Patents

Literature

3686 results about "Electromagnetic heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromagnetic Heating is a process used to increase the thermal energy in a reservoir by using electromagnetic sources. There are two types of Electromagnetic Heating, i.e., radio frequency and conductive heating.

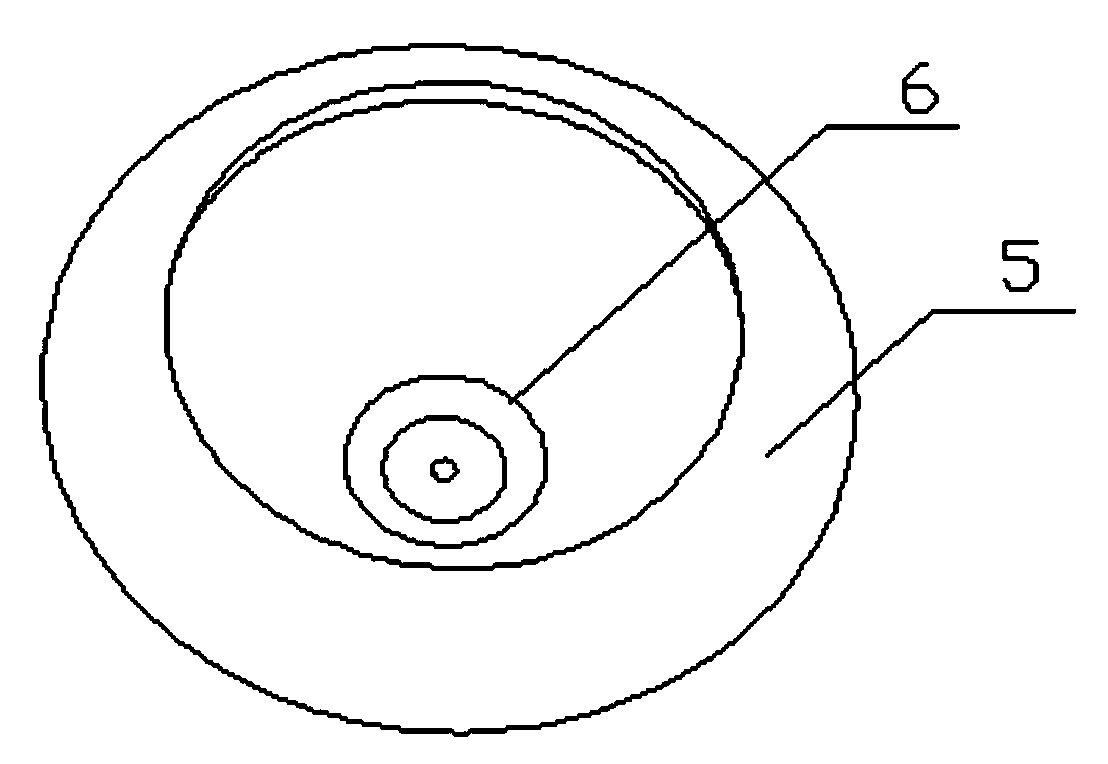

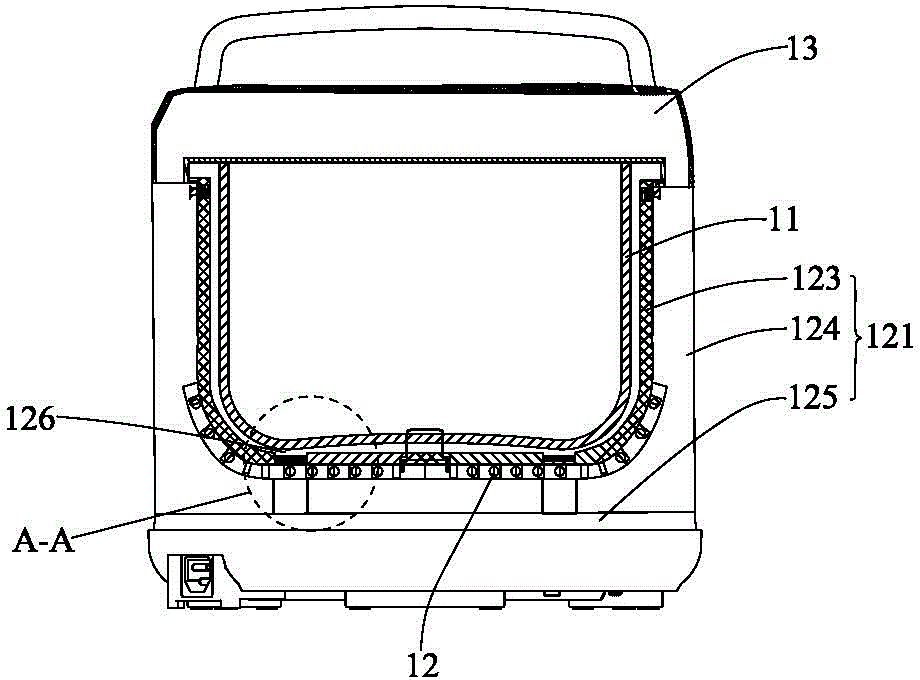

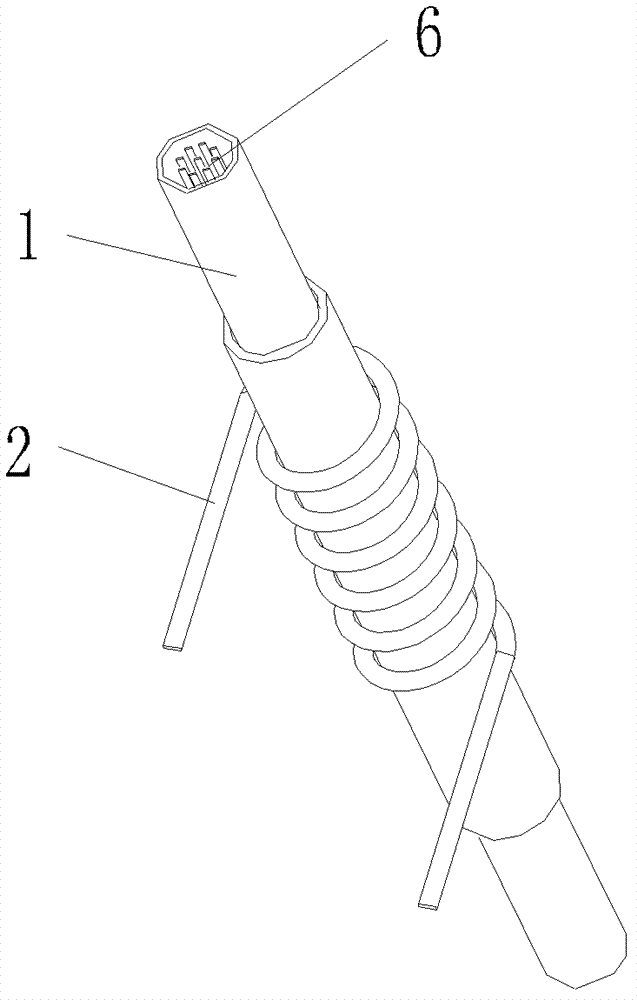

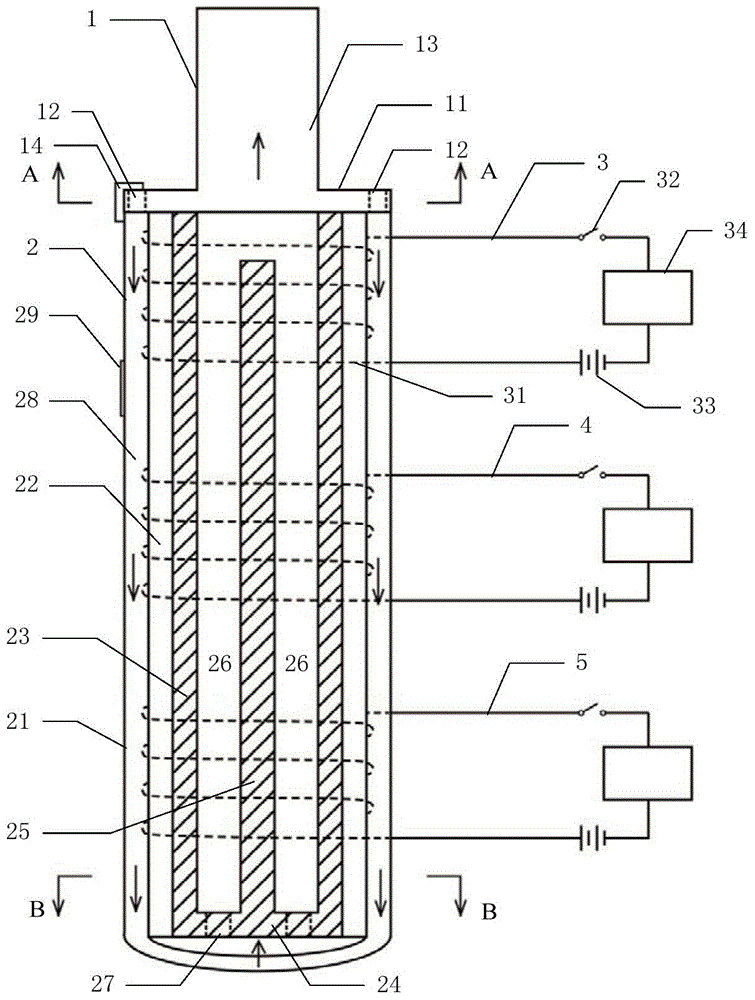

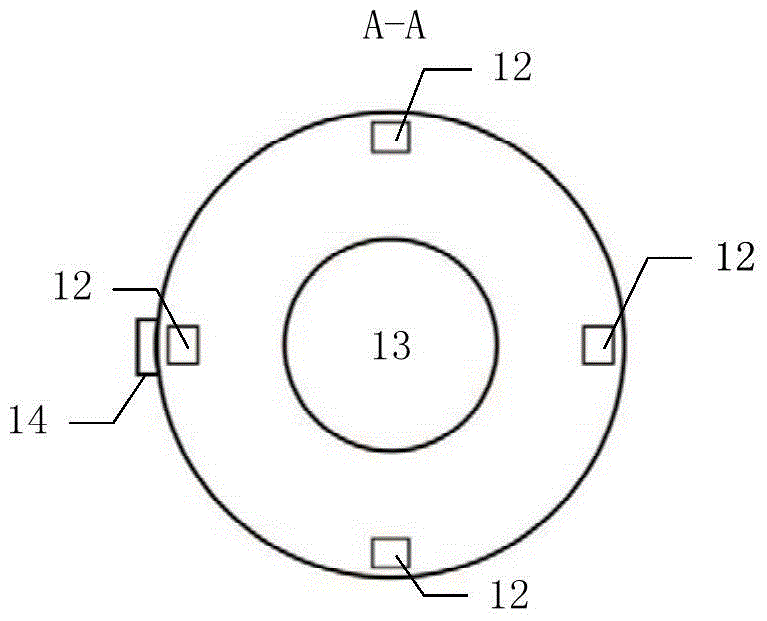

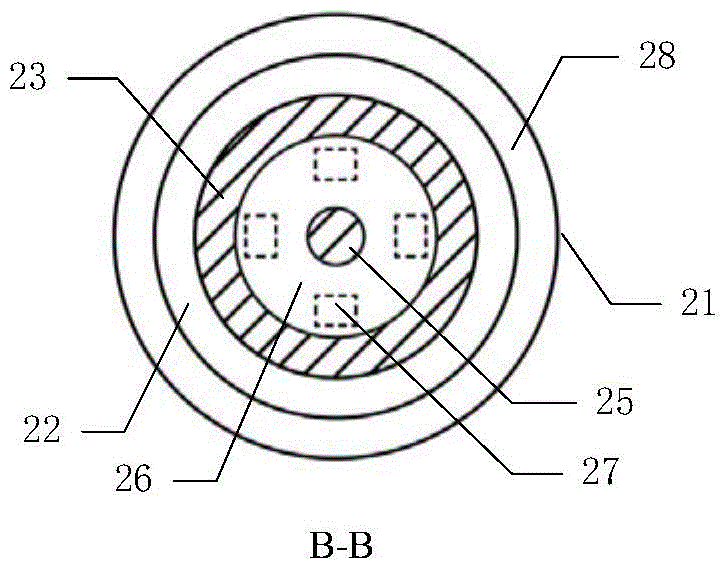

Tobacco suction system based on electromagnetic heating

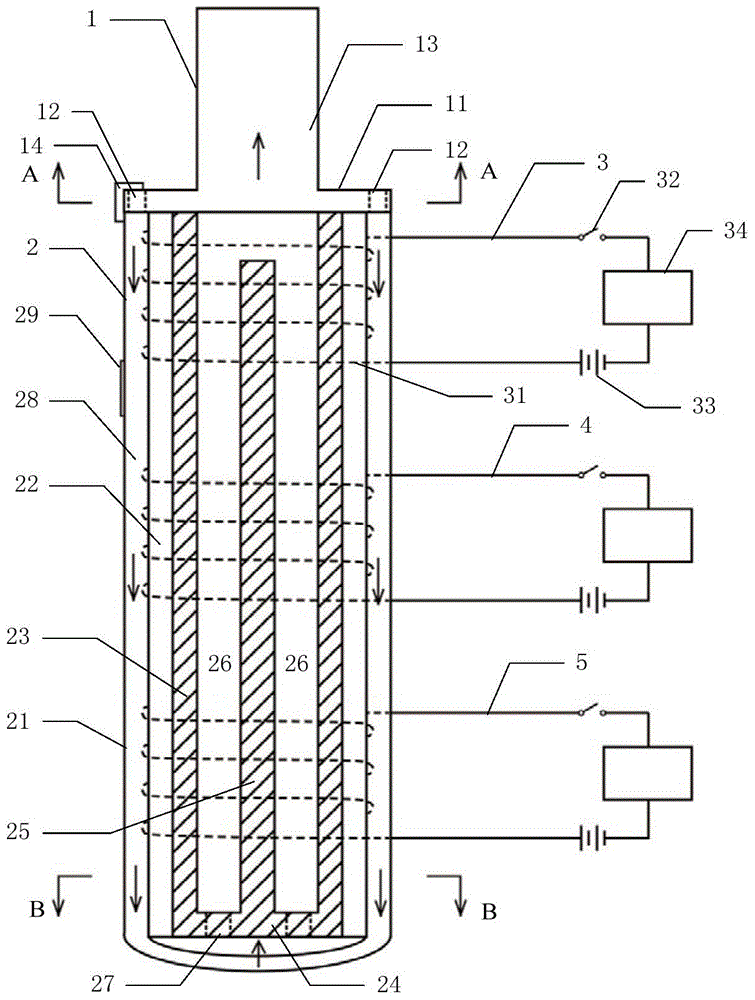

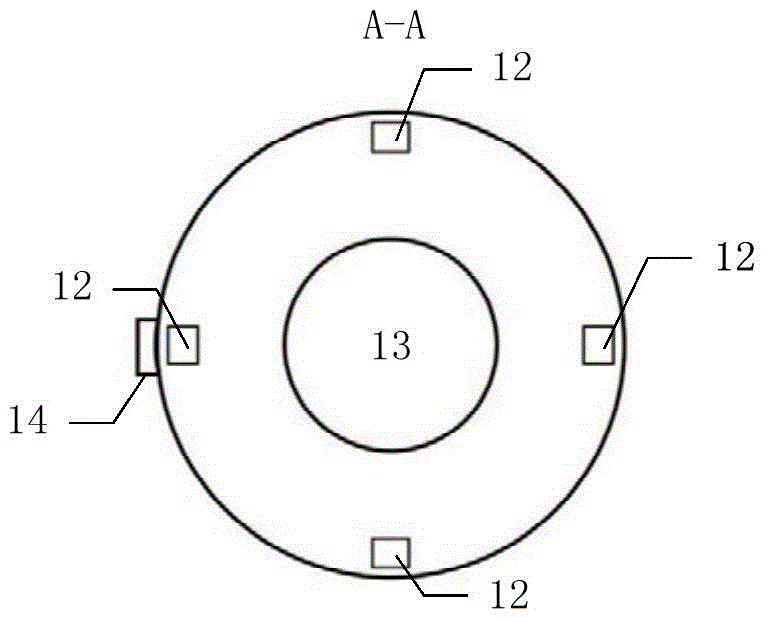

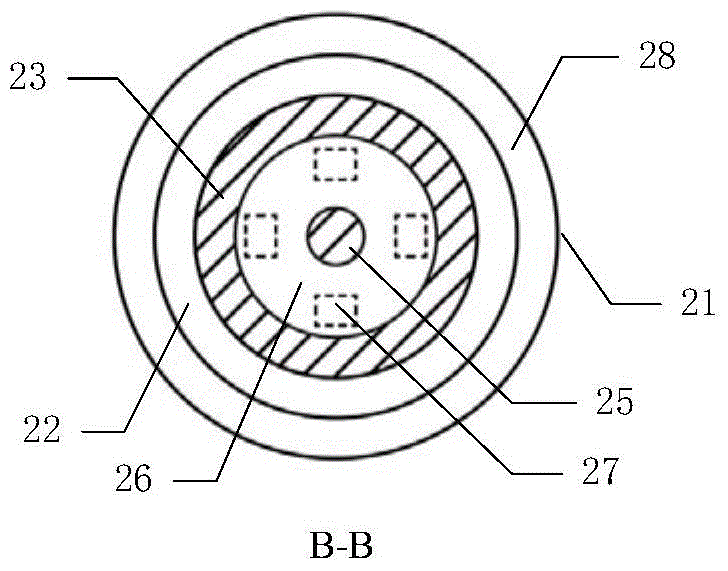

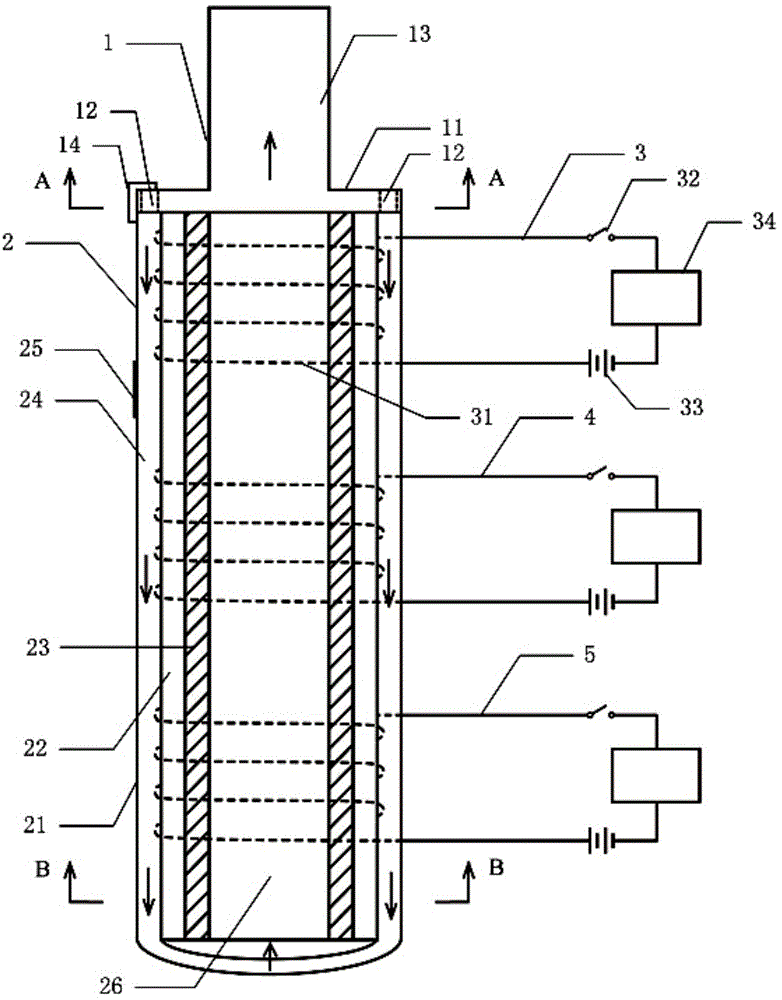

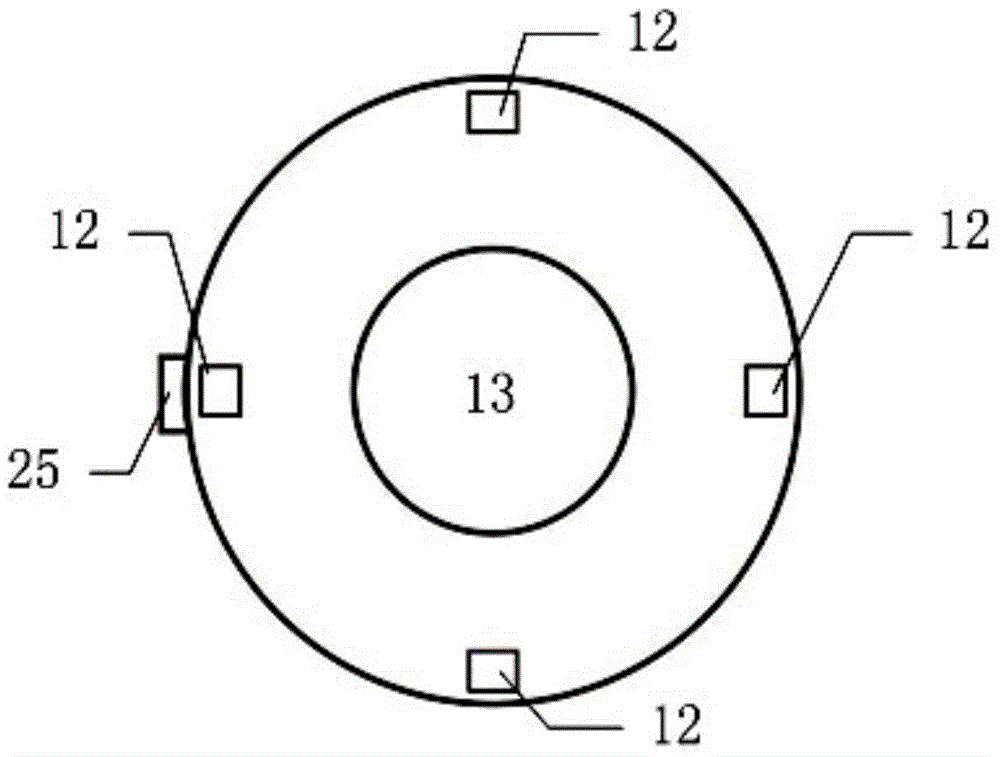

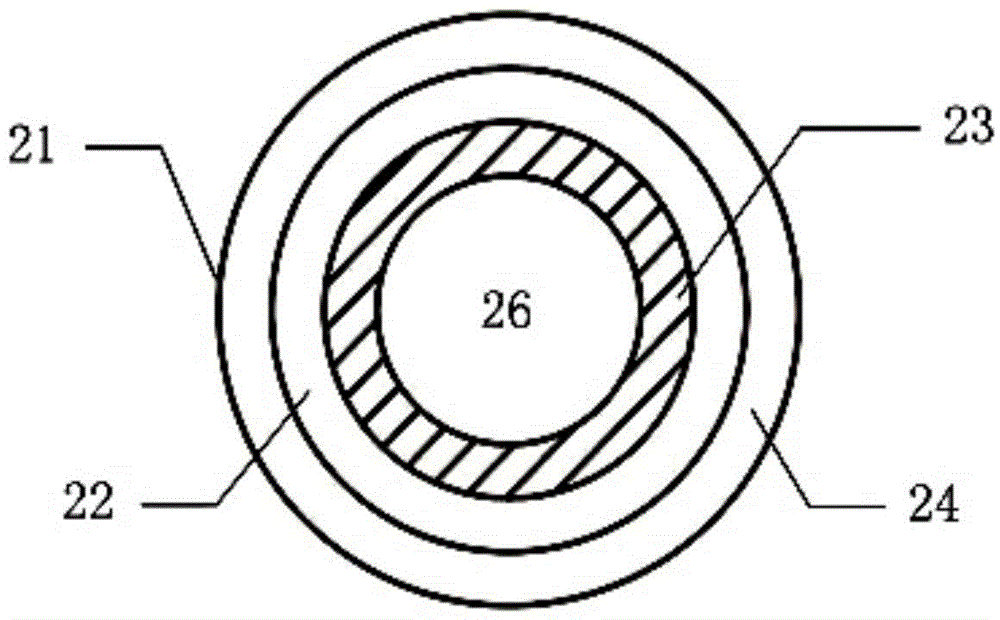

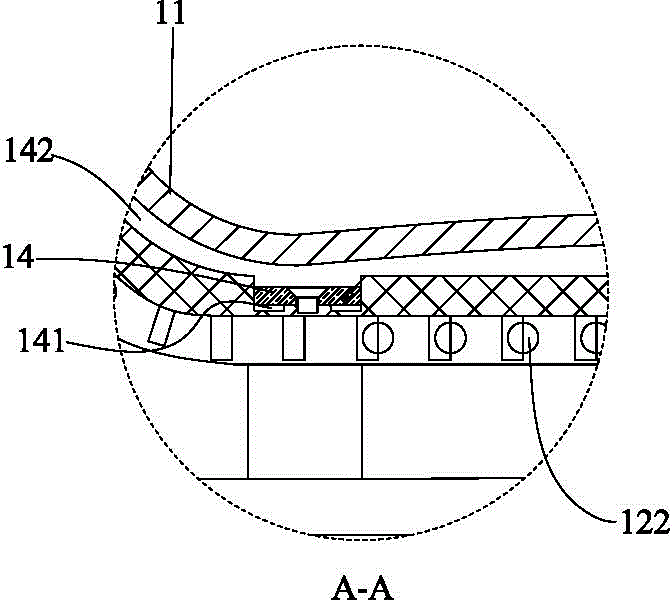

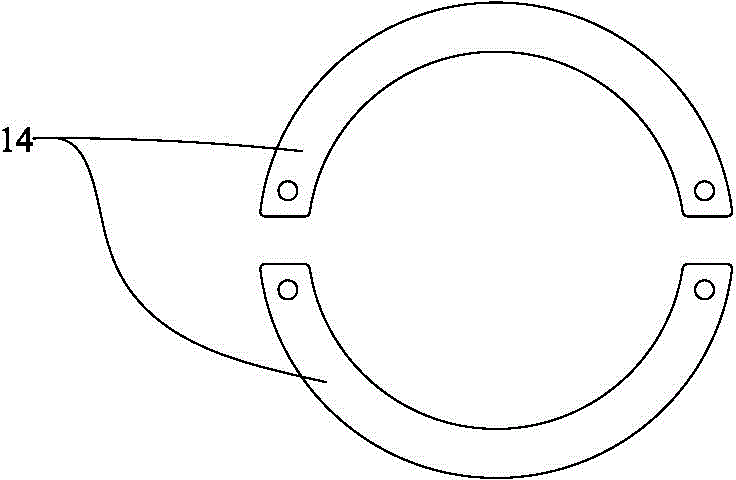

The invention discloses a tobacco suction system based on electromagnetic heating. The tobacco suction system is characterized by comprising an end cover (1), a heater (2) and an electromagnetic induction system, wherein the end cover (1) is detachably connected to the heater (2); the end cover (1) comprises a circular cover (11) and a filter tip (13); the heater (2) comprises a shell (21), an inner container (23), a base plate (24) and a cylindrical iron core (25); the electromagnetic induction system comprises an induction coil for heating the inner container (23), the base plate (24) and the cylindrical iron core (25), and a temperature control circuit. By heating the inner container, the base plate and the cylindrical iron core through the electromagnetic induction system, the heating speed can be increased, the heat efficiency is high, and instant heating can be realized, thereby better meeting the requirement of good suction mouthfeel; due to the arrangement of the cylindrical iron core, tobacco products can be heated uniformly and fully, and waste caused by insufficient heating of the tobacco products can be avoided. The tobacco suction system is suitable to be popularized and applied.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Electromagnetic heating

