Patents

Literature

290results about "Impeller wheels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

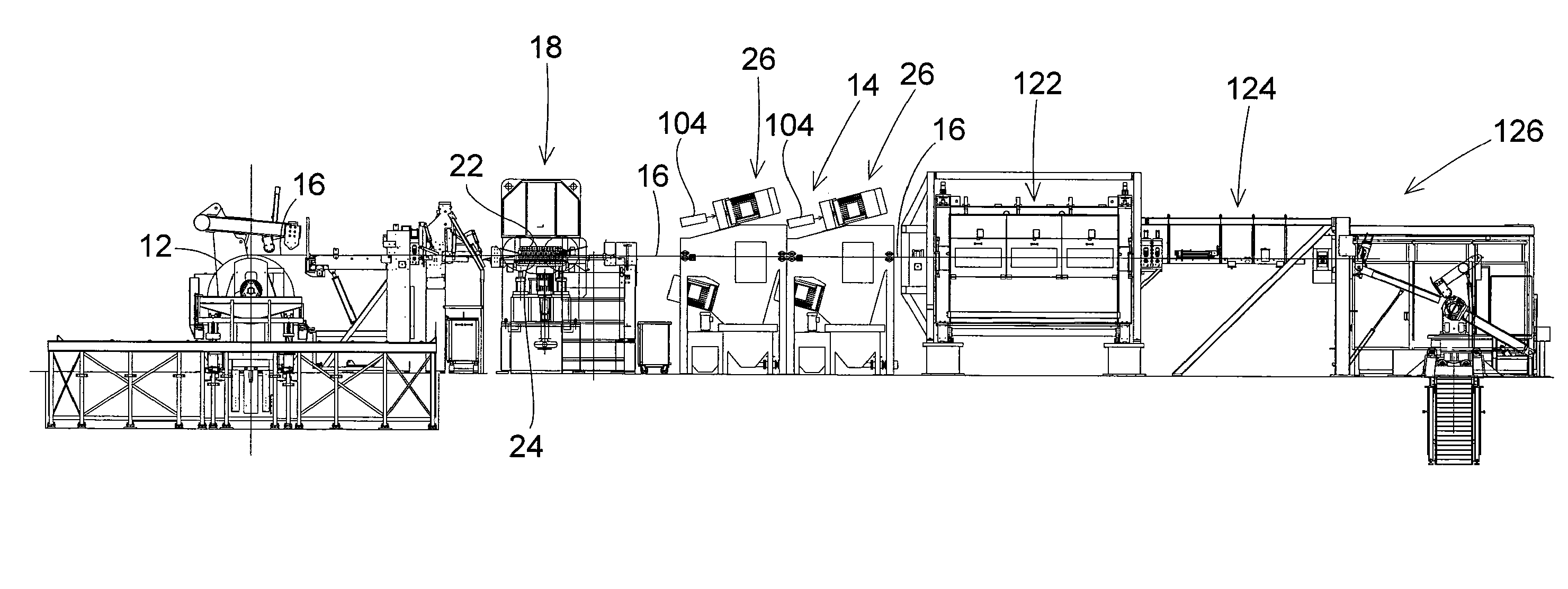

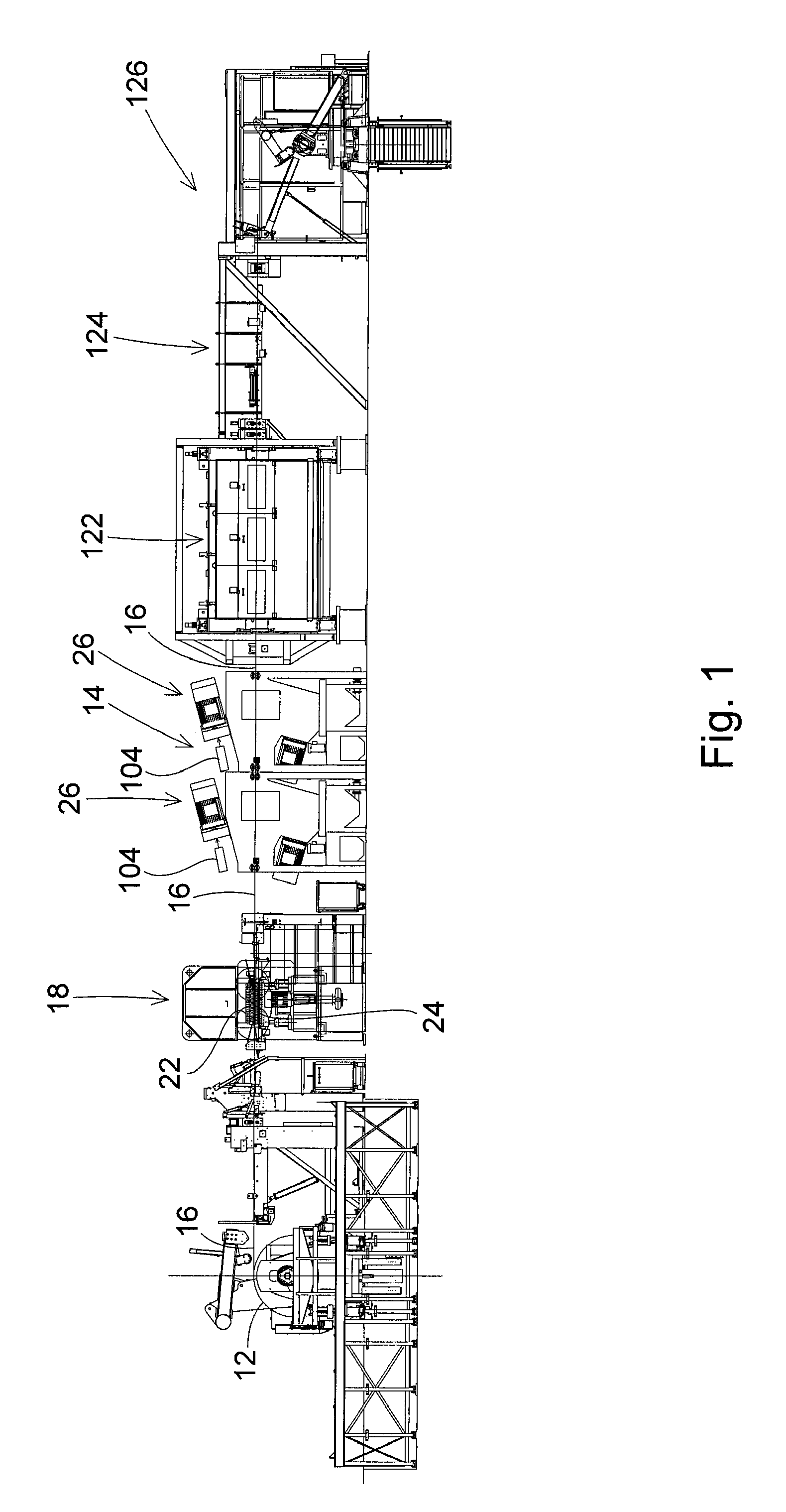

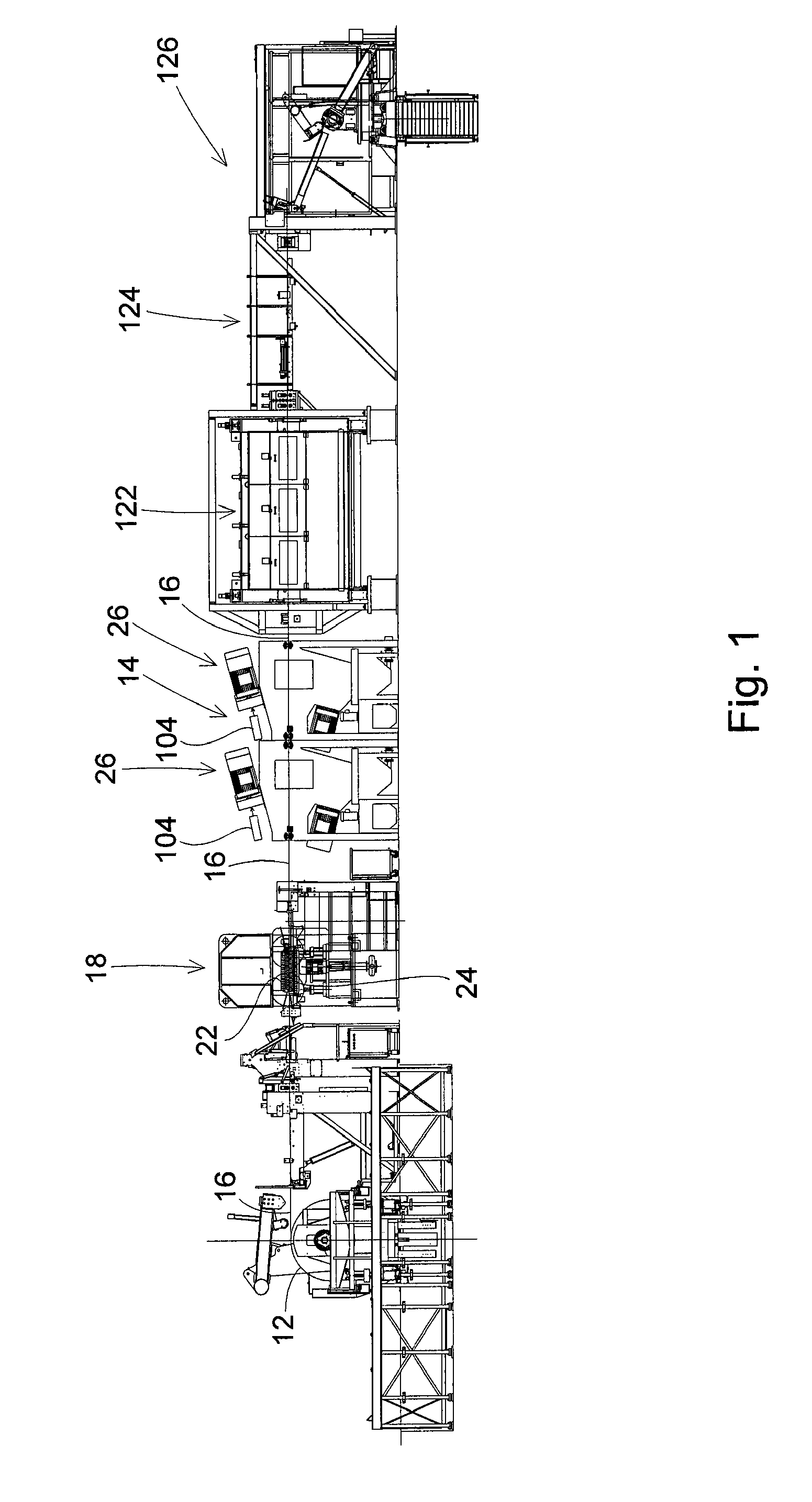

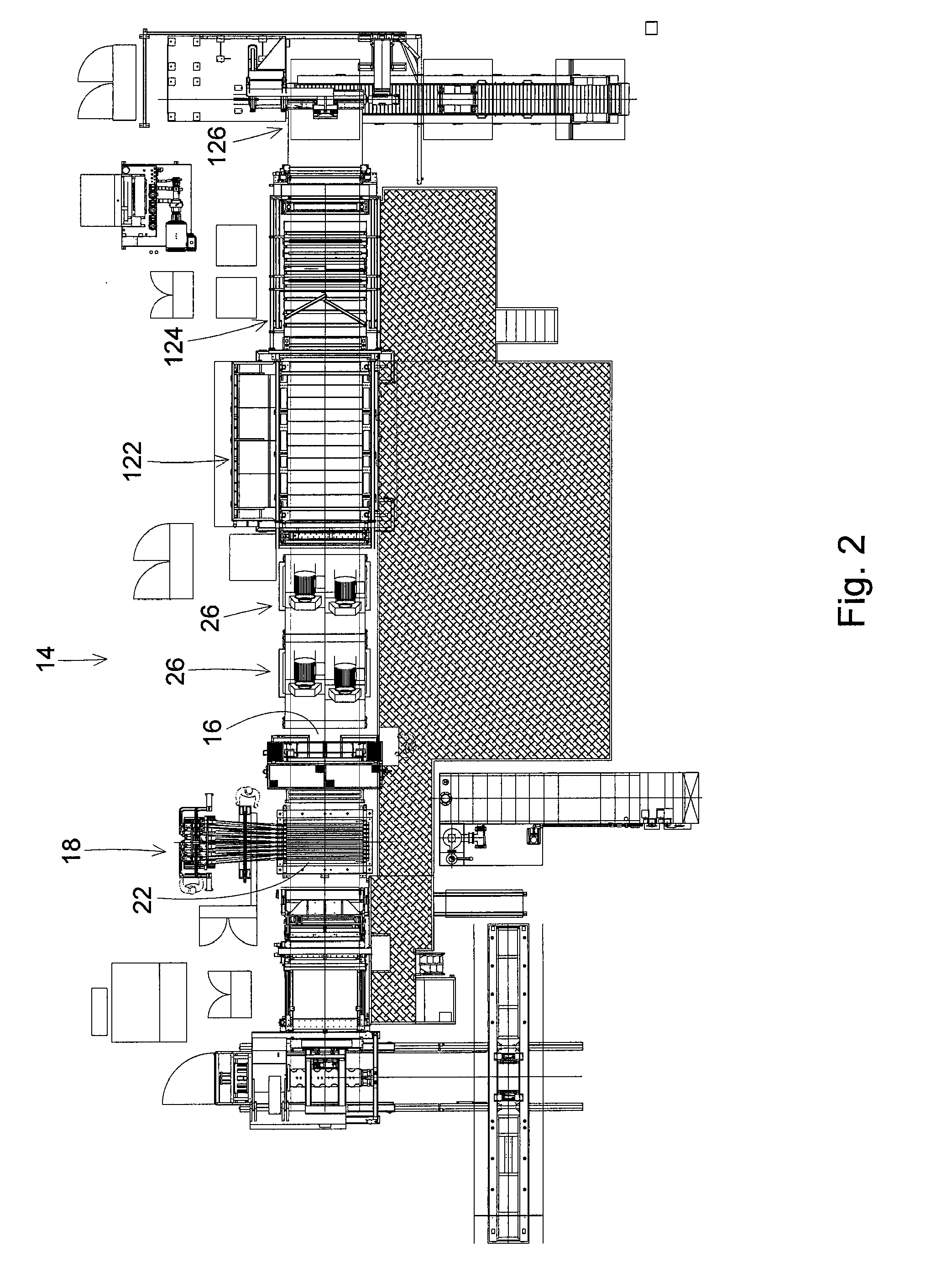

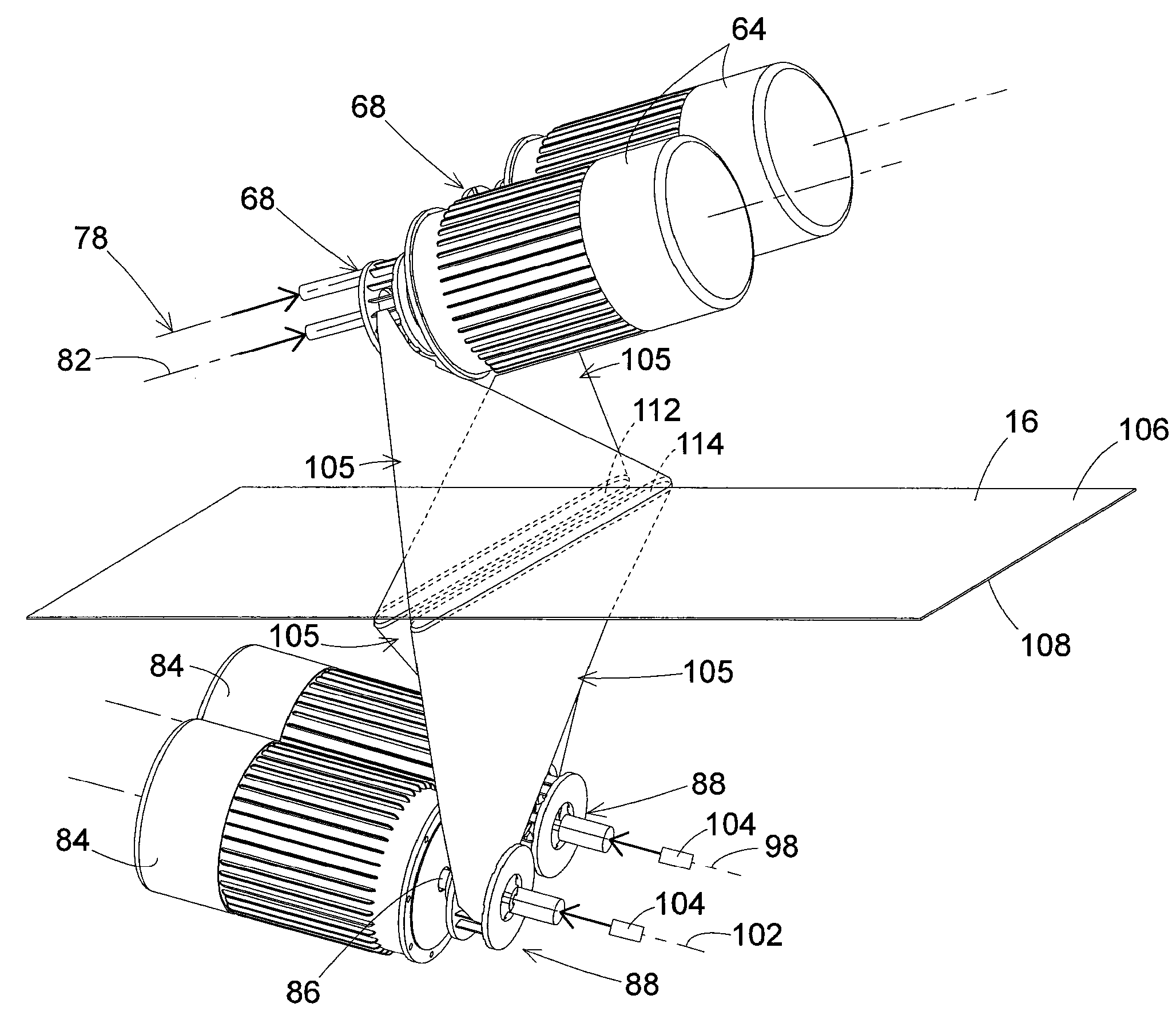

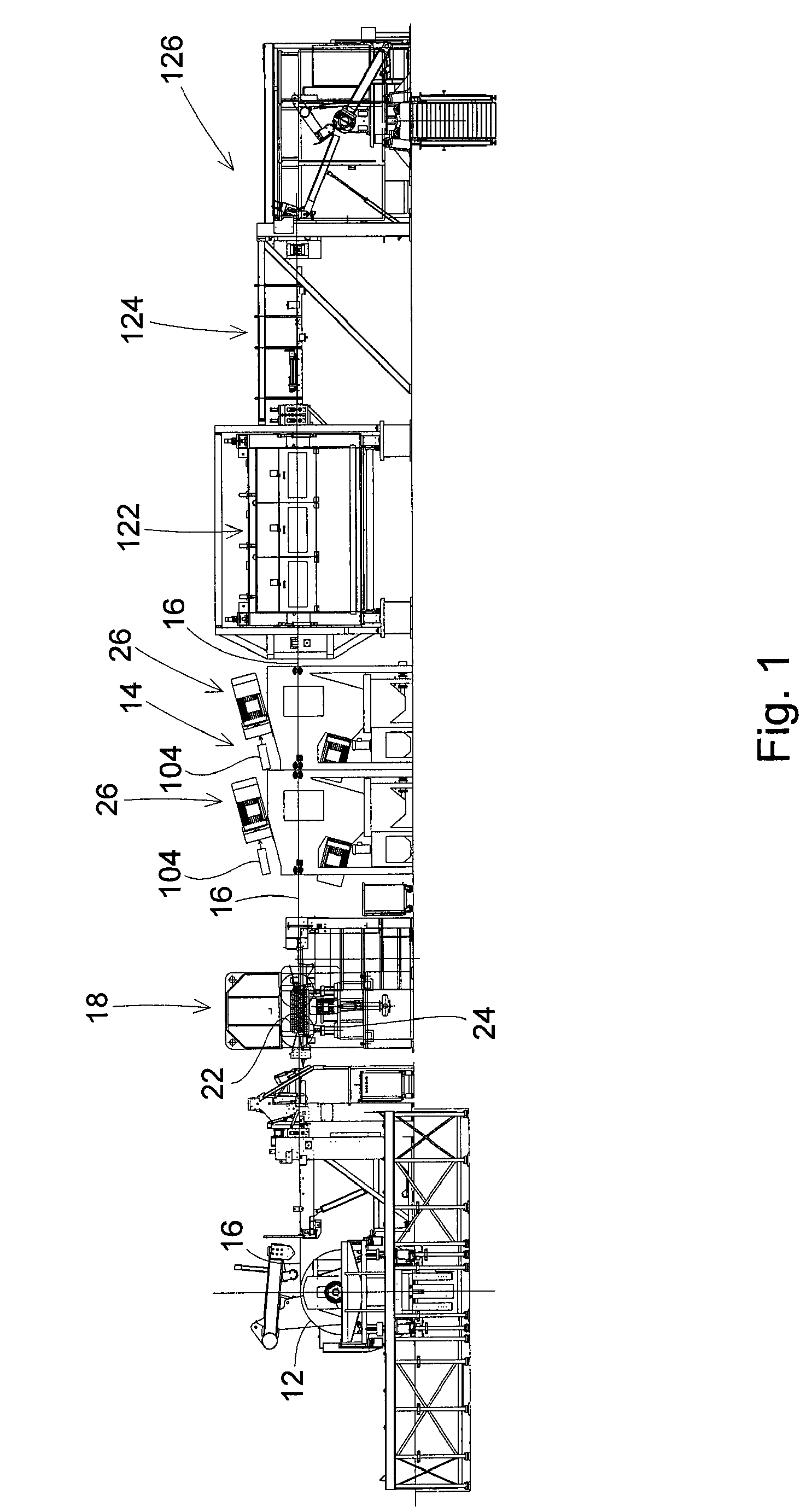

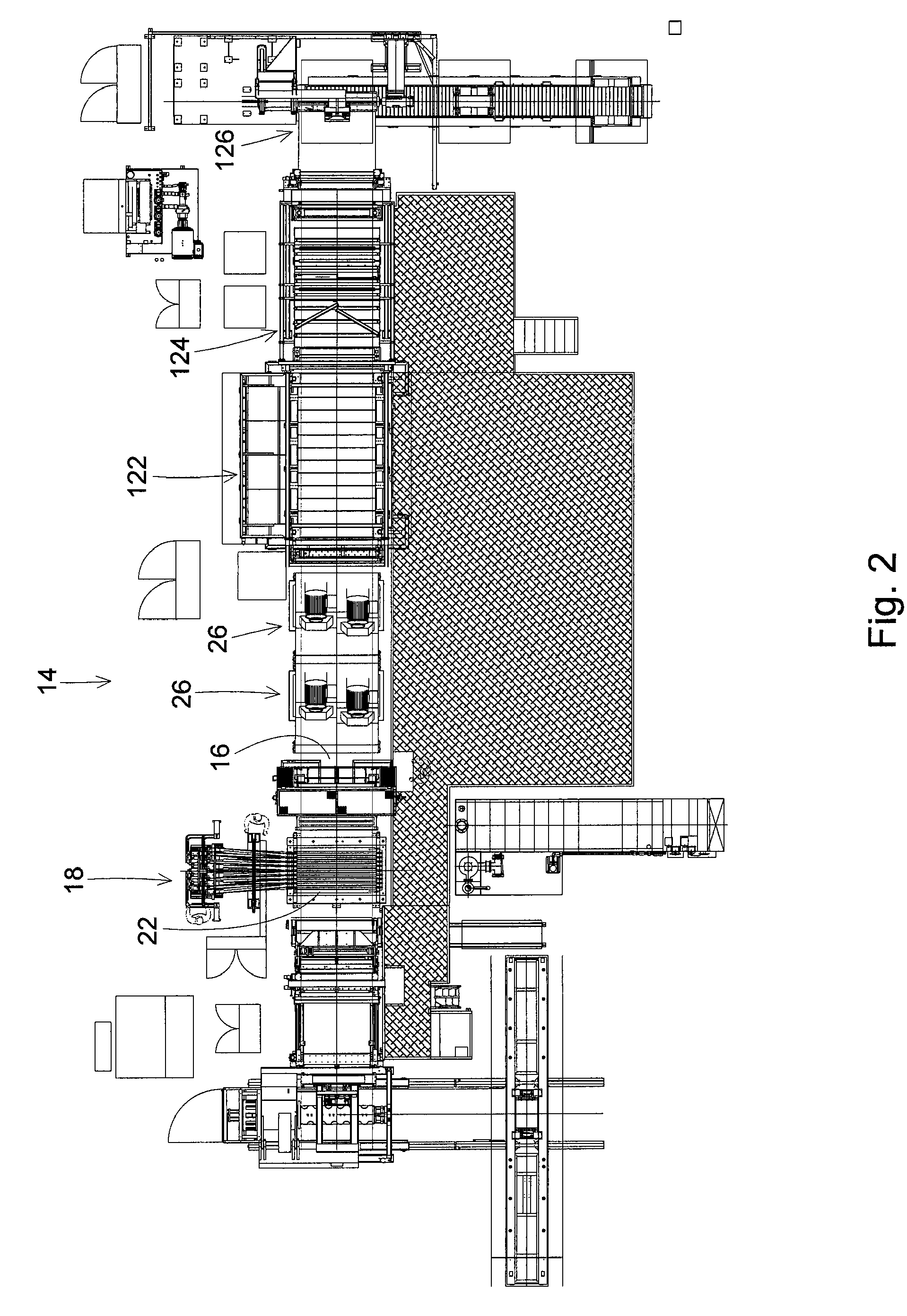

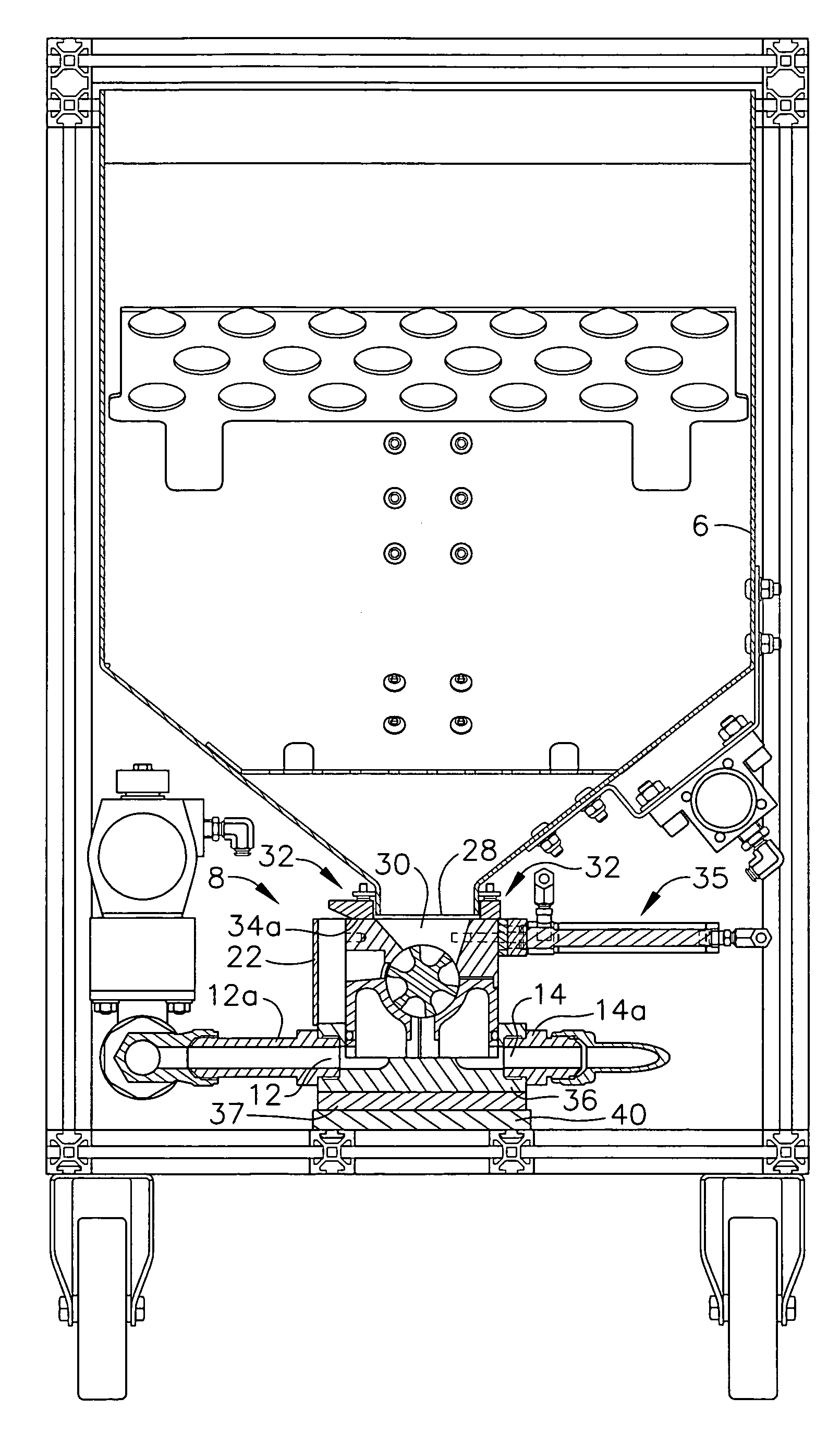

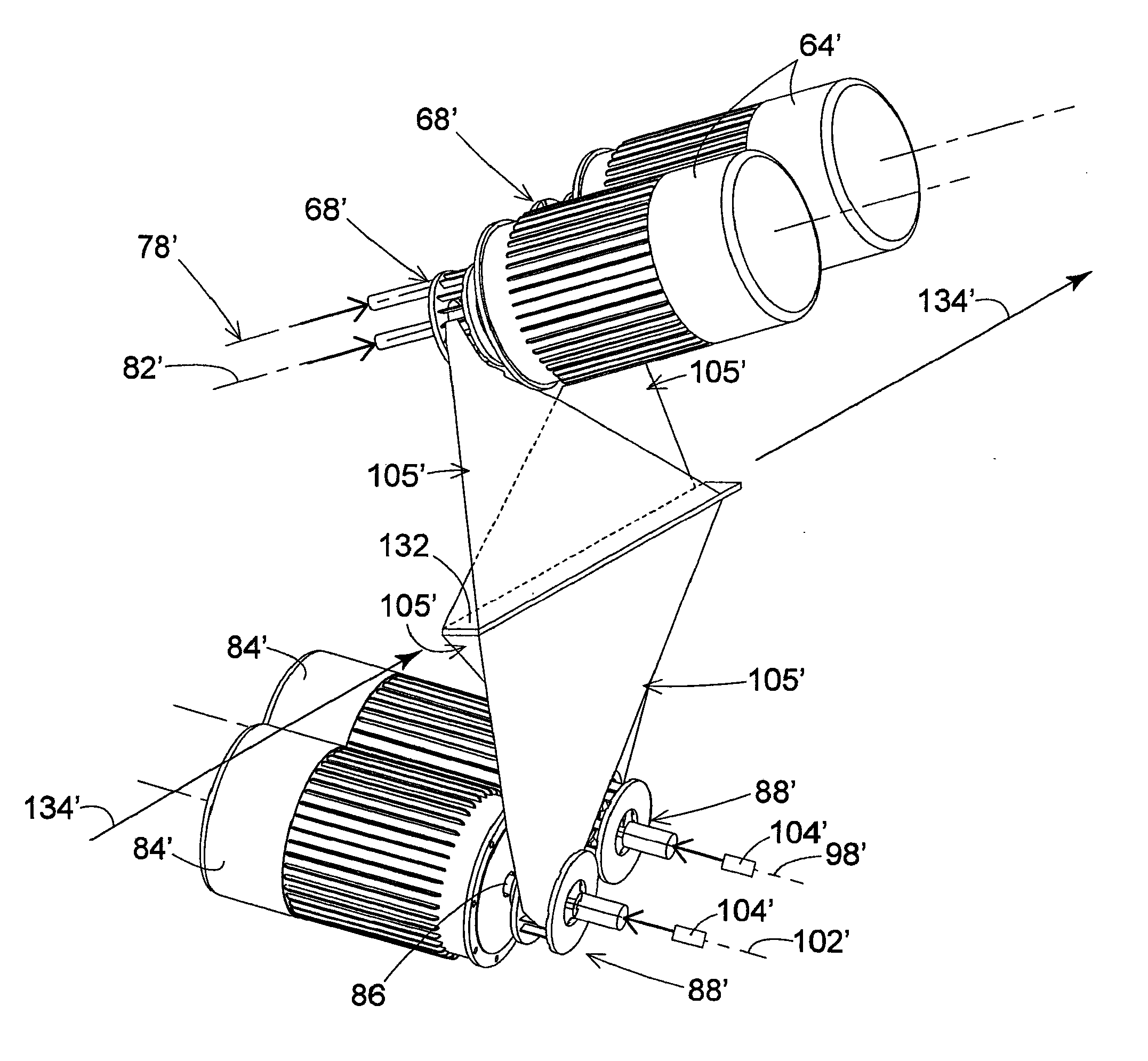

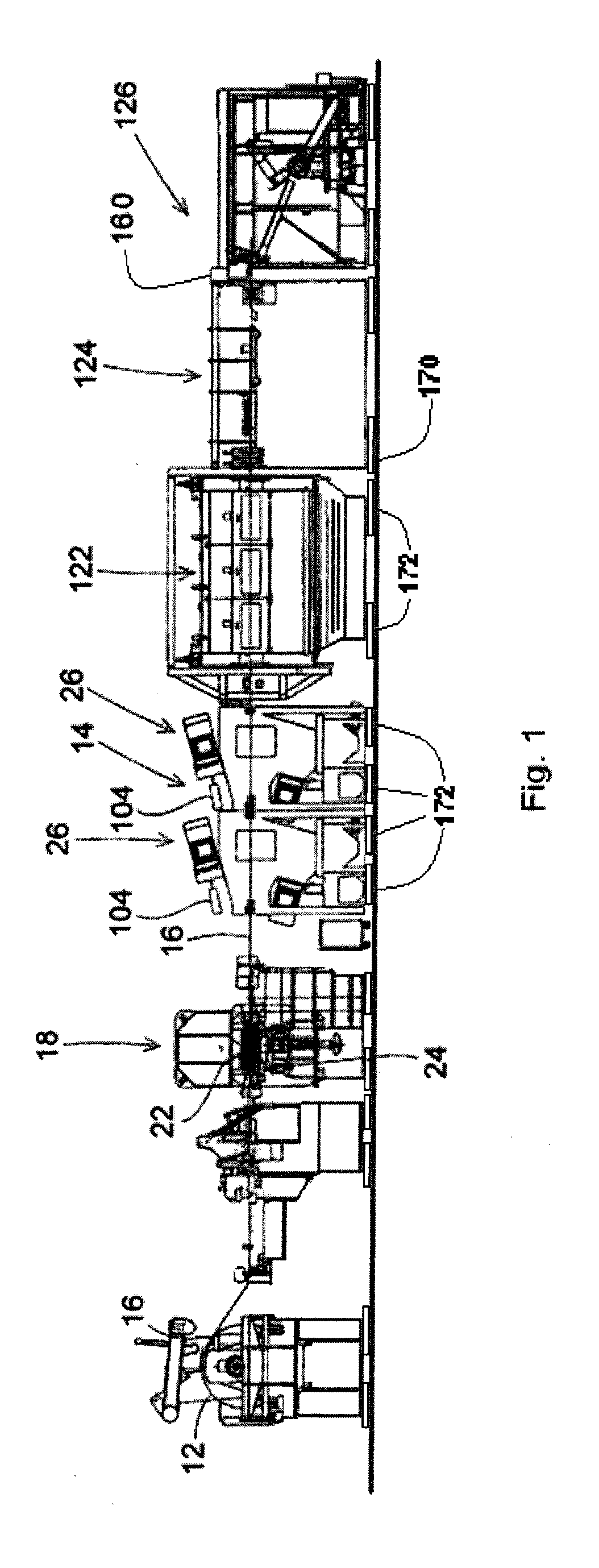

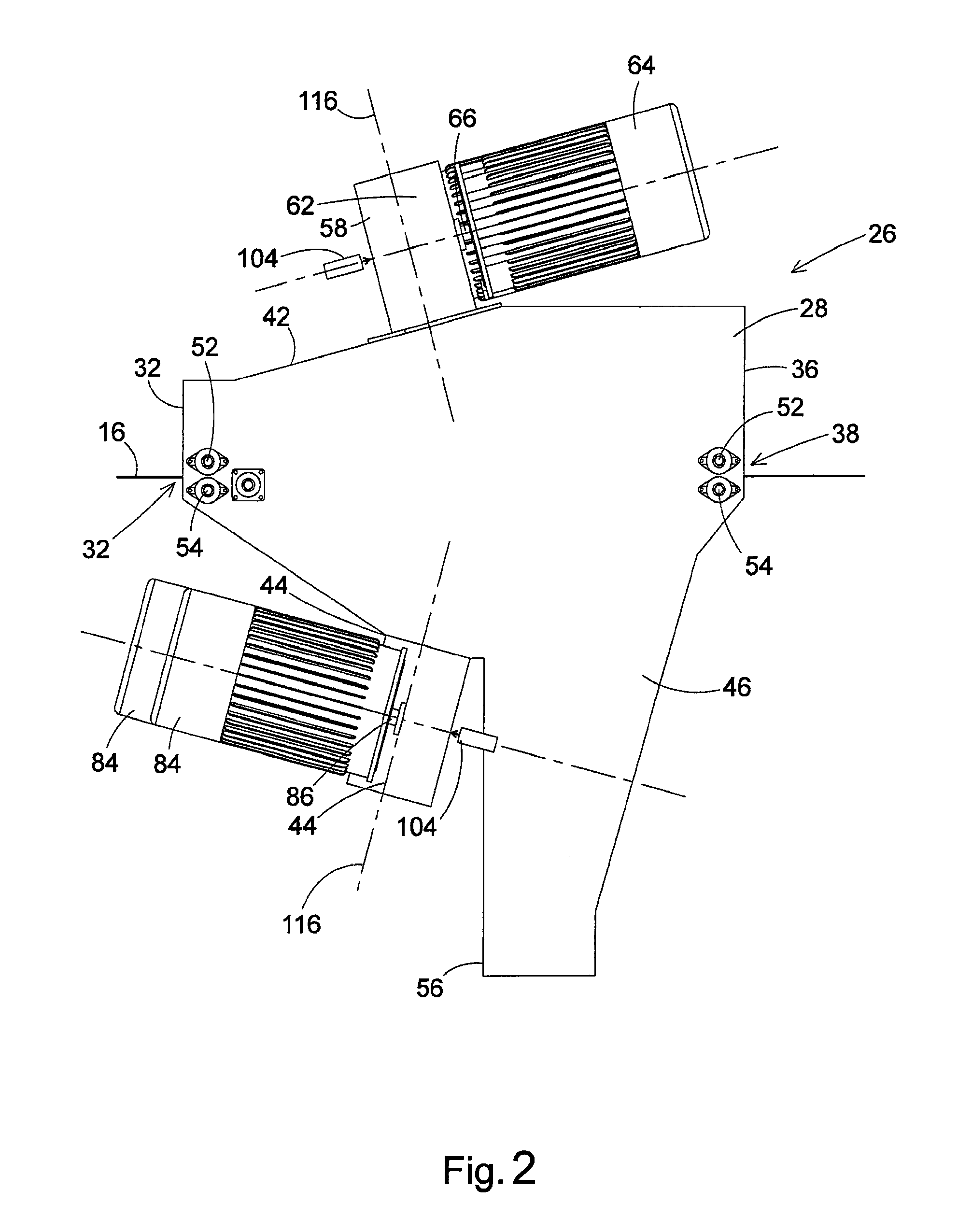

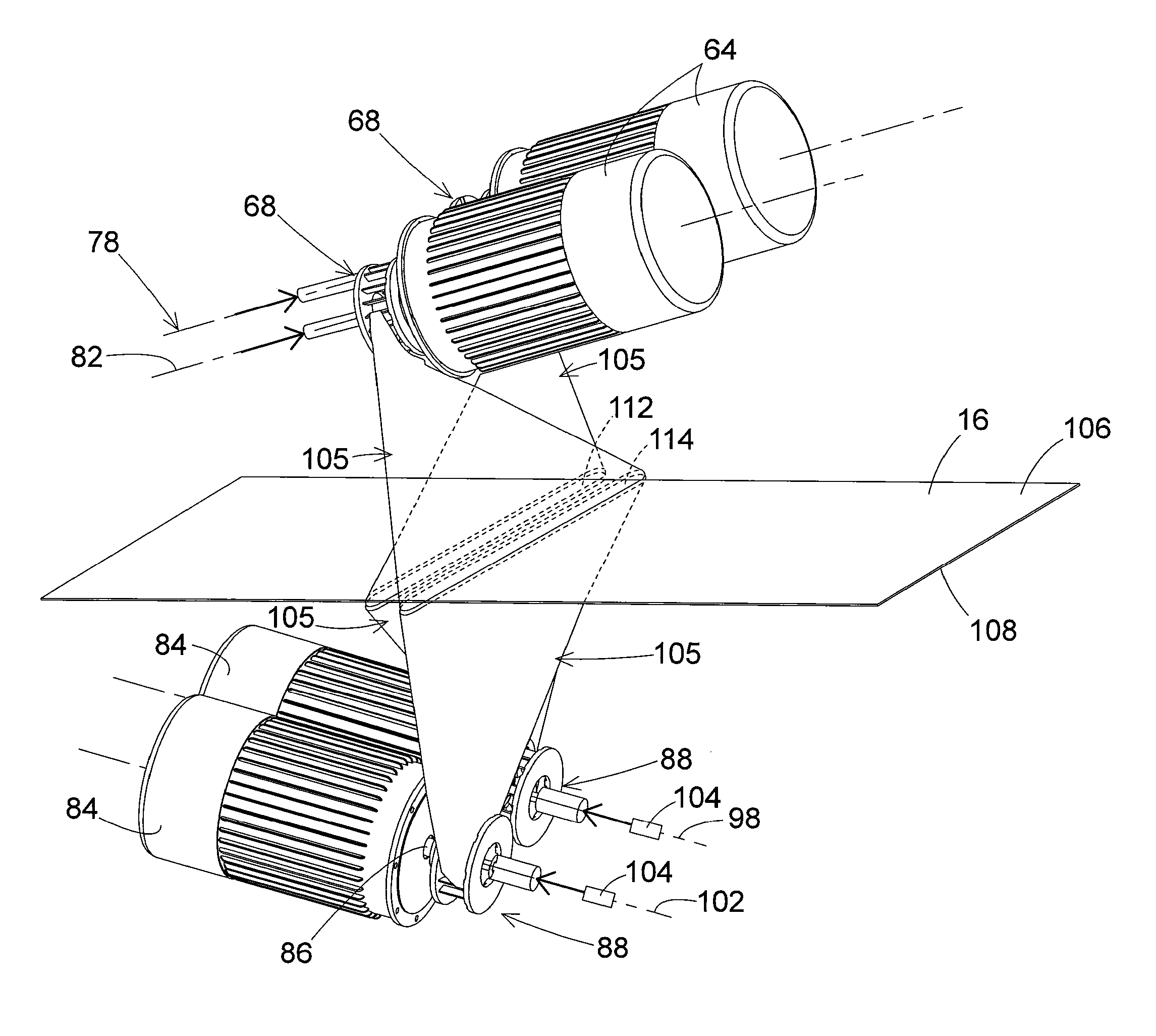

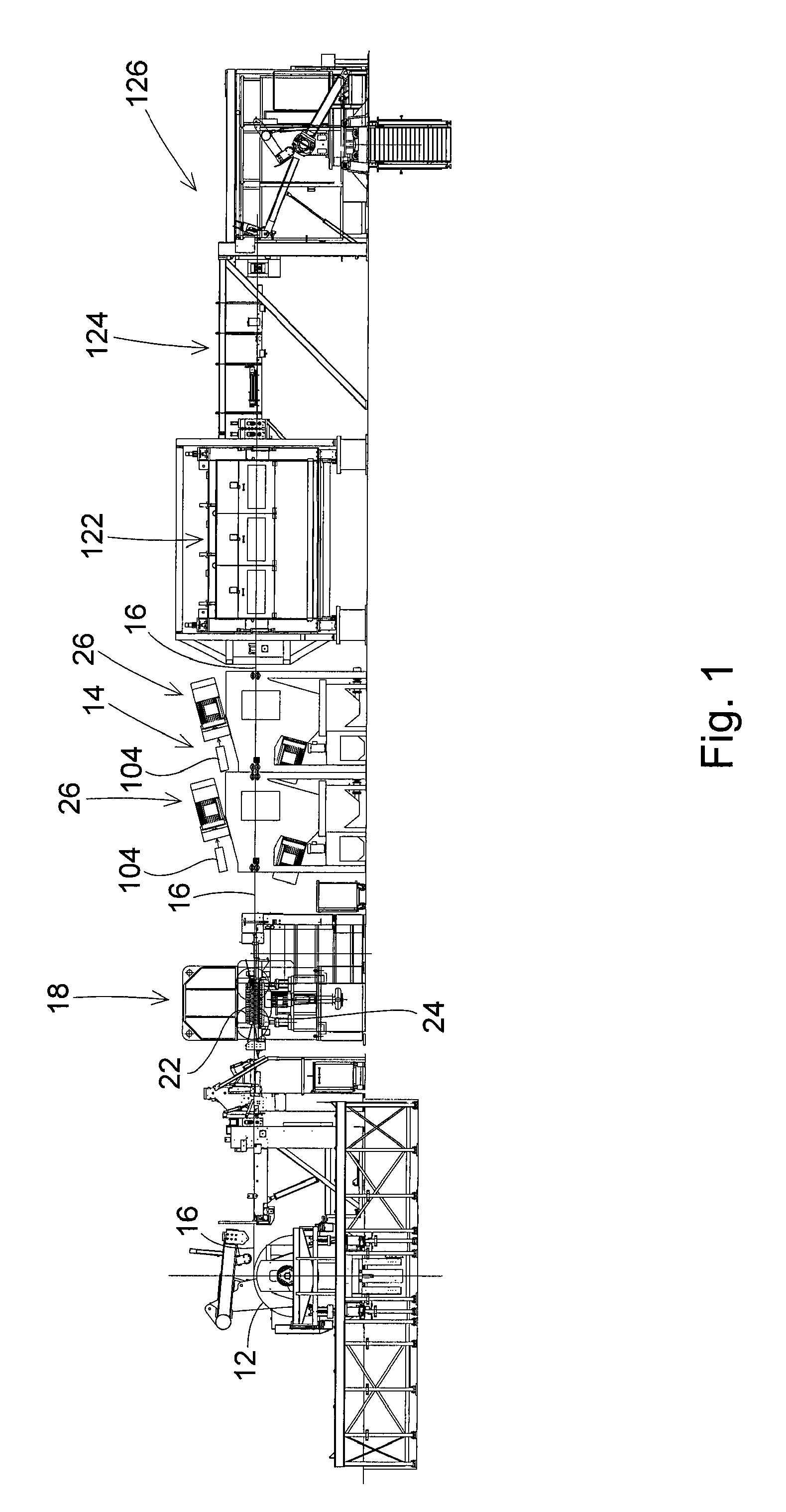

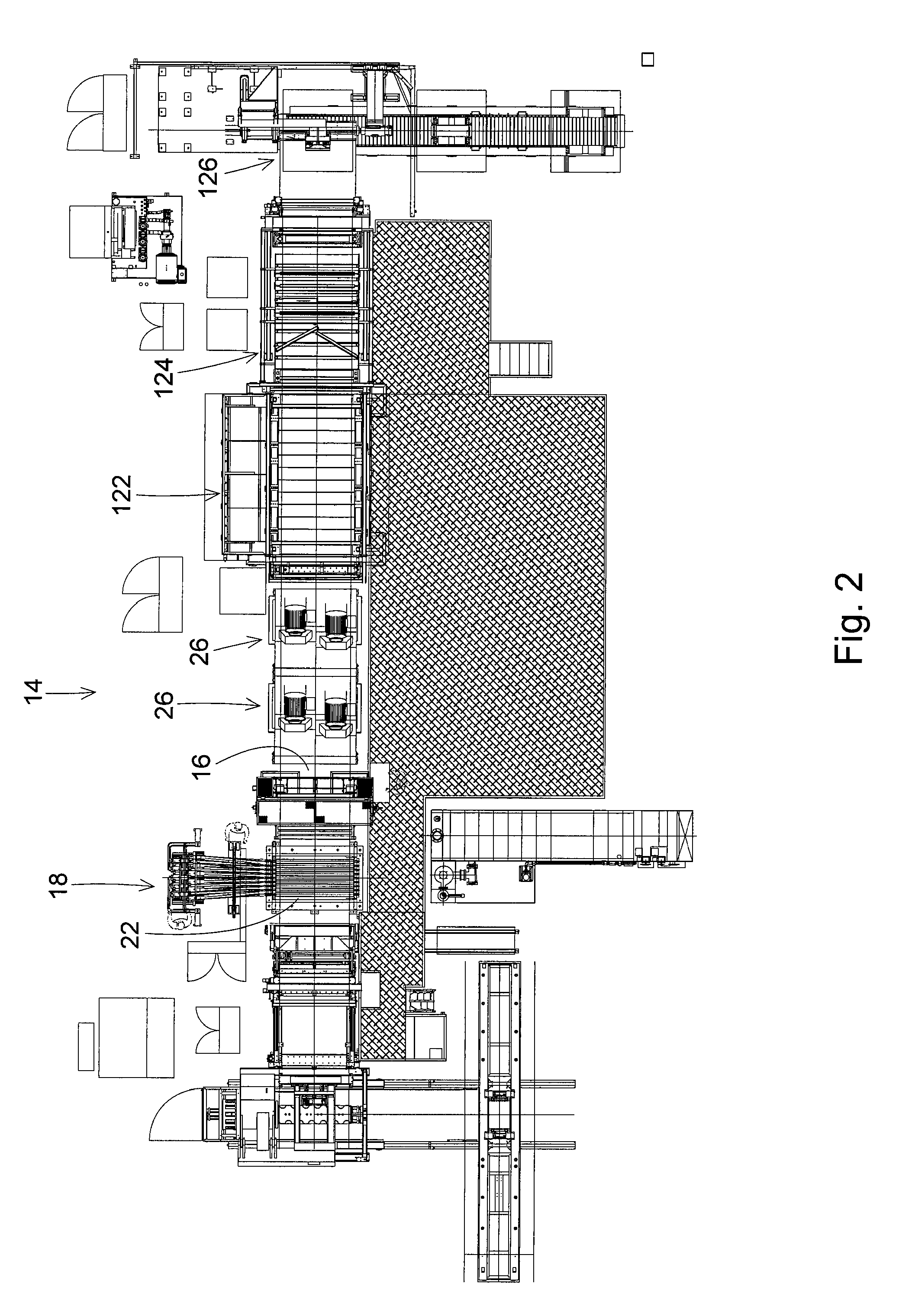

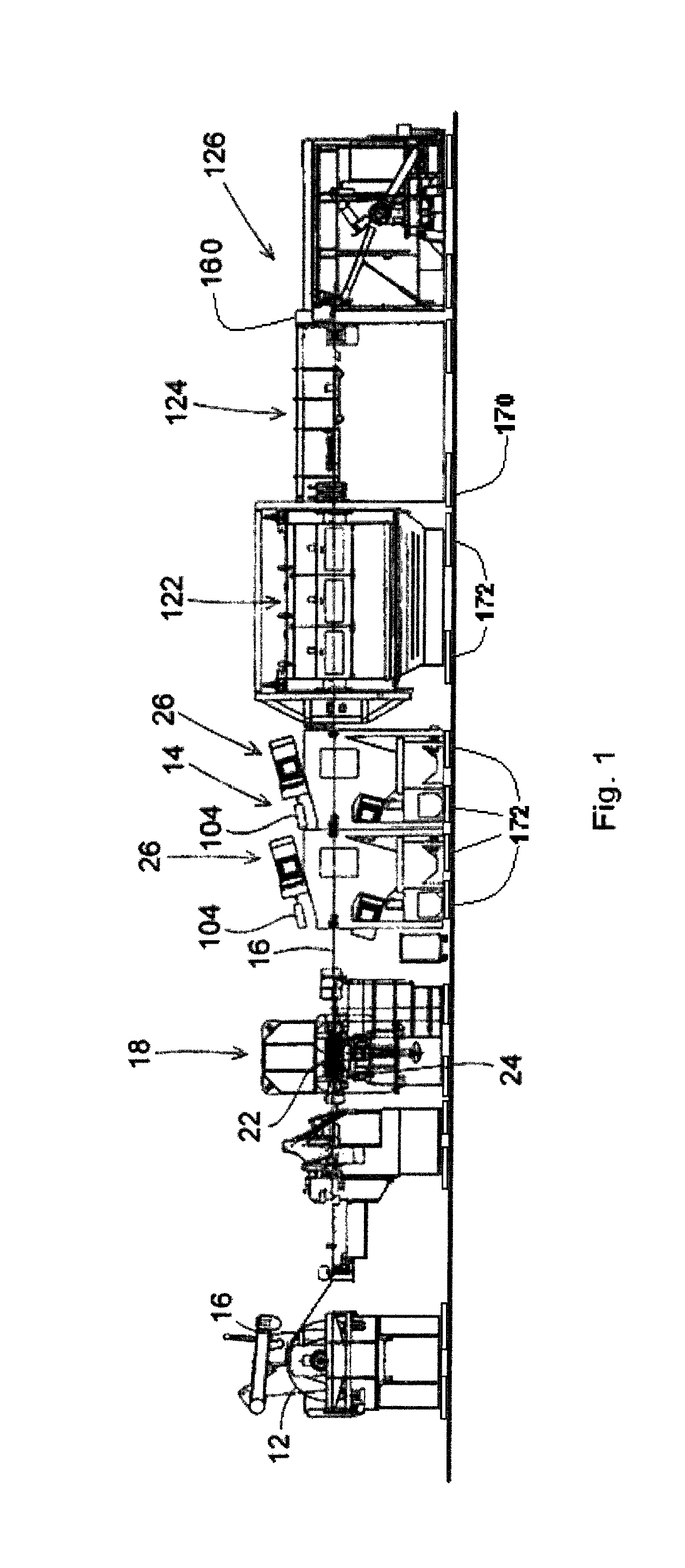

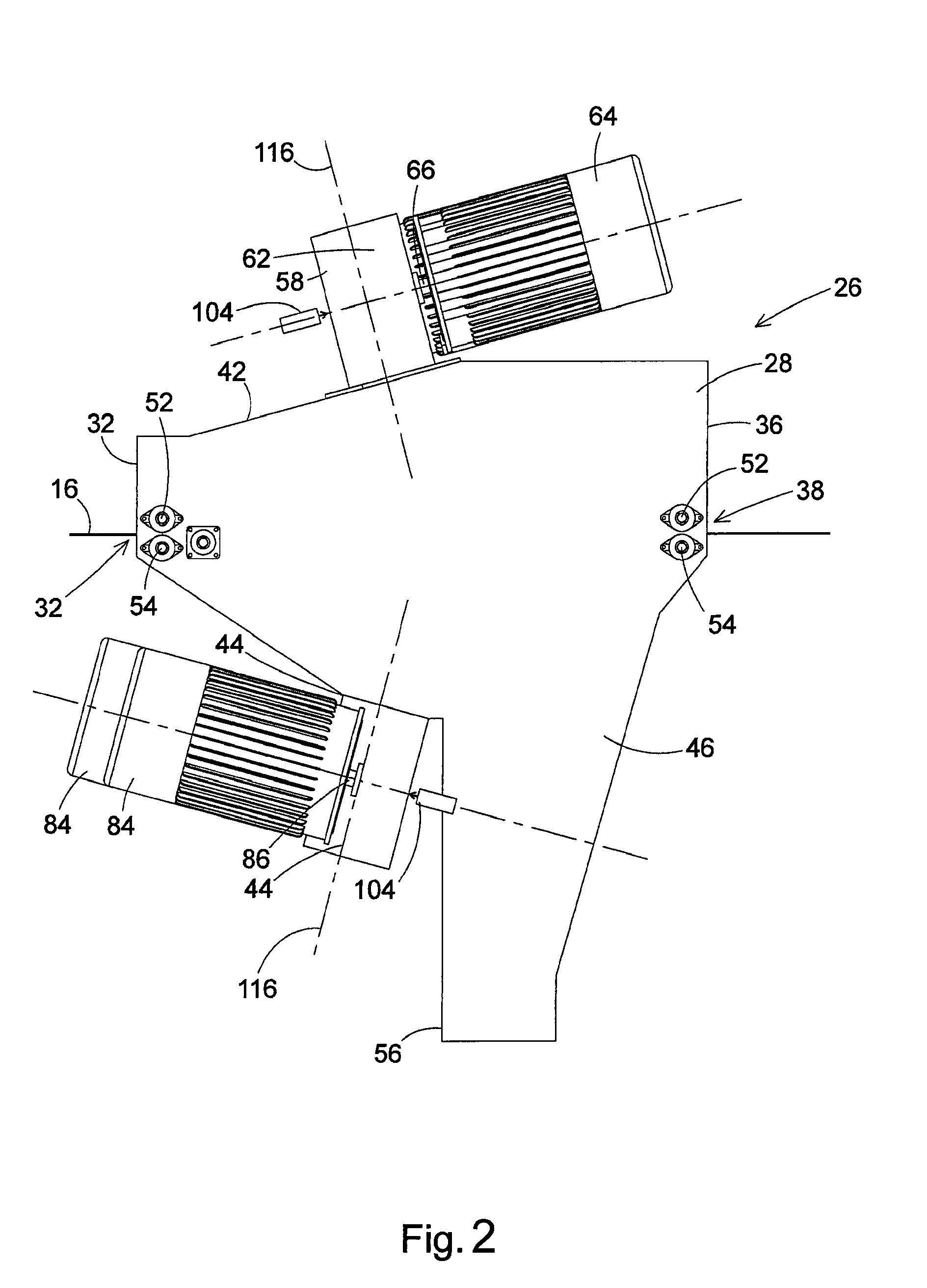

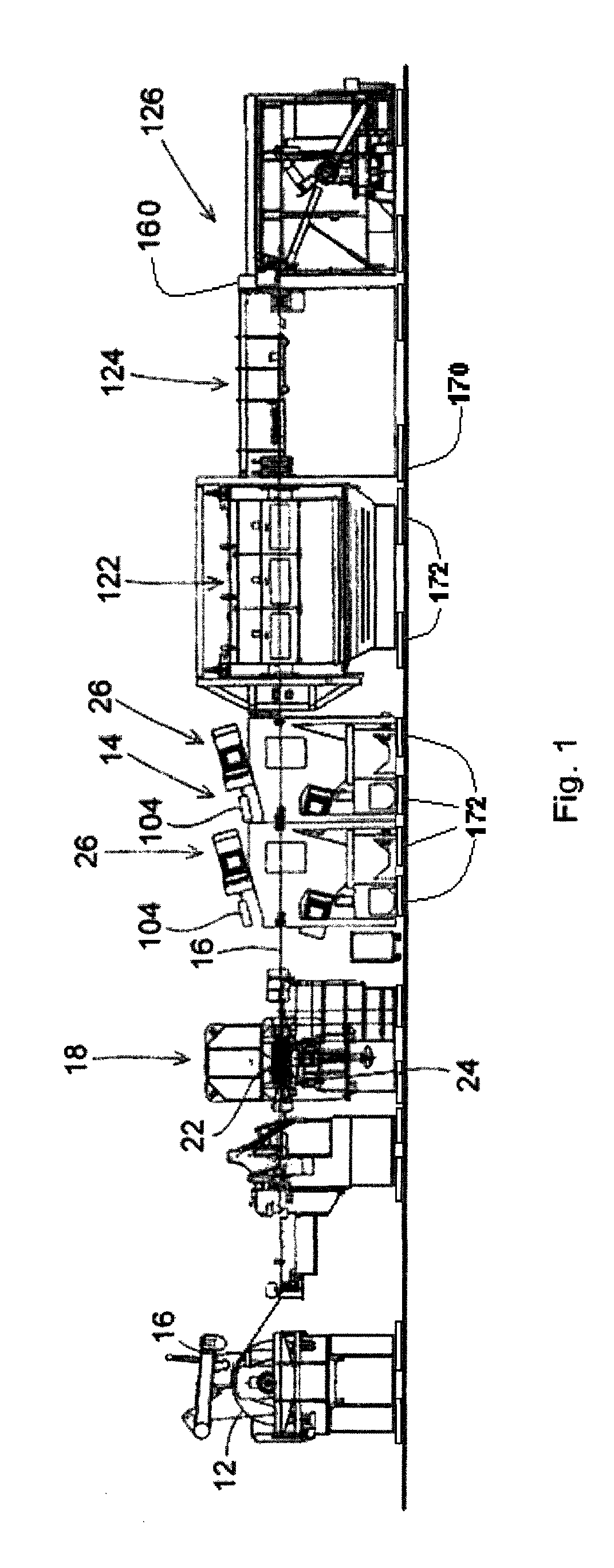

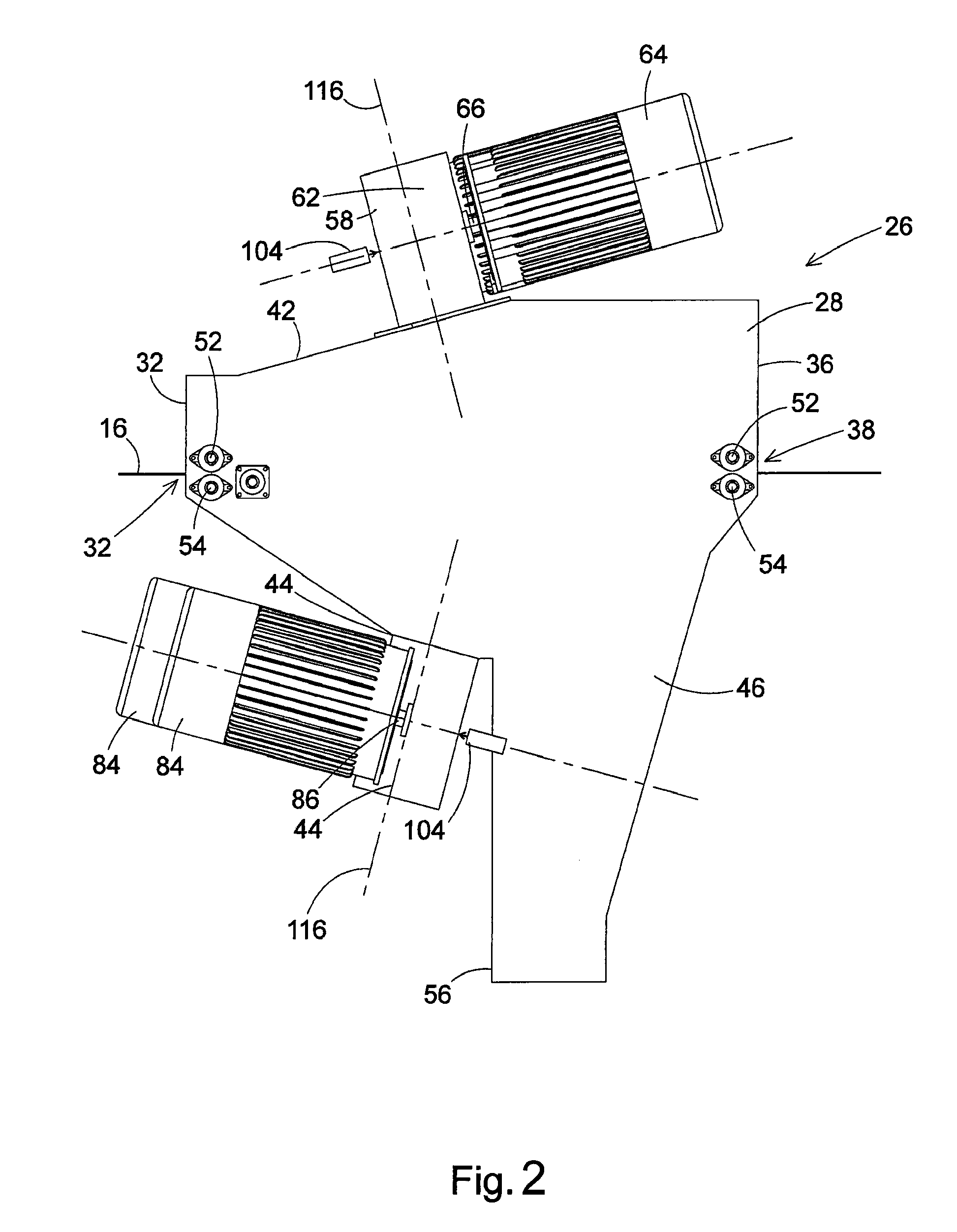

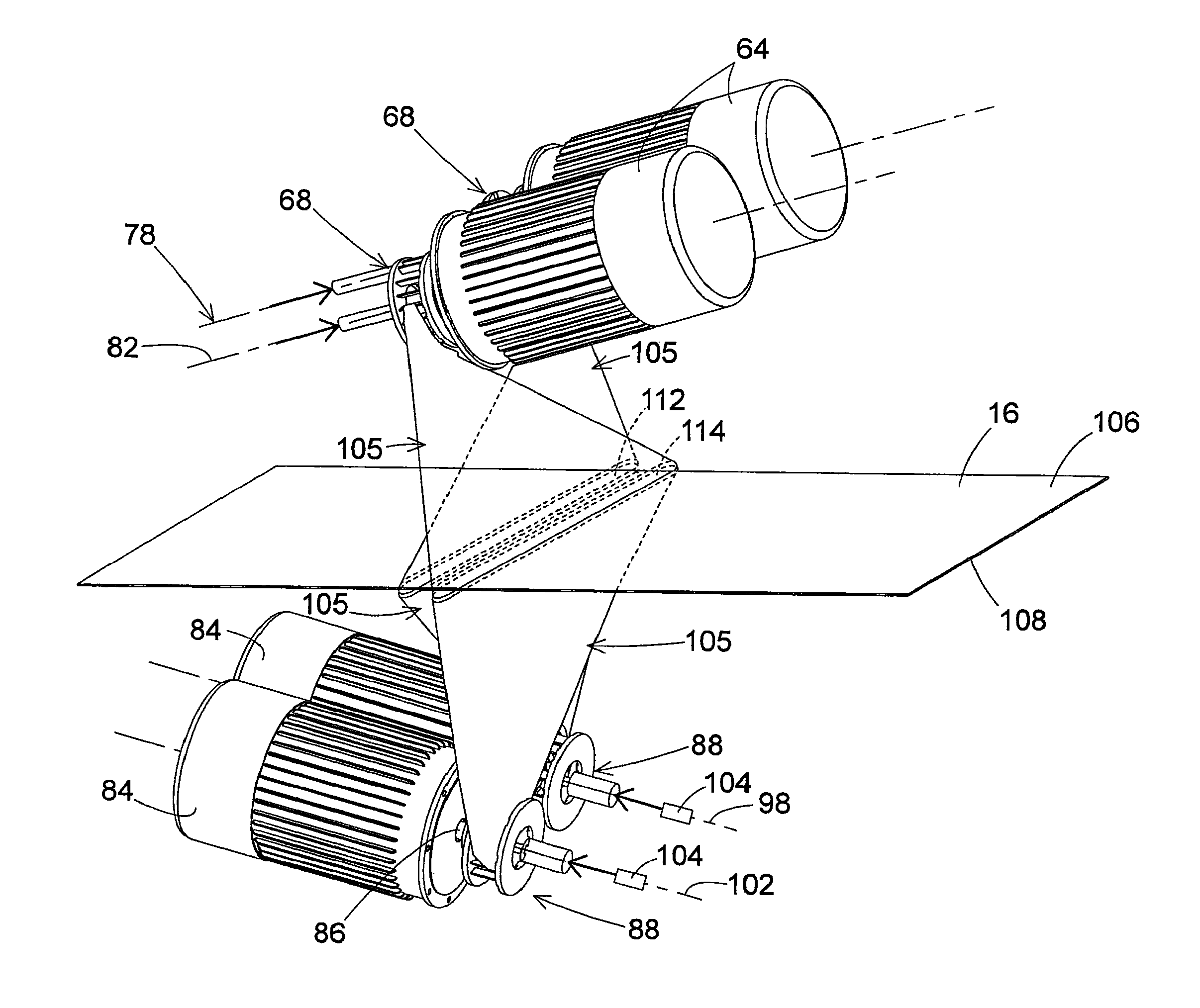

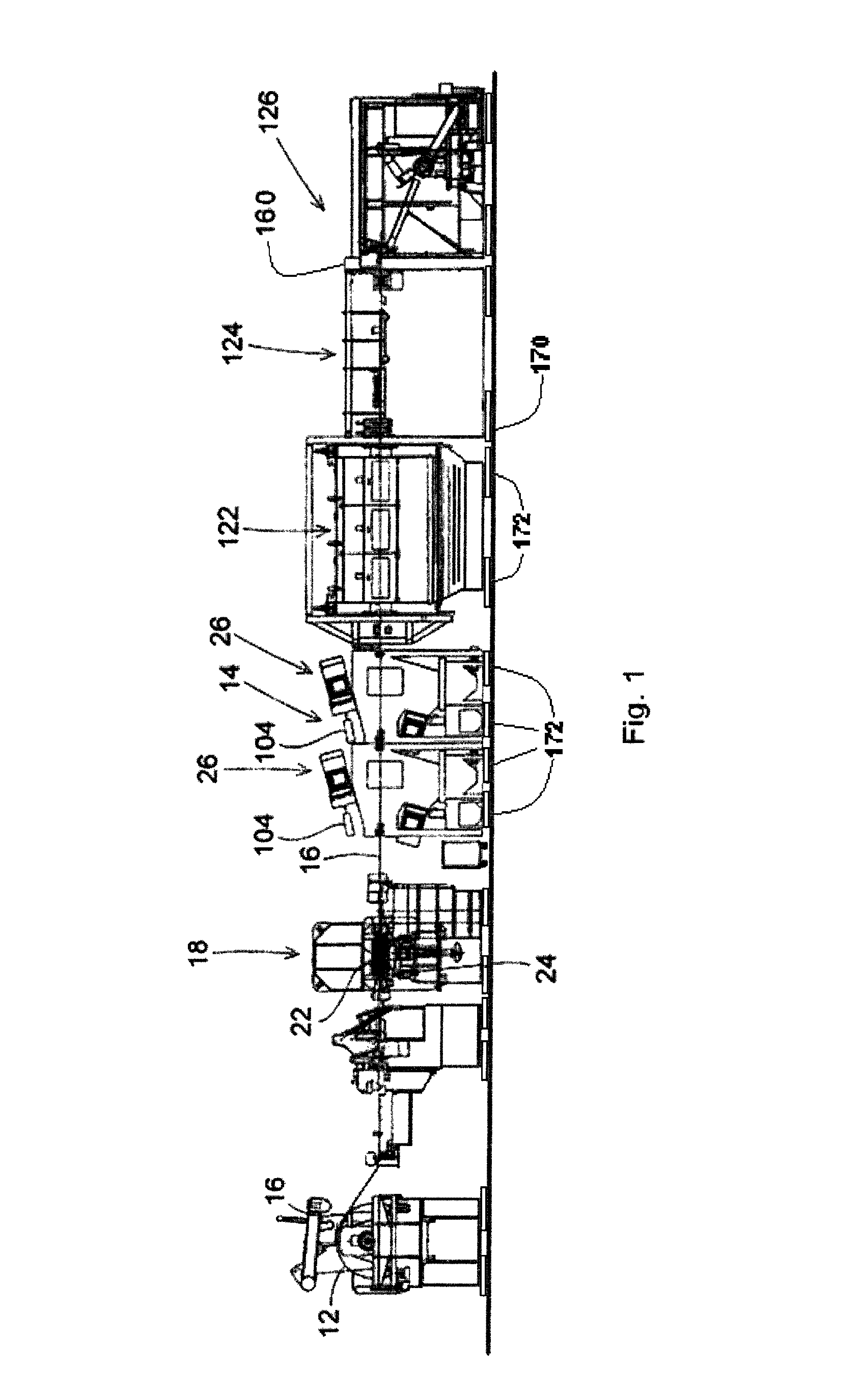

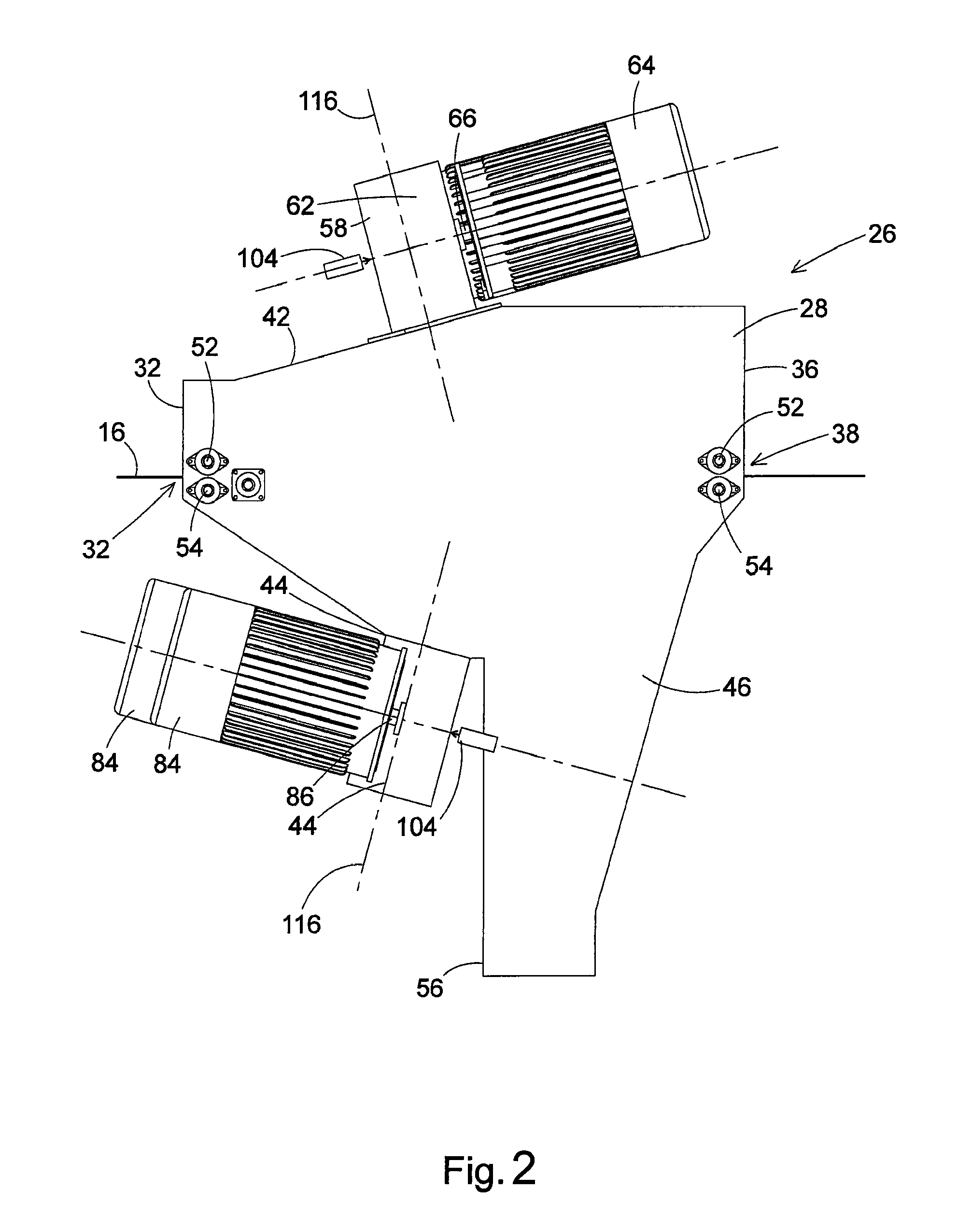

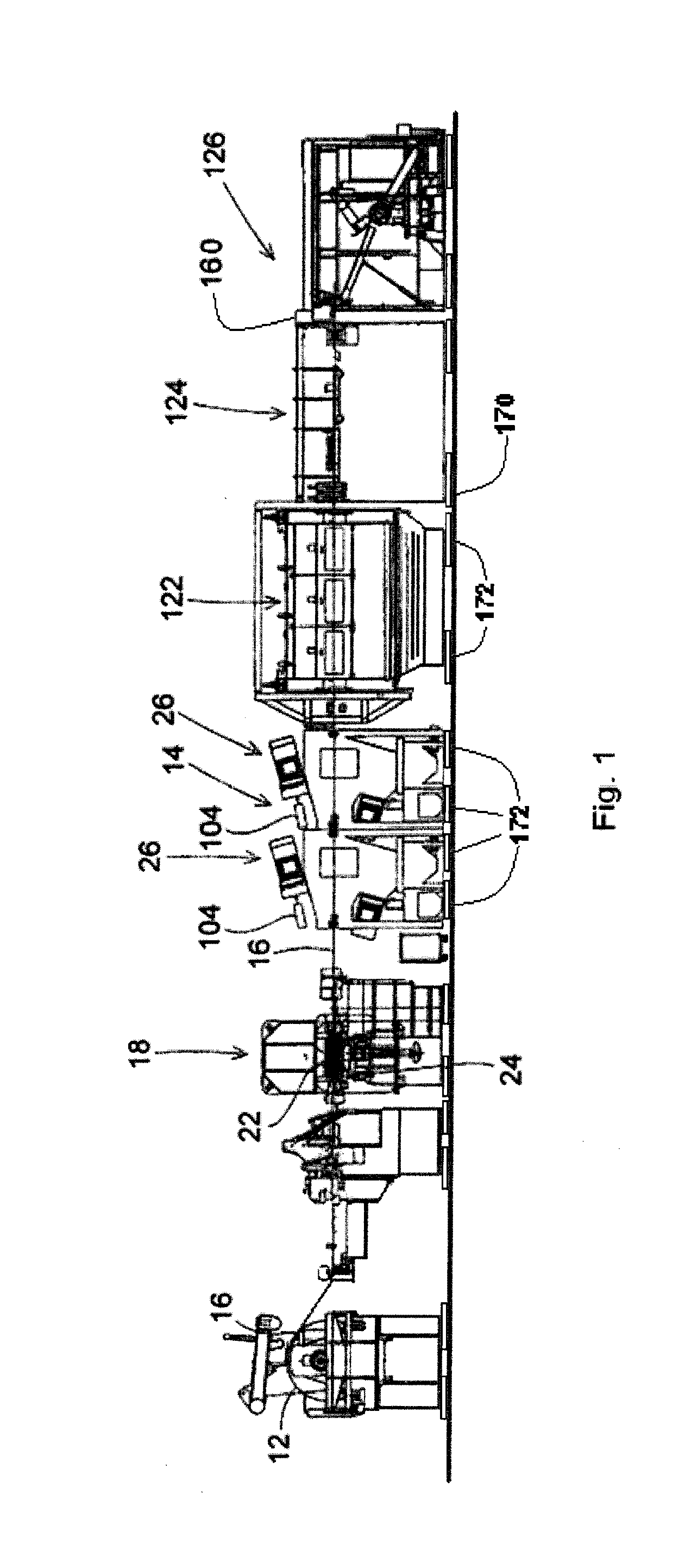

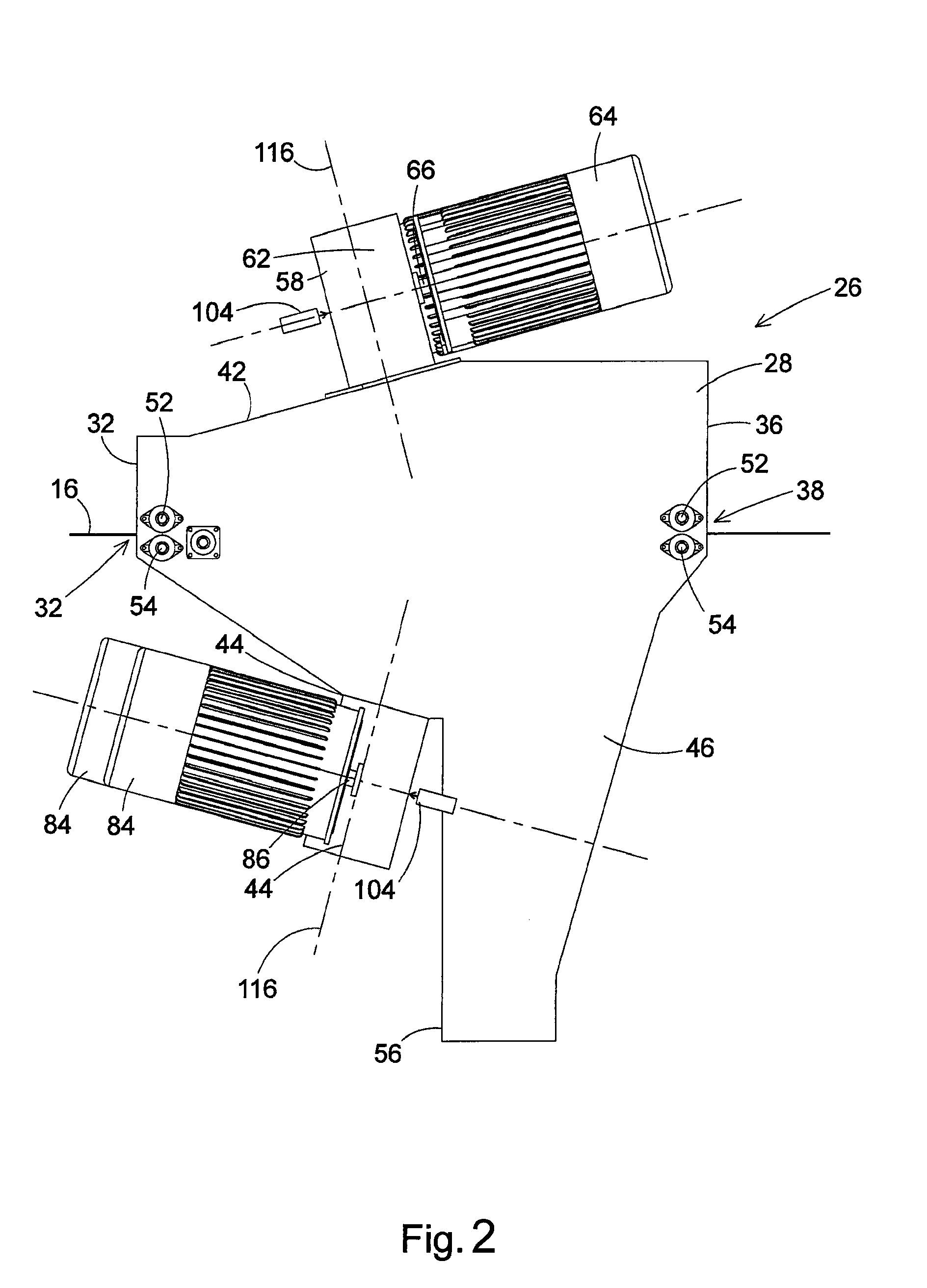

Slurry Blasting Apparatus for Removing Scale From Sheet Metal

ActiveUS20080182486A1Prevent reoxidationAvoid contact damageImpeller wheelsRotor bladesEngineeringMetal

Owner:THE MATERIAL WORKS

Slurry Blasting Apparatus for Removing Scale from Sheet Metal

ActiveUS20080108281A1Prevent reoxidationAvoid contact damageEdge grinding machinesImpeller wheelsEngineeringMetal

Owner:THE MATERIAL WORKS

Slurry blasting apparatus for removing scale from sheet metal

ActiveUS7601226B2Prevent reoxidationAvoid contact damageEdge grinding machinesImpeller wheelsEngineeringMetal

Owner:THE MATERIAL WORKS

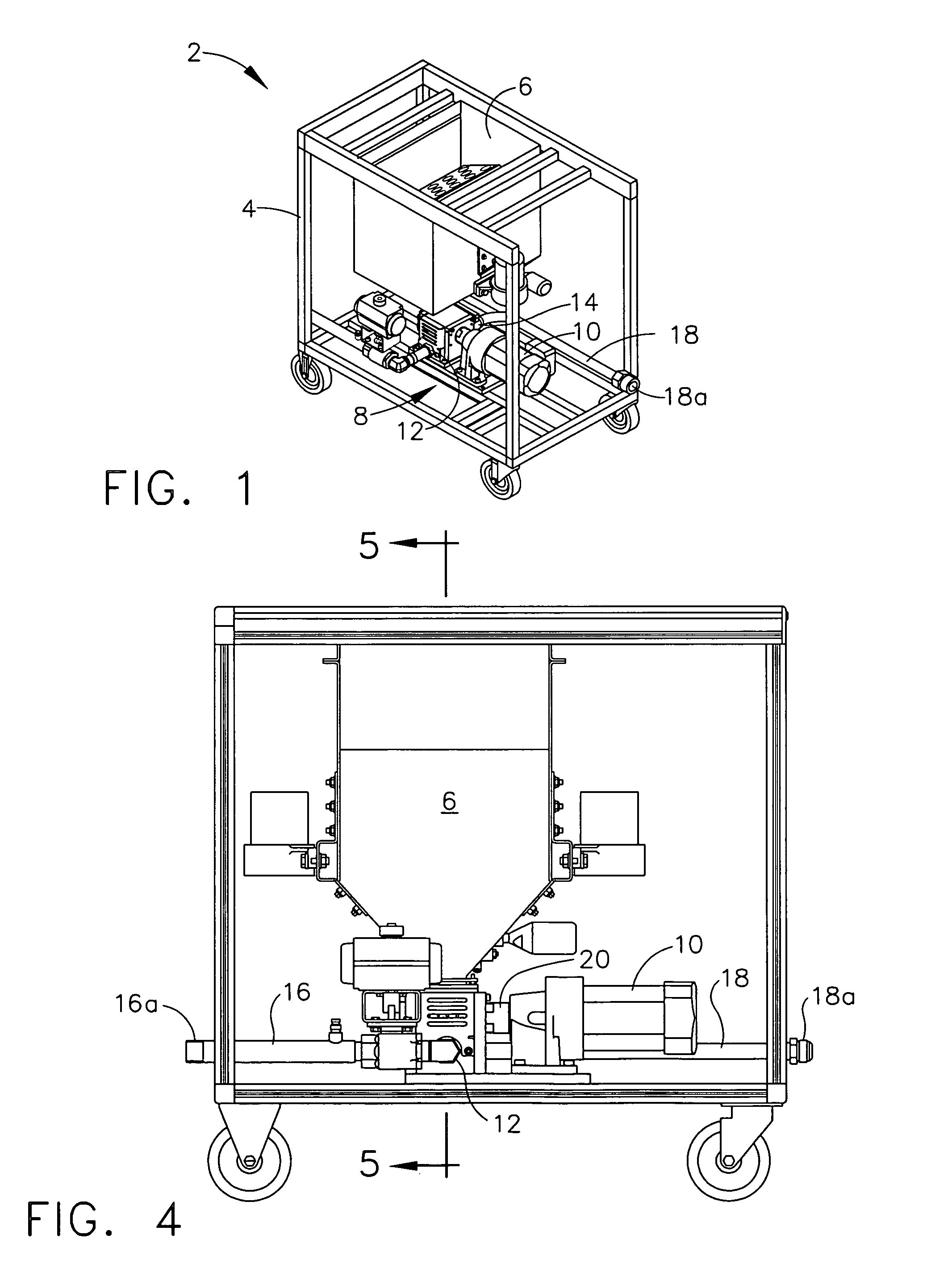

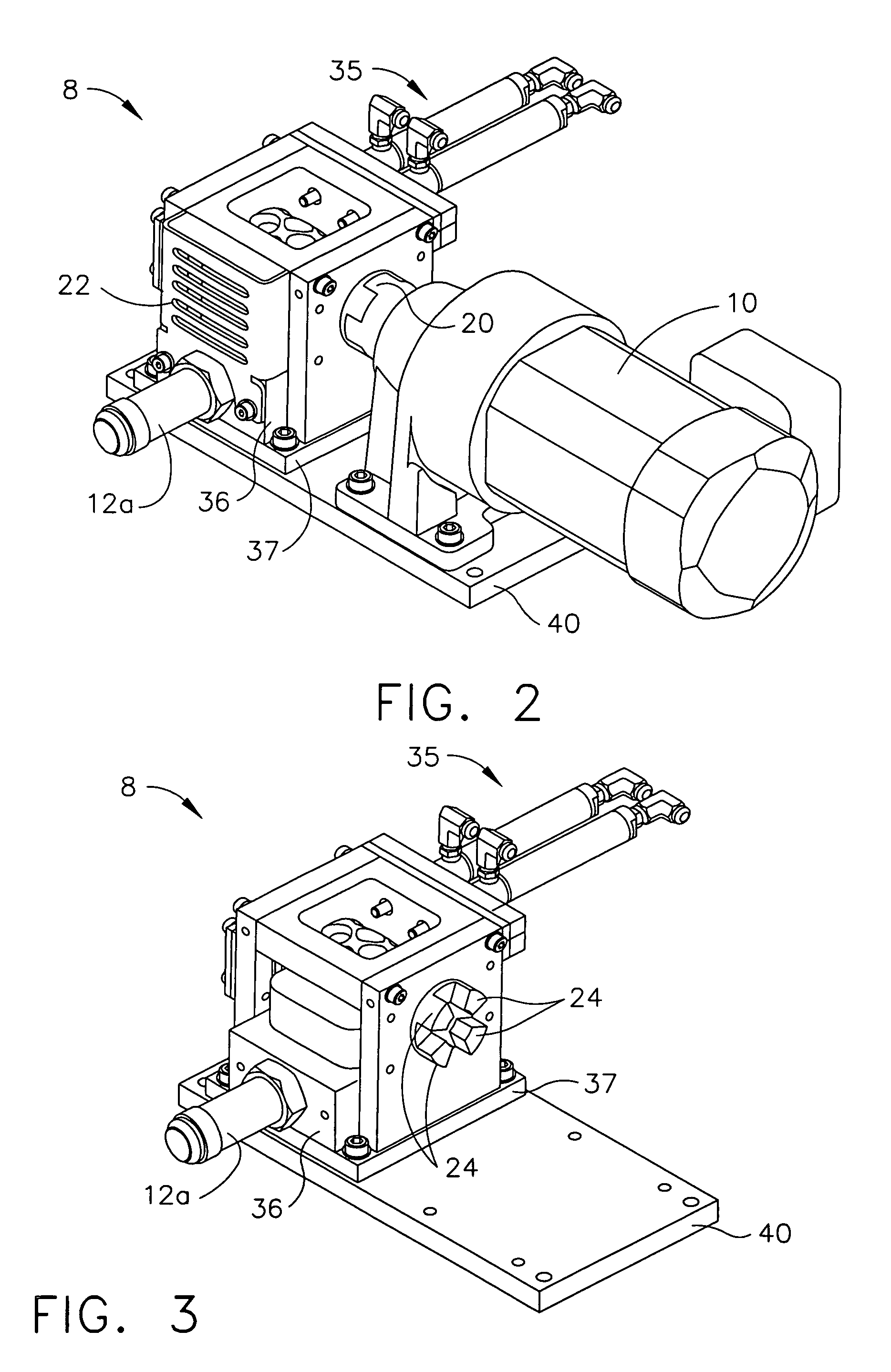

Feeder assembly for particle blast system

A particle blast system includes a feeder assembly having a rotor with a plurality of pockets formed in the peripheral surface. The transport gas flowpath includes the pockets, such that substantially all transport gas flows through the pockets. The seal adjacent the peripheral surface is actuated by the transport gas pressure to urge its sealing surface against the rotor's peripheral surface. At start up, there is no substantial pressure between the seal and the rotor, reducing start up torque requirements.

