Patents

Literature

2232results about "Abrasive feeders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

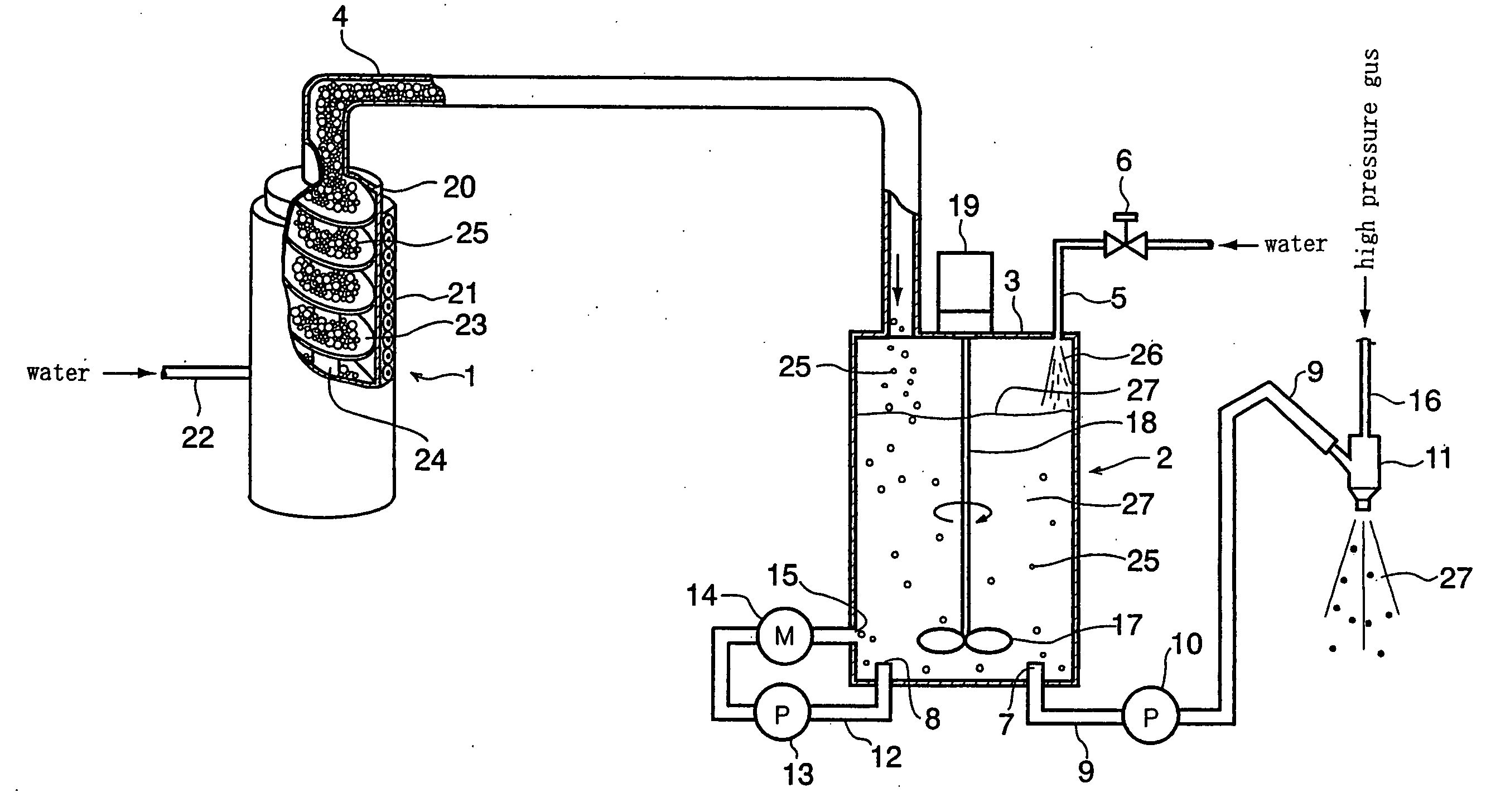

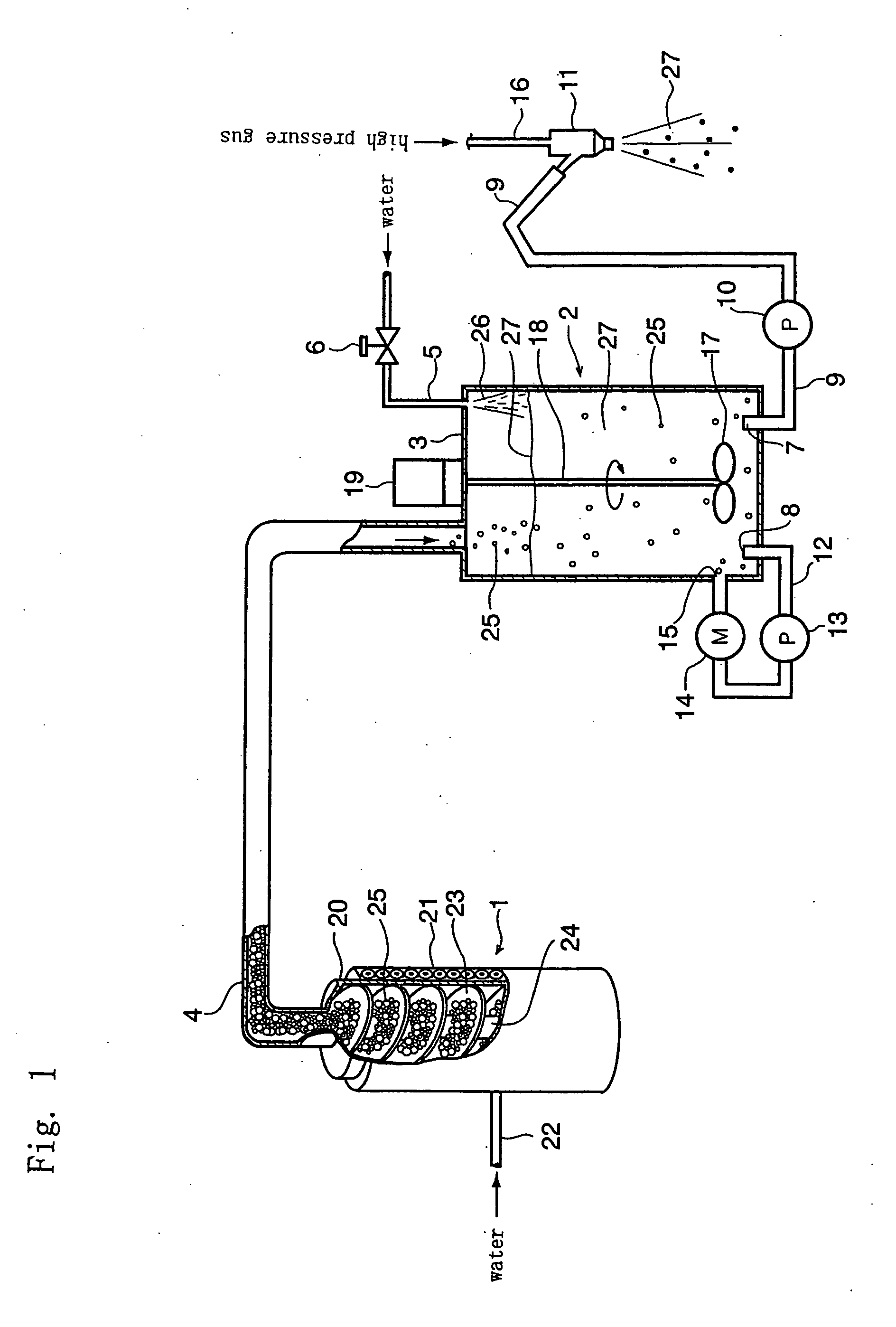

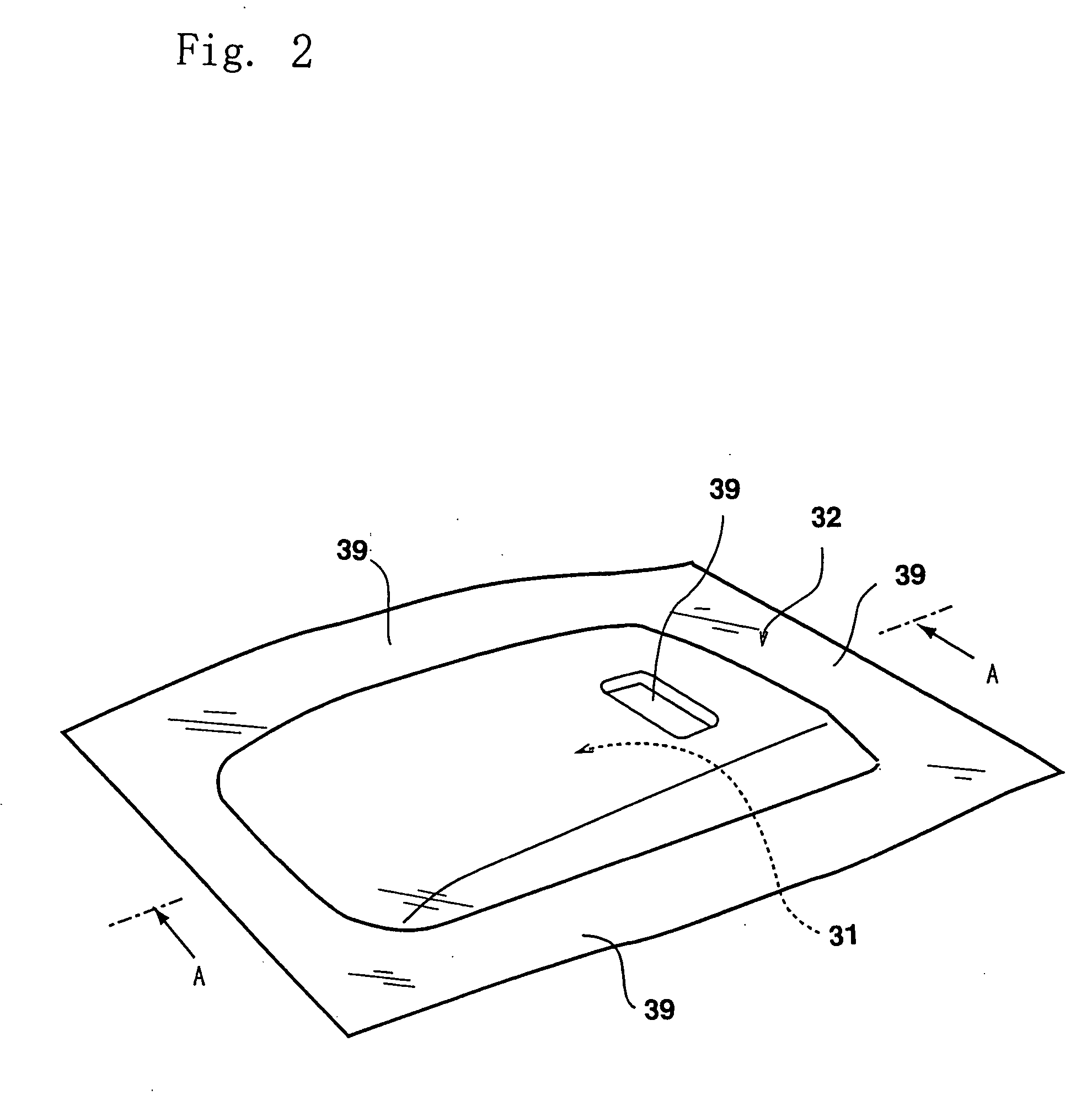

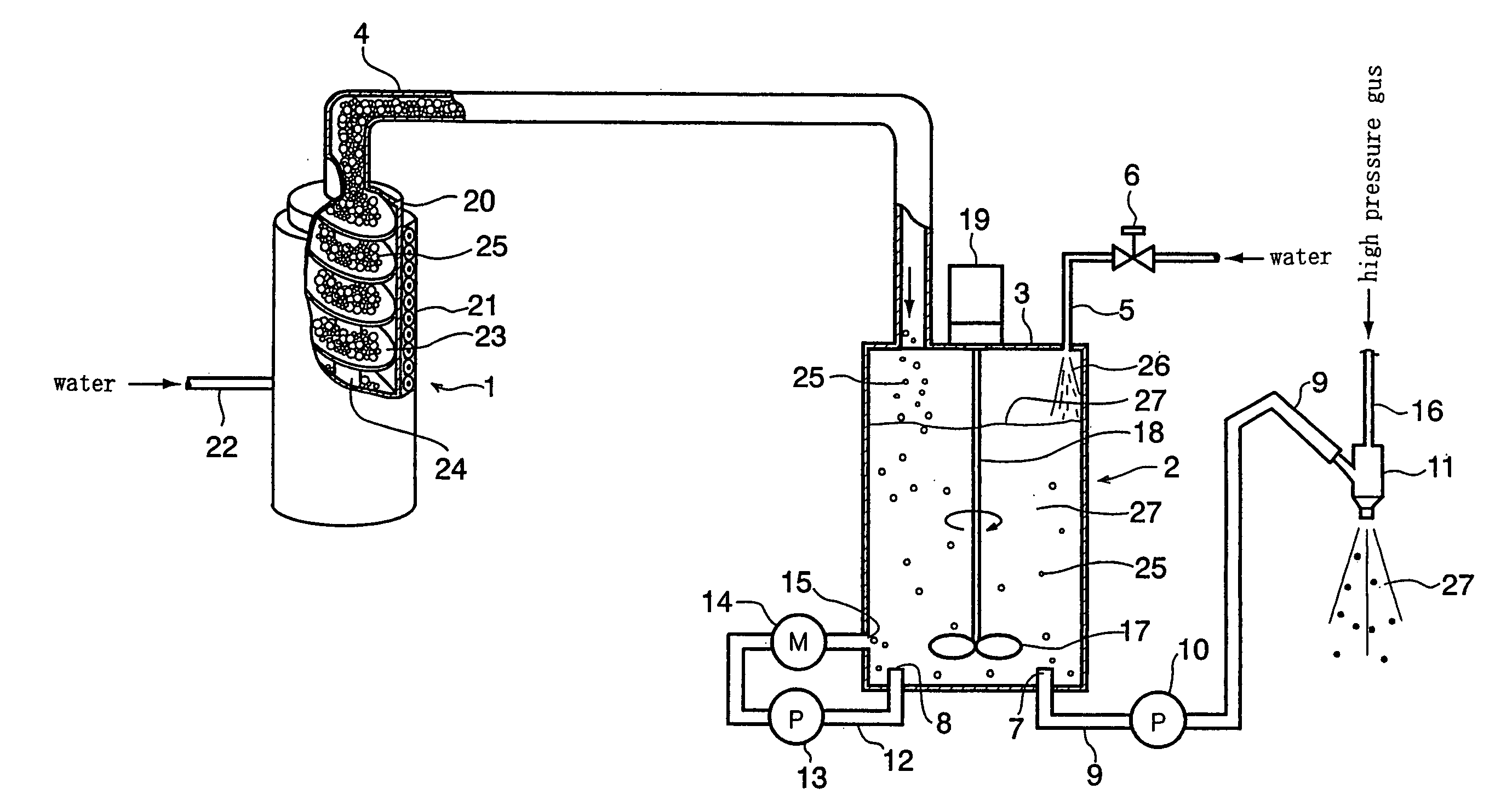

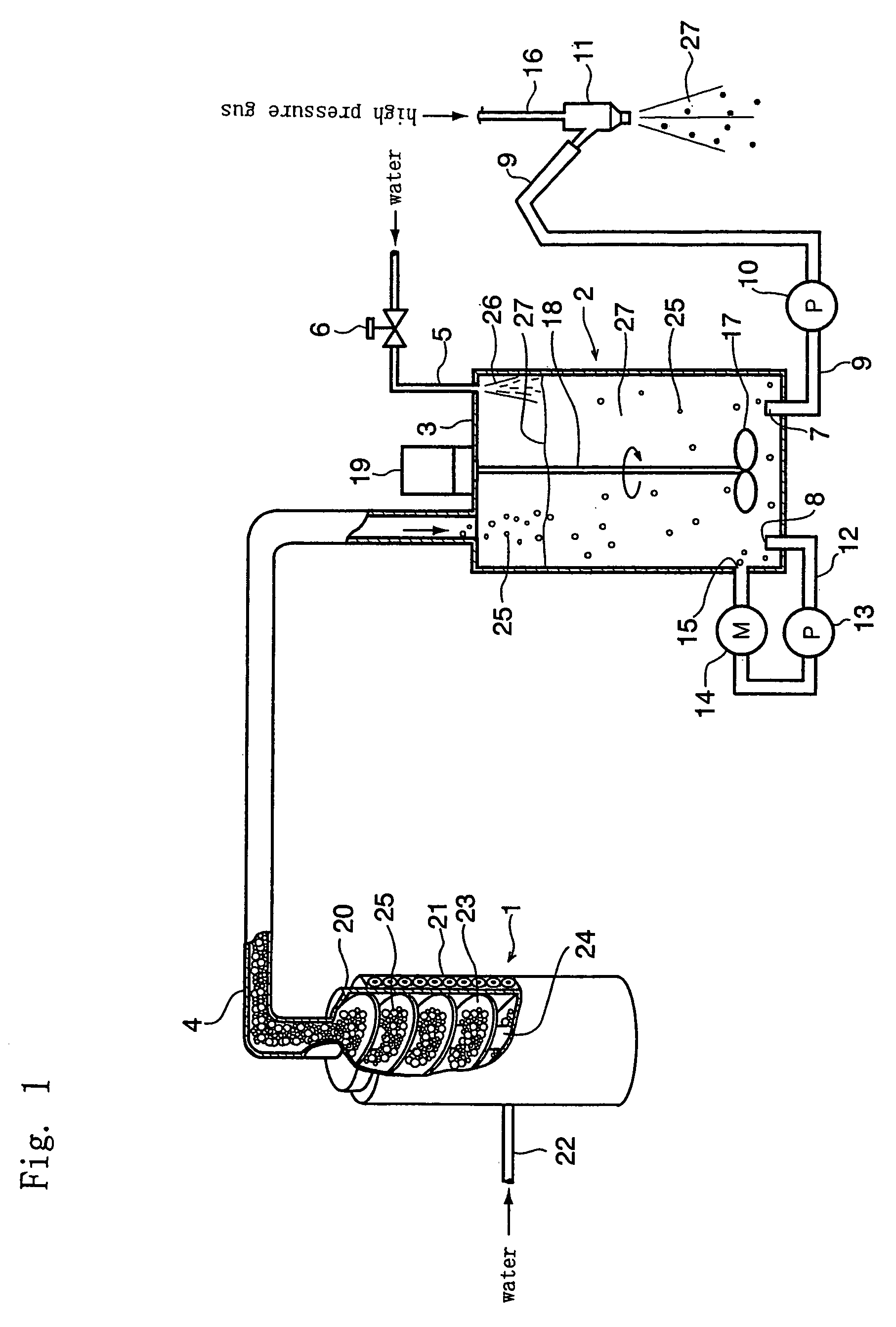

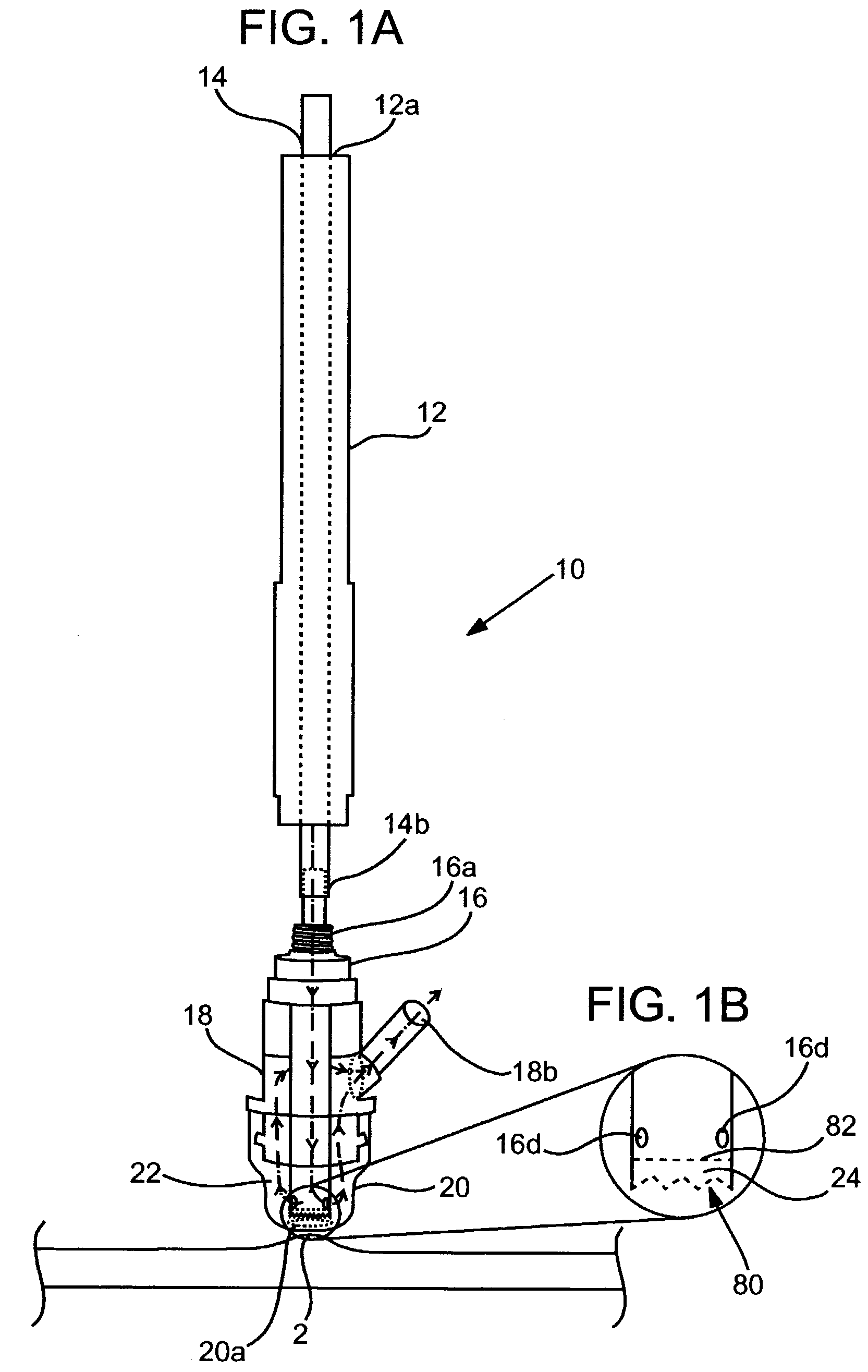

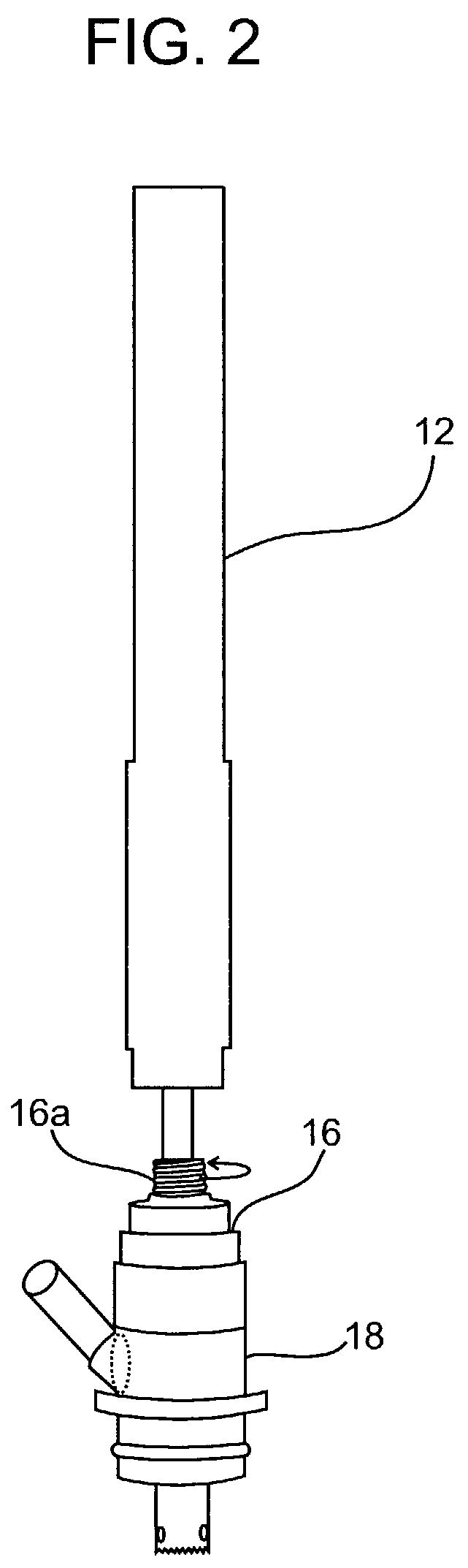

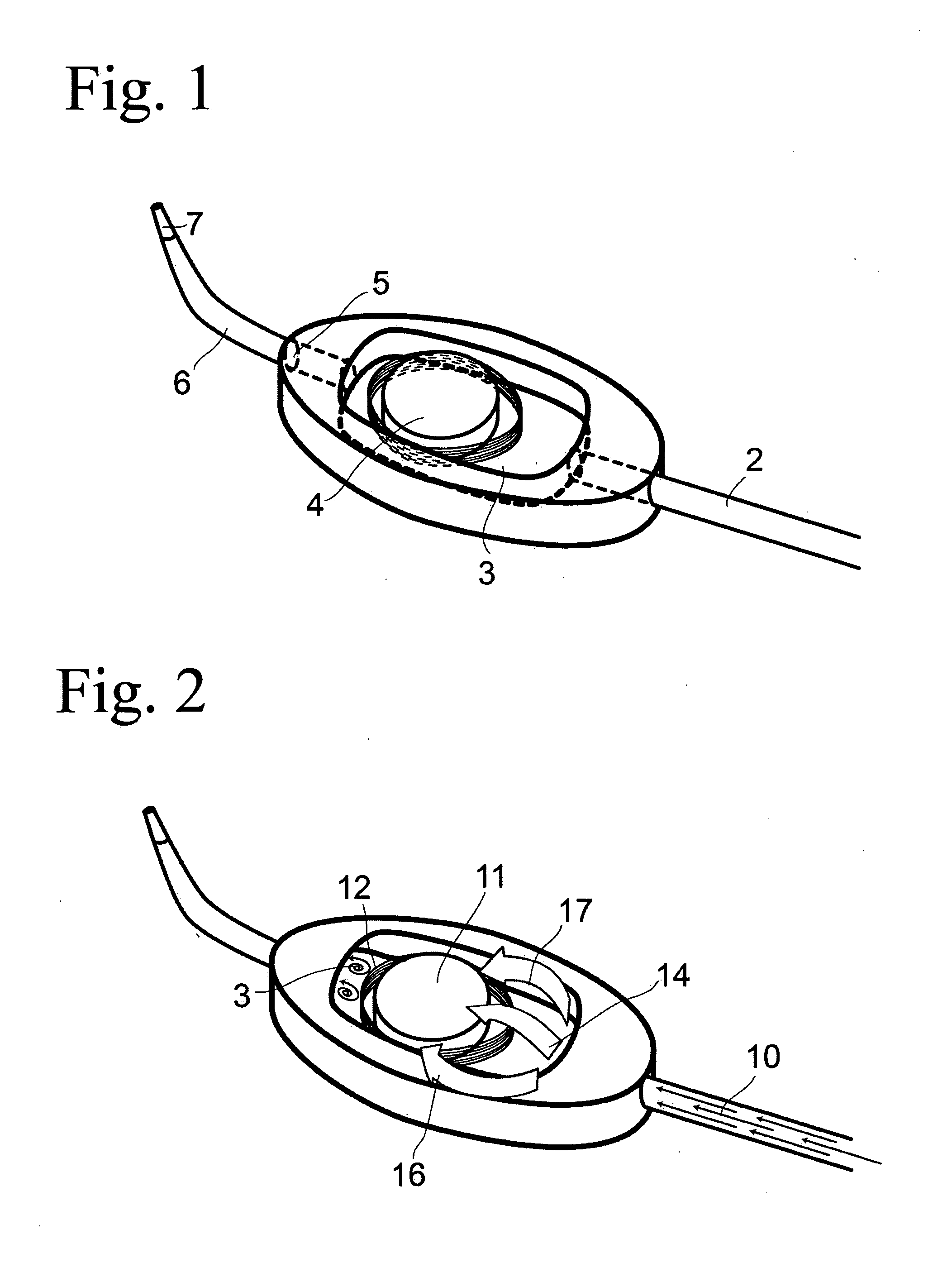

Ice blasting apparatus and trimming method for film insert molding

InactiveUS20050107006A1Lower Reliability RequirementsImprove securityAbrasive feedersAbrasive machine appurtenancesEngineeringSlurry

An ice blasting apparatus comprises: an ice making device operating a cutting blade to shave off ice freezing on an inner wall of the freezing casing and continuously discharges the shaved ice as flake-shaped ice pellets; an ice mixing tank mixing the ice pellets and water and maintaining the resulting ice slurry at a predetermined concentration with a concentration sensor; and a blast gun blasting the ice slurry. A trimming method is performed on a film insert molding with a film material adhering to a face of a resin molding and extending beyond a periphery edge of the resin molding. A blast gun facing the face with the film adhering to it blasts ice slurry of a required concentration toward the vicinity of the periphery edge of the resin molding to remove the unnecessary portion of the film material extending beyond the periphery edge of the resin molding.

Owner:TOSHIBA MASCH CO LTD

Device for comminuting dry ice granules, and dry ice dispensing arrangement having such a device

The invention relates to a device for comminuting dry ice granules, comprising a housing having a flow channel for dry ice granules which can be applied, by means of compressed gas, to a surface to be cleaned, and also comprising a first comminution member for comminuting the dry ice granules which are to be dispensed. In order to provide a device of this kind with which different degrees of comminution of dry ice granules can be achieved in a simple manner, it is proposed according to the invention that the device has at least one second comminution member which can be disposed in the housing in a position in which a total degree of comminution, which is greater than the individual degree of comminution which can be achieved solely by the first comminution member, can be achieved in combination with the first comminution member. A dry ice dispensing arrangement for dispensing a mixture of compressed gas and dry ice granules is also proposed, having a device of the above kind.

Owner:ALFRED KARCHER GMBH & CO KG

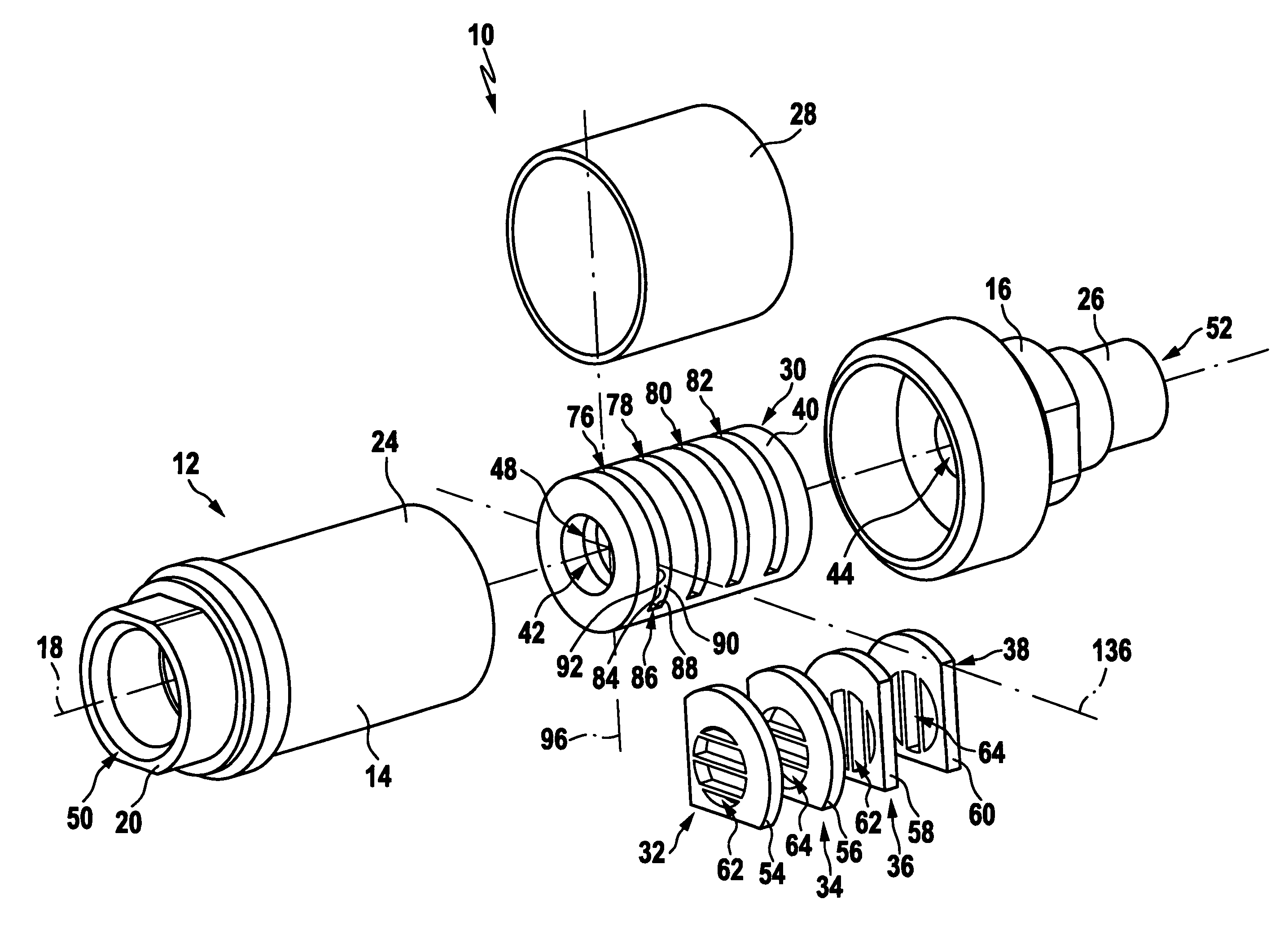

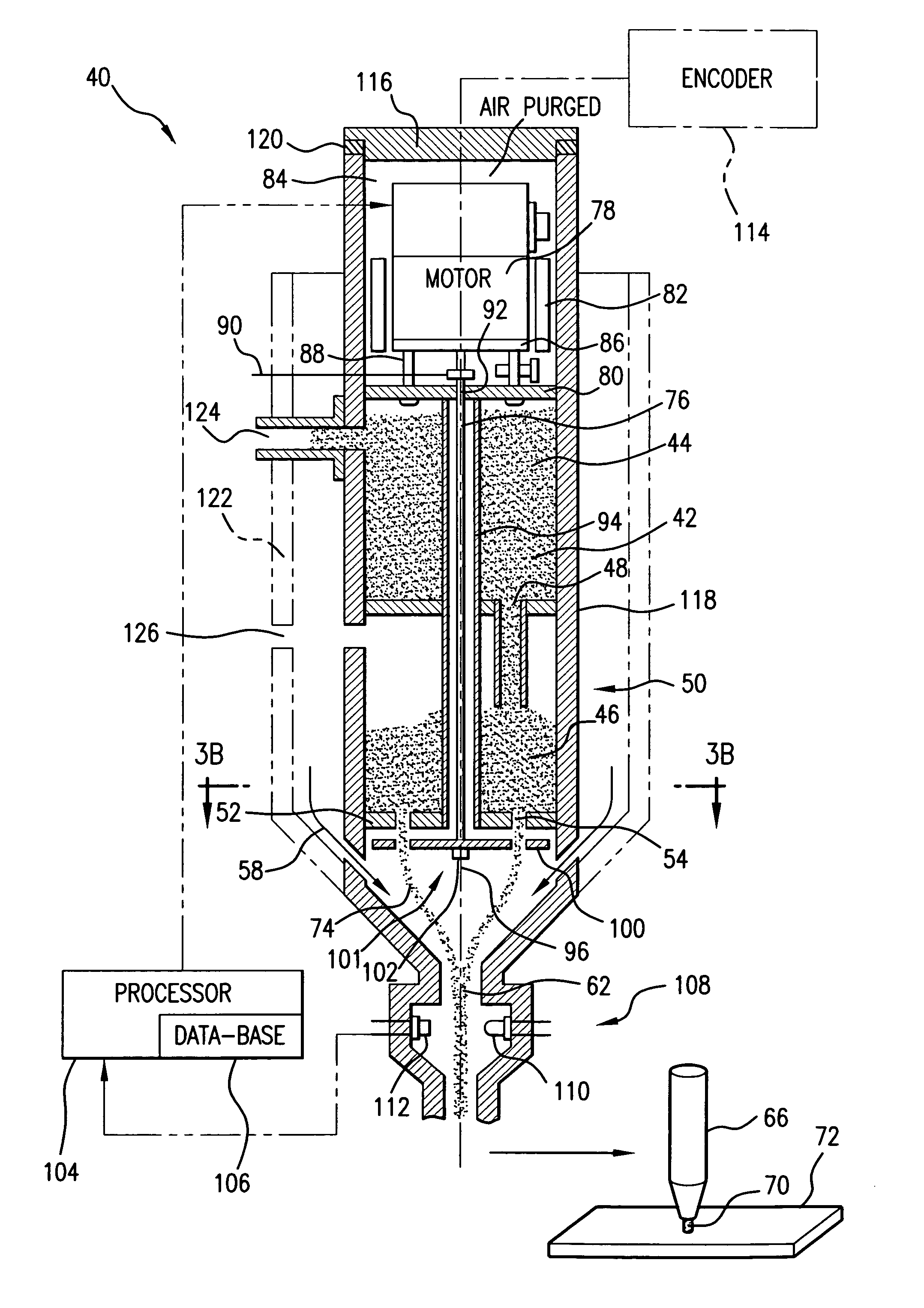

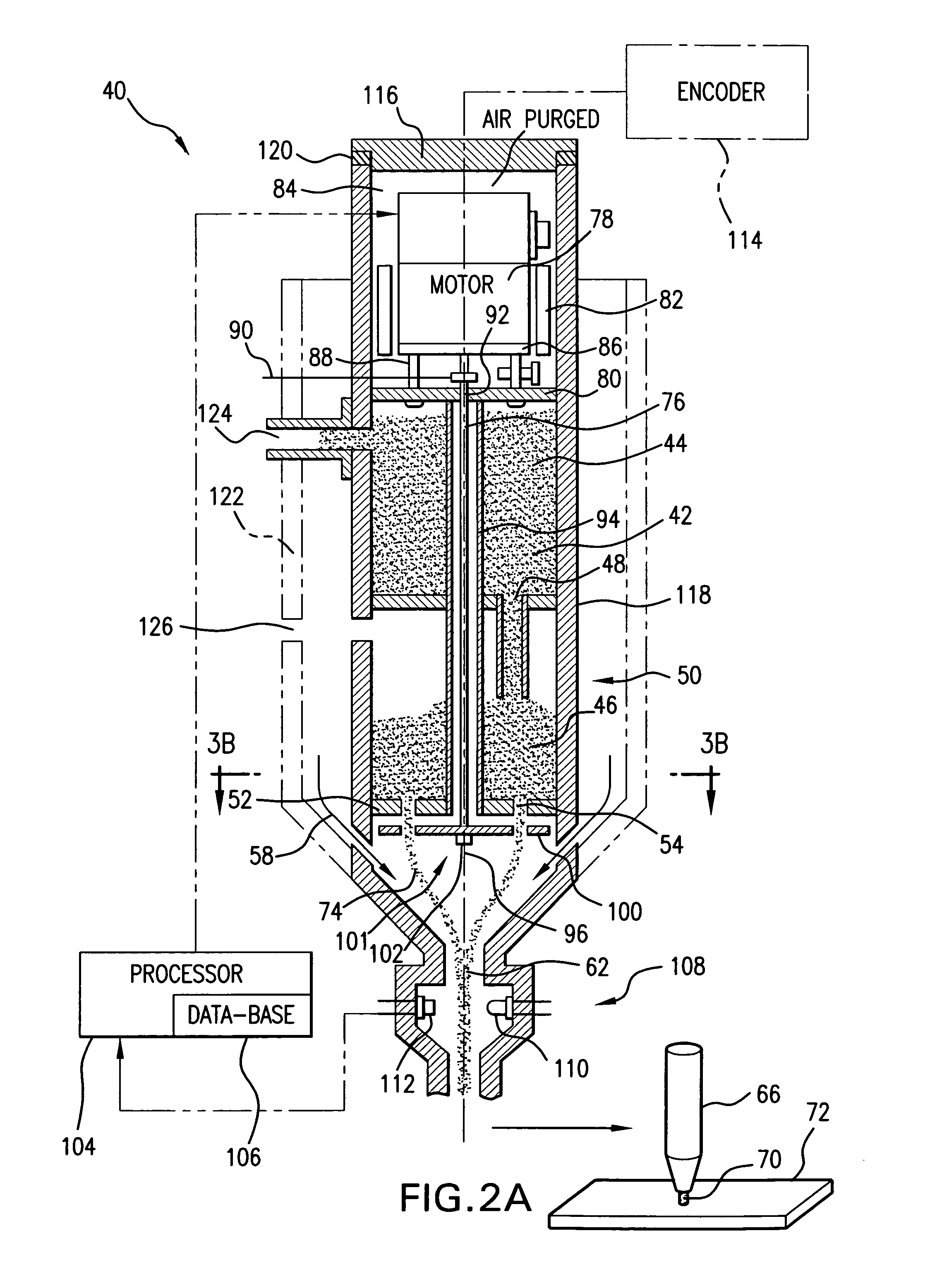

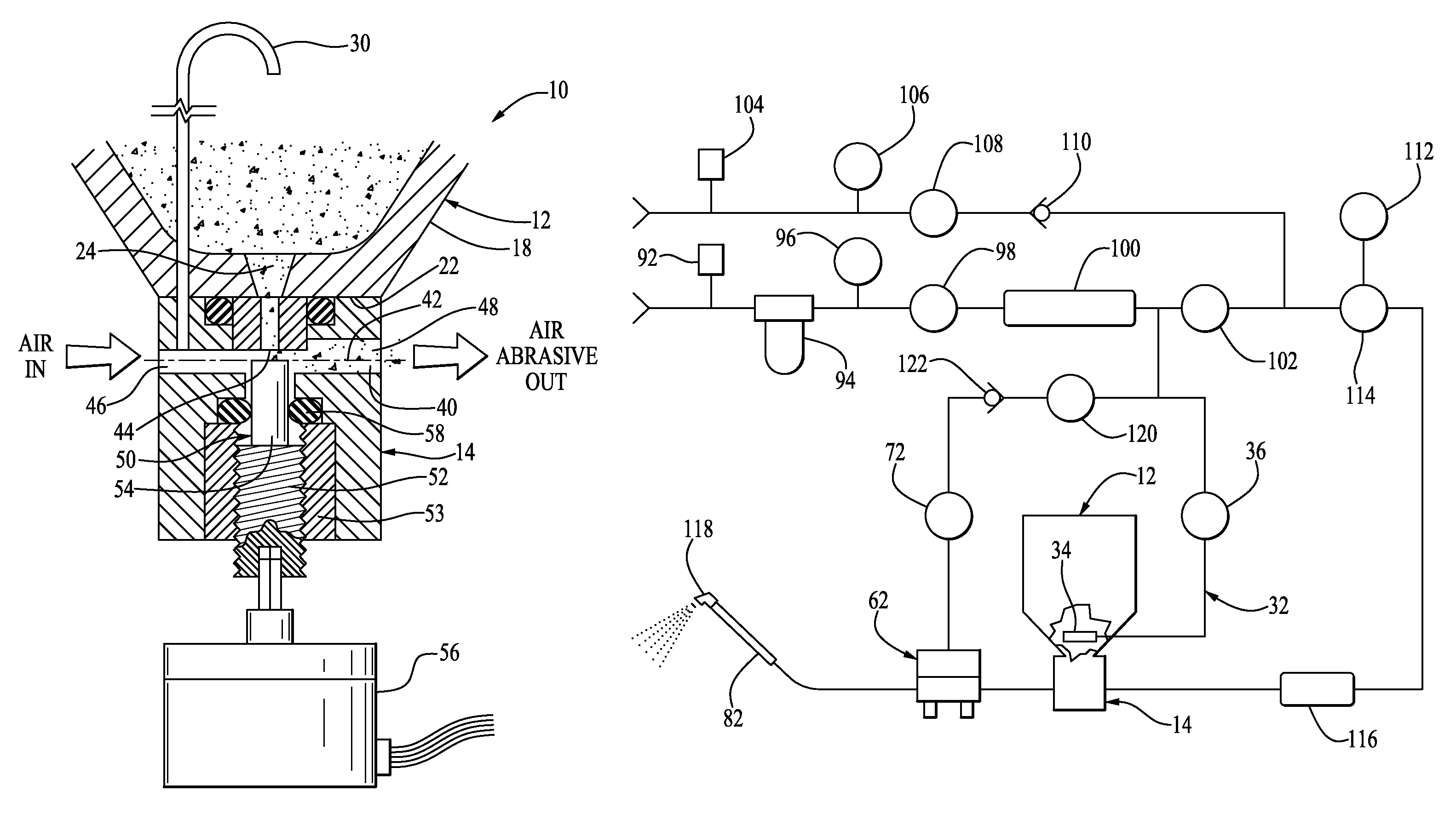

Variable rate dispensing system for abrasive material and method thereof

InactiveUS7040959B1Accurate and reliable yet efficientBlast gunsGrinding feed controlEngineeringActuator