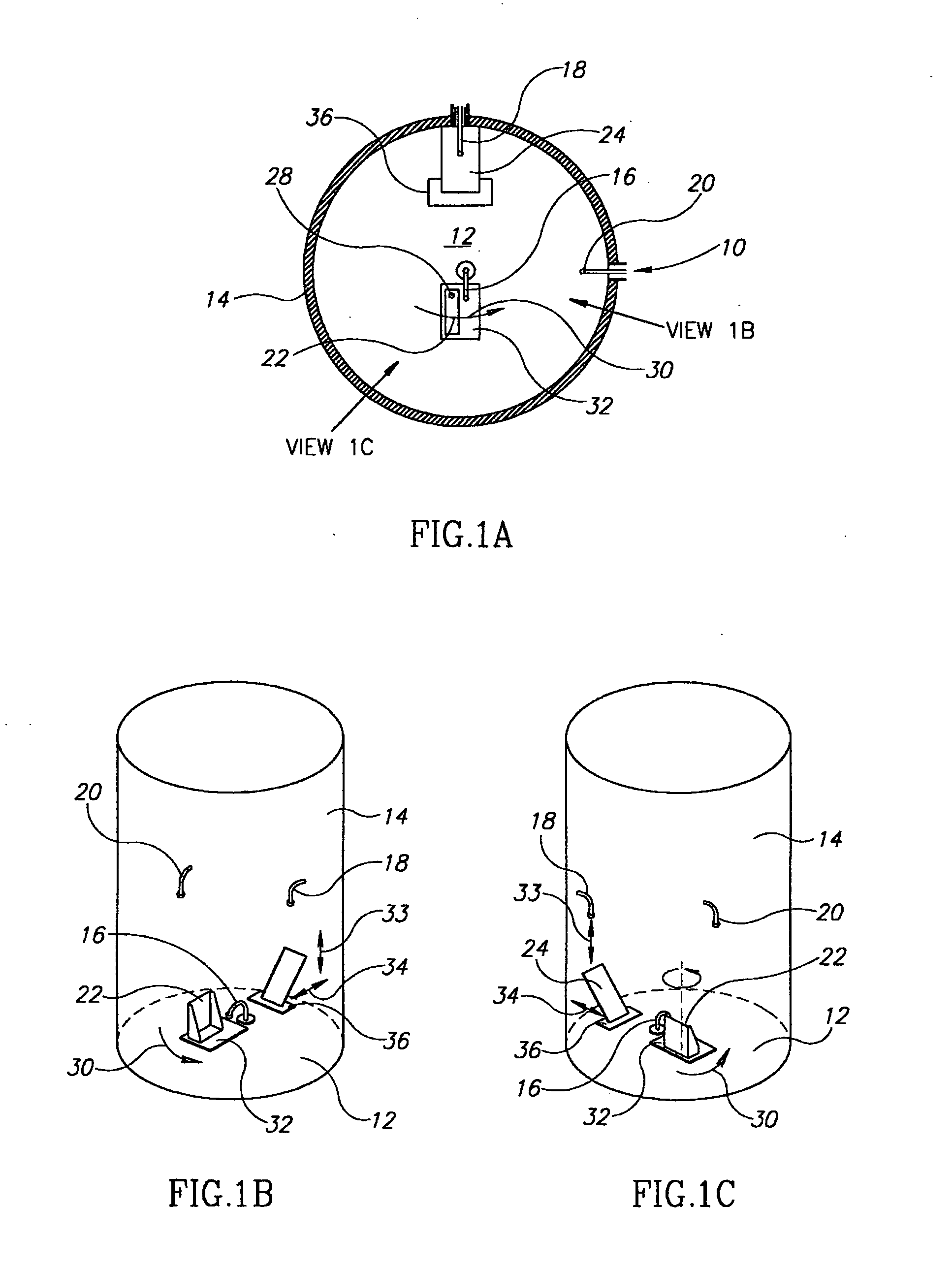

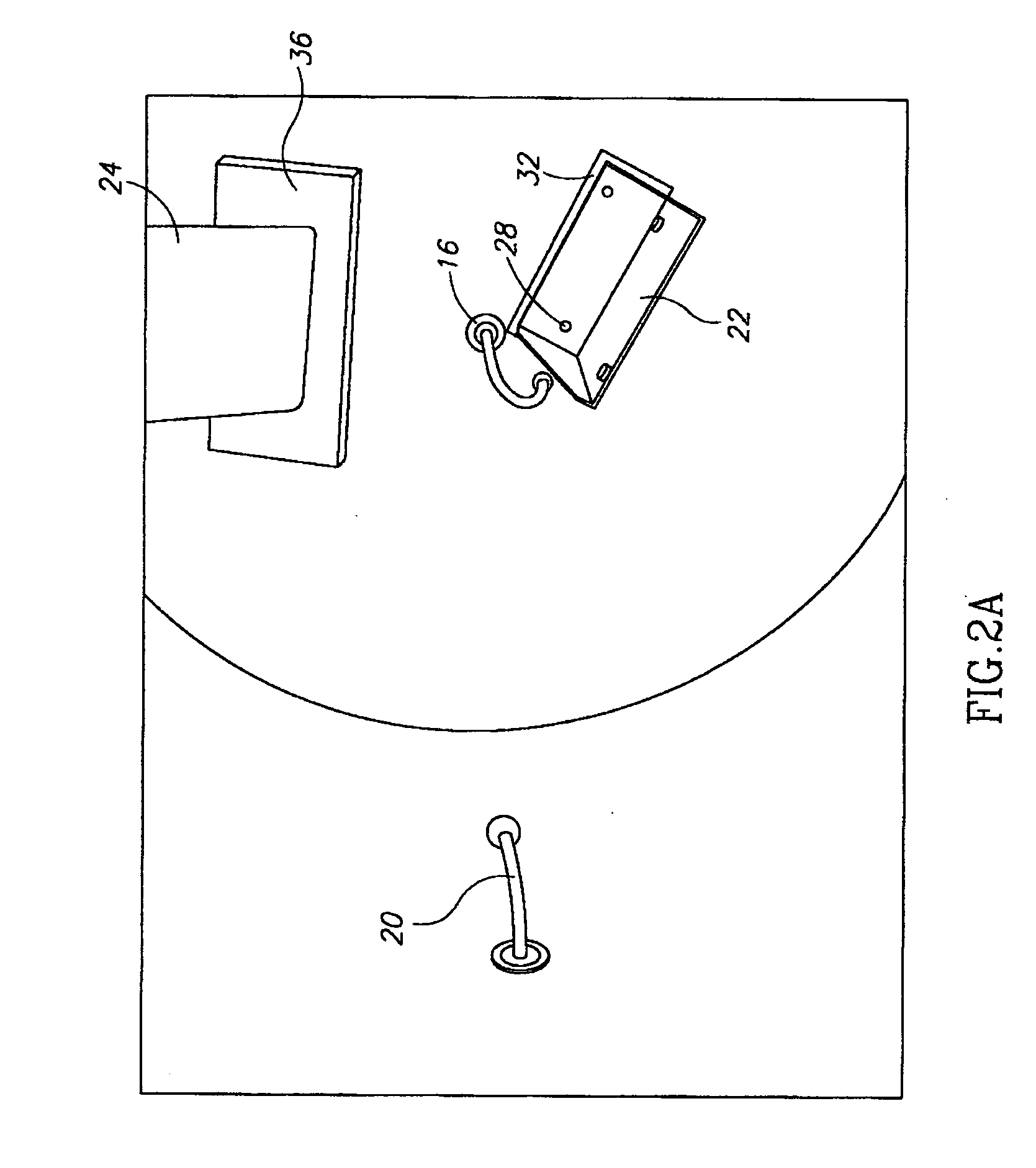

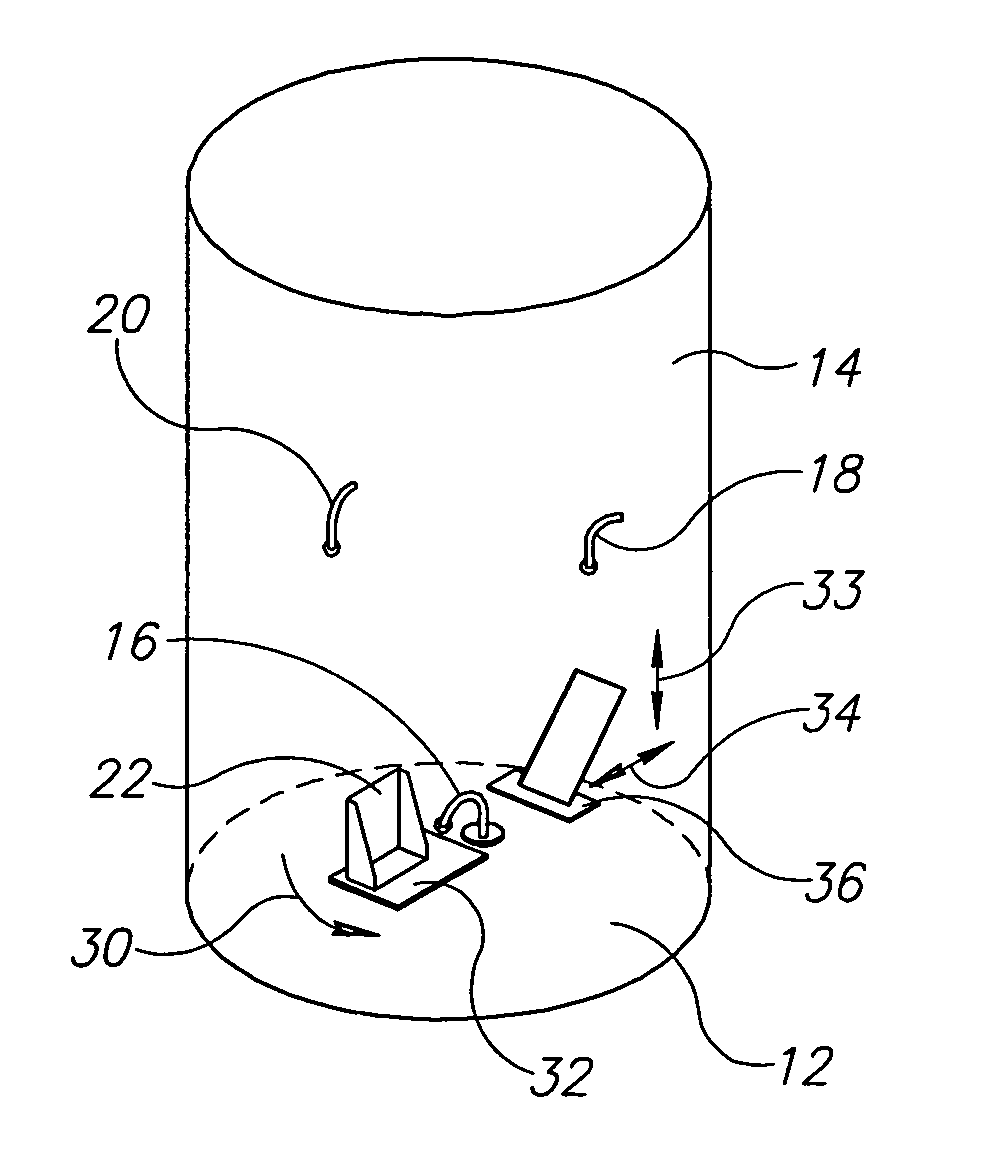

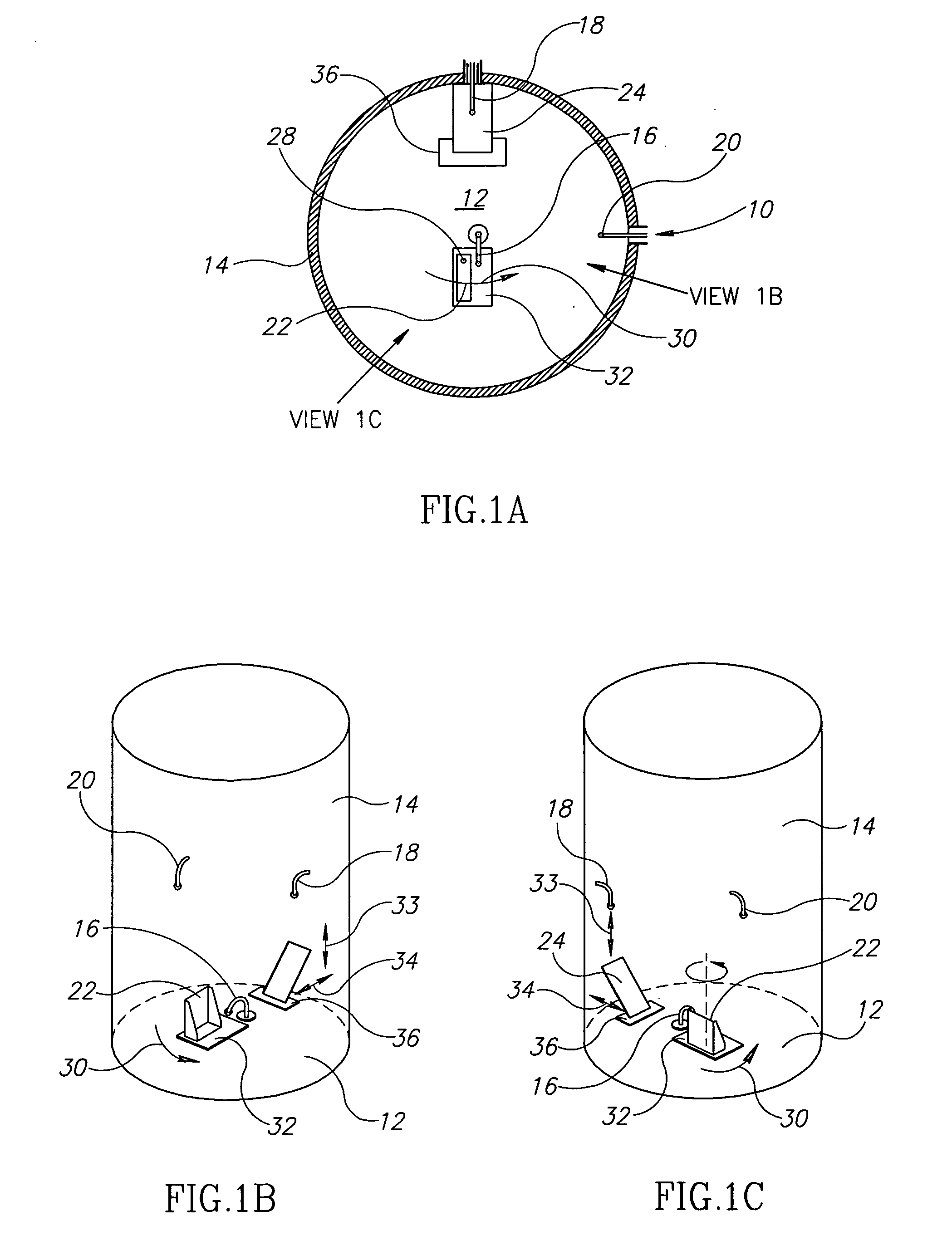

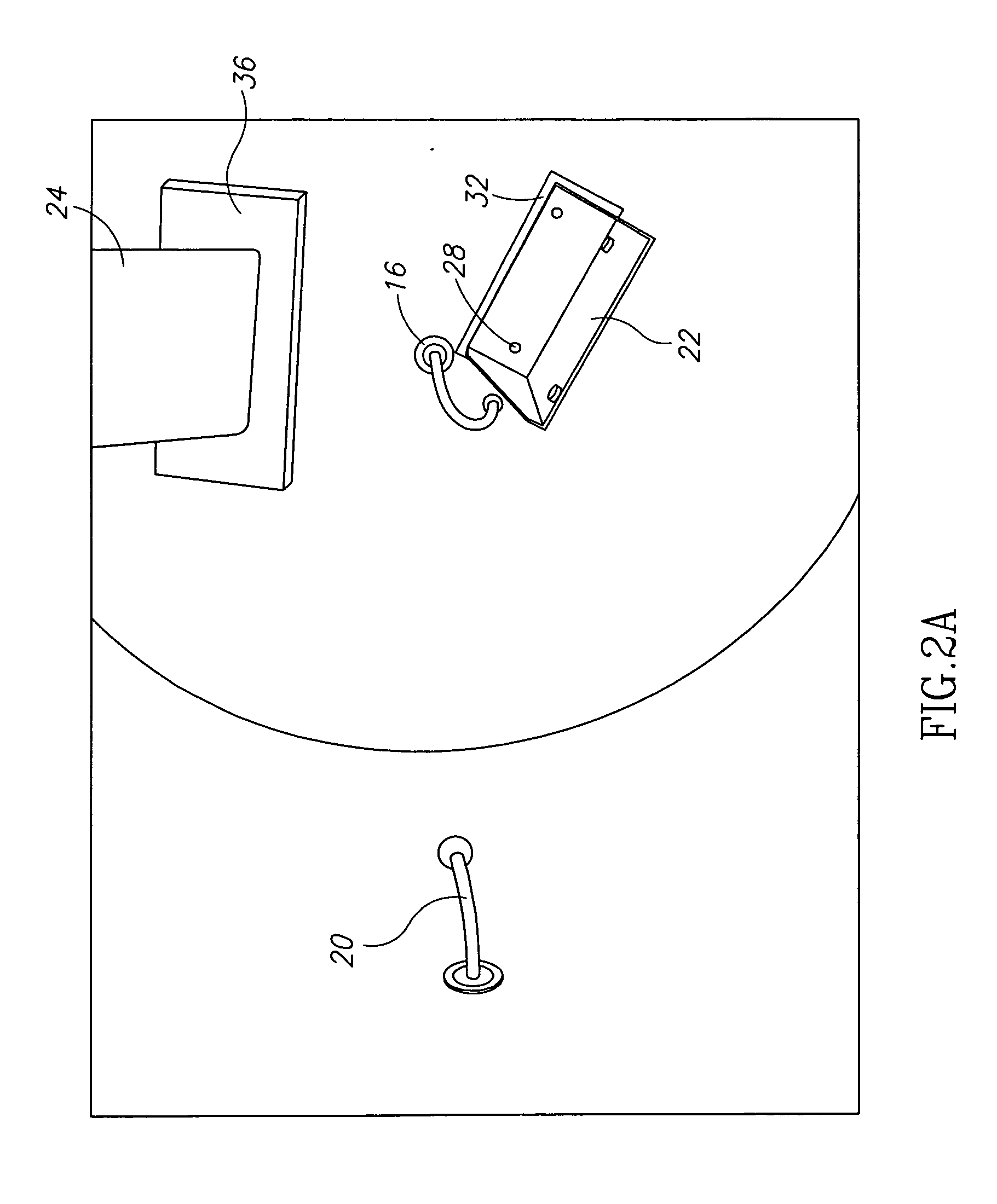

ActiveUS20080290087A1Improve efficiencyIncrease net powerLighting and heating apparatusFood preservationElectromagnetic heatingFast scanning

Owner:JOLIET 2010 LTD

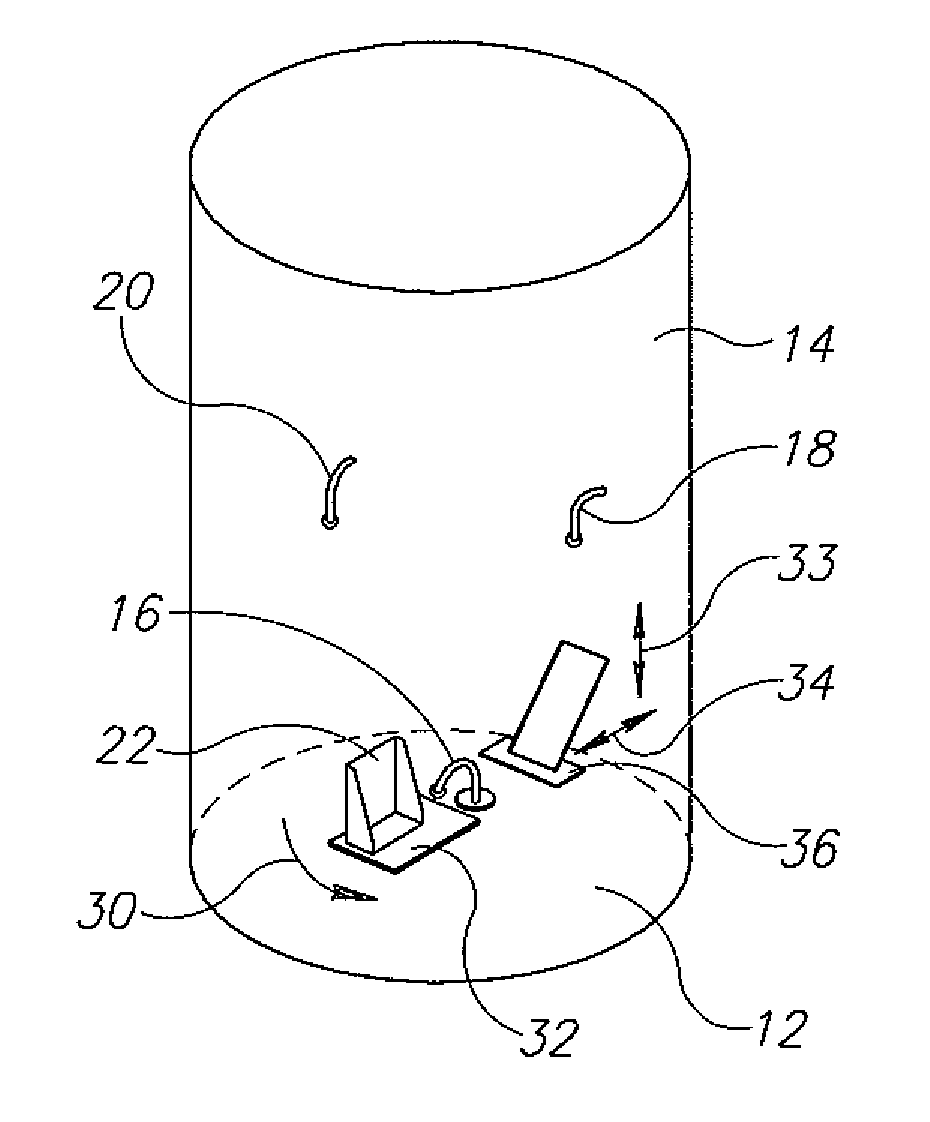

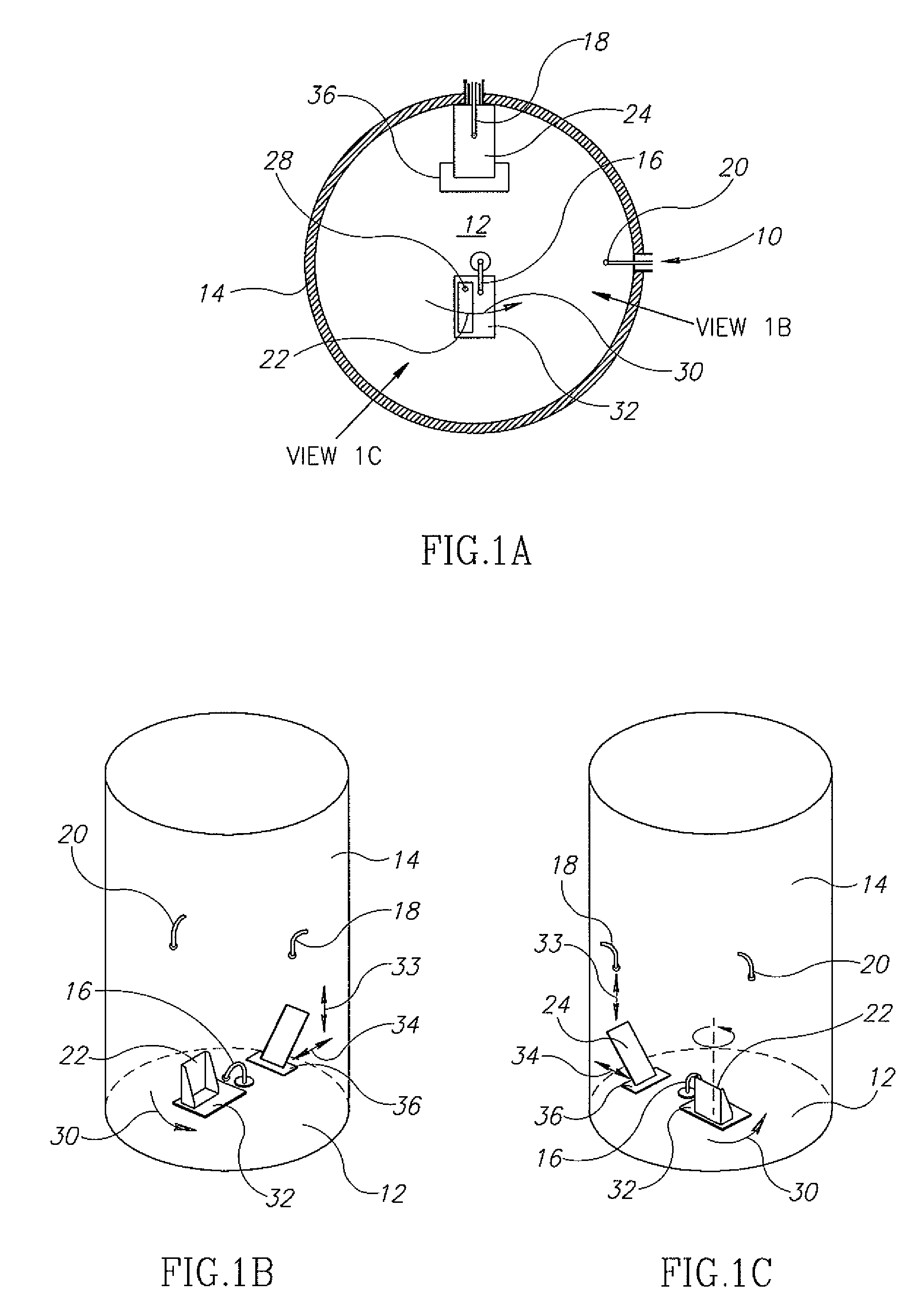

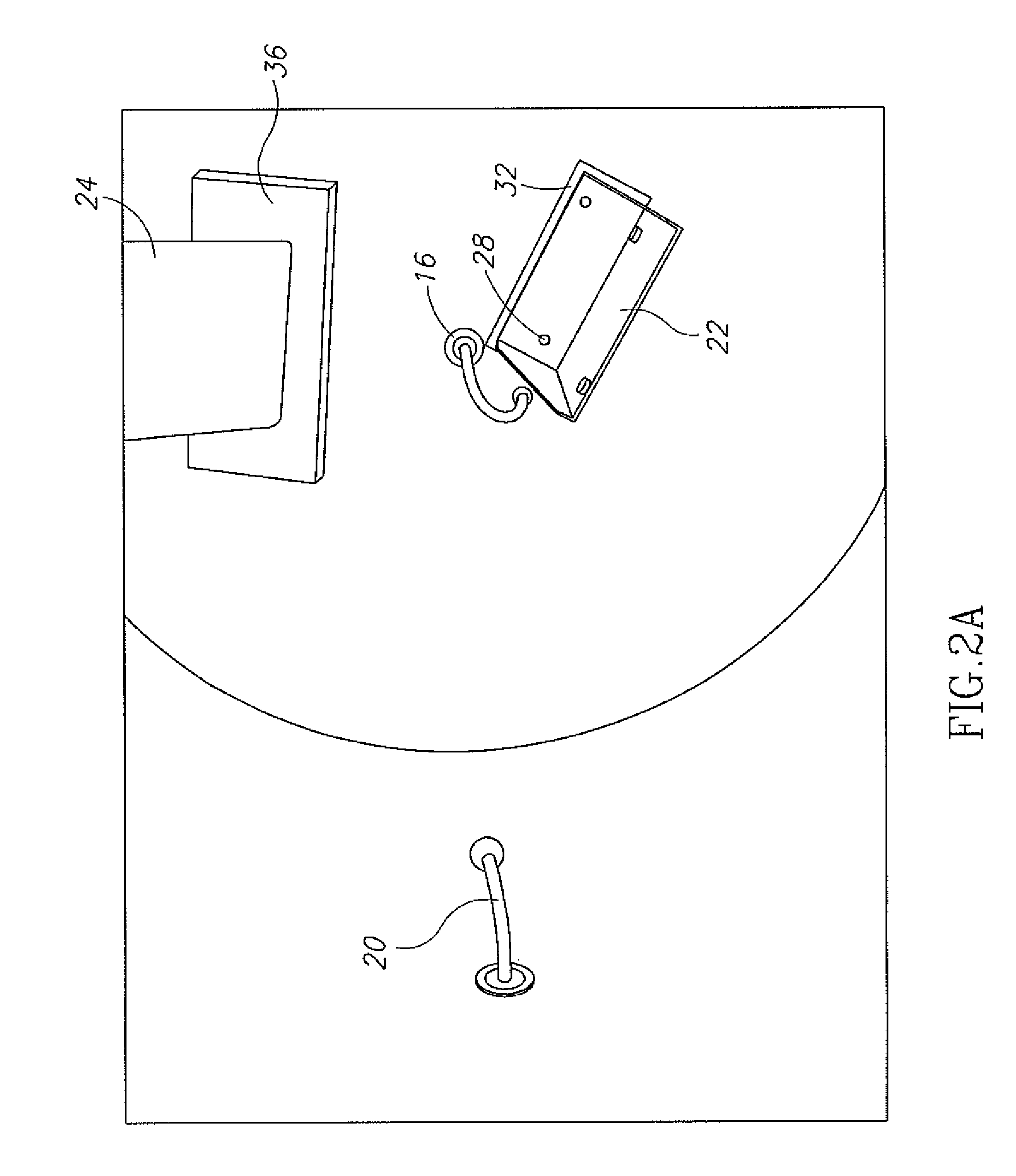

Electromagnetic heating

ActiveUS20090045191A1Improve efficiencyIncrease net powerDomestic stoves or rangesLighting and heating apparatusMicrowaveDisk controller

An electromagnetic heater for heating an irregularly shaped object, including:a cavity within which an object is to be placed;at least one feed which feeds UHF or microwave energy into the cavity; anda controller that controls one or more characteristics of the cavity or energy to assure that the UHF or microwave energy is deposited uniformly in the object within ±30% over at least 80% of the volume of the object.

