Device and method for polishing large parts

A large-scale parts and equipment technology, applied in the field of large-scale parts polishing equipment, can solve problems such as time-consuming and labor-intensive surface conditions, difficult to polish surfaces, uneven polished surfaces, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

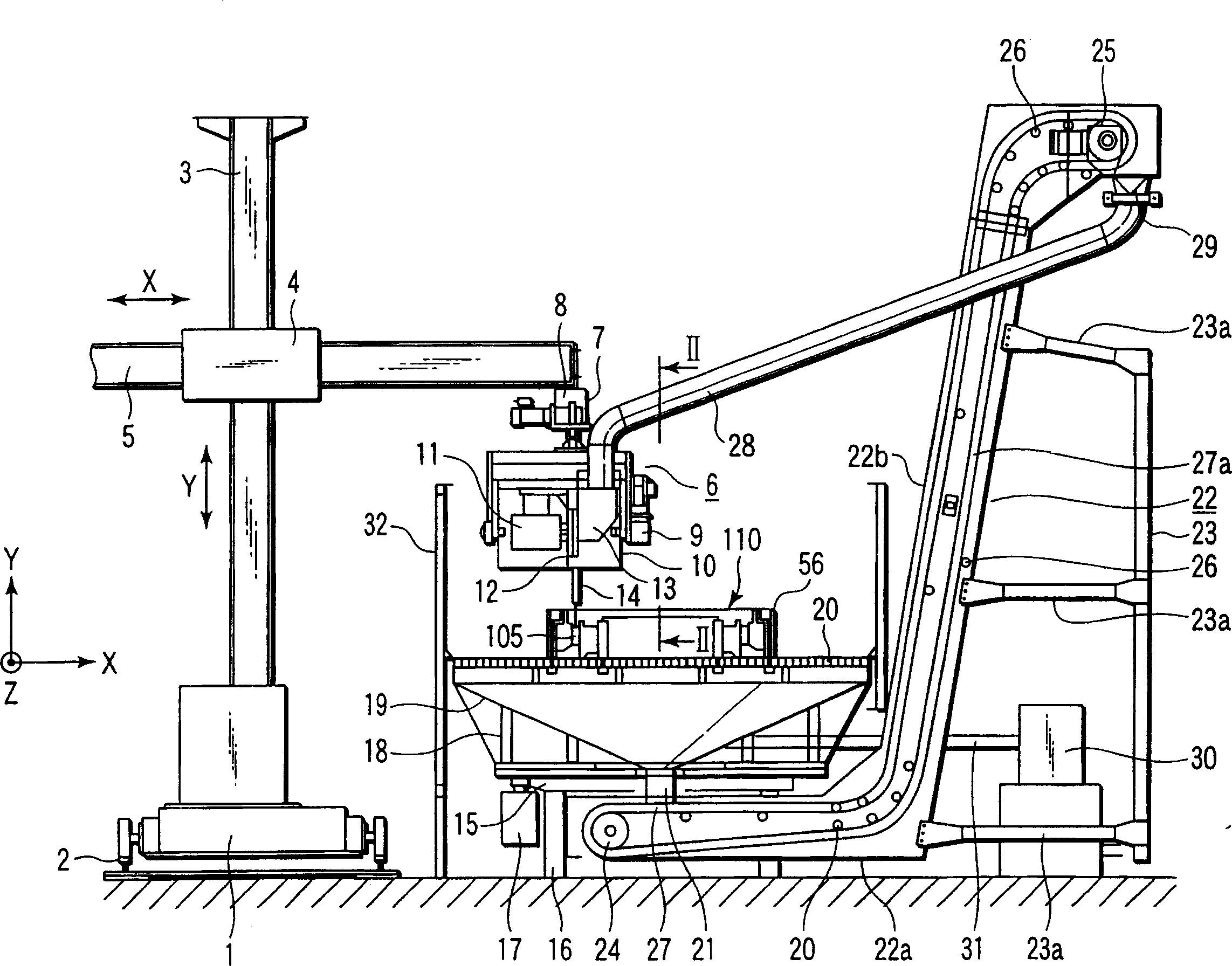

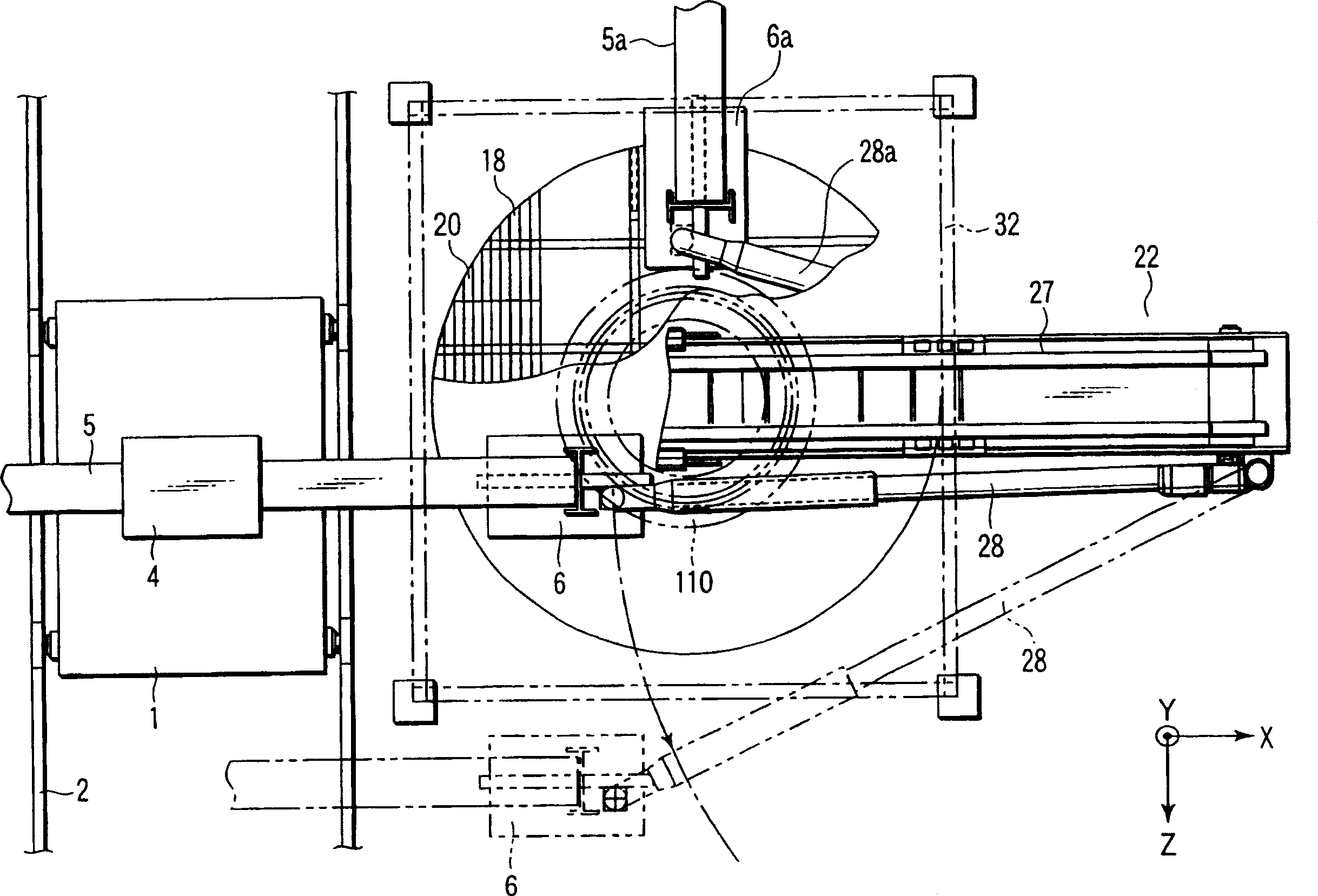

[0036] figure 1 is a front view showing a first embodiment of the large parts polishing apparatus according to the present invention, and figure 2 is a plan view of the first embodiment.