An abrasive jet apparatus is provided which includes an abrasive dispenser defining a compartment for storing a granular abrasive material and at least one metering orifice disposed in open communication therewith for dispensing the granular abrasive material. The apparatus also includes a shutter assembly disposed adjacent the metering orifice, which includes a shutter member angularly displaceable between first and second positions relative to the metering orifice. The shutter member has formed therethrough at least one shutter opening which in the first position is substantially fully aligned with the metering orifice, and in the second position is substantially fully offset therefrom. The apparatus further includes a position actuator operatively coupled to the shutter mechanism for reversibly displacing the shutter member to the first and second positions and a plurality of intermediate positions therebetween for occluding a selective portion of the metering orifice. A flow rate of the abrasive material dispensed through said metering orifice is thereby maintained at a predetermined level.

Owner:LAI INT

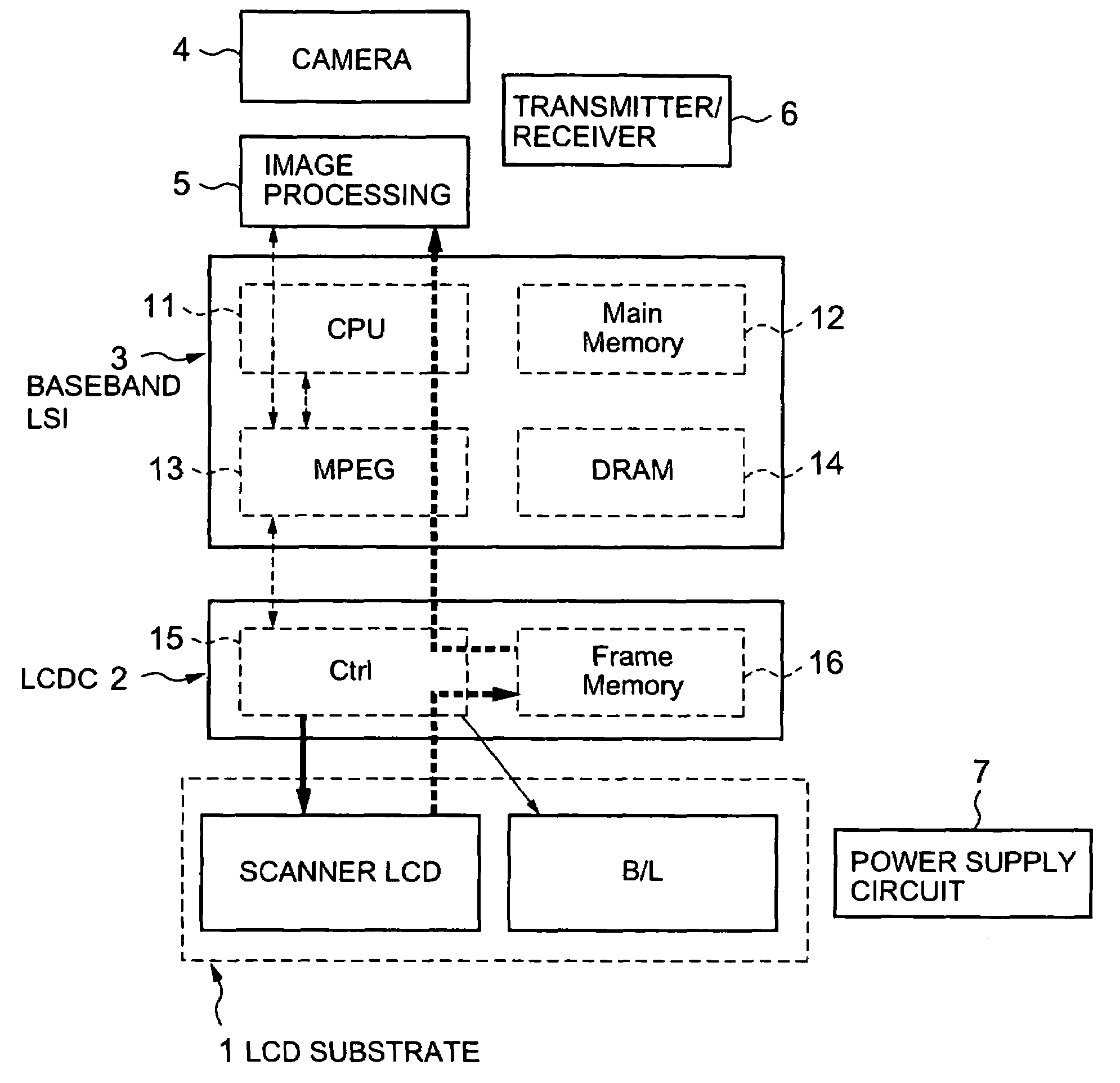

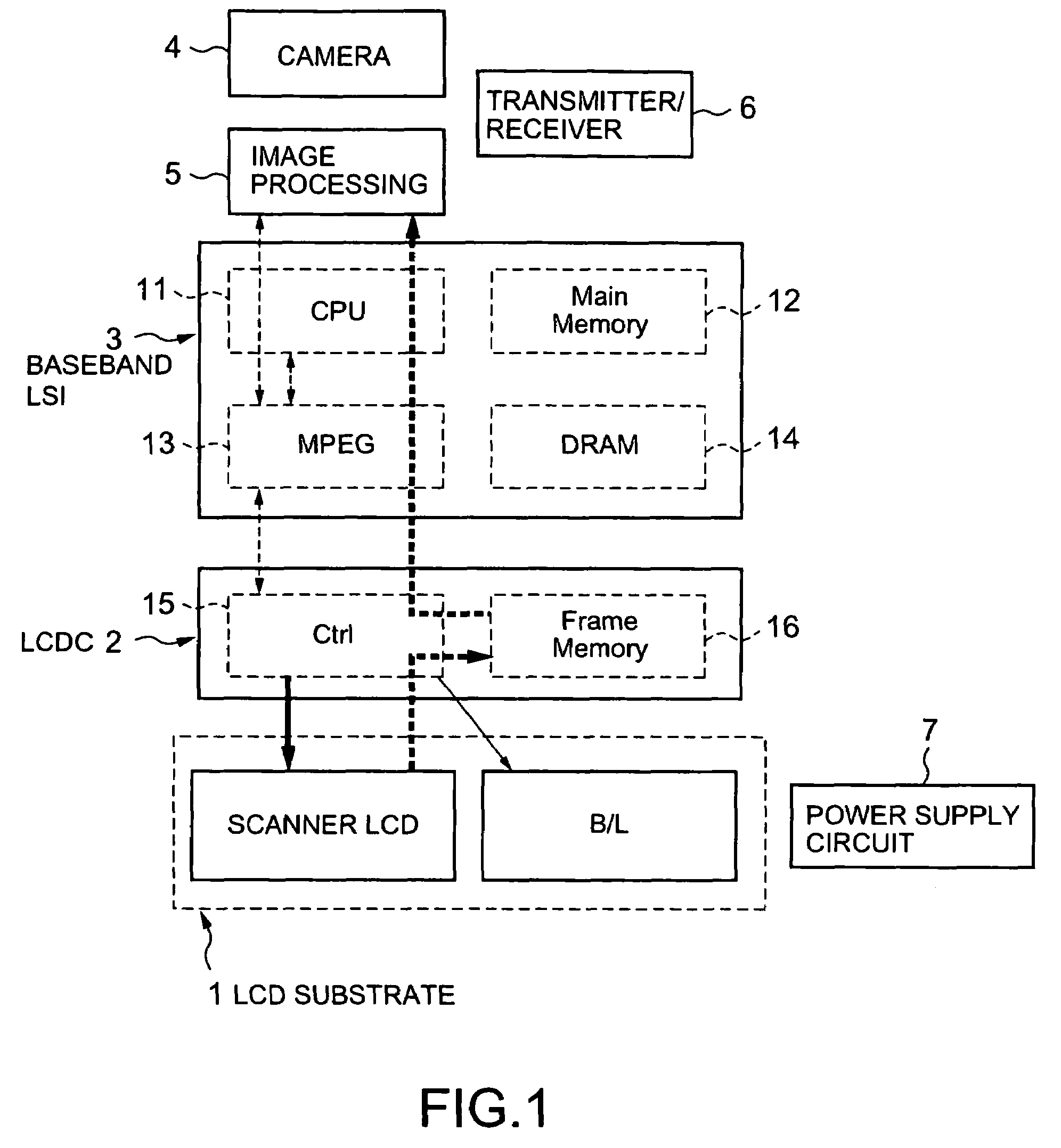

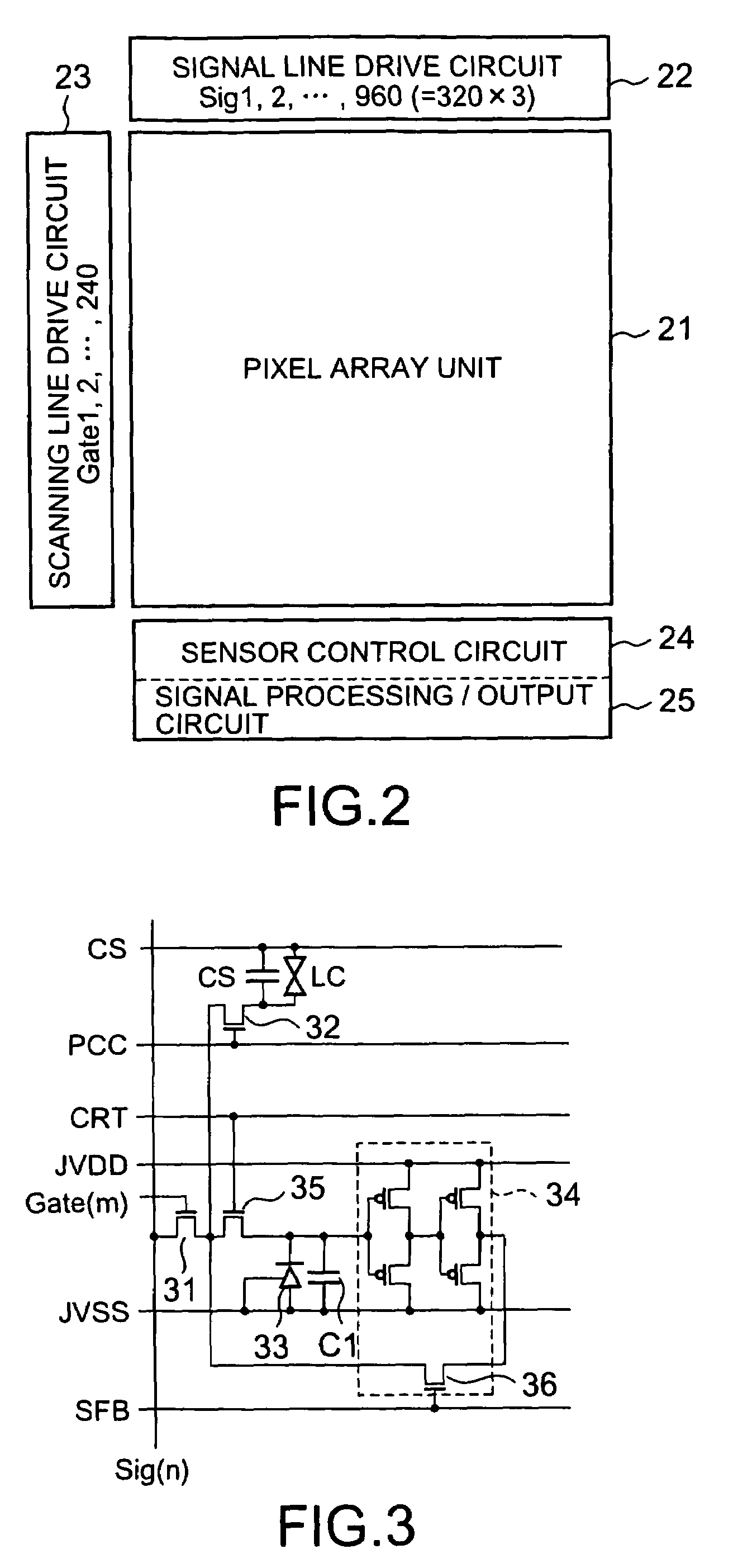

Display device

InactiveUS7450105B2Simple configurationSimplified mannerBlast gunsStatic indicating devicesImaging processingComputer graphics (images)

A display device, comprising: a pixel array unit having display elements formed in vicinity of intersections of signal lines and scanning lines arranged in length and breadth, image pickup units and an output unit which outputs binary data corresponding to image picked up by said image pickup unit; a image pickup device provided separate from said image pickup unit; a first image processing unit configured to generate multiple gradation data based on multiple binary data picked up by said image pickup units based on multiple image pickup conditions; and a second image processing unit configured to receive either the image pickup data picked up by said image pickup device or the multiple gradation data generated by said first image processing unit, to conduct a prescribed image processing.

Owner:JAPAN DISPLAY CENT INC

Ice blasting apparatus and trimming method for film insert molding

InactiveUS7040962B2Lower Reliability RequirementsImprove securityAbrasive feedersAbrasive machine appurtenancesSlurryFilm material

Owner:TOSHIBA MASCH CO LTD

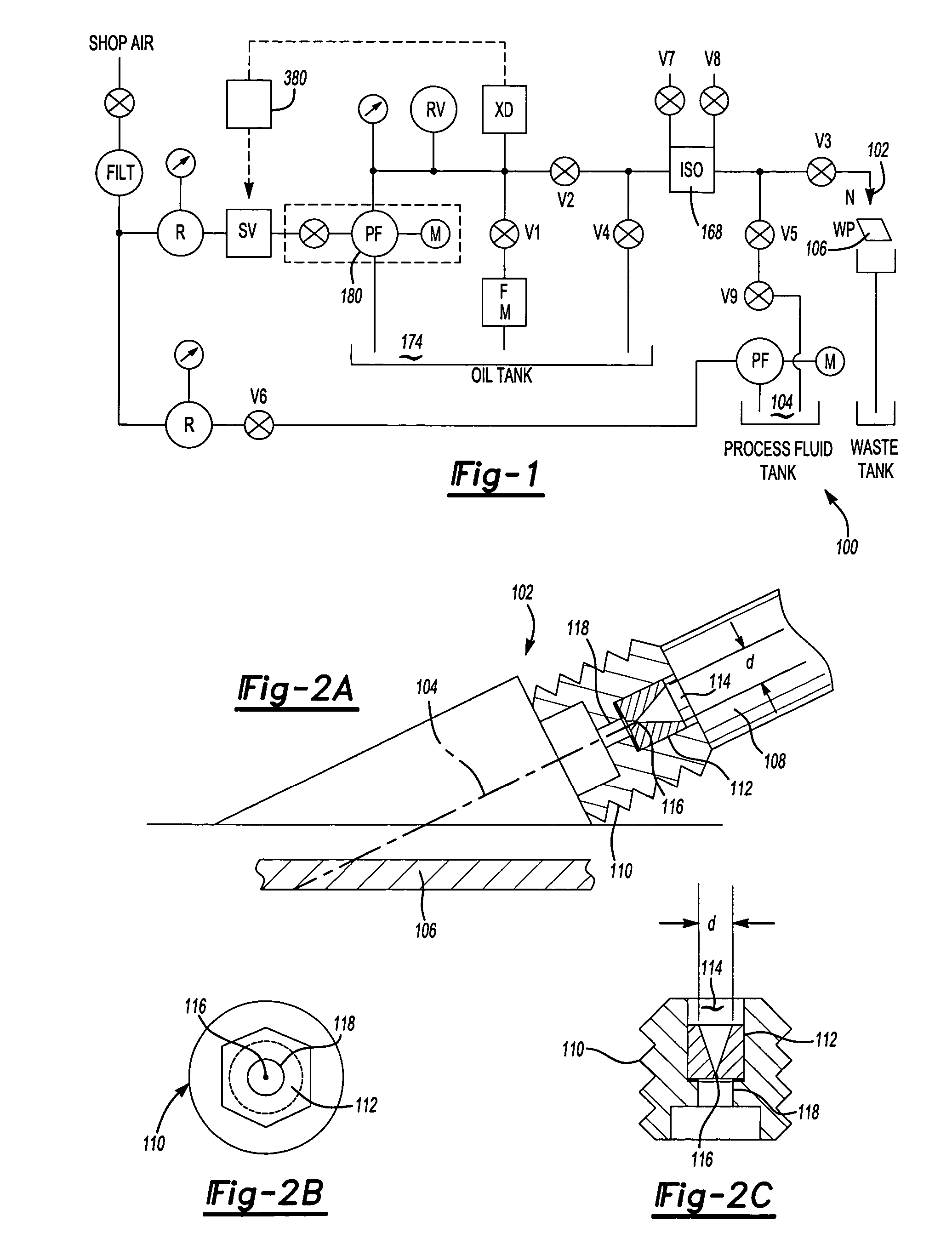

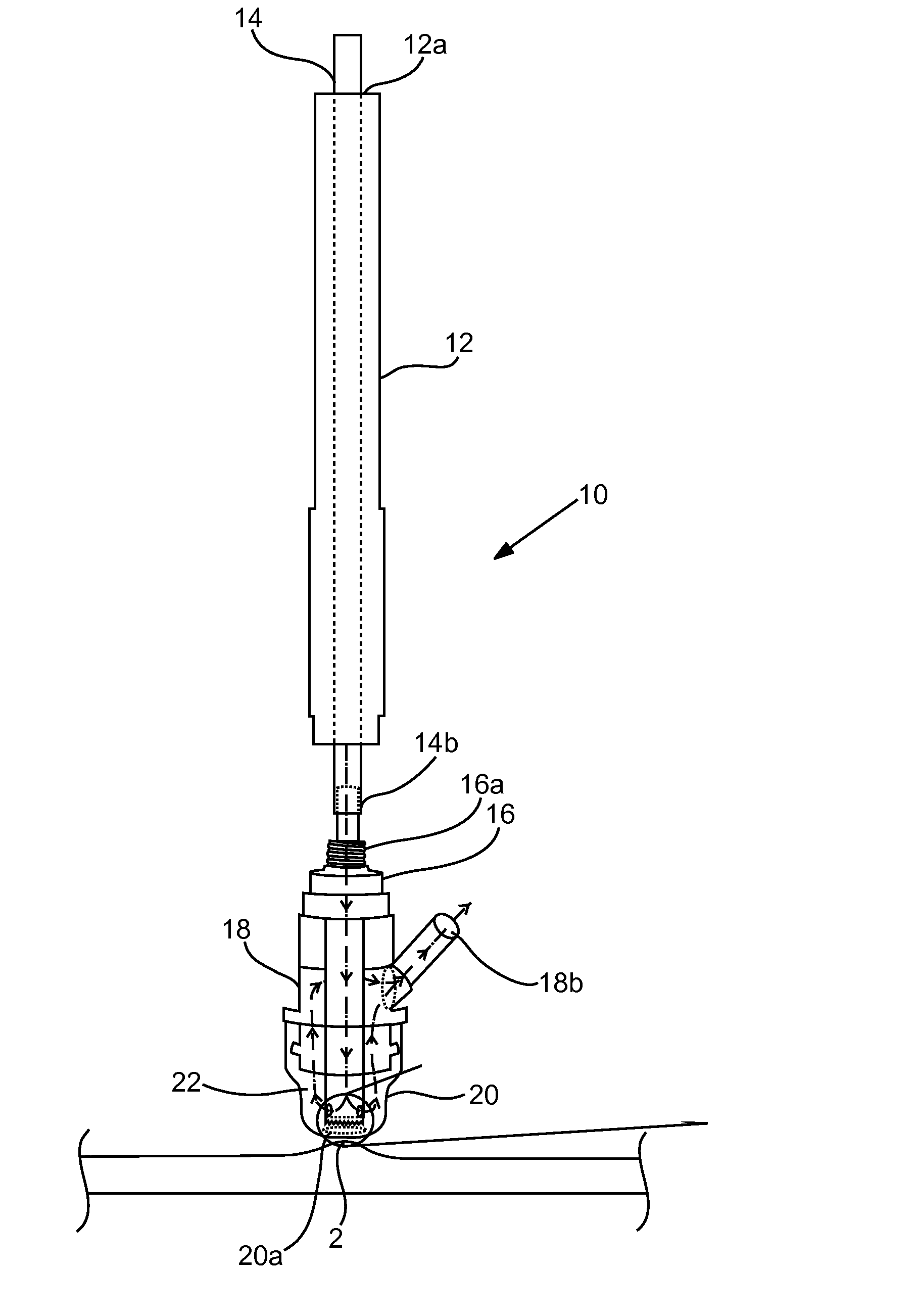

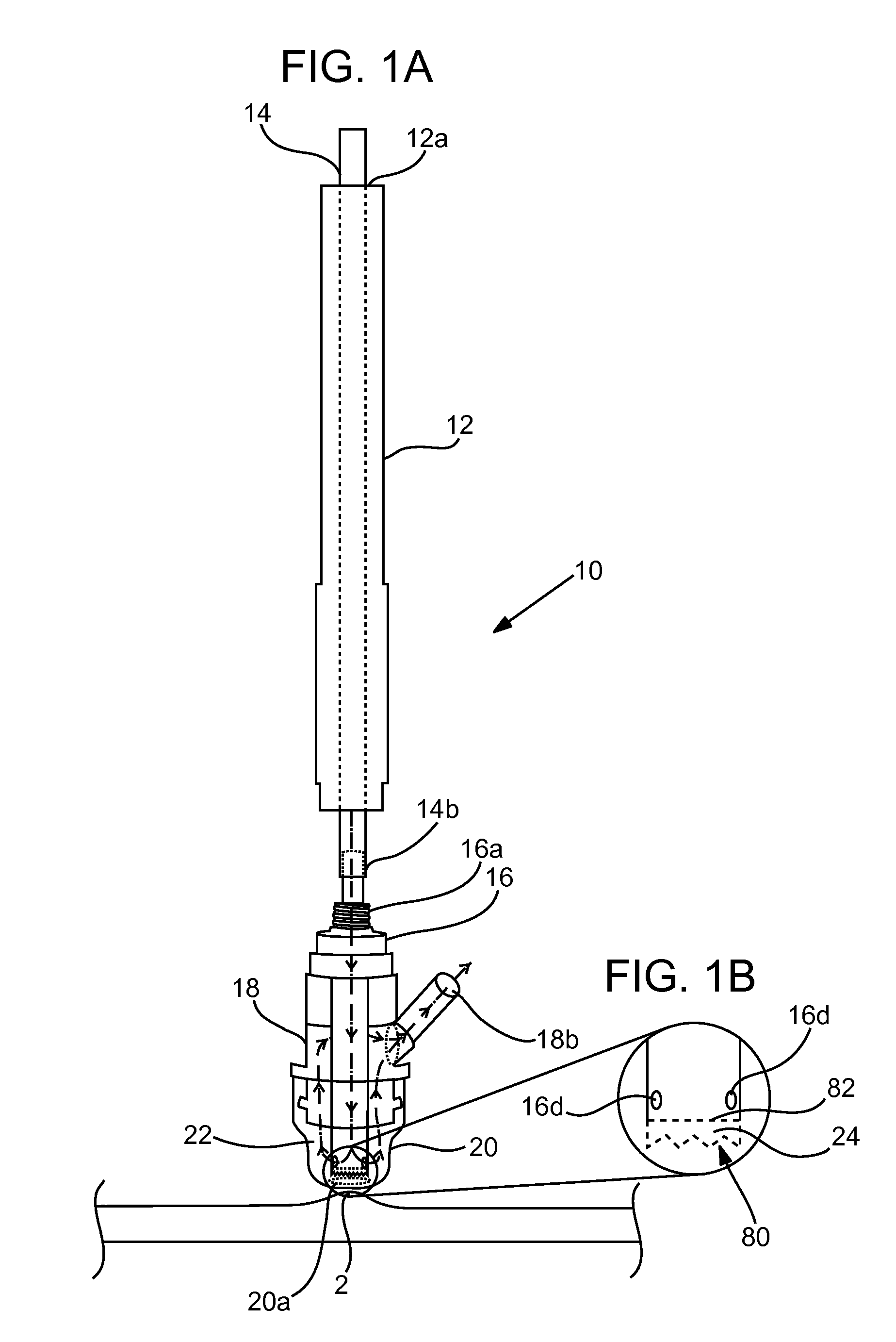

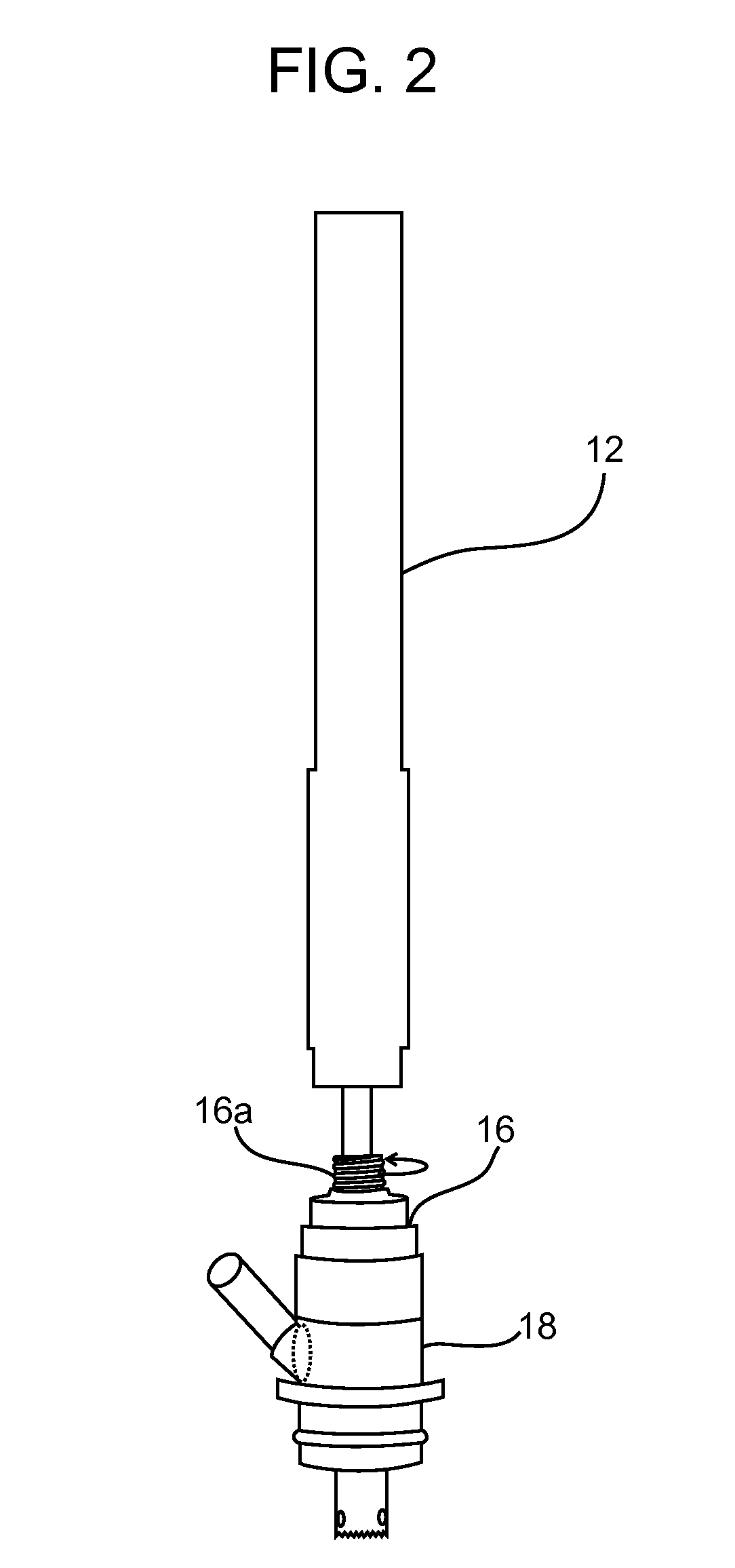

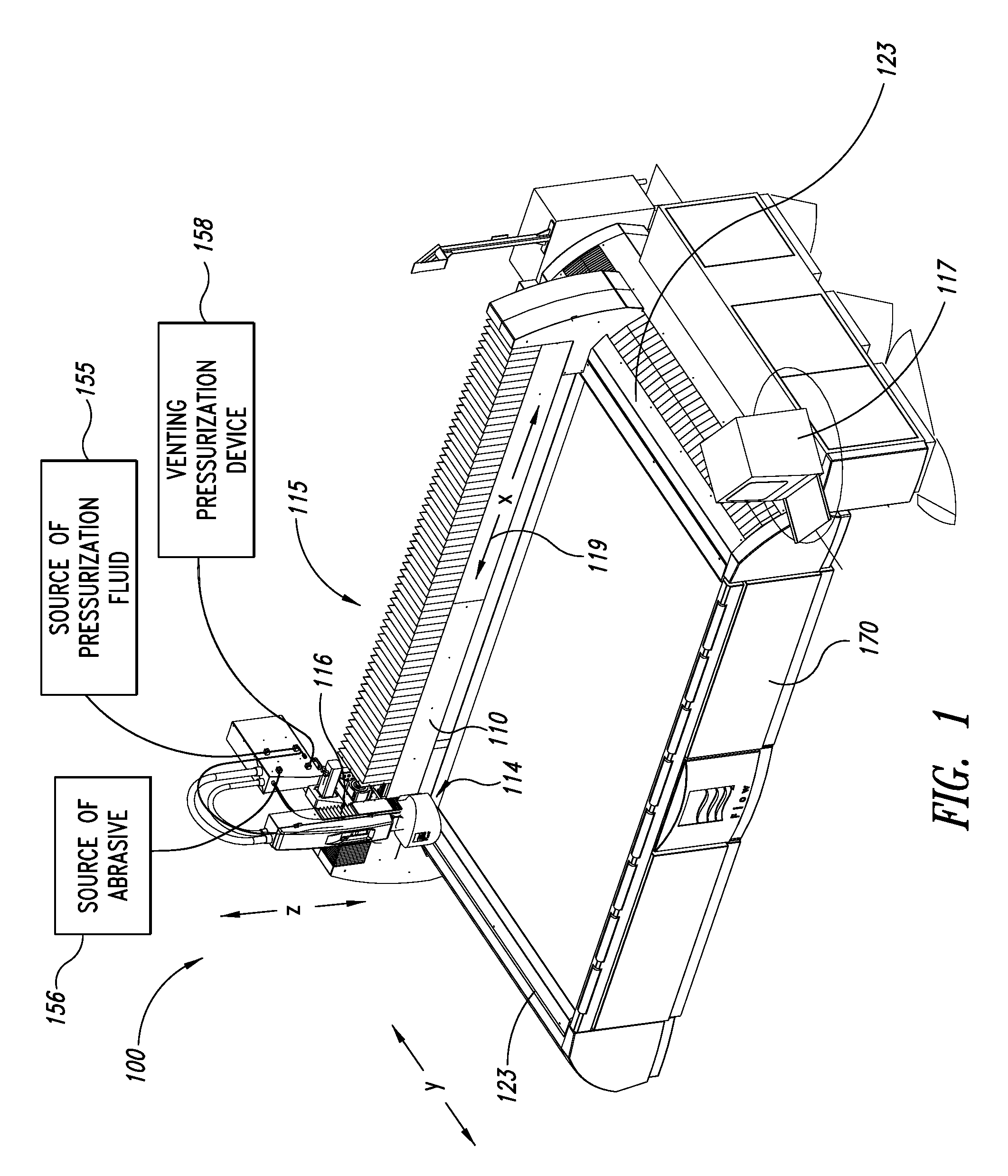

Suspended abrasive waterjet hole drilling system and method

ActiveUS7186167B2High viscosityVelocity increasesBlast gunsLiquid/gas jet drillingEngineeringDrilling system

A suspended abrasive waterjet narrow kerf cutting method is reconfigured to simultaneously drill multiple, closely-spaced holes in a target, including holes in confined non line-of-sight locations. Working fluid nozzles can be located on a flat or non-flat tool surface and arranged in uniform or non-uniform patterns, in an angled or perpendicular orientation, and in parallel or non-parallel arrangements. Individual nozzles or nozzle groups can be easily changed to provide increased or diminished working diameters, allowing control over the hole sizes and resultant airflow thru the drilled workpiece.

