Shot blast machine

a technology of shot blasting machine and rotor blade, which is applied in the direction of rotor blades, grinding/polishing apparatus, manufacturing tools, etc., can solve the problems of projectile damage and inability to use, and achieve the effect of high grindability and increased durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention are described in more detail below referring to the accompanying drawings.

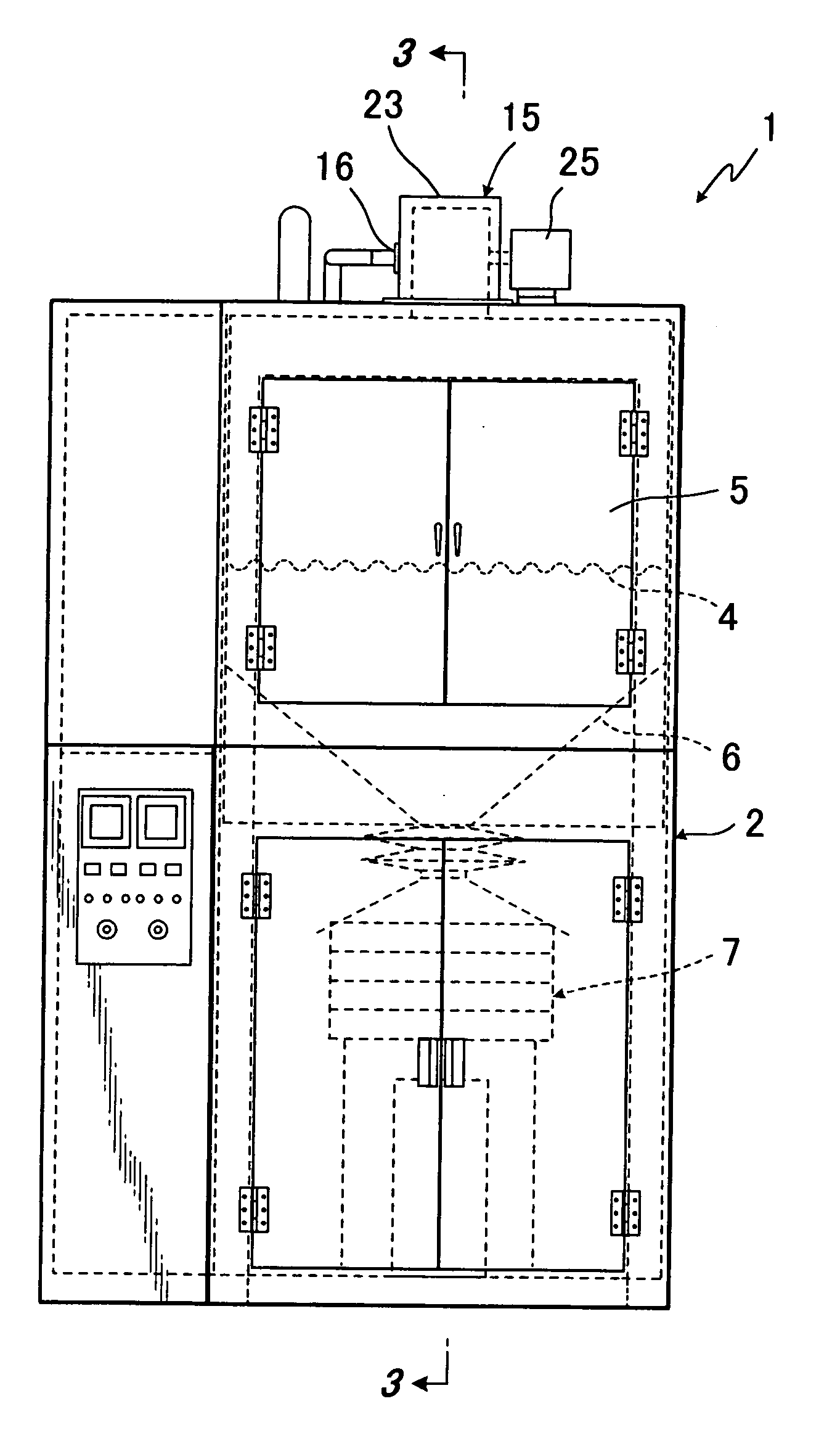

