Patents

Literature

222results about How to "Reduce water usage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

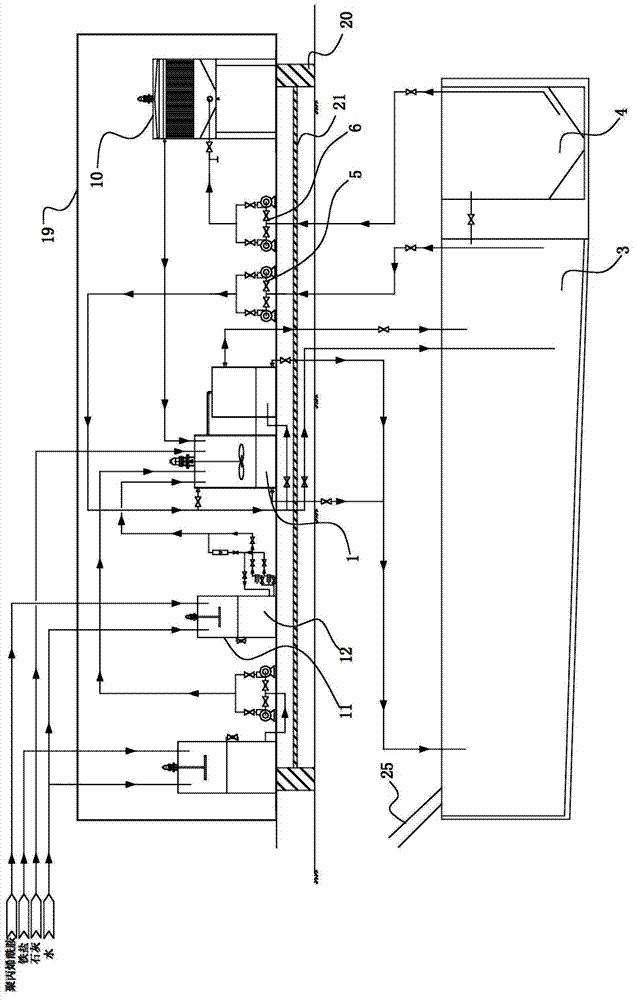

Real-time dynamic 3D water balance monitoring system of power plant and working method of system

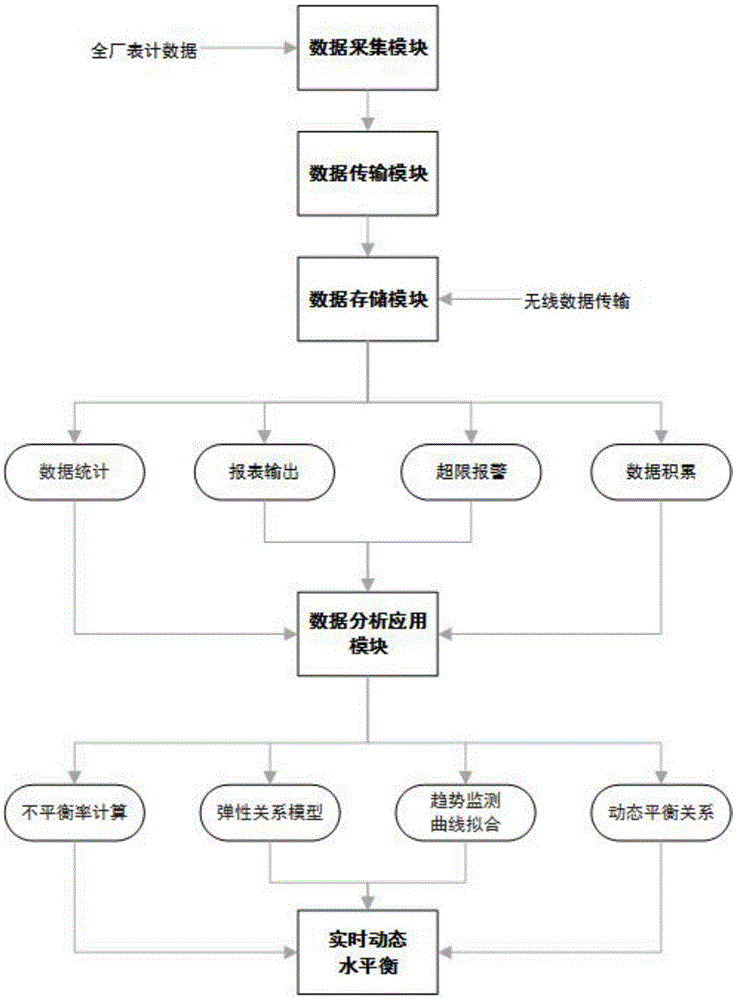

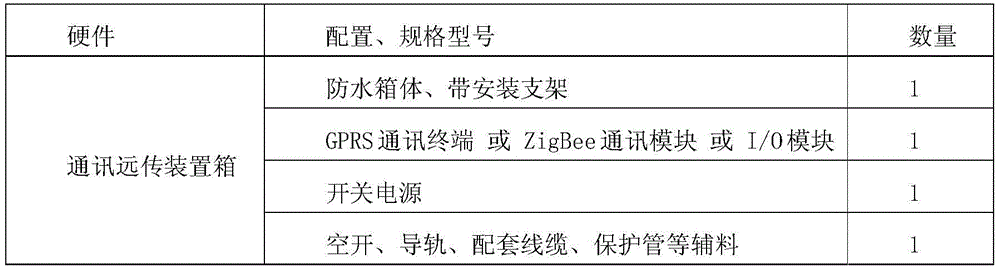

InactiveCN105549557AEffective monitoringEfficient managementTotal factory controlProgramme total factory controlWater balanceApplication module

The invention relates to a real-time dynamic 3D water balance monitoring system of a power plant and a working method of the system. The system is characterized by comprising a data collection module, a data transmission module, a data storage module, a monitoring center and a data analysis and application module, wherein the data collection module collects flow data, and the data transmission module returns data collected by the data collection module in real time. Water volume data of different collection points is collected by the data collection module, transmitted to the data storage module by the data transmission module, and further transmitted to the data analysis and application module by the data storage module. The system and method have the advantages that the relation between water volume change and generating load is found via data analysis, the imbalance rate is calculated, and thus, scientific basis is provided for planning water-saving measures of the power plant.

Owner:TIANJIN AOLANG NEW ENERGY RESOURCES & TECH CORP

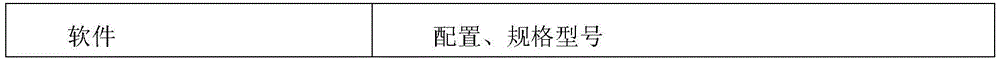

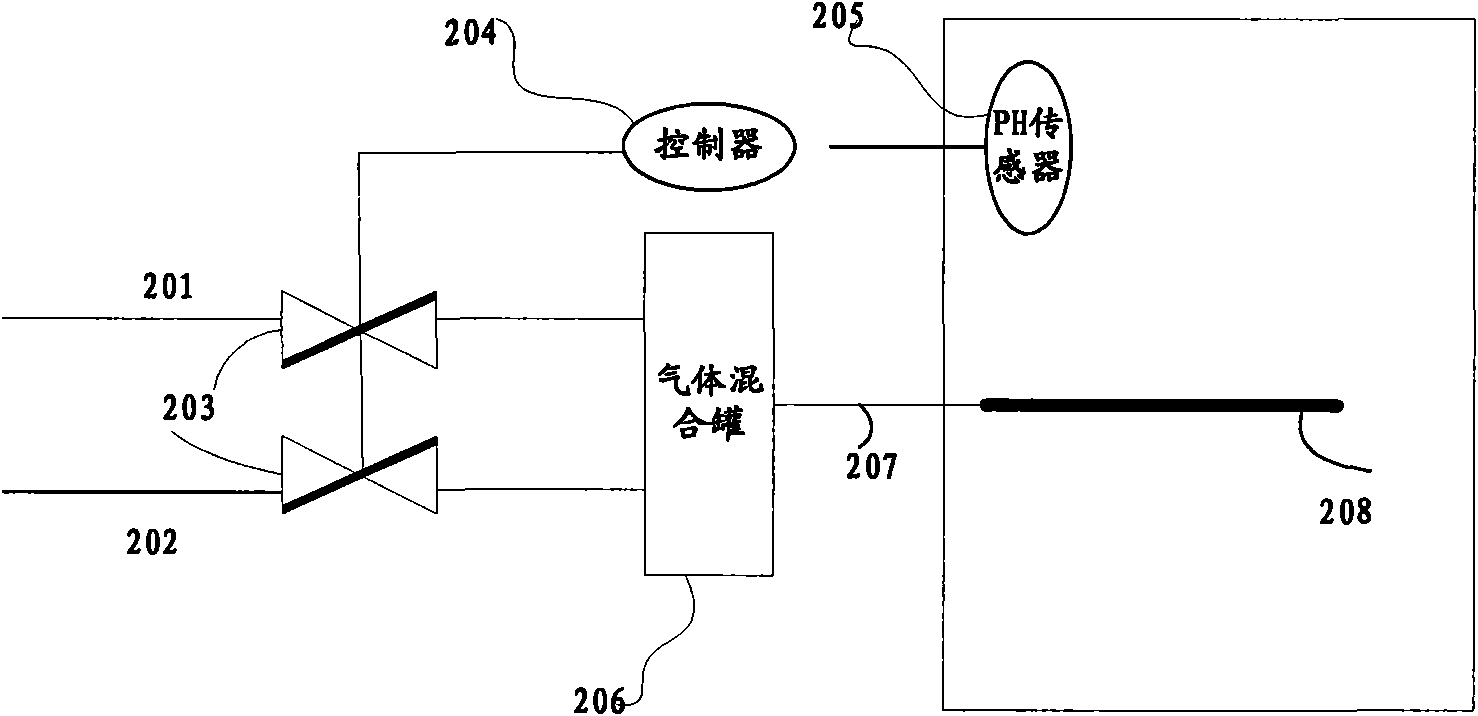

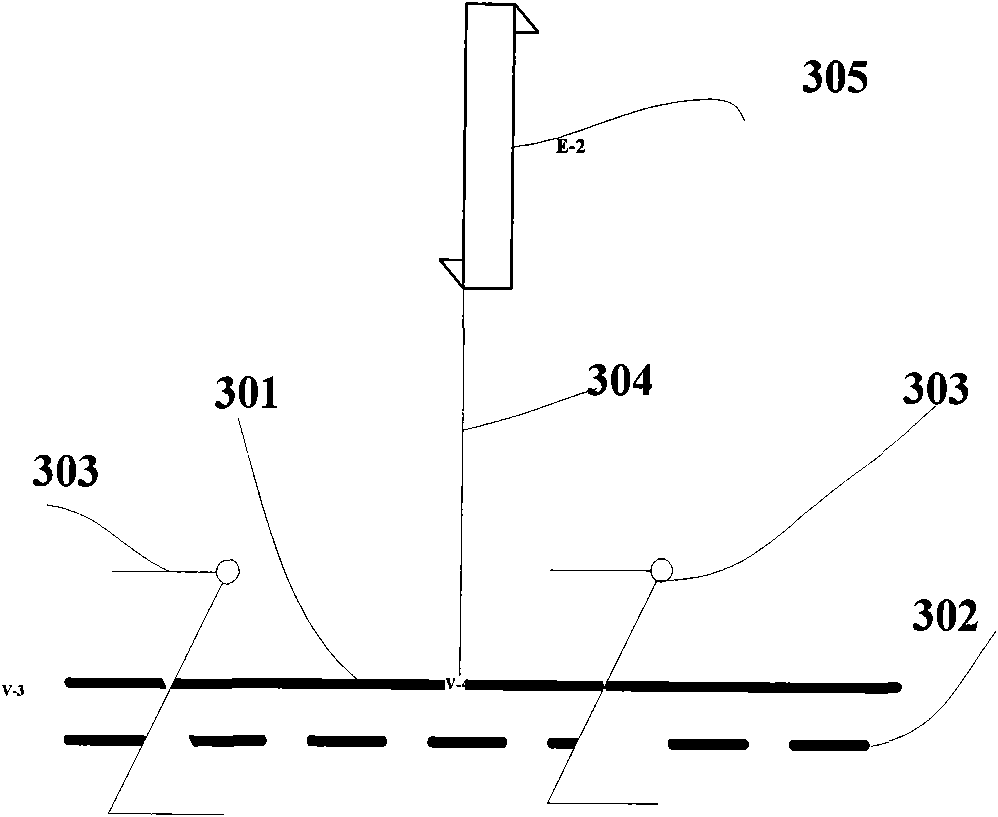

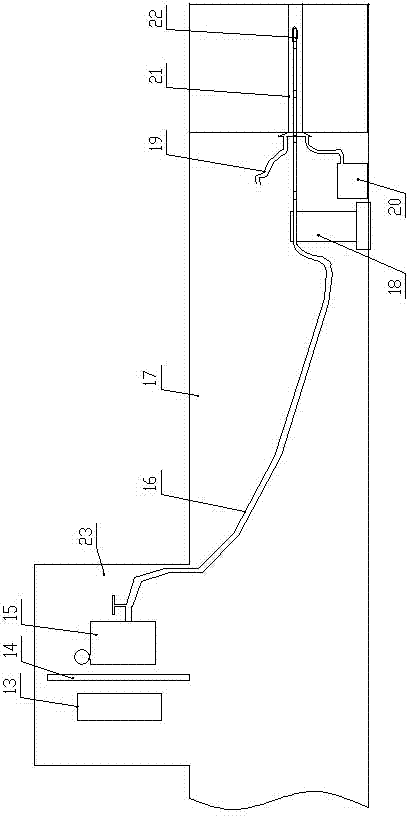

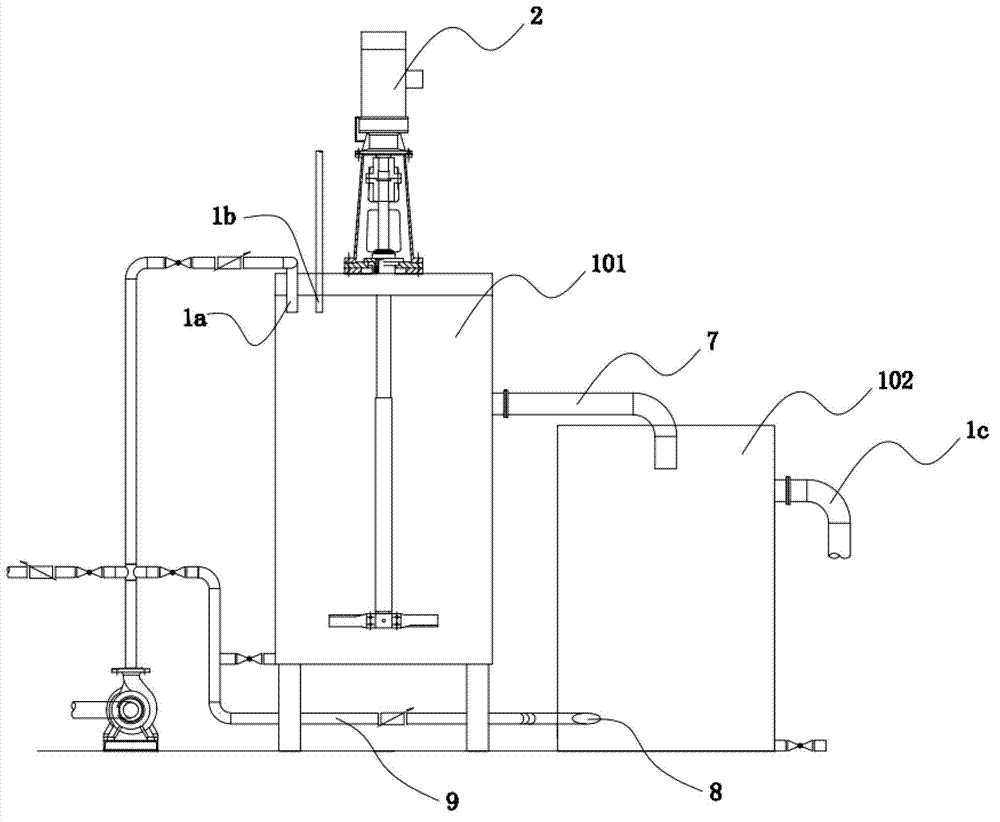

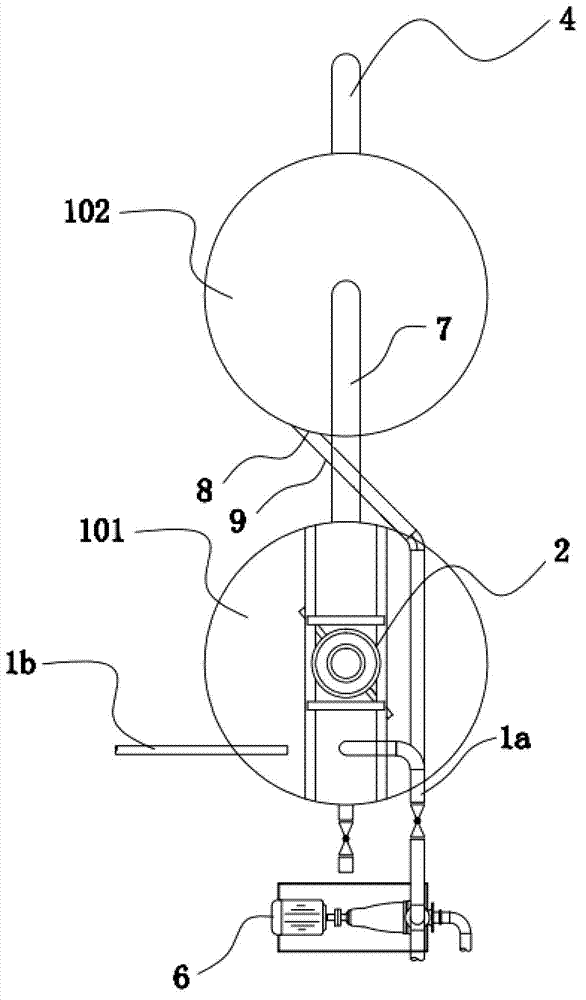

Culture/harvesting method of microalgae and system

ActiveCN101555455ASuitable for collectionIncrease contact areaBioreactor/fermenter combinationsBiological substance pretreatmentsEcologyAir bubble

The invention discloses a culture / harvesting method of microalgae and a system, which are used for solving the problems that in the prior art, when the microalgae is cultured, the utilization ratio of CO2 is low, and when the microalgae is harvested, a gas floatation method has complex steps and high cost. In the growth process of the microalgae, micron-sized bubbles containing CO2 are released to the solution of microalgae in a biological photosynthetic reactor; or micron-sized CO2 bubbles and micron-sized air bubbles are released to the solution of microalgae in the biological photosynthetic reactor; and when the microalgae is harvested, micron-sized air bubbles are released to the solution of microalgae, so as to lead the self-flocculating microalgae to be attached to the micron-sized air bubbles and then suspended on the surface of the solution of microalgae. The adoption of the technical proposal can improve the utilization ratio of CO2 when the microalgae is cultured, improve the yield of the microalgae, and reduce the harvesting steps and cost of the microalgae when the microalgae is harvested.

