Patents

Literature

41results about How to "Suction in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

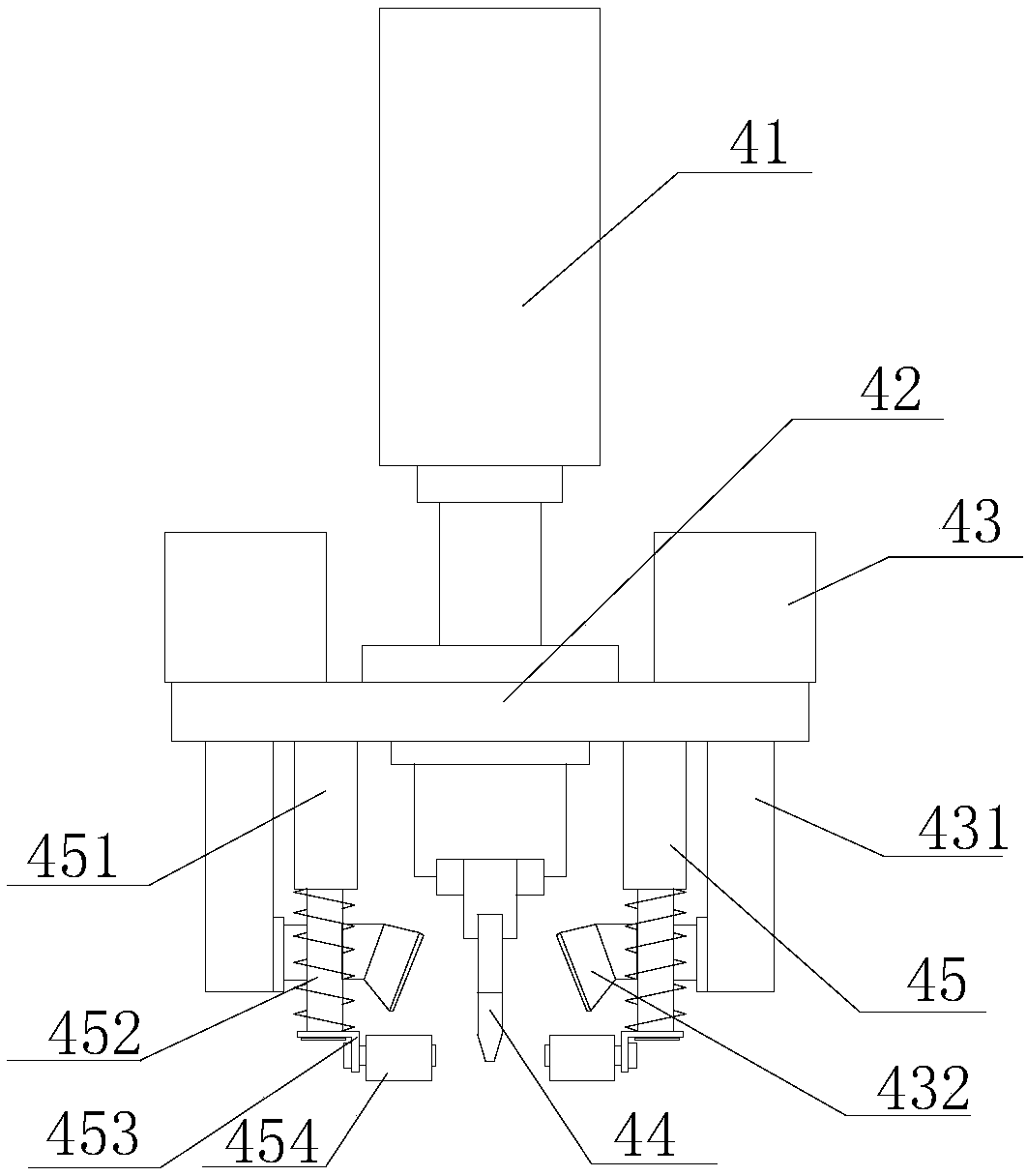

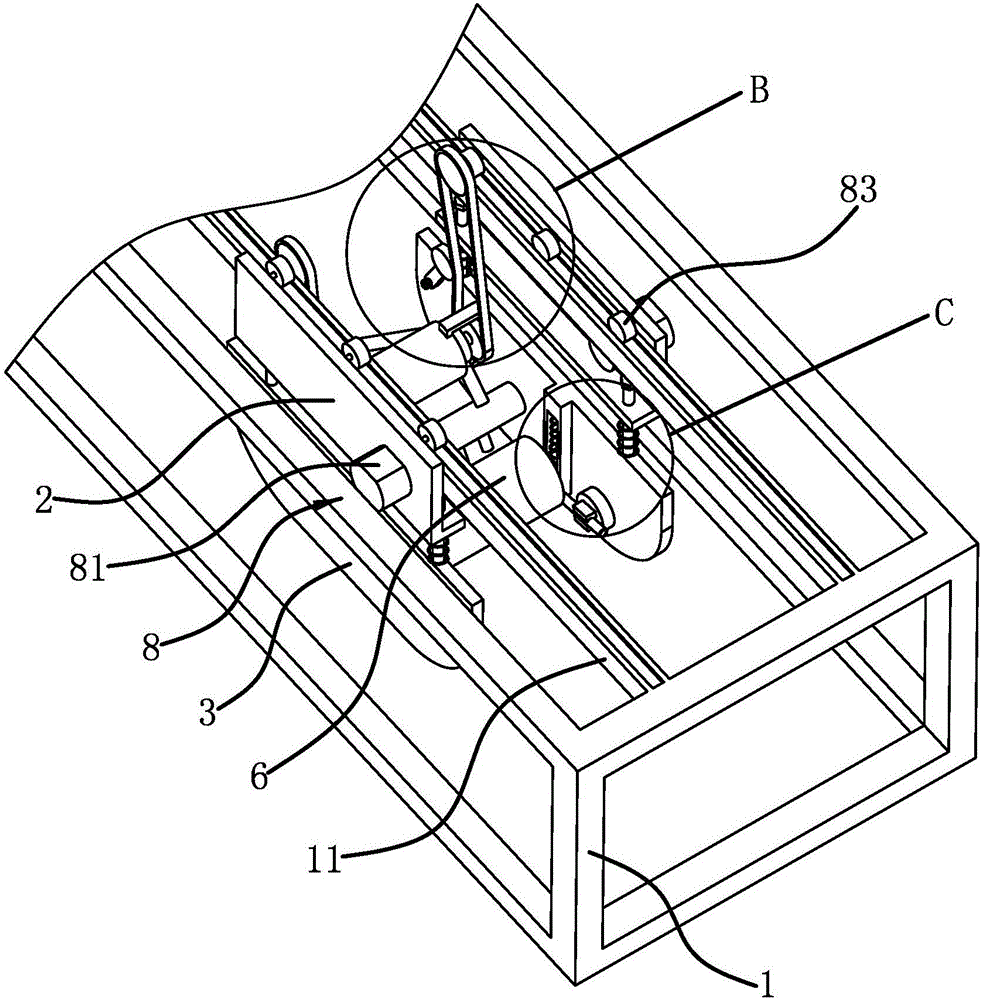

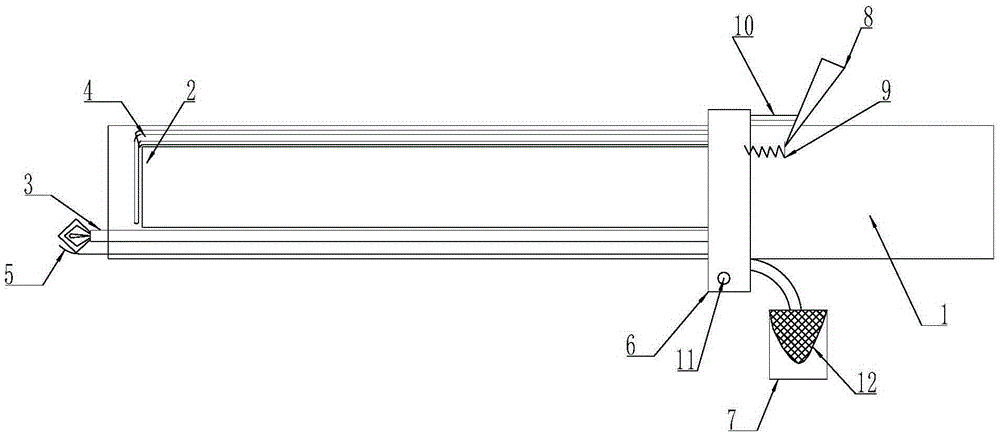

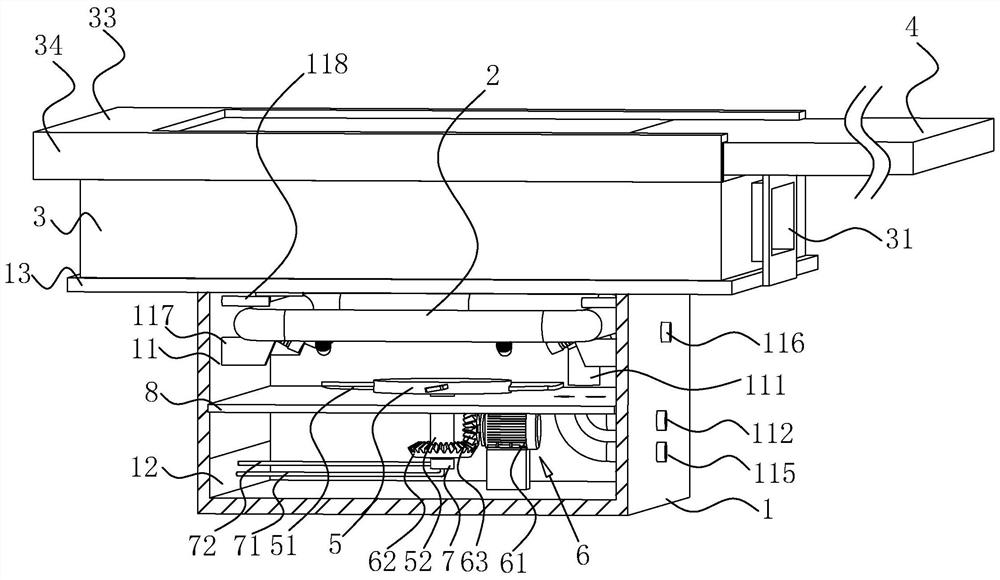

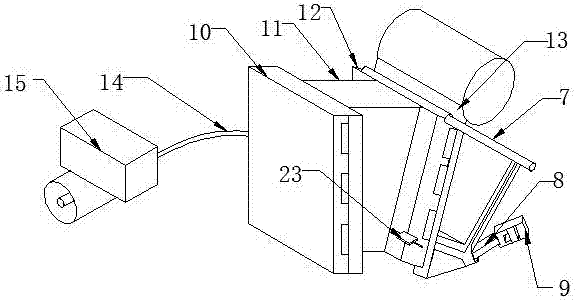

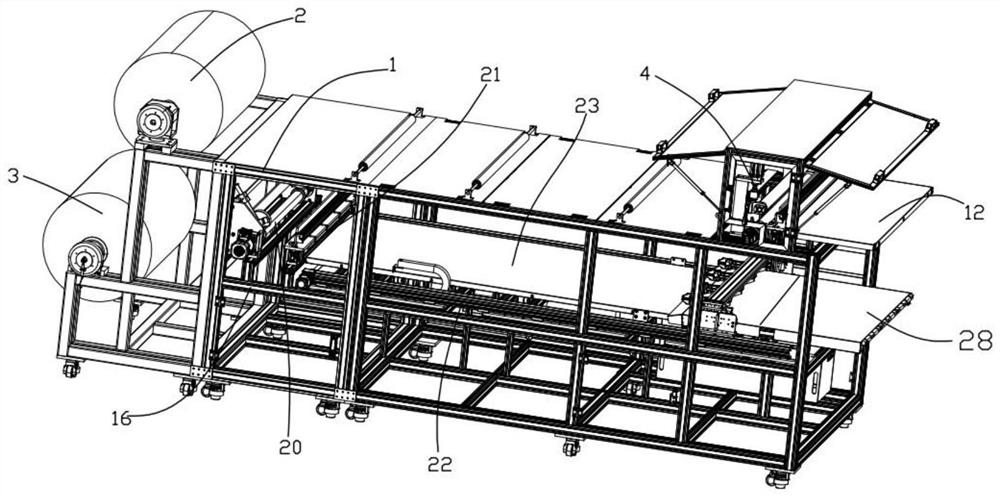

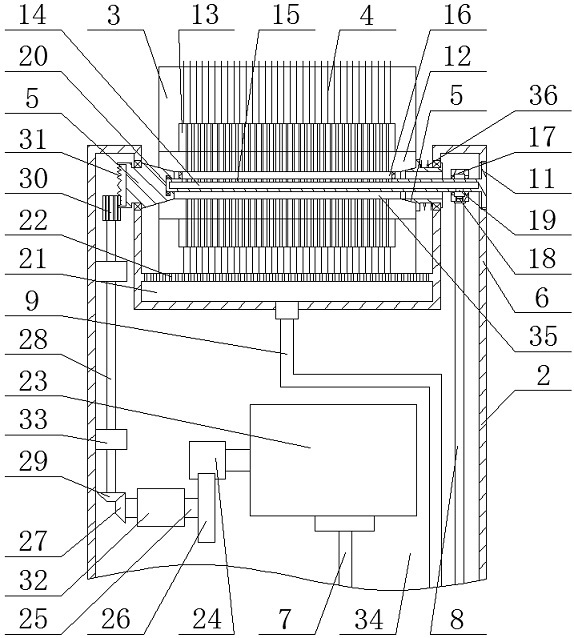

Silk fabric cutting device

PendingCN108867015AReduce intensitySuction in timeSevering textilesMetal working apparatusEngineeringMechanical engineering