Owner:JOLIET 2010 LTD

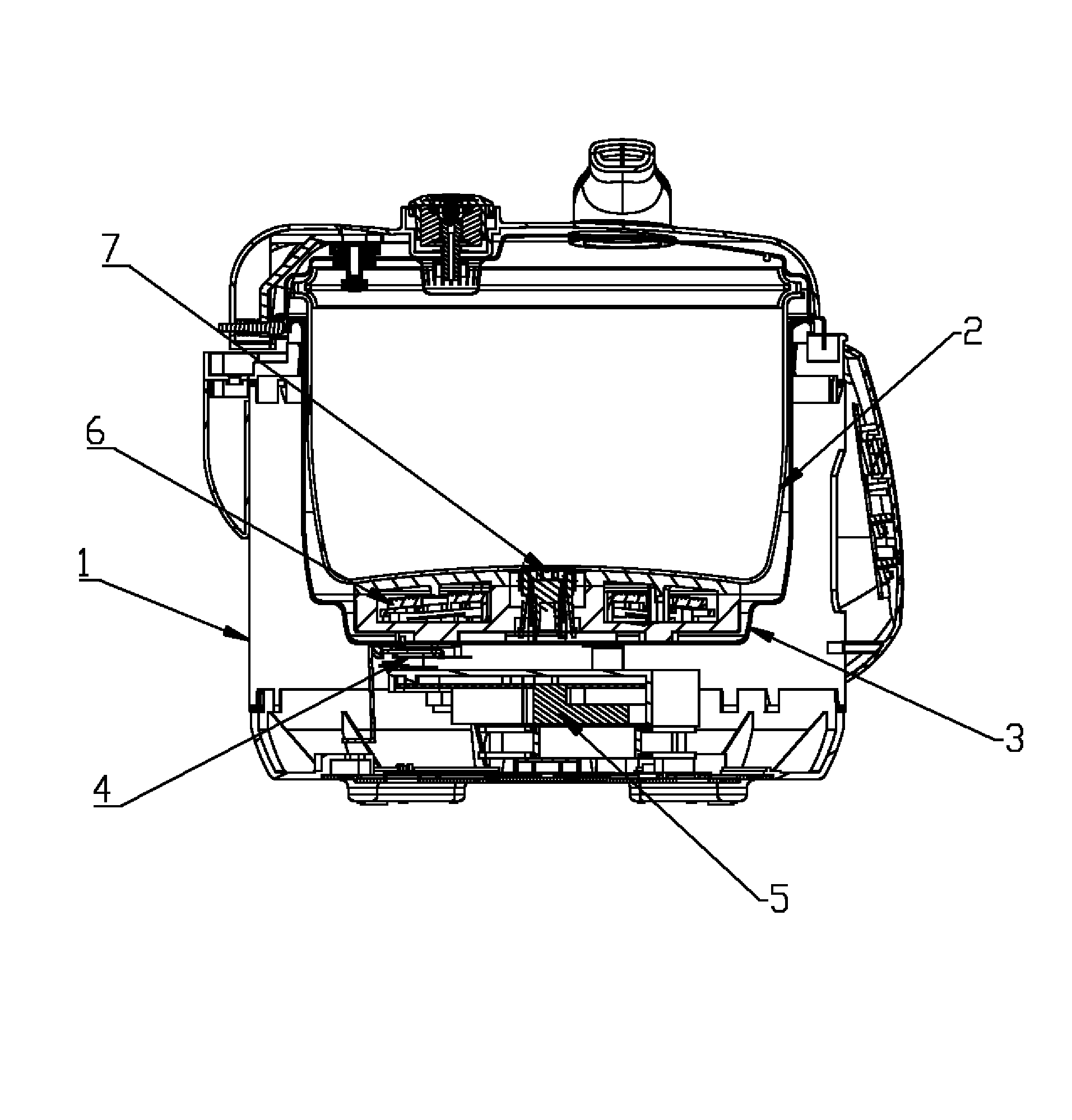

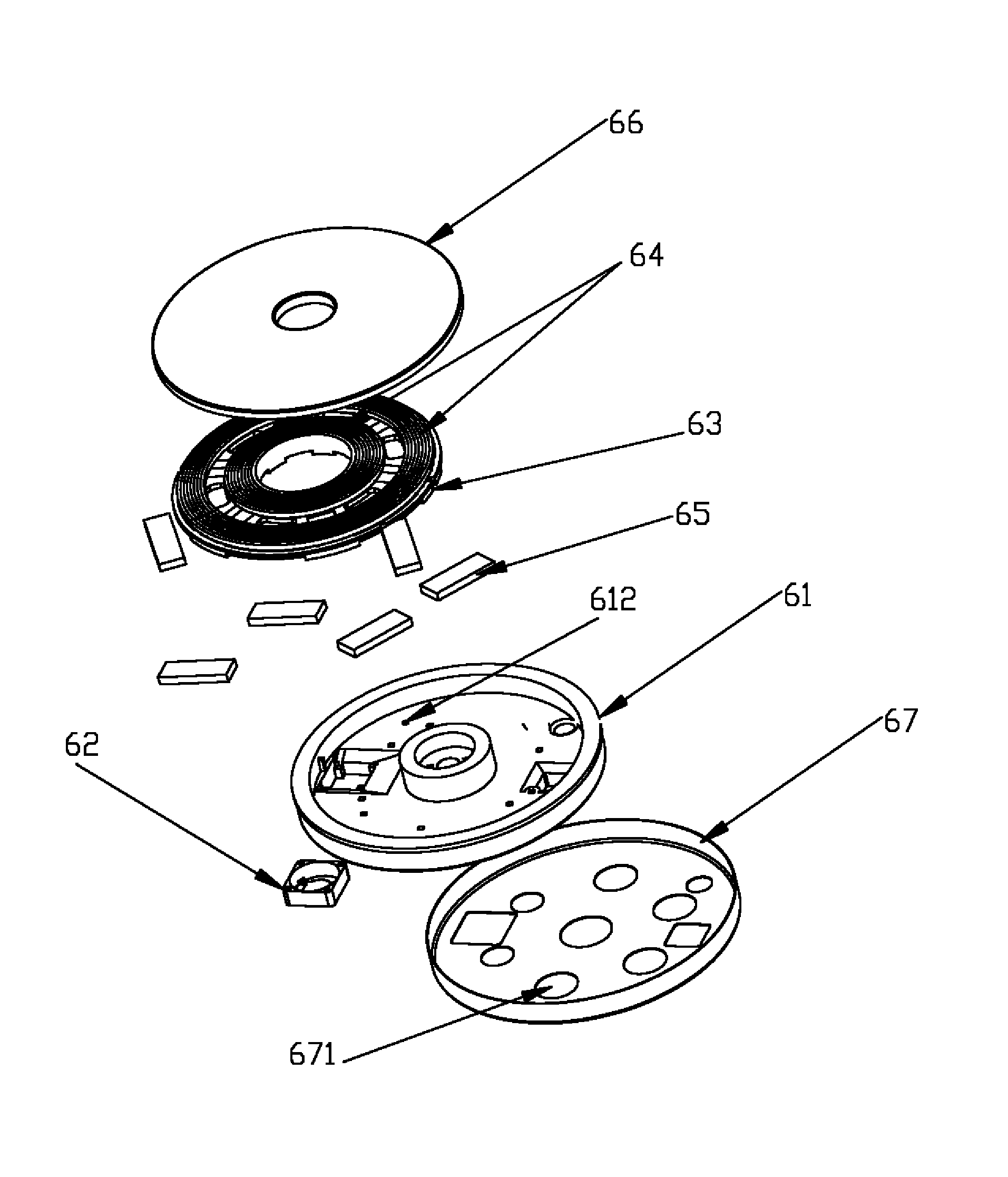

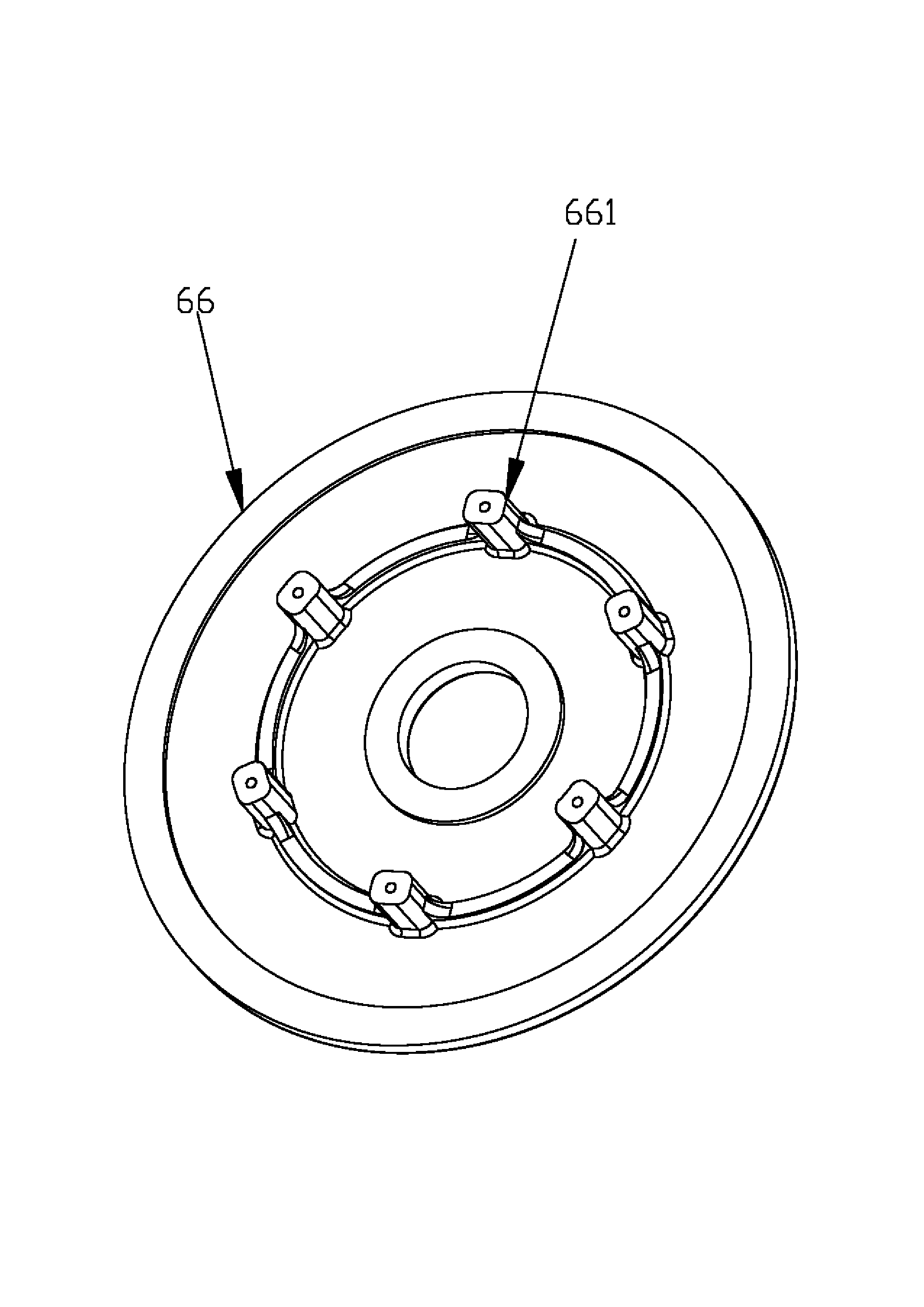

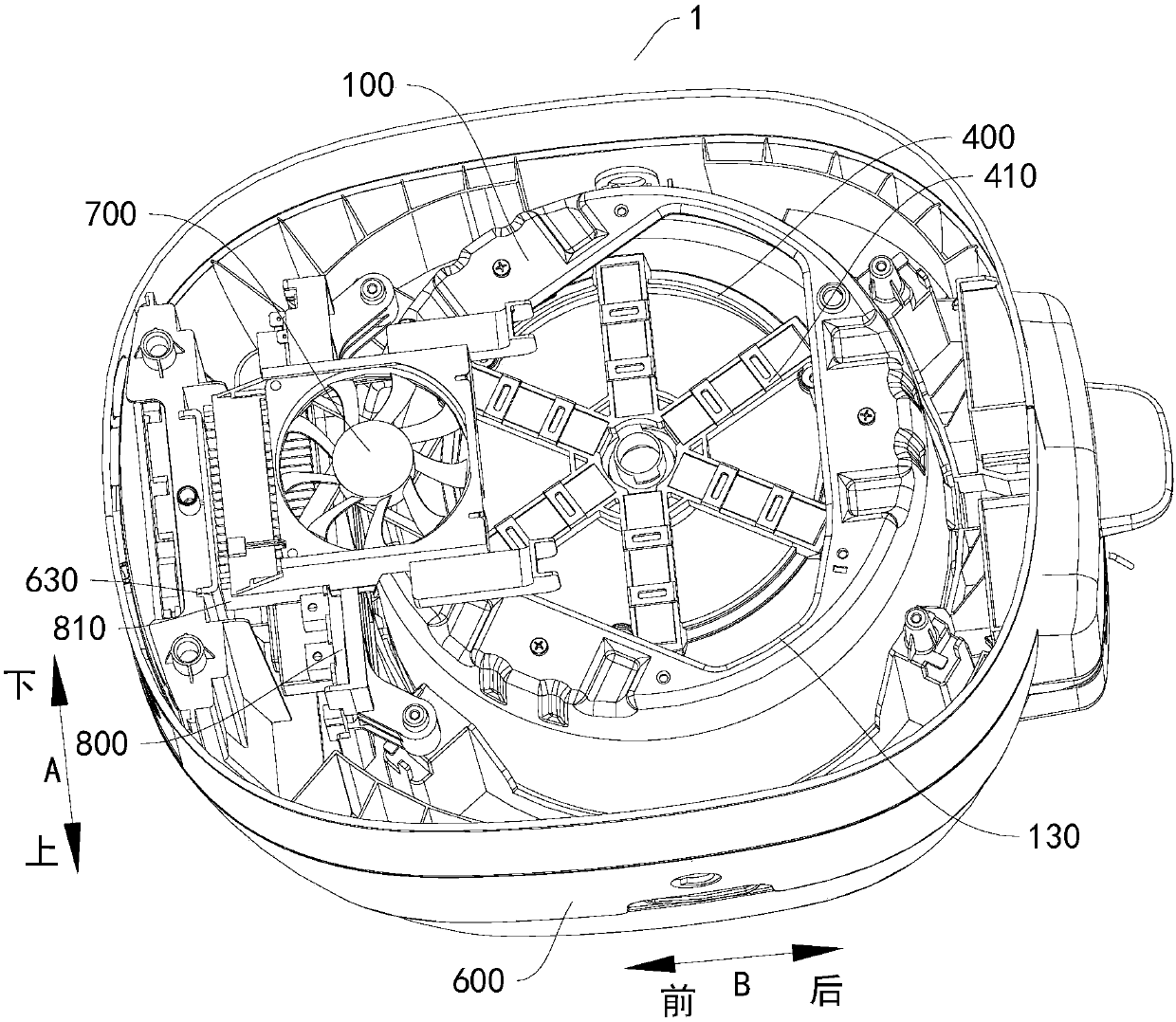

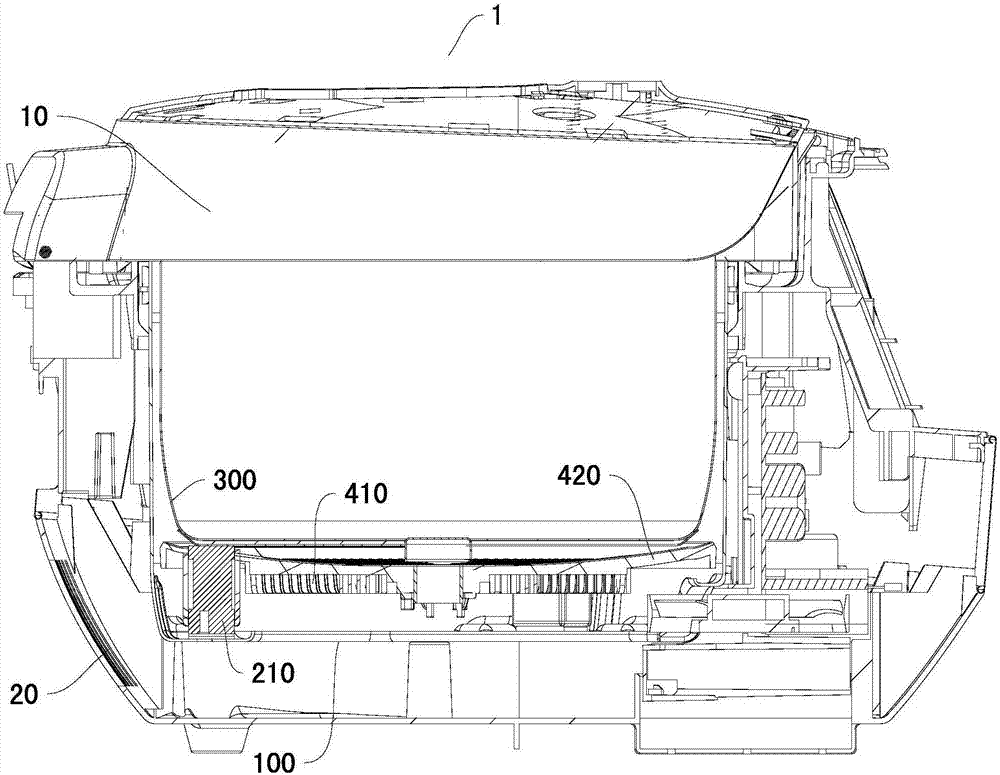

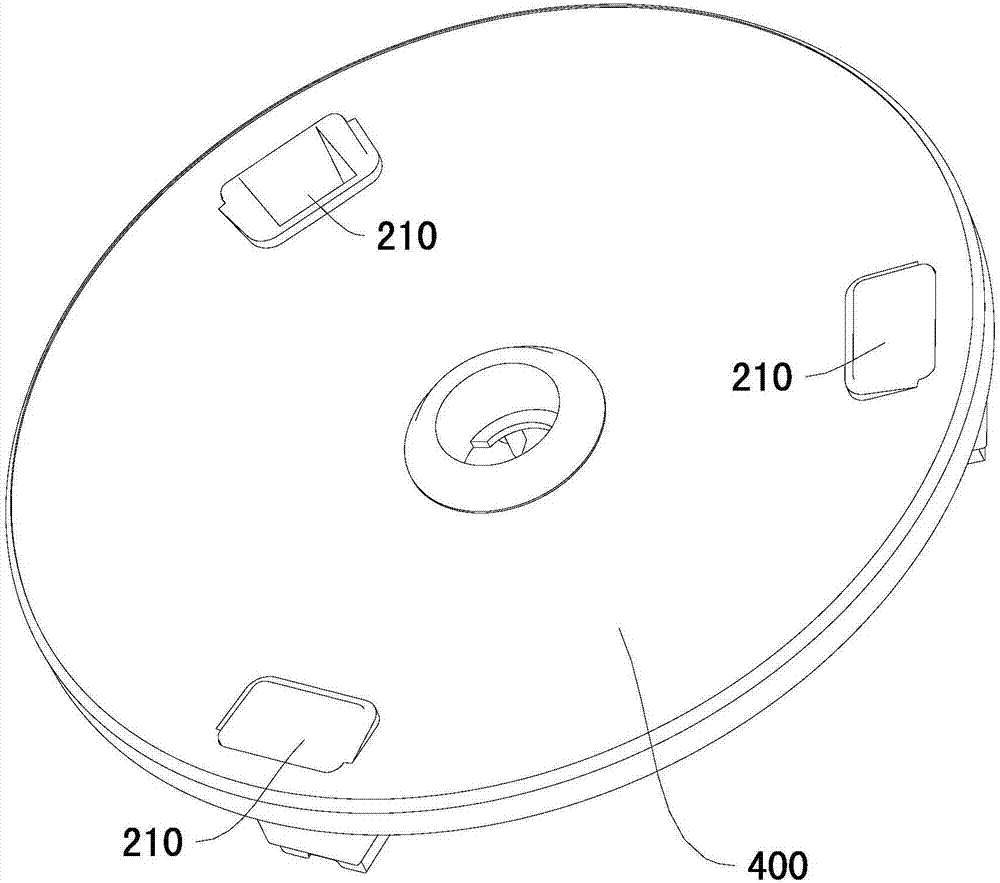

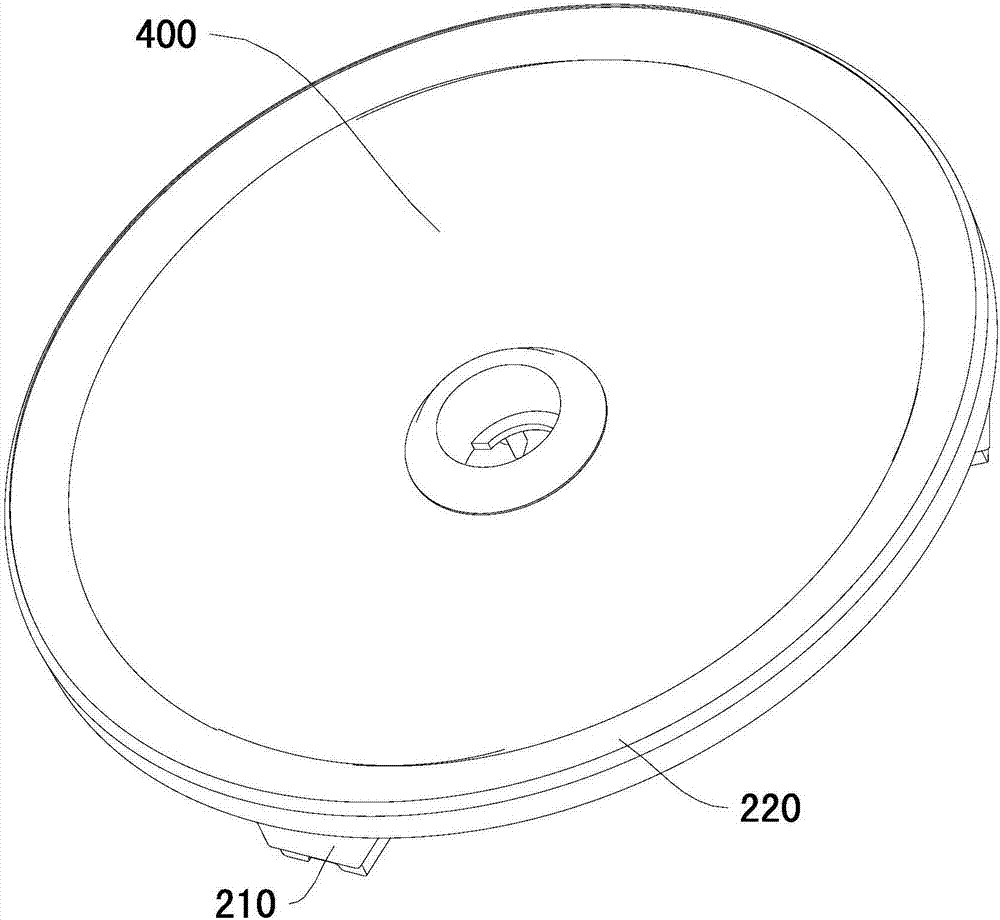

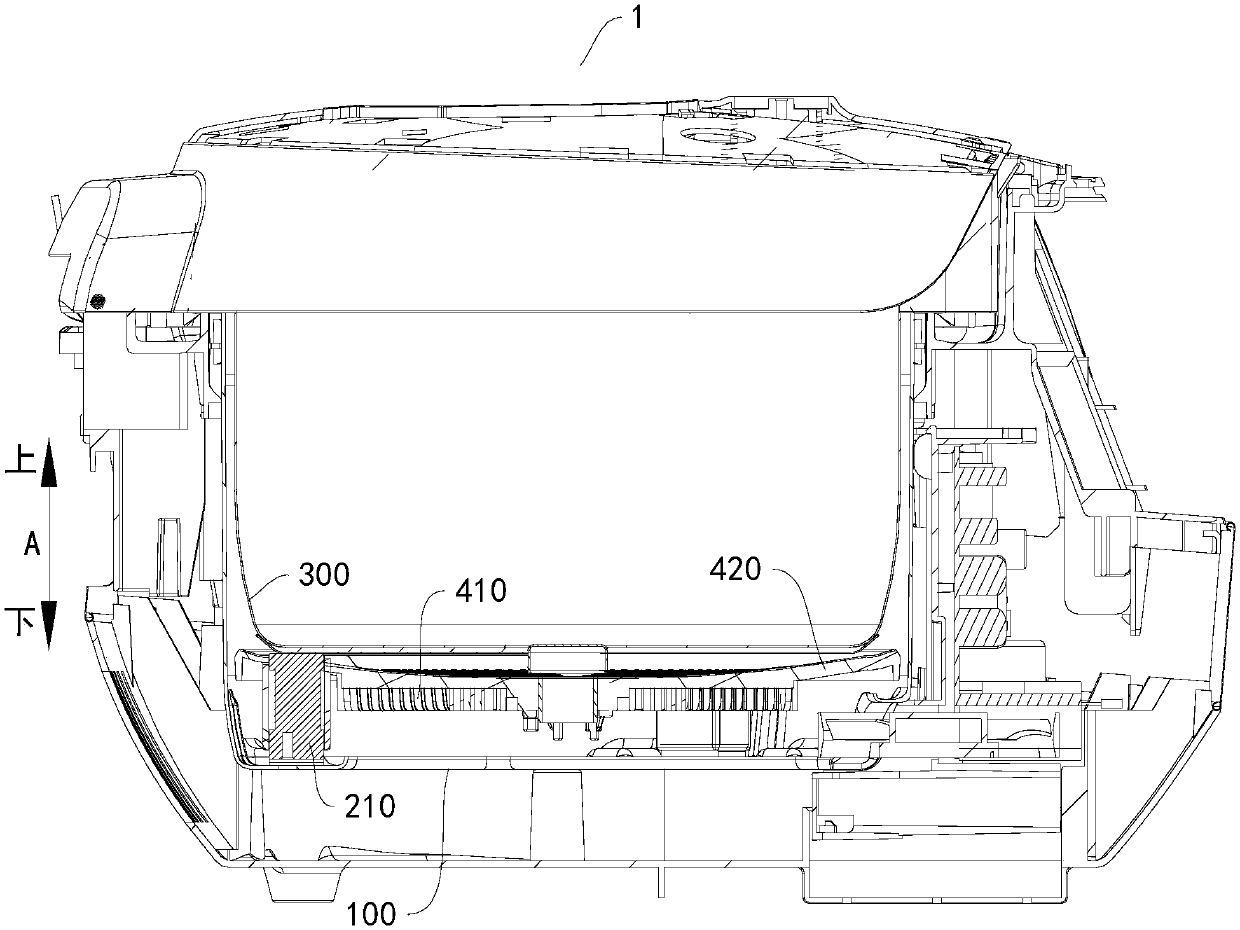

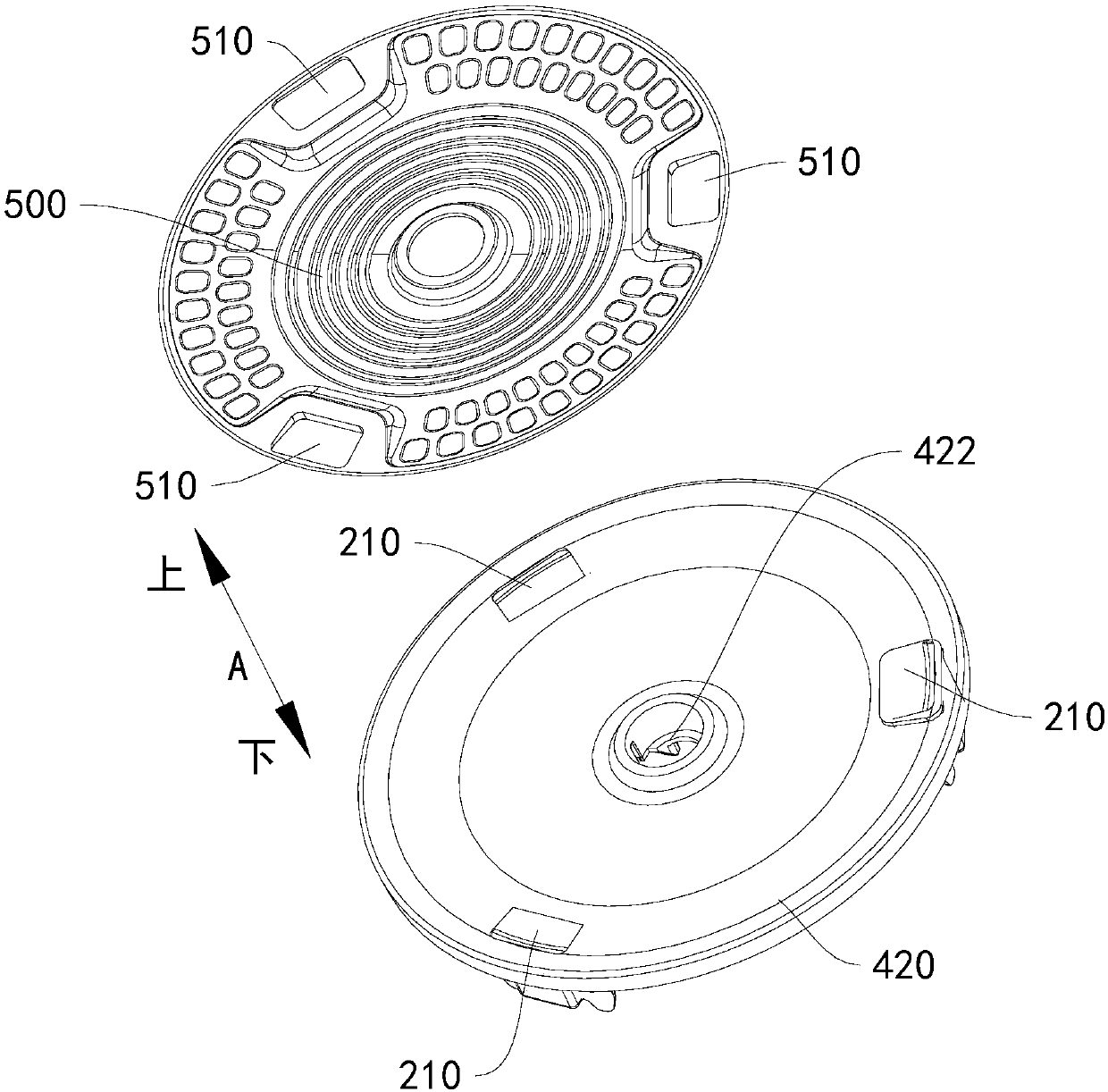

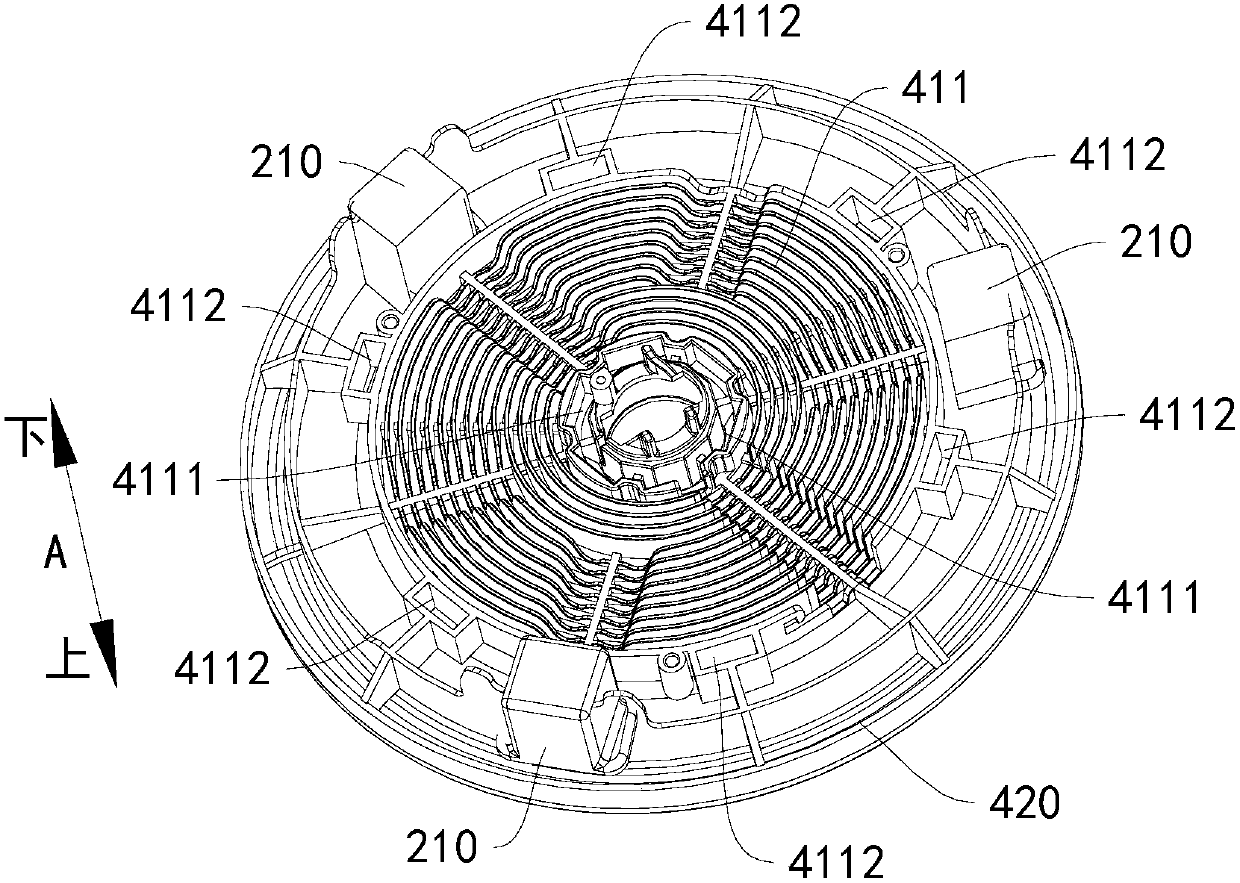

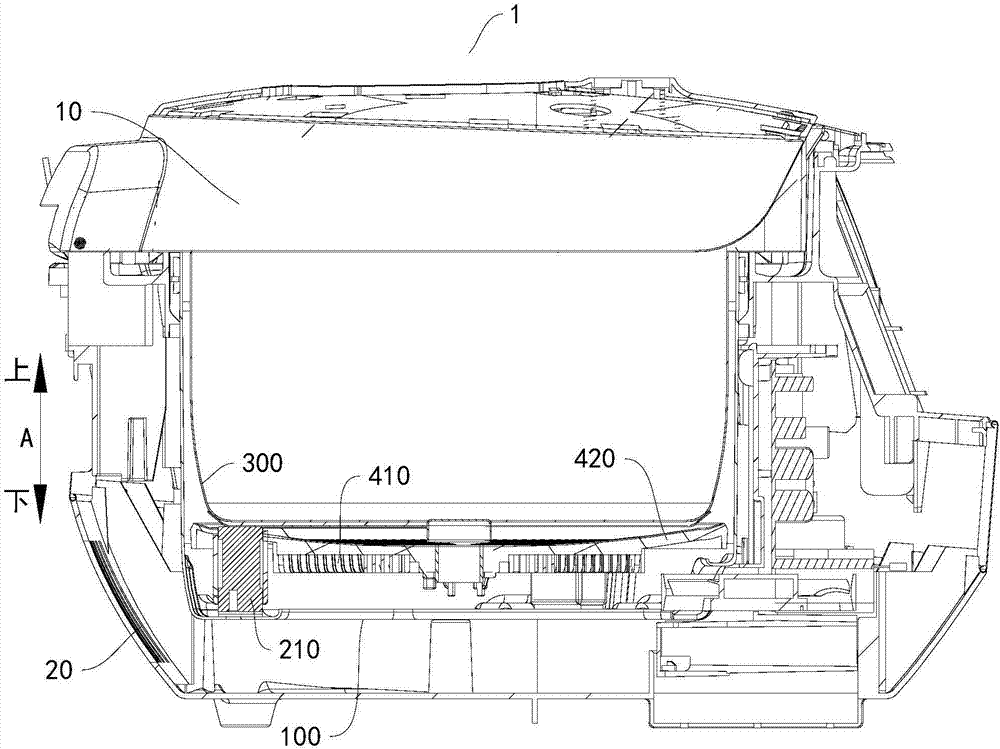

Electromagnetic heating electric pressure cooker

InactiveCN103006045ASolve potential safety hazardsImprove cooling effectCooking vesselsMagnetic heatingEngineering

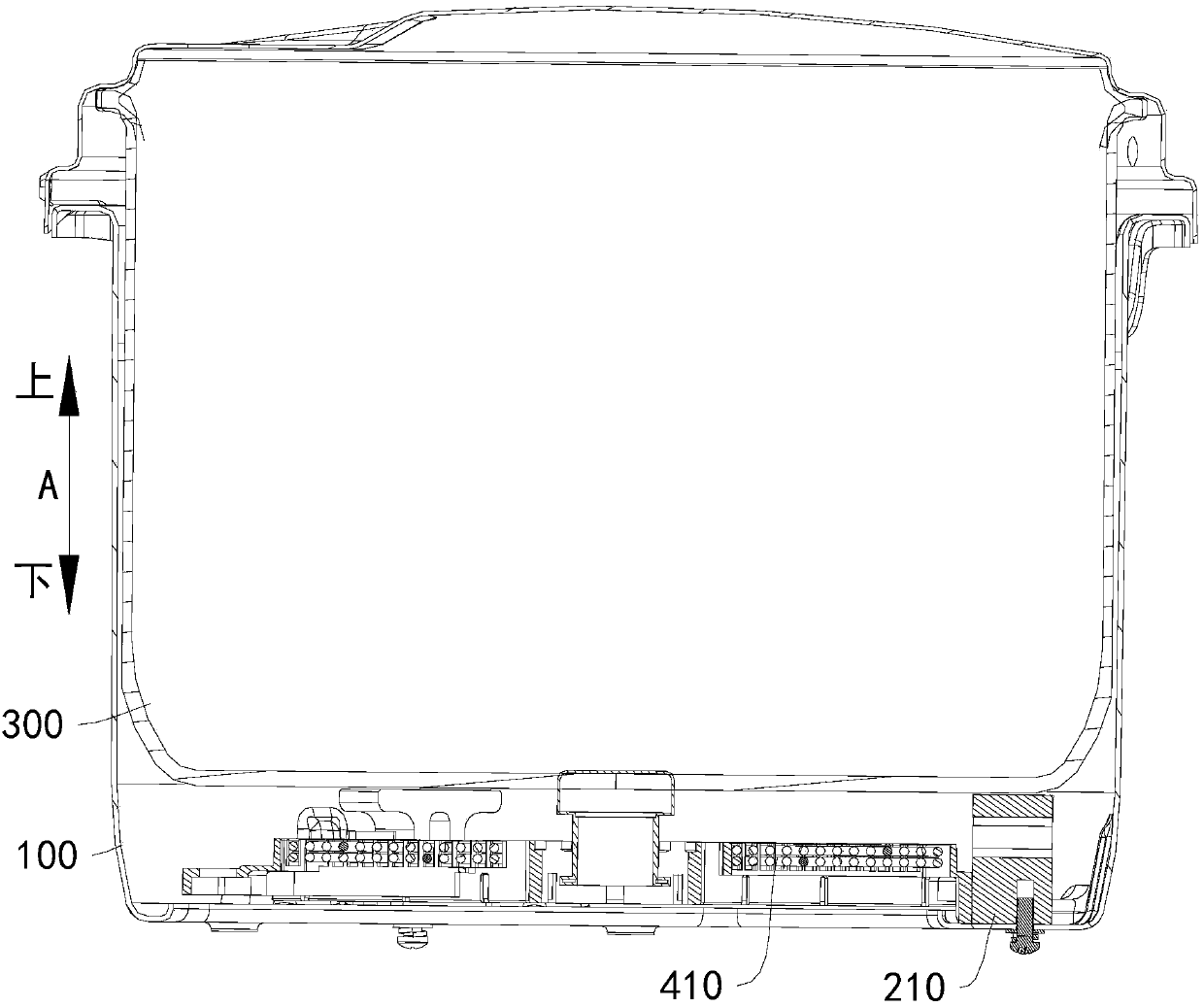

The invention relates to the technical field of electric pressure cookers, in particular to an electromagnetic heating electric pressure cooker. The electromagnetic heating electric pressure cooker structurally comprises a shell, an inner pot and an outer pot, wherein a pressure switch and a control device are arranged at the bottom of the outer pot; an annular heating disk component and a sensor component are arranged between the inner pot and the outer pot; a through hole is formed in the middle of the heating disk component; the sensor component is mounted in the through hole; the heating disk component comprises an electromagnetic heating outer disk, a radiating fan, an electromagnetic heating wire coil, an electromagnetic coil, a plurality of magnetic strips, an electromagnetic heating disk cover and an anti-magnetic disk; the sensor component comprises a fixed frame, a spring arranged on the fixed frame in a sleeving manner, a sensor cap and a thermistor; and the thermistor is electrically connected with the control device. Compared with the prior art, the electric pressure cooker has the advantages of simple structure, high radiating performance, capacity of precisely controlling pressure and temperature and long service life, truly realizes application of an electromagnetic heating technology to the electric pressure cooker, and has a wide market prospect.

