Patents

Literature

189 results about "Magnetic coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

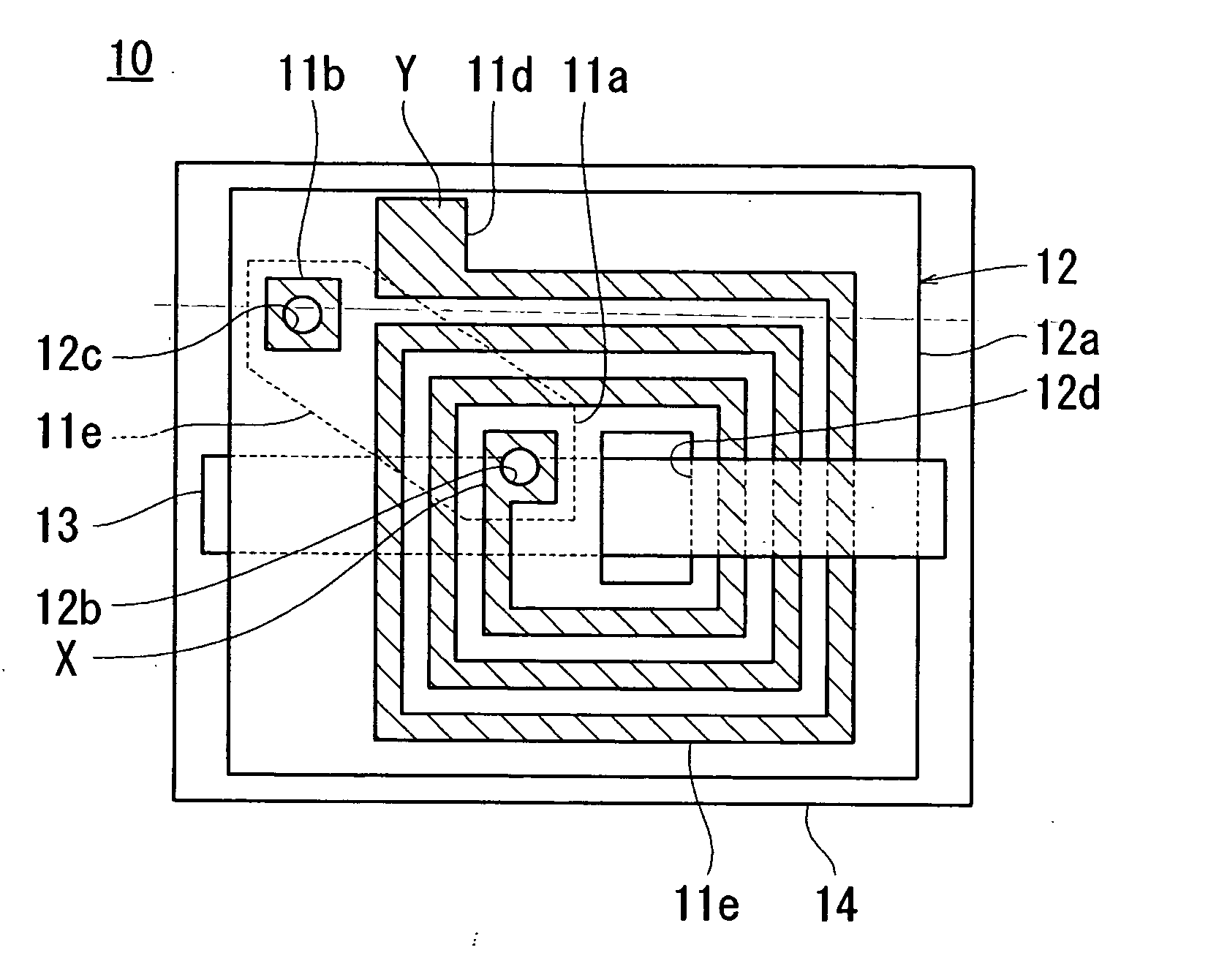

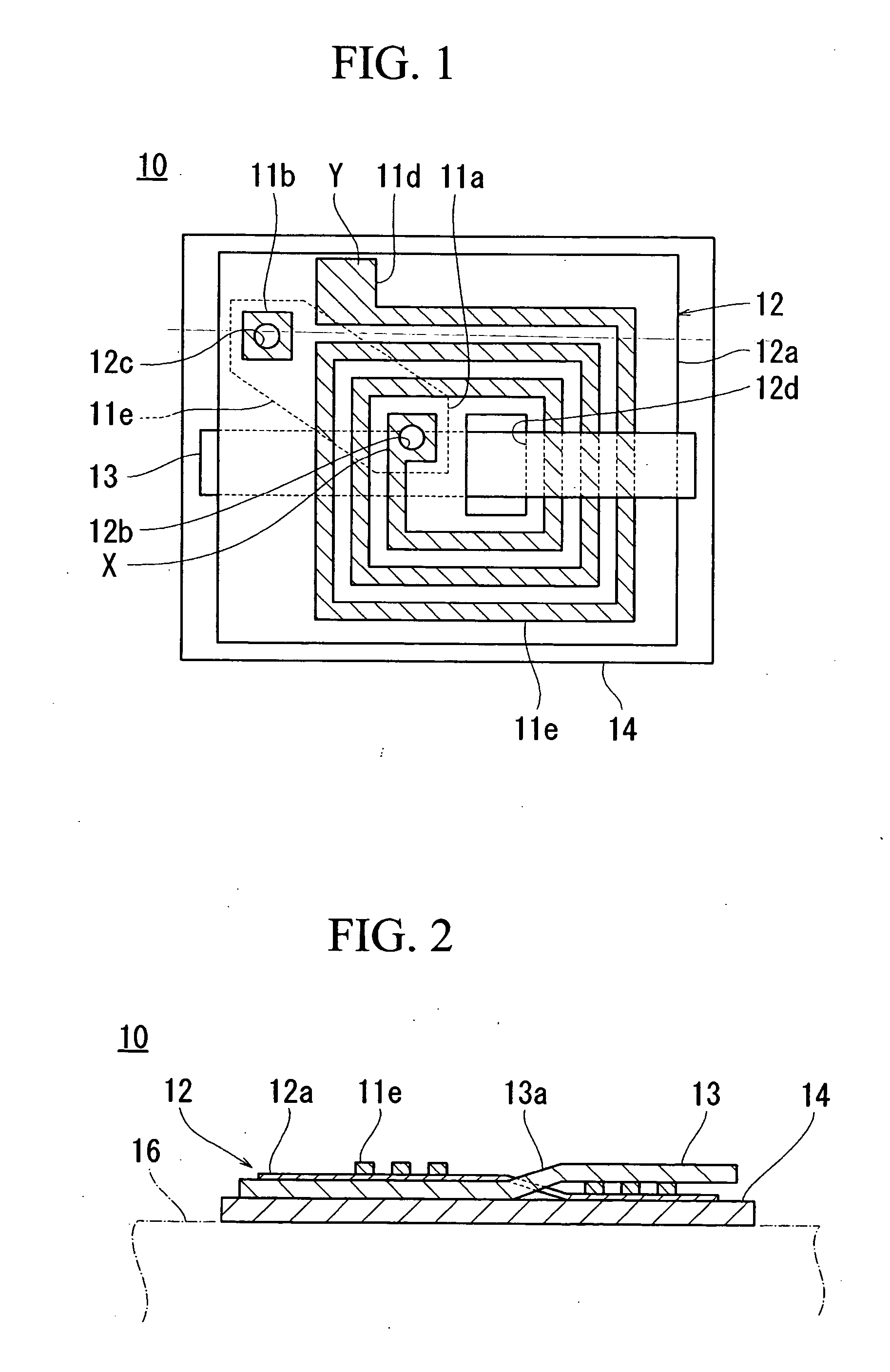

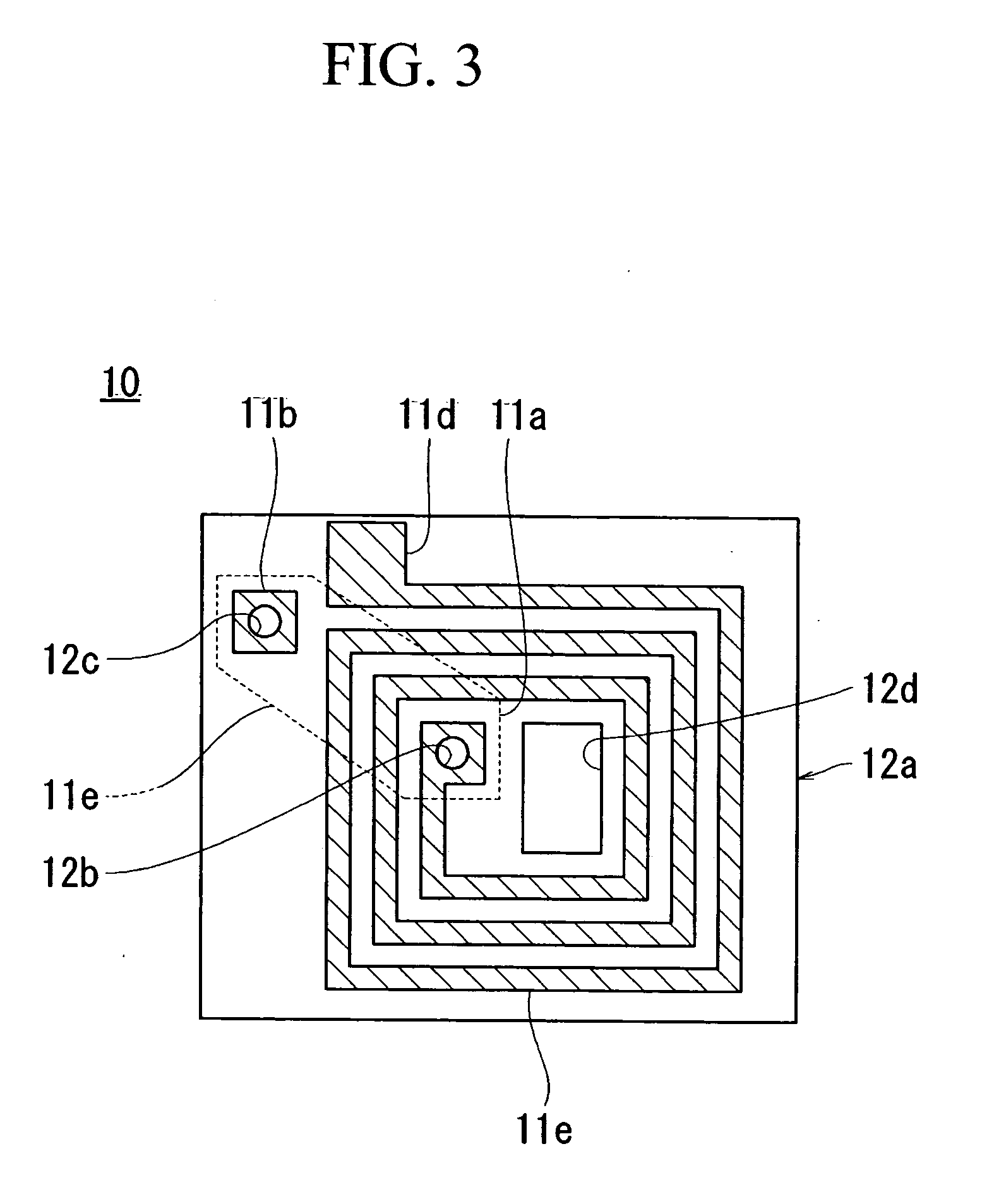

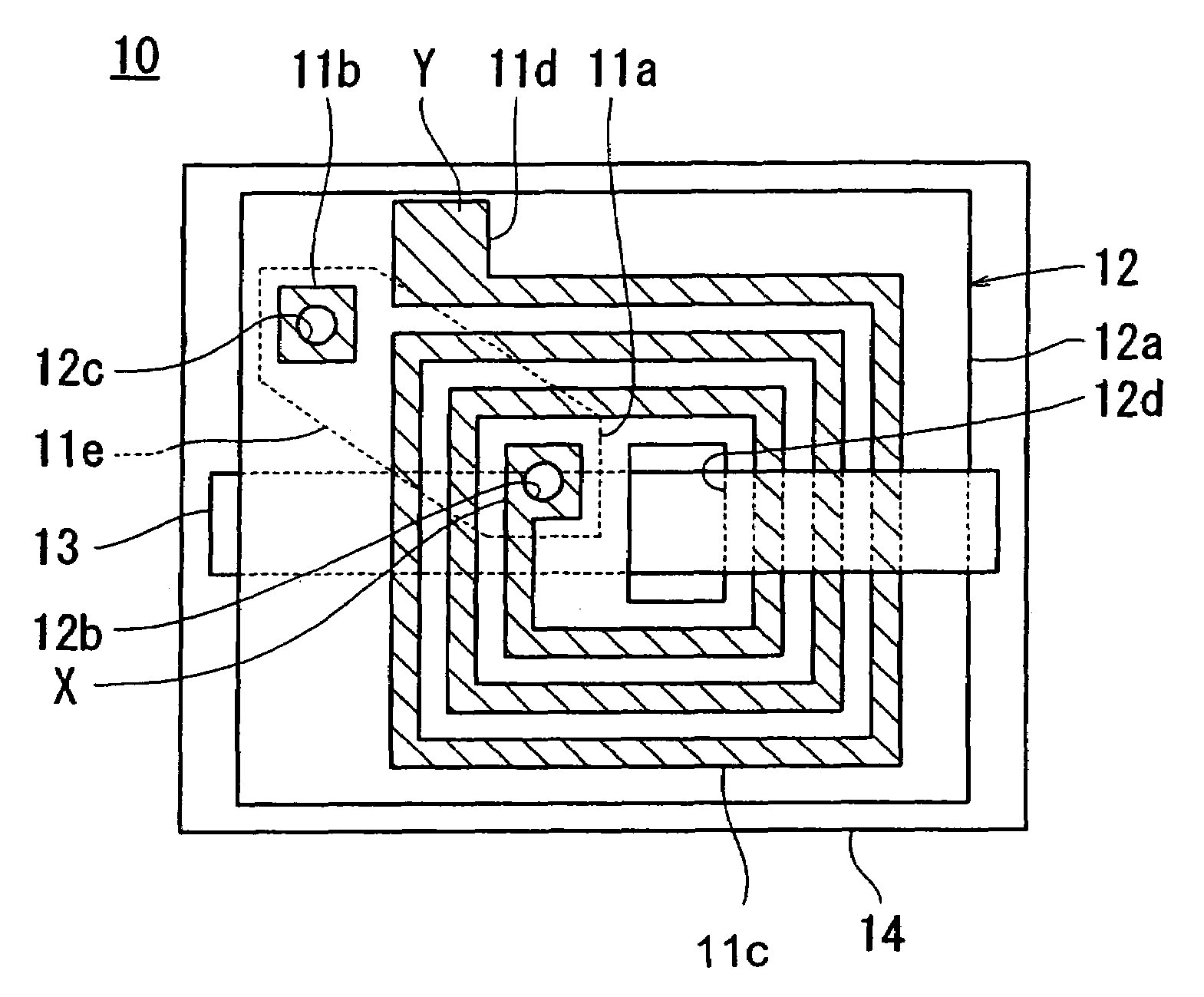

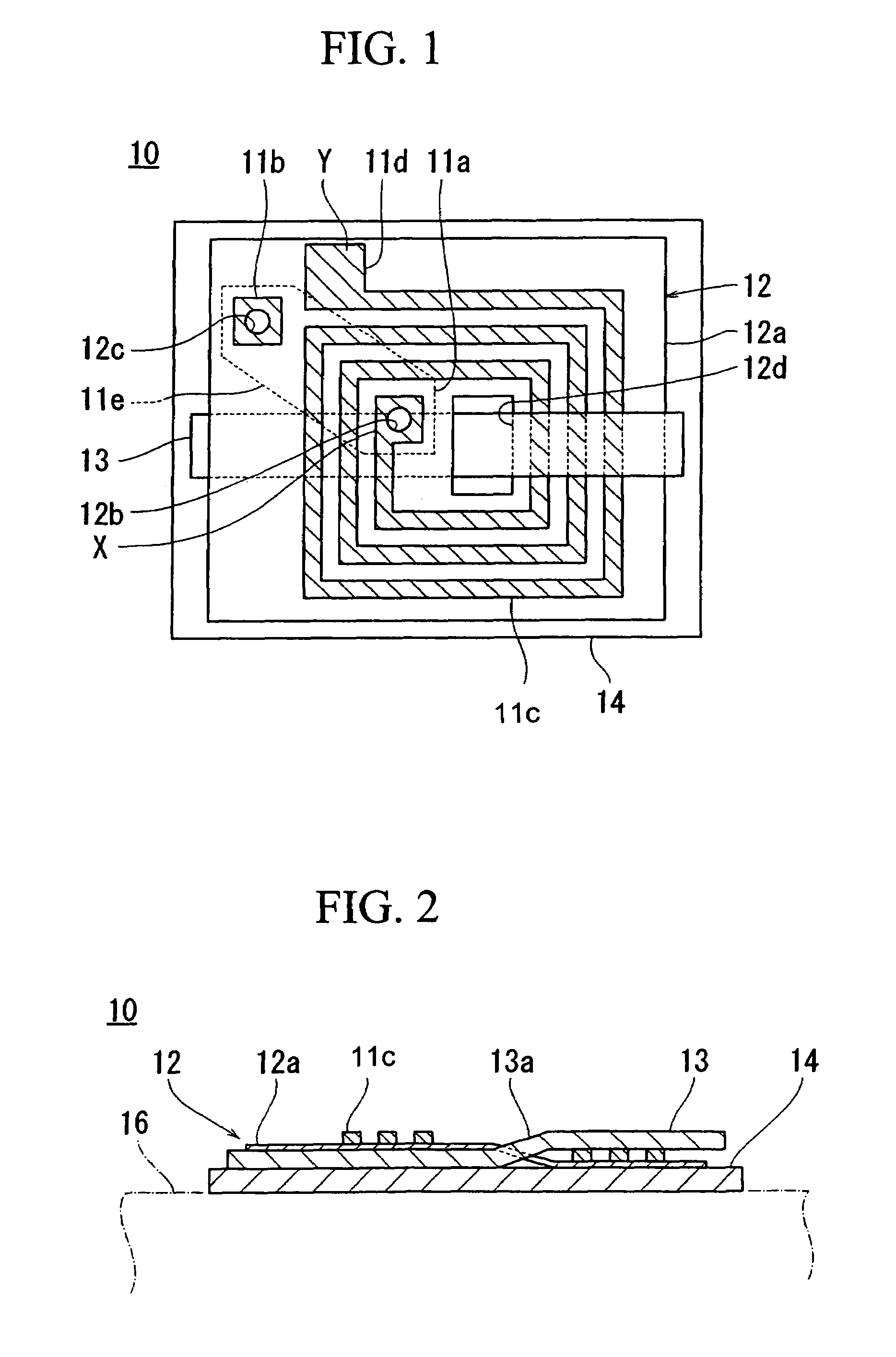

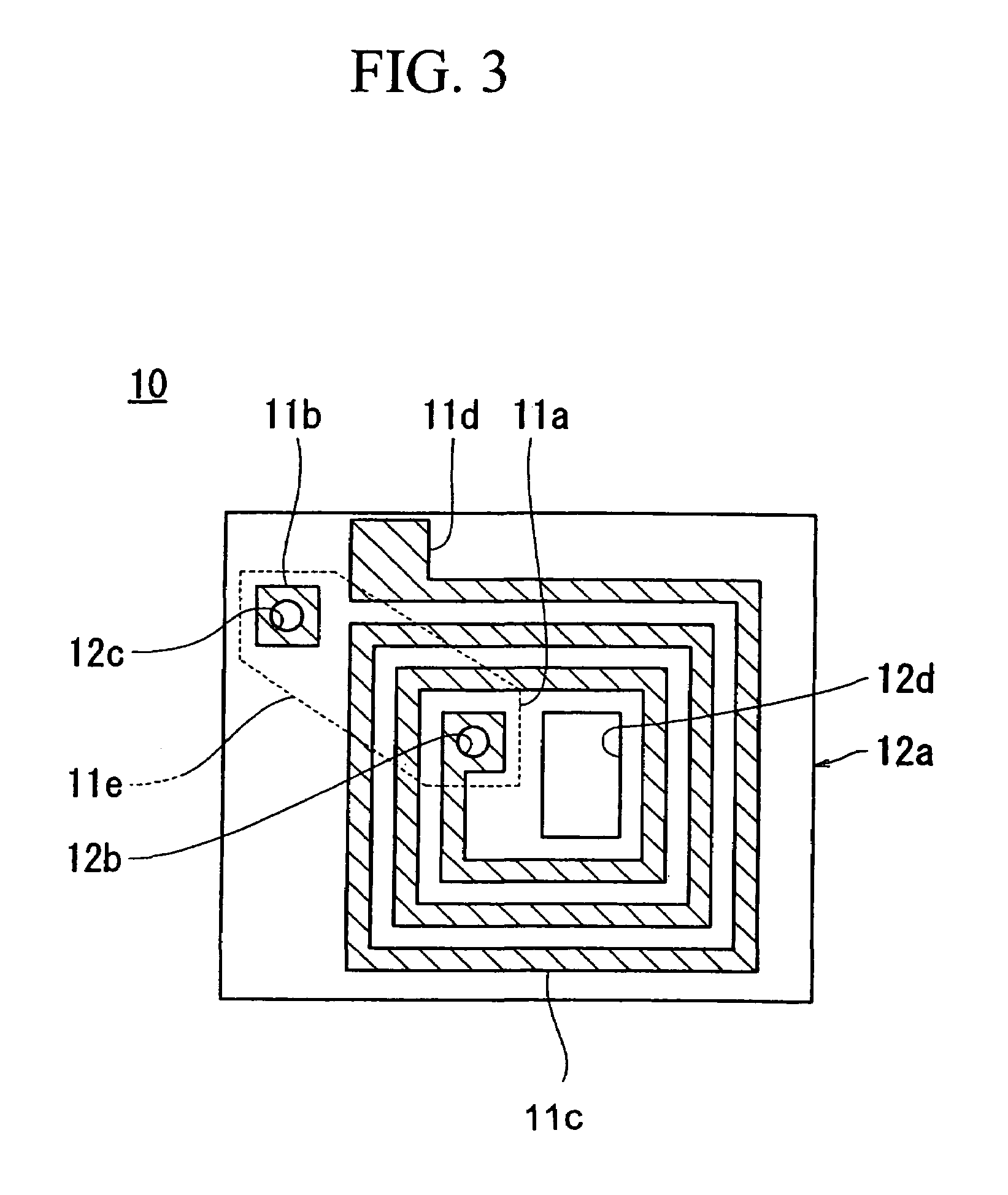

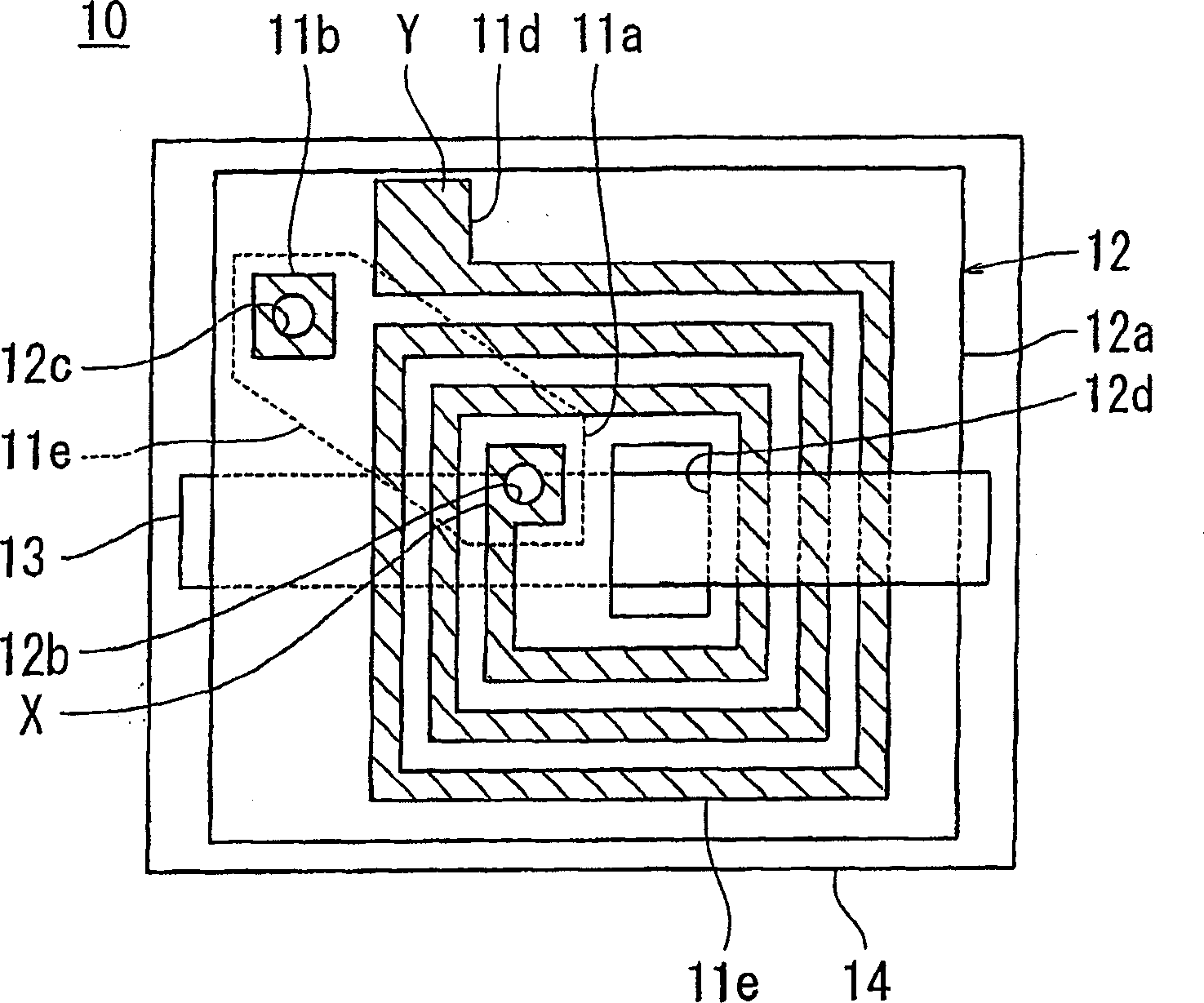

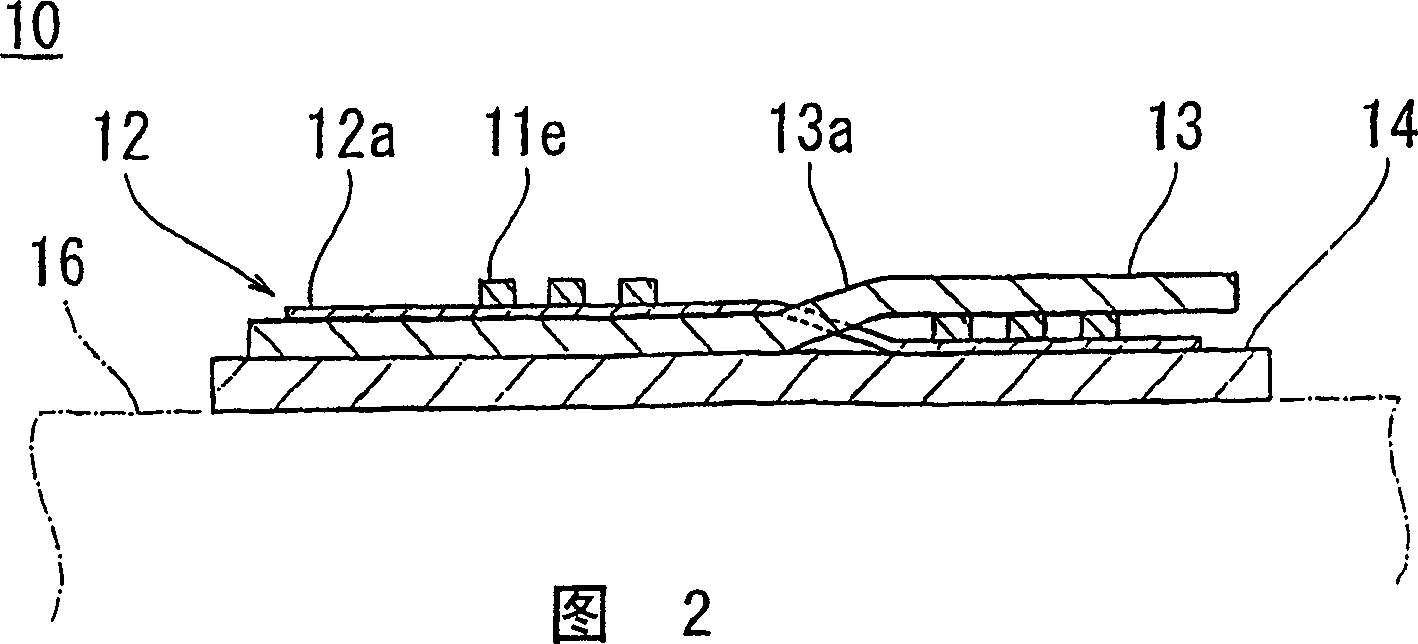

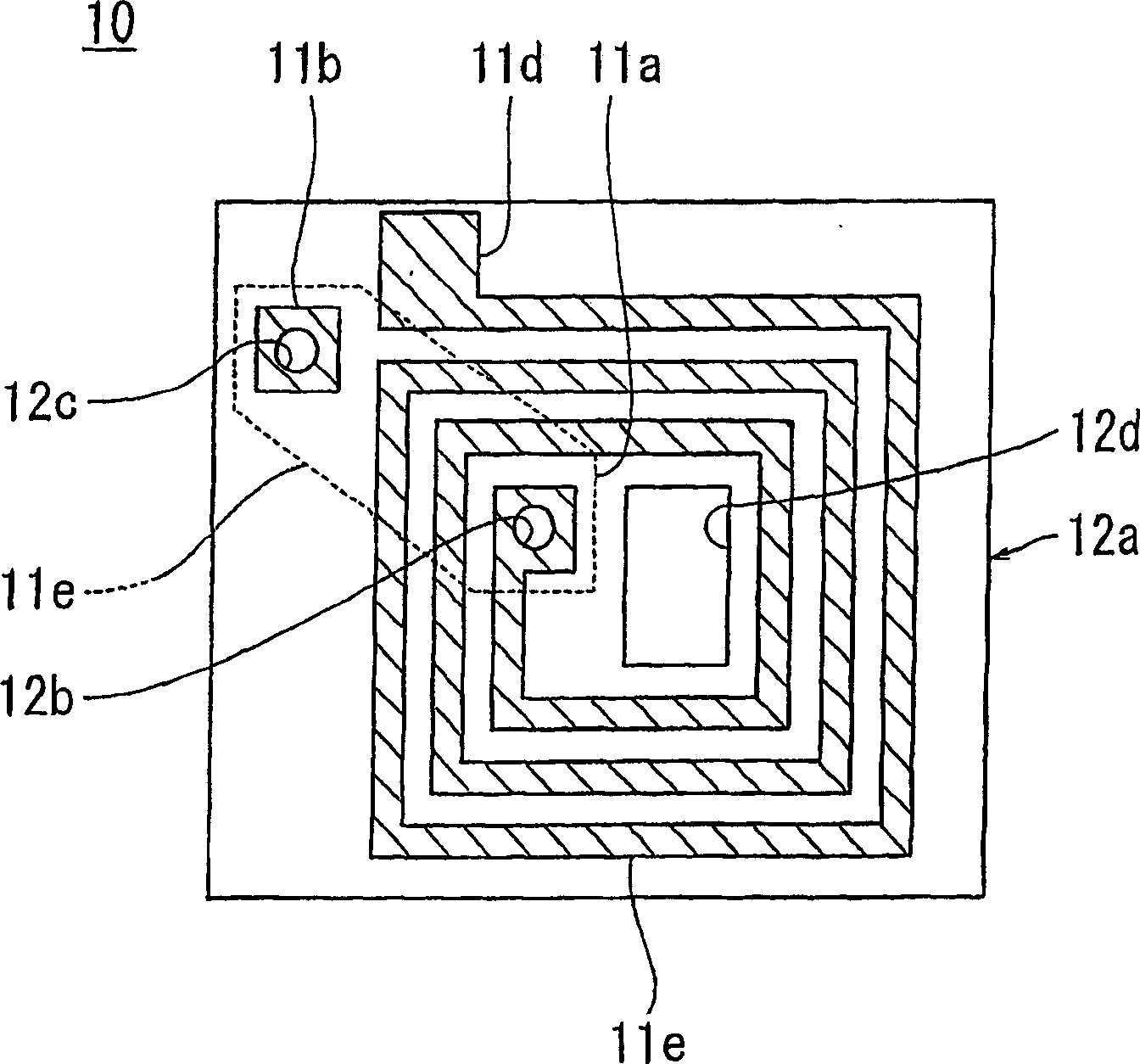

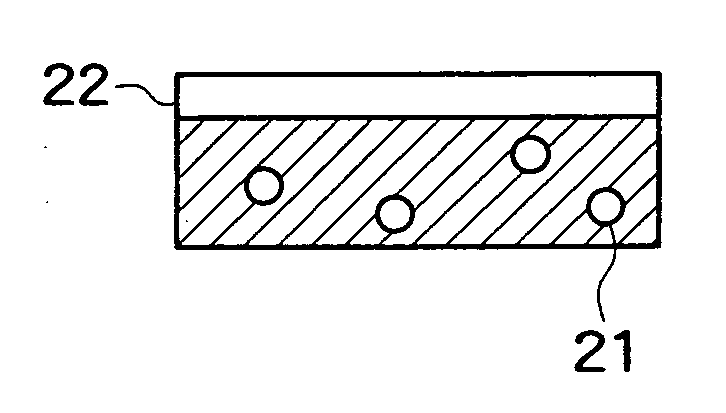

Antenna coil and rfid-use tag using it, transponder-use antenna

InactiveUS20050007296A1Improve rigidityHigh frequencyLoop antennas with ferromagnetic coreOther printing matterAir coreNon magnetic

An antenna coil includes an air-core coil wound helically in a plane and a plate magnetic core member inserted in the air-core coil to be approximately parallel with a plane of the air-core coil. The magnetic core member is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member is a magnetic coating formed by applying and drying the composite member. A non-magnetic conductive plate that has a conductivity is layered on a surface of the air-core coil through which the magnetic core member is inserted. The conductive plate is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. The antenna coil is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

Antenna coil, and RFID-use tag using it, transponder-use antenna

InactiveUS7088304B2Improve rigidityHigh frequencyLoop antennas with ferromagnetic coreOther printing matterEngineeringNon magnetic

An antenna coil includes an air-core coil wound helically in a plane and a plate magnetic core member inserted in the air-core coil to be approximately parallel with a plane of the air-core coil. The magnetic core member is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member is a magnetic coating formed by applying and drying the composite member. A non-magnetic conductive plate that has a conductivity is layered on a surface of the air-core coil through which the magnetic core member is inserted. The conductive plate is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. The antenna coil is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

Antenna coil and RFID-use tag using it, transponder-use antenna

InactiveCN1871743AImprove rigidityEasy to useLoop antennas with ferromagnetic coreOther printing matterNon magneticRadio frequency

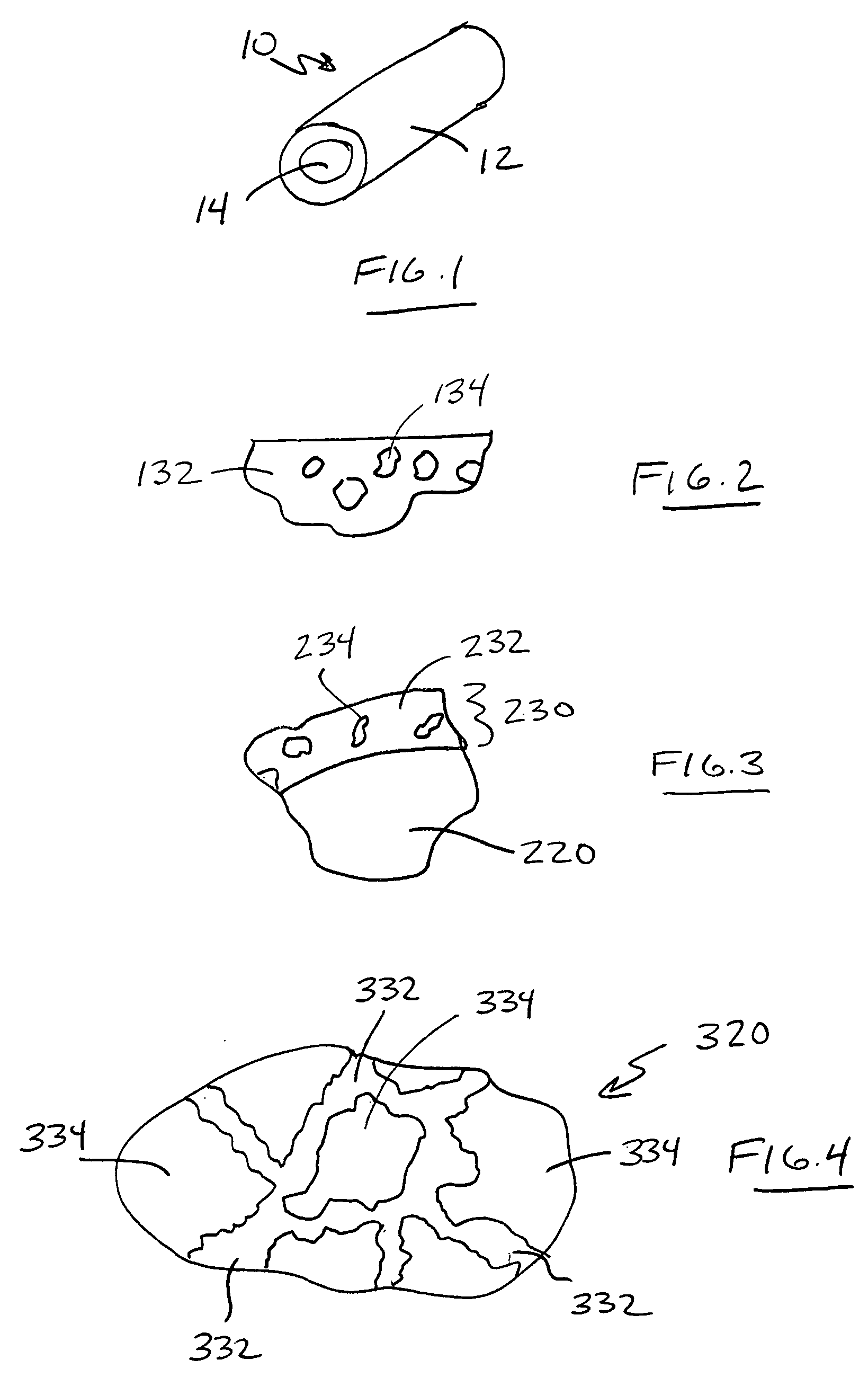