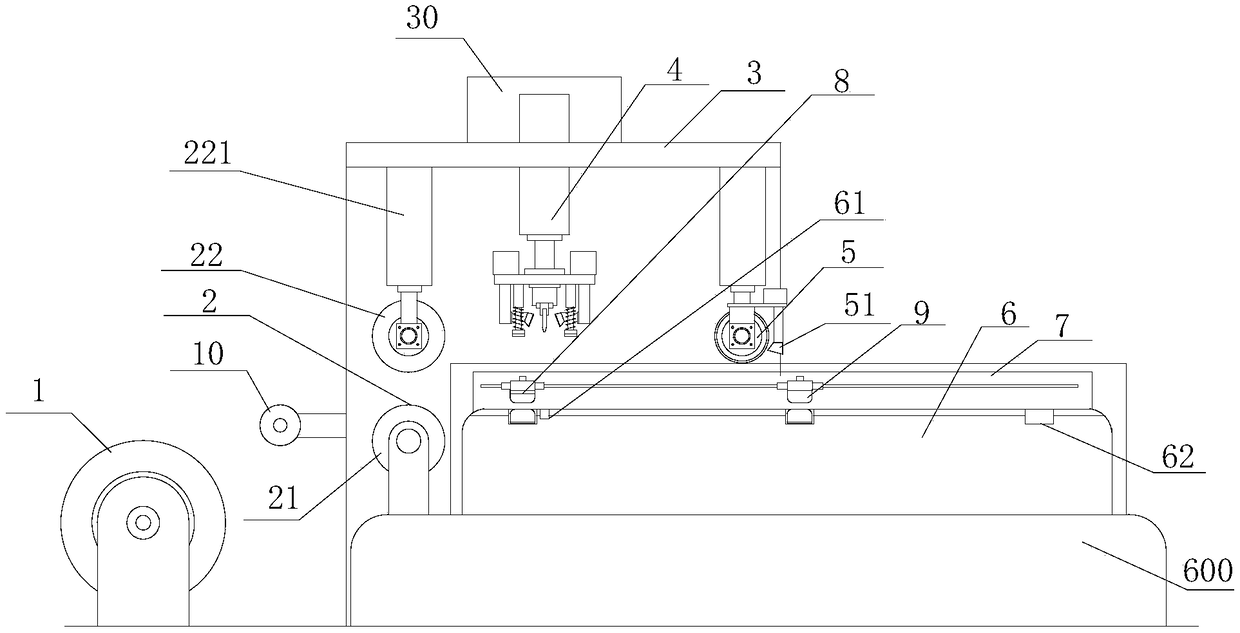

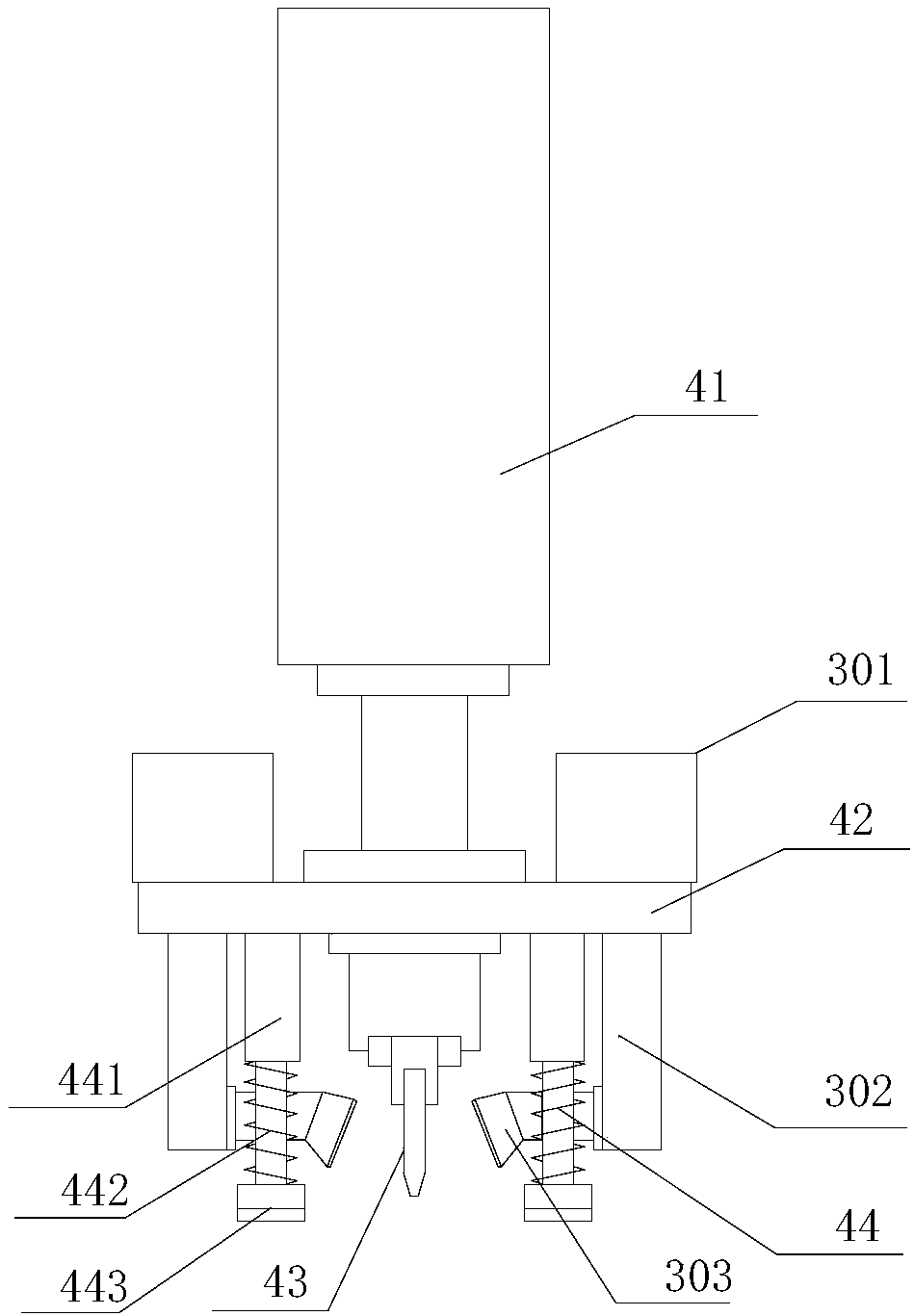

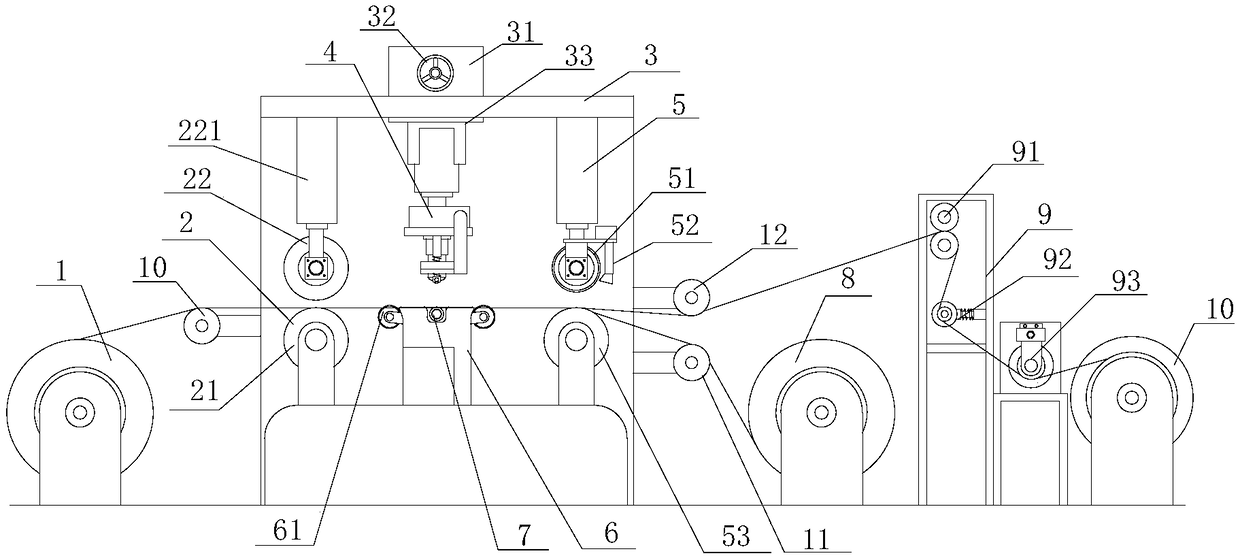

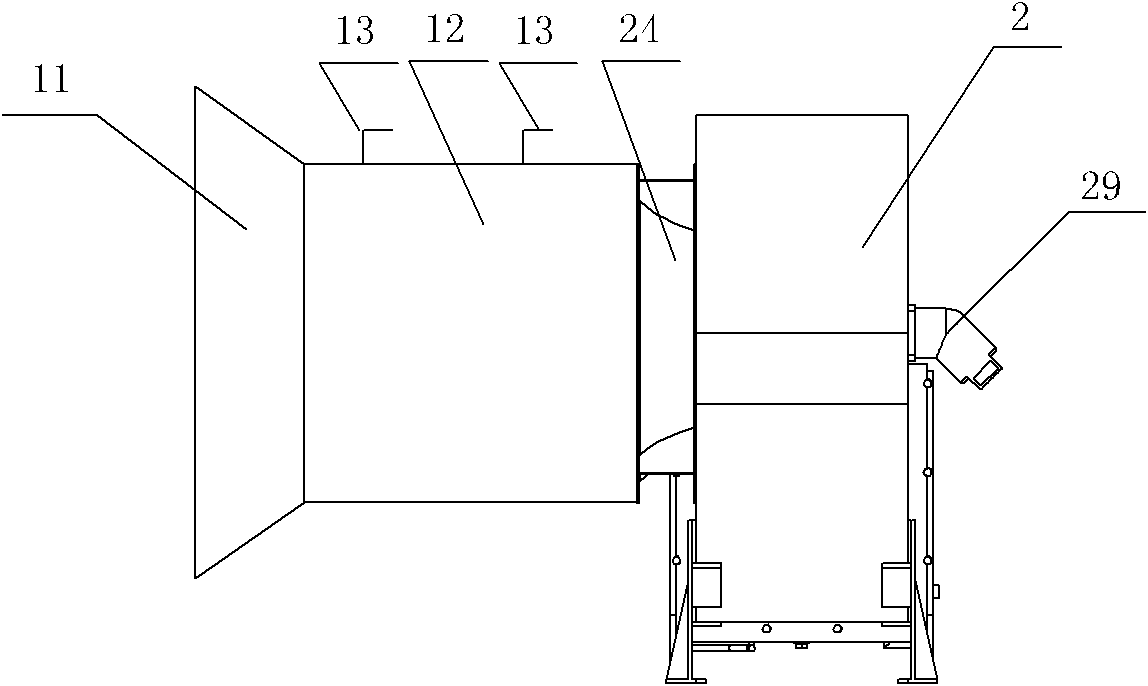

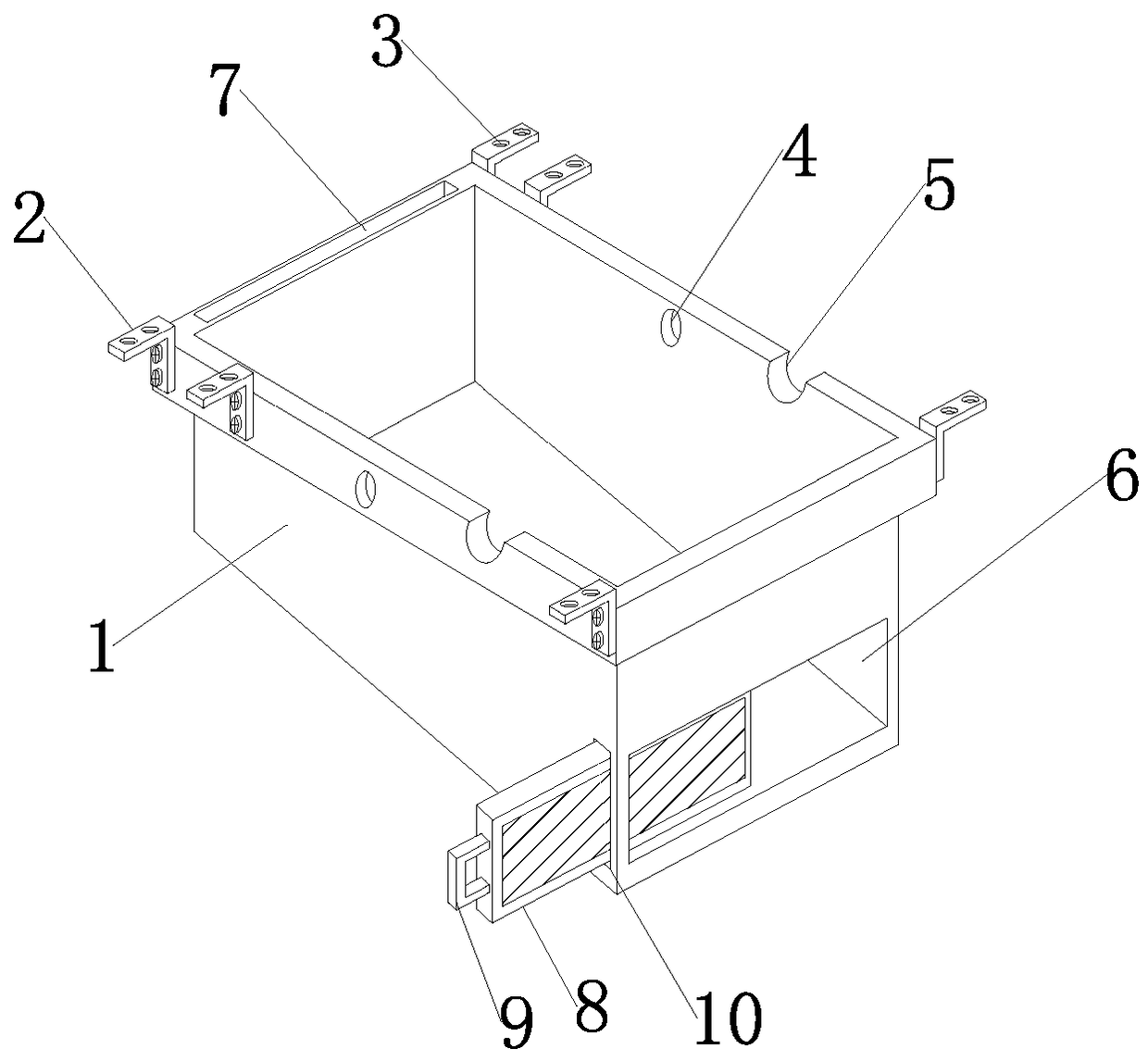

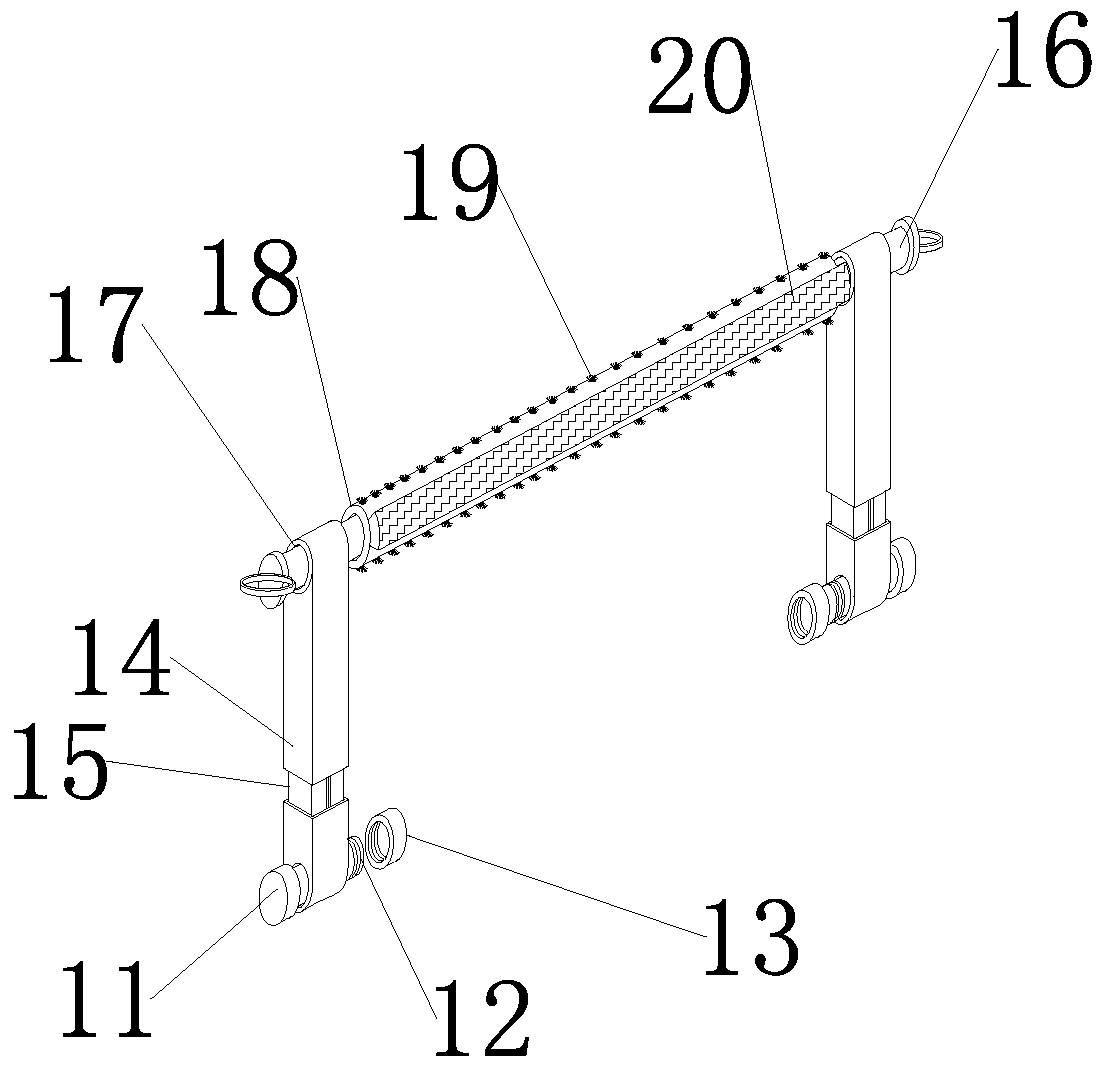

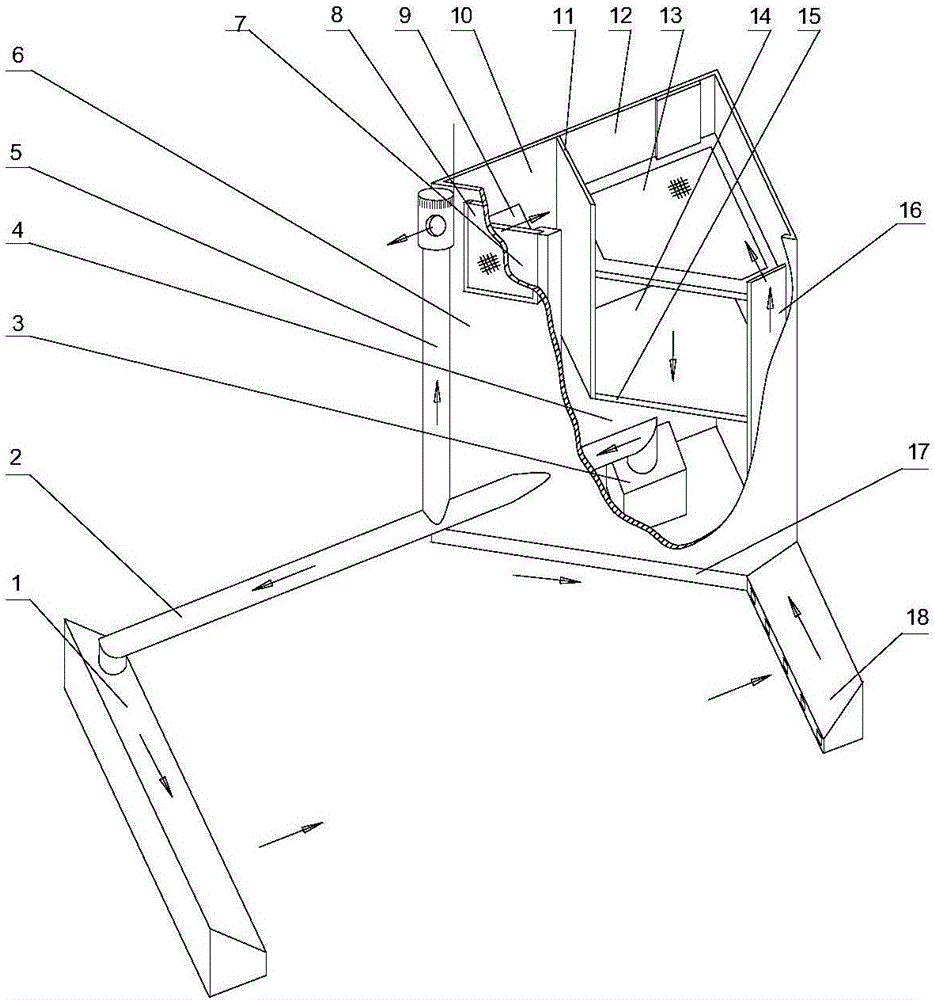

The invention discloses a silk fabric cutting device which comprises an unwinding mechanism, a feeding conveying roller mechanism, an installation supporting frame, a cutting device, a brush roller mechanism, a machine frame, a feeding walking seat, a first cloth feeding mechanism and a second cloth feeding mechanism, wherein a guiding roller assembly is arranged between the unwinding mechanism and the feeding conveying roller mechanism, the cutting device is arranged on the installation supporting frame through a second lifting air cylinder, the cutting device is arranged between the feedingconveying roller mechanism and the brush roller mechanism, a cutter assembly is arranged on the cutting device, the cutter assembly is matched with a cutter groove, a lifting installation seat is arranged on the feeding walking seat, and the first cloth feeding mechanism and the second cloth feeding mechanism are arranged on the lifting installation seat. As the conveying roller mechanism and thecloth feeding mechanisms are matched, the end of cloth to be cut can be tightly clamped to be conveyed in a fixed point mode after once cutting, so that the labor intensity is reduced; a dust collection cover can suck waste chips which are generated in a cutting process in time, so that the comfortableness of production environment is improved.