Owner:GUANGDONG LUBY ELECTRONICS

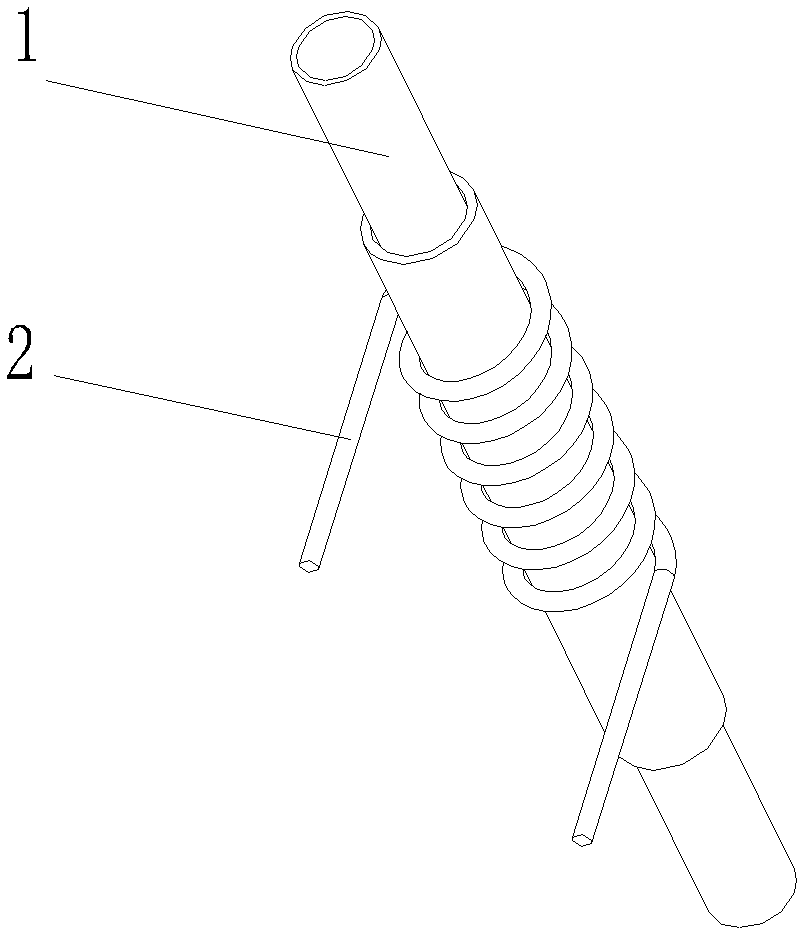

Electromagnetic heating type suction device used for heating non-combustible cigarette

The invention discloses an electromagnetic heating type suction device used for heating a non-combustible cigarette. The electromagnetic heating type suction device used for heating the non-combustible cigarette comprises an end cover, a heater and an electromagnetic induction system, wherein a heating cavity for holding the heated non-combustible cigarette is reserved in the heater, the end cover is detachably and combinably connected to the suction end portion of the heater, a filter tip is arranged on the end cover and is communicated with an inner cavity of the heating cavity, a round cover is arranged on the end cover, a plurality of air inlets are formed in the round cover and are communicated with the inner cavity of the heating cavity, the electromagnetic induction system comprises a temperature control circuit and an induction coil electrically connected onto the temperature control circuit, and the induction coil spirally winds the heating cavity. The electromagnetic heating type suction device used for heating the non-combustible cigarette has the advantages that a liner heating body is heated electromagnetically via the electromagnetic induction system, and the cigarette is heated by the liner heating body, so that heating speed can be increased, heating efficiency and heating speed are high, transient heating can be realized, needs for satisfying suction taste are met, heating is uniform, and the cigarette can be heated fully to prevent cigarette waste resulted from insufficient heating.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Electric pressure pot

InactiveCN107684338ASmall thermal inertiaImprove controllabilityCooking vesselsEngineeringElectromagnetic heating

The invention discloses an electric pressure pot. The electric pressure pot includes an outer pot body, a supporting part, an inner pot body and an electromagnetic heating disc; the supporting part isarranged in the outer pot body and supported on the bottom wall of the outer pot body; the inner pot body is arranged in the outer pot body and supported on the supporting part; the electromagnetic heating disc is used for heating the inner pot body and arranged between the outer bottom surface of the inner pot body and the inner bottom surface of the outer pot body, and the upper surface of theelectromagnetic heating disc is provided with a waterproof layer. The electric pressure pot has the advantages of being low in thermal inertia, great in controllability, high in reliability and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

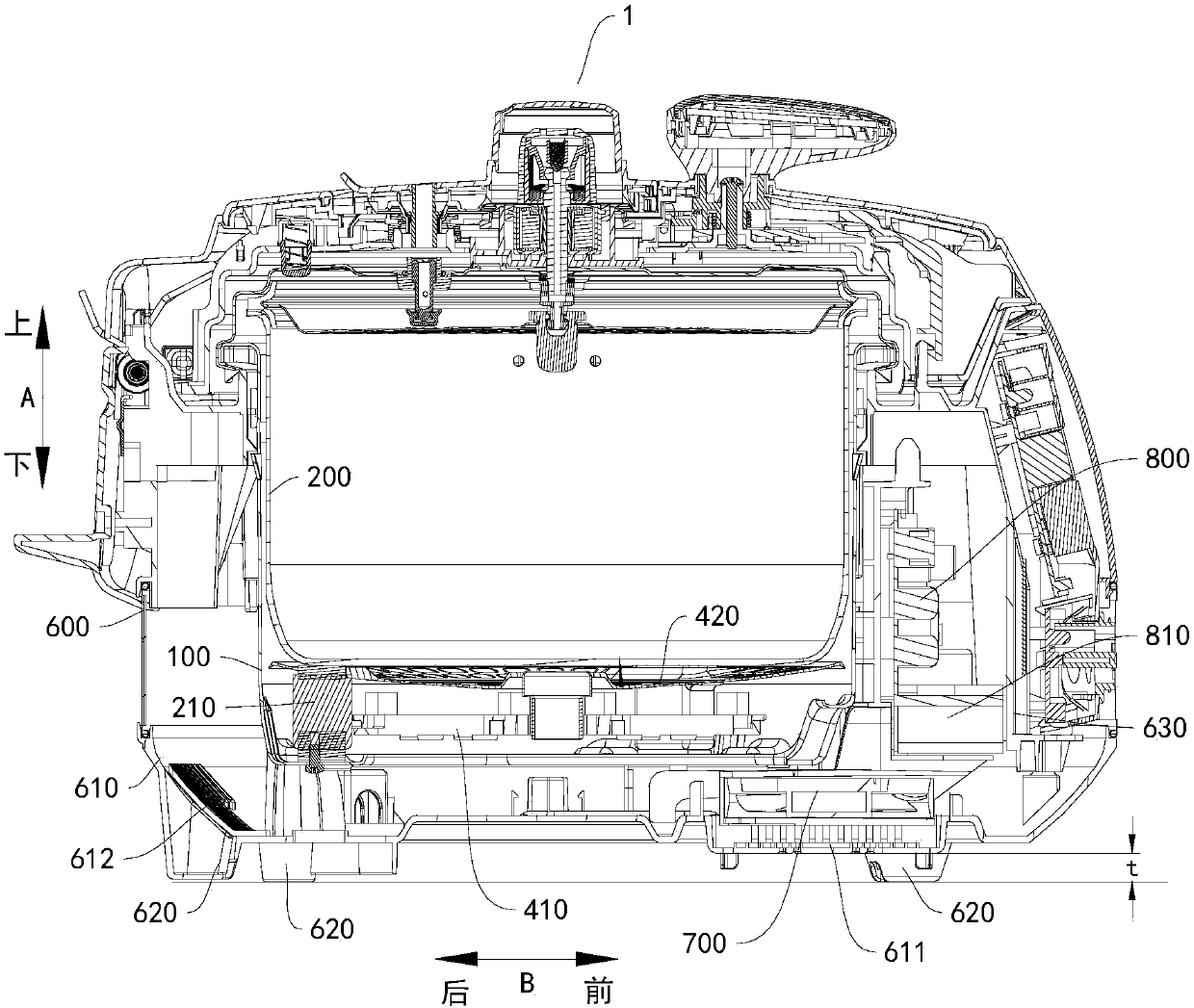

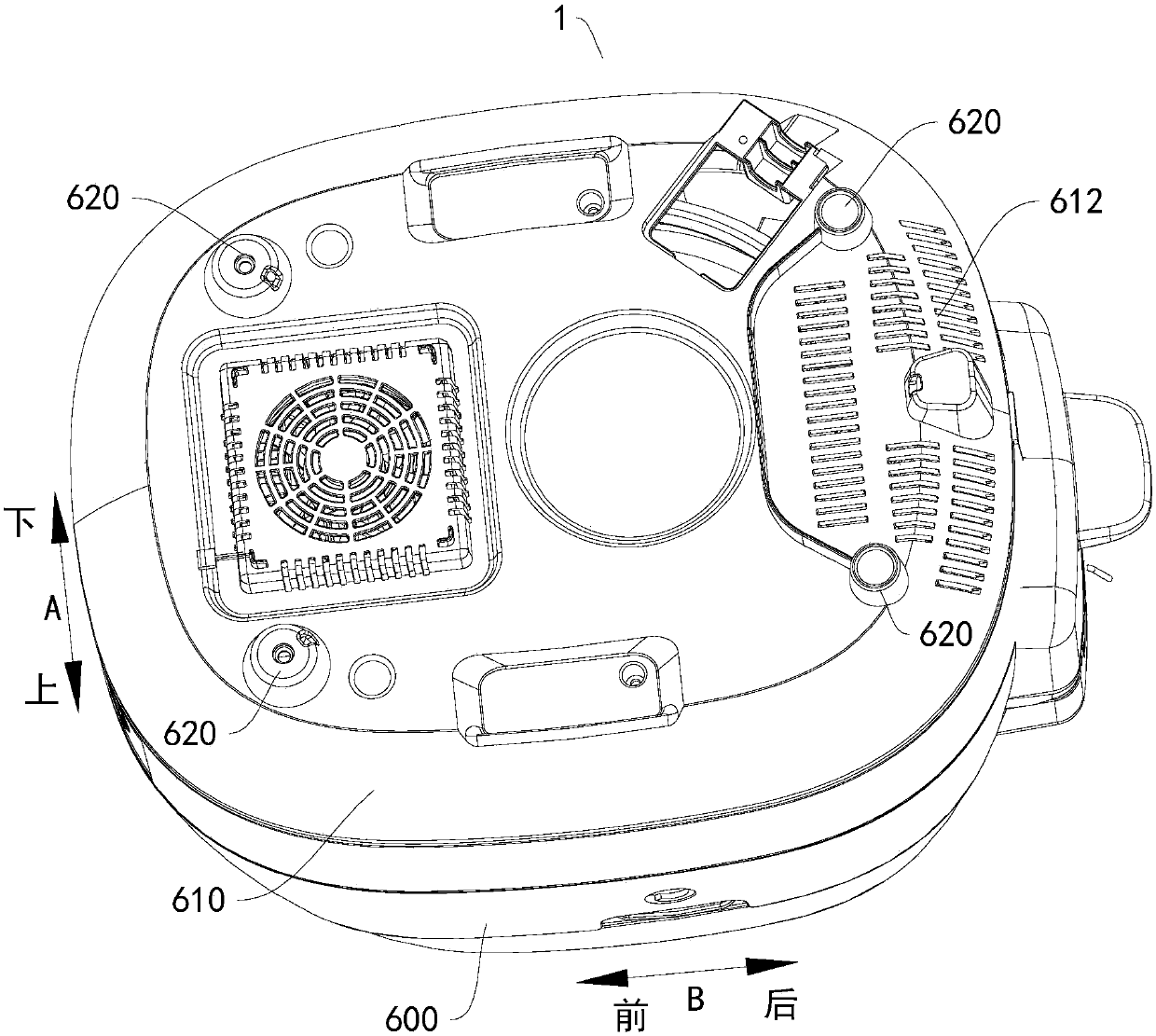

Electric pressure pot

InactiveCN107684342ASmall thermal inertiaImprove controllabilityWarming devicesEngineeringElectromagnetic heating

The invention discloses an electric pressure pot. The electric pressure pot includes a shell, an outer pot body, a rigid supporting part, an inner pot body, an electromagnetic heating device and a fan; the shell is provided with an air inlet and an air outlet; the outer pot body is arranged in the shell; the rigid supporting part is arranged in the outer pot body; the inner pot body is arranged inthe outer pot body and supported on the rigid supporting part, and the outer bottom surface of the inner pot body is separated from the inner bottom surface of the outer pot body under the support ofthe rigid supporting part; the electromagnetic heating device is used for heating the inner pot body and arranged between the outer bottom surface of the inner pot body and the inner bottom surface of the outer pot body; the fan is arranged between the inner surface of the shell and the outer surface of the outer pot body. The electric pressure pot has the advantages of being low in thermal inertia, great in controllability, high in production efficiency and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

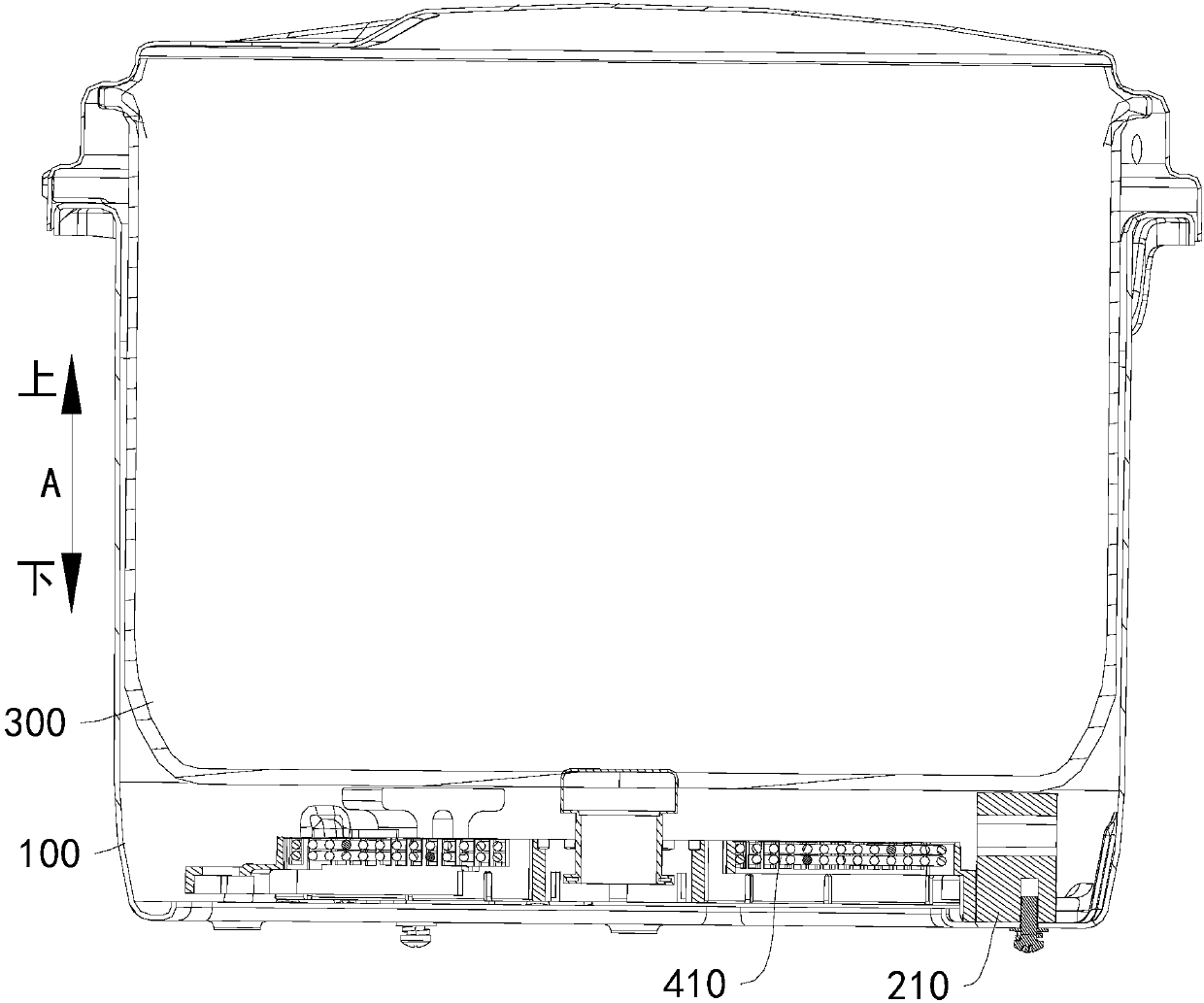

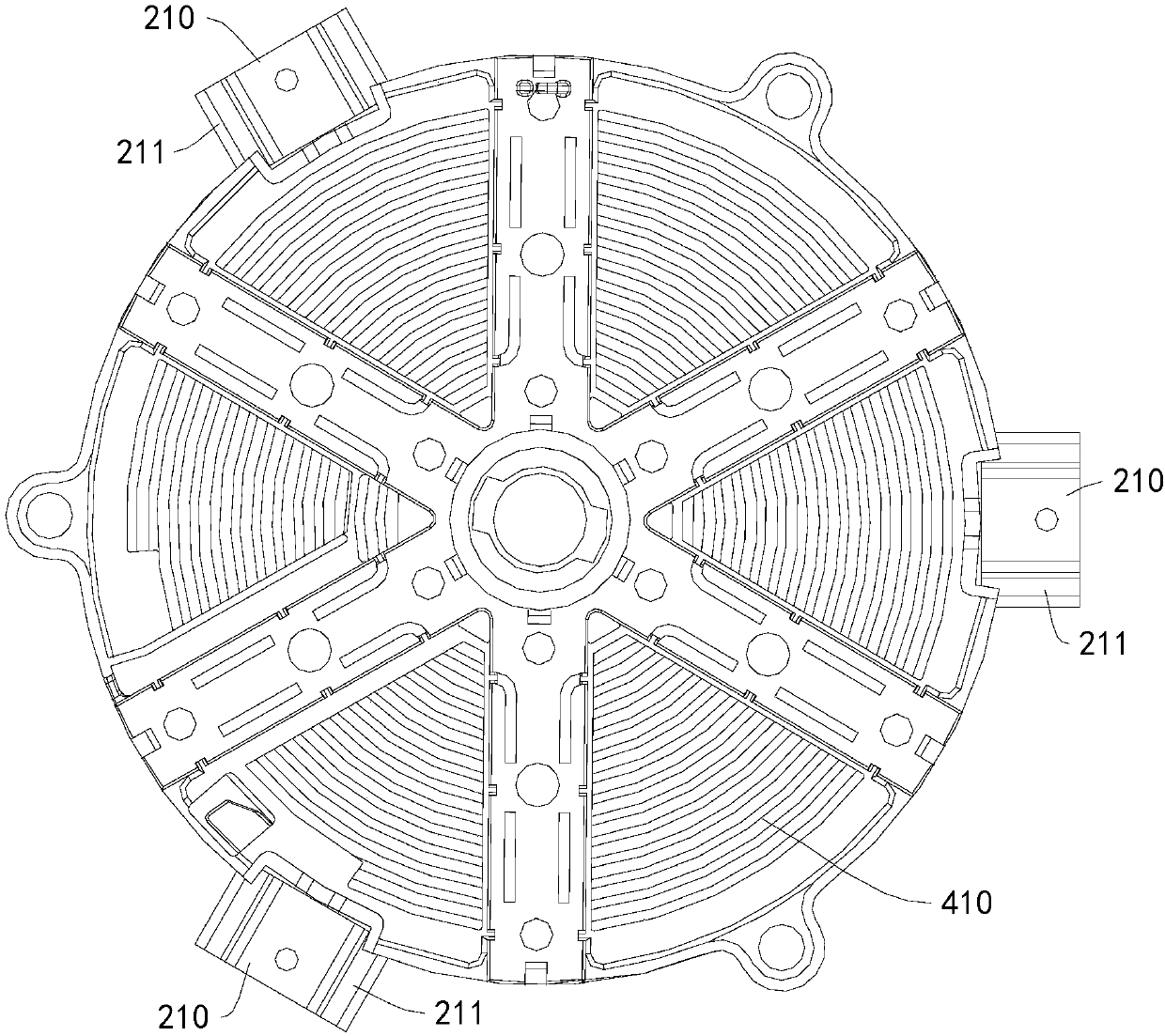

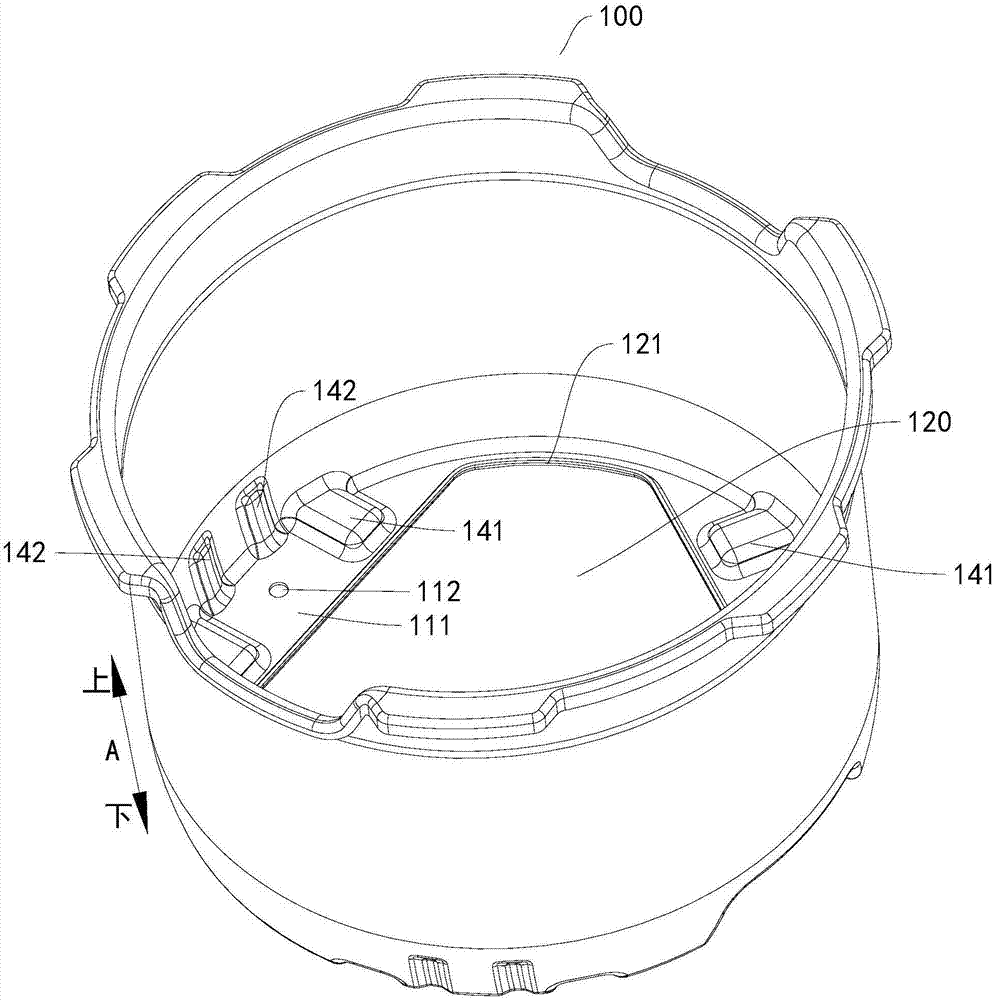

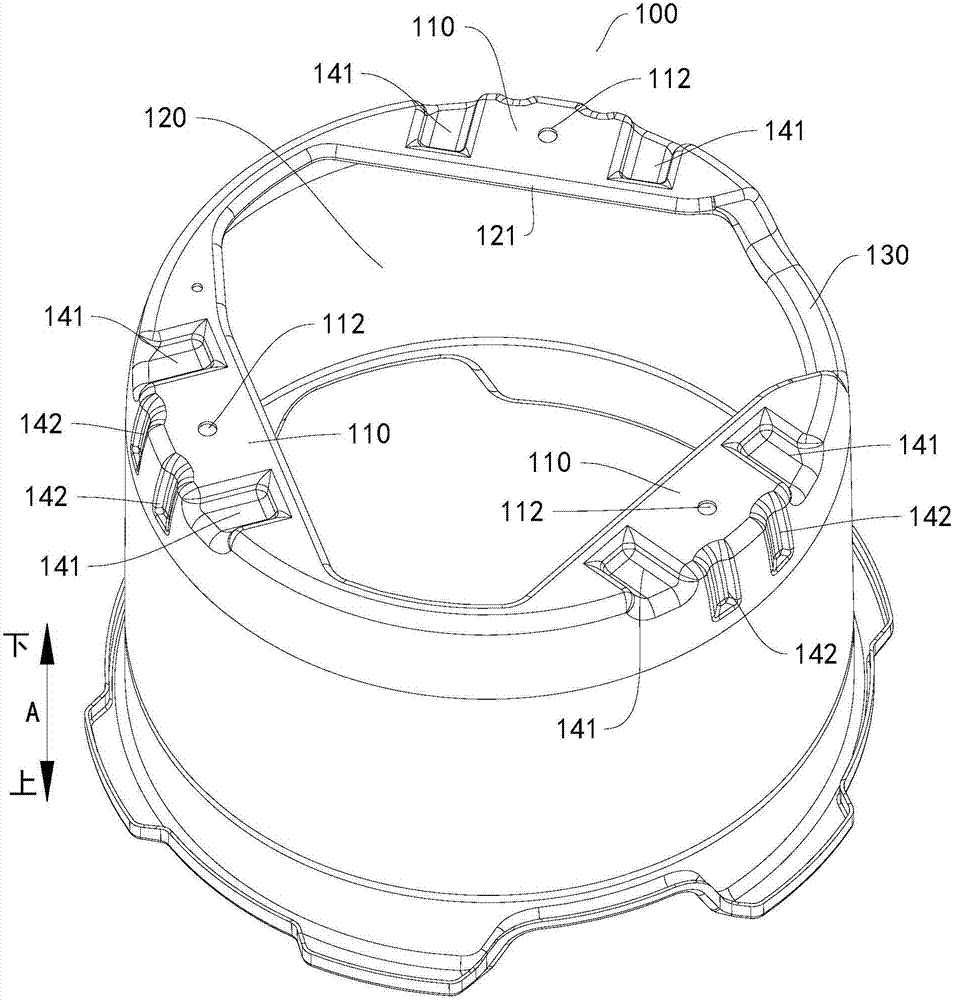

Electric pressure cooker

InactiveCN107296494ASmall thermal inertiaImprove controllabilityWarming devicesEngineeringHeating effect

The invention discloses an electric pressure cooker. The electric pressure cooker comprises an outer pot, a rigid supporting piece, an inner pot and an electromagnetic heating device, wherein the rigid supporting piece is arranged in the inner pot; the inner pot is arranged in the outer pot and supported on the rigid supporting piece, and under the support of the rigid supporting piece, the outer bottom face of the inner pot is spaced from the inner bottom face of the outer pot; the electromagnetic heating device is used for heating the inner pot and arranged between the outer bottom face of the inner pot and the inner bottom face of the outer pot; the electromagnetic heating device comprises an electromagnetic heating plate, and the projection of the electromagnetic heating plate is staggered with the projection of the rigid supporting piece in the horizontal direction. The electric pressure cooker has the advantages of being low in thermal inertia, good in controllability, high in production efficiency, good in heating effect, high in reliability and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

