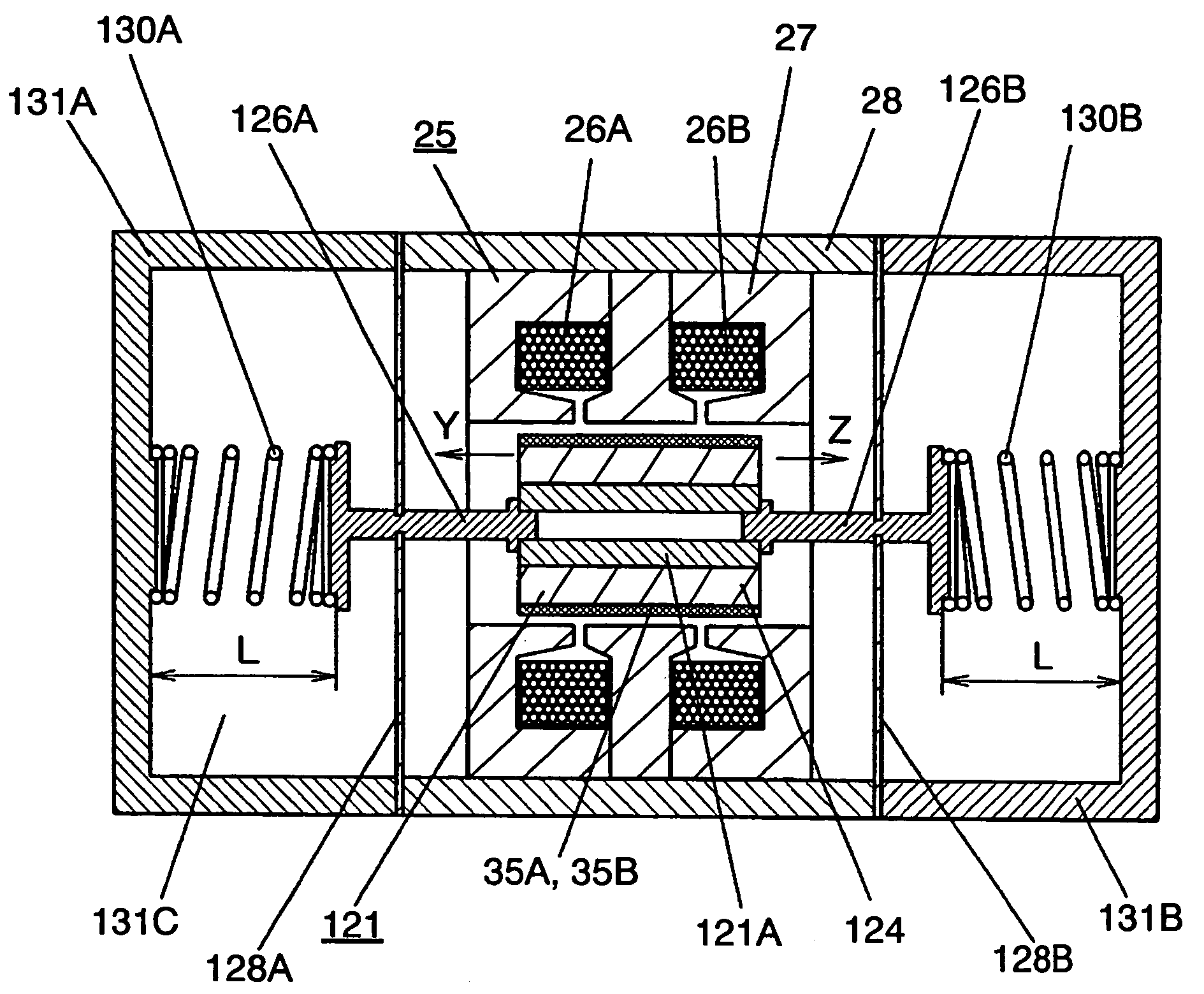

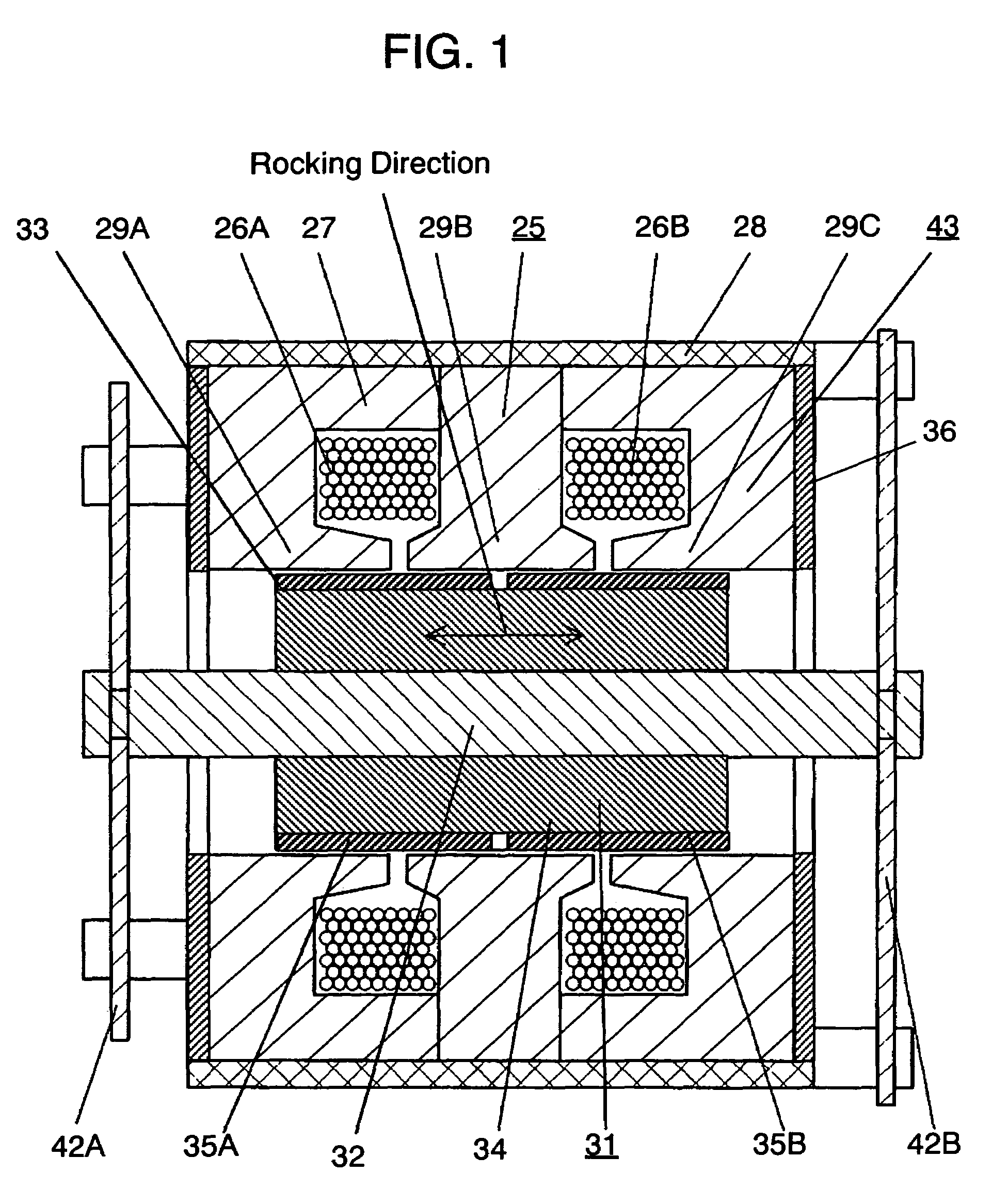

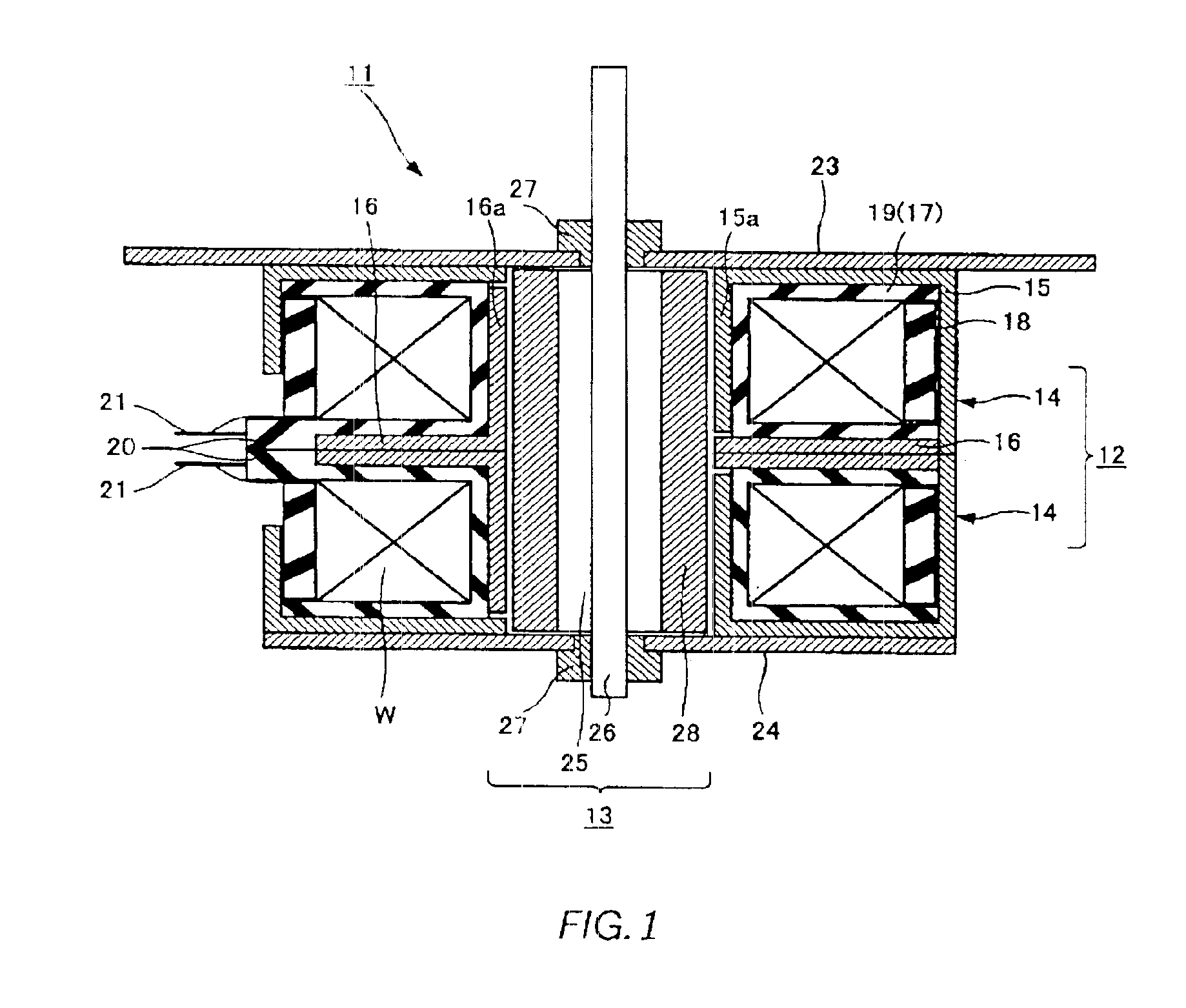

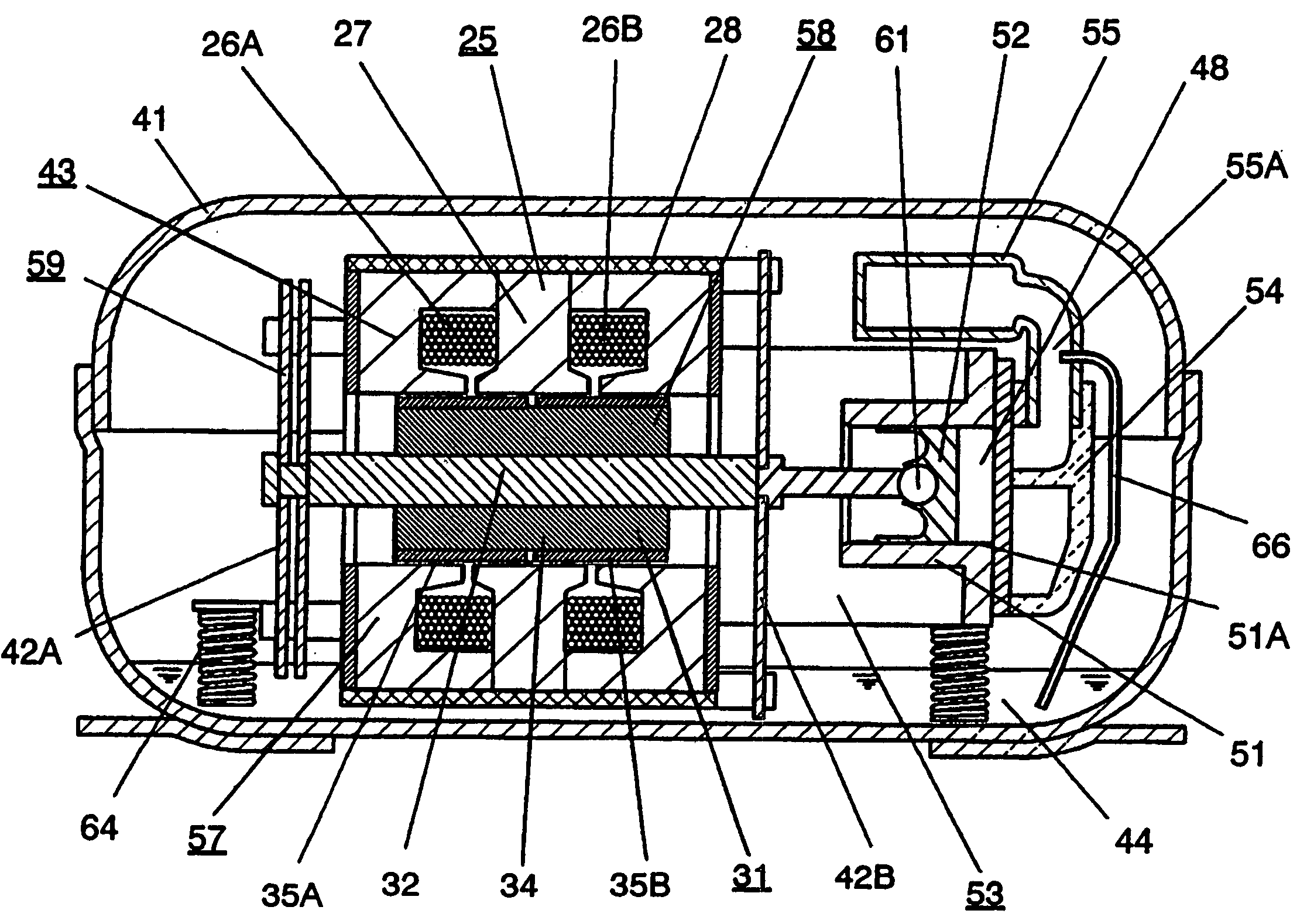

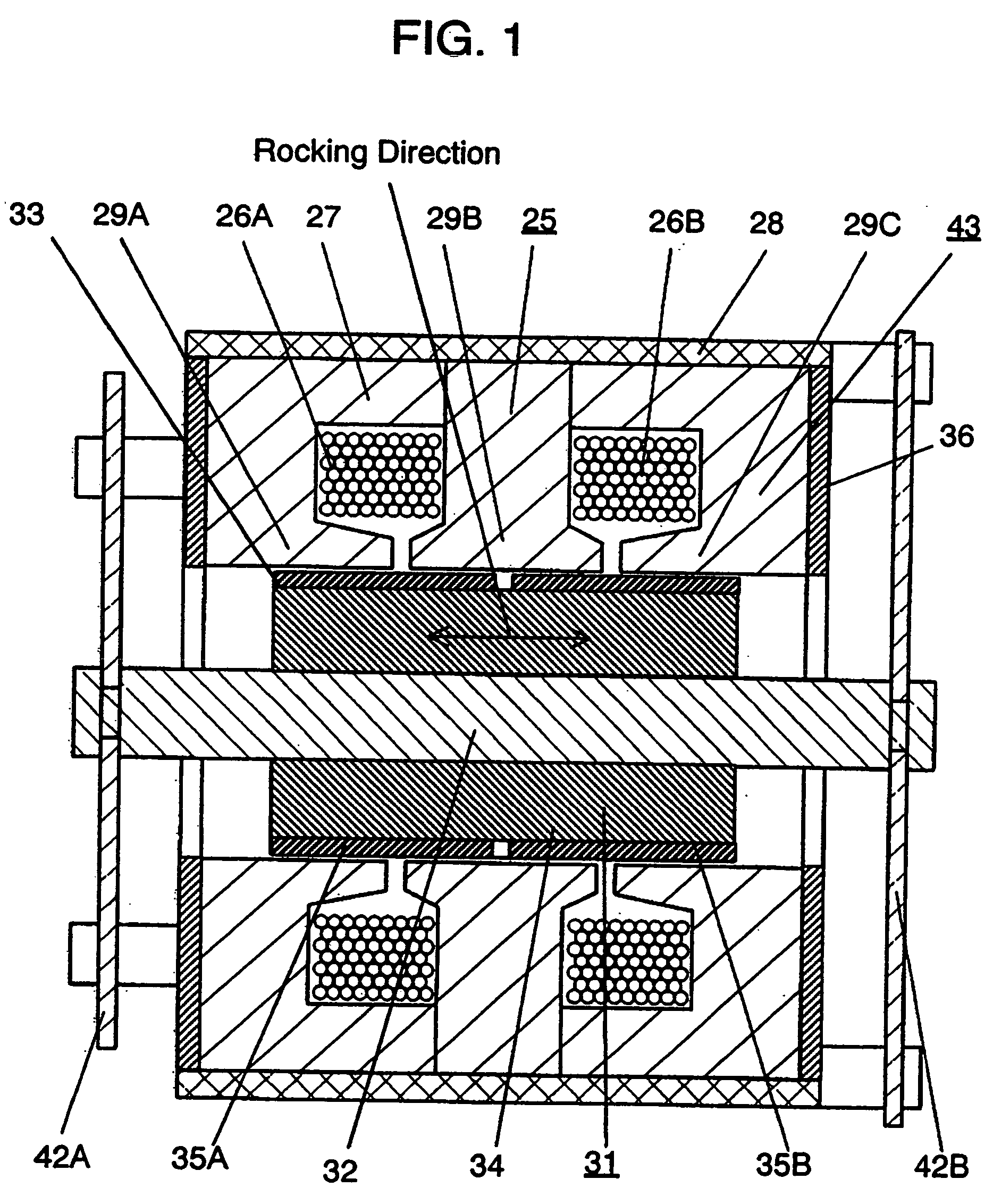

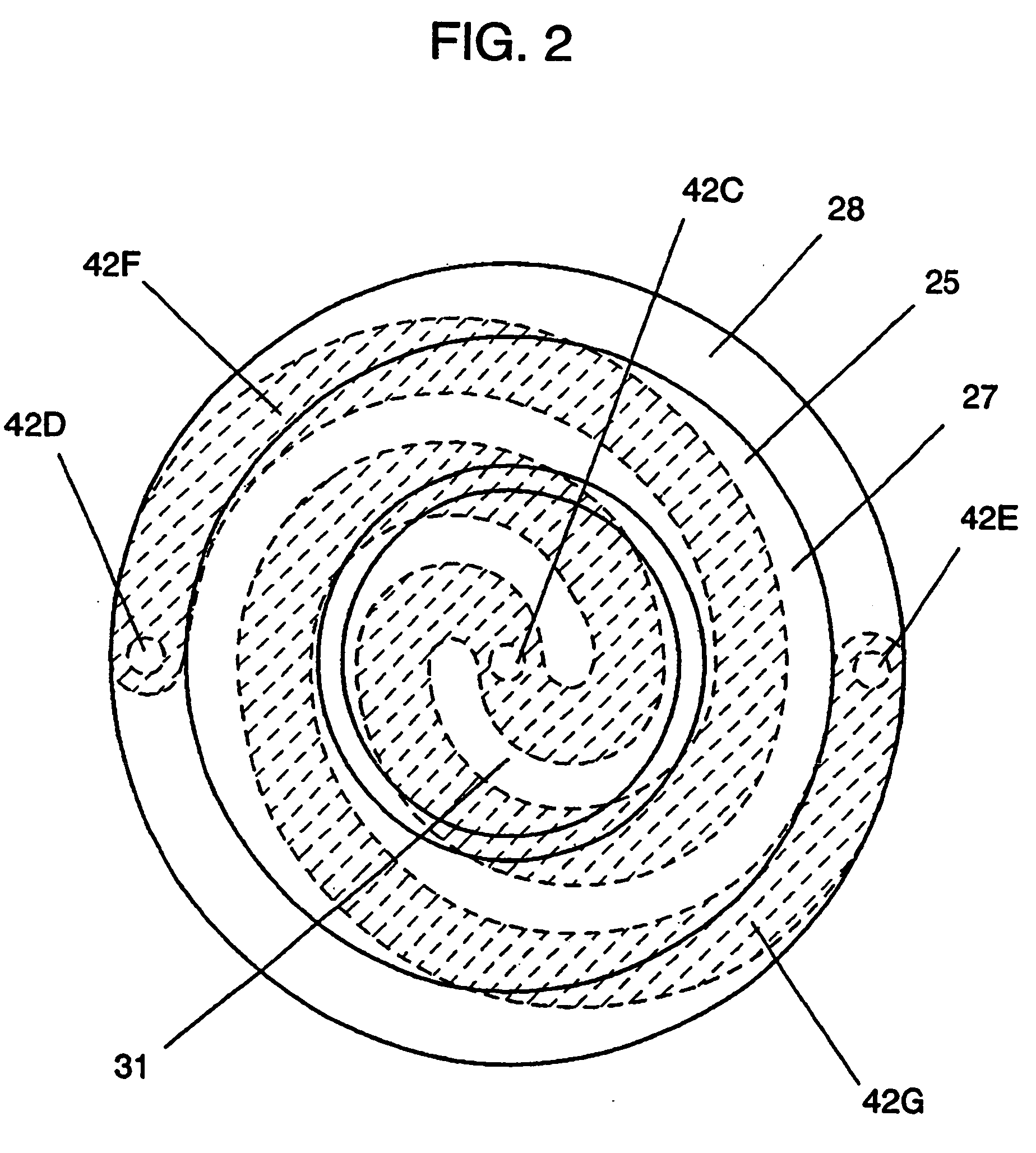

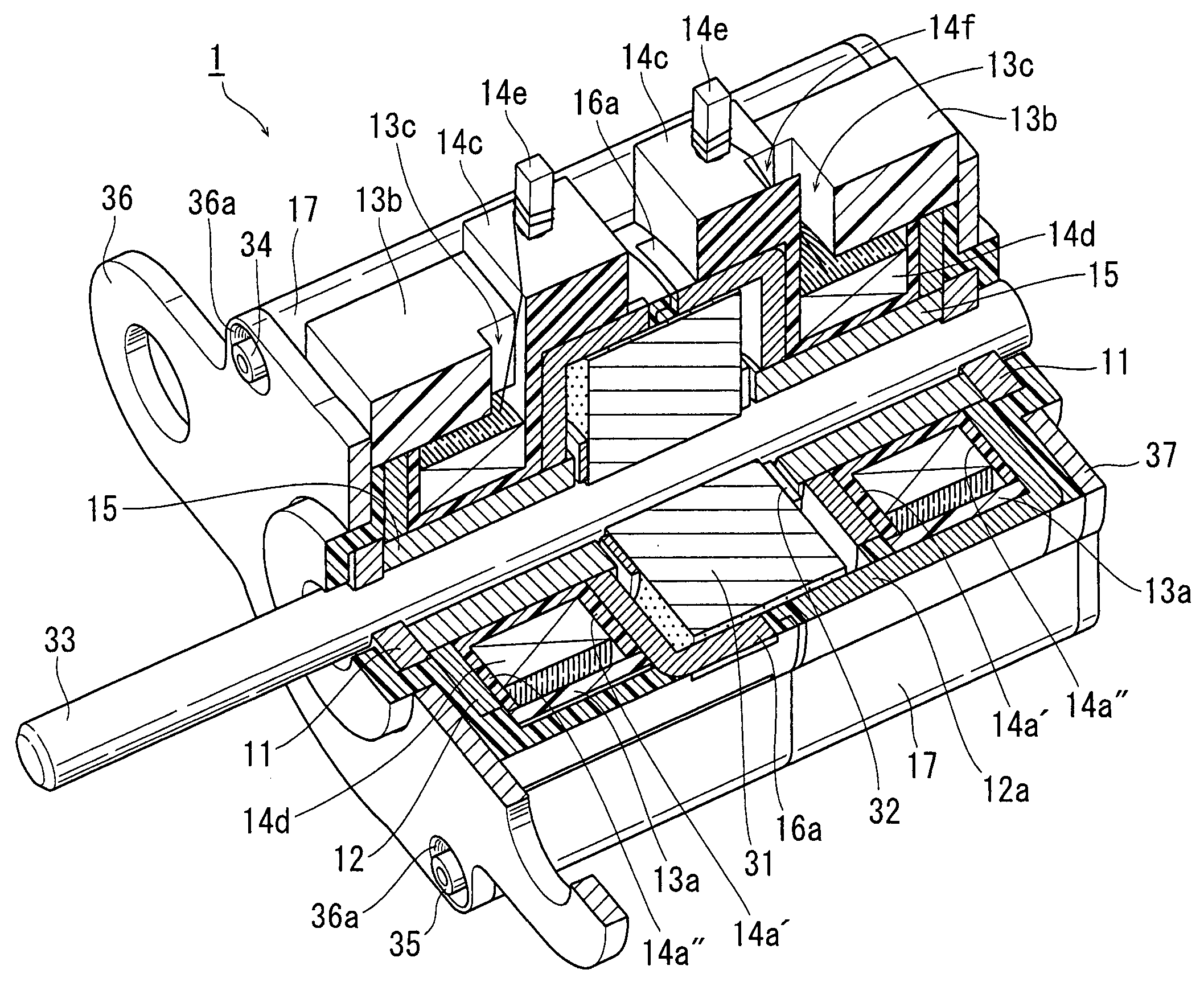

Linear motor, and linear compressor using the same

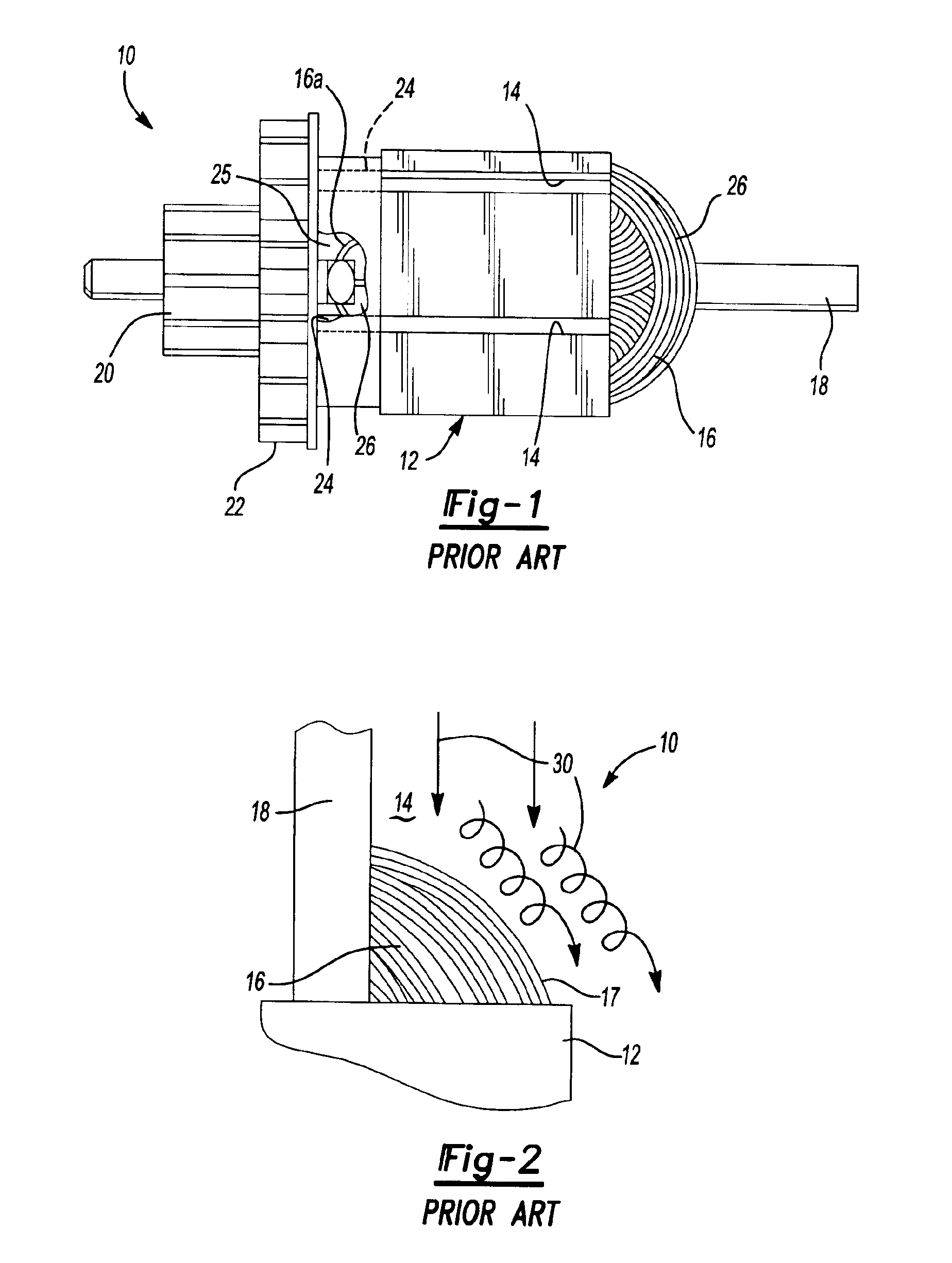

A linear motor of the present invention has: a stator having a stationary iron core and a magnet wire; a mover having a moving iron core and a magnet; and a plate-shaped elastic member for supporting the mover in a manner to rock in the rocking directions. This construction eliminates a sliding portion for supporting the mover so that it can reduce the loss, which might otherwise accompany the reciprocation of the mover. Moreover, a linear compressor using this linear motor is high in efficiency and reliability.