Owner:浙江华越丝绸制品有限公司

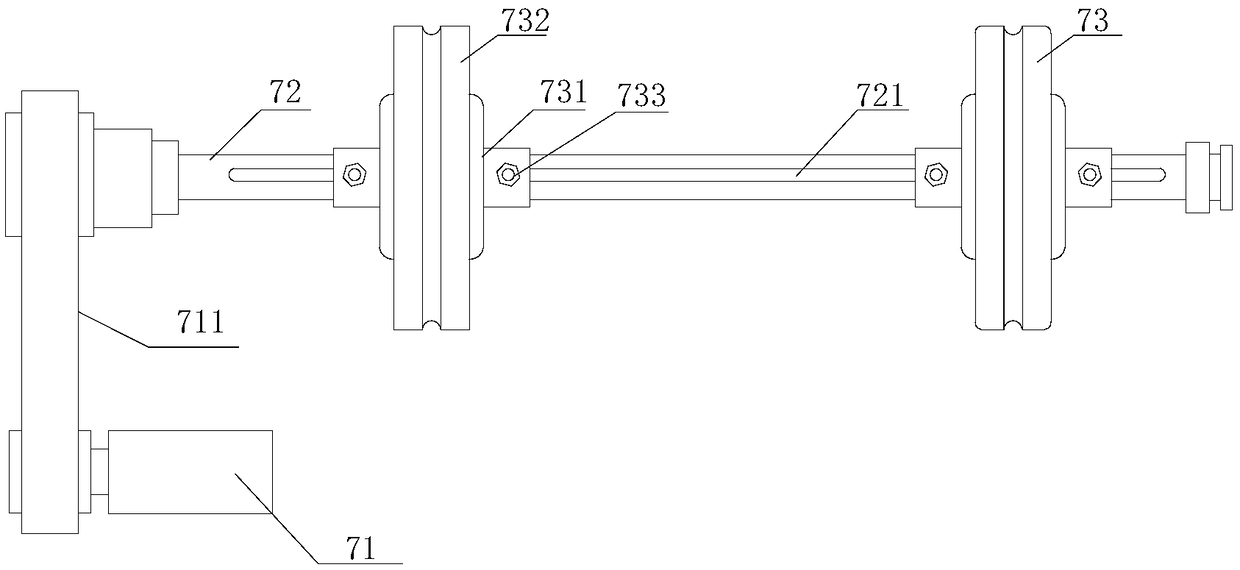

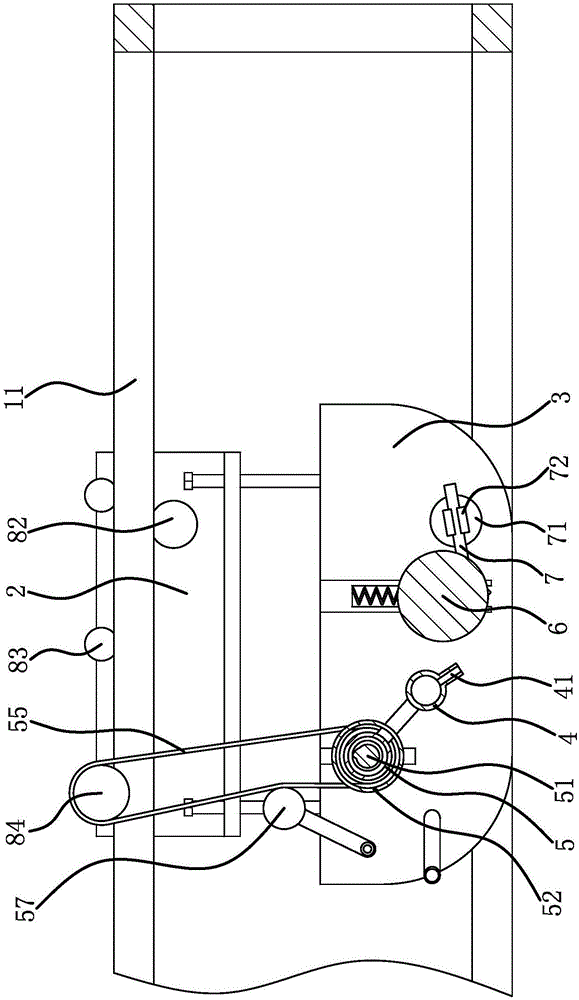

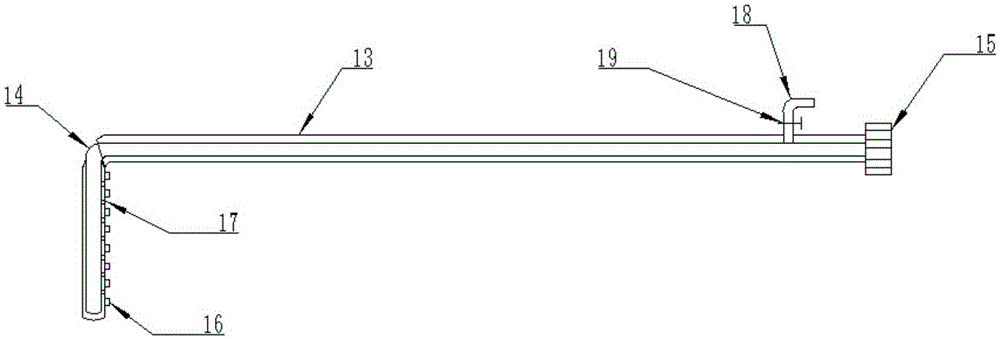

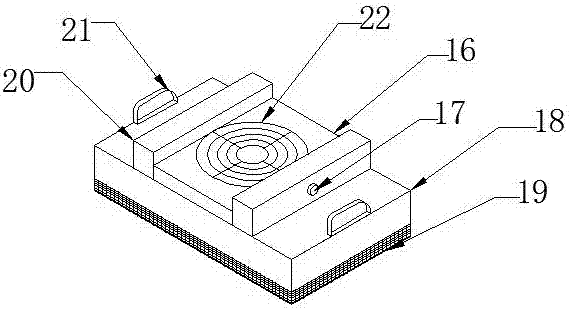

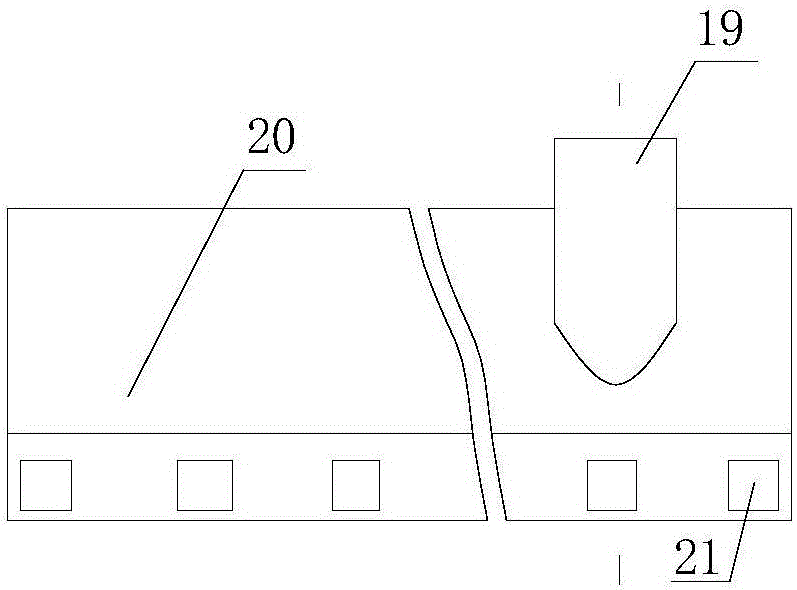

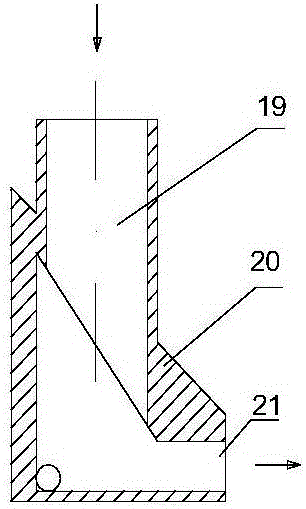

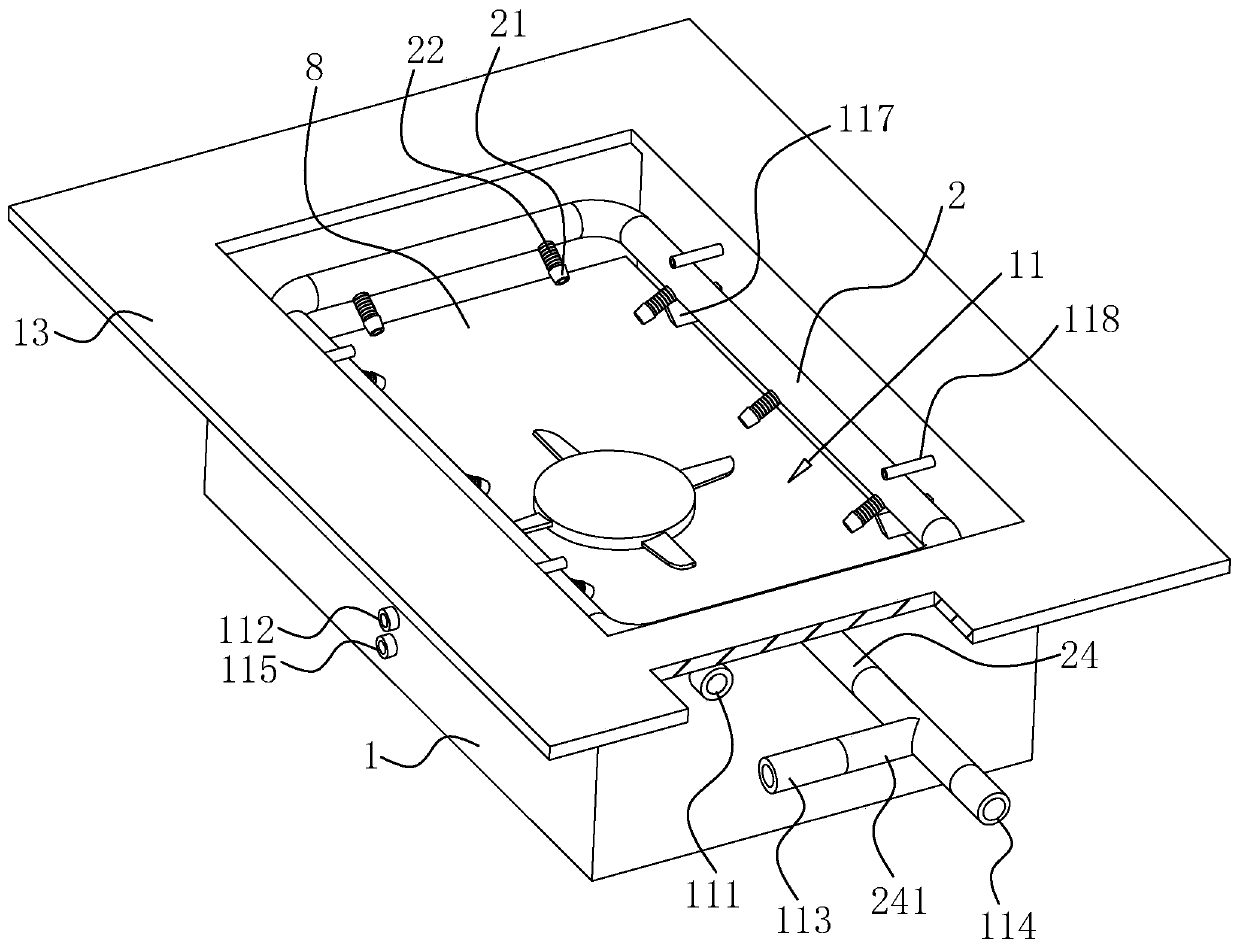

Edge cutting device capable of recycling waste edges

PendingCN109179012ASuction in timeImprove comfortFilament handlingSevering textilesEngineeringMechanical engineering

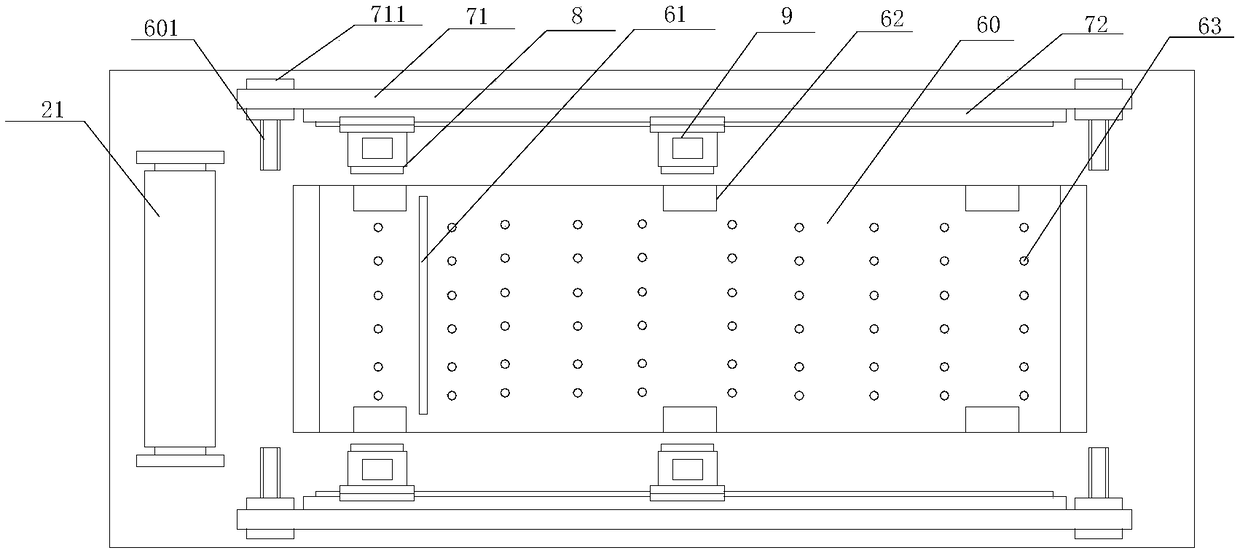

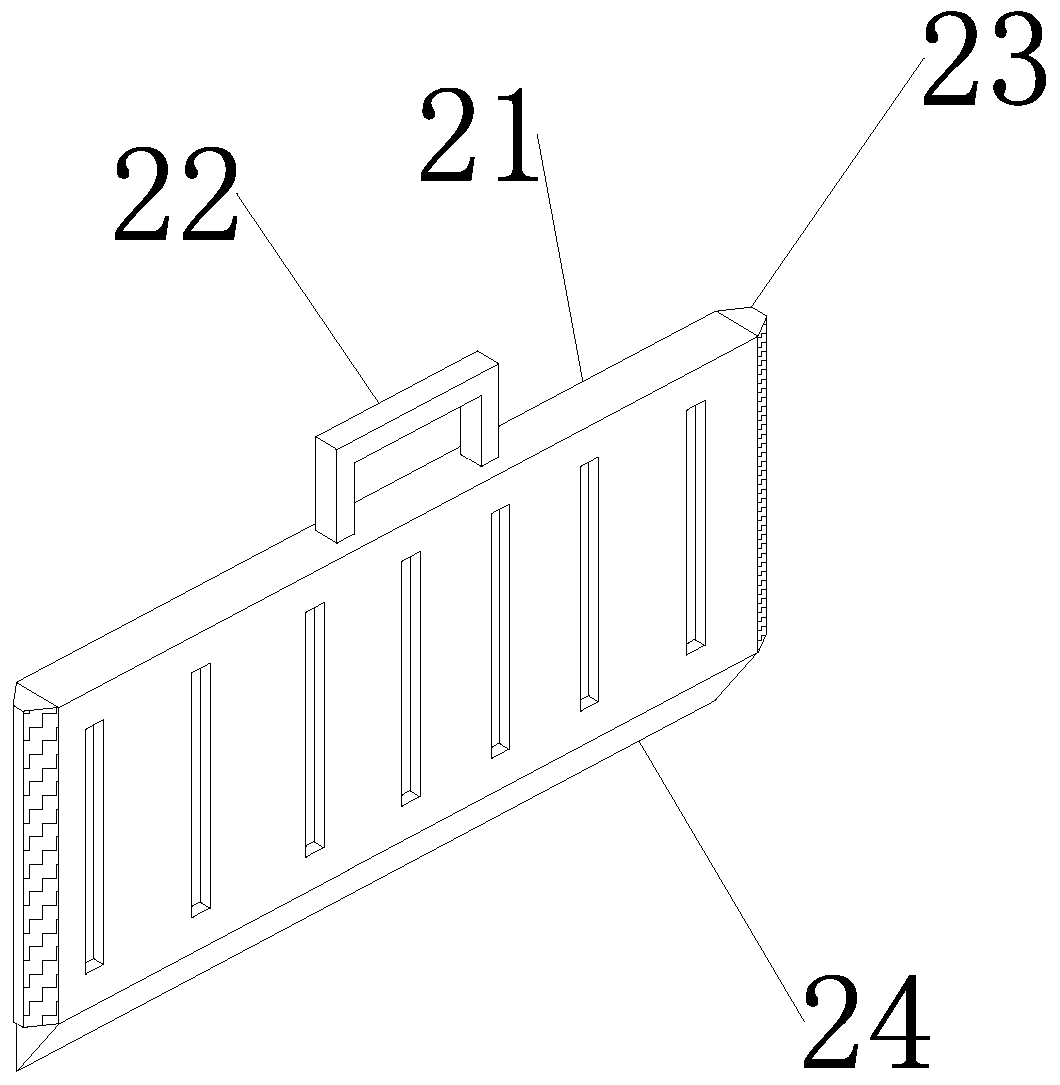

The invention discloses an edge cutting device capable of recycling waste edges. The device comprises an unwinding mechanism, a conveying roller mechanism, a mounting supporting frame, edge cutting device bodies, a brush roller mechanism, an edge cutting supporting table, an edge cutting supporting carrier roller mechanism, a finished product winding mechanism, waste edge guide devices and a wasteedge winding mechanism; the edge cutting device bodies are arranged on the two sides of the mounting supporting frame, the edge cutting supporting table is arranged below the edge cutting device bodies, an edge cutting knife assembly is arranged on the edge cutting device bodies, the edge cutting supporting carrier roller mechanism is arranged in the edge cutting supporting table, a plurality ofedge cutting carrier rollers are arranged on the edge cutting supporting carrier roller mechanism, the waste edge guide devices are symmetrically distributed and are used for guiding cut-down waste edges into the waste edge winding mechanism, the adjustable edge cutting device is adopted and can adapt to multiple edge cutting needs, according to actual needs, two sides of fabric can be simultaneously subjected to edge cutting or single-side edge cutting work, and the waste edges can be subjected to guide and even winding.