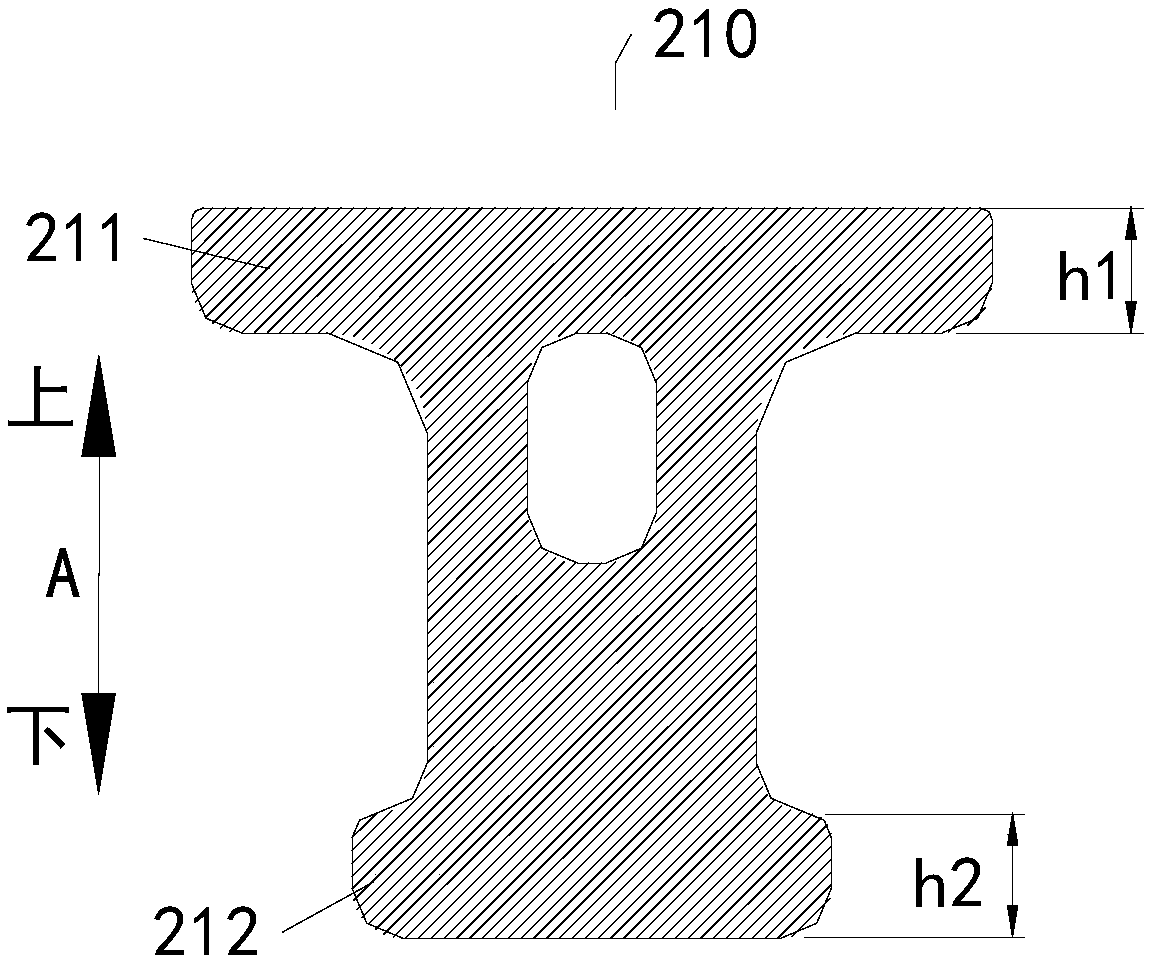

Electric pressure pot and supporting part of electric pressure pot

InactiveCN107684336ASmall thermal inertiaImprove controllabilityPressure-cookersEngineeringElectromagnetic heating

The invention discloses an electric pressure pot and a supporting part of the electric pressure pot. The electric pressure pot includes an outer pot body, the supporting part, an inner pot body and anelectromagnetic heating disc; the supporting part is arranged in the outer pot body and supported on the bottom wall of the outer pot body; the area of the lower surface of the supporting part is smaller than or equal to that of the upper surface of the supporting part; the inner pot body is arranged in the outer pot body and supported on the supporting part, and moves downwards to discharge pressure when the pressure inside the inner pot body reaches a preset value; the electromagnetic heating disc is used for heating the inner pot body and arranged between the outer bottom surface of the inner pot body and the inner bottom surface of the outer pot body. The electric pressure pot has the advantages of being low in thermal inertia, great in controllability, high in reliability and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

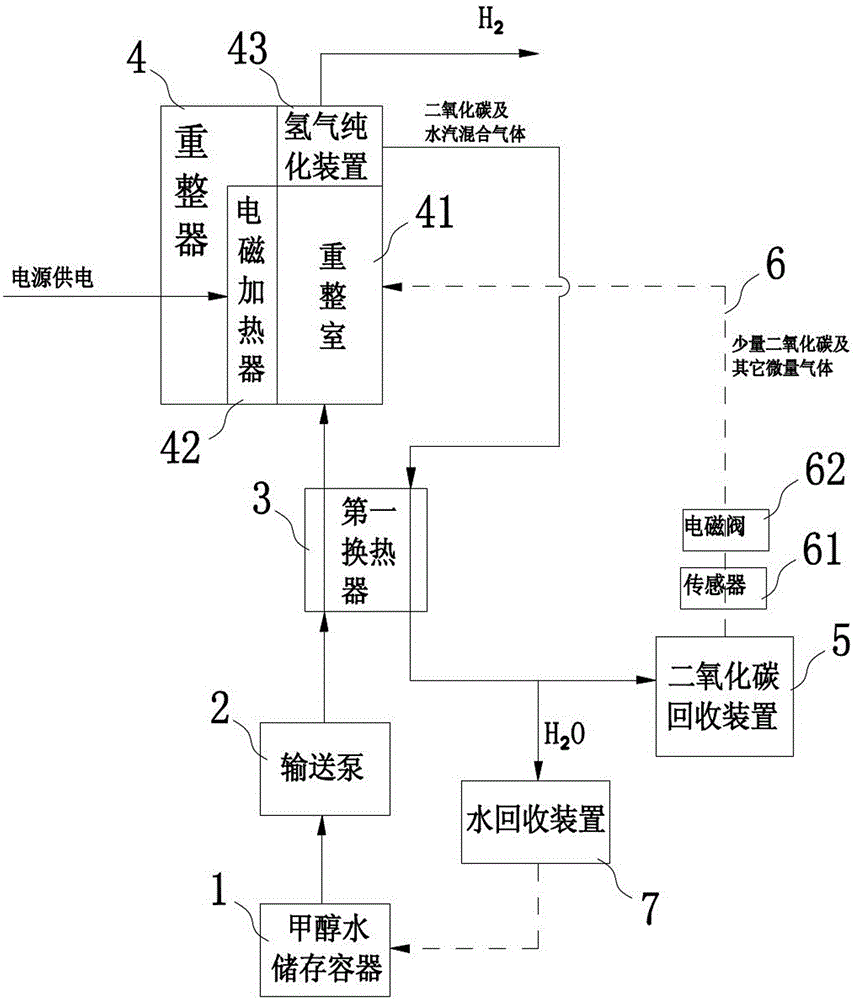

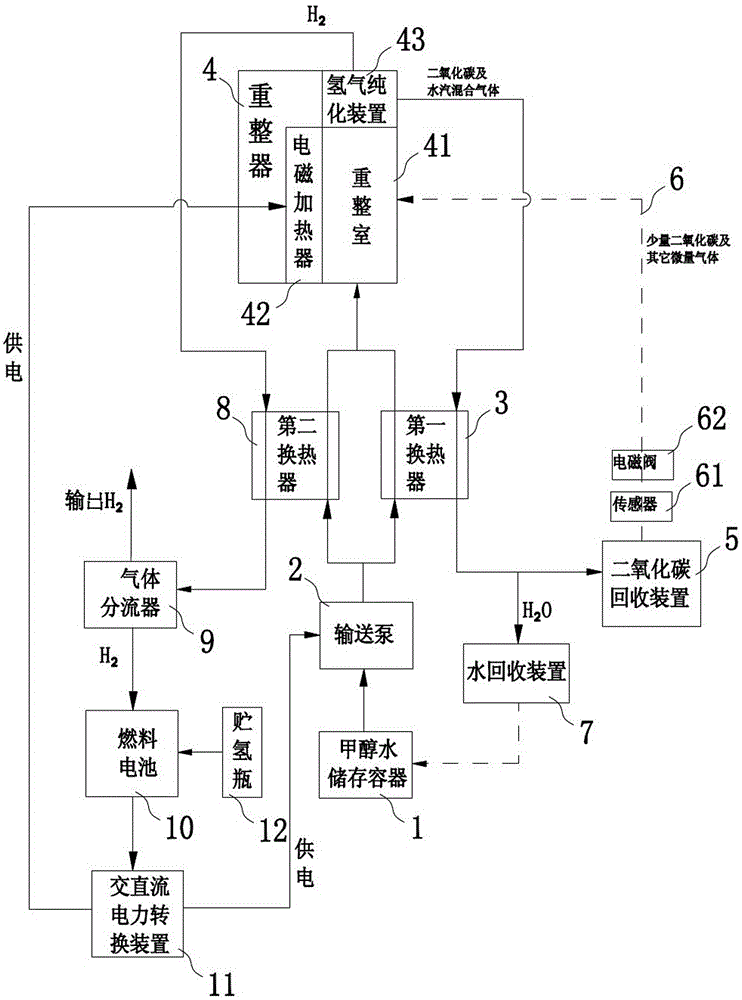

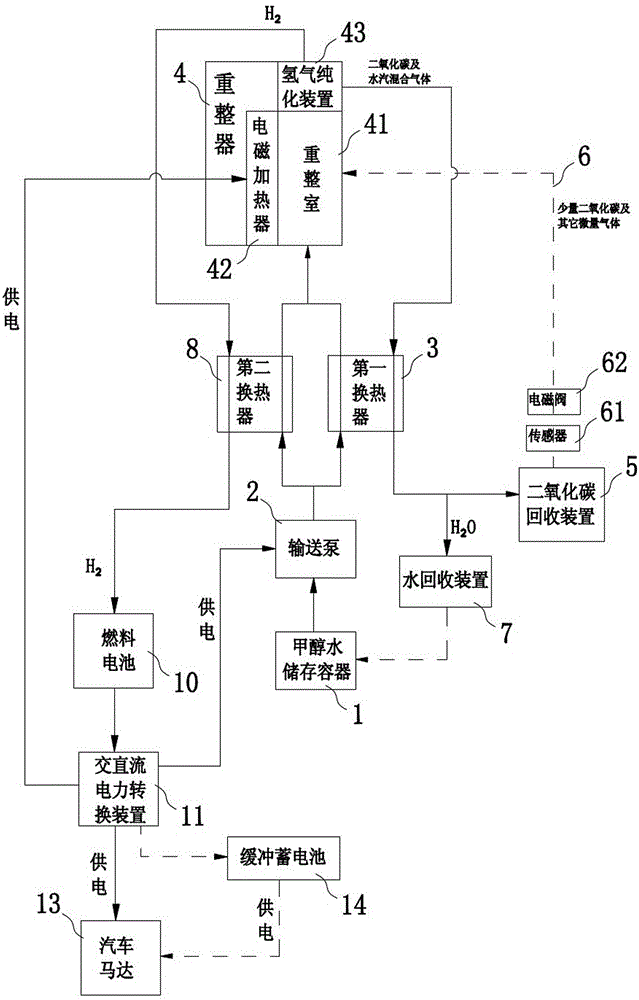

Zero-carbon-emission hydrogen production system by methanol water reforming as well as application and hydrogen production method thereof

The invention discloses a zero-carbon-emission hydrogen production system by methanol water reforming and application and a hydrogen production method thereof. The hydrogen production system comprises a methanol water storage vessel, a delivery pump, a first heat exchanger, a reformer and a carbon dioxide recovery device, wherein the reformer is provided with a reforming chamber, an electromagnetic heater and a hydrogen purification device; the electromagnetic heater provides heat energy for the reforming chamber; the reforming chamber is used for hydrogen production reaction of methanol and water by reforming to obtain carbon dioxide and hydrogen; carbon dioxide and hydrogen are mixed with water vapor to form high-temperature mixed gas, and the high-temperature mixed gas is delivered into the hydrogen purification device; after purification and separation, hydrogen is delivered out, at the same time carbon dioxide and unreacted water vapor mixed gas are also delivered out, and then carbon dioxide and unreacted water vapor mixed gas are delivered into the carbon dioxide recovery device after passing through the first heat exchanger; the carbon dioxide recovery device is a replaceable modular carbon dioxide recovery device and used for recovering carbon dioxide and part of the water vapor. The zero-carbon-emission hydrogen production system provided by the invention can recover carbon dioxide, has no impact on the environment and causes no harm to the hydrogen production system self and is beneficial for popularization and application in the field of new energy resources such as fuel cell cars.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

Electromagnetic heating

ActiveUS8389916B2Duty cycleTime stableLighting and heating apparatusFood preservationElectromagnetic heatingFast scanning

Owner:JOLIET 2010 LTD

Electric pressure pot

InactiveCN107684337ASmall thermal inertiaImprove controllabilityPressure-cookersWarming devicesEngineeringElectromagnetic heating

The invention discloses an electric pressure pot. The electric pressure pot includes an outer pot body, a supporting part, an inner pot body, a bracket and an electromagnetic heating disc; the supporting part is arranged in the outer pot body; the inner pot body is arranged in the outer pot body and supported on the supporting part; the bracket is arranged between the outer bottom surface of the inner pot body and the inner bottom surface of the outer pot body, and the supporting part is arranged on the bracket; the electromagnetic heating disc is used for heating the inner pot body and arranged on the bracket, and the projections of electromagnetic heating disc and the supporting part in the horizontal direction are staggered. The electric pressure pot has the advantages of being low in thermal inertia, great in controllability, high in production efficiency and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Electric pressure cooker

InactiveCN107296493ASmall thermal inertiaImprove controllabilityCooking vesselsEngineeringElectromagnetic heating

The invention discloses an electric pressure cooker. The electric pressure cooker comprises an outer pot, a supporting piece, an inner pot and an electromagnetic heating device, wherein supporting ribs are arranged at the lower end of the outer pot; the supporting piece is arranged in the outer pot and supported on the supporting ribs, and the inner pot is arranged in the outer pot and supported on the supporting piece; under the support of the supporting piece, the outer bottom face of the inner pot is spaced from the inner bottom face of the outer pot; the electromagnetic heating device is used for heating the inner pot and arranged between the outer bottom face of the inner pot and the inner bottom face of the outer pot. The electric pressure cooker has the advantages of being low in thermal inertia, good in controllability, high in production efficiency and the like.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

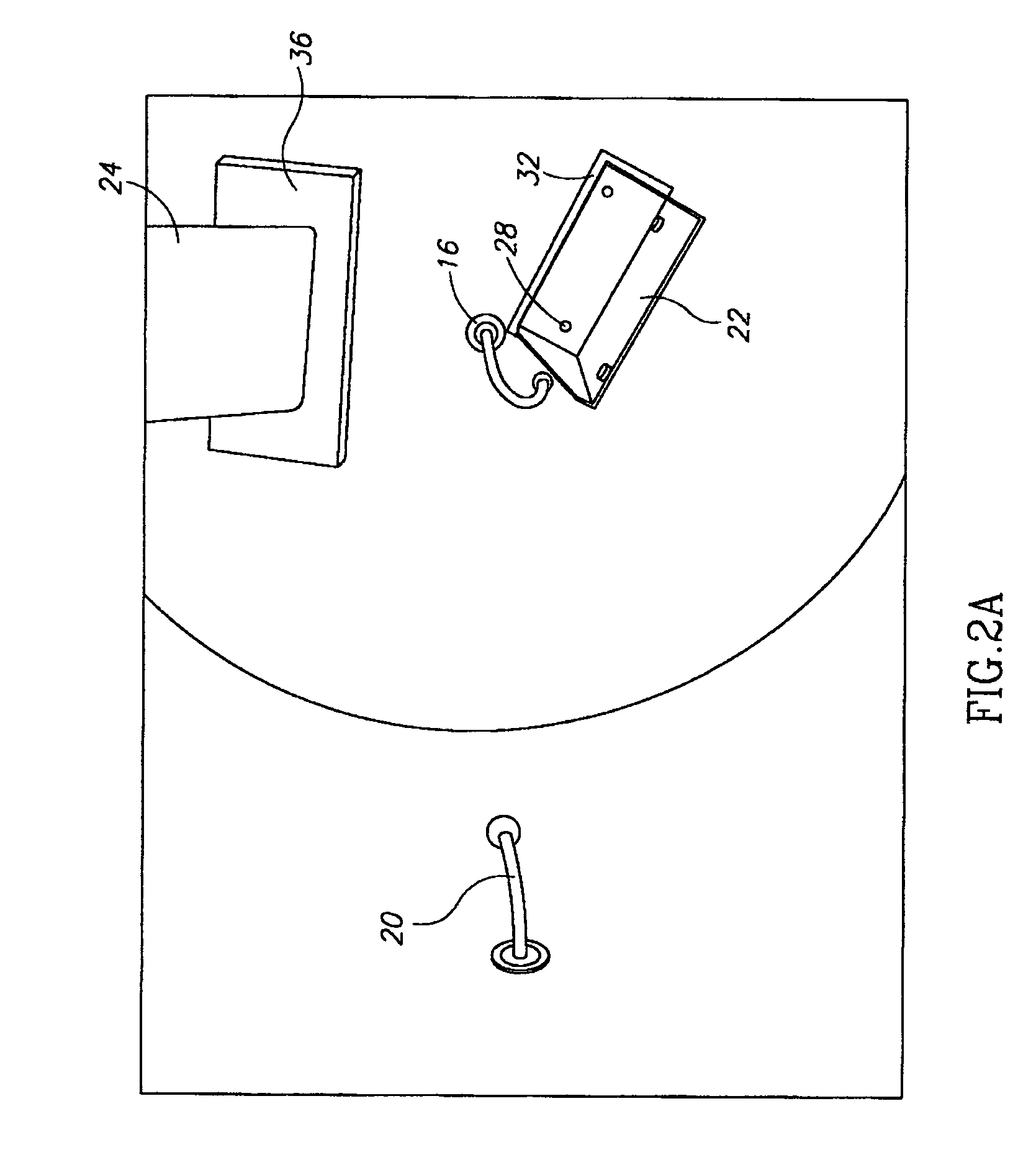

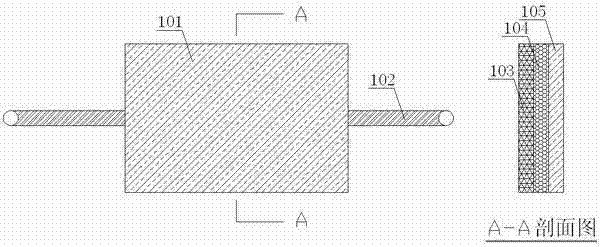

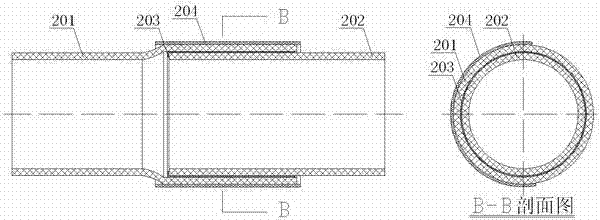

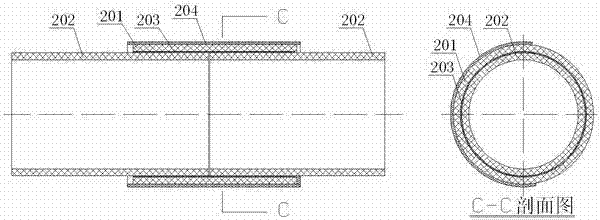

Environment-friendly plastic pipe fusion bonding method

InactiveCN102889446AEasy constructionObvious cost advantagePipe connection arrangementsInduction heating apparatusElectromagnetic pulseEngineering

The invention discloses an environment-friendly plastic pipe fusion bonding method which comprises a magnetic conductivity material net (203) of a plastic pipe fusion bonding material and a portable type electromagnetic heating device. The magnetic conductivity material net (203) is placed in the middle of a flared pipe (201)and a straight cutting pipe (202) of a plastic pipe, and the portable type electromagnetic heating device is spliced on the exterior of the flared pipe (201) of the plastic pipe; the portable type electromagnetic heating device transfers high frequency electromagnetic pulse heating power to act on the magnetic conductivity material net (203) so as to generate vortex to heat, the heat can generate partial fusion with a contact surface of a contacting part, and the fusion splice of the plastic pipe is finished; the portable type electromagnetic heating device drives an electromagnetic heating belt (204), and the heating of the magnetic conductivity material net (203) is finished in step by step; and the fusion splice of the plastic pipe is repeatedly performed for many times, and the splice quality is guaranteed. The plastic pipe fusion bonding method provided by the invention is also suitable for plastic board materials.