An antenna coil 10 comprises an air-core coil 12 which is wound helically in a plane and a plate magnetic core member 13 which is inserted in the air-core coil 12 so as to be approximately parallel with a plane of the air-core coil 12. The magnetic core member 13 is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member 13 is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member 13 is a magnetic coating which is formed by applying and drying the composite member. A non-magnetic conductive plate 14 which has a conductivity is layered on a surface of the air-core coil 12 through which the magnetic core member 13 is inserted. The conductive plate 14 is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. By doing this, it is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

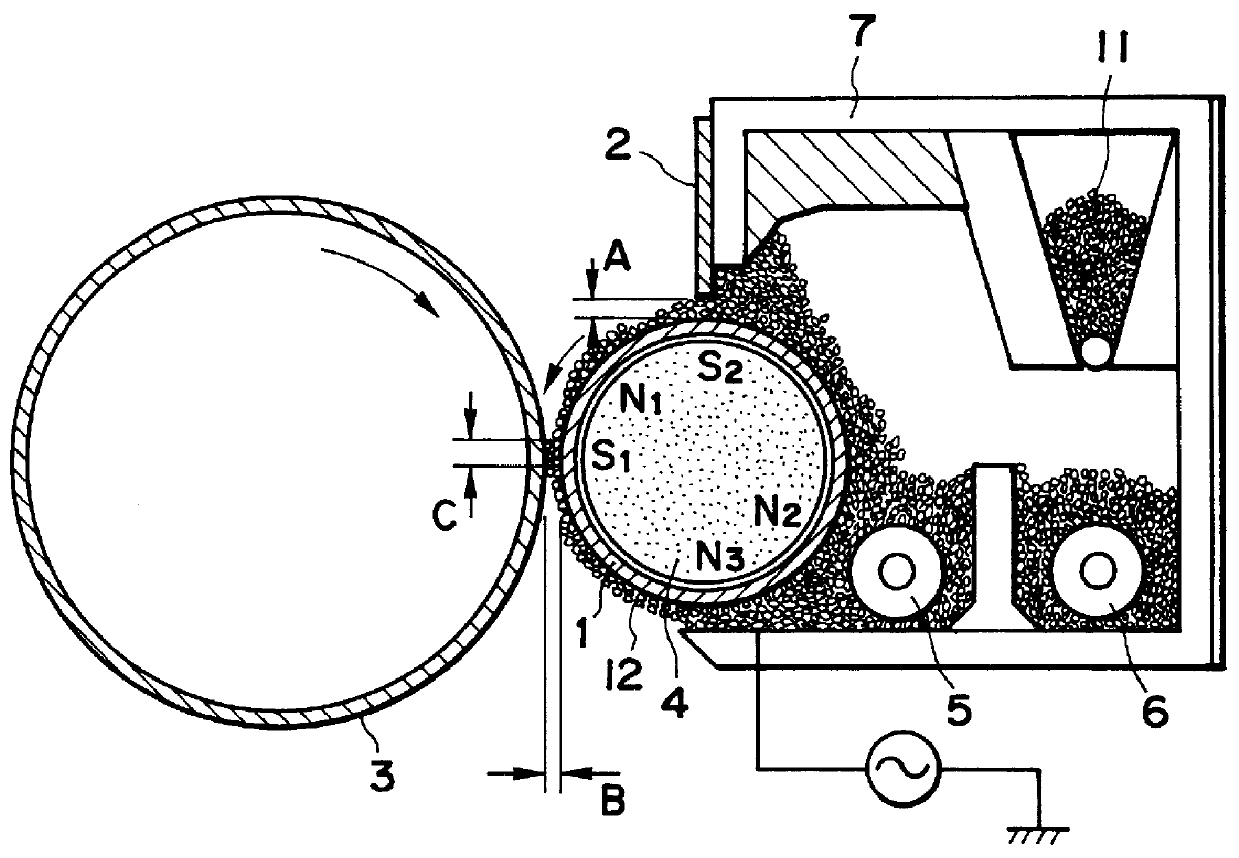

Magnetic coated carrier two-component type developer and developing method

InactiveUS6165663AImprove liquidityIncreased durabilityDevelopersElectrographic processes using charge patternCoated surfaceParticulate metal

A magnetic coated carrier suitable for constituting a two-component type developer for use in electrophotography is composed of magnetic coated carrier particles comprising magnetic coated carrier particles comprising magnetic carrier core particles each comprising a binder resin and metal oxide particles, and a coating layer surface-coating each carrier core particle. The metal oxide particles have been subjected to a surface lipophilicity-imparting treatment. The magnetic carrier core particles have a resistivity of at least 1x1010 ohm.cm, and the magnetic coated carrier has a resistivity of at least 1x1012 ohm.cm. The magnetic coated carrier has a particle size distribution such that (i) it has a number-average particle size Dn of 5-100 mu m, (ii) it satisfies a relationship of Dn / sigma > / =3.5, wherein sigma denotes a standard deviation of number-basis particle size distribution of the carrier, and (iii) it contains at most 25% by number of particles having particle sizes of at most Dnx+E,fra 2 / 3+EE .

Owner:CANON KK

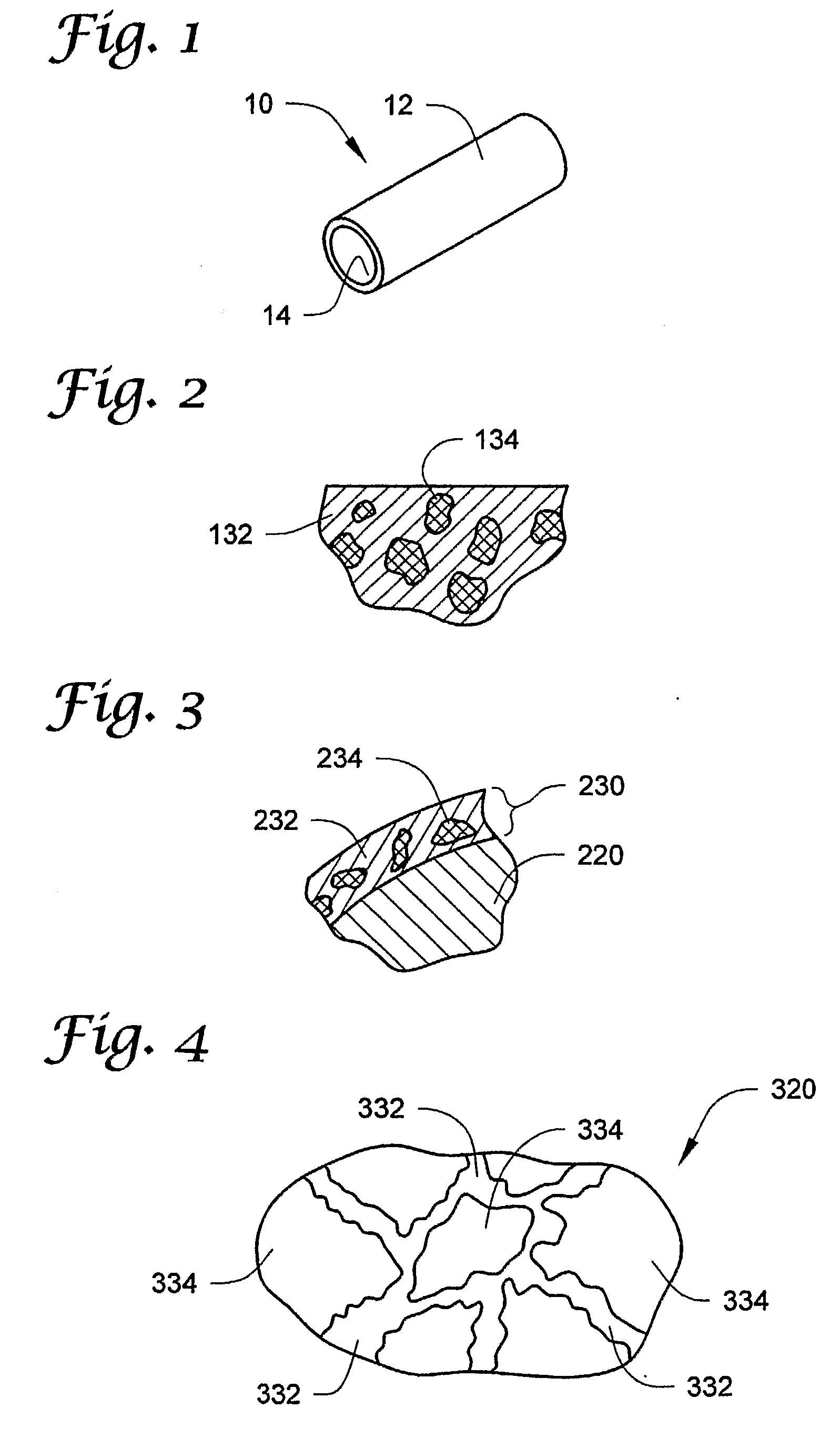

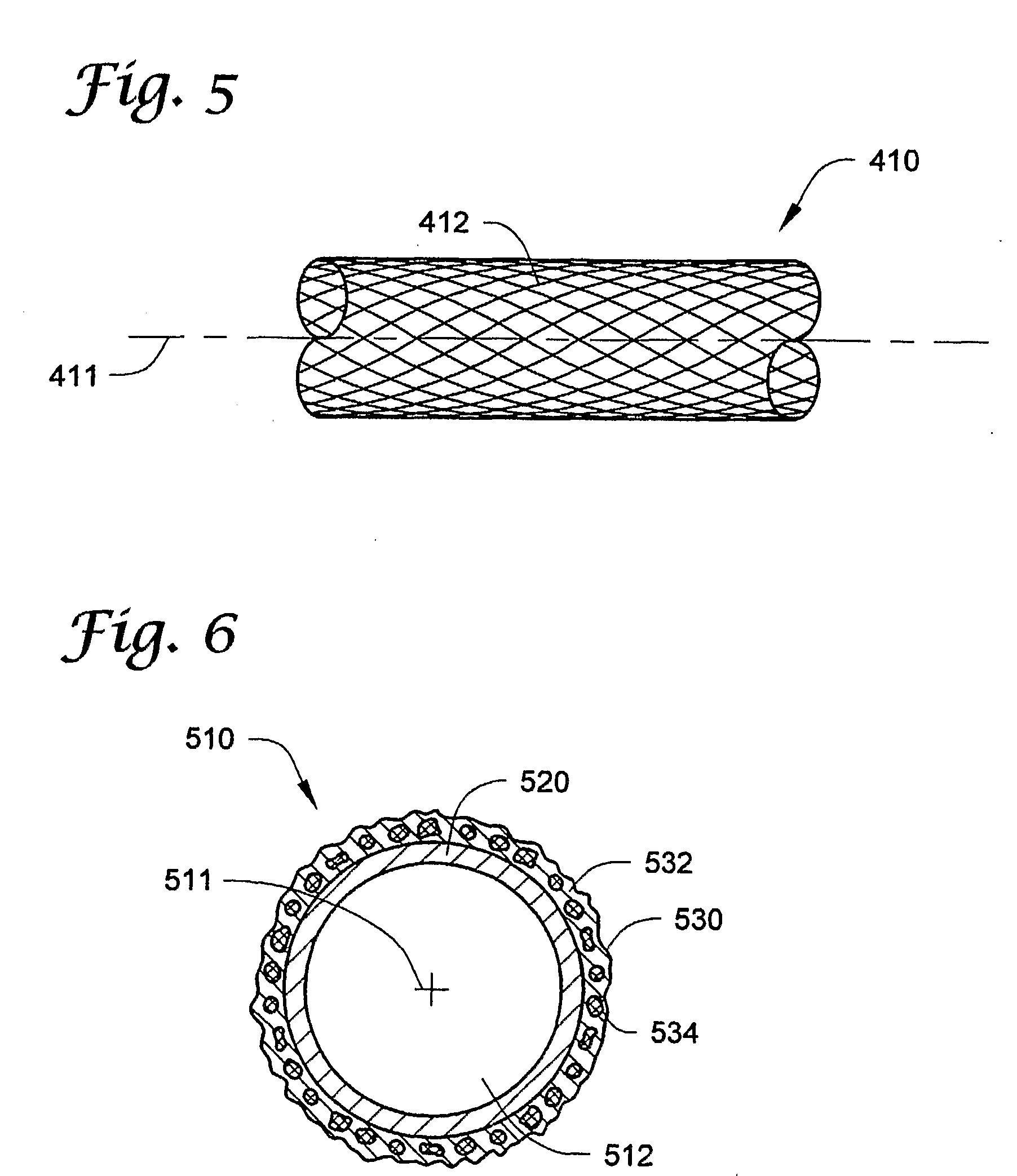

Kits, apparatus and methods for magnetically coating medical devices with living cells

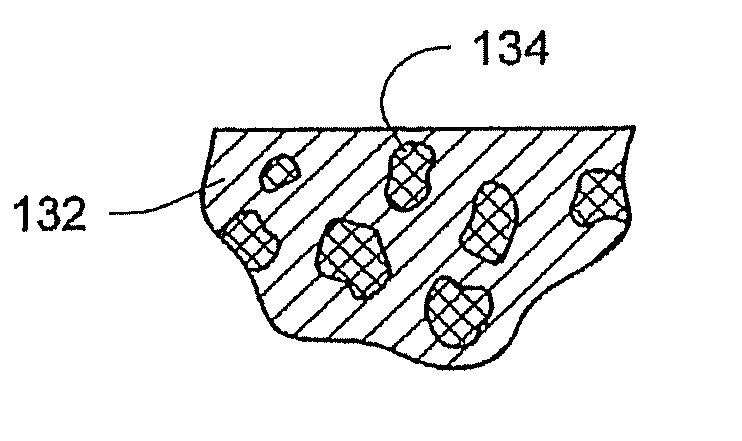

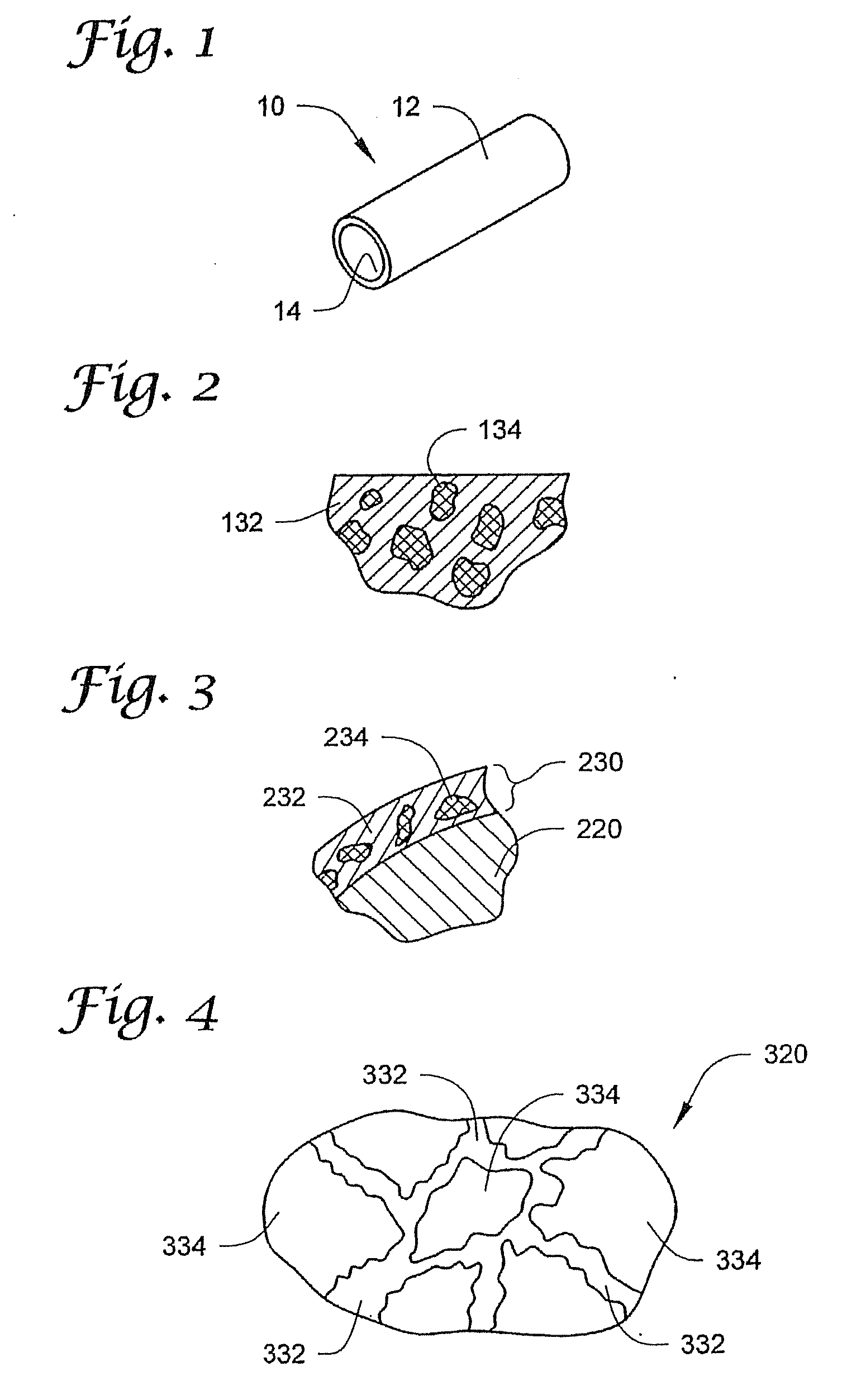

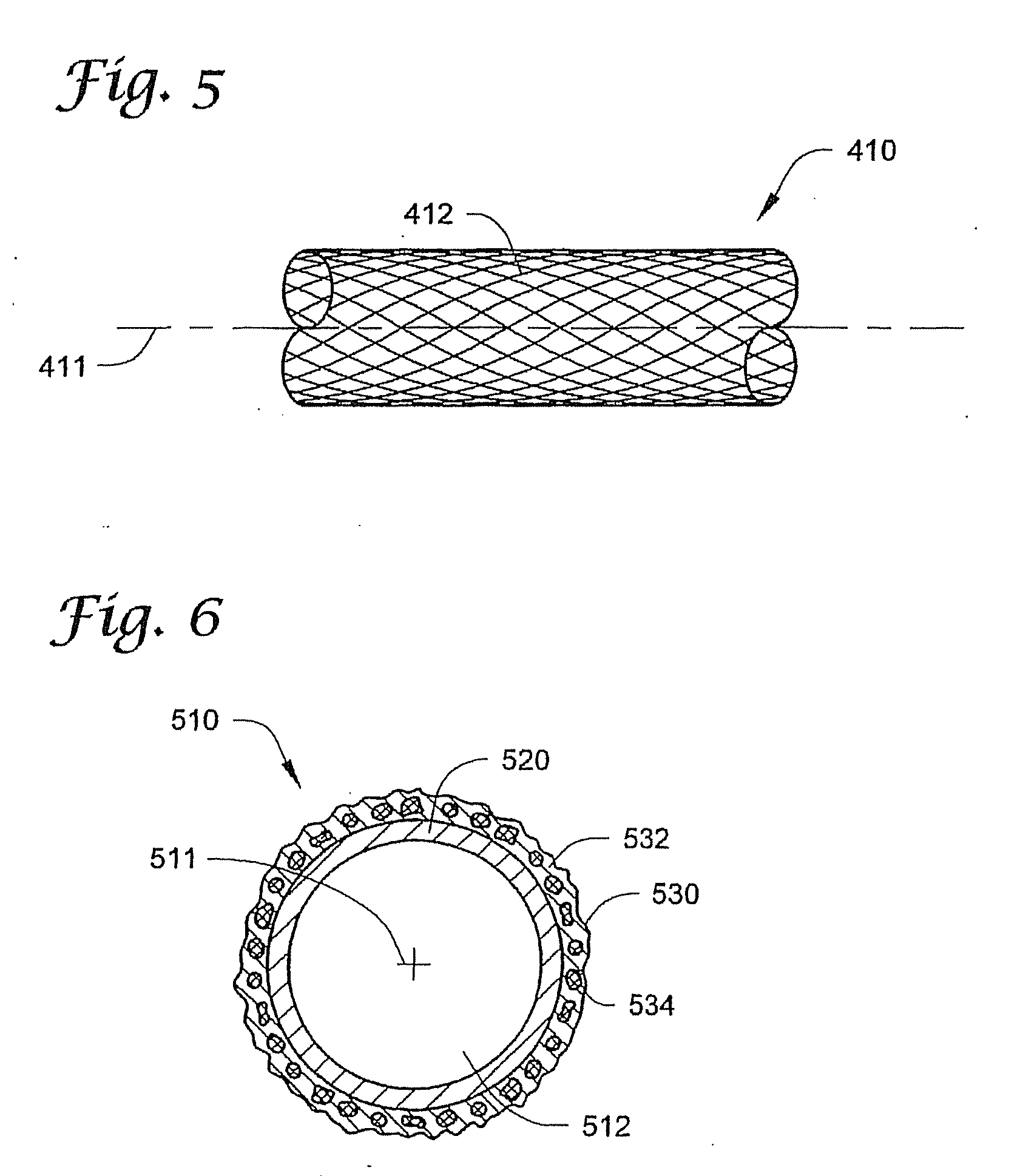

ActiveUS20060286137A1Rapidly attractQuick attachStentsTransvascular endocardial electrodesHigh concentrationMagnetization