Owner:ENN SCI & TECH DEV

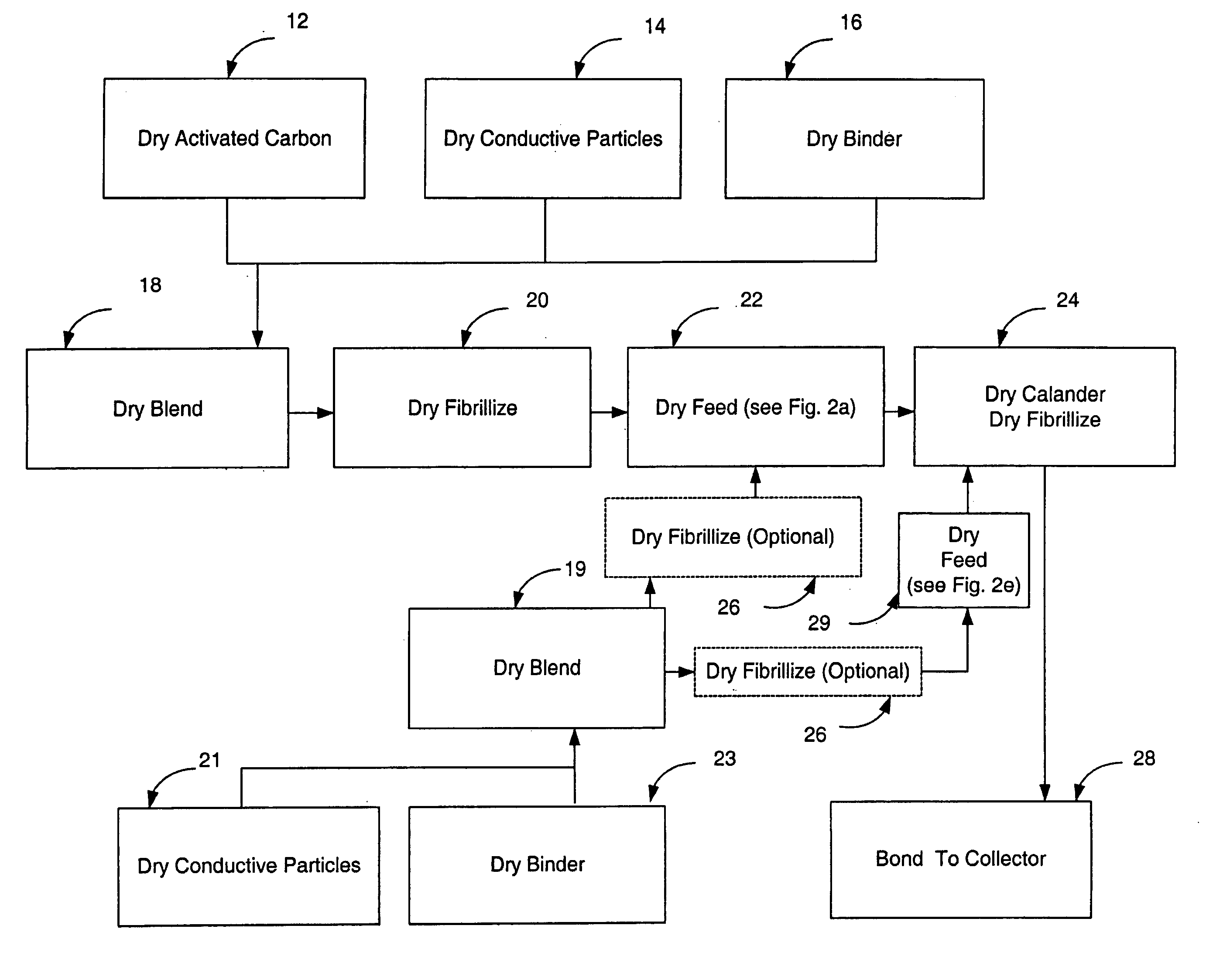

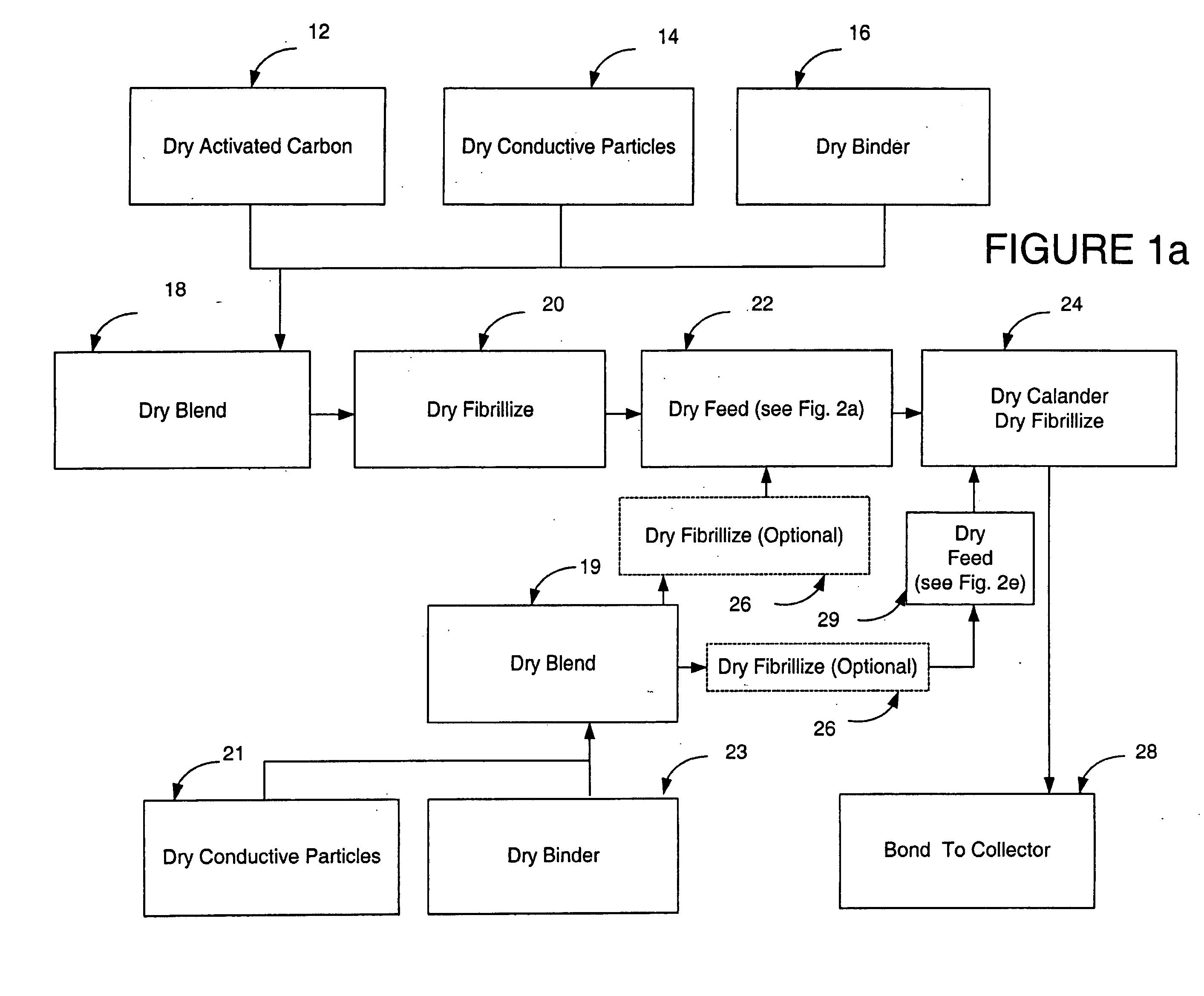

Dry-particle packaging systems and methods of making same

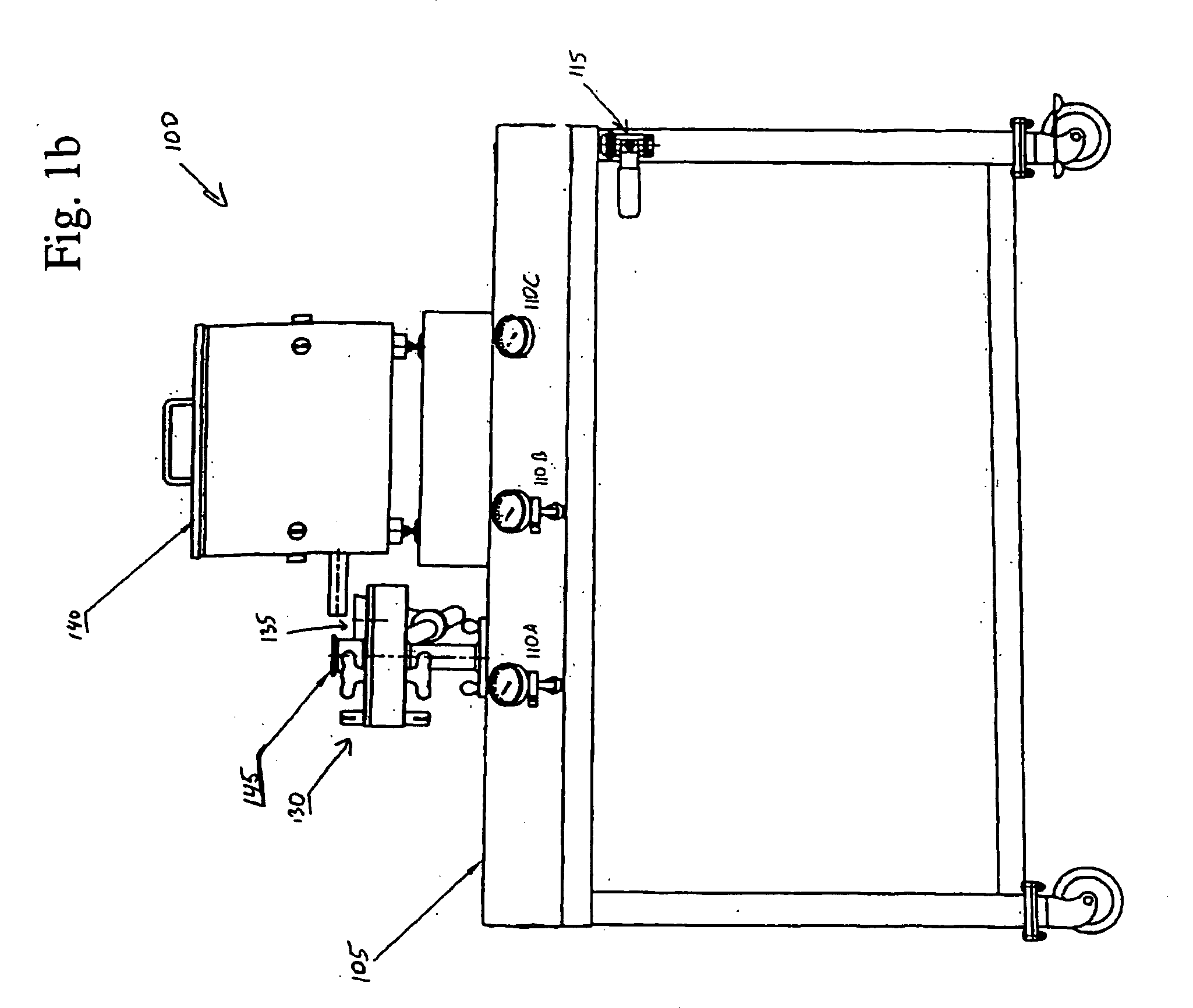

InactiveUS20060137158A1Reduce water usageReduce impurityElectrode rolling/calenderingElectrolytic capacitorsEnergy storageBiochemical engineering