Owner:COLD JET

Method of Producing Rust Inhibitive Sheet Metal Through Scale Removal with a Slurry Blasting Descaling Cell

A method is provided for removing iron oxide scale from sheet metal and producing a sheet metal surface with rust inhibitive properties. The sheet metal is advanced through the descaling cell and a slurry mixture is propelled against at least one of the top surface and bottom surface of the sheet metal across the sheet metal width as the material is advanced through the descaling cell. The rate of slurry impact against the at least one of the top surface and bottom surface of the sheet metal is controlled in a manner to remove substantially all of the scale from a surface of the sheet metal, and in a manner to create a passivation layer on the descaled surface of the sheet metal. The passivation layer comprises at least one of silicon, aluminum, manganese and chromium and inhibits oxidation of the descaled surface of the processed sheet metal.

Owner:THE MATERIAL WORKS

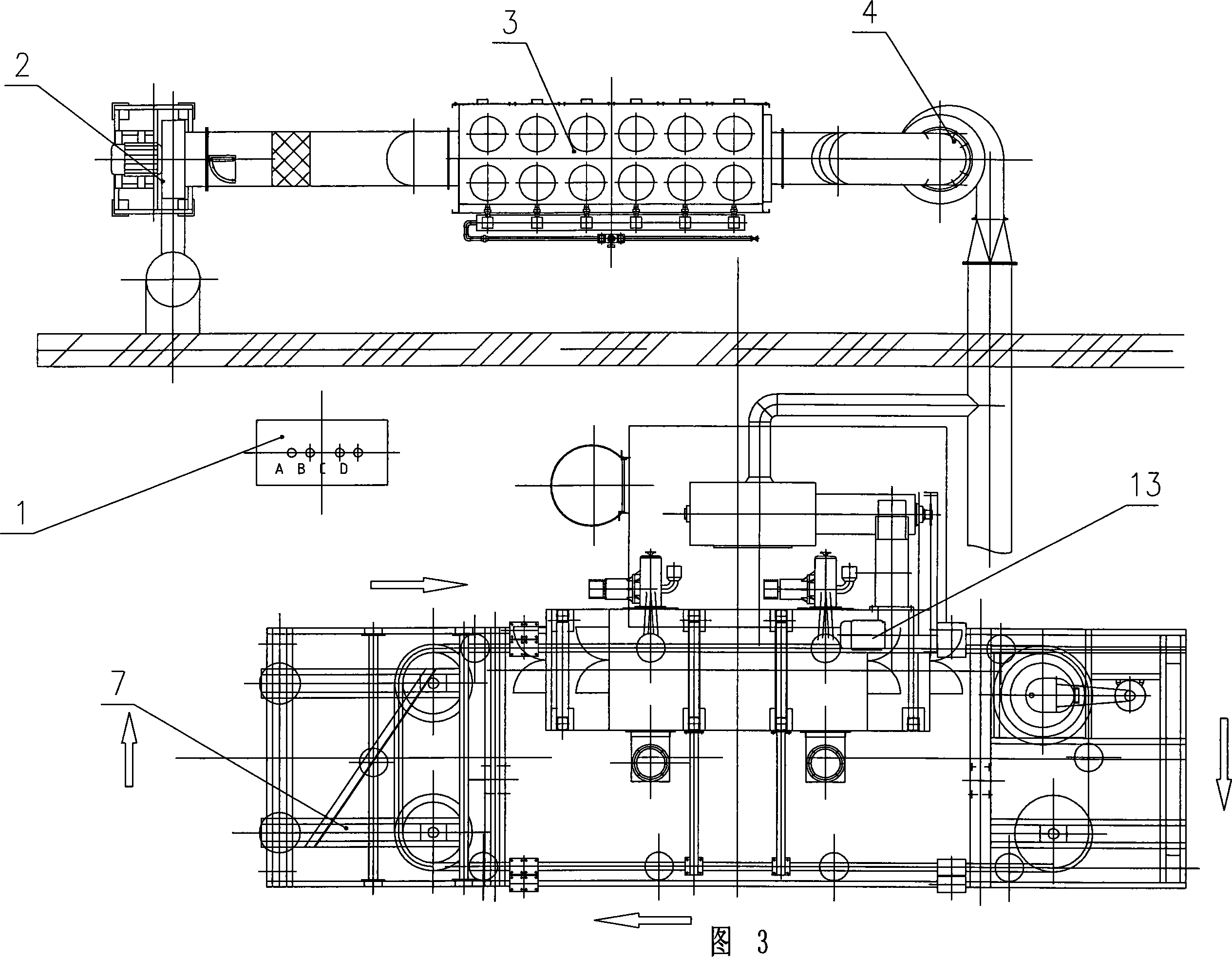

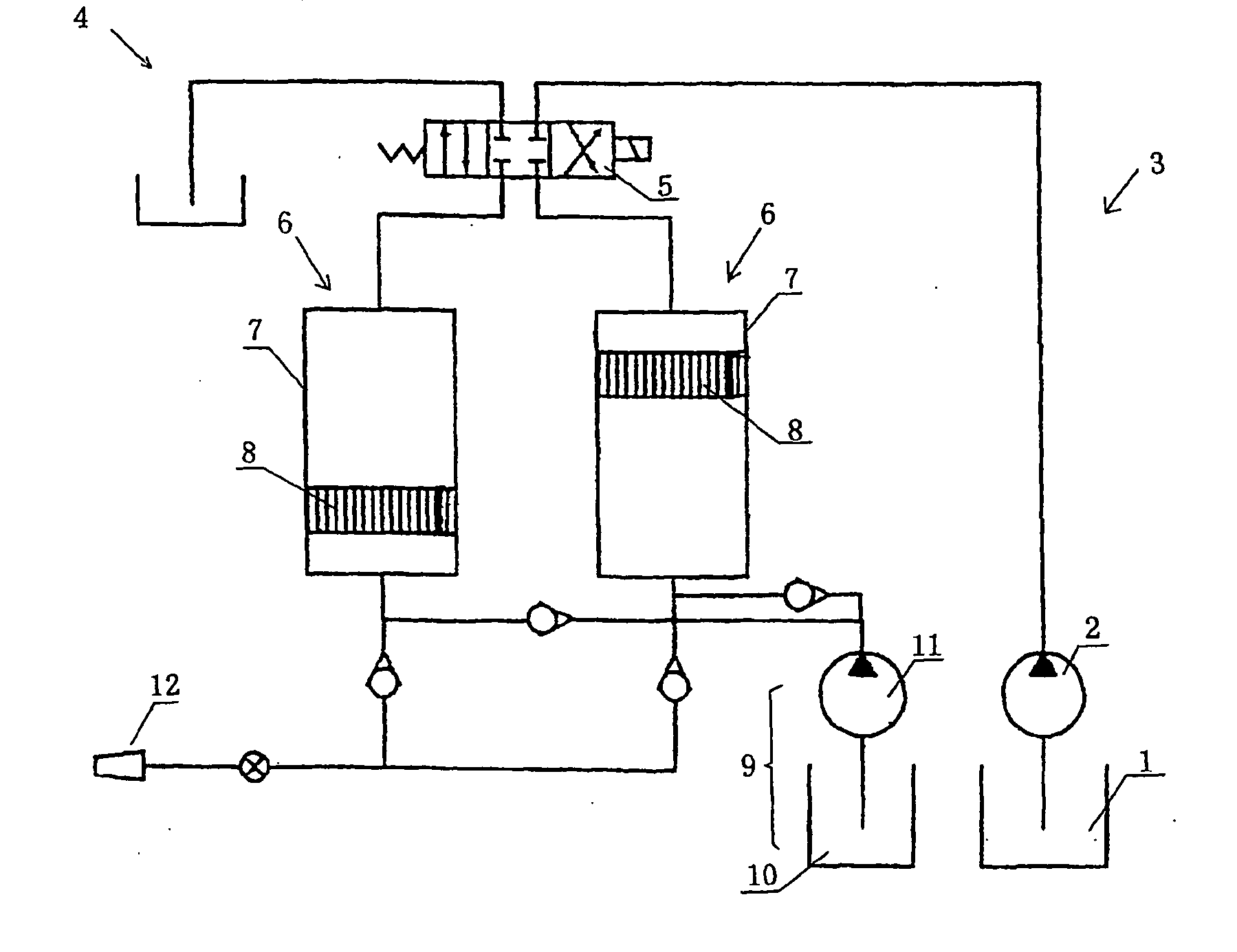

Automobile gear ruggedization shot-blasting machine

InactiveCN101157203AReduce energy consumptionImprove work efficiencyImpeller wheelsBlast gunsGear wheelEngineering

The invention belongs to equipment for cleaning the surface of a machine element by utilizing a shot blasting method, in particular to an automotive gear enhanced shot blasting machine. According to the technical proposal provided by the invention, the shot blasting machine is arranged on a shot blasting cleaning chamber. The invention is characterized in that a suspend conveyer installed on a supporting bracket is arranged at the upper part of the shot blasting cleaning chamber, the suspend conveyer is in a sealed state and circled around the shot blasting cleaning chamber, and one section passes through the shot blasting cleaning chamber, a plurality of rotating racks which can rotate under the driving of the