Medical devices with surfaces on which viable biologic cells are magnetically attracted and retained are disclosed along with methods of magnetic coating. The medical devices can be located in a carrier liquid containing high concentrations of magnetic cells before or after implantation. The carrier liquid with magnetic cells may be contact with the medical device in vitro or in vivo. In either case, the carrier liquid may have a concentration of magnetic cells that is high enough to facilitate coating of the medical device within an acceptable period of time, e.g., several hours or less. Magnetization of medical devices before, during, and / or after implantation and apparatus for performing the same are disclosed. Degaussing of magnetic medical devices is also disclosed.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

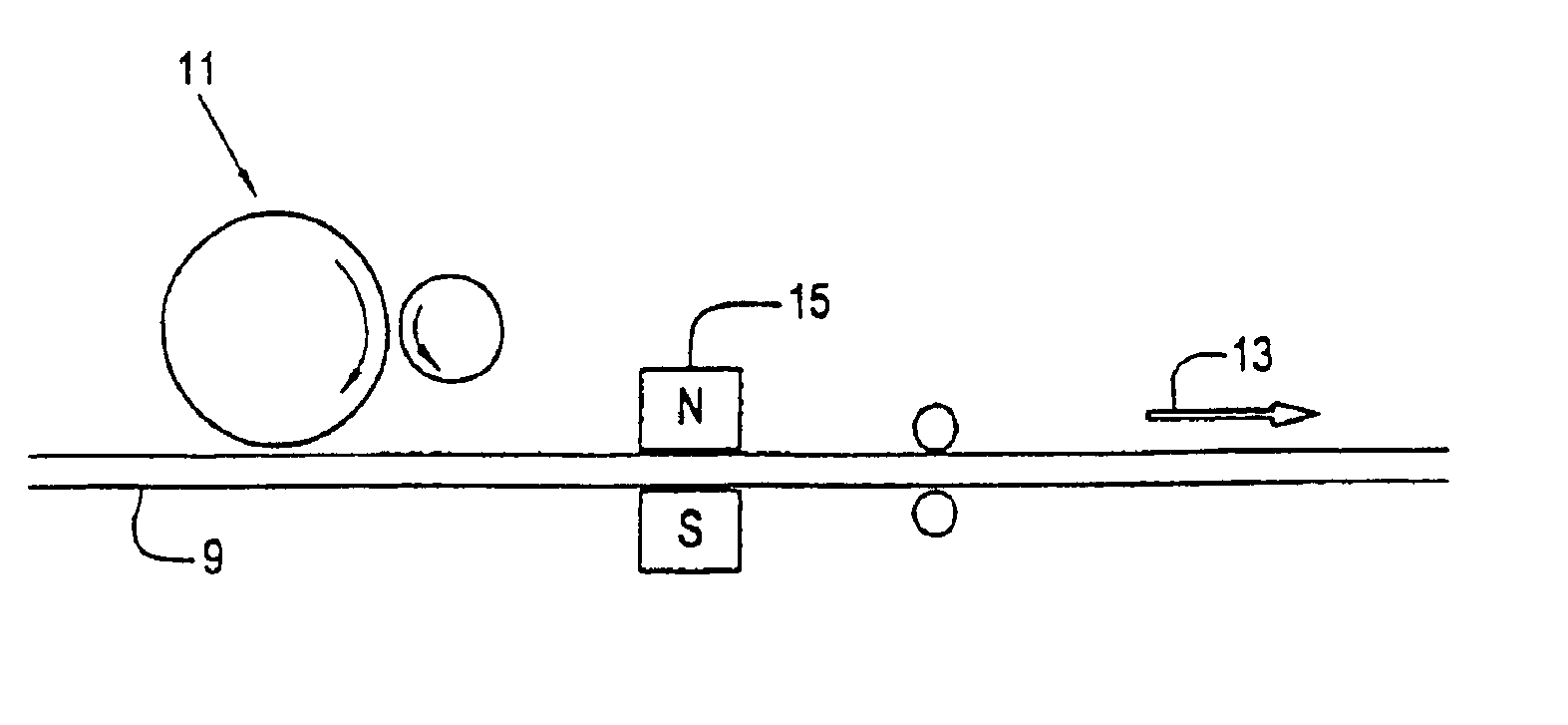

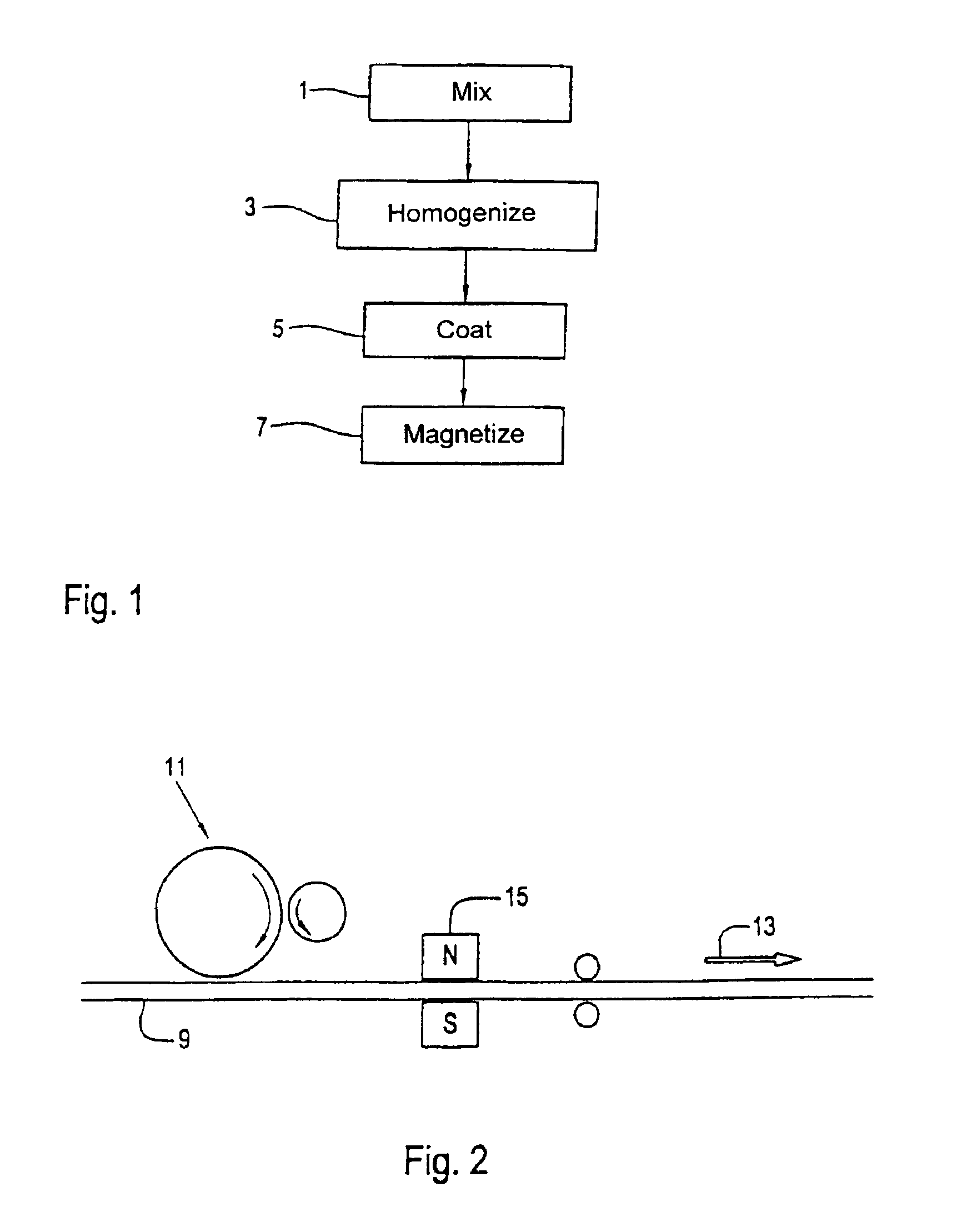

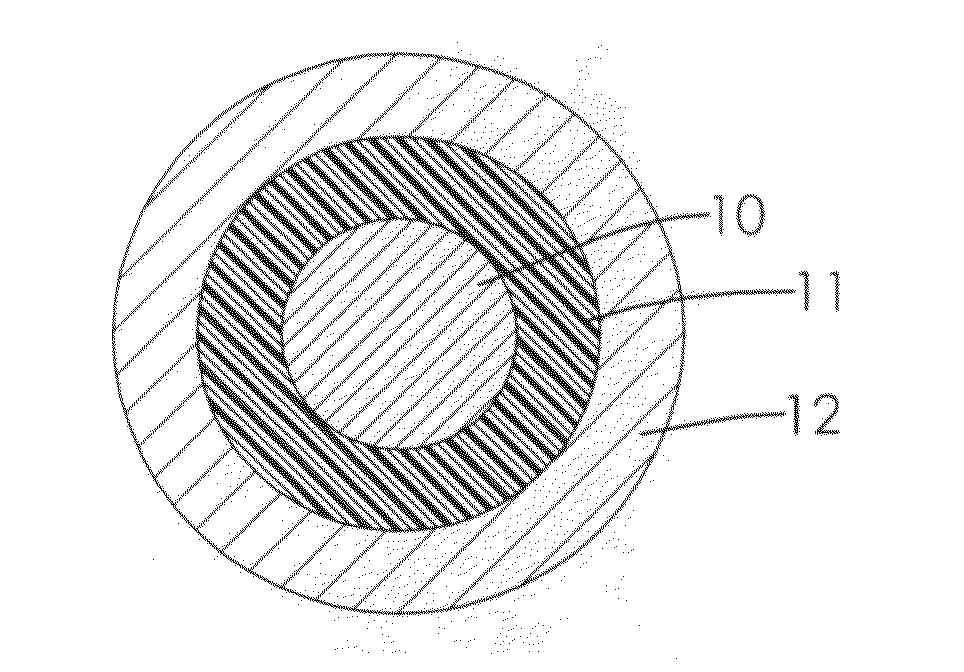

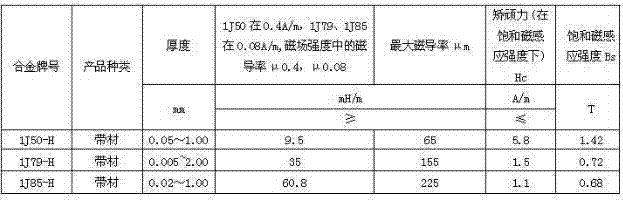

Apparatus and method for making a magnetic coated medium, and a coated medium therefrom

InactiveUS6881450B1Limited penetrationLow costMagnetic paintsLiquid applicationPlastic filmHot-melt adhesive

The invention is directed to a method of magnetically linking a ferromagnetic object to a partially magnetized coating material made by applying a coating to a surface of a continuously-moving medium including the steps of providing a coating material by mixing a binder material suitable for being spread substantially and regularly over the surface and a ferromagnetic component, the binder material being a hot melt adhesive; providing a continuously-moving medium having a top surface to be substantially coated, the surface capable of receiving a substantially and regularly spread coating material; passing the coating material and continuously-moving medium between rollers to form a substantially constant thickness of the coating material substantially covering the top surface and allowing the coating material to set to form the coated medium as a magnetizable component, wherein the medium that is coated is one of a paper, a card, wallpaper, a flexible plastic sheet, a rigid plastic sheet, and walls; partially magnetizing the coating material during continuous movement of the medium to create a magnetized area and an unmagnetized area; and magnetically and temporarily linking a ferromagnetic object to the magnetized area so that the coated medium and ferromagnetic object are held together by magnetic attraction.

Owner:TEXIER CLAUDE

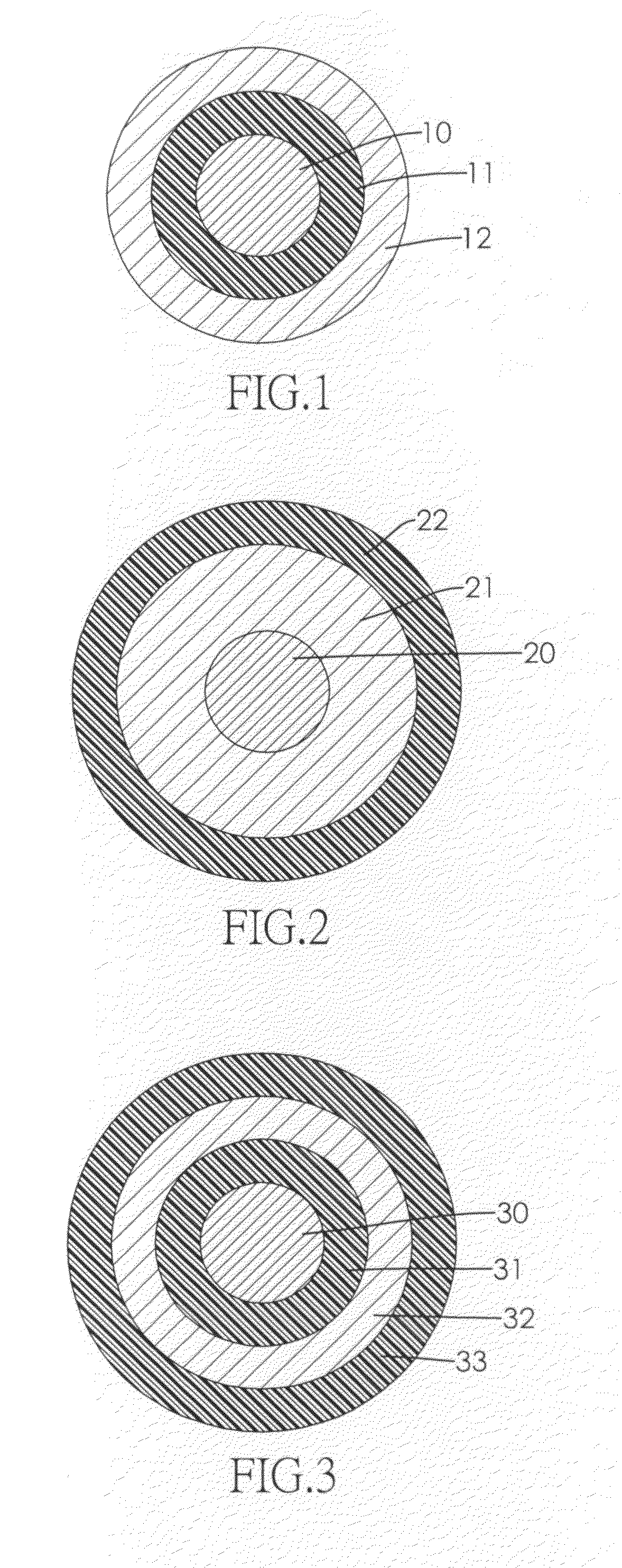

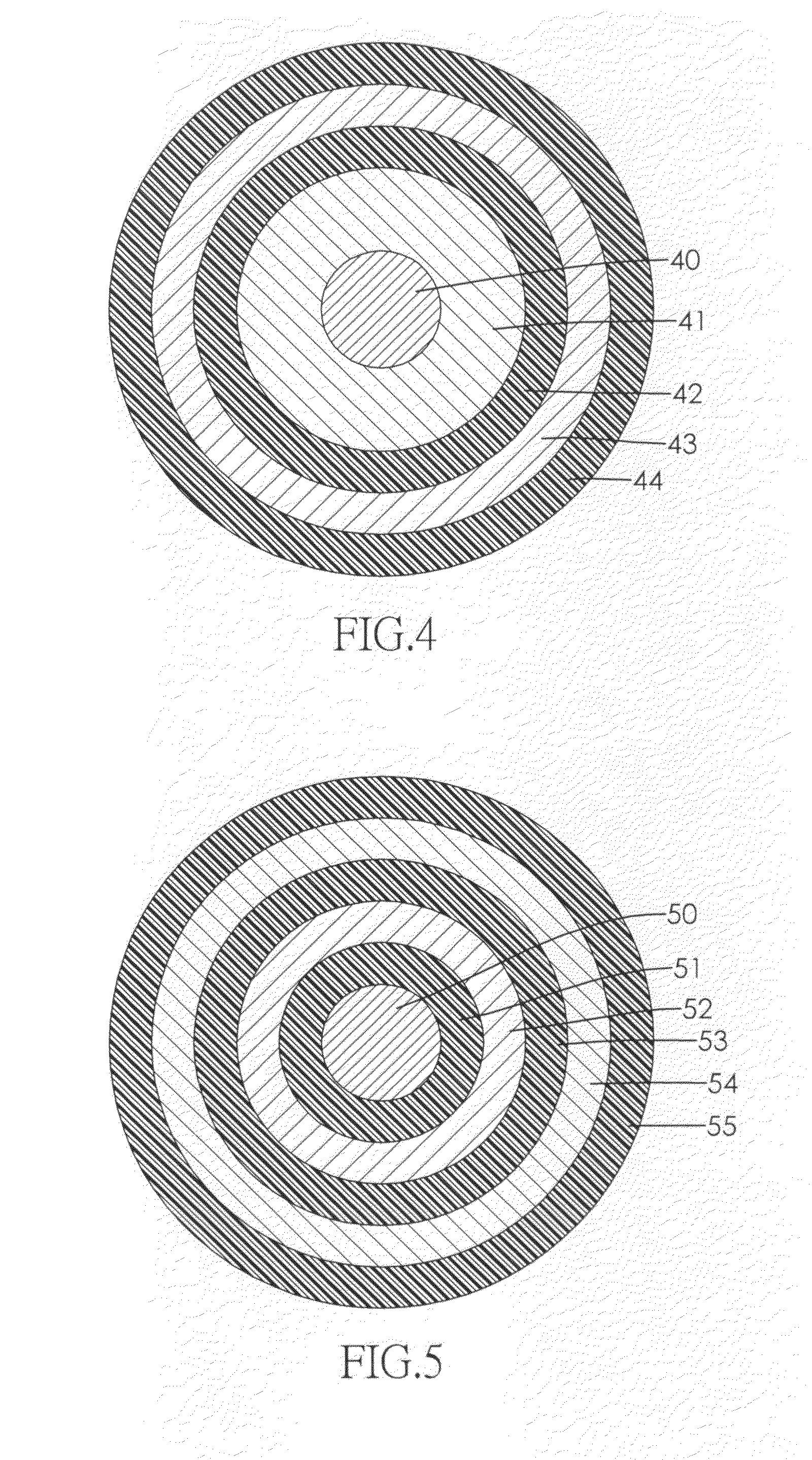

Magnet wire

InactiveUS20110198118A1Lower high-frequency alternating current (AC) resistanceSave energyElectromagnets without armaturesLine/current collector detailsElectricityElectrical conductor

A magnet wire has a conductor and a coating layer. The coated layer is coated around the conductor and has at least one magnetic coating layer; and at least one insulating coating layer. The magnetic coating layer has non-conductive magnetic material. The insulating coating layer and the magnetic coating layer are formed alternately. The alternative structure of the magnetic coating layer and the insulating coating layer prevent precipitation of magnetic material and efficiently offsets the interference between conductors after electricity is supplied, which inhibits occurrence of eddy current and lowers alternative current (AC) resistance.