Owner:浙江华越丝绸制品有限公司

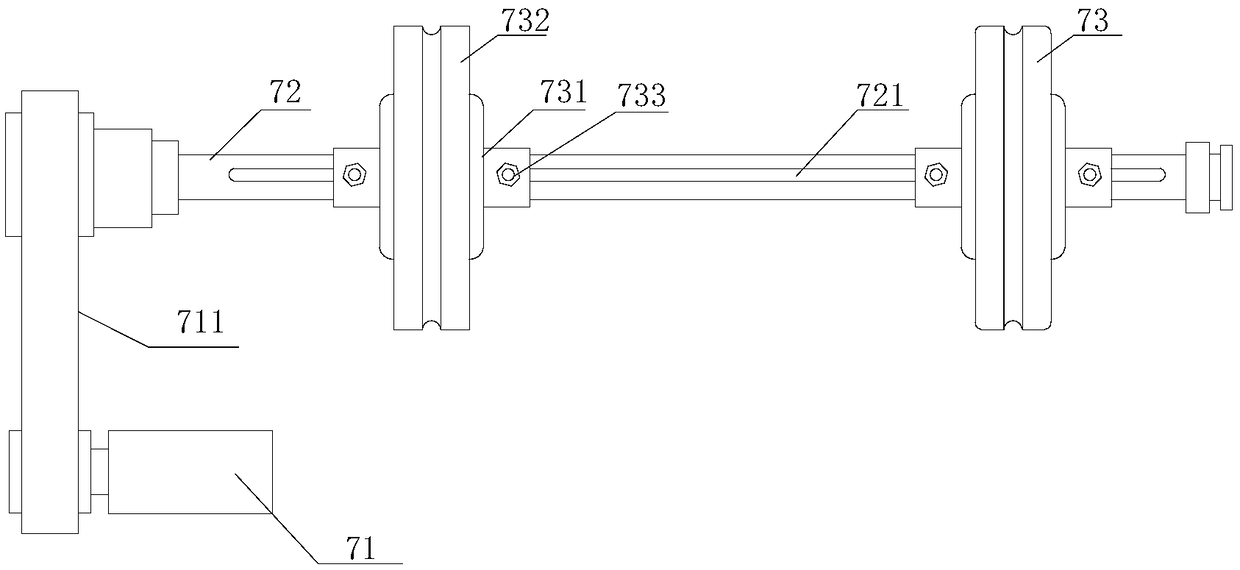

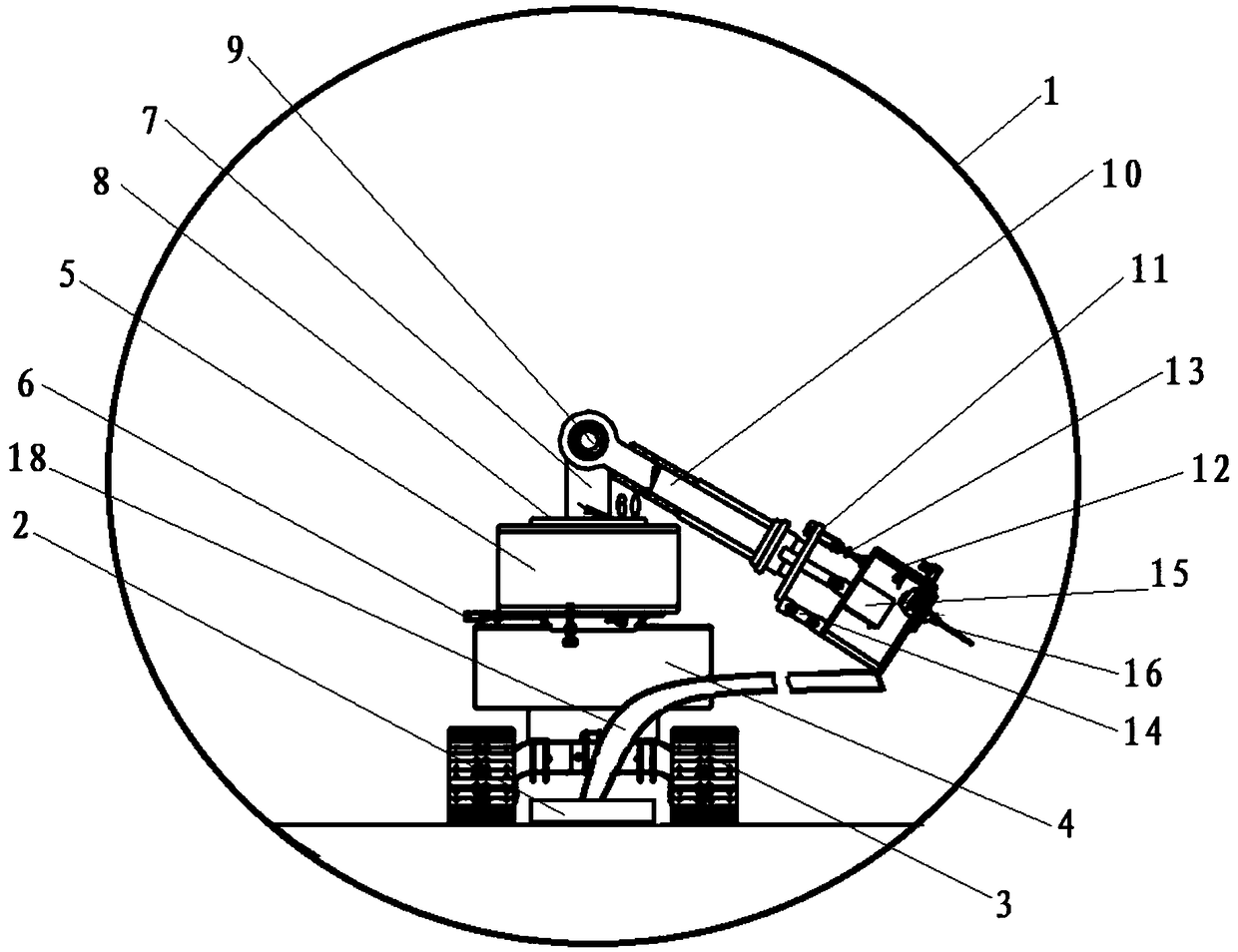

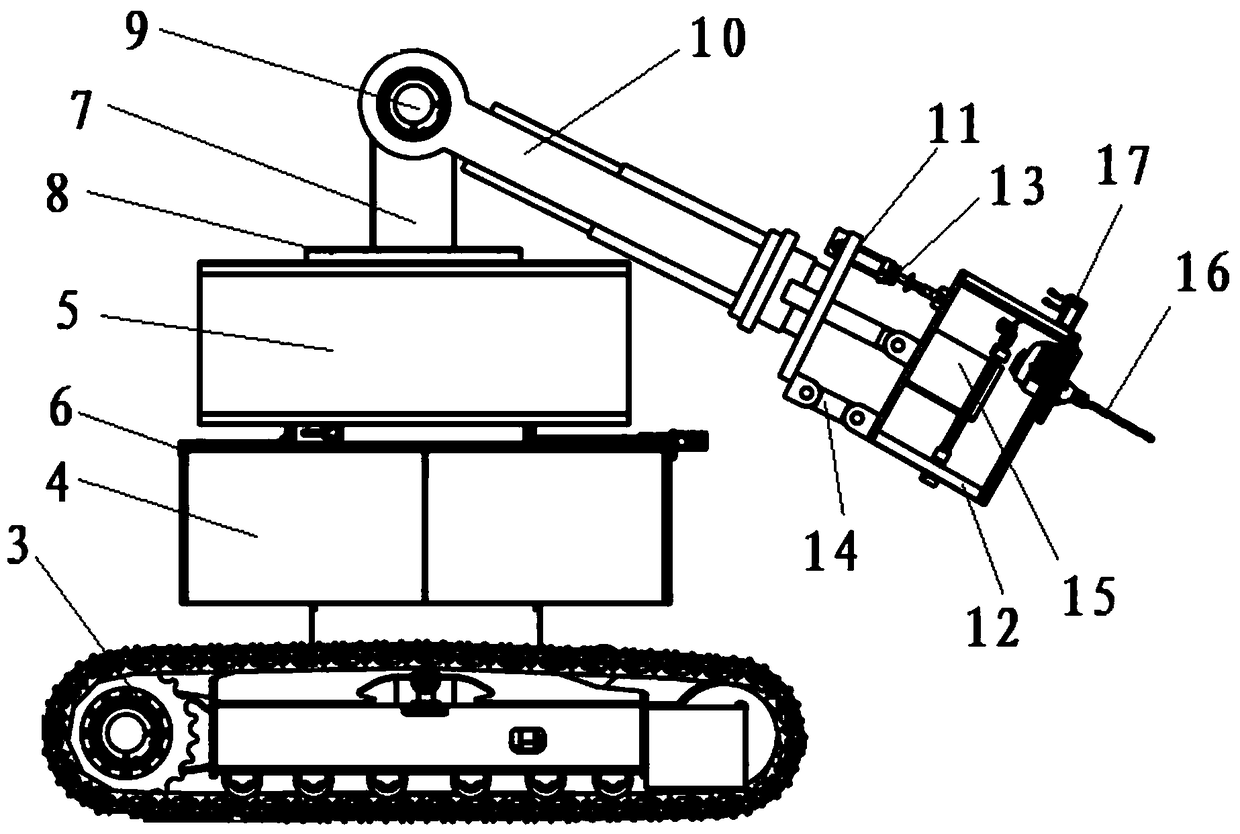

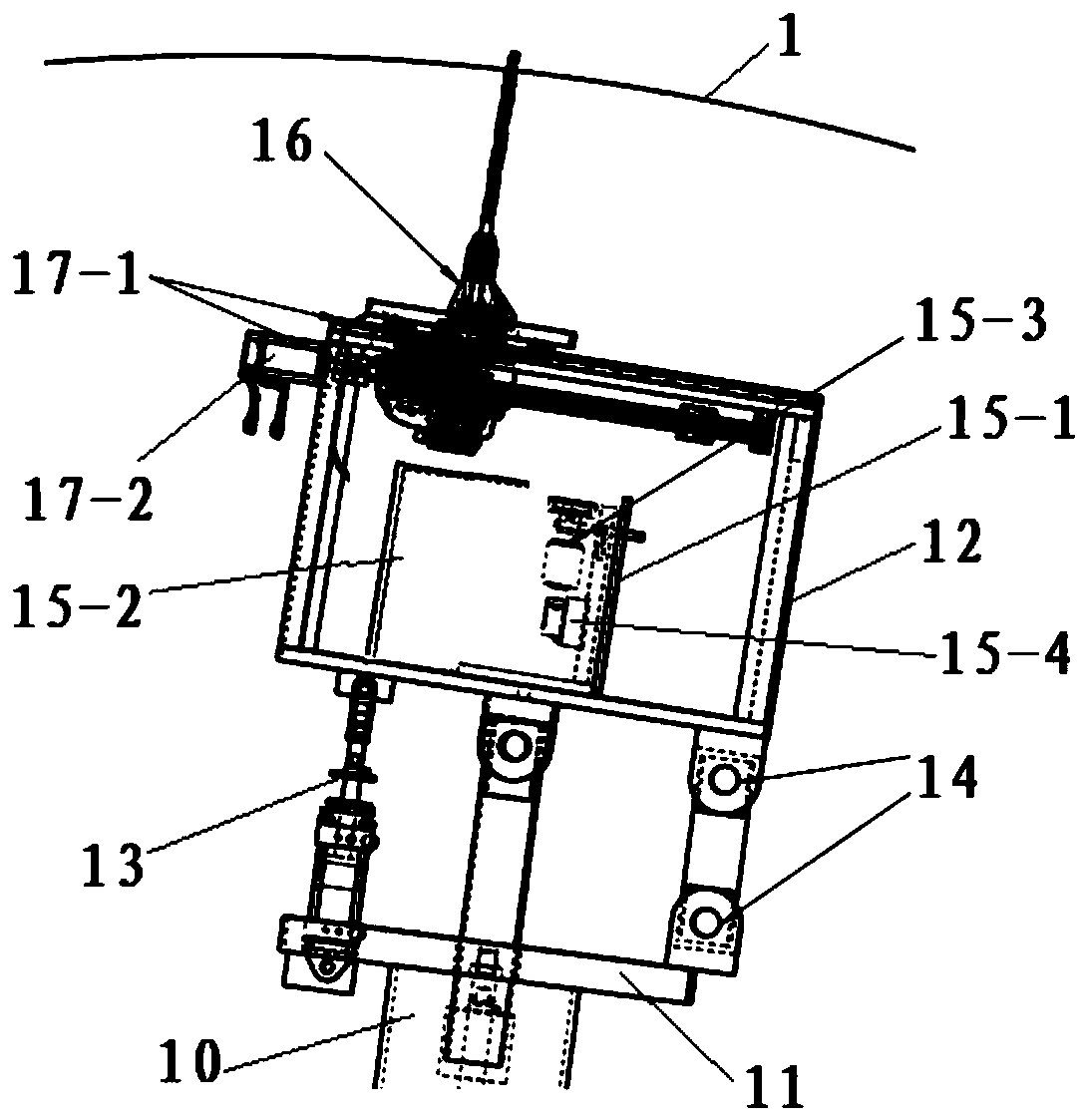

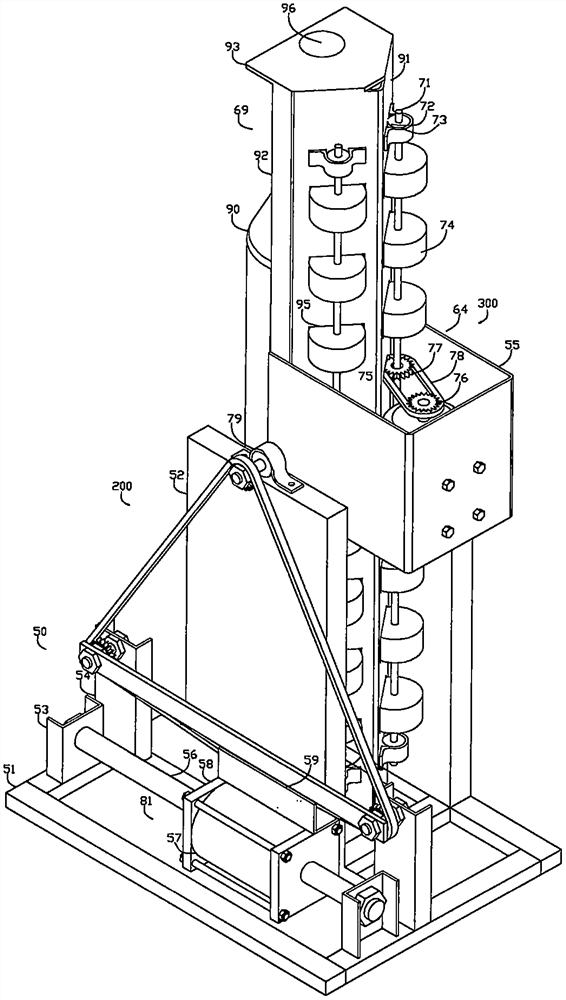

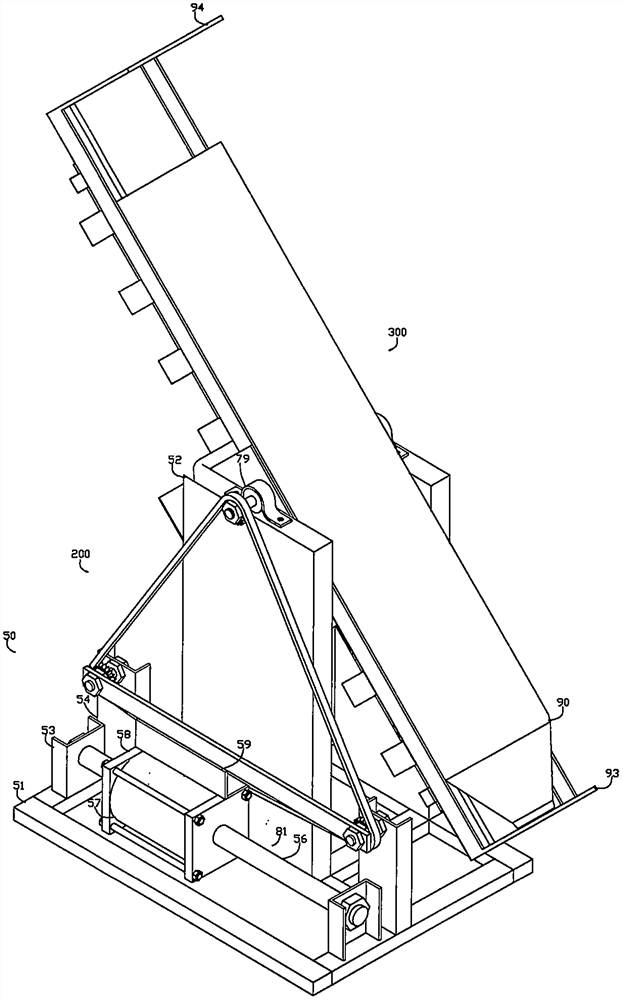

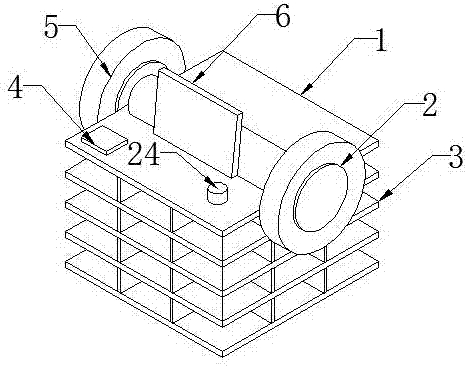

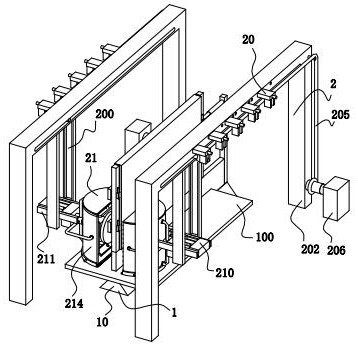

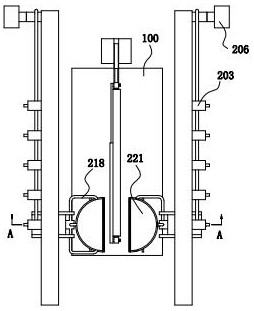

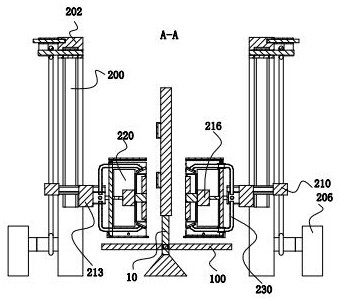

Automatic tunnel drilling machine and method

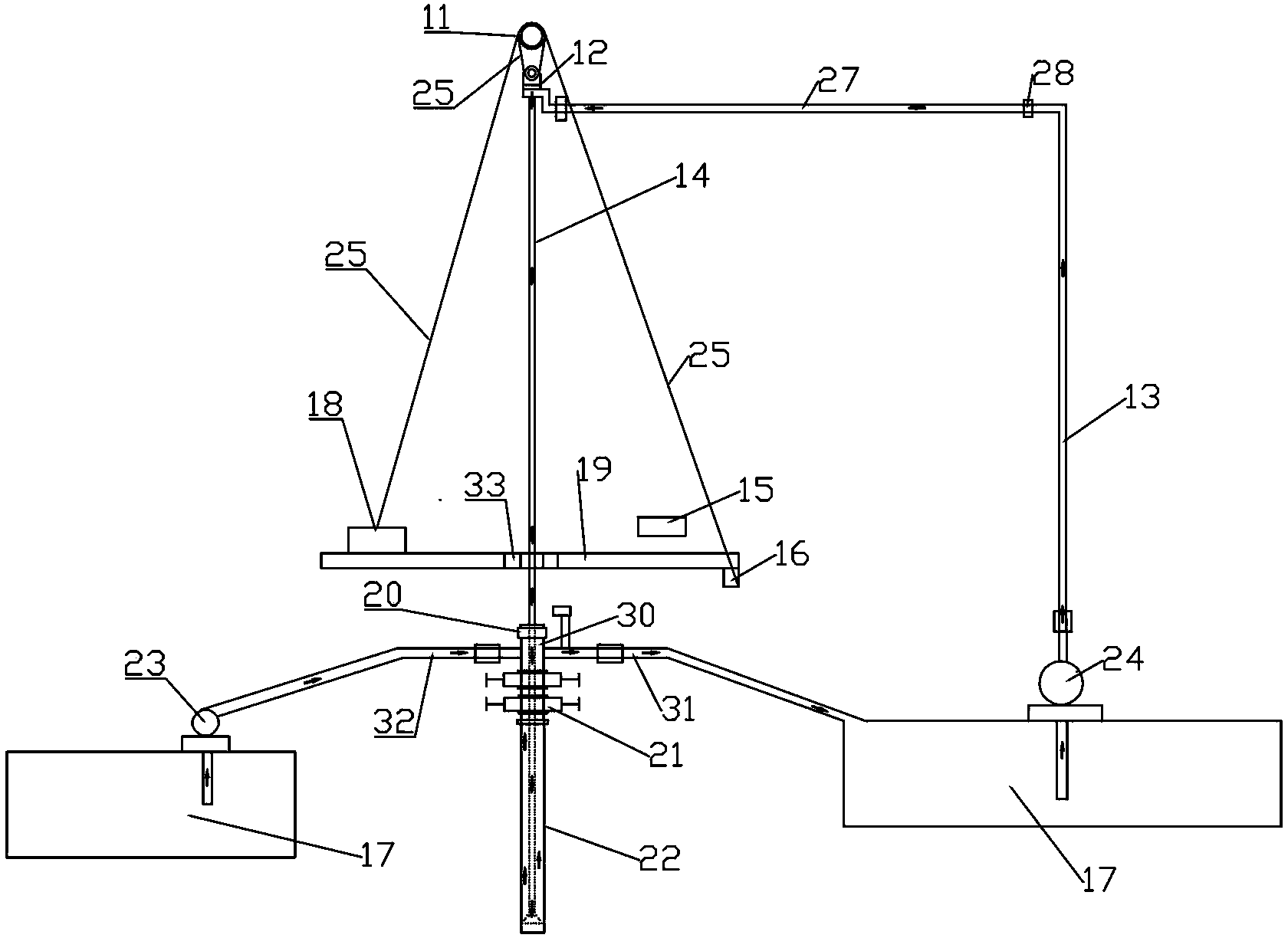

PendingCN109458133AReduce manual assisted movementImprove bearing capacitySurveyConstructionsHydraulic cylinderPhysical well being

The invention discloses an automatic tunnel drilling machine and method. The drilling machine comprises a track vehicle chassis, a control supporting box, a hydraulic control box, a central supportingshaft, a transverse shaft, an electric drill, a positioning detection mechanism and an electric drill fine-adjusting device, wherein a drill bit of the electric drill is provided with a limiting sensor and a speed sensor. The method comprises the steps that 1, hole position marks are arranged; 2, the drilling machine executes automatic drilling in a tunnel section; 3, the drilling machine executes automatic tunnel drilling; 4, troubleshooting is executed. Movement of the drilling machine in the length direction of a tunnel is achieved through the track vehicle chassis, coarse alignment for drilling is achieved, the bearing capacity is large, fine alignment for drilling is achieved through a planar movement mechanism, control is simple, microcosmic fine alignment for drilling is achieved through the cooperation of a dip angle adjusting oil hydraulic cylinder and a main oil cylinder, effort is saved, operation is accurate, labor is saved, the safety risk and construction difficulty arereduced, a large amount of dust is prevented from being inhaled during manual operation, and the harm to body health of constructors and unnecessary personal injuries are decreased.