Owner:PANASONIC CORP

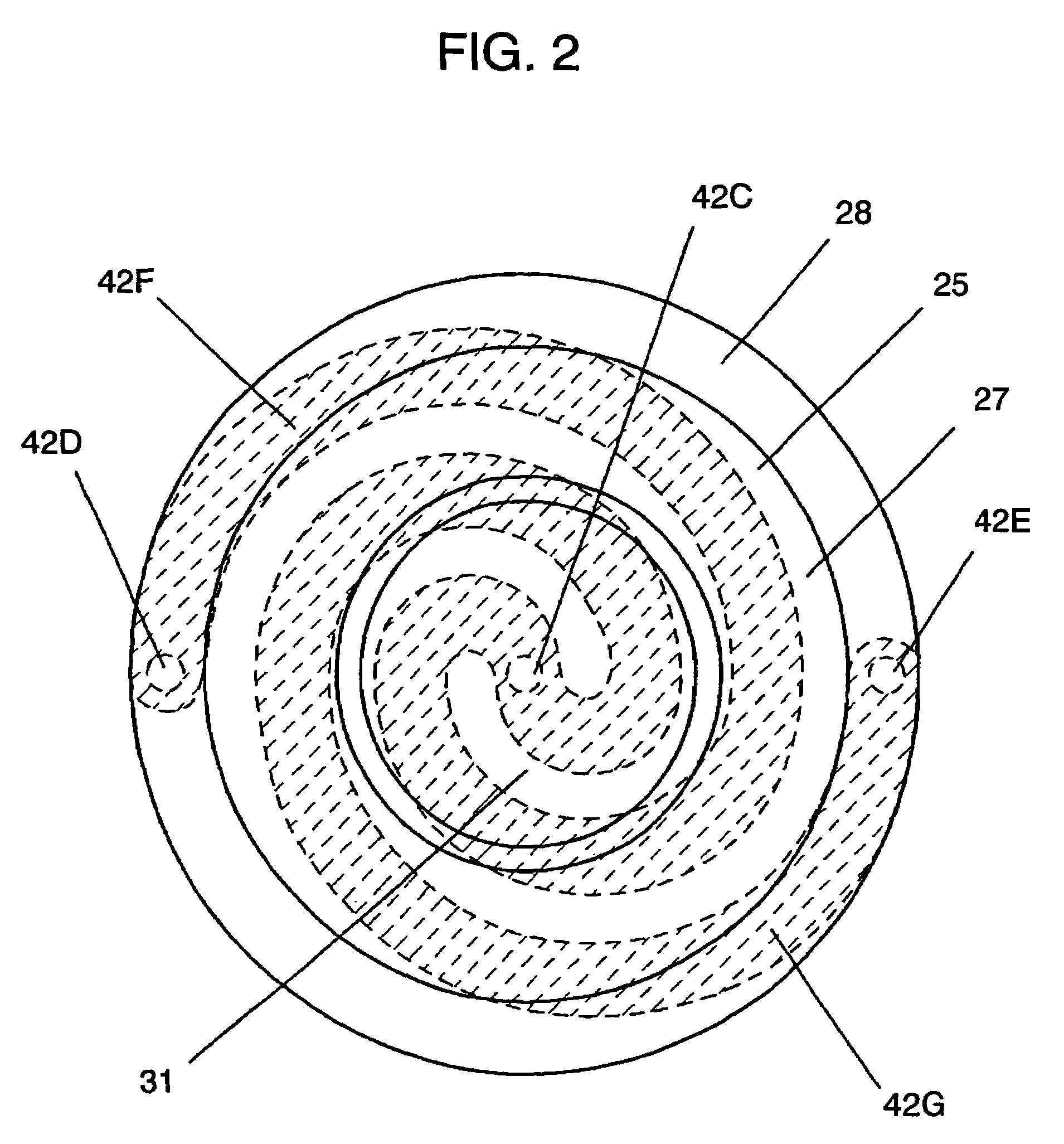

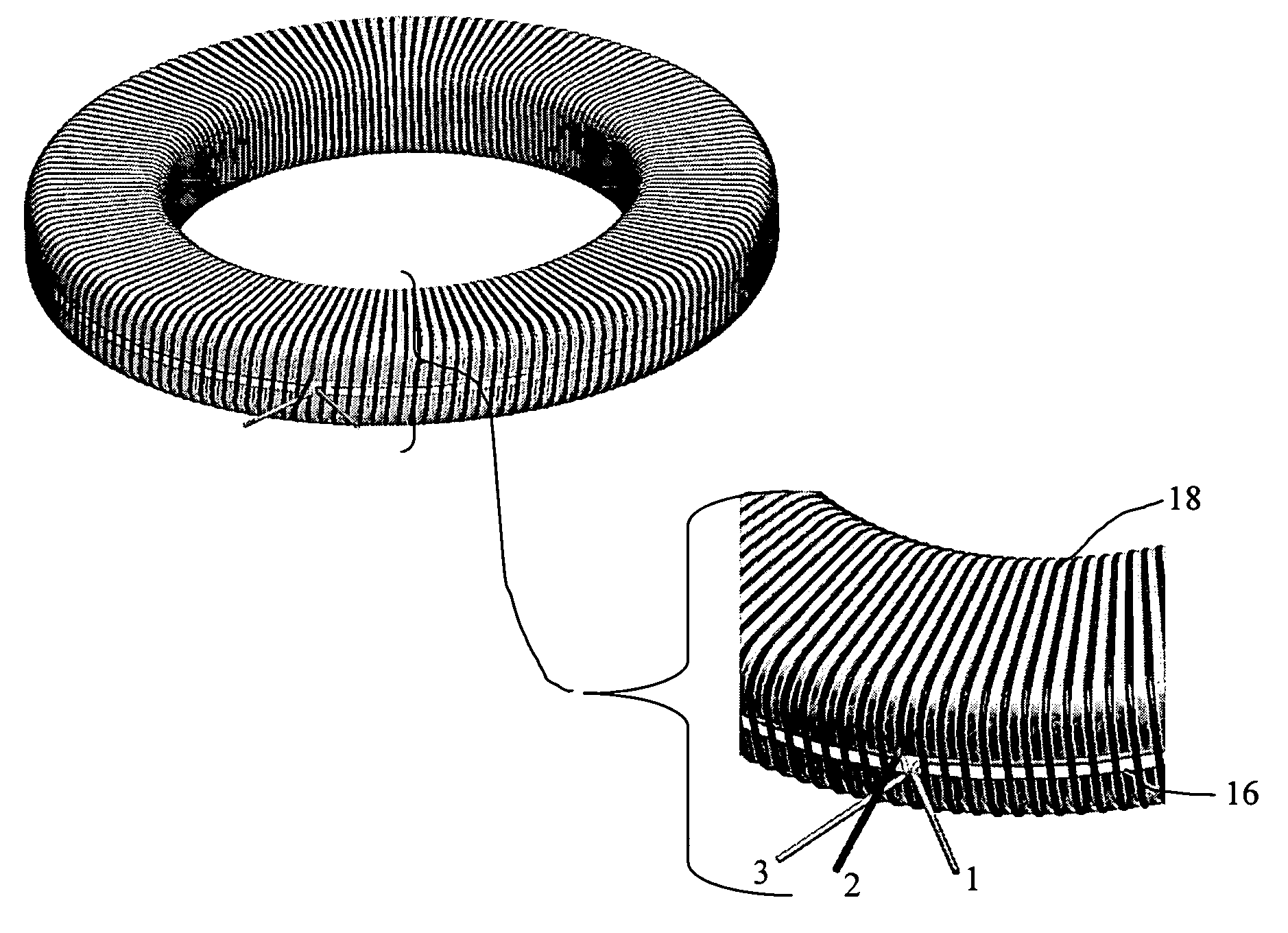

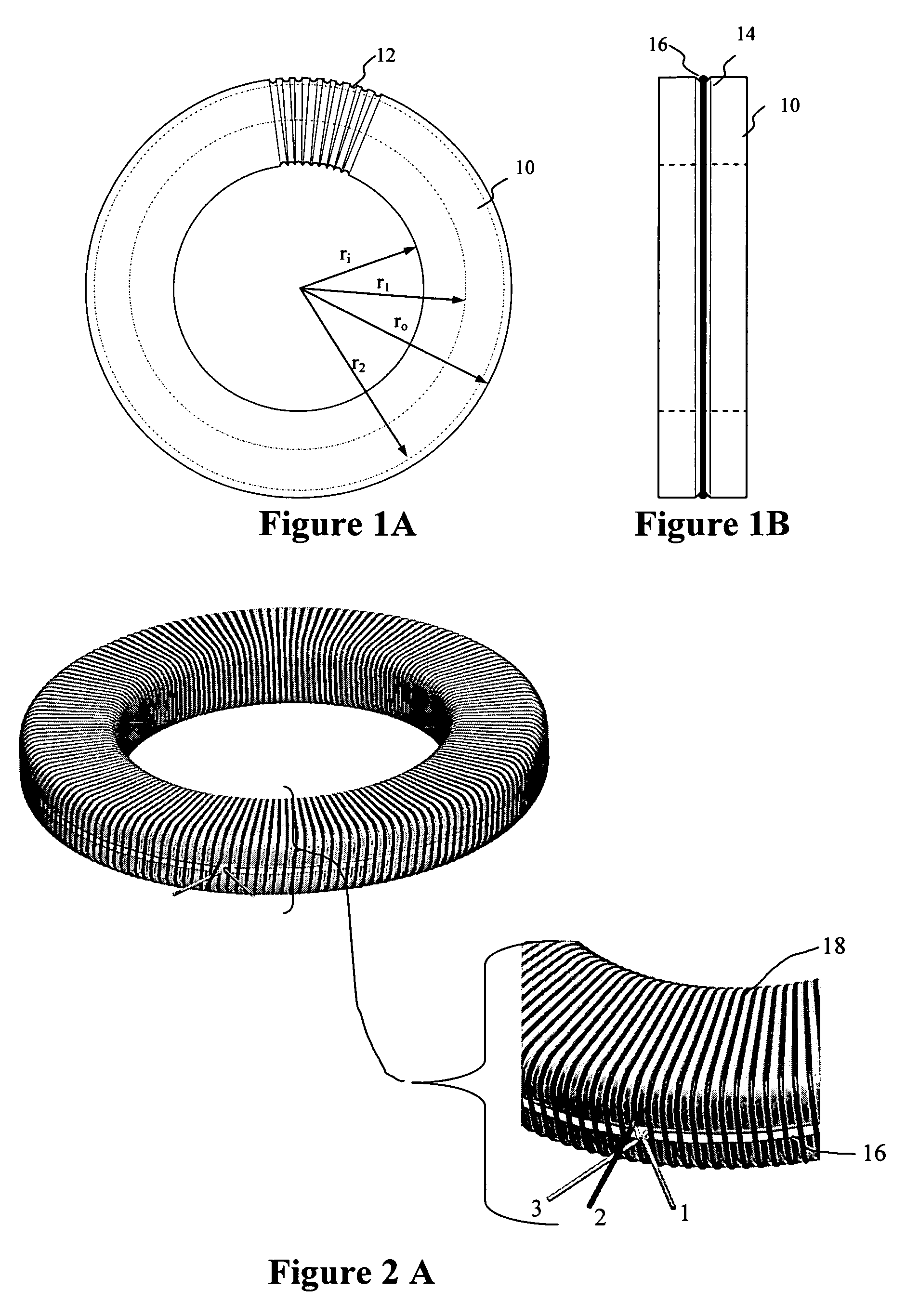

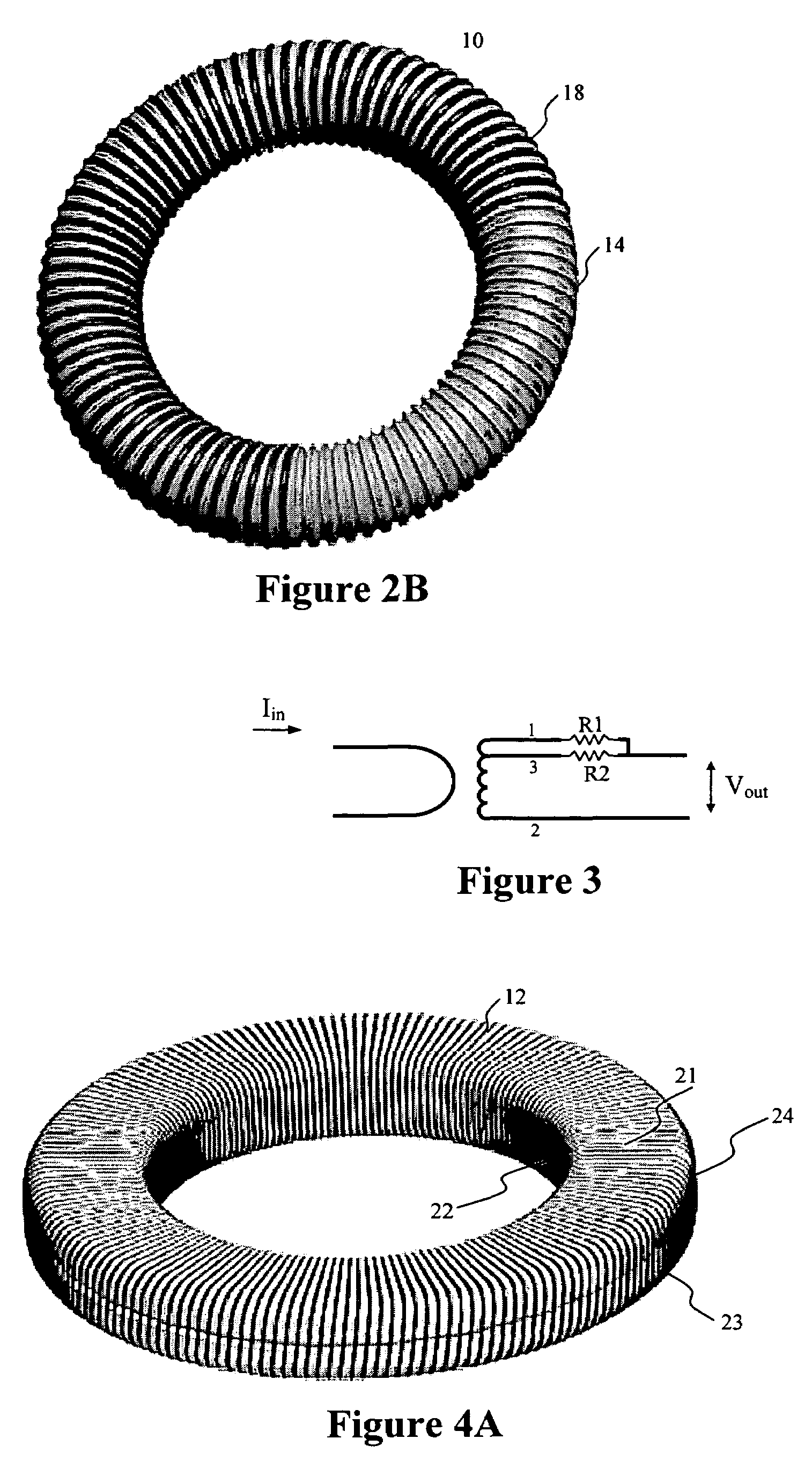

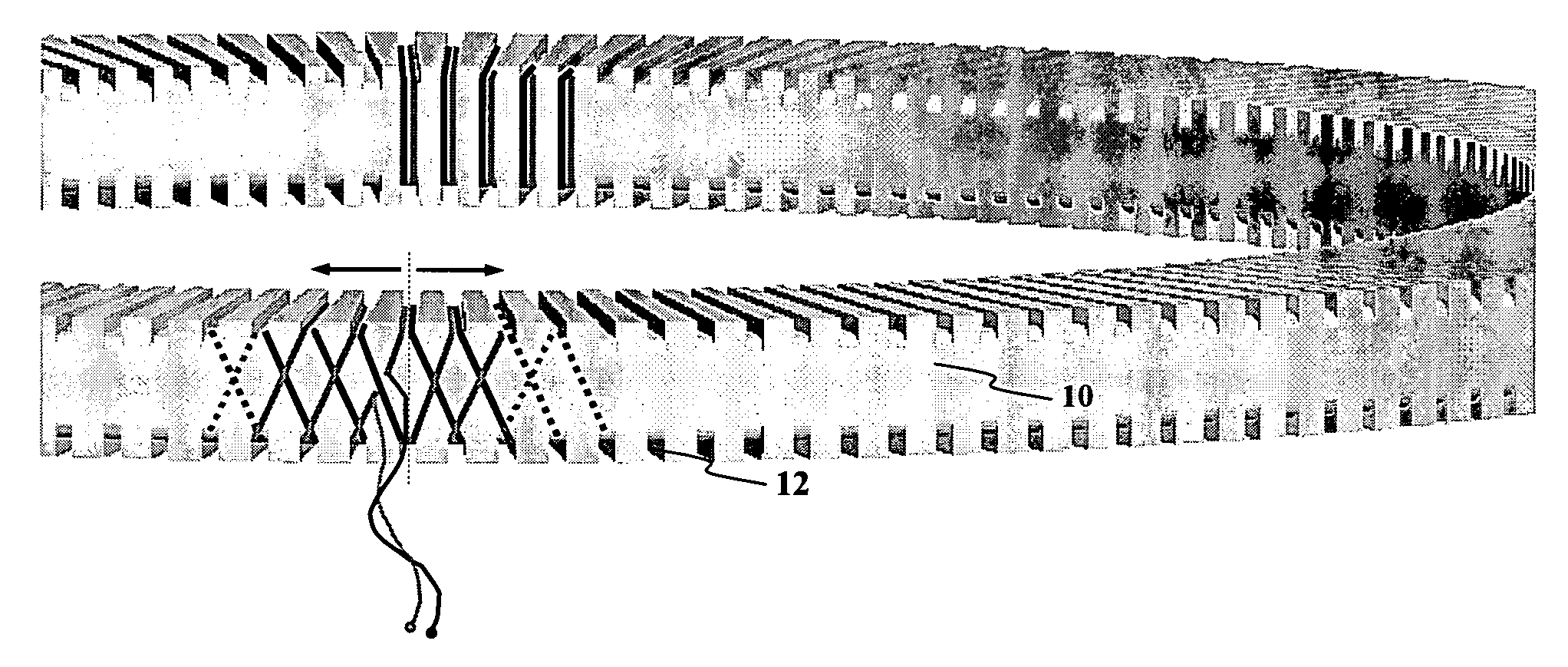

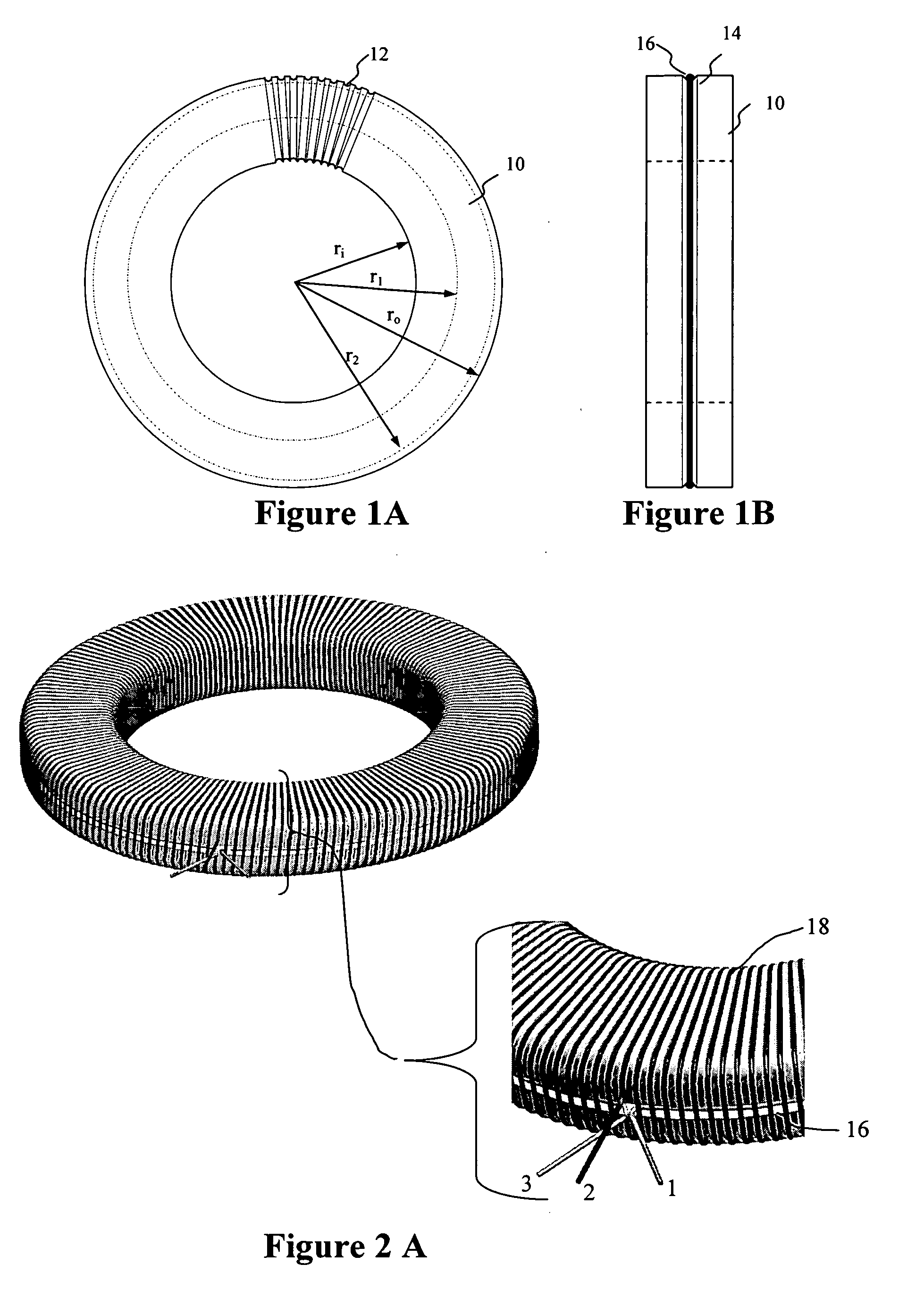

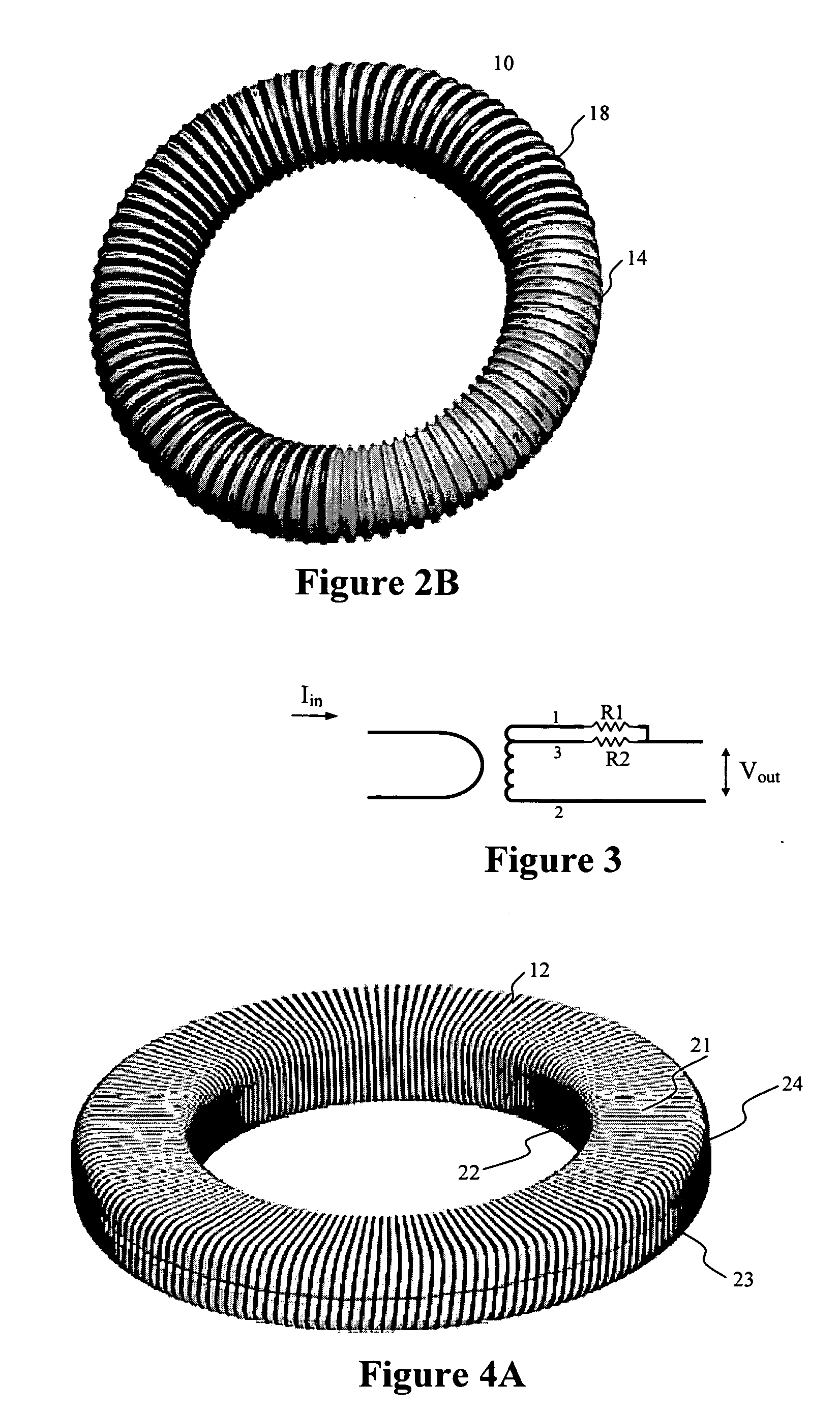

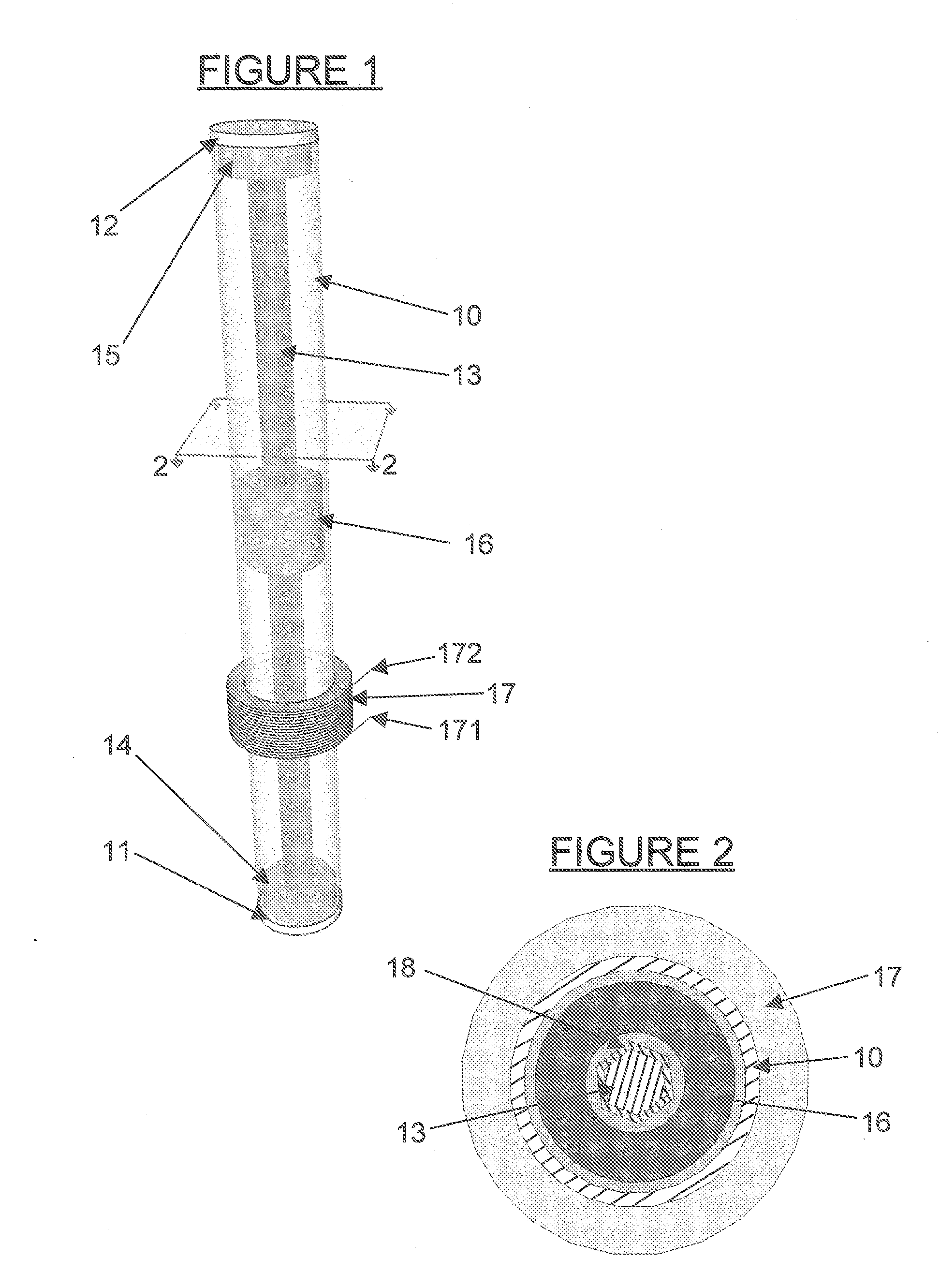

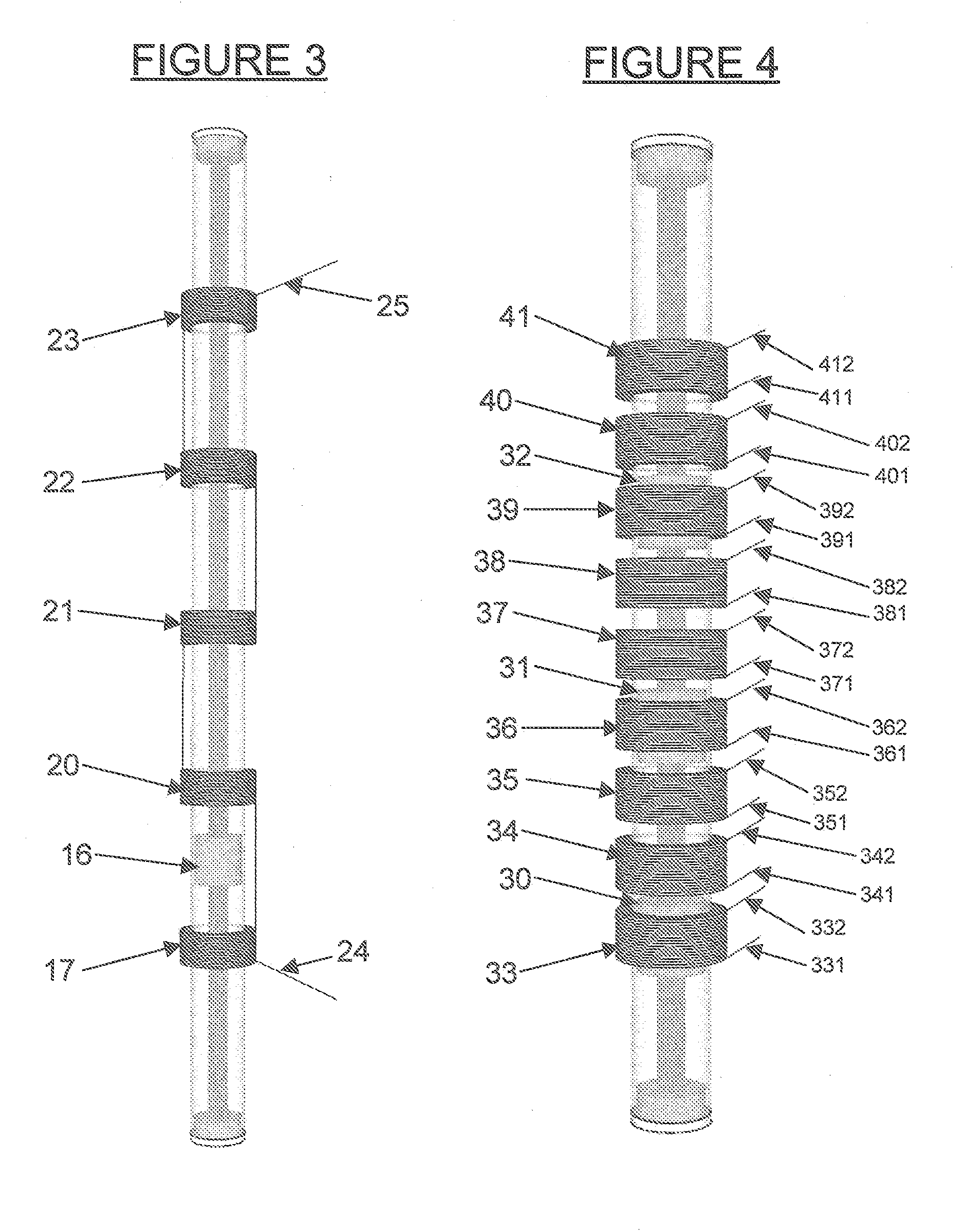

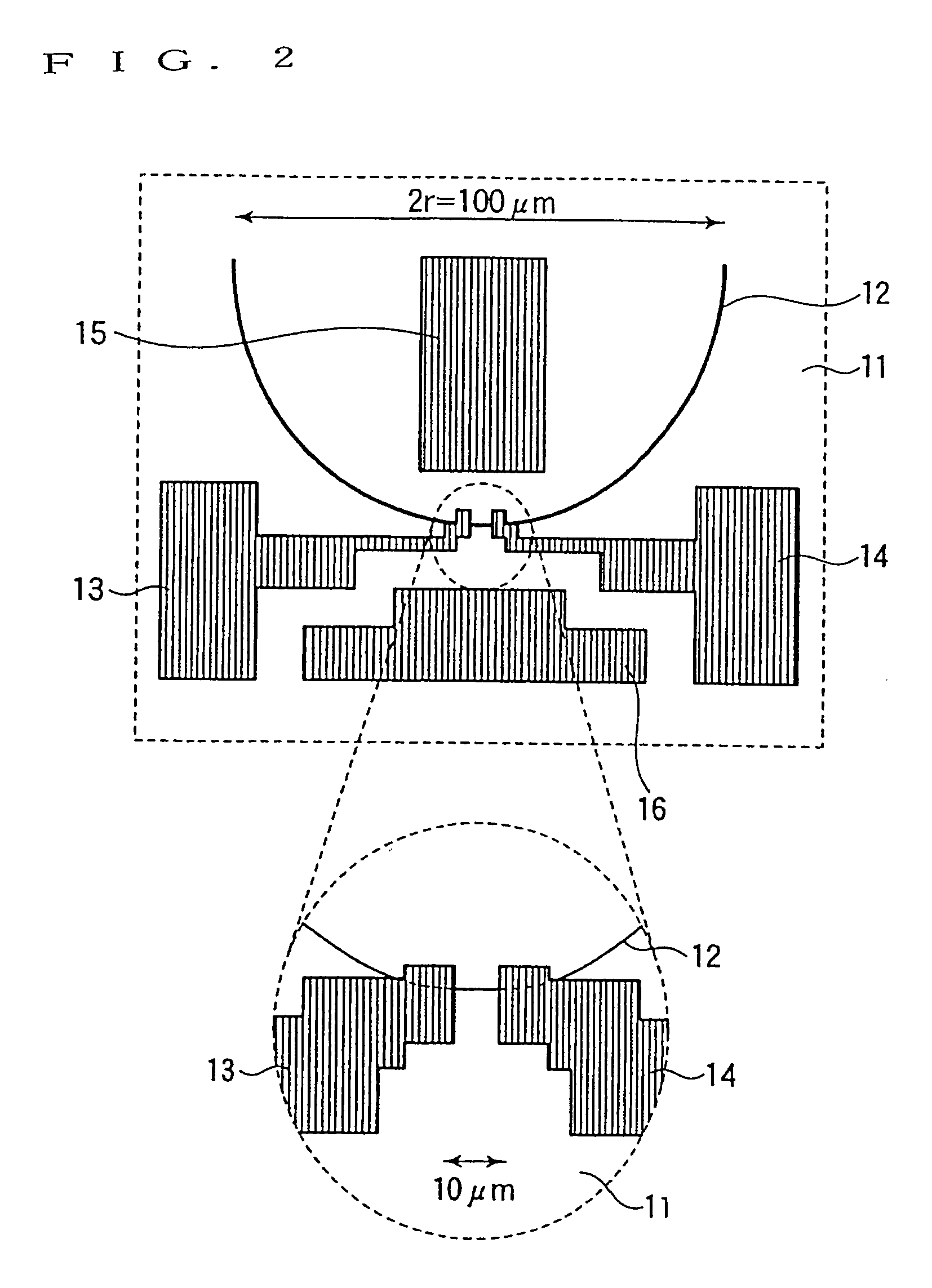

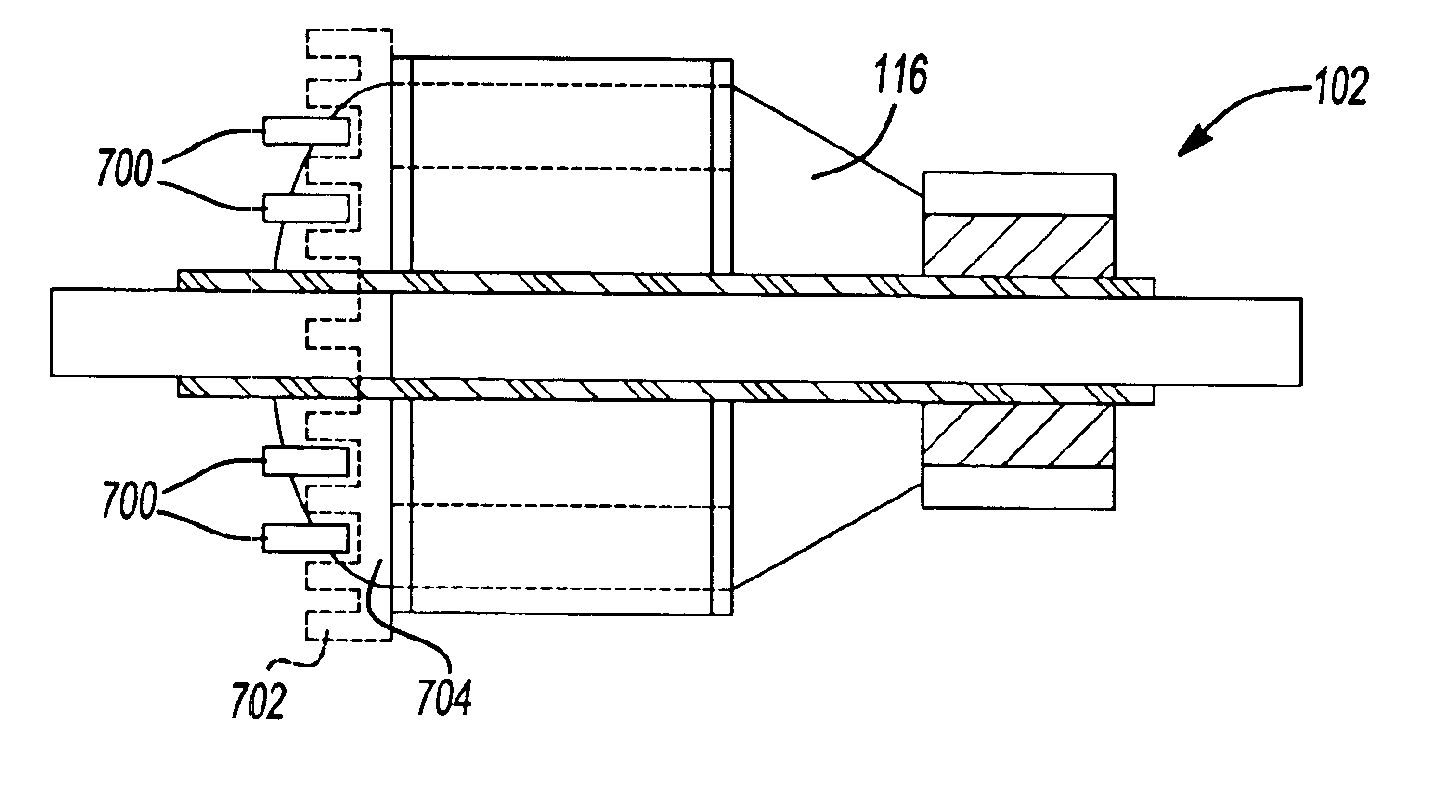

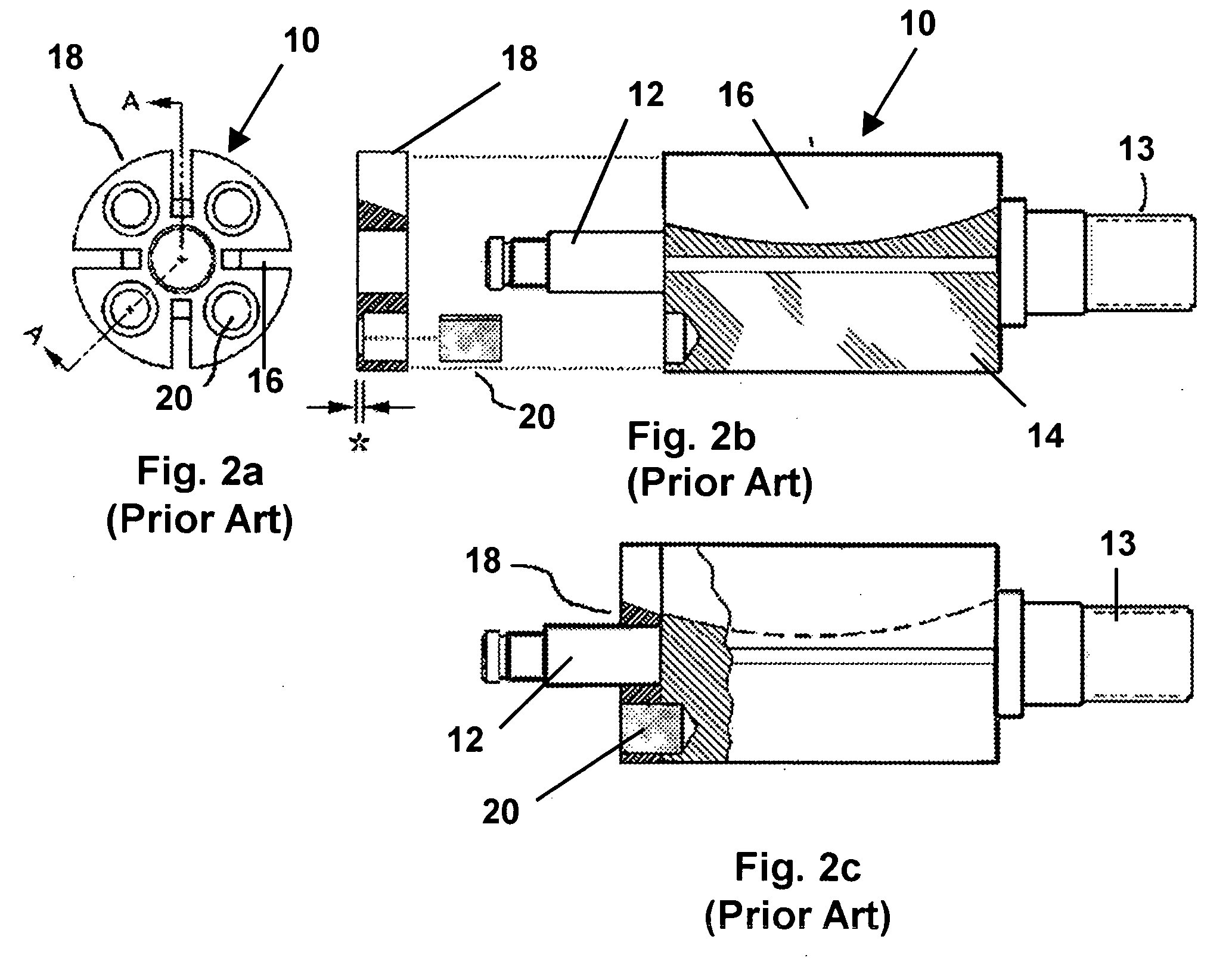

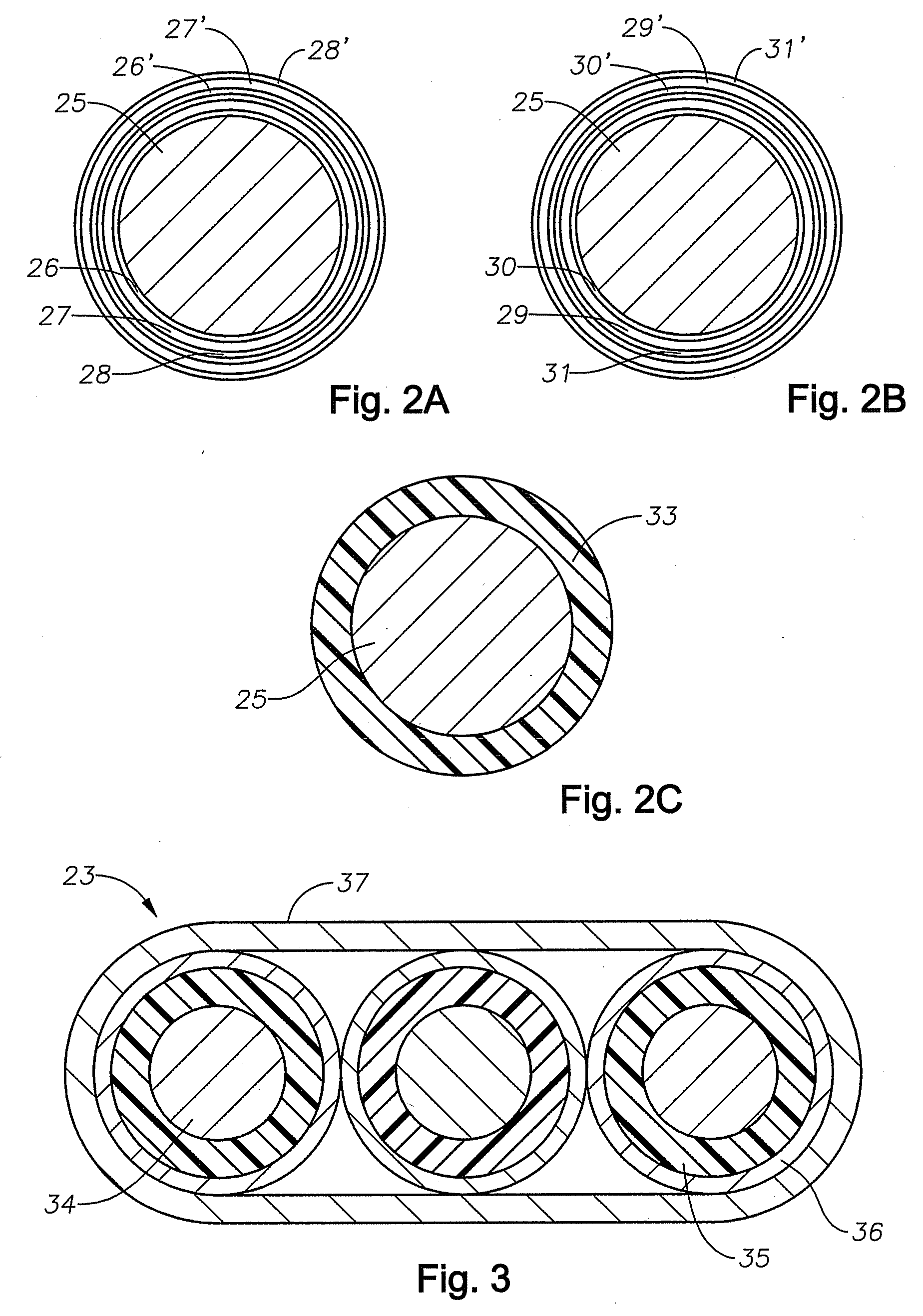

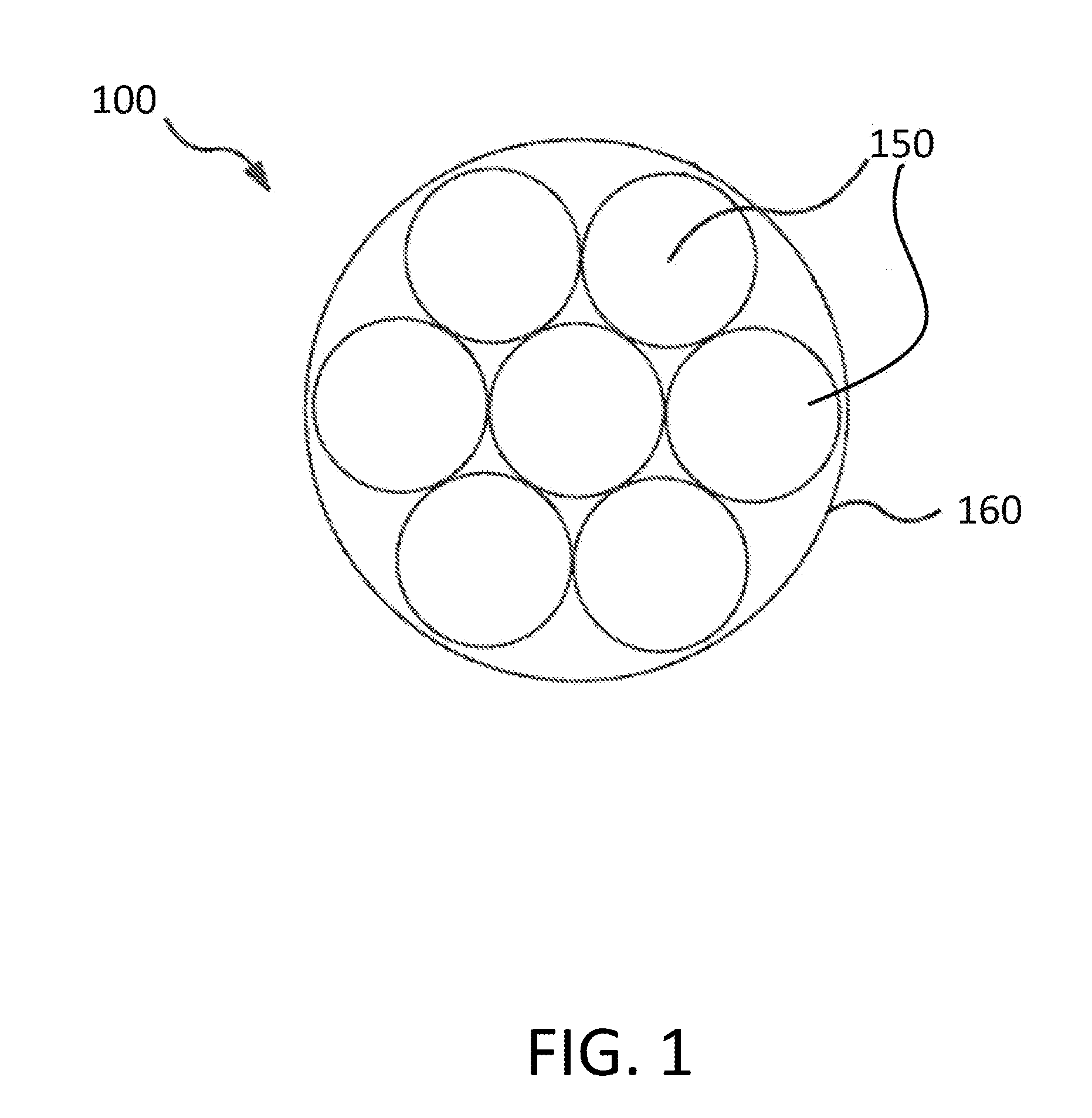

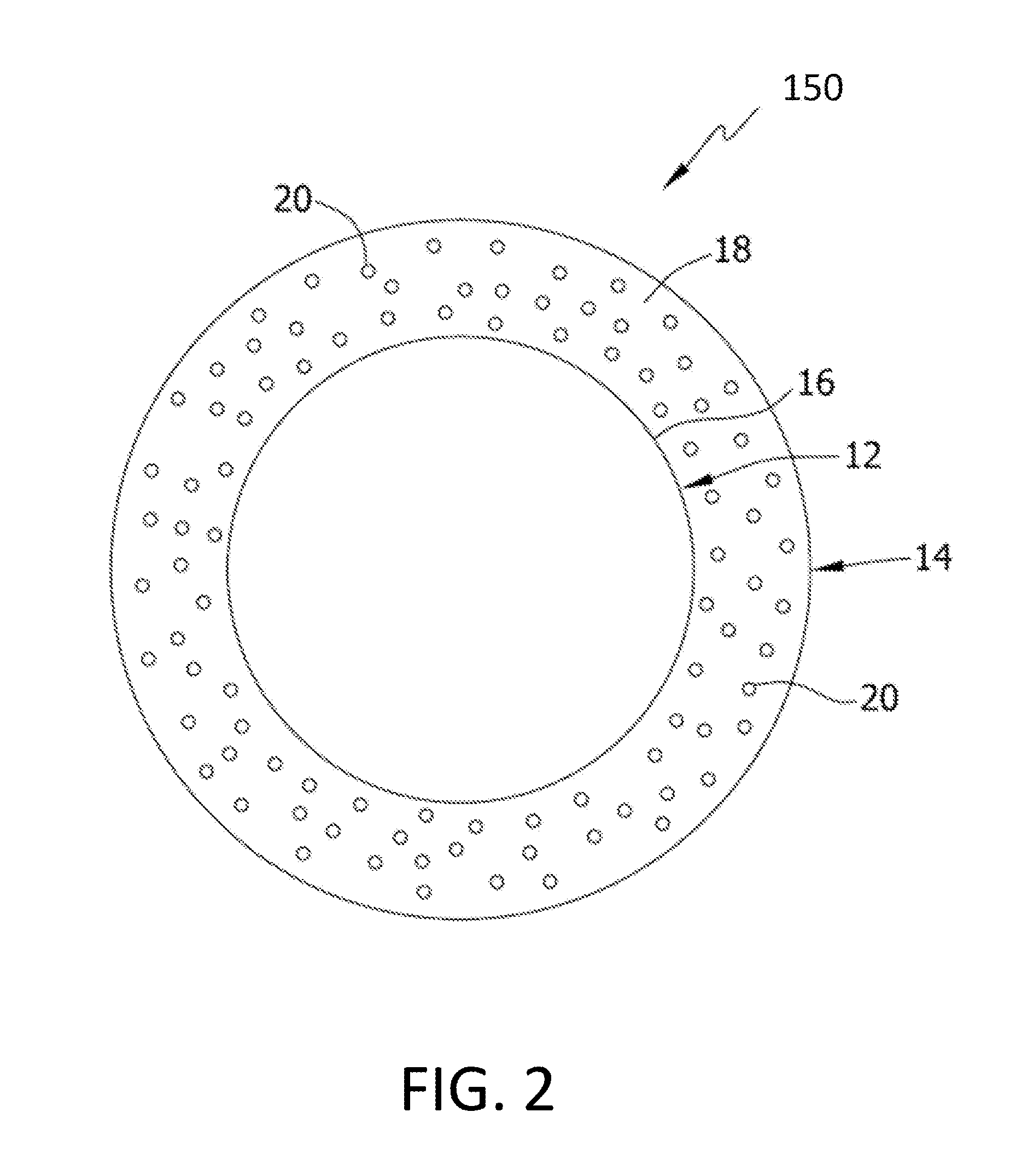

Precision Rogowski coil and method for manufacturing same

InactiveUS7227441B2Transformers/inductances coils/windings/connectionsElectrical measurementsThermoplasticElectrical resistance and conductance

