Patents

Literature

1097results about How to "Reduce impurity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

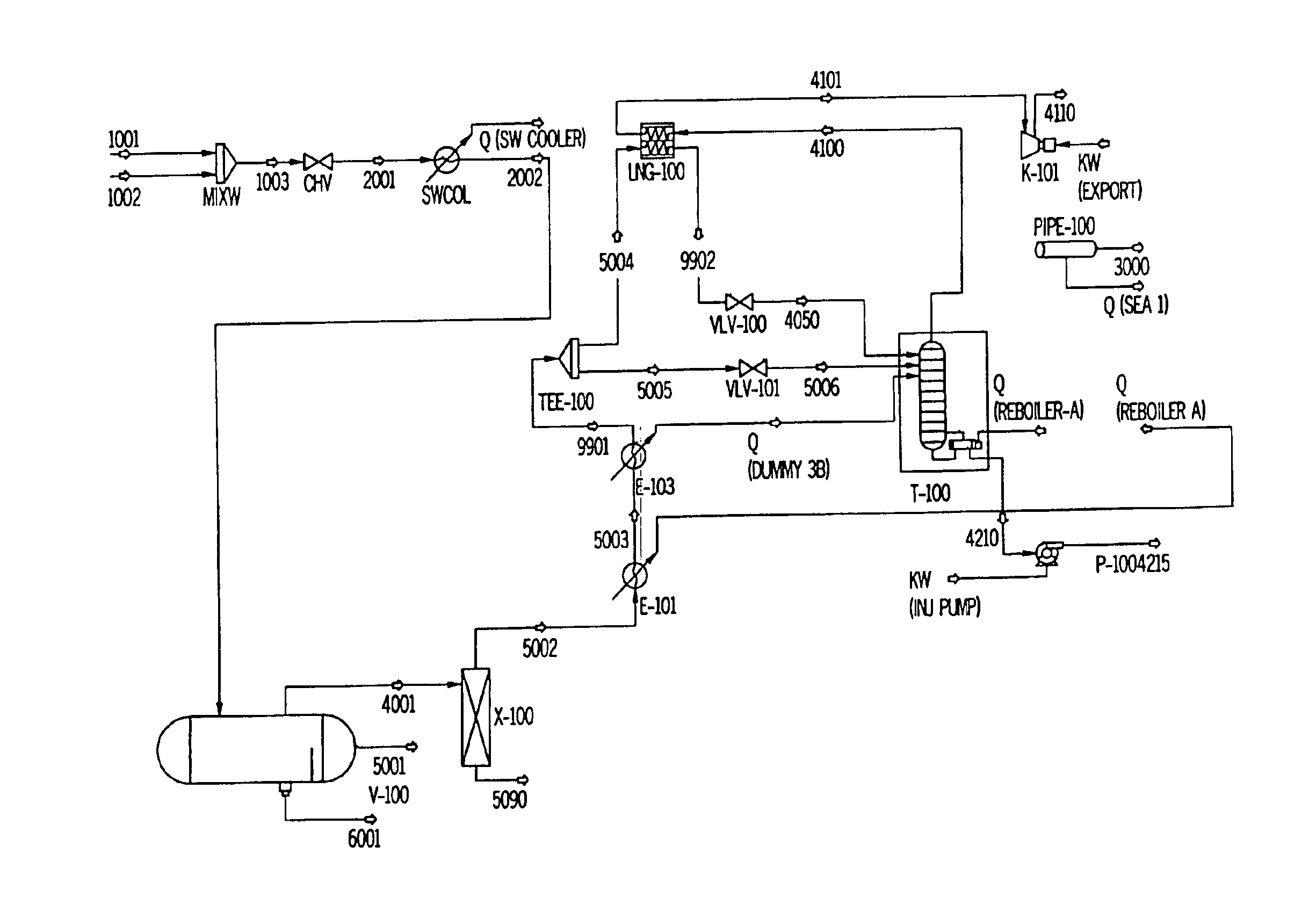

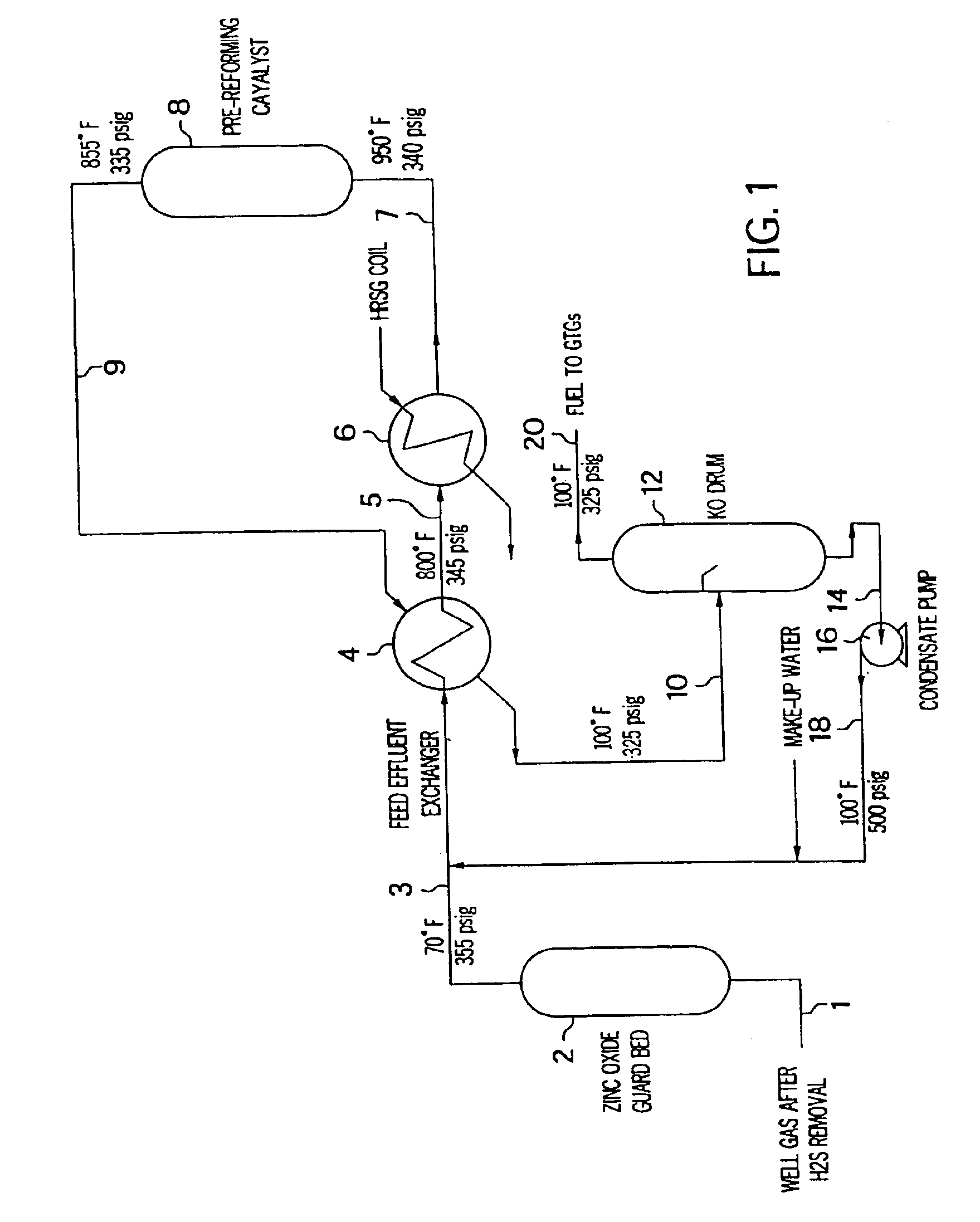

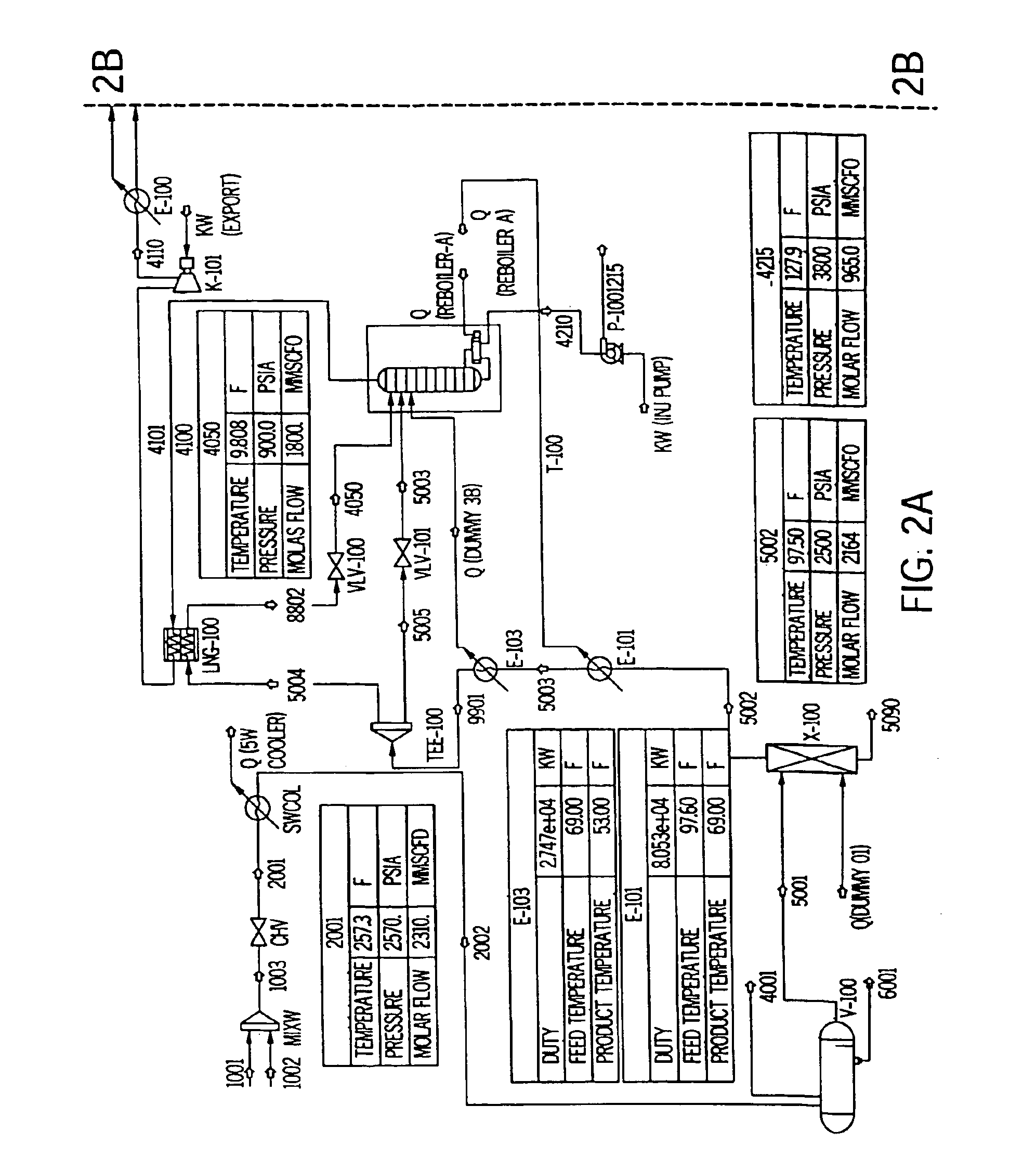

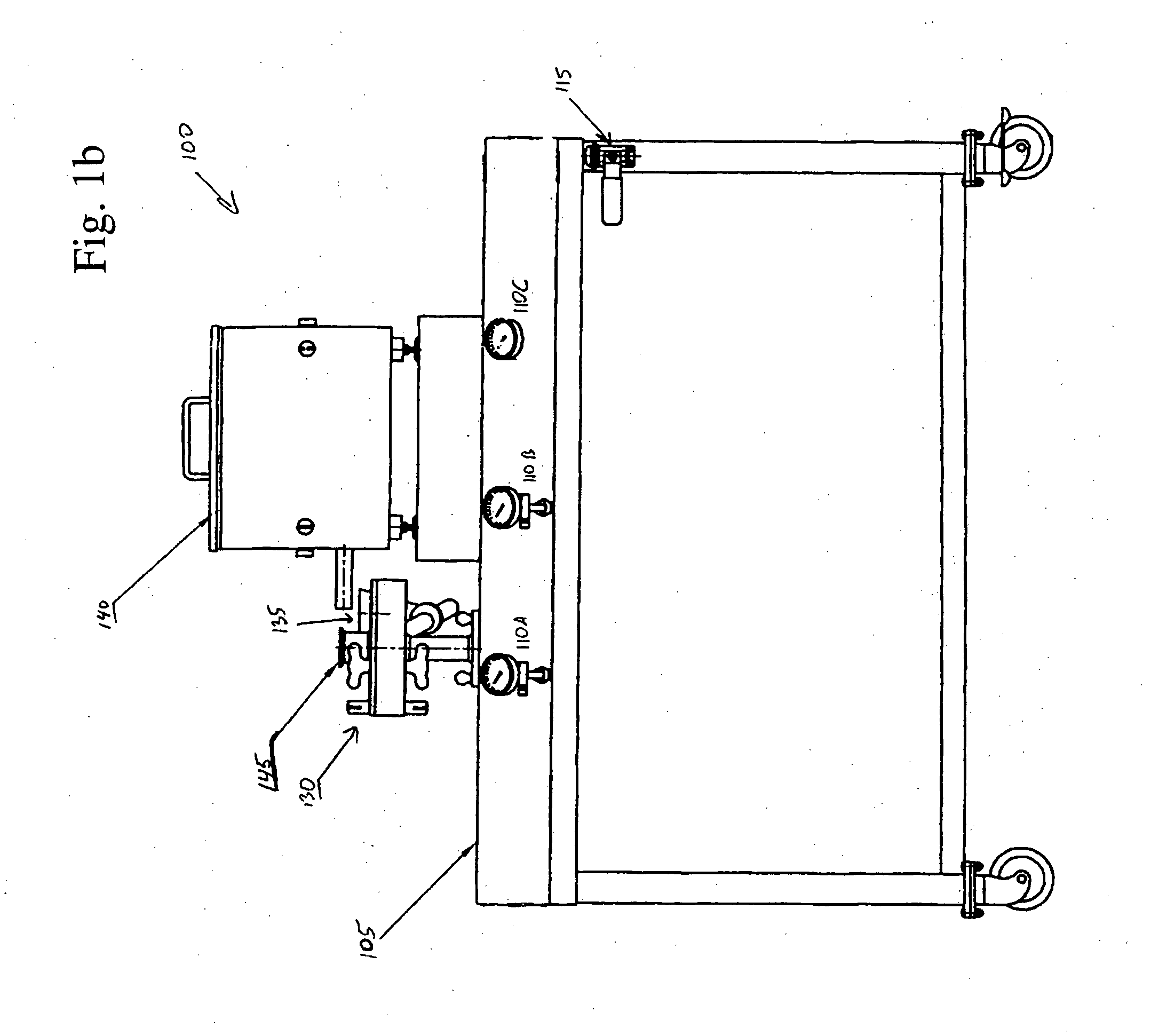

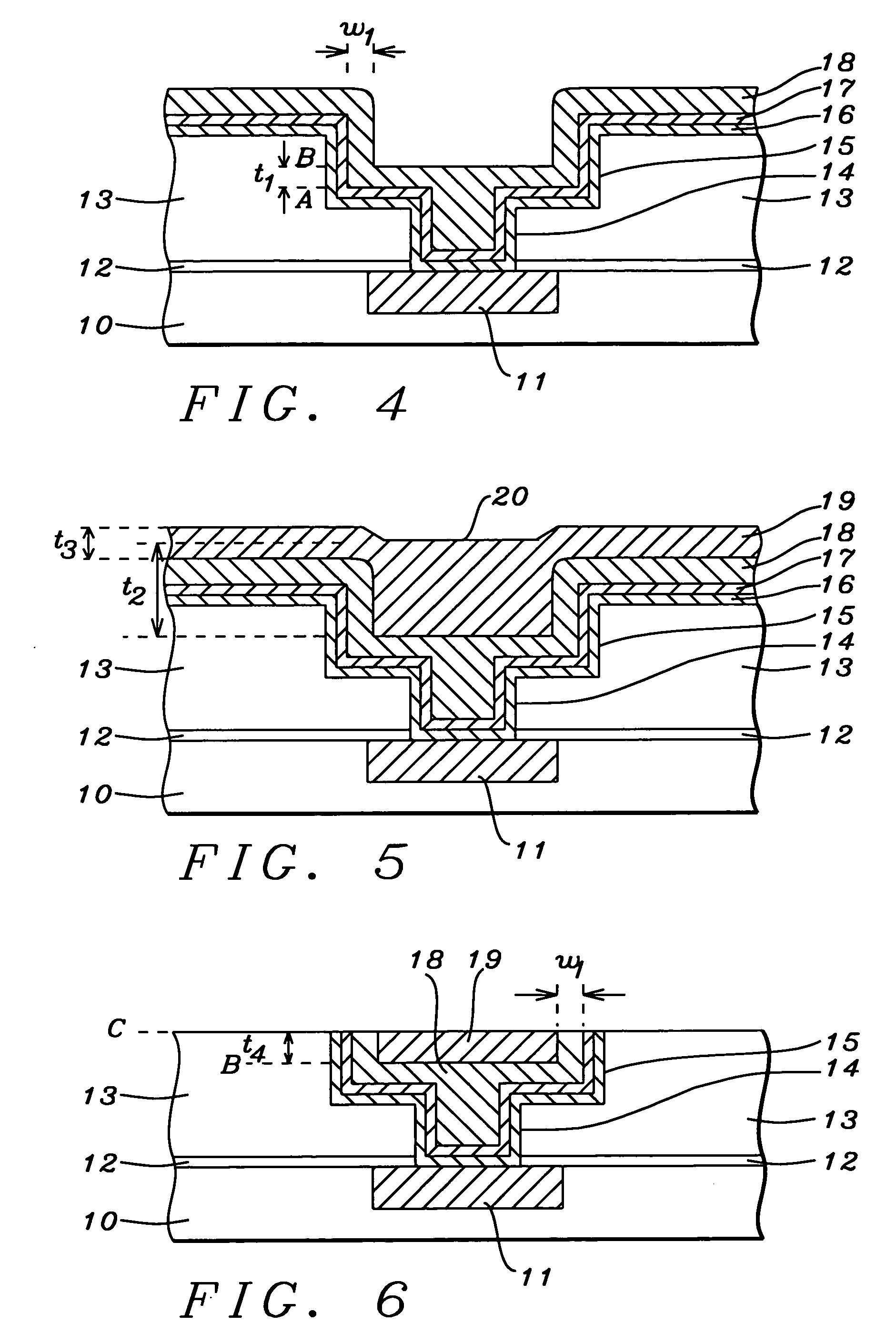

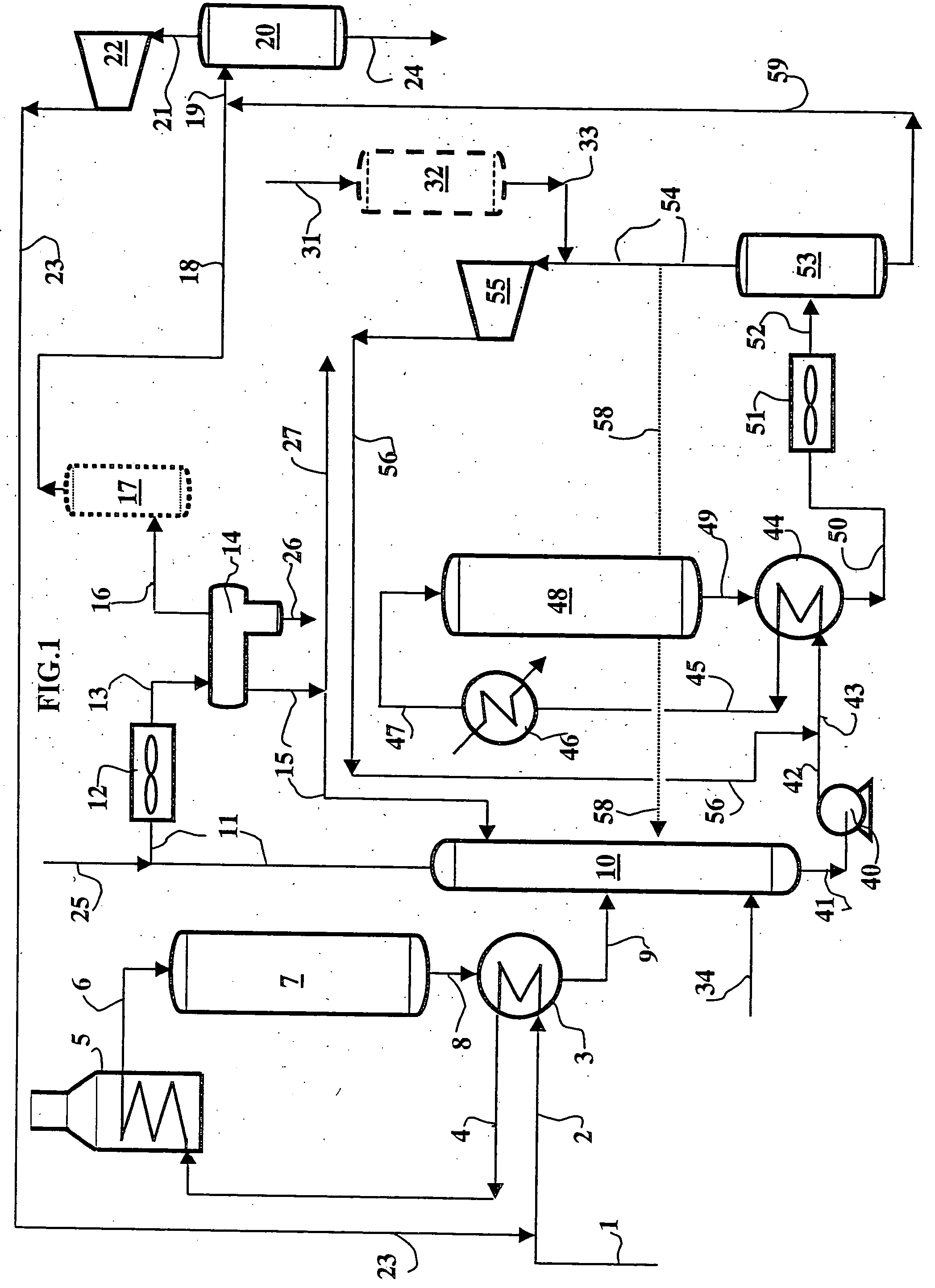

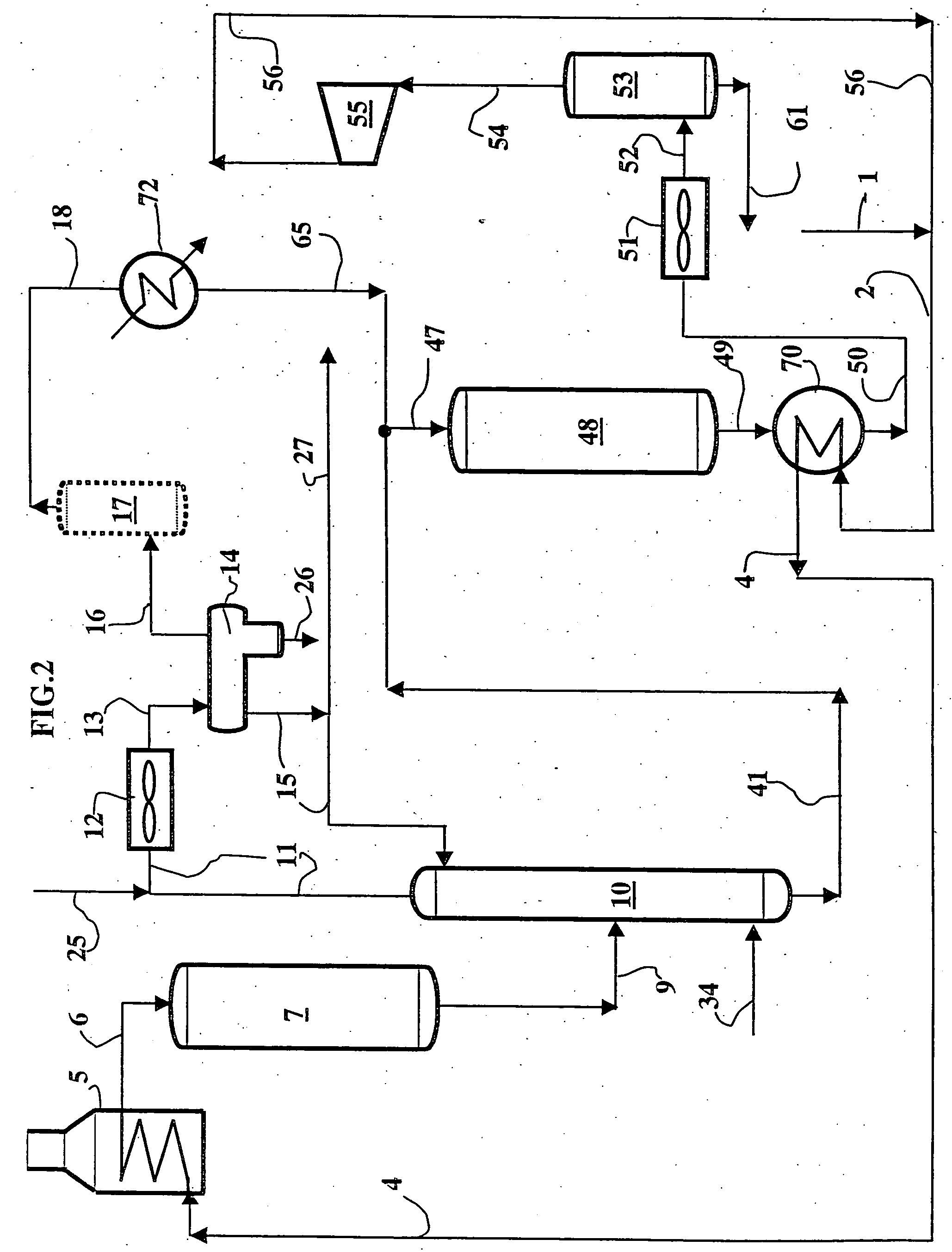

Method for utilizing gas reserves with low methane concentrations and high inert gas concentrations for fueling gas turbines

InactiveUS6907737B2Improve flammabilityLow costSolidificationLiquefactionProcess engineeringCurrent technology

The invention is directed to a method of fueling gas turbines from natural gas reserves with relatively low methane concentrations. The invention uses such reserves to generate electric power. The invention permits the use of these reserves at significantly lower cost than by producing pipeline natural gas to fuel gas turbines to generate electric power. These reserves currently generally are used only after the removal of impurities to produce pipeline natural gas quality turbine fuel. The latter current technology is capital intensive, and at current natural gas prices, economically unattractive. The process of the invention can remove the impurities from the gas from the natural gas reserve necessary for protection of the environment, and leaves inert gasses in the fuel in an amount which will increase the output of a gas turbine for the generation of power by about 5 to about 20%.