Owner:TESLA INC

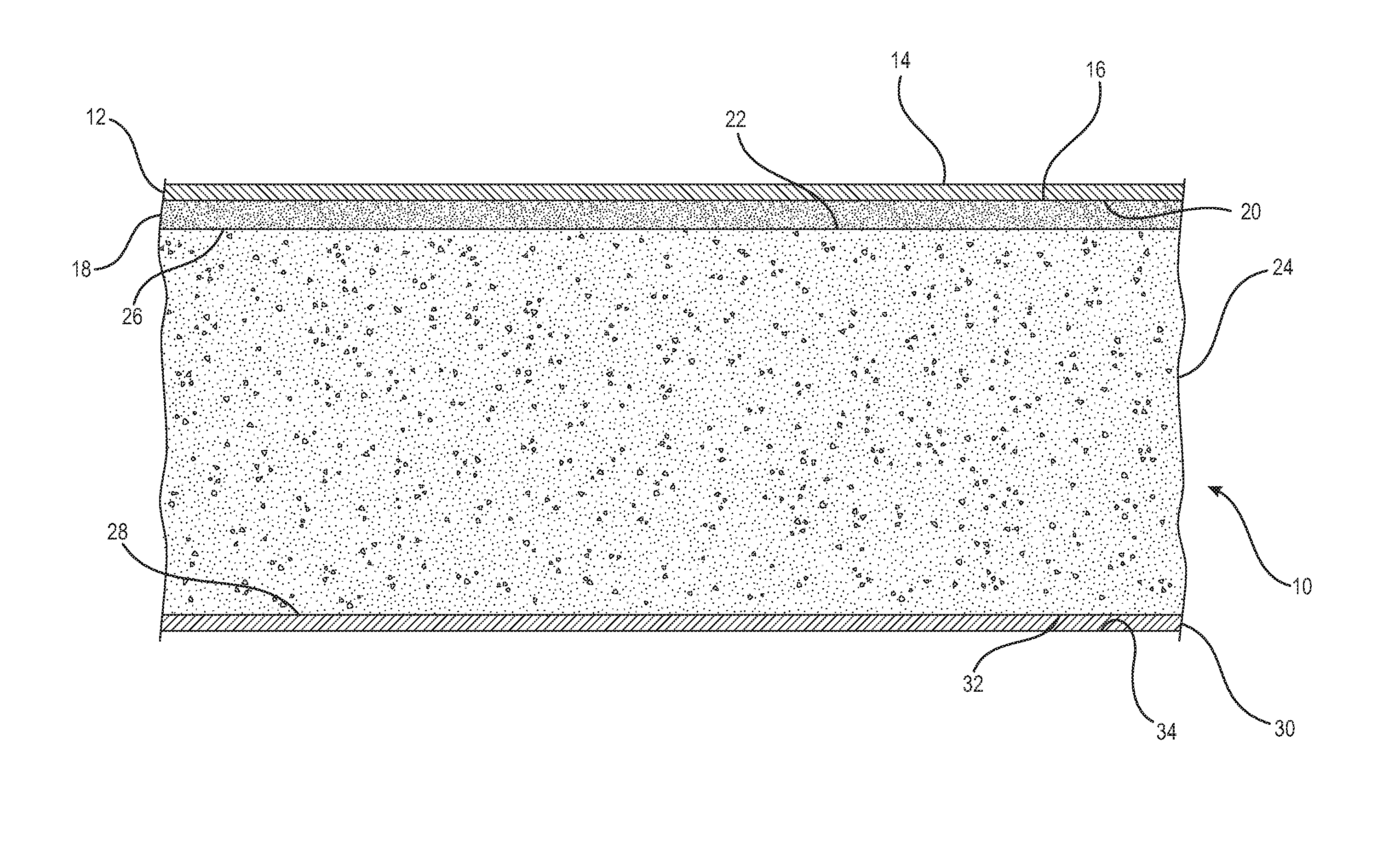

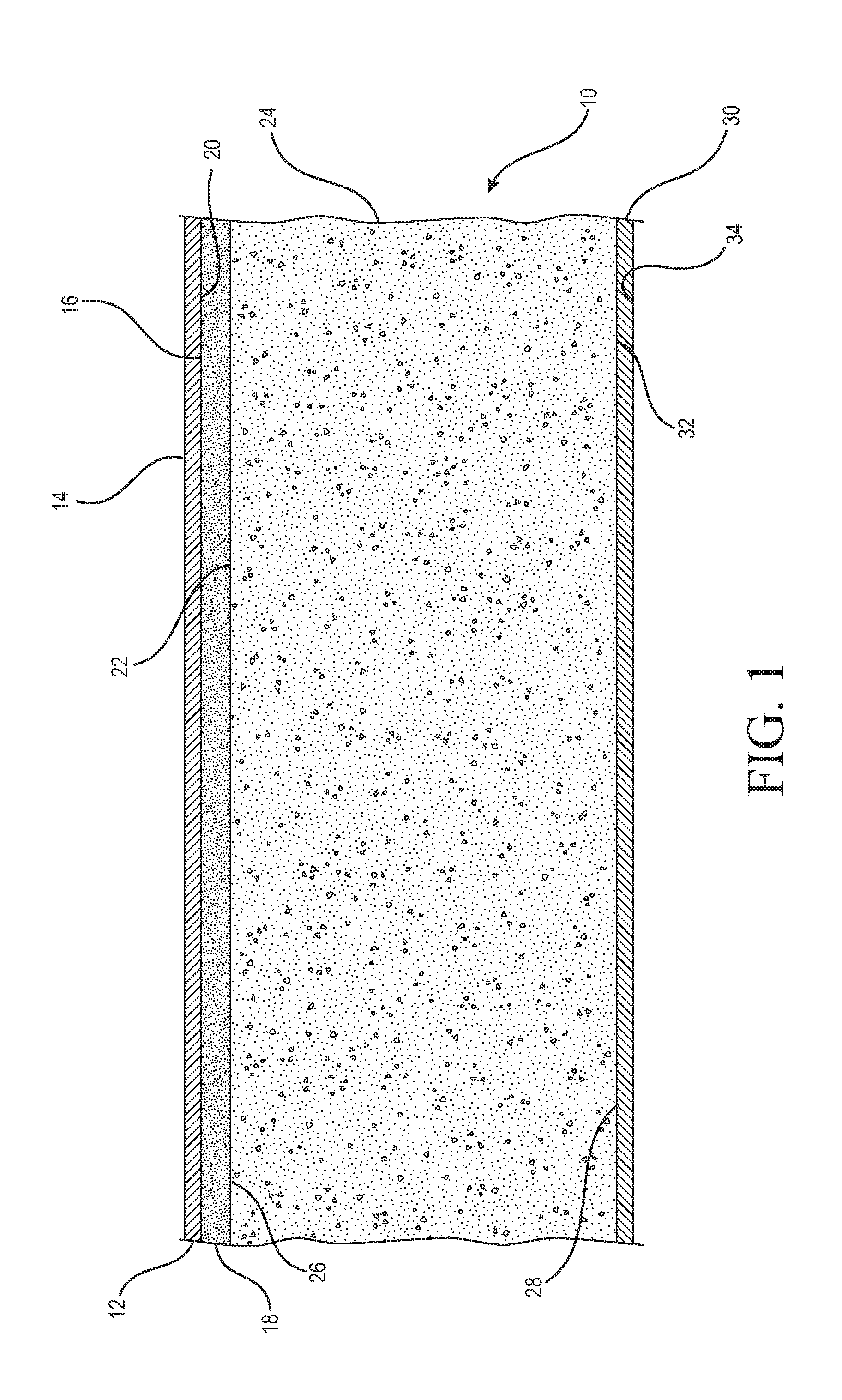

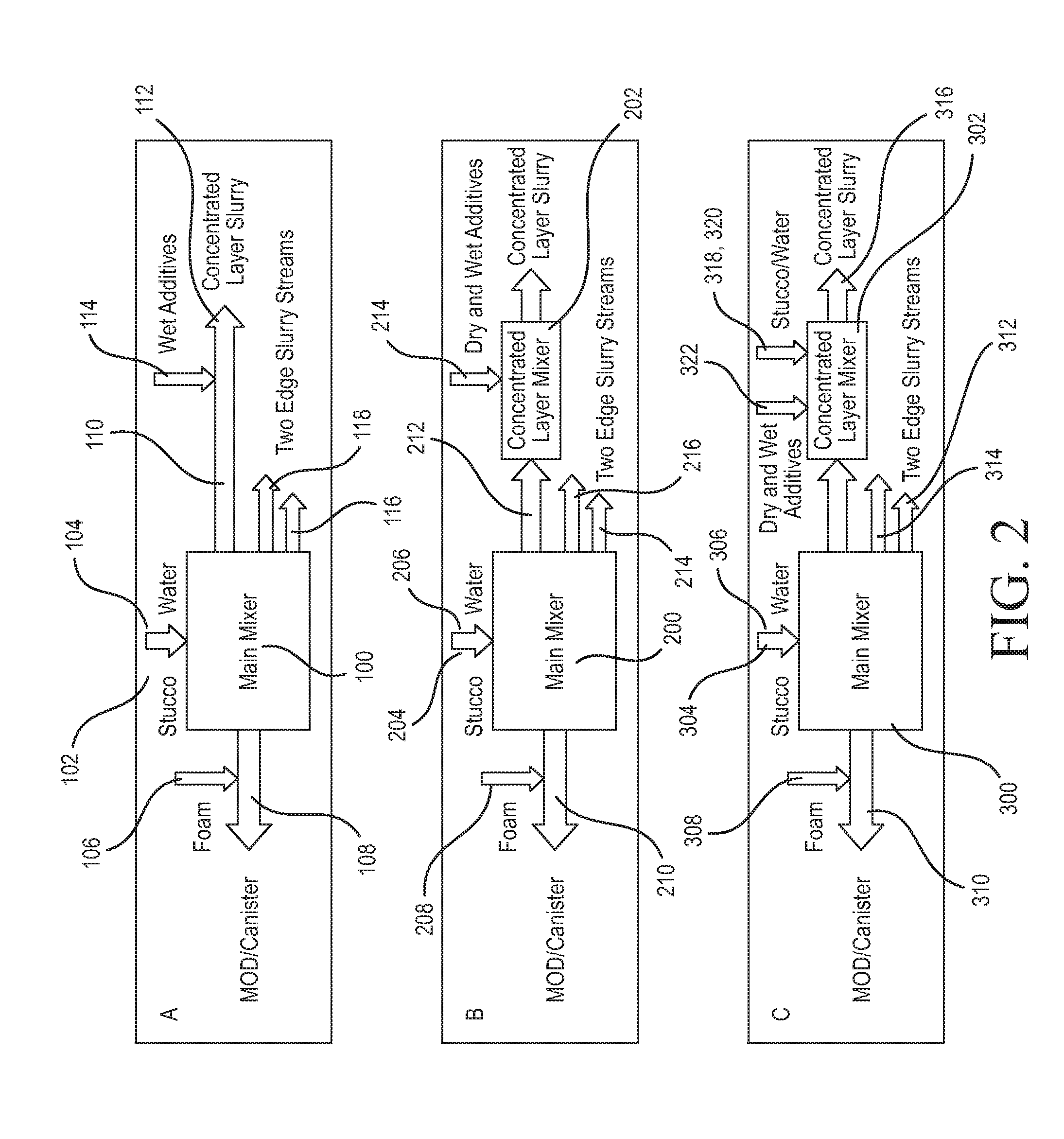

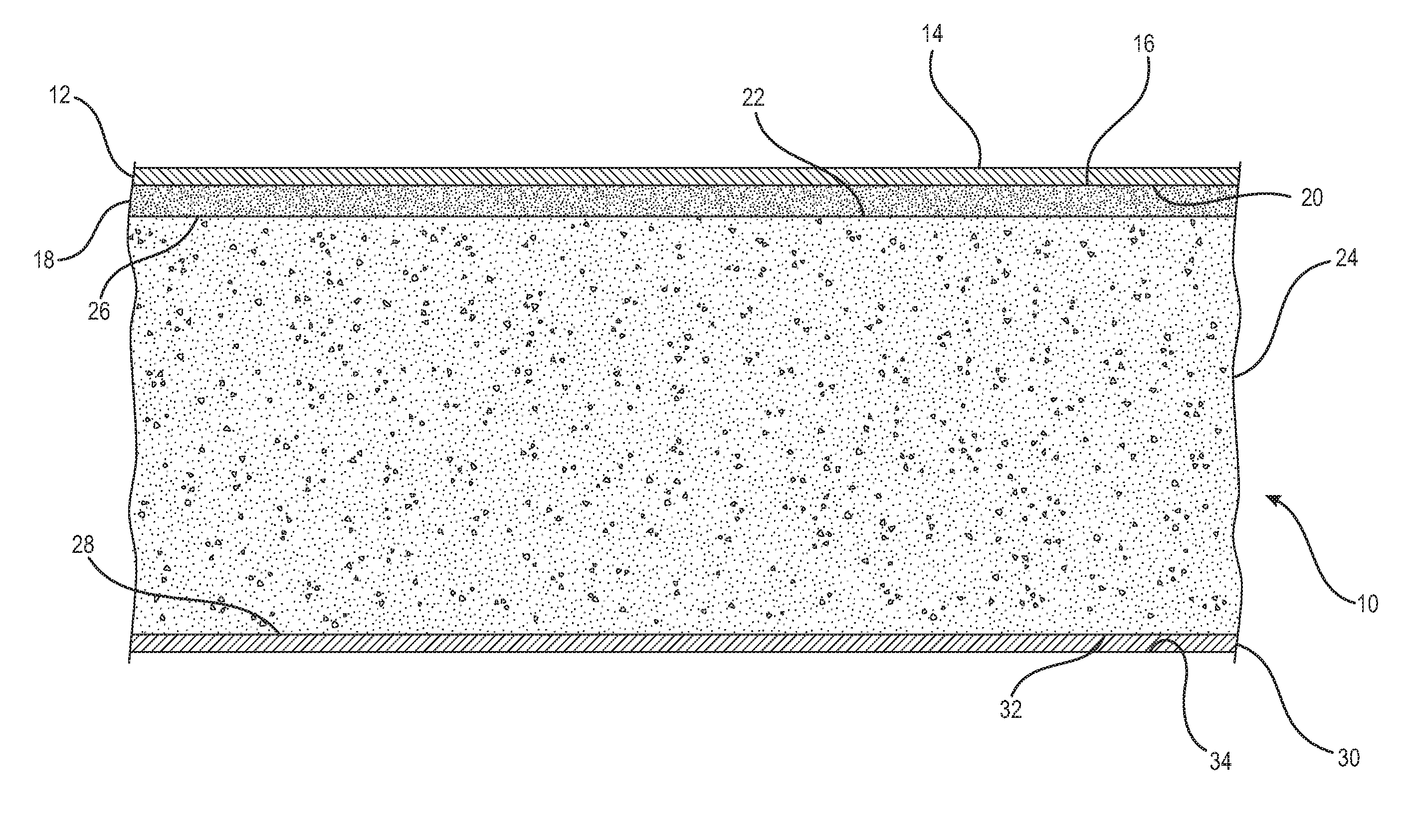

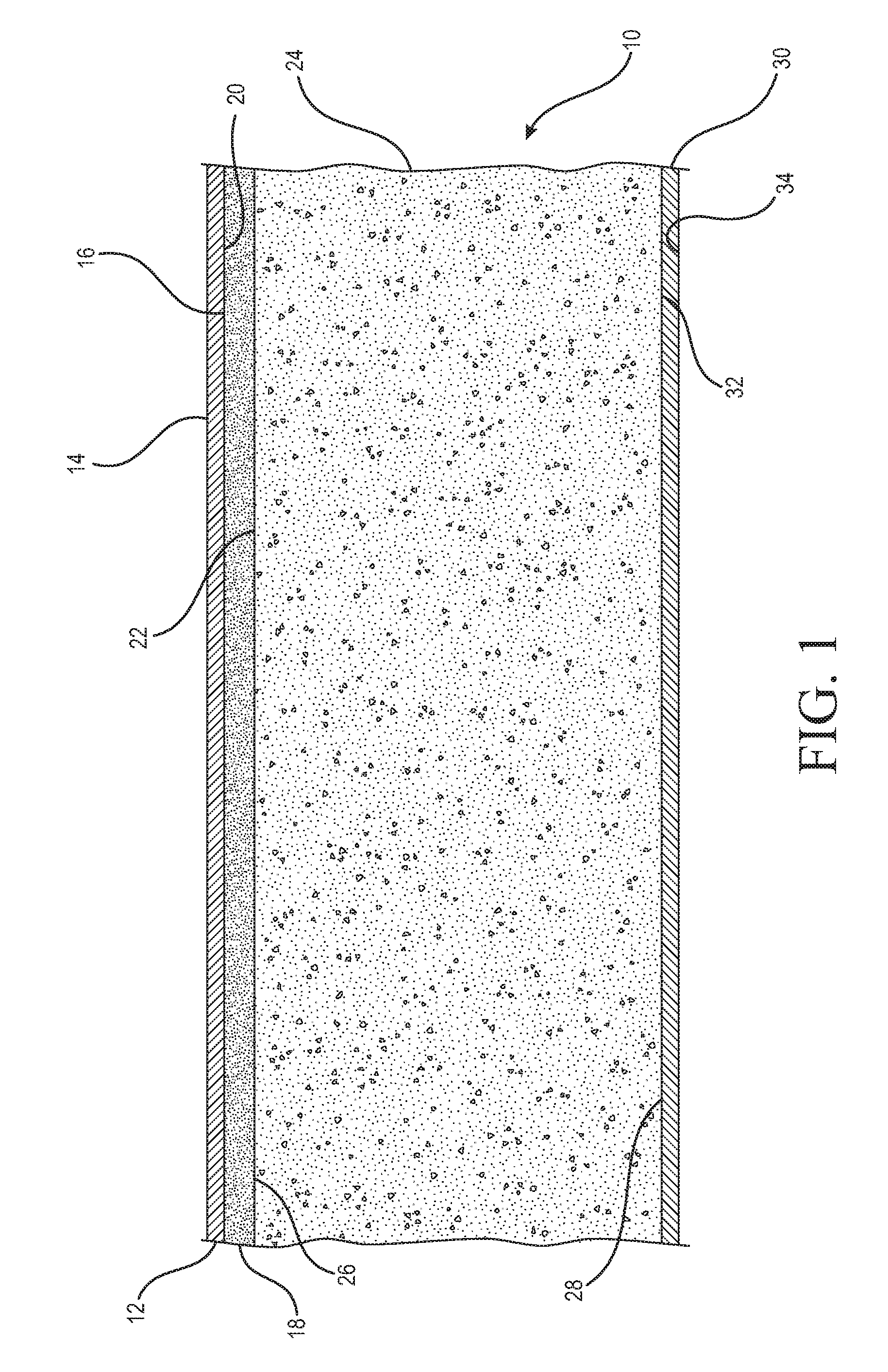

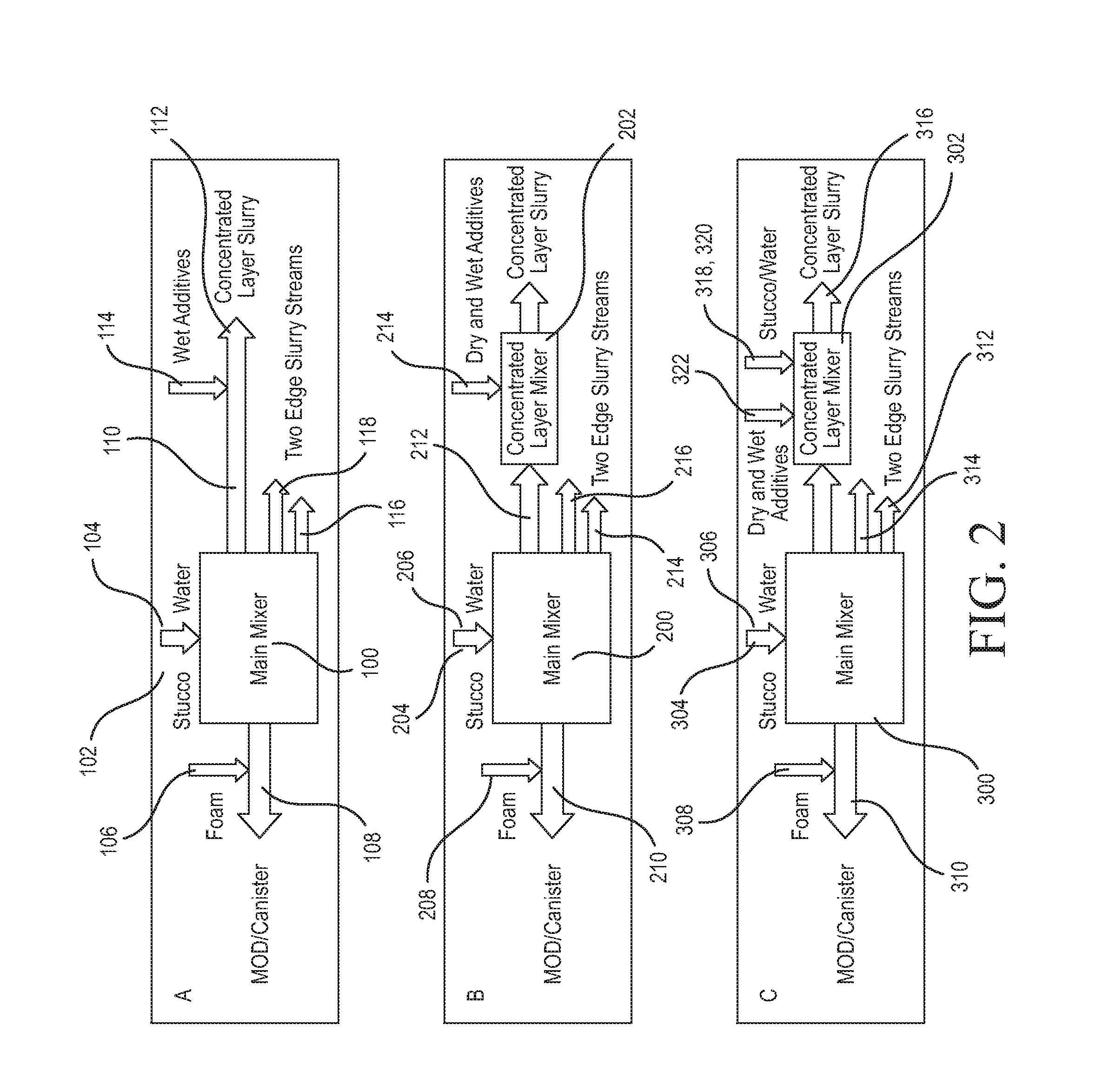

Composite gypsum board and methods related thereto

ActiveUS20160375655A1High weight percentageReduce usageConstruction materialLaminationHigh densityPhysical chemistry

Disclosed is a composite gypsum board comprising a board core and a concentrated layer of substantial thickness (e.g., at least about 0.02 inches). The concentrated layer includes a higher weight percentage of an enhancing additive than the board core. The board core has a thickness greater than the thickness of the concentrated layer and forms the bulk of the board volume. The concentrated layer has a higher density (e.g., at least about 1.1 times greater) than the density of the board core. Also disclosed is a method of preparing a composite gypsum board.

Owner:UNITED STATES GYPSUM CO

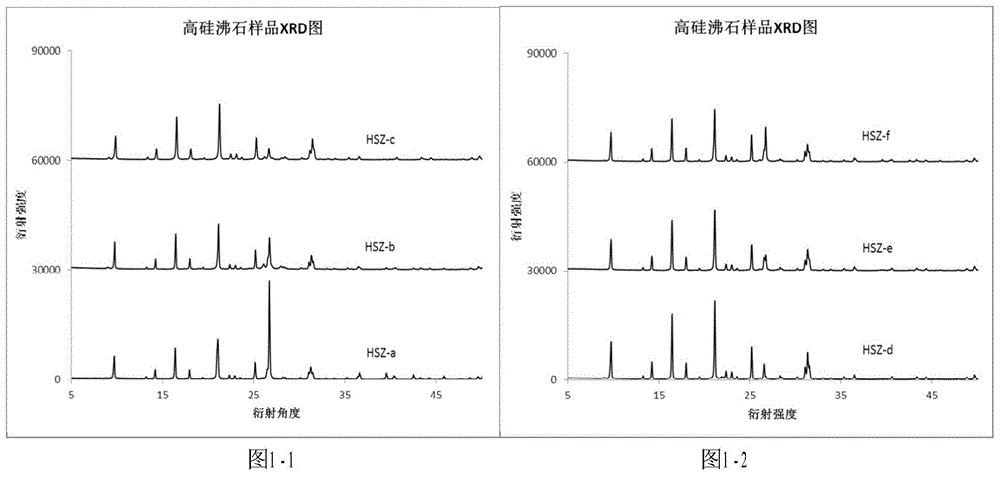

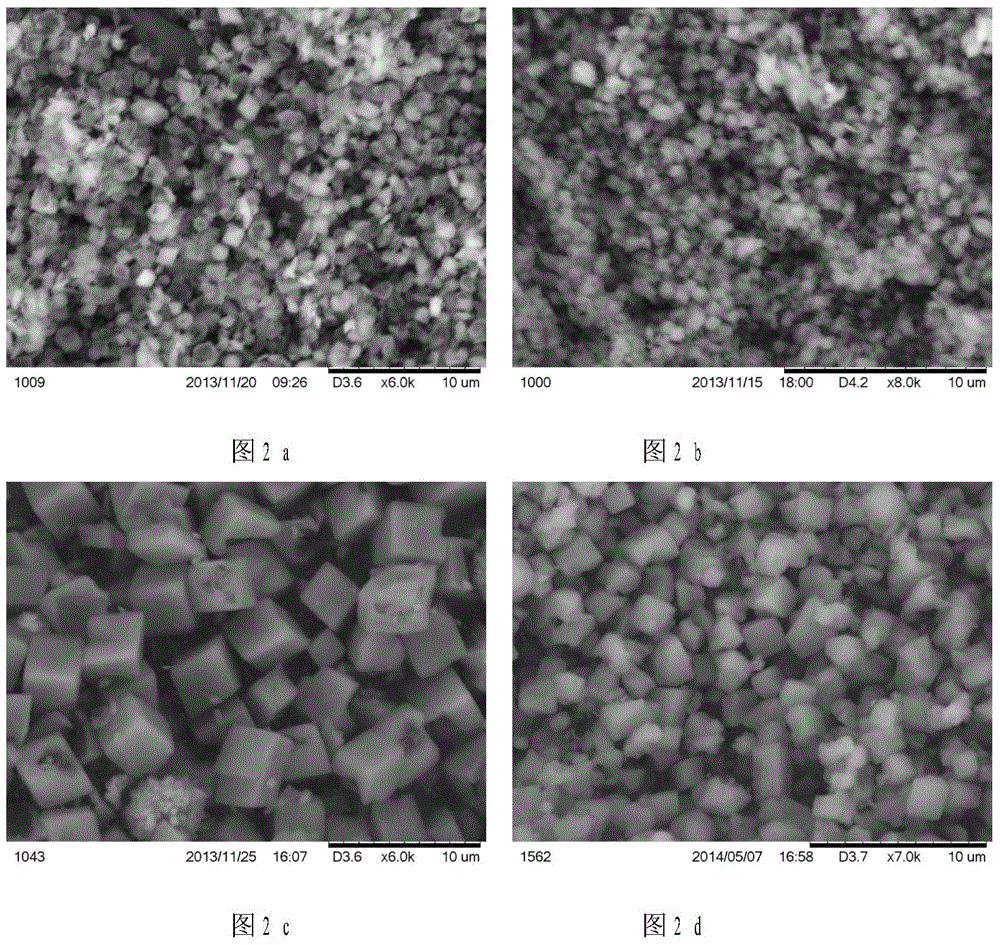

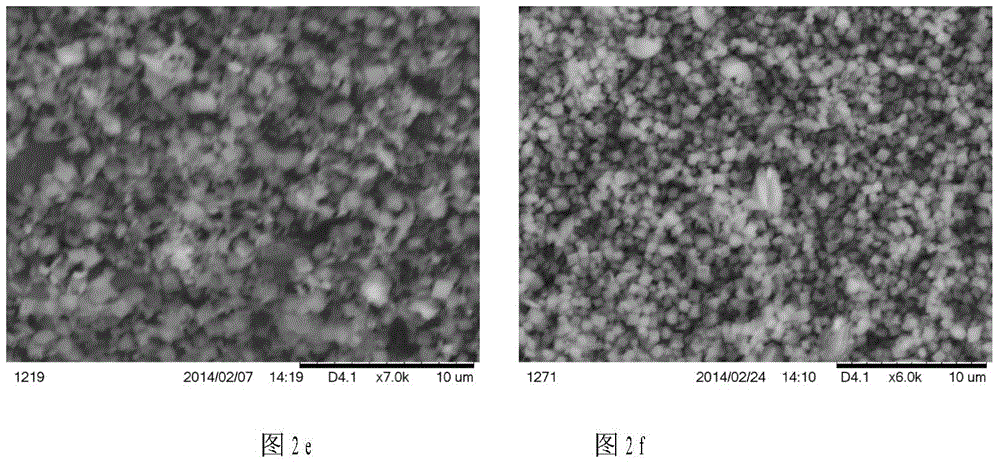

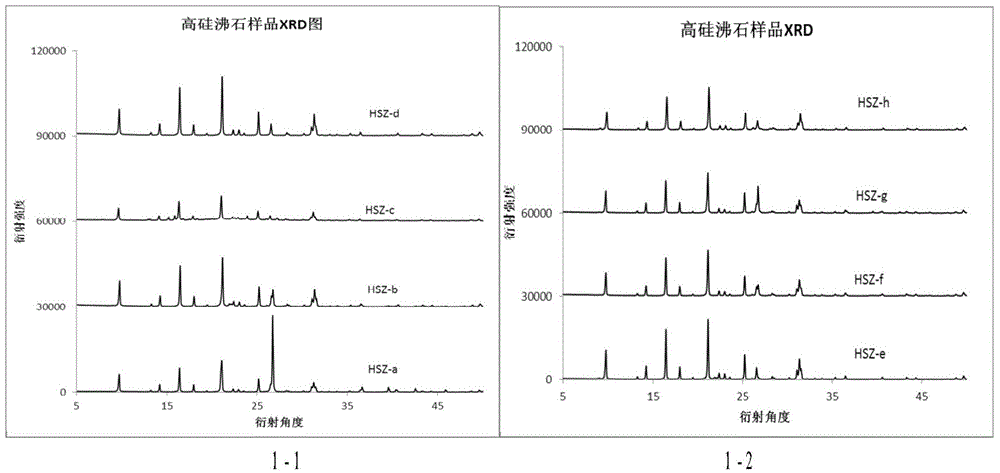

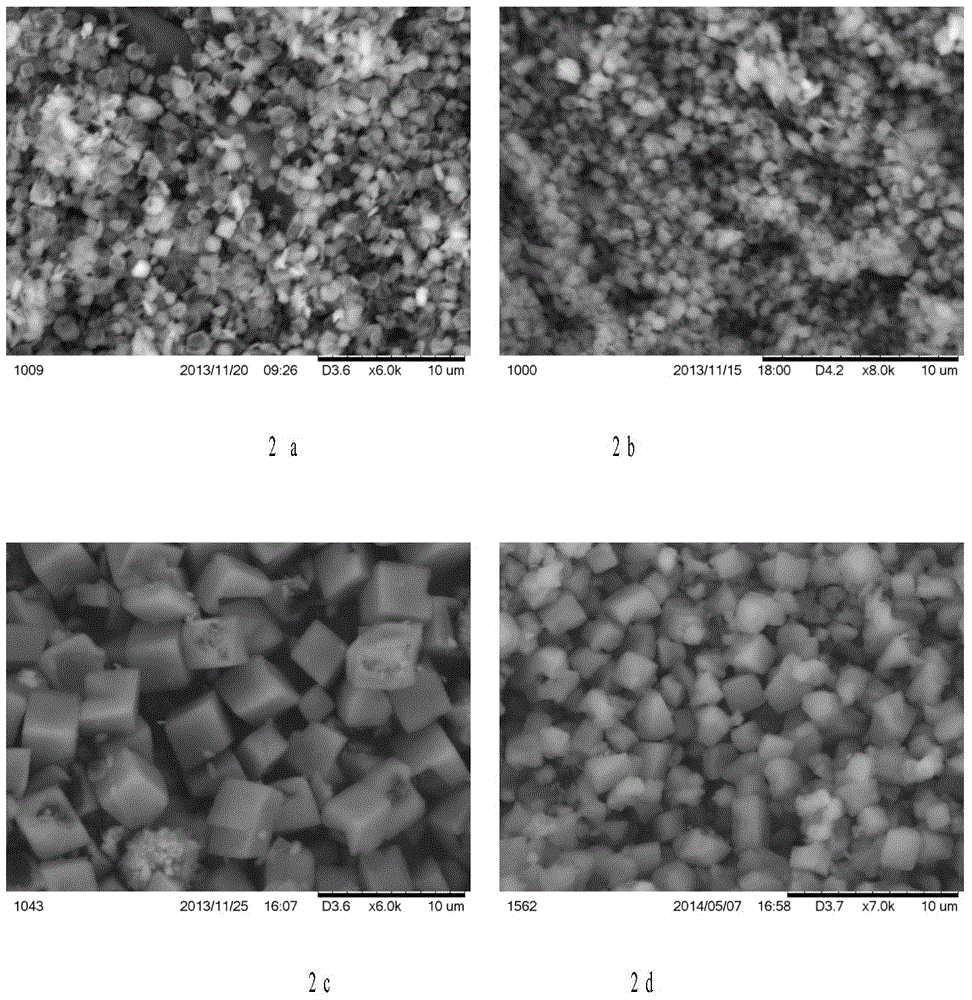

Method for synthesizing chabazite-type molecular sieve with high silica-alumina ratio by using seed crystal and composite inorganic base and application thereof

ActiveCN104129800AReduce water usageHigh solid contentMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePotassium hydroxide

A method synthesizing a chabazite-type molecular sieve with high silica-alumina ratio by using seed crystal and composite inorganic base is as below: evenly mixing an alkaline silica sol and a template; slowly adding potassium hydroxide; adding sodium hydroxide; continuing to stir; then slowly adding an aqueous solution of aluminum sulfate; adding a chabazite crystal phase molecular sieve as the seed crystal; distilling to remove excessive water; sealing, insulating and stirring; conducting high speed shearing to obtain a uniform gel; and conducting crystallization, roasting and ammonium exchange to obtain a product. The invention has the advantages of high silica-alumina ratio, high specific surface area, high MTO diolefin selectivity and pollution-free preparation process.

