Heating device and heating method thereof

The technology of a heating device and an electromagnetic heating device is applied to a heating device for heating rivets and advancing riveting operation and the heating field thereof, which can solve the problems of lack of rivet shooting function, etc., and achieves the improvement of hot riveting accuracy, hot riveting effect and operation accuracy. High, improve the effect of hot riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

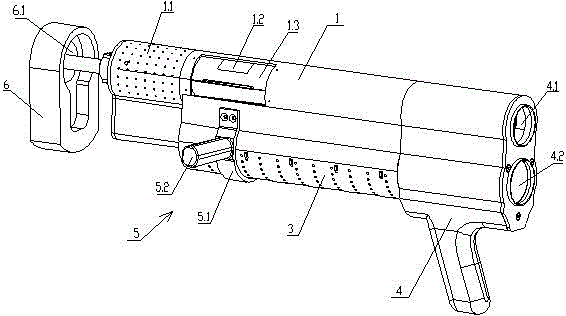

[0033] see Figure 1~4 , a heating device related to the present invention, the heating device includes a housing 1, a manipulator 2 for clamping and pushing rivets, and an electromagnetic heating device 3 for heating the rivets, the front end of the housing 1 is a heating Cavity 1.1, the housing 1 is provided with a feeding window 1.2 near the heating chamber 1.1 for putting in rivets, preferably, the feeding window 1.2 is provided with a flip cover 1.3;

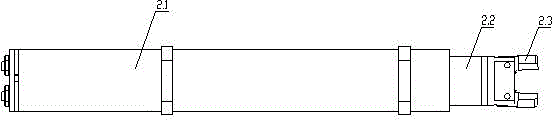

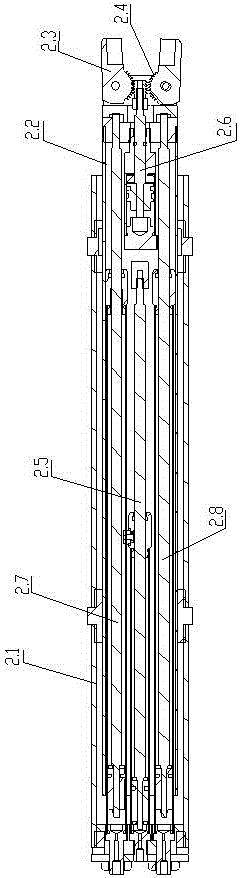

[0034] see figure 2 and image 3 , the manipulator 2 is set in the shell 1, specifically, the manipulator 2 includes an outer shell 2.1 and an inner shell 2.2 set in the outer shell 2.1, and the end of the inner shell 2.2 protruding from the outer shell 2.1 is hinged with two The block clamping block 2.3, and the clamping block 2.3 is provided with a locking tooth 2.4 at the hinged part with the inner shell 2.2, and the piston rod of the clamping cylinder 2.5 arranged in the outer shell 2.1 is connected with a clamping b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com