Owner:ELECTRIC WIRE & CABLE

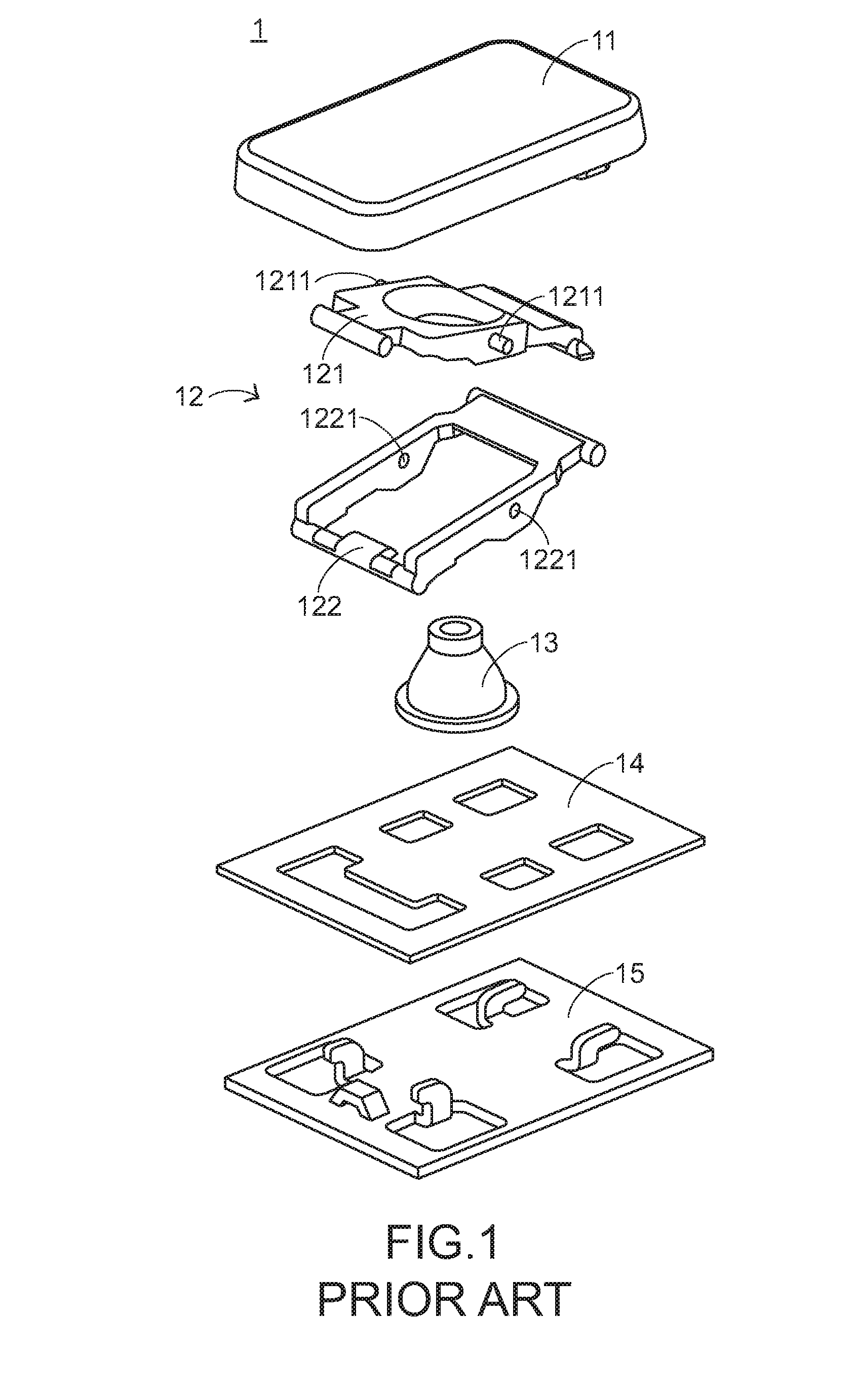

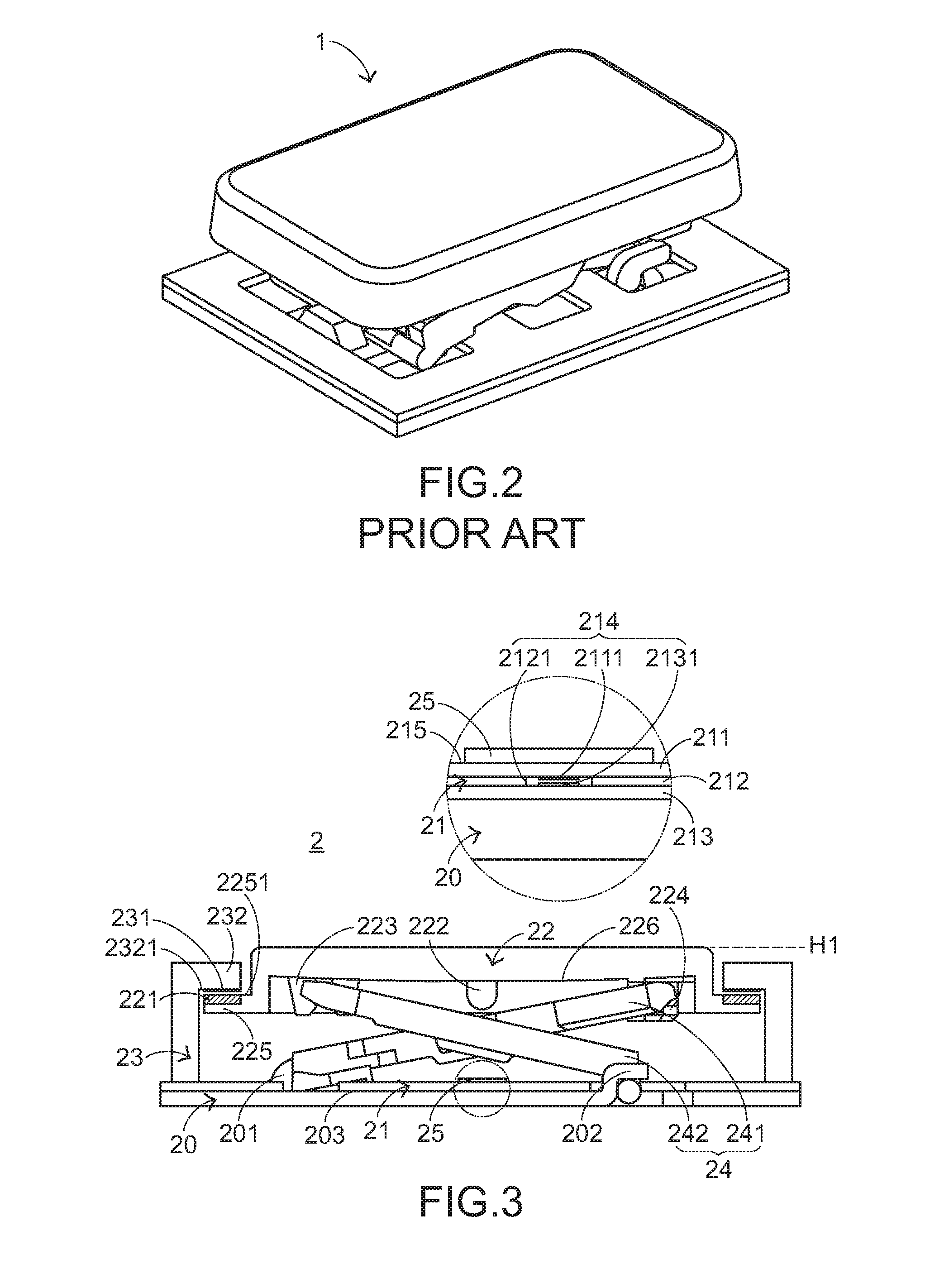

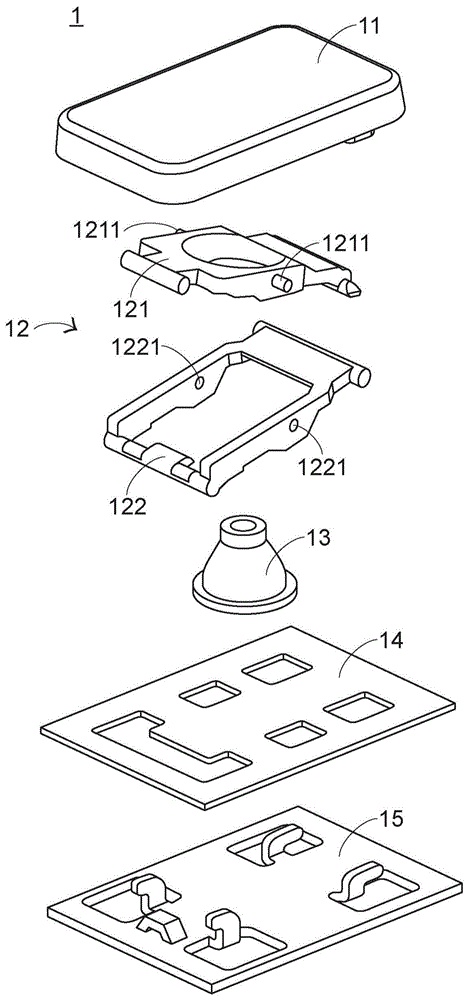

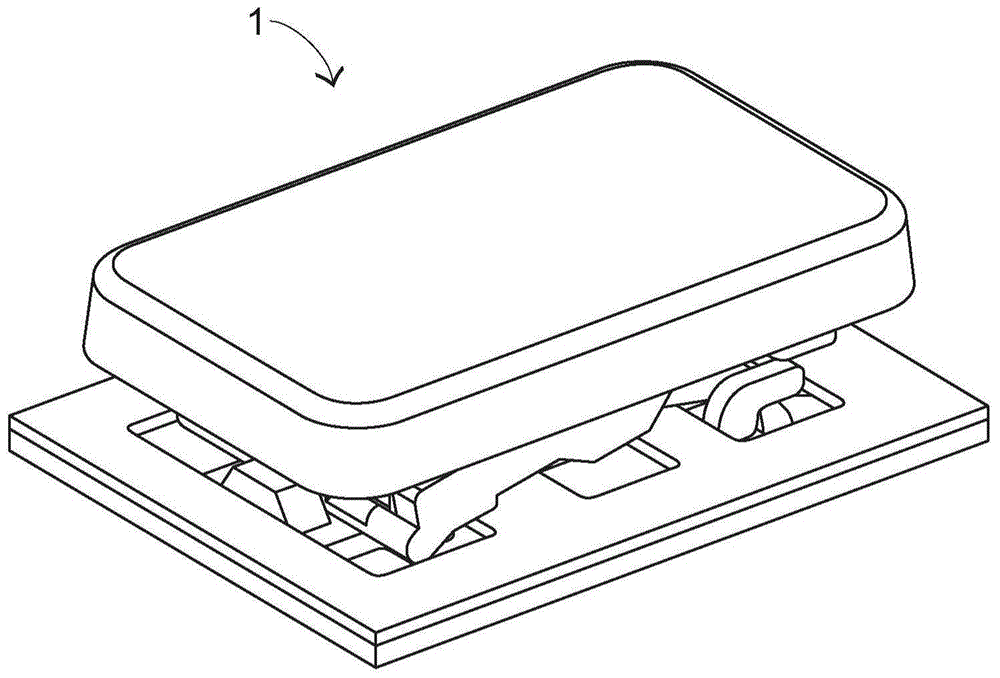

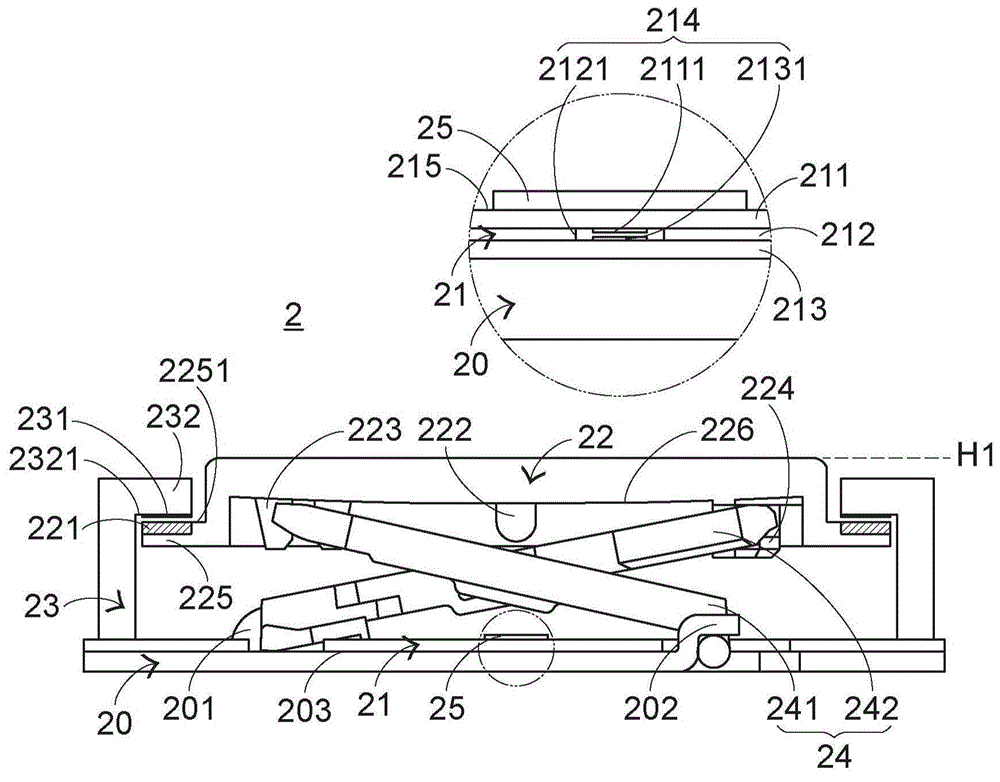

Key structure

InactiveUS20150047959A1Emergency actuatorsContact operating partsEngineeringElectrical and Electronics engineering

A key structure includes a base plate, a switch circuit board, a keycap, and an enclosure frame. The keycap includes a magnetic element. The magnetic element is disposed on an edge part of the keycap. The enclosure frame includes a magnetic coating layer. The magnetic coating layer is formed on an edge part of the enclosure frame and disposed over the magnetic element. When the keycap is depressed, the keycap is moved to trigger the switch circuit board, so that the switch circuit board generates a key signal. When the keycap is no longer depressed, the keycap is moved toward the magnetic coating layer in response to the magnetic force. The key structure can be normally operated without the need of installing an elastic rubbery element.

Owner:PRIMAX ELECTRONICS LTD

Resin-coated metal sheet

InactiveUS20060182948A1Promote absorptionImprove workabilityMagnetic/electric field screeningSynthetic resin layered productsMicrowaveMetallurgy

Disclosed is a resin coated metal sheet for use in electronic equipment components which can provide excellent microwave absorbability and workability by coating a magnetic coating film containing from 20 to 60 mass % of a magnetic powder at a thickness of 3 to 50 μm on at least one surface of a metal sheet and, optionally, also has a favorable heat releasing property; a heat releasing property and a self-cooling property; scratch resistance and fingerprint resistance; and electrical conductivity, and which is particularly useful as a constituent material as a casing for electronic equipment.

Owner:KOBE STEEL LTD

Method of modifying surface of magnetic powder and magnetic coating material

An aspect of the present invention relates to a method of modifying a surface of a magnetic powder, comprising mixing a magnetic powder with a cyclic compound comprising at least one carboxylic group. A further aspect of the present invention relates to a magnetic coating material comprising a magnetic powder and a binder, further comprising a cyclic compound comprising at least one carboxylic group.

Owner:FUJIFILM CORP

Laser holographic anti-counterfeiting stamping foil containing magnetic encryption information and preparation method thereof

InactiveCN101593459AHigh anti-counterfeiting strengthReduce the temperatureStampsVacuum evaporation coatingInstrumentationMedia layer

The invention provides a laser holographic anti-counterfeiting stamping foil containing magnetic encryption information and a preparation method thereof. A separation layer, an information recording layer and a medium layer are arranged in turn between a plastic carrier film layer and a bonding glue layer. The laser holographic anti-counterfeiting stamping foil is characterized in that a magnetic coat is also arranged between the medium layer and the bonding glue layer; moreover, a magnetic material is not printed on the surface of the stamping foil but coated on the medium layer; thus, the magnetic material cannot cover holographic patterns, and magnetic information writing and reading can be carried out through an instrument; therefore, the stamping foil not only contains holographic anti-counterfeiting information, but also has the function of magnetic encryption information anti-counterfeiting protection to obtain the effect of multiple anti counterfeiting.

Owner:WUHAN HUAGONG IMAGE TECH & DEV

UV-cured resin coated soft magnetic powder, preparation method and application thereof

ActiveCN104821219AHydrophobicExtended storage lifeMagnetic paintsInorganic material magnetismWater basedAdhesive