Owner:RTX CORP

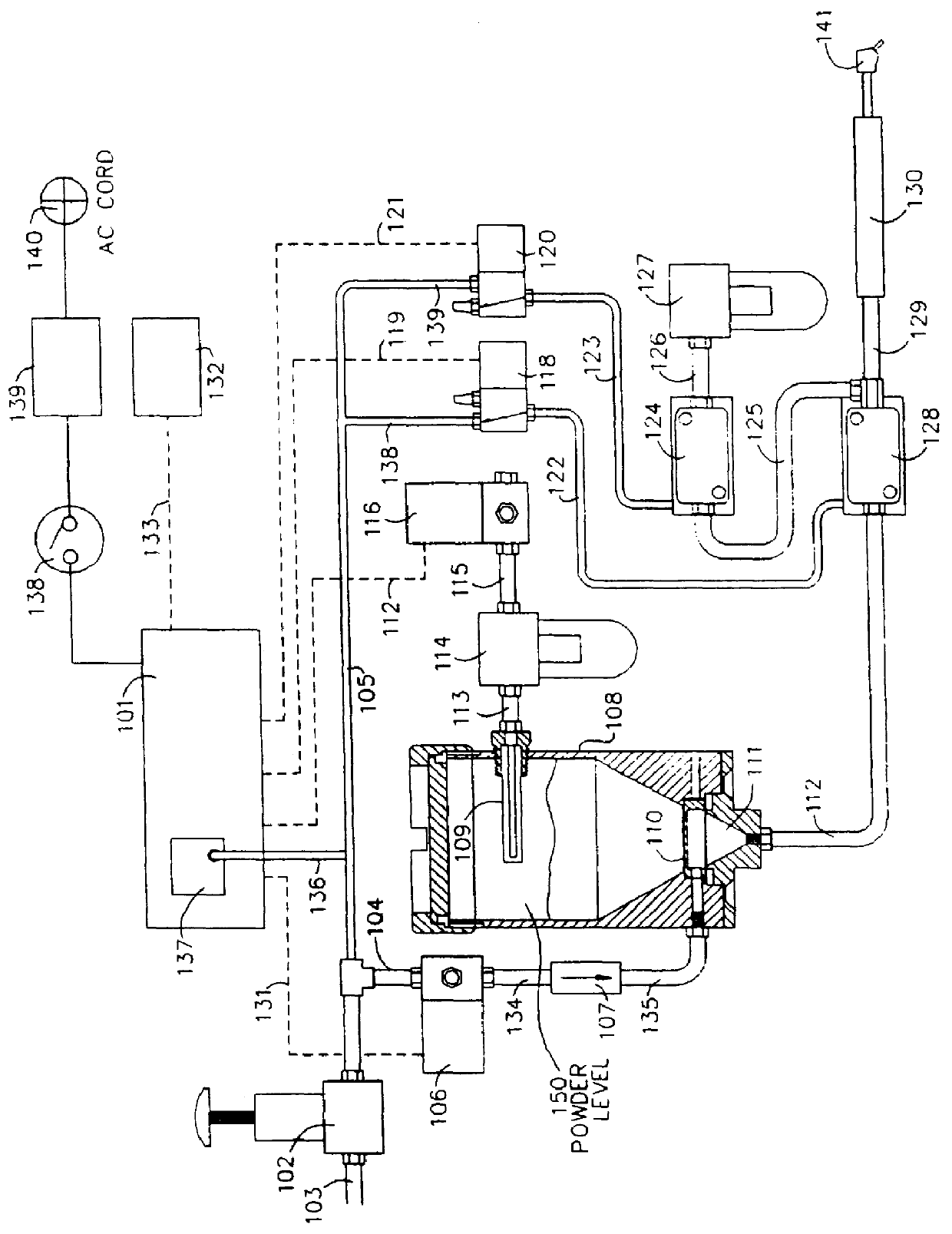

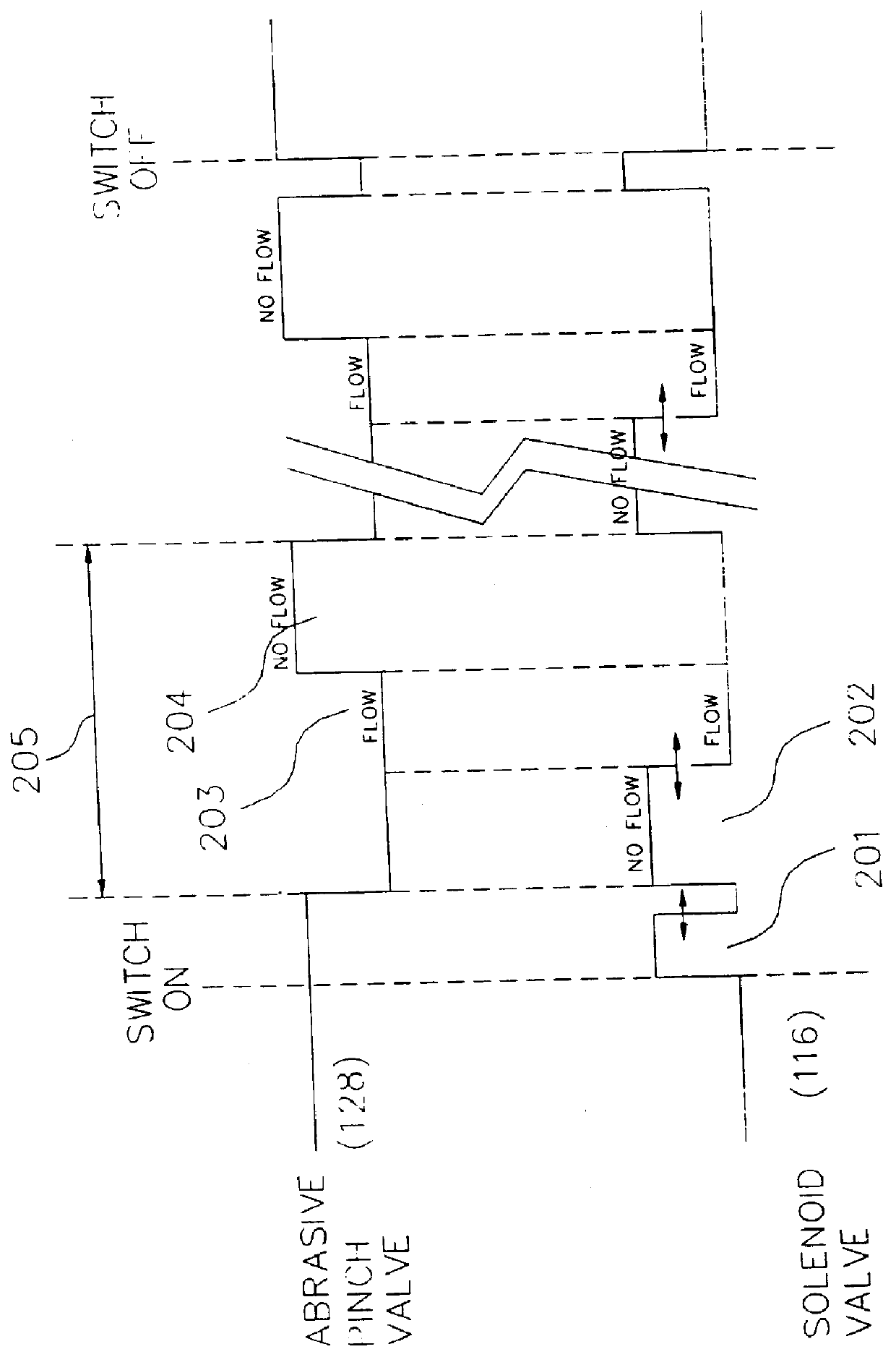

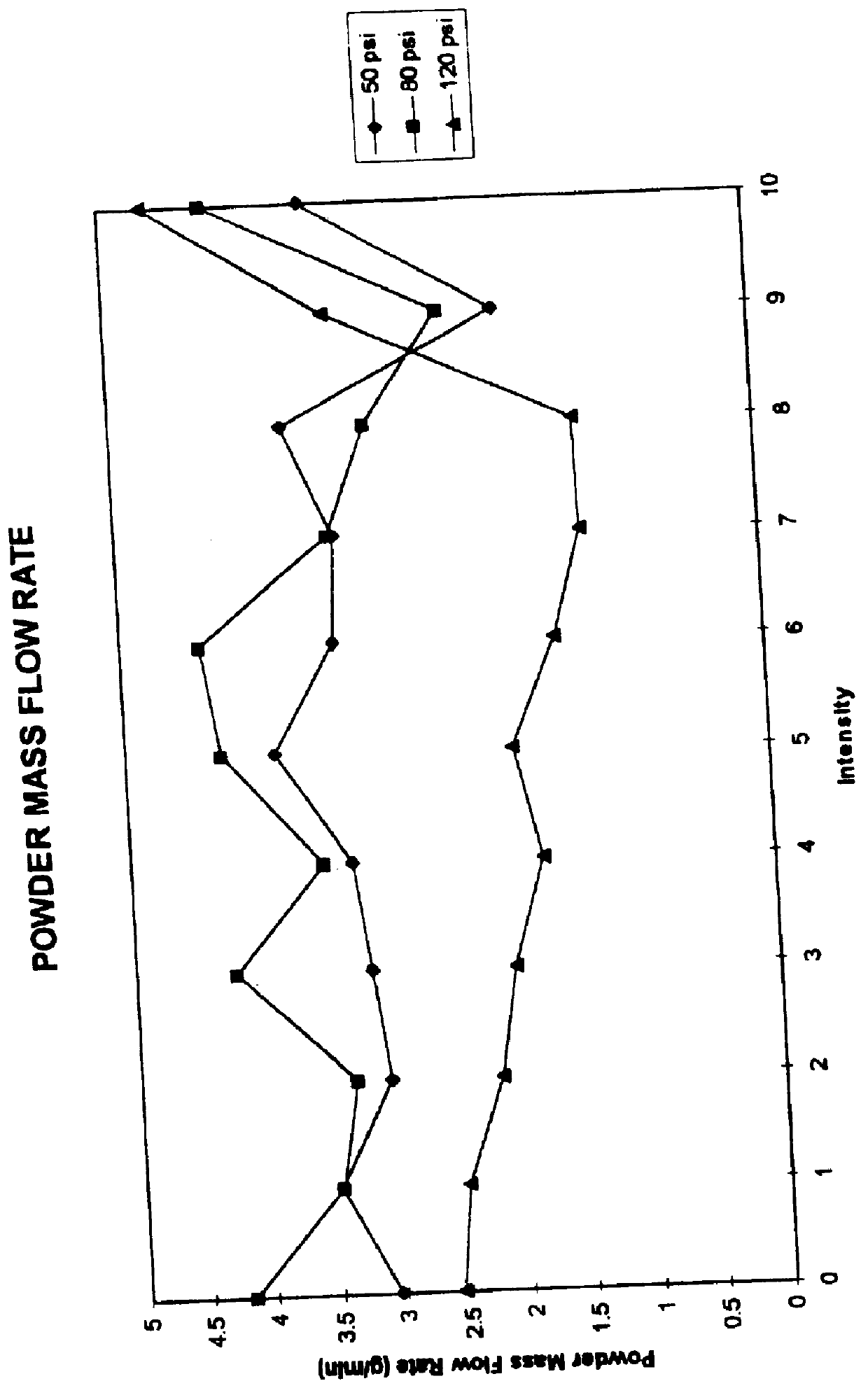

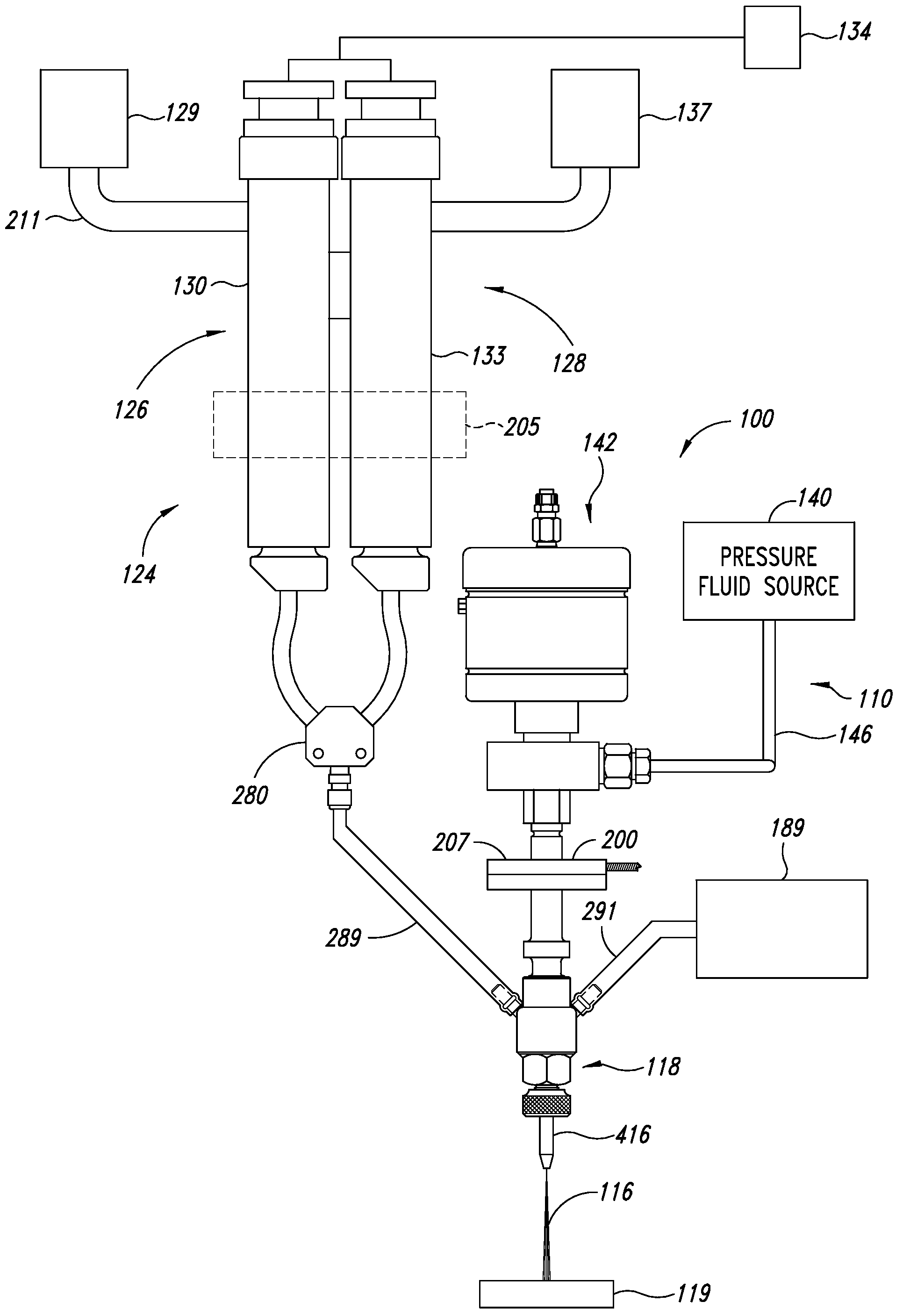

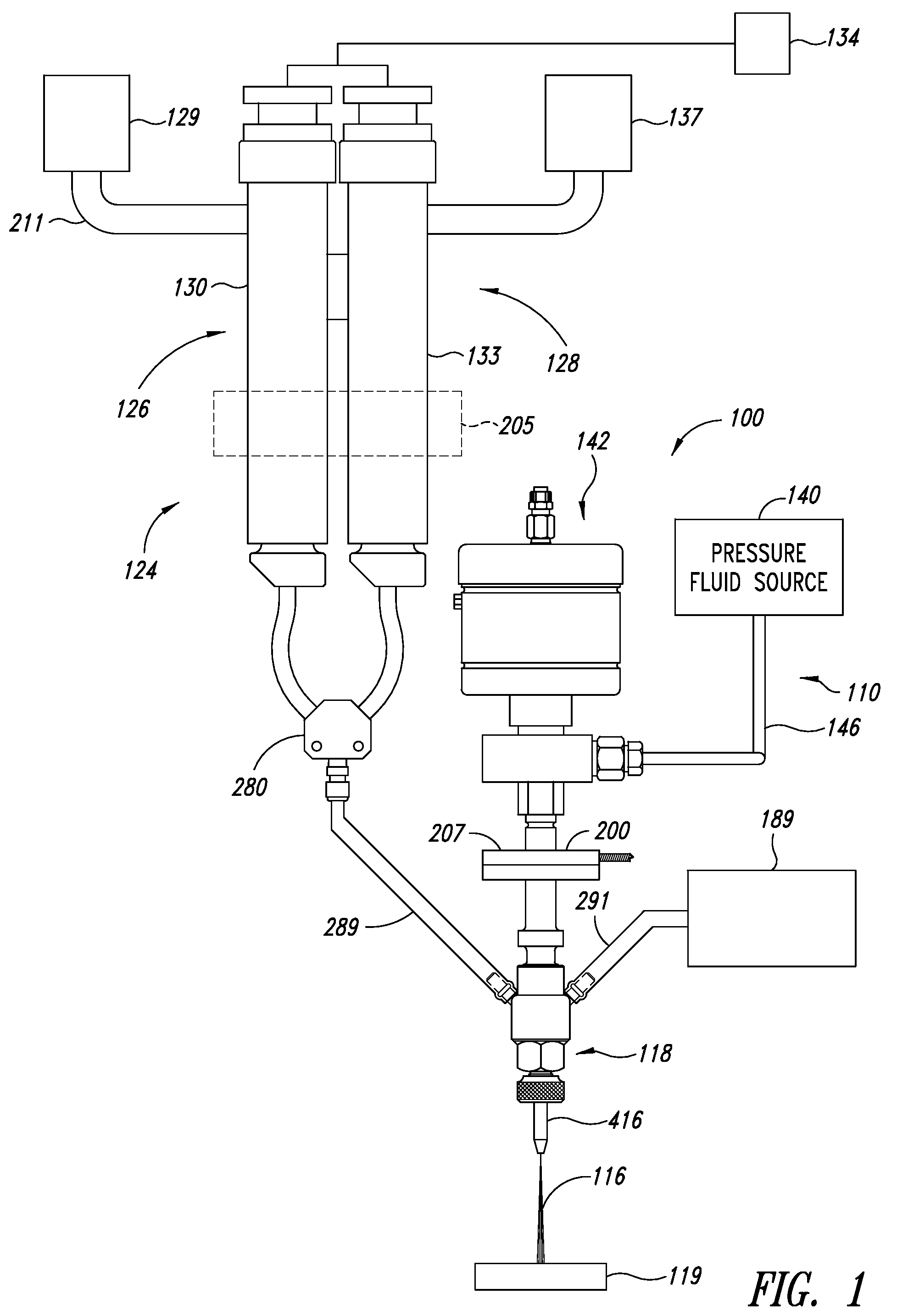

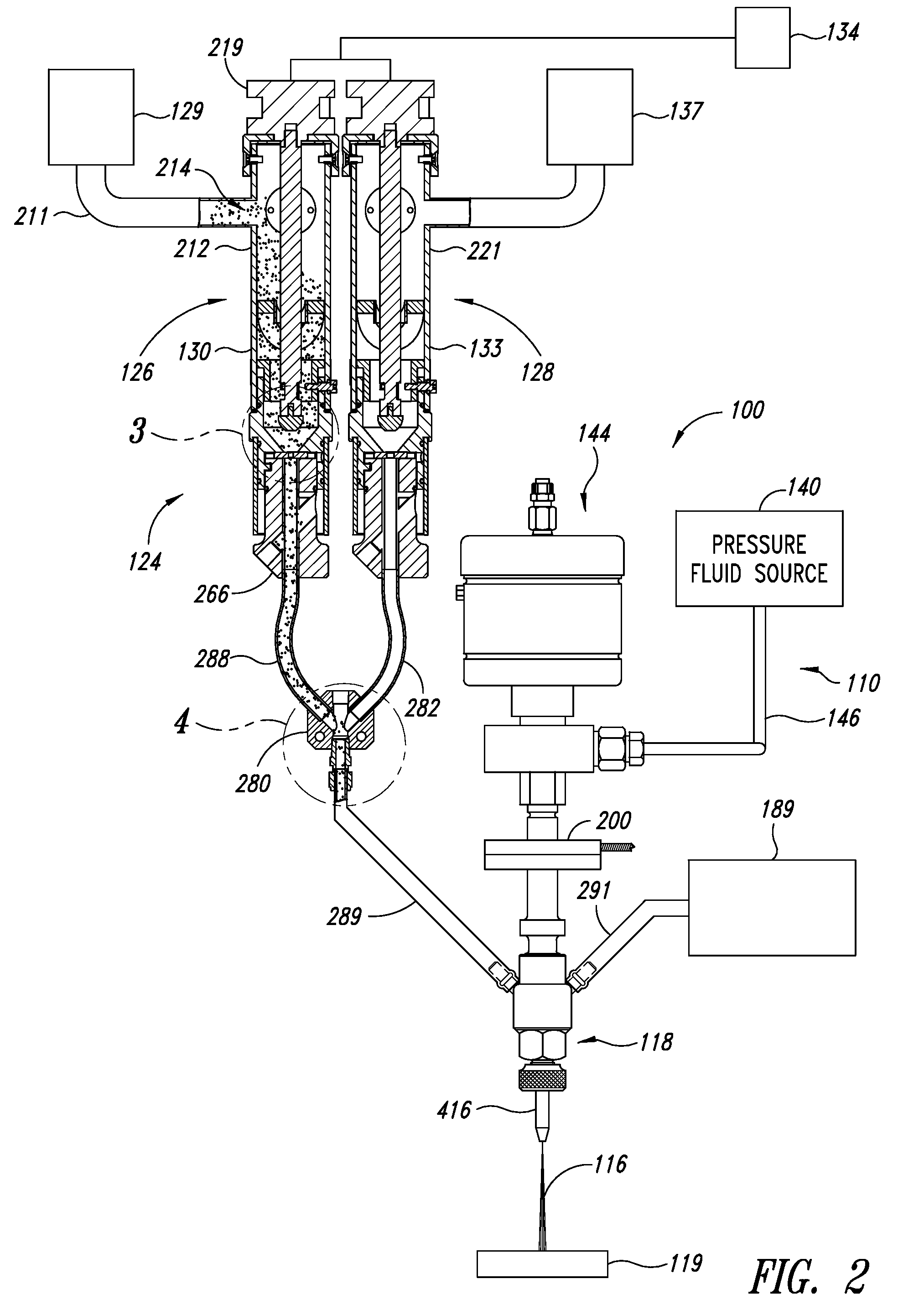

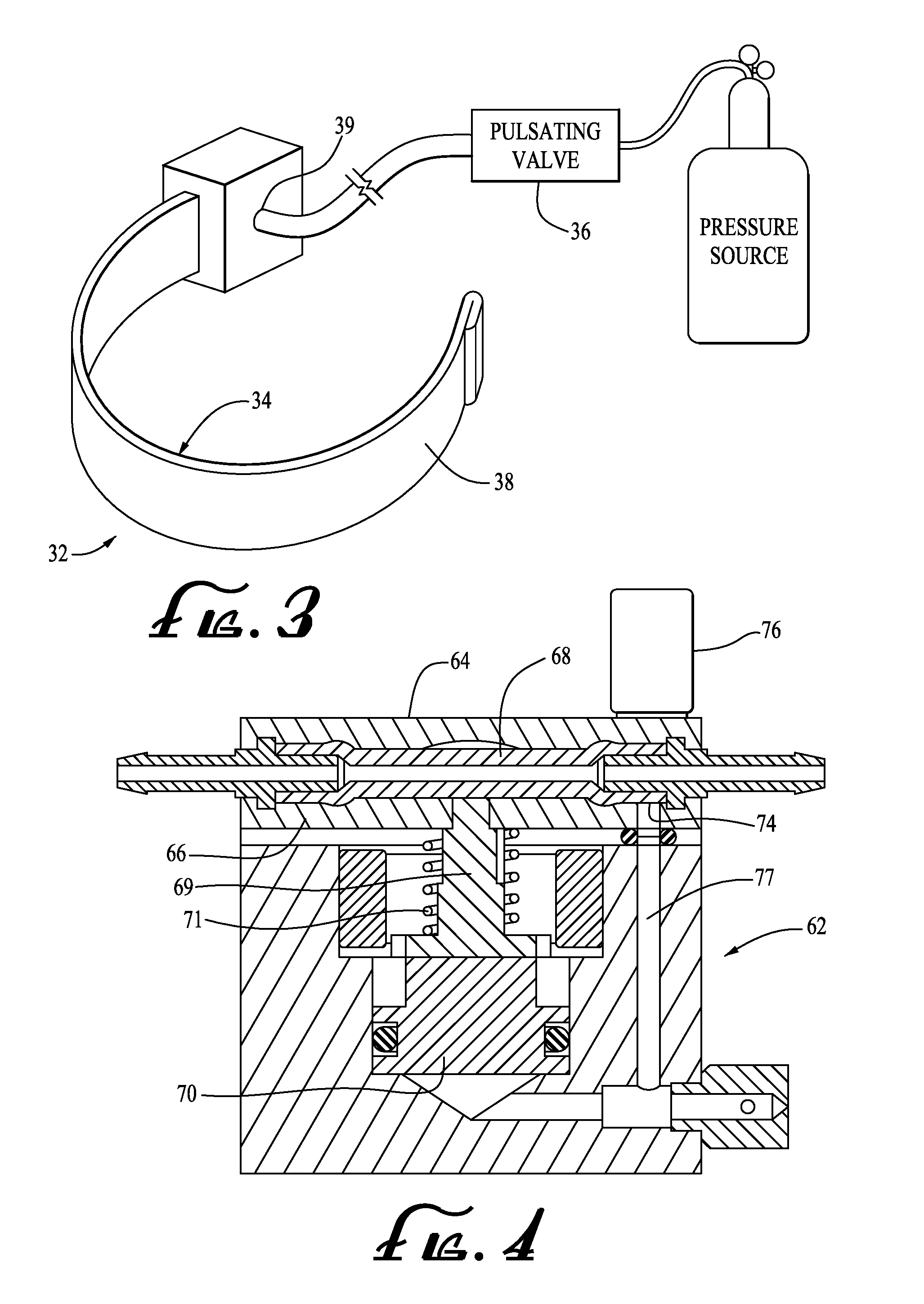

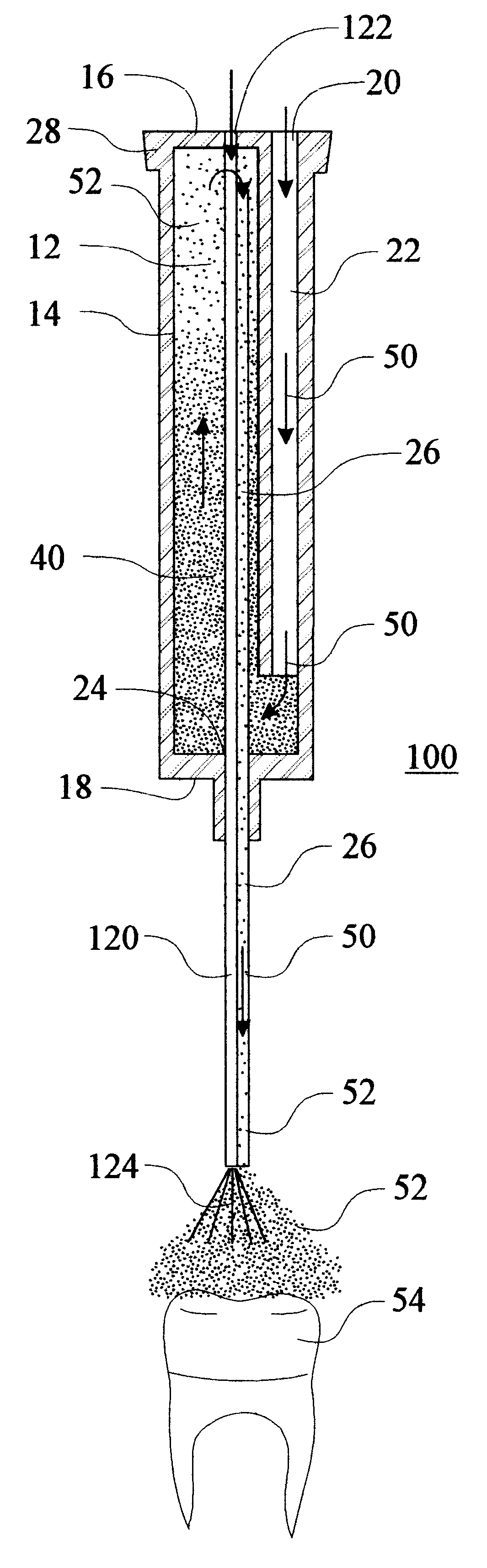

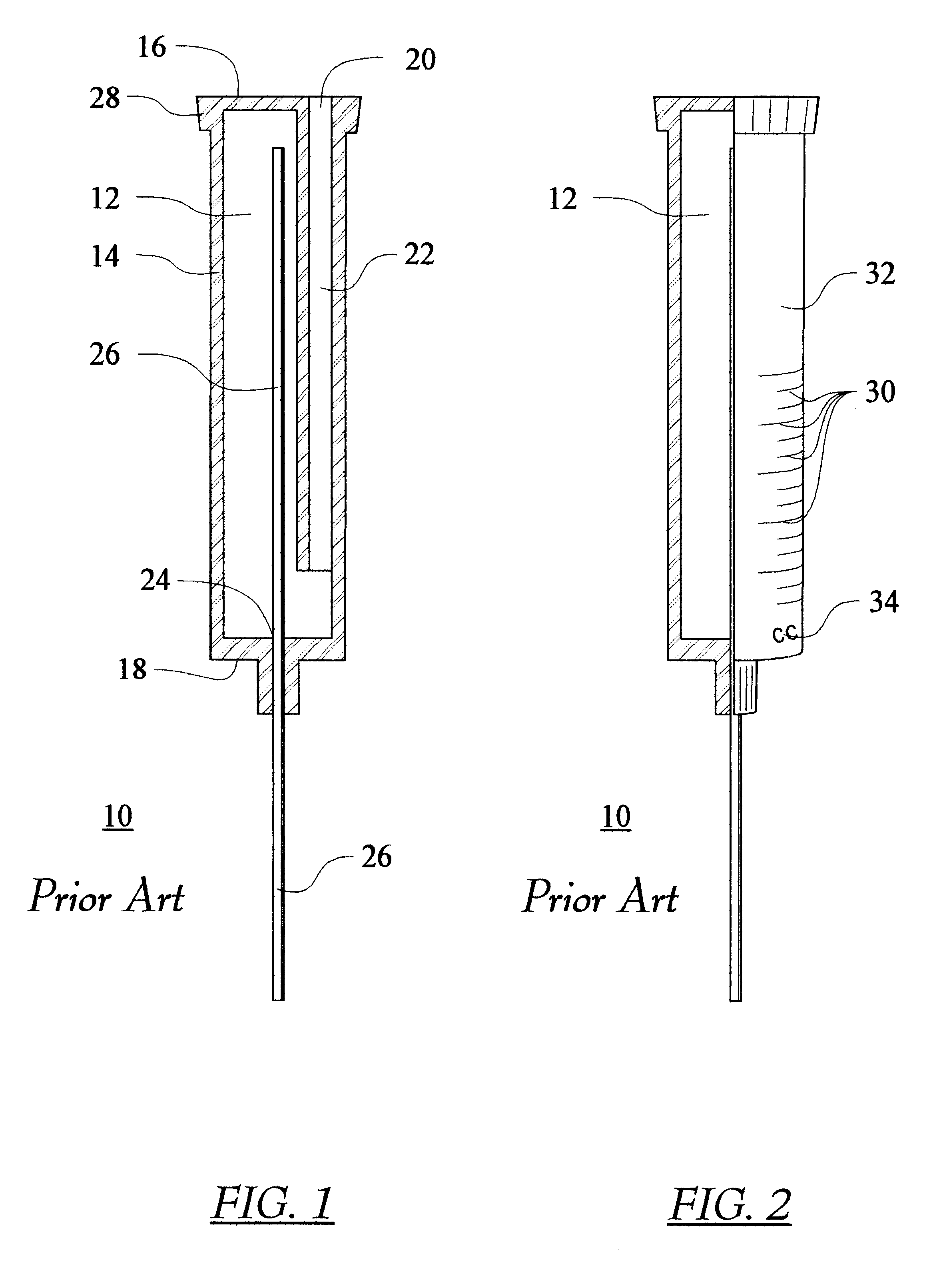

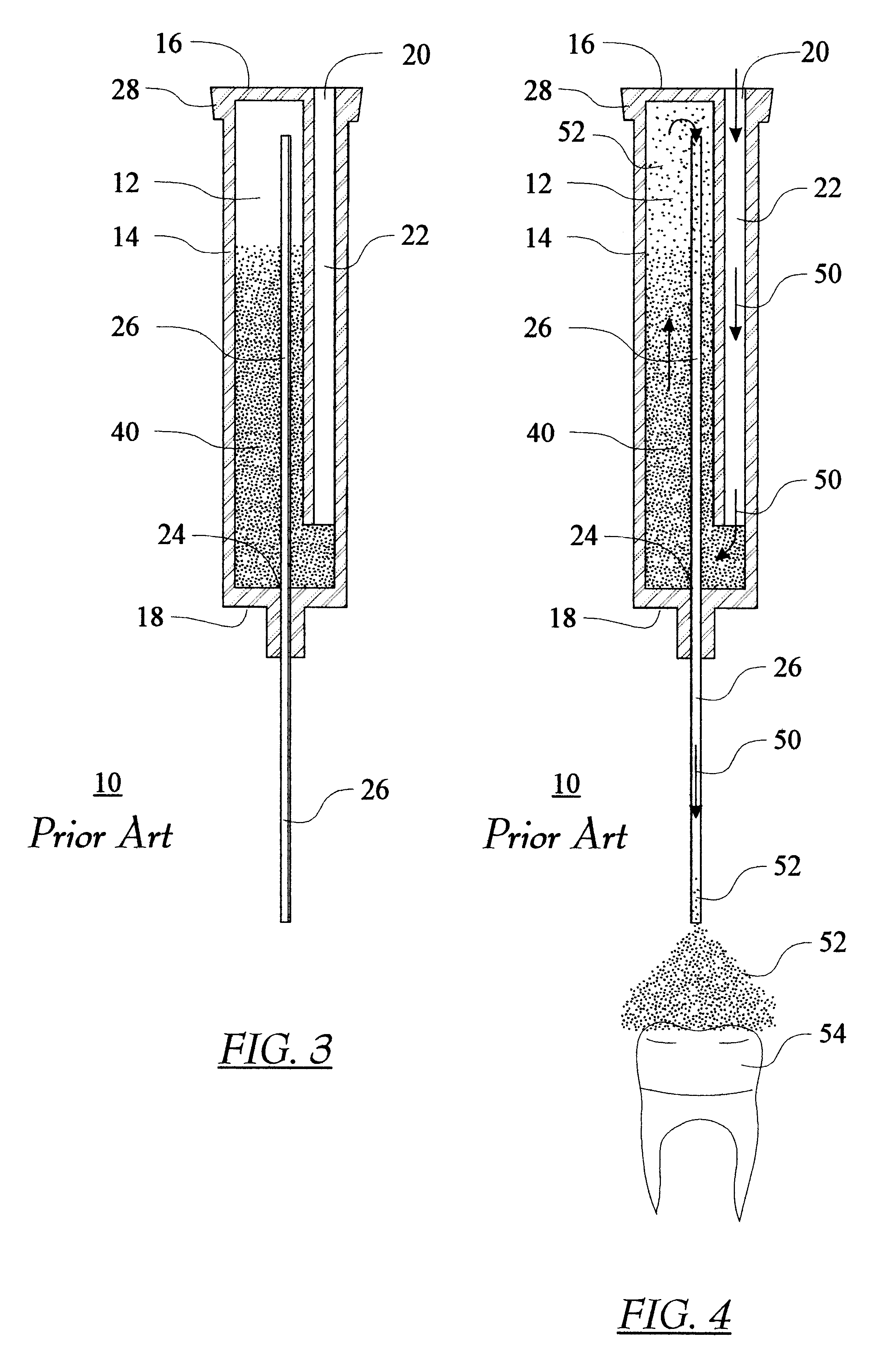

Apparatus and method for particle feeding by pressure regulation

The invention enables accurate control of particle flow with regard to feeding abrasive material to a surface. The unit does not employ a vibrator and may be used to remove undesired material from a surface. A particular application is in a dental air abrasion unit for both cleaning and cutting tooth surfaces. When used in an air abrasion dental instrument, the abrasive material is stored in a container which is separated from a mixing chamber by an orifice member. The flow of particles is electronically controlled by the differential in pressure in the container section above the particle level and the pressure below an orifice member in a mixing chamber. The resulting particle flow to the surface is substantially linear and less erratic than that of prior air abrasion instruments.

Owner:WELCH ALLYN INC

Microdermabrasion System and Method of Use

InactiveUS20070088371A1Avoid the needMaximize utilizationAbrasive feedersAbrasive surgical cuttersSkin treatmentsSkin cell

A device, a system employing the device, and method of performing skin treatment are provided for skin treatment. The device includes a vacuum head base defining a chamber therein and having a substantially smooth treatment tip attached and extending from an end thereof or integral therewith. The tip has at least one central opening that is open to the chamber, and is adapted to contact the skin and traverse the skin in a substantially nonabrasive manner. A vacuum access opening is provided through a side wall of the vacuum head base and adapted to connect with a source of vacuum. A tissue stop member is located within the chamber. It may have an abrasive surface for exfoliating skin cells, or a smoother surface for traversing the skin without substantial abrasion.