Owner:吕永宏

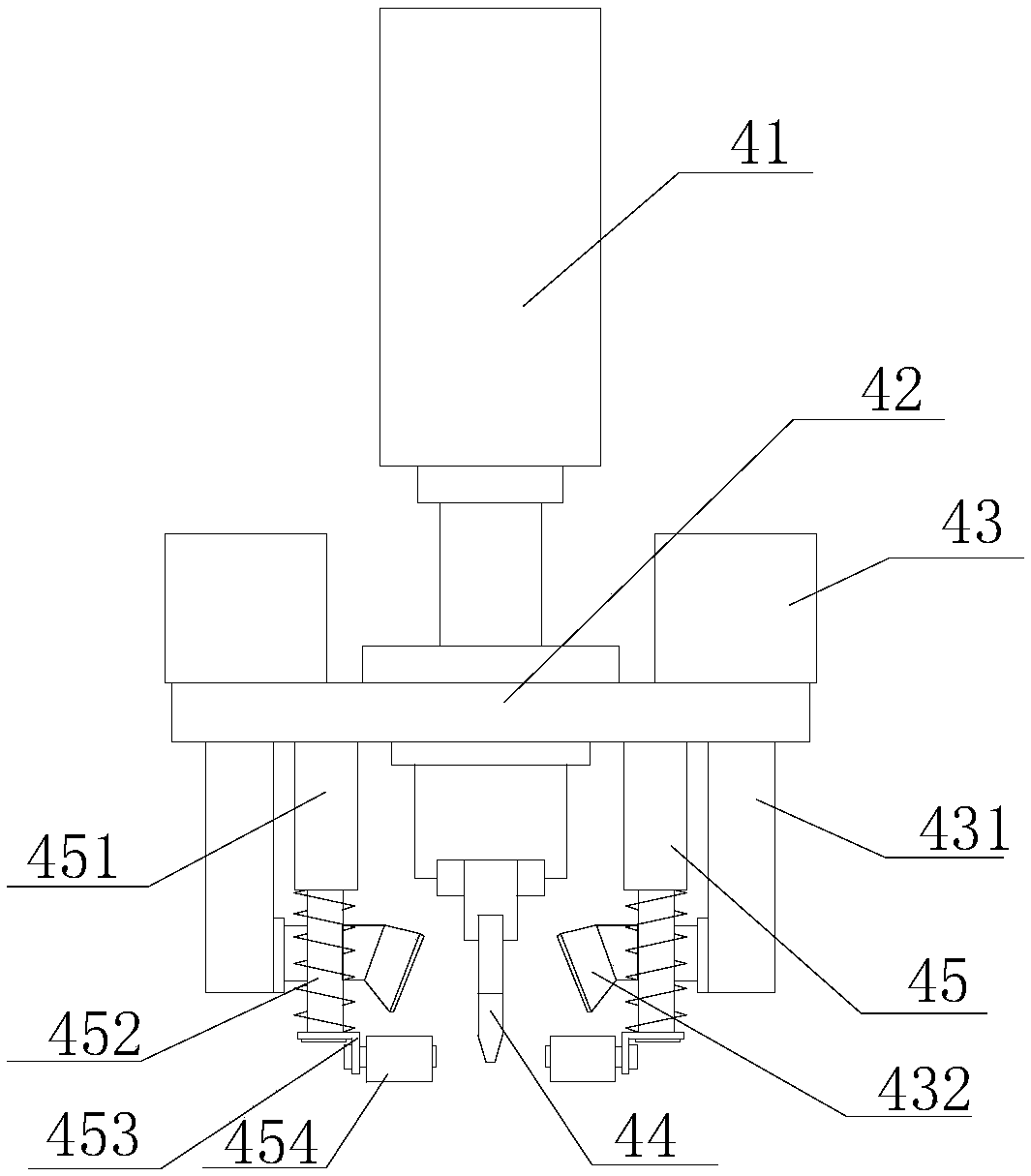

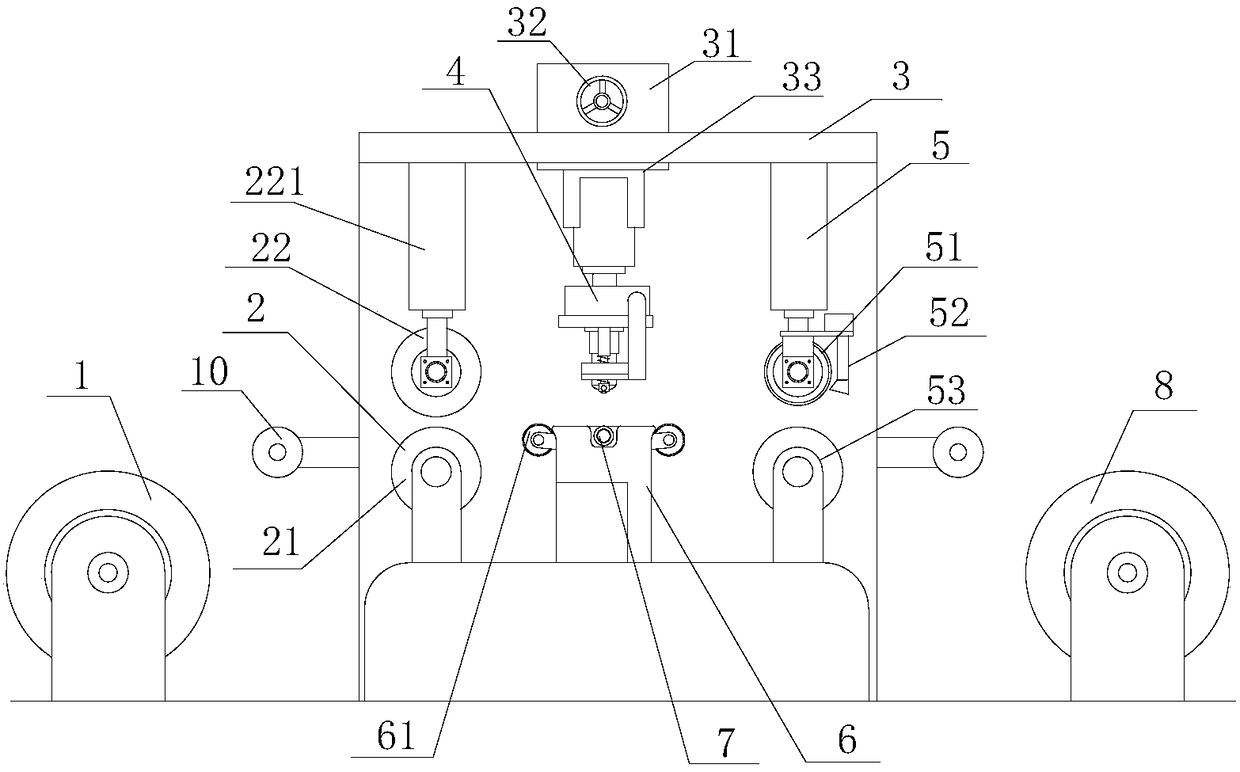

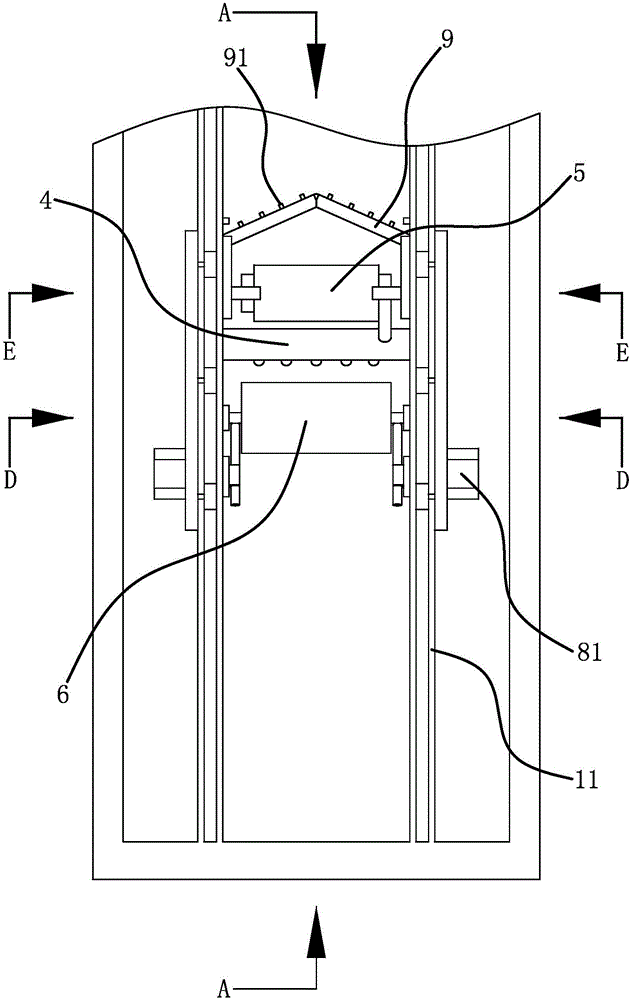

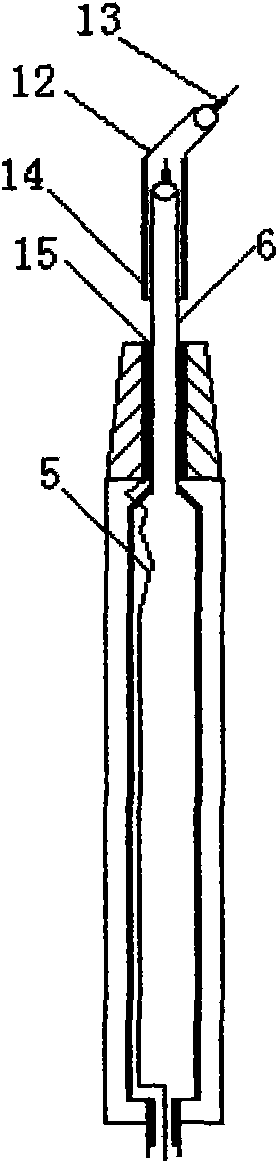

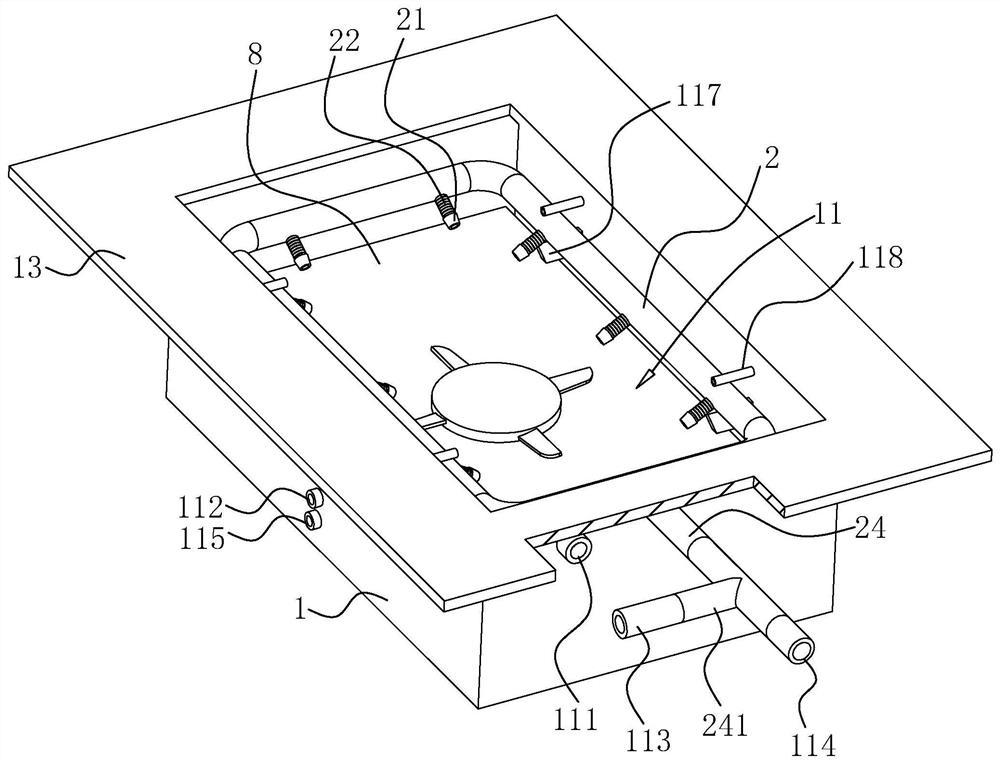

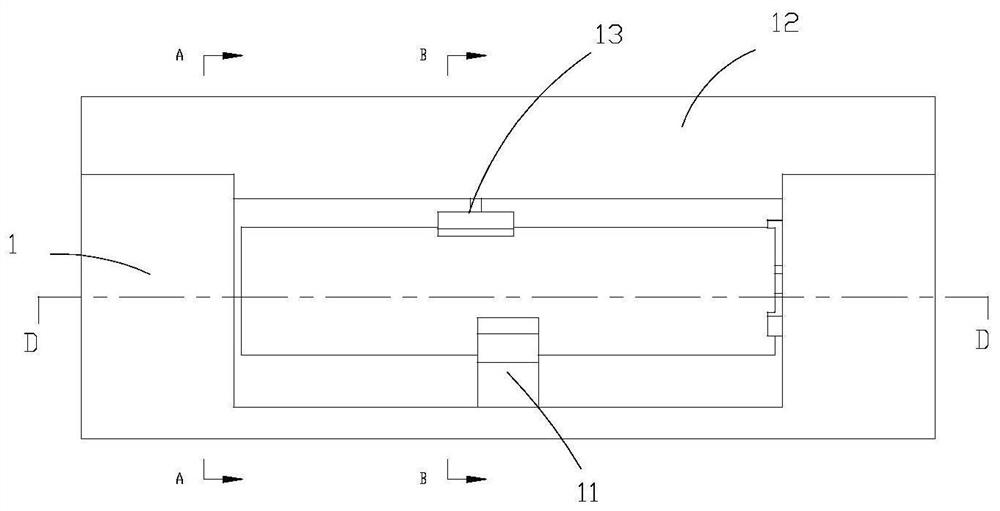

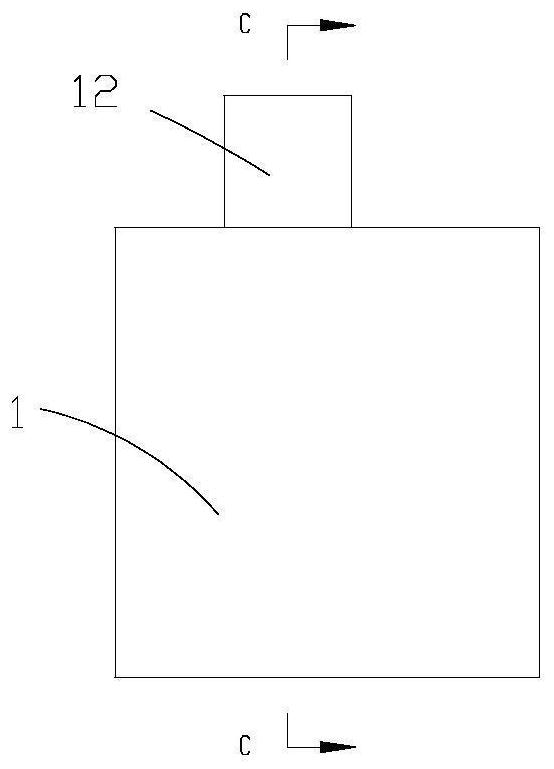

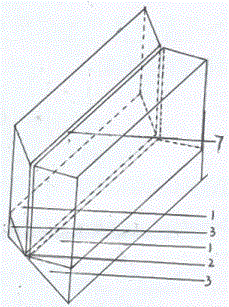

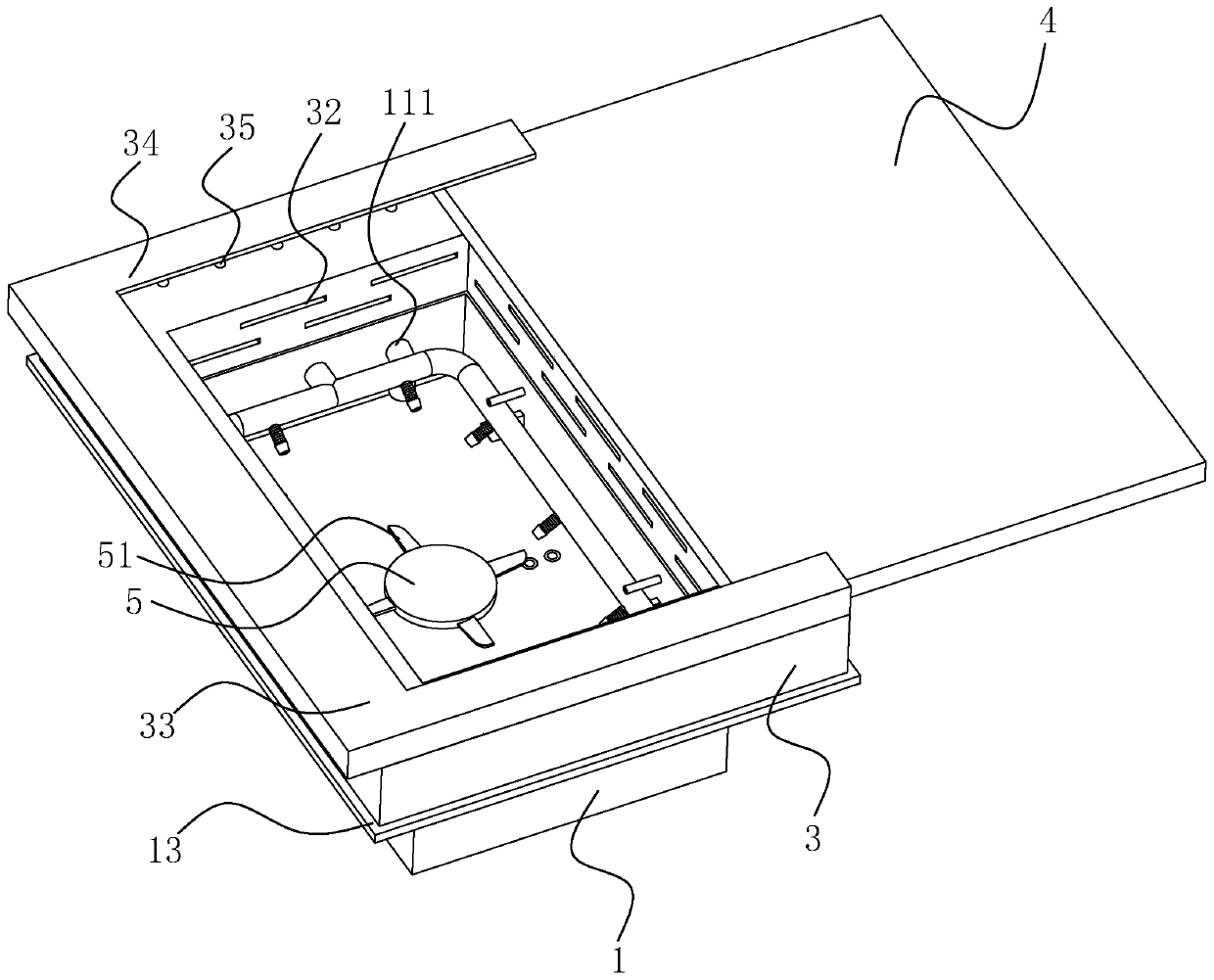

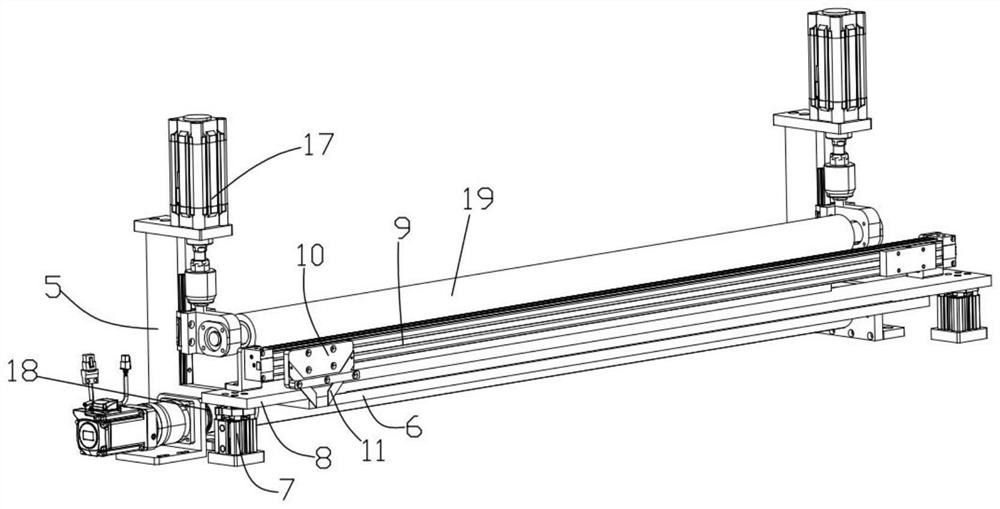

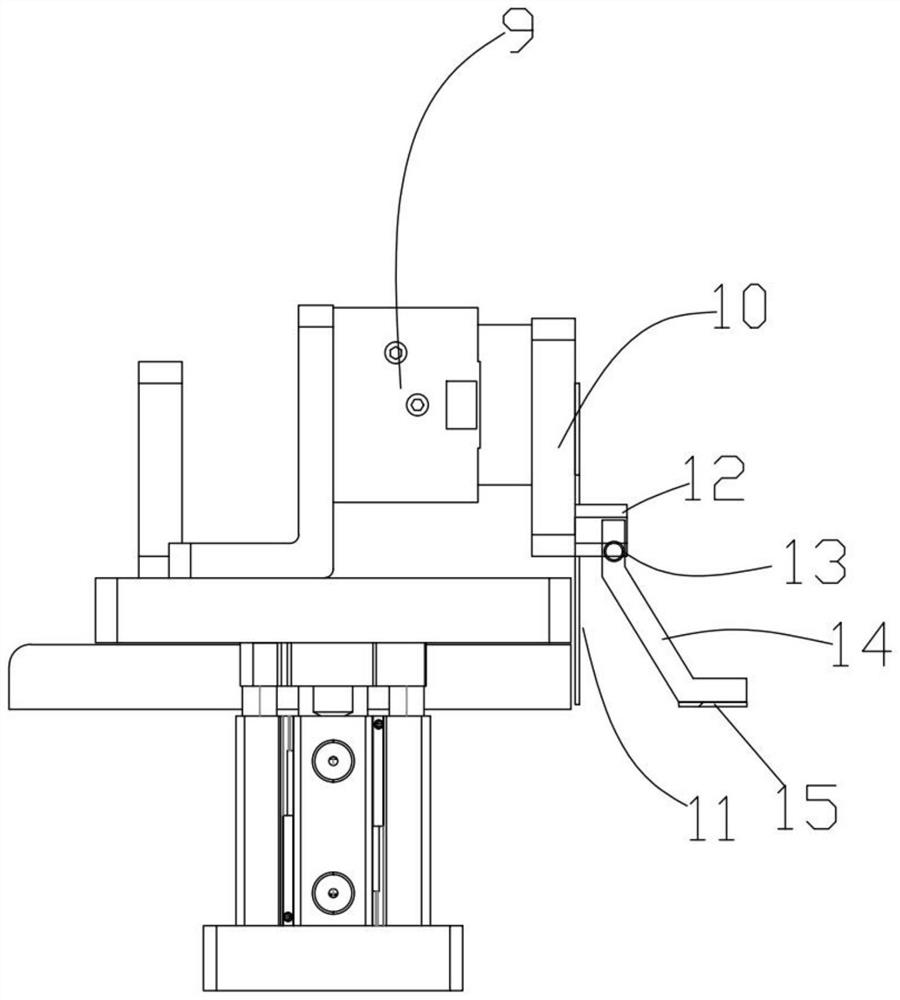

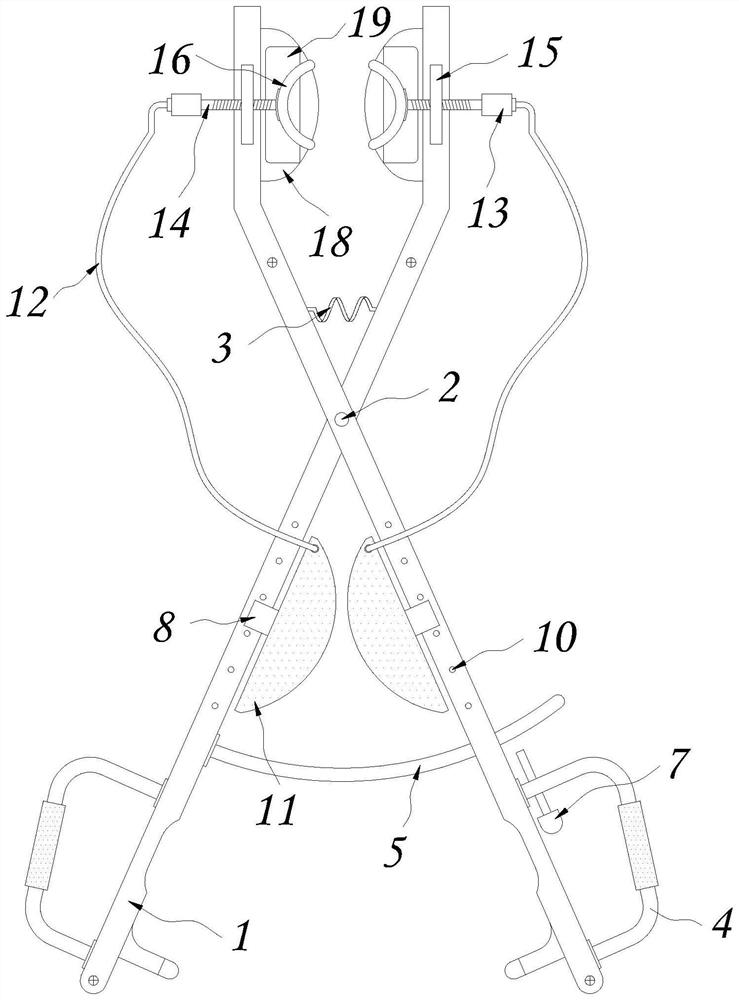

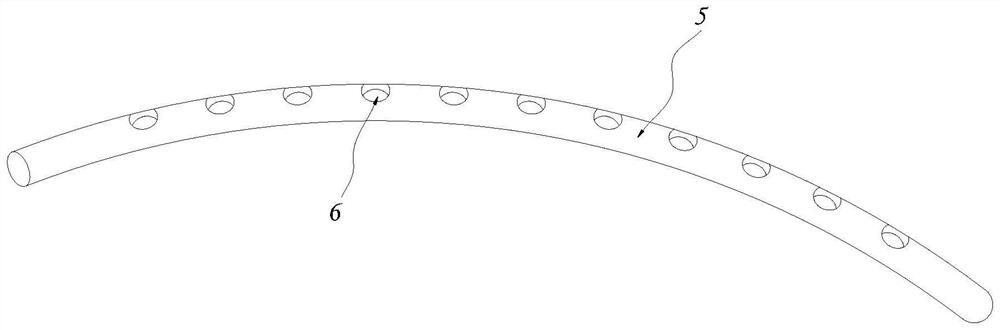

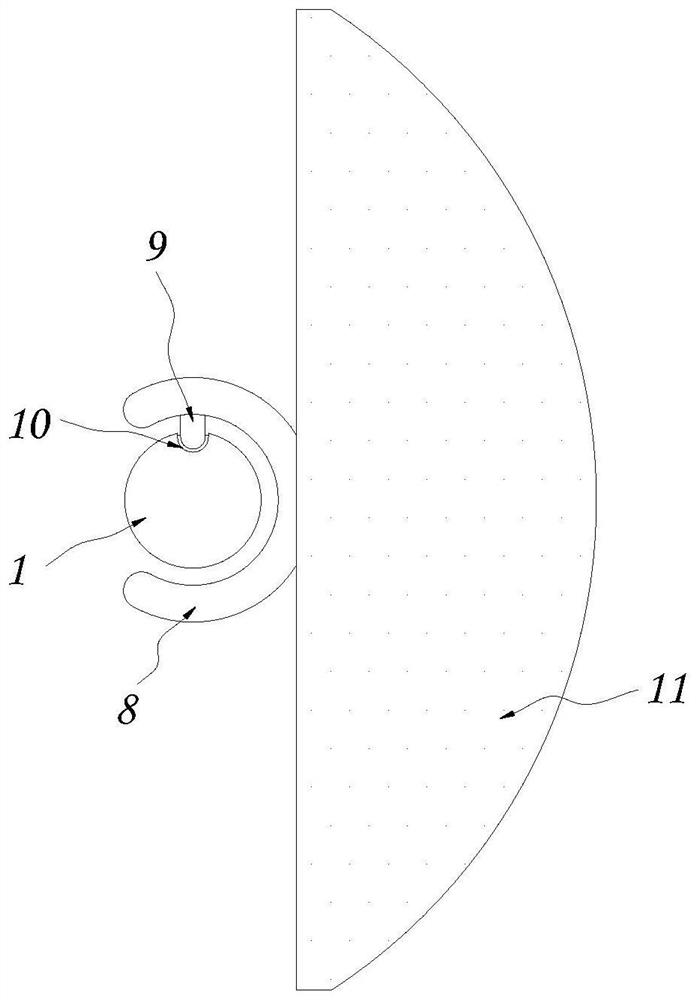

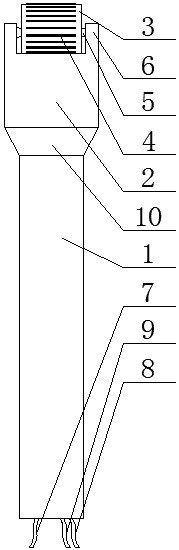

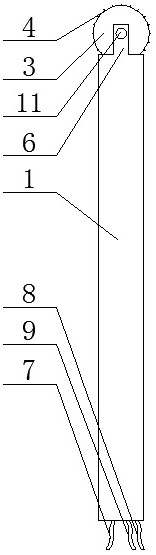

Fabric edge cutting device

PendingCN109179011AImprove comfortSuction in timeSevering textilesArticle deliveryEngineeringMechanical engineering

The invention discloses a fabric edge cutting device. The device comprises an unwinding mechanism, a conveying roller mechanism, a mounting supporting frame, edge cutting device bodies, a brush rollermechanism, an edge cutting supporting table, an edge cutting supporting carrier roller mechanism and a winding mechanism; the mounting supporting frame is arranged between the unwinding mechanism andthe winding mechanism, the edge cutting device bodies are arranged on the two sides of the mounting supporting frame, the edge cutting supporting table is arranged below the edge cutting device bodies, the edge cutting device bodies are located between the conveying roller mechanism and the brush roller mechanism, an edge cutting knife assembly is arranged on the edge cutting device bodies, the edge cutting supporting carrier roller mechanism is arranged in the edge cutting supporting table, pressing roller assemblies are symmetrically arranged on the two sides of the edge cutting knife assembly, the pressing roller assemblies are matched with edge cutting carrier rollers, the adjustable edge cutting device is adopted and can adapt to multiple edge cutting needs, according to actual needs, two sides of fabric can be simultaneously subjected to edge cutting or single-side edge cutting work, a dust collection cover can absorb and remove sweeps in time, and comfort of production environment can be improved.