Owner:GUANGZHOU PANYU ZHIDA SMART FILM

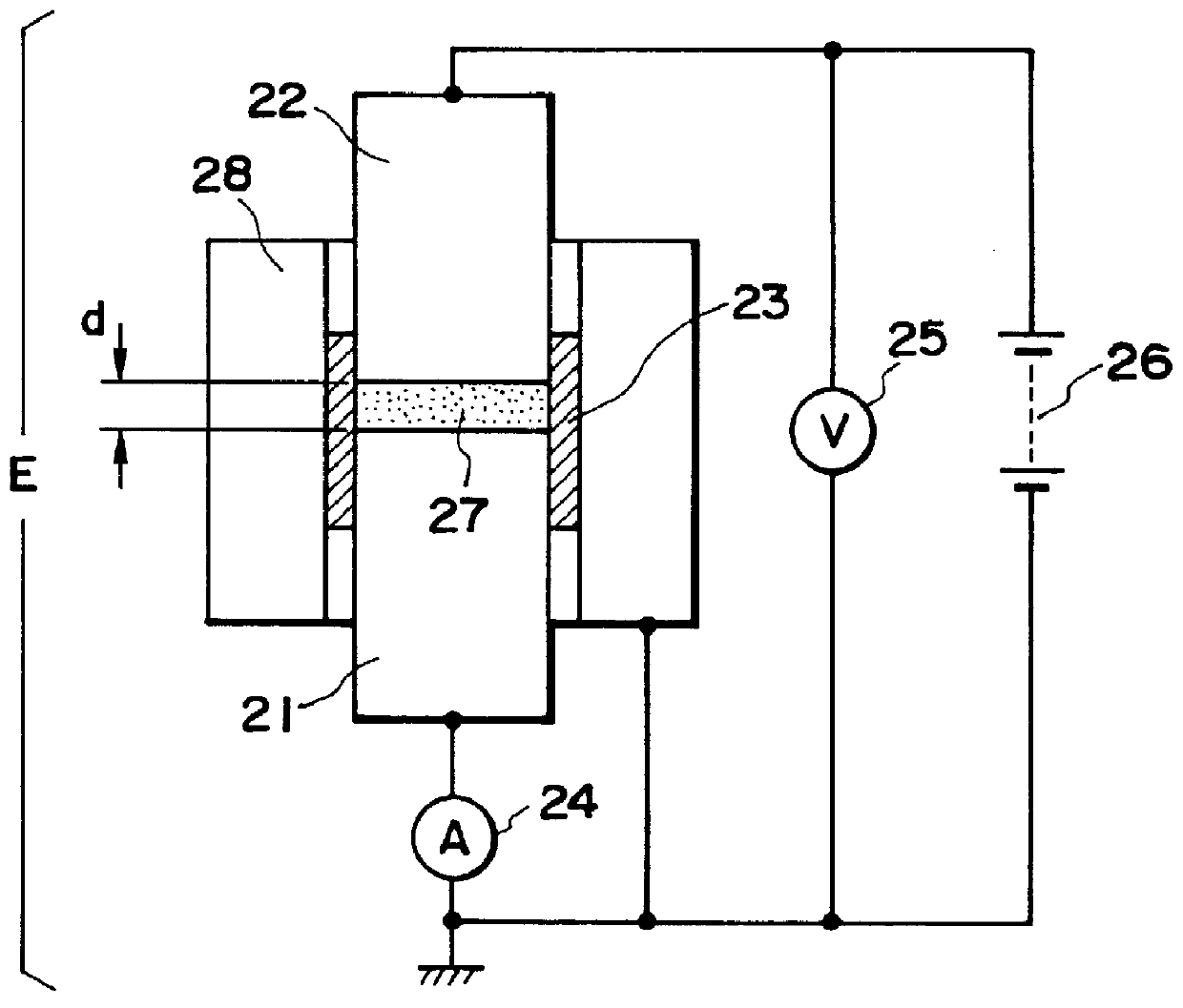

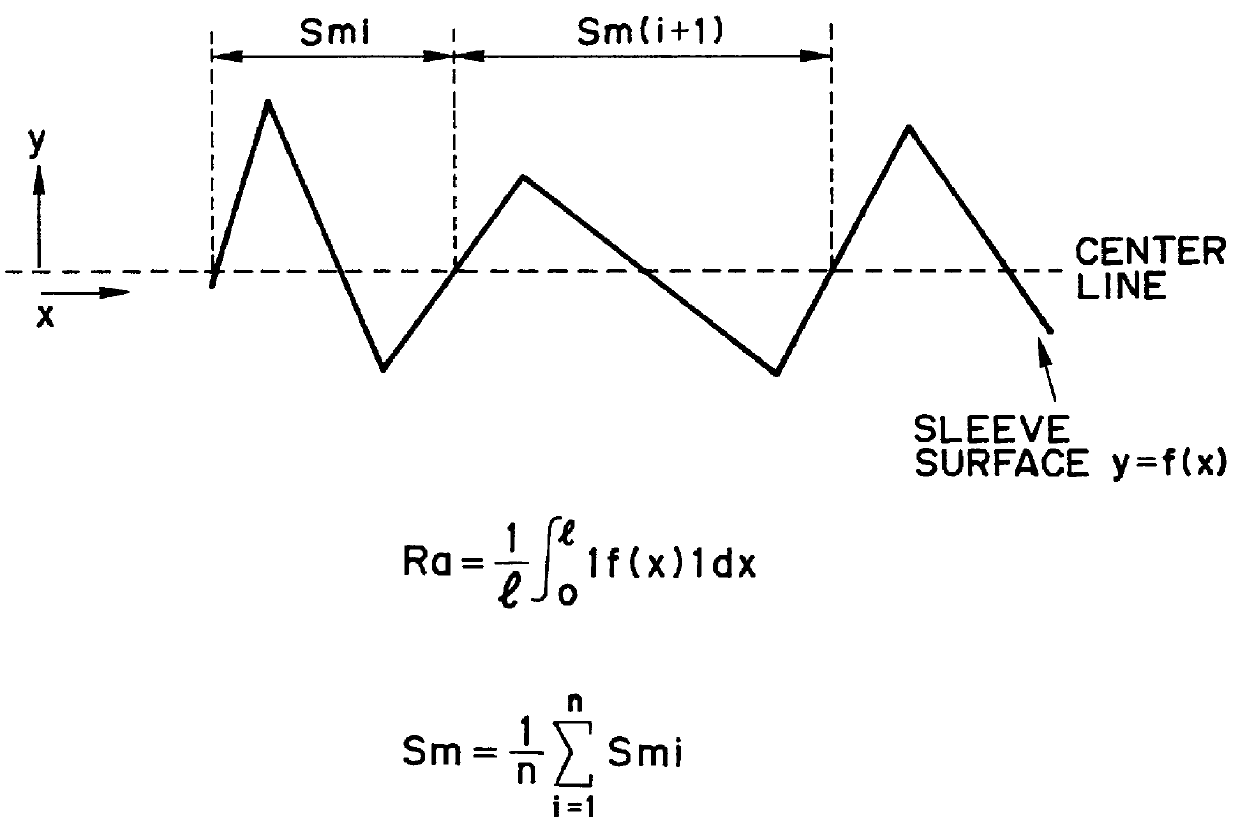

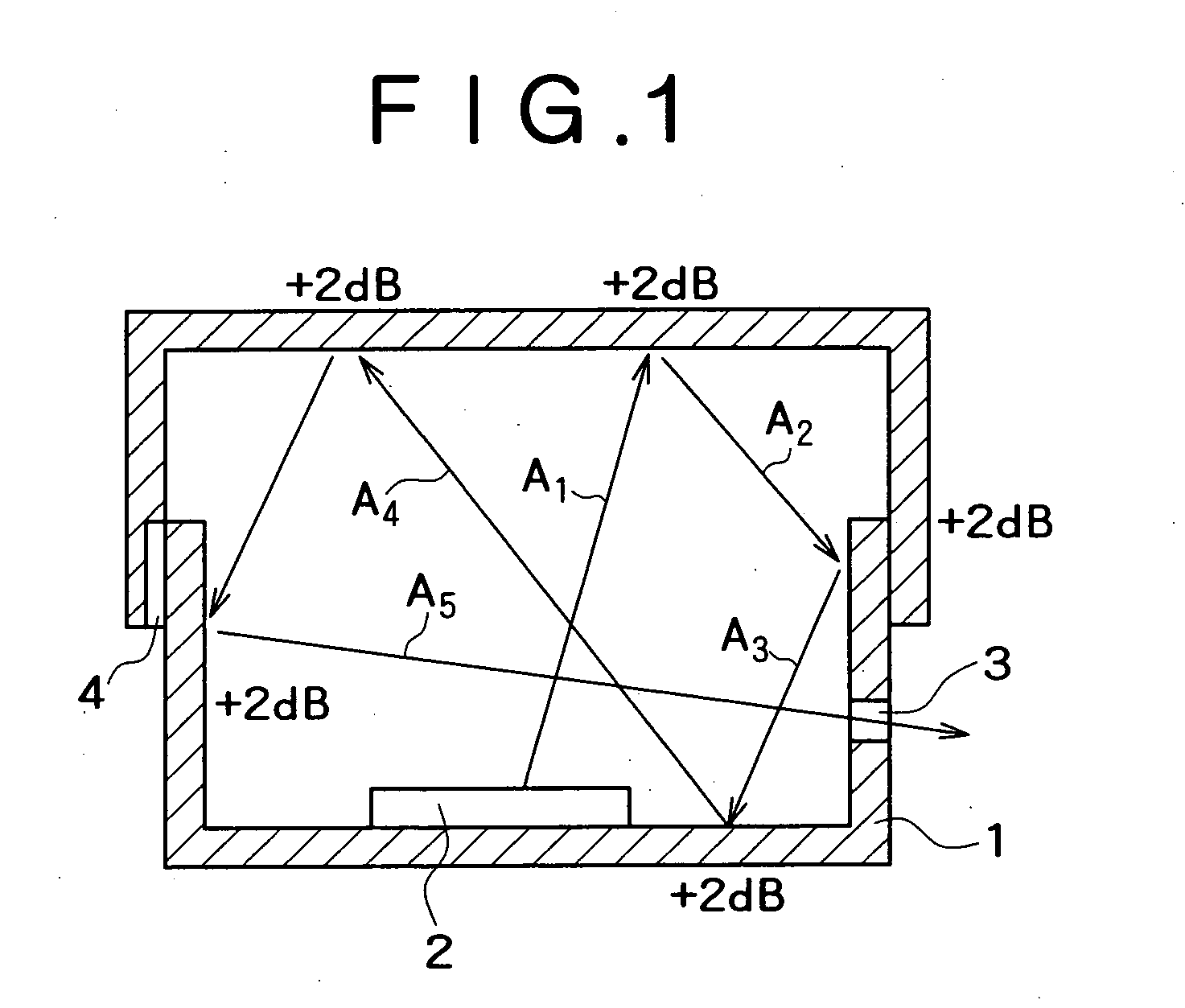

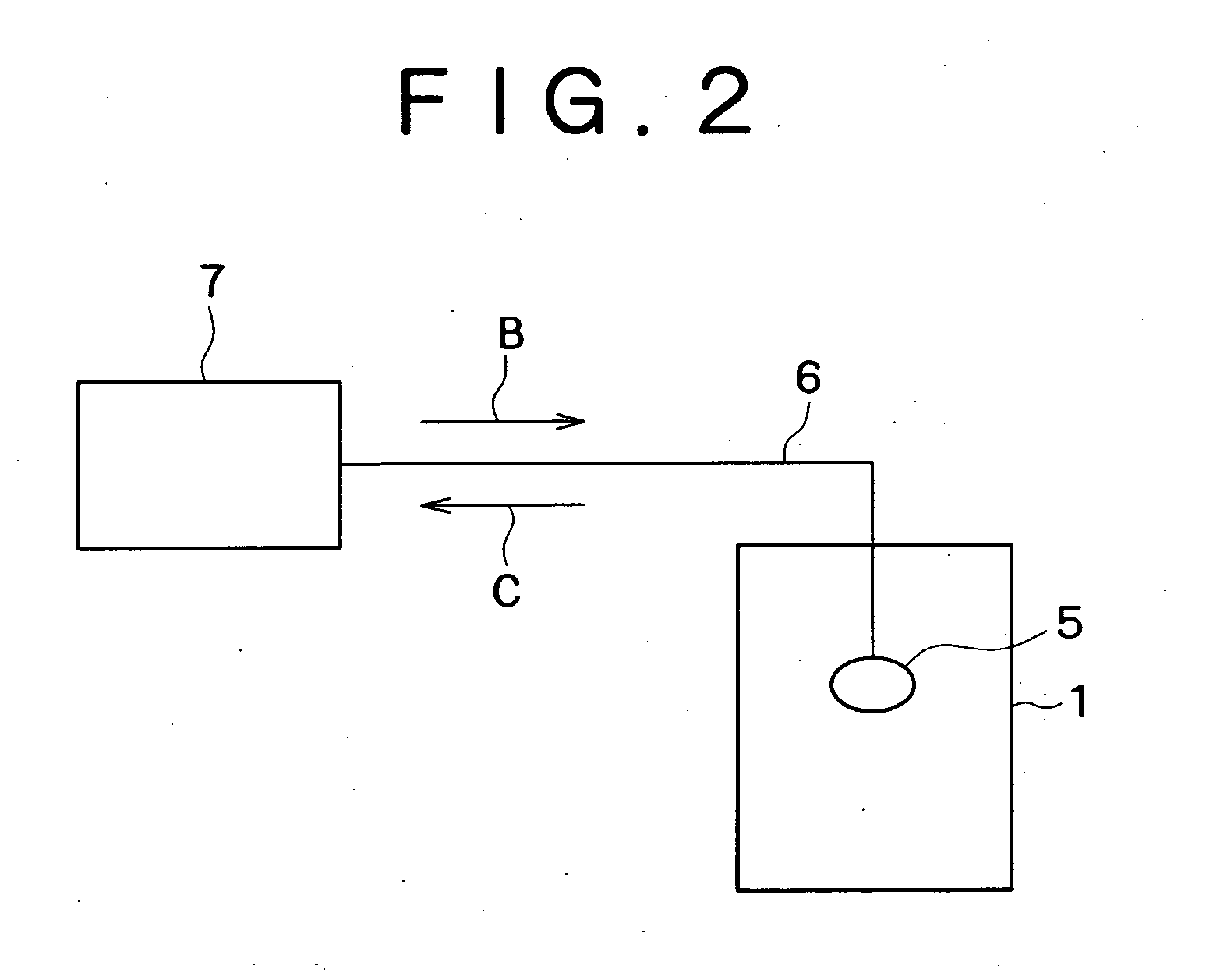

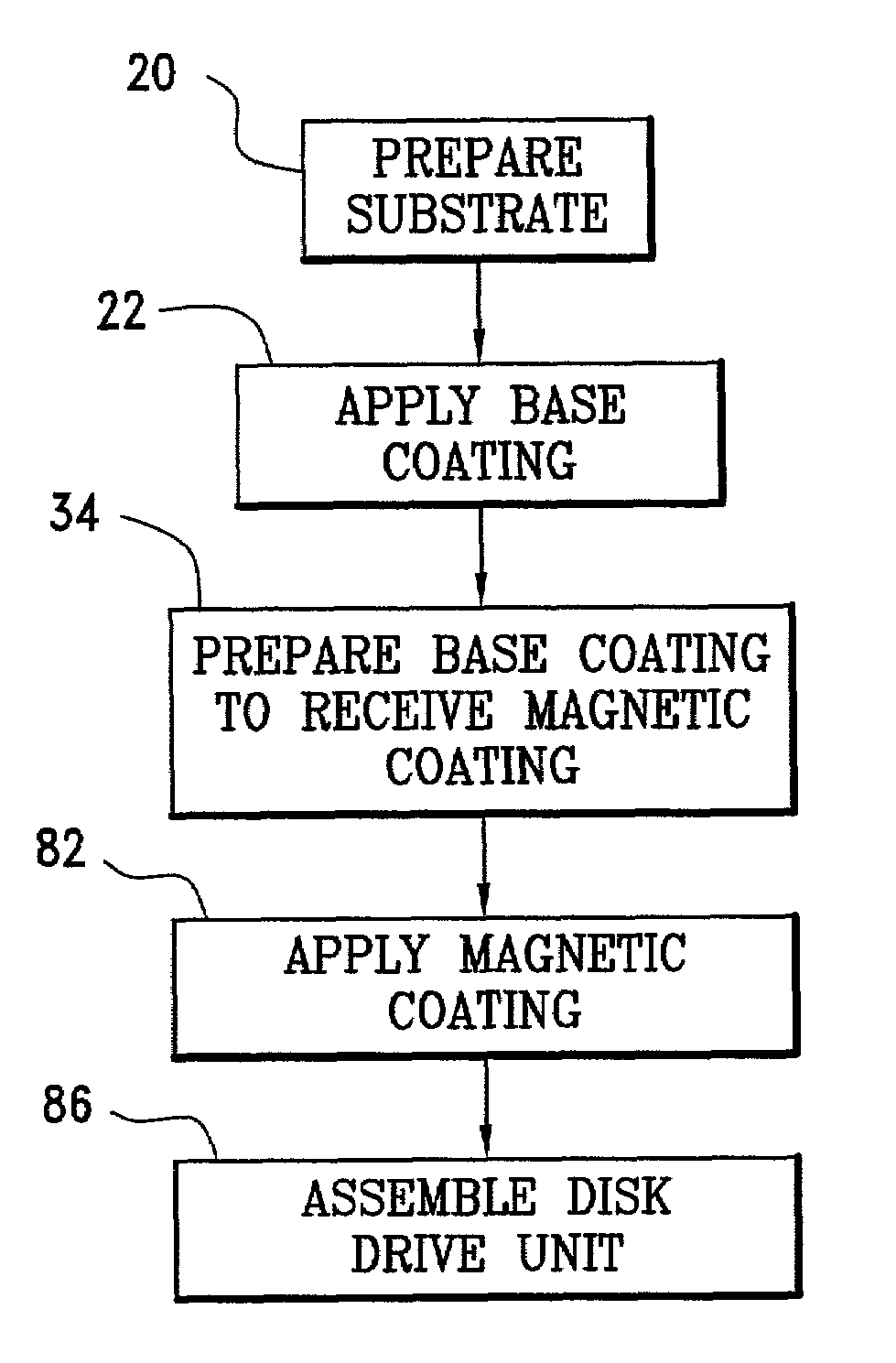

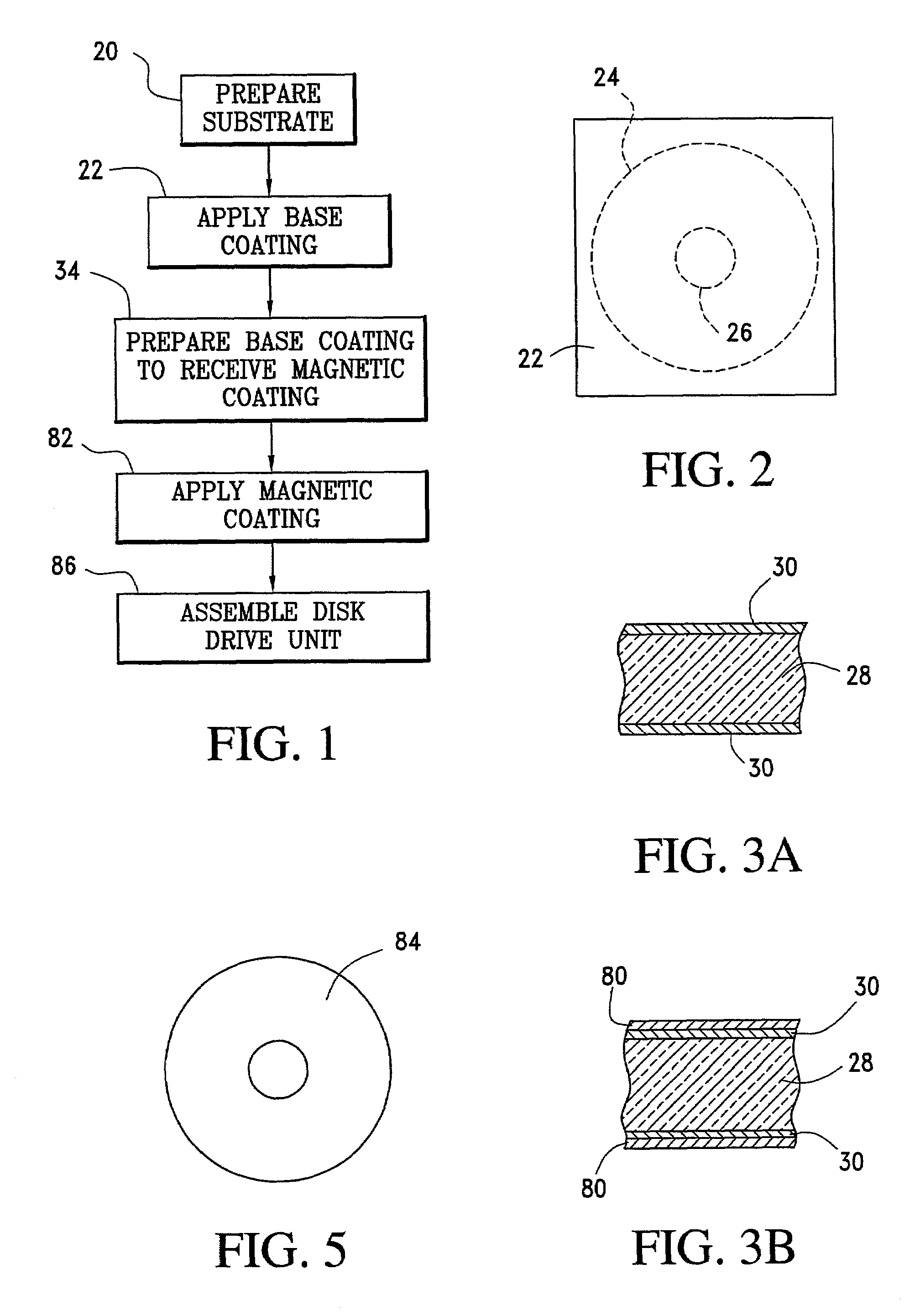

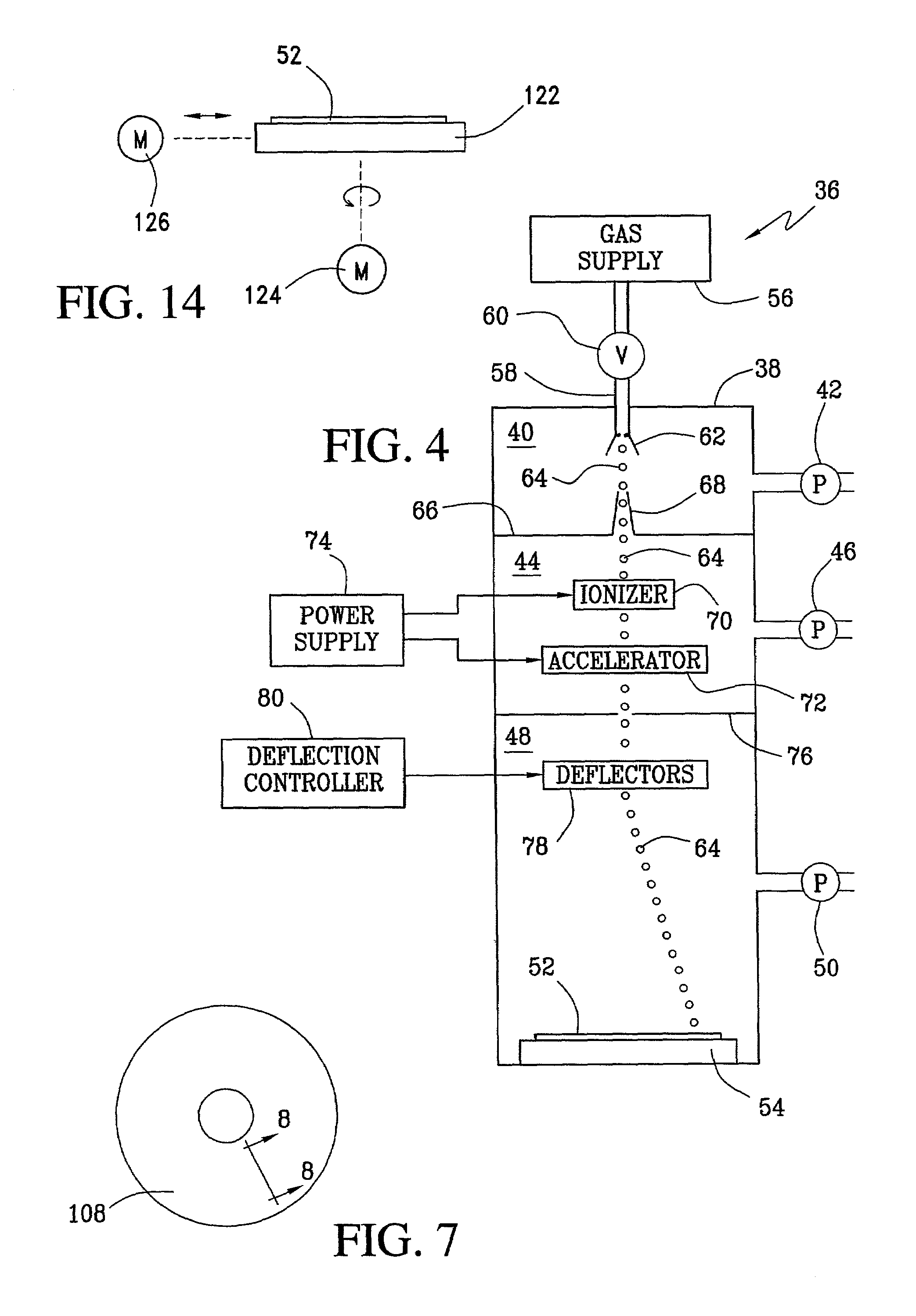

Disk, method for making it free of asperities utilizing a step of exposing a surface of the disk to a gas cluster ion beam and disk drive unit for using the disk

InactiveUS7064927B2Reduce manufacturing costReduce surface roughnessRecord information storageFlat record carrier containersGas cluster ion beamVacuum chamber

A method for making a magnetic disk, without chemical mechanical polishing to remove asperities, includes the steps of placing an annular-shaped element in a vacuum chamber, exposing a surface of the element to a beam of gas clusters while it is in the vacuum chamber, and thereafter applying a magnetic coating. The annular-shaped element may be a substrate, or it may be a substrate with a base coating such as glassy carbon or amorphous carbon. The substrate may be made of glass, preferably high quality fusion glass. The surface of the annular element may be textured by forming a sequence of concentric annular valleys, with plateaus being left between the valleys, before the magnetic coating is applied. A semiconductor wafer may also be smoothed by a beam of gas clusters to prepare the wafer for photolithography.

Owner:WESTERN DIGITAL TECH INC

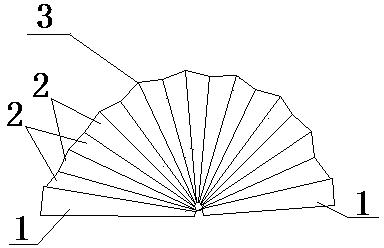

Magnetic coating cloth material

InactiveCN104354379AExtended service lifePrevent fallingLiquid surface applicatorsCoatingsWrinkle skinSuction force

The invention provides a cloth material capable of being automatically folded. The cloth material comprises a wrinkle fabric, a hard magnetic material coating layer and a soft magnetic material coating layer, wherein the hard magnetic material coating layer covers the wrinkle edges at two ends of the wrinkle fabric; the front surface of one folding surface of the wrinkle fabric is covered with the hard magnetic material coating layer, and the back surface of the adjacent folding surface of the wrinkle fabric is covered with the soft magnetic material coating layer; the folding surfaces are covered in sequence. The cloth material has the benefits that 1, the cloth material is folded in order according to folding traces under the suction force between magnetic coating layers with alternate positive and back surfaces, and 2, the magnetic coating layers with the alternate positive and back surfaces can be effectively prevented from falling off, so that the service life of the cloth material is effectively prolonged.

Owner:吴璟荣

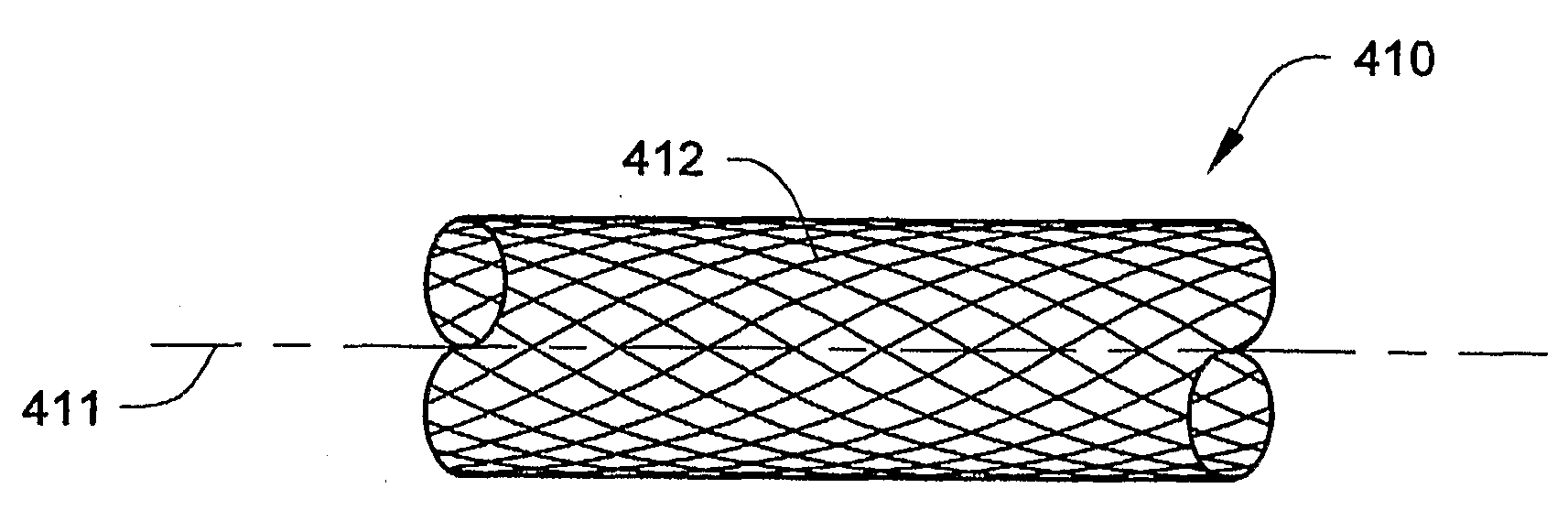

Magnetic Medical Apparatus, Kits, and Methods

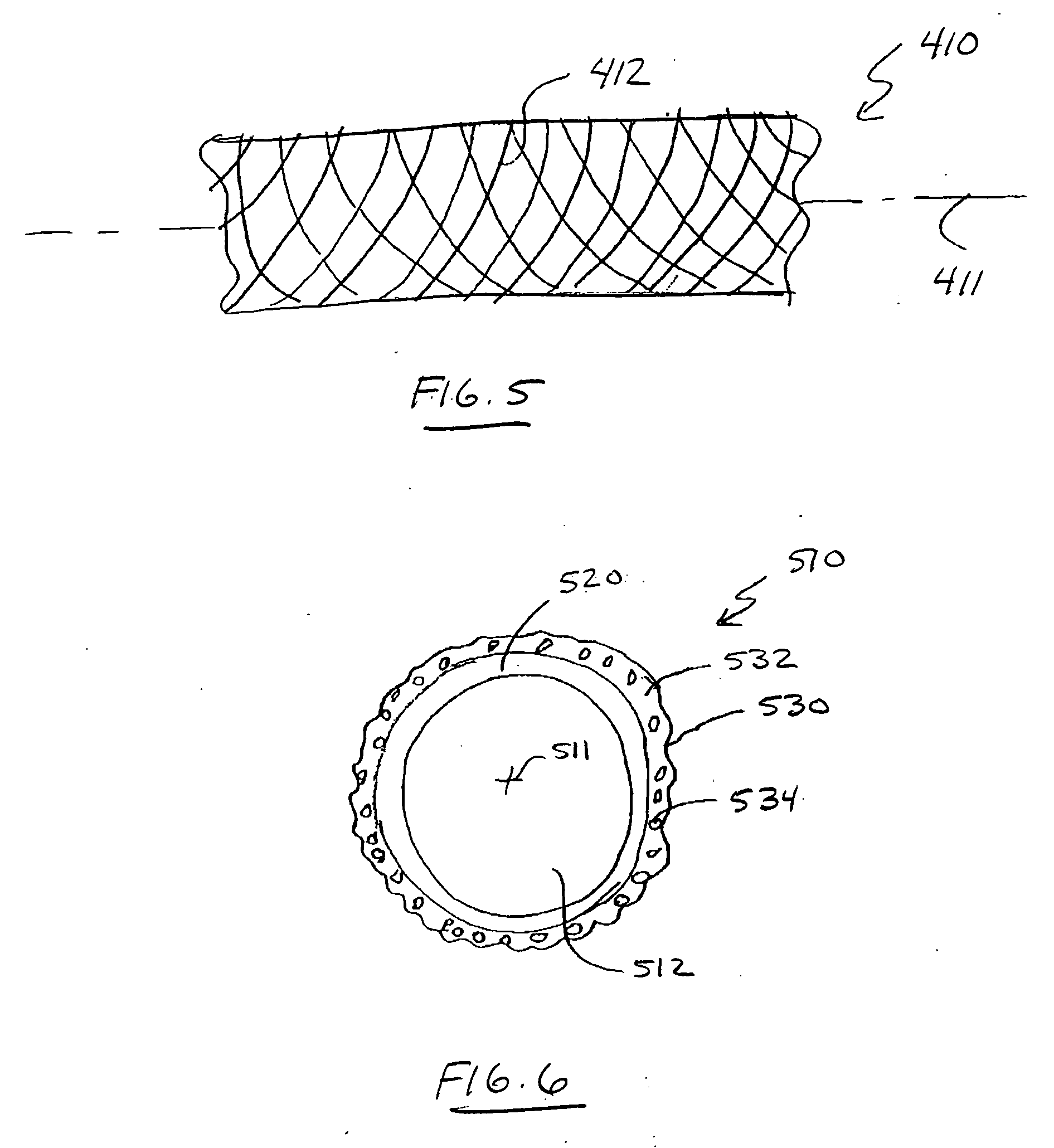

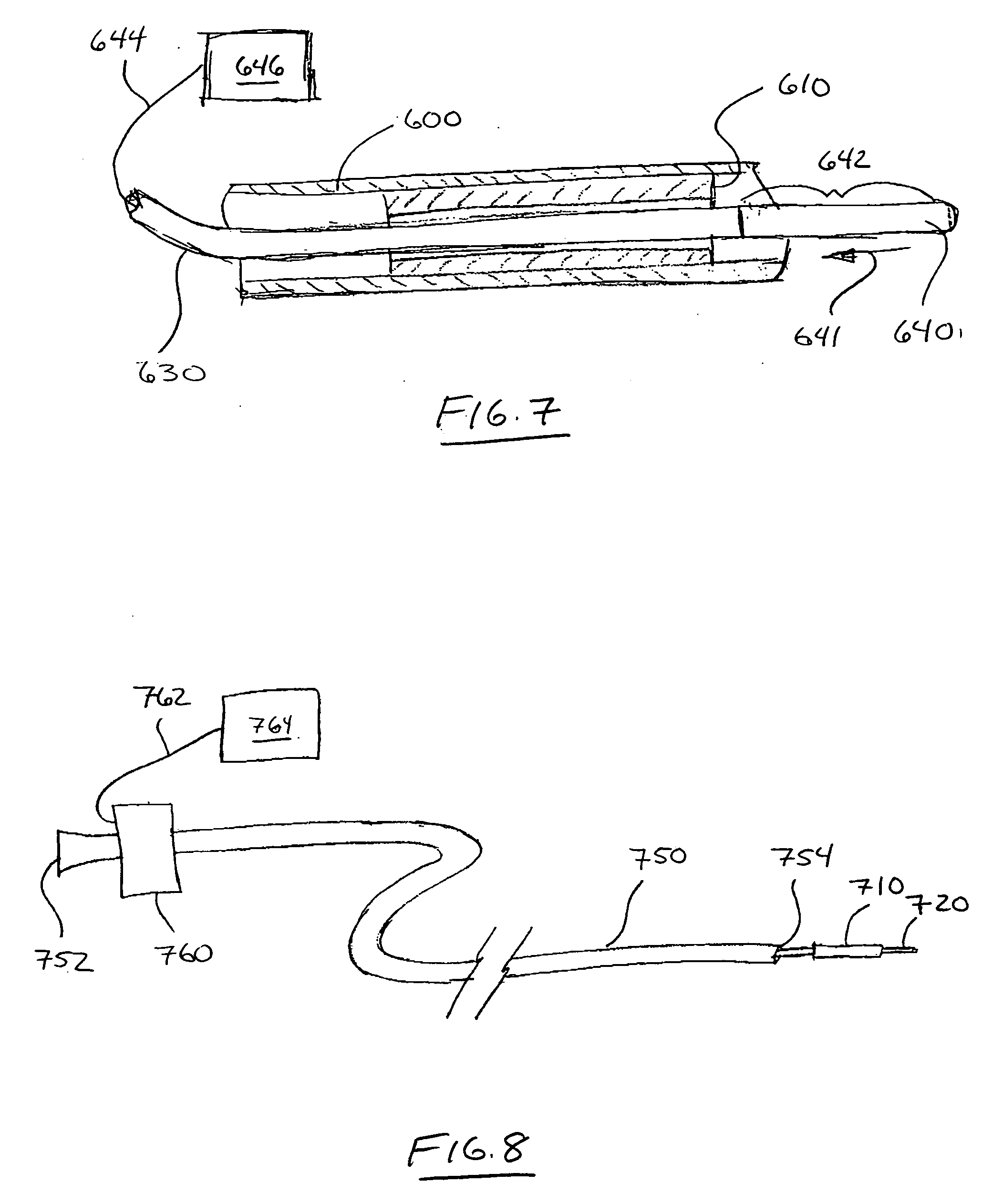

InactiveUS20090118817A1Easy to paintQuick connectionStentsTransvascular endocardial electrodesHigh concentrationMagnetization

Medical devices with surfaces on which viable biologic cells are magnetically attracted and retained are disclosed along with methods of magnetic coating. The medical devices can be located in a carrier liquid containing high concentrations of magnetic cells before or after implantation. The carrier liquid with magnetic cells may be contact with the medical device in vitro or in vivo. In either case, the carrier liquid may have a concentration of magnetic cells that is high enough to facilitate coating of the medical device within an acceptable period of time, e.g., several hours or less. Magnetization of medical devices before, during, and / or after implantation and apparatus for performing the same are disclosed. Degaussing of magnetic medical devices is also disclosed.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

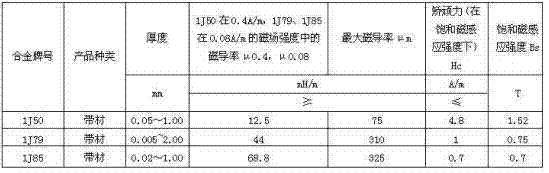

Electromagnetic shielding material, application and manufacturing process for electromagnetic shielding material

ActiveCN102892279AImprove permeabilityImprove shielding effectMagnetic/electric field screeningTransverse magnetic fieldElectrochemistry

The invention discloses an electromagnetic shielding material, application and a manufacturing process for the electromagnetic shielding material. The electromagnetic shielding material comprises at least one magnetic-conducting metal layer, wherein the first surfaces of the magnetic-conducting metal layers are electrochemically treated to form plated layers, and are obtained by transverse magnetic field thermal treatment. Furthermore, magnetic-conducting coatings can be coated on the second surfaces of the magnetic-conducting metal layers. The magnetic-conducting coatings are coated on the magnetic-conducting metal layers to form a composite structure capable of effectively improving magnetic conductivity within a frequency range of 30MHz to 10GHz, so that a shielding effect is improved. In addition, the magnetic-conducting metal layers can be subjected to the transverse magnetic field thermal treatment, and the magnetic conductivity of the obtained electromagnetic shielding material within 2GHz or a frequency range of 10KHz to 30MHz can be effectively improved.

Owner:KUSN ZHONGDI MATERIALS TECH

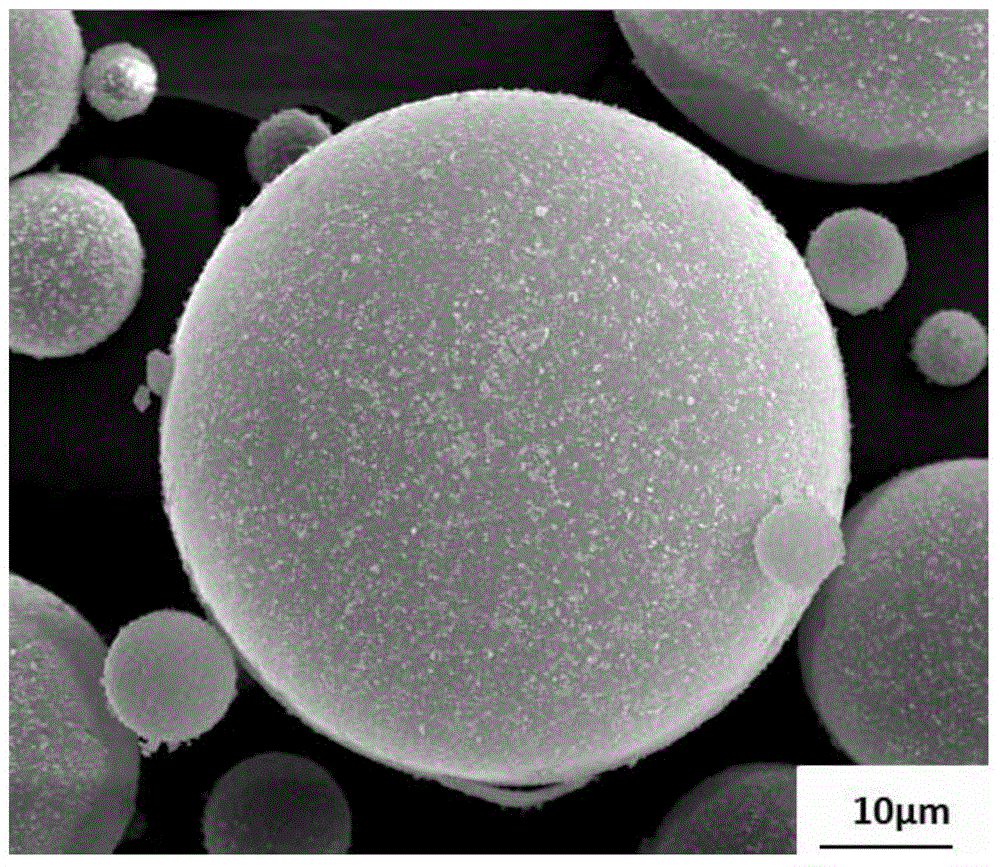

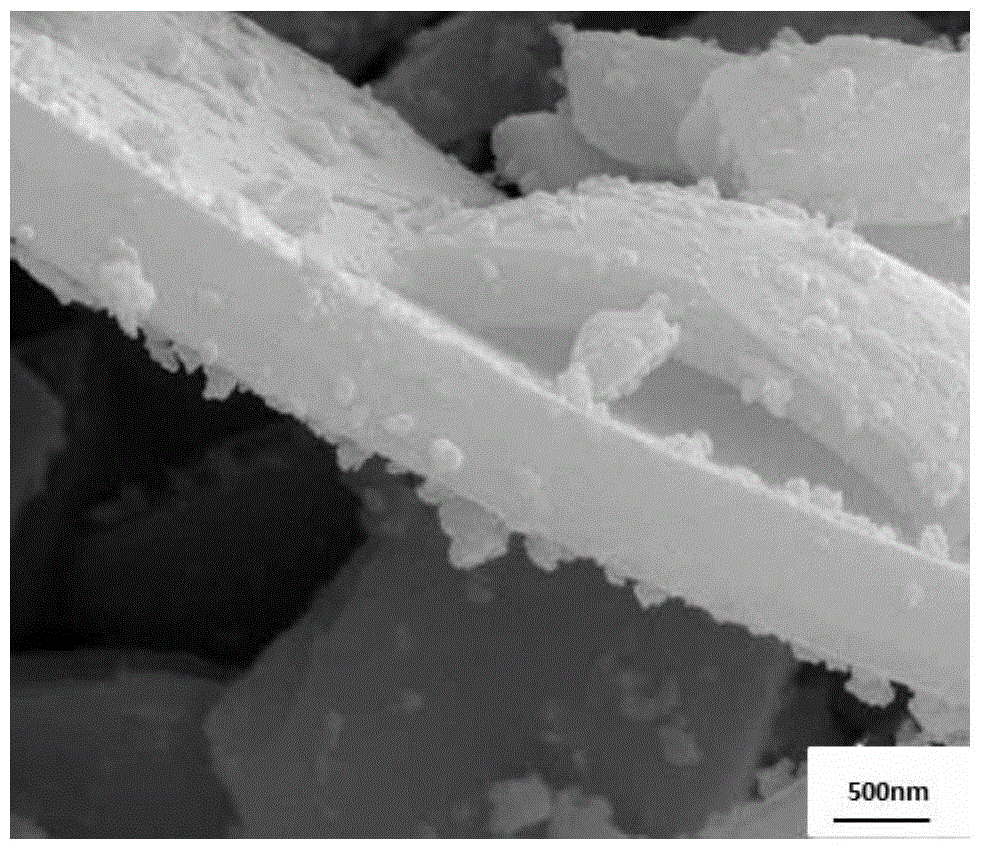

Hollow microsphere/Ni-Fe-P/Cu composite coating and preparation method thereof

ActiveCN104018139AGood soft magneticImprove permeabilityMaterial nanotechnologyLiquid/solution decomposition chemical coatingChemical platingMicrosphere

The invention provides a hollow microsphere / Ni-Fe-P / Cu composite coating and a preparation method thereof, relating to a hollow microsphere composite coating and a preparation method thereof. The hollow microsphere / Ni-Fe-P / Cu composite coating comprises a matrix hollow microsphere, an amorphous Ni-Fe-P soft magnetic coating and a nano Cu conductive coating from inside to outside. The method comprises the following steps: I. washing; II sensitizing with SnCl2; III. activating with PdCl2; IV. chemical plating of Ni-Fe-P; V. chemical plating of Cu. The hollow microsphere composite coating has light weight, high permeability, high conductivity and multiple interfaces, and thus the hollow microsphere composite coating can be used for preparing electromagnetic shielding coatings with good shielding property, wide frequency range and light weight. Besides, the hollow microsphere composite coating can be also applied in the field of wave absorption and is applied in the field of hollow microsphere surface chemical plating.