Owner:ENVY MEDICAL

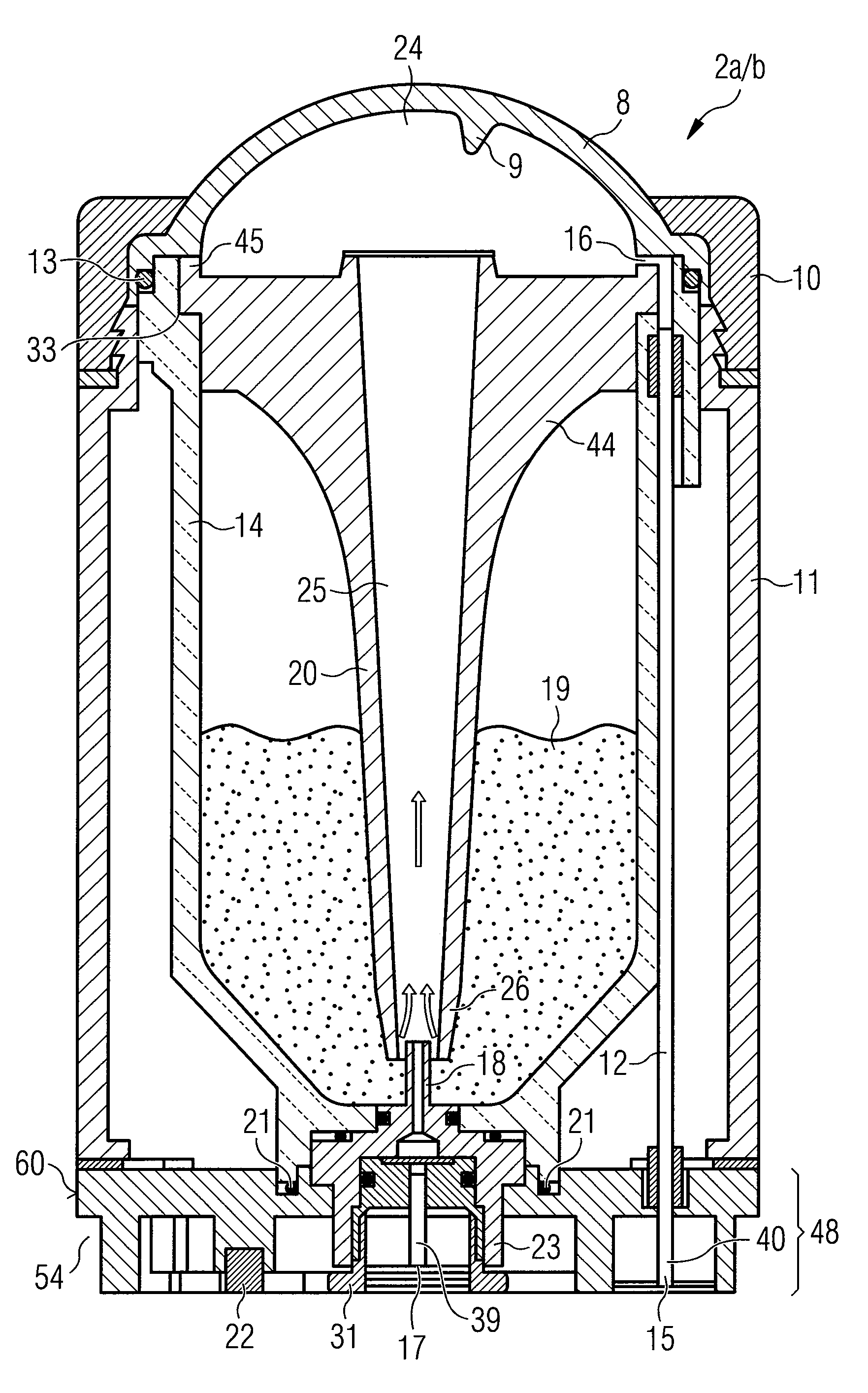

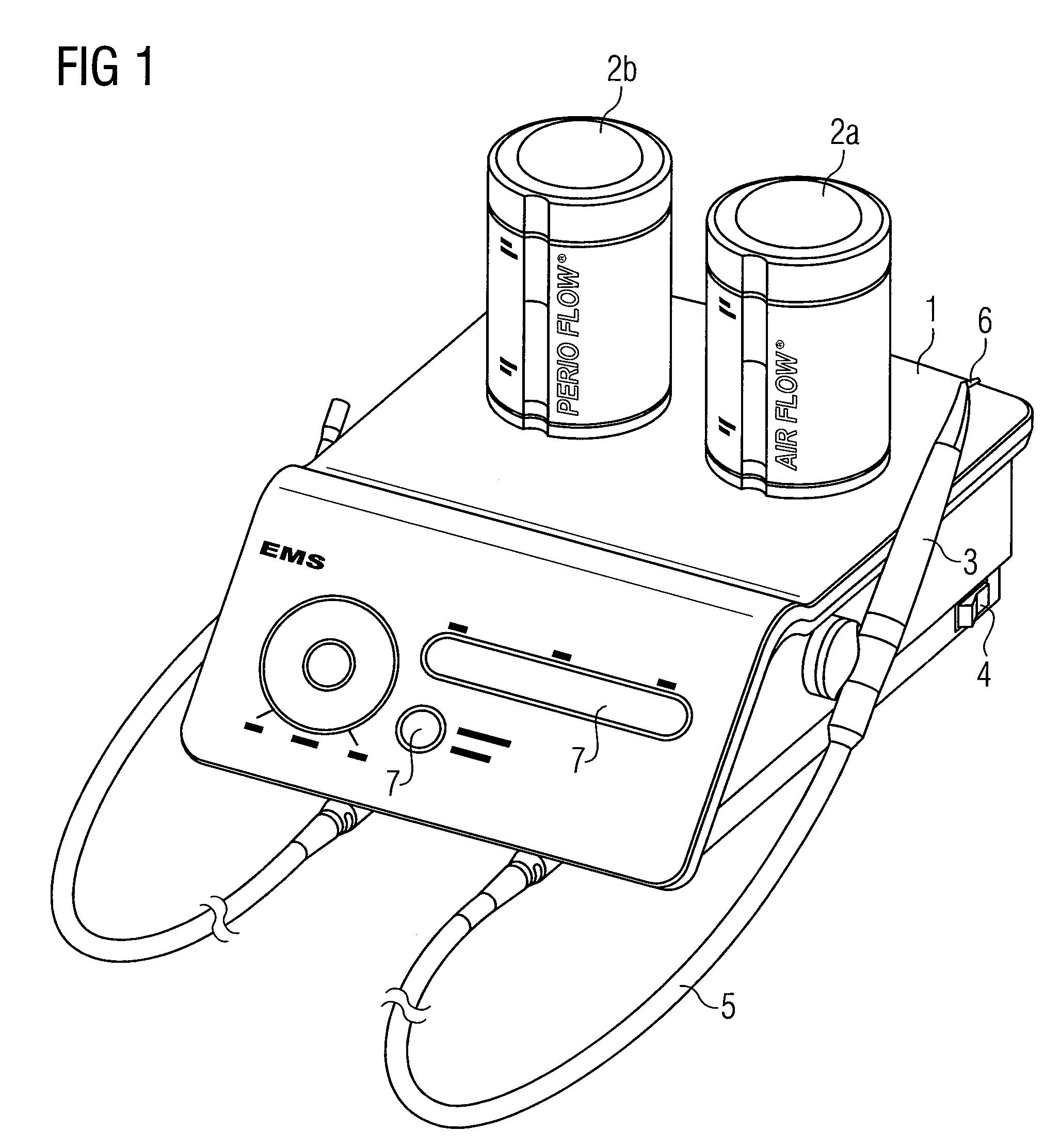

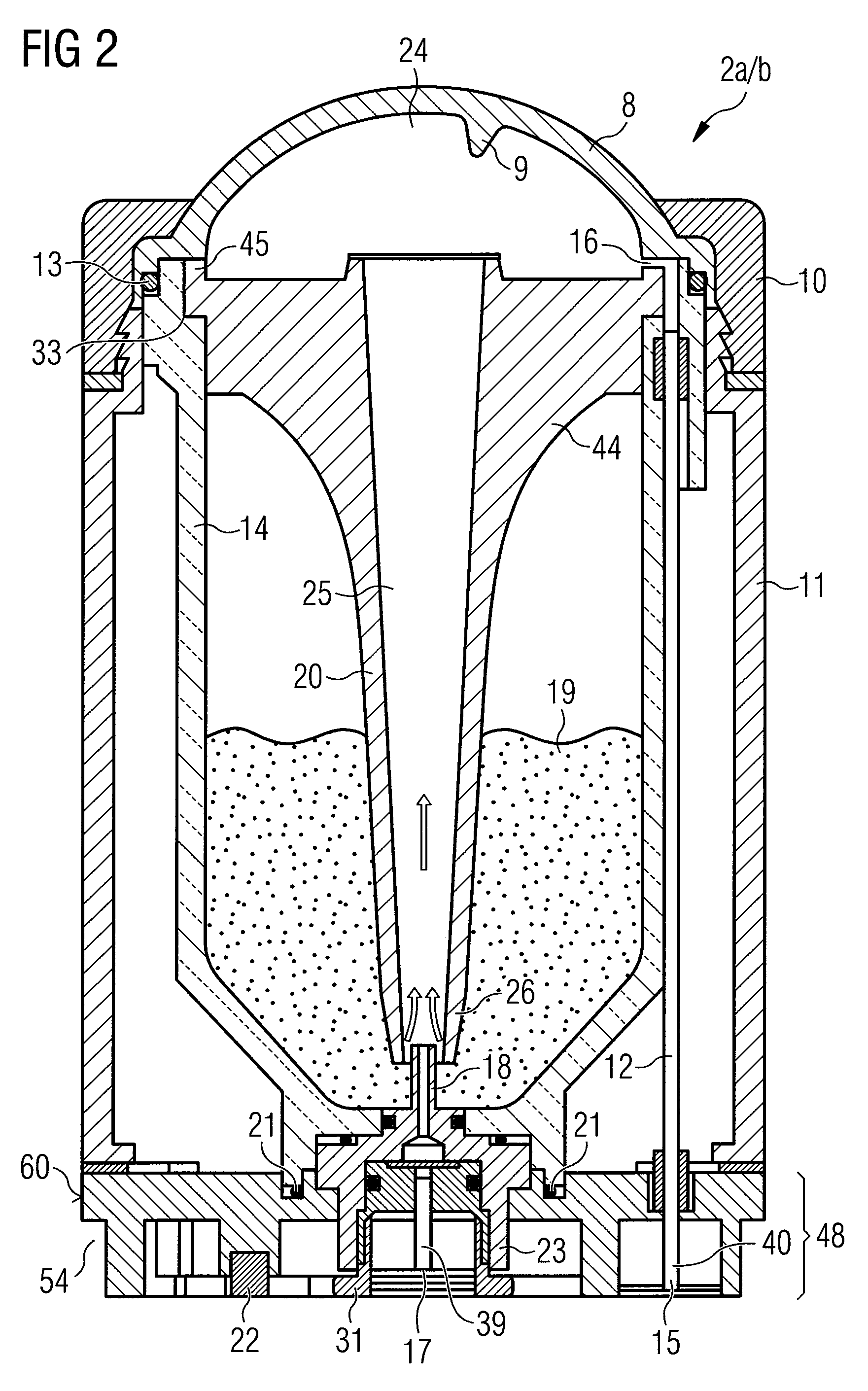

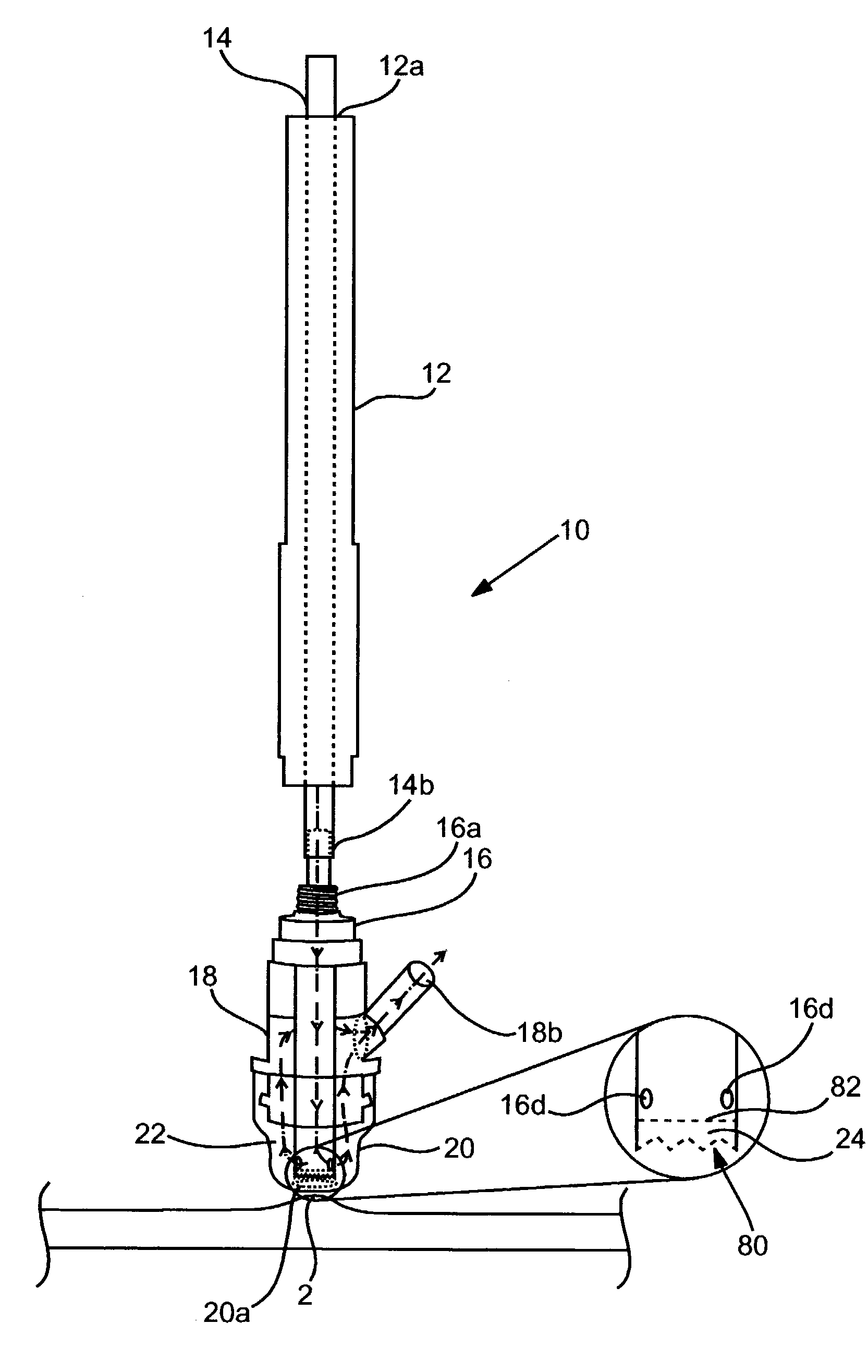

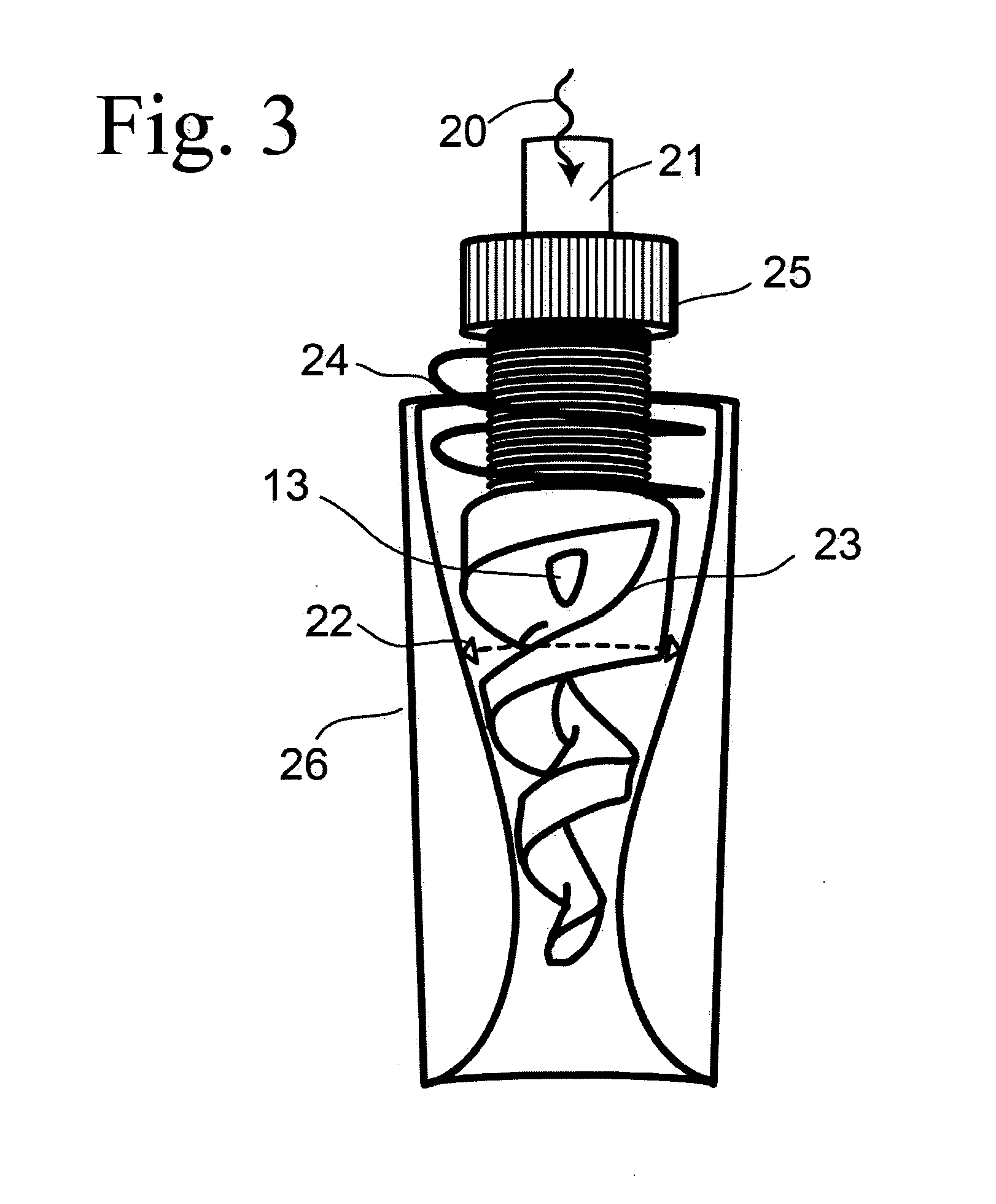

Powder blast tool, powder reservoir, insert for powder reservoir and method of dental treatment

A powder blast tool for mixing a powder with a pressurised gas, having at least one powder reservoir, with supply lines for the pressurised gas, and a discharge line, which is connected to a discharge nozzle, at which a powder-gas mixture and optionally pressurised water are discharged, wherein the powder blast tool can preferably be connected to plural powder reservoirs simultaneously and exchangeably, wherein at least one receiving region with at least one mixture terminal and at least one gas terminal is disposed on the powder blast tool and wherein the powder reservoir has a coupling region for exchangeable connection of the powder reservoir to the powder blast tool. Also disclosed are a suitable powder reservoir and an insert for such powder reservoirs and a corresponding method of dental treatment.

Owner:FERTON HLDG

Skin treatment system and method of use

InactiveUS7658742B2Maximize utilizationAvoid the needAbrasive feedersAbrasive surgical cuttersSkin treatmentsSkin cell

A device, a system employing the device and method of performing skin treatment are provided for skin treatment. The device includes a vacuum head base defining a chamber therein and having a substantially smooth treatment tip attached and extending from an end thereof or integral therewith. The tip has at least one central opening that is open to the chamber, and is adapted to contact the skin and traverse the skin in a substantially non-abrasive manner. A vacuum access opening is provided through a side wall of the vacuum head base and adapted to connect with a source of vacuum. A tissue stop member is located within the chamber. It may have an abrasive surface for exfoliating skin cells, or a smoother surface for traversing the skin without substantial abrasion.

Owner:ENVY MEDICAL

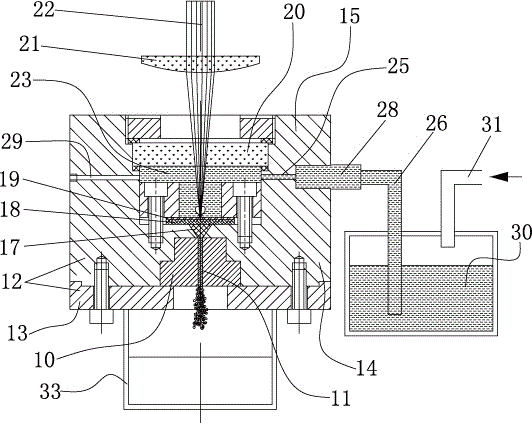

Dynamic pressure cavitation jet polishing device of colloidal flow and method

InactiveCN101670556AImprove quality and efficiencyImprove processing efficiencyBlast gunsAbrasive feedersCavitationSemiconductor materials

The invention discloses a dynamic pressure cavitation jet polishing device of colloidal flow and a method, relating to a polishing device and a method and aiming at solving the problems that the existing polishing method of the ultrasmooth surface has low processing efficiency and high cost, the adaptability of the work piece material is limited and the existing polishing device of the ultrasmoothsurface has complex equipment and high maintenance cost. The device is characterized in that a cavitation jet device is fixed on a bracket; the input end of the cavitation jet device is connected with an outlet of a first flow reversing valve by a pipeline. The method comprises the following steps: (1) the polished work piece is immersed with 10 to 200mm by the colloidal polished liquid level; (2) the oil pressure of the cavitation jet device is 0.5 to 15MPa; (3) the cavitation jet pressure is 0.5 to 15MPa; and (4) the cavitation jet device is arranged in colloidal polishing liquid, the cavitation jet device sprays to the work piece at the speed of 15 to 250m / s, and after polishing, the work piece is taken out, namely the polished work piece. The invention is used for ultraprecise and ultrasmooth polishing of optical glass, microcrystal glass, semiconductor materials and monocrystal materials.

Owner:HARBIN INST OF TECH

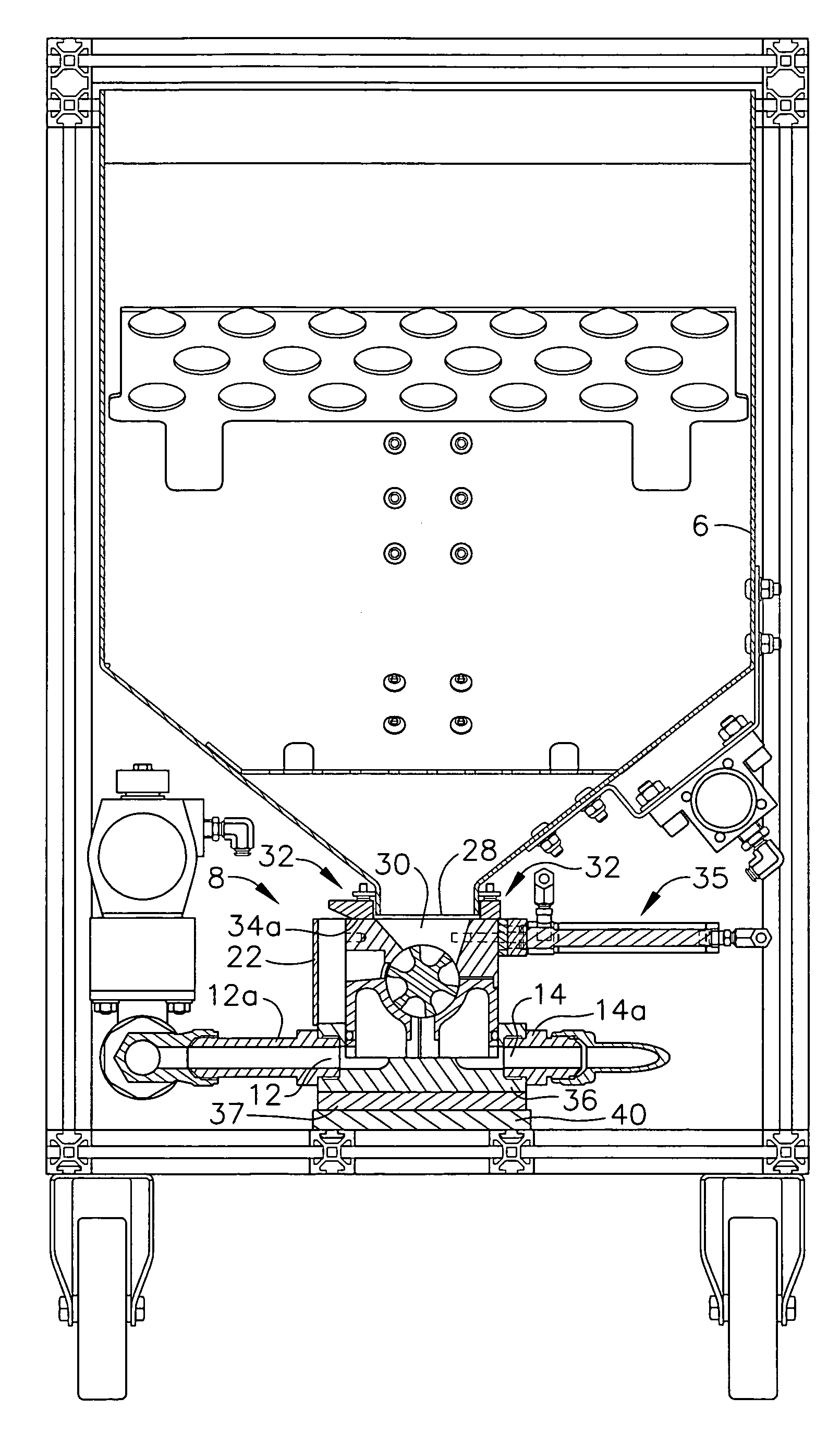

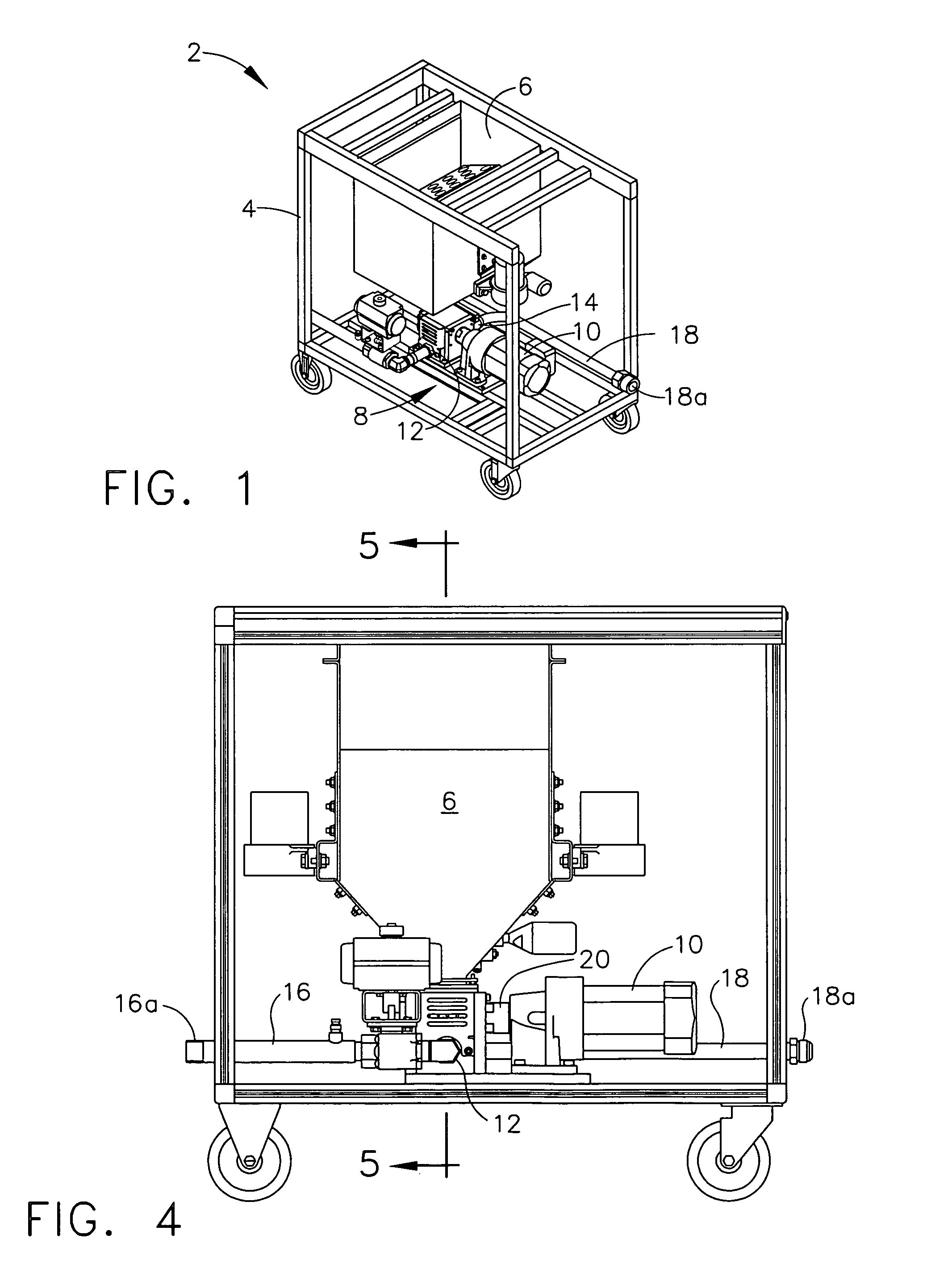

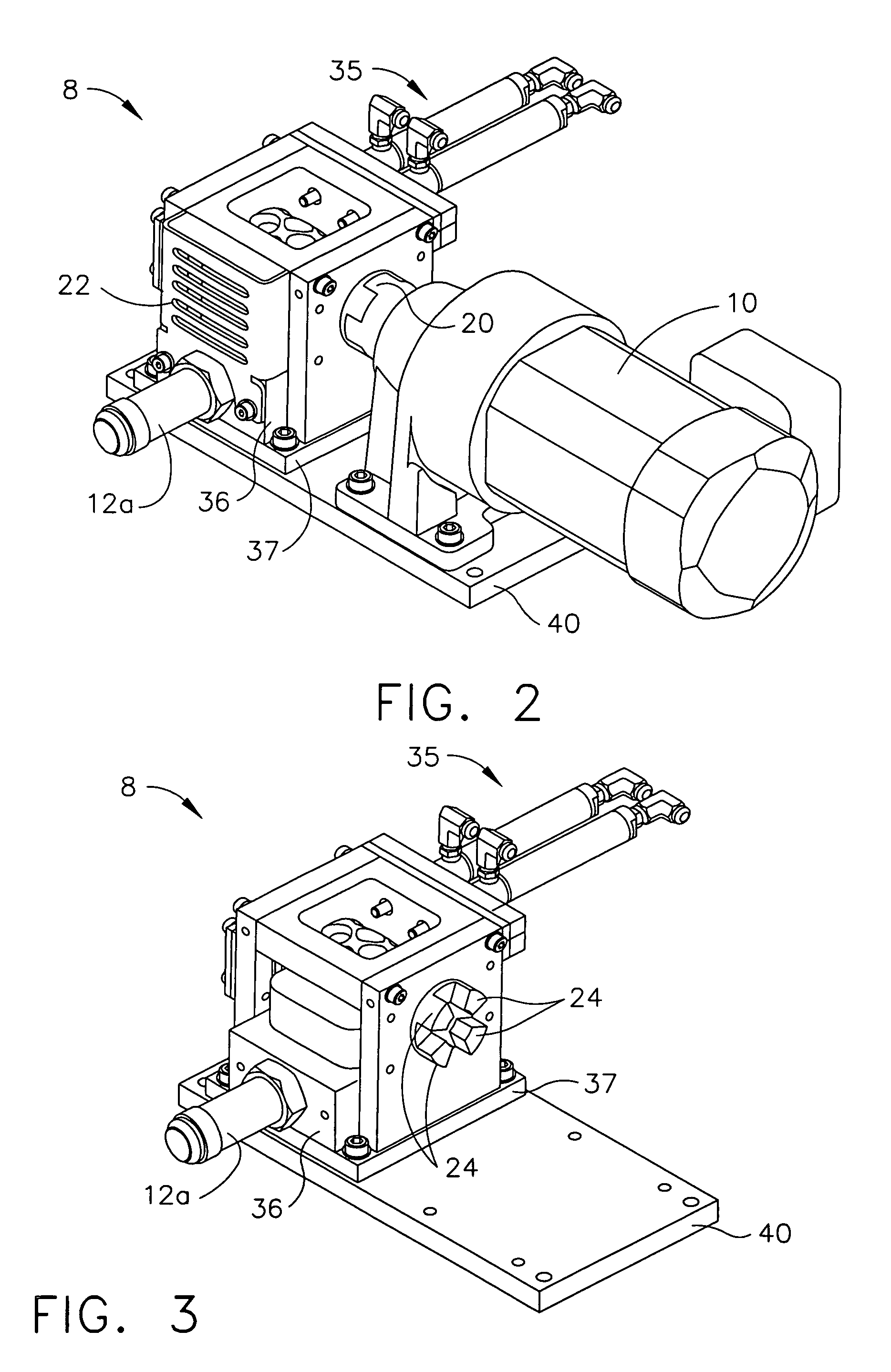

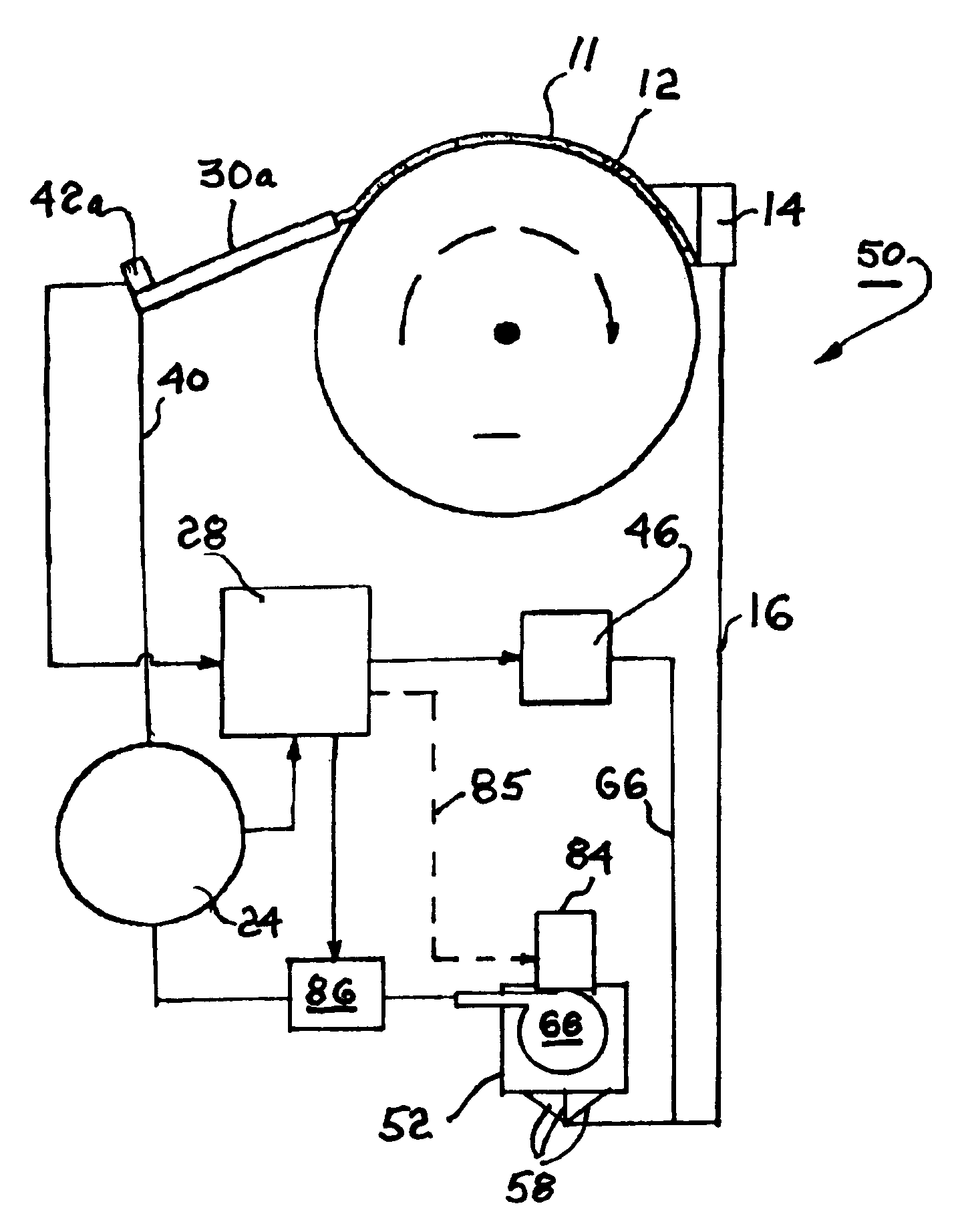

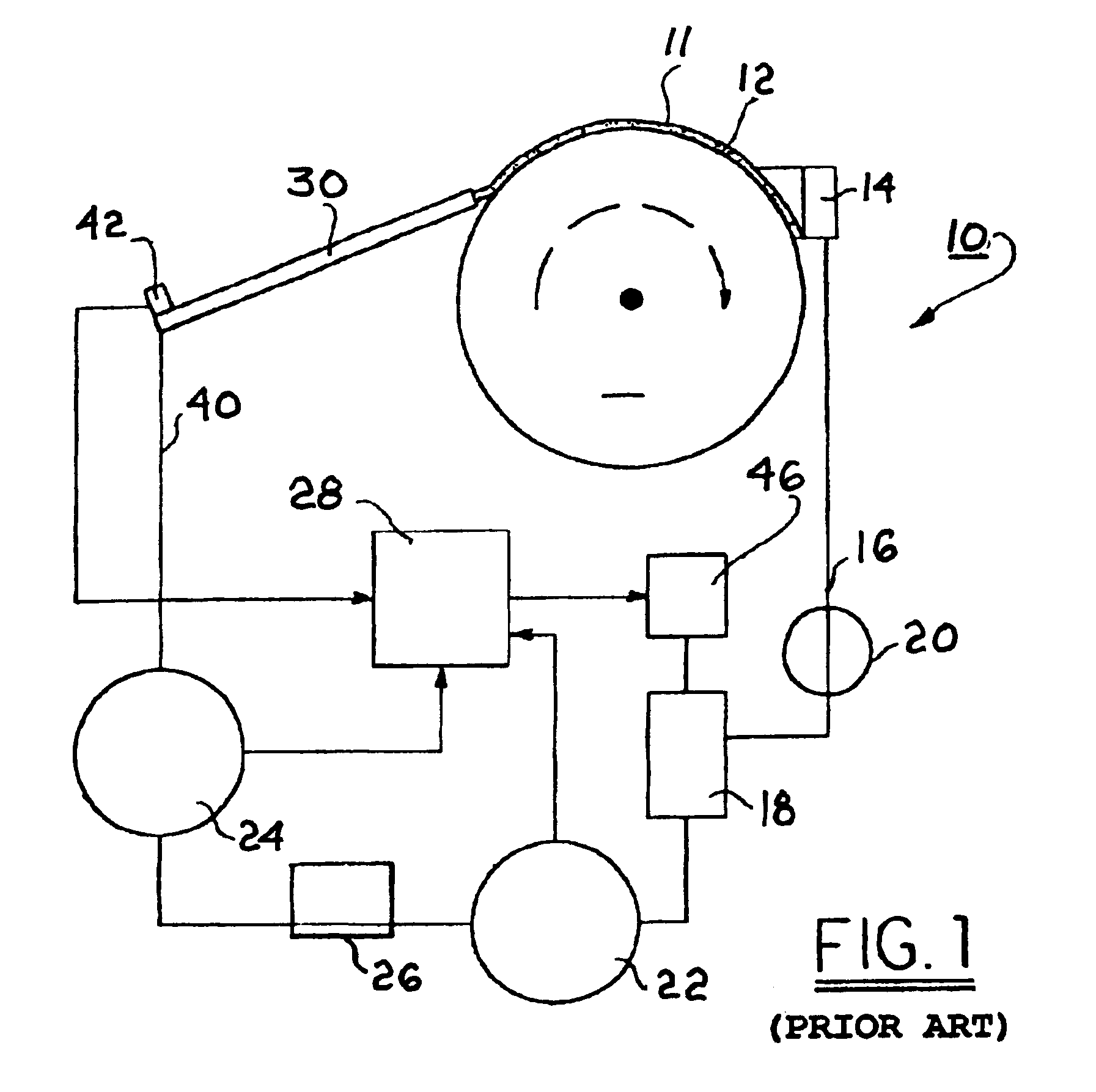

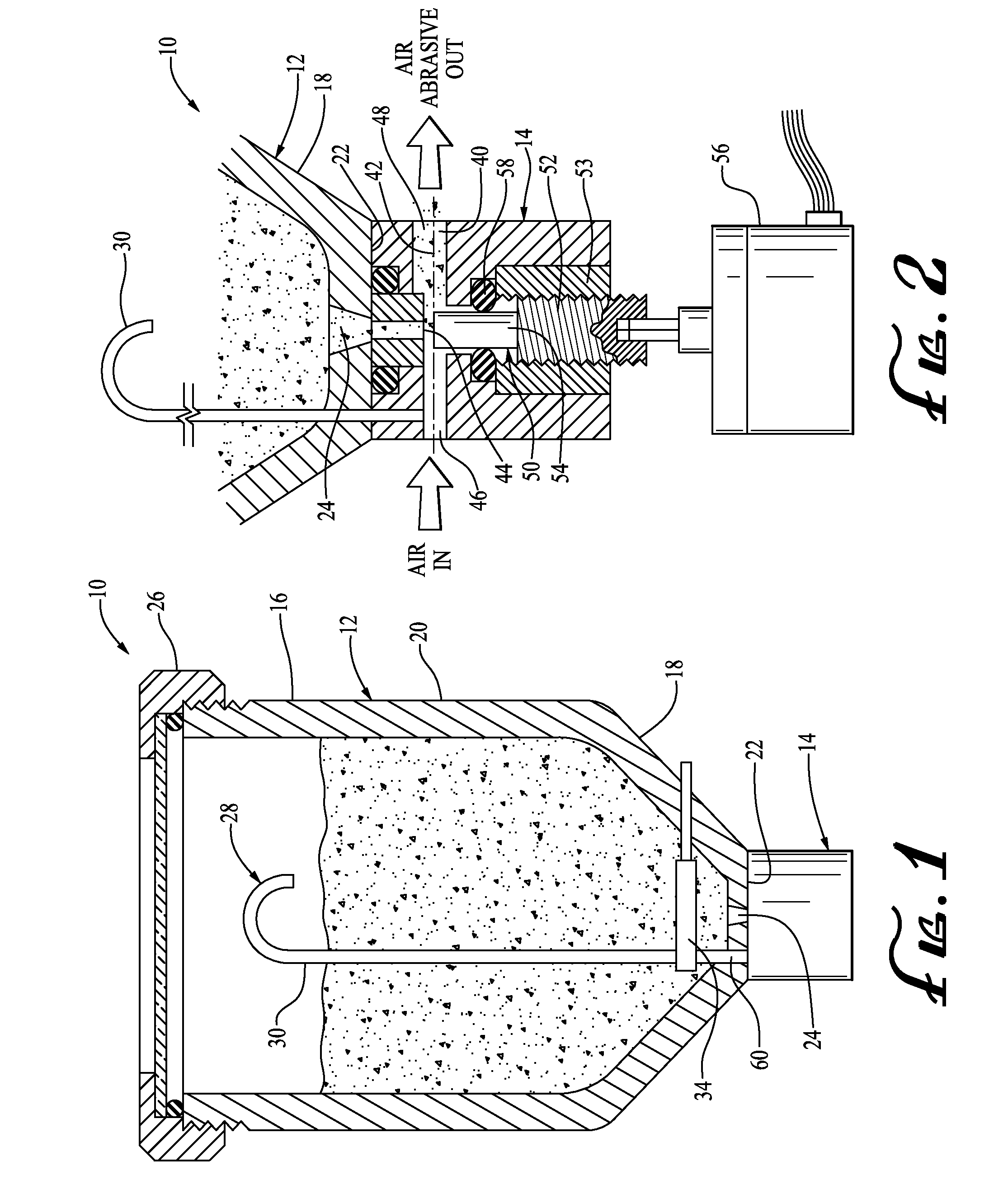

Feeder assembly for particle blast system

A particle blast system includes a feeder assembly having a rotor with a plurality of pockets formed in the peripheral surface. The transport gas flowpath includes the pockets, such that substantially all transport gas flows through the pockets. The seal adjacent the peripheral surface is actuated by the transport gas pressure to urge its sealing surface against the rotor's peripheral surface. At start up, there is no substantial pressure between the seal and the rotor, reducing start up torque requirements.