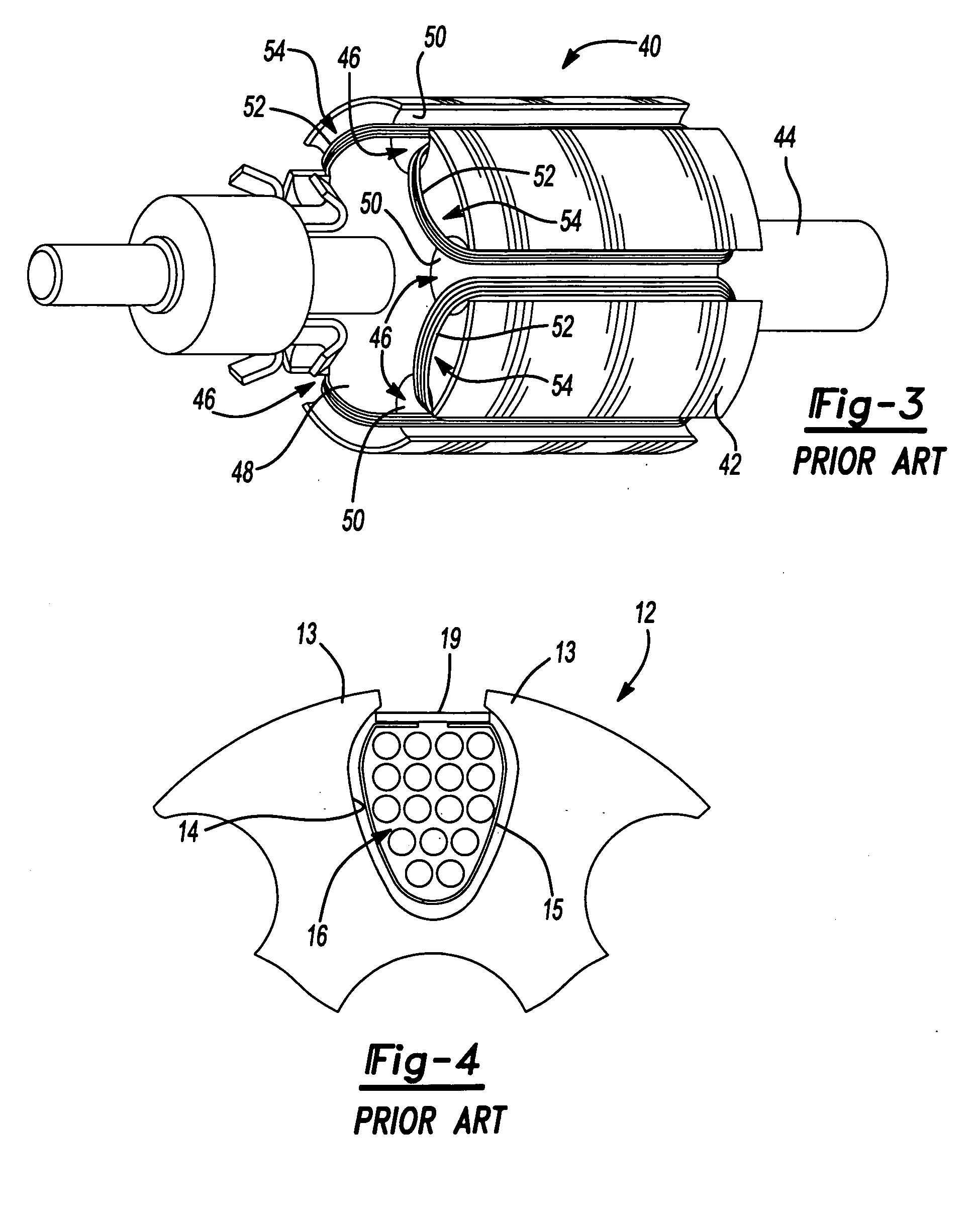

An improved Rogowski coil is formed on a toroidal core made of a thermoplastic or other moldable material, the core having a preferably continuous groove or grooves extending around the core. The grooves correspond in size to magnet wire which registers within the grooves, thus controlling the specific location of the wires. The grooving may be helical. A return loop can be provided for return path cancellation, or a reverse winding can be added in a direction opposite to the direction of advancement of the main coil. In using the return loop, a resistive network can be added to improve the cancellation of the return path due to the effect of geometries. In addition, it can compensate for thermal and other variations.

Owner:SCHWEITZER ENGINEERING LABORATORIES

Precision rogowski coil and method for manufacturing same

InactiveUS20060176140A1The location is limitedTransformers/inductances coils/windings/connectionsElectrical measurementsThermoplasticElectrical resistance and conductance

An improved Rogowski coil is formed on a toroidal core made of a thermoplastic or other moldable material, the core having a preferably continuous groove or grooves extending around the core. The grooves correspond in size to magnet wire which registers within the grooves, thus controlling the specific location of the wires. The grooving may be helical. A return loop can be provided for return path cancellation, or a reverse winding can be added in a direction opposite to the direction of advancement of the main coil. In using the return loop, a resistive network can be added to improve the cancellation of the return path due to the effect of geometries. In addition, it can compensate for thermal and other variations.

Owner:SCHWEITZER ENGINEERING LABORATORIES

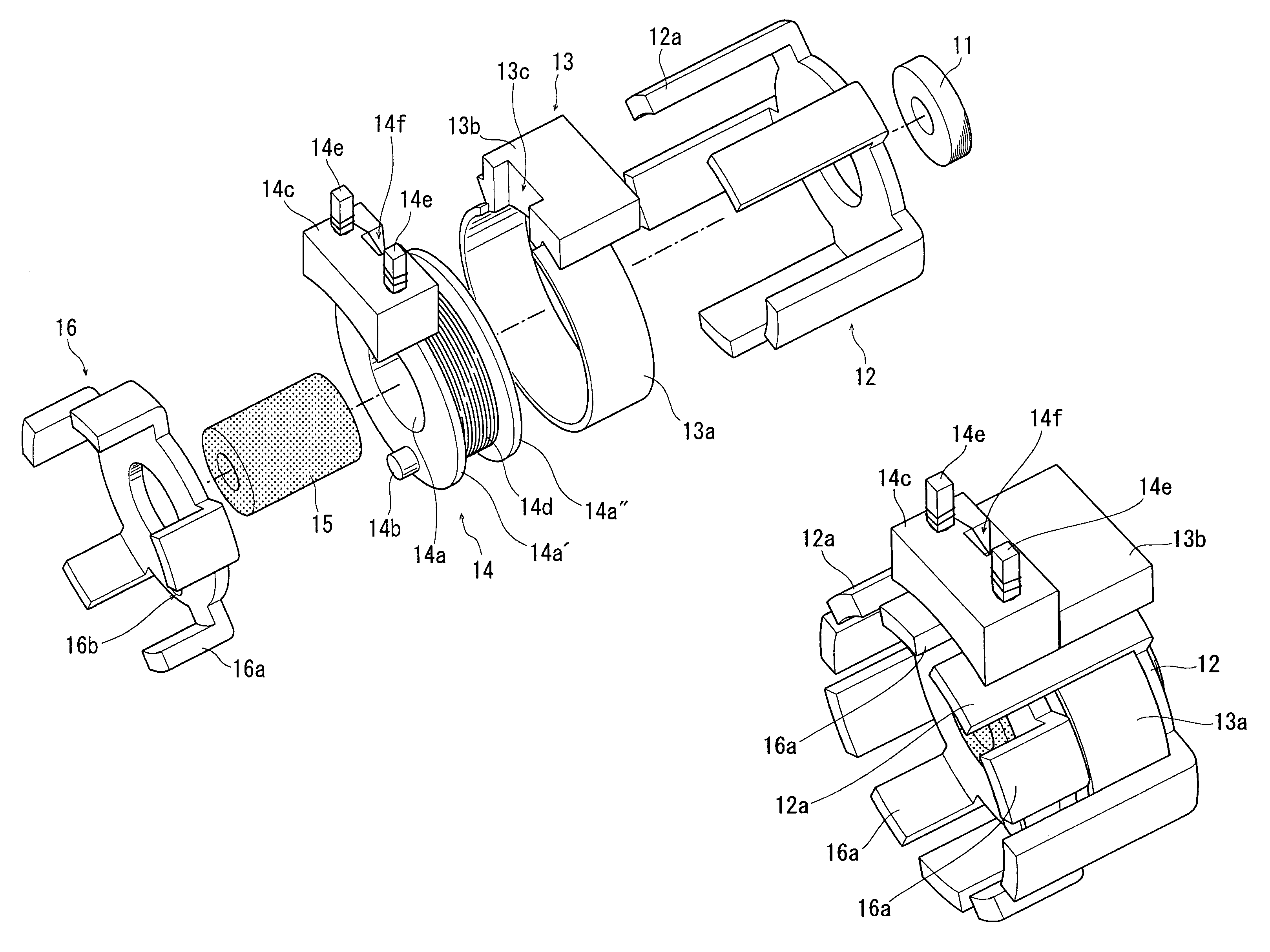

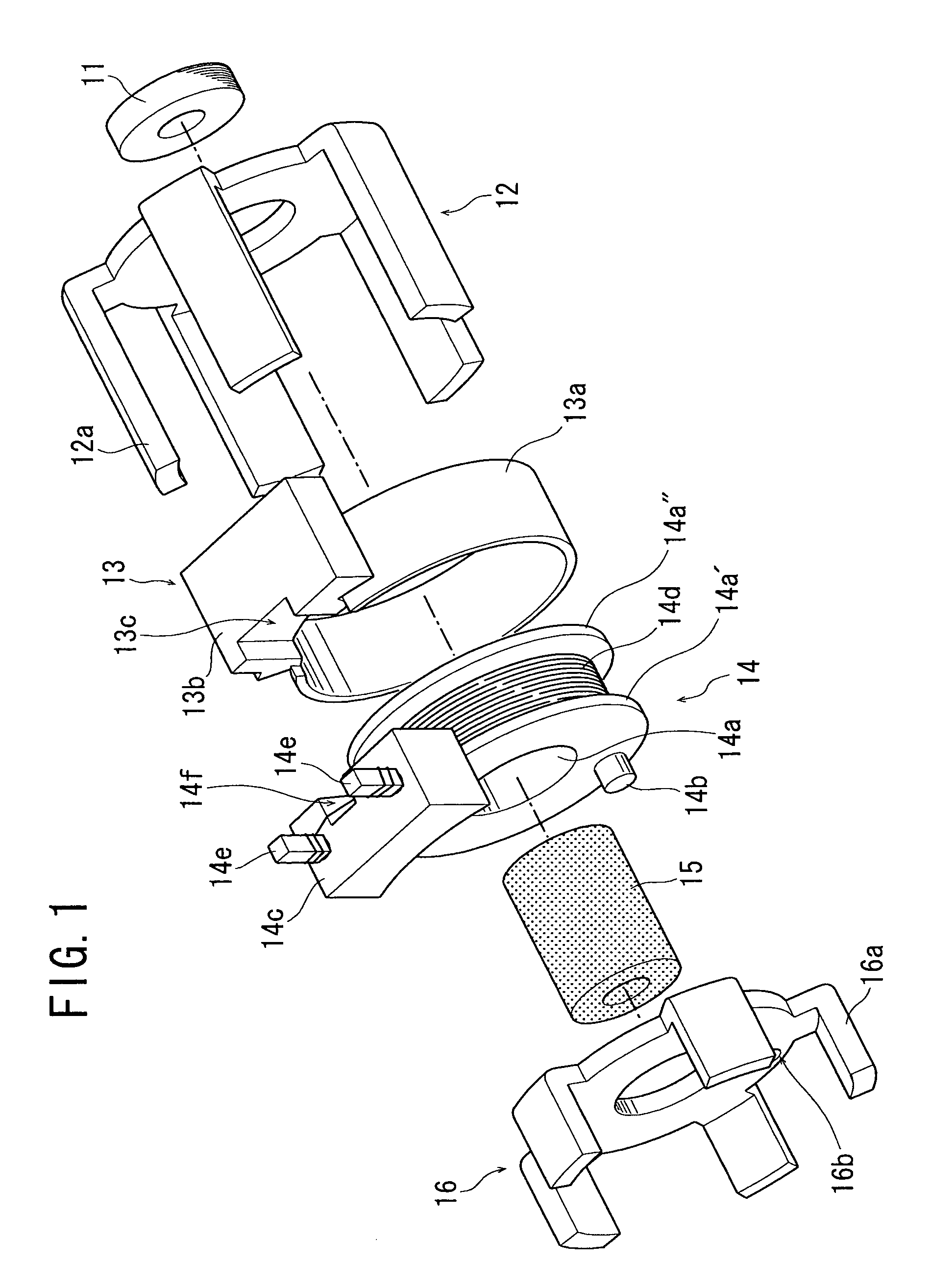

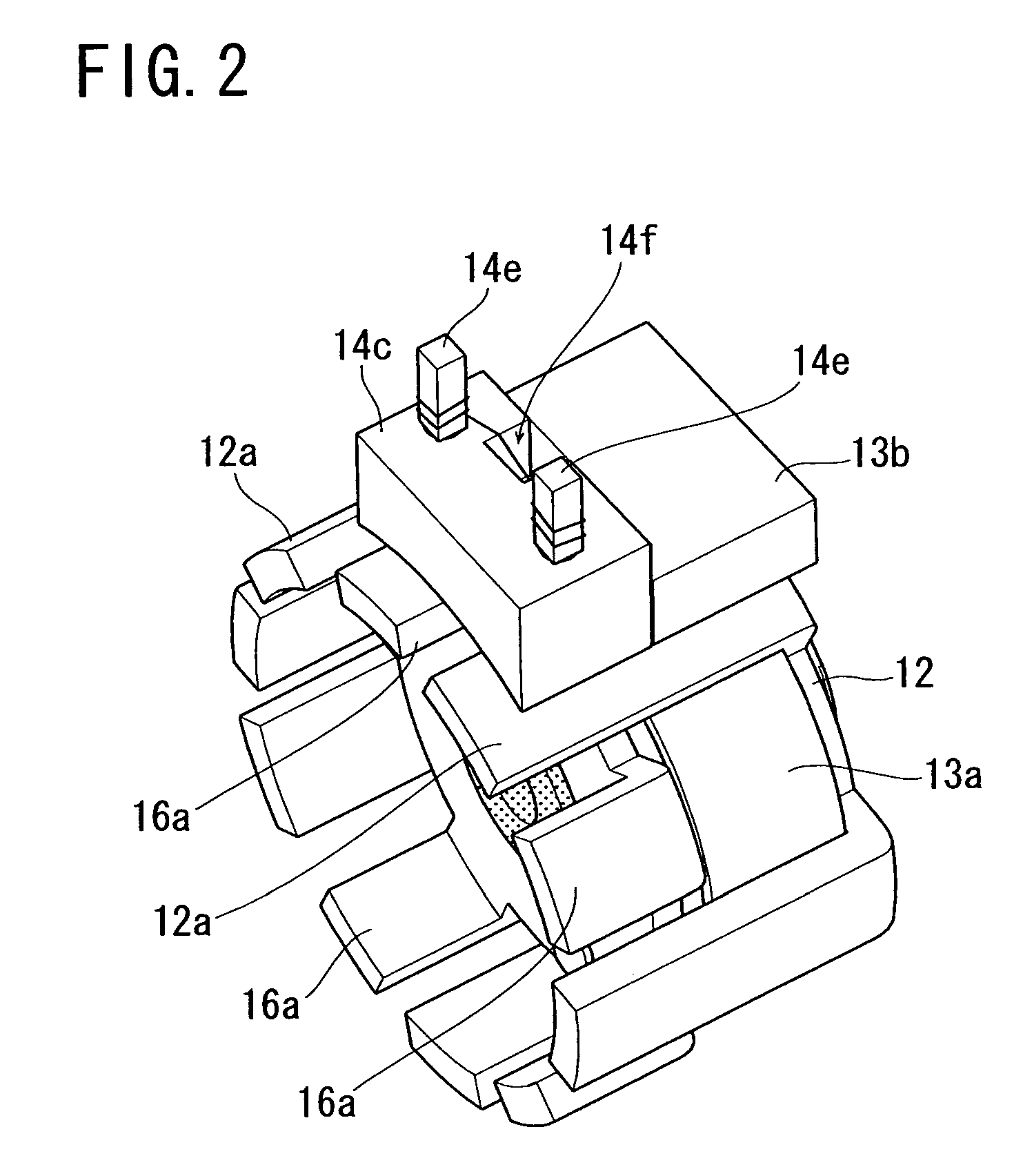

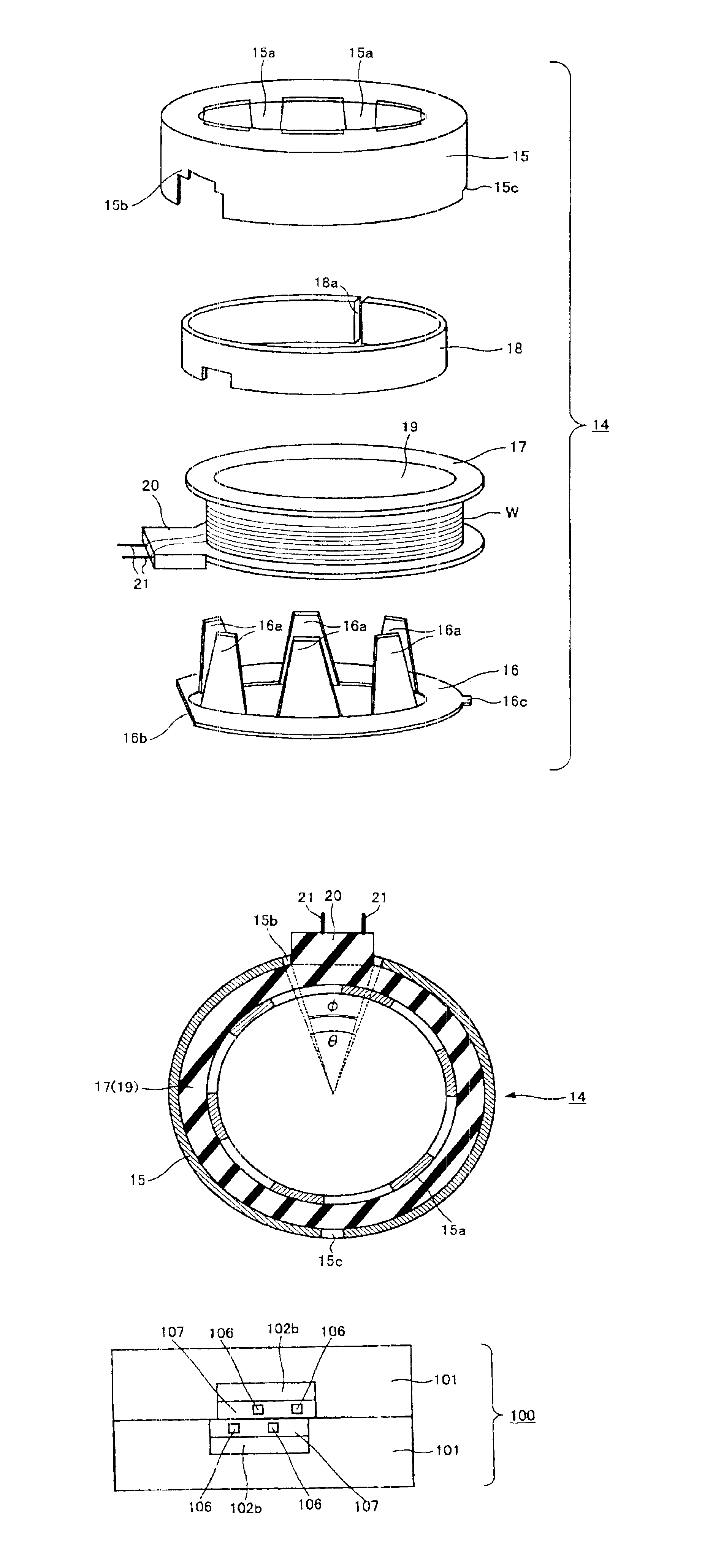

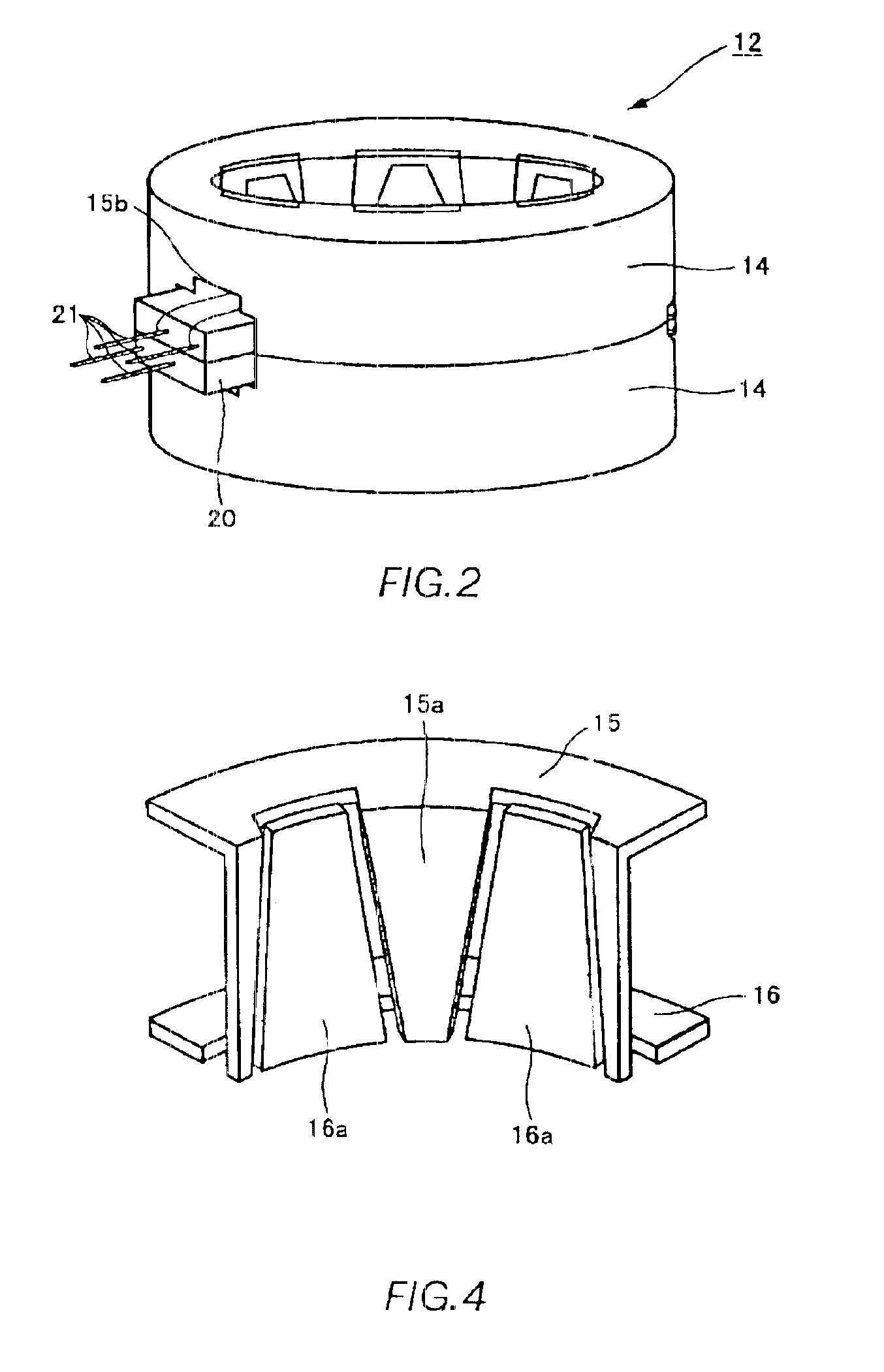

Claw-pole type stepping motor

InactiveUS7071593B2Reduce radial sizeMaintain mechanical strengthSynchronous generatorsWindingsBobbinSolid structure

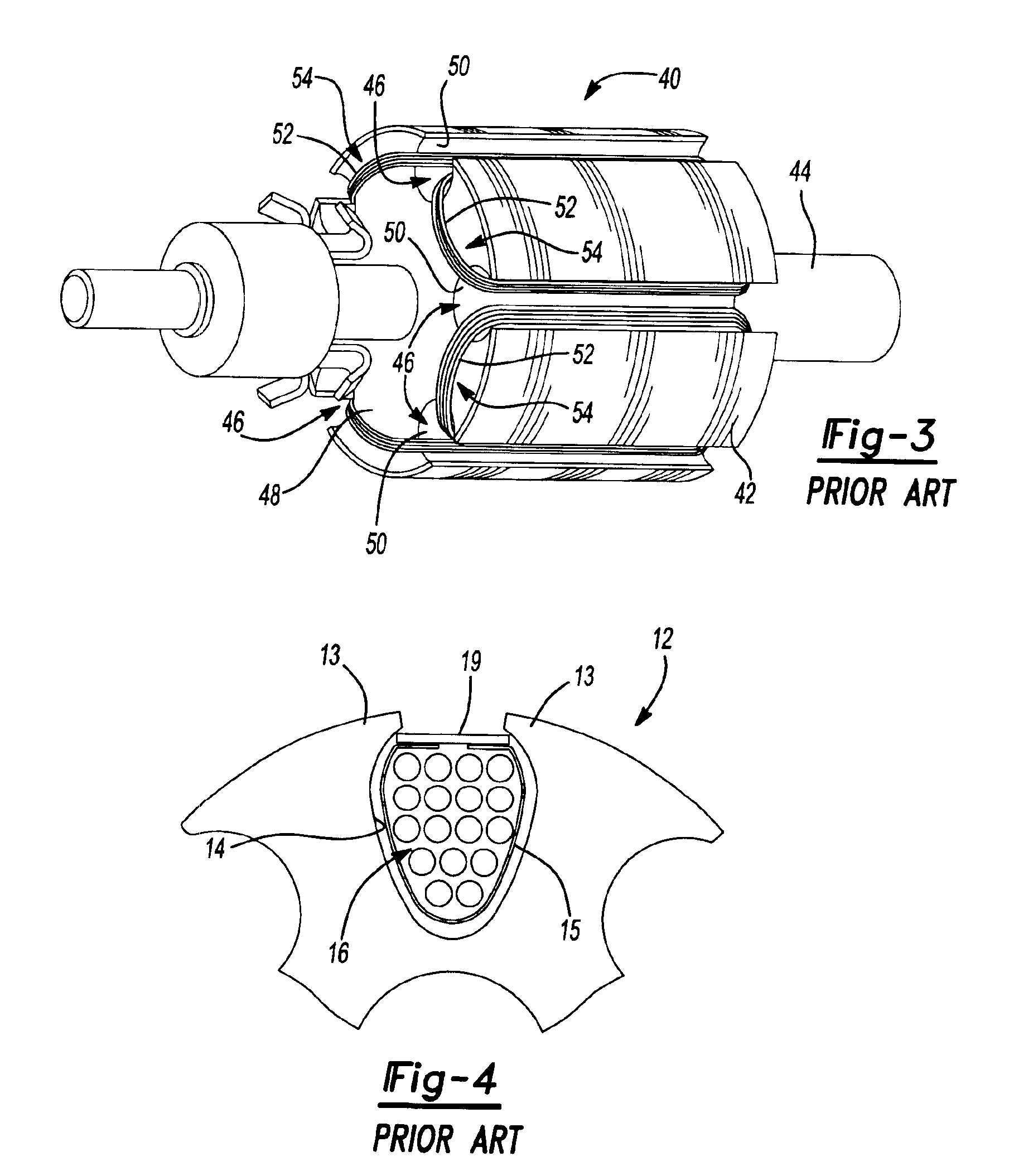

A claw-pole type stepping motor comprises: a rotor assembly shaped substantially cylindrical, and having a center shaft; and a stator assembly composed of two cup-shaped stator units which are coupled to each other coaxially so as to axially sandwich the rotor assembly, and which each include a bobbin having a magnet wire wound therearound, and two pole tooth arrays magnetically connected to each other and shifted in phase from each other by an electrical angle of 180 degrees. In the motor, each stator unit further includes a cover ring which protects the magnet wire wound around the bobbin against resin injected when the stator unit is resin-molded for an integrated solid structure. The motor structured as described above can be successfully resin-molded so as to enable elimination of a motor case, thus achieving downsizing for the dimension of the eliminated motor case while maintaining a sufficient mechanical strength.

Owner:MINEBEA CO LTD

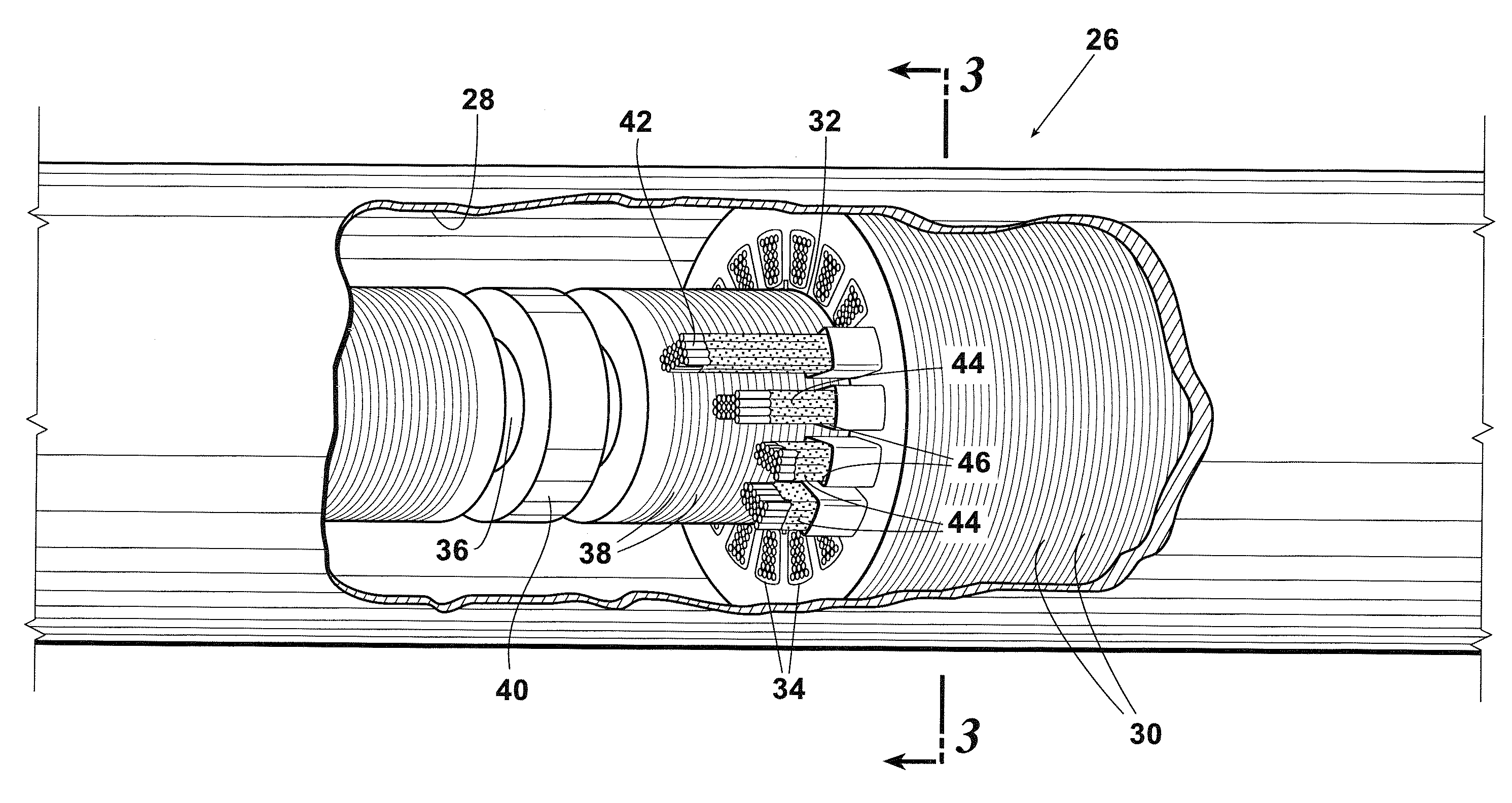

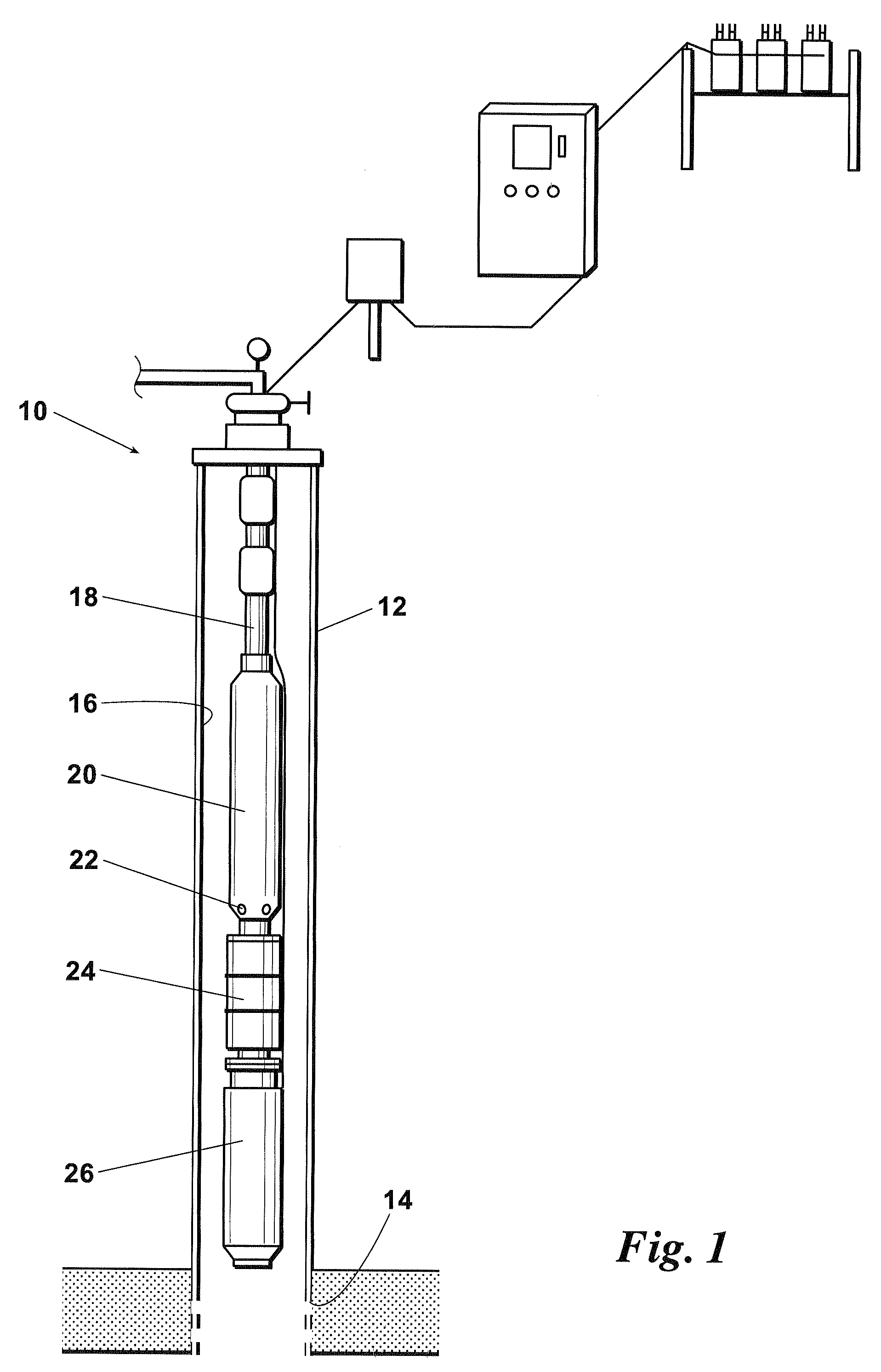

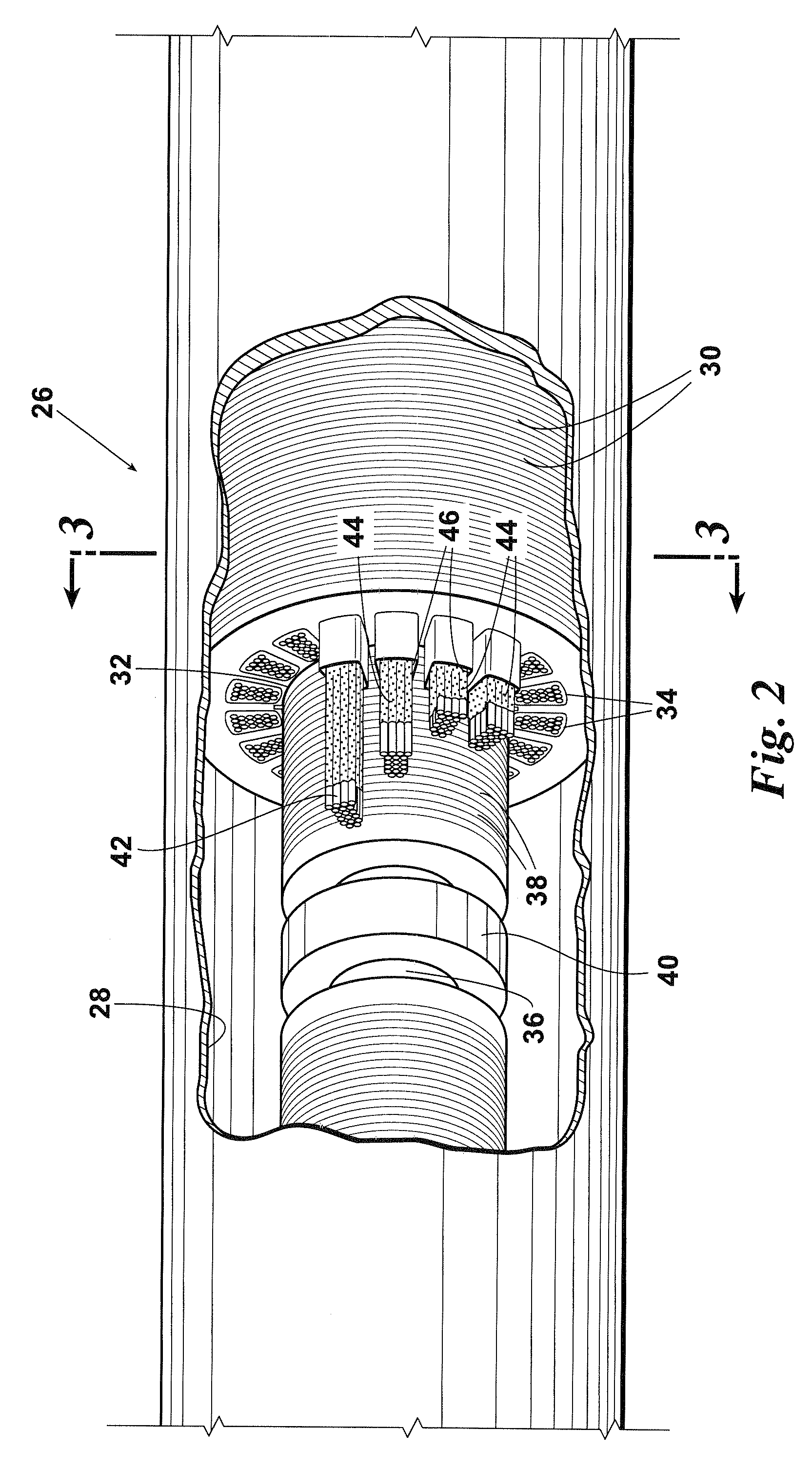

Shrink tube encapsulated magnet wire for electrical submersible motors

InactiveUS20090091202A1Reducing hot spotFreedom of movementWrappers shrinkageWindings insulation shape/form/constructionShrink wrapConductor Coil

An electrical motor for an electrical submersible pump wherein the electrical motor has increased heat transfer capabilities. The electrical motor includes a housing and a plurality of stator laminations within the housing. Each stator lamination defines a central orifice and a plurality of lamination slots. A plurality of magnet wires pass through each of the plurality of lamination slots formed by the stacked plurality of stator laminations. Shrink wrap surrounds each of the plurality of magnet wires to secure the magnet wires in bundles. The result is that the wires are effectively bound together in a manner that allows oil to move freely inside the lamination slots surrounding the wire bundles. Since fluid can pass between and around the windings, the overall winding temperature will be normalized, essentially reducing hot spots that occur in prior art designs.