suspend conveyer are suspended on the suspend conveyer, a curtain separator is arranged above / on the shot blasting cleaning chamber, a chamber hoisting gear is arranged on the flank of the shot blasting cleaning chamber, and a worm conveyer is arranged at the bottom of the shot blasting cleaning chamber. The input end of the curtain separator is connected with the output end of the chamber hoisting gear, and the output end of the worm conveyer is connected with the input end of the chamber hoisting gear. The invention can improve the effect of the shot blasting cleaning and the quality of the product.

Owner:无锡国达机械设备有限公司

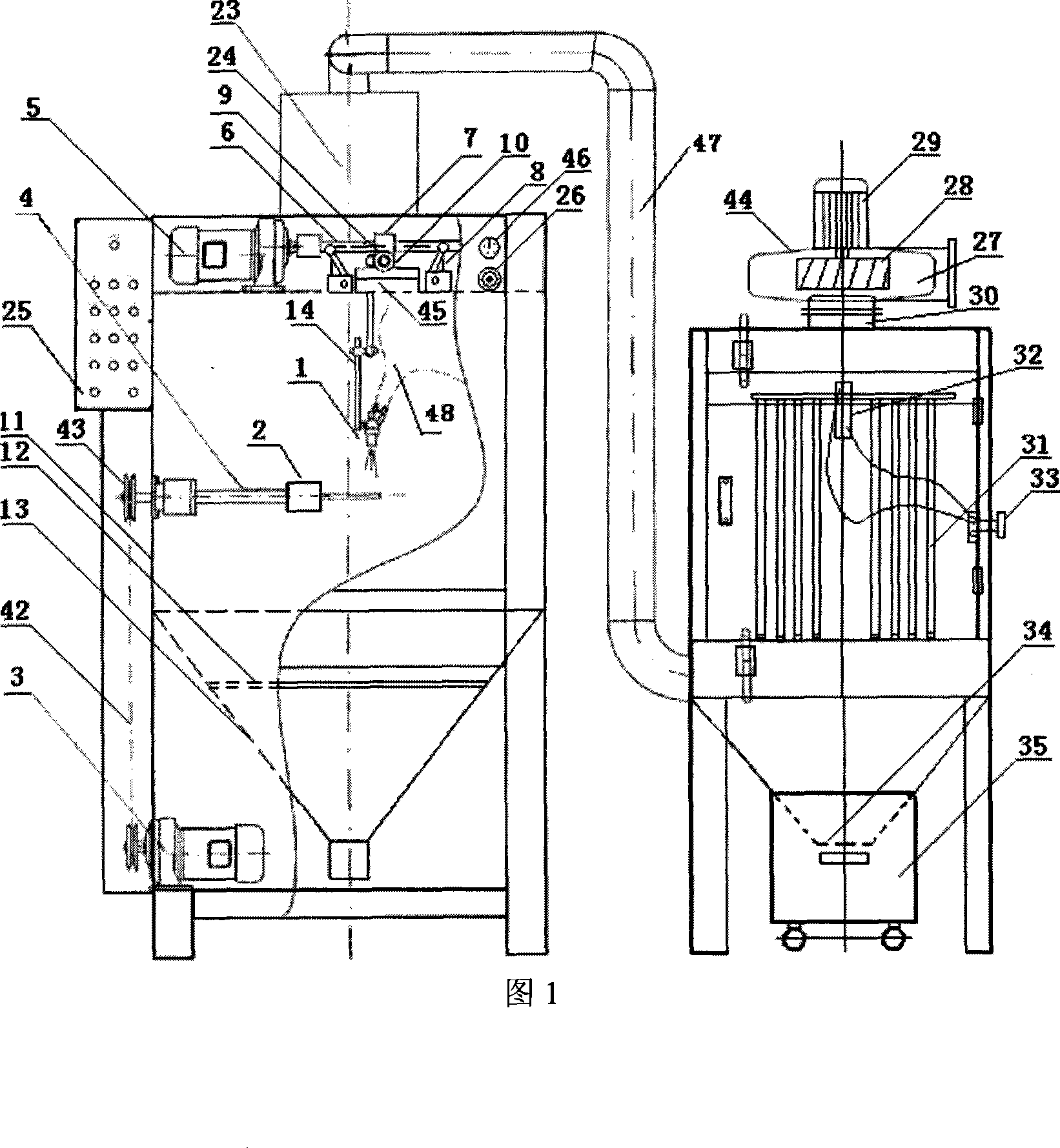

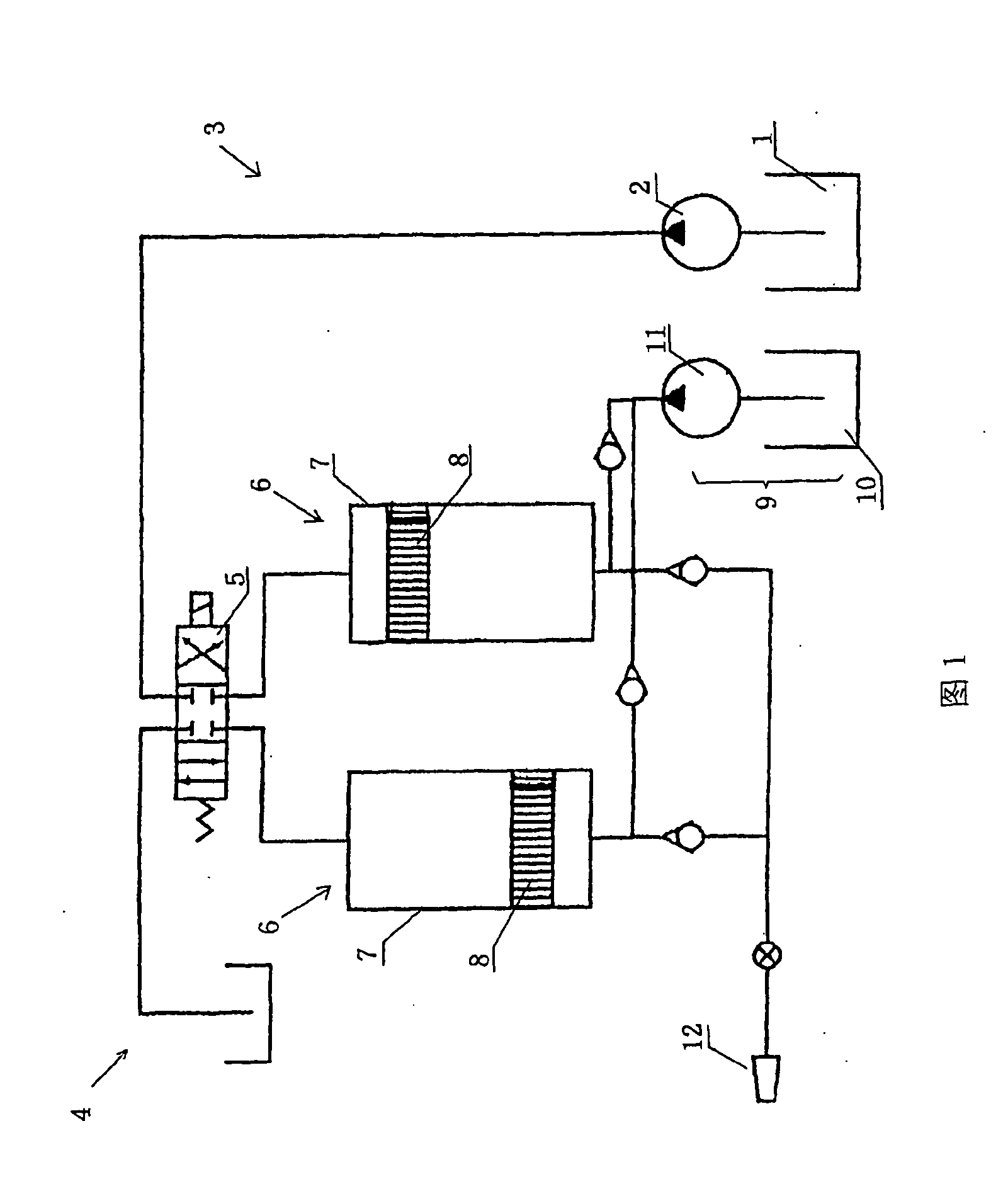

Shot peening machine for processing surface deformation strengthening treatment to magnesium alloy sample

InactiveCN101214633AGuaranteed concentricityGuaranteed parallelismImpeller wheelsBlast gunsAir compressionAbrasive blasting

The present invention relates to a device in the technical field of material processing, in particular to a peener which carries out the surface deformation strengthening process on magnesium alloy samples. The present invention comprises a main peening system, an upper whirlwind separation system, a dedusting system, an air compression system and an electric system, wherein, the upper whirlwind separation system is positioned on the upper end of the main peening system, the lower part of the upper whirlwind separation system is communicated with the main peening system, the upper part is connected with the dedusting system, which is positioned outside the main peening system, the air inlets of both the dedusting system and the main peening system are connected with the air compression system, and the electric system is connected with the main peening system, the upper whirlwind separation system, the dedusting system and the air compression system. The present invention can conveniently assemble and disassemble the samples of the shaft class, the range of the generated peening strenghth is wide, the effect and uniformity of peening is good, and moreover, pollution can be prevented.