Owner:浙江华越丝绸制品有限公司

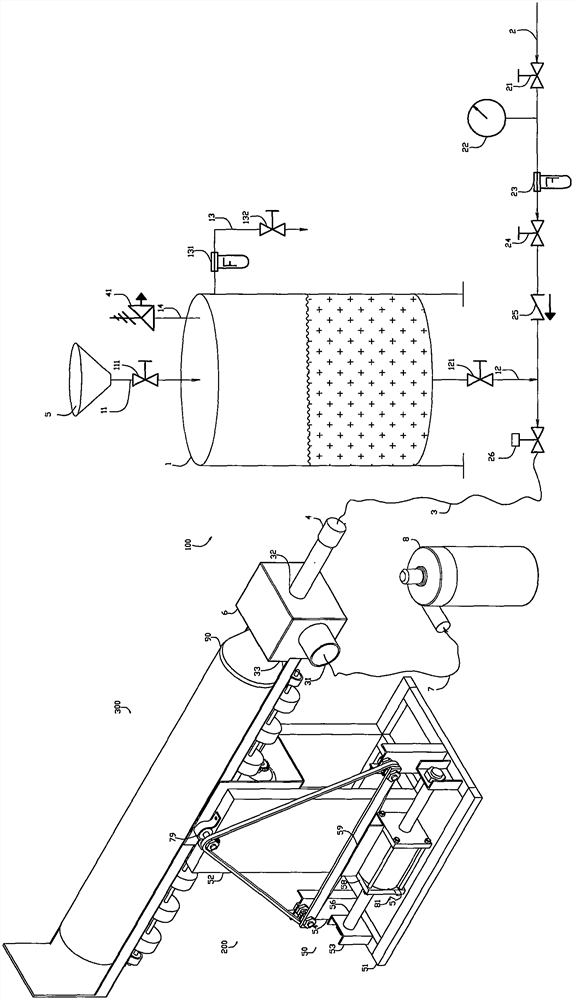

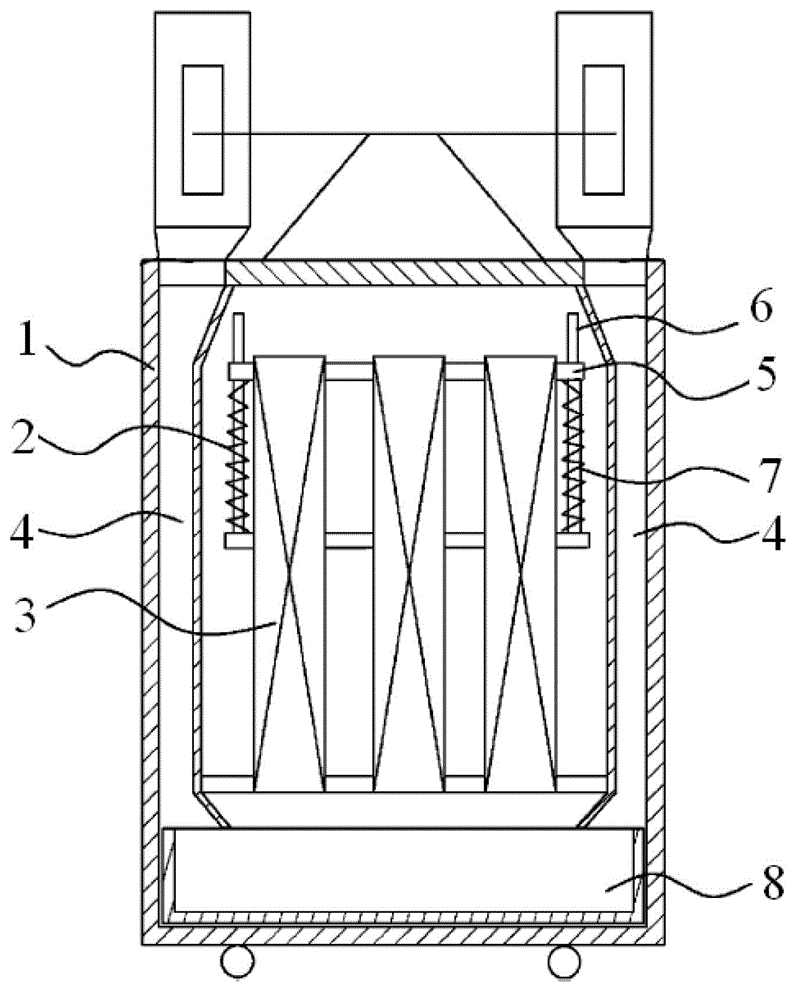

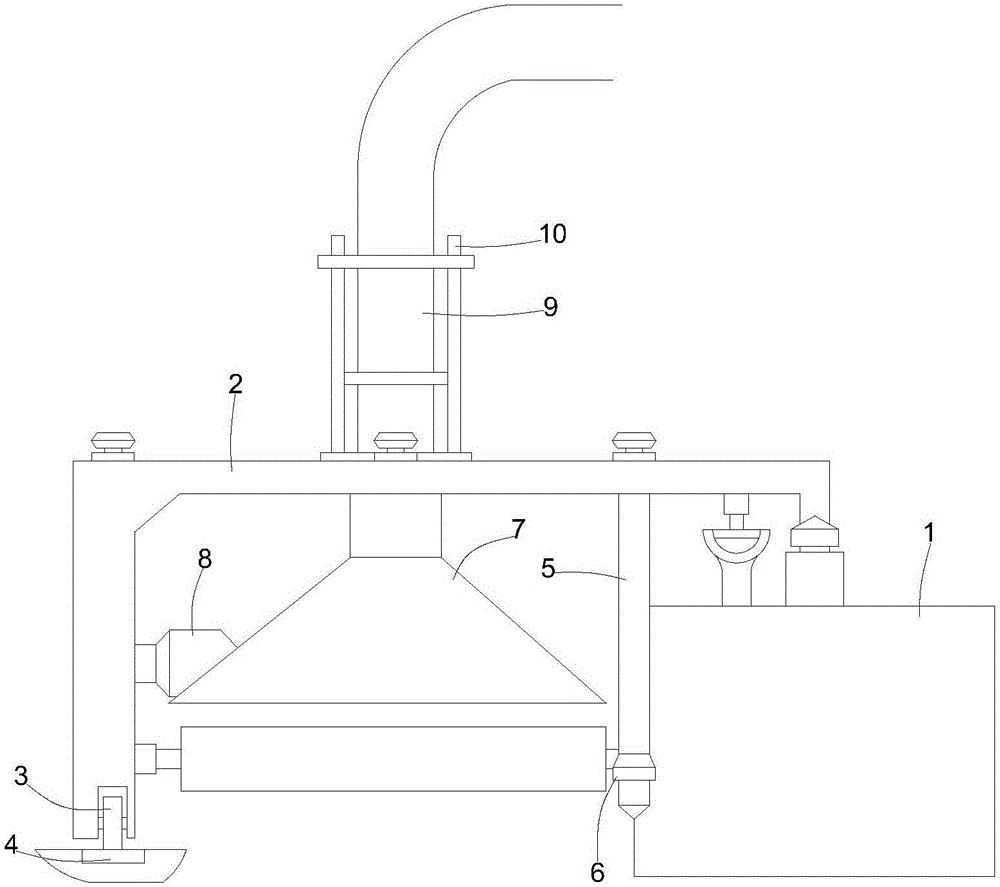

Small mining combined dust remover

InactiveCN102003200ASuction in timeImprove dust removal efficiencyCombination devicesDust removalHydraulic motorEconomic benefits

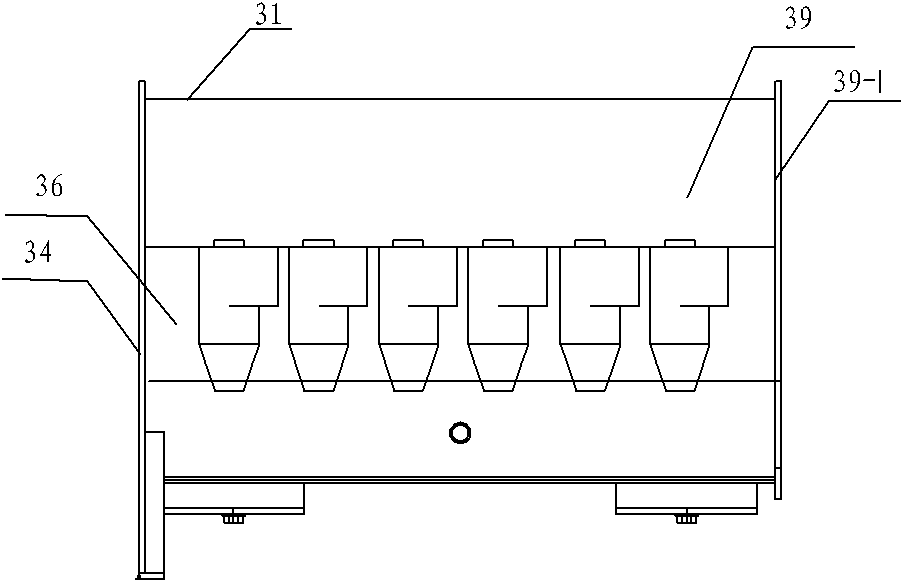

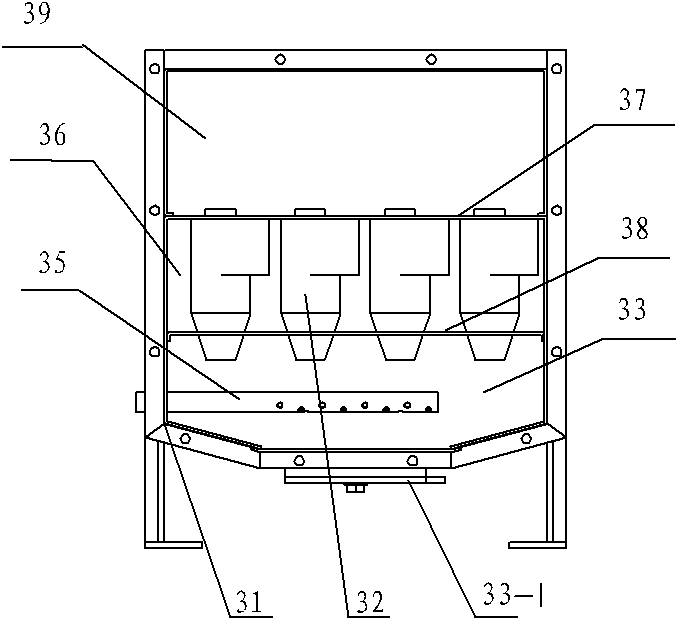

The invention claims a small mining dry combined dust remover, which is in turn provided with an air inlet component, a centrifugal induced draught fan, a cylindrical dust remover and a cylindrical filter in a flowing direction of the air. The air inlet component is in the front of the centrifugal induced draught fan. An air wheel of the induced draught fan is driven by a hydraulic motor. The centrifugal induced draught fan comprises a casing, a mounting base and a centrifugal air wheel. The cylindrical dust remover is a cylindrical small-cyclone dust remover, in which a plurality of small-cyclone separators are arranged perpendicular to an axis of the cylinder. The combined dust remover has high dust removing efficiency; and the hydraulic system of a development machine drives the hydraulic motor draught fan to work. Furthermore, the cylindrical dust remover is shaped to be mounted on the development machine so as to cooperate with the development machine. The dust remover can timely suck and remove the dust during the cutting of the development machine safely and reliably, so the dust remover is very suitable for use in mining, tunnel and subway operation. The application of the technology can change operating environments, reduce the occurrence of occupational diseases and bring greater economic benefits to enterprises.

Owner:杭州洪裕重工机械有限公司

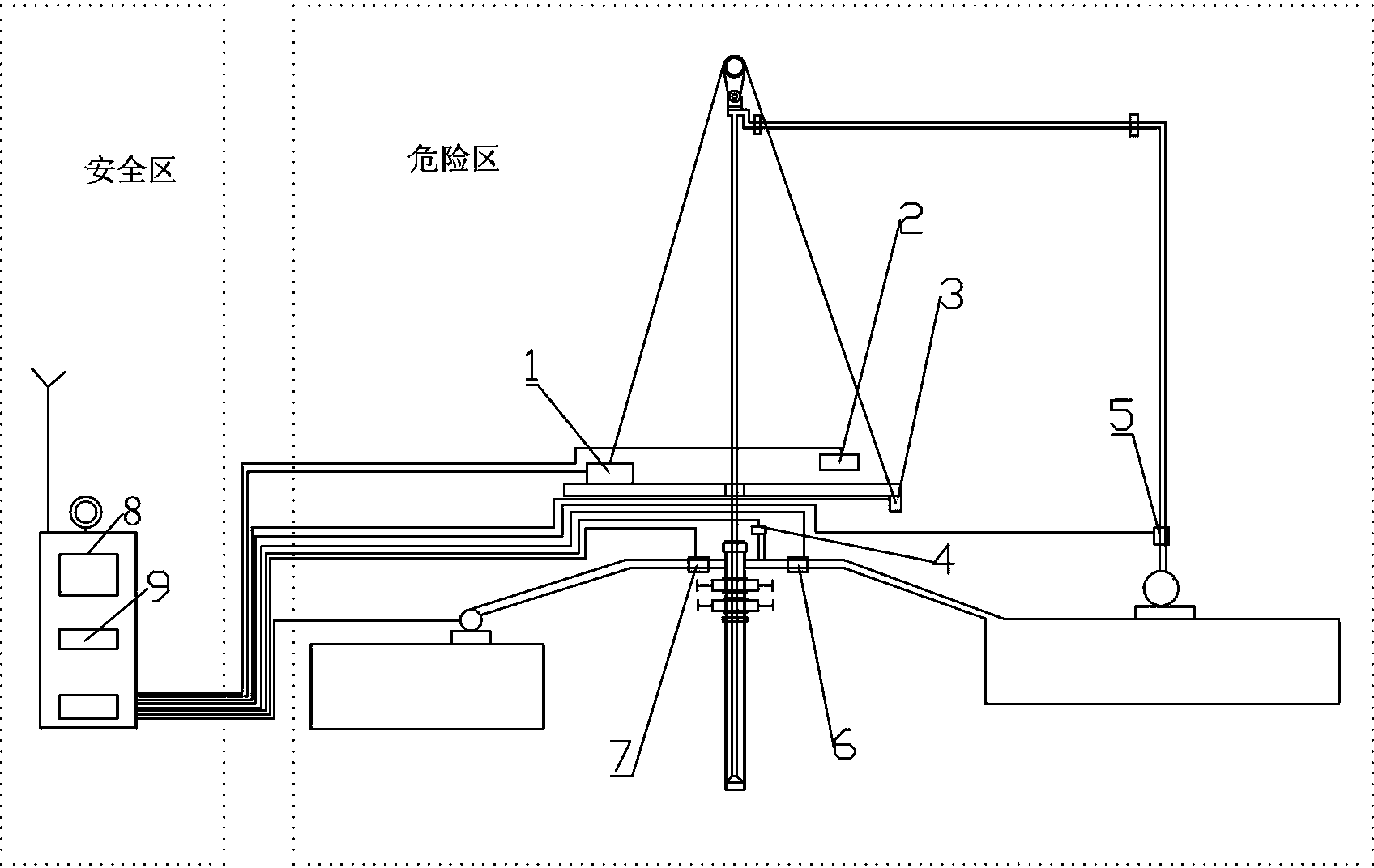

Well control project monitoring system

The invention relates to a well control project monitoring system comprising a drill floor adjusting device, a drilling tool is inserted into a borehole through the drill floor adjusting device, a sludge circulation system passes through an inner cavity of the drilling tool, circulates in the annular space of the borehole out of a circulation tank and then is pumped into the inner cavity of the drilling tool through a sludge pump to form a closed loop, an anti-spilling pipe is connected to the upper portion of the borehole, the upper end of the anti-spilling pipe is provided with a wellhead sealer, a blowout preventer is arranged at the lower portion of the anti-spilling pipe, a grout pipe and a grout pump sequentially pass through the position between the wellhead sealer and the blowout preventer and then are connected with a sludge tank, the grout pipe is provided with a grout pipe flow sensor, a guide pipe flow sensor is arranged at the position, at a guide pipe of an outlet of the anti-spilling pipe, of the sludge circulation system, and a vertical pipe flow sensor is arranged at an inlet of the sludge circulation system. The well control project monitoring system is stable in performance, can achieve recording and wireless remote transmission of on-the-spot working information in real time, and provides the basis for integration of the spot and a foundation, information sharing, remote control commanding, accident replaying and investigation treatment.

Owner:PANJIN CHUNYA PETROLEUM TECH

Municipal road marking device

ActiveCN106087690AUniform widthUniform thicknessRoads maintainenceRoad surfaceMechanical engineering

The invention provides a municipal road marking device and belongs to the technical field of municipal road equipment. The municipal road marking device solves the problem that the municipal road marking quality is low. The municipal road marking device comprises a guide frame. The guide frame comprises two guide rails. Each guide rail is connected with a movable board in a sliding manner. Each movable board is connected with a separation board in a sliding manner and provided with a compression spring. A material spraying pipe and a material grinding pipe are fixedly connected between the two separation boards. A grinding screw is arranged in the material grinding pipe. A roller shaft is further rotationally connected between the two separation boards. When the movable boards move, the roller shaft can roll marking paint on a road surface. Material return suction pipes are further arranged on the two separation boards. The movable boards are provided with drive pieces capable of driving the movable boards to move in a reciprocating manner. The municipal road marking device is good in marking quality.

Owner:临沂临港经济开发区市政工程有限公司

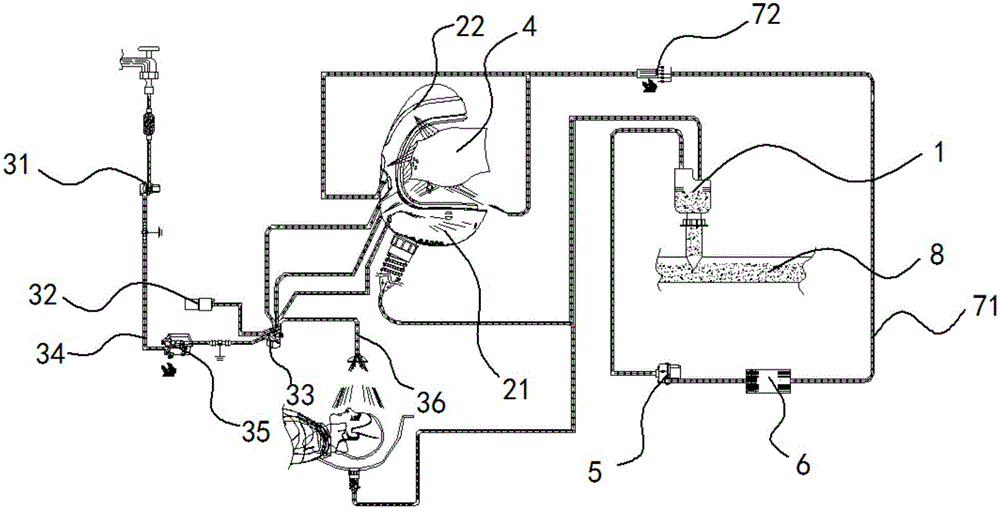

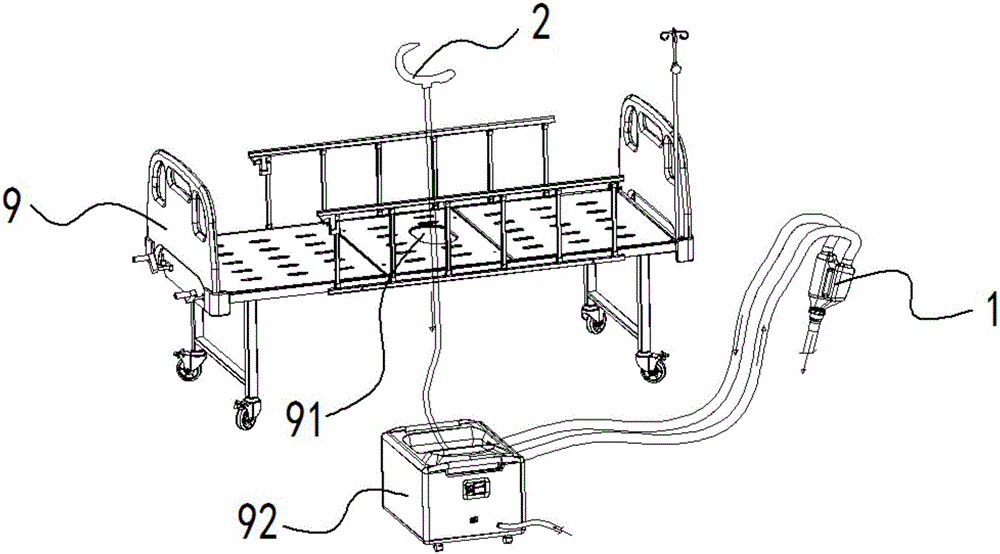

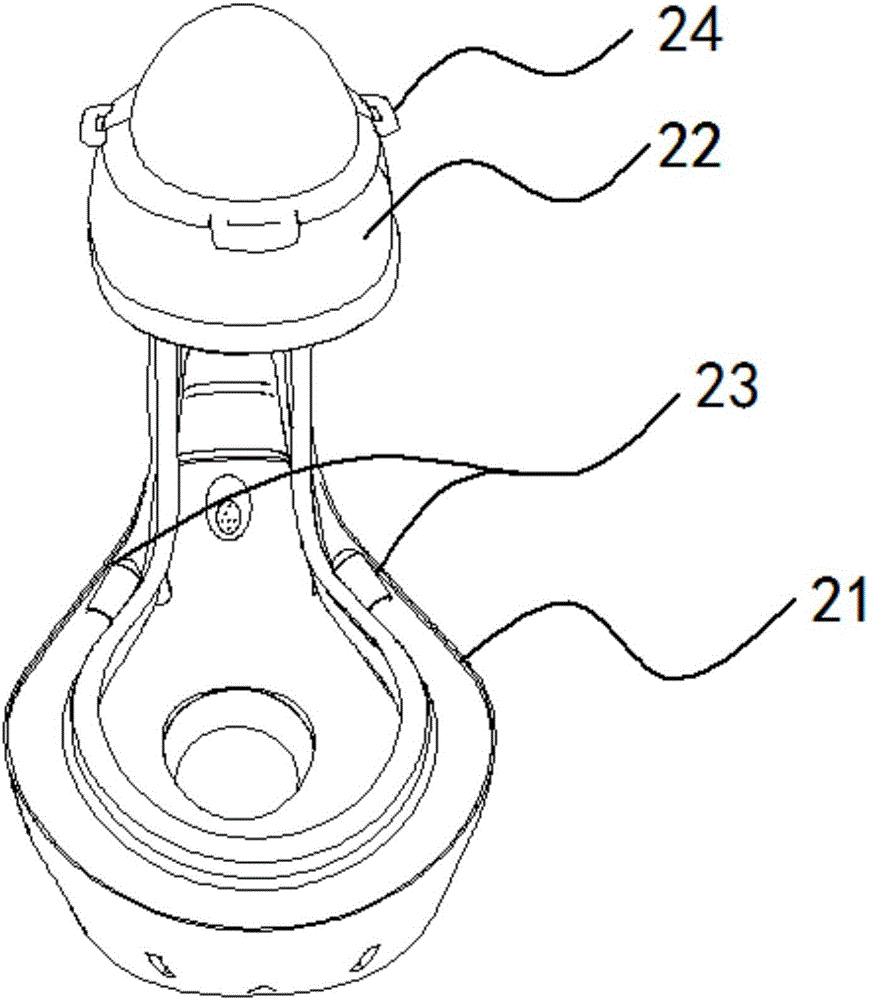

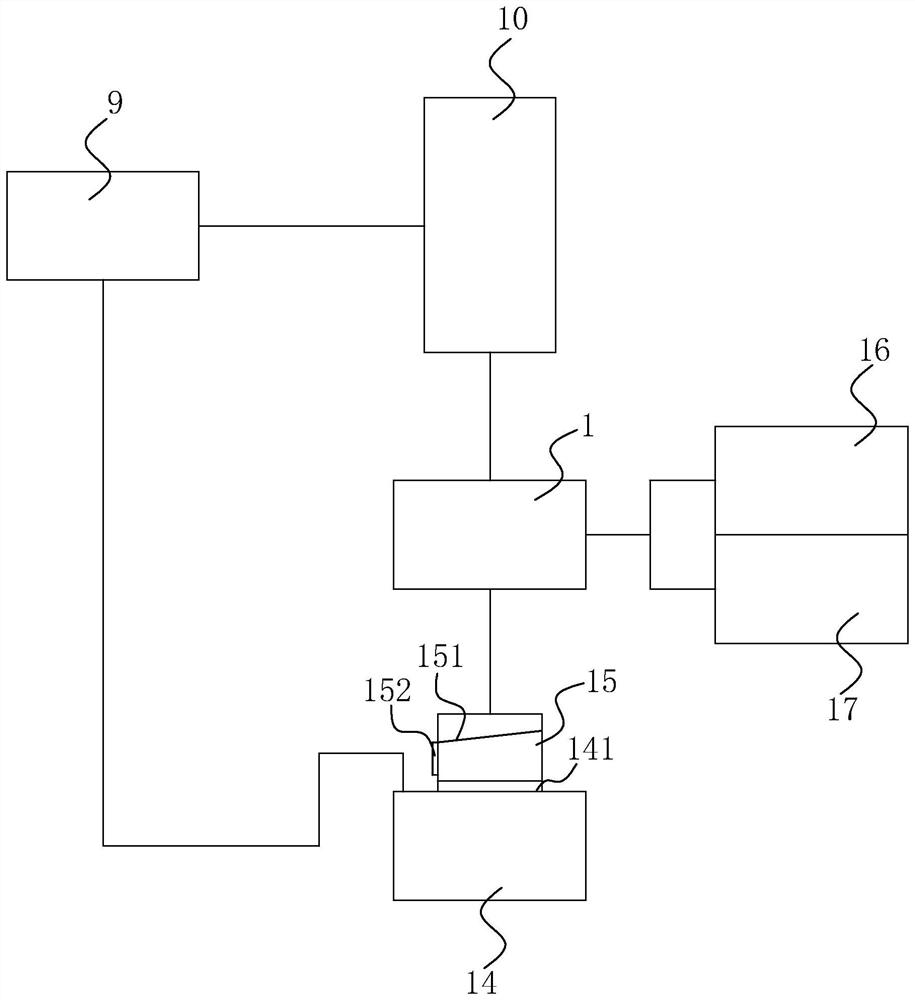

Novel intelligent urination and defecation nursing device and nursing bed including same

The present invention relates to a novel intelligent toilet care device, comprising: a toilet box, a controller, a flushing device and a defecation device, the flushing device and the defecation device are respectively connected with the toilet box through pipelines, and the Both the flushing device and the defecation device are electrically connected to the controller; the defecation device is a bridge negative pressure barrel. The beneficial effects of the present invention are: by setting the flushing device and the negative pressure barrel for crossing the bridge, the user's feces and waste water after flushing can be directly sucked into the negative pressure barrel and then discharged. This process is controlled by the controller, and the use is more convenient. It is convenient, and it can suck the peculiar smell into the negative pressure barrel in time, which is more convenient to use, and the user can use it more comfortably through the overall design, and the device can save manual care.