Owner:EXXONMOBIL UPSTREAM RES CO

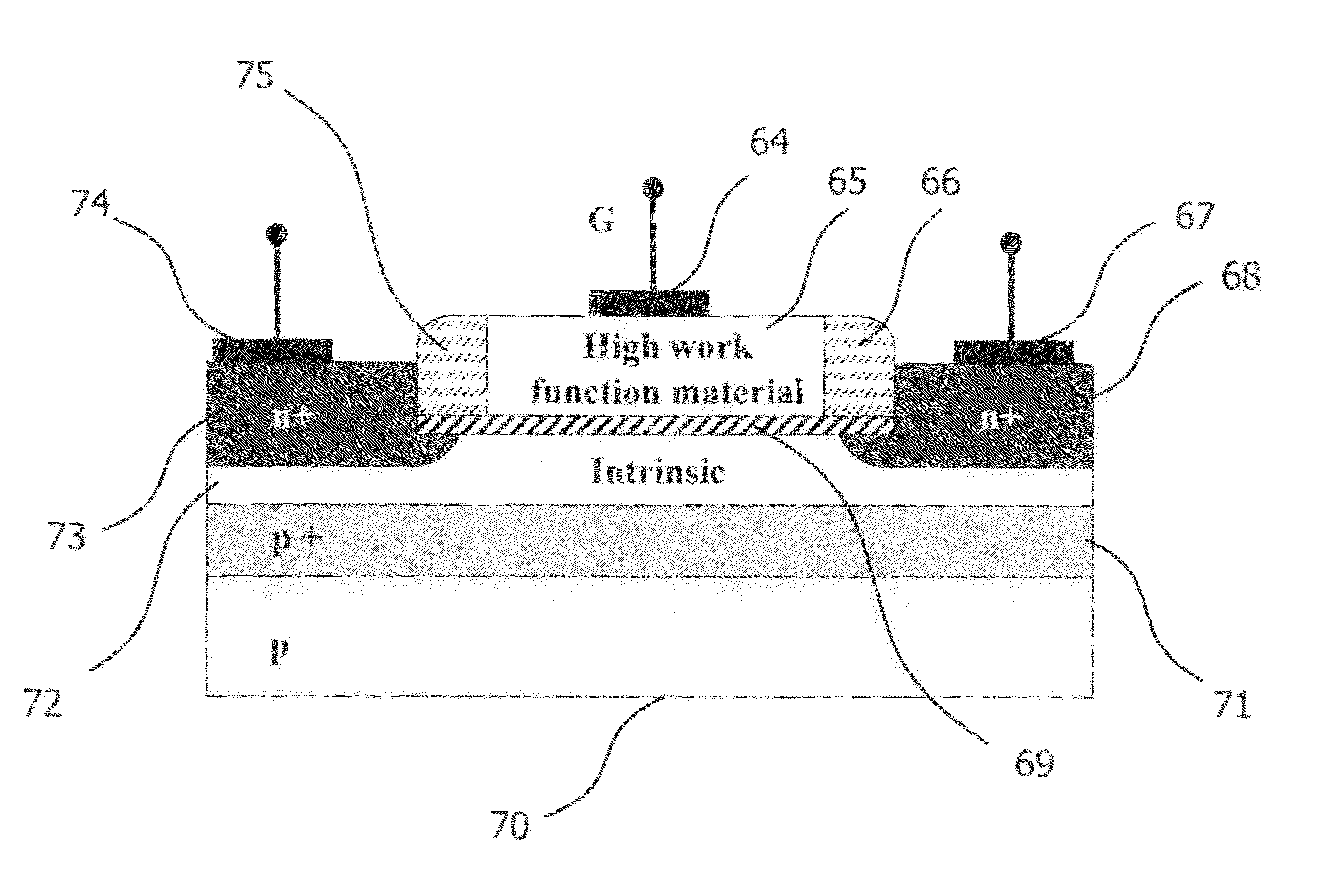

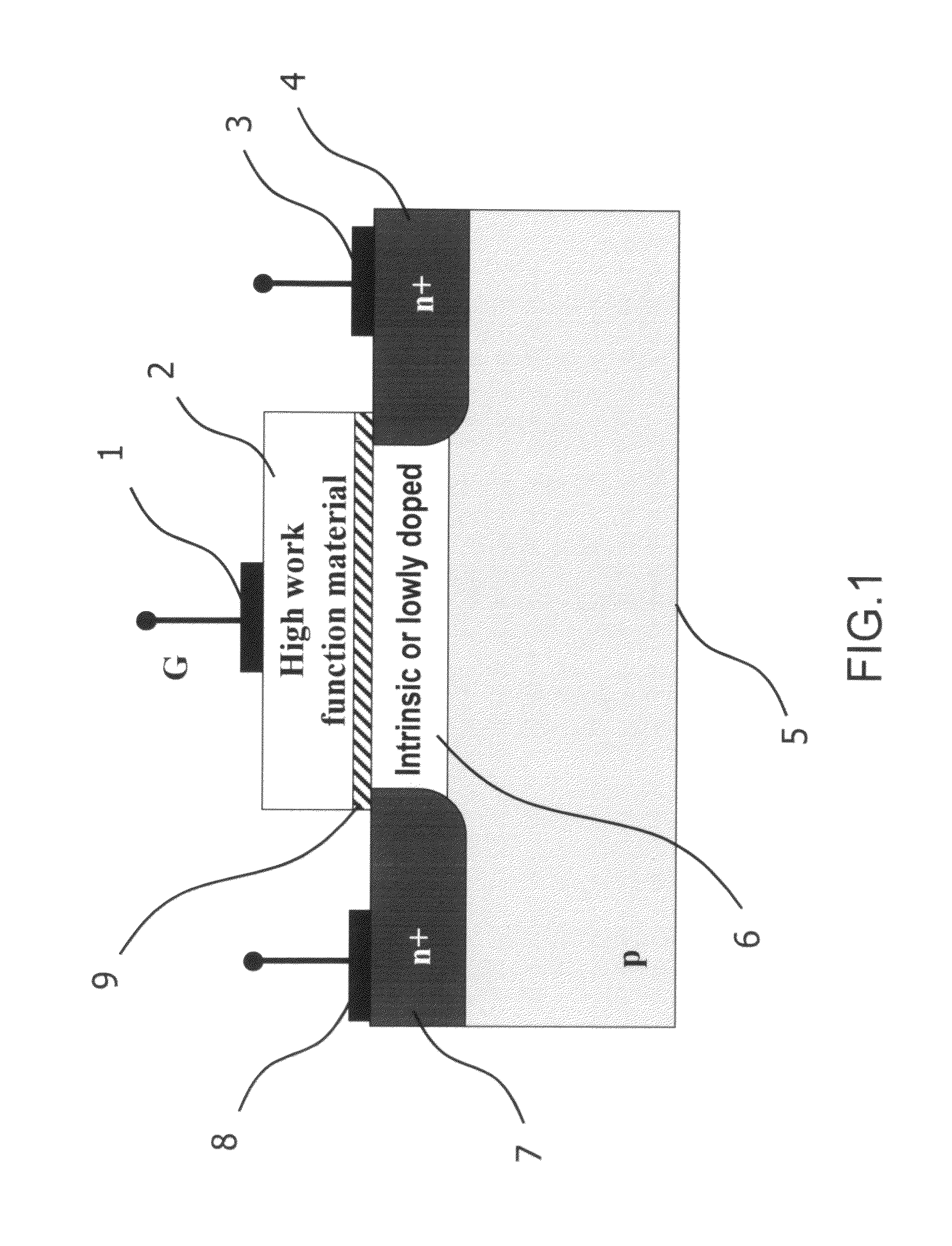

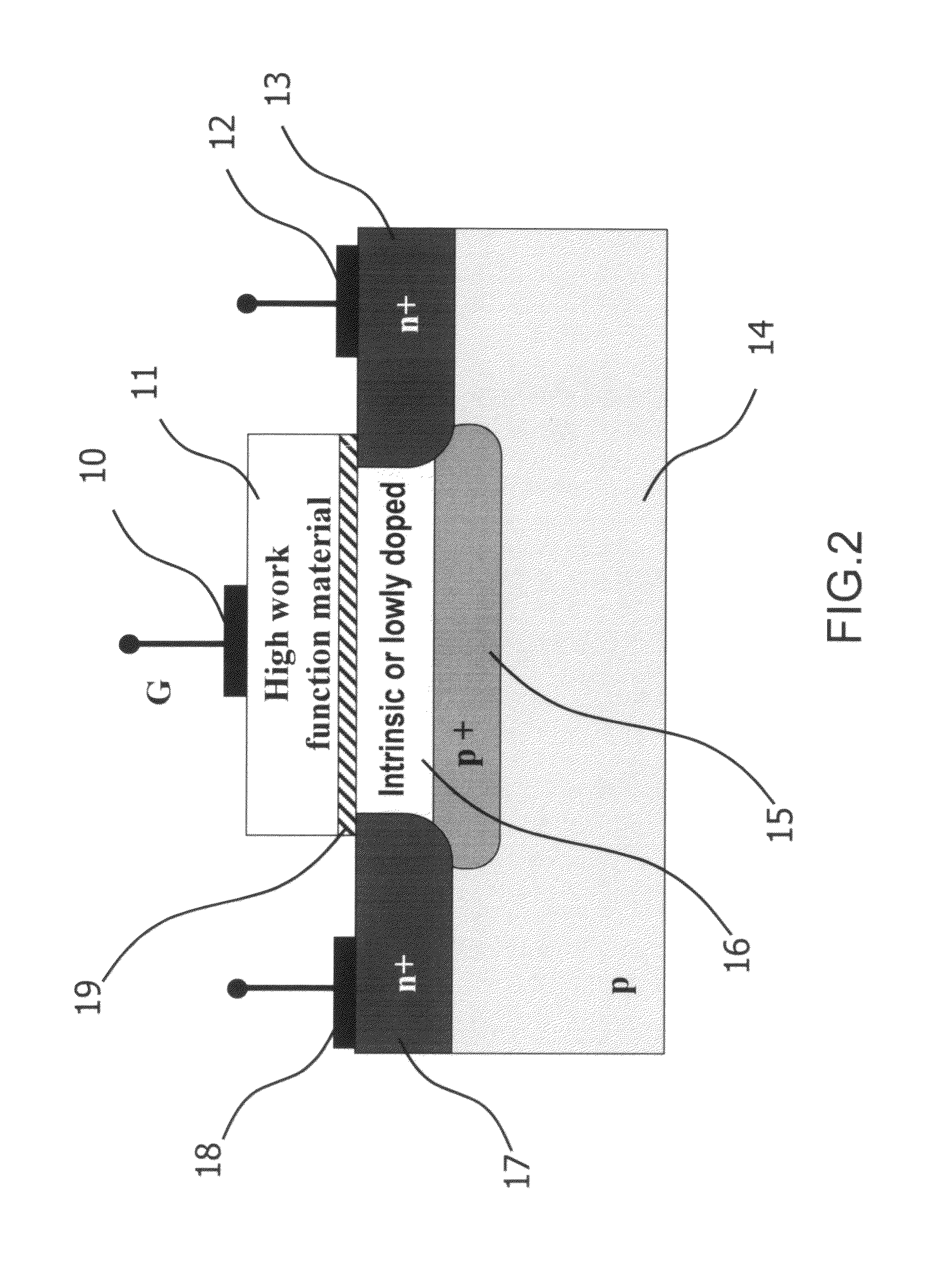

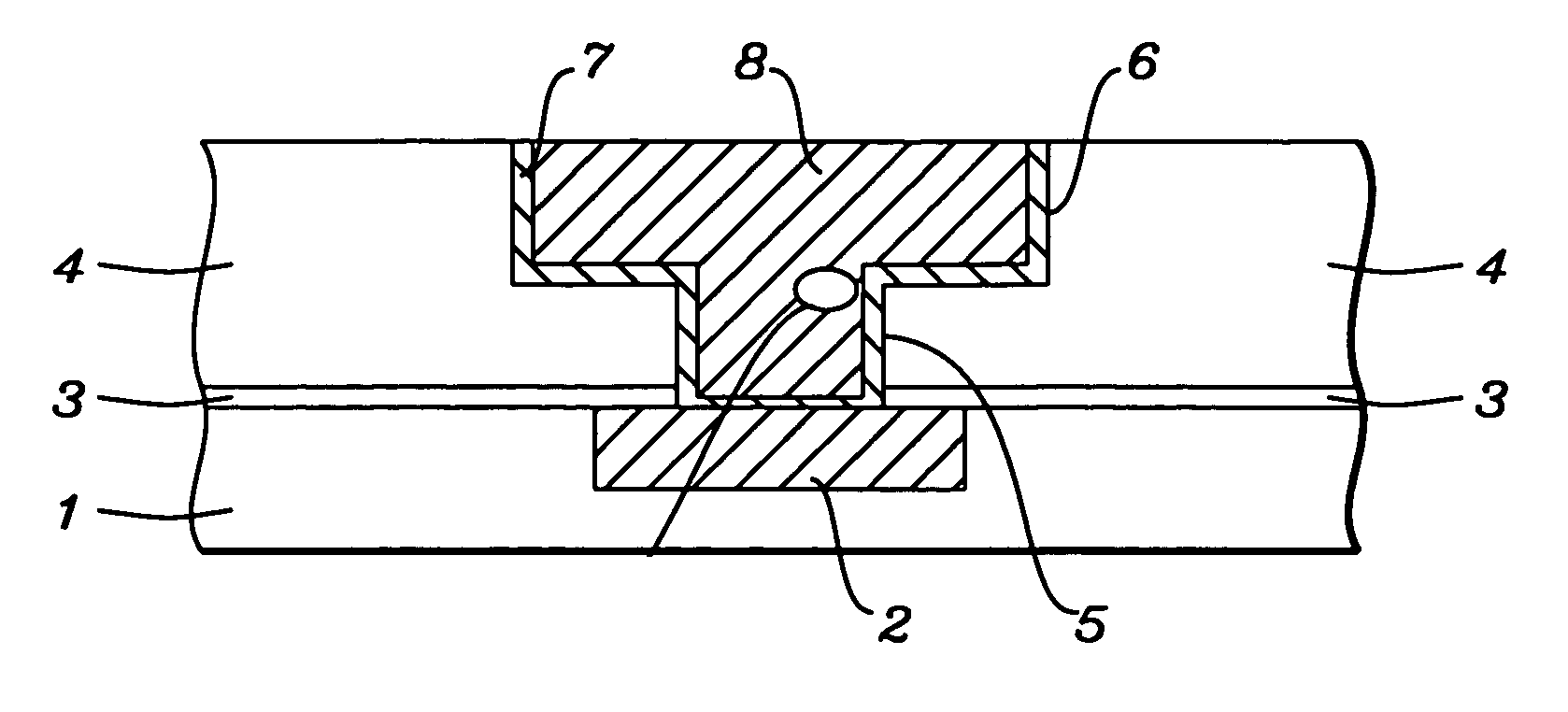

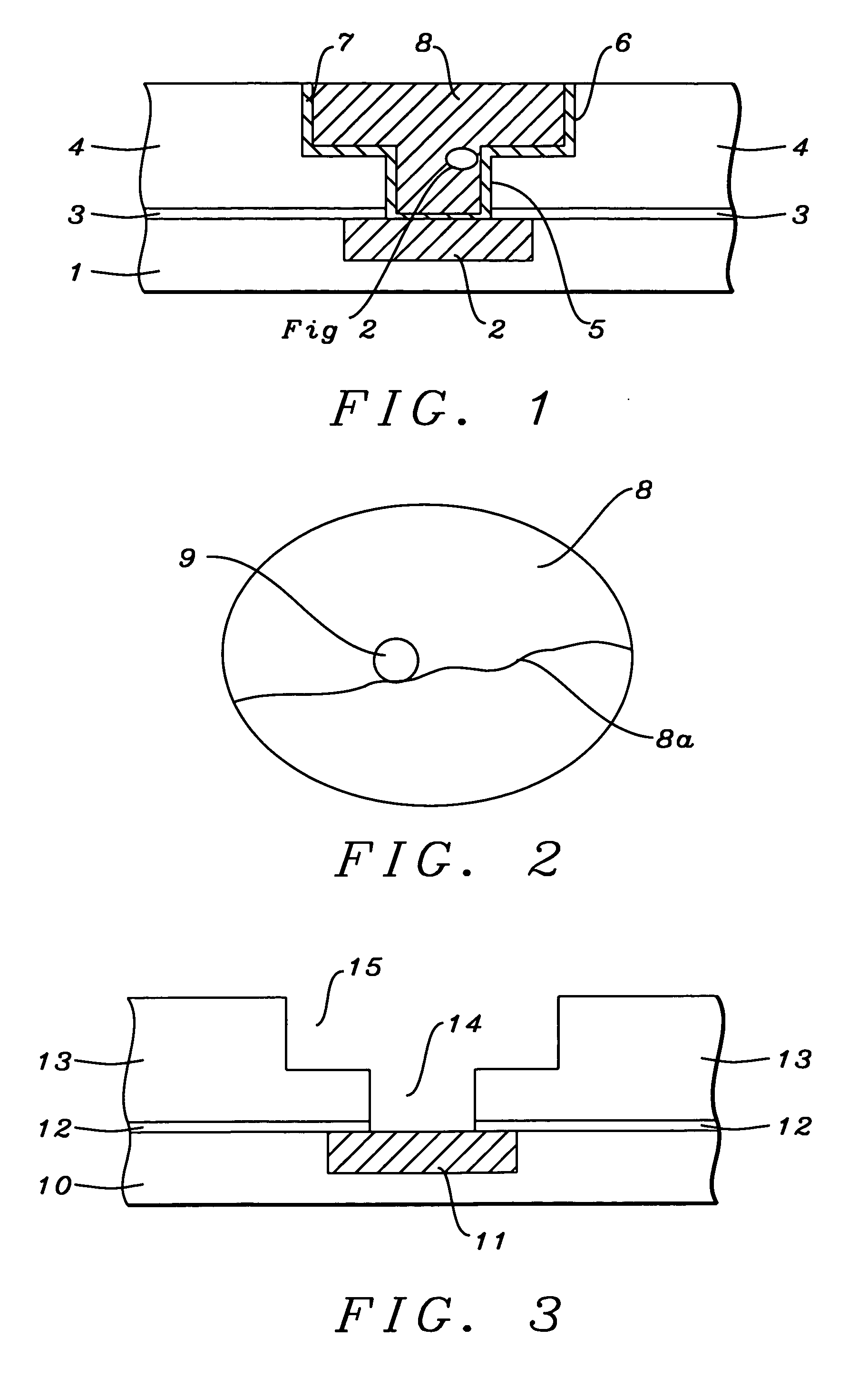

High mobility enhancement mode FET

ActiveUS8803242B2Reduce variationReduce impurityTransistorSolid-state devicesMOSFETSemiconductor structure

A novel semiconductor transistor is presented. The semiconductor structure has a MOSFET like structure, with the difference that the device channel is formed in an intrinsic region, so as to effectively decrease the impurity and surface scattering phenomena deriving from a high doping profile typical of conventional MOS devices. Due to the presence of the un-doped channel region, the proposed structure greatly reduces Random Doping Fluctuation (RDF) phenomena decreasing the threshold voltage variation between different devices. In order to control the threshold voltage of the device, a heavily doped poly-silicon or metallic gate is used. However, differently from standard CMOS devices, a high work-function metallic material, or a heavily p-doped poly-silicon layer, is used for a n-channel device and a low work-function metallic material, or heavily n-doped poly-silicon layer, is used for a p-channel FET.

