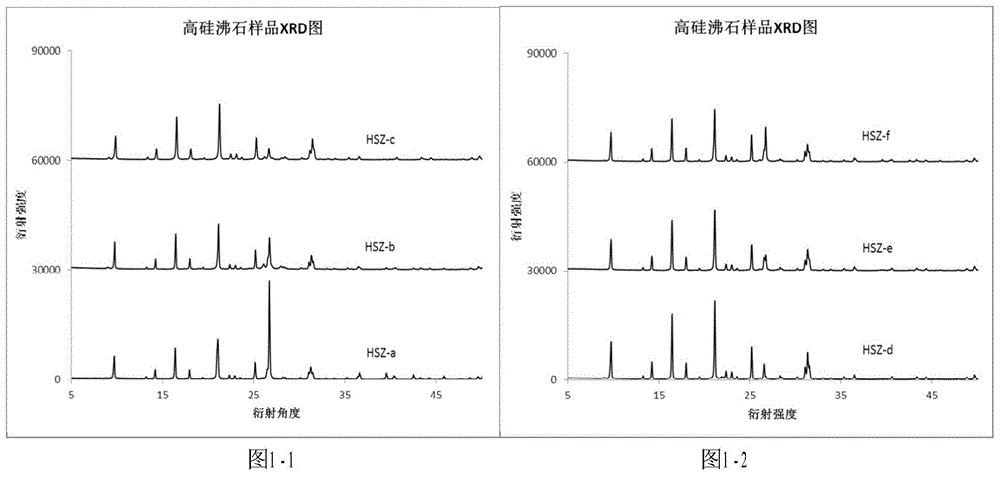

Method for synthesizing chabazite-type molecular sieve with high silica-alumina ratio by using seed crystal and composite inorganic base and application thereof

A high silicon-aluminum ratio, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, molecular sieve catalyst, chemical instrument and method, etc., can solve the problem of CHA zeolite without high specific surface area, high MTO diolefin selectivity, template Eliminate the problems of large dosage of agent, achieve superior MTO reaction performance, shorten crystallization time, and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation of SSZ-13 molecular sieve seed crystals: 14.4g alkaline silica sol (SiO 2 The mass concentration is 30%, Na 2 (0.2% by mass content, the rest being water) was added to the reactor, stirred in a water bath at 30° C., and 17.89 g of a mass concentration of 25% was added to the aqueous solution of N, N, N-trimethyladamantane ammonium hydroxide, stirred evenly, Then add 2.69g of sodium hydroxide, continue to stir evenly, and then slowly add an aqueous solution made of 1.3328g of aluminum sulfate octadecahydrate and 17.355g of distilled water. Stir at 30°C for 4 hours. The above mixture was transferred to a 100ml hydrothermal reaction kettle and subjected to static crystallization at 160°C for 144 hours. After the crystallization is complete, carry out suction filtration, wash with deionized water to pH = 7.0, and dry at 100°C to obtain 2.5 grams of SSZ-13 molecular sieve samples, labeled as Seed-1, which are used as Comparative Example 2, Example 1, Example 2 ...