Owner:天津众智科技有限公司

Composite gypsum board and methods related thereto

ActiveUS20160375651A1High weight percentageReduce usageConstruction materialLaminationHigh densityPhysical chemistry

Disclosed is a composite gypsum board comprising a hoard core and a concentrated layer of substantial thickness (e.g., at least about 0.02 inches). The concentrated layer includes a higher weight percentage of an enhancing additive than the board core. The board core has a thickness greater than the thickness of the concentrated layer and forms the bulk of the board volume. The concentrated layer has a higher density (e.g., at least about 1.1 times greater) than the density of the board core. Also disclosed is a method of preparing a composite gypsum board.

Owner:UNITED STATES GYPSUM CO

Processing method of high-quality olive oil

InactiveCN102965188ASimple processEasy to operateFatty-oils/fats productionUltraviolet absorptionChemistry

The invention discloses a processing method of high-quality olive oil, which comprises the following steps: performing impurity removal on fruits; separating; cleaning; weighing; preheating; pulverizing; fusing, wherein a jacketed kettle with a stirrer is used, the rotation speed of the stirrer is 18-25 r / min, an interlayer of the jacketed kettle is heated by hot water of 30-35 DEG C, the fusing time is 30-50 minutes, and the temperature of fruit pulp is kept at 20-25 DEG C; spreading cakes, wherein the fused fruit pulp is spread into the cakes on a cake spreading vehicle by means of a clean nylon cushion, a cake spreading ring and squeezing disks, the cakes need to be evenly spread, the thickness of each cake is 25 mm, and 4-5 layers of cakes are spread between every two disks; squeezing; roughly filtering; decanting; performing centrifugal separation; filtering in vacuum; and storing. According to the method, olive oil is processed at low temperature (less than 25 DEG C) and is extracted by a mechanical method; no further refining is required, and no chemical substance and additive exist; detection indicates that the acid value of the prepared olive oil is less than 1.0 mg / g, the ultraviolet absorption value (K232) is no more than 0.20, the ultraviolet absorption value (K270) is no more than 0.20, and the peroxide value is no more than 10 mmol / kg; and the prepared olive oil has inherent smell and taste of olive oil and is edible.

Owner:BEIJING FORESTRY UNIVERSITY +2

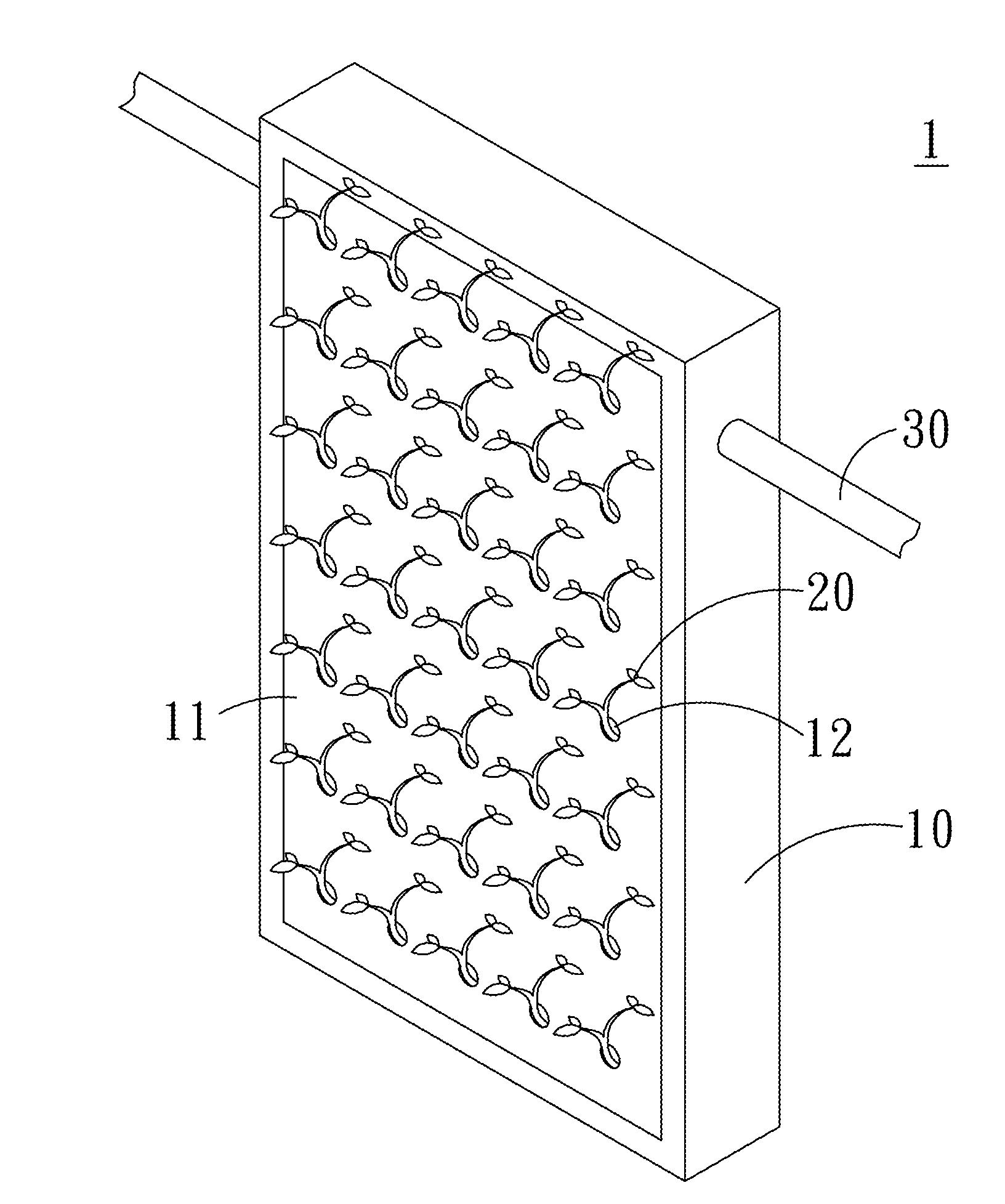

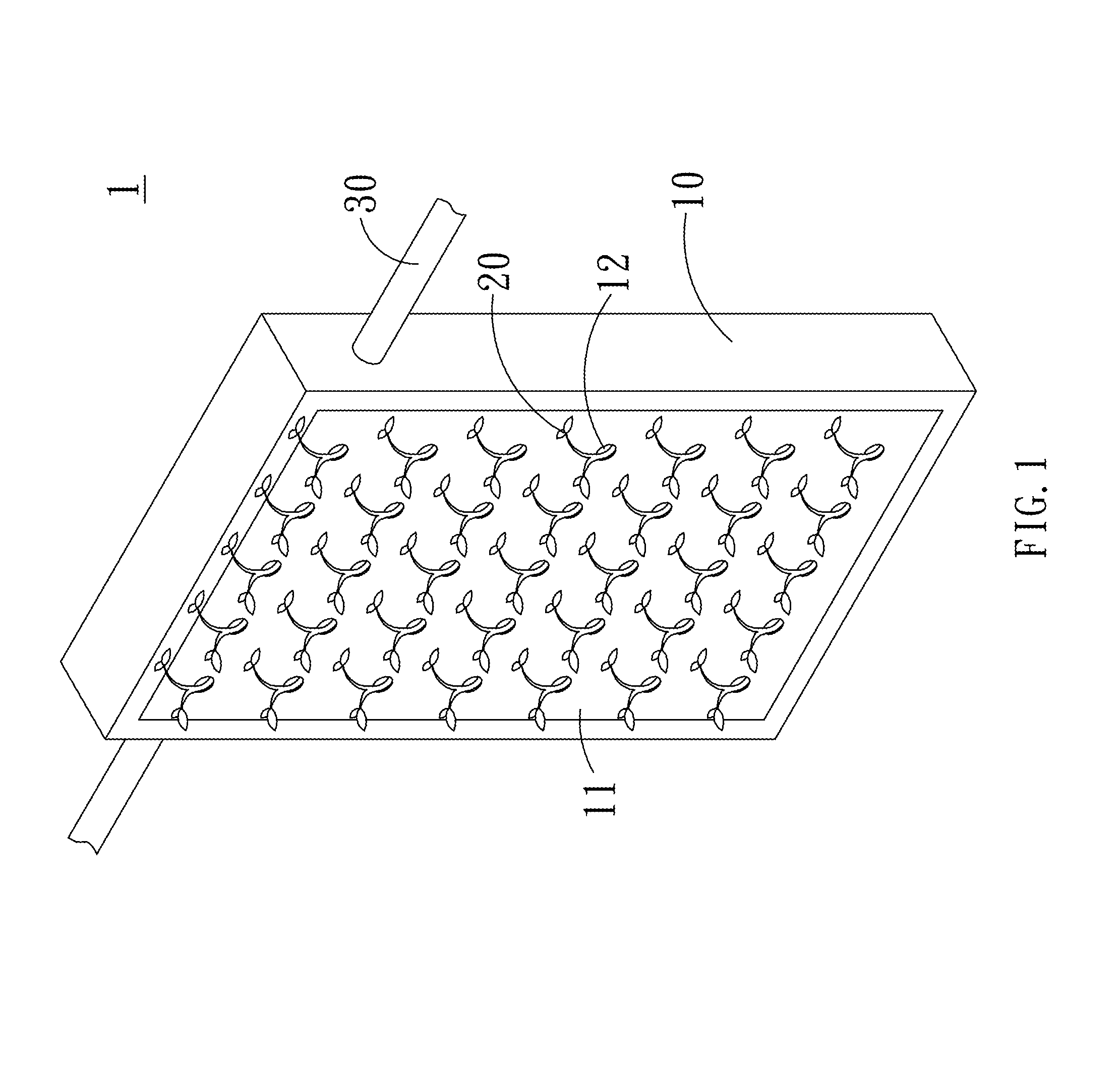

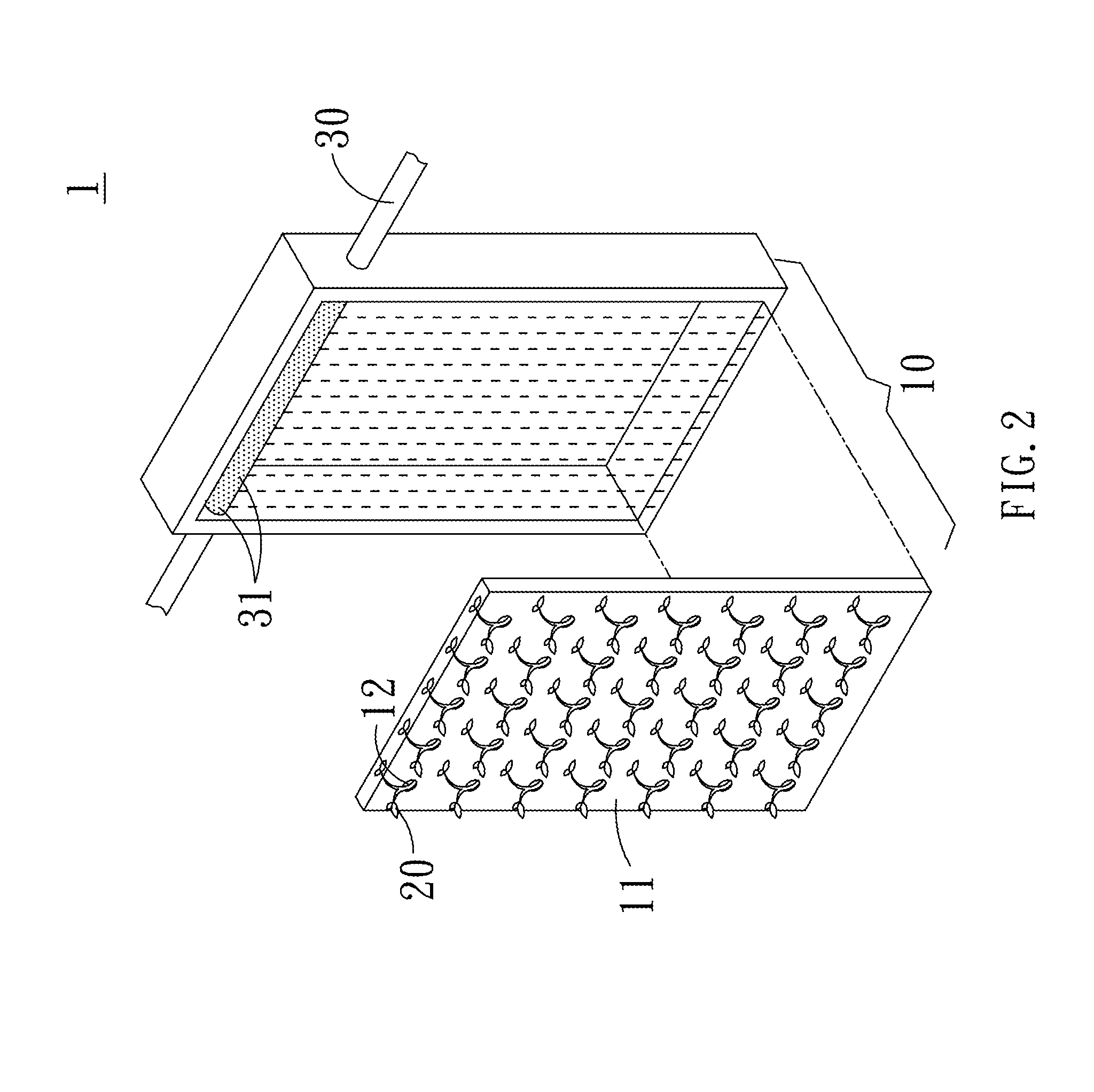

Water culture hydroponics system

InactiveUS20140000163A1Promote efficacyReduce water usageAgriculture gas emission reductionCultivating equipmentsHydroponicsWater pipe

A water culture hydroponics system of the invention is mainly disposed with a box body. At least one vertical plane of the box body is disposed with a plurality of openings for placing plants. At least one water pipe is disposed onto an inner side of the box body. The surface of the water pipe is disposed with a plurality of water spraying holes such that fluid within the water pipe is sprayed toward the plants from each water spraying hole. An exterior of the box body is disposed with at least one lamp wall for providing lateral light source to the plants to allow the inside of the box body to achieve optimum uniform moisture effect, and in conjunction with the irradiation of light beam, an effect of culturing and growing plants can be facilitated.

Owner:LIN MING TSUN

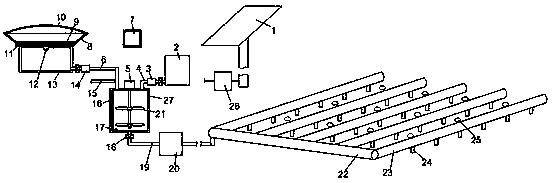

Water-saving irrigation system and irrigation method

PendingCN110178698AReduce dosageReduce water usageGeneral water supply conservationSewerage structuresDrip irrigationRainwater harvesting

The invention discloses a water-saving irrigation system. The system comprises a rainwater collecting device, a nutrition fertilizing device, an energy-saving device, drip irrigation devices and a control box. The rainwater collecting device comprises a rainwater collecting pool, a water inlet pipe is arranged on the top of the rainwater collecting pool, and a buoyancy ball valve is arranged at the lower end of the water inlet pipe. Each drip irrigation device comprises a main pipe and a humidity sensor, wherein the main pipe is connected with a plurality of branch pipes at equal intervals; the drip irrigation devices are uniformly arranged on the branch pipes, and the humidity sensors are electrically connected with the control box. The invention also discloses an irrigation method of thewater-saving irrigation system. The system can collect rainwater for irrigation so as to effectively reduce the water consumption. By adopting the water-saving irrigation control system, the irrigation amount can be effectively controlled, the water-saving effect of the water-saving irrigation control system is further improved, and fertilization can be carried out during irrigation.

Owner:JIANGSU WATER CONSERVANCY SCI RES INST

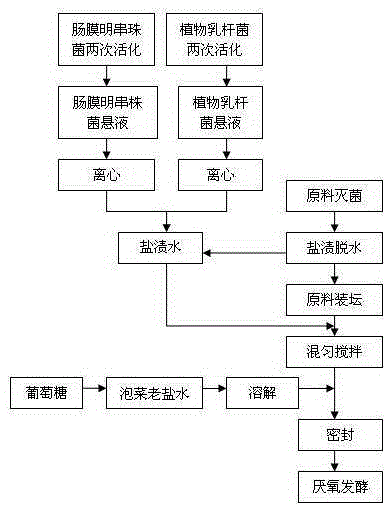

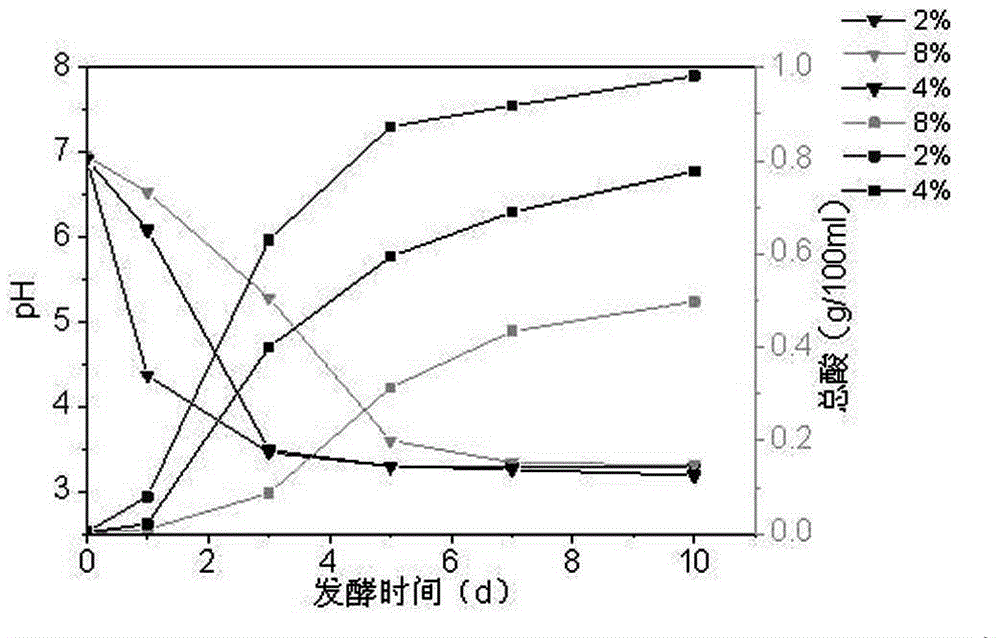

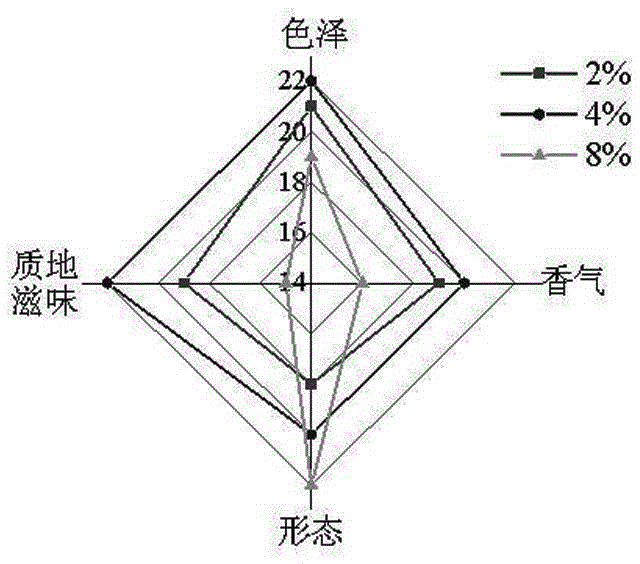

Manufacturing method of novel semisolid quick-fermentation pickle

PendingCN105394669AIncrease concentrationFull of nutritionClimate change adaptationLactobacillusLeuconostoc mesenteroidesSludge

The invention belongs to the field of food processing, and in particular discloses a manufacturing method of a novel semisolid quick-fermentation pickle. The method comprises the following steps: (1) pretreating raw materials; (2) performing disinfection treatment on a pickle jar; (3) salting and dehydrating a pickle; (4) preparing lactobacillus plantarum and leuconostoc mesenteroide bacterial sludge; (5) adding auxiliary materials and a culture; (6) adding pickle old brine and glucose; (7) laying vegetable in the jar flat, adding a layer of film at the opening of the pickle jar, filling up the pickle jar edge water groove with water, thus achieving a double-layer sealing effect, and fermenting under normal temperature. According to the method, the pickle raw materials are firstly salted and dehydrated, and then leuconostoc mesenteroide and the lactobacillus plantarum are added into the pickle jar, so that an obtained pickle substrate is high in concentration, rich in nutrition, and short in fermentation period, and also has the characteristics of preventing pickle mildew, improving pickle taste, and improving pickle quality and safety, and the problem of high cost caused by great salt consumption and water consumption in pickle industrialization can be solved.

