Dust removal device of grinding machine

A technology of dust removal device and grinder, which is applied in the direction of grinding/polishing safety device, cleaning method using gas flow, dispersed particle filtration, etc., which can solve problems such as difficulty in installation and disassembly, personal safety injury, inhalation into the body, etc., to achieve Easy installation and disassembly, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

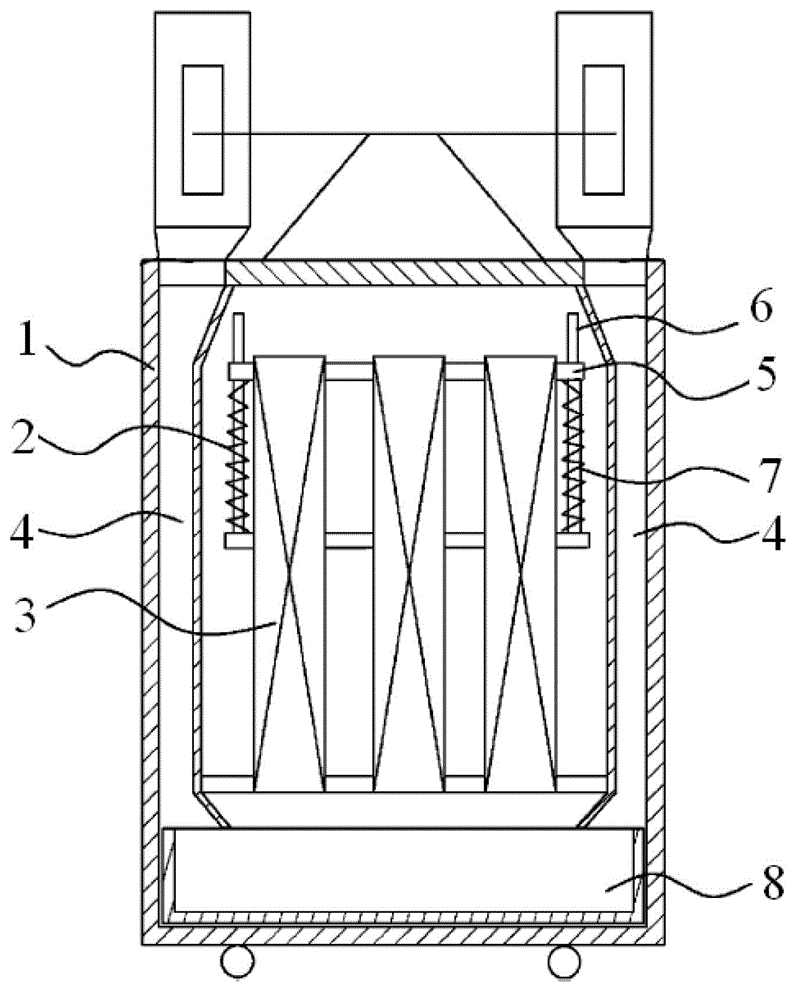

[0016] A dust removal device of a grinder is arranged on the grinder, and its structure is as follows: figure 1 Shown, comprise the box body 1 that the interior is cavity, this box body 1 is provided with the filter box 2 that has inlet and outlet, is provided with the air inlet passage 4 that one end communicates with filter box 2 inlets on box body 1 and One end of the air outlet passage communicated with the outlet of the filter box 2 is provided with a fan on the air outlet passage, and the fan is located on one side of the filter box 2 . Wherein, the inlet is located at the bottom of the filter box 2, and the outlet is located at the top of the filter box 2. A dust collecting pan 8 movably connected with the box body 1 is arranged between the air intake passage 4 and the inlet 2 of the filter box. The filter box 2 includes a housing with an inlet and an outlet and a cylindrical filter cartridge that can divide the housing cavity into two chambers; one chamber communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com