Owner:BAKER HUGHES INC

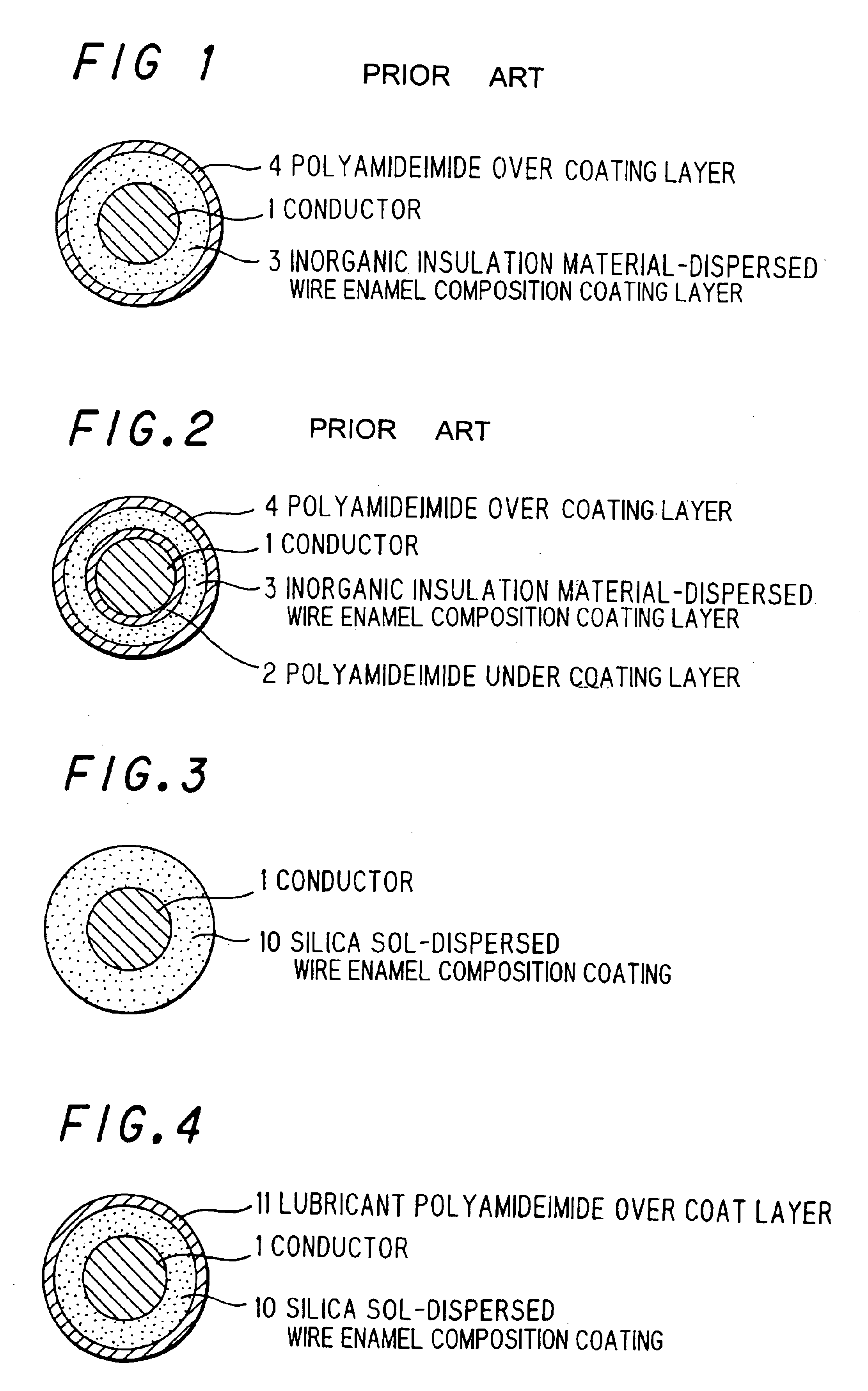

Partial discharging-resistant wire enamel composition and partial discharging-resistant magnet wire

Owner:HITACHI METALS LTD

Magnet wire with coating added with fullerene-type nanostructures

A magnet wire consists of an electrical conductor and a coating around the electric conductor, the coating is resistant to corona and / or of a low coefficient of friction, and is composed of 82% to 99.95% by weight of polymeric resin, and 0.05% to 18% by weight of fullerene-type nanostructures.

Owner:MAGNEKON DE C V

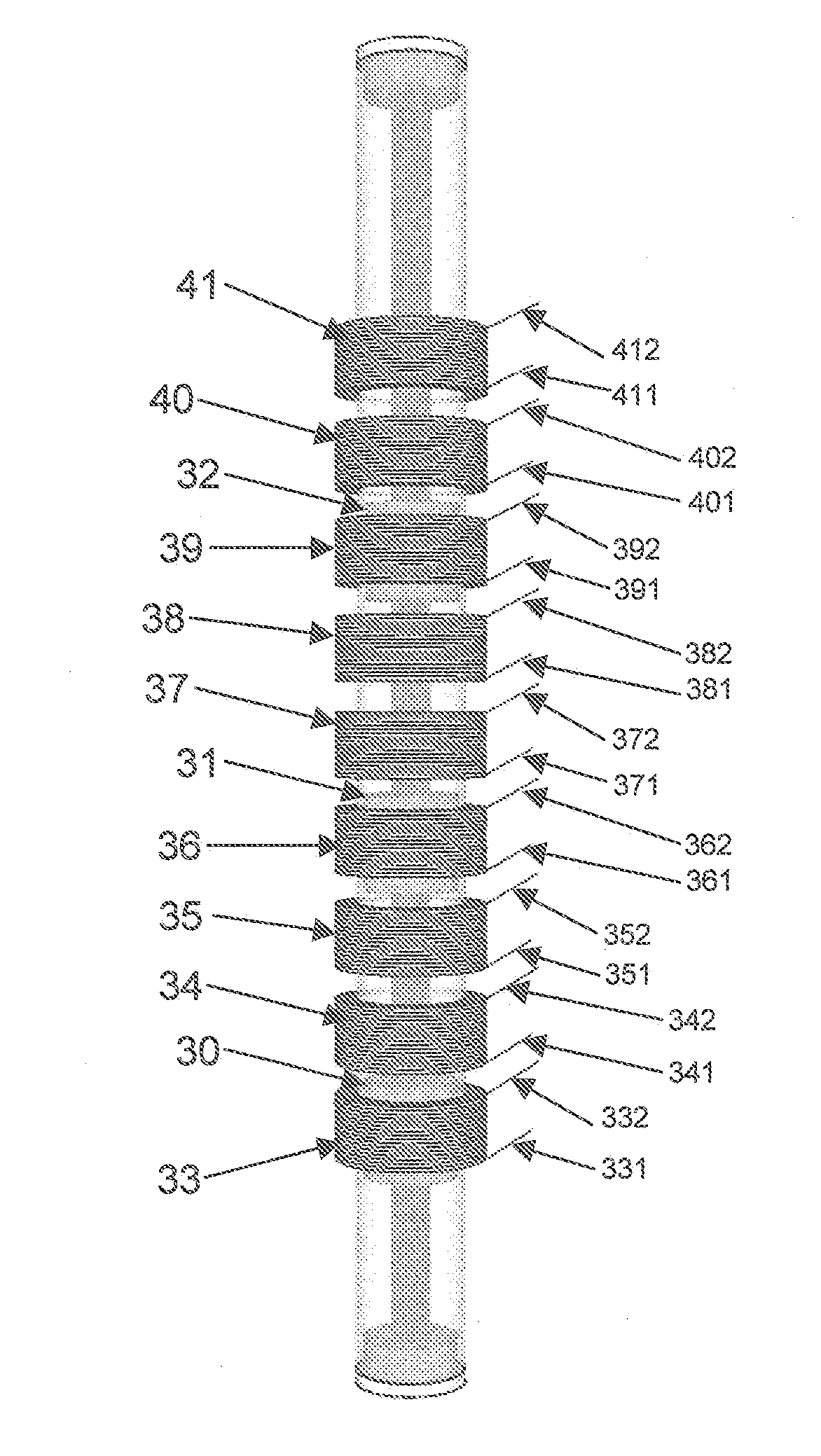

Portable Linear Generator

A portable linear generator for use as a battery charging element inside a portable powered device using multiple permanent magnets arranged linearly with each magnet constrained to repel each nearest magnet, one of the magnets fixed at one or each end of the array, one or more of the magnets free to move along the axis of the array, a guide rod extending through the magnets having a low friction or low friction and diamagnetic surface, and coaxially wound coil or coils of magnet wire arranged to electrically connect outside the device.

Owner:GENNEO

Electromagnetic coil assembly

InactiveUS20050225418A1Prevent exitTransformers/inductances casingsTransformers/inductances coils/windings/connectionsBobbinMagnet wire

An electromagnetic coil assembly is provided. The electromagnetic coil assembly includes a bobbin, a coil of magnet wire and a cover piece. The bobbin includes a hub, a first flange and a second flange. The hub has a longitudinal axis. The first and second flanges are spaced axially from each other. The hub and flanges together define a circumferential bobbin channel. The bobbin is made from a material that is an electrical insulator. The coil of magnet wire is positioned around the hub in the circumferential bobbin channel. The magnet wire has first and second ends. The cover piece is self-supporting and is sized to extend circumferentially around the coil of magnet wire. The cover piece is resilient and exerts a compressive force radially inwardly on the coil of magnet wire.

Owner:POLYMER TECH CORP

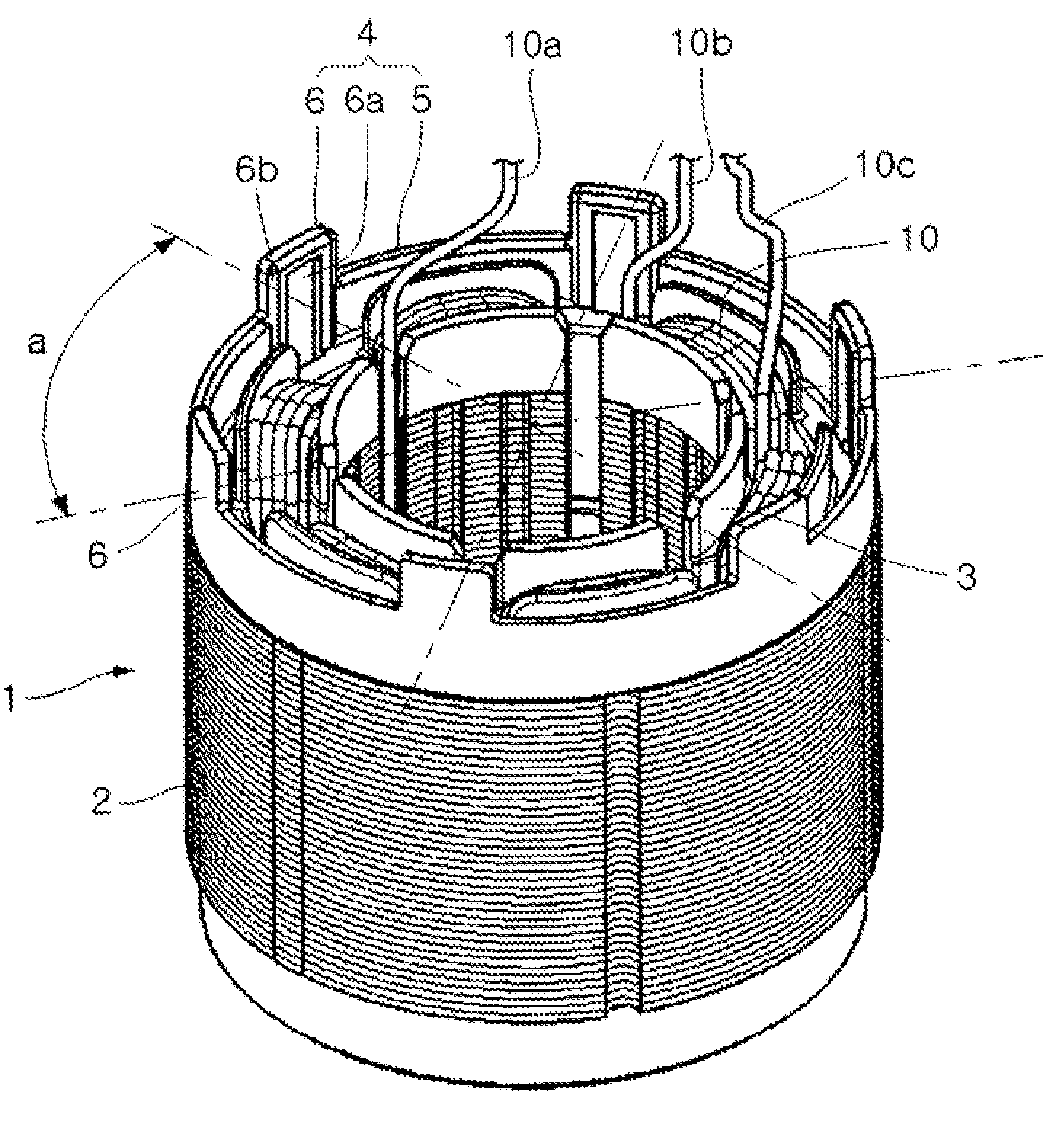

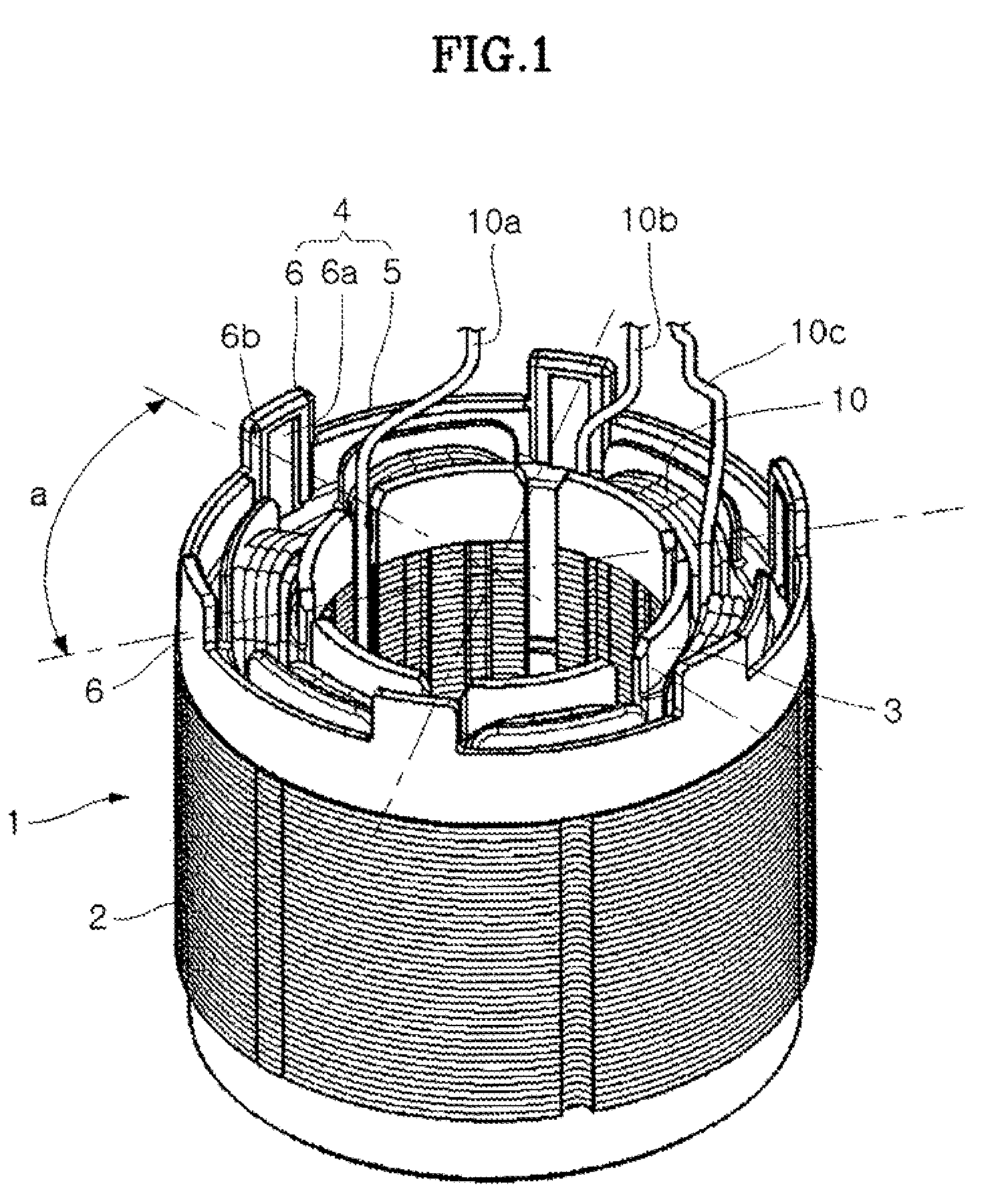

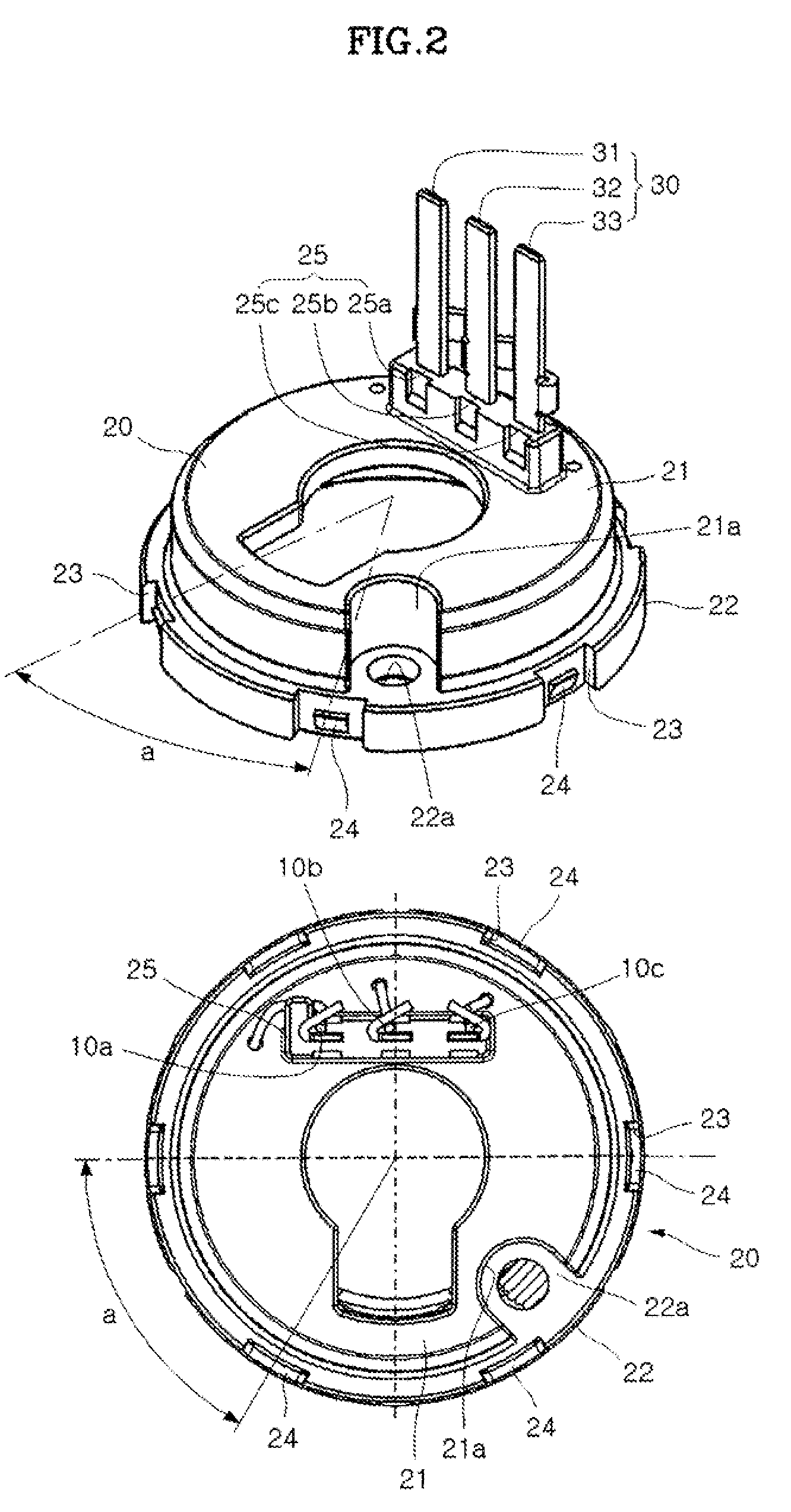

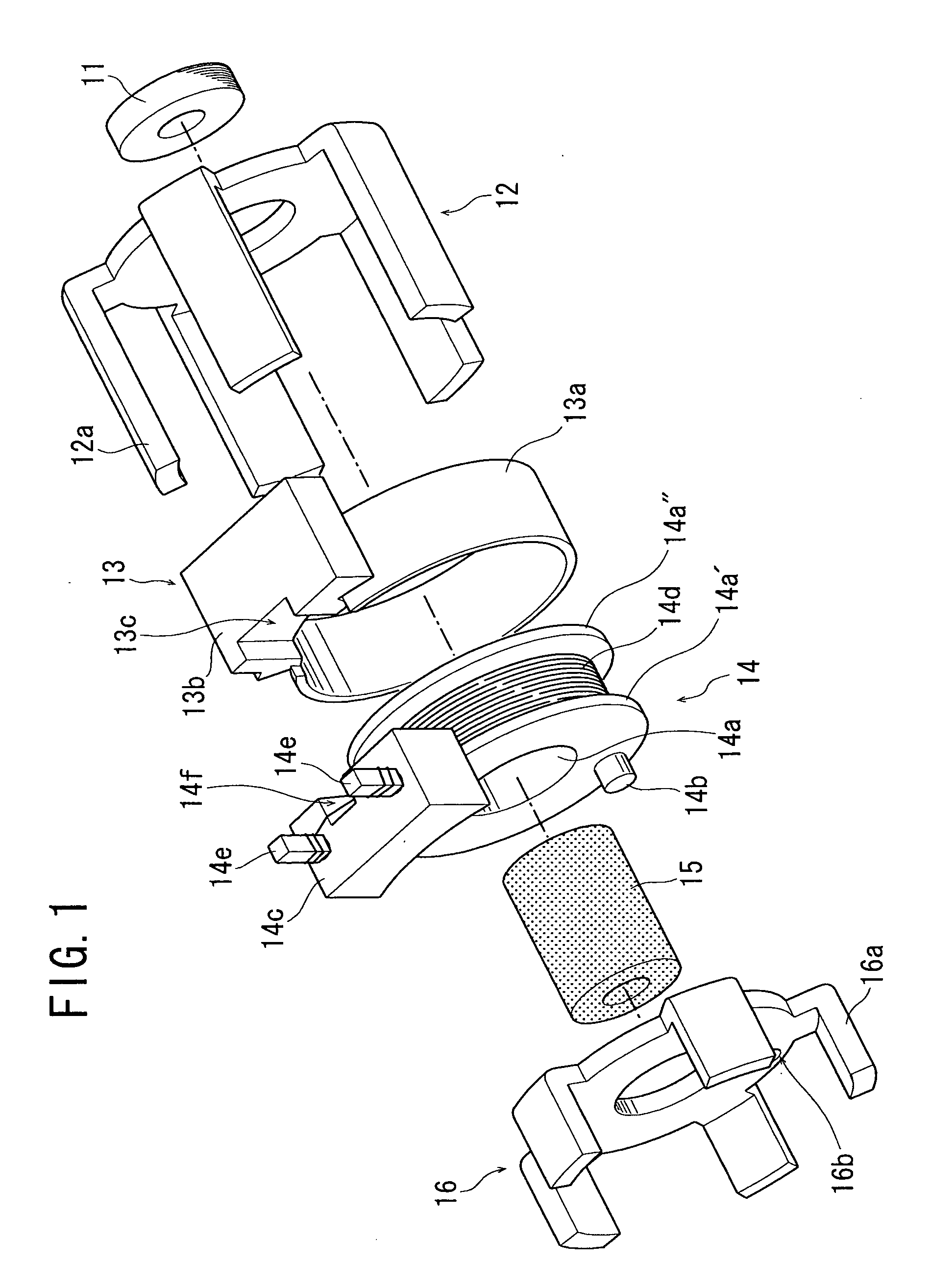

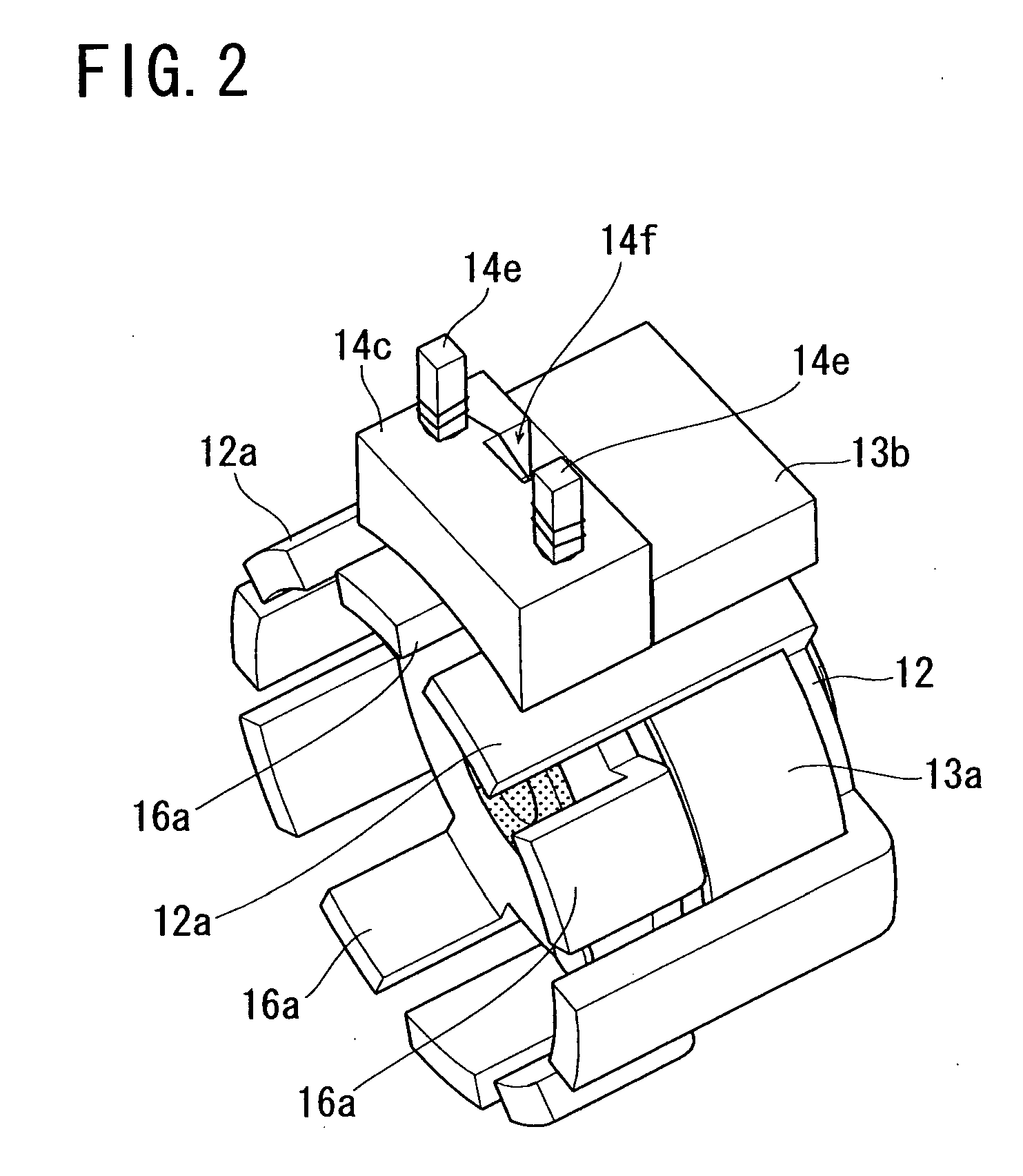

Stator sub-assembly, stator assembly, motor and manufacturing method of stator assembly

A stator sub-assembly comprises: a coil bobbin which is composed of a cylinder having a winding of a magnet wire therearound, and a terminal block provided with terminal pins connected to lead wires of the winding and coupled stator yokes housing said coil bobbin therein and having a cutout for allowing the terminal block to protrude therethrough. The cutout has a width adapted to allow the terminal block to circumferentially shift rotationally about the center of an axial direction of the coil bobbin.

Owner:MINEBEAMITSUMI INC

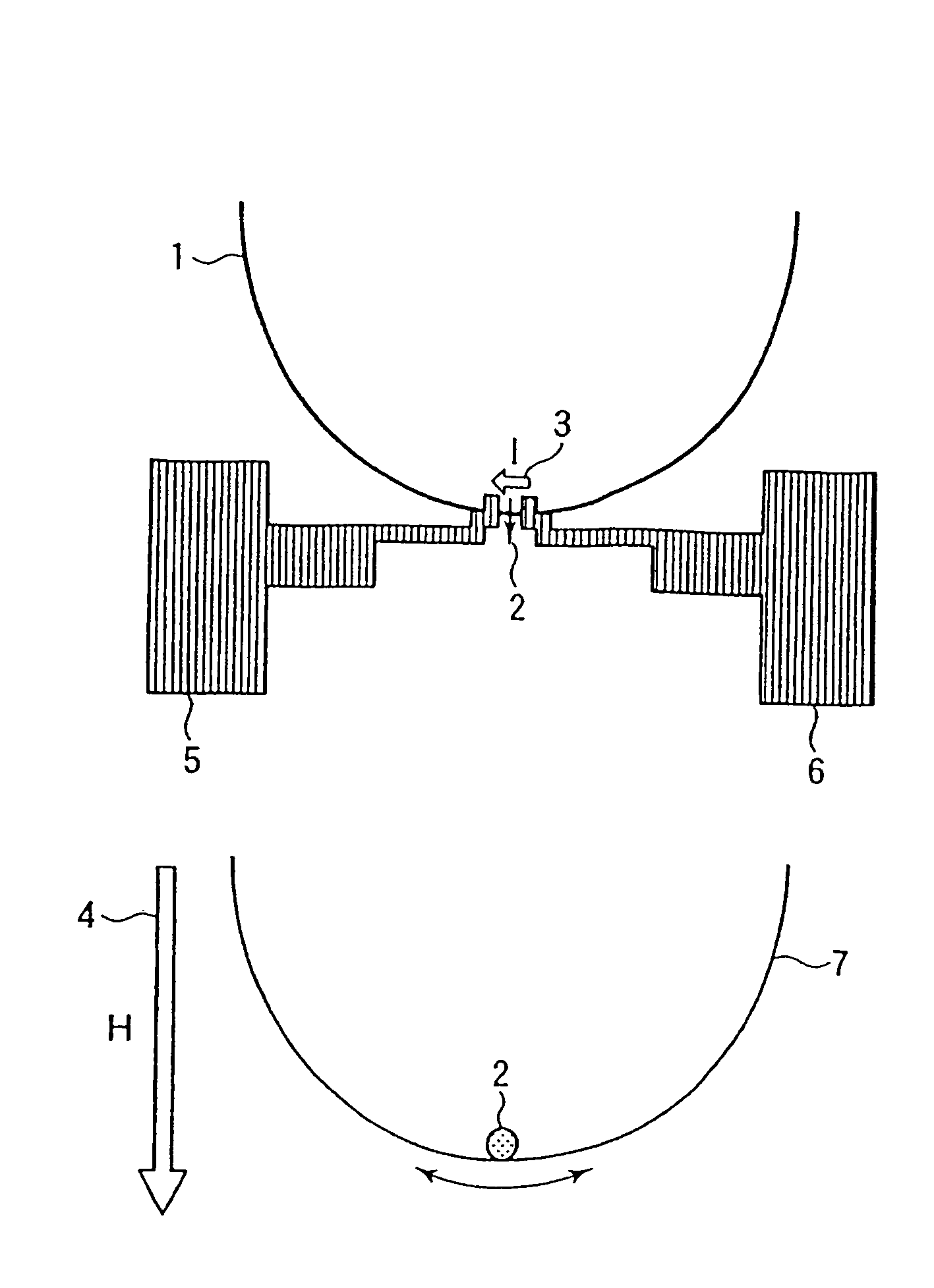

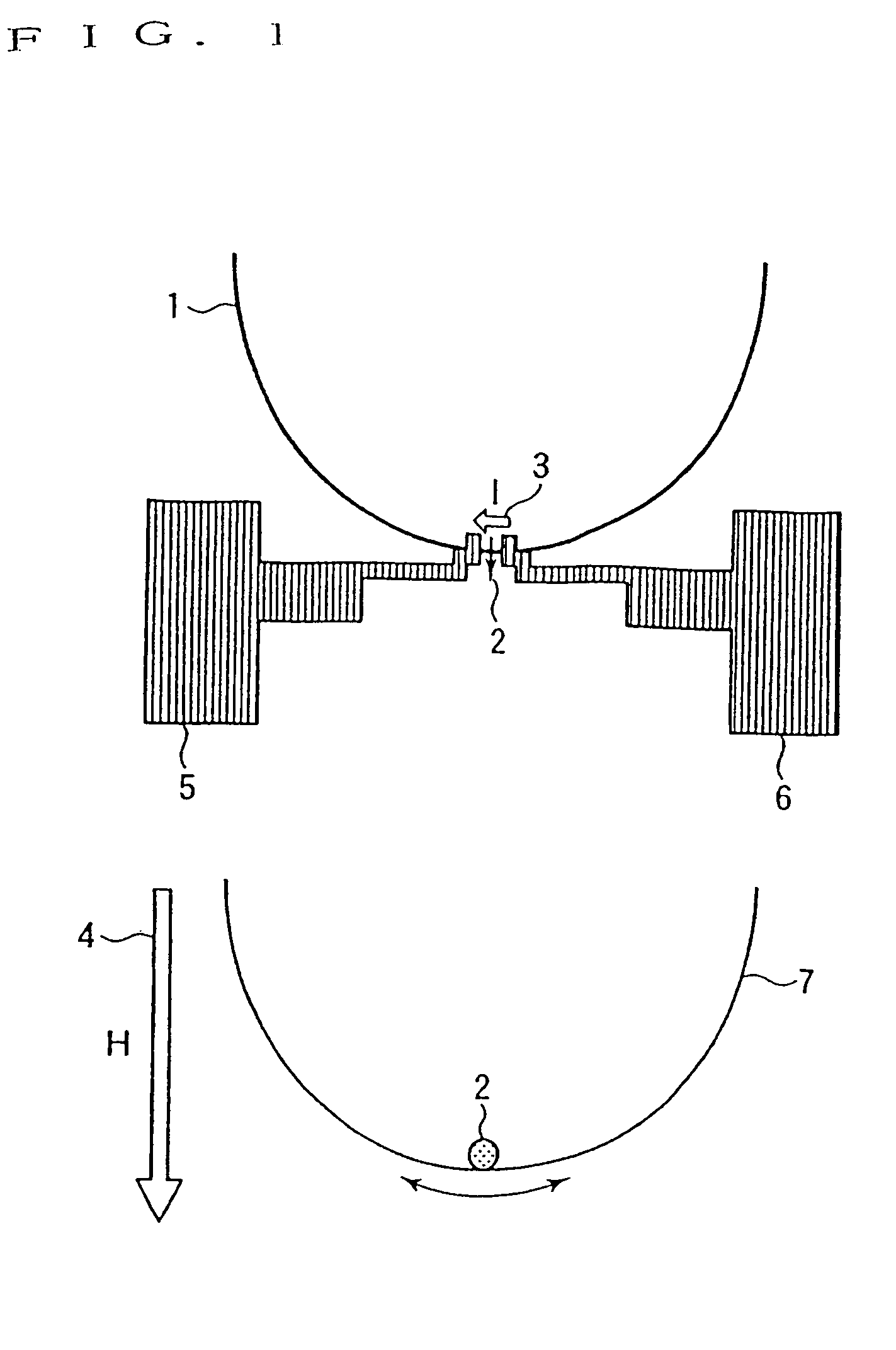

Magneto-resistance effect element and magnetic memory device

InactiveUS7586781B2Lower average currentHigh densityNanomagnetismMagnetic measurementsDriving currentResonance

The invention relates to a magneto-resistance effect element and a magnetic memory device. Lowering the magnetic domain wall movement current and drive at room temperature in a current induction single magnetic domain wall movement phenomenon are achieved.A magneto-resistance effect element is formed by including at least: a magnet wire 1 for forming magnetic domain wall potential 7 binding a single magnetic domain wall 2; a magnetic field applying means for generating a magnetic field for introducing the single magnetic domain wall 2 into the magnet wire 1; and a drive current applying means for applying the current 3 including a resonance frequency component determined on the basis of the magnetic domain wall potential 7.