Owner:李文忠

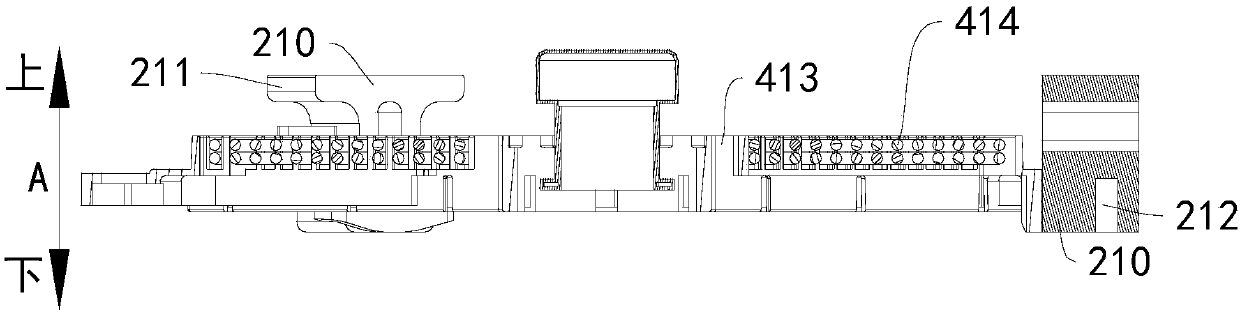

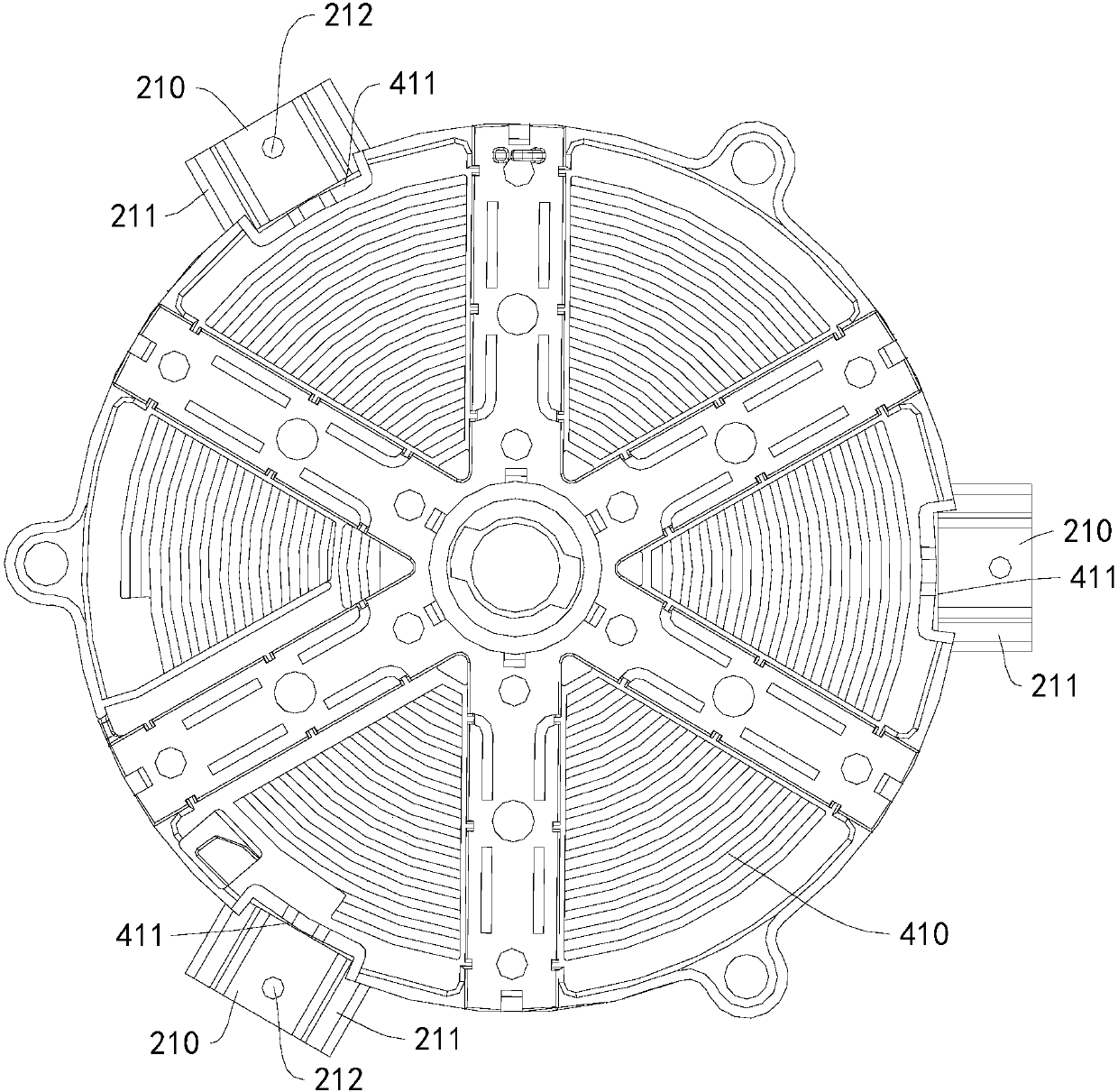

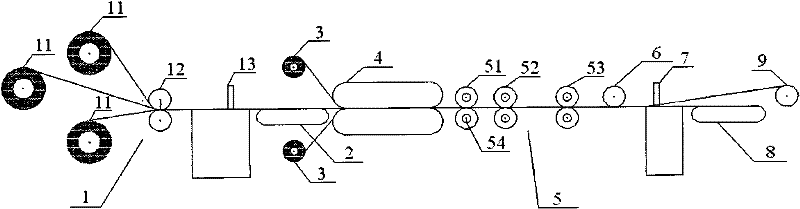

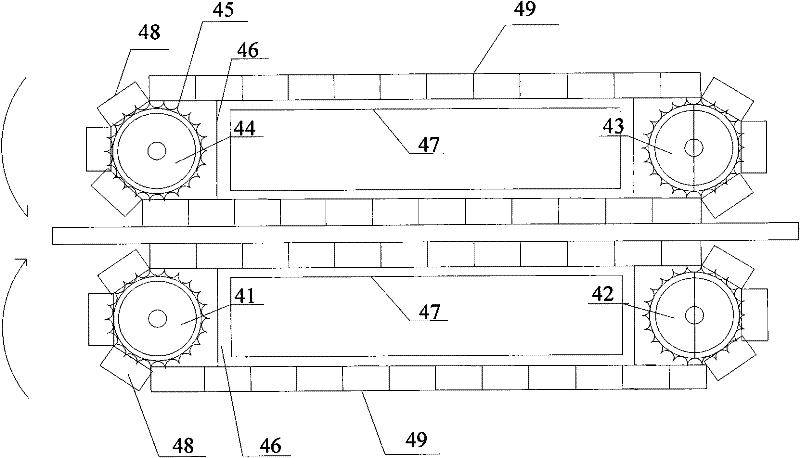

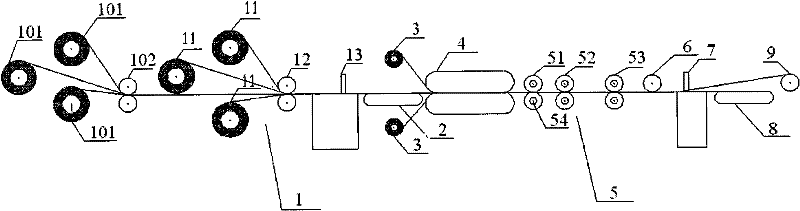

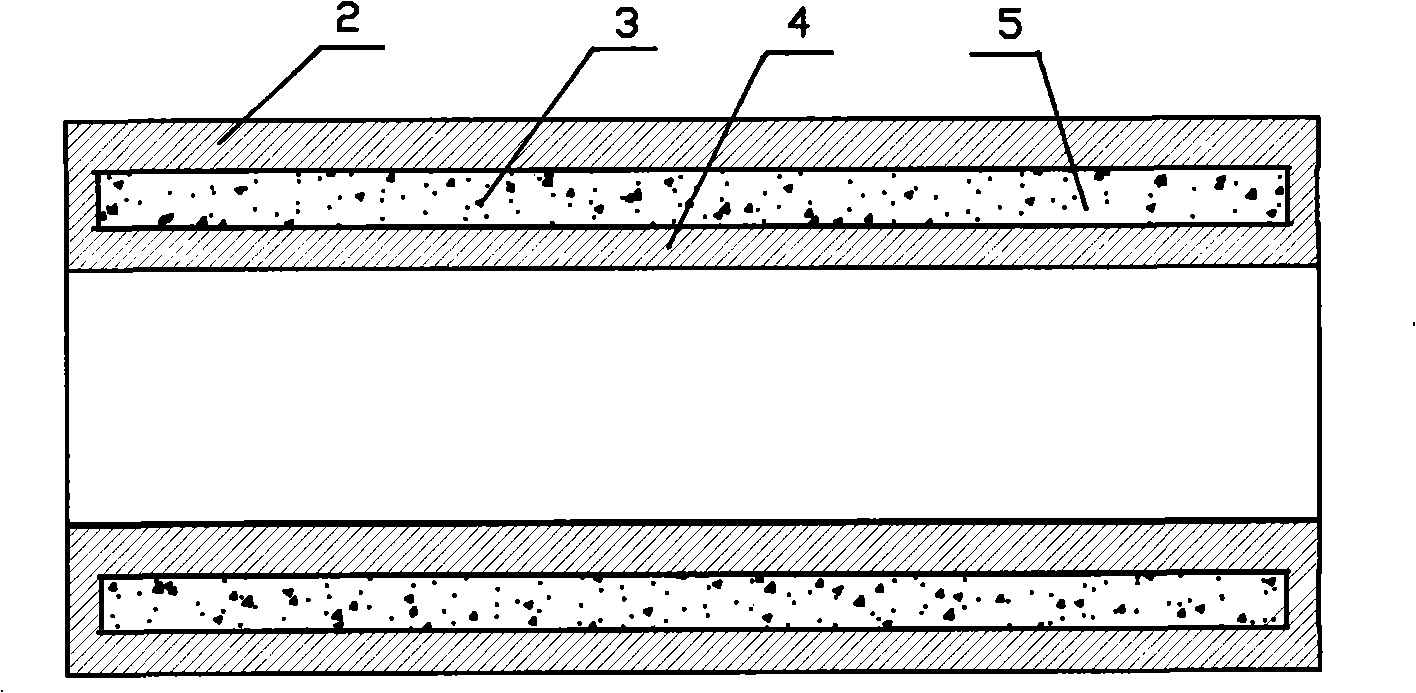

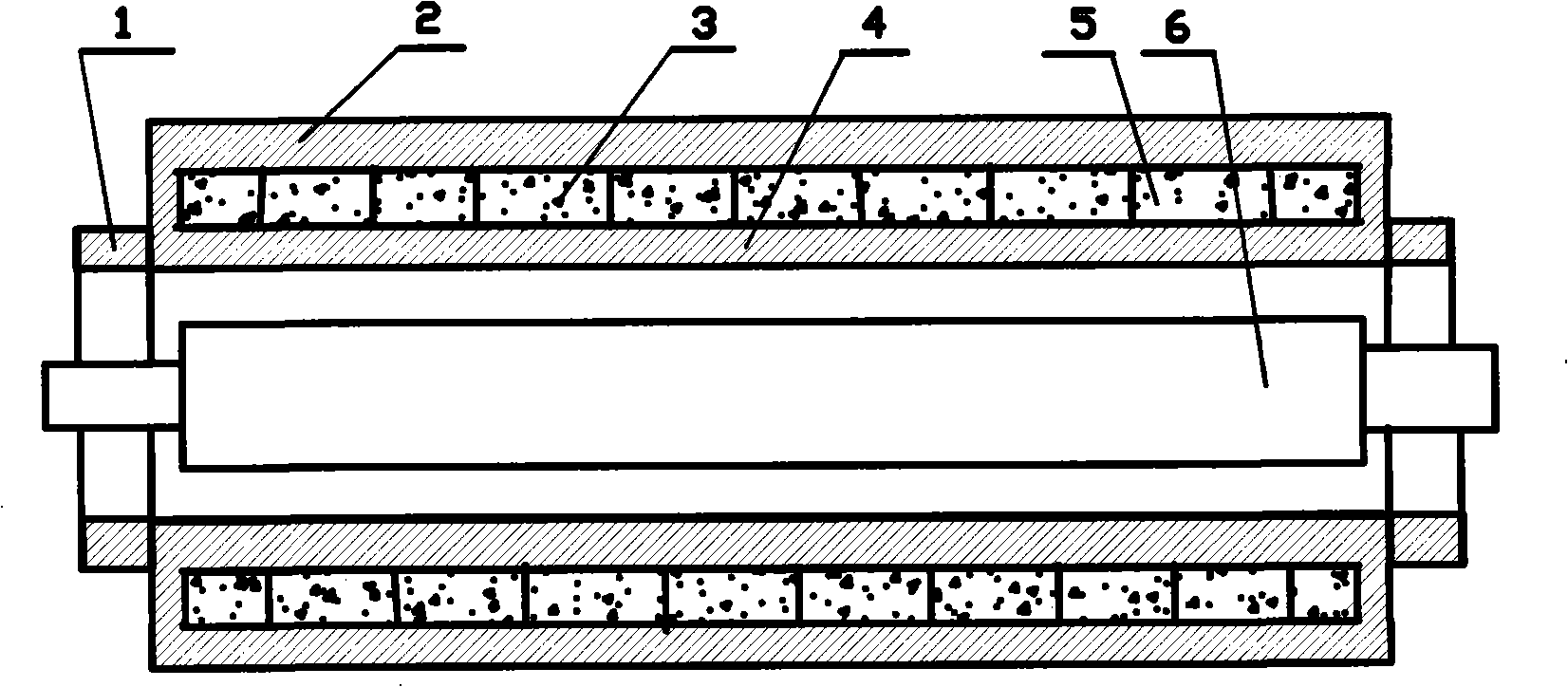

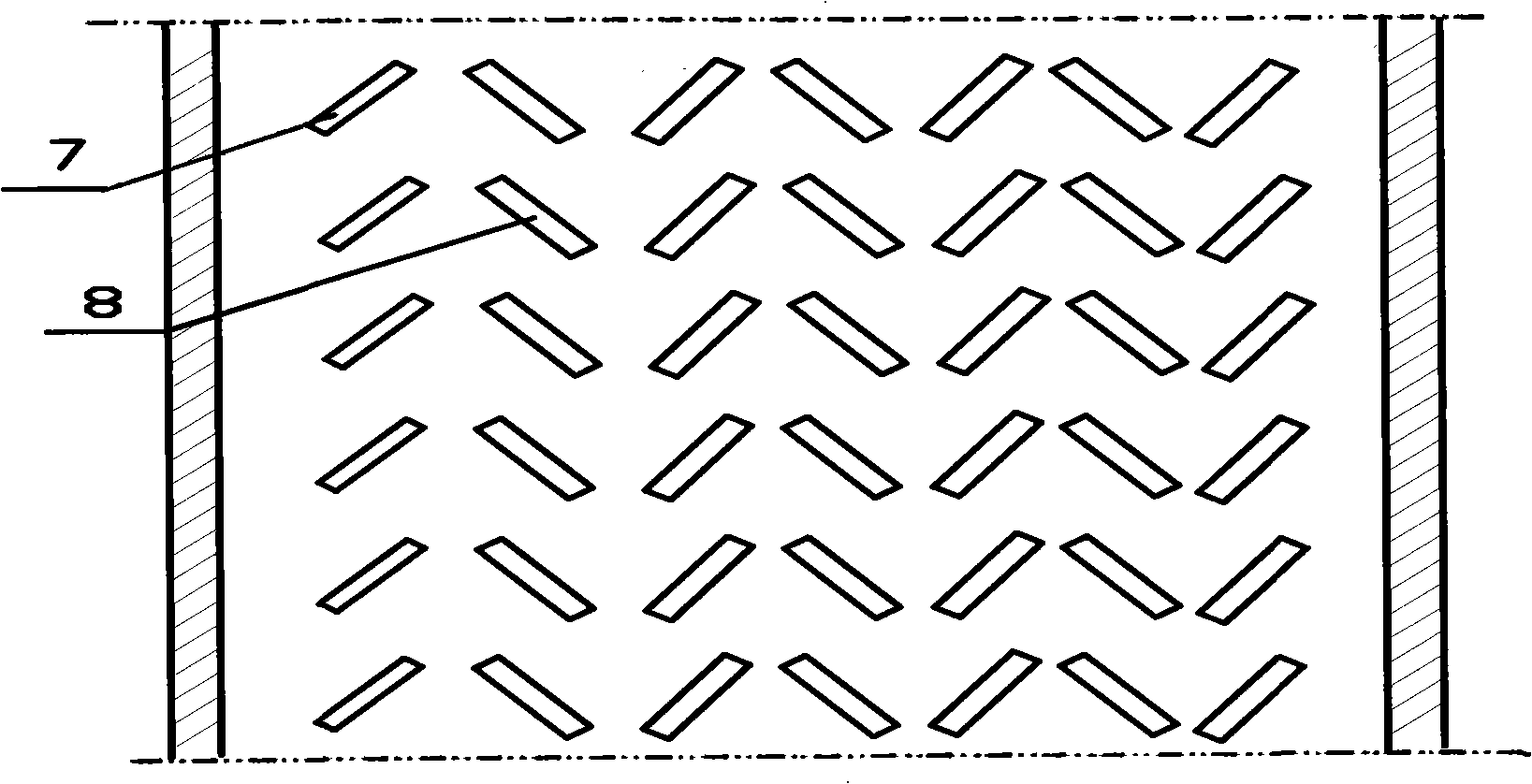

Production equipment for continuous fiber reinforced thermoplastic structural panel

ActiveCN102452209AEasy dischargeHigh degree of production automationLamination ancillary operationsLaminationThermoplasticCompression molding

The invention relates to production equipment for a continuous fiber reinforced thermoplastic structural panel. In the molding process of the panel, a continuous fiber reinforced thermoplastic prepreg tape and a sandwich material are conveyed to a panel compositing place by an automatic conveyer and performed with compression molding by crawler-type hot pressing compositing, and cold pressing molding by a roll shaft. The mode of heating is electromagnetic heating. Compared with prior art, the invention has simple process and high production efficiency and is able to produce continuous panels and large area composite panels. The equipment is suitable for use in sandwich panels formed by the continuous fiber reinforced thermoplastic structural panel and continuous fiber reinforced thermoplastic plastic and composite panels formed by continuous fiber reinforced thermoplastic plastic and metals such as aluminum foil and the like.

Owner:LIAONING LIAOJIE SCI & TECH

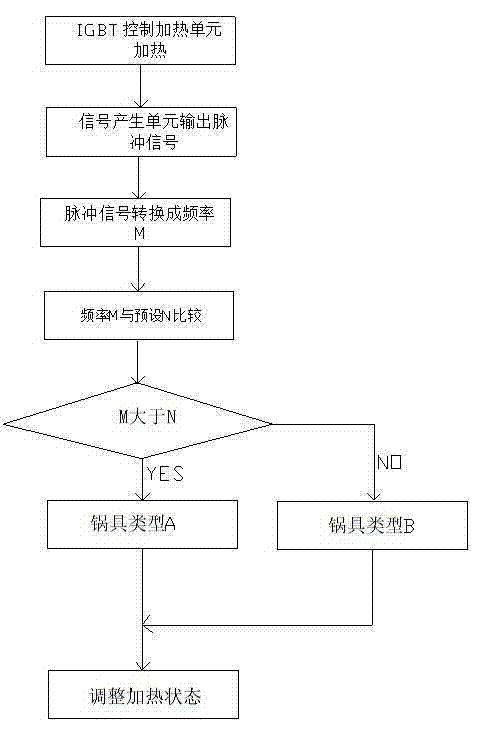

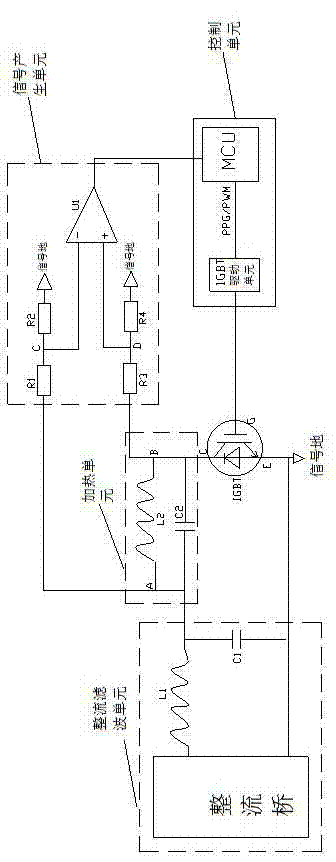

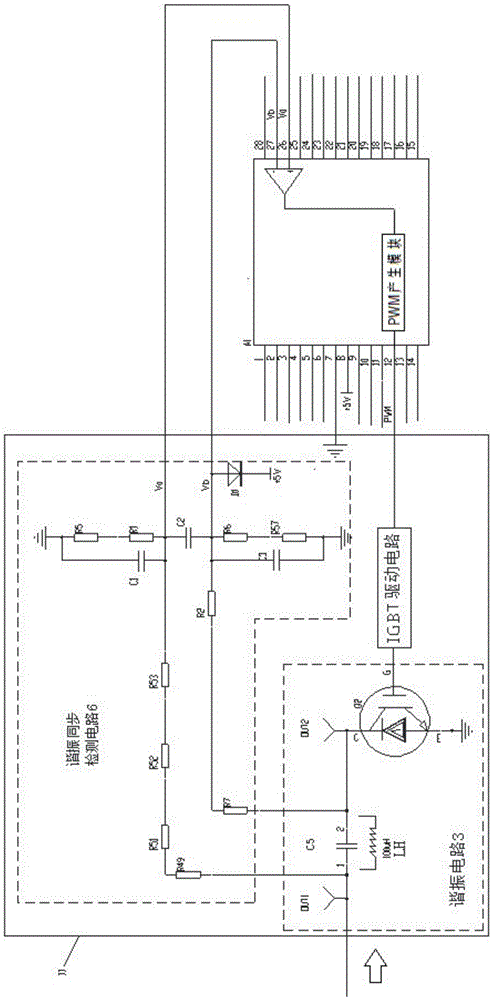

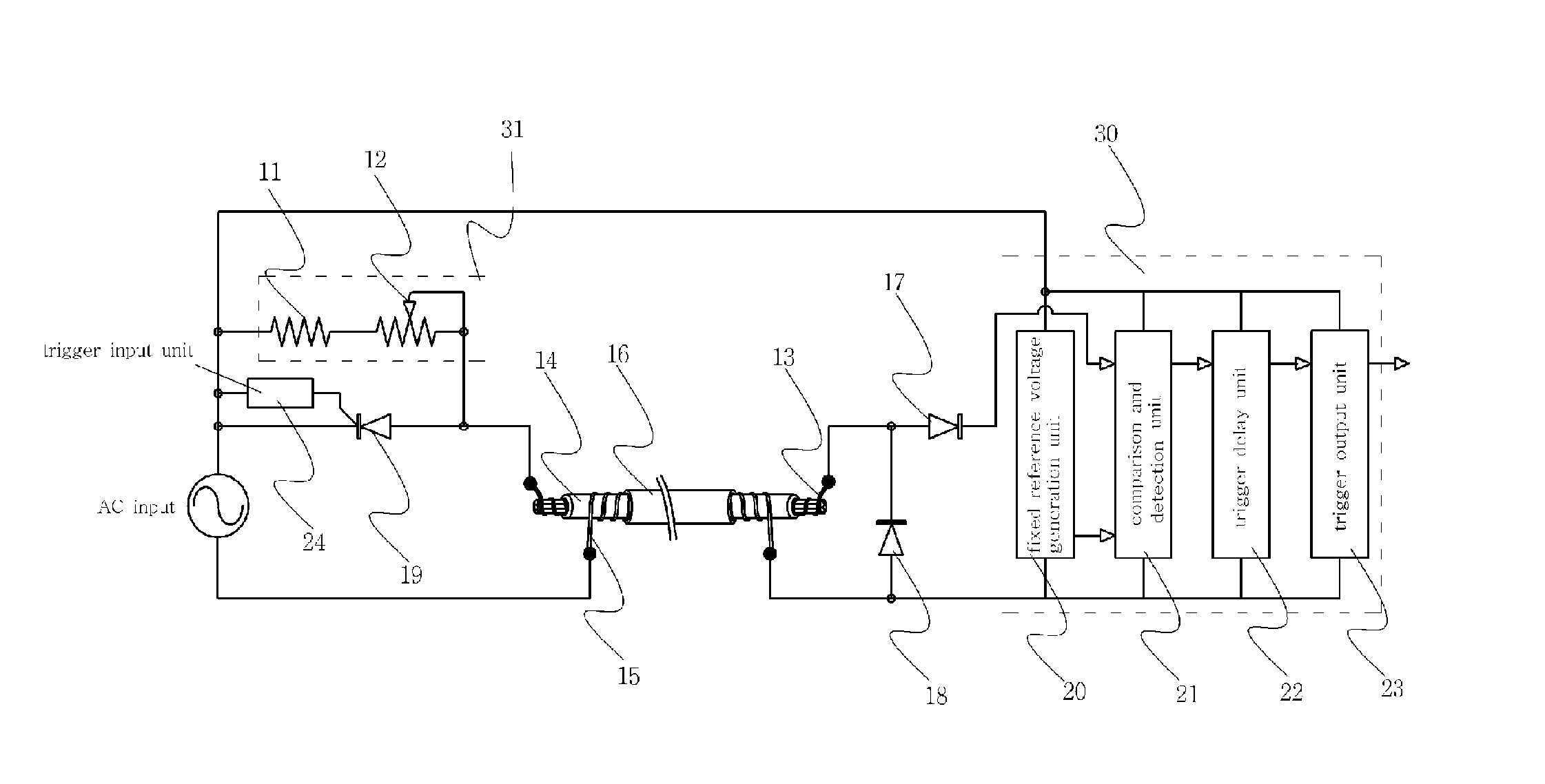

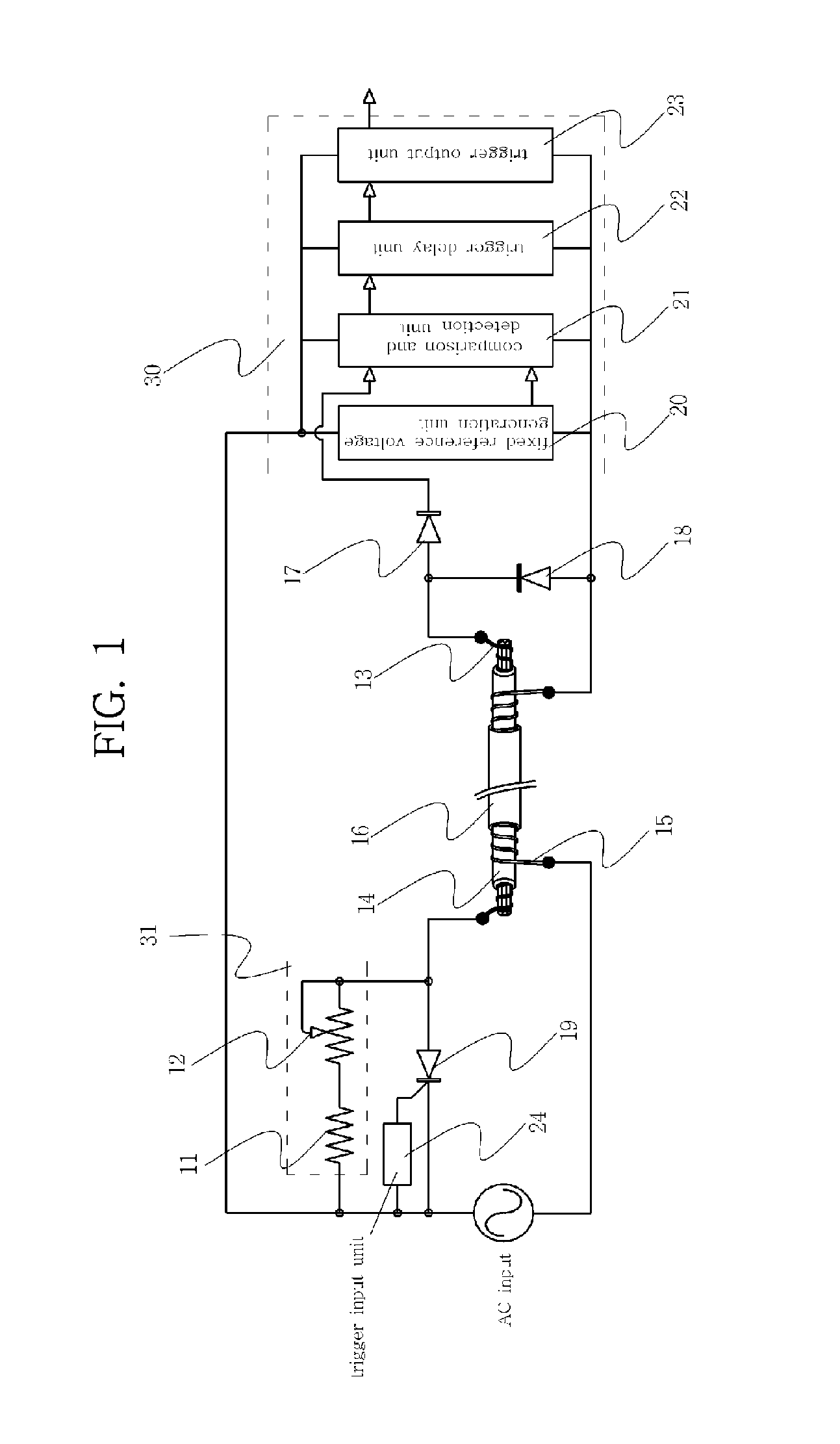

Control circuit for cookware material judgment and method thereof

ActiveCN102905411AAdjust heating statusImprove heating efficiencyInduction heating controlInduction heating apparatusError checkElectromagnetic heating

The invention discloses a control circuit for cookware material judgment and a method thereof. The method comprises the following steps: when an electromagnetic heating device works, a control unit controls an IGBT (Insulated Gate Bipolar Transistor) so as to enable a heating unit to heat; a signal generating unit outputs pulse signals to an MCU (Micro Controller Unit) of the control unit correspondingly according to the on / off state of the IGBT; the MCU records the input pulse signals and converts the pulse signals into frequency M; the frequency M is compared with preset frequency threshold N, and the type of cookware is determined to be A when the frequency M is higher than the preset frequency threshold N; the type of the cookware is determined to be B when the frequency M is less than or equal to the preset frequency threshold N; and the MCU adjusts related heating parameters according to the determined type of the cookware, so as to enable the electromagnetic heating device to adjust a heating state. The control circuit and the method have the advantages that an electromagnetic oven can be adjusted into a working state corresponding to the material of the cookware, the material of the cookware is judged in good time so as to carry out error check, and the like; and the material of the cookware is accurately updated so as to adjust the heating state and increase the heating efficiency.

Owner:MIDEA GRP CO LTD

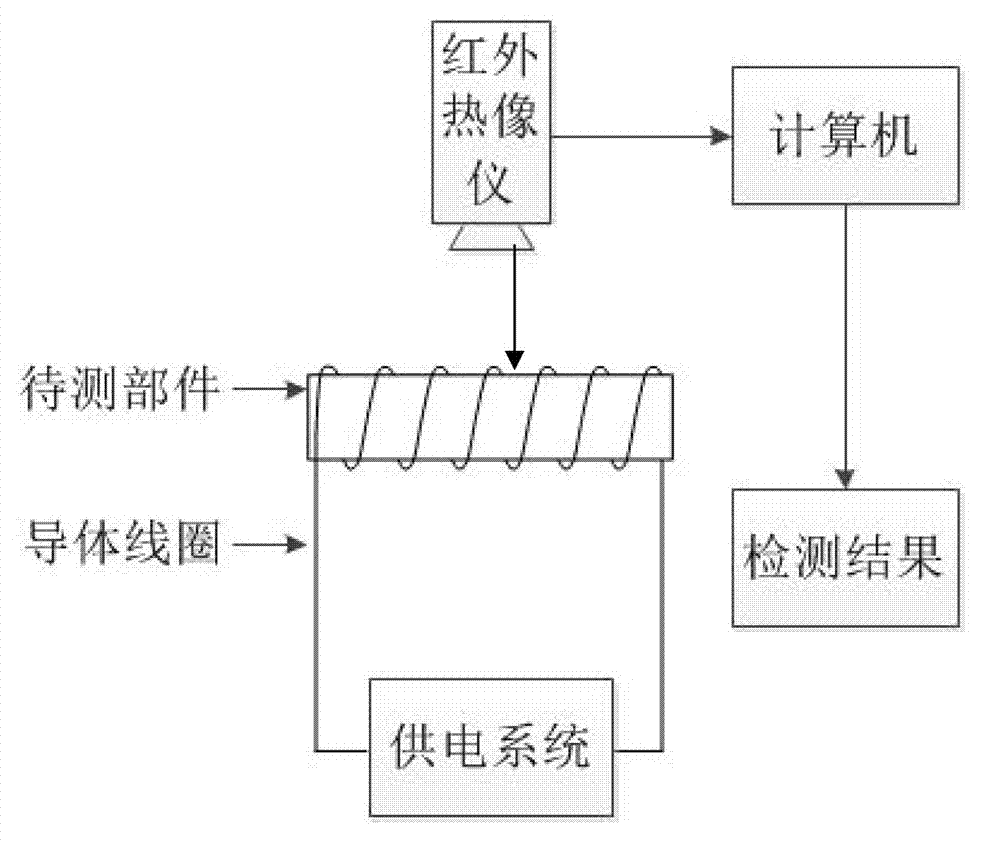

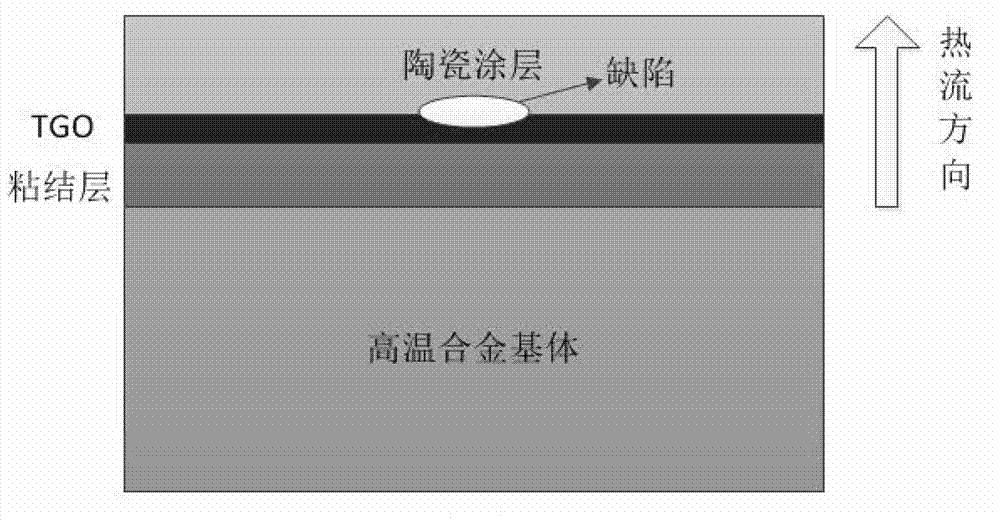

Thermal barrier coating part electromagnetic eddy current thermal imaging non-destructive detection system and detection method thereof

InactiveCN102954968AHigh precisionEvenly distributedOptically investigating flaws/contaminationElectrical conductorCeramic coating

The invention relates to a thermal barrier coating part electromagnetic eddy current thermal imaging non-destructive detection system and a detection method thereof. The detection system comprises an electromagnetic heating device connected with a thermal barrier coating part requiring detection, an infrared thermal imager, and a computer connected with the infrared thermal imager. The detection method comprises that: a conductor coil of the electromagnetic heating device is wound on a thermal barrier coating part requiring detection, the conductor coil is connected with a power supply system, the infrared thermal imager is adopted to carry out infrared image acquisition on a coating surface temperature field of the thermal barrier coating part requiring detection, the acquired image is input into the computer, and computer processing is performed to finally obtain the detection result. According to the present invention, electromagnetic induction is adopted to heat a high temperature alloy substrate, and the ceramic coating surface temperature field is monitored to obtain defect distribution; heat generated by eddy current is uniformly distributed, the detection result has high accuracy, and errors due to different heat flow injection directions are avoided; the detection process does not cause damage on the thermal barrier coating part requiring detection; and detection speed is rapid, efficiency is high, operation is convenient, and cost is low.

Owner:XI AN JIAOTONG UNIV

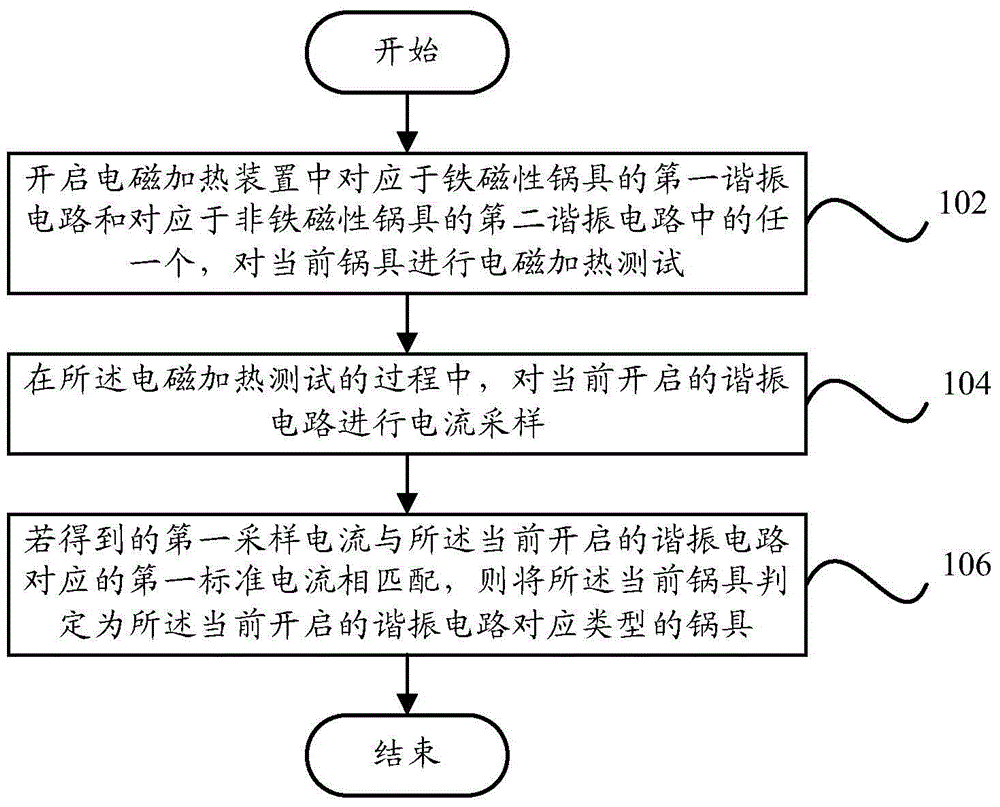

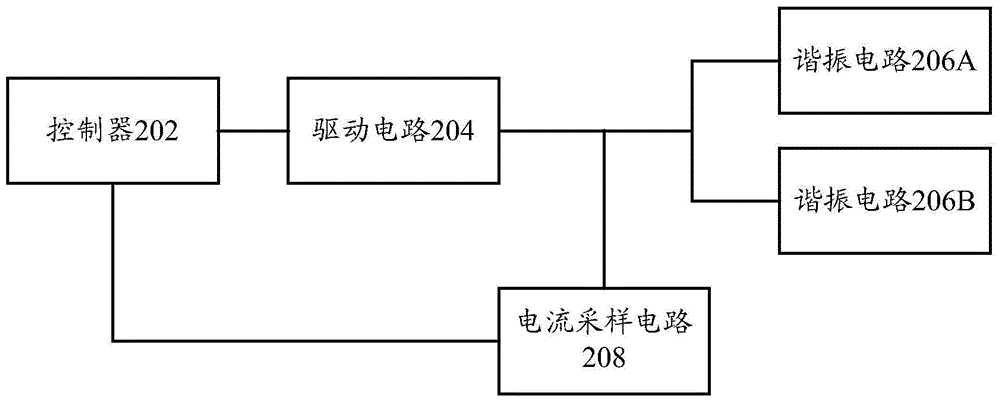

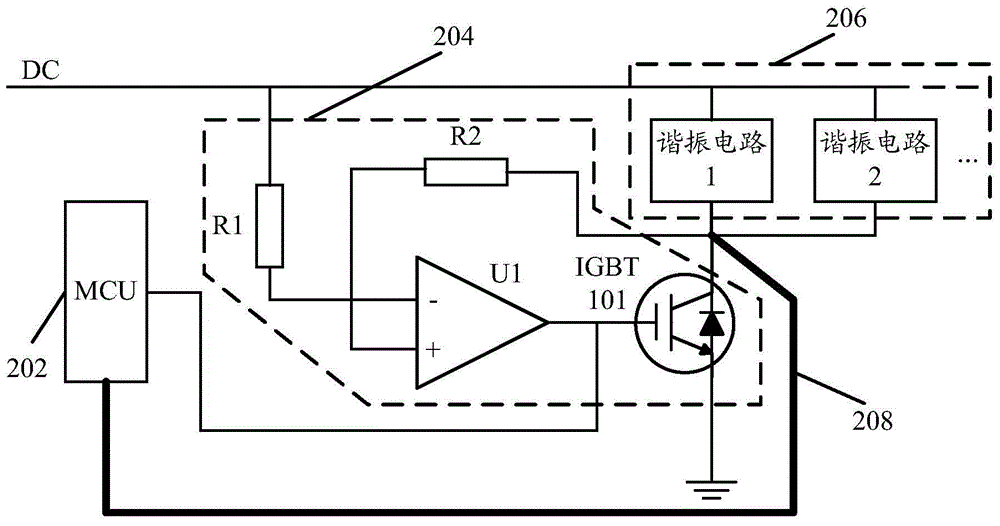

A detection method for types of cookers and an electromagnetic heating apparatus

ActiveCN103607798ARealize automatic judgmentAvoid mixingInduction heating controlResonanceEngineering

The invention provides a detection method for types of cookers. The detection method for the types of the cookers comprises the following steps: any one of a first resonance circuit corresponding to ferromagnetic cookers or a second resonance circuit corresponding to non ferromagnetic cookers in an electromagnetic heating apparatus is switched on, and electromagnetic heating testing is carried out on a present cooker; in the process of the electromagnetic heating testing, current sampling is carried out on the switched-on resonance circuit; if an obtained first sampling current is matched with a first standard corresponding to the switched-on resonance circuit, the cooker is determined to be a cooker of the type corresponding to the switched-on resonance circuit. The invention also brings forward the electromagnetic heating apparatus. Through the technical scheme of the present invention, the types of the cookers which need to be subjected to electromagnetic heating can be accurately determined, so that through selecting an appropriate heating, so that the electromagnetic heating carried out on metal cookers of various types can be realized.