Owner:HARBIN INST OF TECH

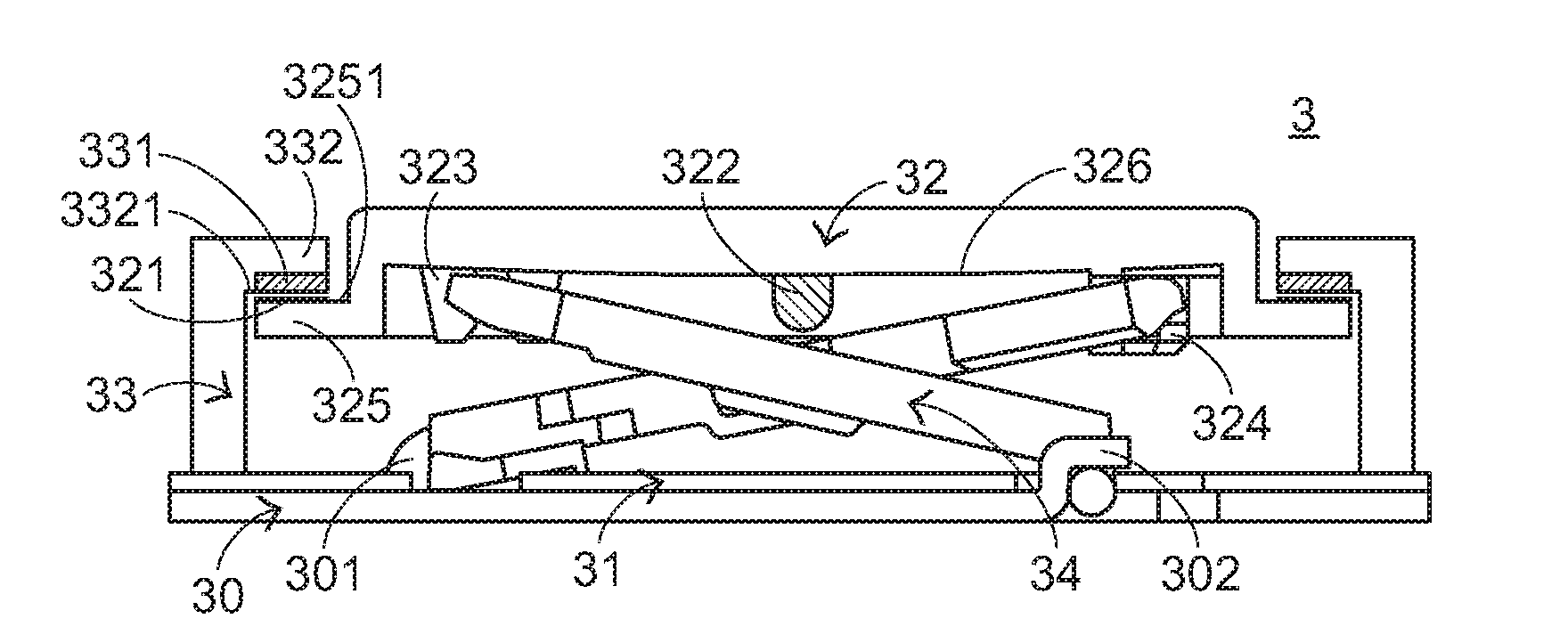

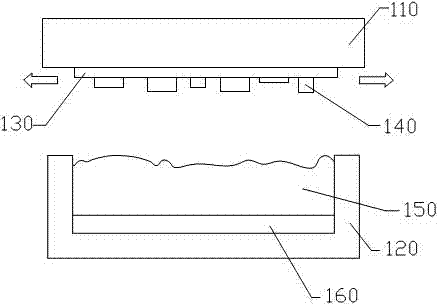

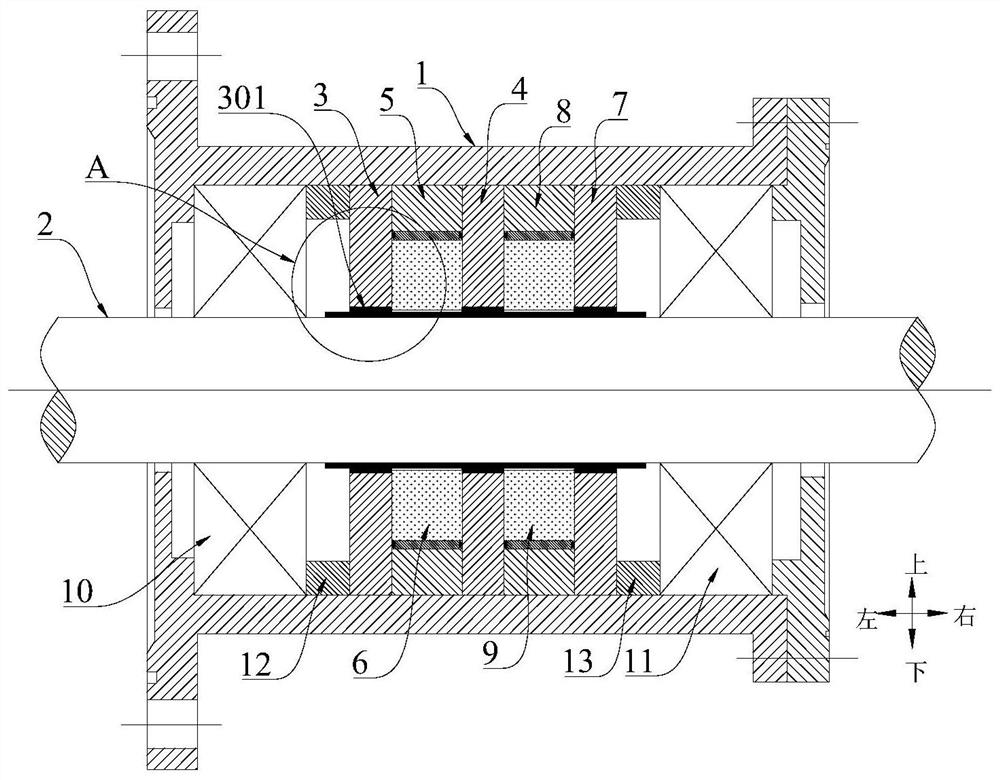

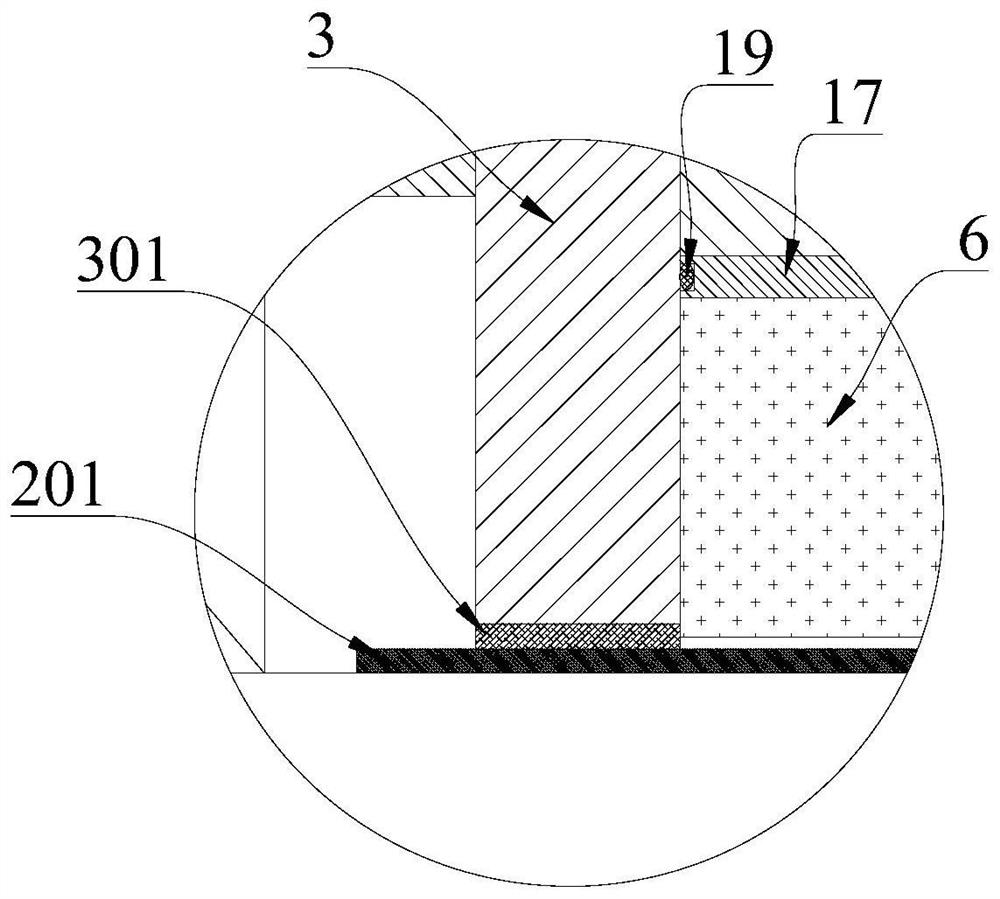

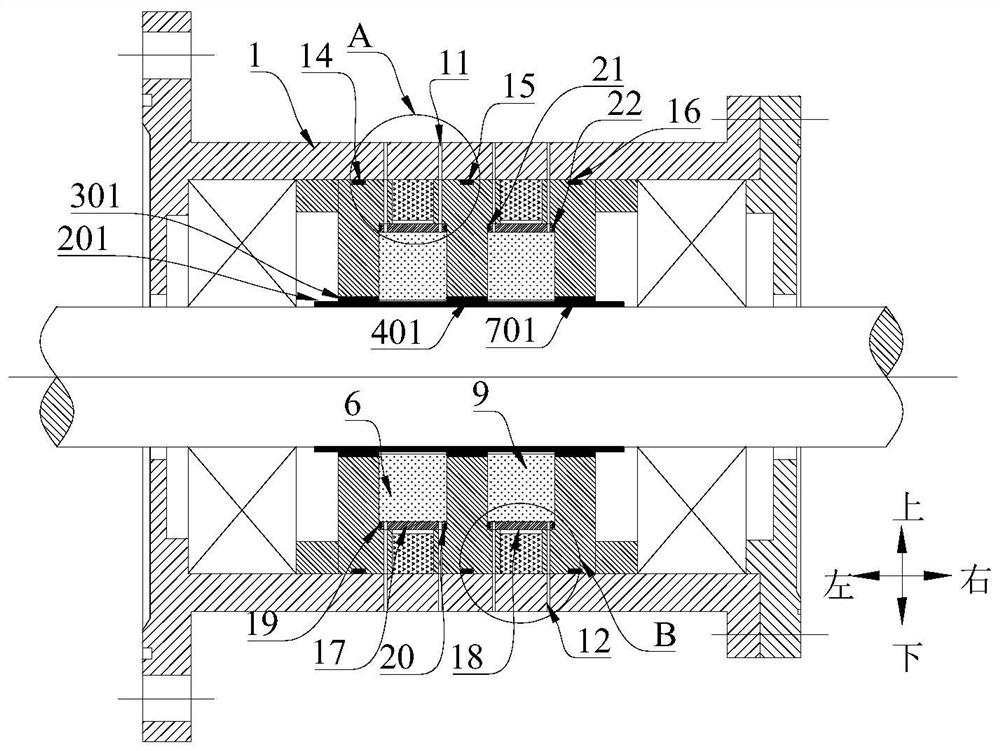

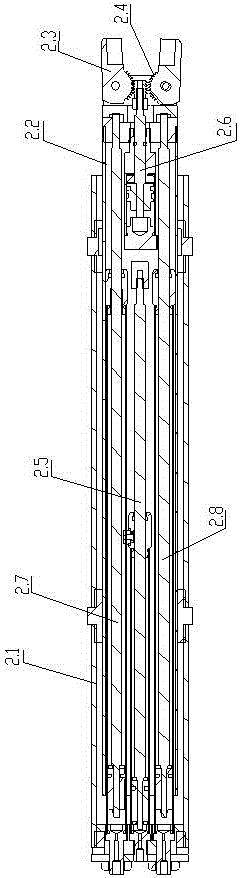

Double-coating magnetic liquid sealing device

The invention discloses a double-coating magnetic liquid sealing device. The sealing device comprises a shell, a rotating shaft, a first pole shoe, a second pole shoe and a first permanent magnet, wherein a shaft chamber is formed in the shell; the rotating shaft is rotationally arranged in the shaft chamber; a first non-magnetic coating is arranged on the outer circumferential surface of the rotating shaft; the first pole shoe and the second pole shoe are arranged on the rotating shaft in a sleeving mode and are arranged at intervals in the axial direction of the rotating shaft; second non-magnetic coatings are arranged on the inner circumferential surface of the first pole shoe and the inner circumferential surface of the second pole shoe; the first permanent magnet is arranged on the rotating shaft in a sleeving mode; the first permanent magnet is located between the first pole shoe and the second pole shoe; a first liquid cavity is formed among the first pole shoe, the second poleshoe, the first permanent magnet and the first non-magnetic coating; and the first liquid cavity is used for storing magnetic liquid. According to the double-coating magnetic liquid sealing device, the machining difficulty and cost are reduced, the magnetic liquid can be supplemented in time, the pressure resistance of the magnetic liquid sealing is maintained, the magnetic liquid further has a lubricating effect, and the torsion moment of the magnetic liquid sealing is reduced.

Owner:TSINGHUA UNIV

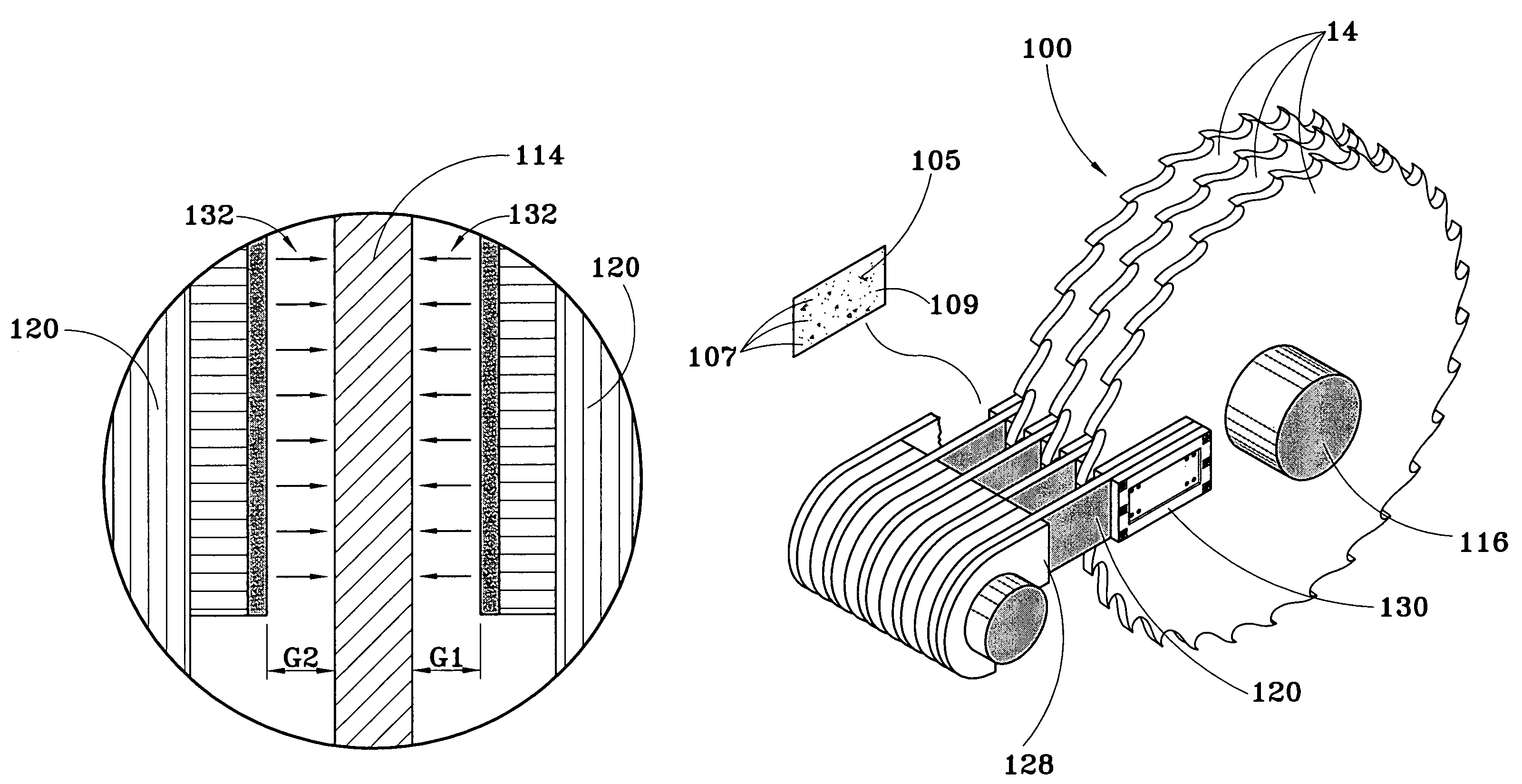

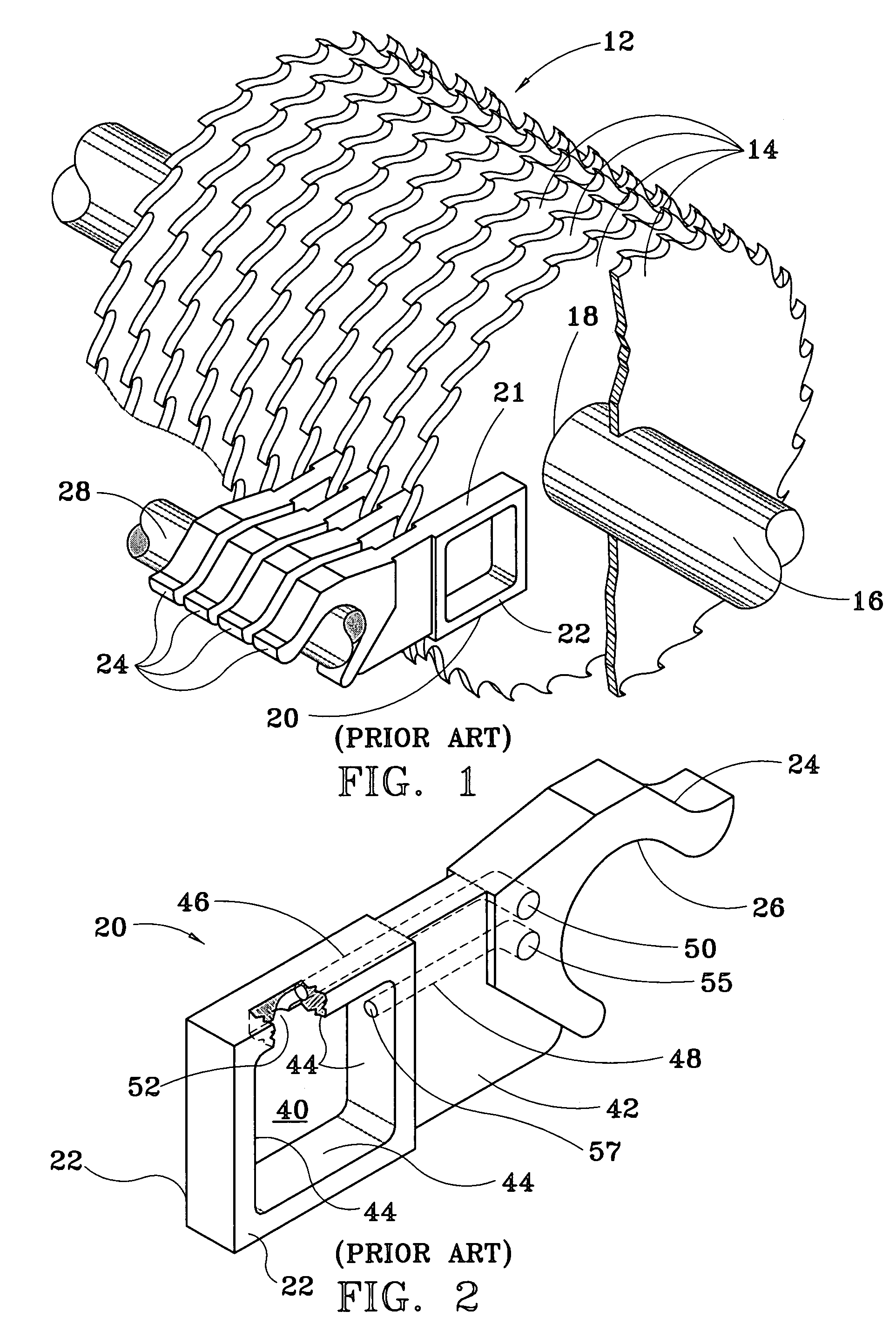

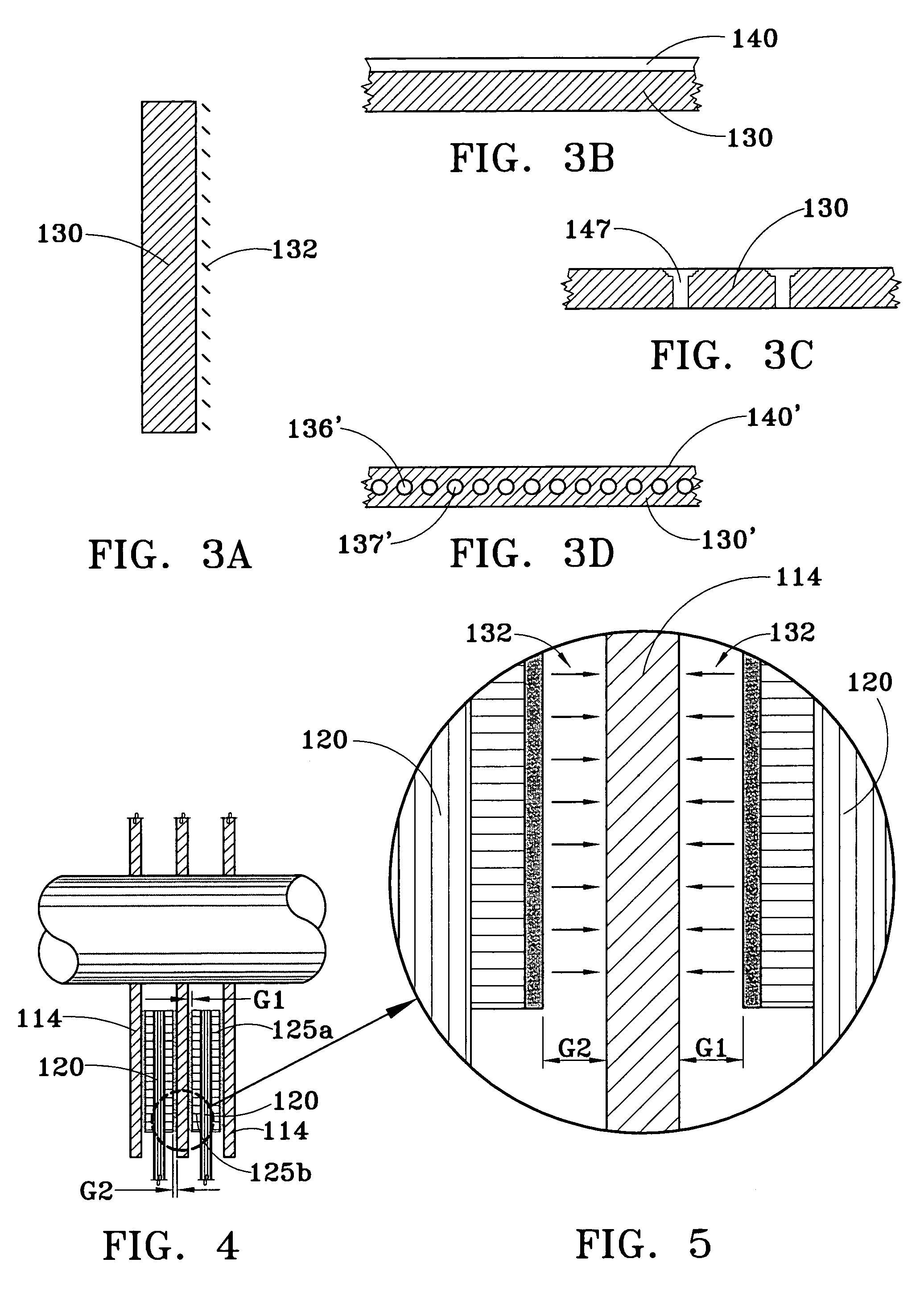

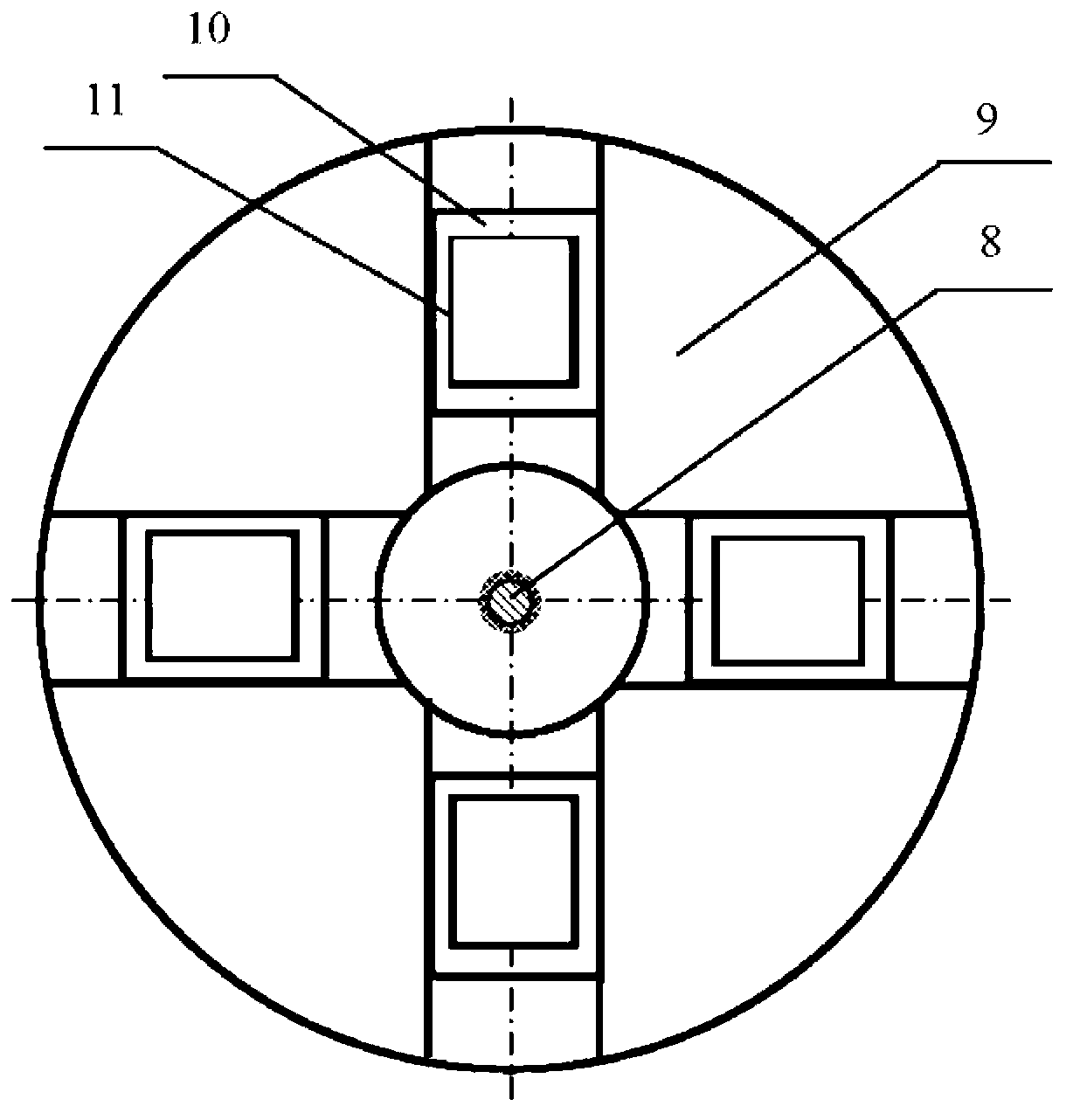

Multiple-blade saw system with magnetic bearing guide blocks and ferromagnetic lubricant, coolant and coating system

InactiveUS7584688B1Increased durabilityMaintain integrityMetal sawing devicesMetal sawing accessoriesMagnetic bearingCoating system

Improved saw guide block and fluid for a multiple blade saw assembly. Individual guide blocks are disposed between adjacent saw blades, which blades are mounted on a common drive shaft and axially spaced. Each of the guide blocks has a pair of oppositely-directed block pads that create a magnetically-padded bearing surface. Each block pad includes magnetic portions and non magnetic portions. Each non magnetic portion has fluid delivery ports to allow the transport of ferromagnetic, lubricant, coolant, coating fluid to the magnetically-padded bearing surfaces. The magnetic portion forms a magnetic field of attraction in its vicinity for capture and adherence of ferromagnetic particles within the fluid, whereby a magnetic coating on the guide block bearings surfaces is continuously regenerated during operation of the saw assembly.