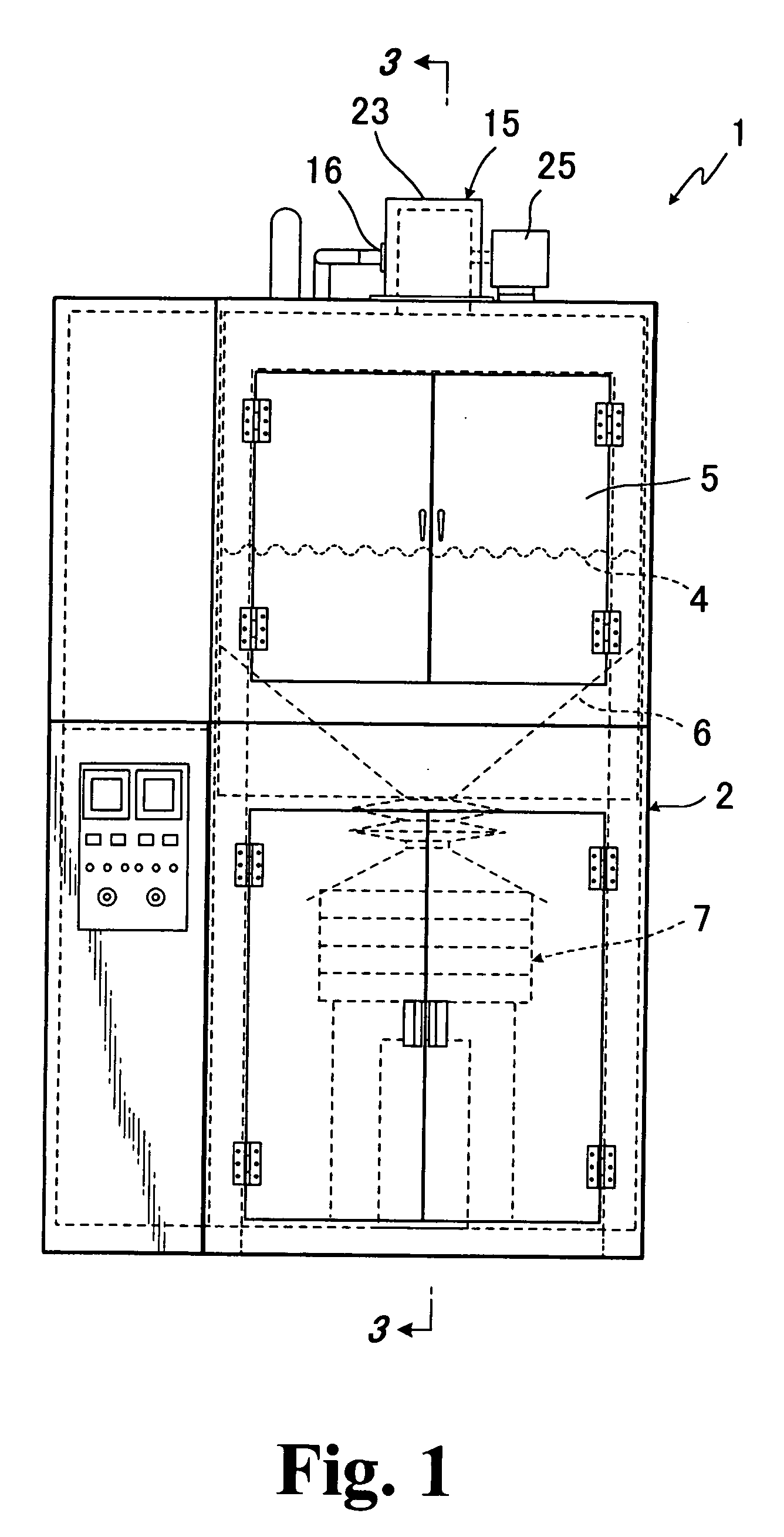

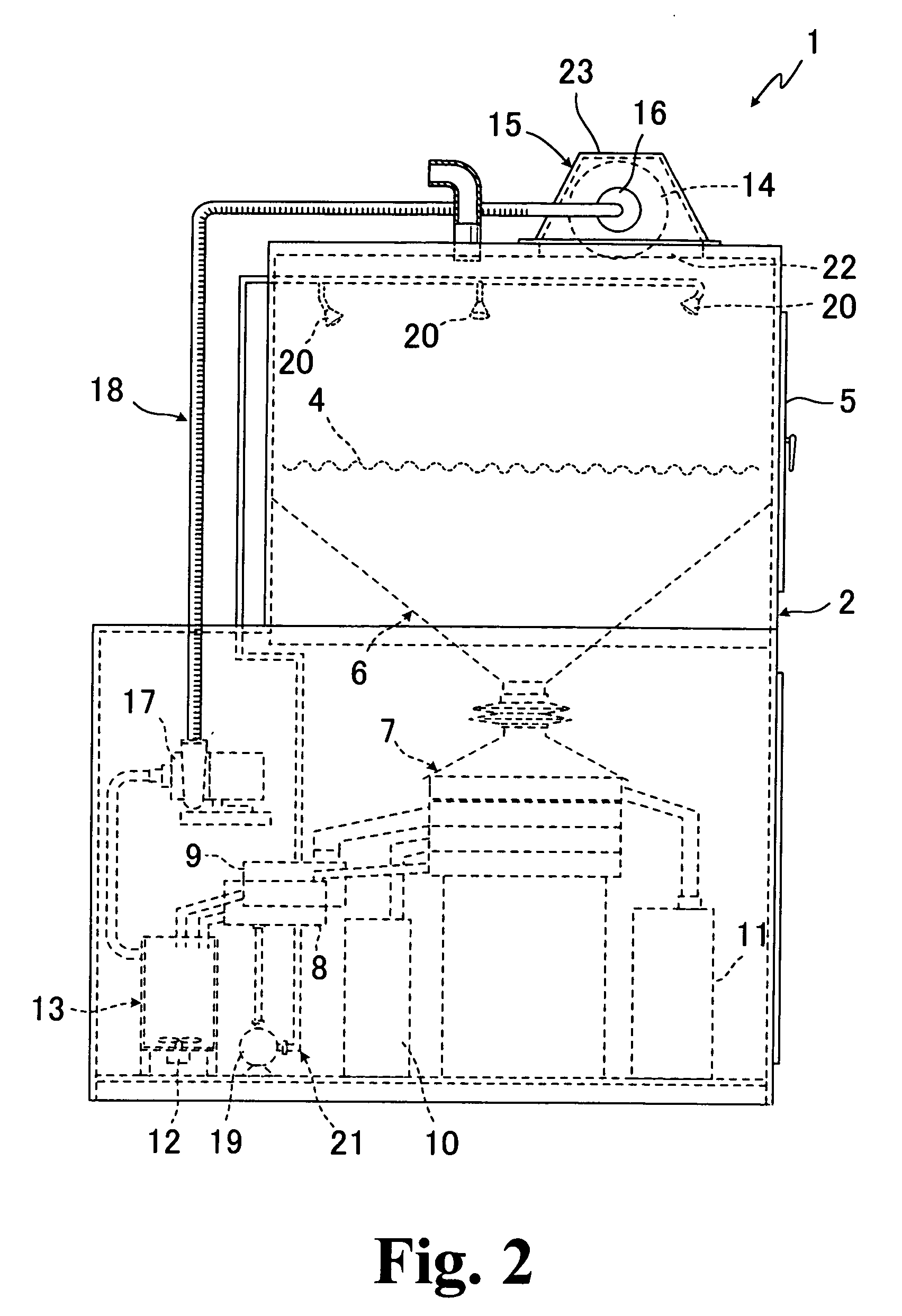

[0024] An understanding of the present invention may be best gained by reference FIGS. 1 to 7. Reference numeral 1 is a shot blast machine which burrs molded goods, treats the surface of molded goods and removes crud attached to the surface of works. The shot blast machine 1 is comprised of a case body 2; a table 4, as a supporting tool supports a work 3, installed into an upper portion of the case body 2, forming of a perforated plate or mesh body; an openable door 5 attached to the case body 2 capable of taking the work 3 in and out the table 4; a picking device 7 with a vibrating screen, providing at a lower position of the table 4 in the case body 2 through the hopper 6; a liquid tank 8 provided liquid including water, cleaning liquid or the like sorted out by the picking device 7 therein, a projectile tank 9 provided the projectile therein, a small du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com