Owner:SHANGHAI AIERSI LIGHT ALLOY

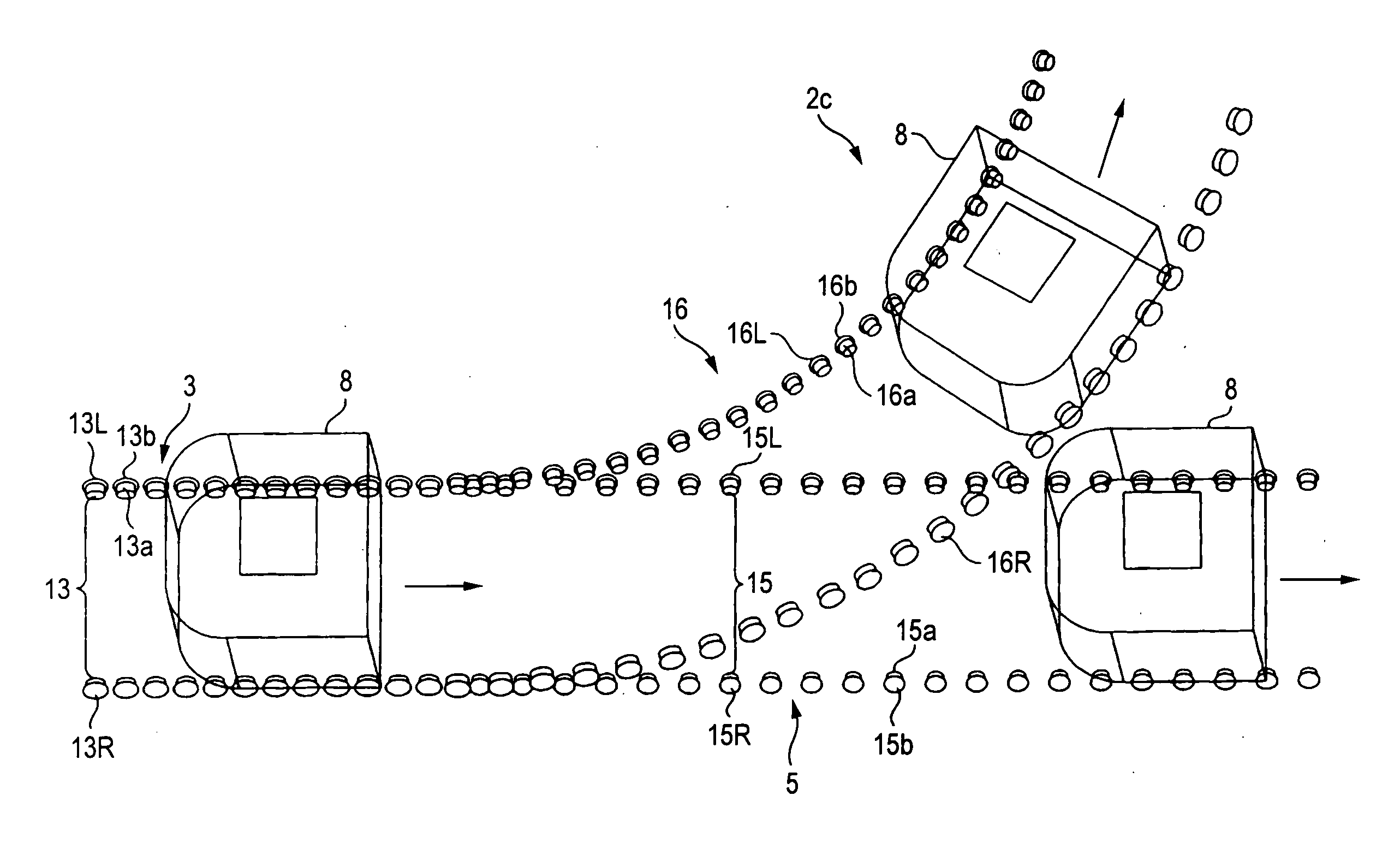

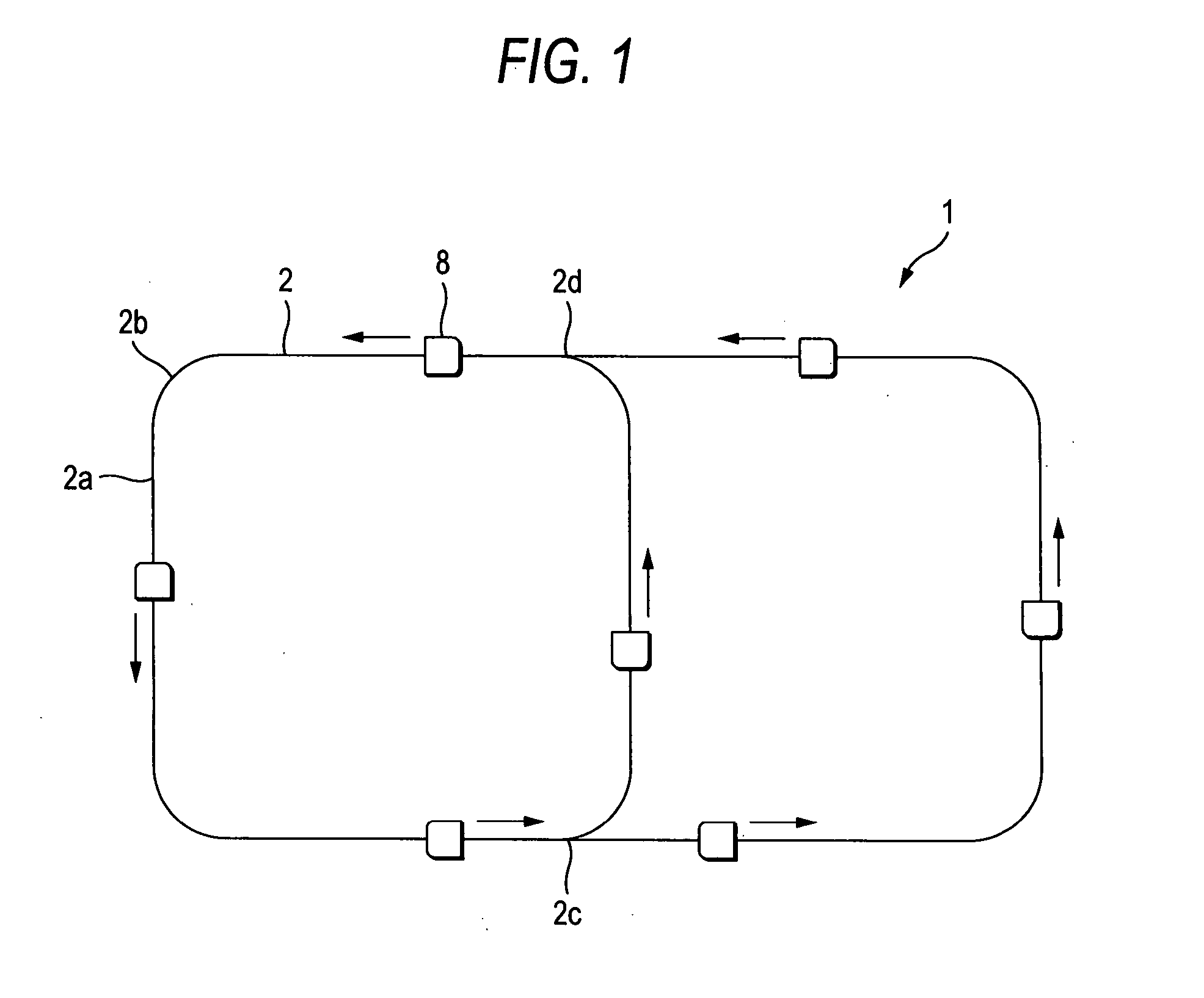

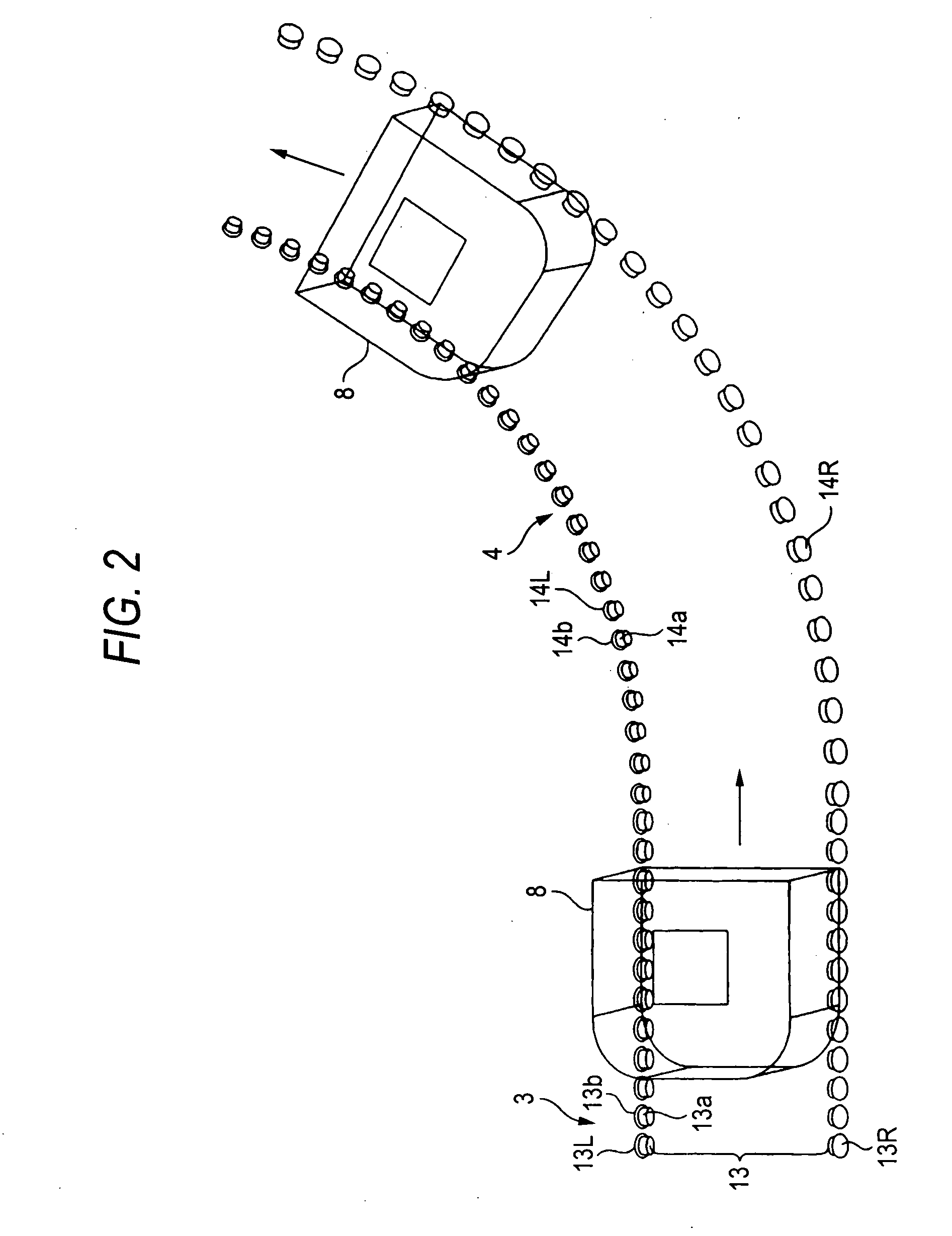

Transport apparatus

InactiveUS20070193859A1Shorten the timeChange timeImpeller wheelsRotor bladesElectrical and Electronics engineeringEngineering

A branch portion 2c is provided with a branch track 6 for guiding a carrier 8 having been guided in a straight line direction so as to change the traveling direction thereof, and a linear track 5 for guiding the carrier in the straight line direction. A switching unit switches between the branch track 6 and the linear track 5 so as to guide the carrier 8 by one of the branch track 6 and the linear track 5 in accordance with the traveling direction of the carrier 8.

Owner:ASYST SHINKO INC

Method of producing rust inhibitive sheet metal through scale removal with a slurry blasting descaling cell having improved grit flow

A method is provided for removing iron oxide scale from sheet metal and producing a sheet metal surface with rust inhibitive properties. The sheet metal is advanced through the descaling cell and a slurry mixture is propelled against at least one of the top surface and bottom surface of the sheet metal across the sheet metal width as the material is advanced through the descaling cell. The rate of slurry impact against the at least one of the top surface and bottom surface of the sheet metal is controlled in a manner to remove substantially all of the scale from a surface of the sheet metal, and in a manner to create a passivation layer on the descaled surface of the sheet metal. The passivation layer comprises at least one of silicon, aluminum, manganese and chromium and inhibits oxidation of the descaled surface of the processed sheet metal.

Owner:THE MATERIAL WORKS

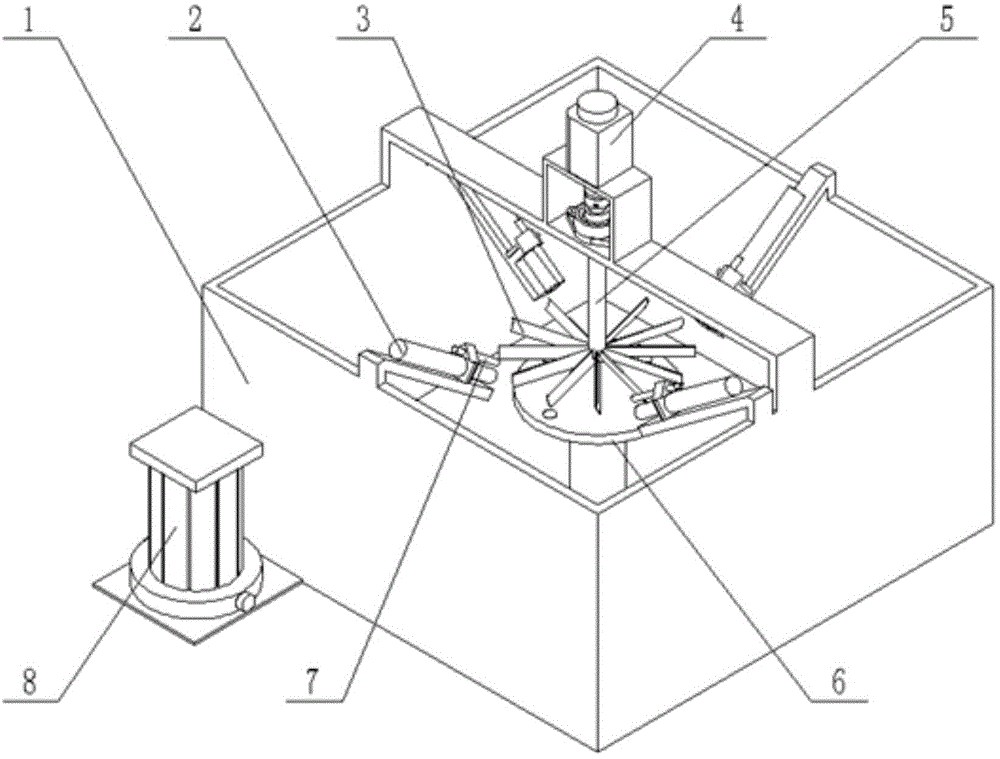

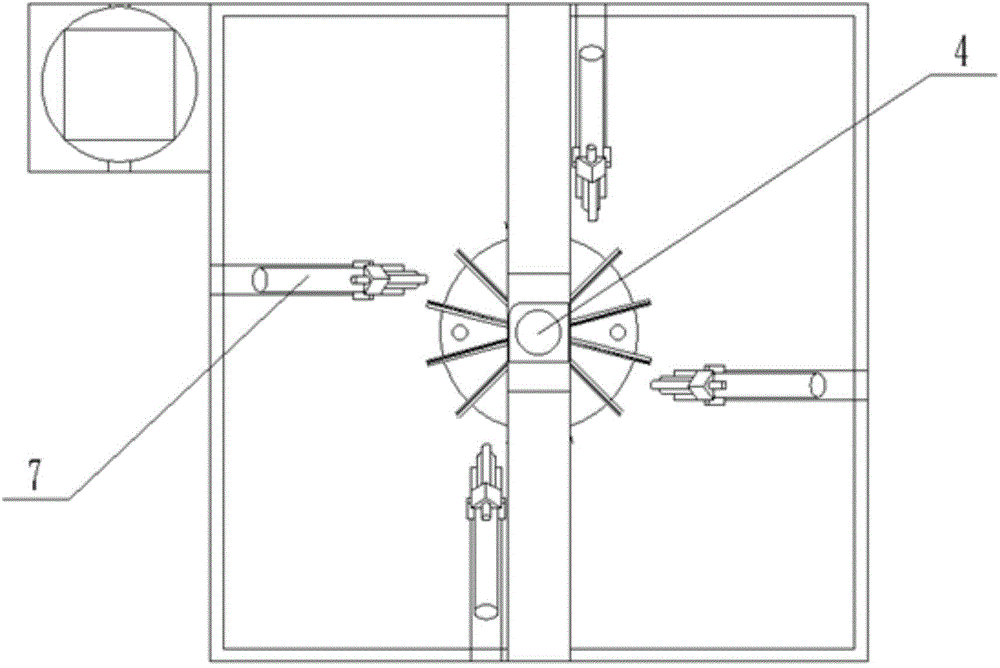

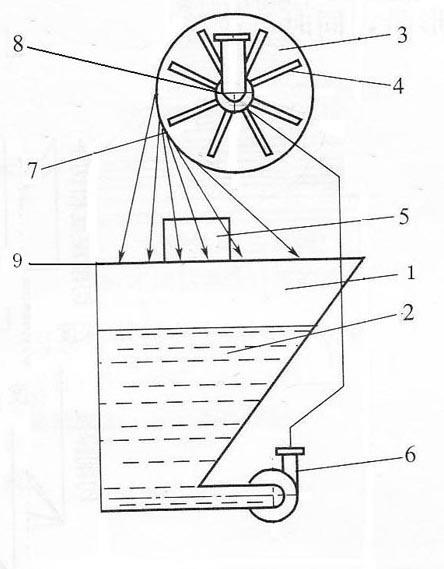

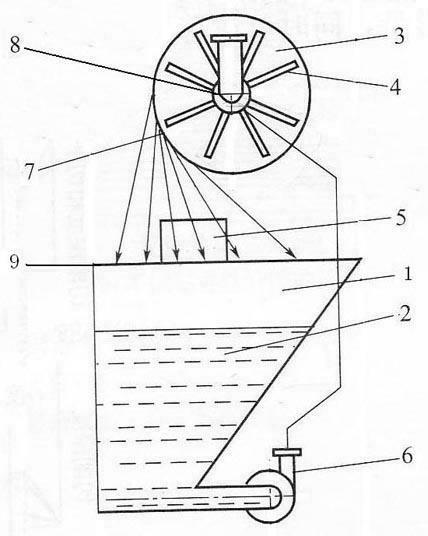

Ultrasonic polishing processing device using gas-liquid-solid three-phase abrasive particle flow

ActiveCN104786157AEliminate the disadvantages of uneven pressure distributionImprove uniformityImpeller wheelsRotor bladesReal time acquisitionUltrasonic generator

The invention discloses an ultrasonic polishing processing device using a gas-liquid-solid three-phase abrasive particle flow, the ultrasonic polishing processing device includes a computer control system, an abrasive particle flow processing pool, an ultrasonic generator, a pneumatic pipeline, a high speed blade rotation device, a workpiece installation platform and an abrasive particle flow mixing pump, a beam is arranged above the abrasive particle flow processing pool, the high speed blade rotation device is fixed on the beam, the workpiece installation platform is fixed in the abrasive particle flow processing pool arranged just below the high speed blade rotation device, the abrasive particle flow mixing pump is arranged on the side face of the abrasive particle flow processing pool, and is used for mixing an abrasive particle flow in the abrasive particle flow processing pool, the ultrasonic generator is fixed on the side face of the abrasive particle flow processing pool, and an emission head is directly faced to the workpiece installation platform. The ultrasonic polishing processing device can be used for real-time acquisition of temperature and viscosity signals for feedback regulation of ultrasonic bubble generator power so as to ensure processing stability; and the ultrasonic bubble generator is cooperated with airflow, and circumferentially arranged, can better improve the uniformity of the number of the workpiece surface bubbles, and improves the processing efficiency.