Owner:SHENZHEN YI HU BAO SMART TECH LTD

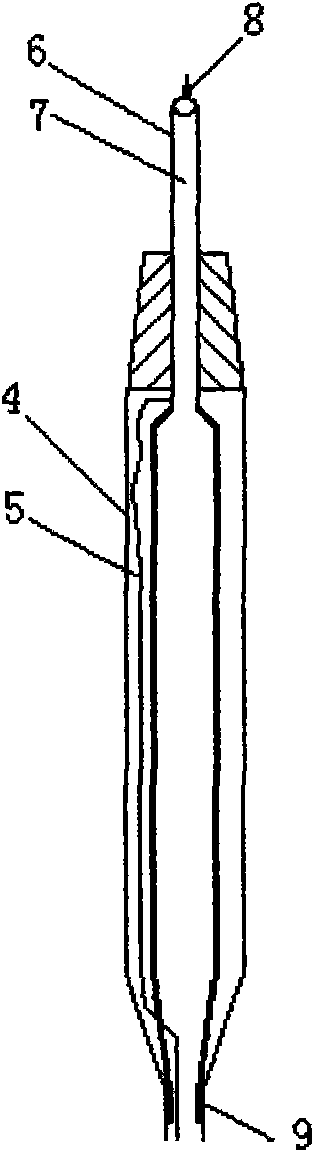

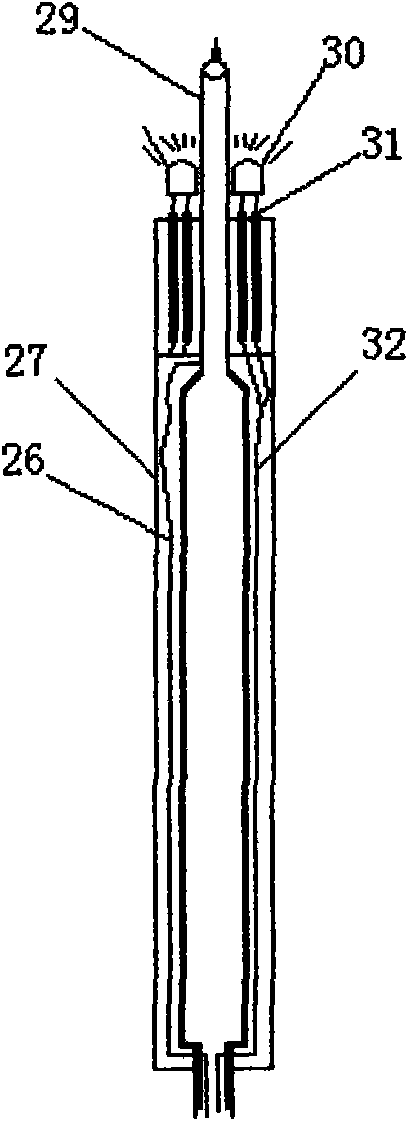

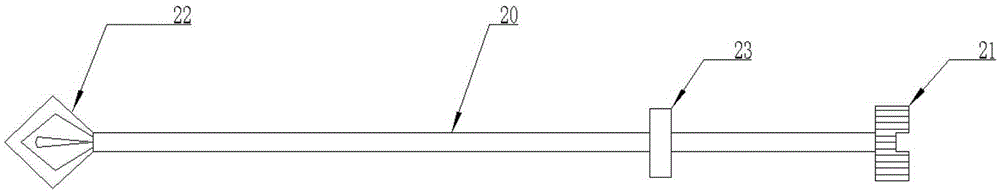

Attraction electrotome

InactiveCN101828961AFree from influenceEasily sucked awaySurgical instruments for heatingEngineeringPower circuits

The invention discloses the electrotome handle, lighting electrotome handle, vacuum suction tube, vacuum pump of an attraction electrotome. In the hollow electrotome handle, a power circuit of the electrotome is arranged in the electrotome handle or the wall of the electrotome handle; an attraction opening is formed the tail of the electrotome handle; a conducting blank pipe is provided with a hollow channel, and the rear end of the conducting blank pipe is arranged in the front of the electrotome handle; and the rear end of the conducting blank pipe is connected with the power circuit of the electrotome, and the front end of the conducting blank pipe extrudes out of the electrotome handle and forms a thin tip suction inlet forward. The electrotome provided by the invention absorbs smoke generated in the process of operation uninterruptedly, and during the operation on a narrow and deep area, the electrotome can penetrate into the area to absorb the generated smoke, liquid impurities and the like close to the electrotome completely in time and discharge the smoke, the liquid impurities and the like to the outside or a sterilizer without blocking the negative pressure suction pipe and the negative pressure pump; and in an operation area of a narrow dark area, an illuminating lamp on the electrotome can also illuminate conveniently and clearly. In addition, an electrotome head, the electrotome handle and the negative pressure pump can be disassembled conveniently and quickly to be replaced and disinfected, and a filter screen and a filter can be replaced conveniently.

Owner:左圣林

Hysteroscope

The invention discloses a hysteroscope. The hysteroscope comprises a hysteroscope sheath and an endoscope which is arranged in the hysteroscope sheath, the hysteroscope sheath comprises an inner sheath body and an outer sheath body, the outer sheath body is provided with a water inlet and a water outlet, an operating electrode is arranged in the inner sheath body, a cleaning device is arranged on the side portion of the endoscope, and the cleaning device is driven by a driving device arranged outside the hysteroscope sheath to scrub the surface of the endoscope; a sliding block is movably arranged on the outer sheath body, a suction tube is arranged between the inner sheath body and the outer sheath body, and the sliding block is connected with the suction tube. The cleaning device is arranged on the hysteroscope sheath to clean the surface of the endoscope, the situation that tissue scraps block the view of the endoscope is avoided, and it is guaranteed that an operation is conducted smoothly. Due to the fact that the suction device is arranged, the detached tissue scraps can be sucked out of the uterine cavity, and the situation that the operation sight line is blocked due to the fact that a large amount of tissue floats in the uterine cavity is avoided. A tissue collection tank is designed to be a two-layer solid-liquid separator device, the blood or other biological interstitial fluid and biological tissue are separated, and collection of biological tissue samples is facilitated.

Owner:SHANDONG PROVINCIAL HOSPITAL

Steel surface acid pickling treatment system

PendingCN111621794ASave resourcesLow costDirt cleaningCleaning using liquidsEngineeringTreatment system

The invention relates to a steel surface acid pickling treatment system, and belongs to the field of steel surface treatment. The steel surface acid pickling treatment system comprises a new acid tank, an acid liquid heater and a steel acid pickling tank with the upper end provided with an opening, wherein the new acid tank, the acid liquid heater and the steel acid pickling tank are sequentiallyconnected through a pipeline. A cyclic heat acid tank and a filter tank are further included. An acid liquid outlet of the steel acid pickling tank is connected with an inlet of the filter tank. A filter piece is arranged in the filter tank. An outlet of the filter tank is connected with an inlet of the cyclic heat acid tank. An outlet of the cyclic heat acid tank is connected with a pipeline between the new acid tank and the acid liquid heater. According to the acid pickling treatment system, acid liquid can be cyclically utilized at constant temperature, equipment used for three procedures of acid pickling, alkali washing and water washing of steel is combined, and accordingly the effects of high efficiency and energy saving are achieved.

Owner:江苏常宏玻璃钢有限公司

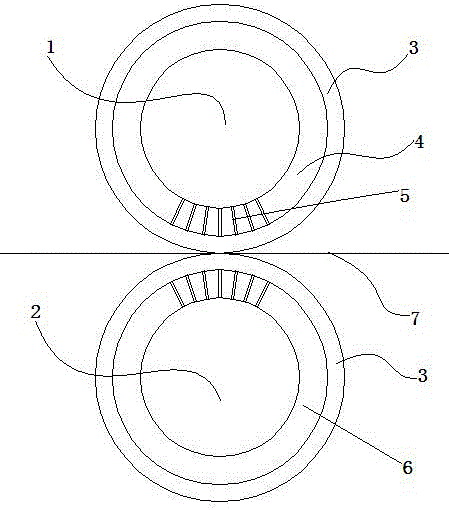

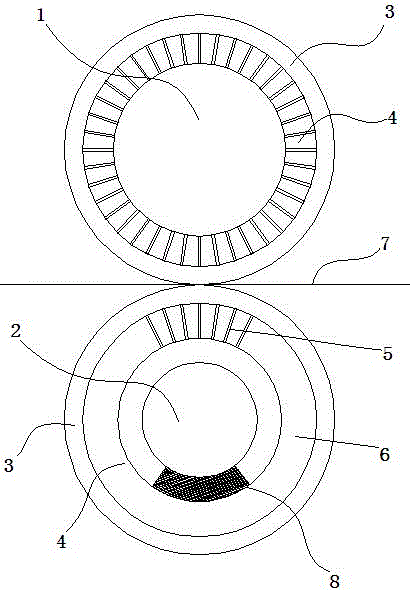

Capillary air pressure pressing roller set for papermaking

The invention relates to a capillary air pressure pressing roller set for papermaking. The capillary air pressure pressing roller set for papermaking comprises two pressing rollers mutually extruded together. The two pressing rollers are arranged up and down and comprise an upper roller and a lower roller; an axial center of each pressing roller is of a hollow structure; a positive air pressure device arranged on the end part of the upper roller communicates with the hollow structure of the upper roller; a negative air pressure device arranged on the end part of the lower roller communicates with the hollow structure of the lower roller; a roller wall of each pressing roller comprises a two-layer structure which is an air flow guiding layer with air holes and a capillary layer located on the outer part of the air flow guiding layer; each capillary layer can relatively rotate around each air flow guiding layer; the air holes of the air flow guiding layer in the upper roller and the air holes of the air flow guiding layer in the lower roller are intensively close to a tangent line position between the upper roller and the lower roller. The two pressing rollers are extruded together, an extrusion force can be formed on paper, water in the paper is extruded, and the capillary layers made of capillary materials are adopted on the outermost layers of the two pressing rollers, so that the extruded water can quickly flow into capillary holes.

Owner:JIANGSU LEE & MAN PAPER MFG

Rust removing device for inner wall of steel gas cylinder

PendingCN112476253AEasy to remove rustConvenient sand dischargeBlast gunsAbrasive feedersSand blastingGas cylinder

The invention provides a rust removing device for the inner wall of a steel gas cylinder. The rust removing device is provided with a sand blasting device, a steel gas cylinder overturning device anda steel gas cylinder rotating device; and the steel gas cylinder rotating device is installed on a support of the steel gas cylinder overturning device. When an operator conducts sand blasting to remove rusting materials on the inner wall of the empty steel gas cylinder, the empty steel gas cylinder is driven by the steel gas cylinder rotating device to rotate, the situation that the rusting materials on each position of the inner wall can be removed, the steel gas cylinder overturning device drives the V-shaped support supporting the empty steel gas cylinder to overturn, and therefore great convenience is brought to bottling as well as rust removing and sand discharging of the inner wall of the steel gas cylinder.

Owner:岳阳凯美特电子特种稀有气体有限公司

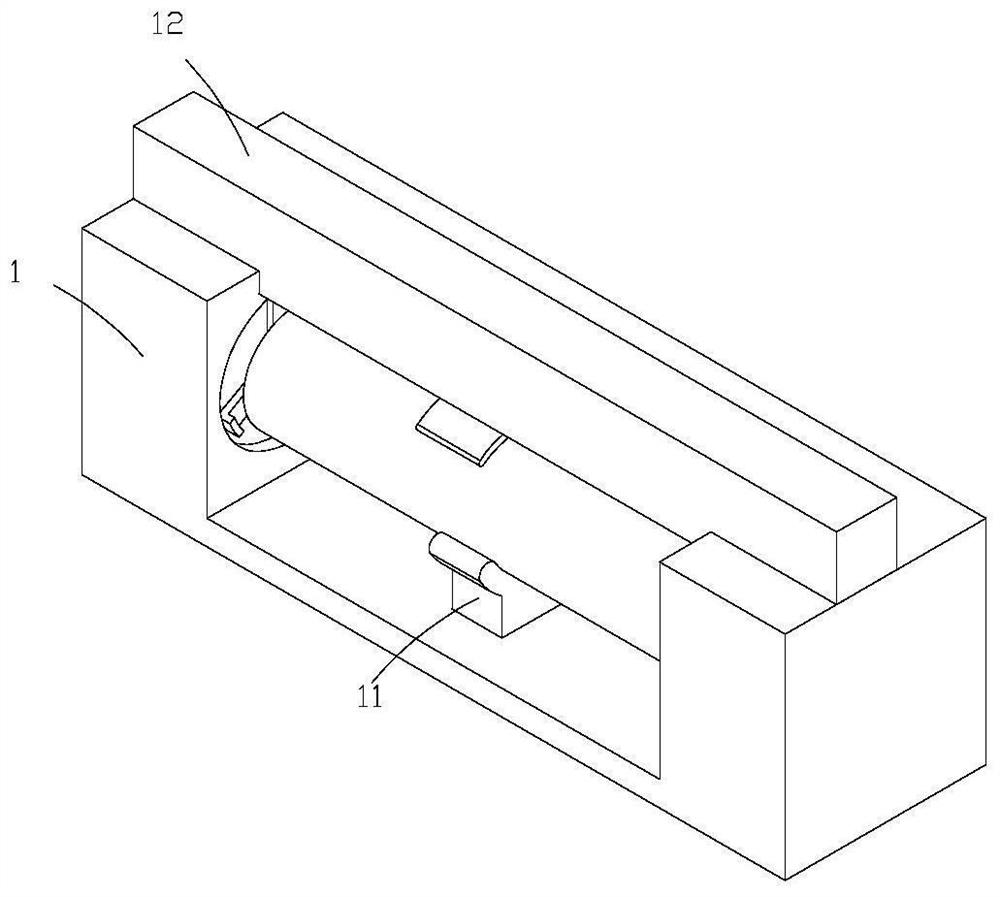

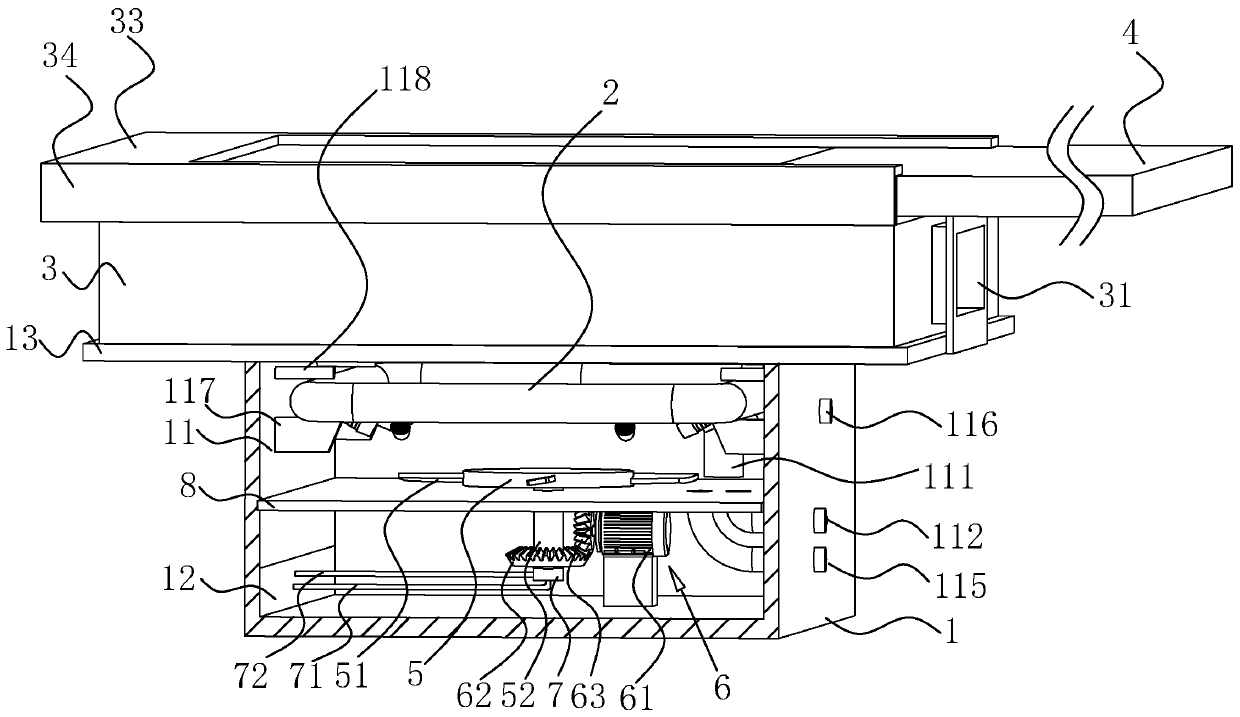

Chip removing device for intelligent machine tool

InactiveCN108857559AFix not workingSuction in timeMaintainance and safety accessoriesTransverse axisScrew thread

The invention provides a chip removing device for an intelligent machine tool and relates to the technical field of chip removing devices. The chip removing device for the intelligent machine tool comprises a chip removing device body, wherein round holes communicated with the chip removing device body are arranged in the centers above the left side and the right side of the chip removing device body, inserting rods are inserted into the two round holes, a thread shaft which is integrated with the inserting rod is fixed to one end of each inserting rod, the threaded shafts penetrate through the round holes and are arranged in an inner wall of the chip removing device body, vertical rods which are in rotating connection with the inserting rods are sleeved above the outer sides of the two inserting rods, inner rods are embedded into the inner sides of the vertical rods, through holes communicated with the vertical rods are arranged above the left sides of the vertical rods, horizontal shafts penetrate through the through holes, the two vertical rods are connected through the horizontal shaft, sleeves are sleeved to the outer sides of the horizontal shafts, brush hair and magnets arearranged on outer walls of the sleeves, the brush hair and the magnets are horizontally distributed on the sleeves in a staggered mode, and pull rings are welded to the two ends of the horizontal shafts. The chip removing device disclosed by the invention has the beneficial effects that normal work of the machine tool is ensured, and a chip removing effect of the chip removing device is improved.

Owner:江苏创良智能数控科技有限公司

Manufacturing method of pressure vessel

The invention discloses a manufacturing method of a pressure vessel. The manufacturing method comprises the following steps that a, cutting treatment is conducted, specifically, a metal plate is cut to obtain a plate; b, bending treatment is conducted, specifically, the plate is bent into a circular ring structure, and a bent plate is obtained; c, welding treatment is conducted, specifically, the bent plate is welded, and a metal circular ring is obtained; d, polishing treatment is conducted, specifically, the metal ring is fixed to a polishing machine for polishing treatment, and an annular tank body is obtained; e, butt joint treatment is conducted, specifically, the annular tank body and end covers on the two sides are welded after being fixed through tools, and the pressure vessel is obtained; the polishing machine in the step d comprises a main body, a lifting frame, a clamping device, a cross beam, a moving block, a polishing plate and a polishing device. The clamping mode of the metal circular ring can be alternated during polishing, so that no dead angle exists during polishing; the smoothness of the tank body is further improved; meanwhile, when the inner wall is polished, metal powder can be sucked away in time, and cleaning work after polishing is facilitated; and the manufacturing efficiency is effectively improved.