Owner:COLD JET

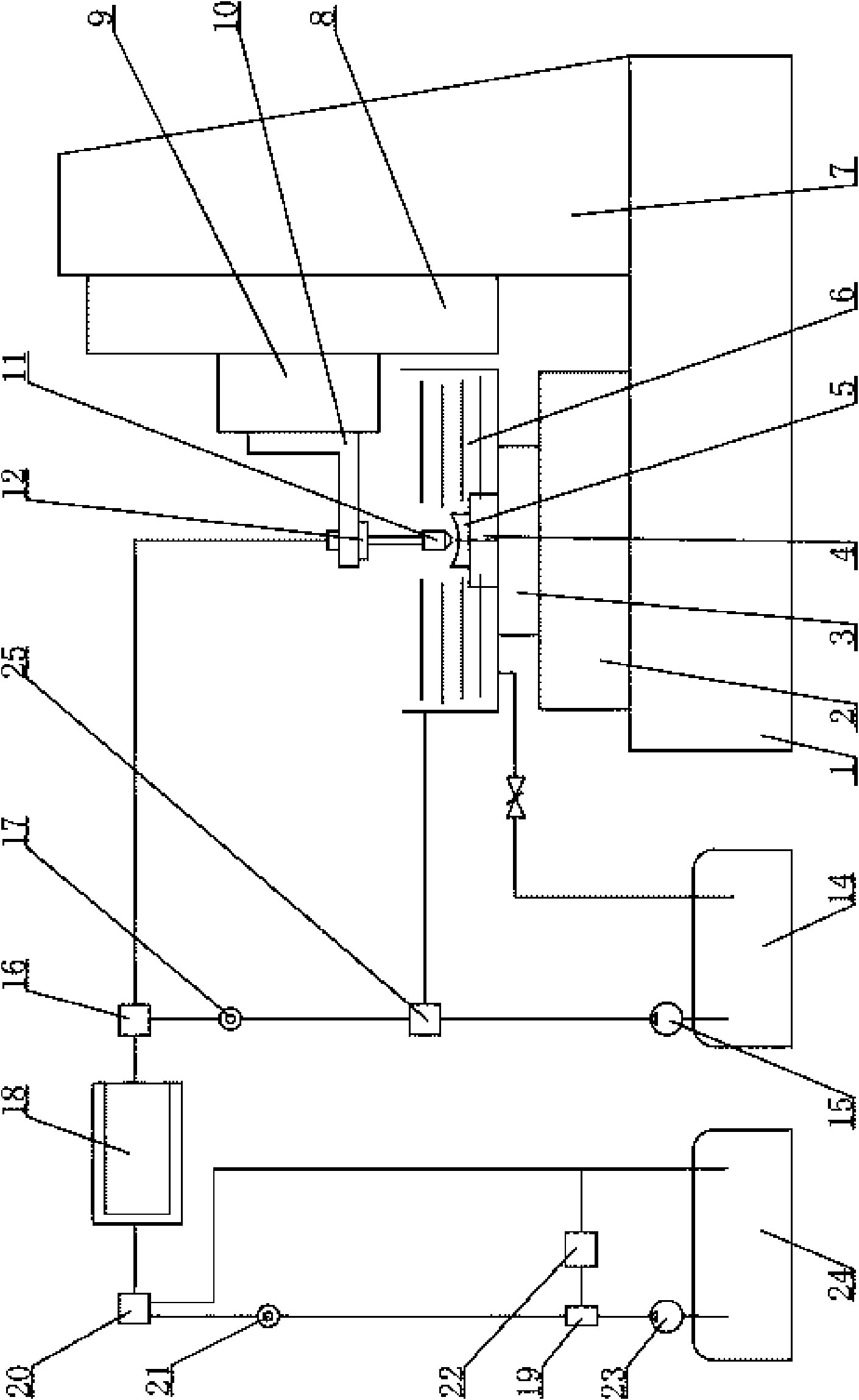

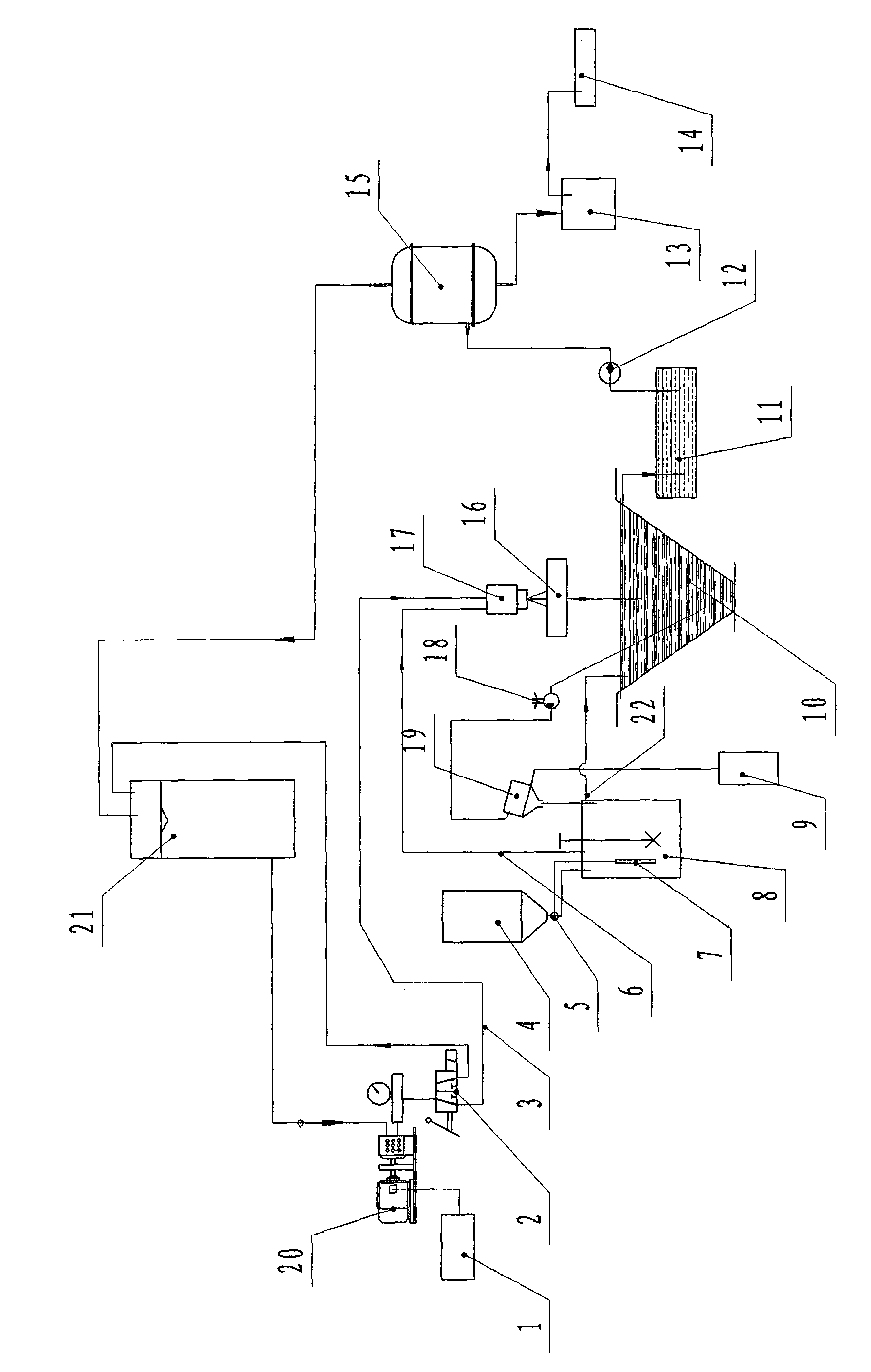

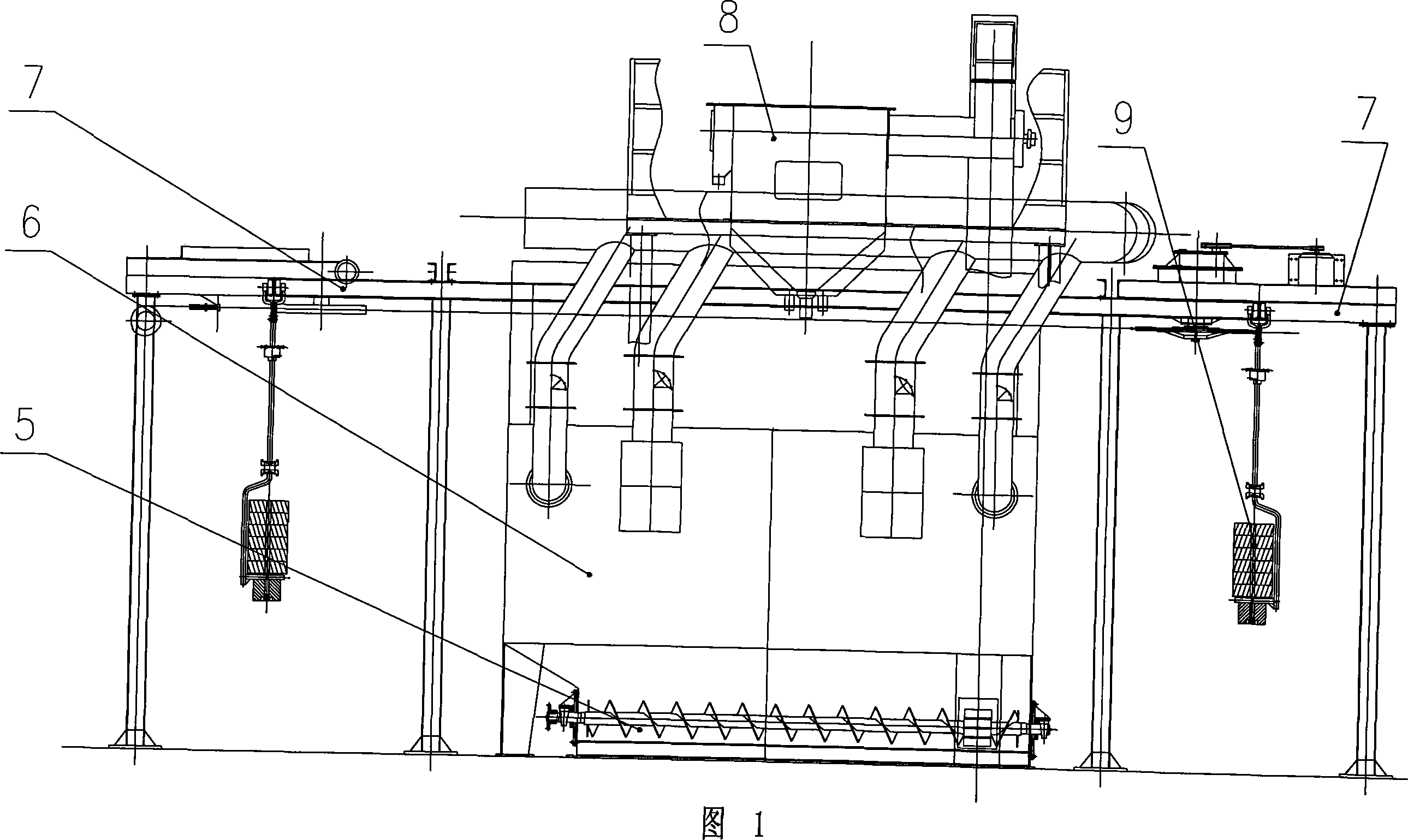

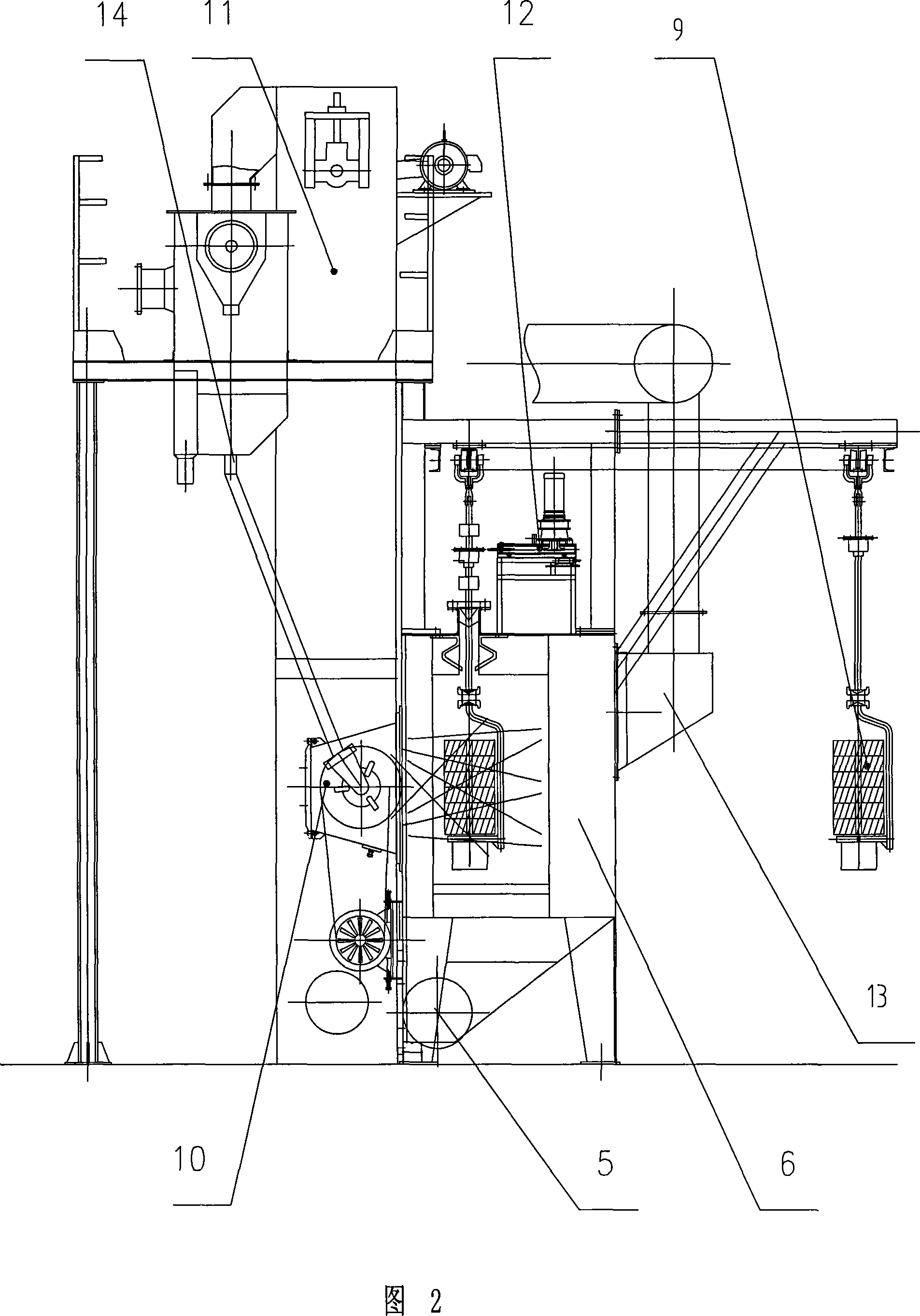

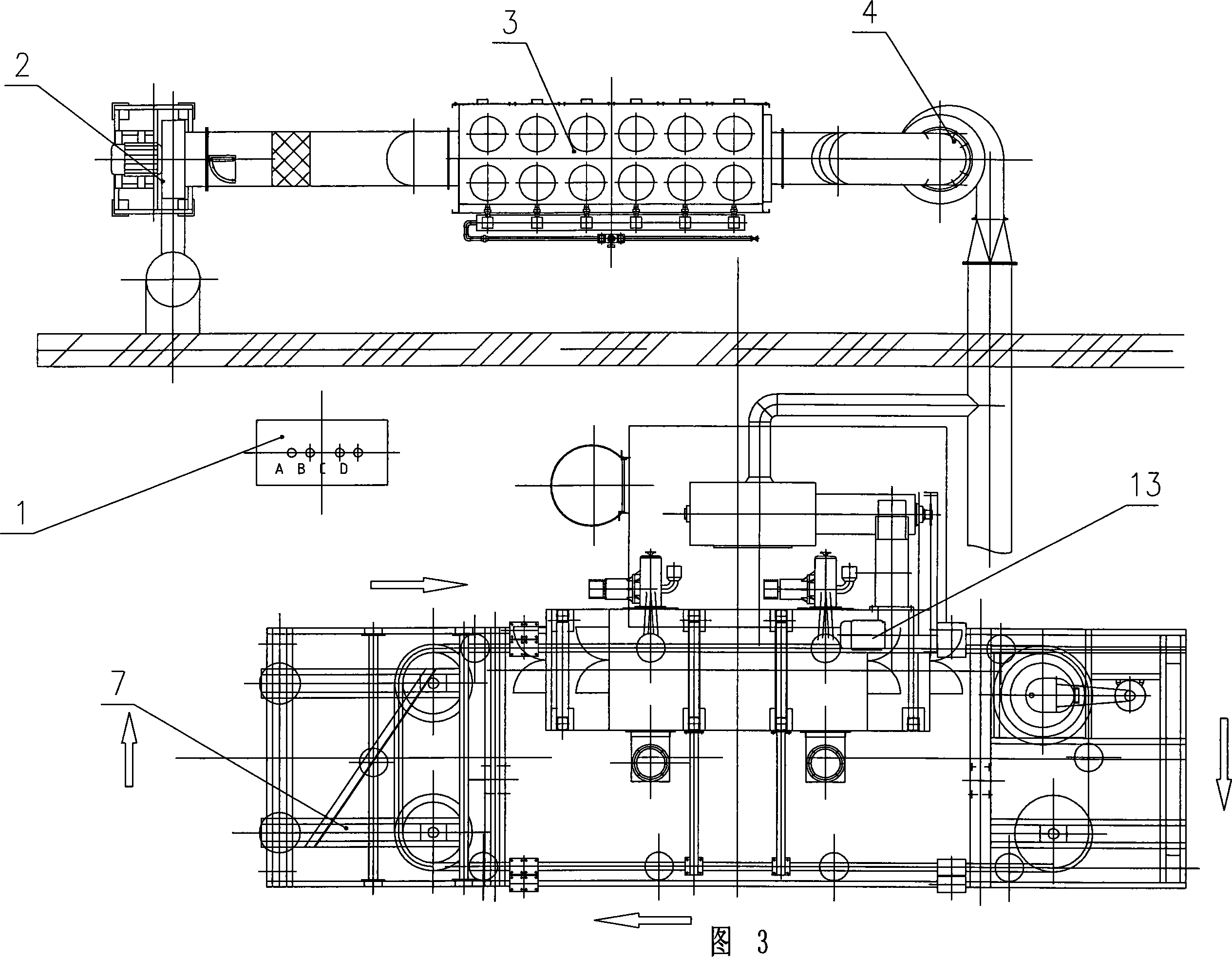

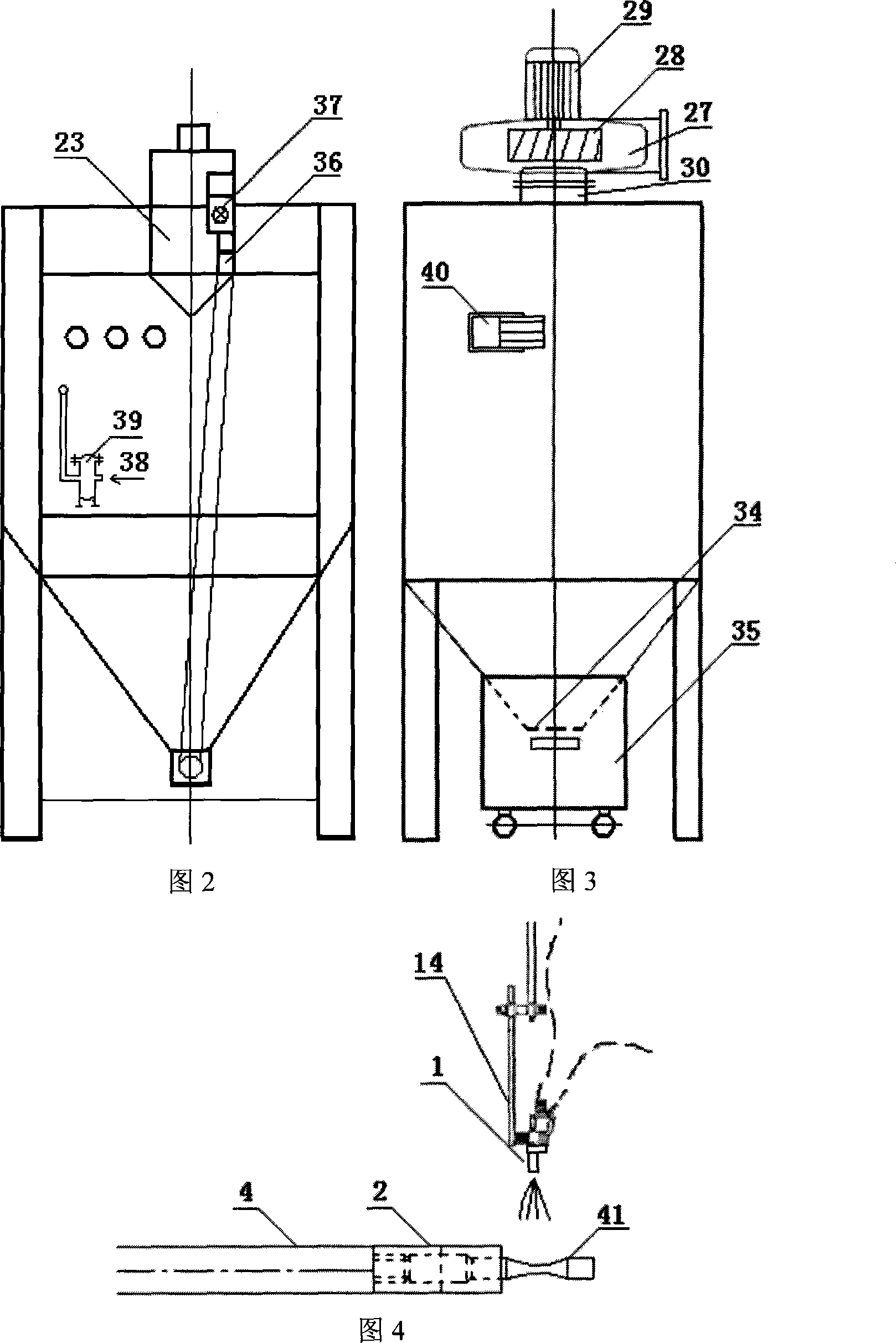

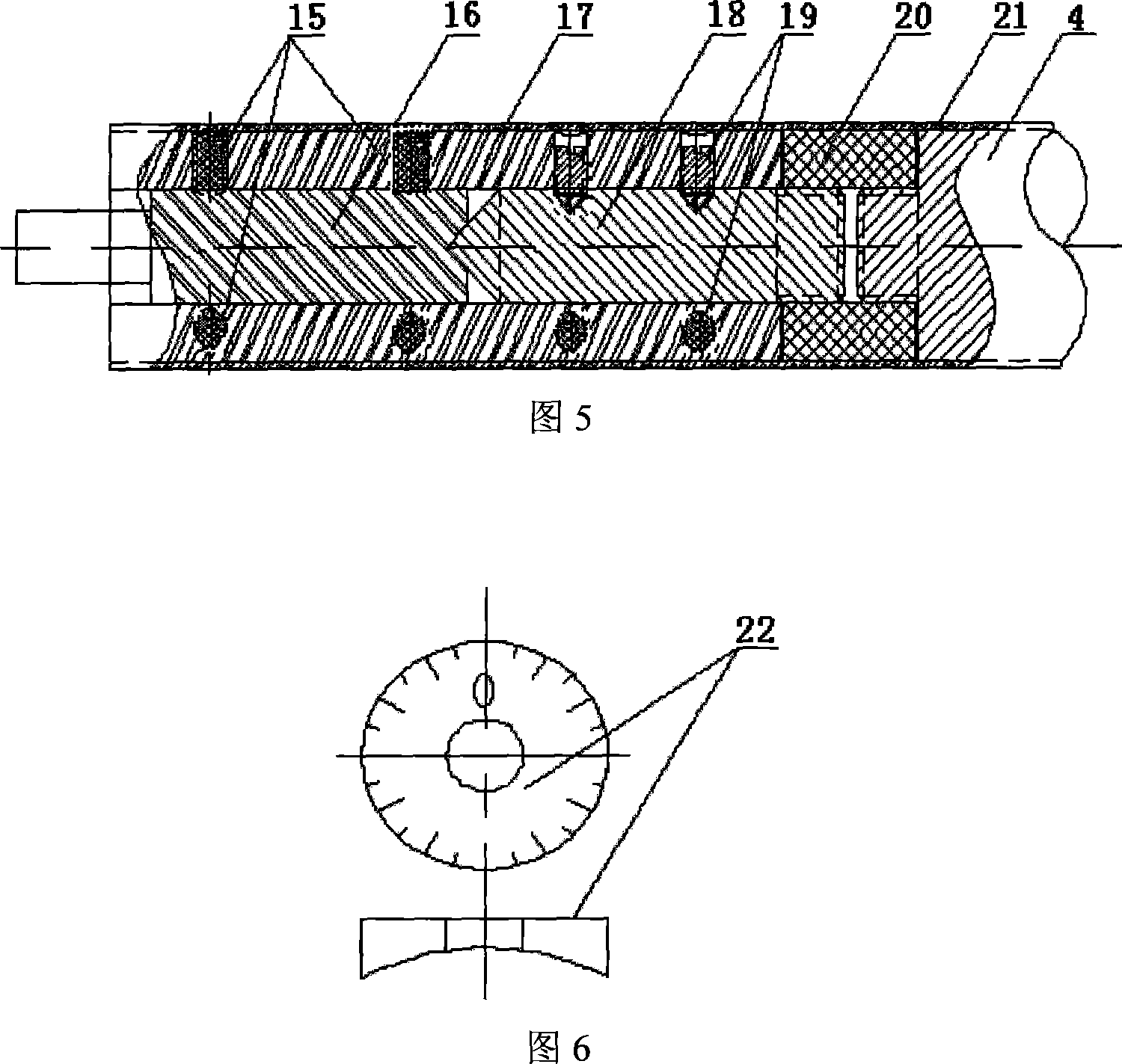

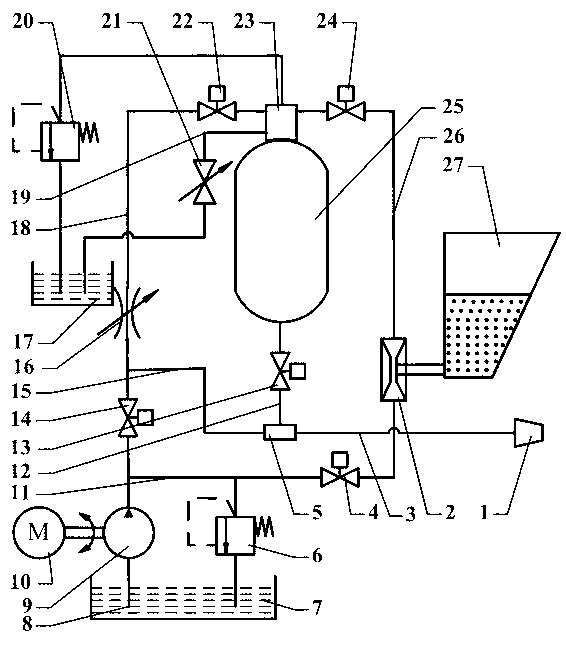

Online high-pressure water-jet blasting surface cleaning system

ActiveCN101633154AUniform supplyGuaranteed uptimeAbrasive feedersAbrasive machine appurtenancesSlagSurface cleaning

An online high-pressure water-jet blasting surface cleaning system comprises a high pressure water feed mechanism, an abrasive material feed mechanism and a spray nozzle. The high pressure water feed mechanism and the abrasive material feed mechanism are communicated with an input end of the spray nozzle, an abrasive material collecting pit is arranged below the spray nozzle, an output end of the abrasive material collecting pit is divided into two paths, one path is connected with an input end of an abrasive material sorting device by an abrasive material cyclical feeding device and a pipeline, and the other path is connected with an input end of a waste water treatment circulating mechanism by a pipeline, an output end of the waste water treatment circulating mechanism is connected with the high pressure water feed mechanism by a pipeline, an output end of the abrasive material sorting device is divided into two paths, one path is connected with the abrasive material feed mechanism, and the other path is connected with a slag collection barrel by a pipeline. The online high-pressure water-jet blasting surface cleaning system has the advantages of simple and compact structure, low energy consumption, good environmental protection, good operational reliability and stability, and recycled water and abrasive materials.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

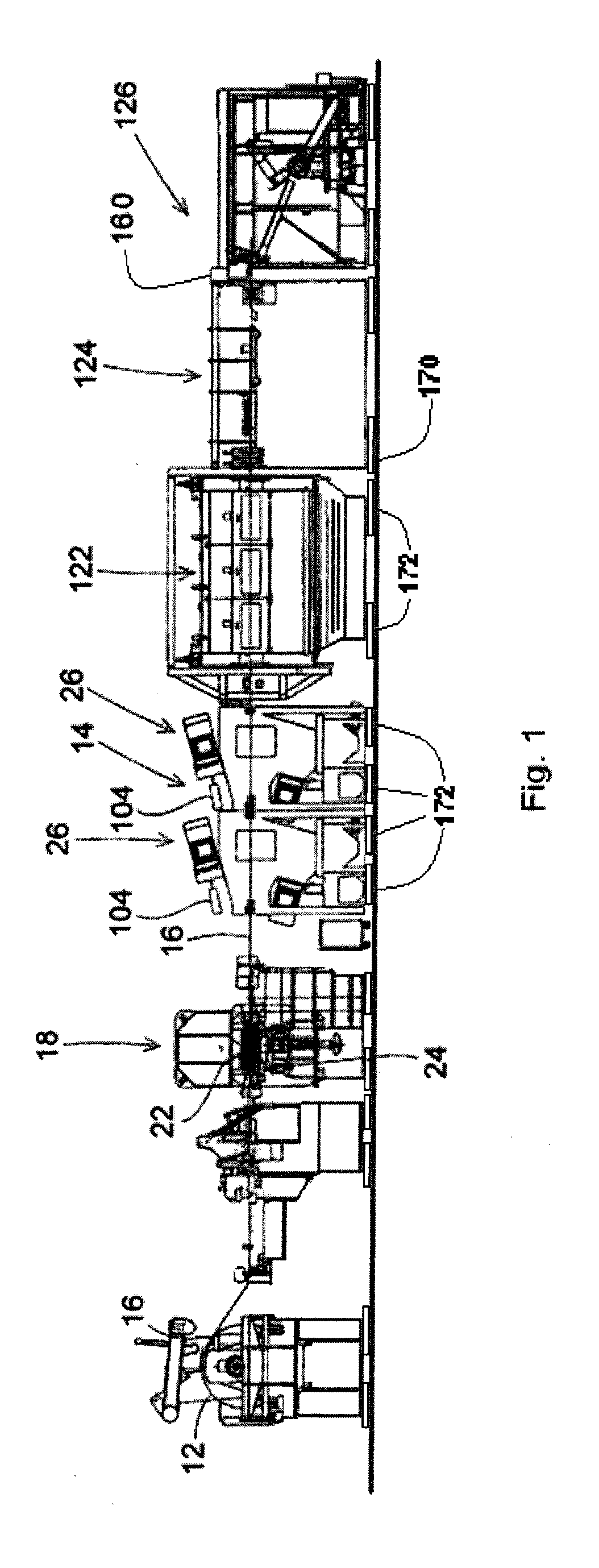

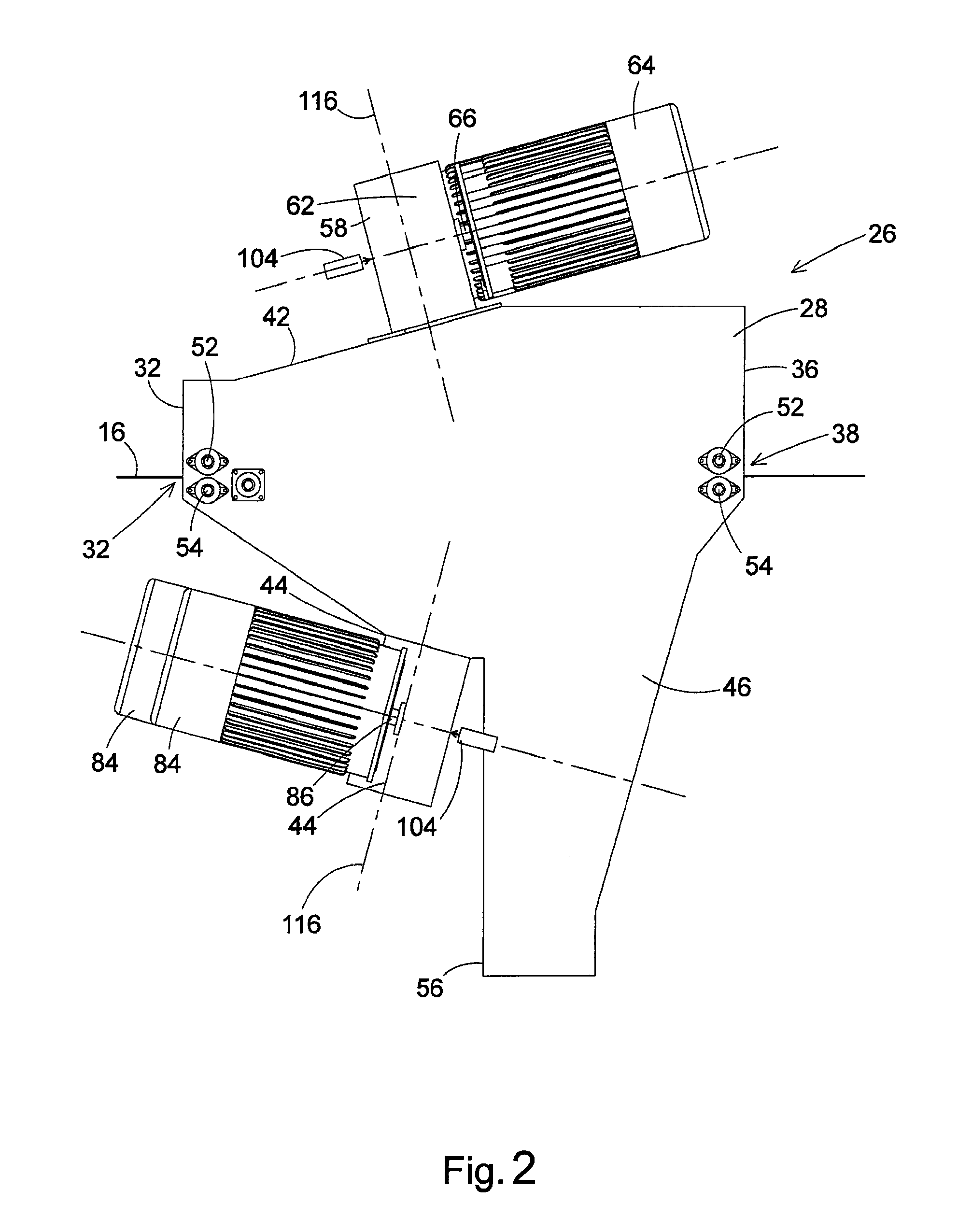

Method of Producing Rust Inhibitive Sheet Metal Through Scale Removal with a Slurry Blasting Descaling Cell

A method is provided for removing iron oxide scale from sheet metal and producing a sheet metal surface with rust inhibitive properties. The sheet metal is advanced through the descaling cell and a slurry mixture is propelled against at least one of the top surface and bottom surface of the sheet metal across the sheet metal width as the material is advanced through the descaling cell. The rate of slurry impact against the at least one of the top surface and bottom surface of the sheet metal is controlled in a manner to remove substantially all of the scale from a surface of the sheet metal, and in a manner to create a passivation layer on the descaled surface of the sheet metal. The passivation layer comprises at least one of silicon, aluminum, manganese and chromium and inhibits oxidation of the descaled surface of the processed sheet metal.