Owner:ZHEJIANG UNIV OF TECH

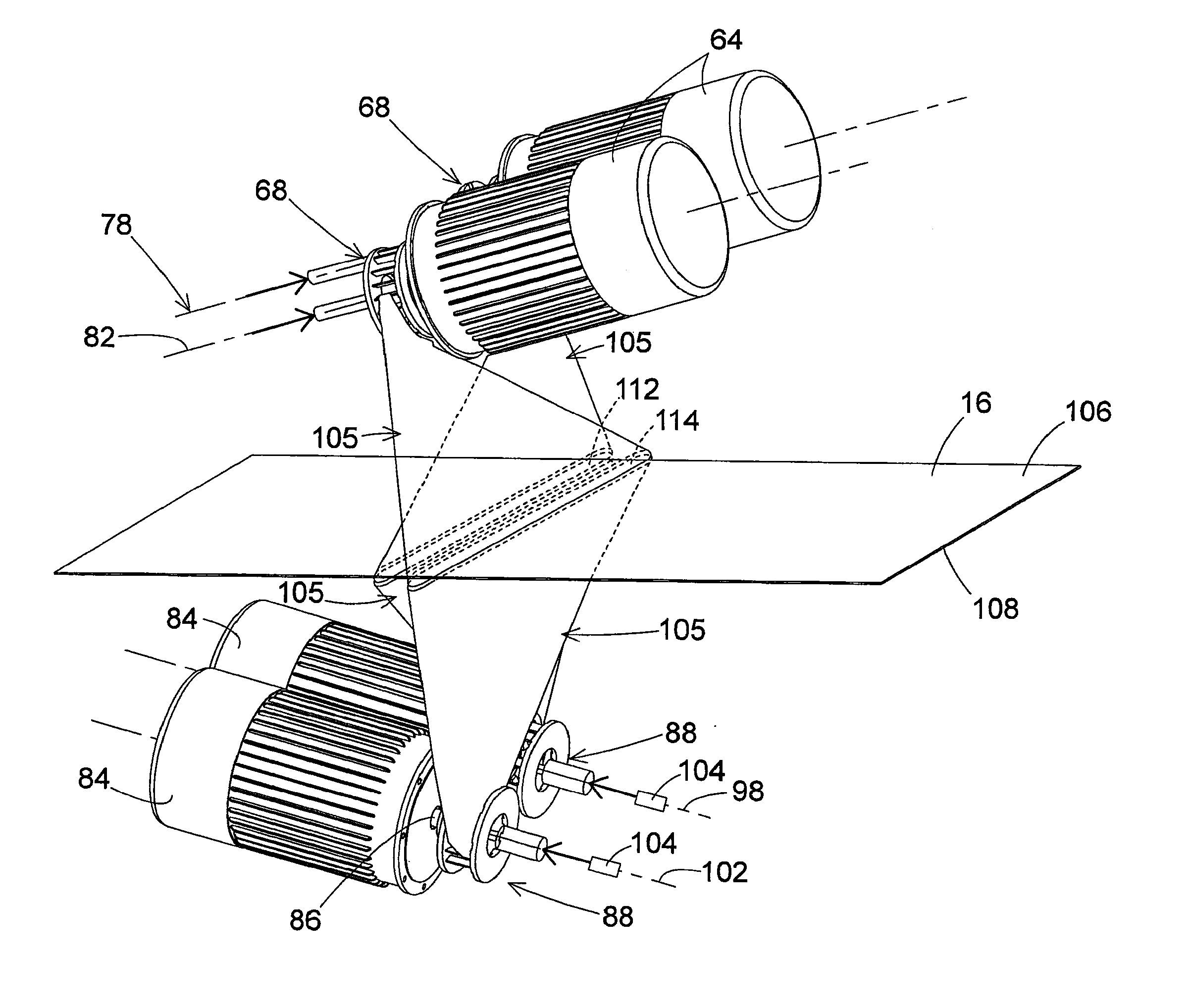

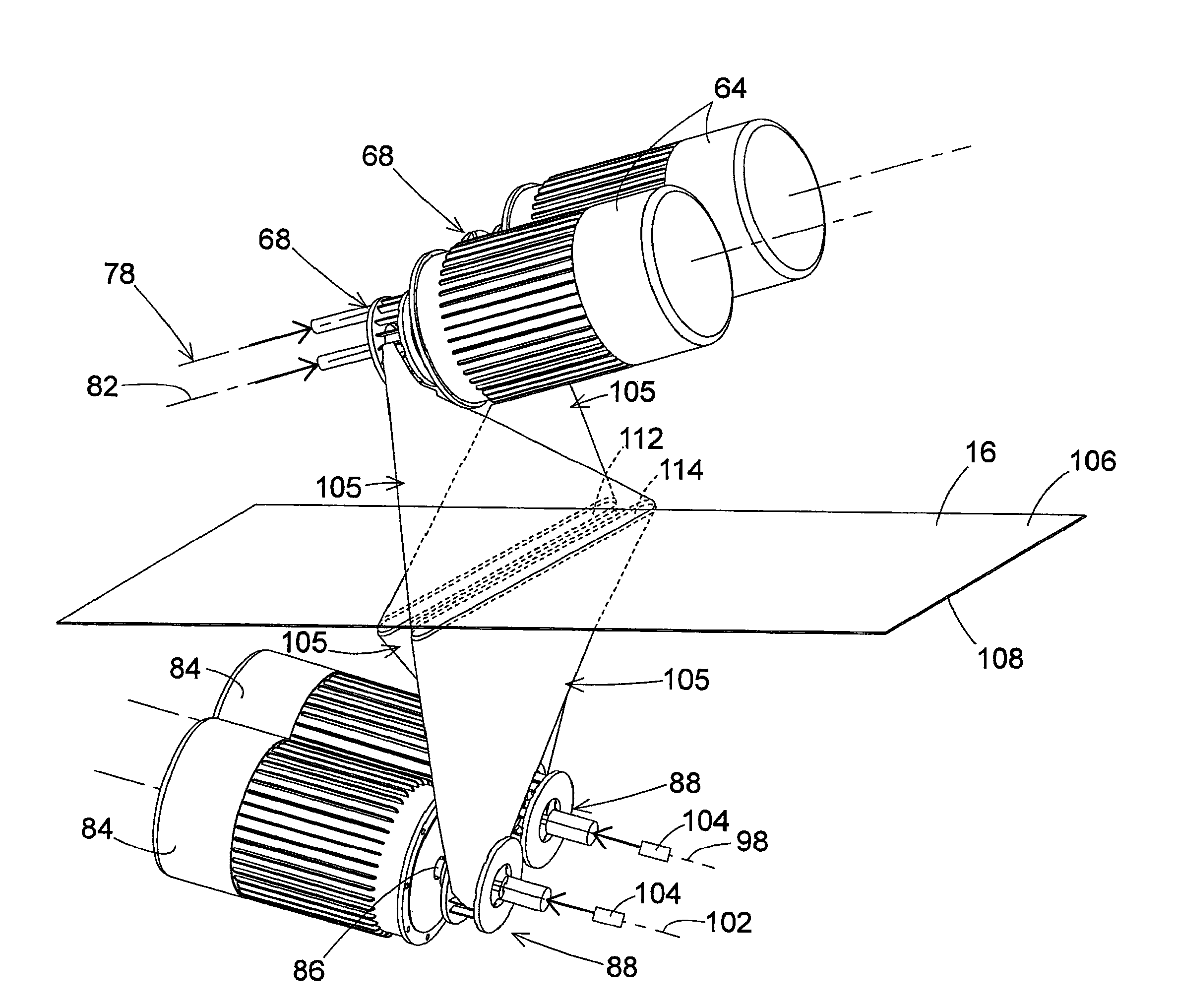

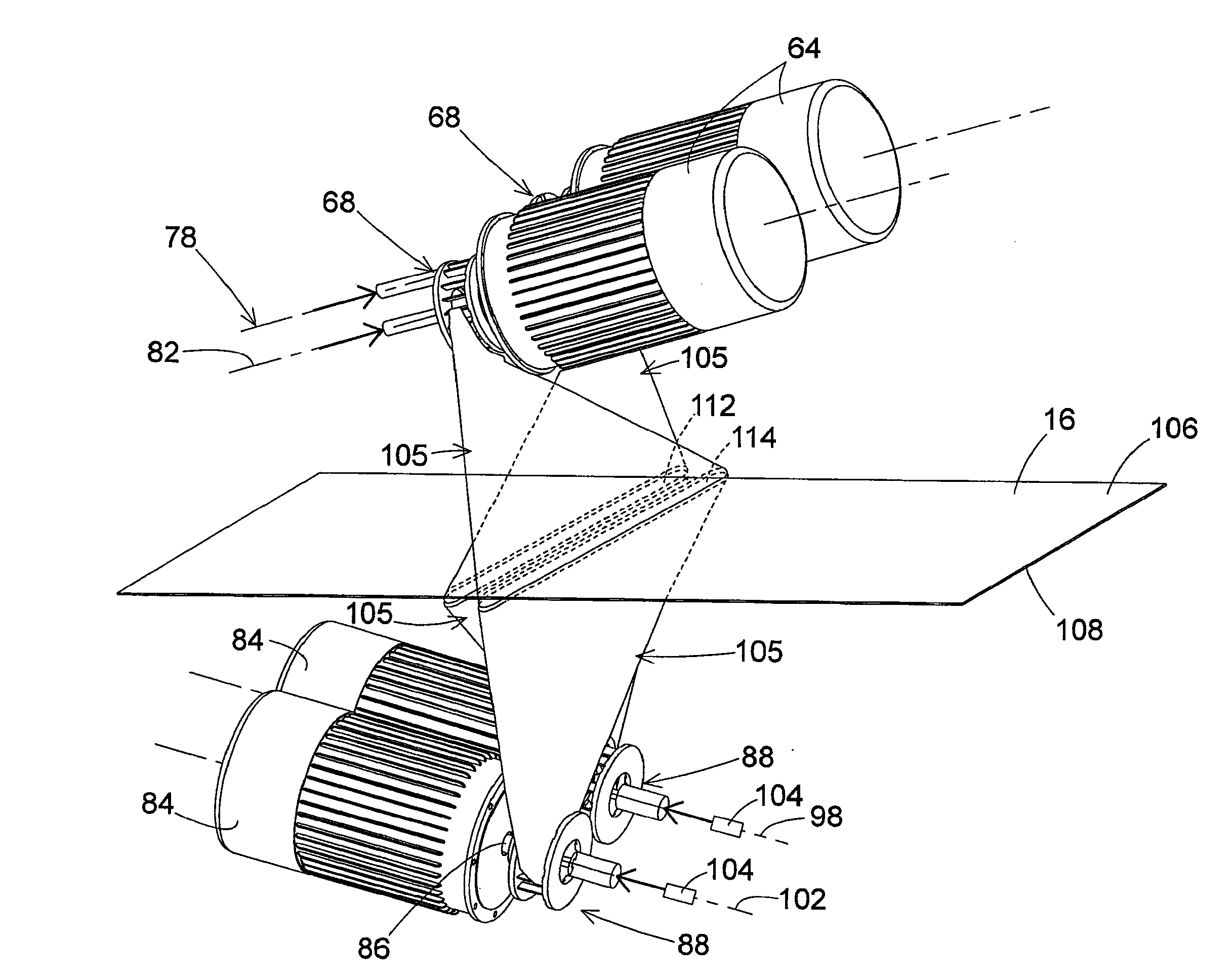

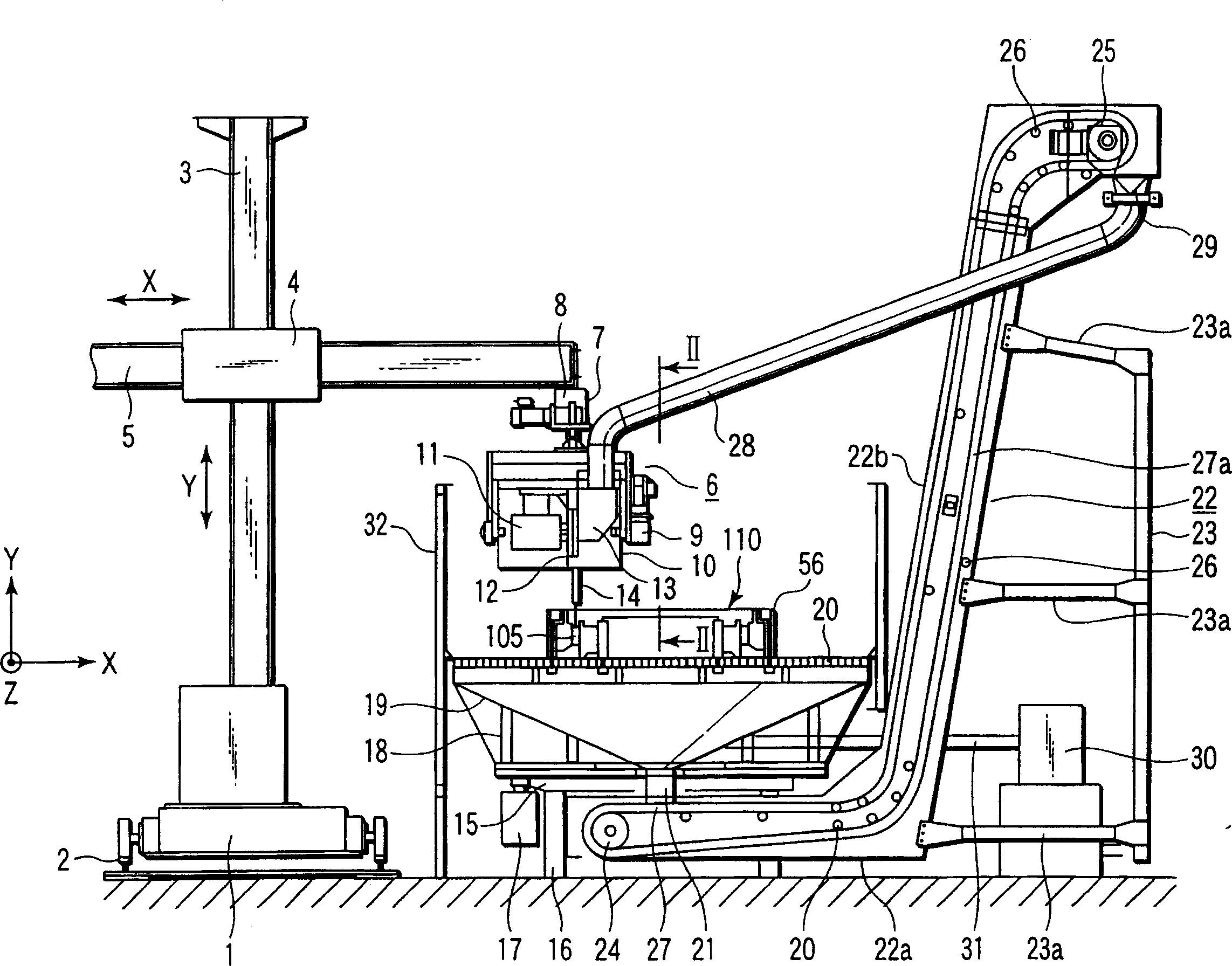

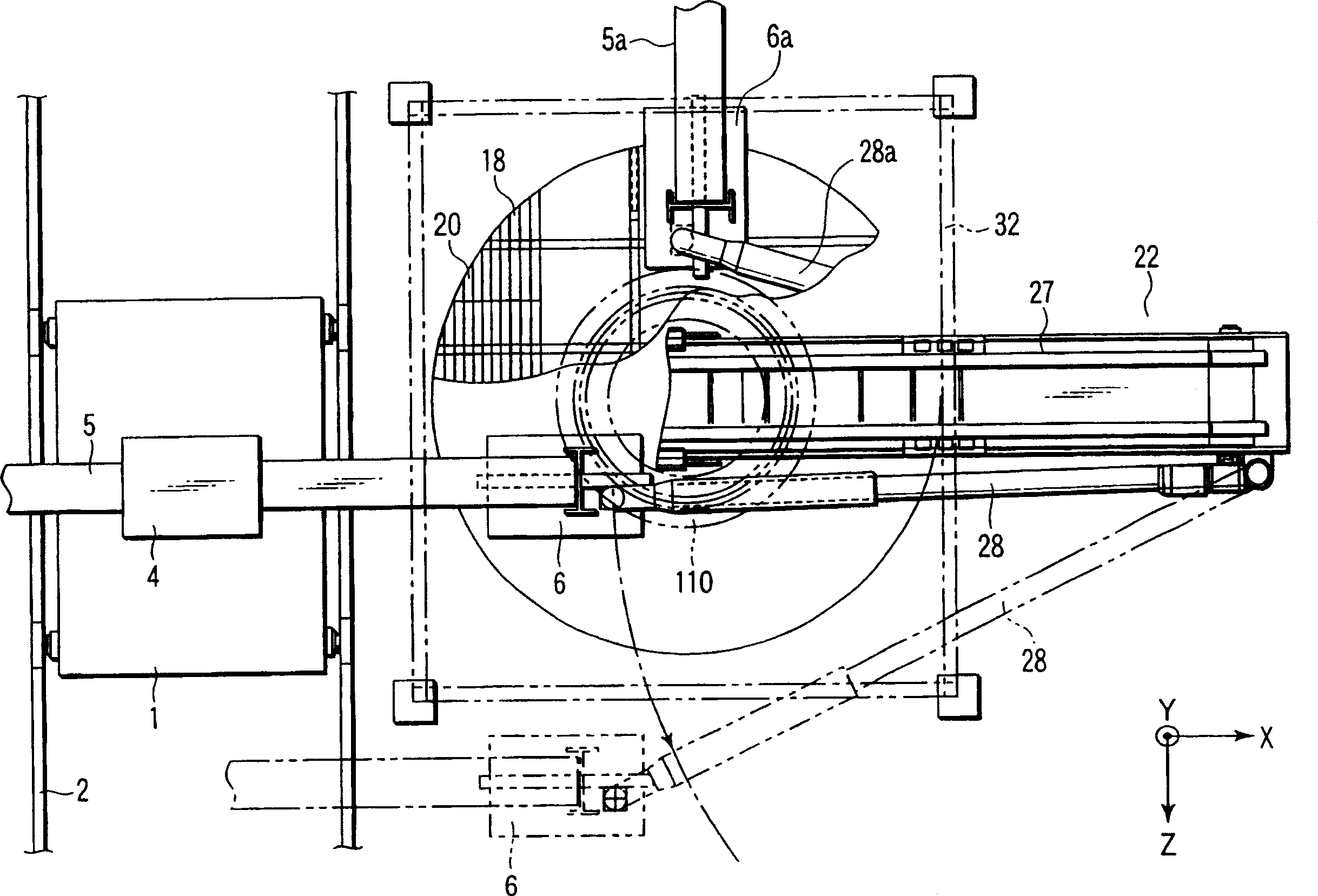

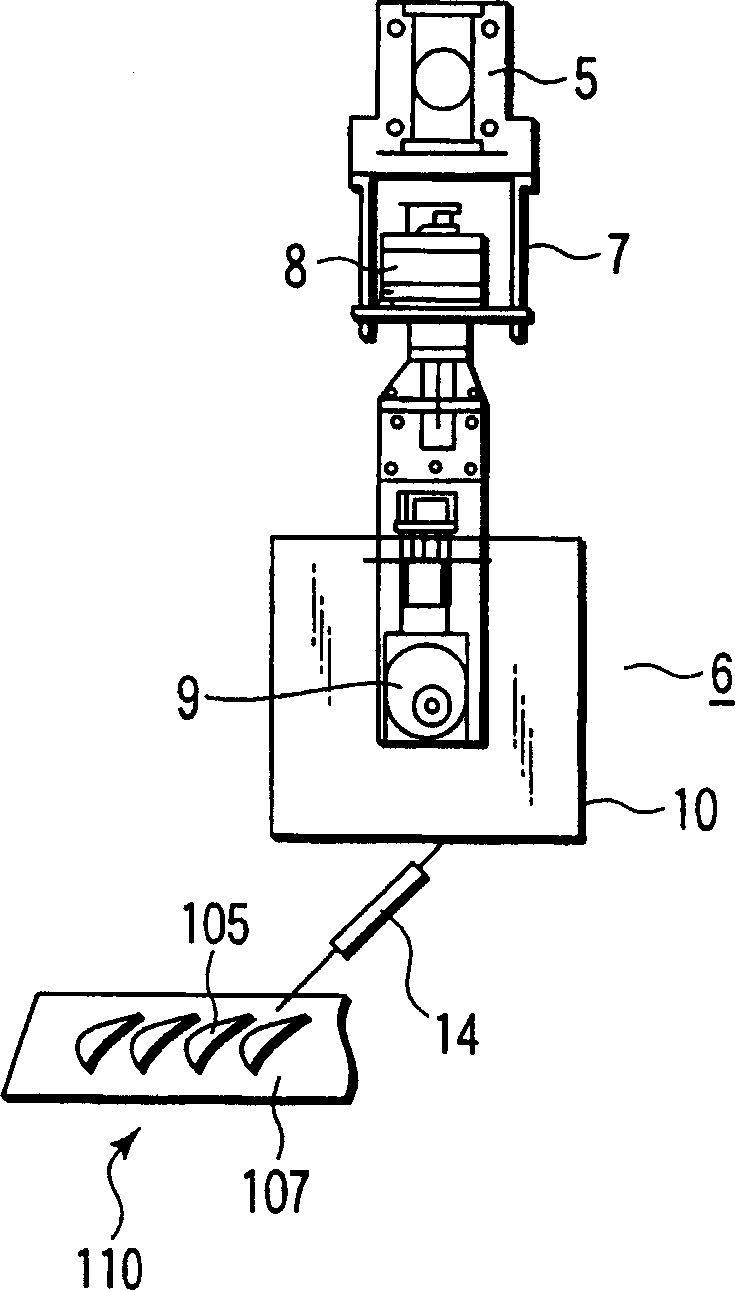

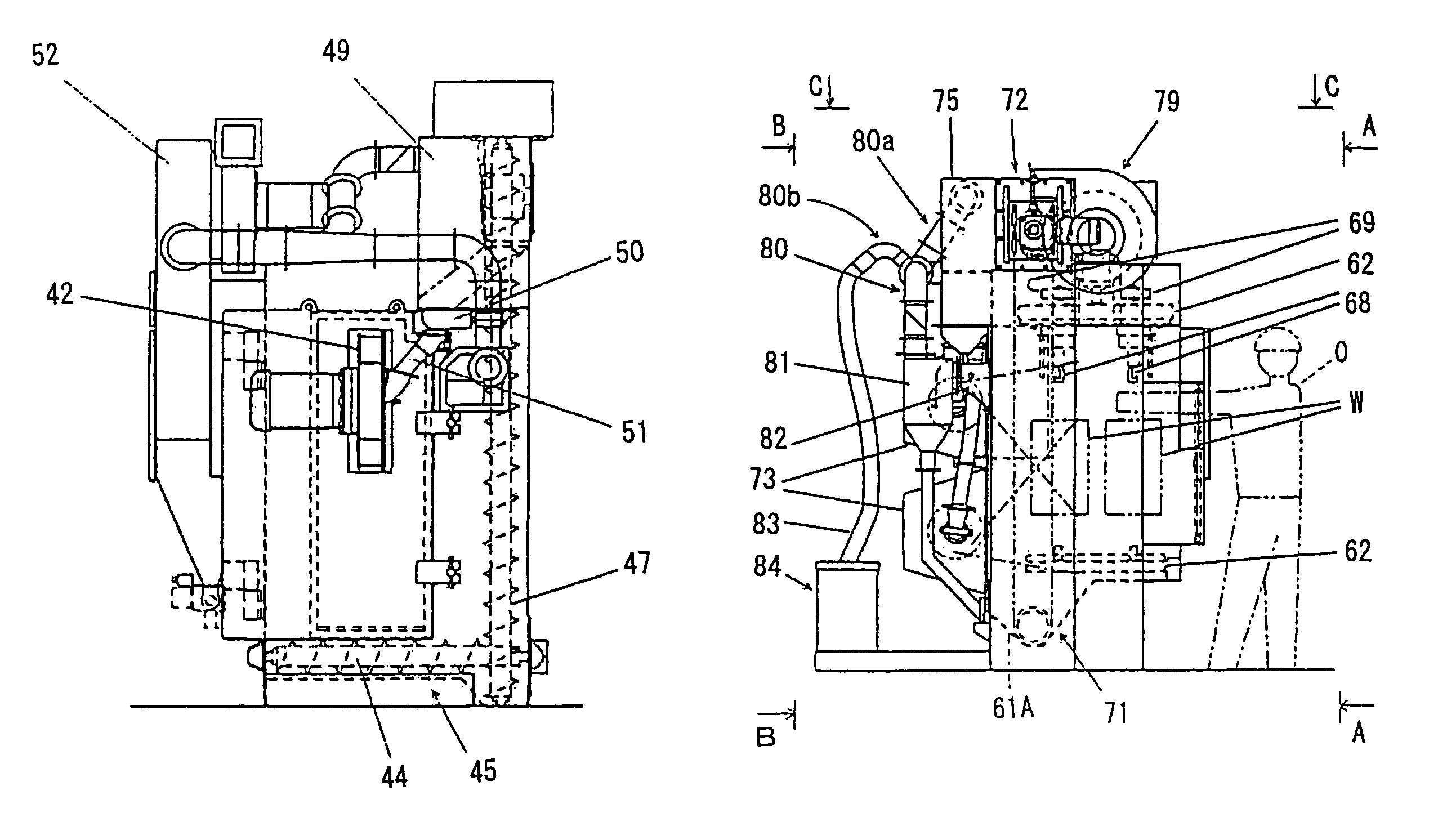

Large part polishing apparatus and polishing method

InactiveUS20060111025A1Reduce surface roughnessPolish surfaceImpeller wheelsRotor bladesImpellerDrive motor

The present invention comprises a turntable which holds a turbine part at a predetermined position, the turn table being rotatably supported by a support member, and rotated and driven by a driving motor, an abrasive feeding unit which feeds an abrasive particle having an elastic material as a core to a predetermined position as an abrasive, and a polishing head including an impeller which is rotated and driven by an impeller driving motor at high speed and applies rotary energy to the abrasive particle to be supplied from the abrasive feeding unit, the polishing head injecting the abrasive particle flying from the tangential direction of the impeller at a predetermined speed toward a surface to be polished of the turbine part held on the turntable, and an abrasive recovery unit which recovers the abrasive particle provided for polishing of the turbine part from the polishing head, and feeding into the abrasive feeding unit.

Owner:KK TOSHIBA

Method of producing rust inhibitive sheet metal through scale removal with a slurry blasting descaling cell having improved grit flow

Owner:THE MATERIAL WORKS

Method of producing rust inhibitive sheet metal through scale removal with a slurry blasting descaling cell

Owner:THE MATERIAL WORKS

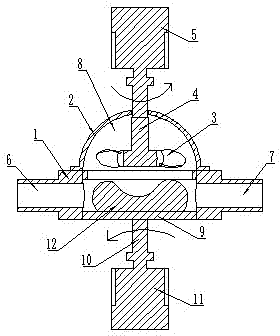

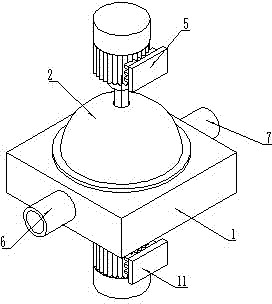

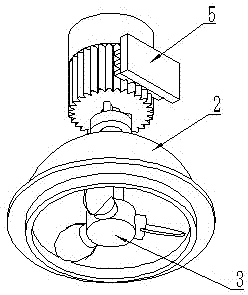

Abrasive grain flow polishing device with vane wheel

ActiveCN103612212AAvoid uneven polishingImprove polishing efficiencyImpeller wheelsRotor bladesArtificial jointsMetallurgy

The invention relates to the field of abrasive grain flow polishing, and in particular relates to an abrasive grain flow polishing device for a titanium alloy artificial joint. The abrasive grain flow polishing device comprises a box body, a cover body and a vane wheel, wherein a rotary device is arranged in the center of the box body; a workpiece is arranged on the rotary device; the cover body is sleeved above the box body; a sealed polishing chamber is formed between inner cavities of the cover body and the box body; an abrasive grain flow incoming port and an abrasive grain flow outgoing port are formed in two sides of the box body respectively and are communicated with the polishing chamber; the vane wheel is arranged in the polishing chamber, is positioned above the workpiece and can rotate around a rotary shaft. According to the abrasive grain flow polishing device, an abrasive grain flow runner is formed in the polishing chamber, the rotary device in the box body can drive the workpiece to rotate, the vane wheel is arranged above the polishing chamber and can rotate under the driving of a motor, and the rotation direction of the vane wheel is opposite to the rotation direction of the workpiece, so that grinding liquid in the polishing chamber performs relatively disordered motion, small-force micro-cutting on the surface is realized, the mirror-level surface roughness is achieved, and the device is good in polishing effect and high in accuracy.