Owner:QUALCOMM INC

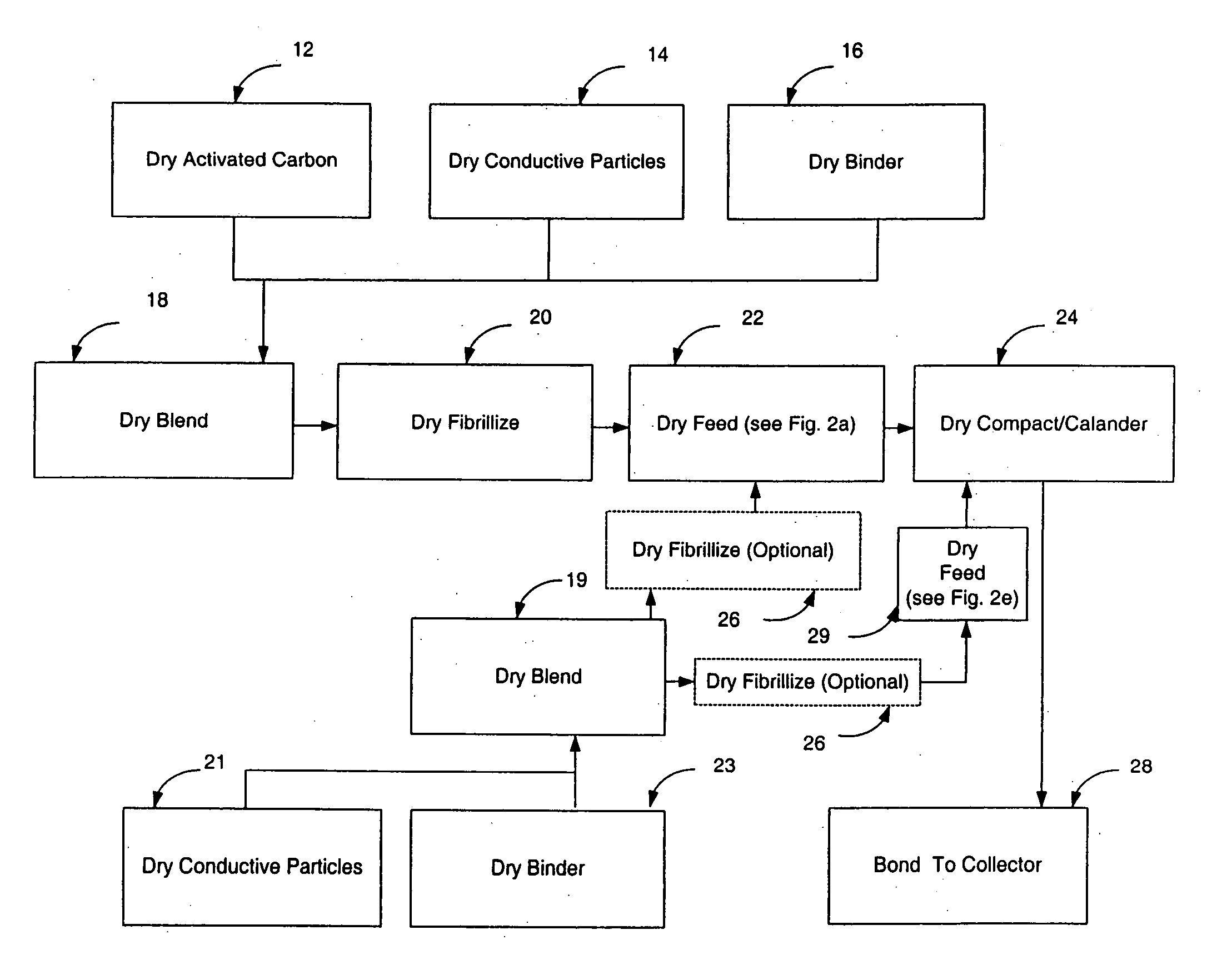

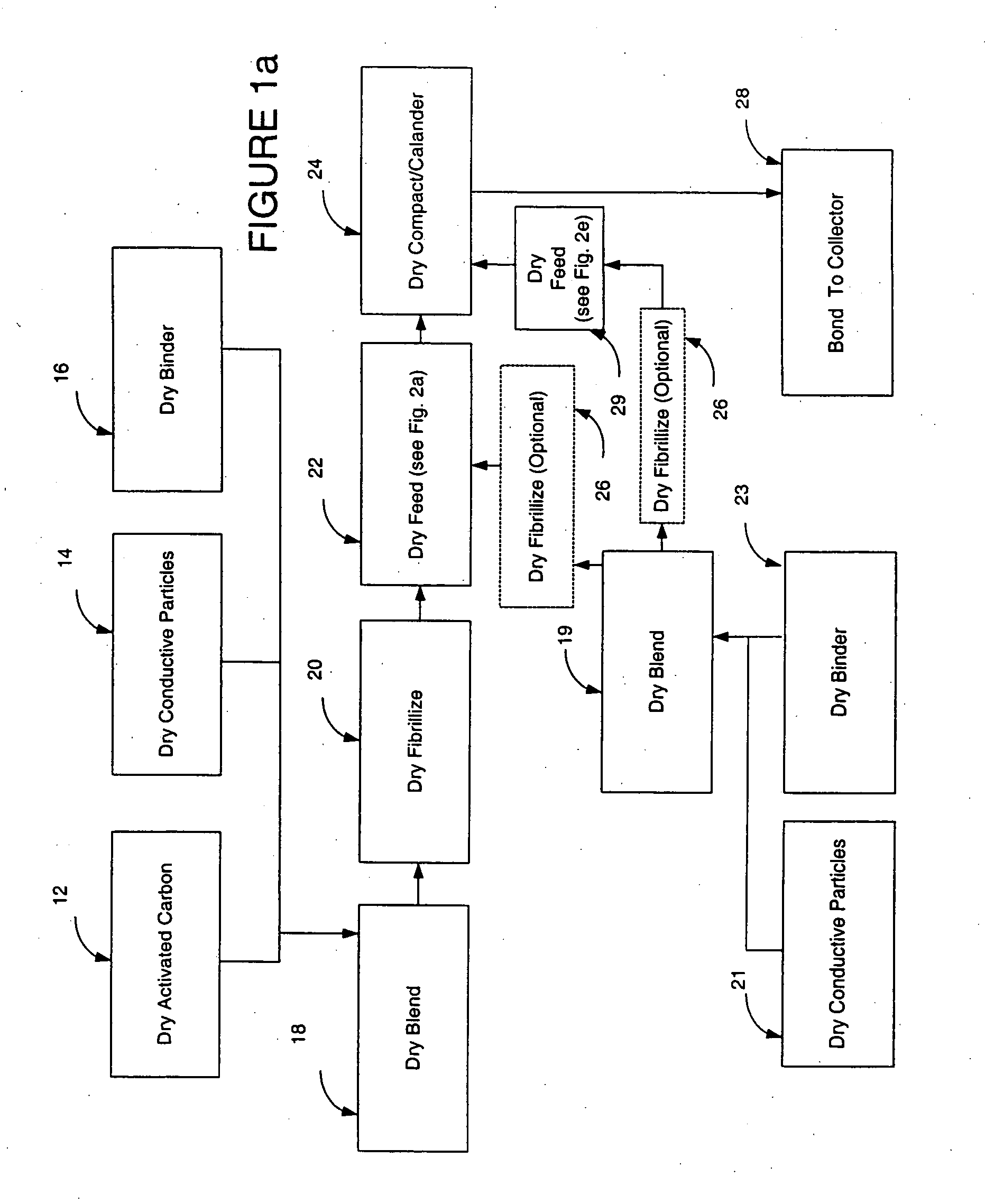

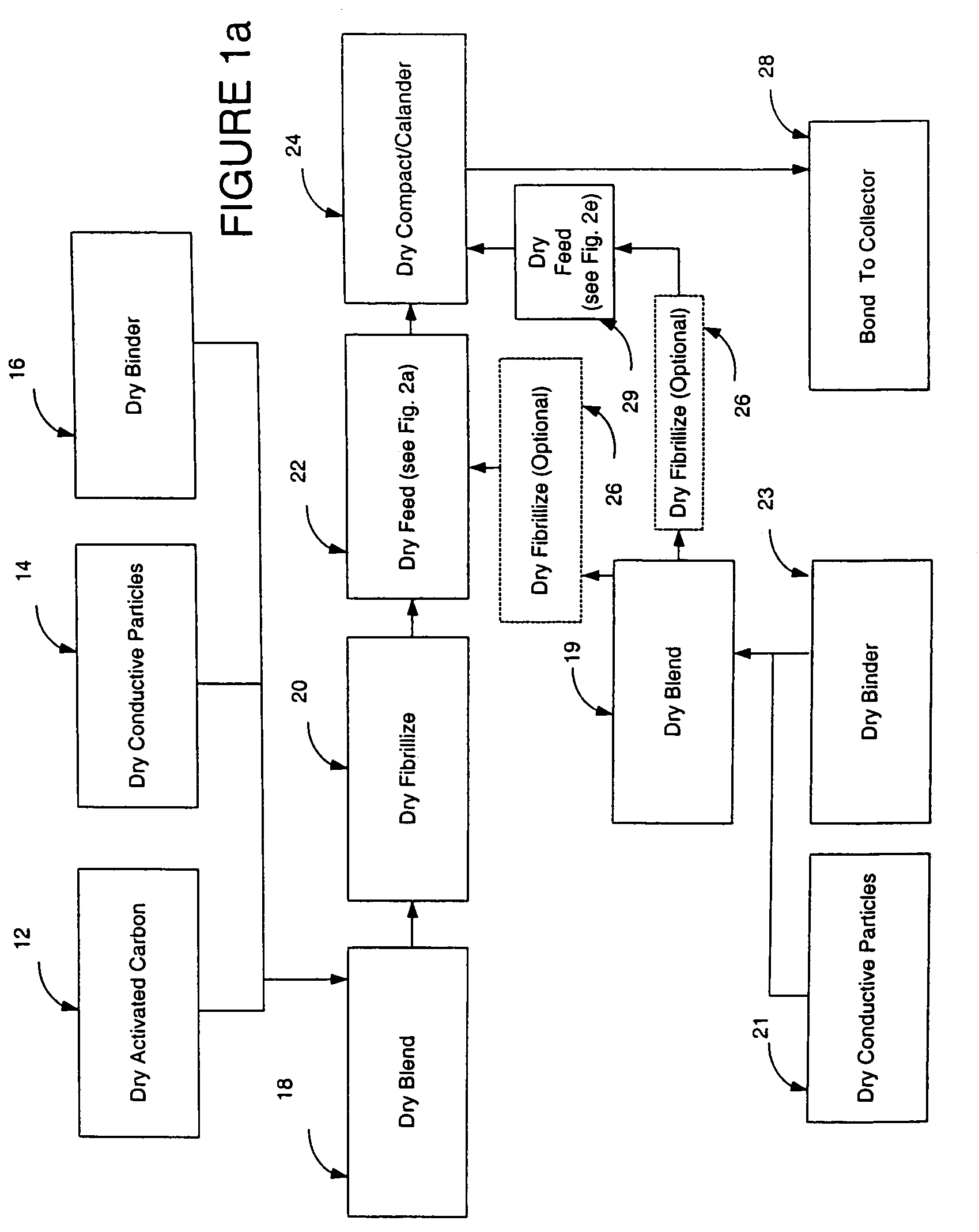

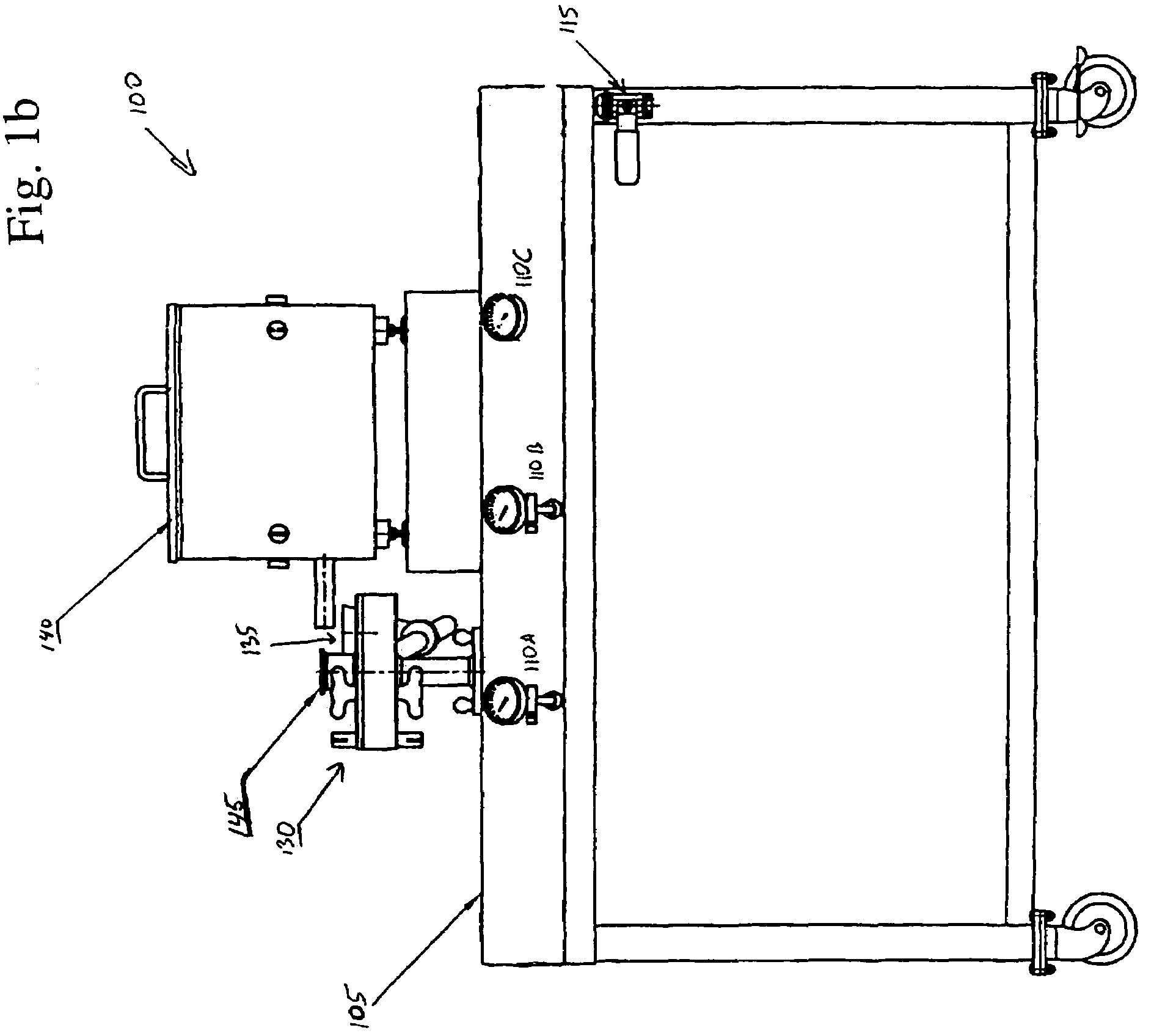

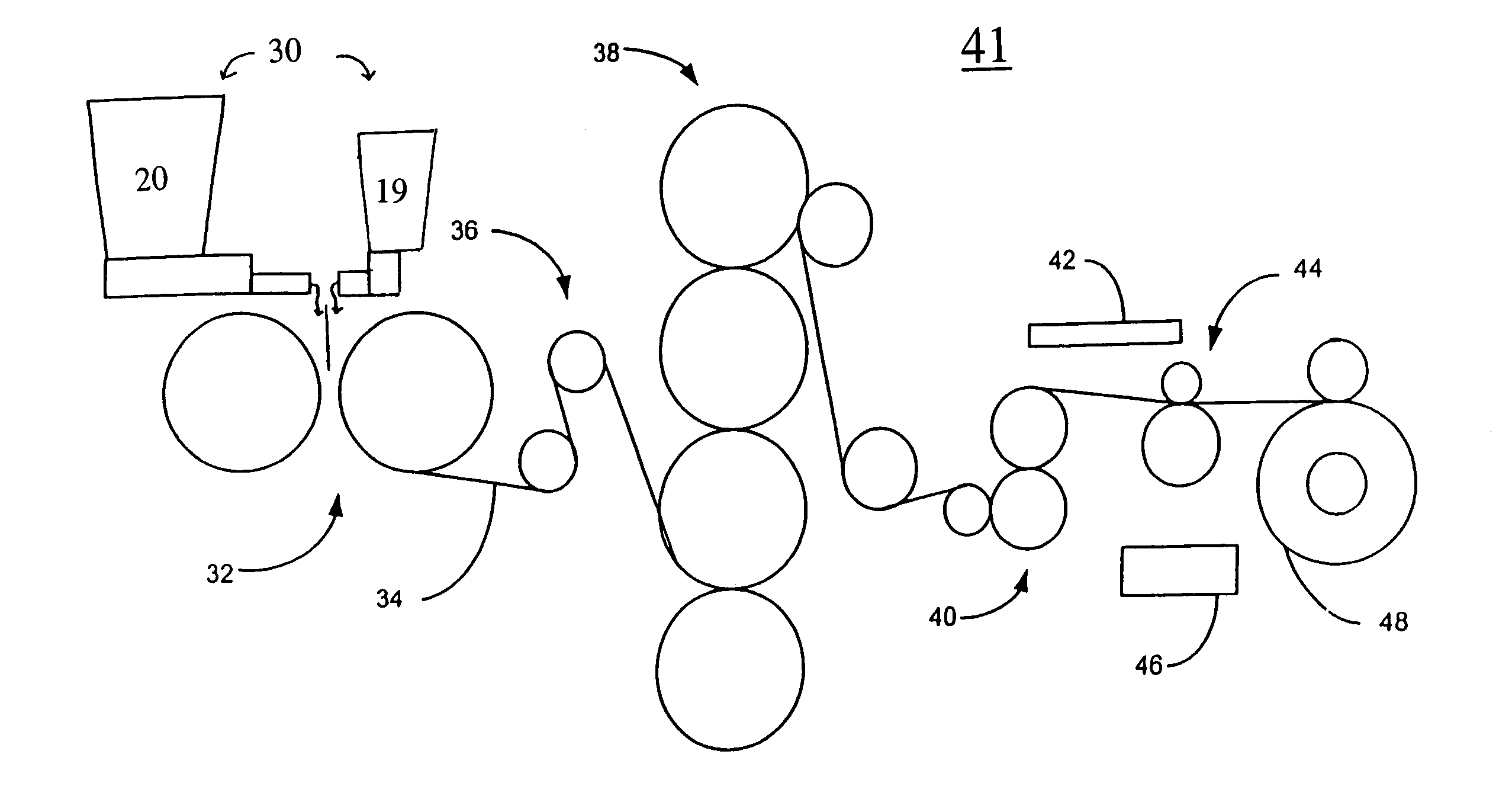

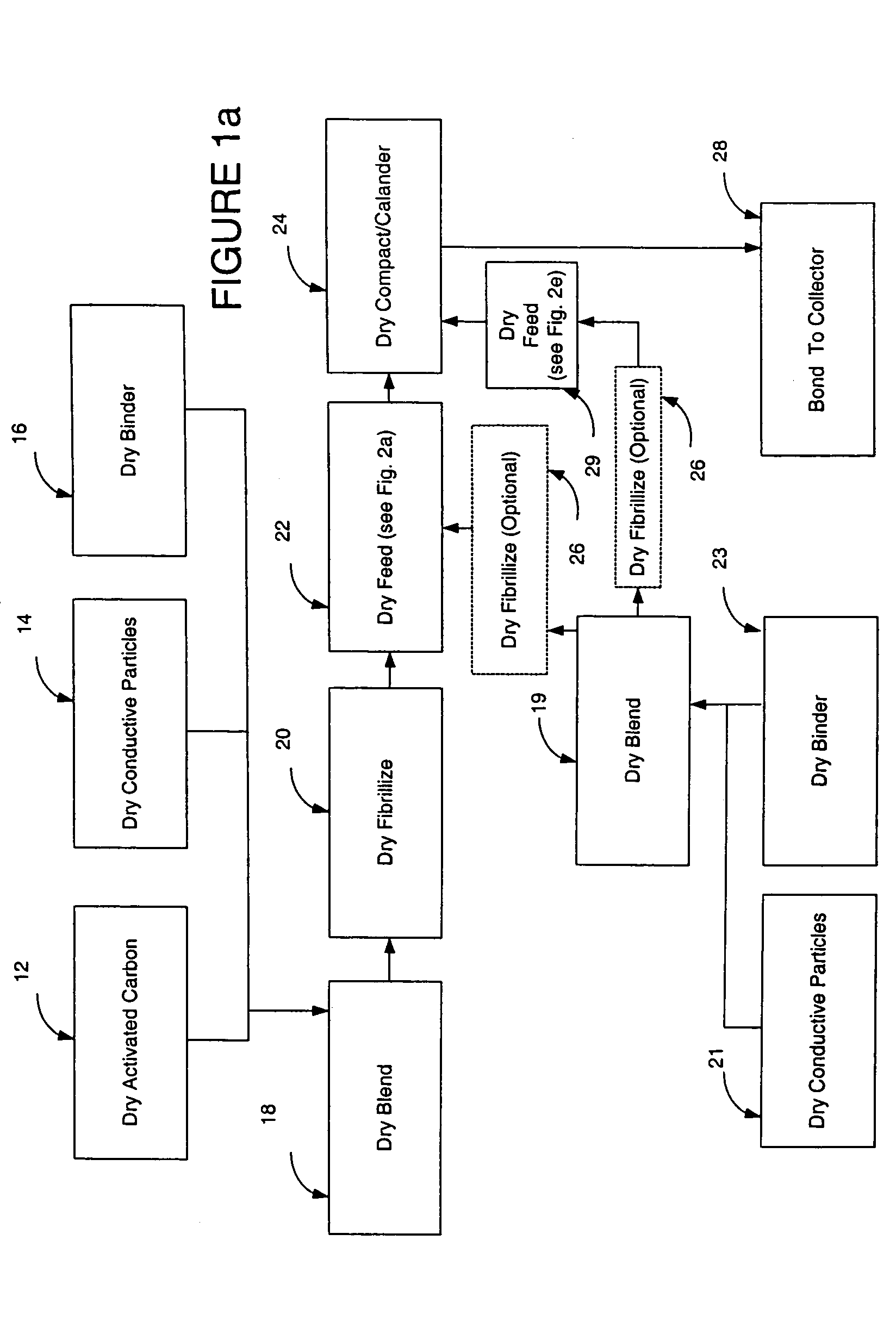

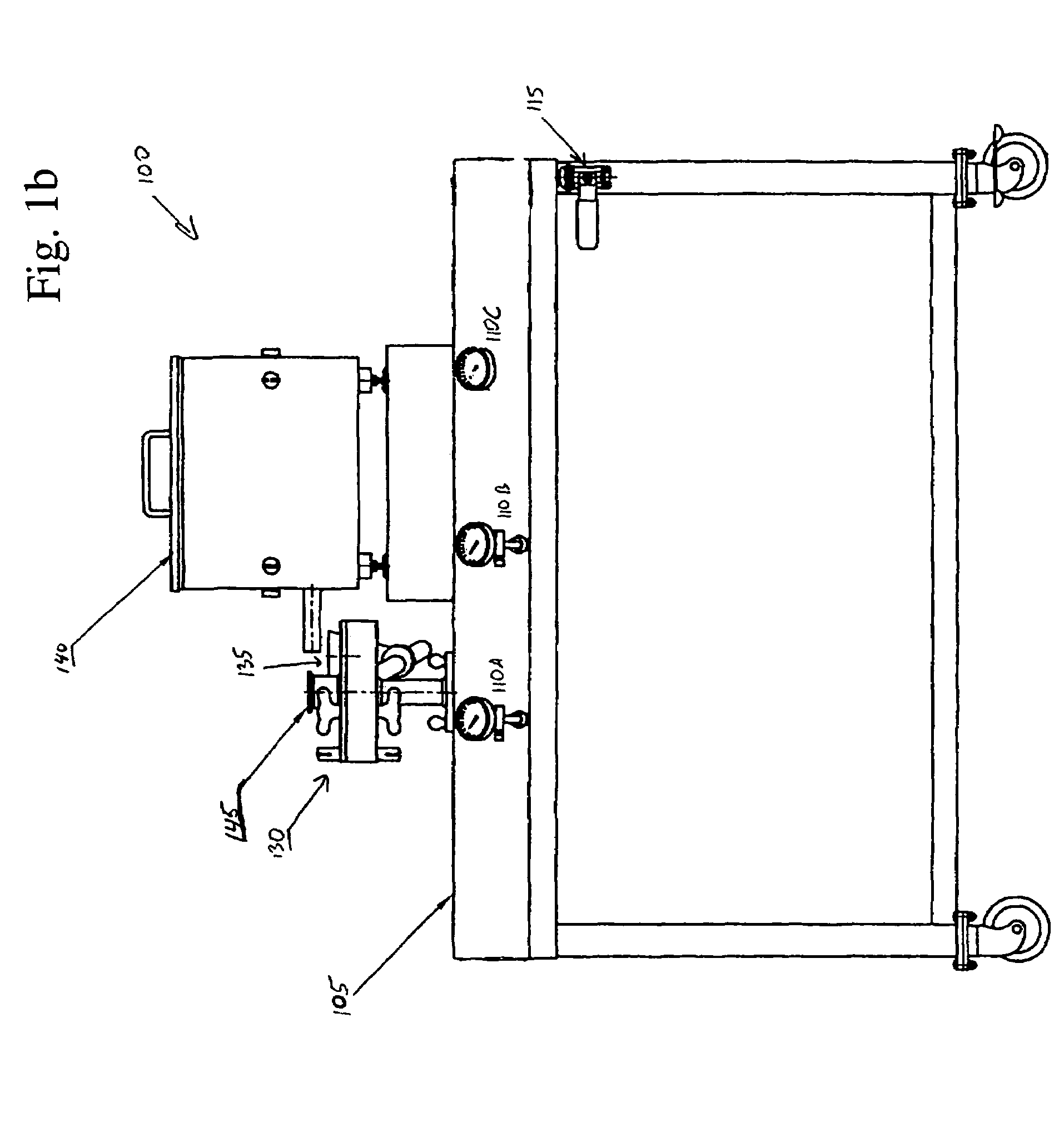

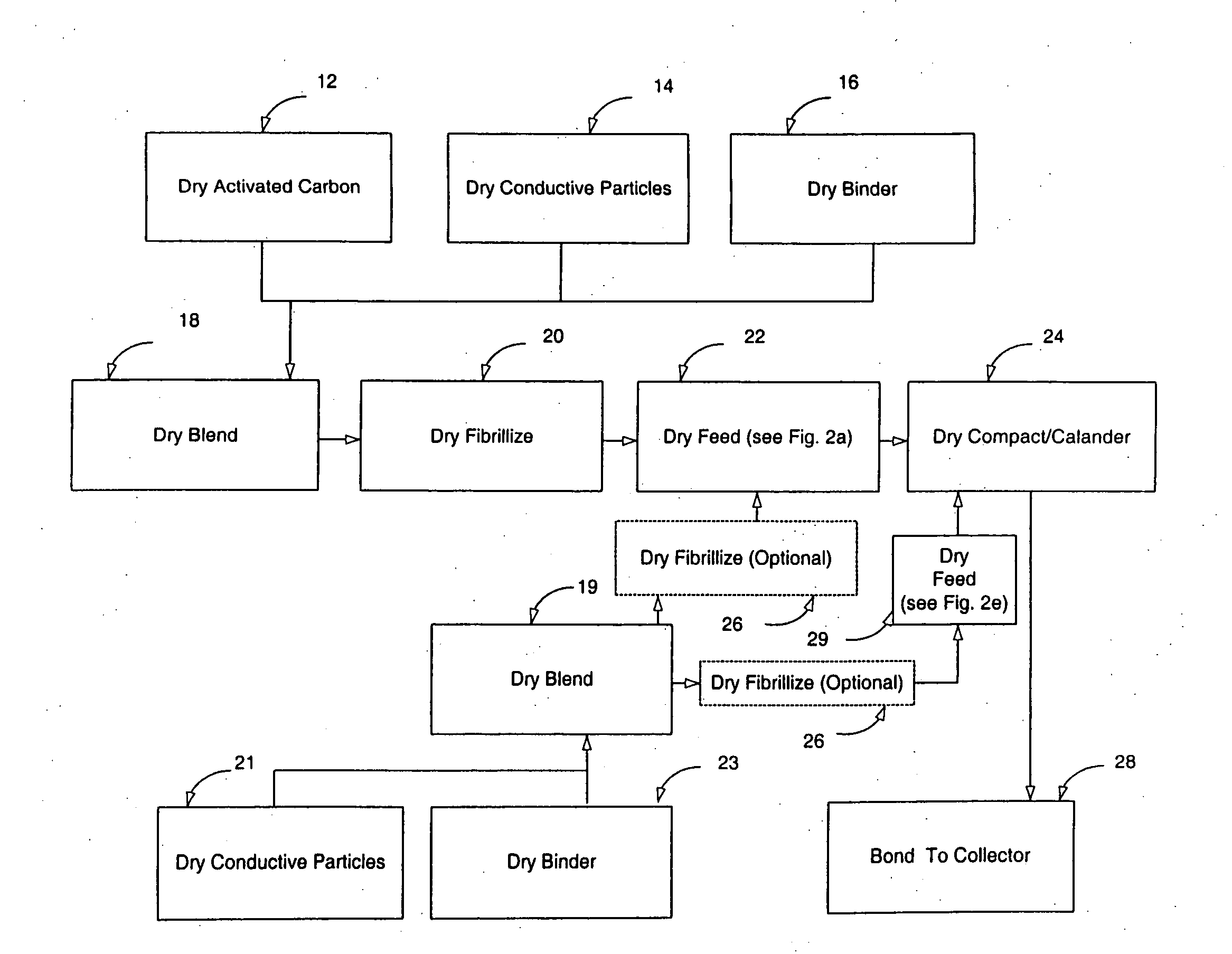

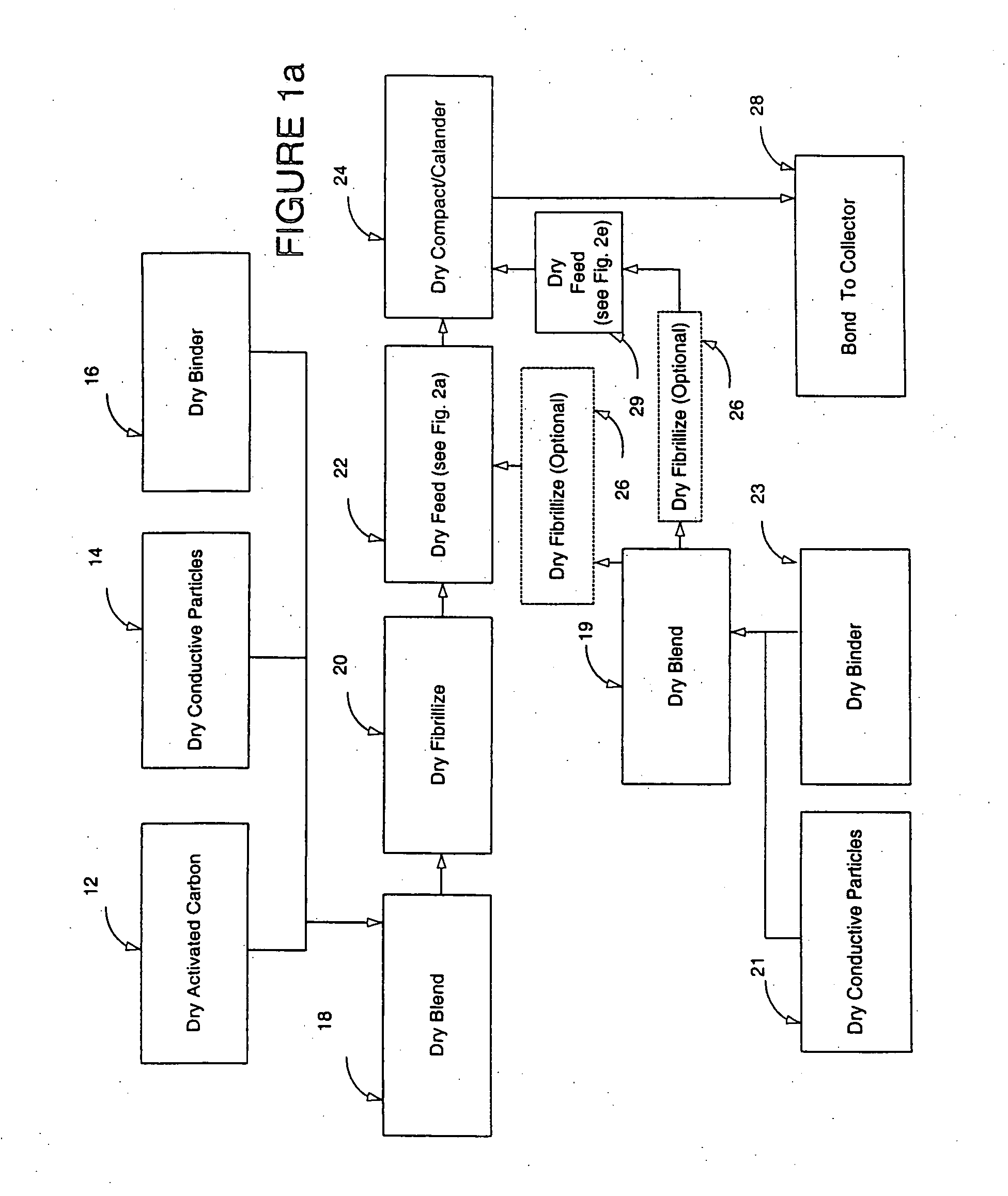

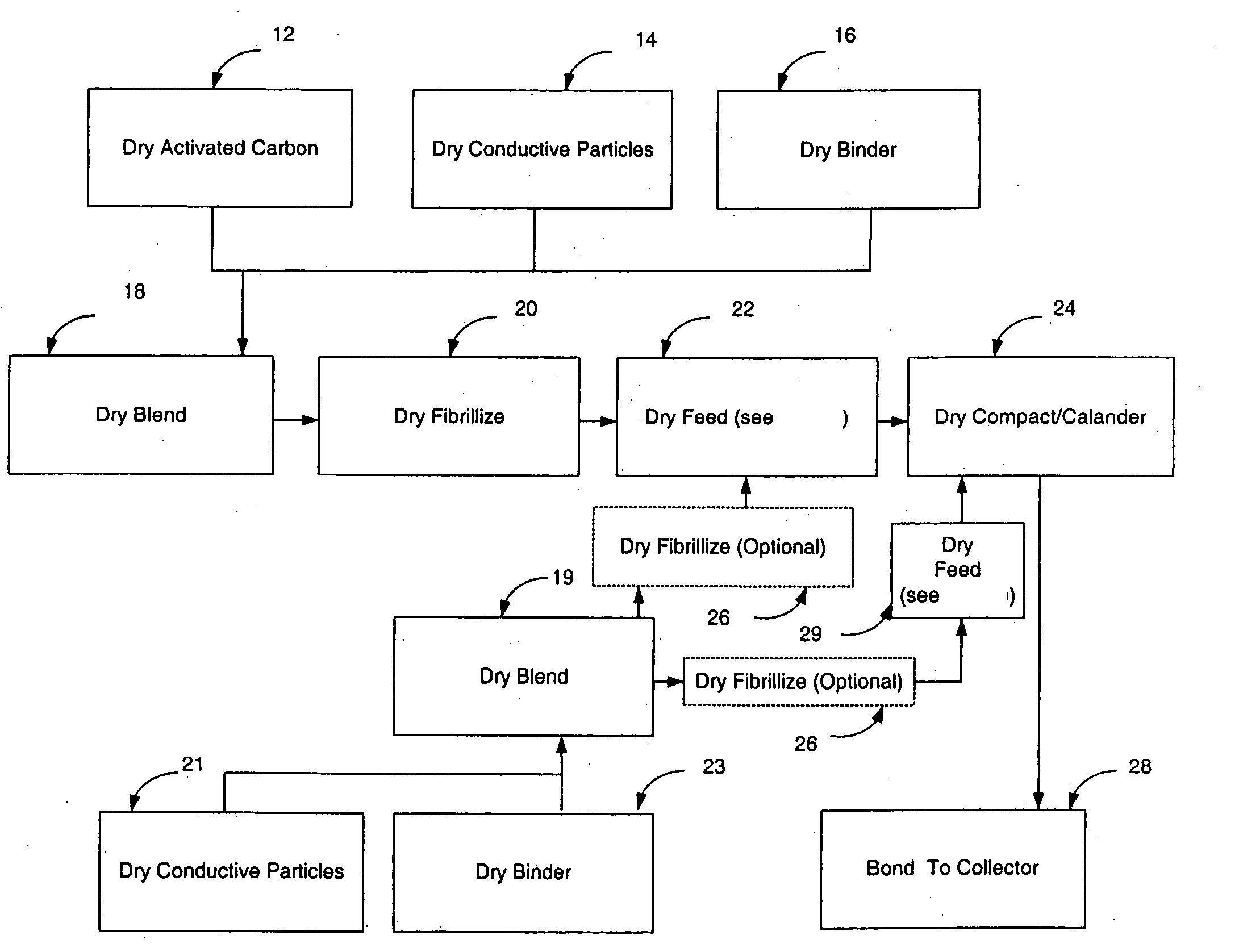

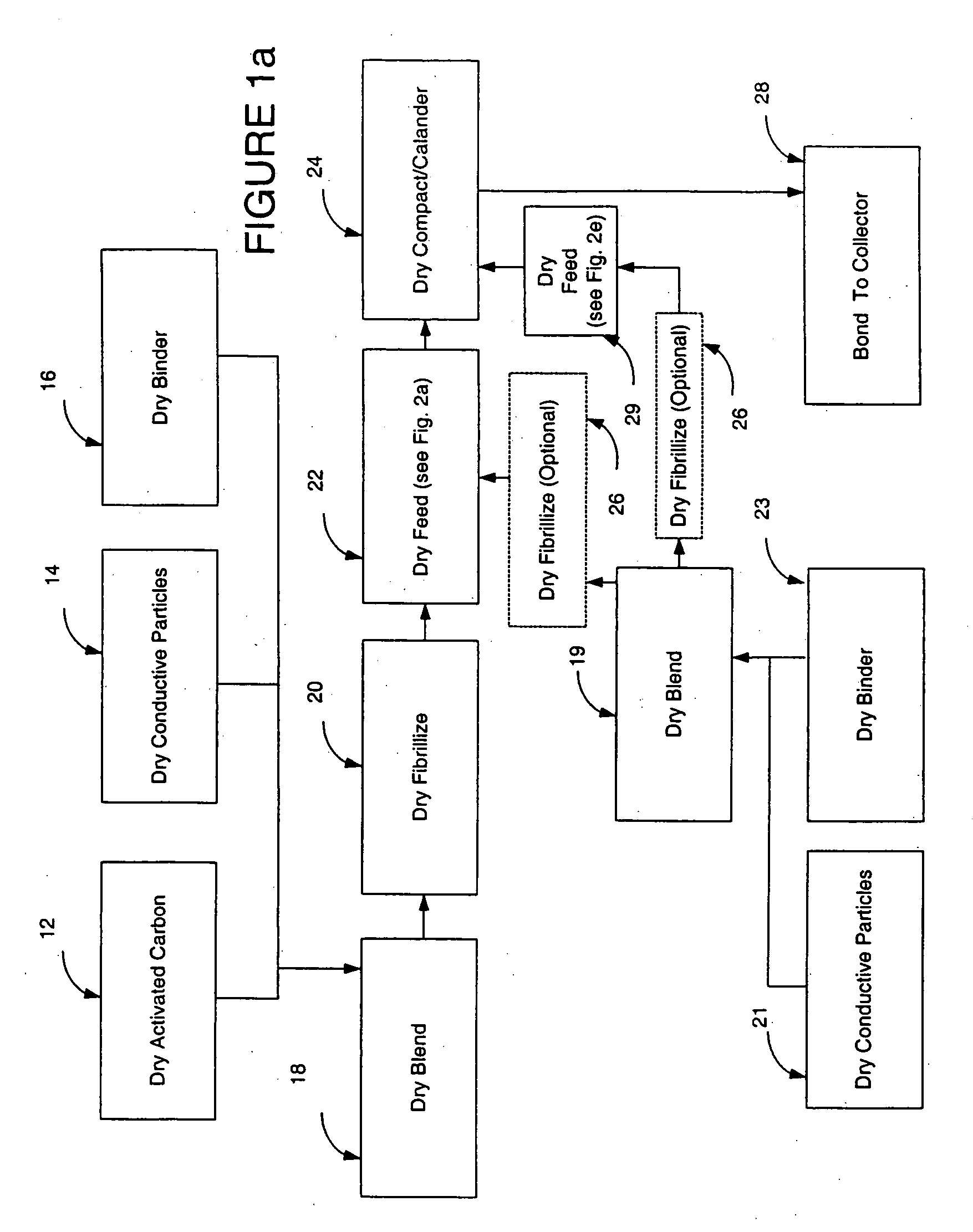

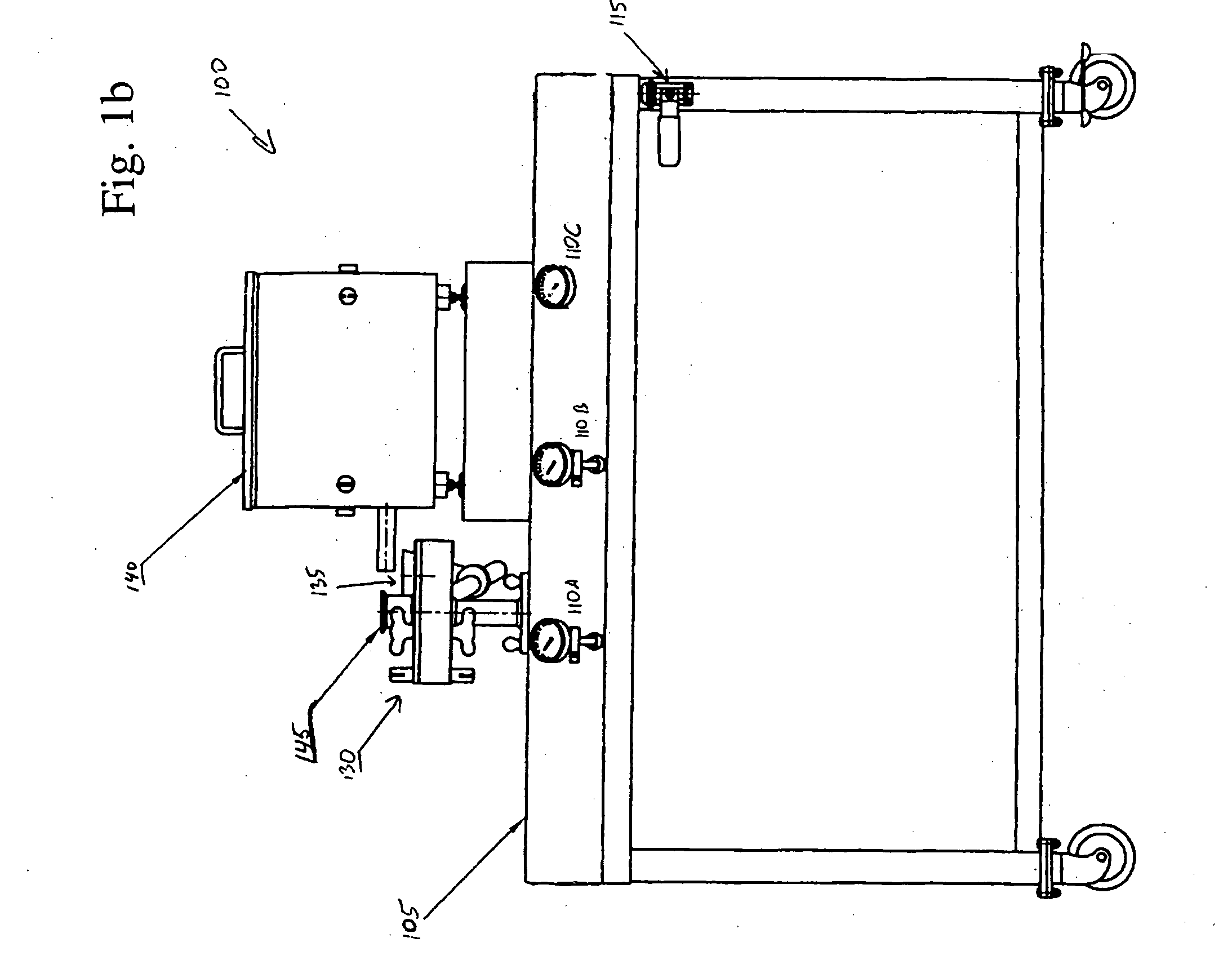

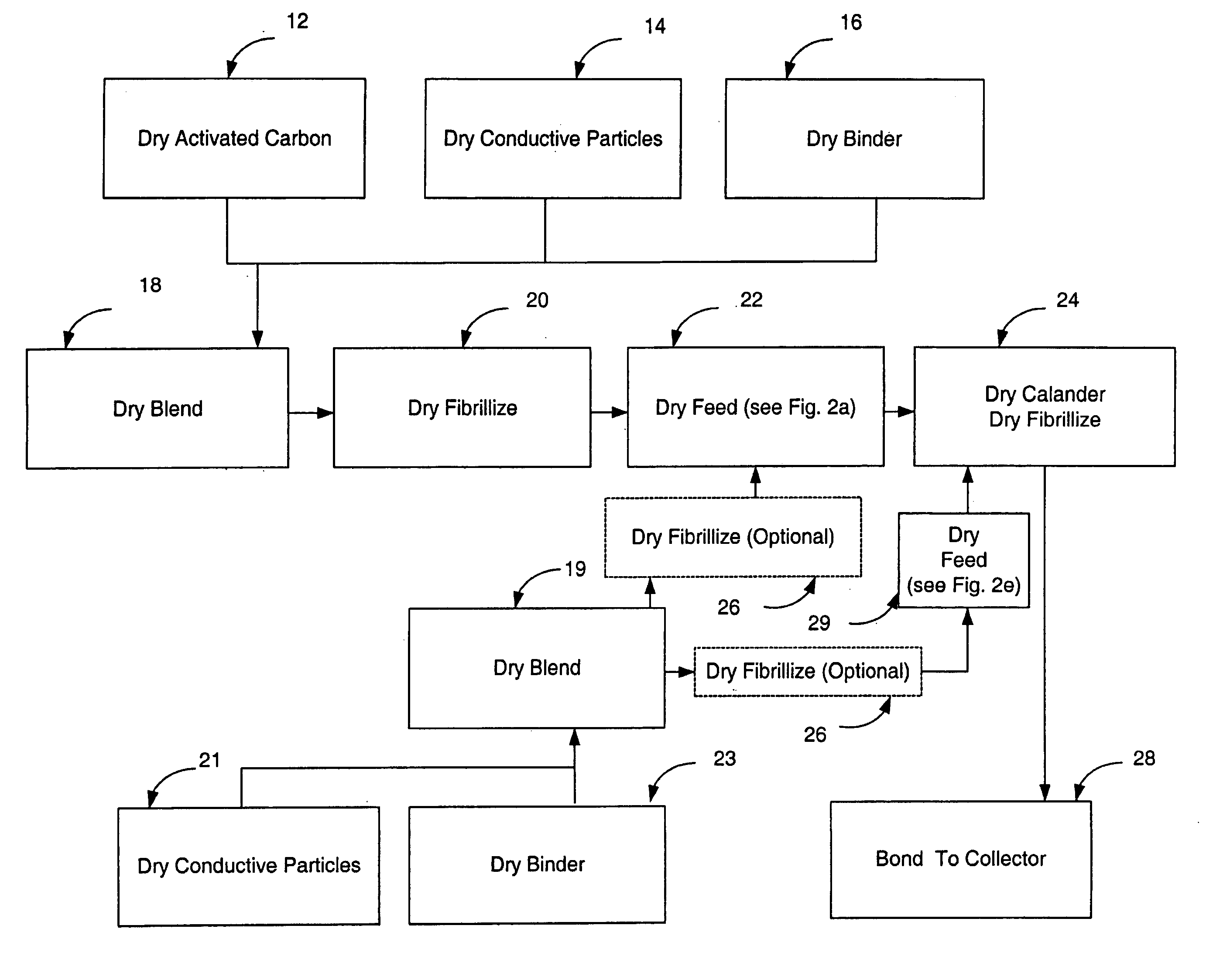

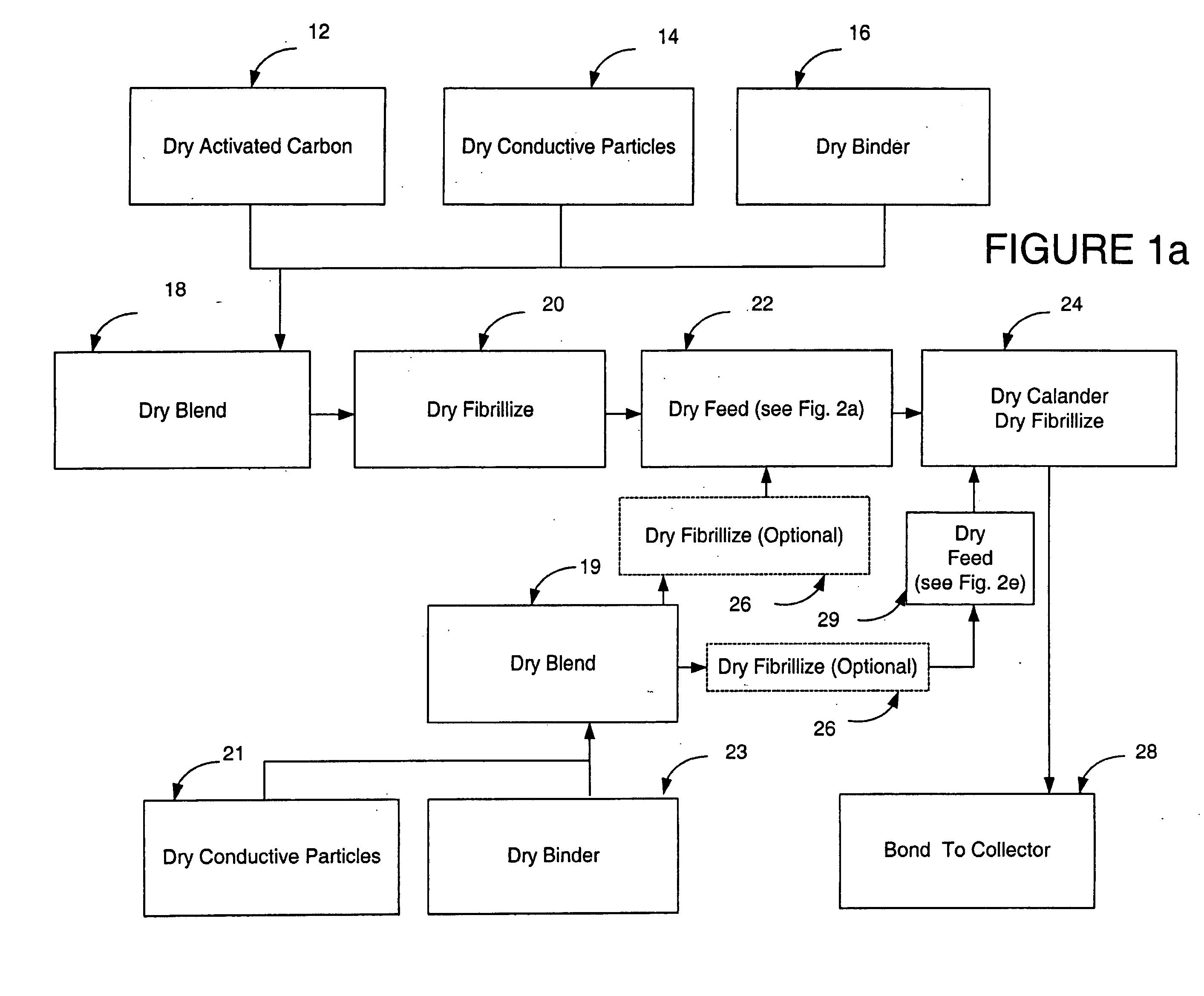

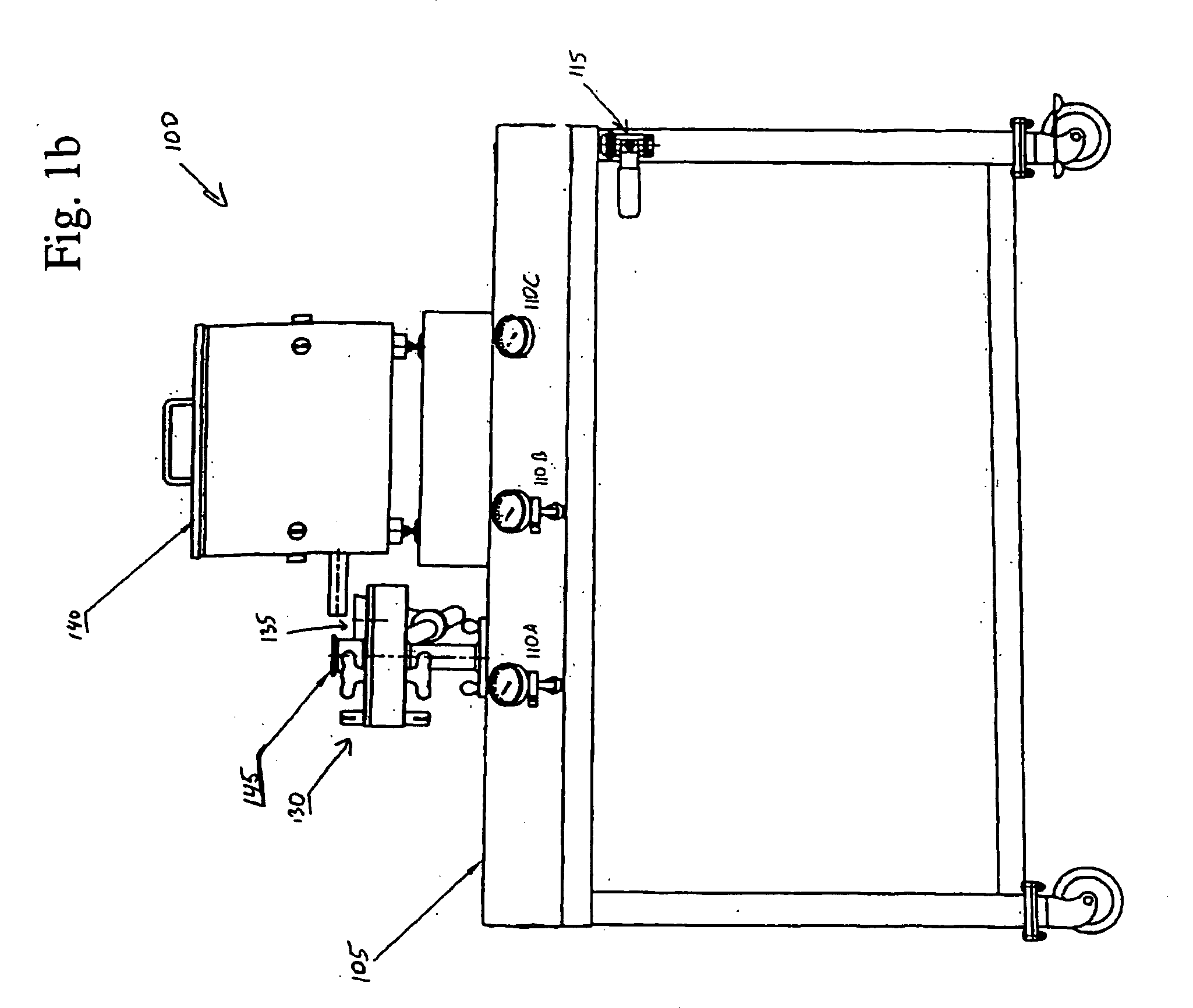

Dry particle based electro-chemical device and methods of making same

InactiveUS20050266298A1Reduce usageHigh yieldElectrode rolling/calenderingFinal product manufactureFuel cellsBiochemical engineering

A dry process-based electro-chemical device and method for making a self-supporting dry electrode film for use therein is disclosed. Cost effective manufacture of electrochemical devices such as batteries, capacitors, and fuel cells is enabled.