Owner:TOHOKU UNIV

Friction electrostatic painting infrared ray cured powder paint for electromagnetic wire and lacquered wire, preparation and use thereof

InactiveCN101469147AWill not polluteImprove labor productivityPlastic/resin/waxes insulatorsPretreated surfacesInfraredResource saving

The invention relates to a functional coating, in particular to a friction electrostatic spraying infrared curing powder coating for an electromagnetic wire and an enamelled wire. The powder coating consists of a resin, a curing agent, a pigment, a filler and an additives; the powdery coating comprises the following compositions by mass percentage: 33 to 62 percent of the thermosetting resin, 5 to 33 percent of the curing agent, 1 to 29 percent of the pigment and the filler, 0.5 to 1 percent of triboelectric additive, 0.5 to 1 percent of powder loosening additive and 1 to 5 percent of other additives; a preparation process comprises: the compositions of a formula are subjected to premixing and melt extrusion and mixing, are cooled to room temperature and are broken into a sheet material; the sheet material is pulverized to ultrafine powder and is separated to obtain a semifinished product of powder coating with less than 160 meshes; and the semifinished product is demagnetized to obtain a finished product. The friction electrostatic spraying infrared curing powder coating for the electromagnetic wire and the enamelled wire does not produce wastewater, waste gas and waste residue in the production process, does not produce any pollution to environment, has high utilization rate and belongs to a resource-saving type product.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

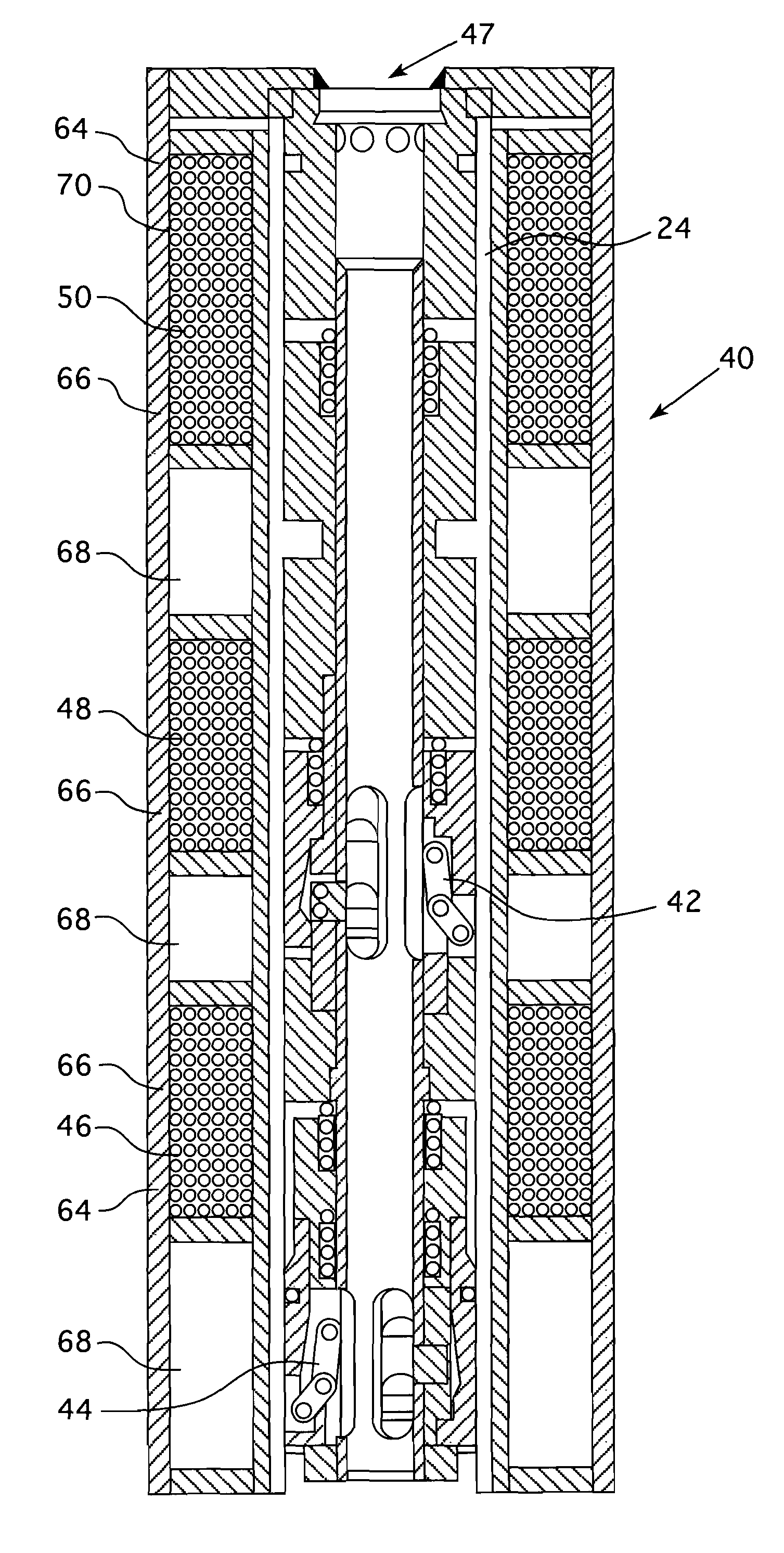

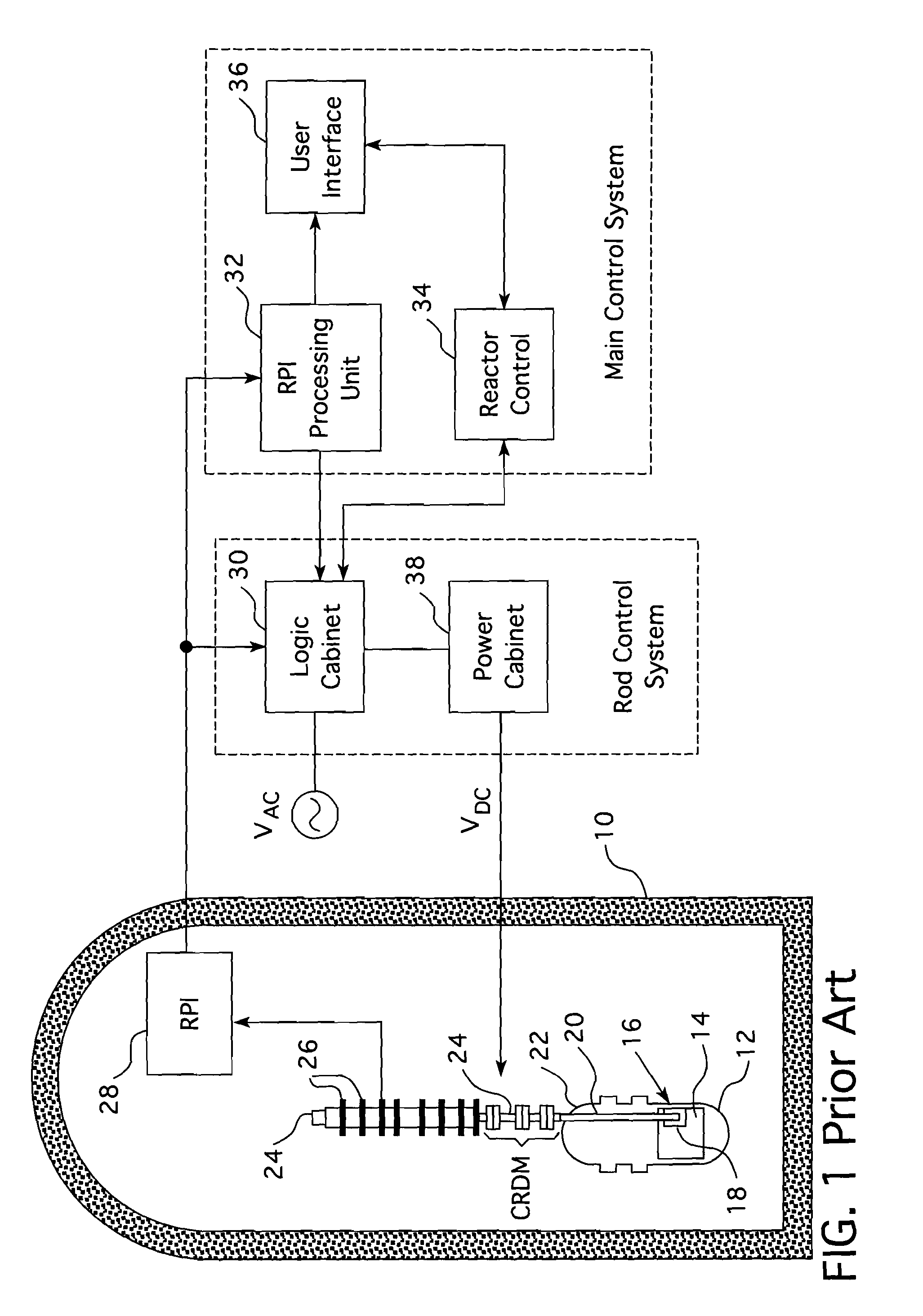

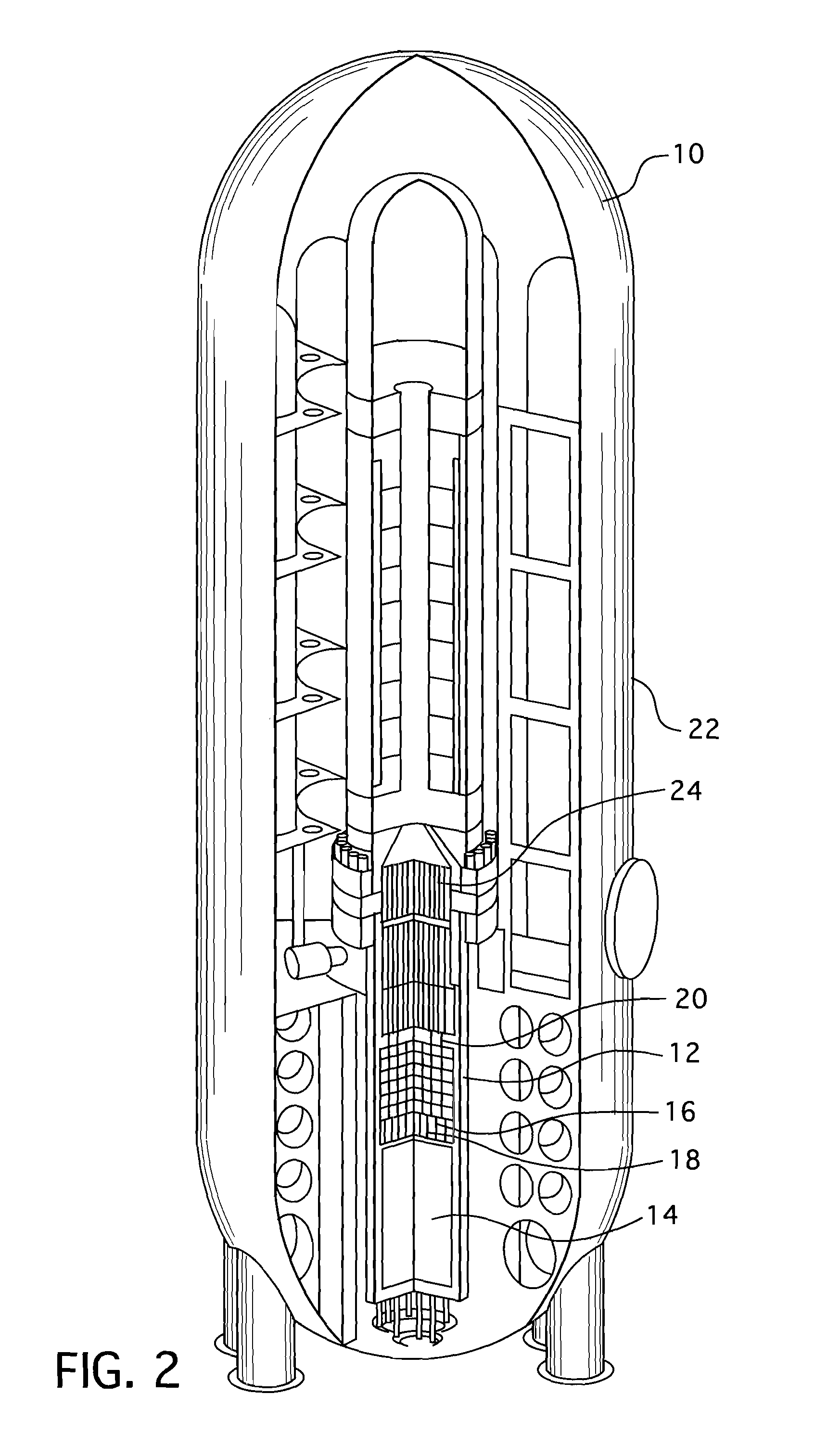

Nuclear reactor internal electric control rod drive mechanism assembly

A magnetic jack control rod drive rod drive system having the magnetic coils that operate the moving parts of the drive system wound from anodized aluminum magnet wire or ceramic coated nickel clad copper and enclosed within a hermetically sealed housing that is pressurized with helium.

Owner:WESTINGHOUSE ELECTRIC CORP

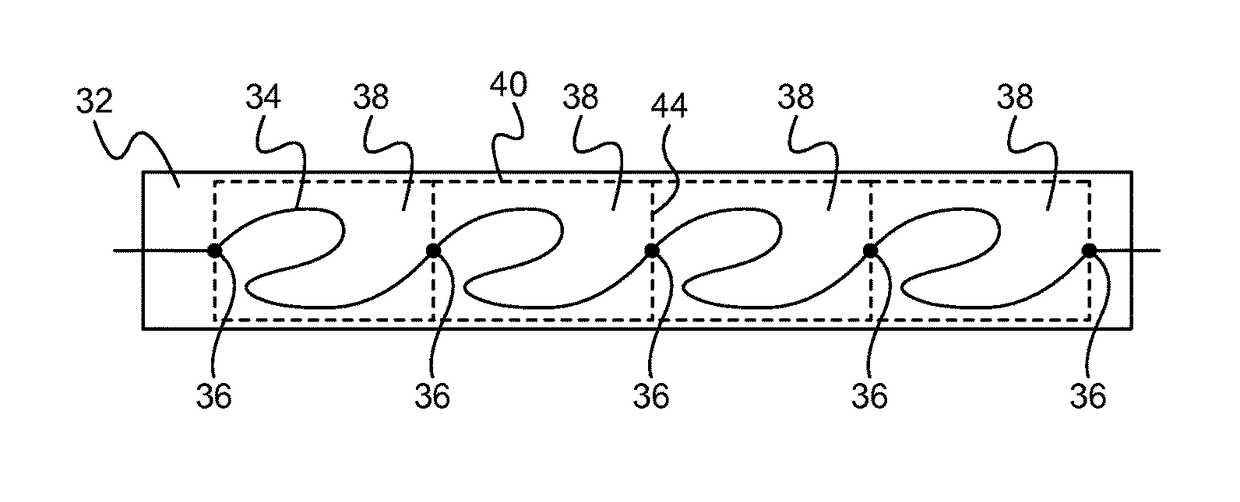

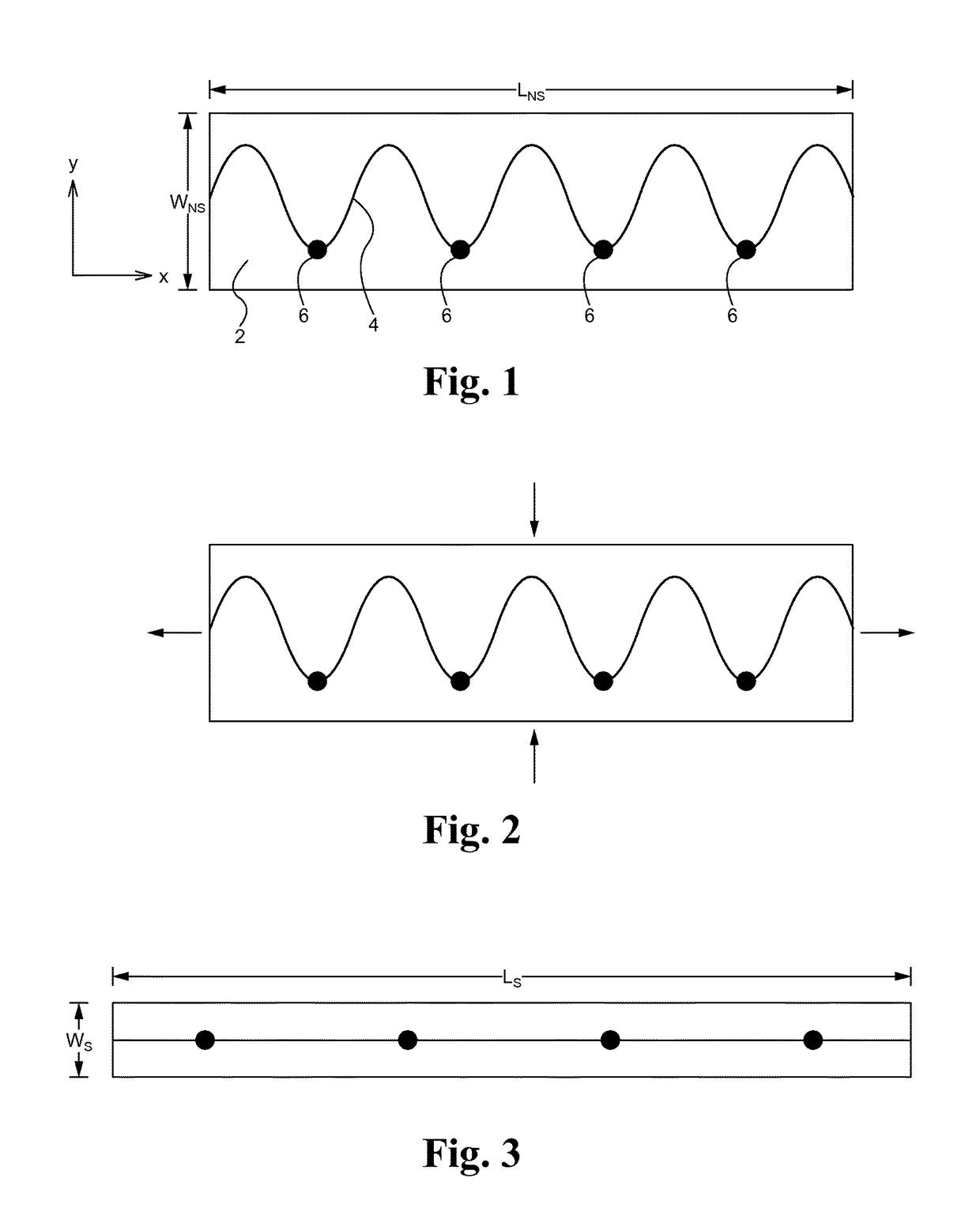

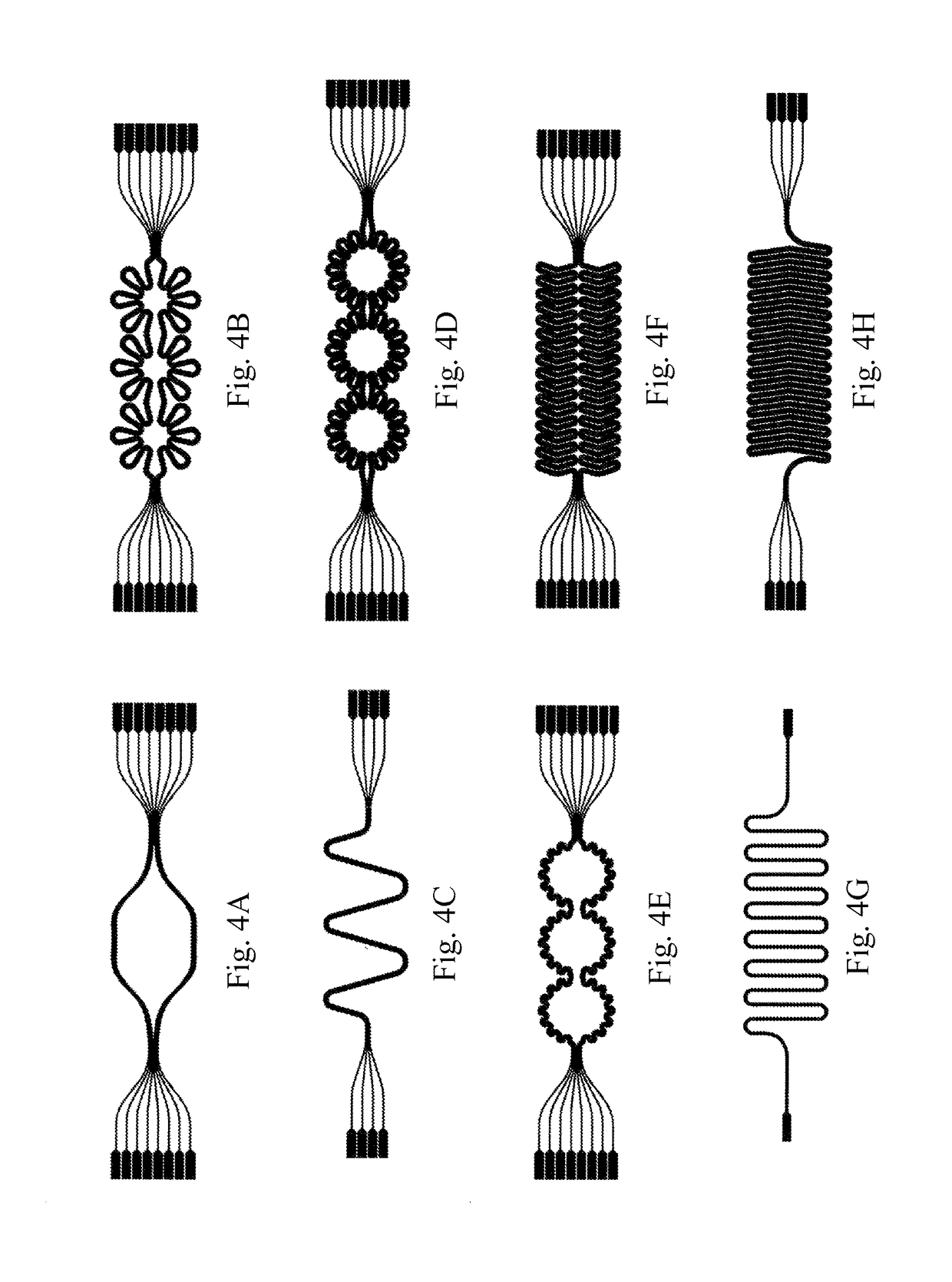

Method of making stretchable interconnect using magnet wires

InactiveUS9674949B1Freedom of movementCircuit bendability/stretchabilityDielectric materialsElastic substrateEngineering

A stretchable wire assembly includes a metal wire coupled between two elastic substrates. The two elastic substrates are selectively coupled together, and the metal wire is attached to one or both elastic substrates at select locations. The form of the metal wire is such that when the elastic substrates are in a relaxed, or non-stretched, state the metal wire forms a tortuous path, such as a waveform, along the coupled elastic substrates. The tortuous path of the metal wire provides slack such that as the elastic substrates are stretched the slack is taken up. Once released, the elastic substrates move from the stretched position to the relaxed, non-stretched position, and slack is reintroduced into the metal wire in the form of the original tortuous path.

Owner:FLEXTRONICS AP LLC

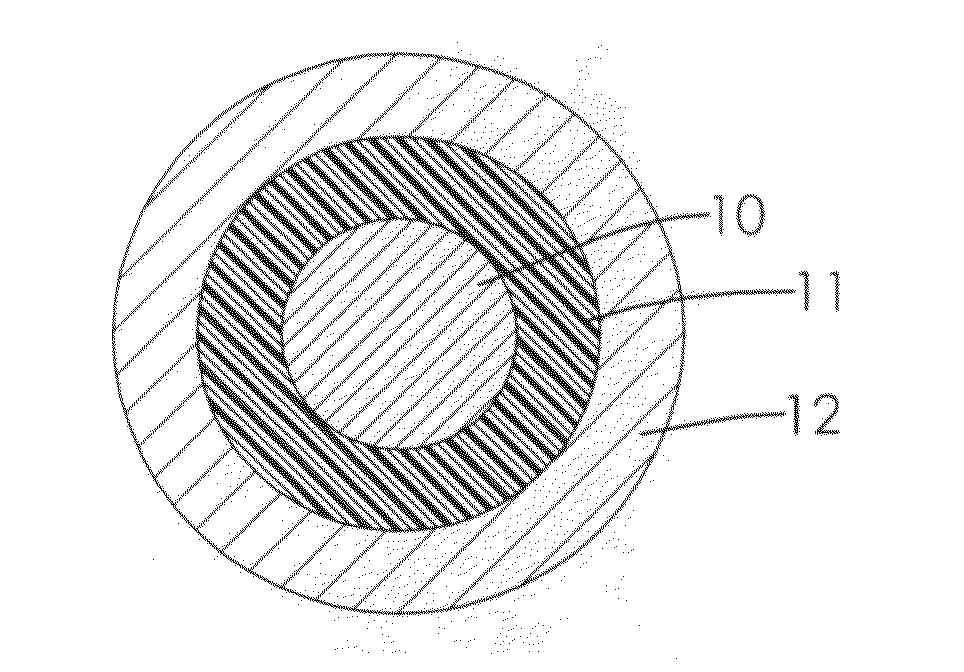

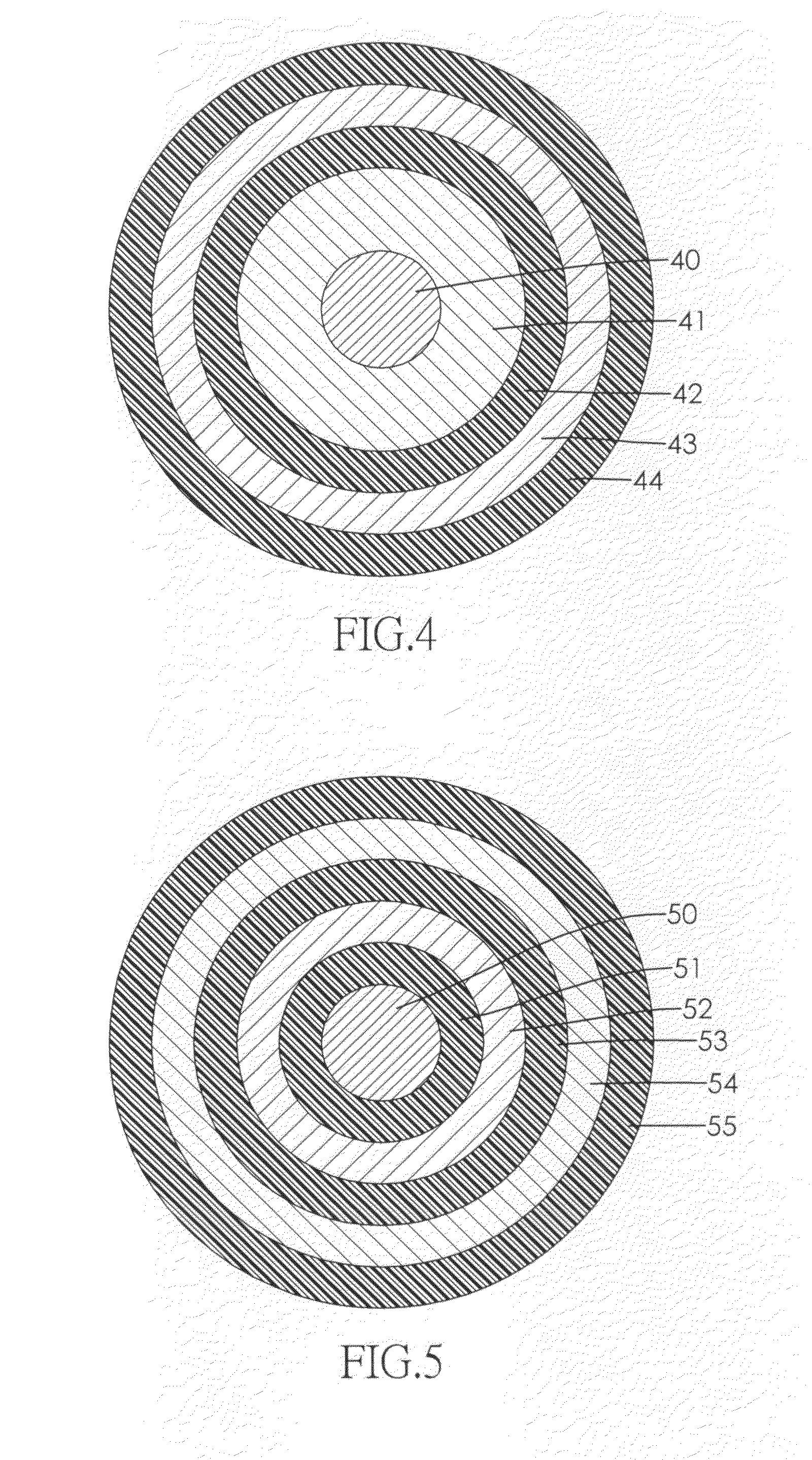

Magnet wire

InactiveUS20110198118A1Lower high-frequency alternating current (AC) resistanceSave energyElectromagnets without armaturesLine/current collector detailsElectricityElectrical conductor

A magnet wire has a conductor and a coating layer. The coated layer is coated around the conductor and has at least one magnetic coating layer; and at least one insulating coating layer. The magnetic coating layer has non-conductive magnetic material. The insulating coating layer and the magnetic coating layer are formed alternately. The alternative structure of the magnetic coating layer and the insulating coating layer prevent precipitation of magnetic material and efficiently offsets the interference between conductors after electricity is supplied, which inhibits occurrence of eddy current and lowers alternative current (AC) resistance.

Owner:ELECTRIC WIRE & CABLE

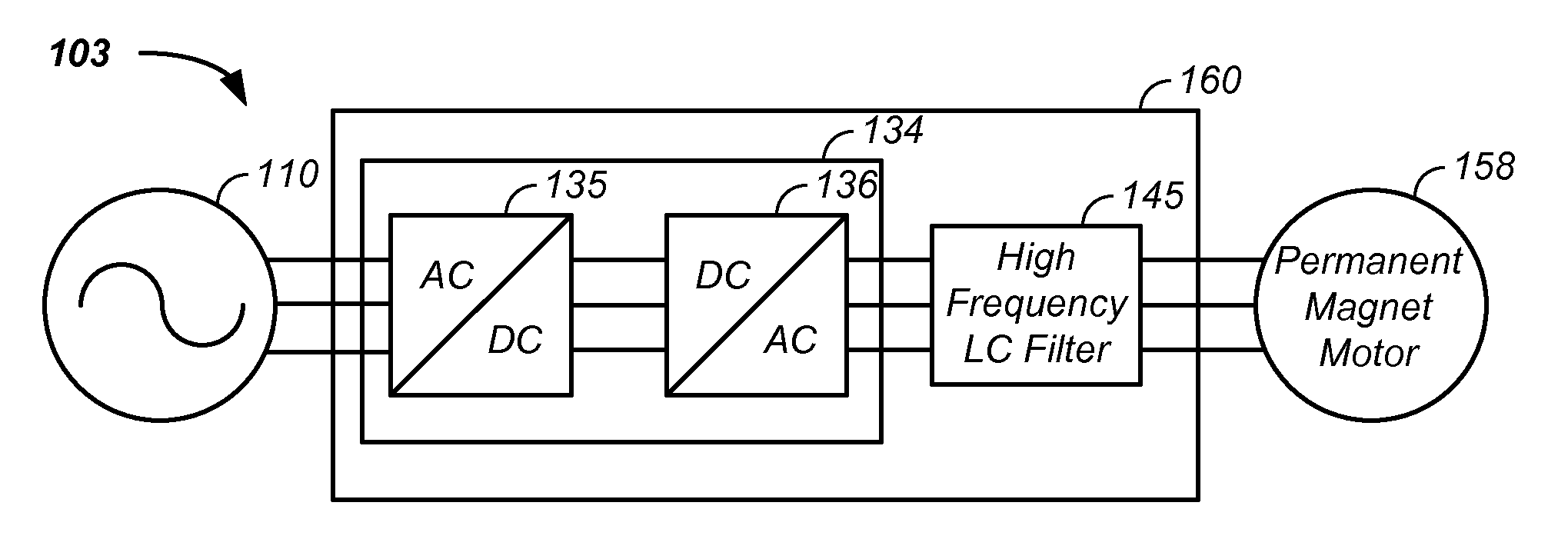

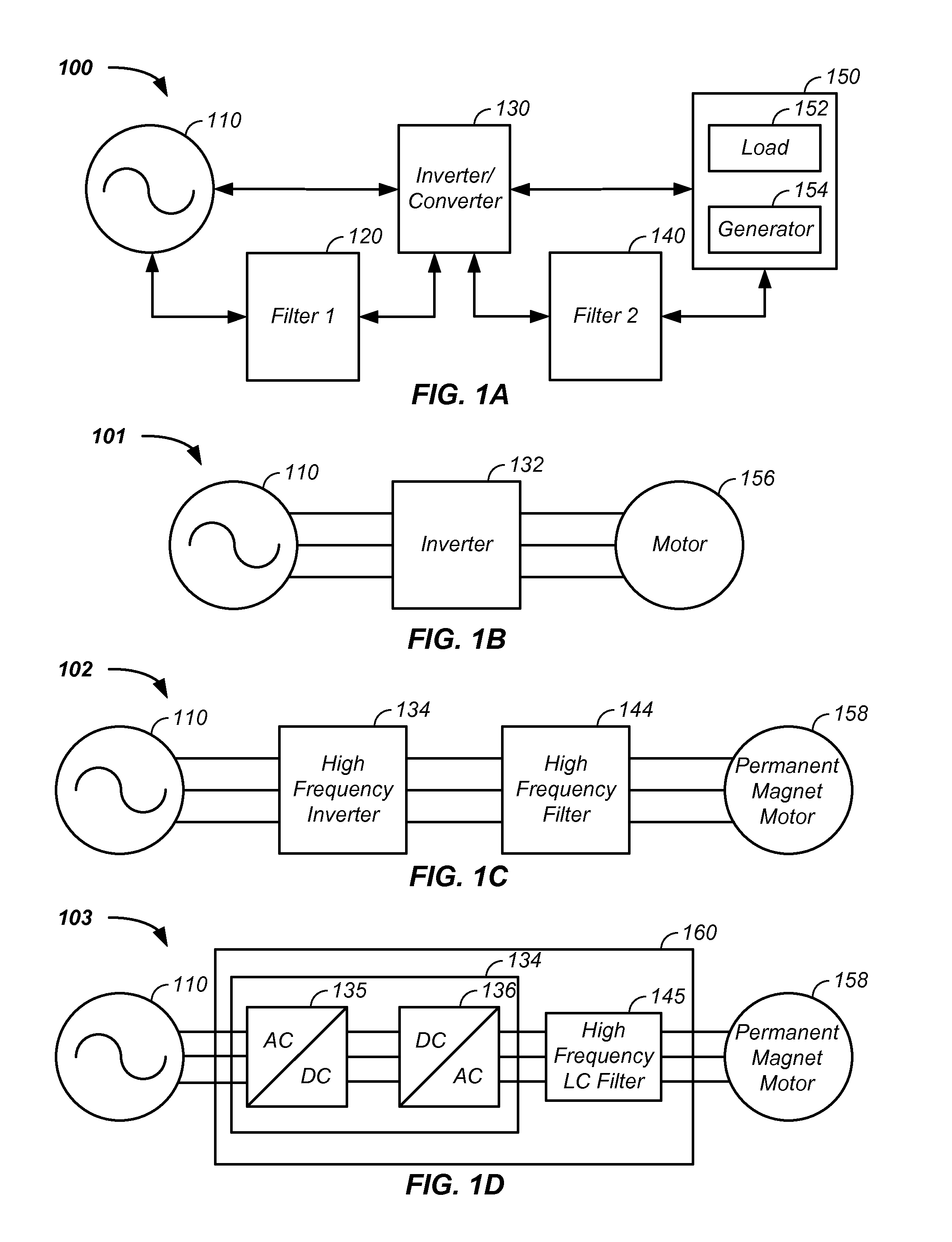

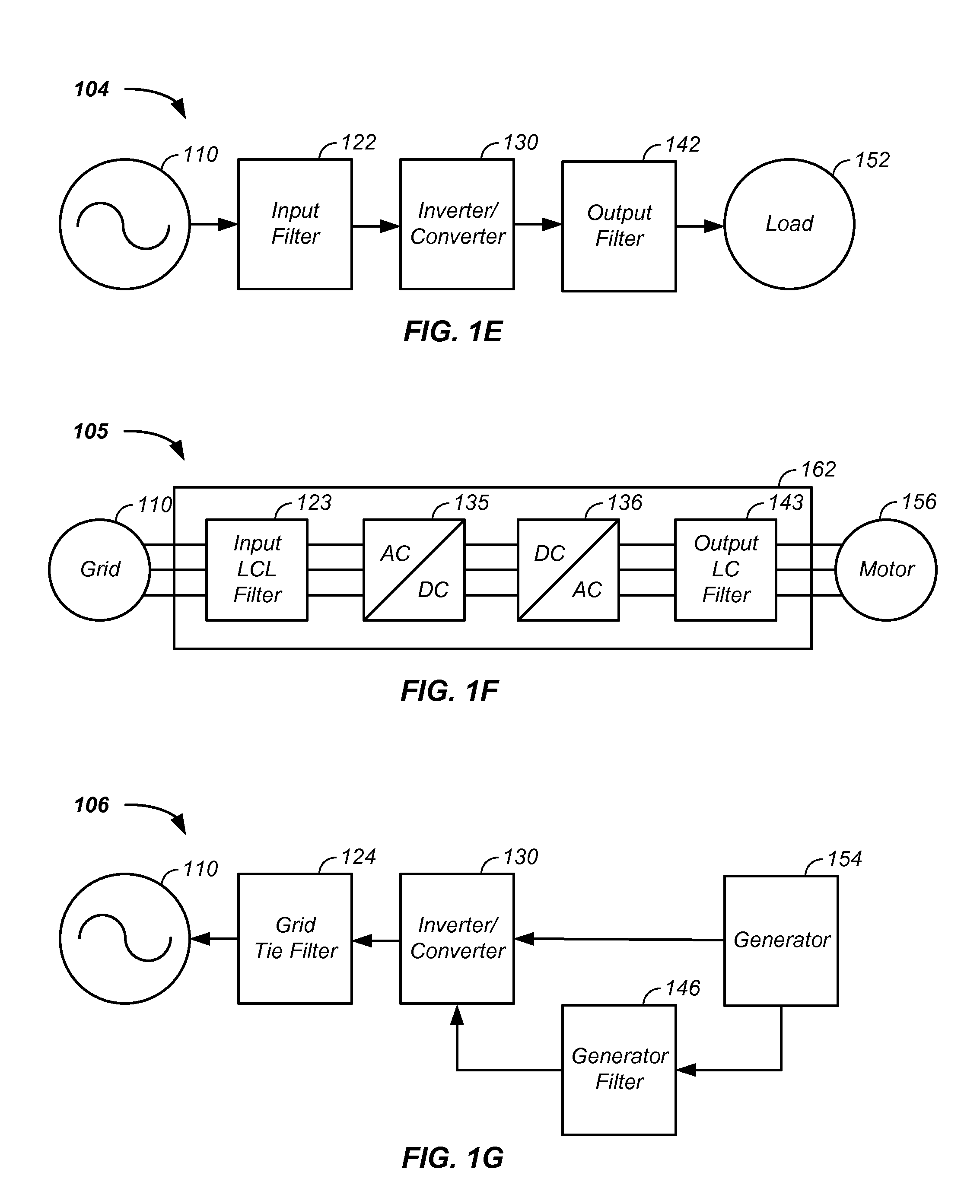

High voltage inductor filter apparatus and method of use thereof

ActiveUS20130308351A1High frequency outputTransformersEfficient power electronics conversionHarmonicInductor

The invention comprises a high frequency inductor filter apparatus coupled with an inverter yielding high frequency harmonics and / or non-sixty Hertz output. For example, an inductor / converter apparatus is provided that uses a silicon carbide transistor to output power having a carrier frequency, modulated by a fundamental frequency, and a set of harmonic frequencies. A filter, comprising an inductor having a distributed gap core material and optional magnet wires, receives power output from the inverter / converter and processes the power by passing the fundamental frequency while reducing amplitude of the harmonic frequencies.

Owner:CTM MAGNETICS

Linear motor, and linear compressor using the same

A linear motor of the present invention has: a stator having a stationary iron core and a magnet wire; a mover having a moving iron core and a magnet; and a plate-shaped elastic member for supporting the mover in a manner to rock in the rocking directions. This construction eliminates a sliding portion for supporting the mover so that it can reduce the loss, which might otherwise accompany the reciprocation of the mover. Moreover, a linear compressor using this linear motor is high in efficiency and reliability.