Owner:NANTONG YUANZHENG FREEZING EQUIP LTD

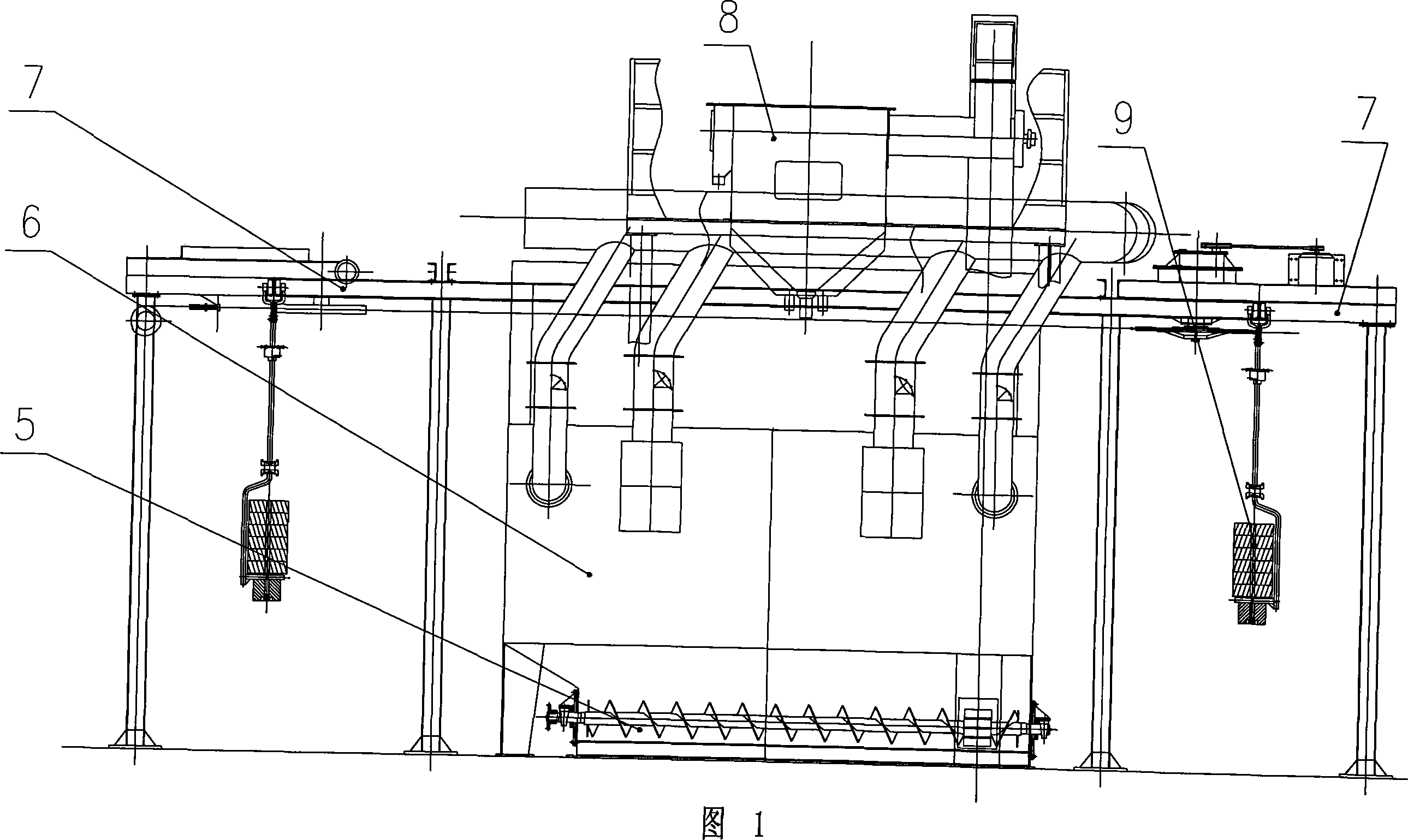

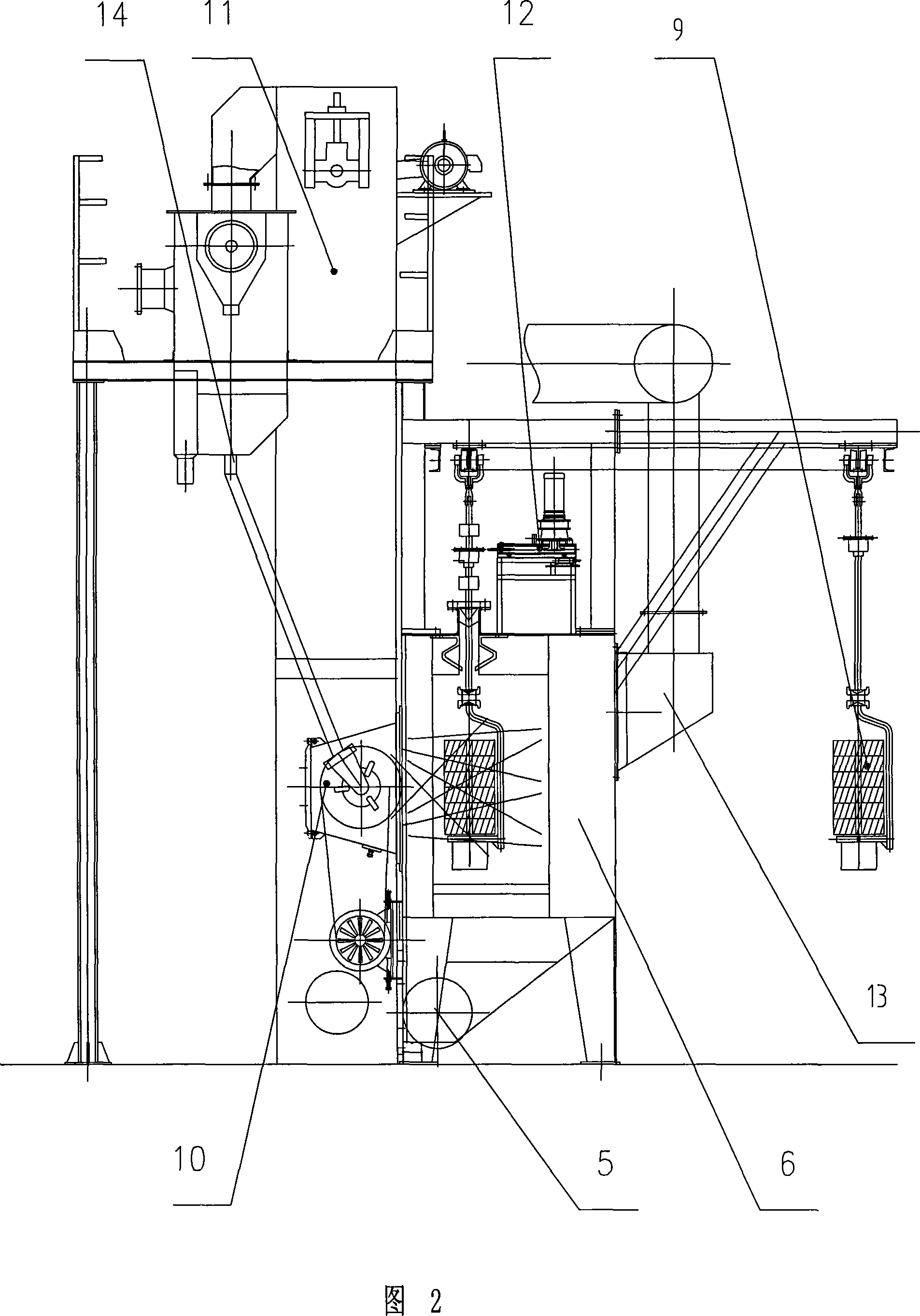

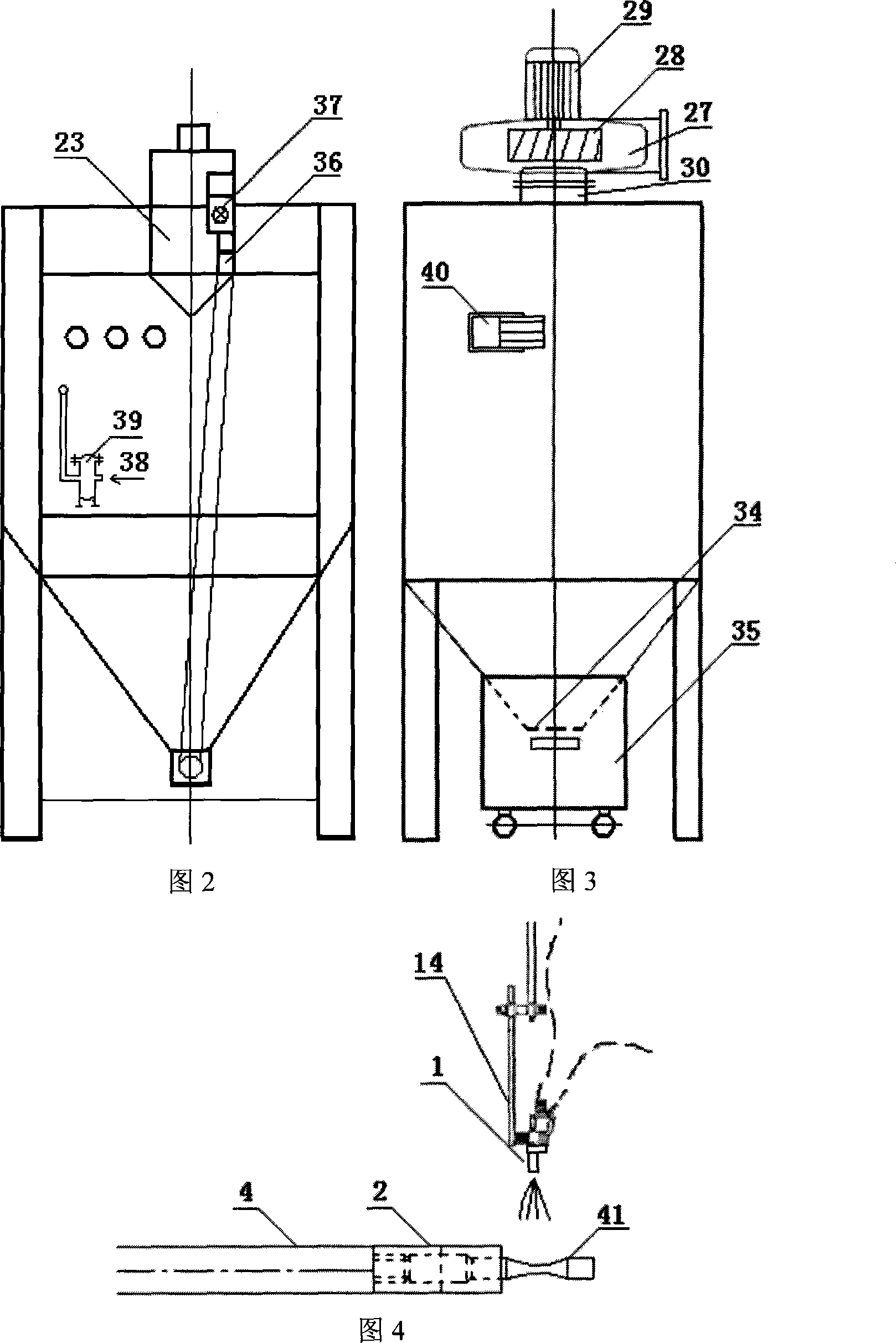

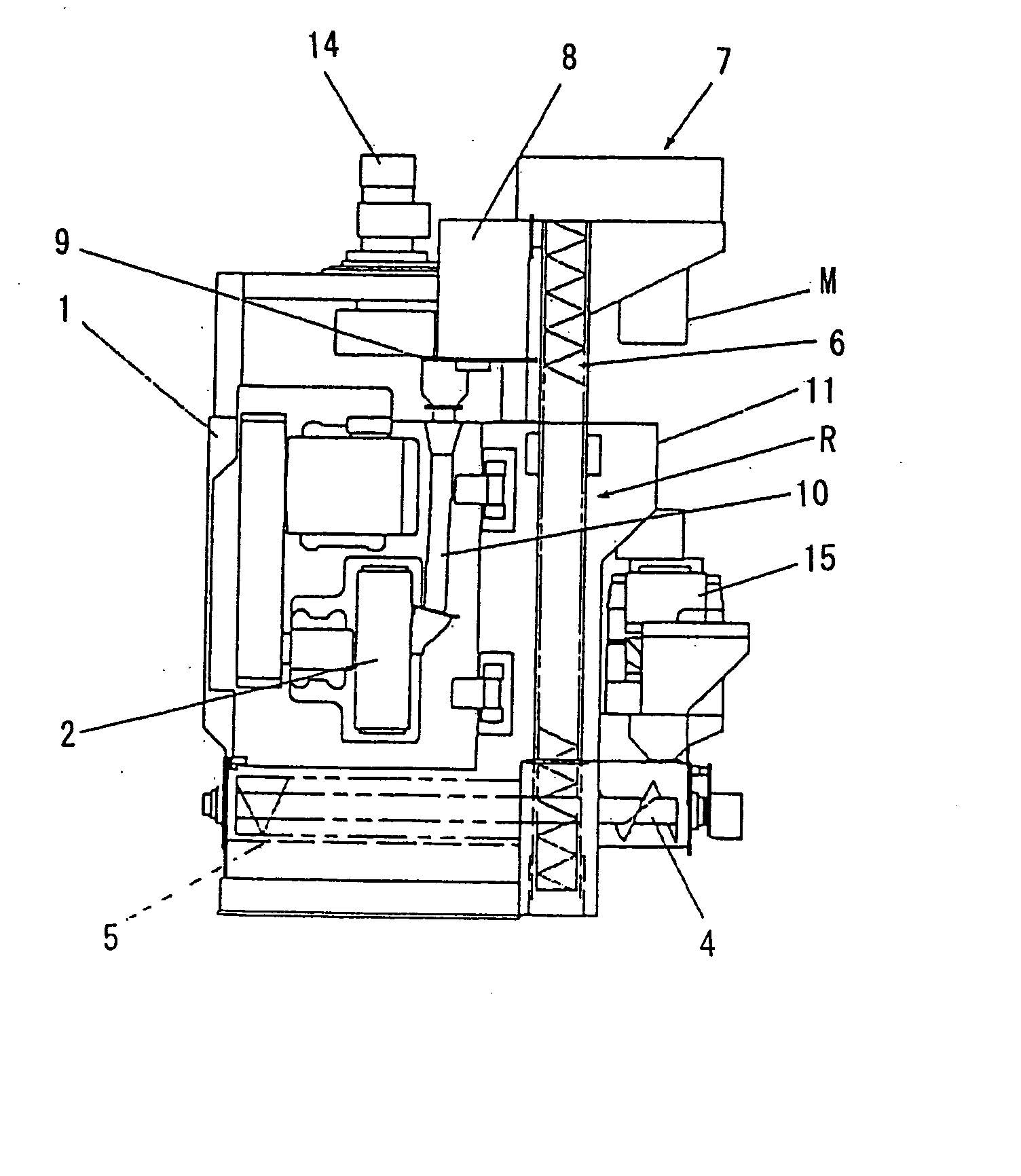

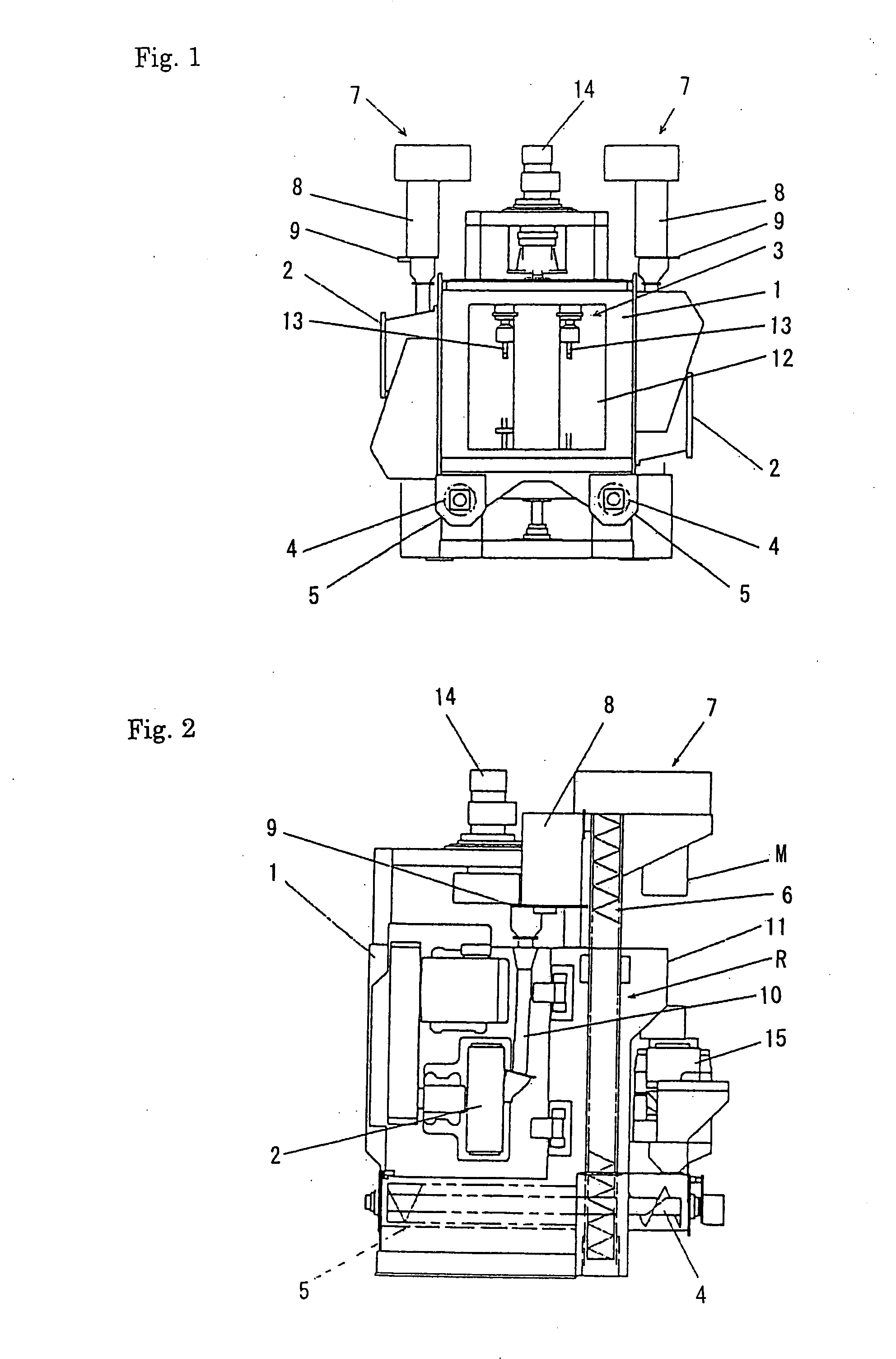

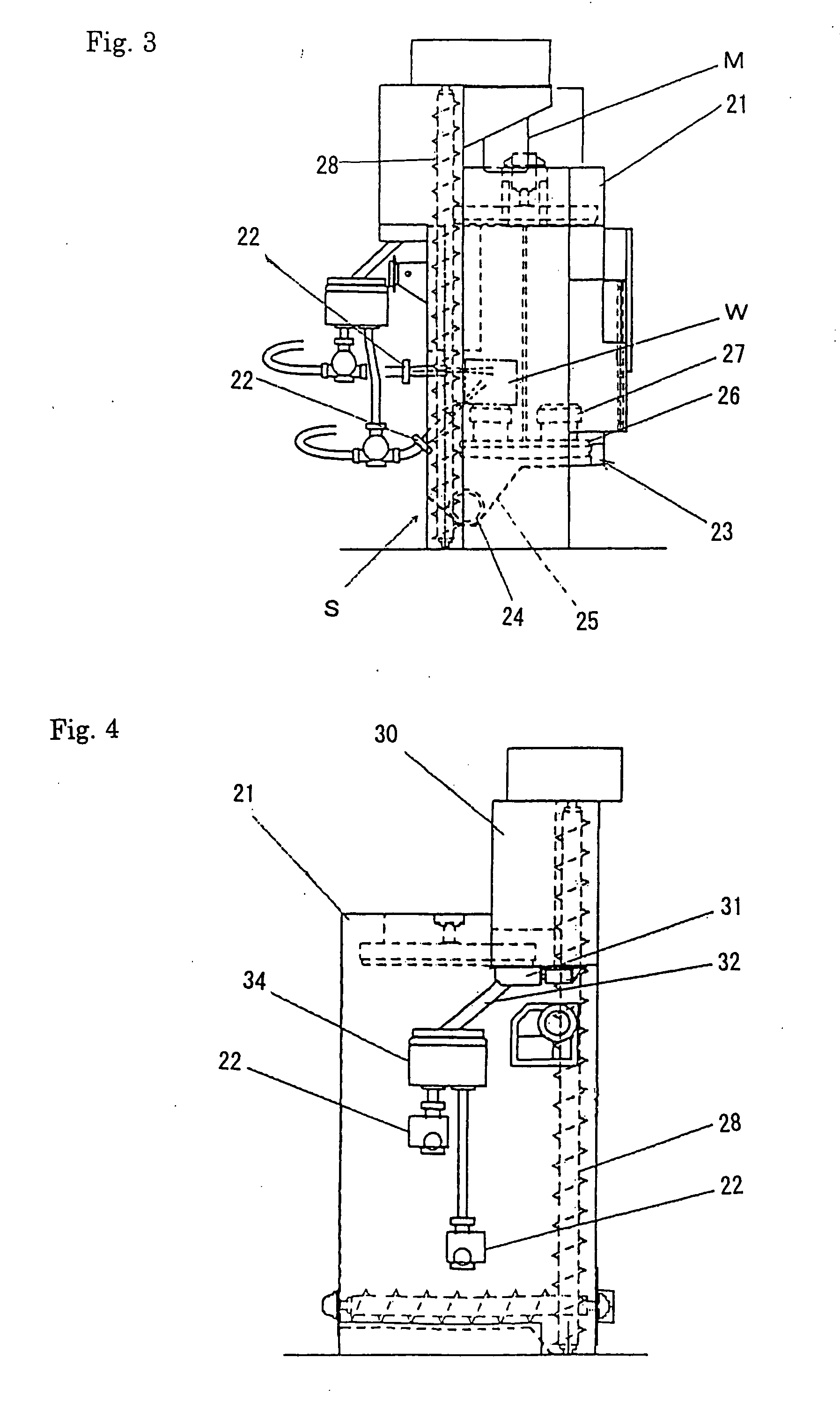

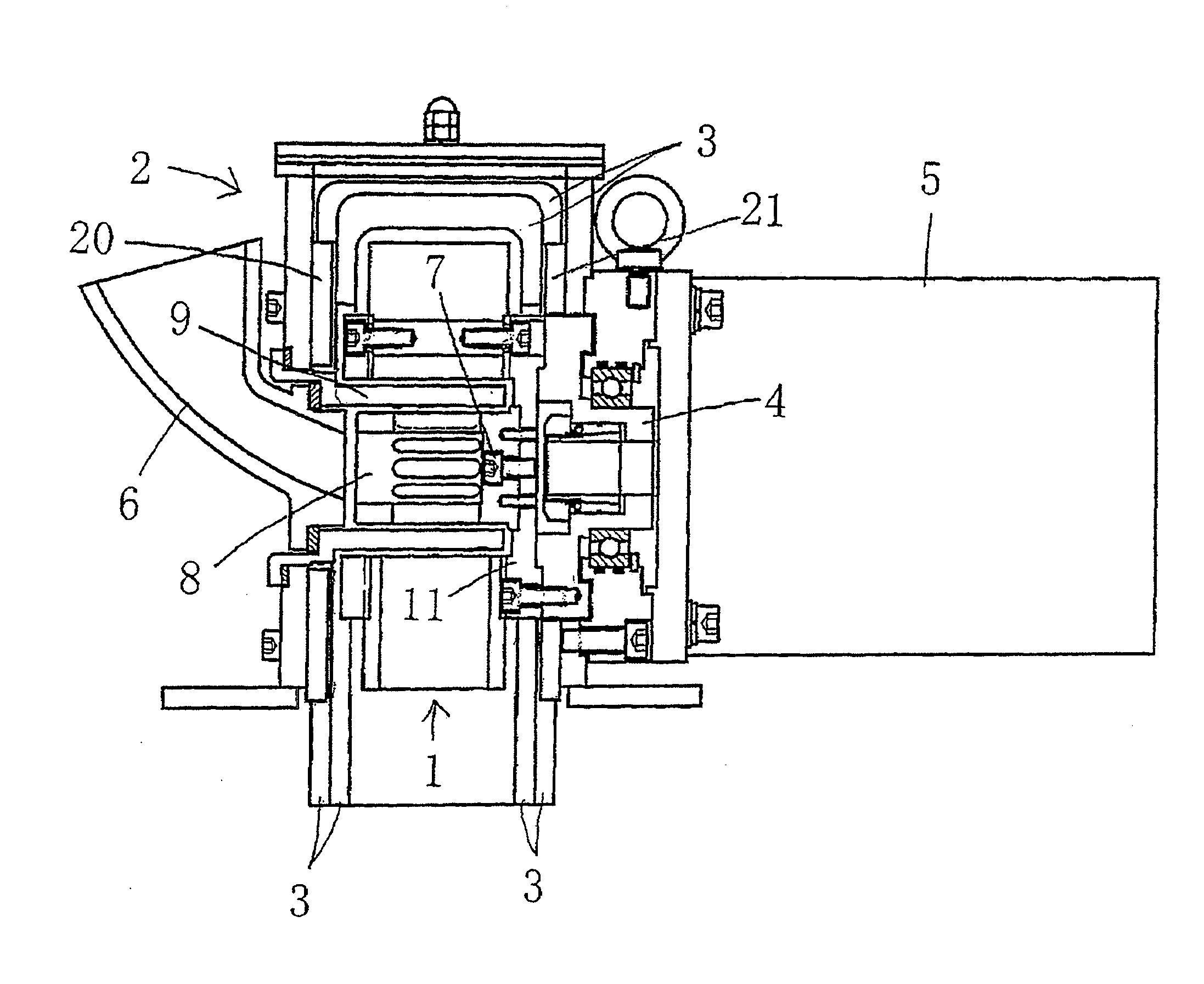

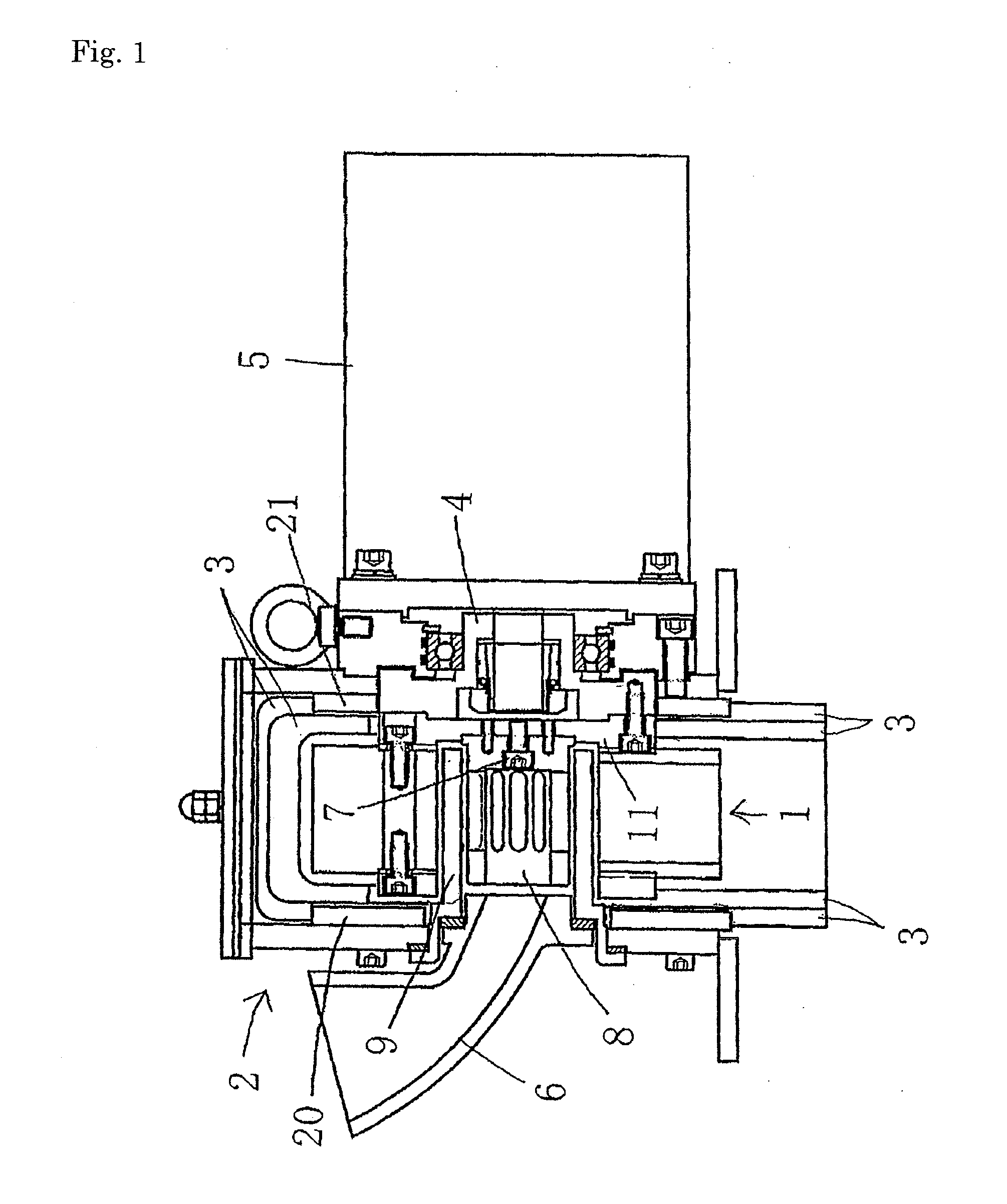

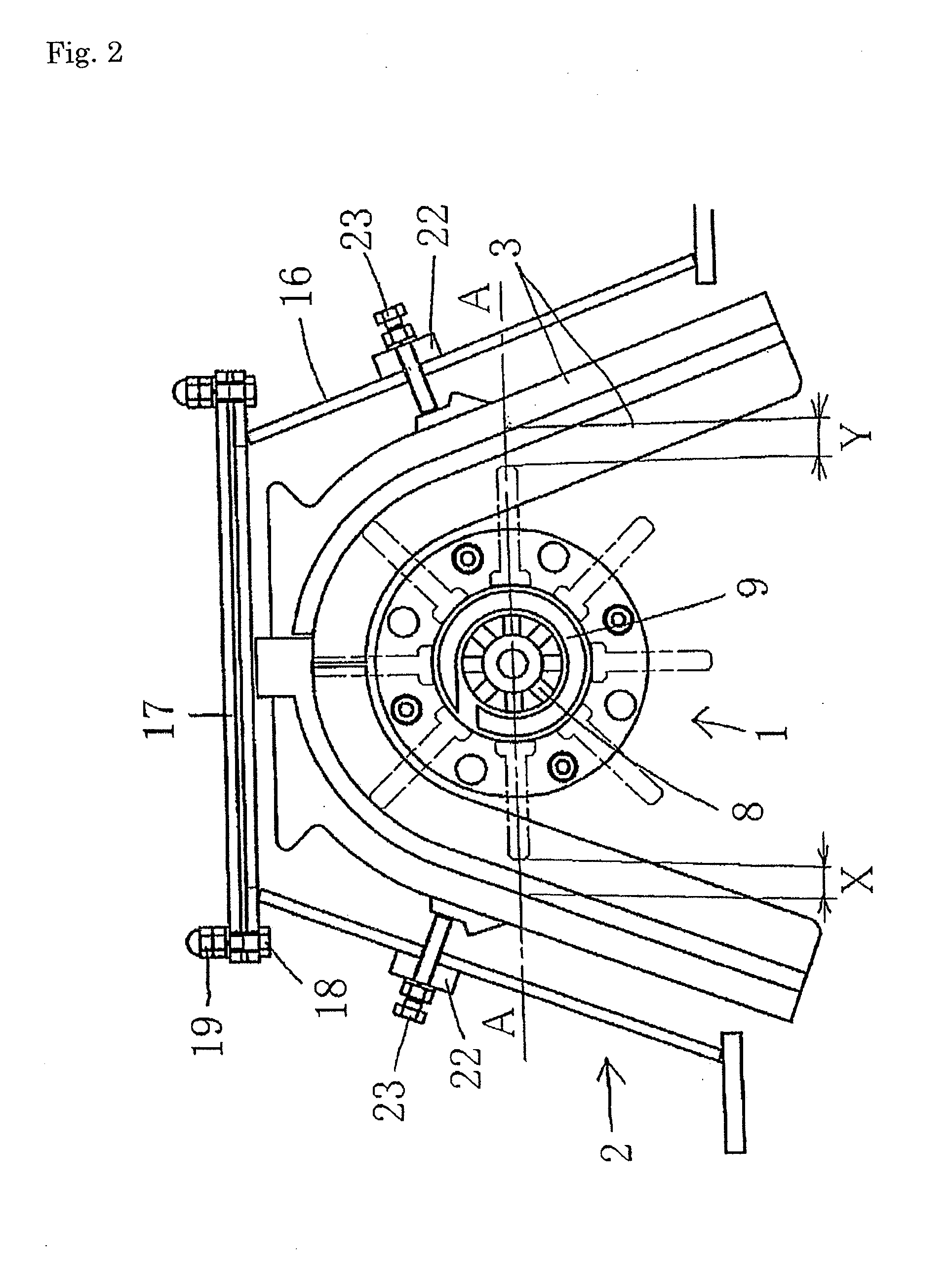

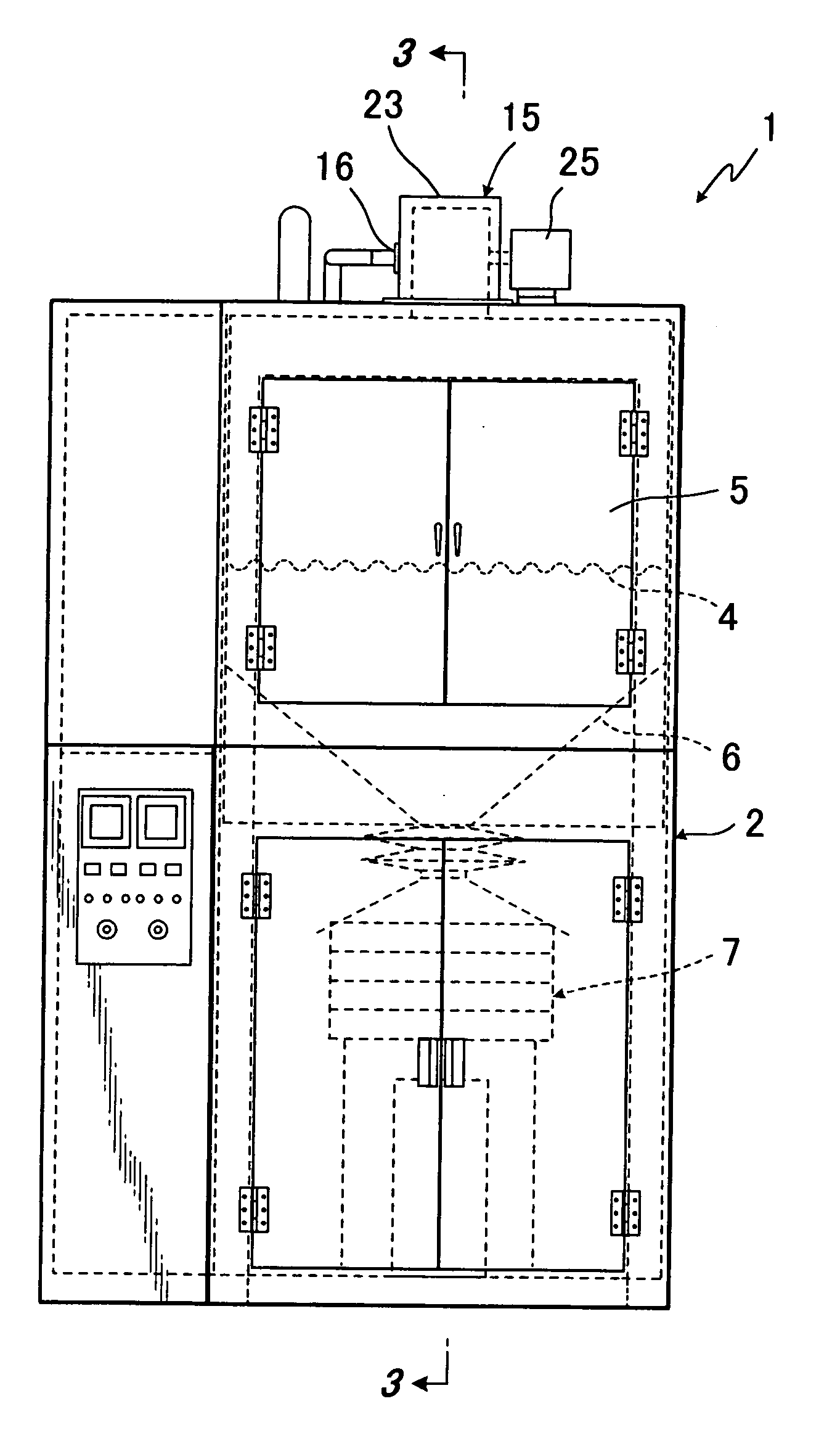

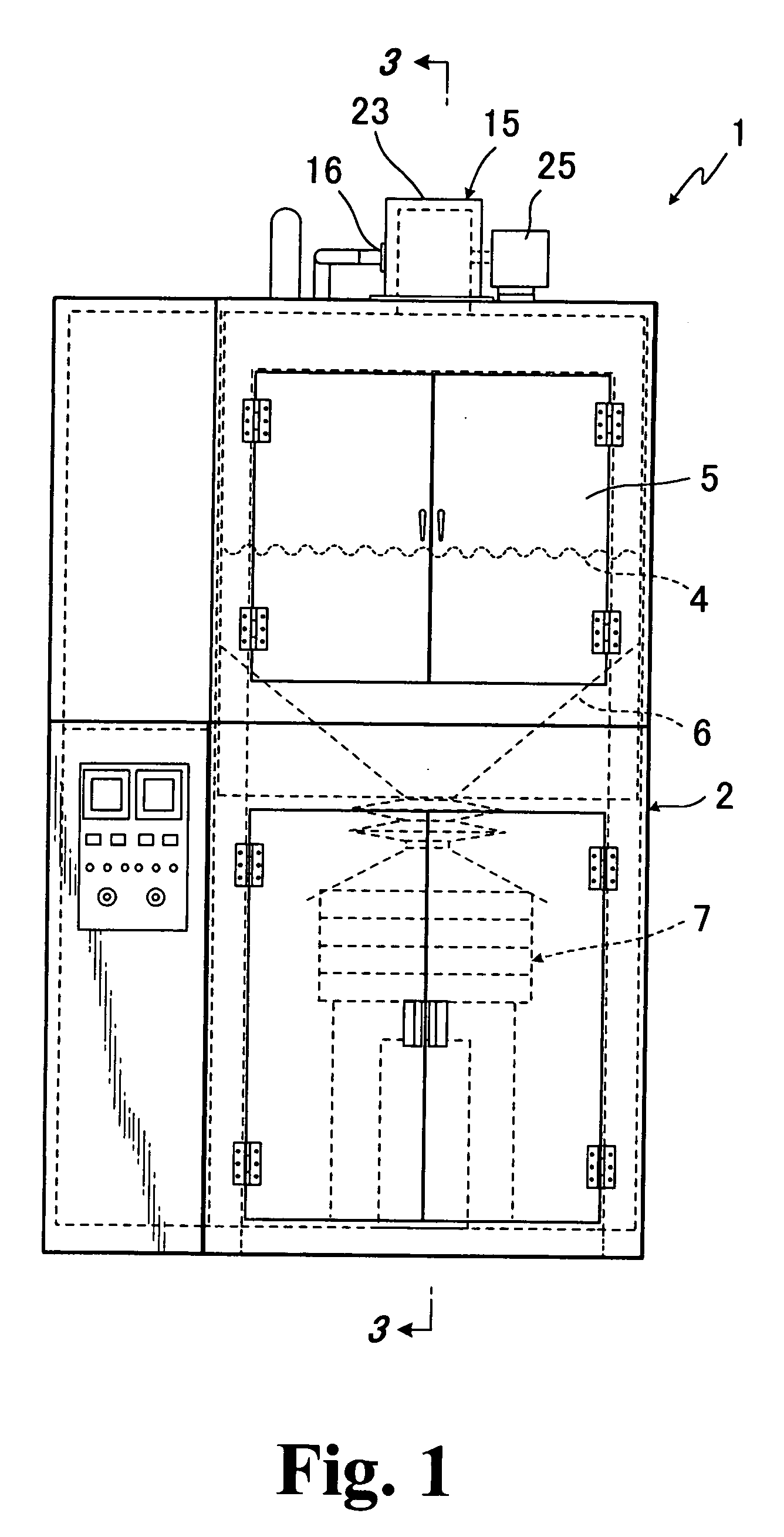

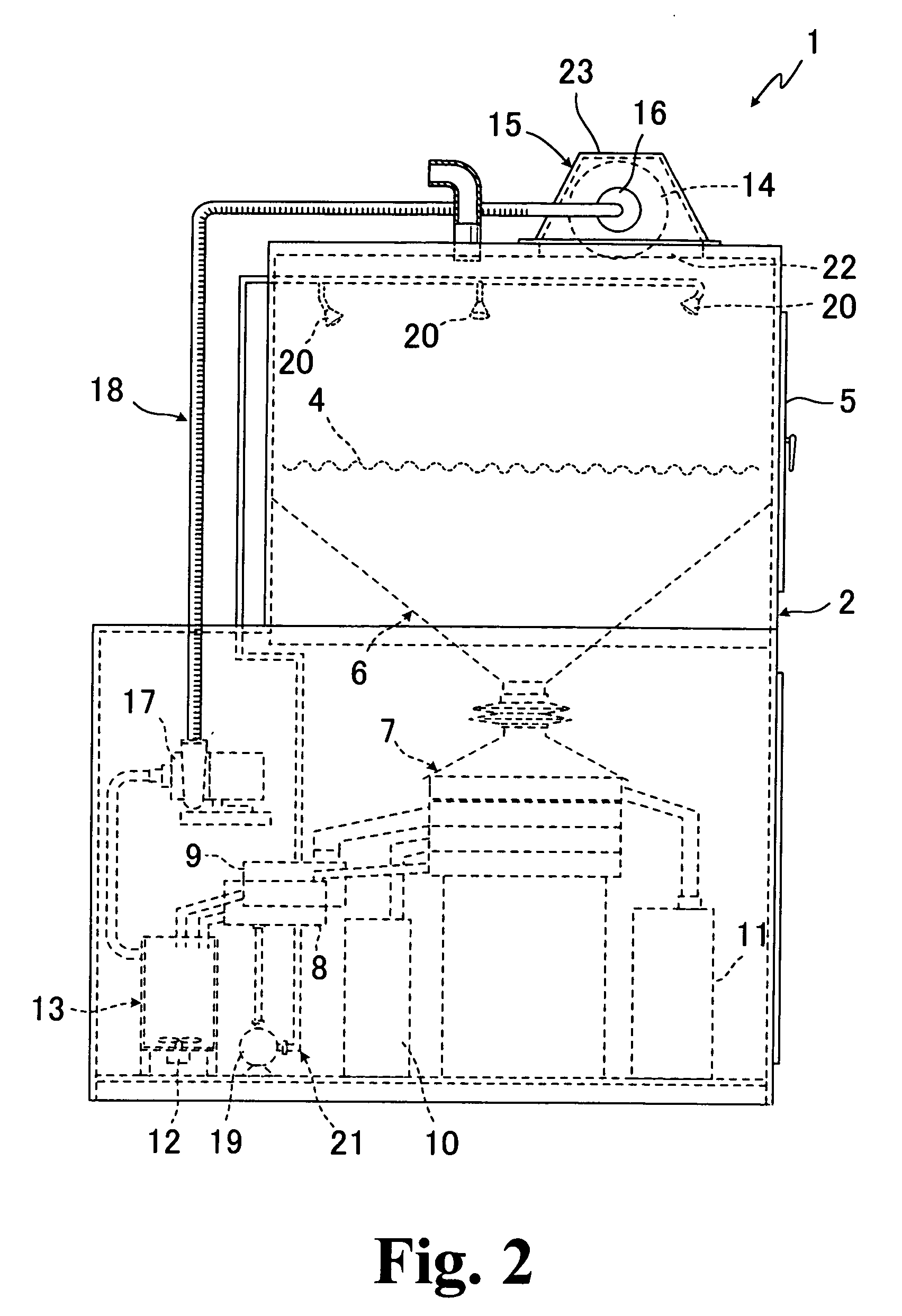

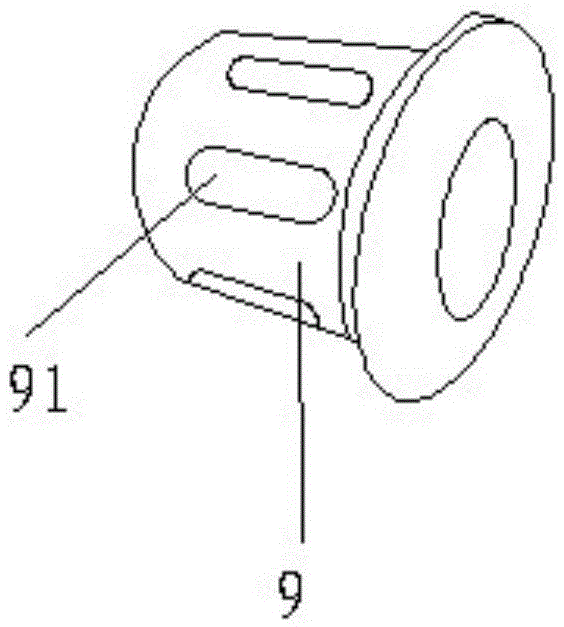

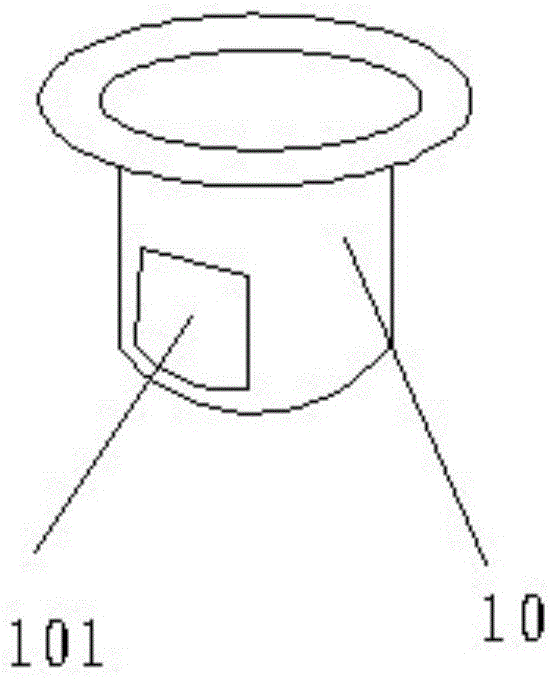

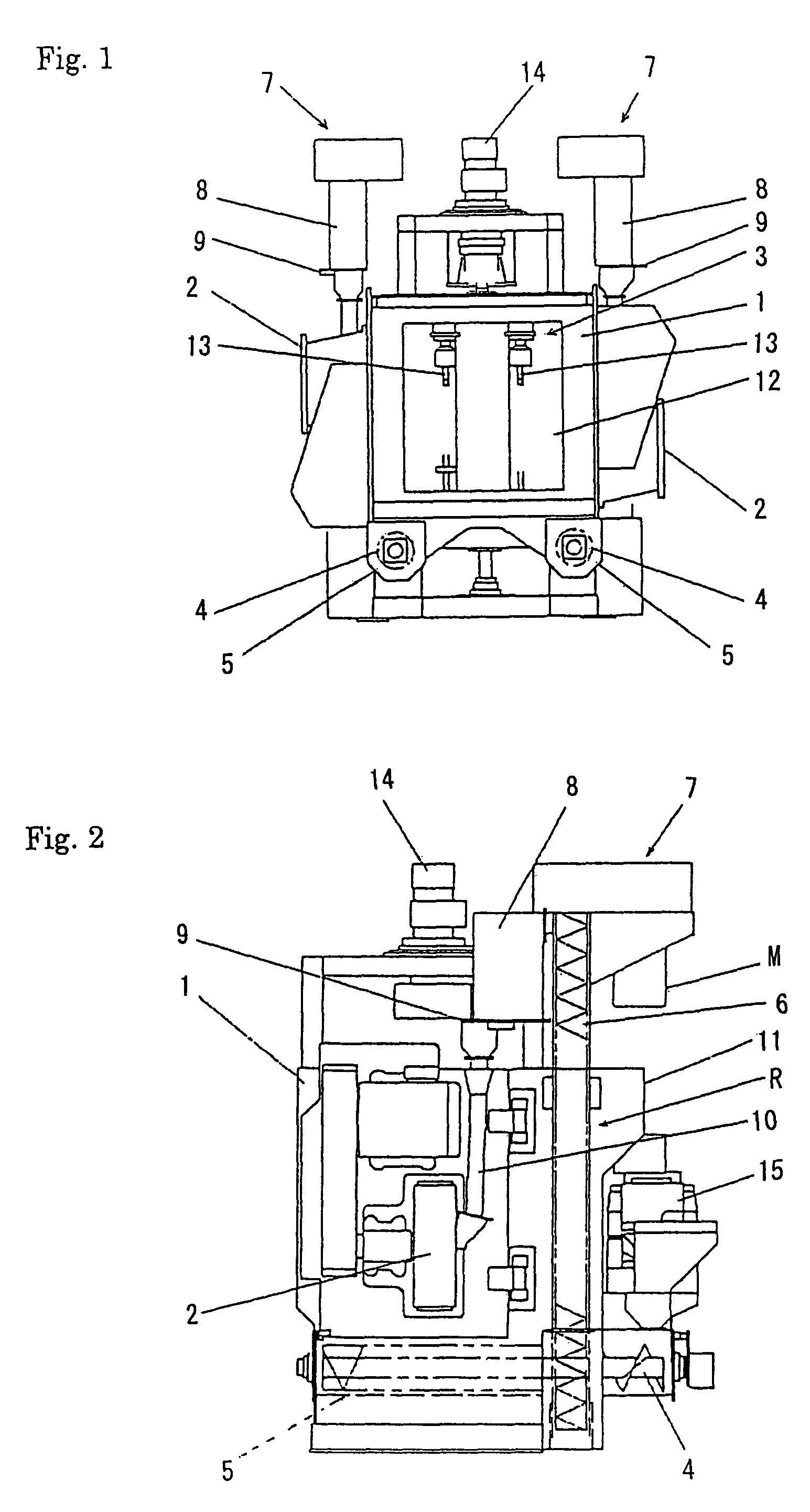

Apparatus For A Shot Peening Treatment

Impeller-type ejectors (2) are installed on the surfaces on both sides of a cabinet (1) defining an ejection chamber in the cabinet. Shots ejected from the ejectors (2) to a workpiece and fallen are conveyed in the horizontal direction by a horizontal screw conveyor (4) positioned above the lower end of the cabinet (1) and then conveyed upward by a vertical screw conveyer (5) whose base end is above the lower end of the cabinet (1). The shots pass from the upper section of the vertical screw conveyer (5) through a chute (8) to reach an opening / closing gate (9). When the gate (9) is opened and the shots are supplied to the ejectors (2) for re-ejection, a portion of the shots is caused to overflow from the gate (9). The overflowed shots are caused to pass through a separator (11) and a sieve device (15) to remove impurities and then returned to the horizontal screw conveyor (4).

Owner:SINTOKOGIO LTD

High chromium cast iron containing SiC powder, preparation method thereof and wear resistant casting

ActiveCN102220541AChange growth morphologyControl growth directionImpeller wheelsRotor bladesGranularityWear resistant

The invention discloses a high chromium cast iron containing SiC powder, a preparation method thereof and a wear resistant casting manufacturing method utilizing the same. A technical scheme is that a high chromium cast iron containing SiC powder is characterized in that the SiC powder is 99.9% SiC and with an average granularity of 20-40 nm, and accounts for 3-6% of a gross weight of the high chromium cast iron. The high chromium cast iron also comprises 3.1-3.9% of C, 18-22% of Cr, 0.5-1.0% of Si, 0.6-1.6% of Mo, 0.6-1.2% of Mn, 0.1-0.4% of Ni, 0.04-0.09% of V, 0.011-0.031% of S, and 0.018-0.030% of P. The beneficial effects are that :1) wear resistance of the casting id substantially raised by the SiC powder; 2) the SiC powder is used to enhance the high chromium cast iron material to form a high impact-resistant, friction-resistant, wearing- resistant high chromium cast iron wear-resistant blast blade. Therefore, the SiC nano powder can not only change growth morphology of high chromium cast iron crystal and growthform of a martensite to substantially enhance material hardness, but also improve material friction and wearing performance at a high temperature to obviously play a role of friction and wearing resistance at a high temperature.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

VN/TiN-powder-containing high-chromium cast iron and preparation method thereof, and wear-resistant part

ActiveCN102212740AChange growth morphologyControl growth directionImpeller wheelsRotor bladesWear resistantNanoparticle

The invention discloses a VN / TiN-powder-containing high-chromium cast iron and a preparation method thereof, and a wear-resistant part. The technical scheme is as follows: the VN / TiN-powder-containing high-chromium cast iron is characterized in that the purity of the VN powder is 99.5%, and the purity of the TiN powder is 99.3%; the VN powder accounts for 2-4 wt% of the high-chromium cast iron, and the TiN powder accounts for 2-4 wt% of the high-chromium cast iron; and the high-chromium cast iron also comprises 3.1-3.9% of C, 18-22% of Cr, 0.5-1.0% of Si, 0.6-1.6% of Mo, 0.6-1.2% of Mn, 0.1-0.4% of Ni, 0.04-0.09% of V, 0.011-0.031% of S, 0.018-0.030% of P and the balance of iron as base material. The VN / TiN powder can be used as a high-chromium cast iron molten metal base and a nucleation core for solidifying carbides, thereby enhancing the wear resistance of the castings; the VN / TiN powder is utilized to reinforce the high-chromium cast iron material, so that wear-resistant shot blasting device blades made of the high-impact-resistant frictional-wear-resistant high-chromium cast iron can be formed; and since the VN / TiN powder is added by an in-furnace addition method, the nanoparticles are added to perform a strengthening effect, and argon gas added into the furnace protects the molten metal.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

Method of Producing Rust Inhibitive Sheet Metal Through Scale Removal with a Slurry Blasting Descaling Cell Having Improved Grit Flow

A method is provided for removing iron oxide scale from sheet metal and producing a sheet metal surface with rust inhibitive properties. The sheet metal is advanced through the descaling cell and a slurry mixture is propelled against at least one of the top surface and bottom surface of the sheet metal across the sheet metal width as the material is advanced through the descaling cell. The rate of slurry impact against the at least one of the top surface and bottom surface of the sheet metal is controlled in a manner to remove substantially all of the scale from a surface of the sheet metal, and in a manner to create a passivation layer on the descaled surface of the sheet metal. The passivation layer comprises at least one of silicon, aluminum, manganese and chromium and inhibits oxidation of the descaled surface of the processed sheet metal.