Owner:TESLA INC

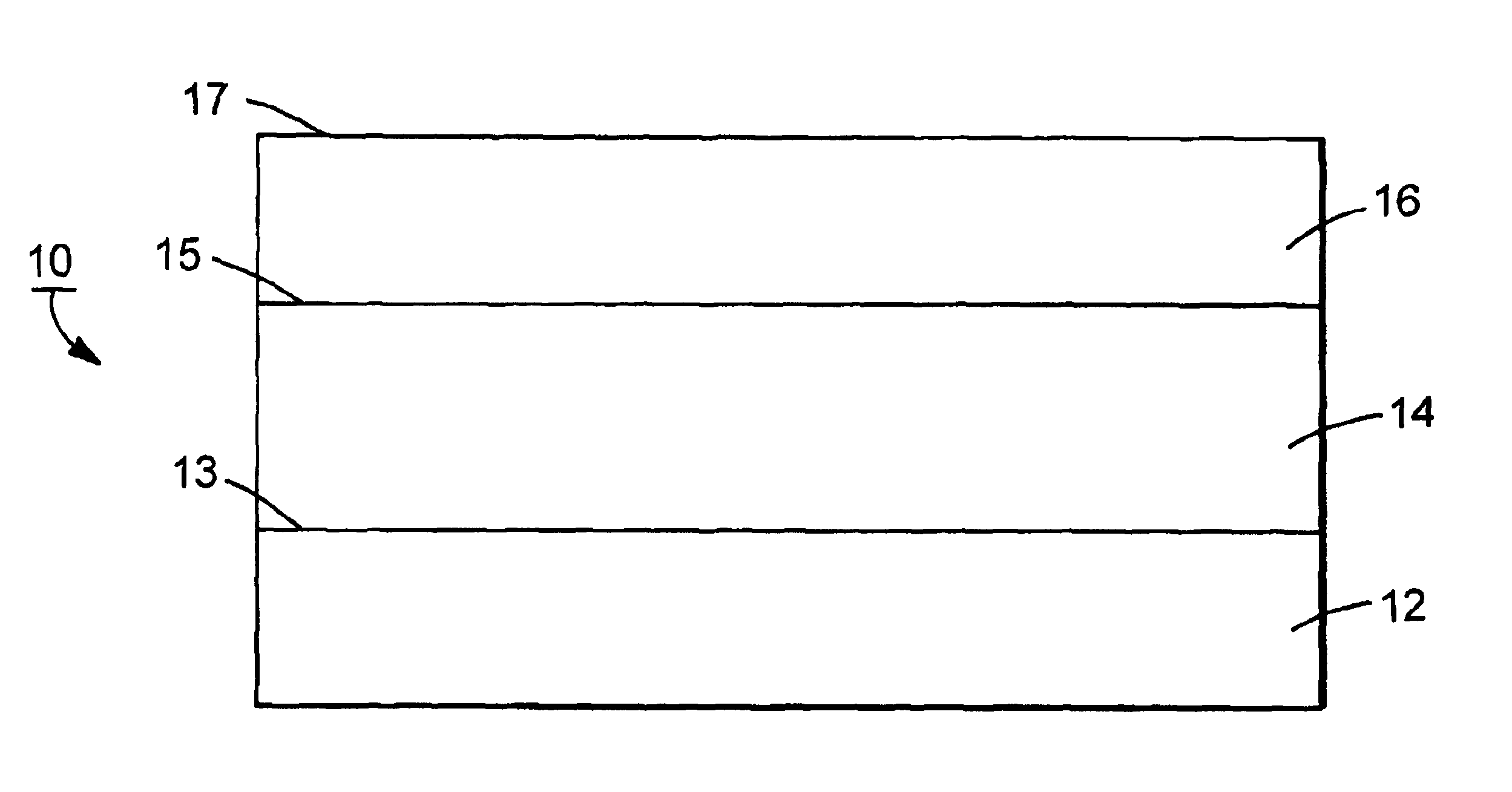

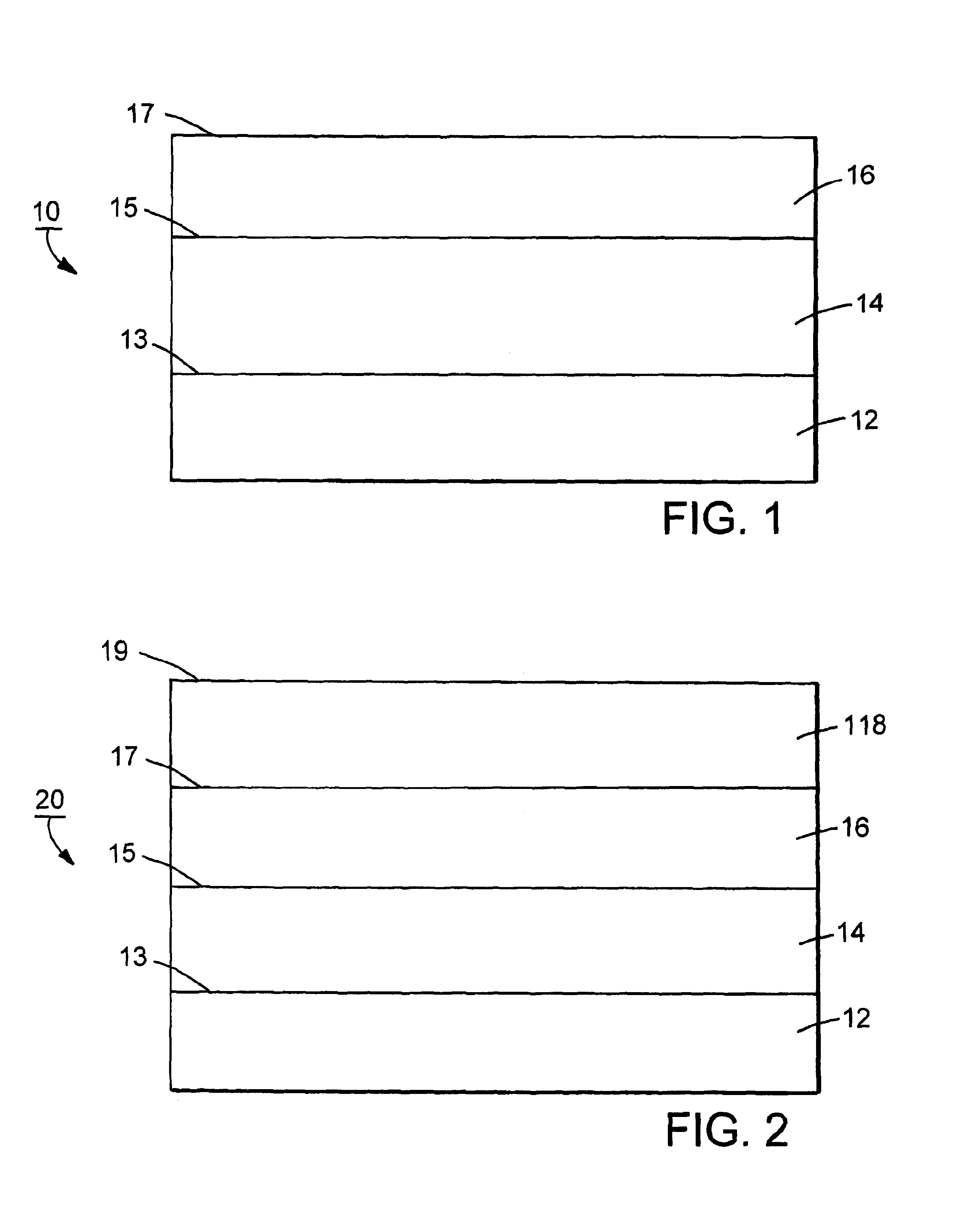

Multi-layer articles and methods of making same

InactiveUS6974501B1High critical current densityHigh densityPolycrystalline material growthFrom normal temperature solutionsPolymer scienceVolumetric Mass Density

The invention relates to multi-layer articles and methods of making such articles. The methods include first conditioning the surface of an underlying layer, such as a buffer layer or a superconductor layer, then disposing a layer of material on the conditioned surface. The conditioned surface can be a high quality surface. Superconductor articles formed by these methods can exhibit relatively high critical current densities.

Owner:AMERICAN SUPERCONDUCTOR

Addition of iridium to the rhodium/inorganic iodide catalyst system

InactiveUS6211405B1High rateReduce productionPhysical/chemical process catalystsOrganic compound preparationPtru catalystCarboxylic acid

The present invention provides a process for the carbonylation of an alcohol, ether or ester to products comprising a carboxylic acid, the anhydride thereof or coproduction of the carboxylic acid and anhydride. More particularly, the present invention provides a process for the carbonylation of methanol to produce acetic acid by reacting methanol with carbon monoxide in a liquid reaction medium containing a catalyst comprising rhodium, iridium, iodide ion, and said reaction medium further comprising water, acetic acid, methyl iodide, and methyl acetate and subsequently recovering acetic acid from the resulting reaction product.

Owner:CELANESE INT CORP

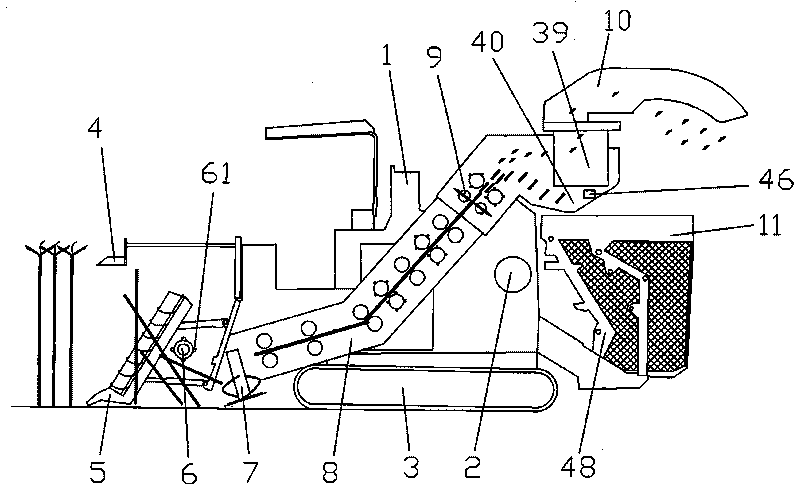

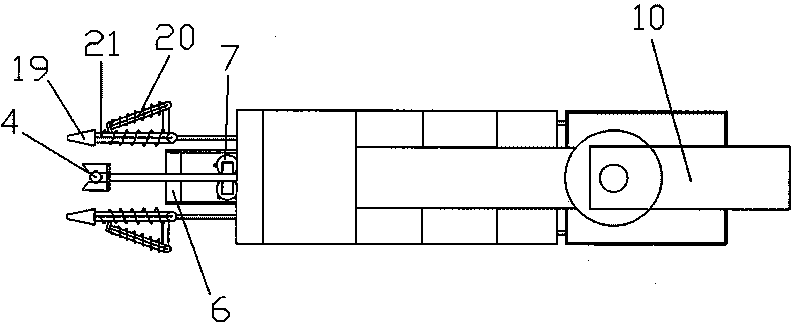

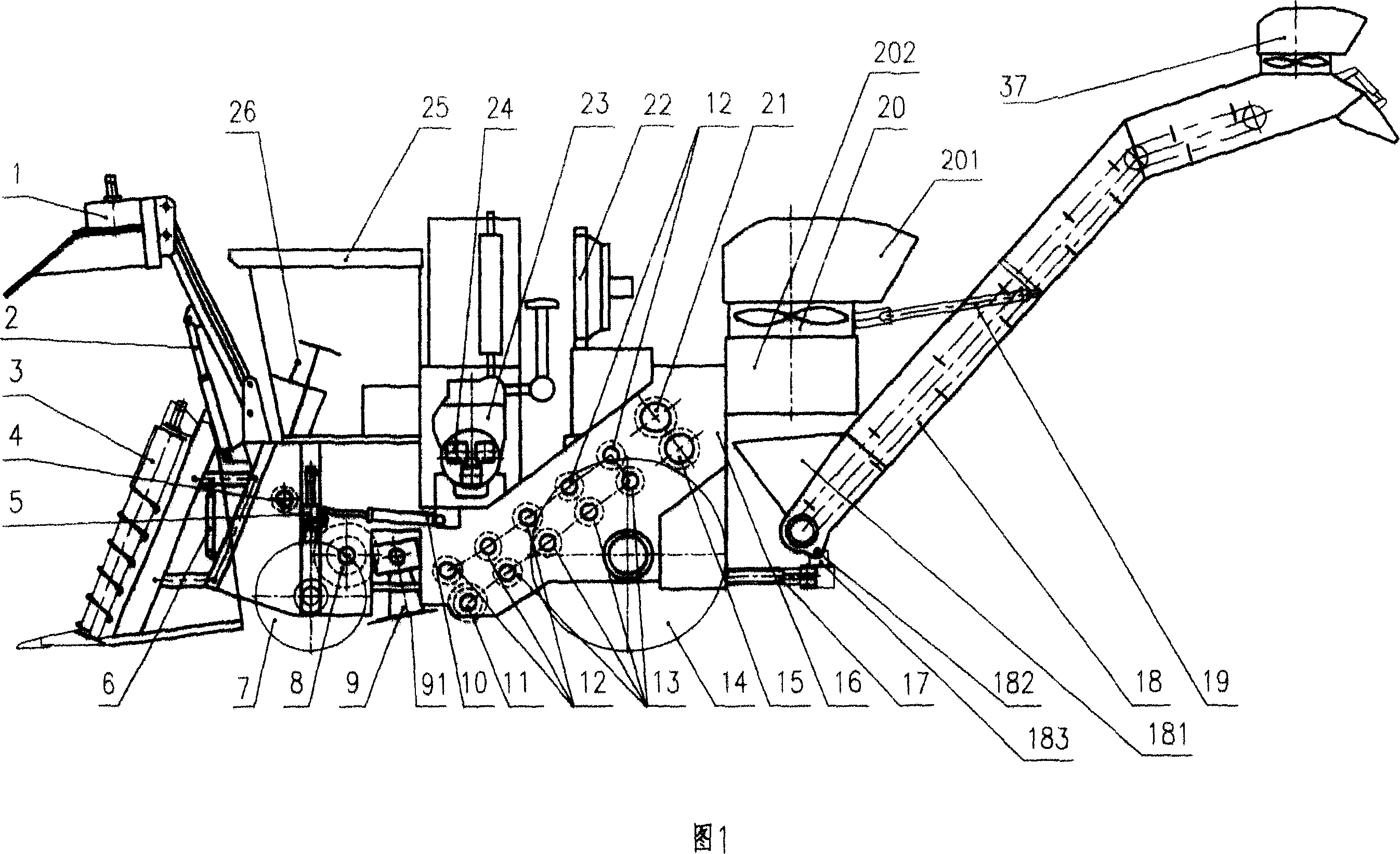

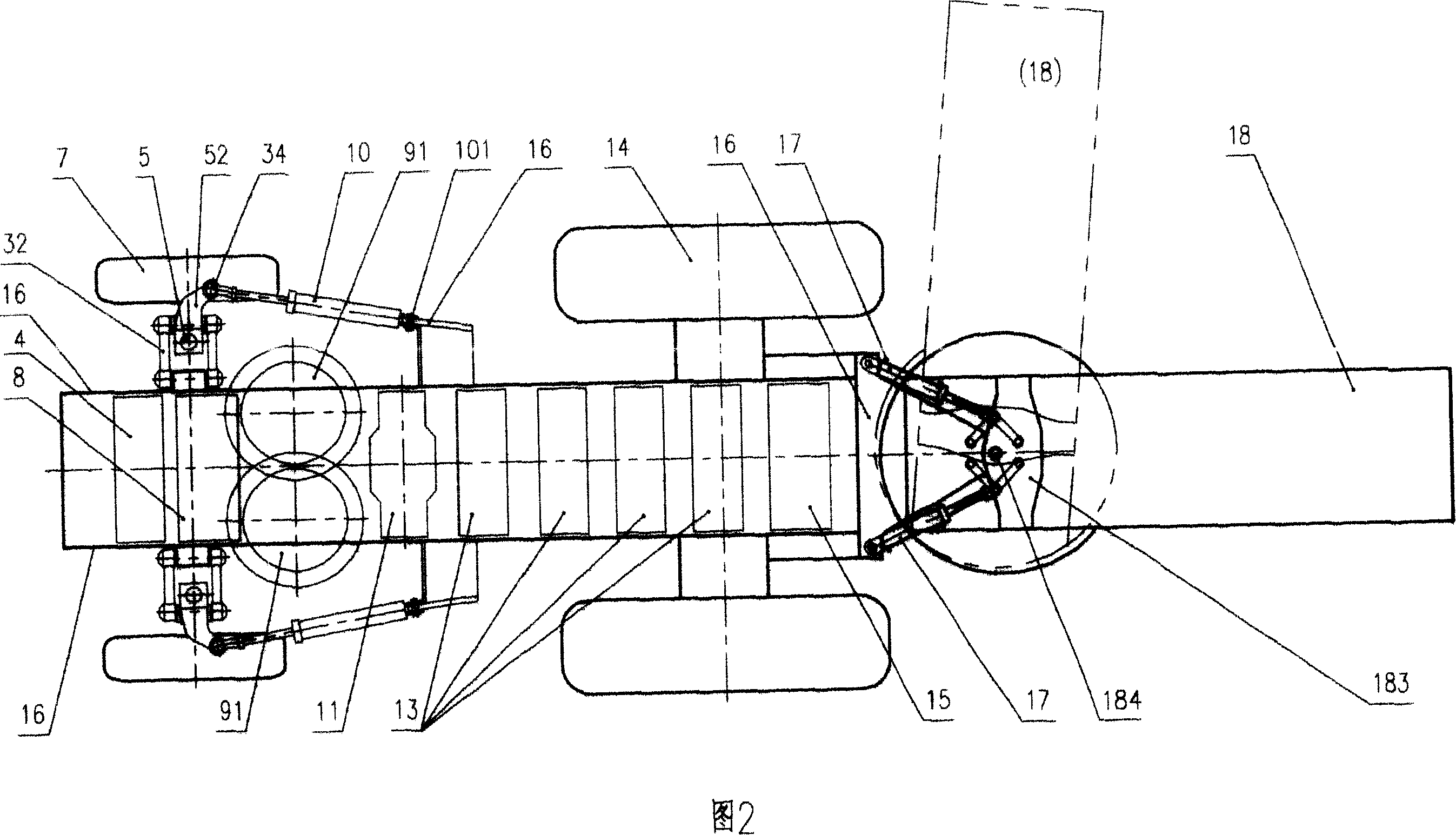

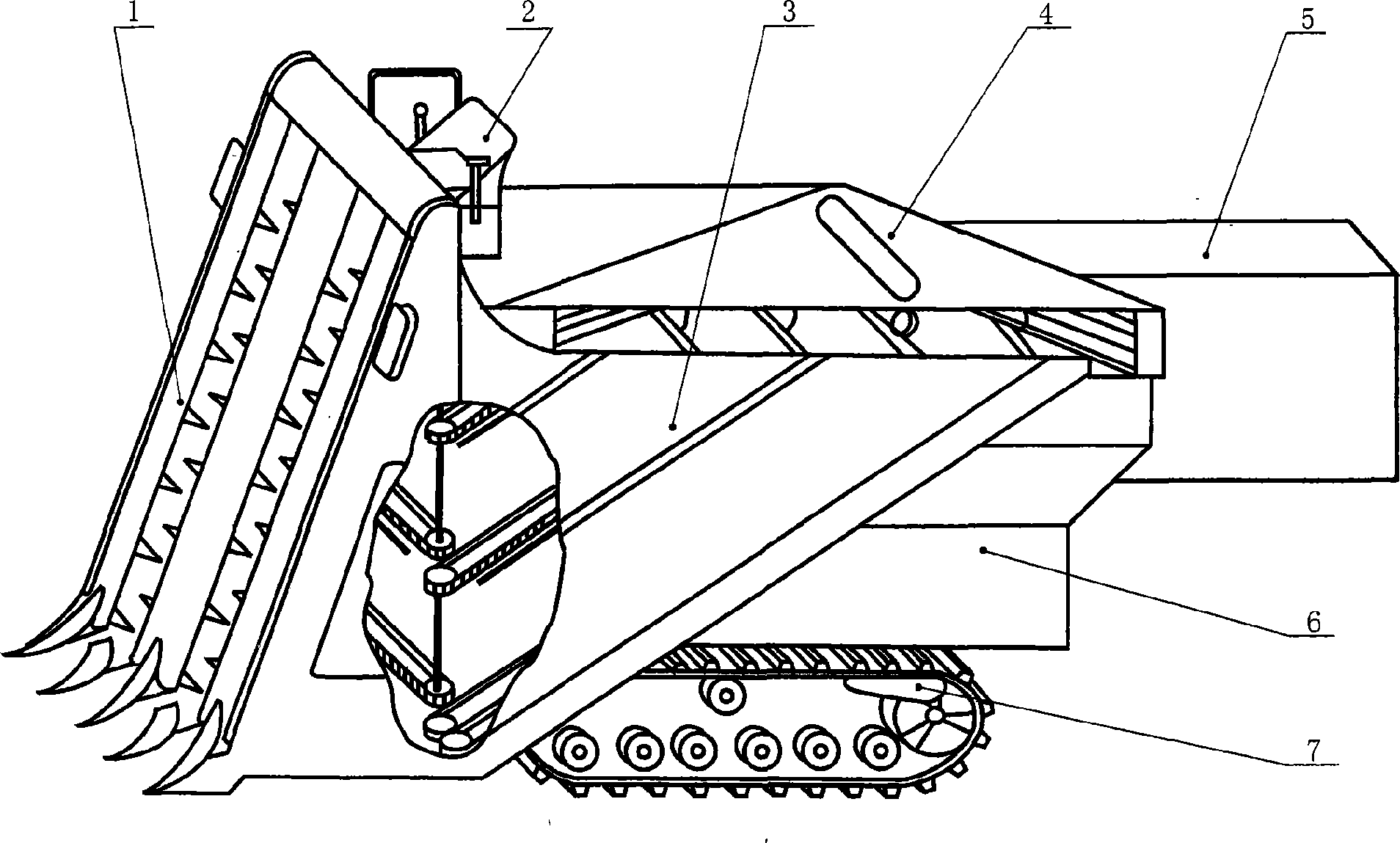

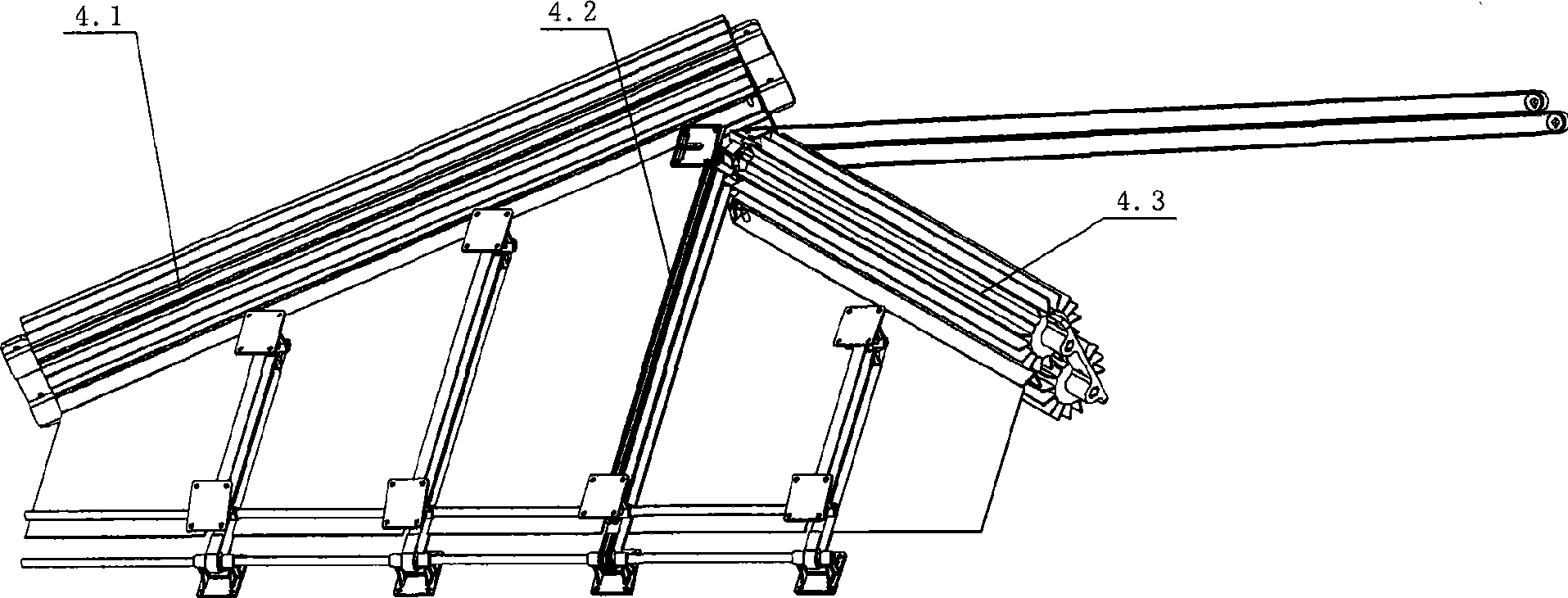

Segmenting type sugar cane combine harvester

InactiveCN101690449AAvoid cloggingReduce cloggingMowersAgricultural lifting devicesControl systemAgricultural engineering

The invention discloses a segmenting type sugar cane combine harvester, which comprises a machine frame, an engine, a crawler type traveling mechanism, a hydraulic power and control system, a sugar cane topper device, a sugar cane supporting device, a sugar cane pressing combing roller, a cutting device, a conveying leaf-removing device, a segmenting device, an impurity discharging device and a collecting device, wherein the cutting device comprises a left set of cutting component and a right set of cutting component, and each set of cutting component comprises a screw conveying rod, a rotary shaft sleeve, a cutter head and a plurality of blades; and the sugar cane supporting device comprises a left set of sugar cane supporting mechanism and a right set of sugar cane supporting mechanism, and each set of sugar cane supporting mechanism is controlled by an independent adjusting mechanism. The segmenting type sugar cane combine harvester has the advantages of having high capability of separating and harvesting sugar canes which are seriously flattened and / or intertwisted, lessening the choking phenomenon occurring in a process of harvesting sugar canes, improving fully removing rate of sugar cane leaves of the harvested sugar canes, reducing the impurity content in sugar cane segments, conveniently collecting sugar cane segments, avoiding the use of a following transport vehicle for collection and storage, along with compact structure, reasonable configuration, convenient travel and use in fields, good harvesting effect, high automation, low manufacturing cost and the like.

Owner:GUANGDONG KOLEA MODERN AGRI EQUIP

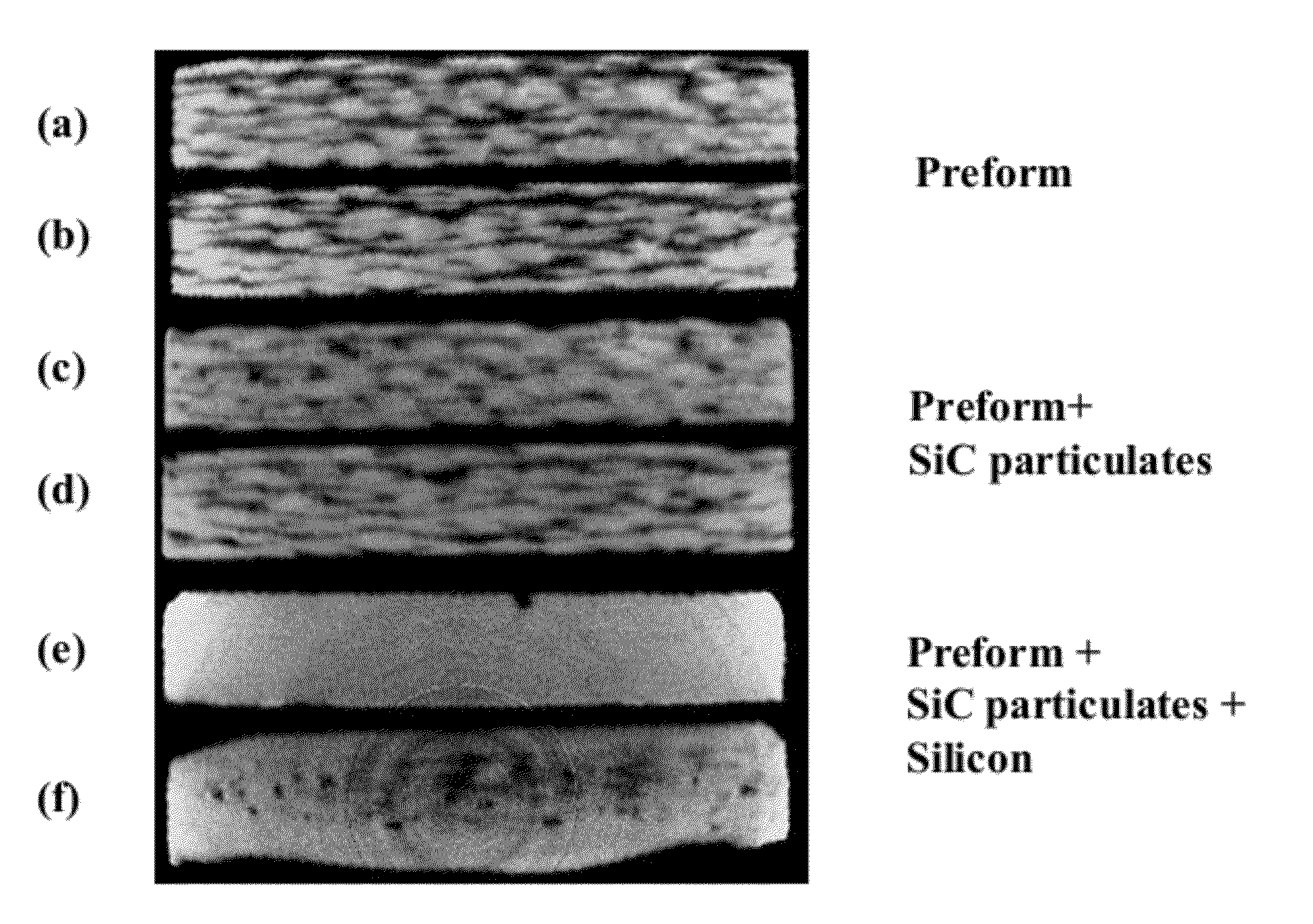

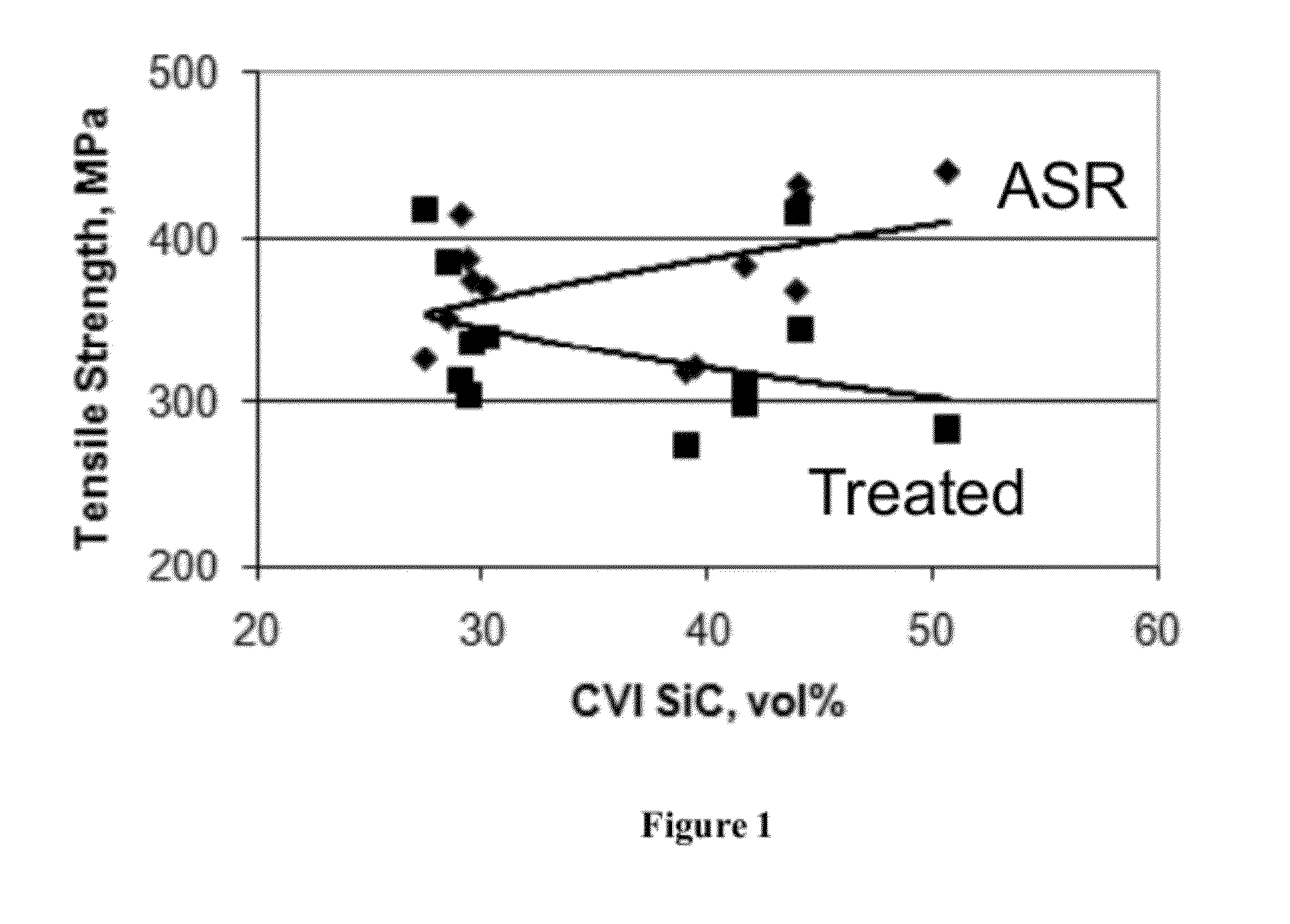

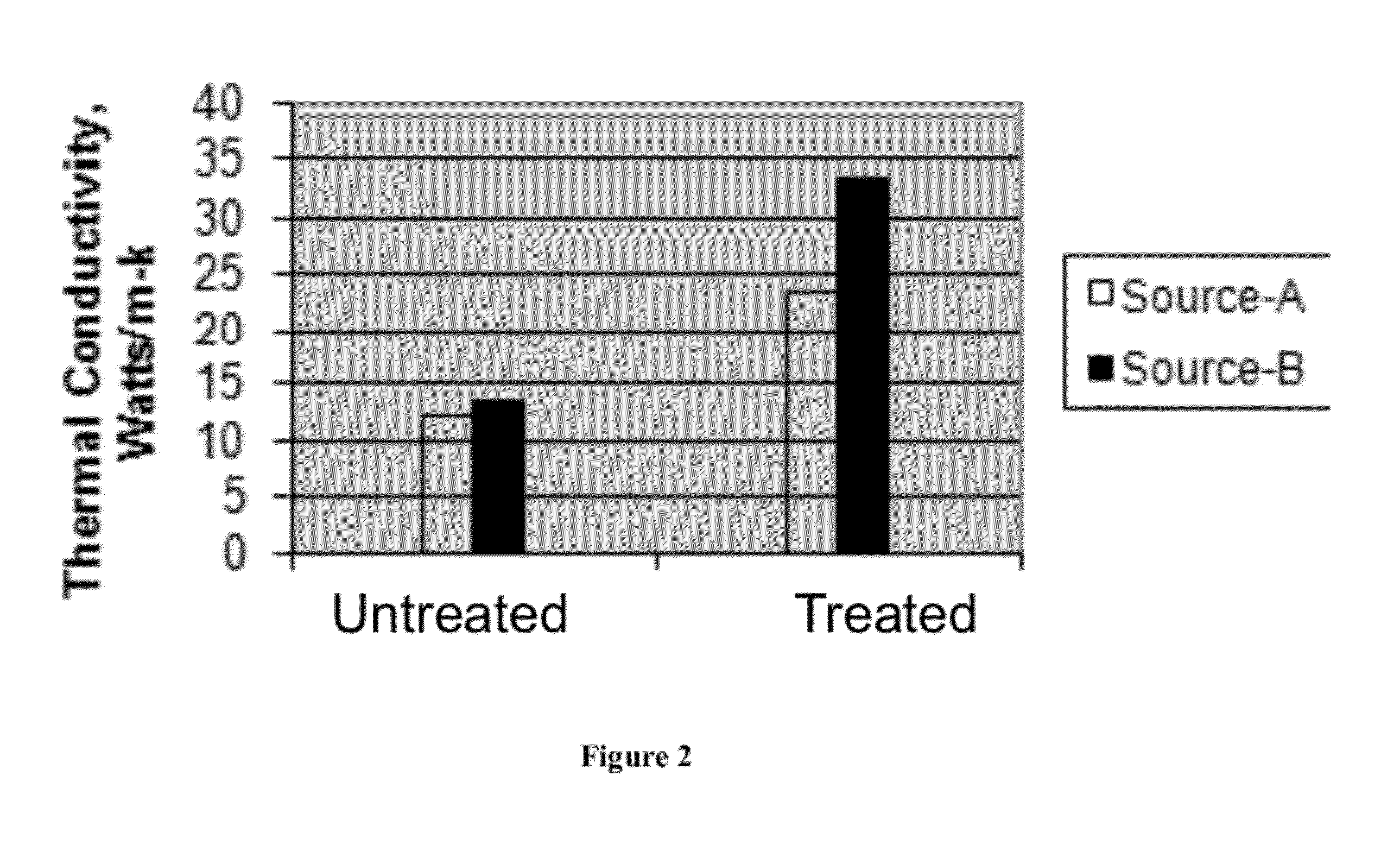

Method of improving the thermo-mechanical properties of fiber-reinforced silicon carbide matrix composites

InactiveUS20120076927A1Improve featuresImprove propertiesCeramic shaping apparatusCoatingsParticulatesGas phase

A thermal treatment process for improving thermo-mechanical properties of ceramic matrix composite materials such as silicon carbide (SiC) matrix composites is described. The treatment process removes excess silicon and / or other process-related defects from the SiC-based matrix as well as the fiber interfacial coating. This invention can be practiced with minimal strength loss for as-fabricated composites formed from high-strength continuous-length ceramic and carbon-based fibers that are functionally stable to 1600° C. and above. The invention provides a method for significantly improving composite thermal conductivity and creep resistance, and for reducing composite porosity. It has been demonstrated using state-of-the-art 2D woven SiC / SiC composites containing Sylramic-iBN SiC fibers, boron-nitride-based interfacial coatings, and hybrid matrices that are based on SIC formed by chemical vapor infiltration (CVI) and by a combination of CNI, SiC particulate infiltration, polymer infiltration and pyrolysis, and melt infiltration of silicon, silicon-based alloys, and silicides.