Owner:PANASONIC CORP

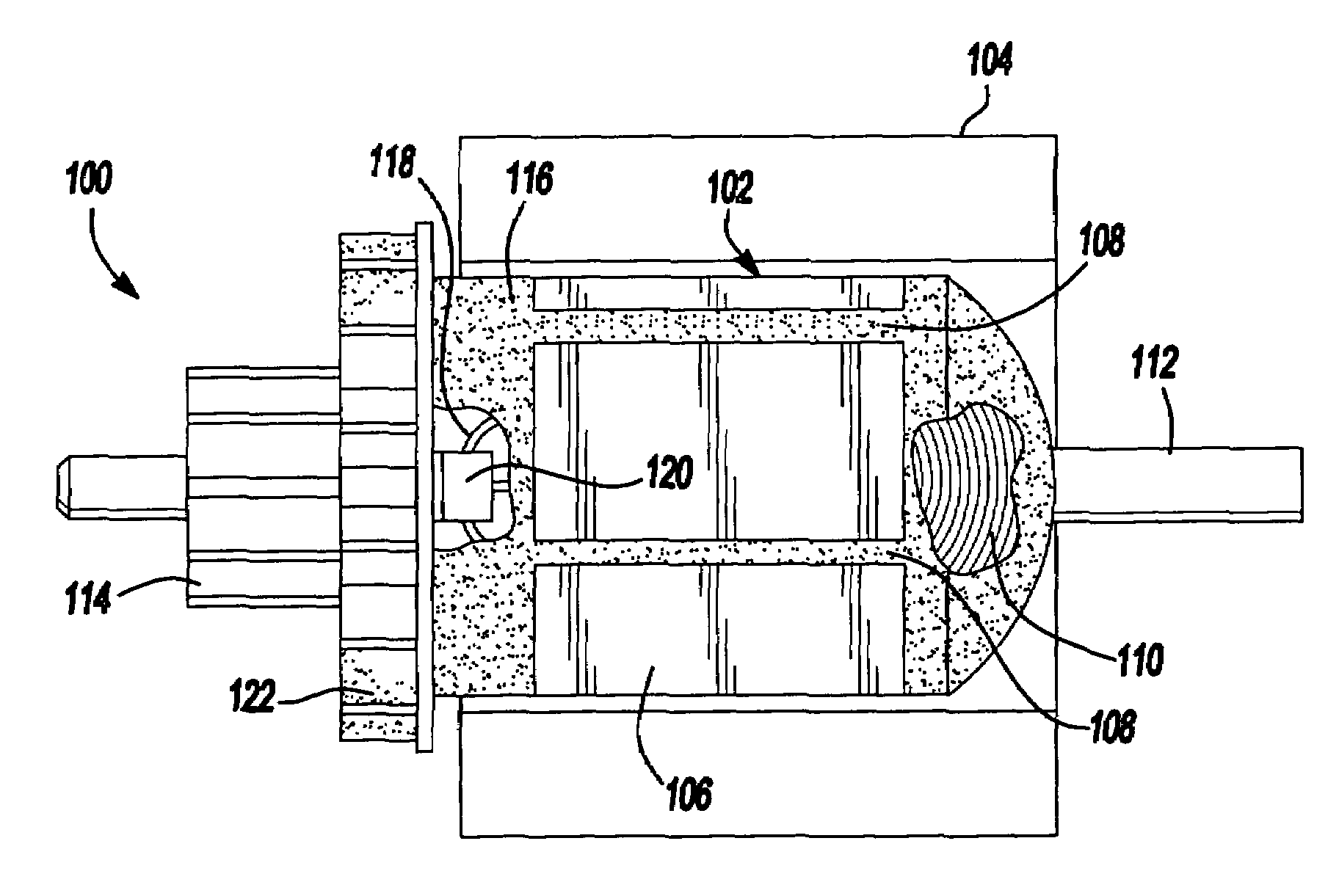

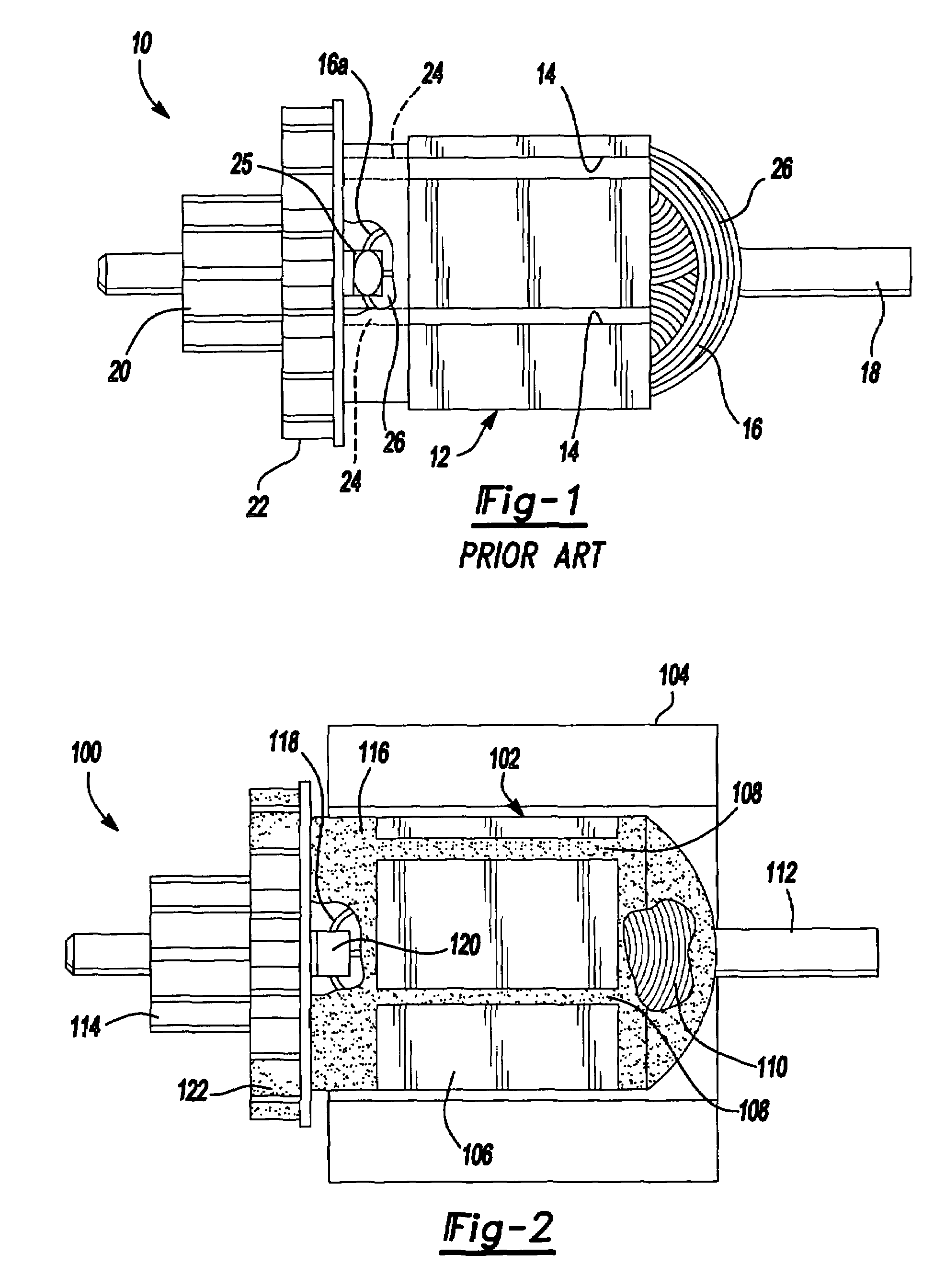

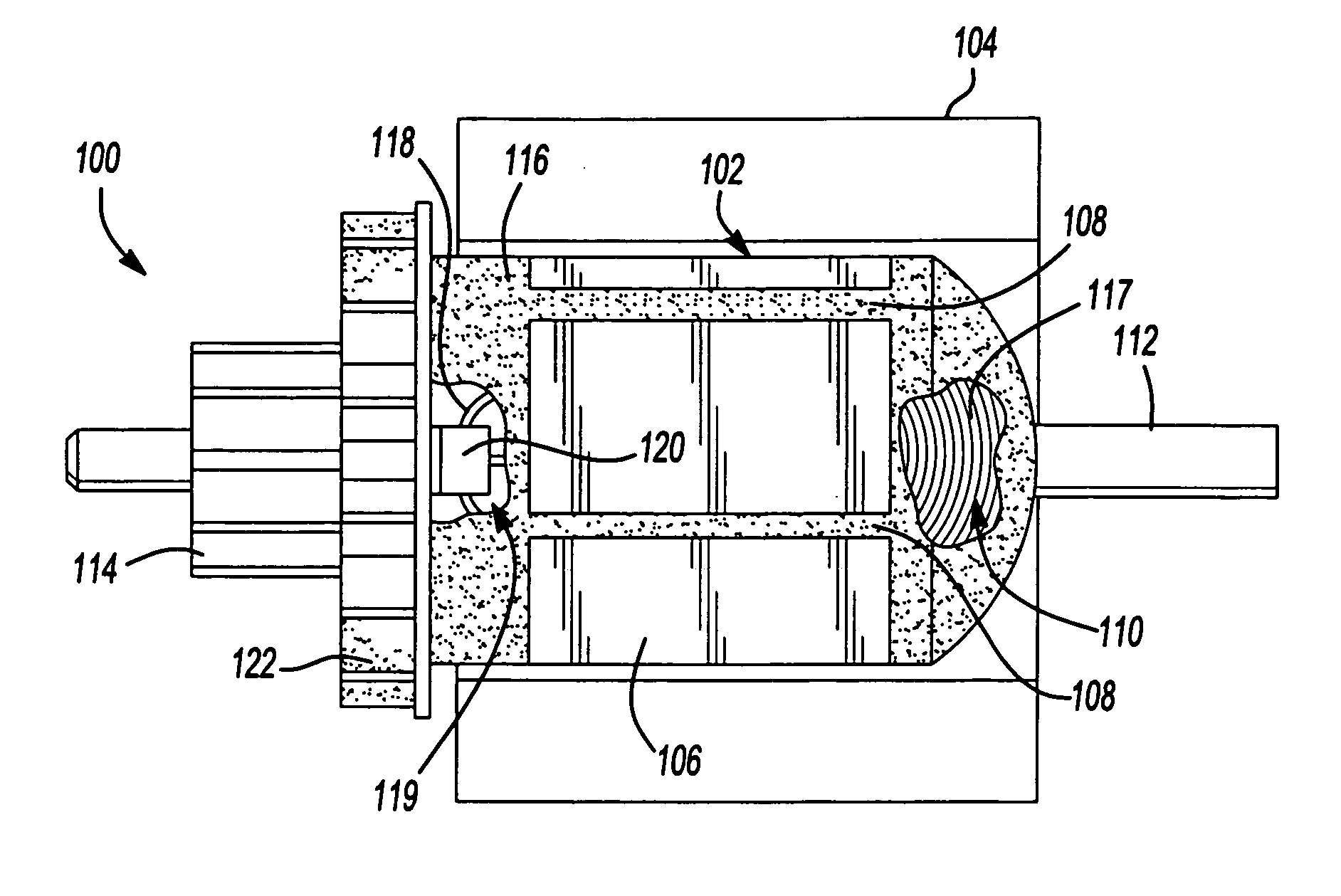

Dynamoelectric machine having encapsulated coil structure with one or more of phase change additives, insert molded features and insulated pinion

InactiveUS6946758B2Increase stiffnessIncrease critical speedWindings insulation materialWindings insulation shape/form/constructionAdhesivePinion

Magnet wires wound in slots in a lamination stack of a dynamoelectric machine are encapsulated, in whole or in part, with thermally conductive plastic. Pre-formed features having a thermal conductivity higher than the thermally conductive plastic are insert molded when the plastic is molded. The pre-formed features may include a finned end cap and a fan. Alternatively, end domes of the plastic over end coils of the wound magnet wires have a metallic layer on them, such as by being metallized. The end domes can be formed with features which are also metallized. The thermally conductive plastic can have a phase change additive in it. The magnet wires can have a layer of heat activated adhesive that is activated when the plastic is molded. Slots in the lamination stack can include slot liners formed of thermally conductive plastic. A fan can be formed when the thermally conductive plastic is molded to encapsulate the magnet wires.

Owner:BLACK & DECKER INC

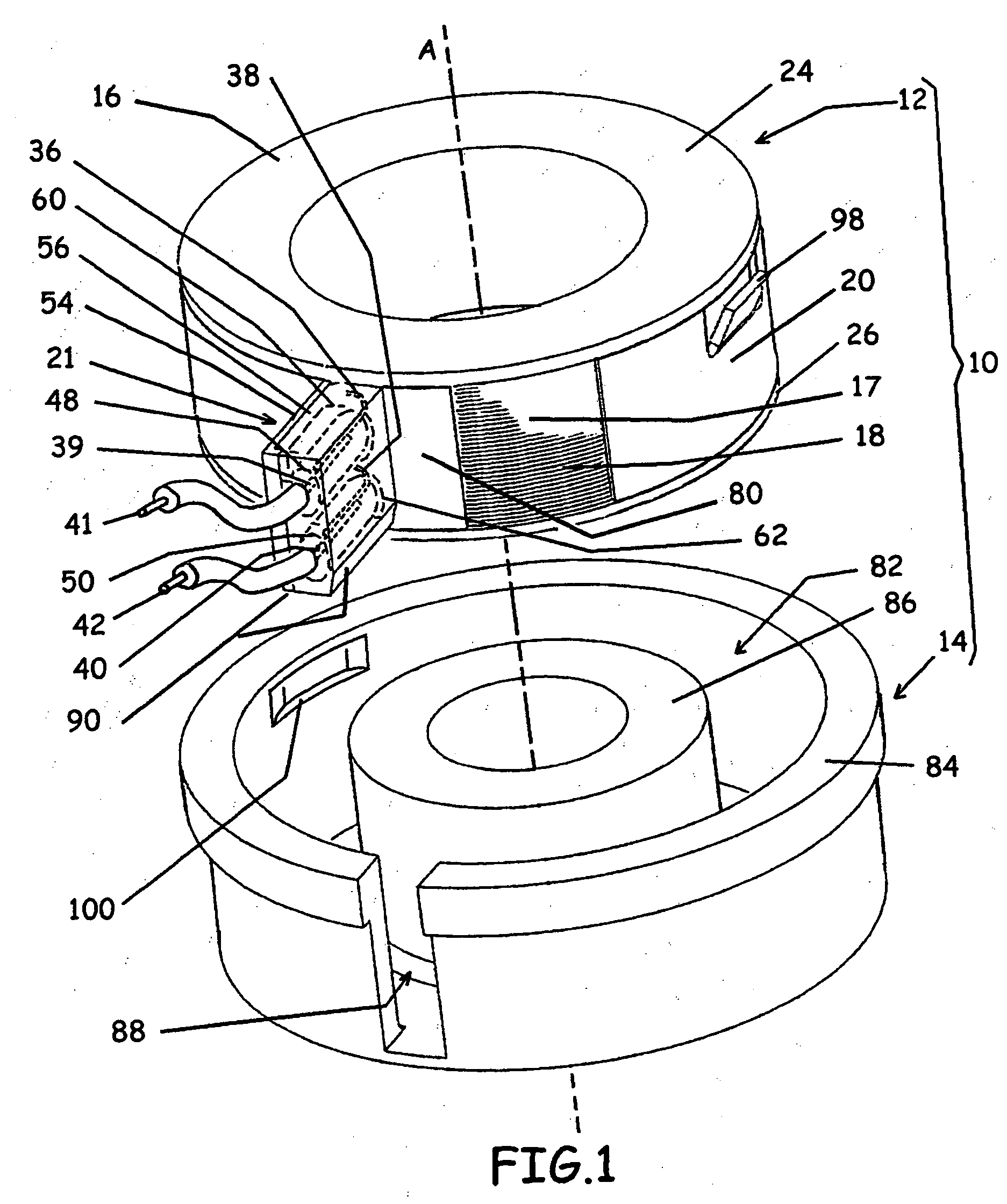

Pneumatic tool with integrated electricity generator

ActiveUS20050258694A1Well formedLess costlyMachines/enginesPortable power-driven toolsElectricityMostly True

A rotor for a pneumatic tool having electricity-generating capabilities comprises a shaft and an integral rotor body. For the most part, the rotor is generally of conventional design for a pneumatic tool, able to receive vanes on the rotor body and having gear teeth on the shaft. However, the rotor body further includes recesses dimensioned to received an insulated subassembly comprising a magnet received within a nonmagnetic insulator. The nonmagnetic insulator acts to allow flux to be concentrated against stator windings. The improved rotor can be used in a conventional pneumatic tool, but can also be fitted with the insulated subassemblies in order to cooperate with a stator in the tool to generate electricity upon rotation of the rotor when pressurized fluid is applied to the vanes. Thus, the differences between a conventional pneumatic tool rotor and its electricity-generating counterpart are greatly reduced compared to prior art configurations. A ring stator is connected to a supporting circuit by a connector and is supportable by a nonmagnetic end plate of the pneumatic tool. The ring stator is disposed between the rotor and the rotor bearing and is preferably formed of Silicon Core Iron “B-FM” and magnet wire.

Owner:VOLT AIRE CORP +1

Brushless DC motor for fuel pump

InactiveUS20110080062A1Reduce manufacturing costReduce processWindings insulation shape/form/constructionManufacturing dynamo-electric machinesMagnet wireDC motor

The present invention is characterized in that it does not require specific fastening tools, which causes breakage or defects, or bonding work, because a brushless DC motor includes an insulator that is inserted in a stator to insulate a coil wound with led magnet wires and has at least one or more locking portions with locking grooves stepped on the inner side along the circumference and an outlet connector that has hooks fitted in the locking protrusions when being assembled with the insulator such that the insulator and the outlet connector are assembled in fitting and locking ways in assembling.

Owner:DONG HEE IND +1

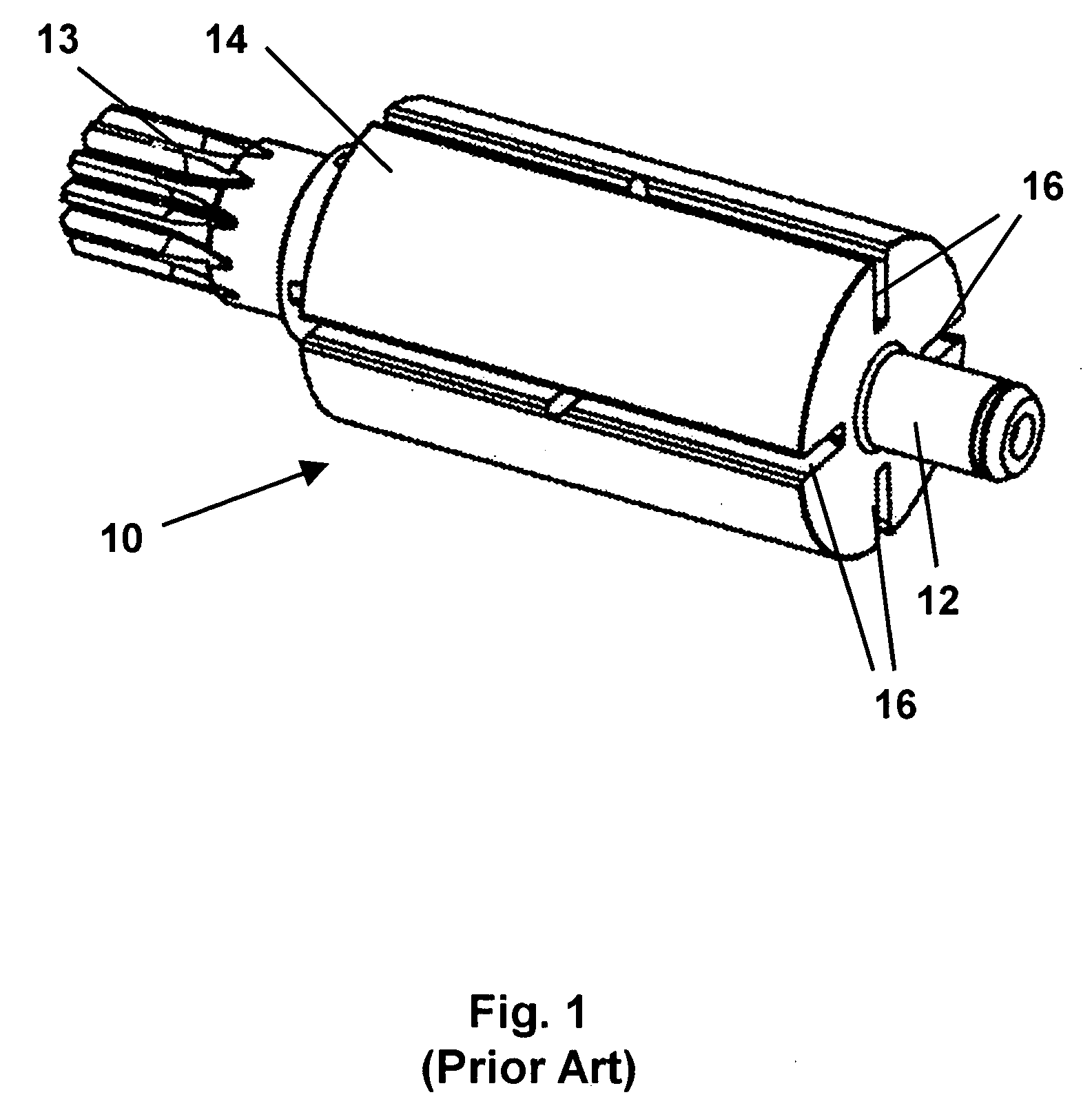

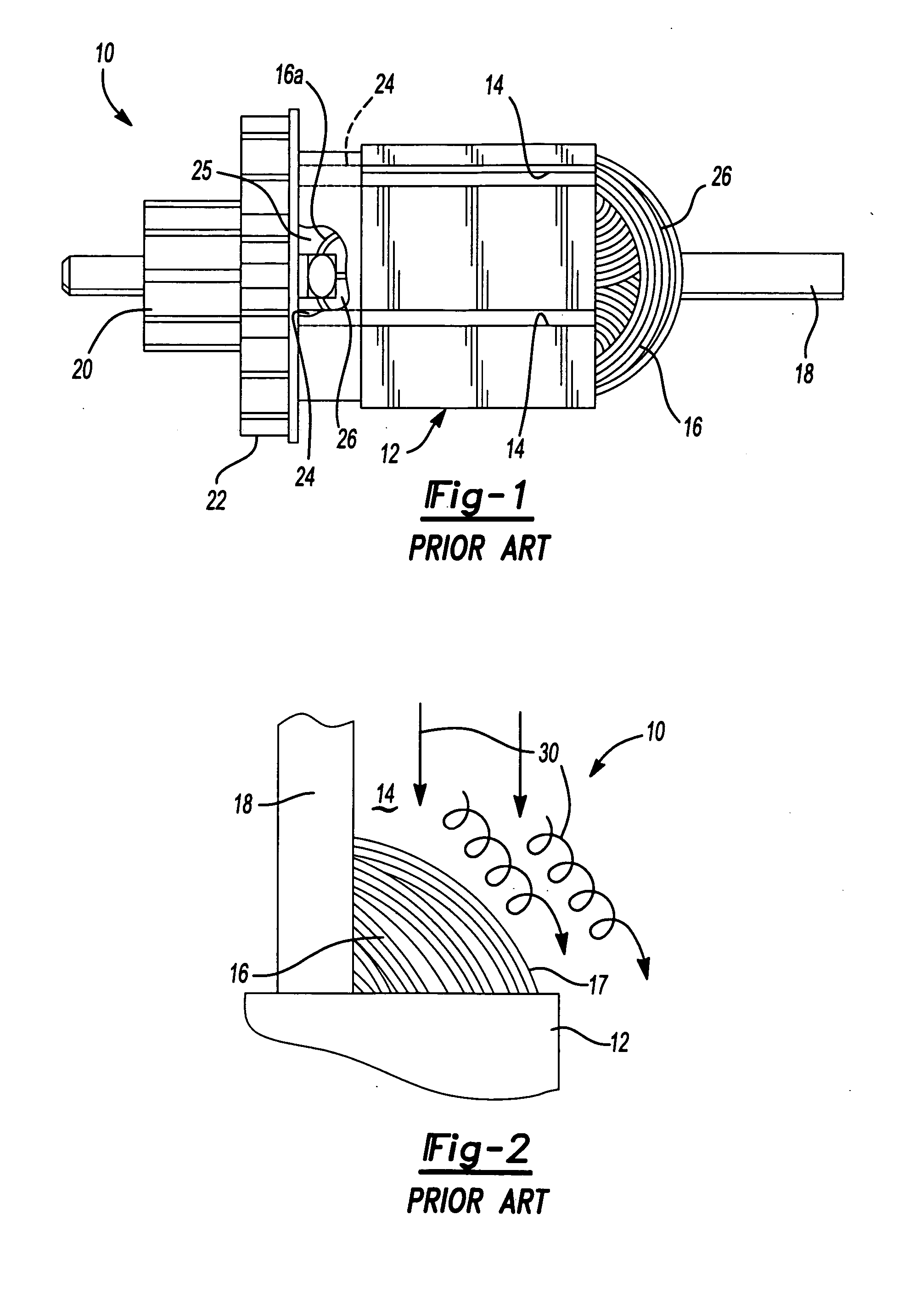

Method for forming an armature for an electric motor for a portable power tool

InactiveUS7013552B2Resists extreme temperatureHeat dissipationWindings insulation materialManufacturing stator/rotor bodiesAdhesiveEngineering

An electric motor having an armature which includes a coating of thermally conductive plastic applied in a conventional injection molding process. The armature also includes a fan which is integrally formed from the thermally conductive plastic applied to the armature. This completely eliminates the need to apply one or more coatings of a trickle resin to the armature. It also eliminates the need to separately form and secure a fan by a suitable adhesive to the armature, which together significantly simplifies the manufacturing and cost of the armature. The plastic coating also better fills the spaces between the magnet wires, thus promoting even more efficient cooling and better holding of the magnet wires stationary relative to one another. The thermally conductive plastic coating may be mixed with other suitable materials to provide a density approximately equal to the magnet wires. This eliminates the need to balance the armature after the injection molding step.

Owner:BLACK & DECKER INC

Electric motor and method of making same and method of making a power tool

InactiveUS20060255678A1Speed up the processWindings insulation materialRotary current collectorPower toolMagnet wire

Owner:BLACK & DECKER INC

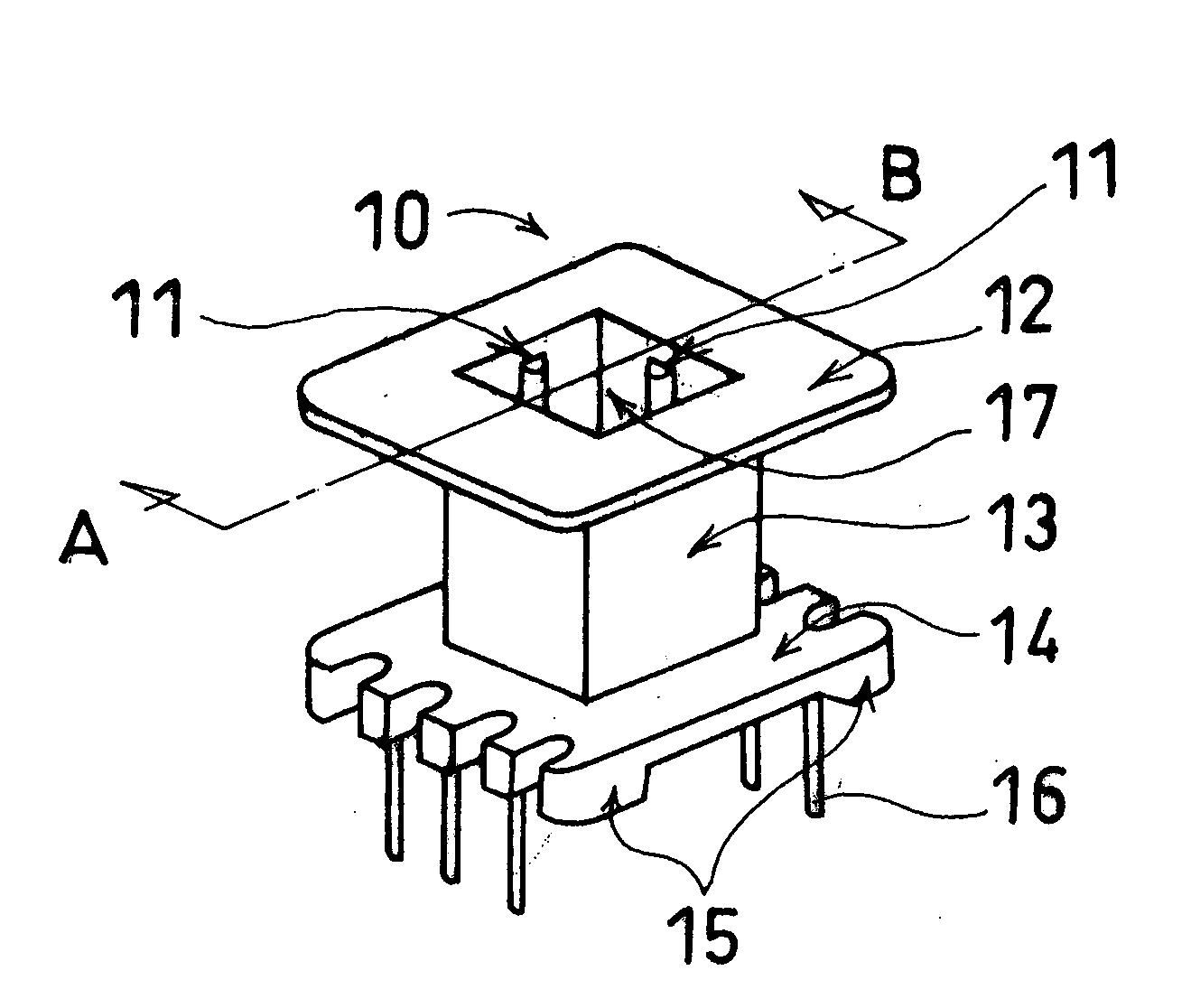

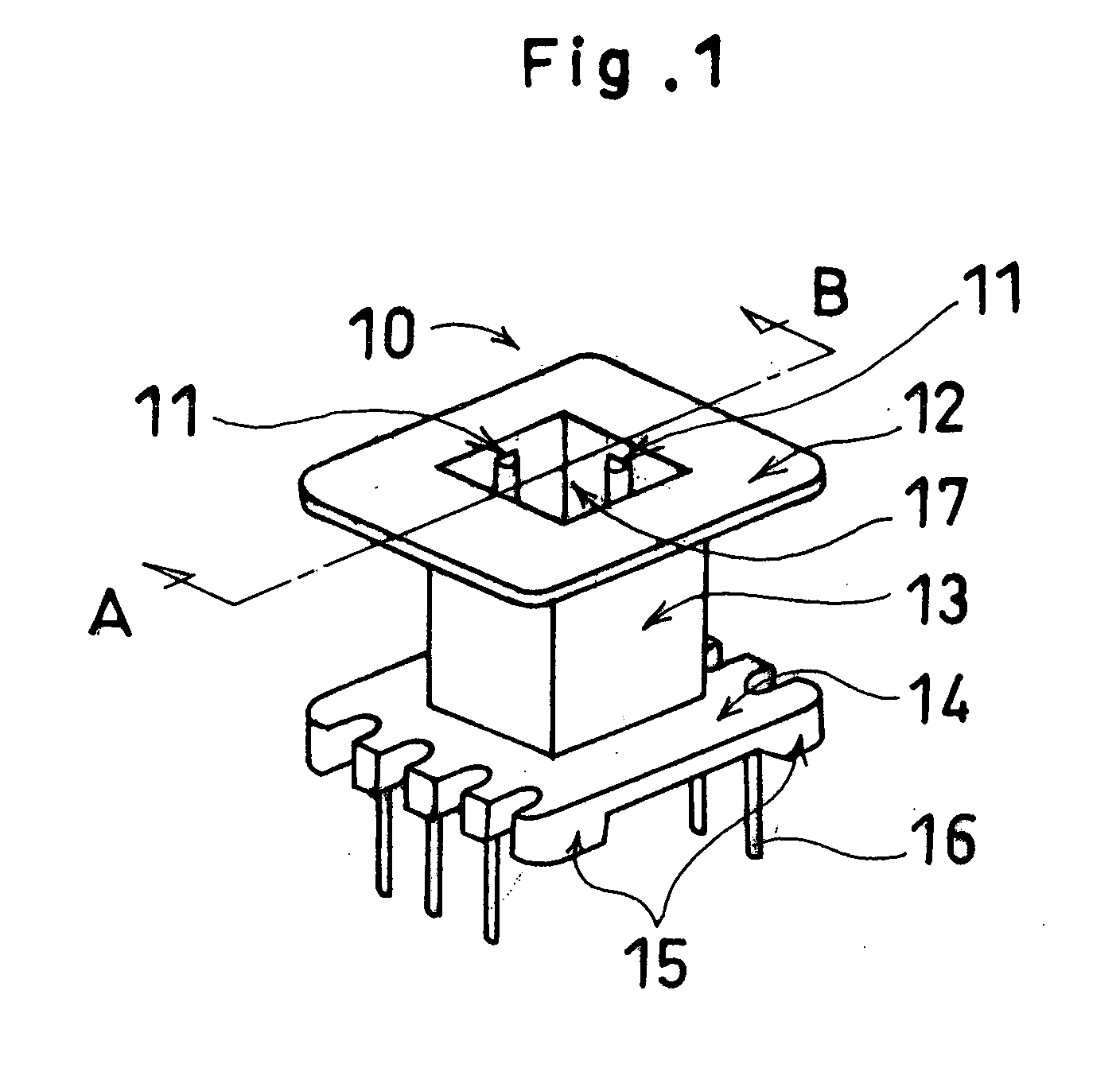

Coil bobbin with core spacing mechanisms

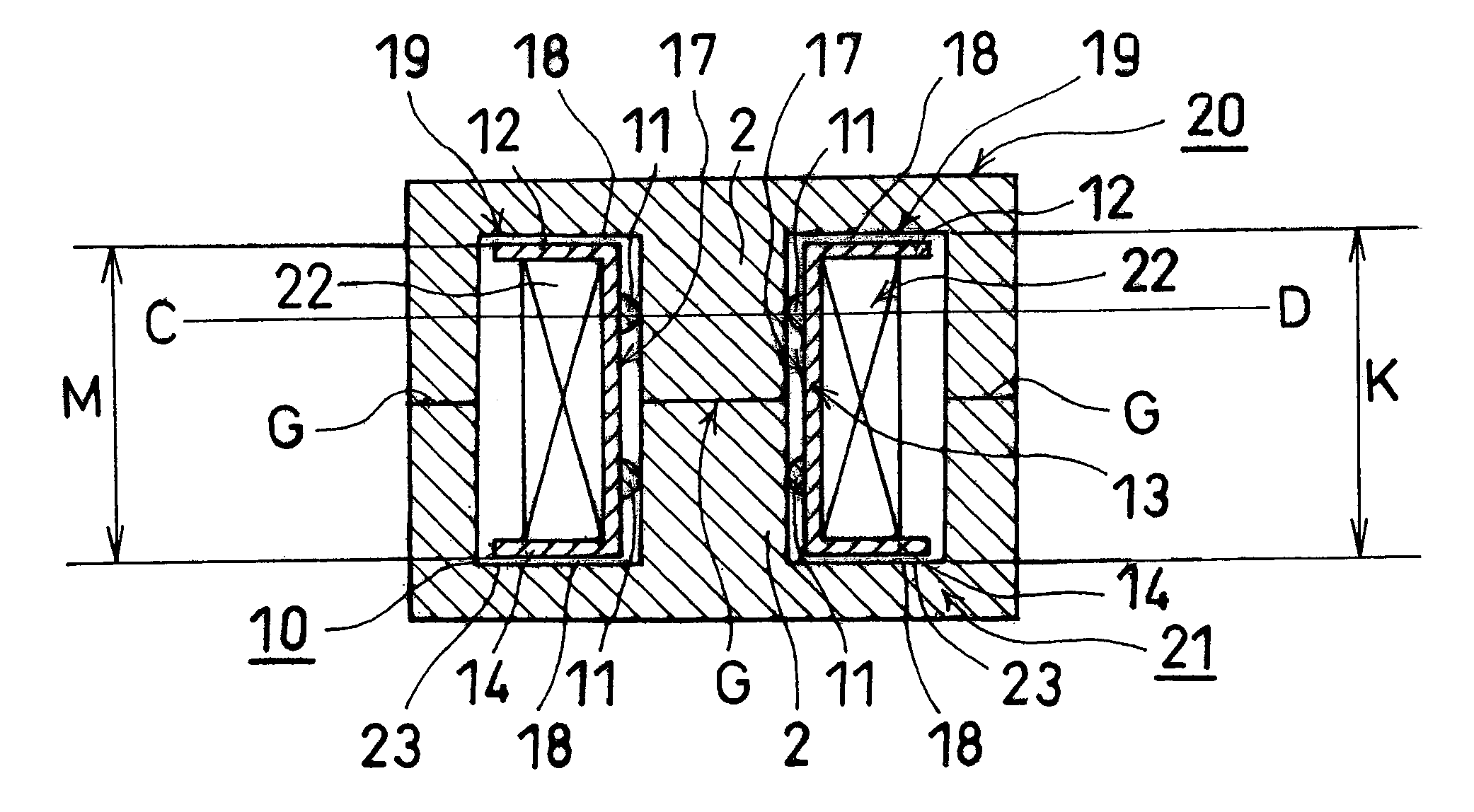

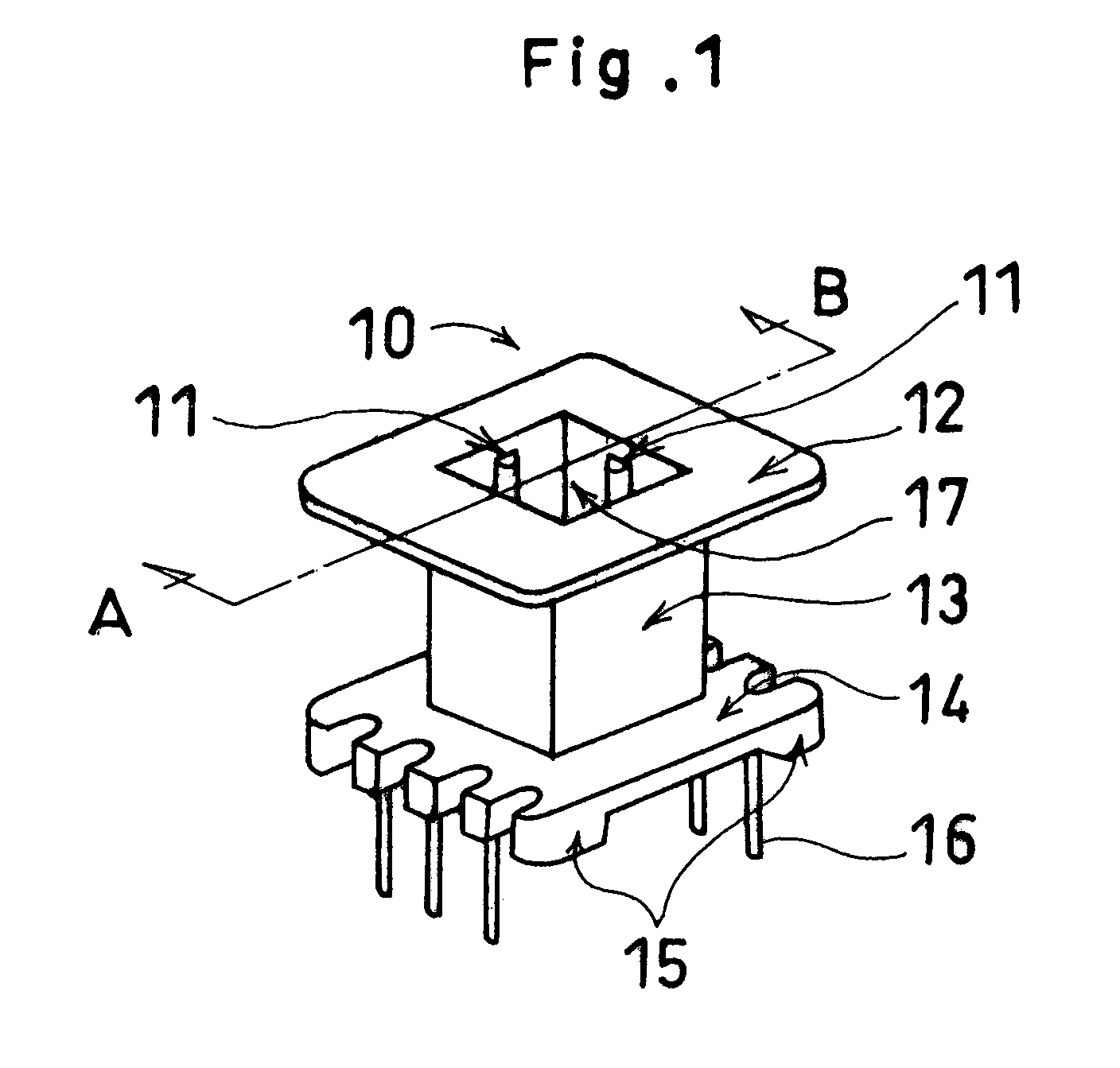

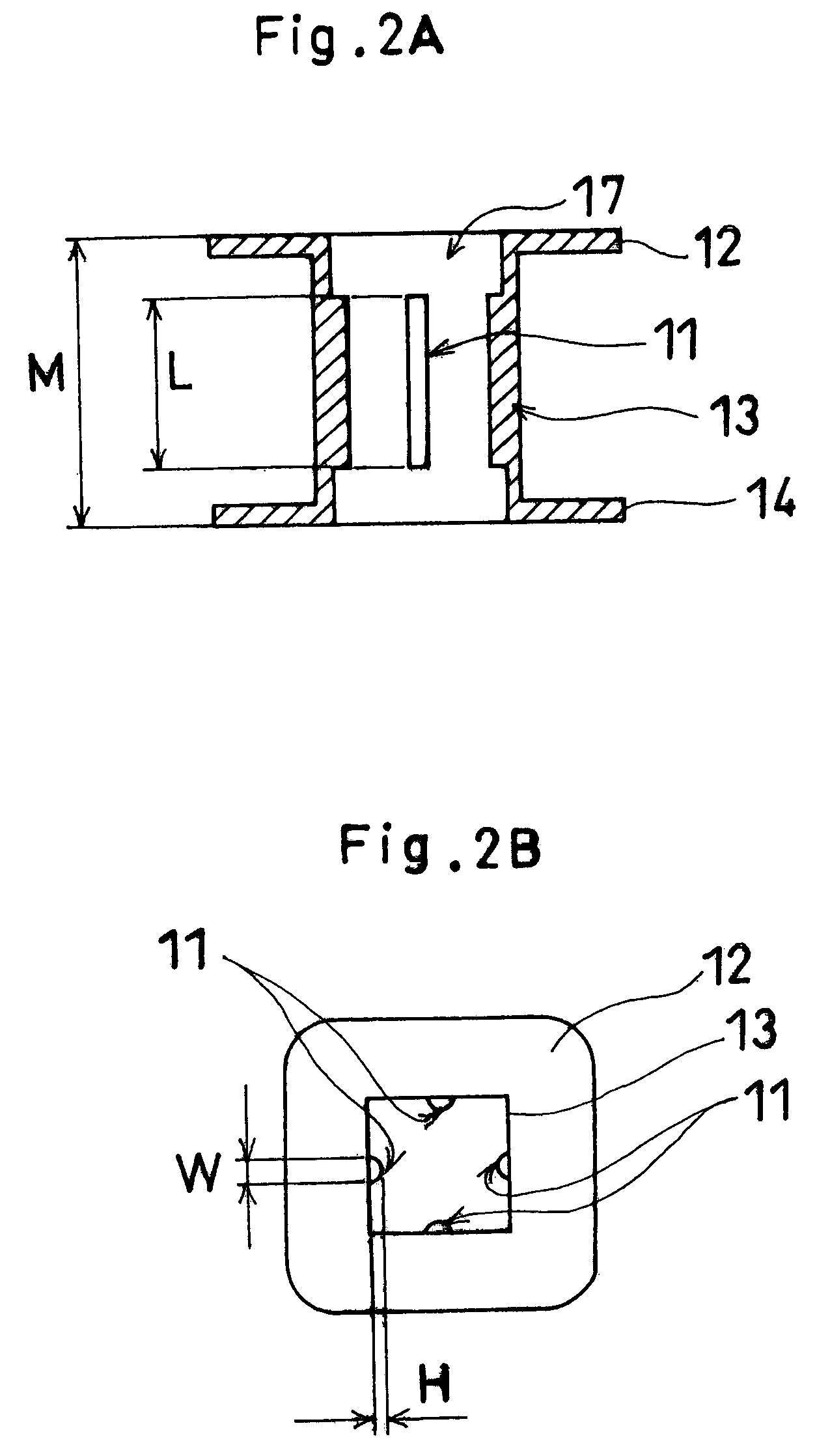

InactiveUS6958673B2Magnetic reluctance is prevented from increasingConstantTransformers/inductances casingsTransformers/inductances coils/windings/connectionsBobbinEngineering

A coil bobbin comprises a core housing portion which has a magnet wire wound therearound, and which undergoes a varnish impregnation treatment together with a magnetic core consisting of two core sections, like an EE type or UU type. Core spacing mechanisms are formed on the inner surfaces of the core housing portion, and control a position of the magnetic core inserted in the core housing portion such that the magnetic core is kept apart from the inner surfaces of the core housing portion.