Owner:THE MATERIAL WORKS

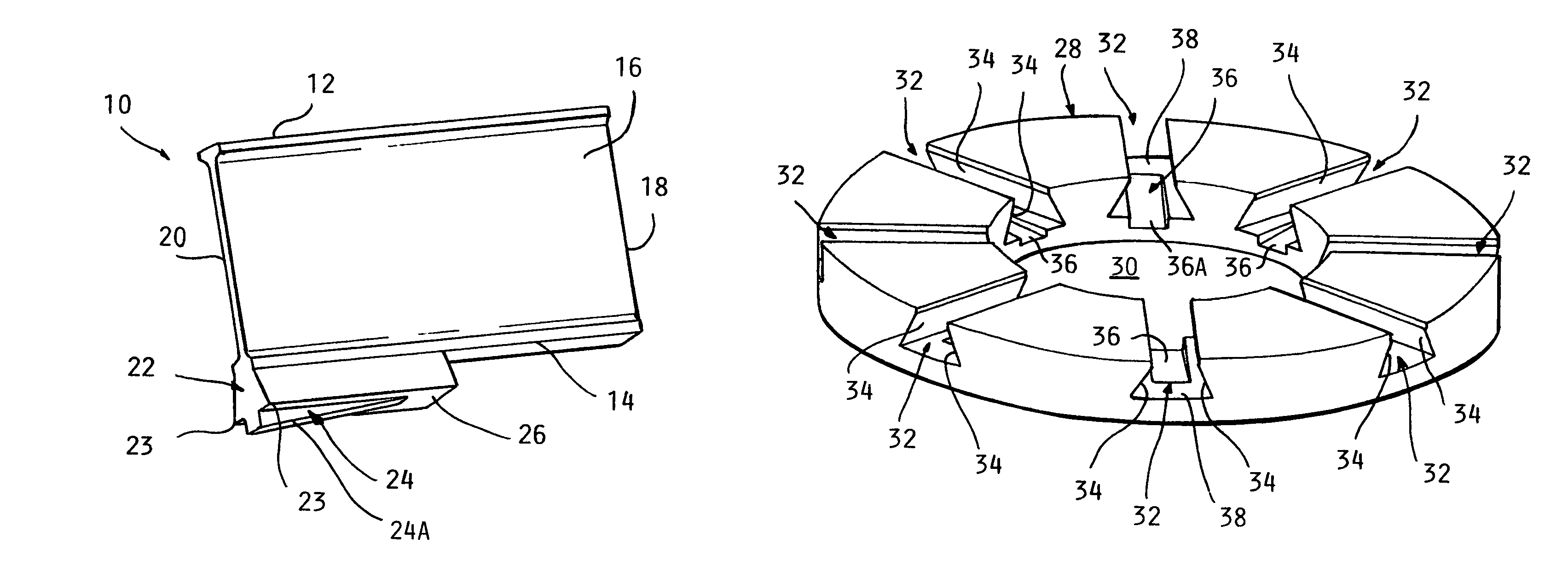

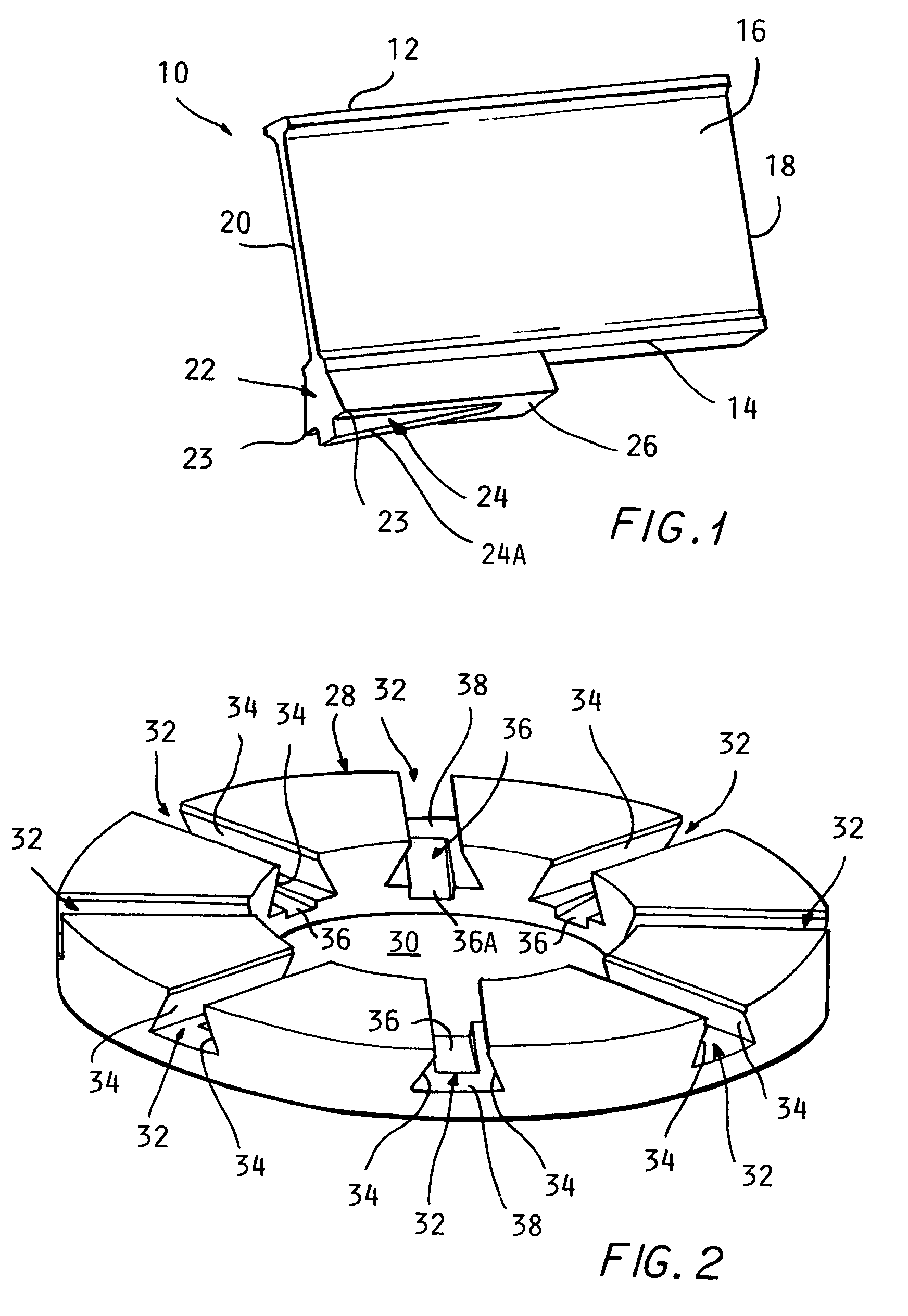

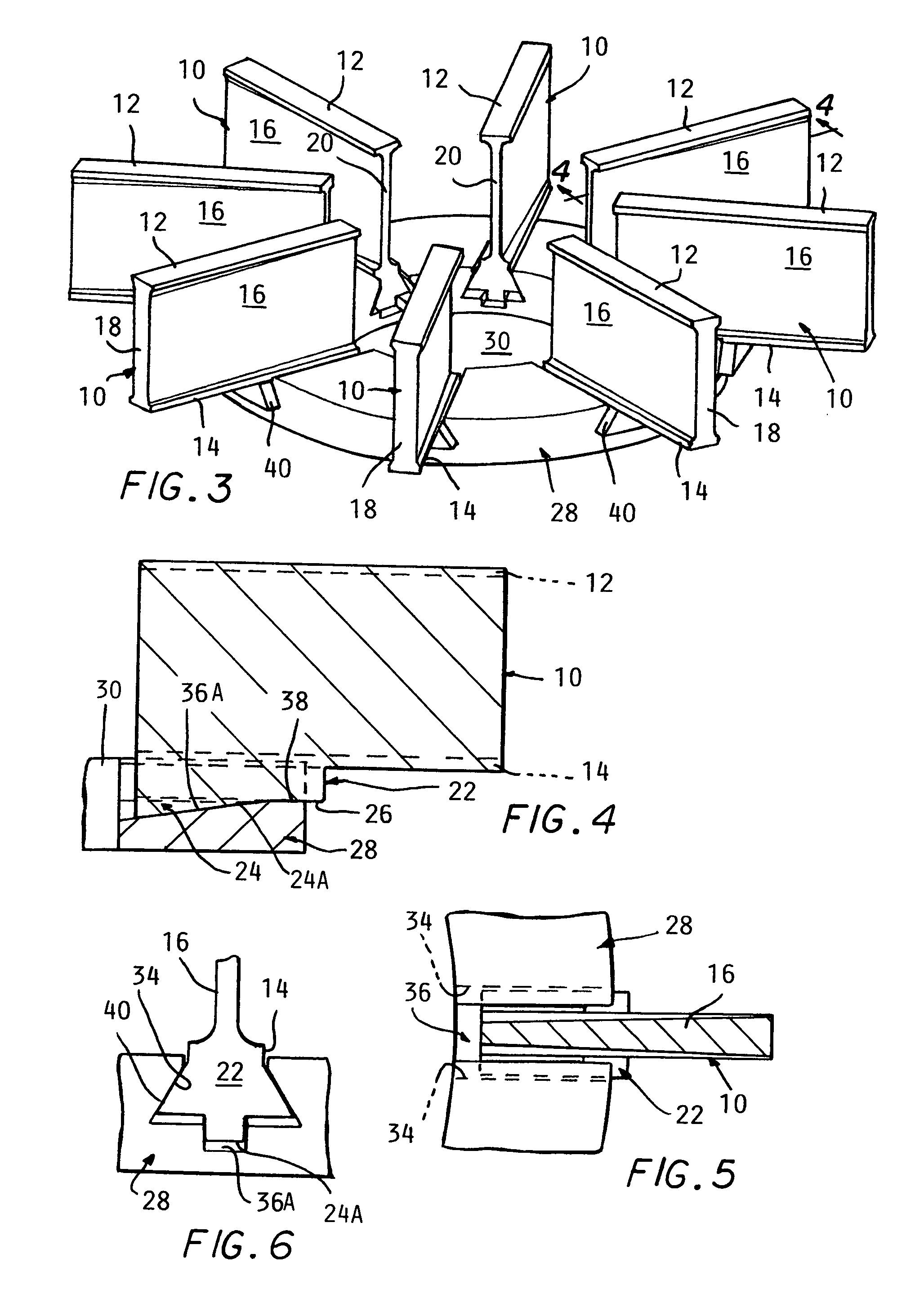

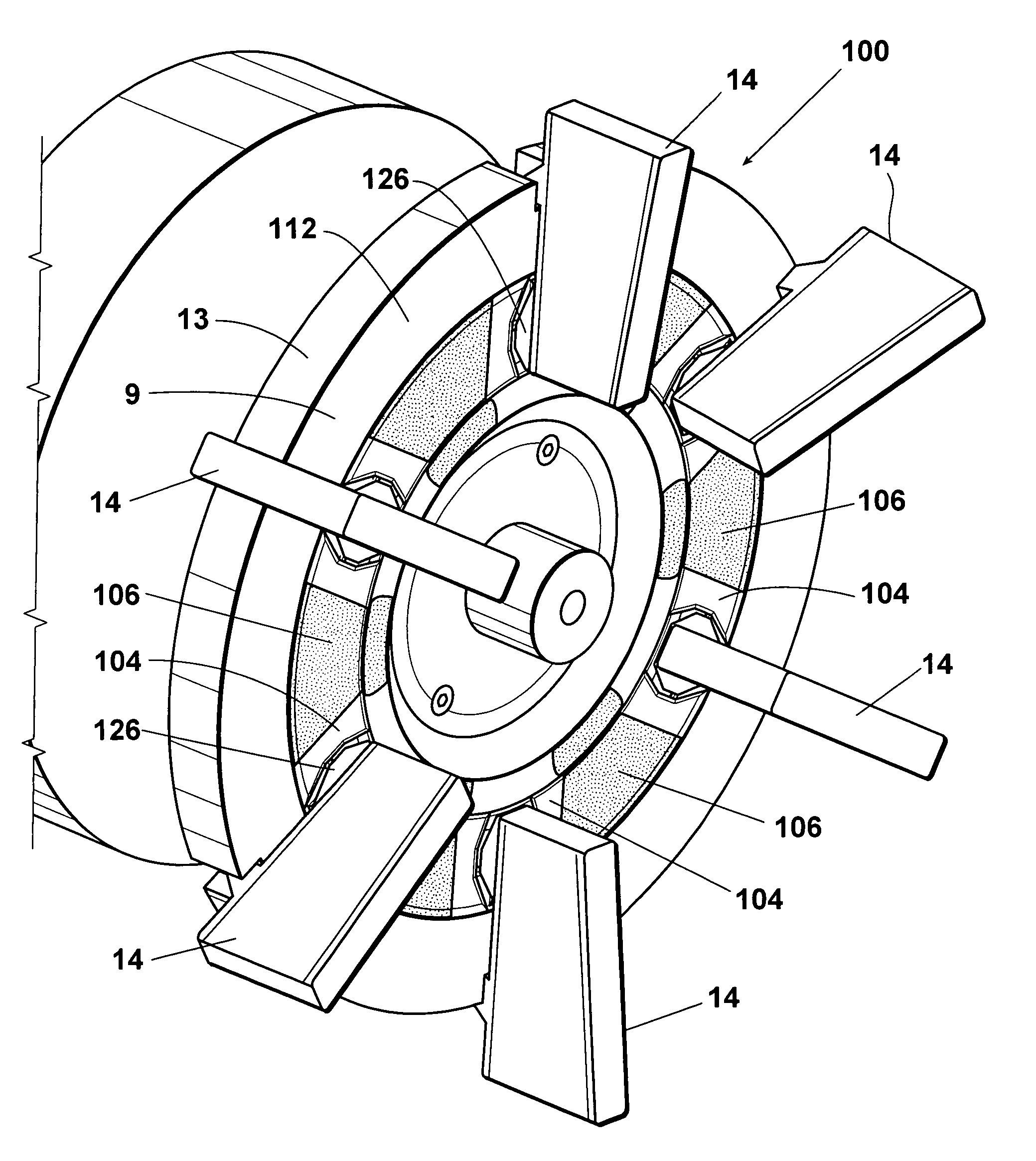

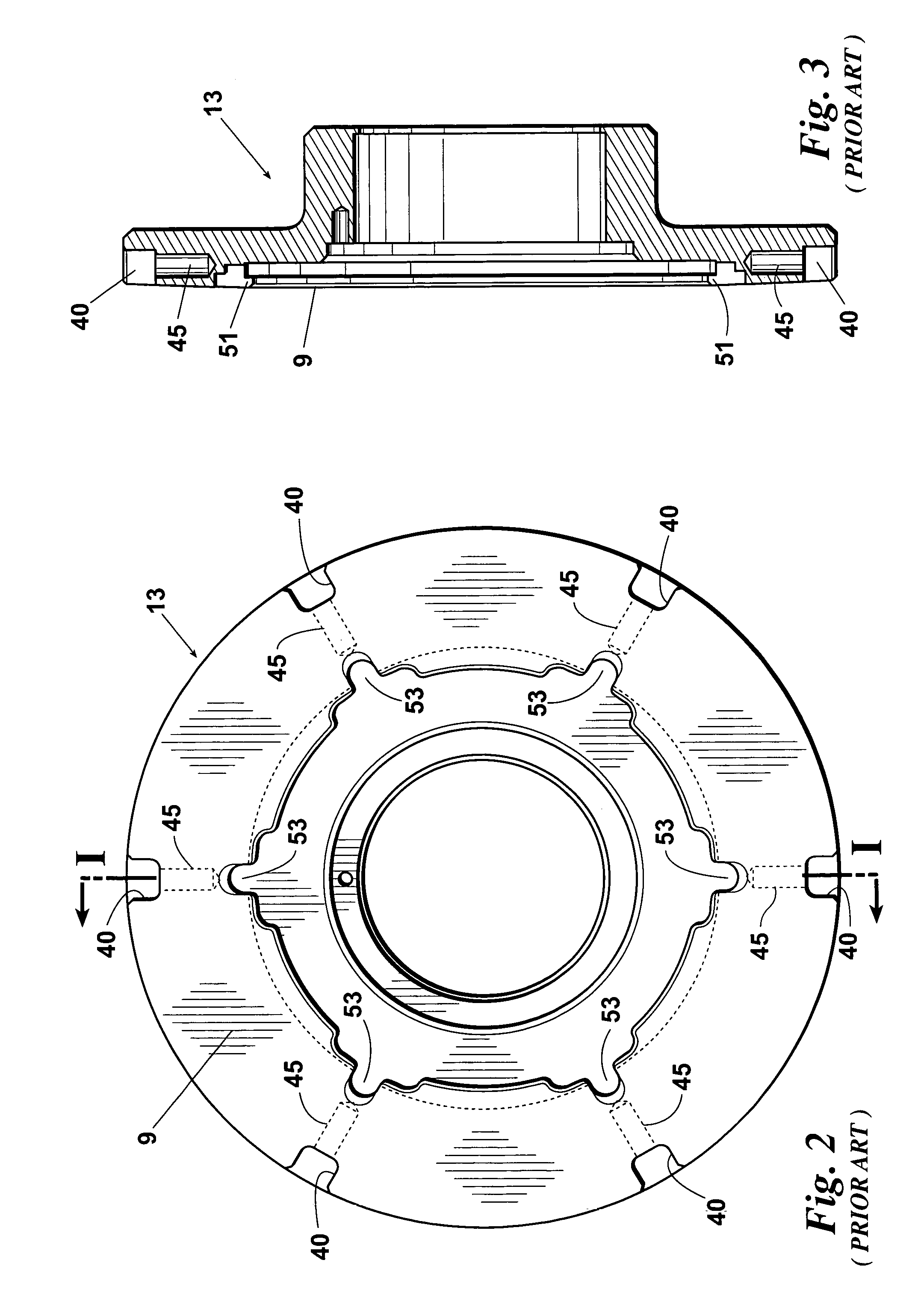

Throwing wheel assembly

InactiveUS7585207B2Accurate radial positioningLock tightlyImpeller wheelsRotor bladesEngineeringMechanical engineering

Owner:ROBERTS SINTO A MICHIGAN

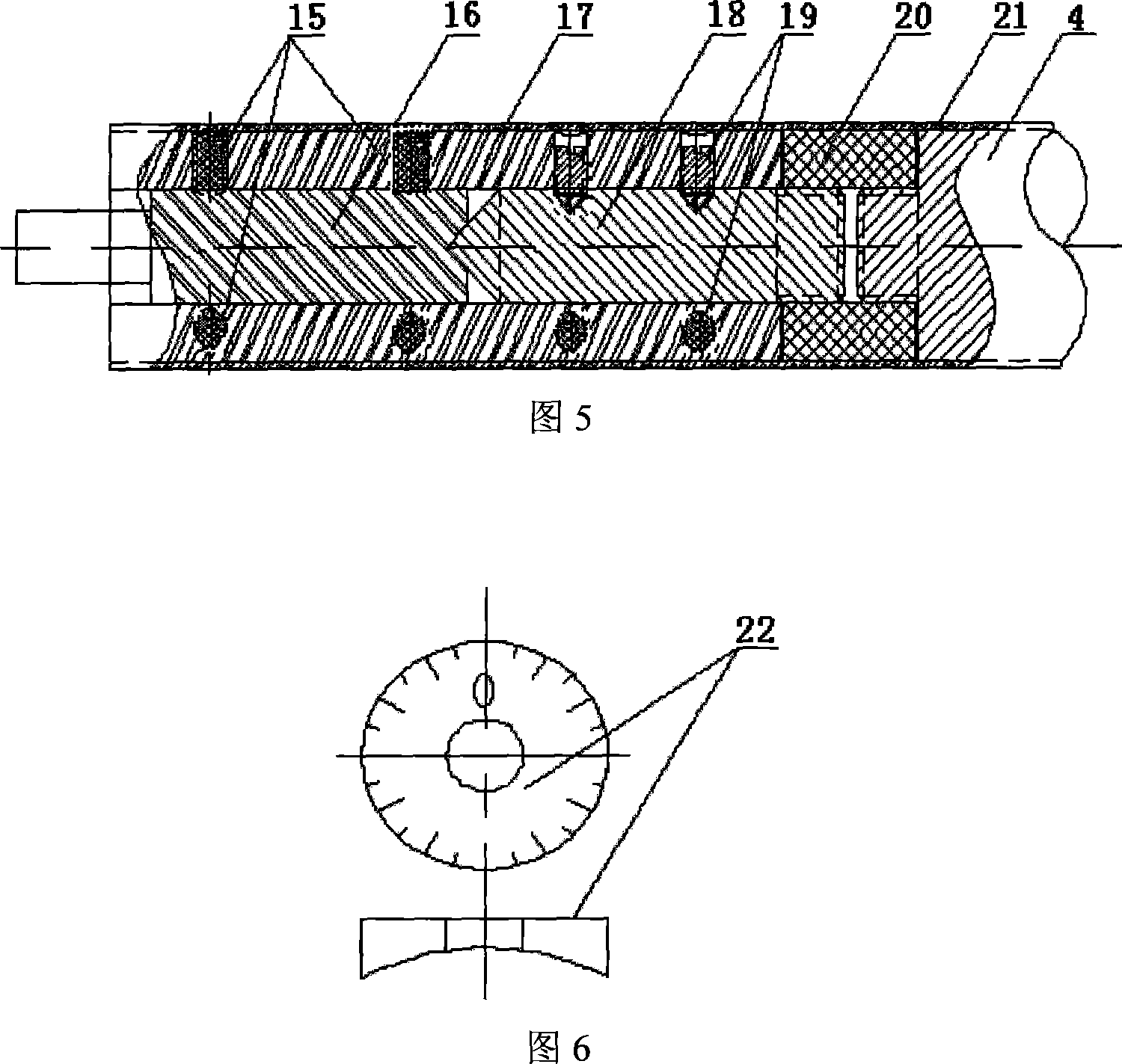

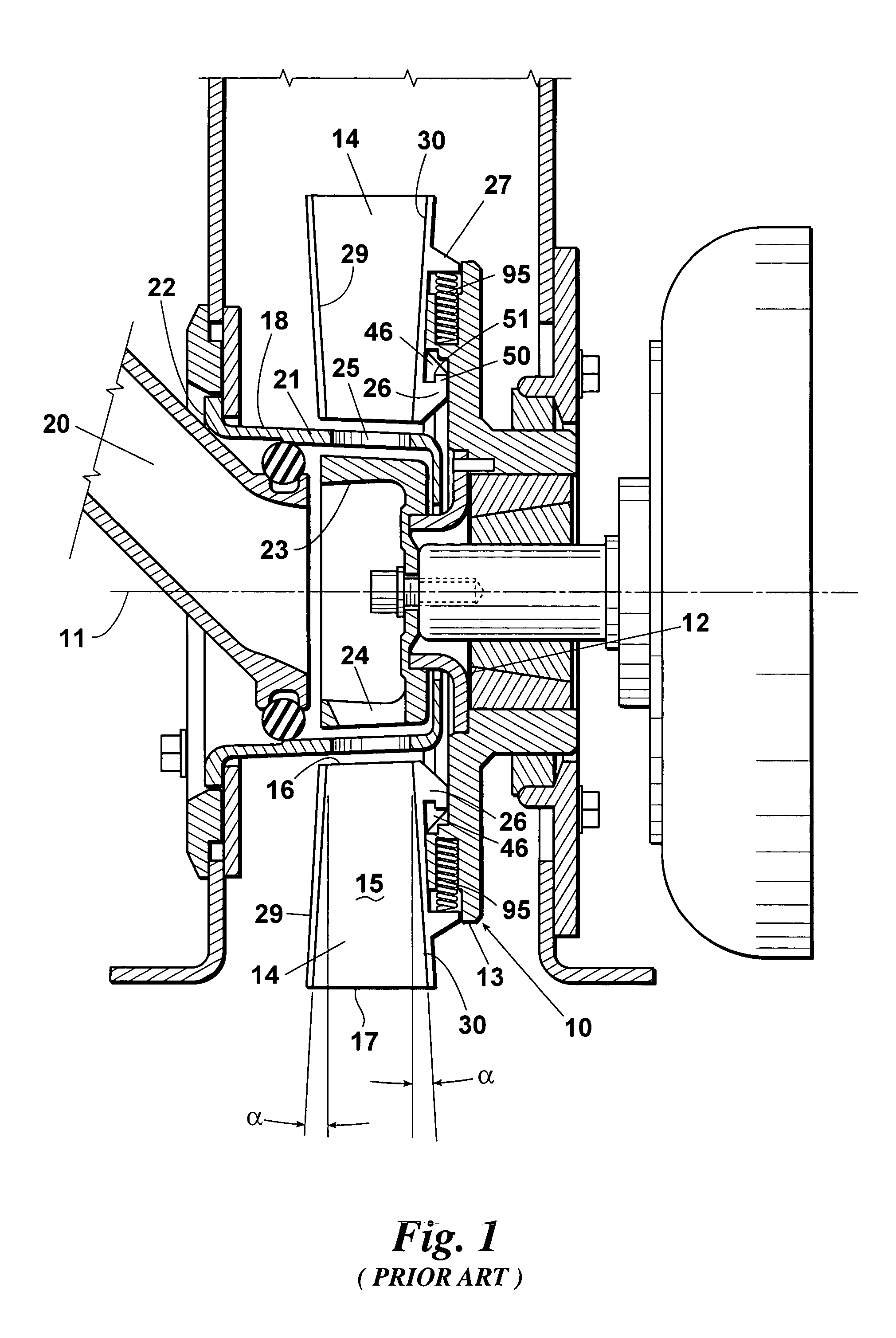

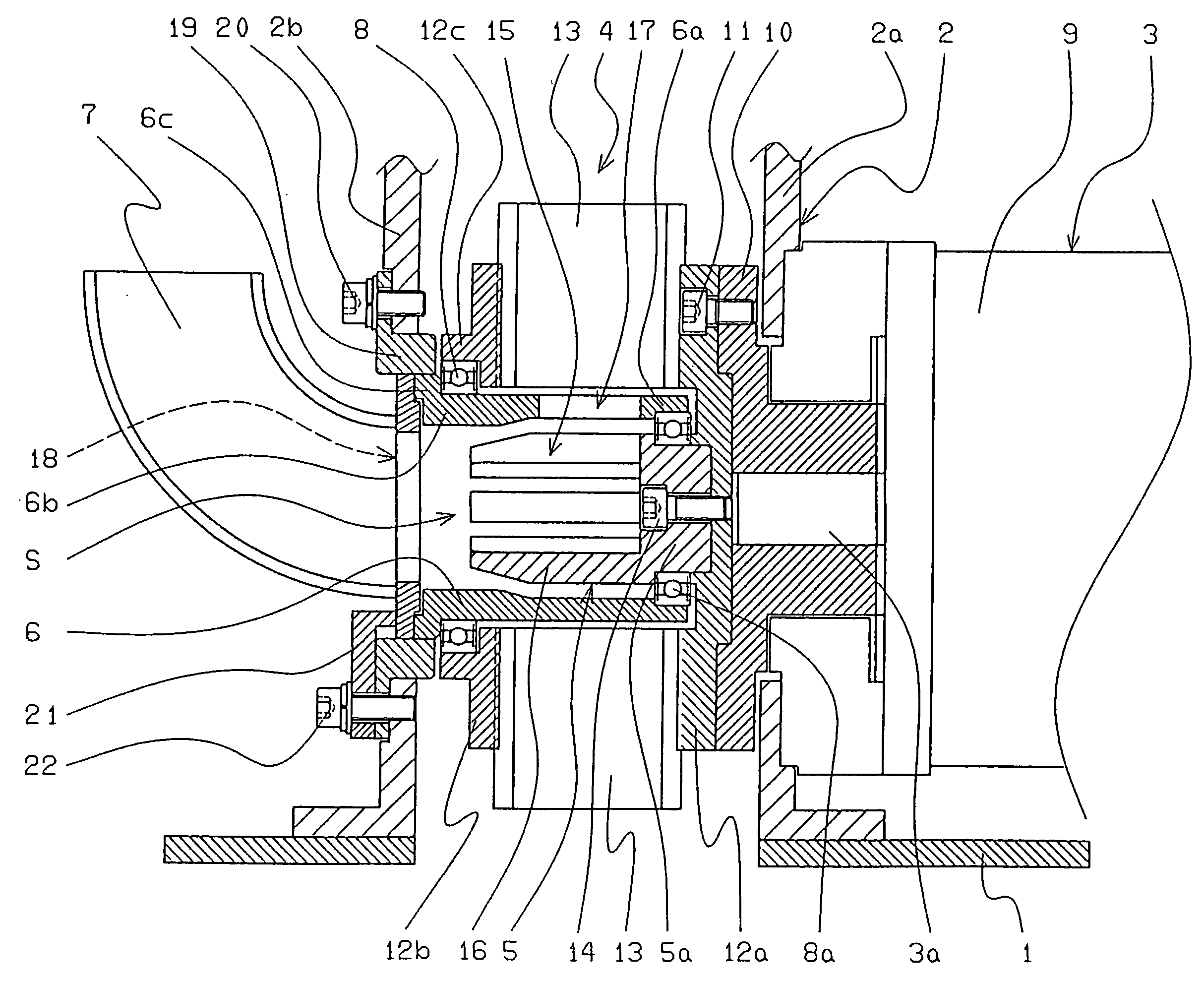

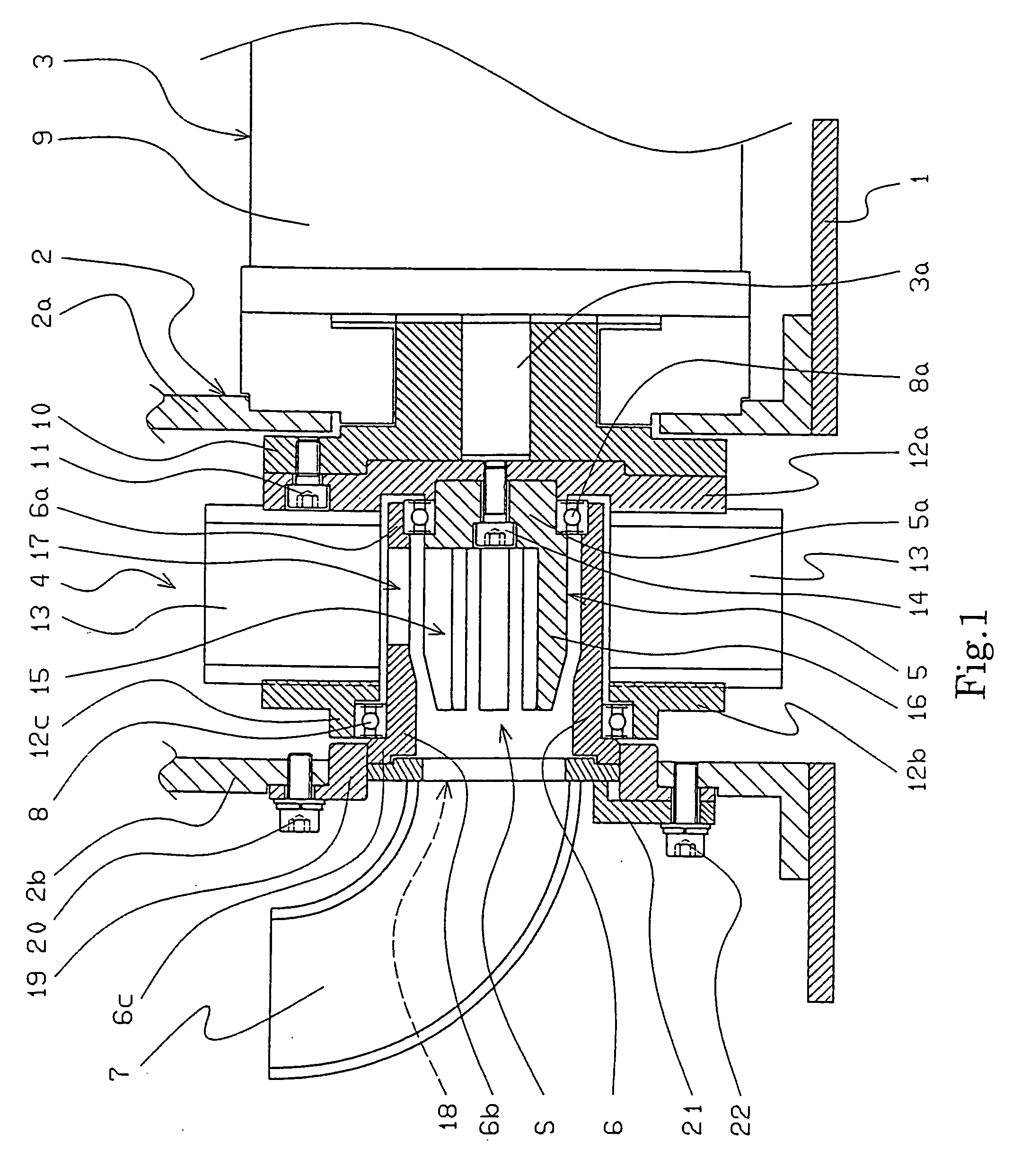

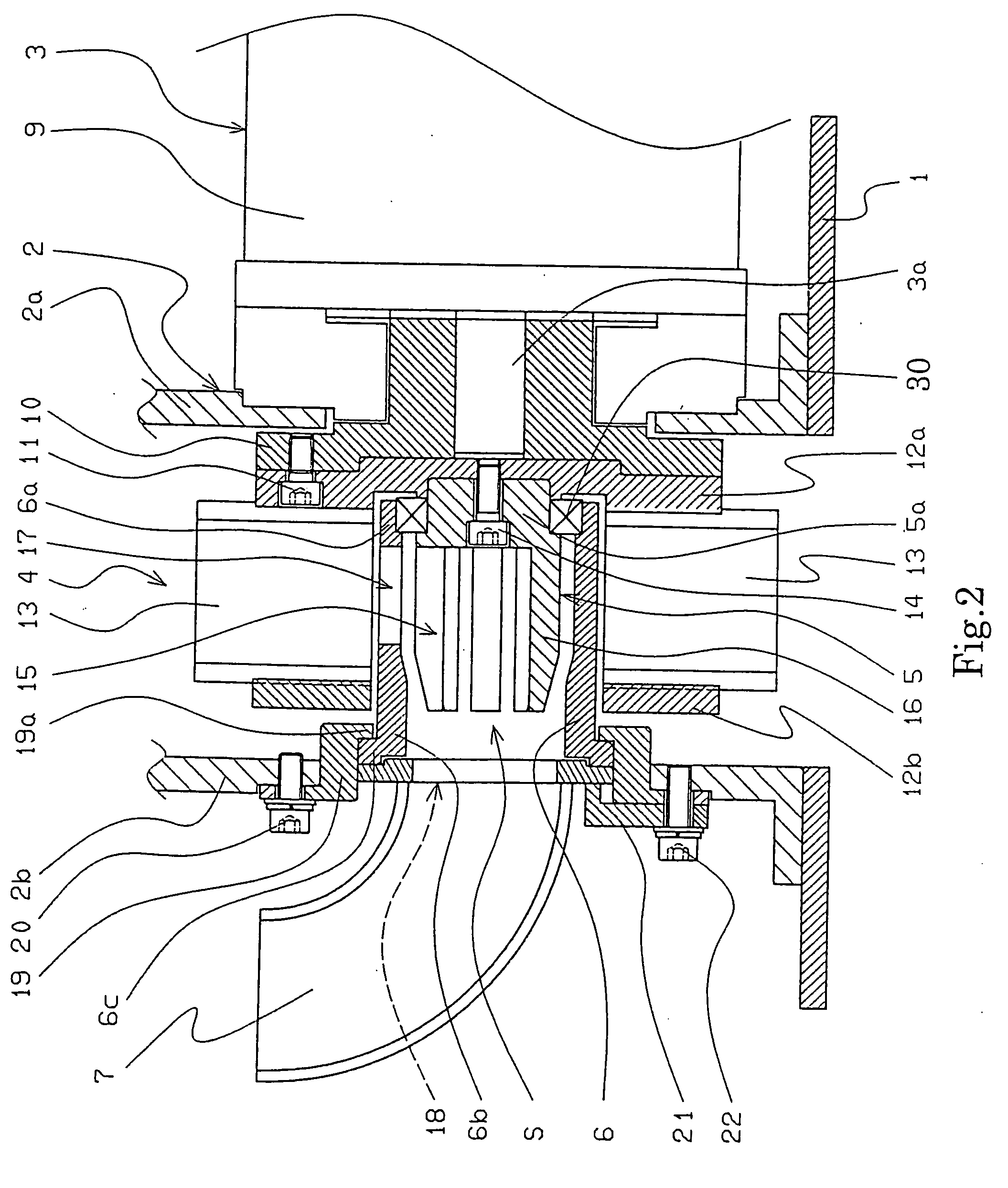

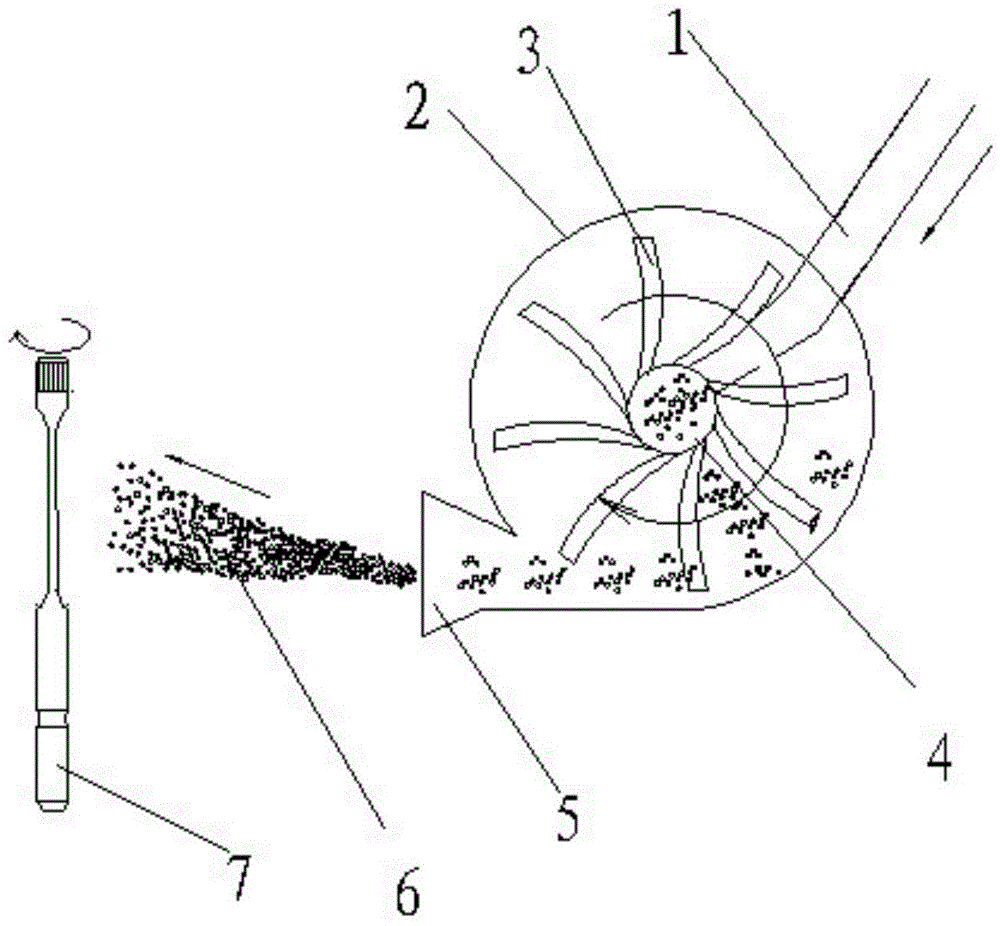

Machine for centrifugally shooting abrasives

A machine for centrifugally shooting abrasives that shoots the abrasives by rotation of an impeller is provided. In the machine, the impeller comprises a pair of disc-shaped side plates that face each other at a predetermined distance and a plurality of blades disposed between the side plates in the radial direction of the side plates. The impeller is mounted on a hub that is fitted into an output shaft of an electric motor. The impeller is covered by a cover. The side liner and blades of the machine can be easily replaced. A side liner 3 that is U-shaped with the longer side facing downward is detachably attached to the inner side of the cover 2. The upper part of the side liner is divisible into two parts. The side liner protects the side wall of the cover 2 from the abrasives that are shot from the impeller. The side liner has a U-shaped cross section. The impeller 1 is fixed to the hub 4 by screwing a bolt 15 on the hub 4 from the inner sides of the side plates 11. The diameter of the impeller 1 is limited to be 200 mm at maximum.

Owner:SINTOKOGIO LTD

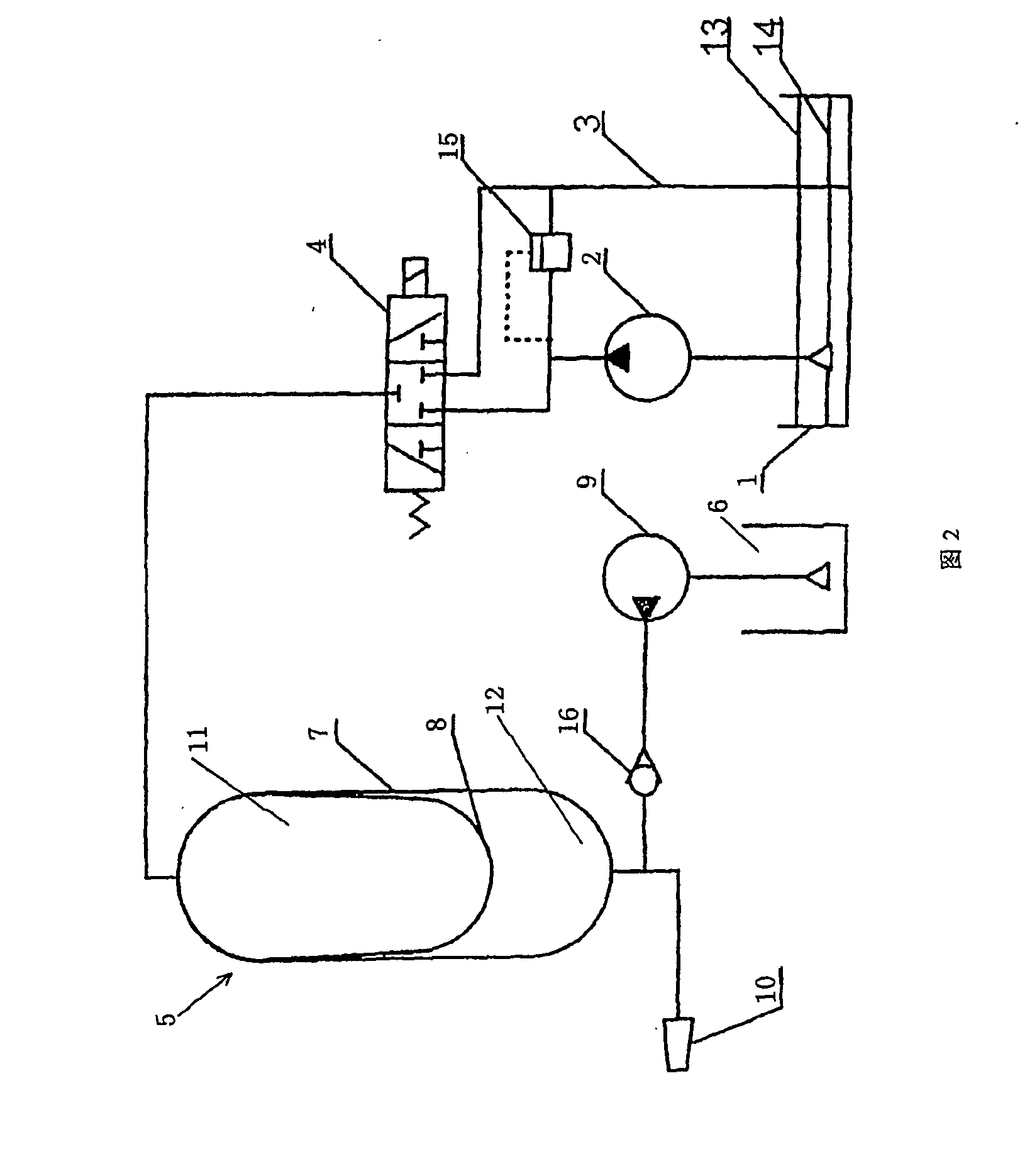

Blasting Device for Premixed Abrasive Slurry Jet

InactiveUS20080299876A1FrictionLow production costImpeller wheelsRotor bladesSlurryPulp and paper industry

The present invention relates to a blasting device for premixed abrasive slurry jet. The device comprise a cylinder, in which defines a hydraulic oil side and a slurry side separated from each other hermetically, and the hydraulic oil side and the slurry side have ports for oil or slurry entry in and out respectively; hydraulic medium feeding system which is connected to the port of the cylinder for oil entry in and out through oil pipe; slurry jet system which is connected to the port of the cylinder for slurry entry in and out through slurry pipe; said cylinder has a sealed bladder to separate the hydraulic oil side and the slurry side. Friction between bladder and body become very little, as the slurry is ejected from the nozzle by utilizing the transformation of the bladder. So service life of the blasting device becomes longer. Furthermore, if the bladder mangles due to wear for use a long time, bladder can be renewed only. It is not necessary to renew the whole cylinder. So the cost of production cuts down.