Owner:US SEC THE ARMY THE

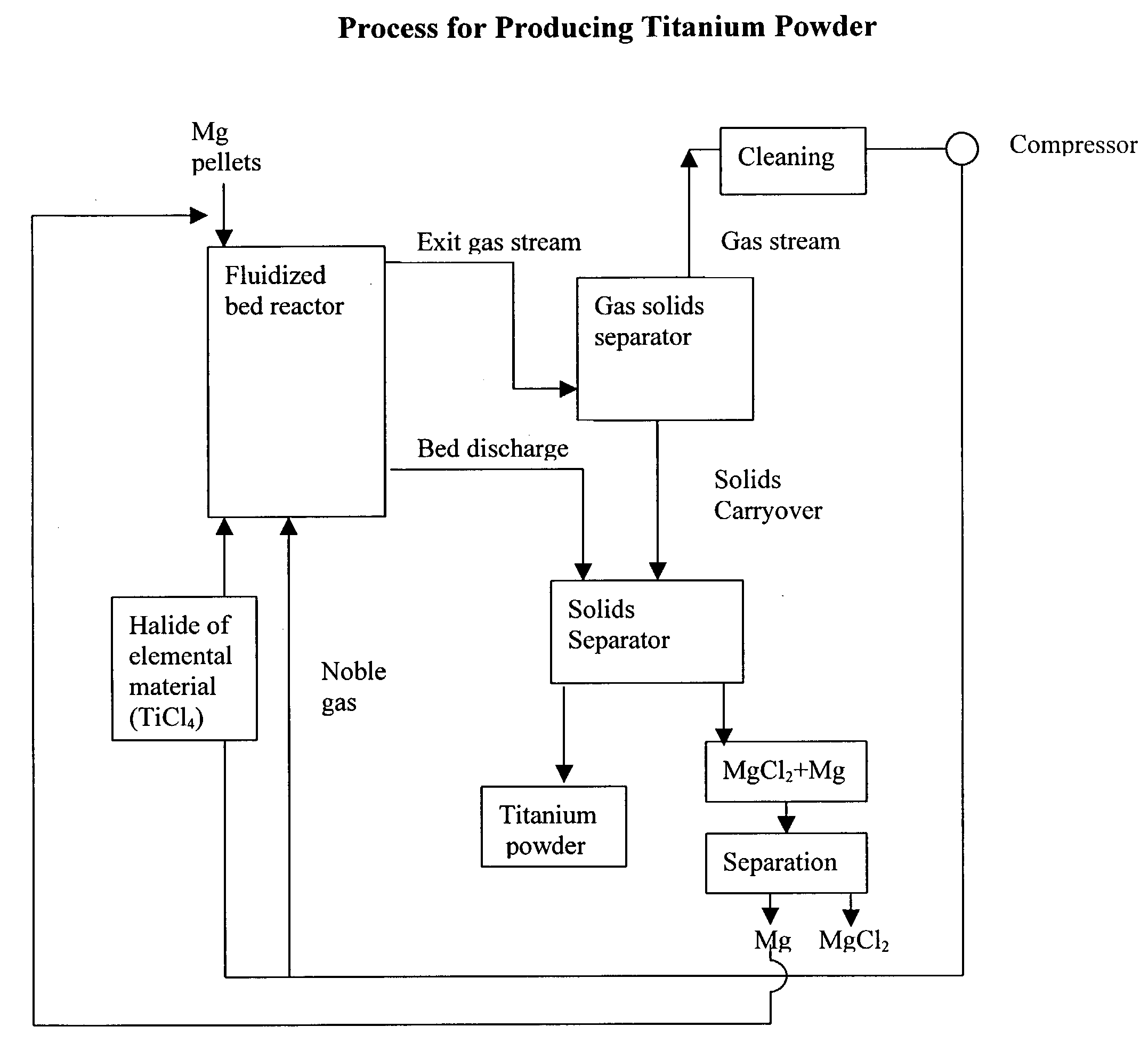

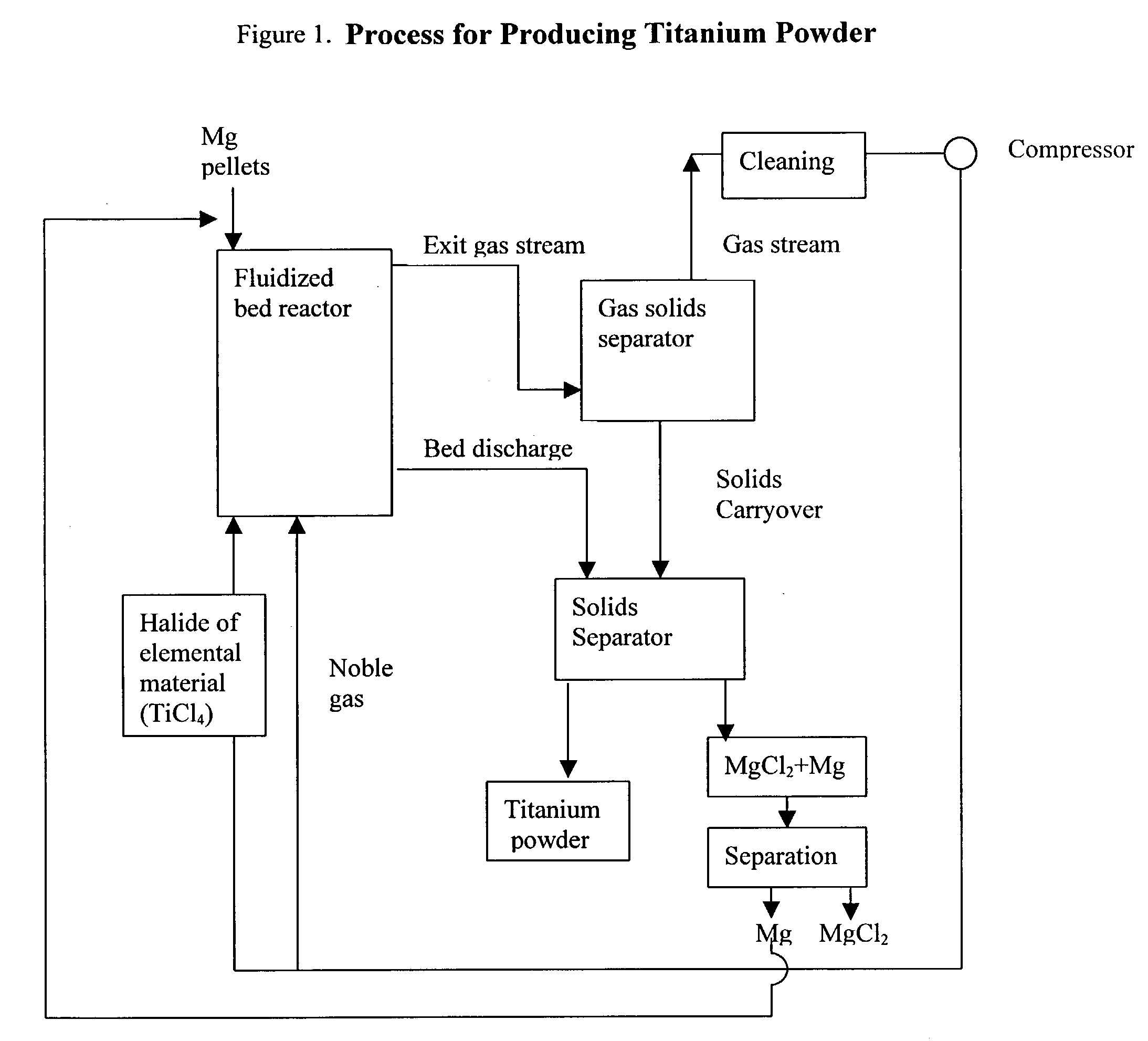

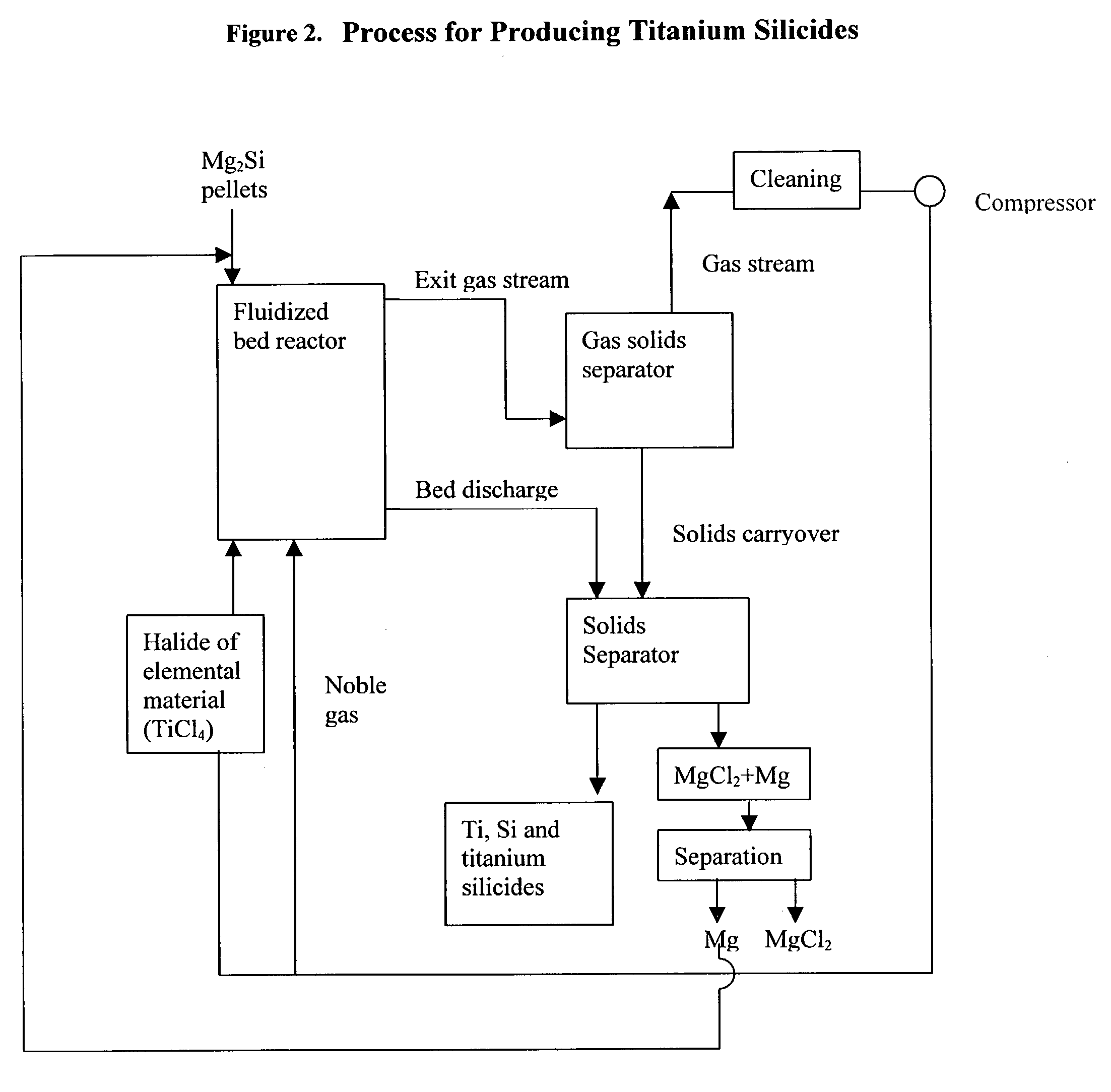

Process for the production of elemental material and alloys

The present invention relates to a process for the production of an elemental material, comprising the step of reacting a halide of the elemental material with a reducing agent in solid form in a fluidized bed reactor at a reaction temperature which is below the melting temperature of the reducing agent. In a preferred embodiment of the present invention, the elemental material is titanium and the titanium is produced in powder form. The invention also relates to the production of alloys or intermetallics of the elemental materials.

Owner:MILLENNIUM INORGANIC CHEM

Sugarcane combine for cutting into pieces

The invention relates to a sectional sugar cane combine harvester, which belongs to the agricultural machine field and comprises a topper shear plate, a left holding device of the sugar cane, a right holding device of the sugar cane, a sugar cane pressing roller, a feeding roller, a cutter, a conveying roller, a plurality of upper conveying rollers, a plurality of down conveying rollers, a down cutting roller, an upper cutting roller, a frame, a lifter and a Level I trash separator. The utility model is characterized in that the sugar cane pressing roller, feeding roller and the cutter are arranged at both plates of the middle frame of the harvester from front to back and high to low; the back of the cutter is provided with the conveying roller, a plurality of the down conveying rollers and down cutting roller from front to back and low to high; a plurality of the upper conveying rollers are respectively arranged corresponding to a plurality of the down conveying rollers; the upper cutting rollers are arranged corresponding to the down cutting roller; the back of the upper and the down cutting rollers are provided with the lifters and the back up of the upper and down cutting rollers are provided with the Level I trash separator. The machine is used for the sugar cane harvest, can continuously finish lifting, topper cutting, feeding, conveying, cutting, trash separating, transportation and loading with high working efficiency.

Owner:广西农业机械研究院有限公司

Post ECP multi-step anneal/H2 treatment to reduce film impurity

InactiveUS20050227479A1Improve reliabilityReduce defect densitySemiconductor/solid-state device manufacturingCopper interconnectCarbon impurities

A method of forming a copper interconnect in a dual damascene scheme is described. After a diffusion barrier layer and seed layer are sequentially formed on the sidewalls and bottoms of a trench and via in a dielectric layer, a first copper layer is deposited by a first ECP process at a 10 mA / cm2 current density to fill the via and part of the trench. A first anneal step is performed to remove carbon impurities and optionally includes a H2 plasma treatment. A second ECP process with a first deposition step at a 40 mA / cm2 current density and second deposition step at a 60 mA / cm2 current density is used to deposit a second copper layer-that overfills the trench. After a second anneal step, a CMP process planarizes the copper layers. Fewer copper defects, reduced S, Cl, and C impurities, and improved Rc performance are achieved by this method.

Owner:TAIWAN SEMICON MFG CO LTD

Two-step method for hydrotreating of a hydrocarbon feedstock comprising intermediate fractionation by rectification stripping

InactiveUS20060118466A1Reduce sulfur contentReduce nitrogen contentHydrocarbon distillation control/regulationTreatment with hydrotreatment processesPtru catalystPhysical chemistry

A process for hydrotreatment of a hydrocarbon feed comprises at least two reaction steps with intermediate fractionation of the effluent from the first step to eliminate unwanted impurities for the catalyst of the second step and to produce a desulphurized light liquid fraction. The intermediate fractionation comprises stripping the liquid effluent from the first step using low pressure hydrogen with rectification of the stripping vapours using a substantially desulphurized liquid reflux. The conditions for said fractionation and for the first hydrotreatment step can produce a substantially desulphurized light liquid fraction which is not supplied to the second step.

Owner:INST FR DU PETROLE

Filter sheet for purifying photoresist composition

InactiveUS6103122AHigh ion exchange capacityReduce impurityNon-fibrous pulp additionNatural cellulose pulp/paperIonPhotoresist

A filter sheet is provided which comprises a self-supporting fibrous matrix having immobilized therein particulate filter aid and particulate ion exchange resin, wherein said particulate filter aid and particulate ion exchange resin are distributed substantially uniformly throughout a cross-section of said matrix. A process for removing ionic impurities from a photoresist solution is also provided which comprises passing the photoresist solution through said filter sheet to remove ionic impurities therefrom.

Owner:3M INNOVATIVE PROPERTIES CO

Dry particle based adhesive electrode and methods of making same

ActiveUS7295423B1Reduce useHigh yieldHybrid capacitor electrodesDouble layer capacitorsCapacitorElectrode

Owner:TESLA INC

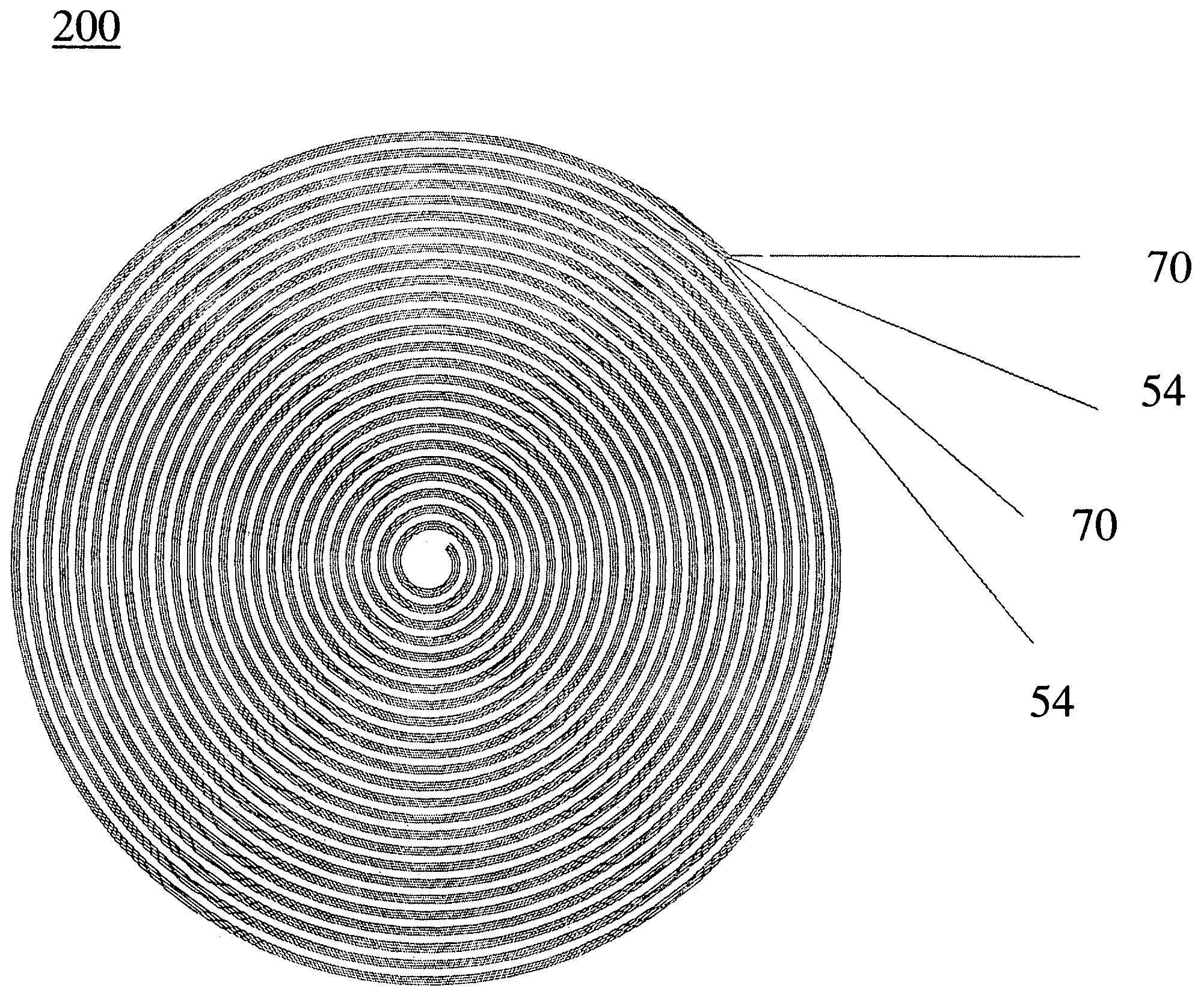

Dry particle based capacitor and methods of making same

ActiveUS7352558B2High yieldInexpensive and durable and highly reliableHybrid capacitor electrodesWound capacitorsFiberDry mixing

An inexpensive and reliable dry process based capacitor and method for making a self-supporting dry electrode film for use therein is disclosed. Also disclosed is an exemplary process for manufacturing an electrode for use in an energy storage device product, the process comprising: supplying dry carbon particles; supplying dry binder; dry mixing the dry carbon particles and dry binder; and dry fibrillizing the dry binder to create a matrix within which to support the dry carbon particles as dry material.

Owner:TESLA INC

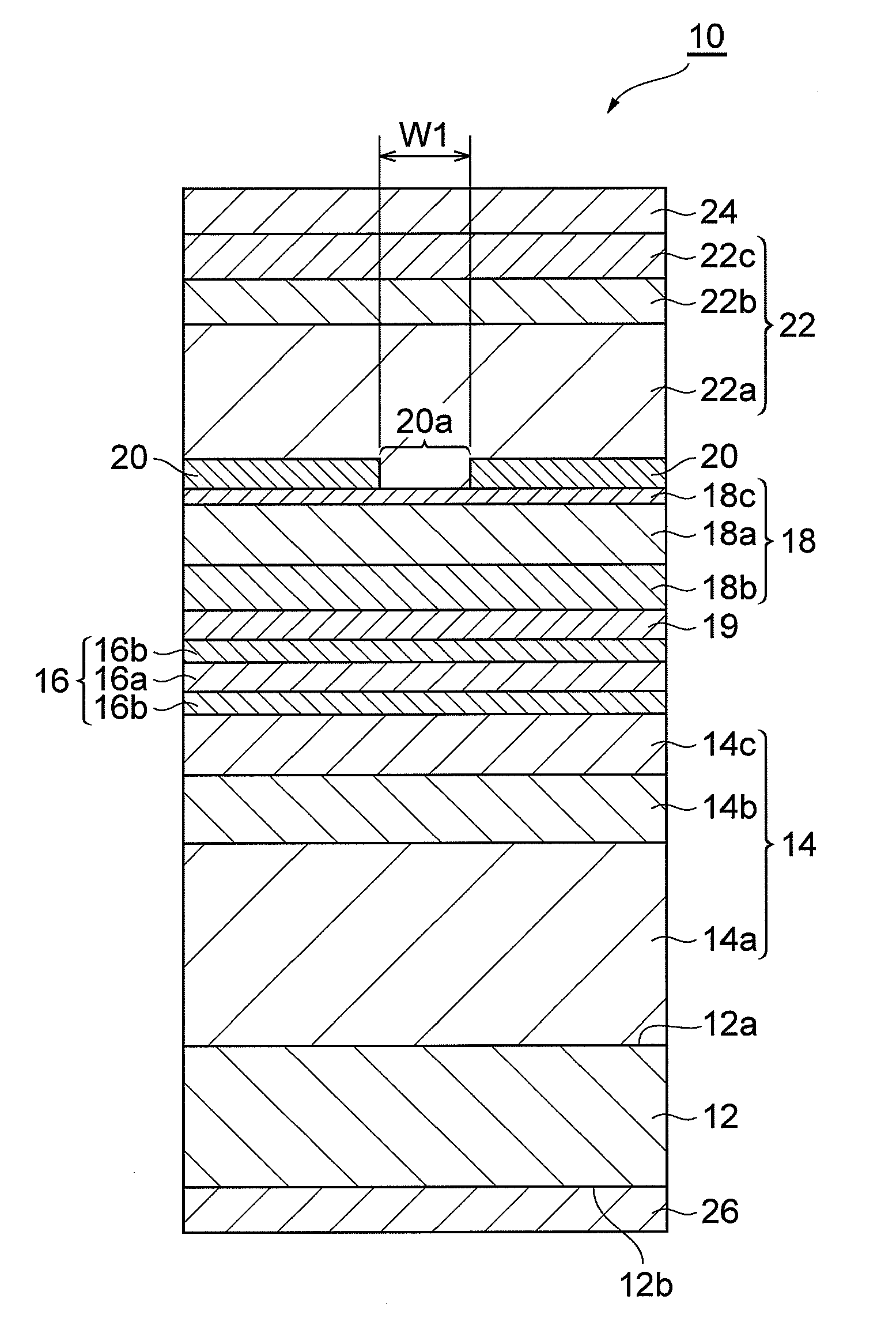

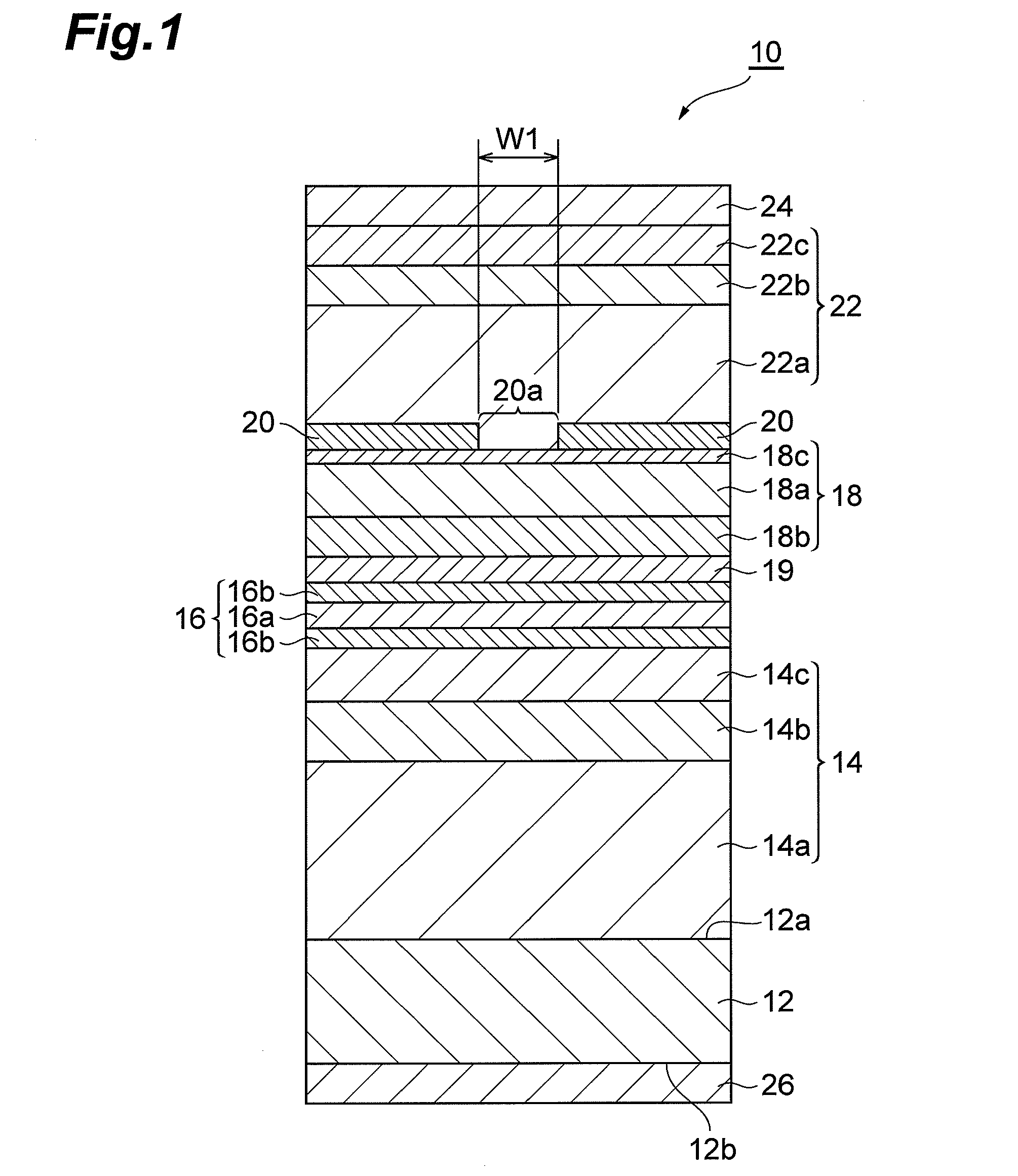

Group iii nitride semiconductor laser device

InactiveUS20130051418A1Increases threshold current densityIncrease the driving voltageLaser detailsNanoopticsOptical cavityPower flow

A group-III nitride semiconductor laser device includes an n-type nitride semiconductor region, an active layer provided over the n-type nitride semiconductor region, a first p-type nitride semiconductor region provided over the active layer, a current confinement layer which is provided over the first p-type nitride semiconductor region and has an opening extending in a optical cavity direction, and a second p-type nitride semiconductor region re-grown on the first nitride semiconductor region and the current confinement layer after the formation of the opening of the current confinement layer. The interface between the first p-type nitride semiconductor region and the second p-type nitride semiconductor region includes a semi-polar plane. At least one of the first or second p-type semiconductor regions includes a highly doped p-type semiconductor layer forming an interface with the first and second p-type semiconductor regions and have a p-type impurity level of 1×1020 cm−3 or greater.

Owner:SUMITOMO ELECTRIC IND LTD

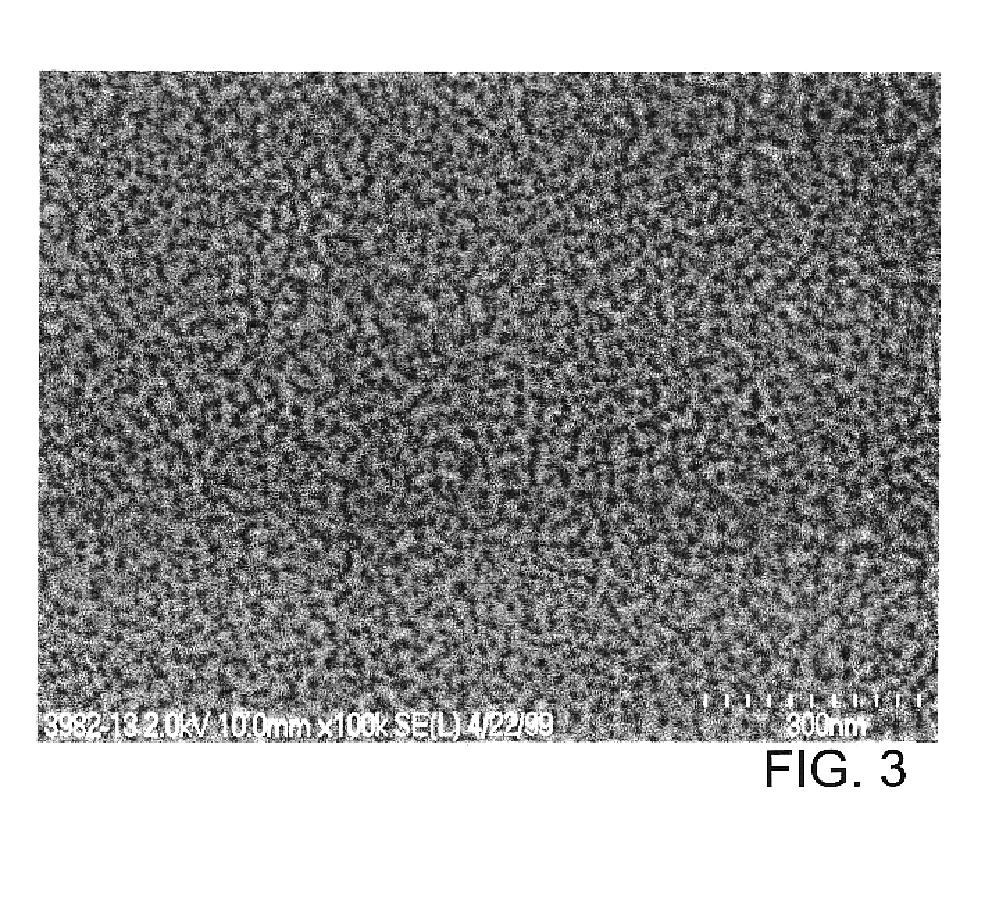

Method of making silane compositions

ActiveUS7498015B1Good ink stabilityDeposition process is enhancedHydride purification/stabilisationSilicon compoundsSilanesCharge carrier mobility

A method of making hydrogenated Group IVA compounds having reduced metal-based impurities, compositions and inks including such Group IVA compounds, and methods for forming a semiconductor thin film. Thin semiconducting films prepared according to the present invention generally exhibit improved conductivity, film morphology and / or carrier mobility relative to an otherwise identical structure made by an identical process, but without the washing step. In addition, the properties of the present thin film are generally more predictable than those of films produced from similarly prepared (cyclo)silanes that have not been washed according to the present invention. The present invention advantageously provides semiconducting thin film structures having qualities suitable for use in electronics applications, such as display devices or RF ID tags, while enabling high-throughput manufacturing processes that form such thin films in seconds or minutes, rather than hours or days as with conventional photolithographic processes.

Owner:ENSURGE MICROPOWER ASA

Method for improving the adhesion of metal films to polyphenylene ether resins

InactiveUS6165309AHigh bonding strengthSufficient amountInsulating substrate metal adhesion improvementNon-macromolecular adhesive additivesEtherPolystyrene

The present invention is directed to a method for improving the adhesion between a conductive laminate and a substrate material. In a preferred embodiment of the present invention, the conductive laminate is a copper film and the substrate material comprises polyphenylene ether resin. The method involves admixing a copolymer of a vinyl aromatic compound and an alpha , beta -unsaturated cyclic anhydride with the polyphenylene ether resin. The copolymer of a vinyl aromatic compound and an alpha , beta -unsaturated cyclic anhydride is preferably a polystyrene maleic anhydride copolymer or a rubber modified polystyrene maleic anhydride copolymer.