Owner:MINEBEA CO LTD

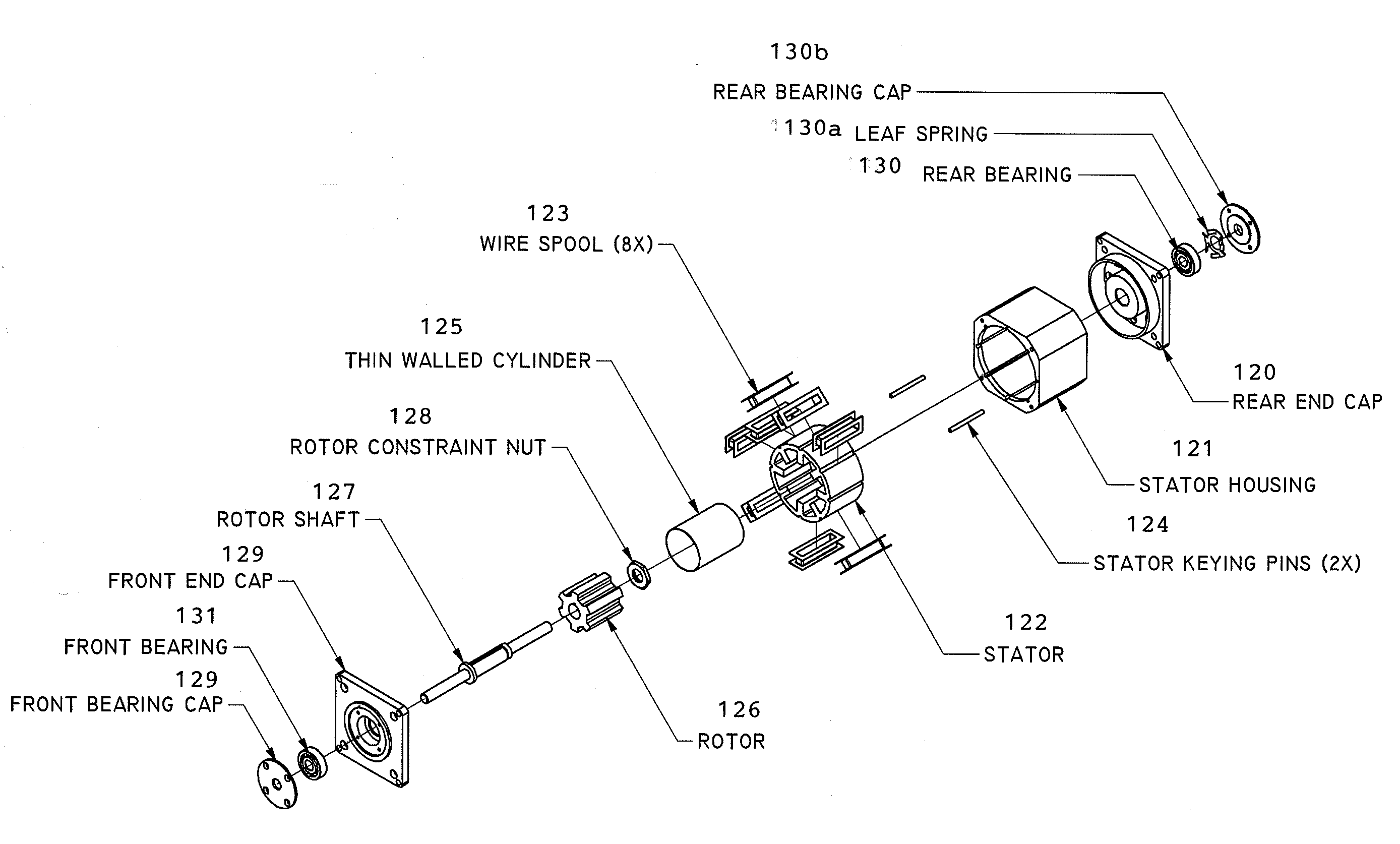

Motor for high temperature applications

ActiveUS20120025636A1Avoid debrisAvoid the needWindings insulation materialWindings insulation shape/form/constructionEpoxyAdhesive

A high temperature motor has a stator with poles formed by wire windings, and a rotor with magnetic poles on a rotor shaft positioned coaxially within the stator. The stator and rotor are built up from stacks of magnetic-alloy laminations. The stator windings are made of high temperature magnet wire insulated with a vitreous enamel film, and the wire windings are bonded together with ceramic binder. A thin-walled cylinder is positioned coaxially between the rotor and the stator to prevent debris from the stator windings from reaching the rotor. The stator windings are wound on wire spools made of ceramic, thereby avoiding need for mica insulation and epoxy / adhesive. The stator and rotor are encased in a stator housing with rear and front end caps, and rear and front bearings for the rotor shaft are mounted on external sides of the end caps to keep debris from the motor migrating into the bearings' races.

Owner:HONEYBEE ROBOTICS

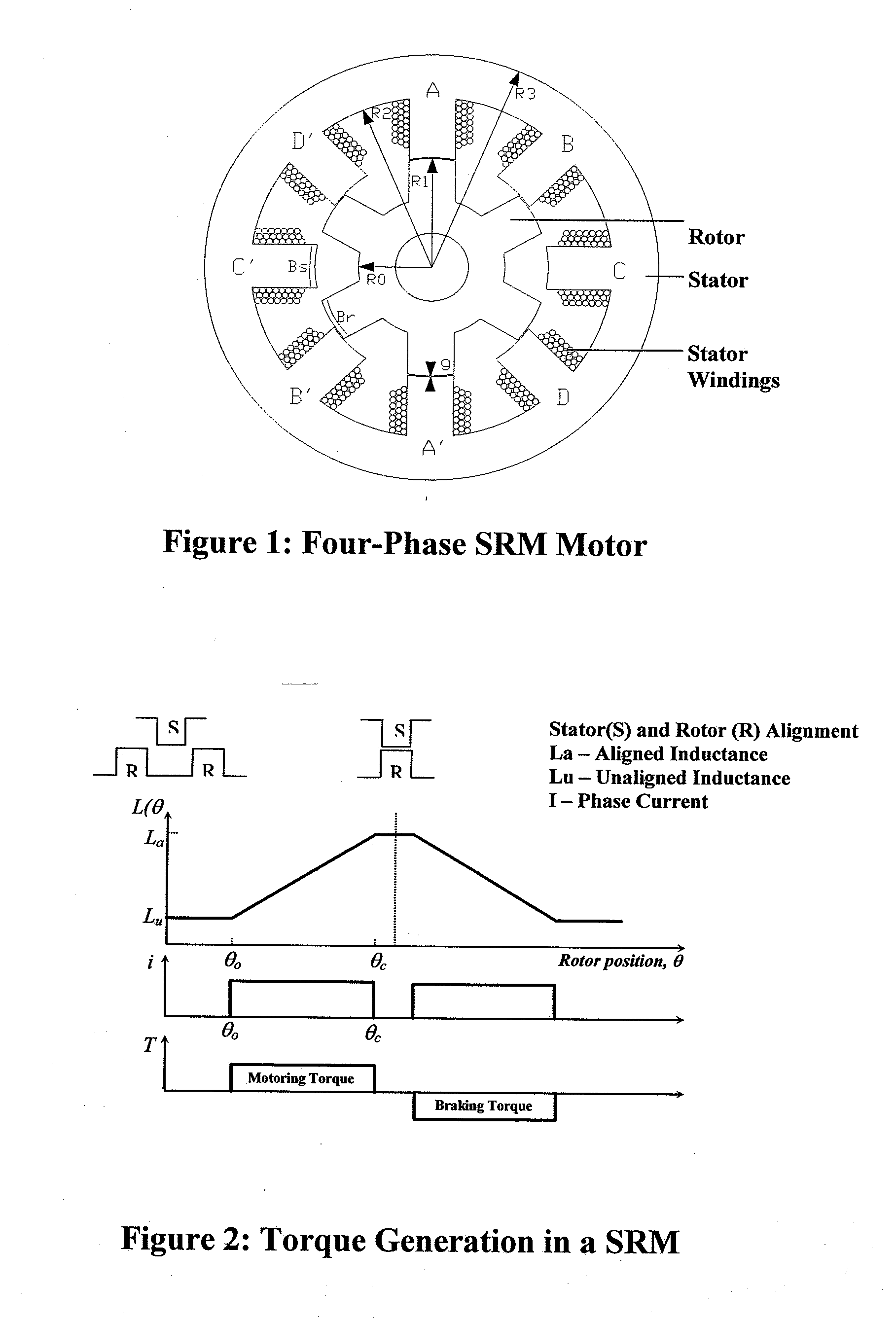

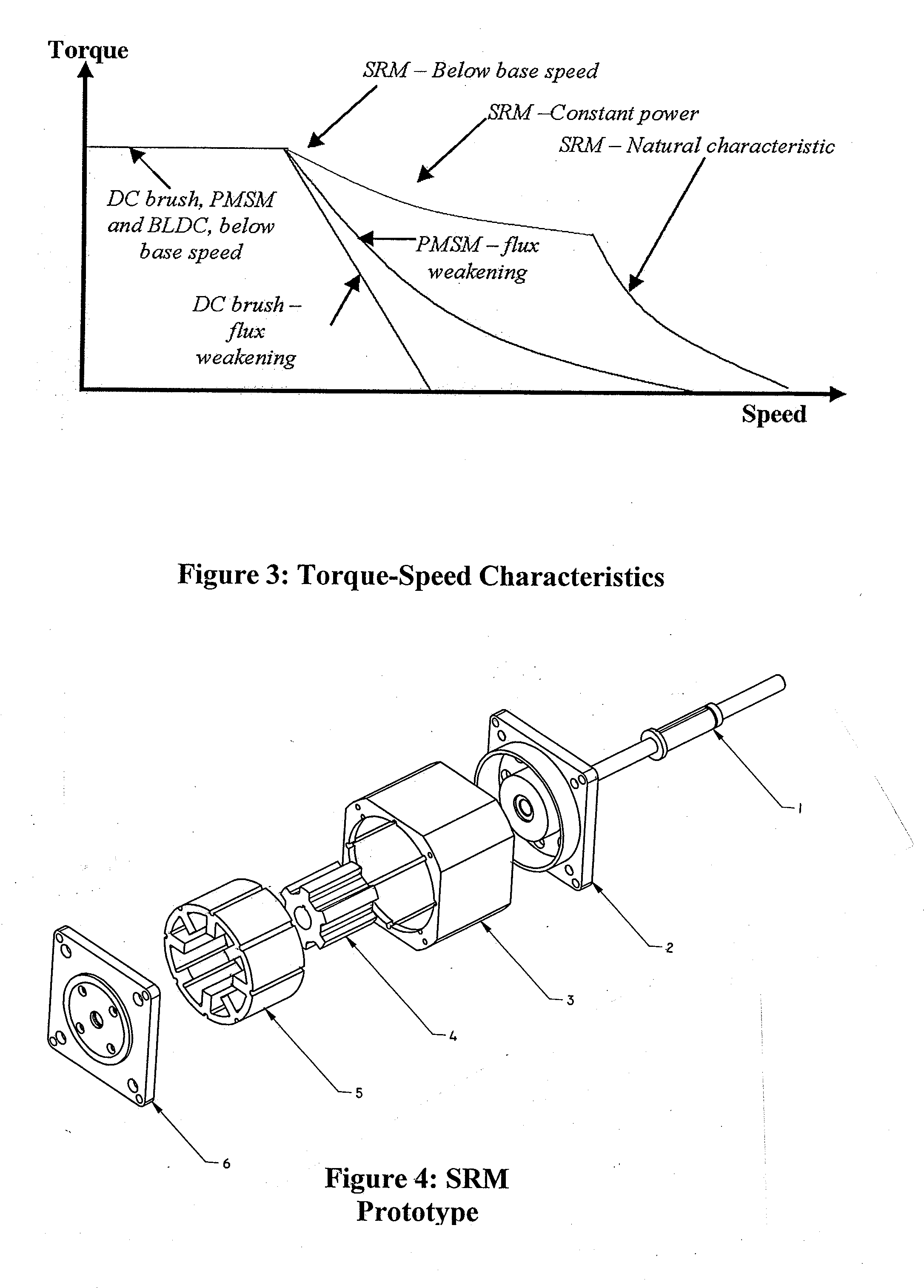

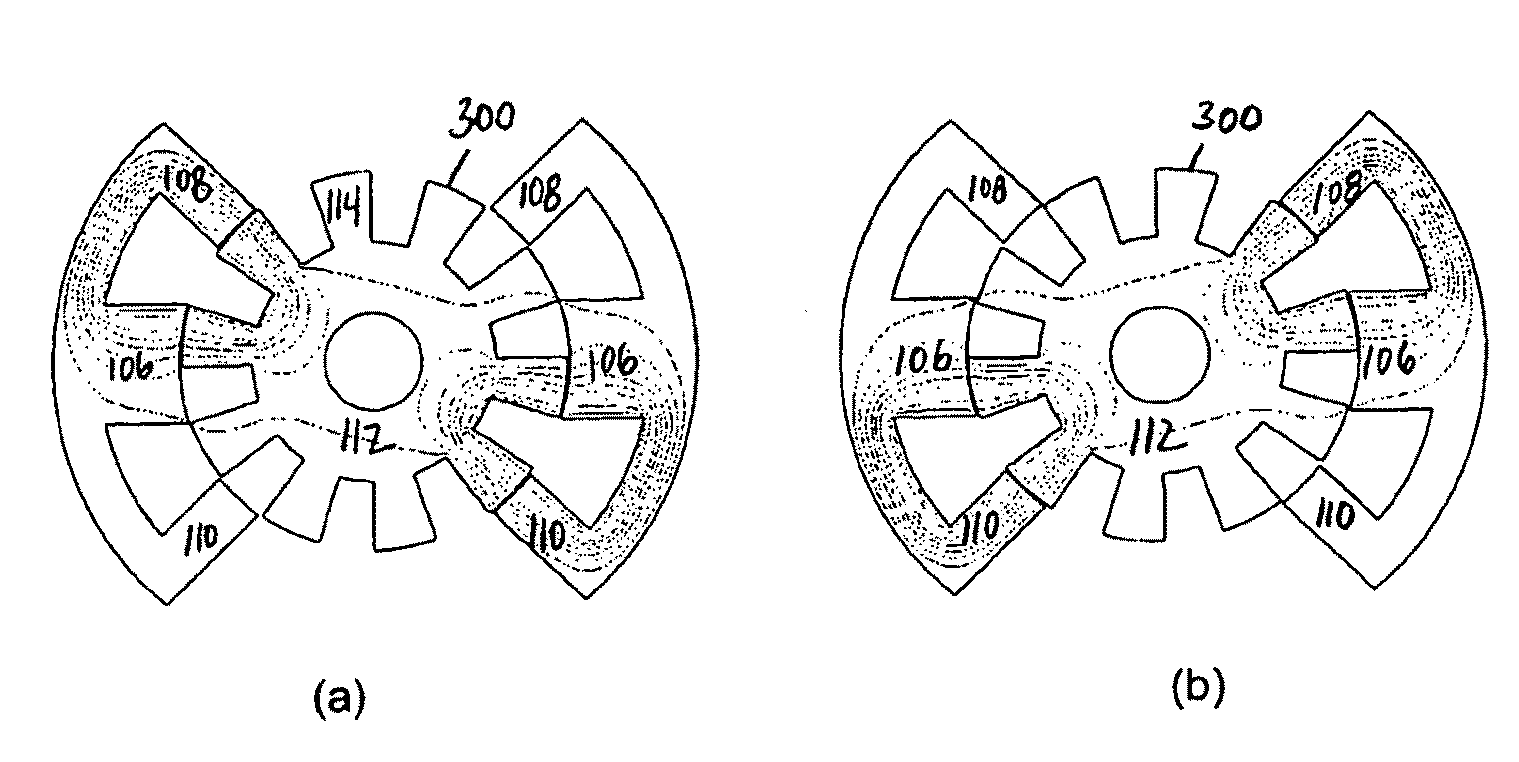

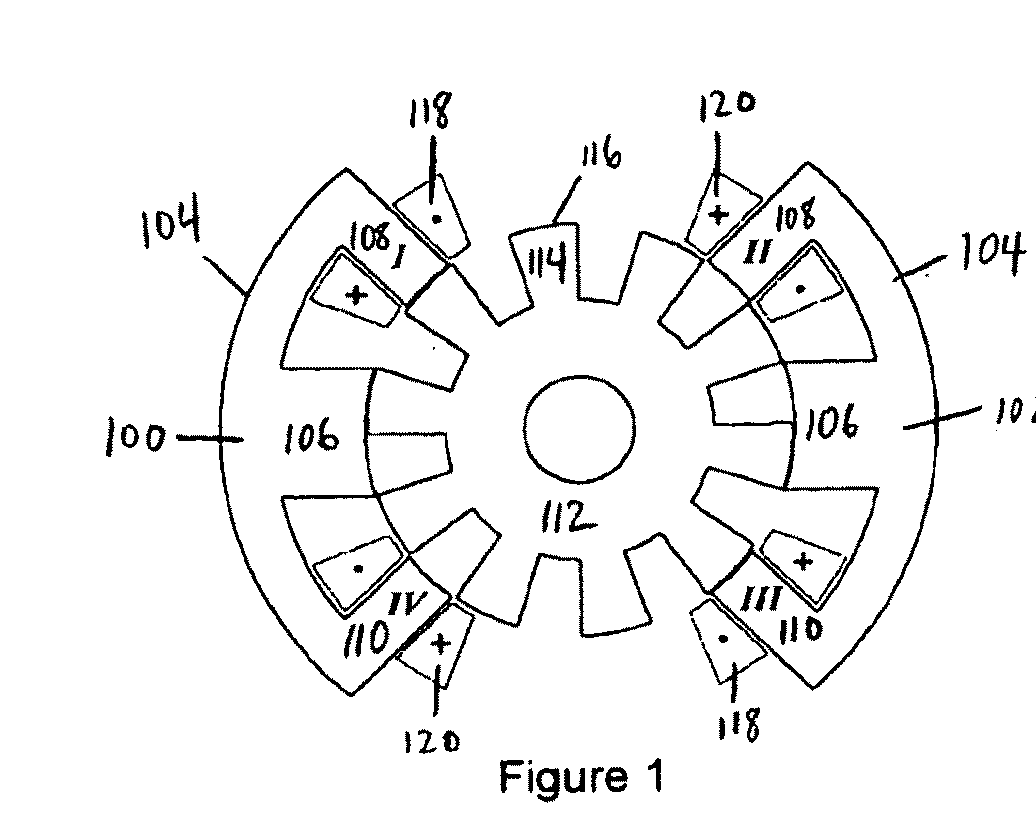

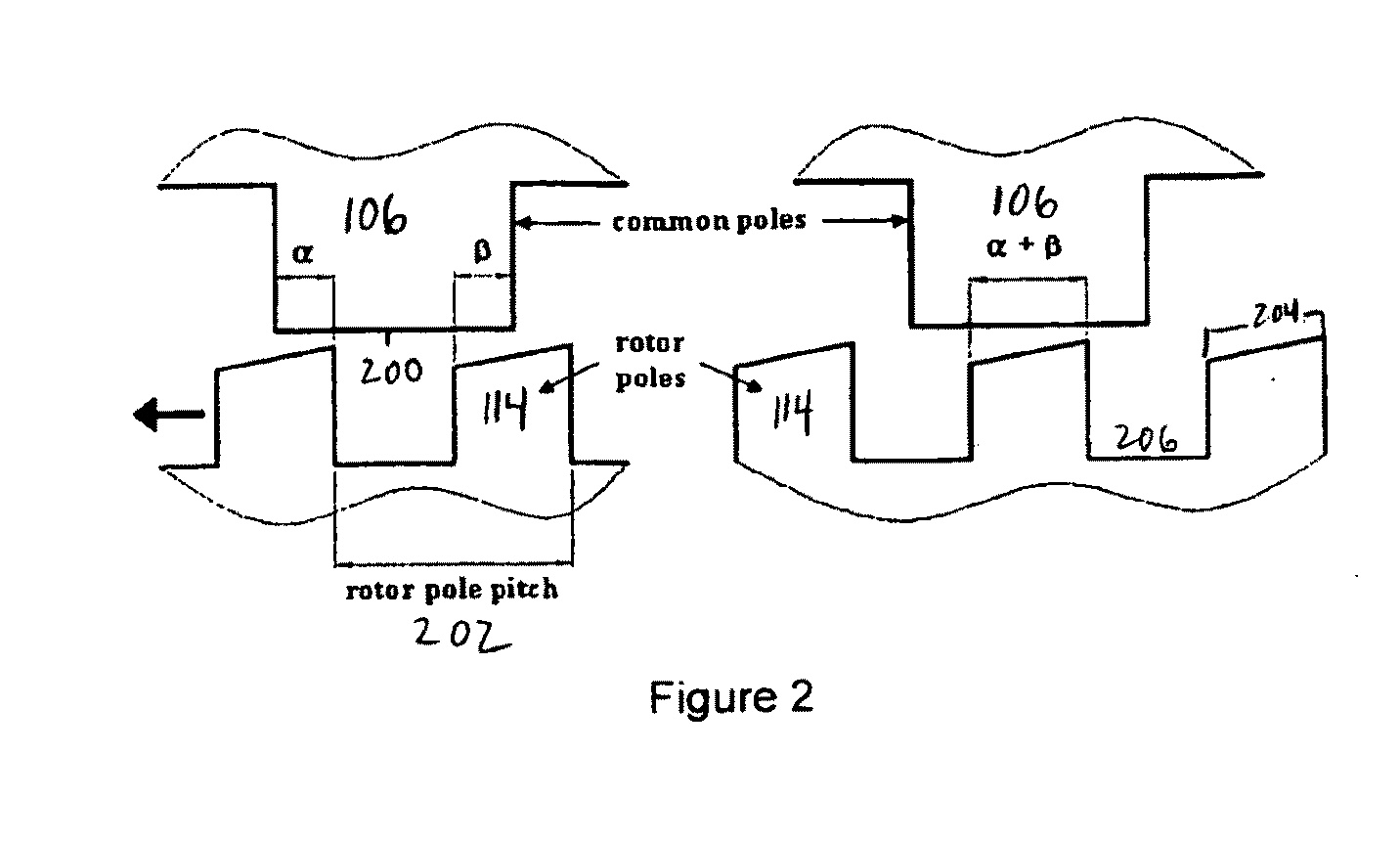

Switched Reluctance Machines with Minimum Stator Core

InactiveUS20100141061A1Minimized in sizeReduce path lengthSynchronous machinesMagnetic circuit stationary partsConductor CoilCost savings

A two-phase switched reluctance machine is provided using discontinuous core structures as the stator for low-cost, high-performance drives. This discontinuous stator core structure contains short flux paths and maximum overlap between the rotor poles and stator poles in the stator discontinuous core structures, regardless of the rotor position. Example configurations of such core structure include E-core, L-core and I-core configurations. Using less steel and magnet wire than in conventional SRM designs results in cost savings of stator material and winding material. Efficiency of this novel SRM is improved because of shorter flux paths resulting in reduction of core losses and decreased phase resistance resulting in reduction of copper losses. Two-phase simultaneous excitation of the novel SRM can reduce torque ripple during commutation as compared with existing two-phase SRMs.

Owner:VIRGINIA TECH INTPROP INC +1

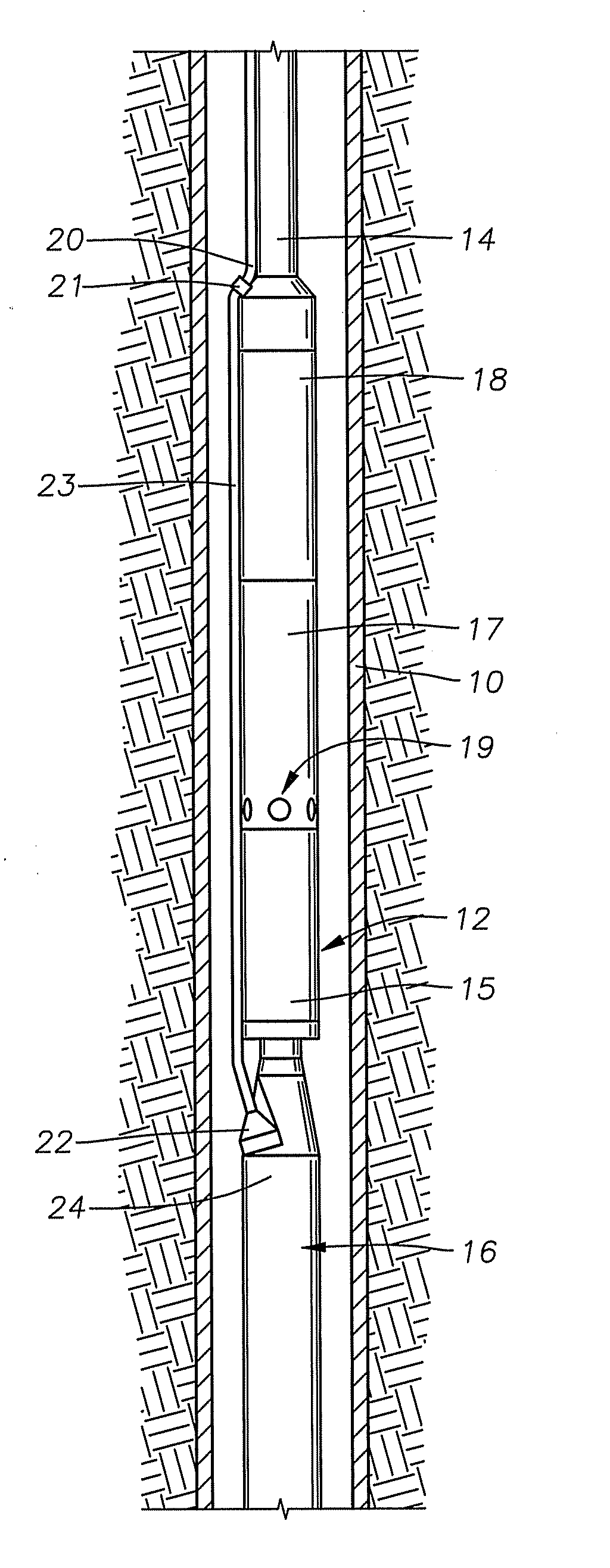

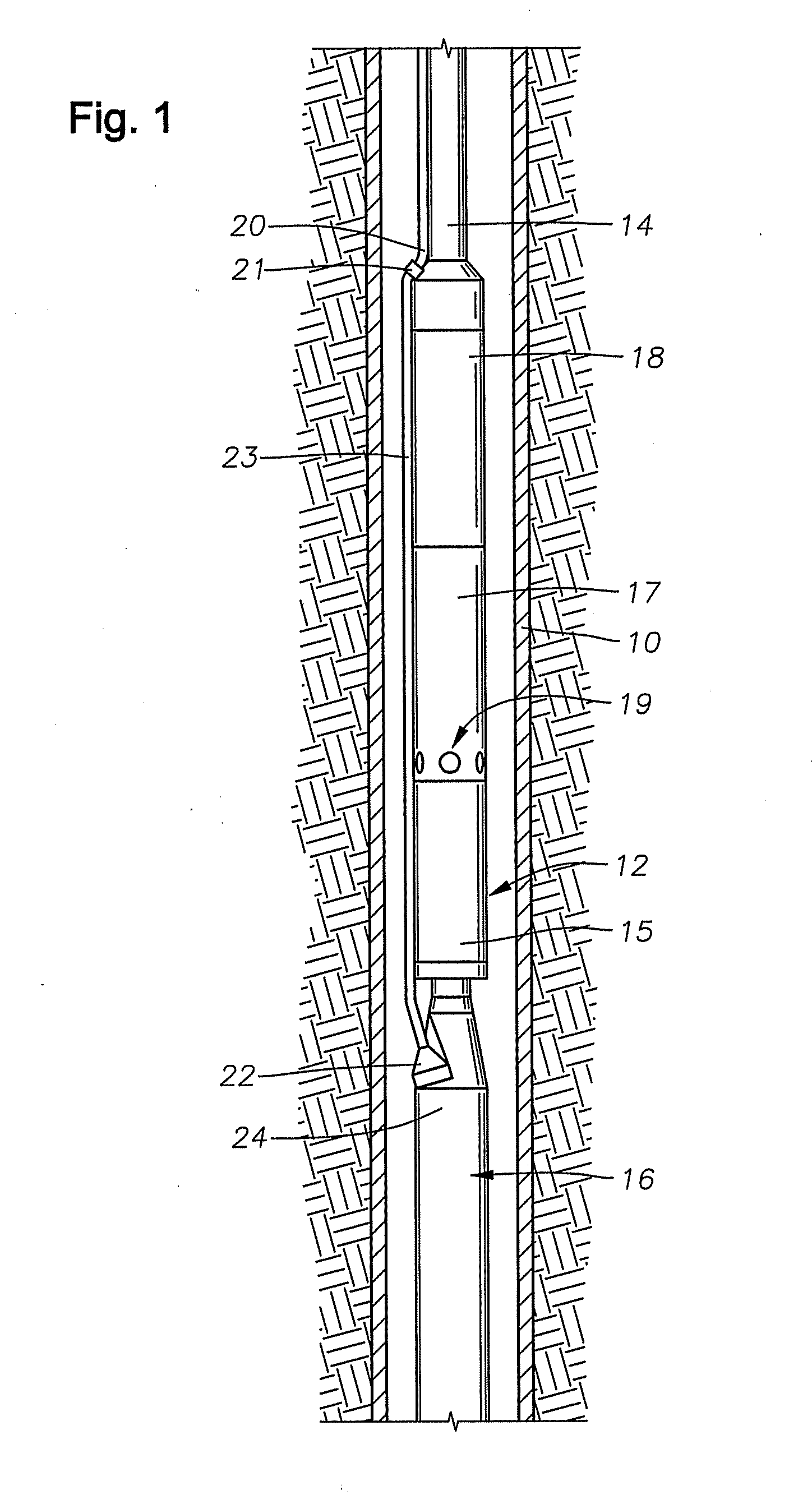

Electrical Submersible Pump System Having High Temperature Insulation Materials

ActiveUS20120063931A1Increase temperatureWindings insulation materialWindings insulation shape/form/constructionEpoxyElectricity

Electric submersible well pumping systems operable in well temperatures of above about 180° C. (356° F.) utilize high temperature electrical insulation. The electrical insulation includes E-base polyimide films or perfluoropolymer TE films on various components. The insulation films are employed around magnet wires that are threaded through slots in the stator. Slot insulation of E-base polyimide or perfluoropolymer TE film surrounds the magnet wires in the stator slots. Sheets of E-base polyimide or perfluoropolymer TE film extend around and between phase loops of the magnet wire at the lower end of the stator. The motor contains a PAO oil having additives to dissipate acid generated by epoxy used in the motor.

Owner:BAKER HUGHES INC

Claw-pole type stepping motor

InactiveUS20050046305A1Reduce radial sizeMaintain mechanical strengthSynchronous generatorsWindingsBobbinSolid structure

A claw-pole type stepping motor comprises: a rotor assembly shaped substantially cylindrical, and having a center shaft; and a stator assembly composed of two cup-shaped stator units which are coupled to each other coaxially so as to axially sandwich the rotor assembly, and which each include a bobbin having a magnet wire wound therearound, and two pole tooth arrays magnetically connected to each other and shifted in phase from each other by an electrical angle of 180 degrees. In the motor, each stator unit further includes a cover ring which protects the magnet wire wound around the bobbin against resin injected when the stator unit is resin-molded for an integrated solid structure. The motor structured as described above can be successfully resin-molded so as to enable elimination of a motor case, thus achieving downsizing for the dimension of the eliminated motor case while maintaining a sufficient mechanical strength.

