Automobile gear ruggedization shot-blasting machine

A technology of automobile gears and shot blasting machines, which is applied in the direction of impellers, abrasive jetting machine tools, used abrasive processing devices, etc., can solve the problems of high price, low work efficiency, and large energy consumption, and achieve high product quality and work efficiency. High efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

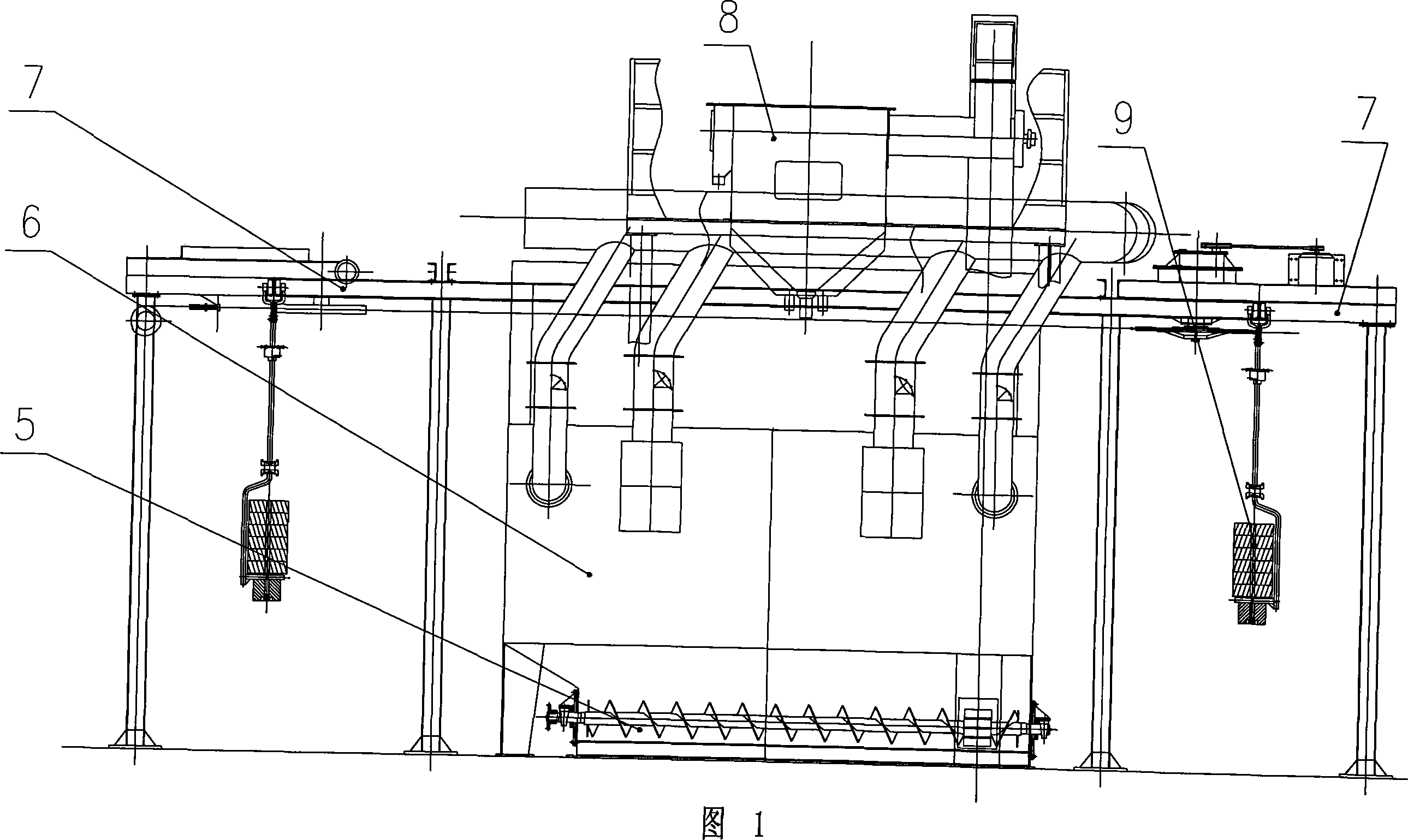

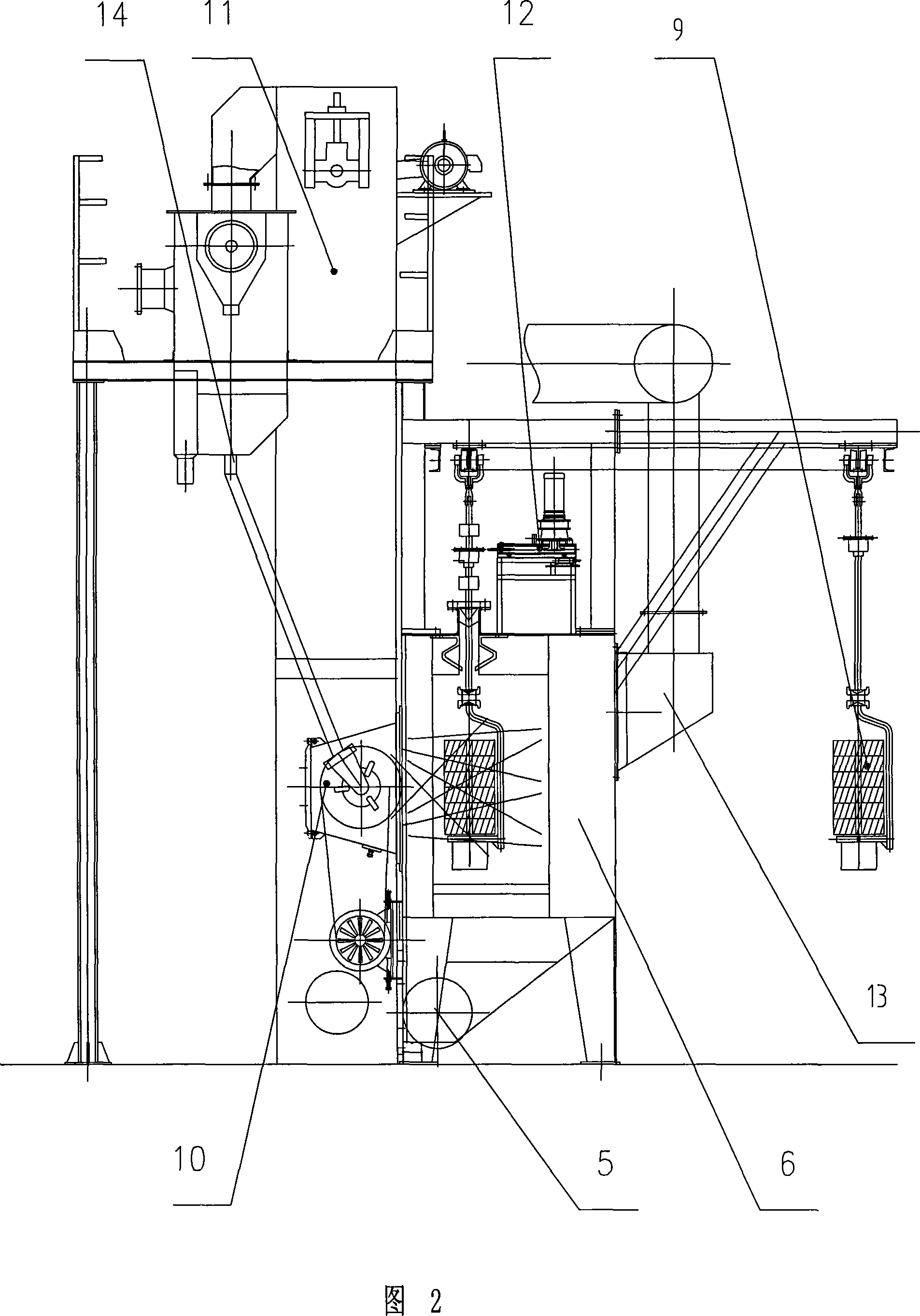