Owner:ZHOU ZHENGCAI

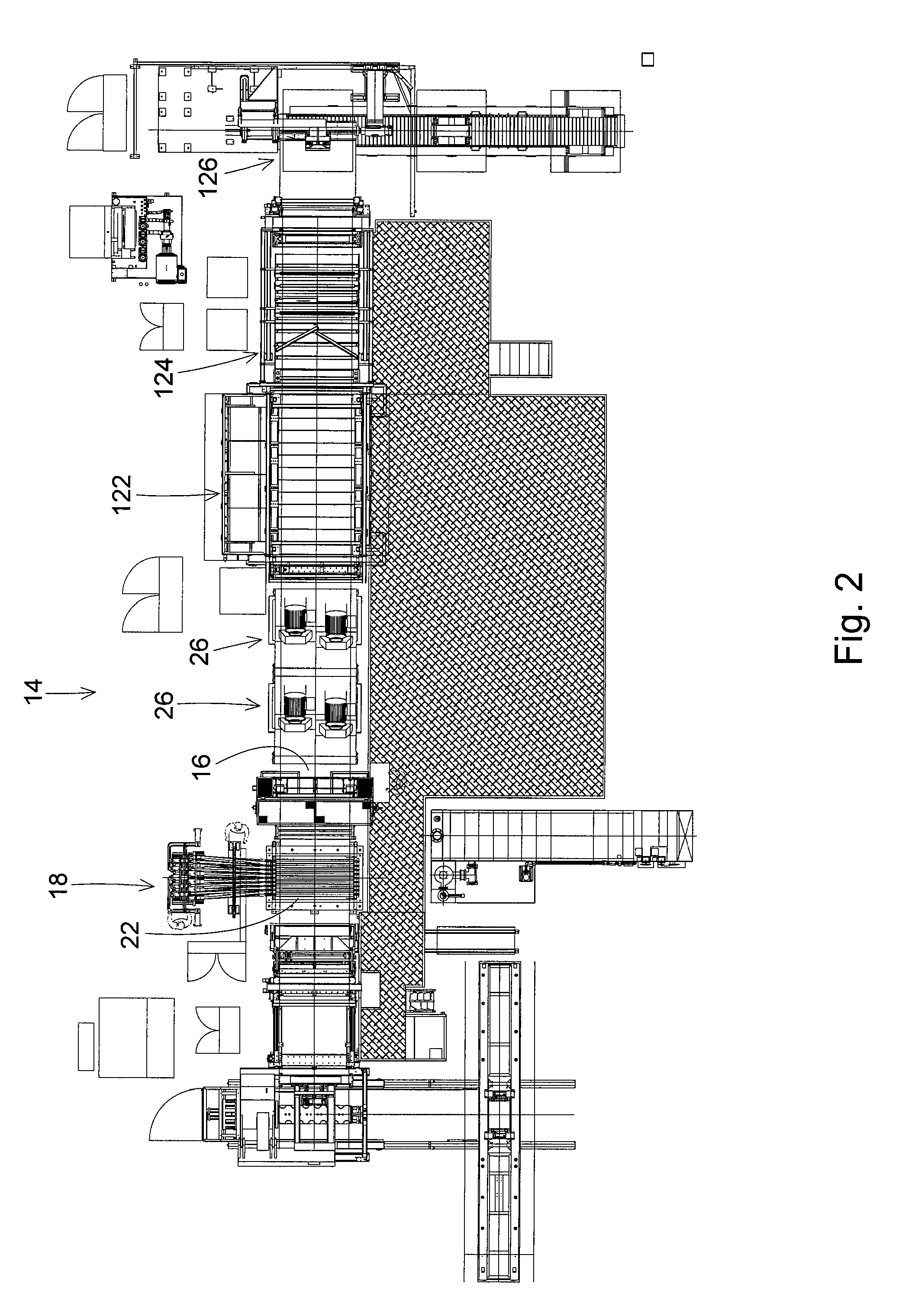

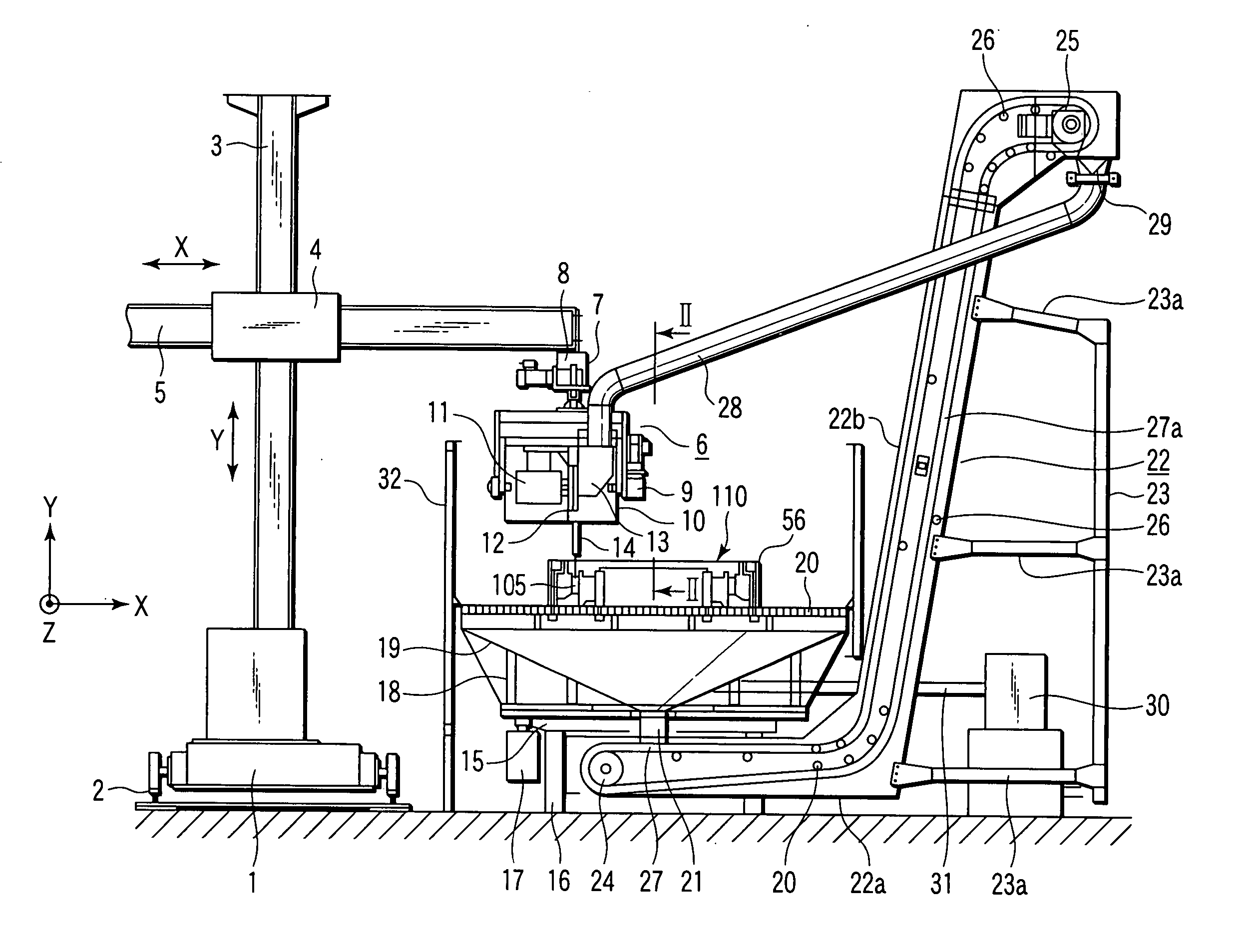

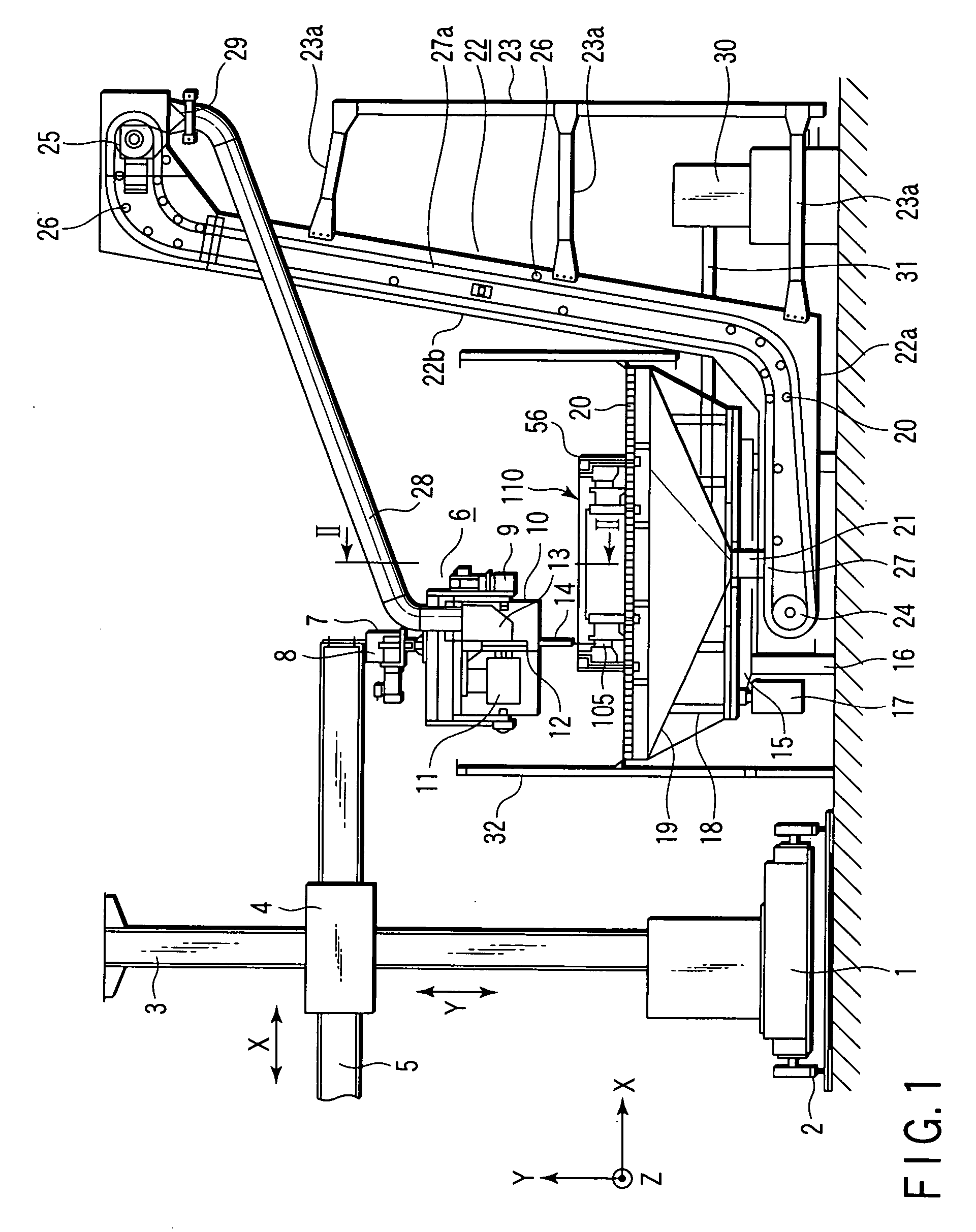

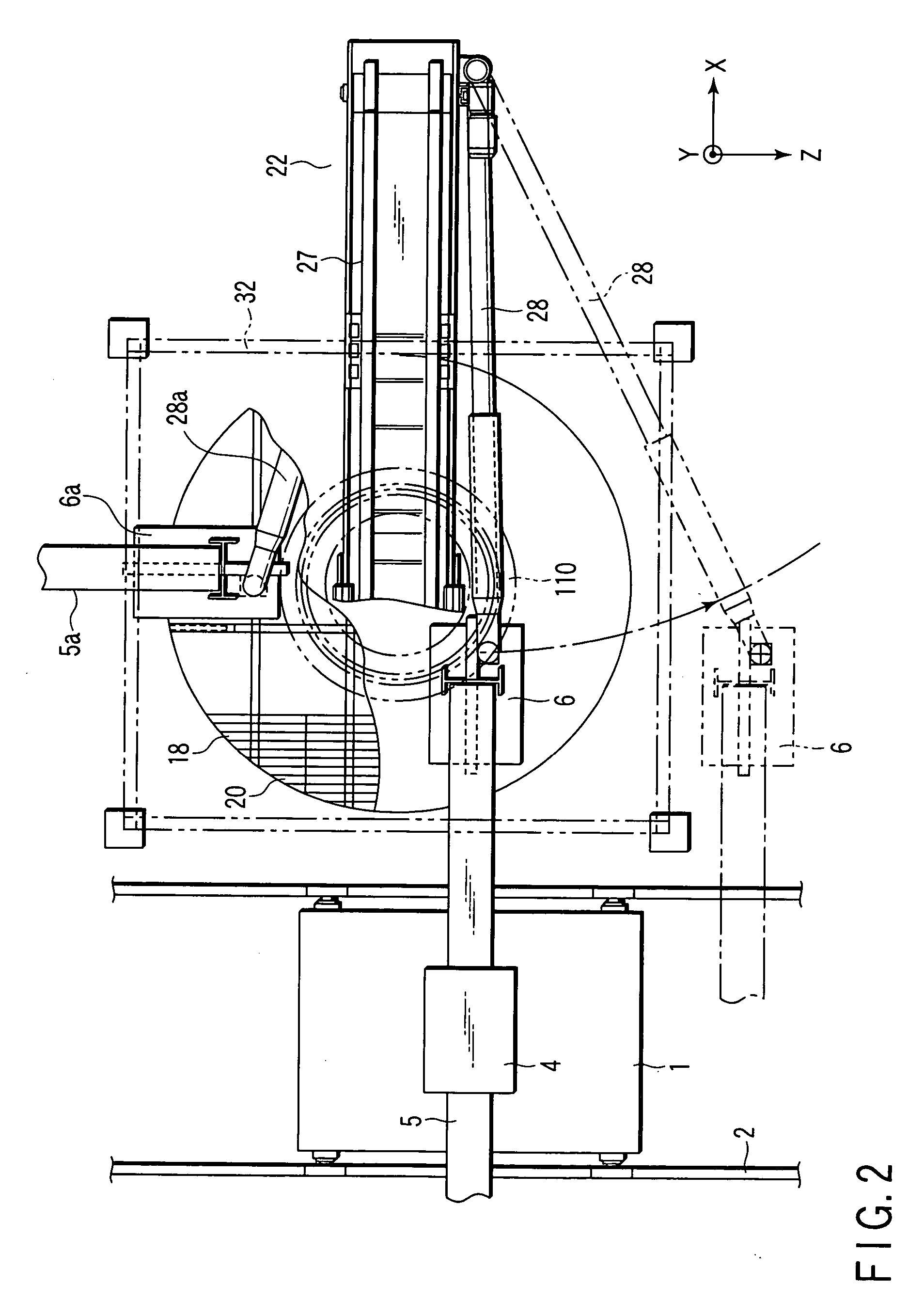

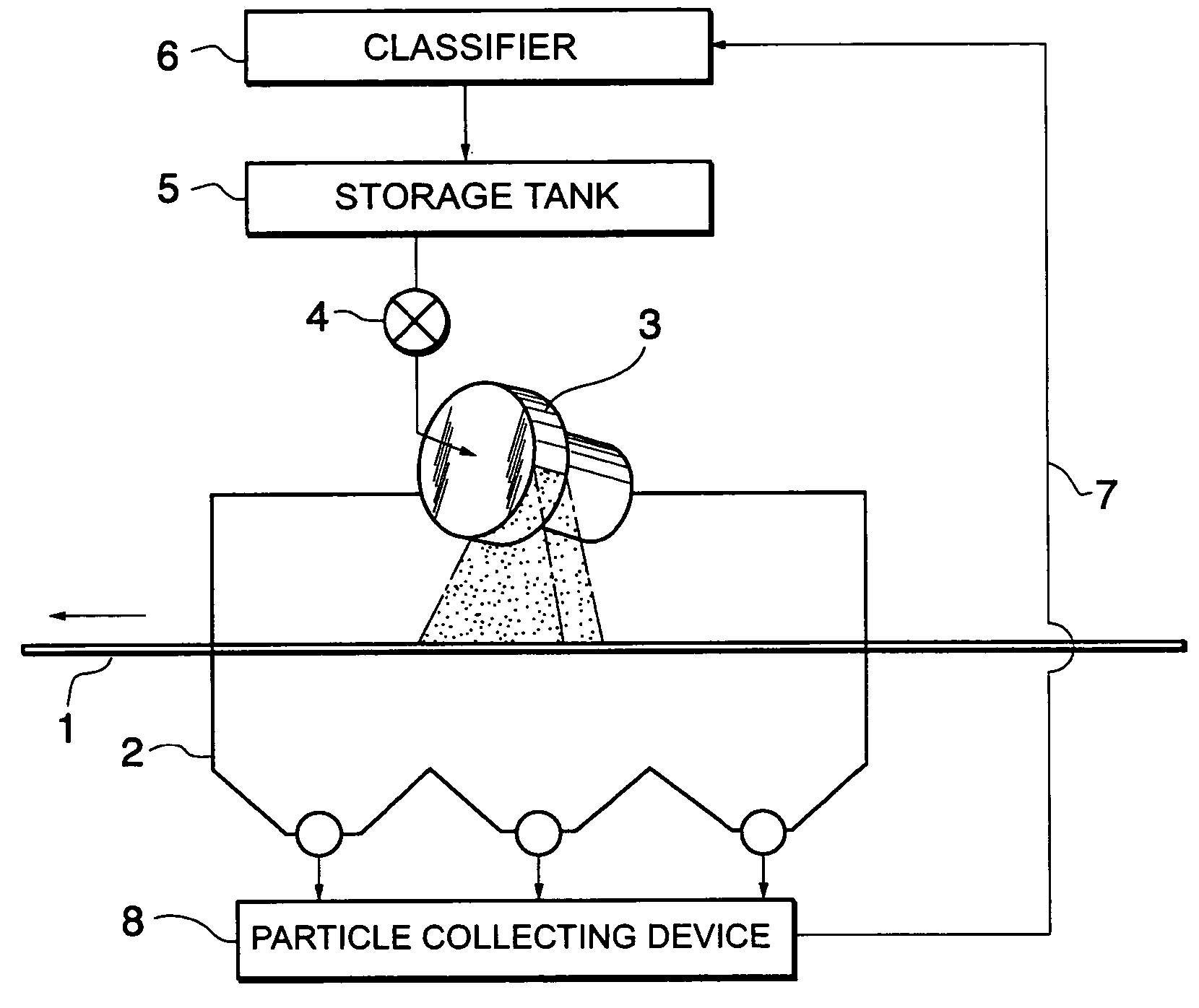

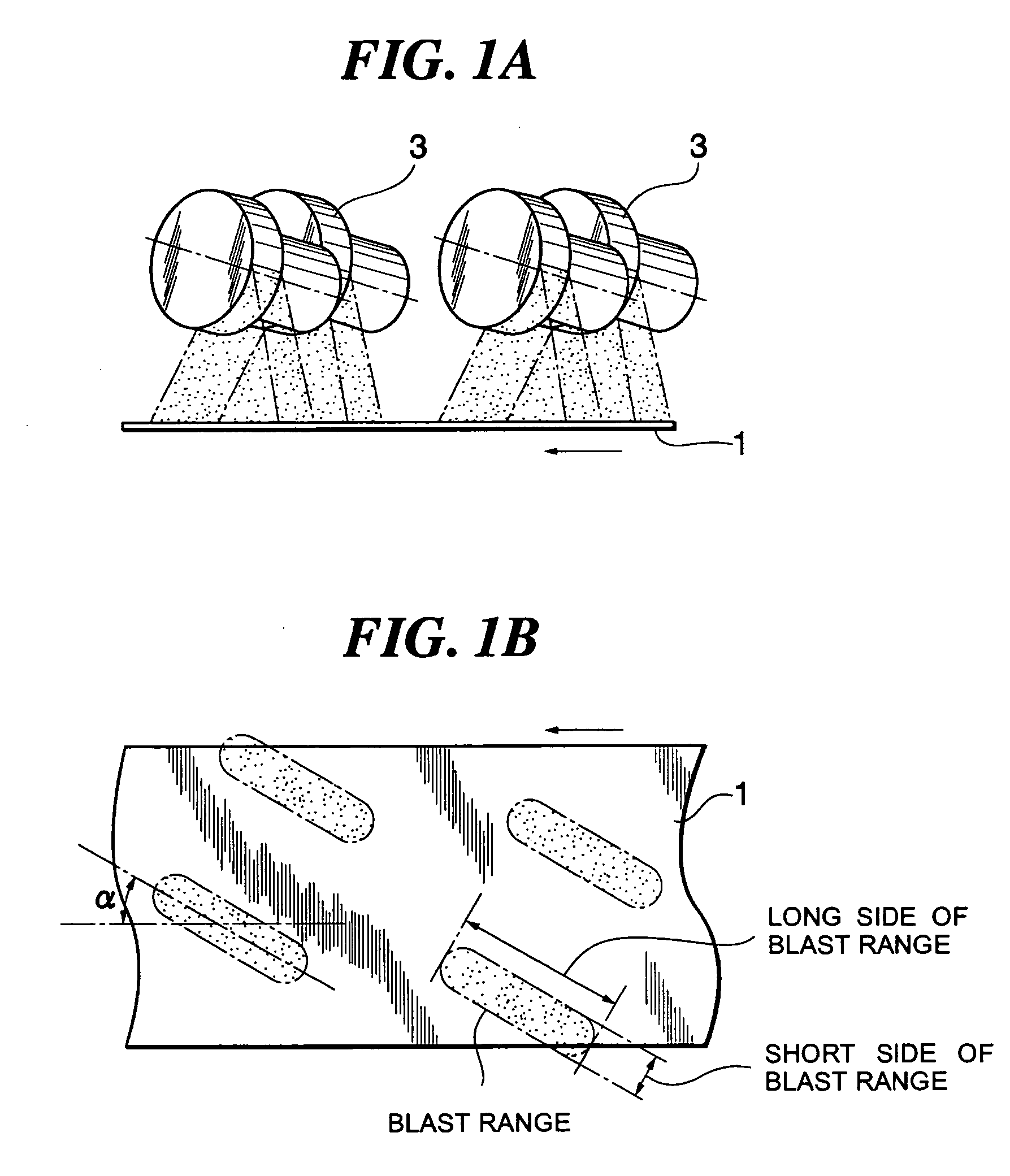

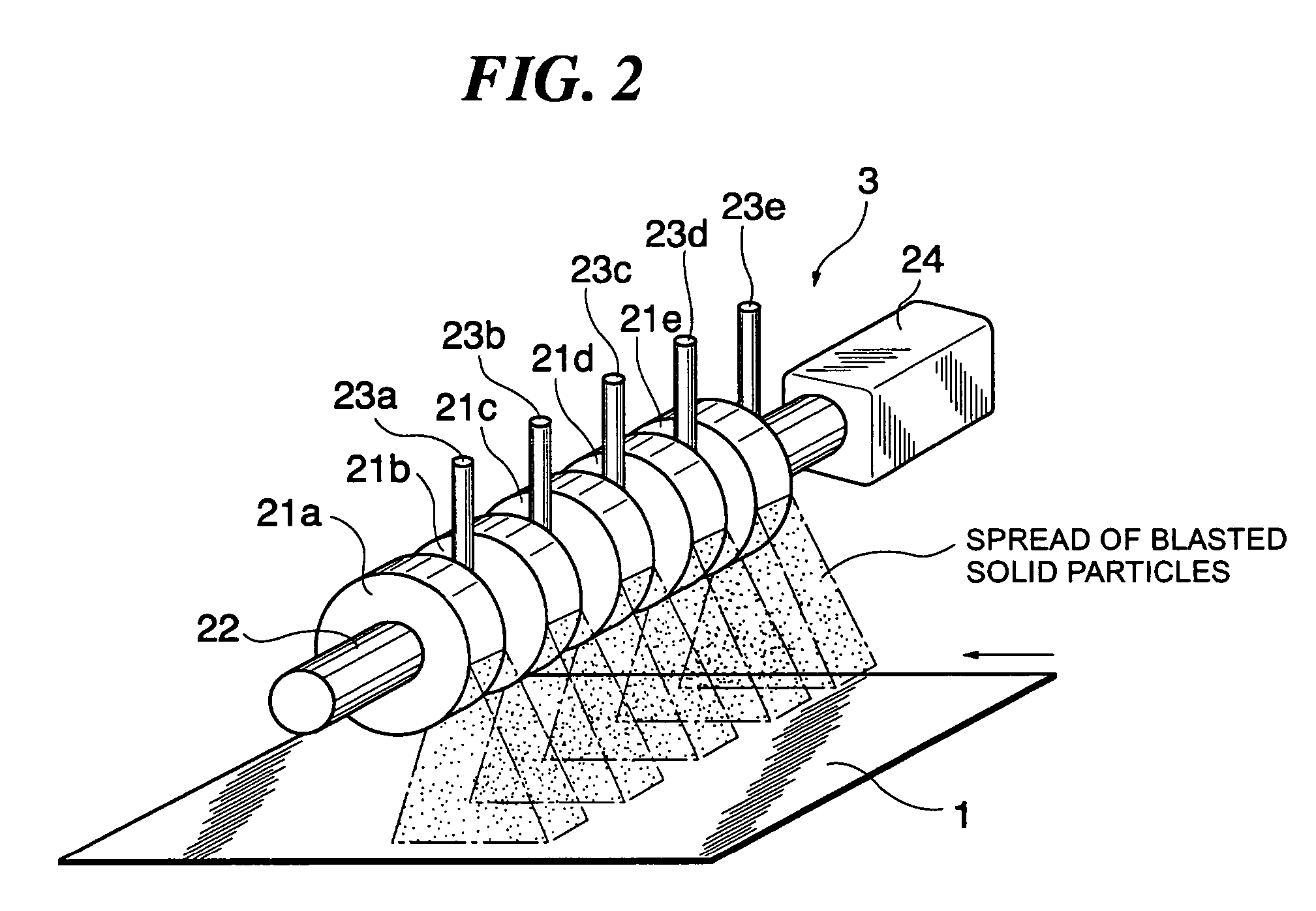

Surface treatment facility of metal plate, method for producing metal plate and system for producing metal plate

InactiveUS20050160780A1Create efficientlyCompact designImpeller wheelsRotor bladesRotational axisSolid particle

A surface treatment apparatus for metallic sheet has at least one centrifugal blasting machine to blast solid particles having 30 to 300 μm of mean particle diameter against the continuously traveling metallic sheet. The blasting machine is structured by a centrifugal rotor having a rotation axis. The line of intersection between the plane vertical to the rotation axis and the plane of the metallic sheet is positioned in parallel to or at 45° or smaller angle to the travel direction of the metallic sheet.

Owner:JFE STEEL CORP

Throwing wheel assembly

A throwing wheel assembly including a rotatable wheel and one or more throwing blades each removably positionable on the face of the wheel in a throwing position, the throwing blades having holding structures projecting therefrom and the improvement comprising one or more retainers which are removably positionable in a recess provided in the wheel face and which and are adapted for removably receiving and retaining the blade holding structures.

Owner:BLAST CLEANING TECH INC

Device and method for polishing large parts

InactiveCN1822920ADoes not reduce surface roughnessQuality improvementImpeller wheelsEngine manufactureImpellerDrive motor

A device for polishing a large part, comprising a rotary table supporting a turbine part at a specified position, rotatably supported on a support member, and drivingly rotated by a drive motor, an abrasive material feed means feeding abrasive particles formed mainly of elastic bodies as an abrasive material to a specified position, a polishing head drivingly rotated by an impeller drive motor at a high speed, having an impeller providing rotating energy to the abrasive particles fed from the abrasive material feed means, and jetting the abrasive particles flying out in the tangential direction of the impeller at a predetermined speed toward the polished surface of the turbine part held on the rotary table, and an abrasive material recovery means recovering the abrasive particles fed from the polishing head thereto for the polishing of the turbine part and feeding the abrasive particles to the abrasive material feed means.

Owner:KK TOSHIBA

Centrifugal abrasive material projection machining device

InactiveCN102672622ARealize processingImprove resection rateImpeller wheelsRotor bladesImpellerLiquid tank

The invention discloses a centrifugal abrasive material projection machining device, comprising an abrasive material liquid tank, abrasive material mixed liquid, an impeller, a blade, a working piece, a pump and an abrasive material. A feeding opening is arranged at the center of the impeller; the blade is arranged in the impeller and is vertically connected with the feeding opening; the abrasive material liquid tank is arranged below the impeller; the working piece is arranged on a cover plate of the abrasive material liquid tank; the abrasive material mixed liquid is mounted in the abrasive material liquid tank; the abrasive material liquid tank is connected with the pump; and the pump is connected with the feeding opening through a guide pipe. According to the centrifugal abrasive material projection machining device provided by the invention, the working piece is machined by using a centrifugal force to project the abrasive material through the rotation of the impeller. The centrifugal abrasive material projection machining device has the advantages of large projection area, uniform distribution and high metal cutting ratio. Furthermore, the centrifugal abrasive material projection machining device provided by the invention is simple in structure, has low manufacturing cost, and is convenient for industrial production.

Owner:TAICANG KAIXIN ELECTRONICS

Centrifugally Projecting Machine

ActiveUS20090137193A1Reduce maintenancePrevent leakageImpeller wheelsRotor bladesImpellerRotational vibration

A centrifugally projecting machine that has an improved life of its driving motor by having a reduced rotational vibration caused by a dynamic imbalance of an impeller, and that reduces maintenance by avoiding usage of liners, the machine comprising:a housing,a driving means disposed at the first side of the housing by means of a flange,an impeller having a plurality of blades, wherein the impeller is connected to a driving shaft of the driving means by means of a hub,a distributor disposed in the inner cylindrical space of the impeller so that it is concentrically arranged in relation to the driving shaft, wherein the distributor has slit-like openings that are circumferentially disposed with substantially equal clearances,a control cage having an opening around its distal end for dispersing shot, wherein the proximal end surface of the control cage is connected to the second side of the housing, opposite its first side, around an opening for an intake disposed at its second side, wherein the control cage is disposed at the clearance between the inner ends of the blades and the outer surface of the distributor and extends over the length of the impeller, anda nozzle connected to the second side of the housing to supply the opening for an intake with shot,(1) wherein a supporting member is disposed at the side of the impeller to support the rotating impeller,(2) wherein a rotating member for sealing is disposed between the proximal end of the distributor and the distal end of the control cage, and(3) wherein a bearing is disposed at the clearance between the inner periphery of the flange and an outer periphery of a hub together with damping members.

Owner:SINTOKOGIO LTD

Shot blast machine

InactiveUS20070032178A1Increased durabilityImprove grindabilityImpeller wheelsRotor bladesImpellerExtreme Cold

The shot blast machine having a projector with an impeller includes the impeller which is made of a high abrasion-resistant rubber. Therefore, it can increase the durability without damage of the impeller and projectile; it can use the projectile with high grindability, with small particle and light gravity; and it can be used at any condition including extreme cold, normal temperature, wet condition and the like.

Owner:NISSANKI

Torsion bar shot blasting machine

InactiveCN103600300AEnsure balanceEvenly distributedImpeller wheelsRotor bladesImpellerRough surface

The invention provides a torsion bar shot blasting machine, and a shot throwing port has a trumpet-shaped opening, thereby increasing a shot throwing distribution; the contact surface of blades and shots is an arc shaped curved surface with rough surface, thereby the thrown shots are distributed uniformly; the number of the blades on each impeller is 6 or 8, thereby guarantying operation balance property of the shot throwing machine, wherein, the balance moment is between 12-15 N.mm, and simultaneously reducing the equipment noise, and the weight difference of each set of blade is not less than 3g. The motor employs a direction connection transmission, thereby minimizing belt power loss and the energy consumption reduces 16-19%. A shot distributing wheel, a control cage, the impeller, the blade and the cover casing all employ wear resistant cast iron whose chromium content is higher than 18%, thereby increasing wear resistance of components and improving machine life; and the shot blasting amount of the shot blasting machine is up to 320kg / min, and the shot blasting speed is up to 88m / s, thereby the component life is increased to 4 times, and the noise is reduced to 45%, and the work efficiency is effectively increased.

Owner:GREEN PRECISION SUZHOU CO LTD

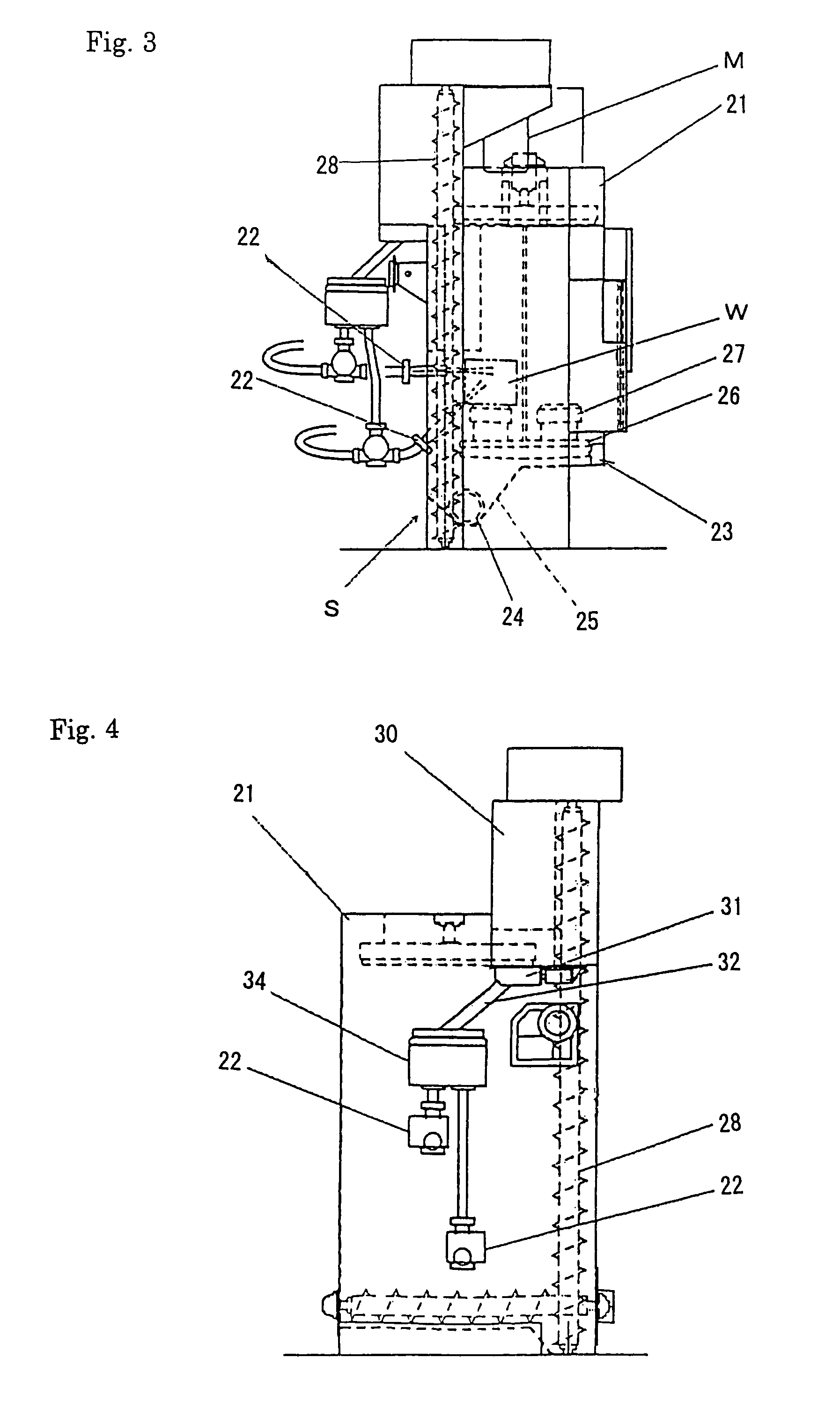

Apparatus for a shot peening treatment

A shot-peening device(s) is installed on a side of a cabinet defining an ejection chamber in the cabinet. Shots ejected from the device to a workpiece fall and are conveyed in a horizontal direction by a horizontal screw conveyor positioned above a lower end of the cabinet and then conveyed upward by a vertical screw conveyor whose base end is above the lower end of the cabinet. The shots pass from an upper section of the vertical screw conveyor through a chute to reach an opening / closing gate. When the gate is opened and the shots are supplied to the device(s) for re-ejeciton, a portion of the shots is cause to overflow from the gate. The overflowed shots are caused to pass through a separator to remove impurities and then returned to the horizontal screw conveyor.

Owner:SINTOKOGIO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com