Owner:THE MATERIAL WORKS

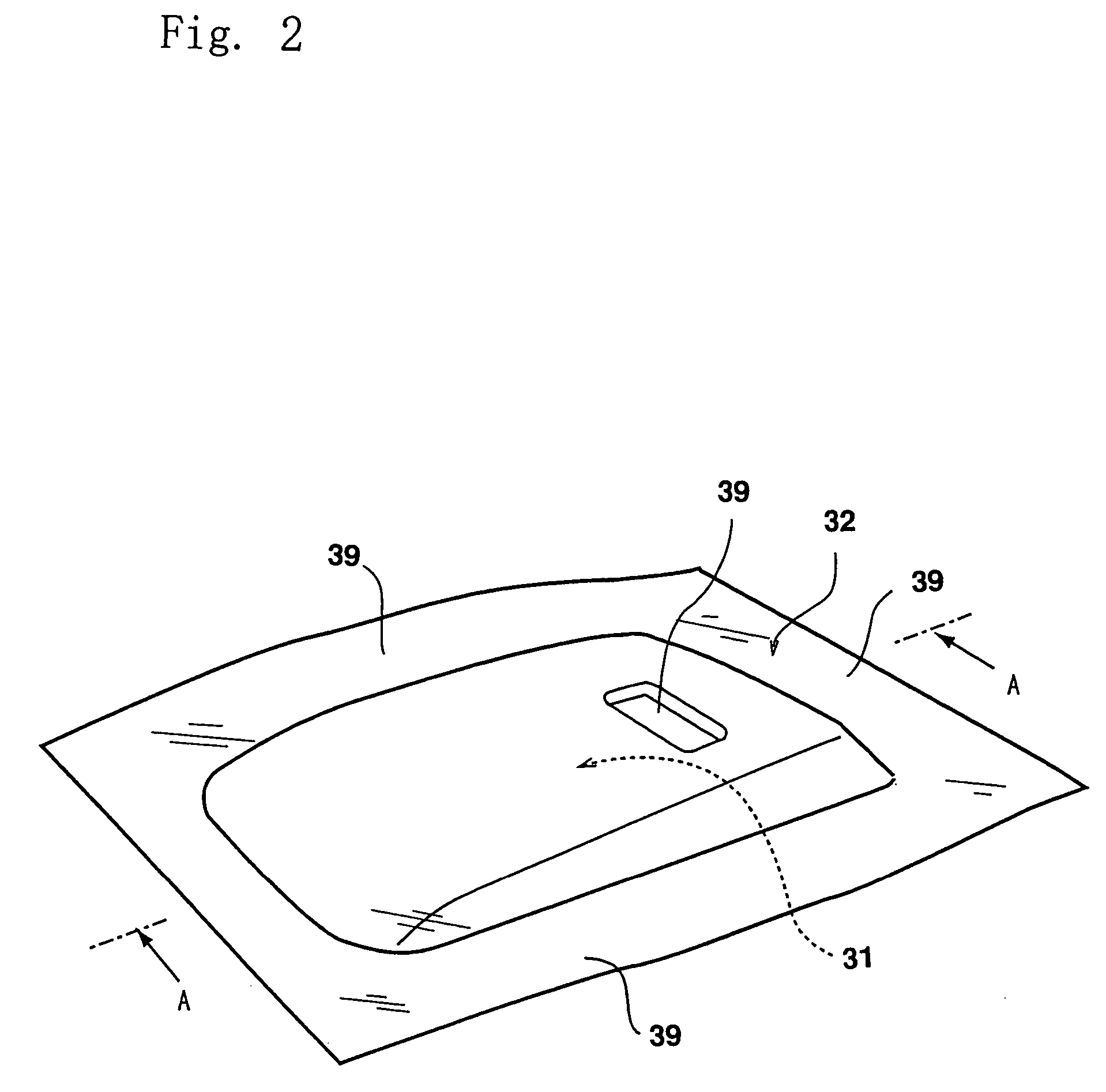

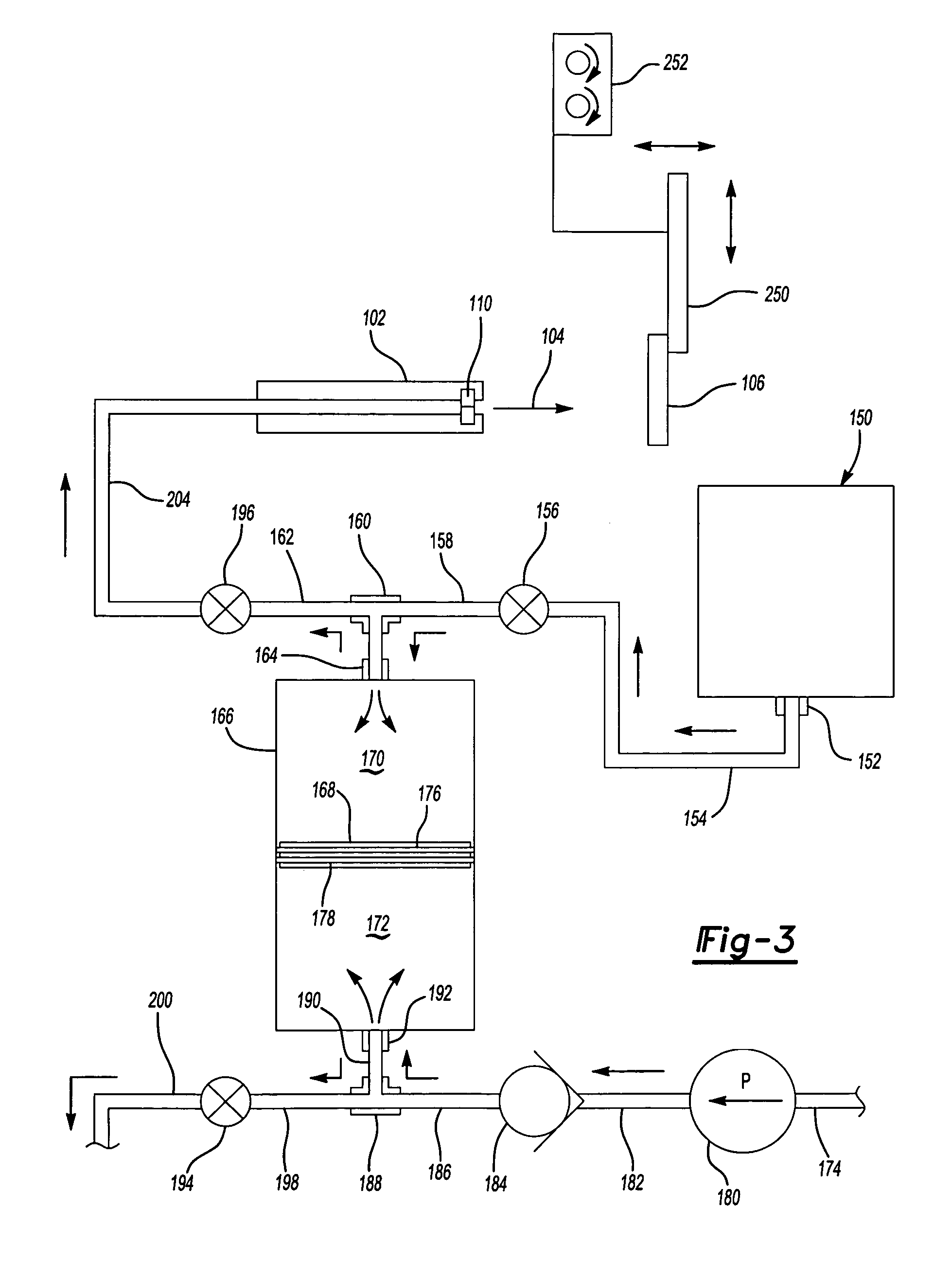

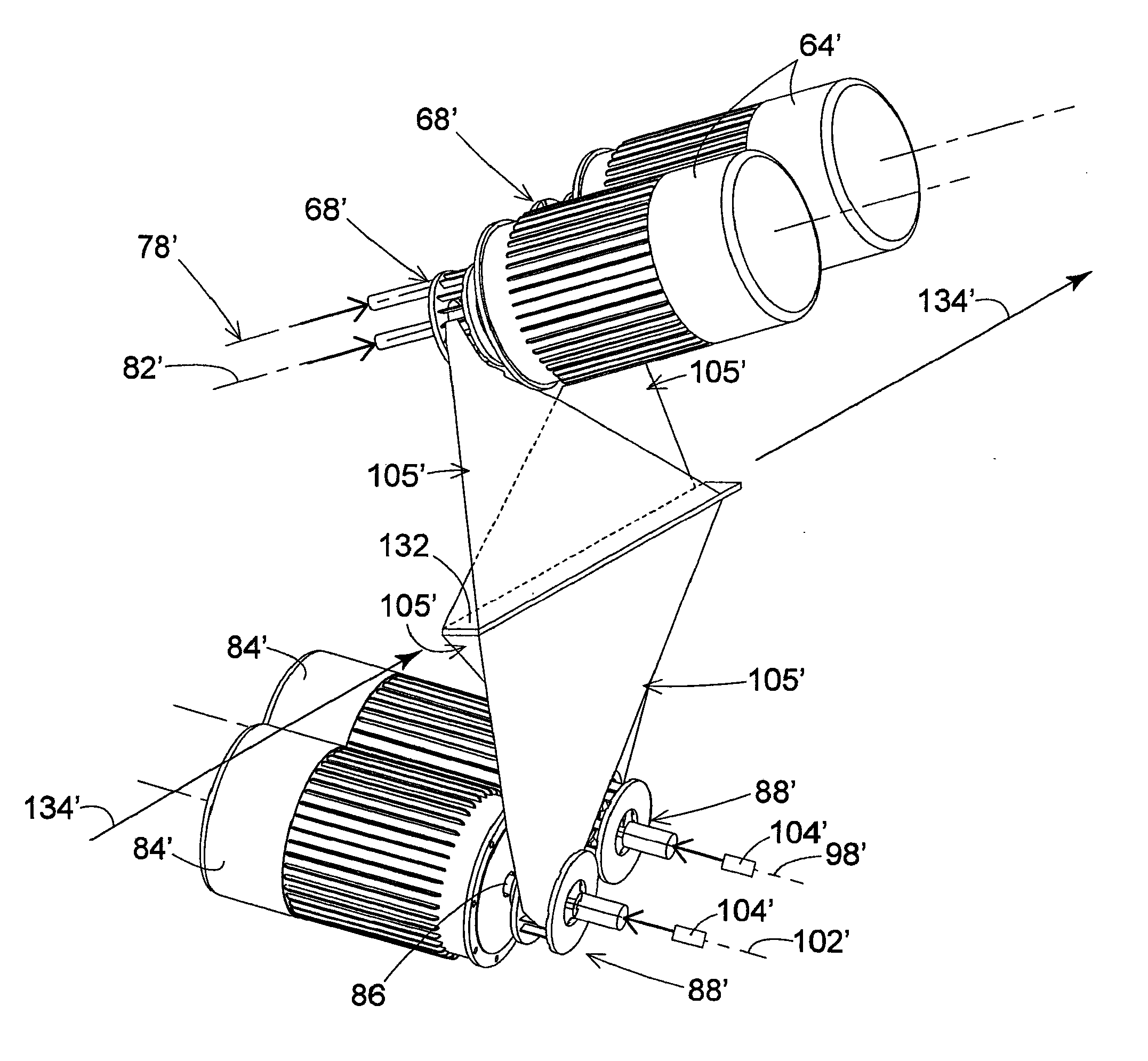

Delivery system for magnetorheological fluid

A magnetorheological fluid delivery system includes a mixing and tempering vessel. Fluid is admitted to the vessel via a plurality of tangential ports, creating a mixing of the fluid in the vessel and promoting homogeneity. Fluid may be reconstituted in the vessel by metered addition of carrier fluid. A fixed-speed centrifugal pump disposed in the vessel pressurizes the system. Fluid is pumped through a magnetic-induction flowmeter and a magnetic flow control valve having solenoid windings whereby MR fluid is magnetically stiffened to restrict flow. A closed-loop feedback control system connects the output of the flowmeter to performance of the valve. A nozzle having a slot-shaped bore dispenses MR fluid for re-use in the work zone. A planar-diaphragm flush-mounted pressure transducer at the entrance to the nozzle and flowmeter inferentially measure relaxed viscosity and provide signals to a computer for dispensing metered amounts of carrier fluid into the mixing vessel to assure correct composition of the reconstituted fluid as it is dispensed.

Owner:QED TECH INT

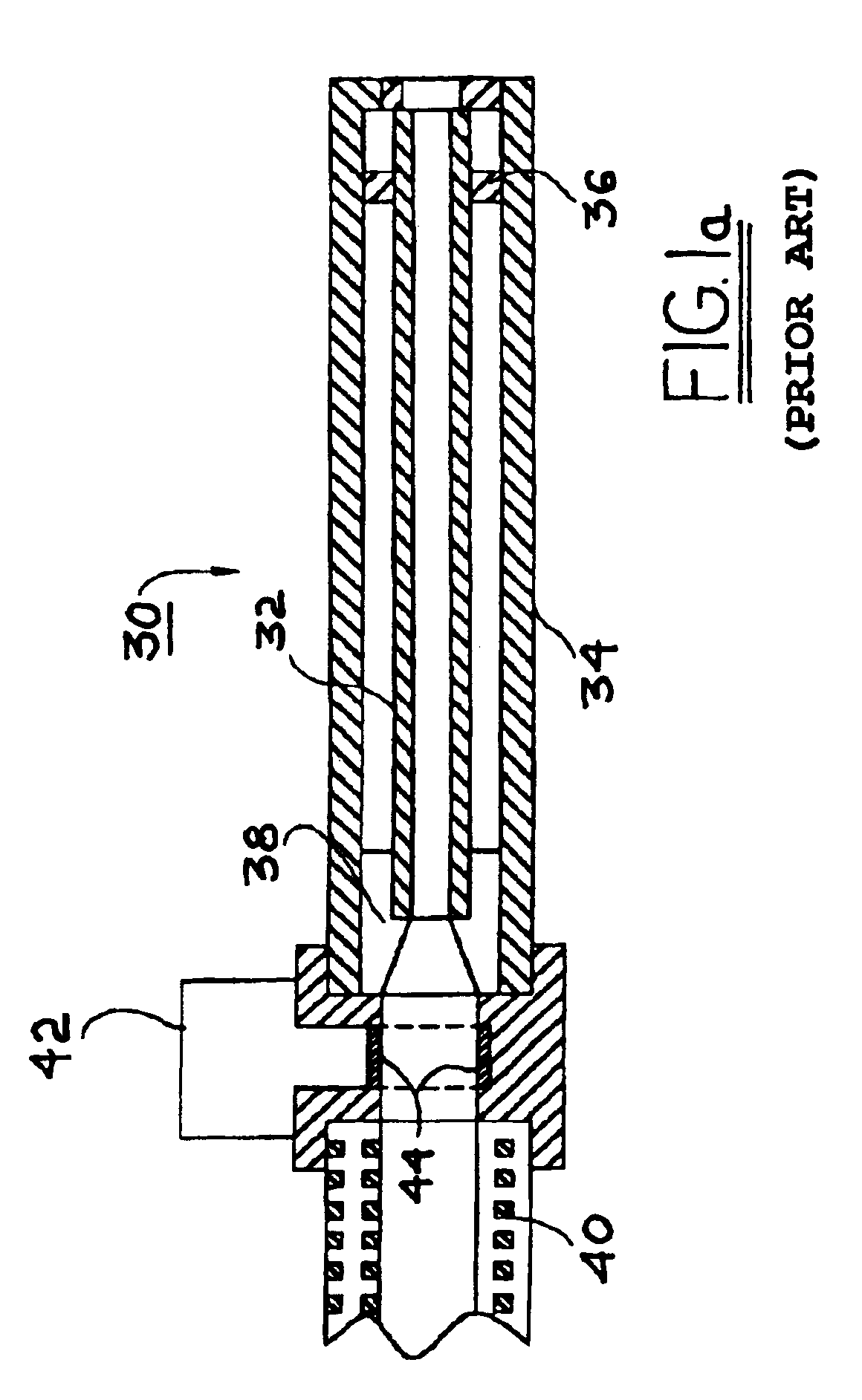

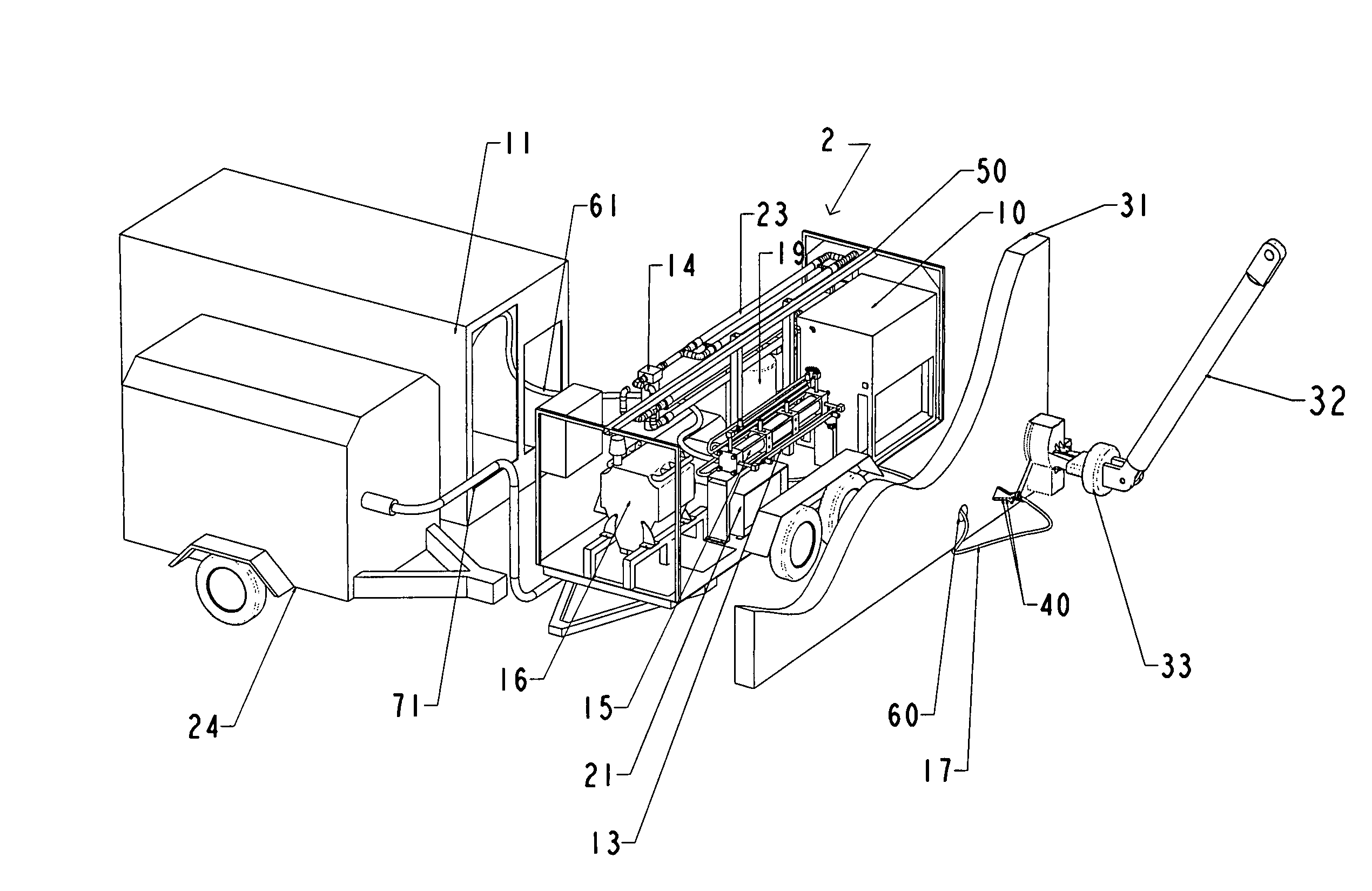

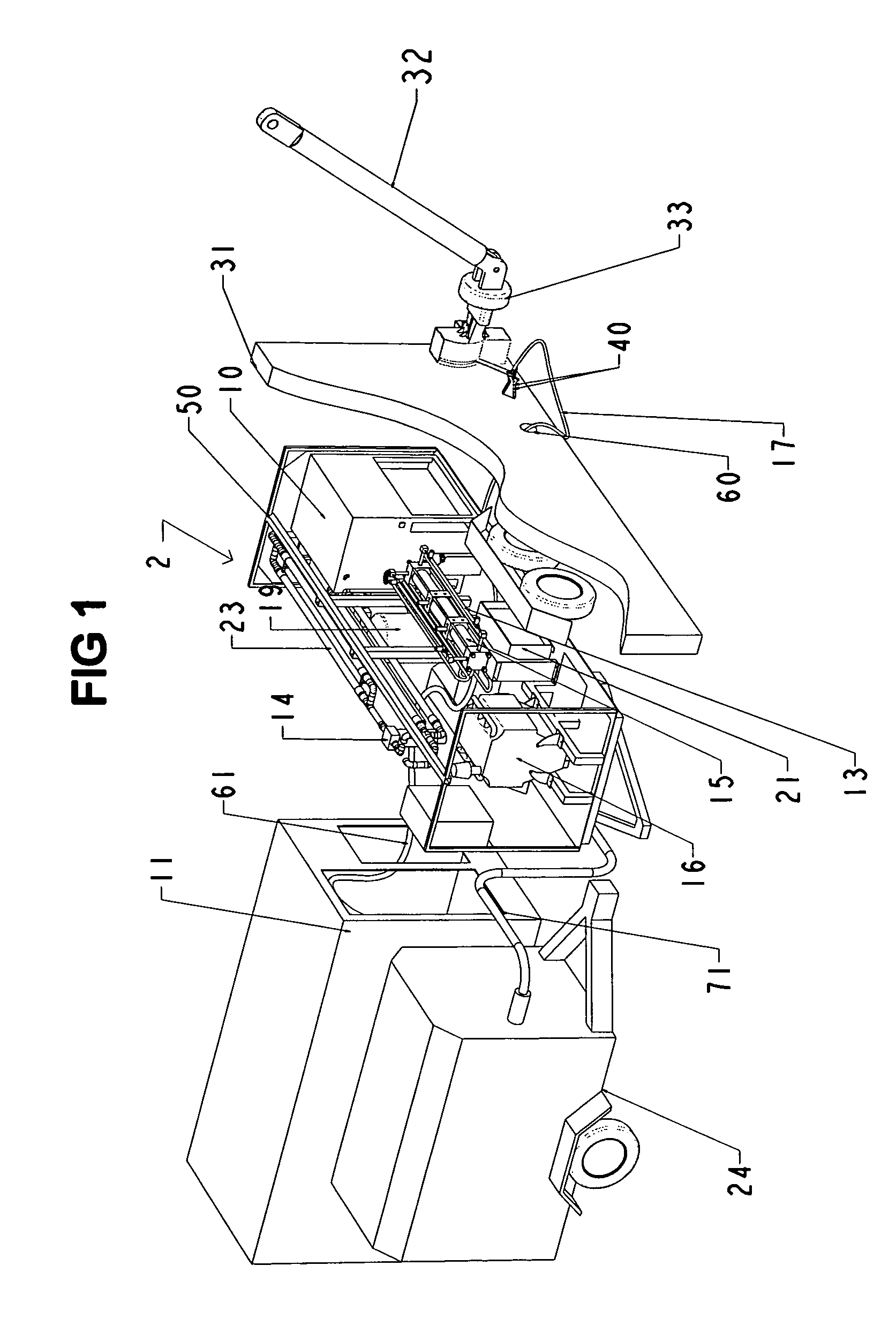

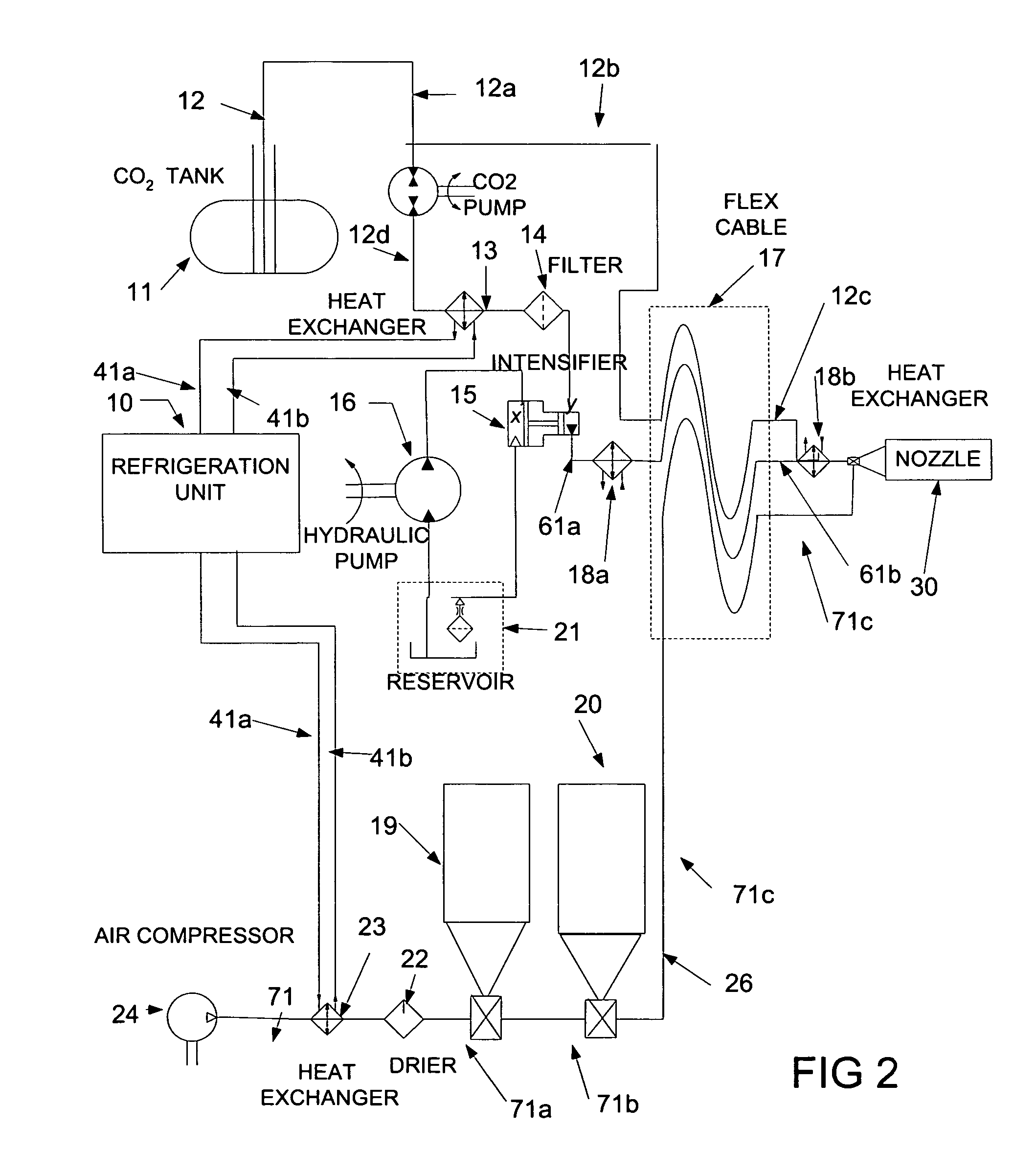

High pressure cleaning and decontamination system

InactiveUS7140954B2Suitable protectionClean effectAbrasive feedersAbrasive machine appurtenancesTriple pointRoom temperature

Abrasive cleaning and decontamination methods and systems are disclosed. The methods and systems use a high pressure liquefied gas, such as carbon dioxide, which produces insignificant quantities of secondary waste. These principles of the invention exploit the properties of the relatively high triple point of CO2 in order to first pressurize it to 35,000 to 60,000 PSI from a pressurized liquid. In the pressurized state, such a fluid can be at or above room temperature, allowing for transport over long distances in a flexible high pressure hose. At a point of use, a heat exchanger may subsequently chill the liquid, so that after expansion through a small high pressure orifice, a significant fraction of the liquid is converted to solid phase crystals exiting at high velocity to effectively clean and decontaminate. For more aggressive cleaning, abrasive particles and / or small diameter solid CO2 pellets can be entrained into the high pressure CO2 slipstream.

Owner:KURION INC

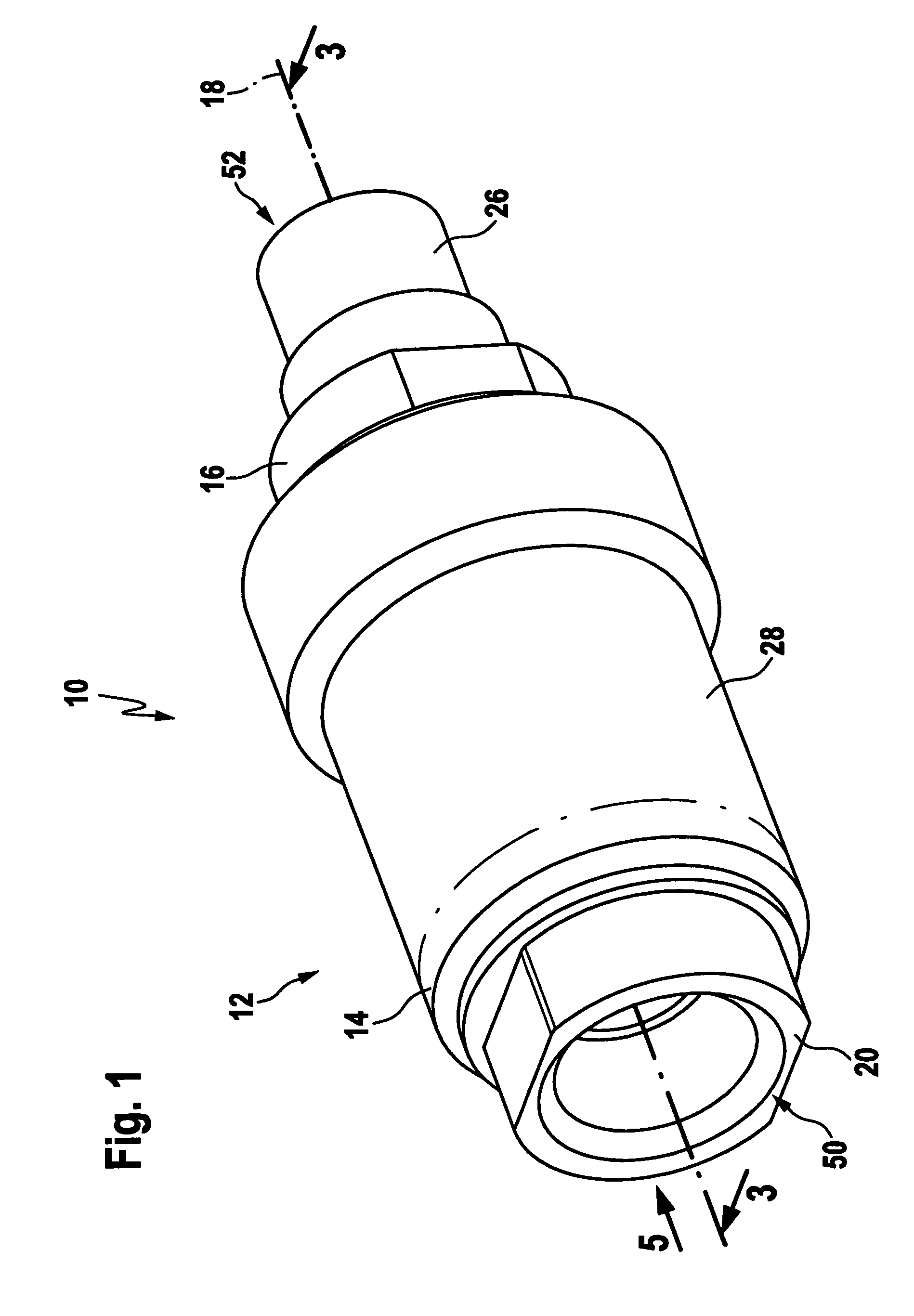

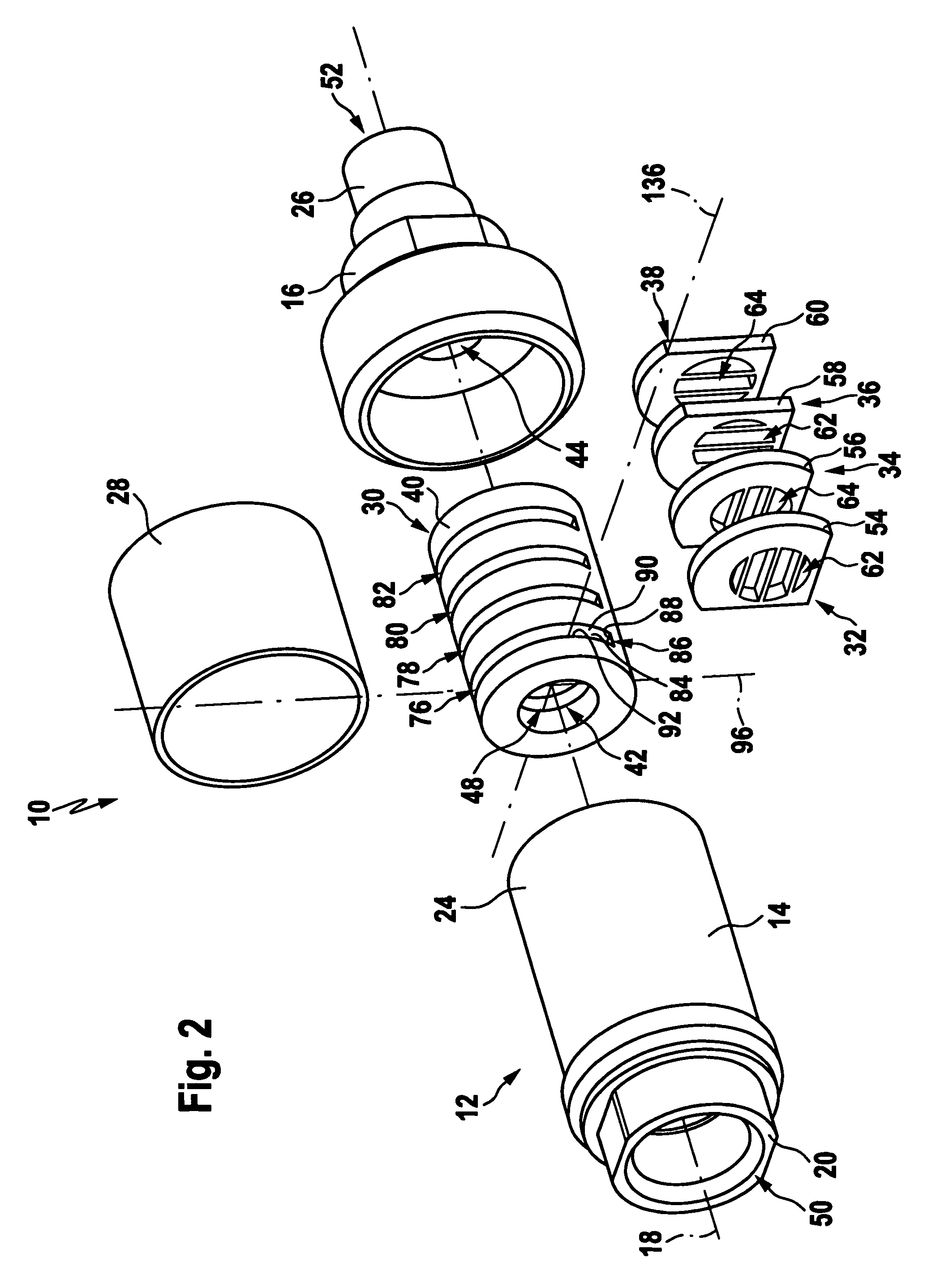

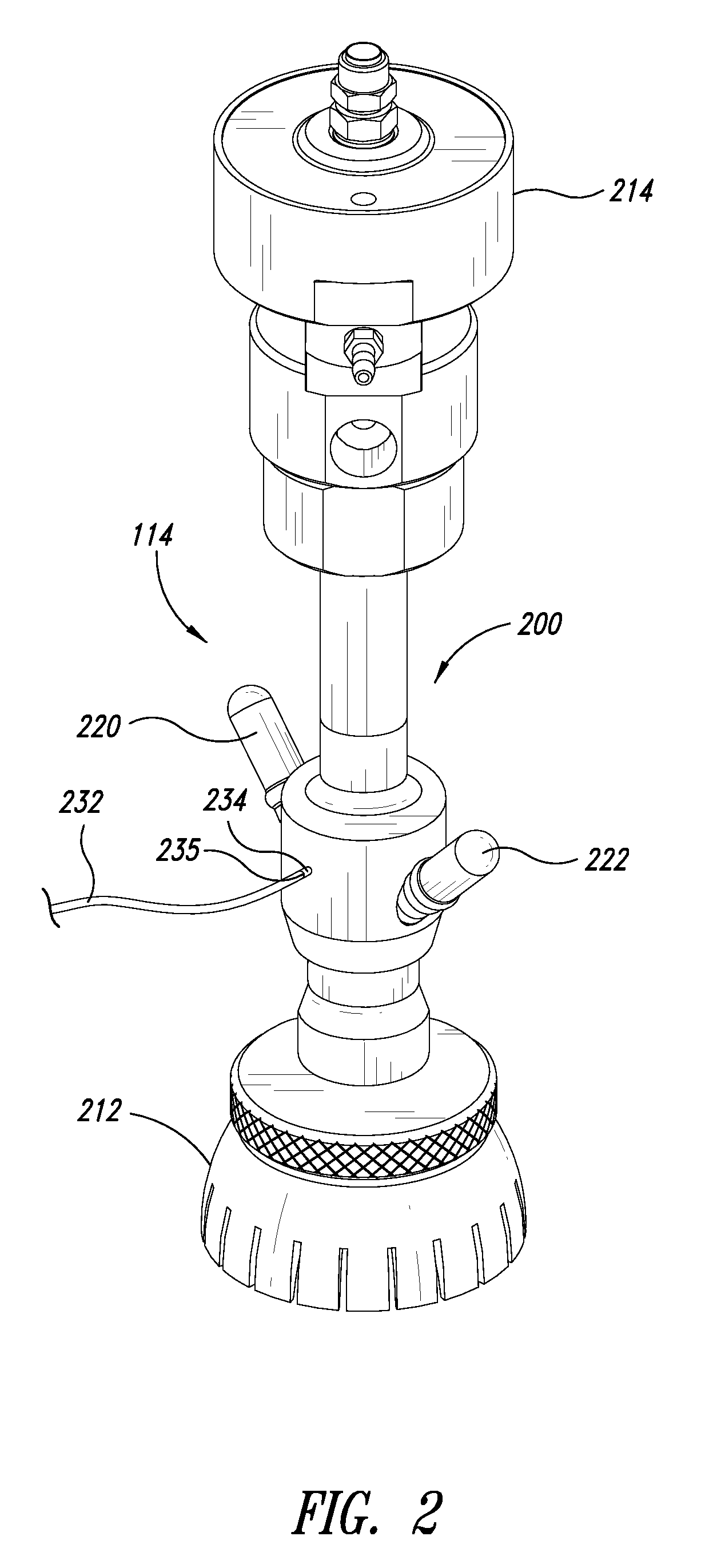

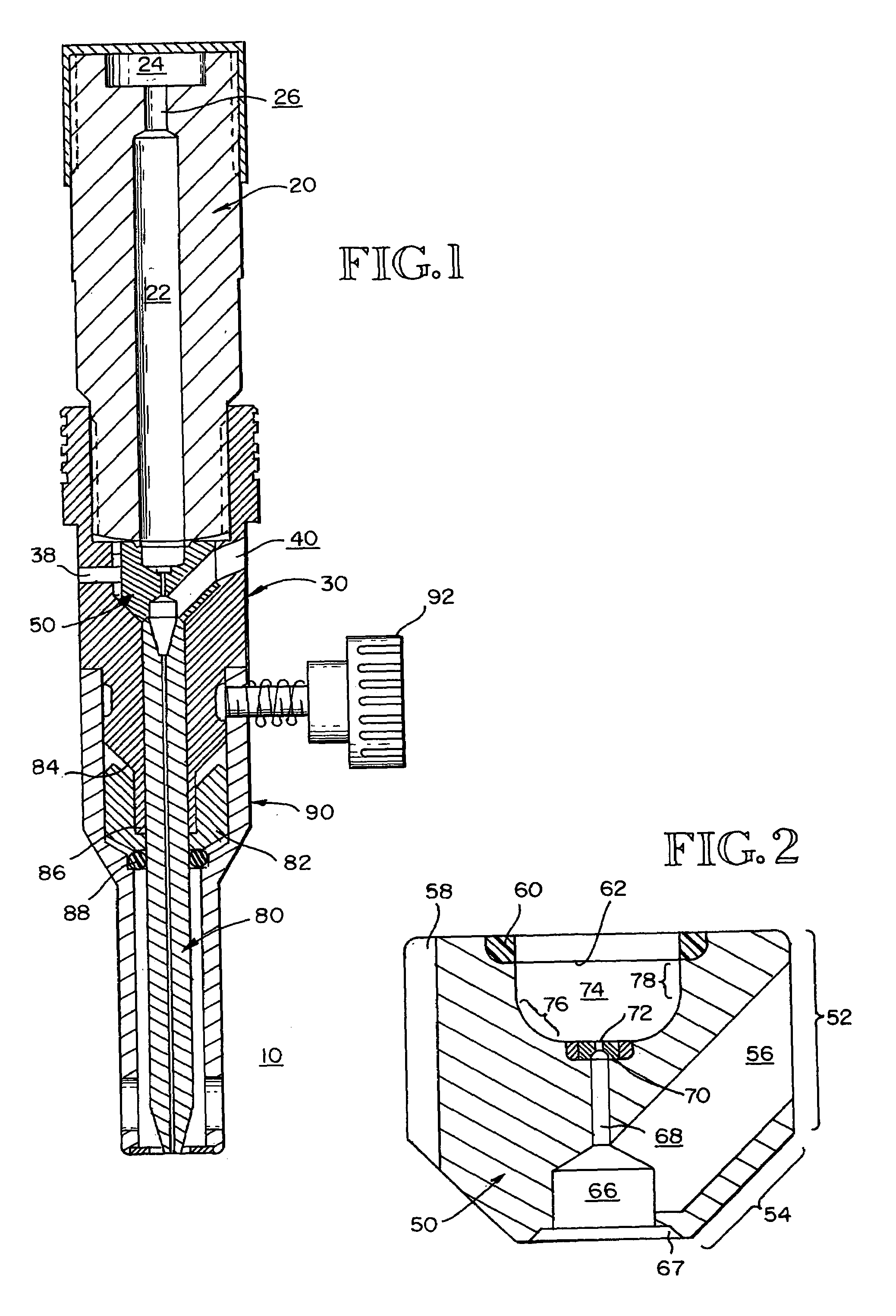

Abrasivejet cutting head with back-flow prevention valve

An abrasivejet cutting head is disclosed that includes a valve assembly for presenting back-flow to the abrasive hopper of abrasive-laden fluid from the cutting head when the discharge path for the abrasivejet becomes clogged or otherwise blocked. The valve assembly is positioned within the abrasive line to conduct abrasive from the hopper towards the abrasivejet nozzle. The valve assembly further includes a discharge path which is scaled off from the abrasive jet nozzle during normal operation in response to the relative lower pressure in the abrasivejet nozzle that results from the flowing fluid therein. If the jet path is blocked or impeded in a manner that causes a backflow of the abrasive-laden slurry therein, the cessation of low-pressure permits the backflowing slurry to exit via the discharge path and bypass the hopper, substantially avoiding the downtime previously required to clean the hopper.