Owner:SABIC INNOVATIVE PLASTICS IP BV

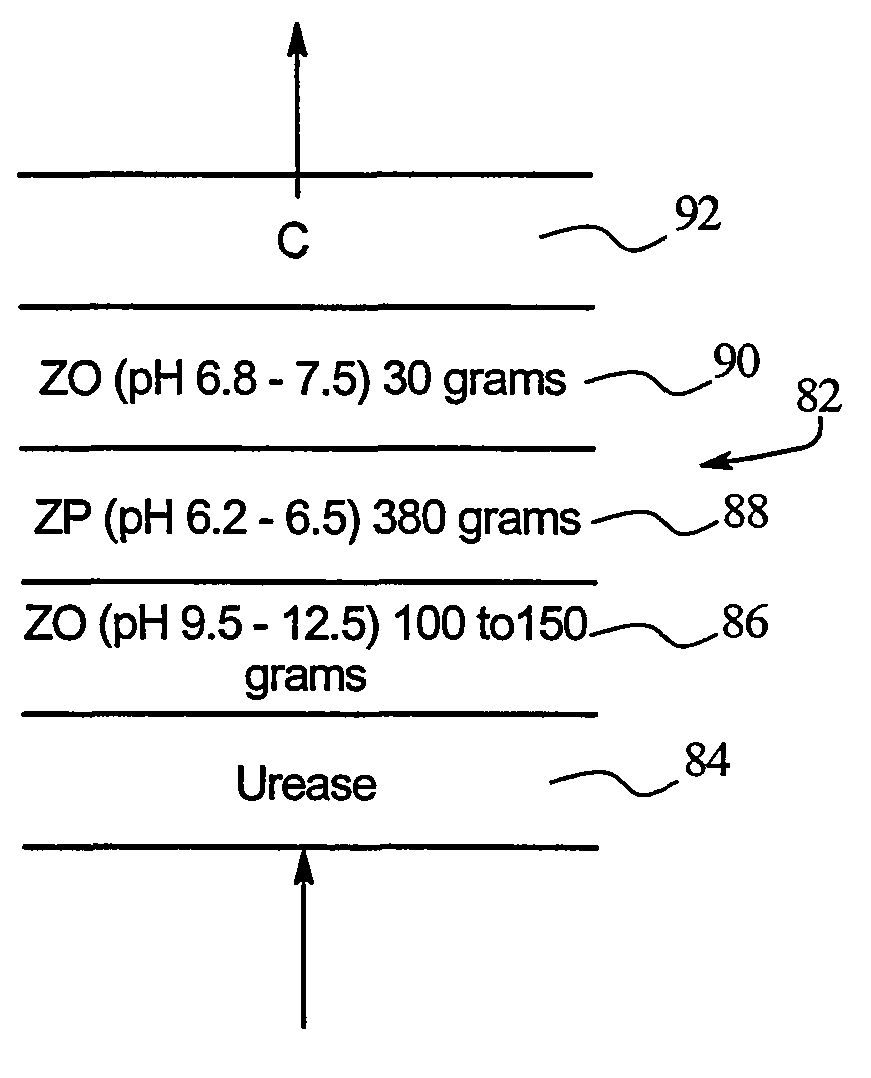

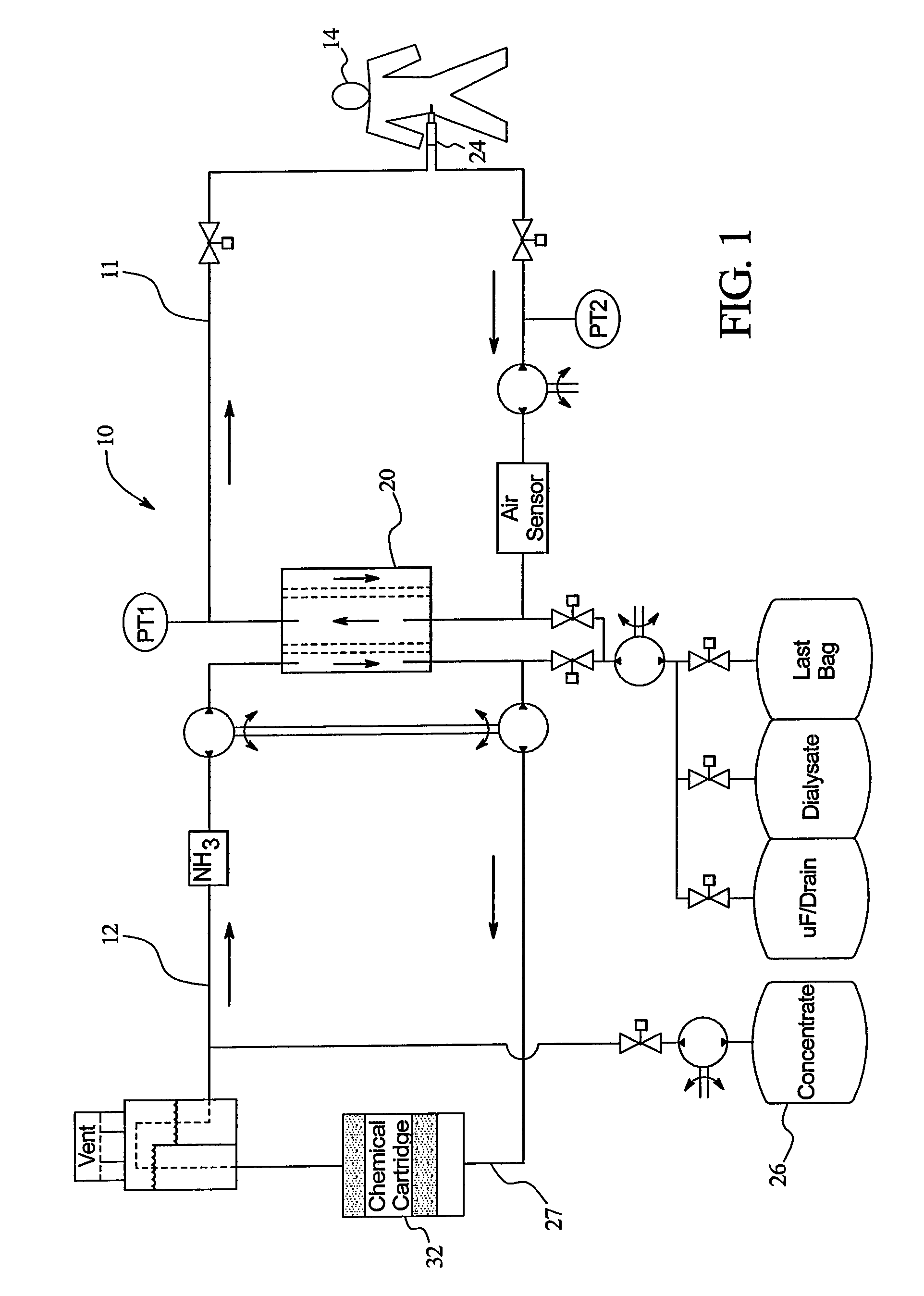

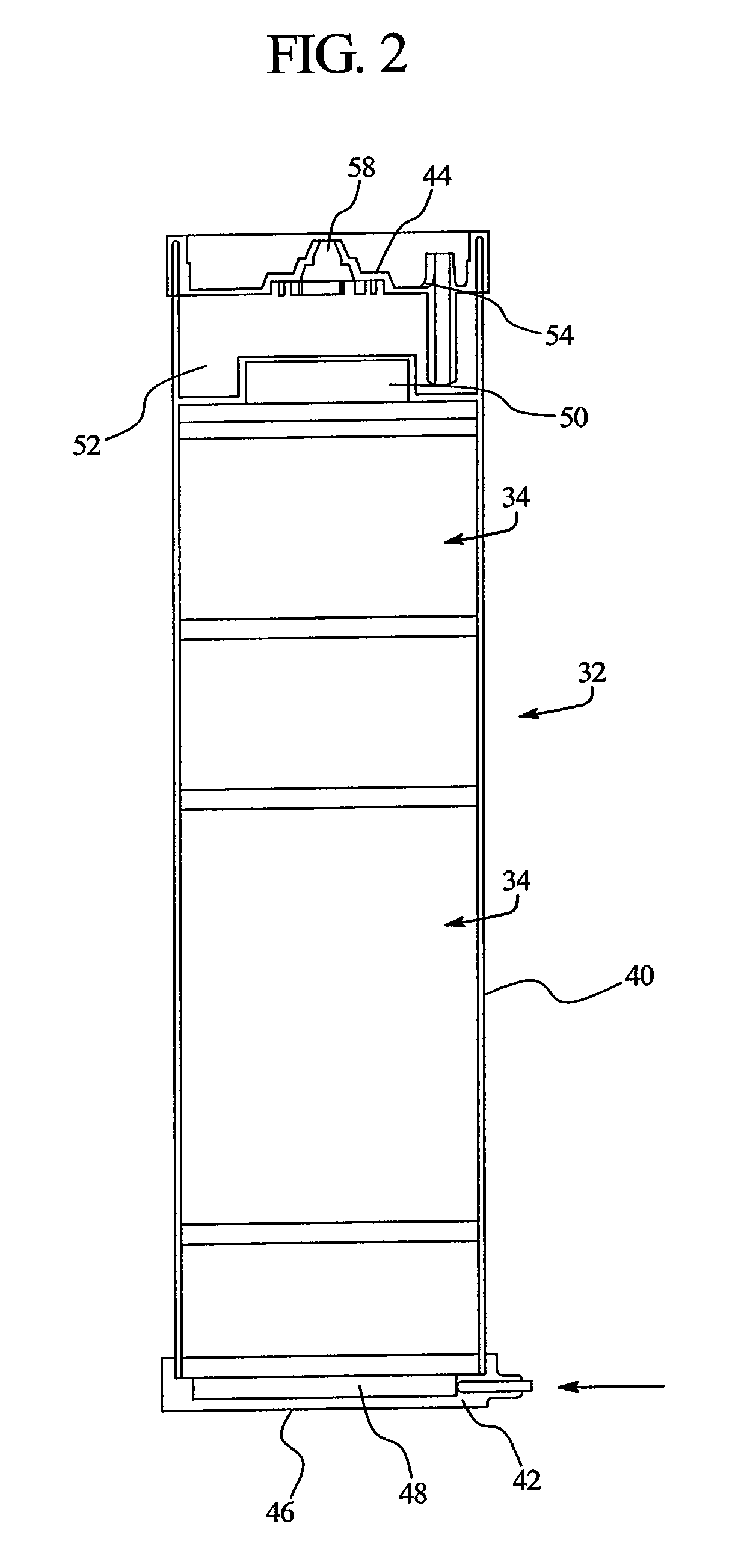

Method and composition for removing uremic toxins in dialysis processes

ActiveUS7955290B2Reduce impuritySimple systemOther chemical processesOther blood circulation devicesToxinUrease

Owner:BAXTER INT INC

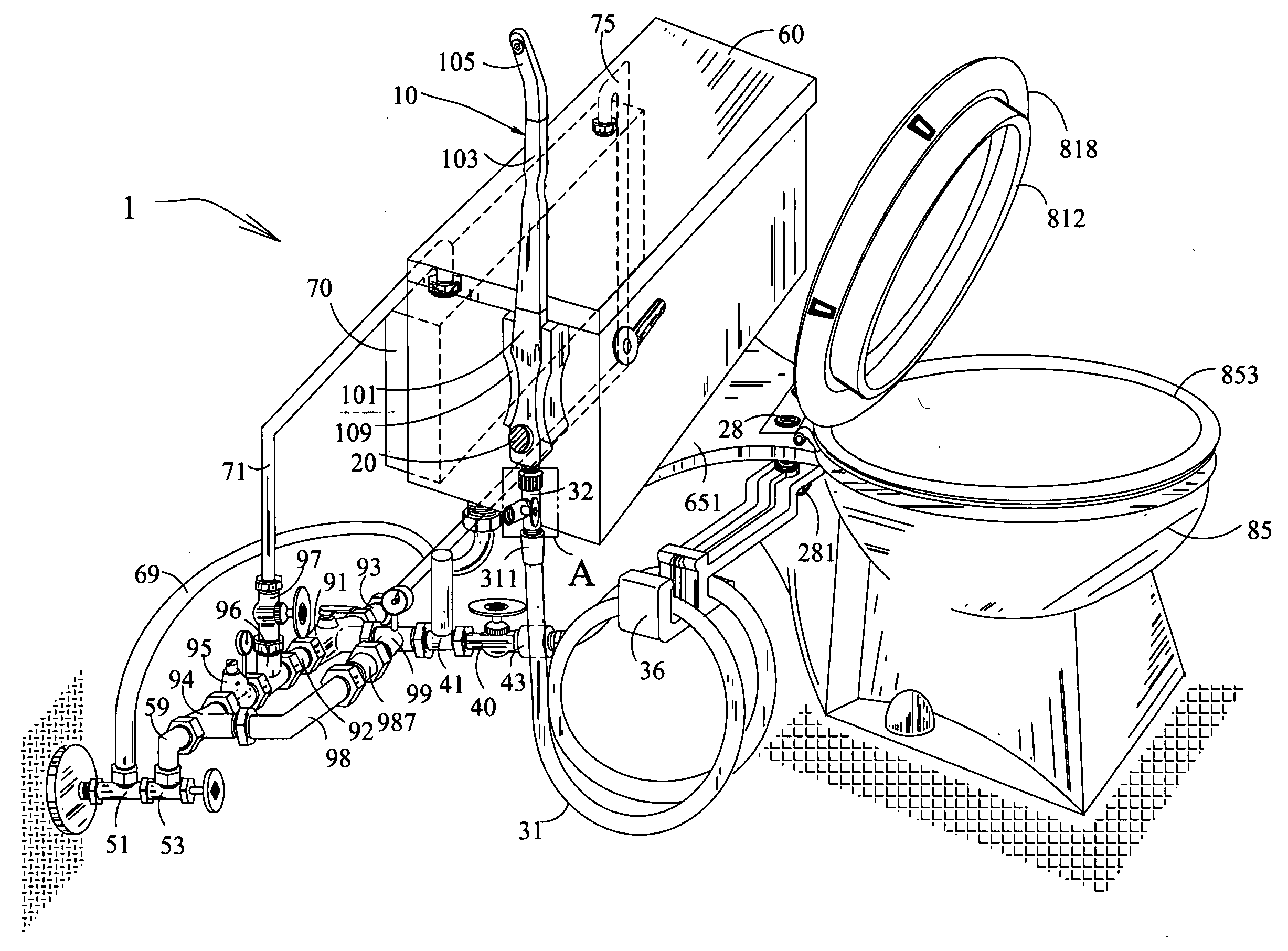

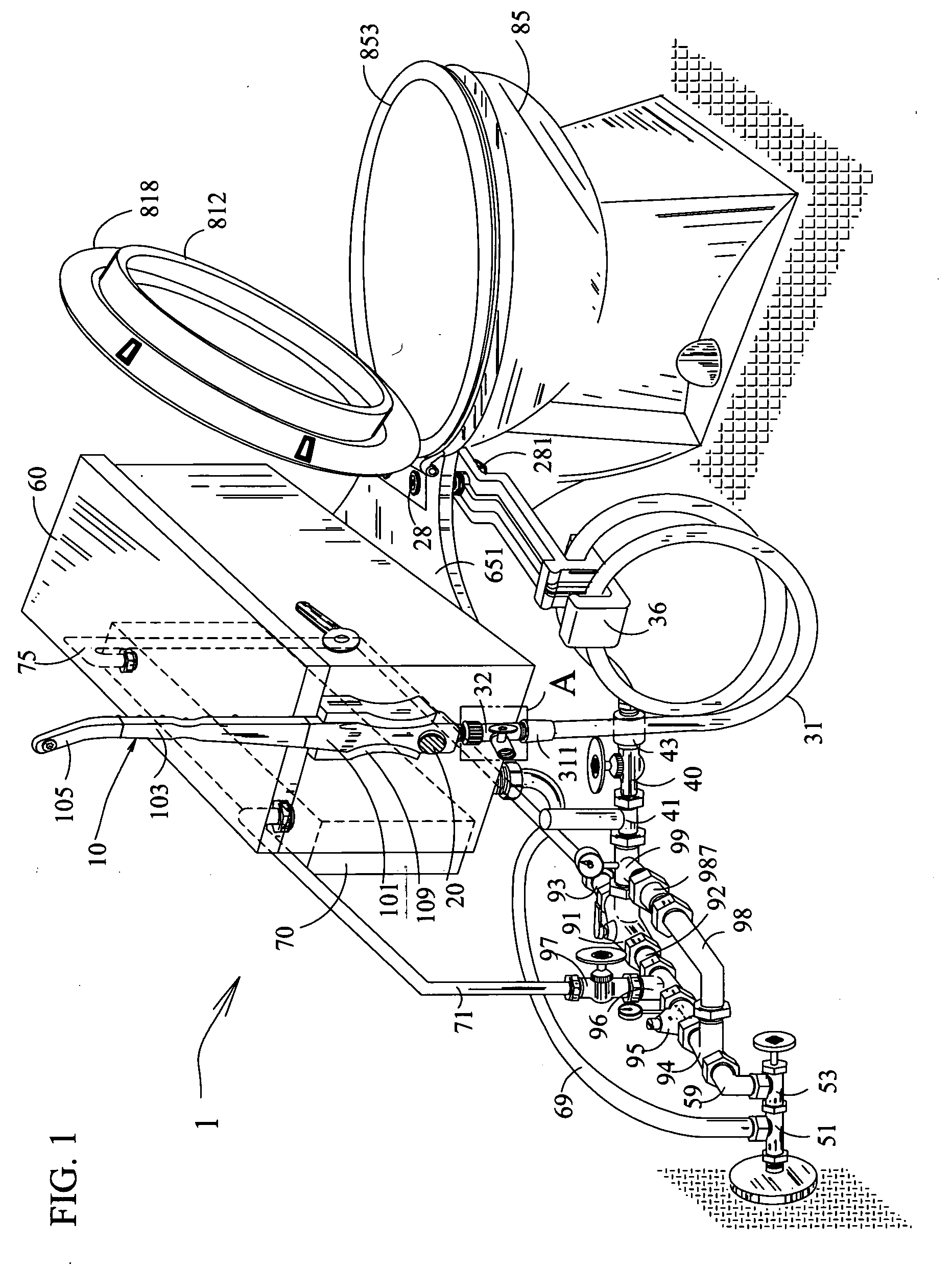

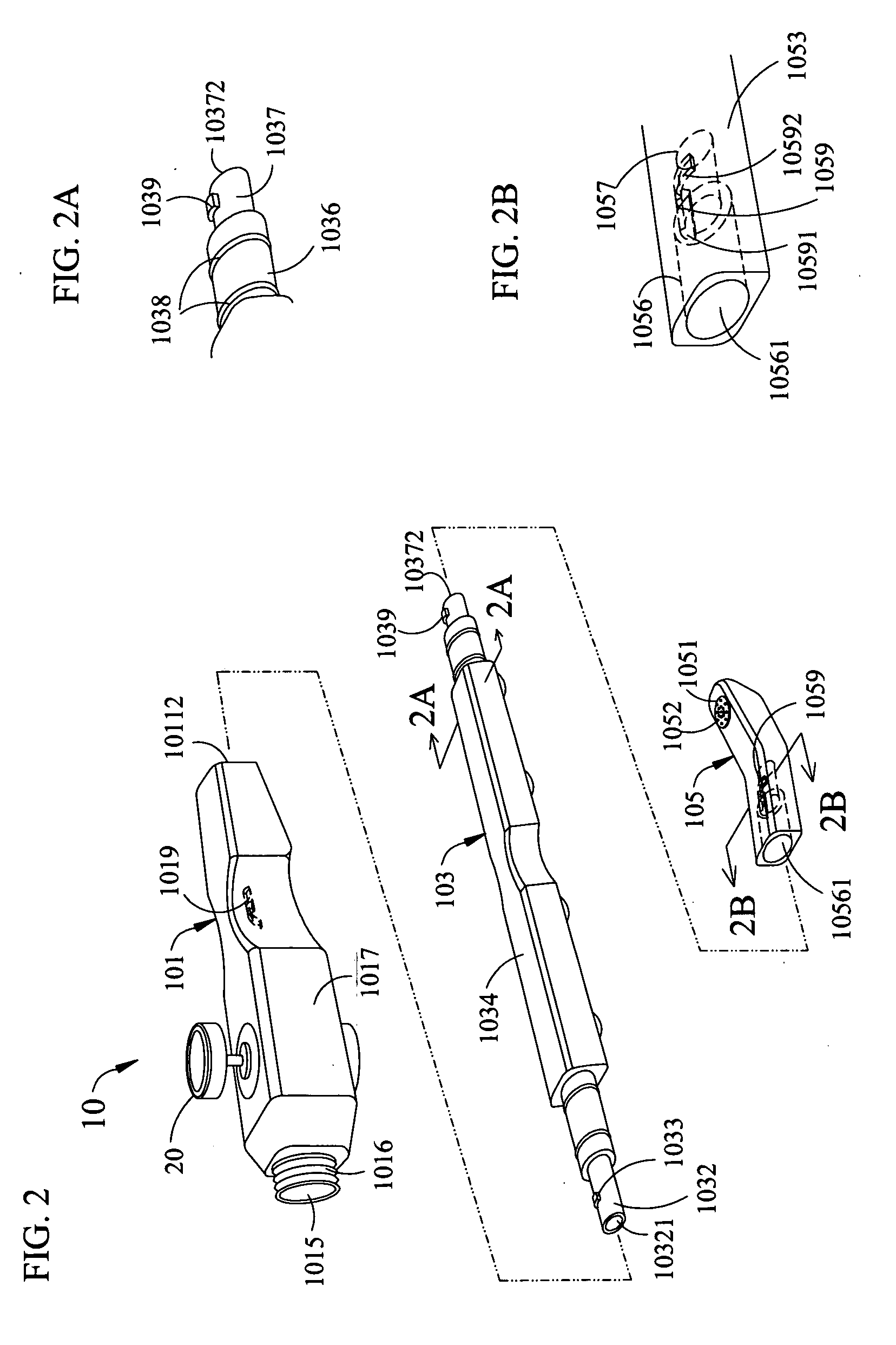

Toilet system attached a multi-purpose hand held water sprayer

InactiveUS20050120471A1More featureEasy to attachBathroom coversLavatory sanitorySprayerWater source

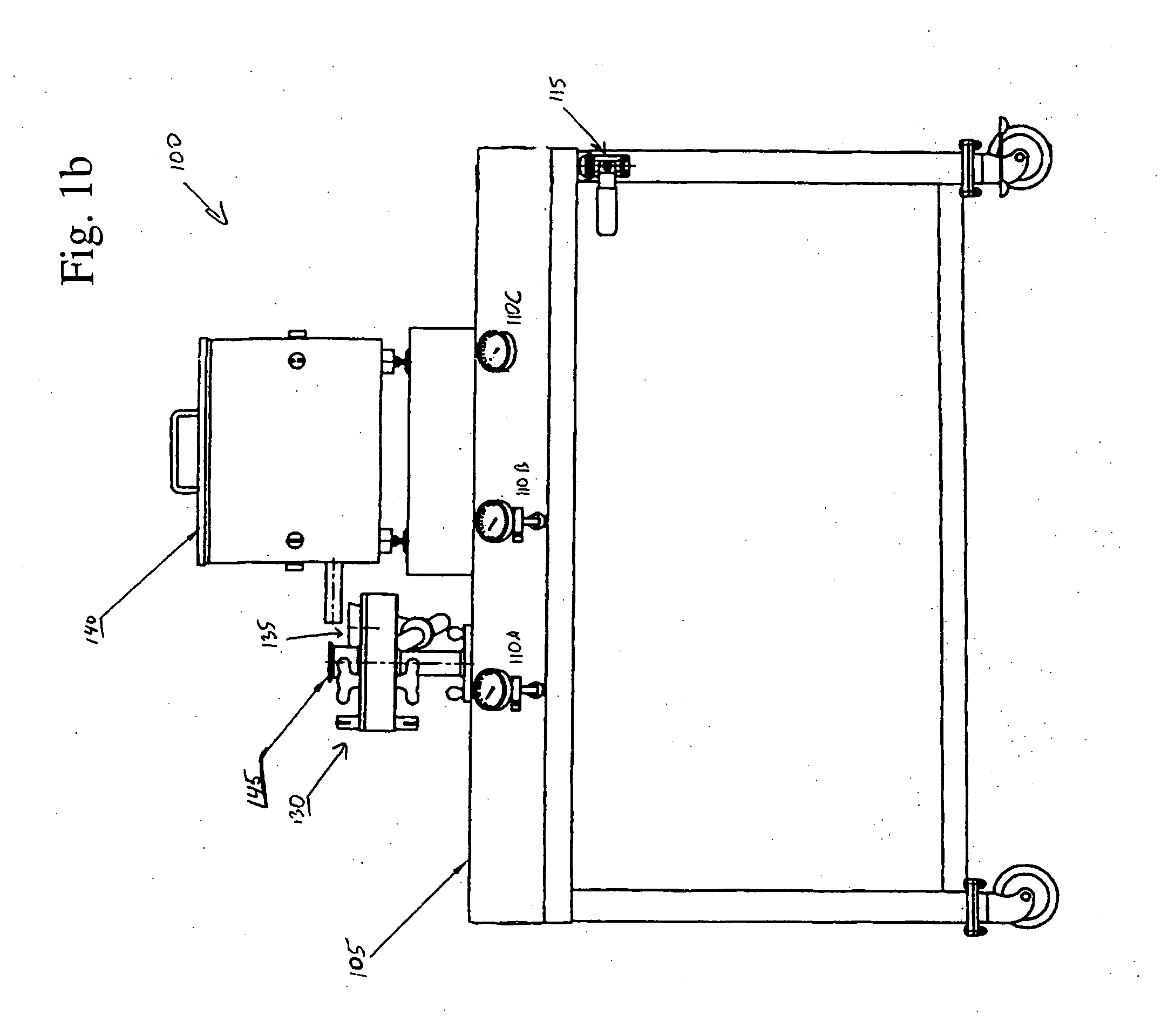

The invention relates to the new features for the earlier applications of toilet system attached a multi-purpose hand held water sprayer affording personal and environmental hygiene. The sprayer that delivers tempered water includes the lock elements on the components to secure connection, various types of spray tip cap for the use of general and medical purposes, an injection apparatus to supply external fluid, a fortified flexible hose, a water hammer arrester or air chamber to reduce water pressure shock, a water heater, a valve to control water flow, a mixing valve, check valves for the mixing valve to stop in reverse flow, a water pressure regulator with a pressure meter, a return line with a check valve for guarding against hot water spike, a thermometer at the outlet, a holder for placement of the sprayer, and various types of valves and sources for the hot and cold water supply. The new features also include the fortified flexible hose having the rollup attachment of middle layers over the flange for reinforcement.