Owner:MIDEA GRP CO LTD +1

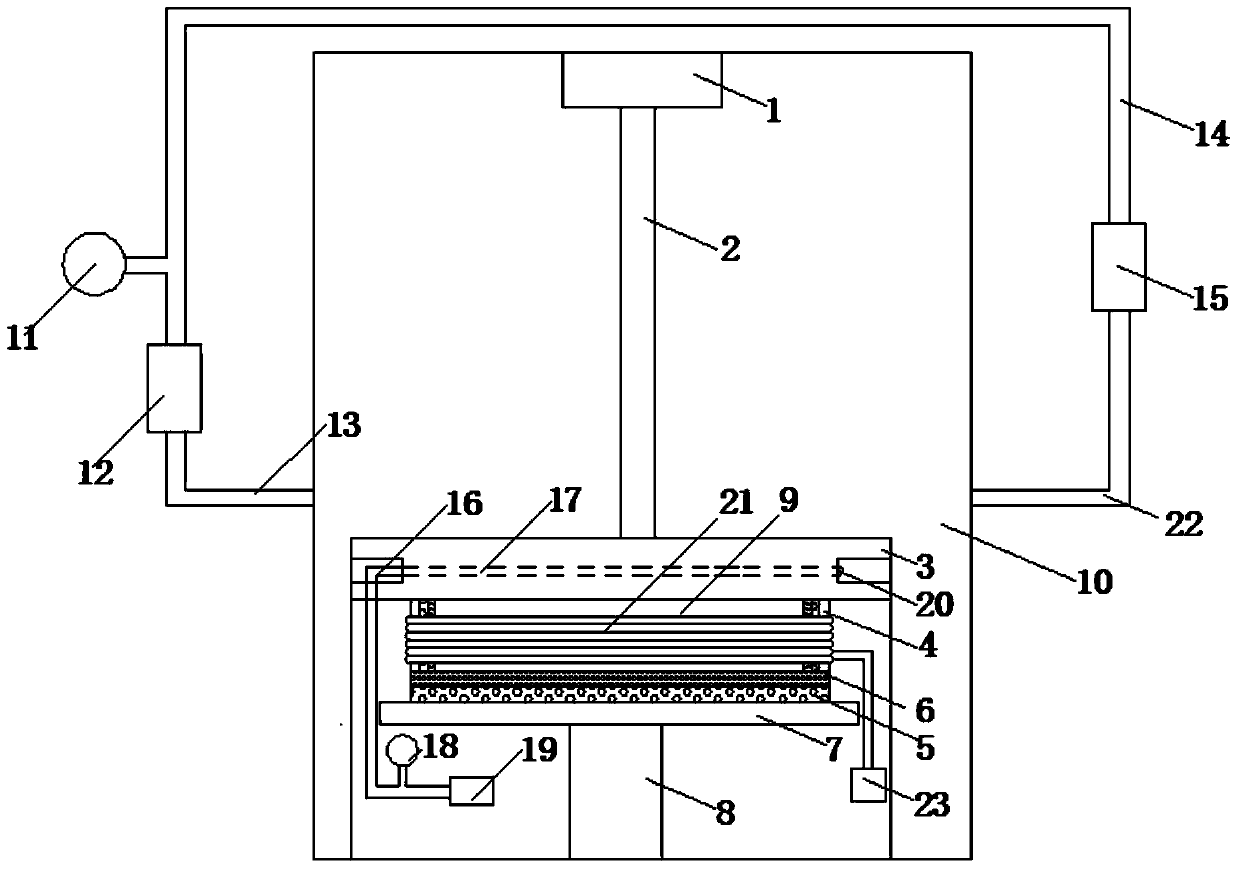

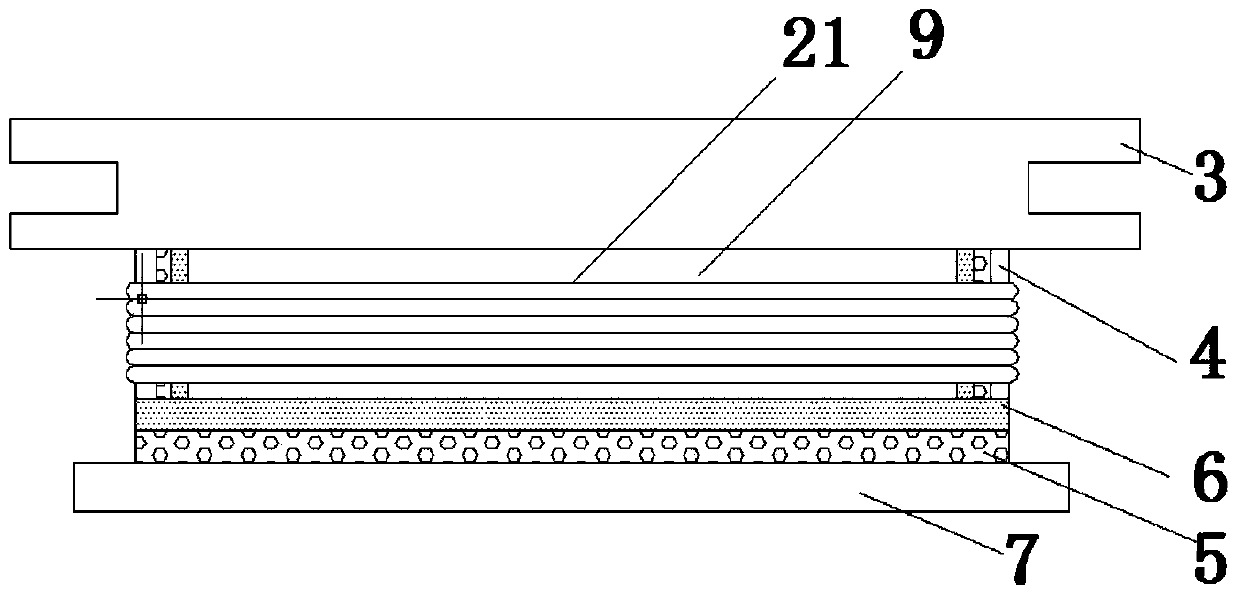

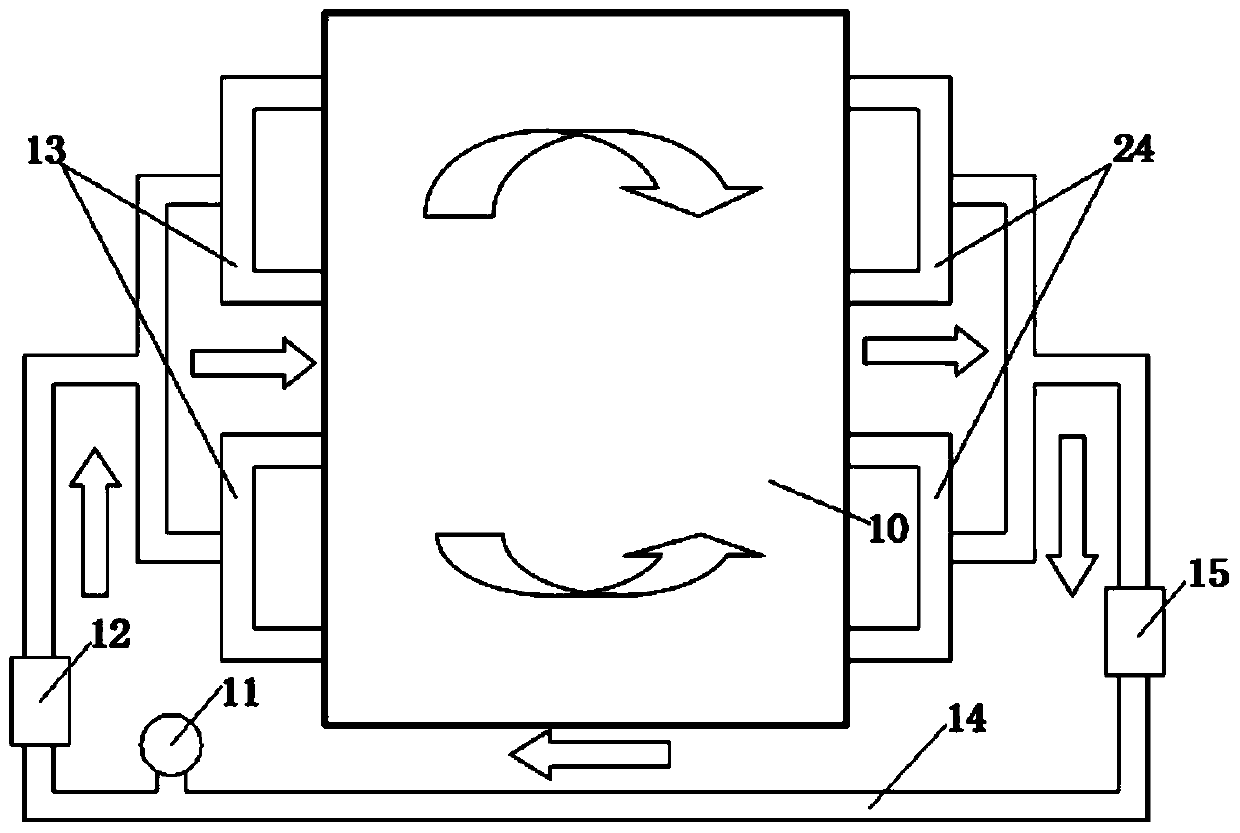

High-temperature powder bed system for laser additive manufacture

ActiveCN103990798AImprove energy utilizationShorten warm-up timeIncreasing energy efficiencyThermodynamicsInsulation layer

The invention discloses a high-temperature powder bed system for laser additive manufacture. The system comprises a working cavity, a laser device, a workbench, an electromagnetic heating layer, a heat insulation component and a laminar flow temperature uniforming component, the workbench is arranged in the working cavity, the electromagnetic heating layer is mainly composed of an electromagnetic induction plate and a coil, the electromagnetic heating layer is placed on the lower surface of the workbench and is attached to the workbench, and heat can be directly conducted to the workbench. A cooling flow way is arranged in the workbench, the bottom face and the side face of the electromagnetic heating layer are surrounded by the heat insulation component, and heat insulation and heat preservation of the electromagnetic heating layer can be achieved. The laminar flow temperature uniforming component is arranged outside the working cavity and used for achieving air flow circulation in the working cavity, and even temperature distribution of the workbench can be achieved. According to the part size, the work table board can be heated to be at the high temperature, heat preservation is performed, and temperature uniformization and the cooling functions after machining can be achieved. The aims of protecting the systems, and improving energy utilization rate and heating efficiency can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

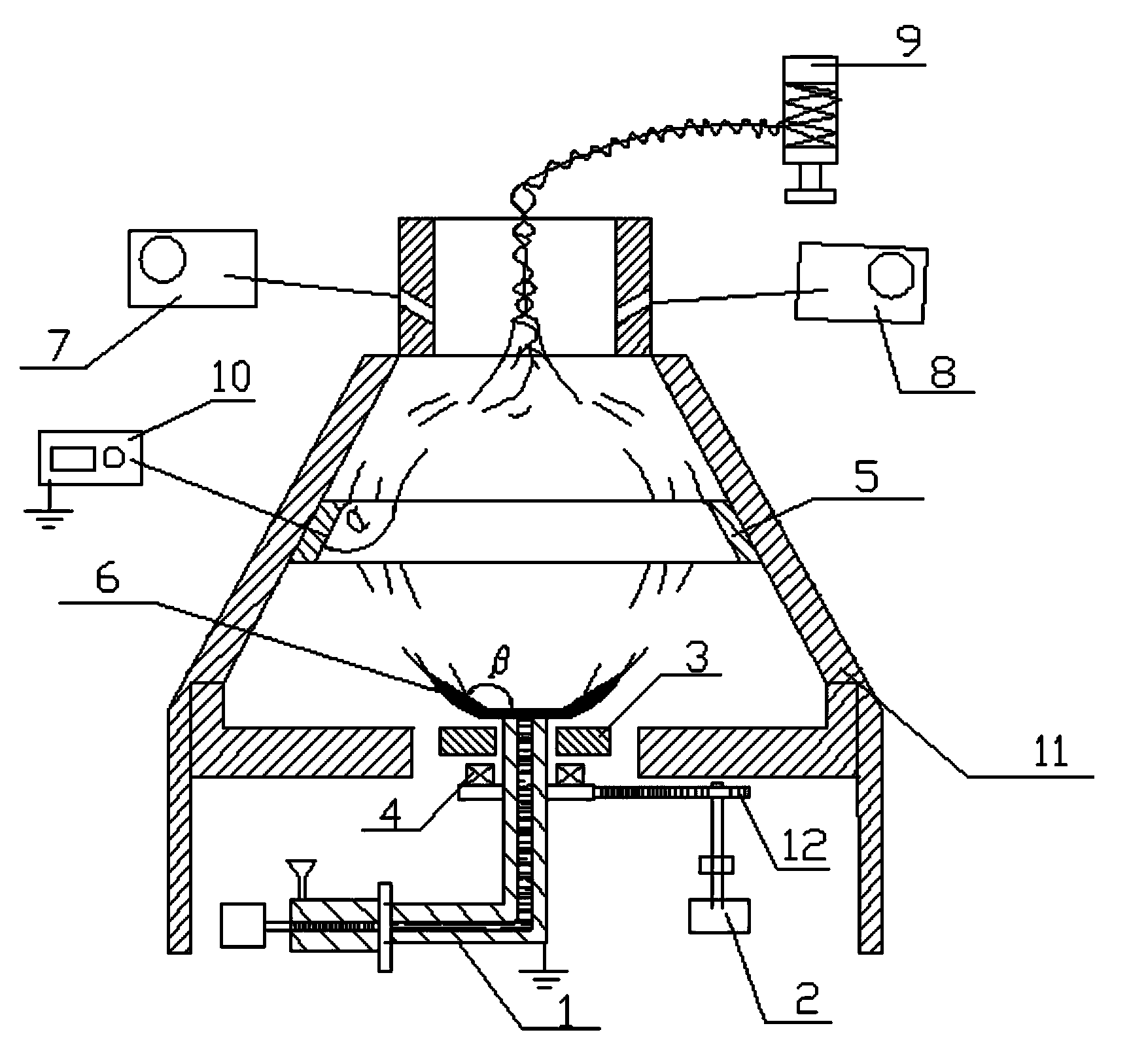

High-speed preparation device and process of centrifugal electrostatic spinning nanometer twisted yarns

ActiveCN103409861AAchieving Orientation ControllabilityIncrease elasticityFilament/thread formingContinuous wound-up machinesFiberYarn

The invention discloses a high-speed preparation device of centrifugal electrostatic spinning nanometer twisted yarns. The high-speed preparation device mainly comprises a feed extrusion device, a motor, an electromagnetic heating coil, a bearing, a conical ring perforated electrode, a centrifugal rotating umbrella-type spray head, an air compressor, a cyclone vacuum generator, a roller receiving device, a high-voltage electrostatic generator, a synchronous toothed belt and a rack, wherein the motor drives the centrifugal rotating umbrella-type spray head to rotate at high speed; the electromagnetic heating coil is in non-contact connection with the centrifugal rotating umbrella-type spray head and is heated through radiation; the feed extrusion device is used for supplying feed to the centrifugal rotating umbrella-type spray head through a hole in the center of the centrifugal rotating umbrella-type spray head; the conical ring perforated electrode is fixed at the middle position of the center of the rack. The high-speed preparation device is combined with an electrostatic spinning technology and a centrifugal spinning technology; a rotating airflow is formed in a chamber by the combined use of the air compressor and the cyclone vacuum generator to guide fiber to form twisted yarns, so that the orientation controllability of nanofiber is achieved; conditions are created for industrial application of the nanofiber in the specific industries, such as water treatment.

Owner:BEIJING UNIV OF CHEM TECH

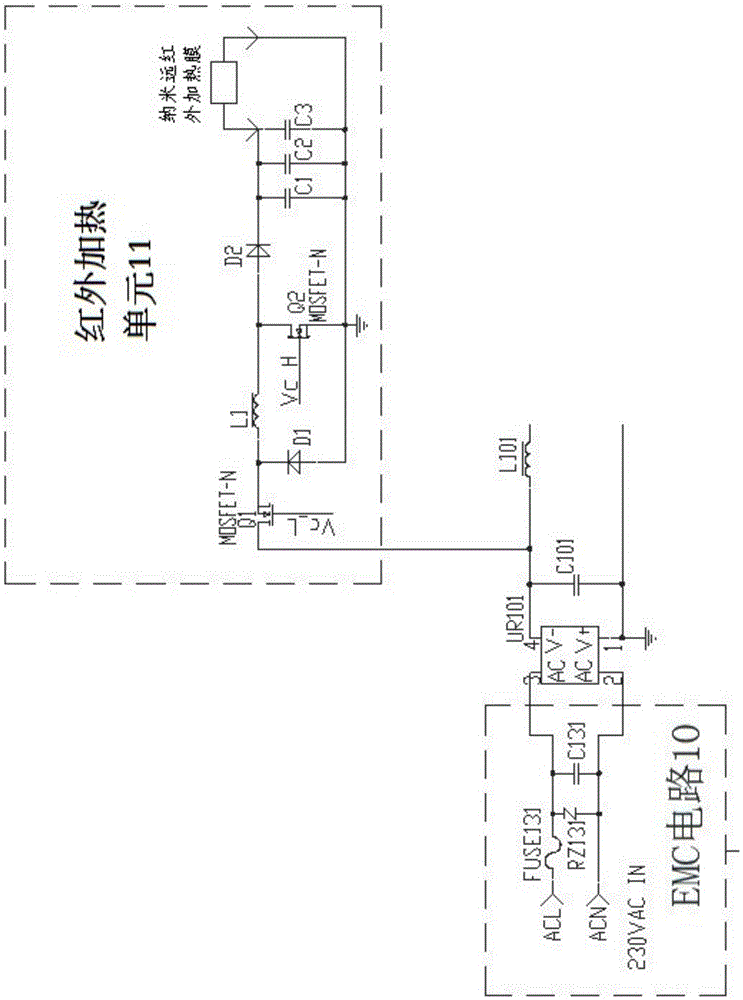

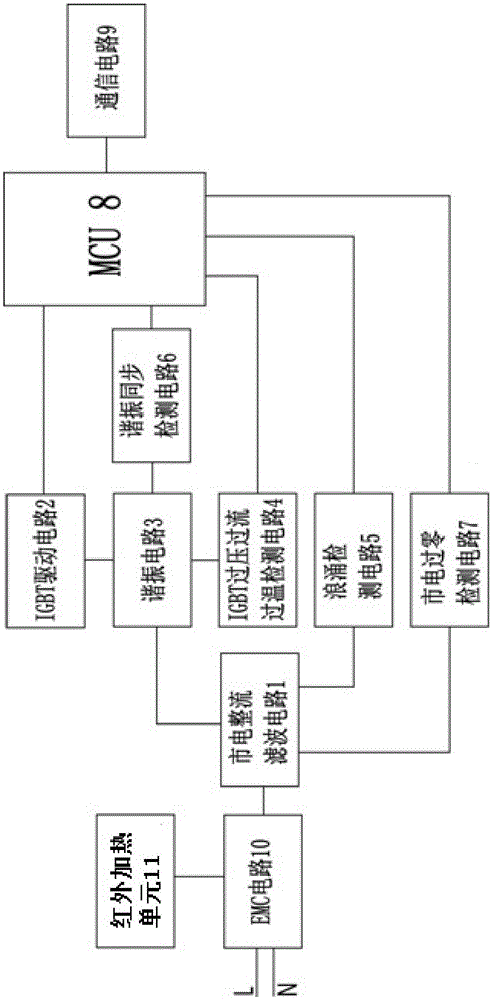

Electromagnetic heating equipment

ActiveCN106813269AUnrestricted heatingUnlimited maximum heating powerDomestic stoves or rangesLighting and heating apparatusEngineeringElectromagnetic heating

The invention relates to the technical field of electromagnetic oven heating and provides electromagnetic heating equipment. The electromagnetic heating equipment comprises an electromagnetic heating unit, an infrared heating unit and an MCU. The MCU is connected with the electromagnetic heating unit and the infrared heating unit and is used for controlling the electromagnetic heating unit and the infrared heating unit to conduct heating separately or simultaneously. The electromagnetic heating equipment comprises the electromagnetic heating unit and the infrared heating unit, therefore, heating appliances with different materials can be heated, and application of the electromagnetic heating equipment is wide and not limited. In addition, the electromagnetic heating equipment comprises the infrared heating unit, and hence the maximum heating power of the electromagnetic heating equipment is not limited by the maximum heating power of a coil disc.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

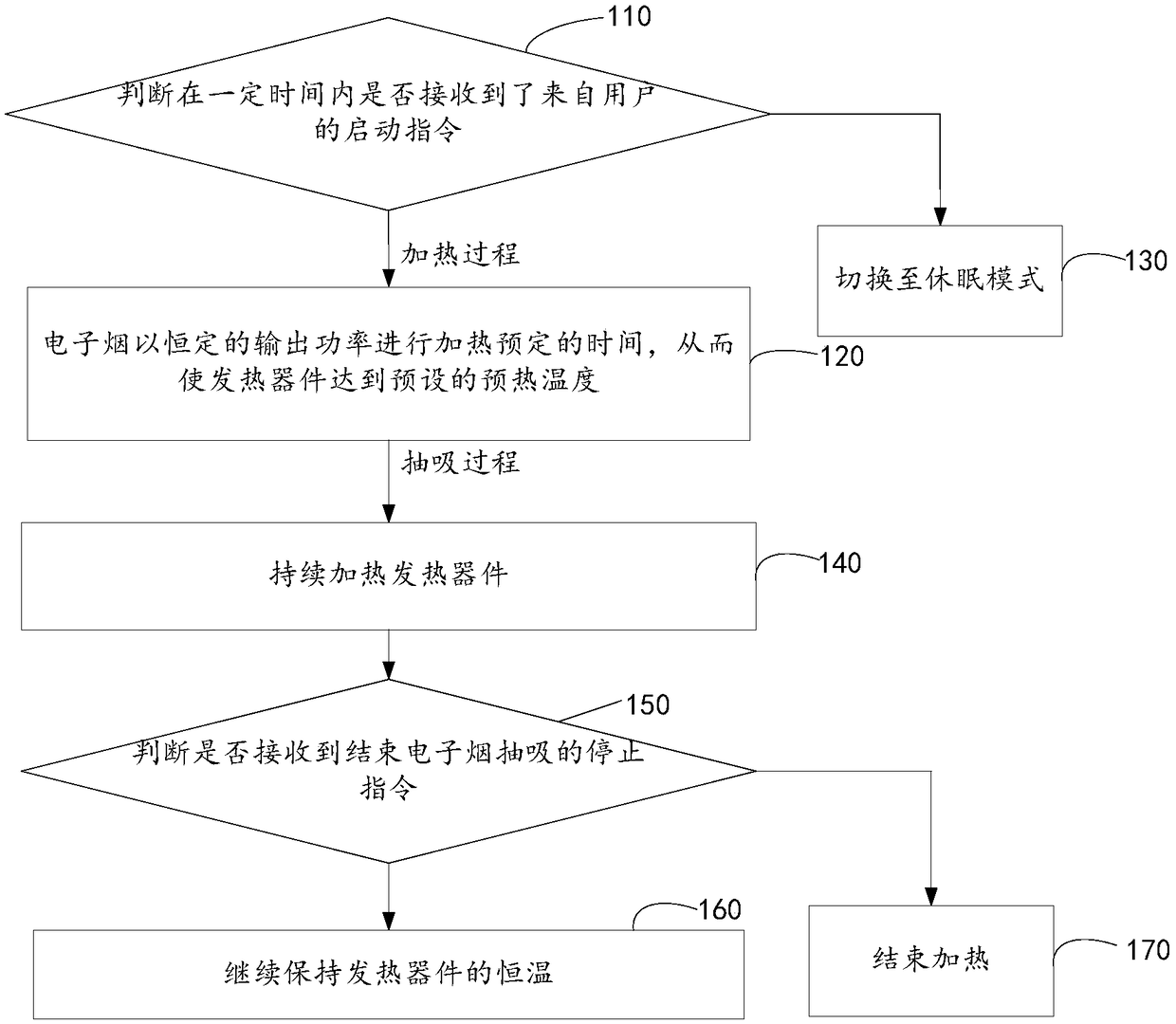

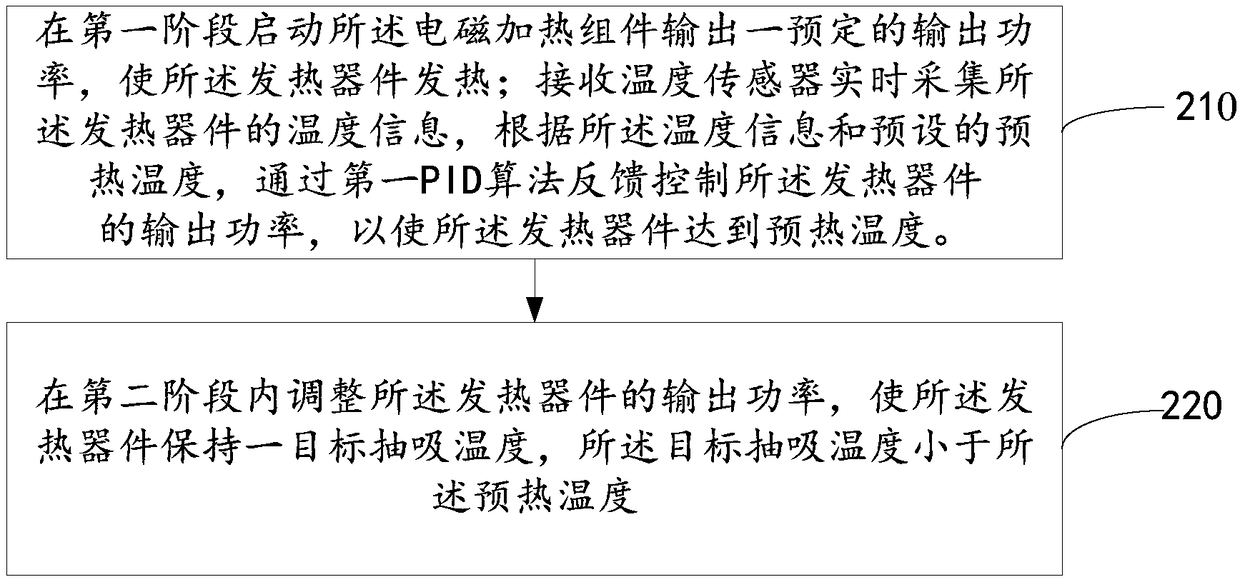

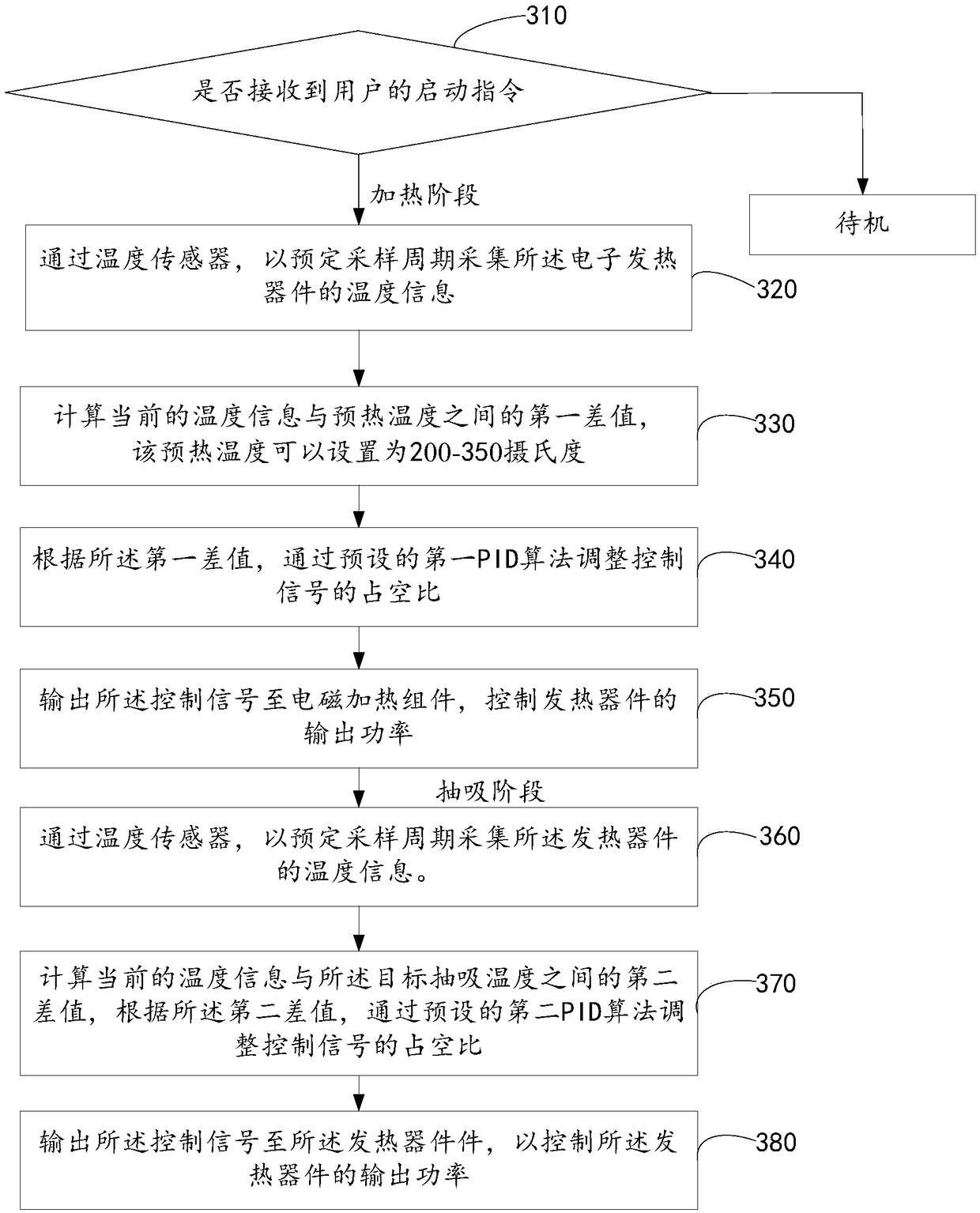

E-cigarette control method and e-cigarette set

InactiveCN108652089AExtension of timeSuction in timeCoil arrangementsTobacco devicesElectronic cigaretteEngineering

The invention relates to the technical field of e-cigarettes, in particular to an e-cigarette control method and an e-cigarette set. The method comprises: an electromagnetic heating element is startedin a first stage to output preset output power, so as to make a heating device emit heat; according to temperature information of the heating device and preset preheating temperature, the output power for the electromagnetic heating module is controlled through feedback of a first PID algorithm, so as to make the heating device reach the preheating temperature; after the heating device reaches the preheating temperature, the output power of the electromagnetic heating module is adjusted in a second stage to make the heating device maintain a target suction temperature, which is lower than thepreheating temperature. The e-cigarette control method provided by the embodiment of the invention adopts the mode of combining the PID algorithm and the electromagnetic heating, effectively improvesthe time for the heating device to reach the preheating temperature, which is basically 3-4 seconds or so, so that a user can feel the body feeling of timely suction.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Food cooking utensil

The invention relates to a food cooking utensil comprising a food container and an electromagnetic heating device. The food container is placed on the electromagnetic heating device; the electromagnetic heating device comprises a machine body, electromagnetic coils and a control circuit board, the electromagnetic coils are located in the machine body, and the control circuit board is electrically connected with the electromagnetic coils; the electromagnetic heating device is further provided with vibrating reeds, vibrating spaces are arranged between the vibrating reeds and the upper surfaces of the electromagnetic coils and between the vibrating reeds and the bottom surface of the food container, and the vibrating reeds induce an alternating magnetic field of the electromagnetic coils to generate ultrasonic waves. The vibrating reeds are arranged above the electromagnetic coils to induce the electromagnetic field to generate the ultrasonic waves which act on food in the food container, mouthfeel of the food is improved, and application of the ultrasonic waves to kitchen household appliances is achieved. The ultrasonic waves are generated and transmitted in a non-contact mode, direct contact with the high-temperature food container and the high-temperature electromagnetic coils can be avoided, temperature influences are small, and performance is stable and reliable. In addition, no driving circuit needs to be added, the structure is simple, and cost is low.