Owner:TEGEN MARK G

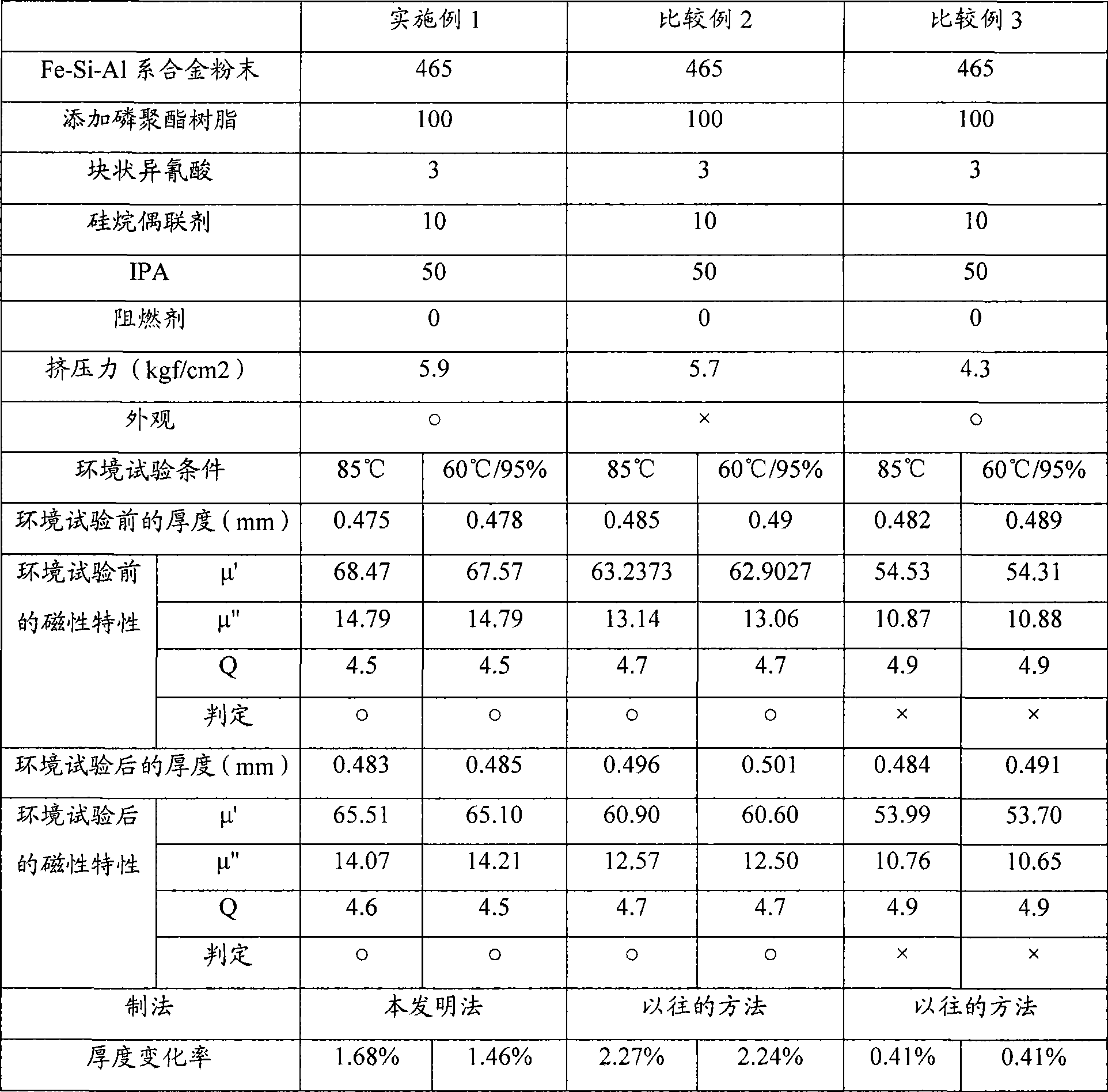

Process for producing magnetic sheet and magnetic sheet

ActiveCN101513153AReduce involvementReduce thickness variationMagnetic/electric field screeningMagnetic liquidsProduction rateSolvent

Owner:DEXERIALS CORP

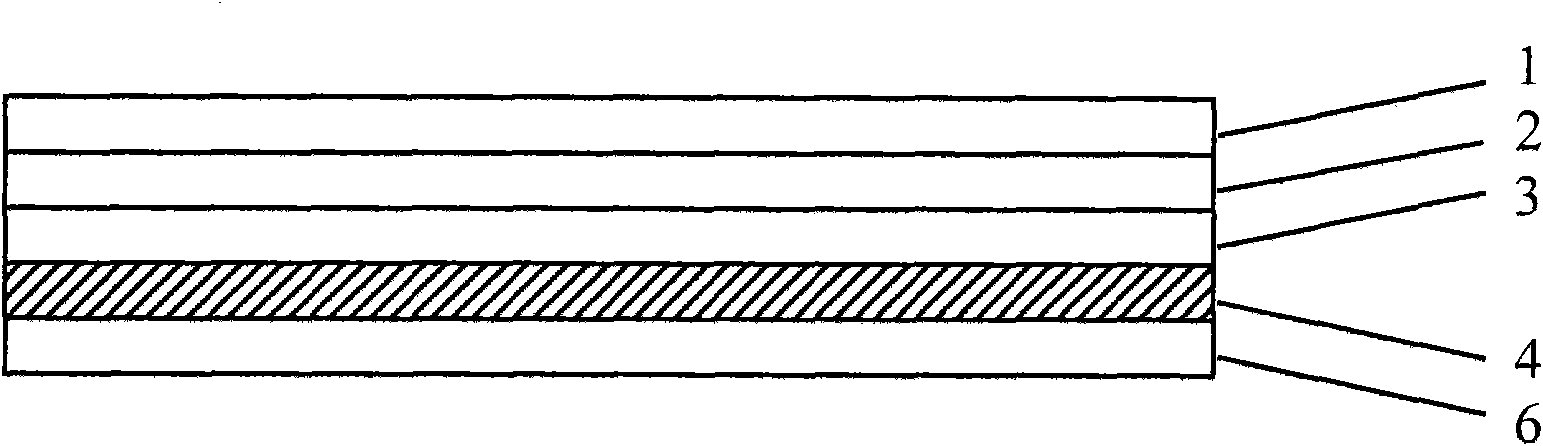

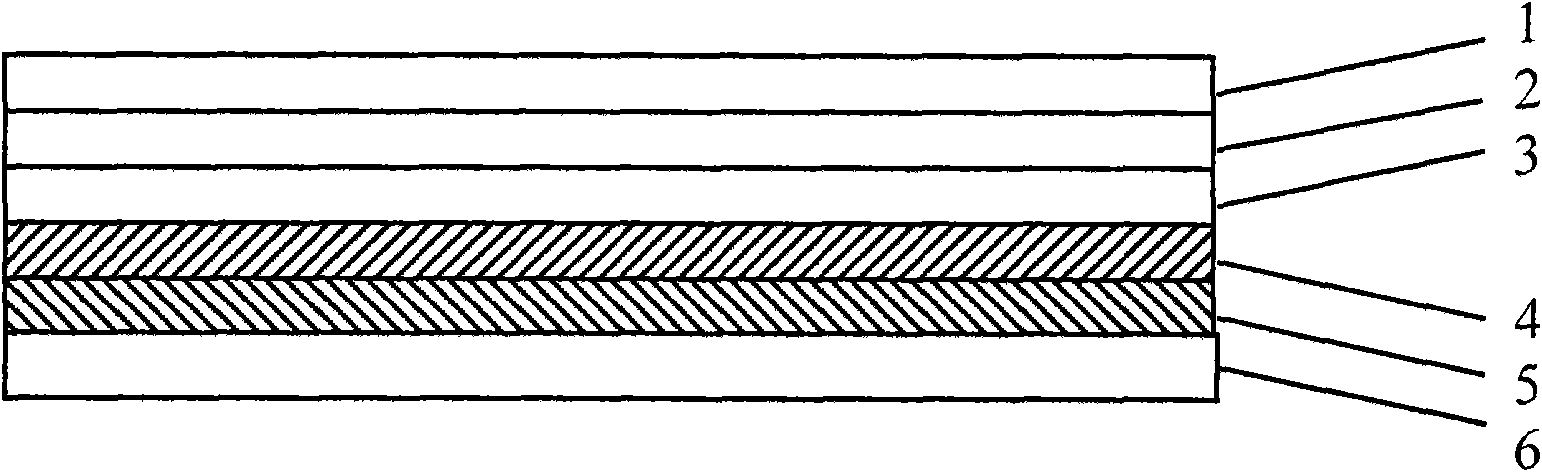

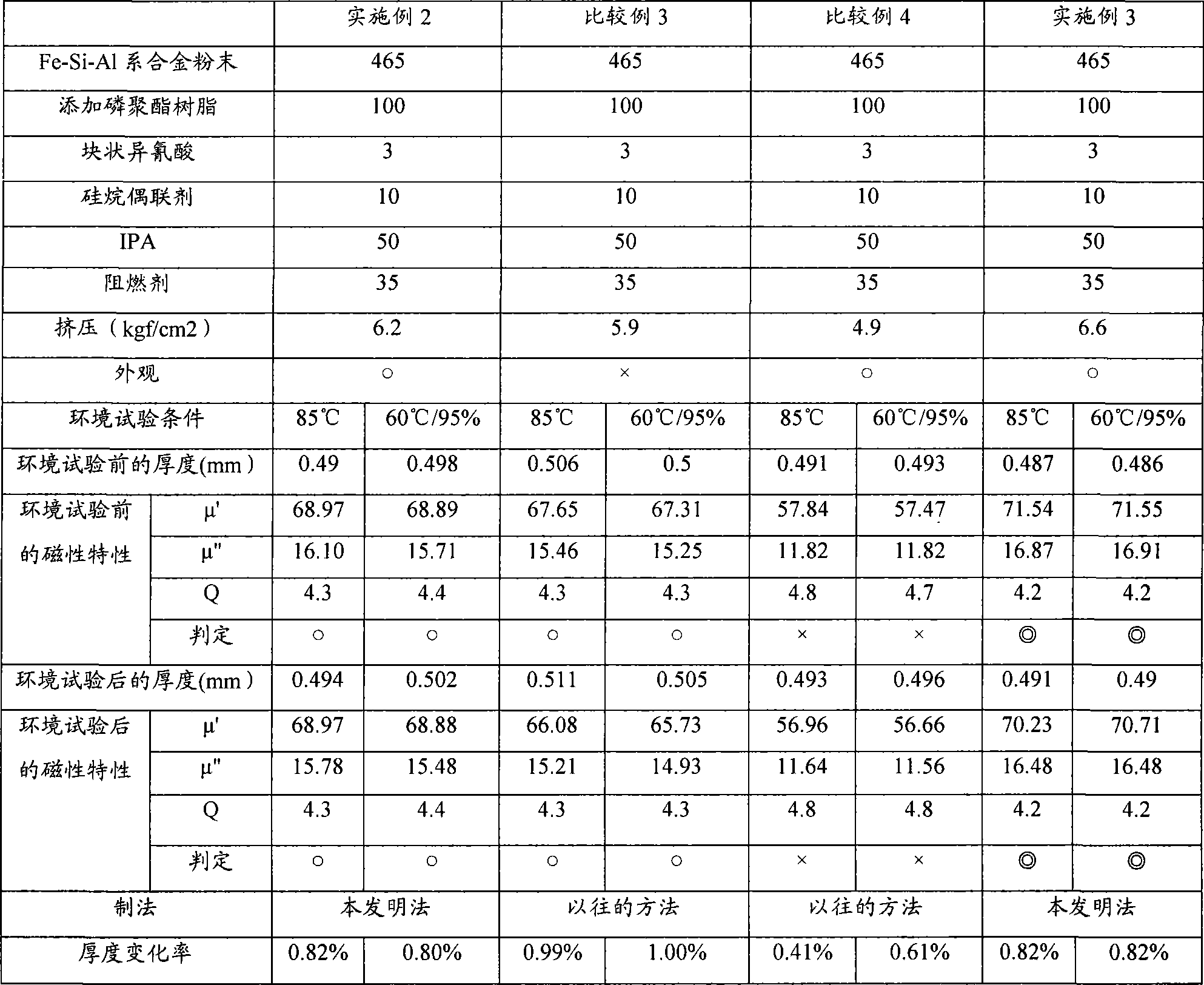

Portable magnetic-therapy mattress

ActiveCN104605684ALose weightImprove portabilityElectrotherapySleeping rugTreatment effectSurface layer

The invention provides a portable magnetic-therapy mattress which comprises an upper fabric layer (1), a magnetic conducting layer (2), a matrix layer (3), a magnetic coating (4), an inner cushion layer (5) and a lower fabric layer (6) in sequence from top to bottom. The lower face of the surface layer of the mattress is coated with magnetic coating instead of embedding magnets in the mattress. Firstly, the weight of the mattress is reduced to a large extent by omitting the magnets, and it can still be guaranteed that a magnetic field with enough magnetic field intensity and space coverage is generated; secondly, due to the fact that strip-shaped and blocky magnets are not adopted, a too thick cushion layer does not need to be additionally arranged to meet human body comfort, the weight of the mattress is further reduced, and the space is saved; finally, the mattress can be freely folded. The portability of the mattress is fully improved on the premise of guaranteeing the magnetic therapy effect.