Owner:MINEBEA CO LTD

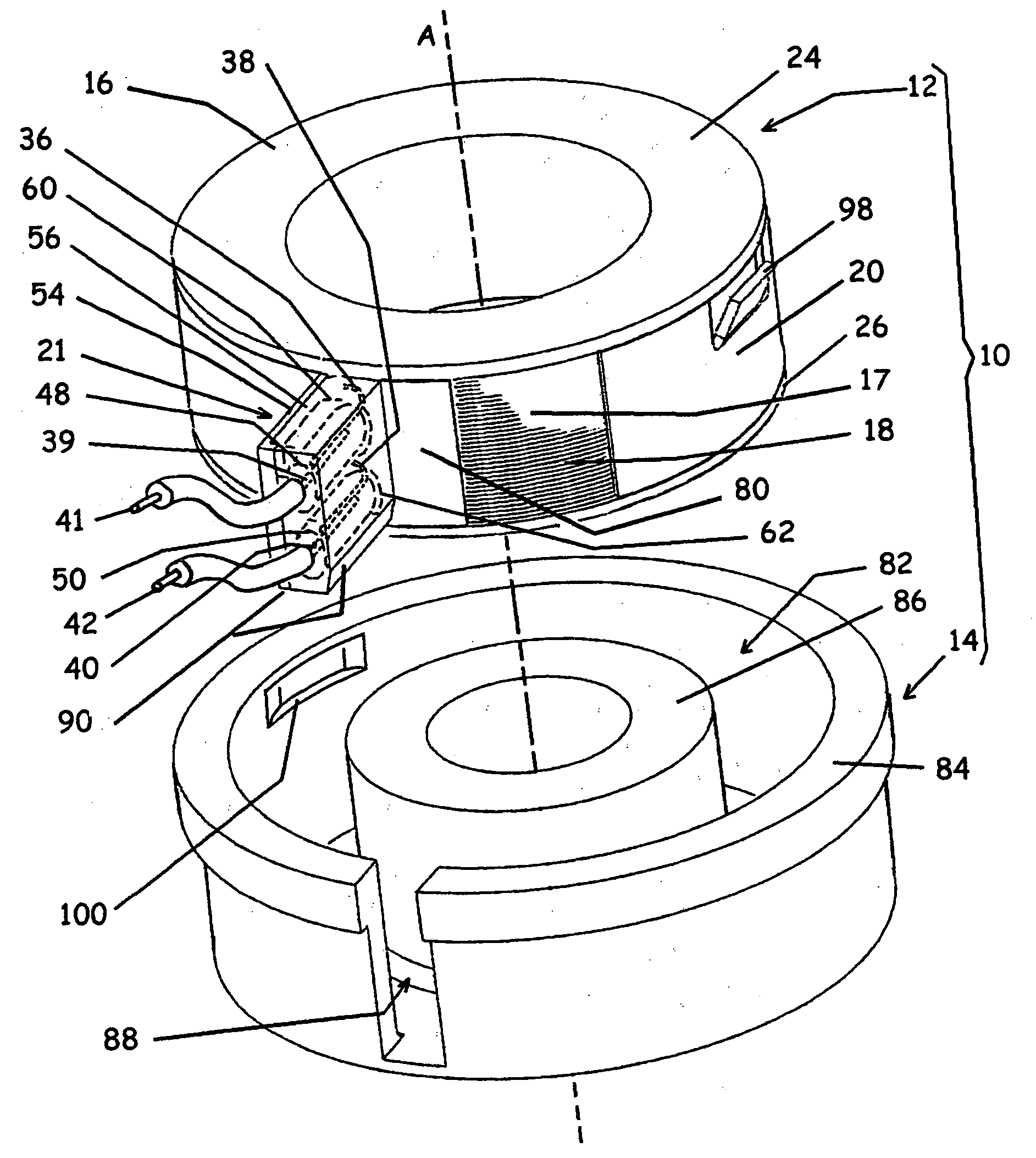

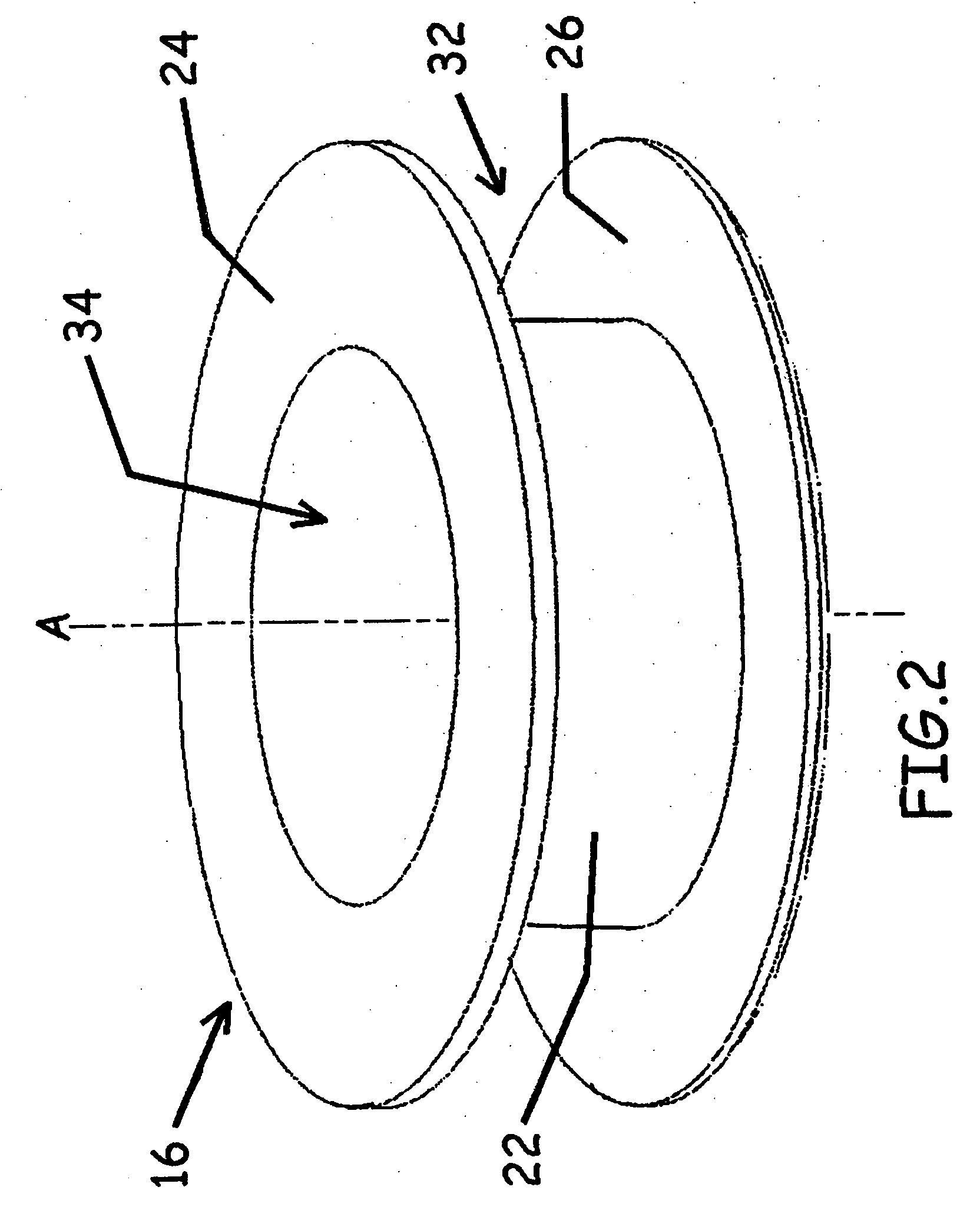

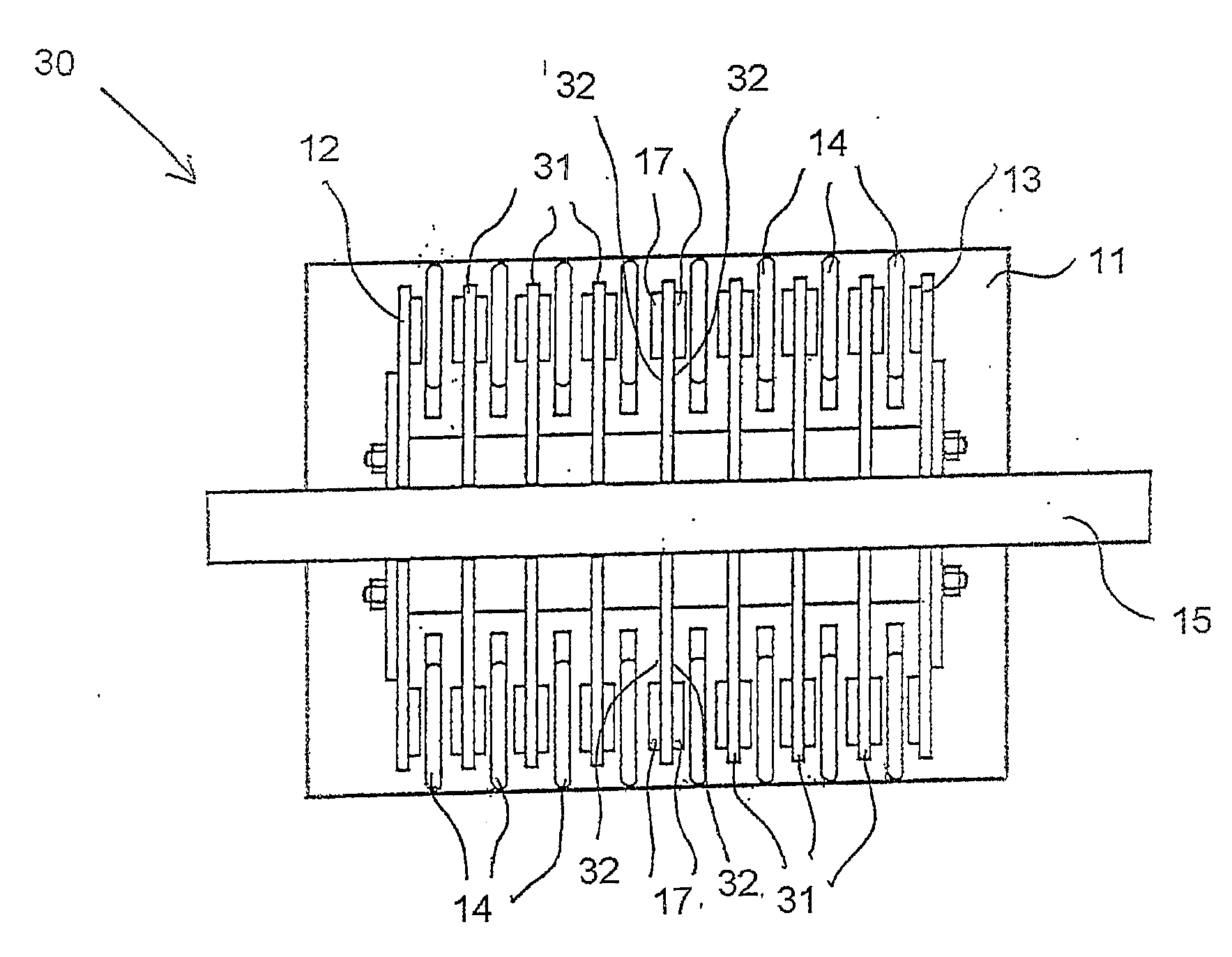

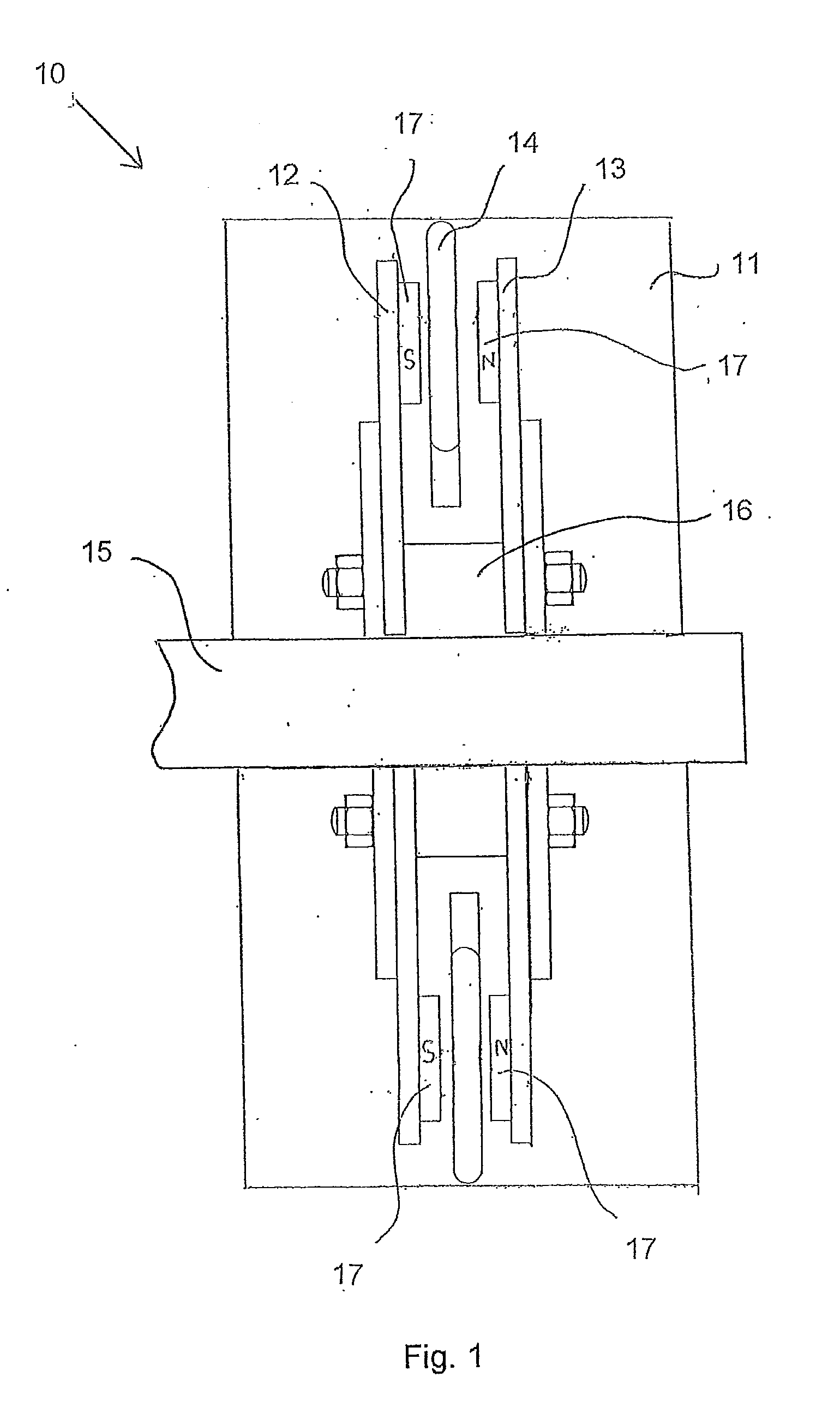

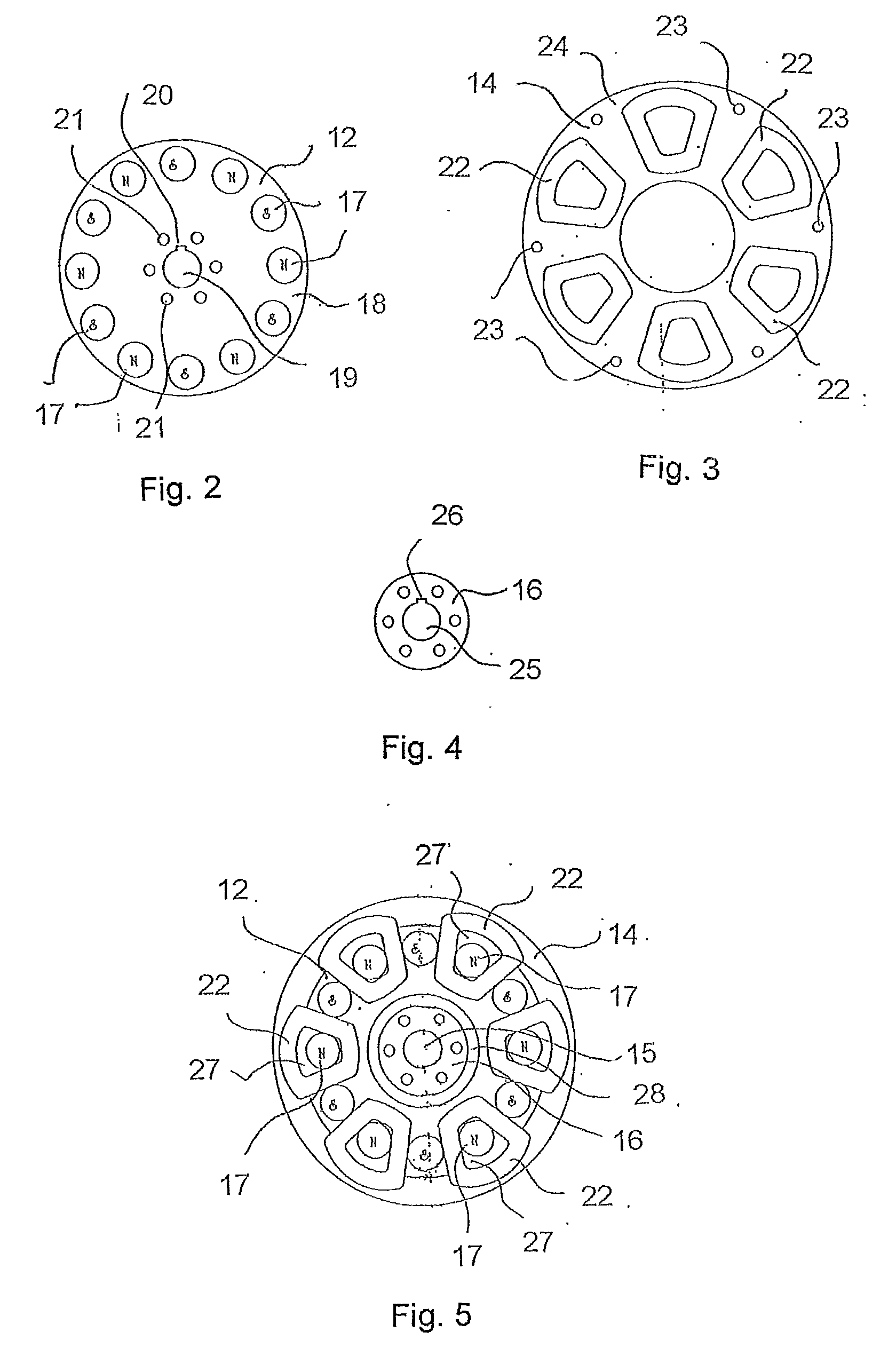

Alternator

InactiveUS20100001533A1High impedanceAvoid voltage spikesSynchronous generatorsEmergency protective circuit arrangementsAlternatorDrive shaft

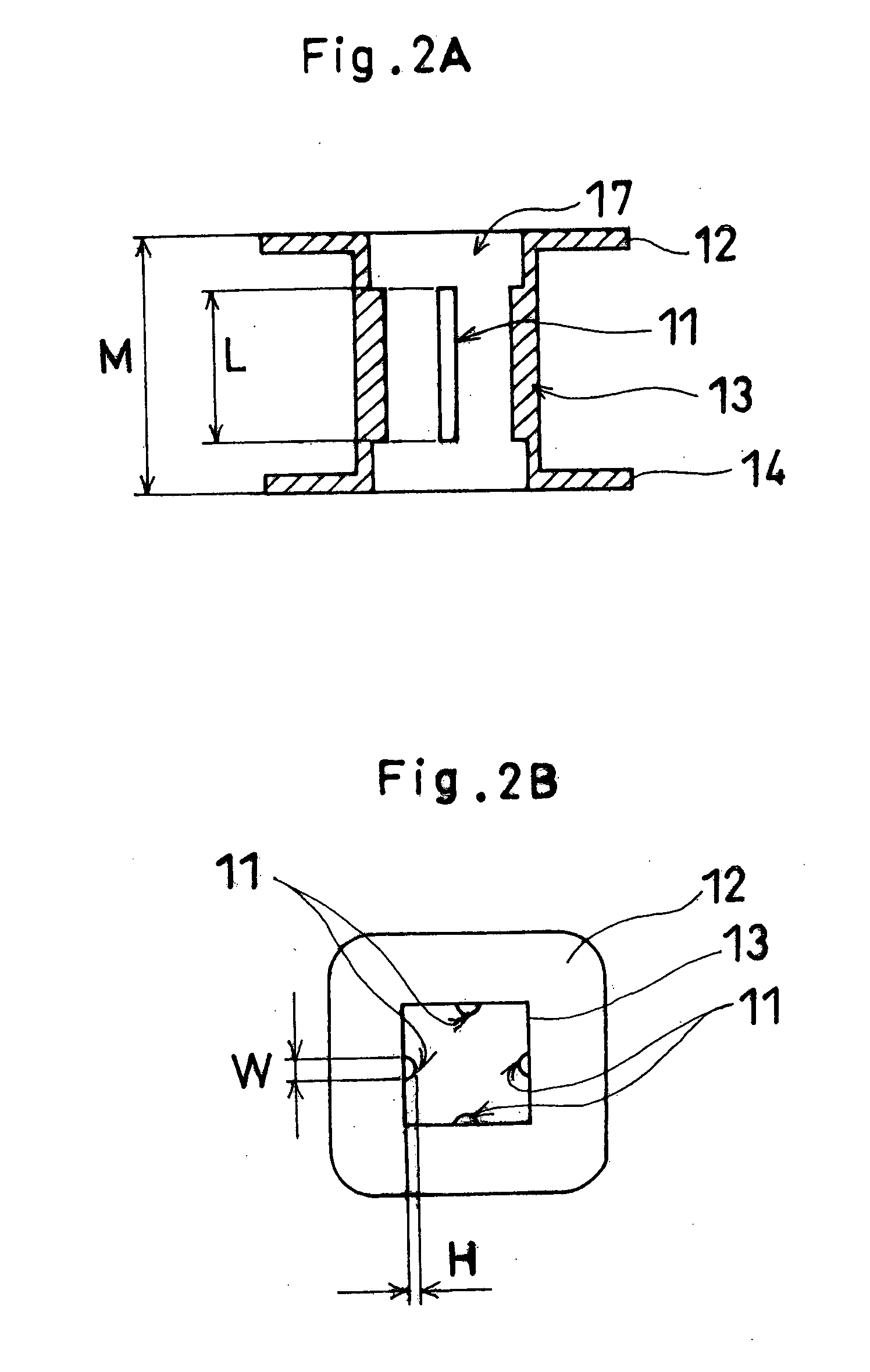

An alternator (10) has a housing (11), a pair of opposed magnet end plates (12, 13) mounted within the housing (11) a coil plate (14) mounted in and held in position within the housing (11), between the pair of magnet end plates (12, 13). A drive shaft (15) is located within housing (11) and is coupled to the pair of magnet end plates (12, 13). Each magnet end plate (12, 13) has a plurality of permanent magnets (17) disposed thereon. The coil plate (14) has a plurality of magnet wire coils (not shown) embedded therewithin such that they can be seen from both sides of the coil plate (14). In use, turning of the drive shaft (15) causes the magnet end plates (12, 13) to move relative to the coil plate (14) thus exciting each magnet wire coil (not shown) on each side resulting in the generation of an alternating current therein.

Owner:WIND CONCEPTS

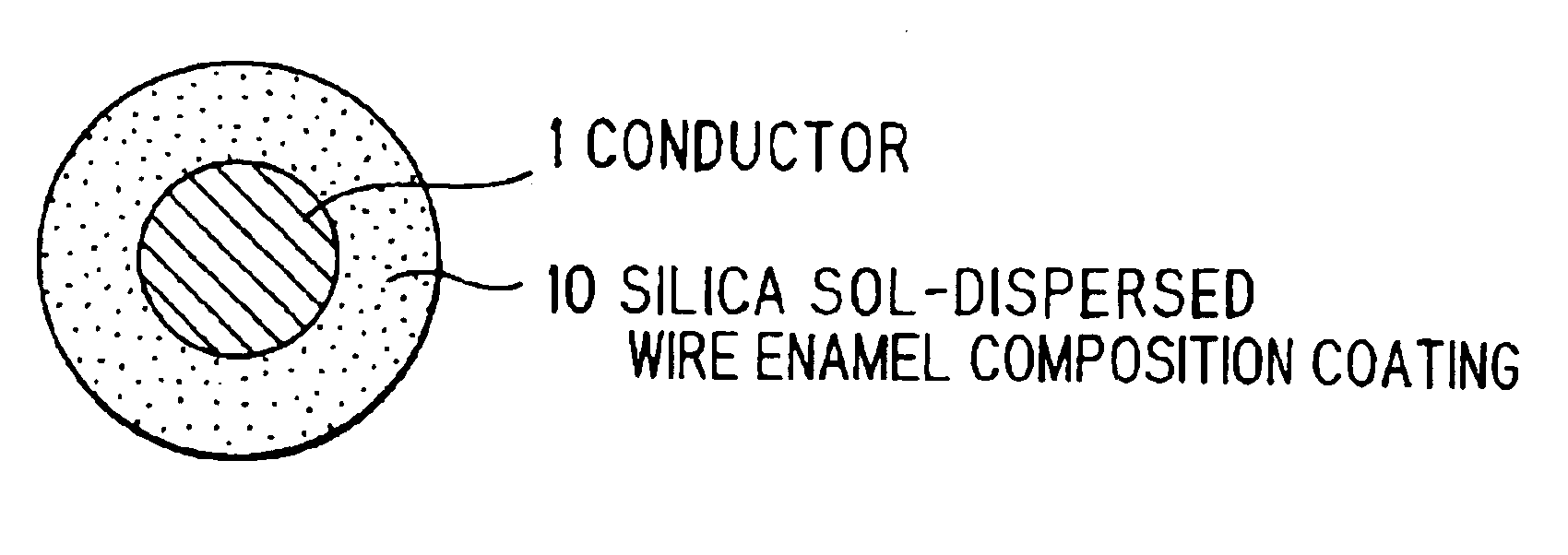

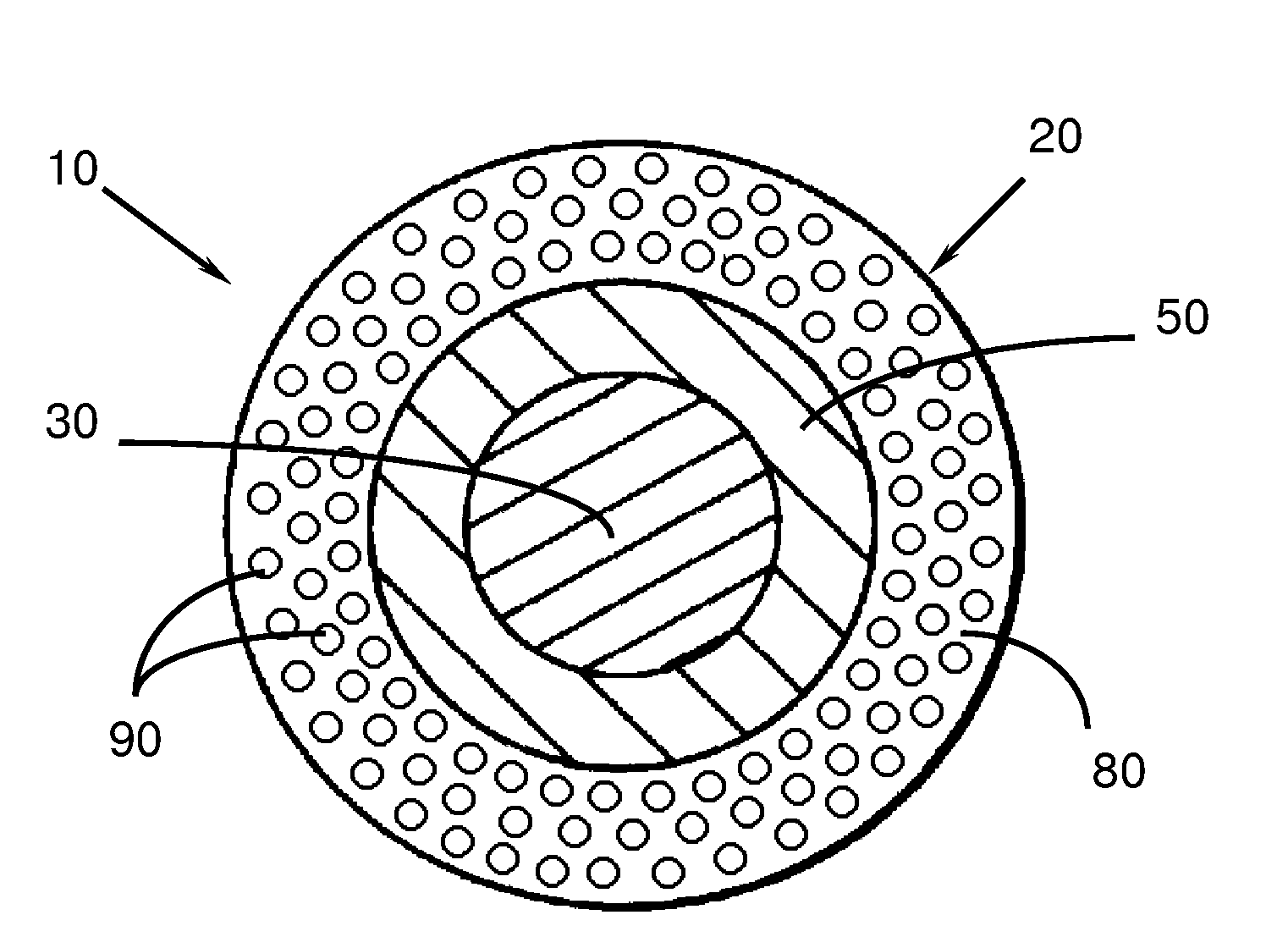

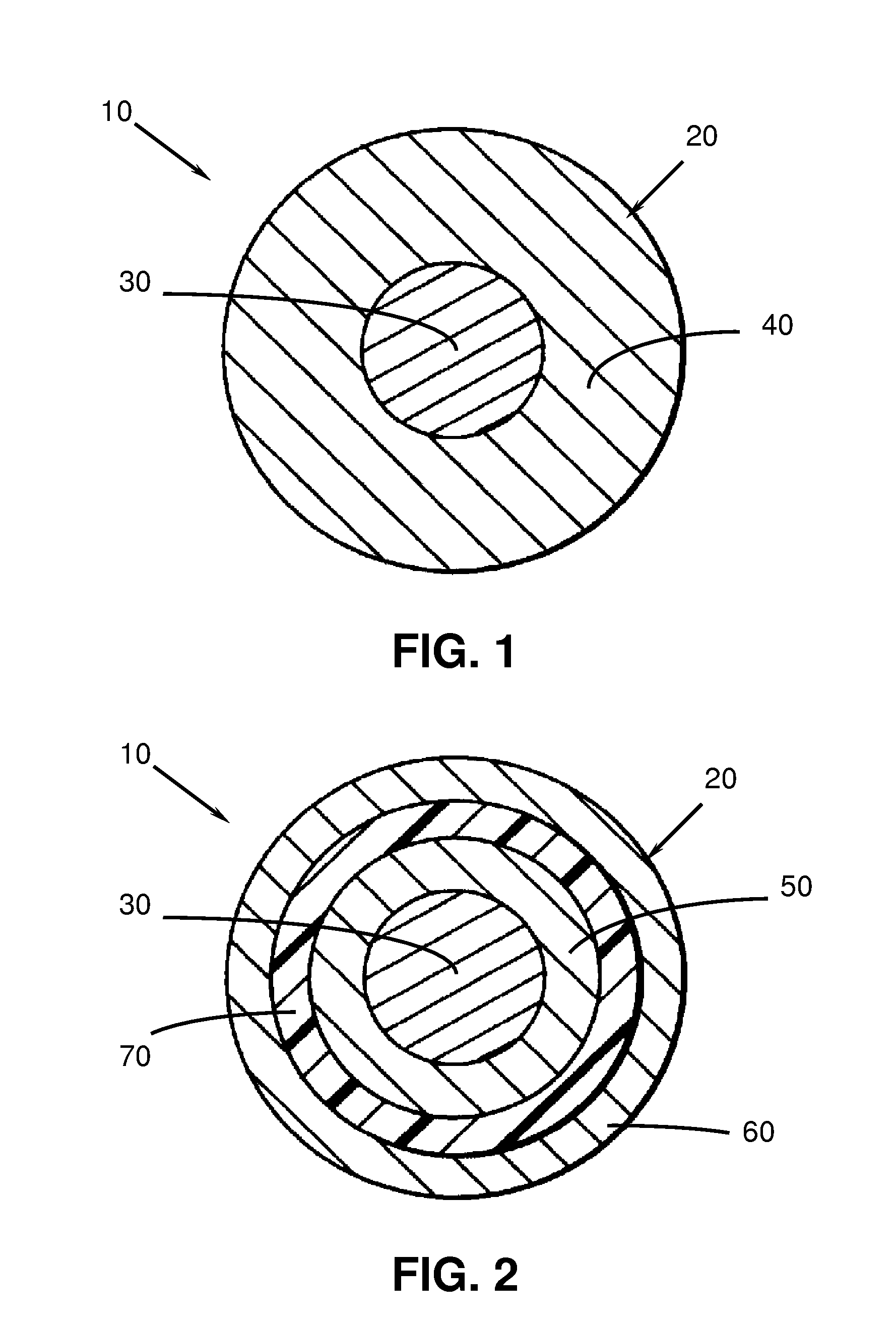

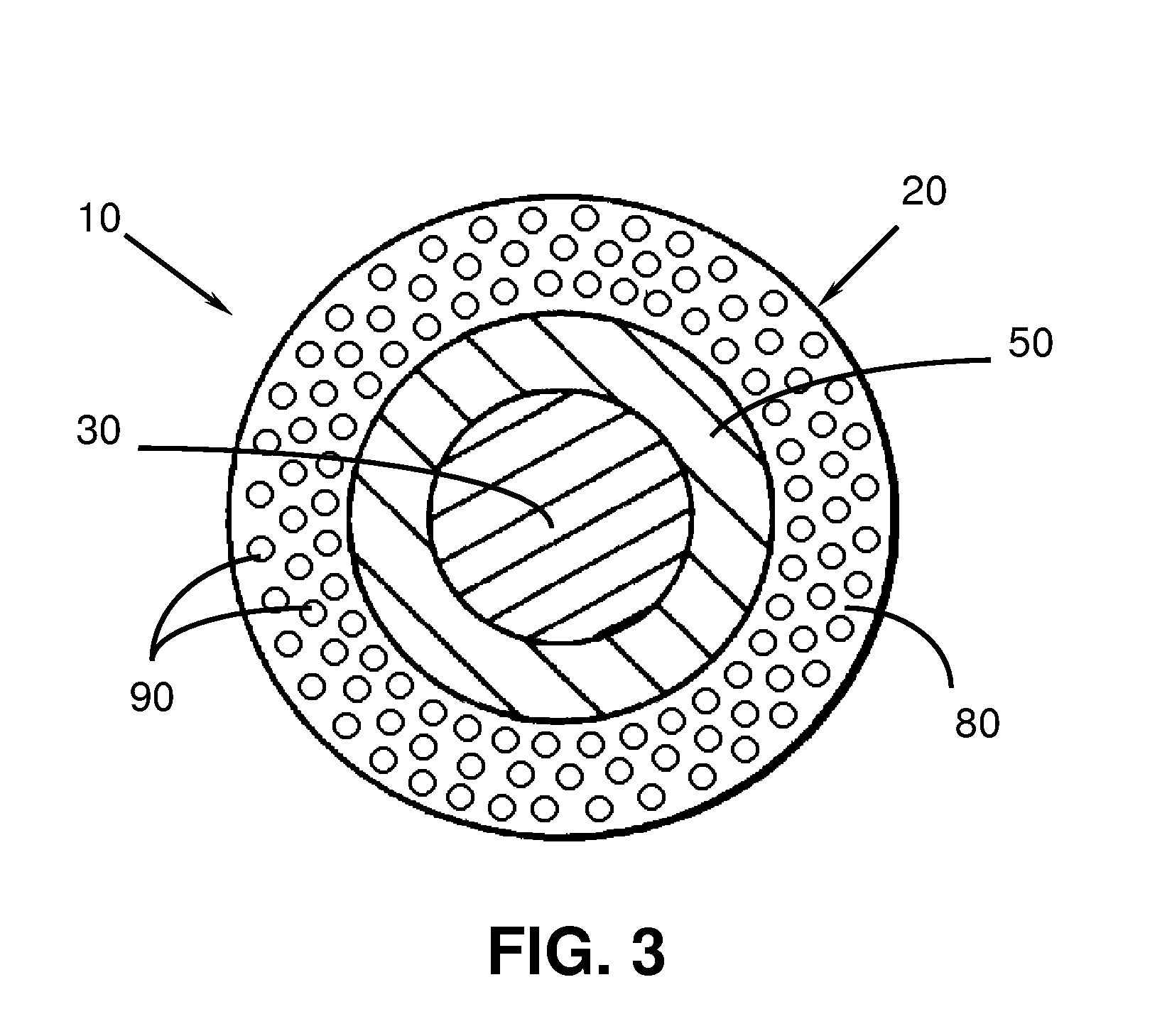

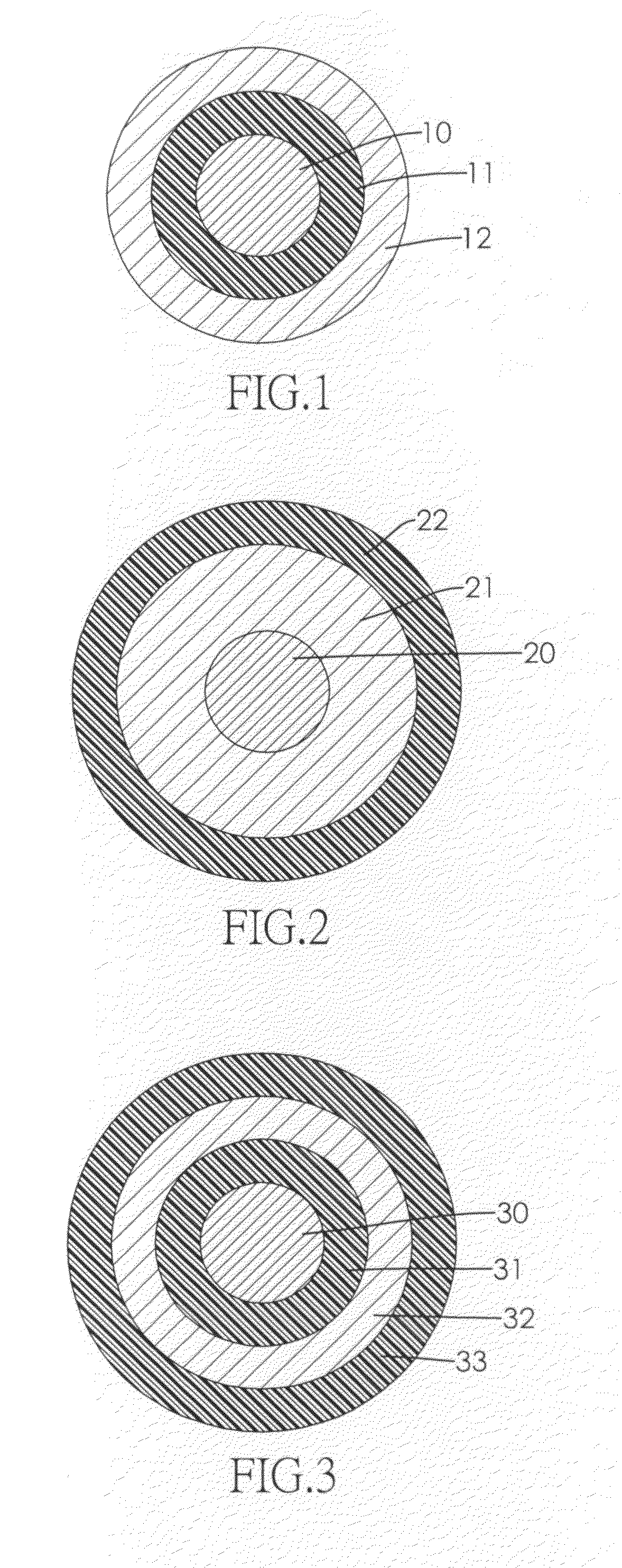

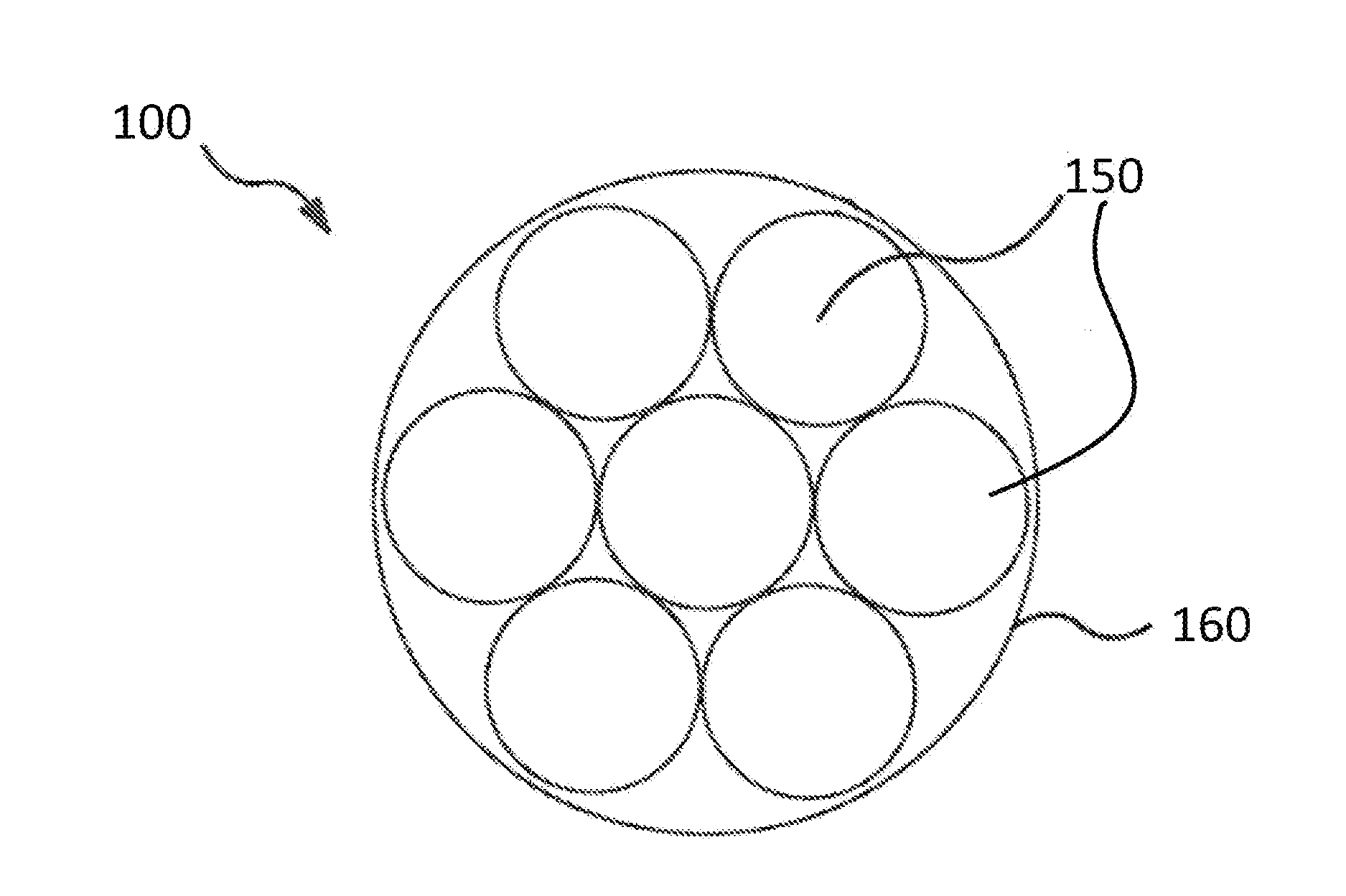

High voltage and high temperature winding insulation for esp motor

A litz wire includes, in one embodiment, a plurality of twisted strands, wherein one or more of the strands includes a composite magnet wire. The composite magnet wire includes a metal wire having a nanocoating on its outer surface. The nanocoating includes an electrical insulating polyimide matrix and a plurality of alumina nano particles dispersed homegenueoslytherein. The alumina nano particles have a phenyl siloxane surface coating. The litz wire has a temperature index of at least 300° C. as obtained in accordance with either ASTM E1641, ASTM E1877, or ASTM D2307. Motors and ESP assemblies utilizing the litz wire are also disclosed.

Owner:GENERAL ELECTRIC CO

Coil bobbin with core spacing mechanisms

InactiveUS20040036568A1Transformers/inductances casingsTransformers/inductances coils/windings/connectionsBobbinEngineering

A coil bobbin comprises a core housing portion which has a magnet wire wound therearound, and which undergoes a varnish impregnation treatment together with a magnetic core consisting of two core sections, like an EE type or UU type. Core spacing mechanisms are formed on the inner surfaces of the core housing portion, and control a position of the magnetic core inserted in the core housing portion such that the magnetic core is kept apart from the inner surfaces of the core housing portion.

Owner:MINEBEA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com