Owner:JOYOUNG CO LTD

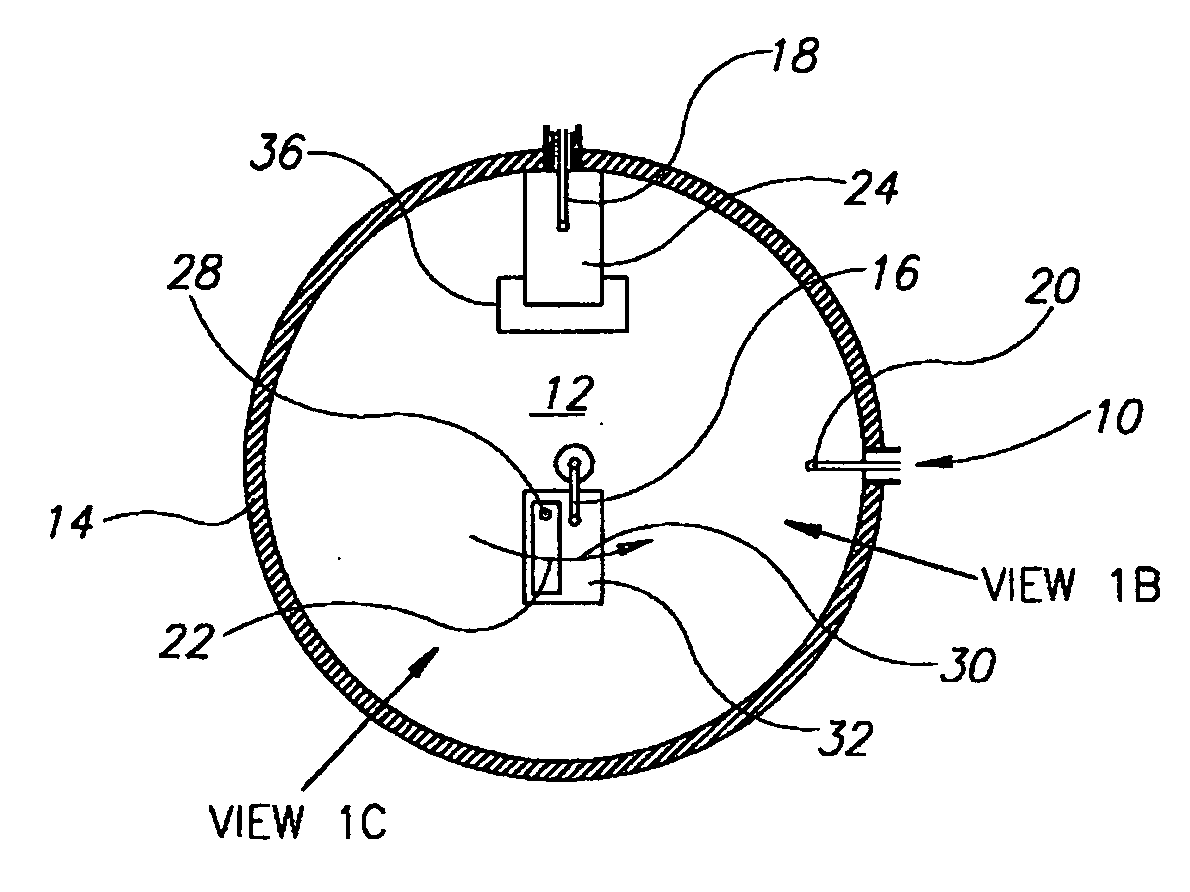

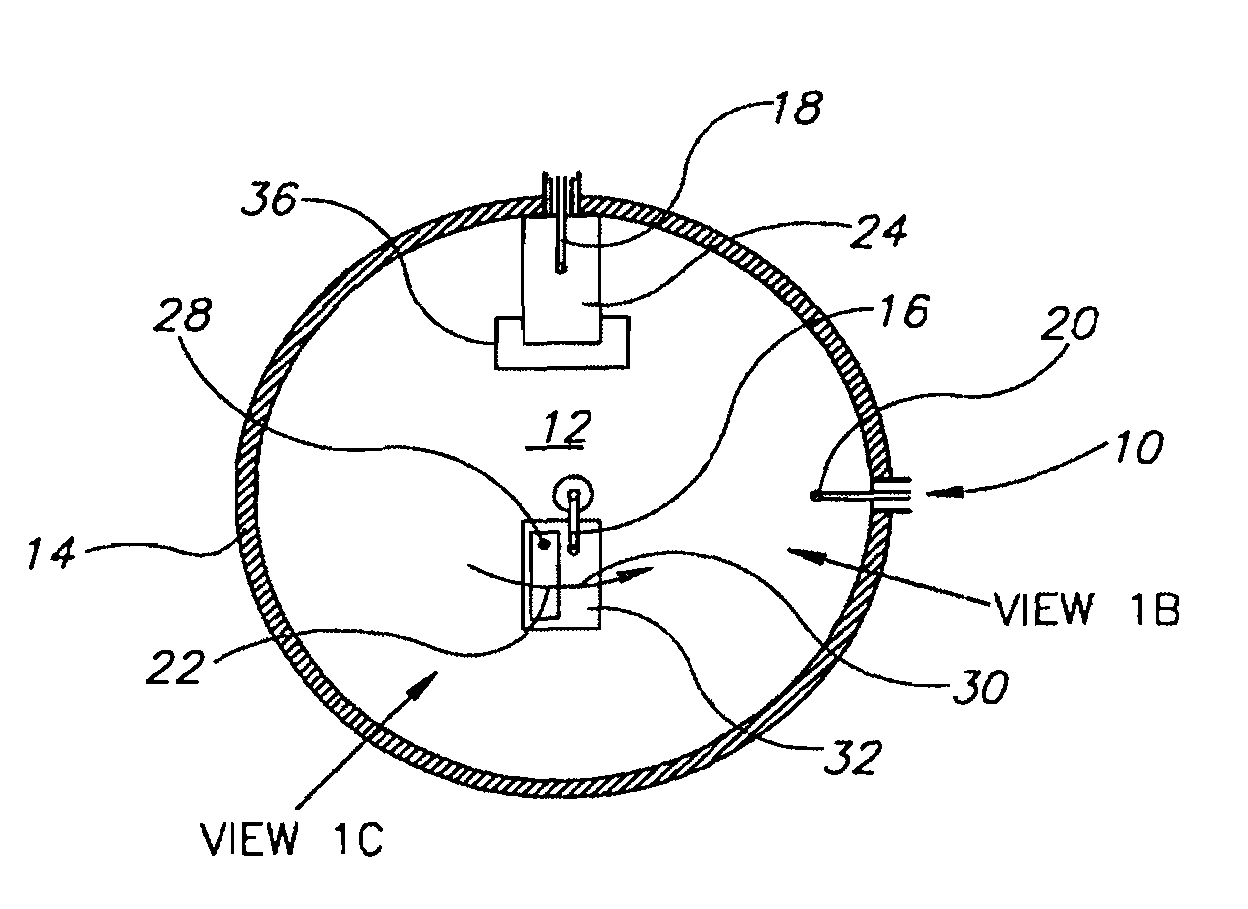

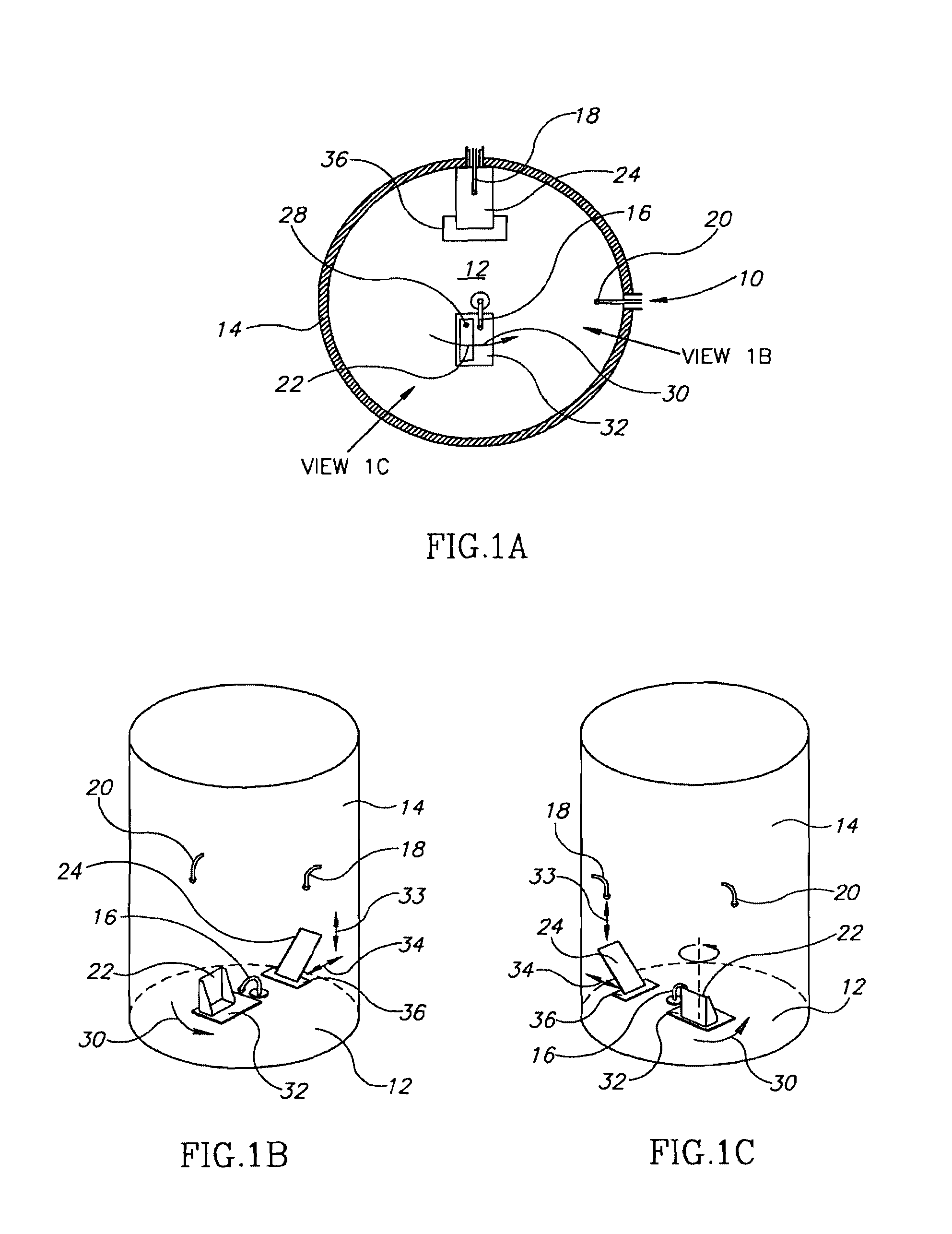

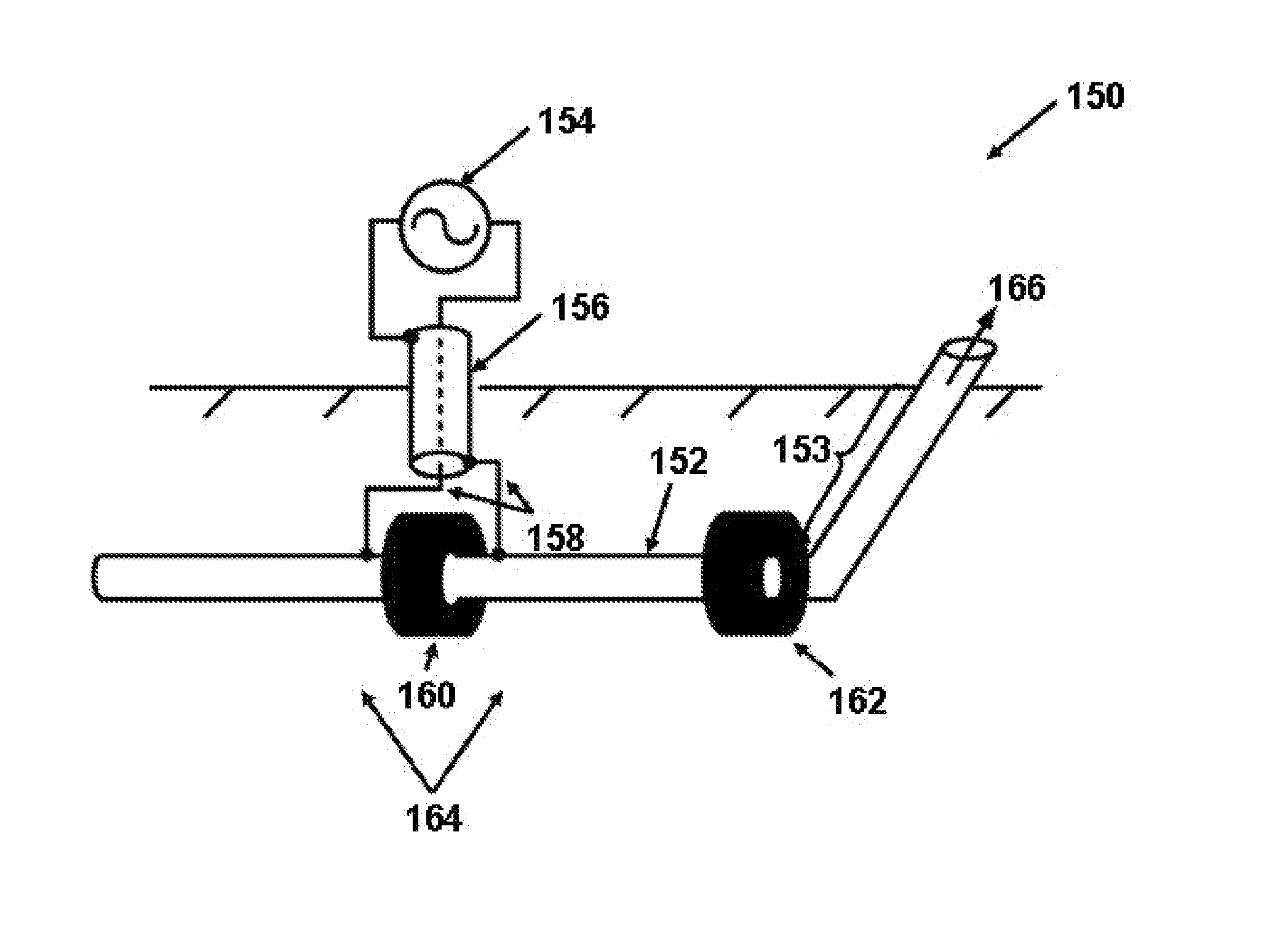

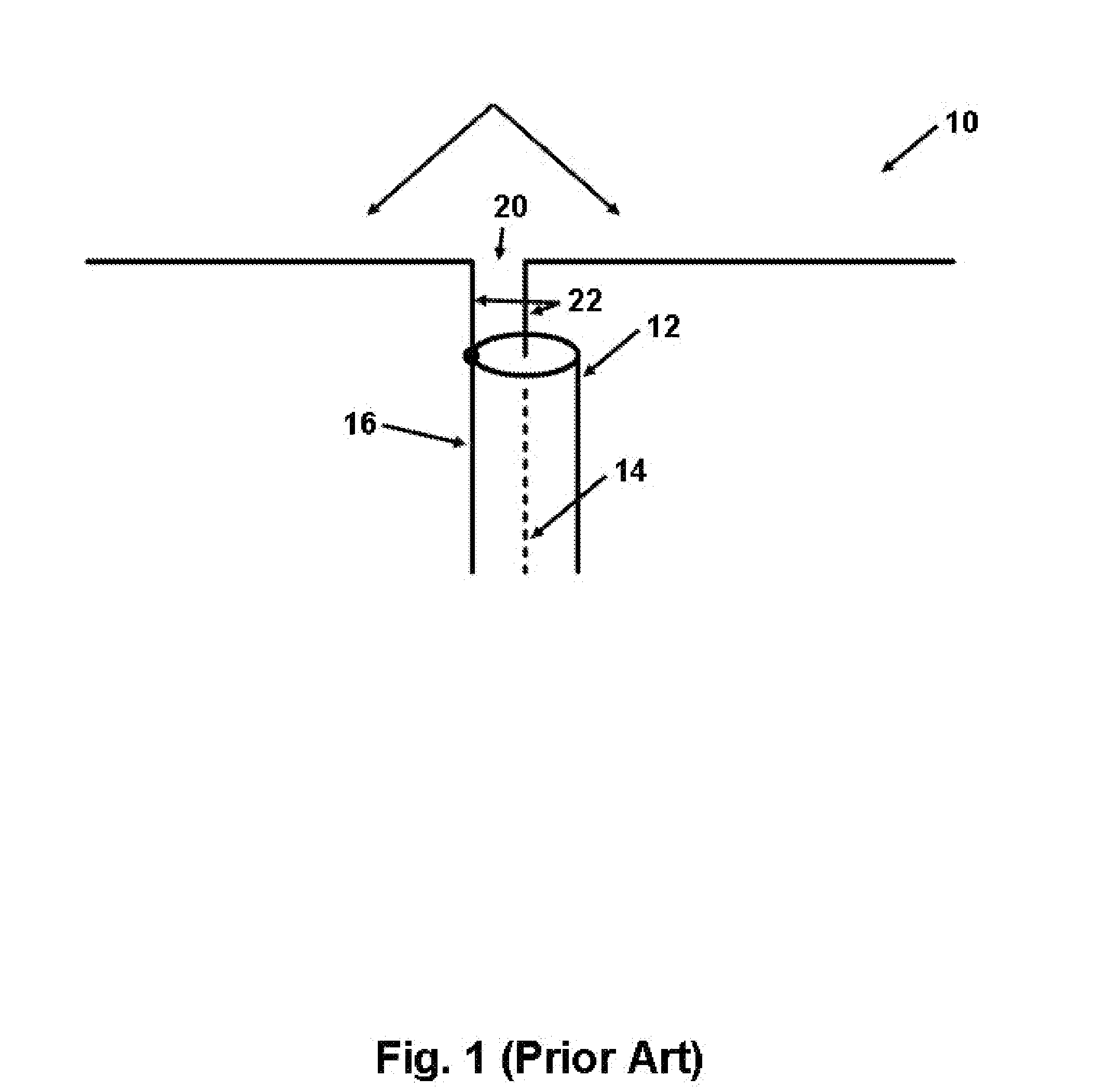

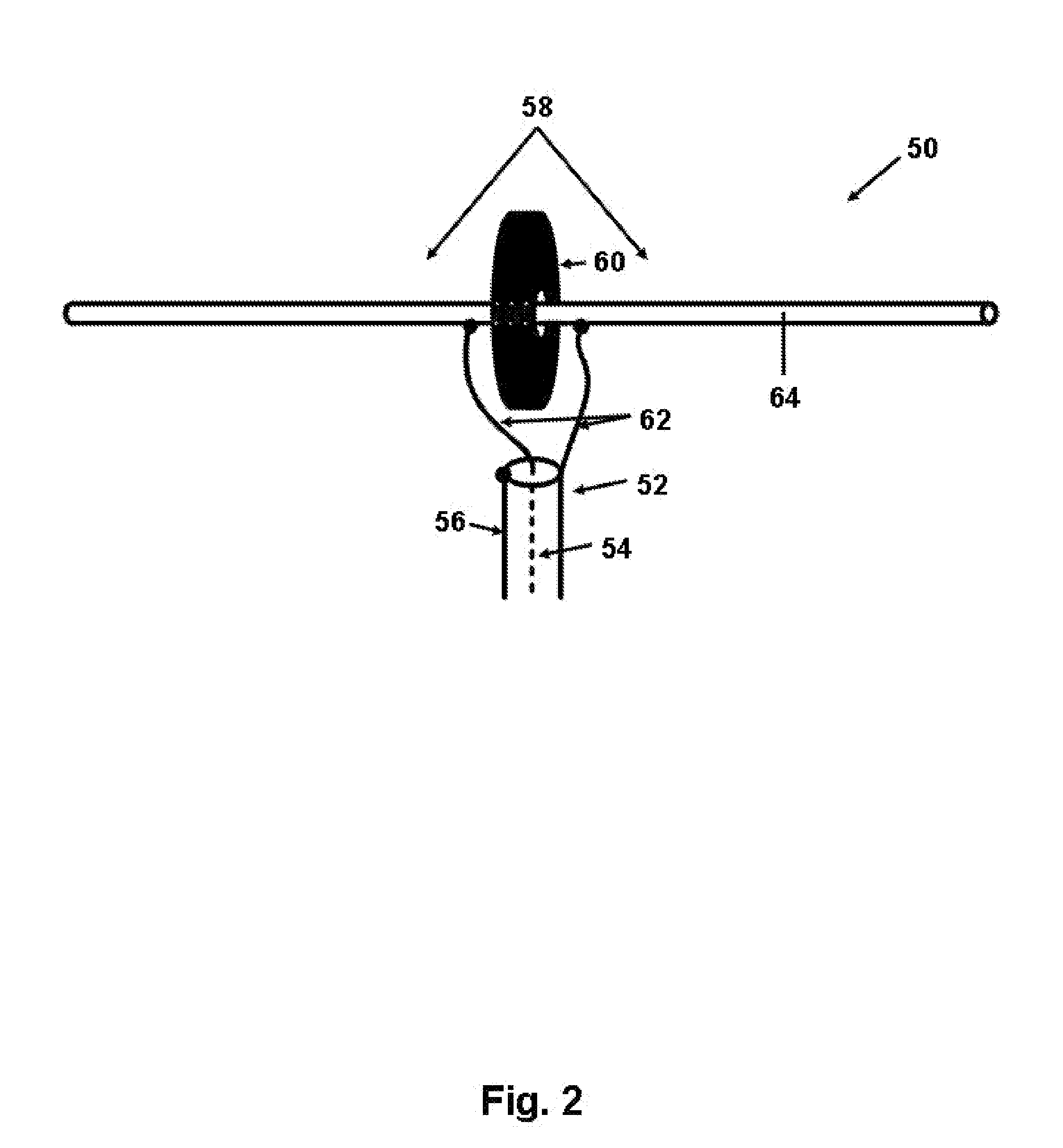

Continuous dipole antenna

A dipole antenna may be created by surrounding a portion of the continuous conductor with a nonconductive magnetic bead, and then applying a power source to the continuous conductor across the nonconductive magnetic bead. The nonconductive magnetic bead creates a driving discontinuity without requiring a break or gap in the conductor. The power source may be connected or applied to the continuous conductor using a variety of preferably shielded configurations, including a coaxial or twin-axial inset or offset feed, a triaxial inset feed, or a diaxial offset feed. A second nonconductive magnetic bead may be positioned to surround a second portion of the continuous conductor to effectively create two nearly equal length dipole antenna sections on either side of the first nonconductive magnetic bead. The nonconductive magnetic beads may be comprised of various nonconductive magnetic materials, and preformed for installation around the conductor, or injected around the conductor in subsurface applications. Electromagnetic heating of hydrocarbon ores may be accomplished.

Owner:HARRIS CORP

Electromagnetic heating

ActiveUS20100006564A1Limited abilityImprove uniformityDomestic stoves or rangesLighting and heating apparatusMicrowaveDisk controller

An electromagnetic heater for heating an irregularly shaped object, including:a cavity within which an object is to be placed;at least one feed which feeds UHF or microwave energy into the cavity; anda controller that controls one or more characteristics of the cavity or energy to assure that the UHF or microwave energy is deposited uniformly in the object within ±30% over at least 80% of the volume of the object.

Owner:JOLIET 2010 LTD

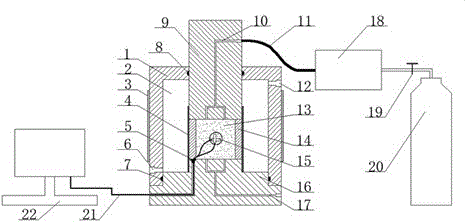

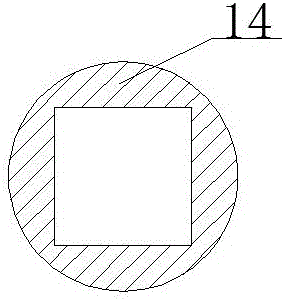

Device and method for measuring permeability and elasticity modulus of anisotropic rocks

ActiveCN106769767AReasonable structureEasy to operateMaterial strength using tensile/compressive forcesPermeability/surface area analysisRock coreEngineering

The invention provides a device and method for measuring the permeability and the elasticity modulus of anisotropic rocks. The device comprises a triaxial pressure kettle for providing different pressure, rubber sleeves for arranging cube rock cores at different azimuths, a strain gauge for measuring strains of the rock cores at different azimuths, an electromagnetic heating coil for providing different temperatures, and a gas channel and an air groove for facilitating gas transportation. The measuring device is reasonable in structure and simple in operation; the permeability and the elasticity modulus of the anisotropic rocks under the conditions of different triaxial stress and temperatures, and the permeability and the elasticity modulus of the same anisotropic rock in three directions can be measured; the anisotropy of the rocks can be better reflected; and the data measurement reasonability and accuracy of the permeability and the elasticity modulus of the anisotropic rocks are improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

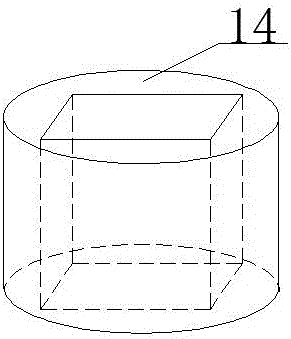

Refrigerant heating device and air conditioner comprising same

InactiveCN103363743ARealize the heating functionPrevent breakdownCorrosion preventionRefrigeration componentsElectricityElectromagnetic heating

The invention provides a refrigerant heating device and an air conditioner comprising the same. The refrigerant heating device comprises a refrigerant heating pipe section which is arranged inside a refrigerant pipe, wherein the refrigerant heating pipe section comprises a refrigerant incoming end and a refrigerant outgoing end and is made of magnetic heating materials, and an electromagnetic induction coil is twined round the outside of the refrigerant heating pipe section and is electrically connected with a power supply device. According to the refrigerant heating device, the electromagnetic induction coil which is connected with the power supply device is twined round the refrigerant heating pipe section, so that a refrigerant can be heated; by the aid of electromagnetic heating, the processing technology is simple, electricity can be completely isolated from the refrigerant, electrical safety problems such as overheating and circuit breakdowns are solved, and electrical safety and reliability are guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

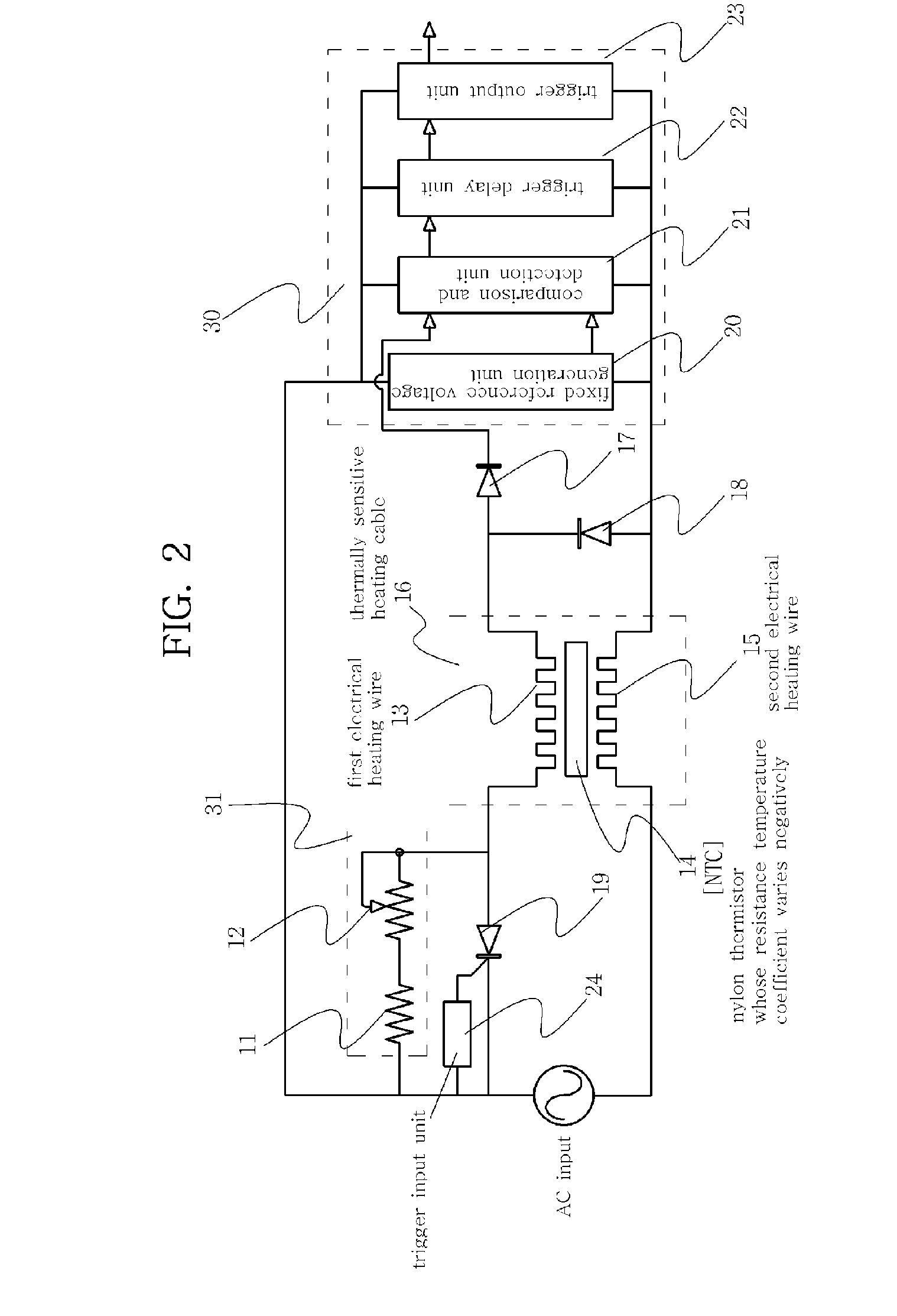

Temperature controller and temperature control method, and heating wire therefor

InactiveUS20060289463A1Preventing emission of harmful electromagnetic waveReduce the amount requiredTemperature control using analogue comparing deviceOhmic-resistance heating detailsTemperature controlElectricity

The present invention relates to a non-electromagnetic wave temperature controller for a heating cable and a method therefor, which can perform heating and temperature detection in a non-electromagnetic fashion without short-circuiting one end of the heating cable that is used in warmers, such as electric floors, electric mats and electric fomentation devices. Furthermore, the present invention relates to a temperature detection non-electromagnetic heating cable and a temperature controller, which can reduce the amount of heat and control temperature without using a separate temperature sensor when the temperature of the heating cable is controlled or an arbitrary portion of the heating cable is overheated, and can prevent a magnetic field from being generated in the heating cable without short-circuiting one end of electrical heating wires and intercept the generation of a leakage electric field.

Owner:KIL JONG JIN

Heating roller heating method and heating roller

InactiveCN101254638AImprove uniformityUniform temperatureTransfer printingBox making operationsLiquid mediumHeat conducting

The invention discloses a heating roller heating method and a heating roller. The heating roller is heated in an oil, steam, electric or electromagnetic heating manner, and is characterized in that the heating roller has an interlayer structure, a thermally-conductive liquid medium is filled in the interlayer of the heating roller for homogenizing the temperature of the heating roller; and the outer surface of the heating roller is heated in a heat conduction manner through the thermally-conductive liquid medium in the interlayer of the heating roller. The heating roller structure comprises a heating roller with the interface structure, and the thermally-conductive liquid medium in the interface of the heating roller for homogenizing the temperature of the heating roller. The thermally-conductive liquid medium can be heat conducting oil, molten metal such as potassium and sodium, pure water, ethanol-like substance, etc.

Owner:株洲科力通用设备有限公司

Tobacco suction system based on electromagnetic heating

The invention discloses a tobacco suction system based on electromagnetic heating, which is characterized in that it comprises an end cover (1), a heater (2) and an electromagnetic induction system, and the end cover (1) is detachably connected to the heater ( 2) above; the end cap (1) includes a round cover (11) and a filter tip (13); the heater (2) includes a shell (21), an inner tank (23) and a chassis (24) and a cylindrical Iron core (25); the electromagnetic induction system includes a heating liner (23), a chassis (24), a cylindrical iron core (25), an induction coil and a temperature control circuit. The present invention can increase the heating speed and high thermal efficiency through the electromagnetic induction system to heat the liner, the chassis and the cylindrical iron core, and can also realize instantaneous heating, so as to better meet the needs of the suction taste; the cylindrical iron core The setting can realize the uniform heating of the tobacco products, so that the tobacco products can be fully heated, which can prevent the waste caused by insufficient heating of the tobacco products, and is suitable for popularization and use.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com