Owner:LIM HOWARD TAK SU

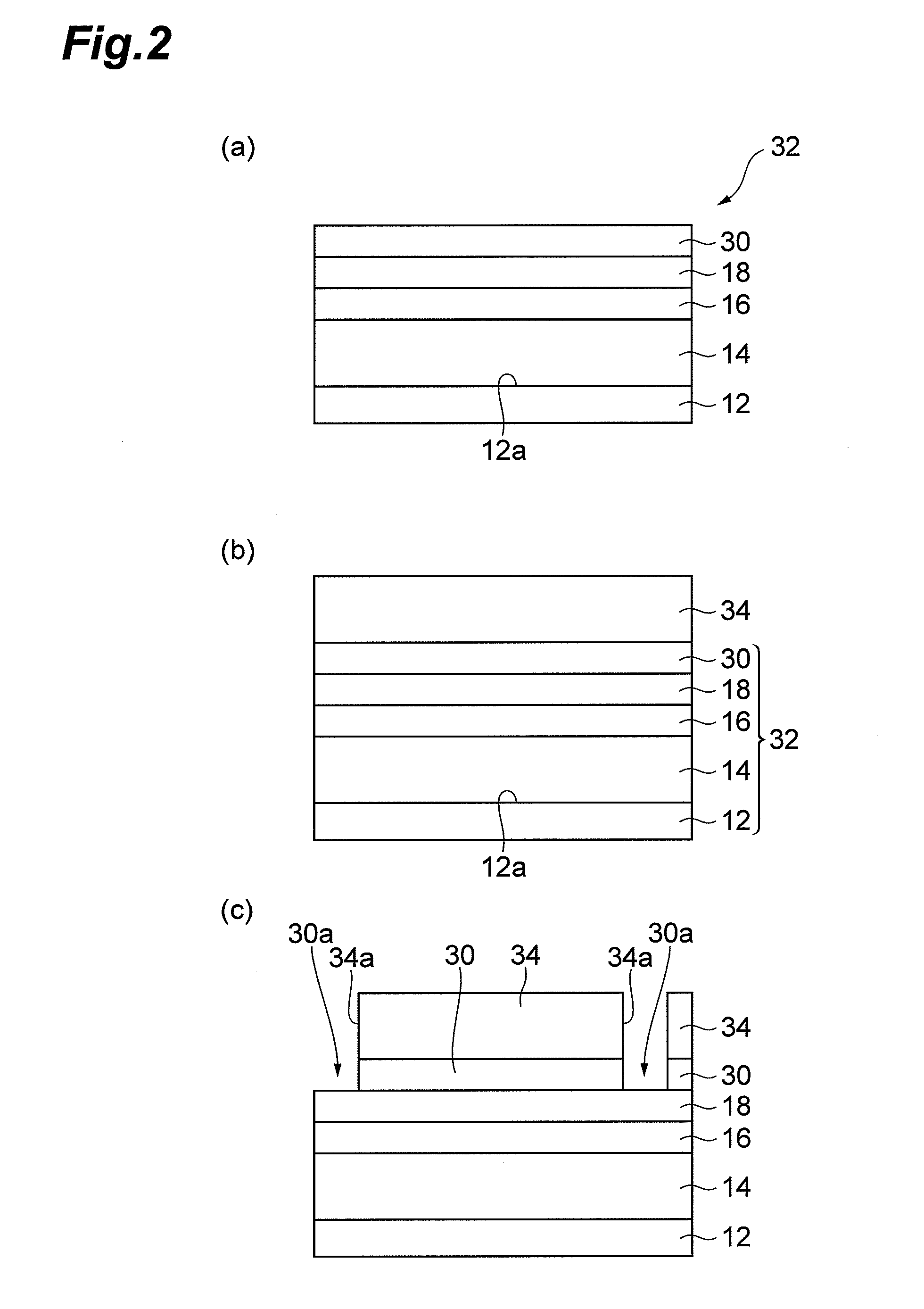

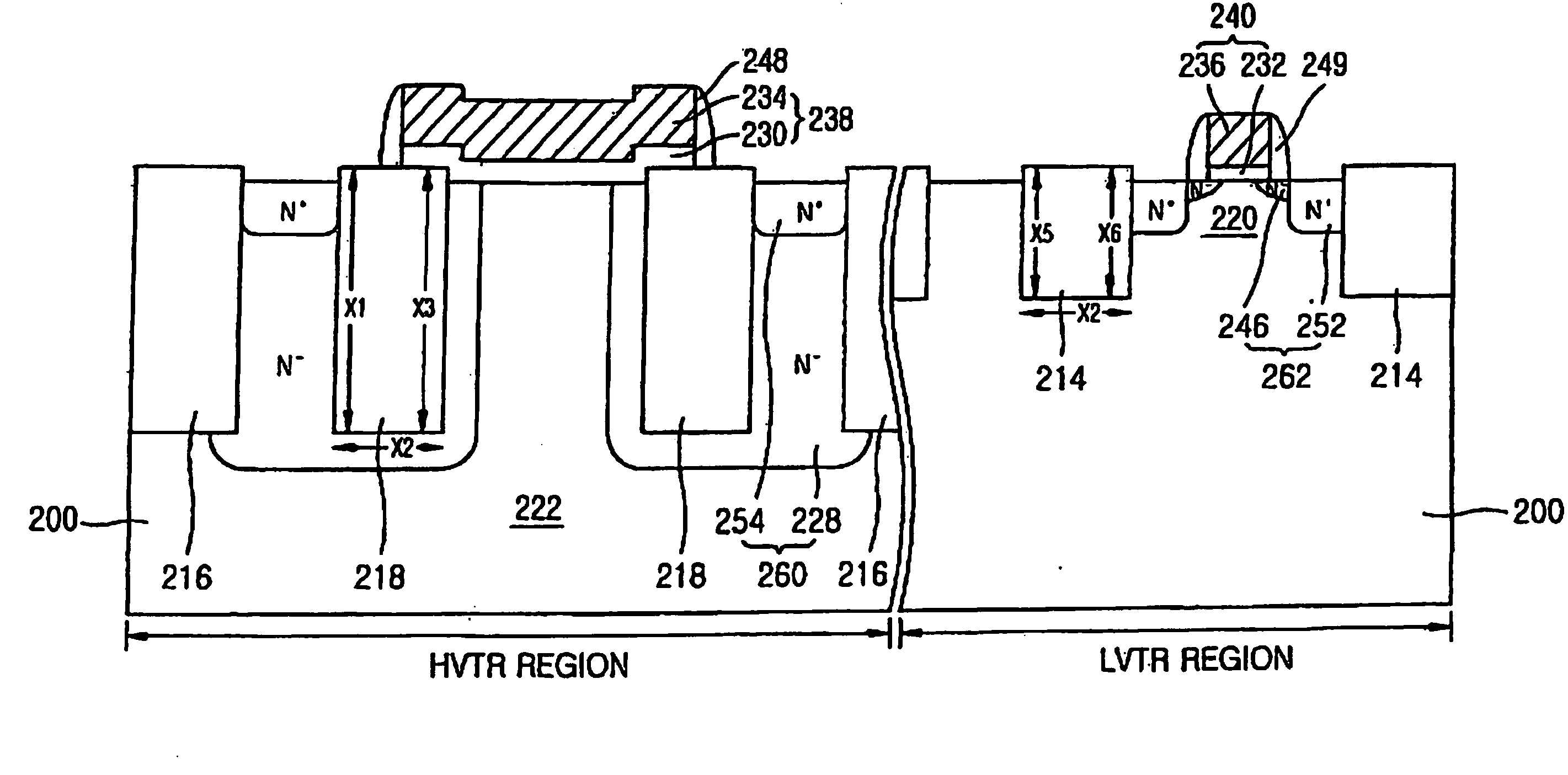

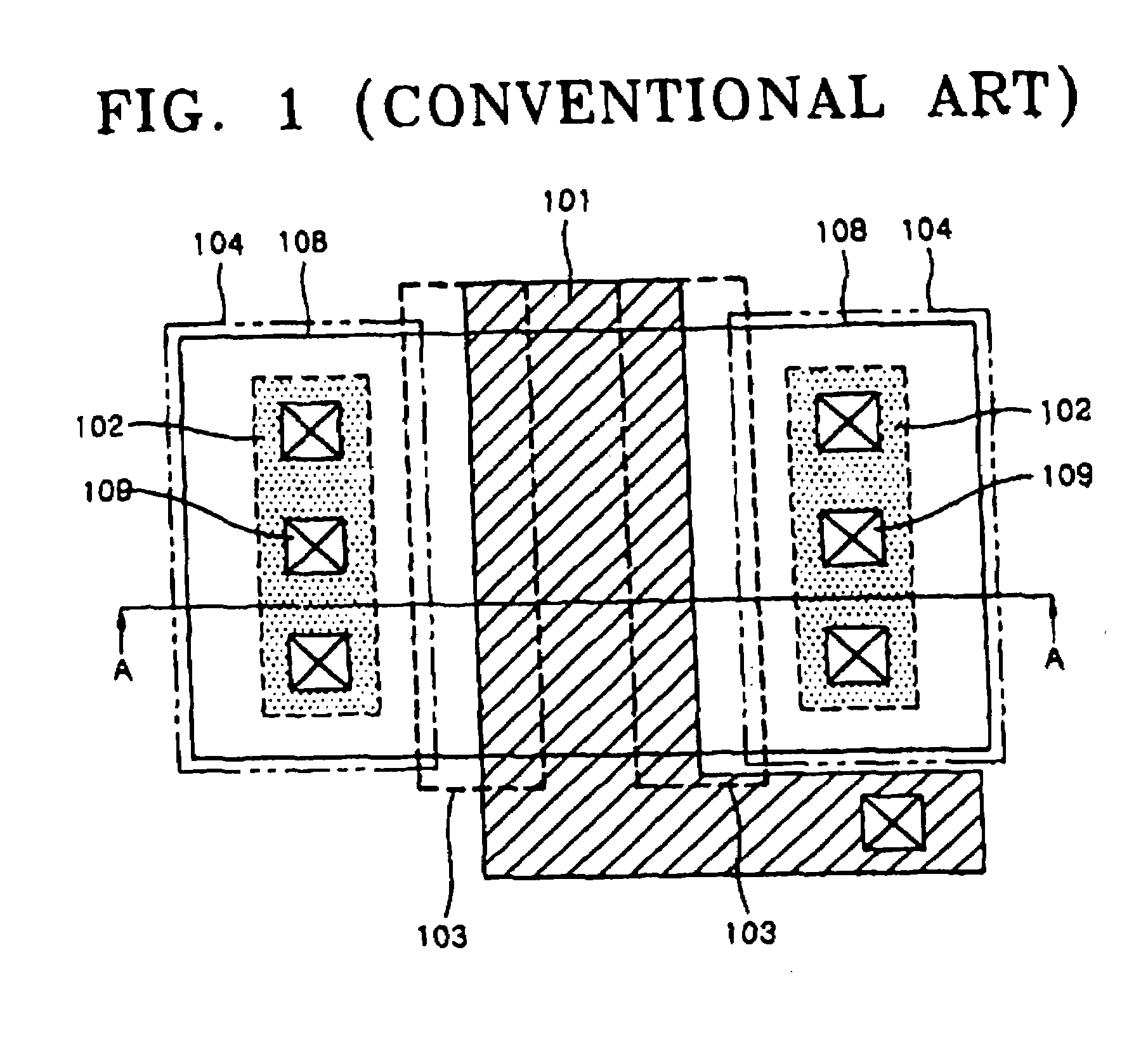

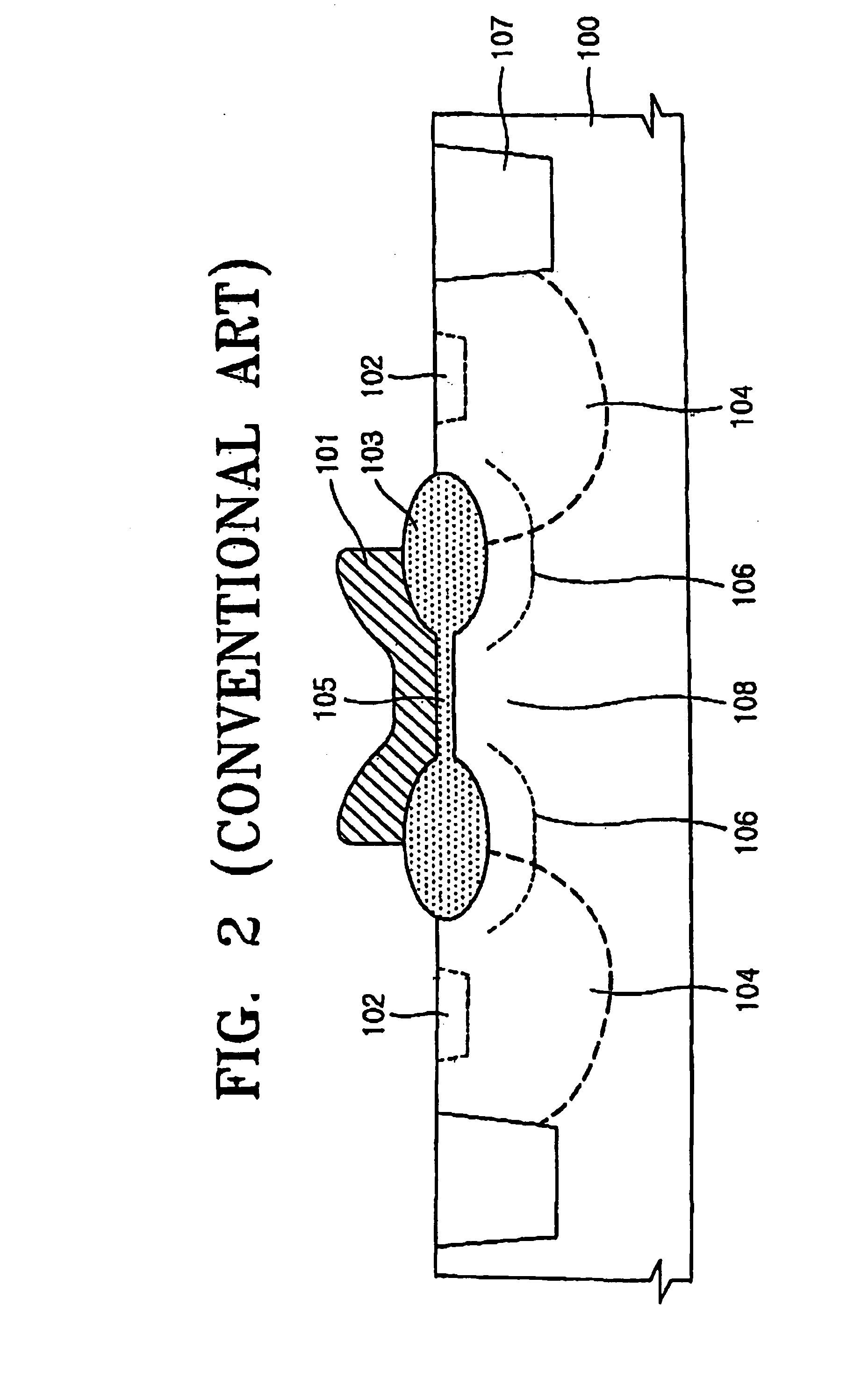

Semiconductor integrated circuit device and method of fabricating the same

InactiveUS20090278208A1Highly integratedReduce impurityTransistorSolid-state devicesEngineeringSemiconductor

Owner:CHANG DONG RYUL

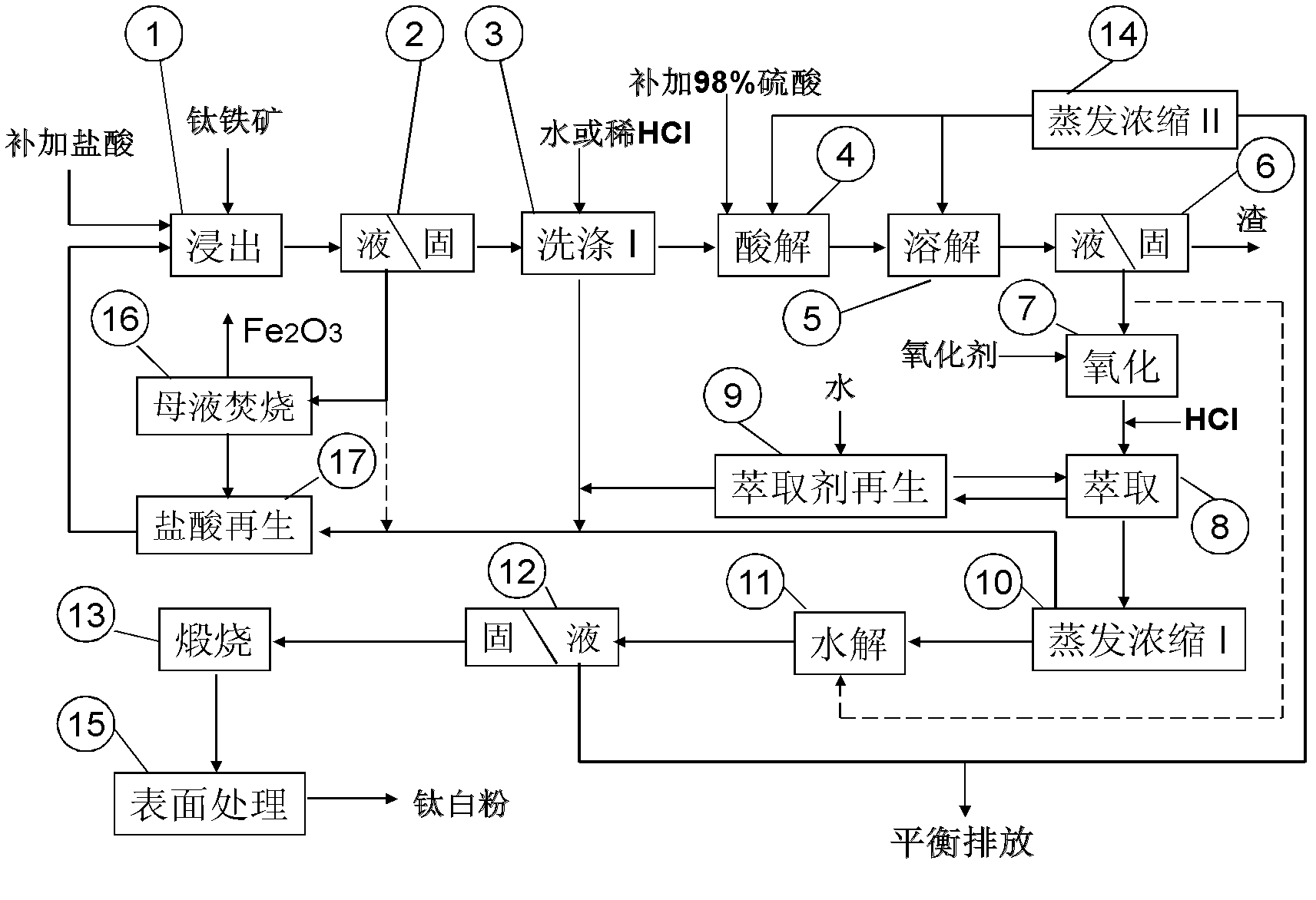

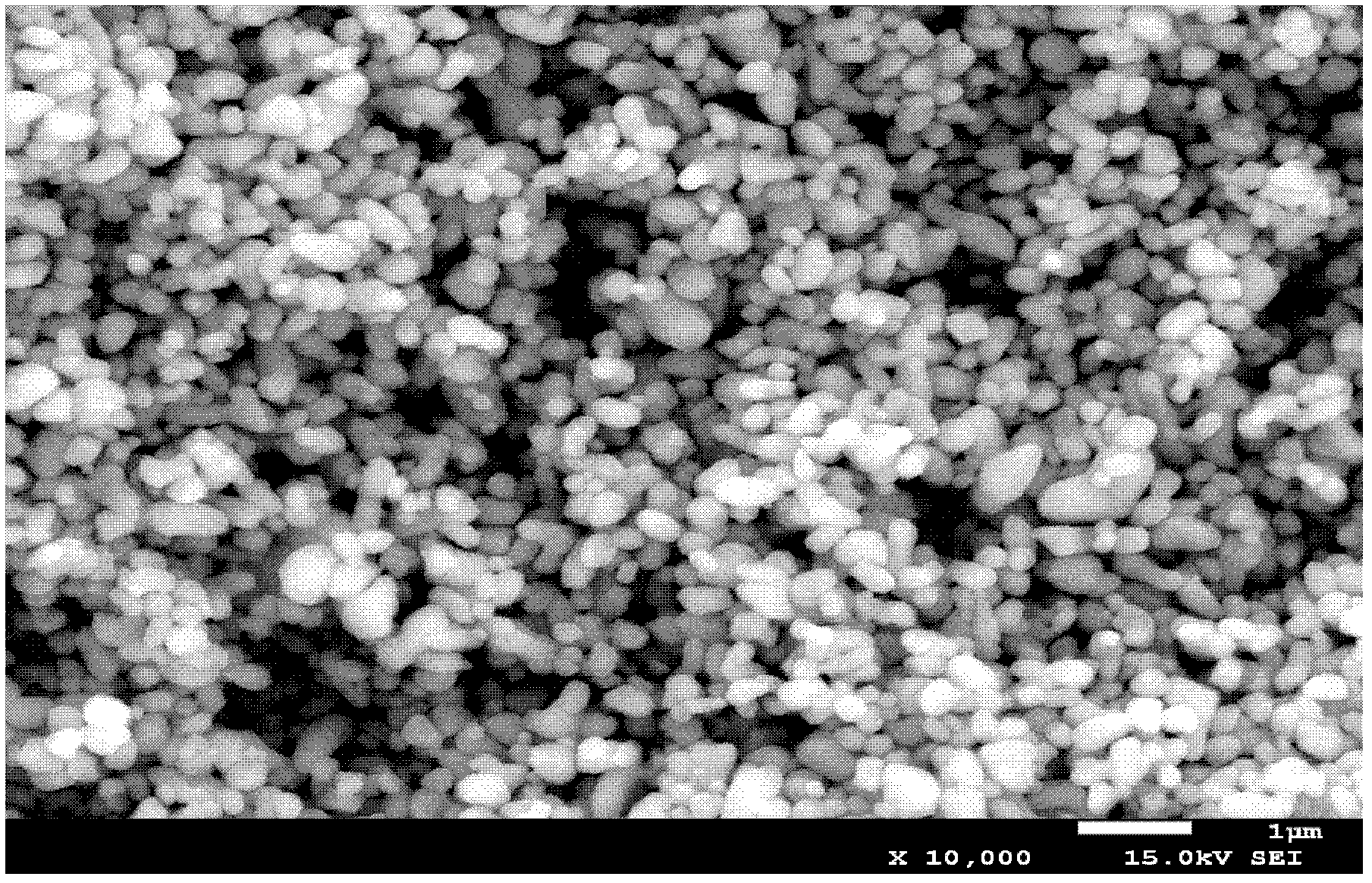

Method for preparing titanium white

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

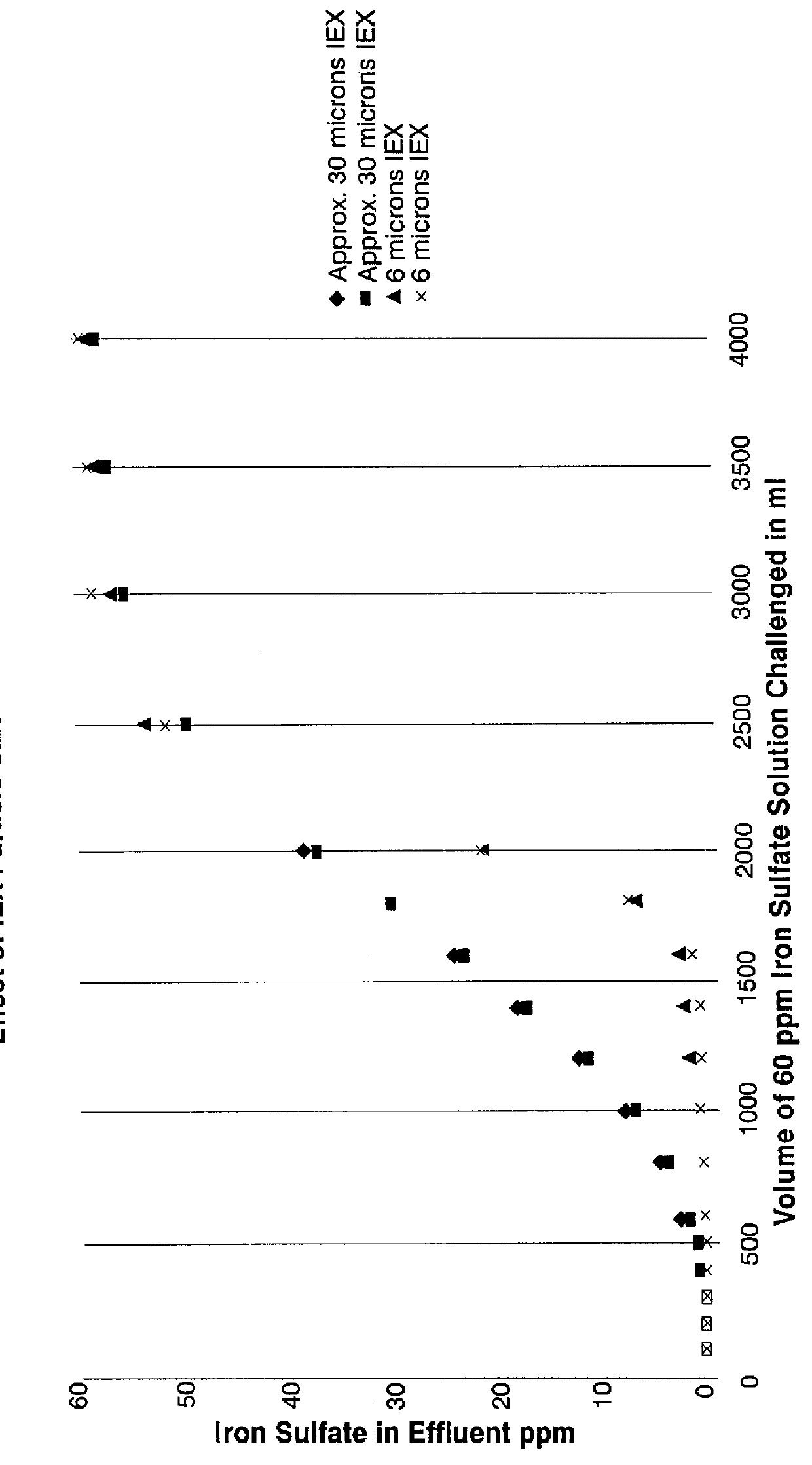

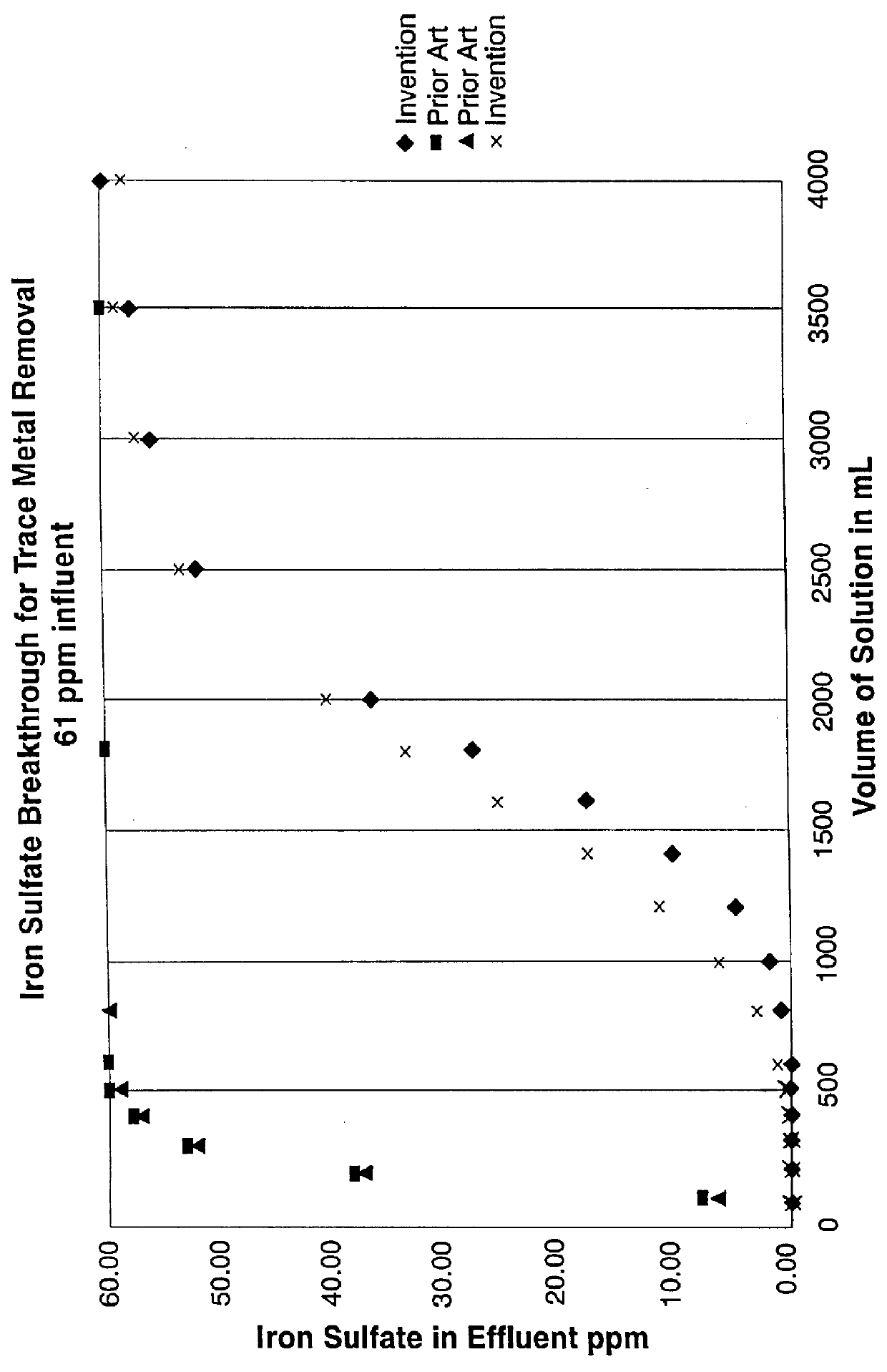

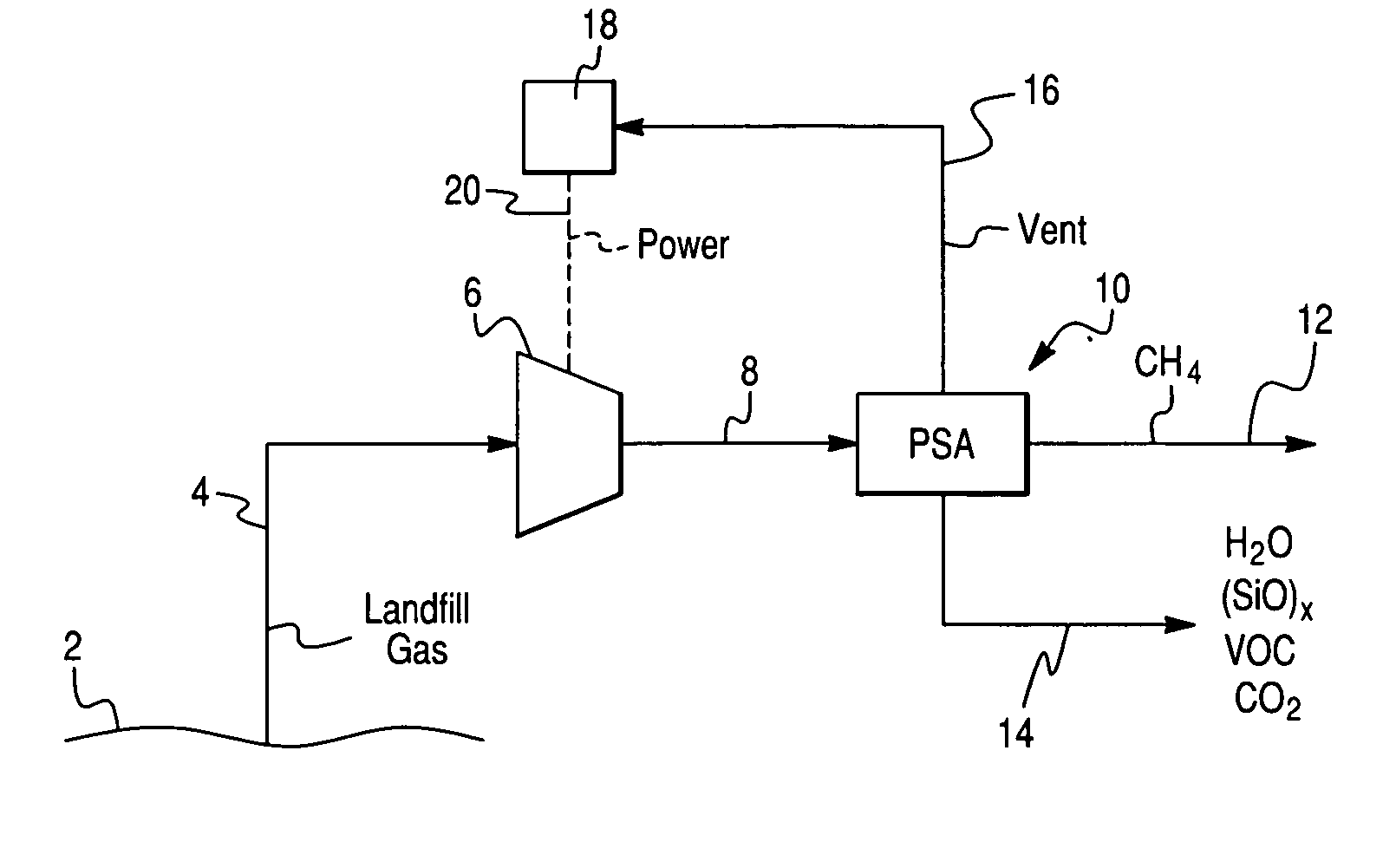

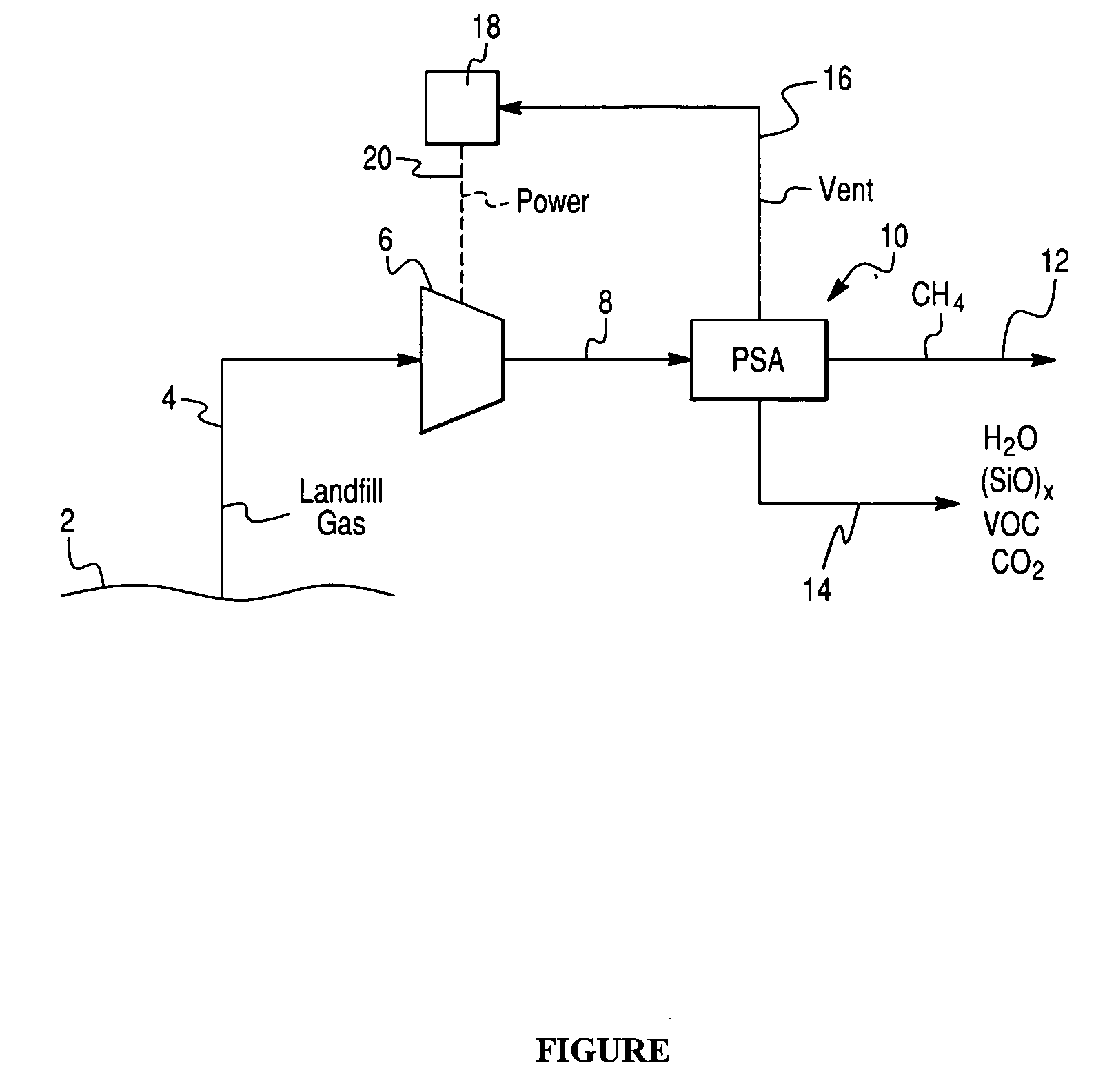

Landfill gas upgrading process

A natural gas stream derived from a landfill and containing impurities including siloxane impurities is purified by a PSA process to produce a methane-rich product stream which is substantially free of siloxane impurities. A methane-rich vent stream having a pressure less than the product stream is formed that is also free of siloxanes and can be used as a fuel stream to run a compressor for the PSA process.

Owner:ENGELHARD CORP

Dry particle based adhesive and dry film and methods of making same

Dry process based energy storage device structures and methods for using a dry adhesive therein are disclosed.

Owner:TESLA INC

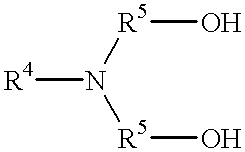

Process for the purification of gases

InactiveUS6277345B1Improve efficiencyIncreased gas throughputHydrogenOrganic chemistryPoly(ethylene glycol) dimethyl etherHydrogen

The present invention relates to the use of an absorption liquid for purifying a gas by removal of gaseous, acidic impurities. The gas to be purified can be any gas, such as synthesis gas or natural gas, which contains gaseous, acidic impurities such as CO2, H2S, SO2, CS2, HCN, COS or mercaptans. The absorption liquid comprises:A) from 0.01 to 4% by weight of at least one compound of the formulaB) from 0.001 to 8.0% by weight of water, andC) at least one polyalkylene glycol alkyl ether of the formulato 100% by weight,whereR1 is C1-C4-alkyl,R2 is ethylene or 2-methylethylene,R3 is hydrogen or C1-C4-alkyl,R4 is hydrogen or C1-C4-alkyl,R5 is C1-C4-alkylene andX is an integer from 1 to 10. The amine may be N-methyldiethanolamine and the ether may be polyethylene glycol dimethyl ether.

Owner:CLARIANT PROD DEUT GMBH

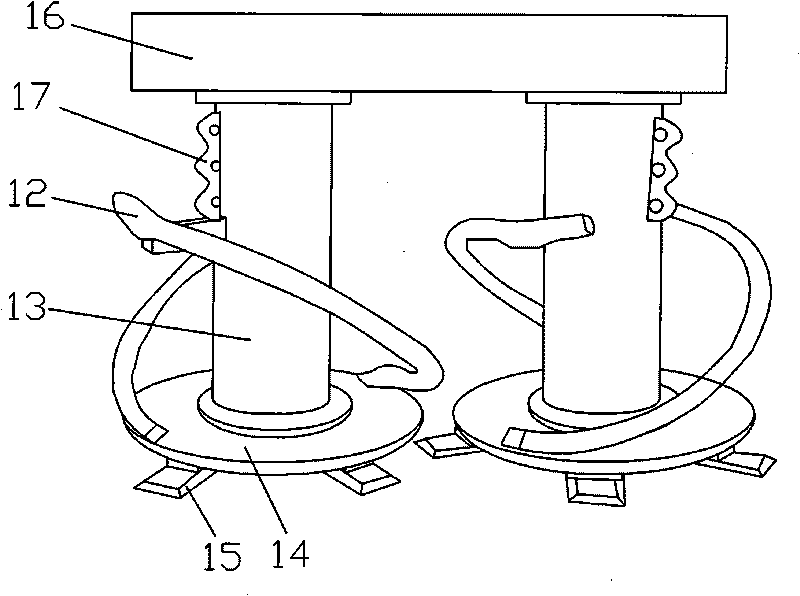

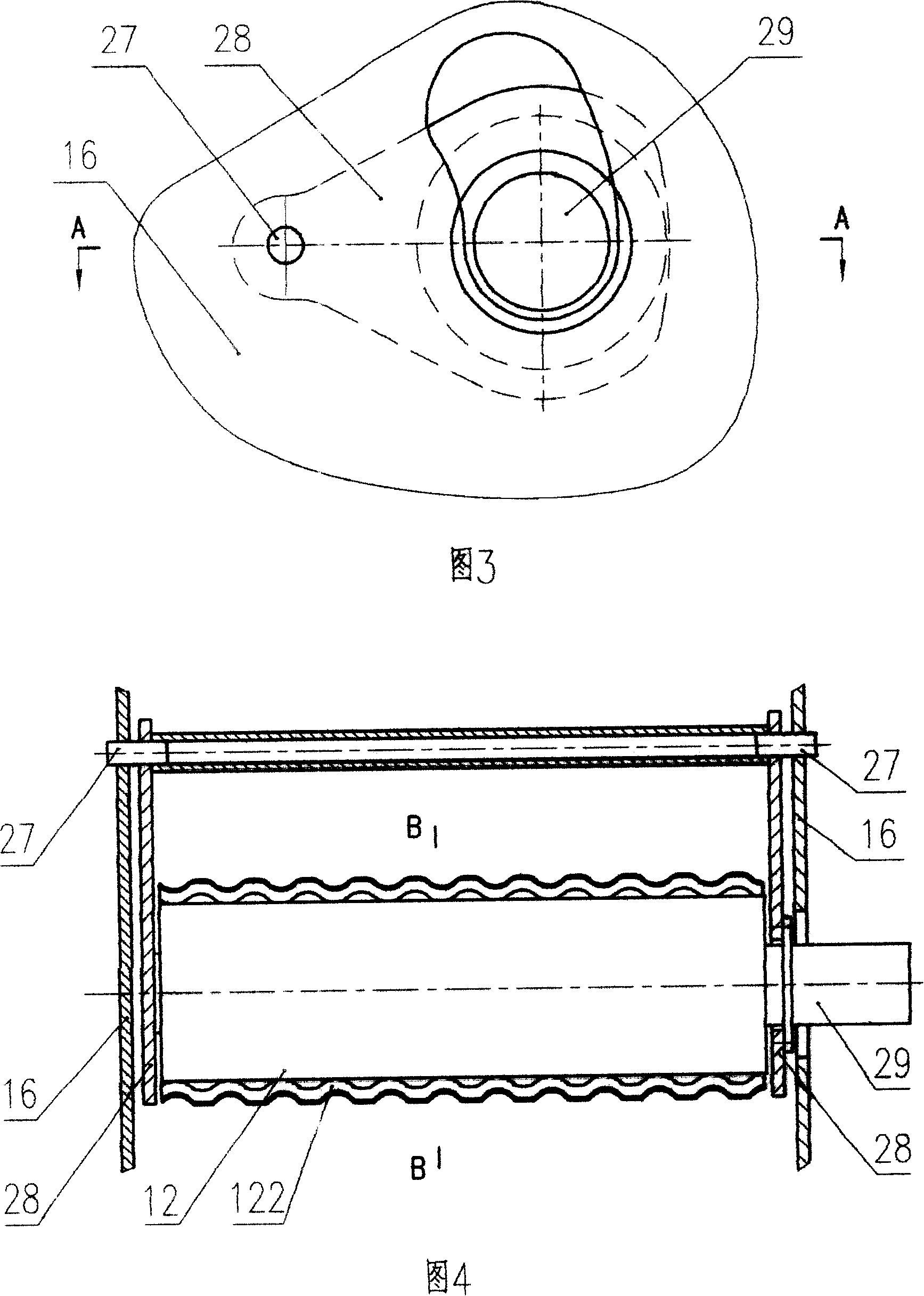

Ramie combine harvester

InactiveCN101518182AReduce impurityIncrease productivityHarvestersMechanical fibre separationEngineeringMechanical equipment

The invention relates to a ramie combine harvester which is applicable to combining harvest of ramie, namely completes ramie cutting and fiber primary processing by one time continuously, belonging to agricultural mechanical equipment. The ramie combine harvester consists of a vertical cutting table, an operating mechanism, a middle conveyor, a two-way automatic ramie removing machine, a mechanism which integrates ramie bin, power and transmission mechanism and a walking device. A bottom plate part is universal with a half head-feed grain combine harvester. A holding conveying belt is a synchronous belt; and the outer surfaces of the two belts are coupled with a longitudinal convex-concave bar groove, one belt at the inner side is a fixed support and the other belt is an elastic pressing support. The two-way ramie removing machine has two sets of ramie removing mechanisms at the front and back which are arranged in a reversed-V shape. After being cut, the ramie stalks are conveyed in a vertical and lateral mode, conveyed by a holding base part in a rotatable and upward mode, continuously fed into two sets of ramie removing mechanism for processing the base part and the tip part in a horizontal mode and the obtained ramie stalks are wound at a ramie blocking pin with an extruding and scratching machine at the tail ends of the ramie removing mechanisms, and the fiber is drawn, thus realizing removing of skin, skeleton and glue. The mechanical equipment has high production efficiency and good ramie removing quality and thoroughly solves the scutching difficulty which restricts the development of the ramie industry.

