Sugarcane combine for cutting into pieces

A combine harvester and section-cutting technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of many auxiliary labor, poor adaptability of sugarcane, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

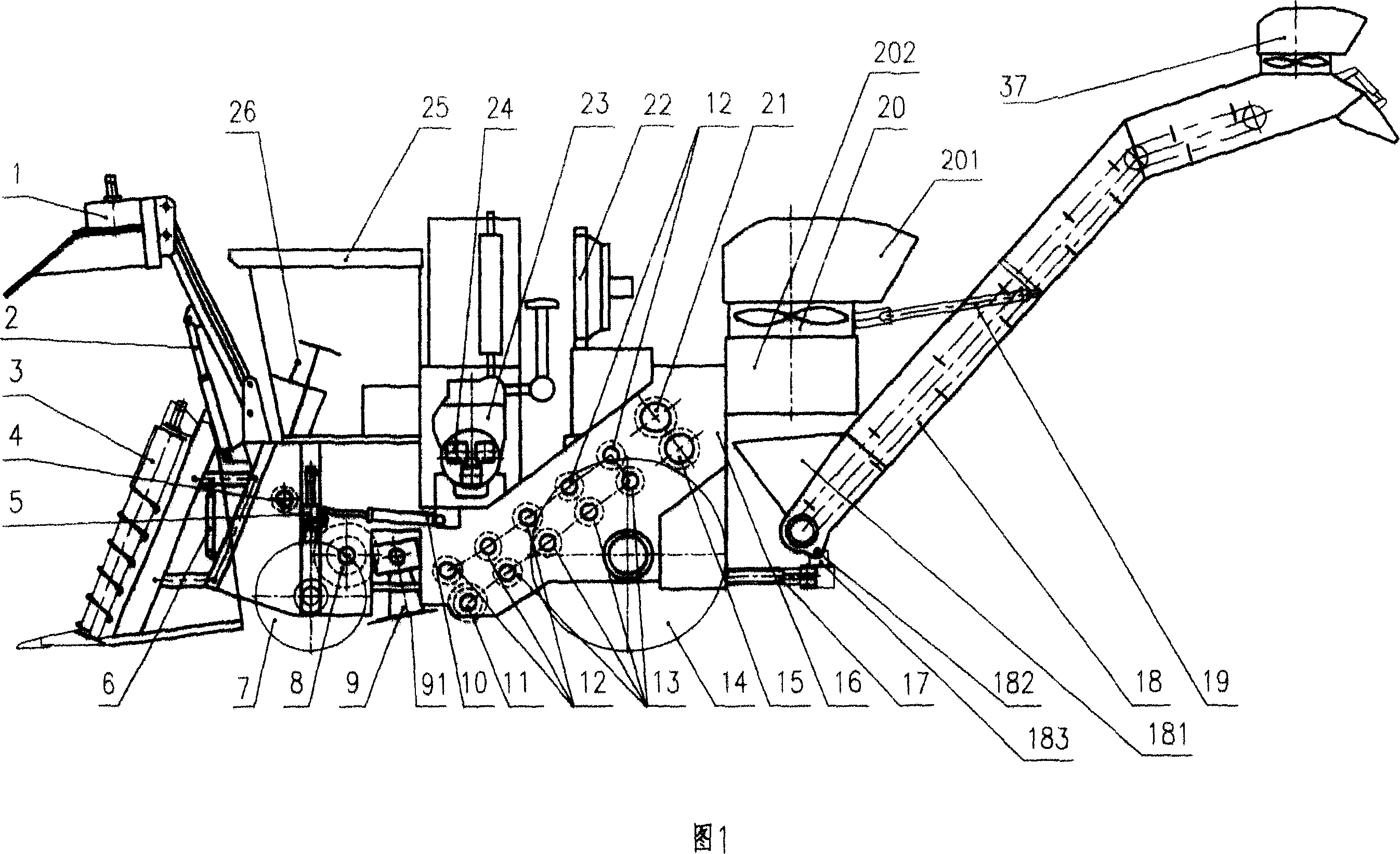

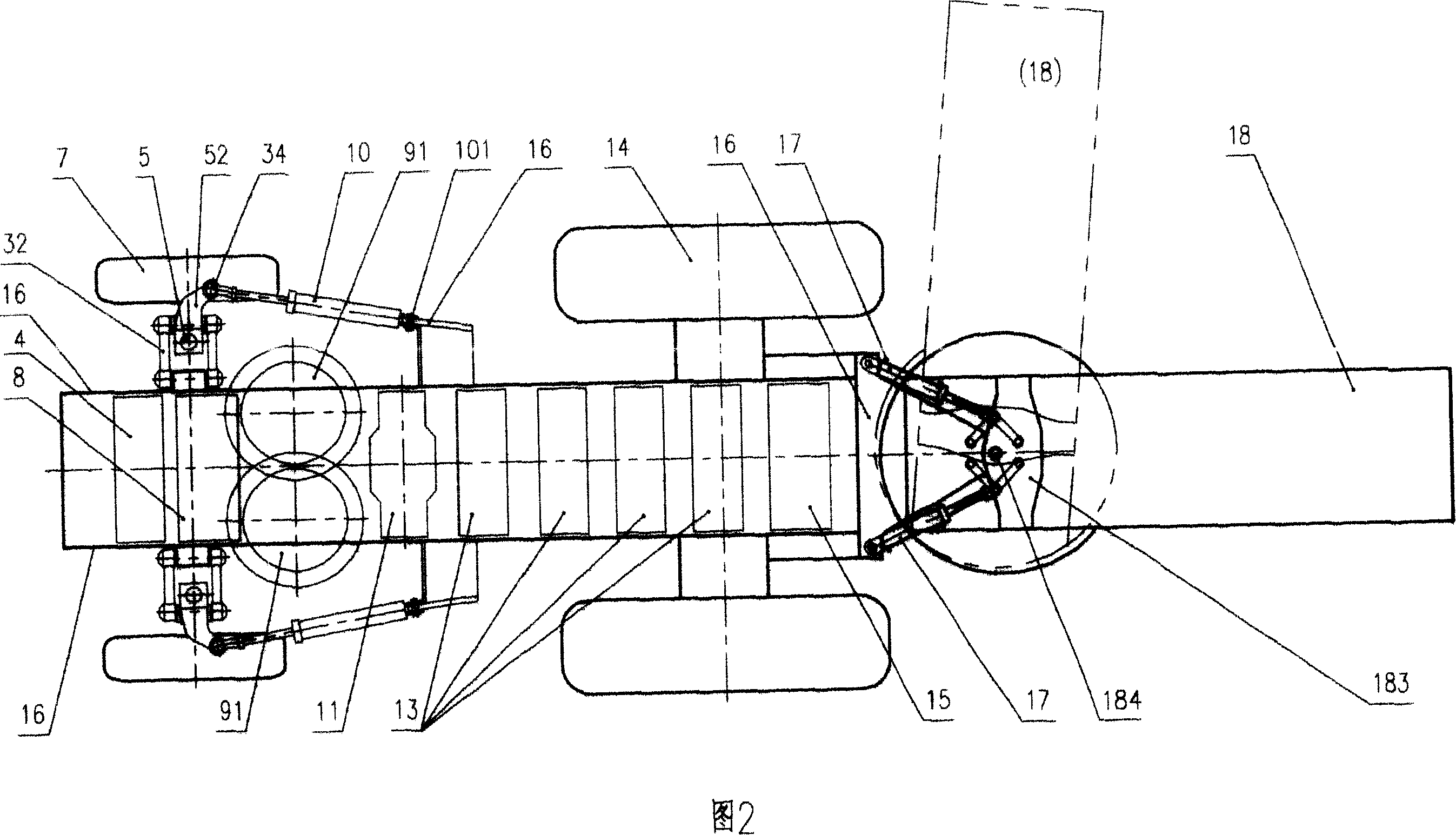

[0036] When embodiment 1 carried out the sugarcane harvesting operation, engine 23 drives the work of several hydraulic pumps 24, and hydraulic pump 24 sucks hydraulic oil from oil tank 22, and the hydraulic oil of hydraulic pump 24 output is distributed to each hydraulic motor and oil cylinder through hydraulic control system 26, Return to the oil tank 22 at last, when the hydraulic motor is not working, the hydraulic oil directly returns to the oil tank 22. The driver of the harvester can control the walking of the harvester by operating the hydraulic system 26, and manipulate the left and right steering cylinders 10 through the steering gear to control the steering of the harvester. The driver of the harvester can start or stop the action of each working part by operating the hydraulic system. When working, the harvester works across the rows and walks directly against the sugarcane row. The walking wheels walk on the open space between the sugarcane rows. As the harvester w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com