Owner:INT WATERJET PARTS INC AN IDAHO CORP

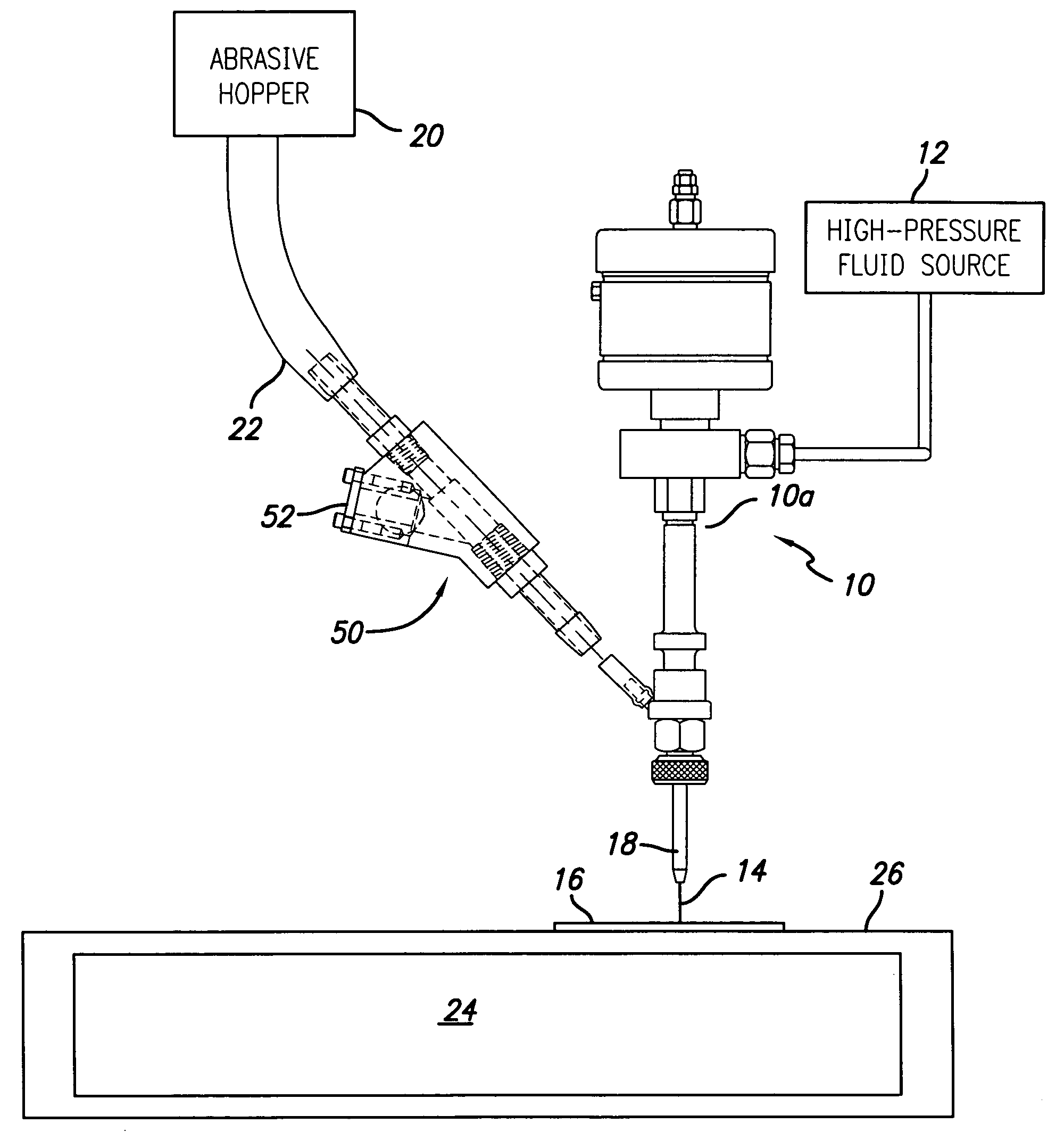

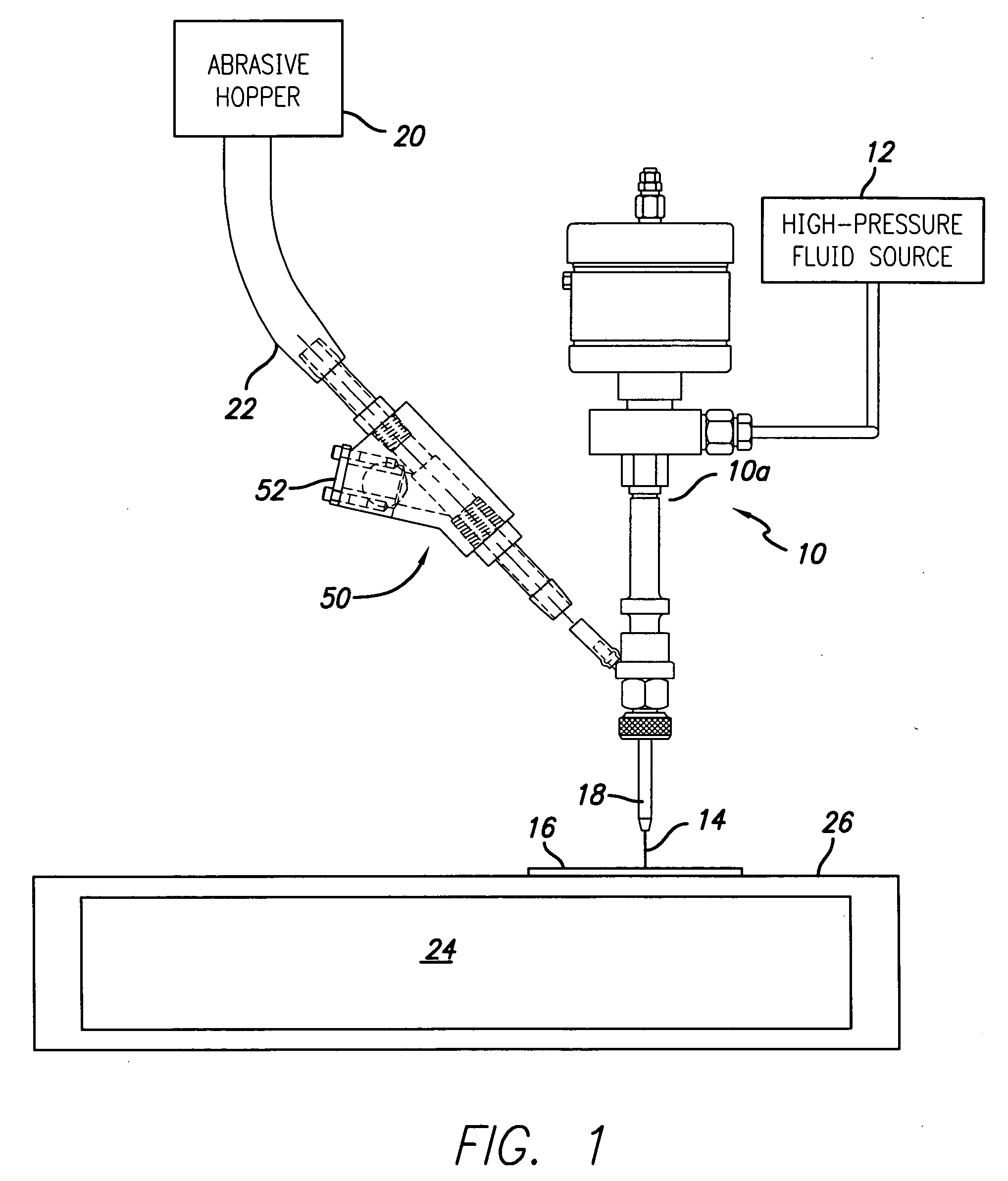

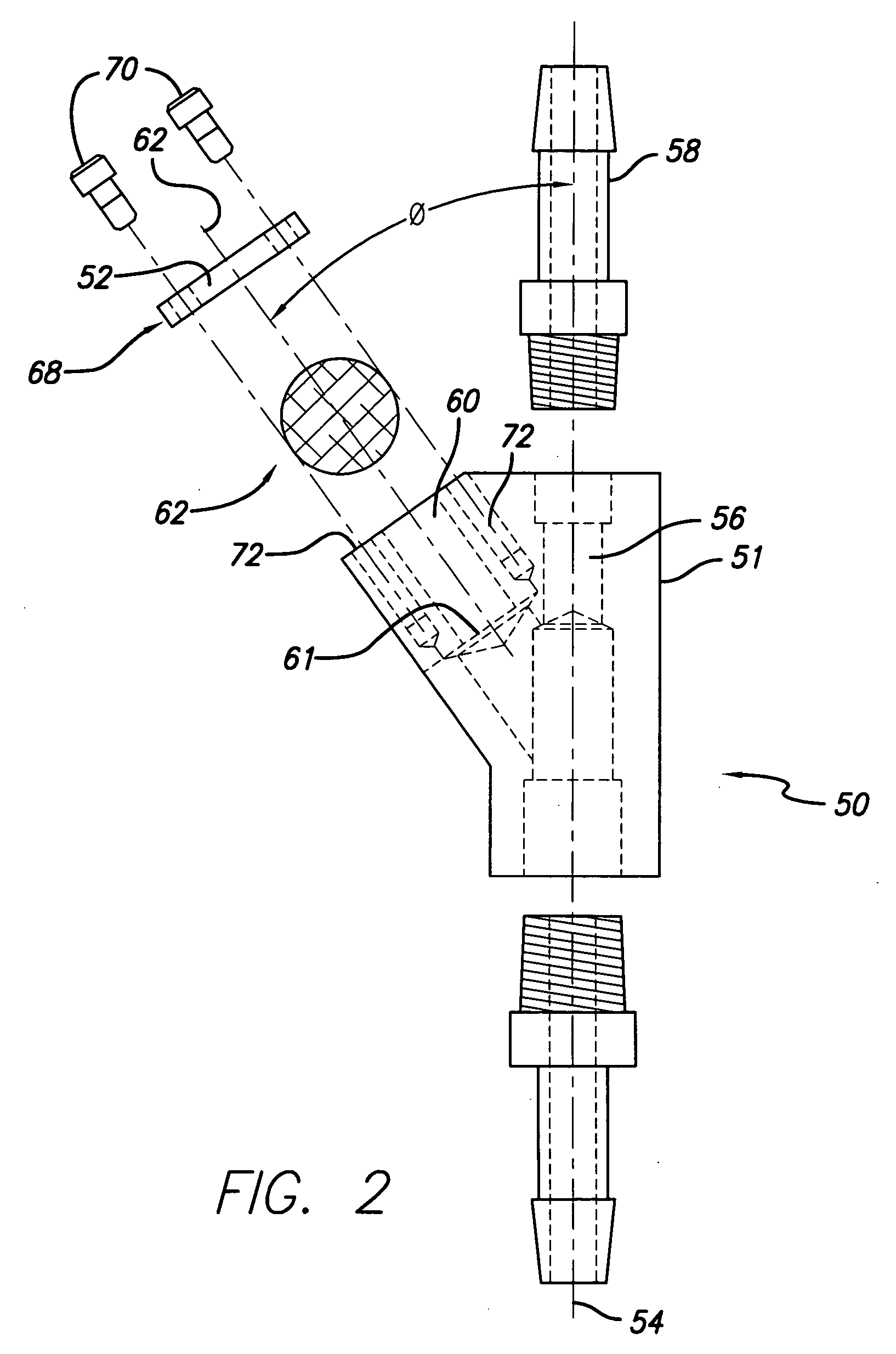

Vented cutting head body for abrasive jet system

An abrasive waterjet assembly has a cutting head assembly with a venting system for controlling the flow of abrasive within a cutting head body. The venting system includes one or more vents for regulating the pressure within a cutting head body to minimize, limit, or substantially eliminate any abrasive from reaching a jewel orifice. The vents include venting ports positioned between an orifice mount that retains the jewel orifice and a mixing region in which abrasive is mixed with a fluid jet produced by the jewel orifice. An isolator retained in the cutting head body further inhibits the upstream flow of abrasive, if any.

Owner:FLOW INT

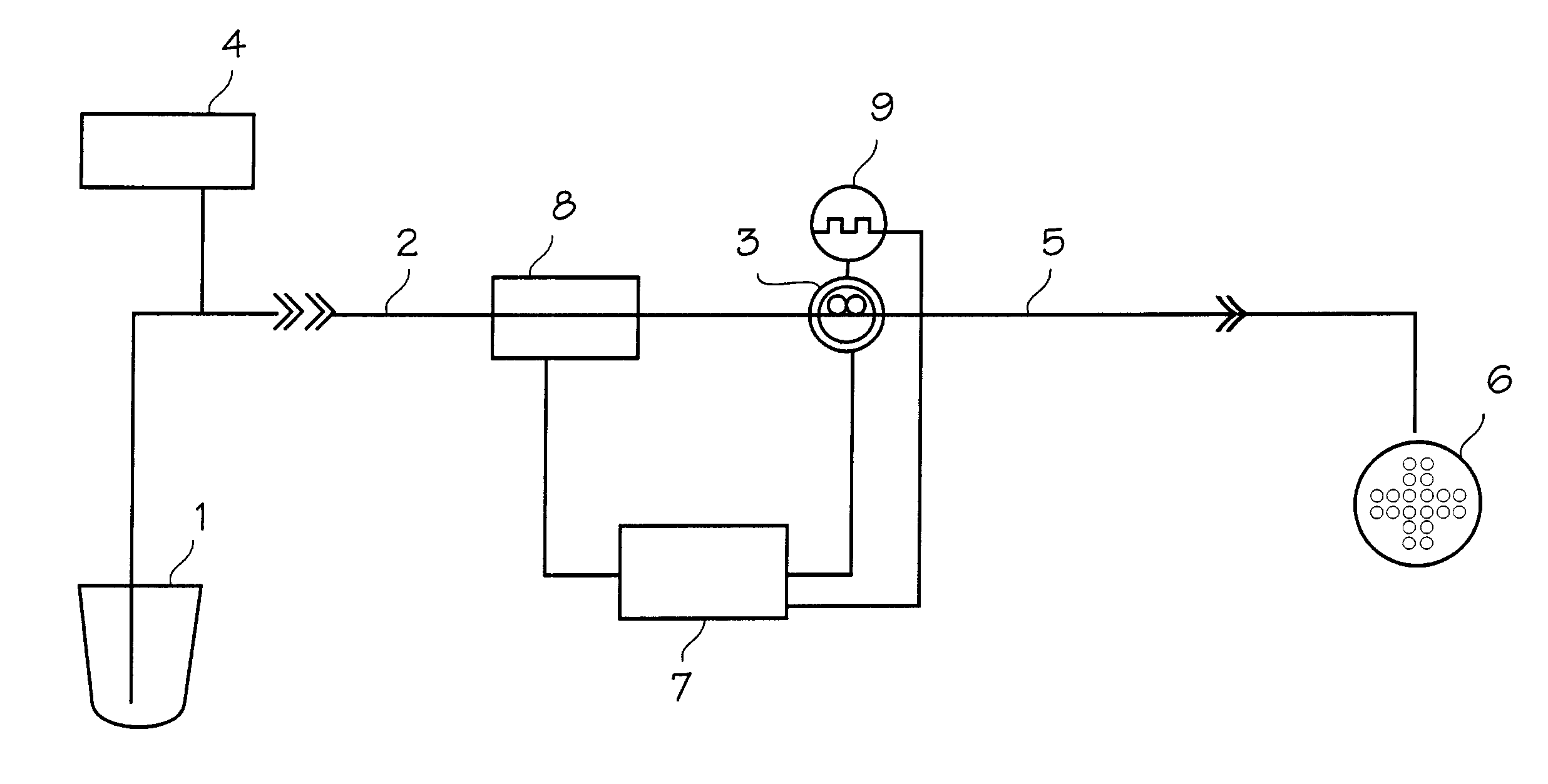

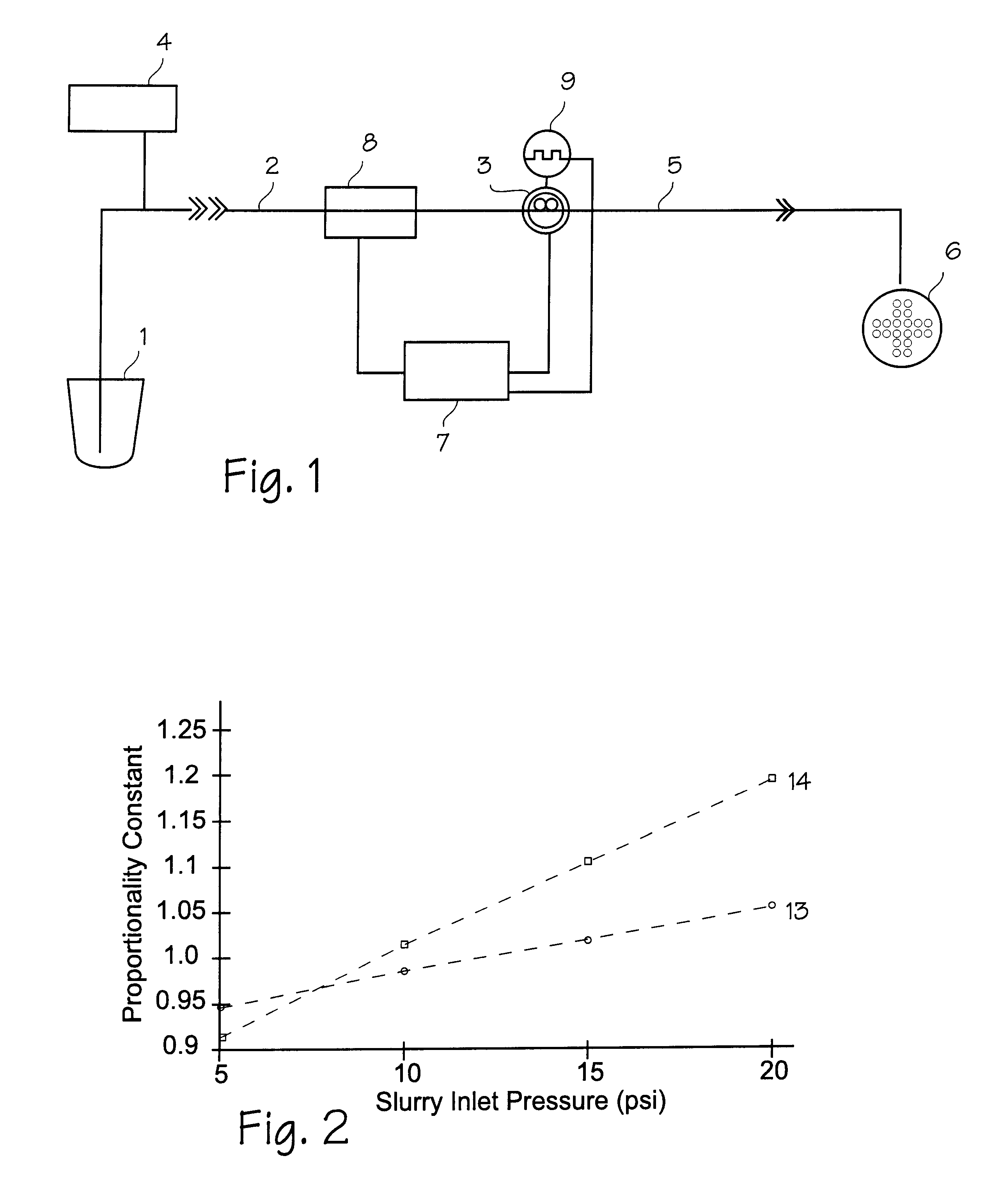

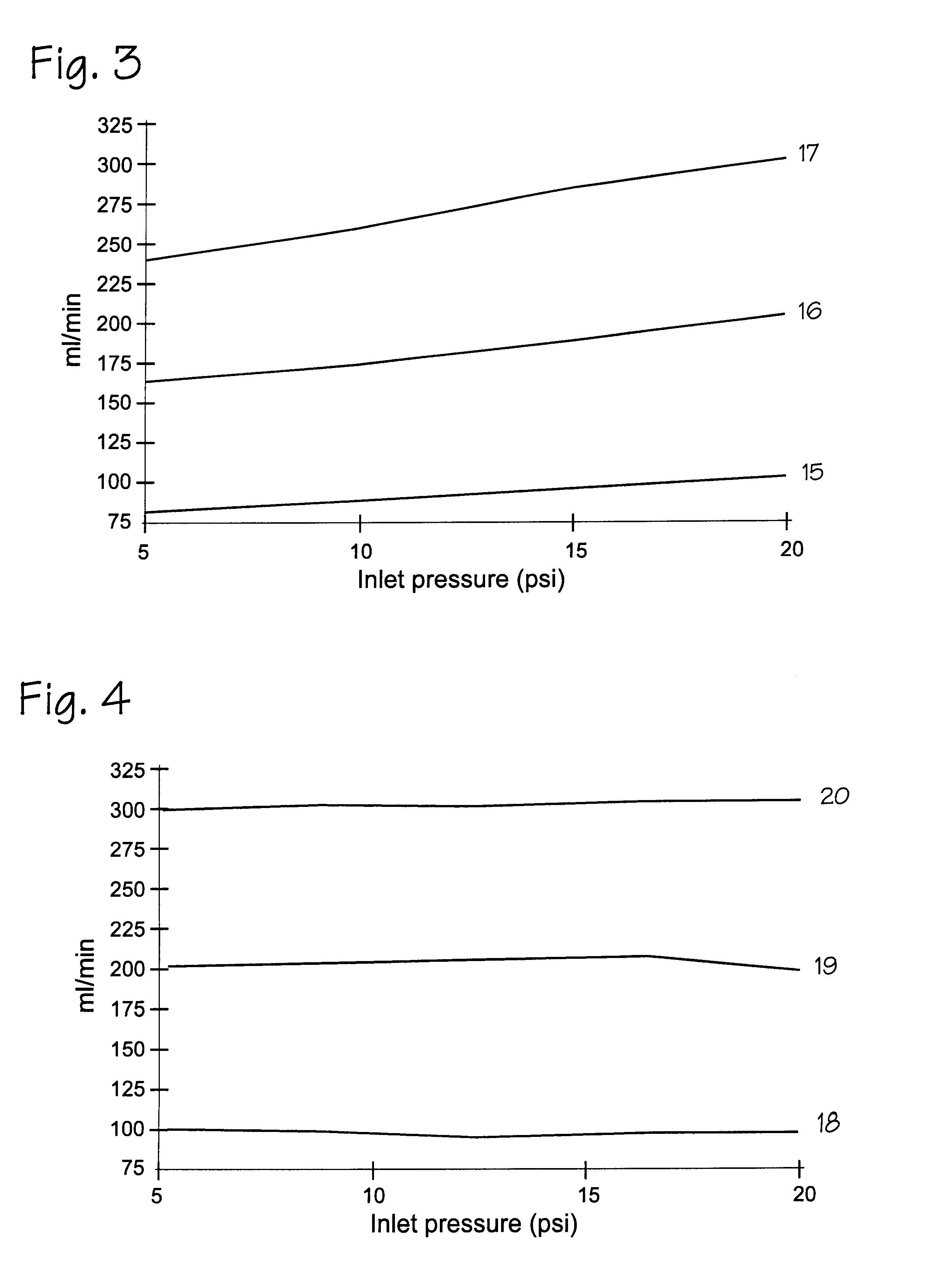

Slurry pump control system

A CMP slurry pumping system which uses the slurry pump inlet pressure as input to the pump controller, and adjusts pump speed to account for variations in inlet pressure.

Owner:REVASUM INC +1

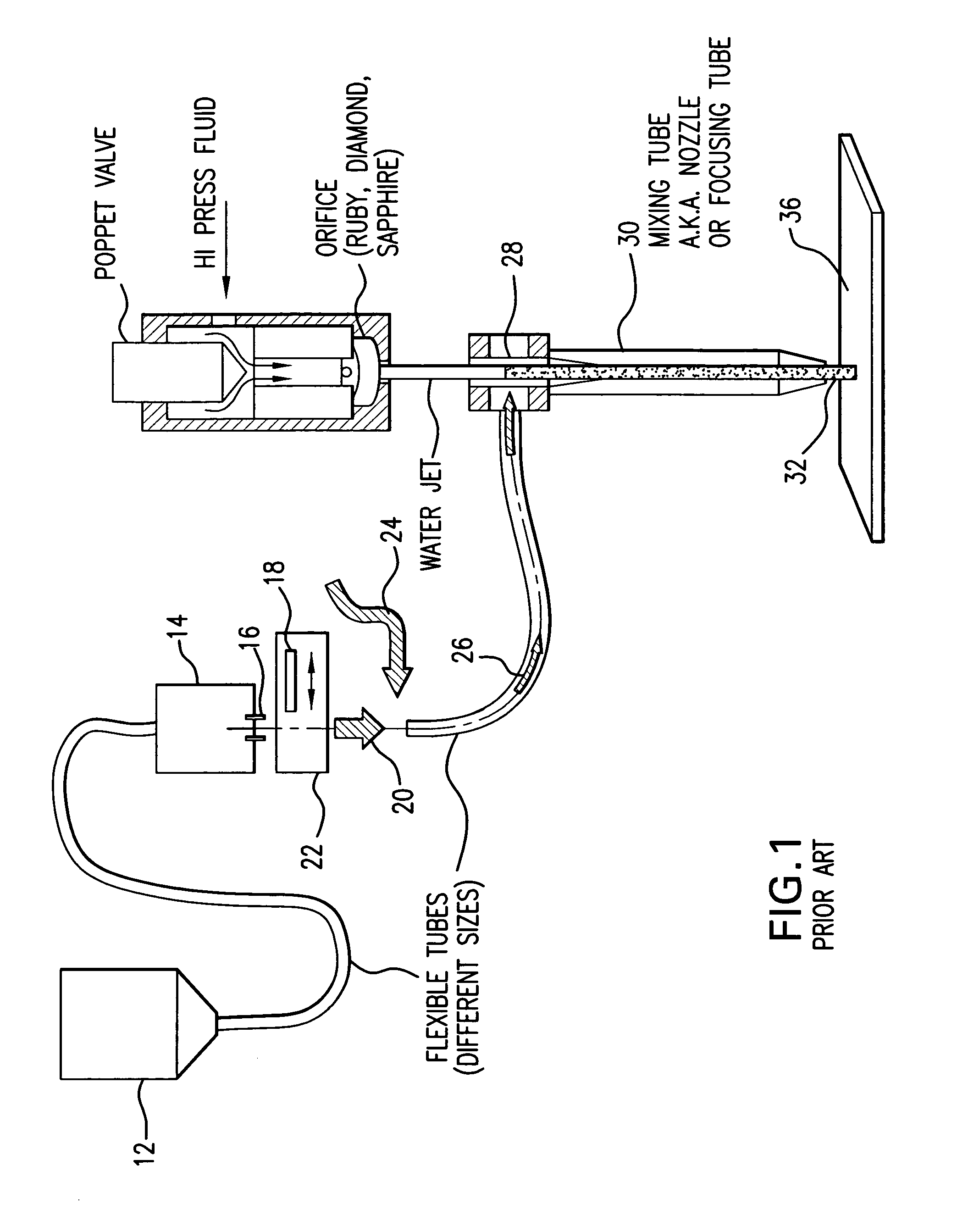

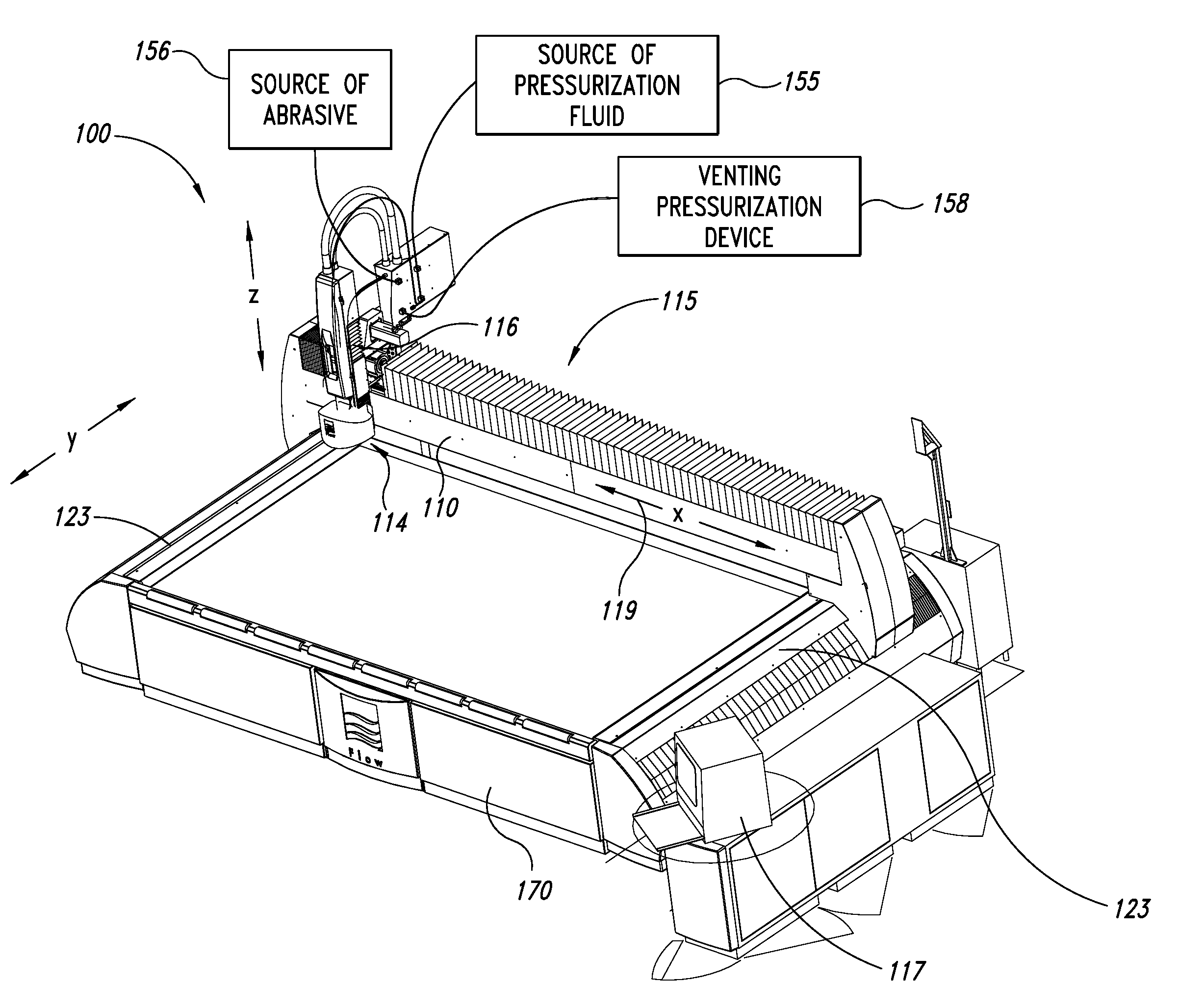

Processes and apparatuses for enhanced cutting using blends of abrasive materials

ActiveUS20100124872A1Composition is limitedBlast gunsControlling ratio of multiple fluid flowsEngineeringDelivery system

A waterjet system selectively produces fluid jets for water jet cutting or abrasive jets for abrasive-waterjet-cutting. The abrasive materials in the abrasive jet are determined based on the properties of the workpiece. The waterjet system includes an abrasive delivery system that is capable of delivering either a single abrasive or a plurality of abrasives as an abrasive blend, to a cutting head assembly. The cutting head assembly entrains the abrasive into a fluid jet to form an abrasive jet.

Owner:FLOW INT

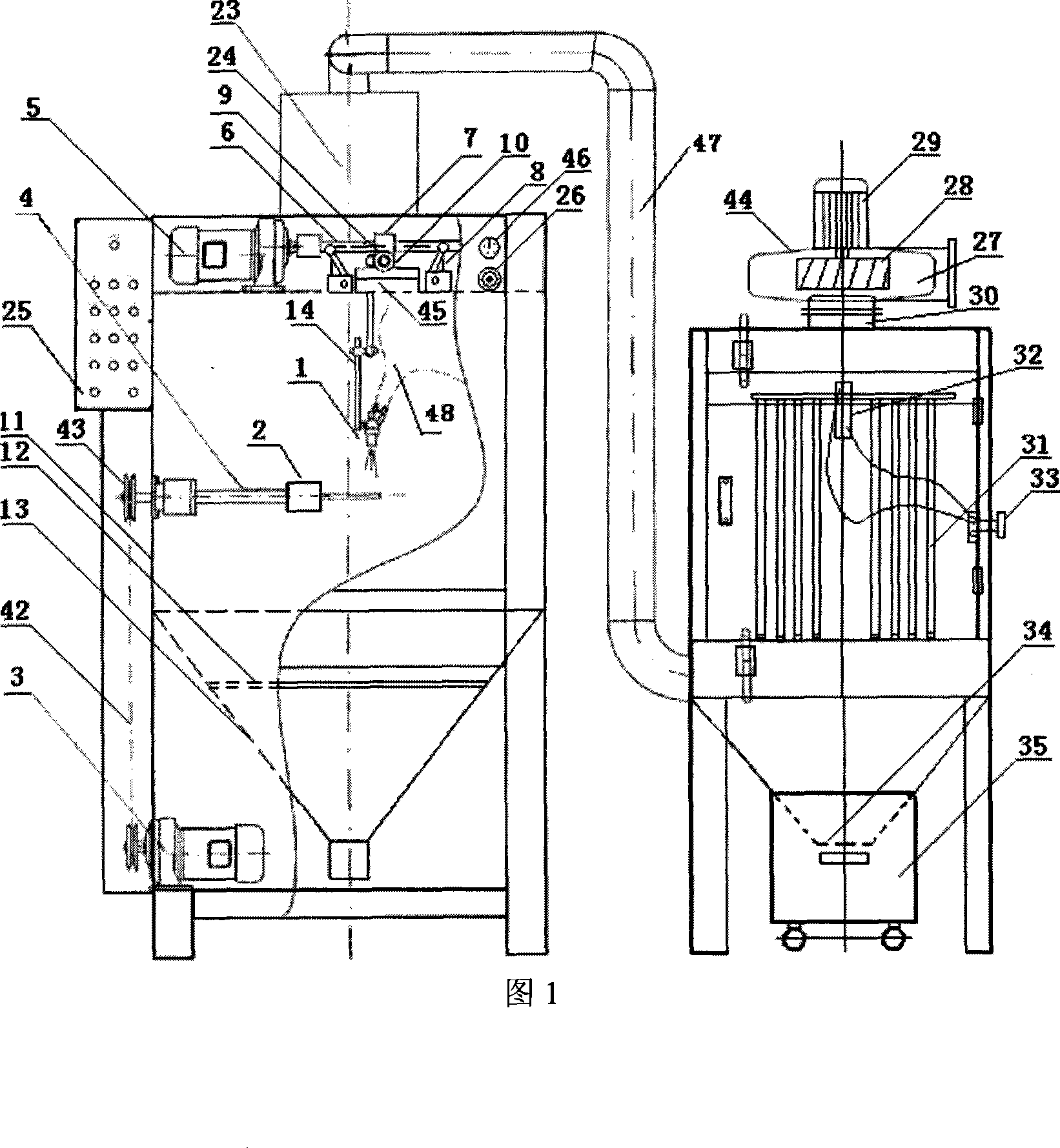

Automobile gear ruggedization shot-blasting machine

InactiveCN101157203AReduce energy consumptionImprove work efficiencyImpeller wheelsBlast gunsGear wheelEngineering

The invention belongs to equipment for cleaning the surface of a machine element by utilizing a shot blasting method, in particular to an automotive gear enhanced shot blasting machine. According to the technical proposal provided by the invention, the shot blasting machine is arranged on a shot blasting cleaning chamber. The invention is characterized in that a suspend conveyer installed on a supporting bracket is arranged at the upper part of the shot blasting cleaning chamber, the suspend conveyer is in a sealed state and circled around the shot blasting cleaning chamber, and one section passes through the shot blasting cleaning chamber, a plurality of rotating racks which can rotate under the driving of the suspend conveyer are suspended on the suspend conveyer, a curtain separator is arranged above / on the shot blasting cleaning chamber, a chamber hoisting gear is arranged on the flank of the shot blasting cleaning chamber, and a worm conveyer is arranged at the bottom of the shot blasting cleaning chamber. The input end of the curtain separator is connected with the output end of the chamber hoisting gear, and the output end of the worm conveyer is connected with the input end of the chamber hoisting gear. The invention can improve the effect of the shot blasting cleaning and the quality of the product.