Owner:SICHUAN DONGPO CHINESE PAOCAI IND TECH RES INST

Preextraction method for organic extraction agent, product and uses thereof

ActiveCN101319276ALow in alkaline earth metalsReduce manufacturing costProcess efficiency improvementRare-earth elementAlkaline earth metal

The invention discloses a pre-extraction method for an organic extraction agent, a product and an application thereof in the extraction and separation of rare earths. The pre-extraction method comprises the following steps that: the organic extraction agent is directly mixed with a rare earth solution and alkaline-earth metal compound powder or water slurry containing magnesium and / or calcium forpre-extraction, rare earth metal ions in an aqueous phase are extracted into an organic phase, exchanged nascent hydrogen ions dissolve an alkaline-earth metal compound to maintain the acidity balance of an extraction system so as to produce a loaded organic extraction agent which contains the rare earth metal ions and is used for nonsaponifiable extraction and separation of rare earth elements. In the extraction method, the organic extraction agent does not need liquid ammonia and liquid alkali to saponify, no ammonia nitrogen waste water is produced during the extraction and separation process of the rare earths, the separation cost for the rare earths is greatly reduced, and a large amount of cost for three-waste treatment is saved. The method is suitable for the extraction and separation of the rare earths in all hydrochloric acid systems, sulphuric acid systems and nitric acid systems, has small investment, and takes effect quickly.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Low-permeability soft coal seam extra-thin layer water jetting exploiting permeability increasing method

InactiveCN104727795AChanges in hardness have a large impactProne to stressFluid removalGas removalSlagRelease time

The invention discloses a low-permeability soft coal seam extra-thin layer water jetting exploiting permeability increasing method. The method includes the following steps that 1 extra-thin layer water jetting exploiting parameters are designed; 2 extra-thin layer water jetting exploiting devices are machined, tested and installed; 3 a water jetting exploiting radius and a corresponding water jetting parameter are measured; 4 slag discharge holes and middle exploiting holes are constructed; 5 water jetting coal mining is started on an extra-thin layer; 6 when the coal mining reaches a designed location, the extra-thin layer water jetting exploiting devices are closed; 7 jetting exploiting drill holes and the slag discharge holes are linked to pumping-releasing pipelines to pump and release; 8 the steps ranging from 5 to 7 are repeated, and next drilling construction and jetting exploiting are conducted; 9 detection is conducted on a extra-thin layer exploiting pressure relief effect. By means of the method, the flow of coal seam hectometer hole drilling gas is increased by times, the pumping and releasing time of the gas is greatly shortened, the pumping and releasing radius is increased by times, the well drilling construction quantity is reduced, the gas overrunning probability is greatly reduced in the tunneling period and stoping period, and valuable time and safety guarantee are provided for the coal mine safety-efficient stoping and tunneling.

Owner:HENAN POLYTECHNIC UNIV

Well drilling wastewater flocculation precipitation treatment device and wastewater treating method

InactiveCN102757143ASlow down hard to transportReduce uniformityWaste water treatment from quariesMultistage water/sewage treatmentFlocculationWater discharge

Owner:四川省环保科技工程有限责任公司

Sodium sulfide-free, lime-free depilation caustic dip method for lining leather of high-grade pig leather shoes

The invention relates to a depilation caustic dipping method of the lining leather of high quality pigskin shoes without using sodium sulfide and lime, which is characterized in that the method can greatly reduce the pollution of S and waste residue in waste water caused by sodium sulfide, sodium sulfhydrate and the lime in the process of traditional leather manufacturing process, and the discharge amount of the waste water is reduced by 40% and is easy to treat compared with the conventional depilation liming working procedure. Meanwhile, a non-ammonia dealkalization method is adopted to greatly reduce the content of NH3-N in the waste water. Compared with the traditional technique, the method can shorten the production period, save materials and reduce the comprehensive cost of production.

Owner:湖南省怀其皮革集团制革有限公司

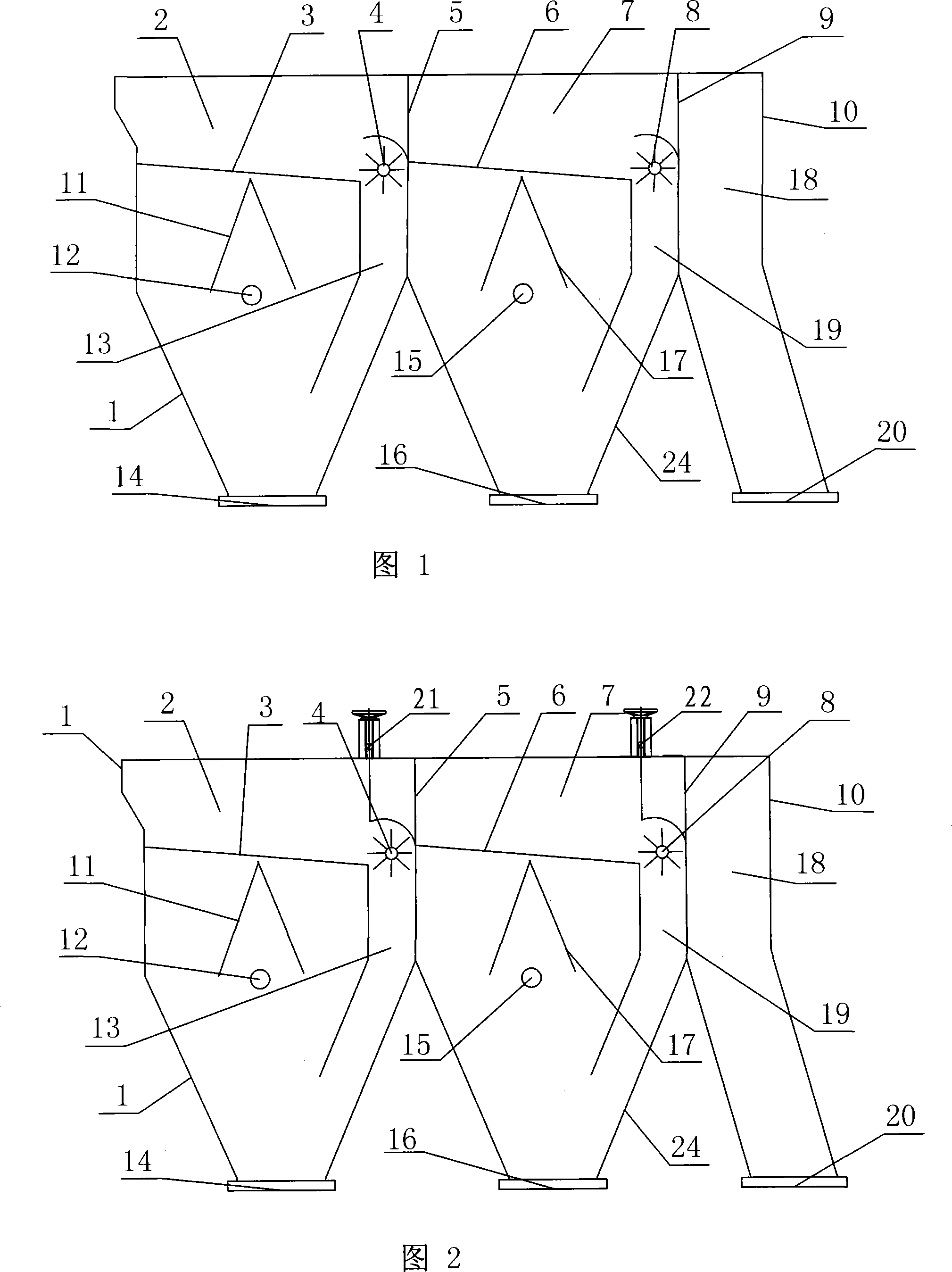

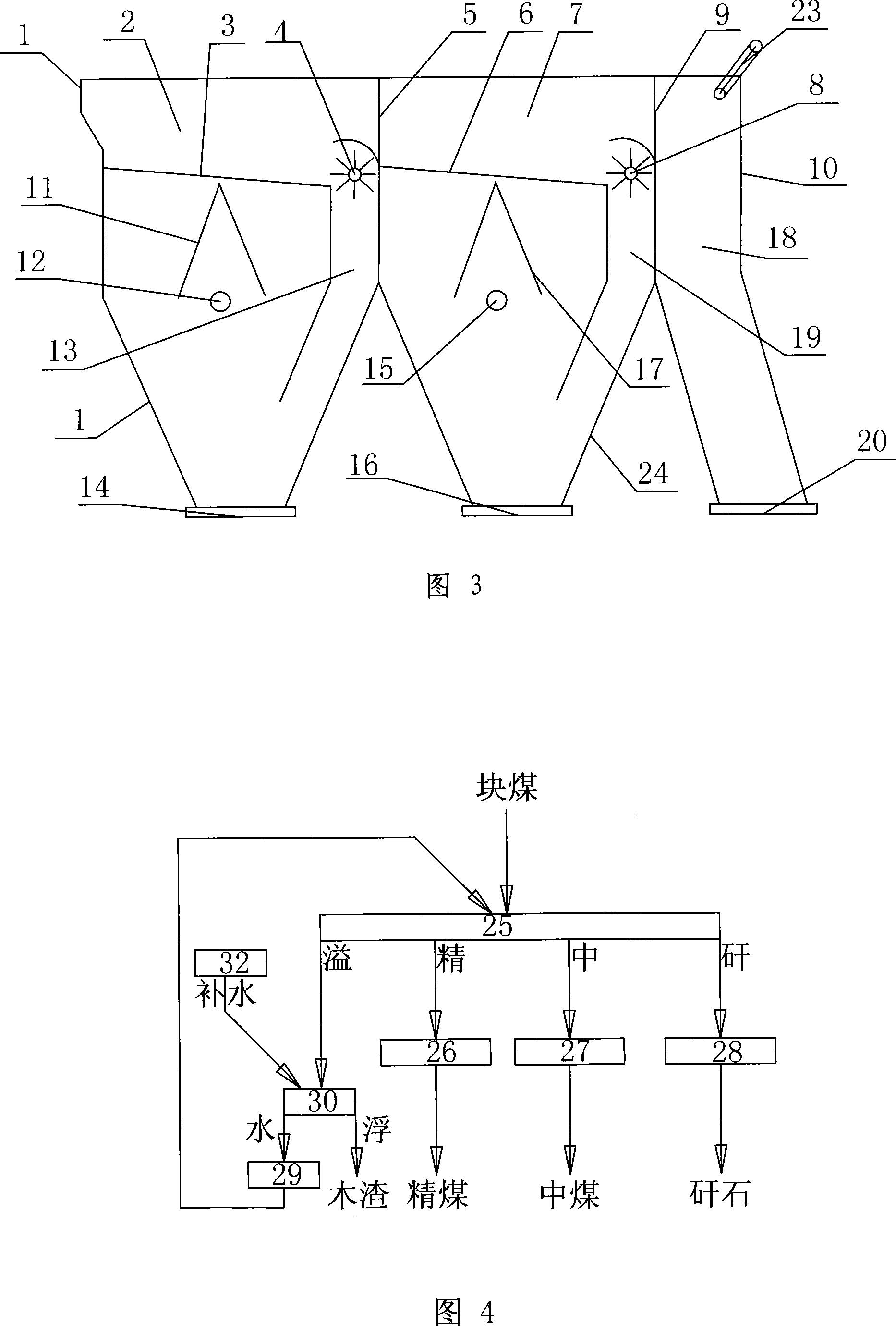

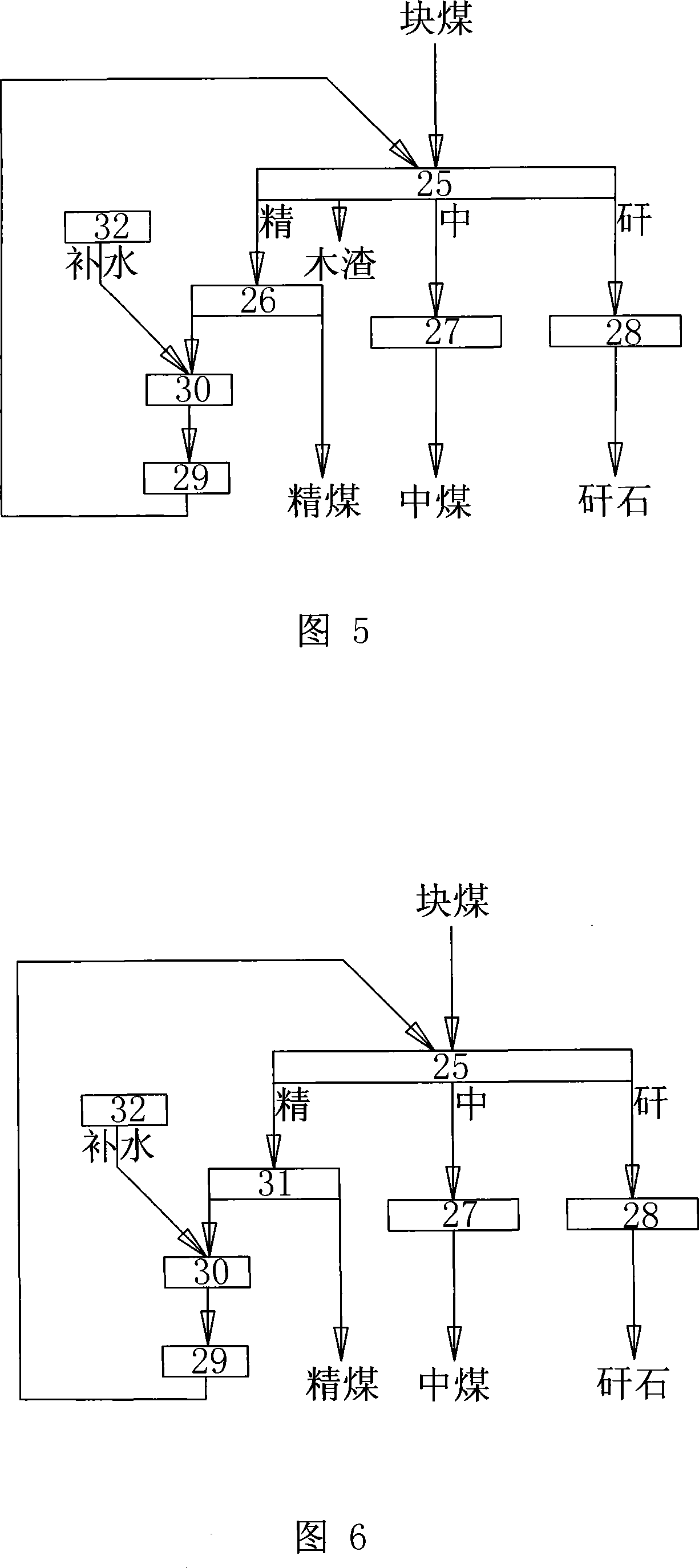

Torbanite washbox, coal separation system and coal separation method thereof

InactiveCN101185912AUse less waterReduce or eliminate top waterWet separationWater savingProcess engineering

The invention discloses a coal block jigger, a coal selection system and a coal selection method, which belongs to coal jigging selection field and is more particularly suitable for select coal blocks. The coal block jigger of the invention is formed by multiplying the inclined angle of a filter board of the existing multi-section jigger and changing a overflow spillway into a clean coal outlet passage; the coal selection system of the coal block jigger comprises the coal block jig, a rock refuse bucket elevator, a middling bucket elevator, a clean coal bucket elevator, a recycling water bucket, a recycling water pump, a water supply device and so on; and the coal selection of the coal block jigger can one-time select rock refuse, middlings, clean coal and a plurality of other products, and the water supply amount in selection is small. By adopting the invention to select coal blocks, processing amount can be increased, a great deal of water can be saved, washing and cleaning cost can be lowered, system steps can be simplified and system overall investment is reduced, thus achieving the effect that can not be achieved by the existing multi-section jigger. The invention is a brand new coal blocks selection jigger, a coal selection system and a coal selection method, which can be used for selecting steam coal and can also substitute dense medium vertical wheelers and inclined wheelers for coal block selection.