Owner:咸宁市农业机械化研究所

Dry particle based adhesive electrode and methods of making same

InactiveUS20060147712A1Reduce usageHigh yieldLiquid surface applicatorsHybrid capacitor electrodesBiomedical engineeringCapacitor

Owner:TESLA INC

Dry-particle packaging systems and methods of making same

InactiveUS20060137158A1Reduce water usageReduce impurityElectrode rolling/calenderingElectrolytic capacitorsEnergy storageBiochemical engineering

Owner:TESLA INC

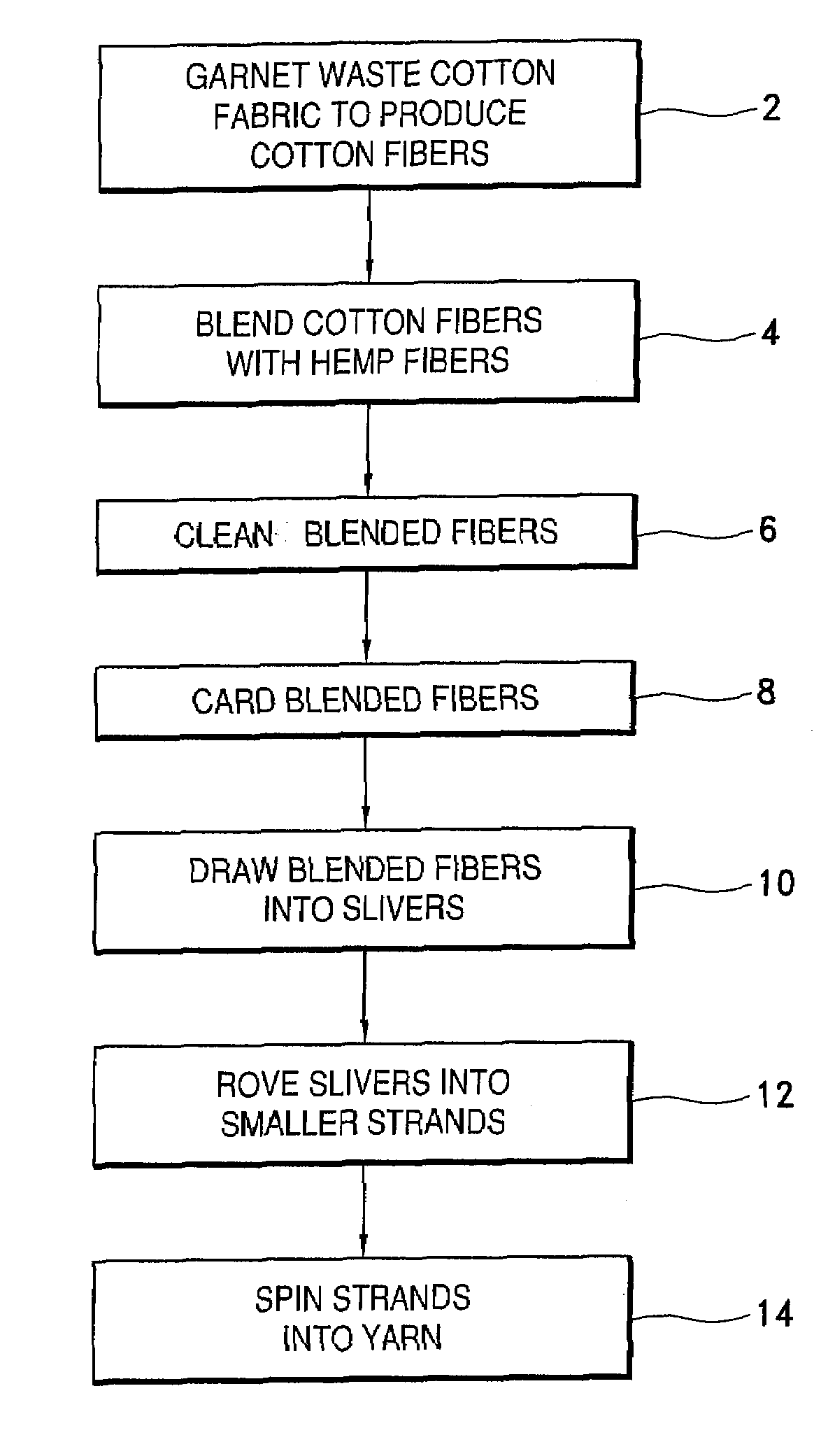

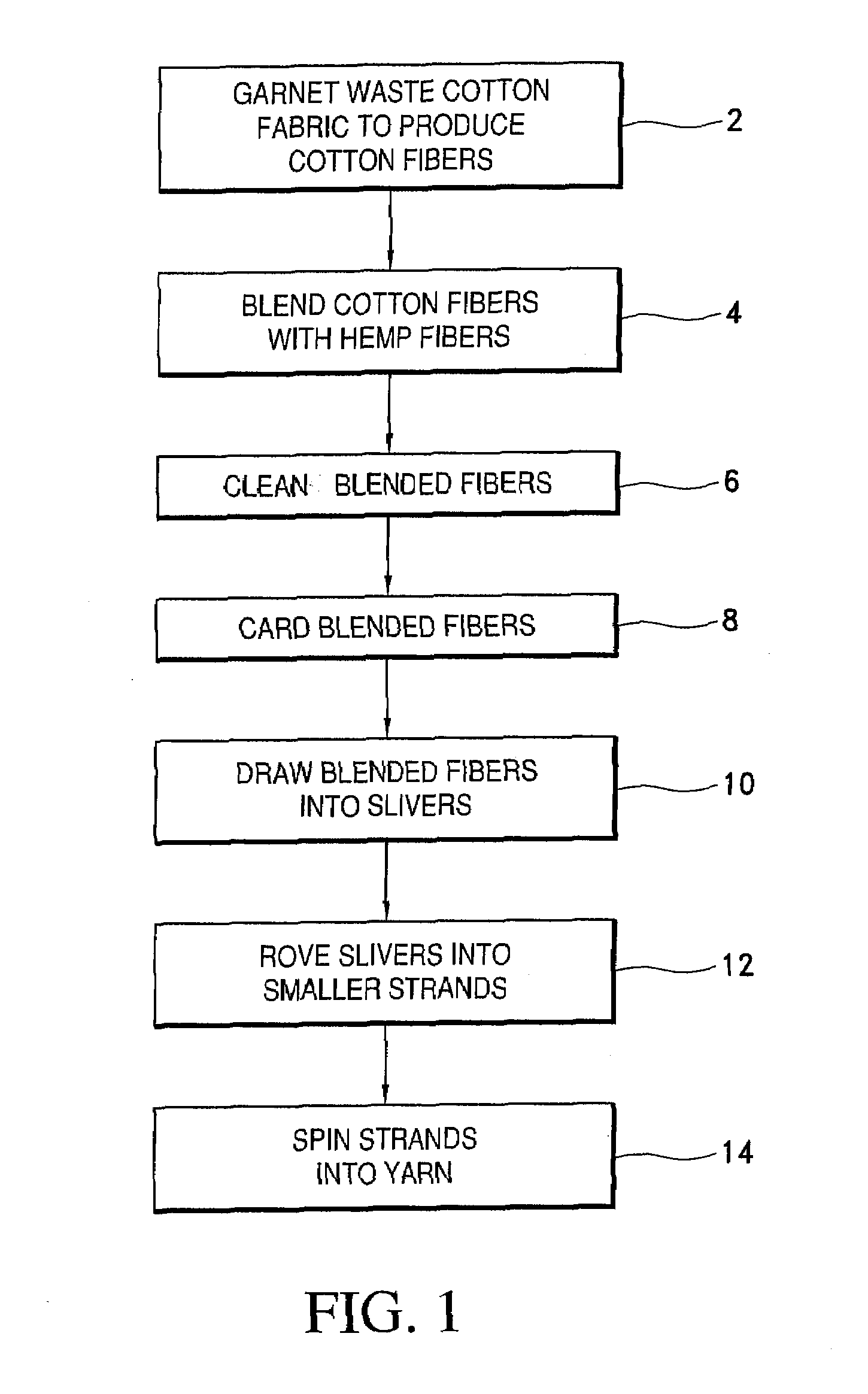

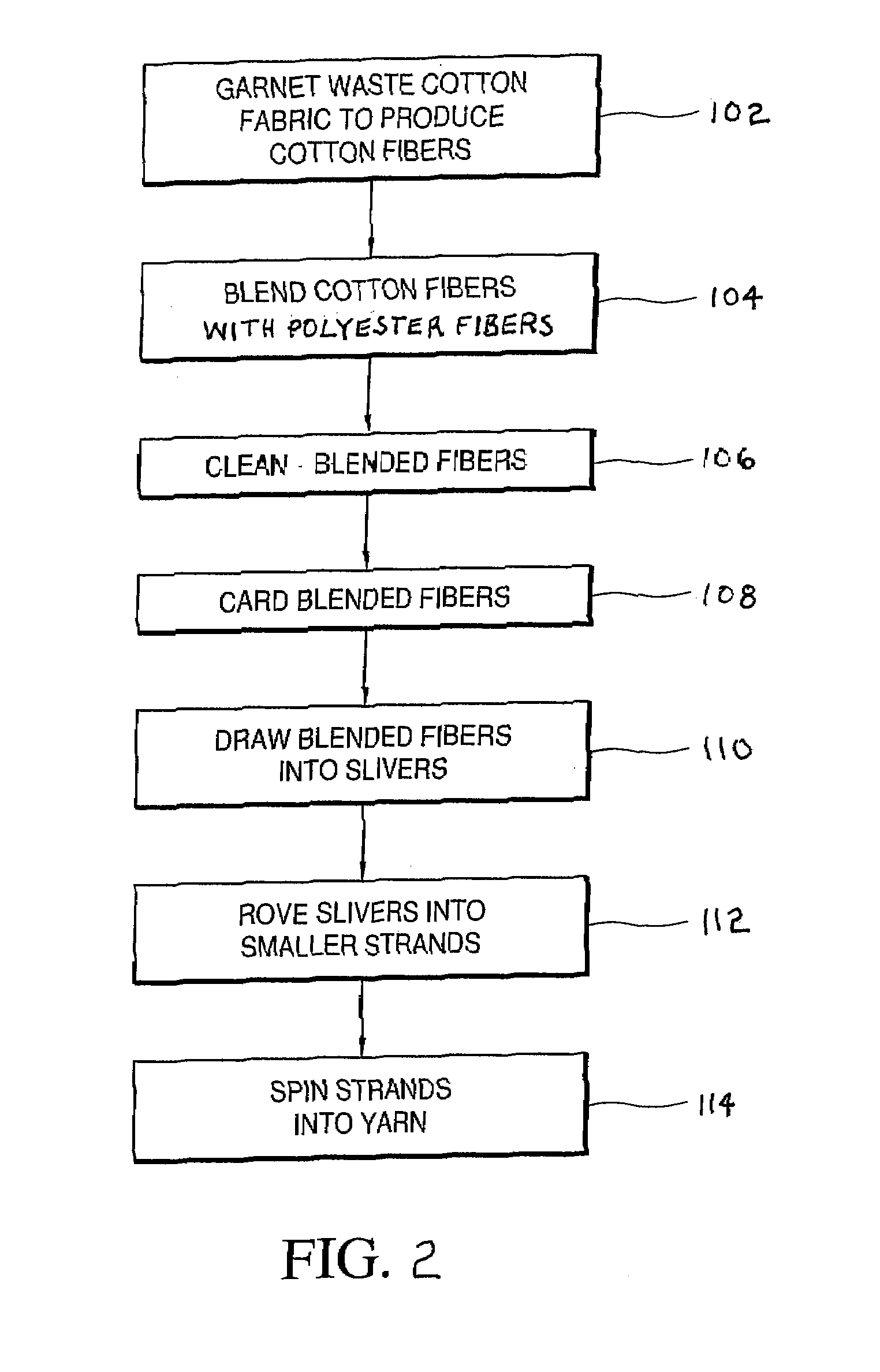

Composite cotton and polyester yarn and method for making same

InactiveUS20090173055A1Reduce impurityFibre mixingTextile disintegration and recoveryCotton fibrePolyester

A composite polyester and cotton yarn is formed by blending polyester fibers with cotton fibers which have been regenerated from waste cotton material such as trimmings and cuttings from the apparel manufacturing industry. The fibers are cleaned and blended, then carded to align the fibers into strands. Depending on the size and texture of the desired yarn, the fibers are stretched and drawn into slivers prior to spinning to join the fibers together. The polyester fibers are preferably recycled polyethylene terephthalate fibers which are up to three time longer than the regenerated cotton fibers, so that the polyethylene terephthalate fibers overlap and braid onto the regenerated cotton fibers during spinning. The resultant yarn is stronger and more absorbent than yarns made solely out of regenerated cotton fibers. The yarn is suitable for producing woven or knit fabric for the production of colorful and functional clothing and home textiles without the need for further bleaching or dyeing.

Owner:SILVER SCOTT

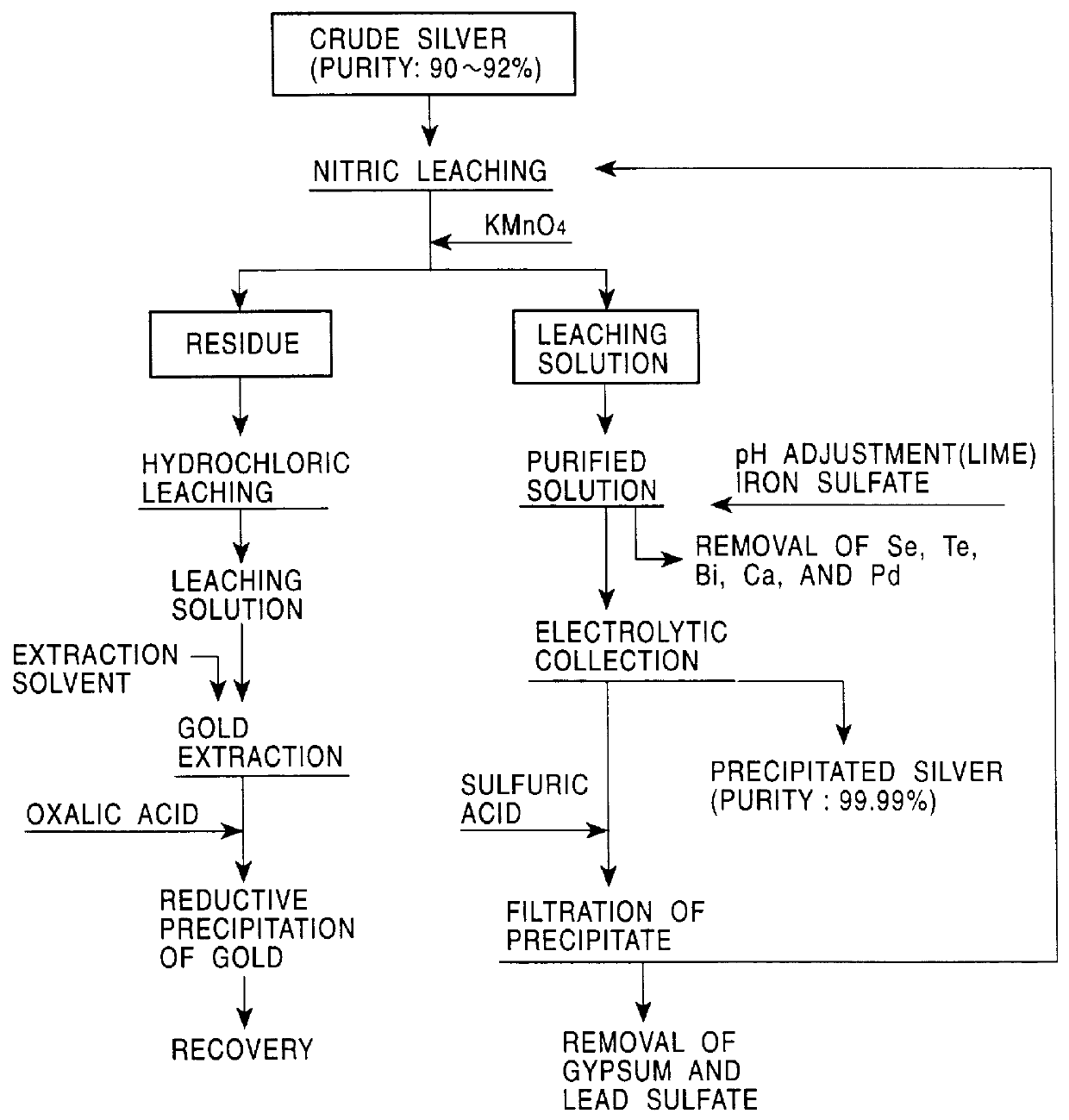

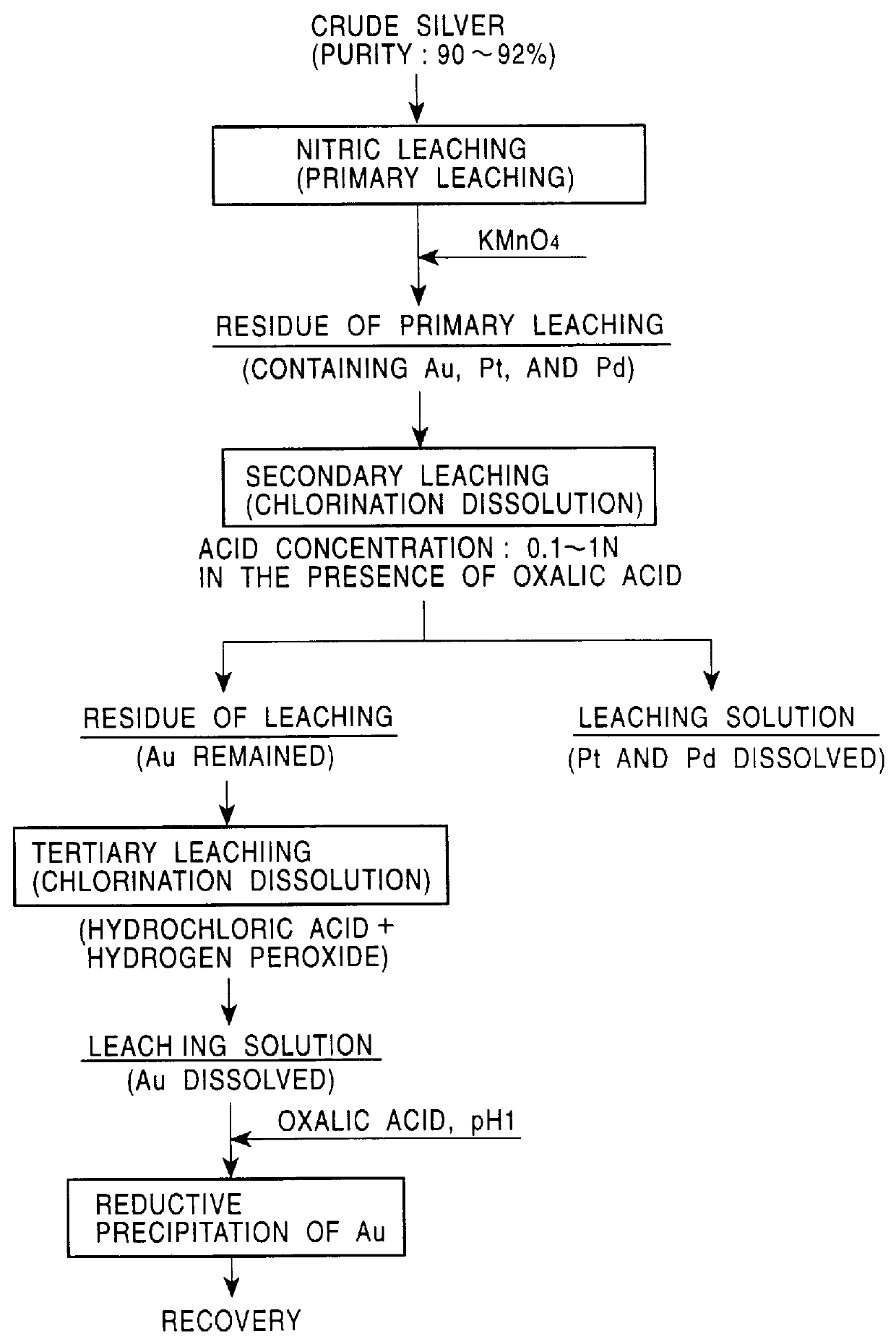

Method for smelting noble metal

InactiveUS6126720AShorten the timeReduce impurityPhotography auxillary processesSolvent extractionDecompositionMaterials science

PCT No. PCT / JP98 / 02479 Sec. 371 Date Jan. 15, 1999 Sec. 102(e) Date Jan. 15, 1999 PCT Filed Jun. 4, 1998 PCT Pub. No. WO98 / 58089 PCT Pub. Date Dec. 23, 1998A method for refining noble metals has a silver treating process including a nitric acid leaching step of silver, a purification step of the leaching solution, an electrolytic decomposition step of silver, and a recycling step after the electrolytic decomposition, wherein in the purification step, lime is added in order to precipitate the metallic impurities, such as selenium, tellurium, bismuth, and copper, by neutralization of the leaching solution, and in the recycling step, sulfuric acid is added to the solution after electrolytic decomposition to regenerate nitric acid for recycling use by precipitation of calcium in the solution as gypsum. Preferably, the refining method has a gold recovery process, as well as the silver treating process, wherein the residue of the nitric leaching of the crude silver is dissolved by chlorination and gold is recovered from the leaching solution by solvent extraction or reductive precipitation. High purity gold and silver can be readily obtained, and the refining time for gold is significantly shorter than that in conventional methods.

Owner:MITSUBISHI MATERIALS CORP

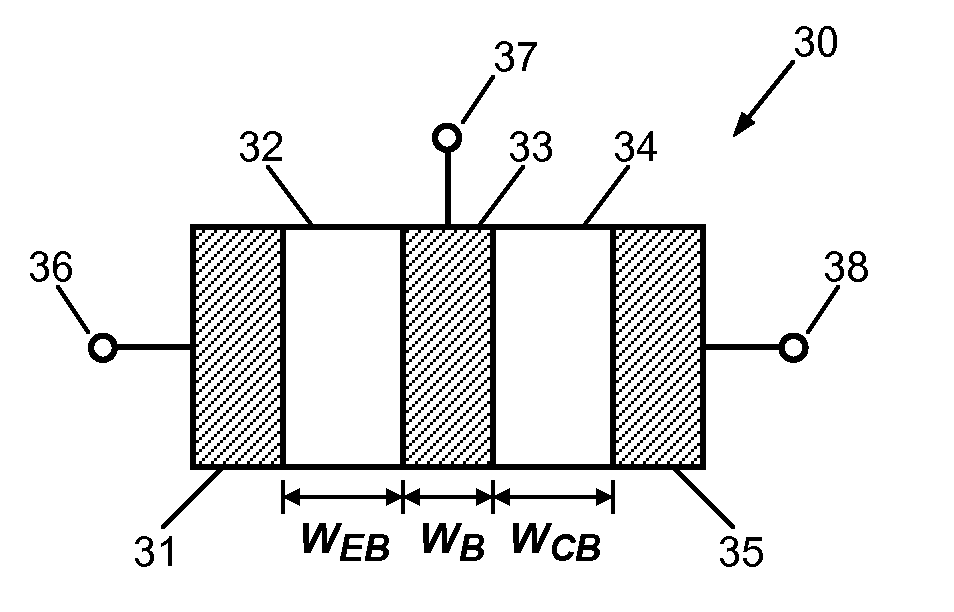

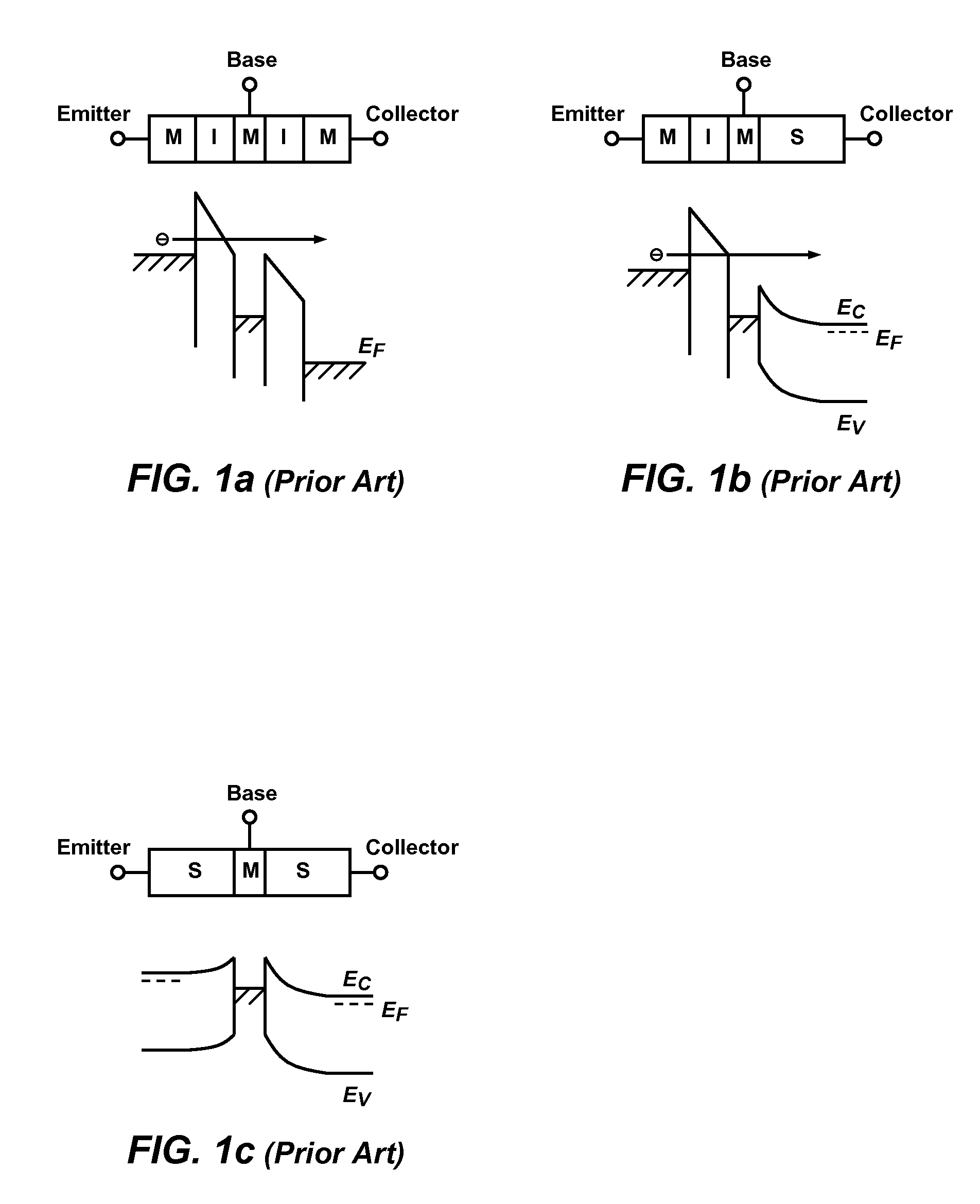

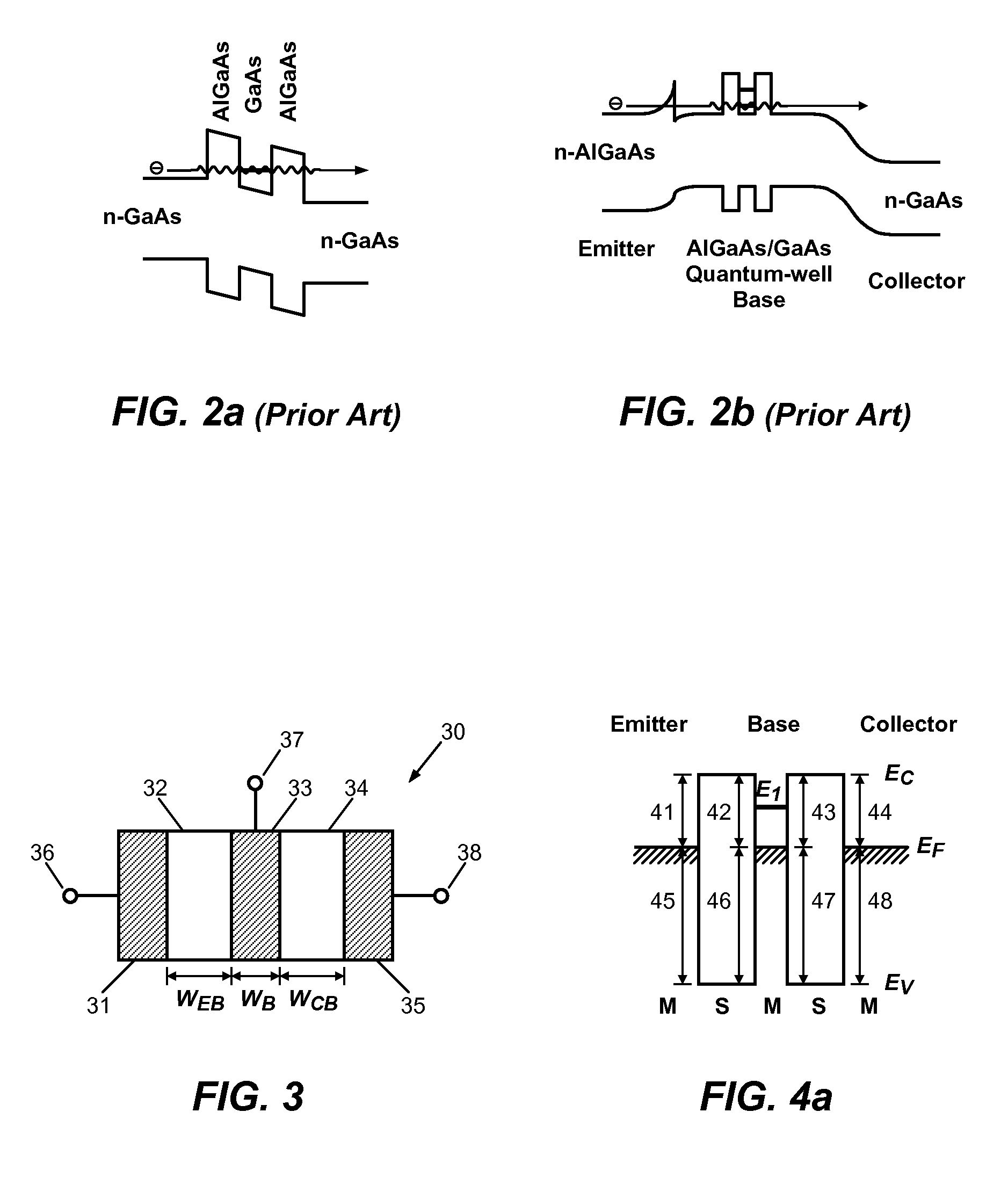

Schottky barrier quantum well resonant tunneling transistor

InactiveUS20100102298A1High speedReduce series resistanceTransistorSolid-state devicesQuantum wellSchottky barrier

A semiconductor transistor device includes one or more conductive base regions, a first semiconductor barrier region, a second semiconductor barrier region, a conductive emitter region, and a conductive collector region. The first semiconductor barrier region or the second semiconductor barrier region has a dimension smaller than 100 Å. A first Schottky barrier junction is formed at the interface of the first semiconductor barrier region and the one or more conductive base regions. A second Schottky barrier junction is formed at the interface of the second semiconductor barrier region and the one or more conductive base regions. A third Schottky barrier junction is formed at the interface of the conductive emitter region and the first semiconductor barrier region. A fourth Schottky barrier junction is formed at the interface of the conductive collector region and the second semiconductor barrier region.

Owner:WU KOUCHENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com