Owner:HEYE HEALTH TECH CO LTD

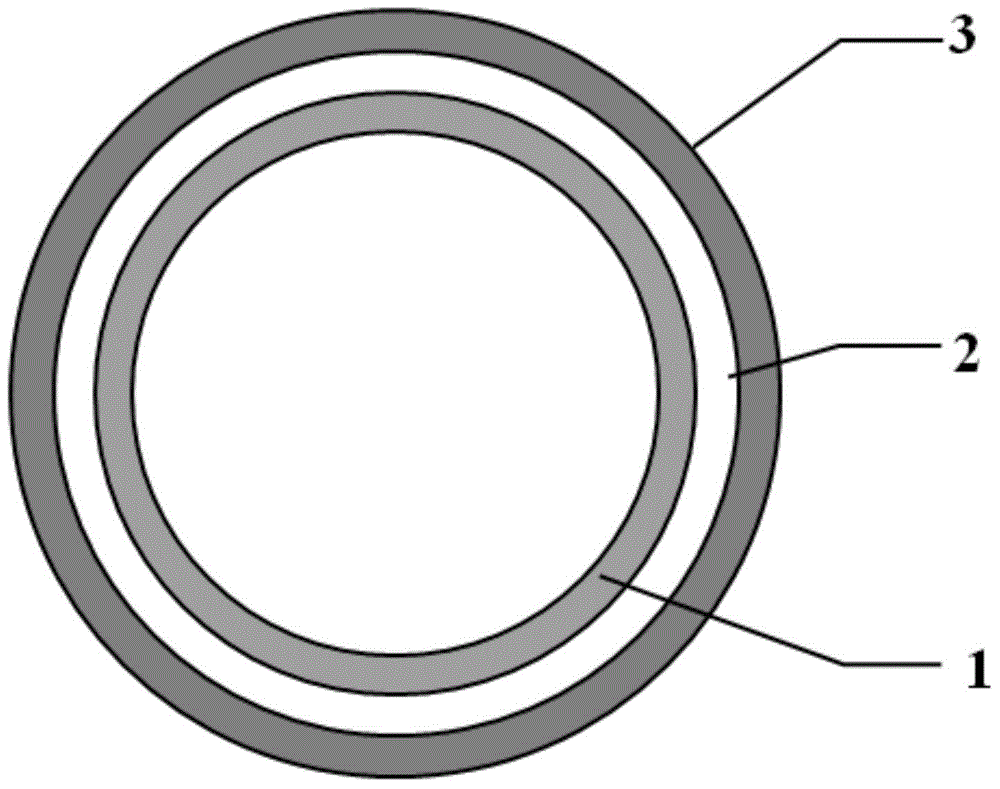

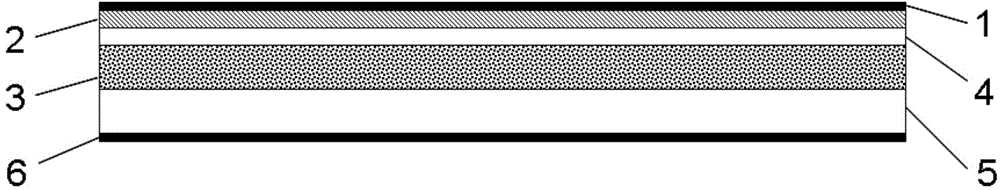

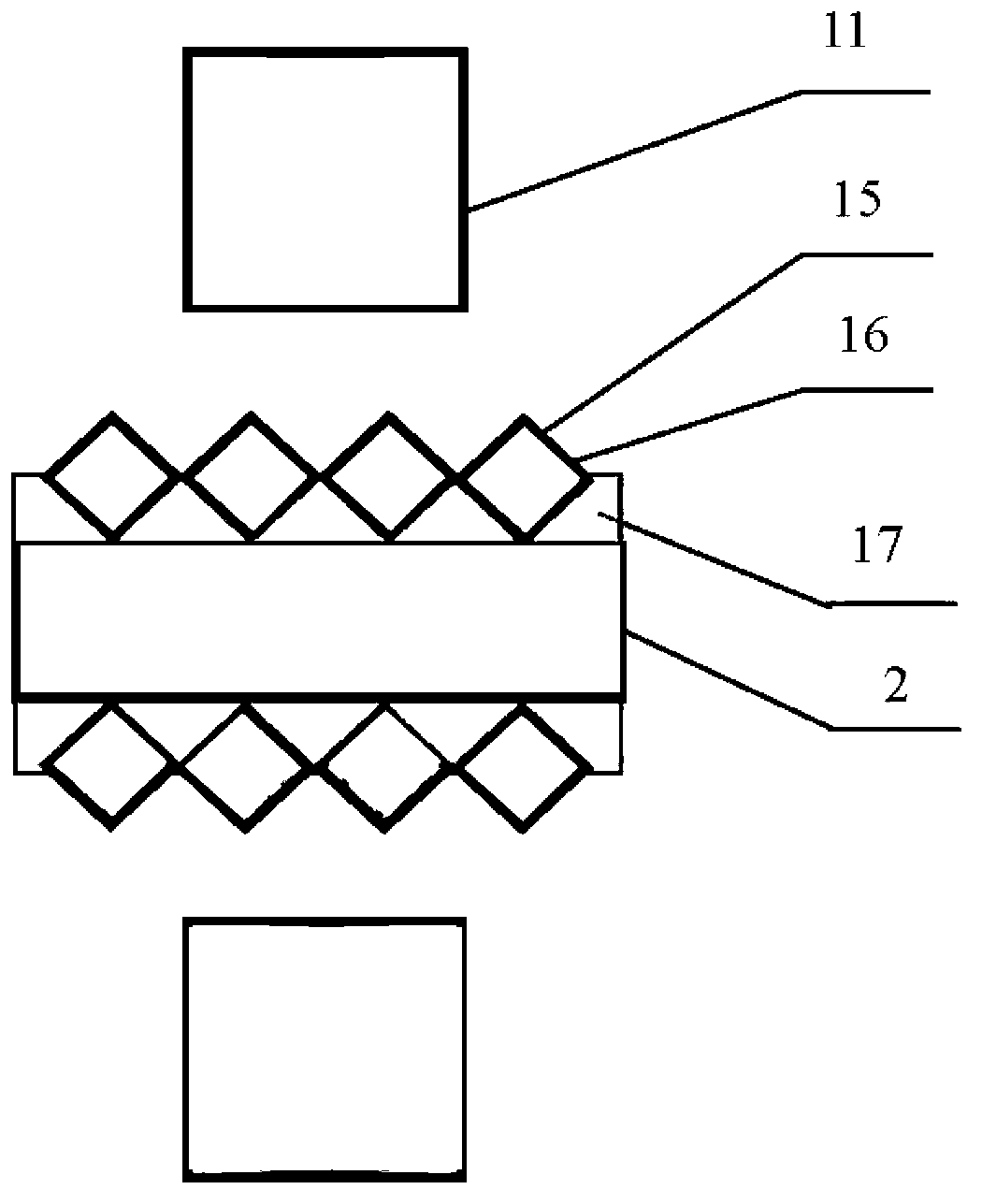

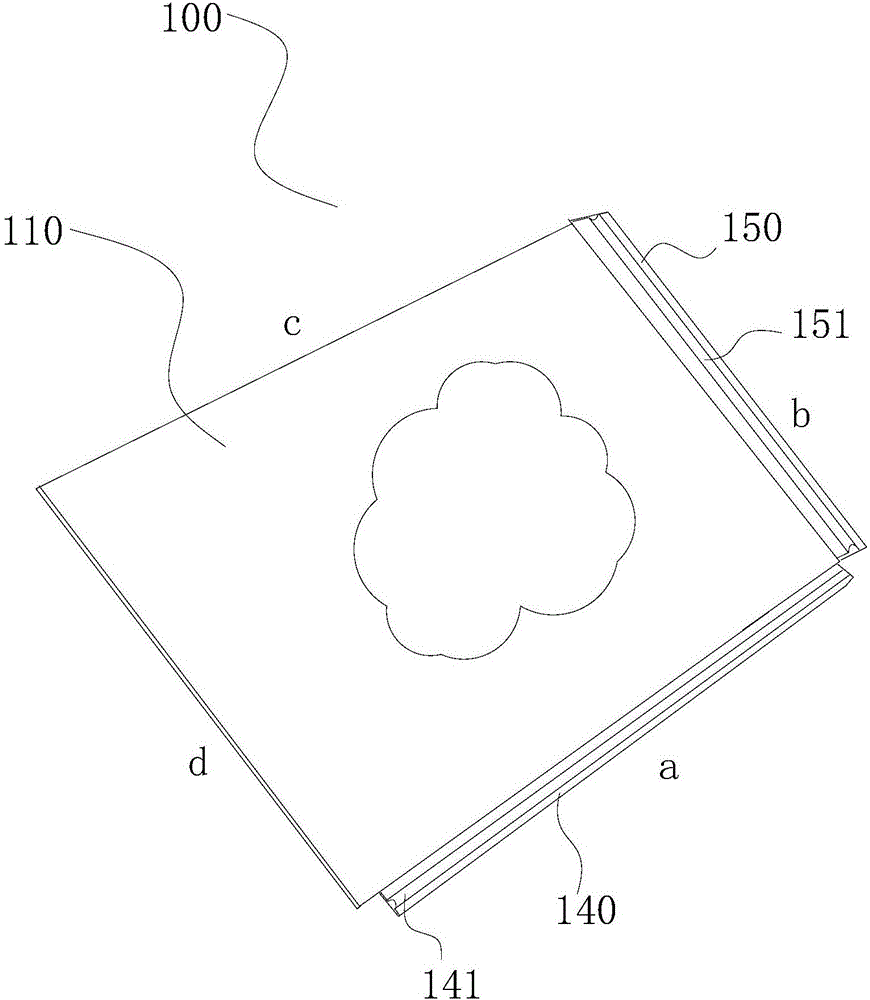

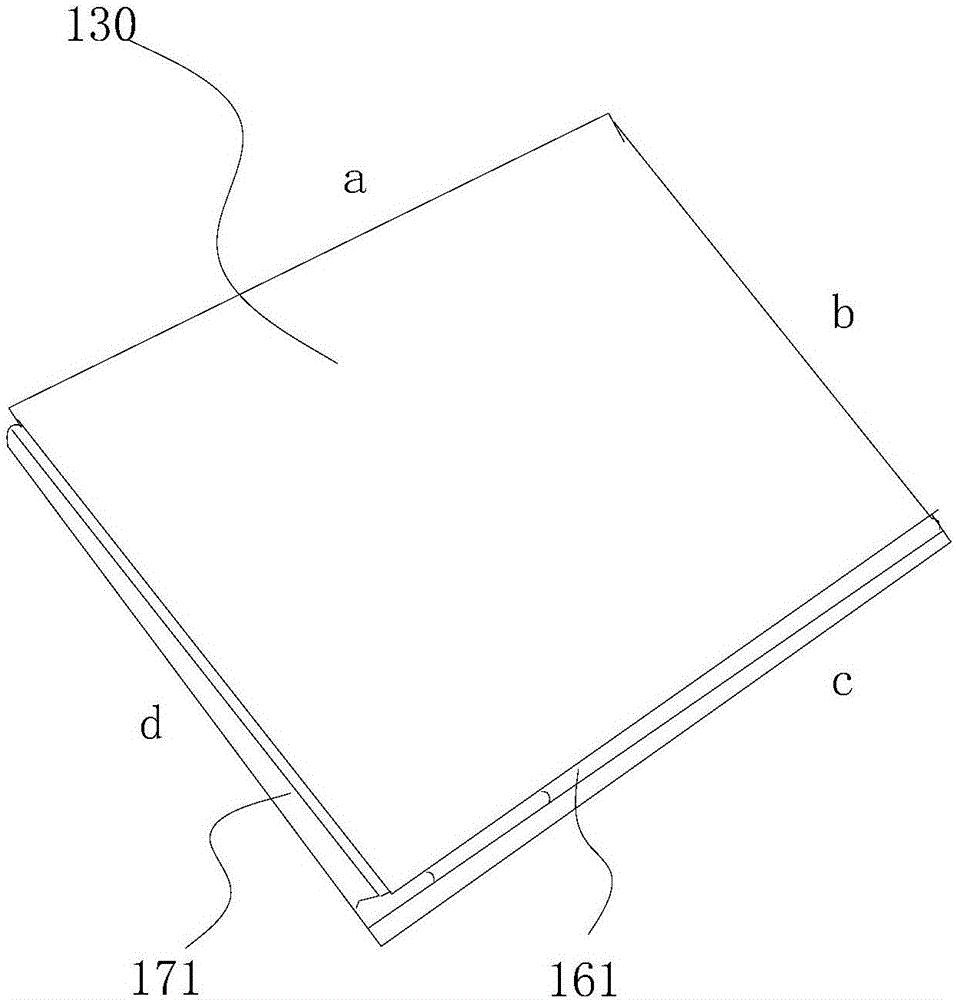

Electromagnetic induction device and manufacturing method therefor

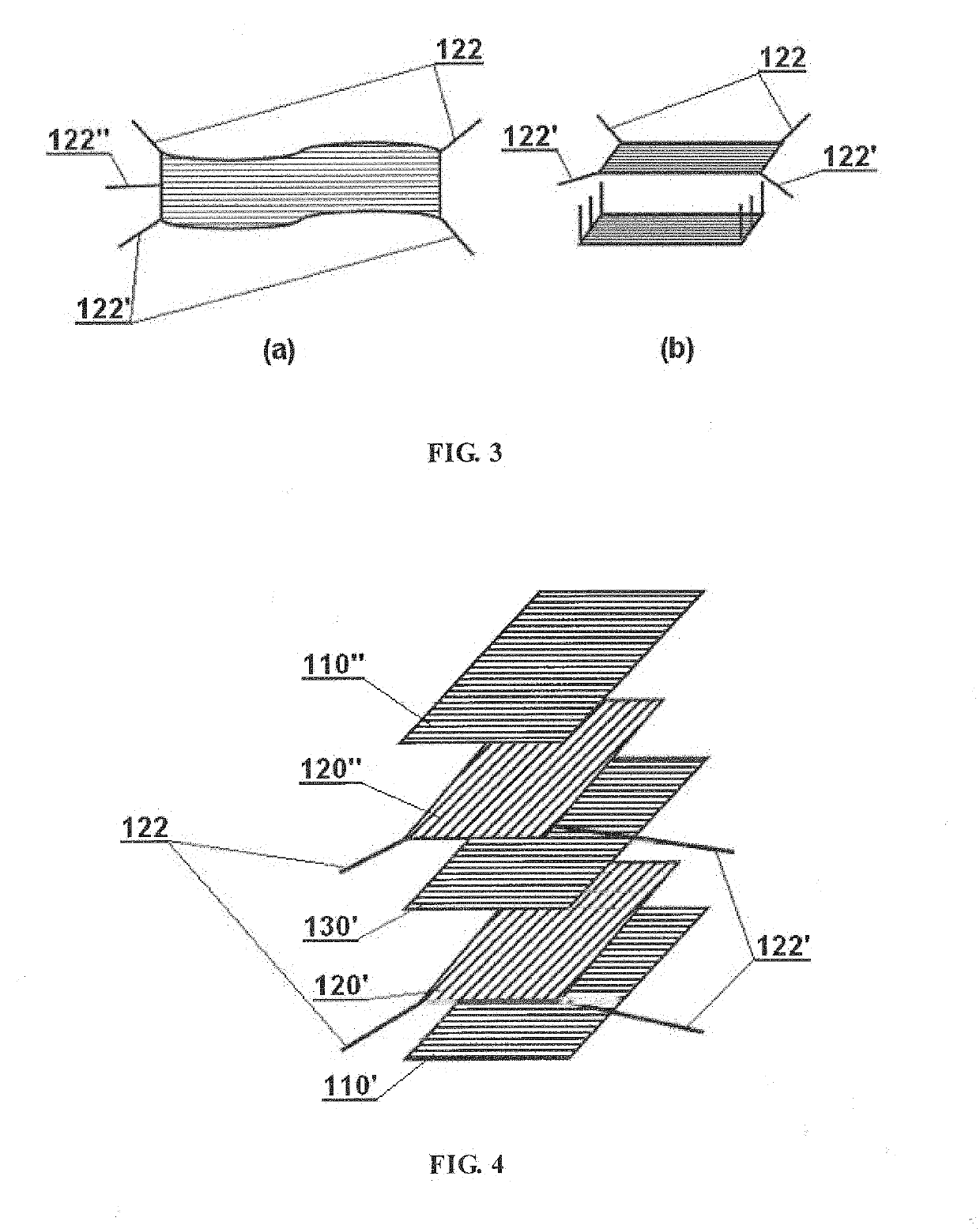

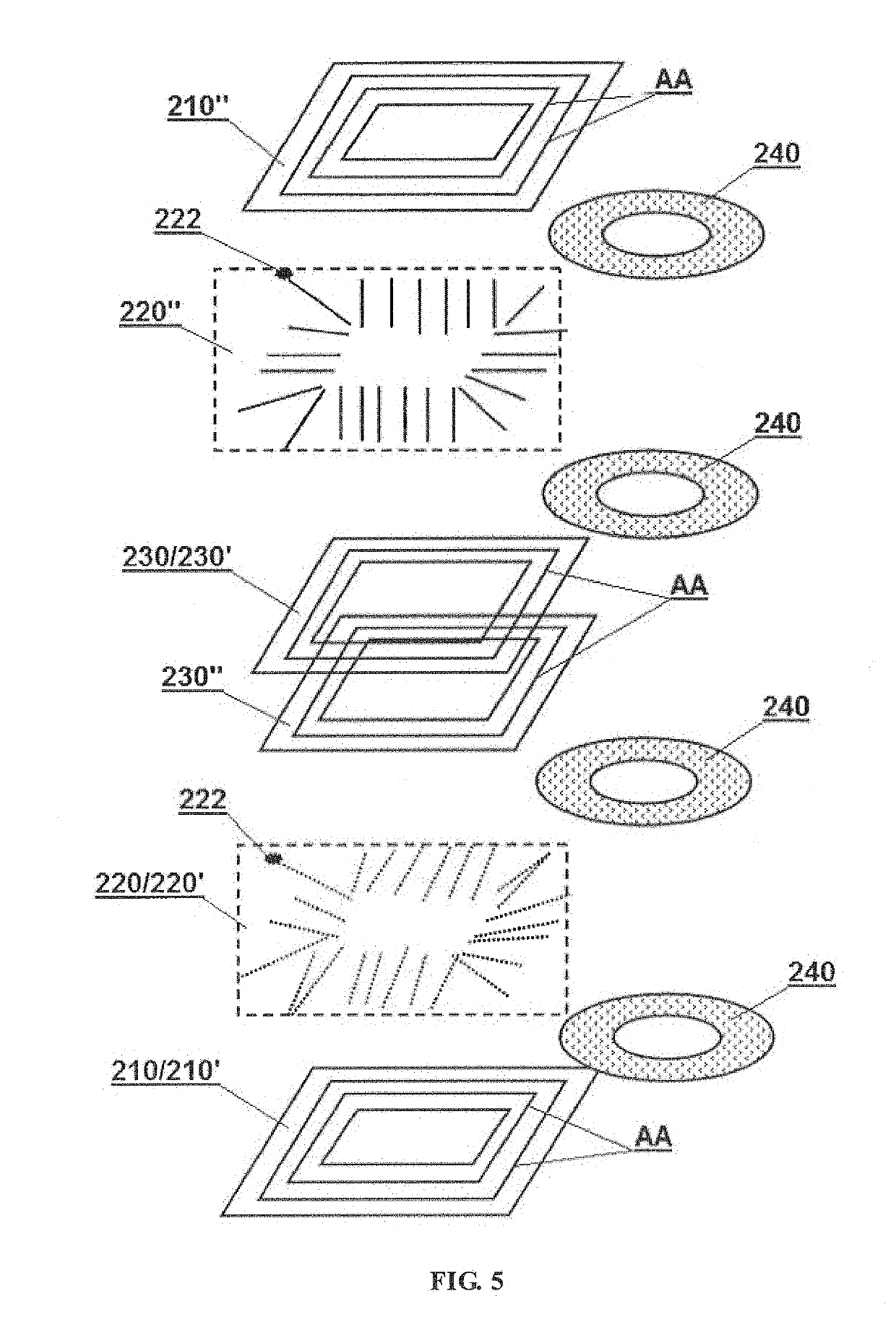

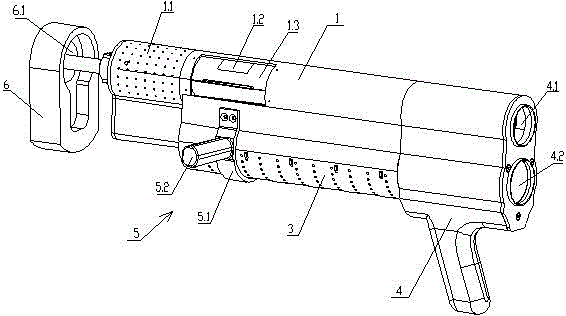

InactiveUS20190156989A1Reduce Flux LeakageReduce magnetic resistanceTransformers/inductances casingsTransformers/inductances coils/windings/connectionsMagnetic reluctanceMagnetic flux

An electromagnetic induction device, comprising a magnetic coating (110) and at least one set of coils (120). The magnetic coating (110) is formed by splicing all magnetic cells together, and is provided therein with at least one cavity. Magnetic division surfaces (AA) between each two magnetic cells are substantially arranged along a magnetic flux loop without cutting off the magnetic flux loop. The coils (120) are placed in a cavity formed by the magnetic coating (110), and the magnetic flux loop in the magnetic coating (110) is formed by the coils (120) after being energized. The overall structure of the magnetic coating (110) comprises at least two magnetically permeable layers (110′, 110″). The electromagnetic induction device, on the one hand, can be substantially closed to reduce leakage flux; on the other hand, since there is no air gap on a magnetic unit, the magnetic reluctance is effectively reduced. In addition, the magnetic coating (110) is of a layered structure so that the electromagnetic induction device can be fabricated in a superposed manner, thereby not only reducing the manufacturing difficulty, but also facilitating obtaining a high-performance flat electromagnetic induction device. Also provided is a corresponding method for manufacturing the electromagnetic induction device.

Owner:BOLYMEDIA HLDG

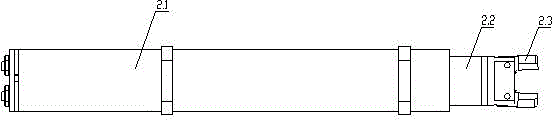

Heating device and heating method thereof

The invention discloses a heating device and a heating method thereof. The heating device comprises a shell (1), a manipulator (2) used for clamping and pushing rivets, and an electromagnetic heating device (3) used for heating the rivets. A heating cavity is formed in the front end of the shell (1), and the manipulator (2) is arranged in the shell (1). The heating device further comprises a positioning seat (6), the positioning seat (6) is made of magnetic materials, or the surface of the positioning seat is coated with a magnetic coating. A positioning hole (6.1) used for positioning and guiding the rivet position is formed in the positioning seat (6). A feeding window (1.2) by which the rivets can be conveniently put in is arranged in the position, near the heating cavity (1.1), of the shell (1), and a turning cover (1.3) is arranged on the feeding window (1.2). According to the heating device and method, the manipulator is used for clamping and shooting the rivets, and the rivets are positioned during riveting, so that the riveting accuracy is improved.

Owner:江阴市勤丰金属制品有限公司

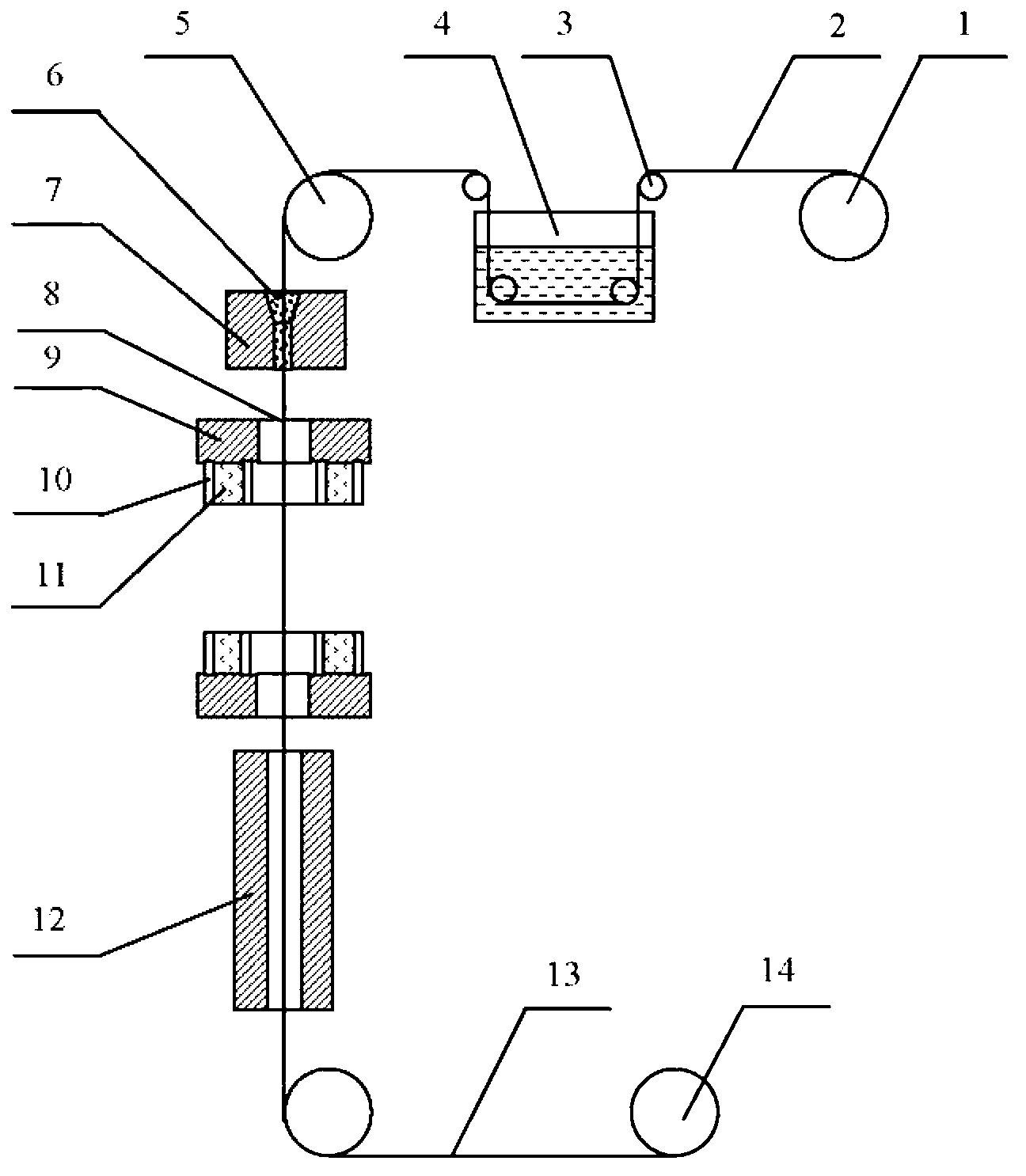

Method for producing resin diamond wire

InactiveCN102935666AGood cutting efficiencyBest edge heightFine working devicesMagnetic tension forceUltimate tensile strength

The invention discloses a method for producing a resin diamond wire by controlling exposure heights of diamond abrasives through the effect of magnetic force. The method comprises the following steps of (1) mixture preparation: evenly mixing the diamond abrasives in a surface magnetic coating, resin and additives according to a certain process proportion; (2) coating: injecting the prepared mixture into a coating mould, and enabling the mixture to be coated on the surface of a steel wire when the steel wire passes through the coating mould; (3) exposure height adjustment: enabling the steel wire subjected to the coating to enter a uniform magnetic field with adjustable magnetic field intensity, and controlling the ratio of the exposure heights to be 0.4-0.6, wherein a diamond with the surface magnetic coating performs displacement in a resin carcass under the effect of magnetic field force in the magnetic field; and (4) enabling the steel wire subjected to the step (3) to be cured and formed in a curing oven. By means of the method for producing the resin diamond wire, good cutting efficiency and long service life of the diamond wire are ensured to the largest extent.

Owner:ZHANGJIAGANG YINGFU NEW MATERIAL TECH

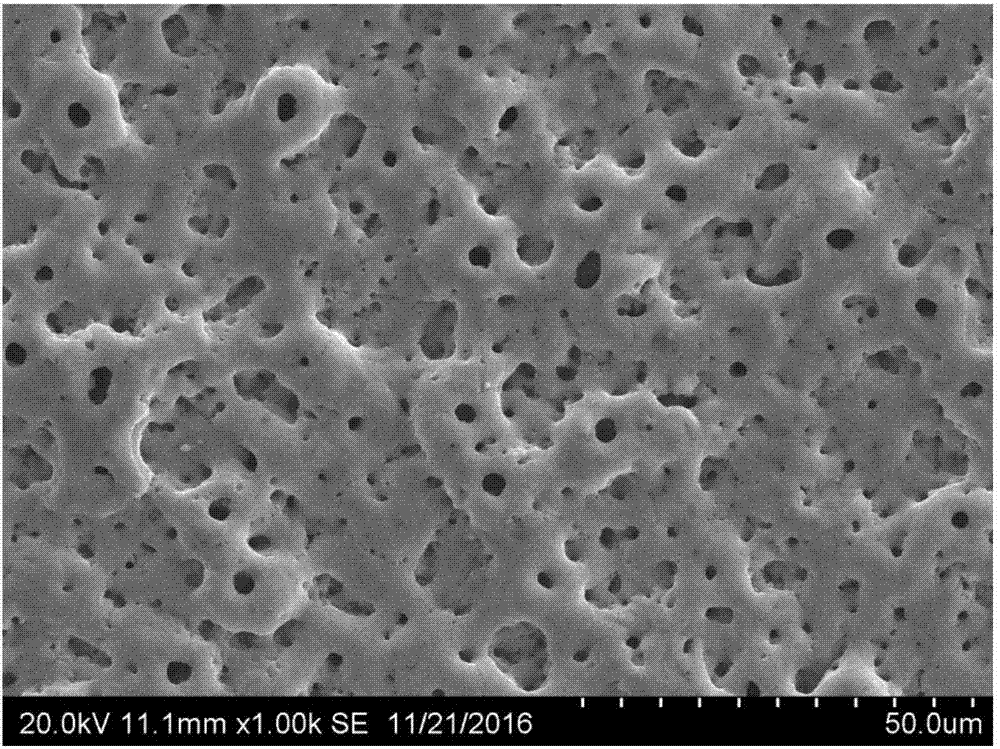

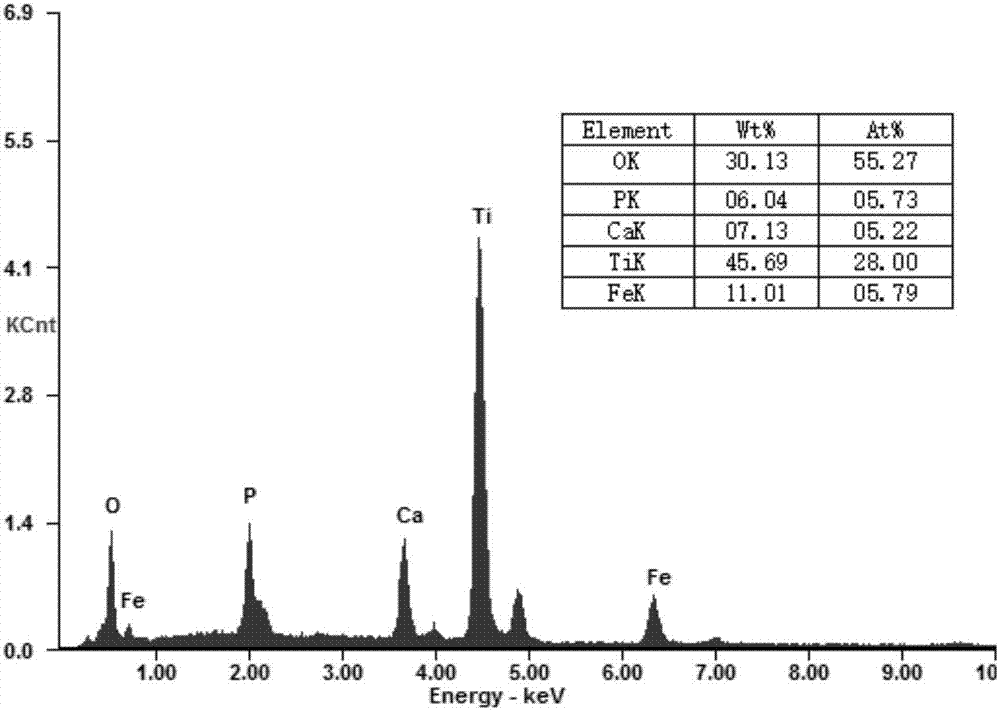

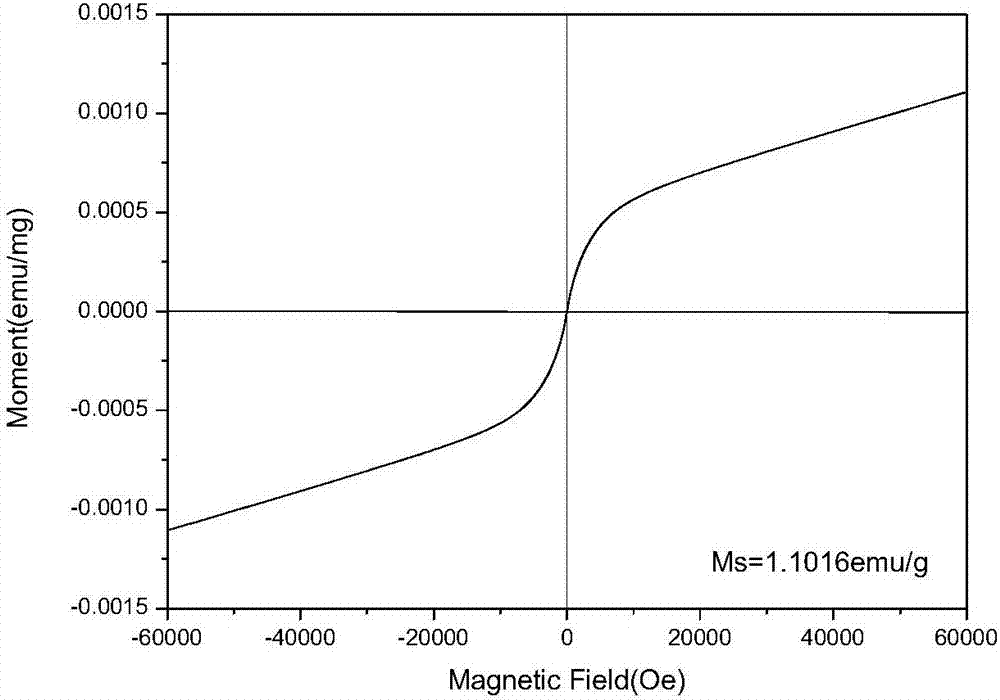

Micro-arc oxidation preparation method of magnetic TiO2 bioactive coating

ActiveCN107119304AMagnetic hasGuaranteed binding effectSurface reaction electrolytic coatingPharmaceutical delivery mechanismPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a micro-arc oxidation preparation method of a magnetic TiO2 bioactive coating. In an air environment, an electrolytic solution containing calcium salt, phosphor salt and molysite is taken, a pH value of the electrolytic solution is adjusted to be 5.0-5.3, titanium or a titanium alloy is taken as an anode, stainless steel is taken as a cathode, and titanium or the titanium alloy is subjected to micro-arc oxidation treatment for 1-8min by adopting a pulsed power supply, with the temperature of the electrolytic solution being kept at 5-25 DEG C, thus the magnetic TiO2 bioactive coating is generated on a surface layer of titanium or the titanium alloy. The magnetic TiO2 coating having magnetism (Ms being 0.2696-1.101emu / g) and good bioactivity can be prepared with the adoption of the micro-arc oxidation preparation method.

Owner:XI AN JIAOTONG UNIV

Key structure

InactiveCN104425162AElectric switchesEmergency protective devicesKey pressingElectrical and Electronics engineering

Disclosed in the invention is a key structure comprising a base plate, a switch circuit board, a key cap, and a frame. The key cap has a magnetic element arranged at the edge of the key cap. The frame has a magnetic coating layer arranged at the frame edge and is below the magnetic element. When the key cap is touched and pressed, the key cap moves and the switch circuit board is triggered to generate a key signal. When the key cap is not touched and pressed, the key cap moves towards the magnetic element based on the magnetic force generated by the magnetic element. Therefore, the key structure can be operated normally without the need of elastic rubber.

Owner:PRIMAX ELECTRONICS LTD

Magnetic attraction type plate structure

InactiveCN106836708ACovering/liningsPolyurea/polyurethane coatingsElectrical and Electronics engineeringMagnetic coating

The invention relates to a magnetic attraction type plate structure, which comprises a magnetic coating layer arranged on a decorated surface for mounting and a plate for being magnetically attracted to the magnetic coating layer; the magnetic coating layer is coated on the decorated surface for mounting; the plate is provided with a magnetic rubber layer, a plastic shaping layer and a surface texture layer, the magnetic rubber layer, the plastic shaping layer and the surface texture layer are sequentially superposed and fixedly connected by a heat bonding method, and the magnetic rubber layer and the magnetic coating layer are attracted to each other. By arranging the magnetic coating layer on the decorated surface for mounting, the invention prevents defects caused by needing to stick a magnetic rubber roll on the floor in the prior art, such as great thickness and inconvenience in operation.

Owner:QING YUAN KUAI DI NEW BUILDING MATERIALS CO LTD

Magnetic force microscopy probe with low magnetic moment and high coercive force and manufacturing method thereof

The invention relates to a magnetic force microscopy probe with a low magnetic moment and a high coercive force and a manufacturing method thereof; the manufacturing method comprises the following steps of: cleaning a Si probe; fixing the cleaned Si probe in a sample chamber of a magnetic control sputtering device, vacuumizing the sample chamber, and then feeding a high-purity inert gas to lead the gas pressure in the sample chamber to be maintained at 0.1-0.5 pascal; sputtering a CoPt magnetic alloy on the surface of the Si probe in a magnetic control sputtering manner, thereby obtaining the Si probe with a magnetic coating; and heating the obtained Si probe with the magnetic coating in a vacuum condition to be 500 DEG C-750 DEG C, and carrying thermal treatment for 15-180 minutes so that the magnetic alloy is converted into the L10-CoPt alloy, thereby obtaining the magnetic force microscopy probe with the low magnetic moment and the high coercive force.

Owner:CENT IRON & STEEL RES INST

Magnetic anti-counterfeiting aluminum-foil paper

ActiveCN107022290AMagnetic hasStrong magnetismFlexible coversCoatings with pigmentsOrganic solventToluene diisocyanate

The invention discloses magnetic anti-counterfeiting aluminum-foil paper, which comprises base paper and an aluminum-foil layer, wherein the surface of the aluminum-foil layer is coated with a layer of magnetic coating with a thickness of 10 to 40 microns; the coating is prepared from the following raw materials in percentage by mass: 15 to 25 percent of polyurethane resin, 5 to 10 percent of magnetic nano silica, 50 to 70 percent of organic solvent, 0.3 to 0.5 percent of aluminum oxide, 0.5 to 1 percent of dispersant, 0.1 to 0.5 percent of coupling agent, 0.5 to 1.5 percent of lubricant, 0.5 to 1 percent of antistatic agent and 2 to 5 percent of toluene diisocyanate. According to the magnetic anti-counterfeiting aluminum-foil paper, the surface of the aluminum-foil paper is coated with a layer of magnetic material; the part into which magnetic powder is added is different from other aluminum-foil paper in hand feeling, and particularly can be identified through a magnetic metal identifier or a magnetic induction device, so as to achieve an anti-counterfeiting purpose.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Magnetic medical apparatus, kits, and methods

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com