Owner:唐山易通科技开发有限公司

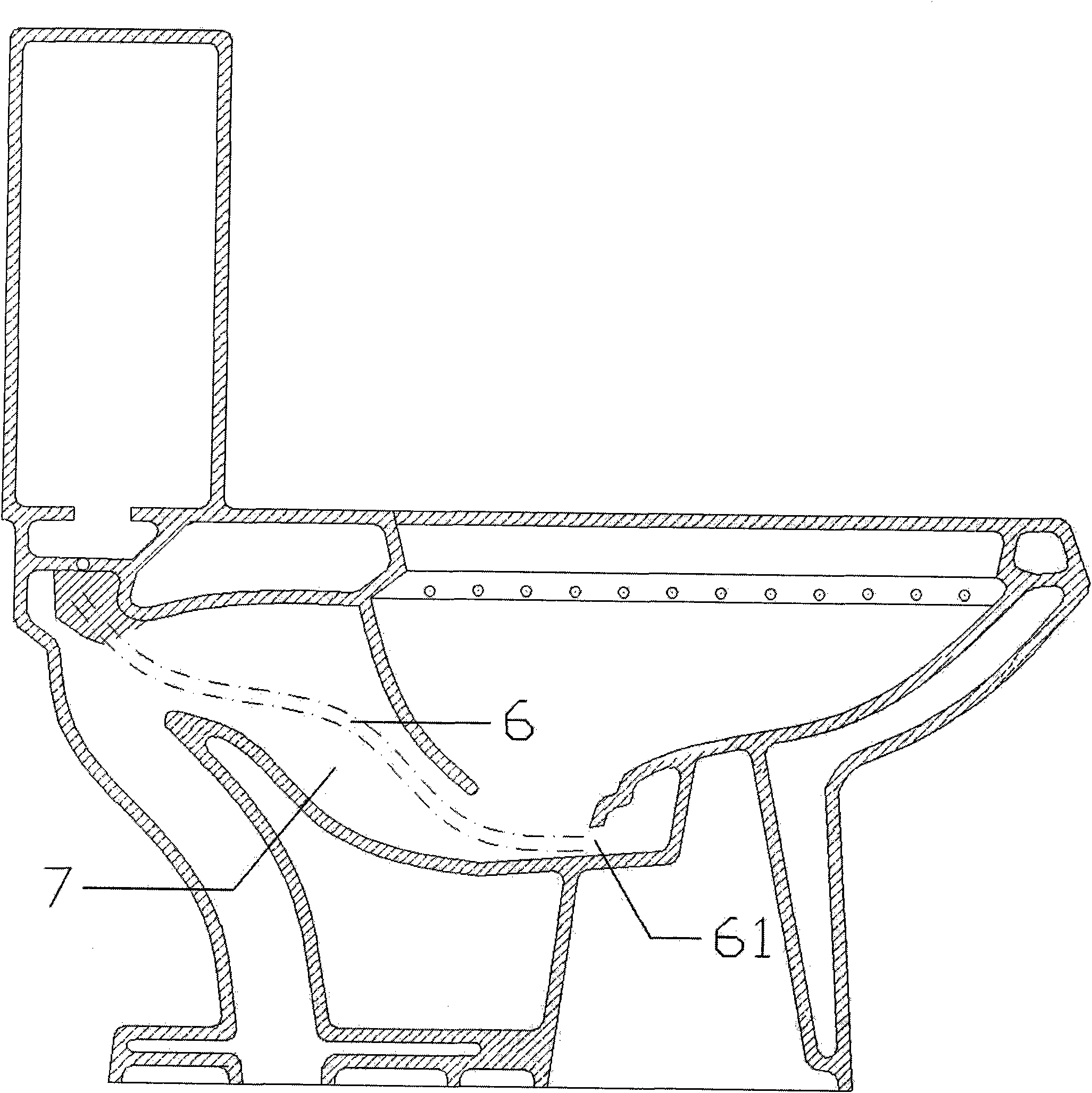

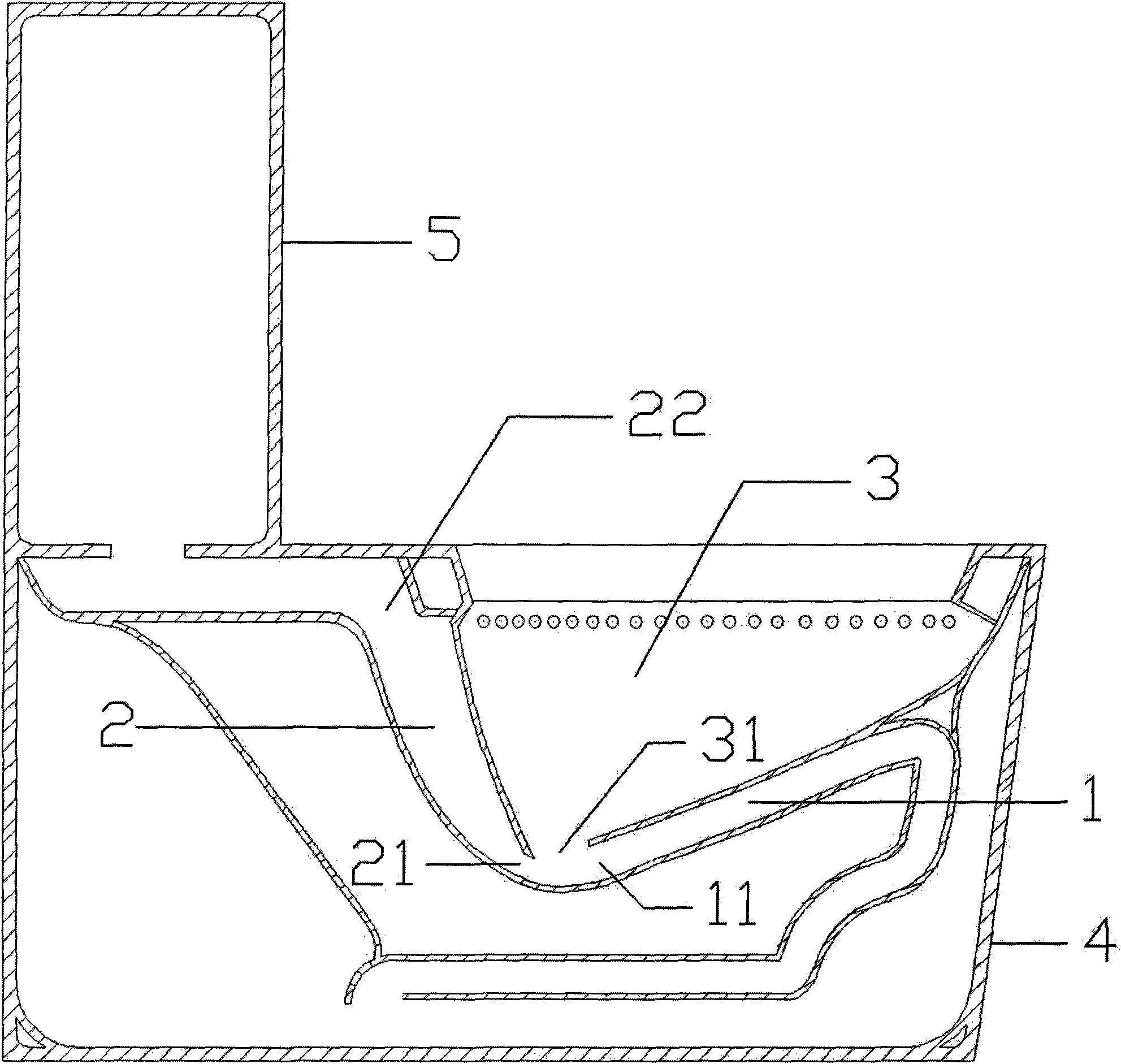

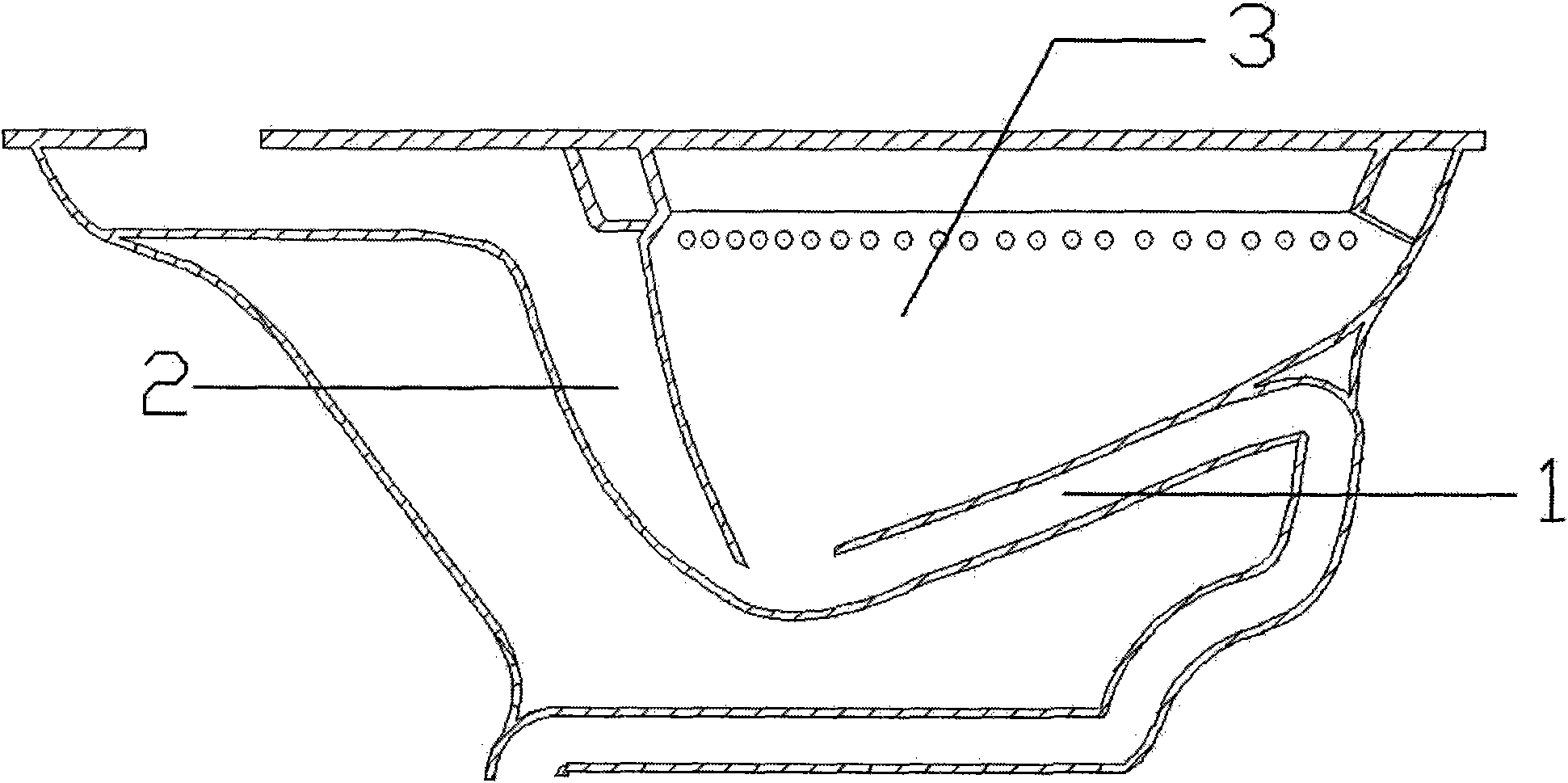

Ceramic pedestal pan with rearmounted flushing pipeline and manufacturing process thereof

InactiveCN101851953AShorten the lengthReduced flushing resistanceWater closetsFlushing devicesWater savingWater consumption

The invention discloses a ceramic pedestal pan with a rearmounted flushing pipeline and a manufacturing process thereof. The ceramic pedestal pan comprises a seat body, a bed pan, a draining curve and a flushing pipeline, and is characterized in that: the outlet of the draining curve and a draining opening of the bed pan are connected in the front, the flushing pipeline is arranged at the back of the bed pan, and a flushing protecting hole of the flushing pipeline and the draining opening of the bed pan are connected at the back, wherein the cross section area of the opening of the flushing pipeline is 16-24cm<2>, and the cross section area of the flushing protecting hole is 2-5cm<2>. The product only needs 3-4L of water for flushing and draining at every time, keeps excellent drainage performance and also realizes the water saving effect; in addition, the product has reasonable structure and does not generate rearmounted center of gravity; and the production process of the product has simple operation, and the yield of the product is high.

Owner:陈旭江

Fabric softener with bactericidal function and preparation method thereof

ActiveCN101514305ASolution synergiesFix stability issuesCationic surface-active compoundsFibre treatmentSolubilityFatty alcohol

The invention relates to a fabric softener with bactericidal function and a preparation method thereof. The fabric softener comprises the following components in portion by weight: 4.5 to 10 portions of quaternary amine ester (C18), 1 to 3 portions of dialkyl quaternary ammonium salt (C8-10), 1 to 2 portions of fatty alcohol polyoxyethylene ether (5), 0.5 to 1.5 portions of fatty alcohol polyoxyethylene ether (7), 0.1 to 0.5 portion of essence, 0.05 to 0.3 portion of citric acid, and 82.7 to 92.8 portions of deionized water. The fabric softener has good solubility and good softness, protects the fabric, has strong sterilizing power, and can reduce washing cost.

Owner:北京绿伞科技股份有限公司

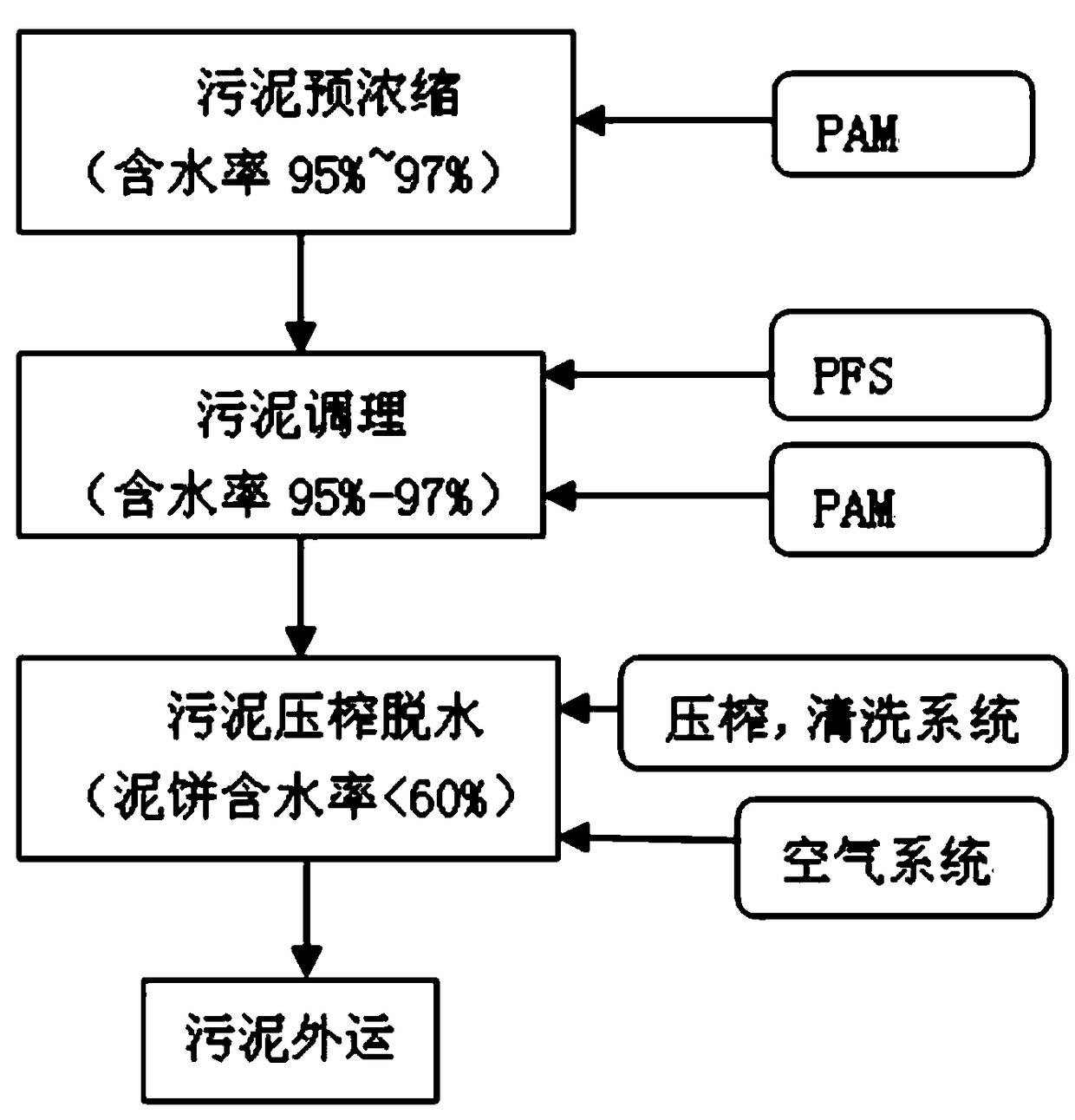

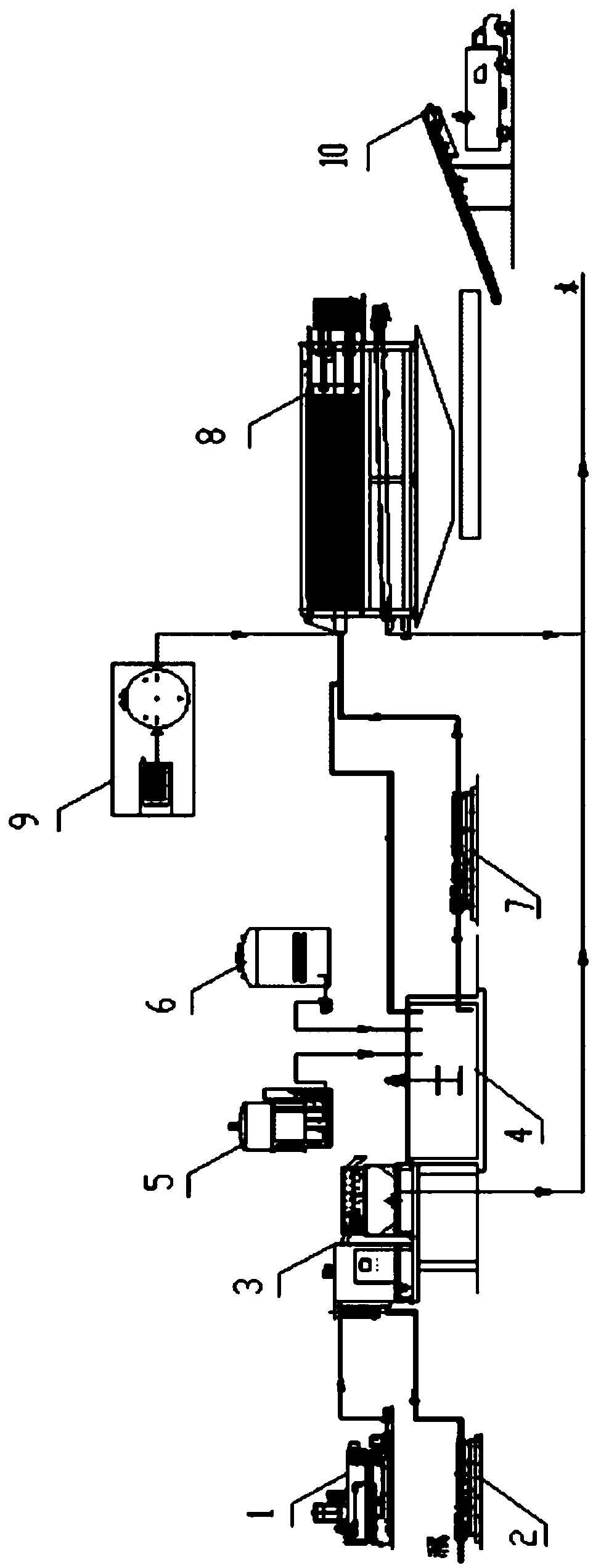

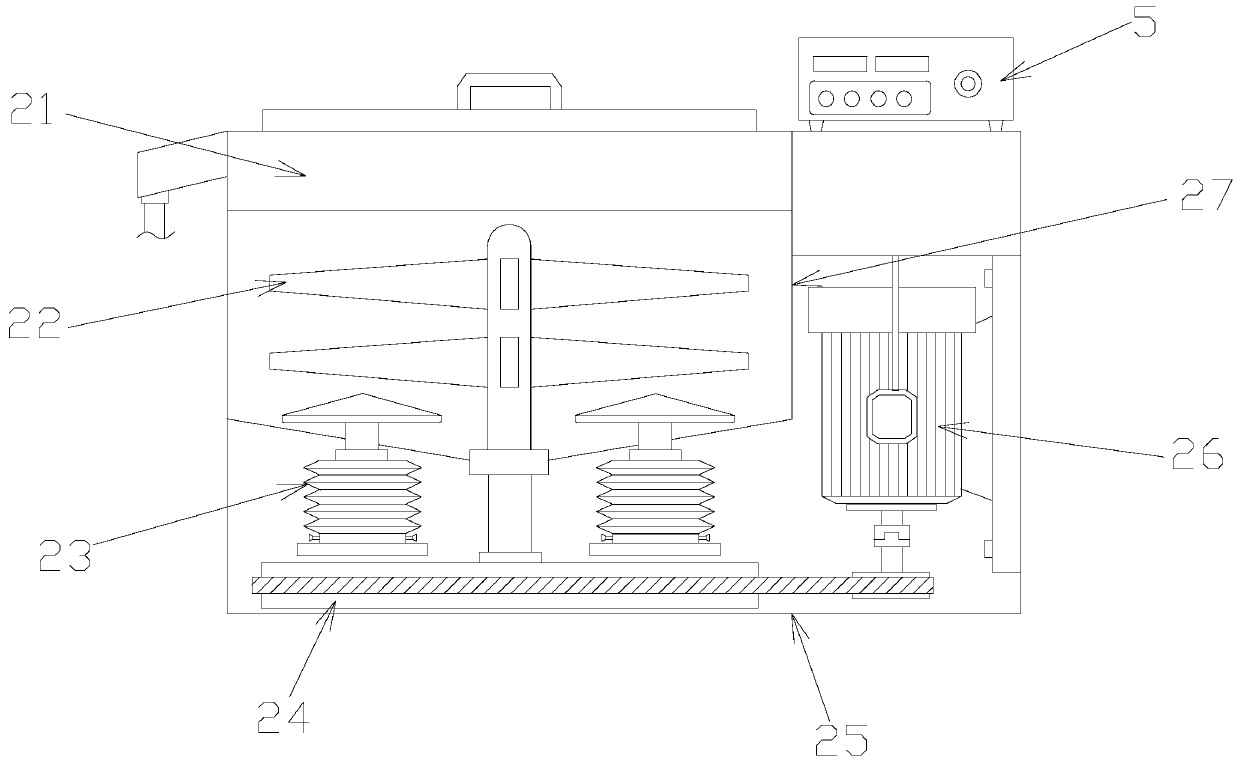

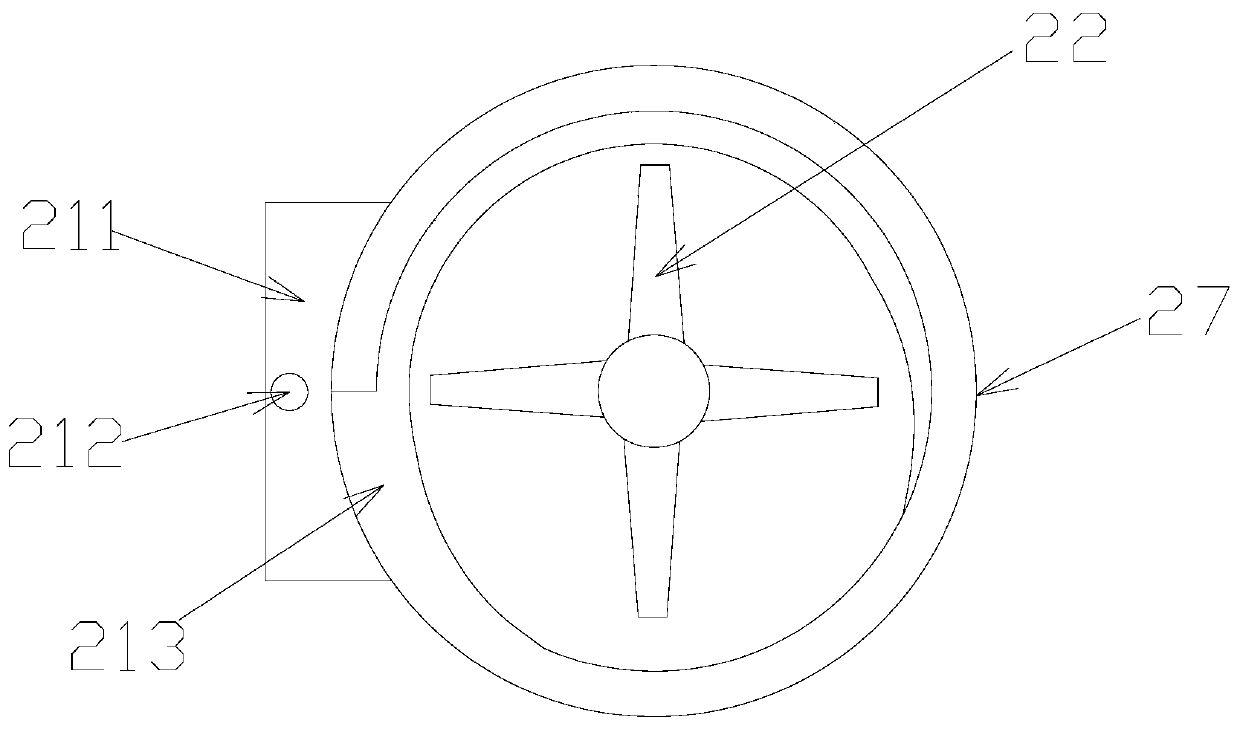

Sludge modified diaphragm compressed deep dehydration process and system

InactiveCN108947185ASimplify the dehydration processLess investmentSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesActivated sludgeTransport system

The invention discloses a sludge modified diaphragm compressed deep dehydration process and system. The process comprises the following steps: (1) metering sludge, and entering an elliptical cascade sludge pre-thickening system for thickening and dehydration; (2) enabling the thickened sludge to directly enter a sludge conditioning tank for conditioning, sequentially adding a conditioner a and a conditioner b to be uniformly stirred, and modifying the sludge; and (3) enabling the modified sludge to enter a special sludge compressed dehydration equipment system for performing deep compressed dehydration treatment, and enabling the finally obtained cake sludge to enter an outwards sludge transport system. The improved process is simple and convenient to operate, and the moisture content of the treated sludge is 60% or less. The invention further provides a sludge modified diaphragm compressed deep dehydration system. According to the system, the dehydration efficiency of a filter press can be improved, the sludge volume is reduced, the cost is reduced, the land utilization efficiency is improved, the low-cost goal of the sludge is achieved, and convenience is brought to subsequent resource treatment.