Owner:无锡国达机械设备有限公司

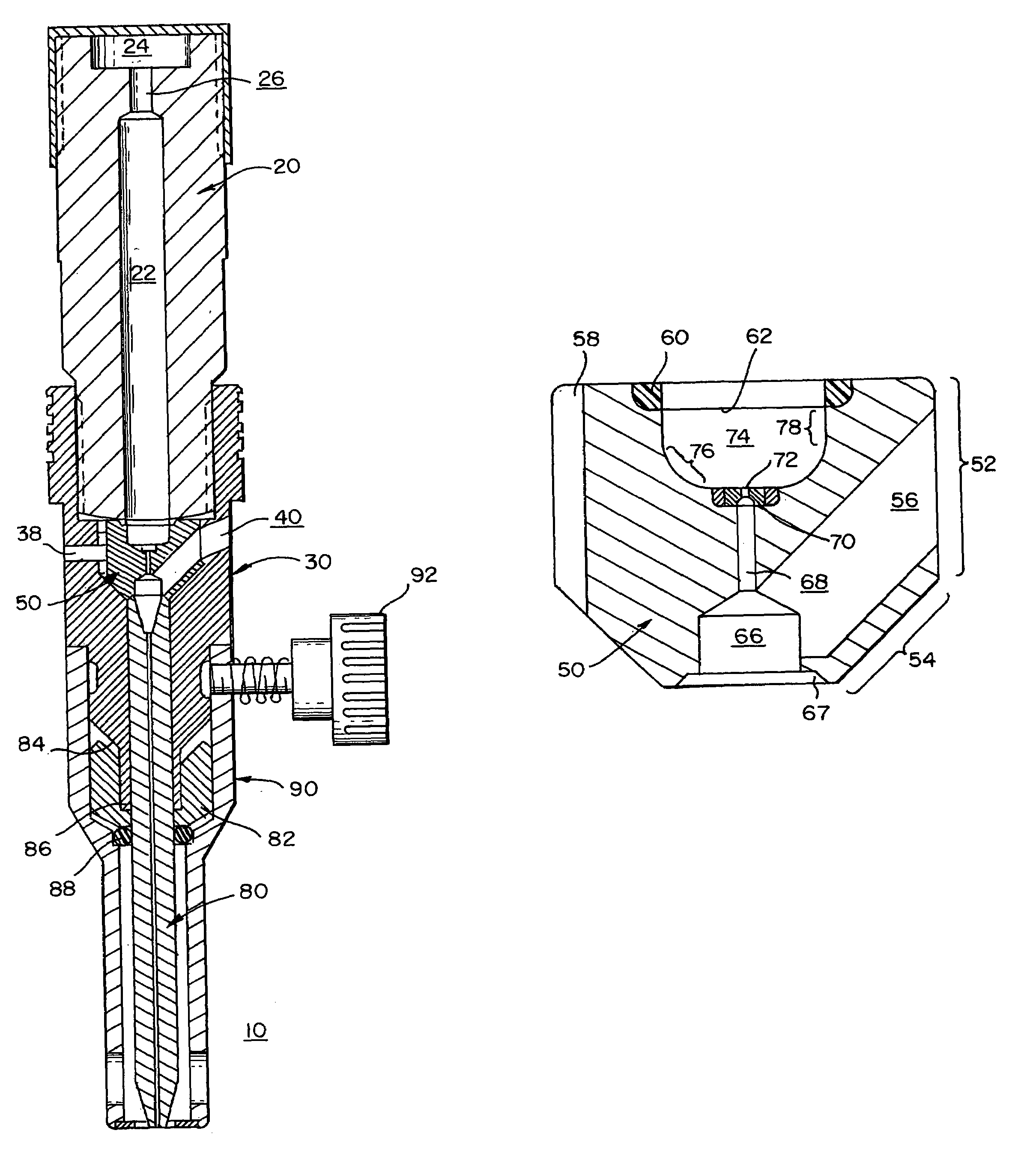

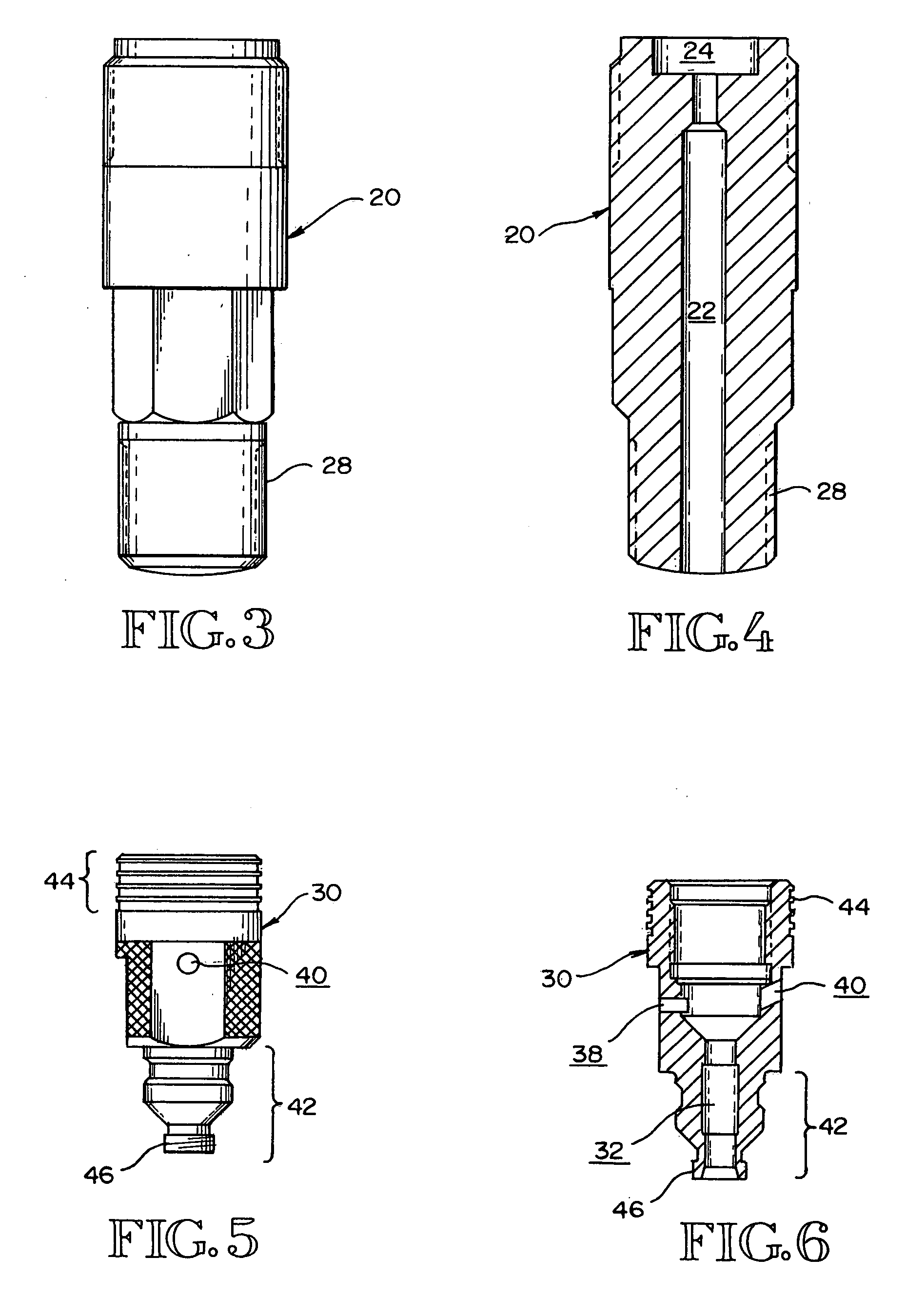

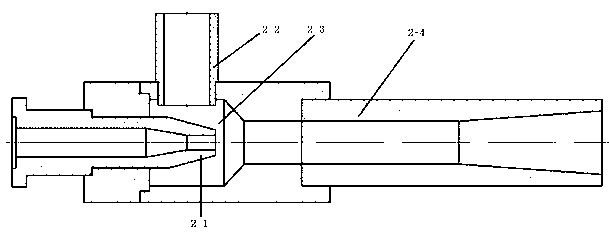

Orifice body with mixing chamber for abrasive water jet cutting

InactiveUS6932285B1Simple designImprove operationDrill bitsBlast gunsUltra high pressureHigh pressure

An improved orifice assembly for use with an ultra high pressure fluid jet cutting apparatus is disclosed. The improved orifice assembly generally includes an orifice body defining a central bore, a high pressure inlet cavity located at an upstream portion of the body, a mixing cavity located at a downstream portion of the body, and an abrasive material inlet bore that is in direct communication with the mixing cavity. The inlet or high pressure cavity preferably has a cylindrical cross section at the side wall portion and a generally flat bottom wall, with a constant radius transition portion between the side and bottom walls. A jeweled orifice is preferably located at the bottom wall and forms a portion thereof. A chamfer at the downstream portion of the mixing chamber permits appropriate coaxial alignment of a mixing tube with the jeweled orifice so as to preserve proper fluid flow characteristics. In addition, the incorporation of a soft seal between the mating surfaces of the inlet body and the orifice assembly permit easy user removal of these components from a cutting jet system.

Owner:SILICON VALLEY BANK

Abrasive flow micropore polishing device and polishing process thereof

InactiveCN104440584AAchieve polishReduce roughnessAbrasive feedersAbrasive machine appurtenancesCavitationWear particle

The invention discloses an abrasive flow micropore polishing device, comprising a clamping tool, a base plate, a cavity, a separation device, a laser high-transparency protective lens, a laser, a focusing lens, a flow guiding passage and a one-way valve, wherein the clamping tool is used for clamping a workpiece and locating micropores of the workpiece; the base plate is arranged on the clamping tool; the cavity is arranged in the base plate and the clamping tool and correspondingly communicate with the micropores; the separation device is arranged in the cavity and divides the cavity into a cavitation cavity and a liquid storage cavity; the laser high-transparent protective lens covers the cavitation cavity; the laser can generate laser beams facing to the cavitation cavity; the focusing lens is arranged between the laser and the laser high-transparent protective lens and is used for focusing laser beams in the cavitation cavity; the flow guiding passage can guide deionized water into the caviation cavity; the one-way valve is arranged in the flow guiding passage. According to the abrasive flow micropore polishing device, lasers are focused to cavitate the deionized water to form a large local pressure and impact the separation device, and the abrasive fluid flows and is pushed into the micropores at high speed and rubs the pore walls of the micropores to reduce the roughness of the inner surface of the micropores, so as to achieve the polishing on the micropores. The invention further discloses an abrasive flow micropore polishing process for highly effectively and ultra-precisely polishing the micropores.

Owner:GUANGDONG UNIV OF TECH

Shot peening machine for processing surface deformation strengthening treatment to magnesium alloy sample

InactiveCN101214633AGuaranteed concentricityGuaranteed parallelismImpeller wheelsBlast gunsAir compressionAbrasive blasting

The present invention relates to a device in the technical field of material processing, in particular to a peener which carries out the surface deformation strengthening process on magnesium alloy samples. The present invention comprises a main peening system, an upper whirlwind separation system, a dedusting system, an air compression system and an electric system, wherein, the upper whirlwind separation system is positioned on the upper end of the main peening system, the lower part of the upper whirlwind separation system is communicated with the main peening system, the upper part is connected with the dedusting system, which is positioned outside the main peening system, the air inlets of both the dedusting system and the main peening system are connected with the air compression system, and the electric system is connected with the main peening system, the upper whirlwind separation system, the dedusting system and the air compression system. The present invention can conveniently assemble and disassemble the samples of the shaft class, the range of the generated peening strenghth is wide, the effect and uniformity of peening is good, and moreover, pollution can be prevented.

Owner:SHANGHAI AIERSI LIGHT ALLOY

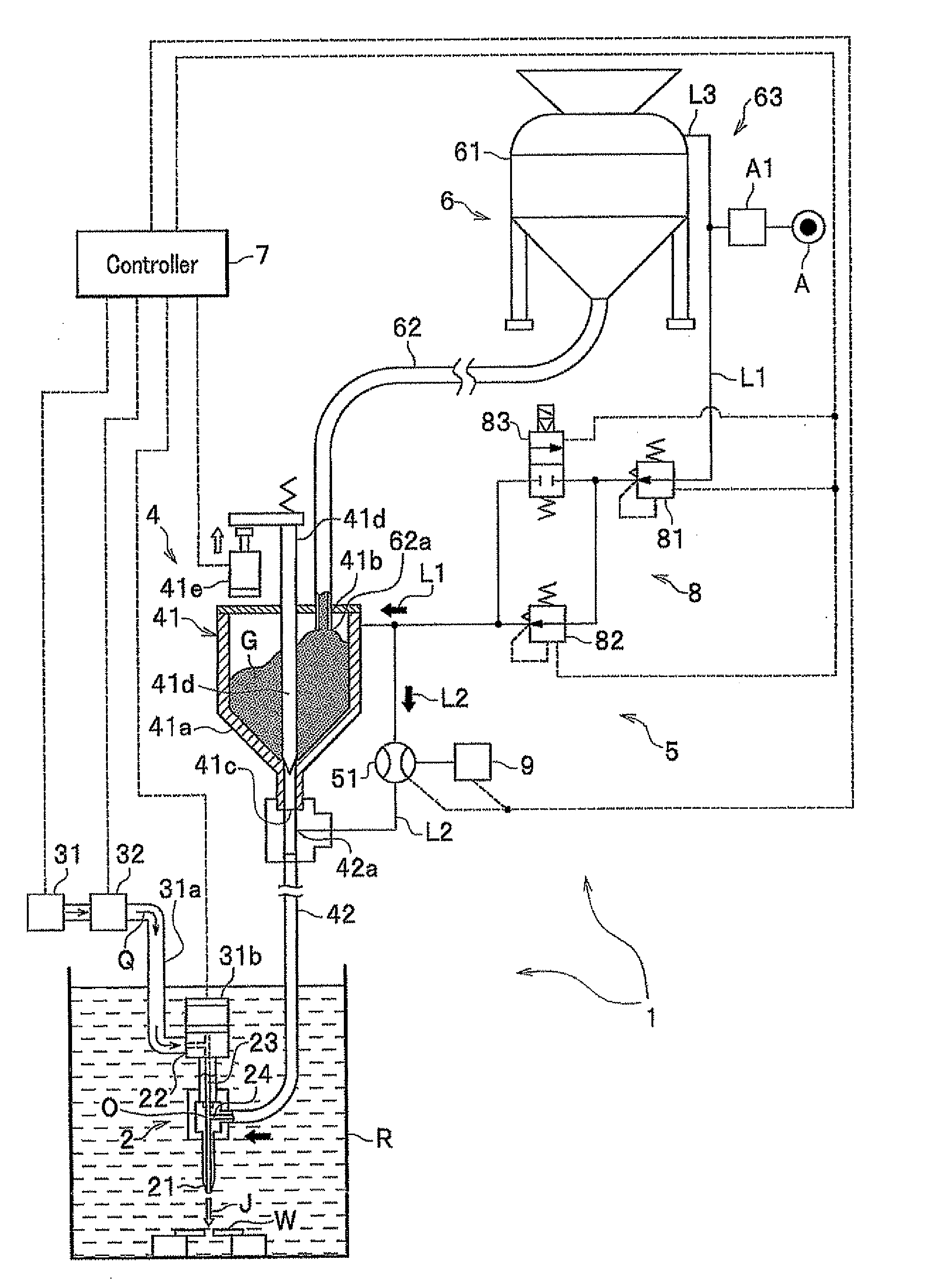

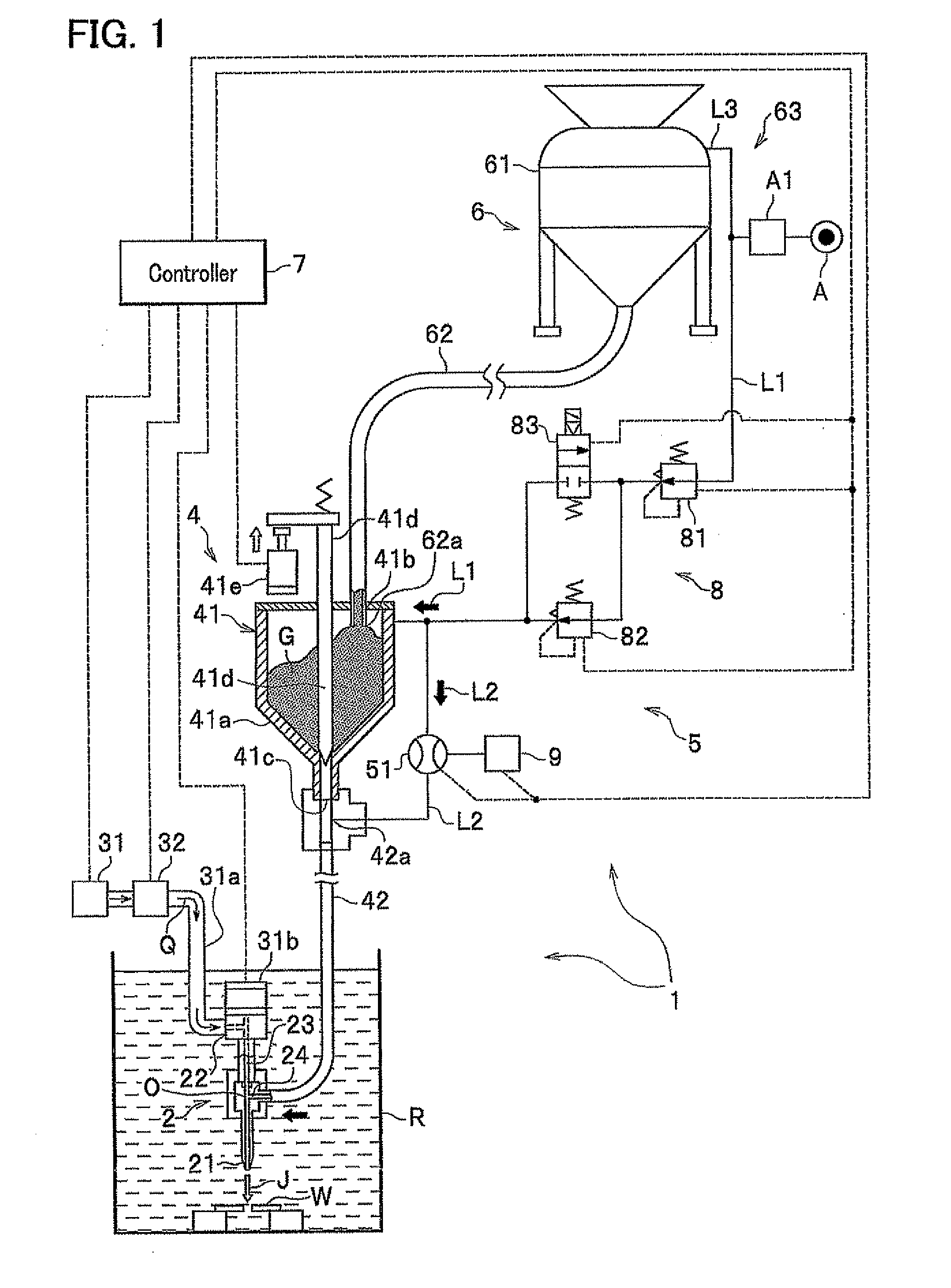

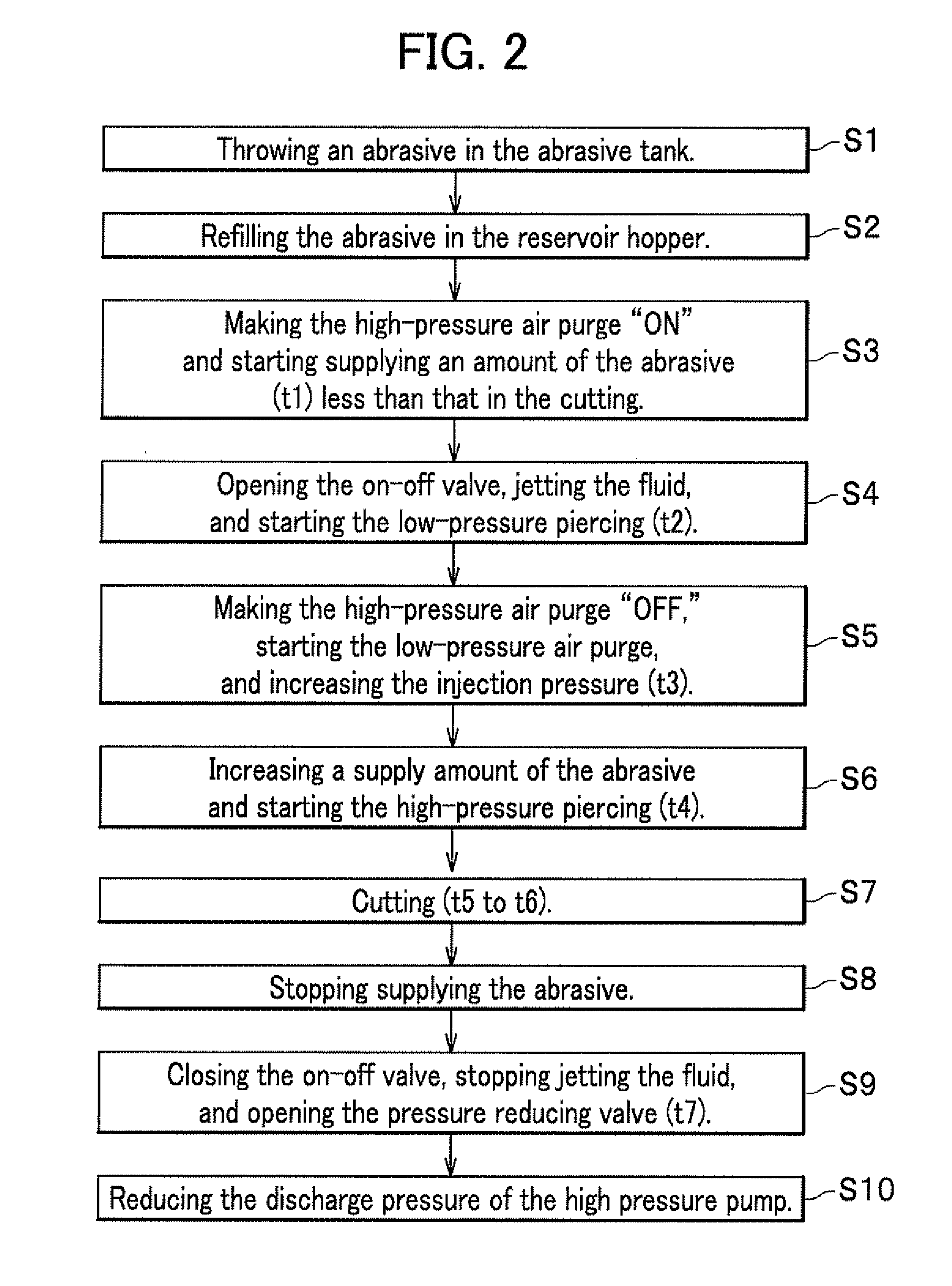

Abrasive water jet processing machine

InactiveUS20120196516A1Stable supplyPrevent backflowAbrasive feedersAbrasive machine appurtenancesInjection pressureEngineering

An abrasive water jet processing machine for jetting a fluid and performing a cutting includes a fluid supply device, an abrasive supply device, an injection pressure controller, wherein the abrasive supply device includes a reservoir hopper consisting of a pressure vessel for reserving the abrasive, an abrasive supply tube for communicating with the reservoir hopper and the nozzle, and an air purge device for supplying compressed air to the abrasive supply tube and the reservoir hopper; the injection pressure controller performs a two-stage control of controlling injection pressure in a piercing; and the air purge device includes a flow pressure controller for controlling flow pressure of compressed air passing through the abrasive supply tube, wherein the flow pressure controller controls the flow pressure in the piercing to be higher than that in the cutting.

Owner:SUGINO MACHINE

Fluidized particle abrasion device with precision control

Owner:CRYSTAL MARK

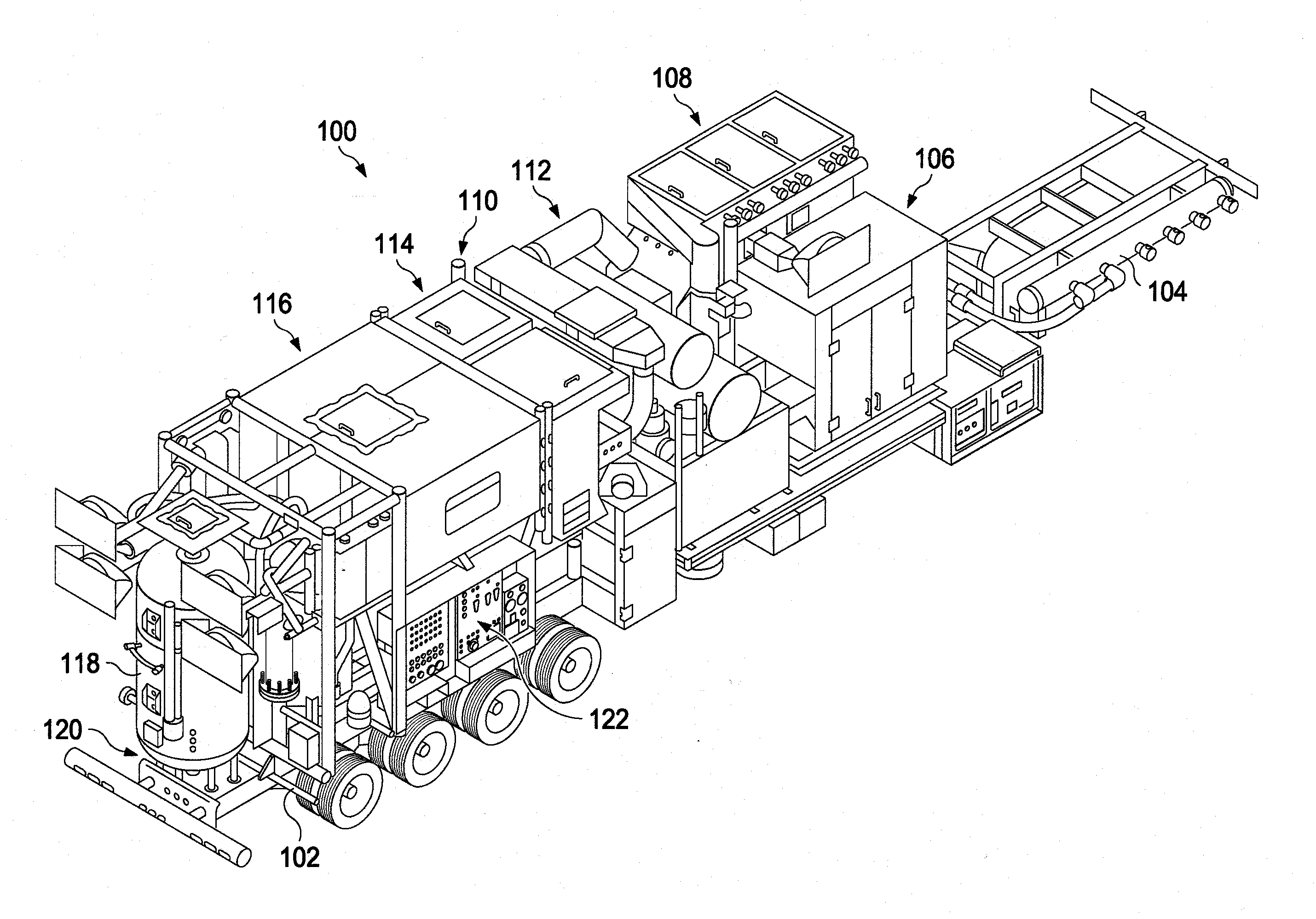

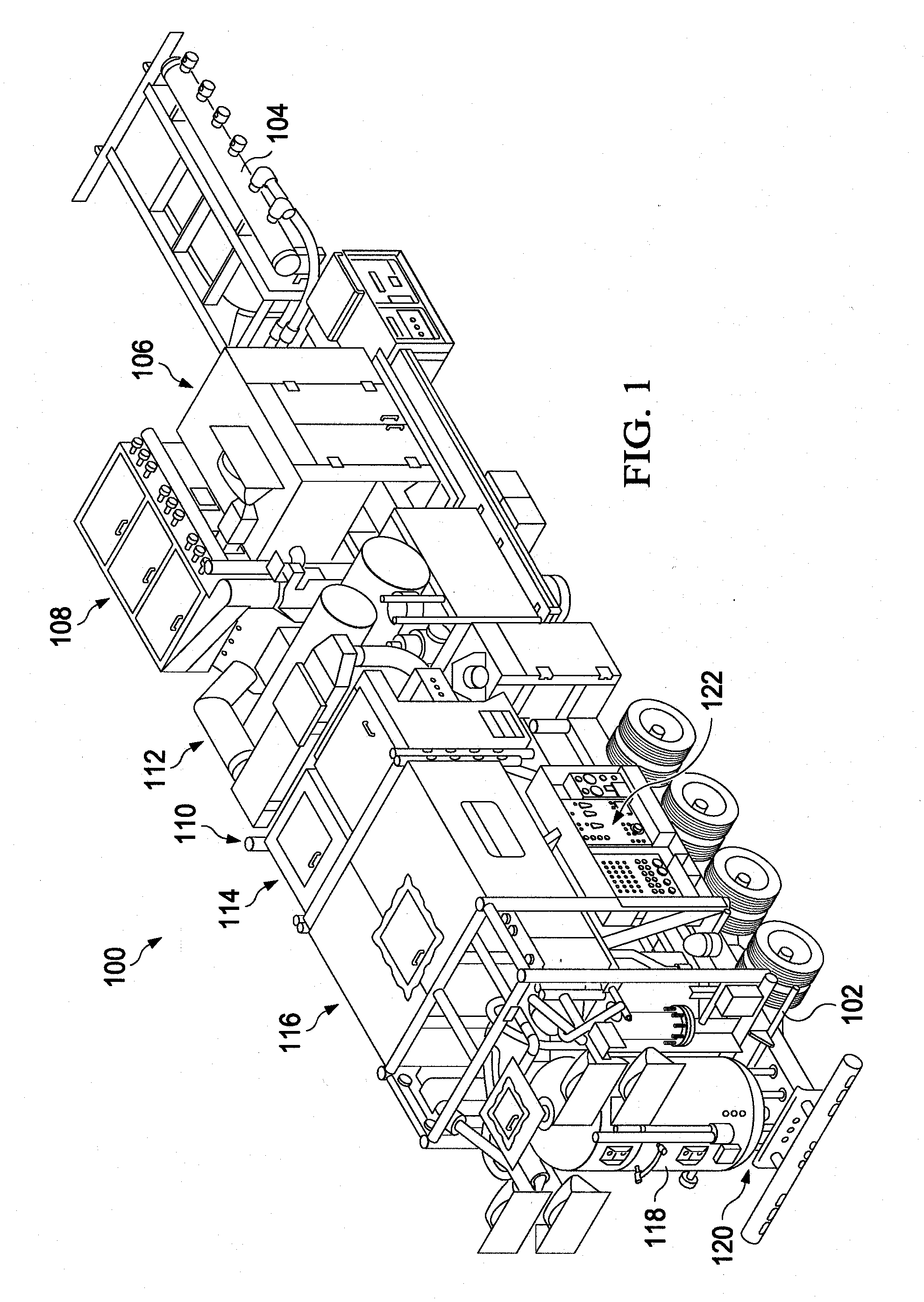

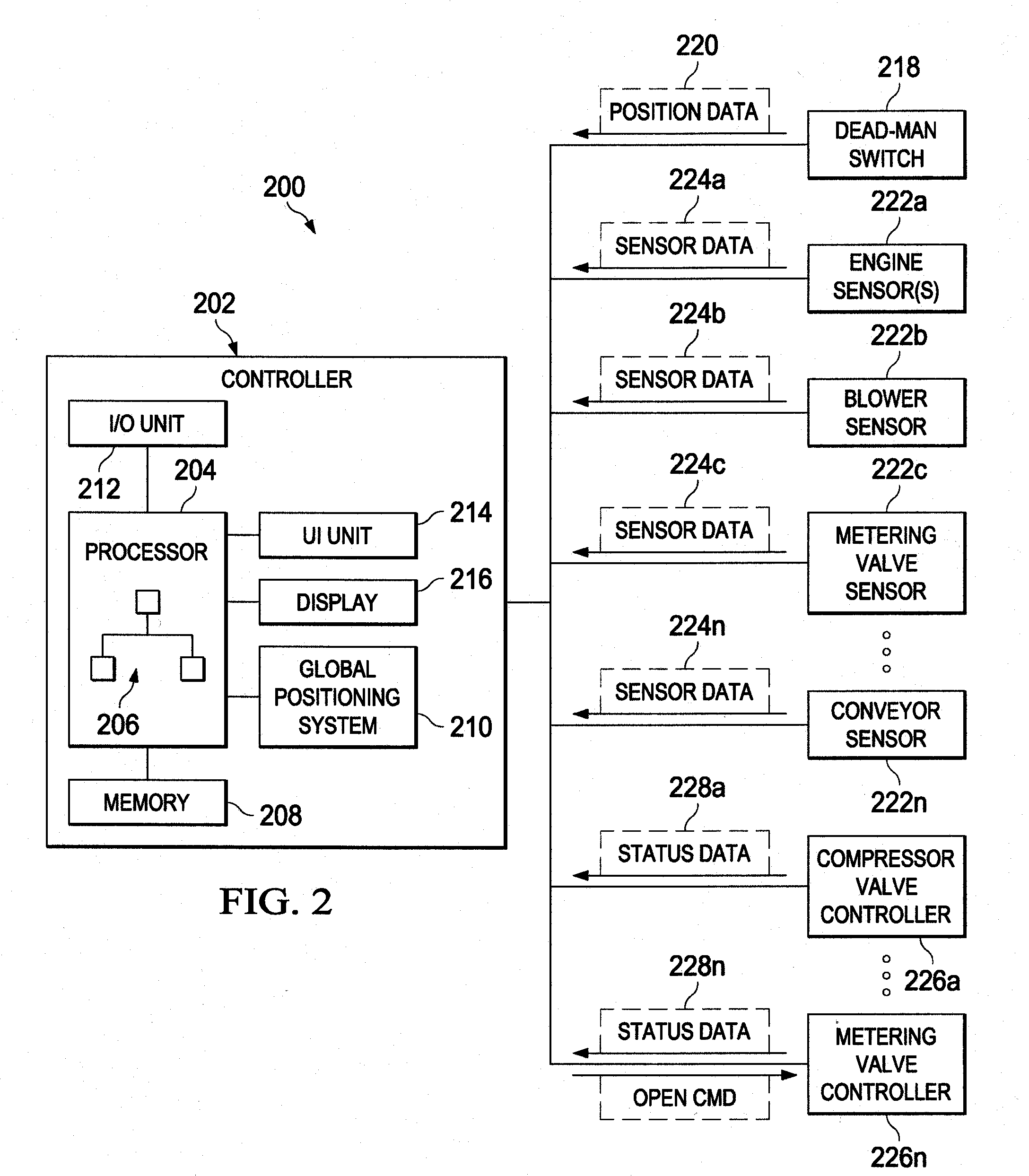

System and method for managing and maintaining abrasive blasting machines

ActiveUS20100211429A1Improve efficiencyReduce downtimeRegistering/indicating time of eventsData processing applicationsAbrasive blastingBusiness efficiency

A system and method for managing abrasive blasting may include timing duration of blast media being blown in performing abrasive blasting using an abrasive blasting machine. Time duration that an operator worked in association with the duration of the blast media being blown may be received. A blasting efficiency ratio may be computed based on the duration of the blasting media being blown and duration of that the operator worked. The blasting efficiency ratio may be displayed to a user.

Owner:ROTO GRIT LLC

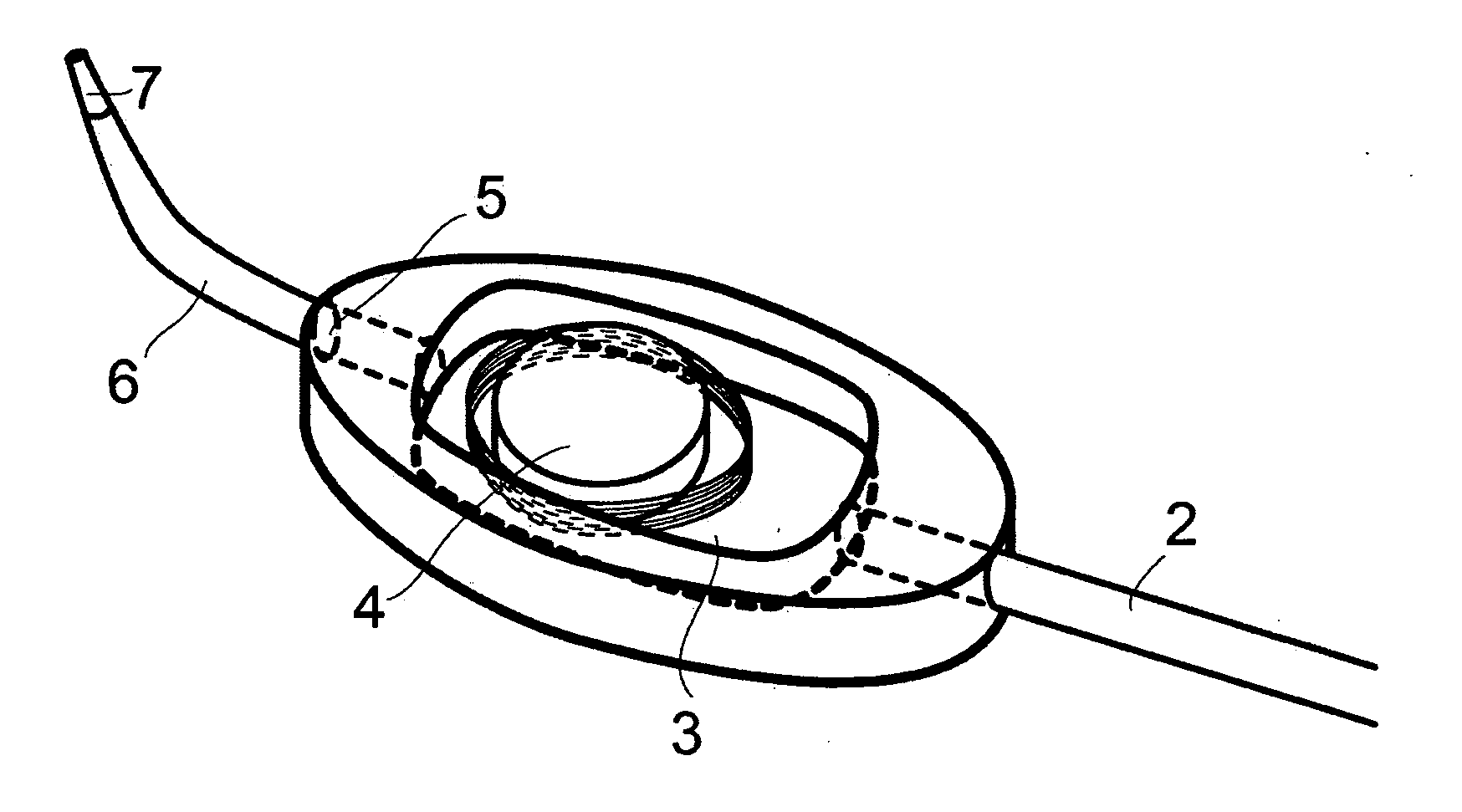

Toothcleaning Device

Equipment for daily dental care: teeth are cleaned by water jet with admixed softly abrasive media for the dissolution of plaques. A particular mixing chamber for the transfer of the ingredients from tabs may be branched either to by passes on faucets or showering mixing taps or to hereditary water jet pumping systems. Pressure and spray characteristics of the jet can be adjusted with a spiral nozzle.

Owner:DENTAL CARE INNOVATION

Abrasive automatic feeding device and using method

ActiveCN103100984AAchieve pure water jetRealize automatic feedingAbrasive feedersHigh pressure waterHigh pressure

The invention discloses an abrasive automatic feeding device for feeding abrasives through mixing abrasive water jet forward. The device is mainly composed of a hopper, a jet flow pump, a high-pressure abrasive tank, a valve seat installed on the upper part of the high-pressure abrasive tank and a mixing cavity installed on the lower part of the high-pressure abrasive tank; the valve seat is connected with a sand adding pipeline, a high-pressure water pipeline, a low-pressure water pipeline and a safety valve; and the mixing cavity is also connected with the high-pressure water pipeline, an abrasive pipeline and an abrasive water jet flow pipeline. Each flow inlet and each flow outlet as well as each functional component are connected through high-pressure pipelines which are internally provided with high-pressure ball valves, throttling valves and pneumatic ball valves for controlling the pipelines; the jet flow pump is arranged between a feeding pump and the sand adding pipeline; and through the negative pressure effect of the jet flow pump, the abrasive adding operation of the high-pressure abrasion tank is realized. Through the connection and disconnection combination of the high-pressure ball valves, throttling valves and pneumatic ball valves, the device can respectively achieve the three kinds of operations including pure water jet flow, automatic feeding and abrasive water jet flow, is simple in structure, is convenient to operate, is safe and reliable, and can be widely applied to a forward mixing abrasion water jet flow generation system.

Owner:CHONGQING UNIV

Disposable, multi-conduit particulate matter propelling apparatus

A disposable apparatus for propelling particulate matter against a surface of a target material includes, a mixing chamber having a chamber wall, a multi-conduit receiving port, a propellant-gas receiving conduit, a discharge conduit, and a flow through conduit. The gas delivery conduit extends from the propellant-gas receiving port into the chamber, a mixture discharge conduit extending from the mixture discharge port into the chamber, and a quantity of particulate matter inside the chamber. The flow through conduit(s) provide a means for transferring flow from the multi-conduit receiving port through the discharge wall to exit proximate the exit of the discharge port. A method is provided for propelling particulate matter against a surface of a target material using the above-described apparatus, including the steps of delivering a stream of gas into the air delivery conduit and into the mixing chamber from the gas source, so that the gas stream blows through the quantity of particulate matter, causing the particulate matter to mix with the gas stream, forming a gas and particle mixture, and discharging the mixture through the discharge conduit and the discharge port to strike the surface of the target material. The method further provides a means for transferring a second (or more) flow through the apparatus. The multiple flows can be externally mixed to increase the versatility of the apparatus. The end of the discharge conduit(s) can be designed to modify the discharge flow of the medium.

Owner:HERTZ REUBEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com