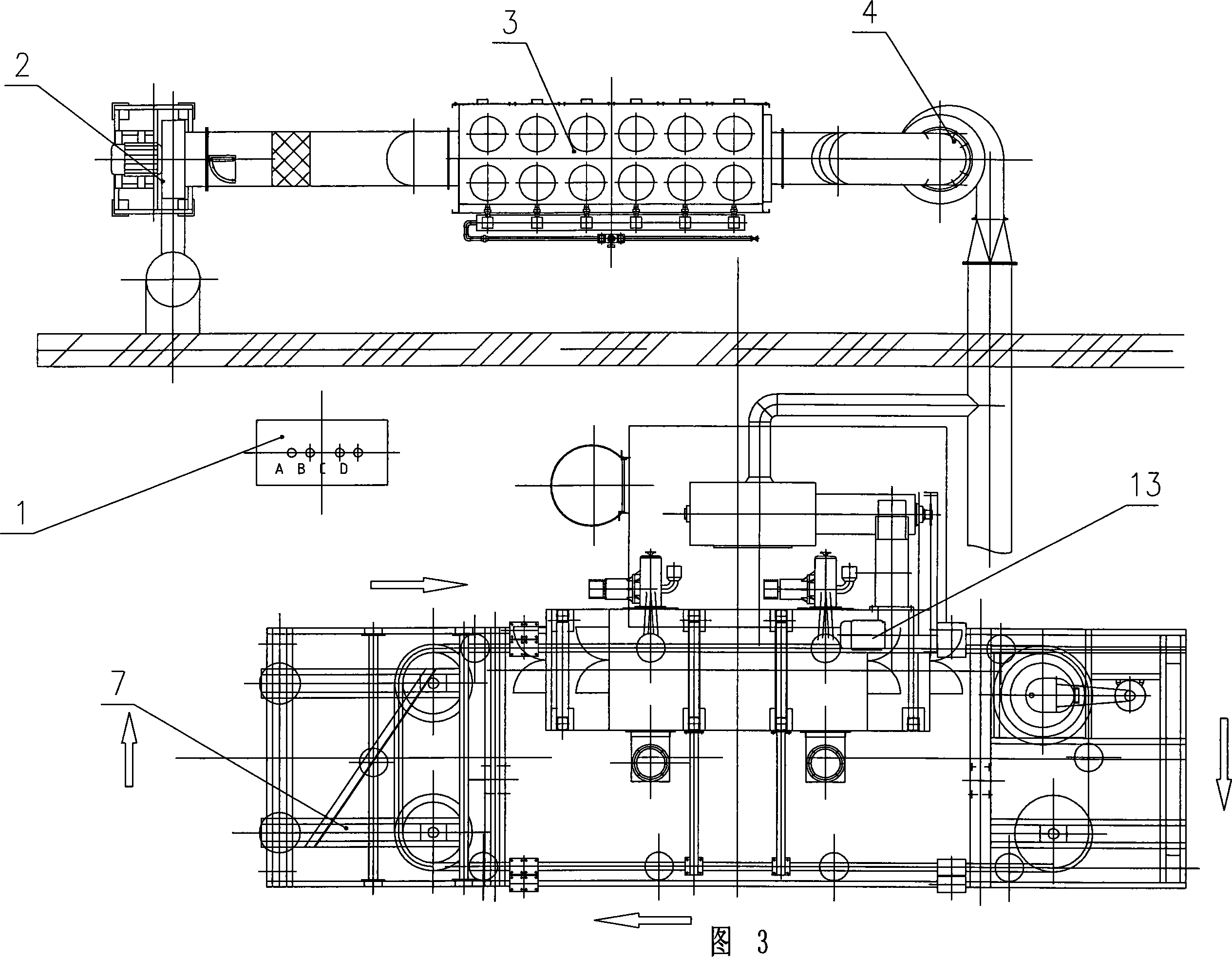

[0018] In the figure: 1. The electric control cabinet is used to control the actuators and monitor the whole process of shot blasting; 2. The fan is used for the ventilation and dust removal of the filter cartridge dust collector, cyclone dust collector, shot blasting cleaning box, and curtain separation. The selector provides air source; 3. Filter cartridge dust collector, which filters fine dust, so that the gas discharge meets the national discharge standard; 4. Cyclone dust collector, large particles of dust are discharged out of the cylinder after rapid cyclone settlement; 5. Spiral conveying 6. Shot blasting room, the workpiece is impacted by projectiles in the shot blasting room to achieve the effect of cleaning and strengthening the tooth surface; 7. Suspension conveying 8. Curtain sorter, the projectiles after impact form a curtain through the sorter, and the qualified projectiles are separated from the broken particles and oxide skin by suction. Separation; 9. Rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com