Owner:浙江三金机电科技有限公司

Dust-free stone crusher for mechanical engineering

InactiveCN107088450ASuction in timeAchieve dust-free effectDirt cleaningGrain treatmentsCrushed stoneEngineering

The invention discloses a dust-free stone crusher for mechanical engineering. The dust-free stone crusher comprises a device body. A shell is arranged on the outer surface of the device body. The two opposite side faces at the top of the device body are each provided with a cylindrical rotating shaft. The inner sides of the rotating shafts are provided with eccentric shafts. A signal lamp and a feeding plate are arranged at the top of the device body. A static jaw plate is arranged inside the device body. The outer side face of the static jaw plate is connected with a wire. One end of the wire is connected with an electric generator. The inner side face of the static jaw plate is provided with a metal edge protective plate. A dynamic jaw plate is arranged on the inner side face of the edge protective plate. The side face of the static jaw plate and the side face of the dynamic jaw plate are both provided with rectangular hollow parts. A dynamic jaw is arranged on the side face of the dynamic jaw plate. The top of the dynamic jaw is provided with a cylindrical dynamic jaw stay bolt. A rectangular safety toggle plate is arranged at a groove of the bottom of the dynamic jaw. The dust-free stone crusher for mechanical engineering is provided with a fan filtering unit, surplus dust generated in the stone crushing process can be absorbed and removed in time, the dust-free effect is achieved, and the durability and convenience of the dust-free stone crusher are improved.

Owner:南宁市健佳网络科技有限公司

Parallel type circulating water culture container system and usage method thereof

PendingCN106069985AWater head reductionReduce energy consumptionPisciculture and aquariaHigh densityWater flow

A parallel type circulating water culture container system and a usage method thereof belong to the aquatic product culture field, and a high density circulating water culture facility fishery equipment system is provided; the system comprises a culture zone, a backflow duct, a night soil settling zone, and a backflow water zone connecting the culture zone with the backflow duct; the culture zone and the backflow duct are isolated by a film and / or plate type and / or dense net material; the backflow water zone is connected with the culture zone, and water flows in one way in the culture zone; the water reversely flows in the backflow duct, thus forming the one-piece enclosed circulating water culture system; the night soil settling zone settles and gathers night soils on one nearby side of the culture zone, thus transferring night soils with high efficiency. The parallel type circulating water culture container system can reduce circulating pipeline system, can reduce construction fee and operational fee, can gather night soils and residual baits with high efficiency, thus solving aquatic product culture non point source pollution problems, promoting technology progress in culture and sewage processing industry, and improving aquatic product culture equipment level.

Owner:SHANGHAI NENGZHENG FISHING TECH DEV CO LTD

Dust removal device of grinding machine

InactiveCN104002243AIncrease the lengthSuction in timeDispersed particle filtrationMembrane filtersInlet channelGrinding wheel

The invention relates to a dust removal device of a grinding machine. The dust removal device of the grinding machine comprises a box with an inner cavity, wherein a filtering box with an inlet and an outlet are arranged in the box, an air inlet channel with one end communicated with the inlet of the filtering box and an air outlet channel with one end communicated with the outlet of the filtering box are arranged on the box, an air fan is arranged on the air outlet channel, and the air fan is located on one side of the filtering box. Compared with the prior art, the dust removal device of the grinding machine is convenient to install and demount, and simultaneously the inner cavity of the filtering box is nearly filled with a filter element in the lengthways direction, the length of the filter element is increased and accordingly the filtering area is enlarged, and work efficiency is improved, and furthermore once the grinding machine is started for polishing, a dust exhaust device motor simultaneously works, and then hazardous materials such as metal filings and grinding wheel filings, which are ground off, are timely and completely absorbed by a dust collector, and furthermore personnel body safety is guaranteed and simultaneously environmental health is improved.

Owner:ARKEMA HYDROGEN PEROXIDE CO LTD SHANGHAI

Concrete precast slab surface layer polishing device

ActiveCN114310532AAvoid stackingSuction in timeGrinding drivesGrinding work supportsPolishingWorking environment

The invention relates to the field of concrete precast slab surface machining, in particular to a concrete precast slab surface layer polishing device which comprises a fixing mechanism and a polishing mechanism, and on the basis that the function of changing the position of a polishing part is achieved, an execution part mainly plays a role in limiting the single-time moving distance of the polishing part, and the polishing part can be used for polishing the surface layer of the concrete precast slab. The situation that the nth grinding part and the (n + 1) th grinding part of the surface of the concrete prefabricated slab are overlapped, and consequently the surface of the concrete prefabricated slab is in a non-uniform grinding state is avoided, and the dust collection plates are arranged in multiple directions, so that the dust collection range is enlarged, dust collection dead corners are reduced, and the dust collection efficiency is improved. The dust generated by polishing is timely sucked by the dust suction machine to the greatest extent, the probability that the dust is scattered into the working environment is reduced, a closed space can be formed when the cover shell is in contact with the concrete precast slab, the effect of covering the dust is achieved, and then the dust suction machine can timely suck the dust and reduce the probability that the dust is scattered all around.

Owner:徐州奥星新型建材有限公司

Vacuum squeezing and dewatering papermaking device for papermaking

The invention relates to a vacuum squeezing and dewatering papermaking device for papermaking. The device comprises two press rollers squeezed together and vertically arranged. The two press rollers are the upper roller and the lower roller. The device is characterized in that the axes of the press rollers are each of a hollow structure, a positive air pressure at one end of the upper roller is communicated with the hollow structure of the upper roller, a negative air pressure at one end of the lower roller is communicated with the hollow structure of the lower roller. The roller wall of each press roller comprises two layers of structures including an air flow guiding layer with vent holes and a capillary layer located outside the air flow guiding layer. The air flow guiding layer in the lower roller is filled with a balancing weight. The capillary layers are connected with the air flow guiding layers through bearings. The vent holes of the air flow guiding layer in the upper roller and the vent holes of the air flow guiding layer in the lower layer are all concentrated at tangent line positions between the upper roller and the lower roller.

Owner:JIANGSU LEE & MAN PAPER MFG

Aquarium water treatment device capable of efficiently and automatically sucking and removing excrement

ActiveCN106386652AReduce pollution sourcesAvoid accumulationPisciculture and aquariaRight triangleWater treatment system

The invention provides an aquarium water treatment device capable of efficiently and automatically sucking and removing excrement, aiming at mainly solving the problem of an existing filter that the effect of removing water in an aquarium is bad. The aquarium water treatment device is characterized in that an underwater cleaner (1), a water treatment system (6) and a water suction device (18) are arranged at one side in an aquarium (1), wherein the underwater cleaner (1) with a right-angled triangular cross section is arranged at the bottom of one side of the aquarium, and is communicated with a filtering pump (3) through a guide pipe (2); the water treatment system (6) is arranged in the other side corner of the aquarium; the water suction device (18) is communicated with the bottom of the water treatment system (6); an oil removing film device (8) is arranged on the outer side of a water supplementing hole (7); a water level difference automatic adjusting chamber (10) is internally provided with a water level difference automatic adjusting device (9); the lower part of an upper water guide pipe (16) is communicated with the water suction device (18); and a filtering pump chamber (4) is arranged below a filtering material chamber (14). The aquarium water treatment device capable of efficiently and automatically sucking and removing the excrement, provided by the invention, has the characteristic of good treatment effect on water in the aquarium.

Owner:李易擎

Dust collection equipment for plate processing

The invention provides dust collection equipment for plate processing. The dust collection equipment comprises a supporting mechanism, a suction mechanism and a mobile mechanism. The suction mechanism and the mobile mechanism are arranged on the supporting mechanism, and the suction mechanism can move on the supporting mechanism through the mobile mechanism; the supporting mechanism comprises a foundation support, a transverse rod is arranged above the foundation support, the outer side segment of the transverse rod is downwards bent, the tail end of the transverse rod is provided with a walking wheel, and a guide rail is arranged below the walking wheel; the inner side end of the transverse rod is provided with a limiting rod, the limiting rod stretches out downwards, and the tail end of the limiting rod is provided with a wheel disc; the side wall of the foundation support is provided with a limiting groove, the wheel disc stretches into the limiting groove, and the limiting groove is parallel to the guide rail so that the transverse rod can move along the guide rail and the limiting groove; and the inner side segment of the transverse rod is bent downwards and stretches into the foundation support. The suction mechanism comprises a cover cap, the outer side end of the transverse rod is provided with a shock excitation motor, and the shock excitation motor is connected with the cover cap; and the top of the cover cap is provided with an air pipe, the tail end of the air pipe communicates with air suction equipment through a corrugated pipe, the top of the transverse rod is provided with a positioning frame, and the air pipe is fixed to the transverse rod through the positioning frame.

Owner:深圳市优住住区产业化科技发展有限公司

Water absorbing fabric

The invention discloses a water absorbing fabric which comprises a warp yarn and a weft yarn, wherein the warp yarn and the weft yarn are vertical to each other and are both formed by twisting multiple fiber bundles; the fiber bundle comprises multiple fibers arranged in the same direction; the section of the fiber is a cross-shaped section; and a convex part and a concave part of the cross-shaped section are both in arc transition. According to the invention, as the water absorbing fabric disclosed by the invention is formed by twisting fibers with a cross-shaped section, grooves are formed on the surfaces of fibers, and the sweat produced by a human body doing exercises can be absorbed in time, thereby ensuring the comfort and health of the human body.

Owner:CHANGSHU MEILI TOWN BINLI GARMENT & CLOTHING FACTORY

Acid-alkali-water integrated steel washing tank

PendingCN111593360AEasy to operateSmall footprintDirt cleaningCleaning using liquidsSpray nozzleEnvironmental engineering

The invention relates to an acid-alkali-water integrated steel washing tank, and belongs to the field of steel surface treatment. The acid-alkali-water integrated steel washing tank comprises a washing tank body with an opening at the upper end, an acid inlet pipe and an acid discharging pipe are connected to the side wall of the washing tank body, a spraying pipe is arranged around the inner sidewall of the washing tank body, a plurality of spraying nozzles are evenly arranged on the spraying pipe, an alkali inlet pipe and a water inlet pipe are connected to an inlet of the spraying pipe, and a waste liquid discharging pipe is connected to the side wall of the washing tank body. According to the acid-alkali-water integrated steel washing tank, devices used in the three procedures of acidpickling, alkali washing and water washing of steel are combined into a whole, so that the effects that the occupied space is small, and meanwhile, other special devices used for transferring the steel among the procedures do not need to be additionally arranged are achieved.

Owner:江苏常宏玻璃钢有限公司

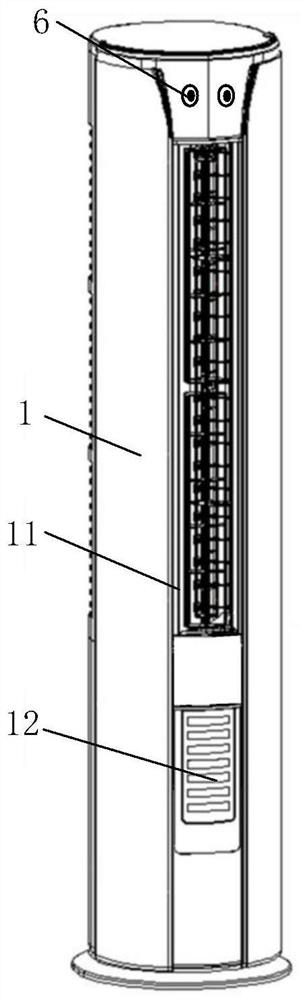

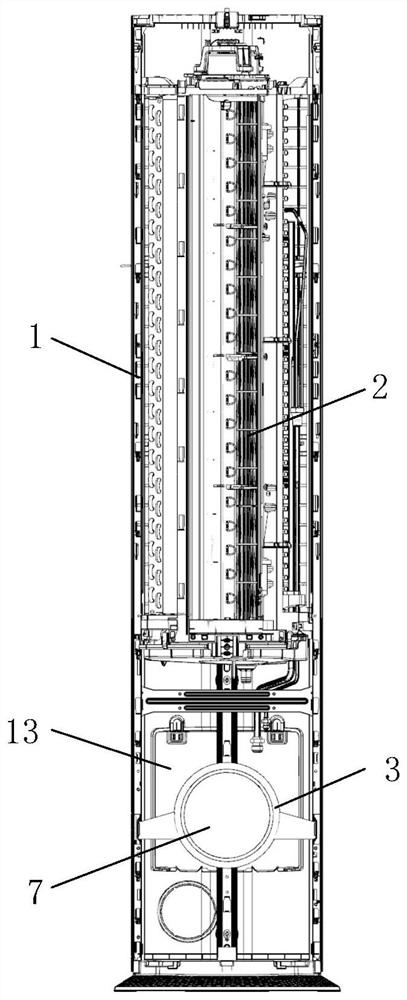

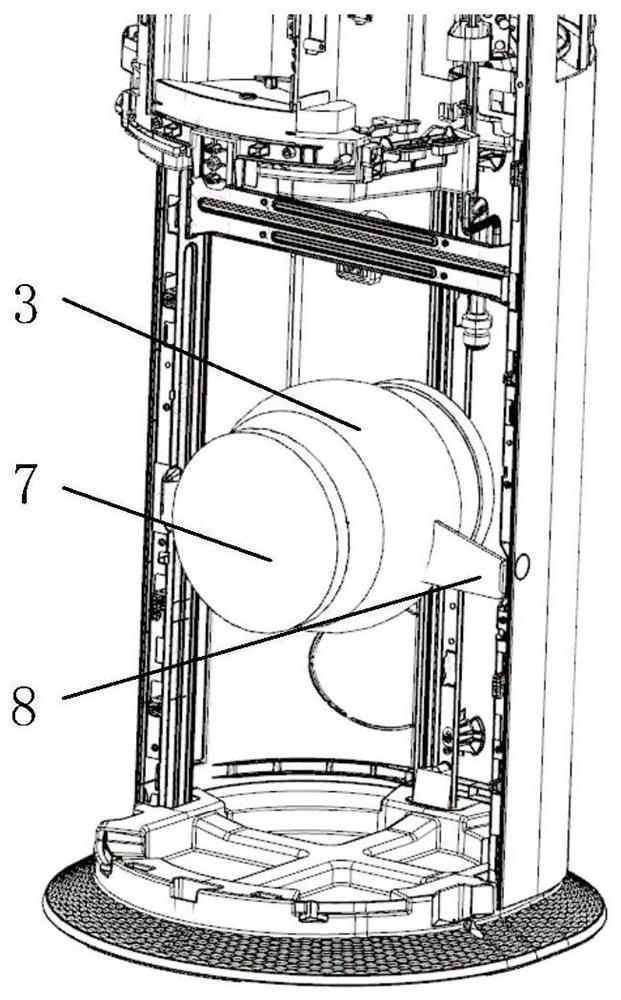

Vertical air conditioner and control method thereof and electronic equipment

ActiveCN113654110AAvoid blowingShort stayMechanical apparatusSpace heating and ventilation safety systemsSmoke EmissionControl theory

The invention provides a vertical air conditioner and a control method thereof and electronic equipment. The vertical air conditioner comprises a chassis; the chassis is provided with a main air outlet and a first lower air opening; the first lower air opening is located below the main air outlet; a main air duct communicating with the main air outlet and a lower air duct communicating with the first lower air opening are arranged in the chassis; a main air outlet fan is installed in the main air duct; an air suction fan and a first purification module are installed in the lower air duct; an image pickup assembly is installed on the chassis; and the image pickup assembly is used for identifying a smoking user and measuring the distance between the smoking user and the chassis. According to the vertical air conditioner and the control method, odor removal and smoke removal can be carried out on the indoor smoking behavior in a targeted mode, the purification effect is good, the purification speed is high, and the residence time of cigarette smoke in a room is shortened.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Water-absorbing nylon fabric

The invention discloses a water-absorbing nylon fabric which comprises warp and weft, wherein the warp and the weft are arranged perpendicular to one another and are formed by twisting a plurality of strands of nylon fiber, the plurality of strands of nylon fiber are arranged in the same direction, each strand of nylon fiber mainly comprises fiber single yarn, and the section of the fiber single yarn is in a straight line shape. With the adoption of the mode, the water-absorbing nylon fabric is formed by twisting the nylon fiber with the straight line shaped section, moisture is ensured to be easy to enter the fiber and is migrated in an internal channel of the fiber, so that the water absorption of the fiber is enhanced, sweat generated during human motion can be timely absorbed and removed, and the comfortableness and the health of human body are ensured.

Owner:CHANGSHU MEILI TOWN BINLI GARMENT & CLOTHING FACTORY

Automatic cutting machine for net film

PendingCN114291632ASmall footprintCut quicklyCleaning using gasesArticle deliveryStructural engineeringWaste material

The invention provides an automatic net film cutting machine which comprises an upper support and a lower support, a first film roller and a pulling film cutting assembly are arranged at the two ends of the upper support, the pulling film cutting assembly comprises a first vertical frame, a film pulling mechanism is arranged on the first vertical frame, and a first film cutting mechanism is arranged on one side of the film pulling mechanism; the first film cutting mechanism comprises a bearing plate, first jacking air cylinders are arranged at the two ends of the bearing plate, the output ends of the first jacking air cylinders are connected with a first pressing plate, the first pressing plate is located above the bearing plate, a first module is arranged on the first pressing plate, and a first cutter block is connected to the first module. The cutting machine is provided with the self-dust-suction waste roller, dust can be sucked away in time when waste is cut, the occupied area is small, when a net film is cut, a pressing tensioning mechanism is particularly arranged, the surface of a die body is effectively tensioned, the cutting stability of the soft net film is greatly improved, the automatic folding function is finally set, manpower input is reduced, and the follow-up process time is shortened.

Owner:昆山仕弗达自动化科技有限公司

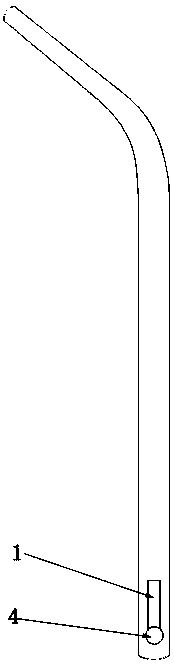

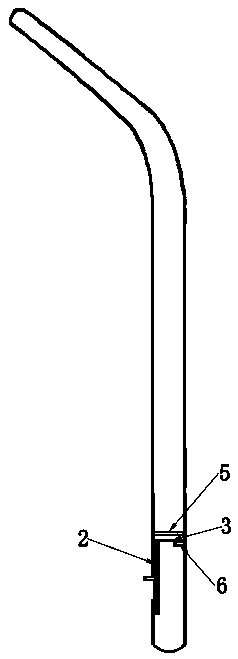

Saliva suction tube capable of movably adjusting filter screen

PendingCN110226983AAvoid aspirationSafe and efficient surgical procedureSaliva removersGranulation tissueEngineering

The invention provides a saliva suction tube capable of movably adjusting a filter screen. The bottom side wall of the saliva suction tube is provided with a linear opening which is far from the suction end, the inside of the saliva suction tube is movably provided with a filter screen assembly at the position of the opening, the filter screen assembly comprises a sliding rod and a filter screen arranged on the top of the sliding rod, the side surface of the sliding rod is provided with a button, the button protrudes out of the opening and is in interference fit with the opening, and both thelength and the width of the sliding rod are larger than the size of the opening; and the interior edge of the saliva suction tube is provided with a circle of limiting ring which is close to the length direction of the opening. The saliva suction tube is suitable for all oral surgery, and other mucogingival surgery and bone grafting surgery which are more difficult and demanding. The saliva suction tube not only can suck and remove oozing blood, saliva and scraped granulation tissue generated in the operation in time, but also can adjust the filter screen according to different types and different operation stages of the operation, thereby avoiding waste and cost increasing caused by aspiration and wrong-suction, and further making the operation process safer and more efficient.

Owner:SUZHOU HEALTH COLLEGE

Wart cutting device for dermatology department

InactiveCN114081586AIncrease efficiency and quicknessSuction in timeSurgical scissorsSurgical forcepsDermatology departmentBiomedical engineering

The invention discloses a wart cutting device for the dermatology department. The wart cutting device for the dermatology department comprises: two clamping grab handles, wherein the two clamping grab handles are movably connected through a rotating shaft; finger ring sleeves, which are fixed to one ends of the clamping grab handles, wherein limiting rods movably penetrate through the interiors of the finger ring sleeves; a fixing rod, which is fixed to the inner side of one clamping grab handle, wherein a fixing hole is reserved in the side, close to a ring sleeve, of the fixing rod; clamping blocks, which are clamped on the outer sides of the clamping grab handles, wherein liquid suction air bags are pasted on the side faces of the clamping blocks; adjusting rods, wherein one ends of the adjusting rods are sleeved with connecting sleeve blocks; and mounting grooves, which are formed in the other ends of the clamping grab handles. According to the wart cutting device for the dermatology department, after a wart on the surface of skin is cut off, the periphery of a wound can be pressed, so hemostasis effect is achieved, liquid generated by the wart can be sucked away in time, the phenomenon of infection caused by the fact that the wart is contaminated with other skin is avoided, and the efficiency and rapidness of wart cutting are improved.

Owner:新乡市第一人民医院

Oral cavity cleaning device for critically ill patient

PendingCN111803749AAvoid choking or even suffocationSuction in timeCannulasEnemata/irrigatorsEngineeringWater spray

The invention discloses an oral cavity cleaning device for a critically ill patient. A cleaning head is arranged at the front end of a handle bar, a cleaning roller is rotationally connected with thefront end of the cleaning head, the roller surface of the cleaning roller is coated with a sponge layer, multiple rows of bristles arranged in the direction parallel to the axis of the cleaning rollerare uniformly arranged on the roller surface of the cleaning roller and penetrate through the sponge layer to extend outwards, an axis through hole is formed in the axis of the cleaning roller, supporting blocks of the cleaning roller are fixedly arranged on two sides of the front end of the cleaning head, the supporting blocks, the cleaning head and the handle bar communicate inside to form an inner cavity, shaft heads circumferentially fixed with two ends of the axis through hole are rotationally connected with the opposite side end surfaces of the supporting blocks respectively, and a water spray tube is arranged between the shaft heads and located in the axis through hole and communicates with a water inlet tube in the cleaning head. According to the structure, the oral cavity cleaning device for the critically ill patient can clean the oral cavity of the critically ill patient and can suck and remove water produced during cleaning and saliva, sputum and the like in the oral cavity in time.

Owner:THE AFFILIATED HOSPITAL OF XUZHOU MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com