Owner:四川欧美华环境工程有限公司

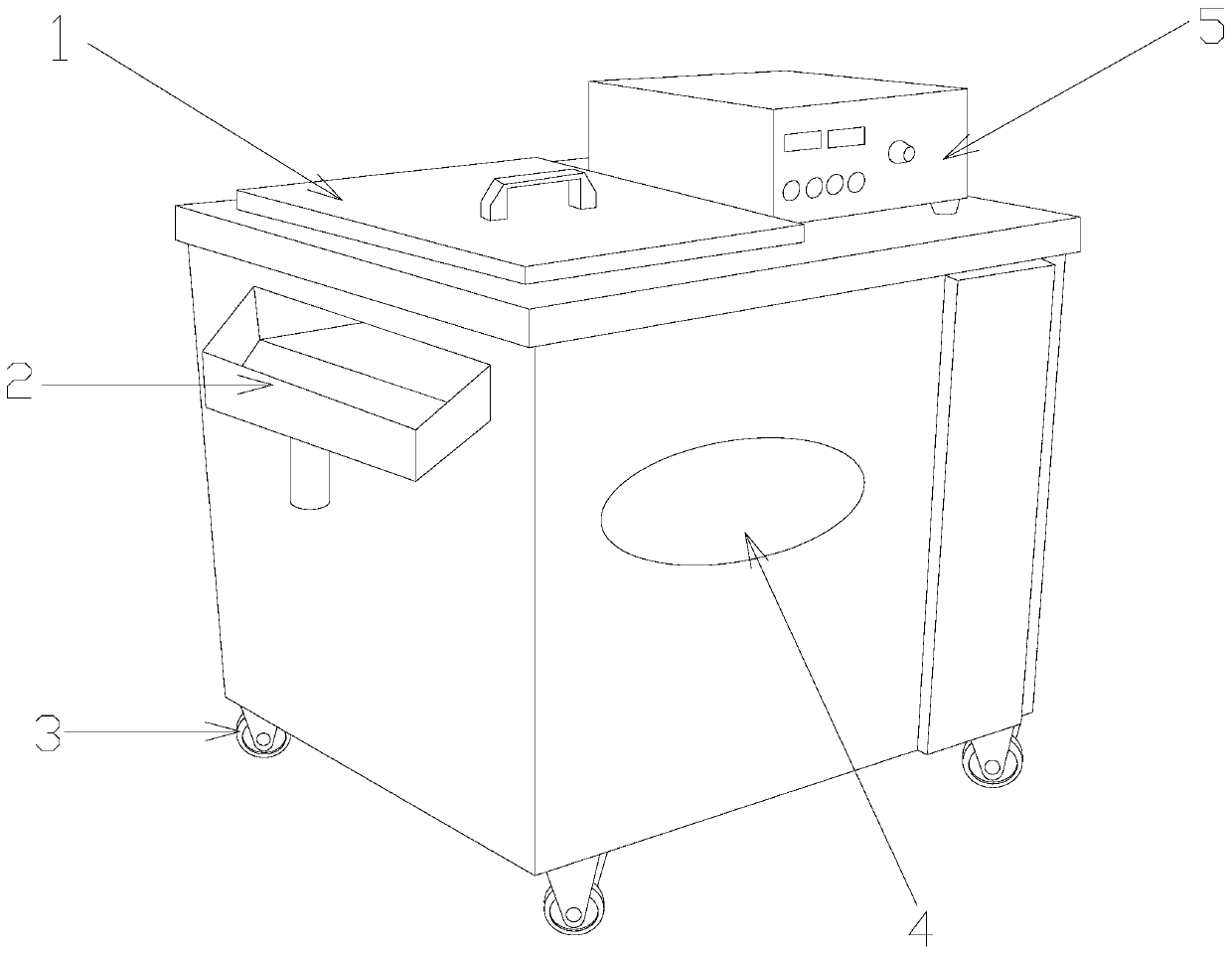

Bearing cleaning machine using bubble enhancement reaction

ActiveCN109865708APromote sheddingImprove cleaning effectCleaning using liquidsMachine controlAir bubble

The invention discloses a bearing cleaning machine using a bubble enhancement reaction. The bearing cleaning machine structurally comprises a splashing proof sealing cover, a cleaning machine main body, universal moving wheels, a product nameplate and a cleaning machine control machine. The bearing cleaning machine is combined with a bubble generating structure through a grease collecting structure, when a bearing is put into the cleaning machine to be cleaned, bubbles can be generated in the cleaning machine through the bubble generating structure, the overturning effect is generated throughthe bubbles and a cleaning solution, thus balls in the bearing rotates, and thus attachments on the surface of the bearing are dropped off; meanwhile the grease floating at the top of the cleaning solution can be effectively collected to be treated centrally, the situation that the grease at the top of the cleaning solution is attached on the surface of the bearing after being sunk when water is discharged from the cleaning machine, and the cleaning effect of the cleaning machine is effectively improved.

Owner:莆田市松尚家具有限公司

Synthesis method of p-chlorophenyl hydrazine

InactiveCN106278935AImprove securityReduce water usageHydrazine preparationHydrazineSolventProcess safety

The invention discloses a synthesis method of p-chlorophenyl hydrazine. The method comprises the following steps: (1) adding hydrazine hydrate into a four-neck flask, starting to stir and adding a hydrochloric acid solution dropwise at a certain reaction temperature to obtain a hydrazine hydrochloride solution; (2) adding p-chloroaniline into the four-neck flask, starting to stir by using glycol as a solvent, adding the hydrazine hydrochloride solution obtained in the step (1) dropwise at the reaction temperature of 100 to 120 DEG C, performing heat-insulating reflux reaction for 2 to 6 hours, and filtering, washing and drying after the reaction is finished to obtain the p-chlorophenyl hydrazine. By the method, one-step synthesis of the p-chlorophenyl hydrazine is realized by using the p-chloroaniline and the hydrazine hydrate, the yield can reach more than 85%, and the method is suitable for enterprise large-scale production; by the method provided by the invention, the tedious operation steps, such as diazotization, reduction and acidolysis, in the traditional method are avoided, and the process safety is improved; by the method, the use amount of water can be reduced, the discharge quantity of waste water is greatly reduced, waste water treatment in the later period is avoided, and the cost is reduced.

Owner:ANHUI COSTAR BIOCHEM CO LTD

Preparation method of cement gum for intermediate frequency furnace

The invention discloses a preparation method of cement gum for an intermediate frequency furnace. The preparation method comprises the following steps: first, uniformly mixing raw materials formed by compact brown aluminum oxide, compact brown aluminum oxide fine powder, a bonder, superfine powder, an additive and a detonation inhibitor; then, stirring the mixed raw materials and plastering the uniformly stirred cement gum around a coil; finally, after construction, naturally drying to complete hydration reaction to ensure the turn-to-turn and integral insulativity of the coil of the intermediate frequency furnace, wherein the coil has corresponding strength. The cement gum prepared by the method is long in furnace life, high in work efficiency, simple to maintain and suitable for a high-heat environment.

Owner:长兴泓矿炉料有限公司

Comprehensive utilization process of glutamic acid crystal mother liquid

InactiveCN103918873AHigh adsorption capacityReduce water consumptionOrganic compound preparationClimate change adaptationIon exchangeChemistry

A comprehensive utilization process of a glutamic acid crystal mother liquid comprises the following steps: one, leading the glutamic acid crystal mother liquid into a membrane separation system, allowing solid particles, thalli, proteins, polysaccharides and a colloid in the mother liquid to be intercepted by a membrane, and making glutamic acid left in a membrane filtrate; and allowing the membrane filtrate to go to a next step for treatment; two, leading the membrane filtrate into an ion exchange system, adsorbing glutamic acid by an ion exchange resin, when the content of glutamic acid in an ion exchange tail liquid is not more than 0.2%, stopping column-loading, adding an eluting agent, eluting, allowing glutamic acid to go into the eluate, collecting the eluate, and recycling glutamic acid from the eluate. The membrane separation technology and the ion exchange technology are combined, recycling of glutamic acid from the crystal mother liquid is realized, at the same time, a protein feed is prepared from the thalli and the proteins intercepted by the membrane, an organic fertilizer is prepared from the ion exchange tail liquid through slurry-spraying granulation, the whole process allows useful substances in the crystal mother liquid to be totally recycled, comprehensive utilization of the resources is thoroughly achieved, waste is turned into treasure, and significant economic benefits are achieved.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

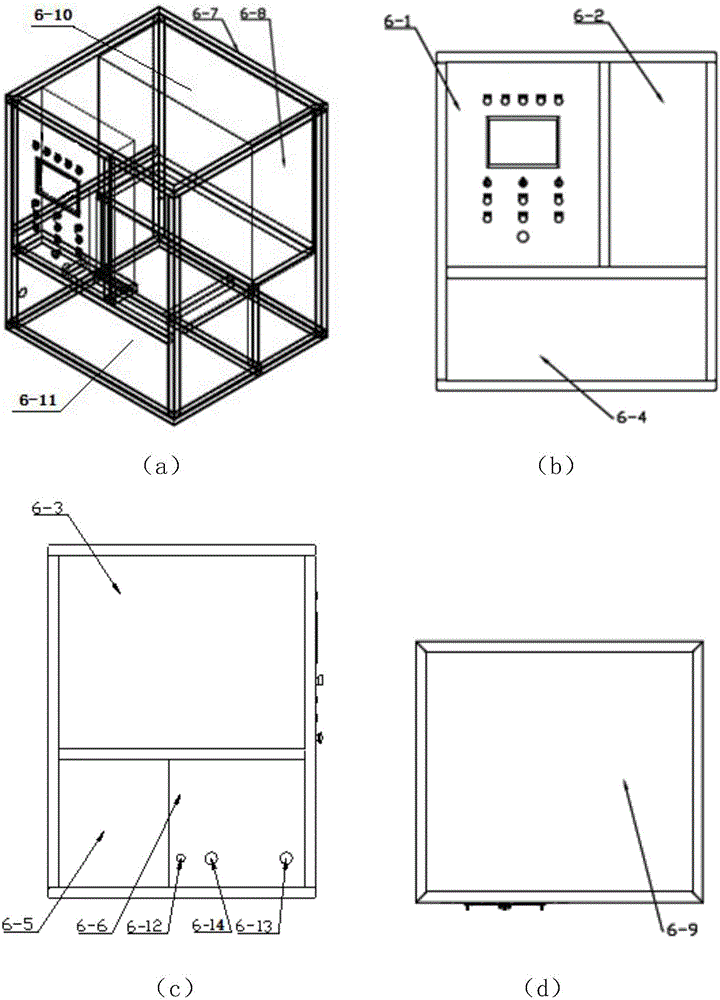

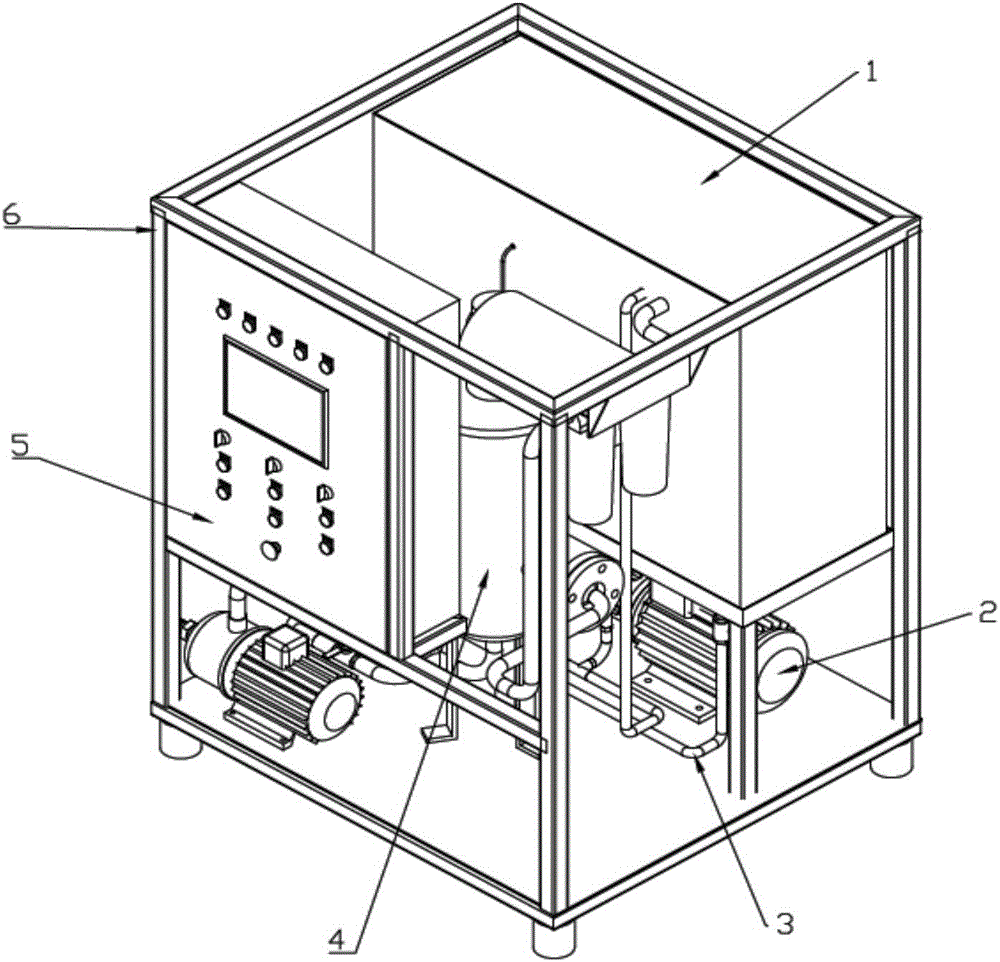

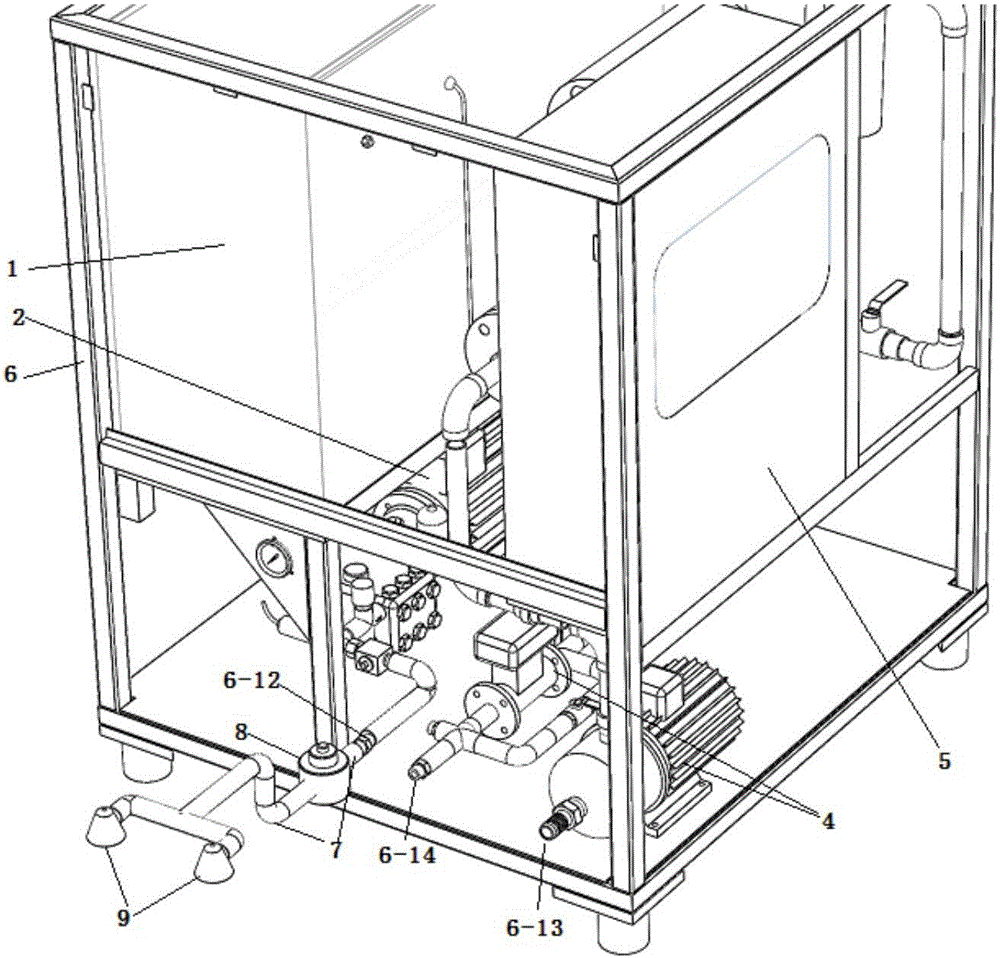

Integrated high-pressure fine water mist dust removal system

InactiveCN105999930AFine and uniform particle sizeHigh densityUsing liquid separation agentSeparation devicesWater storageWater source

The invention discloses an integrated high-pressure fine water mist dust removal system, which comprises a case, a water supplementing filtering device, a water storage device, a supercharging device, a control device and a spraying device, wherein the case is of a detachable structure; the water supplementing filtering device, the water storage device, the supercharging device and the control device are all integrated in the case; the spraying device is arranged on one side of the case; a water inlet of the water supplementing filtering device is connected with an external water source; the water storage device is used for storing filtered water; a water inlet of the supercharging device is connected with a water outlet of a water tank, and a high-pressure water outlet is connected to the spraying device; the supercharging device is used for pumping the water from the water storage device, and supercharging the water into a high-pressure spraying pipeline, and the water is sprayed and atomized into uniformly distributed micron-sized mist particles through a high-pressure centrifugal nozzle to implement dust settling and removal with high-pressure fine water mist. The system is compact in structure, small in occupied area and high in automation degree, and has good dust removal effects.

Owner:湖北嘉泓环保科技有限公司 +1

Cement for intermediate frequency furnace lining

InactiveCN104030704AImprove structural strengthOptimize material functionIntermediate frequencyCorundum

The invention discloses cement for an intermediate frequency furnace lining. The cement is prepared from the components in percentage by mass: 70%-80% of dense corundum, 10%-20% of dense corundum powder, 5%-15% of a binder, 0.5%-2% of superfine powder, 0.5%-3% of an additive and 0.1%-5% of an explosion-proof agent. The cement has the characteristics of prolonged service life of the intermediate frequency furnace, high operation efficiency and simple maintenance and adapts to a highly heat environment.

Owner:长兴泓矿炉料有限公司

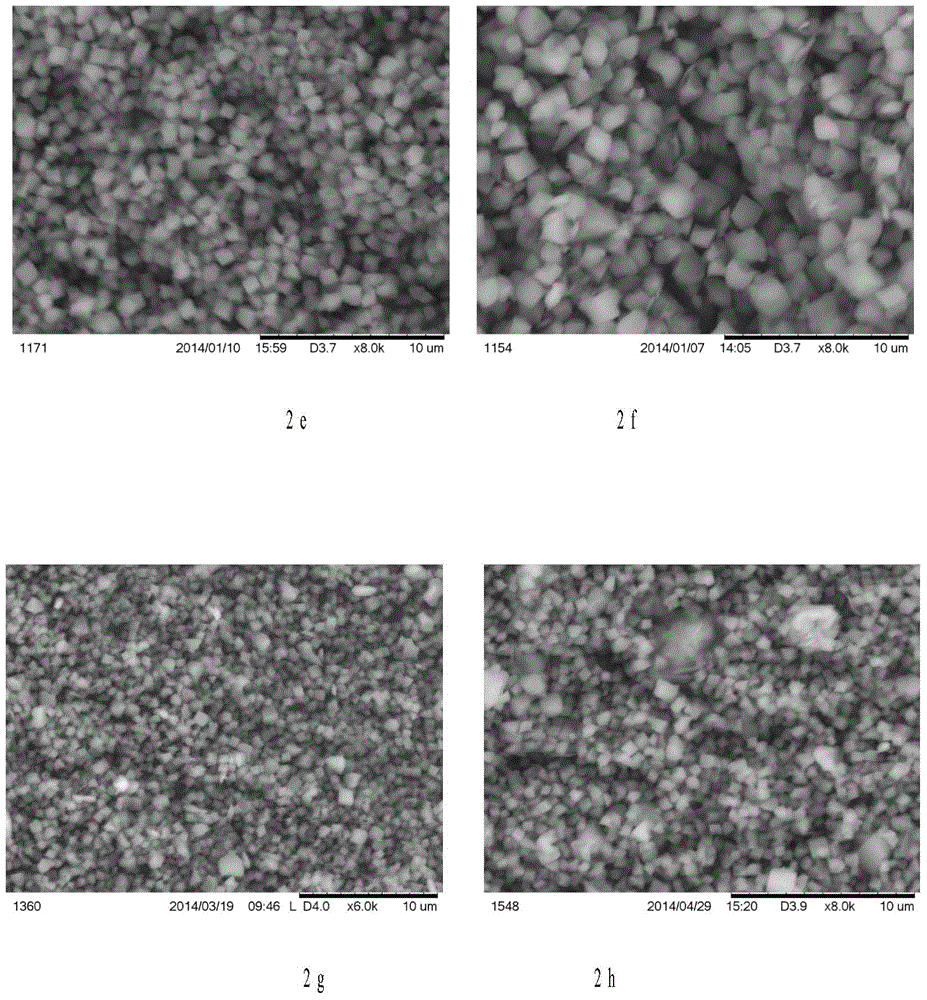

Composite inorganic base method synthesizing chabazite-type molecular sieve with high silica-alumina ratio and application thereof

ActiveCN104129801AReduce water consumptionSolve the problem of easy solidificationMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveAluminium salts

A composite inorganic base method synthesizing a chabazite-type molecular sieve with high silica-alumina ratio is as below: evenly mixing an alkaline silica sol and a template; slowly adding potassium hydroxide; adding sodium hydroxide; continuing to stir; then slowly adding an aqueous solution of aluminum sulfate; distilling to remove excessive water; sealing, insulating and stirring; conducting high speed shearing to obtain a uniform gel; and conducting crystallization, roasting and ammonium exchange to obtain a product. The invention has the advantages of high silica-alumina ratio, high specific surface area, high MTO diolefin selectivity and pollution-free preparation process.