[0037] exist figure 1 and figure 2Among them, reference numeral 1 is a bracket capable of moving along the guide rail 2 in the Z-axis direction (vertical direction in the drawing), and a bracket 3 is vertically mounted on the bracket 1 . On the bracket 3, the manipulator support part 4 is movably installed along the Y-axis direction (vertical direction in the drawings), and the manipulator 5 is supported on the manipulator support part 4 so as to be able to move along the X-axis direction (vertical direction in the drawings). for the horizontal direction) movement. The carriage 1, the manipulator support 4 and the manipulator 5 are driven in respective directions by a driving source not shown in the drawings.

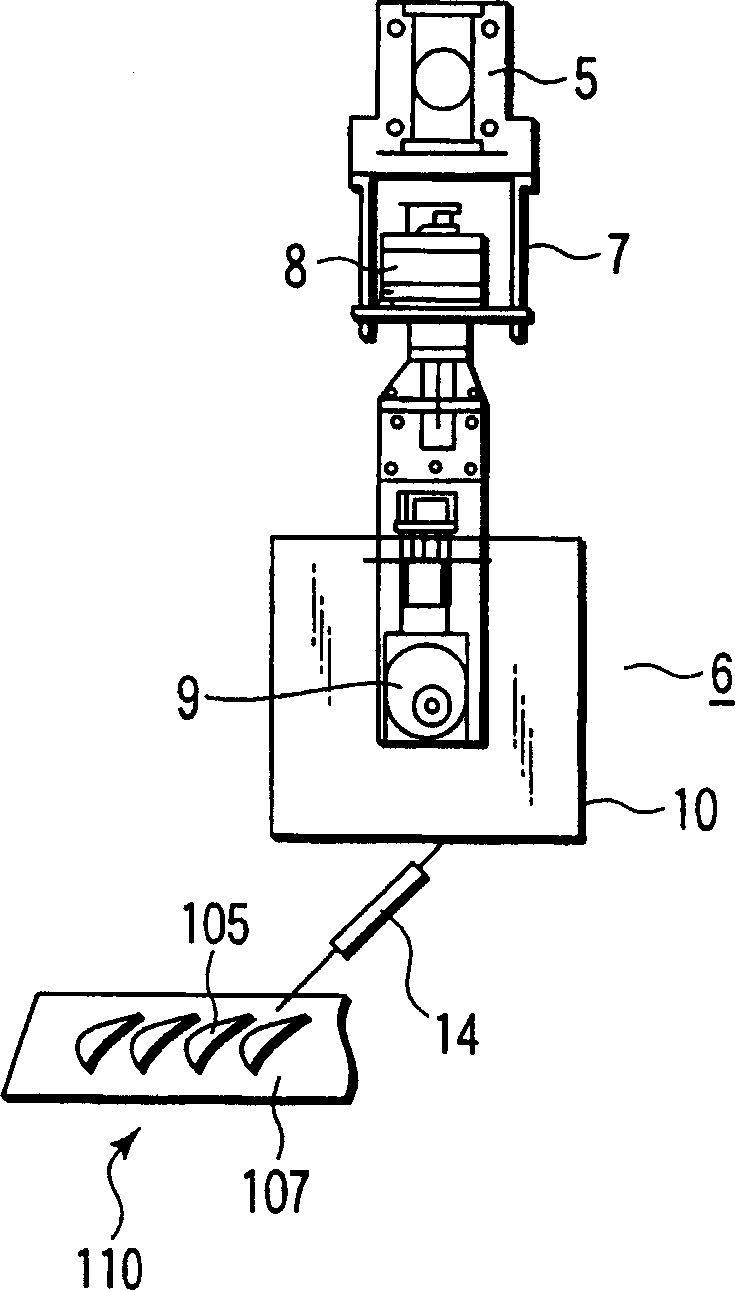

[0038] Reference numeral 6 is a polishing head attached to the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com