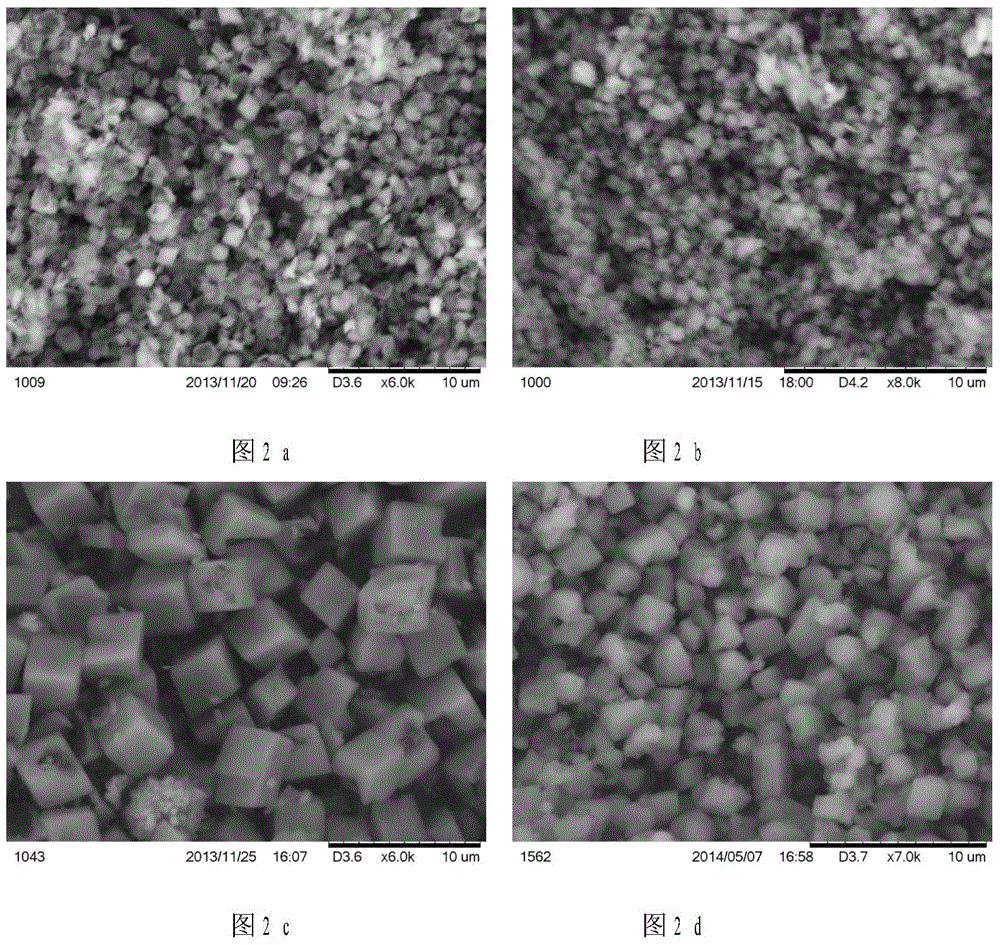

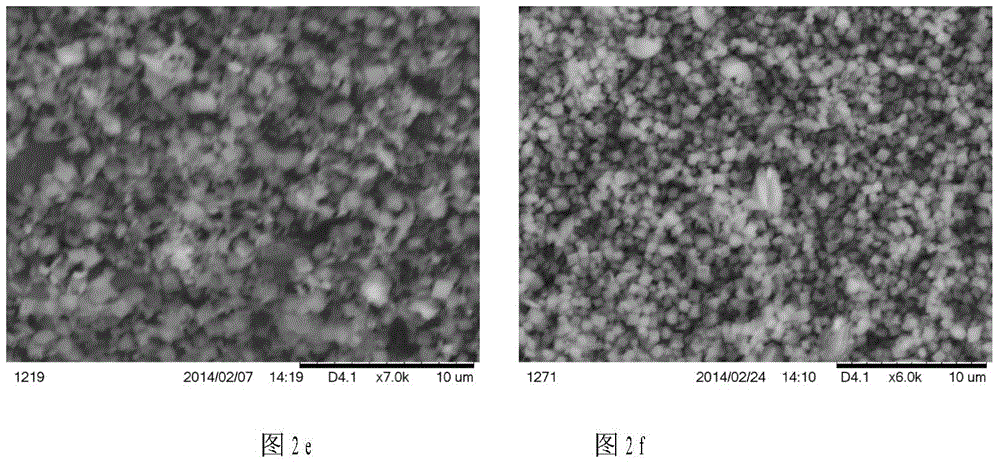

Embodiment 1

[0056] Embodiment 1: Utilize crystal seed and composite inorganic base to synthesize high silicon aluminum ratio chabazite type molecular sieve (molar material ratio is SiO 2 :0.005Al 2 o 3 : 0.02K 2 O: 0.10Na 2 O: 0.07 Templating agent: 5H 2 O (water in the system after adding aluminum sulfate). SSZ-13 molecular sieve marked as Seed-1 was added with 1% of the mass of silica as a seed crystal).

[0057] Gel preparation: 36g of alkaline silica sol (SiO 2 The mass content is 50%, Na 2 (2 mass content 0.4%) joins in the reactor, 20 ℃ of water baths are stirred, then add 10.128g templating agent mass concentration and be the aqueous solution of the hydroxide-N, N, N-trimethyladamantane ammonium of 43.75%, stir evenly, Slowly add 0.672g of potassium hydroxide, then add 2.4g of sodium hydroxide, continue to stir evenly, then slowly add an aqueous solution made of 0.9996g of aluminum sulfate octadecahydrate and 2.961g of distilled water, and add 0.18g of SSZ-13 molecular sieve...

Embodiment 2

[0062] Embodiment 2: Utilize crystal seed and composite inorganic base to synthesize high silicon aluminum ratio chabazite type molecular sieve (molar material ratio is SiO 2 :0.008Al 2 o 3 : 0.05K 2 O: 0.02Na 2 O:0.05 Template agent: 6H 2 O (the water in the system after adding the aluminum source), add SSZ-13 molecular sieve marked as Seed-1 with 0.1% of the mass of silicon dioxide as the seed crystal. )

[0063] Gel preparation: 36g of alkaline silica sol (SiO 2 The mass content is 50%, Na 2 (2 mass content 0.4%) join in the reactor, 30 ℃ of water baths are stirred, then add 7.91g templating agent mass concentration and be the aqueous solution of the hydroxide-N, N, N-trimethyladamantane ammonium of 40%, stir evenly, Slowly add 1.68g of potassium hydroxide, then add 0.48g of sodium hydroxide, continue to stir evenly, then slowly add an aqueous solution made of 1.8g of aluminum nitrate nonahydrate and 9.02g of distilled water, add 0.018g of SSZ-13 molecular sieve as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com