Owner:天津众智科技有限公司

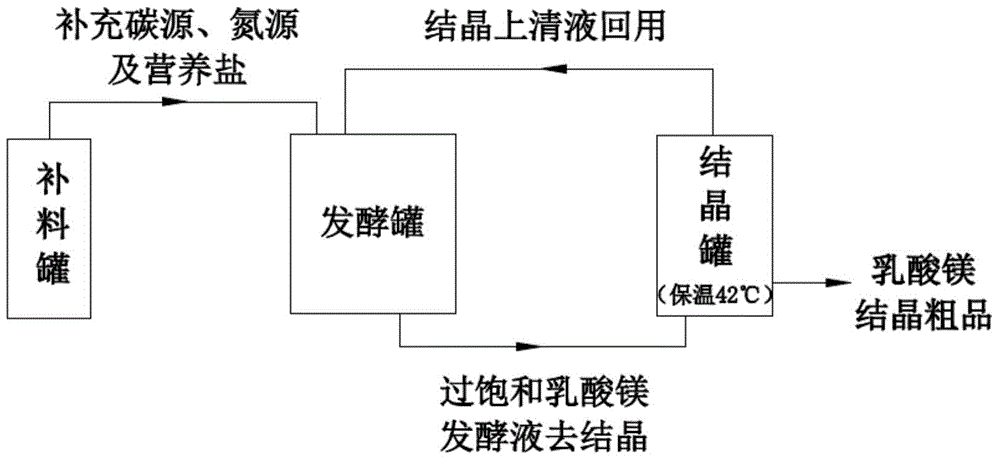

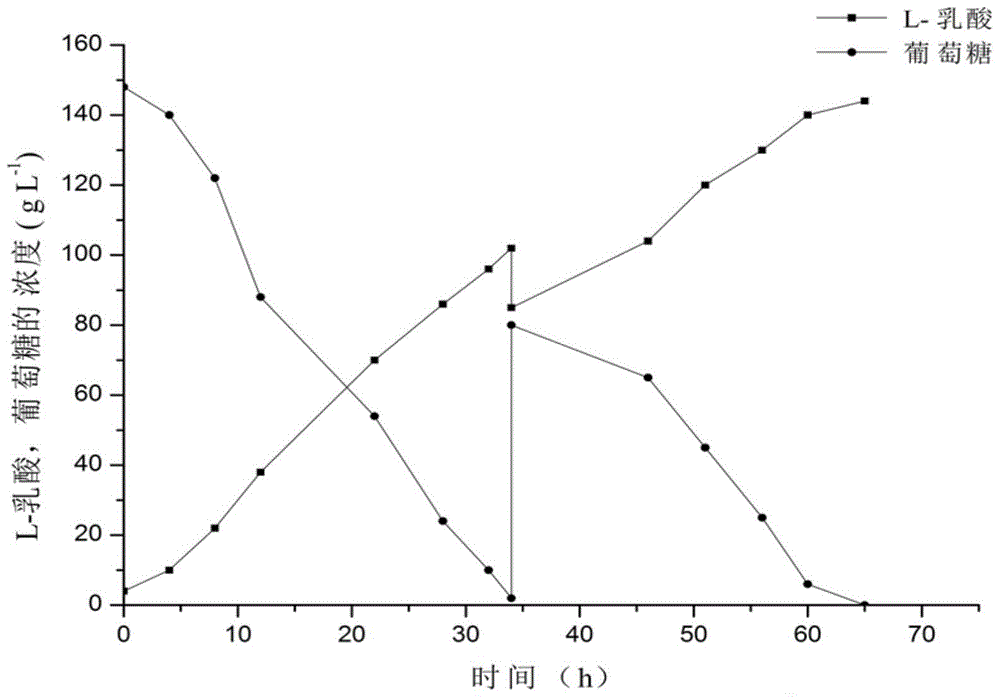

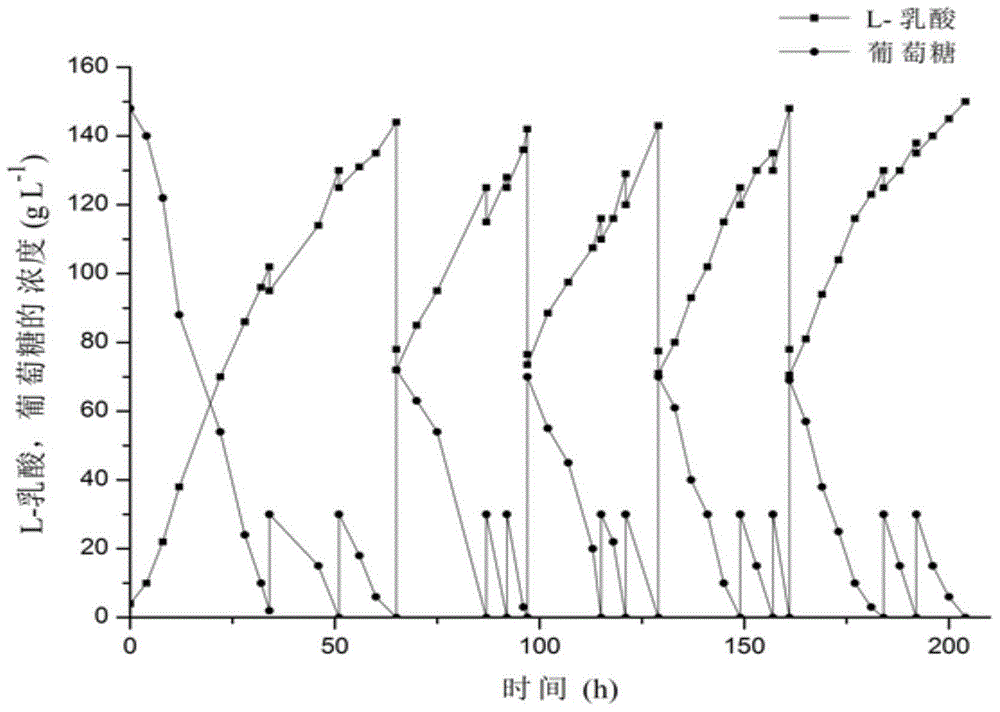

Magnesium lactate production method based on crystallization process for fermentation, separation and coupling

ActiveCN105018538AReduce manufacturing costSave the amount of dipping powderMicroorganism based processesFermentationChemistryCalcium EDTA

The present invention discloses a magnesium lactate production method based on crystallization process for fermentation, separation and coupling. Lactobacillus rhamnosus is subjected to repeated batch fermentation culture for 180-220h manner at 37-42 DEG C, and in-situ separation is performed to obtain the high-purity magnesium lactate crystals. The lactic acid yield in fermentation is 140-150g / L, the production rate is 2.0-2.5g / L / h, and sugar acid conversion rate is 94.5%. In situ separation process in a crystallization mode on the magnesium lactate reaches the removal rate of lactic acid of up to 79.10% and fermentation wastewater reuse rate of 65.57%. Compared to a traditional feeding-batch fermentation process, the method can save 40% of water consumption, 41% of the amount of inorganic salt and 43% of the amount of yeast extract, and reach gross production of L-lactic acid 3.82 times of single batch fermentation in 5 stable fermentation cycles. The process for fermentation production of lactic acid avoids the disadvantages of large amount of solid waste and waste water in calcium salt production process, and does not need external seed addition, cooling or reheating process, simplifies the production steps, shortens production time, and ensures the environmental and sustainable process while reducing the cost of production of lactic acid.

Owner:BEIJING UNIV OF CHEM TECH

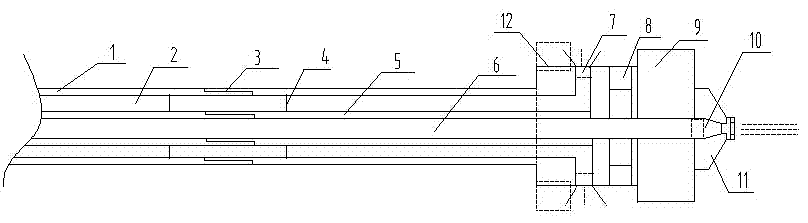

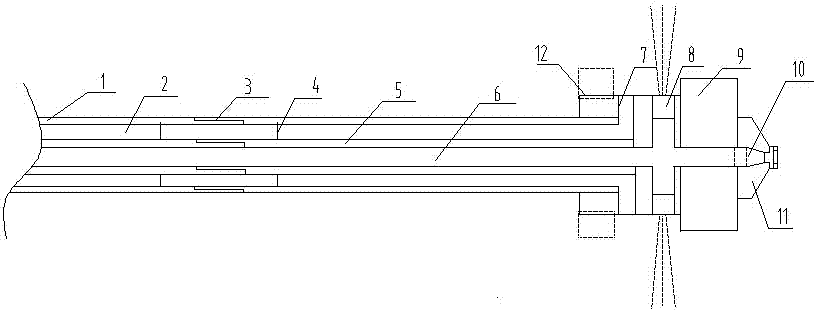

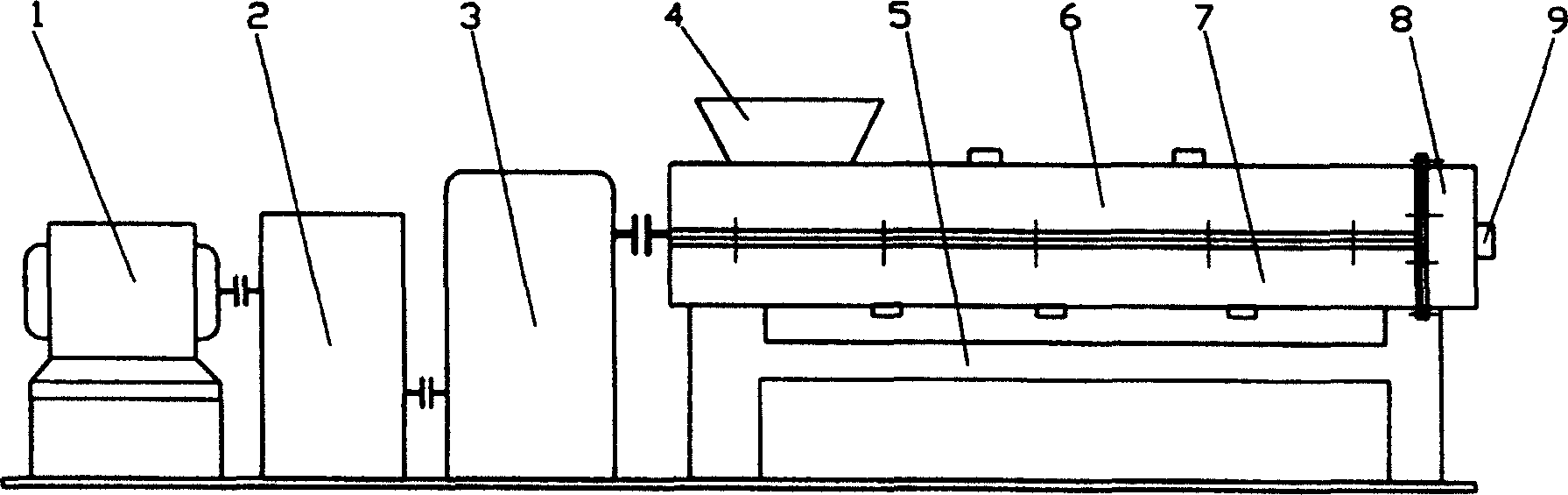

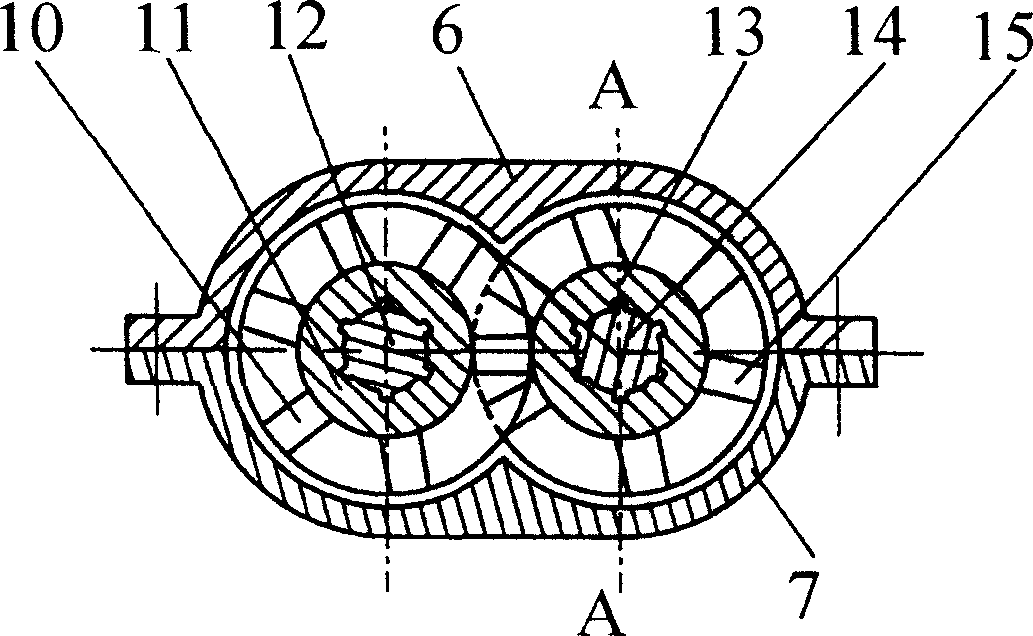

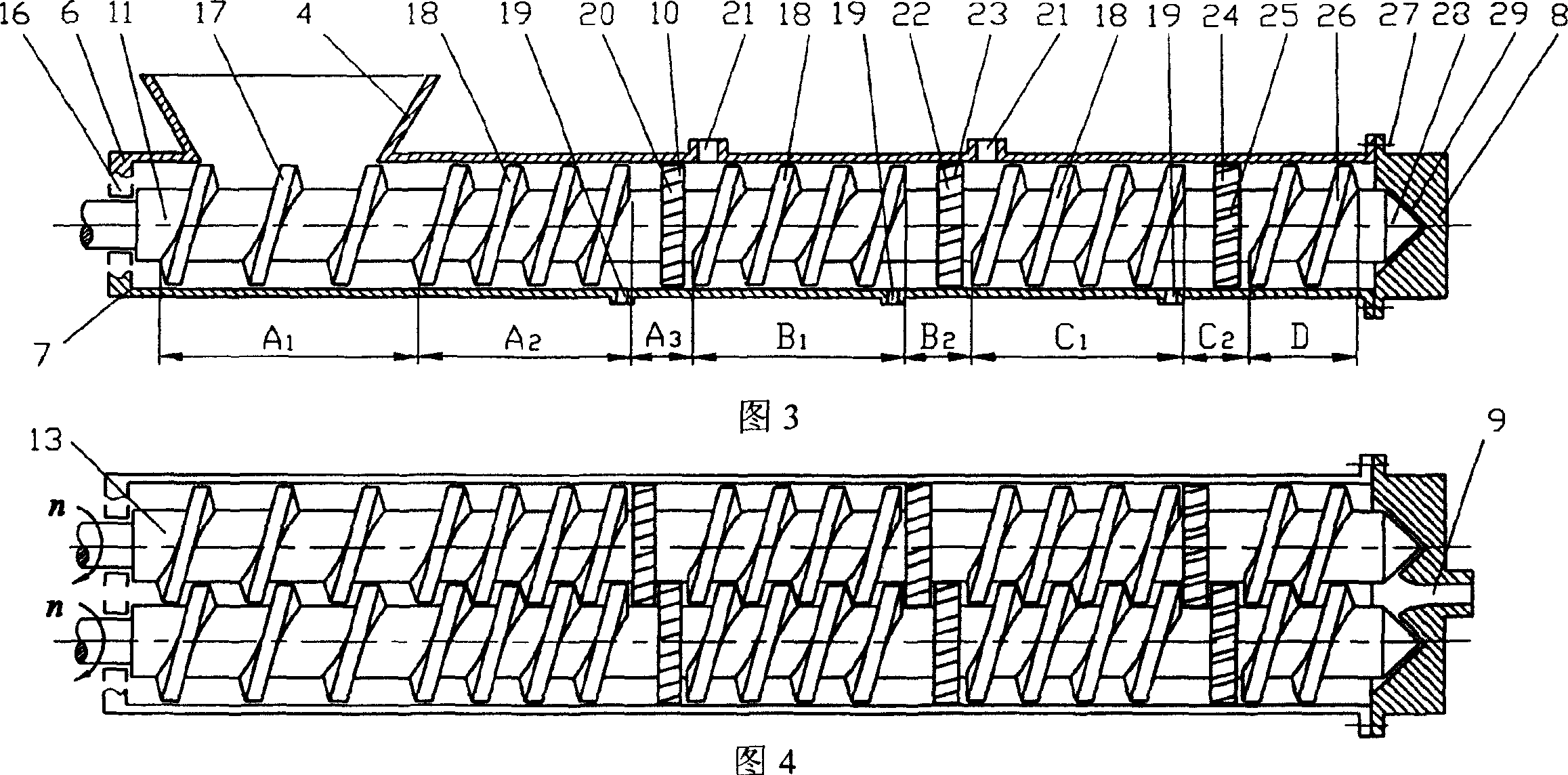

Double-screw fiberizer with tooth-shape disc

The present invention relates to one kind of double screw pulp grinder with toothed disc. The double screw pulp grinder features that inside the mutually buckled upper casing and lower casing, two parallel meshed screws with equal thread inner and outer diameter are mounted and made to rotate in the same direction and constitute one combined structure together with the toothed disc. The width of the inclined slot of the toothed disc is reduced gradually from the material inlet to the outlet, and the screws and the toothed disc are assembled onto the spline shaft with the splines. The present invention is used in producing paper pulp through extruding and shearing plant fiber between two rotating screws and has the features of great fiber length and high brooming effect of paper pulp, low power consumption, low water consumption and less exhaust.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for reducing impurity content in fluorine-containing polymer

The invention discloses a preparation method of a fluorine-containing polymer, which comprises the following steps: (a) preparing the fluorine-containing polymer by emulsion or suspension polymerization; (b) pumping the emulsion after condensation into a filter pressing system for carrying out filter pressing and obtaining a filter cake; (c) adopting the gas phase medium crushing method for carrying out pre-crushing on the filter cake, and obtaining polymer particles with maximum particle size of below 200mm; (d) adopting the liquid phase medium crushing method for crushing the polymer particles into particles with the maximum particle size of less than 60mu m; (e) dispersing the obtained polymer particles in water and obtaining a waterborne dispersion; and (g) drying, thereby obtaining a fluorine-containing polymer product. The invention further discloses a method for reducing the content of the impurity in the fluorine-containing polymer.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD +1

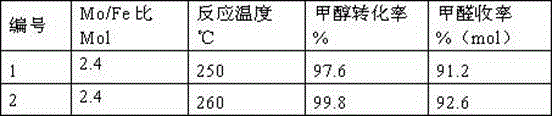

Solid phase reaction preparation method for iron-molybdenum process catalyst used for methanol oxidation to formaldehyde

InactiveCN106582673AReduce water usageSimple processOrganic compound preparationCatalyst activation/preparationChemistrySewage

A solid phase reaction preparation method for an iron-molybdenum process catalyst used for methanol oxidation to formaldehyde includes the steps of mixing and grinding ammonium molybdate and an iron salt to carry out a reaction to obtain ferric molybdate, and drying, washing, roasting, crushing and shaping the ferric molybdate to produce a ferric molybdate catalyst. The preparation method, compared with a conventional diluted water solution reaction with ammonium molybdate and iron salts such as ferric nitrate, ferric chloride and the like, can greatly reduce usage amount of water and quantity of waste water containing iron and molybdenum and ammonium salts, thereby simplifying treatment of waste water and reducing production cost of the catalyst. The catalyst has high activity, selectivity and strength, and can satisfy demand in the methanol oxidation to formaldehyde of iron-molybdenum process.

Owner:大连瑞克科技股份有限公司

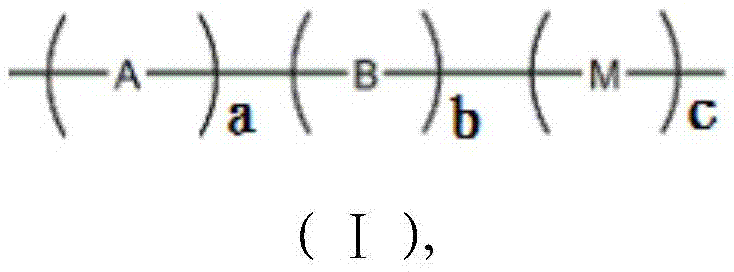

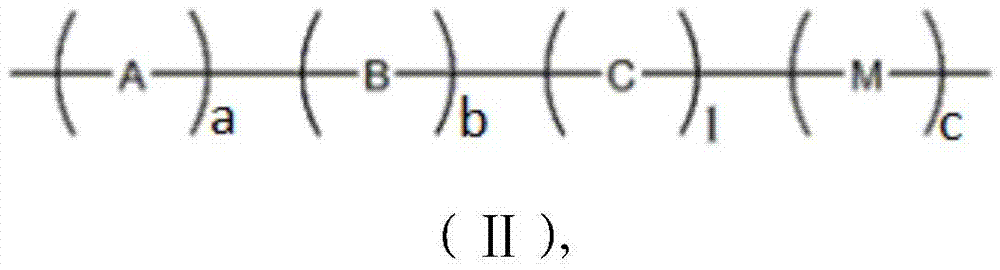

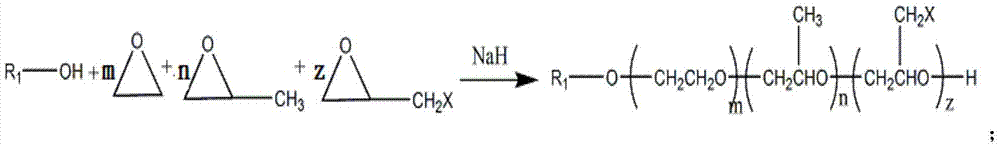

Use of cationic quaternary ammonium salt polycarboxylic acid water reducing agent in preparation of ceramics

The invention provides ceramic slurry. The ceramic slurry comprises ceramic clay, a cationic quaternary ammonium salt polycarboxylic acid water reducing agent and water, wherein the cationic quaternary ammonium salt polycarboxylic acid water reducing agent is a compound represented by the formula (I) or (II). The invention also provides ceramics prepared from the ceramic slurry, and also provides a use of the cationic quaternary ammonium salt polycarboxylic acid water reducing agent in preparation of the ceramics. The cationic quaternary ammonium salt polycarboxylic acid water reducing agent is introduced in the ceramic slurry, has excellent dispersion effect on ceramic clay particles in the ceramic slurry, can reduce the viscosity of the ceramic slurry, can increase the fluidity of the ceramic slurry, improves the stability of the ceramic slurry, reduces the use amount of water, and can be widely used in processes of mud making, slurry grinding and glaze preparation.

Owner:GUANGDONG REDWALL NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com